Patents

Literature

1017results about "Water feed control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

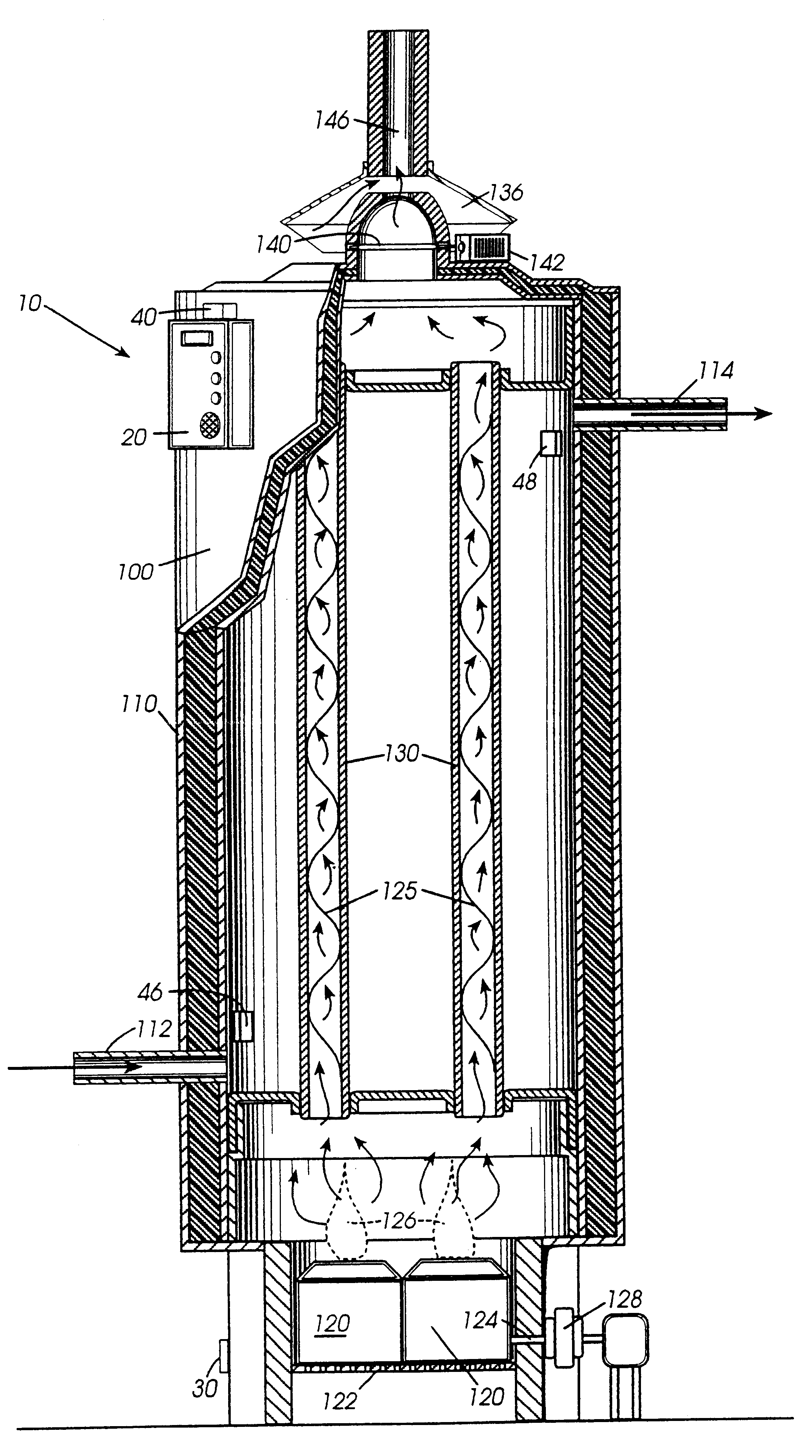

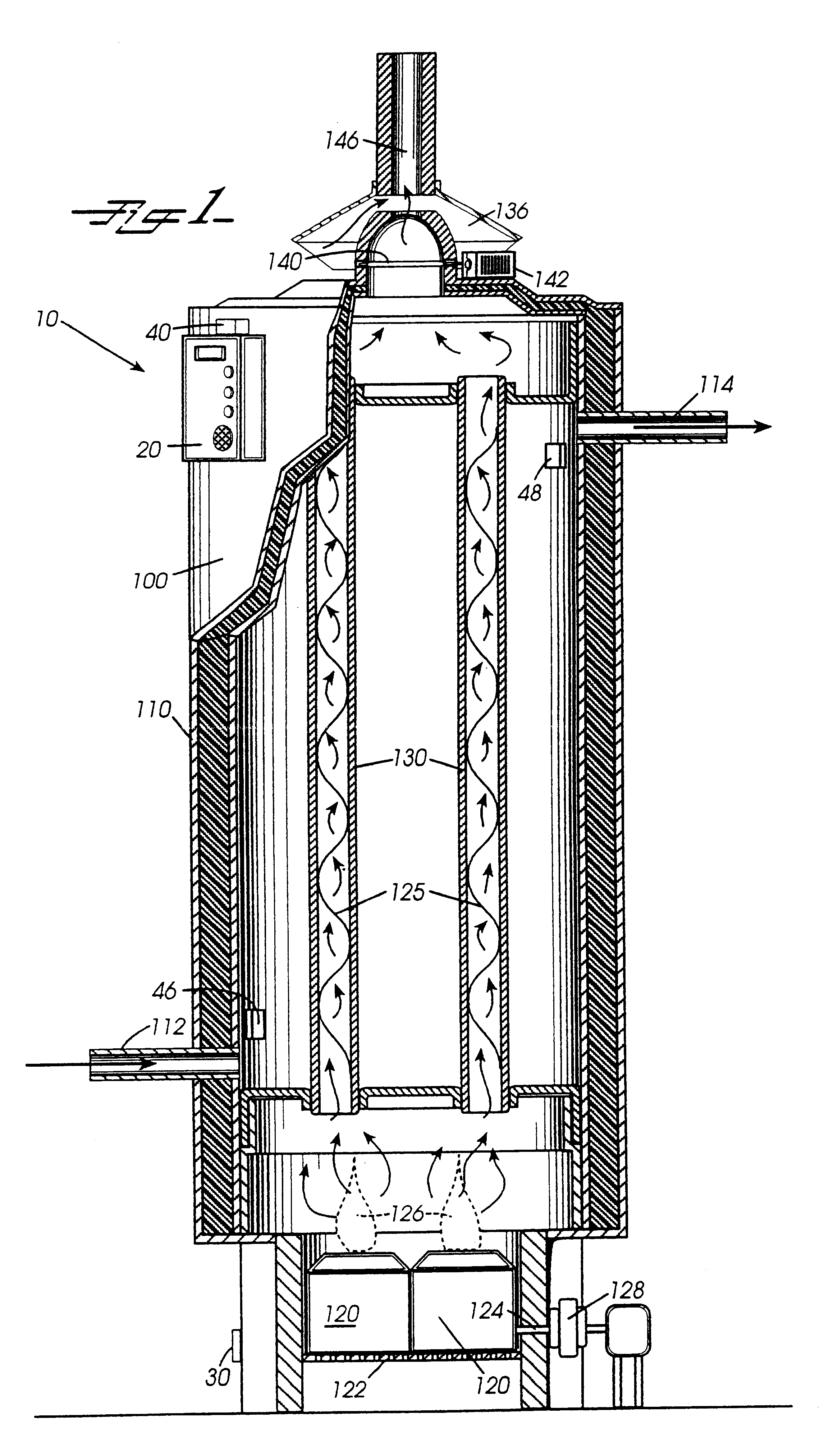

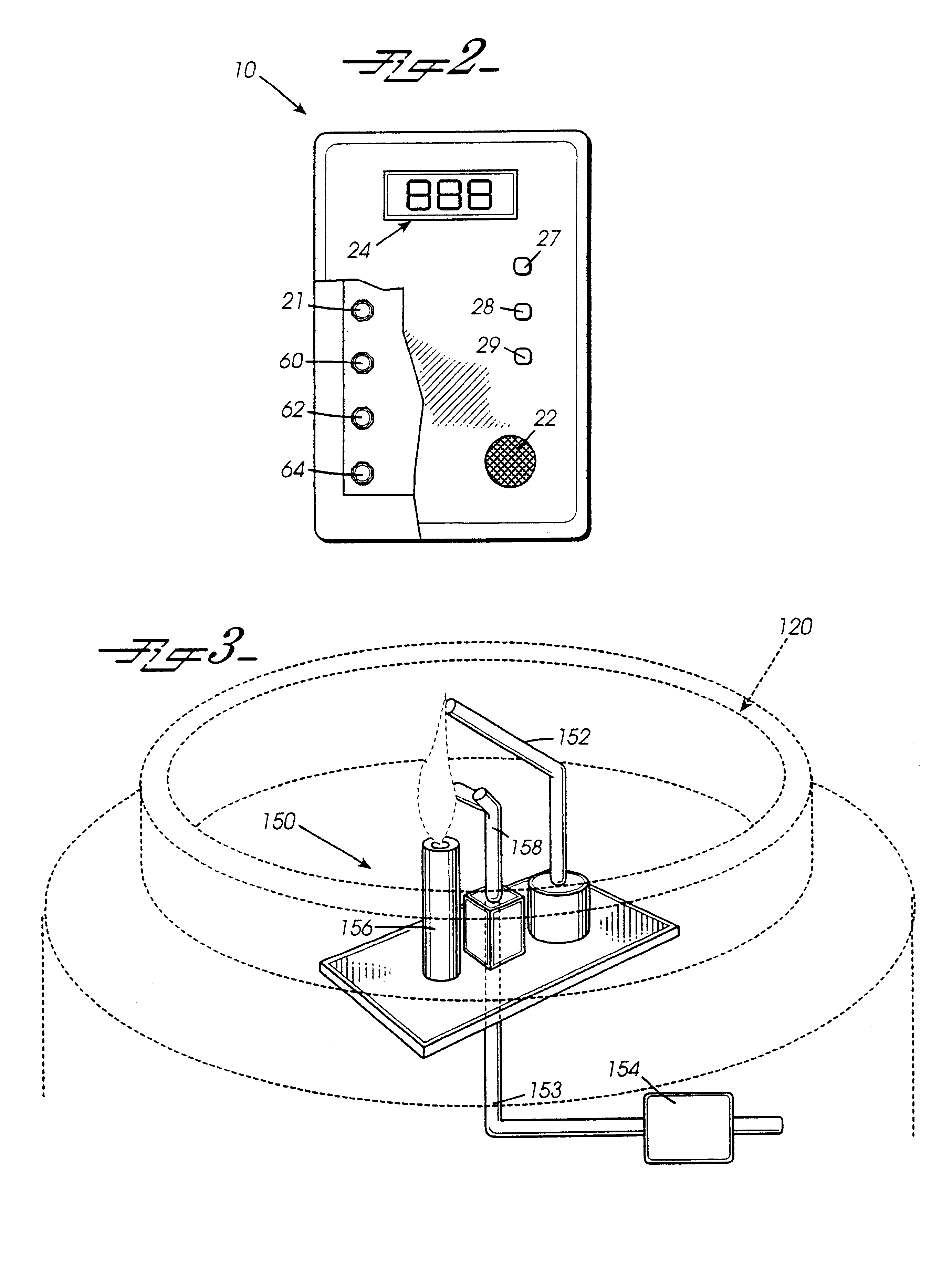

Control system for a water heater

InactiveUSRE37745E1Detect presenceHarmful and dangerousMachines/enginesFuel injecting pumpsCombustorControl system

A multi-function controller for a water heater is advanced comprising a control panel and a plurality of sensors that monitor a variety of functions that impact the operation of a water heater. A flammable gas sensor, placed in proximity to the air intake, detects the presence of an unsafe concentration of gas and issues a signal to the control panel, which subsequently discontinues the operation of the burners. Detection of a blocked vent pipe is achieved by a carbon monoxide sensor placed near the draft hood. The control panel is equipped with circuitry which monitors usage of the heater for a specified time period to develop a pattern of use. Subsequent to the monitoring period, the controller will activate the burners a predetermined time prior to an anticipated period of high use. During periods of low use, the controller will decrease the temperature to which the water is to be heated, thereby resulting in a more efficient heater. Non-volatile memory records data from the sensors so that the operation status of the heater may be ascertained subsequent to a power outage. The control panel contains a plurality of visual alarms, each of which corresponds to a sensor. Consequently, repair and maintenance are simplified because the cause of a malfunction is quickly recognized.

