Lean premixed combustion chamber for gas turbine

A gas turbine and combustor technology, applied in lean premixed combustion premixed fuel injection structure, lean premixed combustor field, can solve problems such as inability to achieve uniform air mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical problem to be solved by the present invention is to improve the mixing effect of the premixed fuel and air in the gas turbine lean premixed combustor, reduce the NO X emission.

[0032] Technical scheme of the present invention is realized like this:

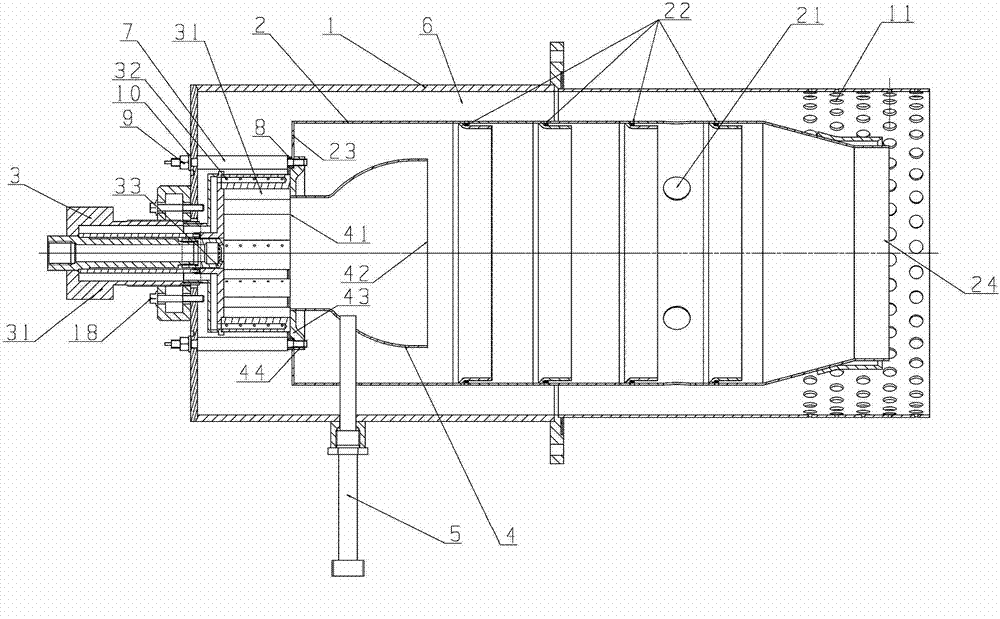

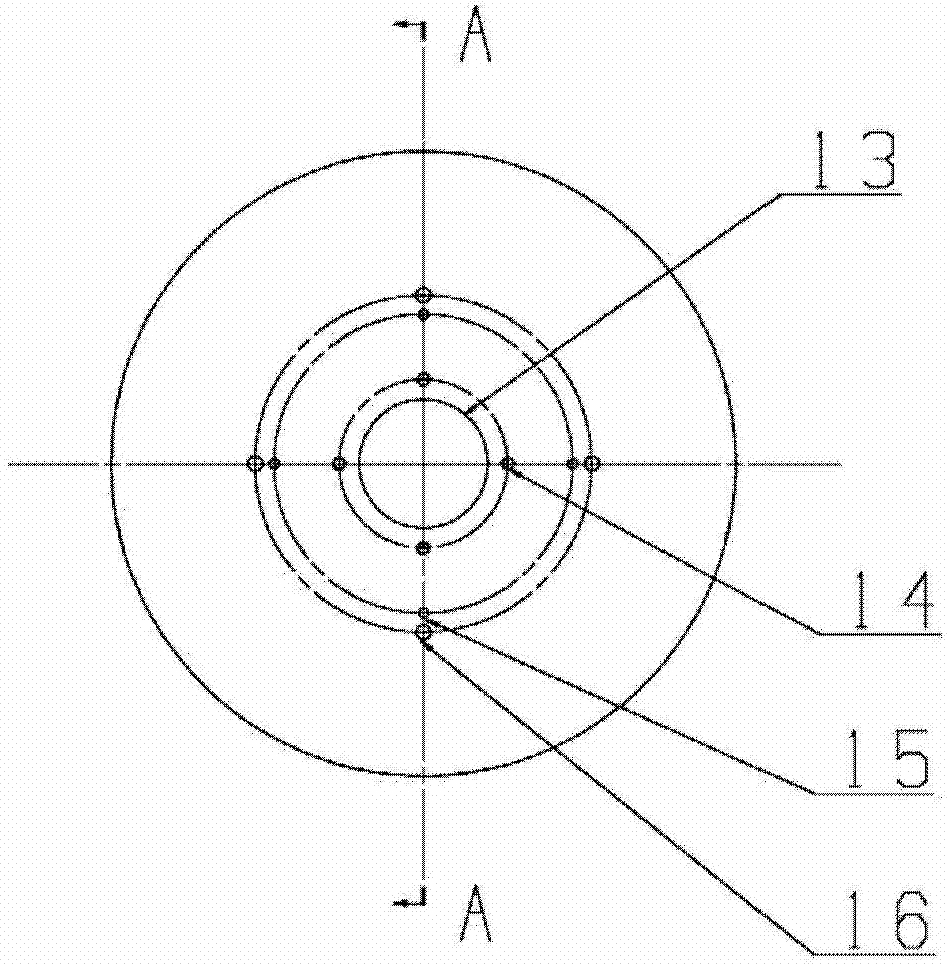

