Low-hardness medical thermoplastic brominated butyl rubber and preparation method thereof

A bromobutyl rubber and thermoplastic technology, which is applied in the field of low-hardness medical thermoplastic bromobutyl rubber and its preparation, can solve the problem that the hardness thermoplastic elastomer material cannot be prepared, the dynamic vulcanizate has poor performance, and the phase inversion cannot be better. problems such as conversion, to achieve the effect of simple and clean material composition, lower product cost, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

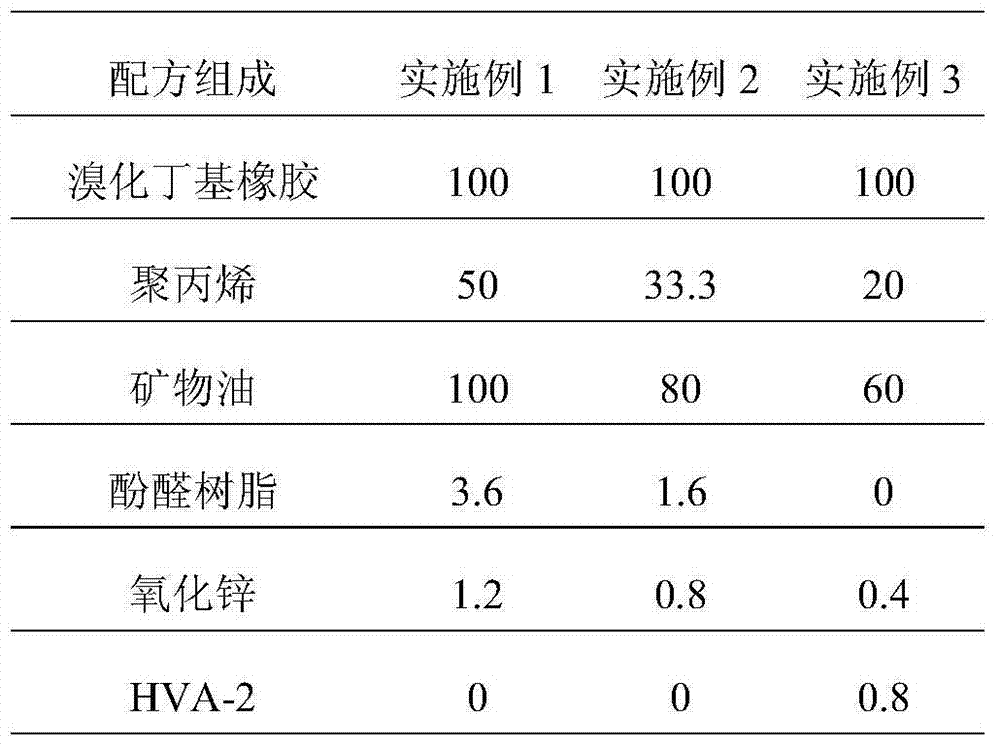

[0032] Embodiment 1: (the part described in embodiment and comparative example is mass part)

[0033]Mix 60 parts of bromobutyl rubber and 50 parts of polypropylene in an internal mixer at 180°C, and gradually add 60 parts of mineral oil; add 2.2 parts of the prepared rubber-plastic blend to an internal mixer at 20-70°C Phenolic resin HY-2045 and 0.7 parts of zinc oxide are evenly mixed, and then the flakes are discharged on the twin-roll mill, and are forced to be fed into the twin-screw extruder, where dynamic cross-linking is performed, and each section of the screw / machine is set The head temperature is 160, 165, 170, 175, 180, 185, 185, 185, 185, 185, 185, 185 / 185°C, the speed is 400rpm, dynamic vulcanization is carried out, and small molecules are vacuumed out at the same time, extruded and granulated to obtain hardness Higher thermoplastic bromobutyl rubber bead intermediate.

[0034] Add 1.4 parts of phenolic resin HY-2045 and 0.5 parts of zinc oxide to the remaining ...

Embodiment 2

[0036] Mix 60 parts of bromobutyl rubber and 33.3 parts of polypropylene in an internal mixer at 180°C, and gradually add 50 parts of mineral oil; add 1 part of the prepared rubber-plastic blend to an internal mixer at 20-70°C The phenolic resin HY-2045 and 0.5 part of zinc oxide are evenly mixed, and then the sheets are produced on a double-roll mill, and the first step of the dynamic vulcanization process is the same as in Example 1.

[0037] Add 0.6 parts of phenolic resin HY-2045 and 0.3 parts of zinc oxide to the remaining part of bromobutyl rubber and 30 parts of mineral oil, mix evenly on an open mill, granulate and mix evenly with intermediate granules, and then proceed to the second step Dynamic vulcanization, process parameters and flow process are the same as embodiment 1.

Embodiment 3

[0039] Mix 60 parts of bromobutyl rubber and 20 parts of polypropylene in an internal mixer at 180°C, and gradually add 40 parts of mineral oil; add 0.5 parts of the prepared rubber-plastic blend to an internal mixer at 20-70°C HVA-2 and 0.3 parts of zinc oxide are uniformly mixed, and then flakes are produced on a double-roll mill, and the first step of dynamic vulcanization process parameters and process are the same as in Example 1.

[0040] Add 0.3 parts of HVA-2 and 0.1 parts of zinc oxide to the remaining part of bromobutyl rubber and 20 parts of mineral oil, mix evenly on the open mill, granulate and mix evenly with intermediate particles, the second step is dynamic vulcanization, process Parameters and flow process are the same as embodiment 1.

[0041] Table 1

[0042]

[0043] Performance

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com