Patents

Literature

487results about How to "Evenly blended" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel multifunctional jam

The invention provides novel multifunctional jam, which comprises fruit flesh particles, wherein the jam comprises the following ingredients through being calculated according to the weight: 70 to 80 parts of fruit flesh, 0.1 to 0.3 parts of vitamin C, 0.3 to 0.8 parts of citric acid, 80 to 120 parts of sweeteners and 0.5 to 1.2 parts of thickeners. The novel multifunctional jam has the beneficial effects that the pigment-free, essence-free and preservative-free green healthy jam integrating nutrition, delicacy and multifunctional eating is provided, the use additives of the jam are few, meanwhile, the jam can be made into fruit tea, fruity milk or fruity yoghourt by warm water, milk, yoghourt and the like, and the requirements of different user groups can be met.

Owner:TIANJIN PENGFANCHENG FOOD

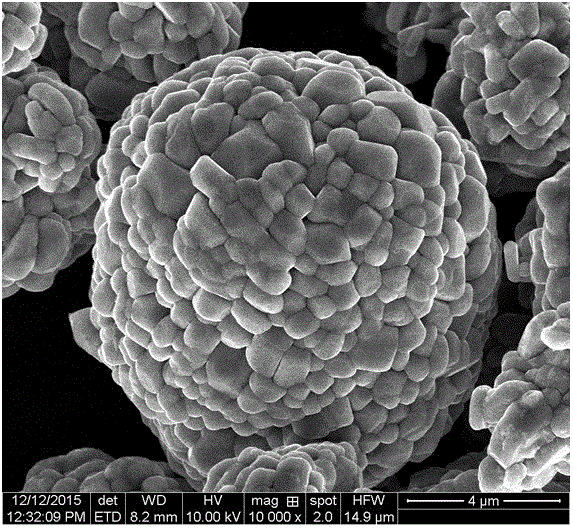

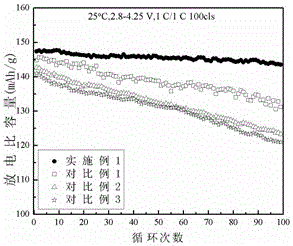

Element co-doping modified ternary lithium ion battery cathode material, and preparation method thereof

ActiveCN106395920AImprove electrochemical cycle performanceHigh magnificationCell electrodesSecondary cellsManganesePhysical chemistry

The invention discloses an element co-doping modified ternary lithium ion battery cathode material, and a preparation method thereof. According to the preparation method, compounds of two kinds of metals Me<1> and Me<2> are respectively selected based on the difference of ion radiuses of lithium ion and transition metal ions in the lithium nickel cobalt manganese ternary material, and are subjected to high temperature sintering with a nickel cobalt manganese precursor, wherein the ion radius of the metal Me<1> ion is close to that of lithium ion, and the metal Me<1> ion is one or a mixture of ions selected from Zn2+ and Zr4+, the radius of the metal Me<2> ion is close to that of transition metal ion Co3+ or Mn4+, and the metal Me<2> is one or a mixture of ions selected from Al3+, V5+, and Ge4+; and then a primary product obtained via high temperature sintering is subjected to second cladding so as to obtain the element co-doping modified ternary lithium ion battery cathode material. The element co-doping modified ternary lithium ion battery cathode material is capable of achieving synergistic effects of two metal elements fully, and improving cycle performance of lithium ion batteries effectively.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

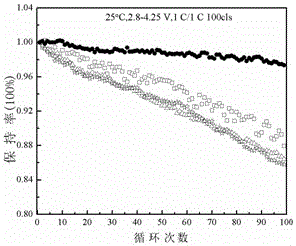

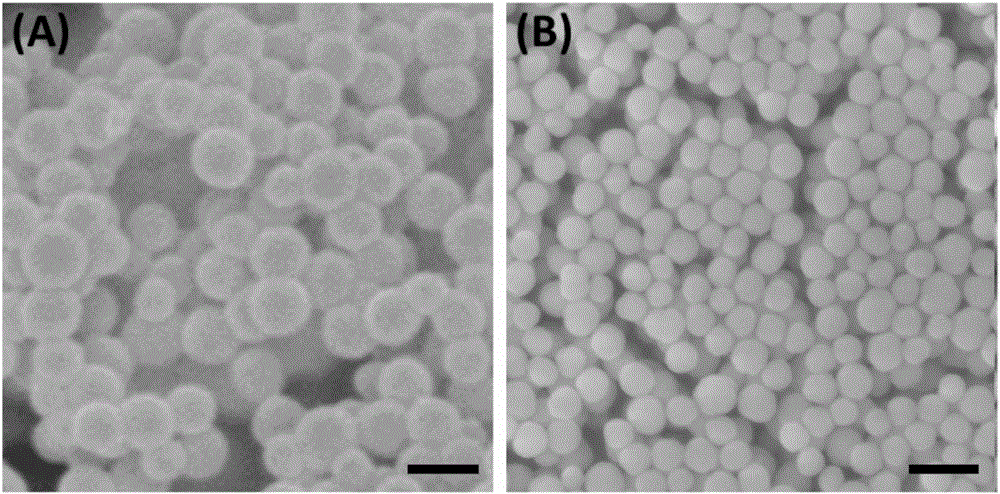

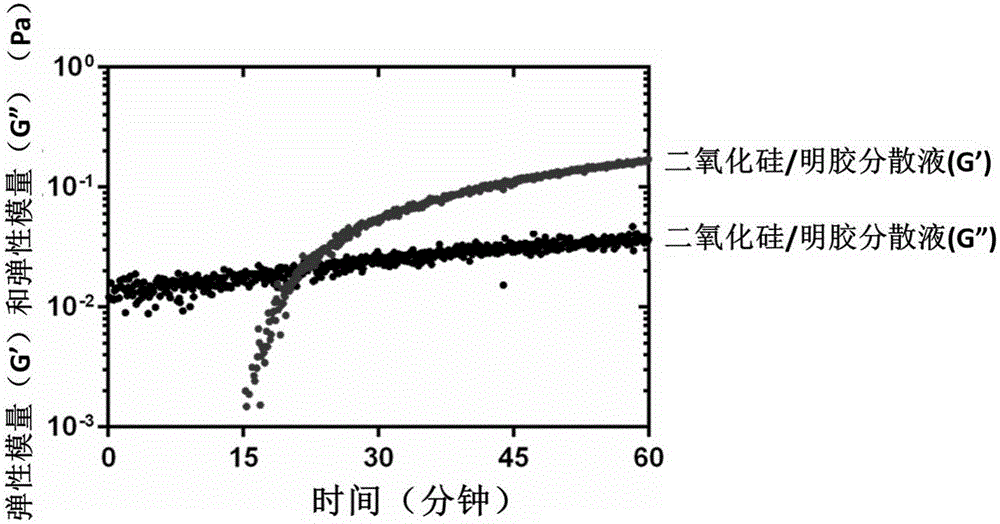

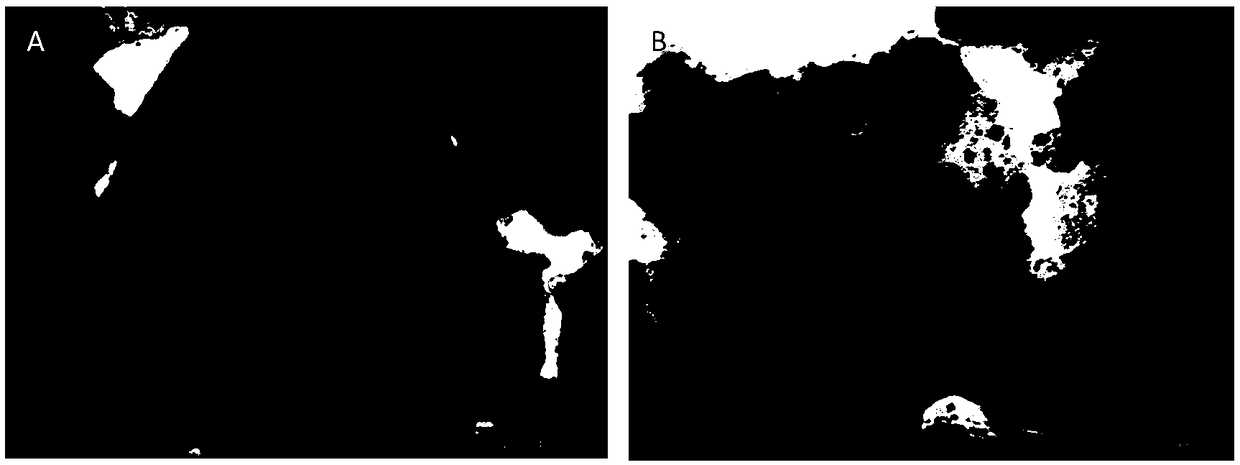

Nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and preparation method and application thereof

InactiveCN105796478AHigh strengthImprove self-healing abilityAerosol deliveryInorganic non-active ingredientsBiological materialsSilicon dioxide

The invention discloses a nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and a preparation method and application thereof. According to the preparation method, two-phase colloid particles with opposite electric charges are uniformly blended in an alkaline or acidic environment, an acidifying agent or alkalizing agent is added to induce the pH of the solution to recover the neutrality, electrostatic self-assembly among the two-phase colloid particles is initiated, and a uniformly-dispersed composite gel network is formed, wherein the gel is high in mechanical strength and wide in regulation and control range, the elasticity modulus of the gel can be regulated and controlled within the range of 10 Pa-100 kPa, and the self-repairing efficiency of the gel is higher than or equal to 100%. The silicon dioxide-gelatin composite colloid gel which has both the high mechanical strength and the self-repairing performance is finally and successfully prepared, and it is verified that the composite gel still can quickly recover the mechanical strength after being broken by shear force many times; in addition, the composite gel has the excellent injectable property and plasticity and can be used for an in-vitro cell culture matrix material by serving as an injectable biological material.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

Preparation technology of diethylene triamine pentacetic acid modified polyvinylidene fluoride separation membrane and resin

InactiveCN101537315AUniform removalImprove hydrophilicitySemi-permeable membranesFiltrationResource utilization

The invention provides a technology for preparing a diethylene triamine pentacetic acid modified polyvinylidene fluoride separation membrane by a physical blending / phase transition technology and a chemical grafting blending / phase transition technology. The technology is as follows: reagents such as diethylene triamine pentacetic acid, polyvinylidene fluoride, melamine, dimethyl sulfoxide, acrylic acid, polyvinylpyrrolidone and the like are taken as raw materials; diethylene triamine pentacetic acid polyamino and polycarboxylic acid compound is uniformly mixed in a polyvinylidene fluoride separation membrane and resin respectively by the physical blending / phase transition technology and the chemical grafting blending / phase transition technology. The technology improves the hydrophobic properties of the conventional polyvinylidene fluoride micro-filtration separation film and the resin, realizes metallic ions in waste water, and has the advantages of simple operation, uniform blending and the like. The diethylene triamine pentacetic acid modified polyvinylidene fluoride separation membrane and the resin increase the purification efficiency of drinking water, realize the resource utilization of the heavy metal in the industrial wastewater, and expand the application field of the polyvinylidene fluoride micro-filtration separation film.

Owner:YANSHAN UNIV

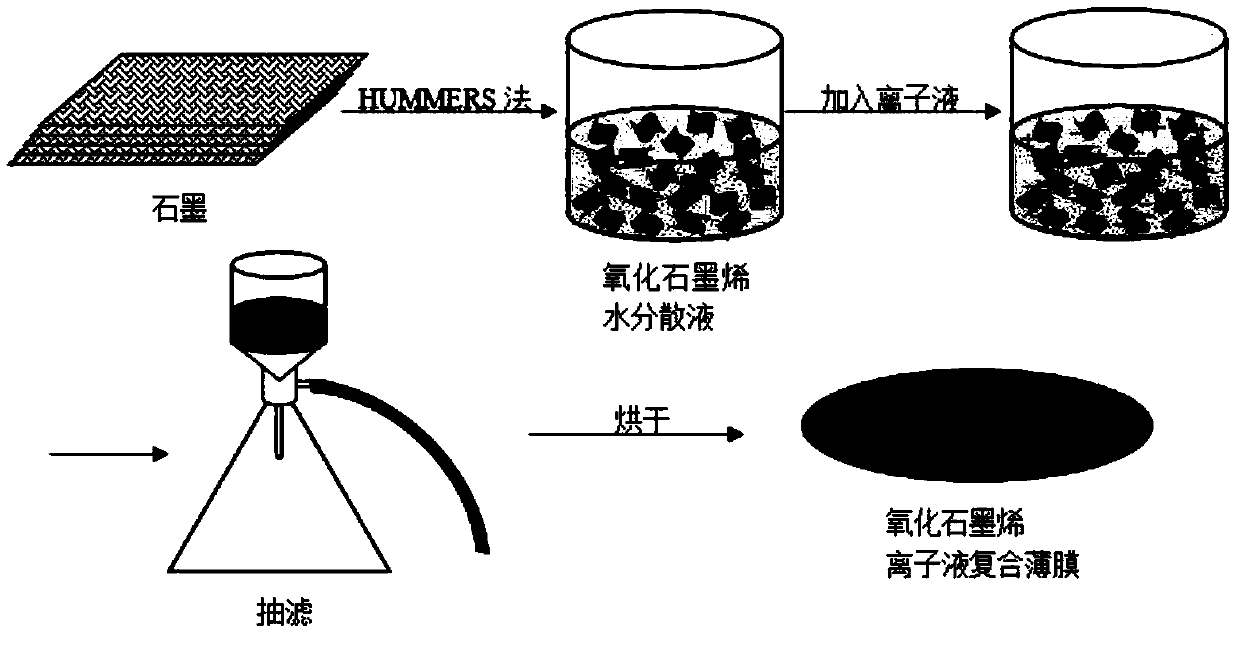

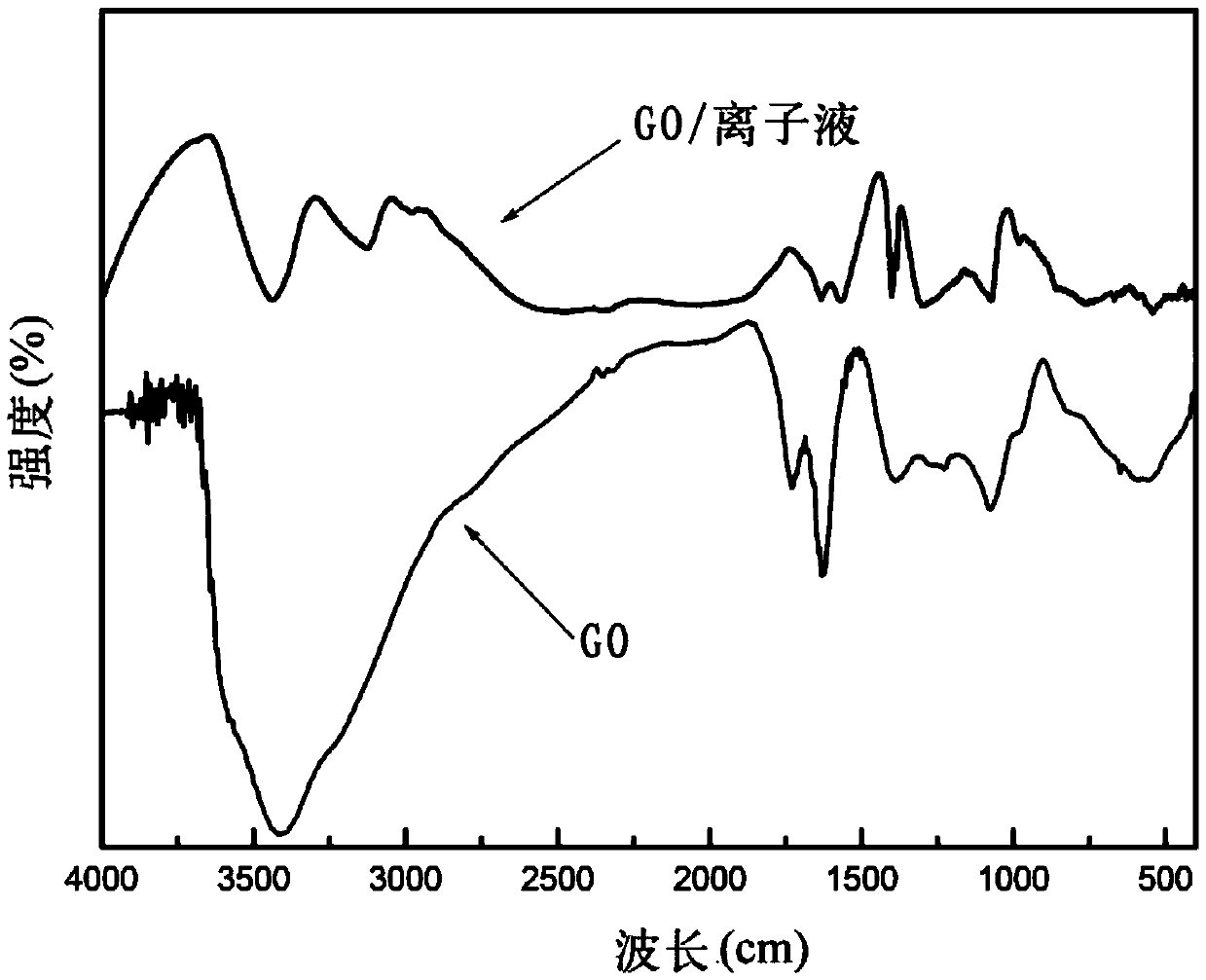

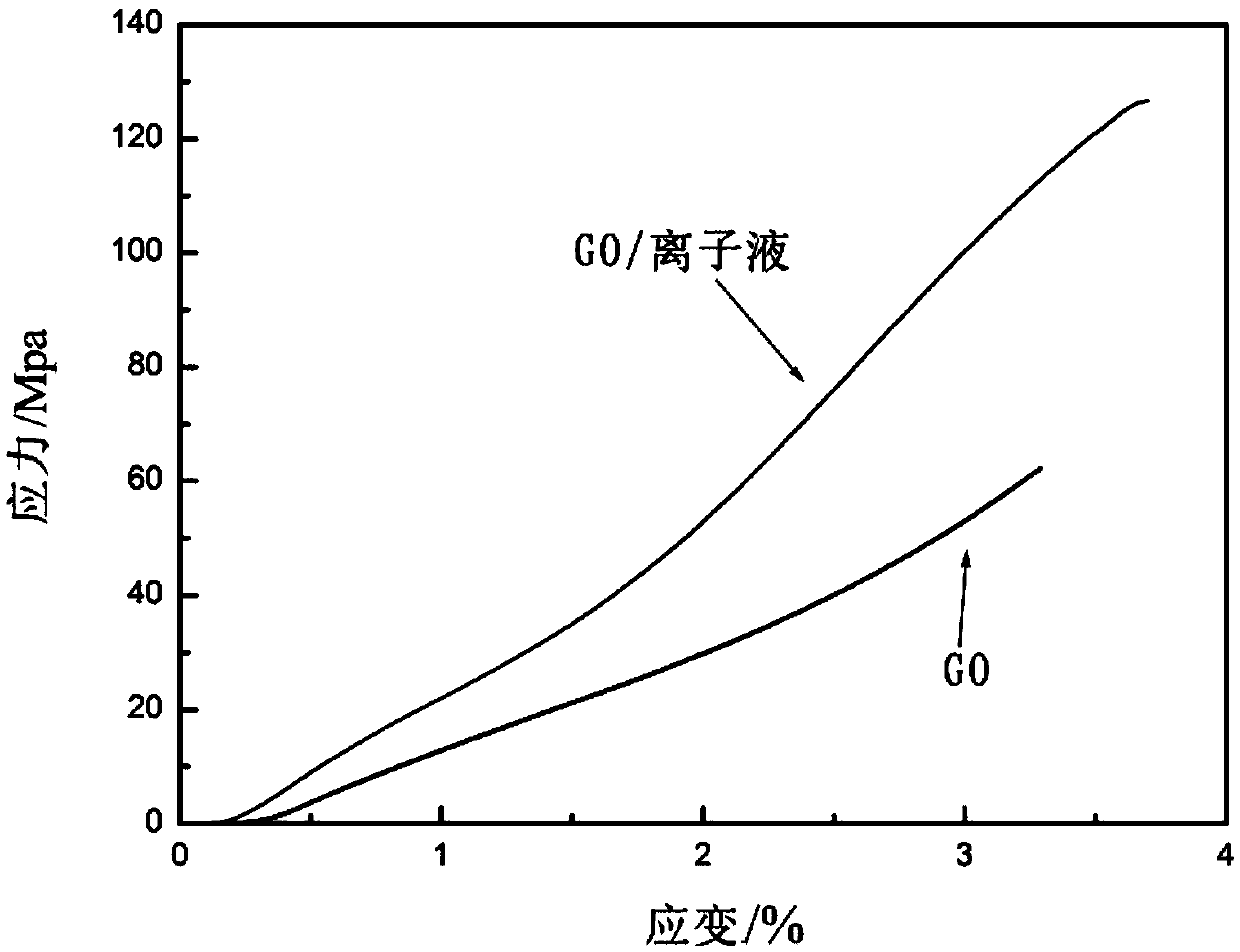

Graphene oxide and ionic liquid composite film and preparation method thereof

InactiveCN105502350AImprove mechanical propertiesFully absorbedSulfonic acids salts preparationComposite filmFiltration

The invention belongs to the technical field of a graphene composite material and specifically relates to a graphene oxide and ionic liquid composite film and its preparation method. The preparation method comprises the following steps: adding a graphene oxide aqueous solution into an ionic liquid solution so as to obtain a blended solution of graphene oxide and ionic liquid, carrying out suction filtration on the blended solution, and draining to obtain the graphene oxide and ionic liquid composite film. The method is simple to operate and is low-cost. The obtained product has high mechanical property and excellent performance. In addition, mass production can be realized. The product has a wide application prospect.

