Patents

Literature

64 results about "Fibre dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dispersion is important because an optical pulse on a fiber is made up of a range of wavelengths that will spread out as they travel down the fiber. Over a long length of fiber, this pulse spreading makes an optical signal undetectable. Dispersion sets the range limit for many fiber-based communication systems.

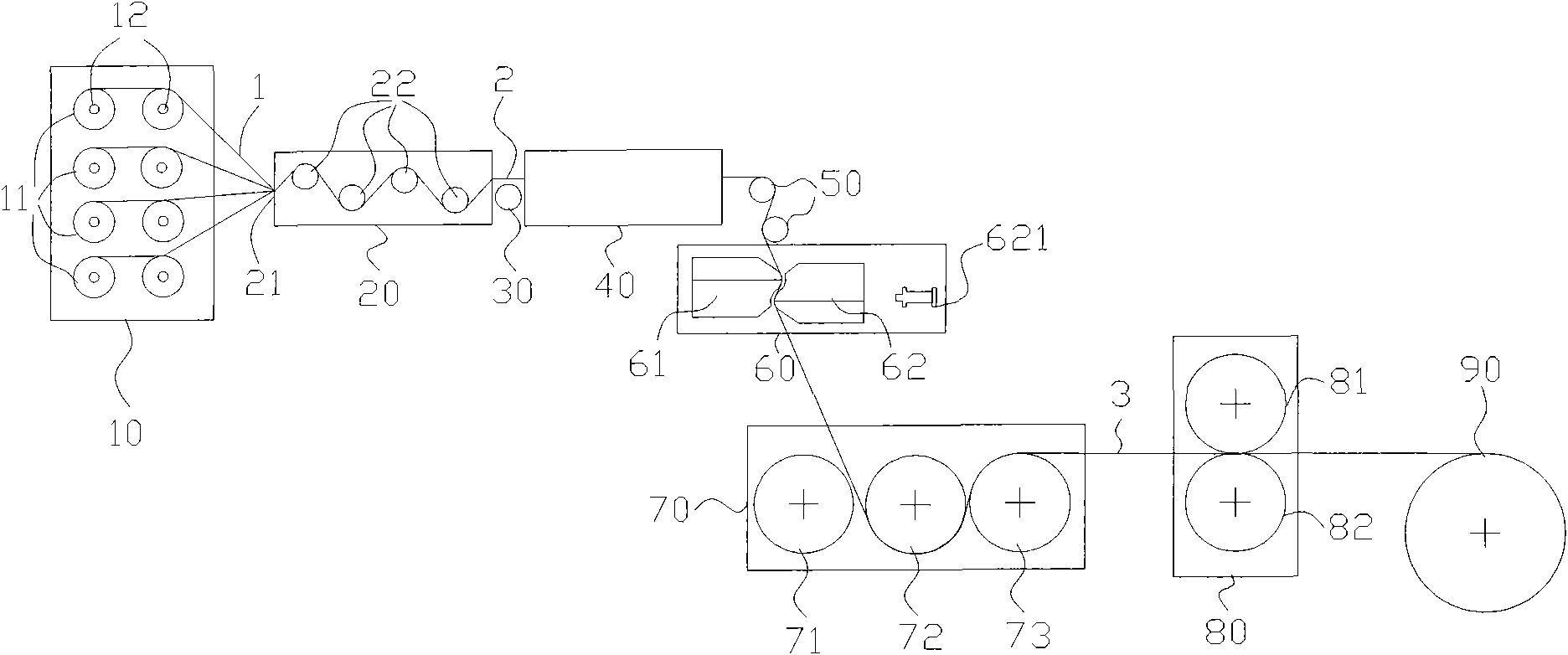

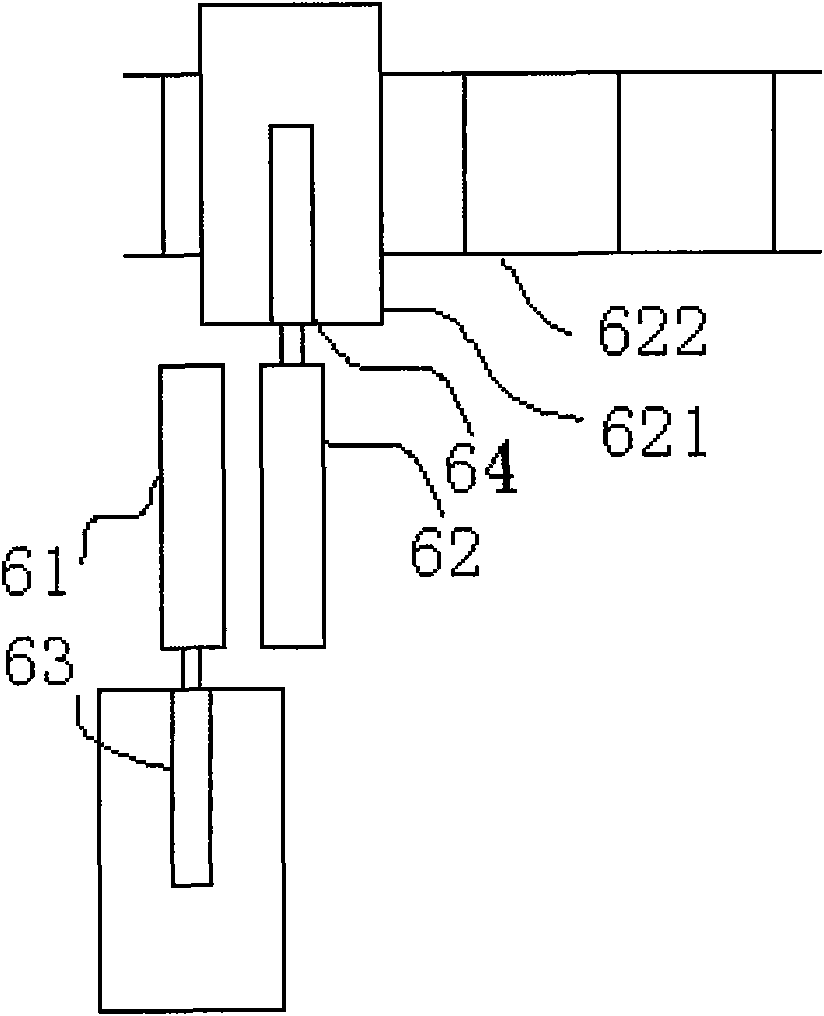

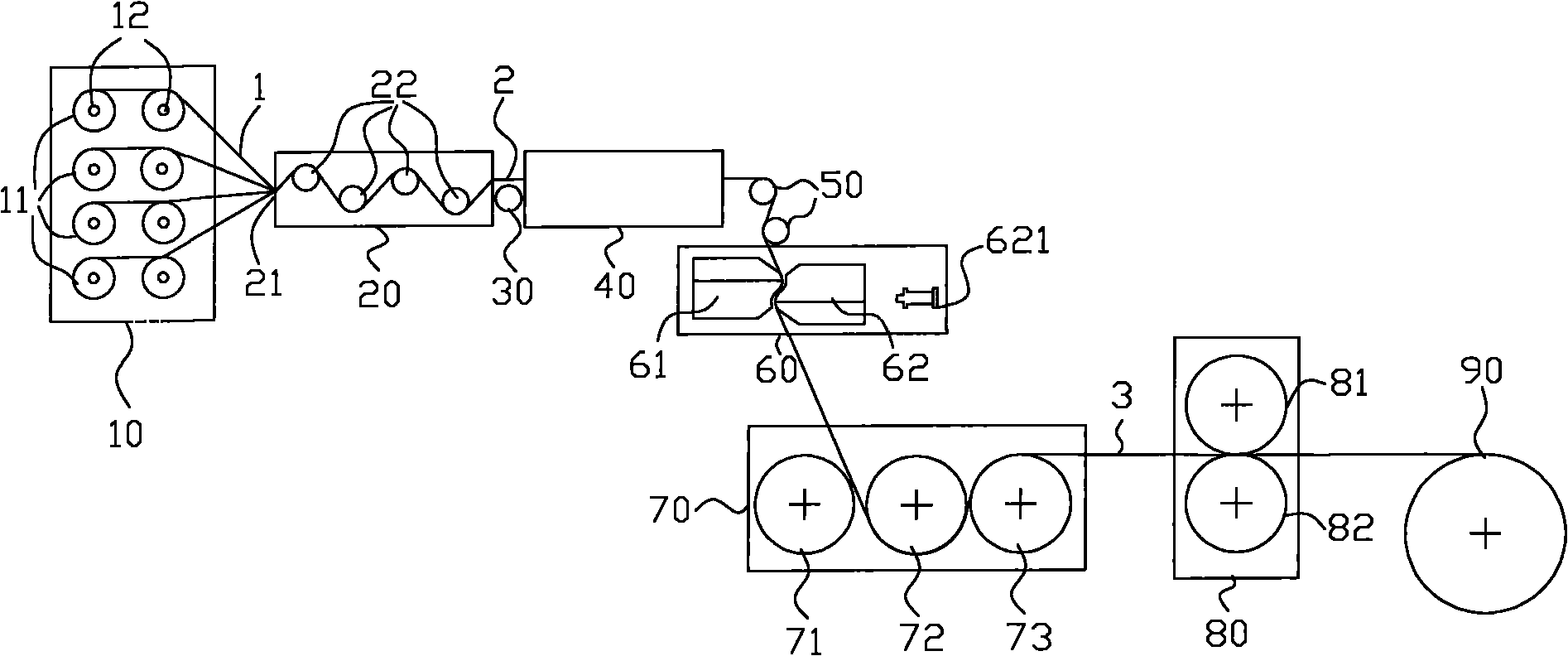

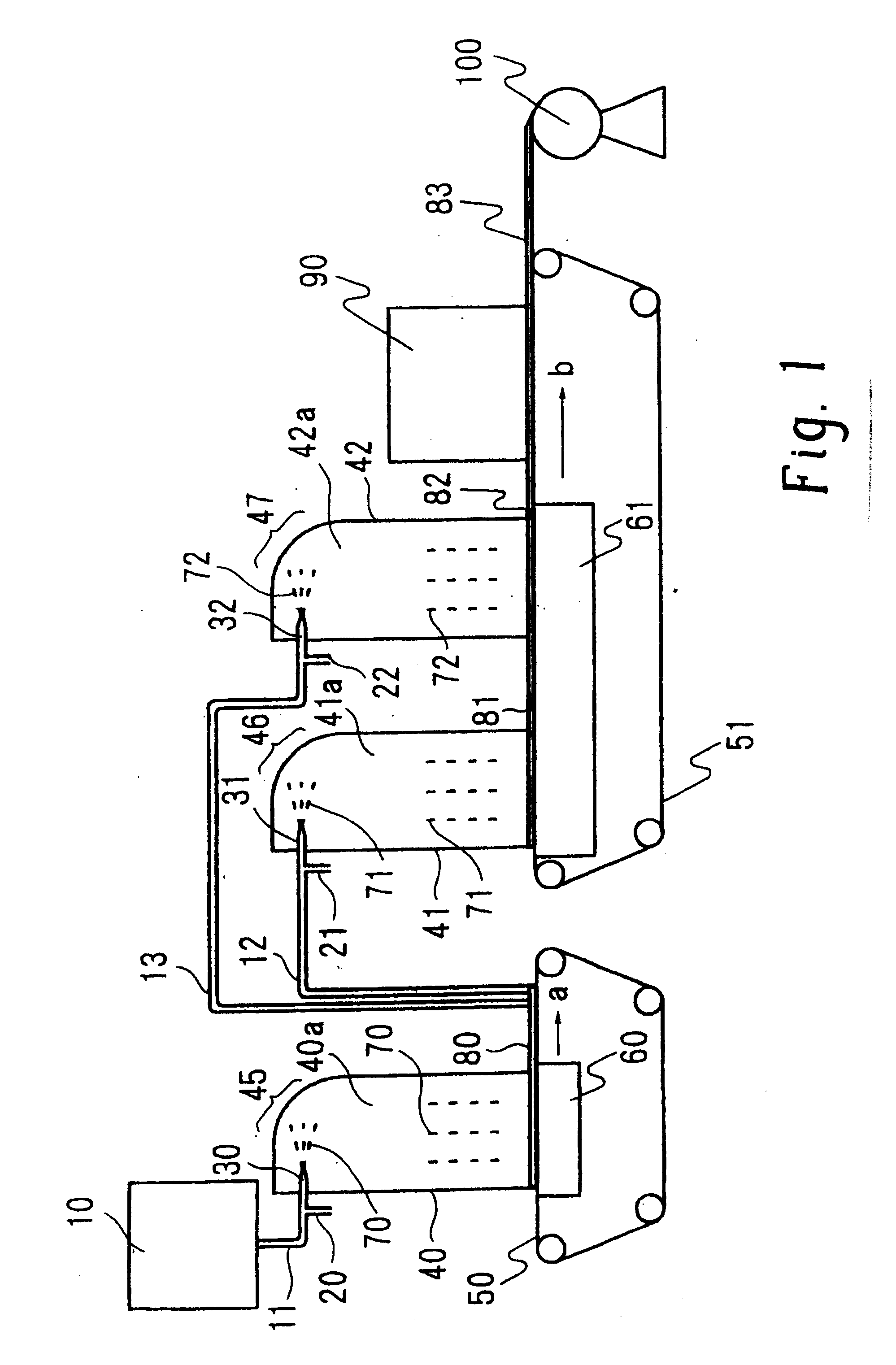

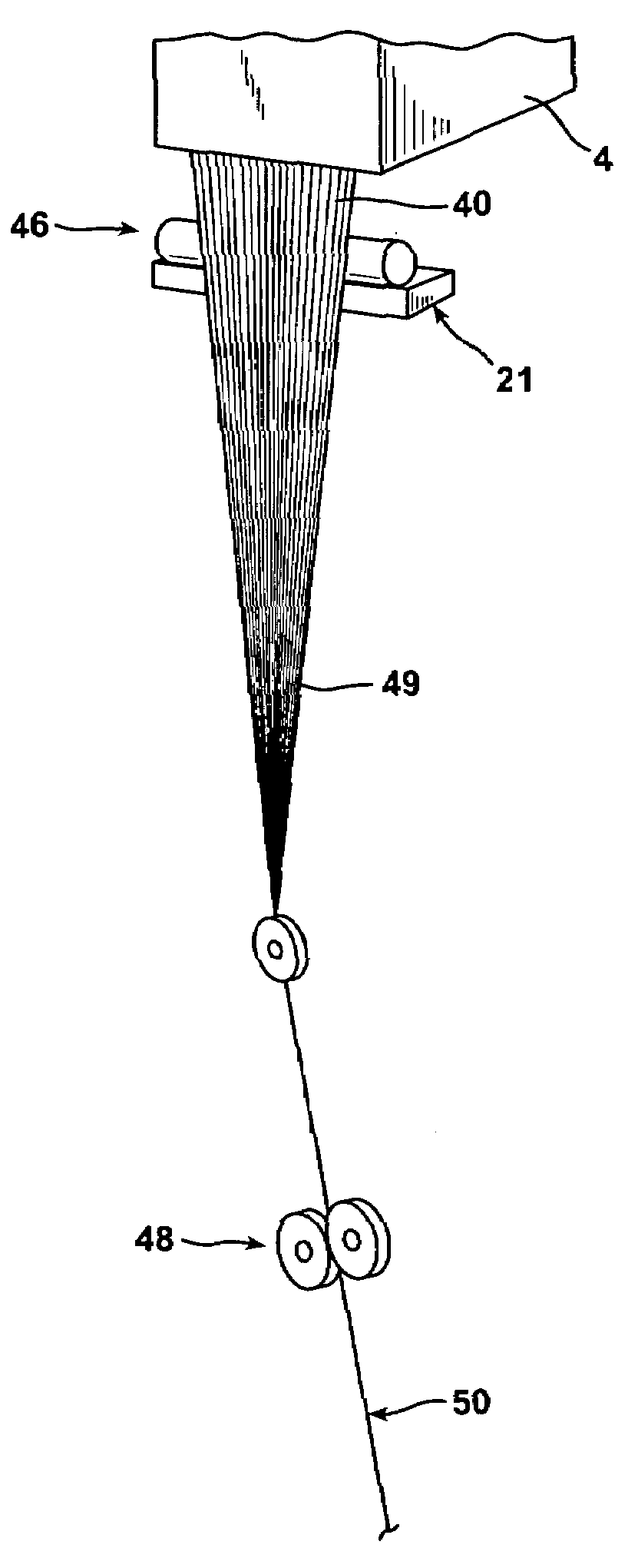

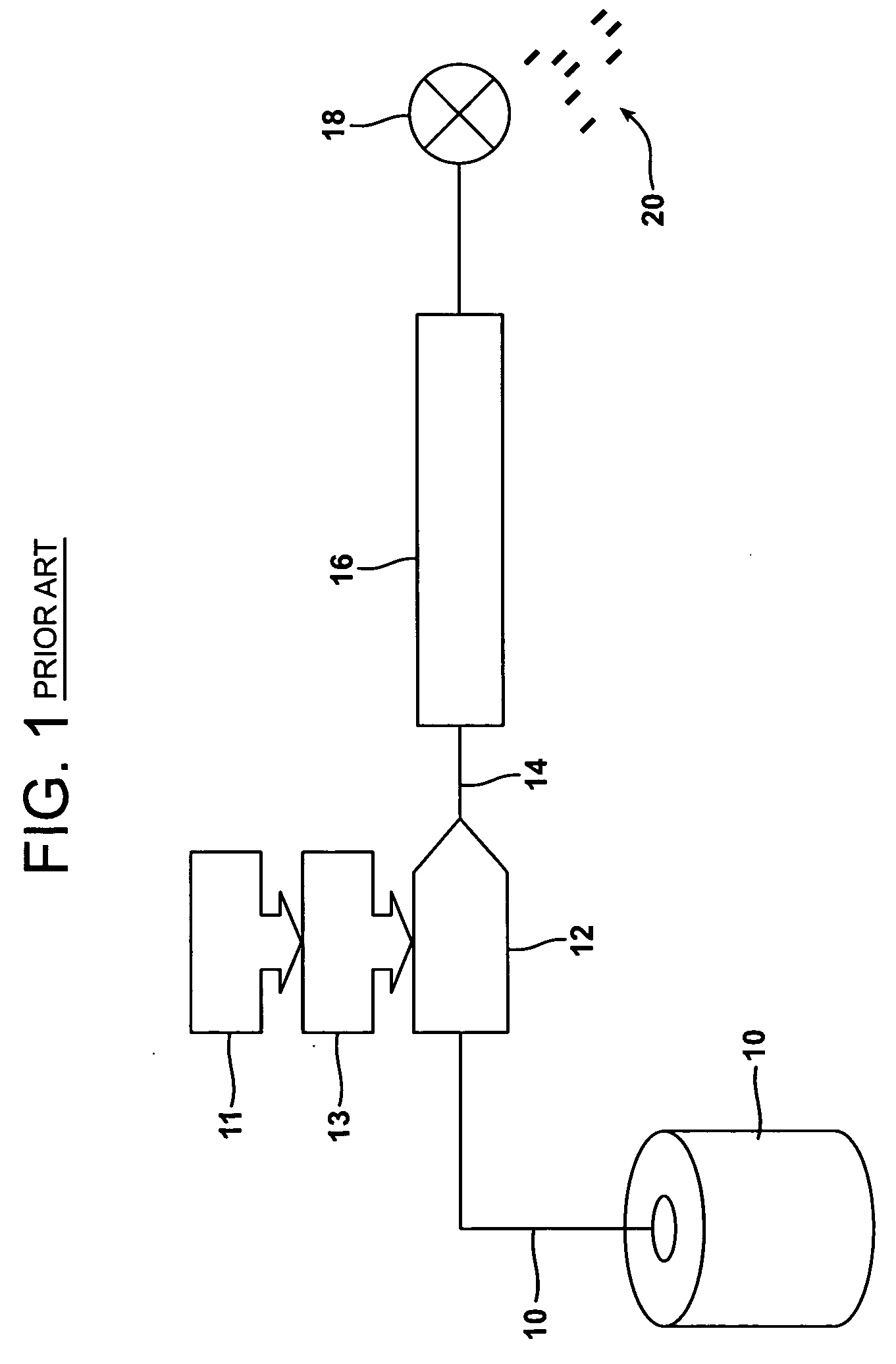

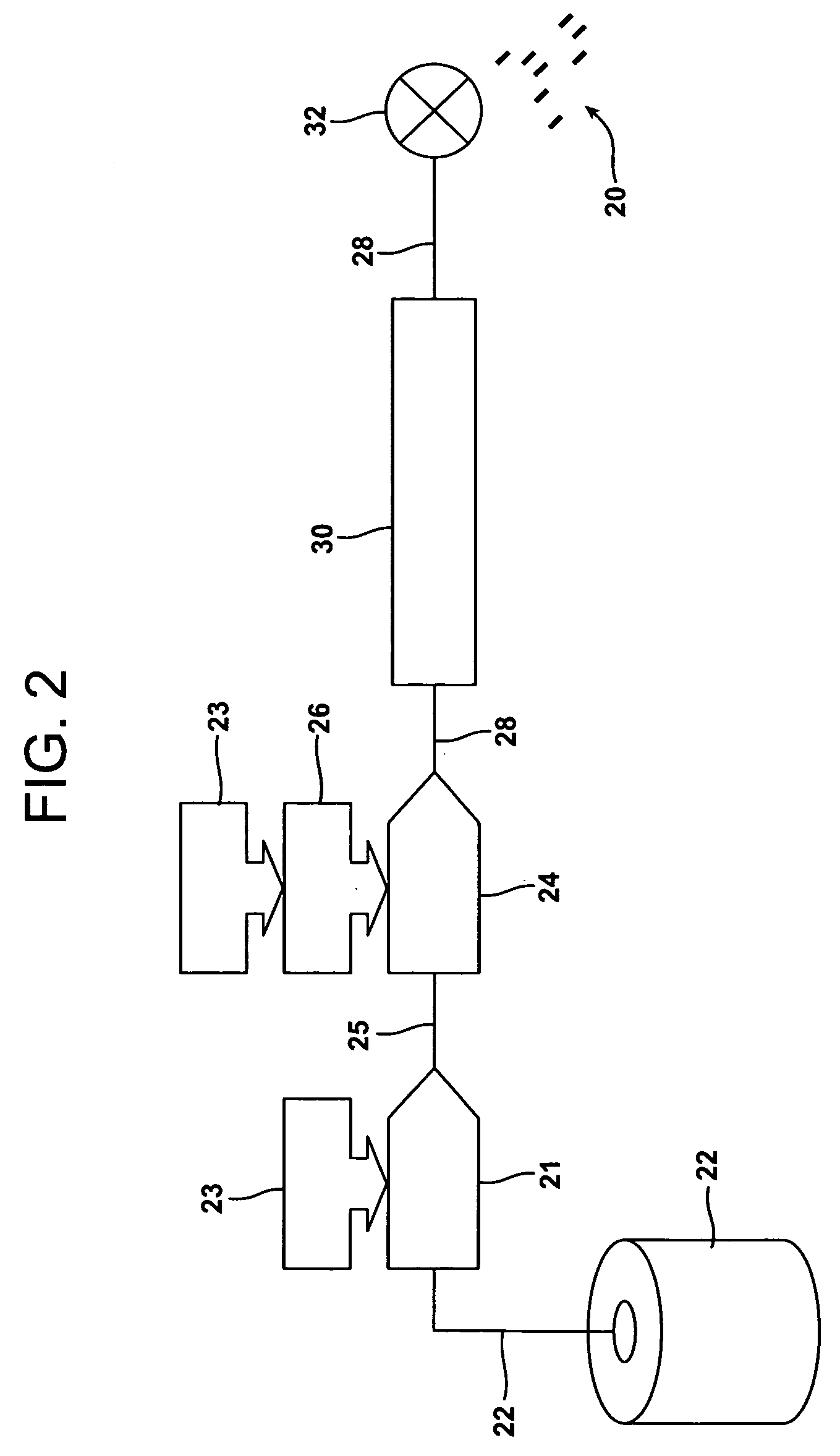

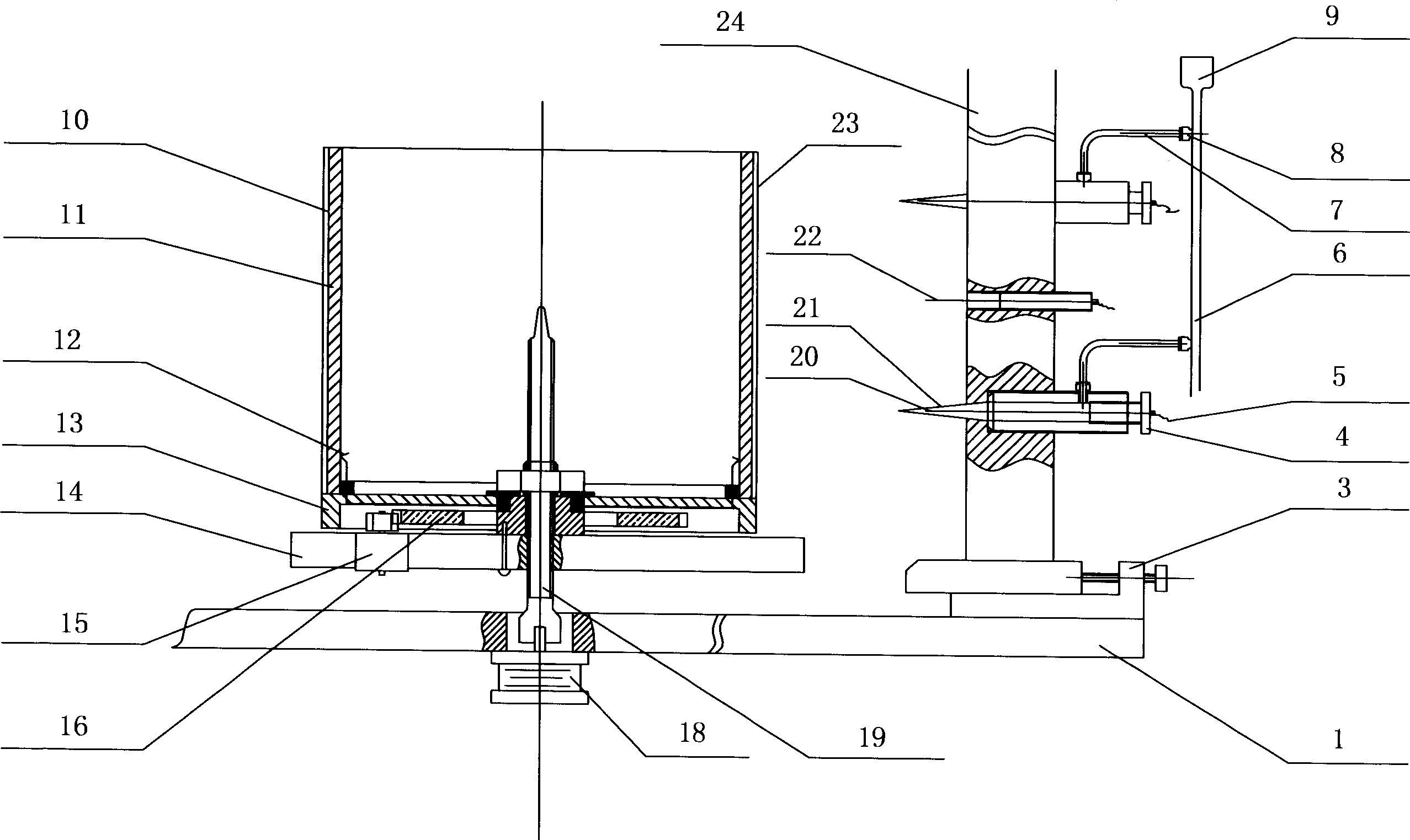

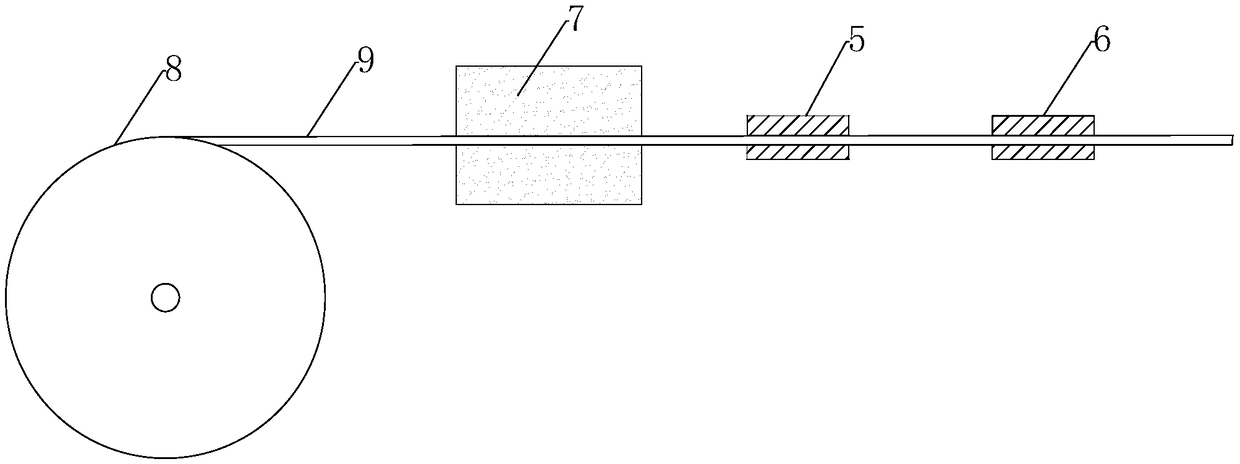

Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

The invention relates to a preparation method of a continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof. The method comprises the following steps: (a) leading out and unfolding continuous fiber from a creel (10) to pass a tension adjusting device (20) and a static elimination device (30) in sequence, sending the fiber to a preheating oven (40) to preheat, and then passing a tension adjusting device (50); (b) leading a preheated continuous fiber band into a dual-extrusion die head set which can be opened and closed in a staggered manner to presoak; and (c) leading the presoaked continuous fiber band into a soaked rolling roll set (70) to soak, then cooling by a cooling roll-in device (80), and finally leading into a traction rolling device (90) for shaping by winding to obtain the product. Compared with the prior art, the invention significantly improve the dispersion, infiltrating property and operability of the fiber, and obtains the continuous fiber reinforced thermoplastic composite material prepreg which has uniformly dispersed and completely soaked fiber.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

