Patents

Literature

4919 results about "Combustion process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Put simply, combustion means to burn. For the combustion process to take place, fuel, oxygen, and an ignition heat source are required to start a chemical chain reaction; in a campfire, for example, wood is the fuel, the surrounding air provides the oxygen, and a match or lighter can ignite the fire.

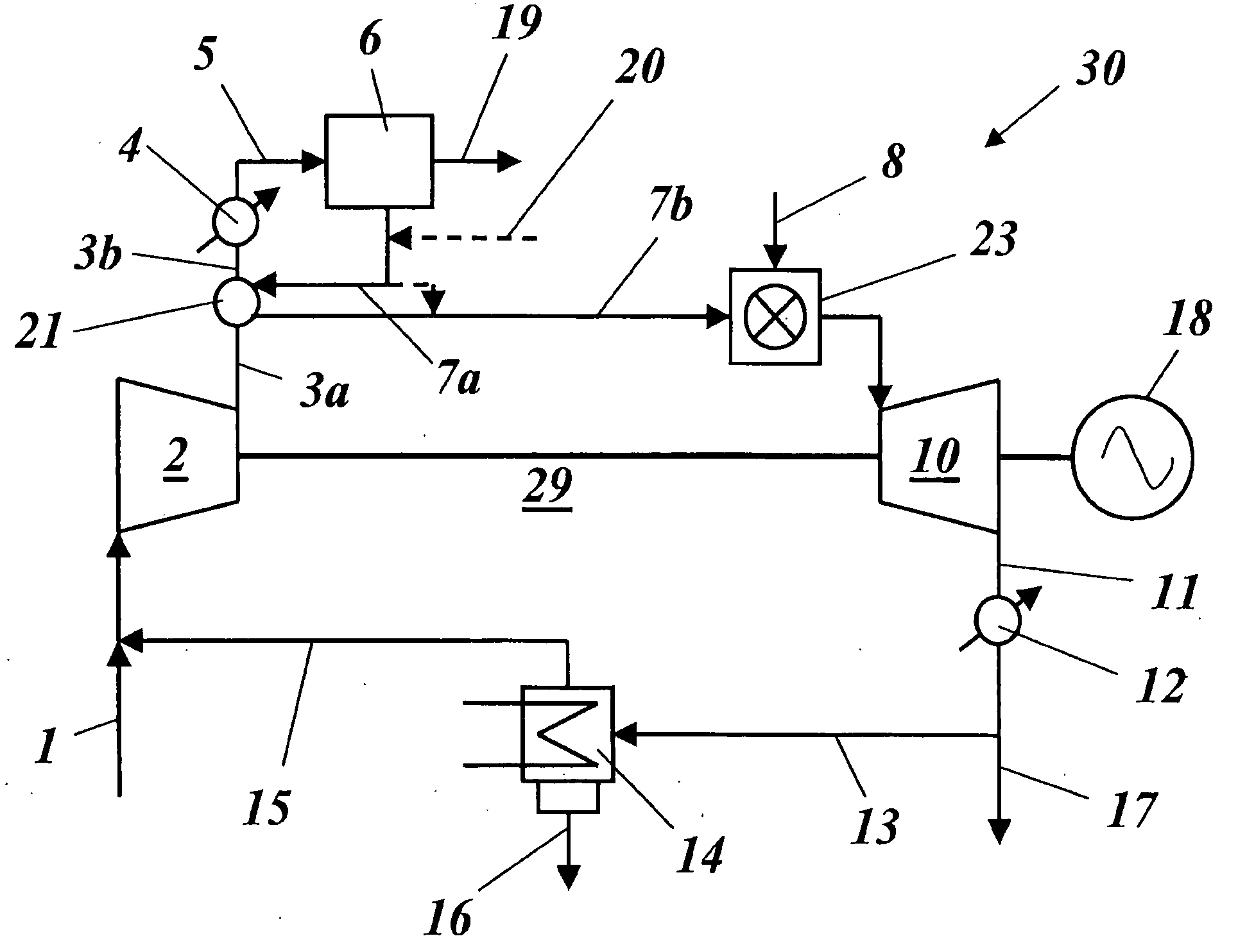

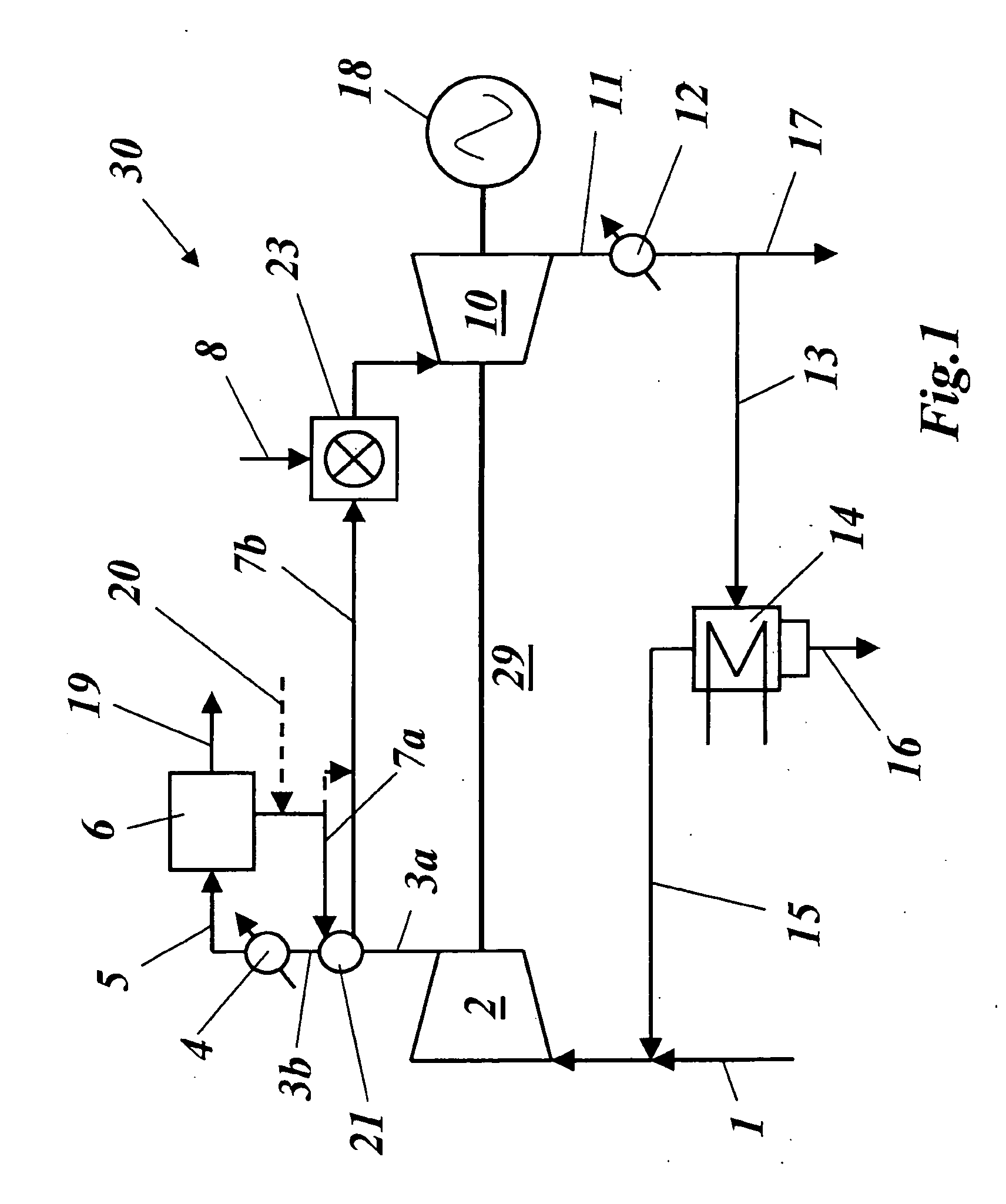

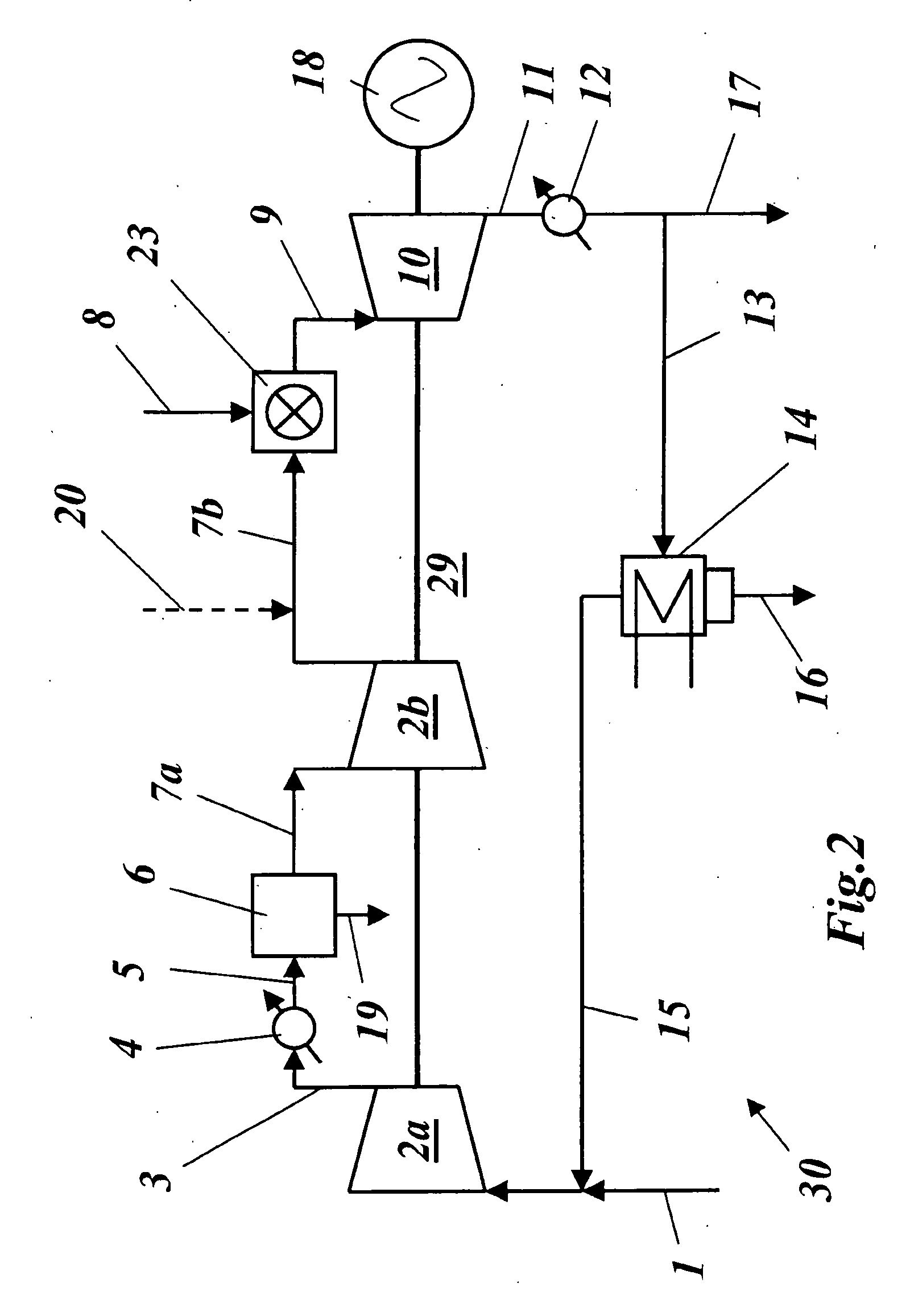

Method of generating energy in a power plant comprising a gas turbine, and power plant for carrying out the method

InactiveUS20050028529A1Small sizeLow costContinuous combustion chamberDispersed particle separationPower stationCombustor

A method of generating energy in a power plant (30) having a gas turbine (29), includes a first step a gas containing air (1) is compressed in a first compressor (2) of the gas turbine (29), a second step the compressed gas (3, 3a, 3b; 5; 7a, 7b) is fed to a combustion process with the addition of fuel (8) in a combustor (23), a third step the hot flue gas (9) from the combustor (23) is expanded in an expander or a turbine (10), driving a generator (18), of the gas turbine (29) while performing work, and a fourth step a partial flow of the expanded flue gas (11) is recirculated to the inlet of the first compressor (2) and admixed with the gas containing air (1). Carbon dioxide (CO2) is separated from the compressed gas (3, 3a, 3b; 5; 7a, 7b) in a CO2 separator (6) before the third step. In such a method, the overall size and energy costs are reduced by virtue of the fact that, to permit increased CO2 concentrations in the CO2 separator (6), not more than about 70% of the carbon dioxide contained in the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b) is removed from the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b).

Owner:ALSTOM TECH LTD

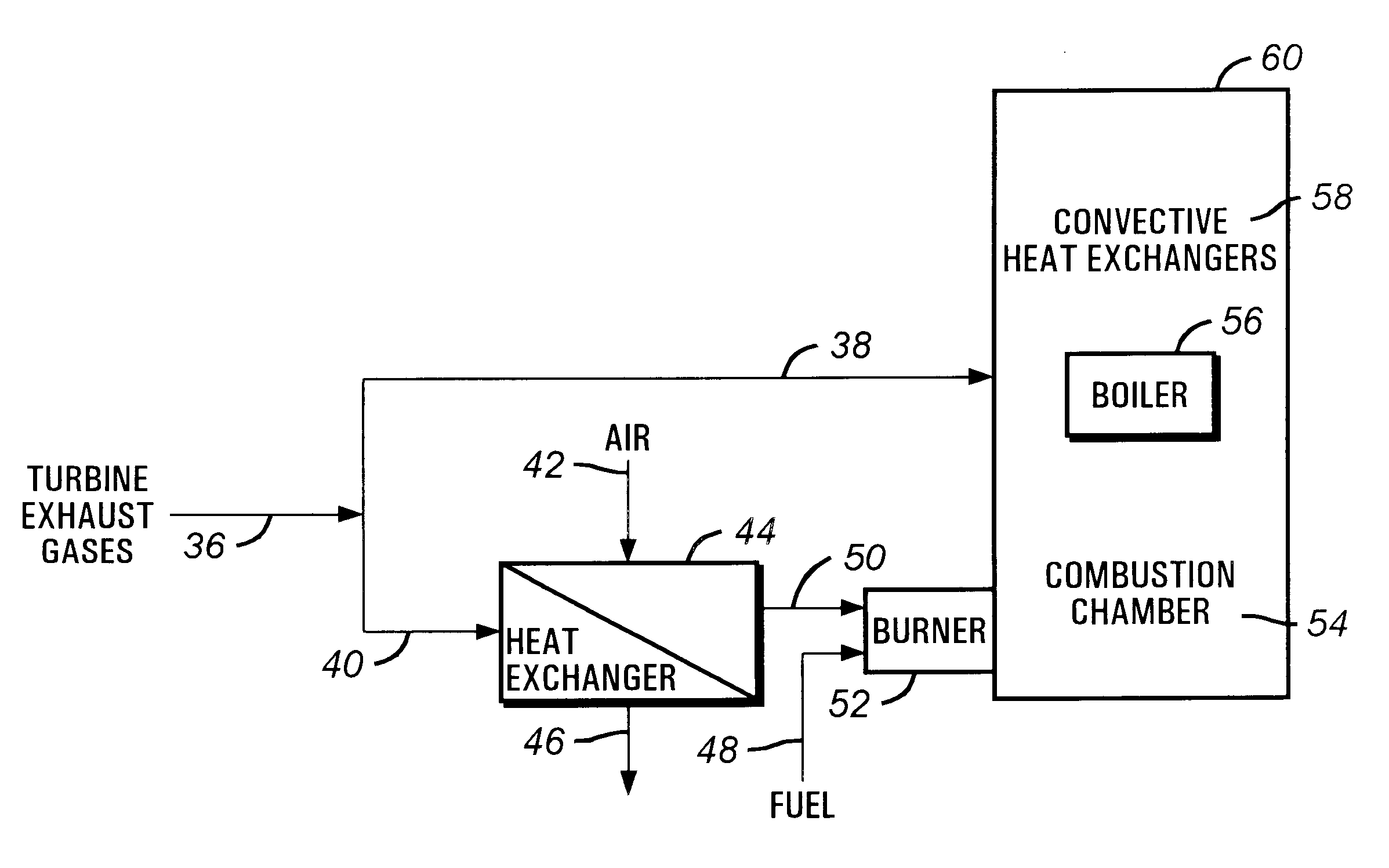

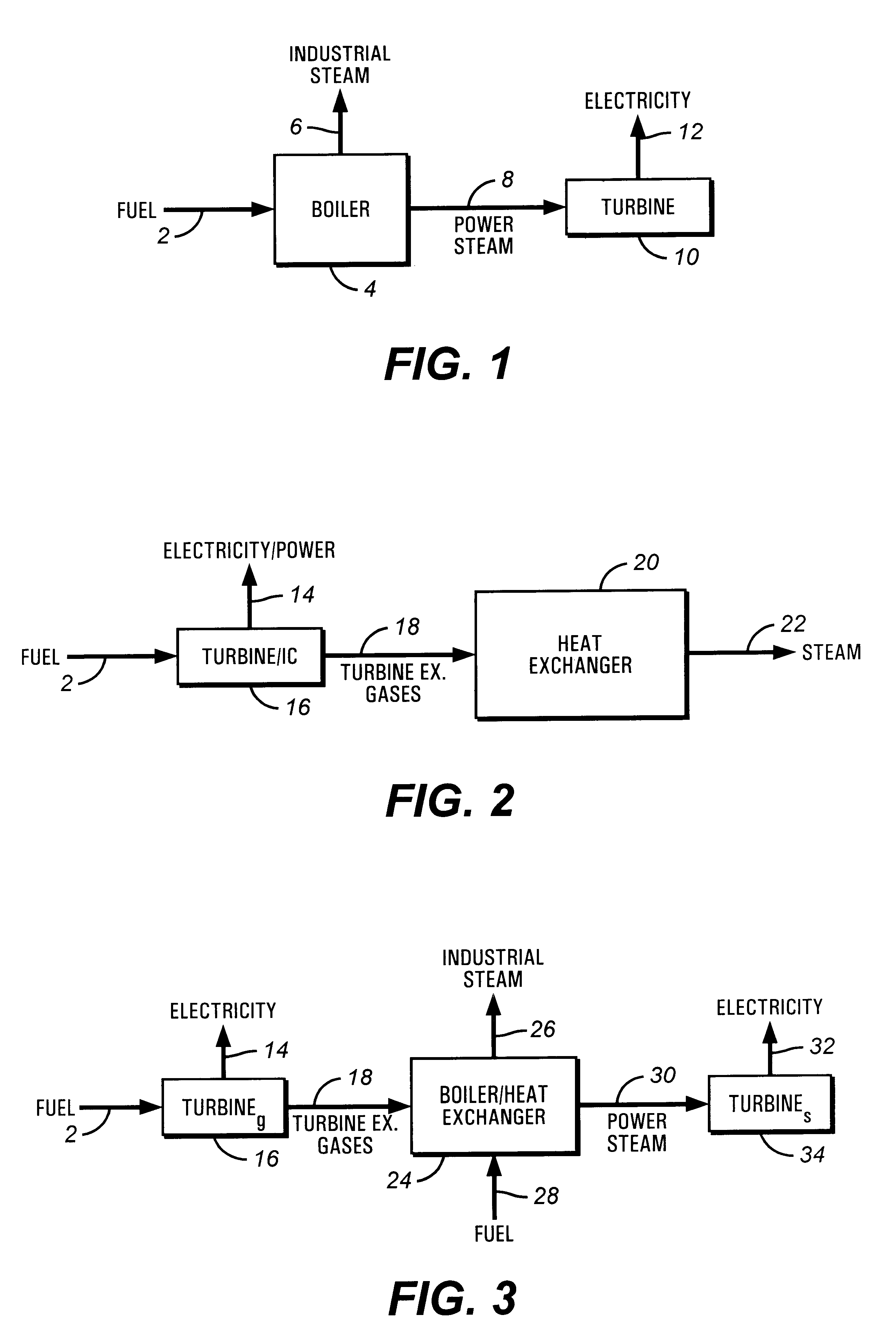

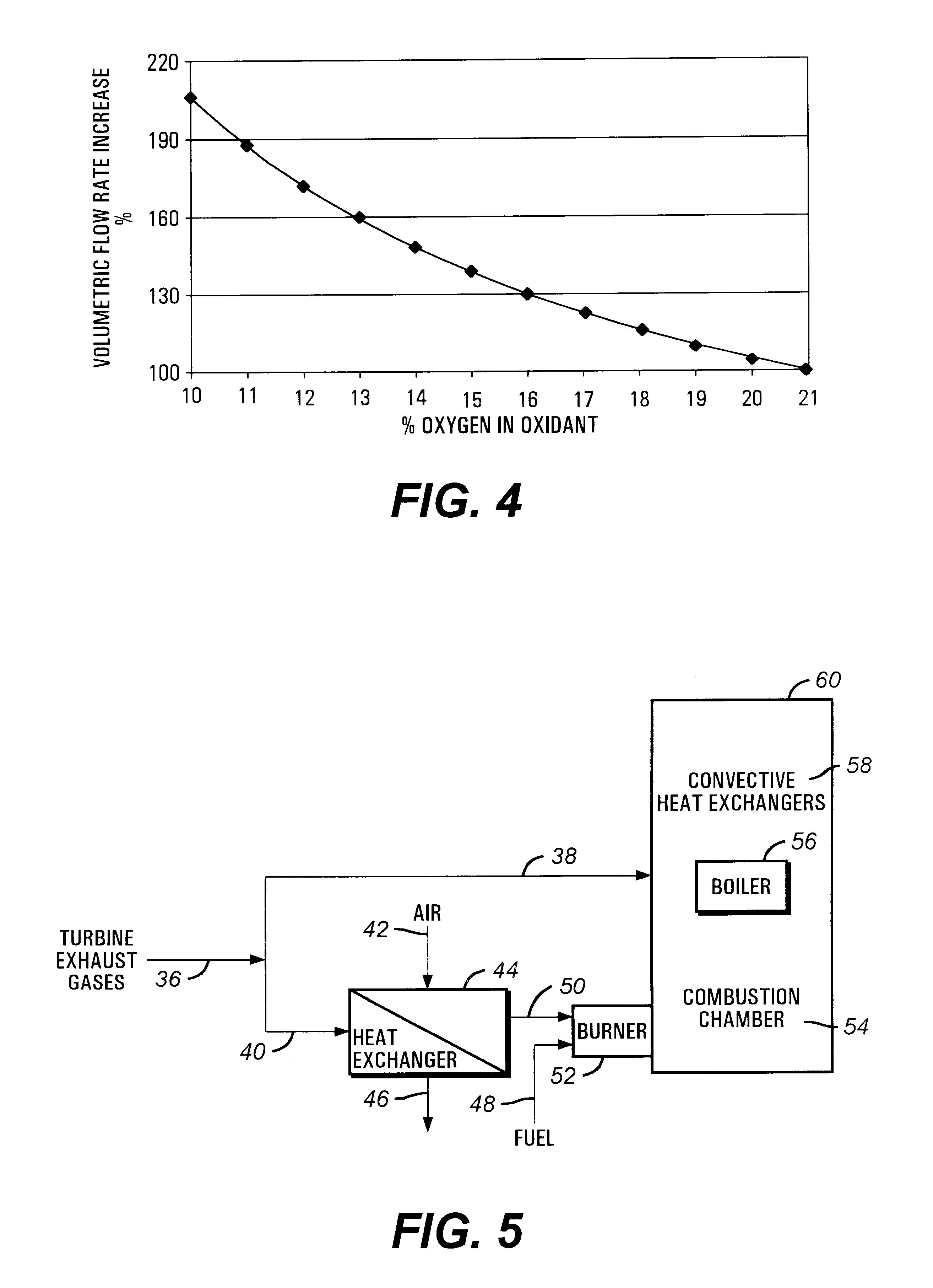

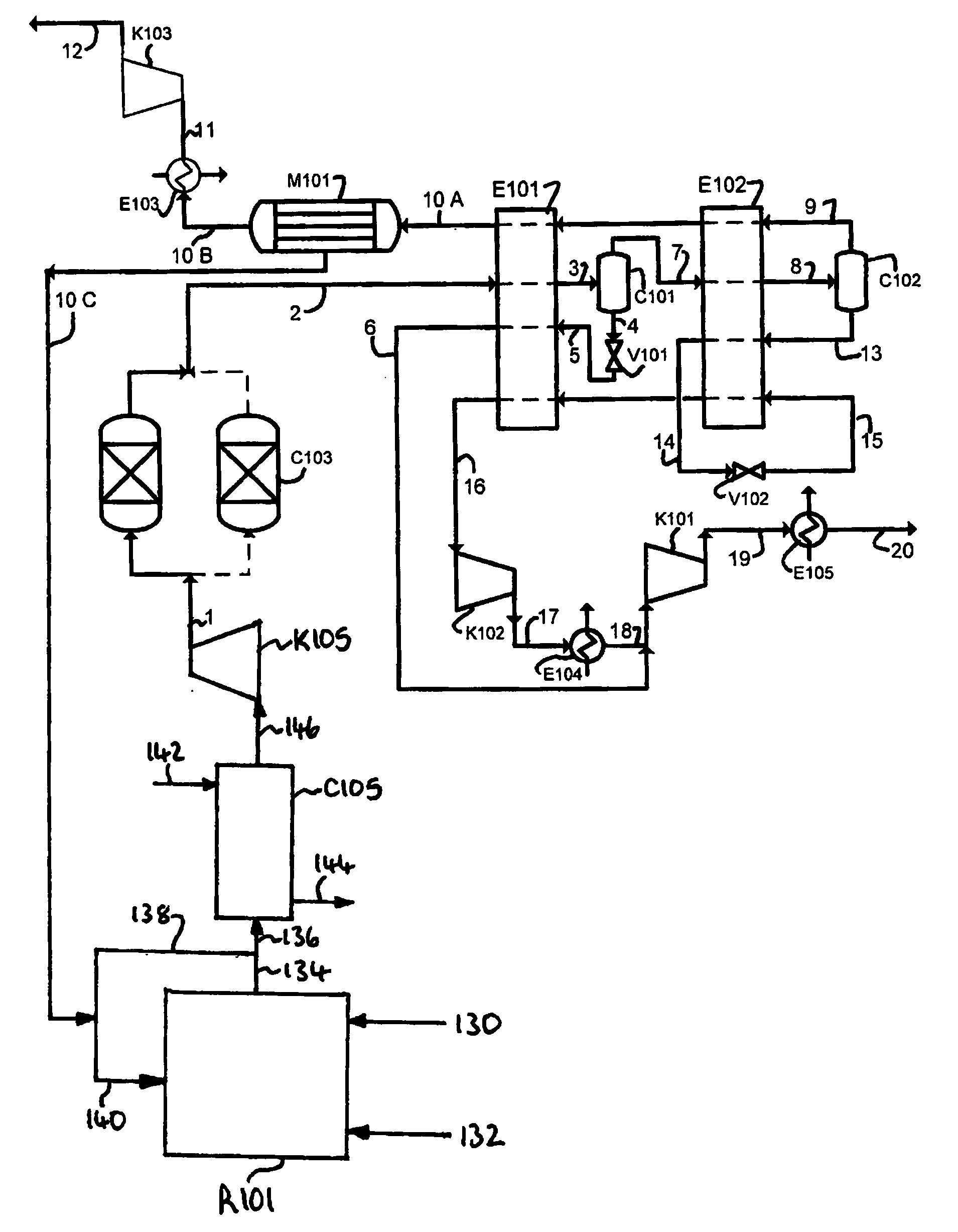

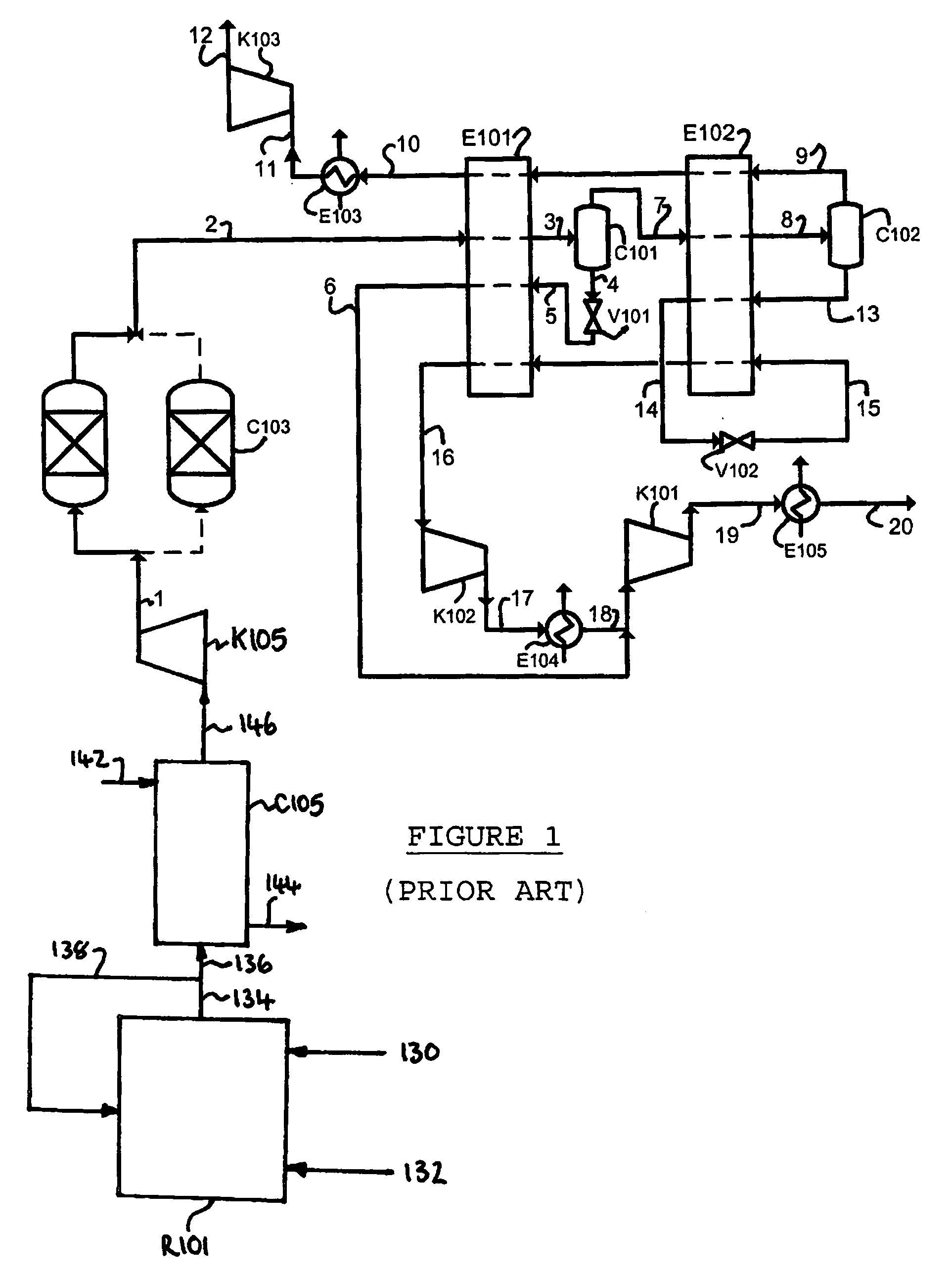

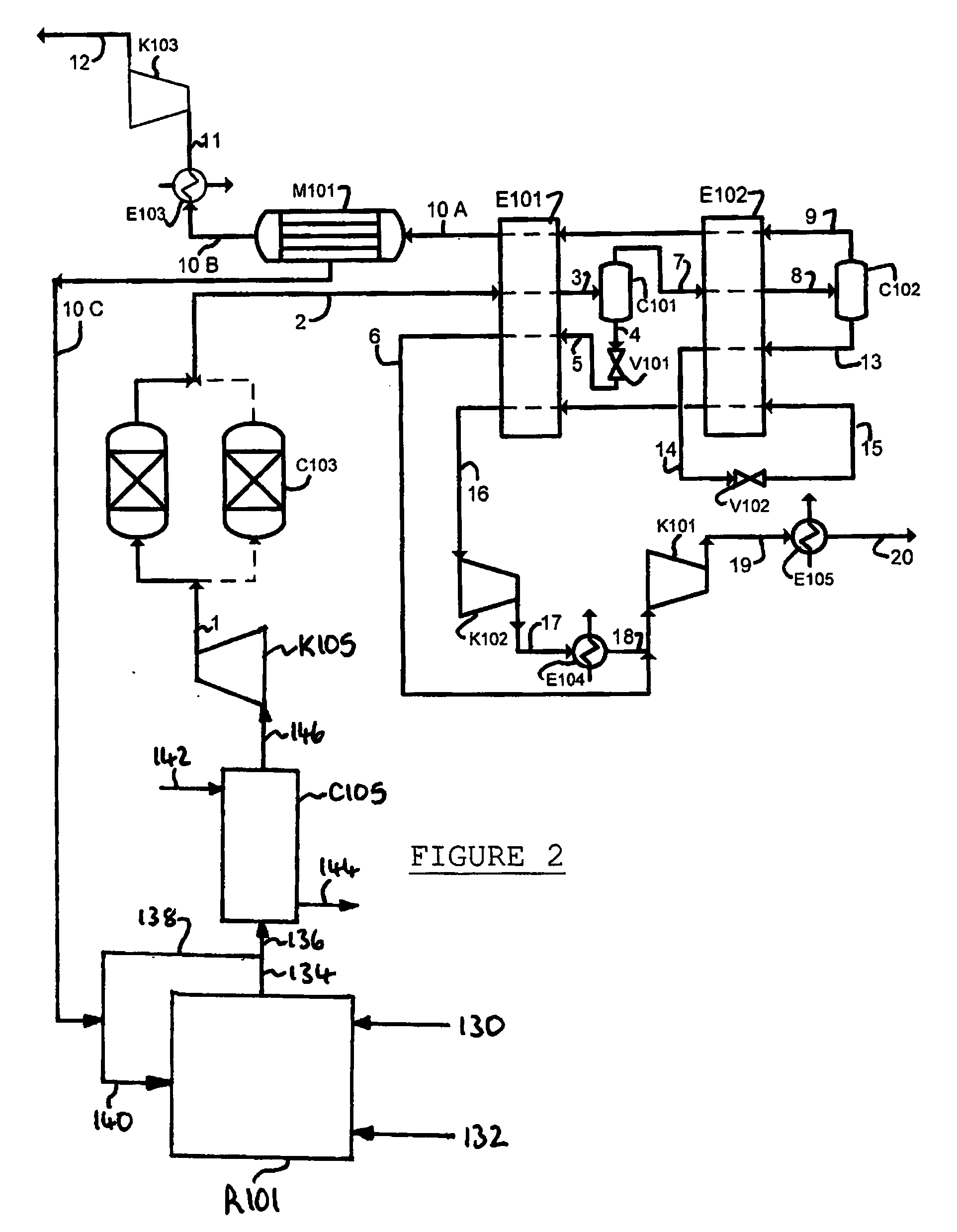

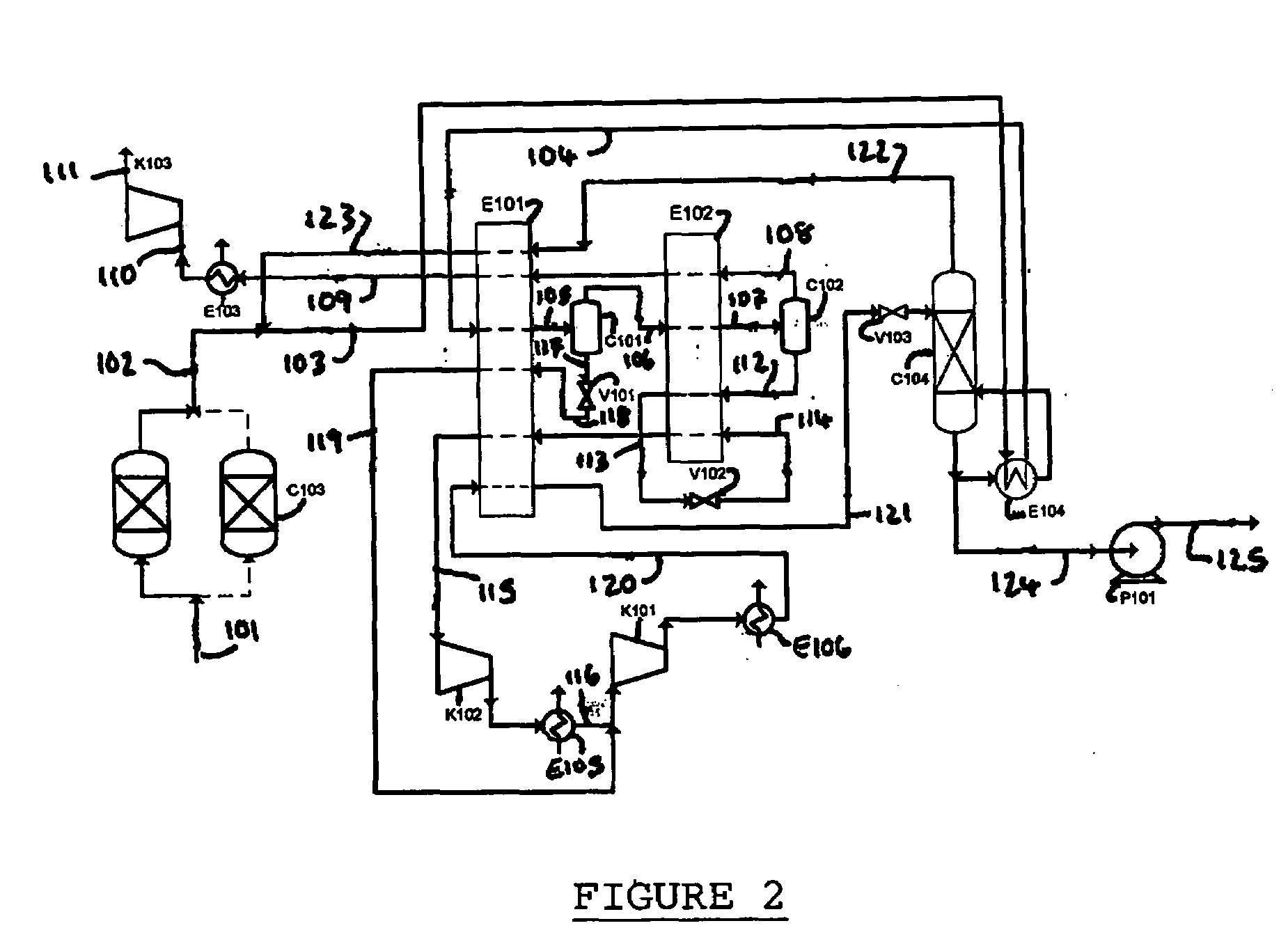

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Purification of carbon dioxide

Carbon dioxide is separated from a feed gas, preferably derived from flue gas from an oxyfuel combustion process, in a membrane separation system to produce separated carbon dioxide gas which is fed to the oxyfuel combustion process to improve the performance of the process.