Owner:NANJING XINYUE MATERIAL SCI & TECH

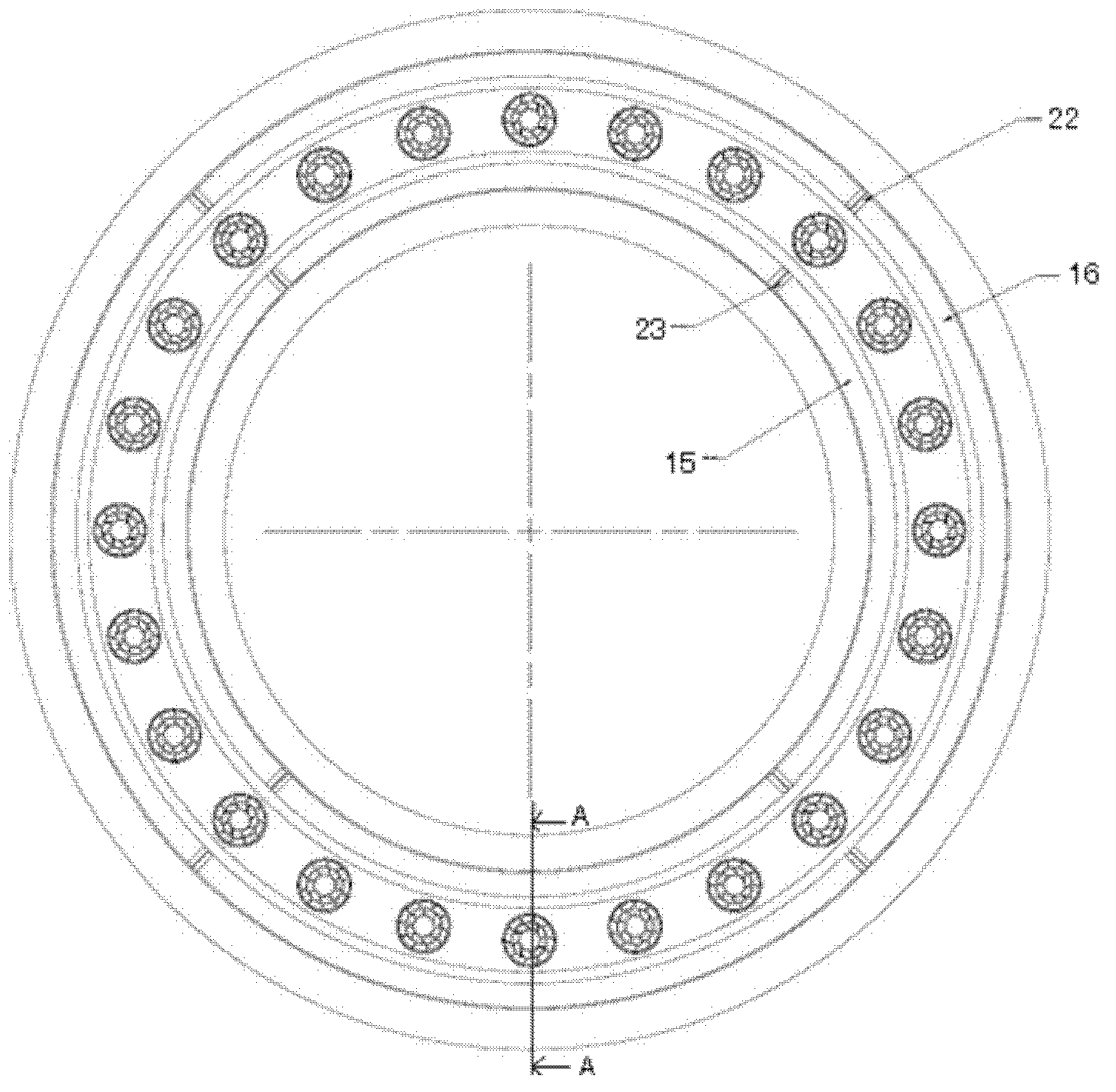

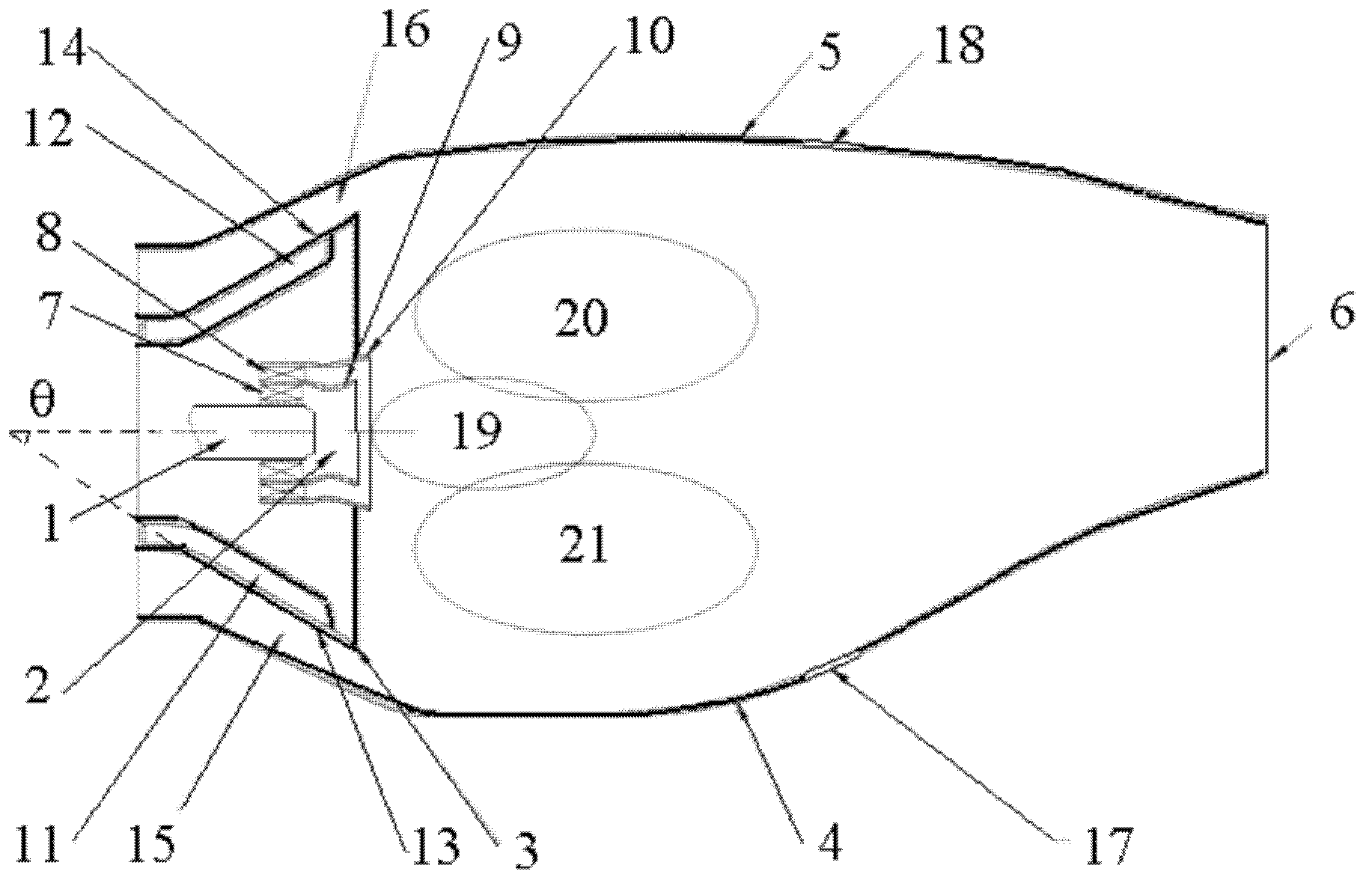

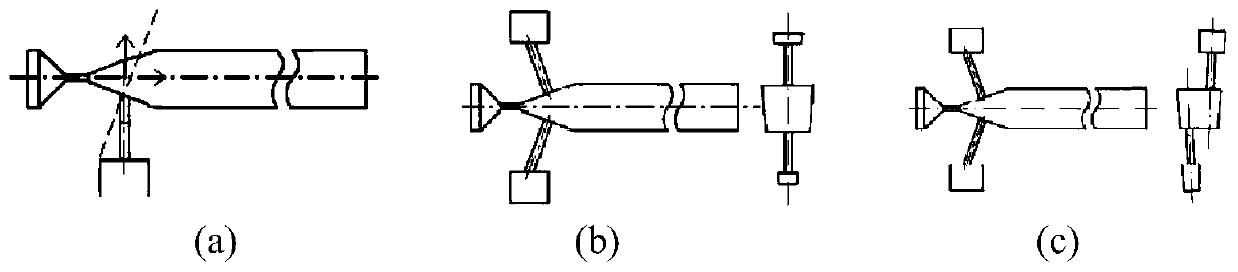

Fractional combustion chamber

InactiveCN103017203ASmall pressure lossReduce fuel consumptionContinuous combustion chamberCombustorCombustion chamber

The invention provides a staged combustion chamber. The staged combustion chamber comprises an annular flame barrel and a main combustion stage assembly, wherein the annular flame barrel comprises a flame barrel inner ring and a flame barrel outer ring which are coaxial with each other; the front section of the annular flame barrel is in the form of a cone of which the inner diameter is increased gradually; and the main combustion stage assembly is positioned at the front section of the annular flame barrel, is used for providing fuel and air needed by combustion of a main combustion stage, and comprises an annular bluff body, an inner / outer ring oil cavity a plurality of duty stage assemblies; the inner ring surface of the annular bluff body constructs an inner ring air flow channel together with the inner surface of the flame barrel inner ring and the outer ring surface of the annular bluff body constructs an outer ring air flow channel together with the inner surface of the flame barrel outer ring; the inner / outer ring oil cavity is attached to the inner / outer side of the annular bluff body and by the inner / outer ring oil cavity, accommodated fuel can be ejected onto the inner ring air flow channel through a plurality of inner ring ejection holes positioned in the inner / outer ring surface of the annular bluff body; and the plurality of duty stage assemblies which are positioned in a space encircled by the annular bluff body. In the staged combustion chamber provided by the invention, main combustion stage air enters the combustion chamber in a full ring air inlet way, so that the pressure loss of the combustion chamber is reduced, and the fuel consumption of an engine is lowered.

Owner:成都中科航空发动机有限公司

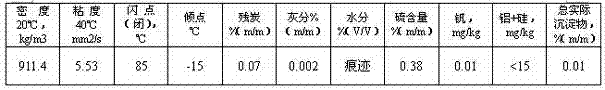

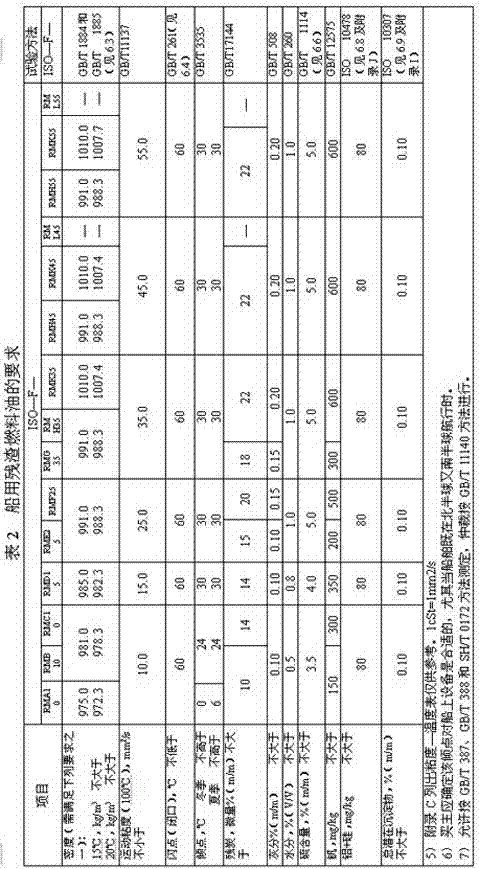

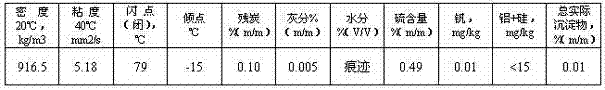

New utilization process for catalytic cracking slurry oil

ActiveCN102786981AFlexible productionReasonable useHydrocarbon distillationLiquid carbonaceous fuelsSlurryNational standard

The present invention discloses a new utilization process for catalytic cracking slurry oil. According to the process, catalytic slurry oil is subjected to vacuum distillation to obtain light slurry oil and topped slurry oil, wherein a distillation outlet temperature is 360-480 DEG C; physical and chemical indicators of the light slurry oil are detected, and are compared with marine fuel oil standards, wherein the light slurry oil meeting the standards is directly adopted as marine residual fuel oil, or a diesel component is adopted to blend to meet the standards so as to adopt the light slurry oil as marine distillate fuel oil, or a residue oil component is adopted to blend to meet the standards so as to adopt the light slurry oil as marine residual fuel oil. The marine fuel oil standards are the national standards ZB / T17411-1998. The diesel component is one or a plurality of materials selected from normal pressure second side oil, normal pressure third side oil, a catalytic diesel and a hydrogenated diesel, and is blended into the light slurry oil, wherein the use amount of the diesel component is 30-95% of the total amount. The residue oil component is one or a plurality of materials selected from vacuum residue oil, viscosity reduction residue oil and deoiled asphalt, and is blended into the light slurry oil, wherein the use amount of the residue oil component is 5-85% of the total amount. The new process of the present invention has characteristics of simple process, wide raw material, and product diversification.

Owner:CHINA PETROLEUM & CHEM CORP

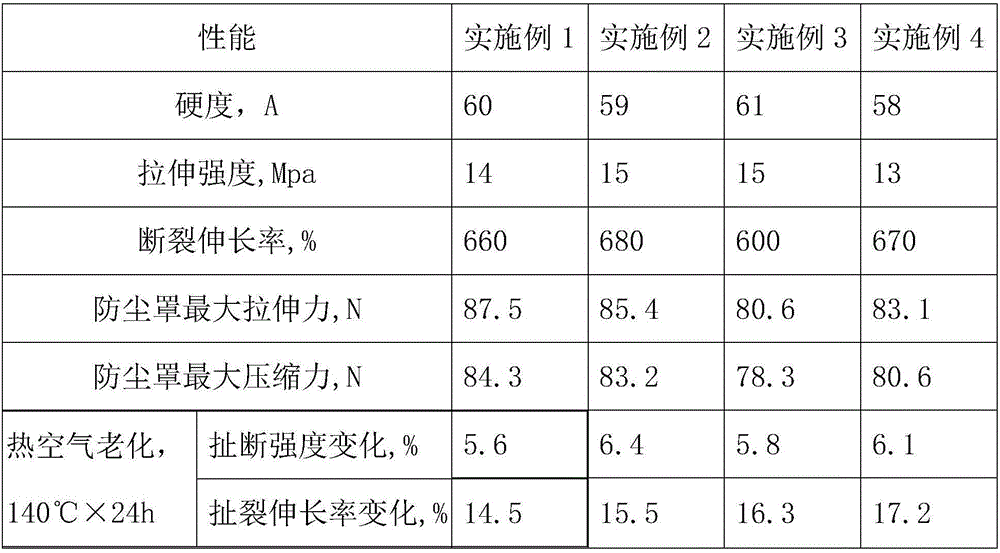

Thermoplastic vulcanized rubber material for automobile turning dust cover and preparation method of thermoplastic vulcanized rubber material

ActiveCN105860284AImprove blow molding processabilityMeet performance requirementsRubber materialThermoplastic

The invention discloses a thermoplastic vulcanized rubber material for an automobile turning dust cover and a preparation method of the thermoplastic vulcanized rubber material. The thermoplastic vulcanized rubber material is prepared from, by weight, 100-300 parts of EPDM, 20-80 parts of polypropylene, 10-50 parts of linear low density polyethylene, 40-100 parts of thermoplastic polyurethane elastomers, 5-15 parts of ethylene-octylene copolymers, 5-15 parts of compatilizer, 10-80 parts of inorganic filler, 3-5 parts of silane coupling agent, 0.2-10 parts of cross-linking agent, 1-5 parts of activated zinc oxide, 1-3 parts of primary antioxidant, 0.5-1 part of auxiliary antioxidant, 1-3 parts of ultraviolet light absorber, 20-100 parts of processing oil and 2-6 parts of lubricating oil. The thermoplastic vulcanized rubber material has excellent strength, high temperature resistance, flexibility and blow molding performance.