Owner:AOS HLDG CO

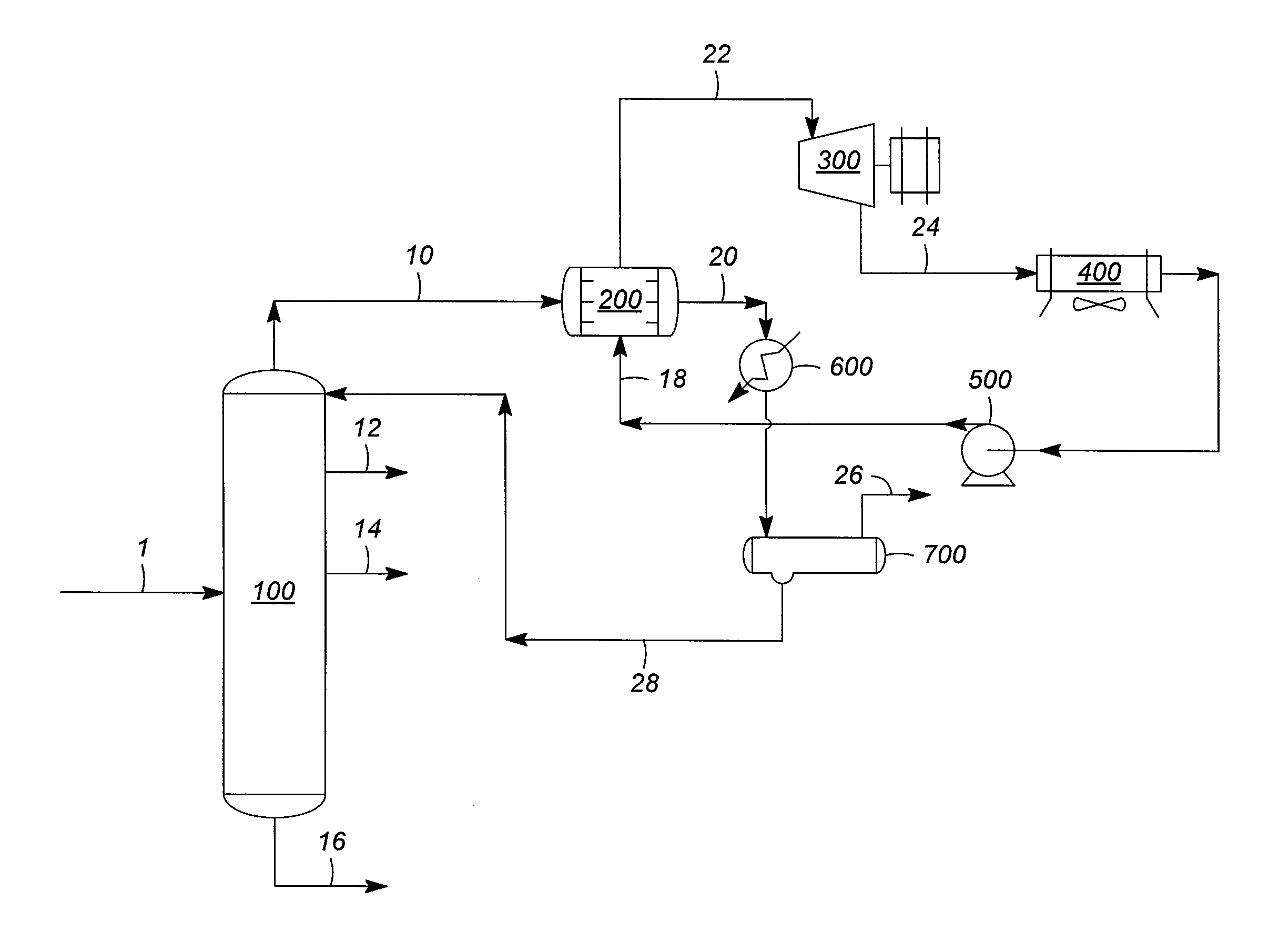

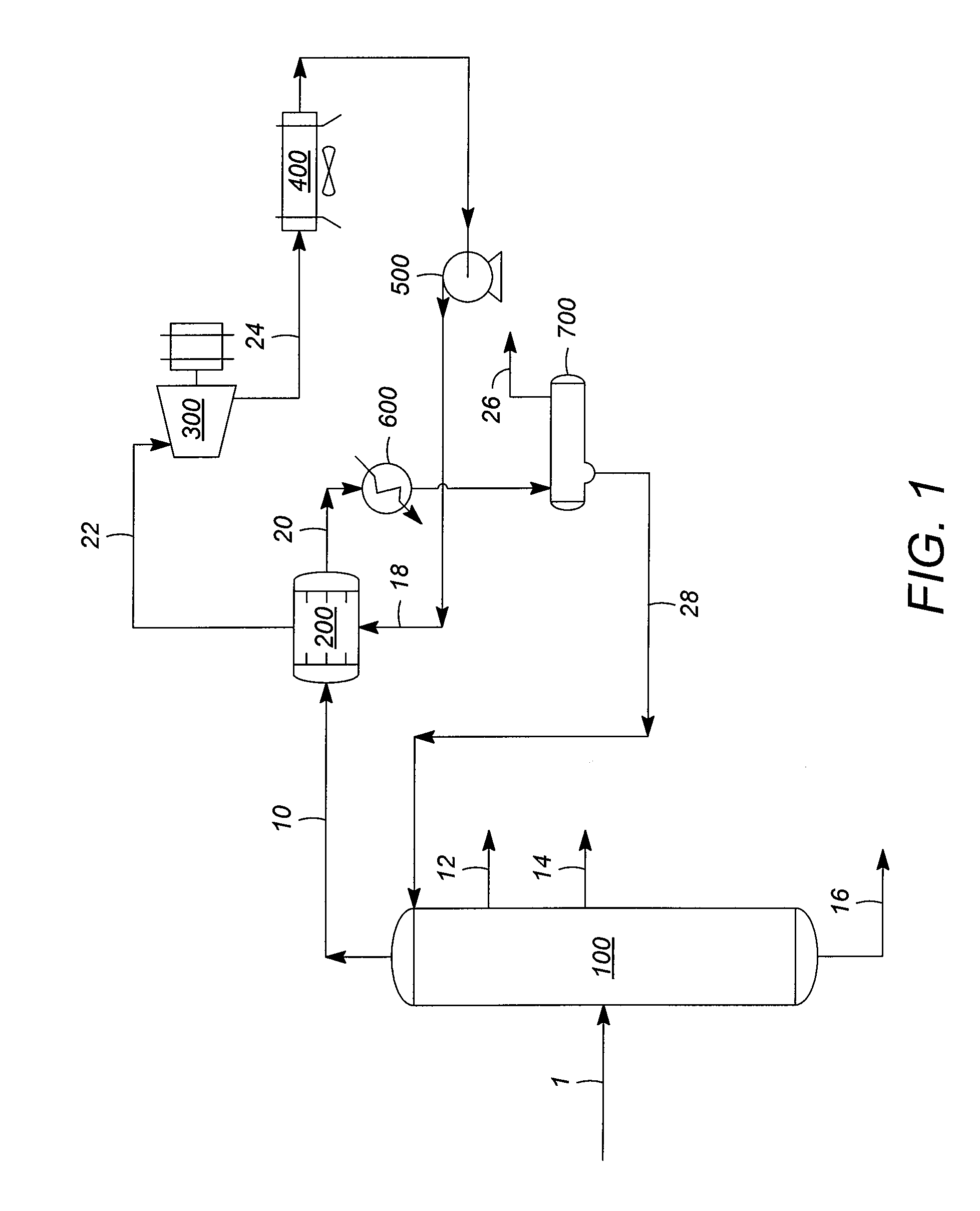

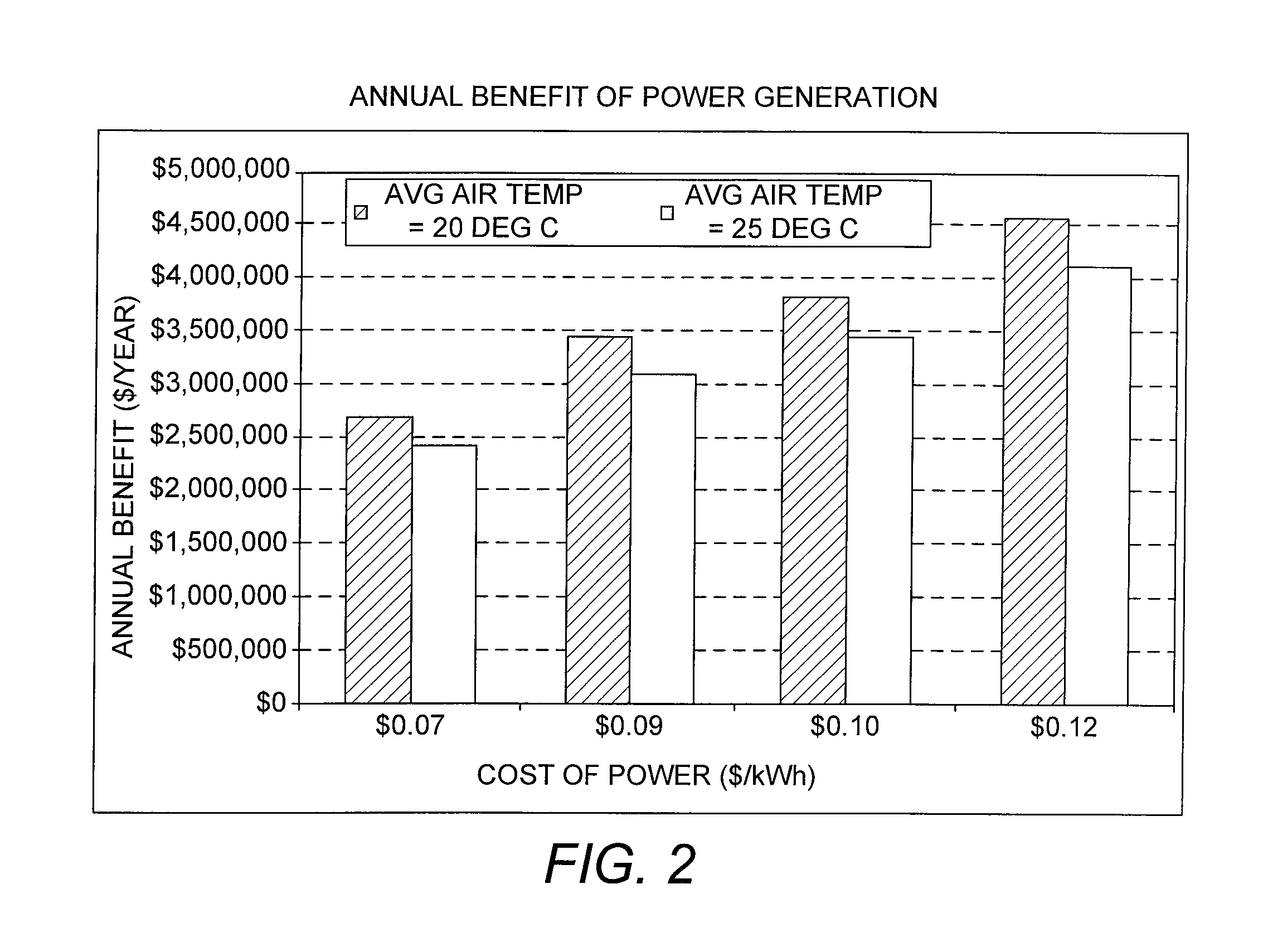

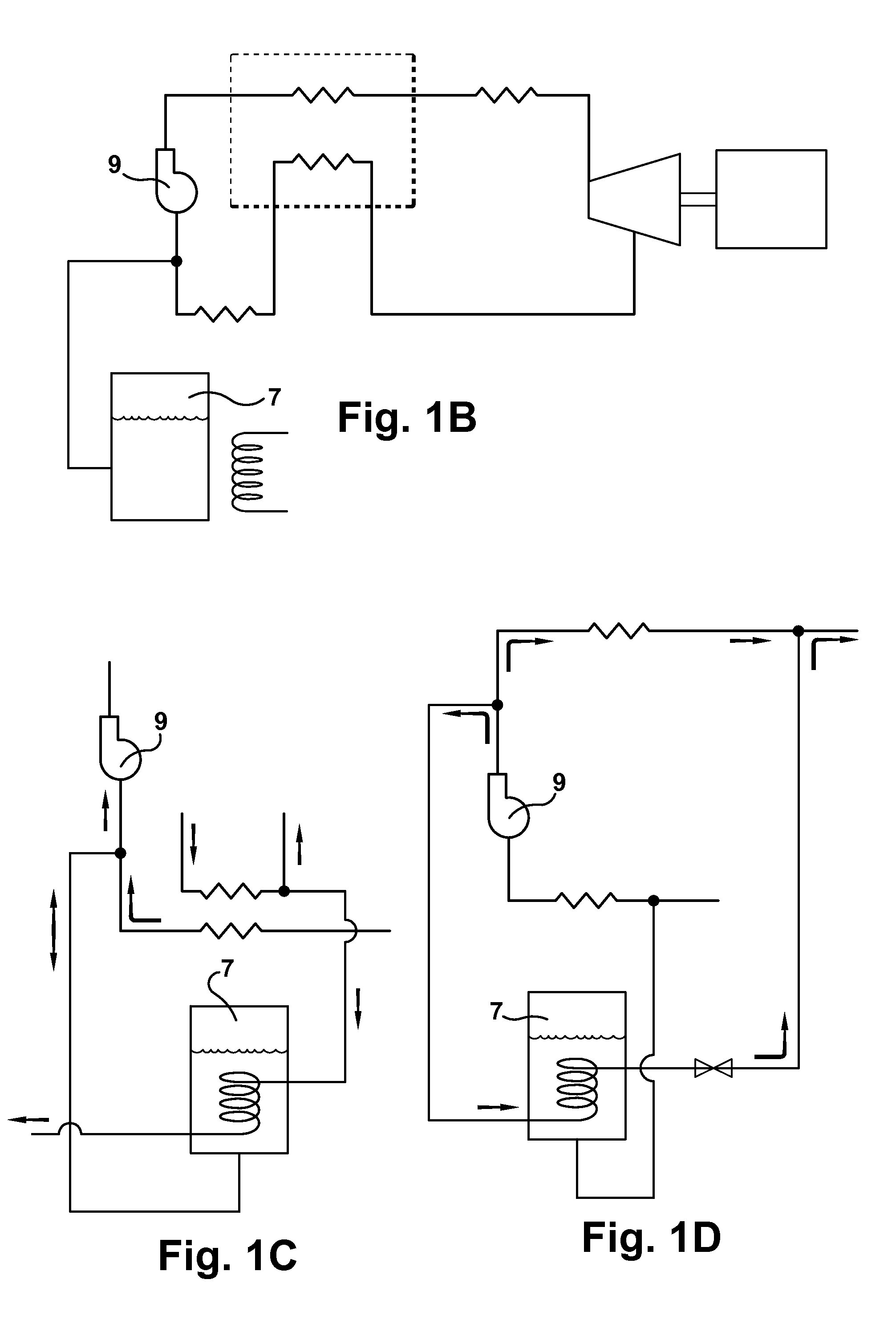

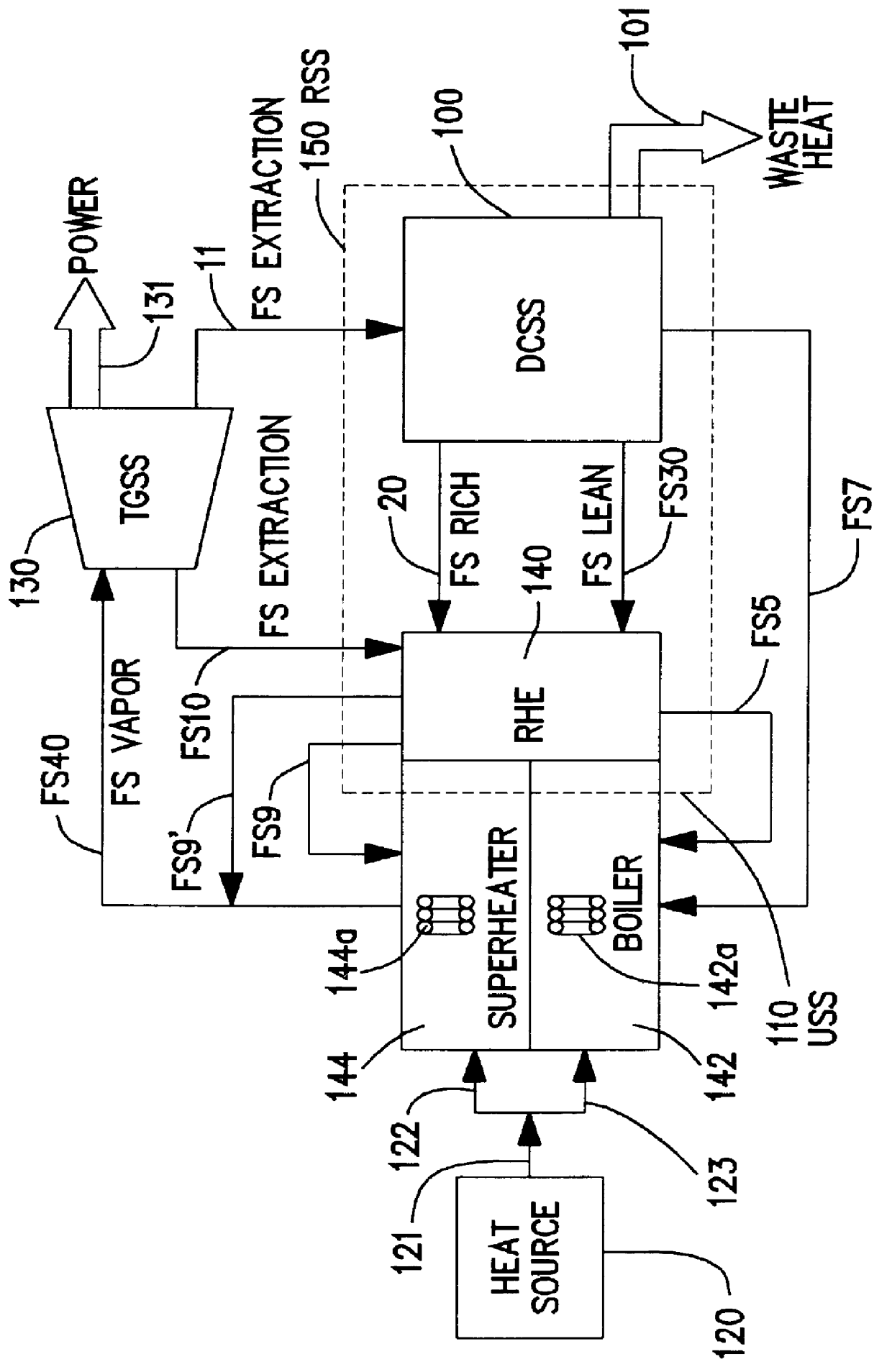

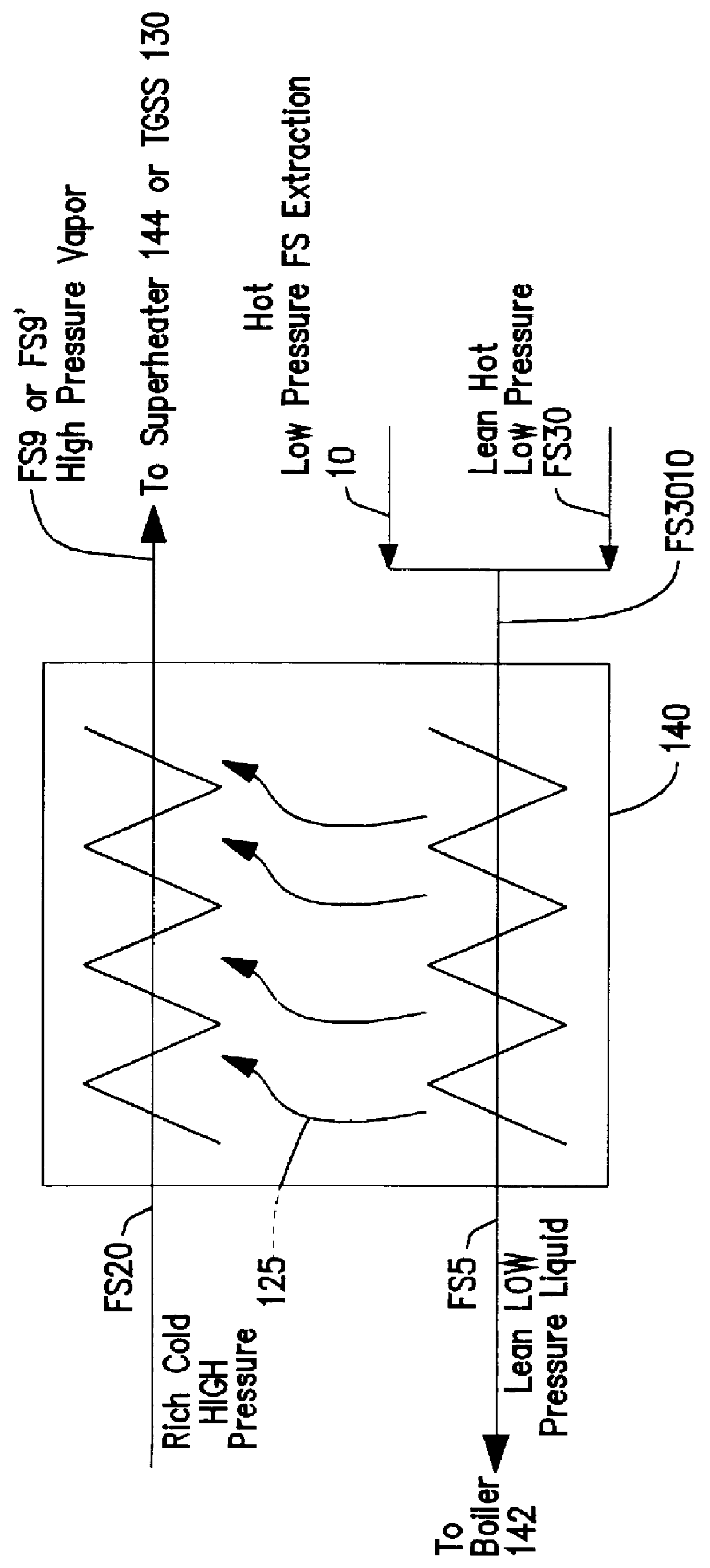

Low Grade Heat Recovery from Process Streams for Power Generation

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

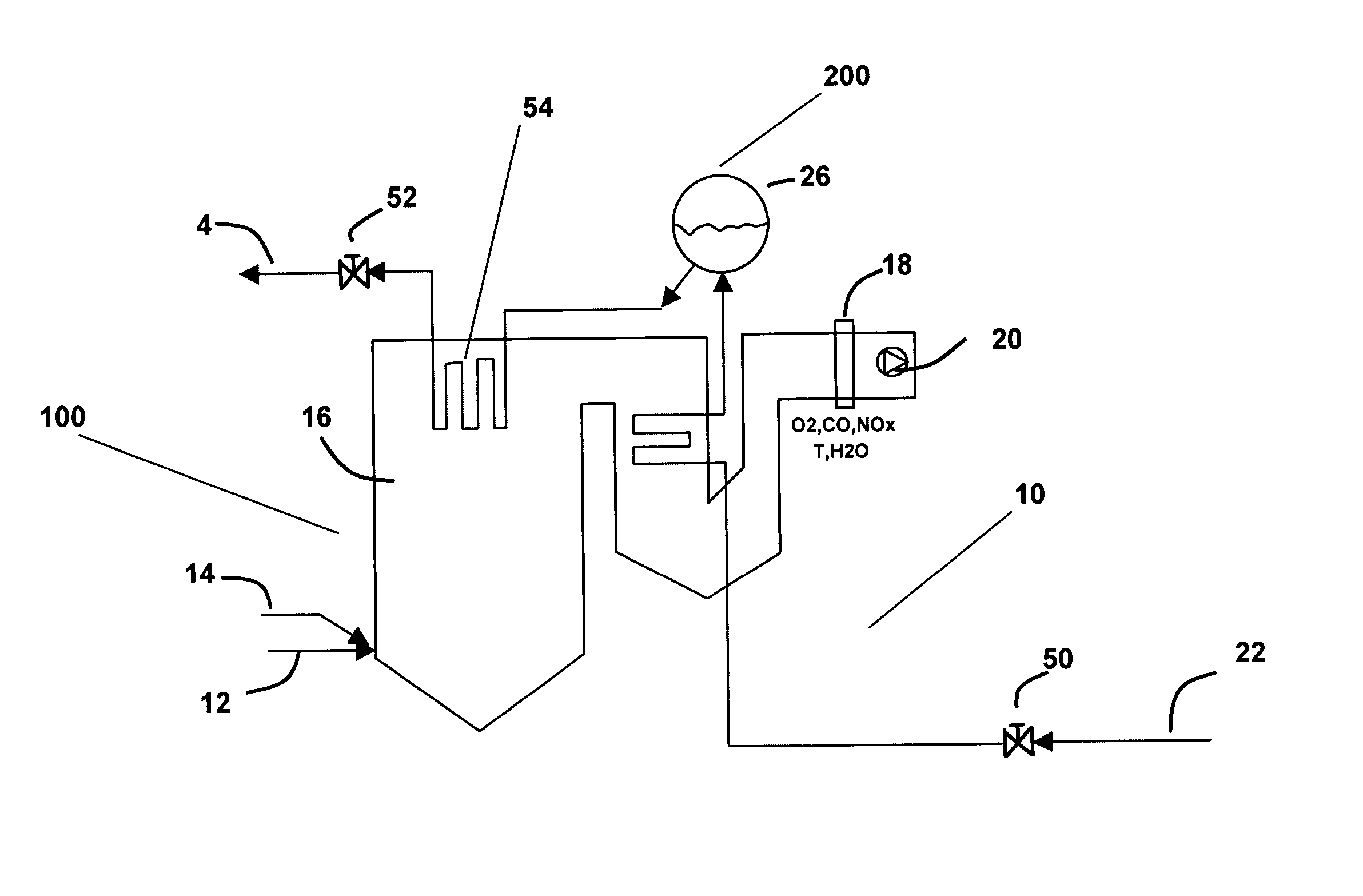

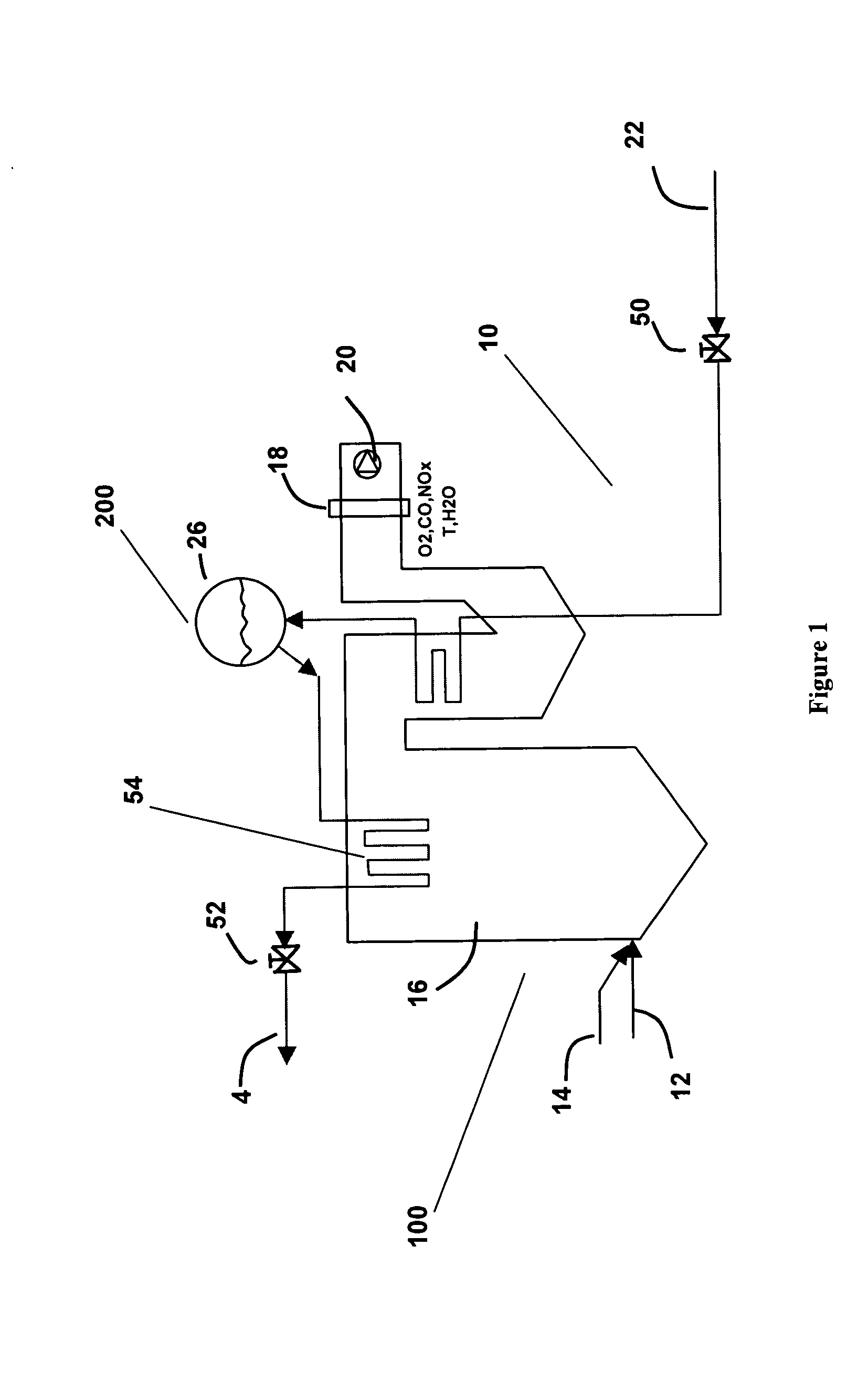

Real time optimization and control of oxygen enhanced boilers

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

Low Energy Vaporization of Liquids: Apparatus and Methods

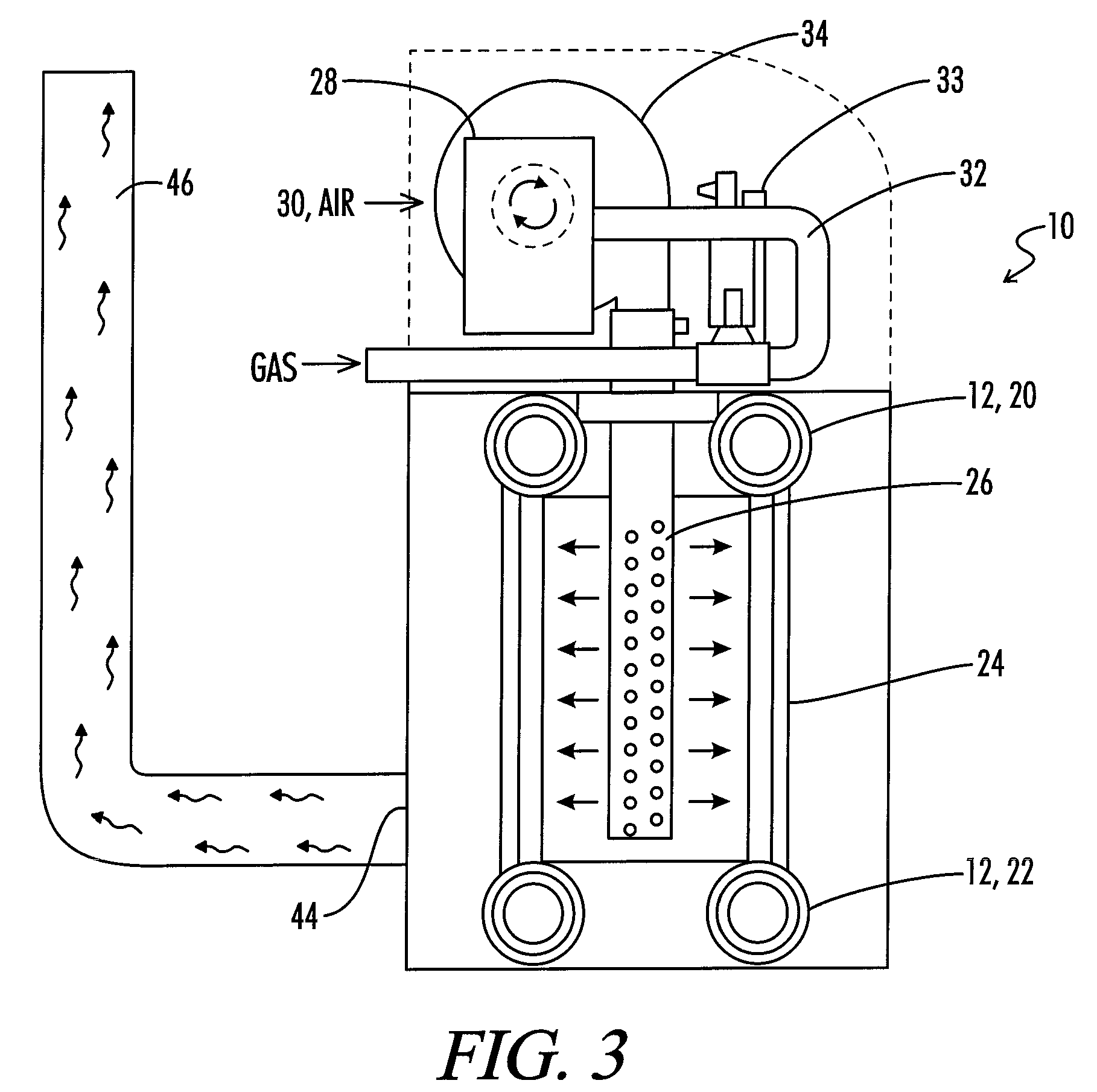

ActiveUS20090224064A1Optimize quantityReduced Power RequirementsSpray nozzlesTobacco devicesAtmospheric airProduct gas

The present invention relates to an apparatus and method for the low energy flash-like vaporization of liquids and the release of the resulting vaporized liquid into the atmosphere in the form of a visible plume, mist or cloud. Vaporization is occasioned in a geometrically small device capable of producing vaporized liquid that varies little in composition in comparison to the starting liquid feed to the device. The apparatus