Continuous combusting regenerative industrial furnace

A regenerative, industrial furnace technology, applied in combustion methods, furnaces, waste heat treatment, etc., can solve problems such as furnace pressure and furnace temperature fluctuations, flame discontinuity, affecting system stability, etc., to achieve simple and continuous pipeline layout Effect of regenerative heat exchange and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described in detail below.

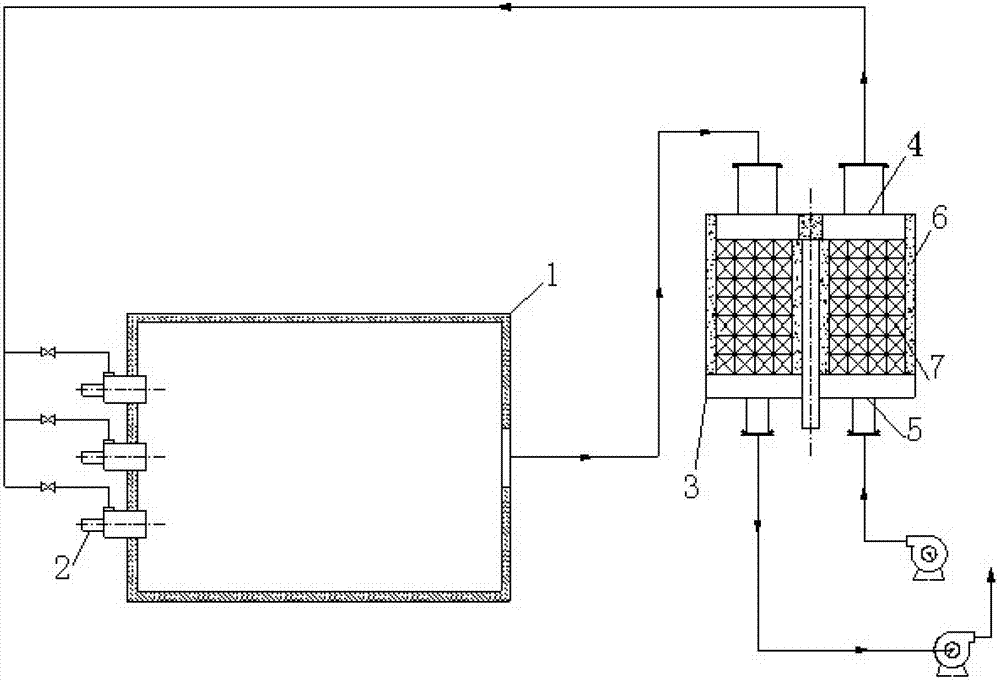

[0020] The continuous combustion regenerative industrial furnace of the present invention, its preferred embodiment is as follows figure 1 , figure 2 Shown:

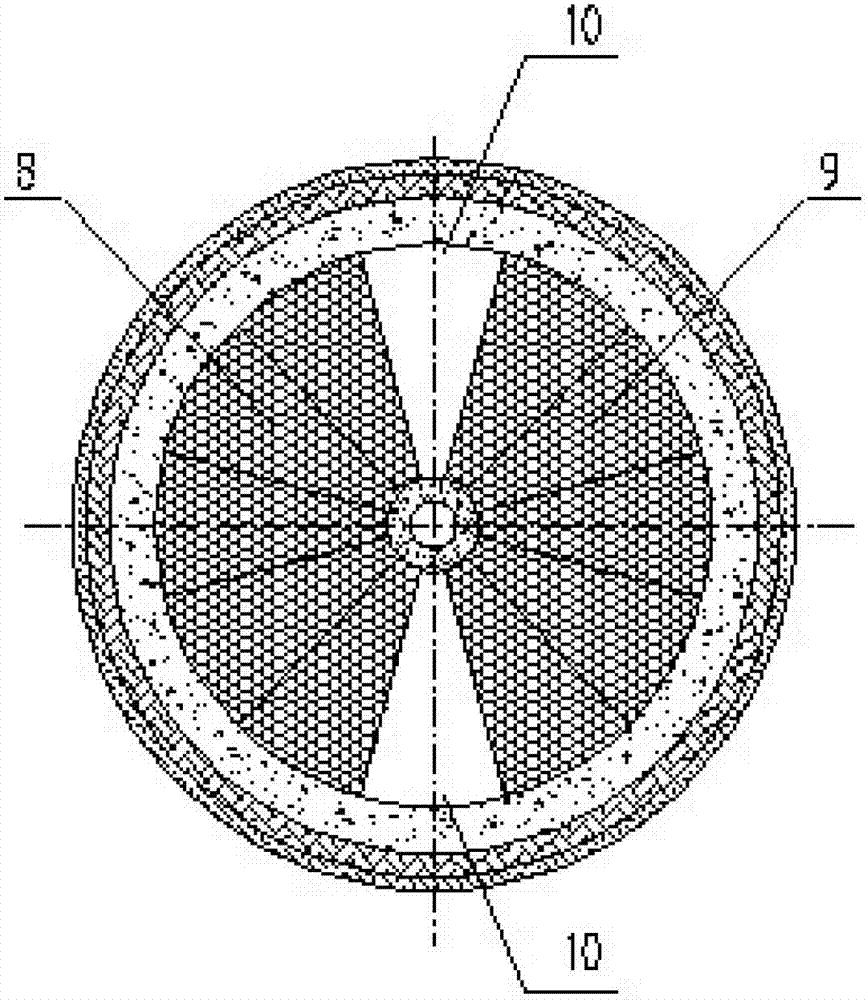

[0021] The furnace body is provided with a burner and a high-temperature flue gas outlet, including a rotating regenerative heat exchanger. The rotating regenerative heat exchanger includes a rotating cylinder, an upper cover, and a lower cover. The inside of the rotating cylinder equipped with a heat storage body;

[0022] The space between the upper surface of the regenerator and the upper cover is divided into two parts by a refractory partition wall, and the upper cover corresponding to the two parts is respectively provided with a high-temperature flue gas inlet and a preheated air outlet;

[0023] The space between the lower surface of the regenerator and the lower cover is divided into two parts by a steel partition, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com