Owner:ANHUI ZHONGDING RUBBER PLASTIC PROD CO LTD

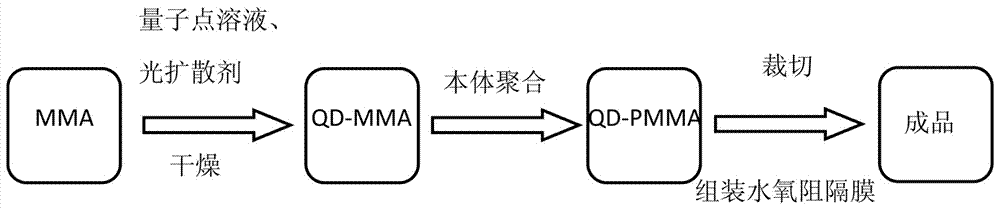

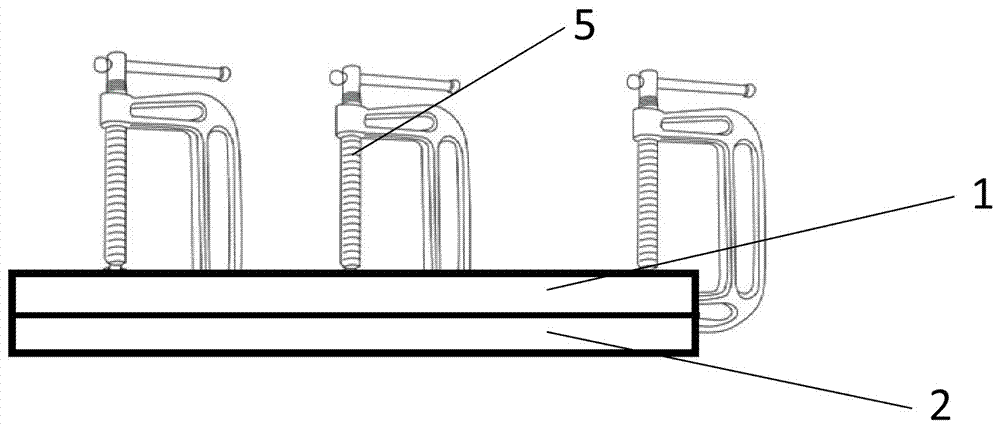

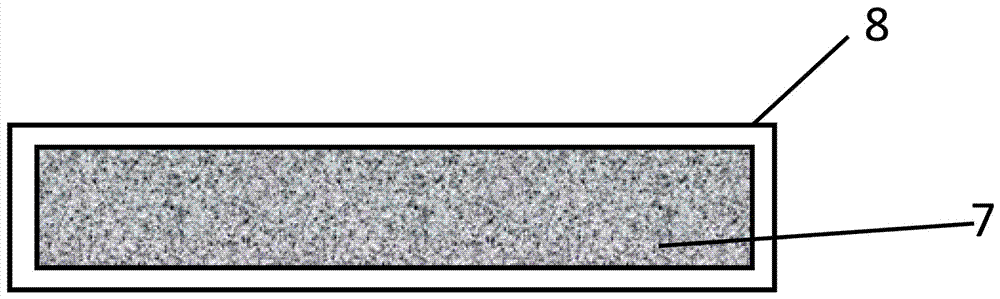

Manufacturing process of quantum dot diffusion plate, and diffusion plate

ActiveCN107011532AEffective stimulationImprove color gamutDiffusing elementsCoatingsDiffusionLight guide

The invention provides a manufacturing process of a quantum dot diffusion plate, and the diffusion plate. According to the manufacturing process of the quantum dot diffusion plate, PMMA is prepared by adding a quantum dot diffusant into MMA. The diffusion plate comprises a plate body and a water oxygen barrier layer; the outer surface of the plate body is coated with the water oxygen barrier layer; quantum dots and light diffusion agents are dispersed in the plate body uniformly.

Owner:厦门市京骏科技有限公司

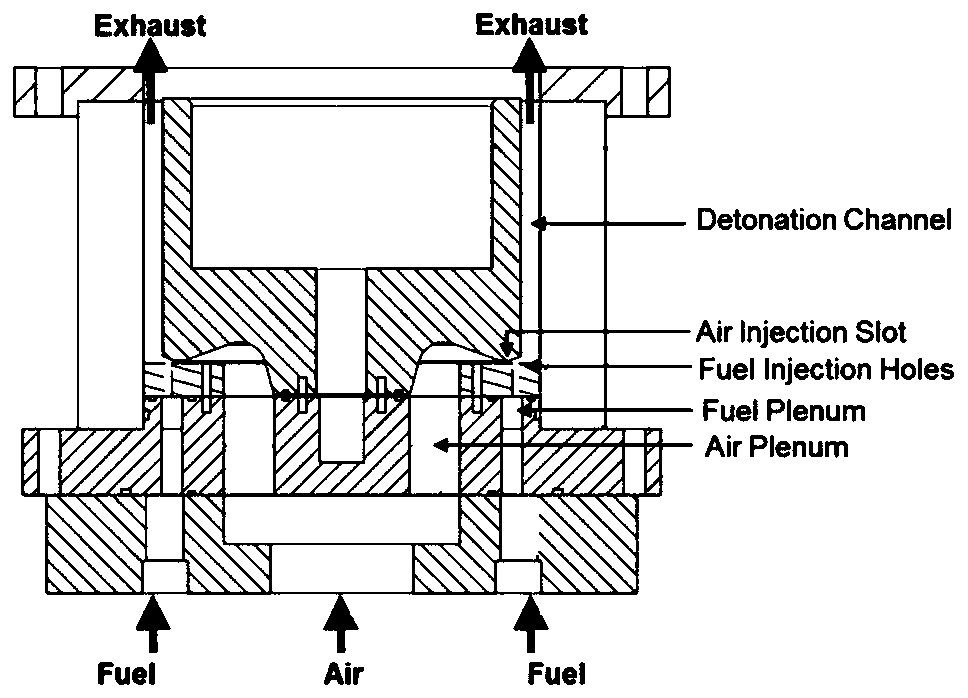

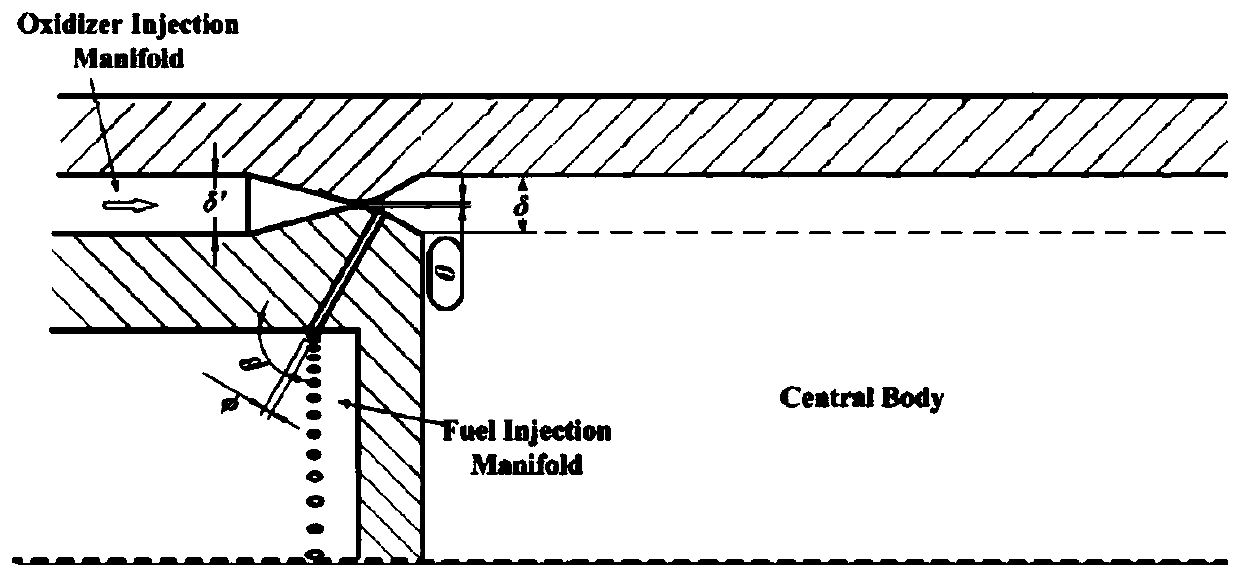

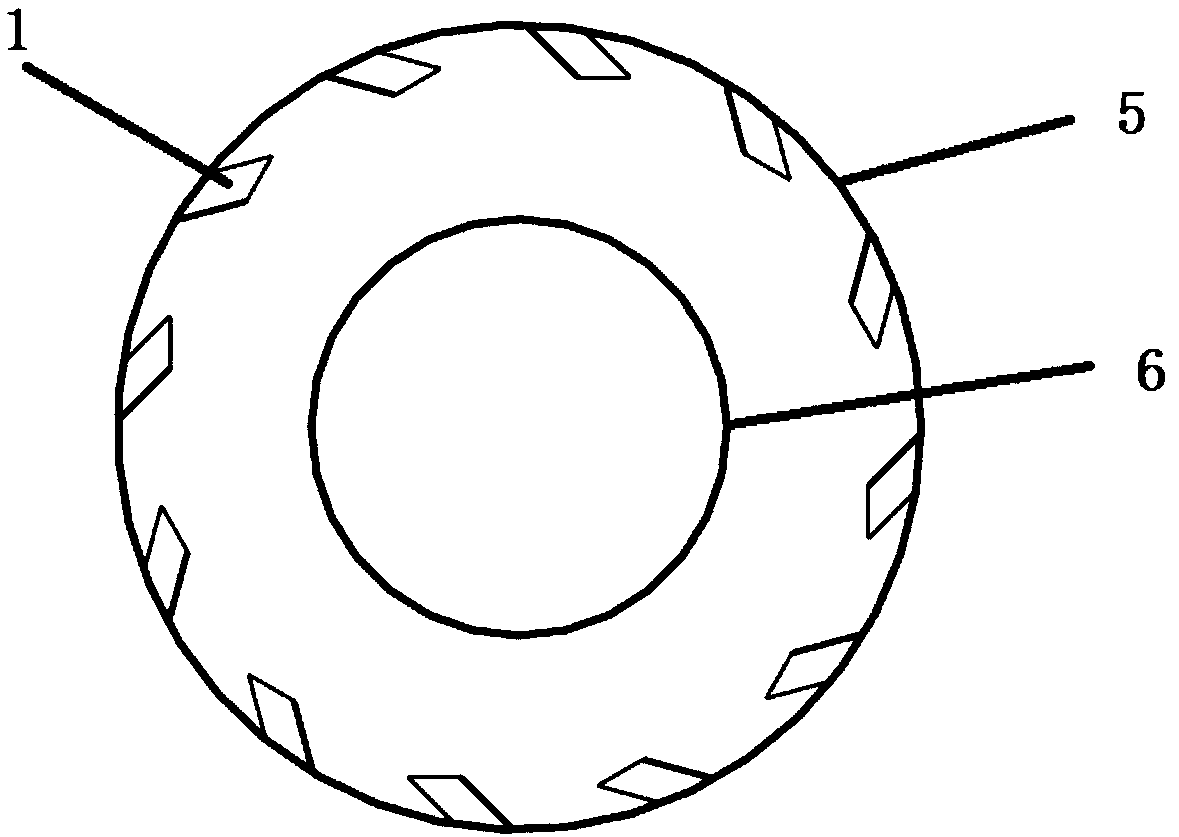

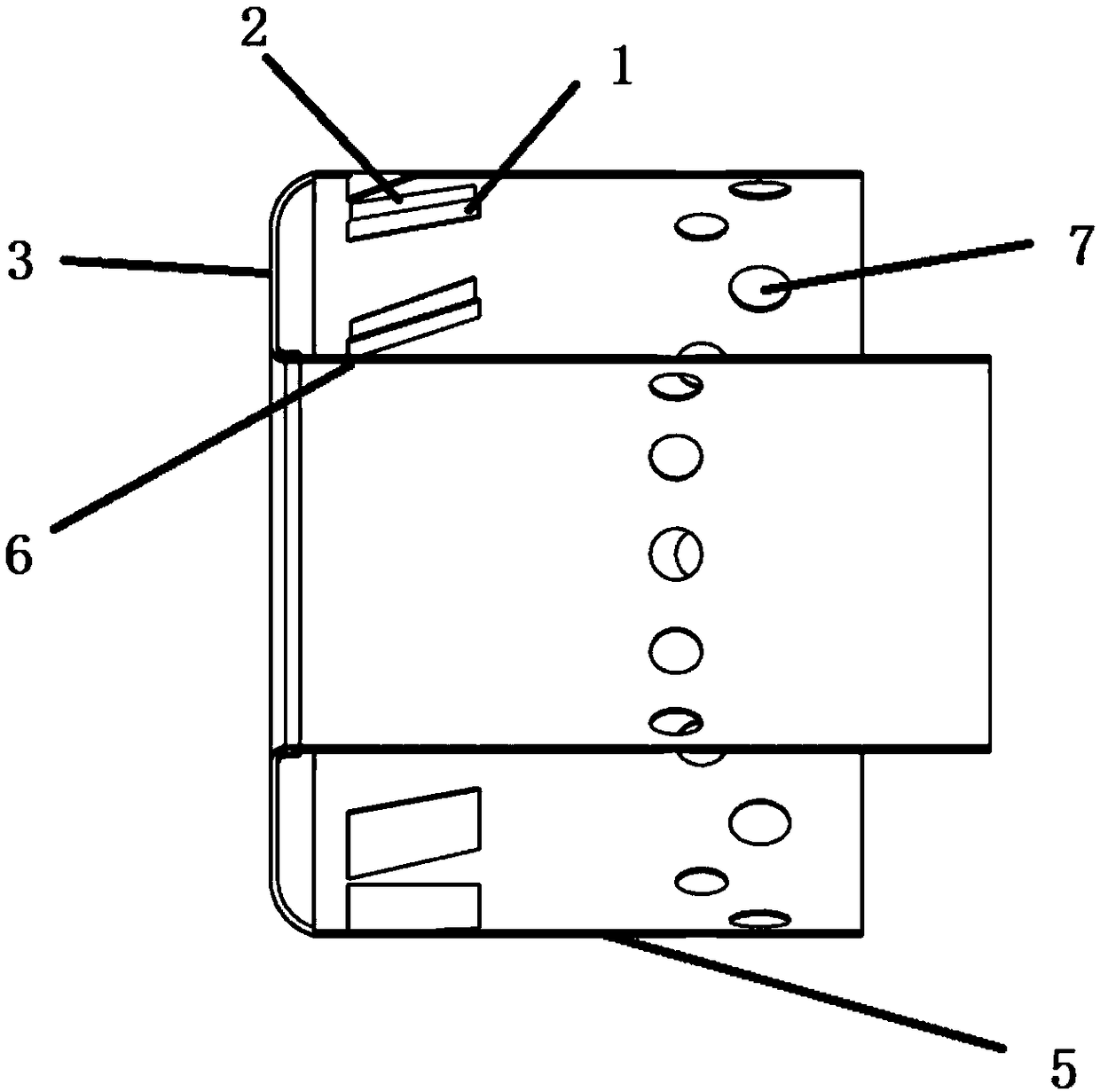

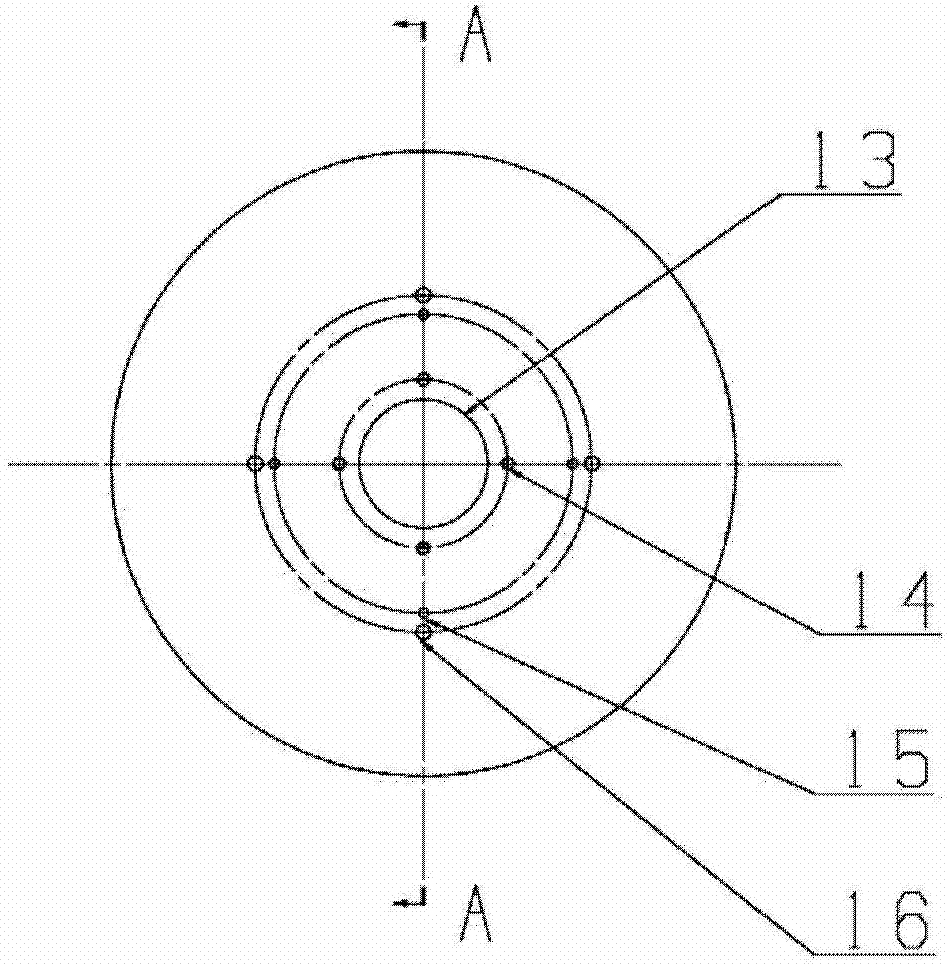

Ring cavity rotational flow opposite spraying structure based on RDE combustion chamber

The invention provides a ring cavity rotational flow opposite spraying structure based on an RDE combustion chamber. An axial symmetry hook face circular seam is adopted in a circular seam of an RDE,an included angle of the obtuse angle is formed between the transverse jet flow and the main jet flow direction of RDE, single-row annular cavity array cylindrical fuel spraying holes are evenly distributed in the inner and outer wall faces of the head of the RDE combustion chamber, and on the basis of the two-dimensional deflection, circumferential deflection is added on the fuel spraying holes.The structure has the advantages that non-linear circular seam configuration is adopted, pressure losses are reduced, and the outlet flow field is more stable. The upstream area of the transverse jetflow is decelerated, the sufficient fuel penetrating and mixing can be achieved, and the mixing efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

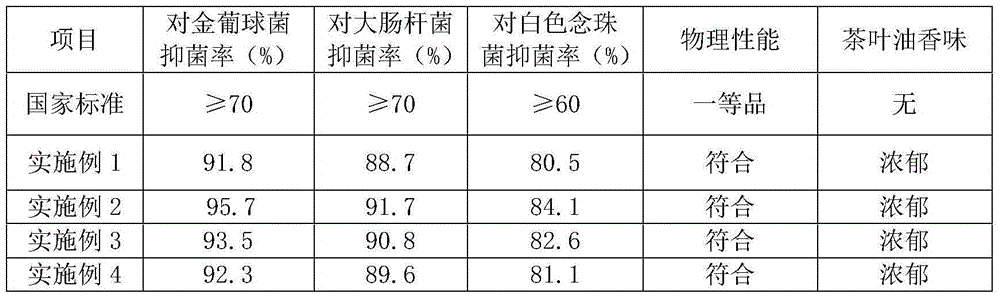

Preparation and application of tea extract oil composite modified additive

InactiveCN105113036AStable performanceChemically stableArtificial filaments from viscoseChemistryViscose fiber

The invention belongs to the technical field of functional fiber, relates to preparation and application of a tea extract oil composite modified additive, and aims to preparation of functional adhesive fiber. The preparation comprises the following steps: preparing a solid adsorbent containing a tea extract; preparing tea oil micro-capsule slurry; uniformly mixing the solid adsorbent and the tea oil micro-capsule slurry, and stirring so as to obtain a composite modified additive; preparing adhesive fiber with a tea fragrance antibacterial deodorization function, wherein preparation of the adhesive fiber comprises the following steps: preparing a commixed spinning liquid, and spinning; the prepared adhesive fiber with the tea fragrance antibacterial deodorization function comprises 1.0-11.0wt% of an adsorbent of a porous structure, 2.0-5.0wt% of a tea extract and 1.0-11.0wt% of a tea oil micro-capsule. The tea extract oil composite modified additive is stable in property, can be uniformly fused with an adhesive stock solution, and has long-lasting tea fragrance and an antibacterial deodorization function, and effective components in fiber are slightly lost in the spinning process and later treatment process.

