Patents

Literature

78 results about "Premixed flame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A premixed flame is a flame formed under certain conditions during the combustion of a premixed charge (also called pre-mixture) of fuel and oxidiser. Since the fuel and oxidiser—the key chemical reactants of combustion—are available throughout a homogeneous stoichiometric premixed charge, the combustion process once initiated sustains itself by way of its own heat release. The majority of the chemical transformation in such a combustion process occurs primarily in a thin interfacial region which separates the unburned and the burned gases. The premixed flame interface propagates through the mixture until the entire charge is depleted. The propagation speed of a premixed flame is known as the flame speed (or burning velocity) which depends on the convection-diffusion-reaction balance within the flame, i.e. on its inner chemical structure. The premixed flame is characterised as laminar or turbulent depending on the velocity distribution in the unburned pre-mixture (which provides the medium of propagation for the flame).

Combustor of a gas turbine

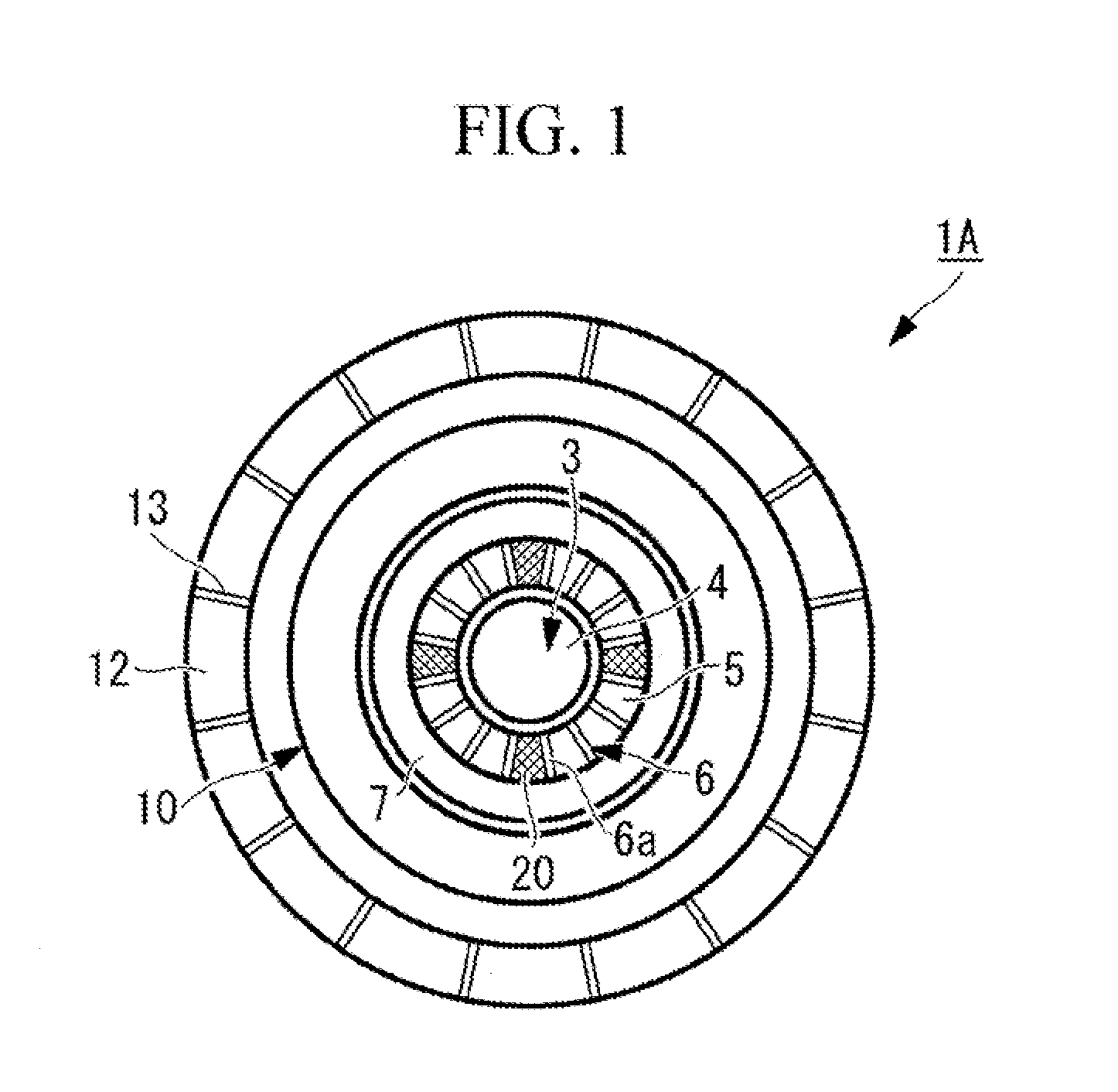

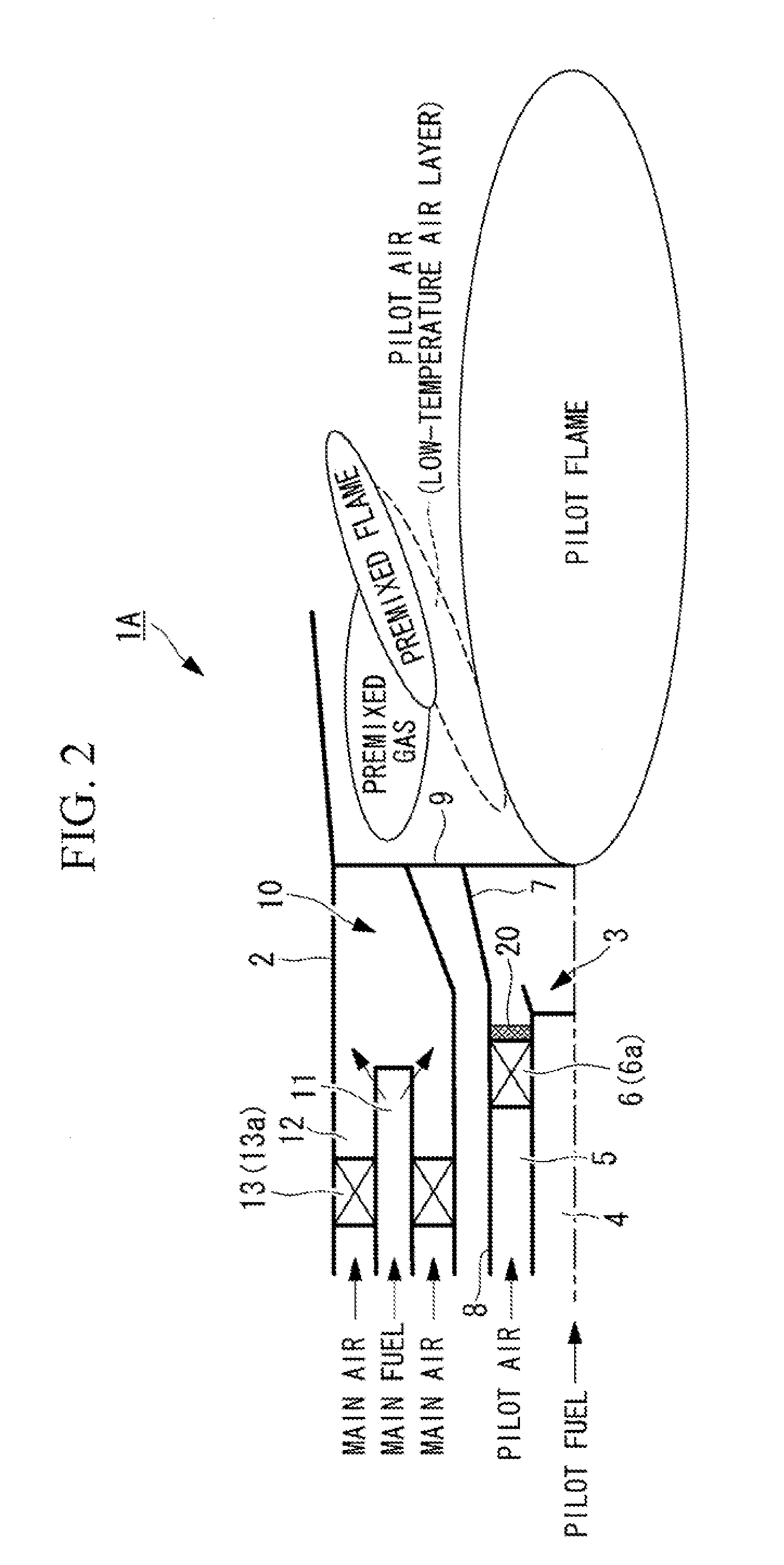

ActiveUS20060101814A1Improve featuresAchieve stablyContinuous combustion chamberTurbine/propulsion fuel supply systemsDiffusion flameCombustion chamber

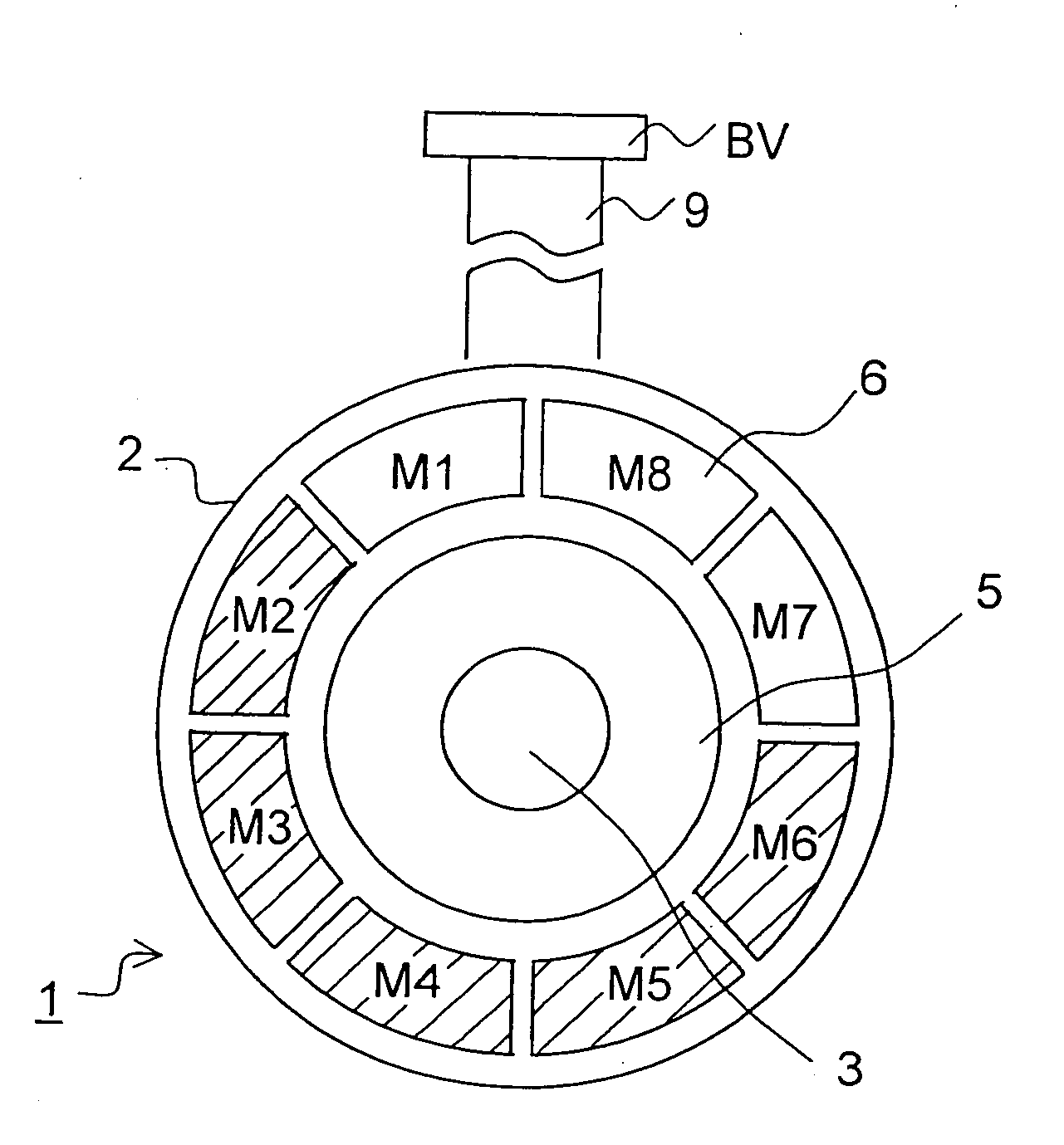

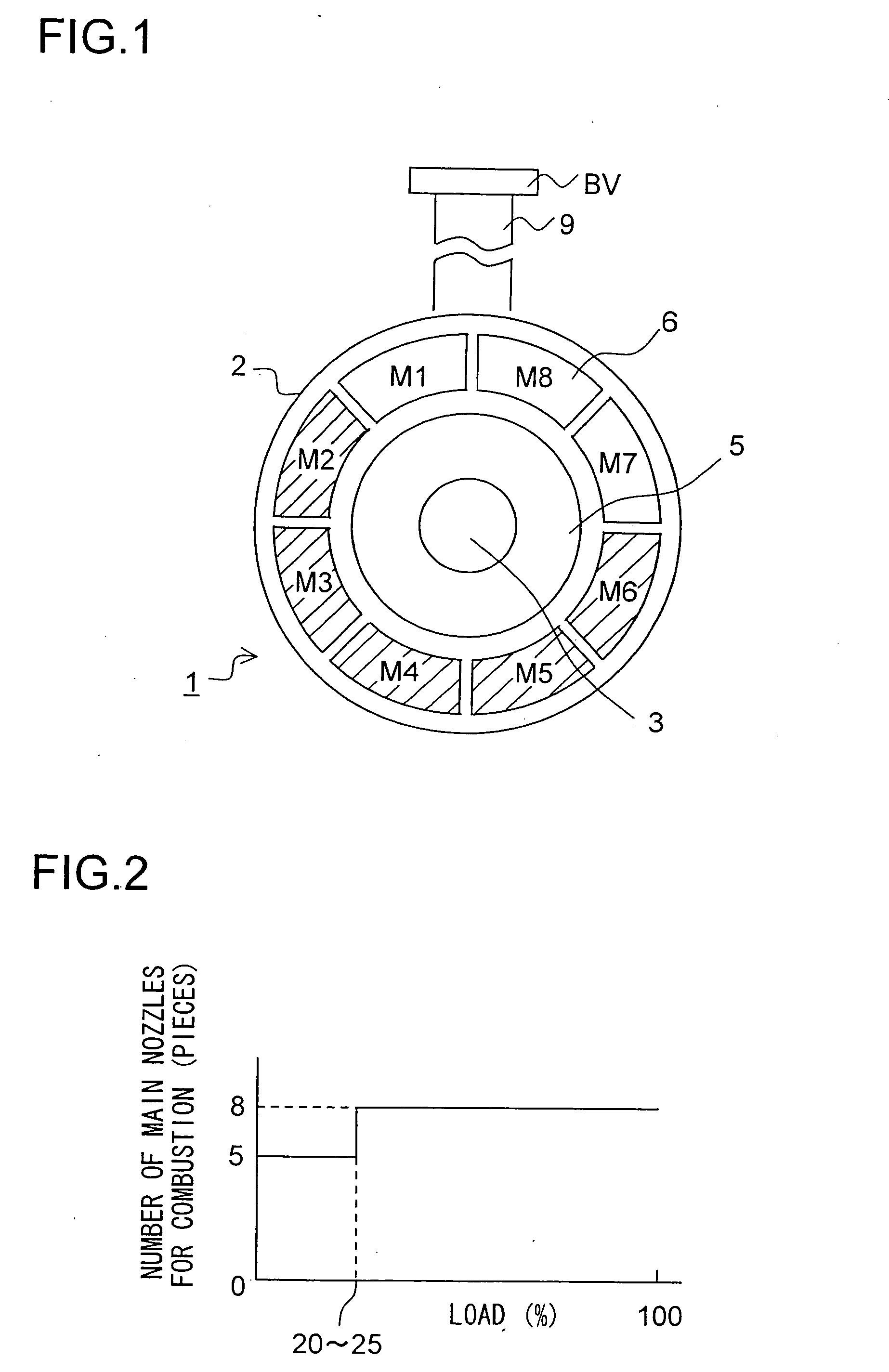

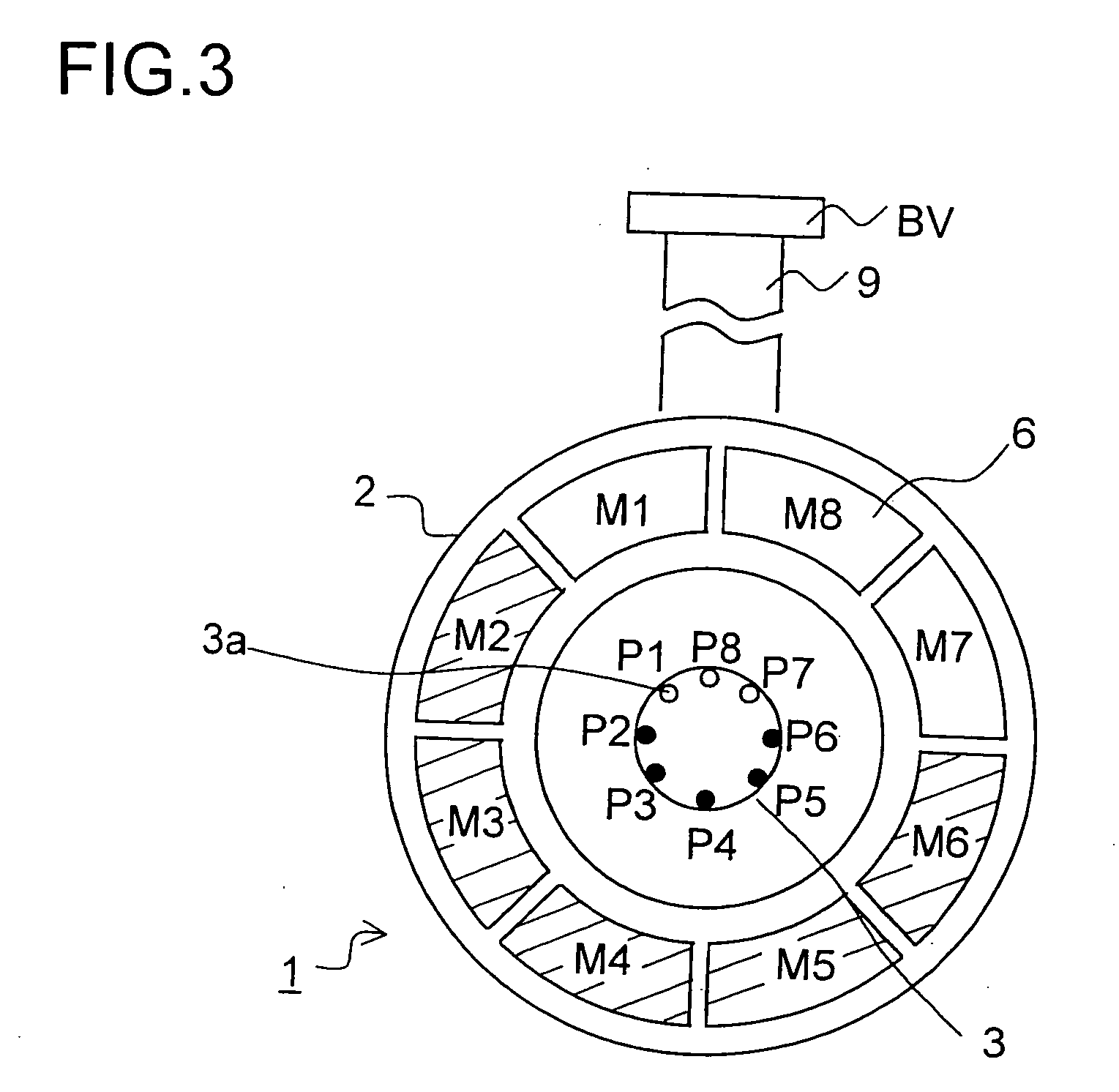

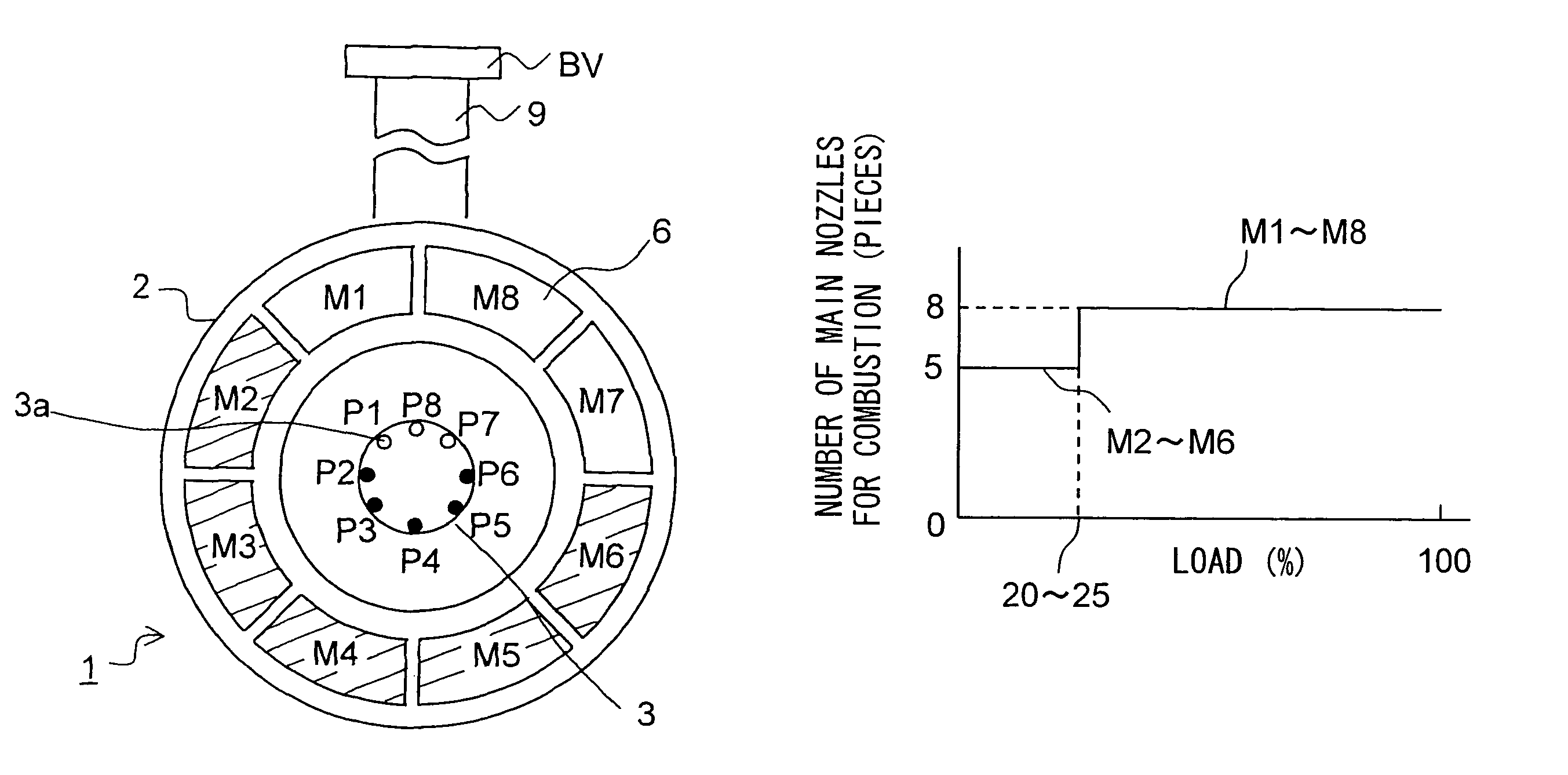

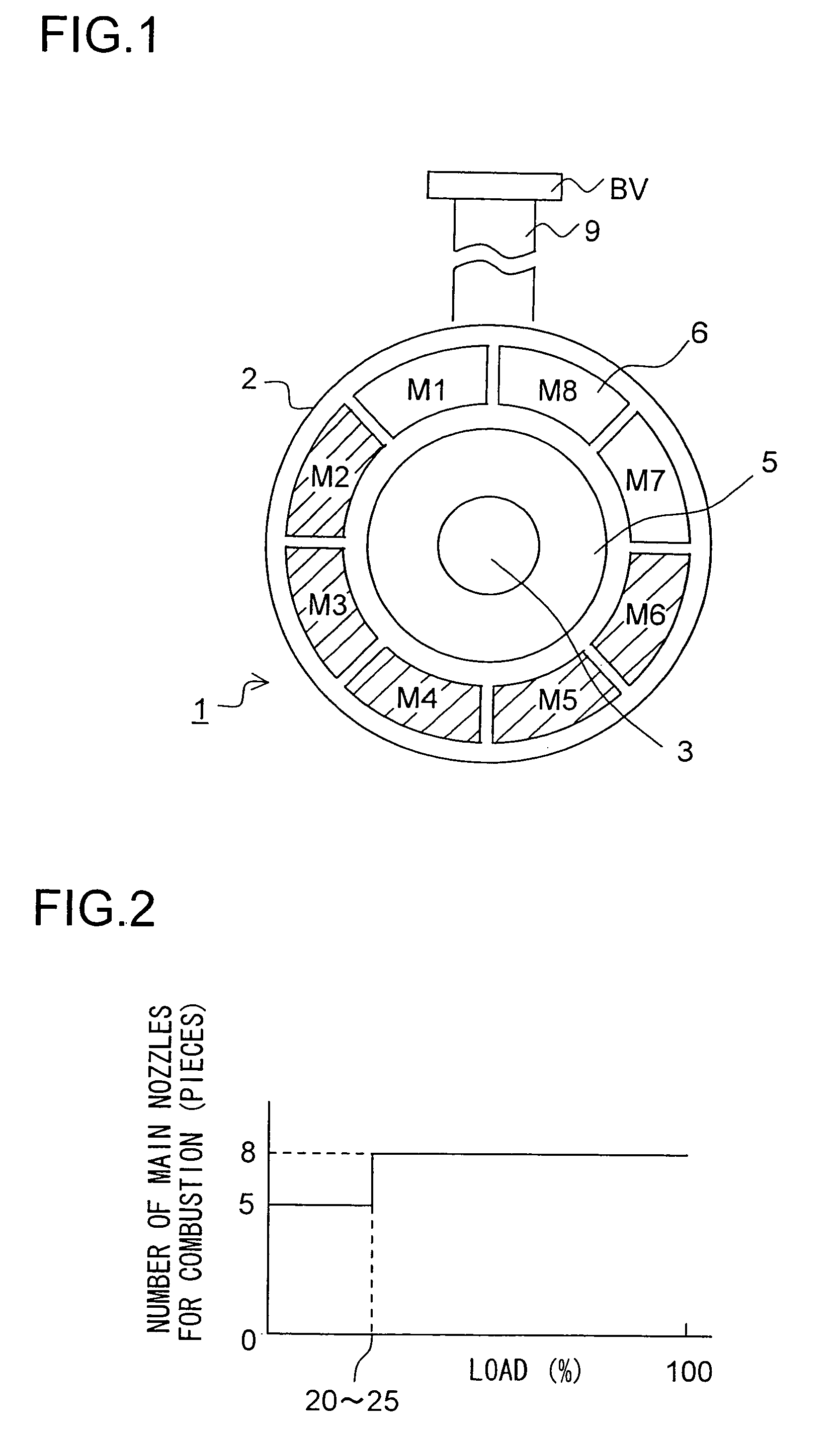

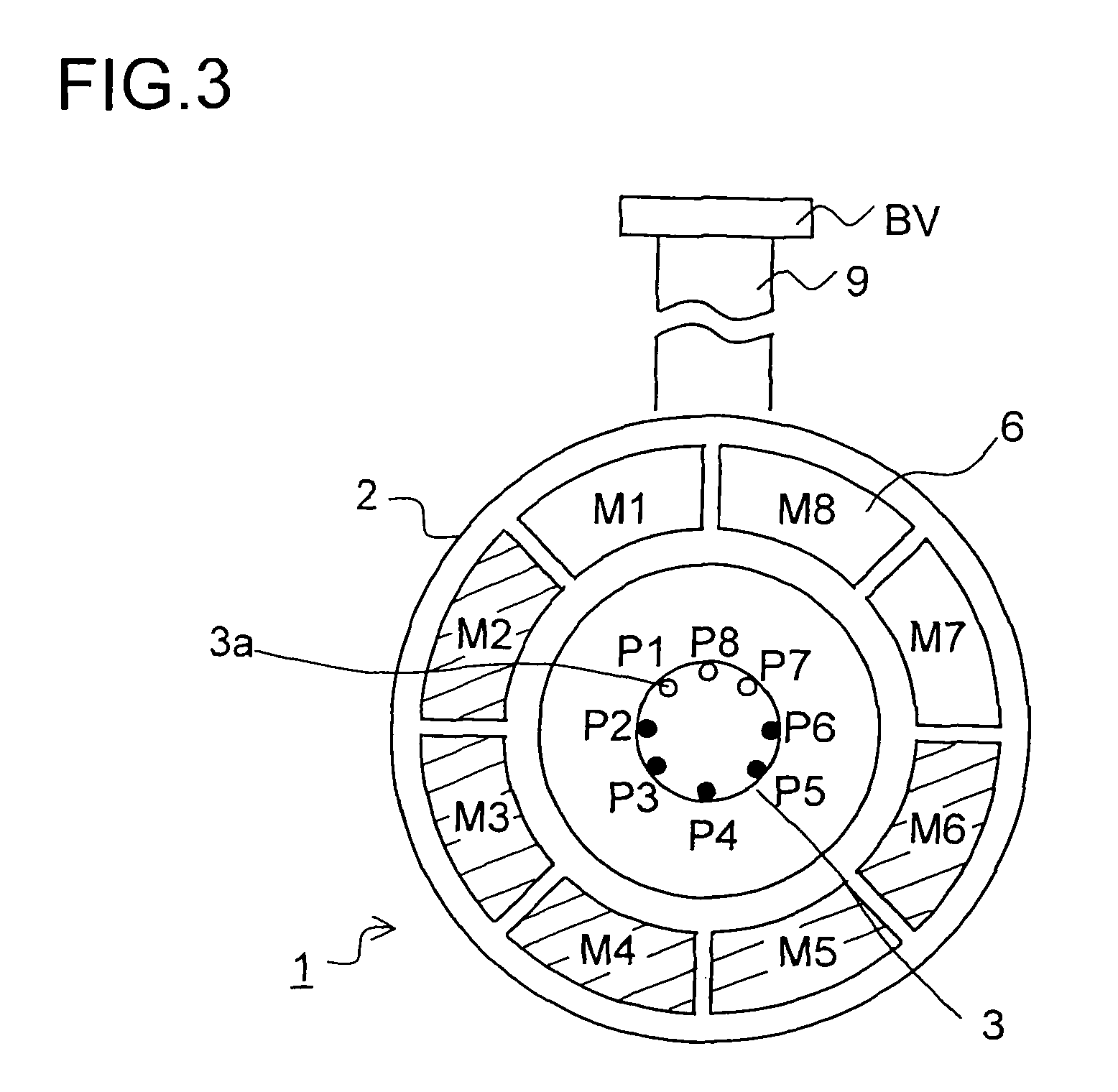

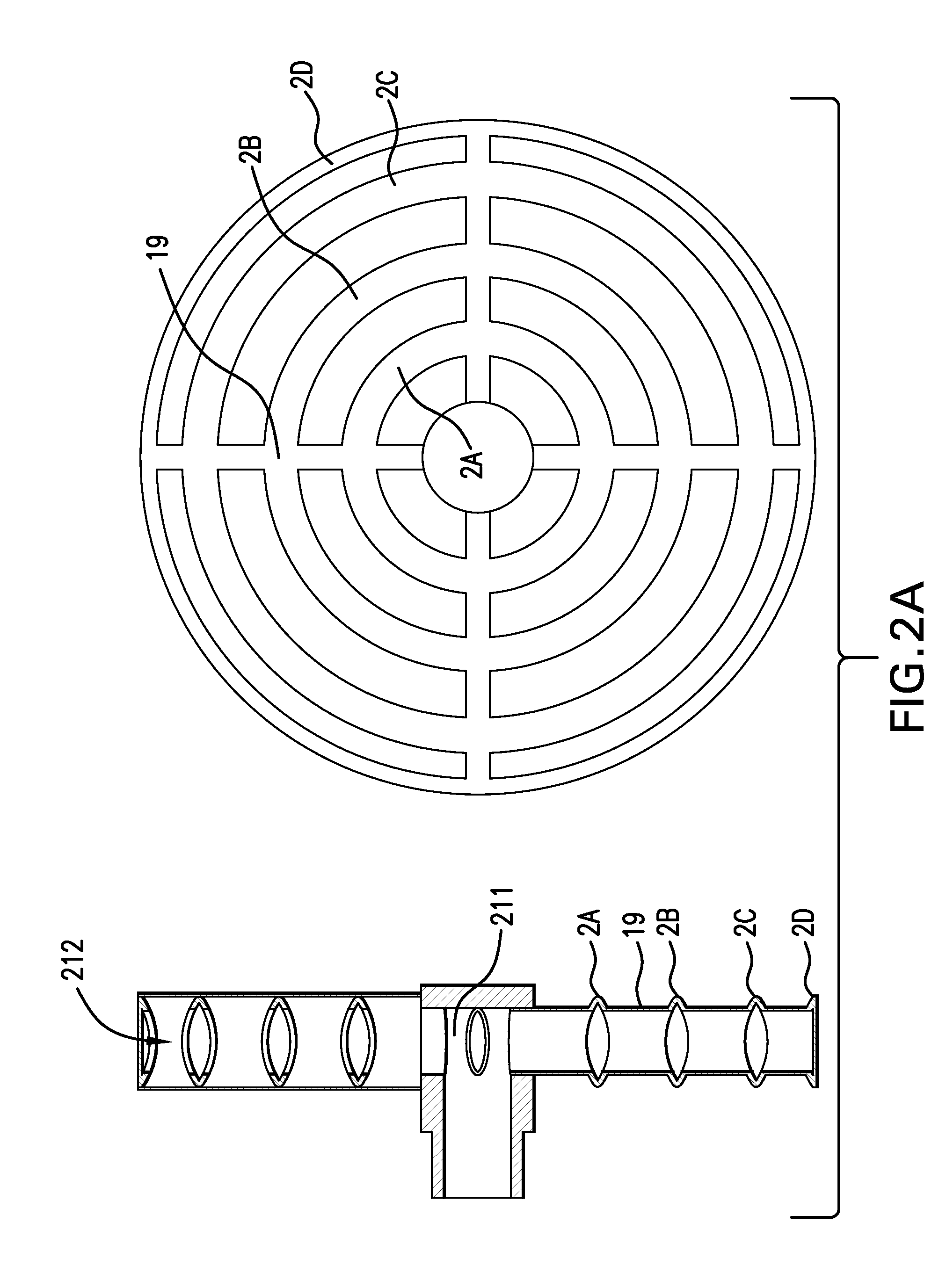

In a combustor of a gas turbine which has a pilot nozzle being installed to the center of the axis of a combustor basket and a plurality of main nozzles being installed to the vicinity of the pilot nozzle and provided with a premixing tool on the outer circumference thereof, wherein, fuel being injected as air-fuel pre-mixture from the main nozzle into the interior of a transition piece forming a combustion chamber downstream of the combustor basket is ignited by diffusion flame being generated by the pilot nozzle in the transition piece so as to generate a premixed flame in the transition piece, wherein combustion is performed by a part of the plurality of main nozzles from start-up until a predetermined load rate and then performed by adding the remaining portion of the plurality of main nozzles when the predetermined load rate is exceeded.

