Patents

Literature

2406 results about "Rolling paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling paper is a specialty paper used for making cigarettes (commercially manufactured filter cigarettes and individually made roll-your-own cigarettes). Rolling papers are packs of several cigarette-size sheets, often folded inside a cardboard wrapper.

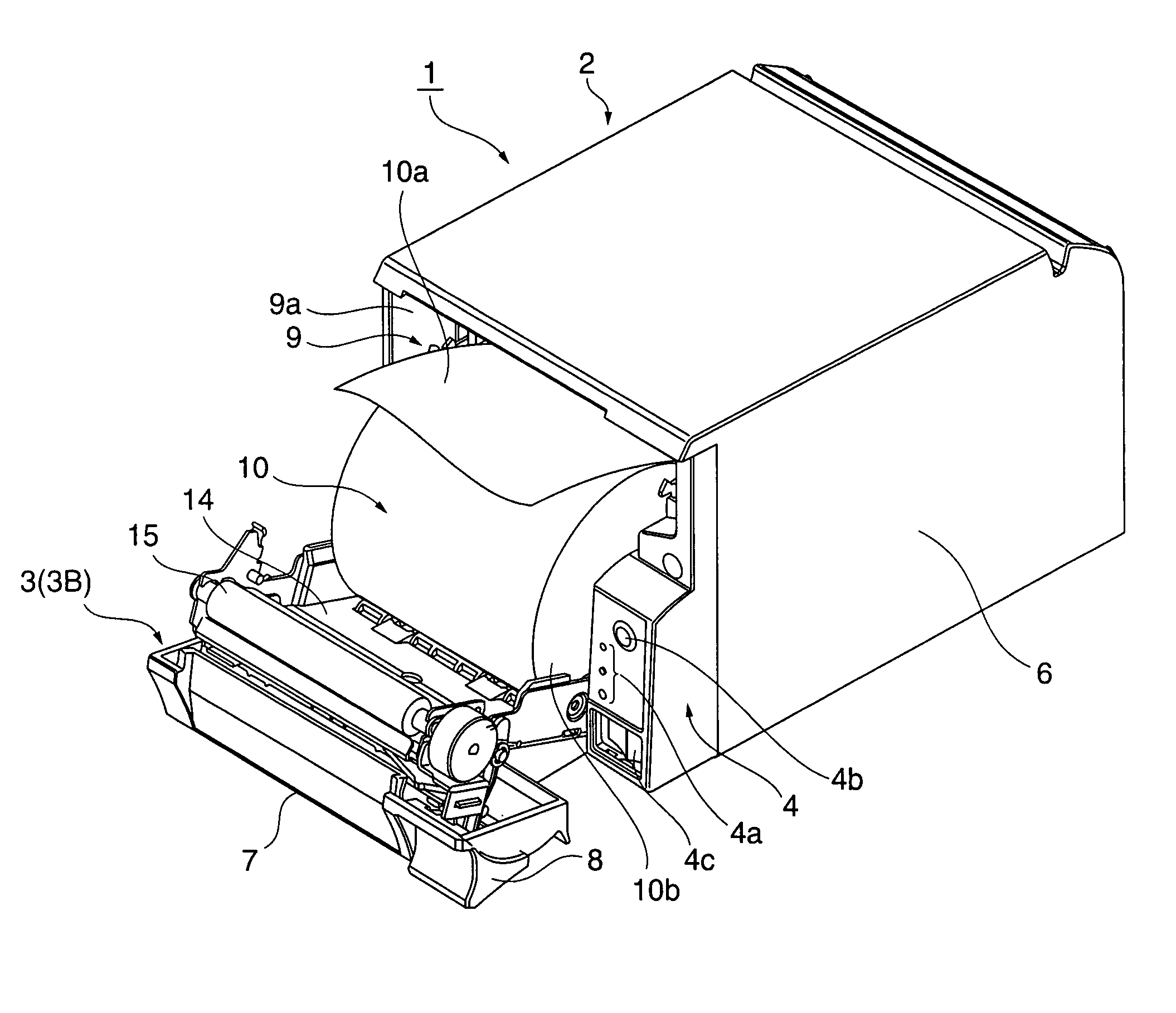

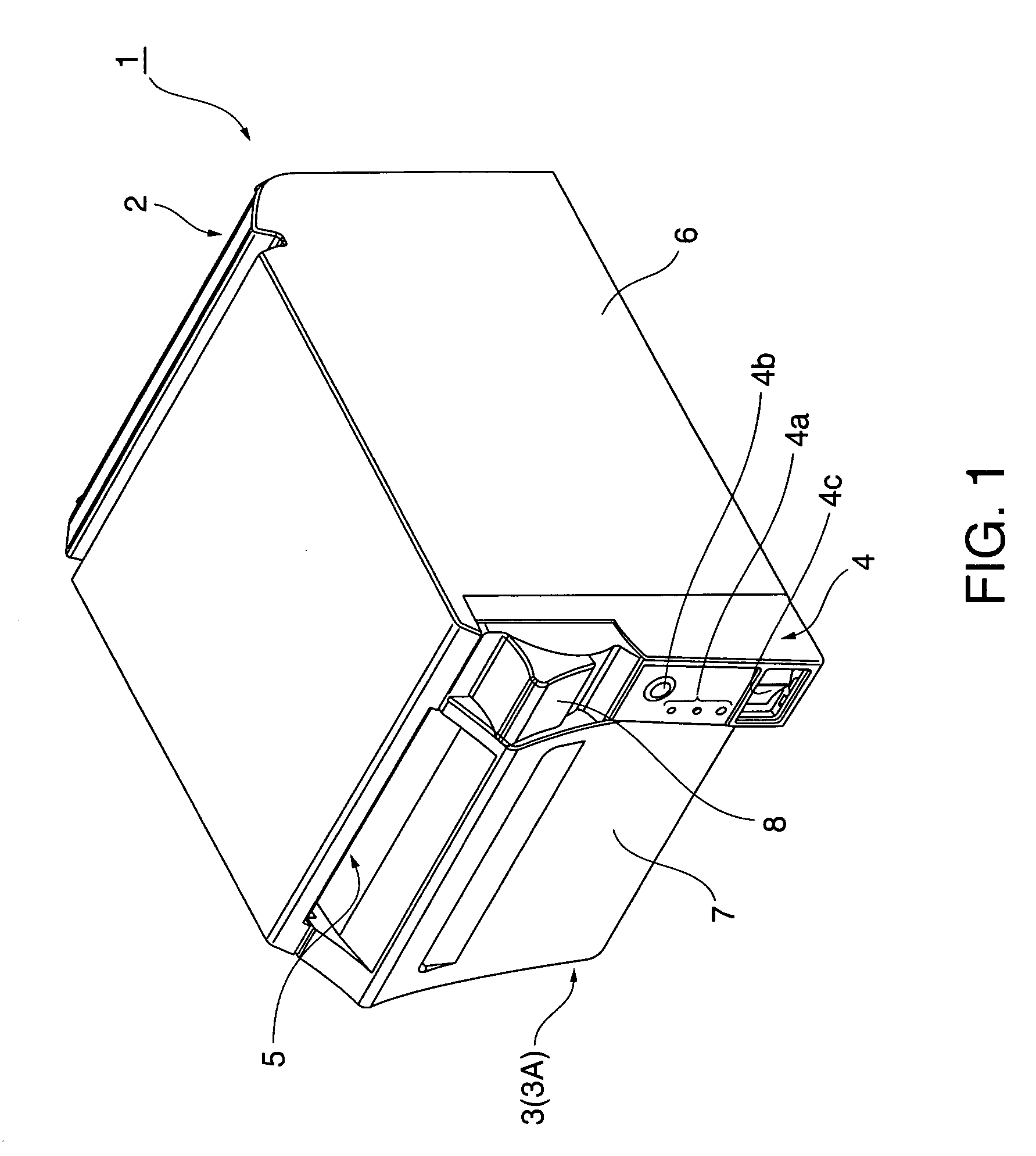

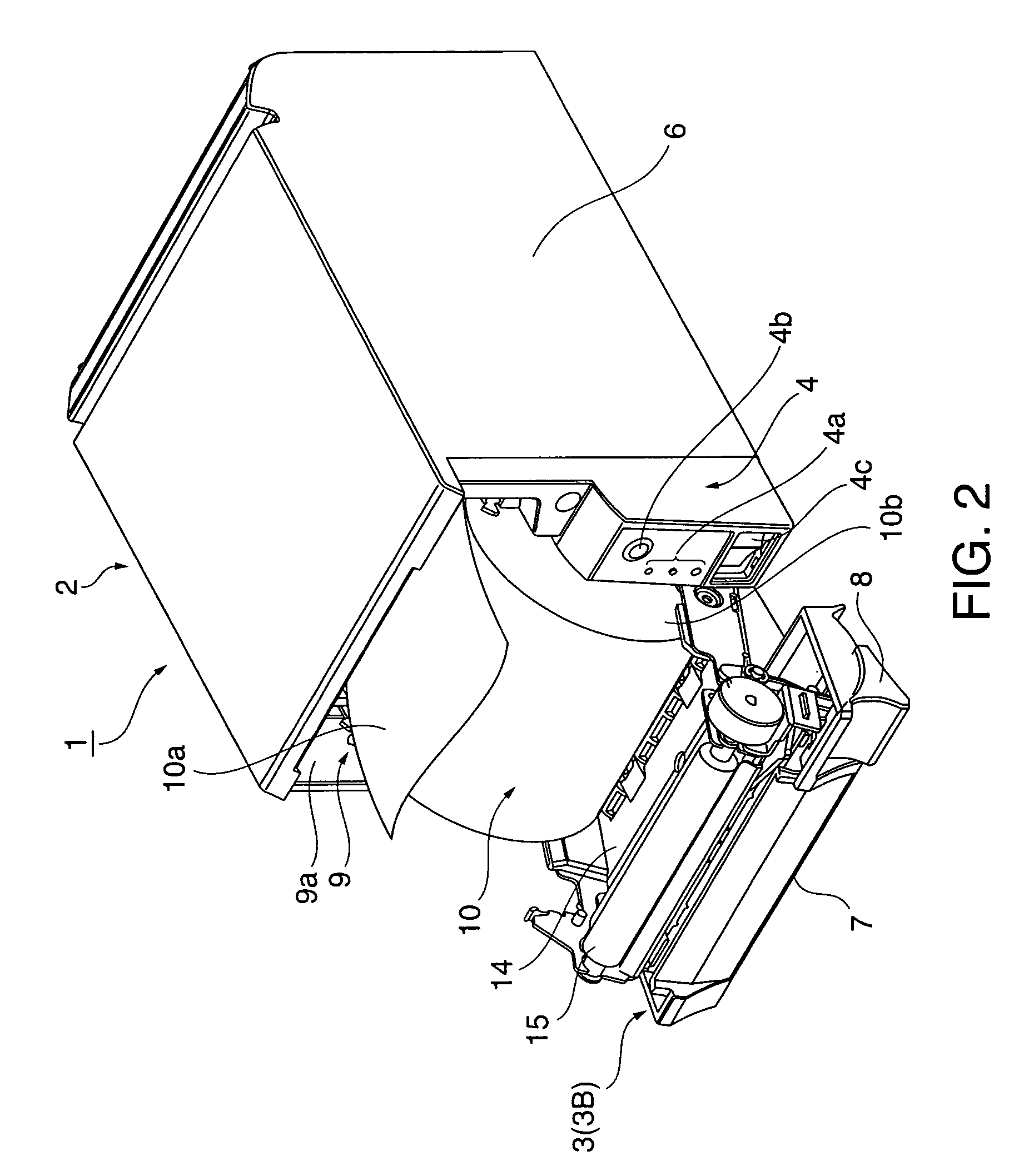

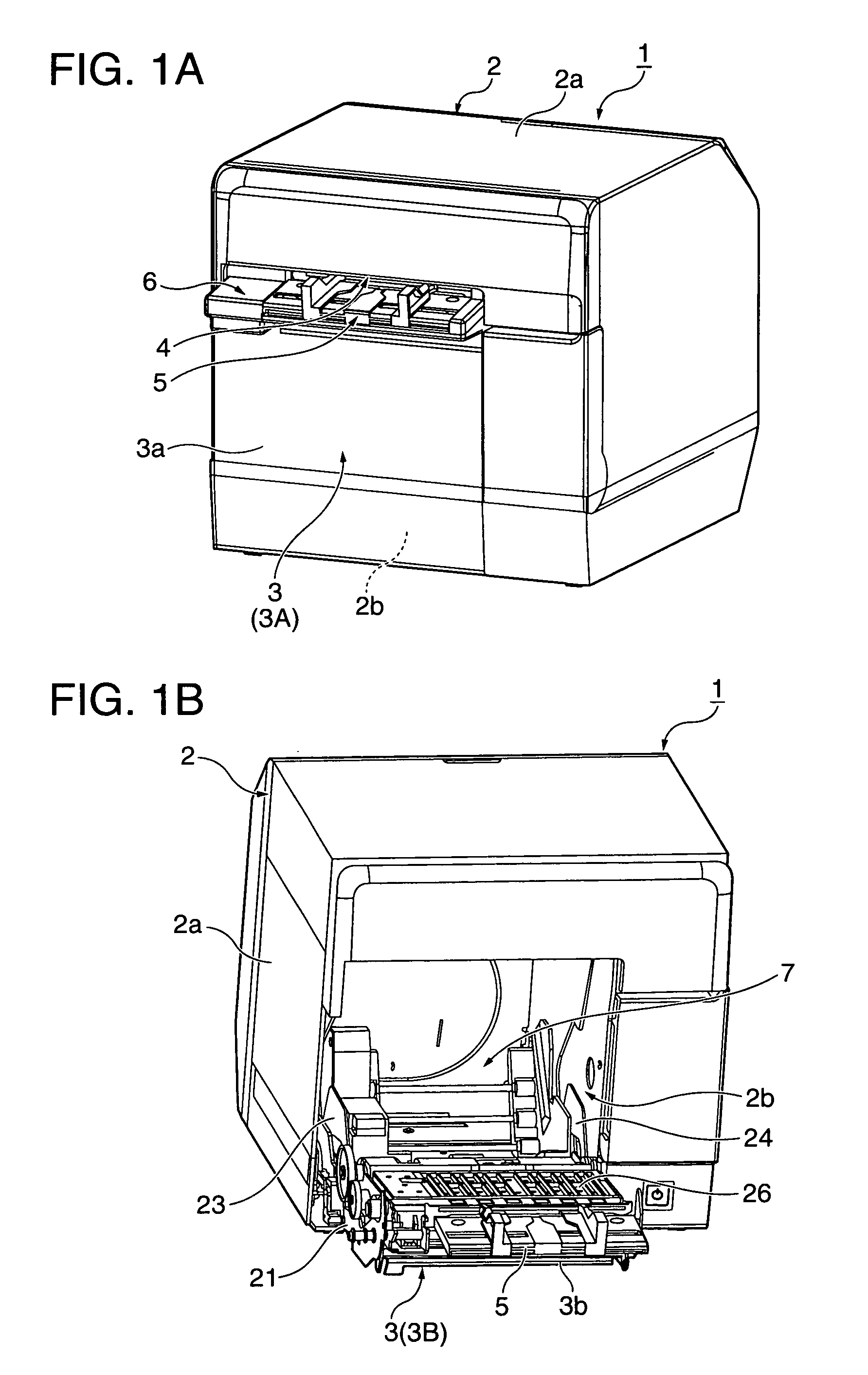

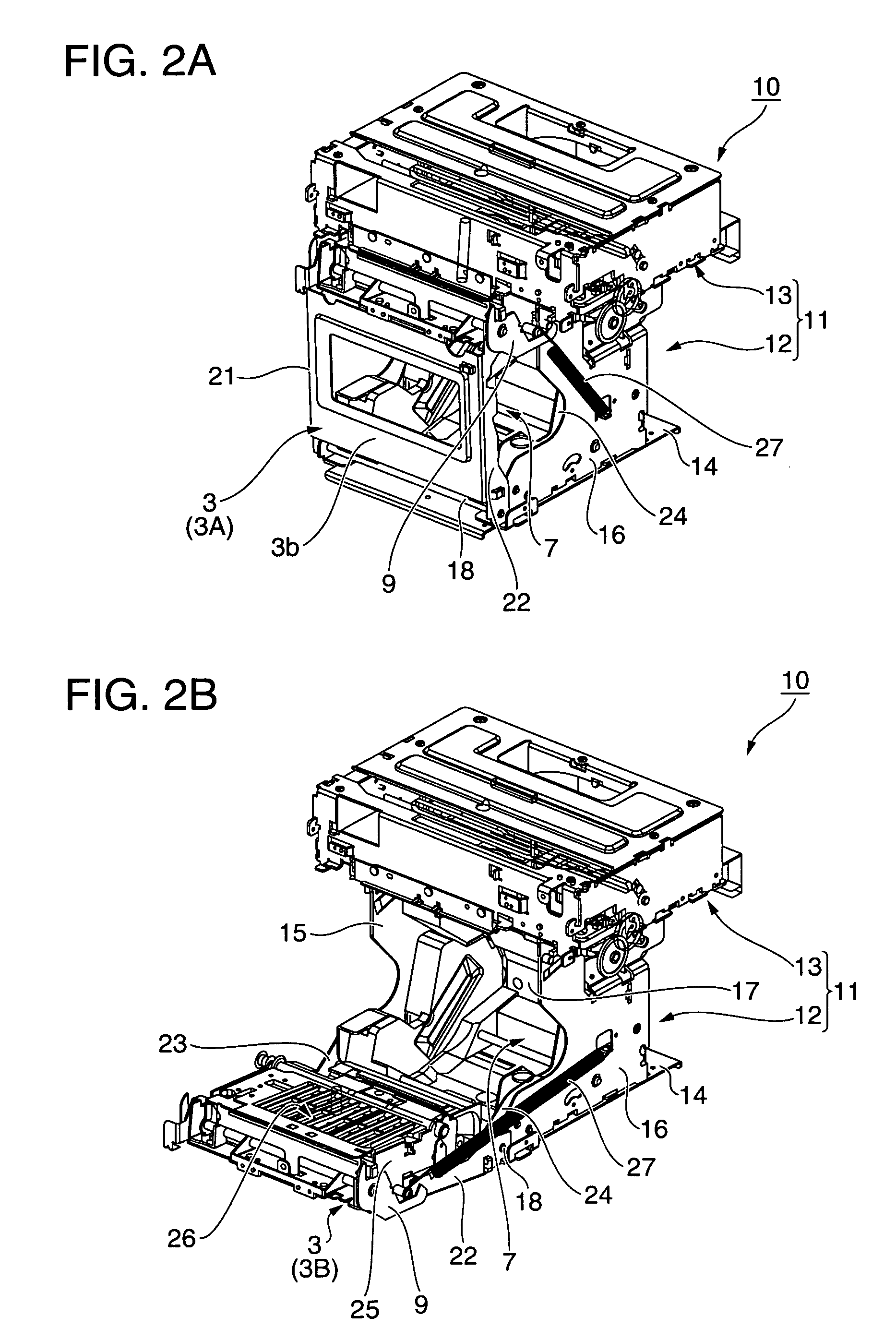

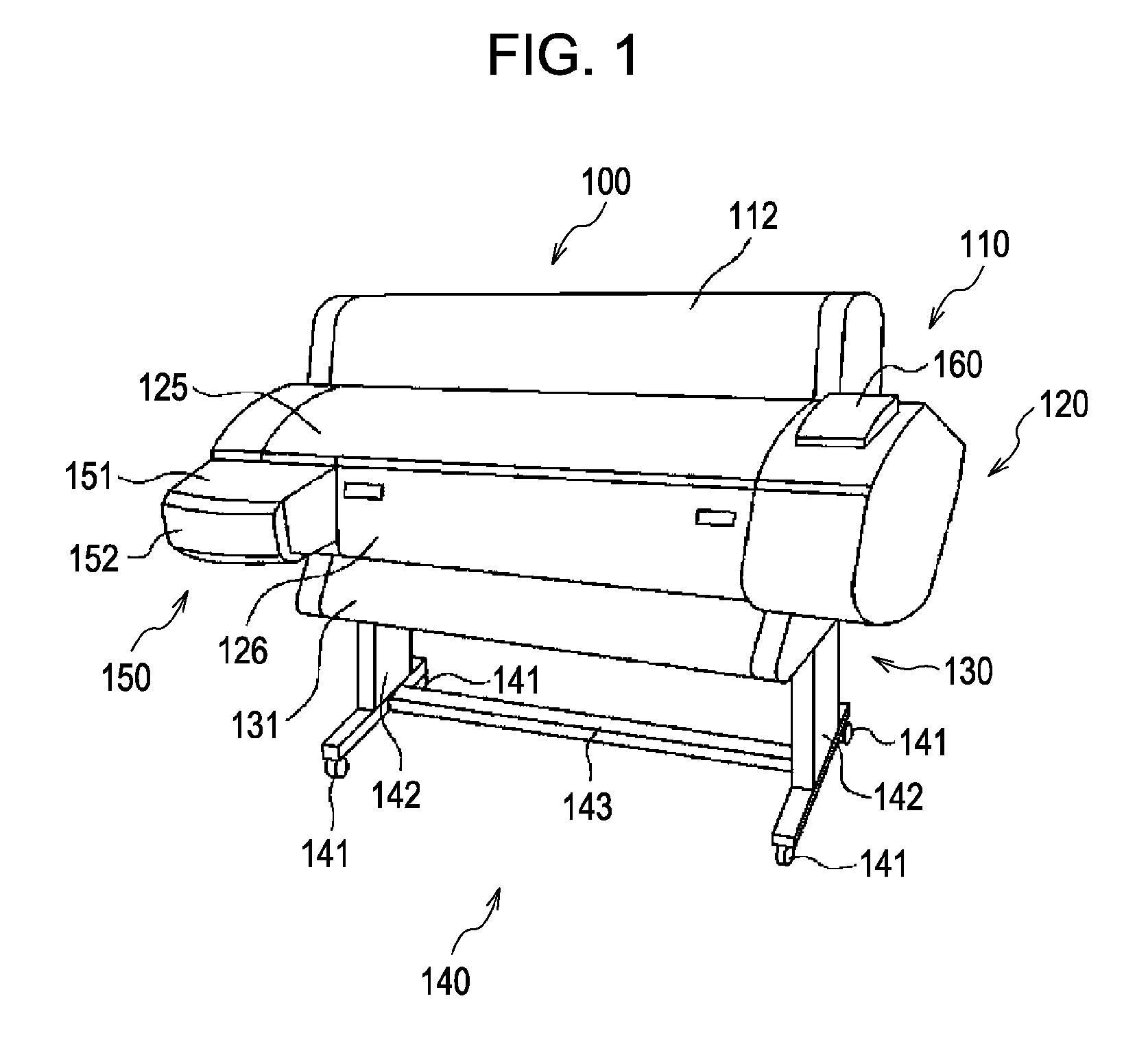

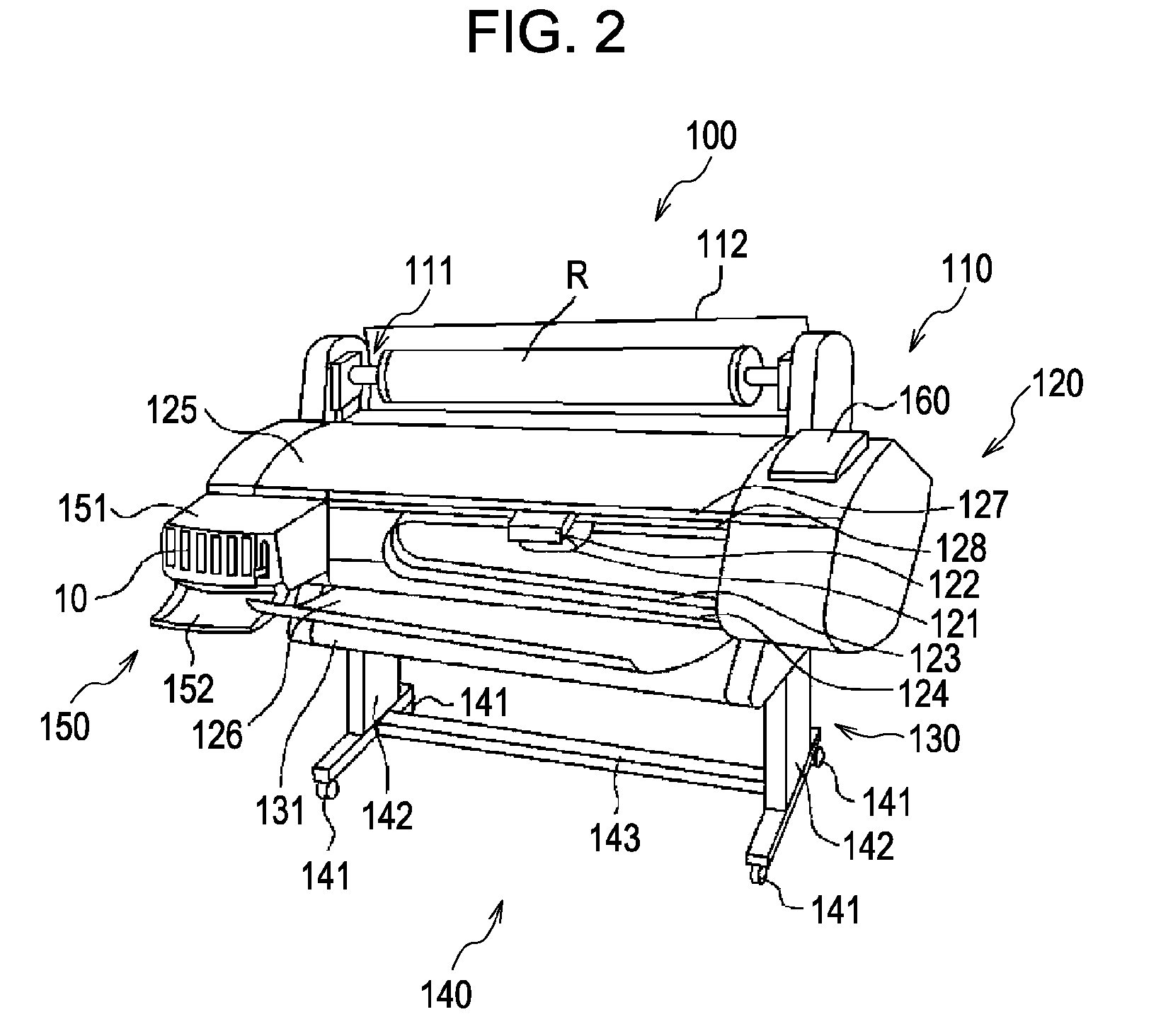

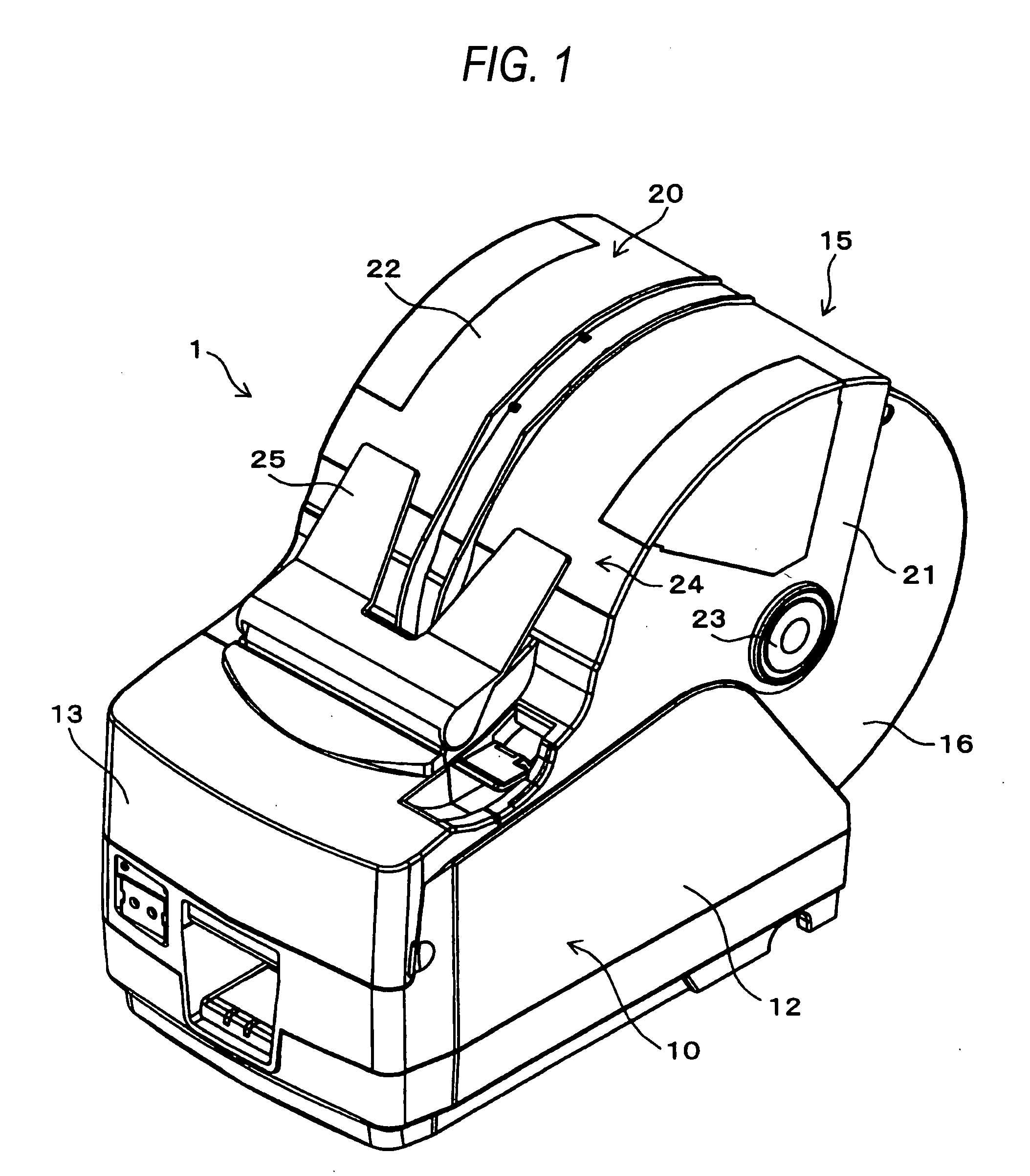

Roll sheet holder and tape printer

ActiveUS7070348B2Avoid partialImprove detection accuracyInking apparatusProjector film strip handlingRolling paperEngineering

Owner:BROTHER KOGYO KK

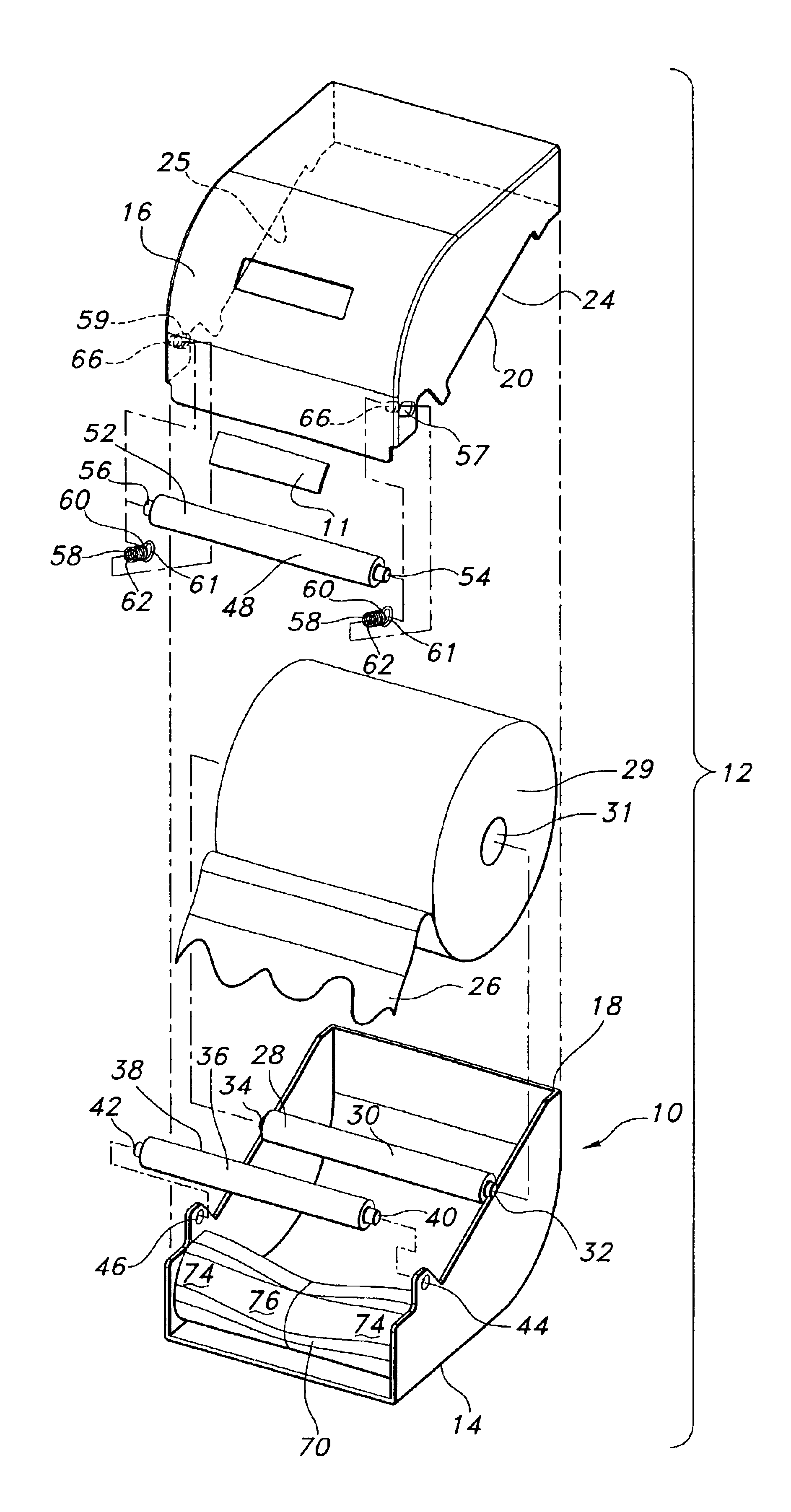

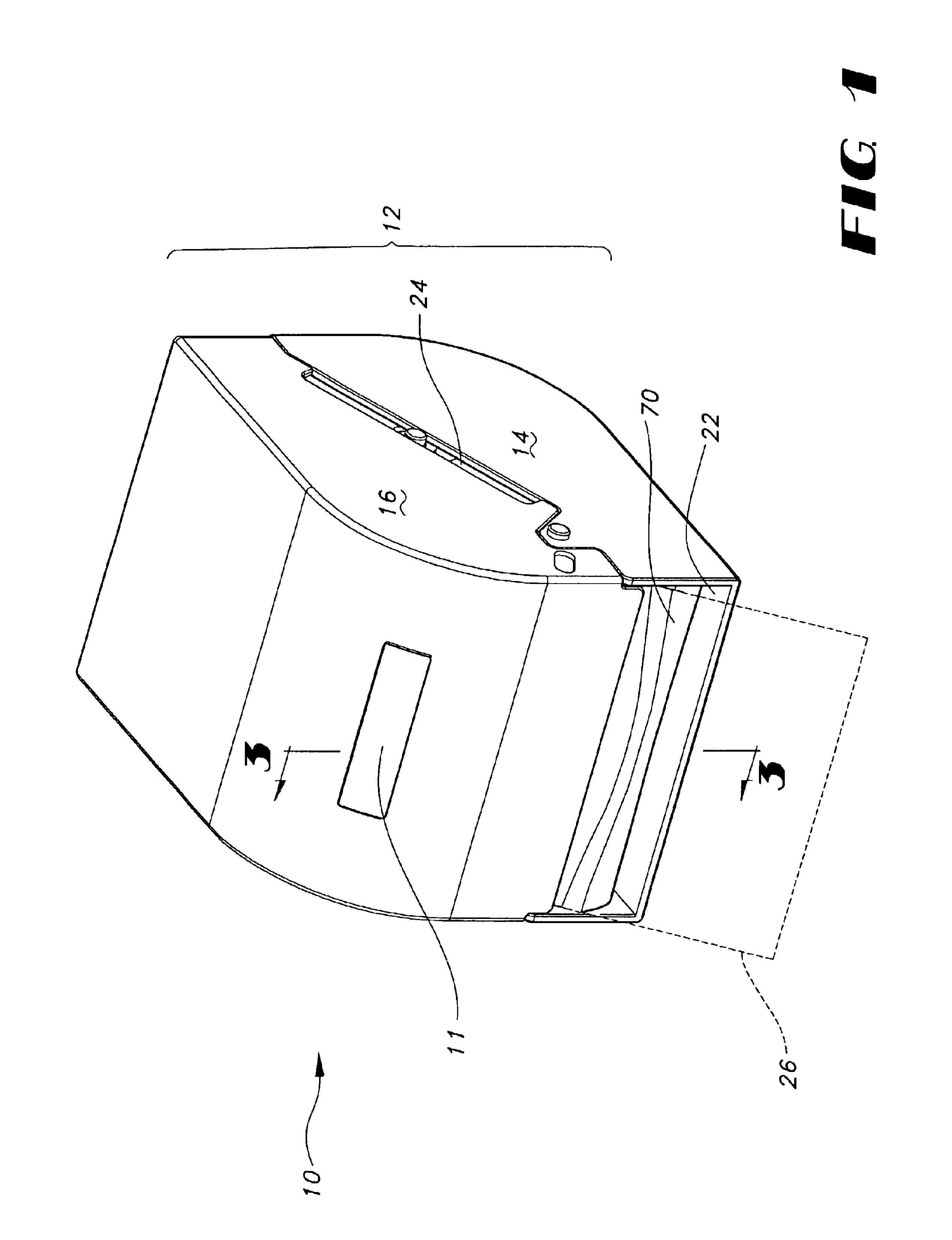

Three roll tissue dispenser

ActiveUS7014140B2Avoid excessive forceTorque is limitedFilament handlingDomestic applicationsRolling paperEngineering