Owner:山传雷

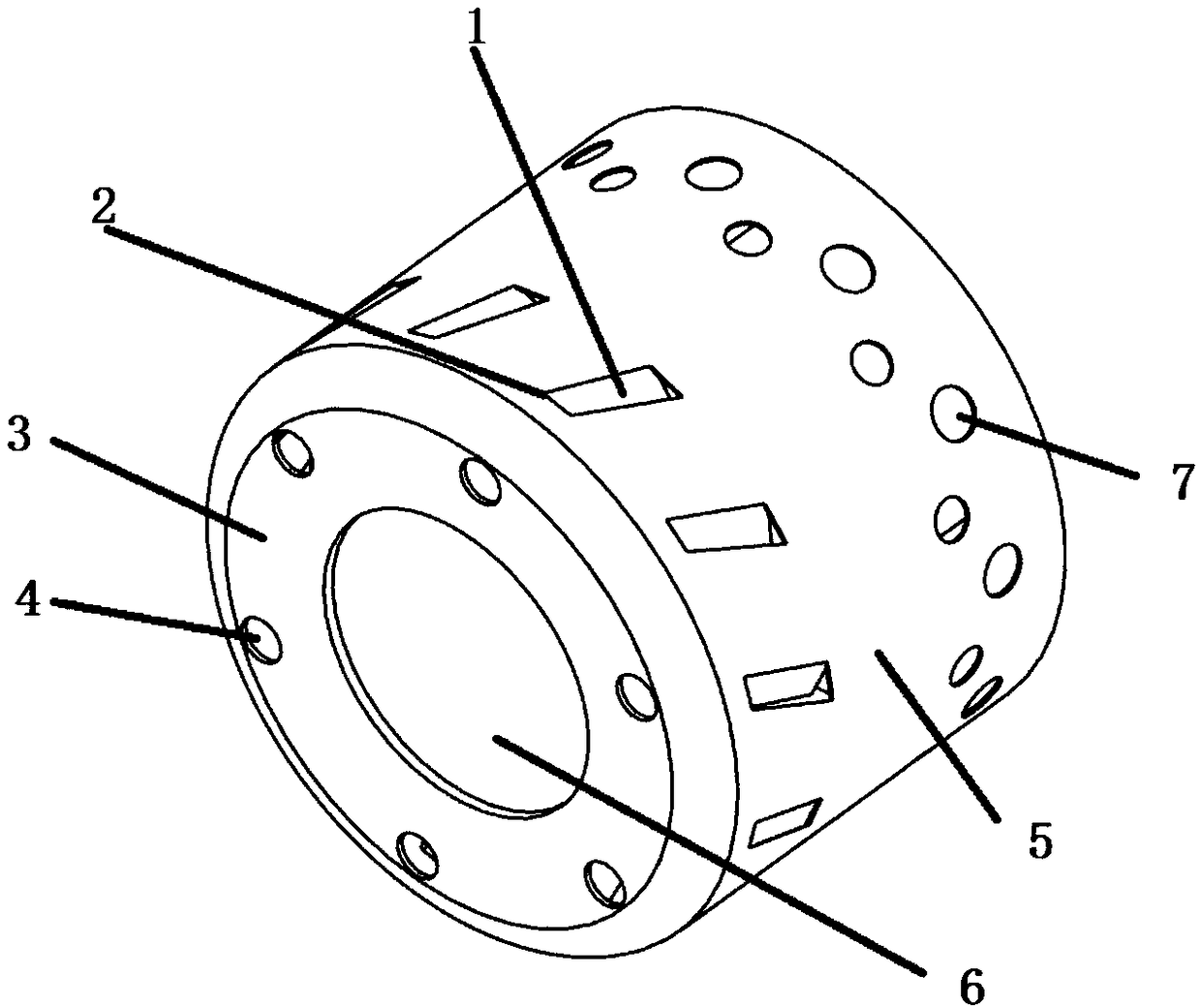

Mini type engine combustion chamber flame barrel with air inlet flow guiding blades

InactiveCN108151068AIncreased turbulenceOptimize dwell timeContinuous combustion chamberCombustion chamberEngineering

The invention provides a structural design scheme for a mini type engine combustion chamber flame barrel with air inlet flow guiding blades. The air inlet flow guiding blades are arranged at the position, close to the front end of the flame barrel, of a flame barrel shell, so that airflow entering the flame barrel through a main combustion hole has the component of velocity in the axial direction,the radial direction and the circumferential direction, a backflow area can be formed by the rotation airflow in the flame barrel, the airflow structure in the flame barrel is effectively improved, the airflow speed is reduced, and the combustion stability of a mini type engine combustion chamber is improved; and due to existence of the backflow area, the airflow turbulivity is improved, fuel oiland fresh air mixing is more sufficient, combustion is safer, and the combustion efficiency is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

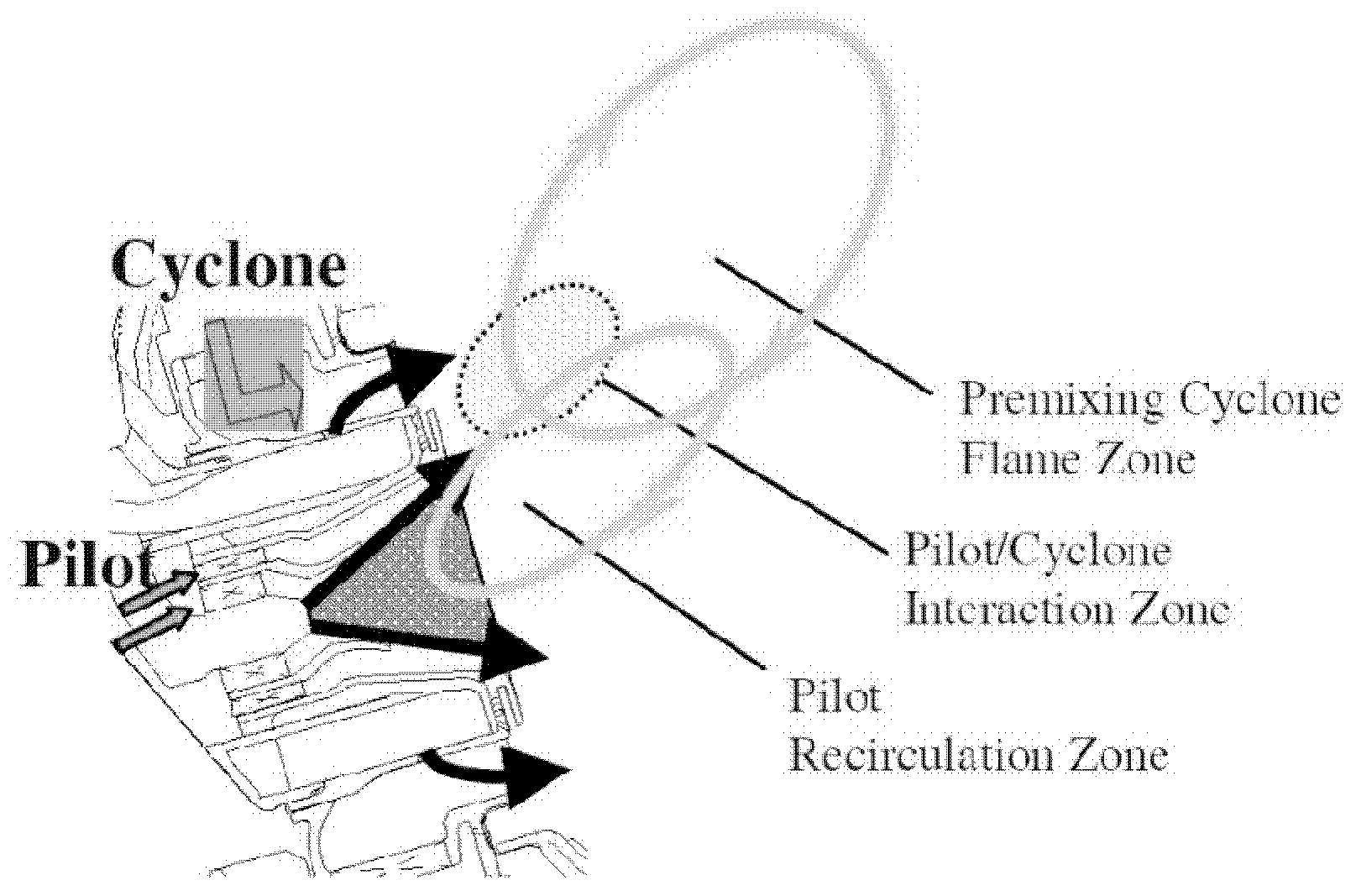

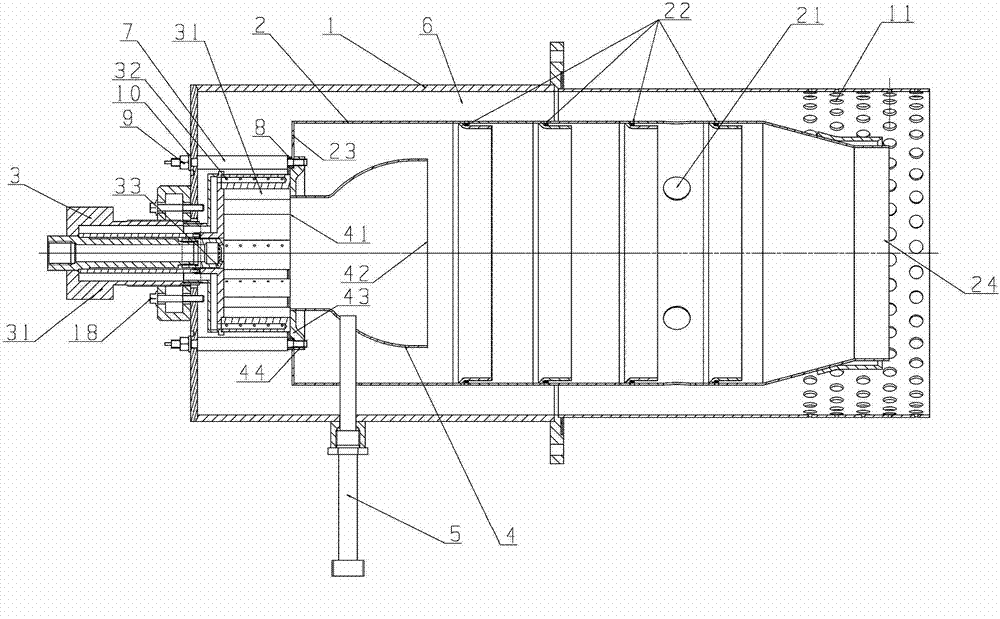

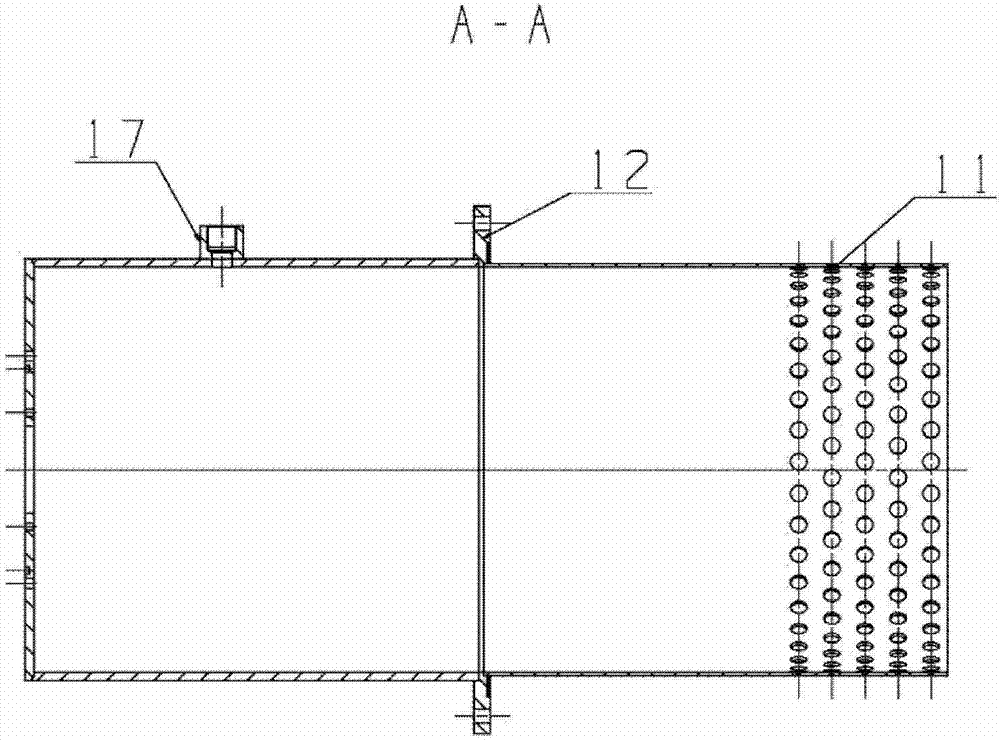

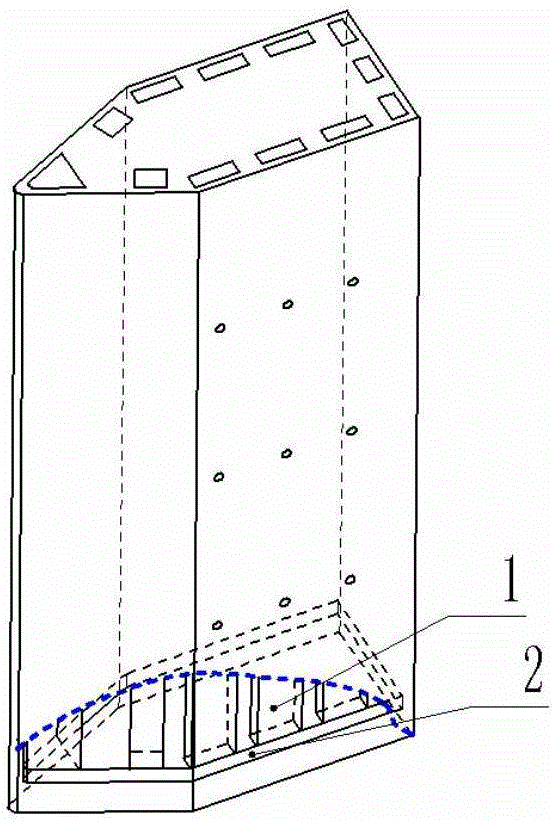

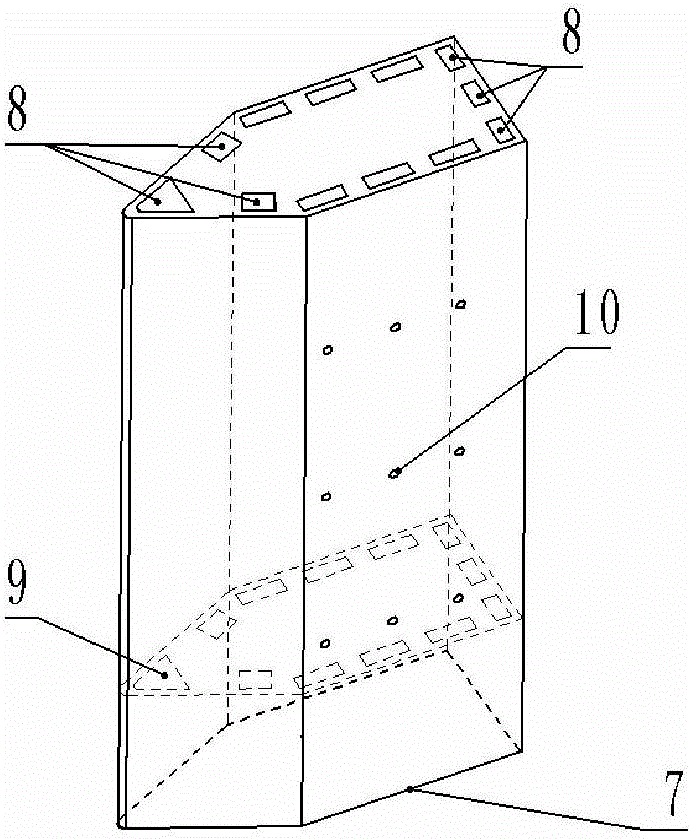

Lean premixed combustion chamber for gas turbine

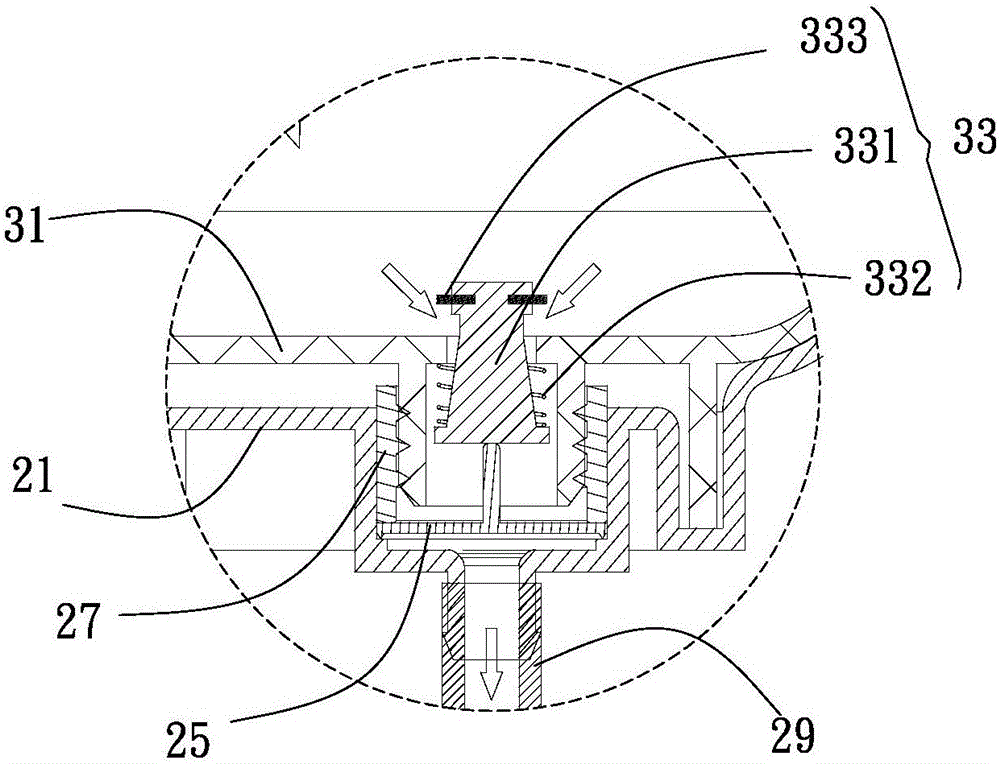

InactiveCN102878580AGuaranteed stabilityEvenly blendedContinuous combustion chamberCombustion chamberEngineering