Owner:MITSUBISHI POWER LTD

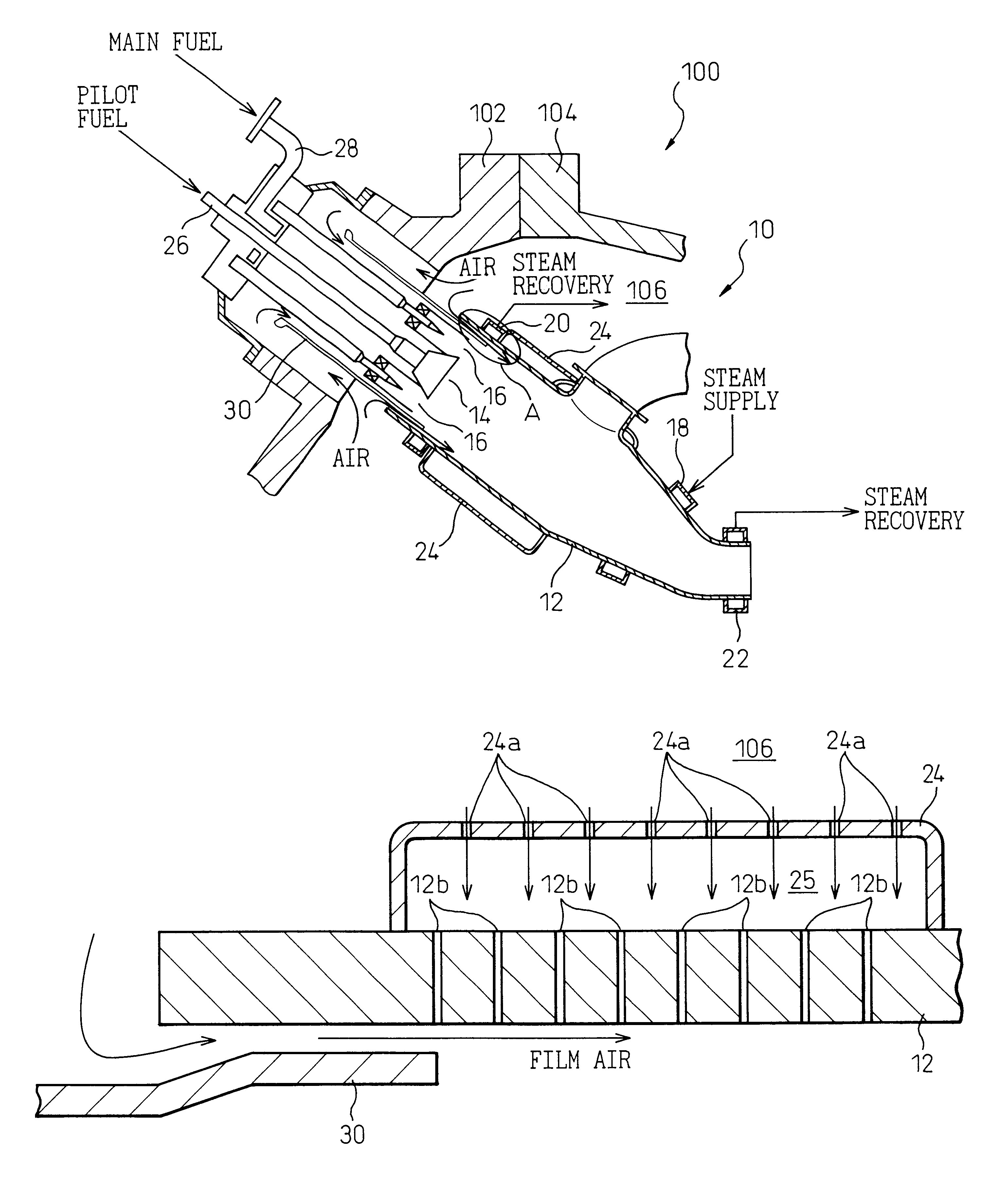

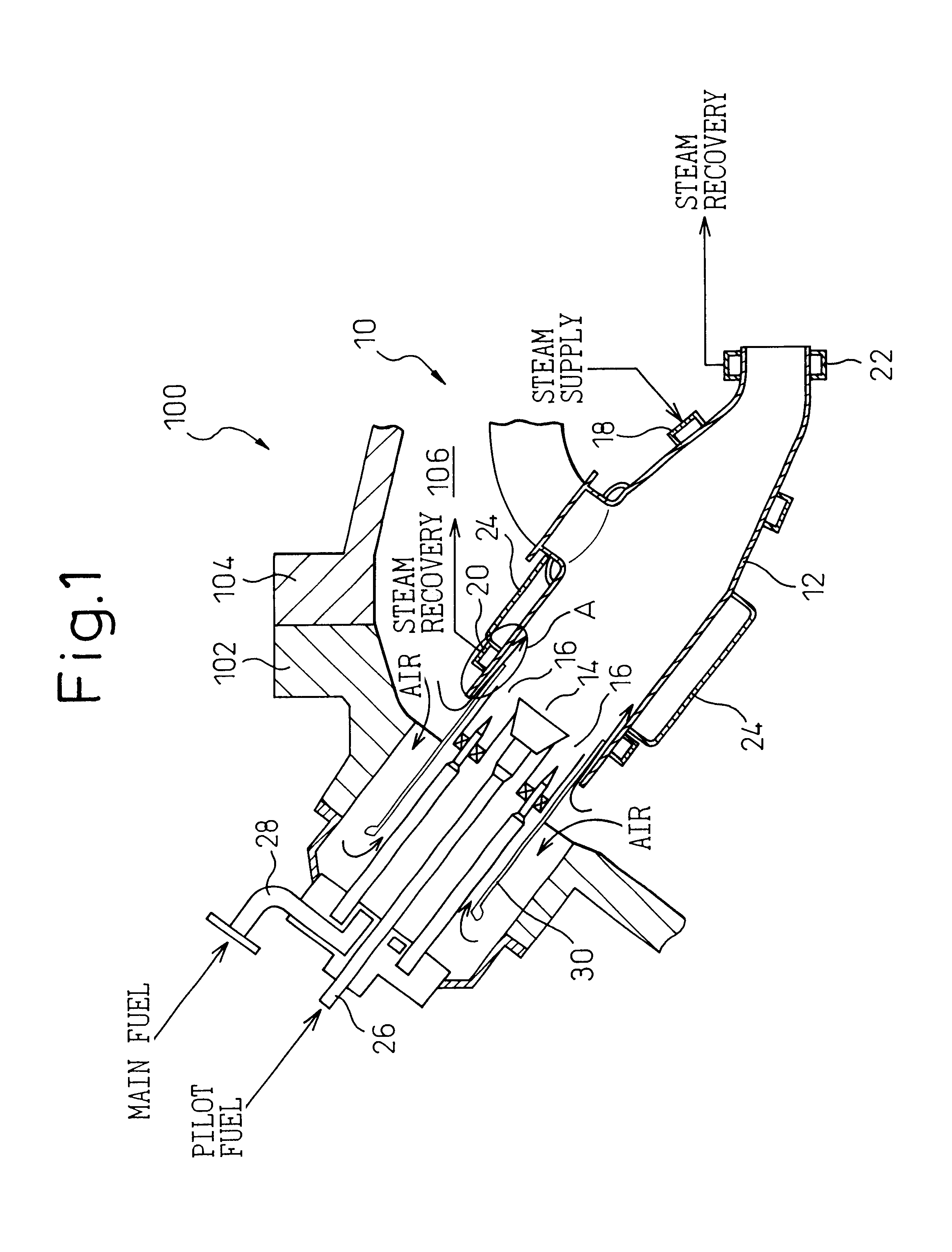

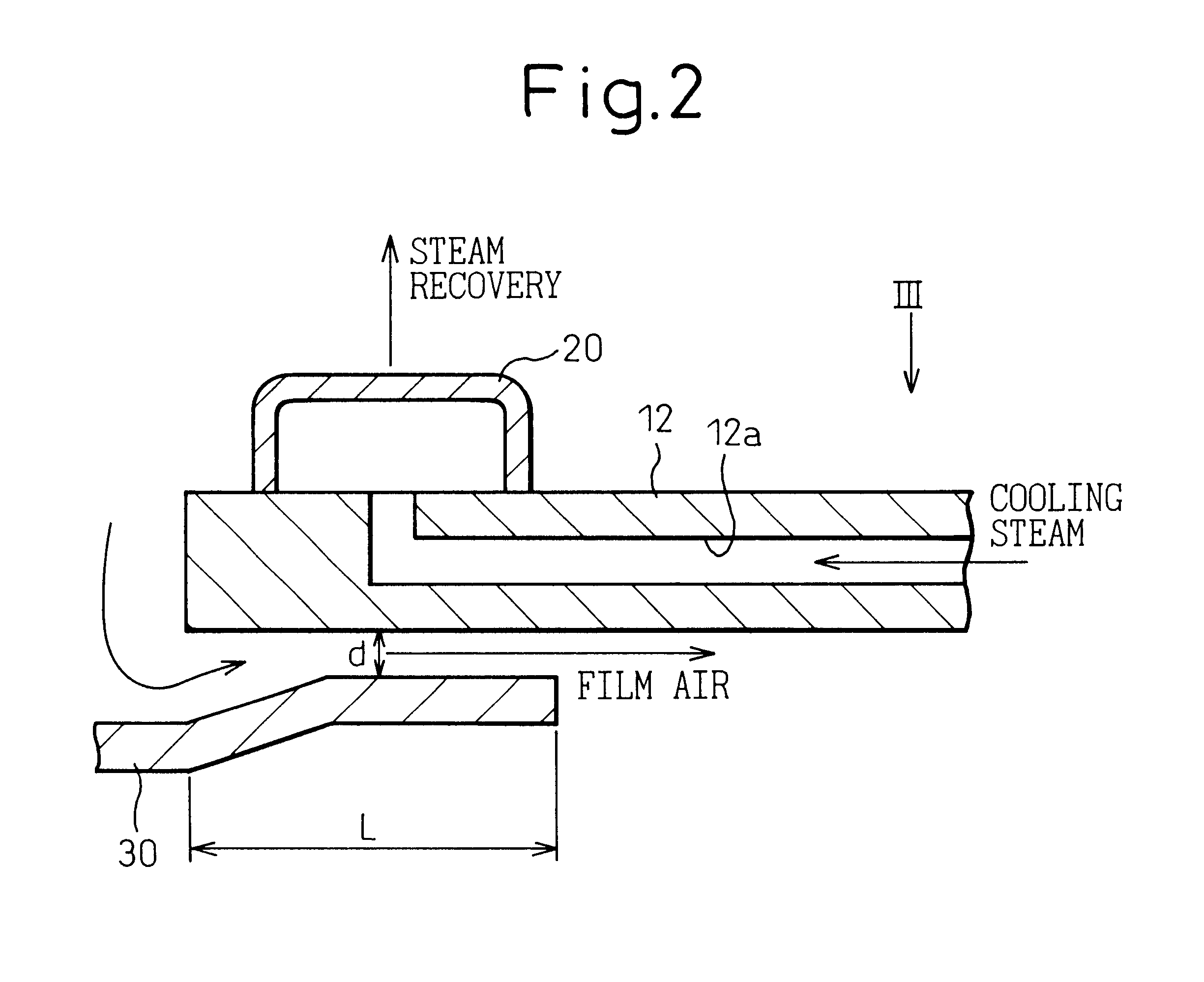

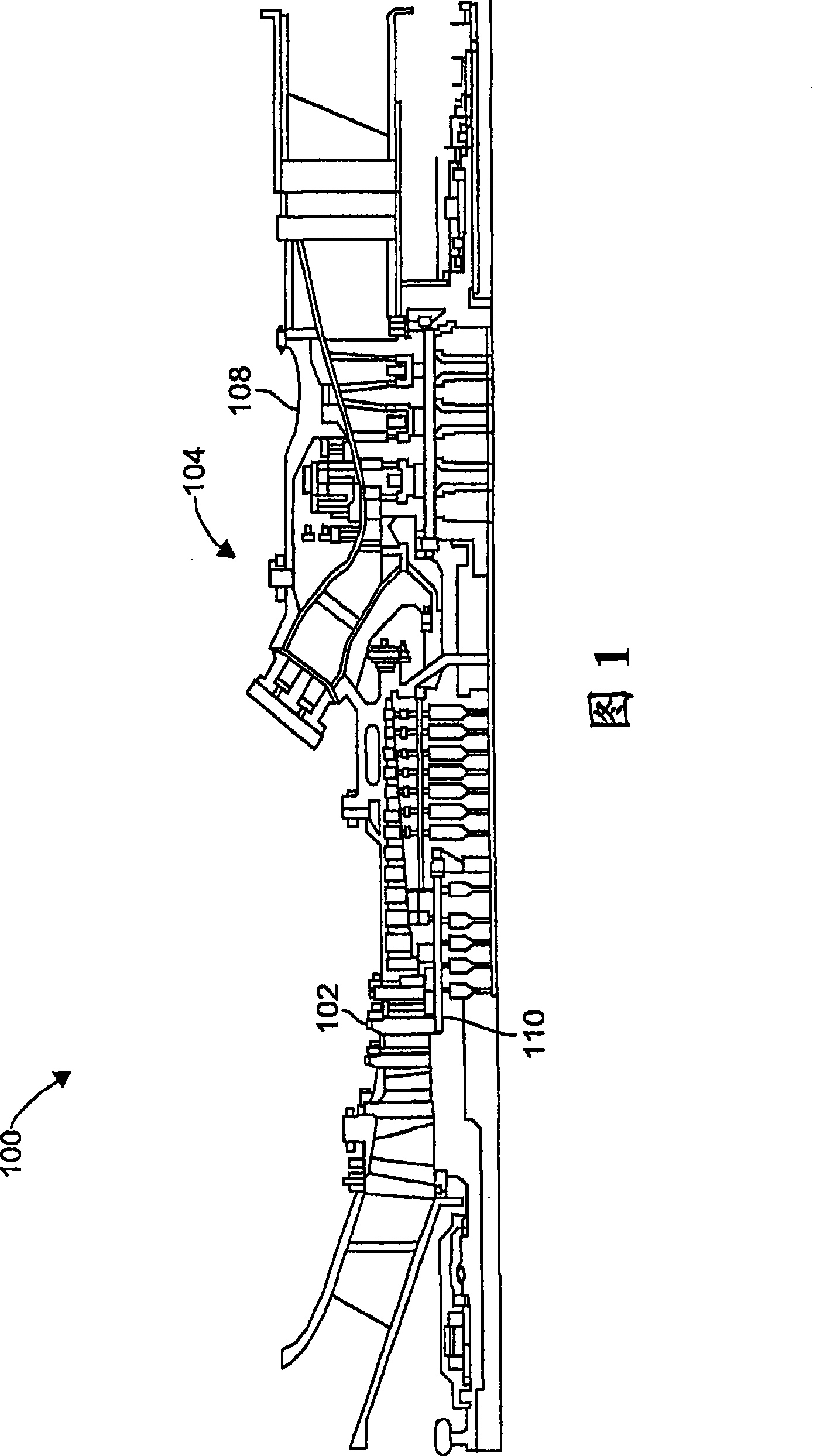

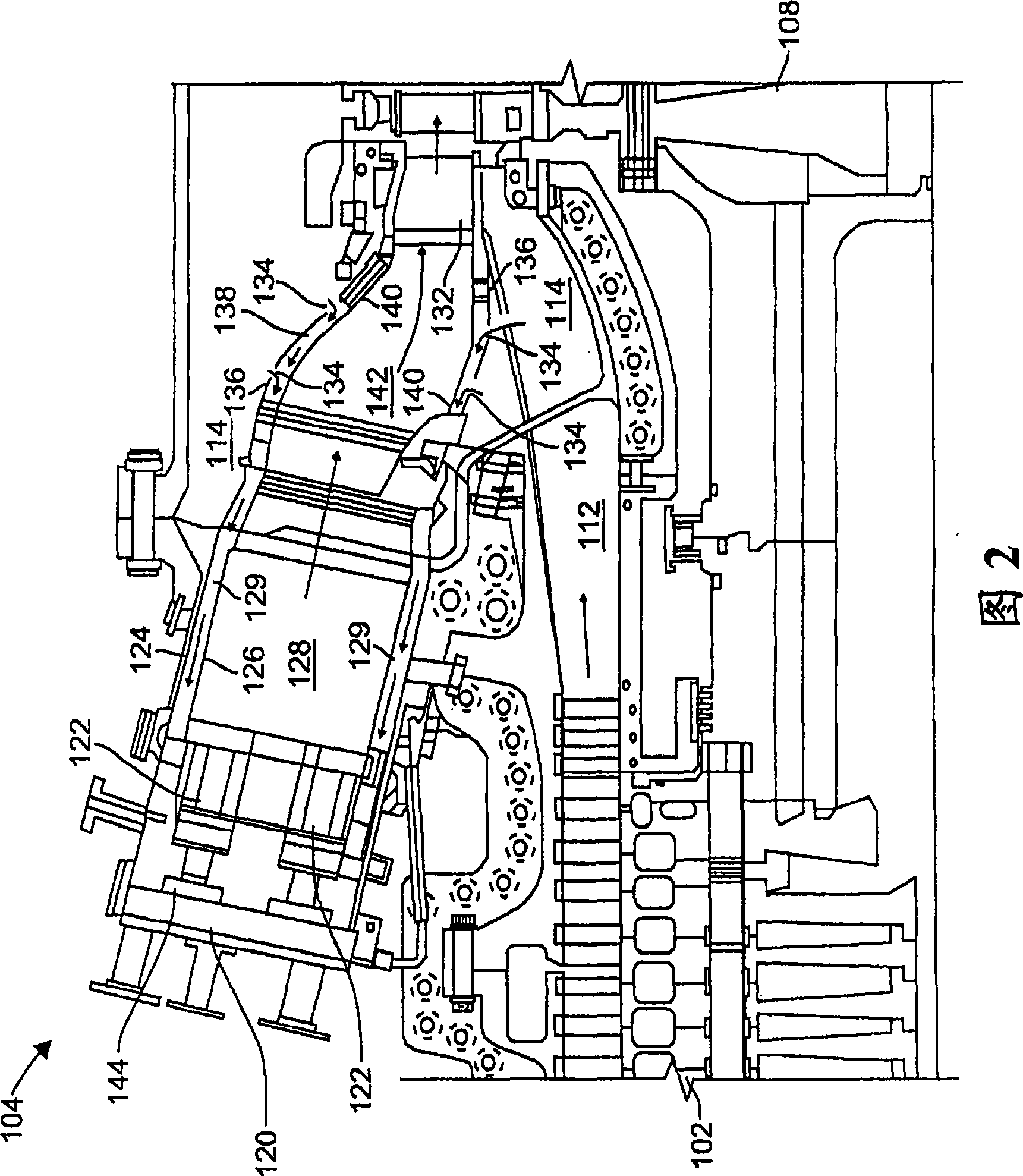

Gas turbine combustor

InactiveUS6837051B2Reduce fuel-air ratioRestrain combustion-drivenBurnersContinuous combustion chamberDiffusion flameCombustion chamber