Owner:ESSITY OPERATIONS WAUSAU LLC

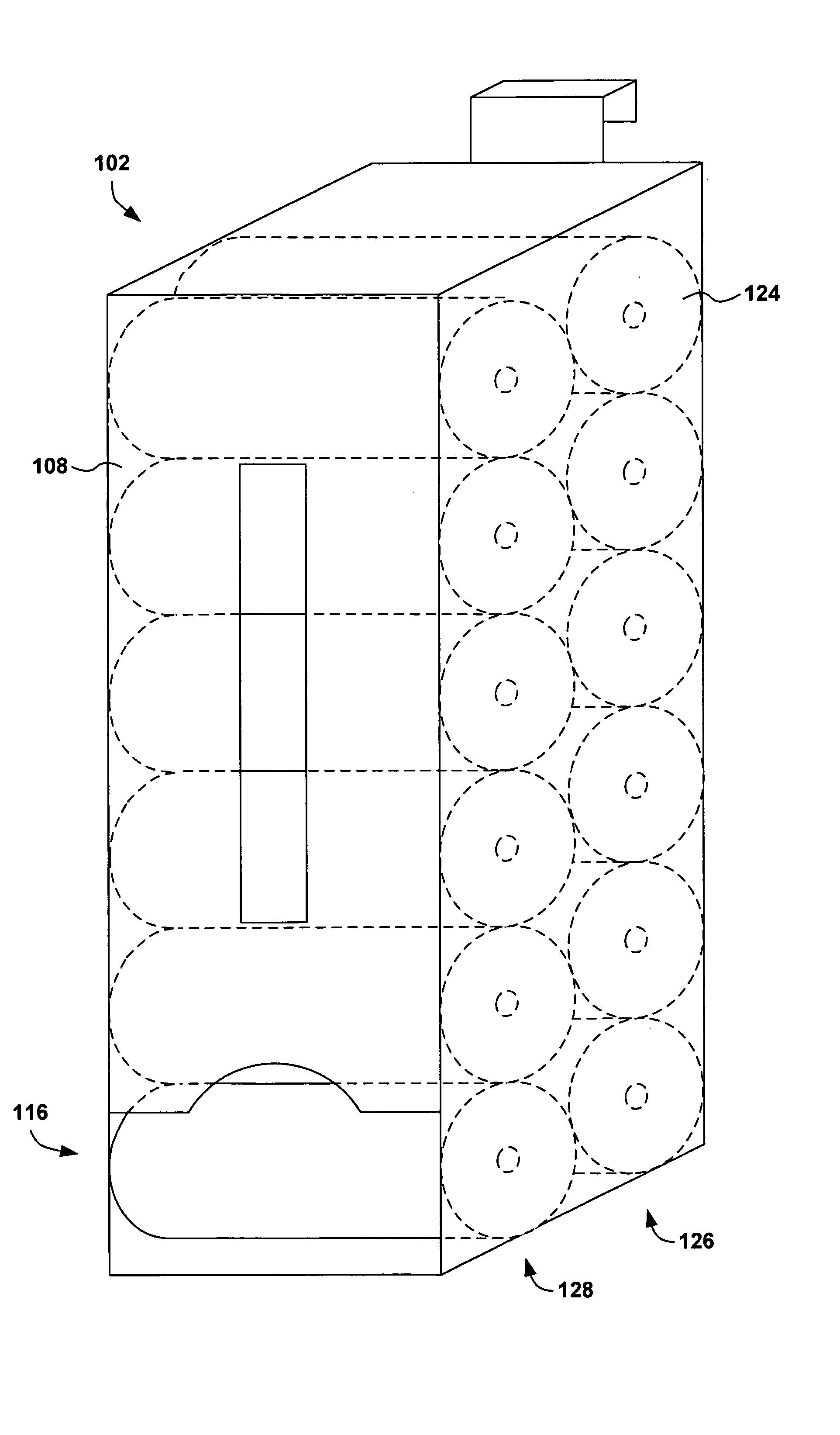

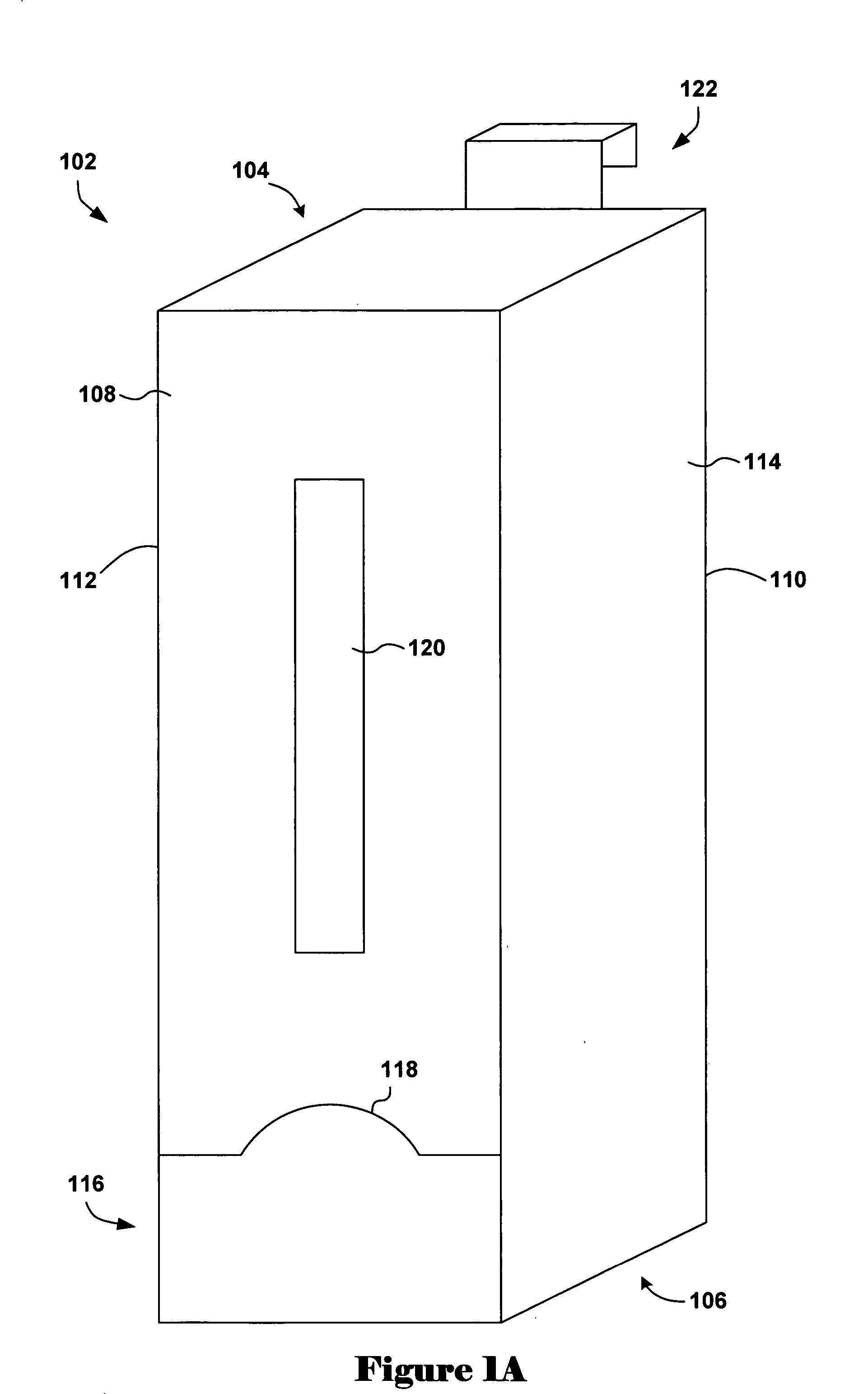

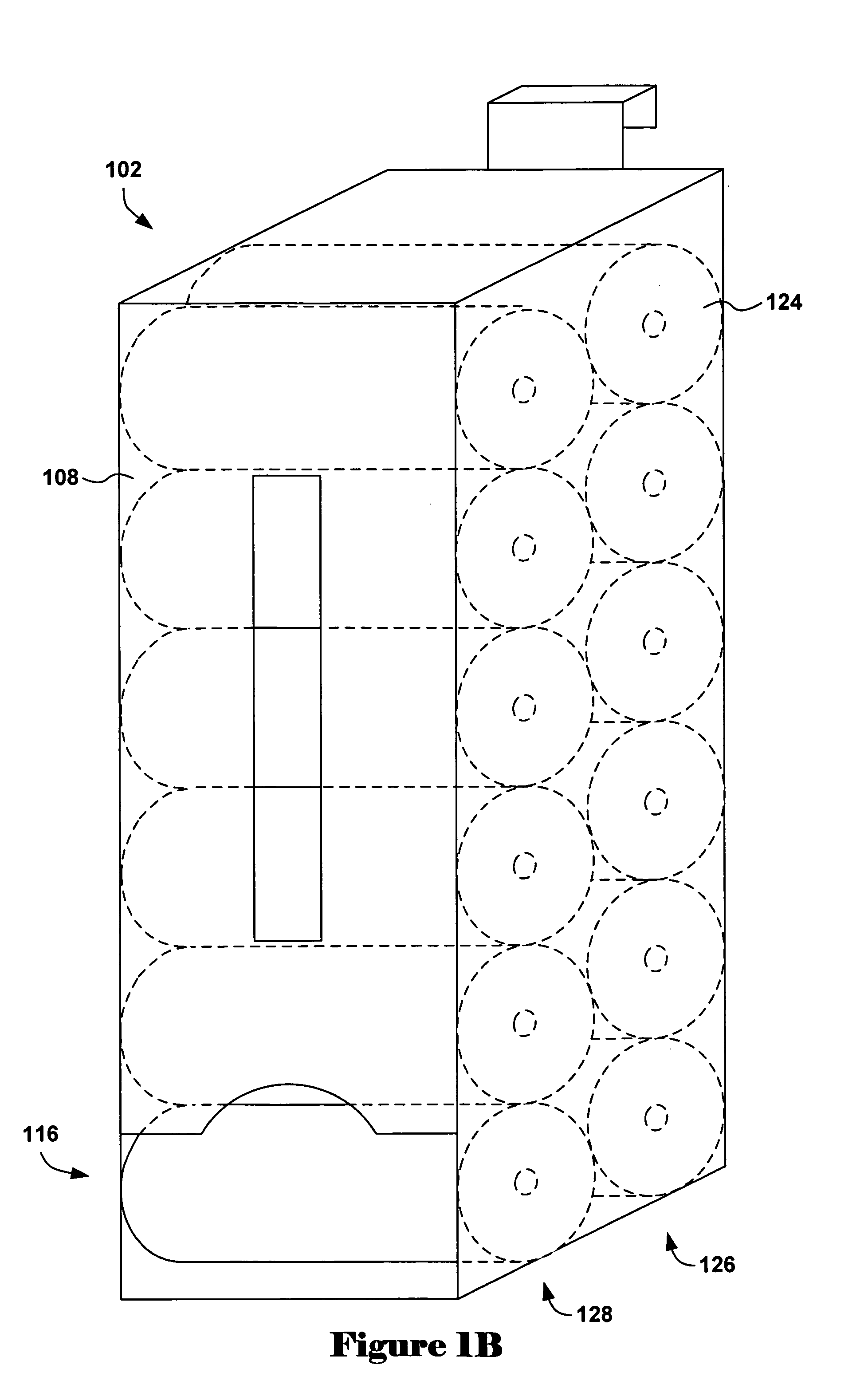

Method and system for storing and dispensing rolled paper products

One embodiment of the present invention comprises a collapsible, manually-extracted paper-towel-roll storage and dispensing container. Paper towel rolls are manually loaded horizontally in one or more vertical stacks inside the storage and dispensing container. A dispensing aperture is included at the bottom of the front face for manual removal of the paper-towel rolls from within the container. A viewing aperture is also contained on the front face of the container for viewing the contents of the storage and dispensing container. A removable door-mounting bracket attaches to the back side of the storage container and dispenser for hanging the container from the top of a door. Either the top or bottom face of the container may be opened for loading and both faces may be opened for folding the container flat for efficient storage when not in use.

Owner:PETERSON FREDERICK R

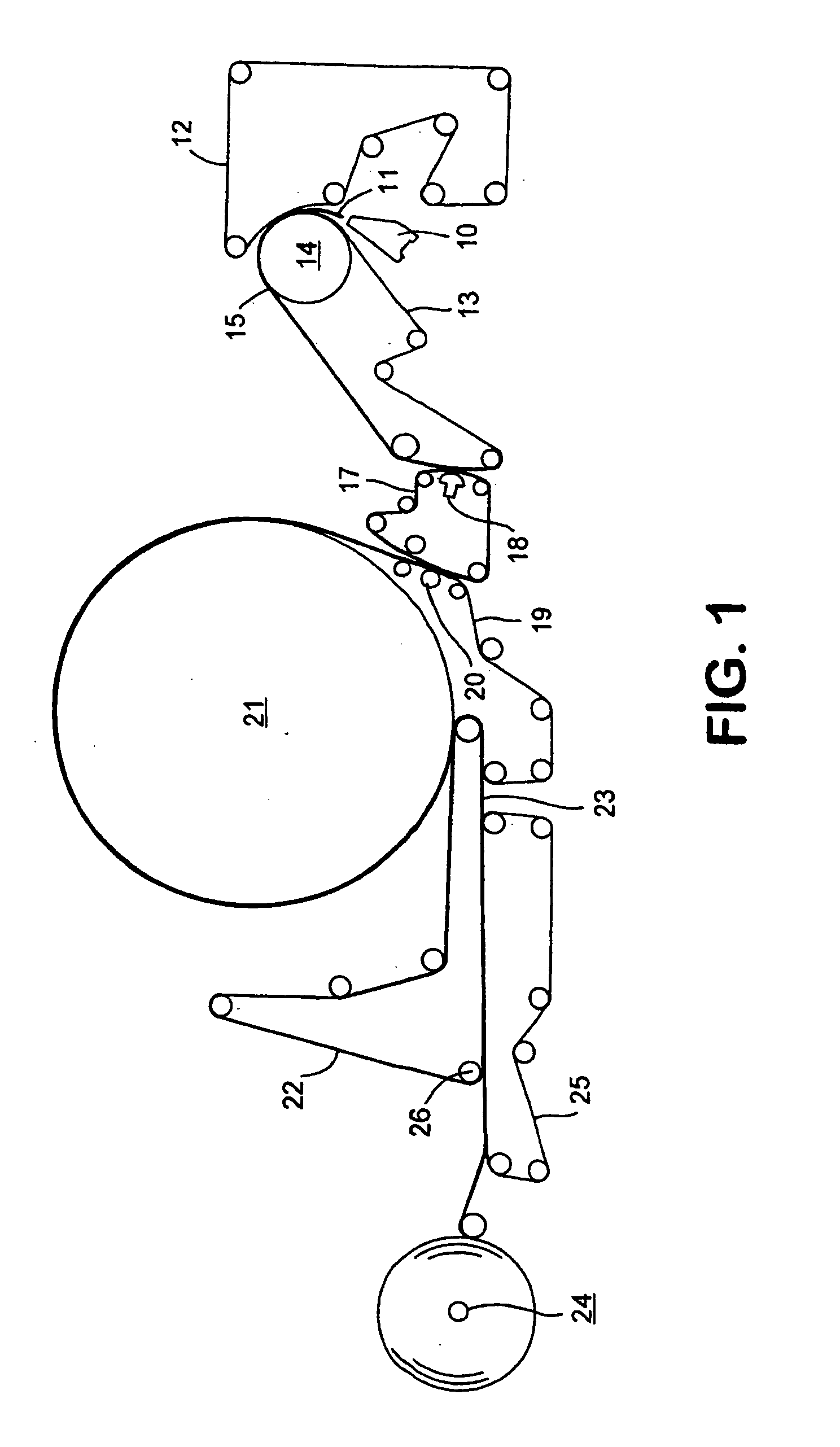

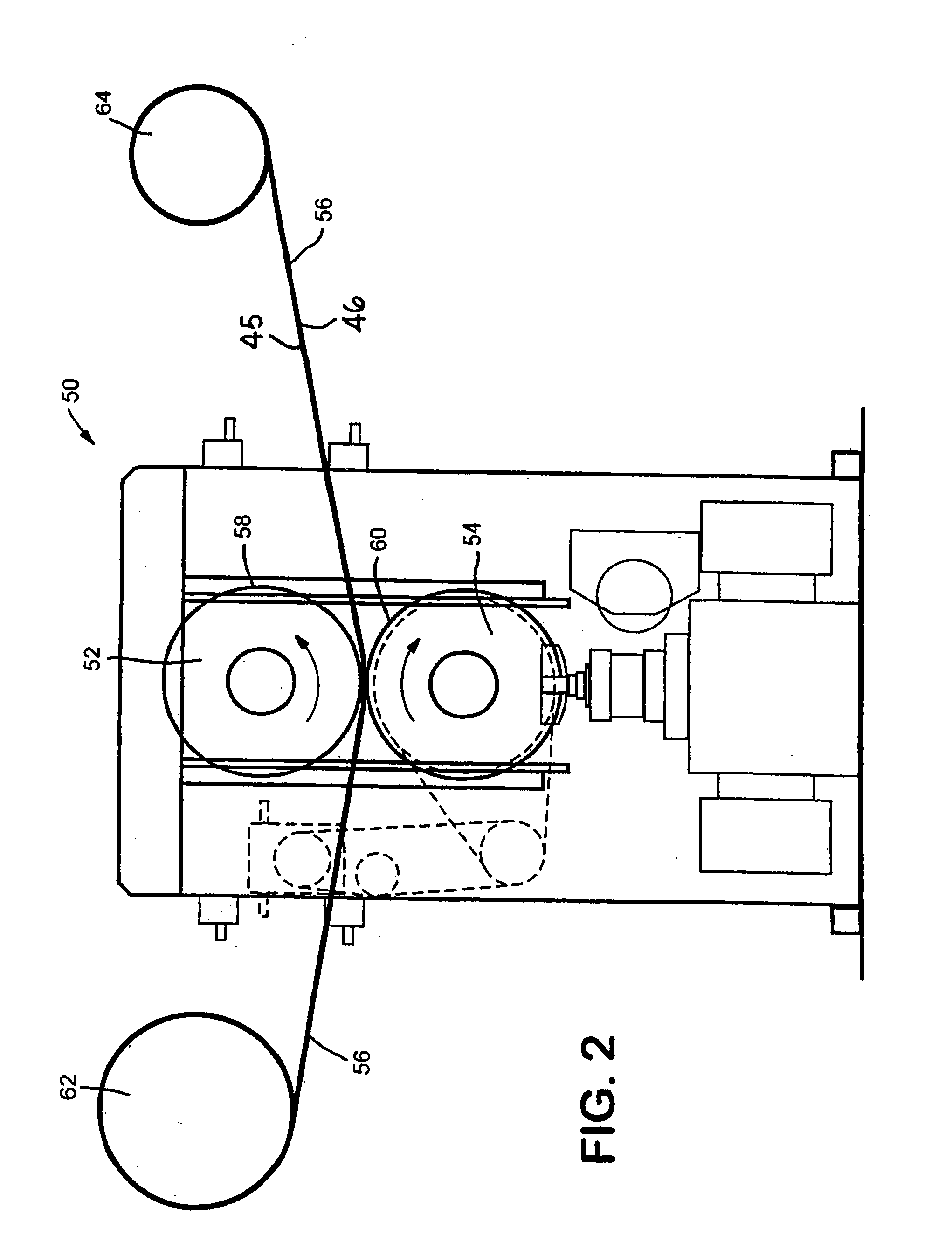

Rolled paper product having high bulk and softness

Spirally wound single-ply web products having a chemical additive applied to at least one surface exhibit desirable roll bulk characteristics and softness properties. The rolled products can be made from a single-ply tissue web formed according to various processes. Once formed, the web is subjected to a shear-calendering device that increases the Fuzz-On-Edge properties of the web and preserves the bulk of the web when wound. The shear-calendered web then has a chemical additive applied to at least one surface by a non-compressive application method helping to maintain the Fuzz-On-Edge properties of the web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