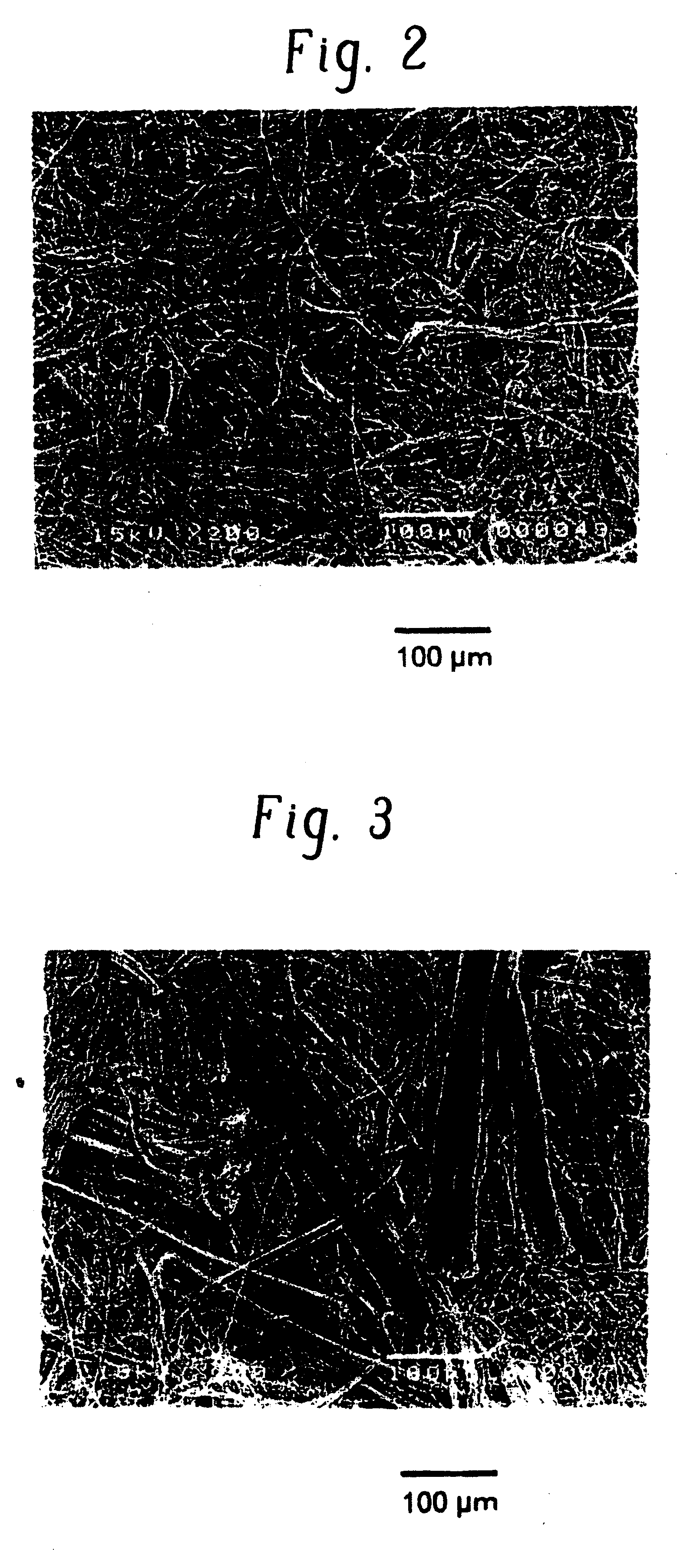

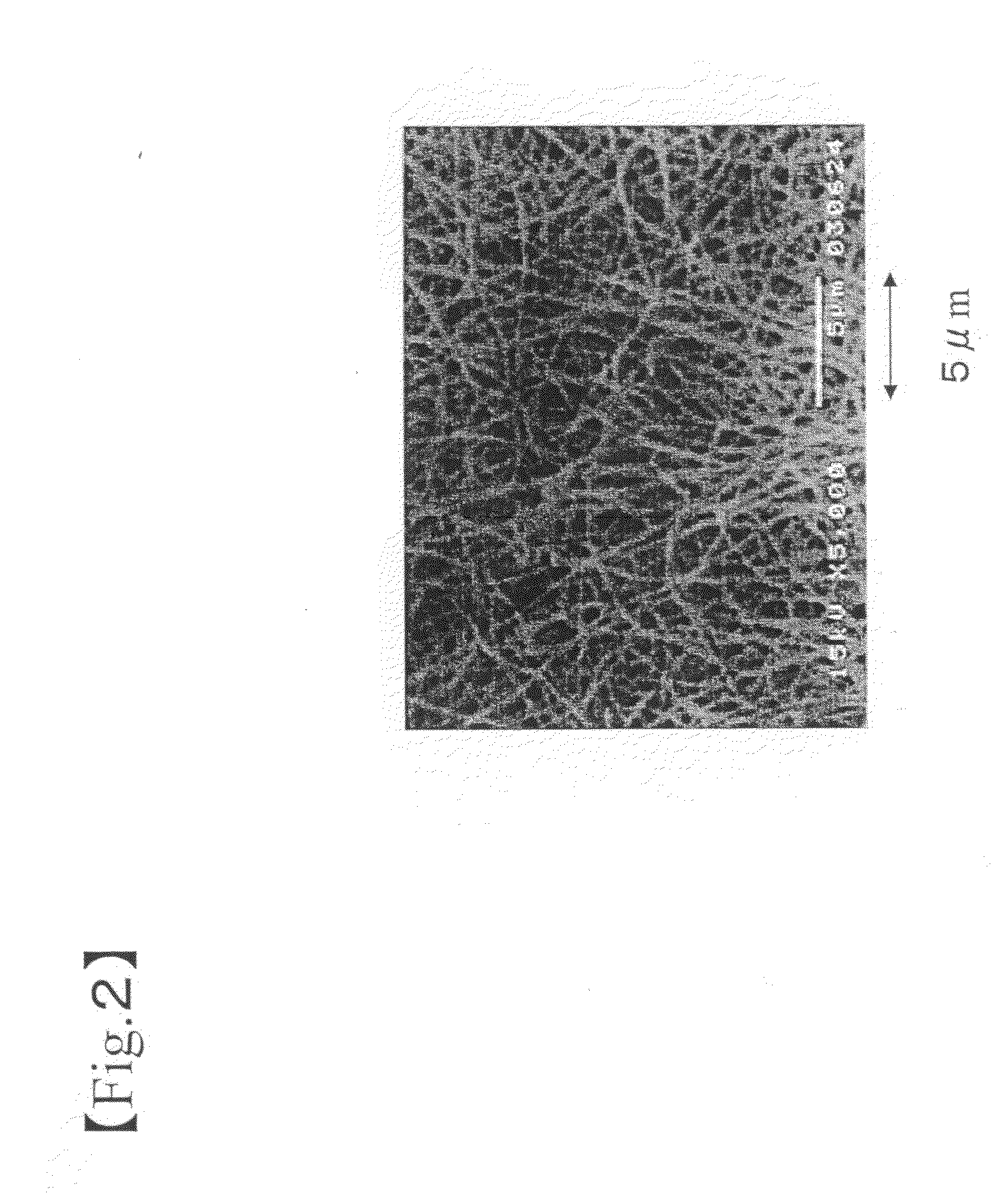

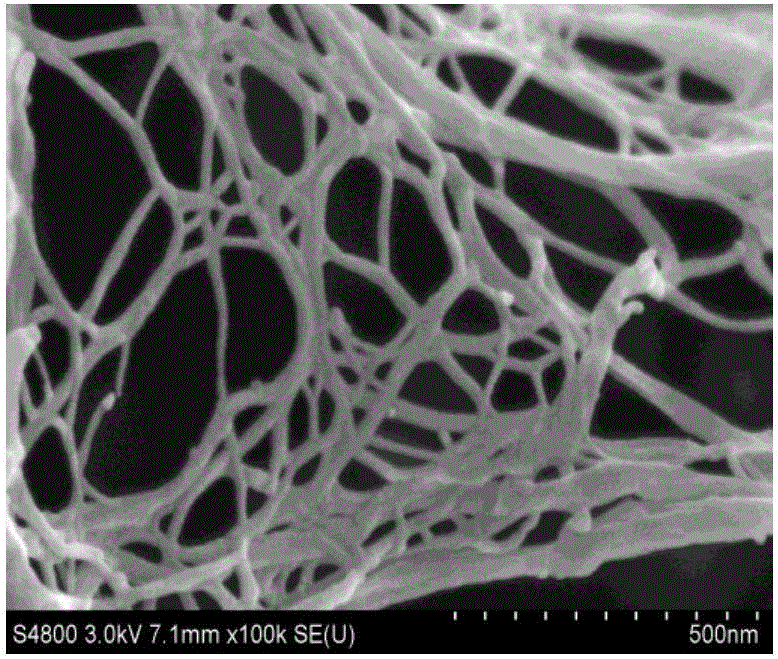

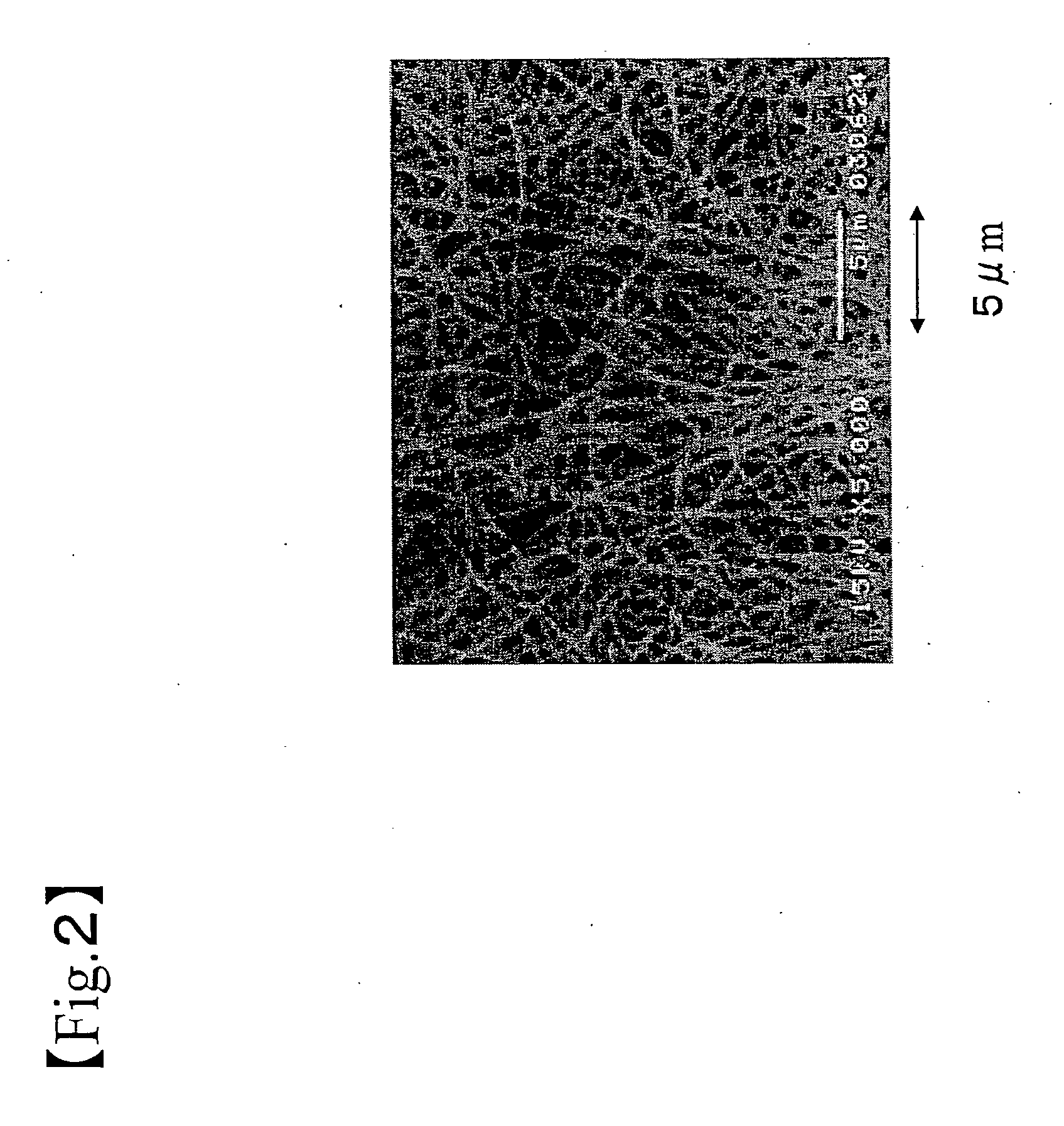

Fine-fibers-dispersed nonwoven fabric, process and apparatus for manufacturing same, and sheet material containing same

InactiveUS20060081330A1Maintain good propertiesSmall pressure lossSynthetic resin layered productsAbrasion apparatusPolymer scienceFiber diameter

Disclosed is a fine-fibers-dispersed nonwoven fabric comprising dispersed fine fibers having a fiber diameter of 4 μm or less and a fiber length of 3 mm or less, wherein an adhesion rate of substances adhered to the nonwoven fabric is 0.5 mass % or less. Further, a process and an apparatus for manufacturing the fine-fibers-dispersed nonwoven fabric, as well as a sheet material comprising the fine-fibers-dispersed nonwoven fabric are also disclosed.

Owner:NIPPON BAIRIIN

Fiber reinforced composites

InactiveUS8187423B1Good dispersionImprove mechanical propertiesNatural cellulose pulp/paperSpecial paperLitterPaperboard

In one aspect, the invention is directed to an efficient and economical process for dispersing fiber in water and clay. In another aspect, the process for dispersing fiber in water and clay is used in methods of making fiber reinforced composite products. In another aspect, the dispersed fiber / clay material is formulated to make products which include, but which are not limited to, fiber reinforced thermoplastic composites, paperboard products, kitty litter, and / or lightweight building materials comprising fiber.