and method are primarily directed towards the treatment of small areas for residential air fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, administration of personal pharmaceuticals or medicaments, as well as other ambient air or surface modification by way of gas, vapor or droplet distribution.

Owner:VAPORE

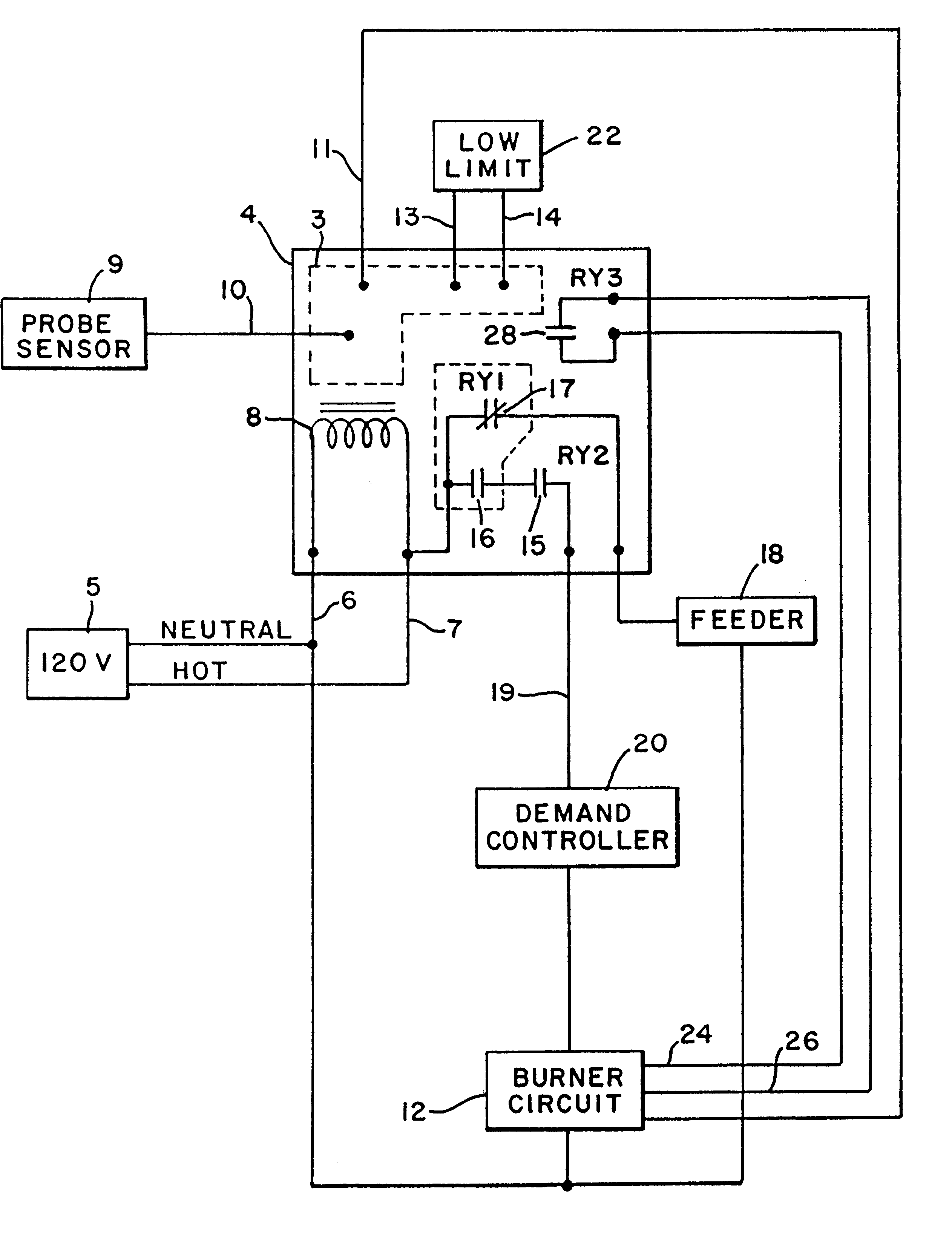

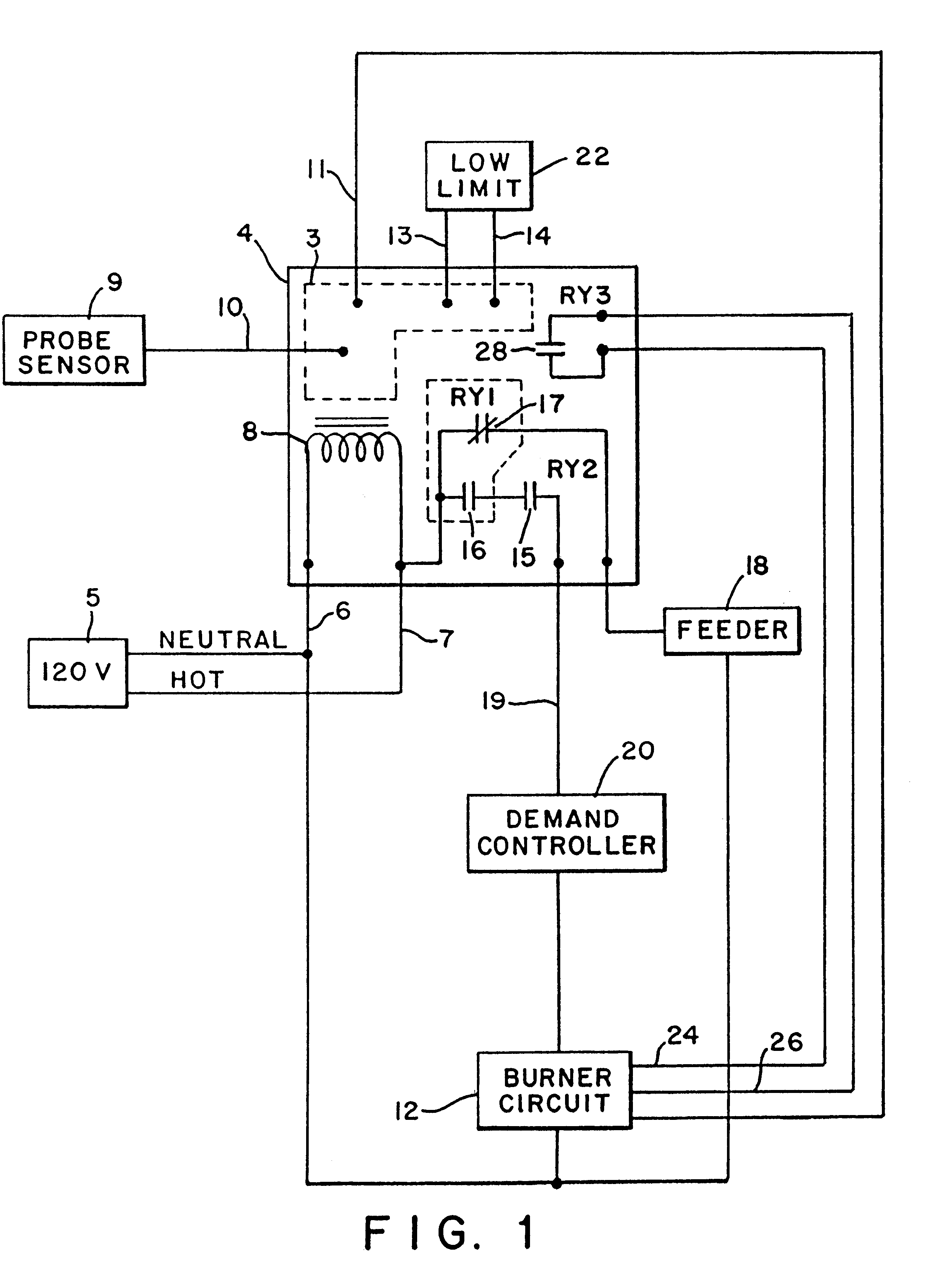

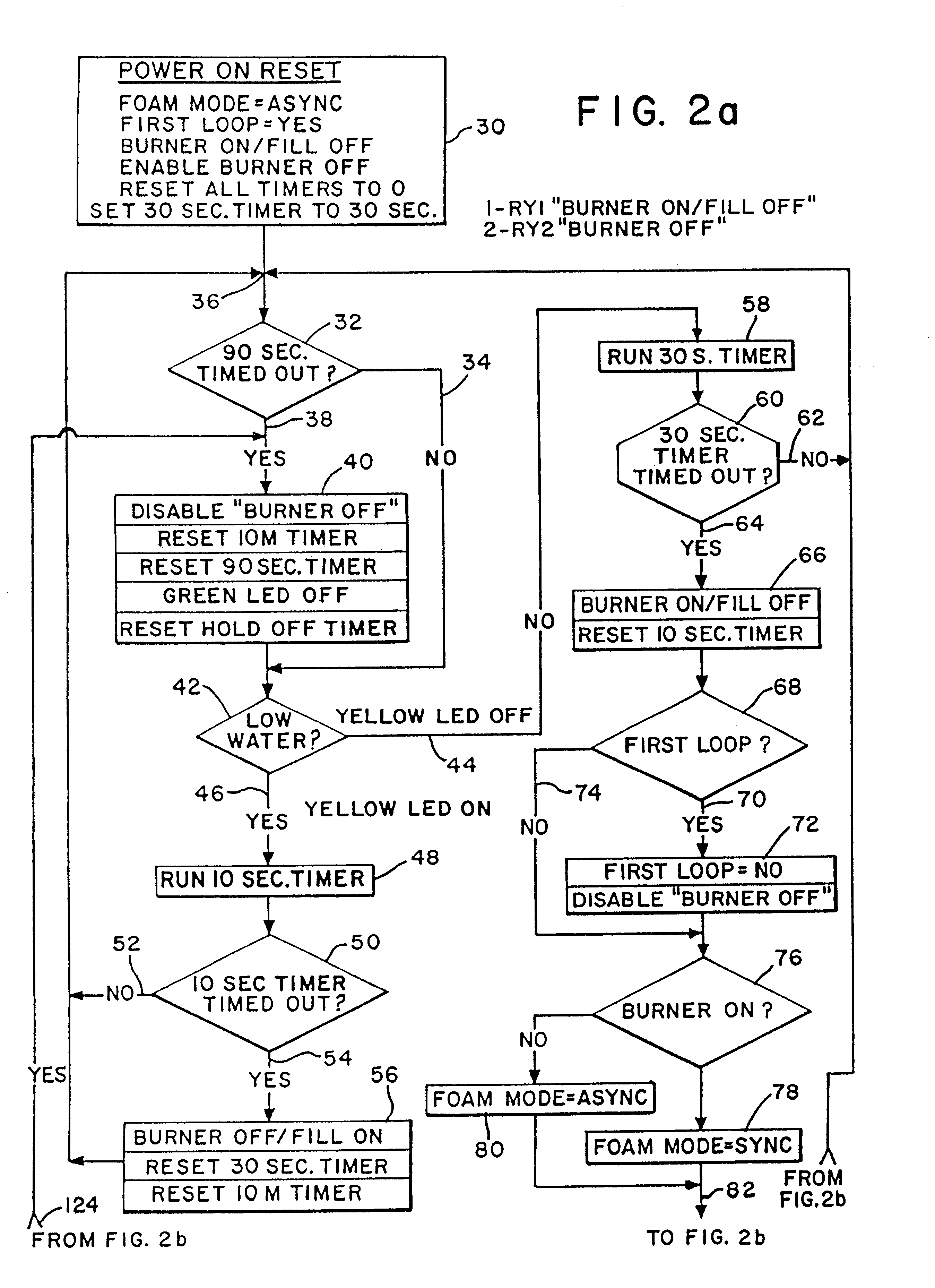

Cycle control system for boiler and associated burner

A cycle control system for use with a boiler having a fluid therein and a method of monitoring a boiler to determine the presence of an adequate level of fluid therein. The cycle control system includes a timing circuit producing a burner control signal having alternating on and off states corresponding to on and off period timers to allow foam to settle so that a probe can accurately check the fluid level in the boiler. A burner monitor circuit monitors when a demand controller turns the burner on and off responsive to demand. The on-period timer is reset whenever the burner monitor circuit indicates the demand control circuit has turned off the burner for a length of time sufficient for the probe to accurately check the fluid level.

