Patents

Literature

787 results about "Melamine formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

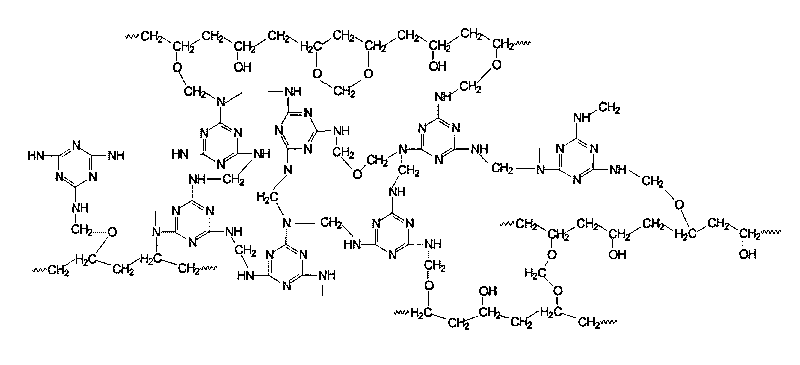

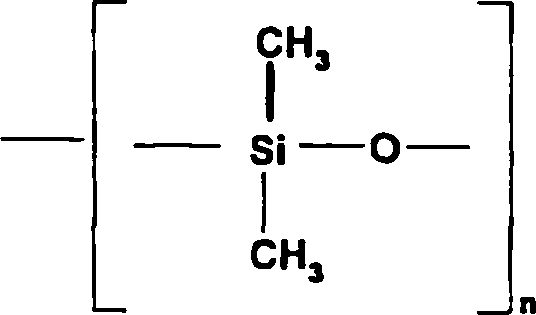

Melamine-formaldehyde resin, any of a class of synthetic resins obtained by chemical combination of melamine (a crystalline solid derived from urea) and formaldehyde (a highly reactive gas obtained from methane).

Perfume encapsulates

InactiveUS20040087477A1Improve stabilityImprove retentionGaseous substancesCapsule deliveryFlavorMelamine formaldehyde

A perfume encapsulate comprises an aminoplast capsule, the capsule shell comprising urea-formaldehyde or melamine-formaldehyde polymer and a second polymer comprising a polymer or copolymer of one or more anhydrides, preferably ethylene / maleic anhydride copolymer. The second polymer improves the stability of the capsules with respect to surfactant, thus improving perfume retention properties and enabling use of the capsules in aqueous surfactant-containing products in a way that has not hitherto been possible.

Owner:QUEST INTERNATIONAL

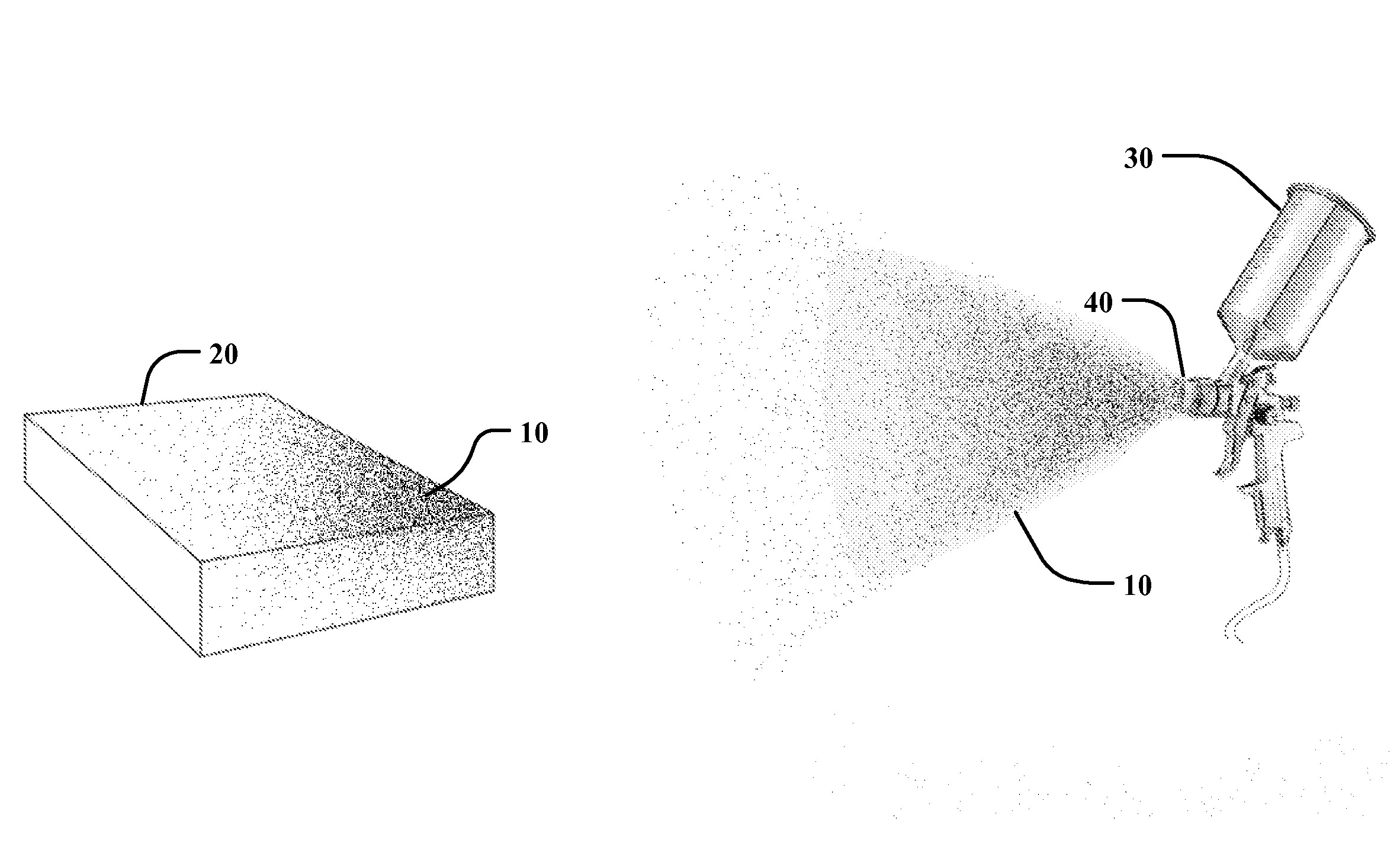

Melamine-formaldehyde microcapsule slurries for fabric article freshening

Described is a method for freshening fabric articles by means of spraying the articles with an aqueous slurry of microcapsules having rupturable melamine-formaldehyde polymeric walls, containing substantive and efficacious functional substances, e.g., malodour counteractants and / or fragrances. The slurry may optionally contain non-confined functional substances, e.g. malodour counteractants and / or fragrances. The method is effective for the deposition of effectively-rupturable malodour suppressant and / or fragrance emitting microcapsules onto fabrics wherein the resulting emitted fragrance activity and / or malodour counteractant activity is long-lasting and where the resulting substantive aroma is aesthetically pleasing over the long period of time for which it is effective. Also described are efficacious and substantive malodour counteractant compositions useful for the aforementioned process containing a malodour composition composed of zinc ricinoleate and at least one of: 1-cyclohexylethan-1-yl butyrate; 1-cyclohexylethan-1-yl acetate; 1-cyclohexylethan-1-ol; 1-(4′-methylethyl)cyclohexylethan-1-yl propionate; and / or 2′-hydroxy-1′-ethyl(2-phenoxy)acetate. In addition, described are efficacious microcapsule slurries useful for the aforementioned process containing microcapsules having melamine-formaldehyde polymeric capsule walls with the microcapsules being in contact with one or more polymeric silicone phospholipids.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