Owner:US SEC AGRI

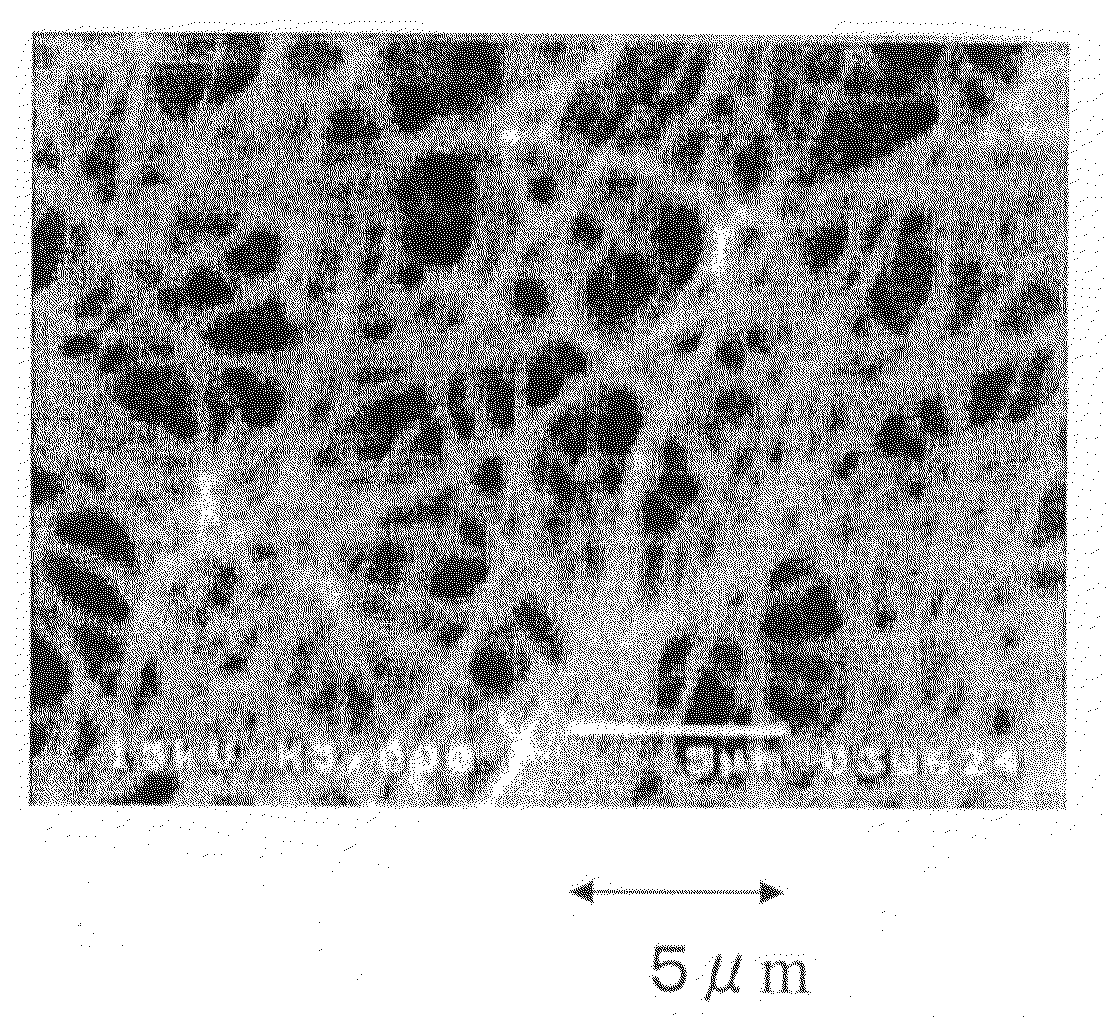

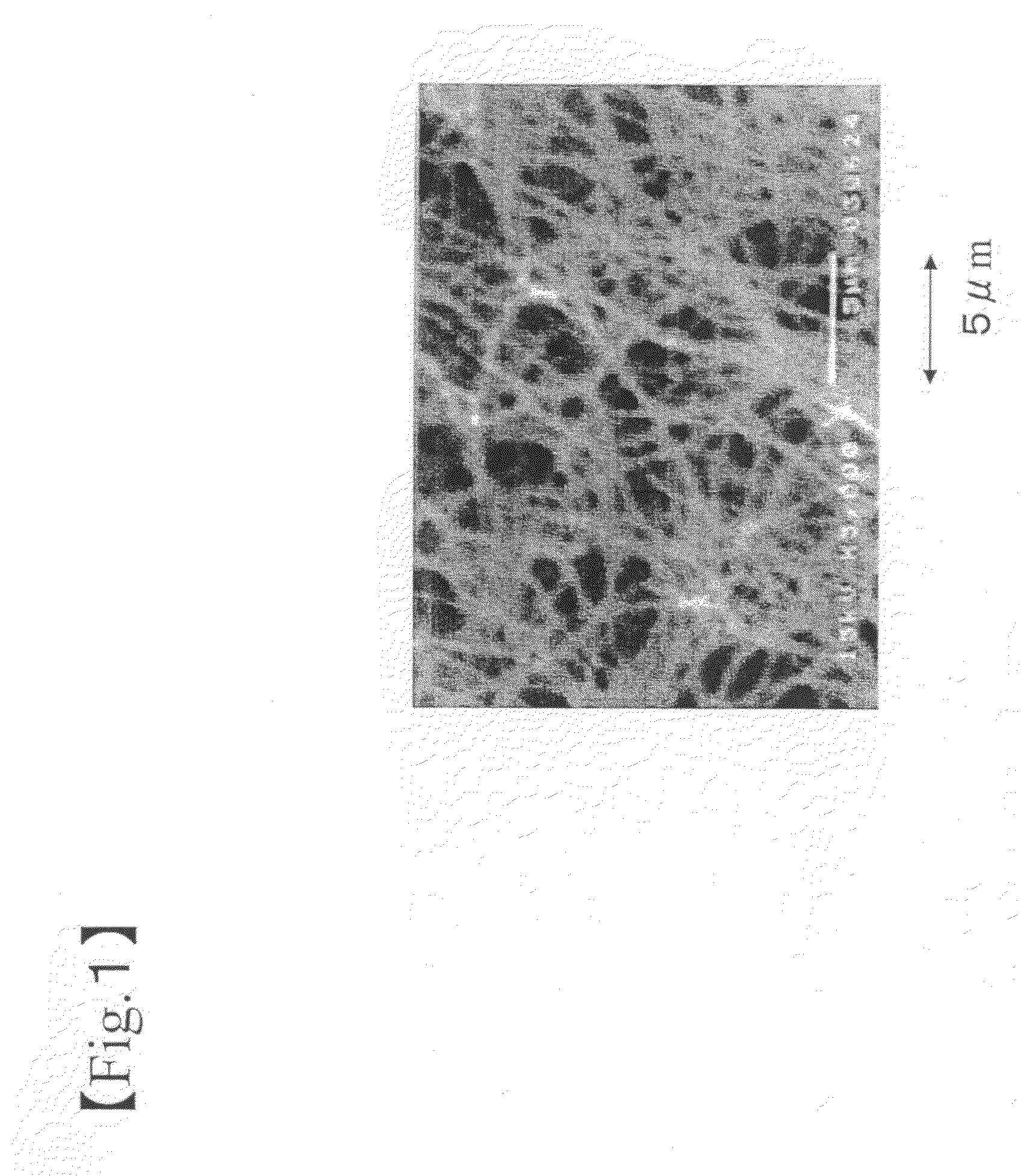

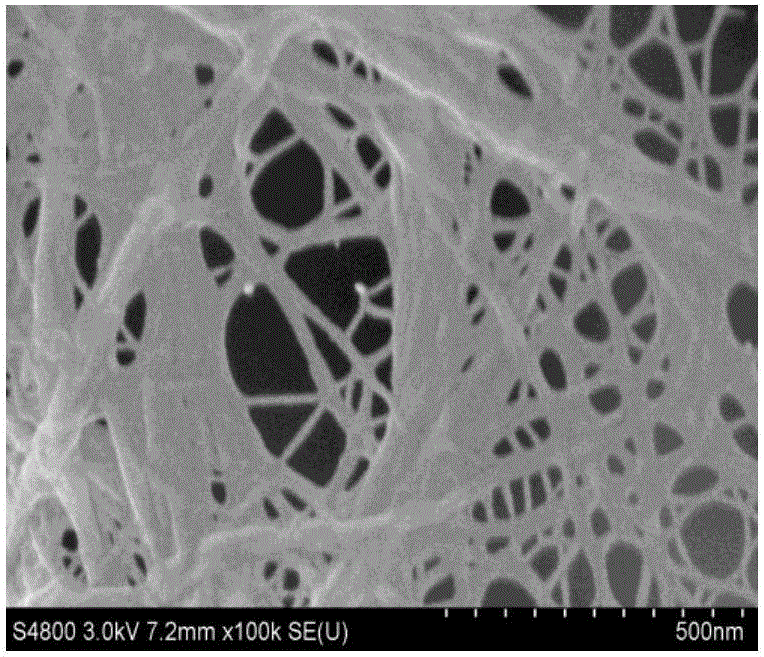

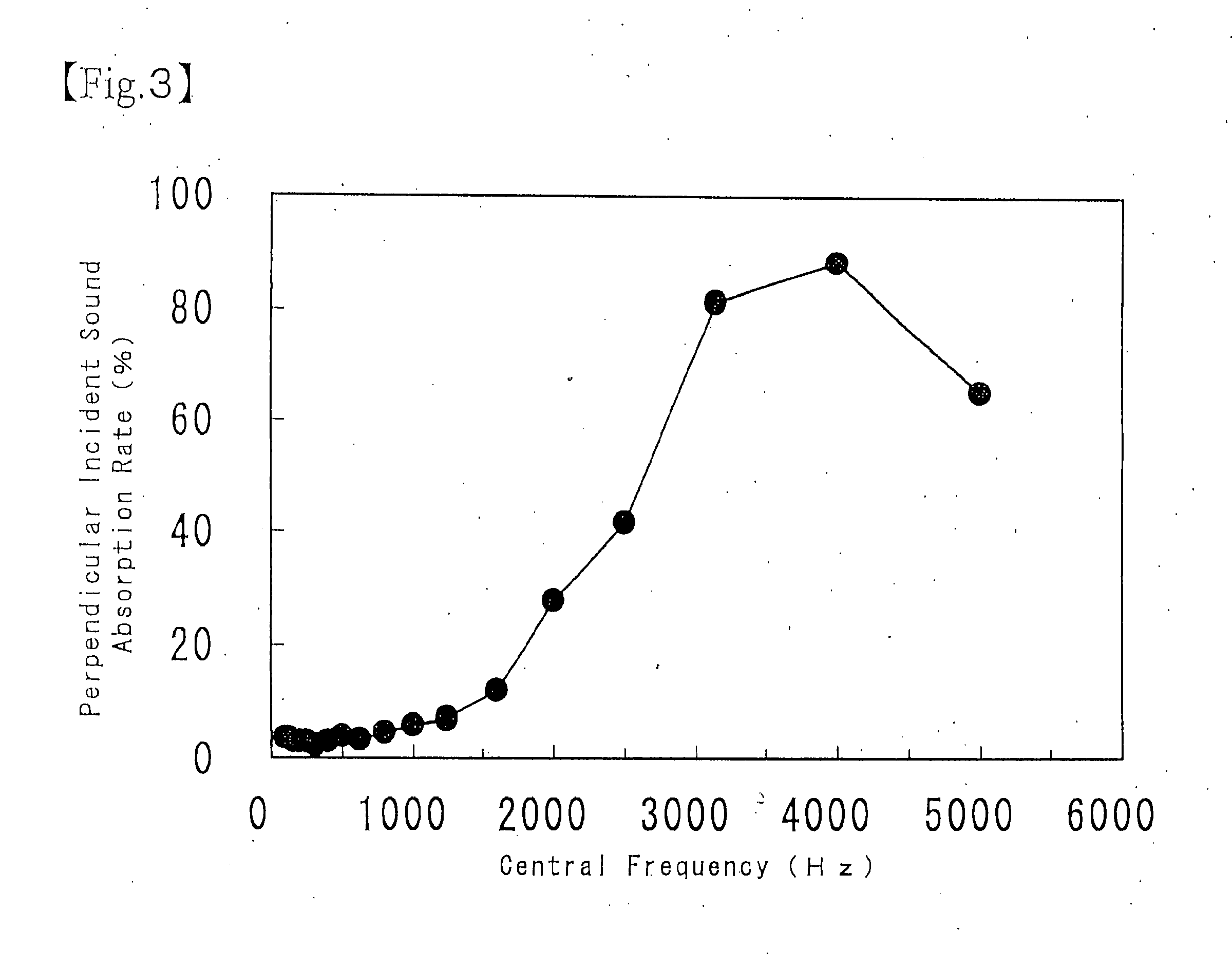

Spongelike Structure and Powder, As Well As Process for Producing the Same

InactiveUS20090060961A1Small apparent densityHigh porosityBioreactor/fermenter combinationsCosmetic preparationsMean diameterApparent density

An object of the present invention is to provide a spongelike structure or a powder having fibers three-dimensionally arranged therein with high dispersibility, whose apparent density can be designed depending on the purpose or utility, as well as a process producing them. A fiber dispersion in which fibers having a number mean diameter in a predetermined range are dispersed in a dispersion medium, and this fiber dispersion is dried to remove the dispersion medium, thereby, a spongelike structure and a powder are produced.

Owner:TORAY IND INC

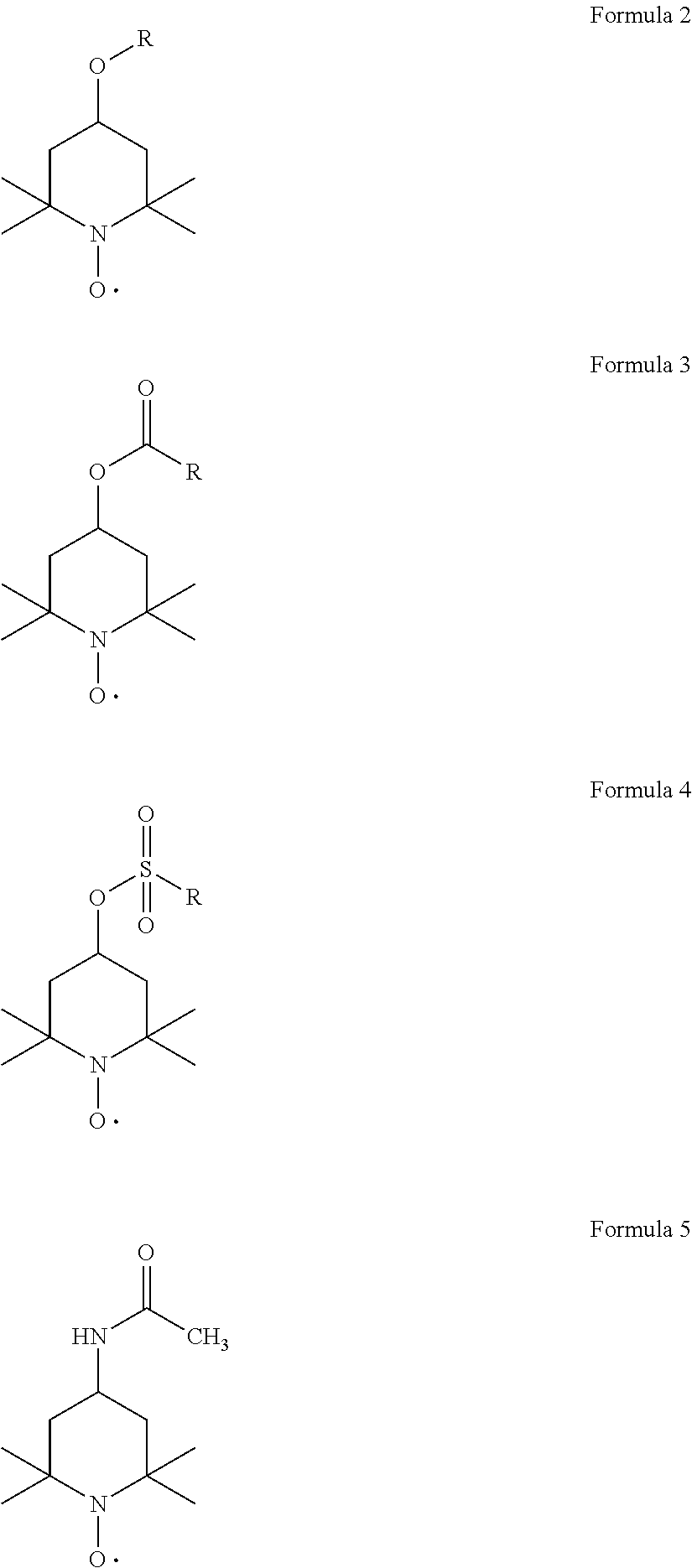

Method for producing cellulose nanofibers

ActiveUS20140238626A1Low viscosityImprove liquidityPretreatment with water/steamPulp properties modificationHigh concentrationWater use

Provided is a method which is capable of producing a cellulose nanofiber dispersion liquid that has a low viscosity and excellent fluidity even at a high concentration, while exhibiting excellent transparency. In a method for producing cellulose nanofibers, wherein a cellulosic starting material is oxidized in water using an oxidant in the presence of an N-oxyl compound and a compound that is selected from the group consisting of a bromide, an iodide and a mixture thereof and the thus obtained oxidized cellulose is defibrated and dispersed, pulp which is obtained by carrying out kraft cooking after a hydrolysis process is used as the cellulosic starting material.

Owner:NIPPON PAPER IND CO LTD

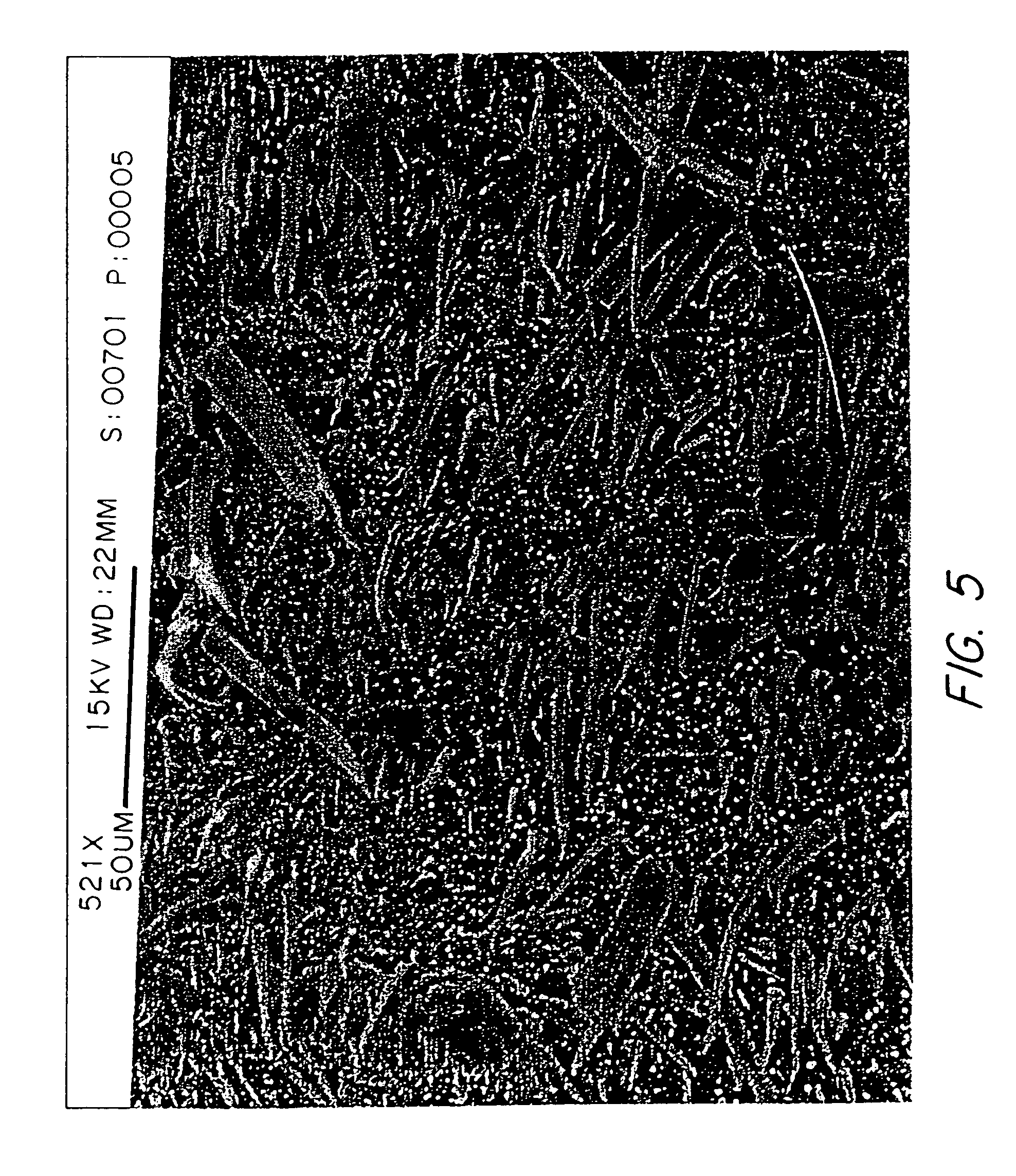

Chemical coating composition for glass fibers for improved fiber dispersion

InactiveUS20080143010A1Improve mechanical propertiesGood fiber dispersionSynthetic resin layered productsCellulosic plastic layered productsFibre dispersionFatty acid

A coating composition that improves fiber dispersion and mechanical properties in reinforced composite articles is provided. The coating composition includes a chemical compound that acts as an emulsifier, a surfactant, and a melt viscosity reducer. In at least one exemplary embodiment, the chemical compound is an ethoxylated fatty acid or an ethoxylated fatty alcohol compound. The coating composition may be applied to the reinforcing fiber strand after a conventional sizing composition has been applied to the reinforcing fiber and prior to wire coating the fiber with a thermoplastic resin. The coated / sized fiber strands may be chopped to form chopped strand segments and then densified or compacted to form a densified reinforcing fiber product, such as pellets. These pellets, in turn, may be used to form polymer reinforced composite articles. In alternative embodiments, the coating composition may be applied directly to the reinforcement fibers directly after fiber formation under the bushing.