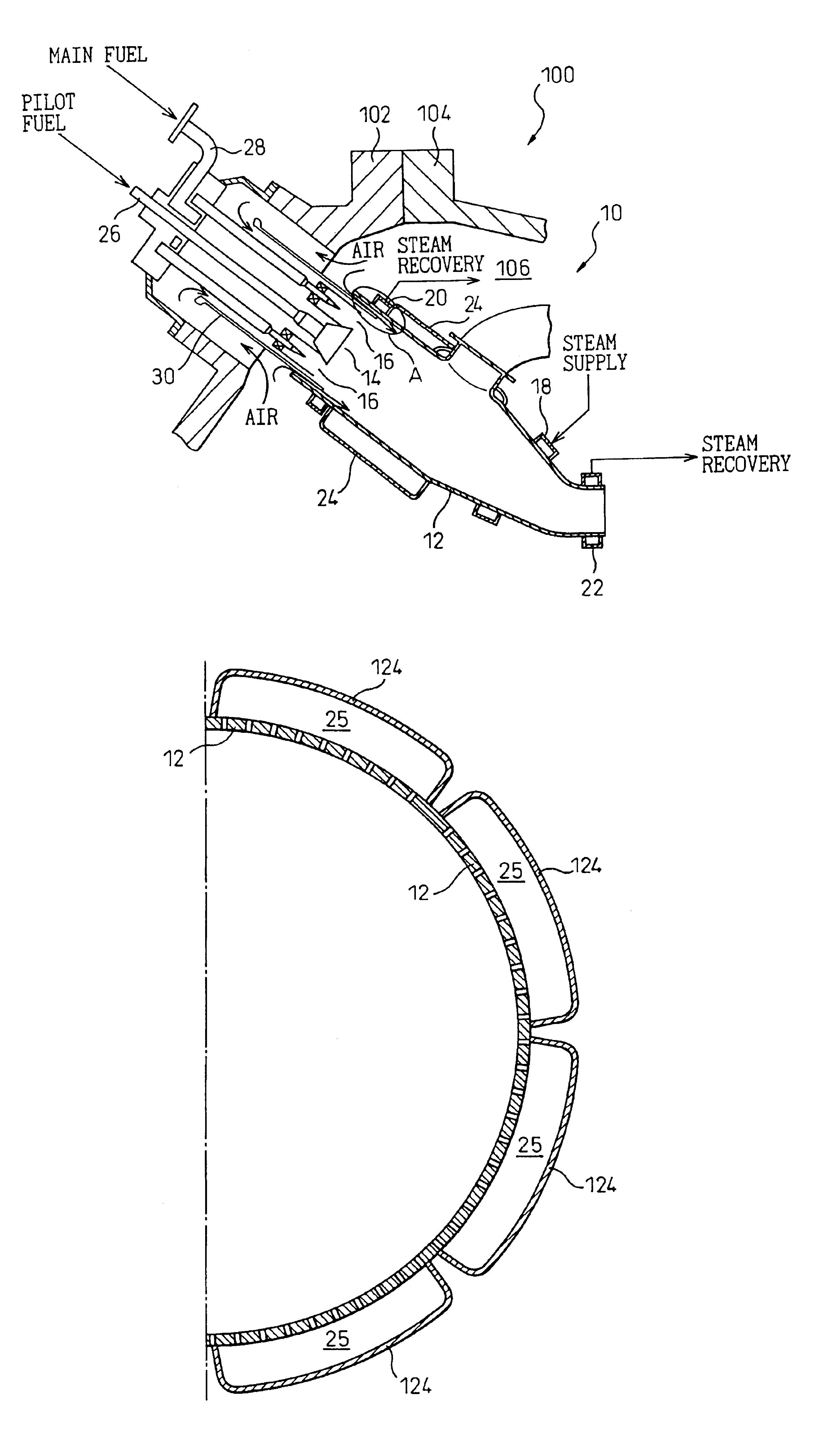

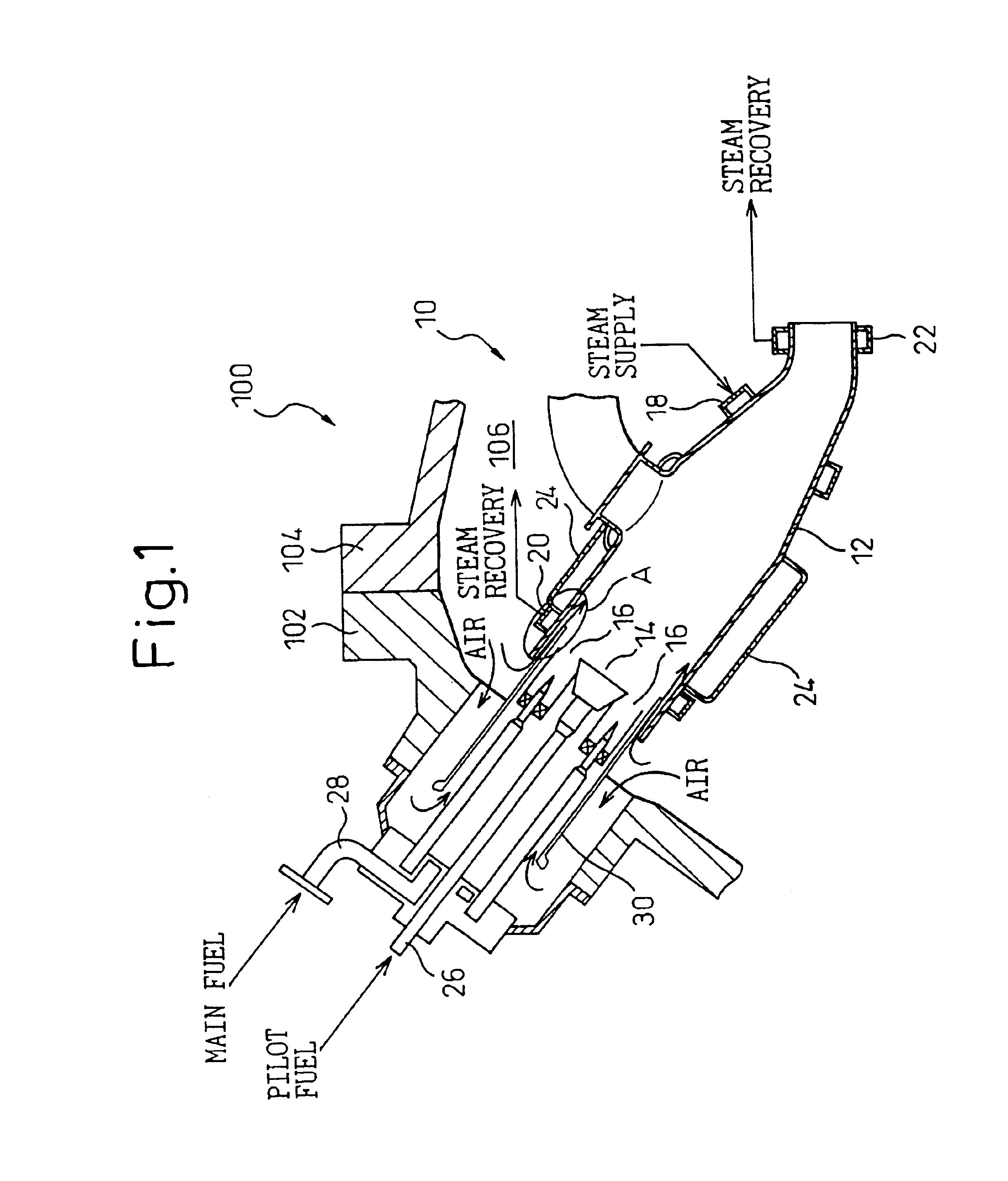

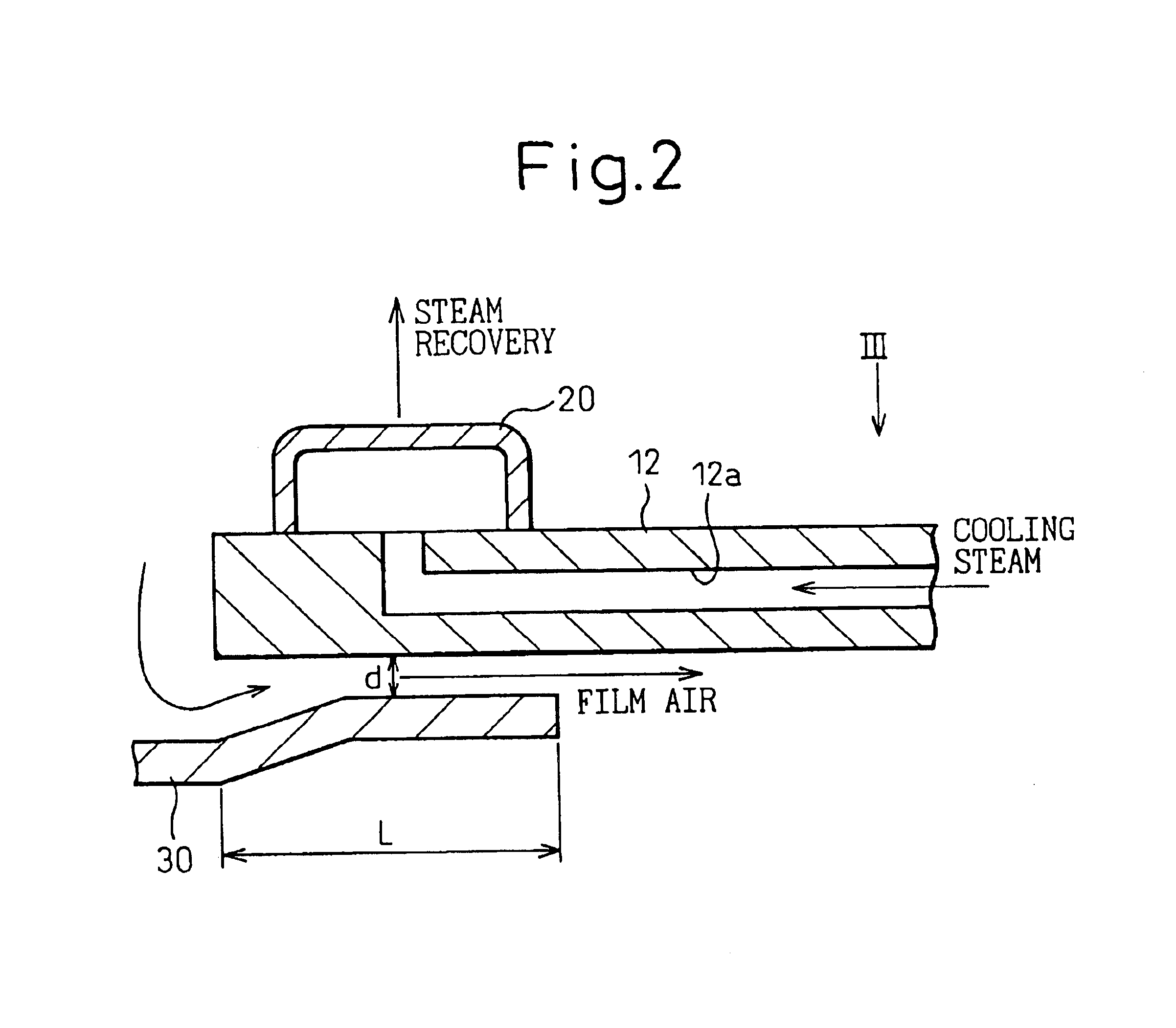

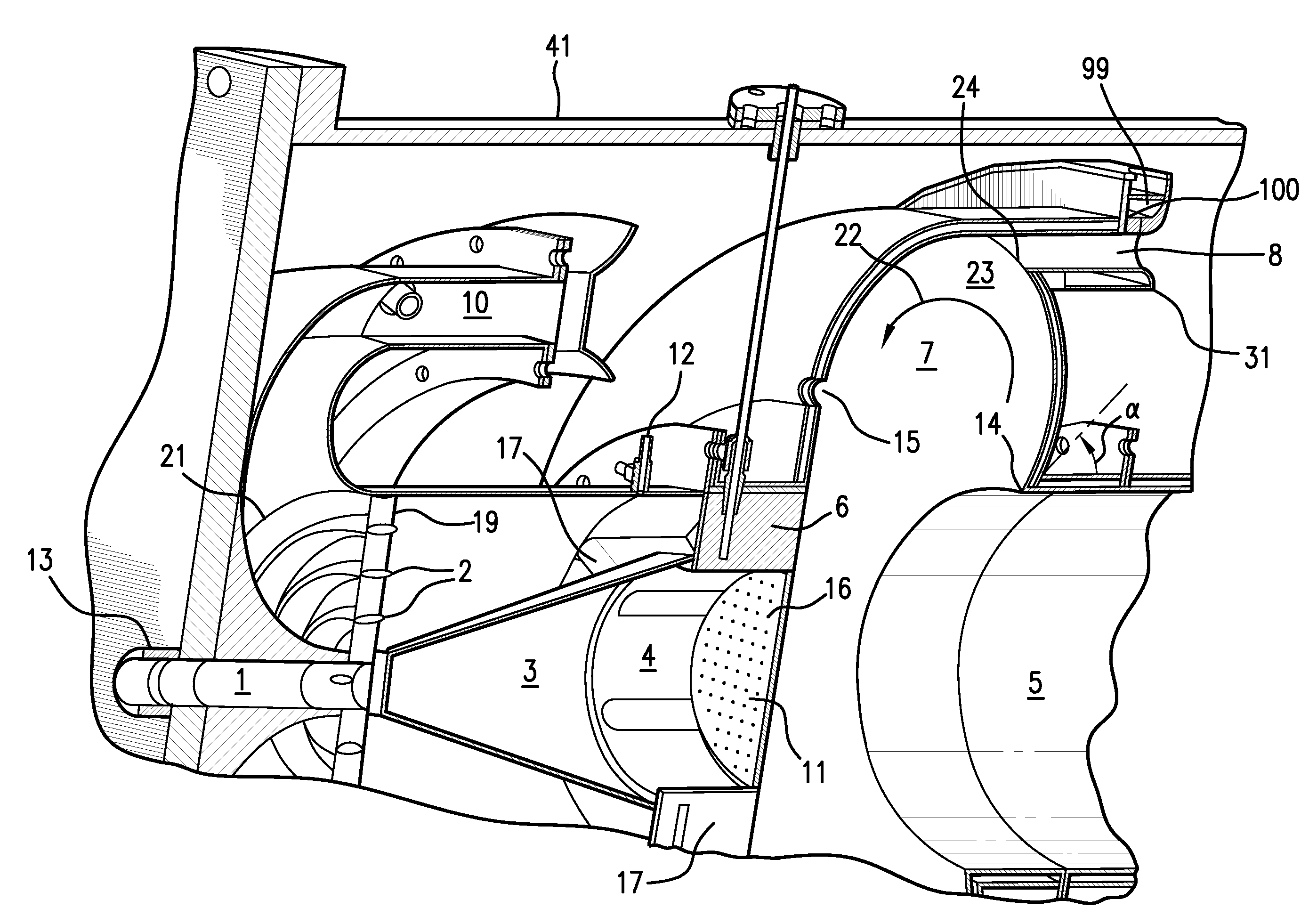

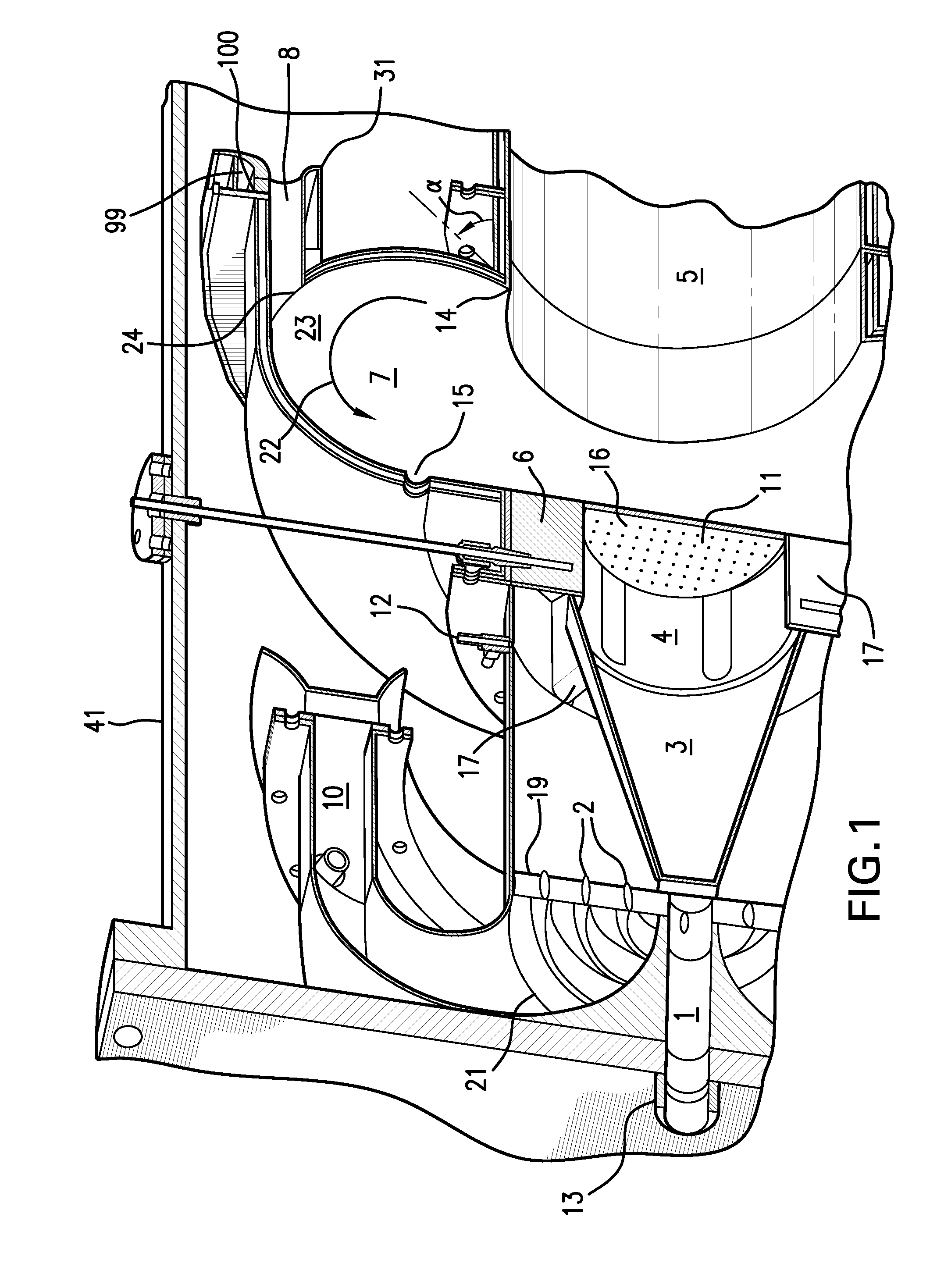

A gas turbine combustor includes a side wall, for defining a combustion volume, having upstream and downstream ends, a pilot nozzle, disposed adjacent the upstream end of the side wall, for discharging a pilot fuel to form a diffusion flame in the combustion volume, and a plurality of main nozzles, provided around the pilot nozzles, for discharging a fuel-air mixture to form premixed flames in the combustion volume. Film air is supplied into the combustion volume downstream of the main nozzles along the inner surface of the side wall to reduce the fuel-air ratio in a region adjacent the inner surface of the side wall and to restrain a combustion-driven oscillation in the combustion volume.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

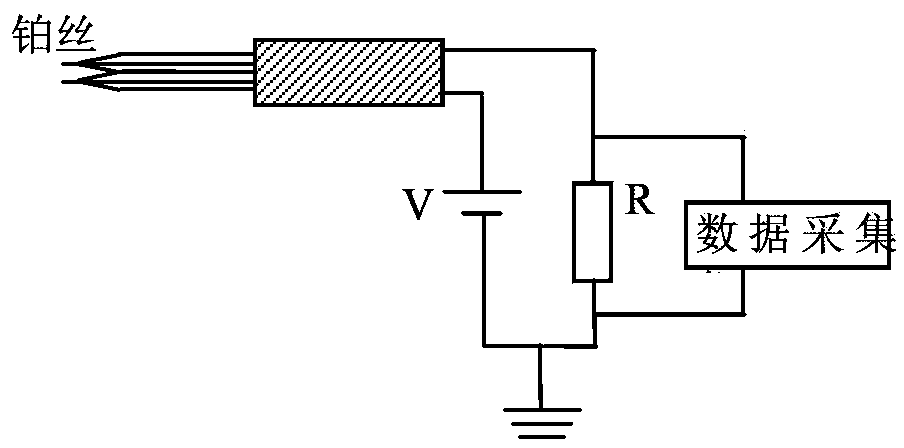

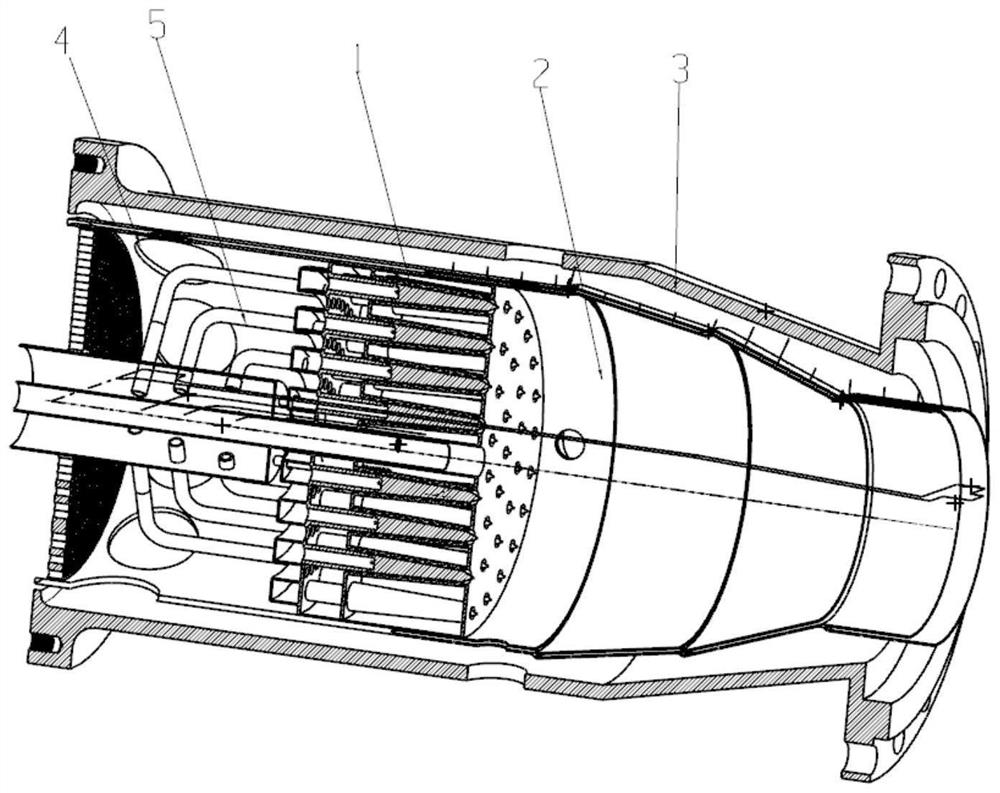

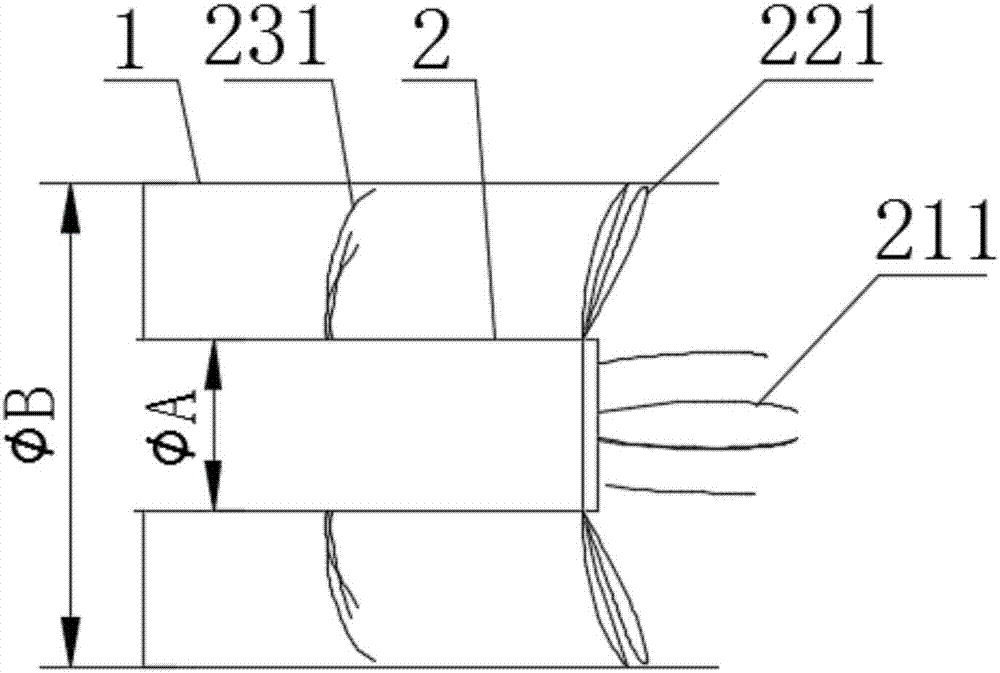

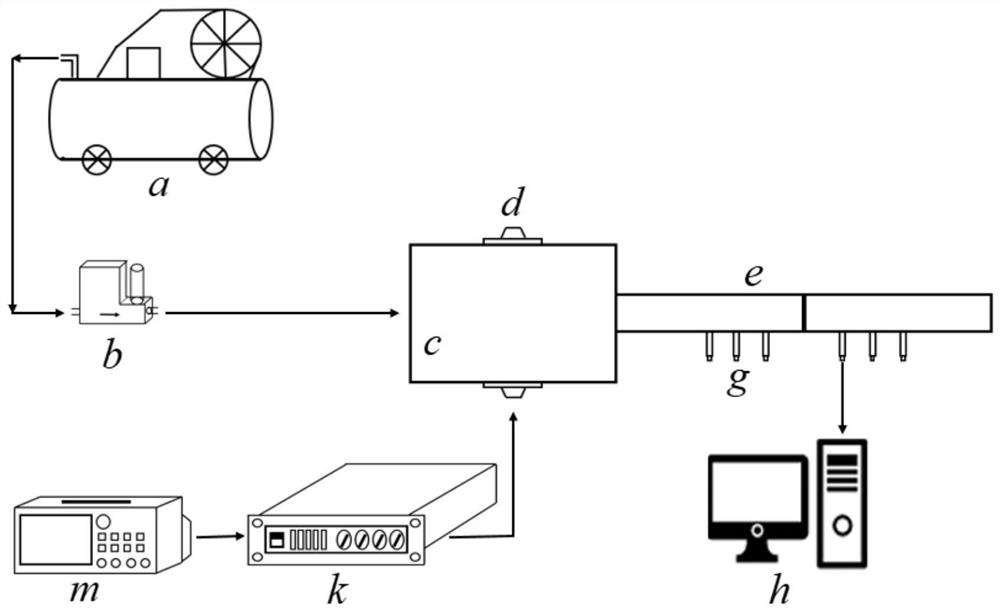

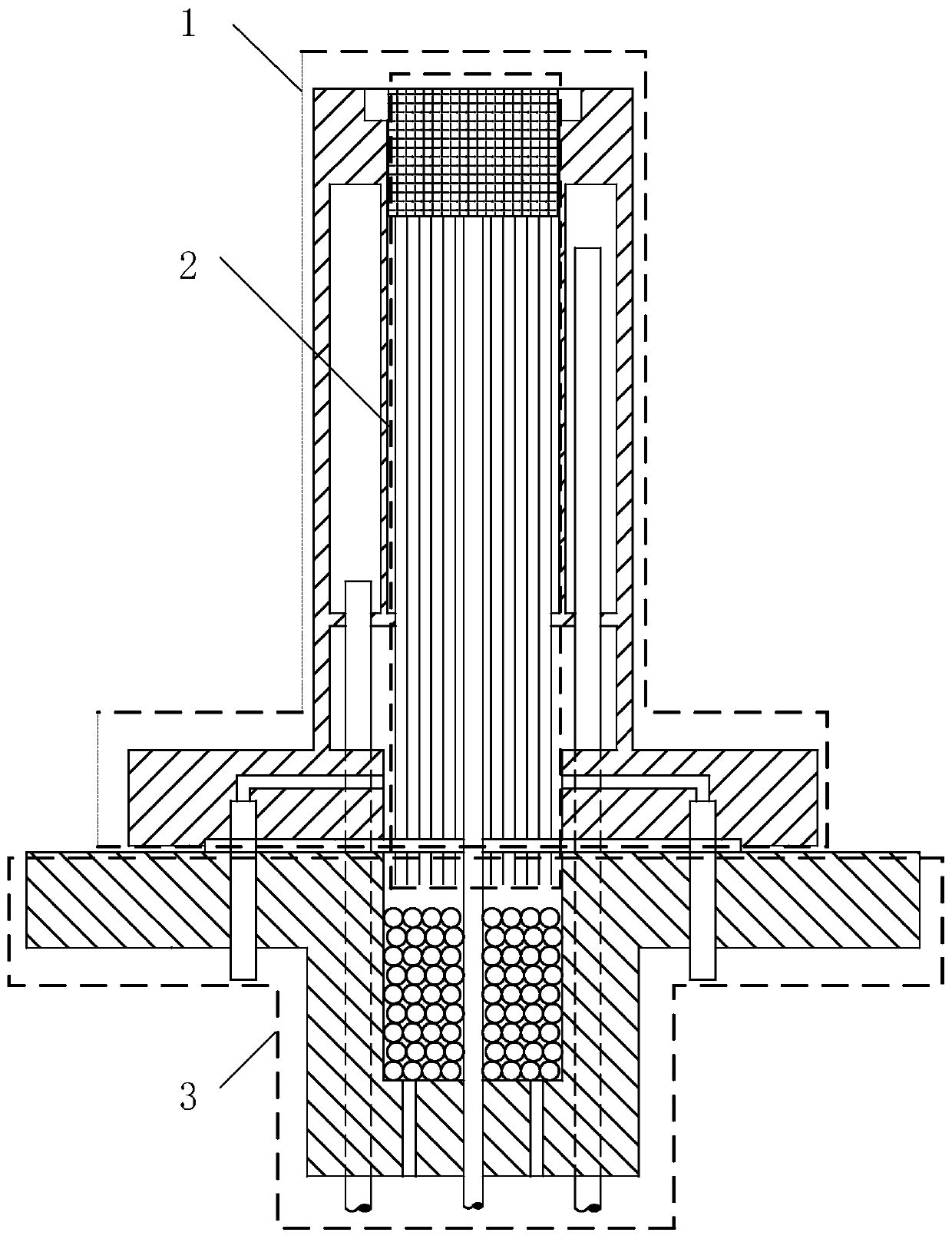

Apparatus for testing flame propagation and flame suppression in flammable gas and air premixed gas explosion process

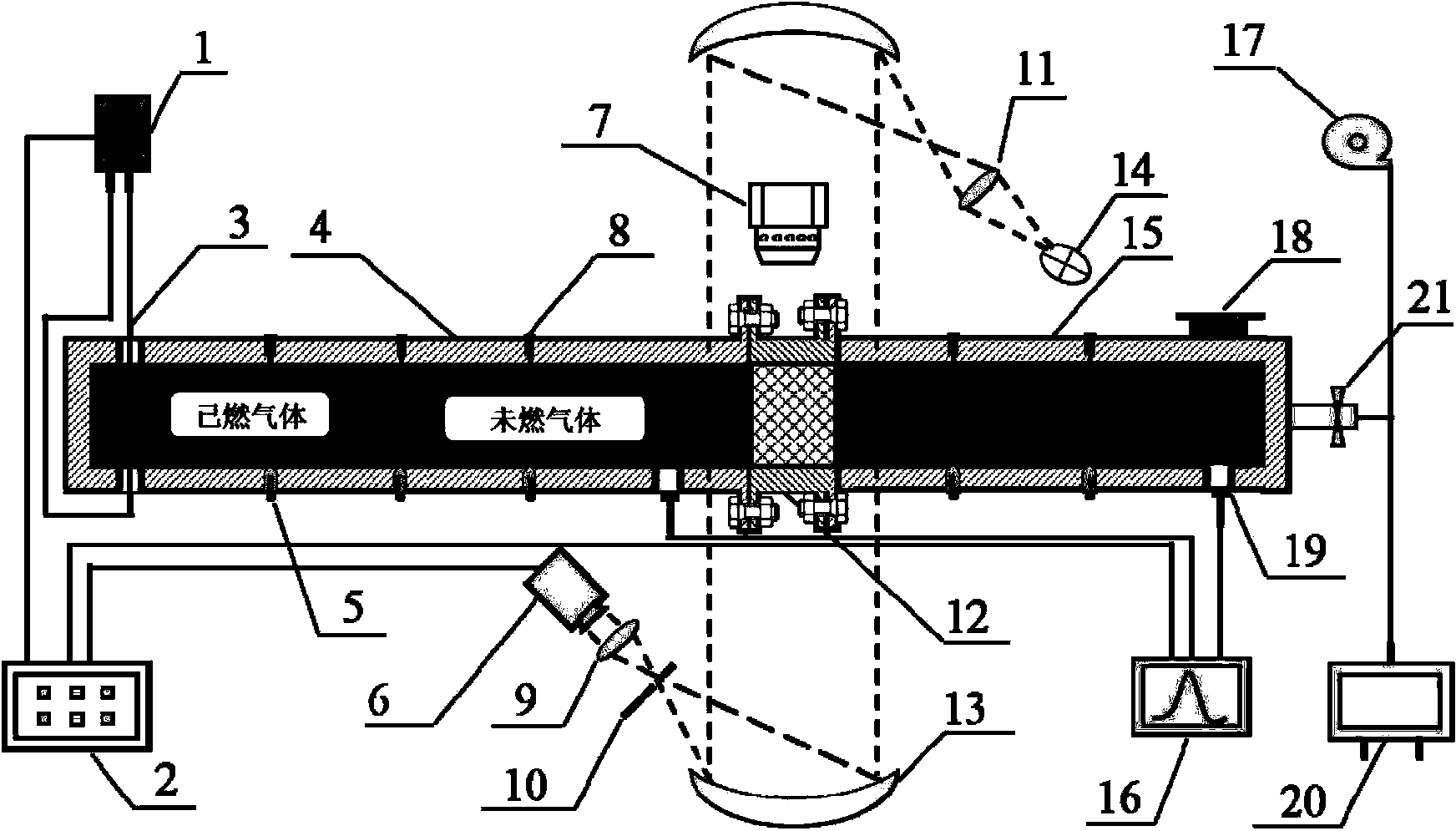

ActiveCN103454308AAccurate and intuitive recordReveal inhibitionMaterial exposibilityData acquisitionInstability

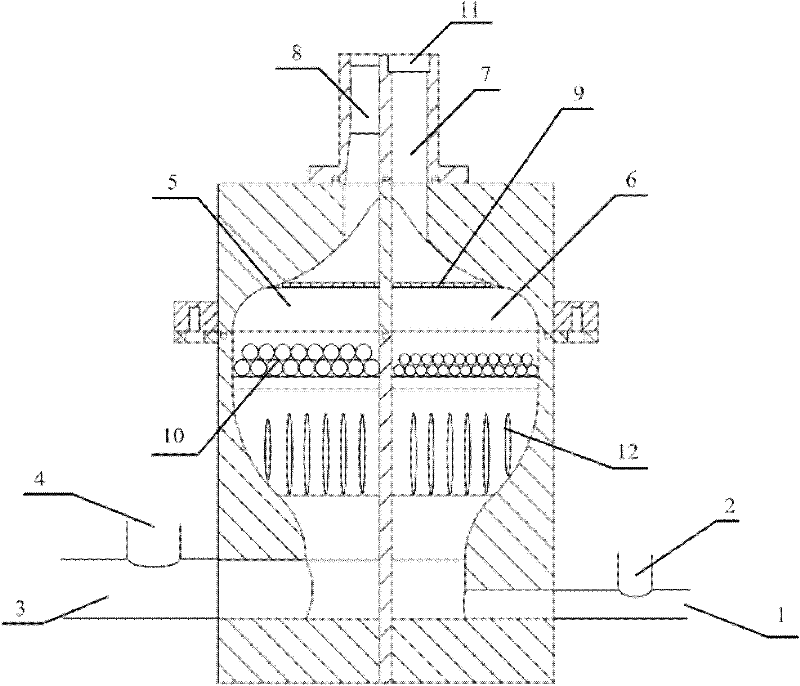

The invention provides an apparatus for testing flame propagation and flame suppression in the flammable gas and air premixed gas explosion process. The whole apparatus comprises a combustion pipeline, a water mist generating device, a metal net fire retardance device, a high-speed camera, a schlieren system, a pressure testing system, an automatic gas distribution system, a temperature testing system, an ion probe detection system, a data acquisition instrument, a high-tension ignition system and a synchronous controller. Through the apparatus, flame propagation characteristics and flame propagation rules are researched in the premixed gas explosion process under the influences of factors such as different flammable gas components, different opening states, different ignition positions and different types of flame instability, the effects of stopping agents, fire-retardant metal nets, water mist and the like on controlling and restraining flame propagation are researched, a method and technology for restraining premixed gas flame propagation are developed under the physical-chemical coupling effect, and the inner mechanism of the apparatus is explained.

Owner:UNIV OF SCI & TECH OF CHINA

Gas turbine combustor

InactiveUS6837050B2Reduce fuel-air ratioRestrain combustion-drivenBurnersContinuous combustion chamberDiffusion flameCombustion chamber

A gas turbine combustor includes a side wall, for defining a combustion volume, having upstream and downstream ends, a pilot nozzle, disposed adjacent the upstream end of the side wall, for discharging a pilot fuel to form a diffusion flame in the combustion volume, and a plurality of main nozzles, provided around the pilot nozzles, for discharging a fuel-air mixture to form premixed flames in the combustion volume. Film air is supplied into the combustion volume downstream of the main nozzles along the inner surface of the side wall to reduce the fuel-air ratio in a region adjacent the inner surface of the side wall and to restrain a combustion-driven oscillation in the combustion volume.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Device for combusting stably of gas flame torch

InactiveCN101201165AStable combustionBright colorCombustion ignitionGaseous fuel burnerDiffusion flameCombustion chamber

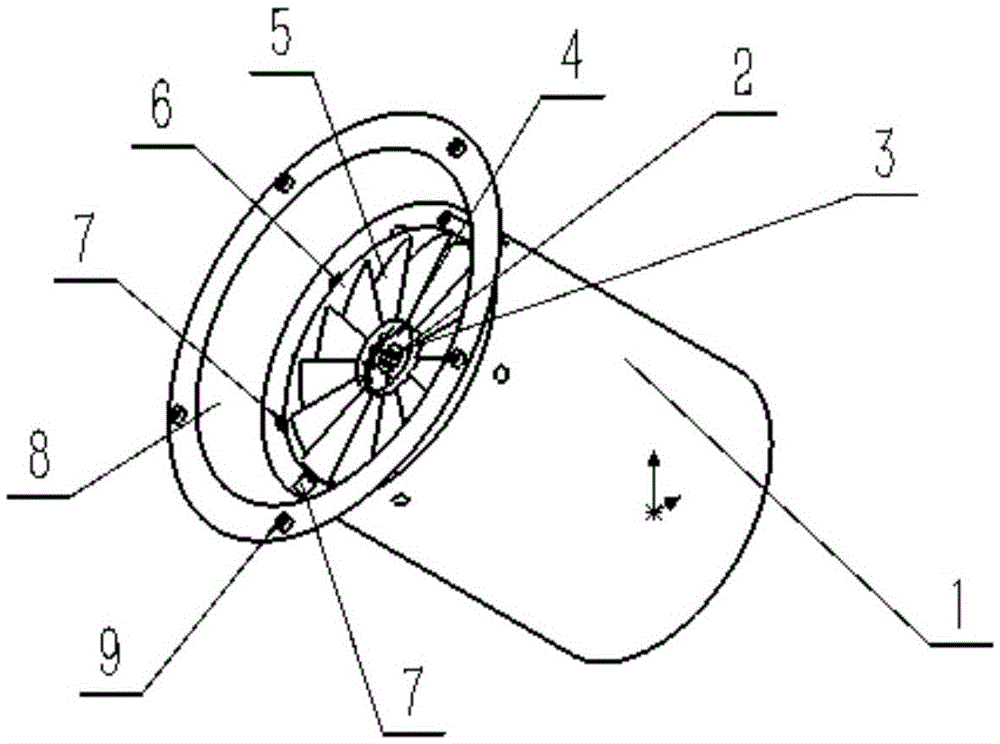

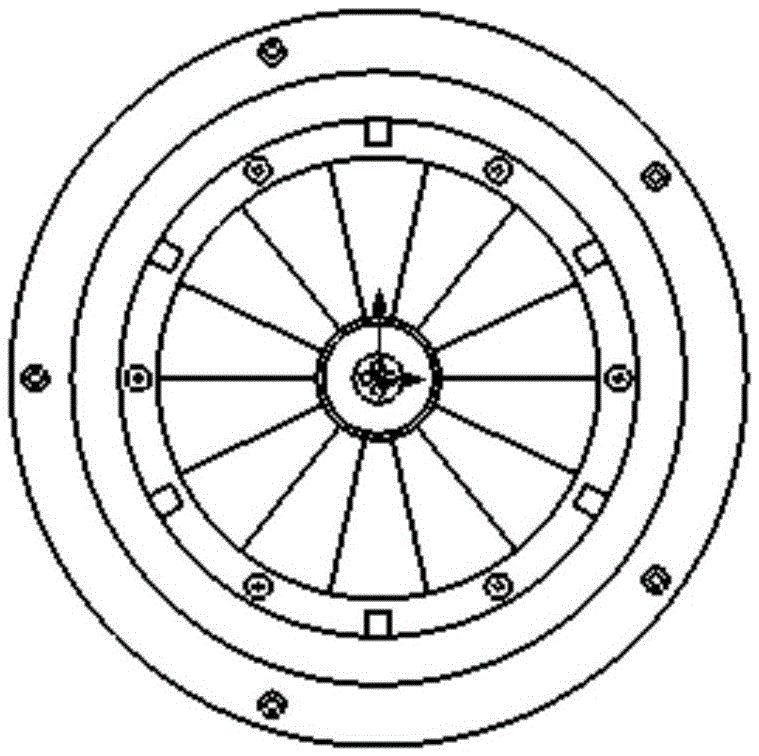

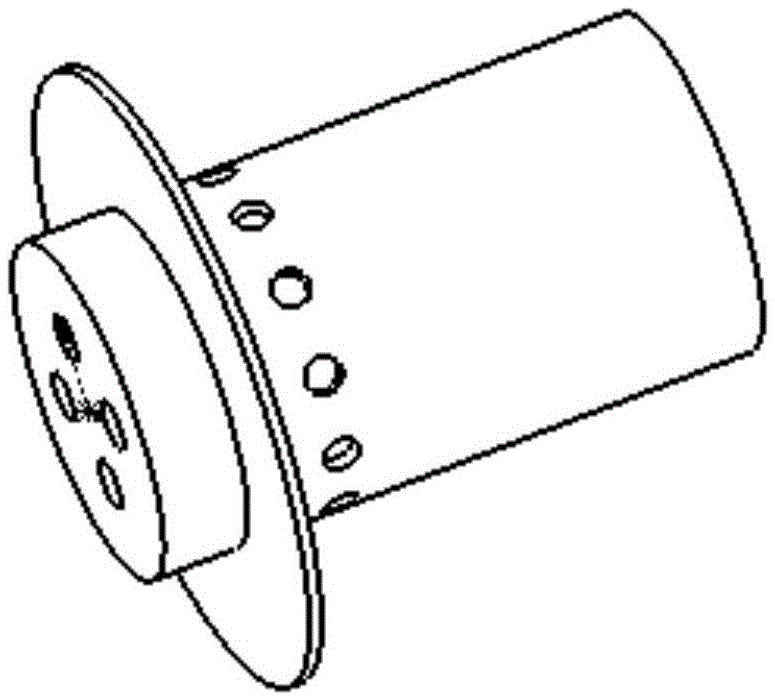

The invention provides an air flame type skyrocket steady burner which mainly comprises a maim combustion chamber housing (1), a heat return tube (2), a prechamber housing (3), a nozzle prechamber nozzle (4),a steady burning device (7) and a wind proofing device (9). The invention also comprises a five-channel for fuel distributing (5) and a main fuel ejection ring (6). The five-channel for fuel distributing (5) is connected with the main fuel ejection ring (6) and the nozzle prechamber nozzle (4). The body of the main fuel ejection ring (6) is arranged in the maim combustion chamber housing (1) and supplies fuel for the main combustion chamber. As the fuel for the prechamber and the main combustion chamber of the air flame type skyrocket steady burner of the invention is supplied respectively, the air is completely mixed, thus generating massive black smoke, the frame changes to be brighter. And as the five-channel for fuel distributing (5) realizes to supply the fuel in two ways, the frames are correspondingly divided into a premixing frame of the prechamber and a diffusion flame of the main combustion chamber; and cooperates the steady burning device (7) and the wind proofing device (9); thereby improving the wind proofing capacity as well as the stability of the frame.