Owner:AIR PROD & CHEM INC

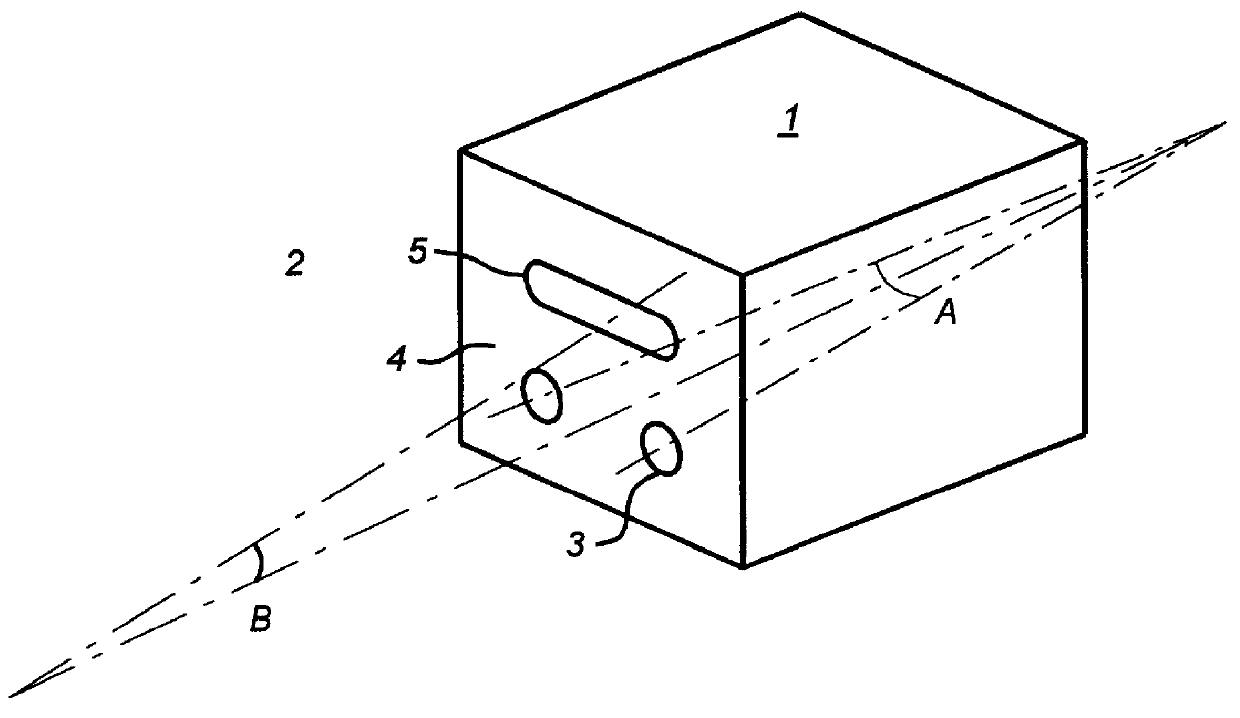

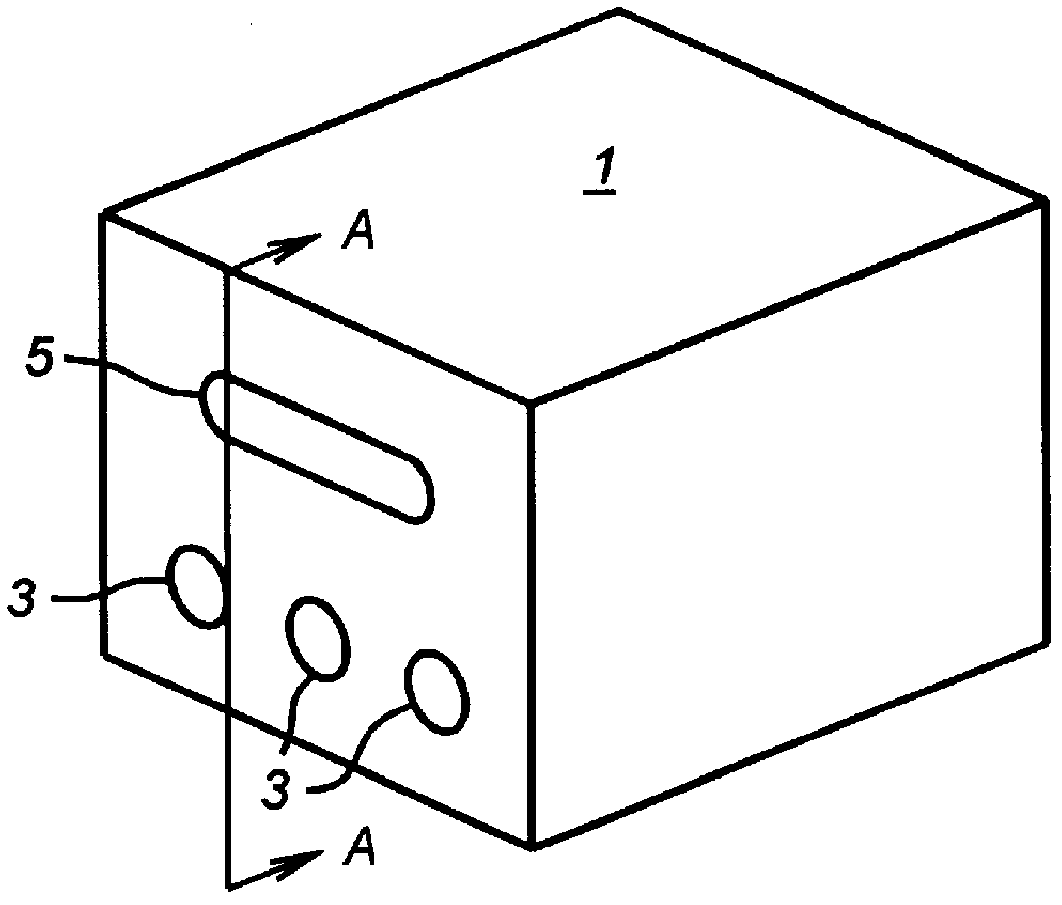

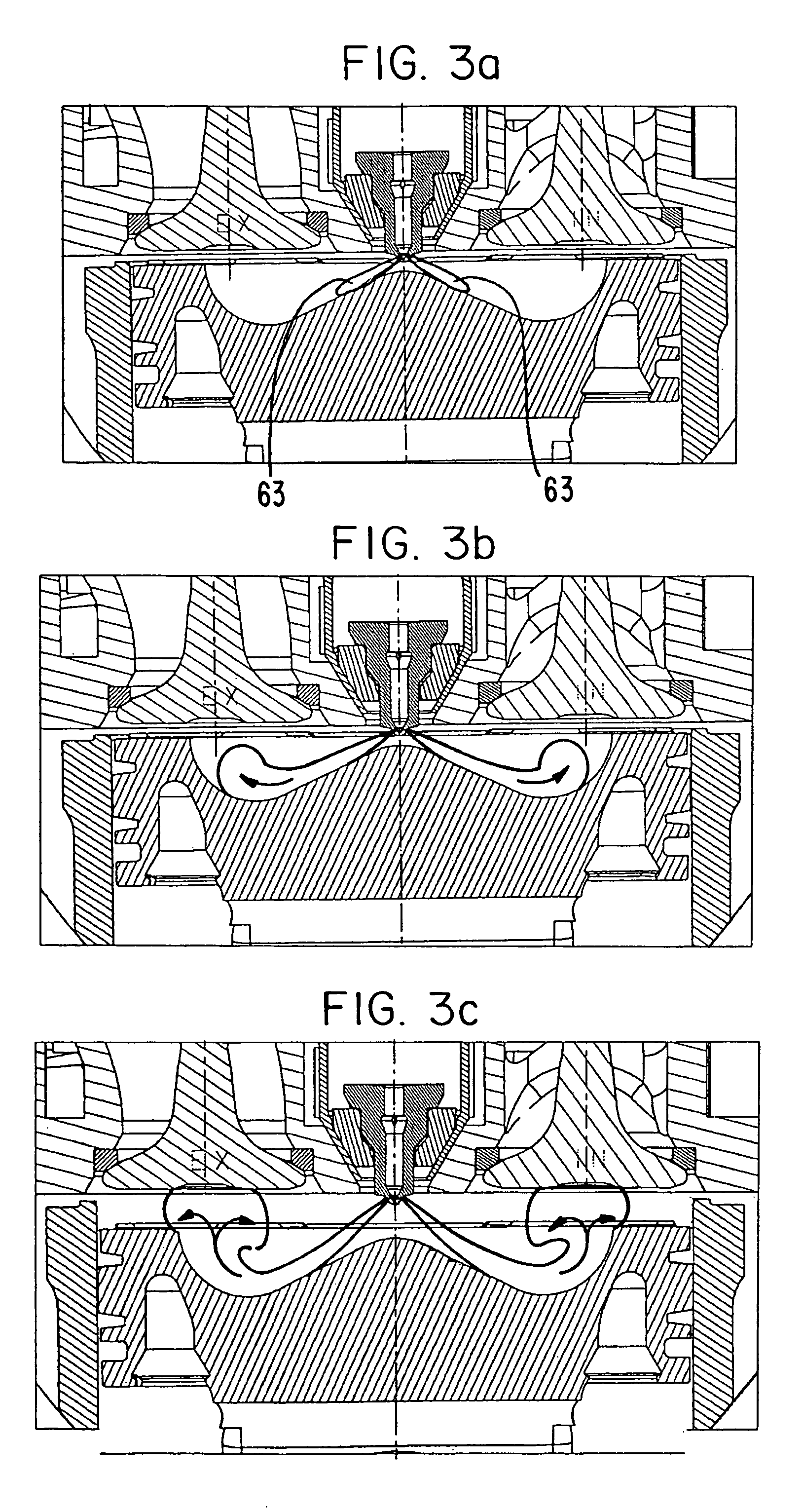

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6074197AReduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

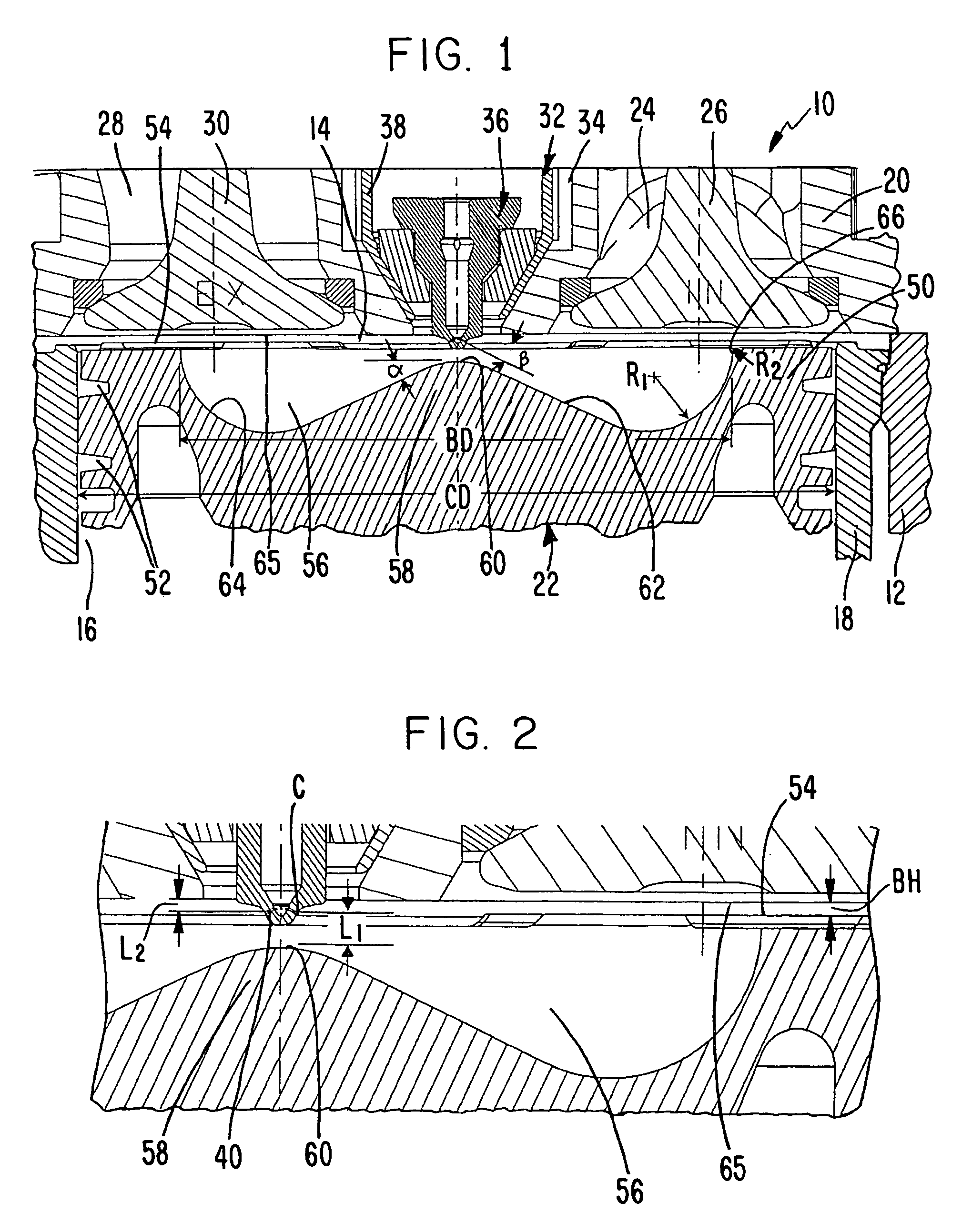

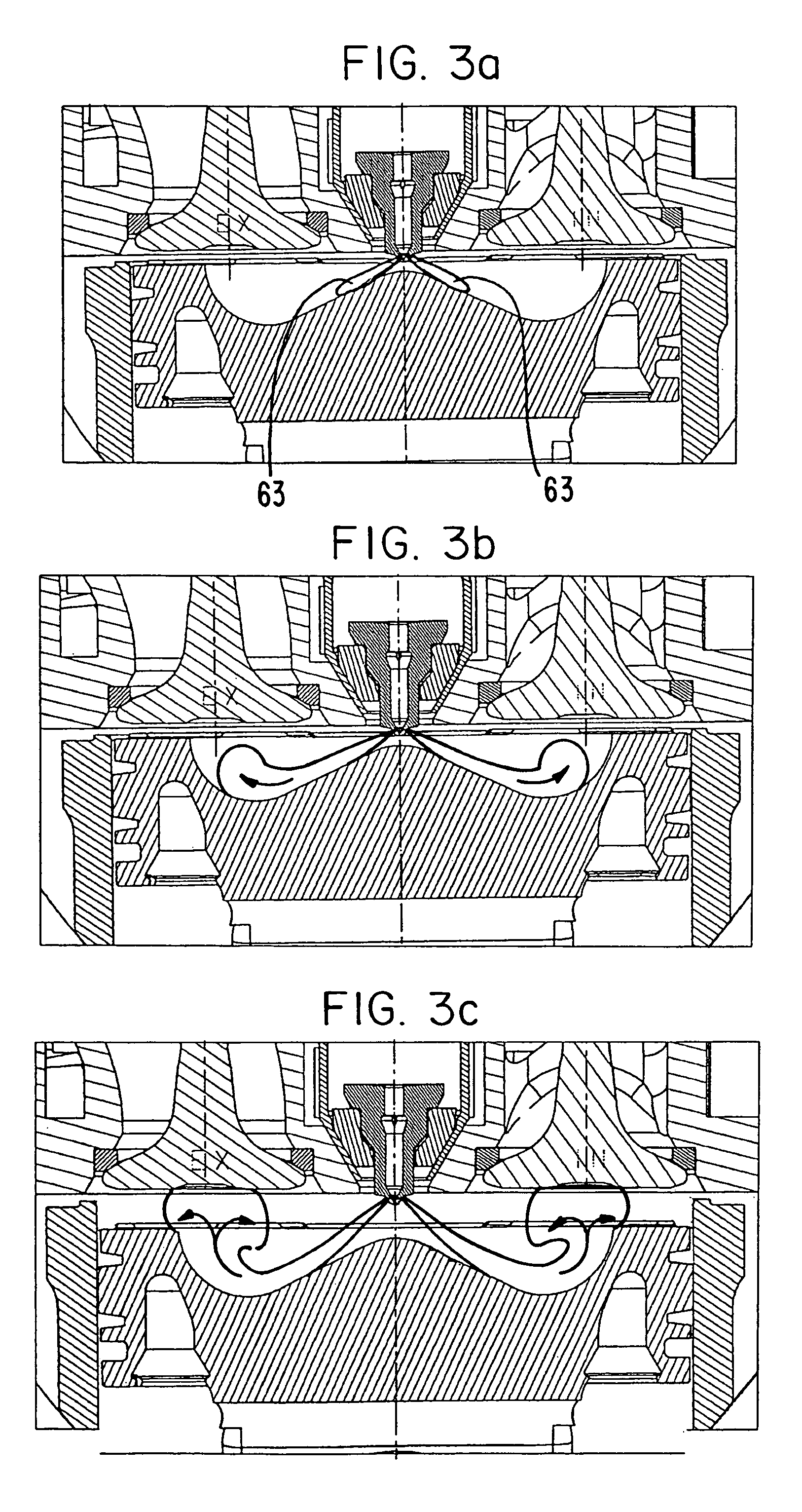

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

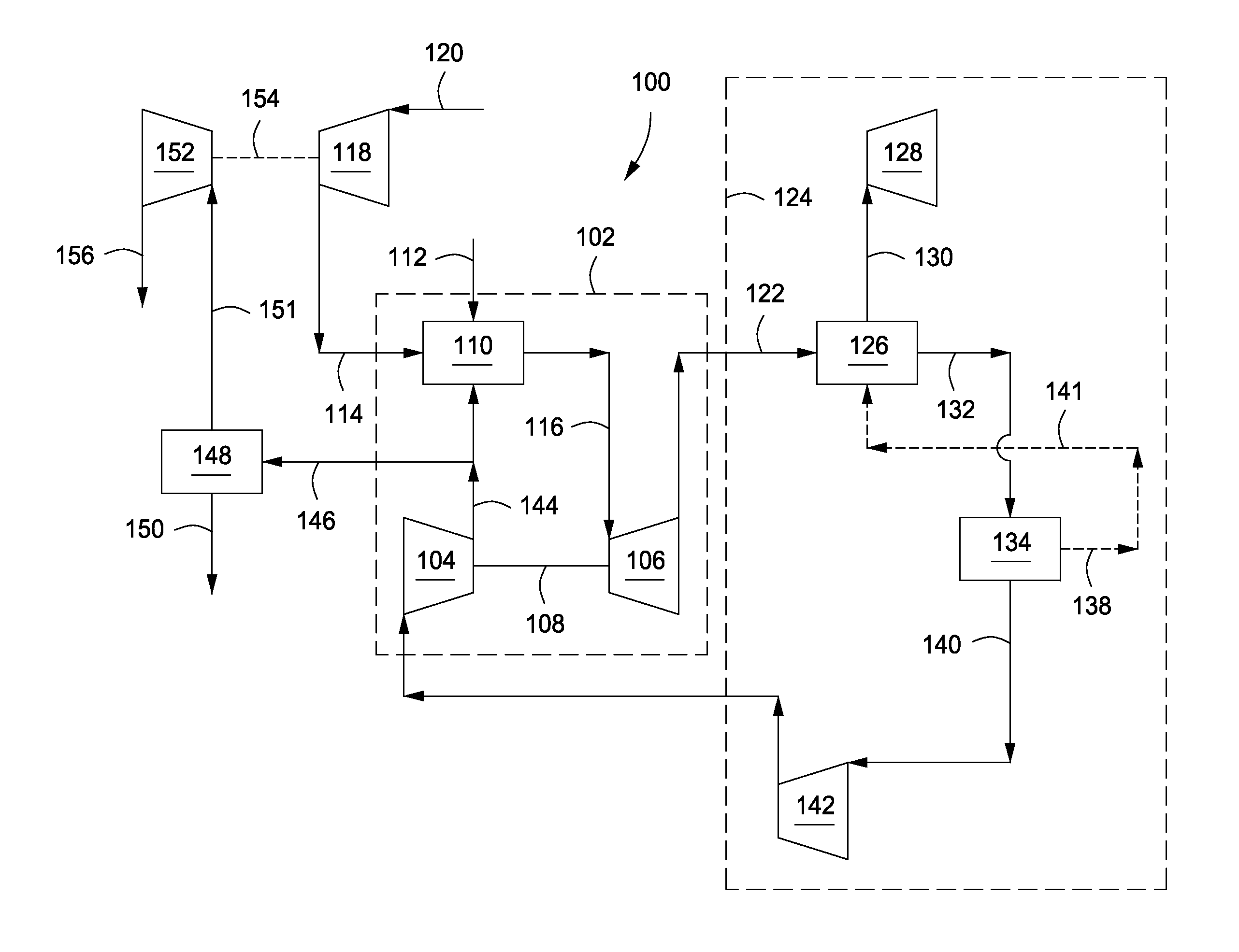

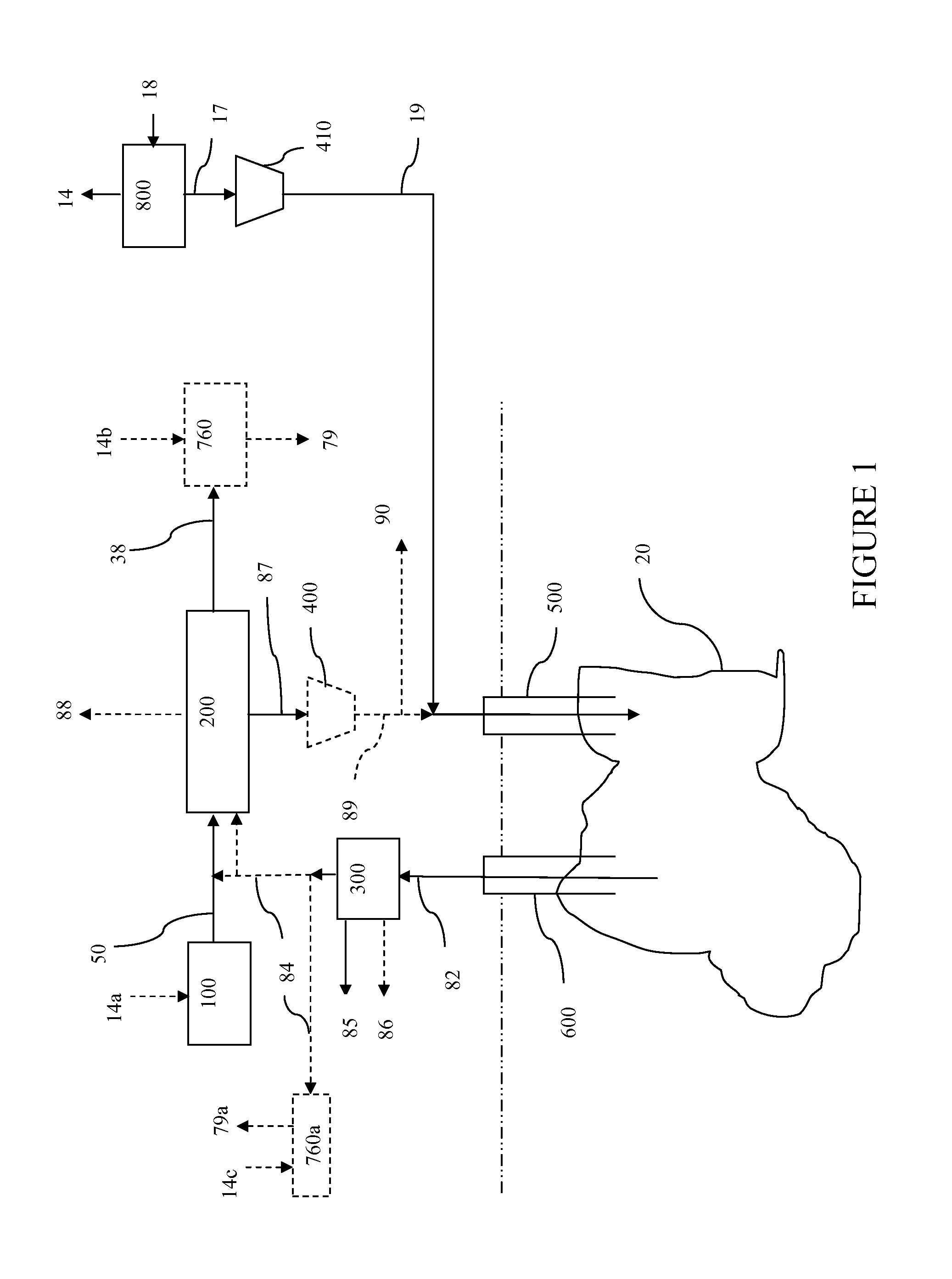

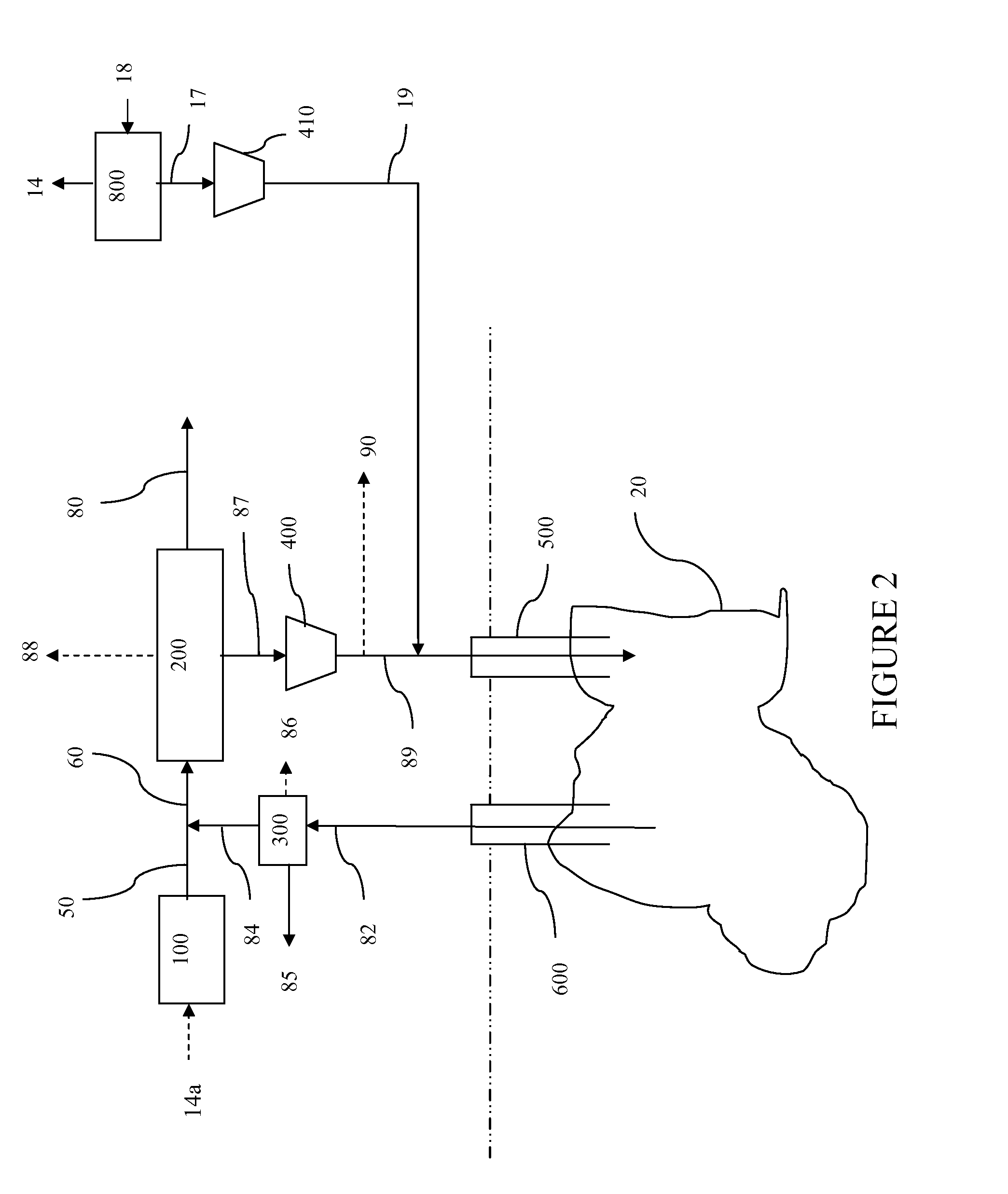

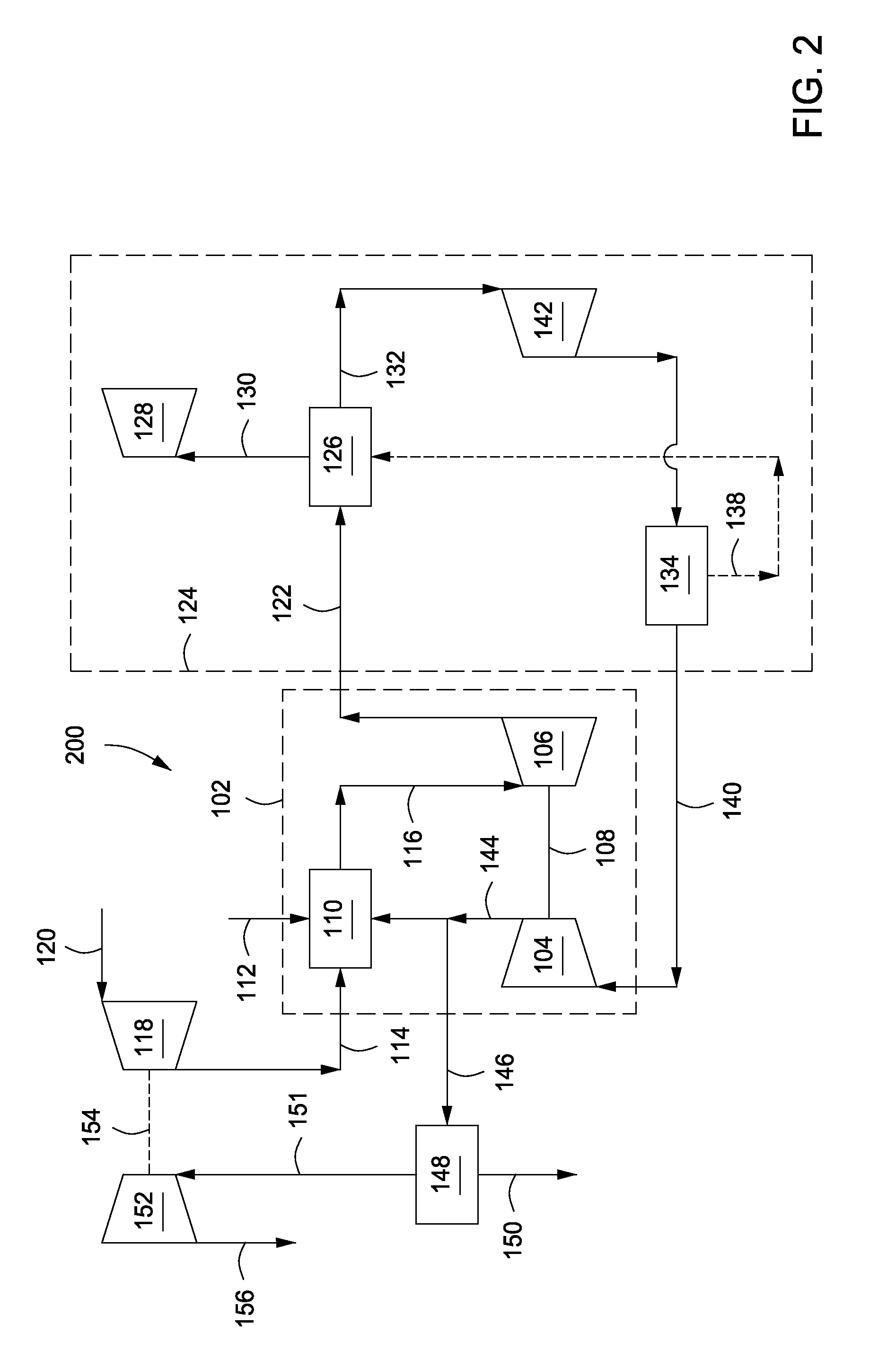

Low Emission Triple-Cycle Power Generation Systems and Methods

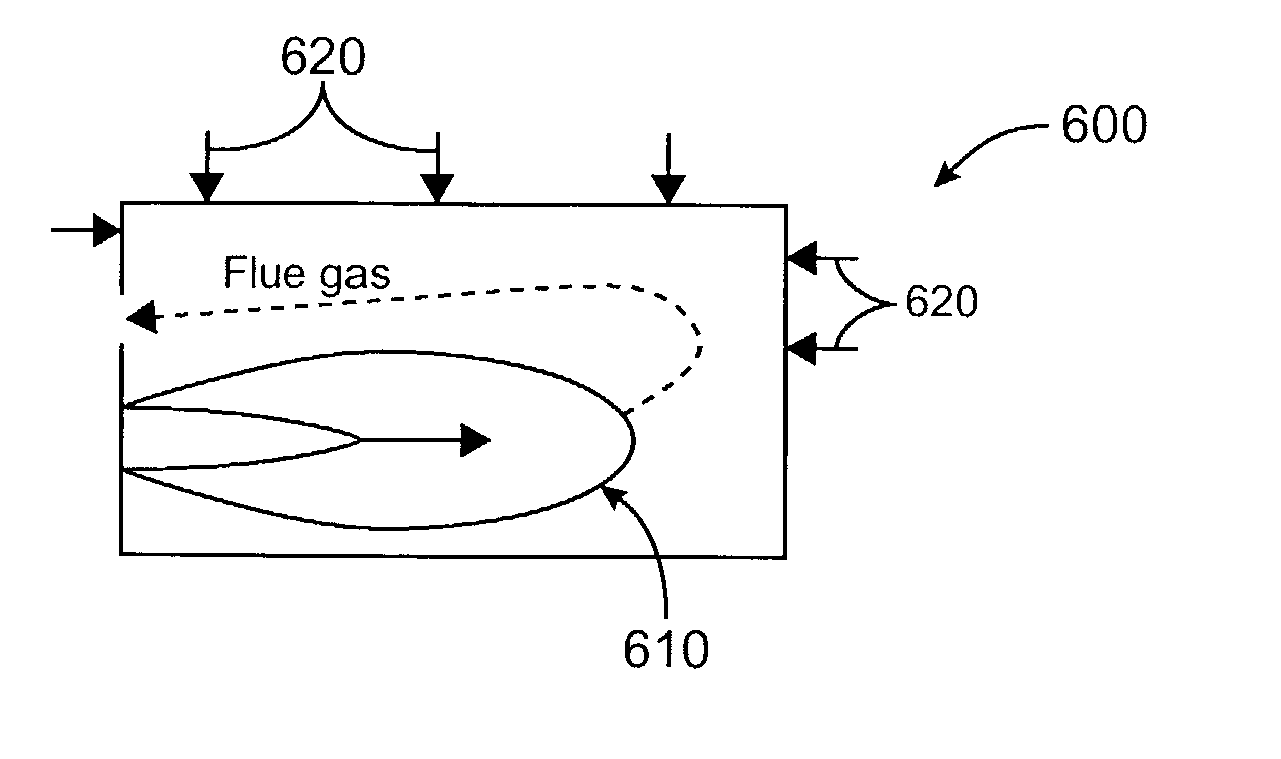

Methods and systems for low emission power generation in combined cycle power plants are provided. One system includes a gas turbine system that stoichiometrically combusts a fuel and an oxidant in the presence of a compressed recycle stream to provide mechanical power and a gaseous exhaust. The compressed recycle stream acts as a diluent to moderate the temperature of the combustion process. A boost compressor can boost the pressure of the gaseous exhaust before being compressed into the compressed recycle stream. A purge stream is tapped off from the compressed recycle stream and directed to a C02 separator which discharges C02 and a nitrogen-rich gas which can be expanded in a gas expander to generate additional mechanical power.