Owner:OCV INTELLECTUAL CAPITAL LLC

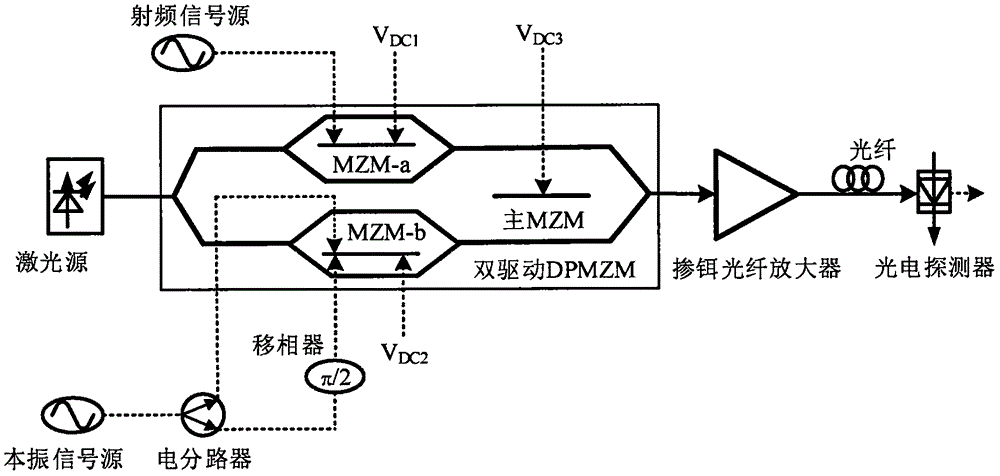

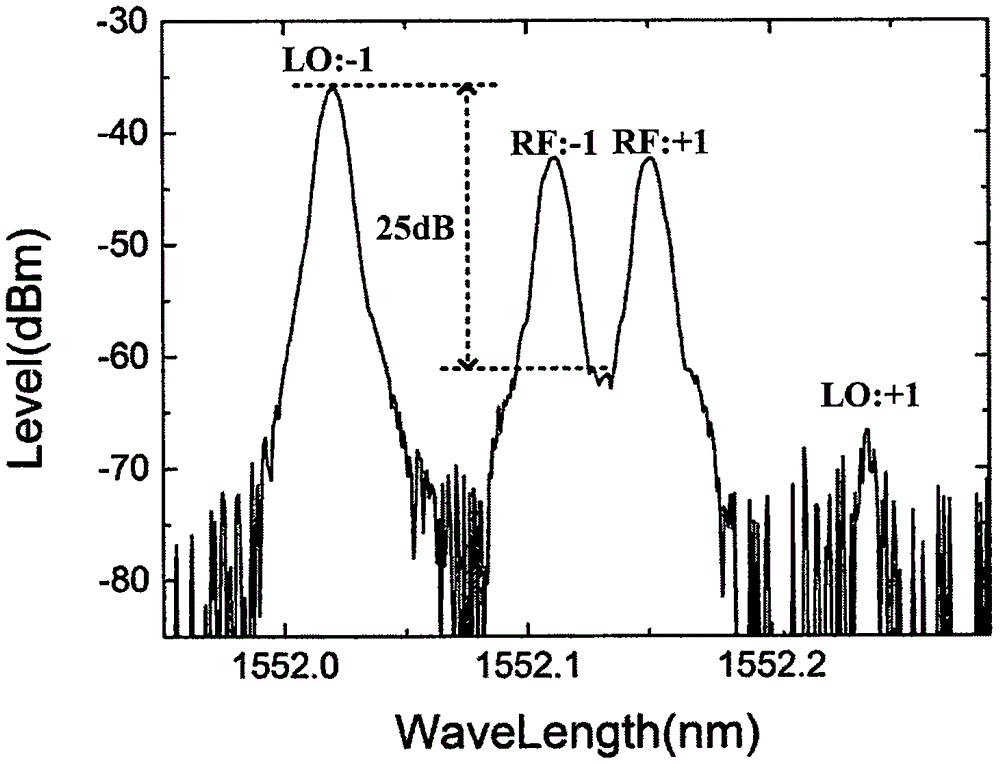

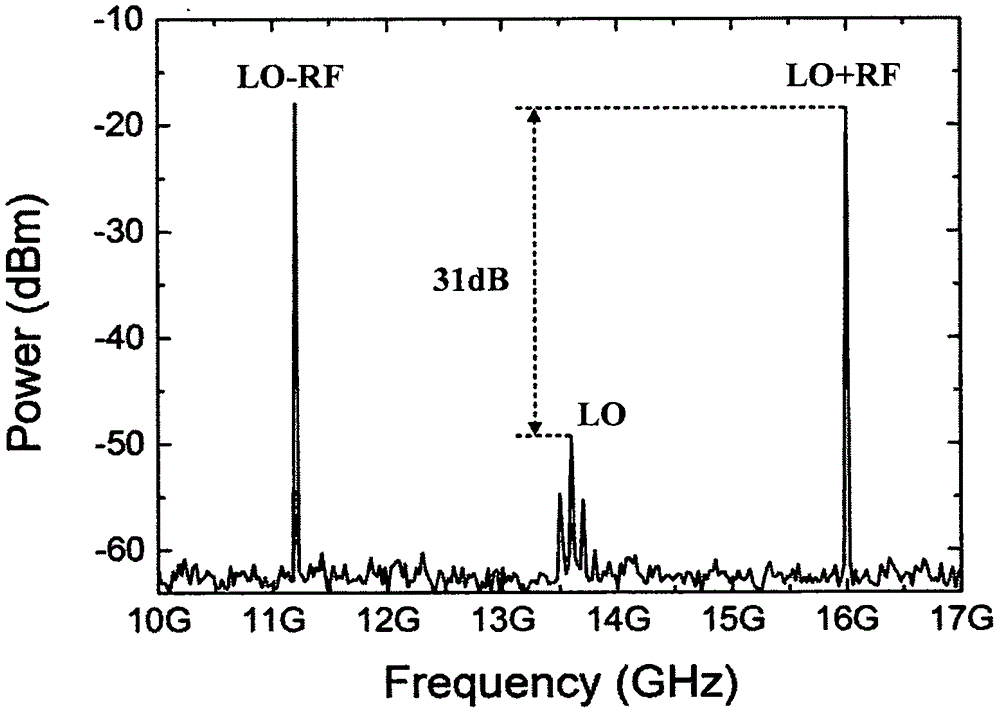

Device and method for realizing microwave frequency conversion by utilizing double-drive DPMZM

InactiveCN106209246AOptical Carrier SuppressionEasy to operateElectromagnetic transmittersElectromagnetic receiversShunt DeviceFiber chromatic dispersion

The invention discloses a device and method for realizing microwave frequency conversion by utilizing a double-drive DPMZM, relates to the technical field of microwaves and the technical field of optical communication, and is mainly used for frequency conversion of a microwave signal. The method comprises a light source, a radio-frequency signal source, an intrinsic signal source, an electric shunt device, a phase shifter, the double-drive DPMZM and a photoelectric detector (as drawing show). Double-sideband modulation of a radio-frequency signal and a single-sideband modulation of an intrinsic signal are respectively realized by utilizing the double-drive DPMZM; an optical carrier of an output signal of the double-drive DPMZM can be inhibited by reasonably setting a parameter; and, a frequency conversion signal can be obtained after the frequency of the output signal of the double-drive DPMZM is beaten through the photoelectric detector. The scheme has relatively high conversion efficiency; and furthermore, the power periodic fading due to optical fibre dispersion in a signal transmission process can be avoided.

Owner:XIDIAN UNIV

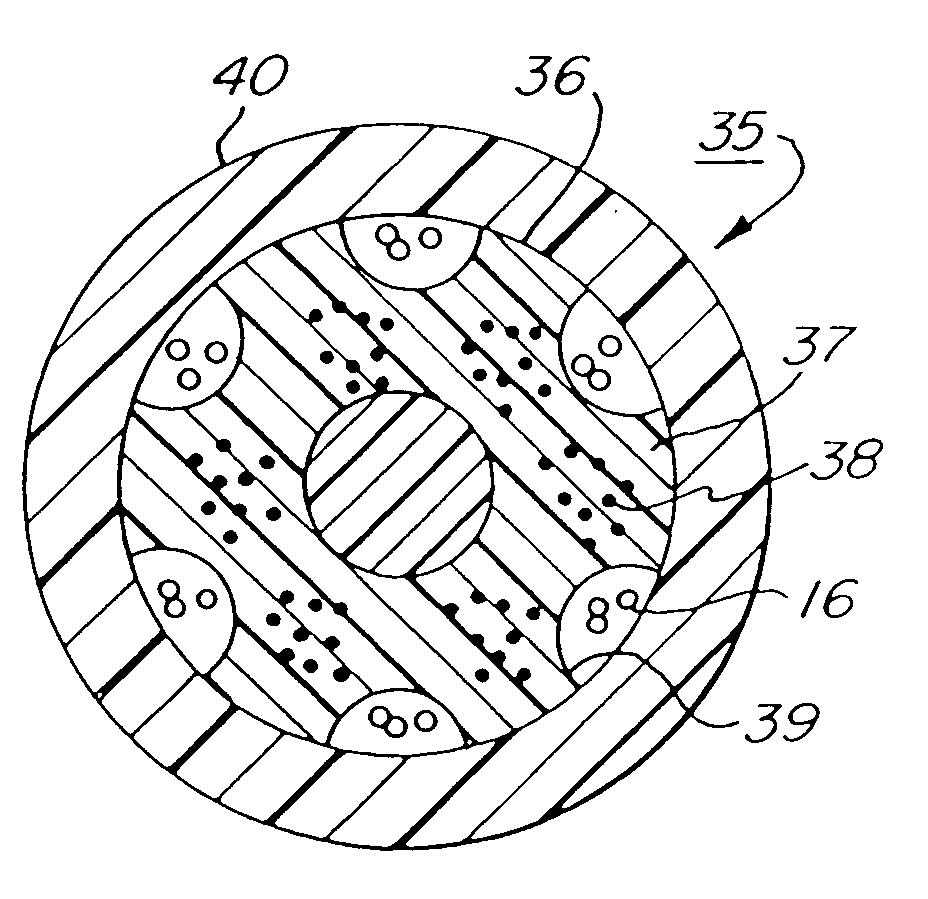

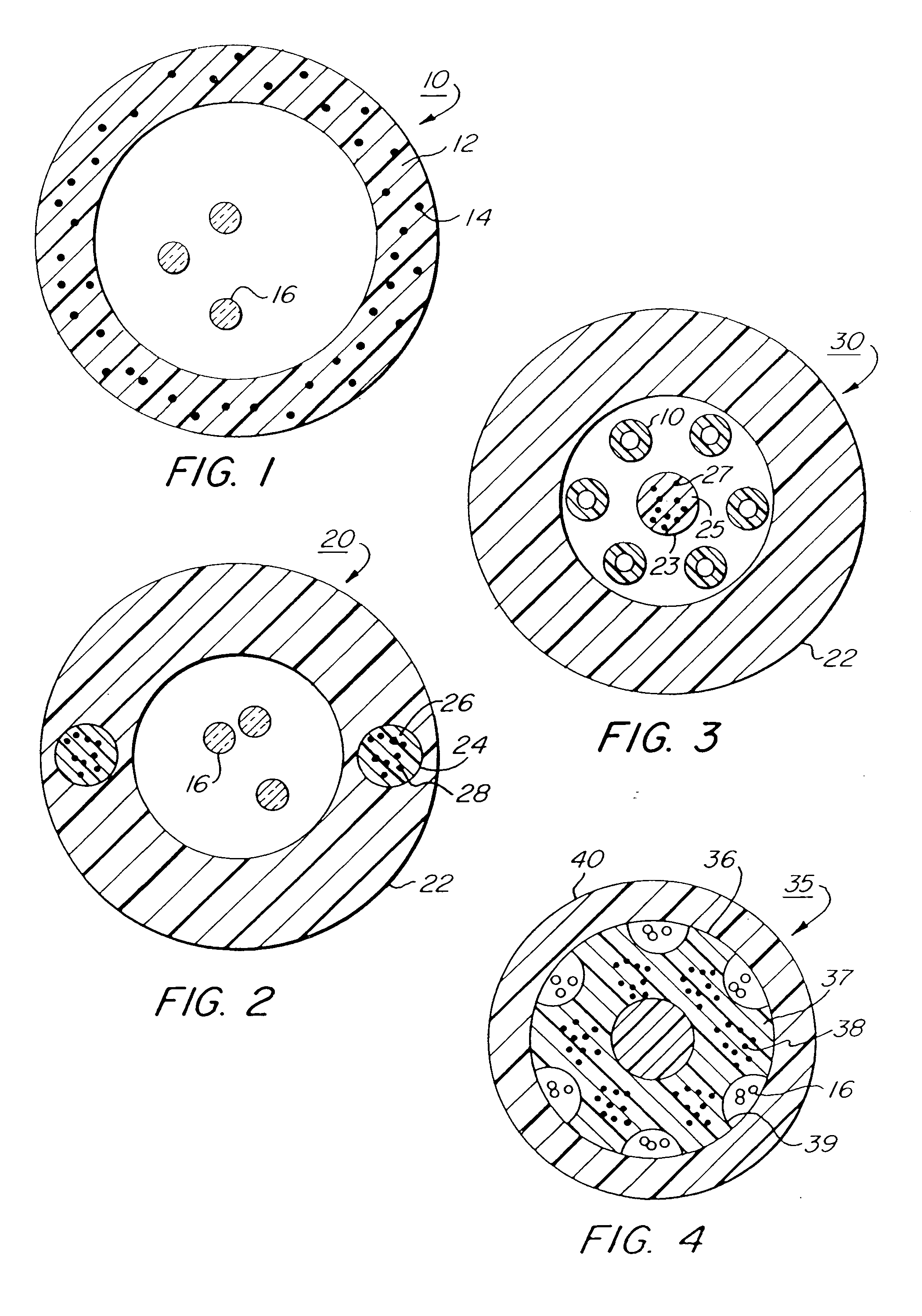

Composite structural components containing thermotropic liquid crystalline polymer reinforcements for optical fiber cables

InactiveUS20050286842A1High strengthAllow coefficientCladded optical fibreFibre mechanical structuresLiquid crystallinePolymer science

A process for producing an optical fiber cable composite structural component, such as reinforcing members, buffer tubes, filler rods, jackets, and slotted cores, is disclosed. The composite structural components are produced by co-extruding a thermotropic liquid crystalline polymer (TLCP) and a thermoplastic matrix material into the composite structural component so that TLCP reinforcing fibrils are dispersed in the thermoplastic matrix material. The TLCP reinforcing fibrils undergo a high level of process induced orientation, are provided with a high aspect ratio, and small diameters. The composite structural component has a high modulus. The TLCP reinforcing fibrils may be made continuous or discontinuous.

Owner:DRAKA COMTEQ BV

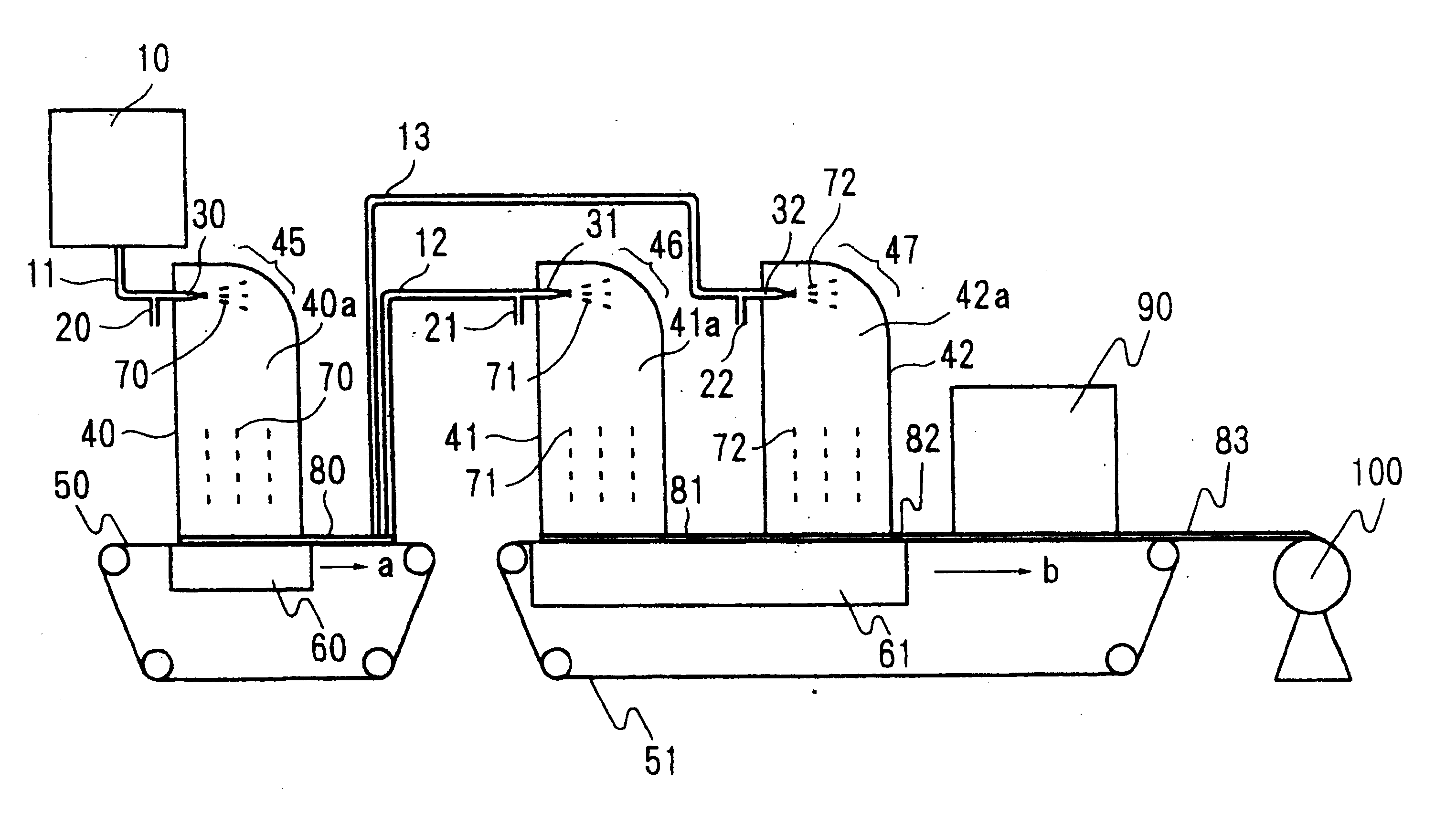

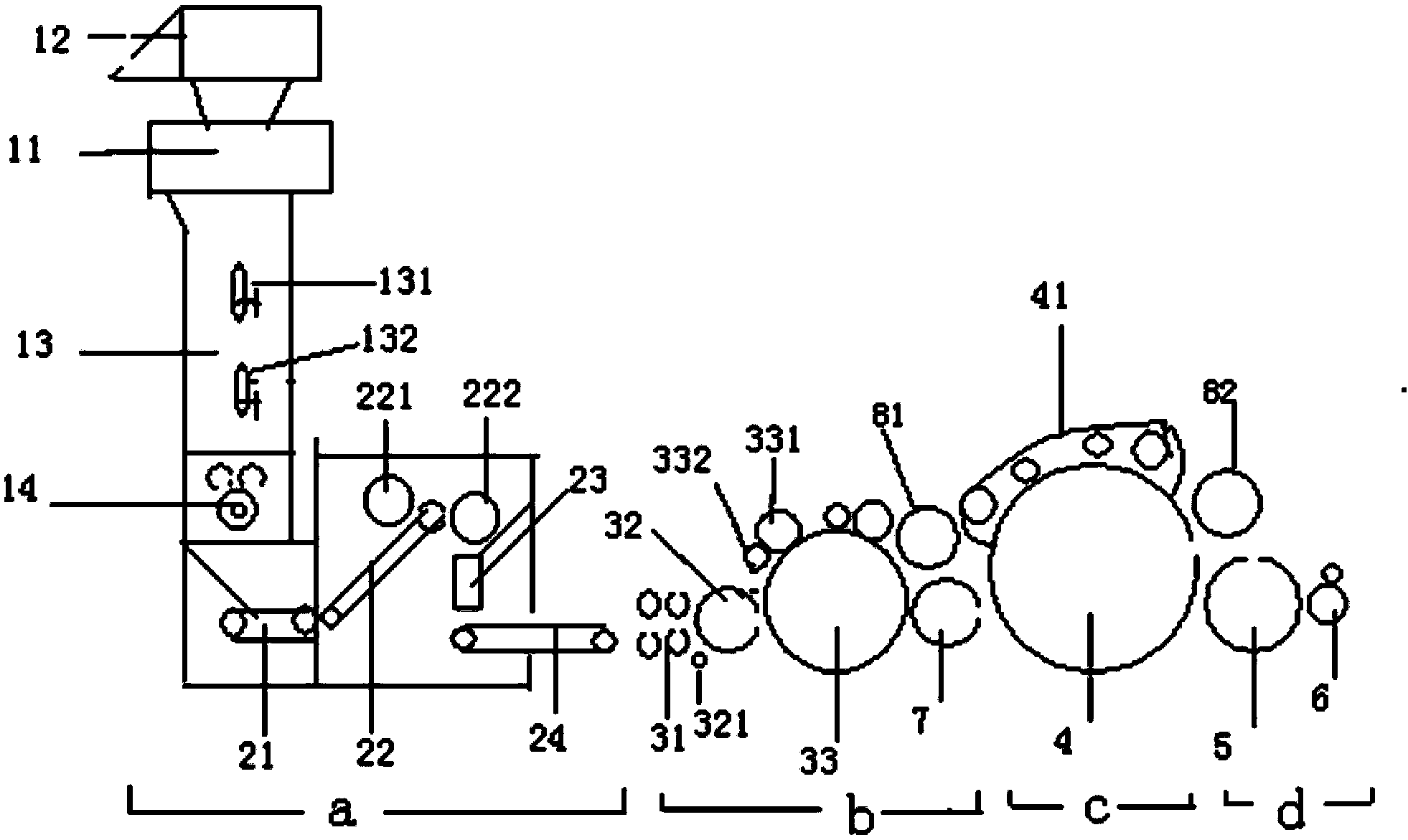

High-performance fiber carding machine for carding blended fabric and carding method thereof

The invention belongs to the technical field of non-woven machinery, and relates to a high-performance fiber carding machine for a carding blended fabric and a carding method thereof. The carding machine comprises a wool feeding mechanism (a), a pre-carding mechanism (b), a main carding mechanism (c) and a finished web peeling mechanism (d) from the front to back in sequence, wherein the wool feeding mechanism (a), the pre-carding mechanism (b), the main carding mechanism (c) and the finished net peeling mechanism (d) are connected in sequence; feeding limiters (131 and 132) are arranged in a feeding hopper (13) in the wool feeding mechanism (a); a pneumatic blending hopper (23) is arranged at the right side part of the wool feeding mechanism (a). The high-performance fiber carding machine has the advantages that manufactured fiber webs are uniform in gram weight, multi-component fiber has good dispersibility, the fiber damage ratio is low, a carding device is not required to be regularly cleaned, production can be continuously performed, the production efficiency is high, product performance is good, and the high-performance fiber carding machine can be widely applied to non-woven carding of fiber blended fabric.

Owner:滁州格美特科技有限公司

Print through elimination in fiber reinforced matrix composite mirrors and method of construction

A fiber reinforced matrix composite mirror that eliminates the problem of “print through”. A layer of small unbundled fibers in the matrix diffuses and randomize any stresses that are created by the weave pattern of the fiber reinforcement so that the coarse texture is not transferred to the optical quality surface thus eliminating “print through”. The layer can be provided in a variety of embodiments using random fibrils, a continuous fiber mat or a weave of single or finely towed continuous fibers. The fiber reinforced mirror is constructed by adding a mixture of matrix pre-cursor and fibers or fibrils to a common graphite fiber reinforced matrix construction.

