Control system for a water heater

a control system and water heater technology, applied in the field of water heaters, can solve problems such as alarms to be initiated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention advances a multi-function controller for a water heater which centrally and simultaneously controls and monitors a variety of operational parameters.

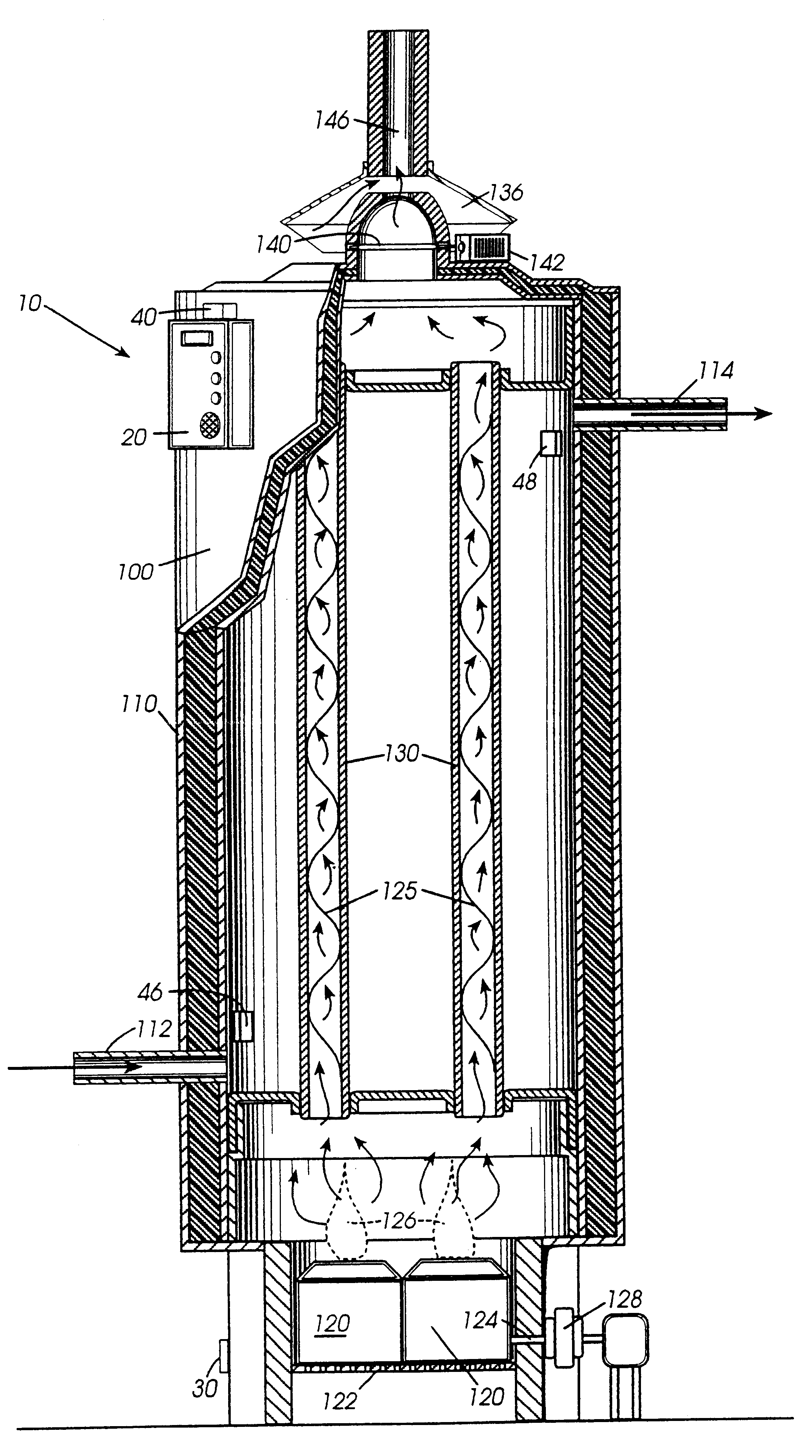

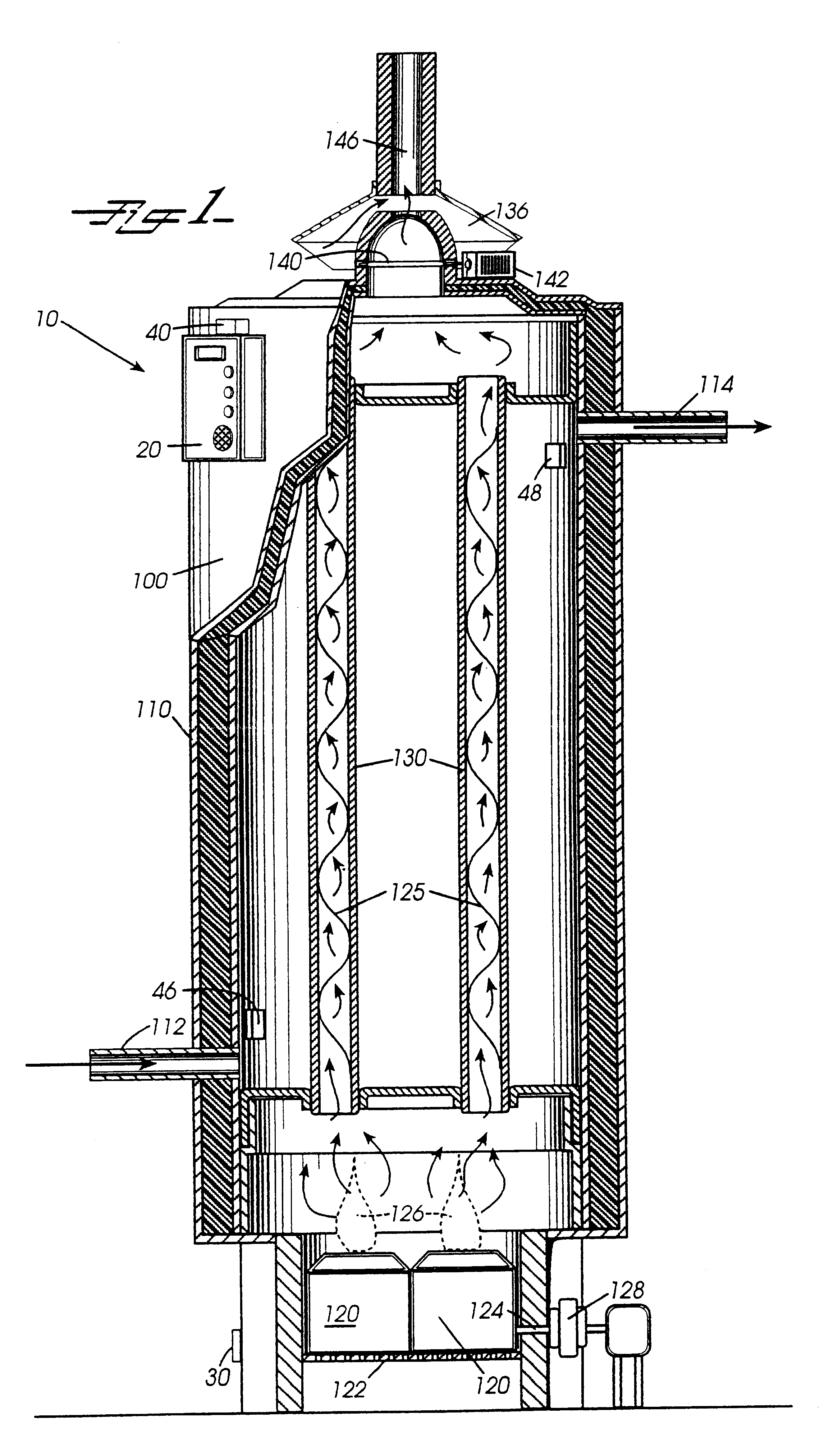

Referring now to the FIGS. 1 and 2, there is shown a partial cross-sectional side view and a partial cut away front view, respectively, of a multi-function controller according to a preferred embodiment of the present invention, designated generally by reference numeral 10.