Owner:EXXONMOBIL UPSTREAM RES CO

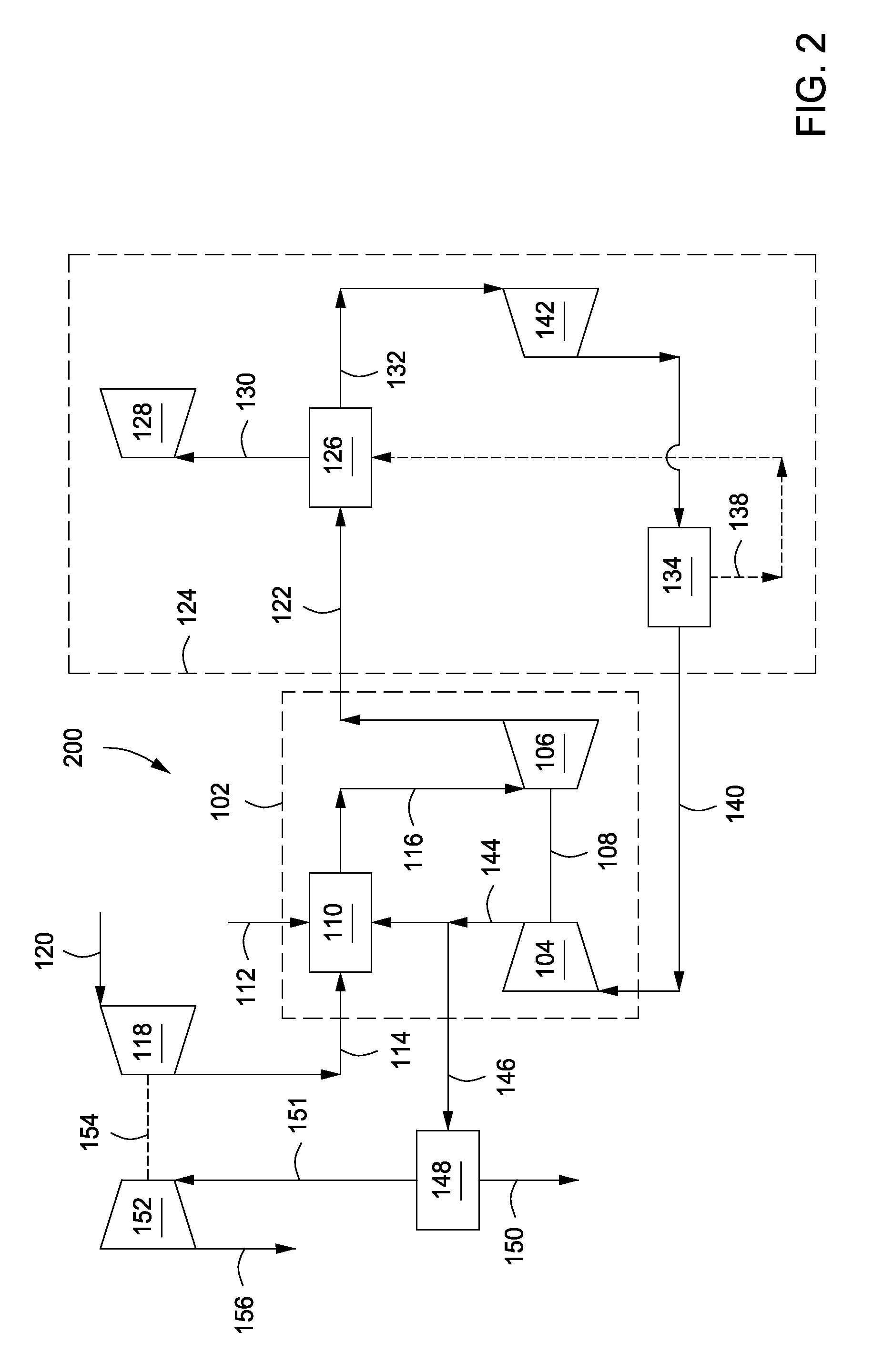

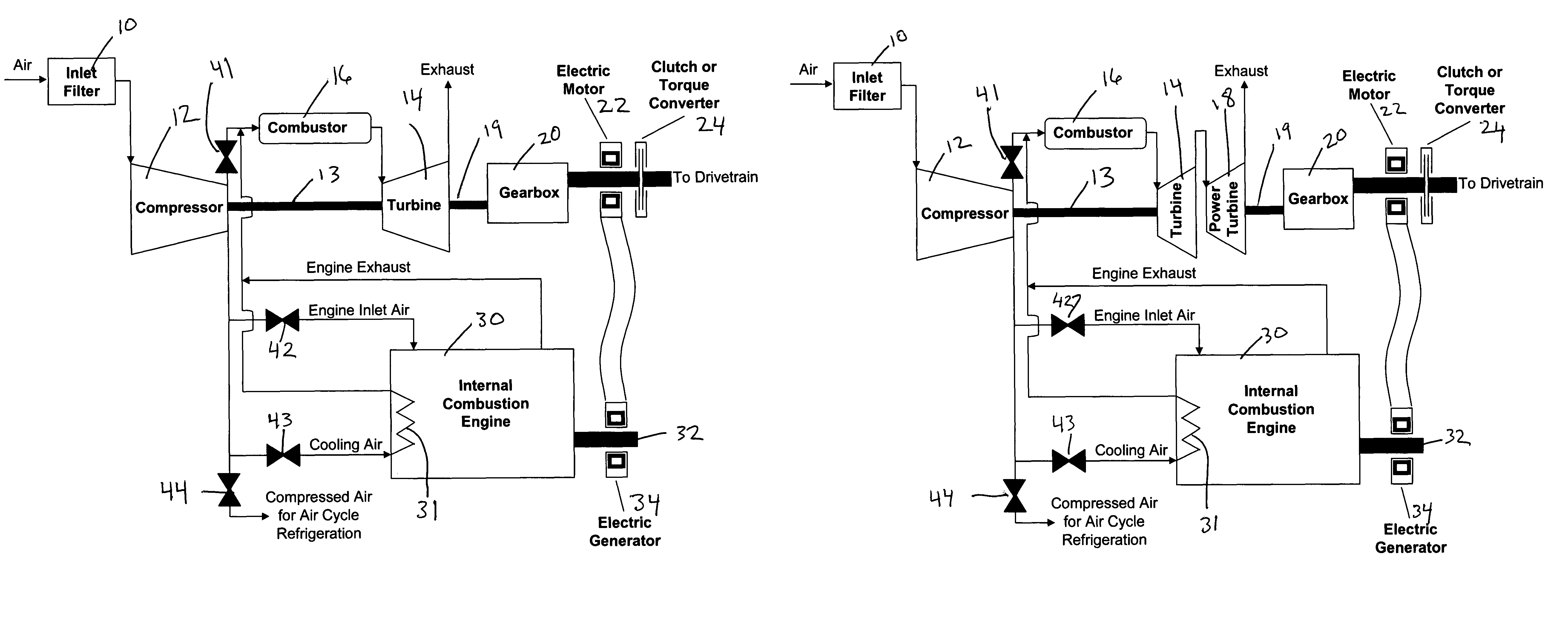

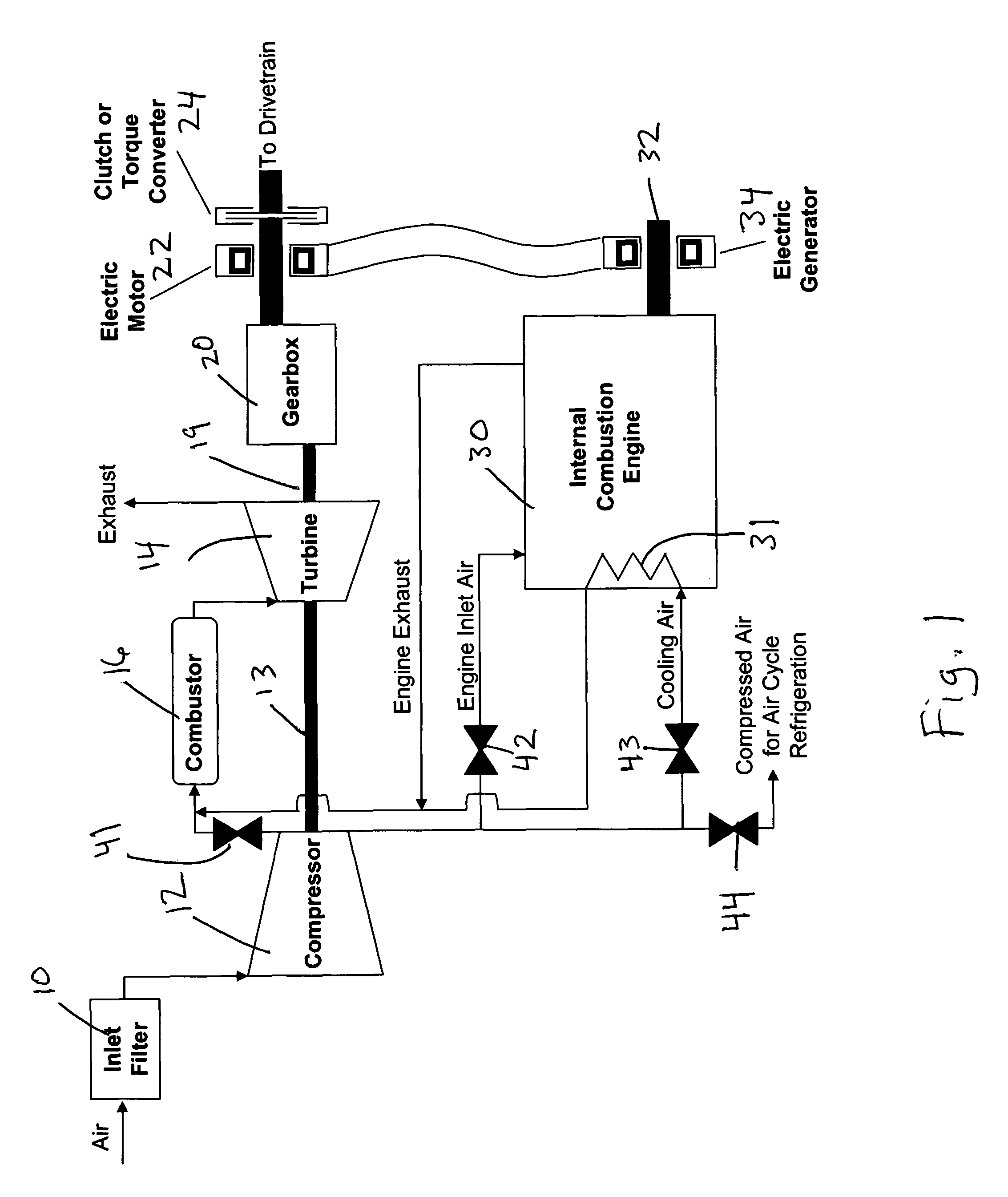

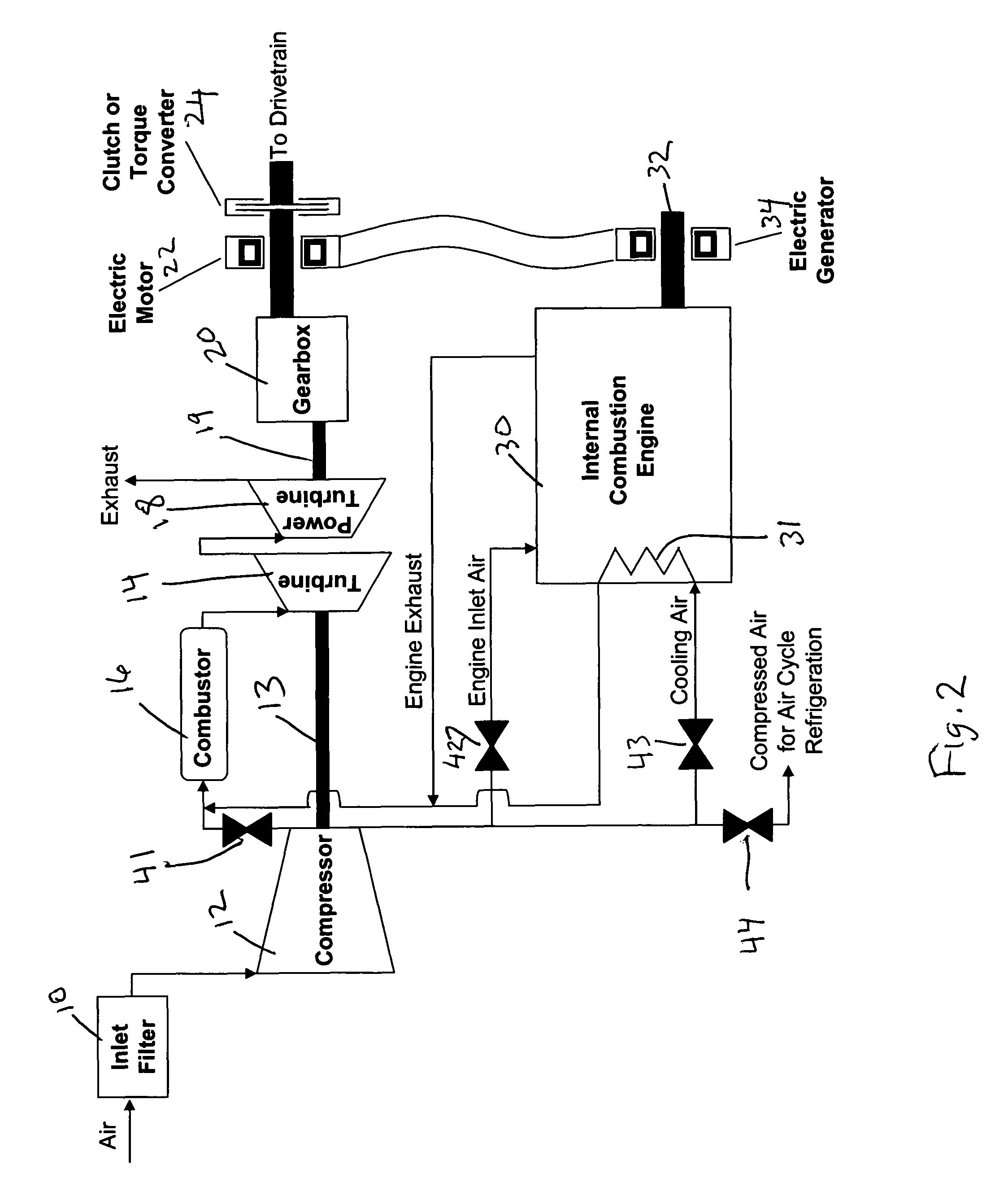

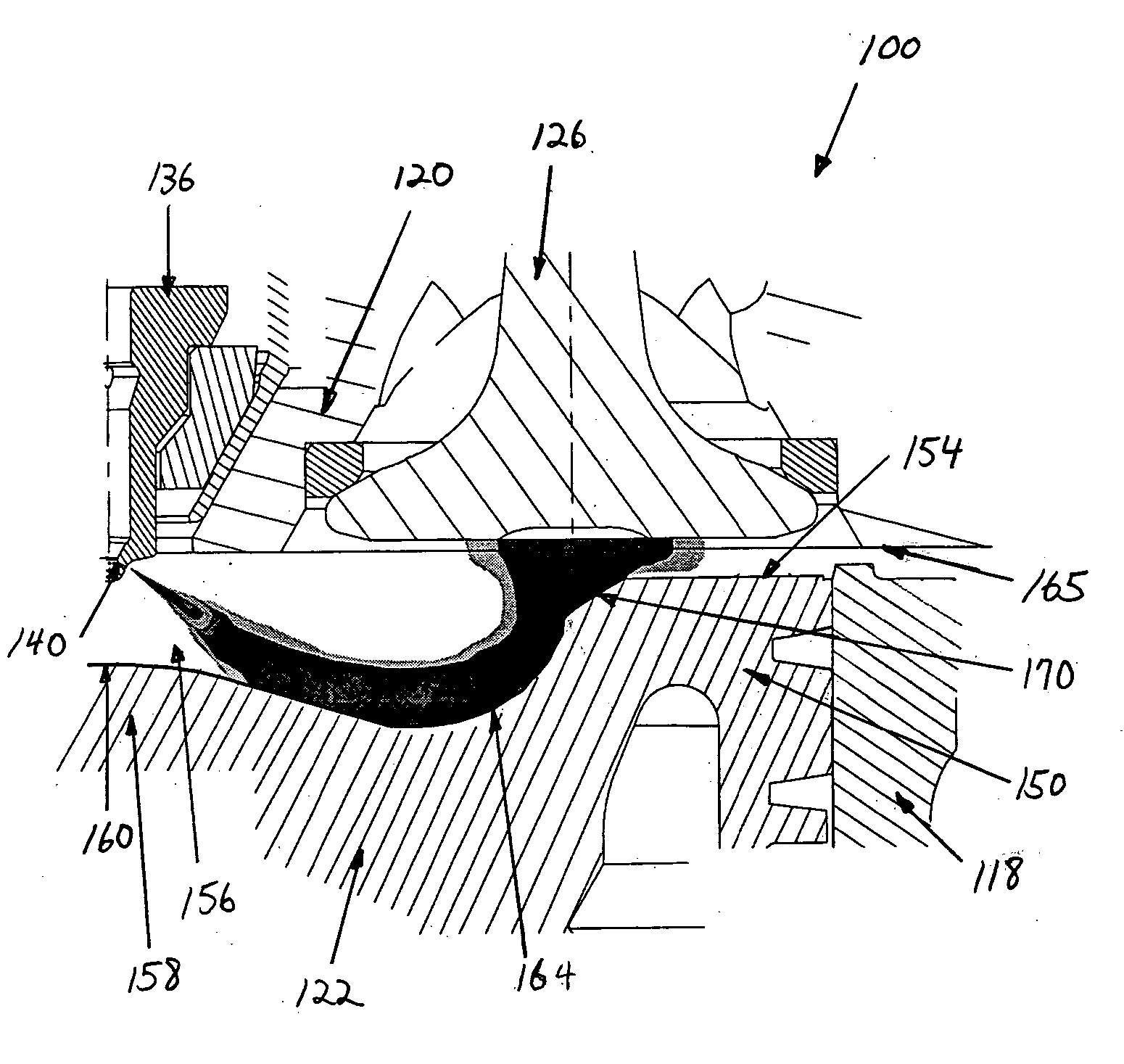

Hybrid gas turbine and internal combustion engine

InactiveUS8141360B1Improve power densityAvoids severe efficiency degradationInternal combustion piston enginesVehicle sub-unit featuresExternal combustion engineFuel efficiency

A hybrid engine having a gas turbine engine and an internal combustion engine, both engines driving a common drive shaft. The compressor delivers compressed air to the combustor and to an inlet of the internal combustion engine, the compressed air picks up heat from the internal combustion engine either from the combustion process or through a heat exchanger, and is delivered to the combustor. When the gas turbine engine is not operating by burning fuel, the heated compressed air from the internal combustion engine is used to maintain the shaft speed sufficient for starting the gas turbine engine without the need to bring the turbine engine up to speed prior to ignition. The apparatus and process of the present invention provides a hybrid engine that is light weight, fuel efficient, and with enough available power for high powered situations.

Owner:FLORIDA TURBINE TECH

Purification of carbon dioxide

Impure carbon dioxide (“CO2”) comprising a first contaminant selected from the group consisting of oxygen (“O2”) and carbon monoxide (“CO”) is purified by separating expanded impure carbon dioxide liquid in a mass transfer separation column system. The impure carbon dioxide may be derived from, for example, flue gas from an oxyfuel combustion process or waste gas from a hydrogen (“H2”) PSA system.

Owner:AIR PROD & CHEM INC

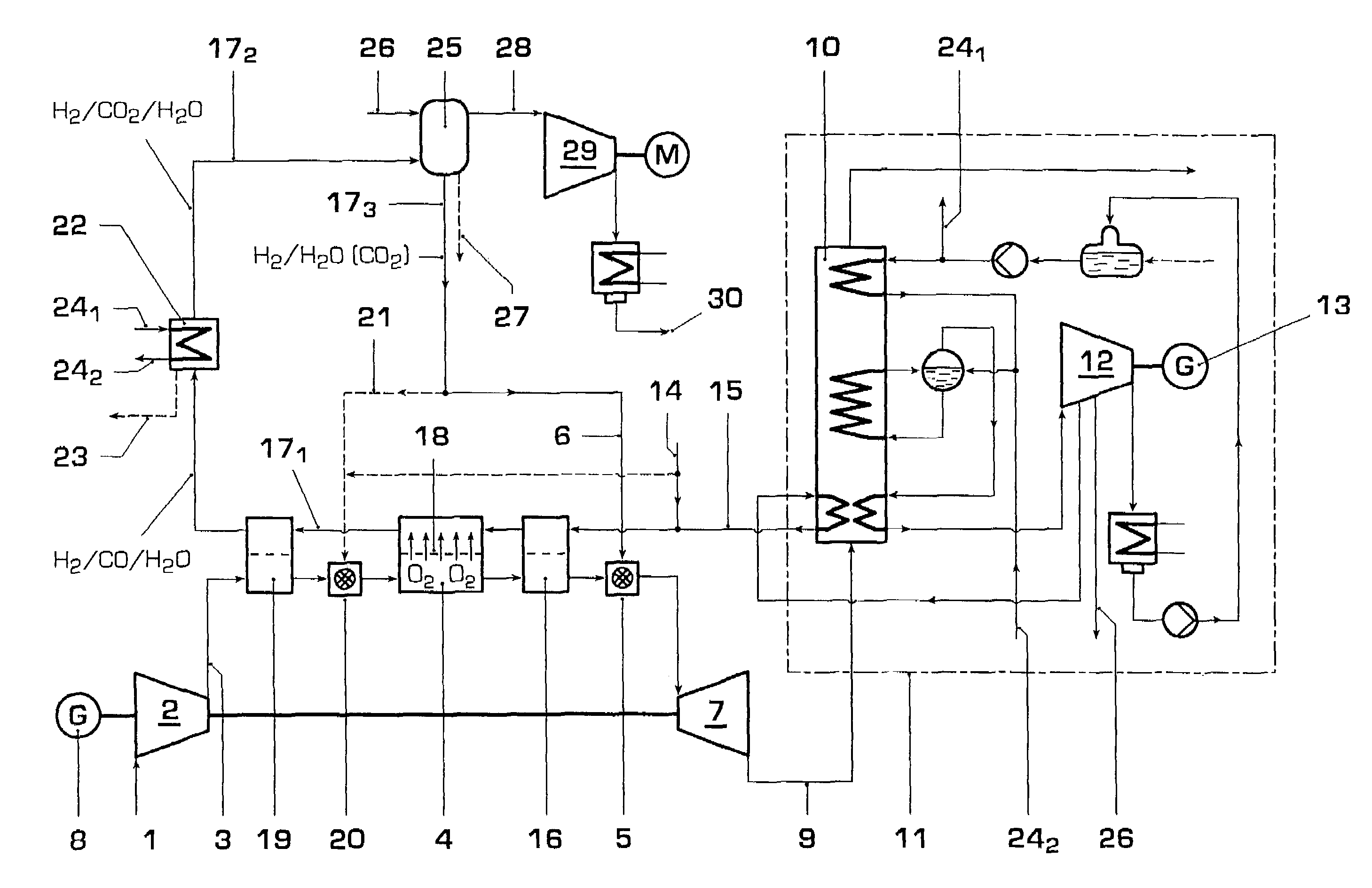

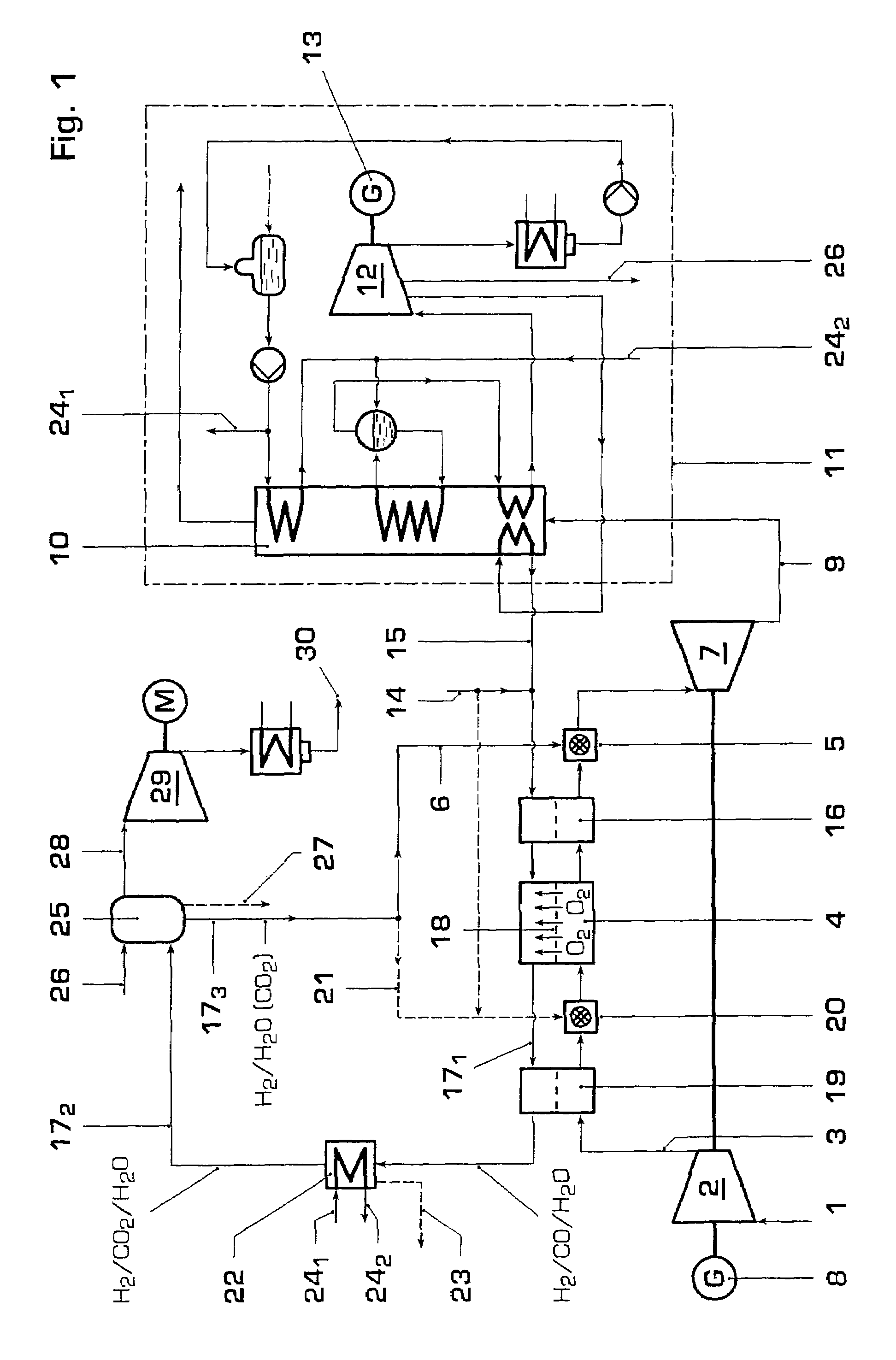

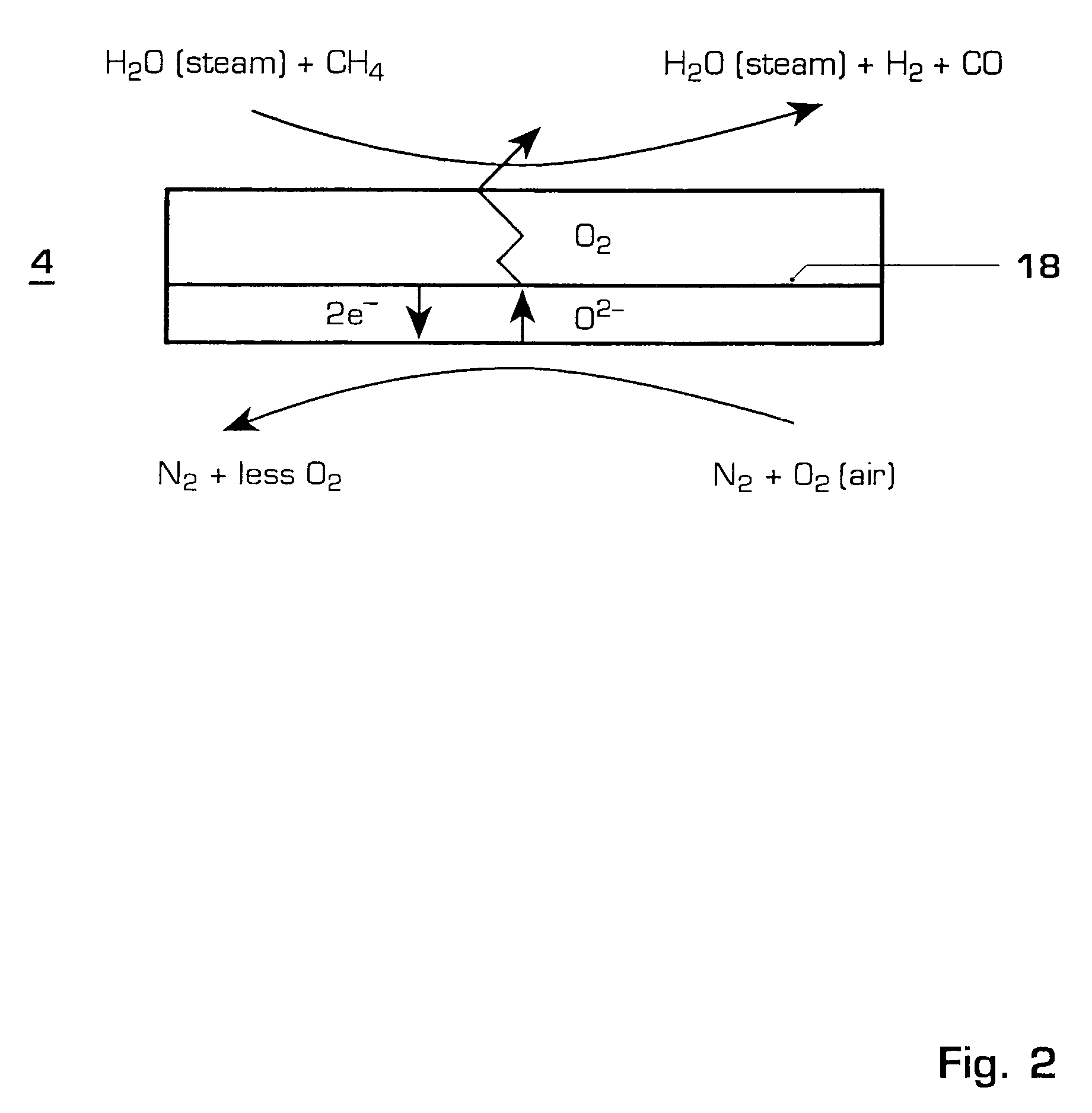

Gas turbine power plant and method of operating the same

InactiveUS7363764B2Improve efficiencyAvoid disadvantagesHydrogenOxygen/ozone/oxide/hydroxideSyngasPartial oxidation

A method of operating a gas turbine power plant and gas turbine power plant are disclosed wherein hydrogen for the combusting process is produced by feeding natural gas mixed with steam through a membrane / partial oxidation reactor and converting the natural gas at least to H2 and CO. Thereby oxygen is transferred from the compressed air through the membrane of the membrane / partial oxidation reactor and the oxygen is used for the partial oxidation process of the natural gas. The process is followed by converting the syngas in a CO shift reactor and a CO shift reactor to a CO2 removal equipment to mainly hydrogen.

Owner:GENERAL ELECTRIC TECH GMBH

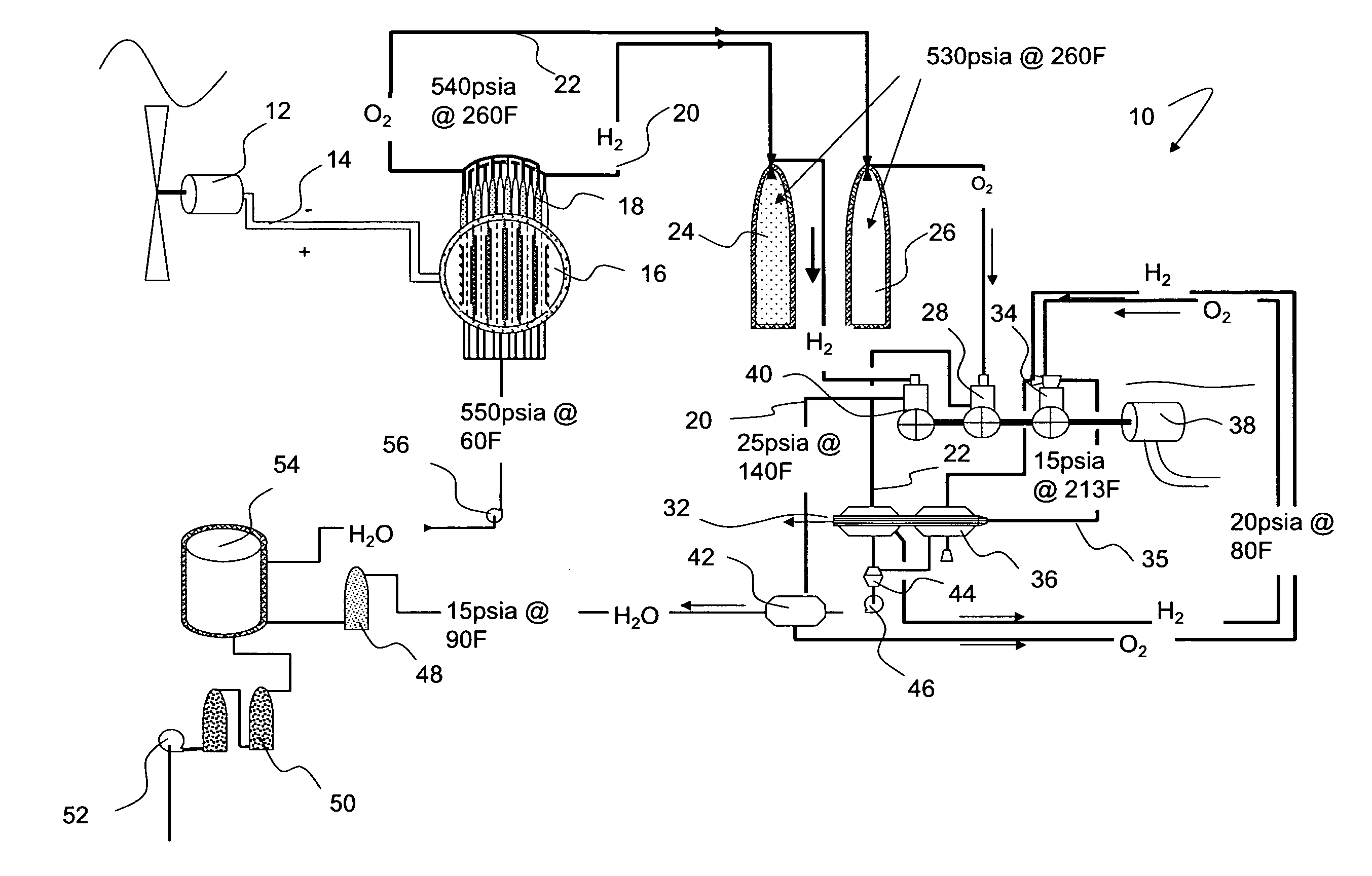

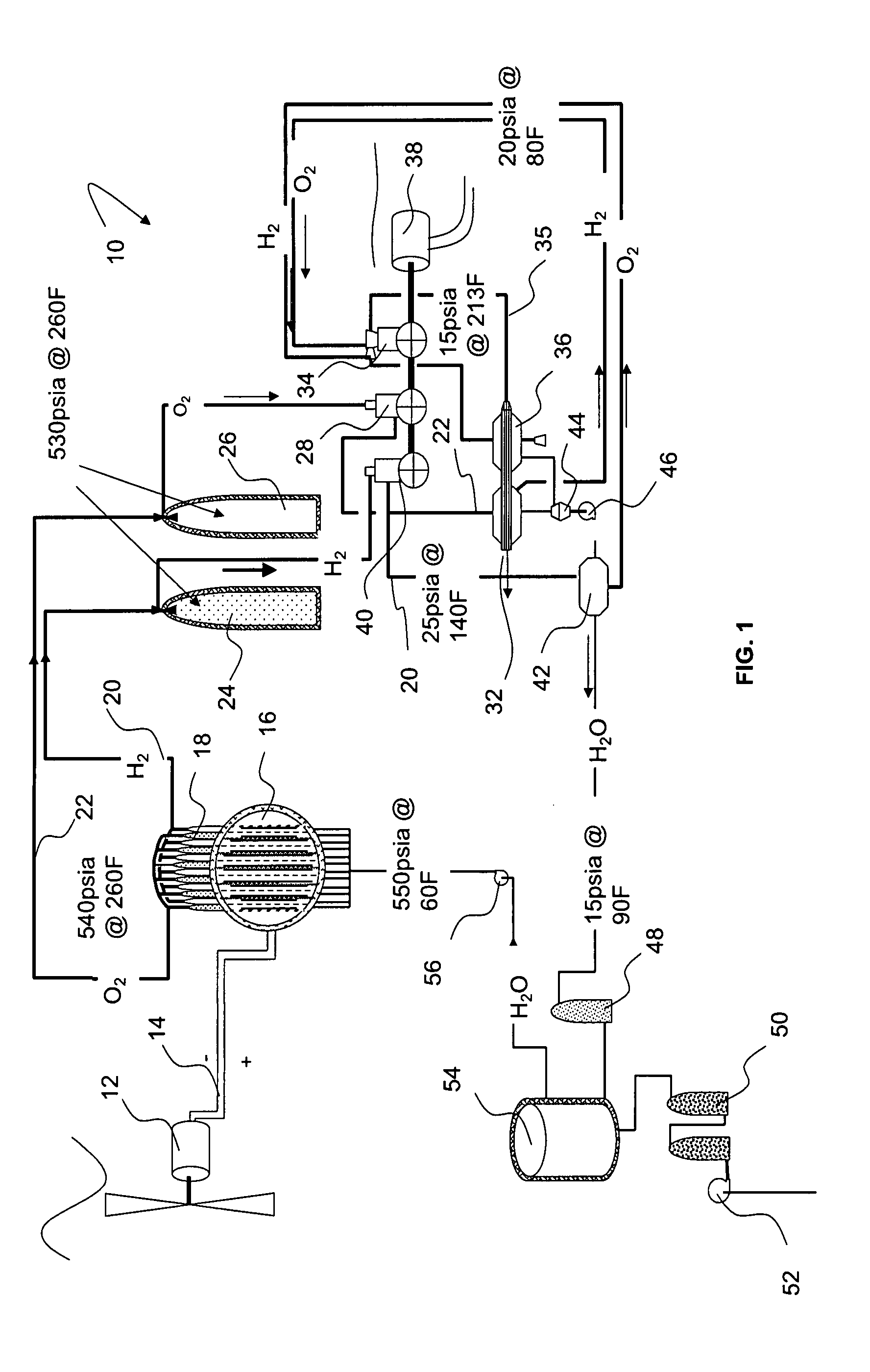

Hybrid Cycle Electrolysis Power System with Hydrogen & Oxygen Energy Storage

InactiveUS20080047502A1Increase fuel consumptionReduce operating costsPhotography auxillary processesInternal combustion piston enginesElectrolysisElectric power system

A method for generating power comprising the steps of feeding water into an electrolyzer, providing electricity to operate the electrolyzer to split at least some of the water into hydrogen and oxygen, and decompressing one or both of the hydrogen and oxygen to generate power. Water can be pressurized prior to being fed into the electrolyzer. The hydrogen and oxygen, which can be stored in insulated storage vessels, can be decompressed isentropically to yield energy, which can be used to power a generator. Heat can be extracted from the hydrogen and oxygen, such as through heat exchangers. Hydrogen and oxygen can combine in an internal combustion process to produce work and heat, which can be recycled into the thermodynamic process.