Owner:THE 31TH INST OF THE THIRD ACAD OF RES CASIC

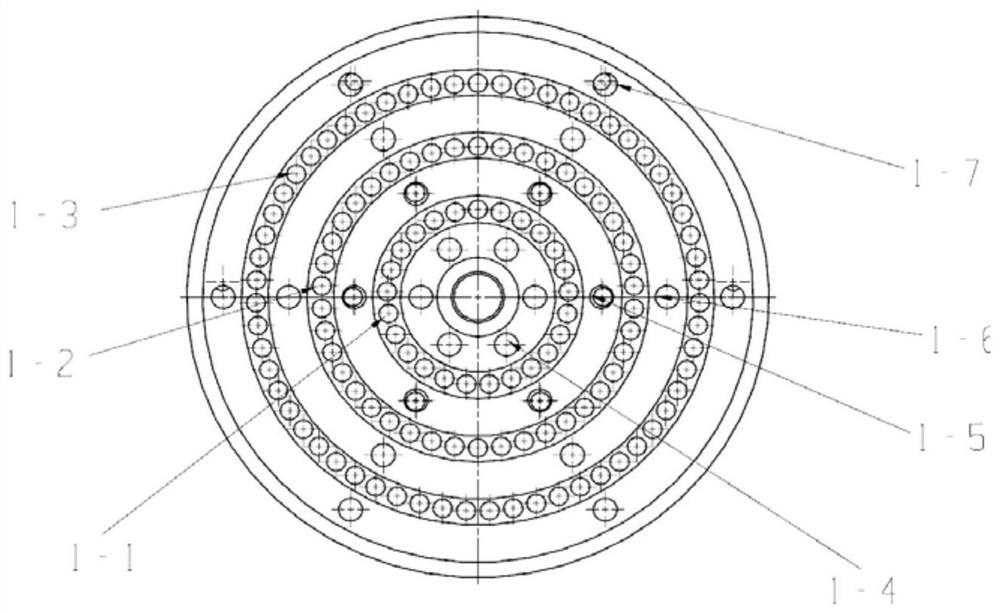

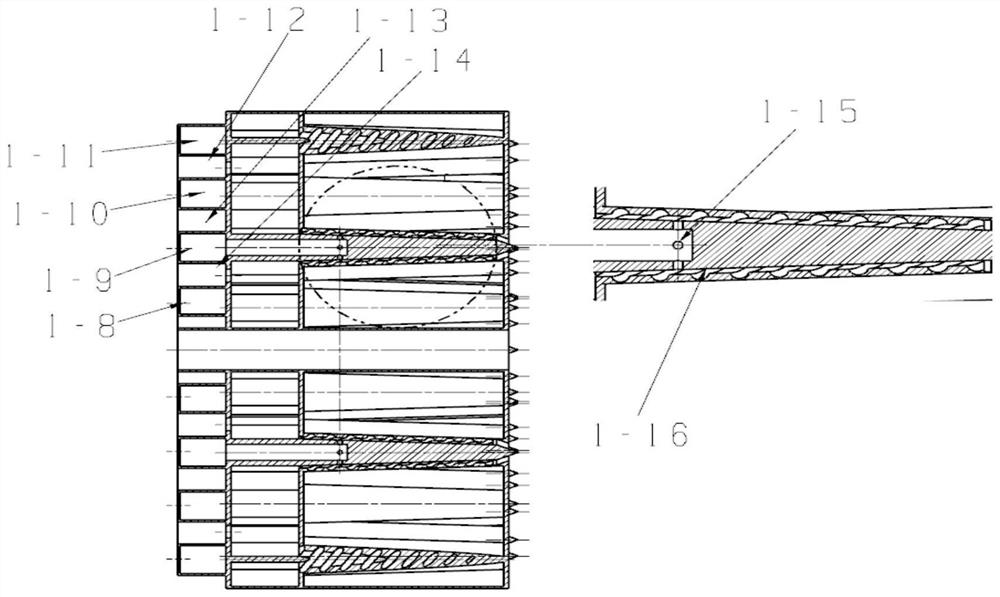

High-efficiency low-emission combustion chamber head capable of premixing hydrogen

InactiveCN114183772AImprove uniformityGuaranteed uniformityContinuous combustion chamberCombustion chamberEngineering

According to the hydrogen premixing efficient low-emission combustion chamber head, the characteristic that hydrogen premixing flames are high in propagation speed and the advantage that the hydrogen flames are thin are combined, the low-emission combustion chamber stable-combustion head structure is designed, the structural design that the multiple stages of fuel annular cavities are connected with the annular cavities is adopted, and the combustion efficiency is improved; the multi-stage premixing flow channel is arranged in the combustor head, the uniformity of fuel entering the combustor head can be greatly improved, the multi-stage premixing flow channel is gradually shrunk, the spiral grooves are formed in the premixing flow channel, mixing of the fuel and air is enhanced, the combustion temperature field is improved, reliable and stable combustion of hydrogen under the premixing condition is achieved, and therefore emission of nitric oxide in the hydrogen combustion process is reduced, and the combustion efficiency is improved. And clean and efficient hydrogen combustion is realized. The scheme has the advantages of light and handy structure, high space utilization rate, high volume heat intensity, low pollutant emission, uniform outlet temperature, good universality, simplicity in processing and maintenance and the like.

Owner:HARBIN ENG UNIV

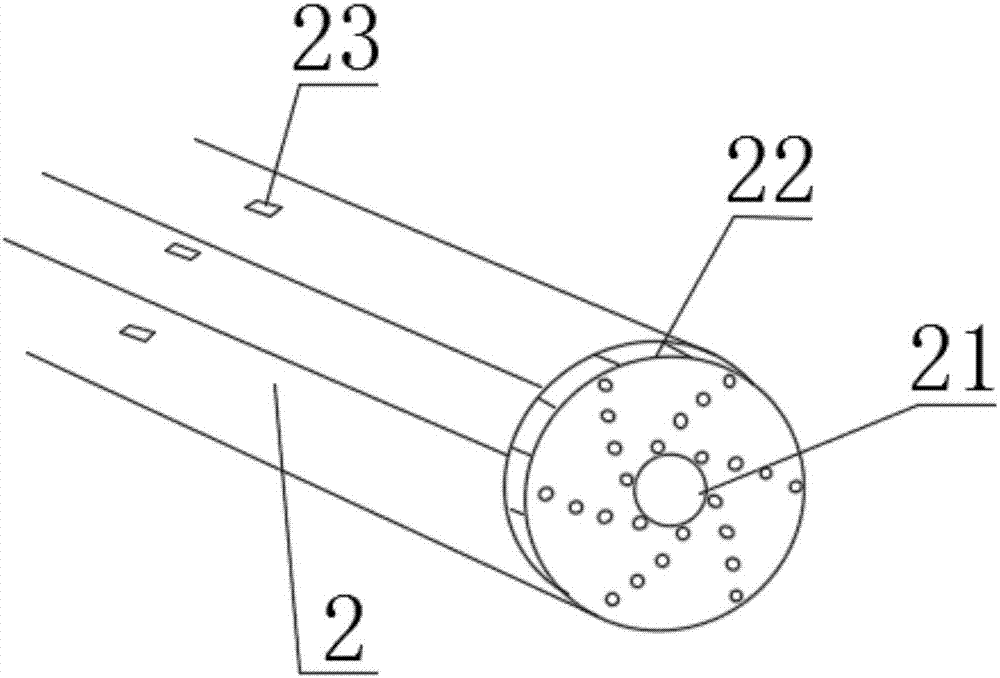

Lean premixed combustion chamber for gas turbine

InactiveCN102878580AGuaranteed stabilityEvenly blendedContinuous combustion chamberCombustion chamberEngineering

The invention discloses a lean premixed combustion chamber for a gas turbine. The lean premixed combustion chamber for the gas turbine is characterized in that a flame tube is fixed in a cartridge receiver, and a plurality of round holes for feeding air are formed in a wall surface of a tail part of the cartridge receiver; an igniter mounting seat for mounting an igniter is arranged on a side surface of the cartridge receiver; a swirl cup with a variable diameter is arranged in the flame tube, and a nozzle swirler combined piece is connected to an inlet of the swirl cup through the cartridge receiver; an on-duty fuel introducing tube is arranged in the center of a nozzle body, and a premixed fuel introducing tube is arranged on an outer ring of the nozzle body; a back cover of a premixed fuel chamber of the swirler combined piece is connected with an inner side of a blade mounting base body to form the premixed fuel chamber; a plurality of blades are fixed on an outer side of the blade mounting base body, a blind hole is formed in every blade along the axial direction, and a plurality of premixed fuel jetting holes are formed in wall surfaces on two sides of every blade; and premixed fuel enters the premixed fuel chamber from the premixed fuel introducing tube, enters a swirler passage through the blind holes and the premixed fuel jetting holes in the blades and is mixed with air. By the lean premixed combustion chamber for the gas turbine, the fuel is uniformly mixed with the air, and the discharge of nitrogen oxide (NOX) of a combustion chamber can be reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

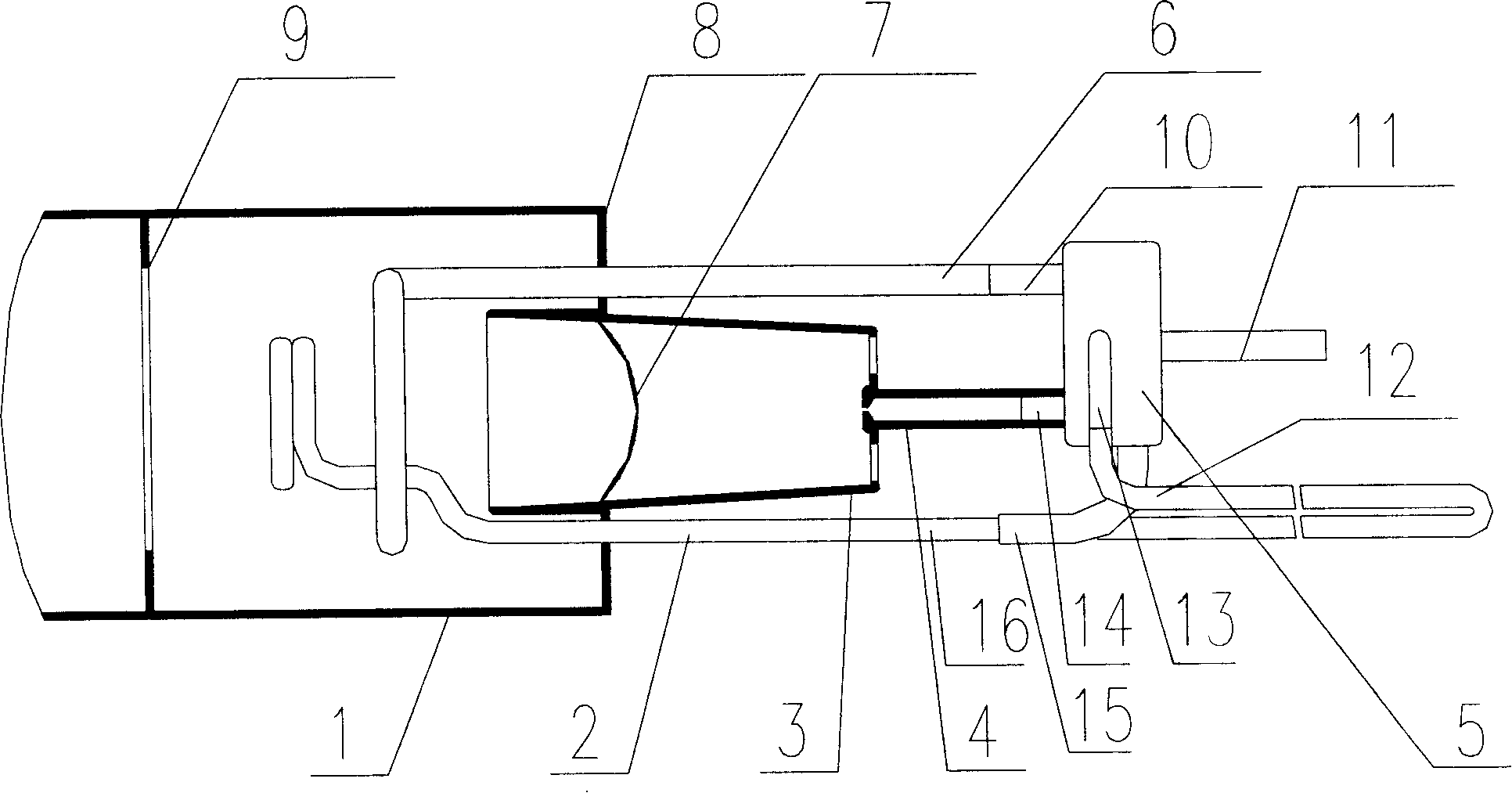

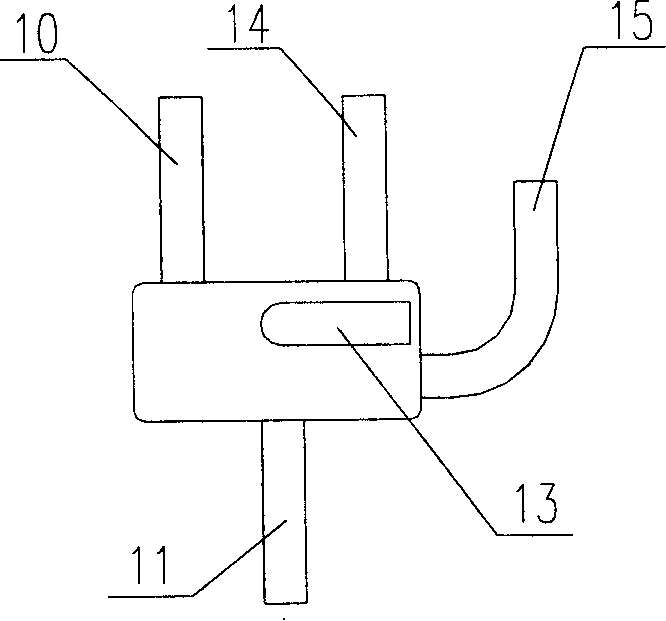

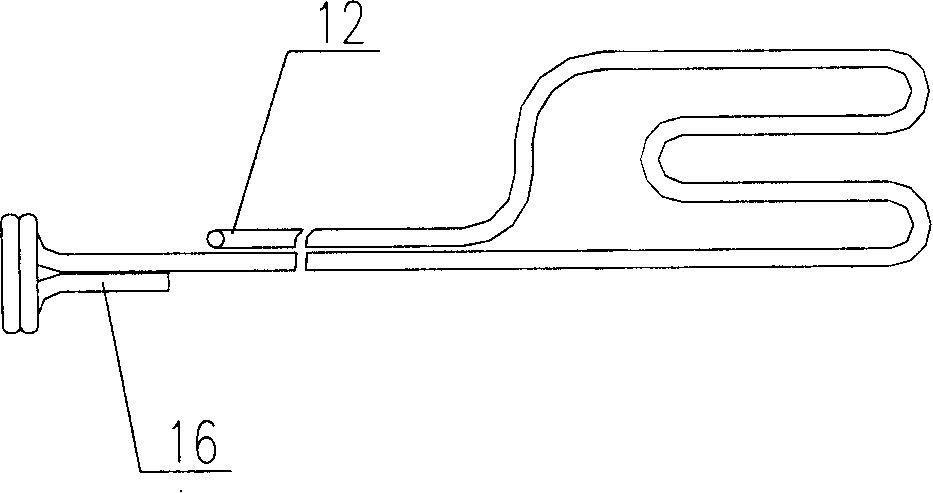

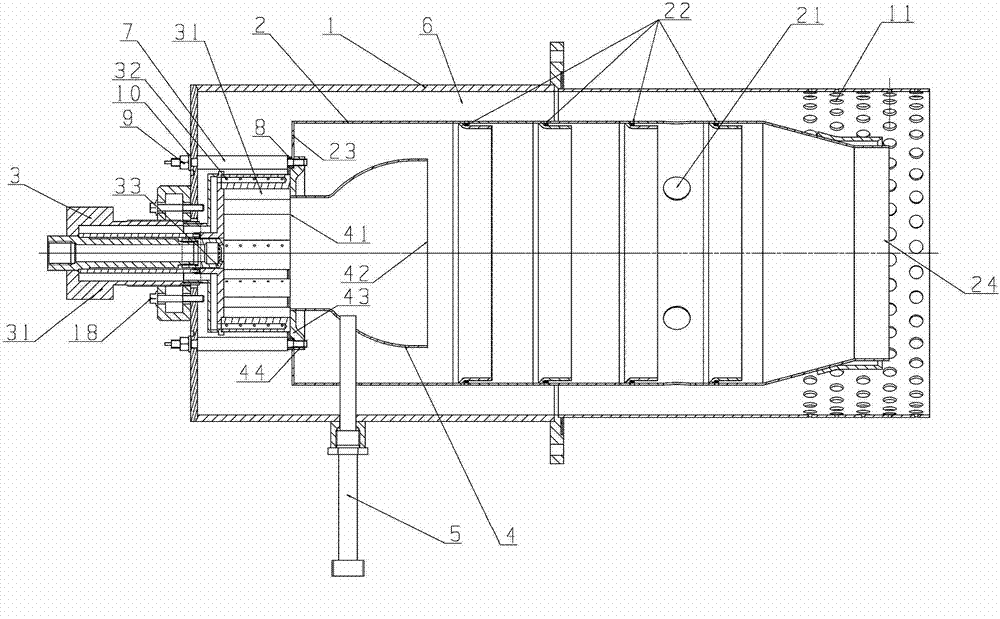

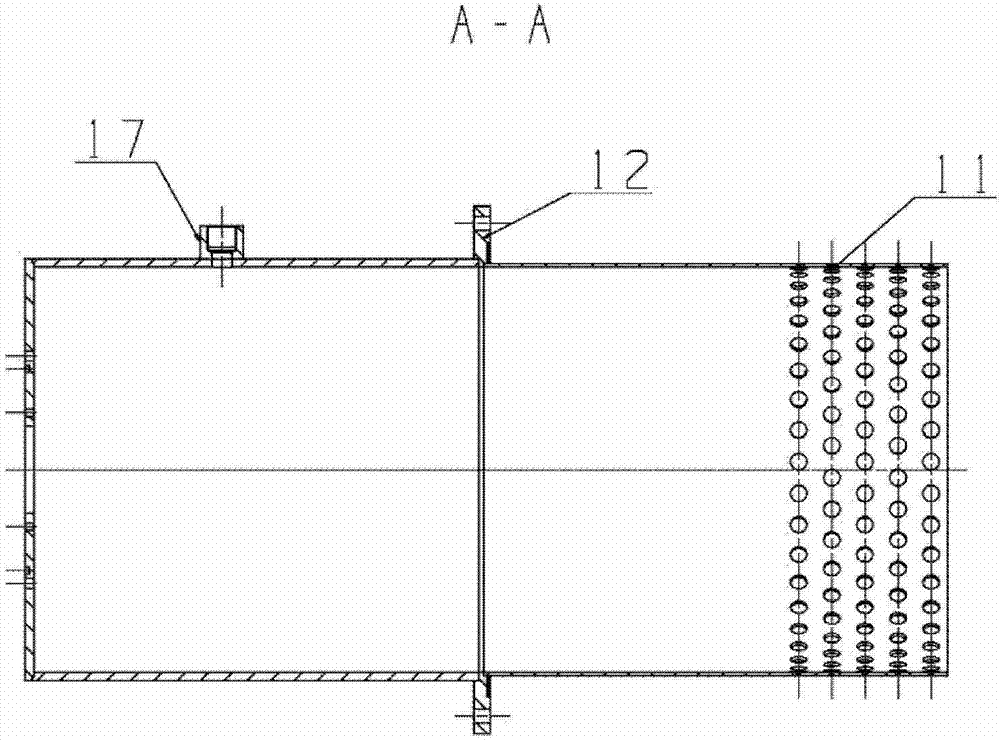

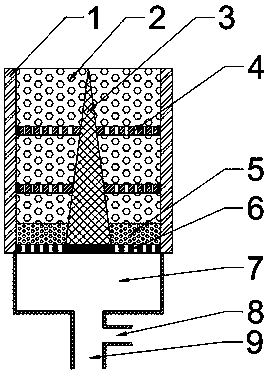

Active heat reclaiming method and device for diesel engine particulate drip catcher

InactiveCN101270685AAvoid the defect that it is not easy to igniteImprove ignition performanceExhaust apparatusSilencing apparatusParticulatesLiquid fuel

The invention relates to an active thermal regenerative method and a device of a collector for diesel micro particle. The method is as follows: liquid fuel, the boiling point of which is higher than normal temperature, is put into the tail gas of an engine or made into high pressure fuel vapor by being heated by electricity; after CPU sends a regeneration instruction, the oxygen content of regenerative environment is adjusted by supplementing auxiliary air and the fuel under high temperature steam enters combustion zone; meanwhile, an ignition plug begins to jump spark; fuel vapor is ignited Under the action of a twin-stage reverse whirl cone, premised flame is fixed on a proper position; heat from fuel burning makes gas flow temperature rise until the temperature of microparticle on filter element is above inflammation point; the microparticle on deposit is ignited when high temperature air flow passes by the filter element; the fuel should be continuously supplied until the microparticle on the deposit is burnt out; and a regenerative cycle is finished. In order to avoid the extreme high temperature of primary chamber part outside the collector, a gaseous film cooling structure is arranged. The active thermal regenerative method and device of the collector for diesel microparticle is easy to be ignited and has the characteristics of stable burning, efficient burning, strong anti-interference ability, little secondary pollution and stable action.

Owner:HUNAN UNIV

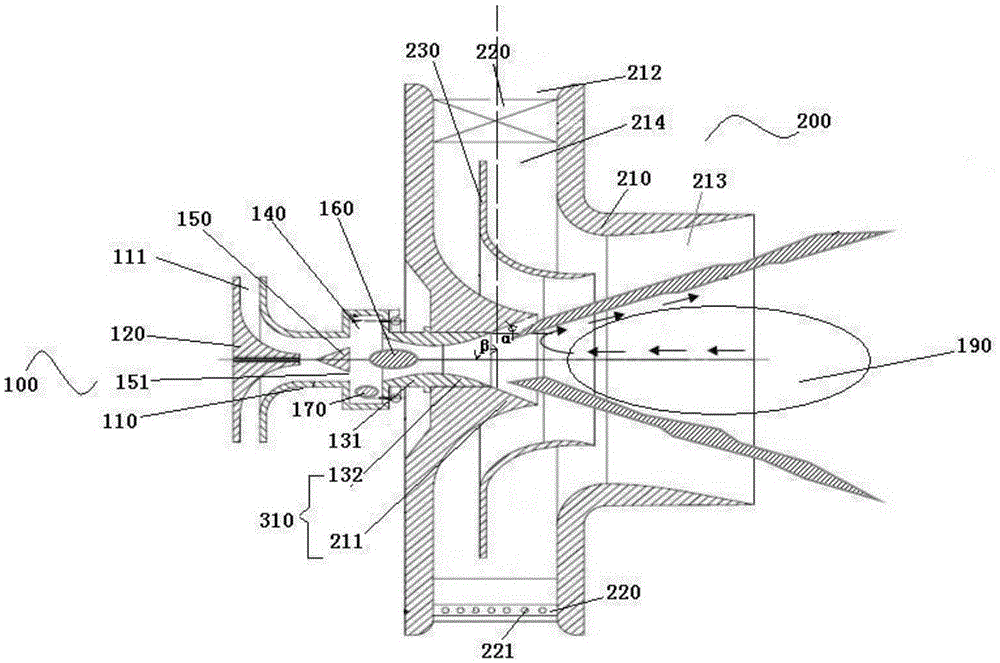

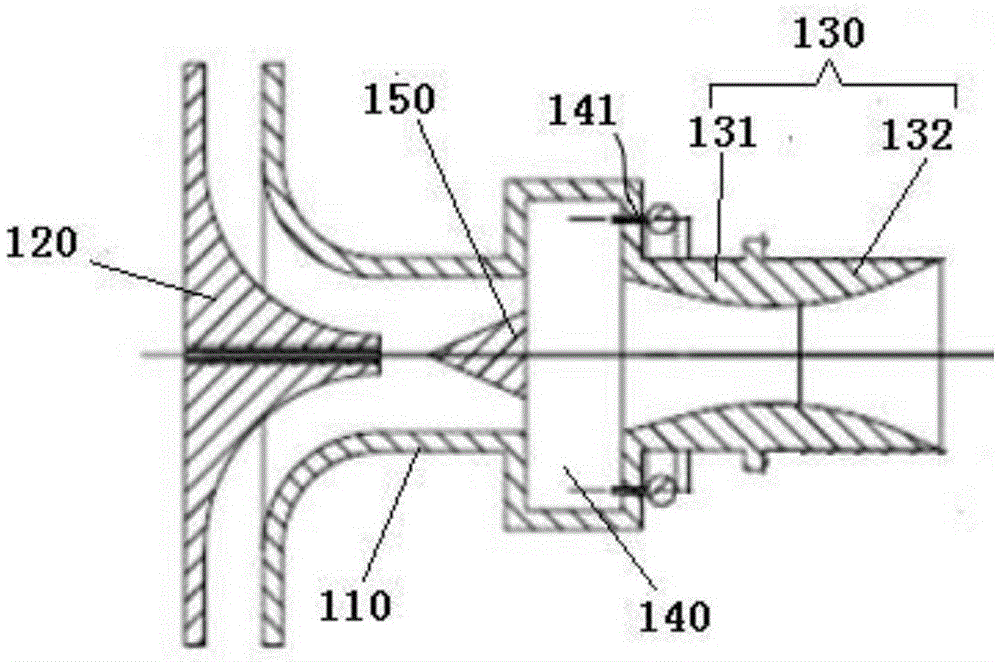

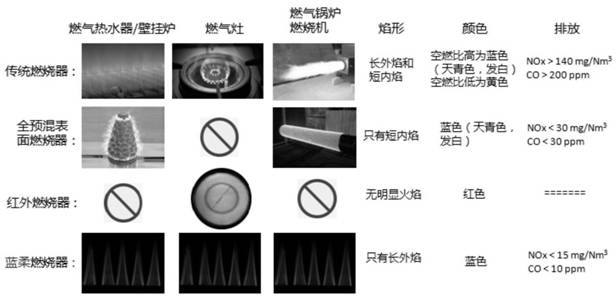

Strong-swirling-flow fuel staging ultra-low-nitrogen gas burner

The invention relates to a strong-swirling-flow fuel staging ultra-low-nitrogen gas burner. A burner head of the burner mainly comprises a cylindrical air flow channel, a swirling flow plate, a primary fuel spray pipe, a primary fuel flame stabilizing plate, a secondary fuel spray pipe, a flared opening and a staged fuel spray pipe, and composition structures of all components and relative structures among all the components are further optimally arranged, so that the strong-swirling-flow fuel staging ultra-low-nitrogen gas burner with broad application prospects is finally achieved. The problems of burning instability, low heat efficiency and the like of premixed flame and flue gas recycling can be solved while generation of NOx is reduced, and the strong-swirling-flow fuel staging ultra-low-nitrogen gas burner has the advantages of being low in burning pollutant emission, sufficient in burning, good in burning stability, high in burning efficiency, simple and reliable in structure and the like, and is suitable for burning of civil and industrial furnaces, reformers and gas turbines.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