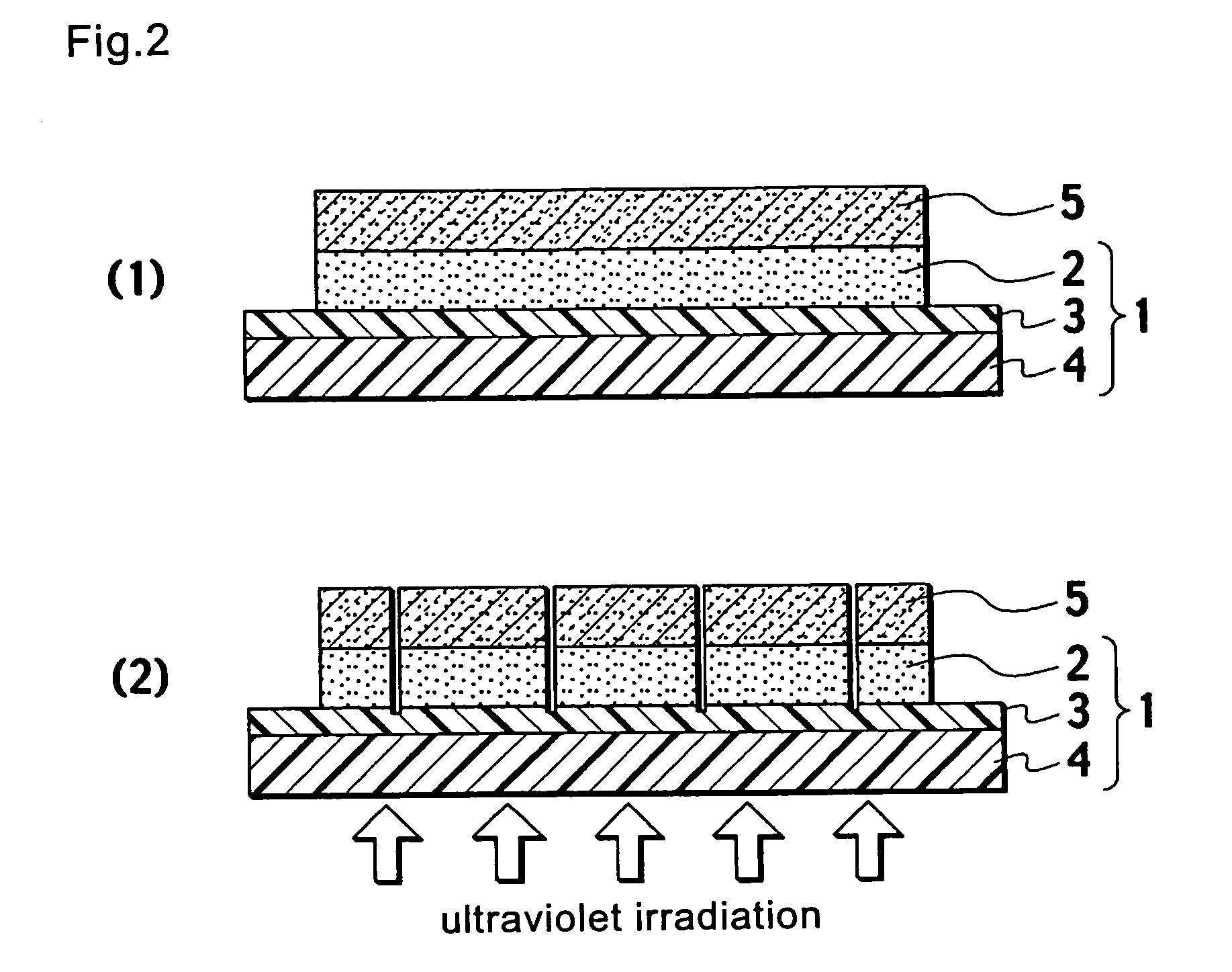

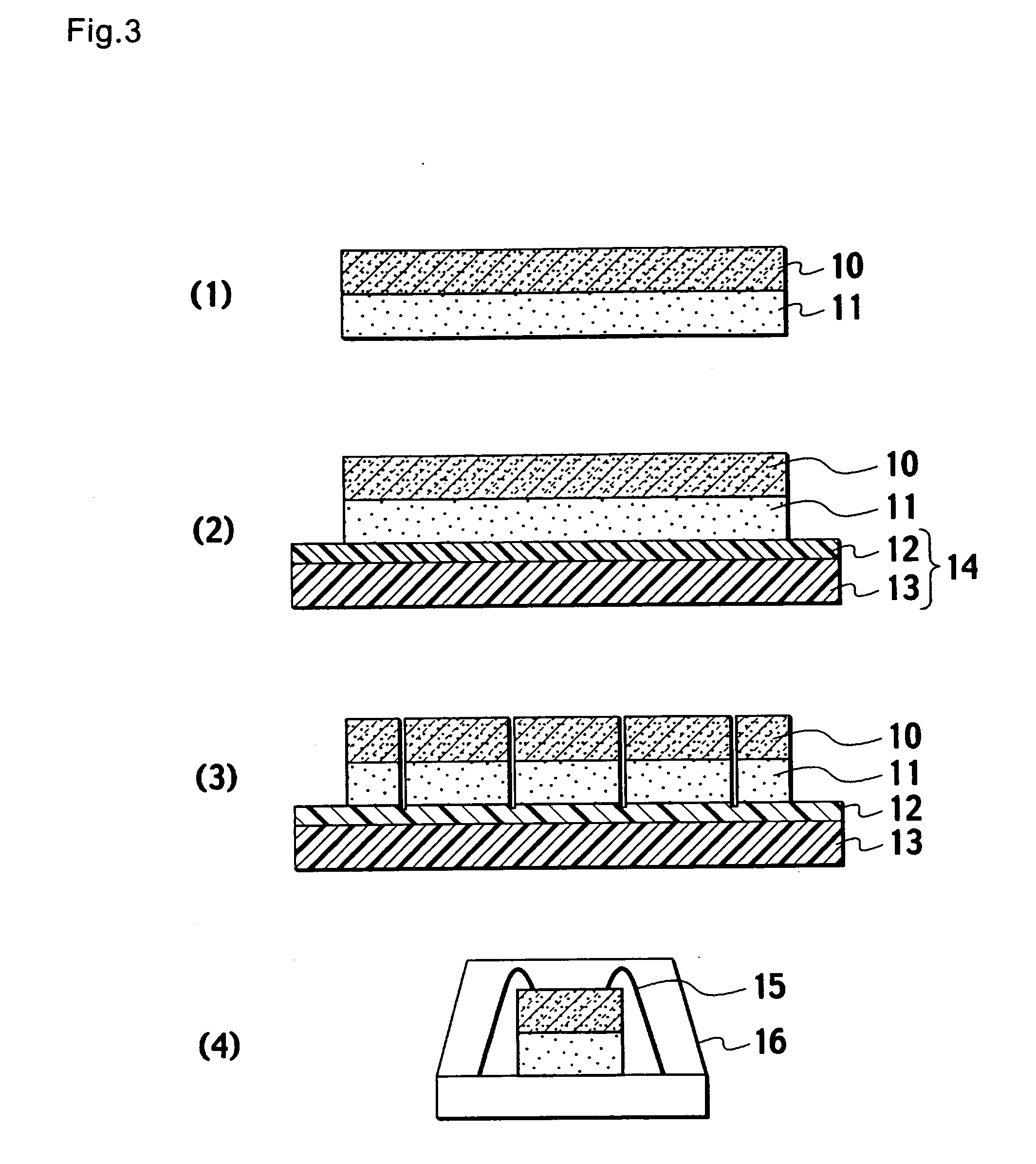

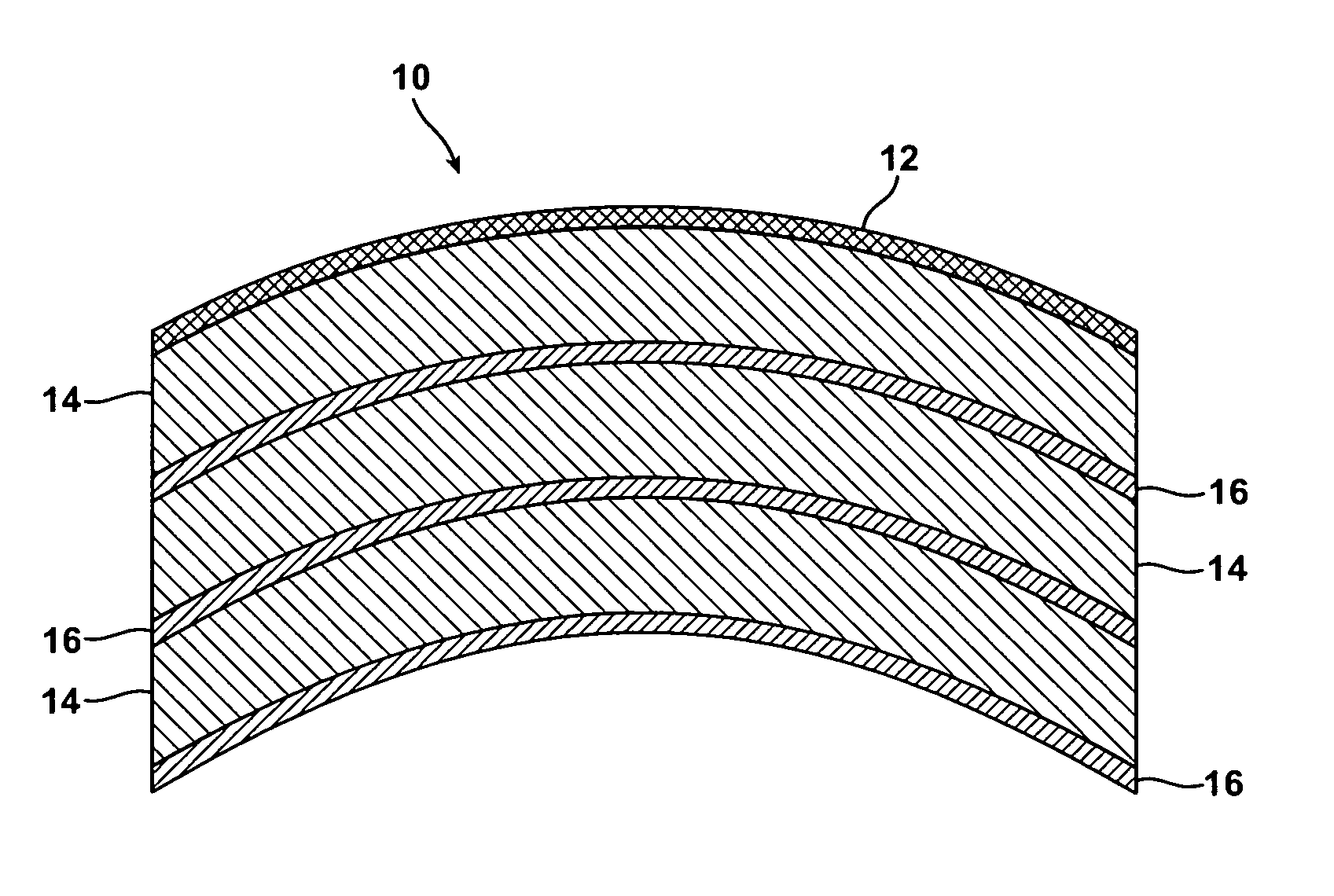

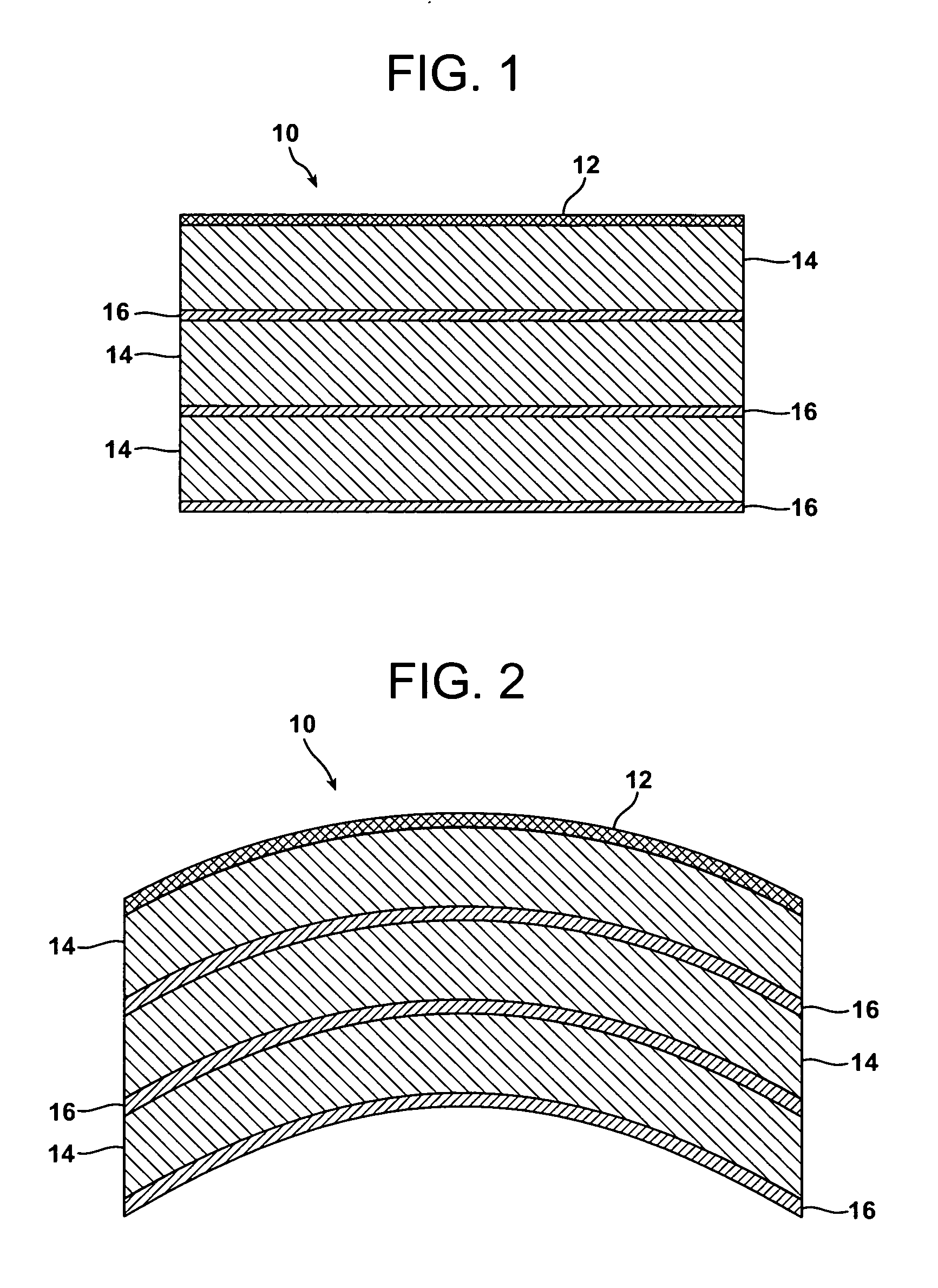

Dicing/die bonding sheet

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

High-flexibility melamino-formaldehyde foam material and preparation method thereof

The invention discloses a high-flexibility melamino-formaldehyde foam material and a preparation method thereof. The preparation method comprises: firstly, preparing melamino-formaldehyde prepolymer modified by polyol into aqueous solution with definite weight concentration; weighting 100 parts by weight of prepolymer aqueous solution; adding 0-15 parts by weight of surfactant, 1-20 parts by weight of foaming agent, 0-10 parts by weight of accelerator and 0-10 parts by weight of curing agent to be fully stirred and mixed to prepare foaming liquid; filling foaming liquid into a microwave chemical reactor or a high-temperature oven; and foaming for 30s-15min at the temperature of 100-300 DEG C to prepare the foam material. The melamino-formaldehyde foam material disclosed by the invention solves the problems of big brittleness, poor flexibility, easy duslting of foam, complex preparation technology, high production cost and the like of the existing melamino-formaldehyde foam material and has wide application prospect.

Owner:SICHUAN UNIV

A kind of warm mix asphalt additive and preparation method thereof

InactiveCN102268189ALower mixing temperatureClimate change adaptationBuilding insulationsMelamine formaldehydeReaction temperature

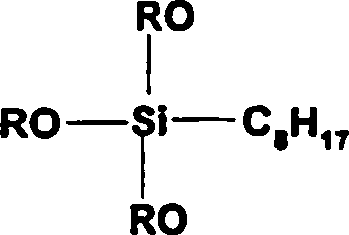

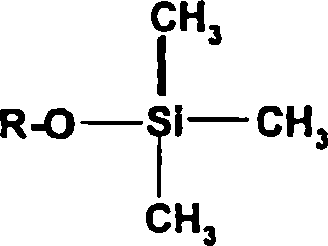

A warm-mix asphalt additive machine preparation method, the additive is formed by reacting the following components in parts by weight: 4-15 parts of alkoxysilane, 1-8 parts of polyether, 0-1 part of melamine formaldehyde resin, and 0 parts of acid catalyst -1 part, 0-1 part of alkali catalyst, 2-10 parts of deionized water, 30-100 parts of solvent; the preparation method comprises the following steps: (1) adding a quantitative amount of solvent and Alkoxysilane, heated to 80°C; (2) Add a mixture of acid catalyst, base catalyst, and deionized water, and react at a constant temperature of 80°C for 90 minutes; (3) Heat up to 100°C, condense and reflux for 120 minutes, and collect about 55ml of distillate; ( 4) Add an acid catalyst and a certain amount of polyether into the flask, heat up the esterification reaction for 180 minutes; (5) evacuate, condense and reflux for 30 minutes, cool down to room temperature, add a certain amount of melamine formaldehyde resin and stir evenly, add an appropriate amount of alkali catalyst to adjust the pH = 8 or so, the finished product is obtained.

