High-performance fiber carding machine for carding blended fabric and carding method thereof

A carding machine and fiber technology, which is applied in fiber processing, textiles and papermaking, deburring devices, etc., can solve the problems of uneven fiber web weight, slow carding machine running speed, and unstable quality, etc., and achieve fiber web weight Uniformity, low fiber damage rate, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

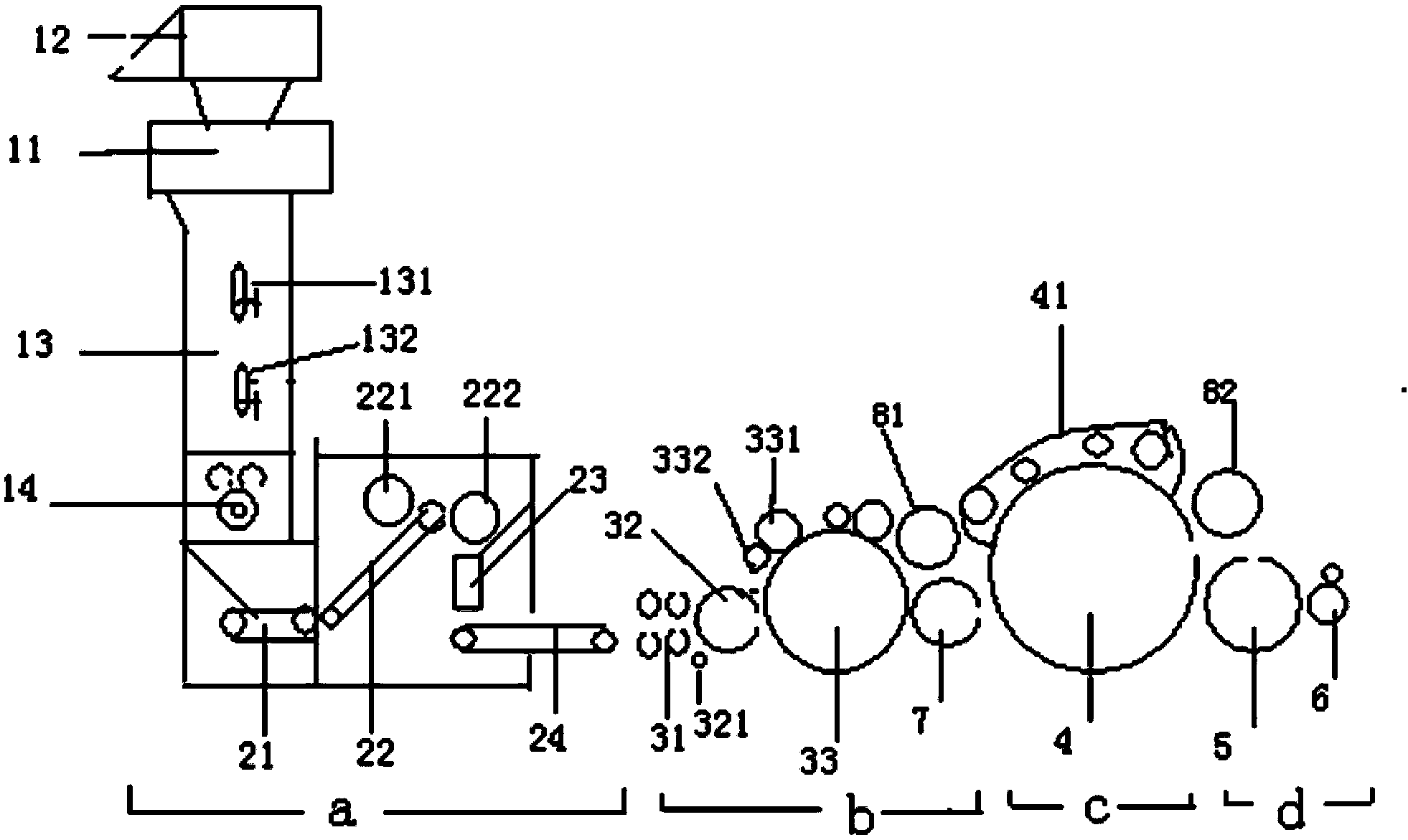

[0045] Such as figure 1 As shown, a fiber carding machine includes a wool feeding mechanism a, a pre-carding mechanism b, a main carding mechanism c, and a web-forming stripping mechanism d from front to back, wherein the wool feeding mechanism a, the pre-carding mechanism b, the main carding mechanism Mechanism c and web-stripping mechanism d are connected sequentially; feed stoppers 131, 132 are provided in the cotton feeding box 13 in the wool feeding mechanism a, and a pneumatic cotton mixing box 23 is provided on the right side of the wool feeding mechanism a.

[0046] Wool feeding mechanism a from top to bottom includes feeding port 12, cotton condenser 11, cotton feeding box 13, licker-in roller 14 and bottom flat curtain 21, and the rear of bottom flat curtain 21 is connected with oblique nail curtain 22, oblique nail curtain Connect with pneumatic cotton mixing box 23 under 22, output curtain 24 is connected with after pneumatic mixing cotton box 23, even hair roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com