Owner:RUSSO MICHAEL

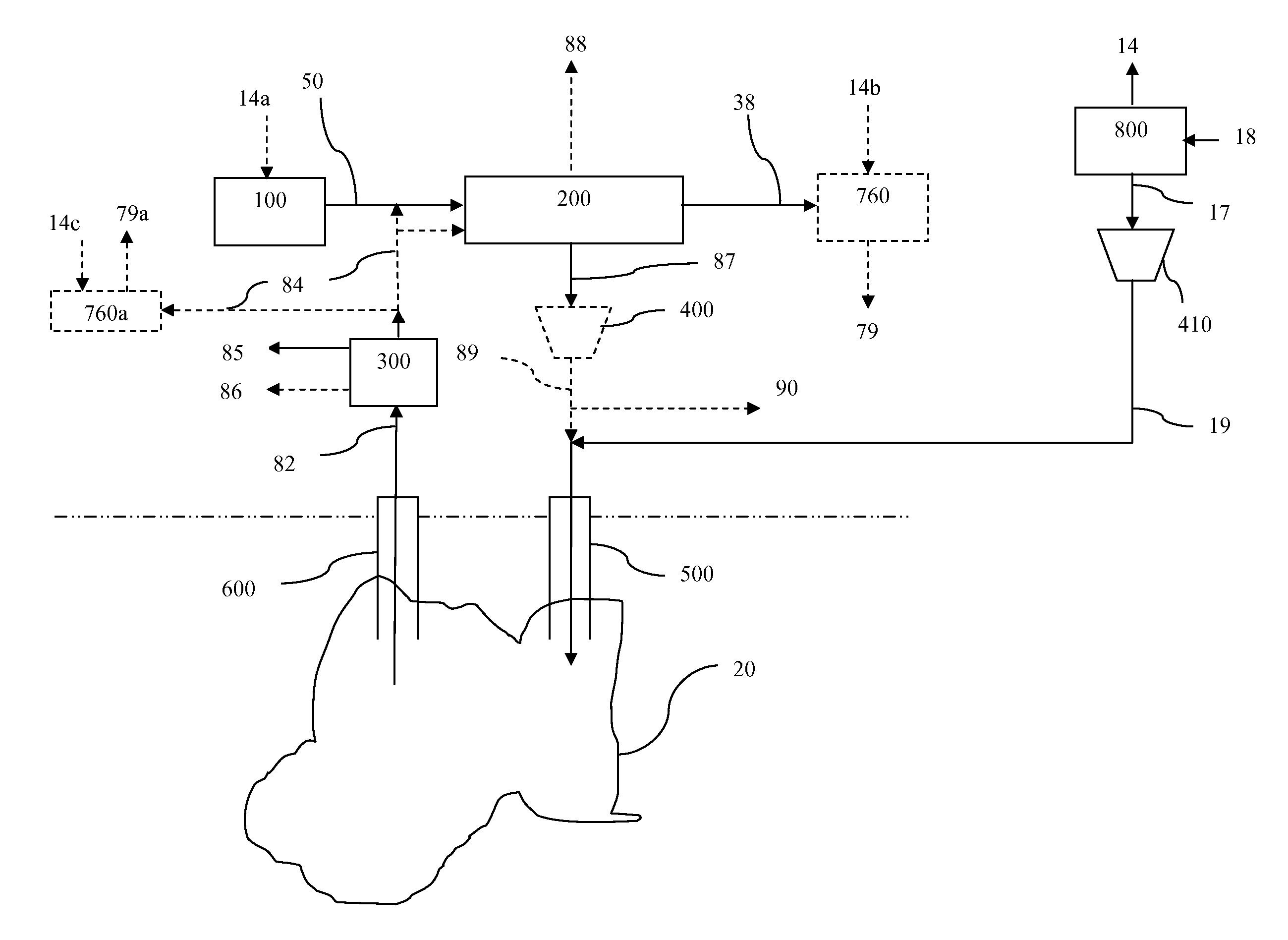

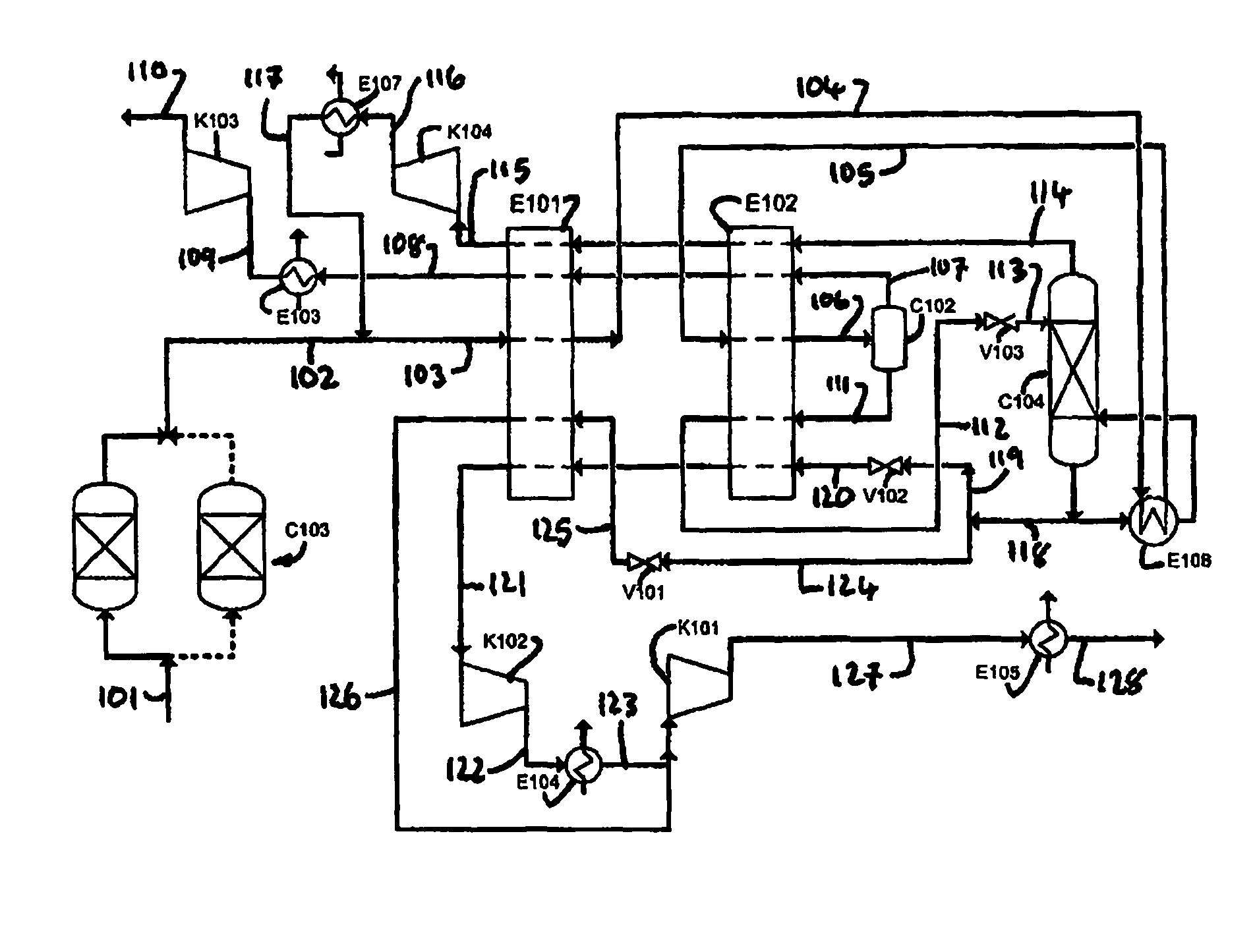

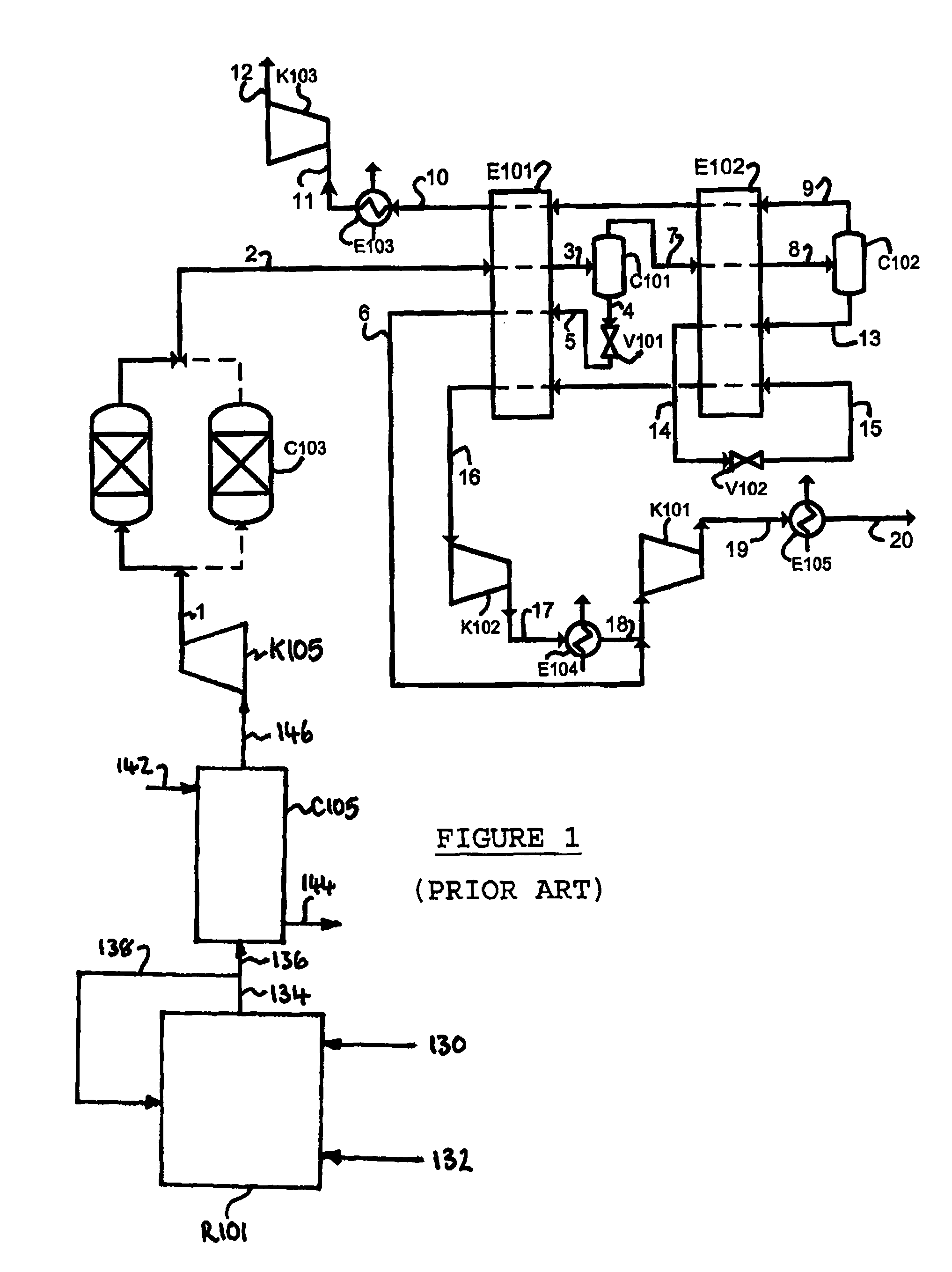

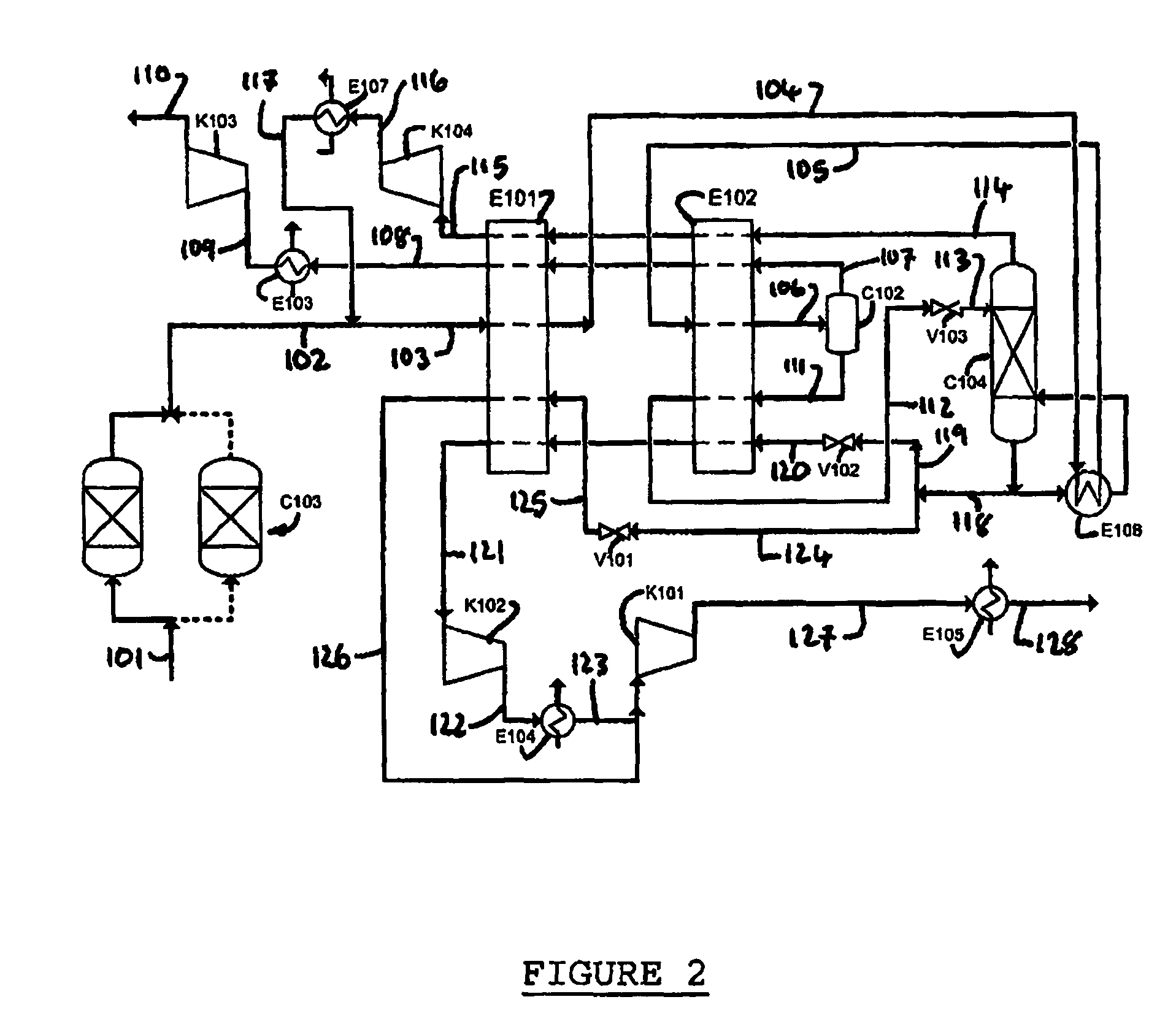

Integrated enhanced oil recovery process

InactiveUS20110146978A1Enhanced overall recoveryIncrease productionSolidificationLiquefactionGeneration processSyngas

The present invention relates to an enhanced oil recovery process that is integrated with a synthesis gas generation process, such as gasification or reforming, and an air separation process for generating (i) an oxygen stream for use, for example, in the syngas process or a combustion process, and (ii) a nitrogen stream for EOR use.

Owner:SURE CHAMPION INVESTMENT LTD

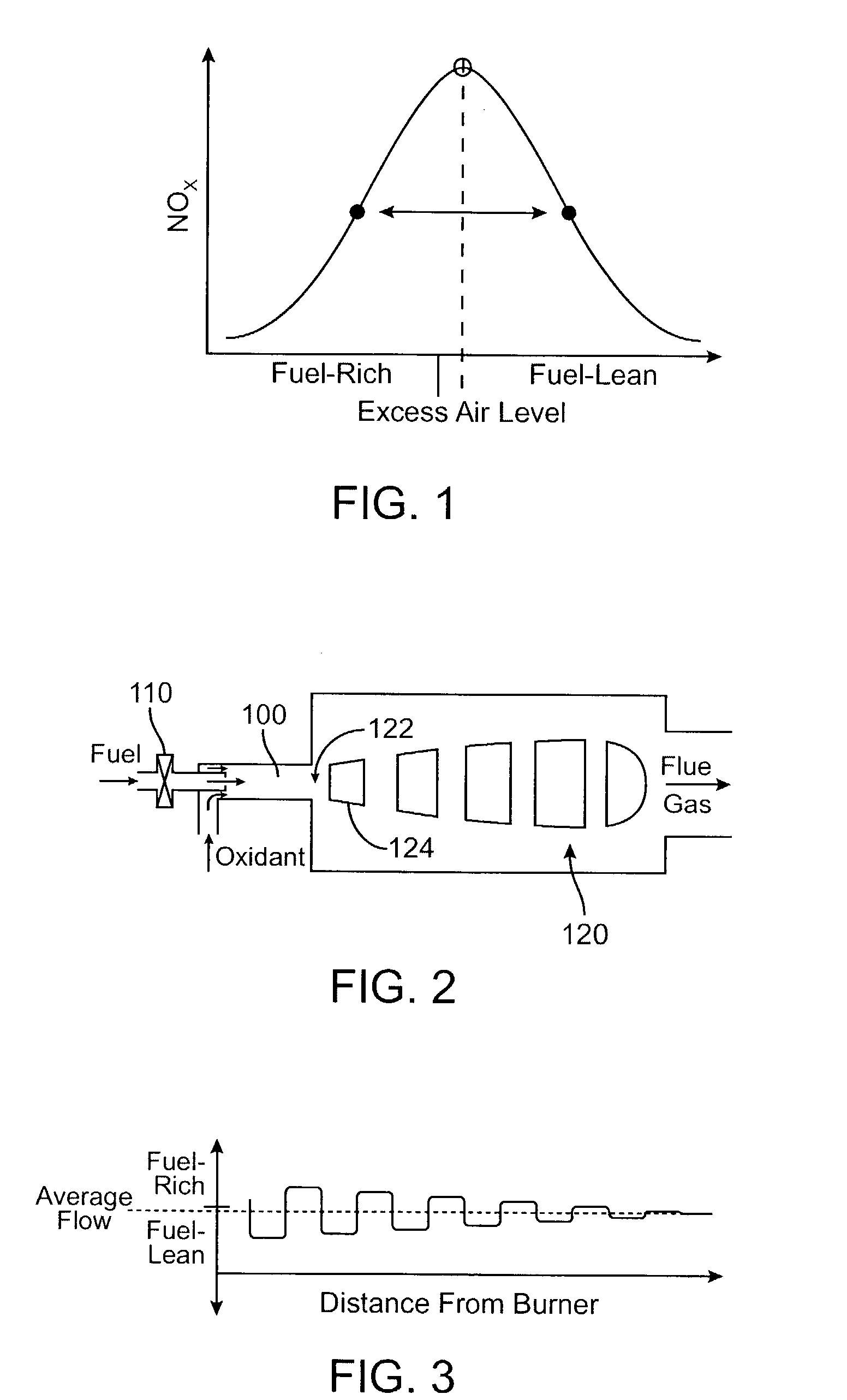

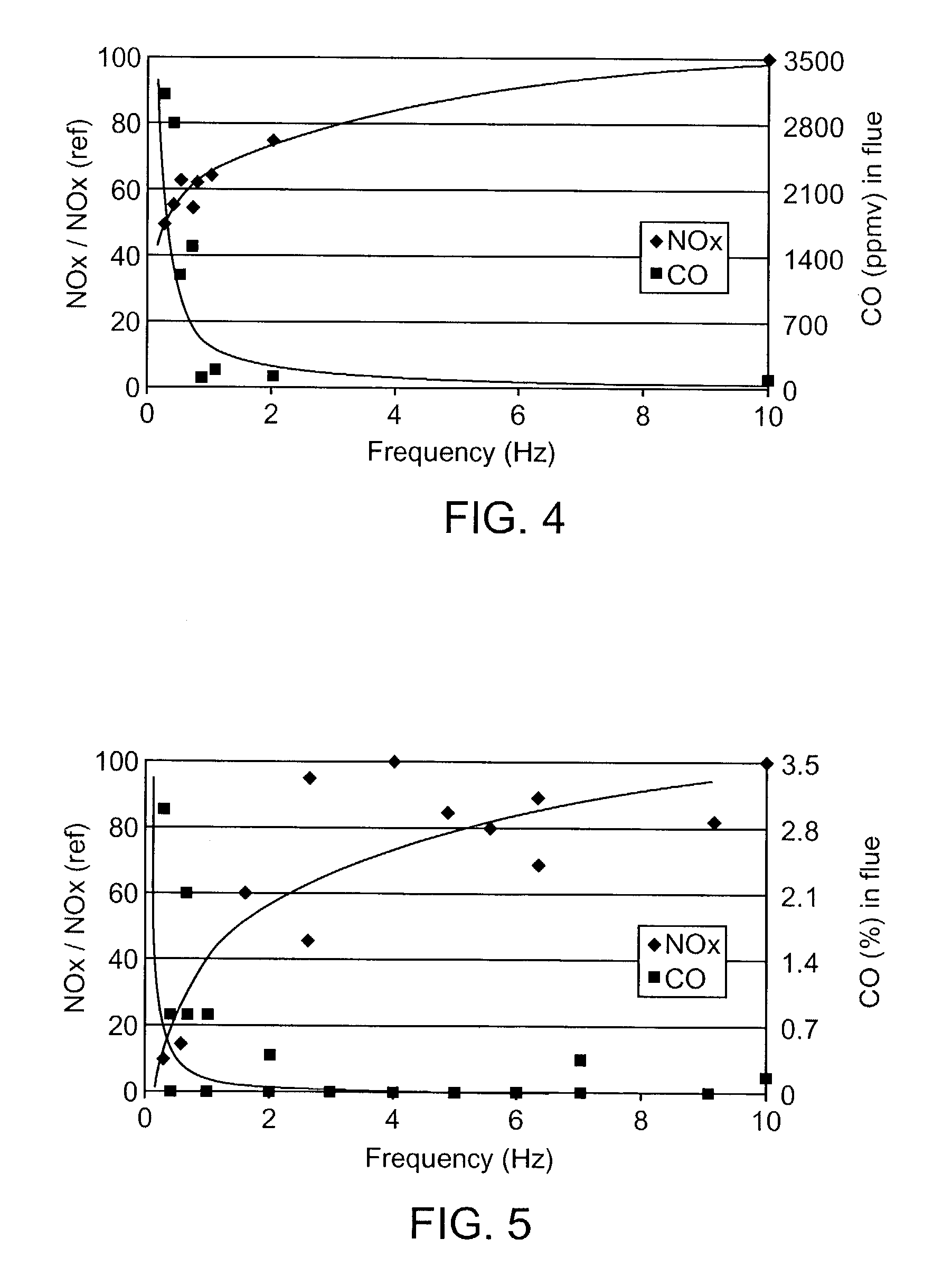

Process and apparatus of combustion for reduction of nitrogen oxide emissions

InactiveUS20030134241A1Special fuel supply arrangementsIndirect carbon-dioxide mitigationNitrogen oxidesControl system

A combustion control system allows the dramatic reduction of NOx emission levels from industrial combustion processes without having recourse to expensive flue gas clean up methods. The system combines the technique of oscillating combustion with an adapted system for post combustion burn out of the excess of CO resulting from the low-NOx combustion zone. A process for fuel combustion includes generating an oscillating combustion zone by oscillating at least one of the fuel flow and the oxidant flow to achieve a reduced nitrogen oxide emission, selecting oscillating parameters and furnace operating parameters to maximize nitrogen oxide reduction efficiency to the detriment of carbon monoxide production, and combusting carbon monoxide downstream of the oscillating combustion zone by injecting a post combustion oxidant.

Owner:MARIN OVIDIU +3

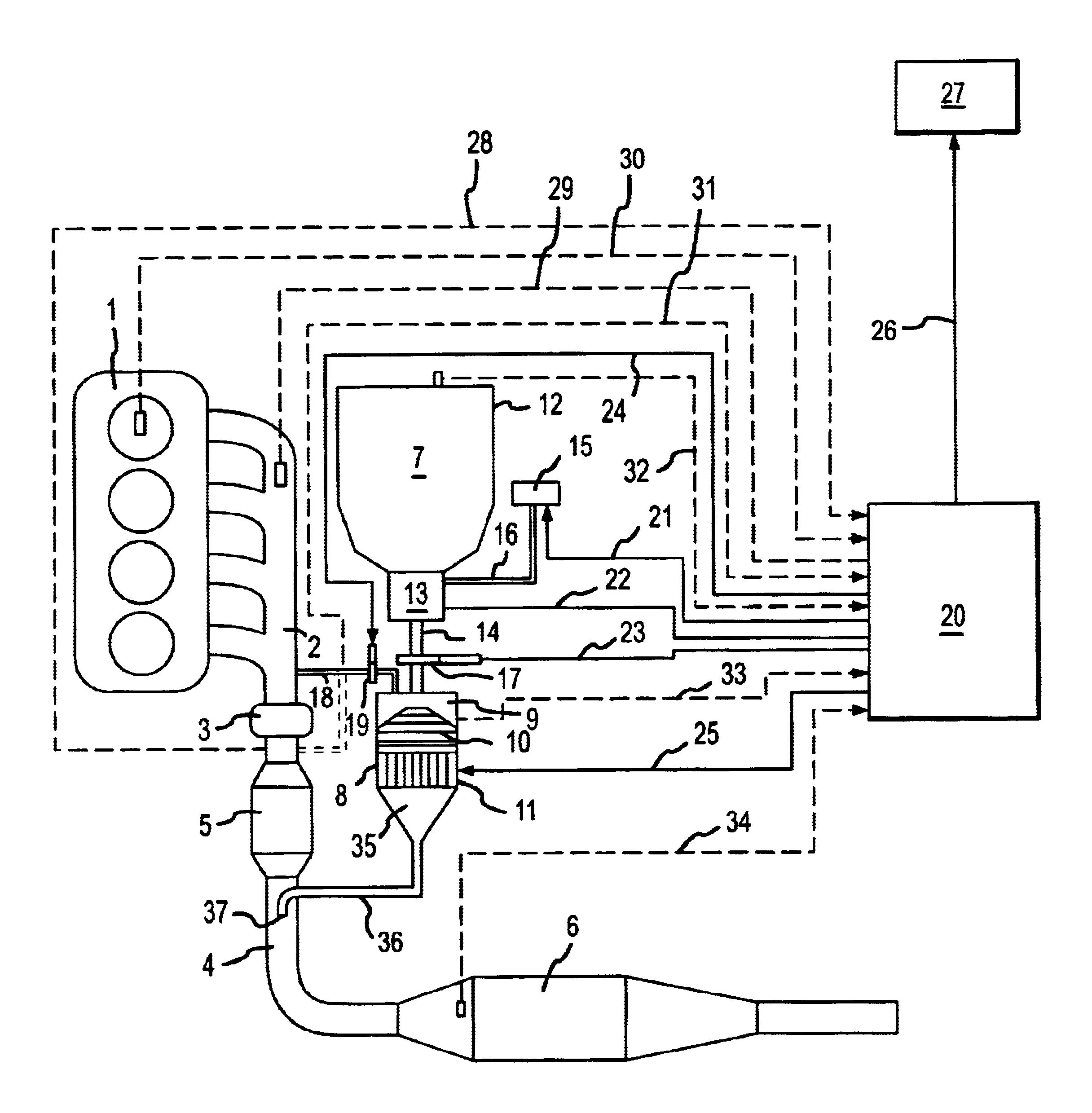

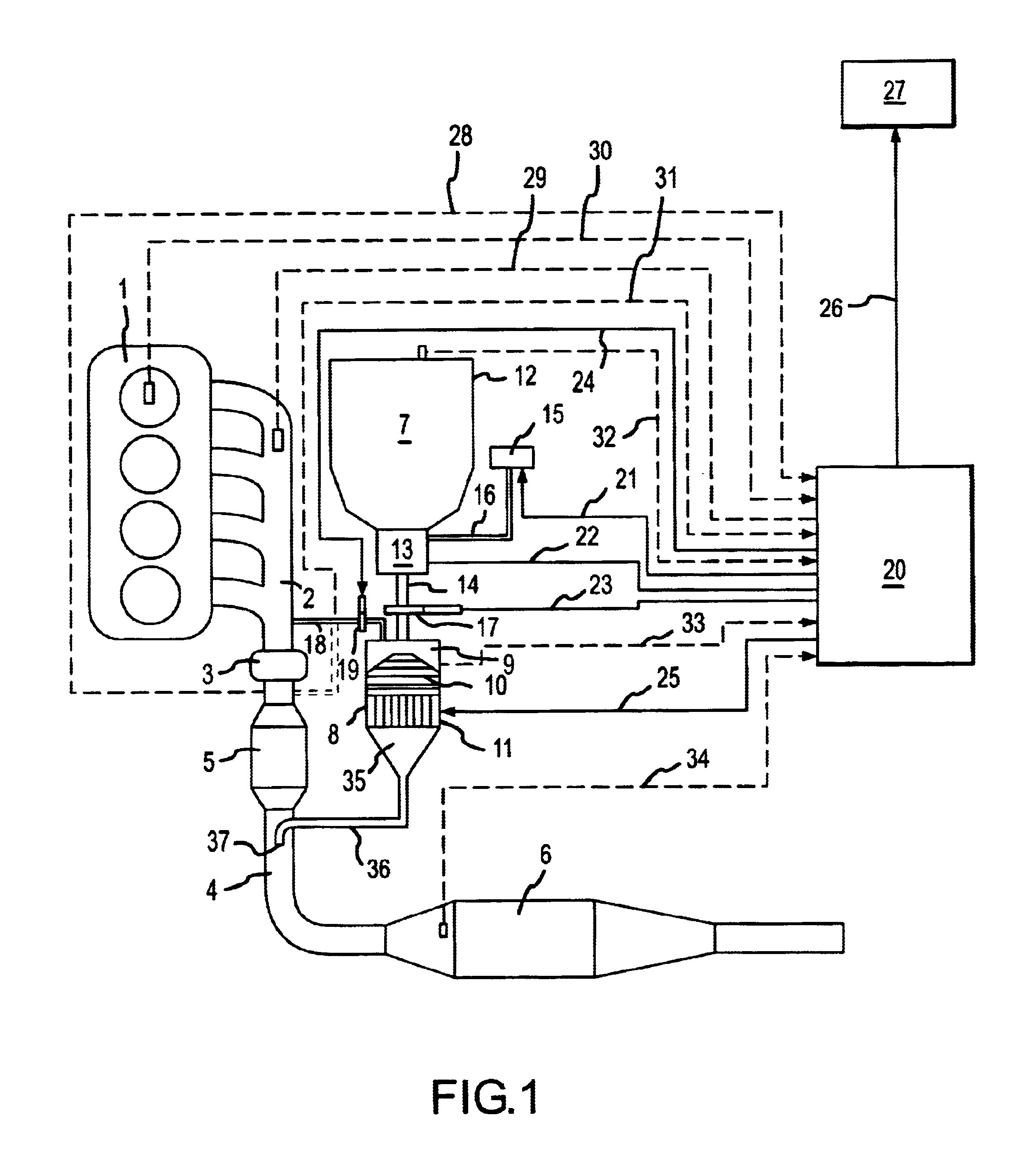

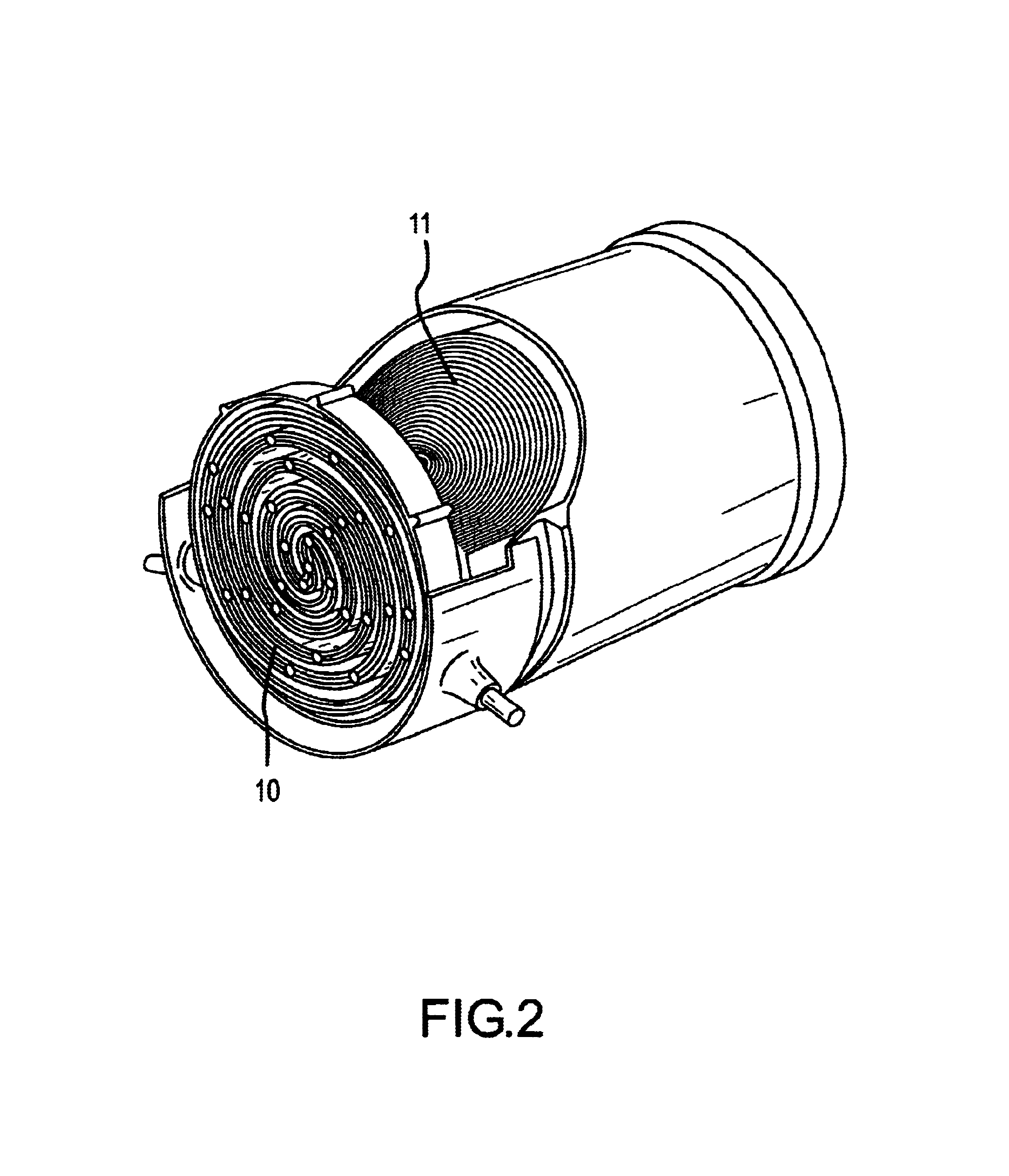

Method and apparatus for producing ammonia (NH3)

InactiveUS6928807B2High activityNitrogen compoundsInternal combustion piston enginesHydrolysisRapid thermal processing

A method is provided for producing ammonia (NH3) and introducing the produced ammonia (NH3) into an exhaust gas stream as a reduction means for selectively catalytically reducing nitrogen oxides contained in the exhaust gas stream, which is an exhaust stream generated by the combustion process of a motor, a gas turbine, or a burner. The method comprises feeding dry urea from a supply container in a controlled amount to reactor and subjecting the dry urea in the reactor to a sufficiently rapid thermal treatment such that a gas mixture comprising the reaction products of ammonia (NH3) and isocyanic acid (HCNO) is created. Also, the method comprises immediately catalytically treating the thus produced gas mixture in the presence of water such that the isocyanic acid (HCNO) resulting from the rapid thermal treatment is converted, via quantitative hydrolysis treatment, into ammonia (NH3) and carbon dioxide (CO2).