Owner:杭州市城市建设科学研究院

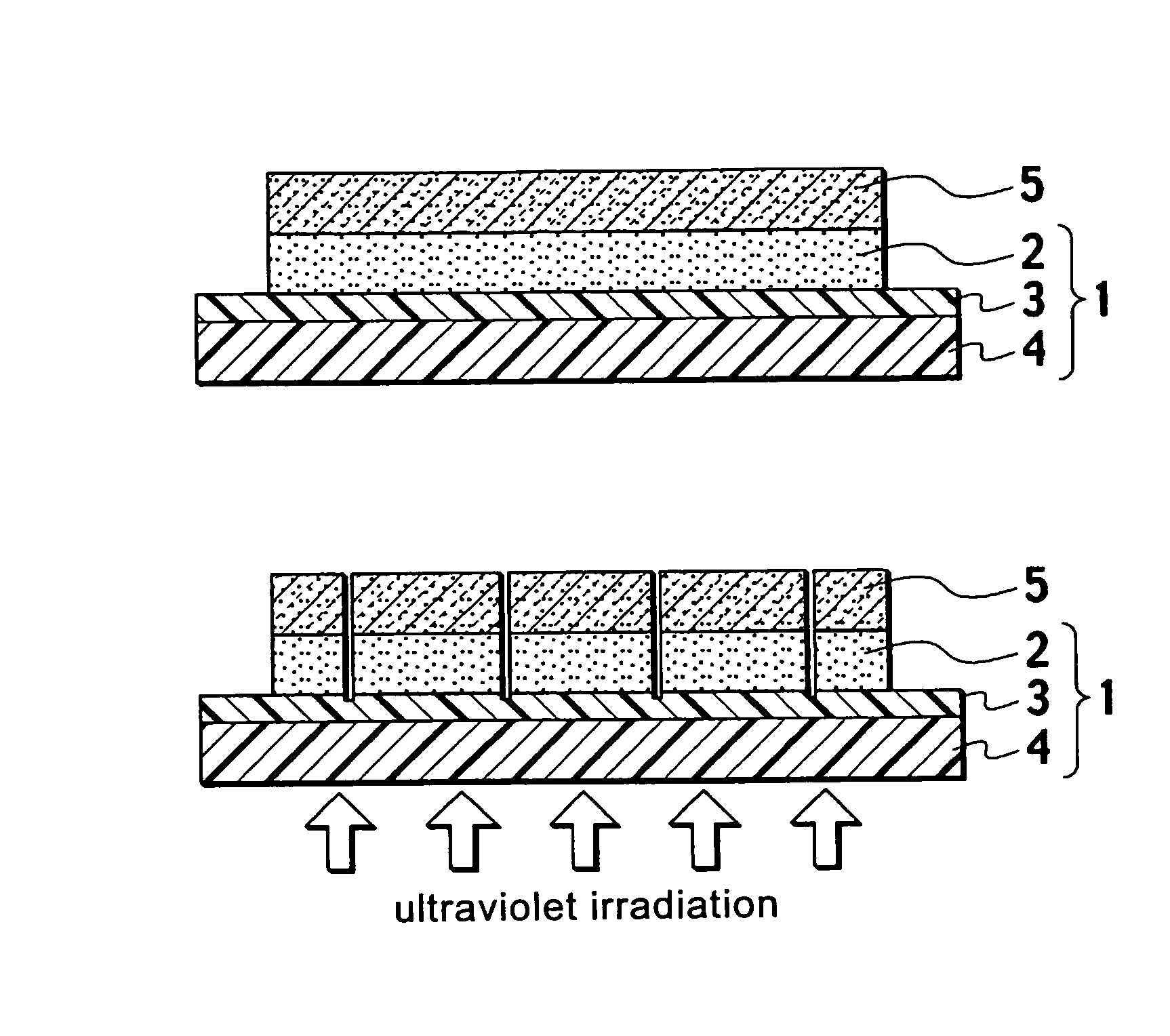

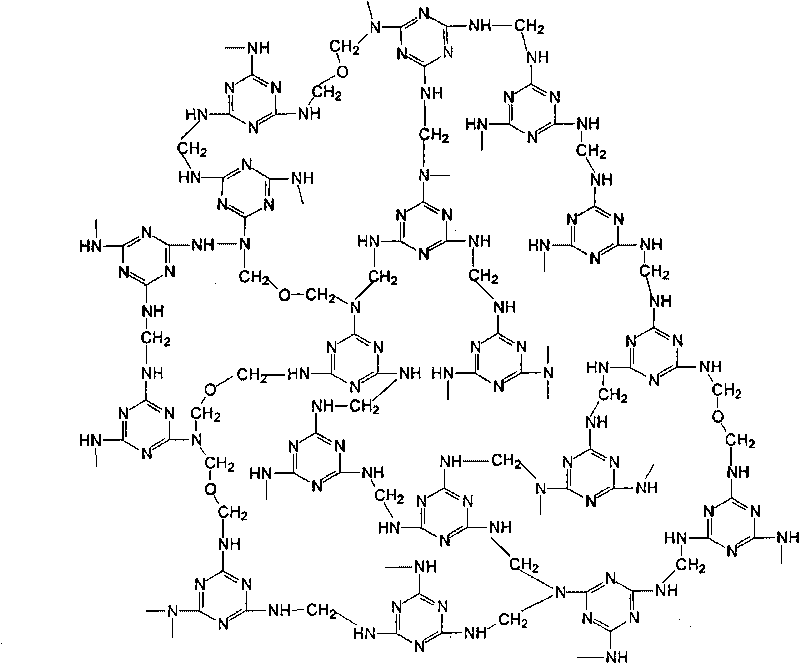

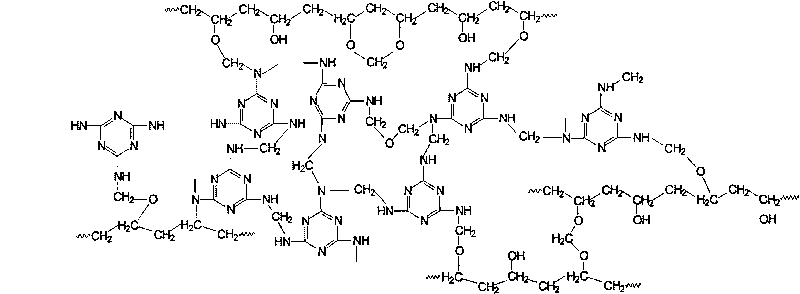

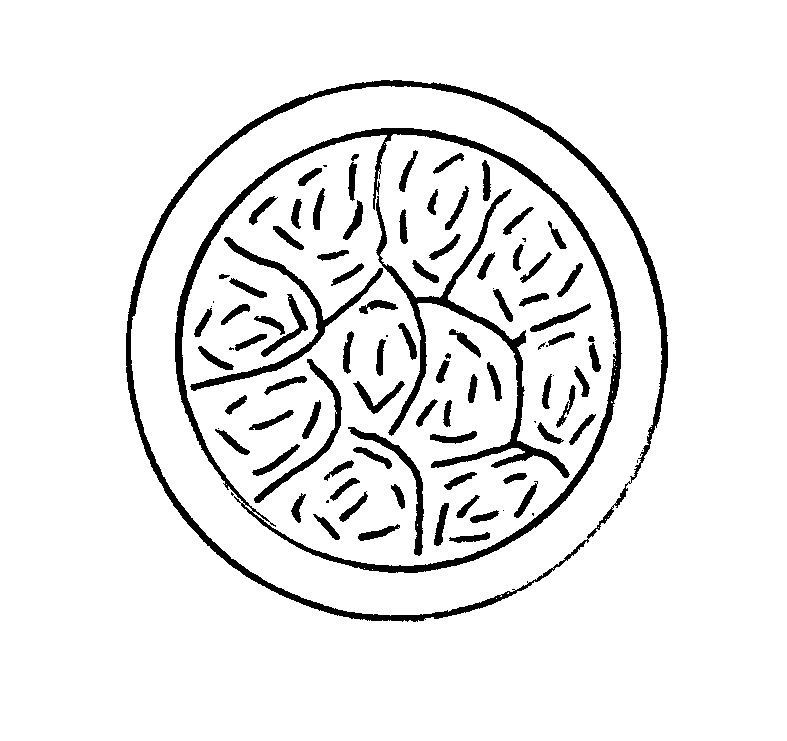

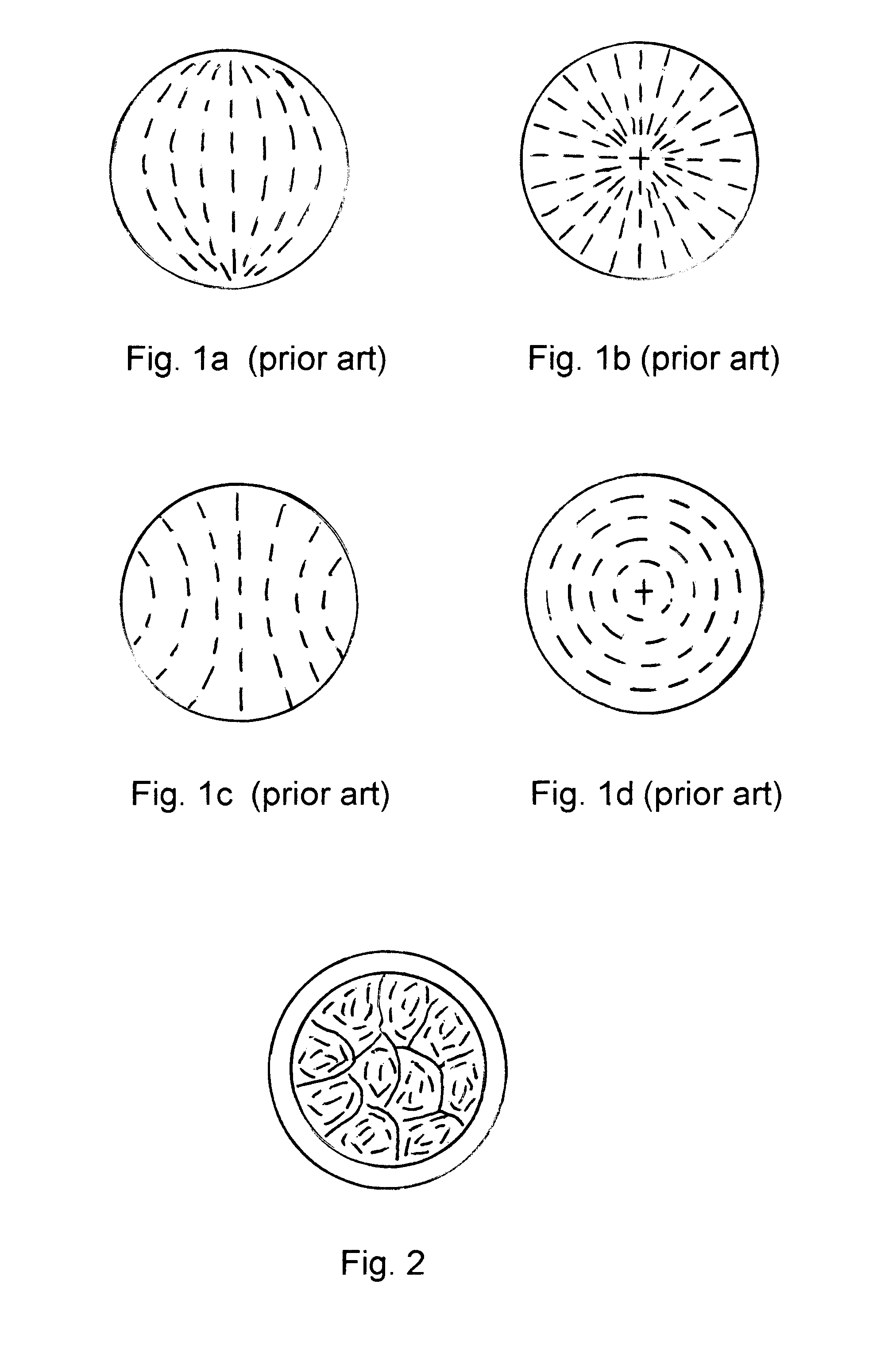

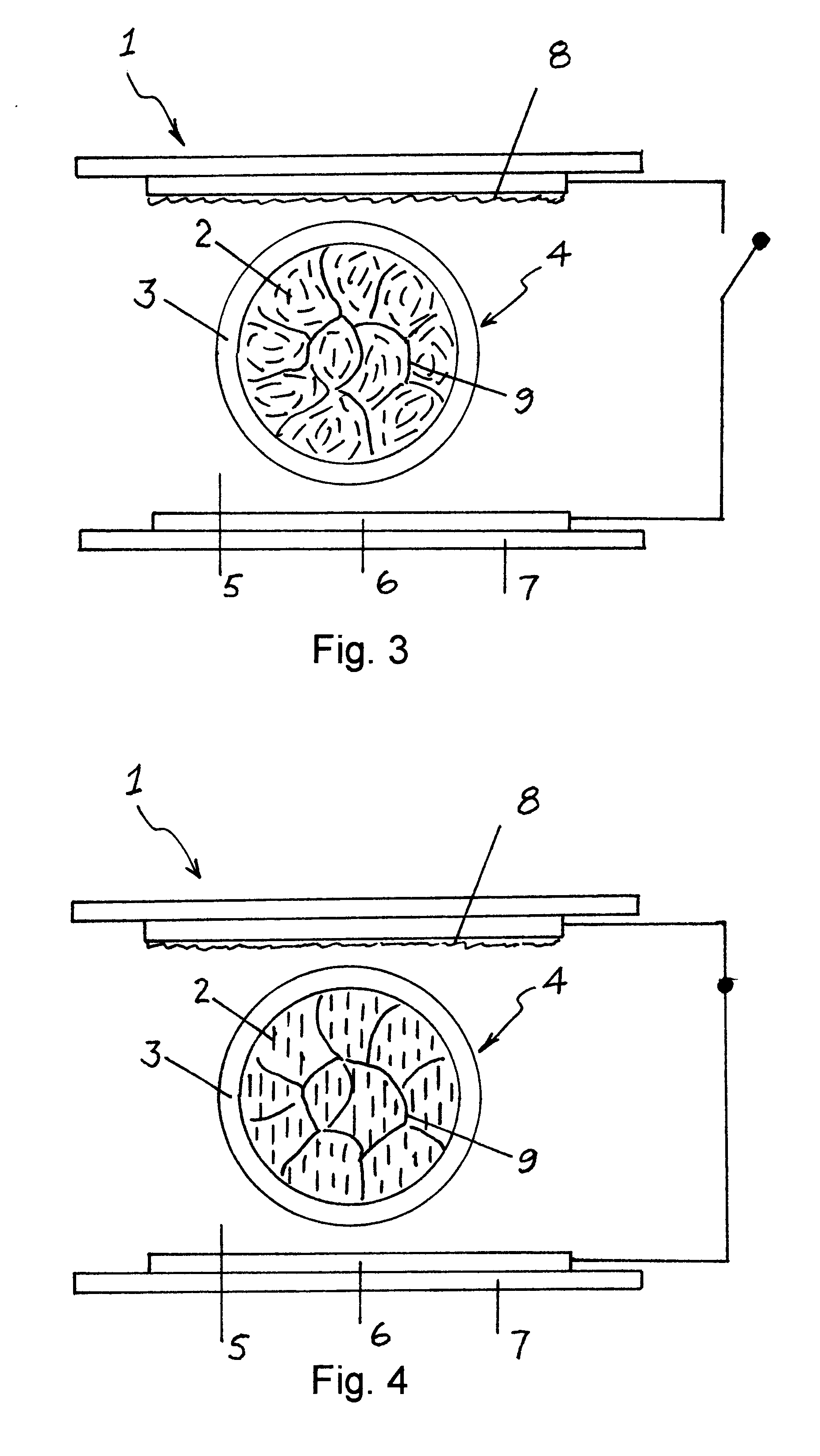

Microencapsulated liquid crystal having multidomains induced by the polymer network and method

A liquid crystal material containing polymer network forming material is microencapsulated by a method utilizing an interfacial polymerization which creates a combination of polyurethane and polyurea polymers or melamine fromaldehyde or urea formaldehyde polymer which form the capsule walls surrounding the discrete liquid crystal droplets. The prepolymer of urethane acrylate and acrylate within the liquid crystal capsules is cured under UV light irradiation to form a web-like structure and induce the formation of polydomain configuration of nematic director. This allows to produce the display having faster switching property and showing significant lower threshold voltage.

Owner:HSU YING YEN

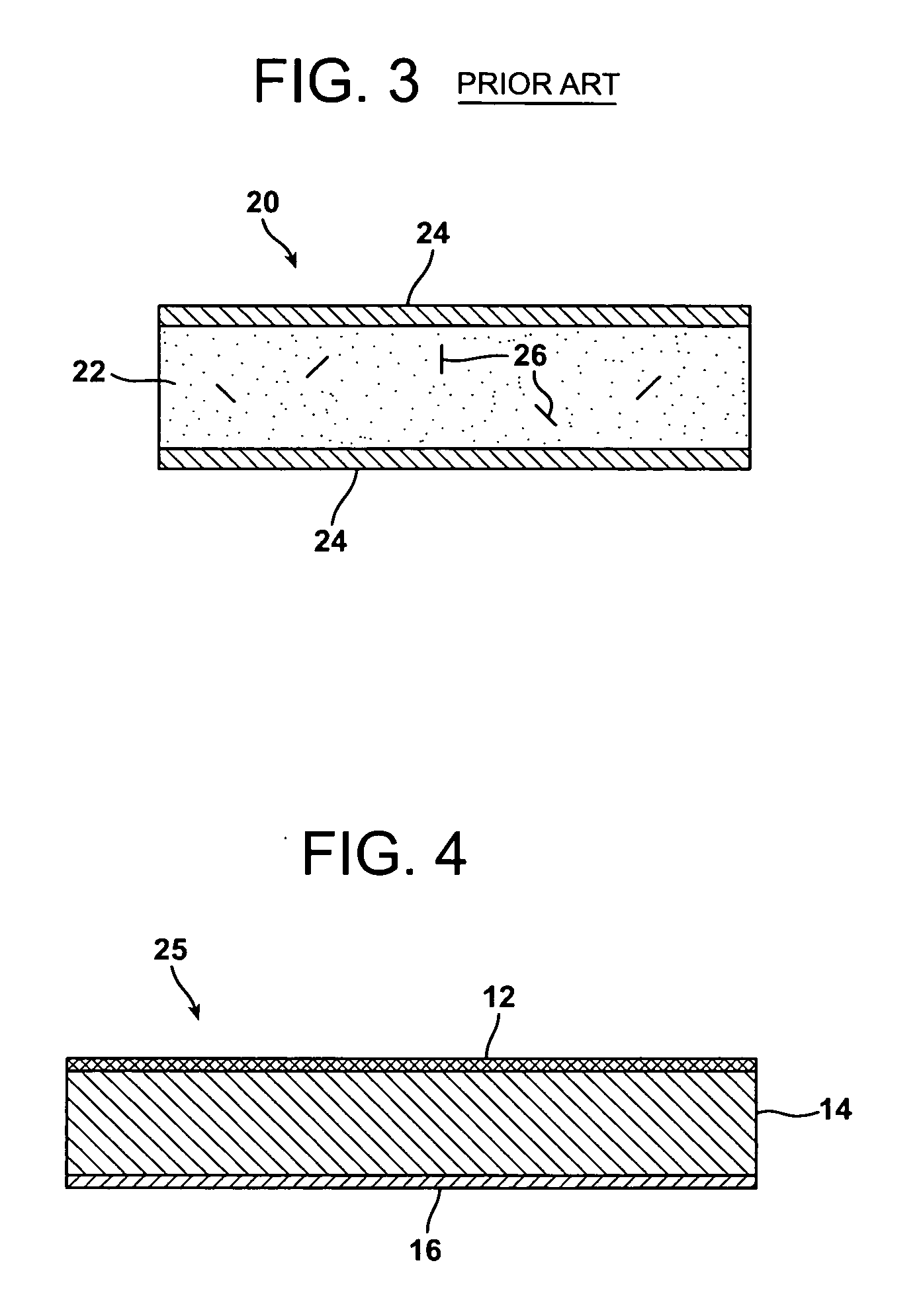

Low density drywall

InactiveUS20080057318A1Good physical propertiesImprove impact resistanceLiquid surface applicatorsBuilding componentsFiberWater dispersible

A thin drywall board that includes a gel coat, at least one polymer / gypsum layer, and a wet glass fiber layer is provided. The gel coat is formed of a gel coat composition that includes a water dispersible polymer, gypsum, and optionally a crosslinking agent and / or a coupling agent. The polymer / gypsum layer is formed of a matrix composition that includes a water dispersible polymeric resin and gypsum. Components including melamine formaldehyde, a filler material, coupling agents, acetic acid, an accelerator, and / or a hardener may also be added to the matrix composition. The wet glass fiber layer is preferably a glass fiber mat. The combination of the water dispersible polymeric resin and the gypsum in the matrix composition have a synergistic effect that creates a thin drywall board that is water resistant, fire resistant, and has improved mechanical properties. A method of forming the inventive thin drywall boards is also provided.

Owner:OCV INTELLECTUAL CAPITAL LLC

Three-source integrated microcapsule intumescent flame retardant and preparation method thereof

InactiveCN101812305AImprove toughnessHas a flame retardant synergistic effectMicroballoon preparationMicrocapsule preparationPolymer scienceMelamine formaldehyde

The invention discloses a three-source integrated microcapsule intumescent flame retardant and a preparation method thereof. The flame retardant integrates an acid source, a carbon source and a gas source; and the preparation method comprises the following steps of: reacting polyethylene glycol, melamine, aqueous solution of formaldehyde, a promoter with distilled water to prepare polyethylene glycol modified melamine-formaldehyde prepolymer; suspending ammonium polyphosphate powder particles in a dispersing agent; and adding the prepolymer and a hardener to finally obtain the three-source integrated microcapsule intumescent flame retardant powder particles. The flame retardant has good compatibility, flame retardancy and waterproofness.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method for melamine formaldehyde resin closed-cell foam

InactiveCN102898778AHigh closed cell rateImprove water resistanceThermal insulationMelamine formaldehyde resin

The present invention discloses a preparation method for melamine formaldehyde resin closed-cell foam. The preparation method comprises the following steps: introducing a modifier to a melamine formaldehyde resin synthesis process to carry out copolymerization, and carrying out a dehydration treatment on the synthesized resin to obtain a modified melamine formaldehyde solid resin with a solid content of more than 85%; adding a viscosity adjusting agent, dissolving the solid resin, respectively adding a curing agent, a foam stabilizer, an emulsifier and a foaming agent, and uniformly stirring; placing the resulting mixture in an oven or a microwave oven to carry out foaming to achieve a predetermined density; and placing the resulting material in the oven or the microwave oven to carry out aging to obtain the melamine formaldehyde foam with a closed-cell rate of more than 90%. The melamine formaldehyde resin closed-cell foam produced by the preparation method has excellent mechanical strength and flame retardant property, and can be applicable for building exterior wall thermal insulation.