Owner:RAYTHEON CO

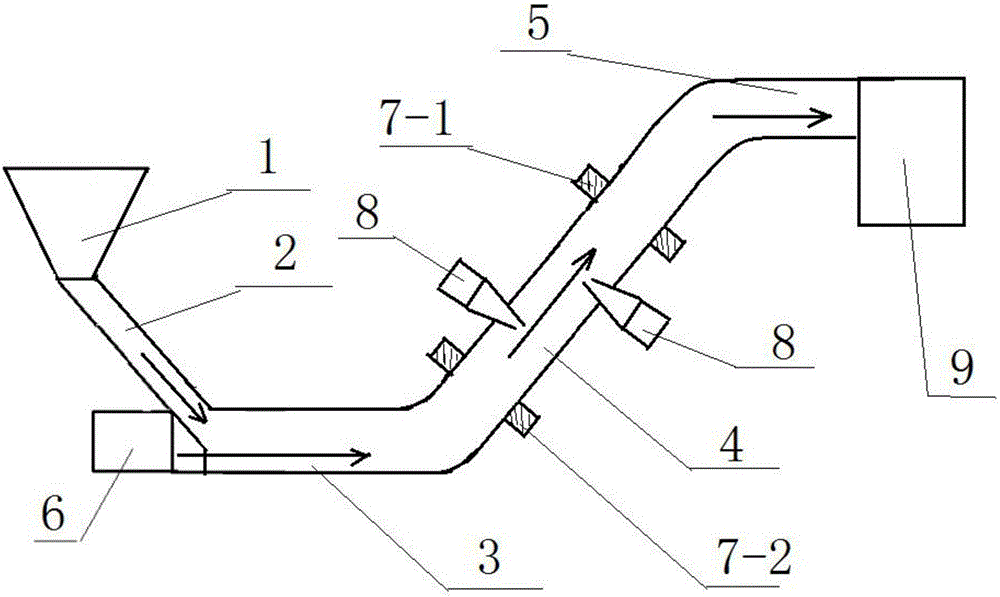

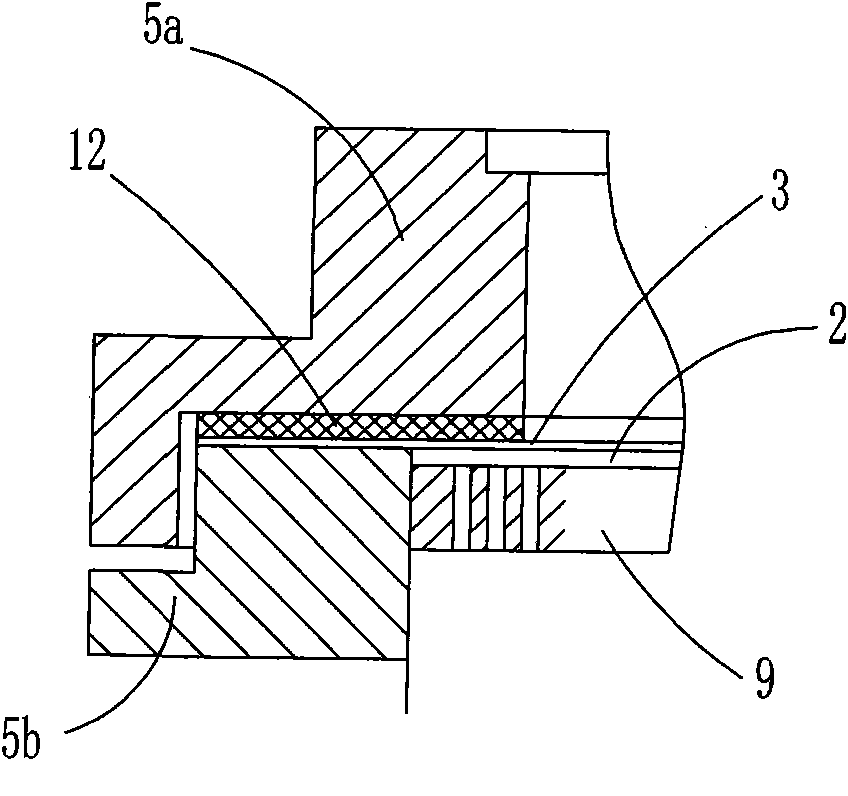

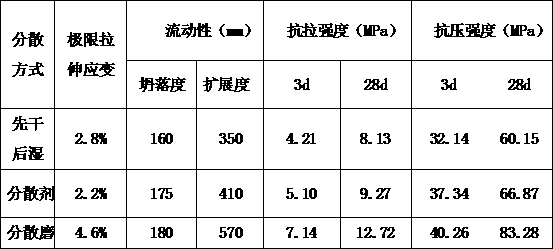

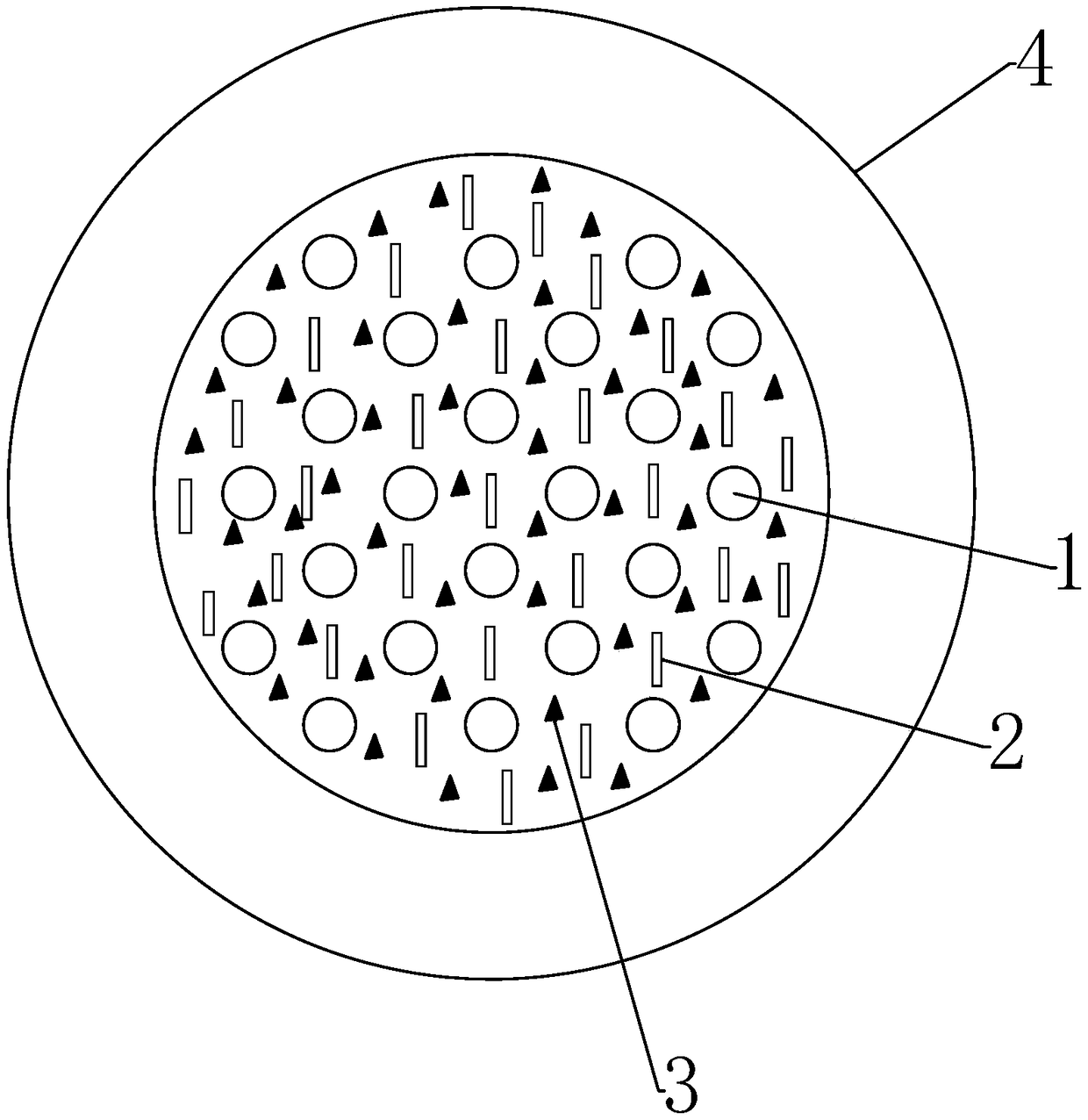

Fiber dispersion method and device applied to building mixture

ActiveCN106626071ASimple structureImprove efficiencyCement mixing apparatusFiber bundleRepulsion force

The invention discloses a fiber dispersion method and device applied to a building mixture. According to the method, fiber bundles are placed in a channel full of the same charges, fibers are electrified, fiber filaments are dispersed under the action of charge repulsion force, and then the dispersed fibers are blown into a building mixture stirring device through the wind force. The device for implementing the method comprises a feeding hopper (1), a downward sliding channel (2), a parallel channel (3), the charge channel (4), a discharging channel (5), a draught fan (6), a first magnetic ring (7-1), a second magnetic ring (7-2) and a charge generator (8). The opposite sides of the first magnetic ring (7-1) and the second magnetic ring (7-2) have the same polarity. The charges generated by the charge generator (8) are injected into the space, between the first magnetic ring (7-1) and the second magnetic ring (7-2), inside the charge channel (4). The device is simple in structure, and the fibers can be dispersed into the filaments and evenly mixed into the building mixture.

Owner:CHINA UNIV OF MINING & TECH

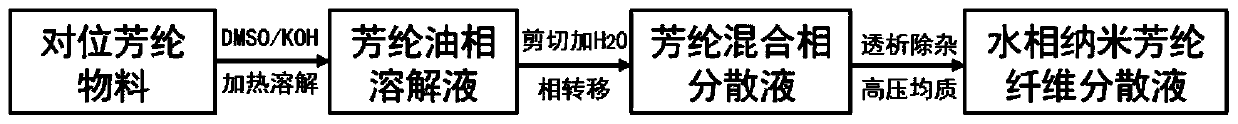

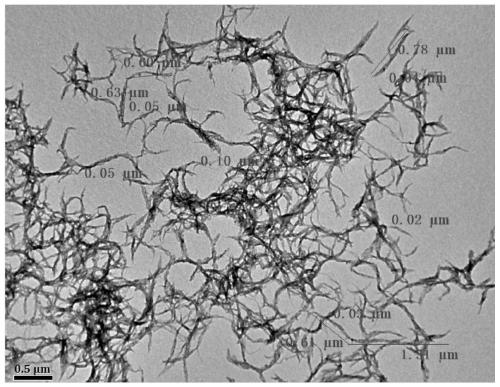

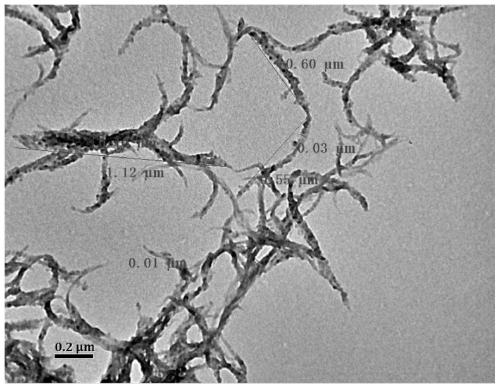

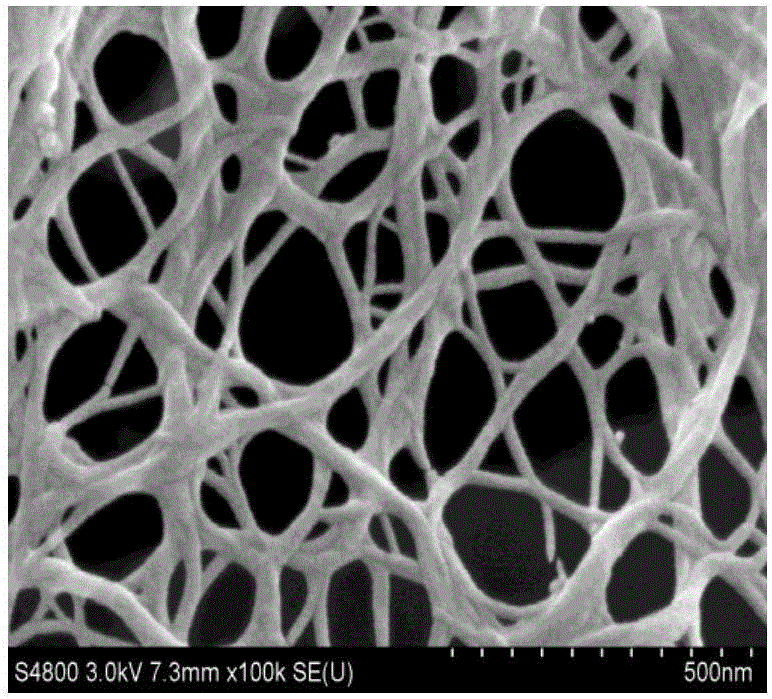

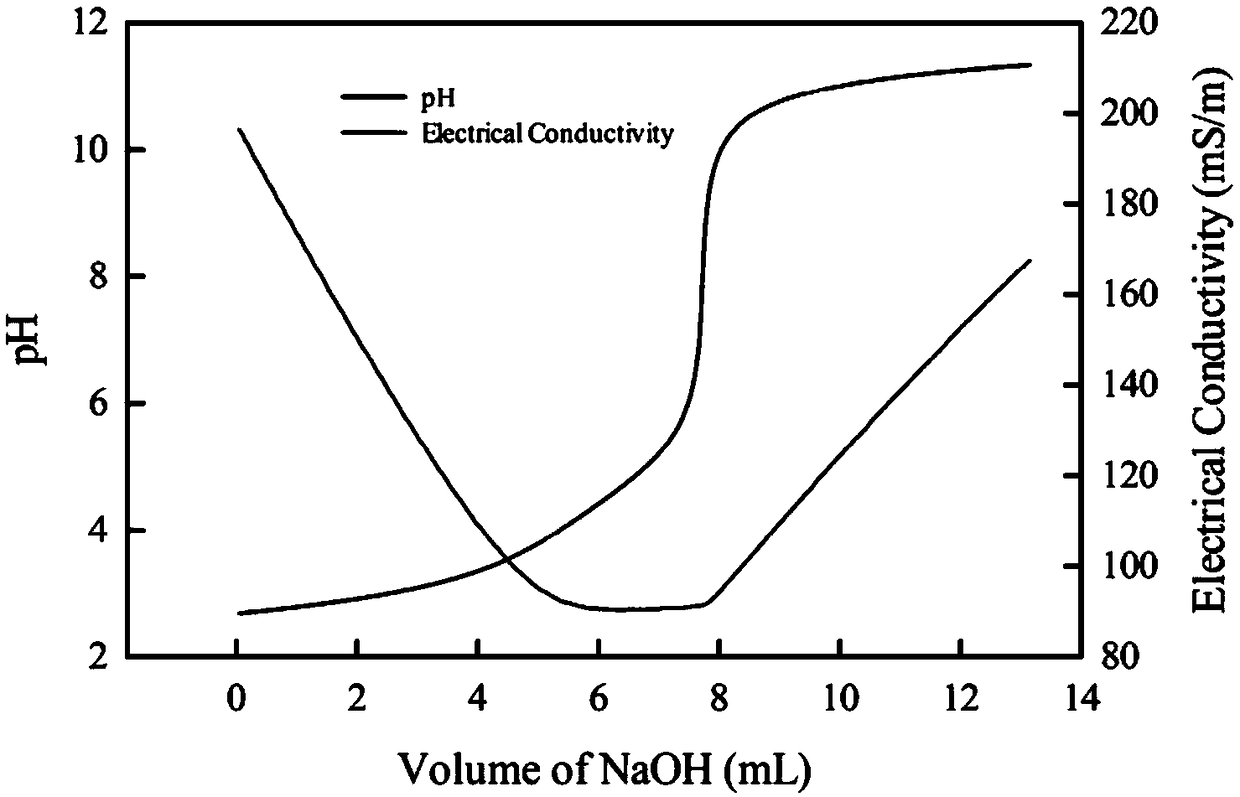

Preparation method of aqueous dispersion of aramid nano-fibers

The invention discloses a preparation method of an aqueous dispersion of aramid nano-fibers. The method comprises the following steps: adding an aramid fiber, potassium hydroxide, a cosolvent and a solvent into a container, and performing heating and stirring for dissolving to obtain aramid nano-fibers dispersed in the KOH / DMSO system; adding deionized water to the dispersed aramid nano-fiber dispersion under the action of high-speed shearing stirring to obtain an aramid nano-fiber dispersion dispersed in the KOH / DMSO / H2O system; immersing the aramid nano-fiber dispersion in deionized water, and carrying out dialysis treatment to obtain an aqueous dispersion of aramid fibers; and carrying out high-pressure homogenization treatment on the aqueous dispersion of aramid fibers to obtain the uniform and stable aqueous dispersion of aramid nano-fibers. The aramid nanofibers prepared in the invention have the advantages of small diameter, high length-diameter ratio and excellent heat resistance, can be stably dispersed in the aqueous system, and has a greatly expanded application range.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD +1

Paper production process and its product

ActiveCN102373649AGood dispersionHigh strengthSynthetic cellulose/non-cellulose material pulp/paperCarboxymethyl cellulosePaper production

The invention discloses a paper production process and its product. The production process provided by the invention mainly comprises a refining step, a slurry forming step, a paper making step, a drying step, a glue applying step and a finishing processing step. Before paper making of a slurry, carboxymethyl hydroxypropyl cellulose (CMHPC) is added into the slurry, wherein carboxymethyl hydroxypropyl cellulose (CMHPC) accounts for 0.01-3.0wt% of the dry weight of paper pulp. A few CMHPC is added into finished paper obtained by the above technology. As CMHPC is an auxiliary agent and has properties similar to CMC, and hydroxypropyl group is introduced into the chemical auxiliary agent, CMHPC comprises carboxymethyl and hydroxypropyl. Nonionic polar group is introduced into a carboxymethyl cellulose molecular chain, thus maintaining original properties of CMC and simultaneously further promoting fiber dispersion to improve drainage and retention and raise paper strength.

Owner:KUNSHAN BANKNOTE PAPER +1

Method for preparing wheat straw cellulose microfibrils by auxiliary enzymatic pretreatment

InactiveCN106436414ARealize high-value reuseFulfill quality requirementsPulp beating/refining methodsCellulose treatment using microorganisms/enzymesFiltrationSlurry

The invention relates to a method for preparing wheat straw cellulose microfibrils by auxiliary enzymatic pretreatment, which comprises the following steps: firstly sieving wheat straw pulp, and collecting the fiber fraction trapped on a sieve mesh; preparing a 1-5 wt% fiber suspension with a buffer solution from the obtained fiber fraction, and adding cellulase into the fiber suspension for hydrolysis to obtain enzyme pretreated fiber slurry, wherein the addition amount of the cellulase is 0.5-25 wt% of the absolute dry mass of the fiber fraction; mechanically stirring and shearing the fiber slurry, preparing a 0.5-1.5 wt% fiber suspension, and carrying out circular homogenization treatment to obtain cellulose microfibril emulsion; and subjecting the cellulose microfibril emulsion to centrifugal separation and filtration in turn to obtain wheat straw cellulose microfibrils. The method provided by the invention can reduce the energy consumption of mechanical dissociation, and is favorable for reducing the amount of enzymes, so that the fibers in the slurry are dispersed uniformly, and the microfibrils can be separated smoothly by using a high pressure homogenizer.

Owner:SHAANXI UNIV OF SCI & TECH

Process for producing spongelike structure

ActiveUS20160017112A1Relative density is smallHigh porosityCosmetic preparationsBody powdersMean diameterApparent density

A spongelike structure or a powder having fibers three-dimensionally arranged therein with high dispersibility, whose apparent density can be designed depending on the purpose or utility, as well as a process producing it. A fiber dispersion in which fibers having a number mean diameter in a predetermined range are dispersed in a dispersion medium, and this fiber dispersion is dried to remove the dispersion medium, thereby, a spongelike structure and a powder are produced.

Owner:TORAY IND INC

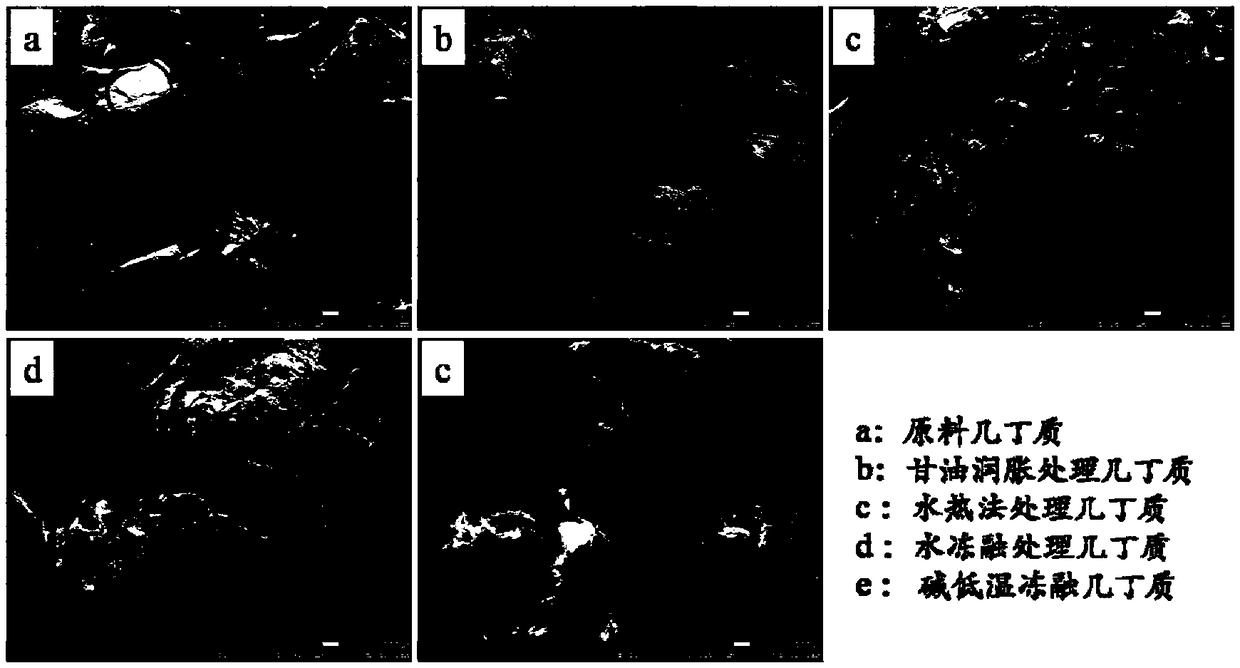

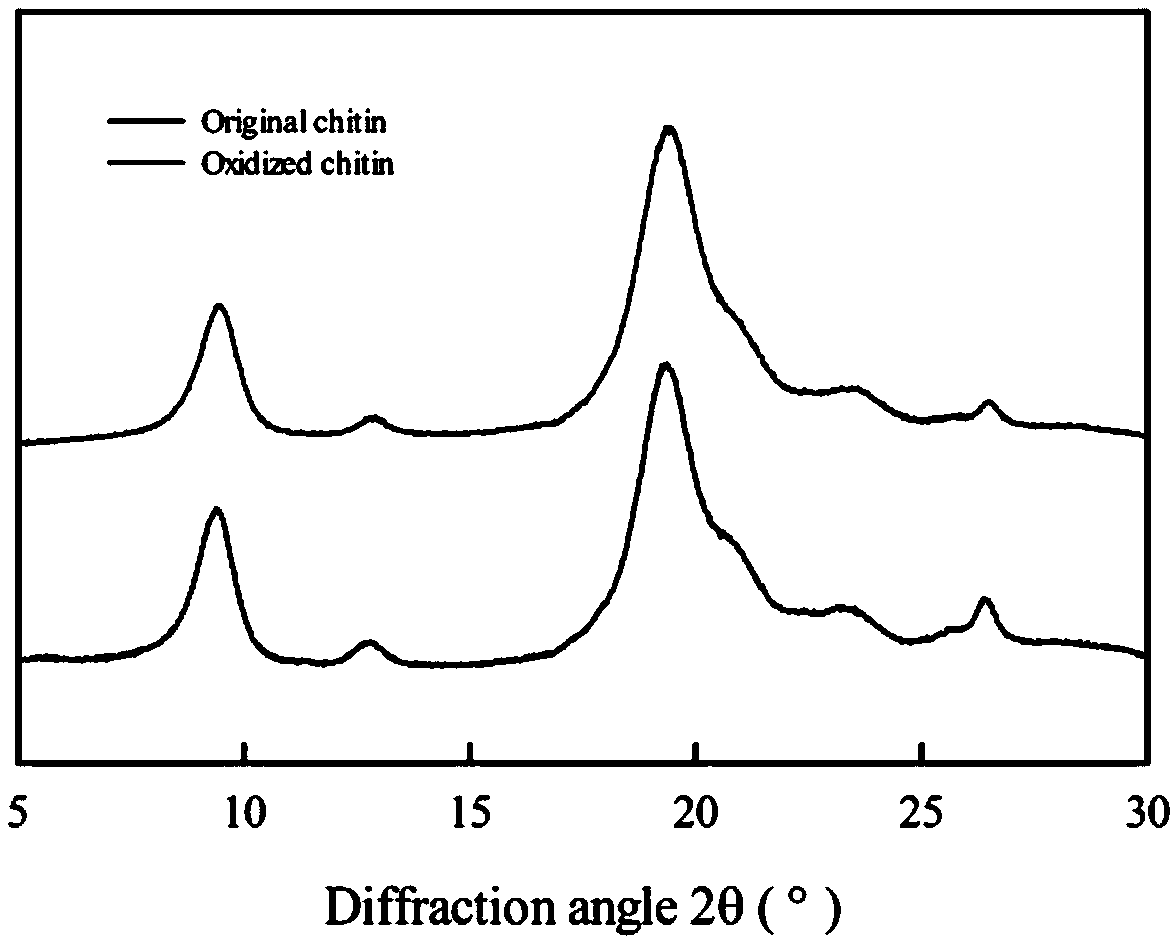

Preparation method of chitin nano fiber dispersion liquid with high carboxyl content, chitin nano fiber dispersion liquid with high carboxyl content and application

The invention belongs to the field of preparation of chitin nano fiber and relates to a preparation method of chitin nano fiber dispersion liquid with high carboxyl content, the chitin nano fiber dispersion liquid with high carboxyl content and application. The preparation method comprises the following steps: pre-treating a chitin raw material to obtain chitin slurry; oxidizing the chitin slurryby utilizing a TEMPO oxidation system to obtain oxidized chitin; and performing homogenization and ultrasonic treatment on the oxidized chitin to obtain the chitin nano fiber dispersion liquid with high carboxyl content. Polar solvent high temperature, polar solvent low temperature and mechanical pre-treatment methods are innovatively combined with the TEMPO oxidation system respectively so as topre-treat chitin, and then, a weakly acidic, neutral and alkaline TEMPO oxidation system is adopted to perform selective oxidation modification, thereby effectively reducing the dosage of a chemical oxidant, reducing the degradation loss of chitin in a chitin nano fiber preparation process, realizing efficient preparation of the chitin nano fiber with high carboxyl content, and providing a new idea for realizing high-value utilization of the chitin nano fiber.