Owner:MAN NUTZFAHRZEUGE AG

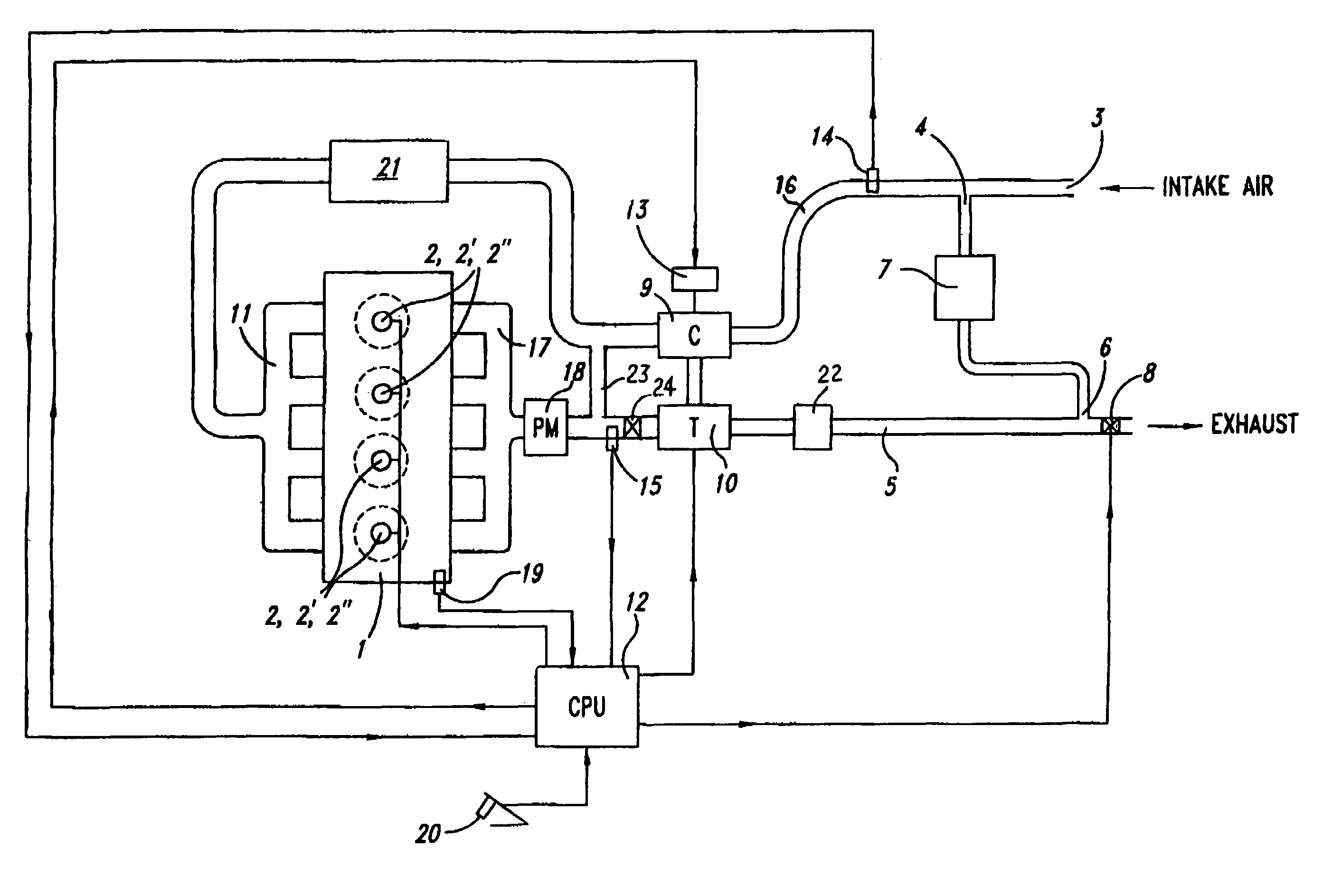

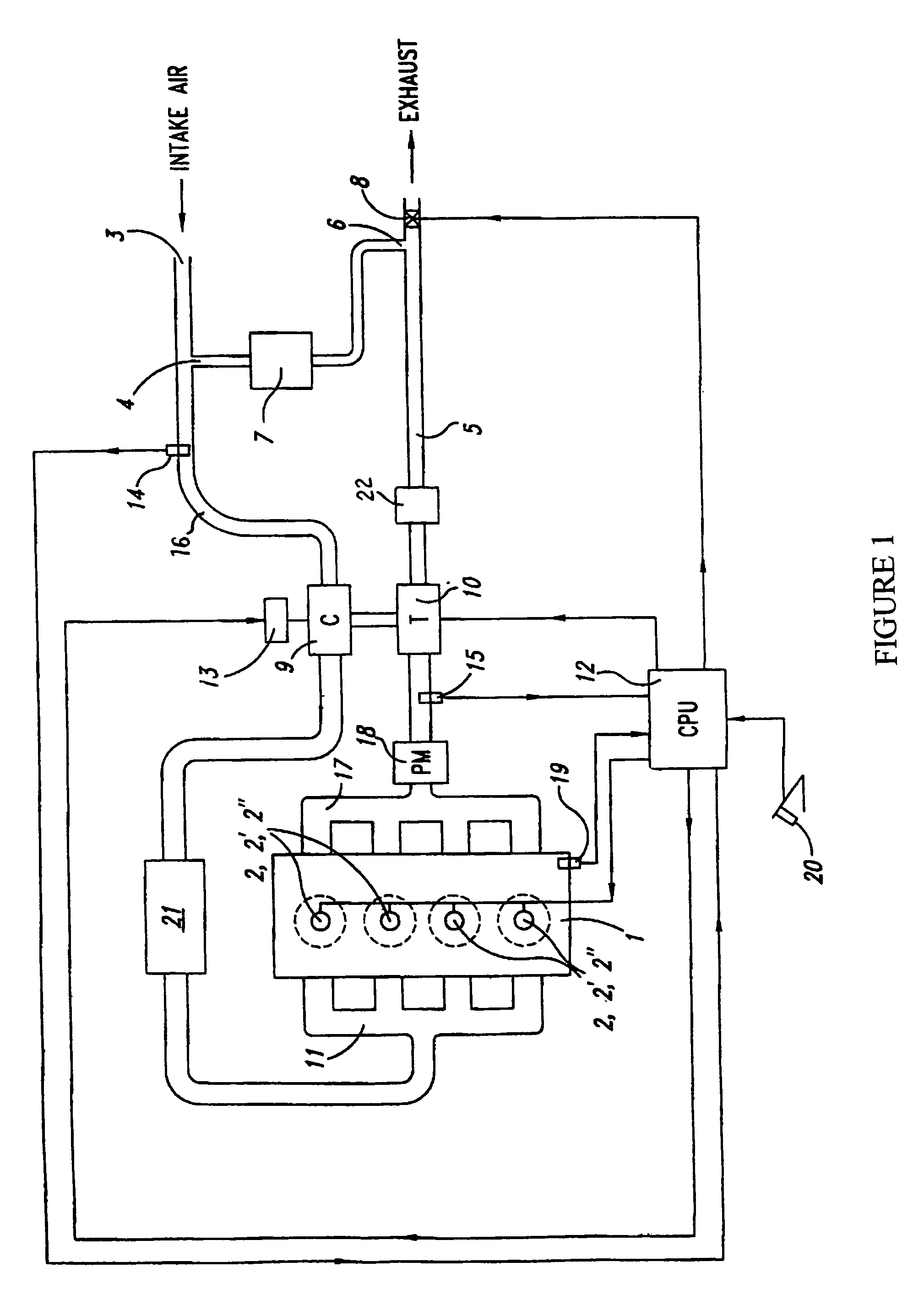

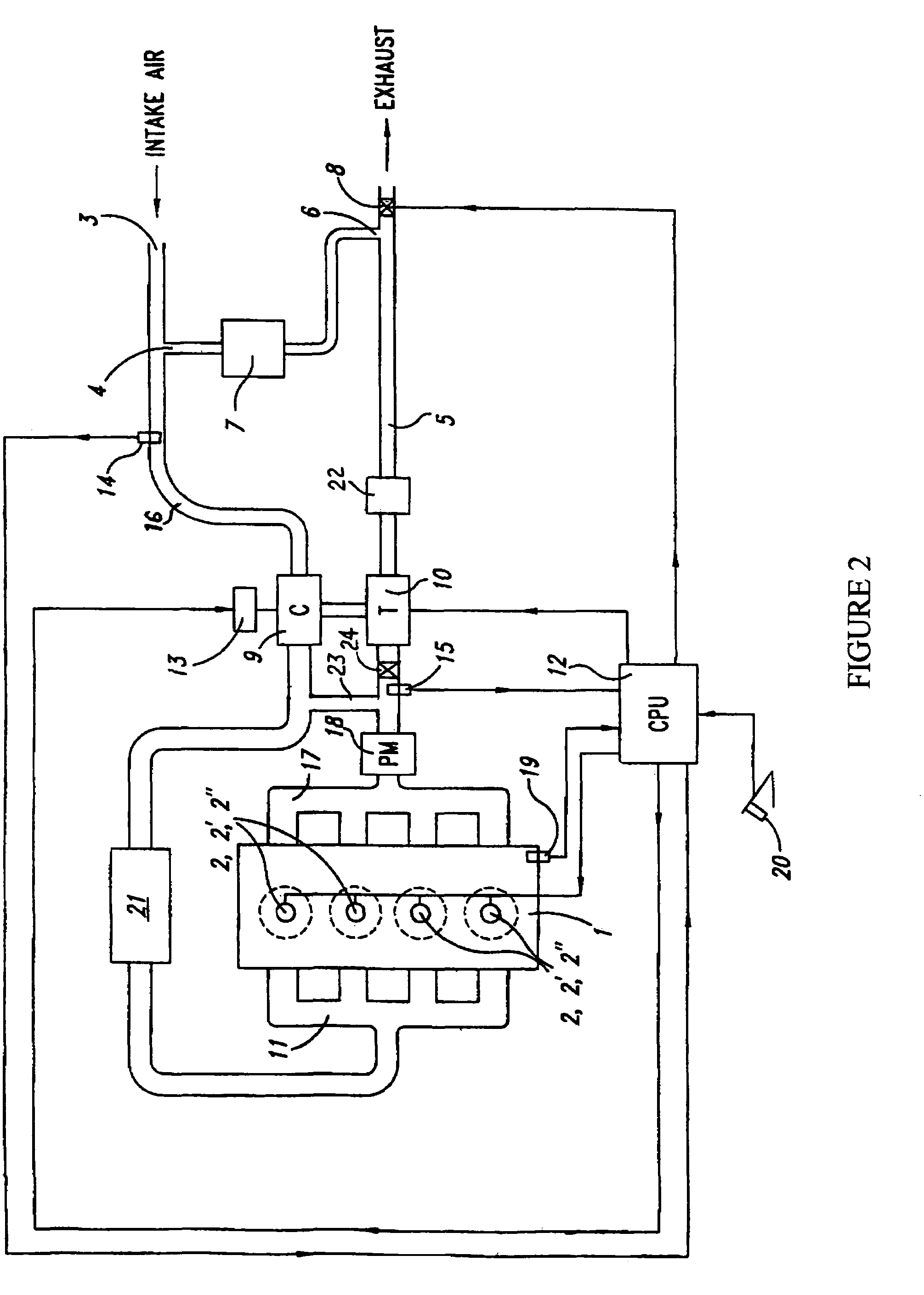

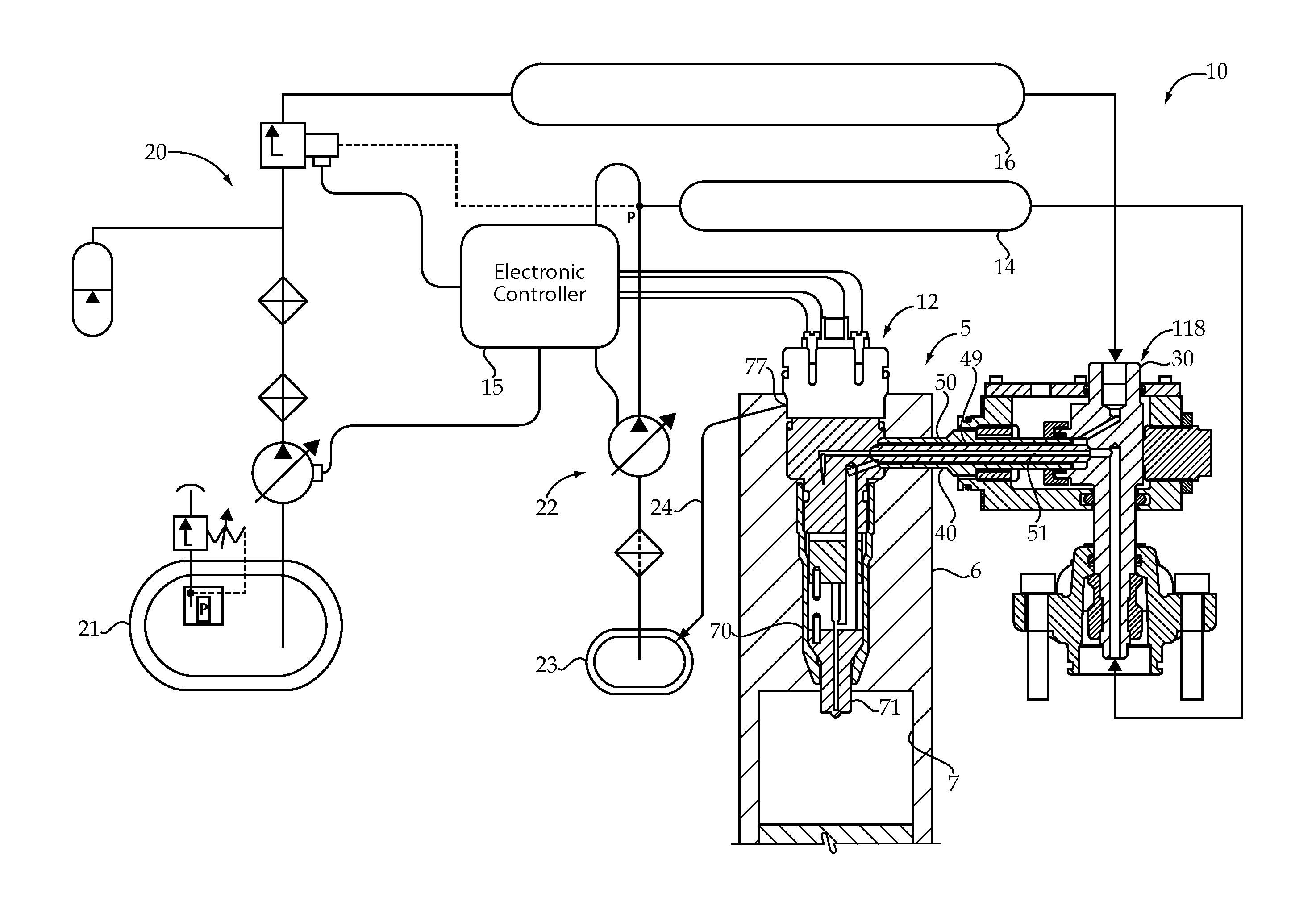

Control methods for low emission internal combustion system

InactiveUS7681394B2Cost-effectiveMaintaining NOx emissionsElectrical controlNon-fuel substance addition to fuelCombustion systemEngineering

Owner:US EPA OFFICE OF GENERAL COUNSEL UNITED STATES OF AMERICA THE

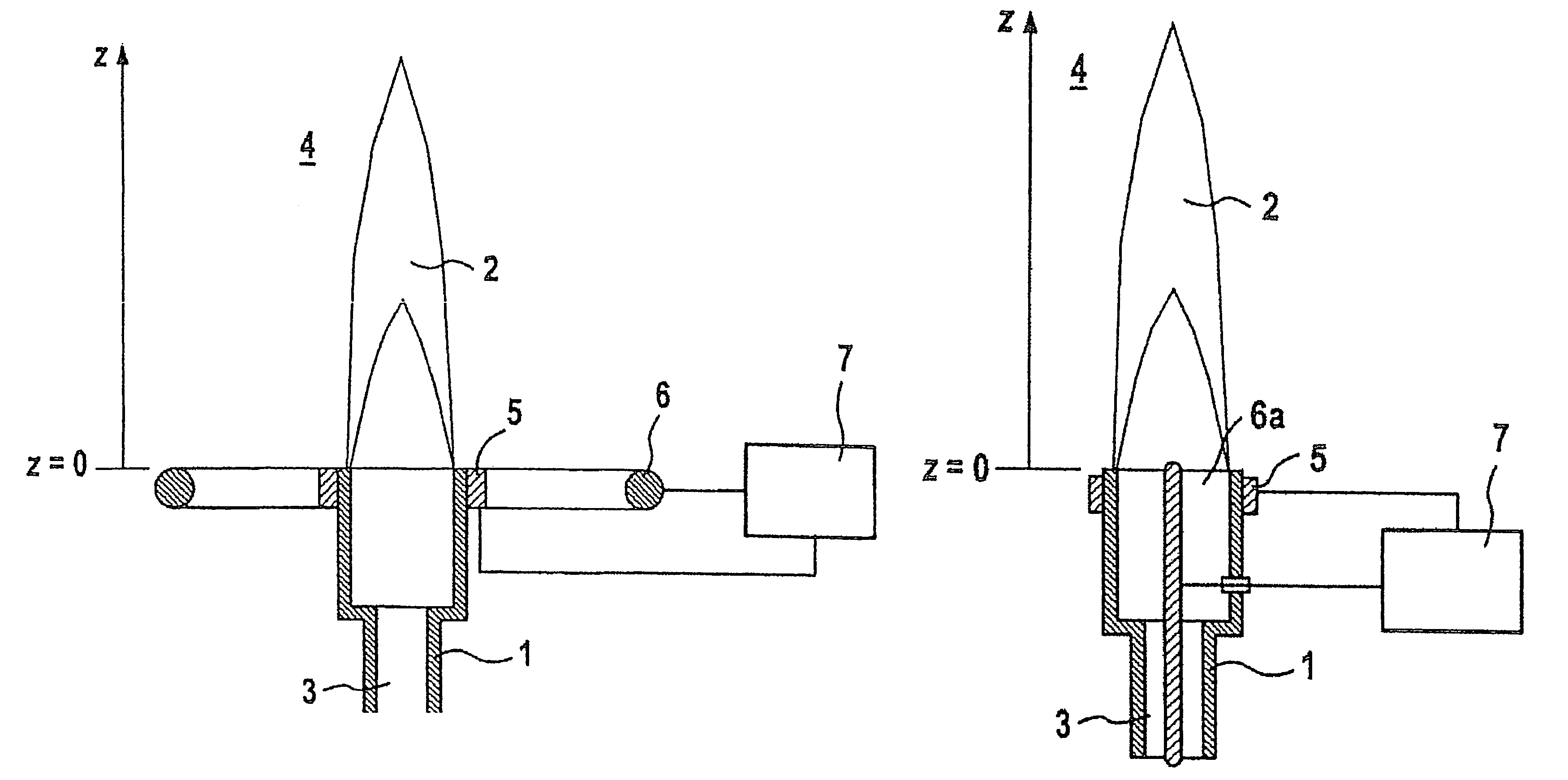

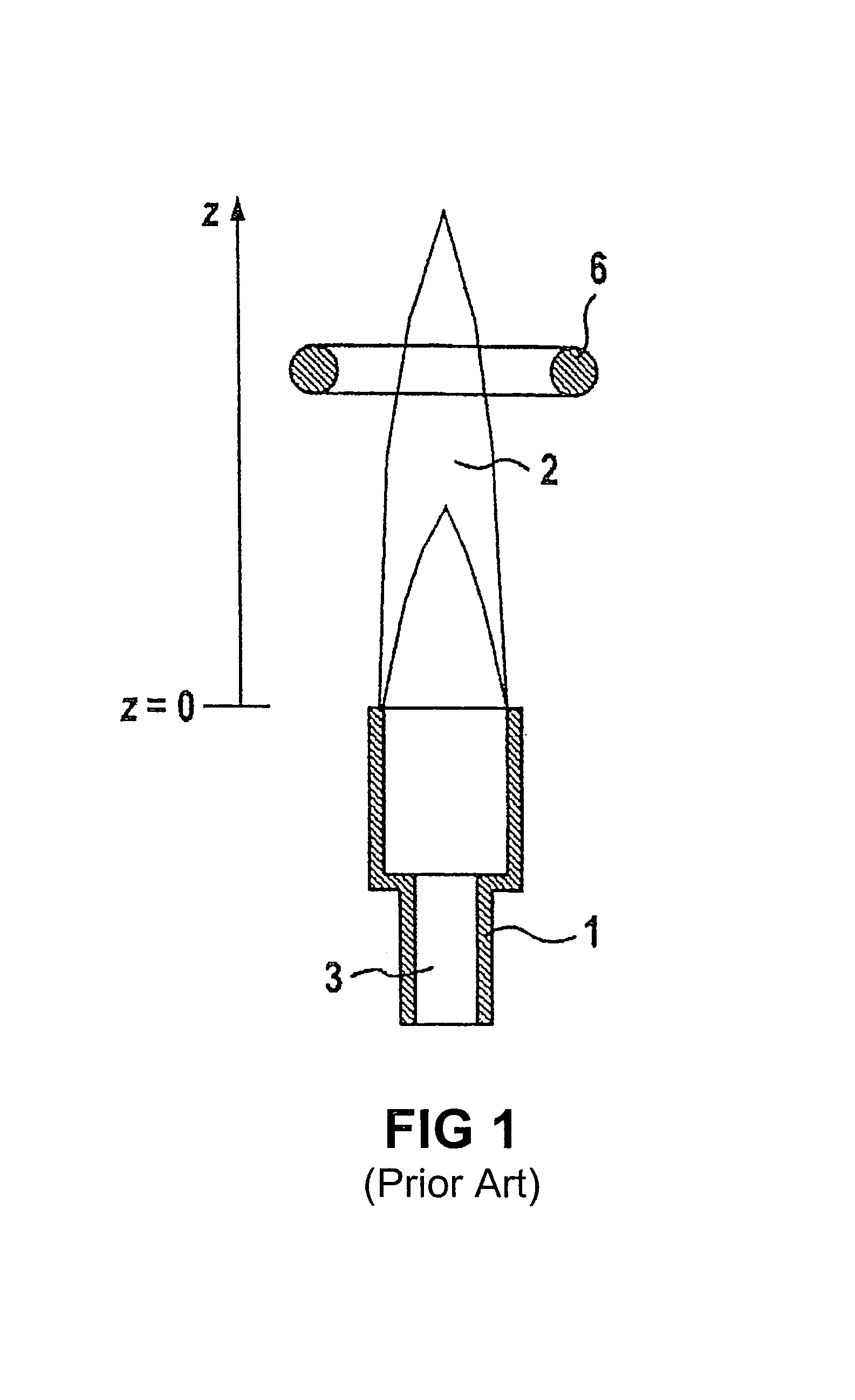

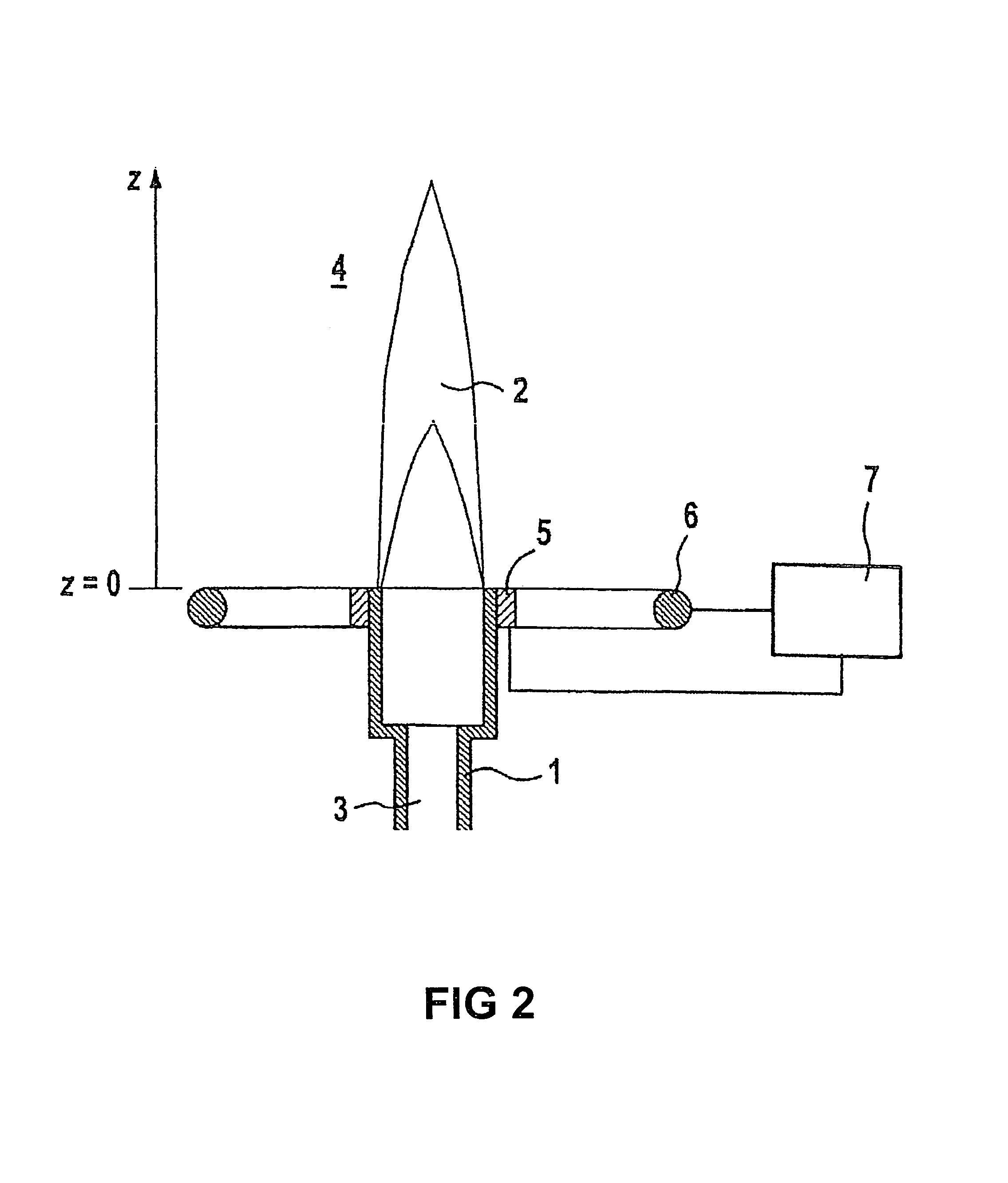

Method and device for influencing combustion processes involving combustibles

InactiveUS7137808B2Increase influenceEconomical and simpleCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHazardous substance

A method and device are for influencing combustion processes, and include an electrical device. The electrical device engages with the flame front so that the electrical field thus produced, only penetrates areas of the flame front in which a stabilizing and harmful-substance-reducing effect is produced. The electrodes of the burner are arranged outside the region of the flame in the associated device.