Owner:COWLES OPERATING CO

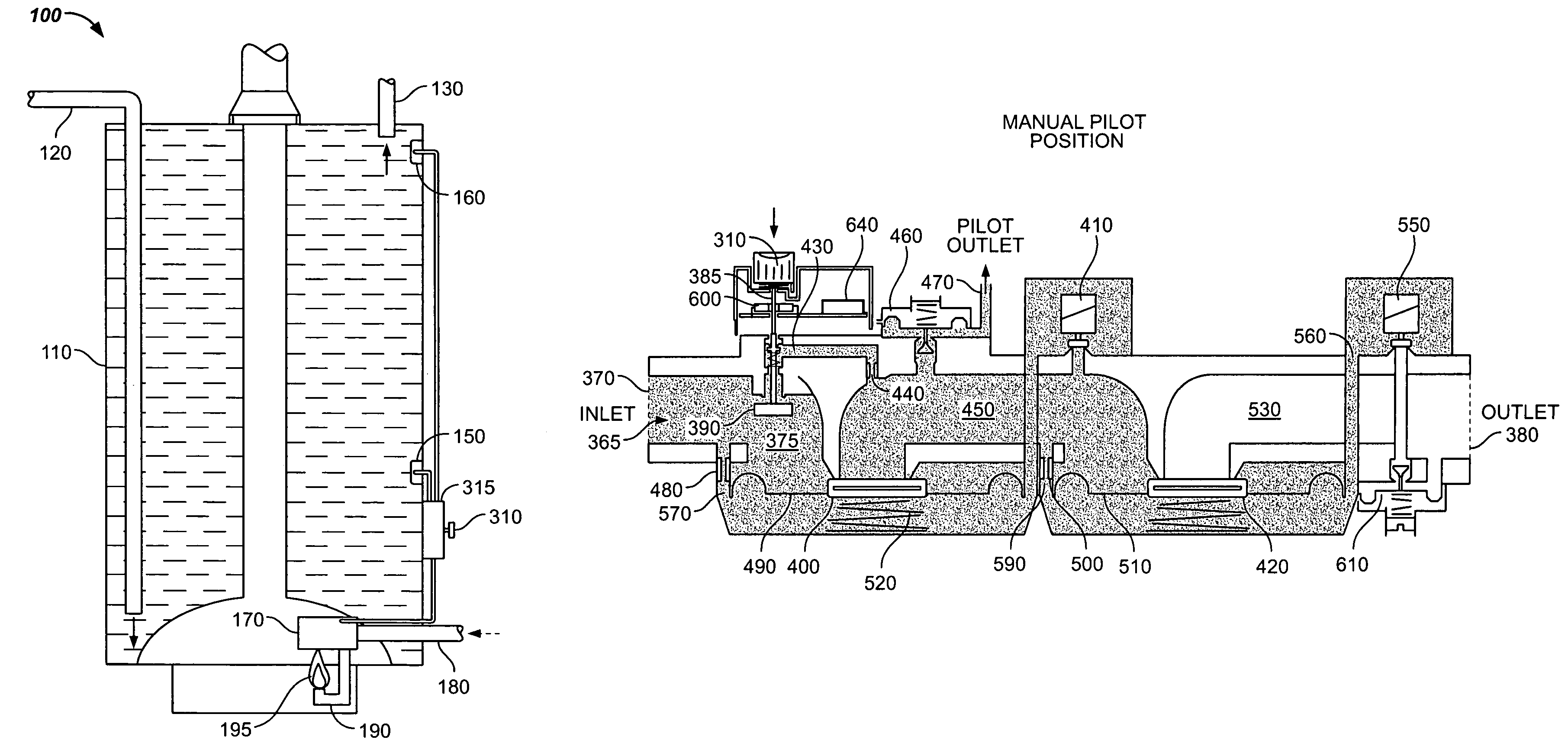

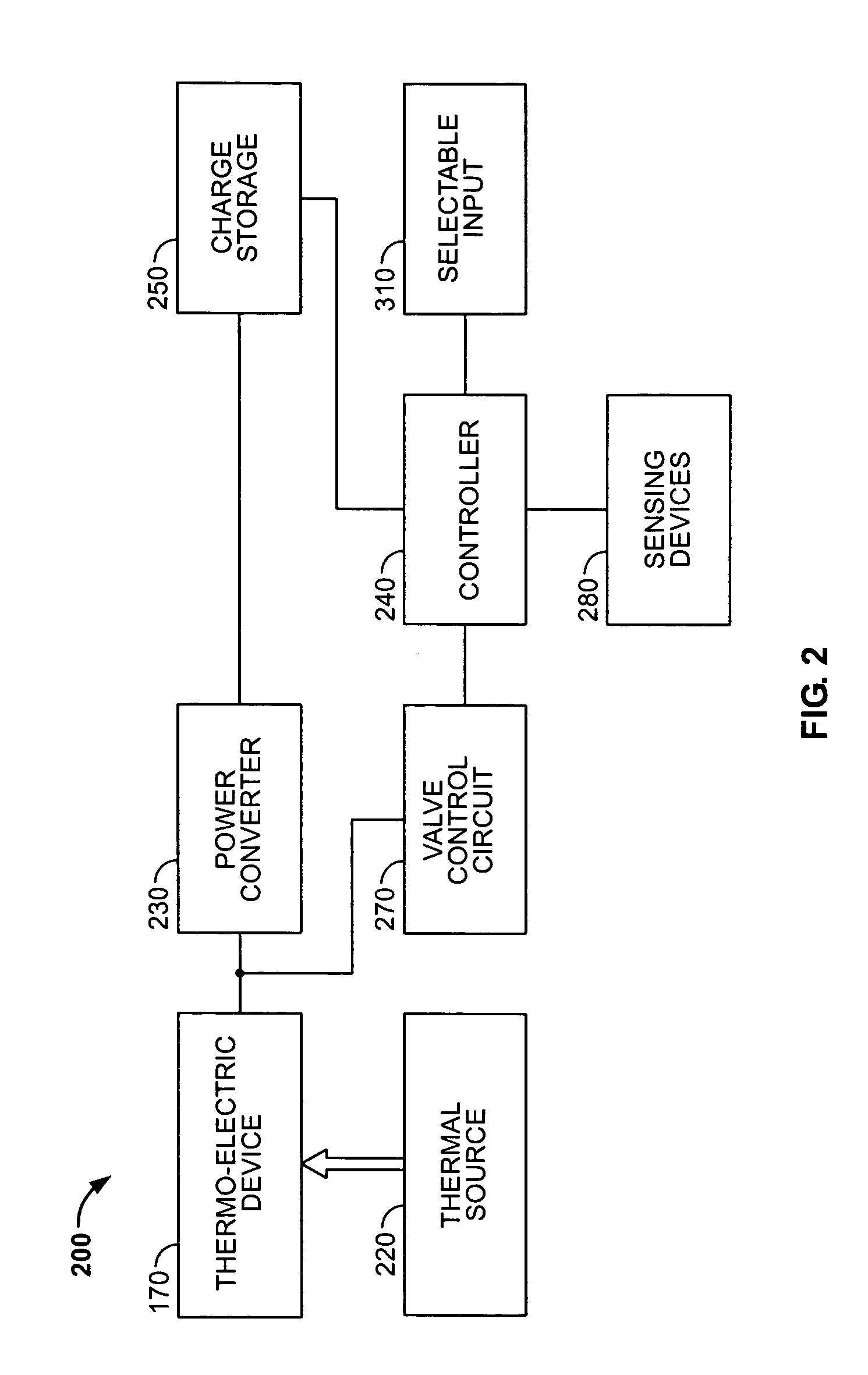

Method and system for combined standing pilot safety and temperature setting

ActiveUS7252502B2Temperature control without auxillary powerFuel supply regulationCombustorElectric potential

The method and apparatus provides a controller (which might comprise a microprocessor) that can control gas flow to a pilot burner in fluid communication with a manual pilot valve and an automatic pilot valve. The exemplary embodiments can comprise a selectable input device that can open the manual pilot valve to allow gas flow to the pilot burner. A pilot flame can then heat one or more thermal detection devices in thermal communication with the pilot burner, wherein the one or more thermal detection devices can output a variable voltage potential to the controller. The controller can then open the automatic pilot valve to maintain gas flow to the pilot burner after the manual pilot valve has been closed. In an exemplary embodiment, the only voltage potential used to power the controller is supplied by the one or more thermal detection devices.