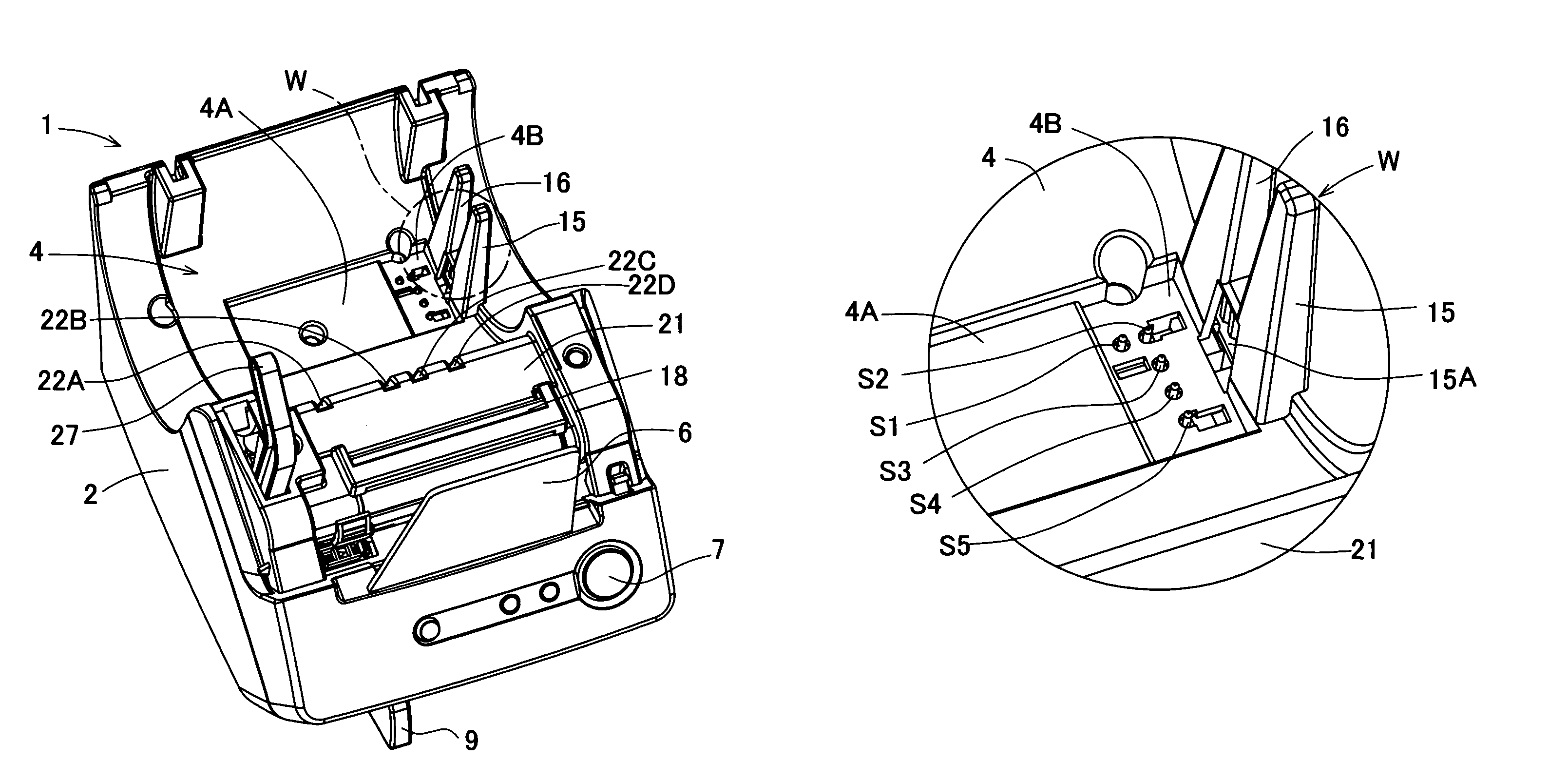

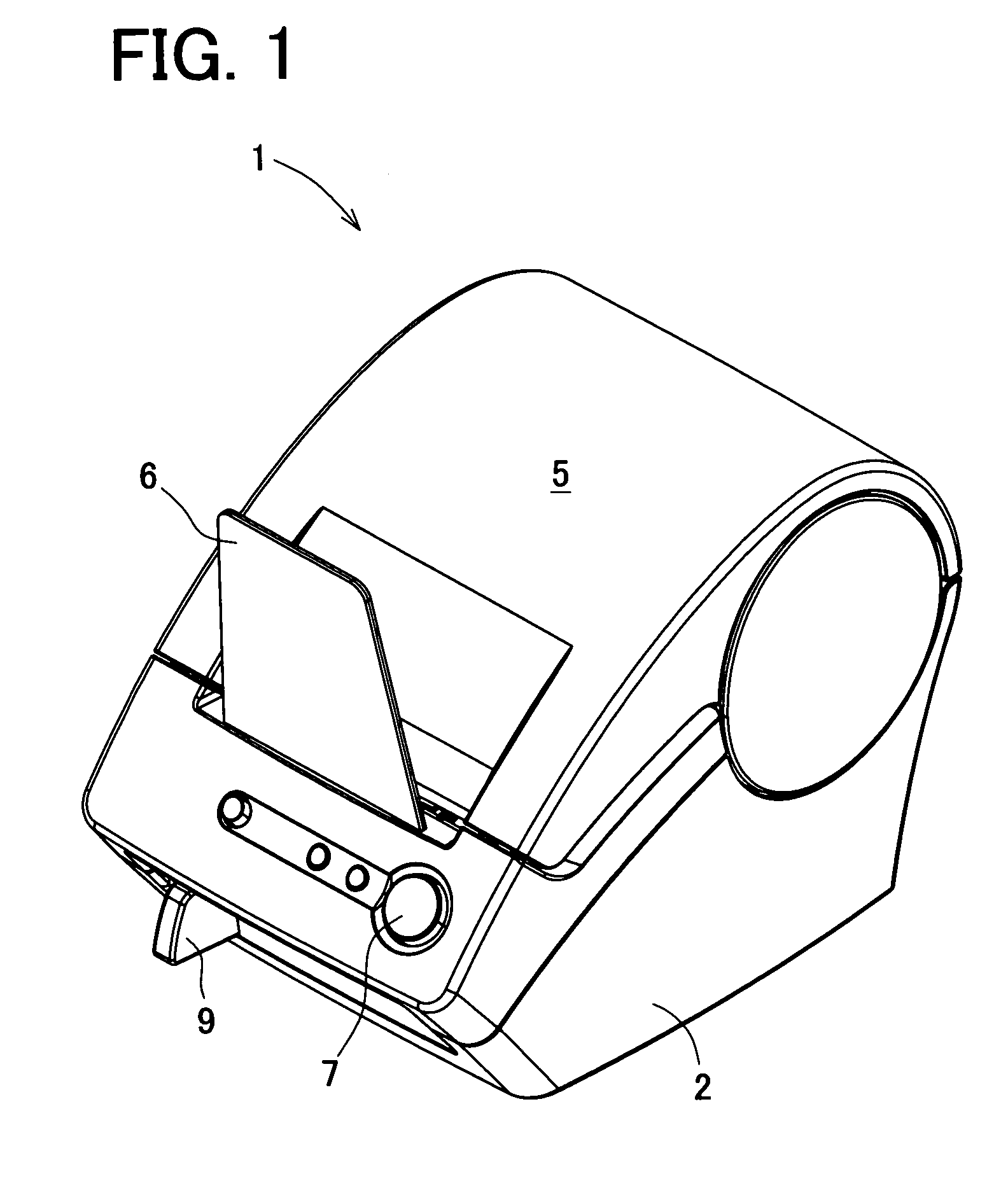

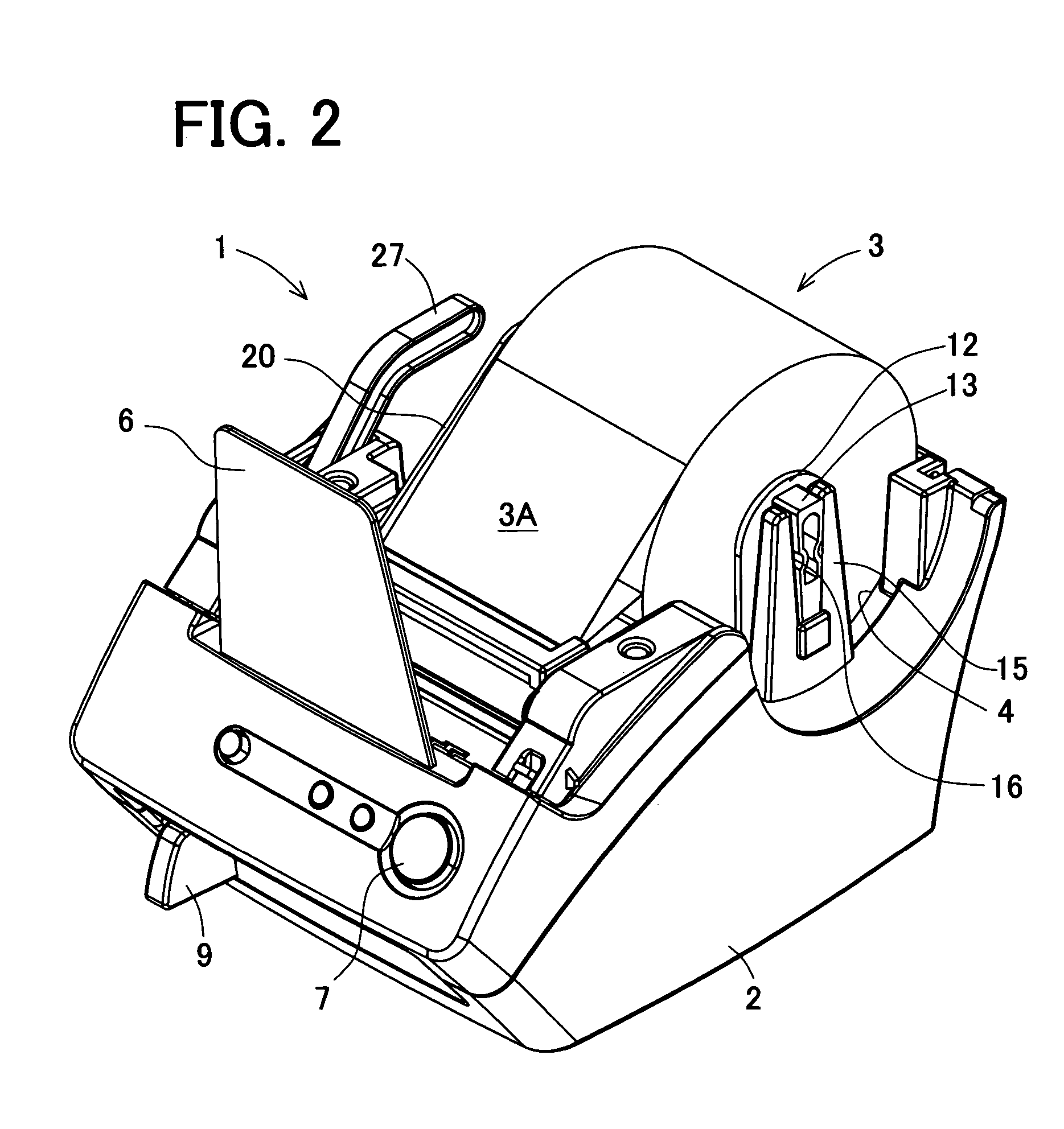

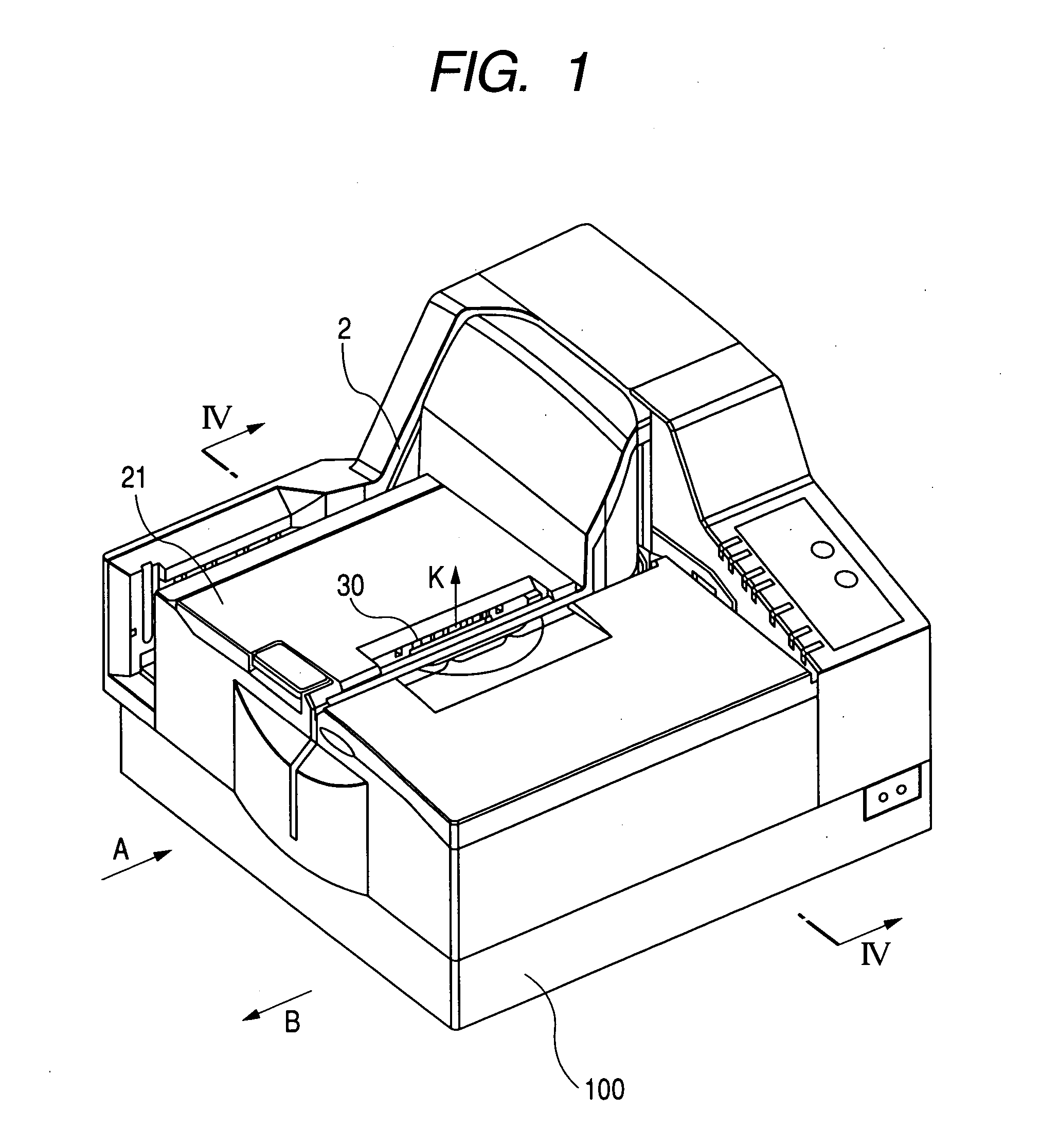

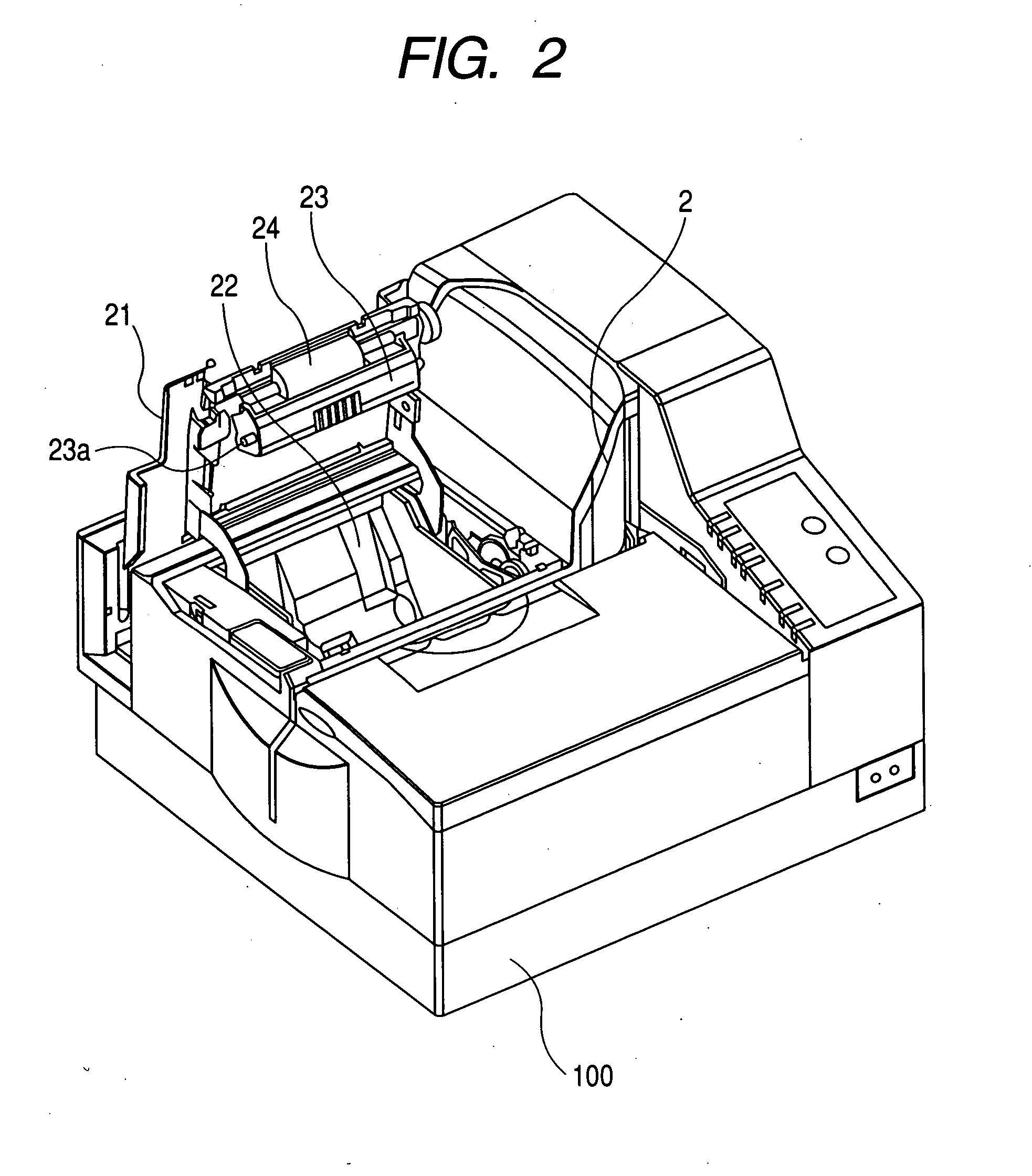

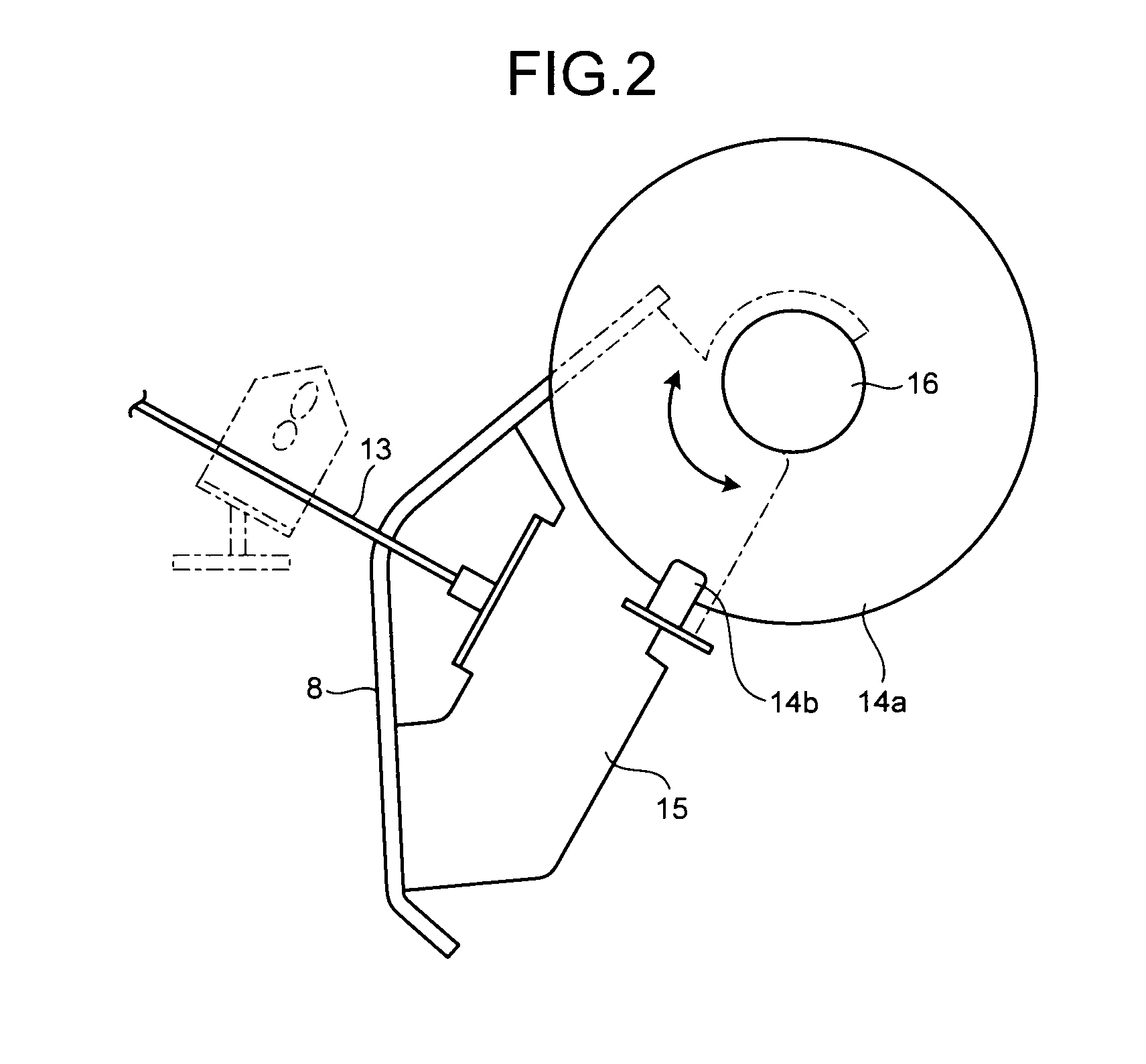

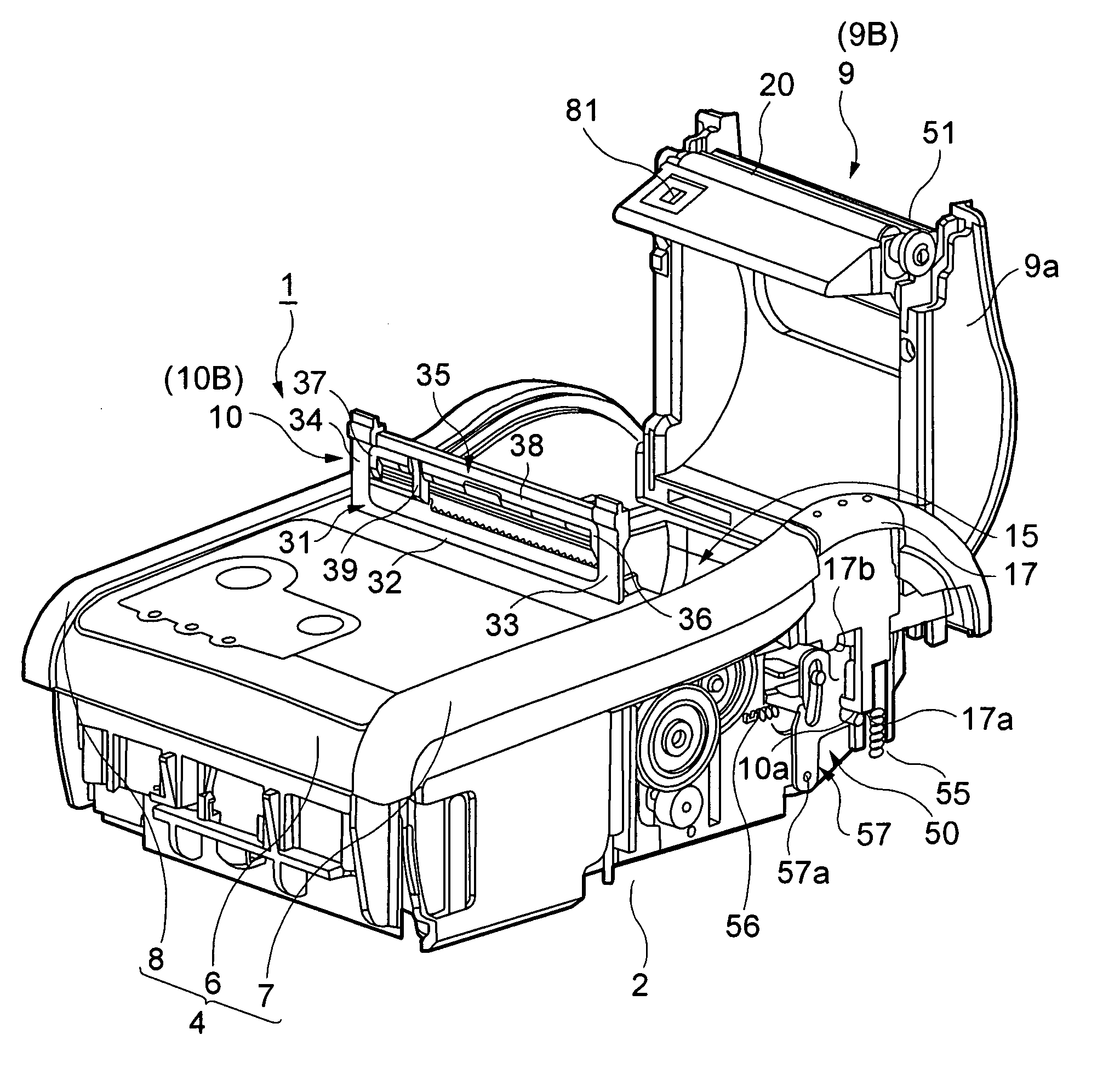

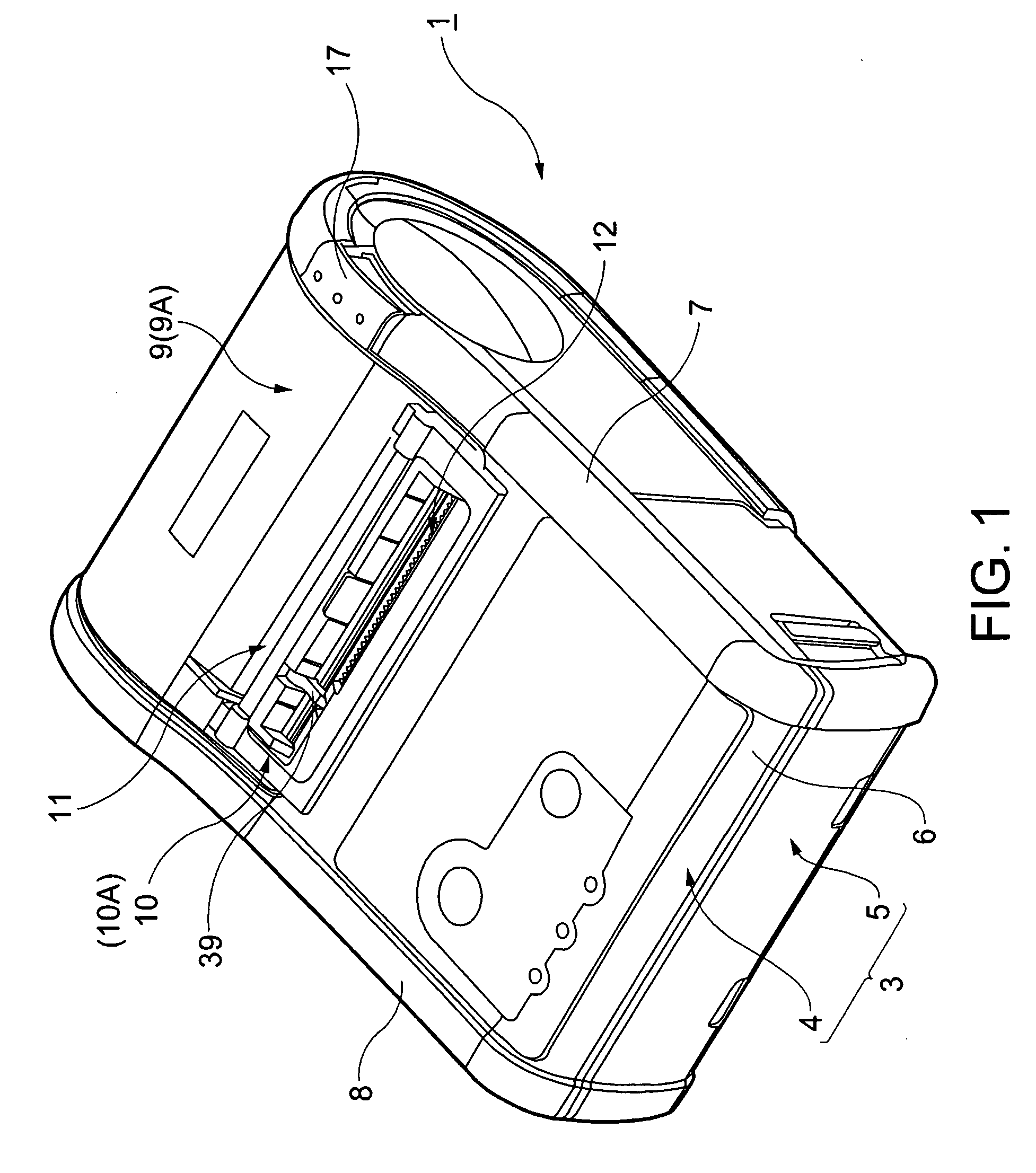

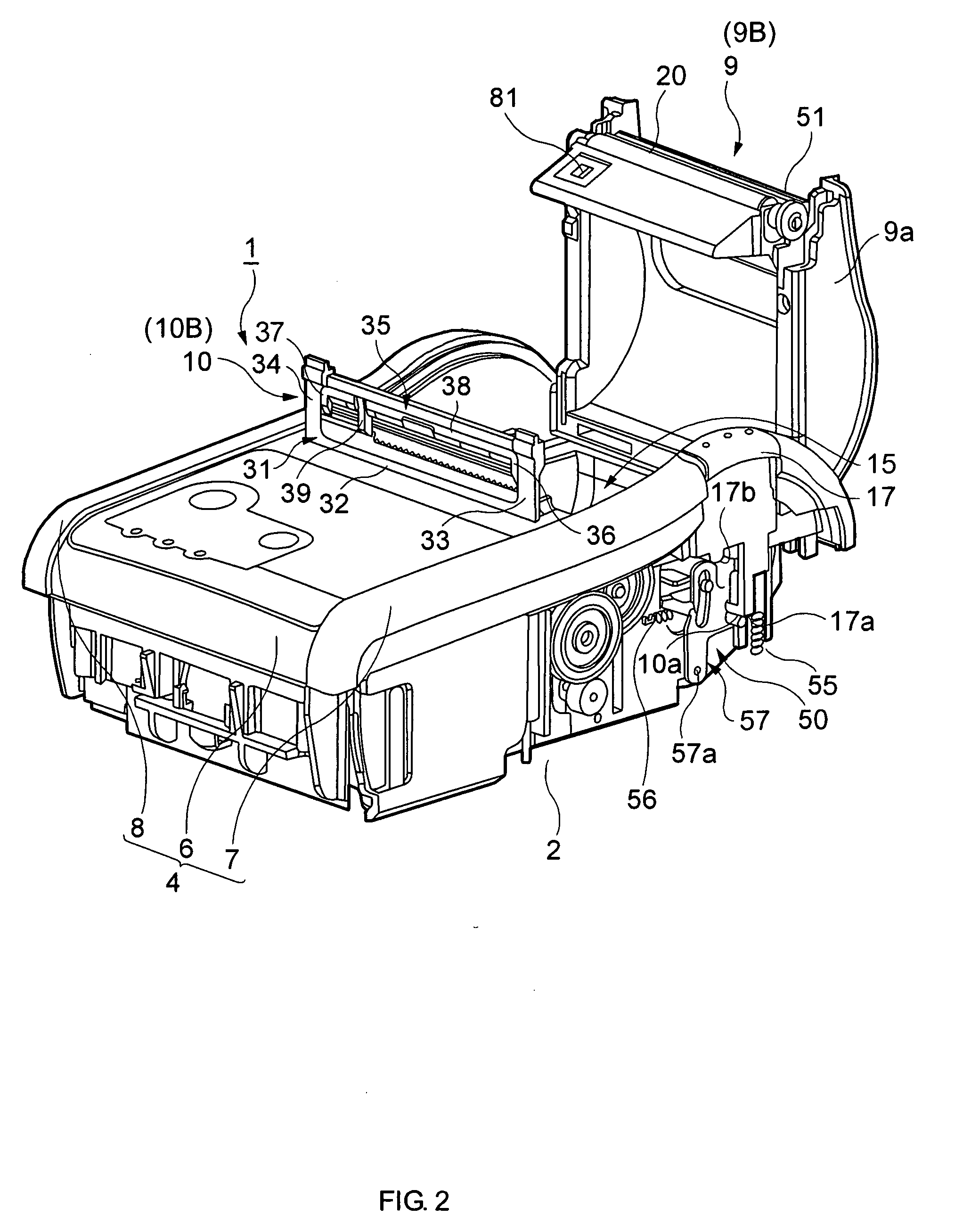

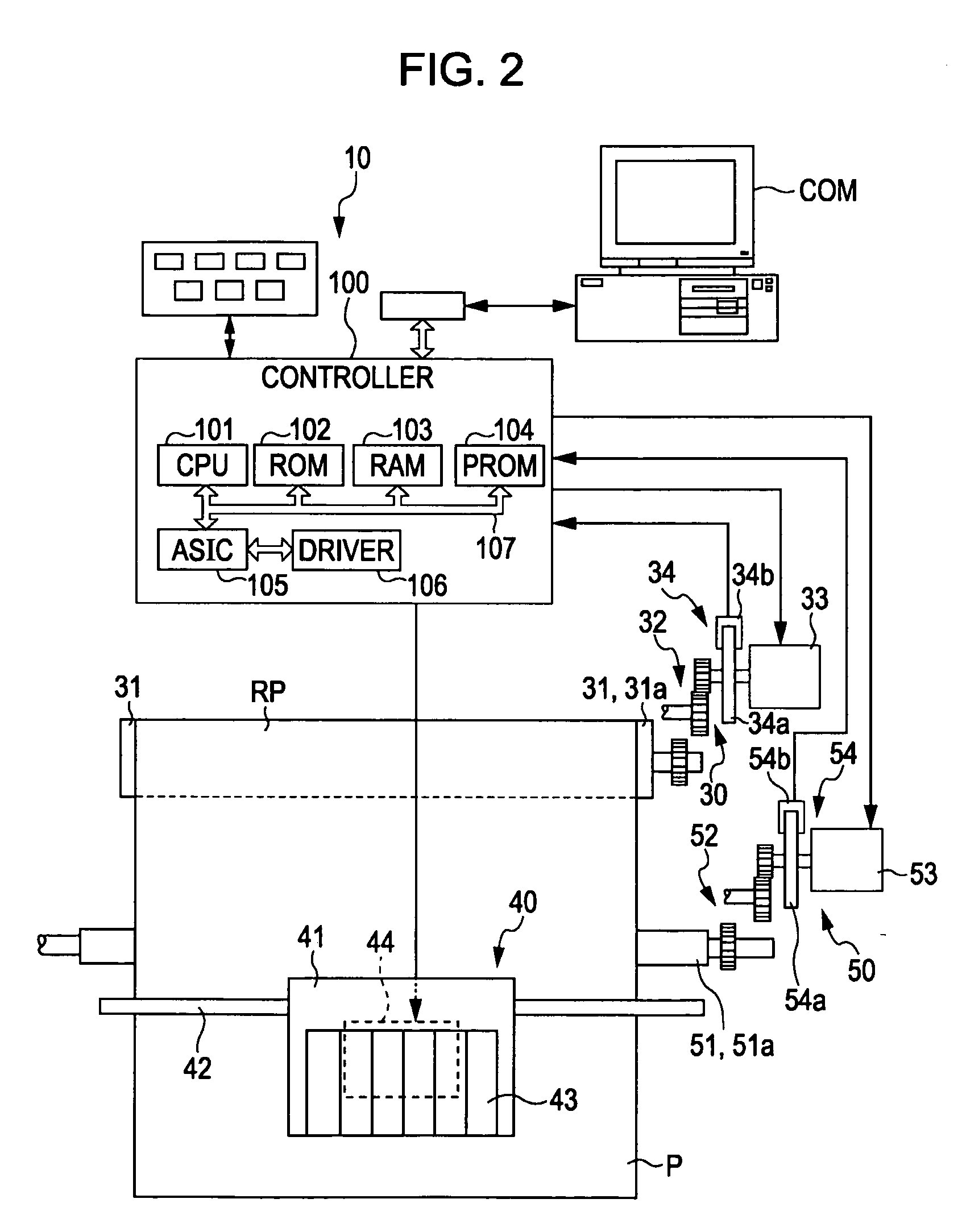

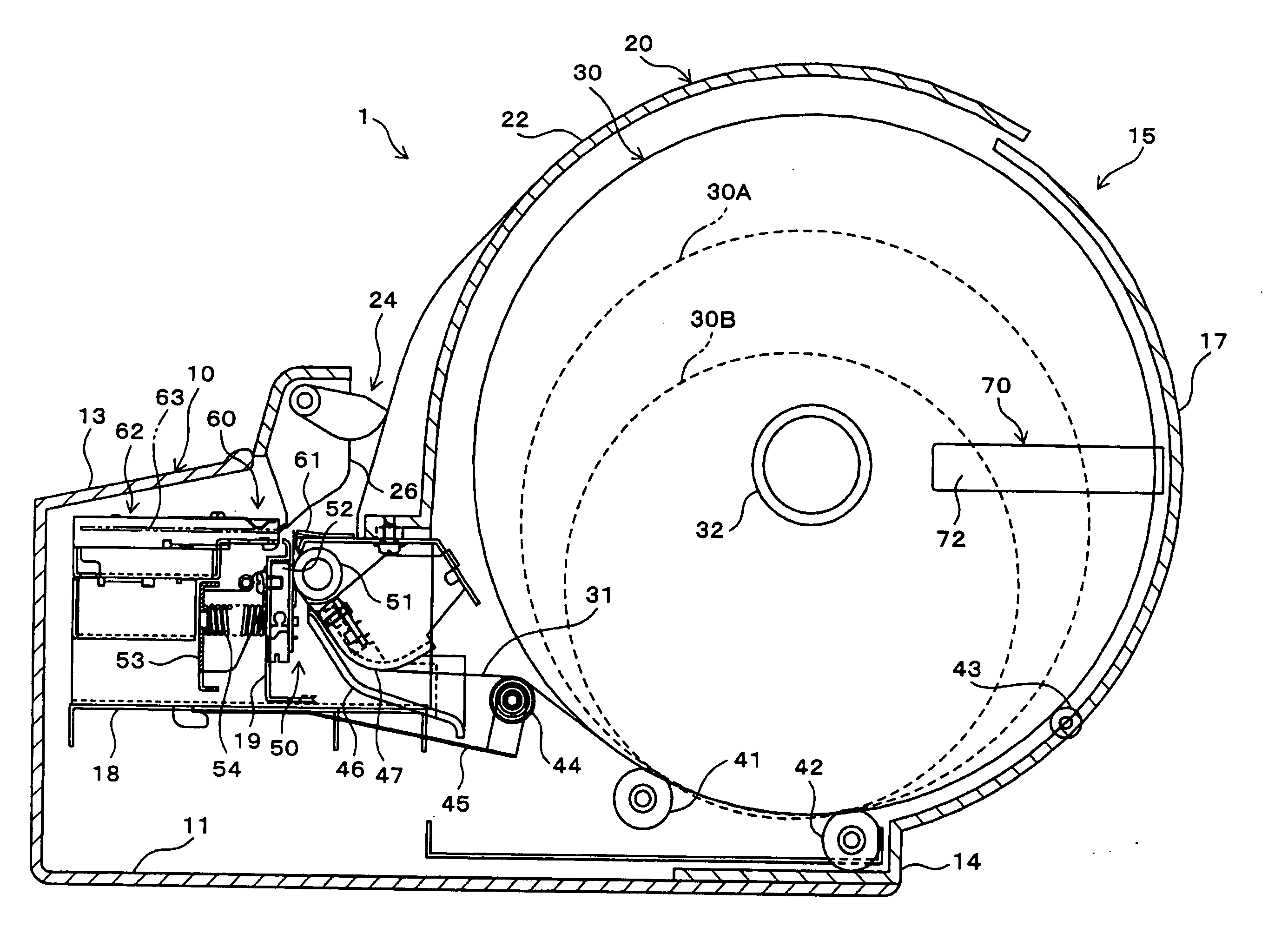

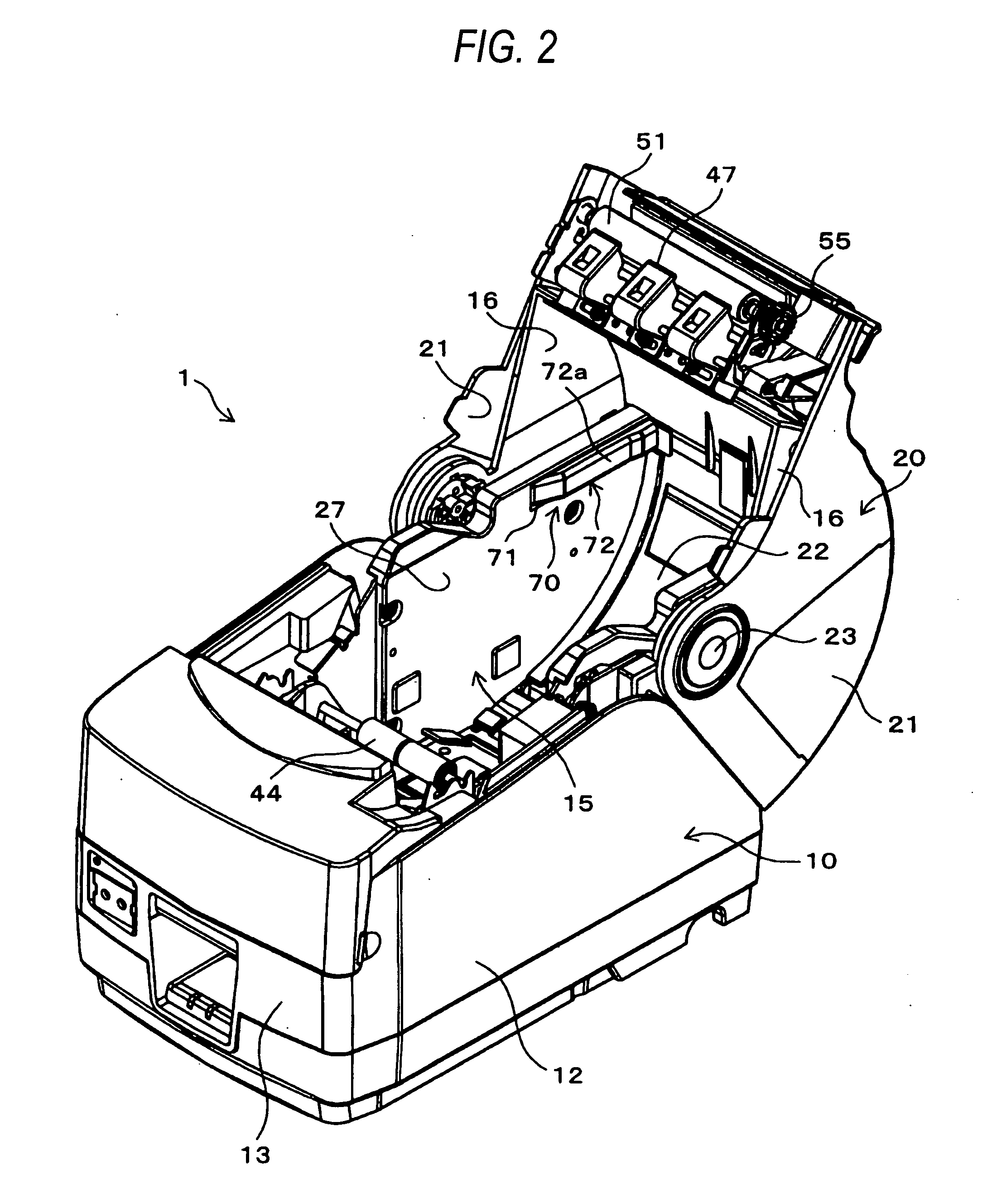

Roll paper printer

InactiveUS7553098B2Easy to disassembleInterfere with contactFilament handlingOther printing apparatusRolling paperPulp and paper industry

A roll paper printer comprising a roll paper storage unit having a bottom surface on which a roll paper is held and rolls, an operable cover unit for opening and closing a roll paper loading opening to the roll paper storage unit, a roll paper size detection mechanism comprising a detection lever that can move in a direction protruding into the roll paper storage unit and a direction retracting from the roll paper storage unit, and an urging member for urging the detection lever in the protruding direction, wherein the detection lever separates from the roll paper and is pushed in the protruding direction when an outside diameter of the roll paper stored in the roll paper storage unit decreases to a predetermined size or less, and a detection lever retraction mechanism for moving the detection lever protruding into the roll paper storage unit in the retracting direction against the urging force of the urging member in conjunction with the operable cover unit opening.

Owner:SEIKO EPSON CORP

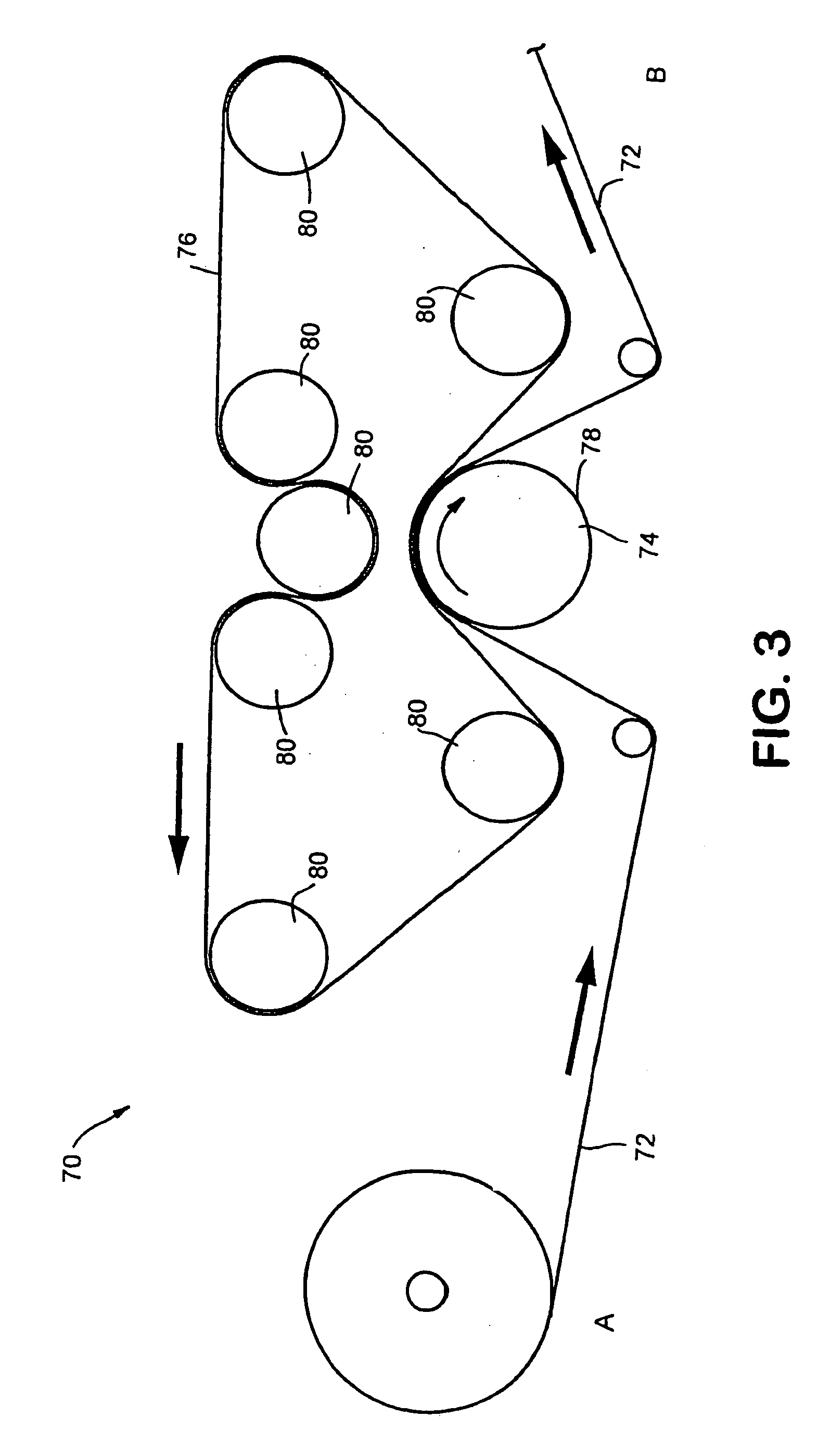

Dispenser for rolled paper

The present invention provides an apparatus for dispensing rolled sheet material, the apparatus including a housing defining an interior adapted to contain rolled sheet material and a dispensing opening for allowing sheet material to be dispensed from the interior of the housing. The apparatus further includes a nip within the housing such as, for example, may be formed by first and second rollers. In addition, the apparatus includes a mobile roll support system adapted to support a roll of sheet material within the housing wherein the roll of sheet material rotates to dispense sheet material and further wherein the mobile roll support system and the roll of sheet material move toward the nip as sheet material is dispensed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