The invention discloses a lean premixed combustion chamber for a gas turbine. The lean premixed combustion chamber for the gas turbine is characterized in that a flame tube is fixed in a cartridge receiver, and a plurality of round holes for feeding air are formed in a wall surface of a tail part of the cartridge receiver; an igniter mounting seat for mounting an igniter is arranged on a side surface of the cartridge receiver; a swirl cup with a variable diameter is arranged in the flame tube, and a nozzle swirler combined piece is connected to an inlet of the swirl cup through the cartridge receiver; an on-duty fuel introducing tube is arranged in the center of a nozzle body, and a premixed fuel introducing tube is arranged on an outer ring of the nozzle body; a back cover of a premixed fuel chamber of the swirler combined piece is connected with an inner side of a blade mounting base body to form the premixed fuel chamber; a plurality of blades are fixed on an outer side of the blade mounting base body, a blind hole is formed in every blade along the axial direction, and a plurality of premixed fuel jetting holes are formed in wall surfaces on two sides of every blade; and premixed fuel enters the premixed fuel chamber from the premixed fuel introducing tube, enters a swirler passage through the blind holes and the premixed fuel jetting holes in the blades and is mixed with air. By the lean premixed combustion chamber for the gas turbine, the fuel is uniformly mixed with the air, and the discharge of nitrogen oxide (NOX) of a combustion chamber can be reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

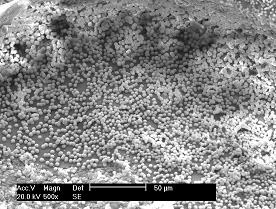

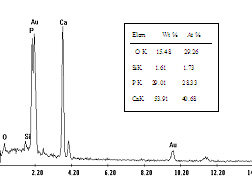

Organic-inorganic composite gel material for bone repair and preparation method thereof

InactiveCN102008753AGood biocompatibilityImprove biological activityProsthesisPolymer scienceSynthetic Polymeric Macromolecules

The invention relates to an organic-inorganic composite gel material for bone repair and a preparation method thereof. The composite gel material is characterized in that the organic material is formed by synthetic polymers or natural polymers; the inorganic material is formed by SiO2, CaO and P2O5 with mole fraction of 50-80%, 10-40% and 1-10% respectively; and the mass ratio of the organic material to the inorganic material is (0.1-1):1. The method is characterized by penetrating the polymer chains with biocompatibility and biodegradability into the SiO2 inorganic network structure to form the semi-interpenetrating structure. In the invention, the good blending of the organic and inorganic components at molecular level is realized, the mechanical property of the materials is simultaneously improved, and the bioactivity of the materials is improved; and the material and preparation method have important development potential in the field of bone defect repair.

Owner:FUZHOU UNIV

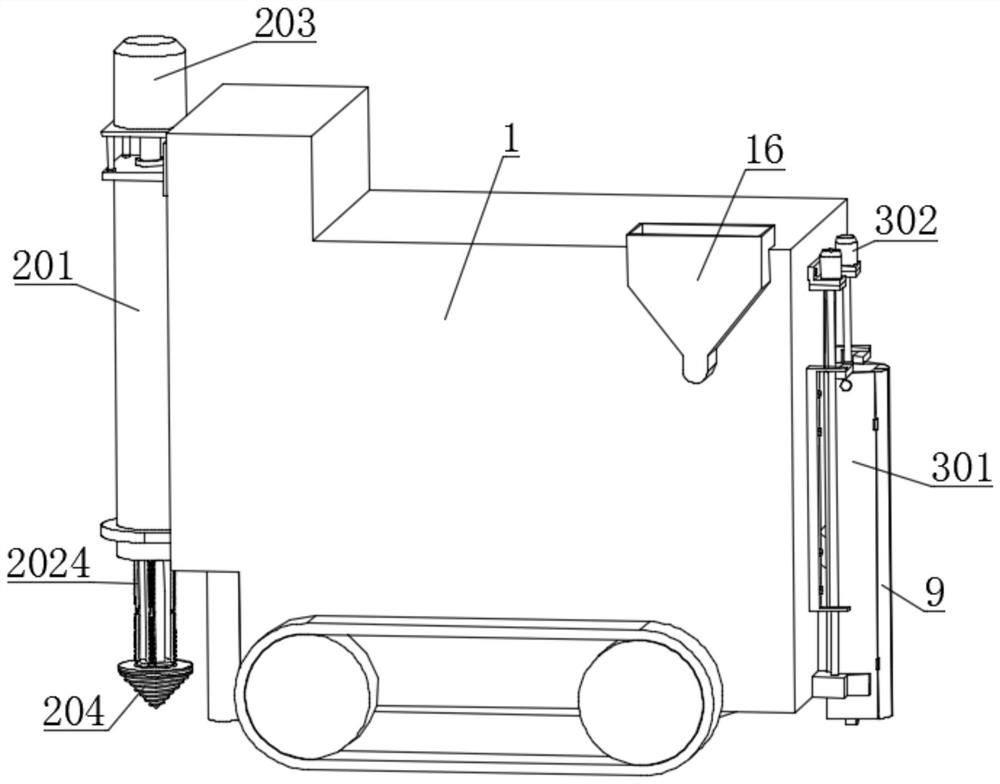

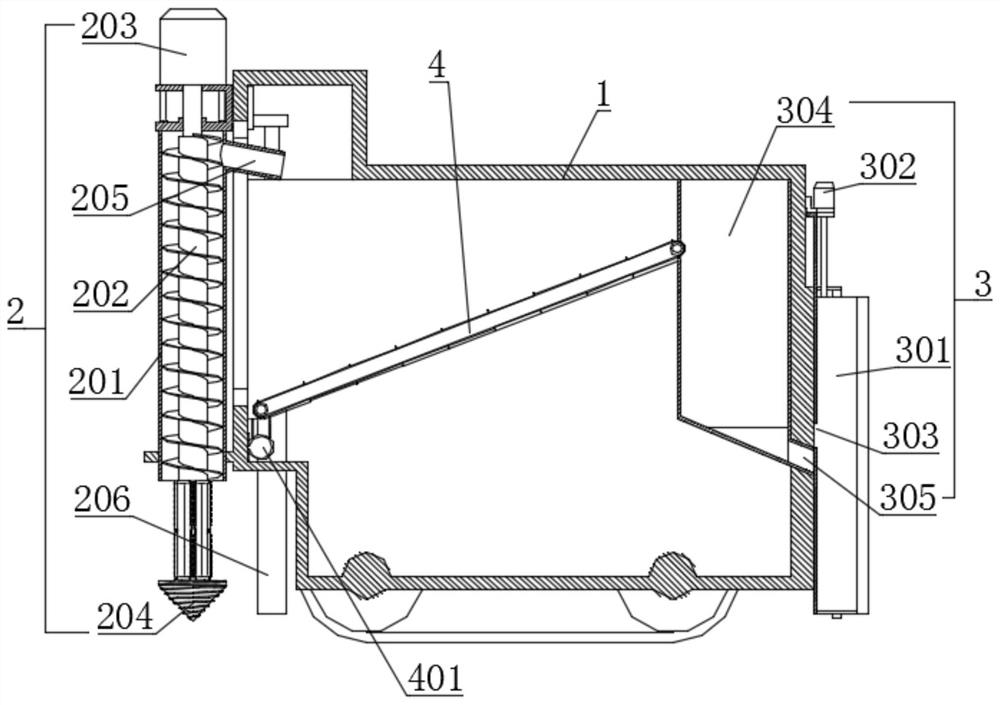

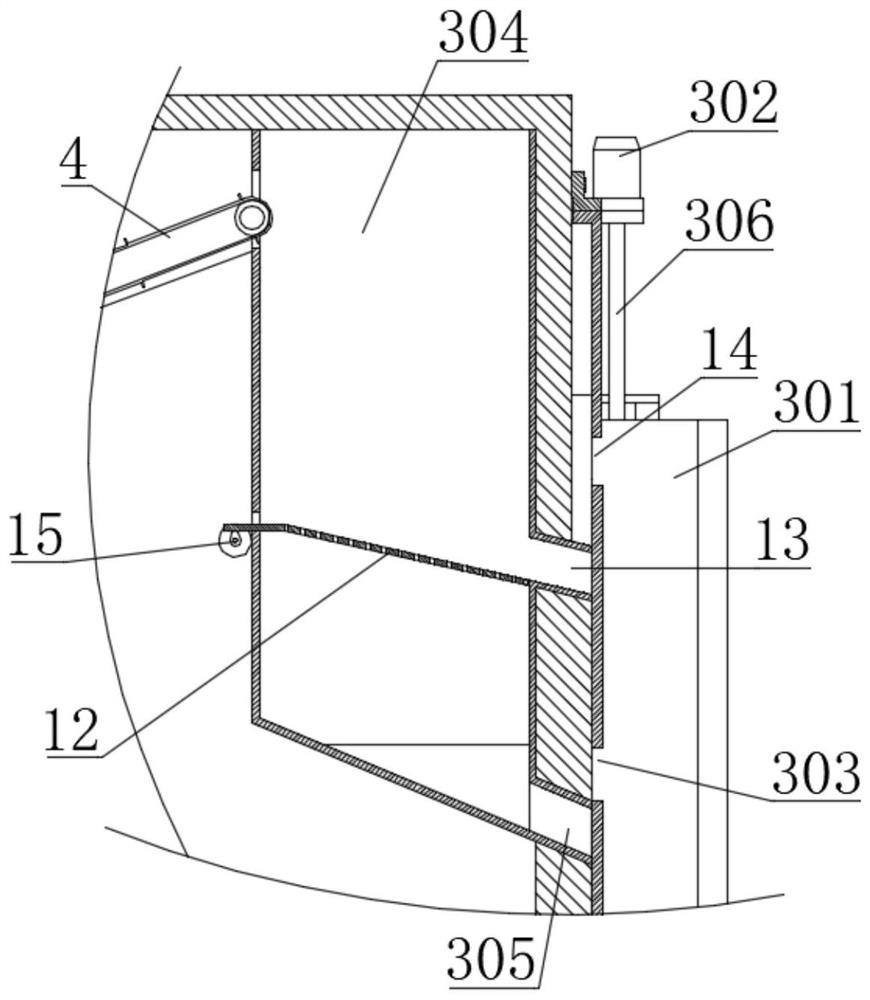

Integrated equipment for planting of camphor tree

ActiveCN111972246APlay the role of locking water and fertilizerEasy to stretchSievingPlantingCinnamomum camphoraAgricultural engineering

The invention discloses integrated equipment for planting of a camphor tree. The integrated equipment comprises a vehicle body, wherein the vehicle body is driven to move through crawlers, a pitting device is arranged at one side of the vehicle body, a backfilling device is arranged at the other side of the vehicle body, the pitting device comprises a lifting pipe, a drill rod is rotatably connected with the interior of the lifting pipe, the lower end of the drill rod is connected with a drill bit for drilling, and the backfilling device comprises a seedling placing pipe which is used for placing a camphor tree seedling into a pit. According to the integrated equipment, a telescopic rod contracts towards the interior of a screw rod and then enables a digging member to strut outwards, thus,a drilled pit has a small opening part and a big internal space, then, a soil layer above roots of the camphor tree seedling is mostly composed of un-dug soil after the camphor tree seedling is placed inside the pit, the soil can better play a role in locking water and fertilizers, the enlarging of the internal space of the pit is beneficial to root extension of the camphor tree seedling, and thesurvival of the tree seedling is facilitated.