Owner:NANJING FORESTRY UNIV

Machine for spinning nano-fiber for production of non-woven cloth

InactiveCN1837436AGuaranteed uniformityEasy to adjustFilament/thread formingNon-woven fabricsNanofiberLiquid tank

This invention discloses a nonwovens spinning machine of nanometer fibre, which mainly includes the high pressure power set, the liquid tank of spinning fluid, receiving device, and at least one group of spinning components. Said liquid tank of spinning fluid is connected with spinning pipe of spinning components by pumps, wherein receiving device including a cylinder vertically disposited on movement devices and metal receiving netting disposited on the cylinder excircle in circle, the movement device having rolling degree of freedom that revolution axis is paralleled with z axis and translation degree of freedom; each group of spinning components including spinning component shelf and at least two spinning pipes fixed on the shelf, the pipe having electric electrode in it, the distance between the spout of the pipe and metal receiving netting is 5-25 centimeters; mounting an isolated electrode between adjacent spinning pipes. The invention comprises the following merits: assuring uniformity of product obtained, avoiding the disturbance of electric field of adjacent spinning pipes, preventing unsteadiness in spinning and inhomogeneity of fibre dispersion.

Owner:SUZHOU UNIV +1

Alumina fiber aggregate and catalytic converter support mat comprising the same

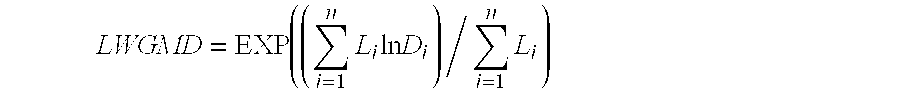

InactiveUS20060216225A1Improve propertiesStable supportNon-woven fabricsThin material handlingLogit-normal distributionEnvironmental hygiene

An alumina fiber aggregate which is minimized in scatter of fibers, excels in handling characteristics and working environmental hygiene and finds its useful application to support mats for catalytic converters and such is provided. An alumina fiber aggregate comprising alumina short fibers having such properties that when diameters of said alumina short fibers are represented by x (μm), the rate at which the natural logarithmic value lnx in lognormal distribution of x is less than ln3 is not more than 2%, and the value left after deducting from the length-weighted geometric mean of said fiber diameters a value twice its standard error is not more than 6 μm; and a support mat for catalytic converters comprising such an alumina fiber aggregate.

Owner:MITSUBISHI CHEM FUNCTIONAL PROD

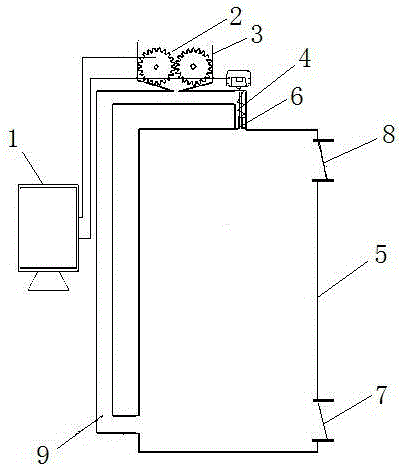

Prefabricated fiber dispersing device and method and application thereof

ActiveCN106215795AEvenly dispersedImprove sand carrying capacityFlow mixersTransportation and packagingCarrying capacityHigh-pressure area

The invention provides a prefabricated fiber dispersing device and method and application thereof. Two-stage dispersion is adopted, fibers are firstly put into a gear disperser composed of two engaged gears for first-stage dispersion, liquid mixed with the fibers is pressurized through a screw pump, a high-pressure area is formed on a throttling device, finally the mixture is injected into a prefabricating tank, second-stage dispersion is achieved, the fibers are expanded and dispersed from the high-pressure area to a low-pressure area, and liquid in which the fibers are evenly dispersed is formed. The whole process is controlled through a controller in real time, and the number of circulating times can be adjusted according to the dispersion degree of the fibers. The need of evenly dispersing the fibers in the liquid can be met through the two stages of dispersion, the sand carrying capacity of the liquid can be improved through the evenly dispersed fibers, the laying degree of a propping agent in a crack can be promoted, the friction of the liquid is reduced, leak off of the liquid in the stratum is reduced, and backflow of the propping agent is prevented.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing short carbon fiber enhanced metal-based composite material through combination of machine and electromagnetic stirring

The invention relates to the technical field of metal-based composite materials, in particular to a method for preparing a short carbon fiber enhanced metal-based composite material through combination of a machine and electromagnetic stirring. The preparation method is also applicable to preparation of aluminum alloy, zinc alloy, cast iron and other carbon fiber enhanced metal-based composite materials. The problems that after melt in a crucible is stable in the prior art, a single flow field exists in the crucible, nonuniform fiber dispersion and single fiber distribution orientation are likely to occur, and dead areas exist in the melt are solved. The machine and electromagnetic stirring are combined to prepare the short carbon fiber enhanced metal-based composite material, the flow field in the melt becomes complex through the synthetic effect between electromagnetism and mechanical stirring, and therefore multi-direction dispersion of fiber is achieved.

Owner:SHENYANG POLYTECHNIC UNIV

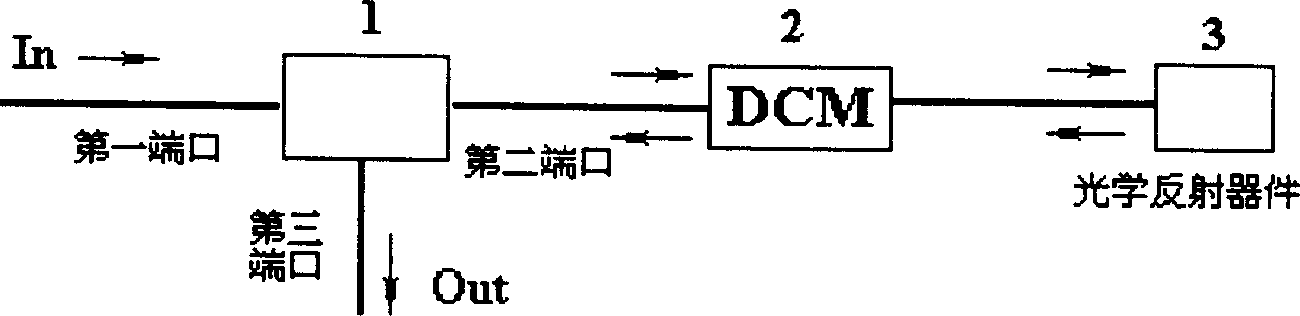

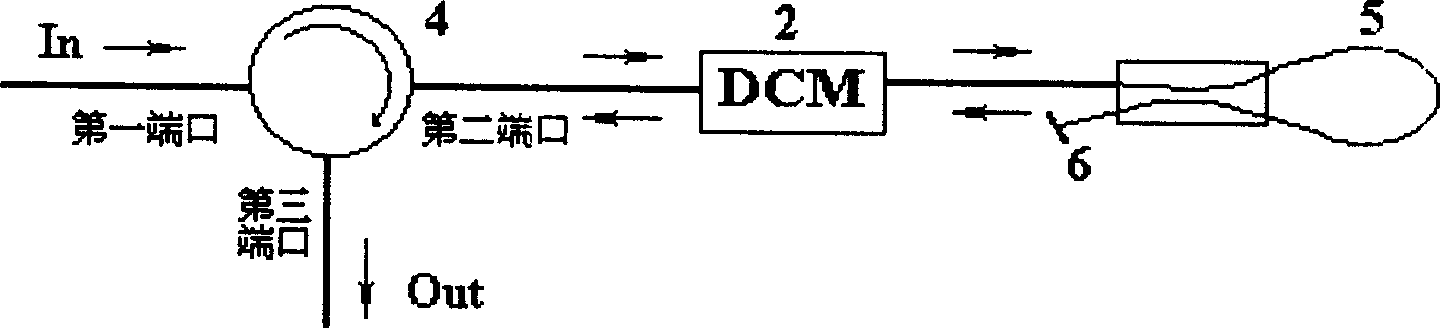

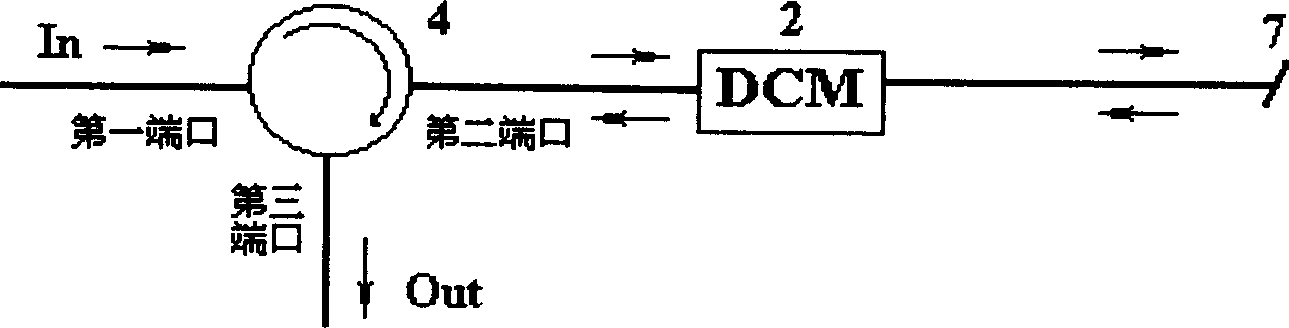

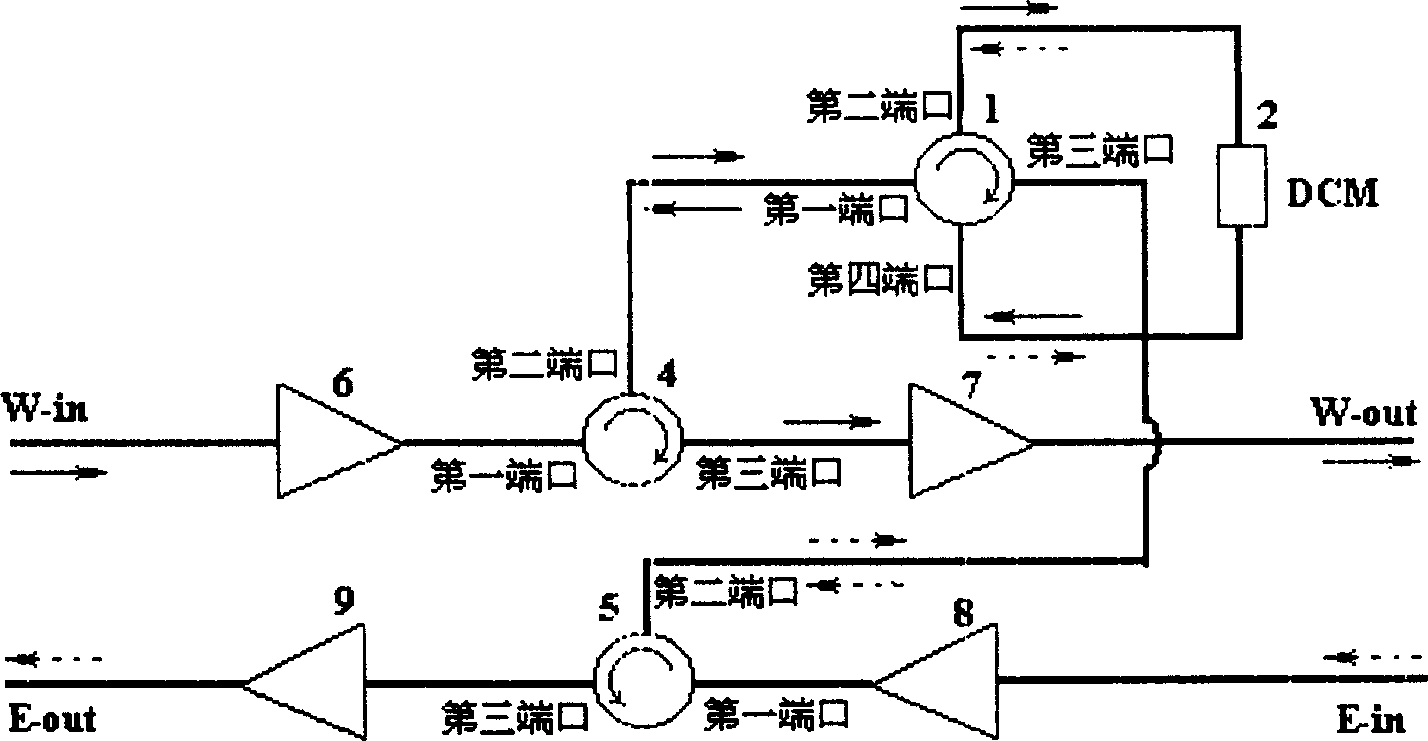

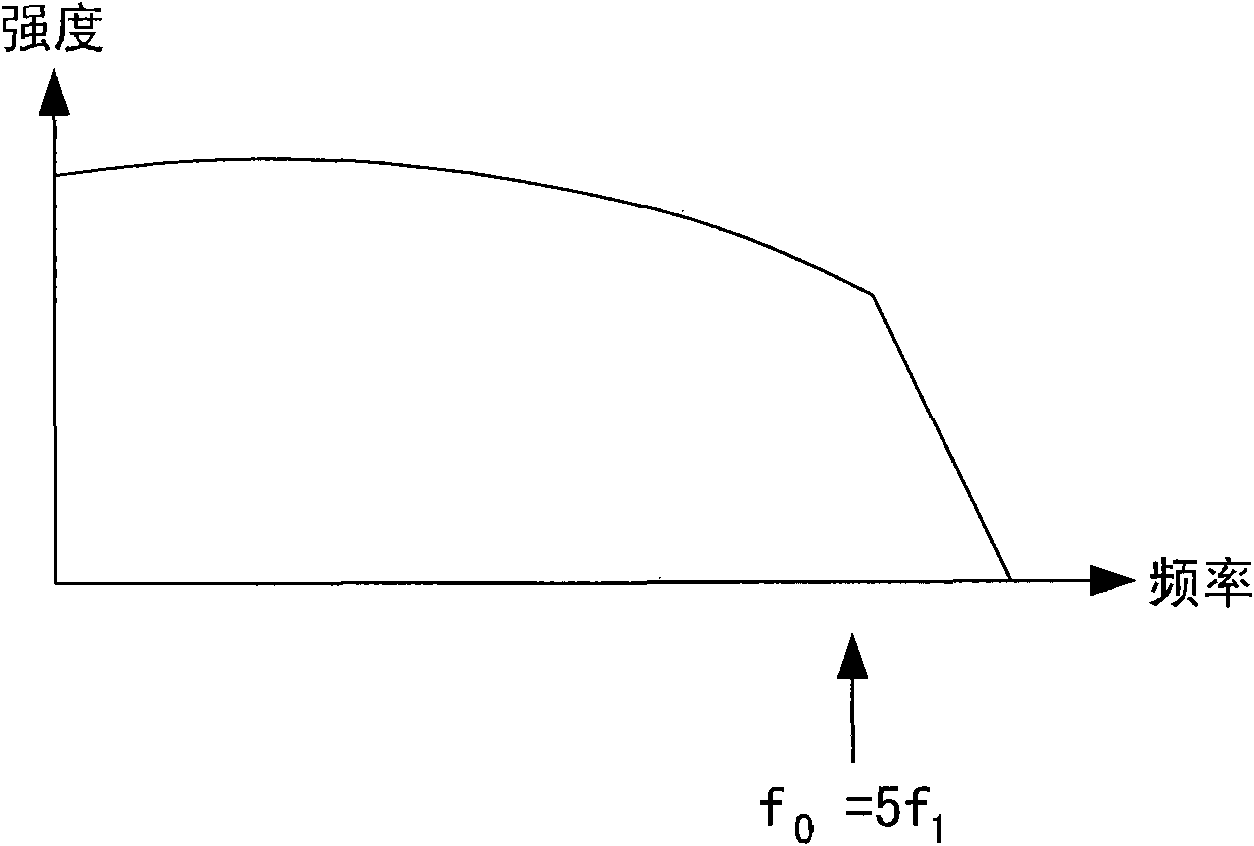

Optical fiber dispersion compensation method and its device

InactiveCN1412966AIncrease profitImprove signal-to-noise ratioWavelength-division multiplex systemsCoupling light guidesOptical reflectionFiber chromatic dispersion

Owner:HUAWEI TECH CO LTD

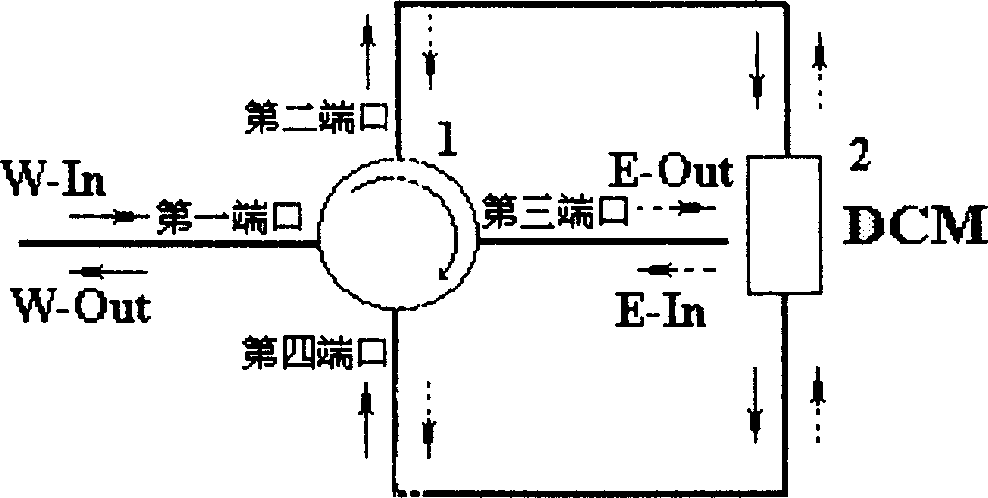

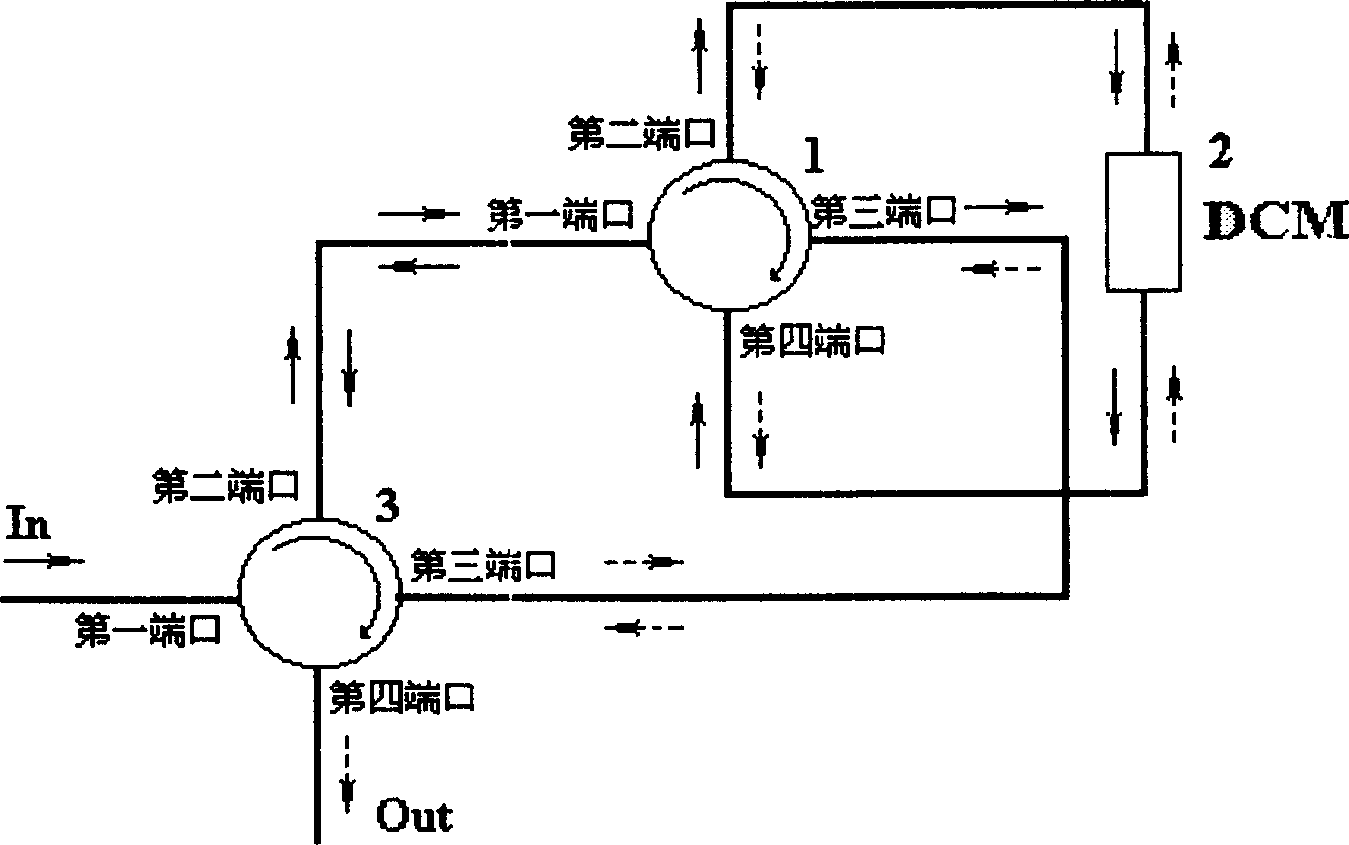

Two-way optical fiber dispersion compensation device

InactiveCN1412967AIncrease profitWavelength-division multiplex systemsCoupling light guidesTransport systemFiber chromatic dispersion

The two-way fibre dispersion compensation equipment includes a dispersion compensation module and a first optical circulator with four ports, in which first port is connected with first transmission channel, third port is connected with second transmission channel, and second port and fourth port are connected by means of dispersion compensation module. Said invention includes an optical circulator with four ports, so that it cna utilize the irrevesible principle of optical circuit to make inputted light from different directions pass through same dispersion compensation module to make dispersion compensation so as to greatly raise utilization rate of dispersion compensation module. By adding one or several optical circulators it can utilize same dispersion compensation module to make dispersion compensation of various optical signals with different fibres and transmission directions.