Owner:NANTONG ZIXIN IND

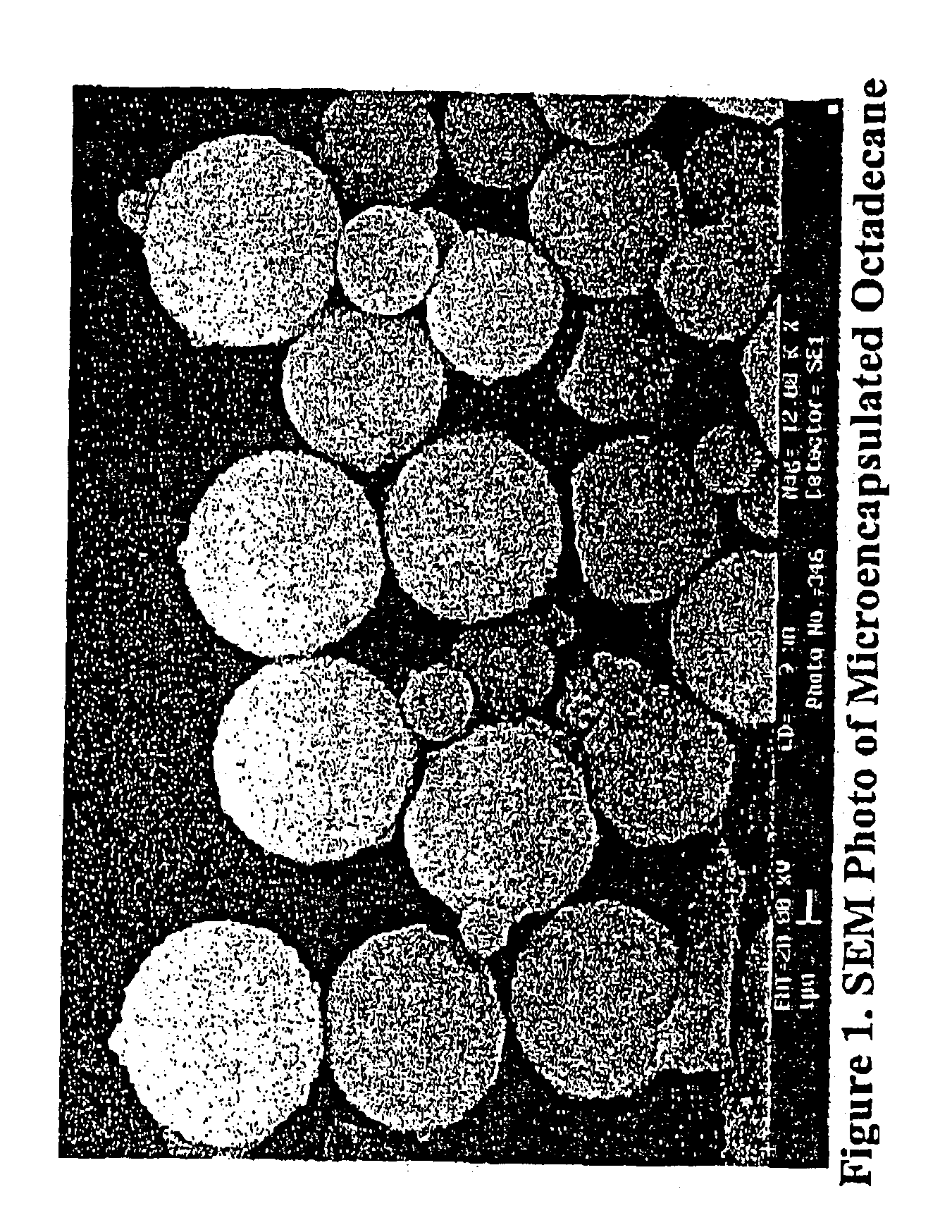

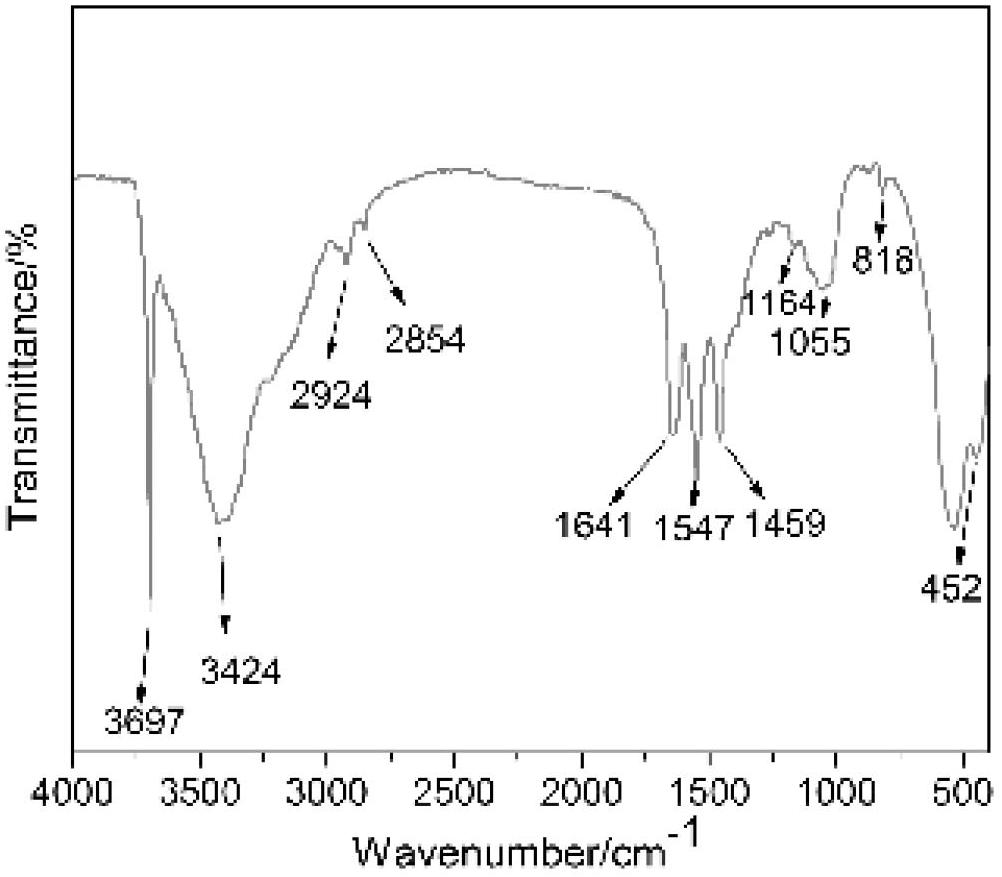

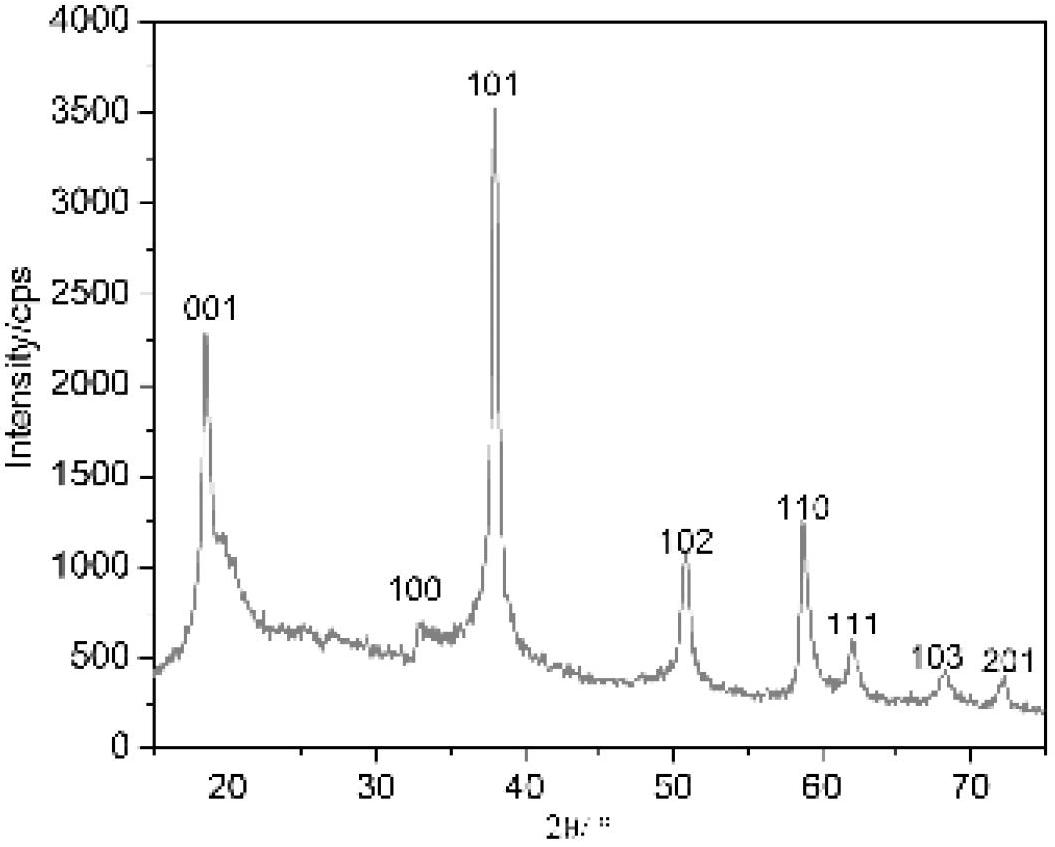

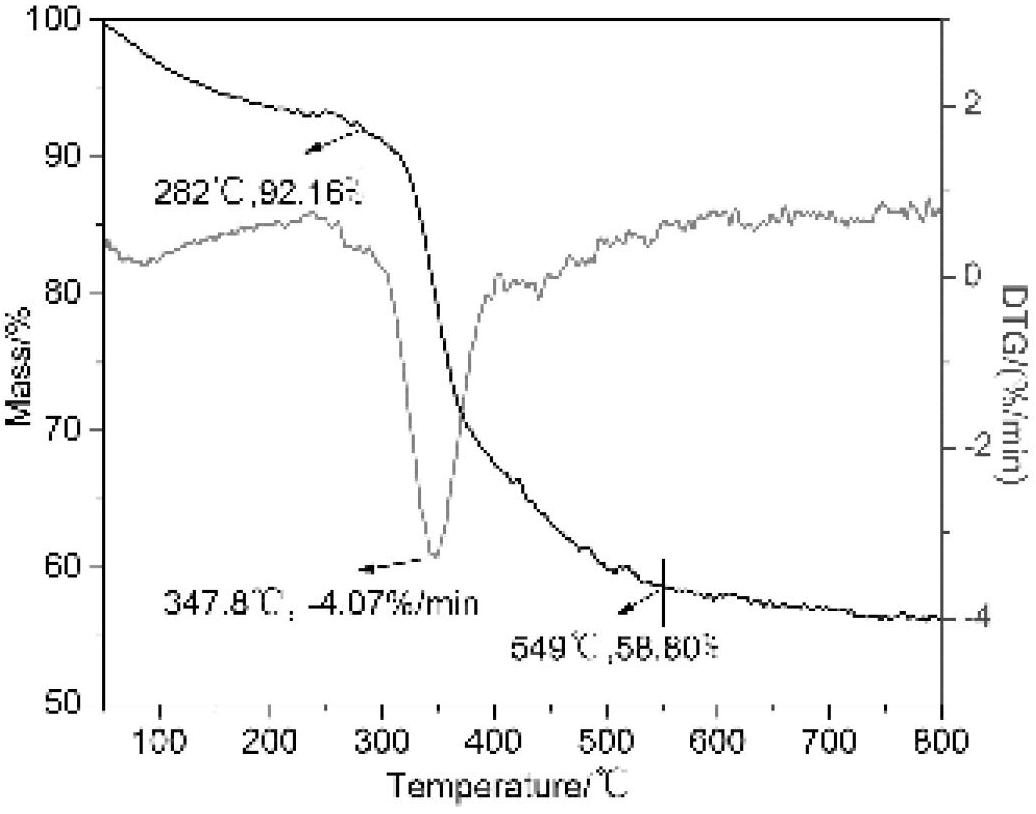

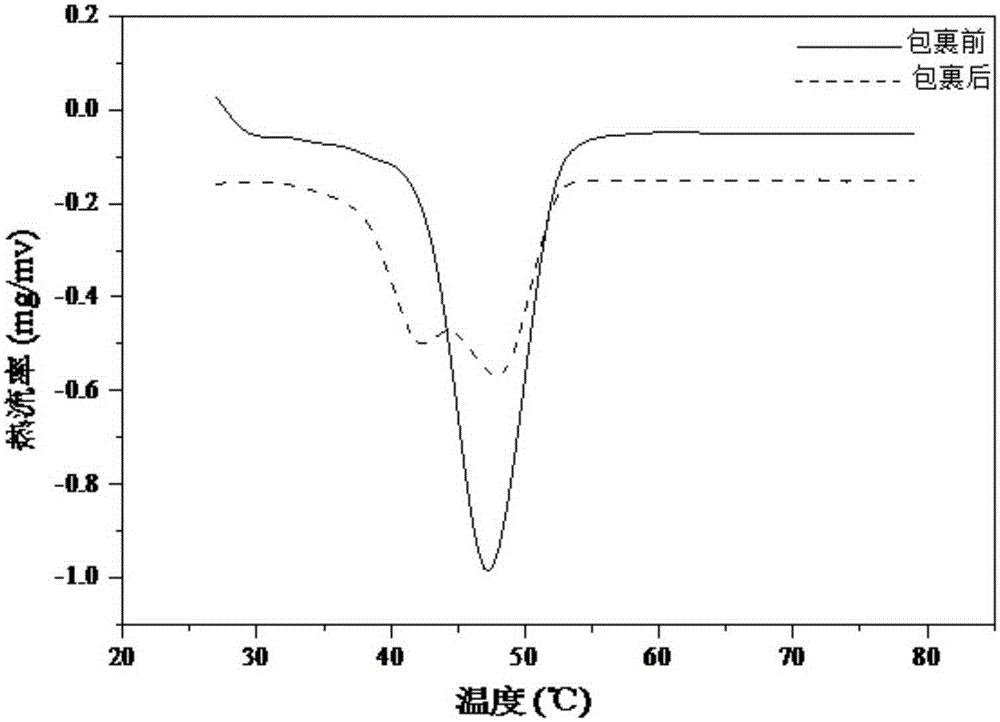

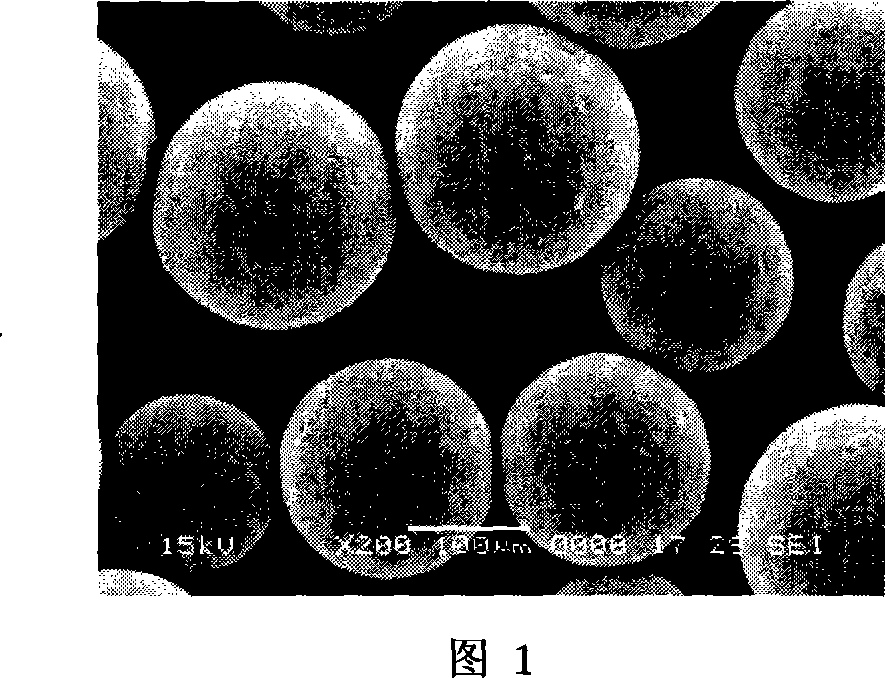

High temperature resistant type phase-change material micro-capsule and preparation thereof

InactiveCN101376800AImprove thermal stabilityLow thermal weight lossHeat-exchange elementsMicroballoon preparationMelamine formaldehydeHeat resistance

The invention relates to a high-temperature resistant phase-change material microcapsule and a preparation method thereof which belong to the technical field of compound materials. The invention needs to solve the technical problem of providing a high-temperature resistant phase-change material microcapsule in the field of melt spinning; the components thereof counted according to weight portions include 100 portions of core phase-change material, 7 to 12 portions of dispersant, 2 to 5 portions of emulsifying agent as well as a wall material prepared by 0.3 to 0.6 portion of modified monomer and 30 to 50 portions of melamine resin. The preparation method of the high-temperature resistant phase-change material microcapsule includes the emulsification of the core, the preparation of the prepolymer of the wall material, the preparation of the microcapsule and the removing of free formaldehyde. The high-temperature resistant phase-change material microcapsule has higher heat stability, heat-resistance as well as uniform grain sizes and can meet the requirements of spinning fibers. The preparation technique is simple, is conveniently operated, can save energies and is environmental friendly; the product is easy for industrialization production and has a better market prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Water-in-oil microencapsulation process and microcapsules produced thereby

A suspension of microcapsules in an organic liquid, the microcapsules containing an aqueous phase, is produced by interfacial polymerization in the presence of a proton transfer catalyst of a water-in-oil emulsion in which the aqueous phase contains a urea / formaldehyde or melamine / formaldehyde prepolymer.