Owner:ADEMCO INC

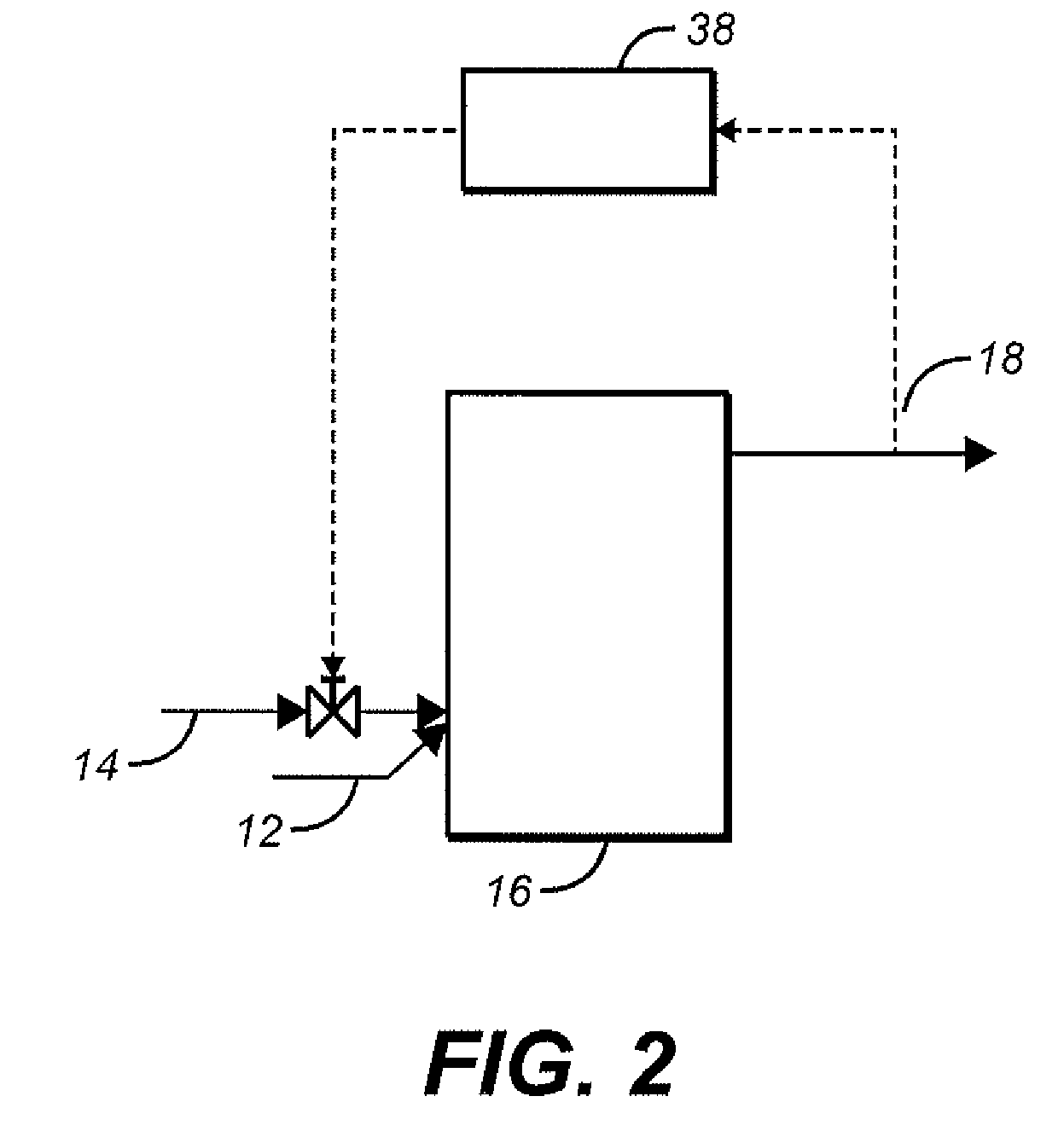

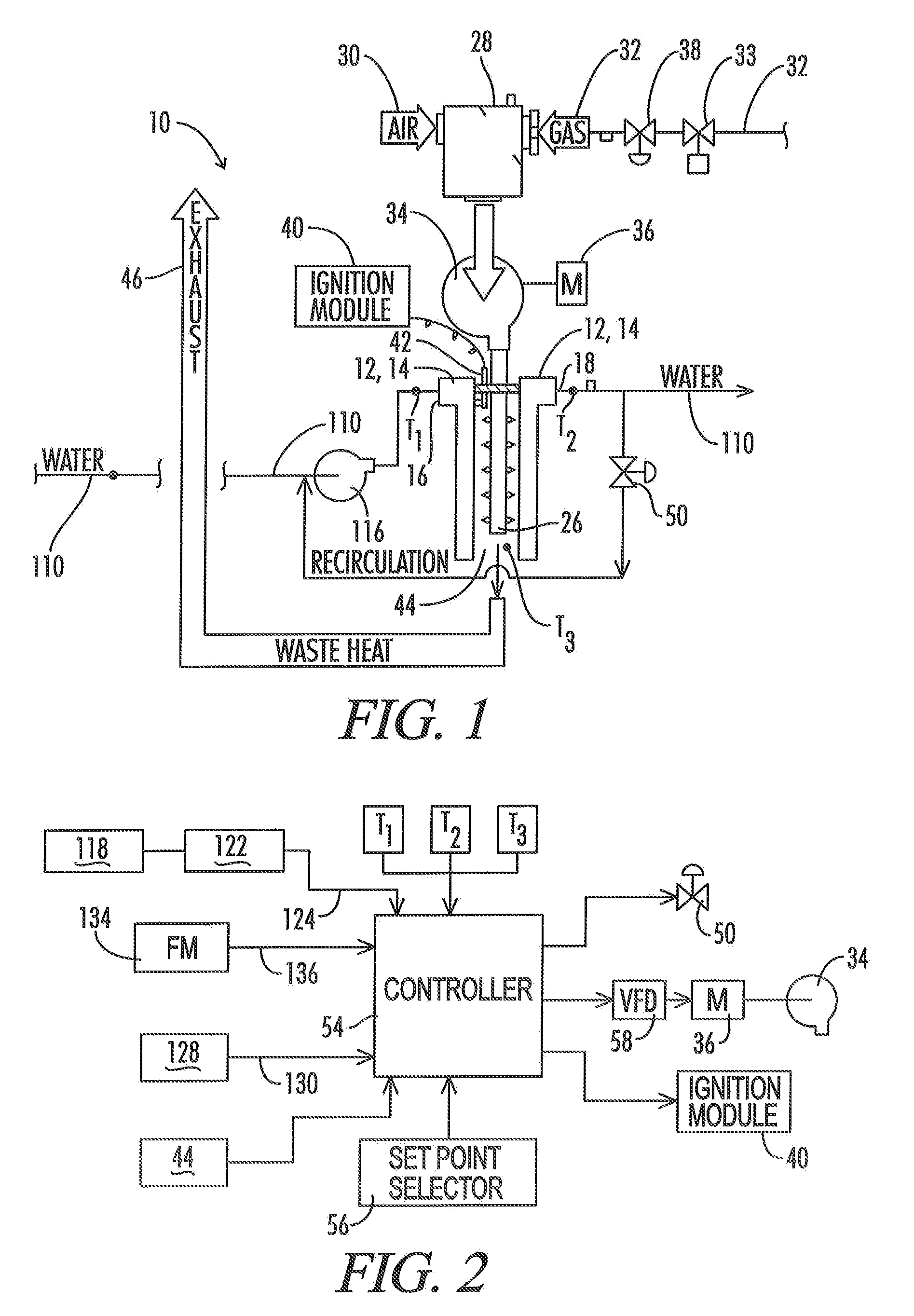

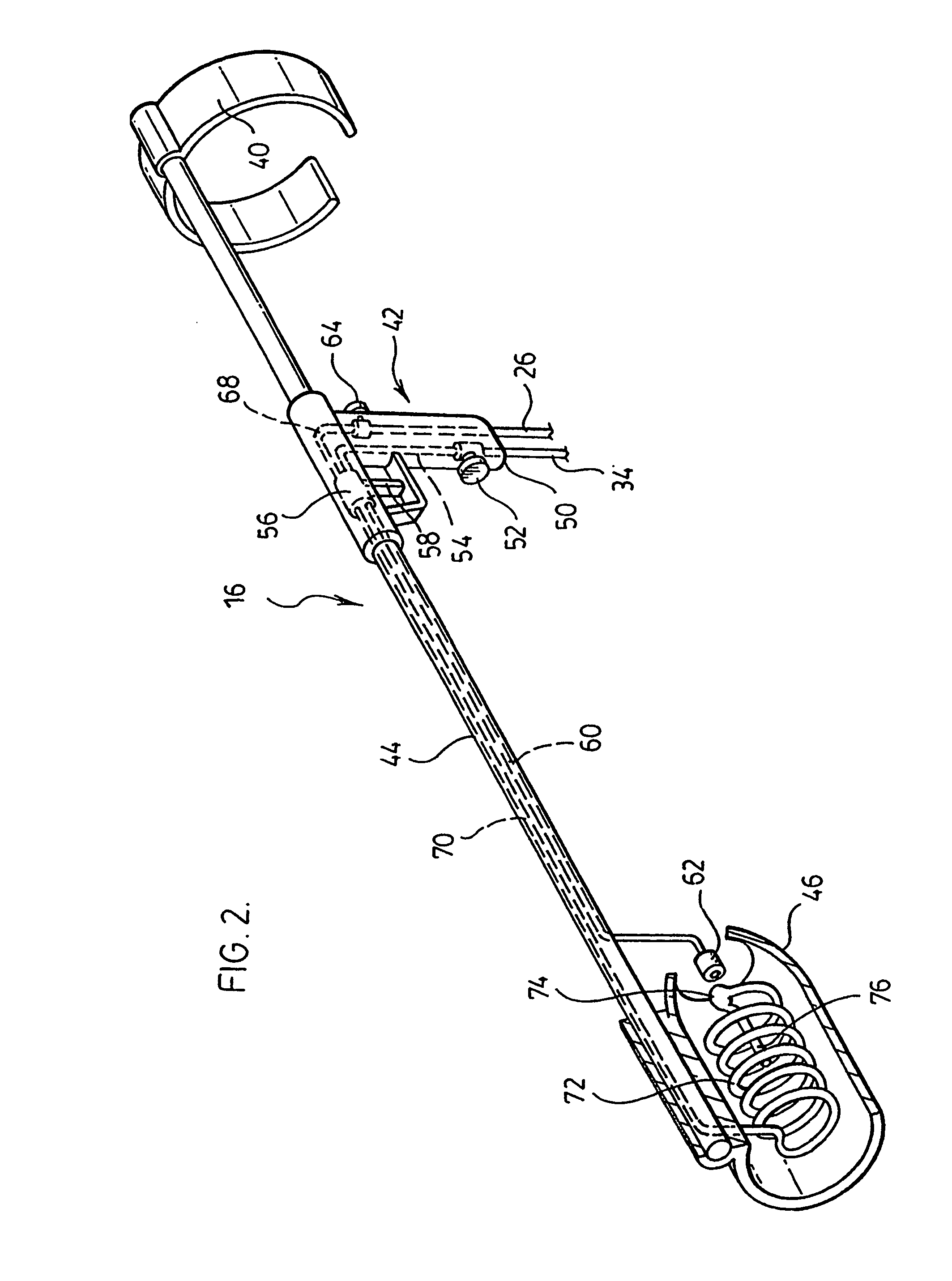

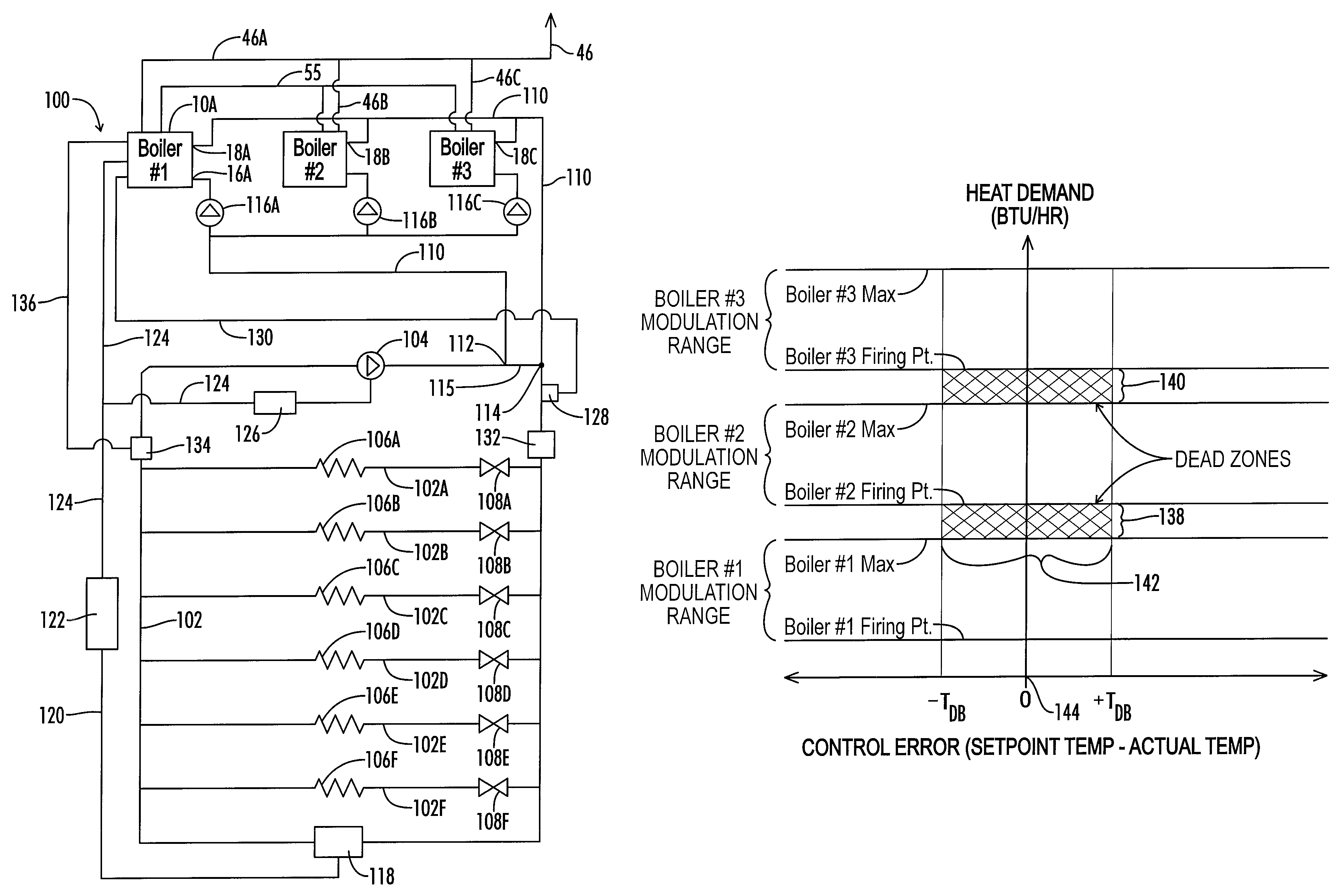

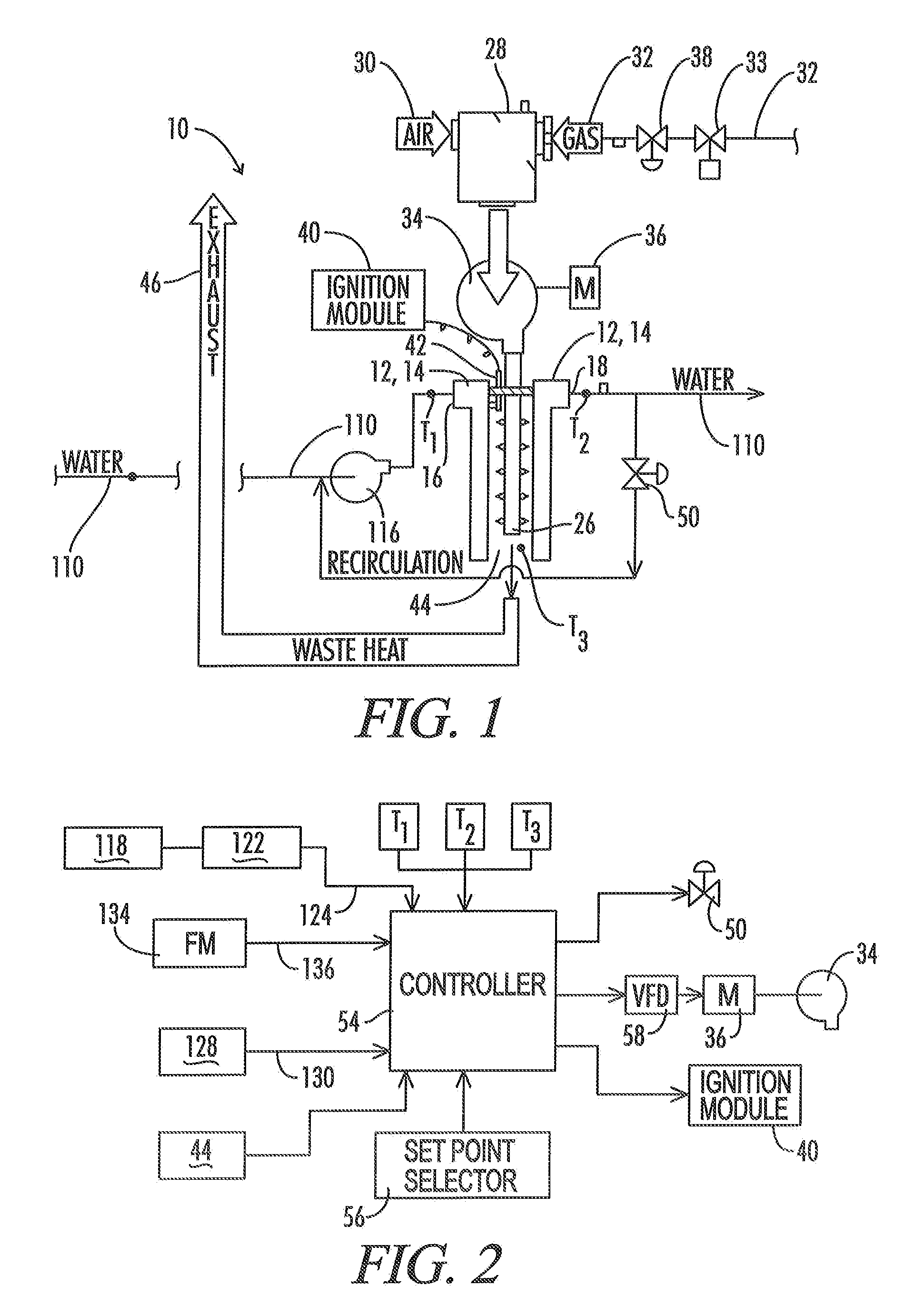

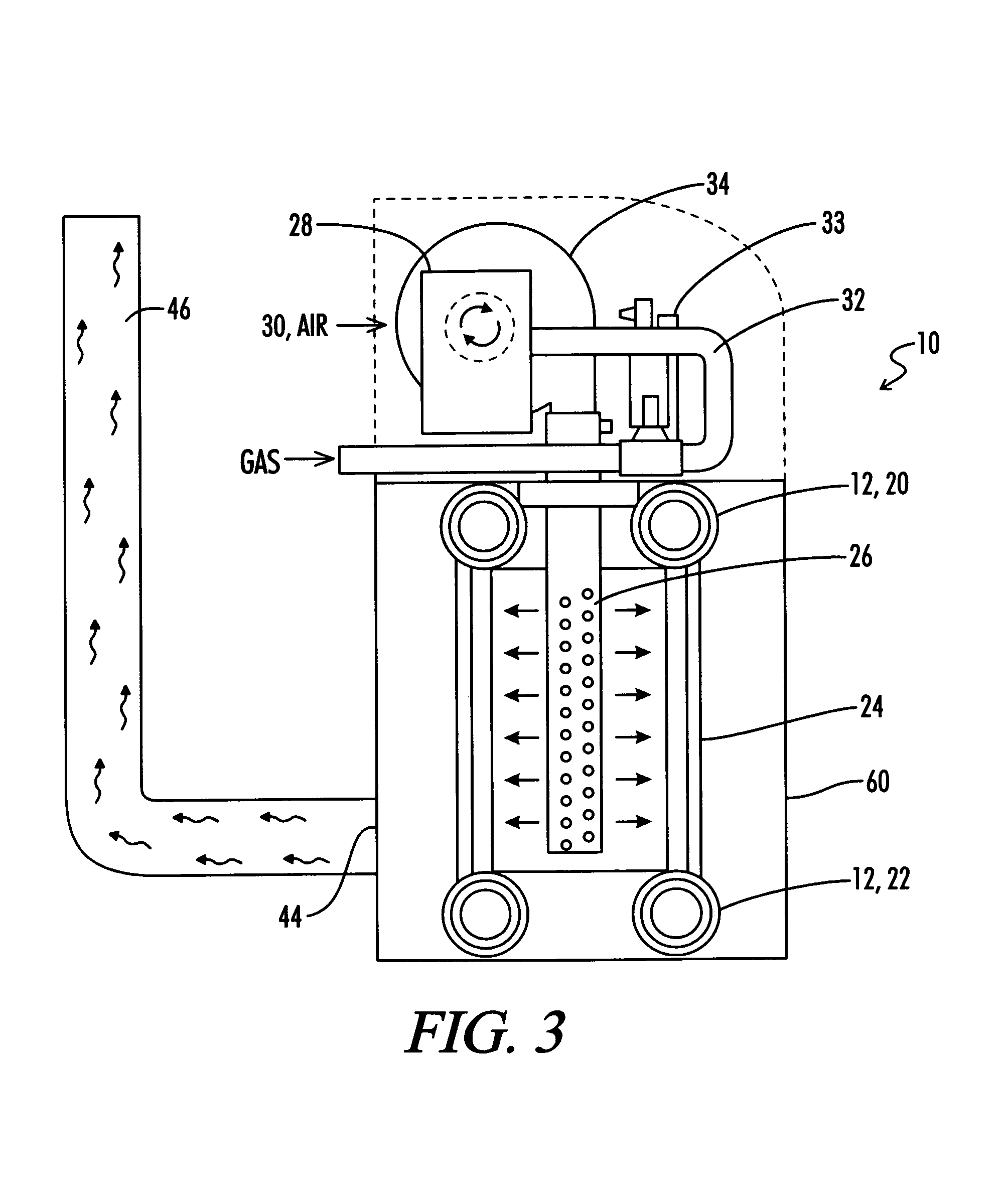

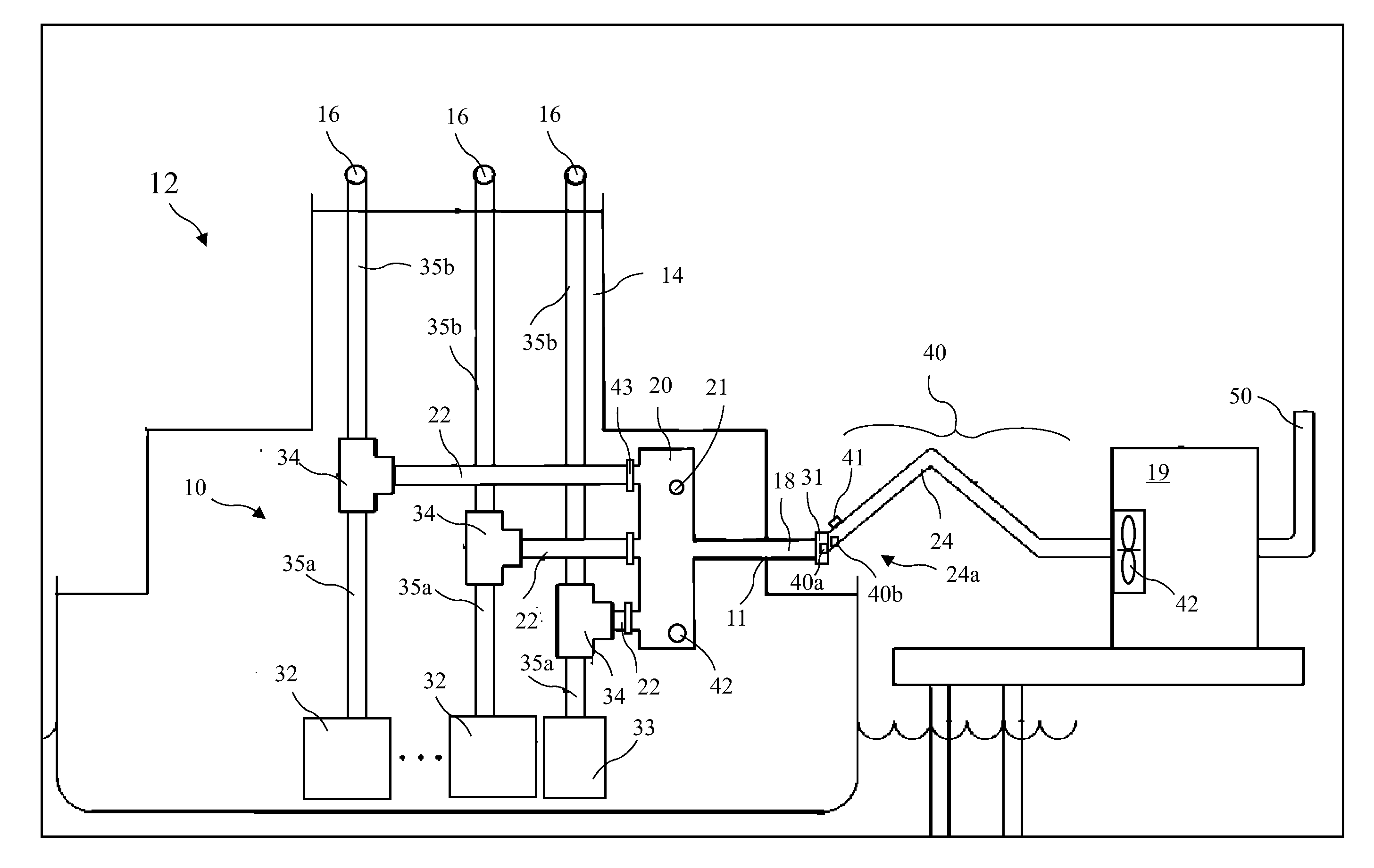

Control System For Modulating Water Heater

ActiveUS20080216771A1Shorten the overall cycleEarly detectionFluid heatersFuel supply regulationDeadbandHeating system

A control system is provided for a modulated heating system including a plurality of modulating water heaters, which may be modulating boilers. A deadband control scheme provides for reduced cycling of the modulating heater when total system heat demand falls between the maximum output of one heater and the sum of the maximum output of that one point and the minimum firing point of the next subsequent heater.