Owner:INST OF BIOLOGICAL RESOURCES JIANGXI ACAD OF SCI

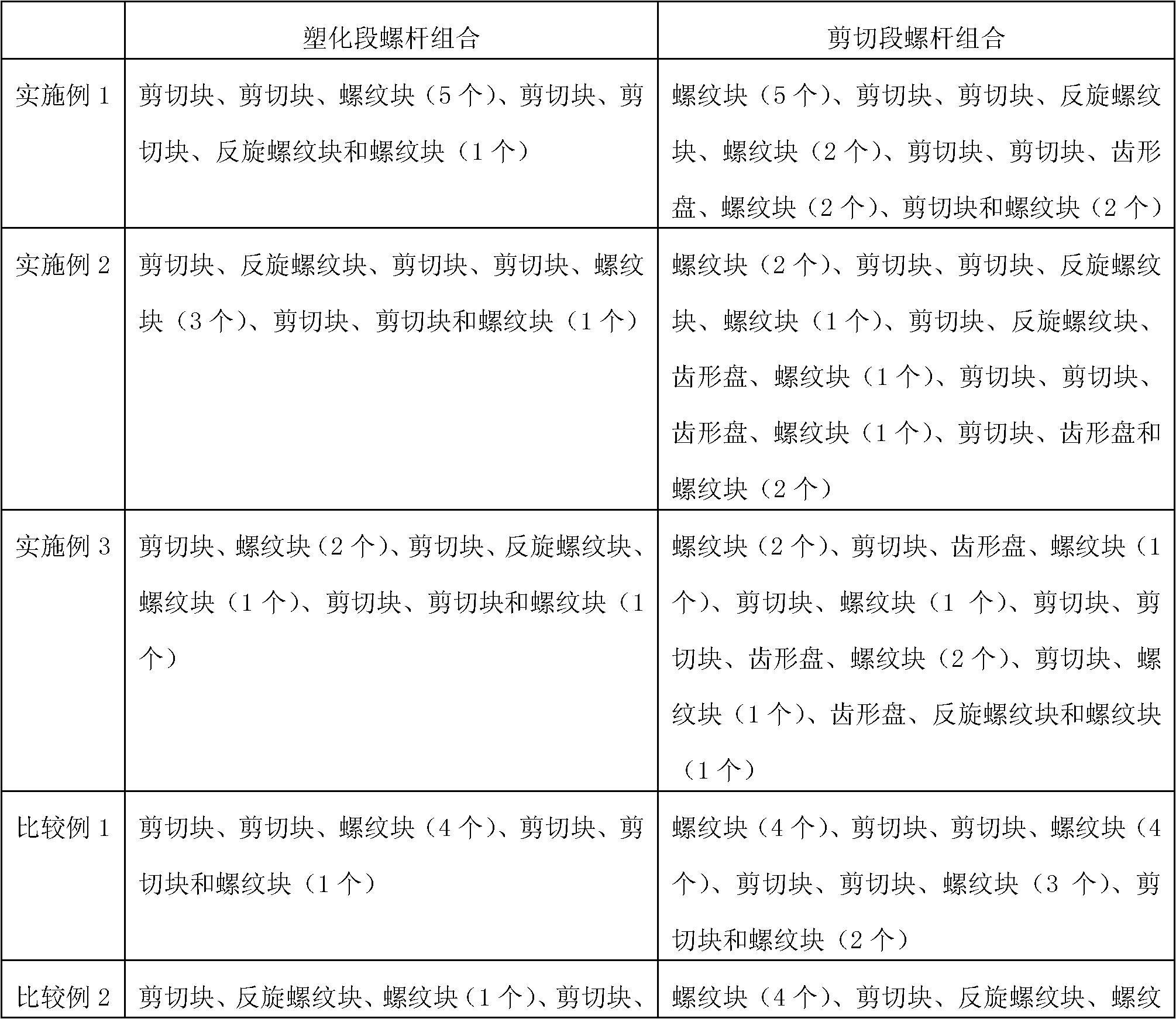

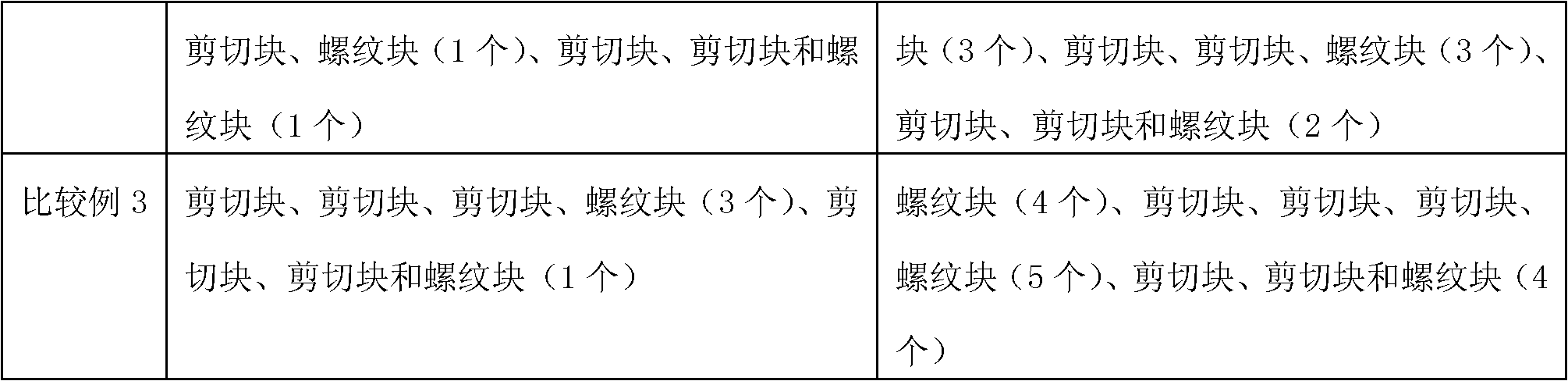

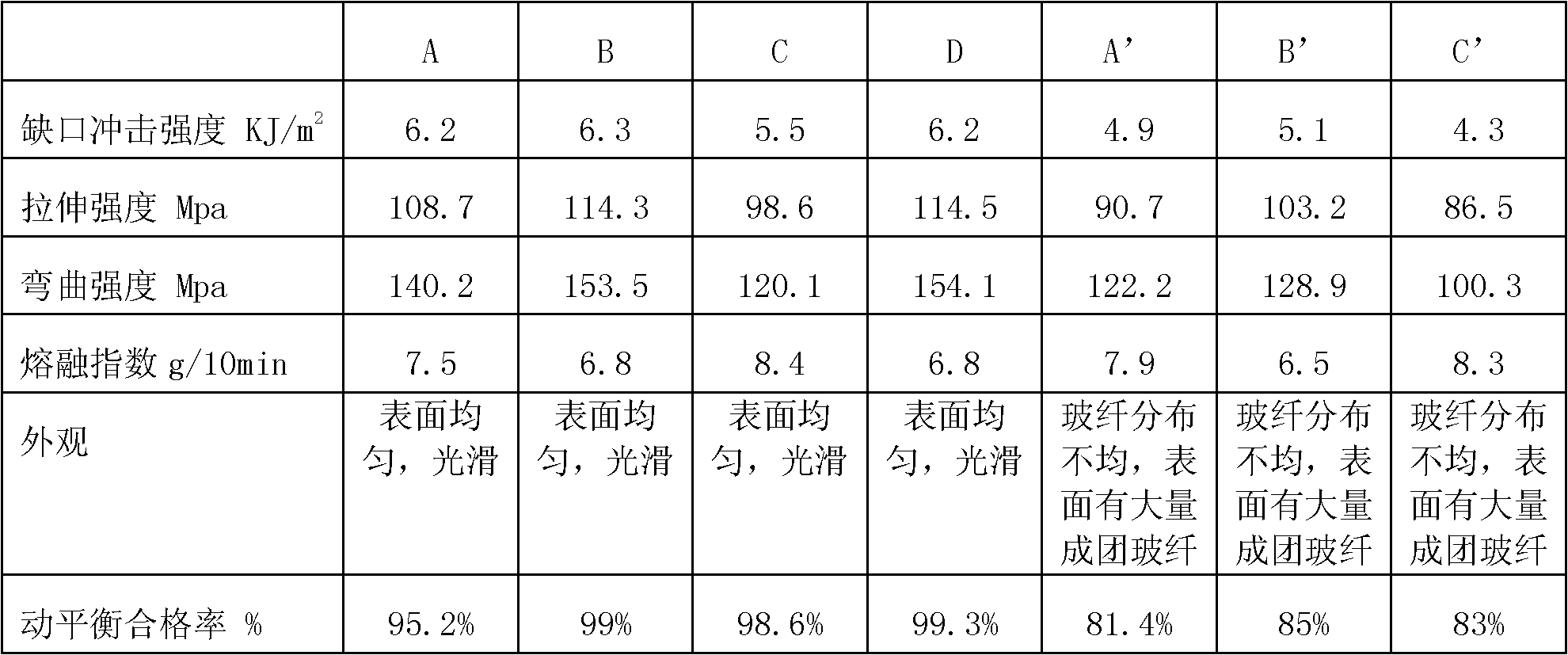

Preparation method for glass fiber reinforced AS (acrylonitrile-styrene) resin

The invention provides a preparation method for a glass fiber reinforced AS (acrylonitrile-styrene) resin, which comprises the following step: inputting raw materials into a double-screw extruder to carry out blending extrusion. A screw combination from a plasticizing section to a shearing section of the double-screw extruder comprises a threaded block, 9-21 shearing blocks, 2-4 left-handed threaded blocks and 1-3 tooth-shaped discs, and the raw materials comprise 63-86.4 wt% (weight percent) of the AS resin, 13-35 wt% of glass fiber, 0.1-0.6 wt% of coupling agent, 0.2-0.6 wt% of antioxidant and 0.3-0.8 wt% of lubricating agent. The glass fiber reinforced AS resin prepared by the preparation method has more uniform density and higher intensity.

Owner:株洲时代工程塑料制品有限责任公司

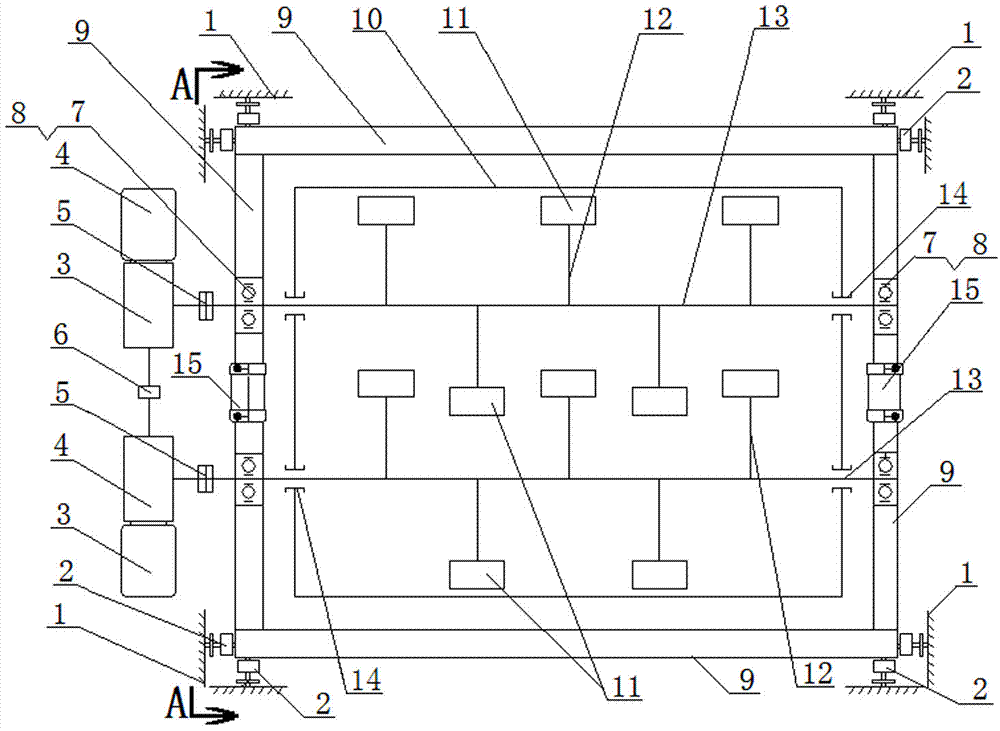

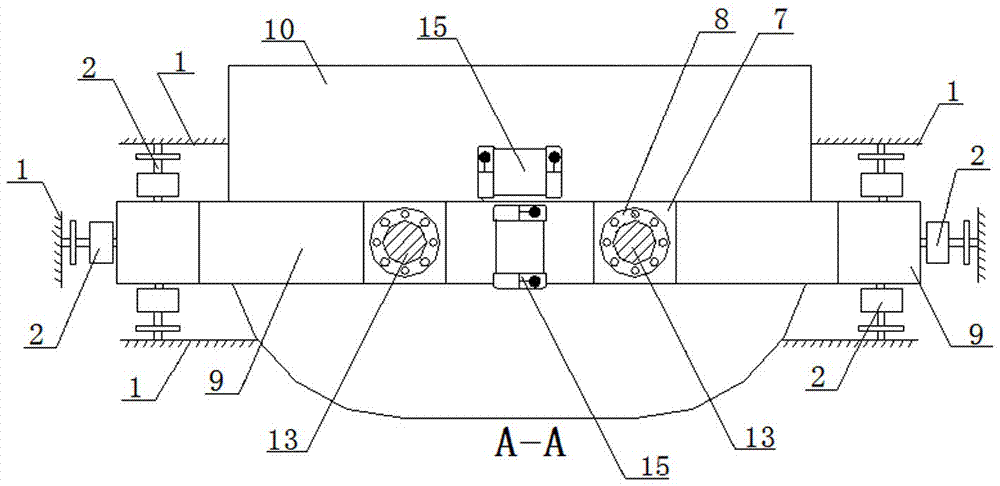

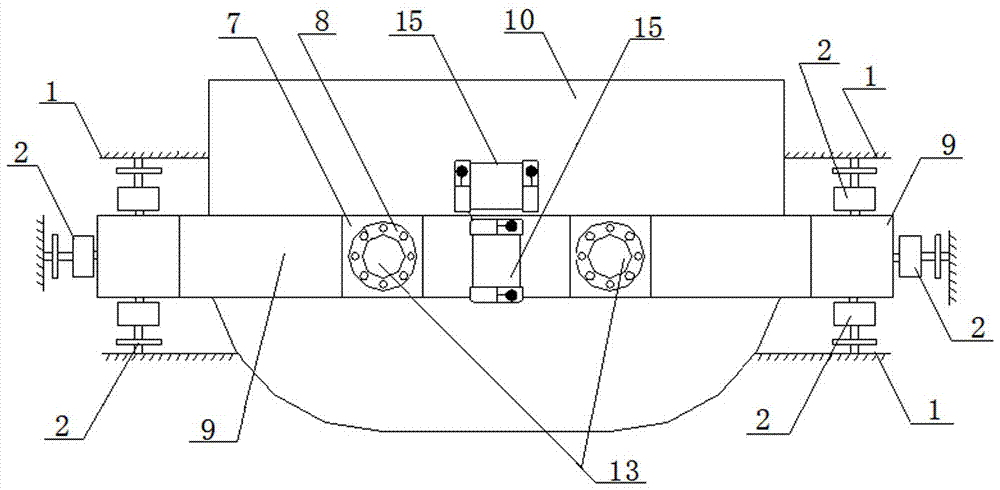

Shaft-vibration forced mixer

PendingCN107116696AImprove performanceImprove adhesionCement mixing apparatusElectric machineryFixed frame

The invention discloses a shaft-vibration forced mixer. The shaft-vibration forced mixer comprises a mixing barrel, mixing shafts, a fixed frame, a speed reducer and a mixing motor. The shaft-vibration forced mixer is characterized by further comprising vibration frames horizontally arranged around the outer side of the mixing barrel, and two vibrators horizontally and vertically arranged on the vibration frames between bearing seats at the two ends of each of the two mixing shafts separately, wherein the two ends of each mixing shaft are fixedly connected with the corresponding vibration frame through the bearing seats and bearings thereof. The mixing shafts and mixing blades of the mixer rotate under the driving of the speed reducer and the mixing motor, and vibration is generated under the driving of the vibrators. A mixture can be adequately dispersed and uniformly fused, so that the mixture realizes macroscopic uniformity and microcosmic uniformity in a real sense; and repeated collision is carried out in the mixture to form high-quality cementing materials, and the cementing materials are uniformly distributed in the mixture and in better firm bonding with aggregates, so that a mixture with higher performance is formed. The shaft-vibration forced mixer is applicable to cement stabilized soil, cement concrete, cement mortar and asphalt mixture.

Owner:归立发

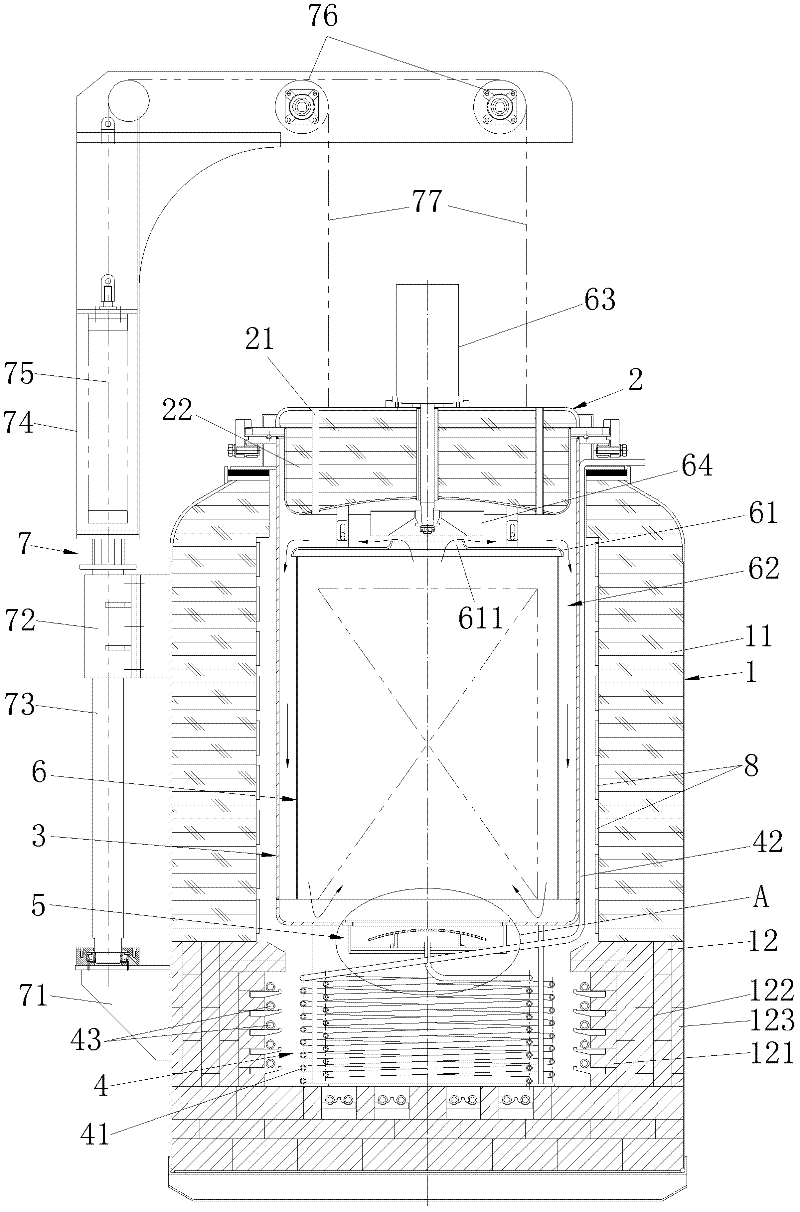

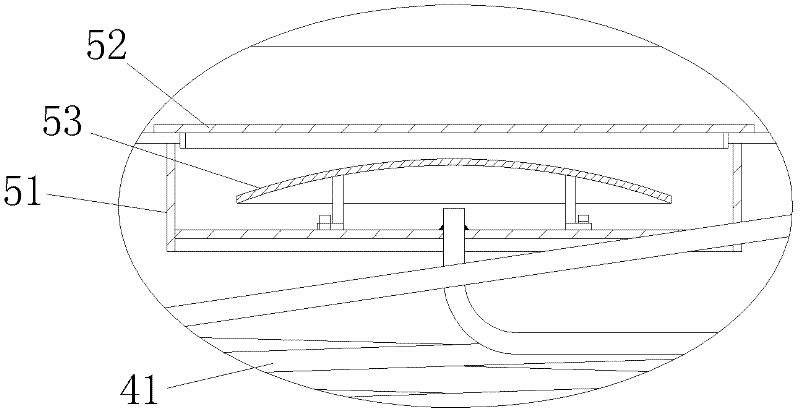

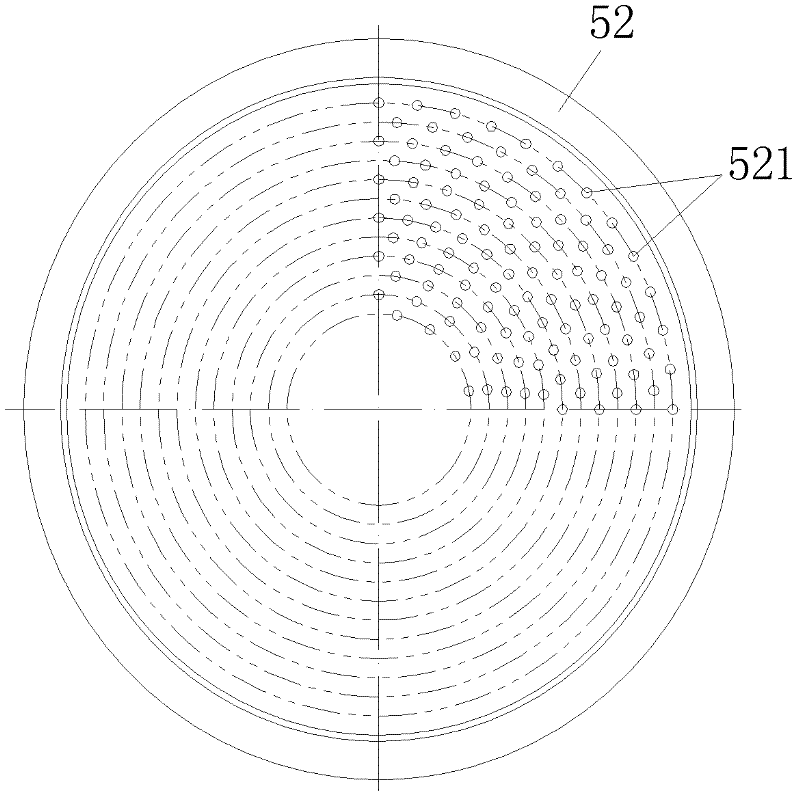

A Steam Oxidation Pit Furnace

ActiveCN102297583ASmall temperature fluctuationsReduce thermal expansion and contractionSolid state diffusion coatingVertical furnacesThermal expansionEngineering

The invention discloses a steam oxidation well furnace which comprises a furnace shell, a furnace cover, a furnace tank and a heating mechanism, wherein the furnace tank is arranged in the furnace shell; the heating mechanism is used for heating work pieces in the furnace tank; the bottom part of the furnace shell is provided with a steam preheating mechanism which is connected with an external steam source; and the steam preheating mechanism is communicated with the bottom part of the furnace tank through the steam diffusion structure. An individual steam preheating mechanism is added below the furnace tank, steam enters the furnace tank after the steam is heated by the steam preheating mechanism and is diffused uniformly by the steam diffusion structure, the temperature vibration in the furnace tank is reduced greatly, the expansion and contraction phenomenon in the furnace body is reduced, the welding point of the steam pipeline is difficult to drop off, and the steam pipeline is difficult to crack; and simultaneously the steam can be fused with metal work pieces more uniformly, the oxidation effect is improved obviously, the density of oxidizing materials on the surfaces of the metal work pieces is better, and the content of ferroferric oxide can reach more than 90%.

