Device for combusting stably of gas flame torch

A technology for stabilizing burners and flames, which is applied in the direction of gas fuel burners, burners, combustion ignition, etc. It can solve the problems of insufficient shape and bright flame, and achieve the effect of full shape, bright color and stable flame combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below with reference to the accompanying drawings.

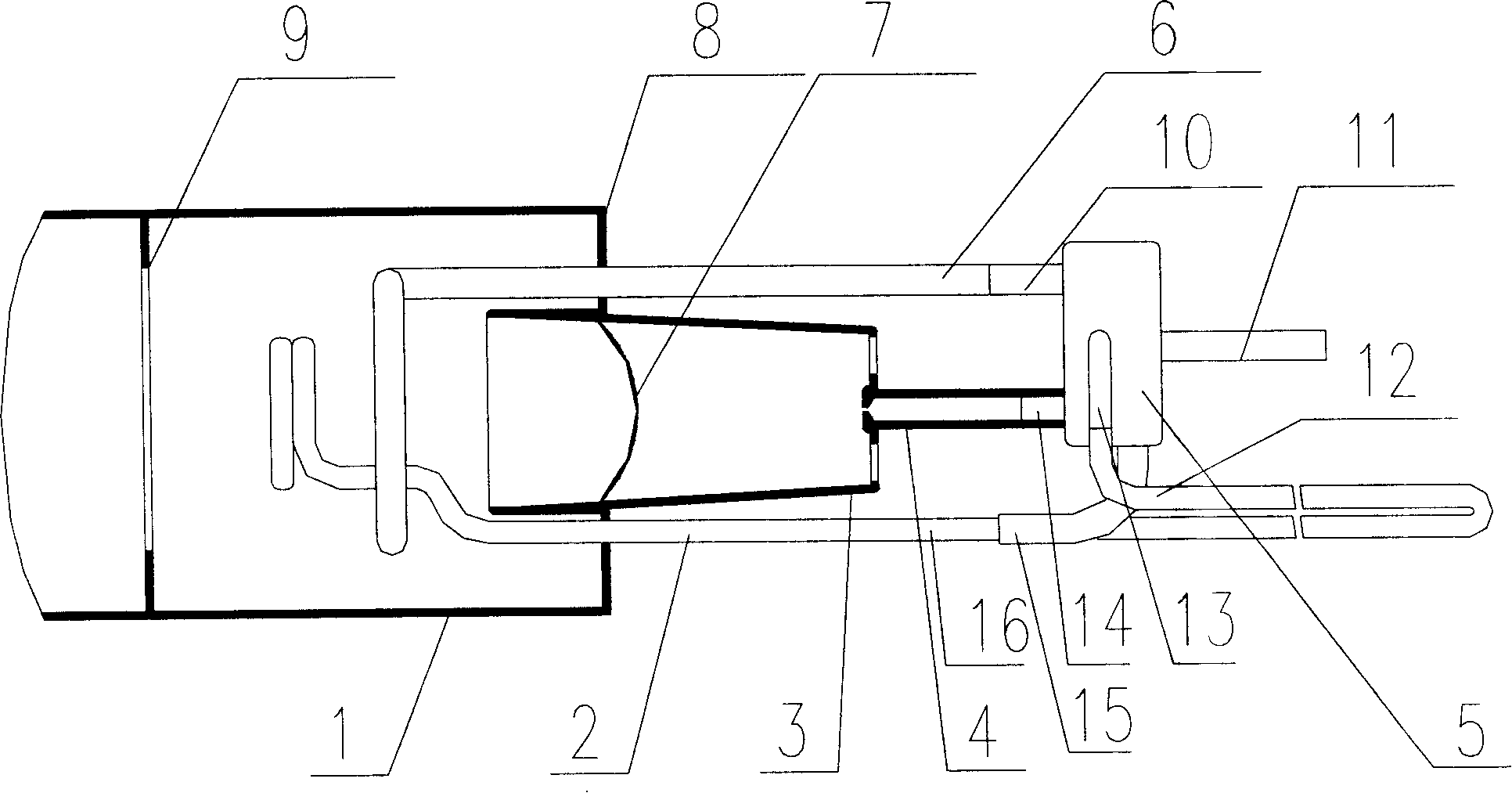

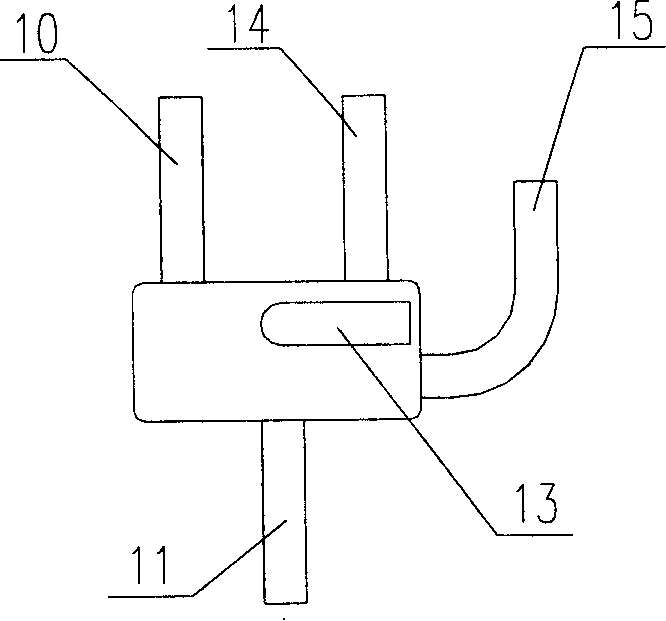

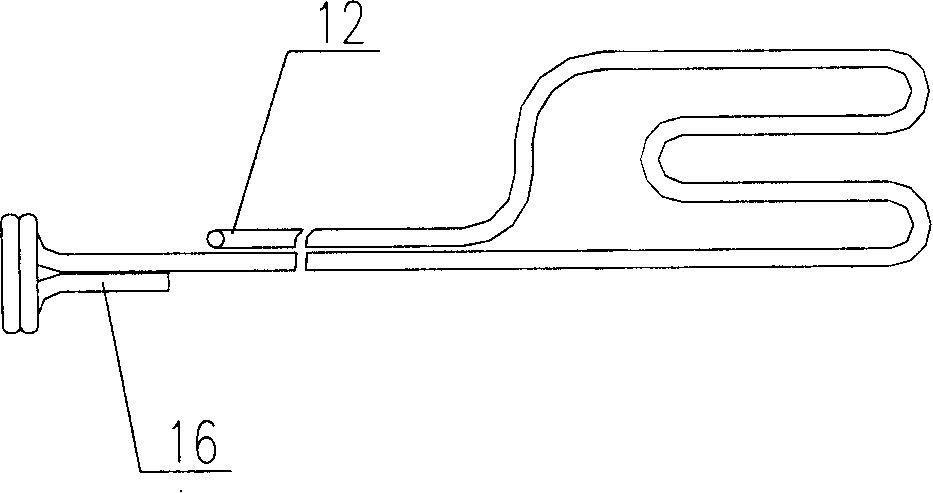

[0014] A gas flame torch stabilizer such as figure 1 , 2 , 3, 4, 5, 6, including main combustion chamber housing 1, heat recovery pipe 2, pre-chamber housing 3, pre-chamber nozzle 4, fuel distribution bracket 5, main fuel injection ring 6, combustion stabilization device 7 , The bottom mounting plate 8 and the windshield device 9 of the main combustion chamber housing. The pre-chamber fuel supply interface 14 of the fuel distribution five-way 5 is connected to the pre-chamber nozzle 4, and the pre-chamber nozzle 4 is located at the bottom of the pre-chamber housing 3, and the pre-chamber housing 3 is connected to the main chamber through the pre-chamber installation hole 19. The bottom mounting plate 8 of the combustion chamber casing is connected, the main combustion chamber casing 1 is connected with the bottom mounting plate 8 of the main combustion chamber casing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com