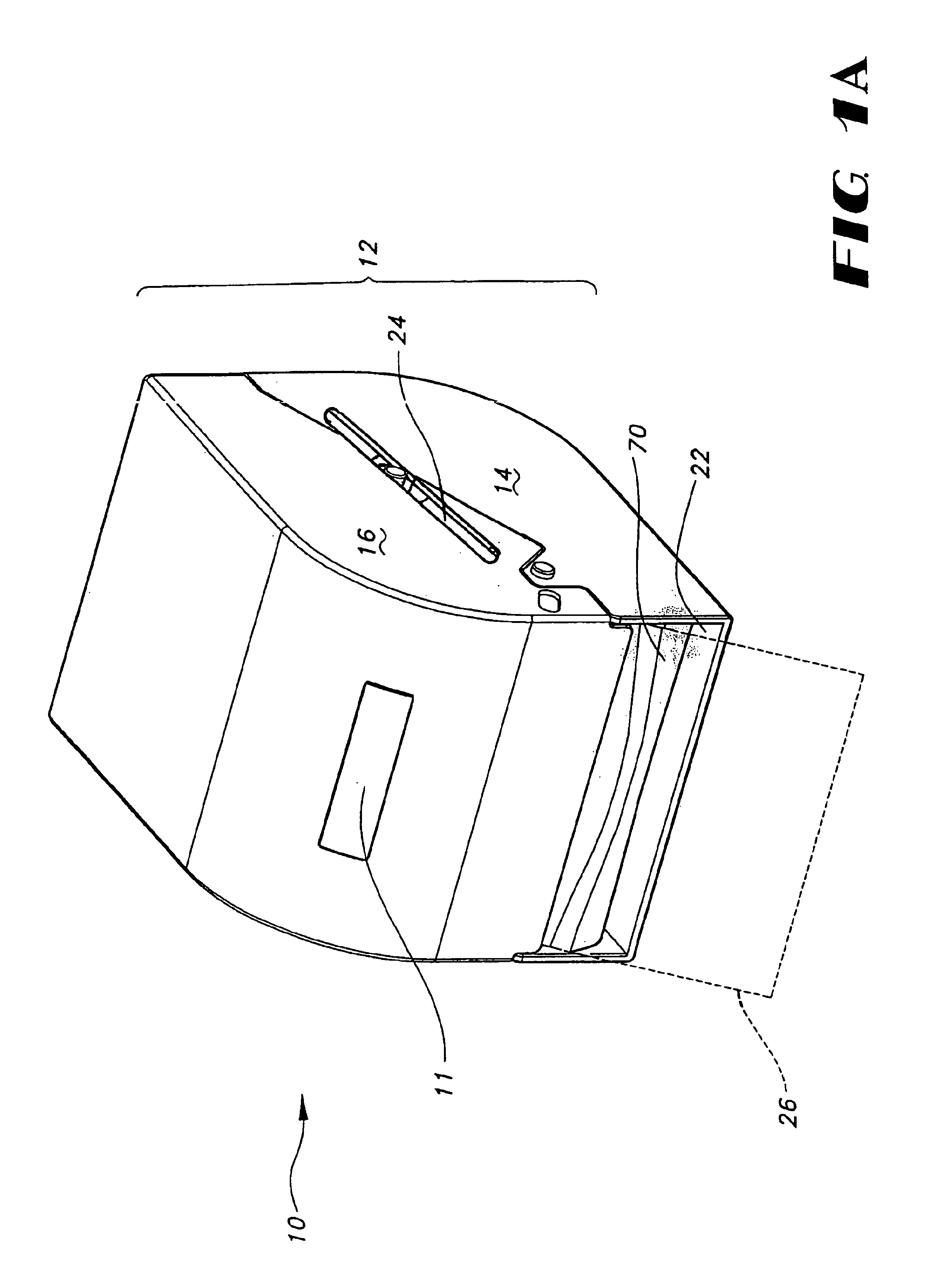

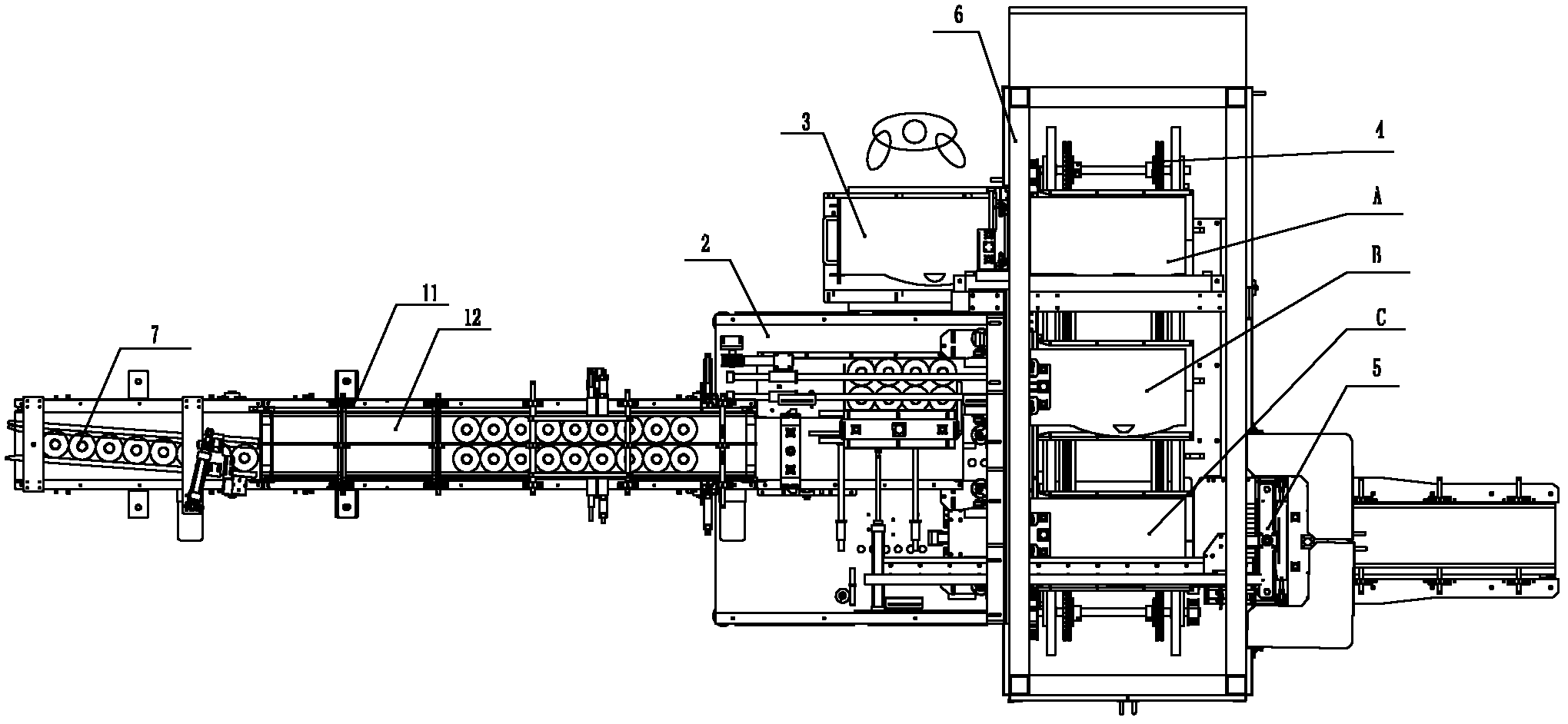

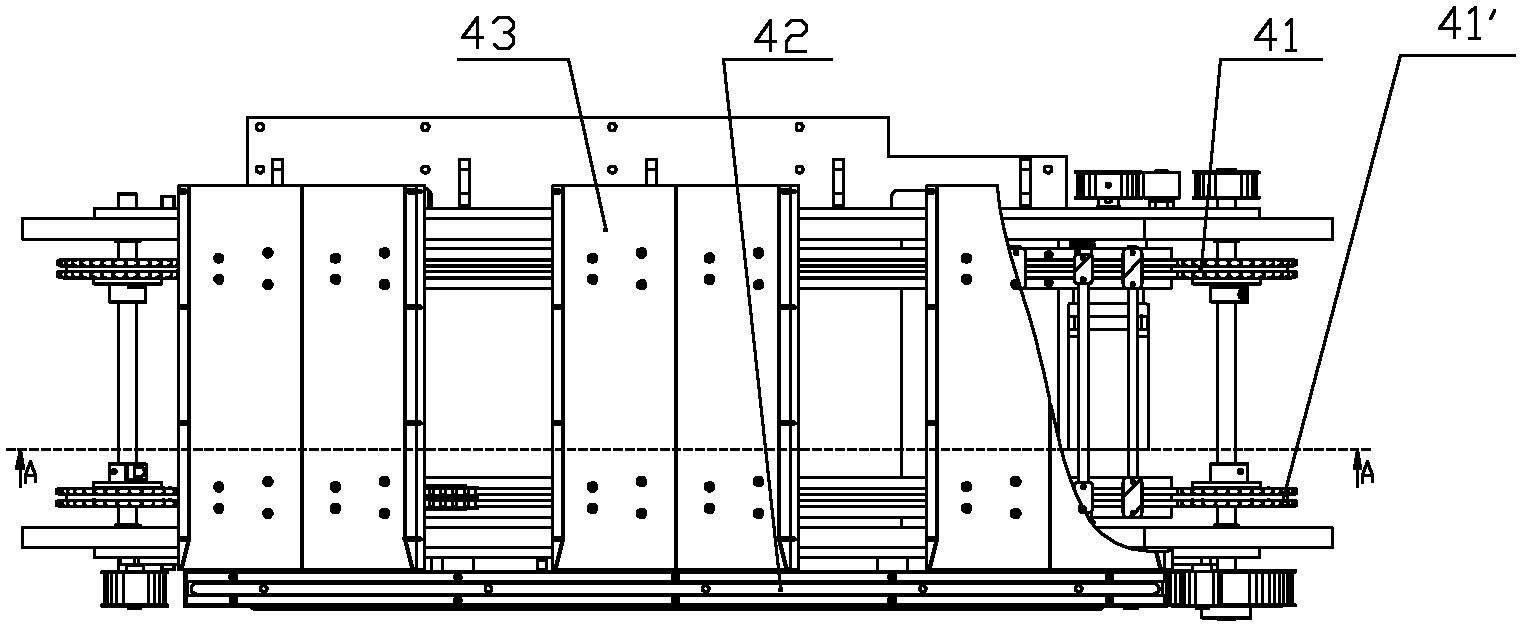

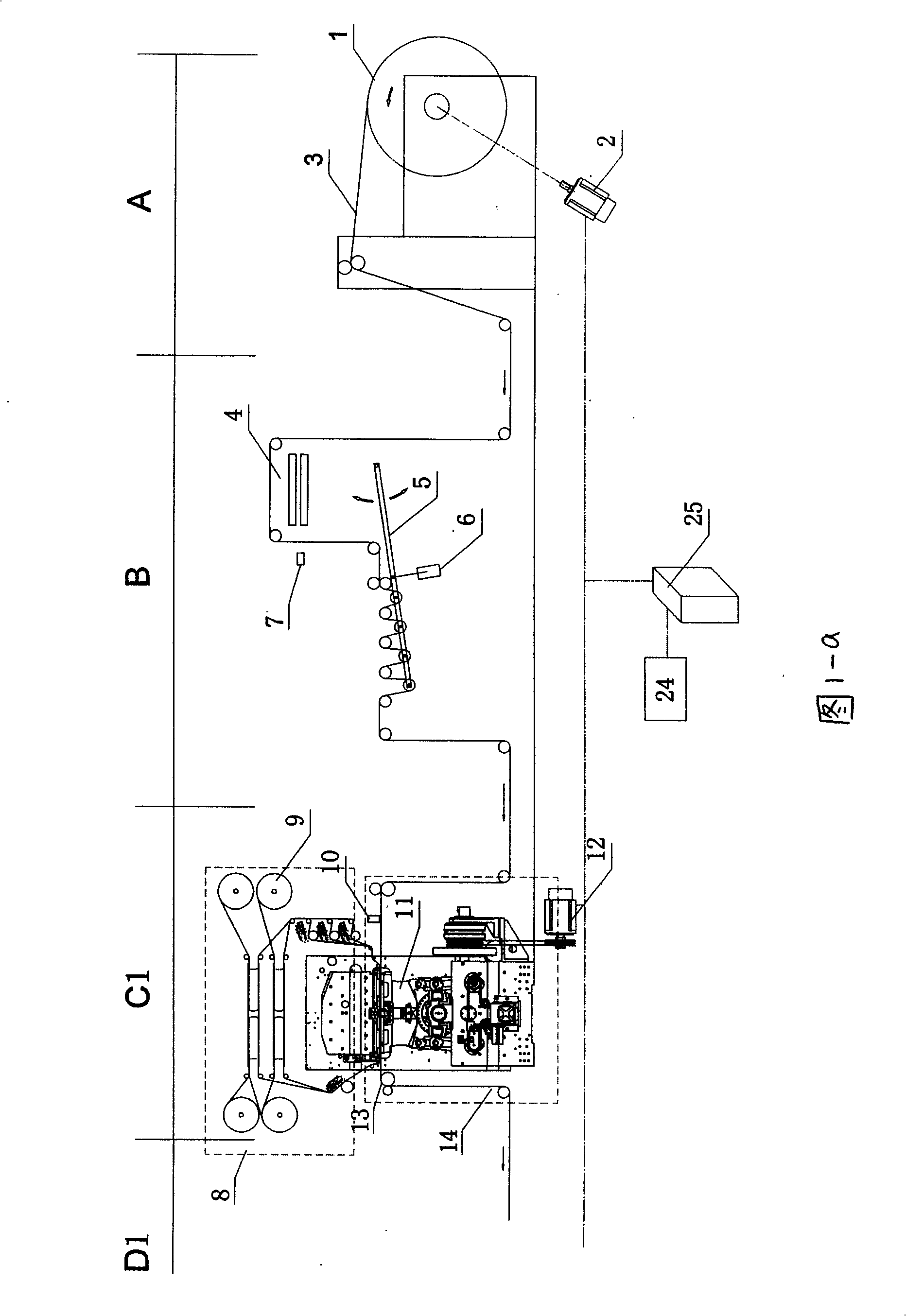

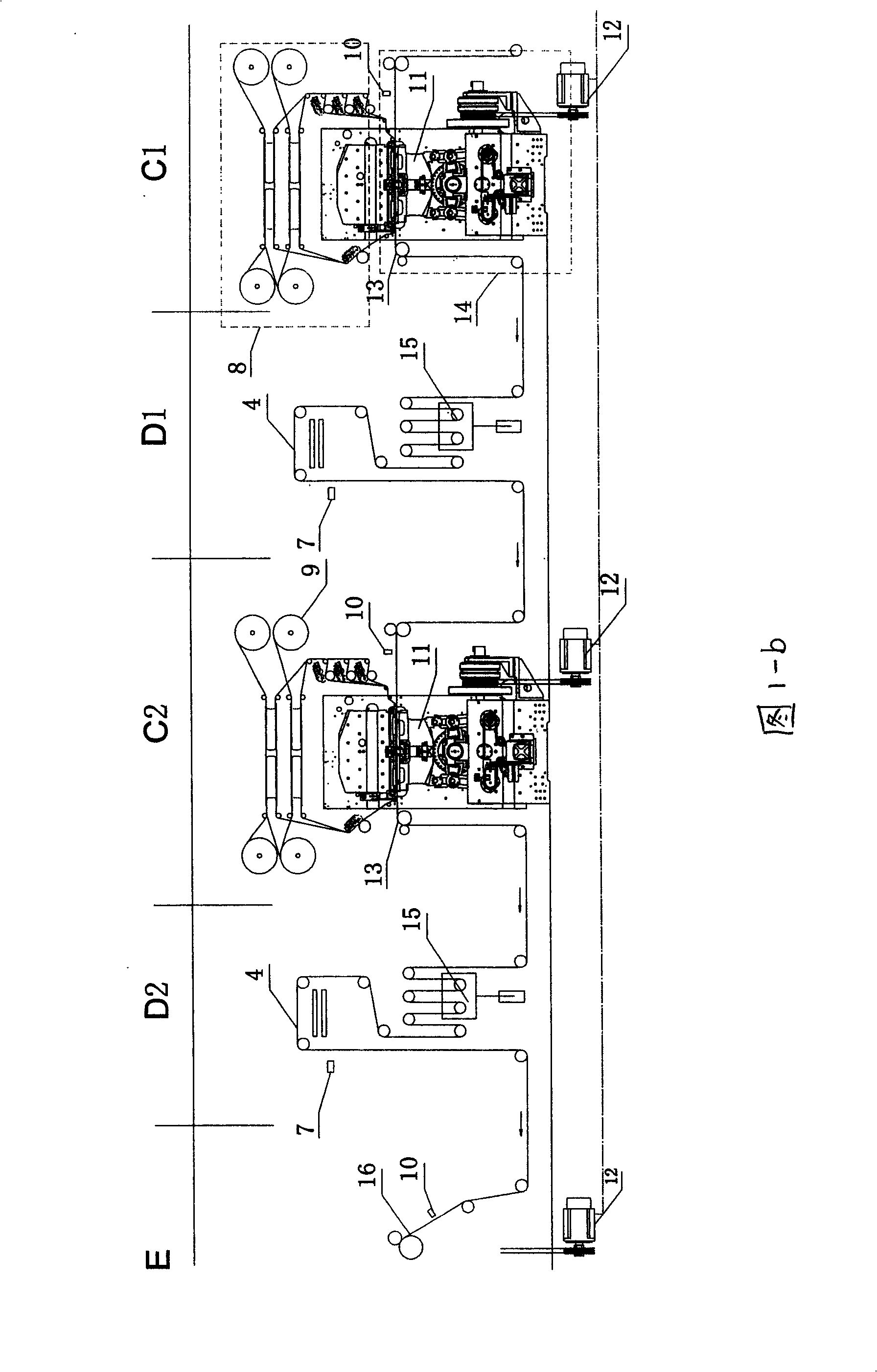

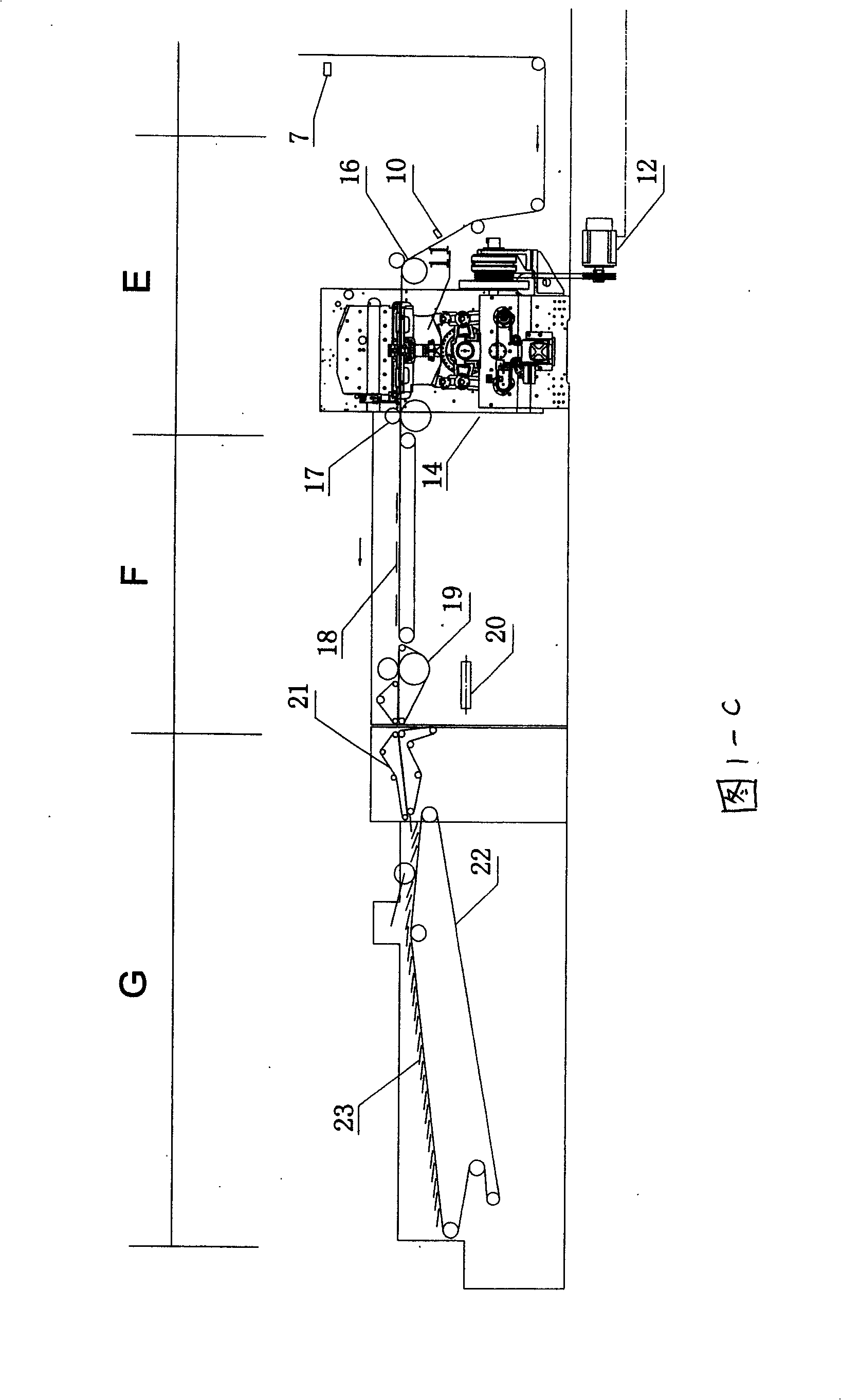

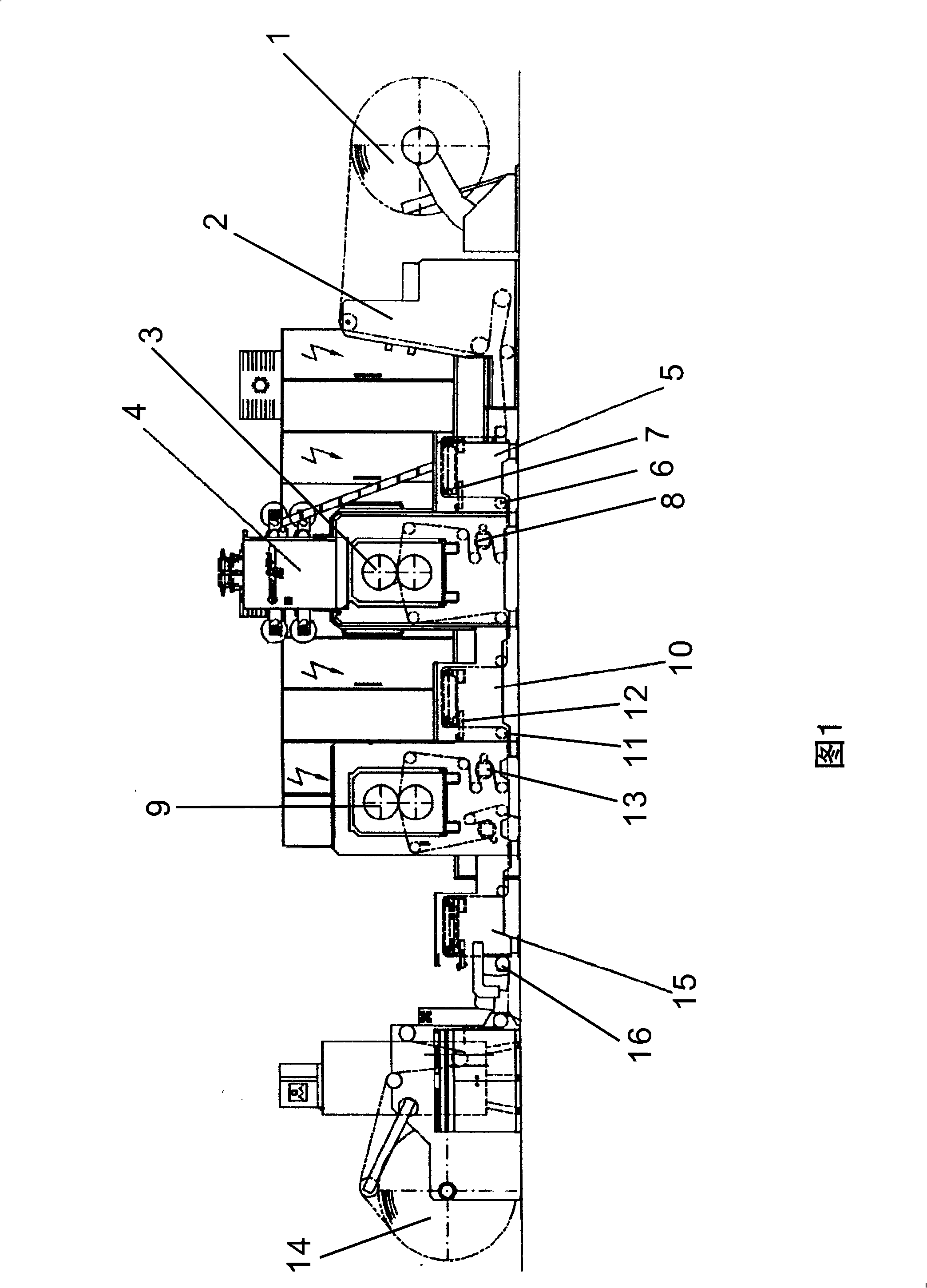

Roll paper packing machine

InactiveCN102556397AGuaranteed uniformityReduce labor costsPaper article packagingContinuous/uninterruptedRolling paper

The invention relates to a packing machine, in particular relates to a packing machine for packing roll paper. The roll paper packing machine is characterized by comprising a split conveying part, a feeding and managing conveying part, a bagging part, a packaging bag warehouse, a drag conveying part, a sealing output part and a frame part. The roll paper packing machine has the obvious advantages that: 1, the roll paper continuously enters the machine and forms the packaged finished products on sale finally, true whole assembly line operation is realized and true automatic operation is achieved; 2, labor cost is saved; and 3, a condition that the manual operation is influenced by different proficiency is avoided, and the automatic operation can fully ensure the unity of the final product quality.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP +2

Printer equipped with cutter mechanism

InactiveUS20050123336A1Simple structureLess spaceOther printing apparatusMetal working apparatusRolling paperComputer printing

A rolled sheet is accommodated in an accommodating section. A cover is movable between an open position for opening the accommodating section and a closed position for covering the accommodating section. A part of the rolled sheet fed from the accommodating section is transported through the transporting path. A print head is disposed in a first side relative to the transporting path and operable to perform printing on the part of the rolled sheet in the transporting path. A cutter is disposed in the first side and movable between an operable position at which the cutter is operable to cut the part of the rolled sheet and a covered position at which the cutter is not operable to cut the part of the rolled sheet. The cutter is moved to the operable position when the cover is moved from the open position to the closed position, and is moved to the covered position when the cover is moved from the closed position to the open position. A cutter cover covers the cutter in the covered position.

Owner:SEIKO EPSON CORP

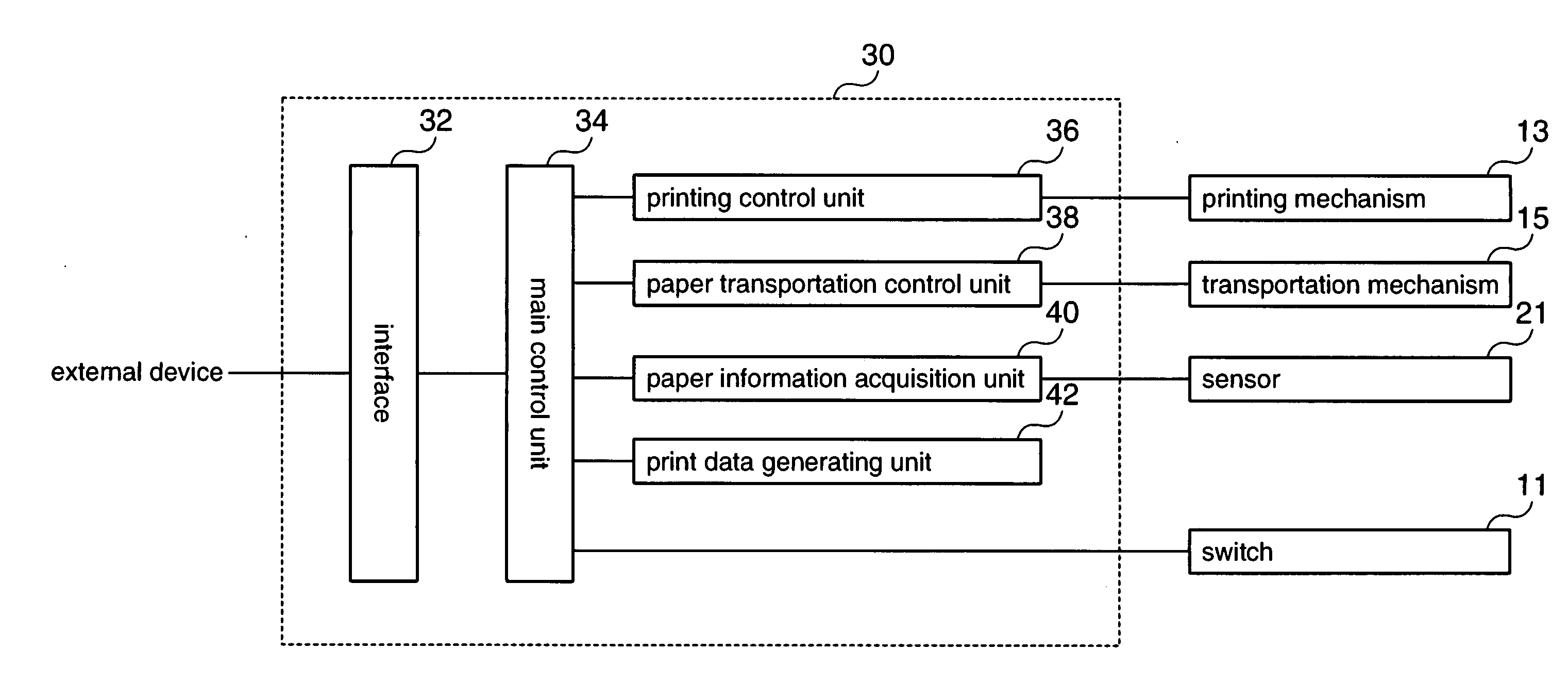

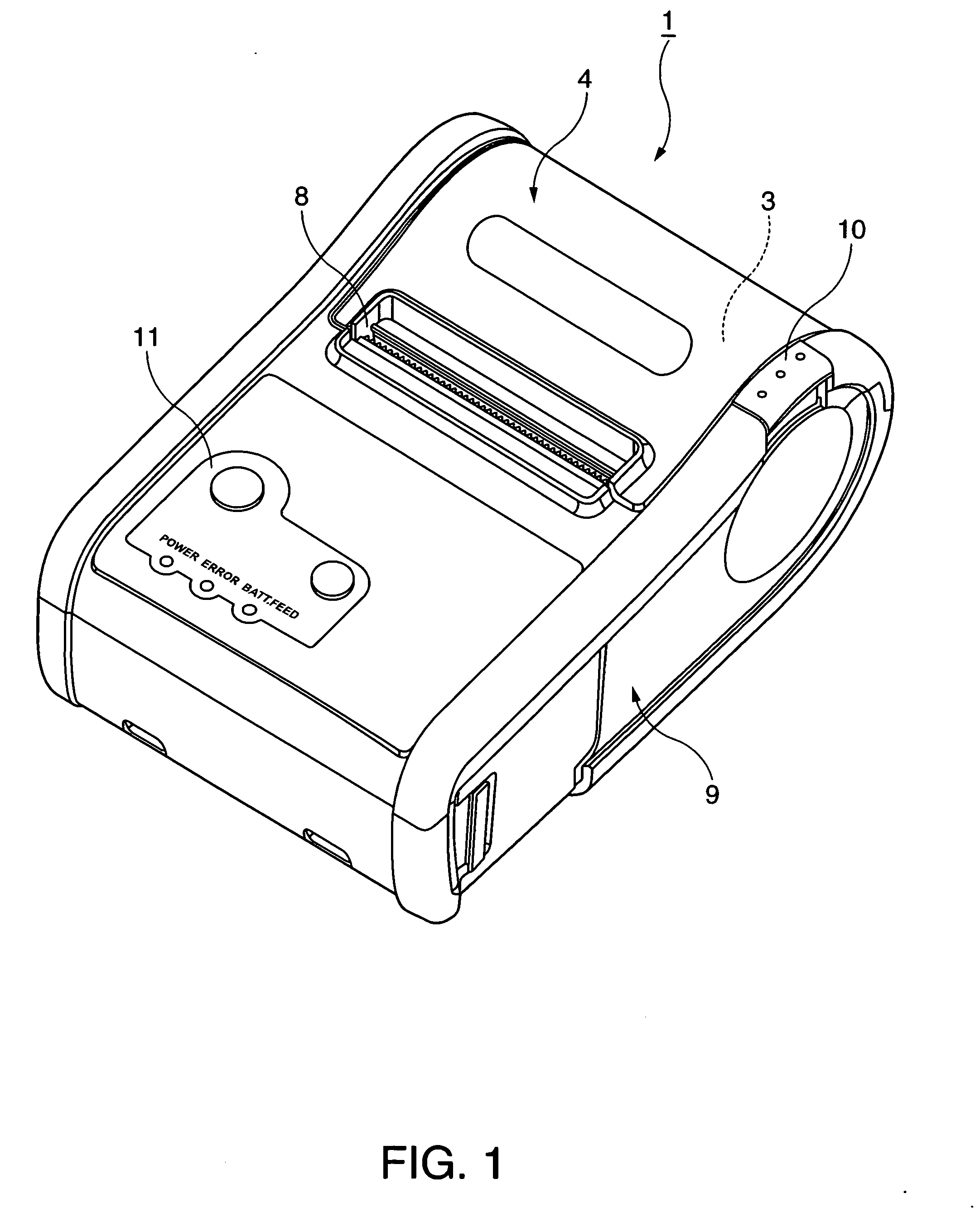

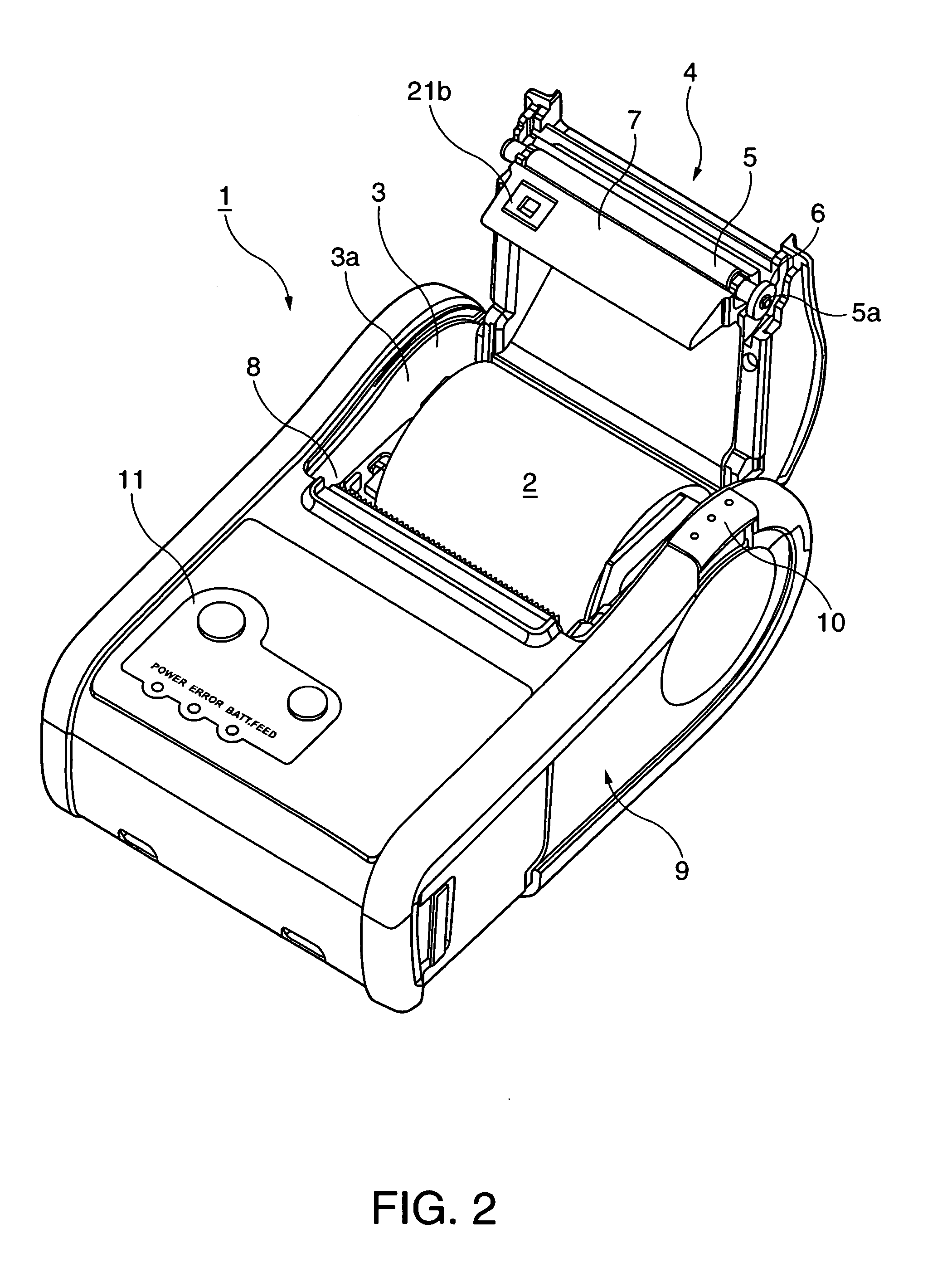

Printer, printing control method for a printer and computer program for a printer

InactiveUS20060279624A1Minimizing continuous paper wasteMinimize wasteRecording apparatusTypewritersRolling paperComputer printing

A printer for printing to label paper and other types of continuous paper minimizes wasteful consumption of continuous paper and enables operating in a self-printing mode conforming to the specifications of the continuous paper currently in use. The printer prints to roll paper including label paper having a plurality of labels affixed to a continuous web backer with a gap between the labels. A paper transportation control unit controls the transportation mechanism for conveying the roll paper along a transportation path. A printing control unit controls a printing mechanism including a print head disposed to the transportation path. A sensor disposed on the upstream side in the transportation direction from the print head detects paper information about the roll paper. A print data generating unit generates the self-printing data based on information stored in the printer. The paper transportation control unit has a printing start position control unit that determines the printing start position of the self-printing data and positions the continuous paper to the print head based on the paper information, and a next-line printing position control unit that determines the printing start position of the self-printing data to be printed next and positions the continuous paper to the print head based on the paper information after printing the self-printing data starts.

Owner:SEIKO EPSON CORP

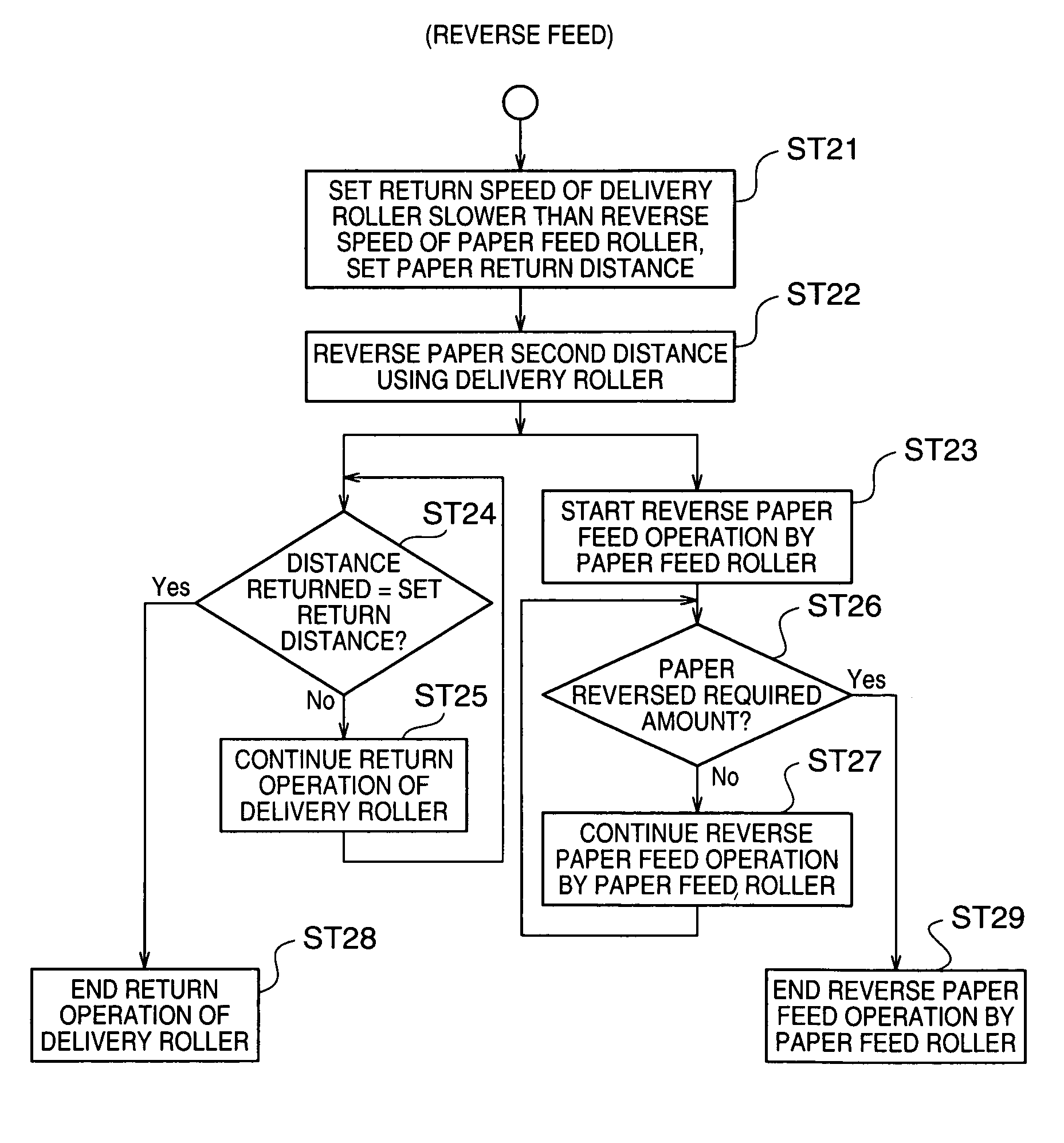

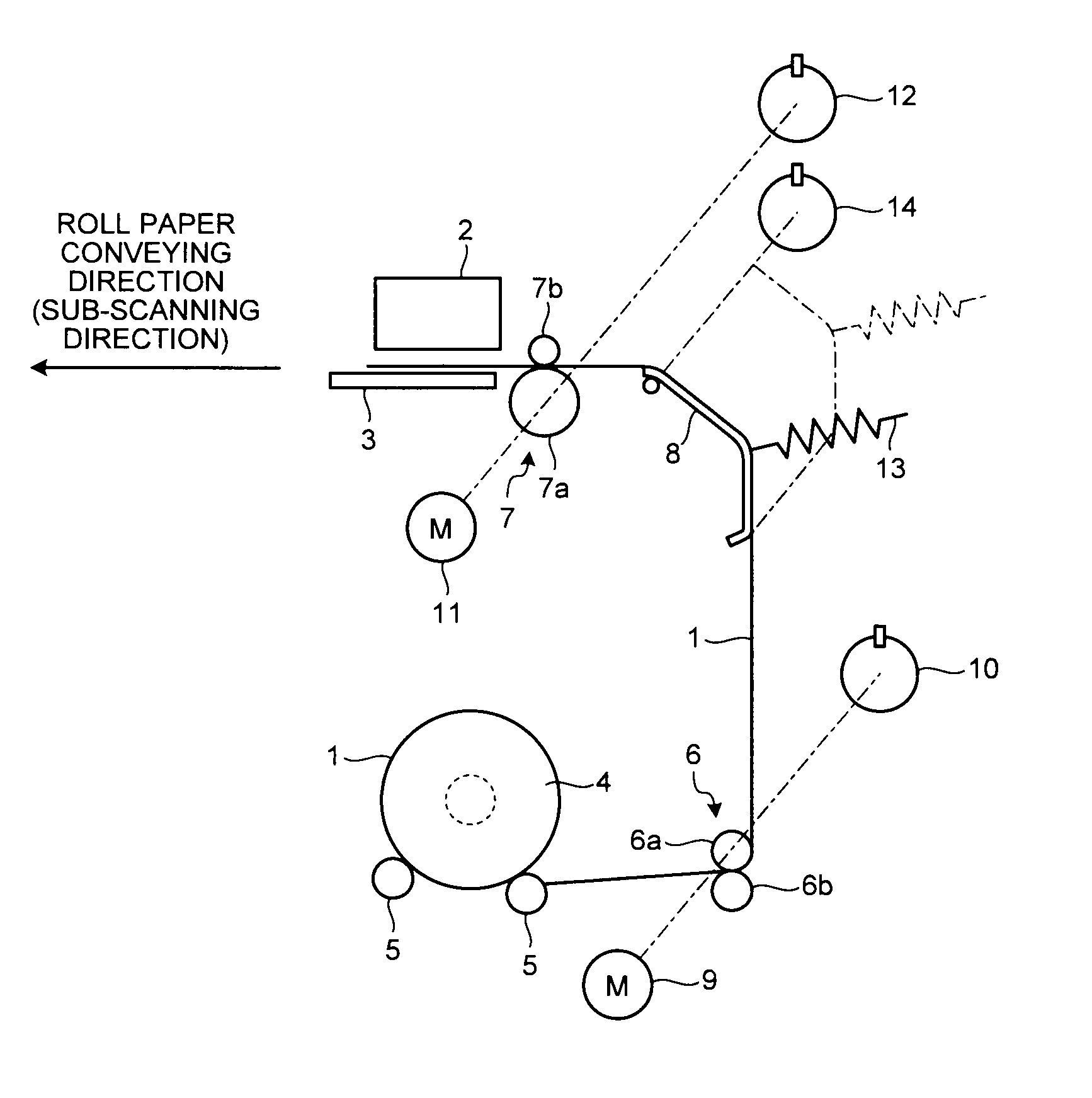

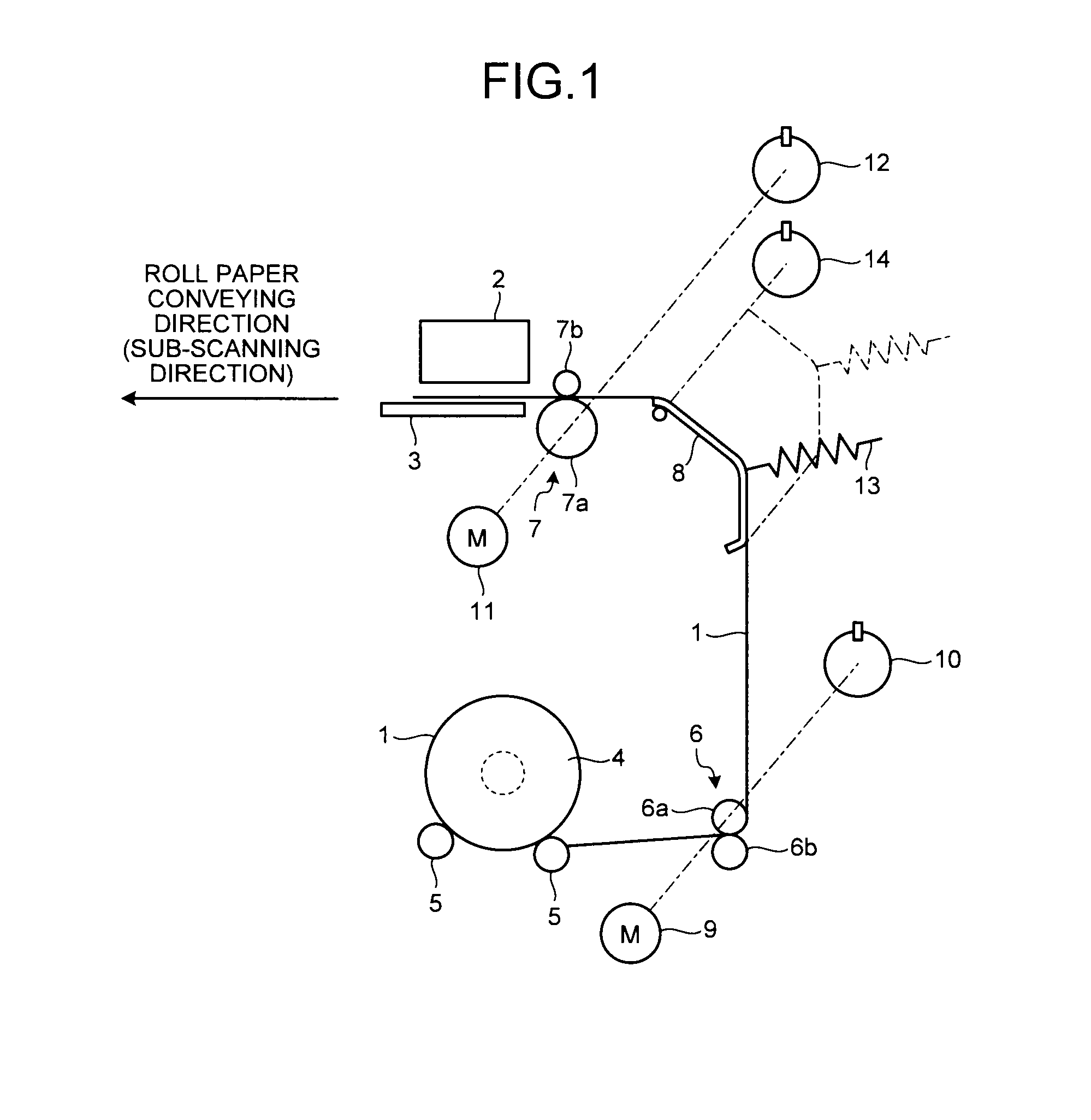

Method of controlling paper transportation in an apparatus, and an apparatus using the method

ActiveUS20090255971A1Shorten the timeReduce variationOther printing apparatusWebs handlingRolling paperDelayed time

A paper transportation control method for an apparatus enables conveying paper with appropriate tension on the paper by appropriately controlling the paper delivery operation of a delivery roller. When paper is conveyed by the paper feed roller pair 34 of a roll paper printer 1, and the tension on the paper 8a is detected to exceed an upper tension limit based on the displacement of a damping mechanism 32 (time t2), the paper delivery operation of a delivery roller pair 33 starts at a time t3 after a start operation delay time DLS (first delay time) corresponding to the feed rate V(34) passes after time t2. When the tension returns to or below the upper tension limit, the paper delivery operation stops at a time t5 after a stop operation delay time DLE (second delay time) similarly corresponding to the feed rate V(34) passes. Tension fluctuation (change in the load on the paper feed roller) can be controlled without causing chattering or fluttering in paper delivery operation control.

