Method of applying mercury reagent with coal

a technology of mercury reagent and coal, which is applied in the field of combustion of fossil fuels, can solve the problems of relatively ineffective current scrubber technology for removing elemental mercury from flue gas, and achieve the effect of substantial economic savings and low mercury emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

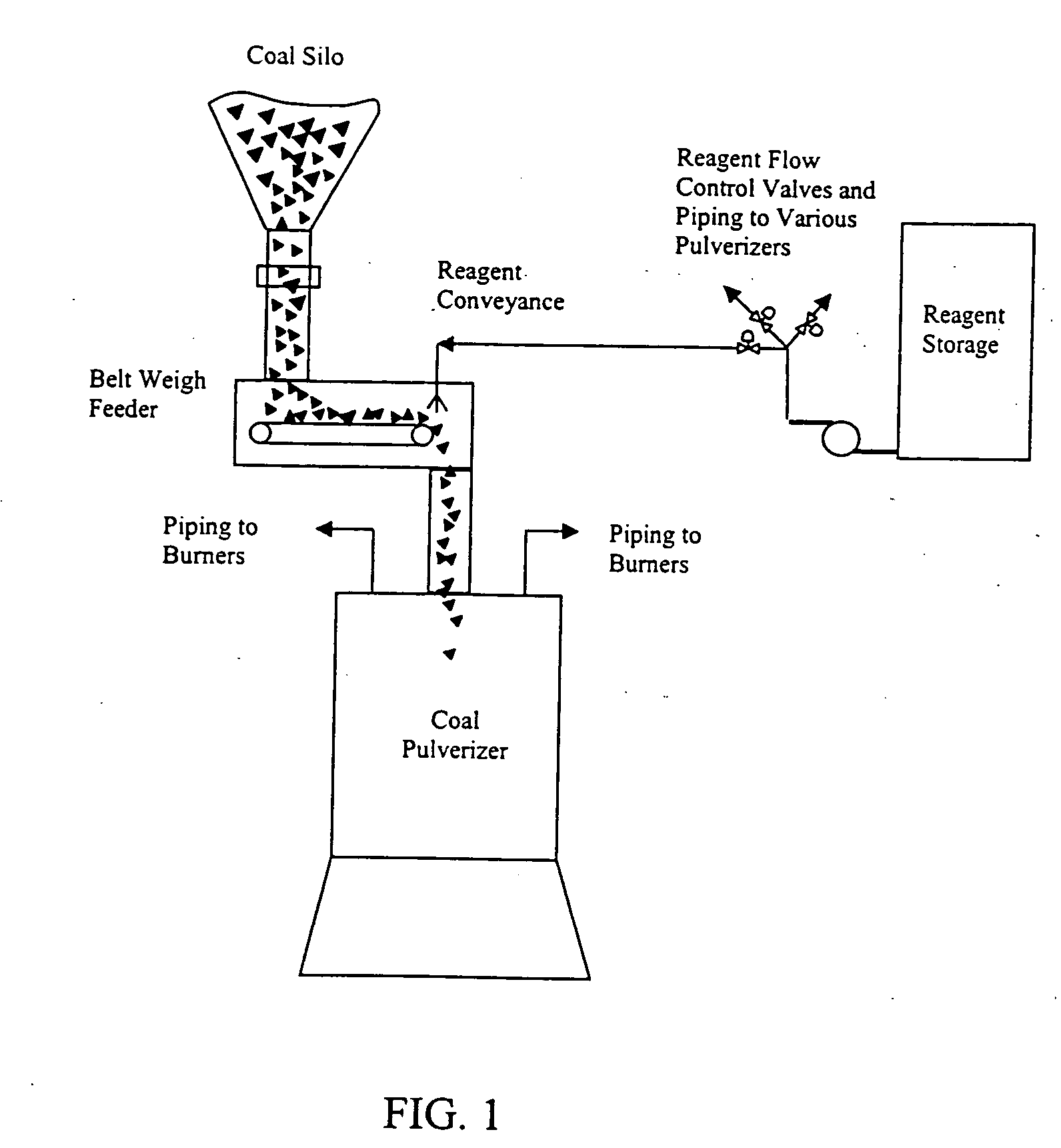

[0013] Referring now to FIG. 1, a schematic diagram of an embodiment of the present invention is shown. A fossil fuel, such as coal, is provided from a coal silo onto a belt feeder, such as a gravimetric feeder or other belt feeding apparatus. The belt feeder in turn provides the coal to the pulverizer wherein the coal is pulverized to a predetermined particle size.

[0014] Prior to being pulverized, preferably while the coal is on the belt feeder or alternatively dropping into the pulverizer, the coal is treated with a liquid or solid chlorine reagent, preferably sodium chloride or calcium chloride. Spray nozzles located above and / or around the belt may be provided to treat the coal with liquid chlorine reagent prior to pulverization. Reagent flow rate may be control manually by valves or alternatively utilize automated means. Alternatively, reagent may be supplied to coal in the form of solid pellets, powder, or granules utilizing a solids feeder in place of the spray nozzle. Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com