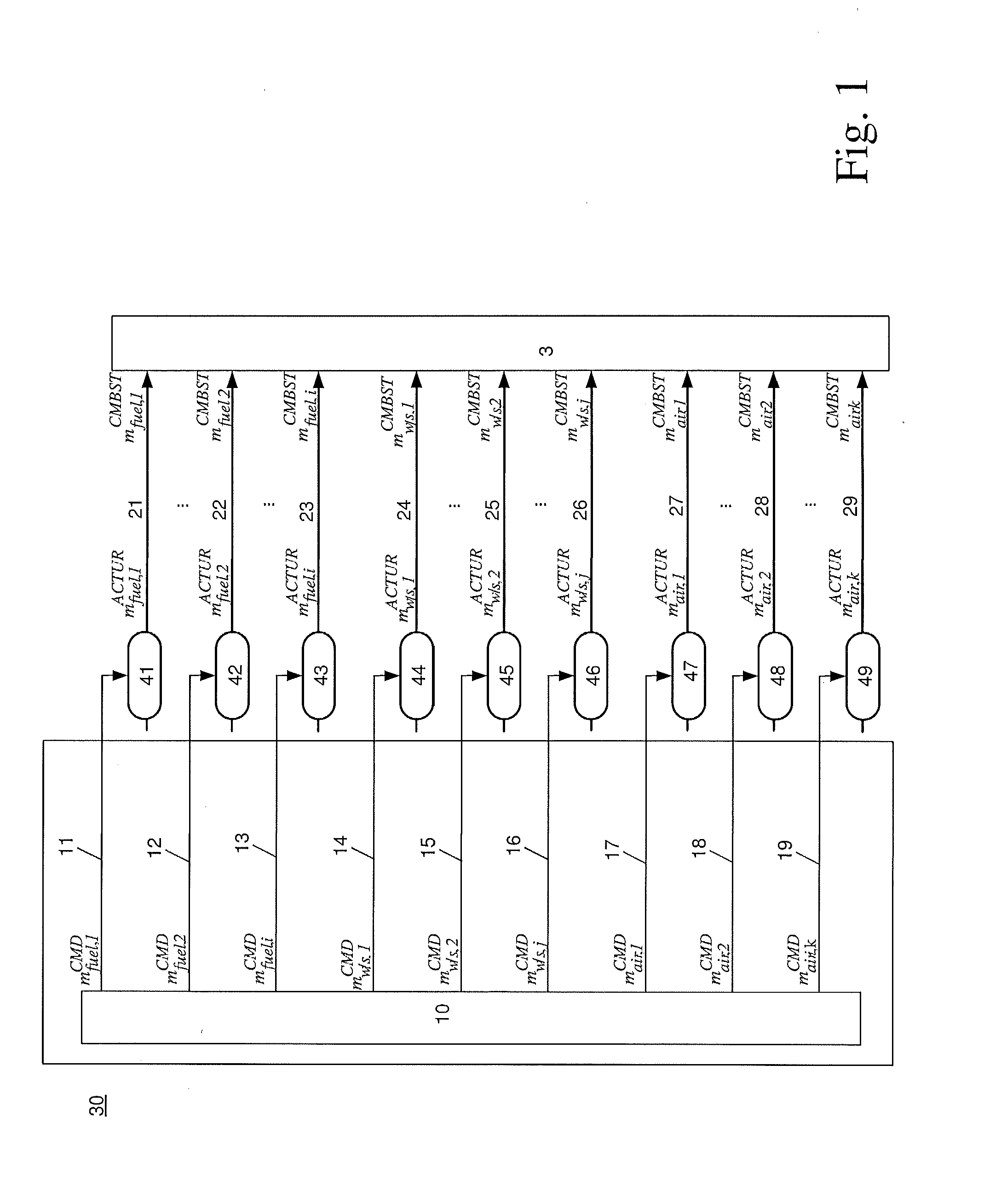

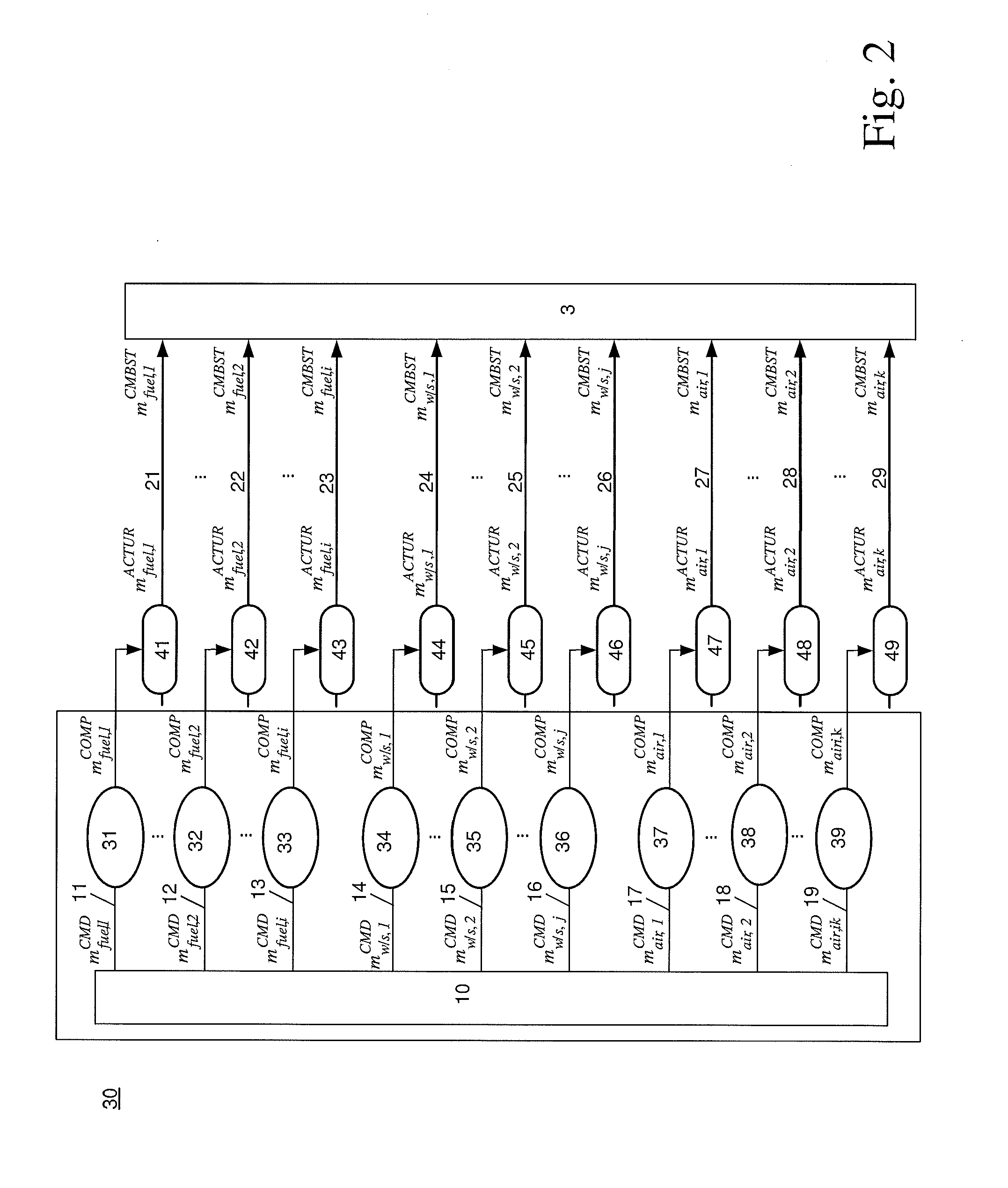

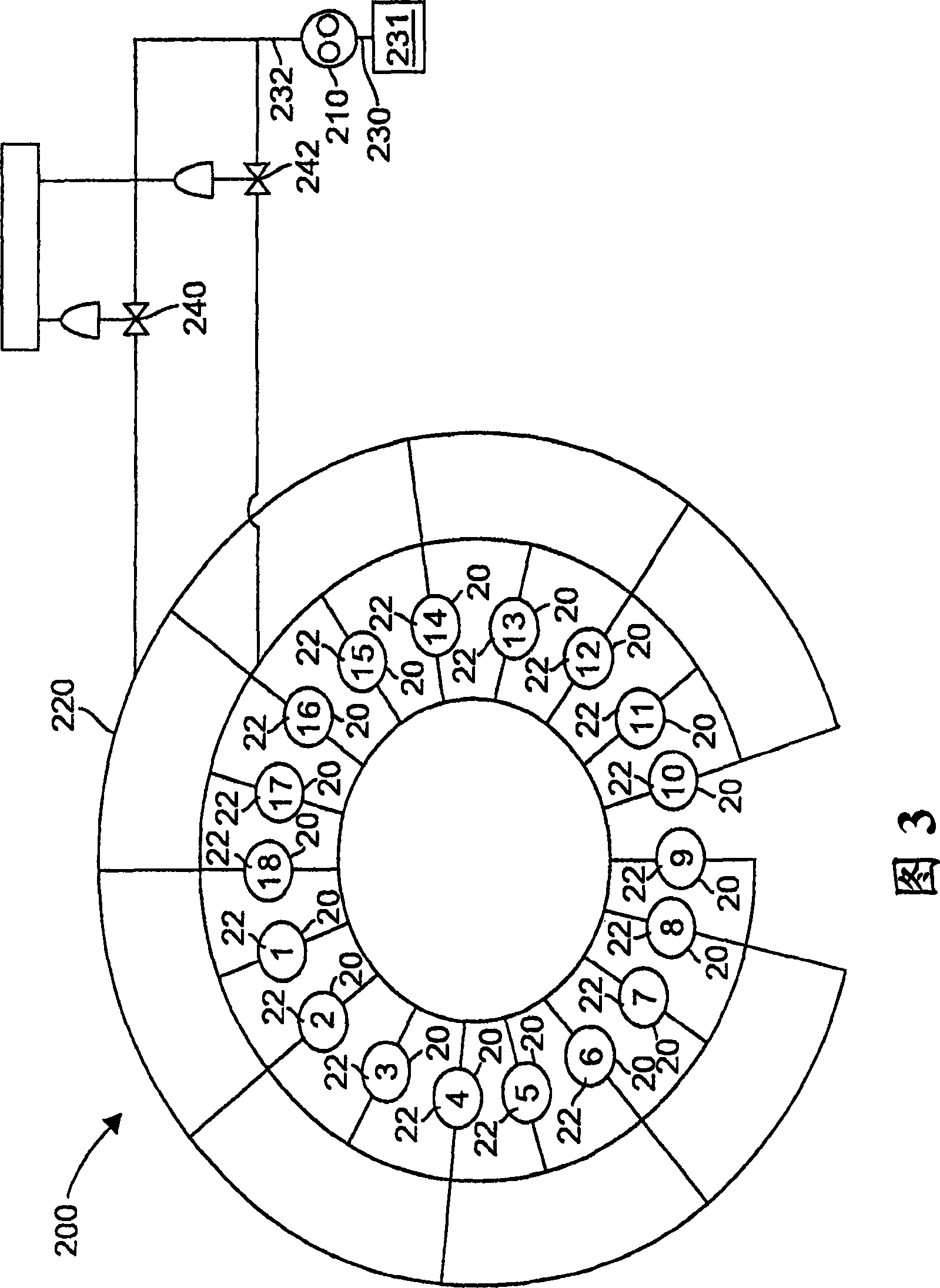

Gas turbine controller and a method for controlling a gas turbine

InactiveUS20140026587A1Gas turbine plantsTurbine/propulsion fuel controlCombustion chamberProcess engineering

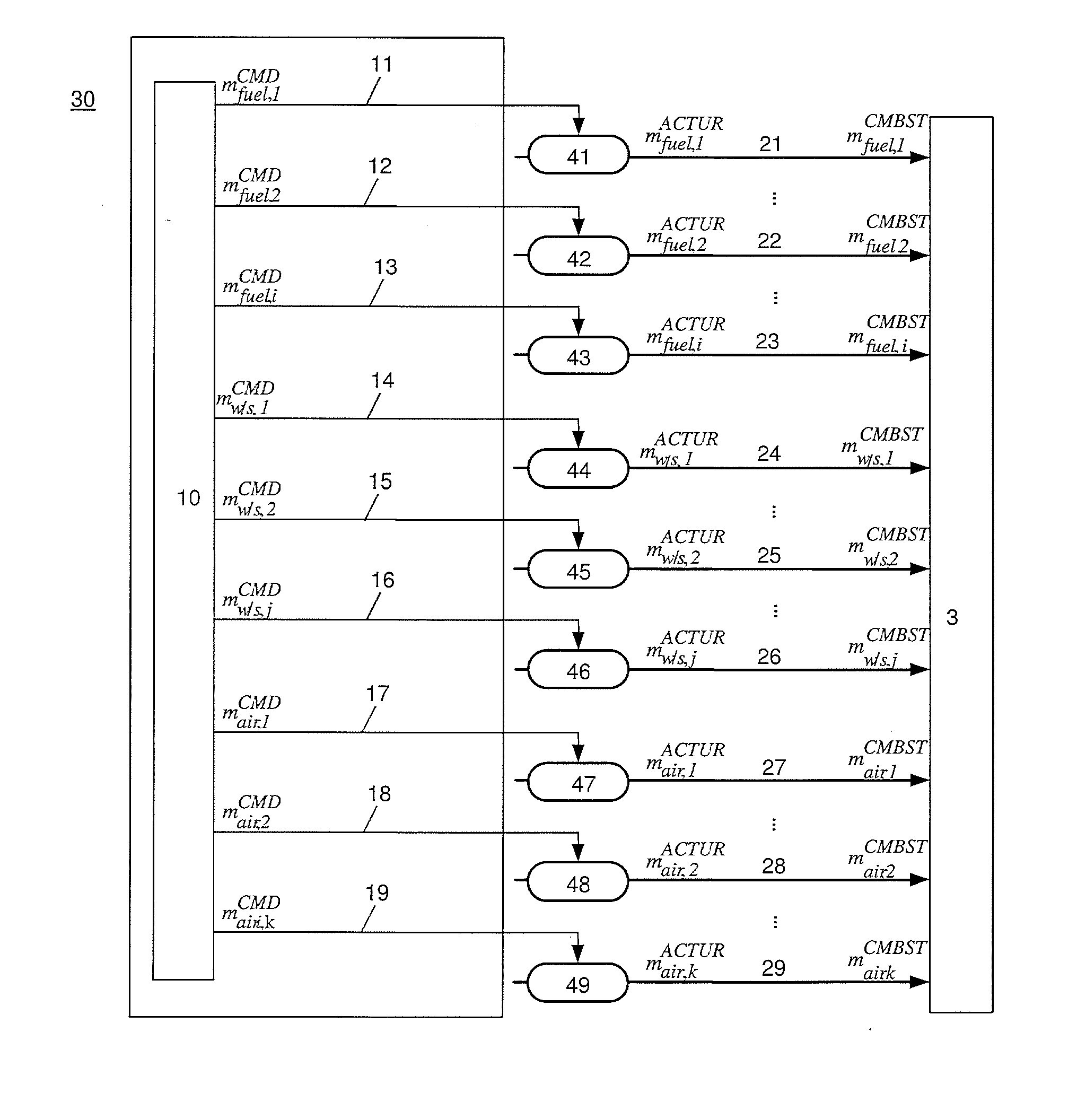

Exemplary embodiments relate to a method and system for transient operating of a gas turbine. Operation of the gas turbine the controller determines command values for an inlet air mass flow, fuel mass flow, and for a water or steam mass flow. In order to allow fast transient operation with a stable premix flame at least one command value is dynamically compensated to compensate for the different system dynamics of the supply systems to synchronize the resulting changes in fuel, water, steam, and / or combustion air mass flows, which reach the combustor, so that the fuel to air ratio stays within the combustible limit.

Owner:ANSALDO ENERGIA IP UK LTD

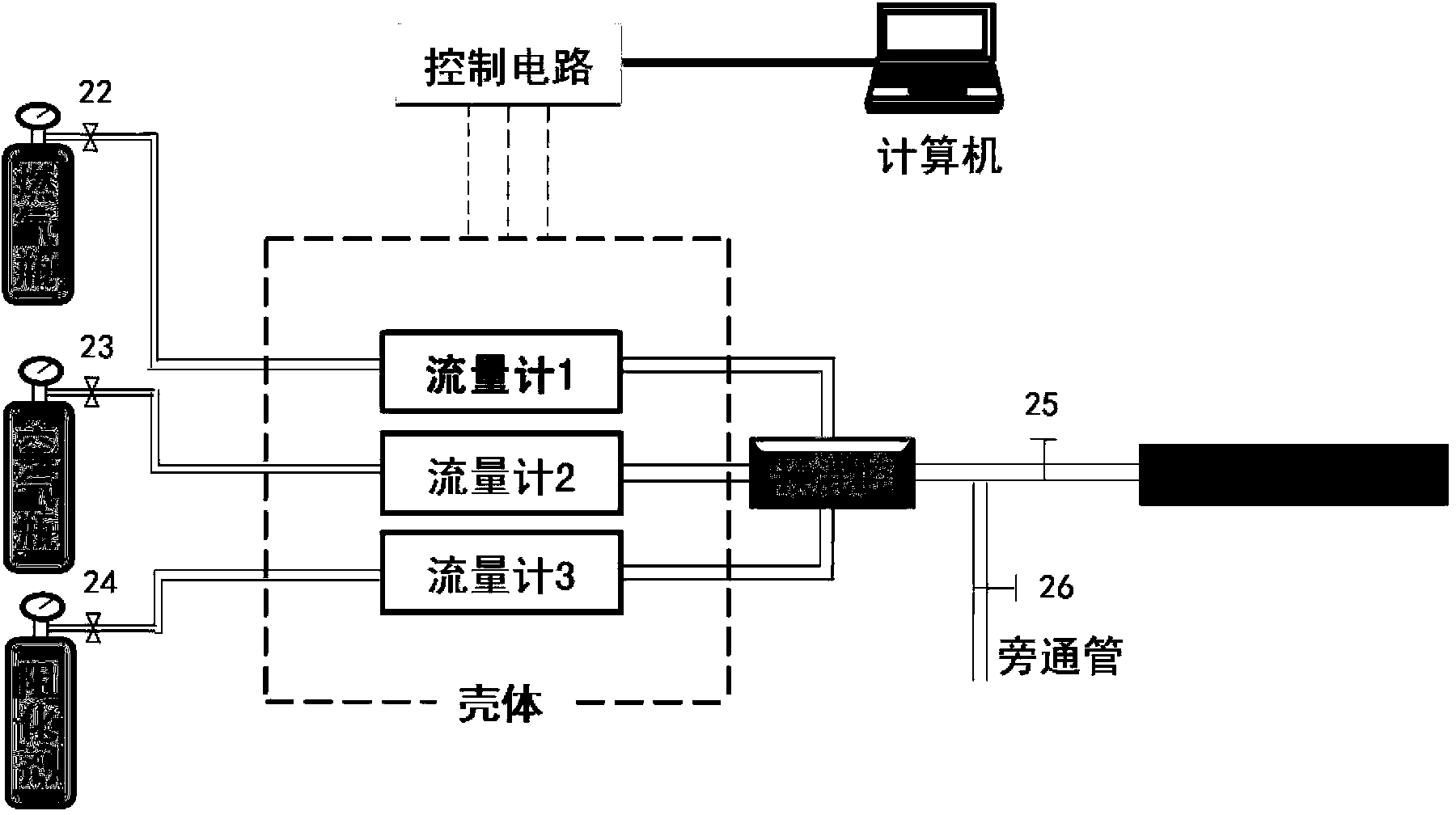

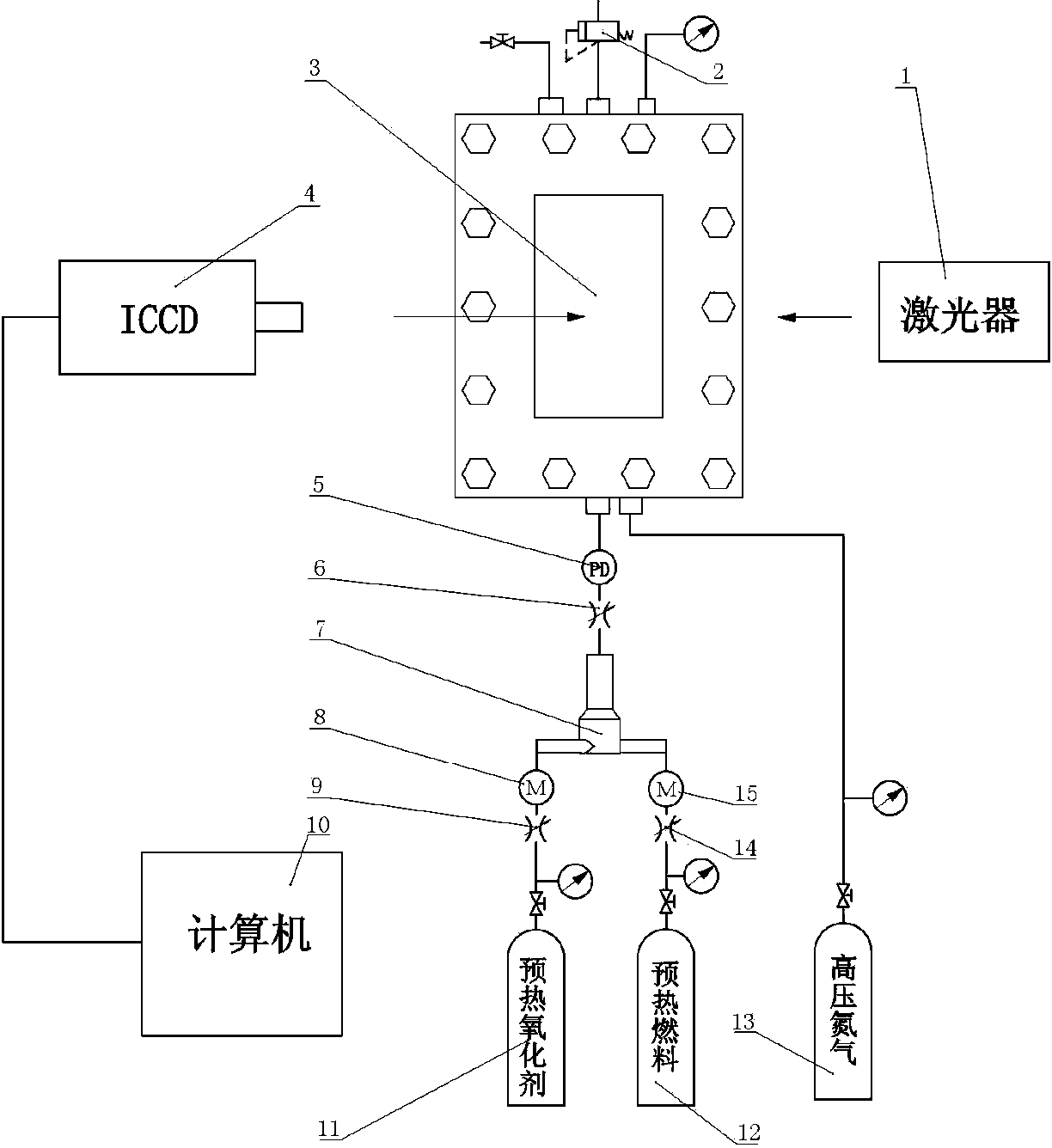

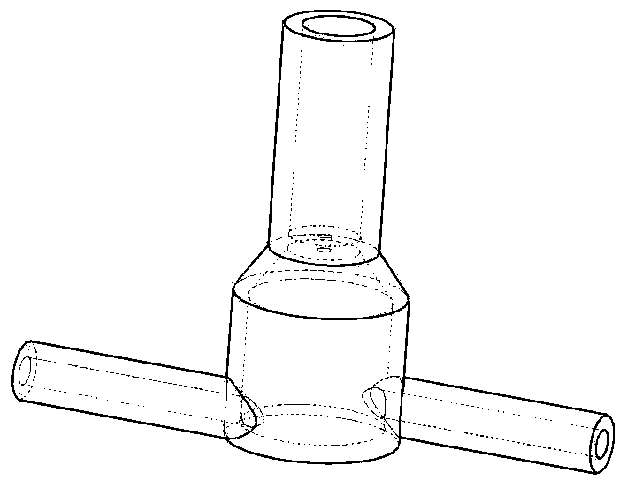

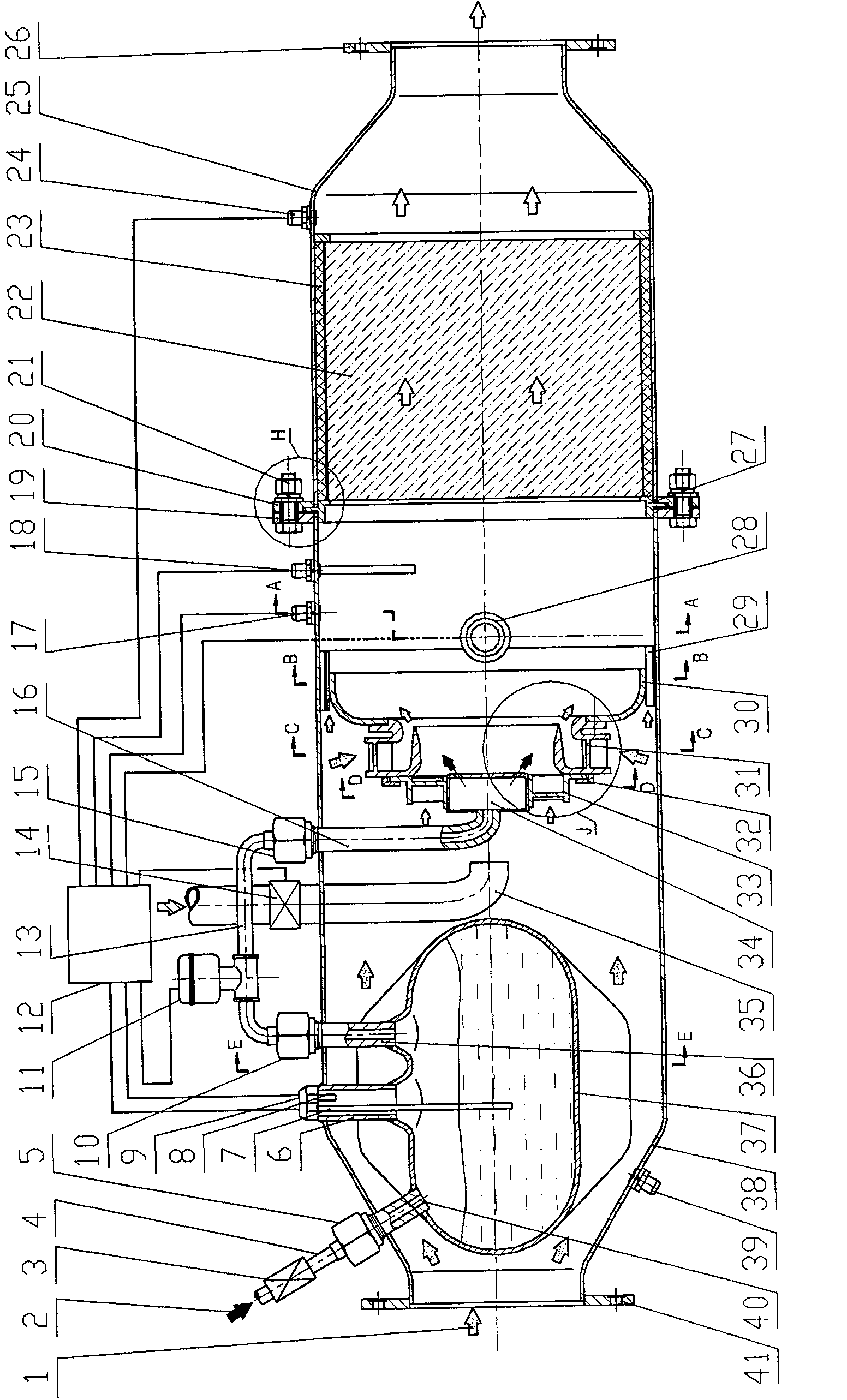

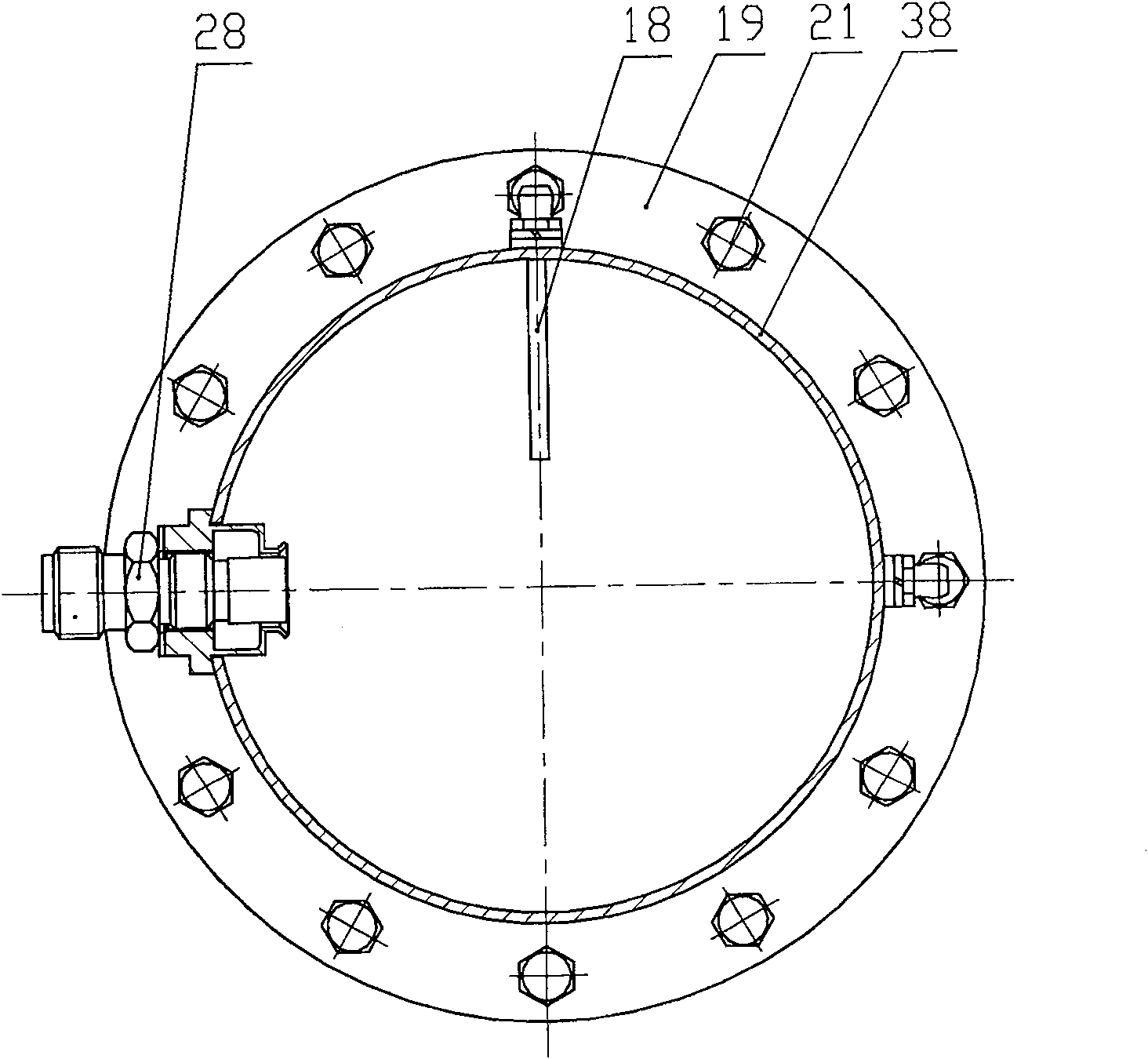

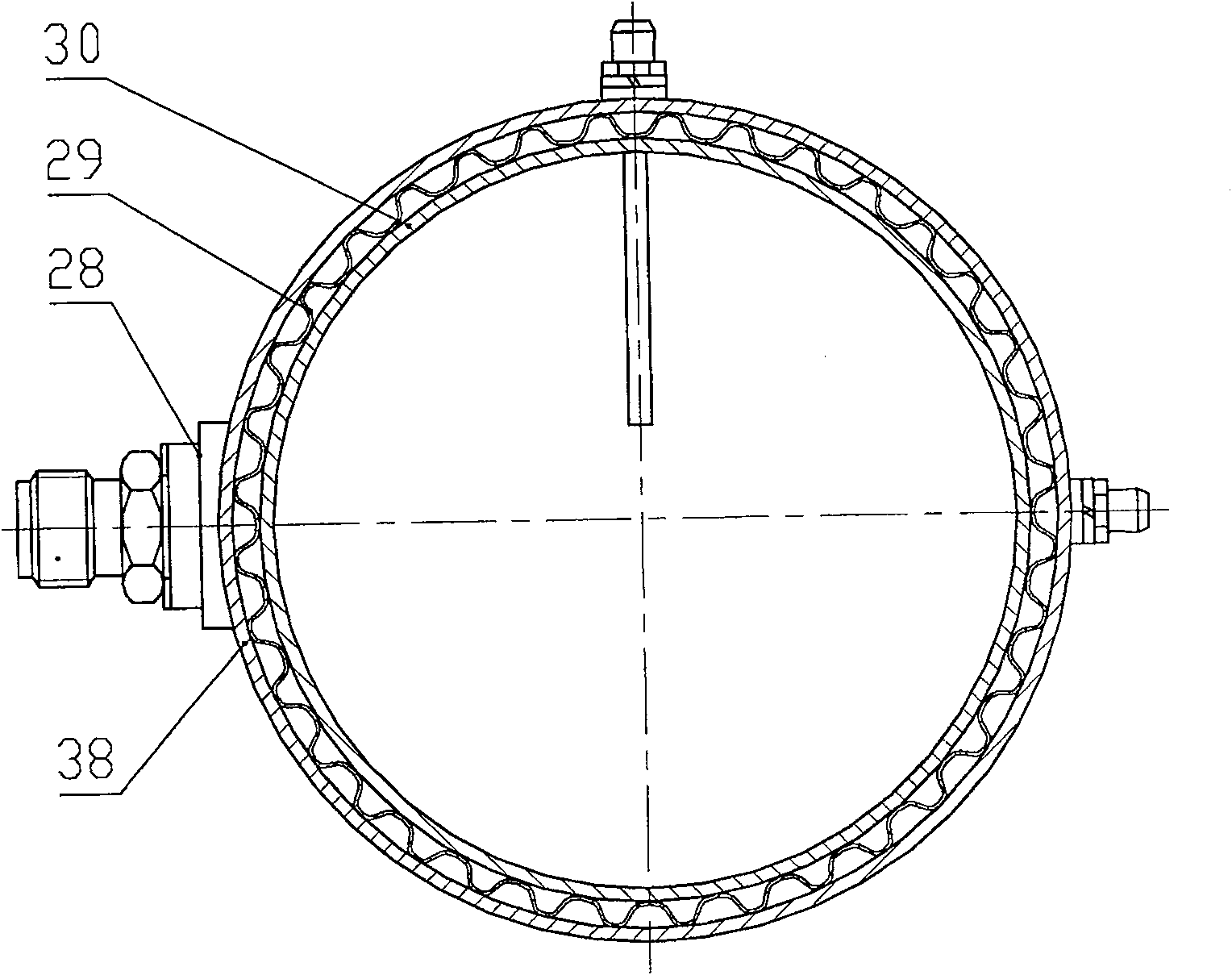

Experimental system for measuring propagation speed of laminar premixed flame under high pressure

InactiveCN103759775AImprove scalabilityEasy to operateMass flow measurement devicesEquivalence ratioEngineering