Owner:ZENECA LTD

Adhesive and sealant systems

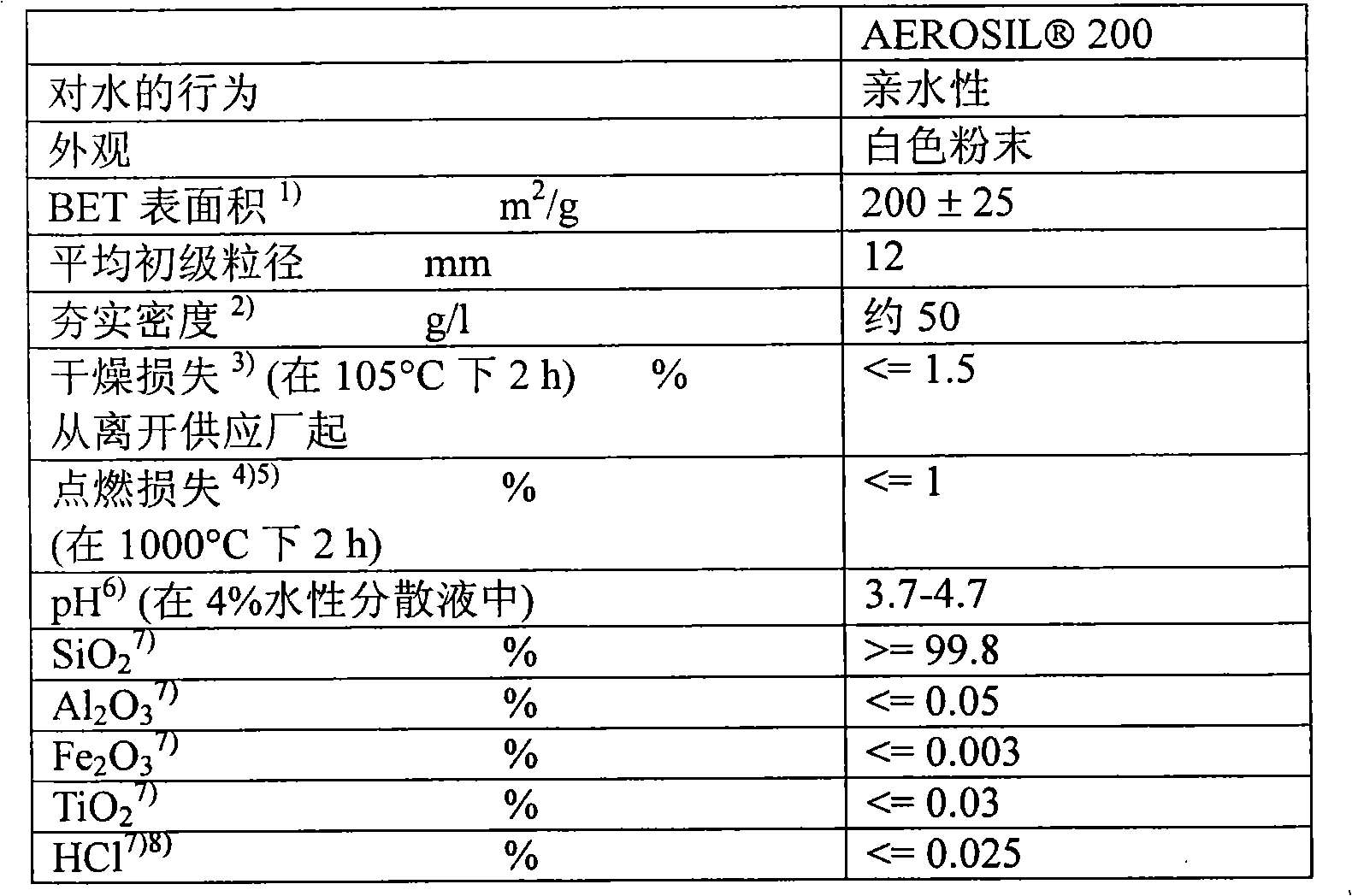

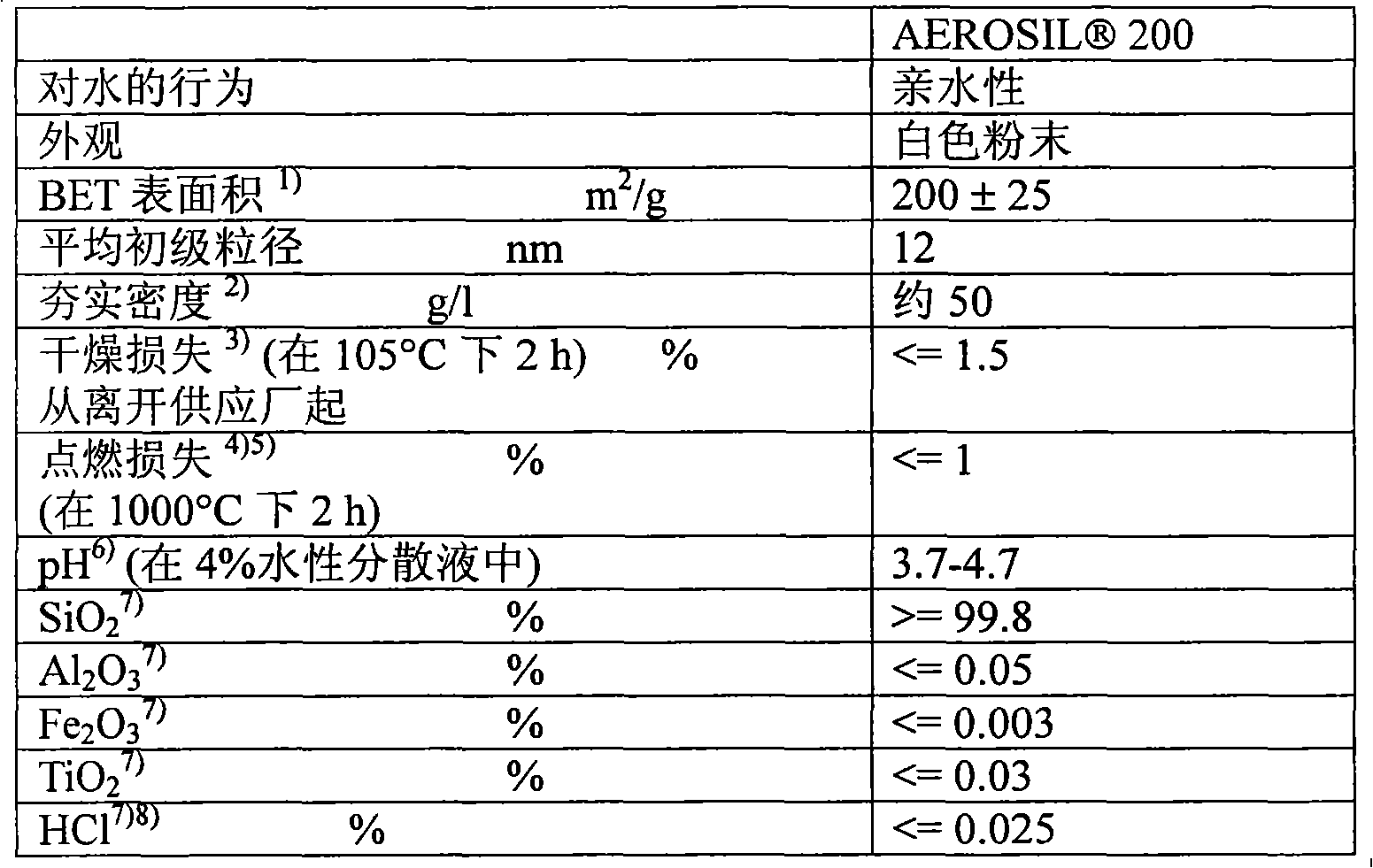

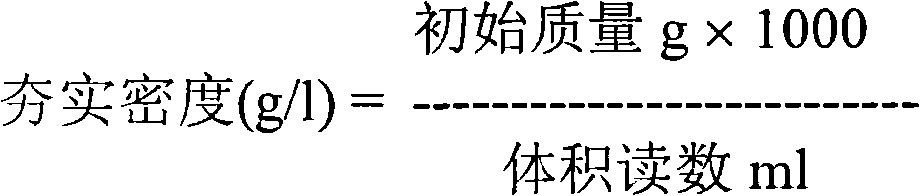

Adhesive and sealant systems based on epoxy resins, polyurethane, silane-terminated polymers, silicones, unsaturated polyester resins, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ether, ethylene vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulfide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles, polysulfones, which contain 1 wt.% to 15 wt.% of a compacted, hydrophobic pyrogenic silica.

Owner:DEGUSSA AG

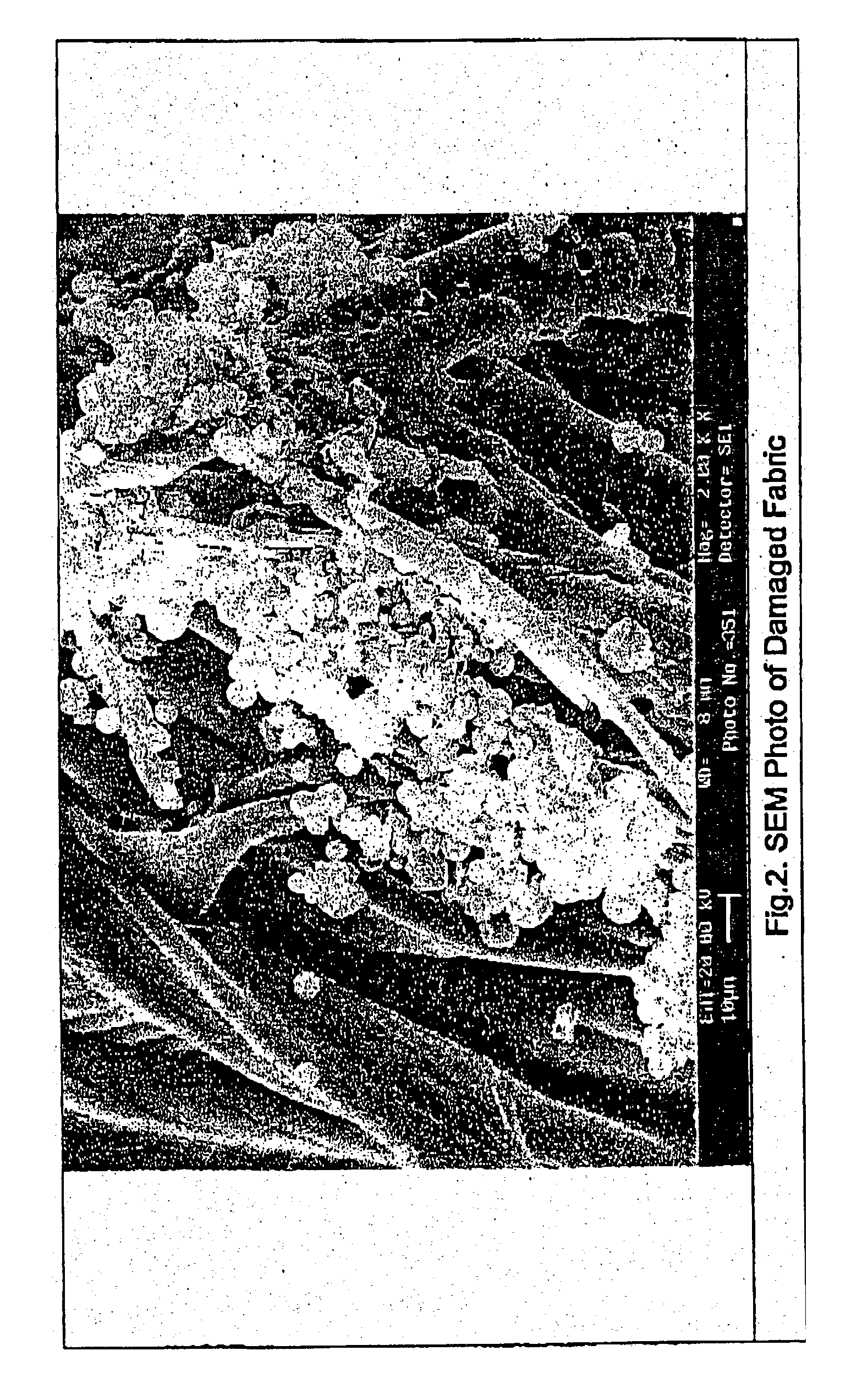

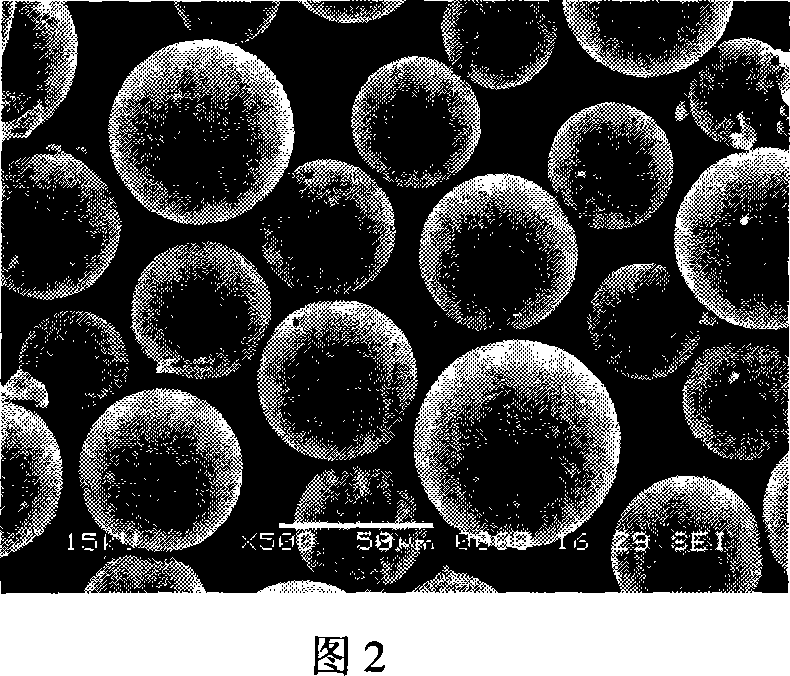

Method for encapsulating phase transitional paraffin compounds using melamine-formaldehyde and microcapsule resulting therefrom

A process for the microencapsulation of phase transitional paraffin compounds is described. Polypropylene glycols with the average molecule weight over 400 were used as the surface tension modifiers for emulsifying the paraffin compounds. Polyisocyanates capable of being dissolved in the phase change materials were employed to promote the deposition of melamine, partially methylolated melamine and the precondensate of melamine-formaldehyde onto the hydrophobic droplets for the microencapsulation. The prepared emulsion of microencapsulated phase change materials was successfully coated on textile fabrics and the coated products showed improved thermal regulation function.