Owner:浙江省长兴精工电炉制造有限公司

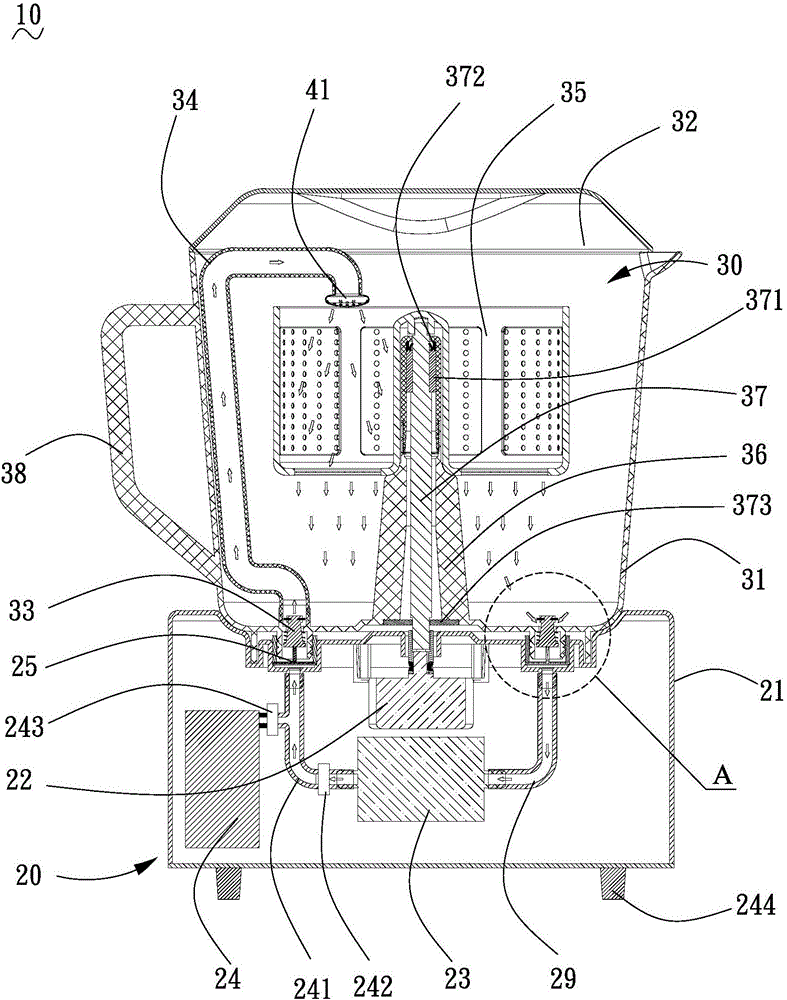

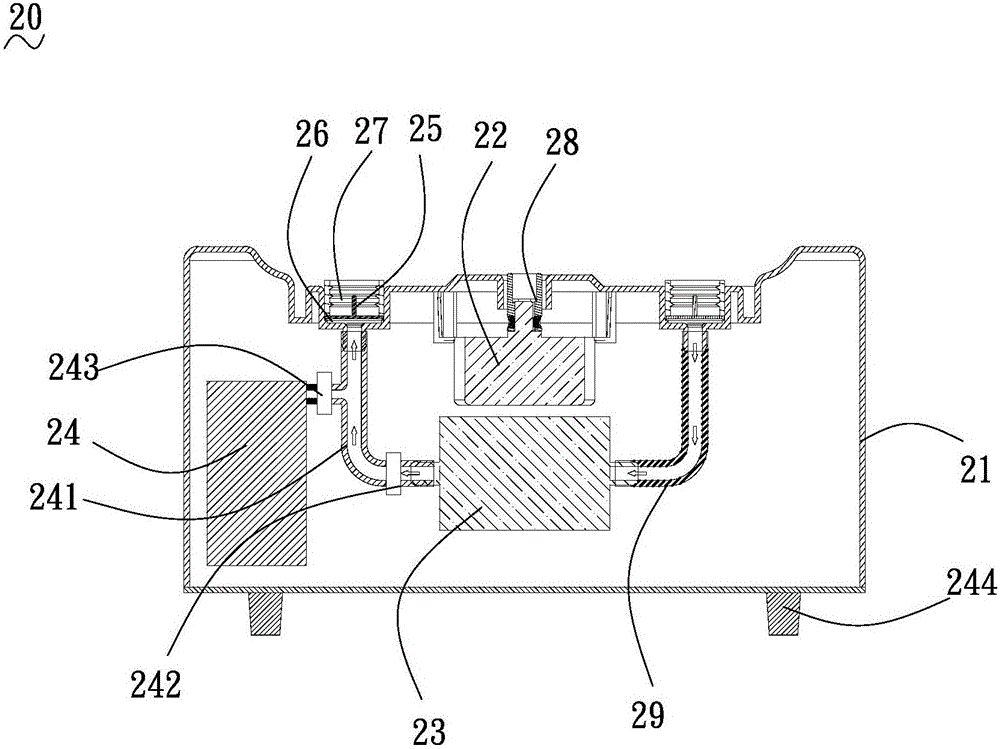

Vacuumized iced coffee machine

ActiveCN106798496AGood fresh-keeping effectImprove the preparation effectBeverage vesselsMotor driveEngineering

The invention relates to a vacuumized iced coffee machine which comprises a main engine assembly, and a coffee cup assembly mounted on the main engine assembly, wherein the main engine assembly comprises a main engine seat, a motor mounted on the main engine seat, a water pump, a vacuum pump and a touch filter disc; a control valve connected with the main engine seat and the water pump is arranged on the vacuum pump; the coffee cup assembly comprises a cup body, a cup cover, a movable valve, a drainage pipe and a net bag; the cup body is mounted on the main engine seat; the cup cover and the movable valve are mounted on the cup body; the drainage pipe and the net bag are arranged in the cup body; the movable valve is positioned at the bottom of the cup body and is opposite to the touch filter disc; the drainage pipe extends to the upper side of the net bag from the movable valve; the net bag is connected with the motor; the motor drives the net bag to rotate during driving. According to the vacuumized iced coffee machine, due to the vacuum pump, the movable valve, the water pump, the motor, the net bag and the like, coffee can be prevented from being oxidized, the preservation effect is good, the coffee in the net bag is repeatedly flushed, the blending ratio accuracy is guaranteed, coffee grounds are avoided, and the vacuumized iced coffee machine is excellent in making effect and simple and efficient in operation.

Owner:SHINY ELEC CO LTD

Process for preparing polyacrylic acid-Kynoar polyblend separation film and polyblend resin

InactiveCN101003004AImprove hydrophilicityAchieve removalSemi-permeable membranesPolymer scienceSludge

A process for preparing polyacrylic acid-polyvinylidene fluoride mixed separating membrane and mixed resin features that the polyvinylidene fluoride, acrylic acid, N, N-dimethyl acetylamine, polyethanediol, polyvinyl pyrrolidone, acrylamide, and p-phenyldimethylacyl are used as raw materials and the acrylic acid polymer is uniformed doped in said separating film and resin to improve their hydrophilicity.

Owner:YANSHAN UNIV

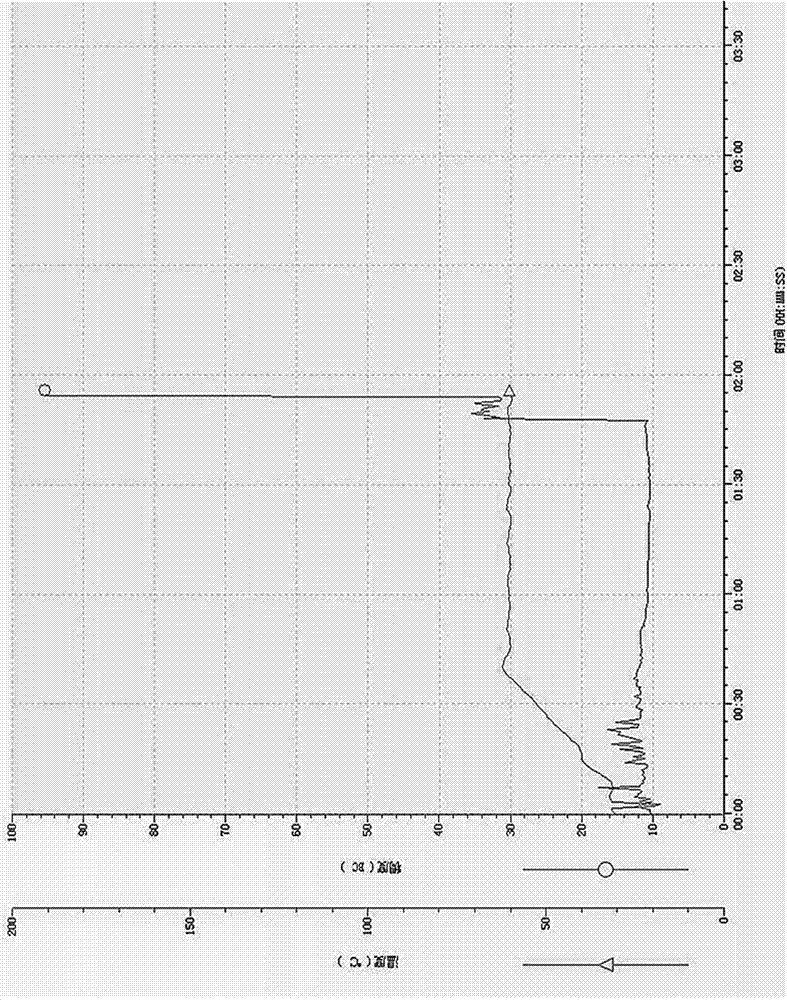

Wine ageing method

ActiveCN1891810AIncreased total phenolic contentImprove sensory qualityAlcoholic beverage preparationAge methodGrape wine

The invention discloses an aging method for grape wine that is realized following the steps of laying the oak board in wine storing jar, adding wine, filling nitrogen, controlling temperature, filling oxygen, cycling, and controlling the micro-oxygen reacting time. It could shorten aging time and production cycle, save manpower and cost, improve producing efficiency and wine quantity. The method could be used for aging dry red wine or dry white wine.

Owner:北京张裕爱斐堡酒庄有限公司

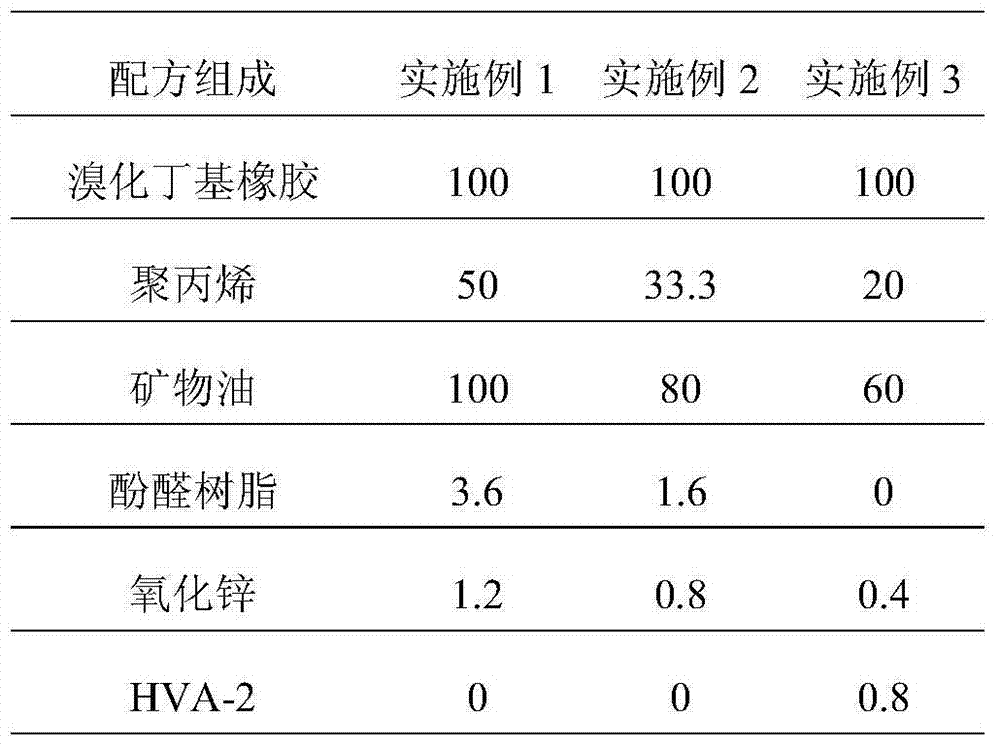

Low-hardness medical thermoplastic brominated butyl rubber and preparation method thereof

The invention provides low-hardness medical thermoplastic brominated butyl rubber and a preparation method thereof, and belongs to the technical field of polymer materials. The low-hardness medical thermoplastic brominated butyl rubber is prepared from a rubber-plastic blend of brominated butyl rubber and polypropylene by a complete pre-dispersion two-step method and dynamic vulcanization technology, can be thermoplastically processed and has the application performance of thermoplastic brominated butyl rubber, the material composition is simple, clean and sulfur-free, or antioxidant or stabilizer is added, the safety and sealing property of an elastomer material in pharmaceutical package application, the low-hardness medical thermoplastic brominated butyl rubber can be directly injection molded into gaskets of rubber plugs, combined covers and infusion bags (bottles), the production process is cleaner, the energy consumption is greatly reduced, and the product cost is greatly reduced.

Owner:SHANDONG DAWN POLYMER CO LTD

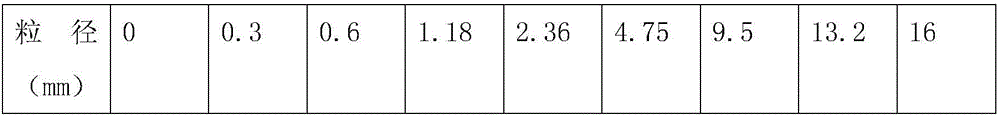

Plant hot-mix recycled asphalt mixture and preparation method thereof

The invention belongs to the technical field of road engineering, and concretely relates to a plant hot-mix recycled asphalt mixture and a preparation method thereof. The plant hot-mix recycled asphalt mixture and the preparation method thereof are provided against the problem of difficult improvement of the admixture of wastes in the plant hot-mix recycled asphalt mixture on the basis of meeting the performances of the asphalt mixture. The recycled mixture comprises, by weight, 70-90 parts of milling wastes, 10-15 parts of heavy aromatic hydrocarbons, 10-15 parts of acrylamide, 15-30 parts of new aggregates, 3-6 parts of mineral powder, 3-6 parts of new asphalt and 2-5 parts of a regenerant. The recycled asphalt mixture has the advantages of high admixture and high recycling efficiency; and a new mixture has uniform texture and stable performances, and meets performance requirements of the hot-mix asphalt mixture.

Owner:HEILONGJIANG ZHONGXIN ROAD & BRIDGE MATERIAL CO LTD

Full-degradable plastic film used for far-infrared food fresh-keeping and preparation method thereof

InactiveCN104910430AHigh strengthSmall particle sizeFlat articlesPolyvinyl alcoholPolyethylene glycol

The invention discloses a full-degradable plastic film used for far-infrared food fresh-keeping. The full-degradable plastic film is prepared from, by weight, 60 to 65 parts of corn starch, 7 to 9 parts of nano montmorillonite, 0.6 to 0.7 part of peanut oil, 1.2 to 1.4 parts of tetrabutyl titanate, 12 to 14 parts of ramie straw, 30 to 35 parts of polyvinyl alcohol, 13 to 15 parts of tributyl citrate, 5 to 7 parts of tourmaline, 2 to 3 parts of chitosan, 1.5 to 2 parts of magnesium stearate, 3 to 5 parts of polyethylene glycol, and 1 to 2 parts of talcum powder. The combination of the full-degradable plastic film is reasonable; the full-degradable plastic film can be made into food preservative film or fruit packaging bags, contains tourmaline powder, is capable of emitting far infrared ray and negative ions, and can be used for food fresh-keeping; a preparation method is convenient for industrialized control; obtained products are safe and nontoxic; complete biodegradation after discarding can be realized; and no harm is caused on the environment.