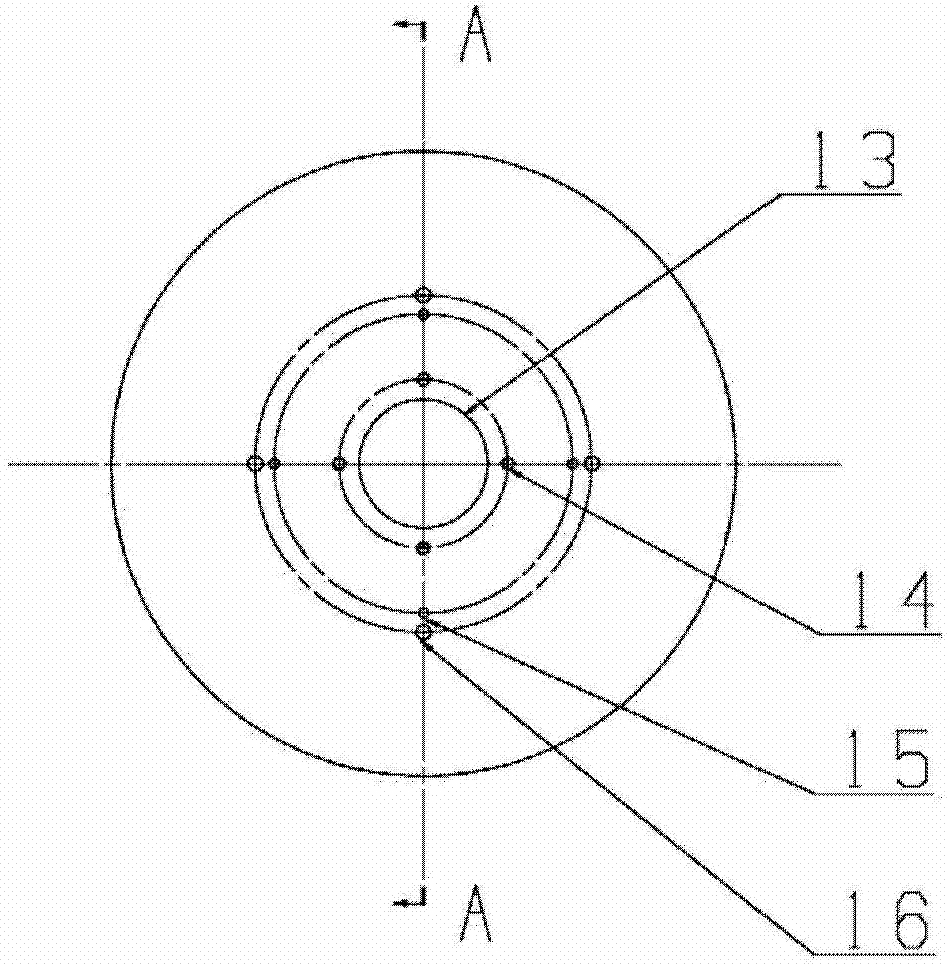

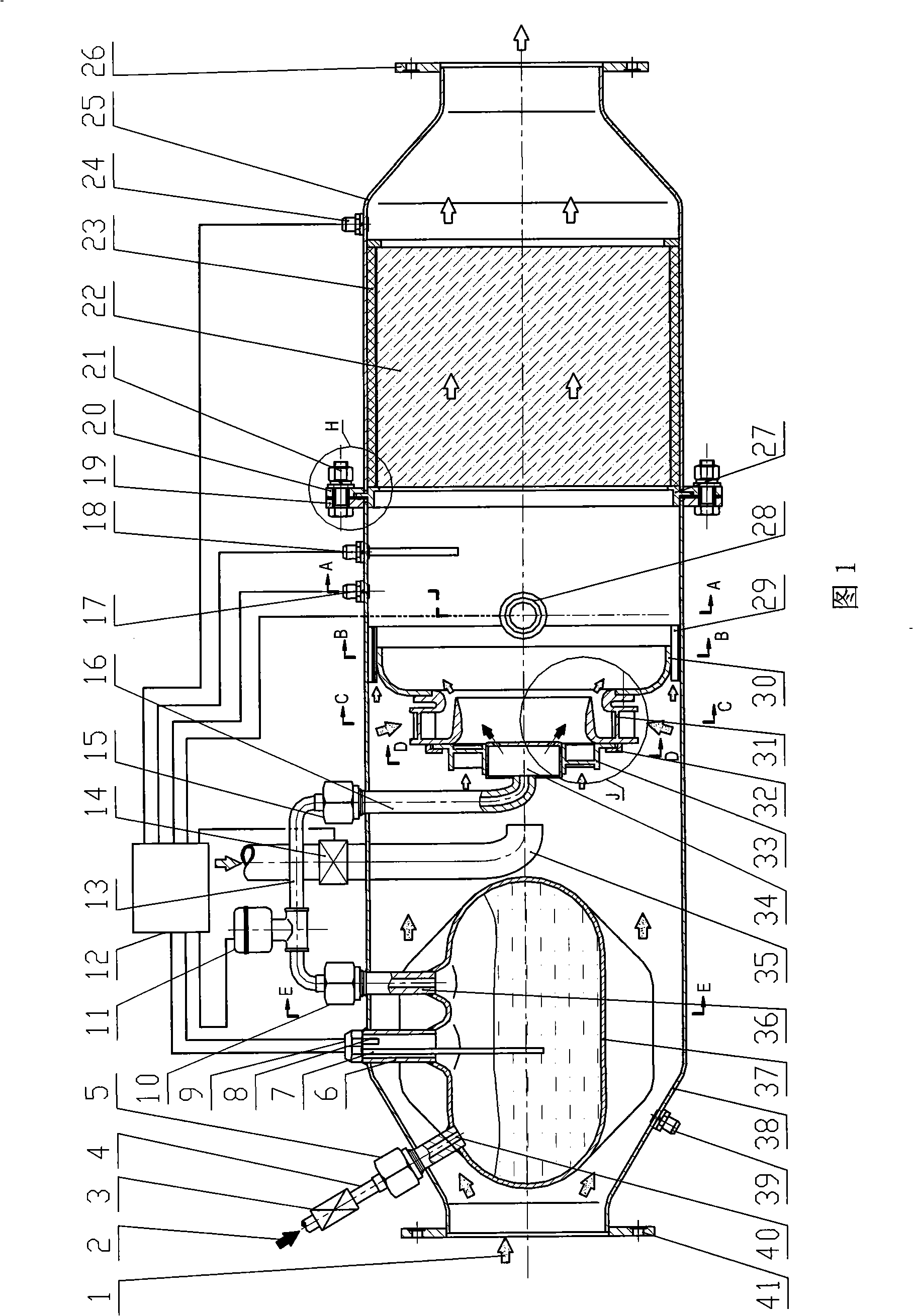

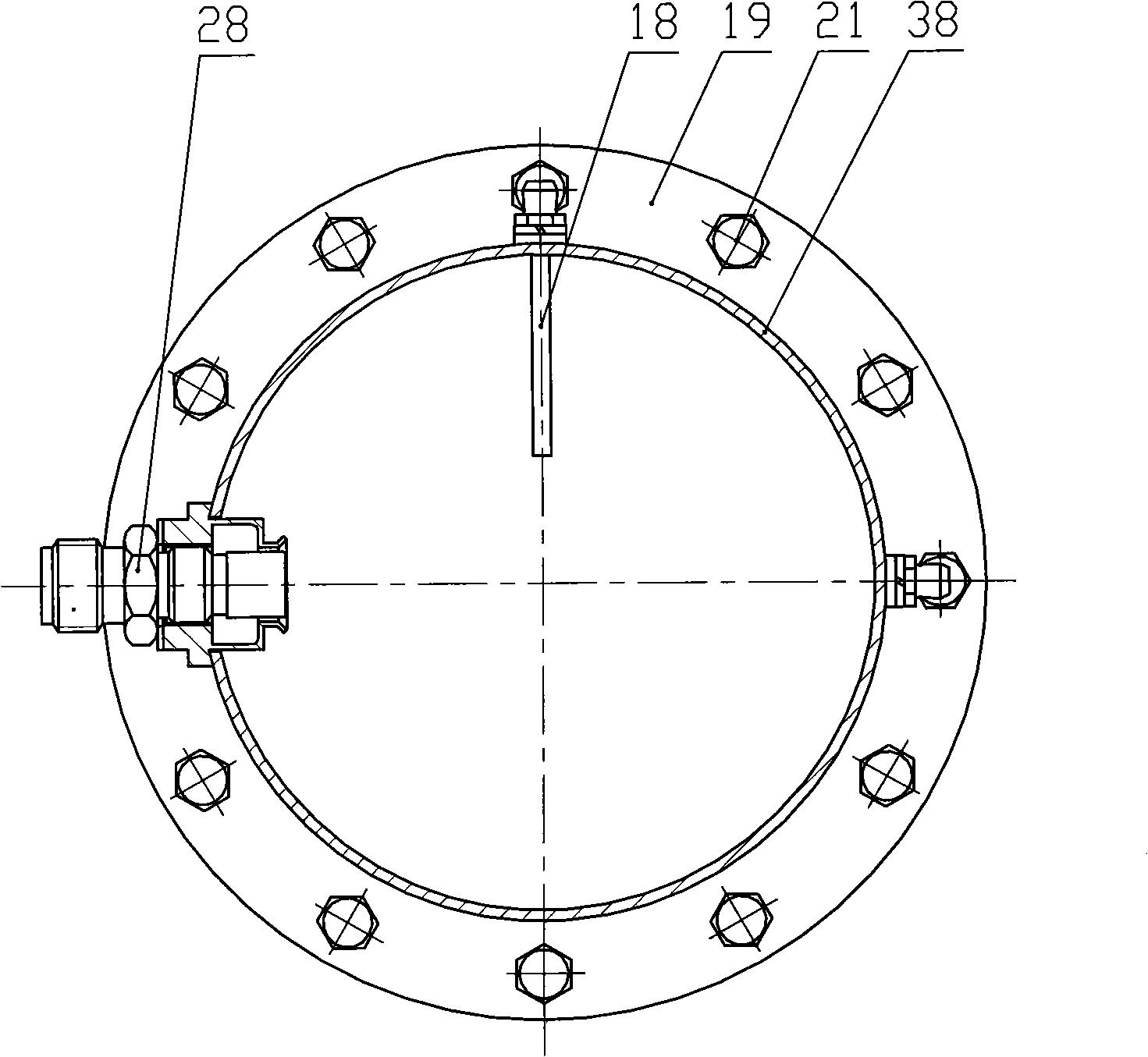

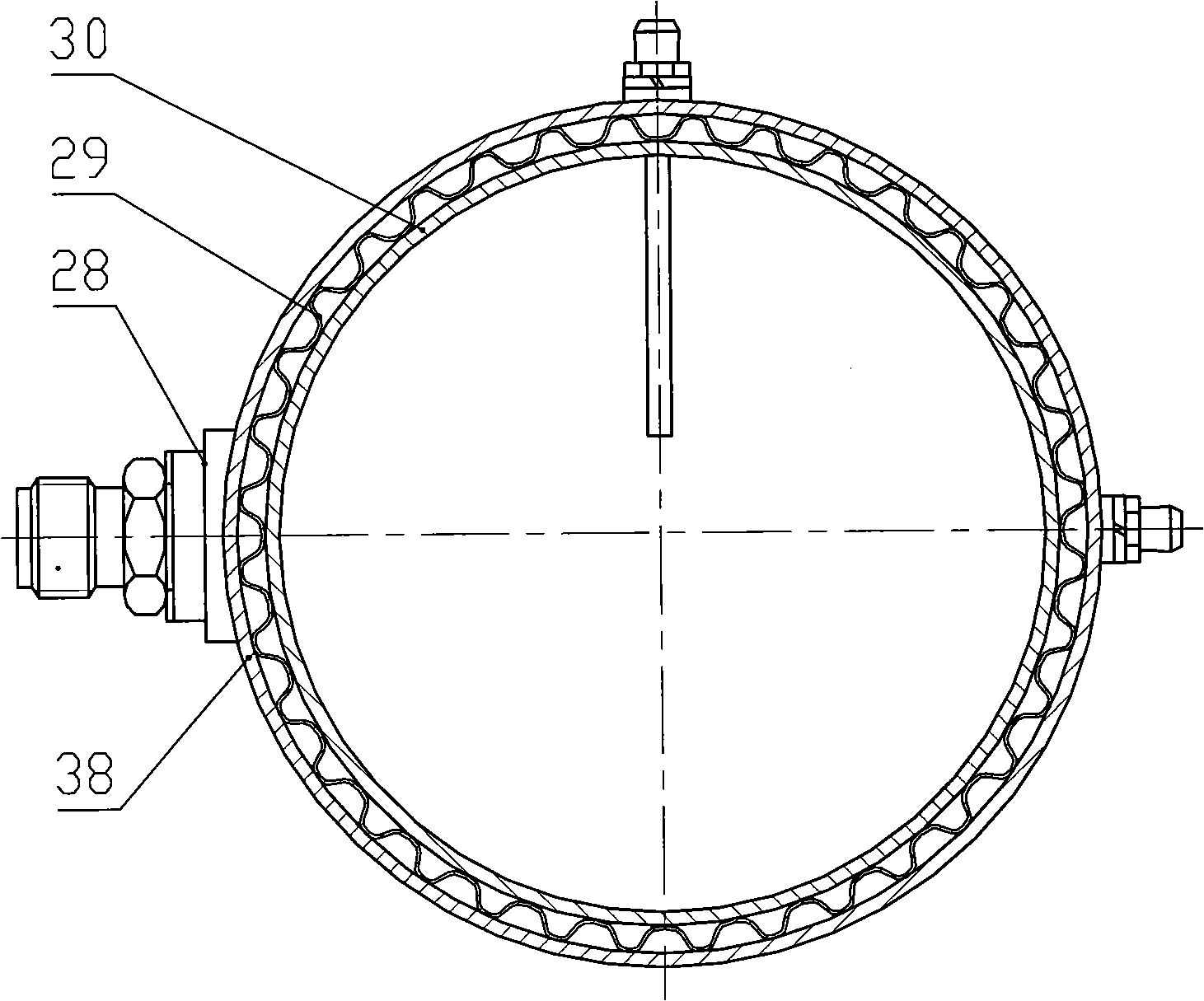

The invention discloses an experimental system for measuring propagation speed of a laminar premixed flame under high pressure. The experimental system is fixed to a rack, a laser and an ICCD camera are arranged at the positions, opposite to two observation windows, on a high pressure cavity, and the ICCD camera is connected with a computer. A constant pressure valve is arranged at the top of the high pressure cavity, a high-pressure nitrogen connector and a nozzle are arranged at the bottom of the high pressure cavity, and the high pressure cavity is inflated with high-pressure nitrogen through the nitrogen connector. Preheated oxidants and preheated fuel are sprayed into the high pressure cavity through the nozzle after passing through a premixer, premixed gas is ignited by a sparking plug, and the numerical value of a volume flowmeter is read. The propagation speed of the laminar premixed flame is calculated according to the numerical value of the volume flowmeter and the area of an outlet of the nozzle. The laminar premixed flame propagation speed under different equivalence ratios is acquired by adjusting the flow of the oxidants and the fuel. The laminar premixed flame propagation speed under different environmental pressures is acquired by changing the pressure of the high pressure cavity. Flame component distribution diagrams and temperature profiles under all work conditions are acquired through a PLIF system.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

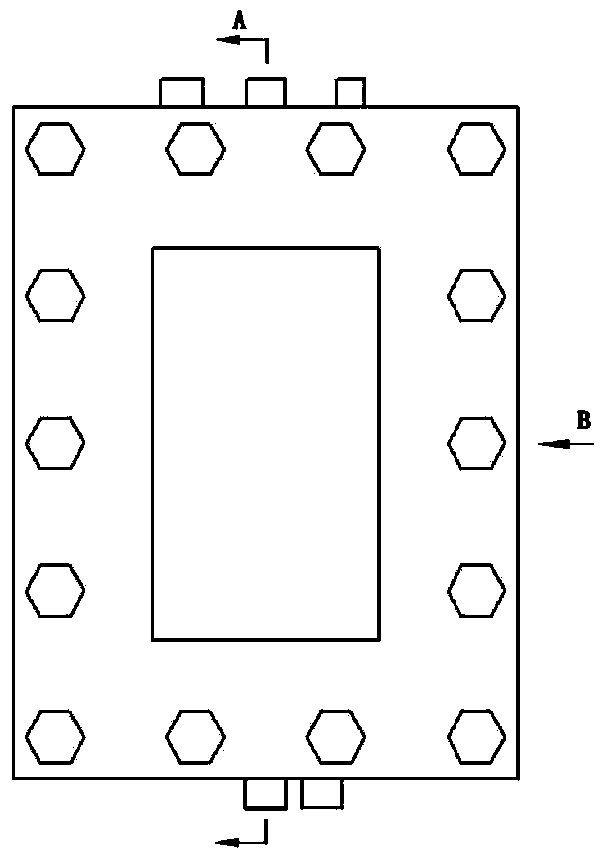

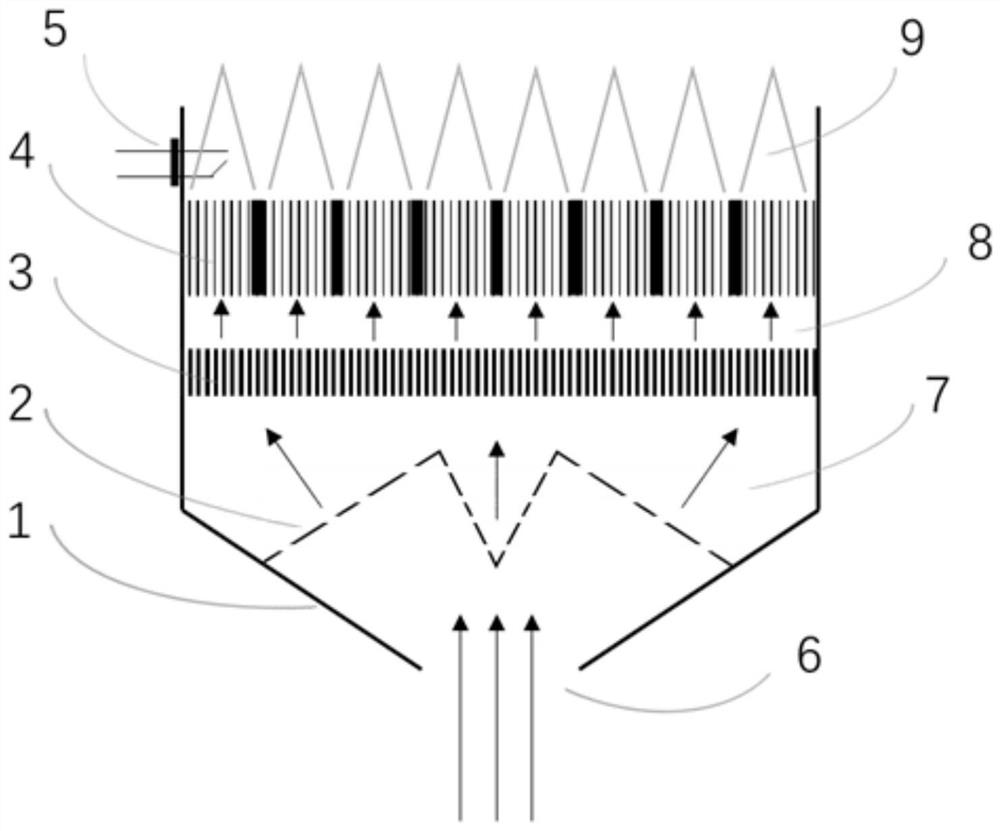

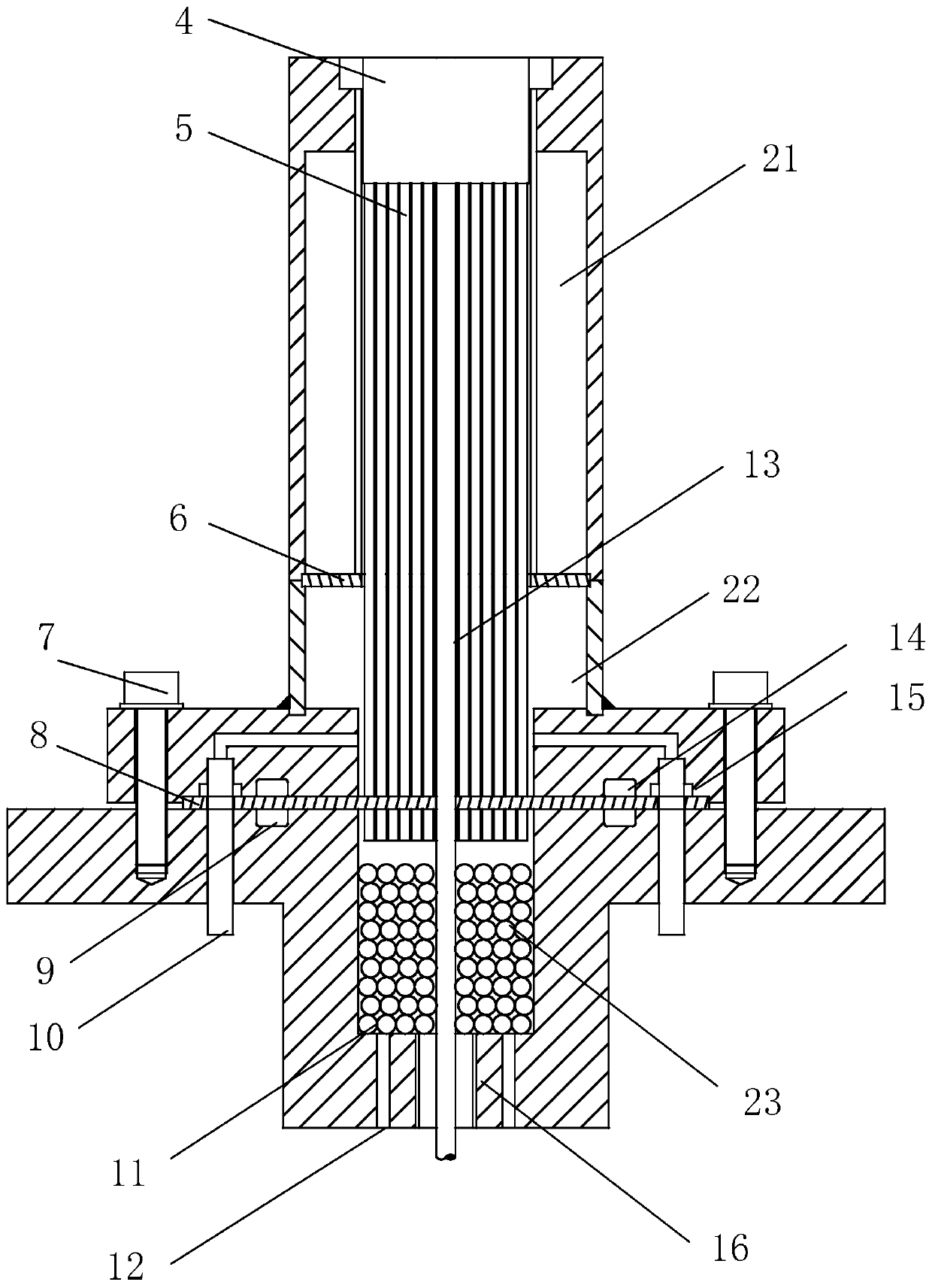

Gas premixing porous-medium combustor achieving axial and radial stable combustion

PendingCN108180475AImprove uniformityImprove stabilityBurner safety arrangementsGaseous fuel burnerPorous mediumPollutant emissions

The invention relates to a porous-medium combustor, in particular to a gas premixing porous-medium combustor achieving axial and radial stable combustion. The gas premixing porous-medium combustor achieving axial and radial stable combustion comprises a heat preservation layer, a combustion area porous medium, a stable combustion body, a stable combustion porous plate, a backfire preventing area porous medium, a flow equalizing board, a premixing chamber, a gas inlet and an air inlet. The gas inlet and the air inlet are connected with the premixing chamber. The flow equalizing plate, the backfire preventing area porous medium, the stable combustion porous plate and the combustion area porous medium are sequentially arranged on the premixing chamber from bottom to top. The stable combustionbody is a conical body and made of a high-temperature-resistant austenite steel material, and the stable combustion body is arranged at the axis of the combustor. The pore diameters of the stable combustion porous plate are sequentially reduced in the radial direction from inside to outside. The stable combustion porous plate is made of the high-temperature-resistant austenite steel material andarranged on the stable combustion body in a sleeving manner. The stable combustion body and the stable combustion porous plate improve the heat load distribution evenness of the porous medium in the axial direction and the radial direction, the stability of a premixed flame is improved, the combustion efficiency is improved, and the pollutant emission is lowered.

Owner:SHENYANG INST OF ENG

Low-emission cold flame multistage premixed combustor

ActiveCN106949471APre-mixed wellIndirect carbon-dioxide mitigationGaseous fuel burnerNitrogen oxidesFlue gas

The invention provides a low-emission cold flame multistage premixed combustor. The low-emission cold flame multistage premixed combustor comprises an ignition gun and a gas injection pipe. The gas injection pipe is provided with three gas injection outlets, and staged combustion is conducted through combustion areas. A premixed flame is injected at a high speed from the gas injection outlets and rapidly makes contact with a heat transfer pipe, the temperature of the flame is rapidly lowered, and the flame making contact with a refrigerant is reflected back to form a combustion gas curtain, so that combusted waste gas participates in secondary combustion and serves as flue gas to be recycled, and generation of nitrogen oxides is effectively reduced. Through a unique Venturi premixed structure, air and fuel are mixed more sufficiently. By means of the ignition gun which is high in adjusting ratio and wide in air excess coefficient range, the effect that the flame can be successfully built is ensured.

Owner:ANDERSON THERMAL SOLUTION SUZHOU CO LTD

Method and system for controlling gas turbine

Owner:GENERAL ELECTRIC CO

Gas turbine combustor having multiple independently operable burners and staging method thereof

ActiveUS7797942B2Improve featuresAchieve stablyContinuous combustion chamberTurbine/propulsion fuel supply systemsDiffusion flameCombustion chamber

Owner:MITSUBISHI POWER LTD

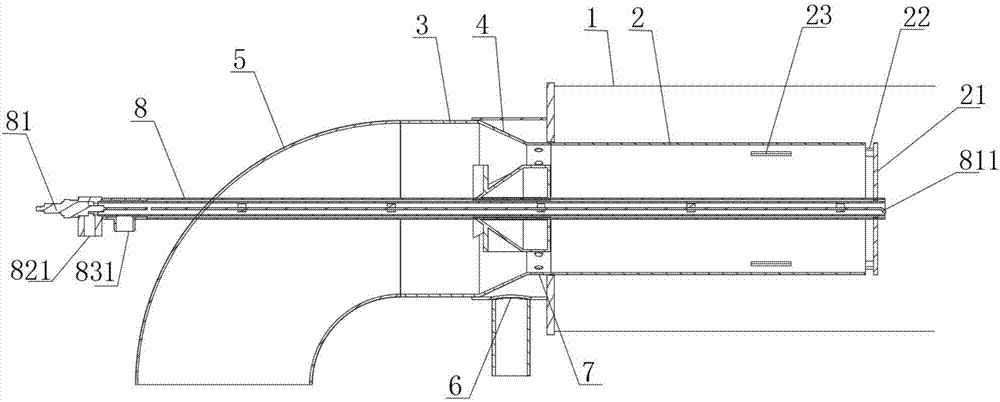

High-speed premixed flame furnace for supersonic burning research

The invention relates to a high-speed premixed flame furnace for supersonic burning research. The high-speed premixed flame furnace comprises a main stream mixing chamber (5), a supersonic nozzle (8), a wake plenum chamber (6) and a low-speed nozzle (7), wherein the whole high-speed premixed flame furnace is of a streamline structure with two smaller ends and one larger middle; the high-speed premixed flame furnace is equally divided into two parts lengthways, namely a supersonic main stream side and a sub-sound velocity wake side; the main stream mixing chamber (5) and the supersonic nozzle (8) are positioned on the supersonic main stream side; and the wake plenum chamber (6) and the low-speed nozzle (7) are positioned on the sub-sound velocity wake side. The premixed flame furnace provided by the invention has the advantages of compact structure, simple processing technique, low test cost, short test period, accurate and adjustable premix equivalent ratio large range, large total temperature, total pressure and airflow mach number adjustable range and the like.