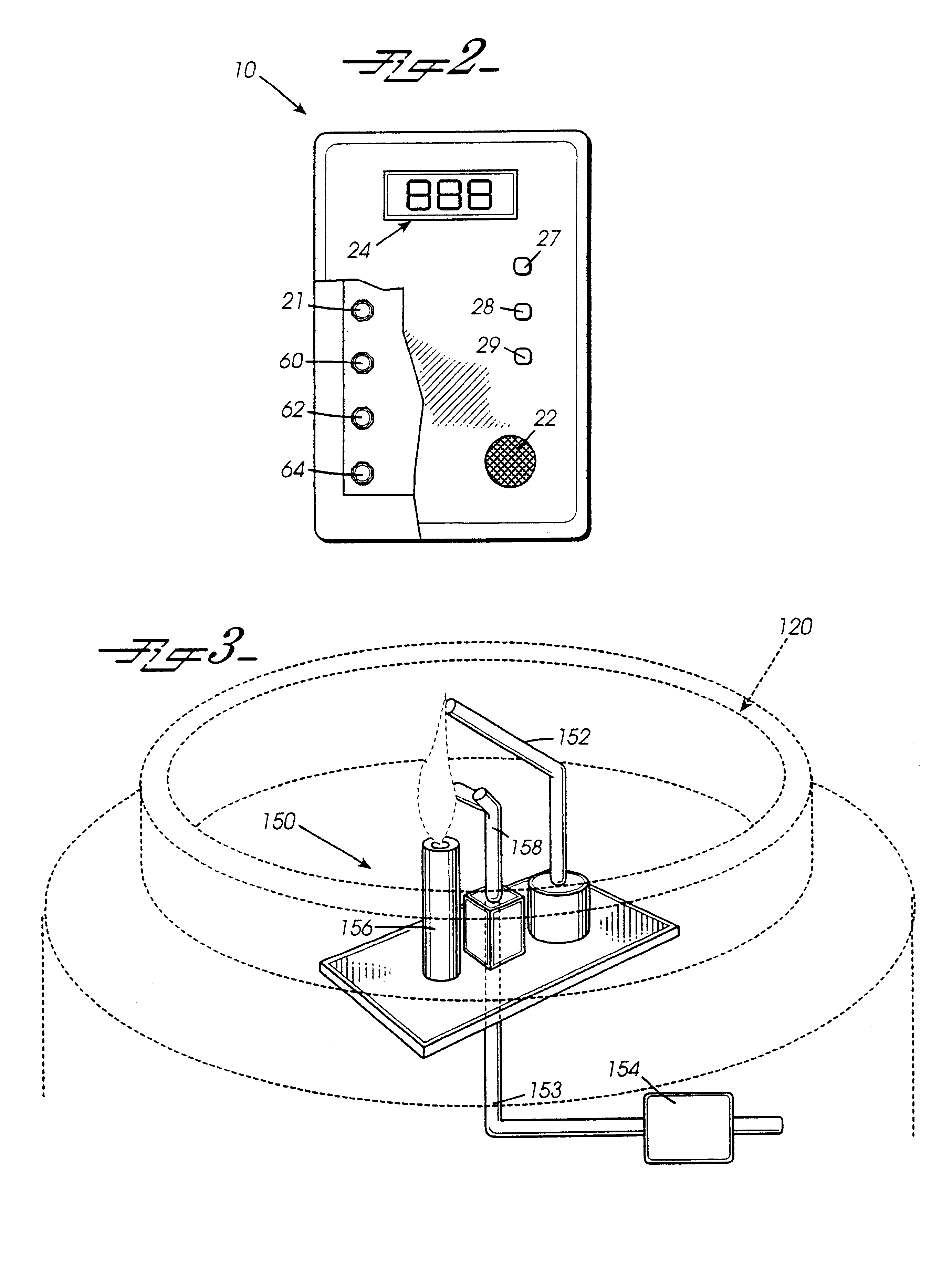

Water heater 100 is comprised of a tank 110 dimensioned to hold a quantity of water therein. Disposed about the bottom of heater 100 is a series of combustion burners 120. In fluid communication with burners 120 are flue baffles 125 positioned inside flues 130. Both baffles 125 and flues 130 are positioned vertically within the interior of tank 110. Positioned atop heater 100 is a draft hood 136 in fluid communication with flues 130. Within draft hood 136 is a damper 140 controlled by a motor 142. Extending from draft hood 136 is a vent pipe 146....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com