Method for manufacturing surface wear-resisting impregnated paper of laminate floor by dry-spraying Al2O3

A technology for wear-resistant impregnated paper and composite flooring, which is applied in the directions of papermaking, textiles and papermaking, coating, etc., which can solve the problems affecting the production cost, production efficiency and application effect of the surface layer of wear-resistant impregnated paper, and it is difficult to uniformly distribute and spray particles. Uniformity, large differences in the wear resistance of the floor, etc., to achieve the effect of increasing wettability and coating effect, reliable quality, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

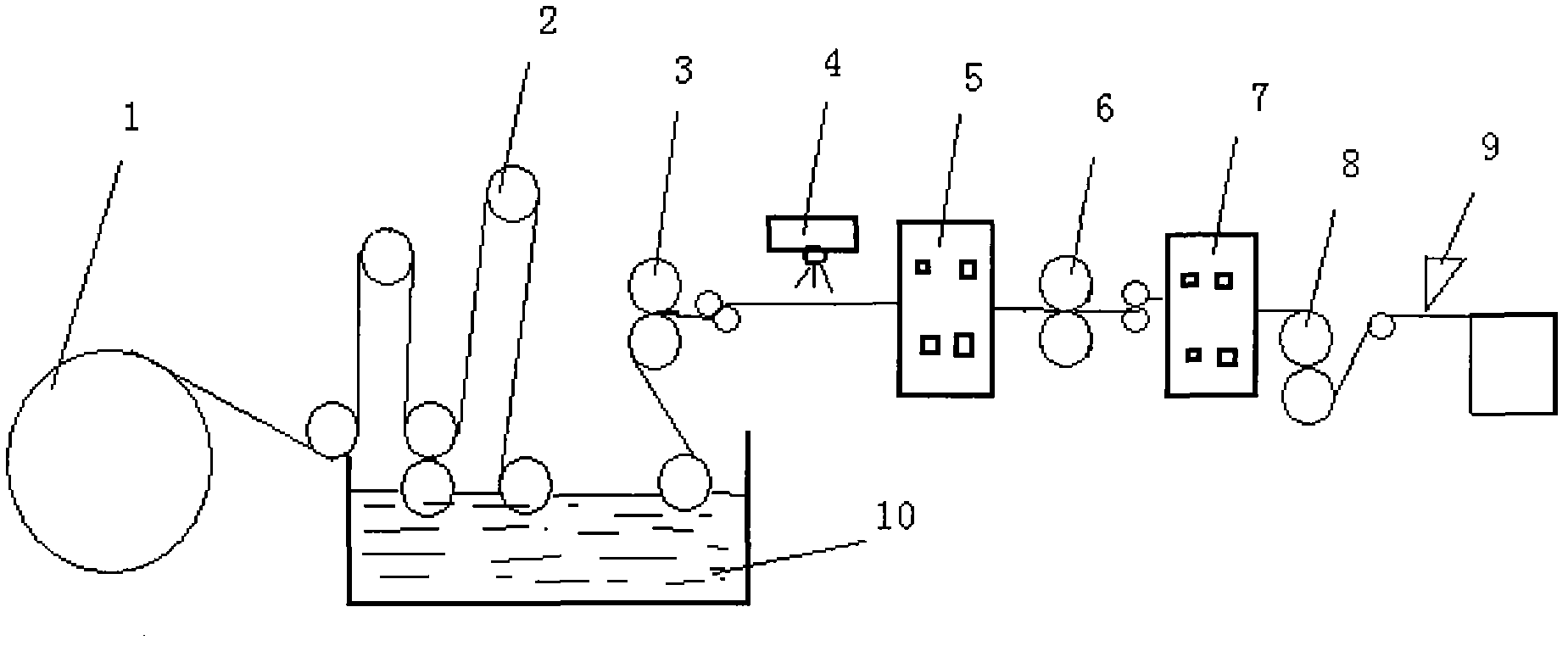

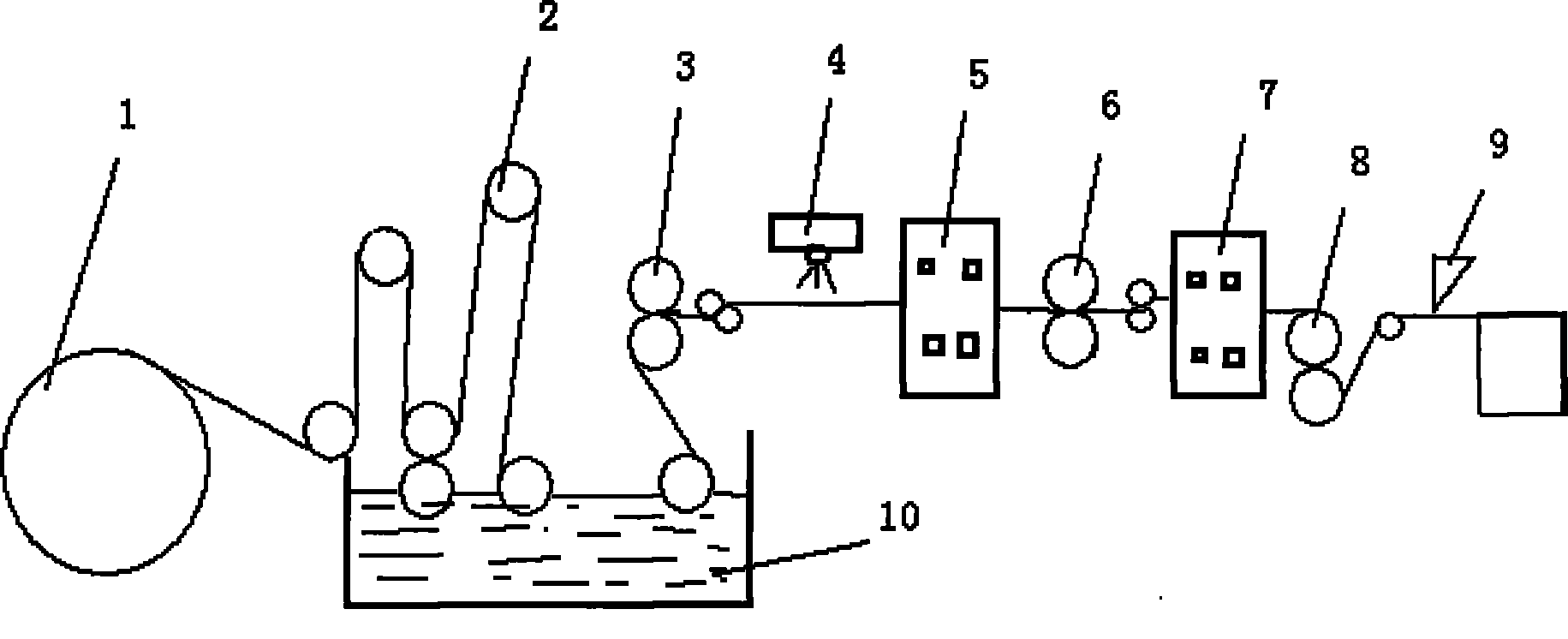

[0031] A dry spray Al 2 o 3 The method for manufacturing the wear-resistant impregnated paper on the surface layer of composite floor, the implementation steps are as follows:

[0032] (1) Use 22 g / m 2 Pure wood pulp web (Soho, Germany), impregnated through a melamine formaldehyde resin bath. Adjust the quantitative roller to control the amount of glue to 100 g / m 2 .

[0033] (2) After the paper is impregnated, it is filled with Al between the impregnation tank and the first suspension oven. 2 o 3 dry spraying machine (Siemens, specification 1400mm, can automatically display the spray volume), Al 2 o 3 It is evenly sprayed and glued to the surface of the paper to control Al 2 o 3 The ejection volume is 18g / m 2 .

[0034] (3) The impregnated and sprayed paper enters the first suspension oven to dry at 130°C, and then adheres Al on the surface of the paper. 2 o 3 The upper surface of the roller is coated with melamine formaldehyde resin, and the amount of glue is co...

Embodiment 2

[0048] (1) Use 22 g / m 2 Pure wood pulp web (Soho, Germany), impregnated through a melamine formaldehyde resin bath. Adjust the quantitative roller to control the amount of glue to 100 g / m 2 .