Owner:LOCHINVAR

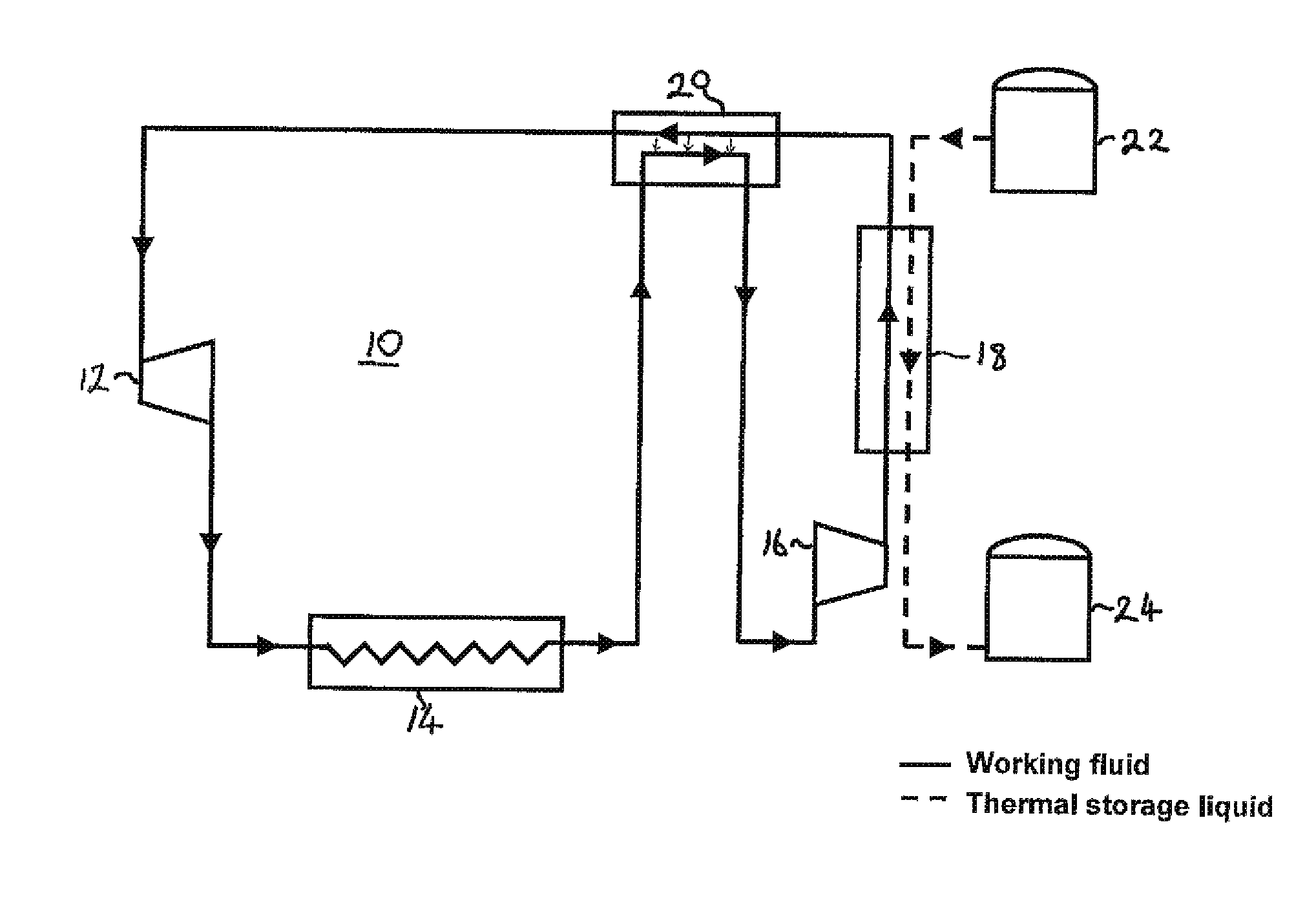

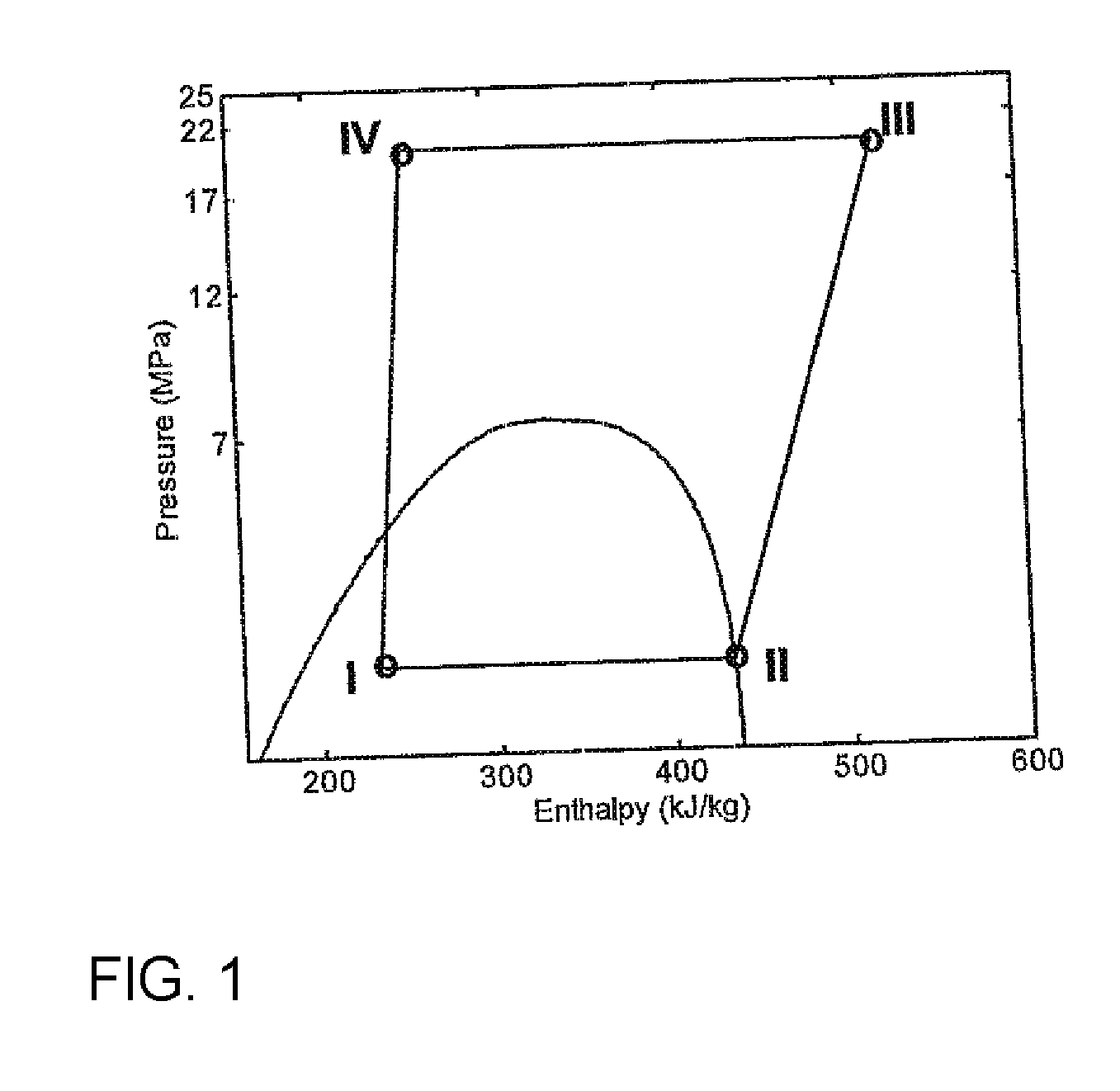

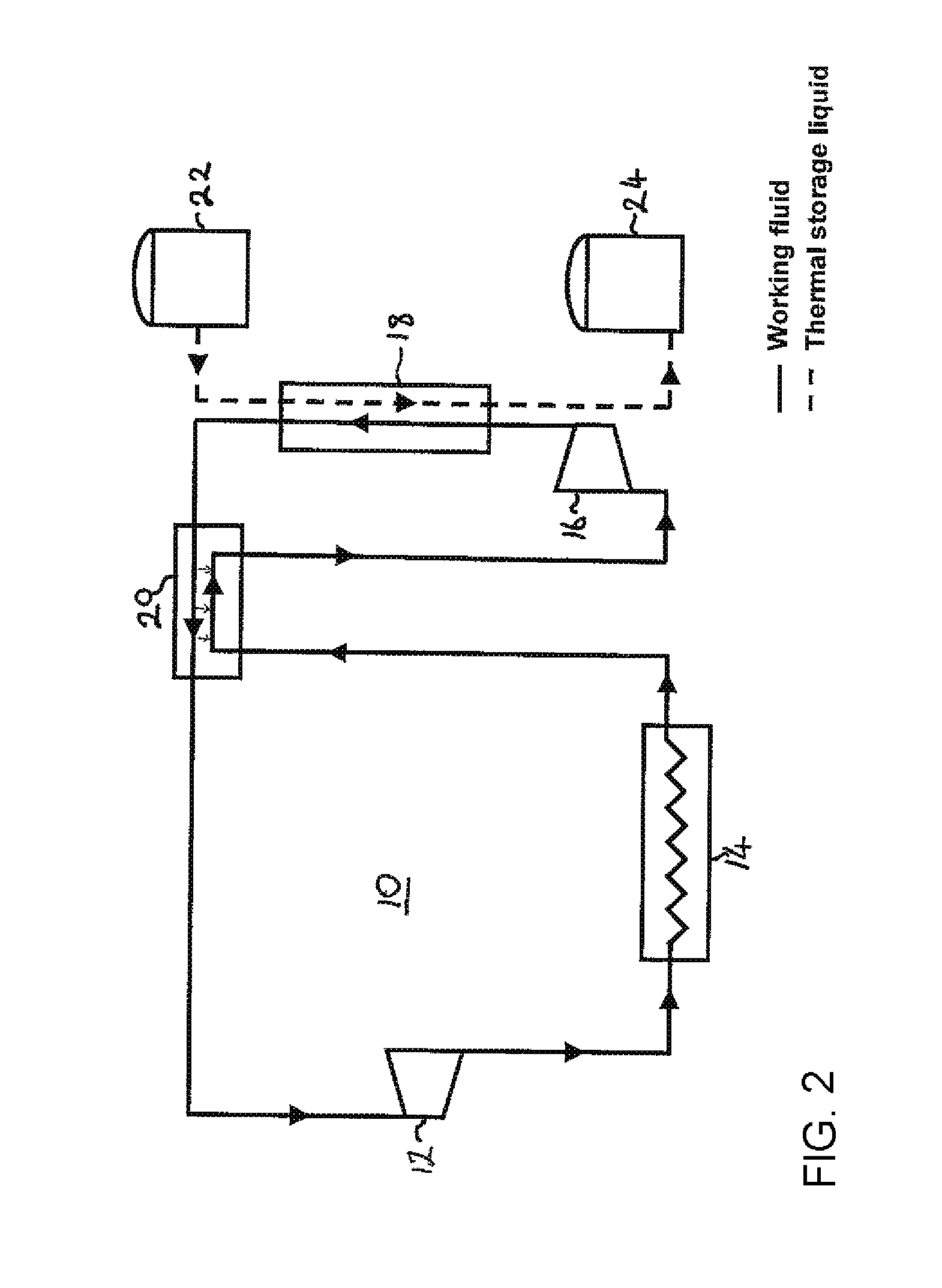

Thermoelectric energy storage system having an internal heat exchanger and method for storing thermoelectric energy

InactiveUS20120222423A1Minimized in sizeMaximizes workFeed water supplySteam accumulatorsThermal energyWorking fluid

Exemplary embodiments are directed to a thermoelectric energy storage system (TEES) and method for converting electrical energy into thermal energy to be stored and converted back to electrical energy with an improved round-trip efficiency are disclosed. The TEES includes a working fluid circuit for circulating a working fluid through a first heat exchanger and a second heat exchanger, a thermal storage medium circuit for circulating a thermal storage medium, the thermal storage medium circuit having at least one hot storage tank coupled to a cold storage tank via the first heat exchanger. The arrangement maximizes the work performed by the cycle during charging and discharging for a given maximum pressure and maximum temperature of the working fluid.

Owner:ABB RES LTD

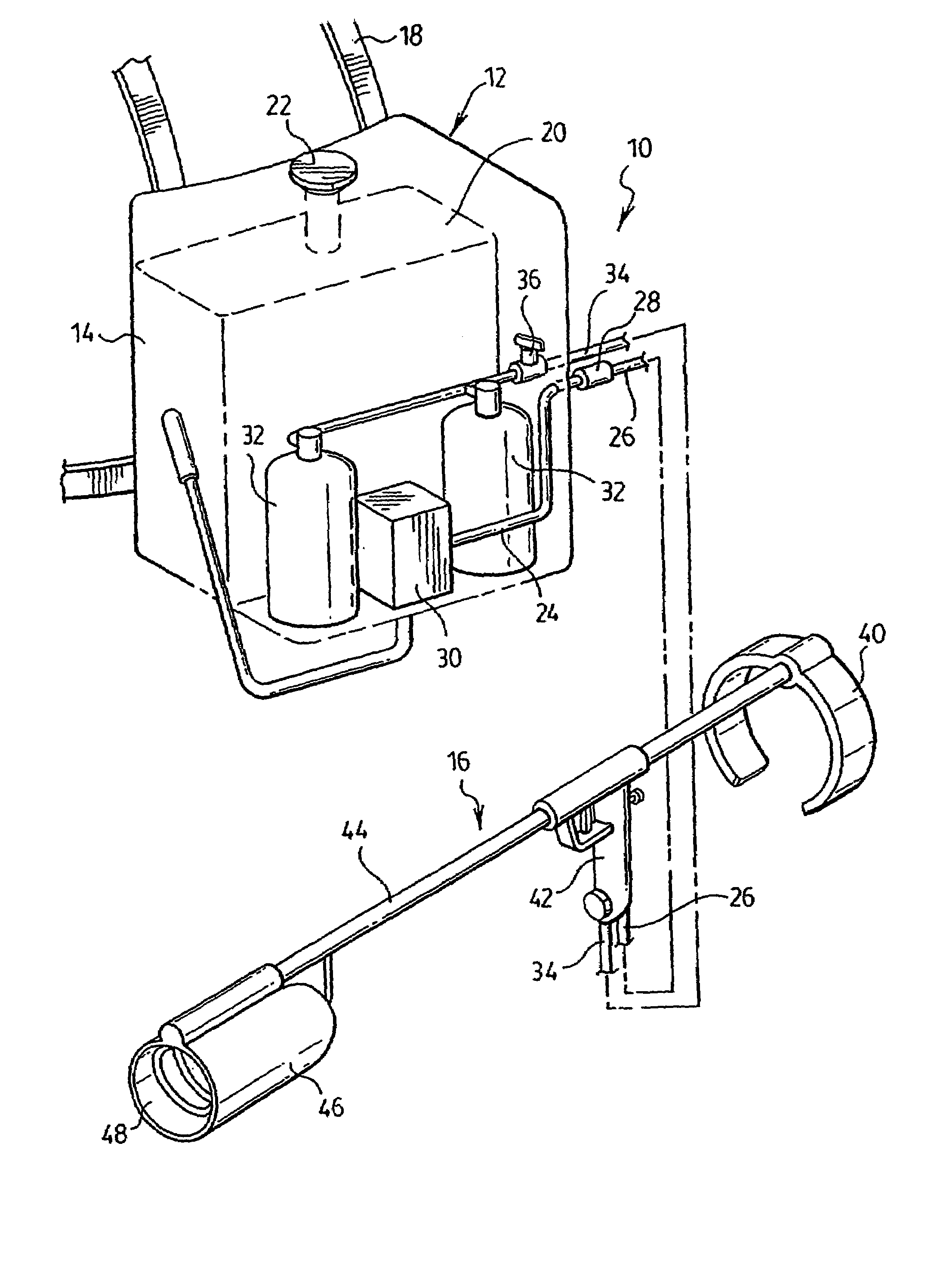

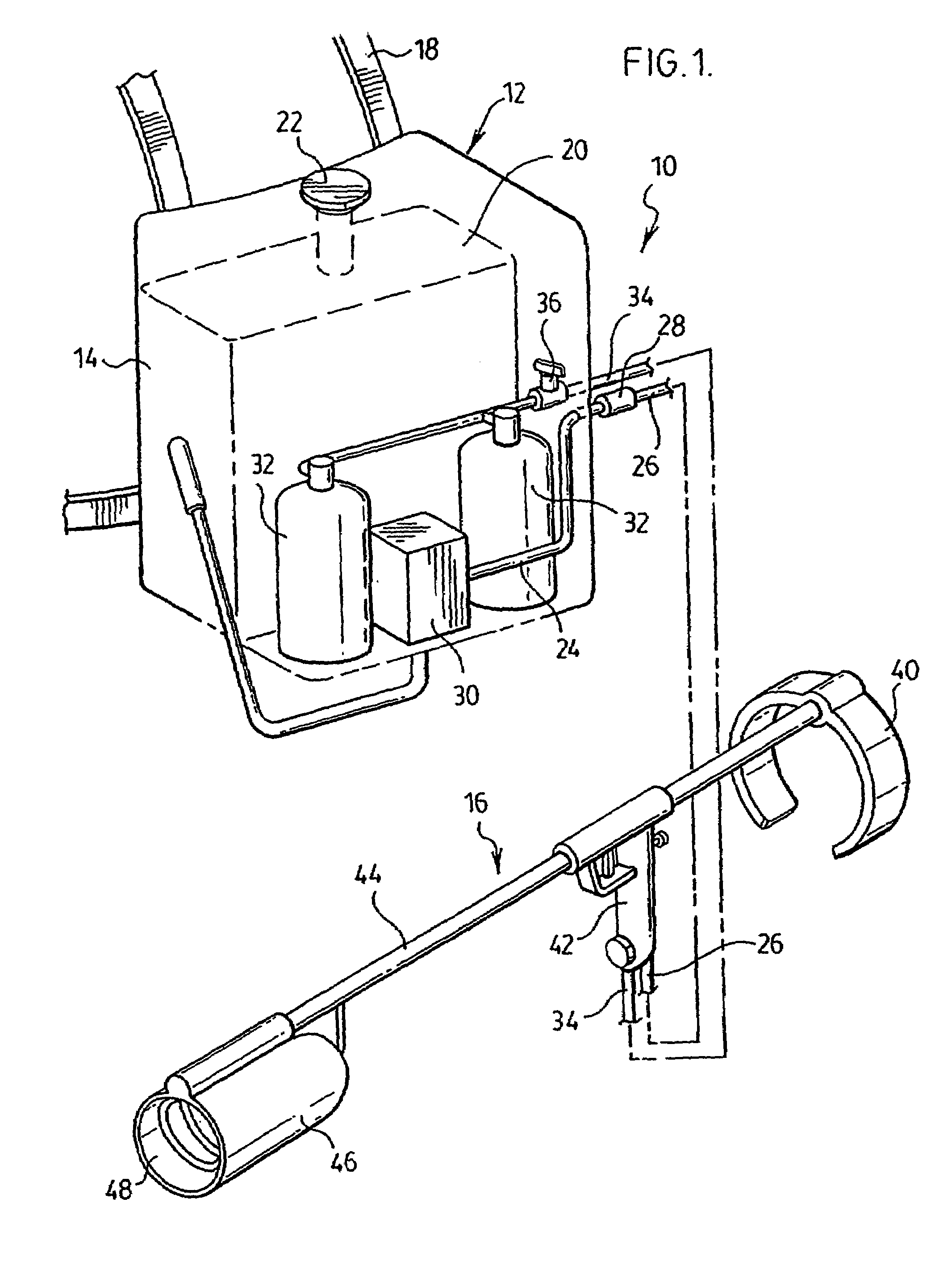

Portable steam and heat generator

The present invention is directed to an apparatus for directing steam, hot water or hot water vapor and hot air onto a target area, the apparatus comprising a water container and a fuel container connected and supplying water and fuel to an applicator wand with an applicator head which generates steam and heat for application adjacent to the target area of application to the unwanted vegetation. Steam is generated immediately adjacent to the target area within the applicator head and combined with surplus heat from the steam generation process to produce heated steam and water vapor for application to the target area. In a preferred embodiment of the invention, the applicator wand is hand held, the applicator head having an inlet, an outlet and a body therebetween, the water and fuel being supplied to a steam generator and burner within the body of the applicator head which generates steam and hot air adjacent to the target area for application through the outlet to the target area.

Owner:GREENSTEAM

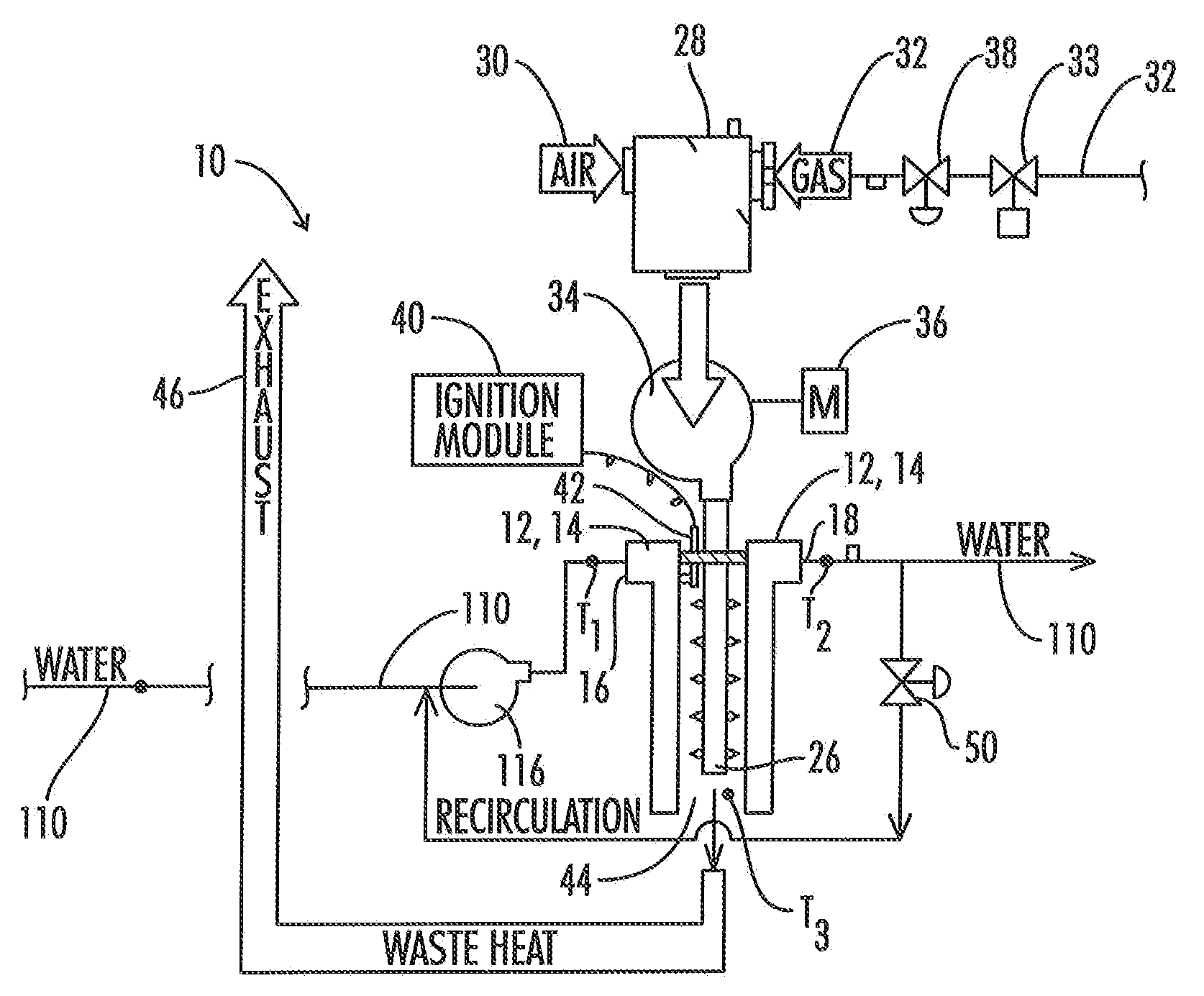

Control system for modulating water heater

ActiveUS7506617B2Reduce temperature fluctuationsReact much more quicklyMechanical apparatusTemperatue controlDeadbandHeating system

A control system is provided for a modulated heating system including a plurality of modulating water heaters, which may be modulating boilers. A deadband control scheme provides for reduced cycling of the modulating heater when total system heat demand falls between the maximum output of one heater and the sum of the maximum output of that one point and the minimum firing point of the next subsequent heater.