Owner:SEIKO EPSON CORP

Roll paper conveying apparatus, inkjet printer, and roll paper conveying method

A movable member encoder is used to detect the position of a movable member, and a correction value calculator calculates a correction value corresponding to the amount of displacement of the movable member from a reference position and the integration of the amount of displacement. The correction value calculated by the correction value calculator is then used in correcting a voltage instruction value output from a feed motor controller to a feed motor.

Owner:RICOH KK

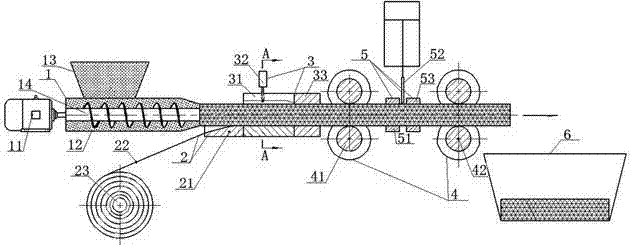

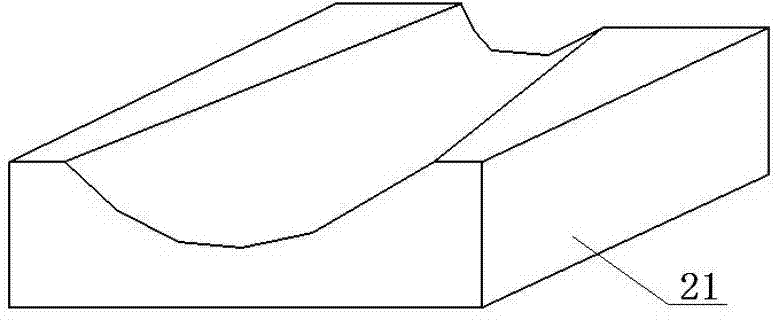

Moxa cone coiling forming machine

ActiveCN104490593AImprove medicinal qualityEasy to operateDevices for heating/cooling reflex pointsConveyorsRolling paperMolding machine

The invention discloses a moxa cone coiling forming machine which comprises a spiral conveying mechanism, a paper tape winding mechanism, a gluing and forming mechanism and a shearing mechanism which are arranged in sequence, wherein the spiral conveying mechanism is used for forming a naked moxa cone; the paper tape winding mechanism mainly consists of a paper coiling disc and a paper tape; a conical guide groove of which the front part is large and the rear part is small is formed in the paper coiling disc; the width of the paper tape is greater than the perimeter of the naked moxa cone; the paper tape is paved inside the conical guide groove in the paper coiling disc in a dynamic conveying manner; the gluing and forming mechanism mainly consists of a gluing machine and a sealing ring; the gluing machine is used for gluing the paper tape; the sealing ring is used for shifting, guiding and compacting the glued paper tape when the paper tape is dynamically conveyed, so as to coil and seal the paper tape; the shearing mechanism is used for shearing the coiled and formed moxa cone output from the gluing and forming mechanism. The moxa cone coiling forming machine is capable of automatically and continuously producing coiled paper moxa cones and is applicable to large-scale in-batch production, the whole production process is clean, sanitary, free of pollution, high in production efficiency and low in cost, and the formed moxa cones are high in medicinal quality.

Owner:SICHUAN ENG TECHN COLLEGE

Printer with a peeler mechanism

Owner:SEIKO EPSON CORP

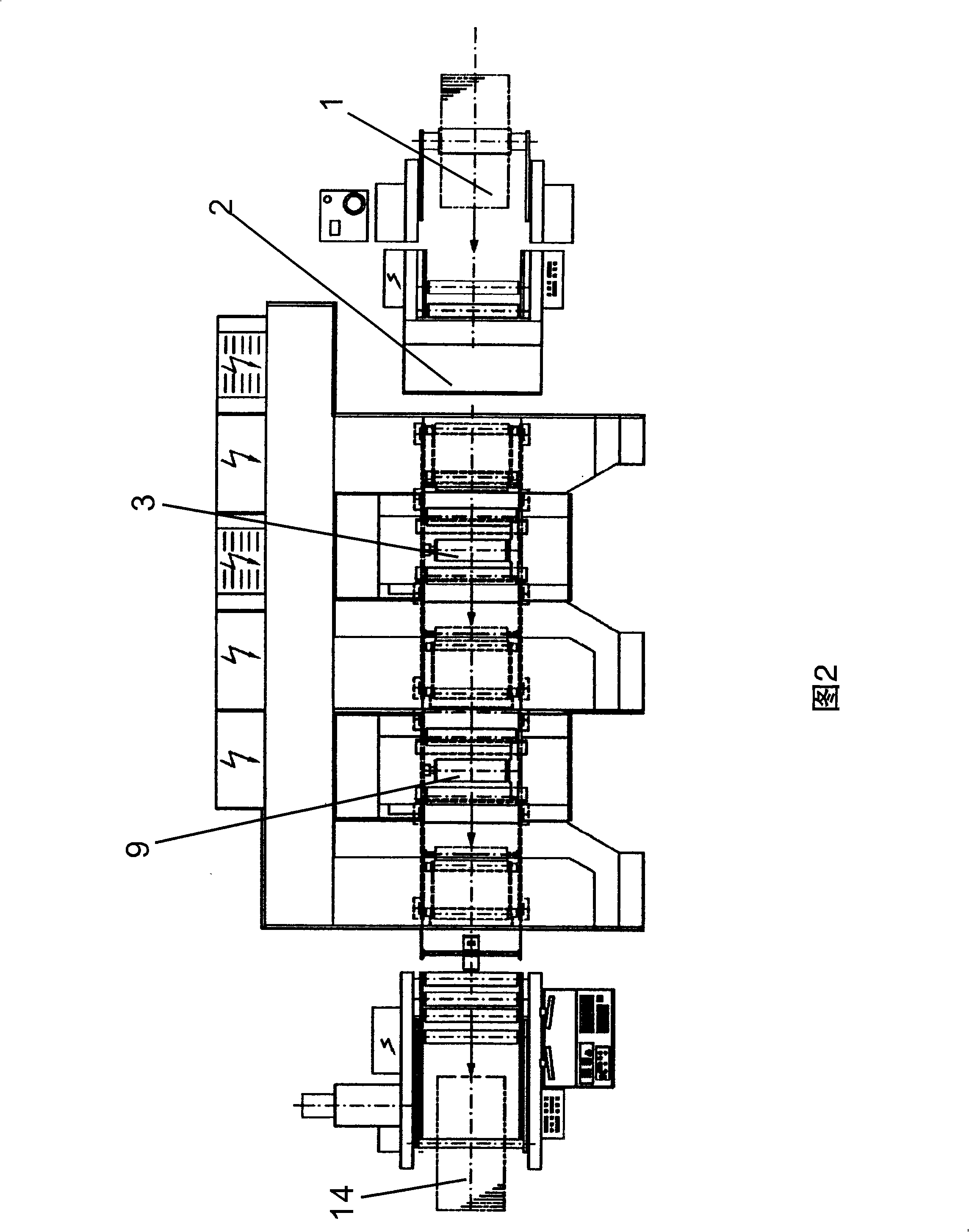

Unit type mold cutter for reeled paper

ActiveCN101407127AProduction effectively adapts toProduction adaptationTransfer printingPlaten pressesHot stampingRolling paper

The invention relates to a roll paper unit-type die cutting machine. The machine consists of a roll paper releasing and winding device, a paper storage device, a hot stamping unit, a tensile force control device, a die cutting unit and a waste cleaning device, wherein the roll paper releasing and winding device consists of roll paper, a motor and paper, the paper storage device consists of a deviation rectifying device, a swinging rod, a constant-force device and a detection sensor of the deviation rectifying device, the hot stamping unit consists of an aluminum foil conveying device, aluminum foil, a sensor, a moving platform, a motor, a paper drawing device and a press mould device, the tensile force control device consists of a deviation rectifying device, a detection sensor of the deviation rectifying device and a constant-force device, the die cutting device consists of a sensor, a motor, a press mould device, a paper drawing device and a paper receiving device, the waste cleaning device consists of paper, waste cleaning device and a slitter edge conveying device, and a sheet material collecting device consists of a paper separating and conveying device, a conveyor belt and paper.

Owner:MASTERWORK GROUP CO LTD

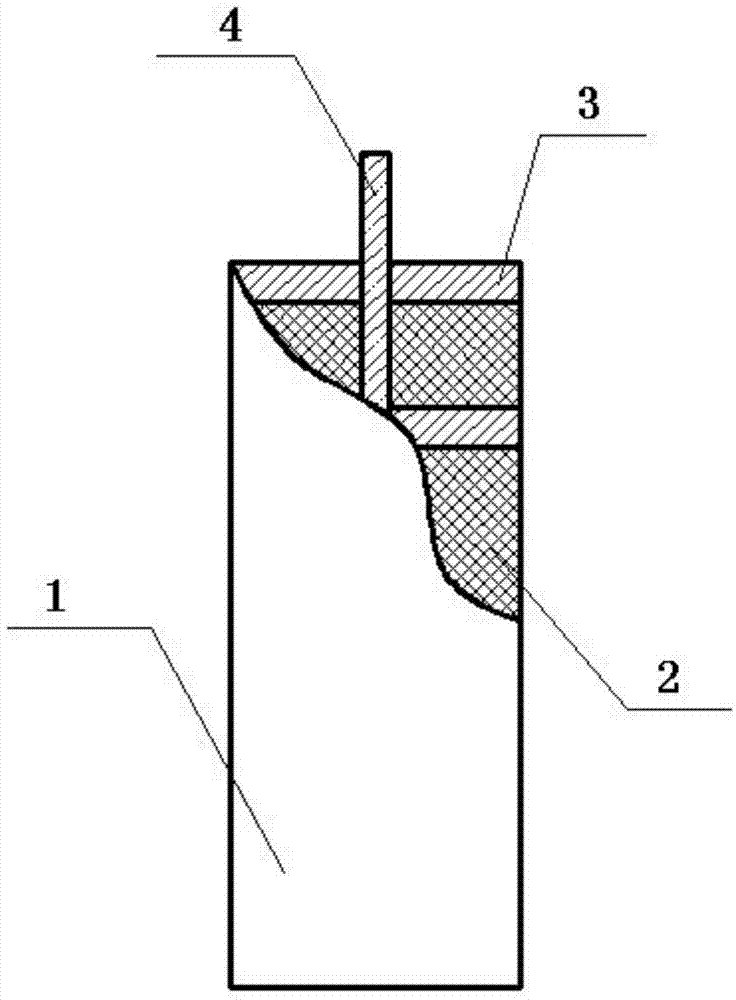

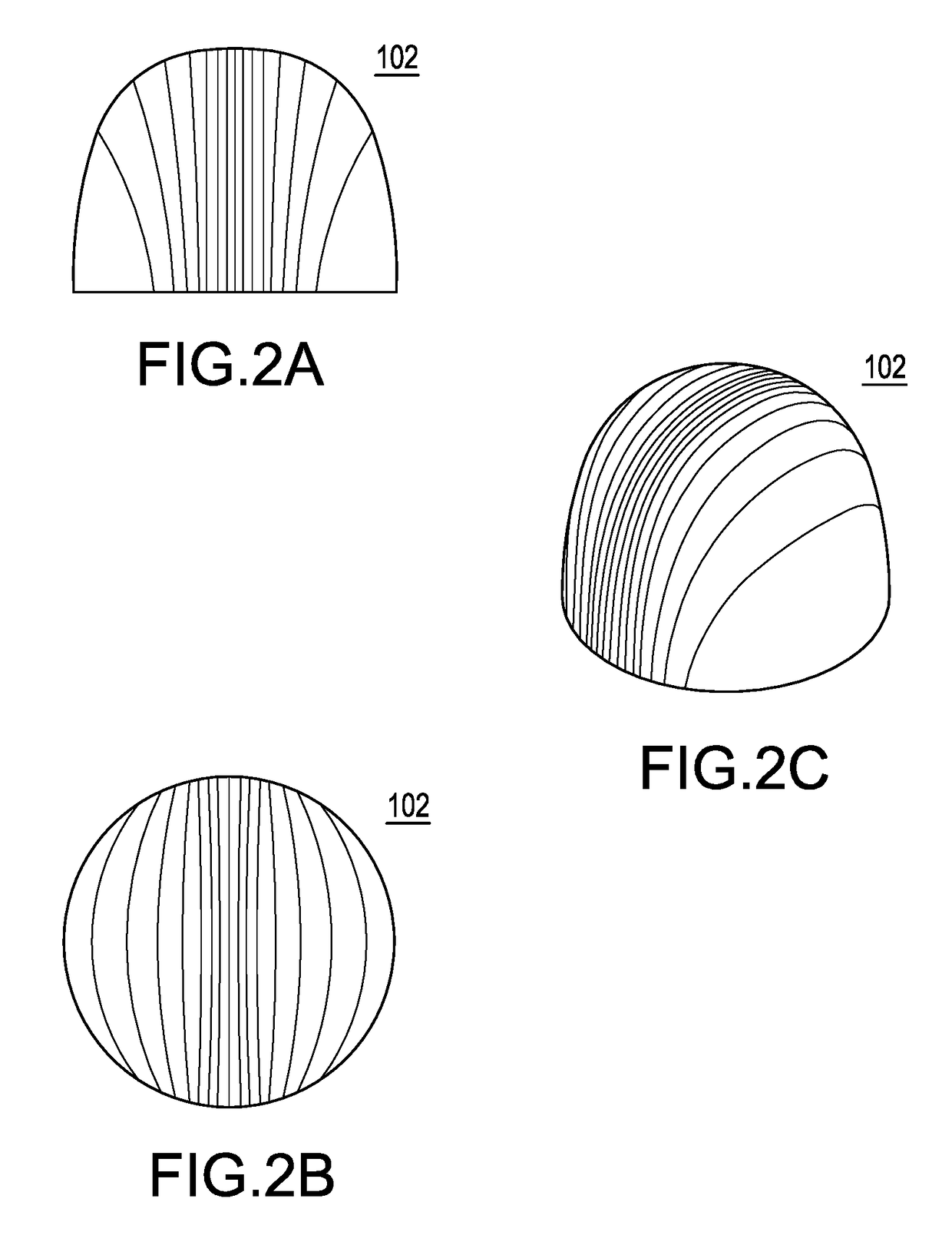

Moxa cone

InactiveCN104739638AEasy to igniteDevices for heating/cooling reflex pointsRolling paperPulp and paper industry

The invention relates to a moxa cone which comprises wrapping and rolling paper, a moxa cone body, an artemisia argyl oil layer and an ignition wick. The wrapping and rolling paper wraps the outer side face of the moxa cone body, the ignition wick penetrates through the moxa cone body, the ignition wick exceeds the top of the moxa cone body, and the artemisia argyl oil layer is arranged at the top of the moxa cone body. The moxa cone can be ignited easily, and can be ignited easily after the moxa cone is used for the first time and when the moxa cone is used next time.

Owner:金艳

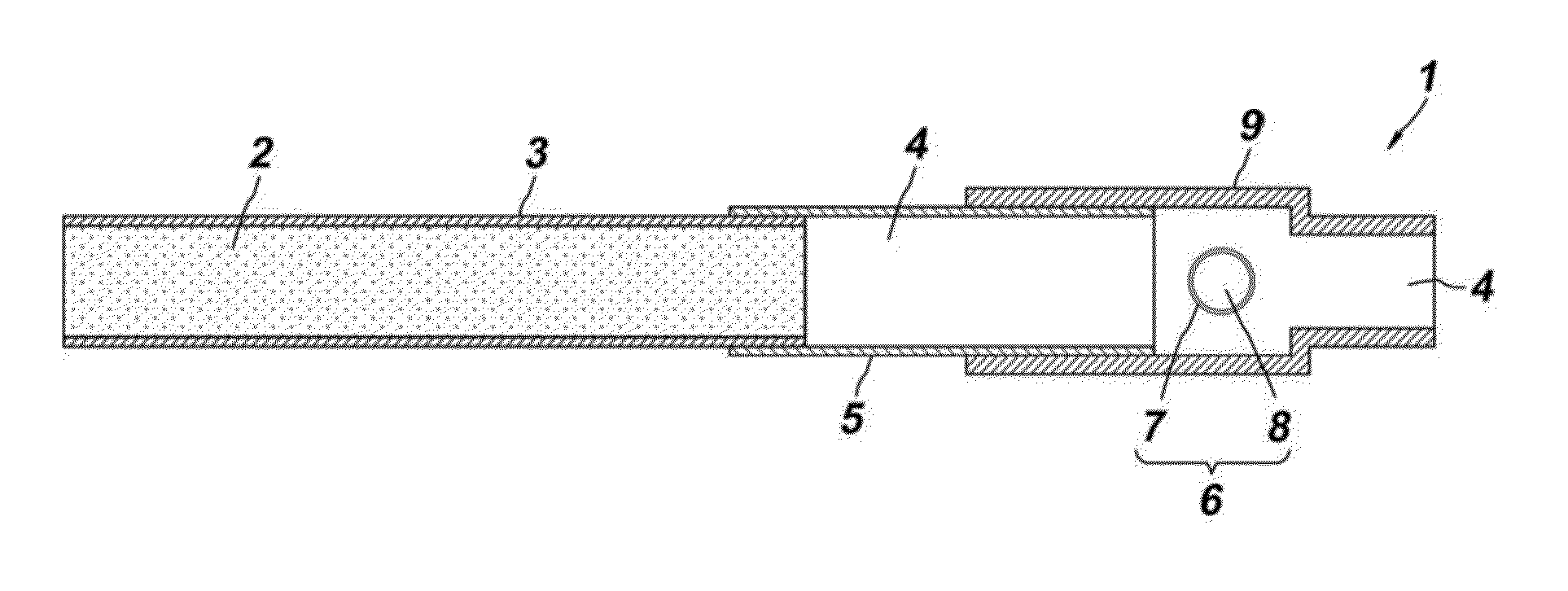

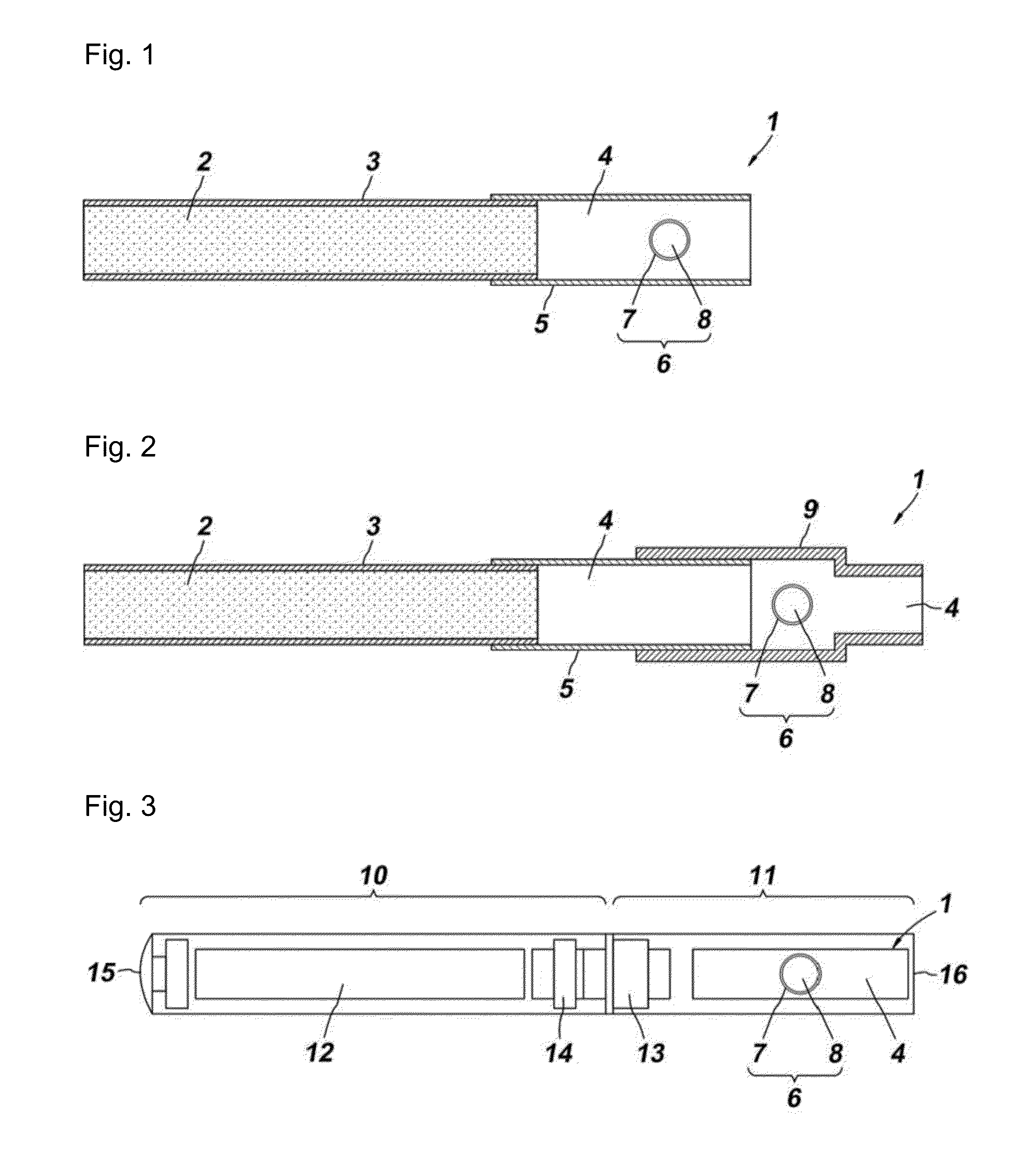

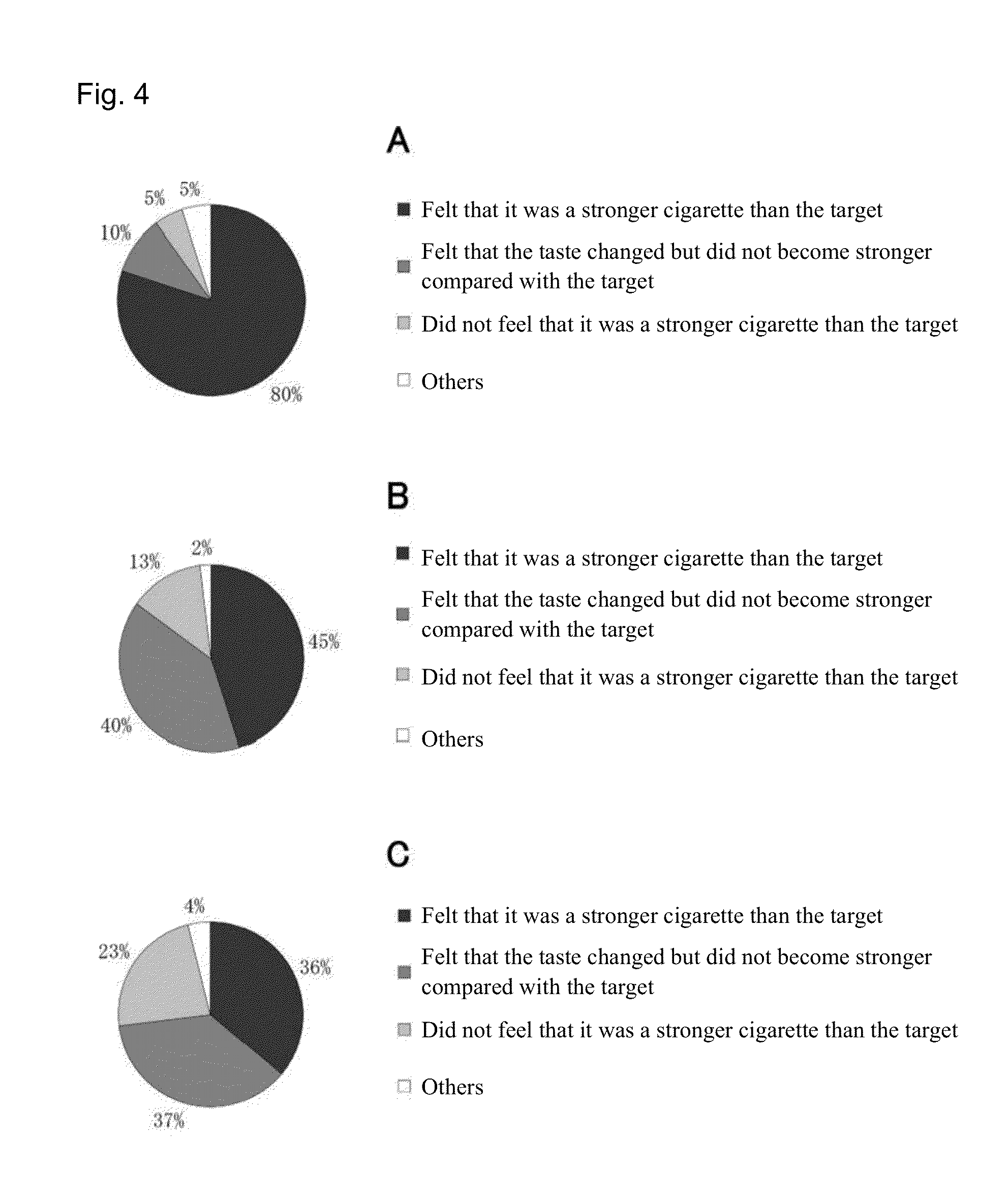

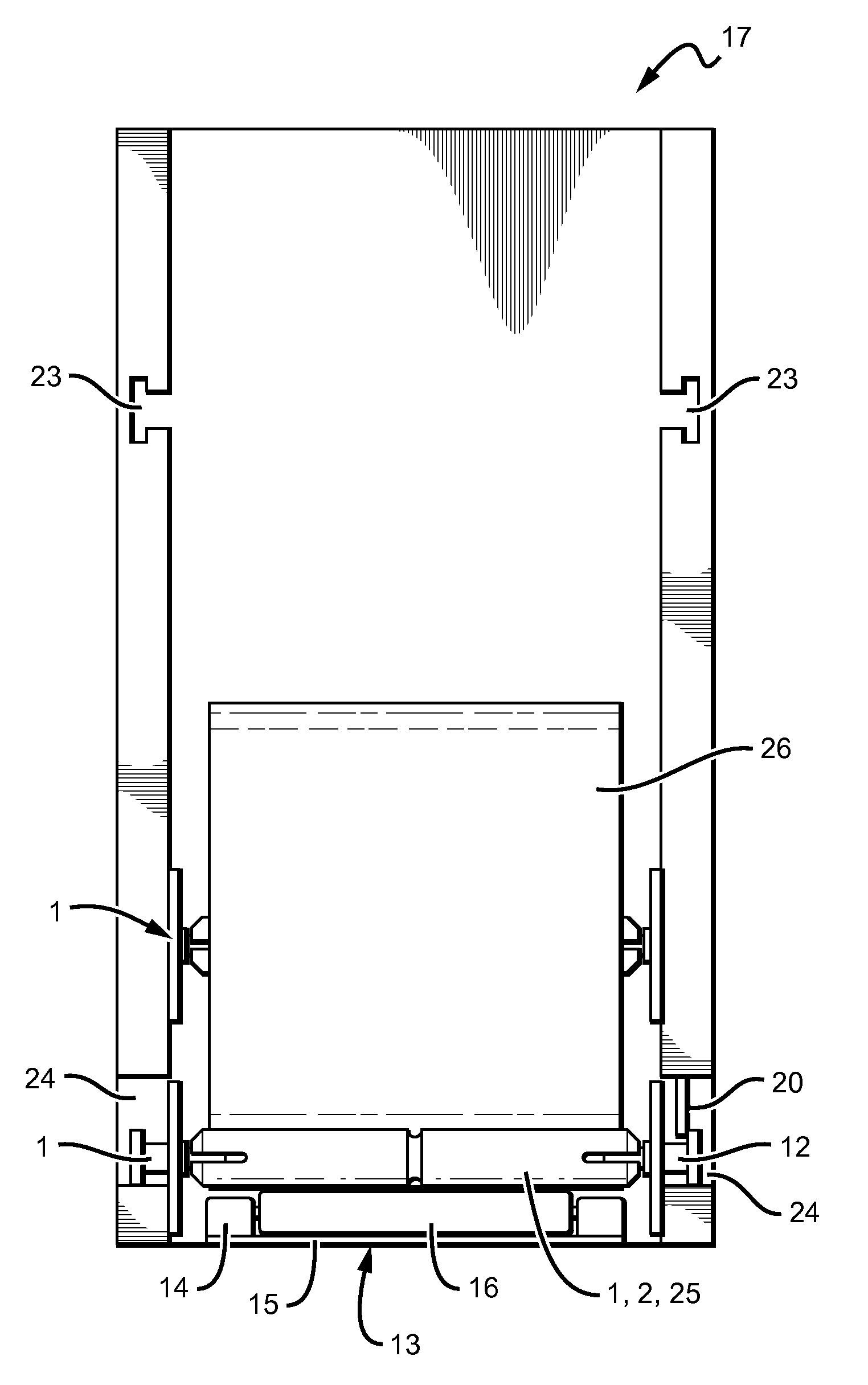

Filter containing built-in capsule, cigarette provided with filter and cigarette substitute provided with filter

InactiveUS20150027477A1Providing with same flavorIncrease aromaTobacco treatmentCigar manufactureFlavorRolling paper

[Problems] The present invention provides a filter containing built-in capsule in which a tobacco flavor enhancing liquid that can enhance flavor aspects such as taste, aroma, and richness is encapsulated, along with a cigarette and cigarette substitute comprising this filter.[Resolution means] The cigarette in which filter containing built-in capsule 1 according to the present invention is incorporated includes cut leaf 2, rolling paper 3, filter 4, and tip paper 5, with easily breakable capsule 6 incorporated in filter 4, and tobacco flavor enhancing liquid 8 including natural cacao extract encapsulated in film 7. When smoking, by pinching the filter part to crush capsule 6, film 7 bursts, causing tobacco flavor enhancing liquid 8 to ooze into filter 4 and enabling enhancement of the taste, aroma, richness, etc. specific to tobacco.

Owner:KABUSHIKI KAISHA KAMATA +1

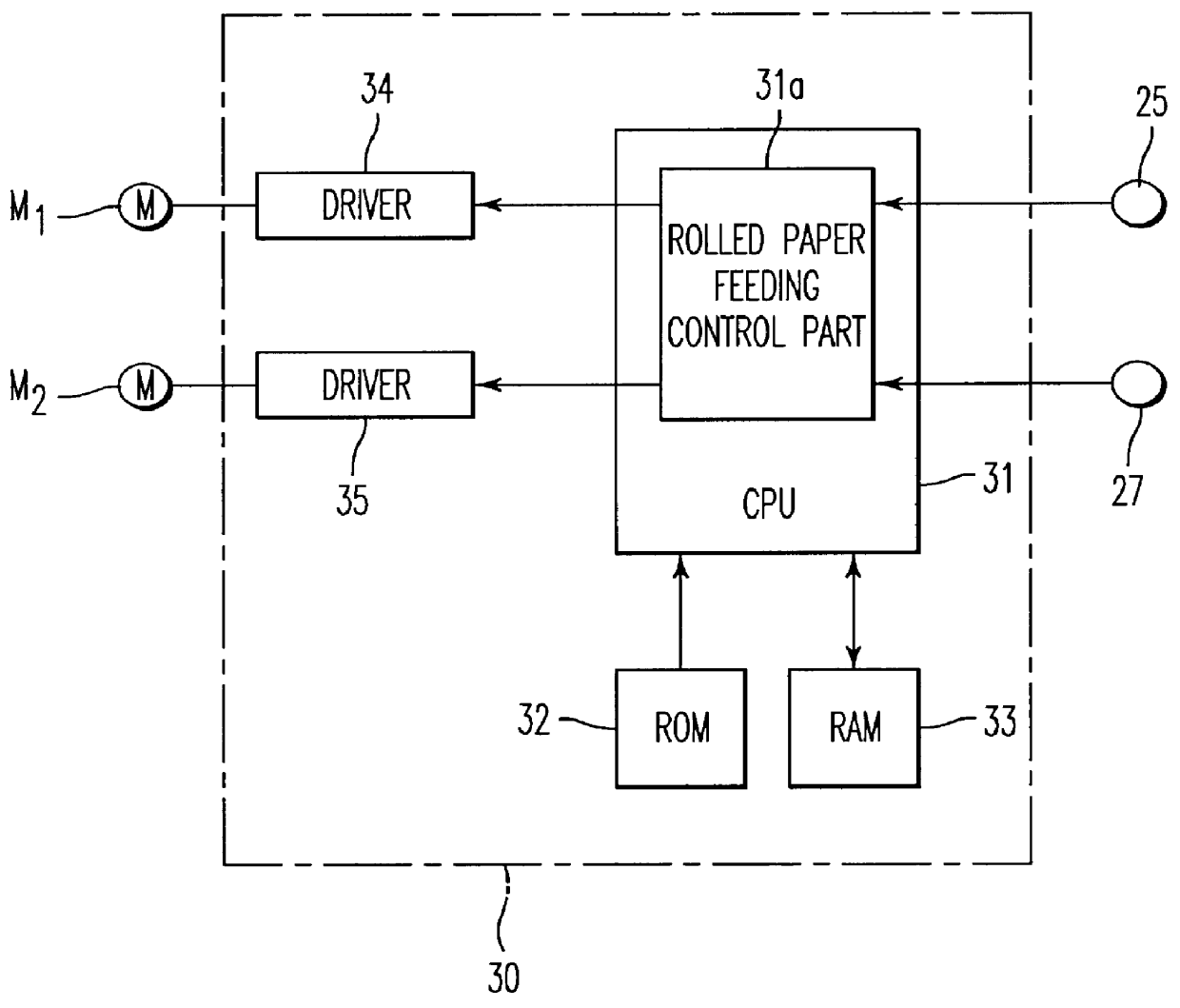

Motor control device, fluid ejection device, and motor control method

ActiveUS20090245912A1Avoid changePrecise transportationElectric controllersTypewritersRolling paperMotor control

A motor control device includes: a first motor that provides a driving force for rotating a roll on which a roll paper is wound to supply the roll paper from the roll; a second motor that provides a driving force for driving a transport driving roller which is provided on a downstream side than the roll along a supply direction of the roll paper and used for transporting the roll paper; a load measuring unit that measures a relationship between a load on the first motor and a driving speed of the first motor when the second motor is not driven and the first motor is driven; and a motor control unit that simultaneously drives the first and second motors at a certain timing, provides to the first motor an interpolation output based on the measurement result of the load measurement unit and a driving speed of the second motor during the control, and transports the roll paper to the downstream side by driving the second motor.