[0049] (2) After the paper is impregnated, it is filled with Al 2 o 3 Dry Spray Machine, Al 2 o 3 It is evenly sprayed and glued to the surface of the paper to control Al 2 o 3 The ejection volume is 18g / m 2 .

[0050] (3) The impregnated and sprayed paper enters the first suspension oven to dry at 135°C, and then adheres Al on the surface of the paper. 2 o 3 The upper surface of the roller is coated with melamine formaldehyde resin, and the amount of glue is controlled with a 1mm concave-convex roller.

[0051] (4) The paper after roller coating enters the second suspension oven and is dried at 140°C. The paper running speed is controlled at 10m / min, and then cooled by a cooling roller. Detection: volatile content 6.8%, pre-curing degree 49% (according to LY / T1143-2006 for...

Embodiment 3

[0054] (1) Use 22 g / m 2 Pure wood pulp web (Soho, Germany), impregnated through a melamine formaldehyde resin bath. Adjust the quantitative roller to control the amount of glue to 100 g / m 2 .

[0055] (2) After the paper is impregnated, it is filled with Al 2 o 3 Dry Spray Machine, Al 2 o 3 It is evenly sprayed and glued to the surface of the paper to control Al 2 o 3 The ejection volume is 18g / m 2 .

[0056] (3) The impregnated and sprayed paper enters the first suspension oven to dry at 135°C, and then adheres Al on the surface of the paper. 2 o 3 The upper surface of the roller is coated with melamine formaldehyde resin, and the amount of glue is controlled with a 1mm concave-convex roller.

[0057] (4) The paper after roller coating enters the second suspension oven and is dried at 140°C. The paper running speed is controlled at 10m / min, and then cooled by a cooling roller. Detection: volatile matter 6.5%, pre-curing degree 45% (according to LY / T1143-2006 fore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com