Owner:SIEMENS AG

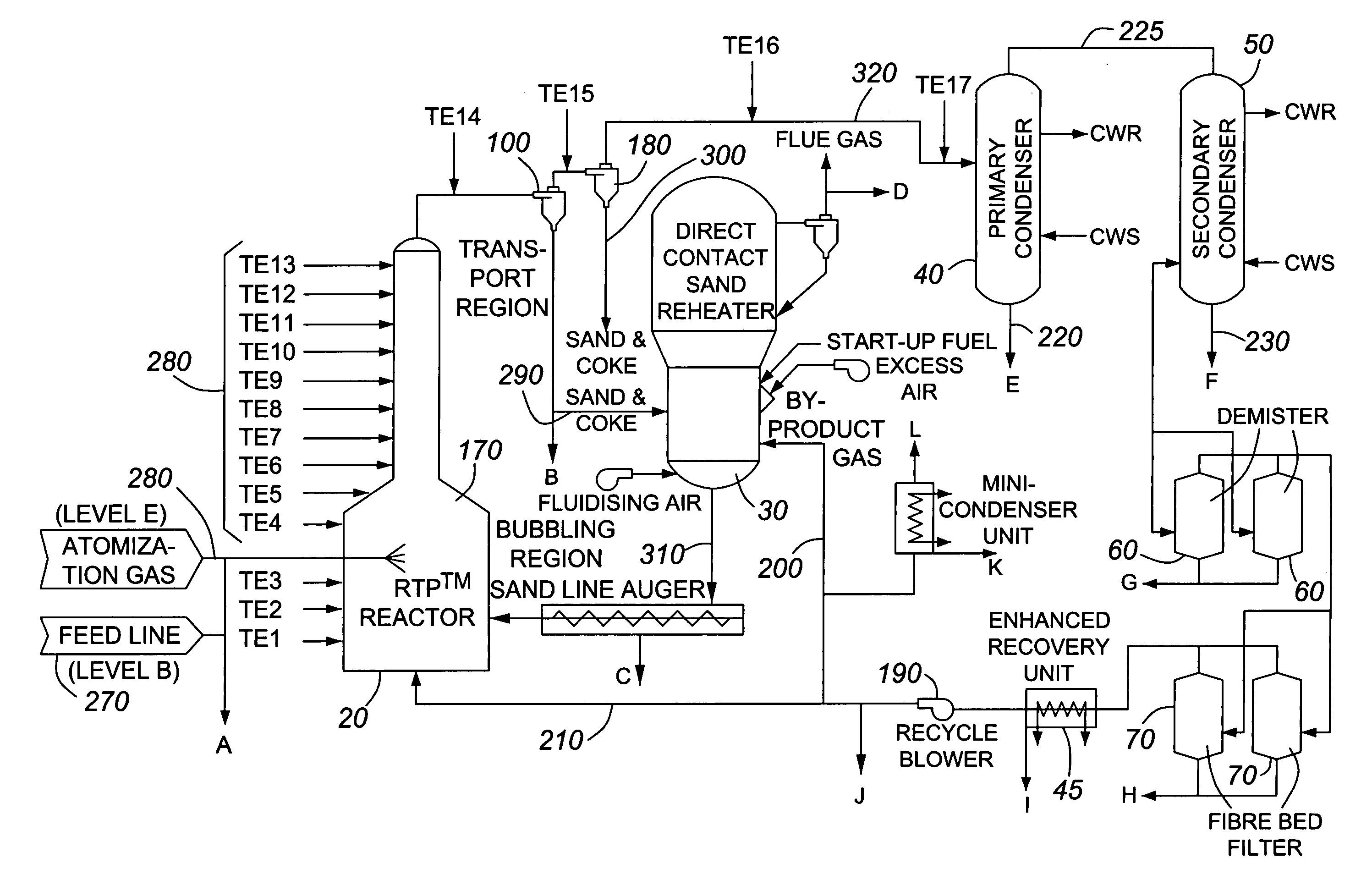

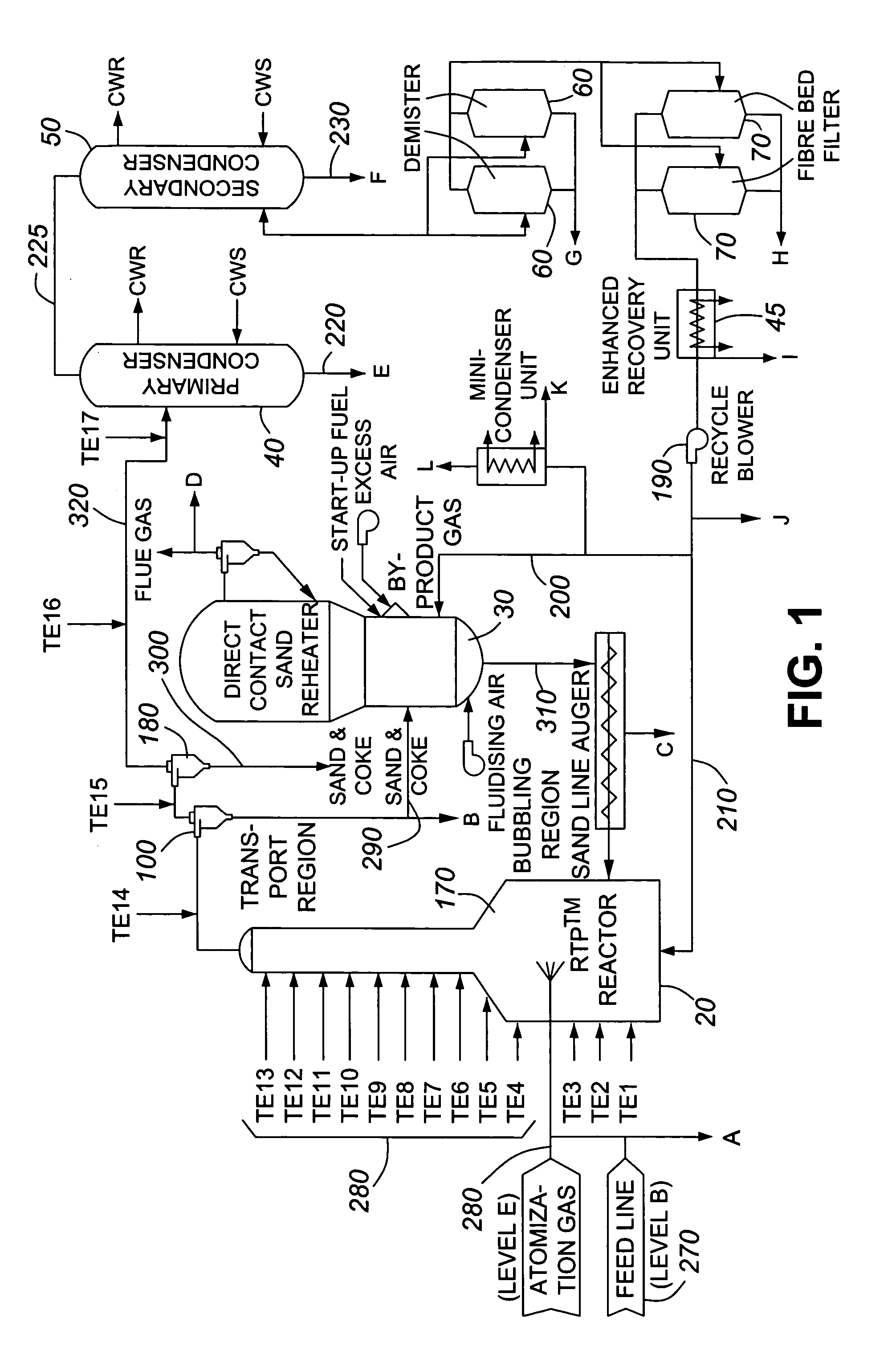

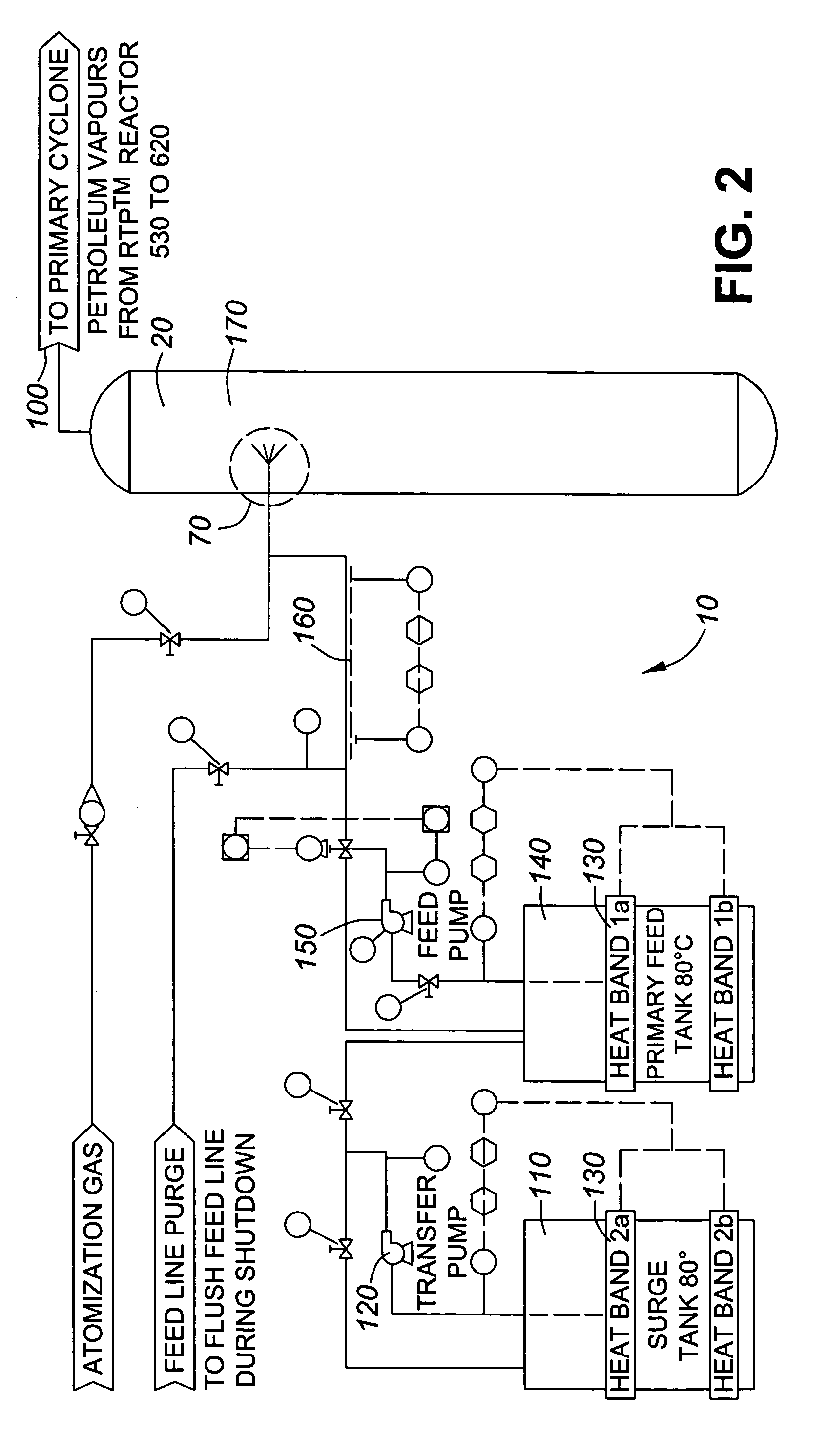

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

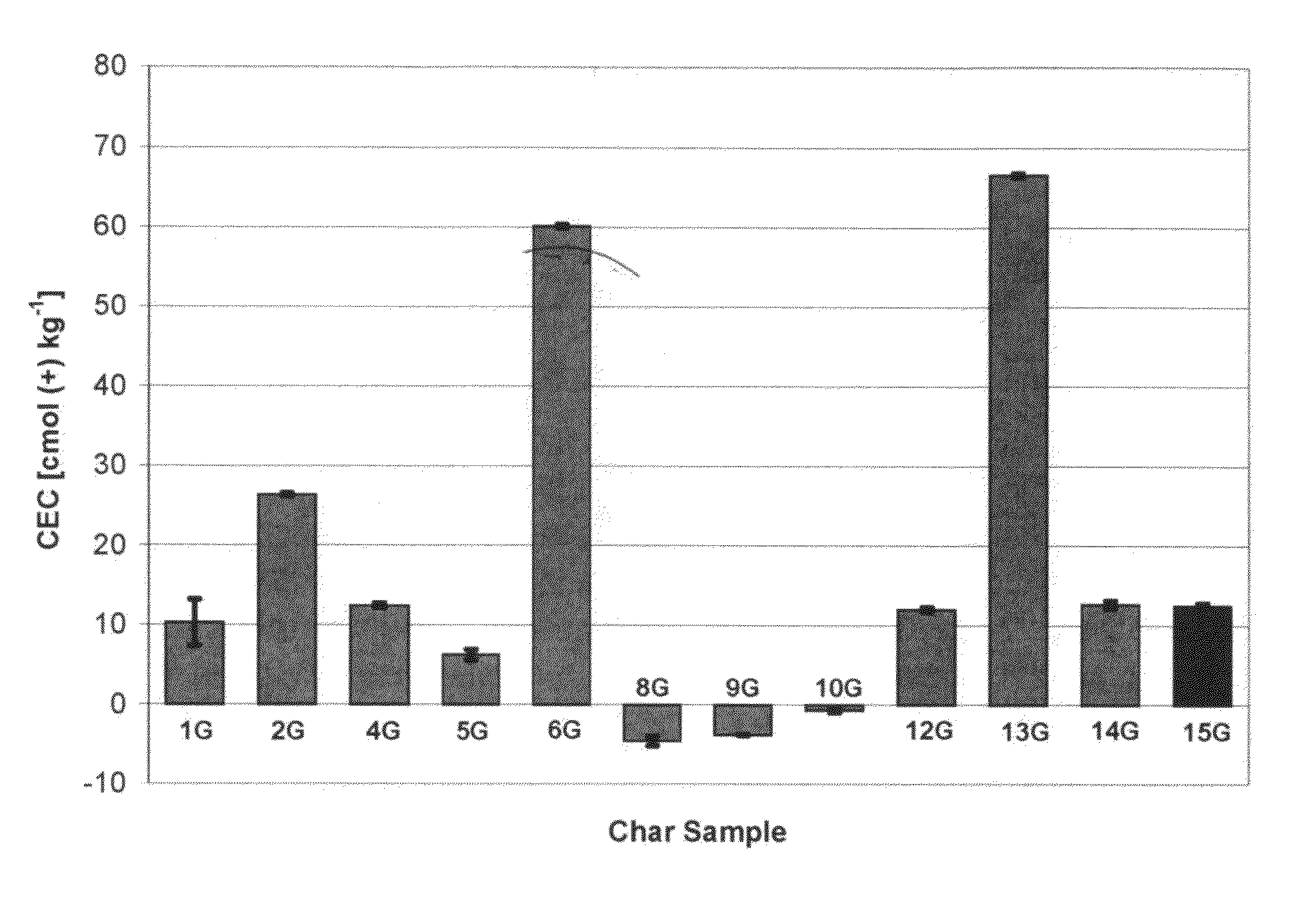

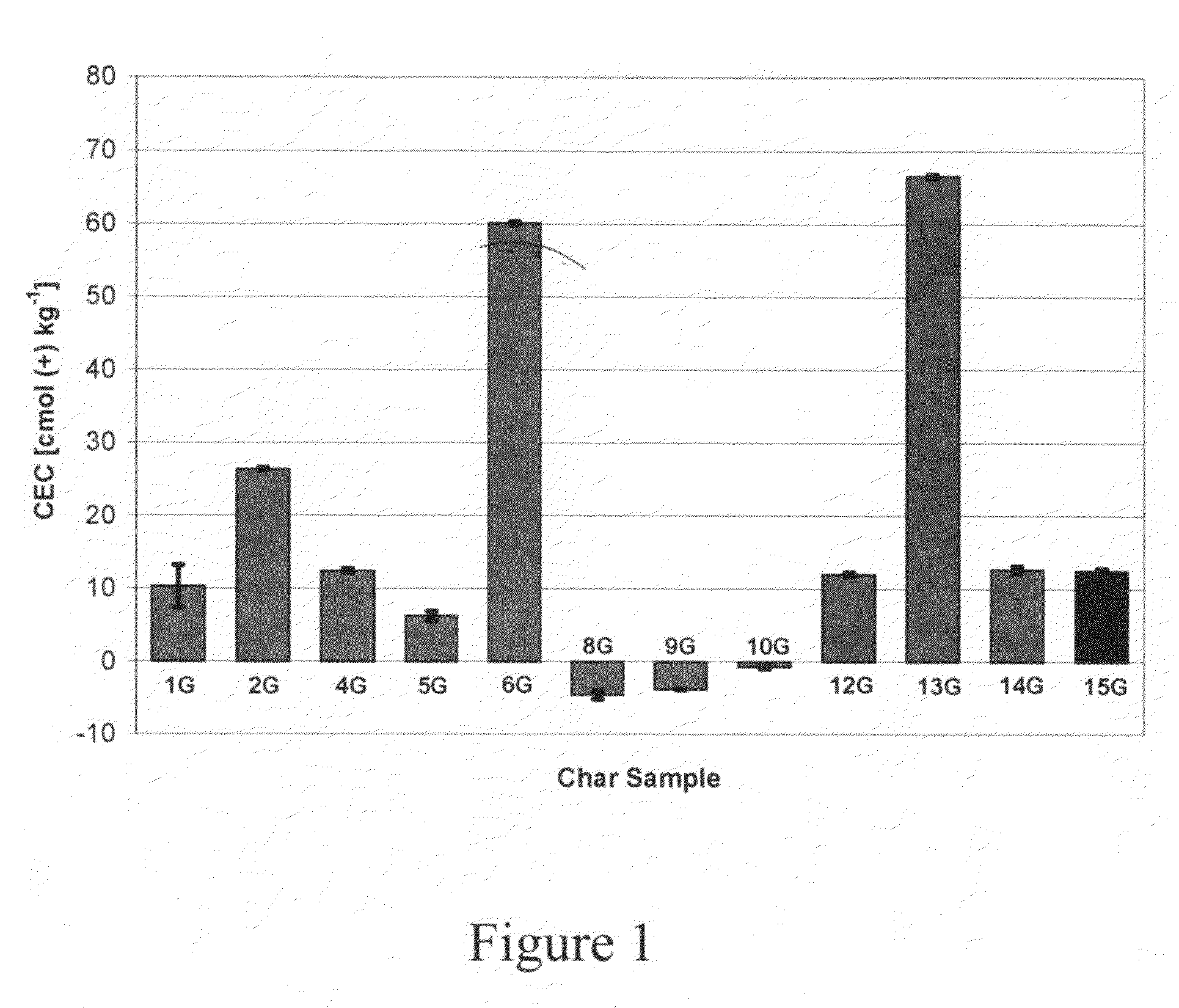

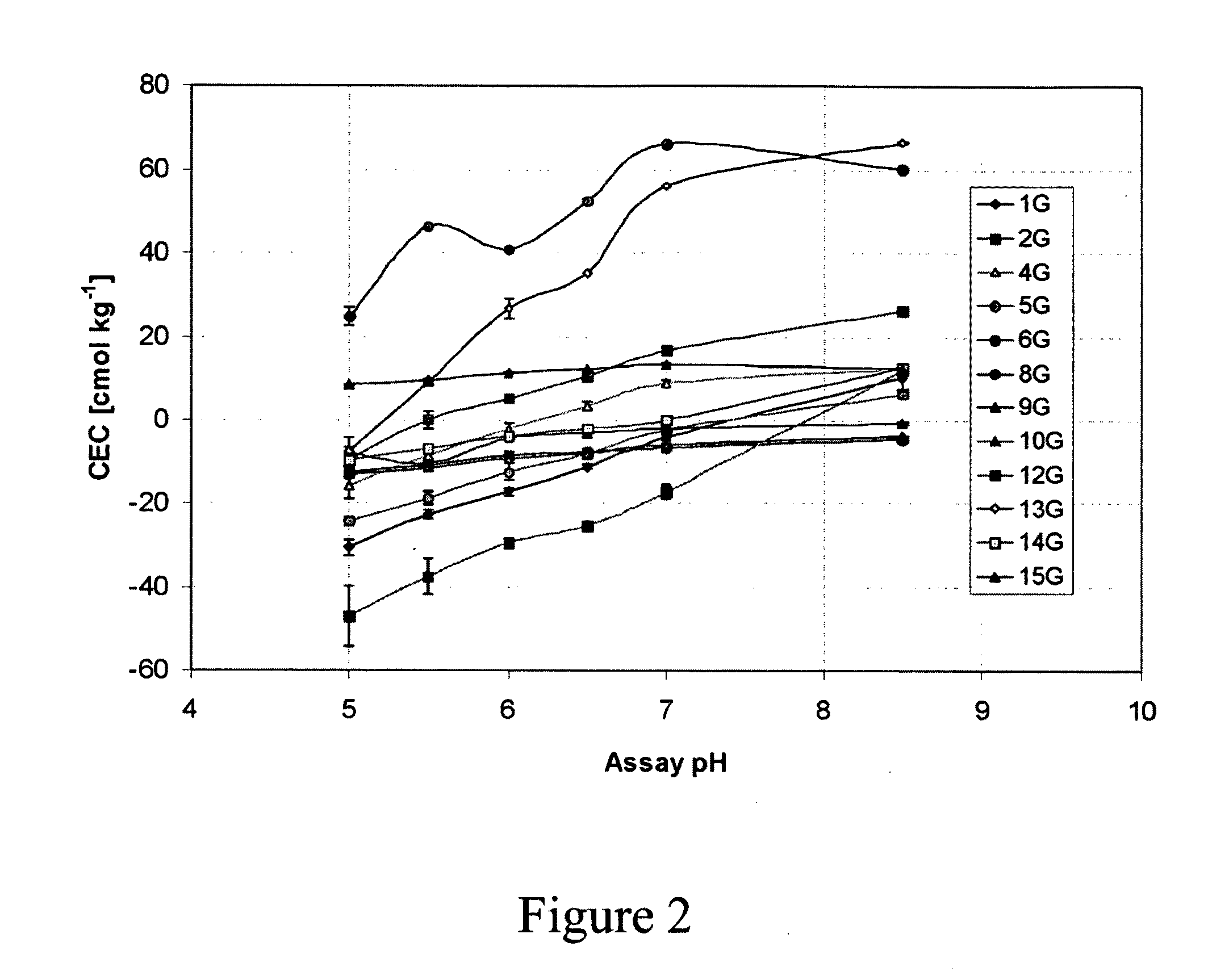

Biochar Production Method and Composition Therefrom

InactiveUS20110172092A1Low batch-to-batchMany of characteristicAmmonium nitratesCarbon compoundsIon exchangeOxygen

The invention is directed to a method for producing an oxygenated biochar material possessing a cation-exchanging property, wherein a biochar source is reacted with one or more oxygenating compounds in such a manner that the biochar source homogeneously acquires oxygen-containing cation-exchanging groups in an incomplete combustion process. The invention is also directed to oxygenated biochar compositions and soil formulations containing the oxygenated biochar material.

Owner:UT BATTELLE LLC

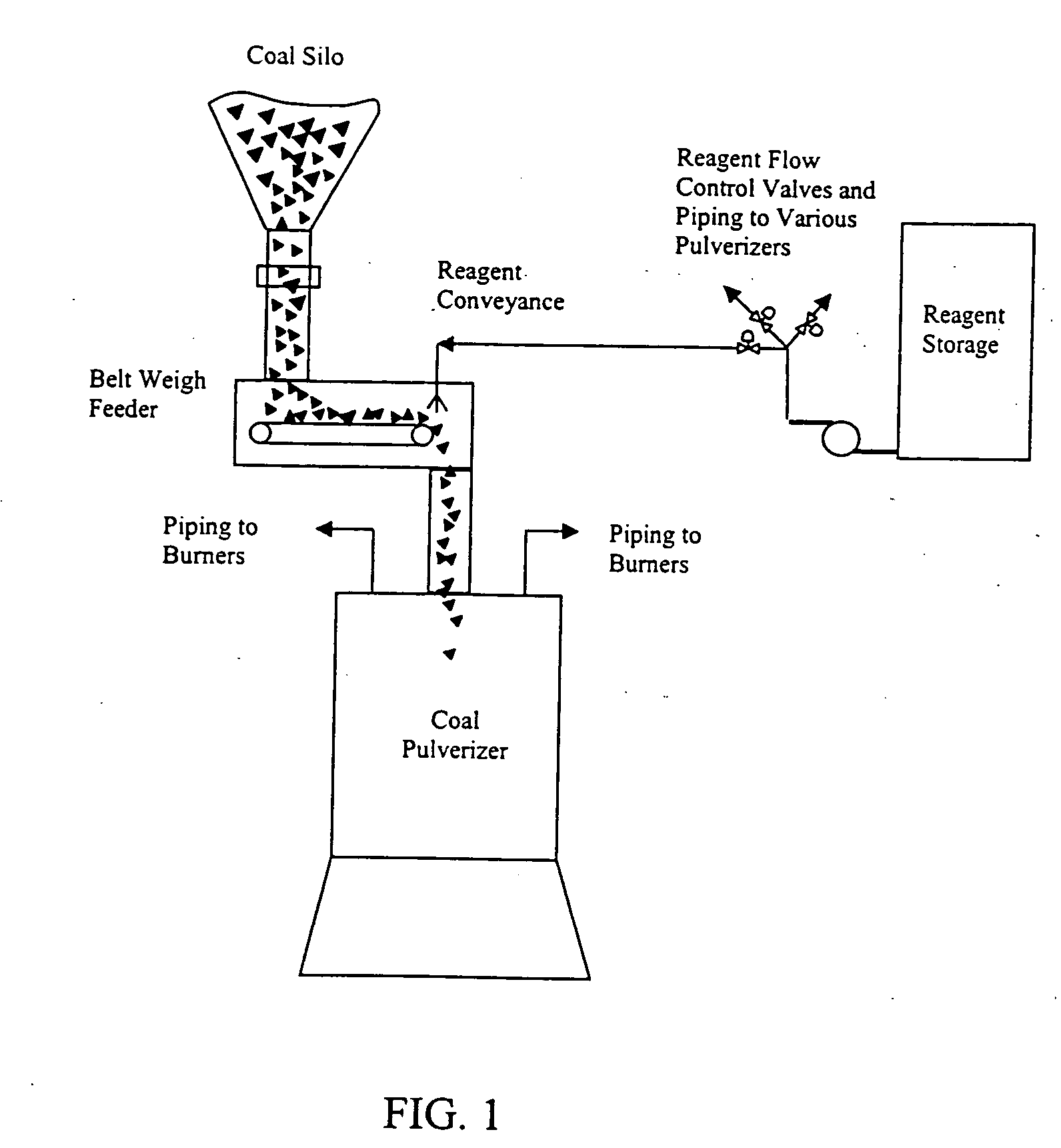

Method of applying mercury reagent with coal

InactiveUS20060185226A1Mercury emissionSubstantial economic savingSolid fuelsCombustorEnvironmental engineering

A method of halogenating coal prior to combustion, wherein the coal is treated with a halogen prior to pulverization and the pulverized halogenated coal is delivered to a burner as fuel for a combustion process.

Owner:THE BABCOCK & WILCOX CO

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

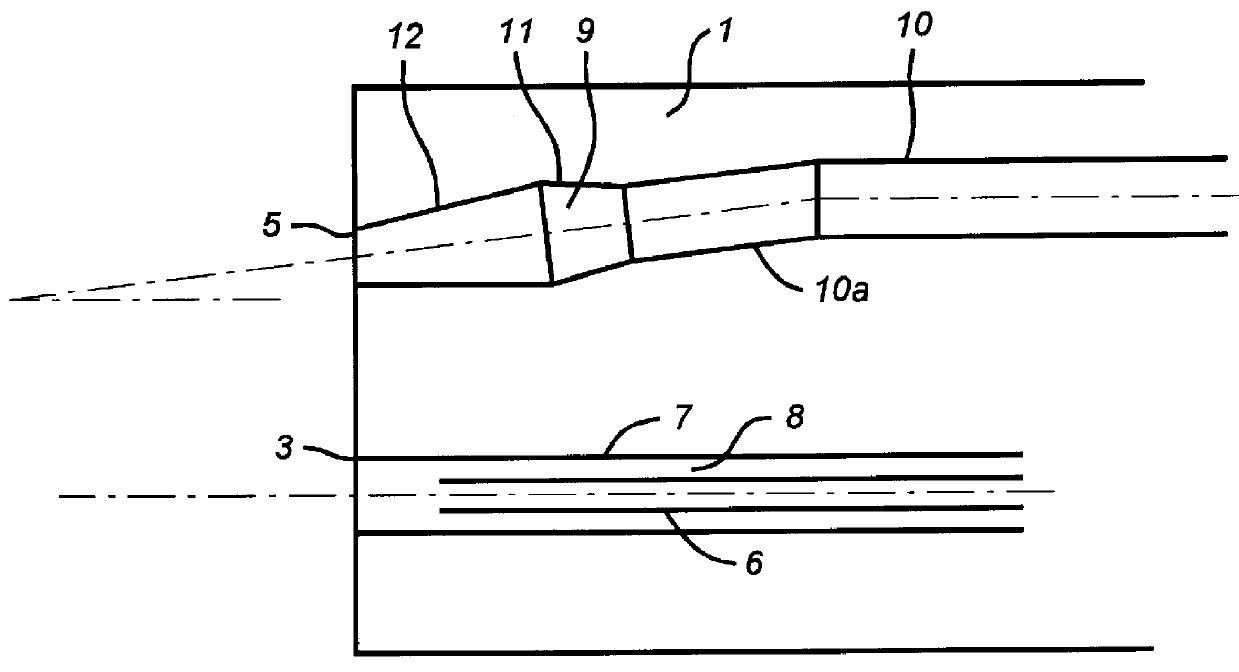

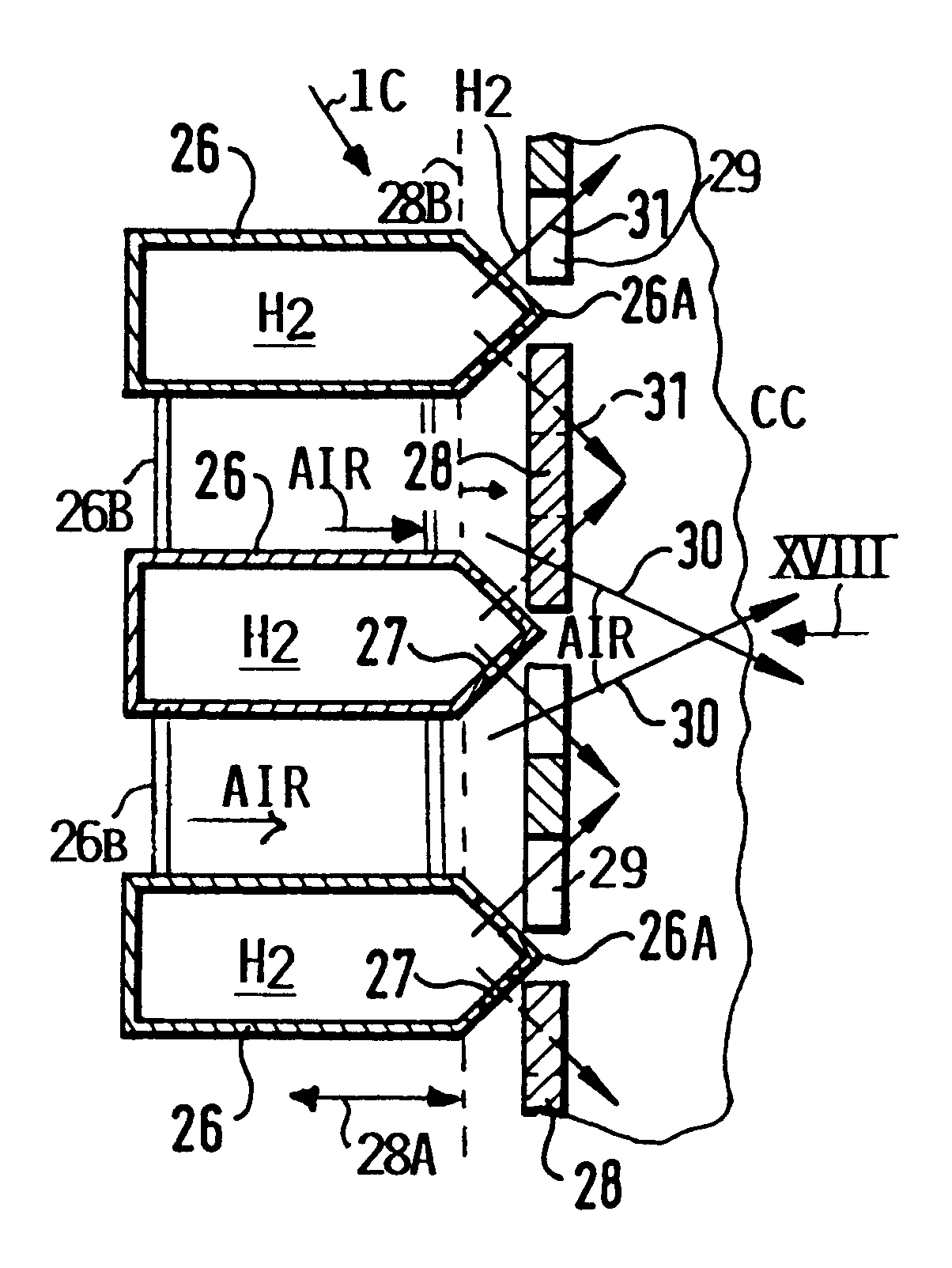

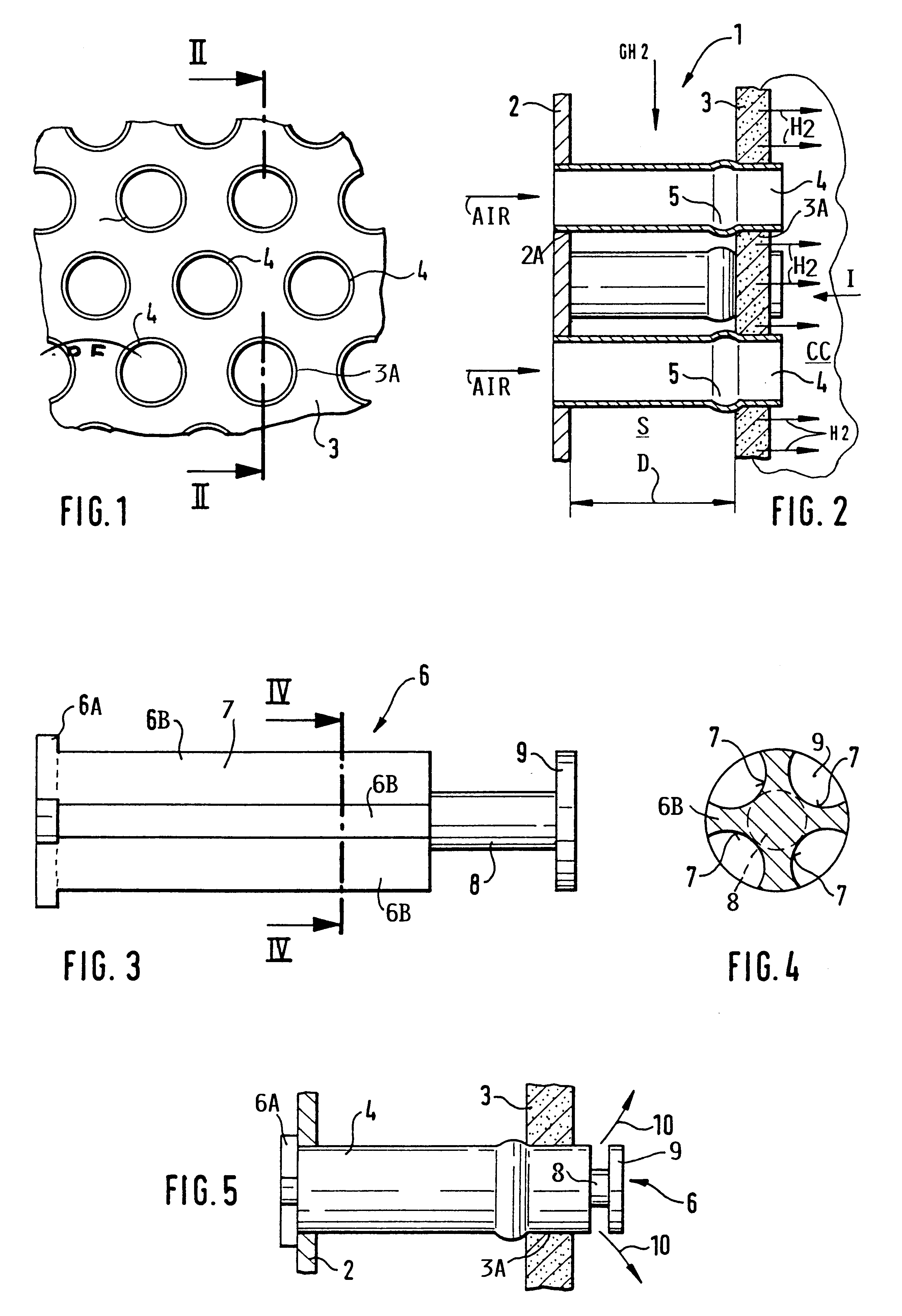

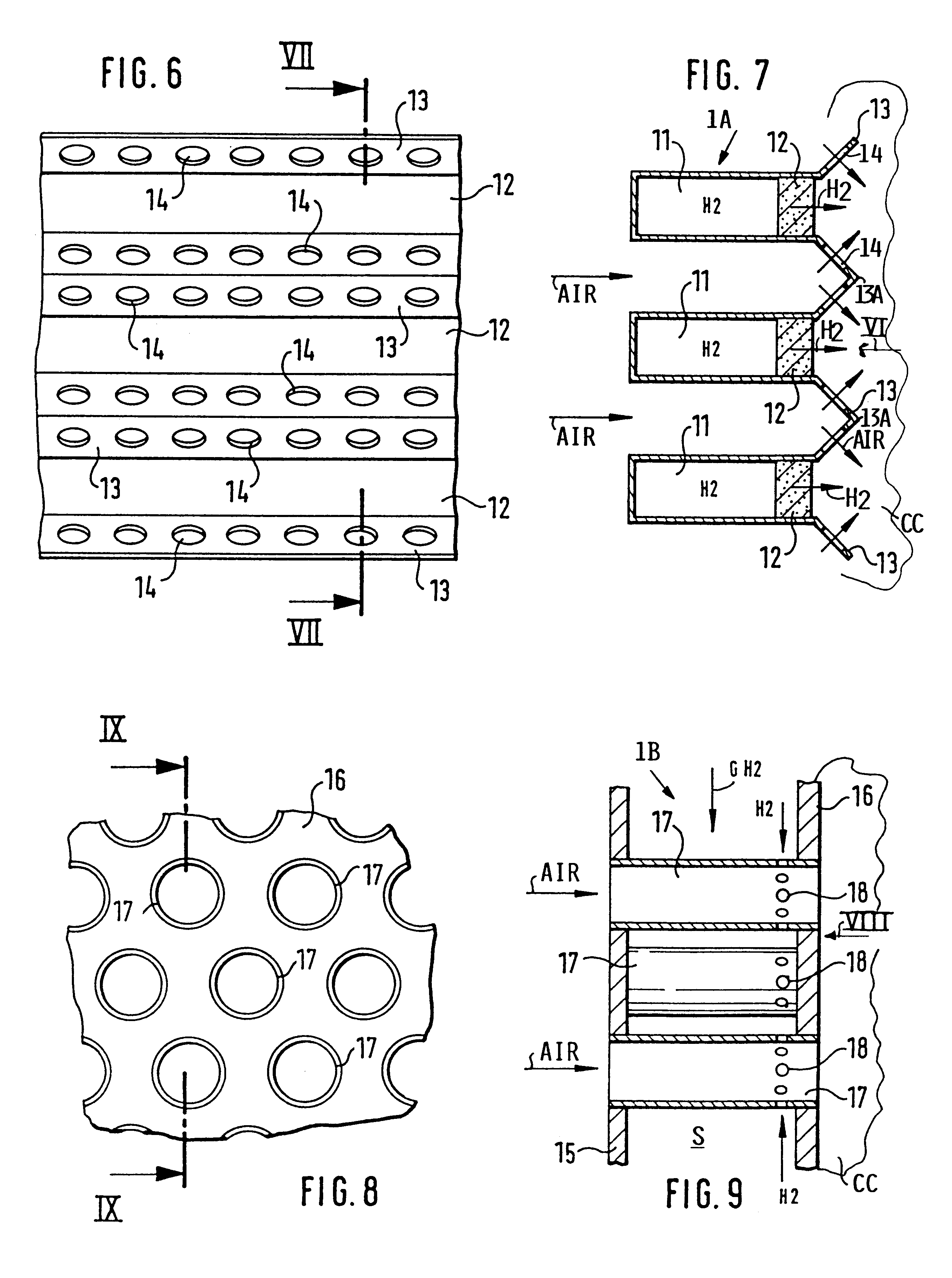

Method and combustor for combusting hydrogen

InactiveUS6267585B1Inhibit combustionSmall mixing scaleCombustion using gaseous and pulverulent fuelBurner safety arrangementsExhaust gasGas turbines

A plate burner for combusting hydrogen with air as an oxidizer forms a wall portion of a combustion chamber for example of a gas turbine. The plate burner is so constructed that air and hydrogen are separately guided to the downstream surface area facing into the combustion chamber for forming a large number of diffusive microcombustion flames, thus achieving a very low mixing scale simultaneously with a high nixing intensity. The number of diffusive micorcombustion flames is so selected that the NOx content in the exhaust gas from the combustion chamber is at the most 10x10-6 cubic foot per cubic foot of exhaust gas. The hydrogen enters the entrance area into the combustion chamber either through a porous wall, and air is injected into the hydrogen environment to form inverse diffusive microcombustion flames or the hydrogen is injected through a multitude of fine holes into high velocity air jets forming regular diffusion flames. In both instances, the formation of NOx in the exhaust gas during combustion is reduced to the above level or below.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

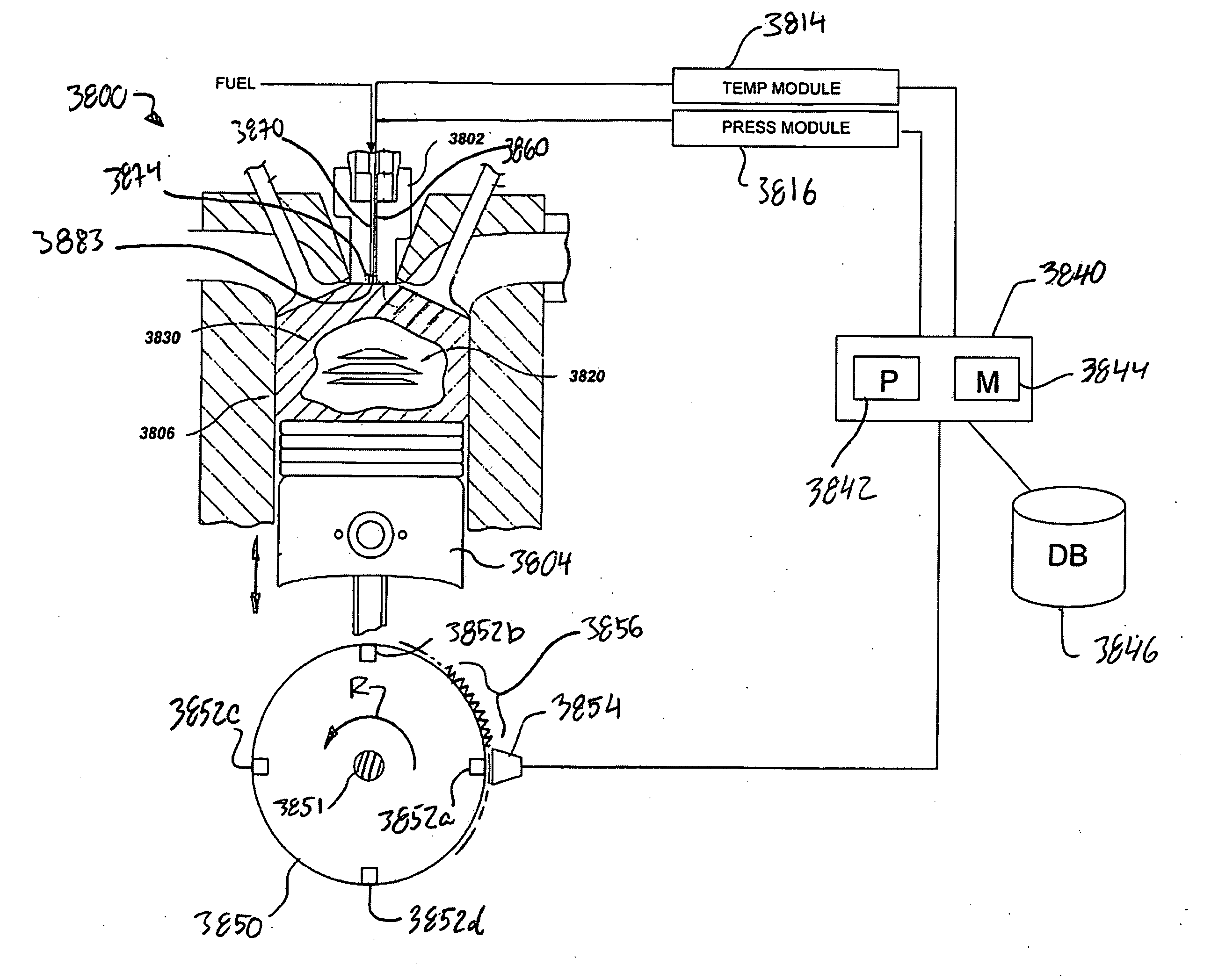

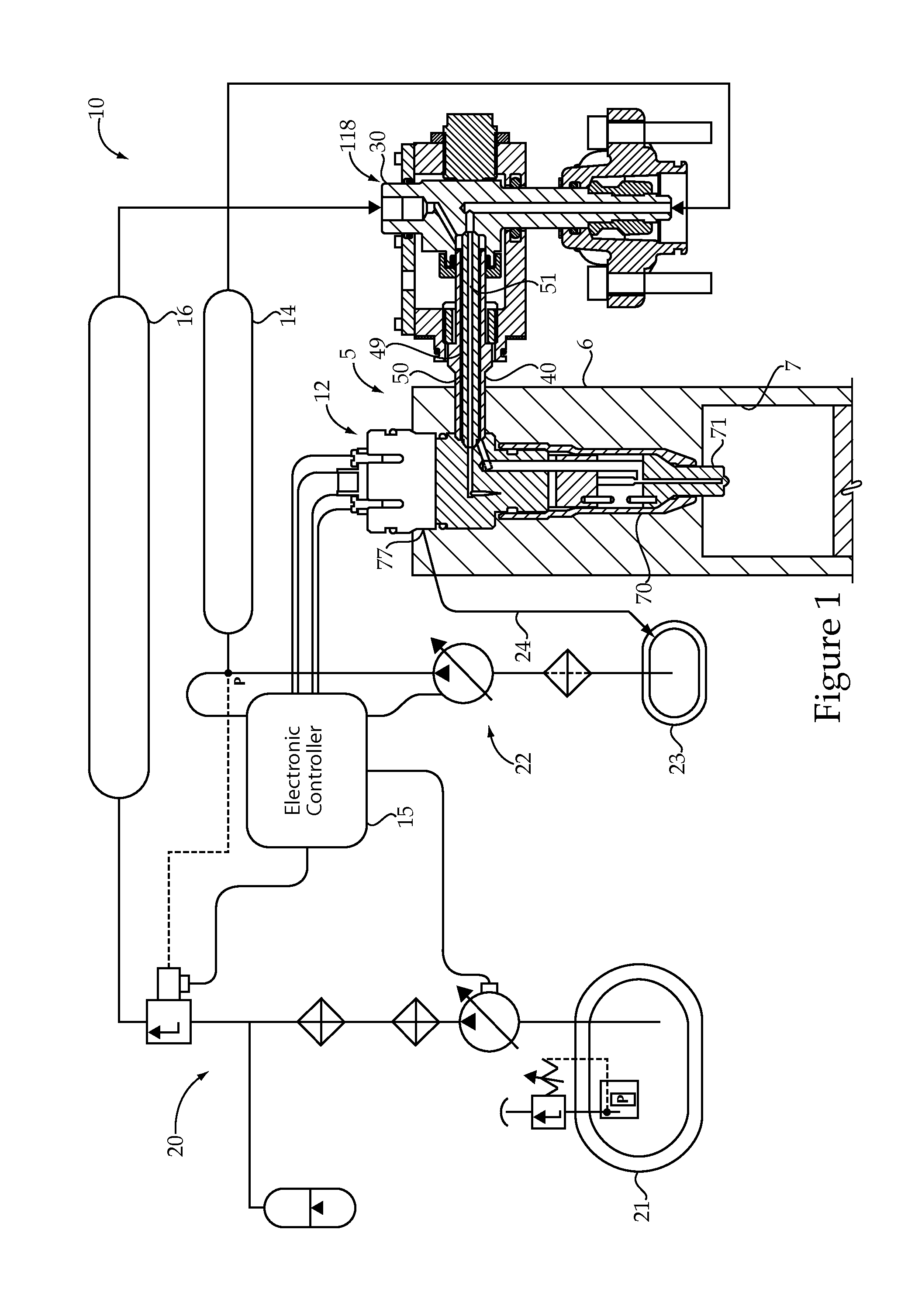

Methods and systems for reducing the formation of oxides of nitrogen during combustion in engines

The present disclosure is directed to various embodiments of systems and methods for reducing the production of harmful emissions in combustion engines. One method includes correlating combustion chamber temperature to acceleration of a power train component, such as a crankshaft. Once the relationship between acceleration / deceleration of the component and combustion temperature are known, an engine control module can be configured to adjust combustion parameters to reduce combustion temperature when acceleration data indicates peak combustion temperature is approaching a harmful level, such as a level conducive to the formation of undesirable oxides of nitrogen. Various embodiments of the methods and systems disclosed herein can employ injectors with integrated igniters providing efficient injection, ignition, and complete combustion of various types of fuels.

Owner:ADVANCED GREEN INNOVATIONS LLC +1

Purification of carbon dioxide

Owner:AIR PROD & CHEM INC

Dual Fuel Injection Compression Ignition Engine And Method Of Operating Same

A method of operating an electronically controlled dual fuel compression ignition engine includes injecting a pilot ignition quantity of liquid fuel into an engine cylinder from a dual fuel injector in an engine cycle during an auto ignition condition. An amount of gaseous fuel is also injected into the engine cylinder from the dual fuel injector in the same engine cycle. The amount of gaseous fuel is divided between a pre-mix quantity of gaseous fuel, which may be injected about 90° before top dead center, and a post ignition quantity of gaseous fuel that may be injected after top dead center, with both quantities being greater than zero. An engine controller may change a ratio of the pre-mix quantity of gaseous fuel to the post ignition quantity of gaseous fuel responsive to changing from a first engine speed and load to a second engine speed and load. The pilot ignition quantity of liquid fuel is compression ignited, which in turn causes the gaseous fuel to be ignited. A pre-mix quantity of liquid fuel may also be included in order to speed the combustion process at higher engine speeds.