[0033] A cylindrical gas turbine combustor for burning gaseous fuel, comprising five parts in total, including a casing, a flame cylinder, a nozzle swirler assembly, a swirl cup assembly and an igniter.

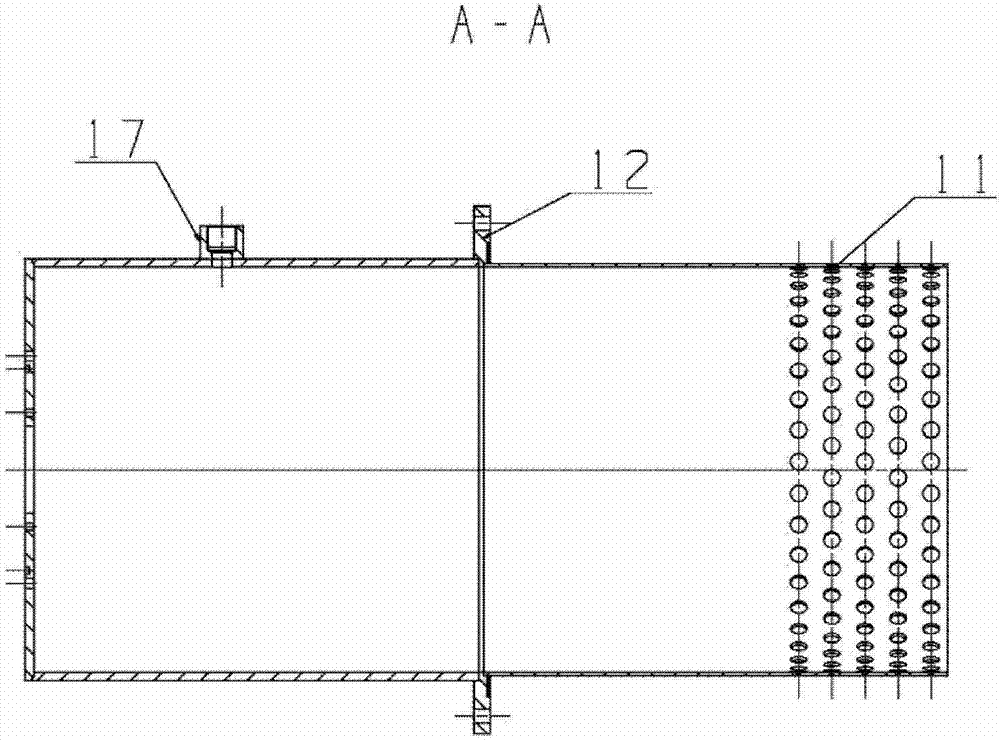

[0034]The combustion chamber is generally divided into two layers, the outer side is the casing, and the inner side is the flame tube. A secondary channel of air is formed between the casing and the flame tube. There are a large number of circular holes on the wall of the rear of the casing, and the air from the compressor enters the secondary channel through these circular holes. The total area of the circular holes will be greater than twice the cross-sectional area of the two passages, to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com