Owner:NAT UNIV OF DEFENSE TECH

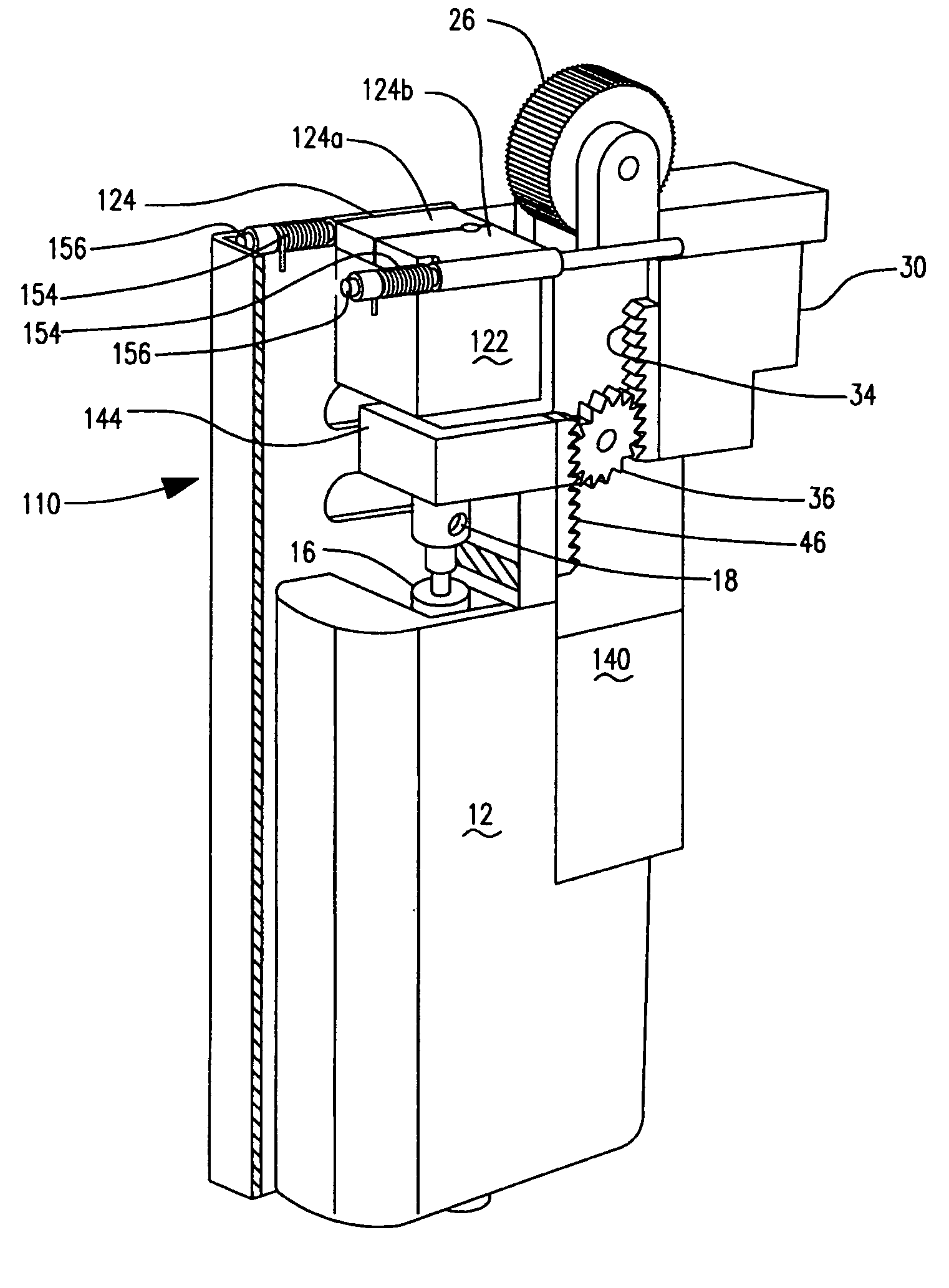

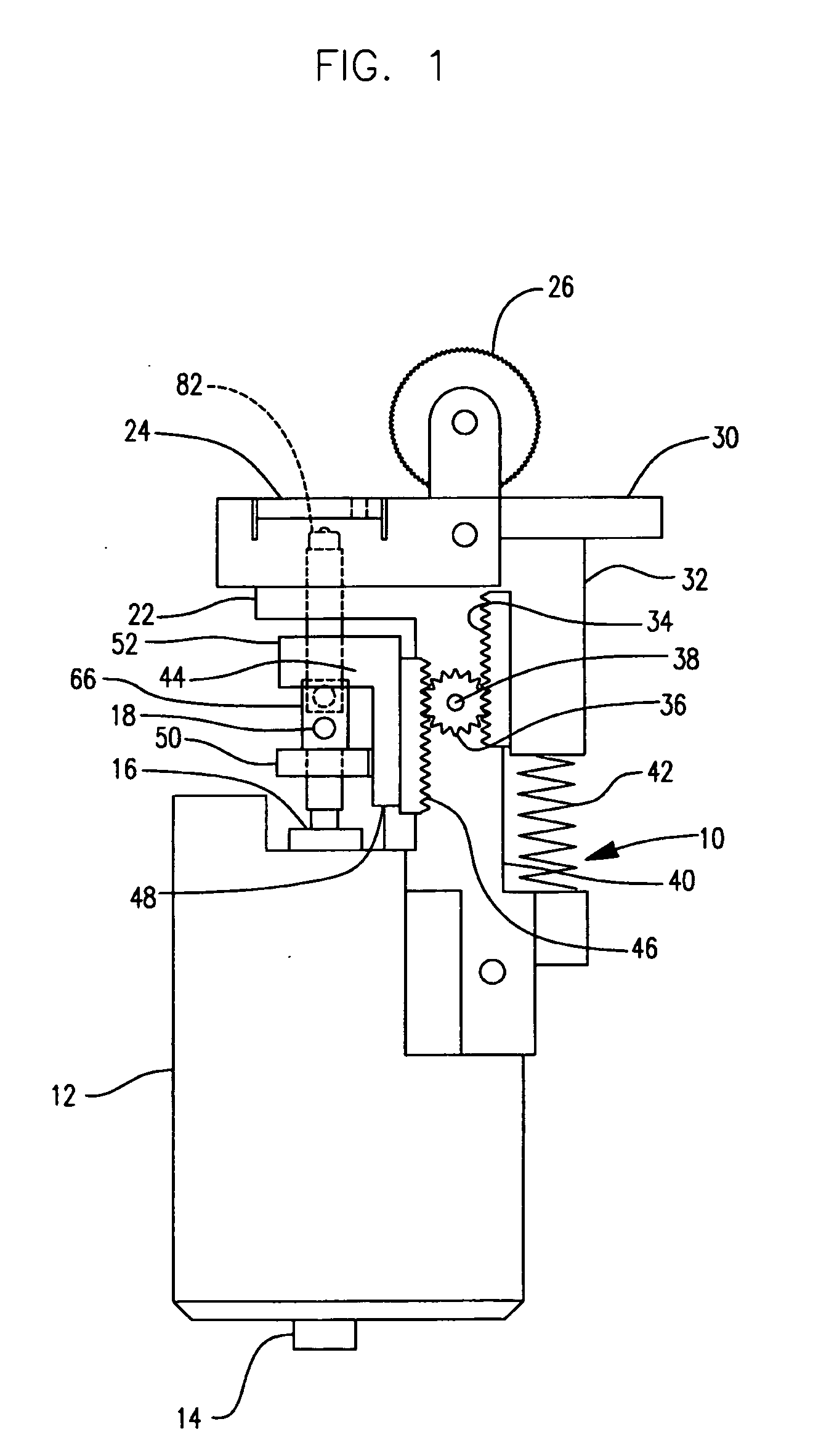

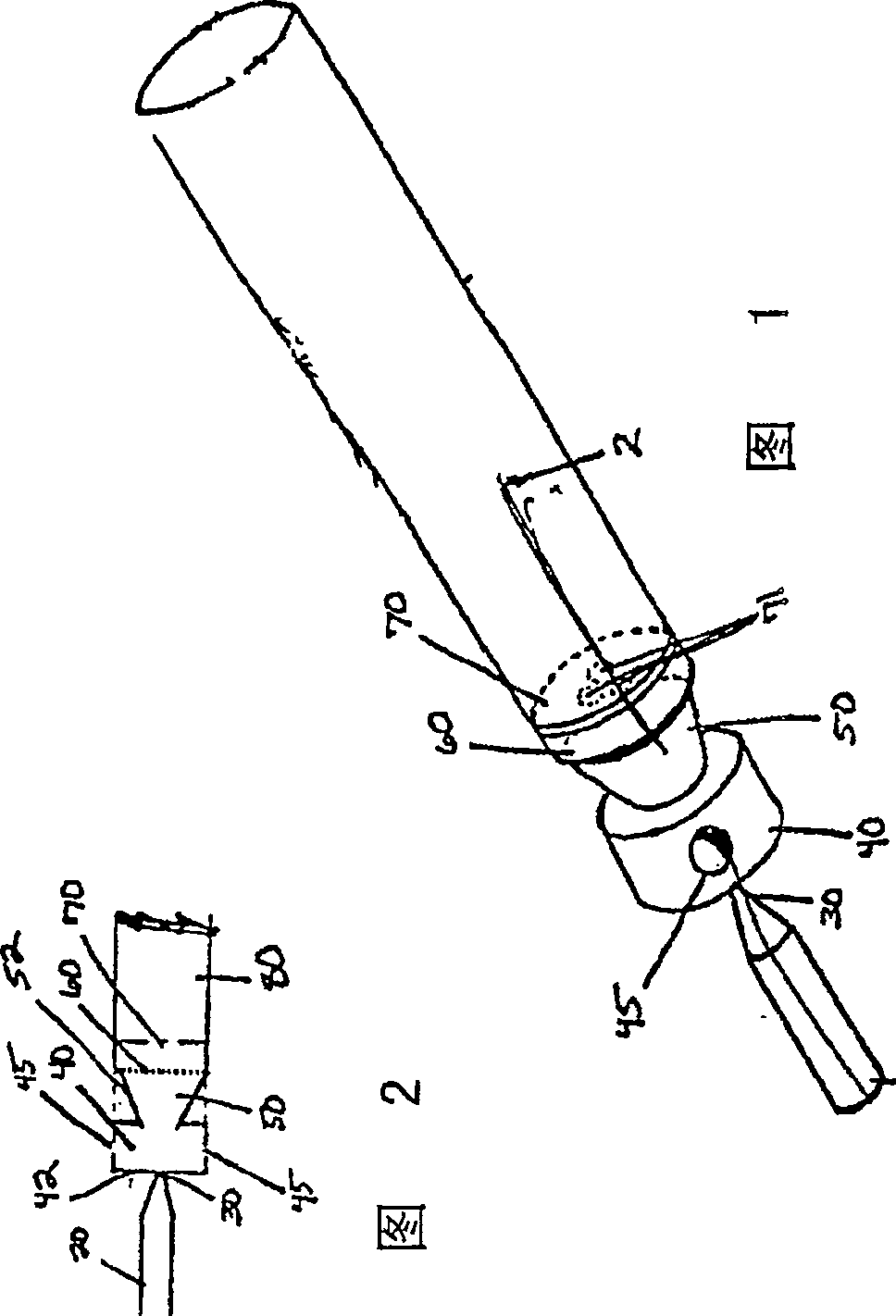

Flint ignited premixed lighter and method of operating a lighter

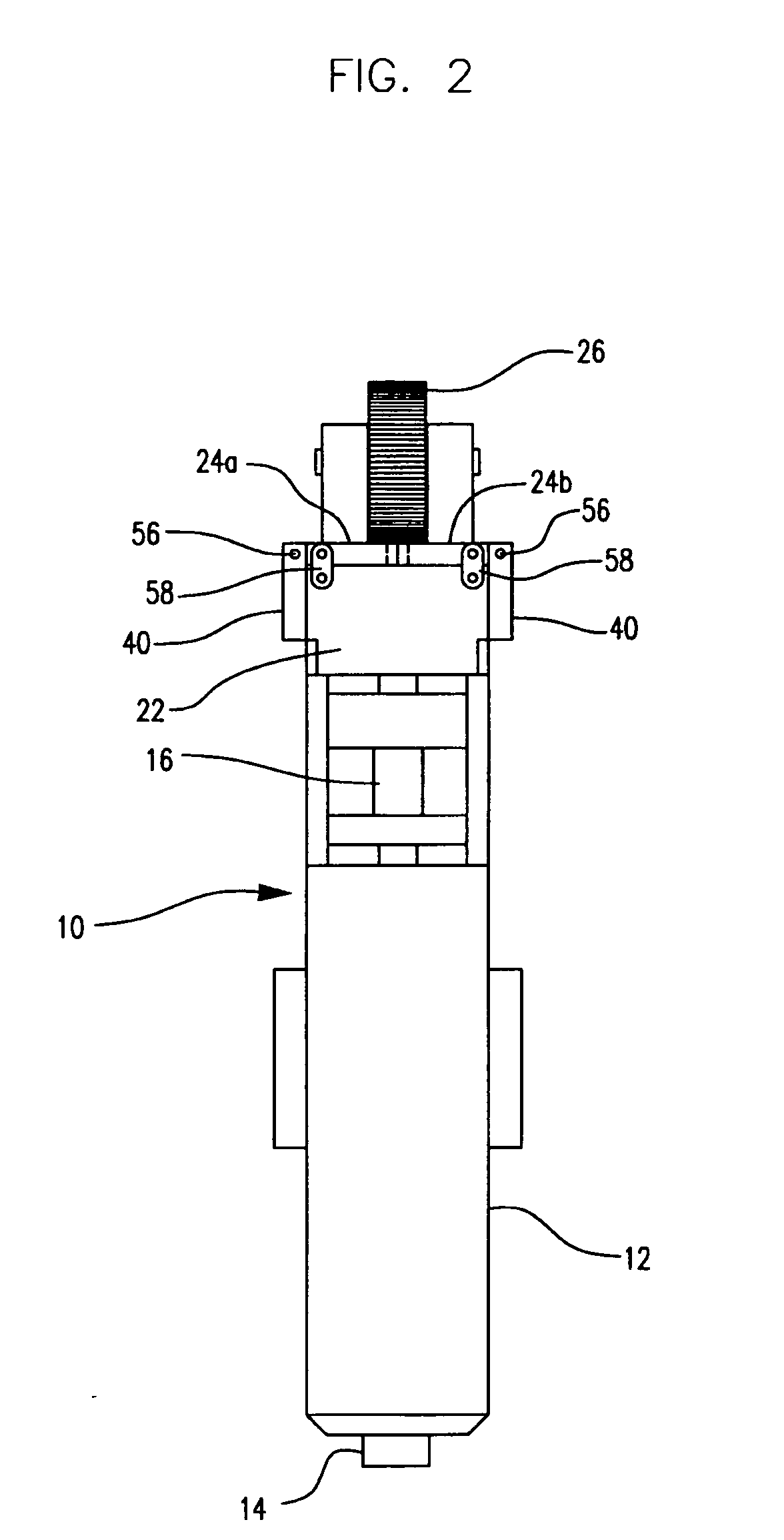

InactiveUS20050181320A1Reliable ignition characteristicReliably and repeatedly ignitedFuel lightersGaseous fuel burnerCombustionEngineering

A lighter includes a butane fuel reservoir, a valve, a mixer with a choke, a movable combustion space and movable top door over the combustion space which interact to allow a wheel and flint igniter to initiate a post mix flame above the top of the combustion space followed by the opening of the top and migration of the flame into the combustion space to create a strong torch-like premixed flame thereafter.

Owner:ZIPPO MFG

Engine device

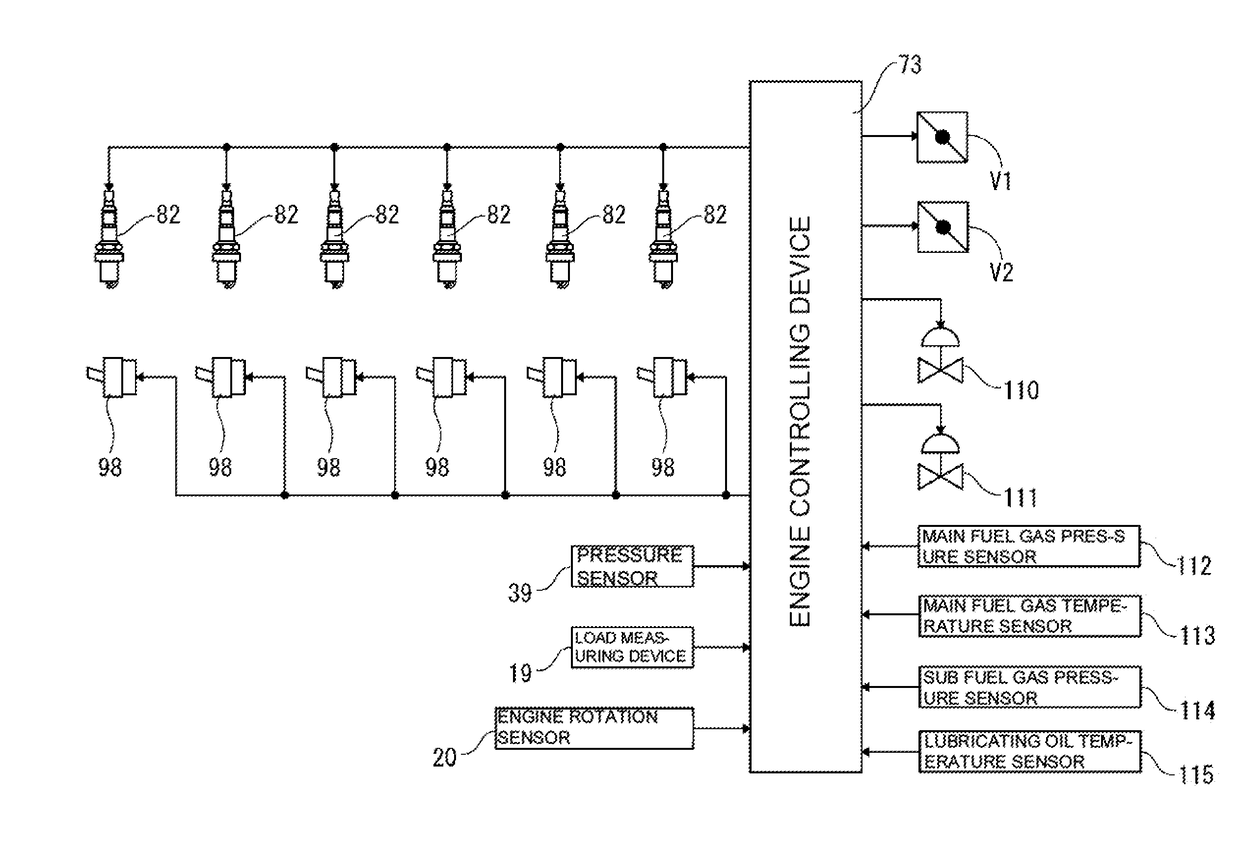

ActiveUS20180298840A1Reduce riskSafely sustainedElectrical controlInternal combustion piston enginesMixed gasInlet manifold

An engine device including: an intake manifold (67) configured to supply air into a cylinder (77); a gas injector (98) configured to mix fuel gas with air supplied from the intake manifold (67), and supply mixed gas to the cylinder (77); an igniter (79) configured to ignite, in the cylinder (77), premixed fuel obtained by pre-mixing the fuel gas with the air; and a control unit (73) configured to execute a combustion control of a premixed fuel based on the output signal indicative of an output from the engine device. When the air amount is determined to be insufficient and when the output signal is lost, the control unit (73) estimates an output signal based on the fuel gas injection amount from the gas injector (98), and executes the combustion control based on the estimated output signal.

Owner:YANMAR POWER TECHNOLOGY CO LTD

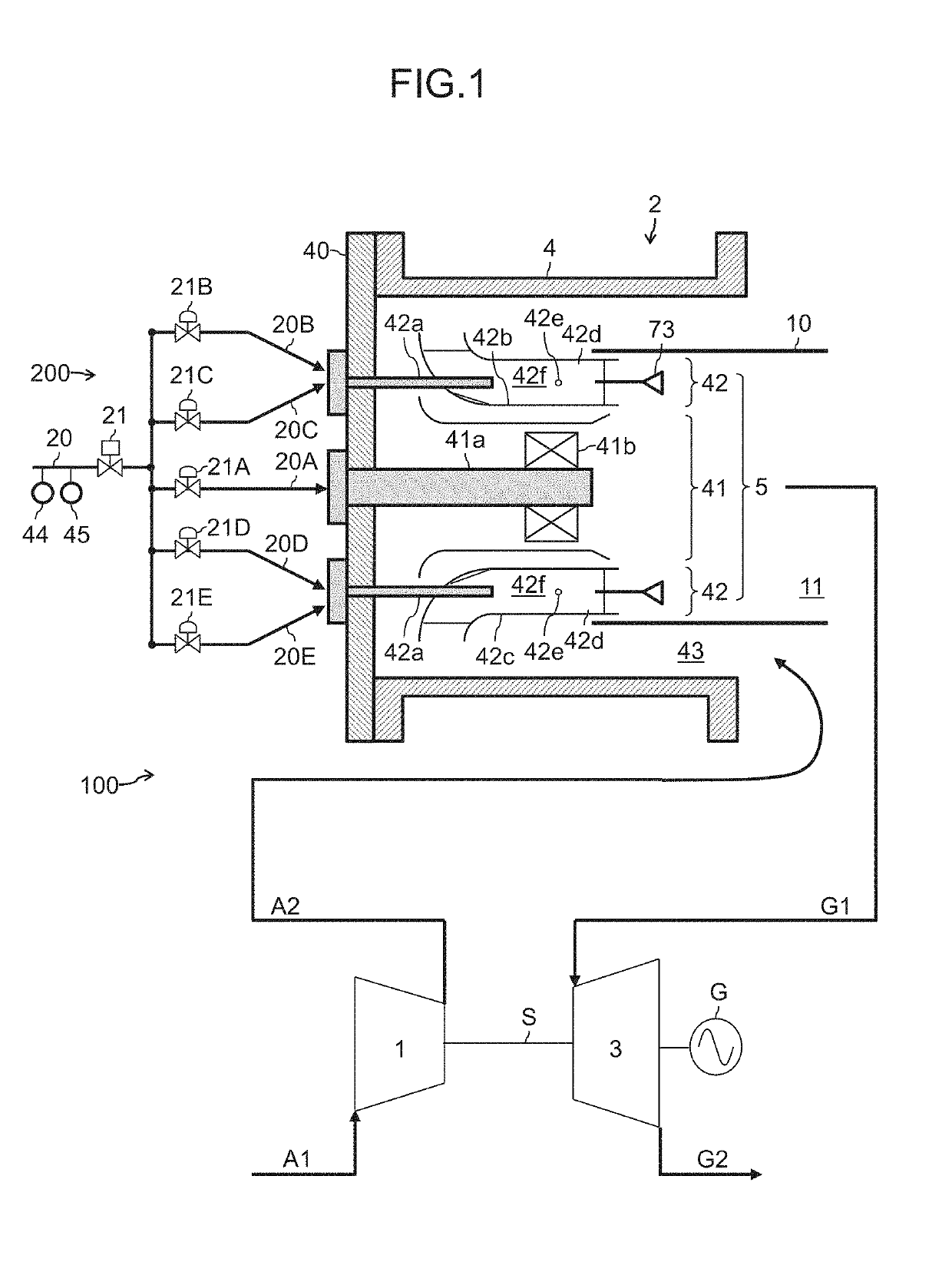

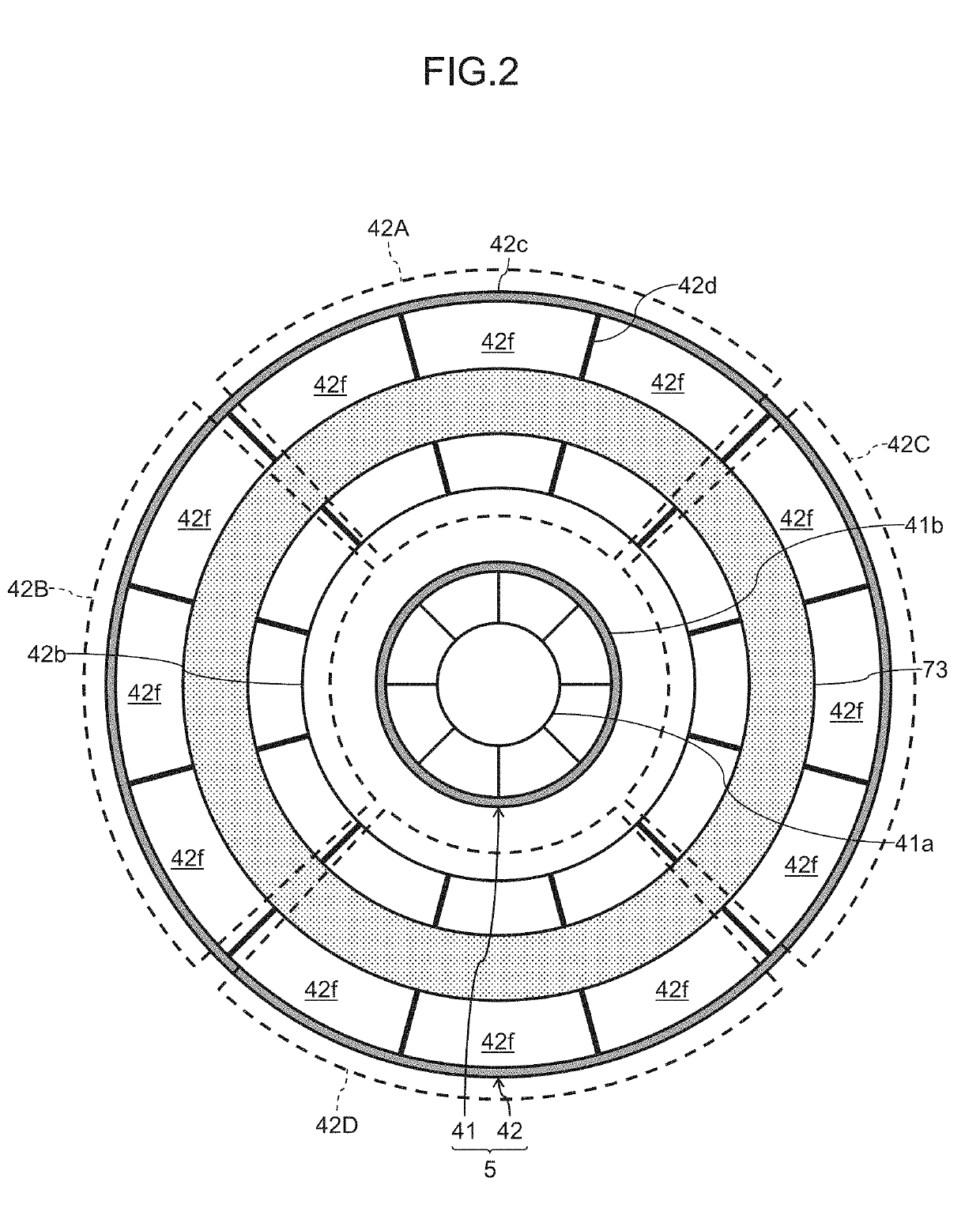

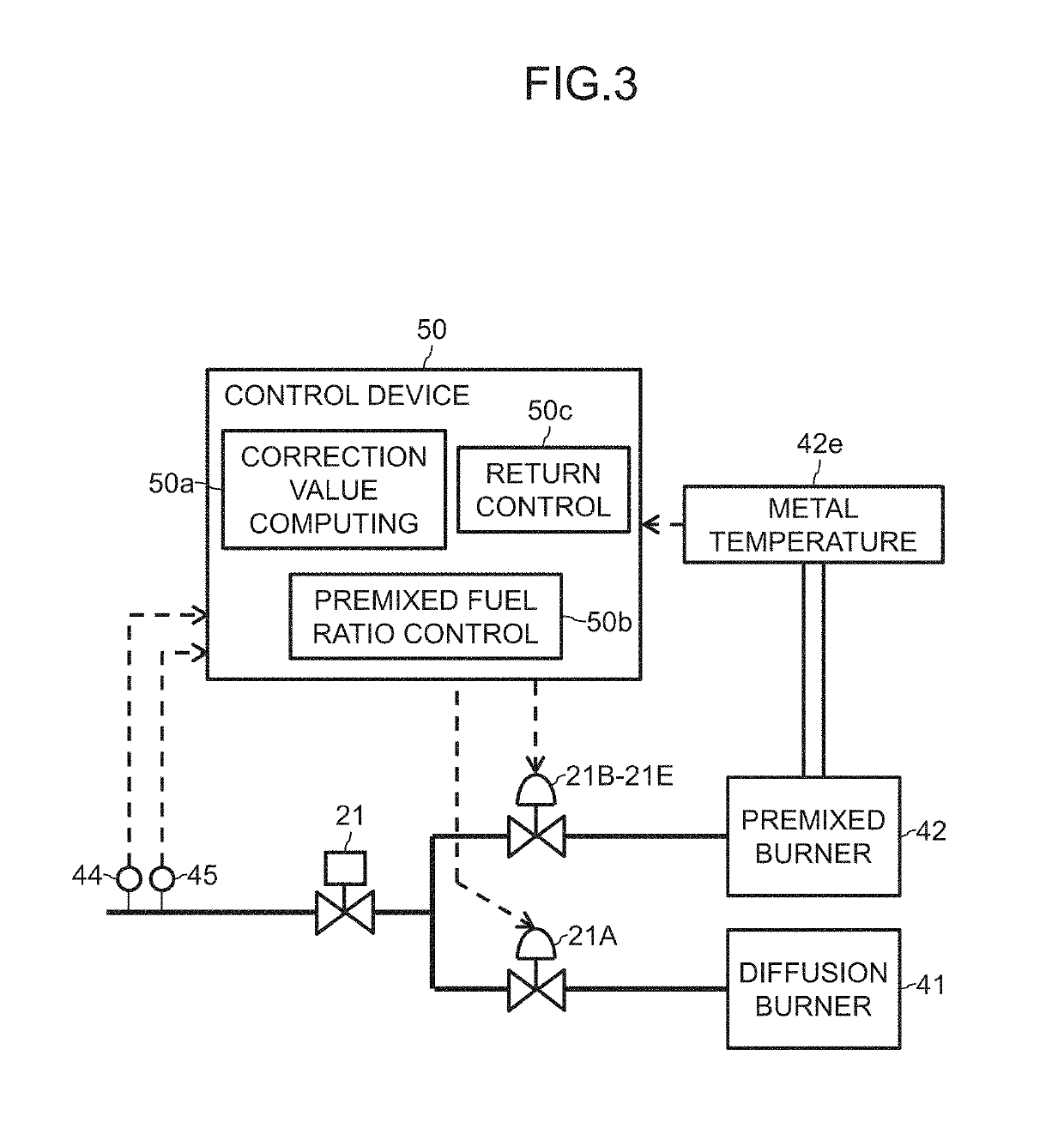

Gas Turbine Combustor, Gas Turbine, and Control Method for Gas Turbine Combustor

ActiveUS20190242581A1Suppress in output powerEnsure reliabilityContinuous combustion chamberTurbine/propulsion fuel controlCombustion chamberEngineering

A flame produced within a premixer is promptly extinguished and a reduction in output power of a gas turbine associated with extinguishment is suppressed. In a gas turbine combustor including a diffusion burner and a premixed burner, the premixed burner is configured with a burner liner that surrounds the diffusion burner; a burner casing that surrounds the burner liner; a plurality of vanes that separate a cylindrical space between the burner liner and the burner casing into a plurality of premixers arranged side by side in a circumferential direction; a plurality of premixed fuel nozzles that inject a premixed fuel to the premixers; at least one thermometer installed to be buried in one of the vanes, and the like, and in a case in which a detection value of the thermometer exceeds a corresponding set value, an opening of each of premixed gas control valves is reduced and an opening of a diffusion gas control valve is increased in such a manner that a sum of flow rates of fuels supplied to the diffusion burner and the premixed burner remains unchanged.

Owner:MITSUBISHI POWER LTD

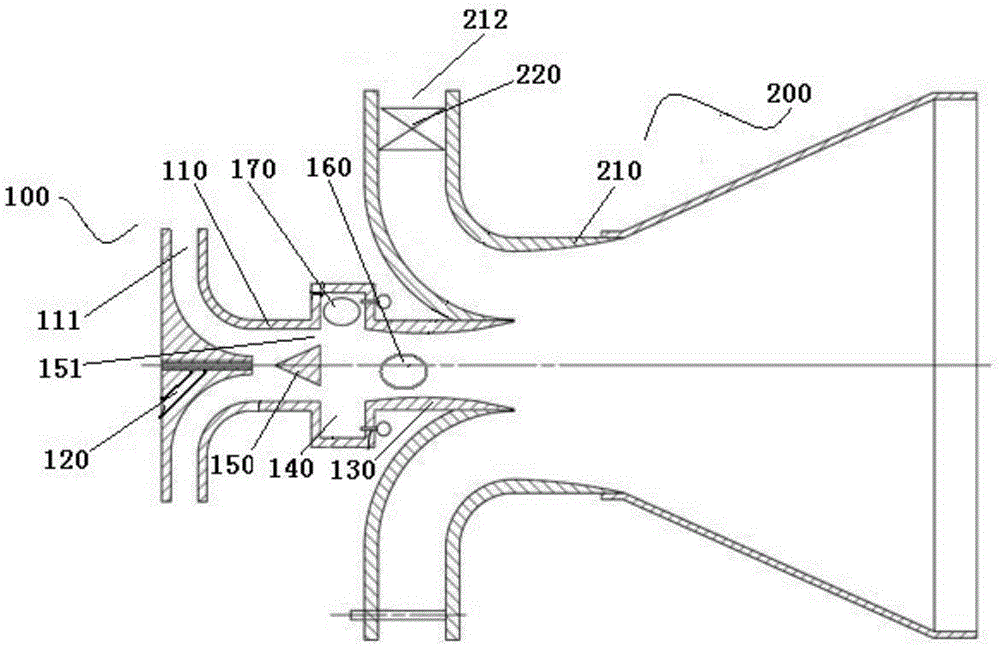

Combustor for gas turbine and flame combustion method

ActiveCN105605616AAvoid interactionImprove flame stabilityContinuous combustion chamberGas turbinesPremixed flame

The invention provides a combustor for a gas turbine and a flame combustion method. The combustor comprises a central on-duty combustor and a main premix combustor which are connected with each other, wherein the central on-duty combustor comprises an on-duty combustor body; the on-duty combustor body is provided with a central on-duty nozzle; a gas outlet of the on-duty combustor body is provided with a flame control pipeline; the inner wall of the flame control pipeline is an inwardly bulging cambered structure; a concave cavity is arranged along the circumferential direction of the inner wall of the on-duty combustor body; the concave cavity is positioned between the central on-duty nozzle and flame control pipeline, and is provided with a cavity fuel port and a cavity gas inlet; a central blunt body is arranged inside the on-duty combustor body; the central blunt body is positioned between the central on-duty nozzle and concave cavity; a blunt body ventilation clearance is arranged between the central blunt body and the inner wall of the on-duty combustor body; and the blunt body ventilation clearance communicates with the concave cavity. The on-duty flame and main premix flame are positioned in different regions, thereby avoiding the interaction between the two flames, and enhancing the combustion stability.