Owner:CATERPILLAR INC

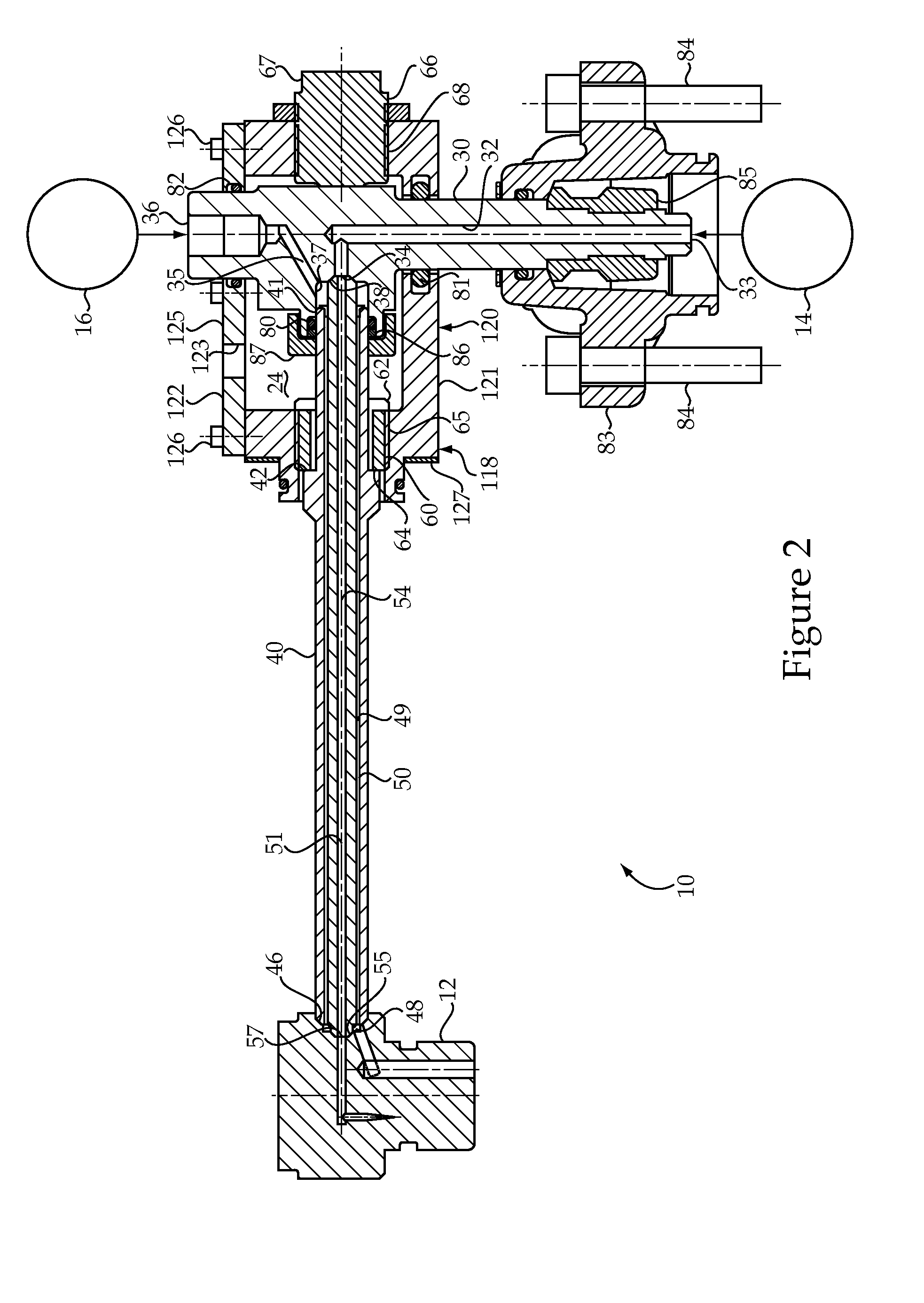

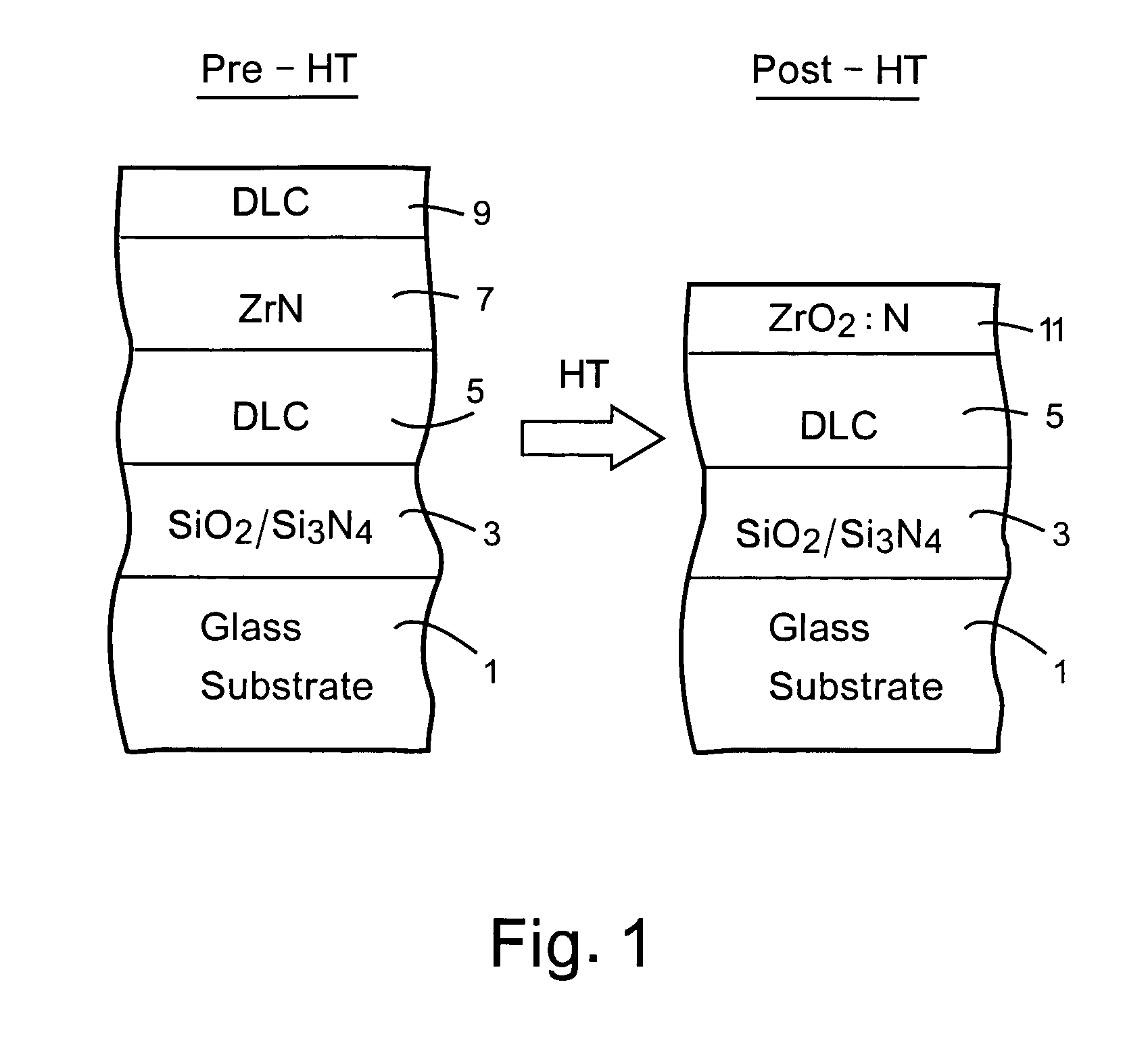

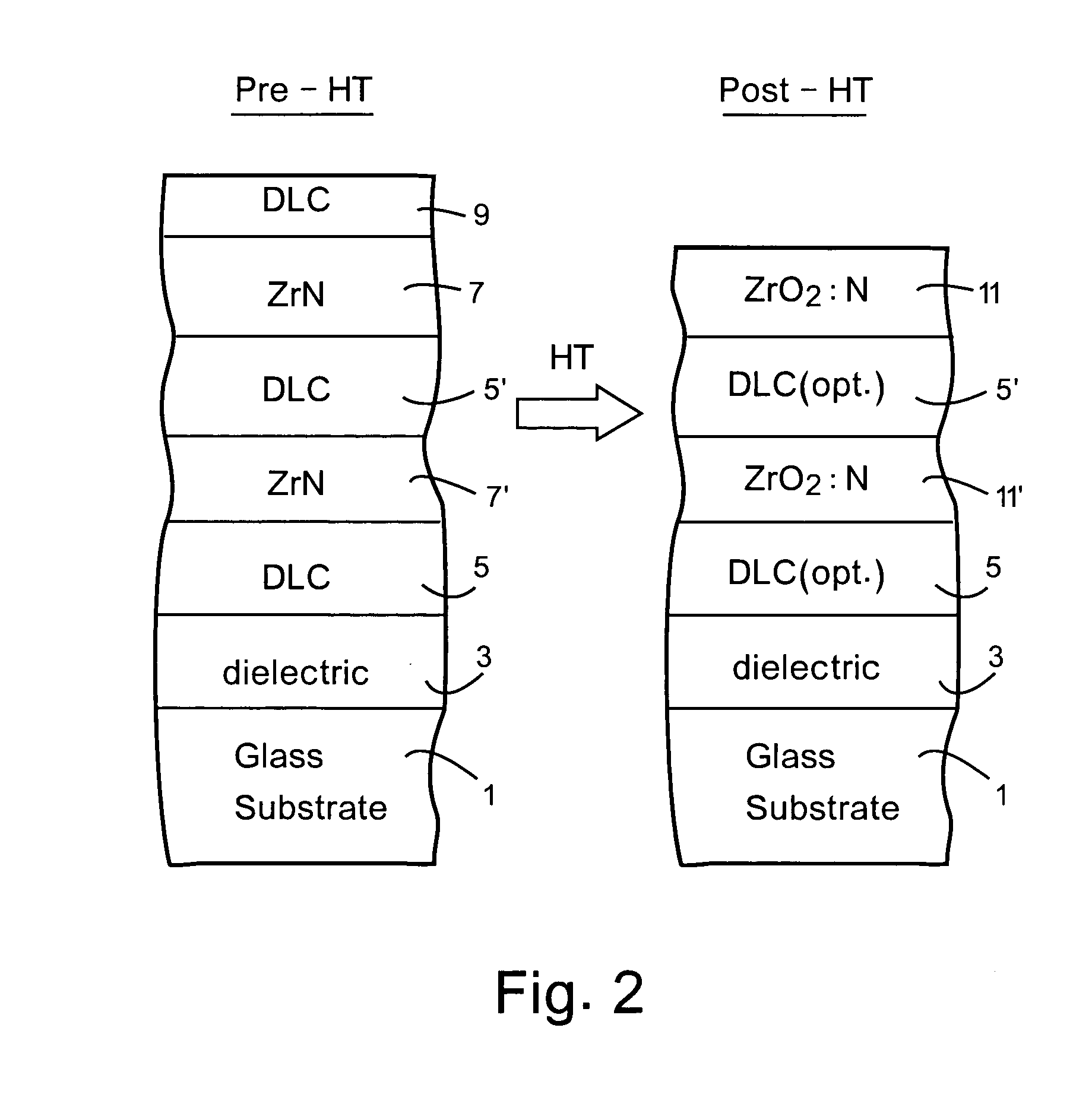

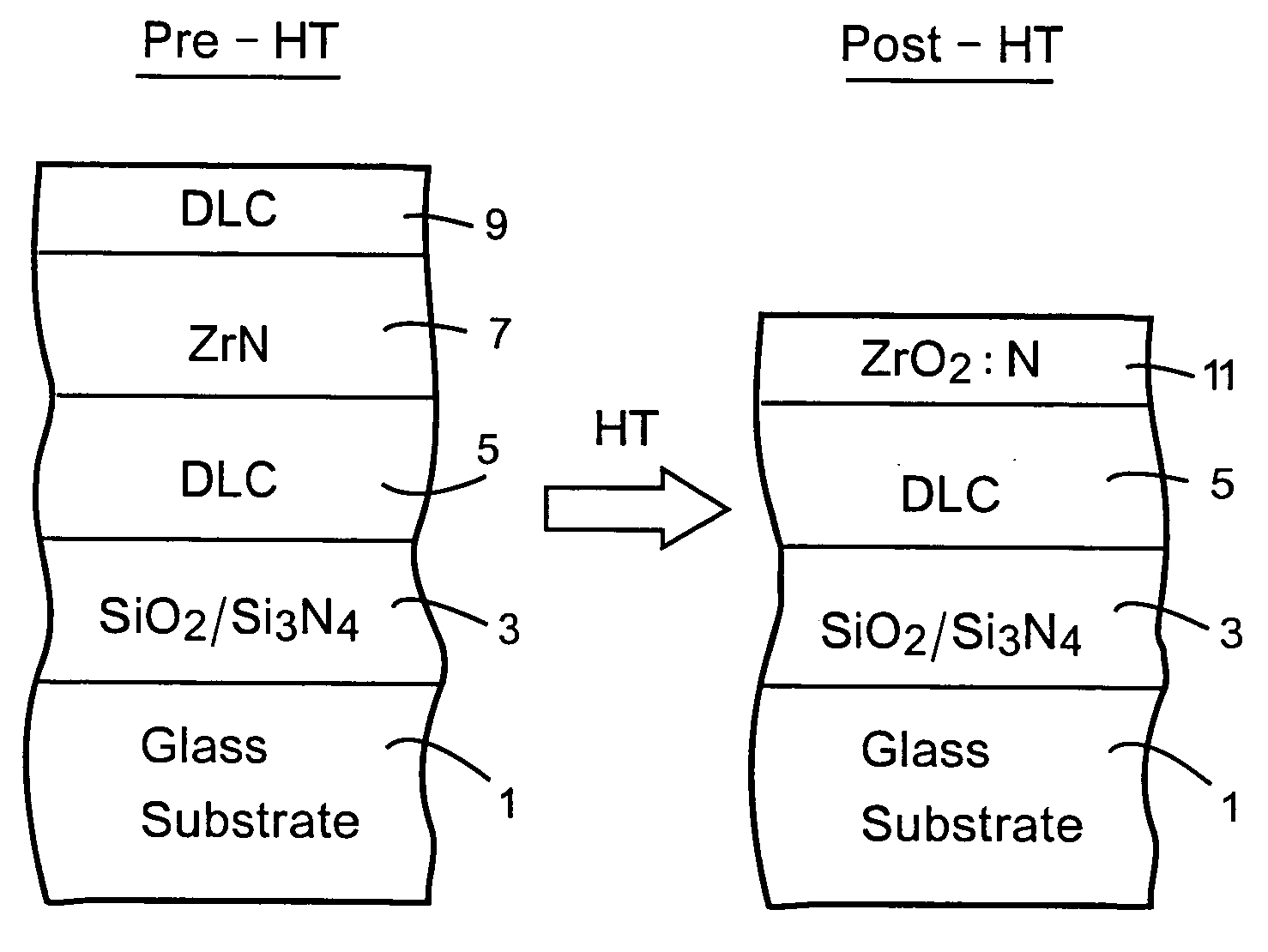

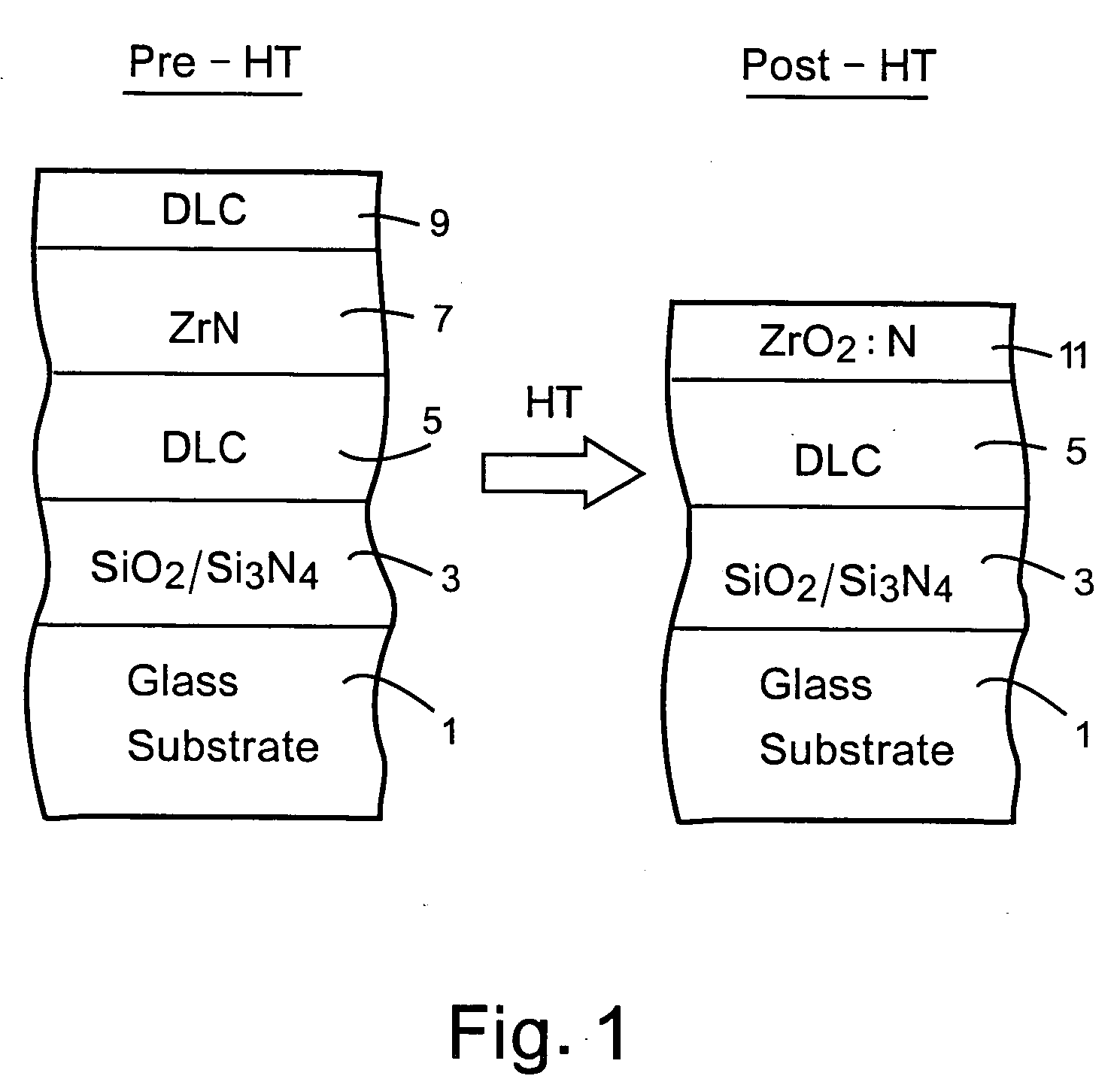

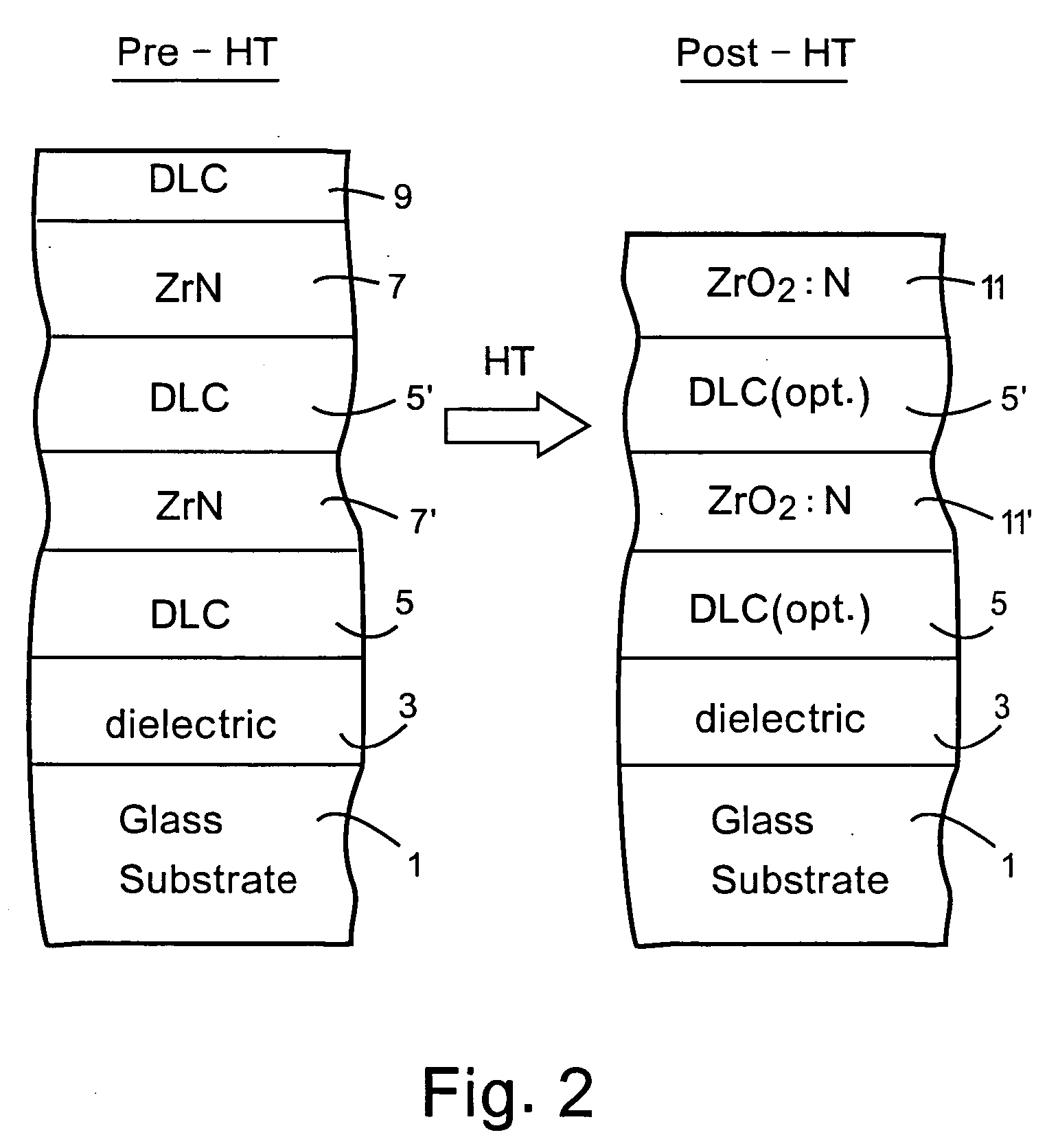

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

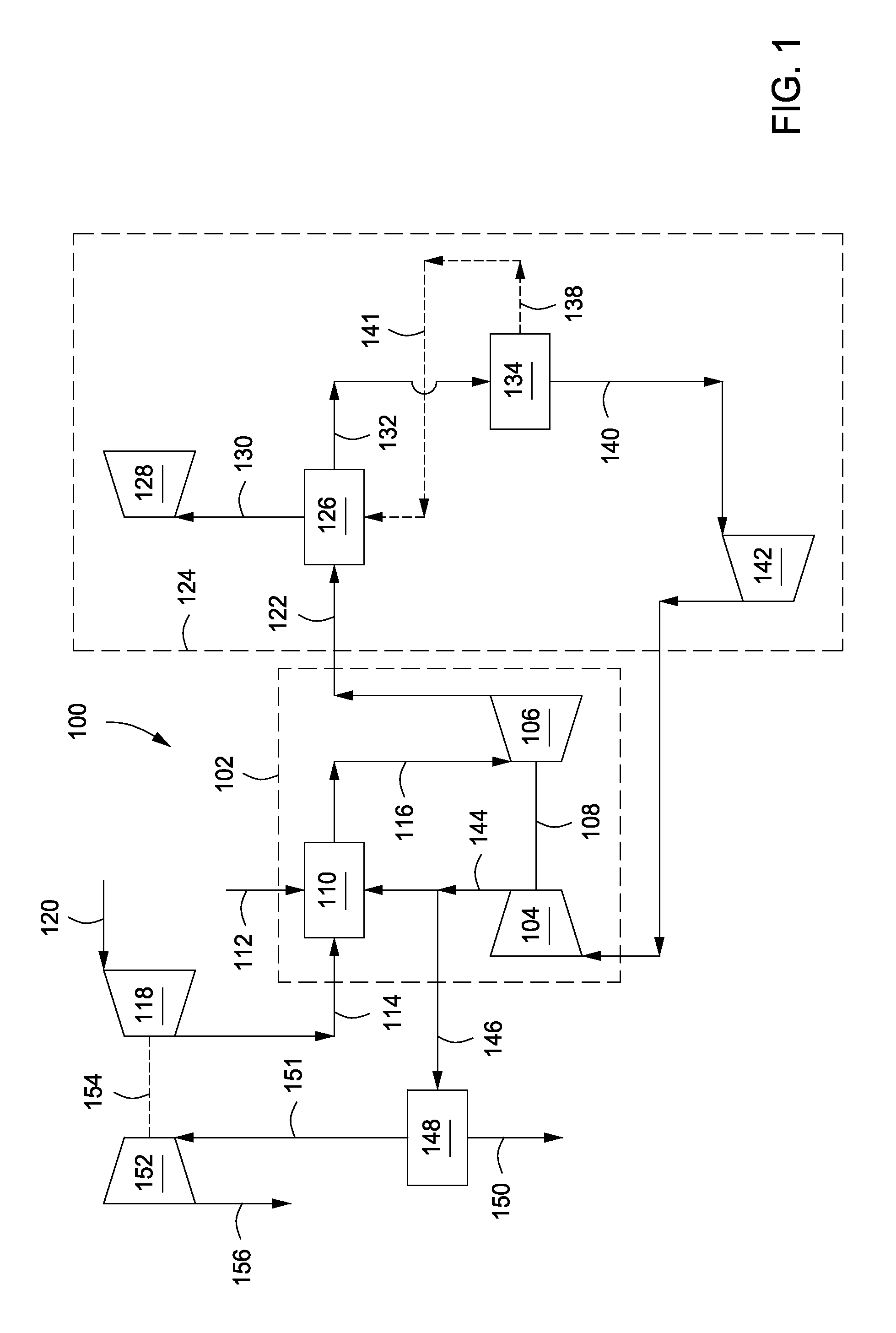

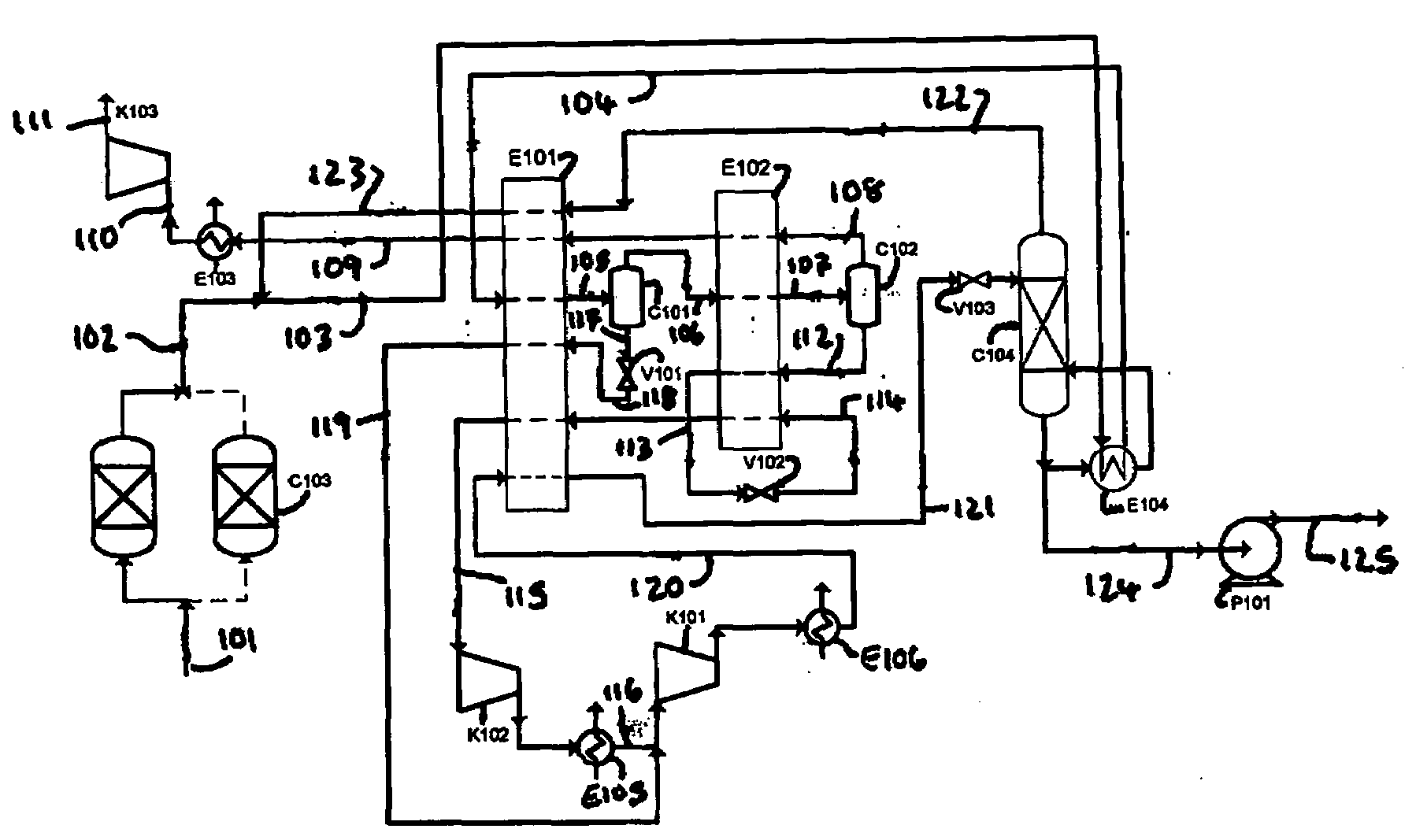

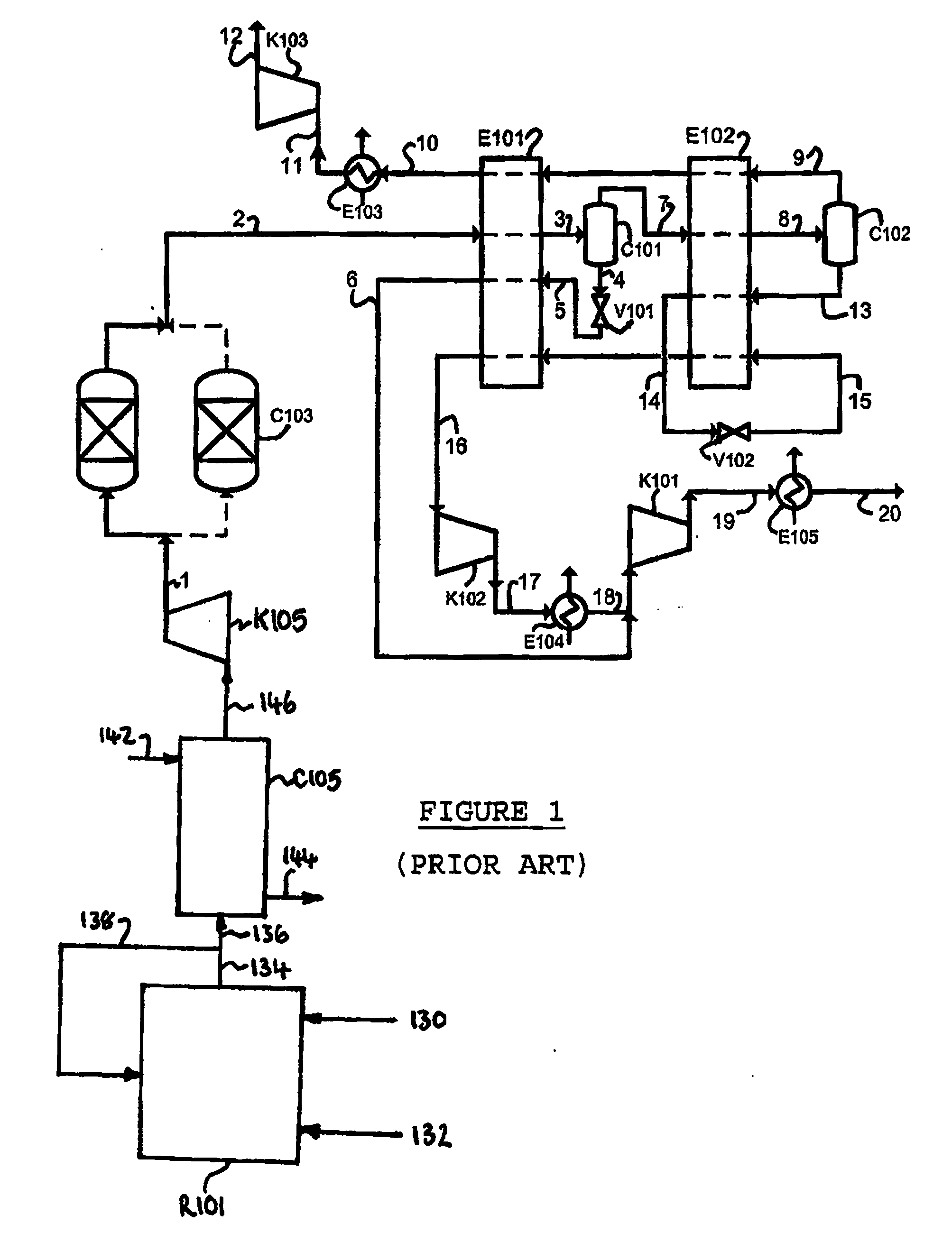

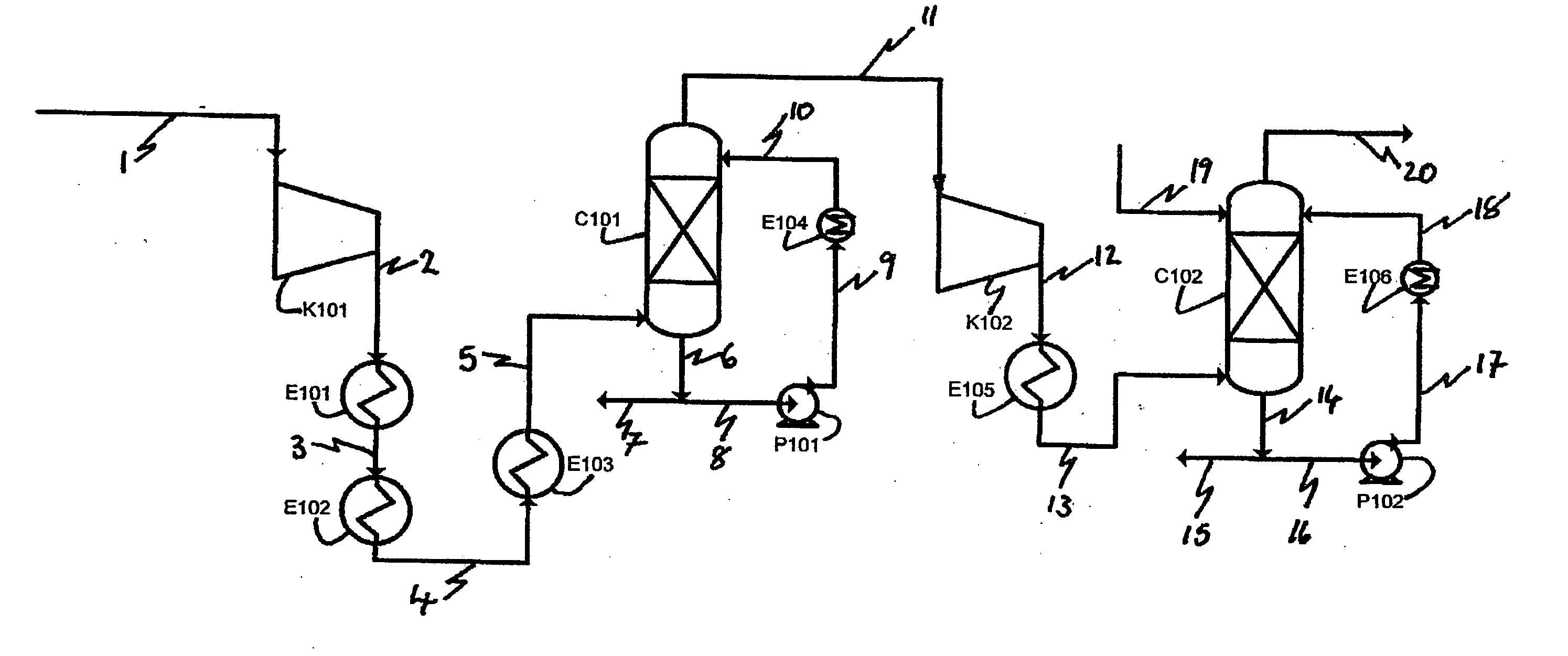

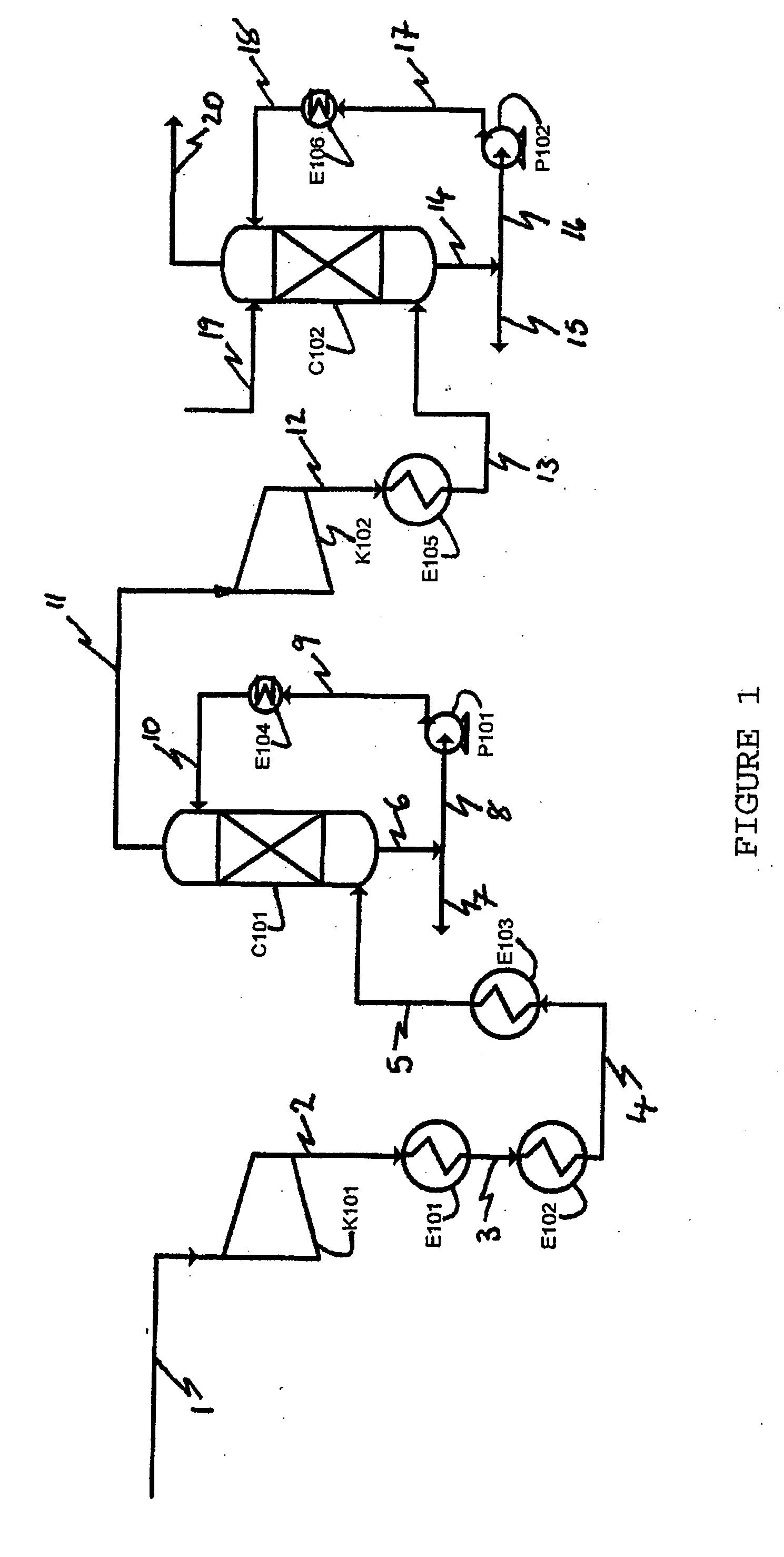

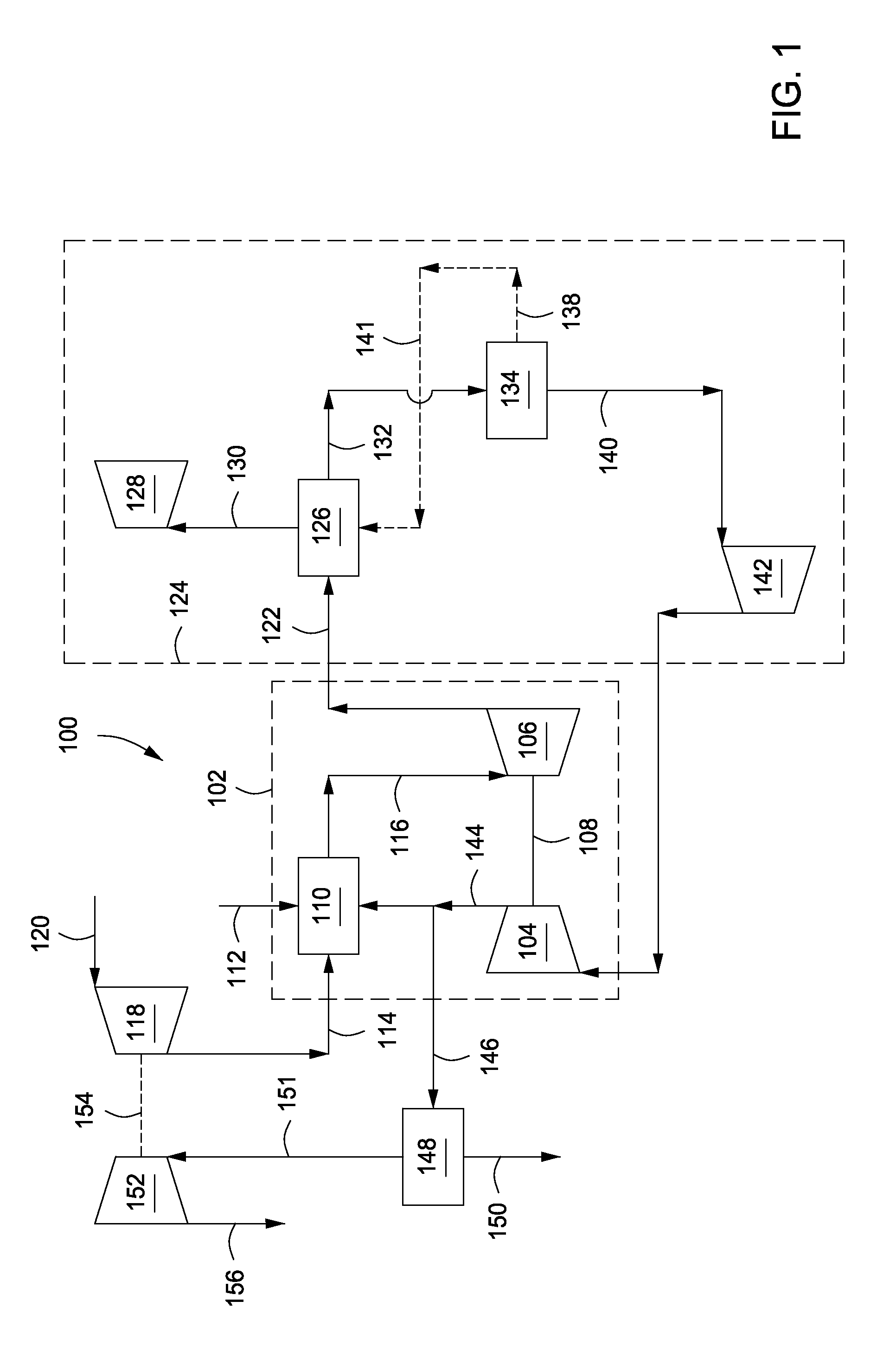

Low Emission Power Generation Systems and Methods

Methods and systems for C02 separation for low emission power generation in combined-cycle power plants are provided. One system includes a gas turbine system that stoichiometrically combusts a fuel and an oxidant in the presence of a compressed recycle stream to provide mechanical power and a gaseous exhaust. The compressed recycle stream acts as a diluent to moderate the temperature of the combustion process. A boost compressor can boost the pressure of the gaseous exhaust before being compressed into the compressed recycle stream. A purge stream is tapped off from the compressed recycle stream and directed to a C02 separator configured to absorb C02 from the purge stream using a potassium carbonate solvent.

