Fiber dispersion method and device applied to building mixture

A technology for fiber dispersion and admixture, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of heavy workload, low efficiency, unsatisfactory dispersion effect, etc., and achieve simple structure and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

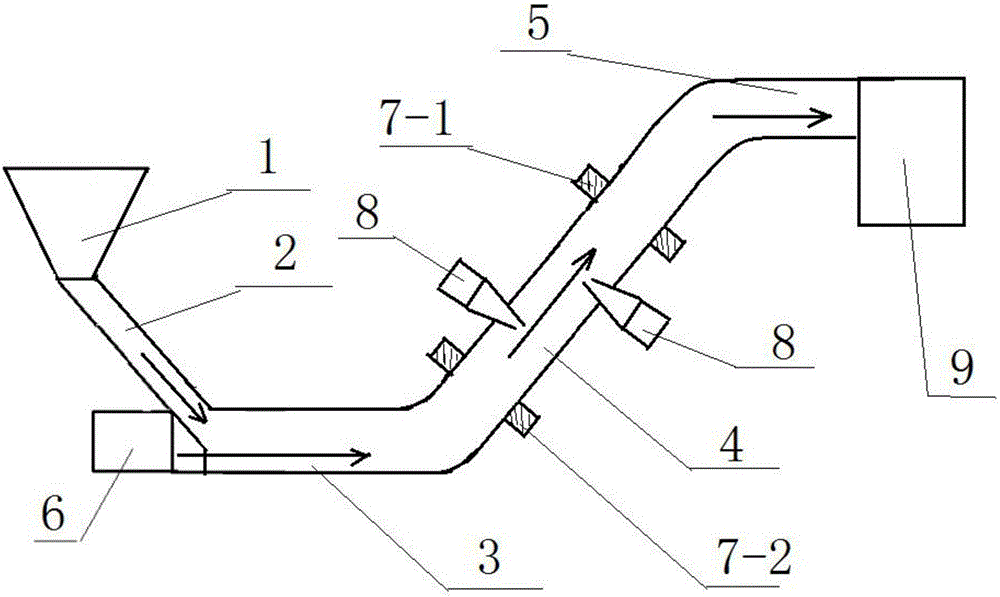

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] A fiber dispersion method applied to construction mixtures. By placing the fiber bundles in a channel full of charges, the fibers are charged, and the fiber monofilaments are mutually dispersed under the repulsion of the same-sex charges, and then the dispersed fibers are dispersed by wind force. Blow into the building mix stirring device.

[0012] Such as figure 1 As shown, a fiber dispersing device applied to construction mixtures includes a feed hopper 1, a sliding channel 2, a parallel channel 3, a charge channel 4, a discharge channel 5, a fan 6, a first magnetic coil 7-1, The second magnetic coil 7-2 is connected to the charge generator 8, and the feed hopper 1, the glide passage 2, the parallel passage 3, the charge passage 4, the discharge passage 5 and the mixer 9 are connected in sequence; At the junction of the parallel channel 3, the air outlet is facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com