Owner:NANO SPORTS TECH

Hybrid fire retardant and preparing method thereof

InactiveCN102690661AImprove flame retardant performanceFireproof paintsMelamine formaldehydeSynthesis methods

The invention relates to the technical field of a hybrid fire retardant and relates to the hybrid fire retardant and a preparing method thereof. The hybrid fire retardant, which is mainly used as an adding type fire retardant, can be added to a polymer material. A nano-scale melamine formaldehyde polycondensate is synthesized in an acid bittern solution, and the melamine formaldehyde polycondensate is used as a nucleating agent used in the synthesis process of magnesium hydroxide so as to prepare a magnesium hydroxide / nano-scale melamine formaldehyde polycondensate hybrid fire retardant. According to the invention, a magnesium hydroxide fire retardant is provided, and at the same time a fire retardant element N is added, thus the hybrid fire retardant synthesized by using the method is high in fire retardant efficiency, simple in synthesis method and better in market prospect.

Owner:CHANGZHOU UNIV

Non-halogen flame-proof urethane elastomer flame resisting agent and method of preparing the same

ActiveCN101108914ADoes not affect mechanical propertiesGood compatibilityPolyurethane elastomerPolymer science

The invention relates to a halogen-free flame retardant polyurethane elastomer flame retardant and the preparation method. The flame retardant comprises the following components and contents (weight per cent): melamine-formaldehyde coating ammonium phosphate 30 per cent to 70 per cent, triethylol isocyanurate 10 per cent to 35 per cent, melamine cyanurate 5 per cent to 20 per cent, phosphonate 10 per cent to 20 per cent, organic silane coupling agent 0.1 per cent to 0.5 per cent and antioxidant 0.1 per cent to 0.8 per cent. The preparation method of the flame retardant comprises the process steps such as the mixture of the melamine-formaldehyde coating ammonium phosphate. Compared with the prior art, the invention overcomes the defect of harm of halogen flame retardant polyurethane elastomer on the environment and the human body, endows the materials with certain difficult-flammability, has good compatibility with the polyurethane and has no effect on the mechanical properties of the polyurethane.

Owner:SHANGHAI RES INST OF CHEM IND

Non-yellowing polyester coating composition

A non-yellowing coating composition particularly useful as primer that has a low VOC and excellent adhesion and chip resistance and comprises an aqueous coating composition having a VOC of less than 0.12 kg / L (1.0 pounds / gallon) comprising 25-70% by weight of a film forming binder and correspondingly, 75-30% by weight of an aqueous carrier for the binder and the composition contains pigment in a pigment to binder weight ratio of 5 / 100 to 150 / 100 and has a pH of 7-10; wherein the binder comprisesa. 50-90% by weight, based on the weight of the binder, of a blend of the following constituents: a dispersed acrylic polymer, a dispersed polyester having an acid value of 15-60, a number average molecular weight from 1500-7000 and a hydroxyl value of not more than 95 and a hydroxy terminated component that is either a polyalkylene ether polyol or a urethane diol or a mixture of the above hydroxy terminated components, andb. 10-50% by weight, based on the weight of the binder, of a water-compatible alkylated melamine formaldehyde crosslinking agent; andwherein a hydroxy functional alkyl amine is used to neutralize the binder and adjust the pH of the composition.

Owner:AXALTA COATING SYST IP CO LLC

Preparation method of flame-retardant melamine hard foam

The invention belongs to the technical field of macromolecular foam materials, and in particular relates to a preparation method of flame-retardant melamine hard foam. The method comprises the steps of performing reaction on melamine and paraformaldehyde according to a mole ratio of 1:(1.5 to 3.5), melamine and a modifier I according to a mass ratio of 1:(0.1 to 0.6) and alcohol serving as a solvent under a water bath of 75 DEG C till the materials are clarified and transparent, adding a modifier II and melamine into resin according to a mass ratio of (0.05 to 0.2):1, continuously performing reaction for 0.5-2 hours, removing the solvent, and adjusting the solid content by water to 85-92 percent to obtain a foam prepolymer. The flame-retardant melamine hard foam prepared by the preparation method disclosed by the invention has the advantages of high compressive strength, high closing rate, excellent flame retardancy and the like, cannot enable powder to fall off and can be applied to the air conditioner air pipe, laminboard and external wall heat preservation material markets.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Method for the production of abrasive foams

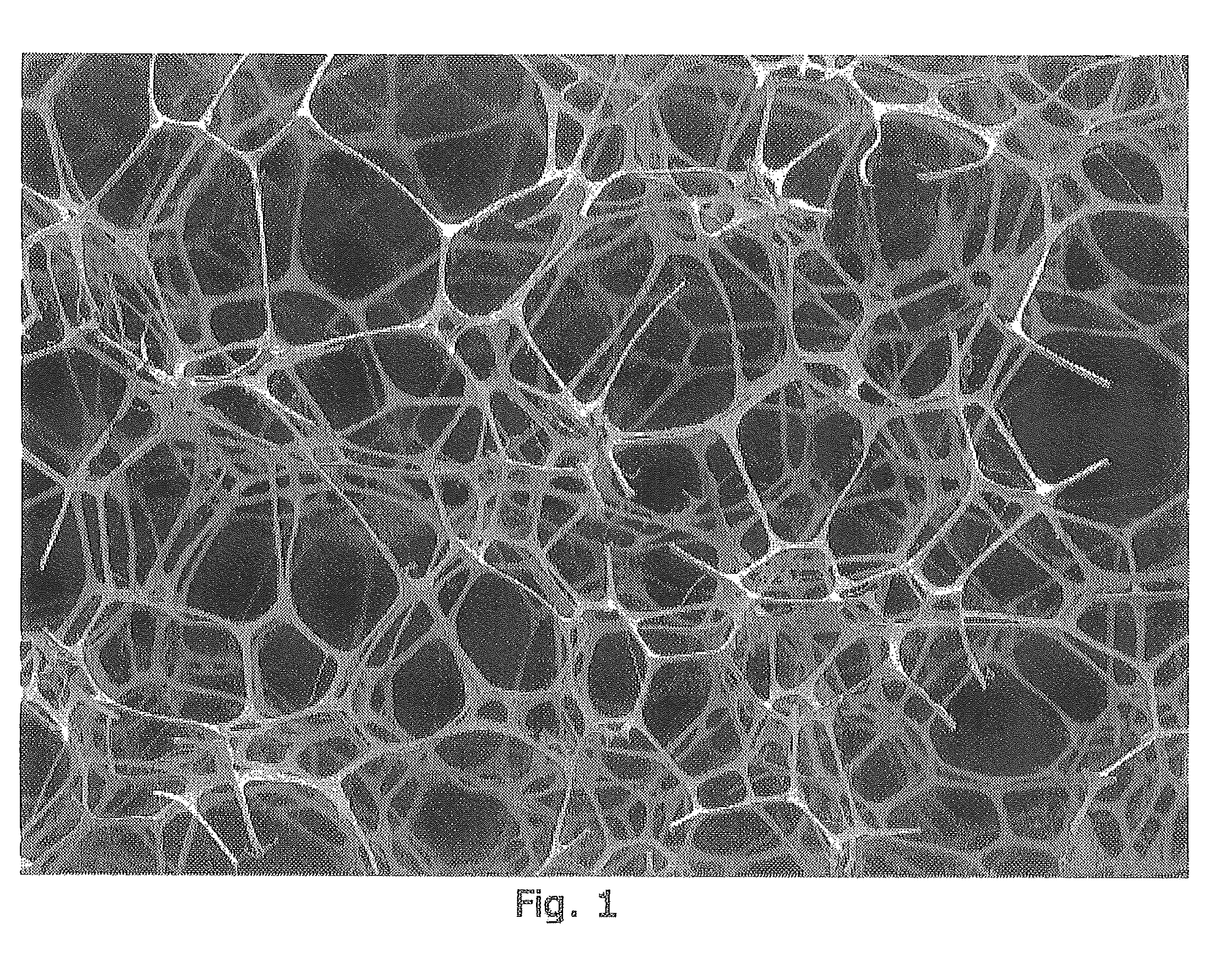

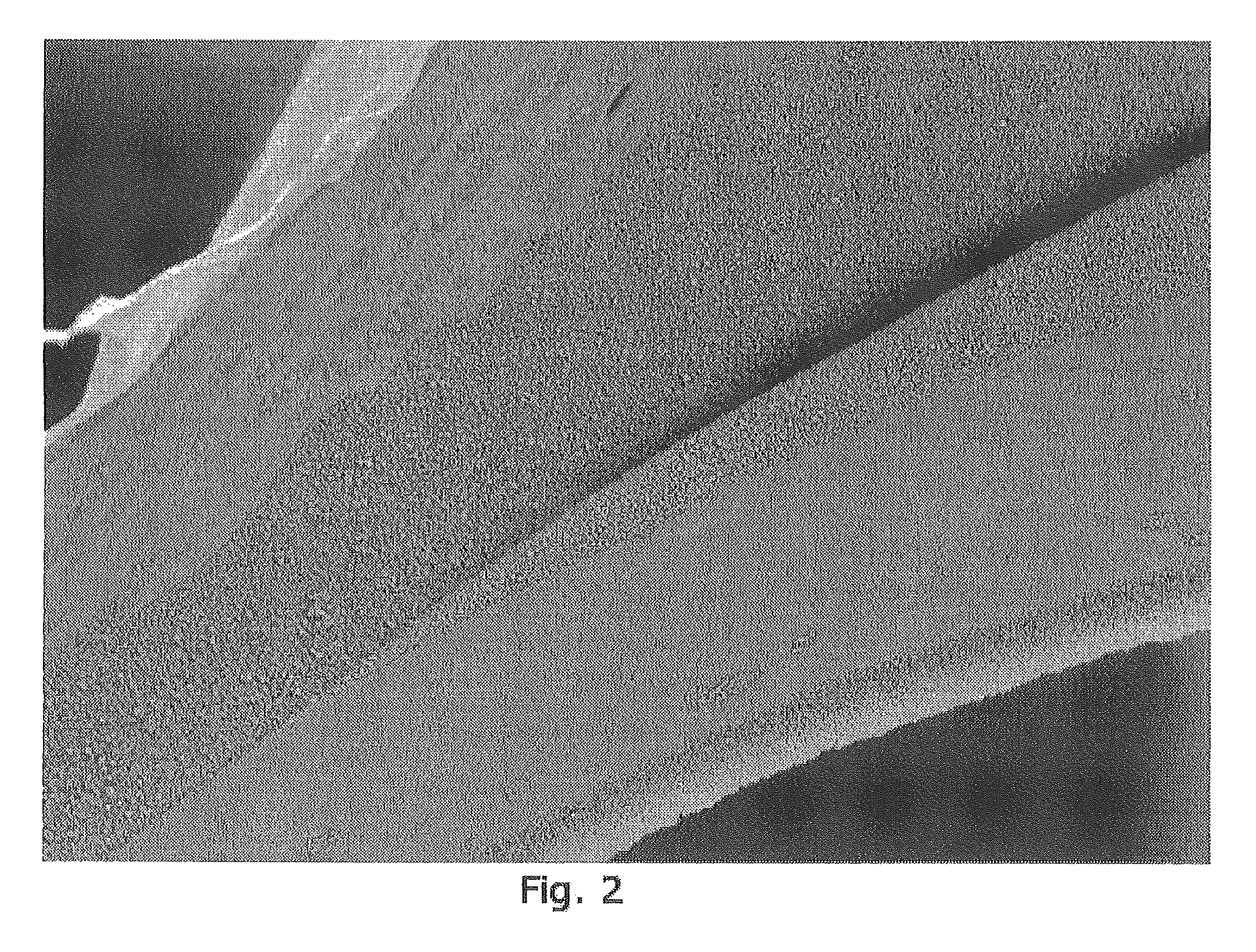

InactiveUS8546457B2Increase elasticityMarkedly abrasive propertiesCarpet cleanersFloor cleanersMelamine formaldehydePolymer chemistry

A process for production of an abrasive foam based on a melamine-formaldehyde condensate comprising inorganic nanoparticles, comprising the steps of:(1) preparation of a solution or dispersion comprising a precondensate of the foam to be produced, and also comprising inorganic nanoparticles,(2) foaming of the precondensate via heating of the solution or dispersion from step (1), in order to obtain a foam which comprises inorganic nanoparticles, and also, if appropriate,(3) heat-conditioning of the foam obtained in step (2),leads to improved abrasion in the polishing of delicate surfaces.

Owner:BASF AG

Paper or board treating composition of carboxylated surface size, polyacrylamide and crosslinker

InactiveUS6281291B1Less viscousEasy to handleNatural cellulose pulp/paperSpecial paperCardboardMeth-

A composition useful in paper and board making comprises a carboxylated surface size containing at least 40 mole percent of hydrophobic groups and at least about 25 mole percent of carboxylated groups such as styrene-(meth)acrylic aicd copolymers or styrene-maleic acid (anhydride or salt) copolymers, a hydrophilic polyacrylamide and a crosslinking agent such as glyoxylated vinylamide polymers, formaldehyde, melamine-formaldehyde condensates and glyoxyl-extended materials.