Owner:HUAWEI TECH CO LTD

Water dispersion type fibre and method for making same

The invention discloses a moisture dispersible fibre which comprises the following components by weight: fibre, 60-80 portions; water with the hardness of 0.02-1.50mmol / L, 20-40 portions; dispersing agent, 0.1-0.5 portions; antifoaming agent, 0.1-0.6 portions; and mouldproof bactericides, 0.1-0.4 portions. With the invention, uniform dispersion of the fibre in the concrete can be realized without lowering and damage of various performances of the fibre, and the overall performance of the concrete is excellent, thereby engineering quality requirements can be met; fibre dispersion has high security and long storage time, and can not only be mixed and used in field but also be mixed and stored for further use; simultaneously the fibre dispersion is safe to use with no influence on the health of workers, the addition is accurate and the dosing of concrete water mixed is saved.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

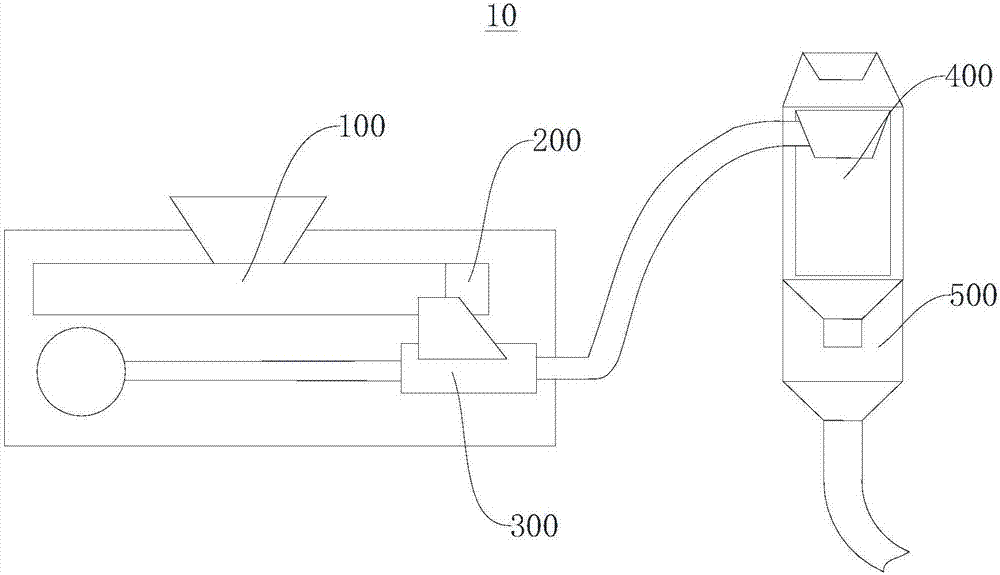

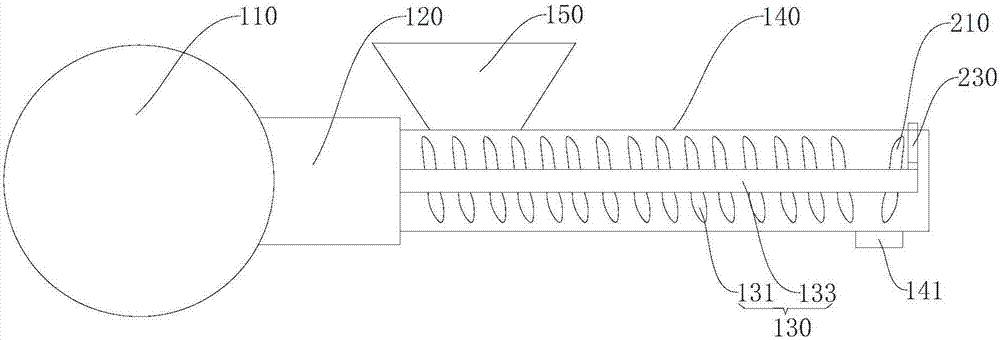

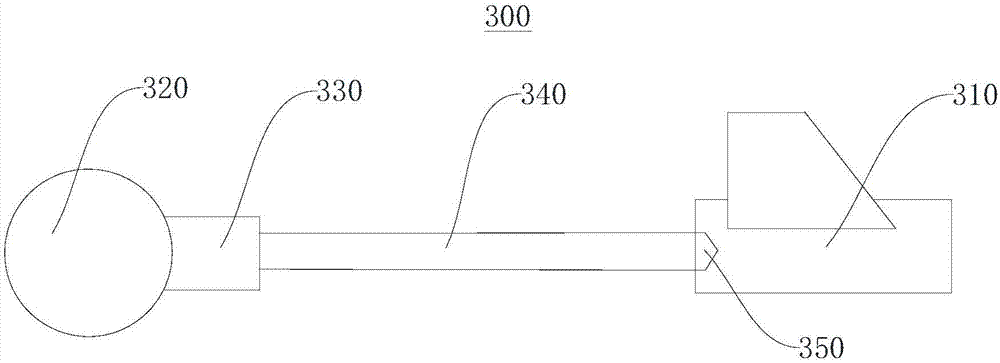

Fiber material dispersion method and fiber material dispersion apparatus

InactiveCN106902696AEasy to useDisperse fastMixing methodsTransportation and packagingFibre dispersionMixed gas

The present invention provides a fiber material dispersion method and a fiber material dispersion apparatus, and relates to the technical field of fiber fracturing and fiber sand prevention. According to the fiber material dispersion method, a fiber material is spirally conveyed while the fiber material is subjected to primary stirring dispersion, the fiber material obtained after the primary stirring dispersion is subjected to complete blowing dispersion under the action of wind, the obtained fiber material is conveyed forward along with a gas flow, the mixed gas flow is separated, the dispersed fiber material falls down, and the dispersed fiber material rapidly settles under the action of water so as to complete the uniform dispersion. Compared to the fiber dispersion method in the prior art, the fiber material dispersion method of the invention has the following characteristics that the tightly continuous four steps such as spiral conveying, fiber mixing with wind, gas and material separation, and rapid settling are used in the fiber material dispersion method, such that the fiber material can be rapidly and uniformly dispersed, the construction risk is reduced, the use effect of the fiber during the fracturing construction process is improved, and the practicality is extremely strong.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

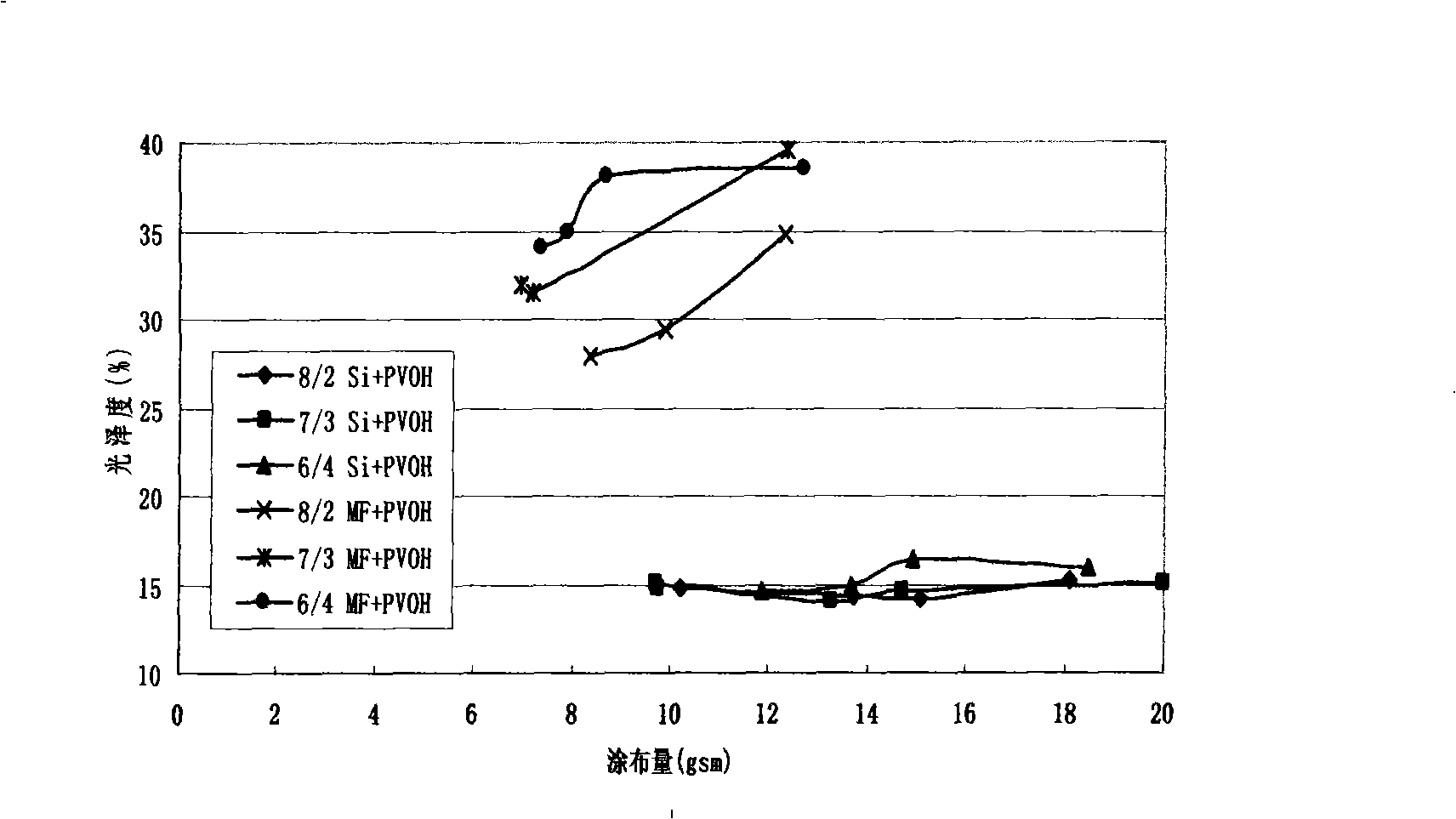

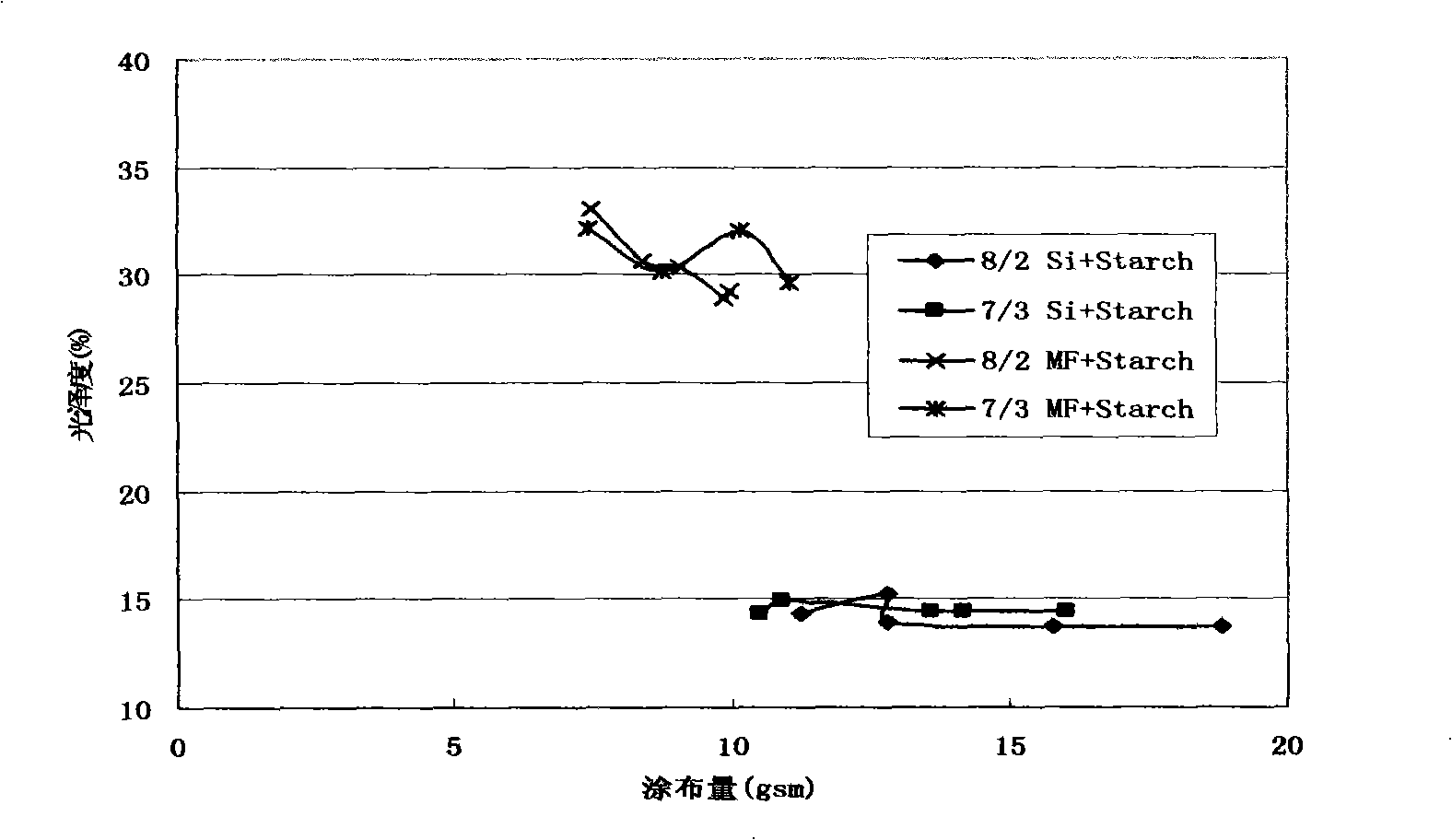

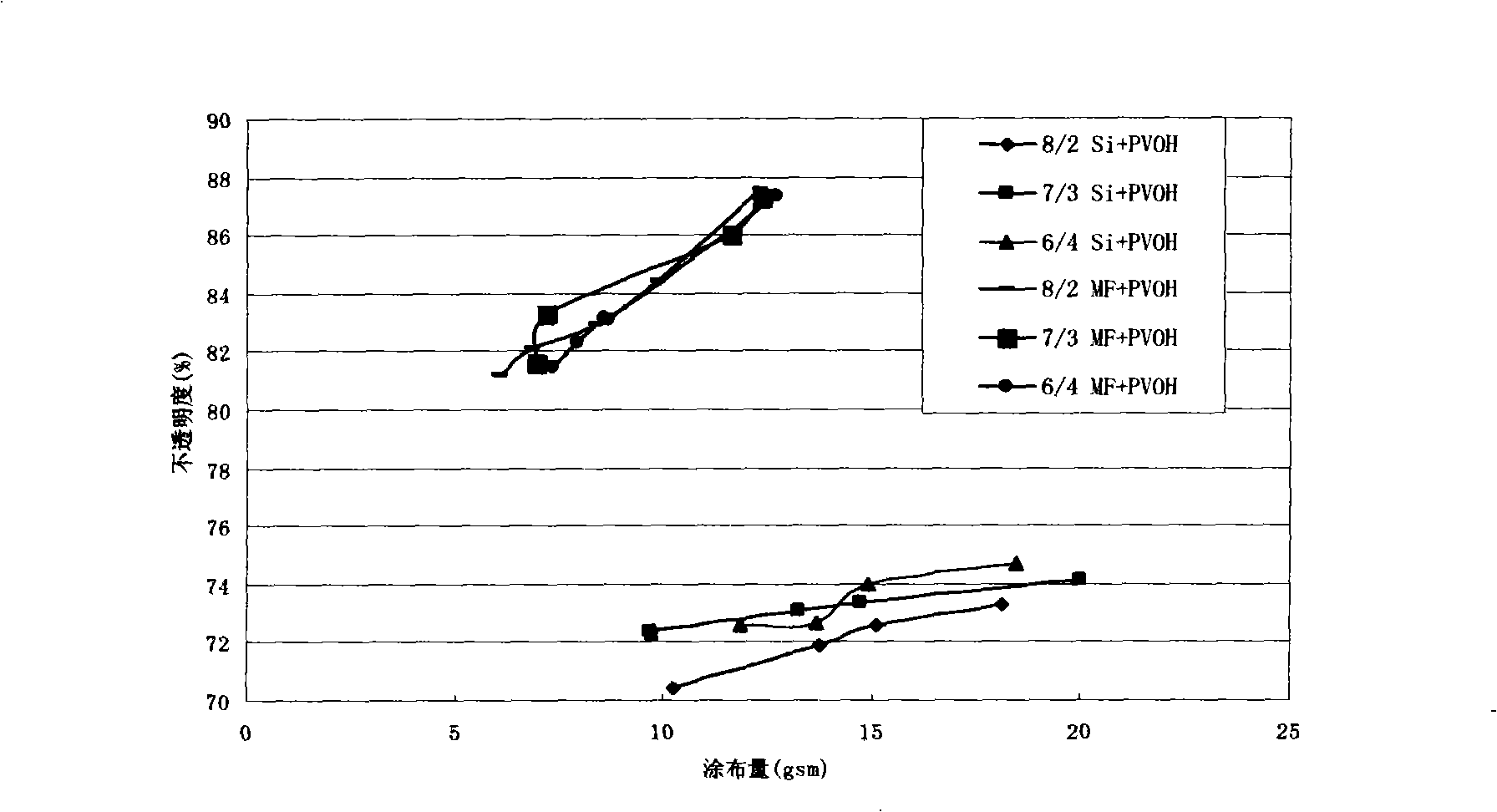

High-gloss high-opacity coefficient paint for papers, preparation method and application thereof

InactiveCN101270558AReduce dosageHigh glossPaper coatingPaper/cardboardFibre dispersionAqueous solution

The invention discloses a dope used for high-luster high-opacity paper as well as a manufacture method and application thereof. The dope used for paper is manufactured and obtained according to the following methods: dispersing a microfine fiber into a dispersing suspension liquid with a mass concentration of 10 to 30 percent, namely obtaining a microfine fiber pulp, mixing with a macromolecule aqueous liquid with a mass concentration of 10 to 50 percent and stirring uniformly, namely obtaining the dope used for high-luster high-opacity paper; the oven dry mass proportion of the microfine fiber and the macromolecule aqueous liquid is 1.5:1 to 4:1. Compared with the existing dope used for paper, the paper coat formed by the dope used for paper of the invention has more excellent lustrousness, opacity and brightness.

Owner:GUANGDONG IND TECHN COLLEGE

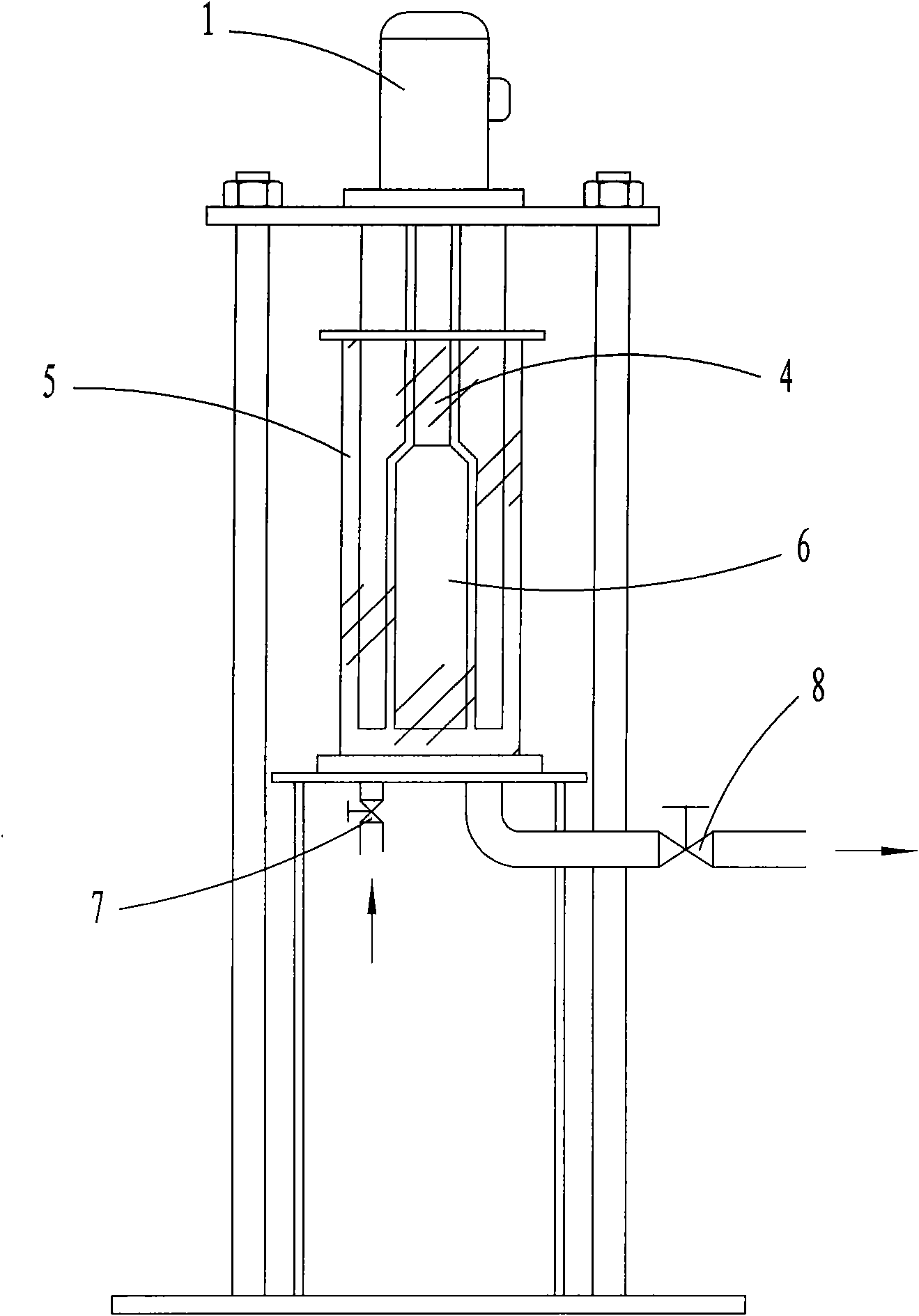

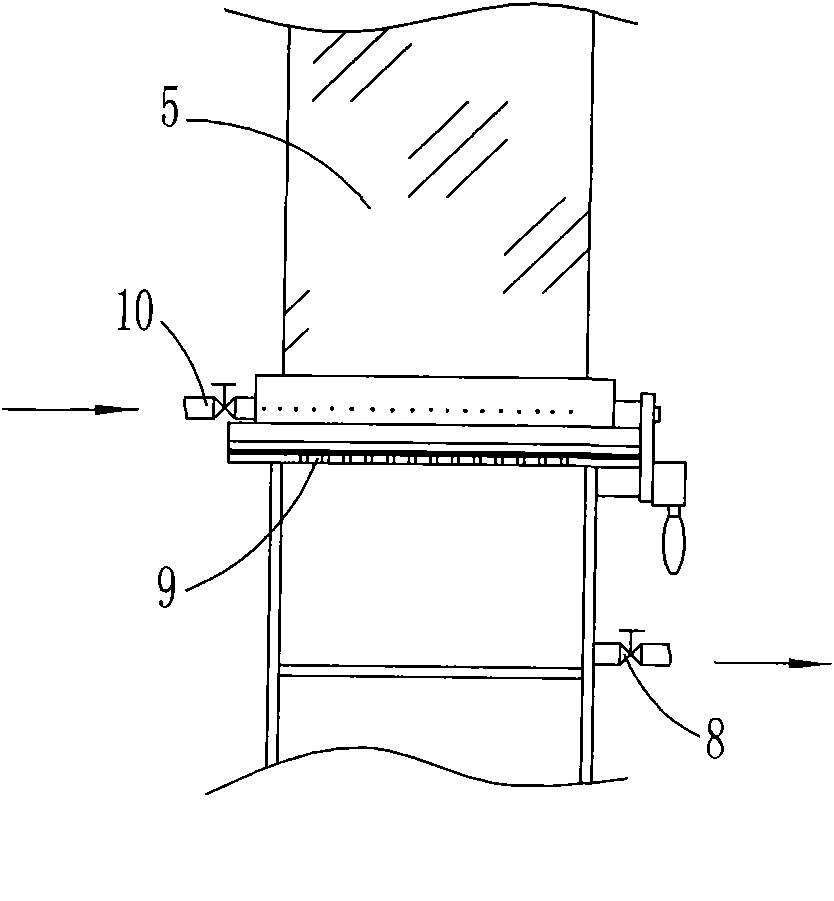

Device and method for detecting dispersing performance of chemical synthesized short fibers