Owner:LOCHINVAR

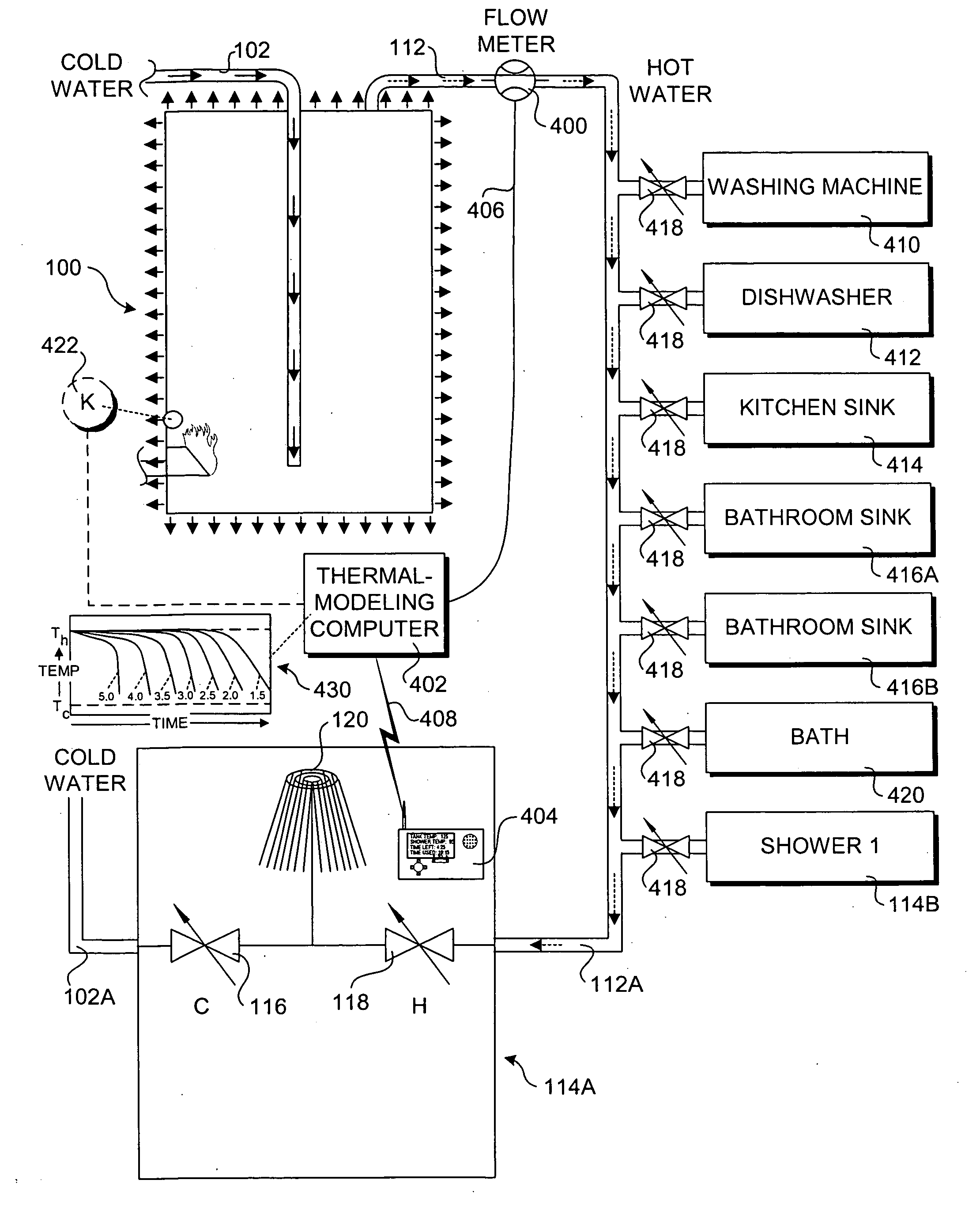

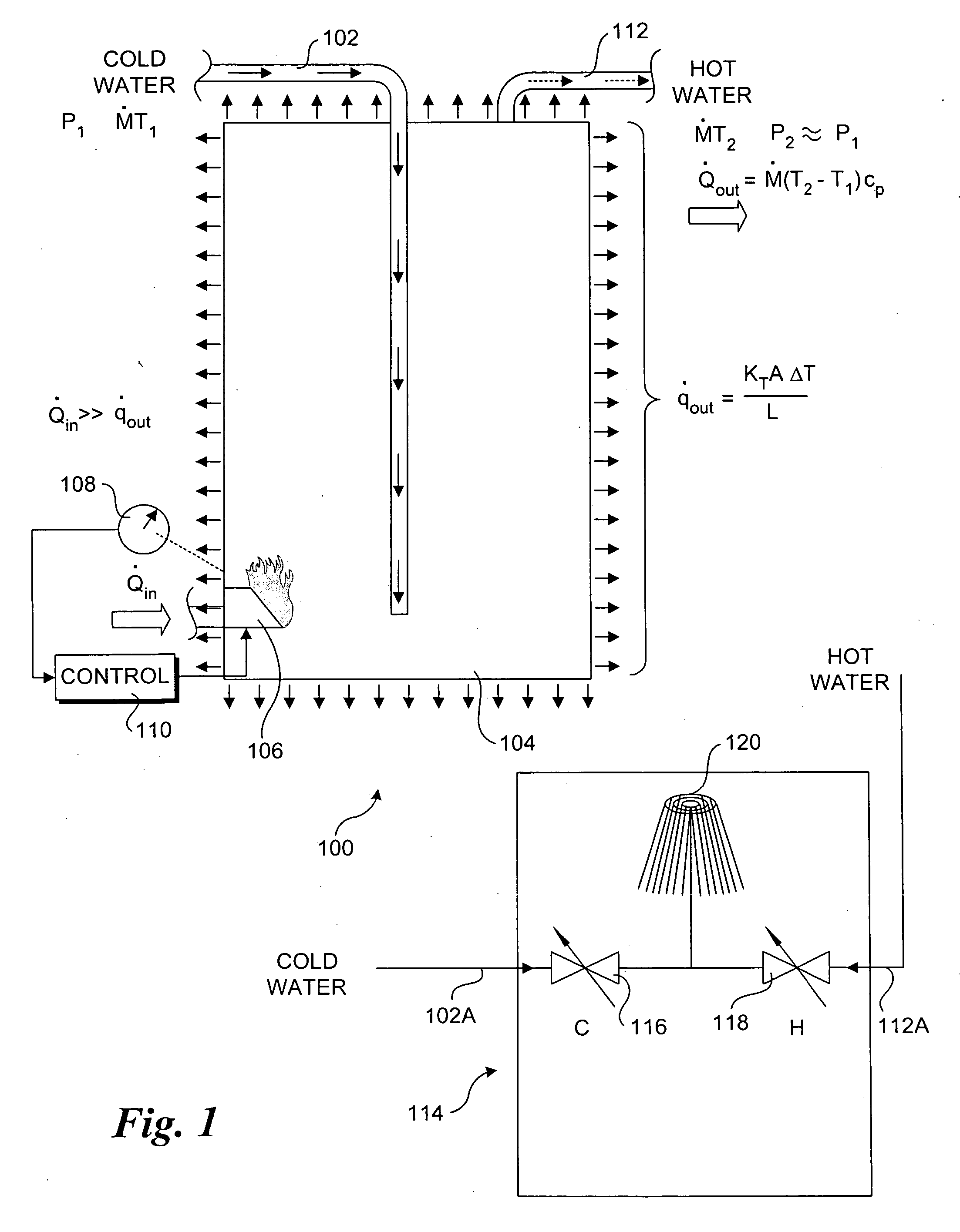

Method, apparatus, and system for projecting hot water availability for showering and bathing

Methods and apparatus for predicting the availability of hot water for showering and bathing. One or more parameters corresponding to the operation of a water heater are monitored over time. Data corresponding to the monitored parameters are processed to determine a rate at which hot water is being consumed by the shower / bath and / or other hot water consumers. Based on a hot water consumption rate and determination of a current hot water availability condition, a time at which the temperature of hot water supplied by the water heater is projected to fall below a minimum temperature threshold is determined. In one embodiment, the apparatus include a thermal-modeling computer and a control / monitor interface that is disposed in or proximate to a shower. In one embodiment, the thermal-modeling computer is installed at a water heater and data is transmitted between the thermal-modeling computer and the control / monitor interface via a wireless signal. The techniques also can be used to determine whether an adequate supply of hot water exists for a bath prior to drawing the bath.

Owner:FEINLEIB DAVID A +2

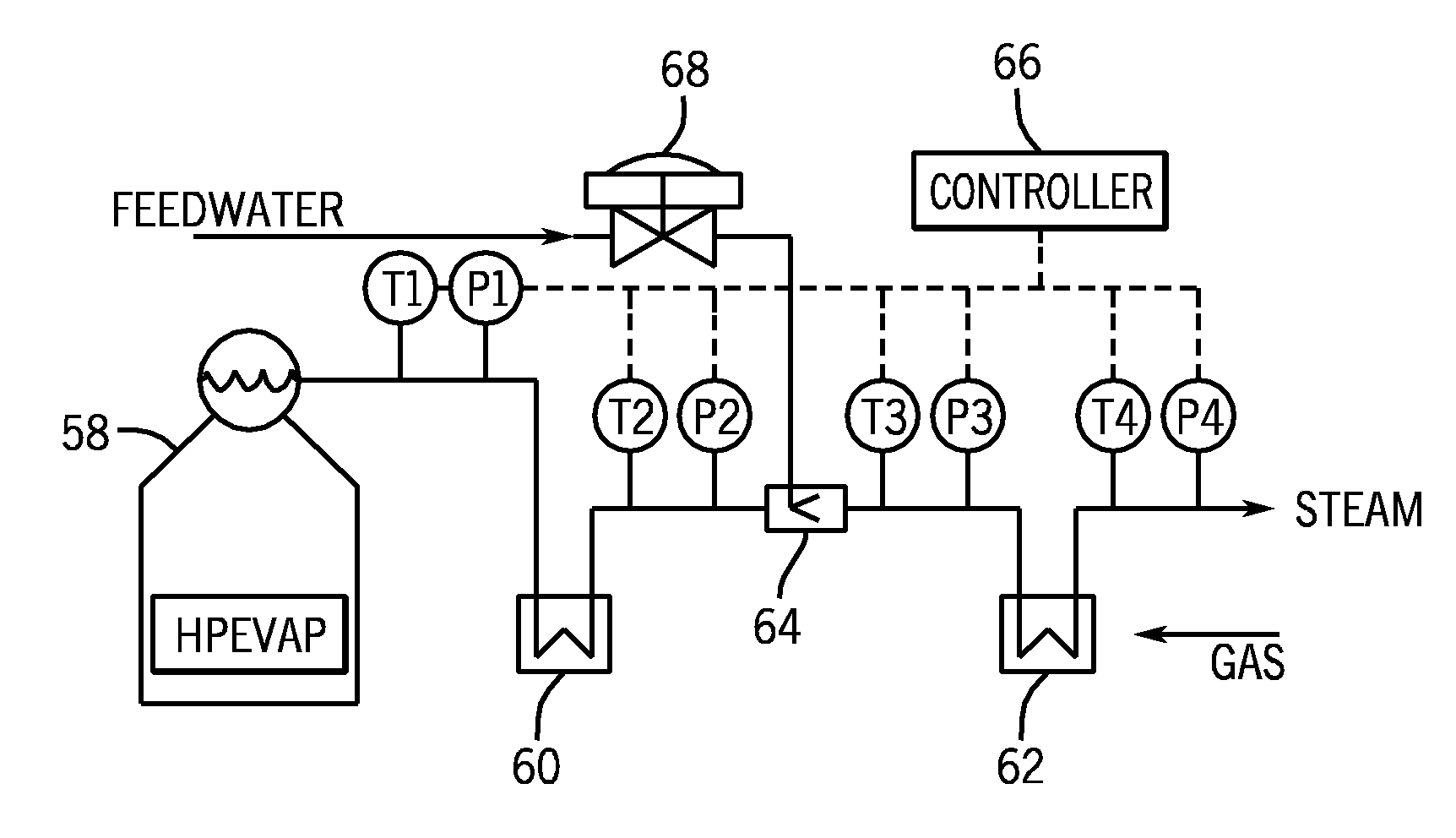

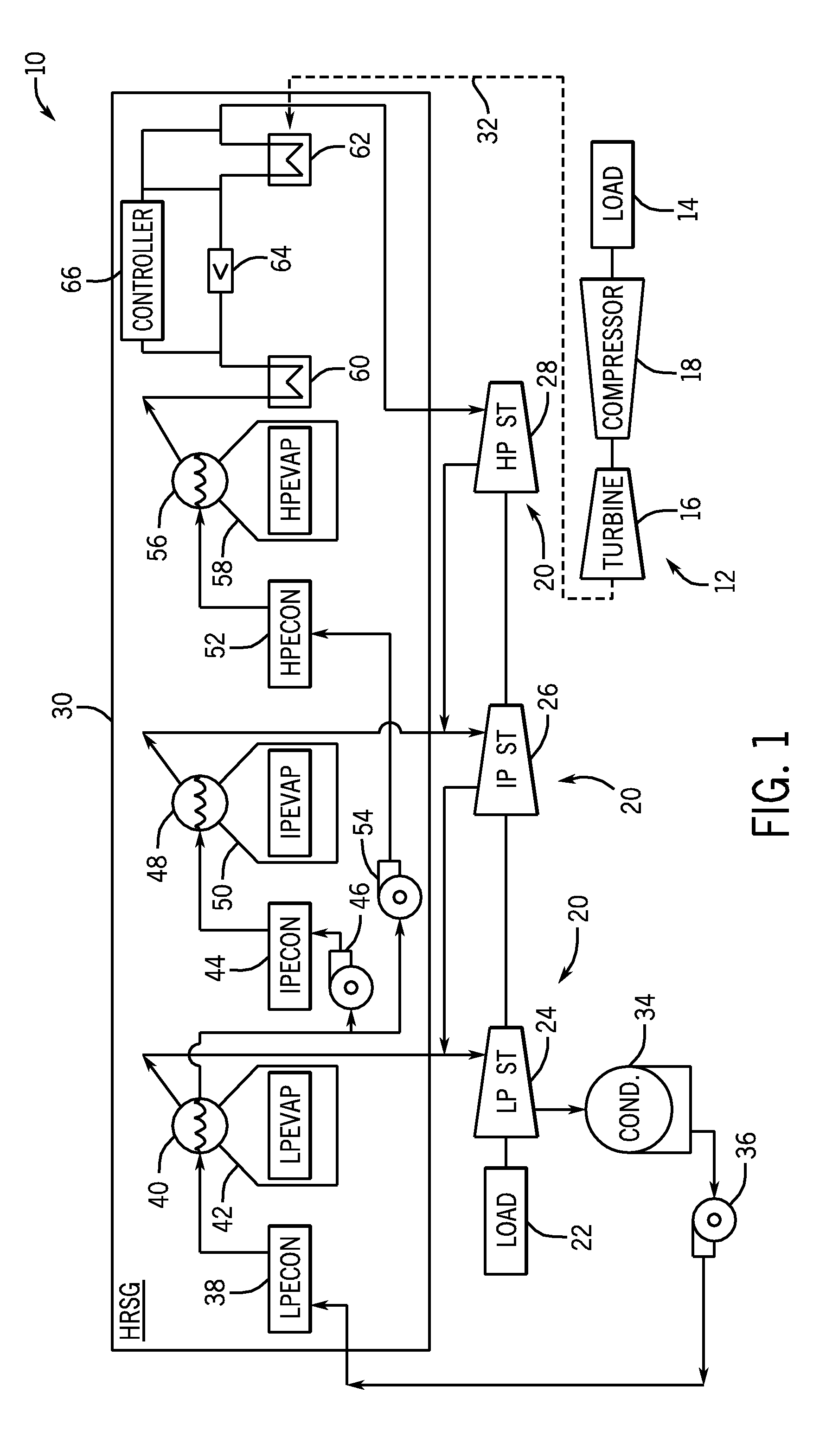

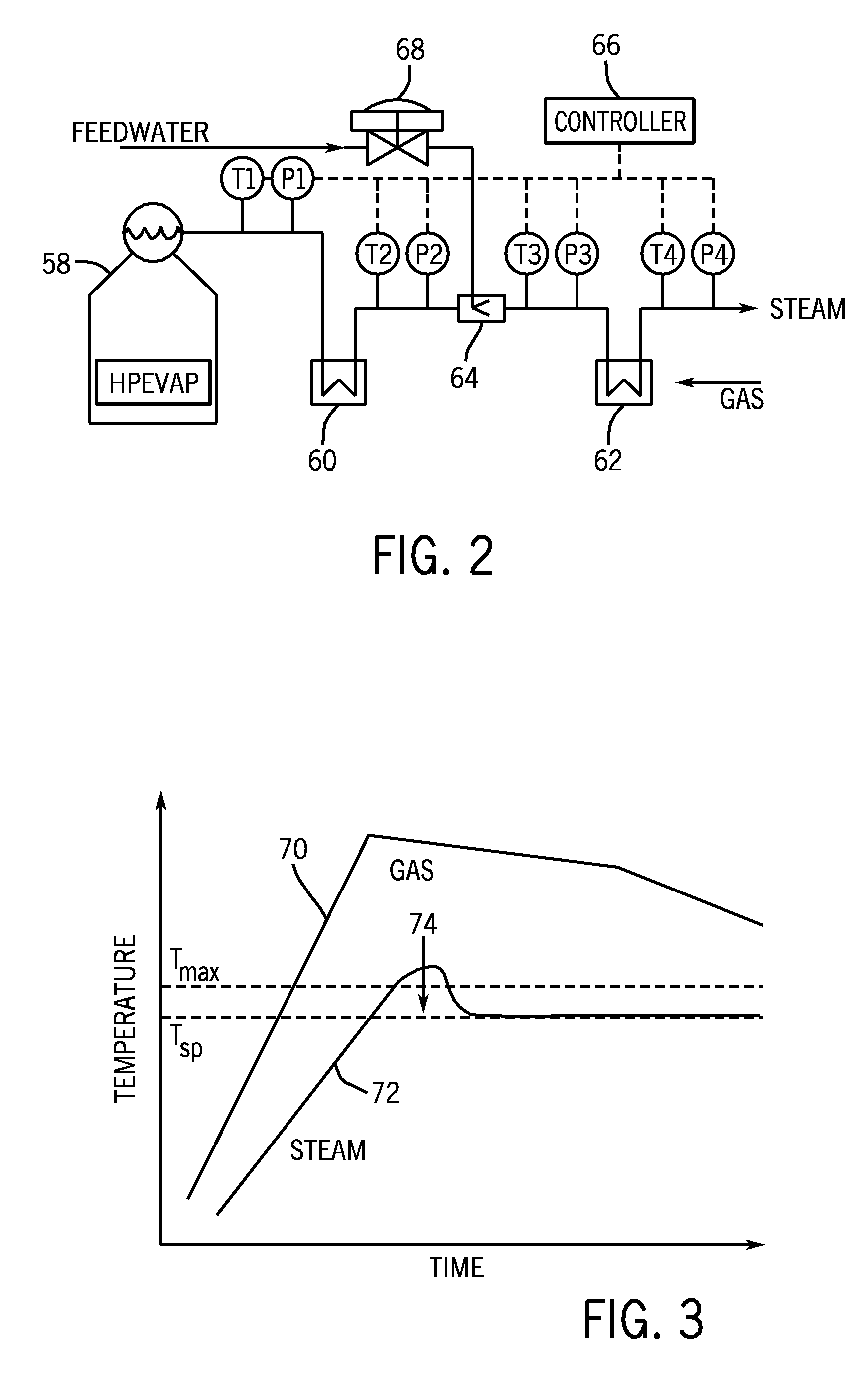

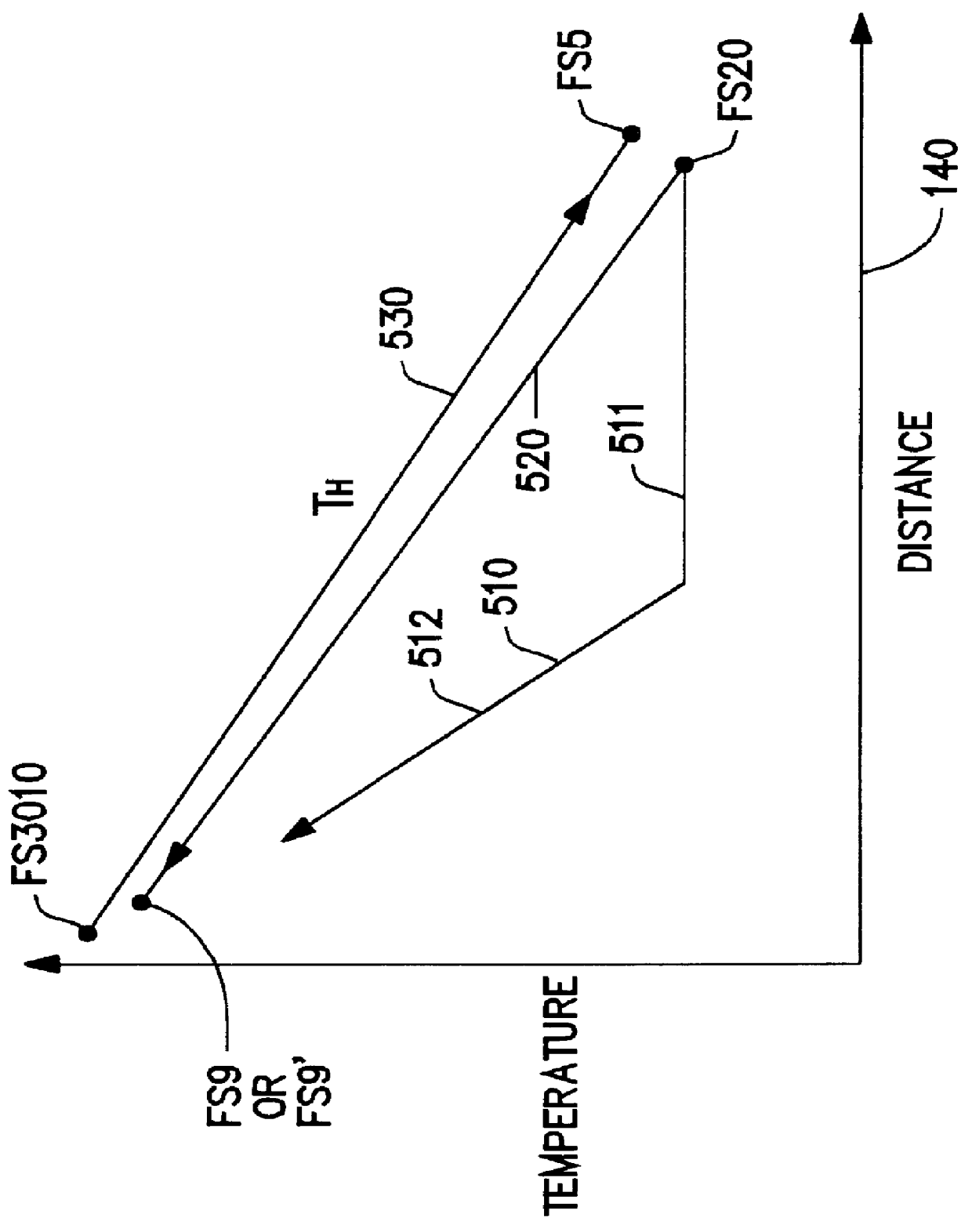

Inter-stage attemperation system and method

Systems and methods for controlling exhaust steam temperatures from a finishing superheater are provided. In certain embodiments, the system includes a controller which includes control logic for predicting an exhaust temperature of steam from the finishing superheater using model-based predictive techniques (e.g., based on empirical data or thermodynamic calculations). Based on the predicted exhaust temperature of steam, the control logic may use feed-forward control techniques to control the operation of an inter-stage attemperation system upstream of the finishing superheater. The control logic may determine if attemperation is required based on whether the predicted exhaust temperature of steam from the finishing superheater exceeds a set point temperature as well as whether the inlet temperature of steam into the finishing superheater drops below a set point temperature of steam. The attemperation system may include a characterizing function to linearize the valve operation controlled by the control logic to inject cooled, high-pressure feedwater into the steam upstream of the finishing superheater, which may, in turn, control the exhaust temperature of steam from the finishing superheater. The disclosed embodiments may also be applied to any systems where an outlet temperature of a fluid from a heat transfer device may be controlled.

