Fiber material dispersion method and fiber material dispersion apparatus

A material dispersion and fiber technology, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of uneven fiber concentration, high fiber addition, and reduced fiber use effect, so as to reduce construction risks, Quickly and evenly disperse and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

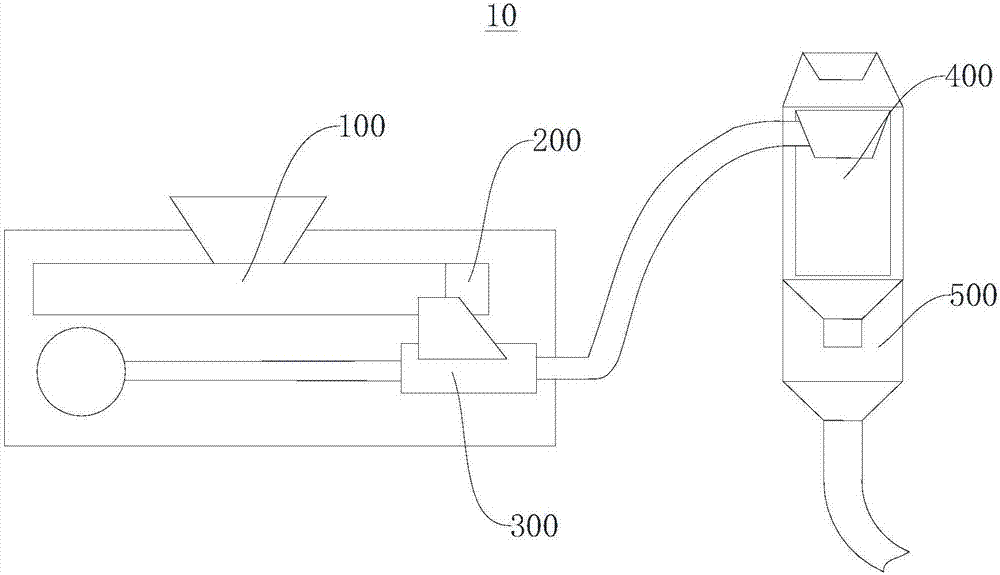

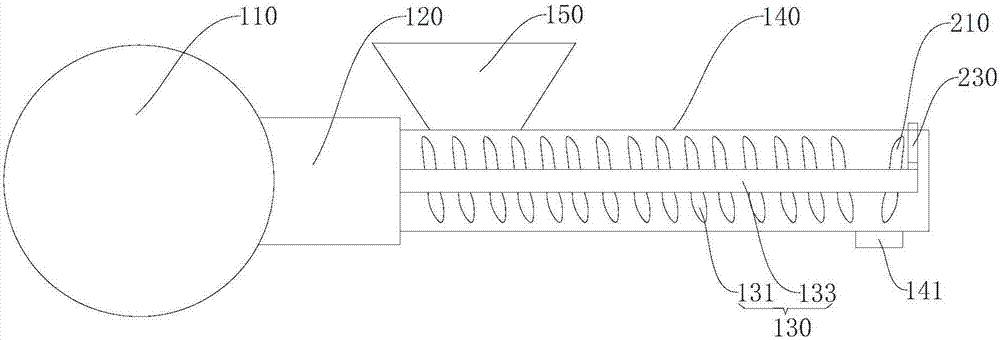

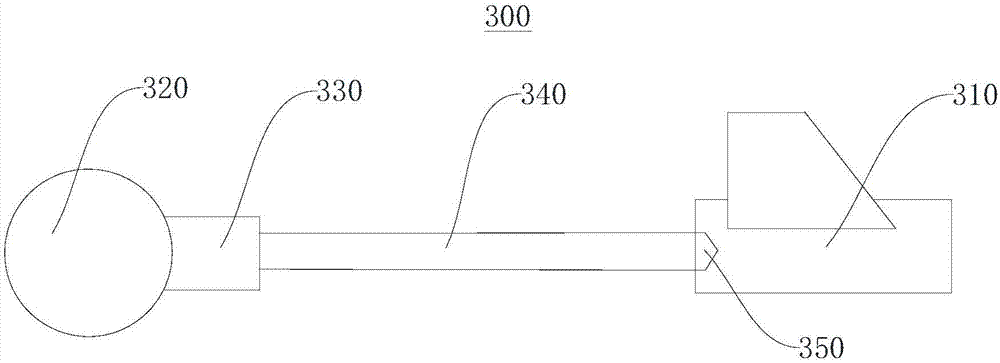

[0046] Please refer to figure 1 , the embodiment of the present invention provides a fiber material dispersing device 10, which is used to implement the fiber material dispersing method to quickly and uniformly disperse the fiber material, reduce the construction risk, and improve the use effect of the fiber in the fracturing construction process. The structure is simple, Very practical. The fiber material dispersing device 10 includes a screw conveying device 100 , a stopper and anti-jamming device 200 , a fiber air mixing device 300 , an air material separation device 400 and a rapid settling device 500 . Wherein, the stopper and anti-jamming device 200 is installed on the screw conveying device 100, and the screw conveying device 100, the fiber air mixing device 300, the air-material separating device 400 and the rapid sinking device 500 are connected in sequence.

[0047] The screw conveying device 100 is used to screw forward the fiber material, so as to preliminarily di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com