Owner:SEIKO EPSON CORP

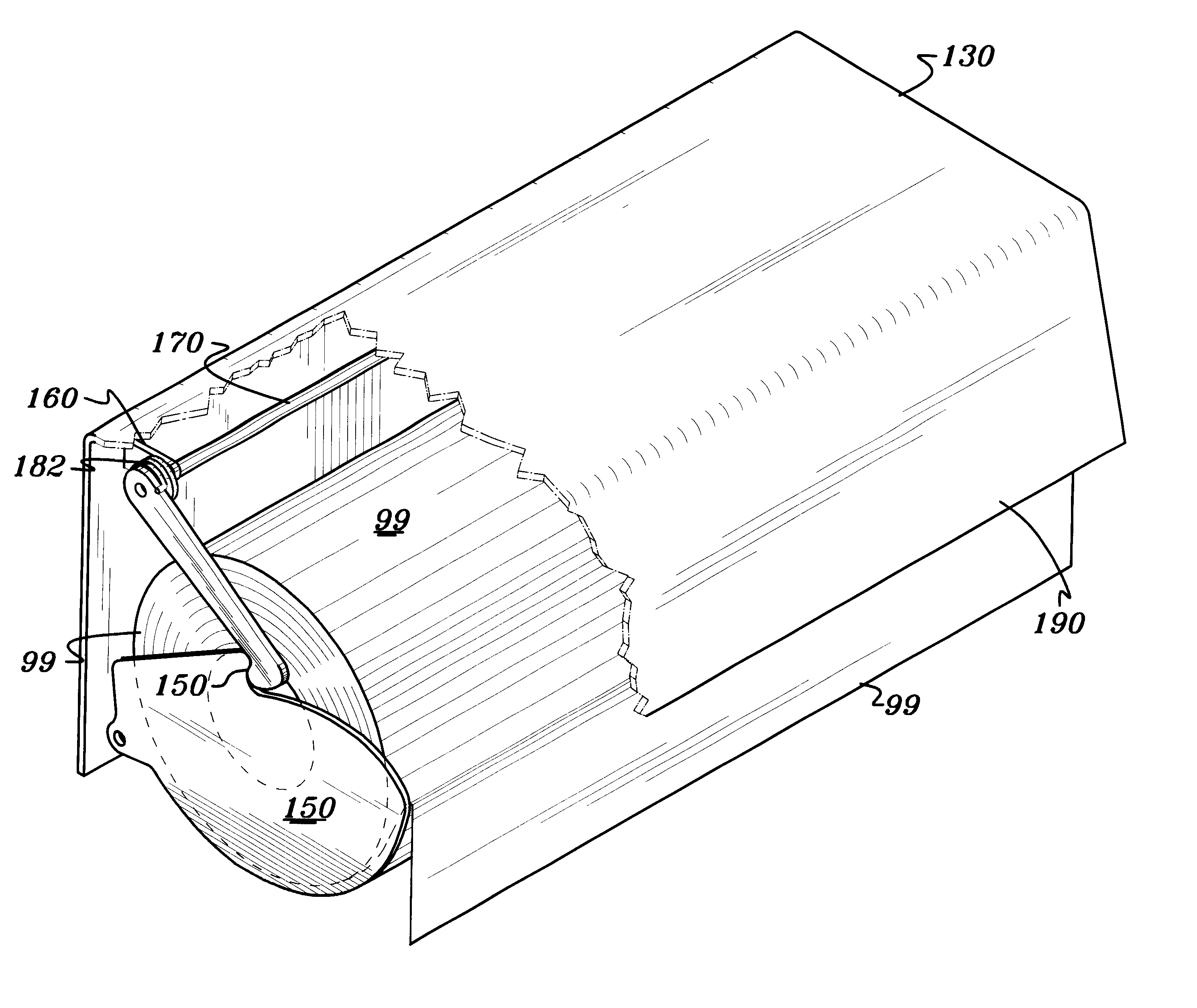

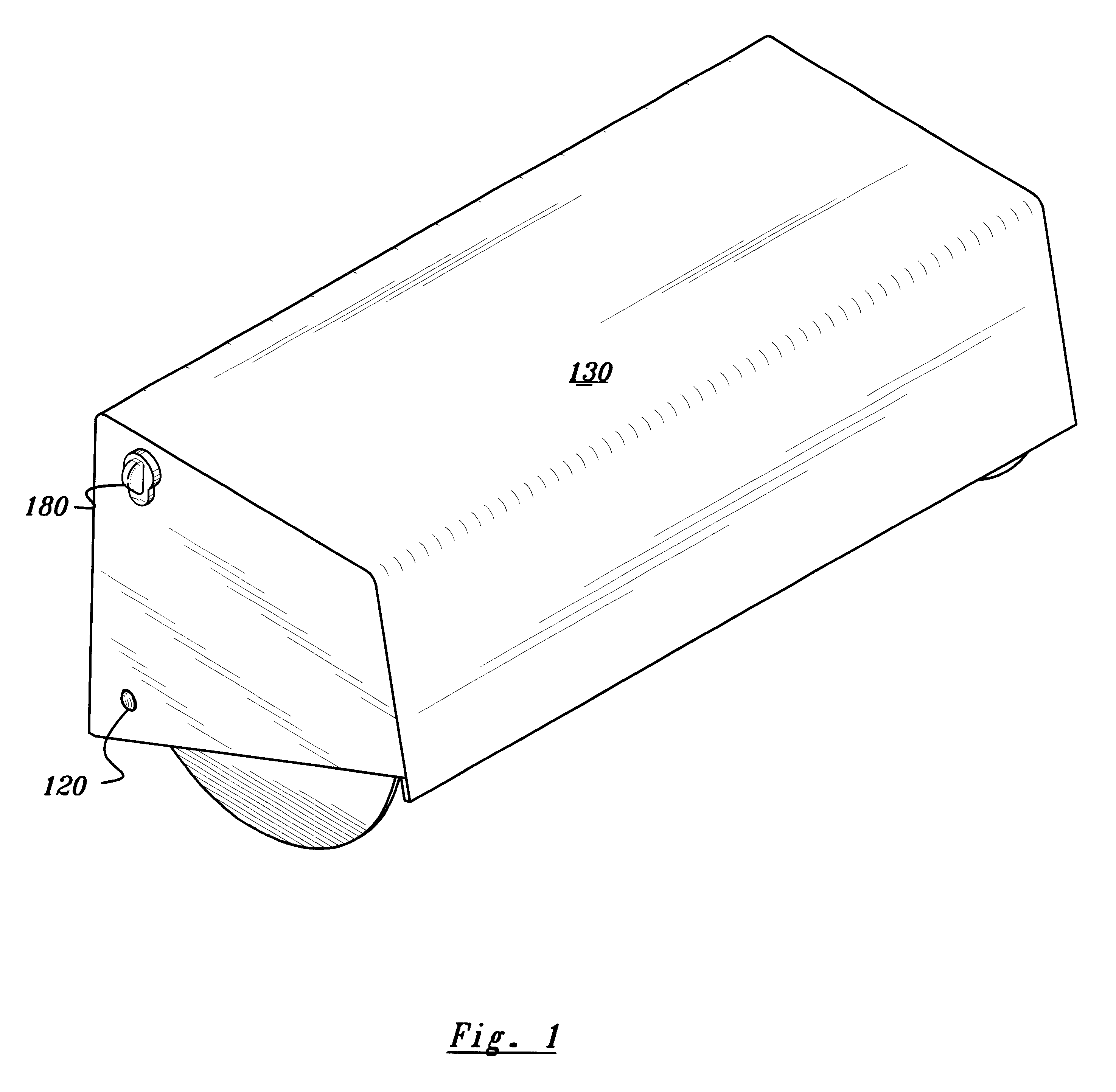

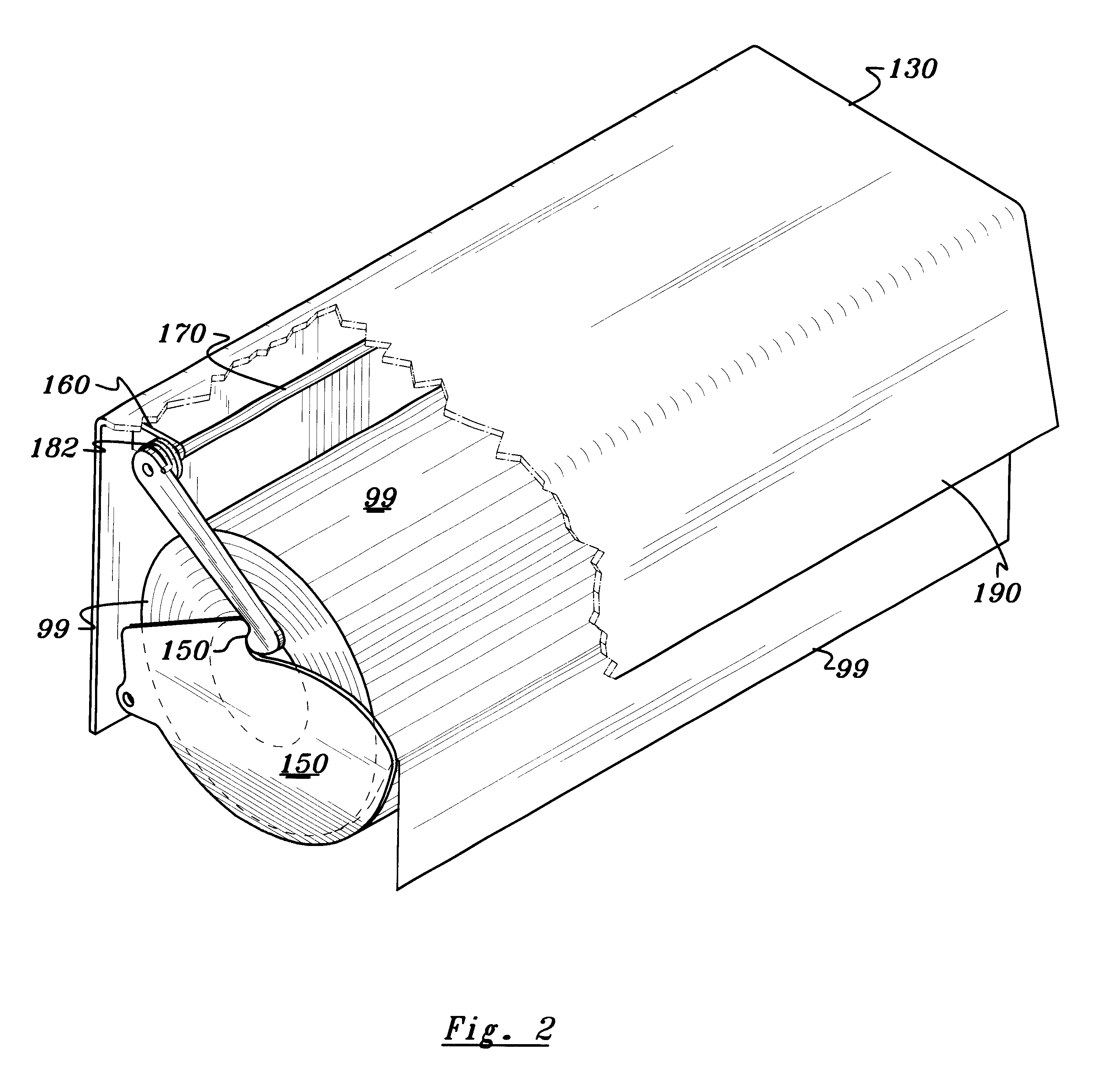

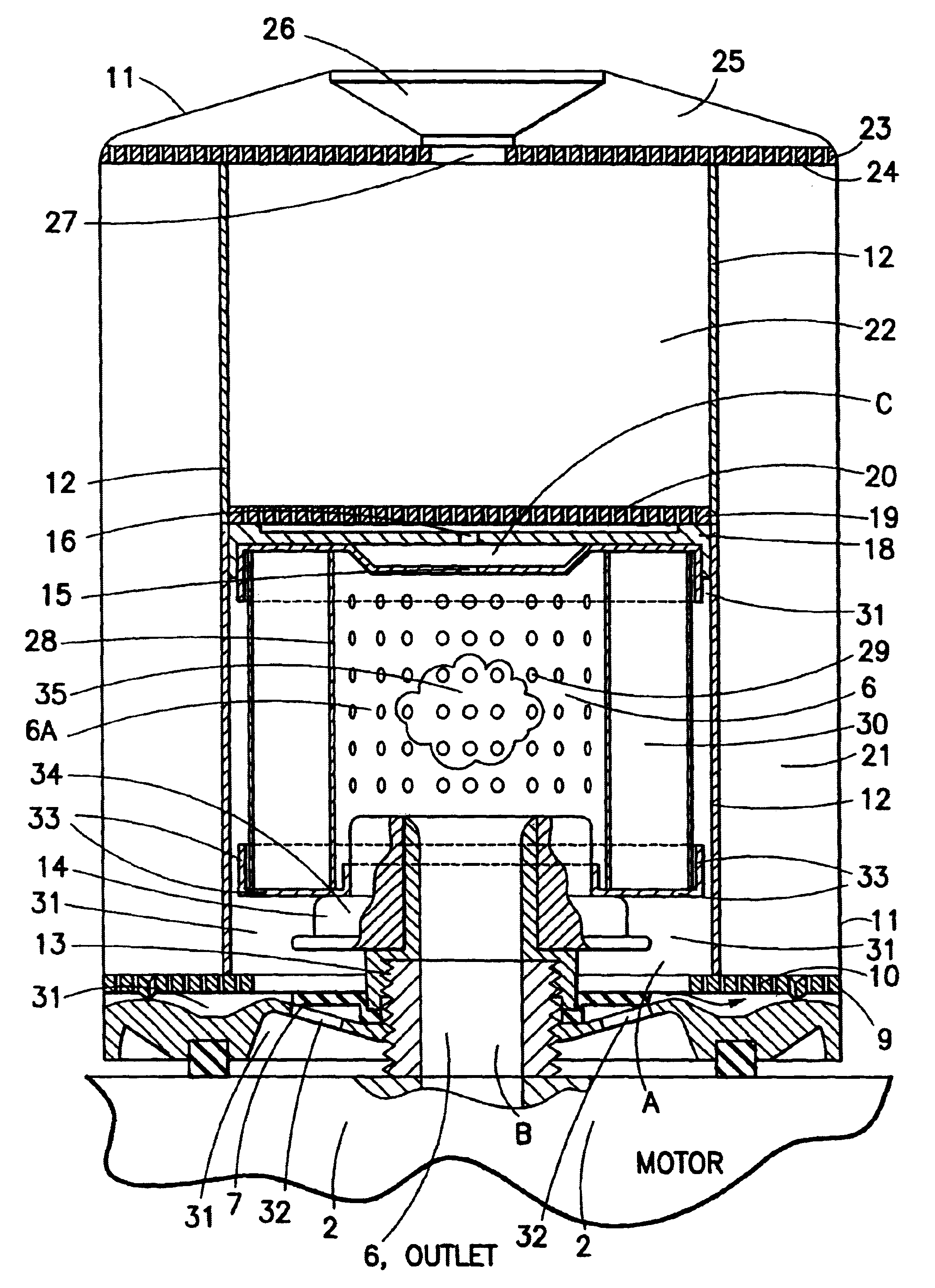

Rolled paper dispensing system

InactiveUS6592013B1Precise positioningUseful brakingFilament handlingDomestic applicationsRolling paperEngineering

The perforated roll dispensing system comprises a hinged cradle within a housing enclosure with easily releasable latch lock. The semi-circular cradle trough provides a stable storage means for perforated roll products. The textured surface of the trough gives useful braking from the friction with the rotating roll for controlled metering and provides adequate resistance to tear and extract unity of the sheet material from the dispenser without unraveling. The hinge and latch feature make it easy to deploy and retract the cradle trough to the loading mode or the dispensing mode. The right angled top enclosure and back panel of the housing can be mounted on a vertical and horizontal surface.

Owner:FUJIWARA JAYME ATSUKO

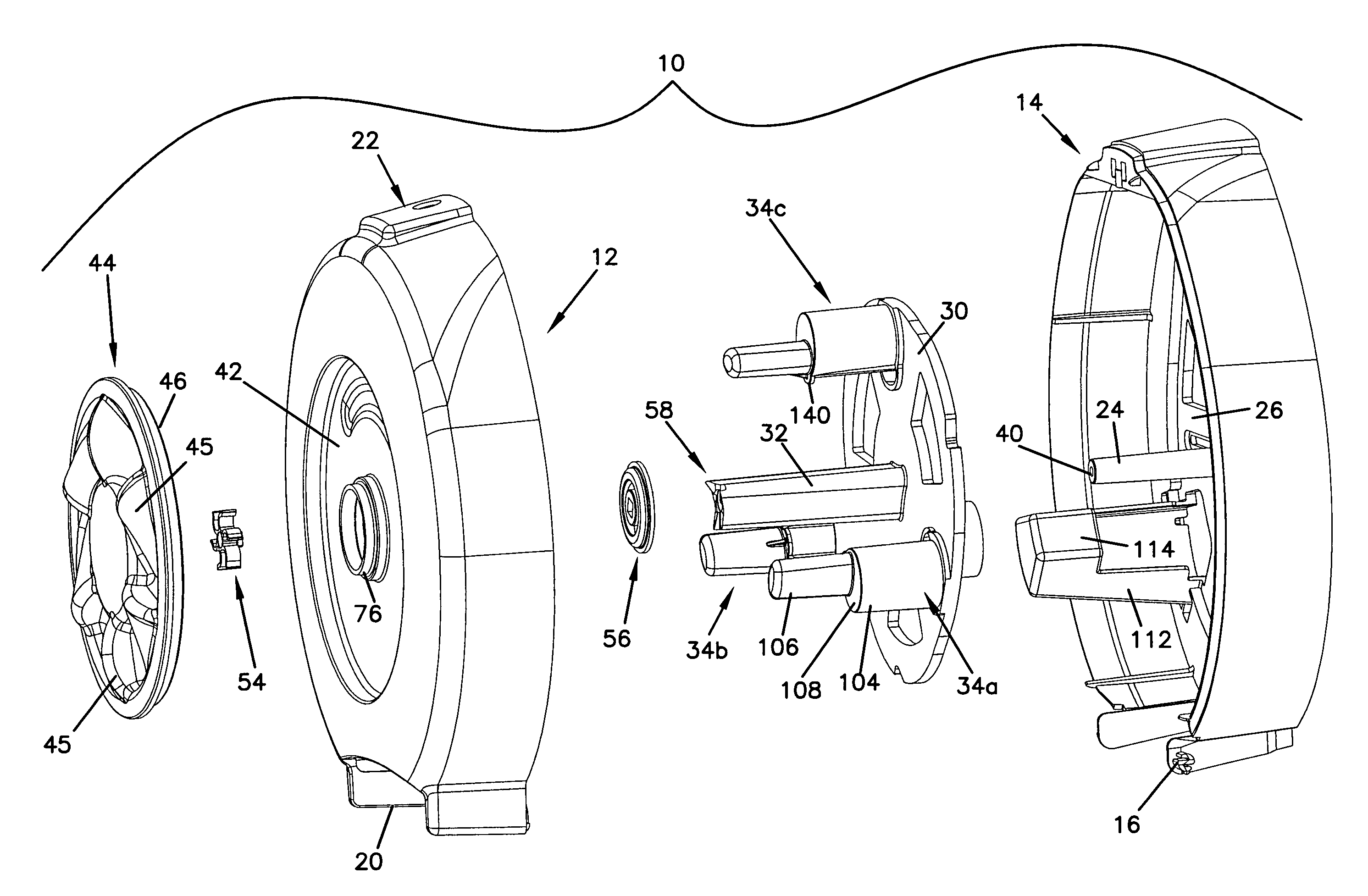

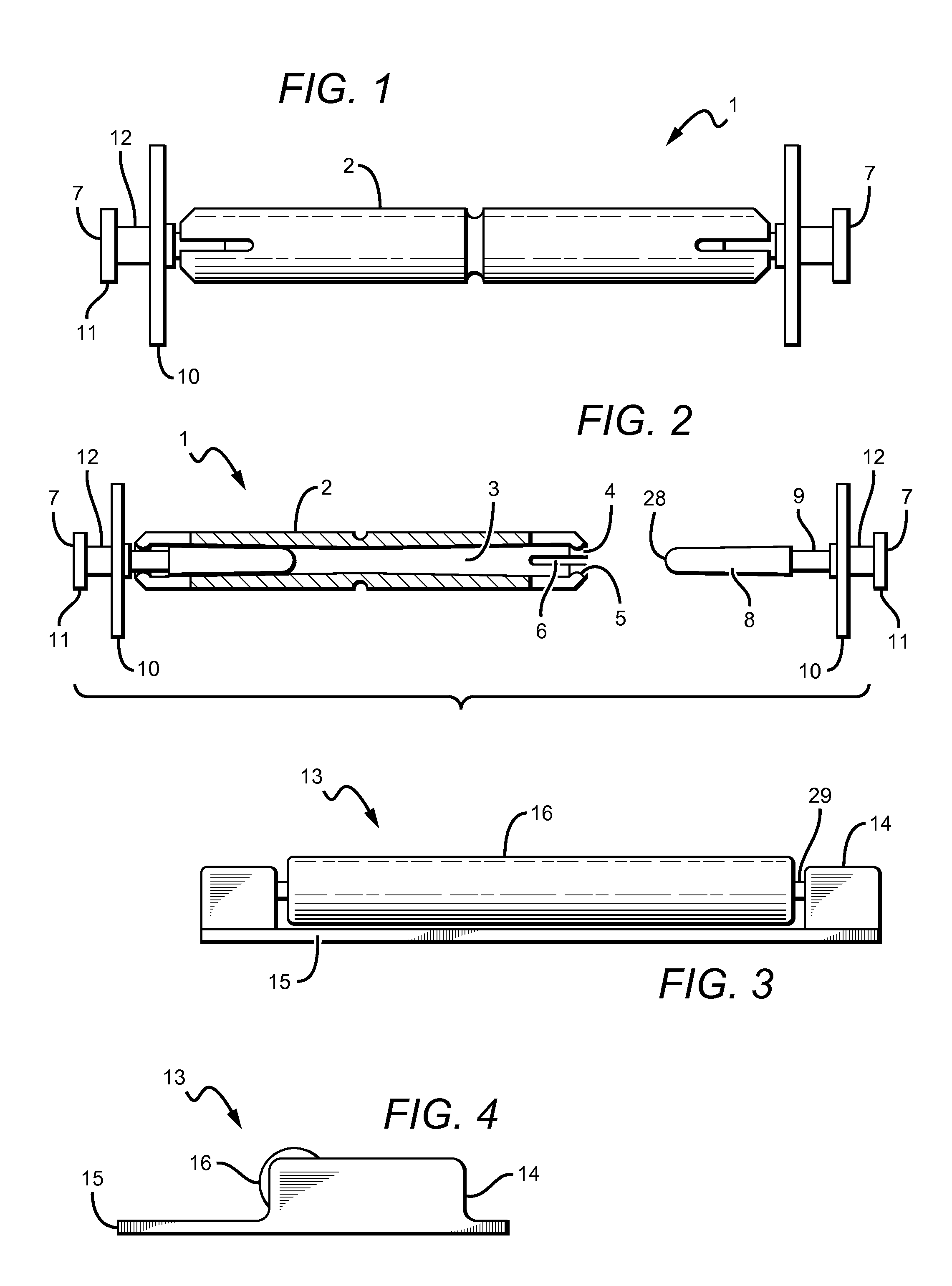

Spindle and adapter for roll paper product dispensers

ActiveUS20120111987A1Solving the Insufficiency of ElasticityEasy to insertProjector film strip handlingCamera film strip handlingRolling paperEngineering

A spindle for dispensing a roll of paper product is described. The spindle has an elongated member rotatably coupled with two side members. The side members have different sections of various diameters, which are configured to allow a portion of the side members to be inserted into a hollow interior of the elongated member. The elongated member has sufficient elasticity to provide a snap connection with the side members. The side members are configured to engage a track in a dispenser. Furthermore, at least one of the side members is removable. Also described herein is a roller assembly for adapting a dispenser. The assembly comprises a spindle rotatably coupled with a housing. The housing includes a fastener for attaching the housing to a dispenser. The roller assembly is configured to raise a roll of paper product, thus allowing dispensers originally designed for core rolls to be used with coreless rolls.

Owner:SOLARIS PAPER

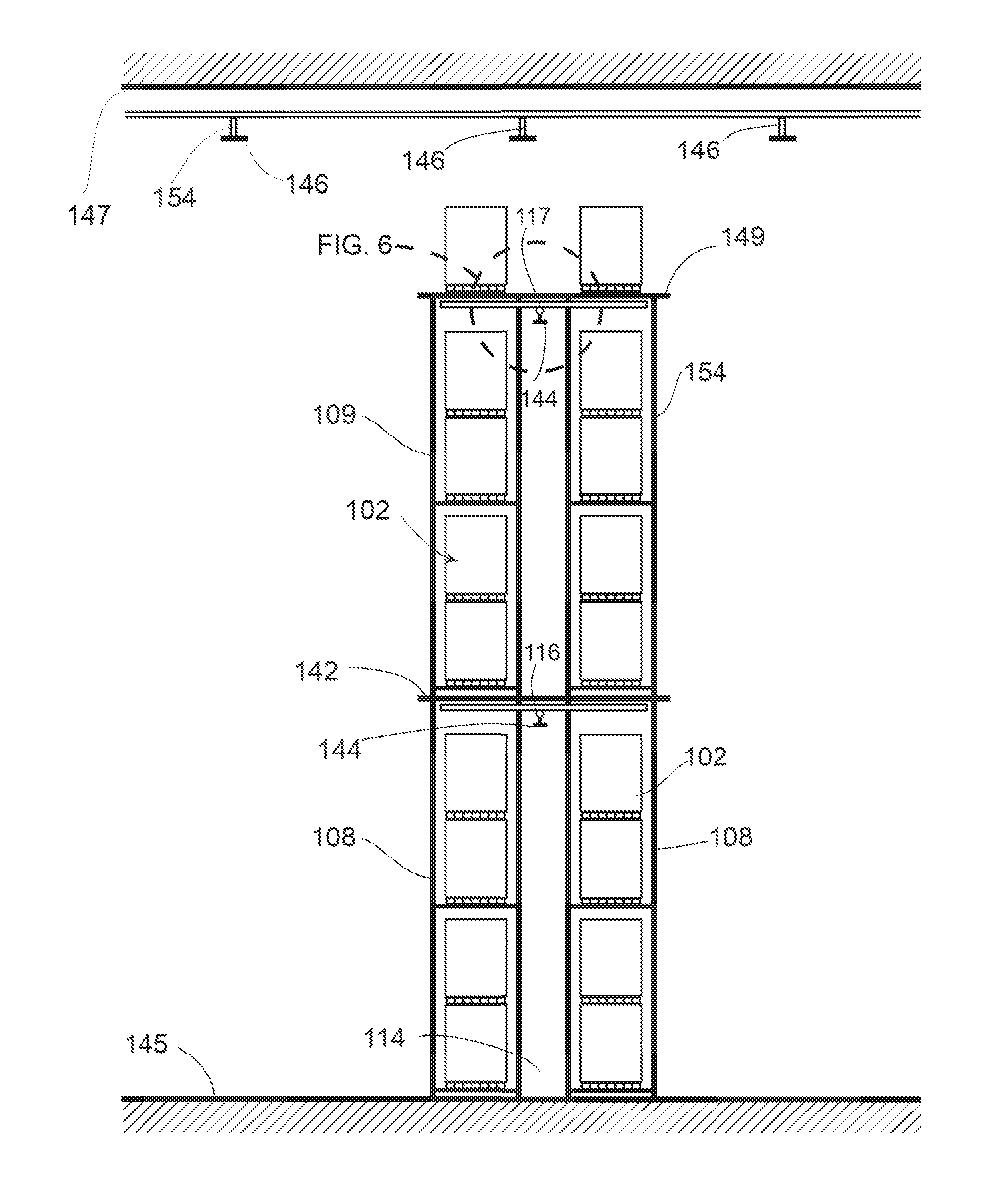

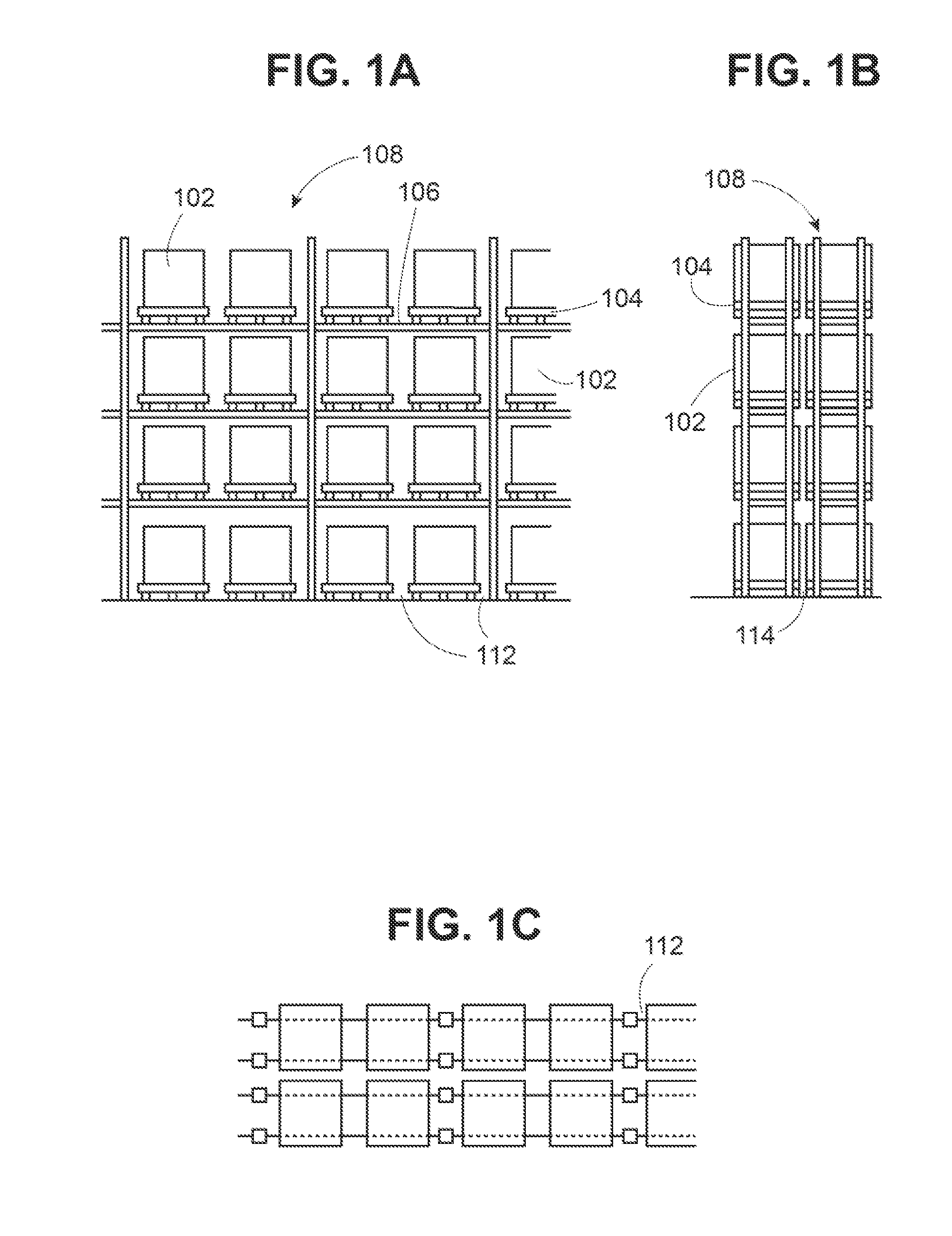

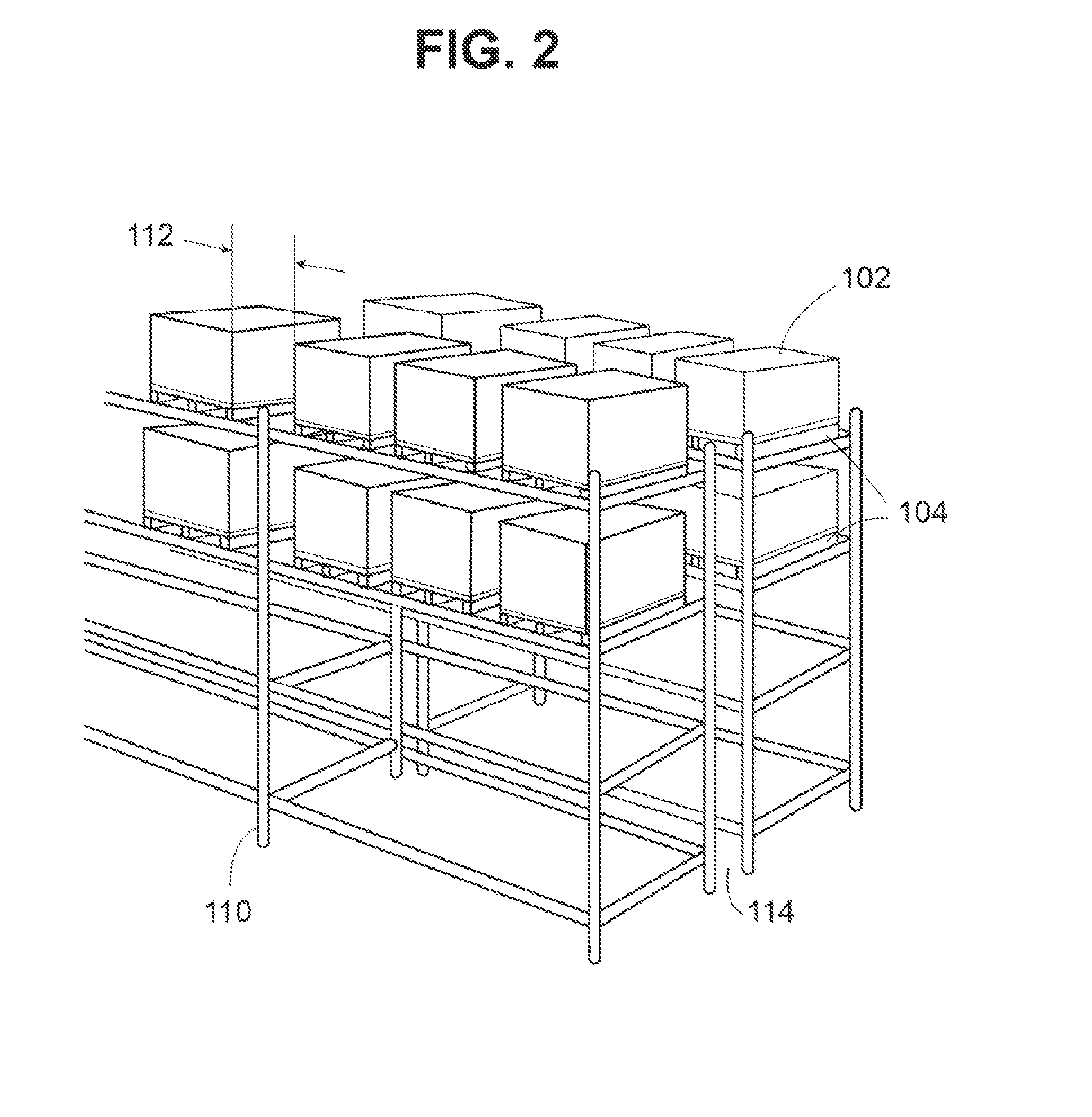

In-rack fire protection sprinkler system

A fire protection sprinkler system is provided for the protection of commodities including Class I-IV hazards, Group A cartoned and exposed plastics (expanded and unexpanded), flammable liquids, tires, roll paper, and aerosols, stored in a plurality of adjoining racks having a longitudinal flue space between the racks. The system includes at least one fluid supply conduit in fluid communication with a source of a fire protection fluid. The system also includes at least one solid horizontal barrier covering each rack and the longitudinal flue space at a predetermined vertical spacing. The system further includes one or more rack-level fire protection sprinklers in fluid communication with the fluid supply. The sprinklers are disposed in the vertical flue space between adjacent horizontal barriers, and each sprinkler is spaced vertically from the commodities stored between adjacent horizontal barriers.