Owner:EXXONMOBIL UPSTREAM RES CO

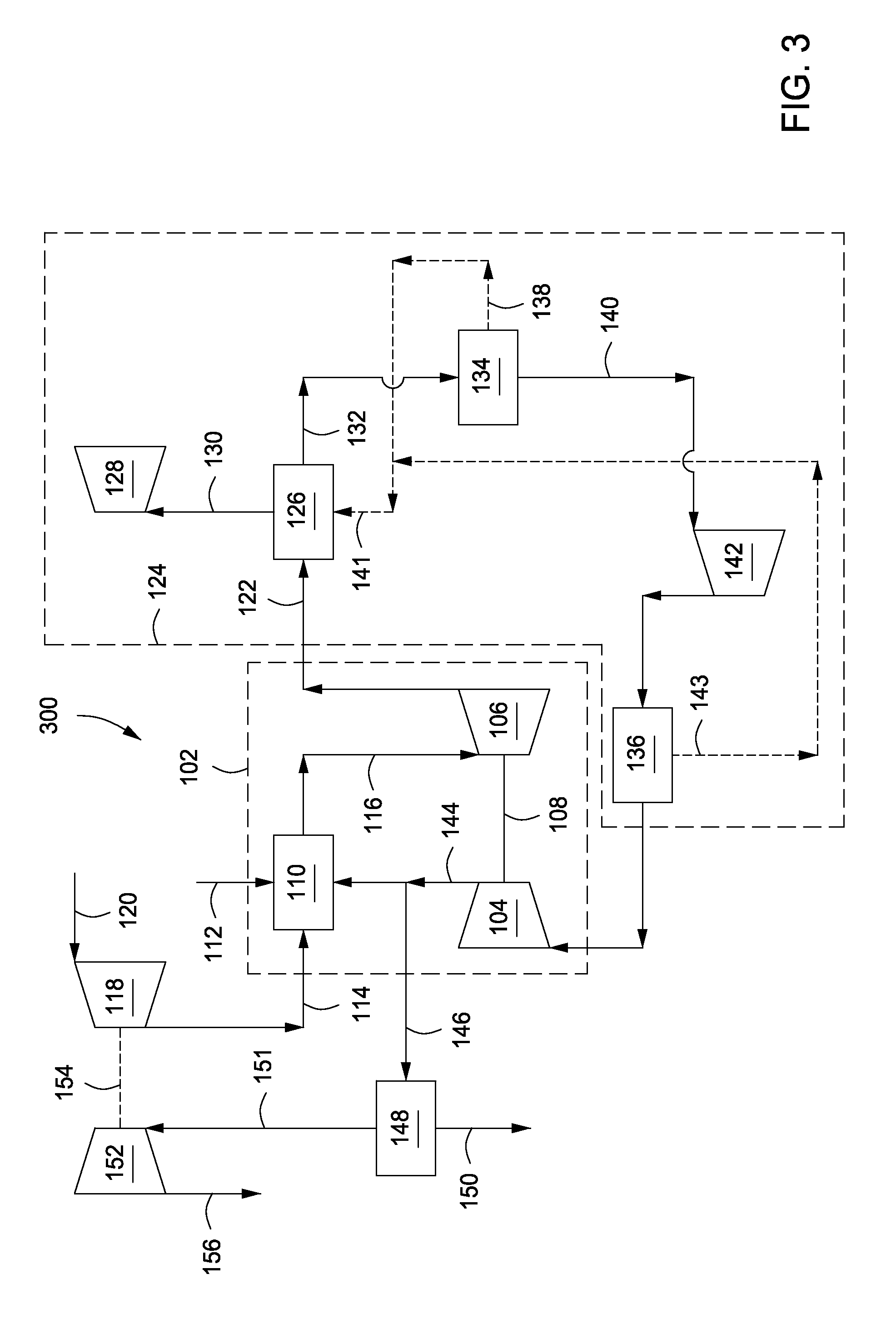

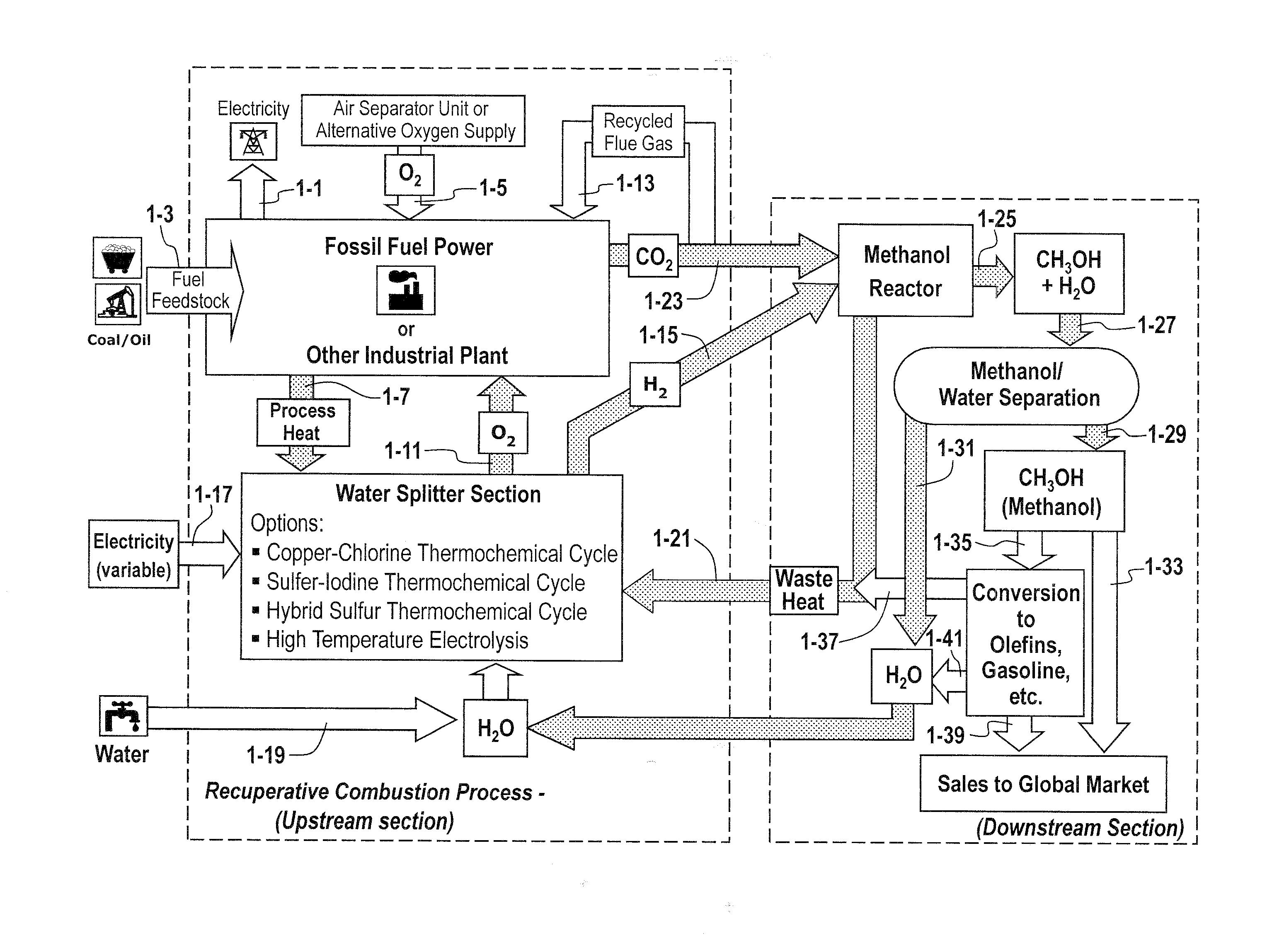

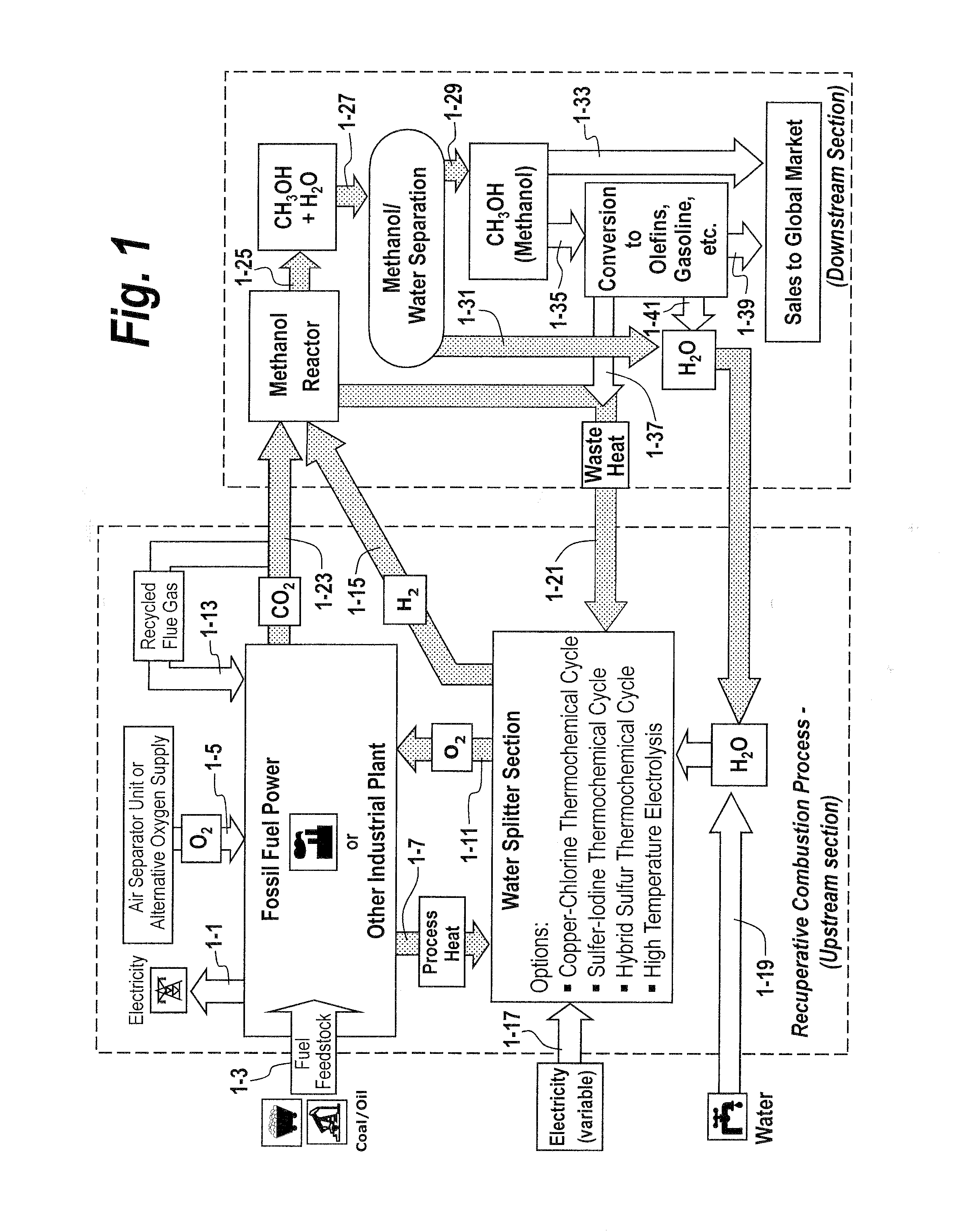

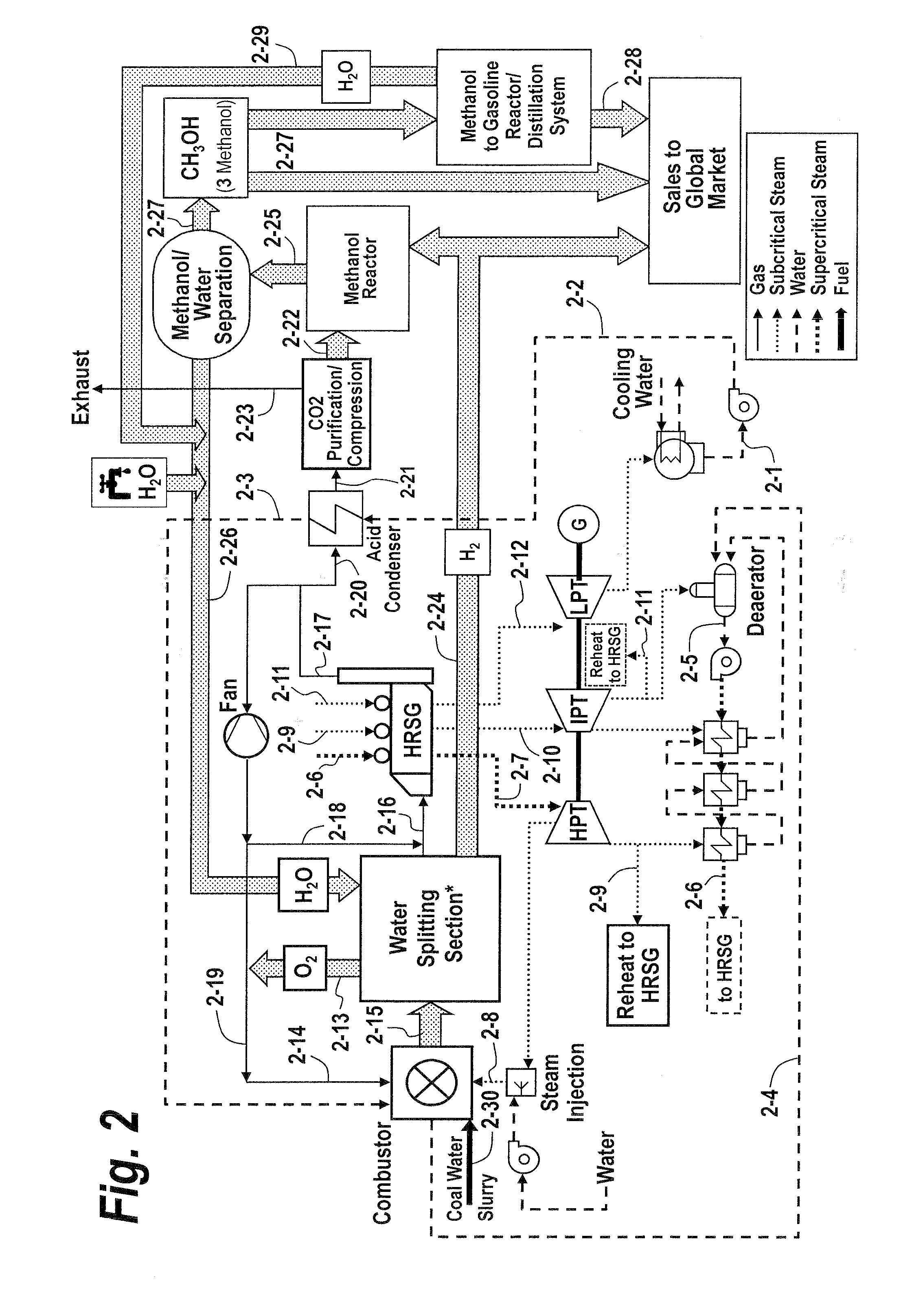

Recuperative combustion system

InactiveUS20110041740A1Reducing and eliminating amount of oxygenSolid fuel combustionIndirect carbon-dioxide mitigationOxygenDimethyl ether

The methods and systems described herein relate to a recuperative combustion system that recuperates energy from fuel combustion that would otherwise be lost. The recuperative combustion system minimizes or eliminates the need for an air separator unit through the use of a clean water splitter section, consisting of a thermochemical cycle or high-temperature electrolysis. Water is split into its component hydrogen and oxygen, primarily with process heat from the combustion process. The oxygen produced by the water splitter provides oxygen necessary for oxy-fuel combustion, thereby reducing or eliminating the need for the power intensive air separator unit and / or external oxygen source, significantly increasing the efficiency of the oxy-fuel combustion cycle. Hydrogen produced by the water splitter may be used for a variety of industrial uses, or combined with carbon dioxide (captured from the flue gases produced by said combustion process) to produce methanol. Methanol can further be refined in a methanol to gasoline reactor to produce dimethyl ether, olefins or high grade gasoline. Described herein are methods and systems that 1) increase oxy-fuel combustion efficiency, 2) produce hydrogen for a suite of industrial / energy uses, and 3) capture carbon dioxide and convert it to high value hydrocarbons.

Owner:REILLY TIMOTHY J

Method of removing mercury from exhaust gases

InactiveUS6962617B2Effectively adsorbing and reacting mercurySimple methodGas treatmentUsing liquid separation agentHydrogenSorbent

Efficient removal of mercury from the exhaust gases of an industrial process or combustion process can be achieved using an adsorbent that can be regenerated by a simple and efficient method. The mercury is contacted with a sorbent material, the sorbent material being hydrogen mordenite or hydrogen clinoptilolite, for adsorbing mercury and causing the mercury to react with the sorbent material to produce mercury-laden sorbent material. The mercury-laden sorbent material can be heated to a temperature of at least about 400° C. so as to remove mercury from the mercury-laden sorbent material and to regenerate the sorbent material to allow reusing of the sorbent material for mercury removal.

Owner:LEHIGH UNIVERSITY

Reducing mercury emissions from the burning of coal

ActiveUS7758827B2Reduce waste disposal costsReduce concrete costsSolid waste managementUsing liquid separation agentCombustionHalogen

Sorbent components containing calcium, alumina, silica, and halogen are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame, preferably at minimum temperatures to assure complete formation of the refractory structures that result in various advantages of the methods. When used together, the components ● reduce emissions of mercury and sulfur; ● reduce emissions of elemental and oxidized mercury; ● increase the efficiency of the coal burning process through de-slagging of boiler tubes; ● increase the level of Hg, As, Pb, and / or Cl in the coal ash; ● decrease the levels of leachable heavy metals (such as Hg) in the ash, preferably to levels below the detectable limits; and ● make a highly cementitious ash product.

Owner:NOX II LTD

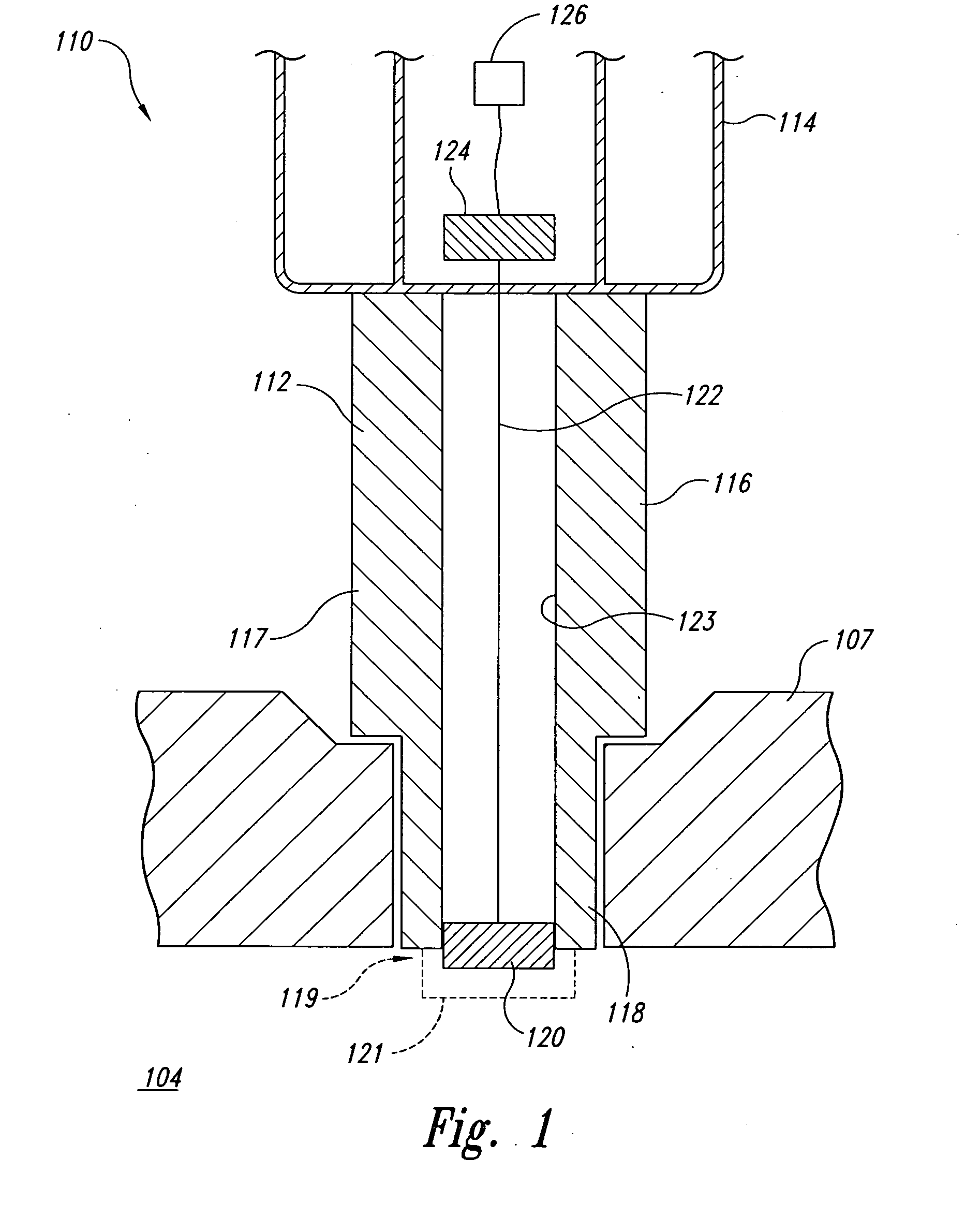

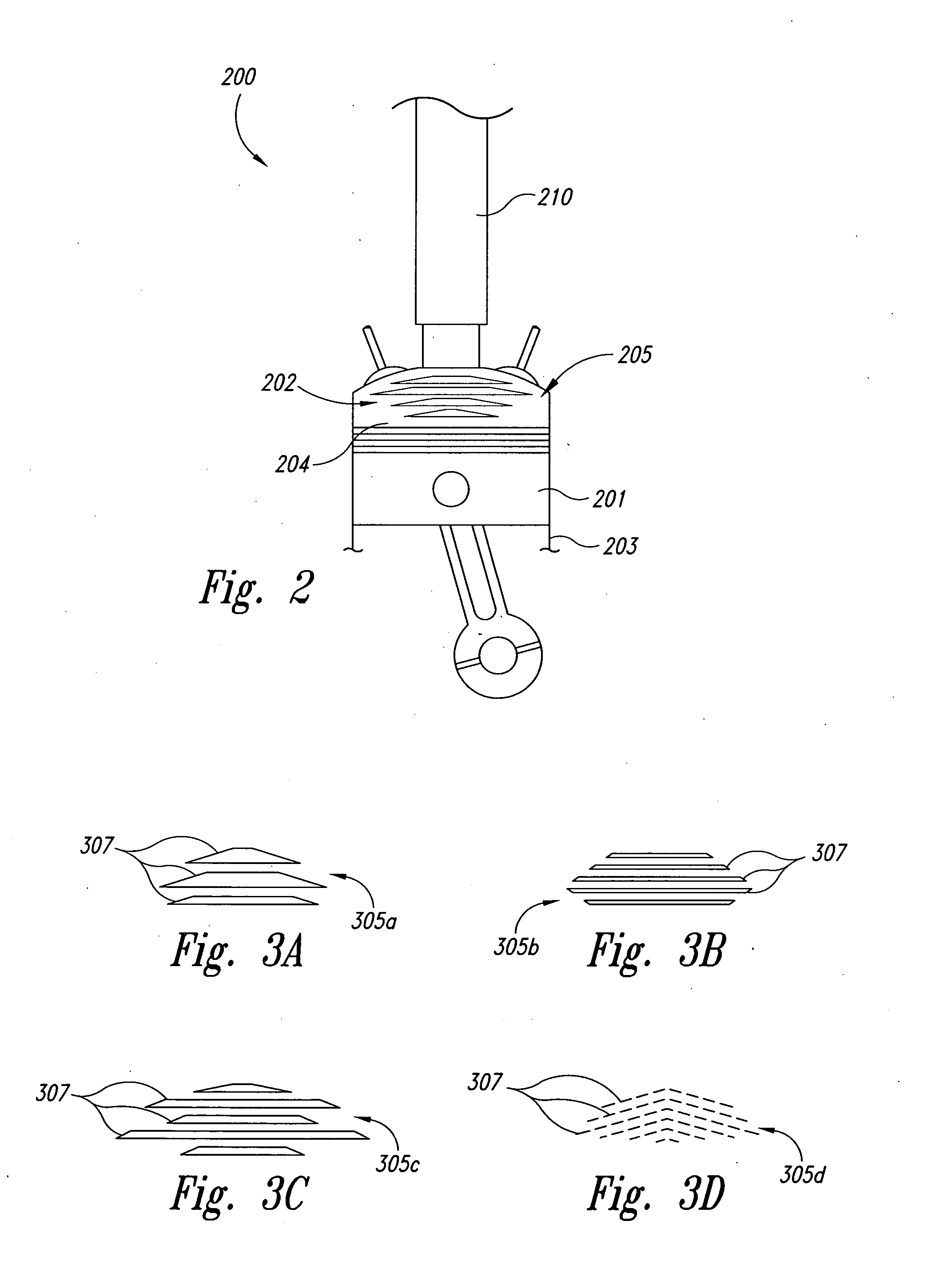

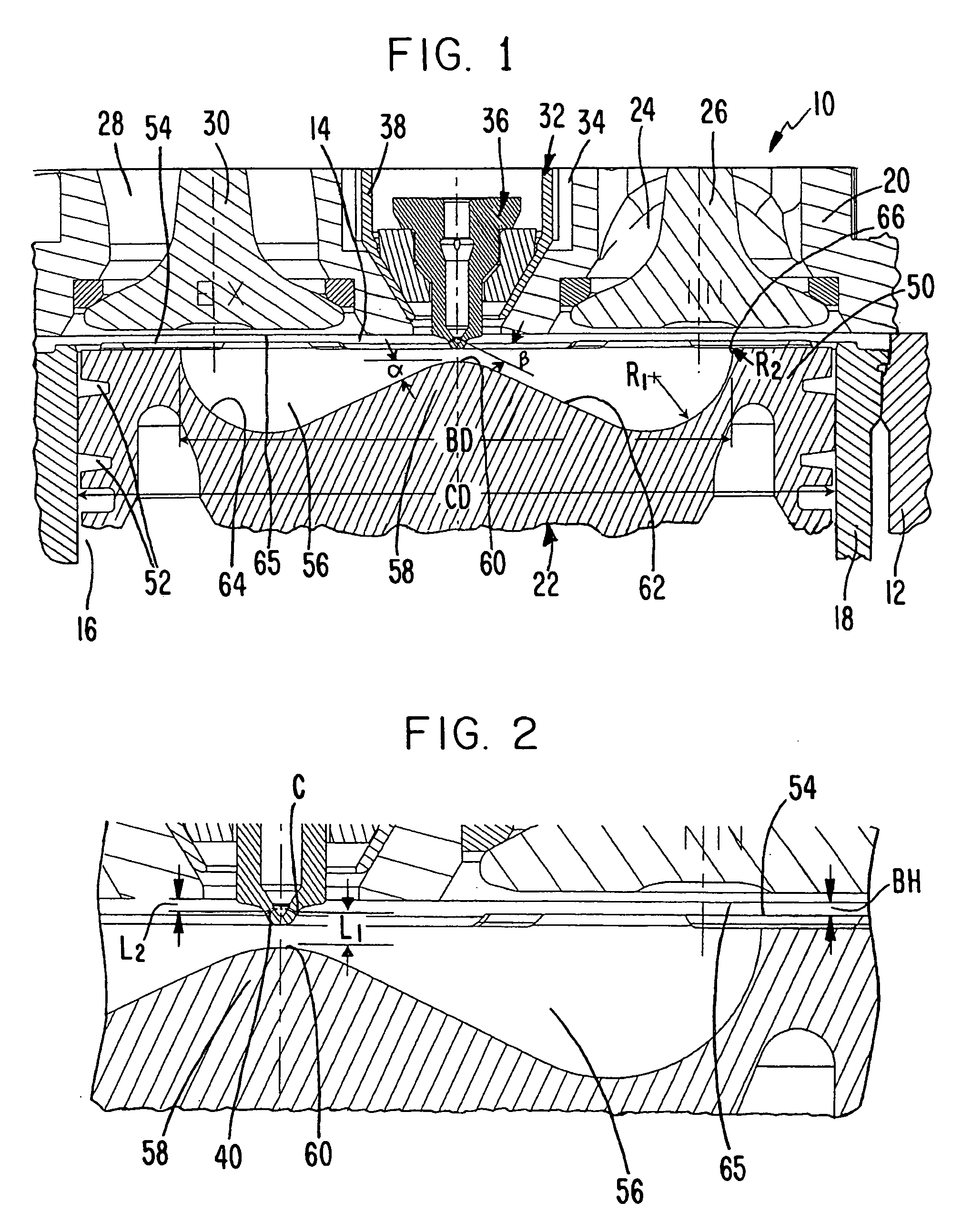

Internal combustion engine producing low emissions

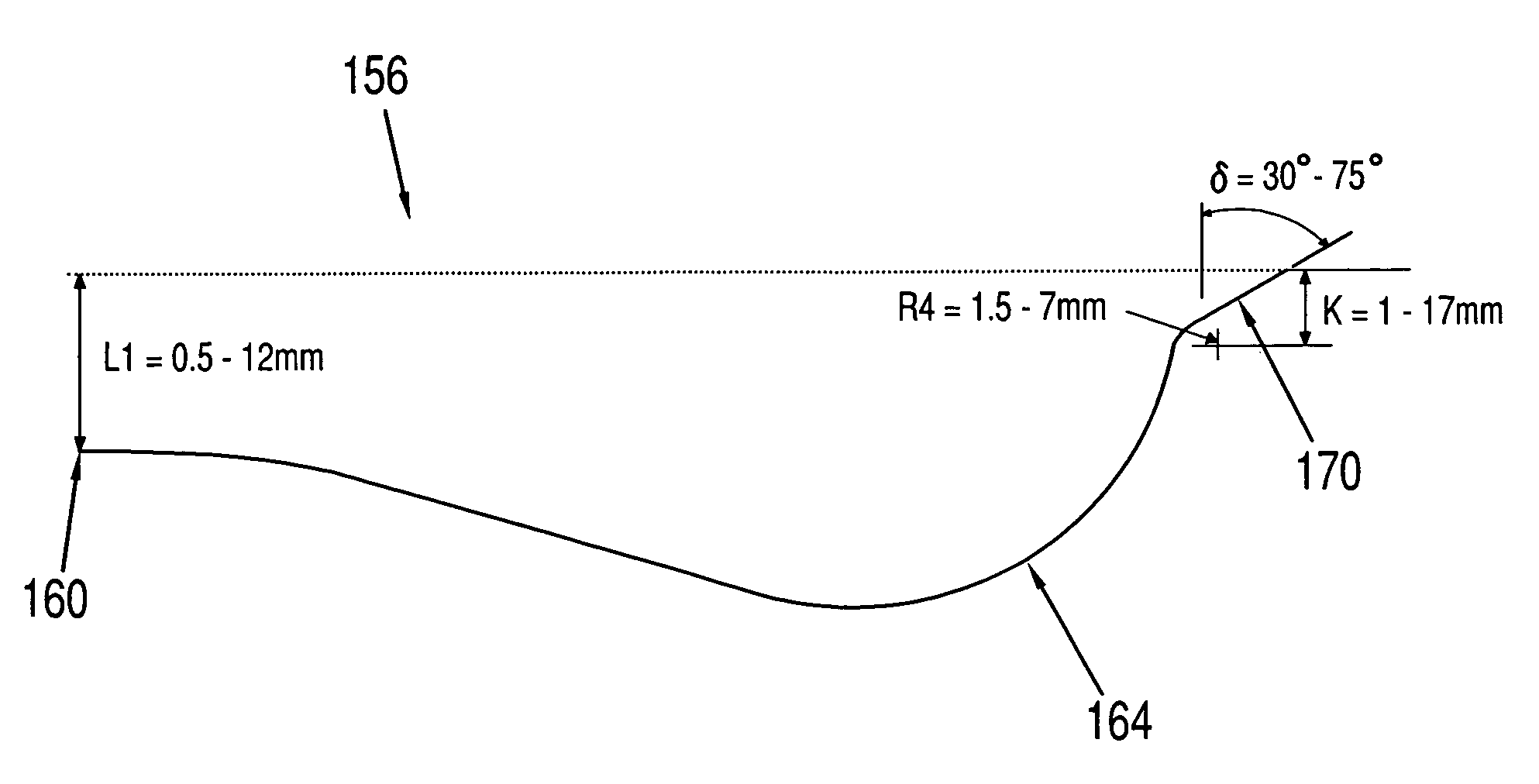

InactiveUS7210448B2Emission reductionMinimizing sootInternal combustion piston enginesFuel injection apparatusParticulatesCombustion chamber

An engine is provided which includes various precise configuration parameters, including dimensions, shape and / or relative positioning of the combustion chamber features, resulting in a combustion process minimizing NOx emissions and particulates. The combustion chamber includes one or more of the following: a spray angle relative to an inner bowl floor angle; a vertical distance from the tip of the piston bowl to the injection orifices; a number of injection orifices; a swirl ratio; a vertical distance from the injection orifices to an inner face of the cylinder head; a radius of curvature of an outer bowl section; chamfer with dimensional parameters; and a transition radius.

Owner:CUMMINS INC

Internal combustion engine producing low emissions

InactiveUS20060070603A1Emission reductionMinimizing sootInternal combustion piston enginesFuel injection apparatusParticulatesCombustion chamber

An engine is provided which includes various precise configuration parameters, including dimensions, shape and / or relative positioning of the combustion chamber features, resulting in a combustion process minimizing NOx emissions and particulates. The combustion chamber includes one or more of the following: a spray angle relative to an inner bowl floor angle; a vertical distance from the tip of the piston bowl to the injection orifices; a number of injection orifices; a swirl ratio; a vertical distance from the injection orifices to an inner face of the cylinder head; a radius of curvature of an outer bowl section; chamfer with dimensional parameters; and a transition radius.

Owner:CUMMINS INC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

InactiveUS20050191494A1Scratch resistantPretreated surfacesGlass/slag layered productsDiamond-like carbonOxygen

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable. In certain example embodiments, the zirconium nitride and / or zirconium oxide may be doped with F and / or C.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com