Owner:SHANGHAI ELECTRIC GAS TURBINE CO LTD

Combustor and application thereof

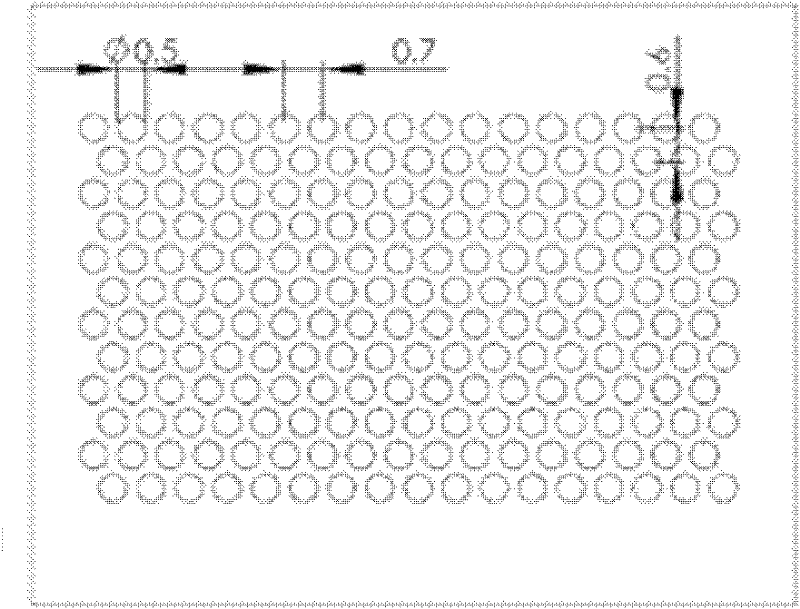

PendingCN112212328AHigh densityAperture limitFluid heatersDomestic stoves or rangesThermodynamicsMechanical engineering

The invention provides a combustor. The combustor comprises a shell, a draught fan, a burner head and an ignition mechanism, and an air inlet of the shell and the input end of the burner head form a pressure equalizing cavity; the ignition mechanism is arranged at the output end of the burner head, and the burner head comprises a main frame body and at least one stable combustion isolation belt; the interior of the main frame body is divided into at least two ventilation areas in the direction of a gas channel through the stable combustion isolation belt; a plurality of separation mechanisms are arranged in each ventilation area, and the ventilation areas are divided into a plurality of through holes distributed in the direction of the gas channel through the separation mechanisms; and thethrough holes are used for allowing mixed gas to pass through and strengthening the mixing effect of the gas and air, and combustion flame of the combustion face of the main frame body can be dividedinto independent flames through the stable combustion isolation belt. According to the combustor, the power of a combustion component can be changed with the area of the combustor, and fuel gas and air are highly and evenly mixed after entering micropore channels, and ignited to form even premixed flame after being sprayed out from the micropore channels; and the flames are independent through arrangement of the isolation belt, and the flames are stable, clean and efficient.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

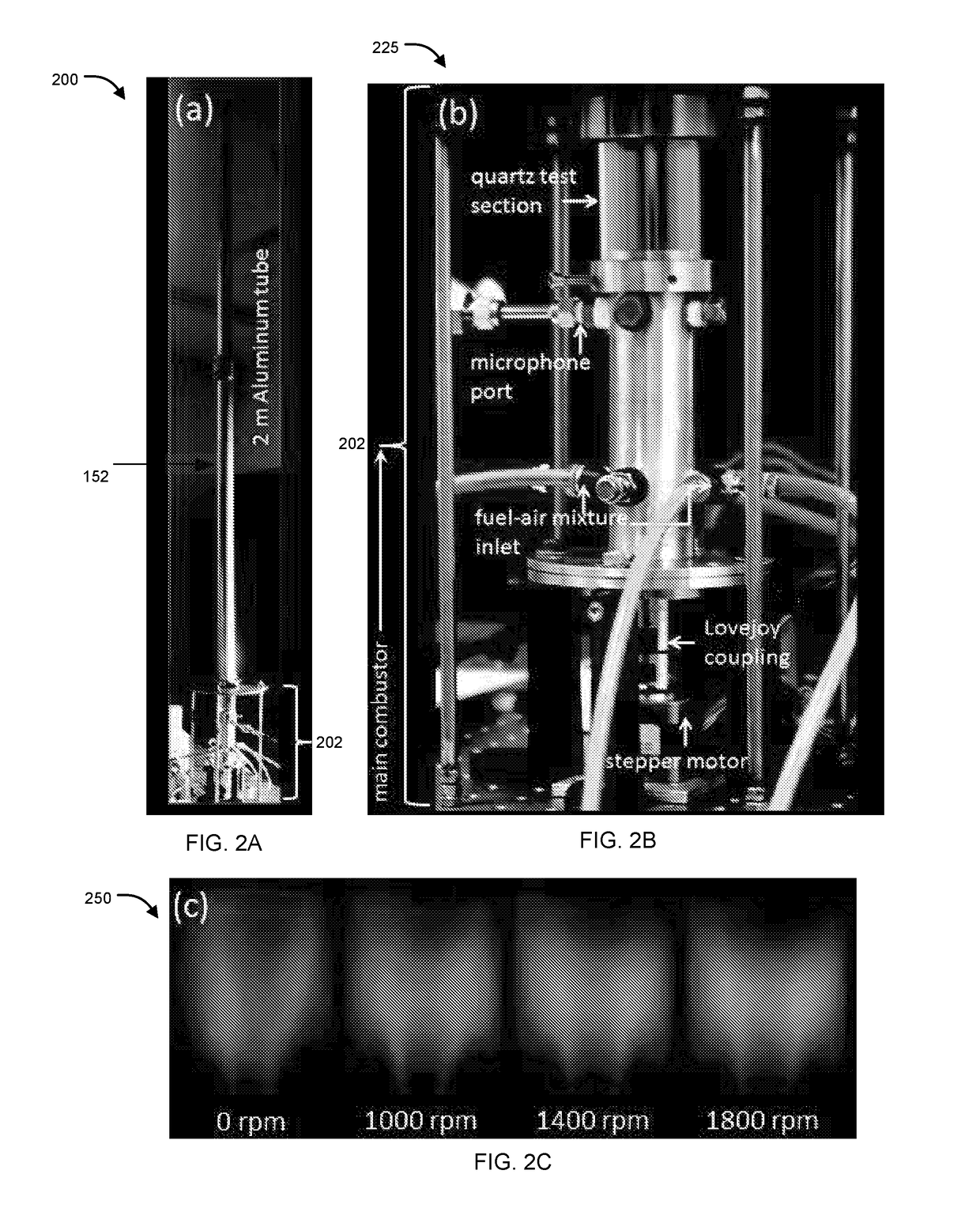

Vortex premixer for combustion apparatus

InactiveUS20110061391A1Easy to optimizeWide power rangeTurbine/propulsion fuel supply systemsContinuous combustion chamberPremixed flameWaste management

Owner:LEAN FLAME INC

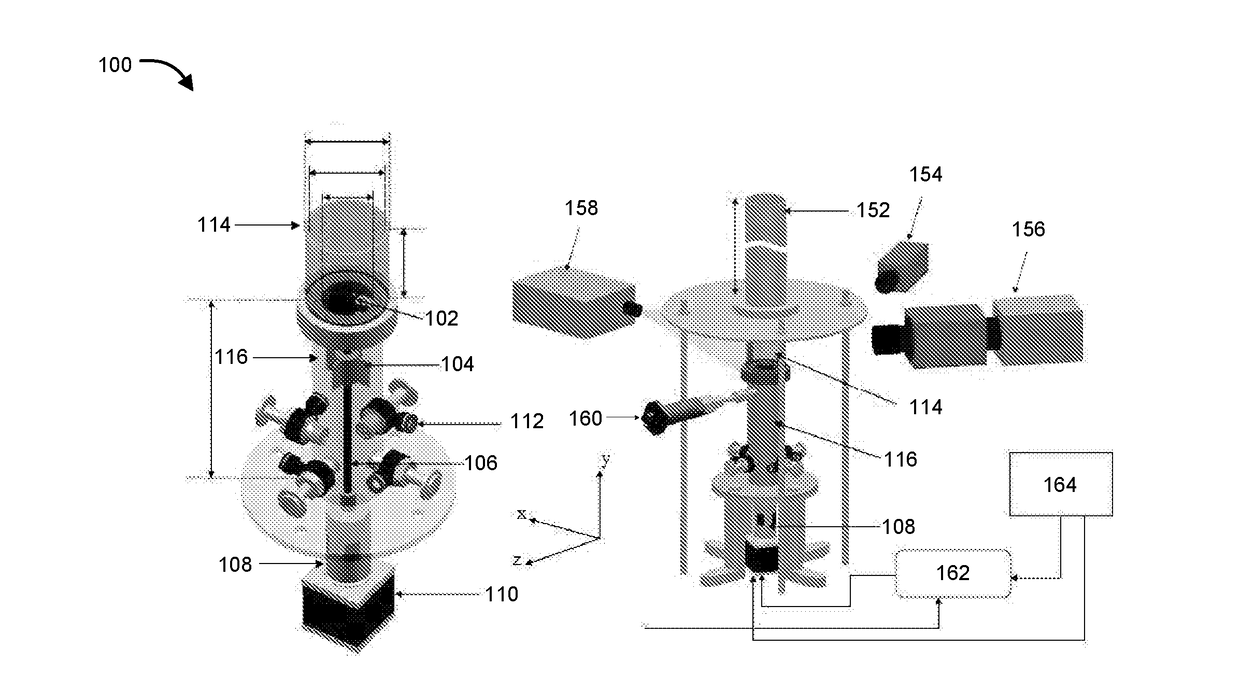

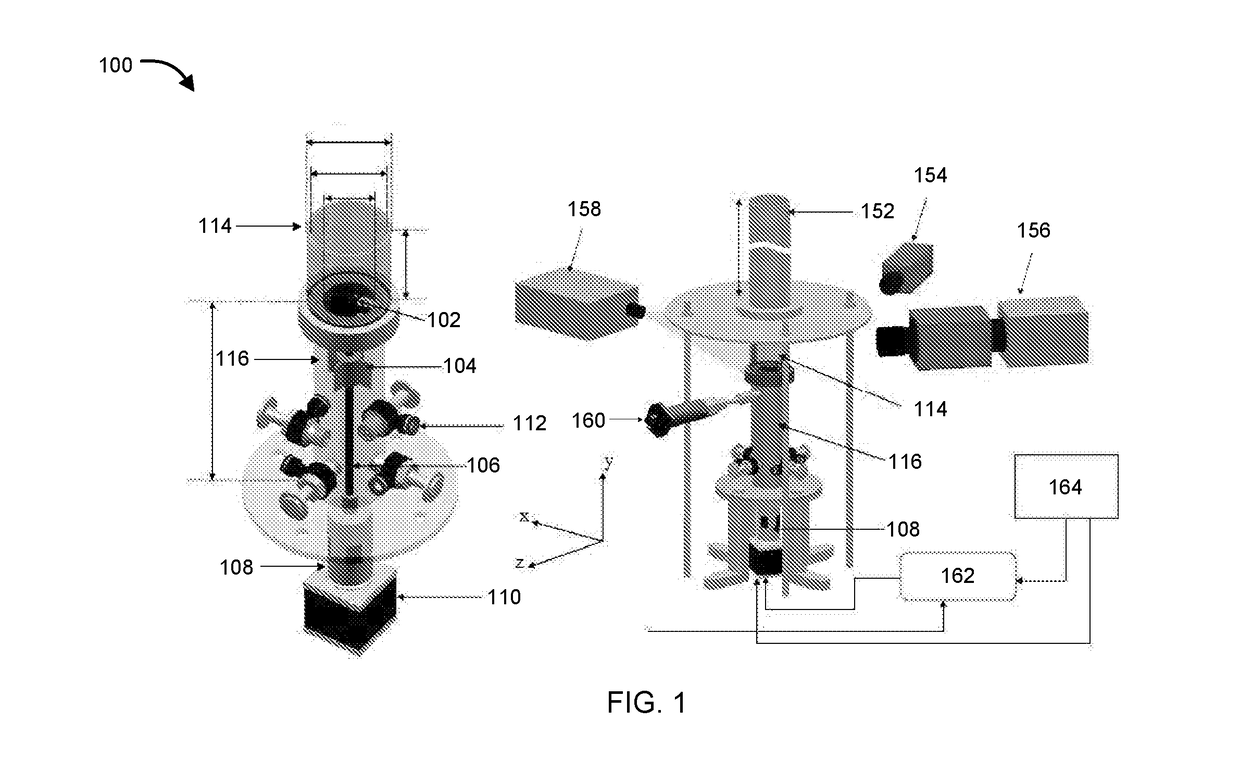

Mitigating instability by actuating the swirler in a combustor

InactiveUS20180202660A1Reduce decreaseStable conditionContinuous combustion chamberEfficient propulsion technologiesMomentumAcoustic energy

The present disclosure relates to a method and apparatus to mitigate thermo-acoustic instabilities in combustor of gas turbine engines using a lean premixed flame; and provides a dynamic control strategy for mitigating thermo-acoustic instability in a swirl stabilized, lean premixed combustor by rotating the otherwise static swirler meant for stabilizing the lean premixed flame. The swirler is subjected to a controlled rotation for imparting increased turbulence intensity and higher tangential momentum to the premixed reactants towards mitigating thermo-acoustic instability. The rotating swirler induces vortex breakdown and increased turbulence intensity to decimate periodic interactions found during a particular phase of the instability cycle on account of periodic collision of diverging flame base with the flame segment above the dump plane in the combustor. This prevents flame-flame interactions and emergence of strongly positive Rayleigh indices which contribute as sources of acoustic energy to drive the self-excited instability.

Owner:INDIAN INSTITUTE OF SCIENCE

Gas turbine combustor

ActiveUS20140305095A1Small sizeImprove flame stabilityContinuous combustion chamberGas turbine plantsCombustion chamberGas turbines

Provided is a gas turbine combustor capable of reducing the size of a low-temperature air layer of pilot air formed between a pilot flame and a premixed flame and of improving the flame stability of the premixed flame. A gas turbine combustor, which is provided with a pilot burner that is provided at the center portion of a combustor main body formed in a cylindrical shape to form a pilot flame, and a plurality of main burners arranged so as to surround the outer periphery of the pilot burner to form a premixed flame, includes, as the ignition improving part, a channel blocking member that reduces the size of the low-temperature air layer of the pilot air formed between the pilot flame and the premixed flame.

Owner:MITSUBISHI POWER LTD

Trace element premixed feed for piglets and preparation method of premixed feed

InactiveCN104522421AReduce diarrhea rateReduce pollutionAnimal feeding stuffPhytasePhosphorus excretion

The invention discloses trace element premixed feed for piglets and a preparation method of the premixed feed. According to reasonable use of trace element components in the feed disclosed by the invention, the diarrhea ratio of the piglets is reduced, and pollution to the environment and soil is reduced; basic zinc sulfate and basic chrome sulfate are subjected to moisture-proof agglomeration treatment, dampening of the feed is well avoided, and due to the addition of amino acid chelate manganese, amino acid chelate iron, amino acid chelate zinc and amino acid chelate calcium, the absorption rate of the pigs on manganese, iron, zinc and calcium is improved, and due to the addition of lysine, the utilization rate of nitrogen in the feed can be effectively improved, so that the nitrogen excretion in the pig manure is reduced; protein germanium serves as a trace element germanium source additive in animal feed, so that the biological activity of the germanium trace element can be improved, the germanium element is easily absorbed, the animal growth can be effectively promoted, and the body immunity of the animal is improved; and moreover, phytase is added into the feed, and the phosphorus excretion in the pig manure is reduced.

Owner:SICHUAN AGRI UNIV +1

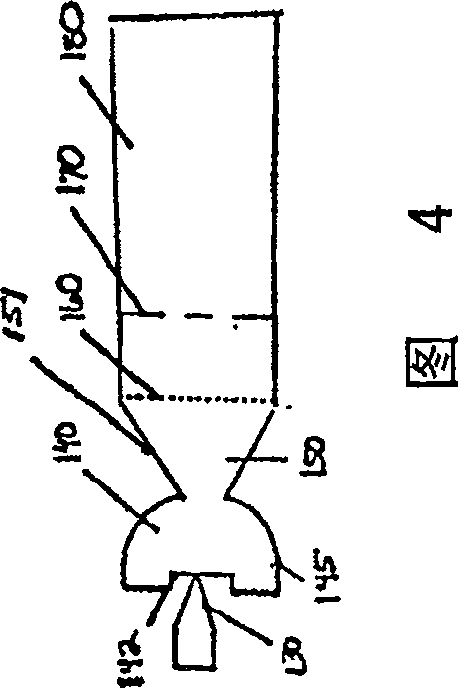

Micro gas burner

Provides a micro gas burner with a stable, premixed flame that produces little or no soot or unburned hydrocarbons. A gas burner includes a fuel inlet, a nozzle, an oxidation chamber with at least one air inlet, a mixing chamber with a frusto-conical inner wall, at least one penetrable barrier, and a flame stabilizer. Gas burners thoroughly mix fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. Gas burners thoroughly mix fuel and air, making them require lower fuel flow velocities than are required to produce a stable, premixed flame. Gas burners include optional flame tubes in which the flame is contained and isolated from diffusing air.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Active heat reclaiming method and device for diesel engine particulate drip catcher

InactiveCN100595422CAvoid the defect that it is not easy to igniteImprove ignition performanceExhaust apparatusSilencing apparatusParticulatesLiquid fuel

The invention relates to an active thermal regenerative method and a device of a collector for diesel micro particle. The method is as follows: liquid fuel, the boiling point of which is higher than normal temperature, is put into the tail gas of an engine or made into high pressure fuel vapor by being heated by electricity; after CPU sends a regeneration instruction, the oxygen content of regenerative environment is adjusted by supplementing auxiliary air and the fuel under high temperature steam enters combustion zone; meanwhile, an ignition plug begins to jump spark; fuel vapor is ignited Under the action of a twin-stage reverse whirl cone, premised flame is fixed on a proper position; heat from fuel burning makes gas flow temperature rise until the temperature of microparticle on filter element is above inflammation point; the microparticle on deposit is ignited when high temperature air flow passes by the filter element; the fuel should be continuously supplied until the microparticle on the deposit is burnt out; and a regenerative cycle is finished. In order to avoid the extreme high temperature of primary chamber part outside the collector, a gaseous film cooling structure is arranged. The active thermal regenerative method and device of the collector for diesel microparticle is easy to be ignited and has the characteristics of stable burning, efficient burning, strong anti-interference ability, little secondary pollution and stable action.

Owner:HUNAN UNIV

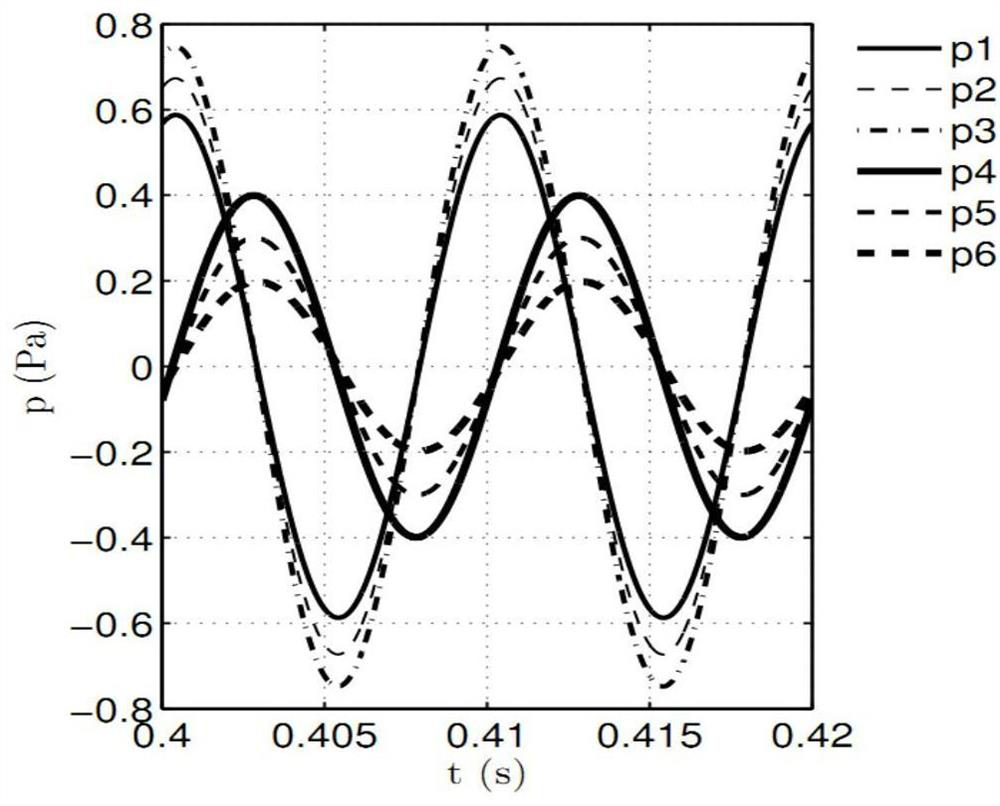

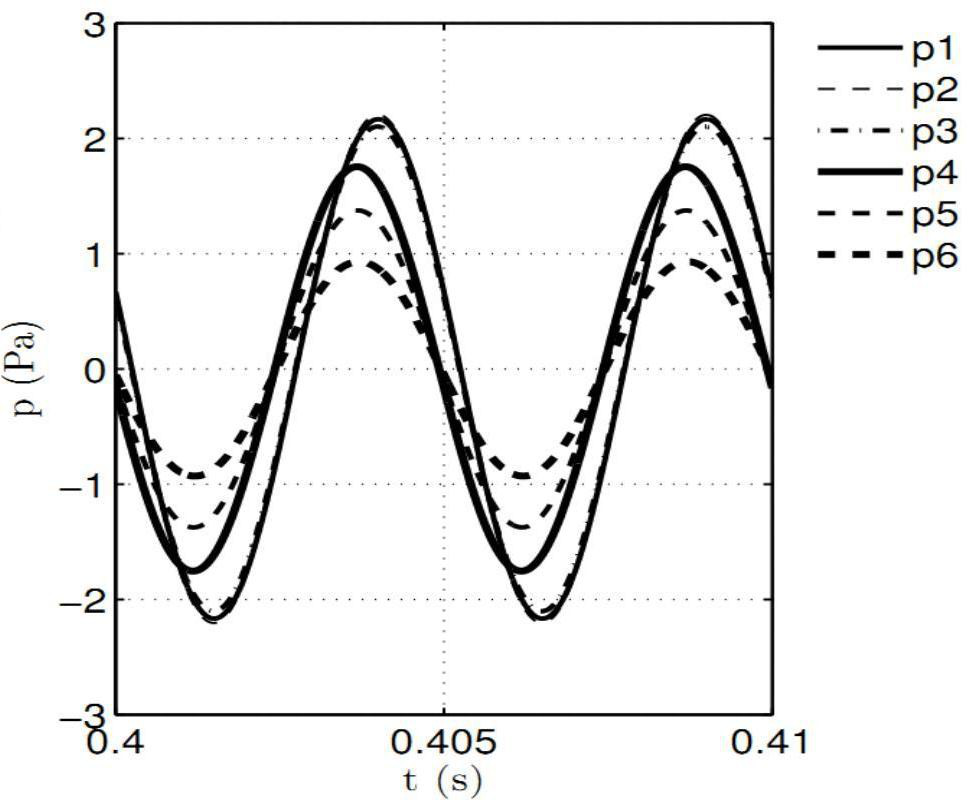

Experimental method and device for measuring heat release rate pulsation by adopting multiple microphones

InactiveCN112326730AEasy to operateEasy to adjustMaterial heat developmentCombustion instabilityCombustion chamber

The invention relates to an experimental method and device for measuring heat release rate pulsation by adopting multiple microphones. The experimental method and device are used for research on measurement of combustion instability of an aerospace engine. The sound field pressures before and after a heat source in a combustion chamber are measured based on a multi-microphone method, and heat release rate pulsation of the heat source is obtained through step function derivation at the heat source. The experimental device is composed of multi-microphone pressure measuring systems installed on the upstream and the downstream of a heat source and a sound source installed on the upstream of the heat source. A conventional measurement method is mainly an optical method, and when a heat source is flame, indirect measurement is realized by measuring the concentration of an intermediate product generated by combustion and the method is limited to premixed flame; when the heat source is not flame, no measuring method exists. According to the acoustic measurement method provided by the invention, the heat release rate pulsation is calculated by measuring the pressure fluctuation in the system, so that the acoustic measurement method is suitable for measuring the heat release rates of various heat sources, has the advantages of low cost, simple structure, convenience in adjustment and thelike, and is favorable for researching the measurement of the combustion instability of the aerospace engine.

Owner:BEIHANG UNIV

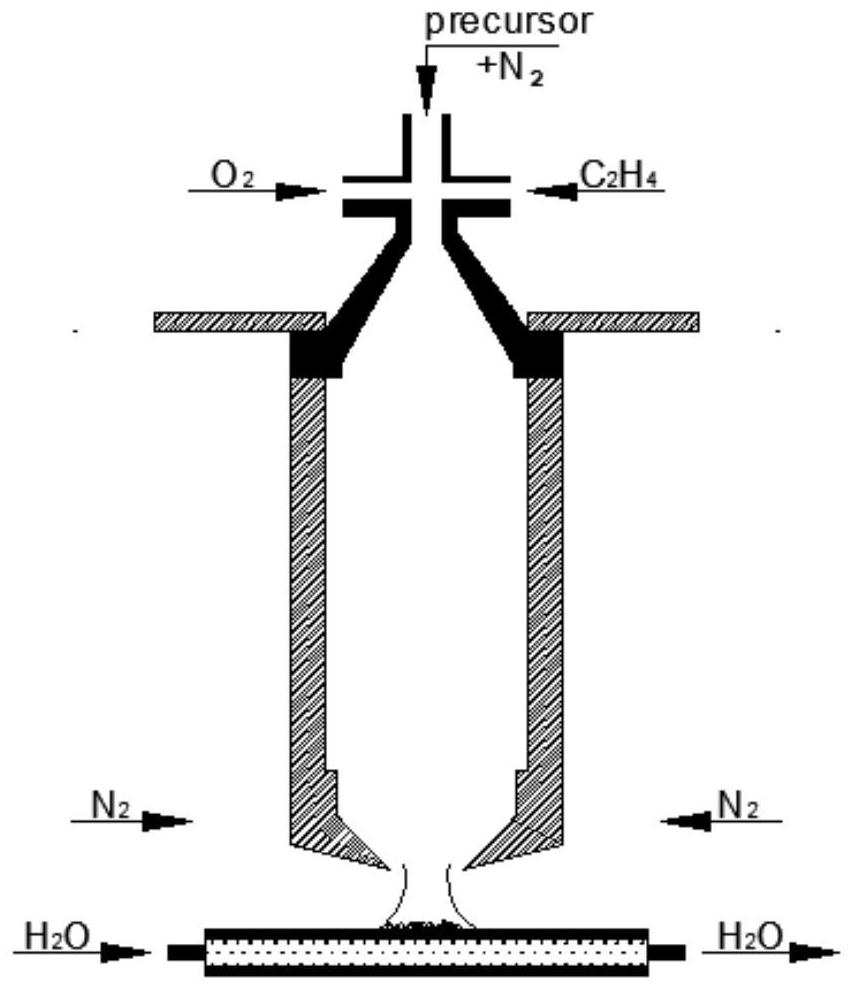

Pressurized plane flame combustion device

ActiveCN110425525ALong term workStable jobEngine sealsDomestic cooling apparatusEngineeringHigh pressure

The invention belongs to the field of research of reaction dynamics characteristics such as ignition, combustion and gasification of solid fuel particles, and discloses a pressurized plane flame combustion device. A combustor main body of the device is provided with an oxidizing gas cavity and a water cooling cavity; the upper end of the oxidizing gas cavity is opened, and an inner core is arranged in the center of the oxidizing gas cavity; an independent isolated cooling cavity is arranged in the side wall of the oxidizing gas cavity; a base comprises a fuel gas cavity, the fuel gas cavity islocated below the oxidizing gas cavity, and a sealing plate isolates the oxidizing gas cavity form the fuel gas cavity; and a planar flame capillary inner core comprises a honeycomb ceramic block, acapillary array and powder feeding tube. According to the pressurized plane flame combustion device, oxidation gas and fuel gas are transmitted and rectified separately, and finally a stable non-premixed plane flame is formed on the top surface of the honeycomb ceramic block to form a high-temperature and high-heating-rate flue gas environment is formed; and the hot-pressing deformation and heat failure are prevented through water cooling, and the sealing plate is matched with O-shaped rings for sealing, so that the pressurized plane flame combustion device can stably work in a high-temperature and high-pressure environment for a long time.

Owner:HUAZHONG UNIV OF SCI & TECH

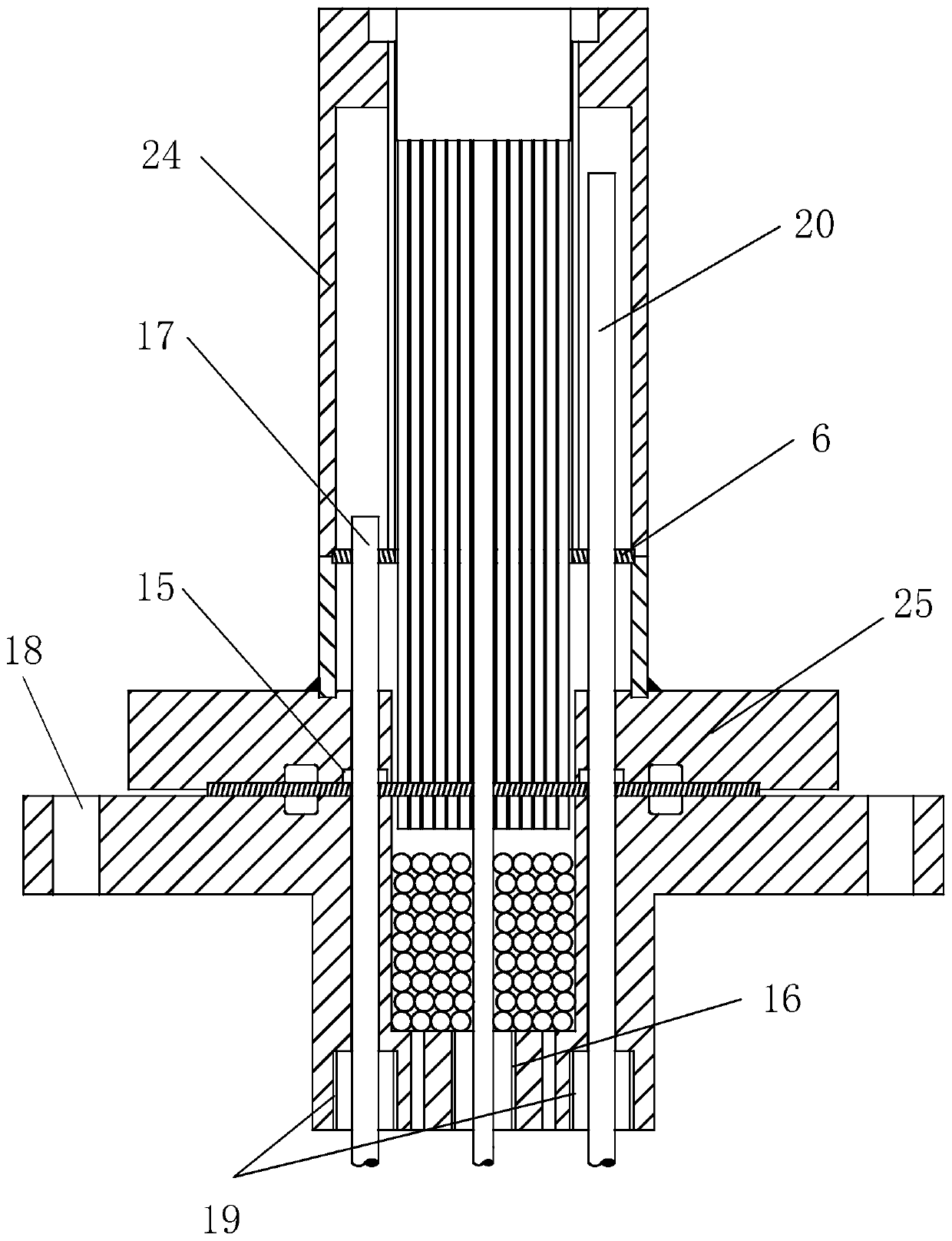

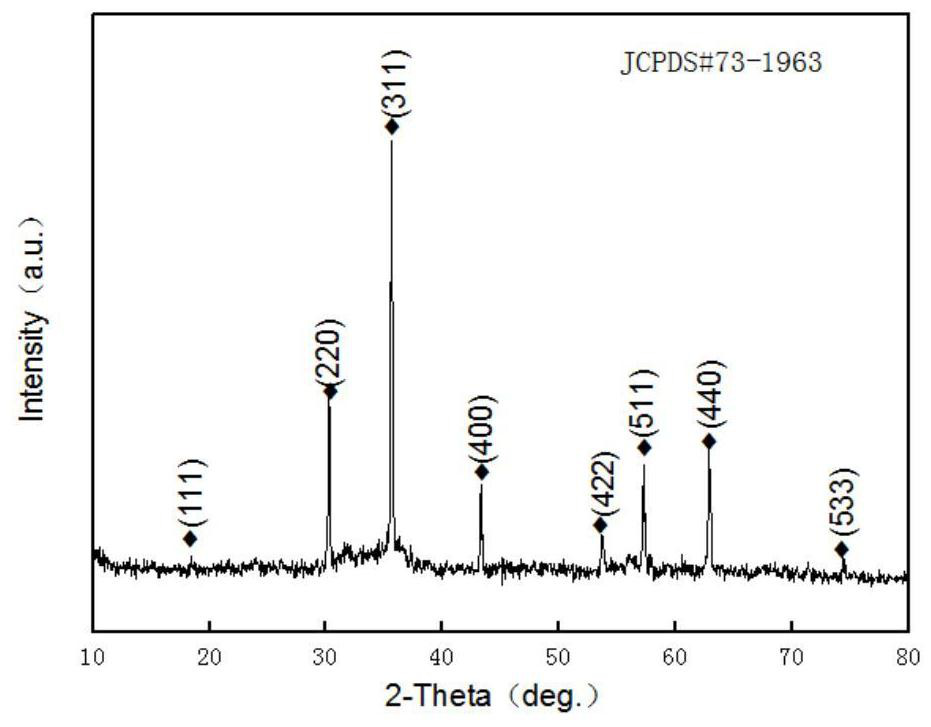

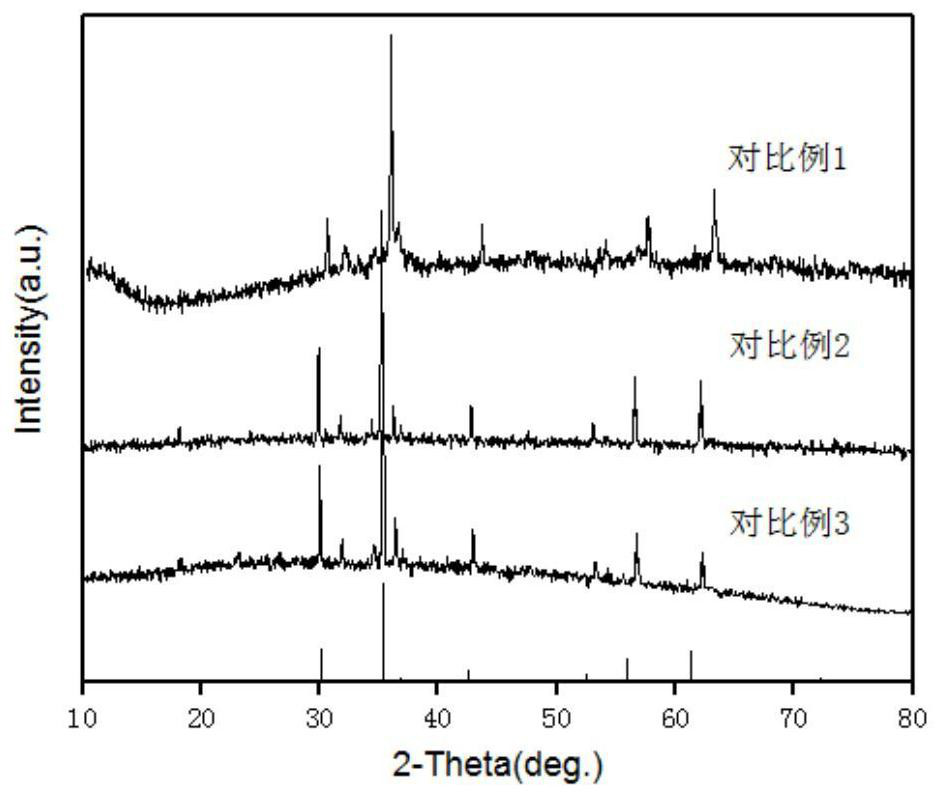

Method for synthesizing zinc ferrite spherical nano material by premixed flame

ActiveCN112194187ALarge specific surface areaMultiple active sitesNanotechnologyIron compoundsCrystallinityImpurity

The invention discloses a method for synthesizing a zinc ferrite spherical nano material by premixed flame. According to the method, Zn(NO3)2.6H2O and Fe(NO3)3.9H2O are adopted as precursors, stable high-temperature plane flame is formed by adjusting the flow of premixed gas of carrier gas, combustible gas and oxygen and adjusting the distance between a base plate and a nozzle, the atomized precursors are brought into the formed high-temperature flame surface through the carrier gas, and finally the ZnFe2O4 spherical nano material is successfully prepared. The method has the advantages of simple operation steps, low cost, one-step rapid synthesis and good product reproducibility, the prepared product has good crystallinity and no impurity phase, the product morphology is spherical particles with uniform dispersion, the particle size is 300-400nm, and the product is assembled by a large number of small particles with a particle size of about 10nm.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com