Owner:RELIABLE AUTOMATIC SPRINKLER

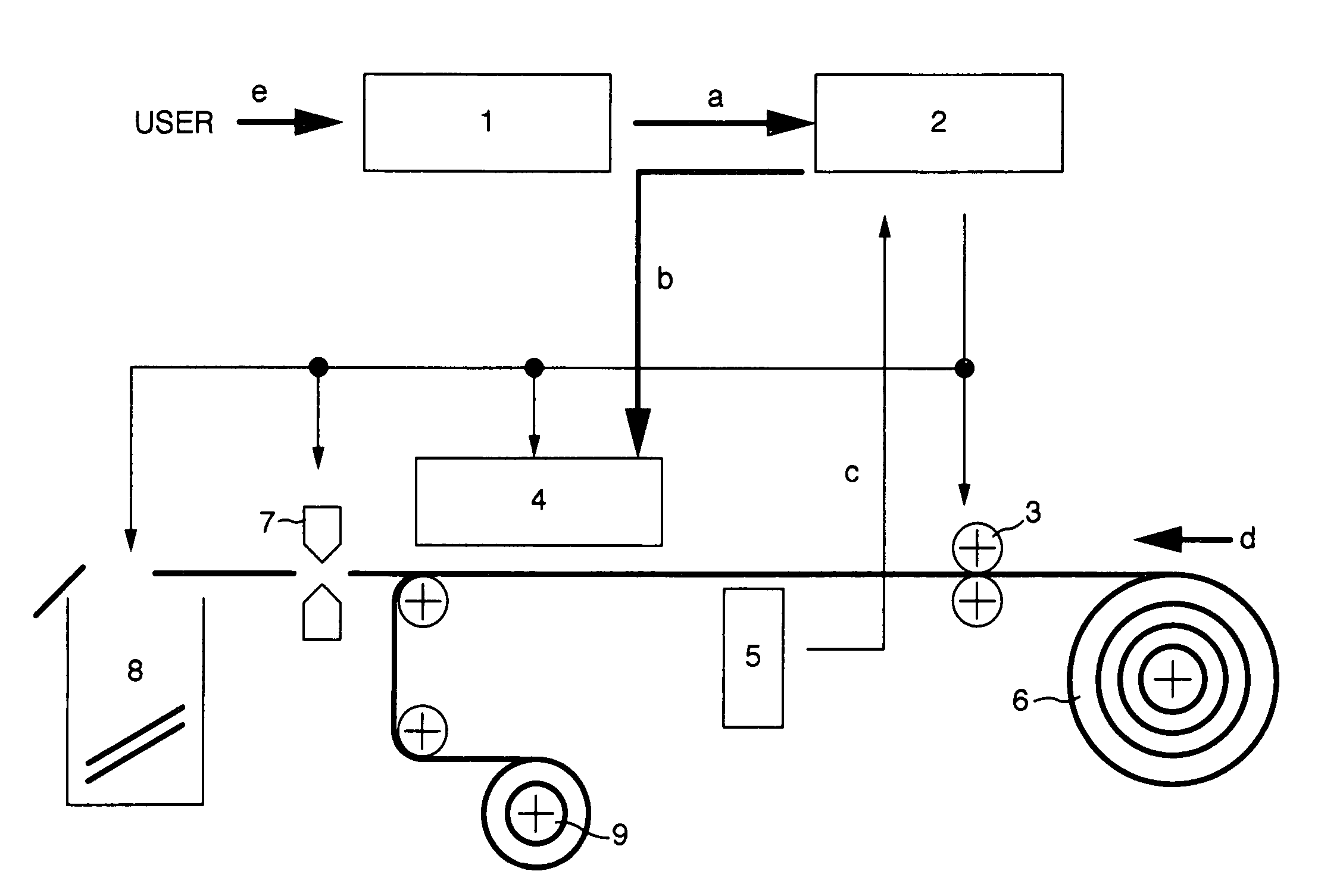

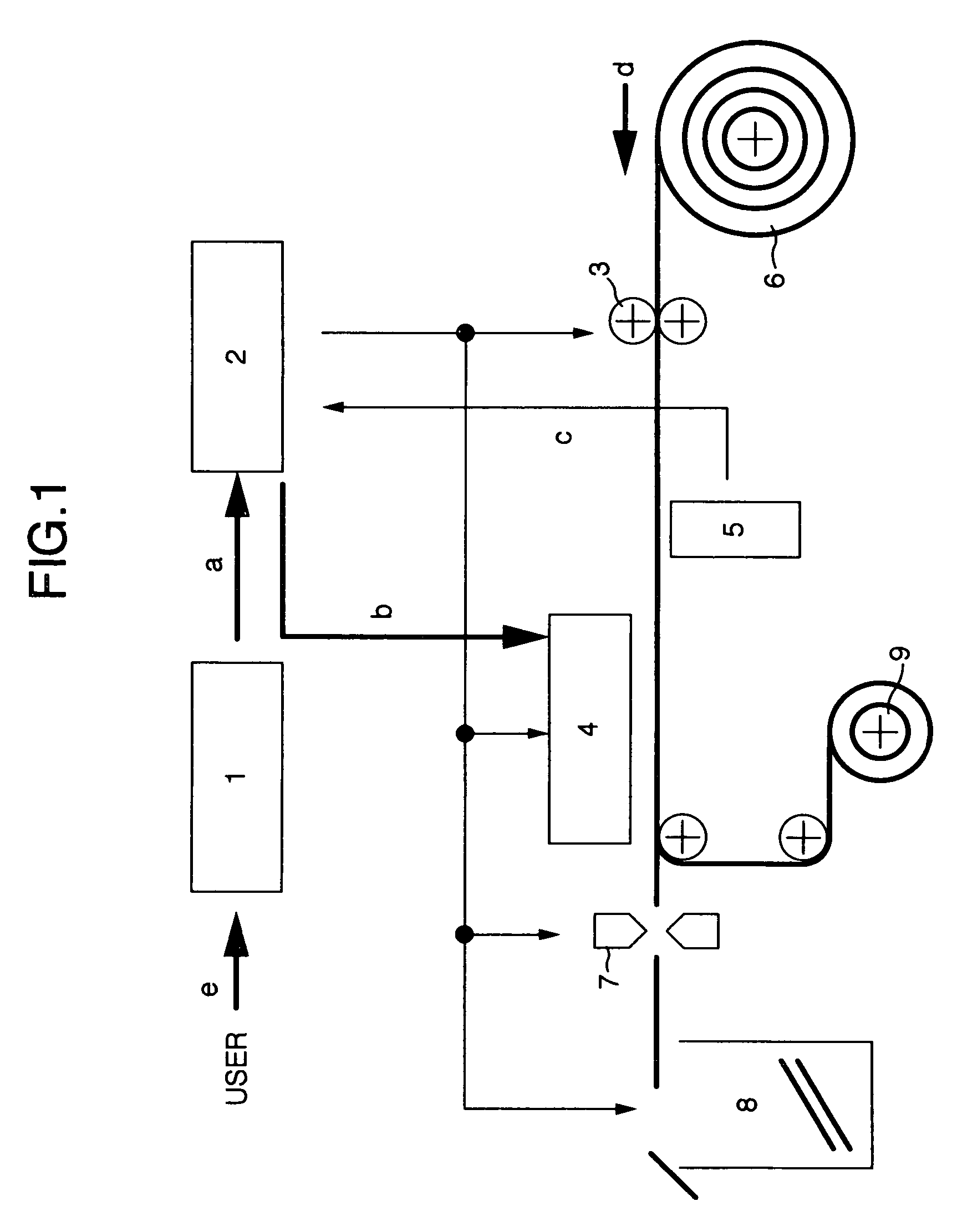

Ink-jet print system

InactiveUS7441887B2Quality improvementHigh quality imagingOther printing apparatusRolling paperEngineering

An object of the present invention is to provide an ink jet print system in which quality troubles (e.g. banding and ink overflow) caused by an unsuitable combination of ink and an ink jet recording medium in an ink jet recording apparatus in the case where the ink jet recording medium is an imitation, are obviated on the basis of printing control information obtained from the ink jet recording medium with an information-detecting sensor, and it is possible to prevent the employment of an ink jet recording medium which a user cannot judge to be a genuine product or an imitation. According to the present invention, an ink jet print system can be obtained in which printing information obtained from an image processor and the printing control information of the ink jet recording medium obtained from the information-detecting sensor are processed and on the basis of information of these kinds, the best image is always formed with the ink jet recording apparatus by the use of a genuine product. The printing control information of the ink jet recording medium is preferably a logo print or a cord image print. The ink jet recording medium is preferably of a rolled paper type. The system is stopped when an imitation is used which does not match with the printing control information.

Owner:MITSUBISHI PAPER MILLS LTD

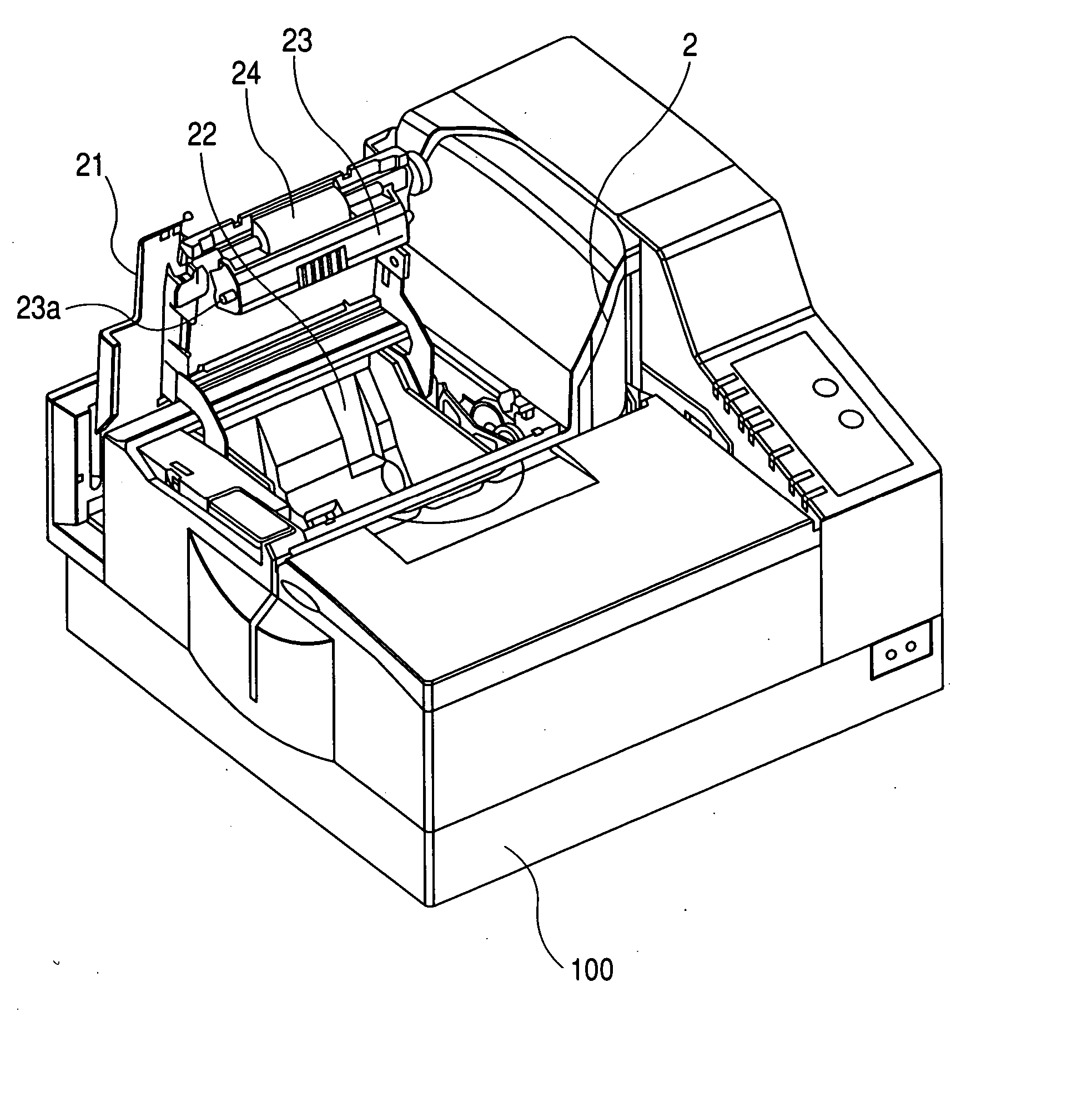

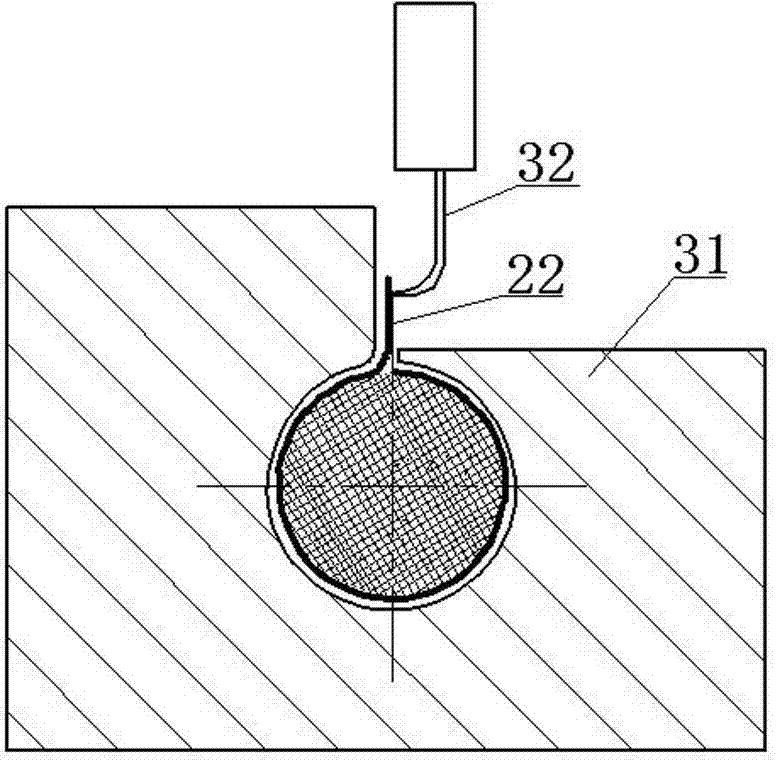

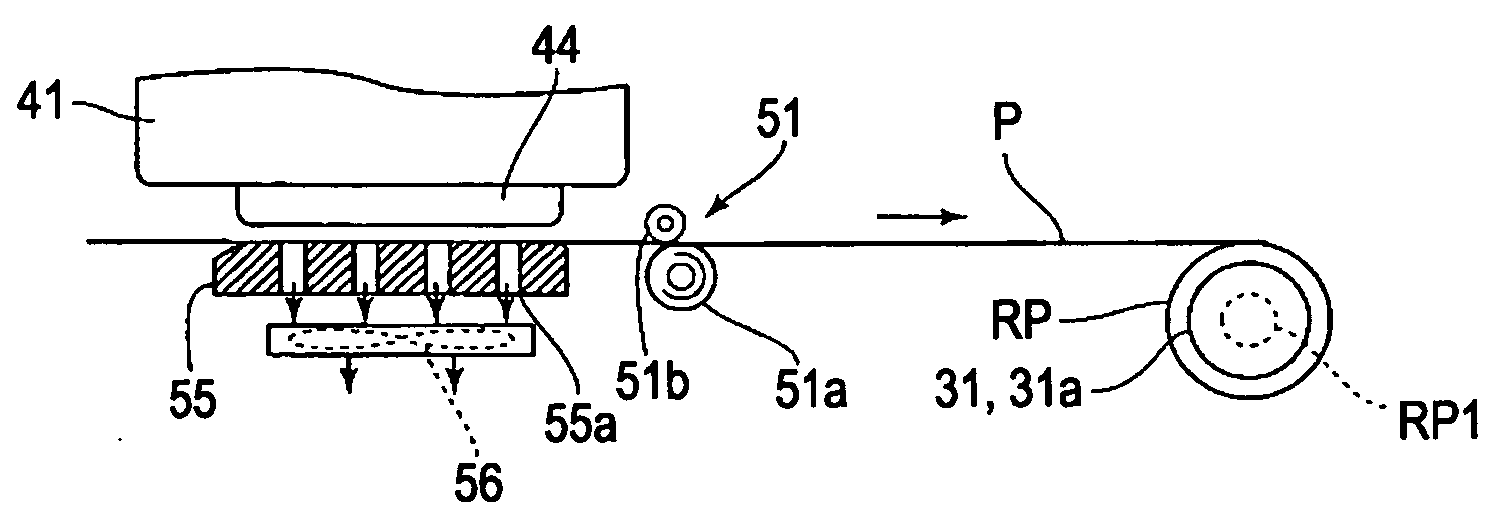

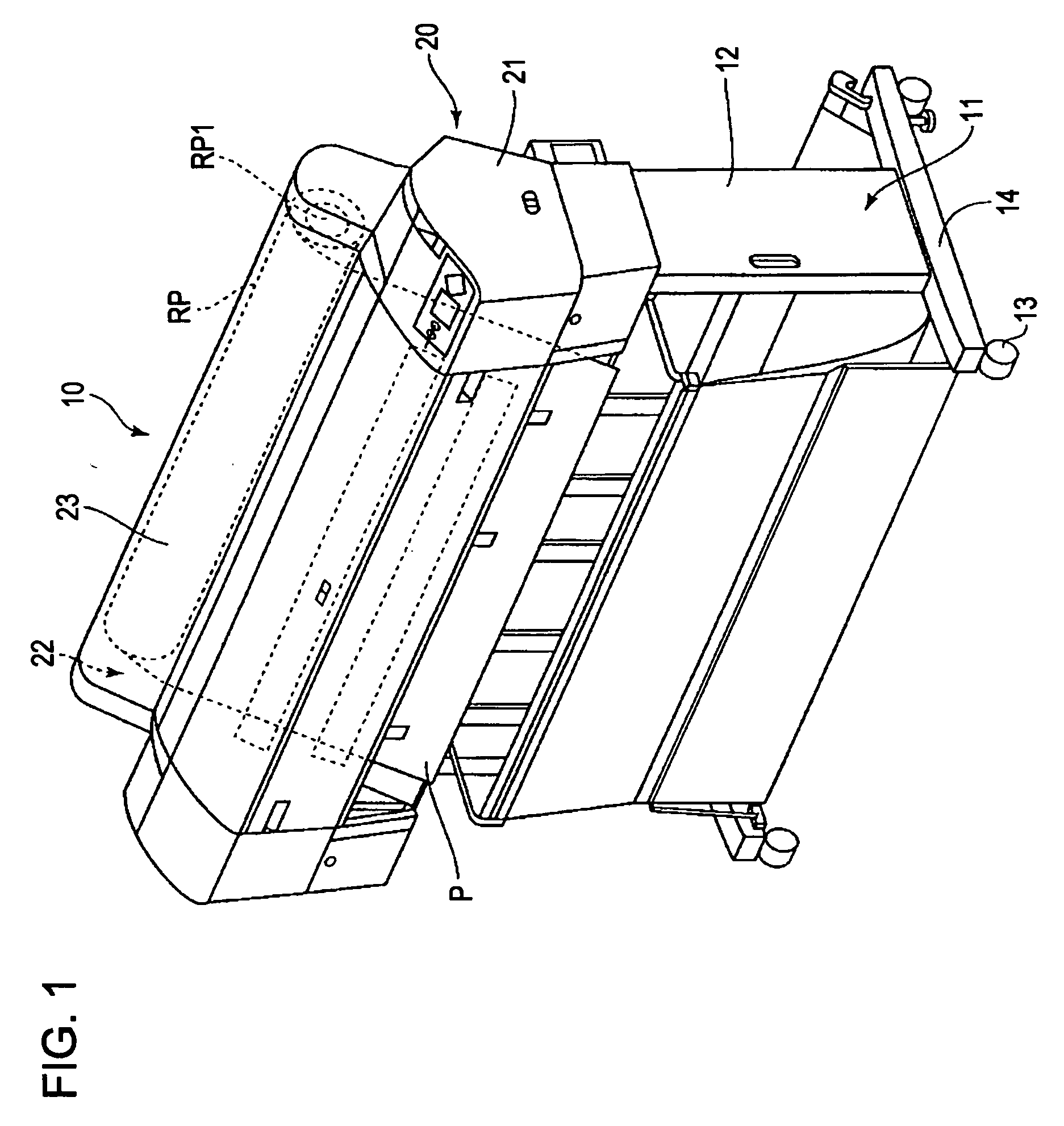

Printing device

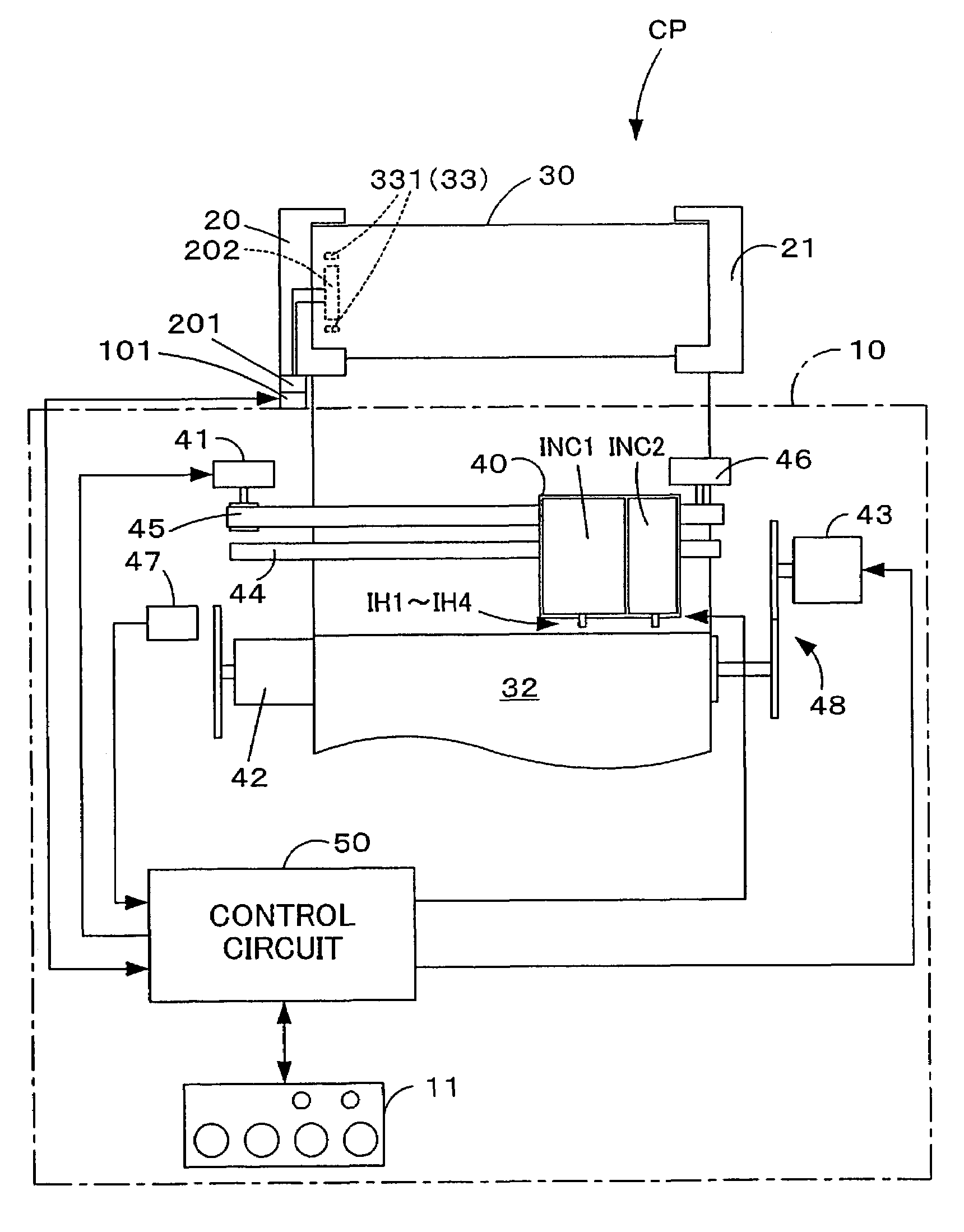

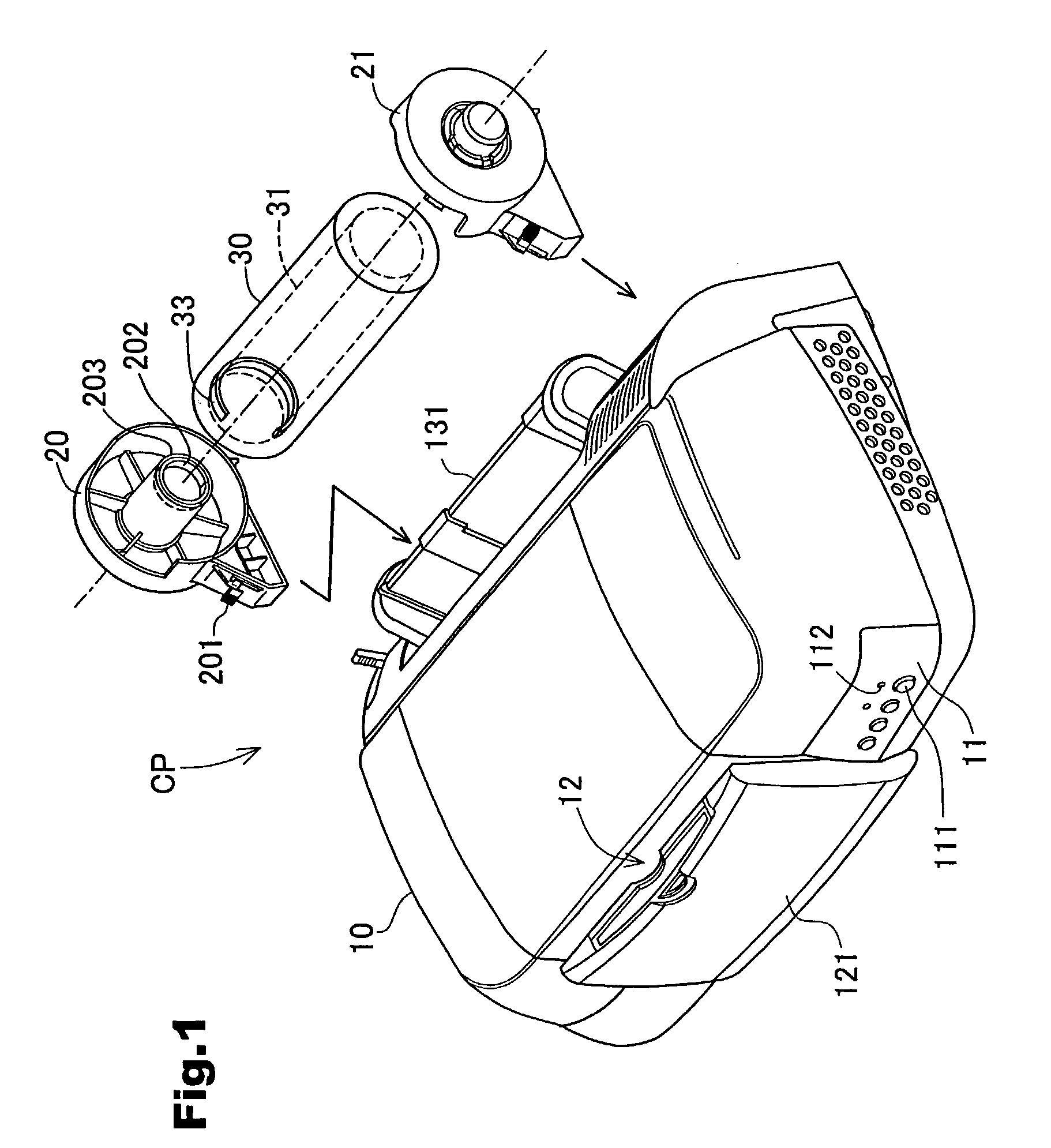

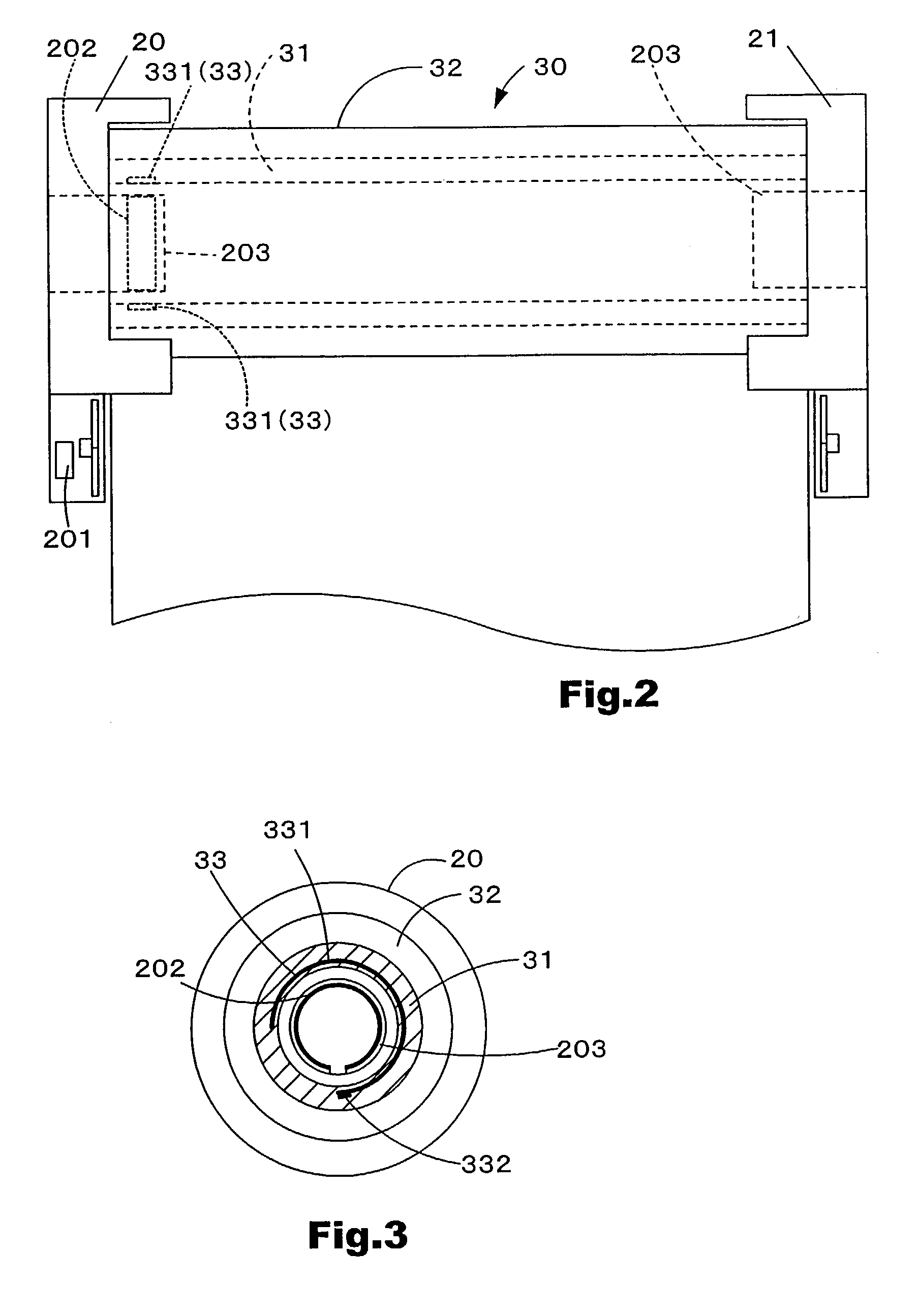

InactiveUS7008125B2Improve reliabilityAppropriately executedRecording apparatusInking apparatusRolling paperControl circuit

An IC memory module 33 for storing paper-related information is embedded in a core 31 of a roll paper member 30. A control circuit 50 accesses the IC memory module 33 embedded in the core 31 of roll paper member 30 via a transmission-reception antenna 202 at a timing, for example, when a power source is turned on, the roll paper member 30 is replaced, and power source is turned off, and acquires the paper-related information. The control circuit 50 controls the printing processing by taking account of the information acquired from the IC memory module 33.

Owner:SEIKO EPSON CORP

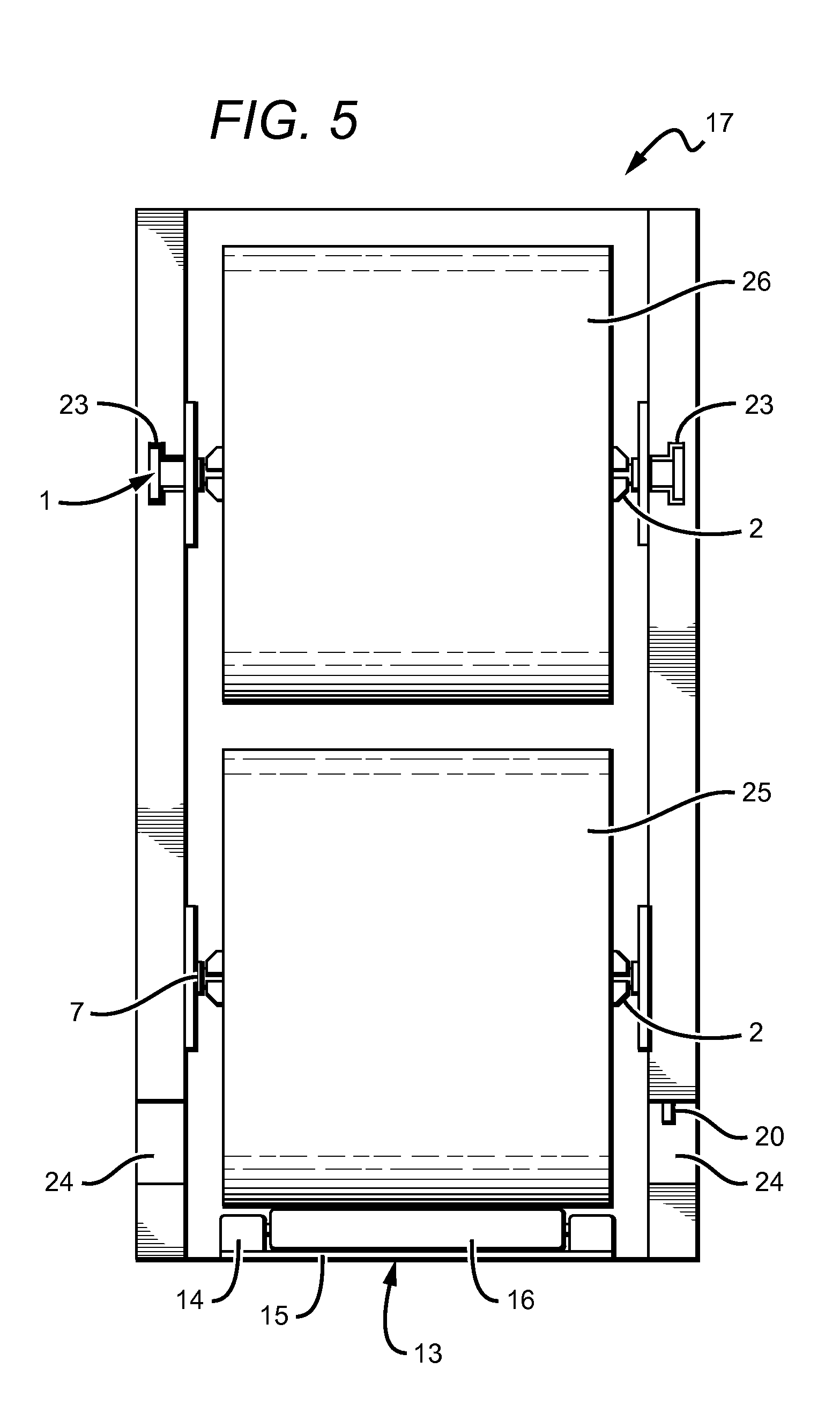

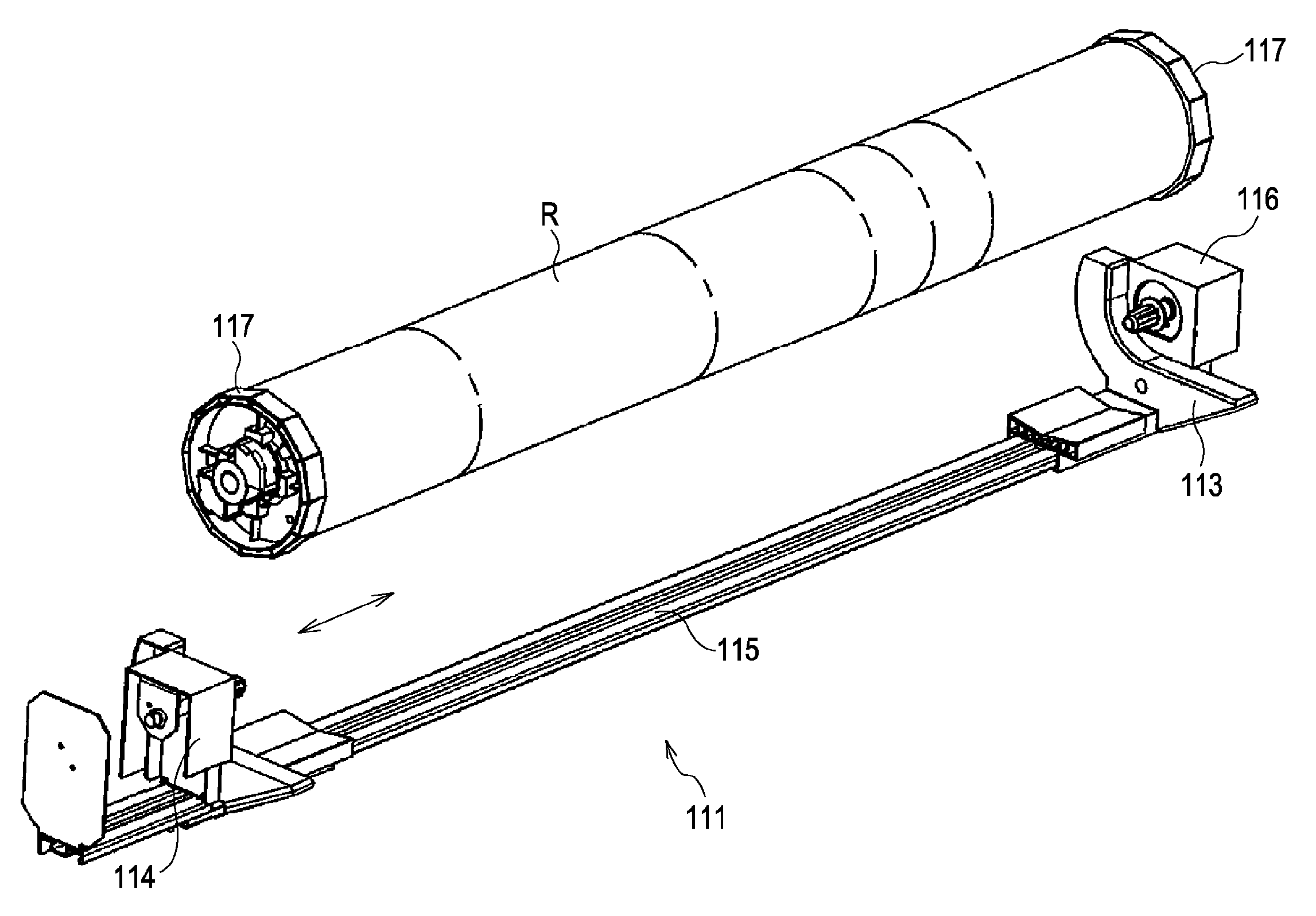

Rolled medium supporting device for supporting both ends of rolled medium and recording apparatus having the rolled medium supporting device

InactiveUS20080277851A1Improve accuracySimple wayLarge fixed membersOther printing apparatusRolling paperEngineering

A roll-like medium supporting device includes flange members 117 that are fitted to both ends of the roll-like medium; a first holder member 113 that is fixed to a main body of the device so as to support one of the flange members; and a second holder member 114 that is disposed in the main body of the device to be movable in the axial direction of the roll-like medium so as to support the other flange member. With such a configuration, it is possible to eliminate necessity of a conventional lengthy roll shaft and thus to set the roll paper in a simple manner.