Owner:TONGLING FOUNDER PLASTICS TECH

Heat-resistant recycled asphalt concrete and preparation method thereof

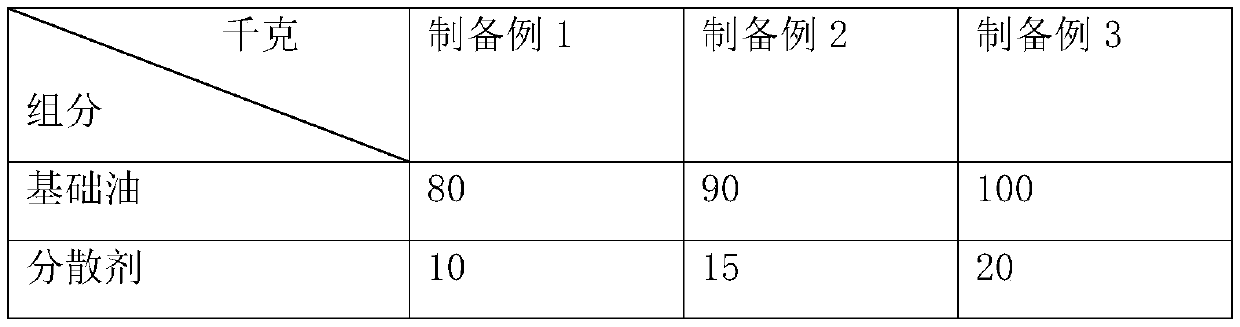

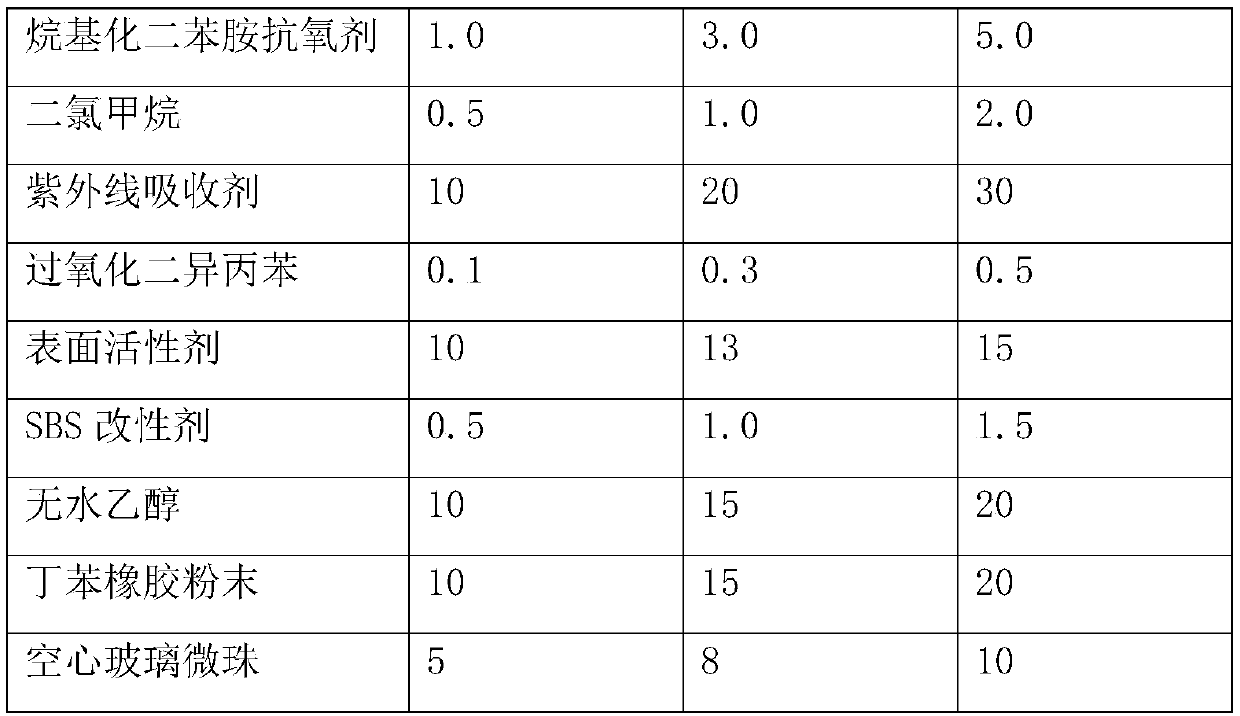

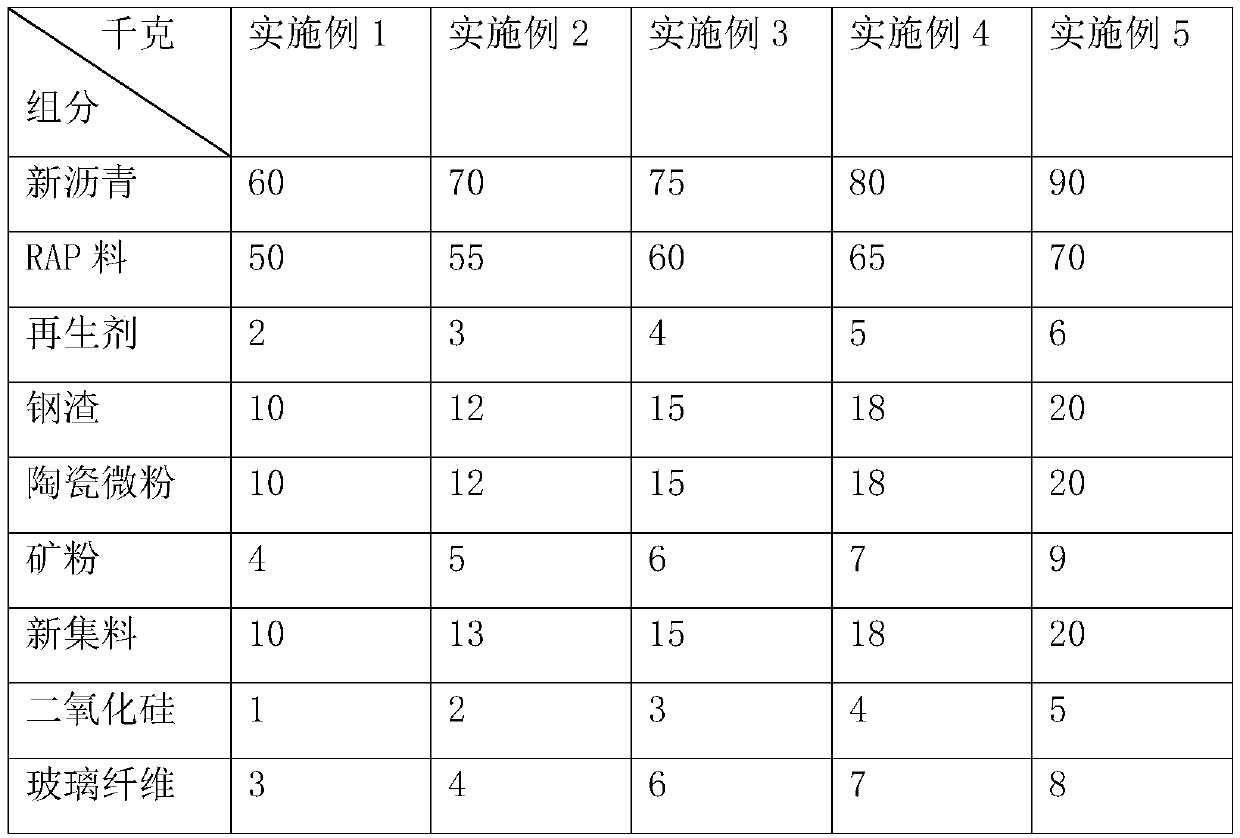

The invention discloses heat-resistant reclaimed asphalt concrete and a preparation method thereof. The heat-resistant reclaimed asphalt concrete comprises the following components: new asphalt, a RAPmaterial, a regenerant, steel slag, ceramic micropowder, mineral powder, a new aggregate, silica and glass fiber; the regenerant includes the following components: base oil, a dispersant, an alkylated diphenylamine antioxidant, dichloromethane, an ultraviolet absorber, dicumyl peroxide, a surfactant, a SBS modifier, anhydrous ethanol, styrene butadiene rubber powder and hollow glass microspheres;and the preparation thereof is as follows: S1, collecting the RAP material; S2, preparing a first mixture; S3, preparing a second mixture; S4, preparing a third mixture; and S5, preparing the finished product. The heat-resistant reclaimed asphalt concrete of the present invention is excellent in crack resistance, durability, and high-temperature and rutting deformation resistance; in addition, the preparation method of the present invention has the advantage of making asphalt distribution uniform.

Owner:江苏盛达飞建筑材料有限公司

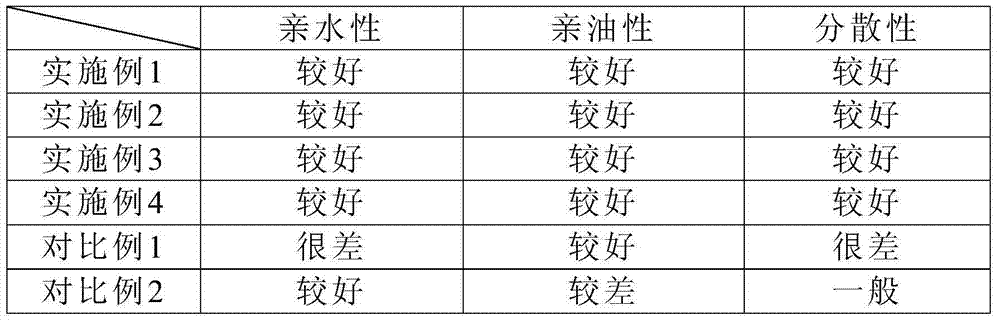

Hydrophilic and oleophilic polytetrafluoroethylene micro-powder and preparation method thereof

InactiveCN103923264AHas the function of hydrophilic and lipophilicEasy to prepareDispersityTetrafluoroethylene

The present invention relates to hydrophilic and oleophilic polytetrafluoroethylene micro-powder and a preparation method thereof. According to the hydrophilic and oleophilic polytetrafluoroethylene micro-powder, in a solvent, in the presence of 5-10 parts of a surfactant, 1-3 parts of concentrated H2SO4, and 1-3 parts of a polymerization inhibitor, 15-30 parts of polytetrafluoroethylene micro-powder crushed through electron beam irradiation, 25-50 parts of a water-soluble monomer and 40-80 parts of an oil-soluble monomer are grafted to prepare the hydrophilic and oleophilic polytetrafluoroethylene micro-powder. According to the present invention, the water-soluble monomer and the oil-soluble monomer are grafted on the polytetrafluoroethylene micro-powder, such that the polytetrafluoroethylene micro-powder maintains the original excellent performance, further has functions of hydrophilicity and lipophilicity, has good dispersity, and can be uniformly blended with other materials.

Owner:ZHEJIANG GREEN NEW MATERIALS

Method for preparing oxide dispersion strengthened copper composite material

The invention relates to a method for preparing an oxide dispersion strengthened copper composite material, and belongs to the field of preparation of copper alloy materials. The method is as follows:firstly reducing Cu powder; alloying element powder, to be more specific, thoroughly mixing the reduced Cu powder with an appropriate amount of Y powder to obtain a Cu powder and Y powder mixture, then packaging the Cu powder and Y powder mixture and grinding balls in a stainless steel ball mill tank, and performing ball milling under an inert gas atmosphere; after the ball milling, annealing alloyed alloy powder by a muffle furnace, and sintering the annealed alloy powder into a block by a discharge plasma sintering furnace, and then rolling the block into a desiring thickness; and finally using a muffle furnace to perform heat treatment on the rolled copper alloy, and cooling in the furnace to obtain the oxide dispersion strengthened copper composite material. The oxide dispersion strengthened copper composite material prepared by the method has uniform distribution of nano-oxide particles with an average size of 5-6 nm, the powder production rate is over 95%, and the process is simple and easy to operate.

Owner:UNIV OF SCI & TECH BEIJING

Toughened anti-channeling agent for cement and toughened cement for cementing shale gas horizontal well

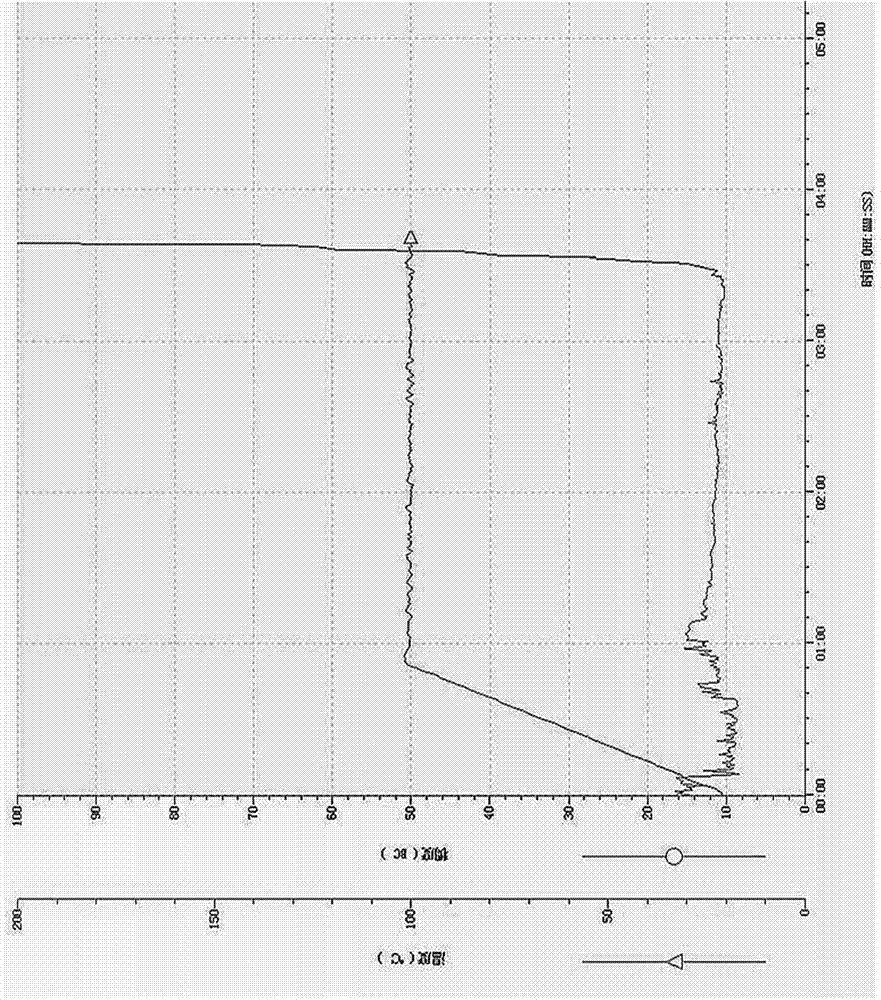

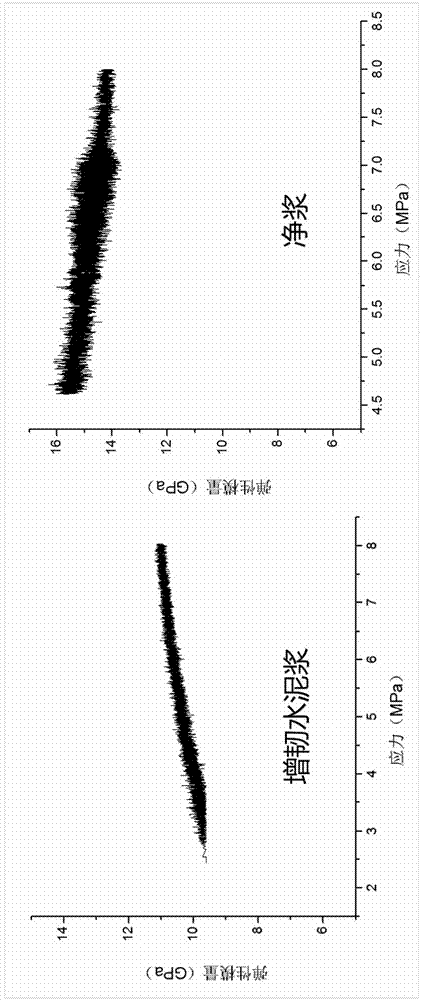

ActiveCN104291733AStable performanceThickening time is easy to adjustDrilling compositionShale gasSilane coupling

The invention relates to cement paste used when a shale gas horizontal well is cemented, and a toughened additive added to the cement paste, and belongs to the technical field of oil-gas well cement engineering. A toughened anti-channeling agent for cement is prepared from butadiene styrene rubber powder and re-dispersible rubber latex powder at the mass ratio of 2 to 1 in a mixing manner, wherein the butadiene styrene rubber powder is subjected to treatment comprising the following steps before use: firstly, preparing a silane coupling agent solution with the mss percent content being 1.5%; adding butadiene styrene rubber powder, standing for 24 hours, and then filtering; and drying in the sun, wherein the system is stable in performance after the cement paste is prepared; the thickening time is easy to adjust; the water loss is smaller than 30ml; free fluid with an inclination angle of 45 degrees and the difference of densities are 0; the compressive strength at 50 DEG C for 24 hours is greater than 30MPa; the applicable temperature range is 50-120 DEG C; the thickening time is 110-240 minutes; and the toughened anti-channeling agent for cement is added to the toughened cement for cementing the shale gas horizontal well. The cement paste system disclosed by the invention is good in stability, and low in water loss and leakage, and can meet the requirements of multistage fracturing of the shale gas horizontal well on the cement paste system.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

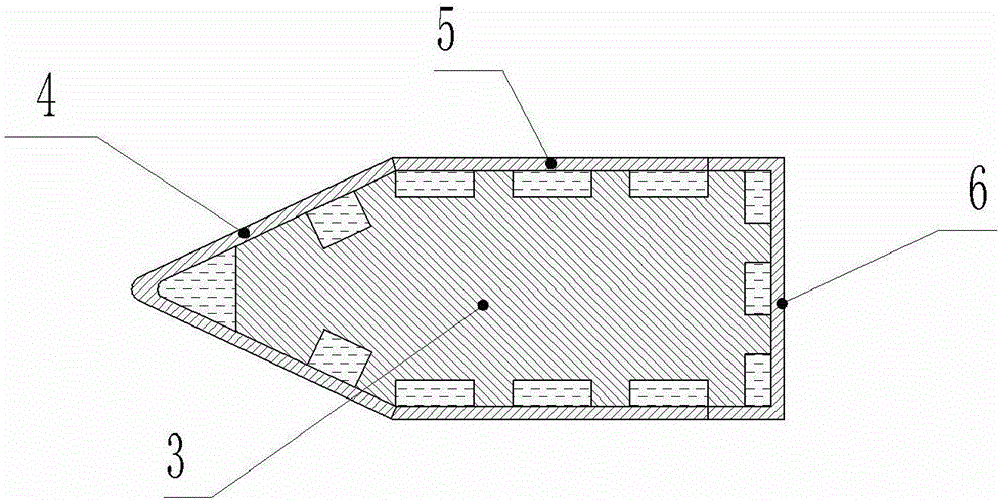

Fuel strut injector

InactiveCN106247407AImprove thermal protection performanceSimple structureContinuous combustion chamberForce convectionEngineering

The invention discloses a fuel strut injector. Fuel of a scramjet engine and a combined circulatory power engine is adopted as a cooling agent, the cooling agent flows in a cooling channel for cooling a strut and is sprayed into a combustion chamber for being subjected to mixing combustion together with fuel gas, and therefore long-time normal work of the strut can be realized. The front edge of the strut is of a rounding wedge-shaped structure, and a flowing channel is located on the inner side of the front edge of the strut; a plurality of channel inlets are formed in each of the inner side of a front part of the strut and the inner side of a rear wall of the strut, a plurality of fuel spraying holes are formed in each of side wall surfaces of the strut, a liquid collection cavity is formed in the bottom of the strut and communicates with the flowing channel and the cooling channel, and the cooling agent enters the channel inlets, flows to the bottom of the strut along the channel, is gathered in the liquid collection cavity and finally is sprayed out of the strut through the fuel spraying holes; and the cooling agent absorbs heat in the channel in a flowing heat exchange mode of forced convection before being sprayed into the combustion chamber, and therefore the temperature of the strut can be lowered, and the fuel can be preheated. The strut injector is simple in structure, the thermal protection effect on the strut is good, and the strut can realize the function of injecting the fuel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

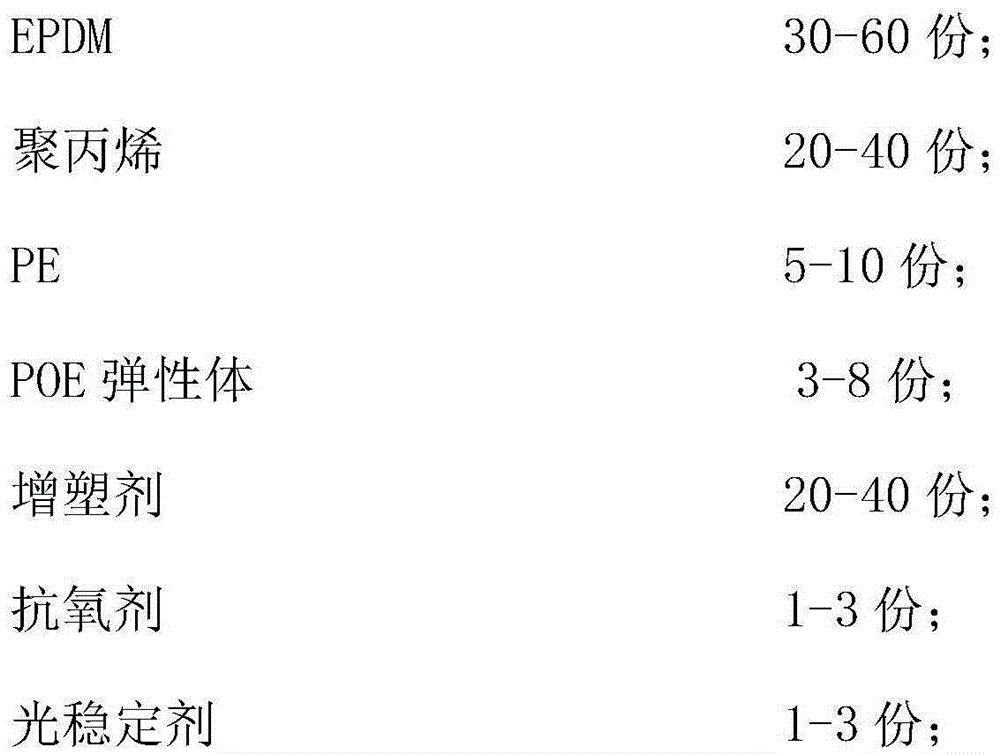

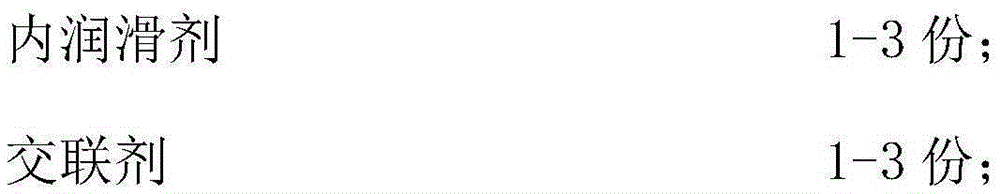

High-fluidity TPV material and preparing method thereof

The invention discloses a high-fluidity TPV material. The high-fluidity TPV material is prepared from, by weight, 30-60 parts of EPDM, 20-40 parts of polypropylene, 5-10 parts of PE, 3-8 parts of POE elastomer, 20-40 parts of plasticizer, 1-3 parts of antioxidant, 1-3 parts of light stabilizer, 1-3 parts of internal lubricating agents and 1-3 parts of cross-linking agents. The high-fluidity TPV material has high fluidity, low compressive deformation, and excellent shock resistance, chemical resistance and oil resistance.

Owner:安徽韧达高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com