Owner:KEMIRA OY

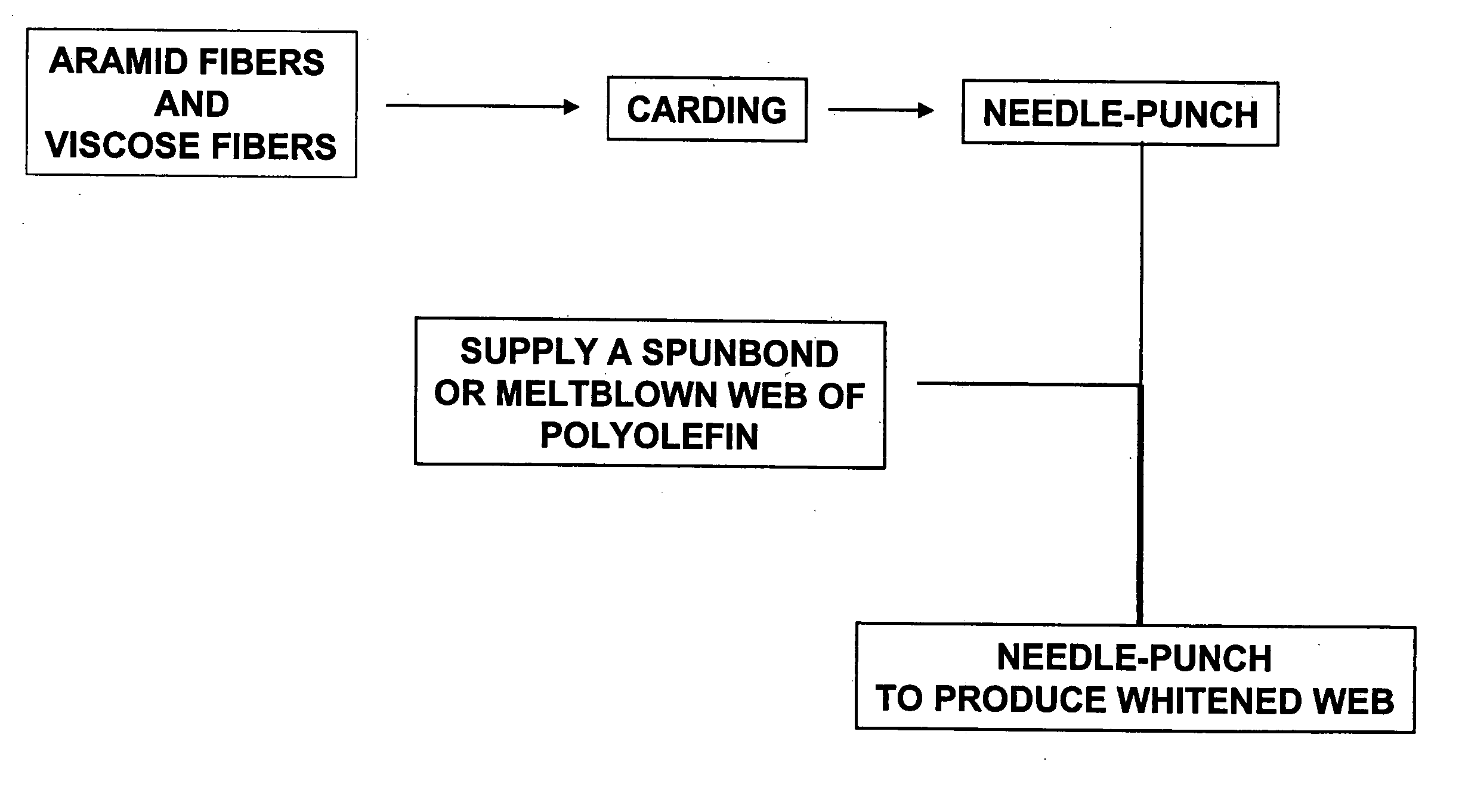

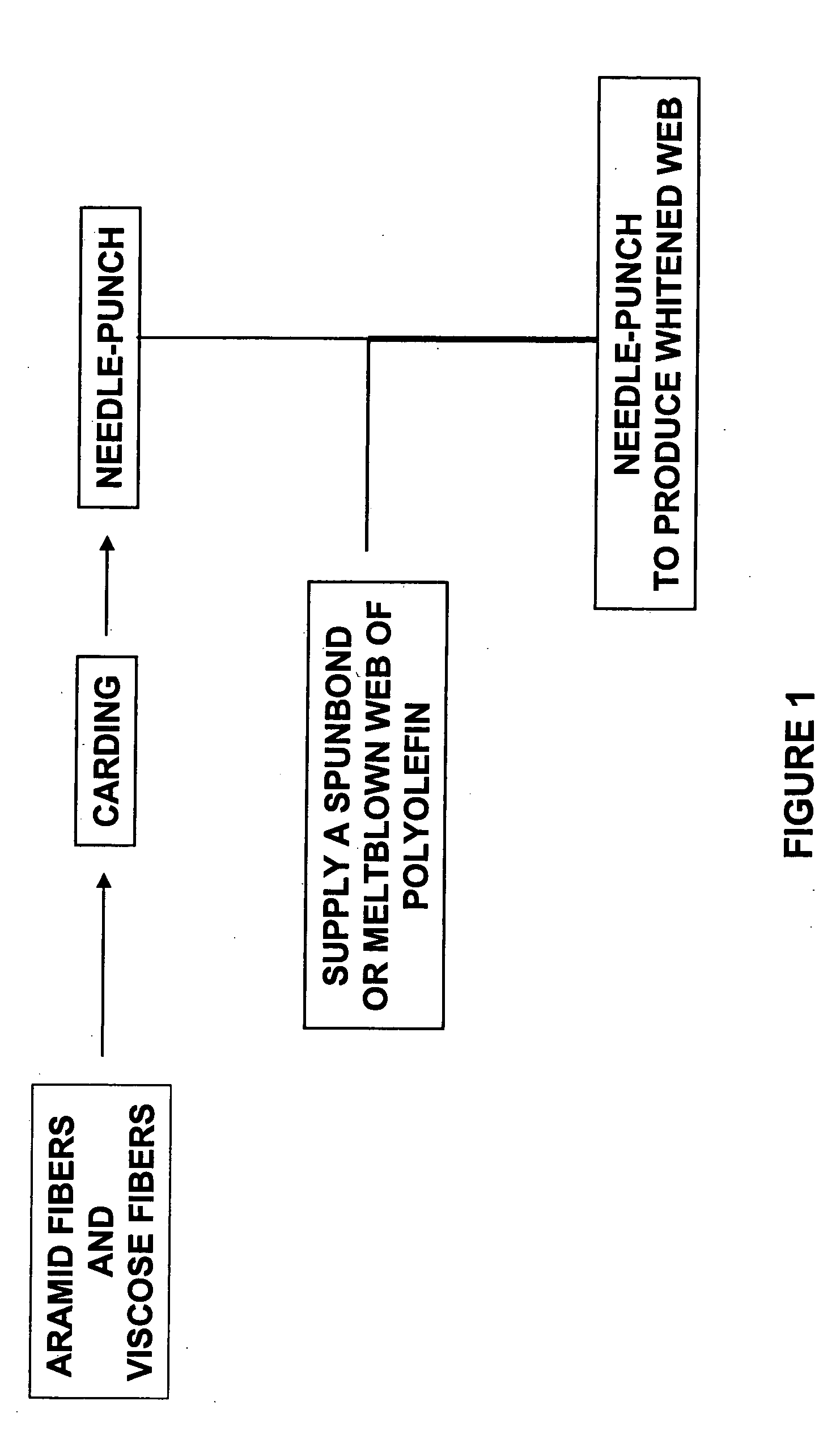

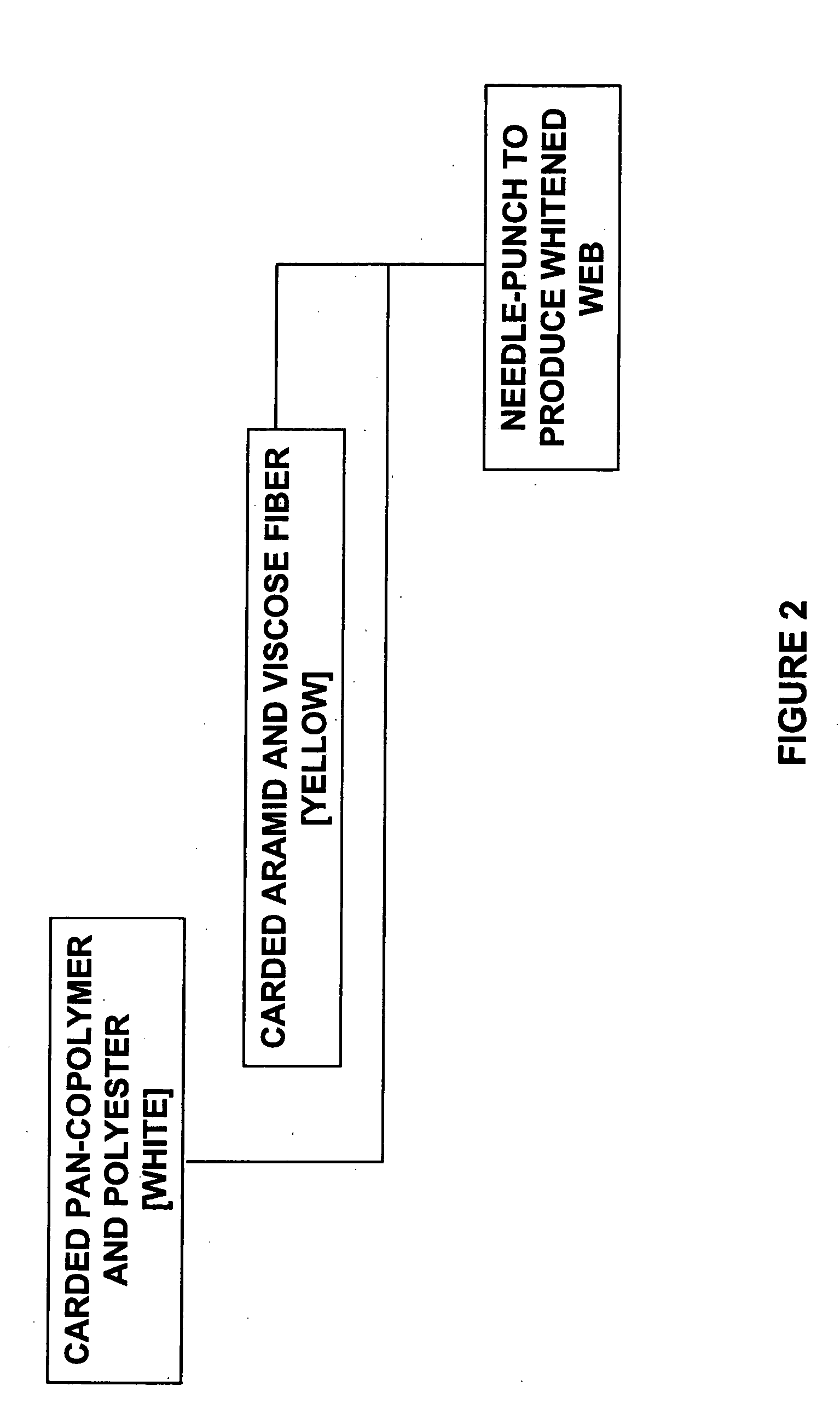

Flame blocking liner materials

A fire blocking non-woven needle-punched textile structure, comprising a first fiber component containing polyacrylonitrile copolymer with a halogen containing monomer, a second fiber component comprising a viscose fiber containing silicic acid or a regenerated cellulose fiber and a third fiber component comprising an aramid fiber or a melamine / formaldehyde fiber or a polyester fiber.

Owner:FREUDENBERG NONWOVENS LTD

Fabric Treatment Compositions

The invention provides an encapsulate comprising a benefit agent core (preferably containing perfume), one or more inner shells (preferably of melamine urea or melamine formaldehyde) and an outer shell comprising a polymer (for example locust bean gum, tamarind xyloglucan, guar gum or mixtures thereof) which is substantive to cellulose (preferably in the form of cotton), at least one of said shells being impermeable to the benefit agent.

Owner:CONOPCO INC D B A UNILEVER

Adhesive and sealant systems

Adhesive and sealant systems Adhesive and sealant systems on the basis of unsaturated polyester resins, epoxy resins, polyurethane, silane-terminated polymers, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ethers, ethylene-vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulphide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles or polysulphones and containing 1% to 15% by weight of a hydrophilic fumed silica structurally modified by grinding.

Owner:EVONIK DEGUSSA GMBH

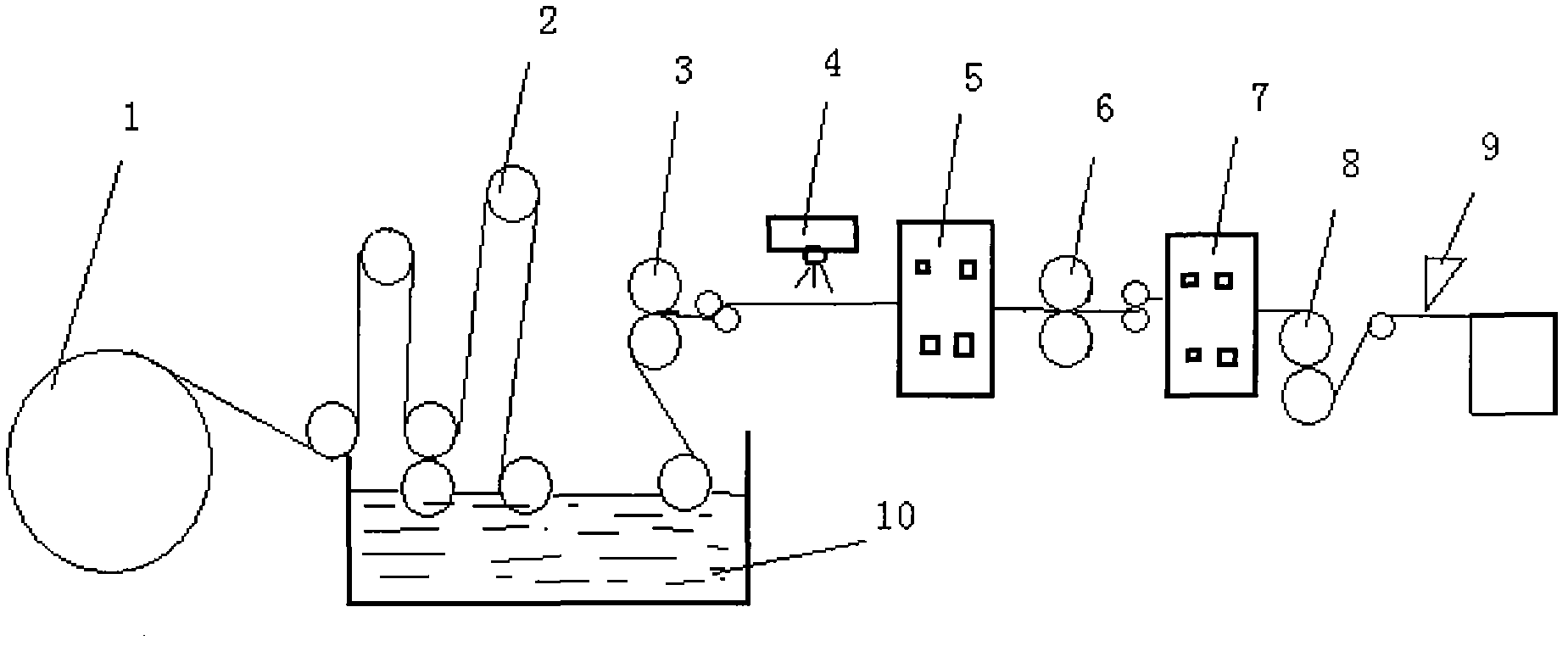

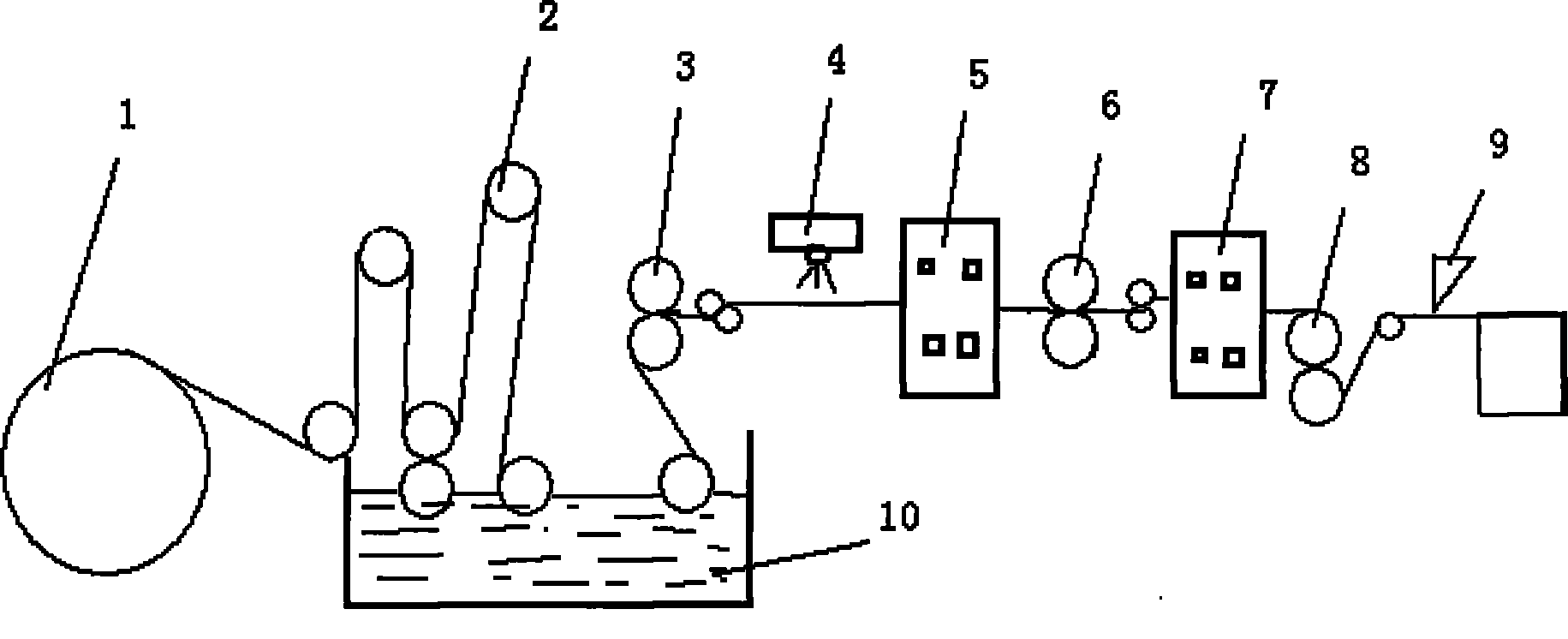

Method for manufacturing surface wear-resisting impregnated paper of laminate floor by dry-spraying Al2O3

ActiveCN102086616AImprove wettabilityImprove the wrapping effectNon-fibrous pulp additionPaper coatingRolling paperMelamine formaldehyde

The invention relates to a method for manufacturing surface wear-resisting impregnated paper of a laminate floor by dry-spraying Al2O3. The method comprises the following steps: impregnating pure wood pulp roll paper with a melamine-formaldehyde (MF) resin liquid; uniformly spraying the Al2O3 on the surface of the impregnated paper by utilizing a dry sprayer; allowing the impregnated and sprayed paper to enter a first oven for drying at the temperature of 100-150 DEG C; roll-coating 300-500% (relative to the weight of the paper) of the MF resin liquid on the paper surface after preliminary drying; and allowing the roll-coated paper to enter a second oven for drying at the temperature of 100-150 DEG C, controlling the whole-course running speed of the paper at 10-12m / minute, cooling, adjusting the temperature of the oven and machine speed so as to reach 6.0-7.5% of volatile matters and 40-60% of pre-curing degree, cutting and packaging. By means of the method, the defects of the prior art are overcome, and the spray quantity of the Al2O3 can be adjusted by controlling the dry sprayer so as to obtain the surface wear-resisting impregnated paper with reliable quality according to different wear-resisting requirements; and the method has the advantages of reasonable process and obvious effect, and is simple in operation, thus effectively improving the product quality.