Owner:SEIKO EPSON CORP

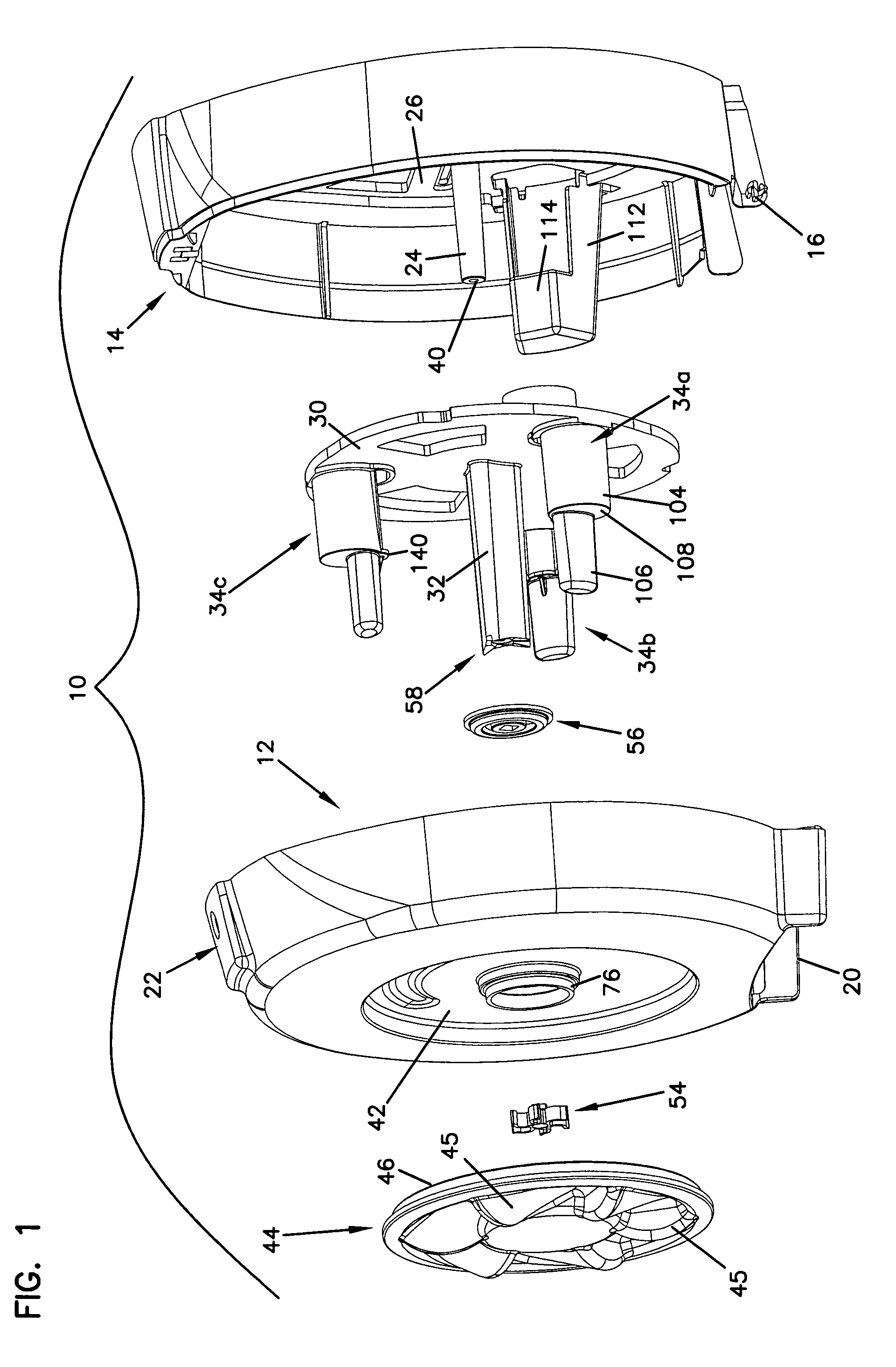

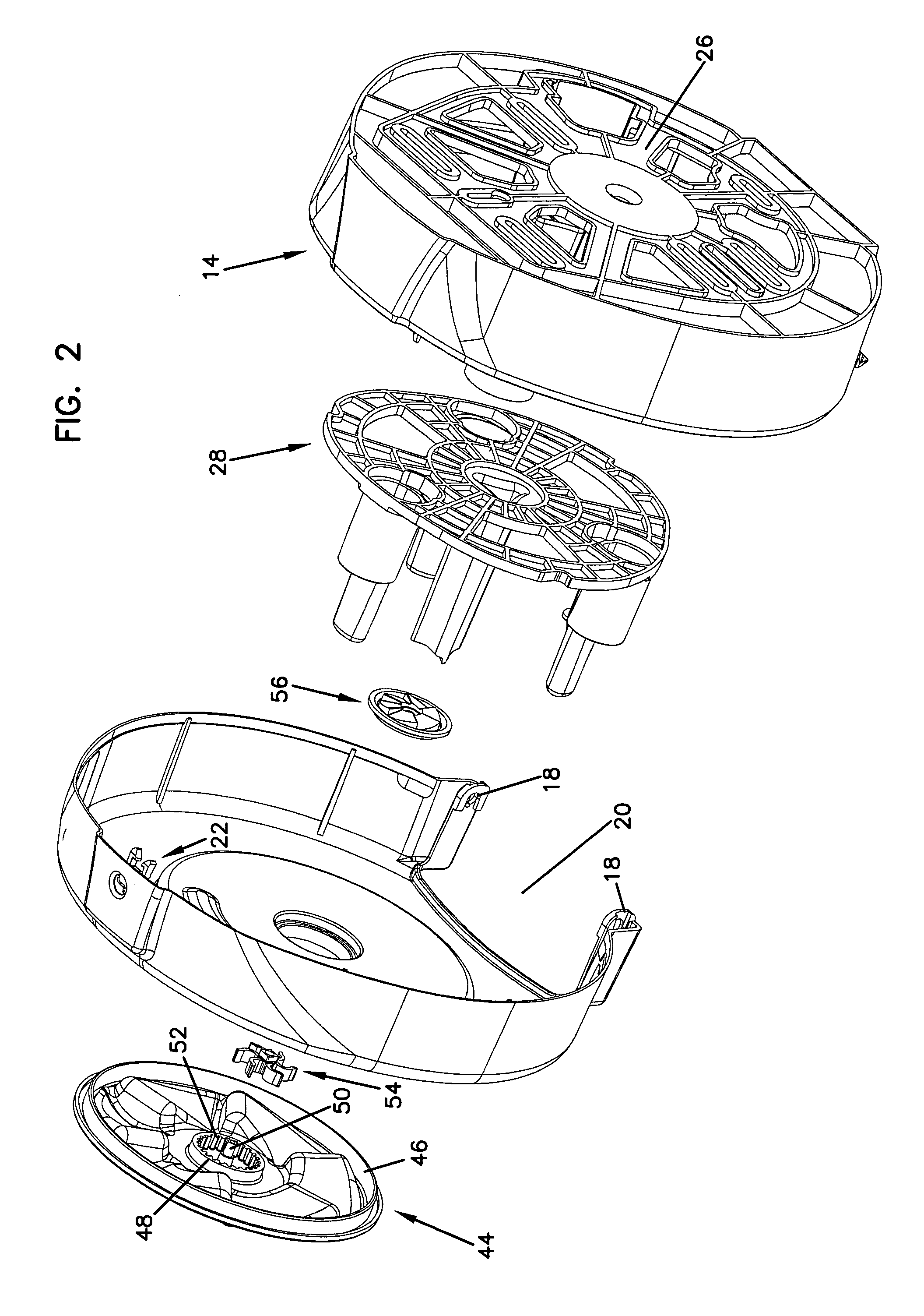

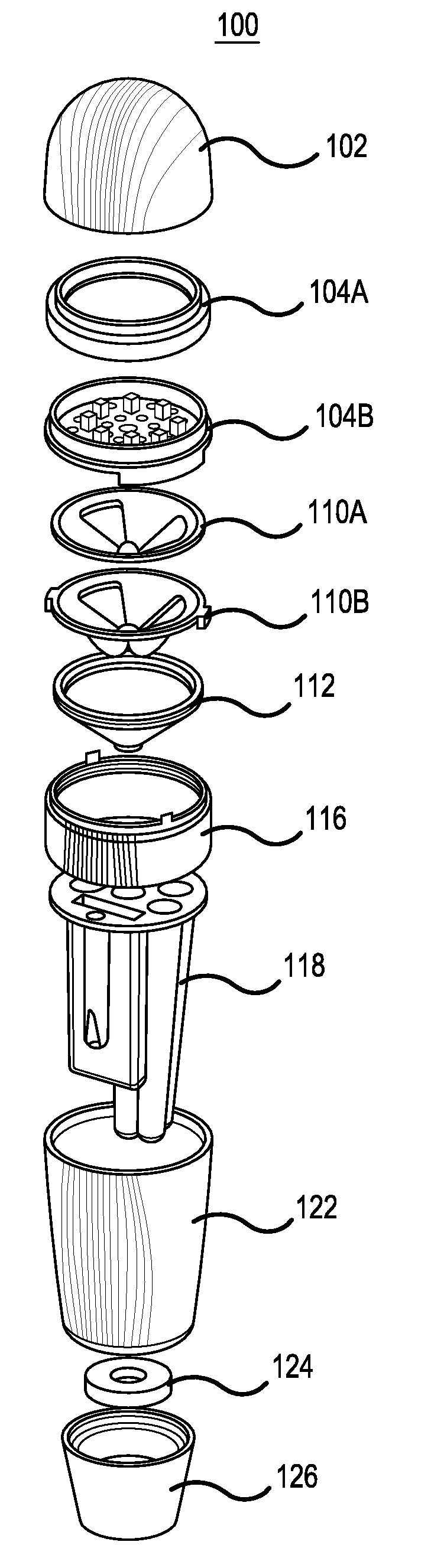

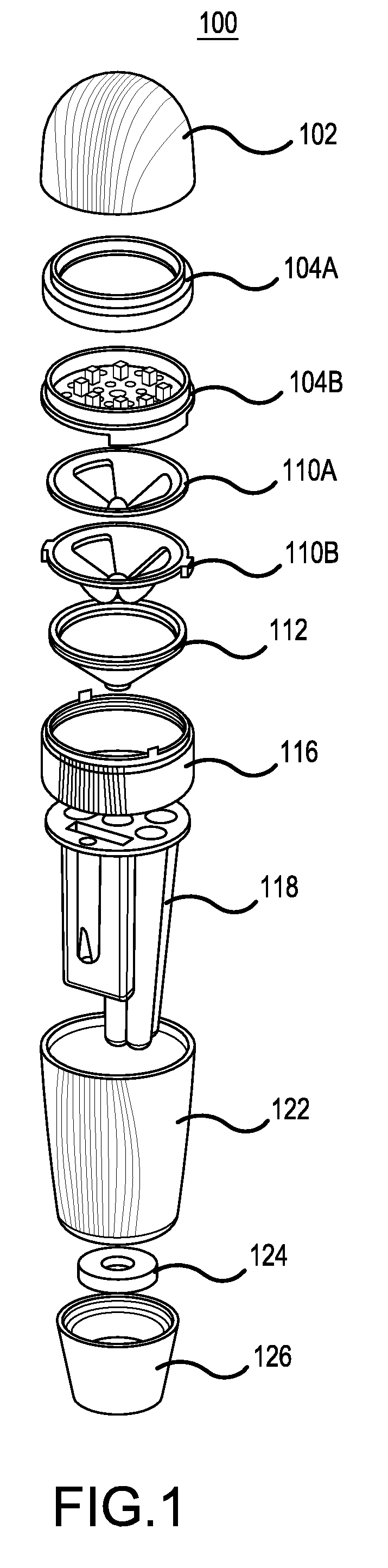

Combination herb holder and grinder system

InactiveUS20170245541A1Efficient and easy to smokeCoffee millsTobacco treatmentRolling paperEngineering

The invention features device for grinding and storing herbs and tobacco having a grinder and dispenser that grinds and dispenses the herbs and also holds the herbs and its paraphernalia. The device features storage compartments to hold herb paraphernalia. Release mechanisms such as a push button, slider or aperture allow the herbs to be dispensed directly into rolling paper for immediate use.

Owner:PAGAN MICHAEL

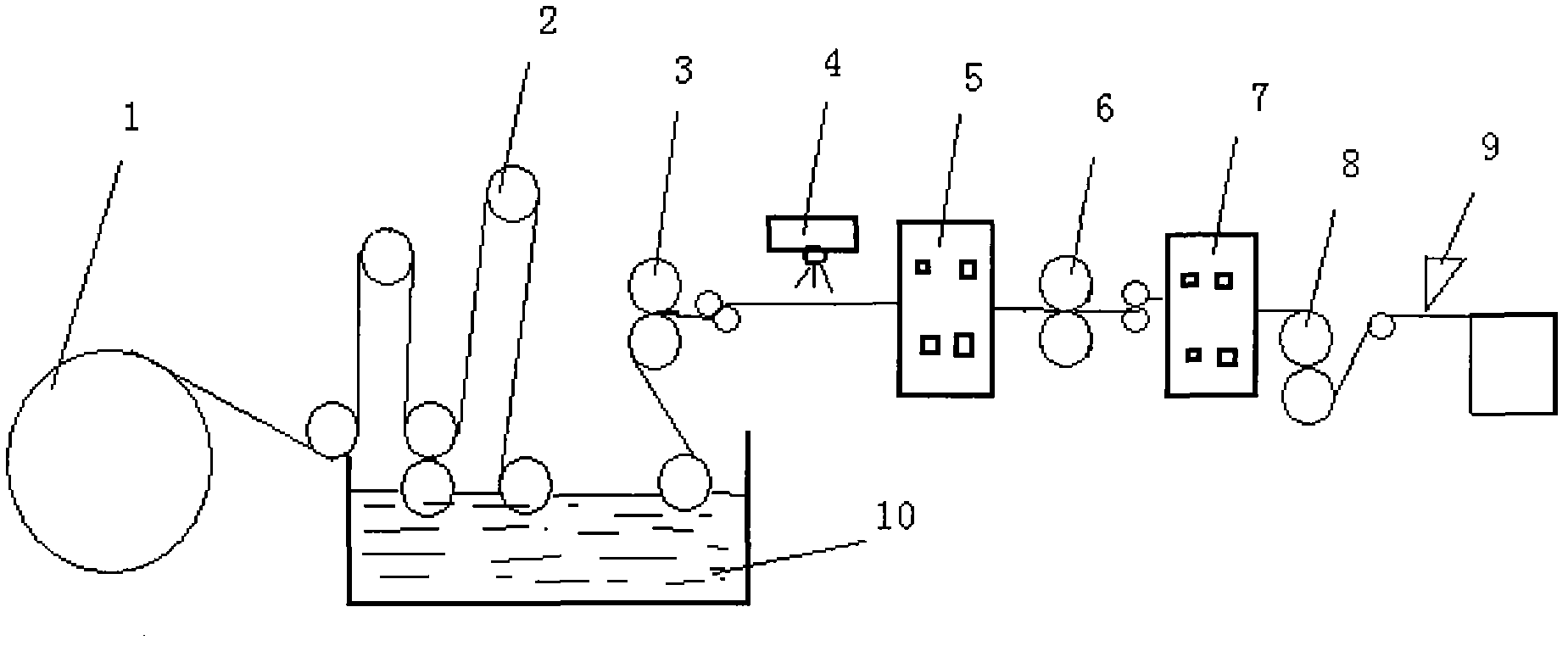

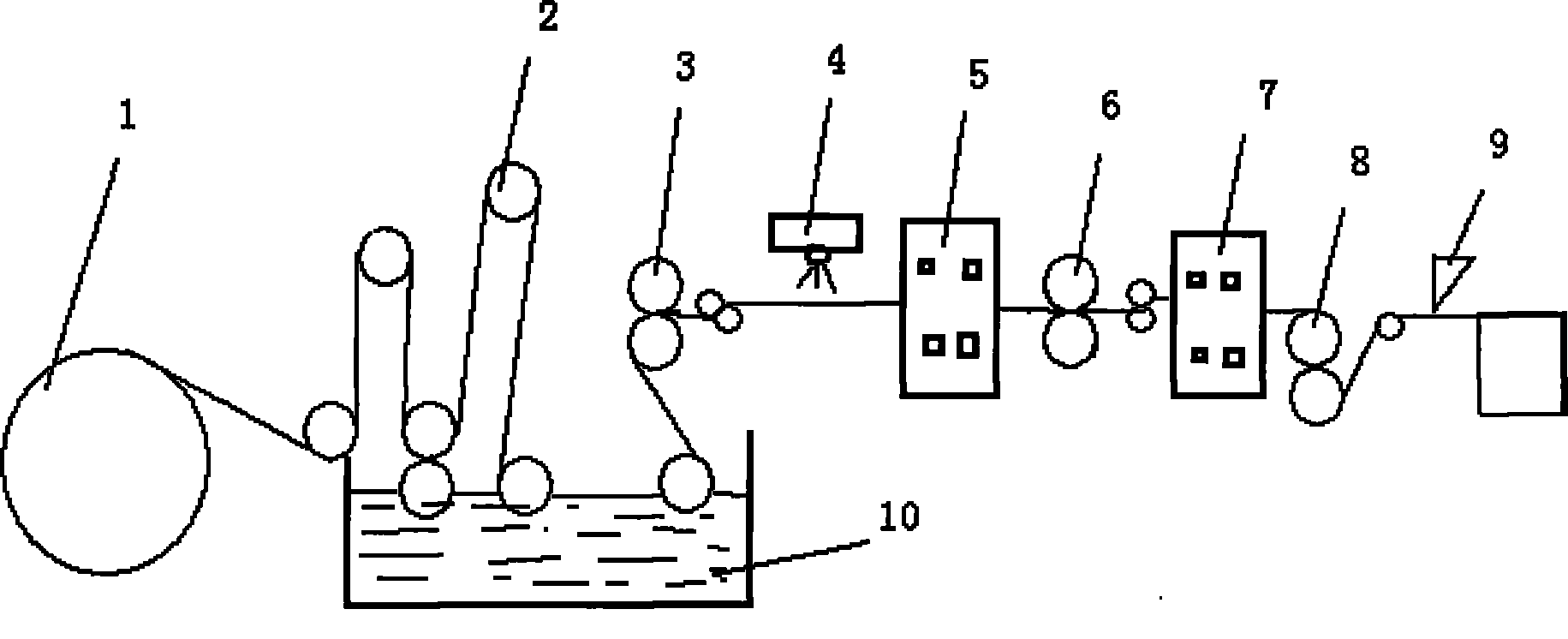

Method for manufacturing surface wear-resisting impregnated paper of laminate floor by dry-spraying Al2O3

ActiveCN102086616AImprove wettabilityImprove the wrapping effectNon-fibrous pulp additionPaper coatingRolling paperMelamine formaldehyde

The invention relates to a method for manufacturing surface wear-resisting impregnated paper of a laminate floor by dry-spraying Al2O3. The method comprises the following steps: impregnating pure wood pulp roll paper with a melamine-formaldehyde (MF) resin liquid; uniformly spraying the Al2O3 on the surface of the impregnated paper by utilizing a dry sprayer; allowing the impregnated and sprayed paper to enter a first oven for drying at the temperature of 100-150 DEG C; roll-coating 300-500% (relative to the weight of the paper) of the MF resin liquid on the paper surface after preliminary drying; and allowing the roll-coated paper to enter a second oven for drying at the temperature of 100-150 DEG C, controlling the whole-course running speed of the paper at 10-12m / minute, cooling, adjusting the temperature of the oven and machine speed so as to reach 6.0-7.5% of volatile matters and 40-60% of pre-curing degree, cutting and packaging. By means of the method, the defects of the prior art are overcome, and the spray quantity of the Al2O3 can be adjusted by controlling the dry sprayer so as to obtain the surface wear-resisting impregnated paper with reliable quality according to different wear-resisting requirements; and the method has the advantages of reasonable process and obvious effect, and is simple in operation, thus effectively improving the product quality.

Owner:天津市瑞鸿装饰材料销售有限公司

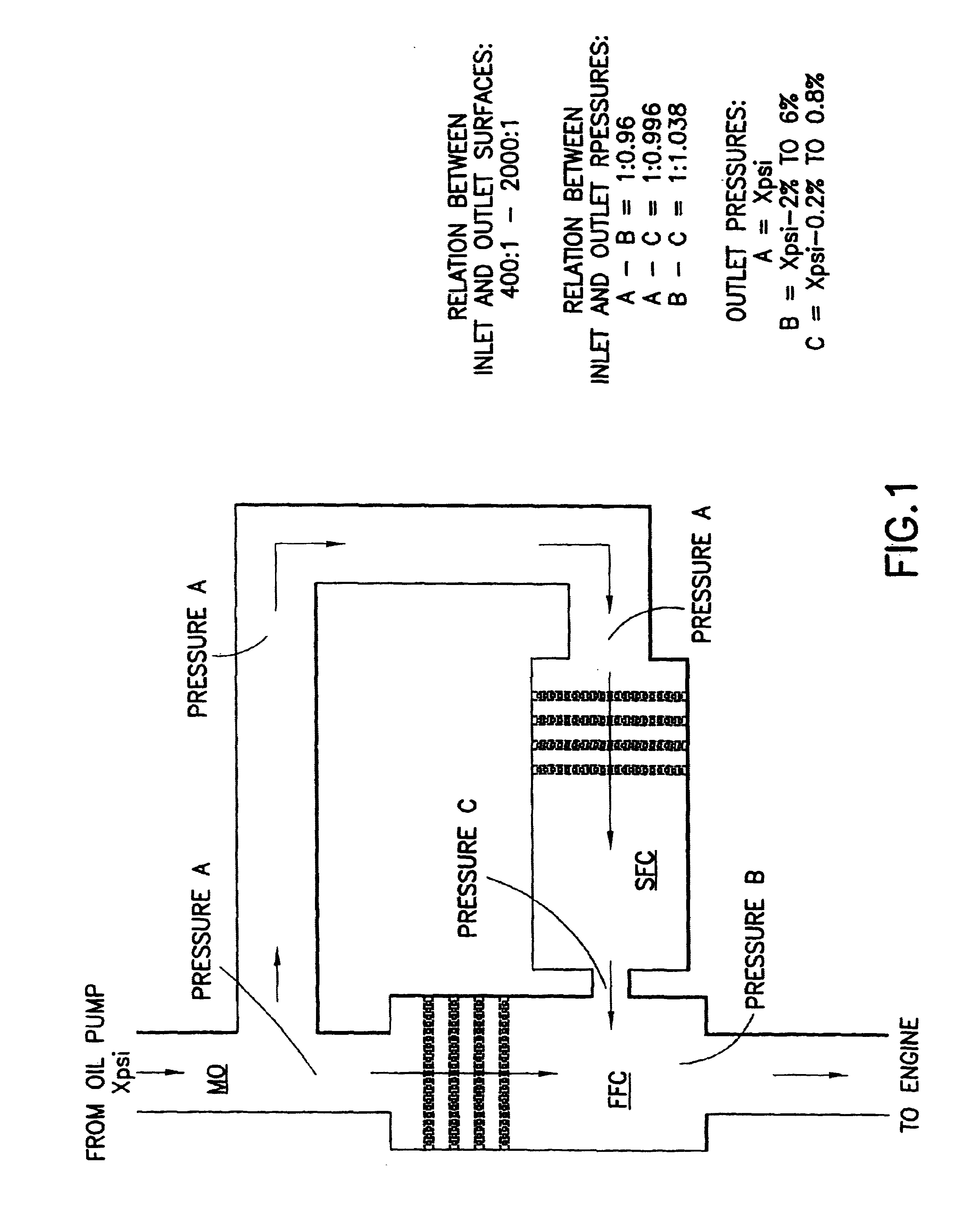

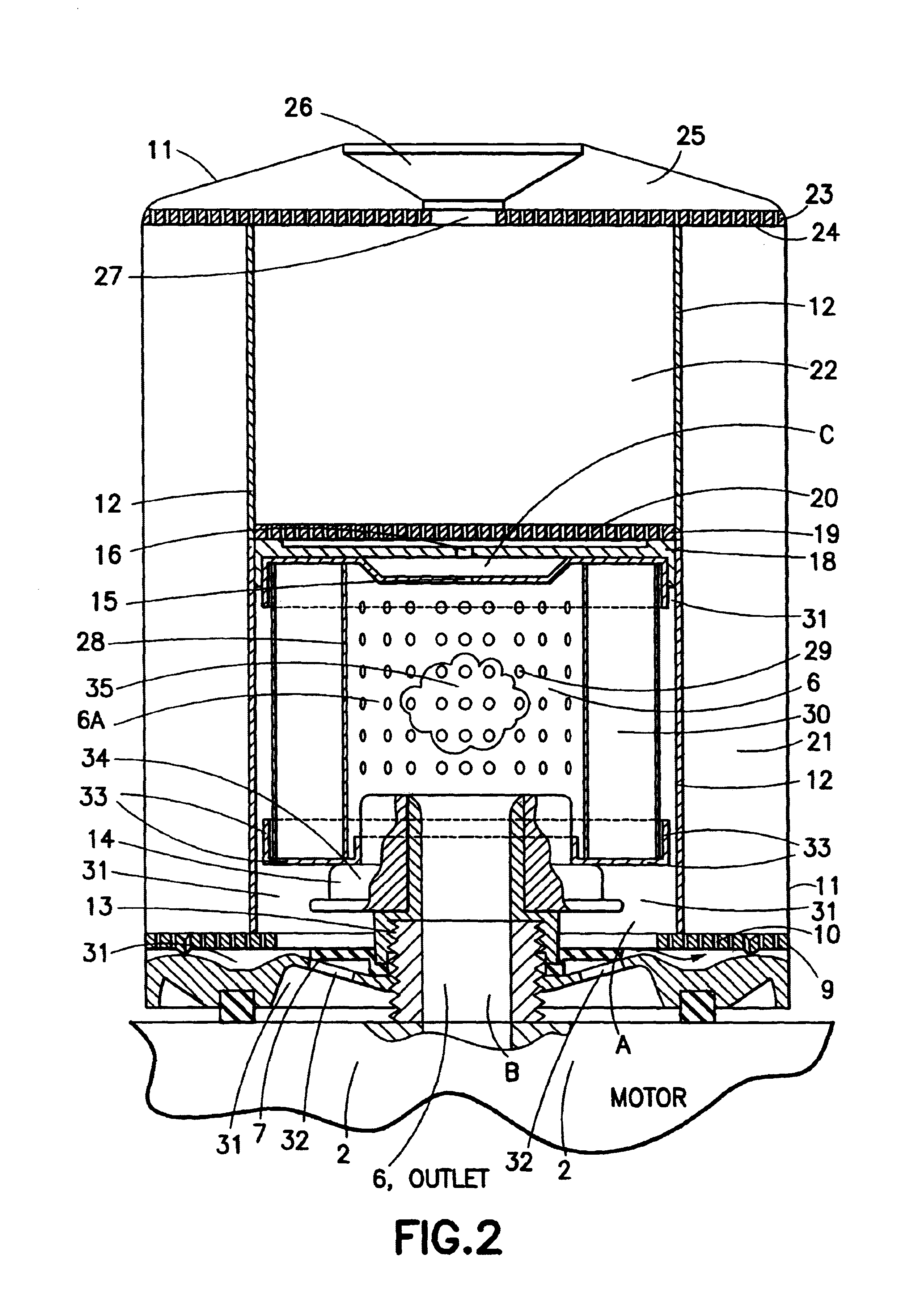

Hybrid spin-on filter

InactiveUS7048848B2Overcome problemsCompetitive costSettling tanks feed/dischargeSeparation devicesRolling paperSpins

A hybrid oil filter assembly includes a housing and a first (e.g., conventional) oil filter element disposed in proximity to a bottom portion of the housing. The first oil filter element contains an open inner volume. A second oil filter element having a generally circular cylindrical shape is disposed circumferentially about a length of the first oil filter element. The second oil filter element may be made of rolled paper and filters particles of a smaller size than the first oil filter element (e.g., down to about one microns, thereby providing micro-filtering of the engine oil).

Owner:ASSION NORBERT

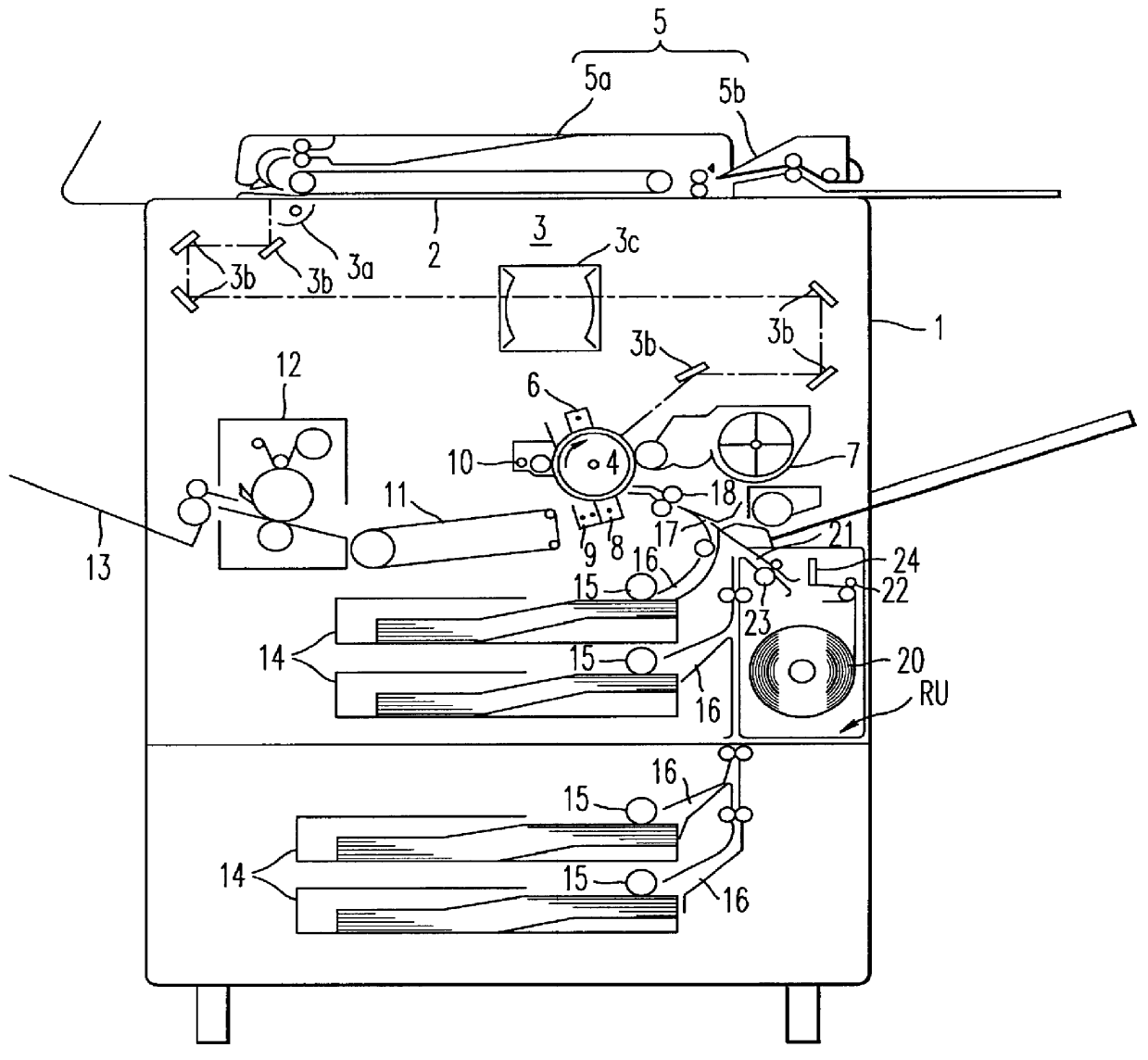

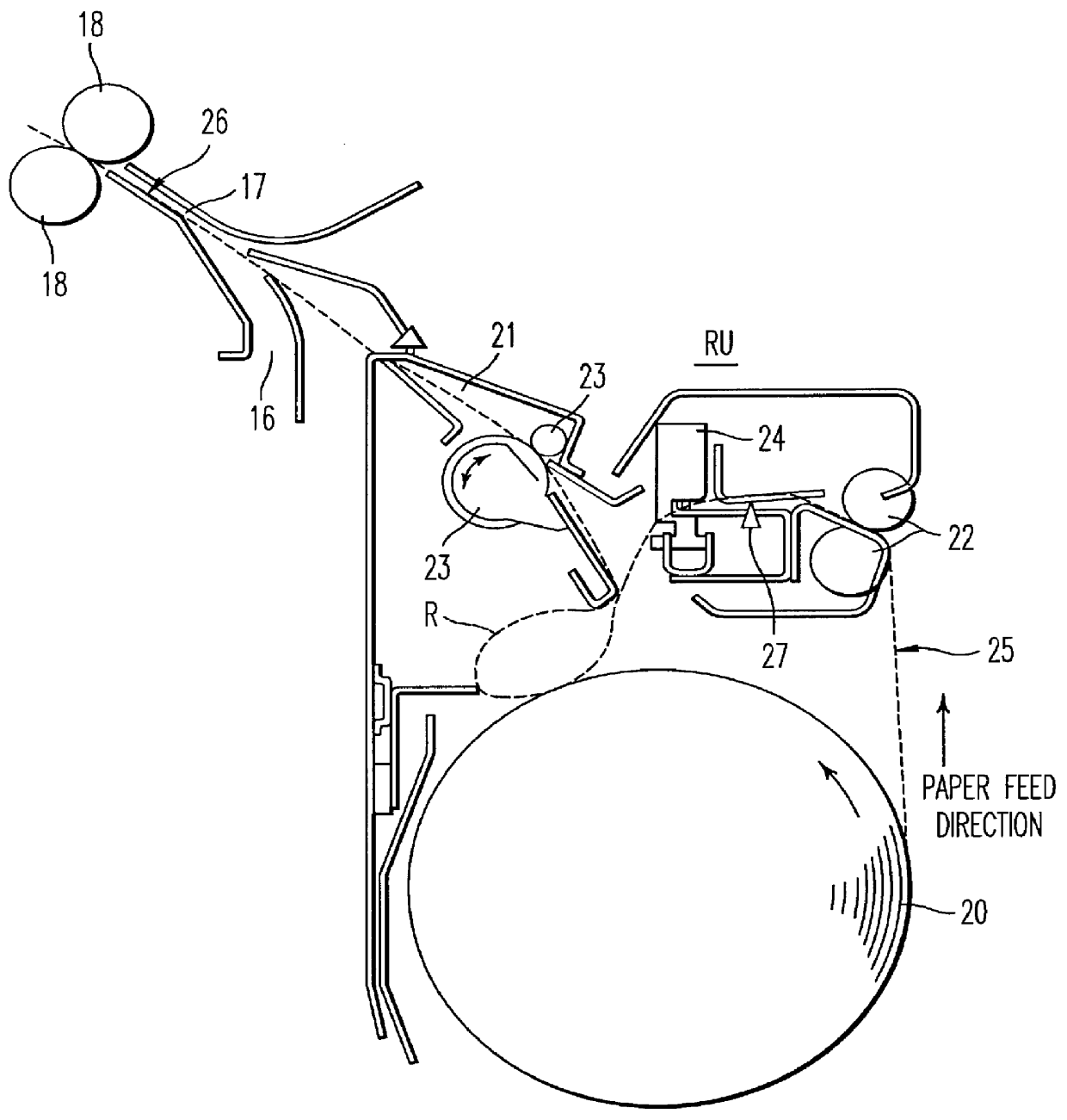

Rolled paper supply device for image forming apparatuses

InactiveUS6091928AEfficient processingEasy to disassembleFunction indicatorsElectrographic process apparatusRolling paperPulp and paper industry

Owner:COPYER

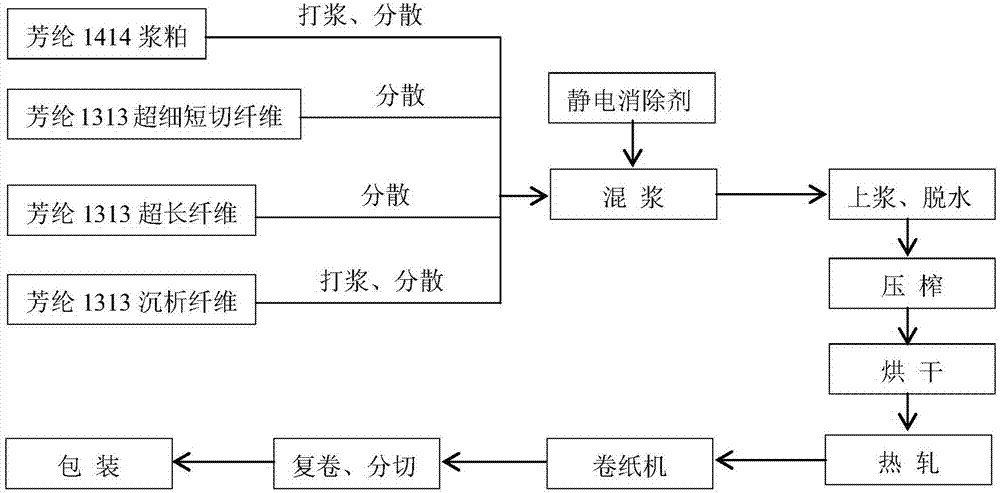

Battery diaphragm formed by aramid fibers and preparation method thereof

ActiveCN103943806AHigh mechanical strengthImprove thermal stabilityCell component detailsRolling paperThermal stability

The invention discloses a battery diaphragm formed by aramid fibers. The battery diaphragm is prepared from the following raw materials in proportion: 10-80% of aramid fiber 1414 pulp, 5-40% of aramid fiber 1313 superfine chopped fiber, less than or equal to 10% of aramid fiber 1313 overlength fiber, and 10-50% of aramid fiber 1313 fiber. A preparation process of the battery diaphragm formed by aramid fibers comprises the following steps: (1) weighing raw materials; (2) carrying out pretreatment on the raw materials; (3) preparing a sizing material and adding a static remover; (4) diluting the sizing material; (5) squeezing, drying, hot rolling, rolling paper, rewinding, cutting off and packaging to prepare the battery diaphragm. The battery diaphragm formed by aramid fibers has excellent mechanical strength, thermal stability, fatigue resistance and chemical corrosion resistance, and can be widely applied to the production of ion batteries.

Owner:YANTAI METASTAR SPECIAL PAPER

Roll paper holding mechanism and printer

InactiveUS20050232677A1Guaranteed uptimeAvoid inertia forceOther printing apparatusWebs handlingRolling paperCoil spring

Pressing plates press side faces of a roll paper loaded into a roll paper holder unit of the drop-in type, thereby preventing overrun of the roll paper caused by an inertia force from occurring. Each of the pressing plates is urged by two coil springs which are placed respectively on inner and outer circumference sides of the roll paper. The coil spring on the outer circumference side has a higher elasticity than the coil spring on the inner circumference side. According to the configuration, the pressing force of the pressing plates due to the elasticity of the coil springs is gradually reduced in accordance with reduction of a diameter of the roll paper.

Owner:STAR MICRONICS

Material-saving cigarette trade mark printing method

ActiveCN101318418ASimplify the calibration processReduce investmentRotary pressesOther printing apparatusHot stampingUltrasound attenuation

A cigarette brand printing method which saves the materials includes three working procedures o printing, stamping holography and die-cutting. The three working procedures are: (1) printing from roll to roll, namely slot-free printing is carried out; besides, a registration mark is printed on paper; (2) stamping holography is carried out on roll paper circle by circle; automatic hot stamping, a stamping holography device which is provided with a locating registration device, is carried out; (3) die-cutting is carried out circle by circle by a roll paper die-cutting machine which is provided with the registration device and an under-pressure convex-concave device. As mark lines are arranged along the length directions of each screen period, the invention is provided with multiple sets of registration correcting devices and the length of each screen period is only 0.5 to 1 m, the calibration on the devices is much easier. The cigarette brand printing method has the advantages of saving energy and pressing convex during die-cutting, thus effectively avoiding roll-to-roll gravure, namely the attenuation problem of the pressing convex effect during on-line pressing convex; stamping holography circuit by circle stops the phenomena of fogging and frothing during the original printing process.

Owner:CHANGDE JINPENG PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com