ActiveCN101876139ACompact structureSimple and fast operationInspecting textilesYarnChemical synthesis

The invention discloses a device and a method for detecting the dispersing performance of chemical synthesized short fibers. The device is characterized by being vertically provided with a cylinder; a middle filtering layer is arranged in the cylinder; a stirring shaft for forming a dispersing stirrer is axially arranged above the middle filtering layer; a water inlet pipe which is provided with a water inlet valve and a liquid discharge pipe which is provided with a liquid discharge valve are respectively arranged below the middle filtering layer; the middle filtering layer comprises a filter screen and a filter cloth which is arranged on the filter screen; and an air inlet pipe is radially arranged on the side wall of the cylinder, at the bottom of the stirring shaft and above a middle interlayer. The invention has compact device structure and simple and convenient method operation and can be used for rapidly and accurately detecting various defects of paralleled yarns, sticking yarns, doubling yarns, gommures, and the like existing in the chemical synthesized short fibers by the dispersing situation of the short fibers in water.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

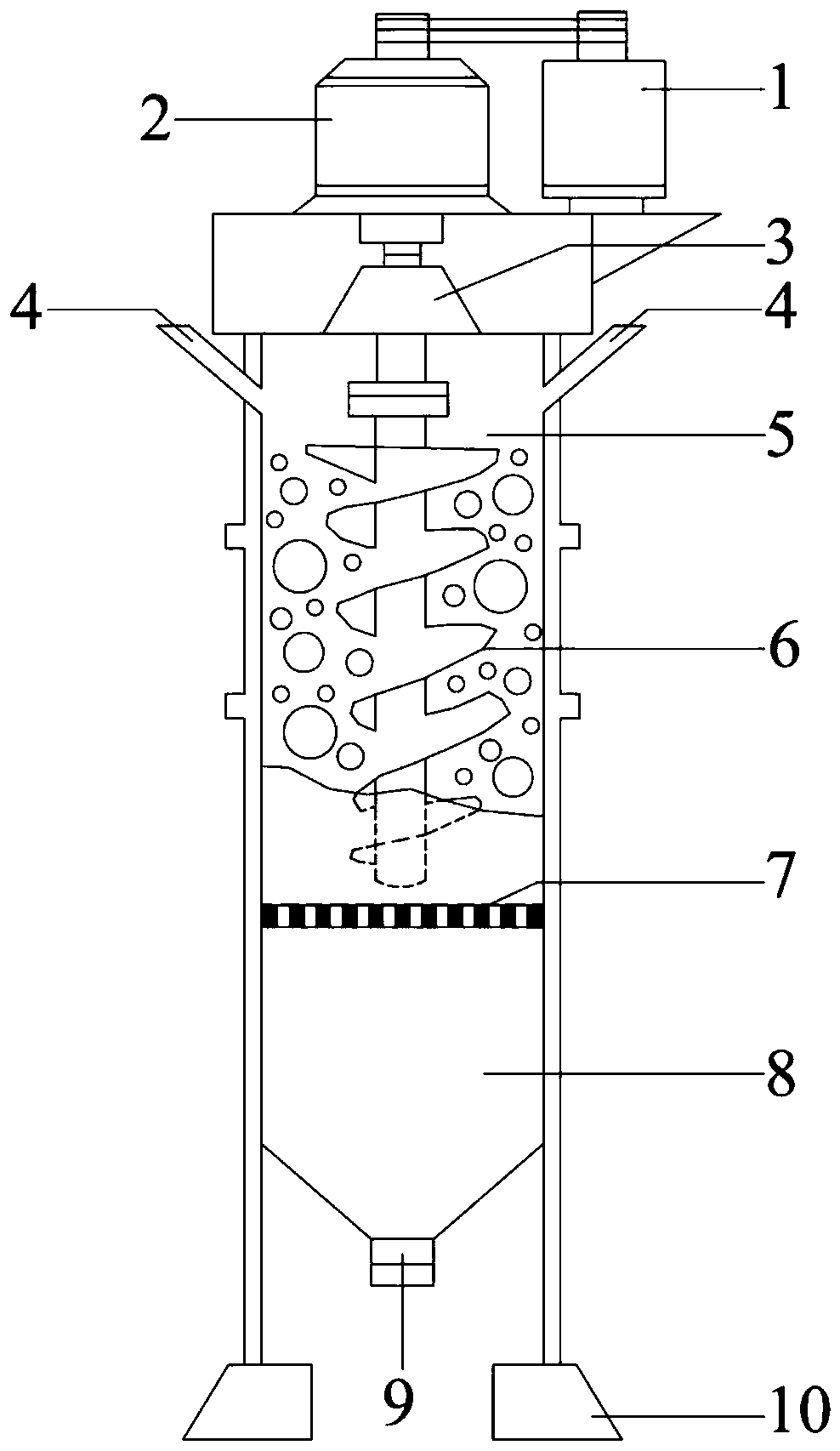

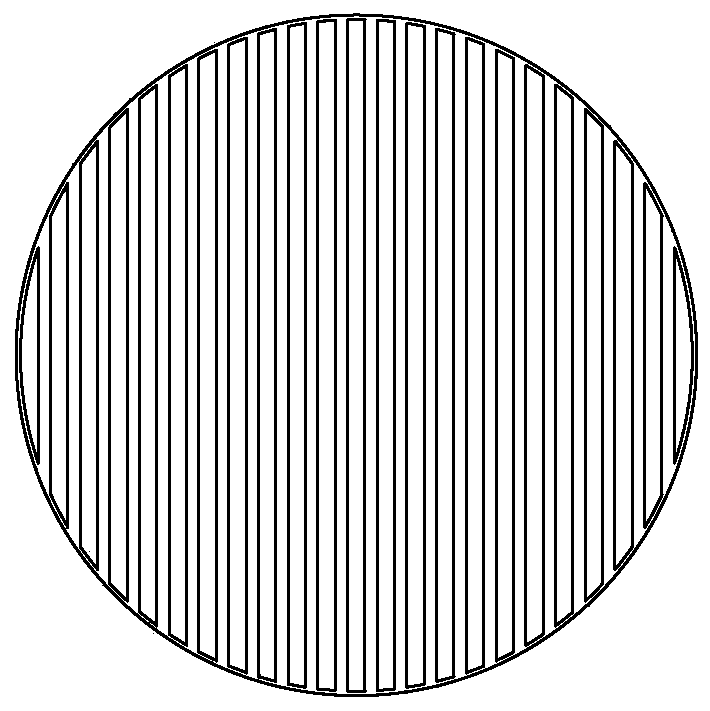

Fiber dispersion mill of organic fiber enhanced composite material and fiber dispersion method

InactiveCN108501210AGood dispersionRealize mixed grindingDischarging apparatusMixing operation control apparatusDispersityFiber-reinforced composite

The invention discloses a fiber dispersion mill of an organic fiber enhanced composite material and a fiber dispersion method. The fiber dispersion mill comprises a barrel body, a stirrer, a speed reducer and a motor. The fiber dispersion mill adopts a double-bin design; the upper part of the fiber dispersion mill is a mixing and milling bin and the lower part of the fiber dispersion mill is an aggregate bin. The stirrer and a steel ball in the mixing and milling bin can be used for effectively realizing joint mixing and milling of fibers and cement, surface properties of the fibers are changed and the dispersity of the fibers is improved; the aggregate bin can be used for temporarily storing a mixed and milled composite material; a lower discharging opening of the aggregate bin is connected with a concrete stirring machine and the composite material with a certain mass is discharged at fixed time according to the mixing proportion of the concrete and technological parameters of the stirring machine; meanwhile, the cement and the fibers are added at fixed time respectively through a feeding opening of the mixing and milling bin according to the ratio required by production, so thatcontinuous production work of the concrete stirring machine is realized.

Owner:CHINA UNIV OF MINING & TECH

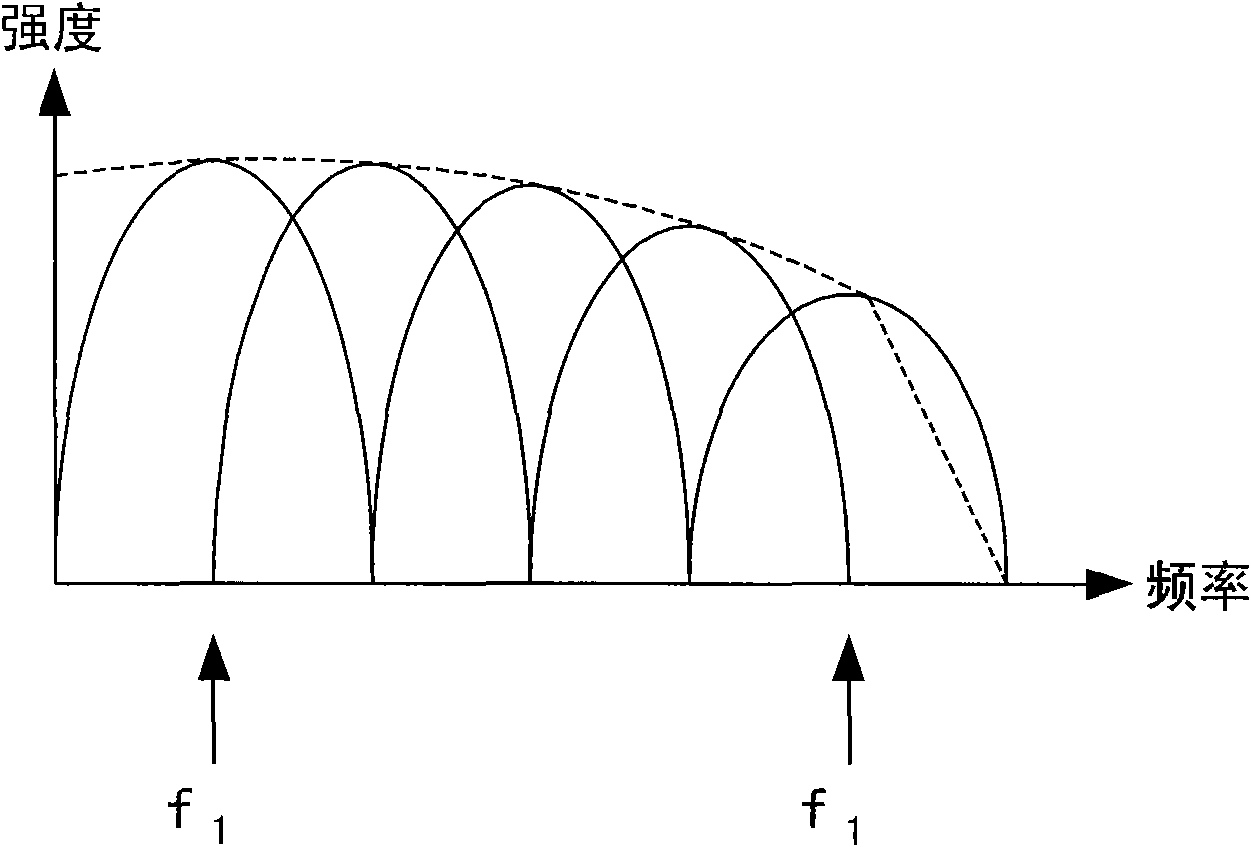

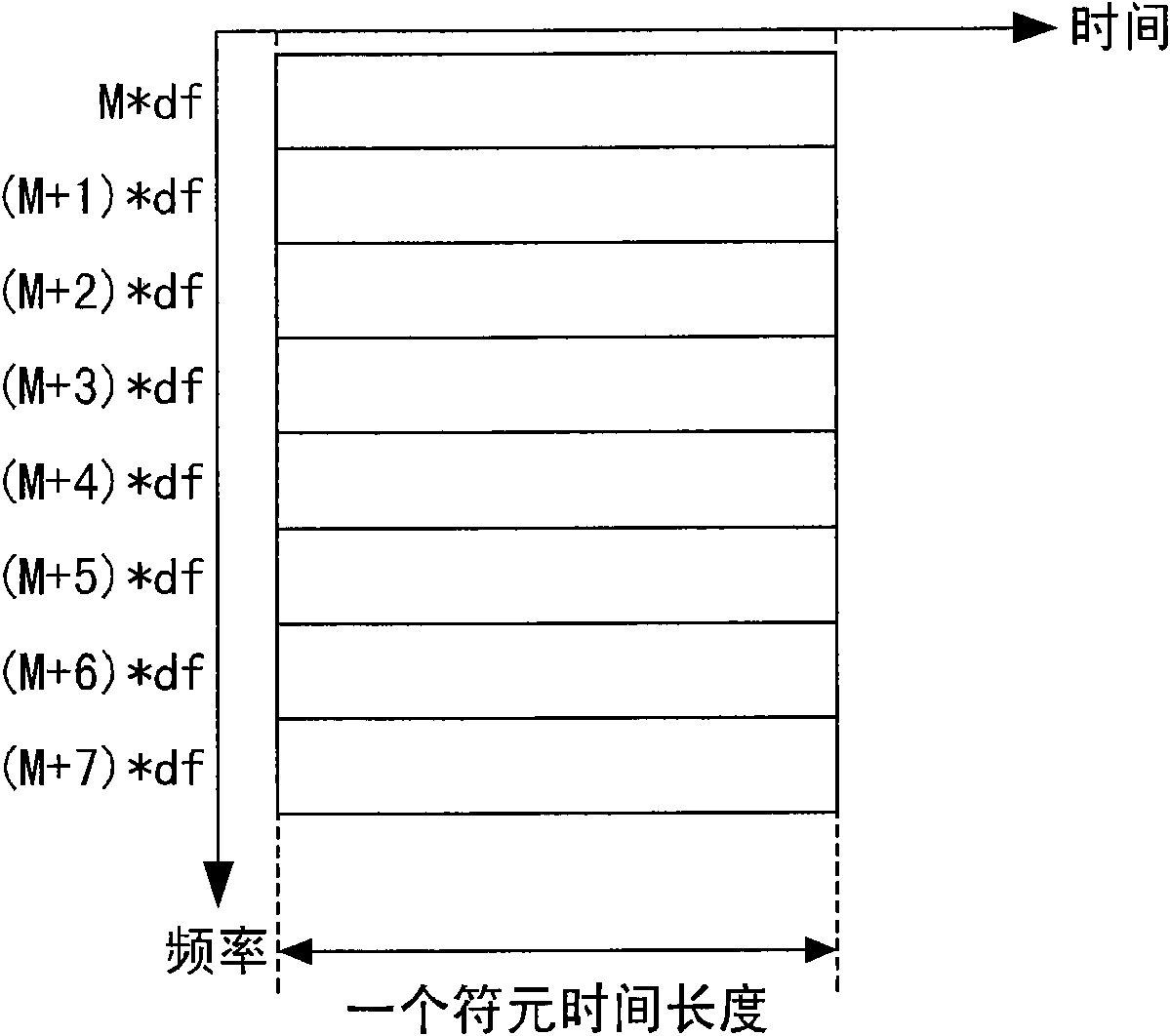

Transmitter of OOFDM system and method of delay caused by pre-compensated optical fibre dispersion

ActiveCN101895346AMultiplex system selection arrangementsMulti-frequency code systemsFiber chromatic dispersionCarrier signal

The invention discloses a transmitter of an OOFDM system and a method of delay caused by pre-compensated optical fibre dispersion. The pre-compensated method comprises the steps of: receiving a plurality of pre-compensated values corresponding to a subcarrier; transmitting the subcarrier after the time for delaying the corresponding pre-compensated value; estimating the delay time among the subcarriers at the receiver end and setting the pre-compensated value of the transmitter based on the delay time. The transmitter delays the pre-compensated value when the subcarrier is transmitted out so that the subcarrier reaches the receiver during the period of time consistent to achieve the purpose of delay caused by the pre-compensated optical fibre dispersion.

Owner:IND TECH RES INST

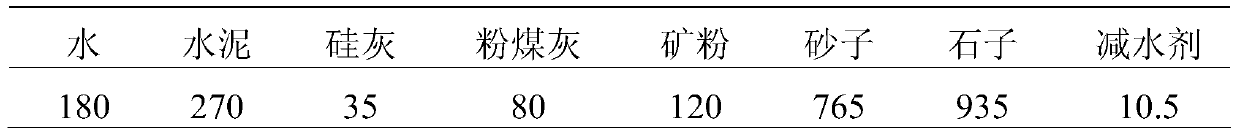

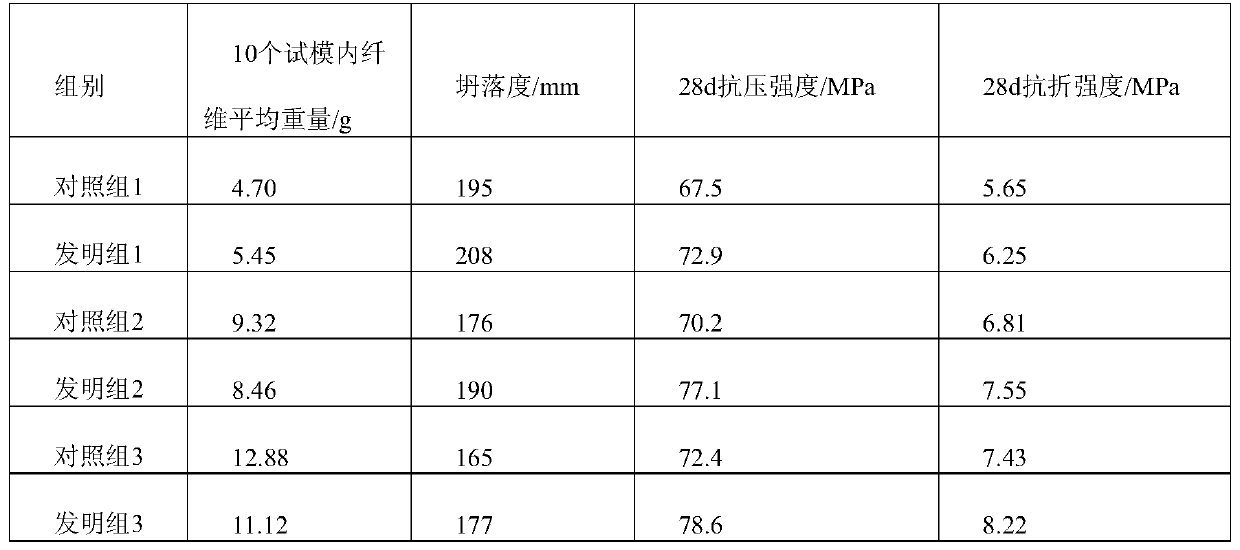

Preparation method for fiber reinforced concrete with uniformly-dispersed basalt fibers

The invention relates to a preparation method for fiber reinforced concrete with uniformly-dispersed basalt fibers. According to the invention, a fiber dispersant is divided into two types, wherein afiber dispersant A is composed of a 4-amino-1,2-catechol hydrochloride solution with a concentration of 1 to 3 g / L and a trishydroxymethylamino methane solution with a concentration of 10 to 12 g / L; and a fiber dispersant B is composed of a sodium chloroacetate solution with a concentration of 12 to 15 g / L, a sodium hydrogen carbonate solution with a concentration of 3 to 5 g / L and a dimethylformamide solution with a concentration of 15 to 20 g / L. The preparation method for the fiber reinforced concrete with uniformly-dispersed basalt fibers comprises the following steps: placing the basalt fibers into the dispersant A, carrying out stirring for 3 to 5 minutes, then placing an obtained mixture into the dispersant B, and carrying out stirring for 1 to 3 minutes so as to obtain treated basalt fibers; and mixing a weighed cementitious material with the treated basalt fibers under stirring for 1 to 3 minutes, then adding sand stones, clear water and a polycarboxylate water-reducing agent,placing an obtained mixture on a horizontal vibration table, and carrying out vibration under stirring for 2 to 5 minutes so as to obtain the fiber reinforced concrete with uniformly-dispersed basaltfibers. The method provided by the invention effectively solves the defect of difficulty in uniform dispersion of fibers in concrete.

Owner:BEIJING UNIV OF TECH

Thermoplastic composite core for overhead conductor and manufacturing method thereof

PendingCN109243698AWon't wasteIncrease productivityApparatus for heat treatmentInsulated cablesThermoplastic elastomerFibre dispersion

The invention relates to a thermoplastic composite core for an overhead conductor and a manufacturing method thereof. As the matrix fiber made of the thermoplastic material is used as the matrix material, the reinforcing fibers are dispersed among the matrix fibers, and the matrix fibers are bonded to each other into an integrated structure by the thermoplastic molding method, so that the reinforcing fibers are wrapped to form a composite core. As such, on that one hand, the matrix fib made of the thermoplastic material can be quickly molded into an integral body with the reinforce fiber without completely melting the matrix material and then solidifying molding as in the prior art, and therefore, the production efficiency is high; On the other hand, the manufacturing process does not completely melt the matrix fibers, and the matrix fibers do not adhere to the mold to generate waste, so the production cost is low.

Owner:SHANGHAI ELECTRIC CABLE RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com