Owner:天津市瑞鸿装饰材料销售有限公司

Reversible thermochromic microcapsule pigment preparation method

InactiveCN105170041AIncrease coverageImprove stabilityOrganic dyesTenebresent compositionsColor changesFORMALDEHYDE SOLUTION

The present invention discloses a reversible thermochromic microcapsule pigment preparation method, which comprises: weighing 0.08-0.1% by mass of crystal violet lactone, 0.4-0.5% by mass of bisphenol A, 3-6% by mass of hexadecanol, 2-4% by mass of melamine, 4.03-5% by mass of a formaldehyde solution, 0.4-0.6% by mass of sodium dodecyl benzene sulfonate, 0.09-0.11% by mass of sodium dodecyl sulfate ammonium, and 87-90% by mass of distilled water, preparing a complex A, preparing an O / W type emulsion and a melamine-formaldehyde pre-polymerization liquid, and carrying out a condensation polymerization reaction to prepare the pigment. According to the present invention, advantages of high color change sensitivity, low color change temperature and good color change stability are provided when the prepared monomer thermochromic material is adopted as the pigment, and the prepared reversible thermochromic microcapsule pigment can be widely used in the fields of anti-counterfeiting inks, temperature showing materials, and the like.

Owner:XIAN UNIV OF TECH

Method for preparing enhanced epoxy resin/curing agent double-wall microcapsule

InactiveCN102205225ARich varietyImprove repair effectMicroballoon preparationMicrocapsule preparationEpoxySimple Organic Compounds

The invention provides a method for preparing a double-wall self-repairing microcapsule by compounding an epoxy resin or a mixture of epoxy resins and carbon nanotubes as an inner capsule core repairing agent and using a curing agent as an outer capsule core. The invention belongs to the field of organic compound materials. The method comprises the following steps: intensely stirring and ultrasonically dispersing the epoxy resin or the mixture of epoxy resins and carbon nanotubes under the action of an emulsifier, so as to form an epoxy resin emulsion or an epoxy resin carbon nanotube emulsion; after preparing a melamine formaldehyde pre-polymer solution, preparing a single-wall microcapsule by using the melamine formaldehyde pre-polymer solution together with the epoxy resin emulsion or the epoxy resin carbon nanotube emulsion under an acid condition; after preparing a curing agent emulsion, stirring the curing agent emulsion and the single-wall microcapsule under an acid environment, thereby leading the curing agent grains to be uniformly attached on the periphery of the single-wall microcapsule; and then generating a second capsule wall layer by adding the melamine formaldehydepre-polymer solution. The prepared microcapsule contains the enhancing repairing agent and the curing agent, which can further enhance the repairing effect of the microcapsule and increase the mechanical property.

Owner:UNIV OF SCI & TECH BEIJING +1

Nano composite modified melamine-formaldehyde abrasion-resisting resin and preparation method thereof

InactiveCN102219884AImprove stabilityExtended shelf lifeNon-fibrous pulp additionPaper/cardboardMelamine formaldehydeNano al2o3

The invention discloses a nano composite modified melamine-formaldehyde abrasion-resisting resin and a preparation method thereof. The resin is mainly prepared from a mixture of nano alumina and nano silica, melamine, water, formaldehyde, a stabilizer and an alcohol substance by process steps of mixing, warming polycondensation and cooling discharging. The production method of the modified melamine-formaldehyde abrasion-resisting resin prepared by using the method is very simple and product property is stable; and decorative paper impregnated with the resin still remains the patterns of the surface of the original paper. The resin can be used for the production of impregnated glue film paper facing artificial boards and impregnated paper laminated wood floors, and the wear resistance of the resin reaches 4000 turns.

Owner:FUJIAN AGRI & FORESTRY UNIV

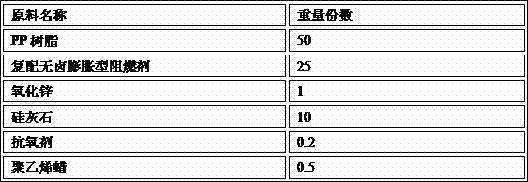

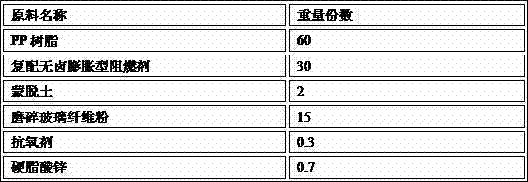

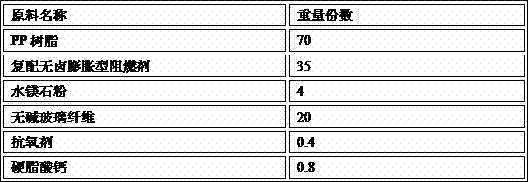

High-glowing filament anti-soaking separate-out-free halogen-free inflaming retarding polypropylene materials and preparation method thereof

The invention discloses high-glowing filament anti-soaking separate-out-free halogen-free inflaming retarding polypropylene materials which comprise the following components: by weight, 40-80 parts of polypropylene (PP) resins, 20-40 parts of compound halogen-free flame retarding agents, 0.5-5 parts of flame retardant synergists, 0-30 parts of inorganic fillers, 0.1-0.5 part of antioxidants, and 0.4-1 part of lubricating agents. The compound halogen-free flame retarding agents are composed of the following components: by weight, 30-50 parts of silane-wrapped organic or inorganic hypophosphite, 35-50 parts of melamine formaldehyde resin (MF)-wrapped halogen-free organic phosphate ester or the ramification thereof, and 15-40 parts of melamine cyanuric acid ester. The compound halogen-free flame retarding agents are easy to disperse in the process of processing, so that processing is convenient. The halogen-free inflaming retarding polypropylene materials prepared by the method have high-glow filaments, and have the advantages of being anti-soaking, separate-out-free and the like. In addition, the production process is simple, so that industrial production can be achieved.

Owner:聚石化学(苏州)有限公司

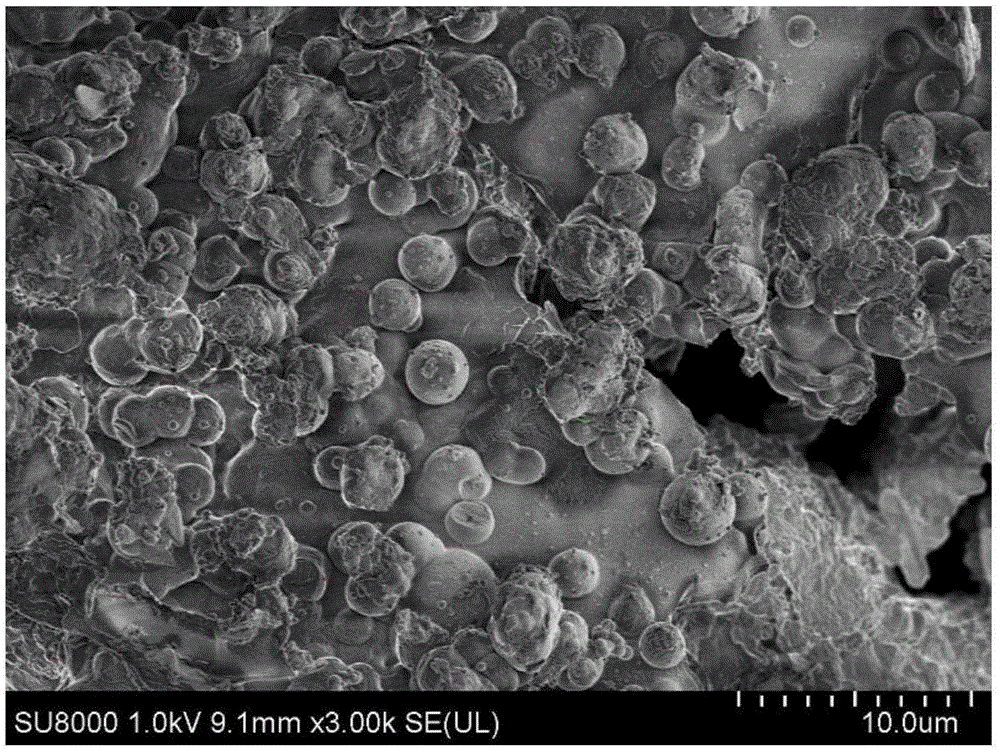

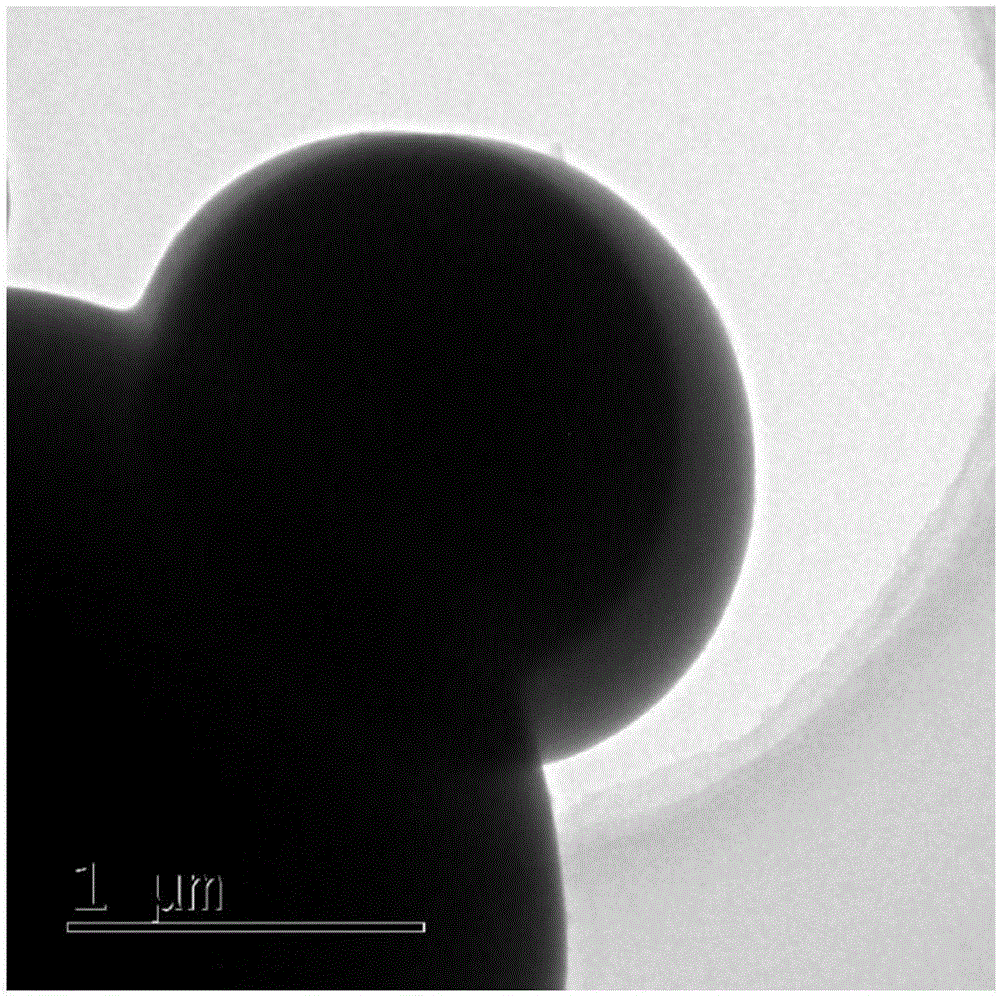

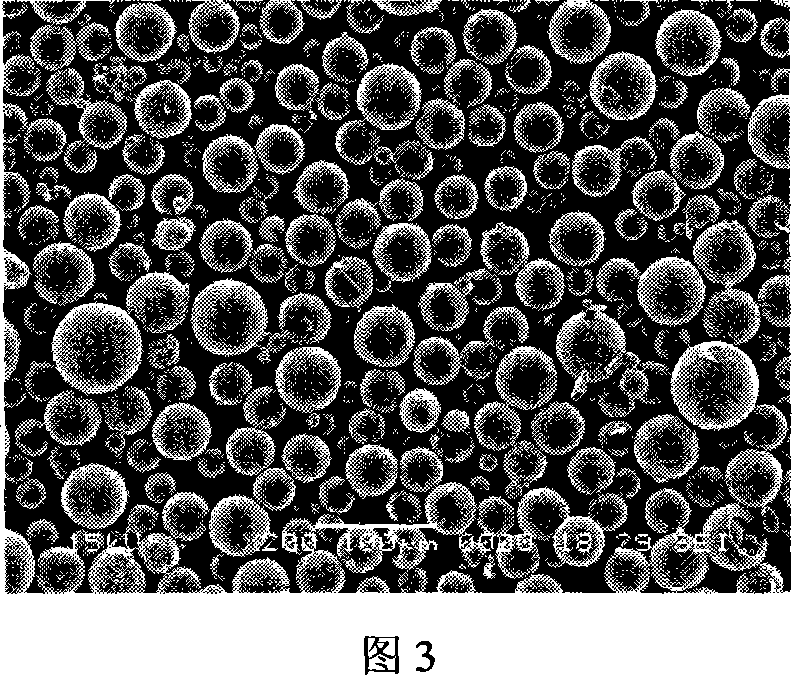

Preparation method of spherical charcoal-aero gel

InactiveCN101041430AShorten the synthesis processShort synthesis timeNanostructure manufactureSupercritical dryingPhenol

The invention discloses a preparing method of globular char gas gel, which comprises the following steps: making phenol- melamine-formaldehyde or water soluble phenol resin- melamine-formaldehyde as raw material; forming colloidal sols through pre-polymerization; adding into discontinuous phase with surface activator; forming floating system under the function of stirring; generating colloidal sols- gel transition at 60-85 deg.c; forming globular aquagel; proceeding organic solvent replace and hypercritical dry; getting organic aerogel; proceeding high temperature degradation; getting globular char gas gel; setting the specific surface area at 400-1000m2 / g, bore diameter at 3-20 nanometer and ball calipers at 0.01-3 millimeter.

Owner:EAST CHINA UNIV OF SCI & TECH

Aqueous fire-retardant non-corrosive composition for topical application to products and articles

Owner:LOPEZ RICHARD A +1

Resin solution for preparing melamine formaldehyde resin foam plastics and preparation method thereof

The invention discloses resin solution for preparing melamine formaldehyde resin foam plastics and a preparation method thereof. The preparation method for melamine formaldehyde resin solution comprises the following steps: adding weak-acid-strong-alkali salts into the resin solution, and evenly mixing to prepare the melamine formaldehyde resin solution, wherein the resin solution is a reaction product of melamine and formaldehyde. The melamine formaldehyde resin solution has good storage stability, and has shelf life of above 72 hours when preparing the melamine formaldehyde resin foam plastics so as to greatly facilitate preparing the melamine formaldehyde resin foam plastics. Experiments show that the melamine formaldehyde resin flexible foam plastics prepared from the melamine formaldehyde resin solution have good mechanical property, physiochemical performance and flame resistance.

Owner:SHANGHAI HAOHAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com