Owner:GENERAL ELECTRIC CO

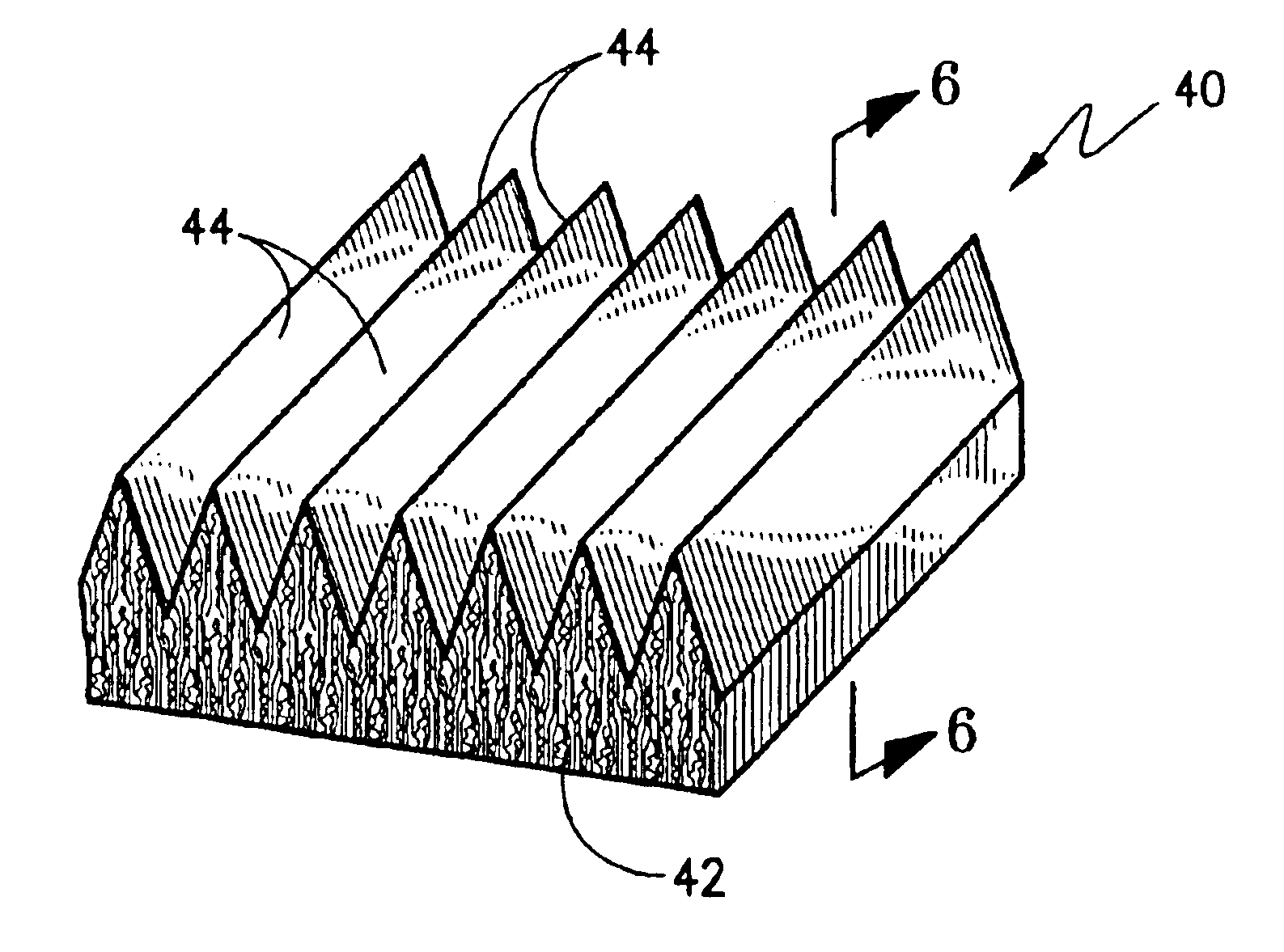

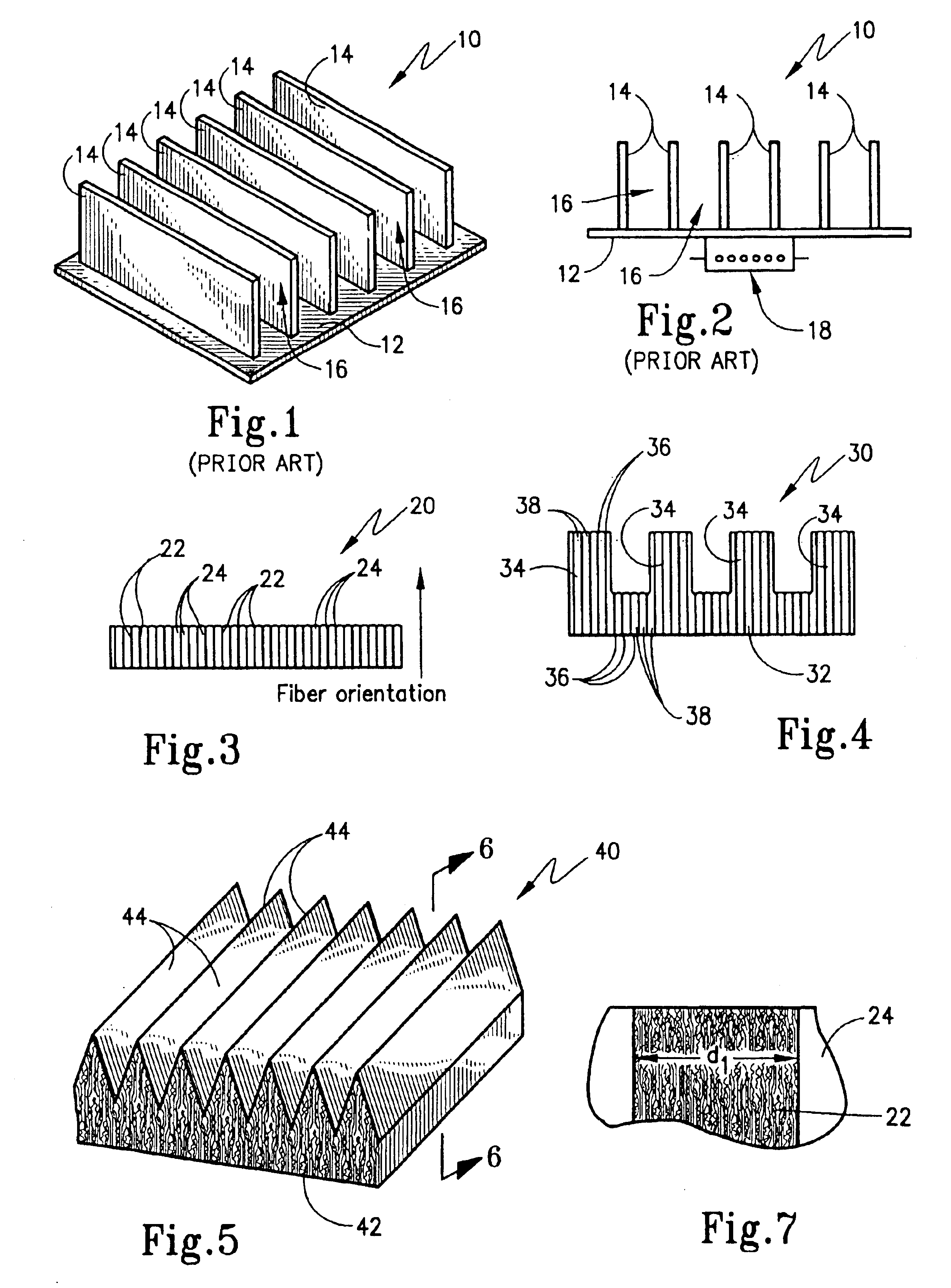

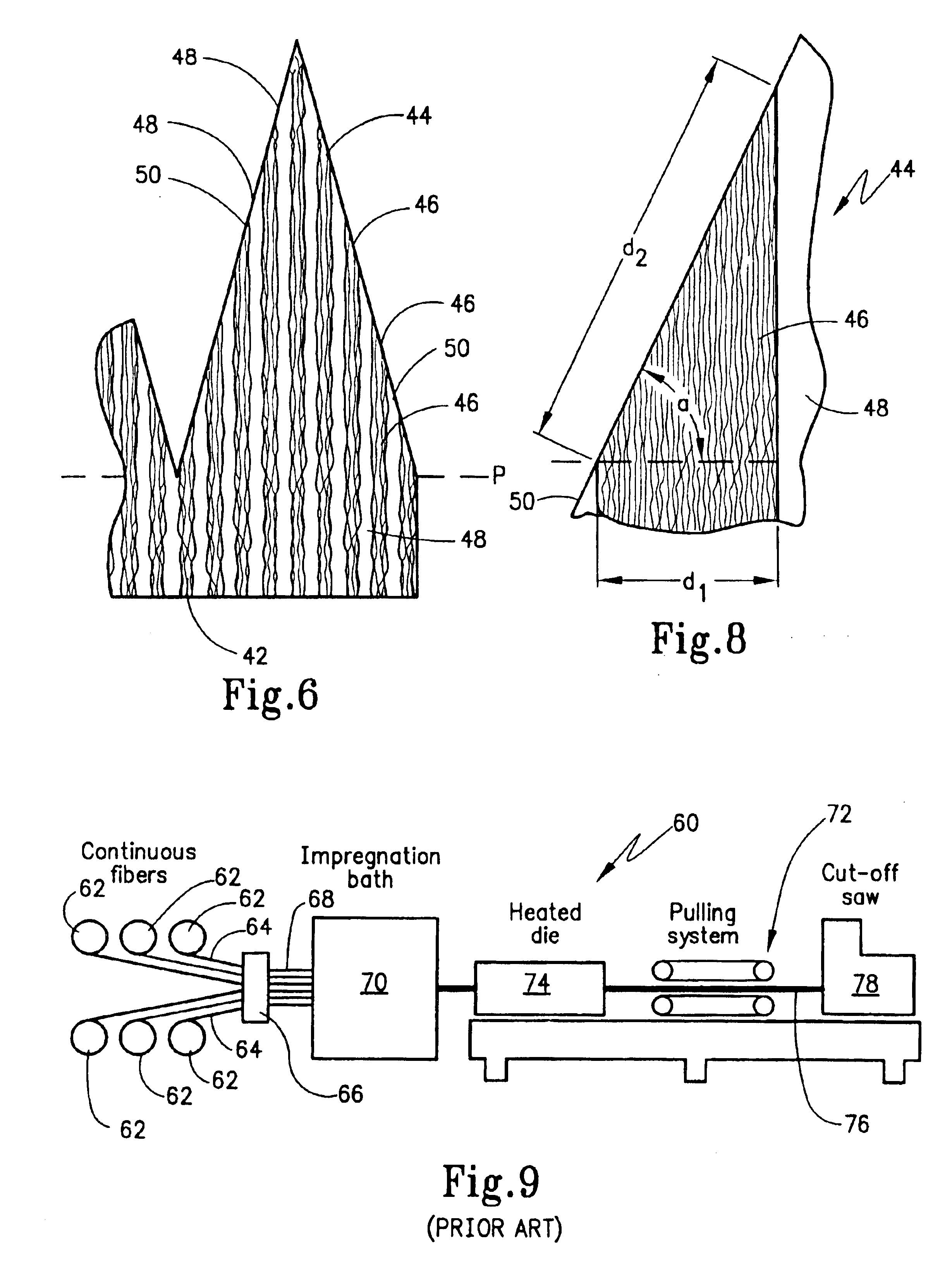

Thermal management material, devices and methods therefor

InactiveUS6844054B2Low costImprove thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesThermal energyFiber

The present invention provides thermal devices, materials and methods for use in transferring heat from heat sources. One embodiment comprises a thermal transfer body that has first and second end portions and includes a thermally anisotropic material that conducts more thermal energy in a longitudinal direction than in a direction transverse thereto, wherein at least one of the first and second end portions includes a projection having a surface area oriented obliquely to the longitudinal direction. Multiple projections may be provided of various geometries, such as pyramids, cones, triangular prismoids and domes. The thermally anisotropic material may include an ensemble of longitudinally thermally conductive fibers, such as carbon fibers derived from precursors such as petroleum or coal pitch, which may be embedded in a support matrix of various materials.

Owner:THERMO COMPOSITE LLC

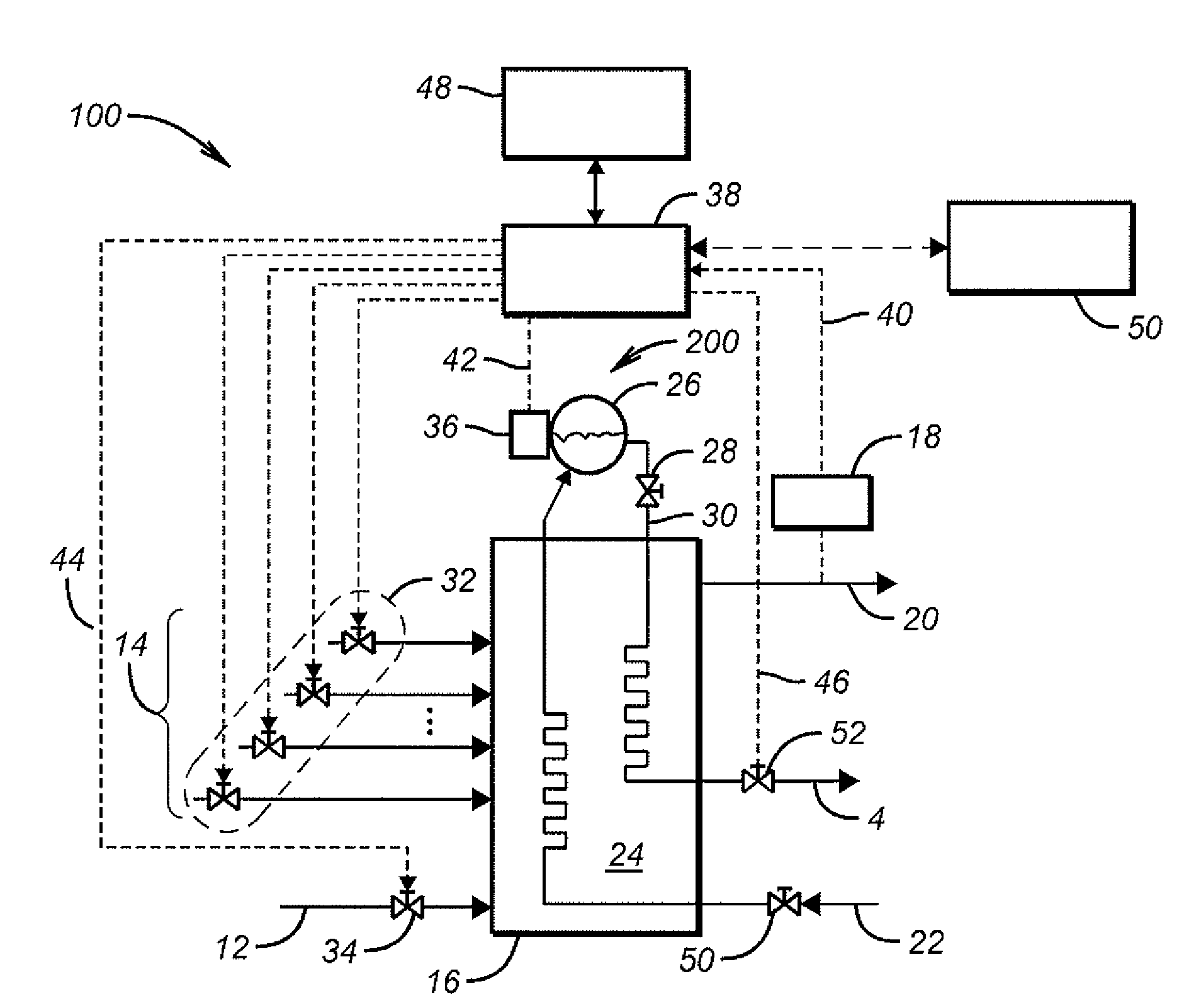

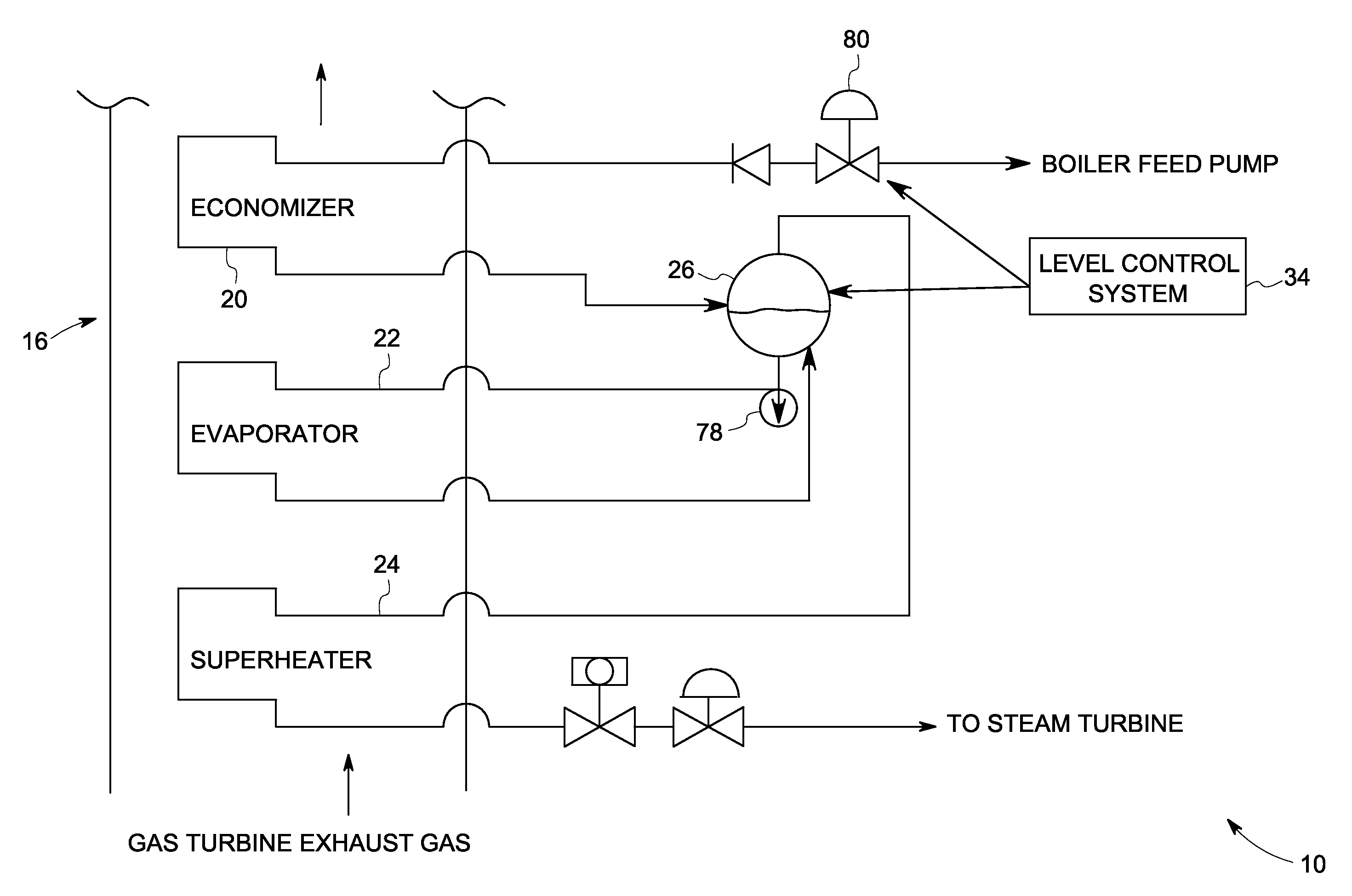

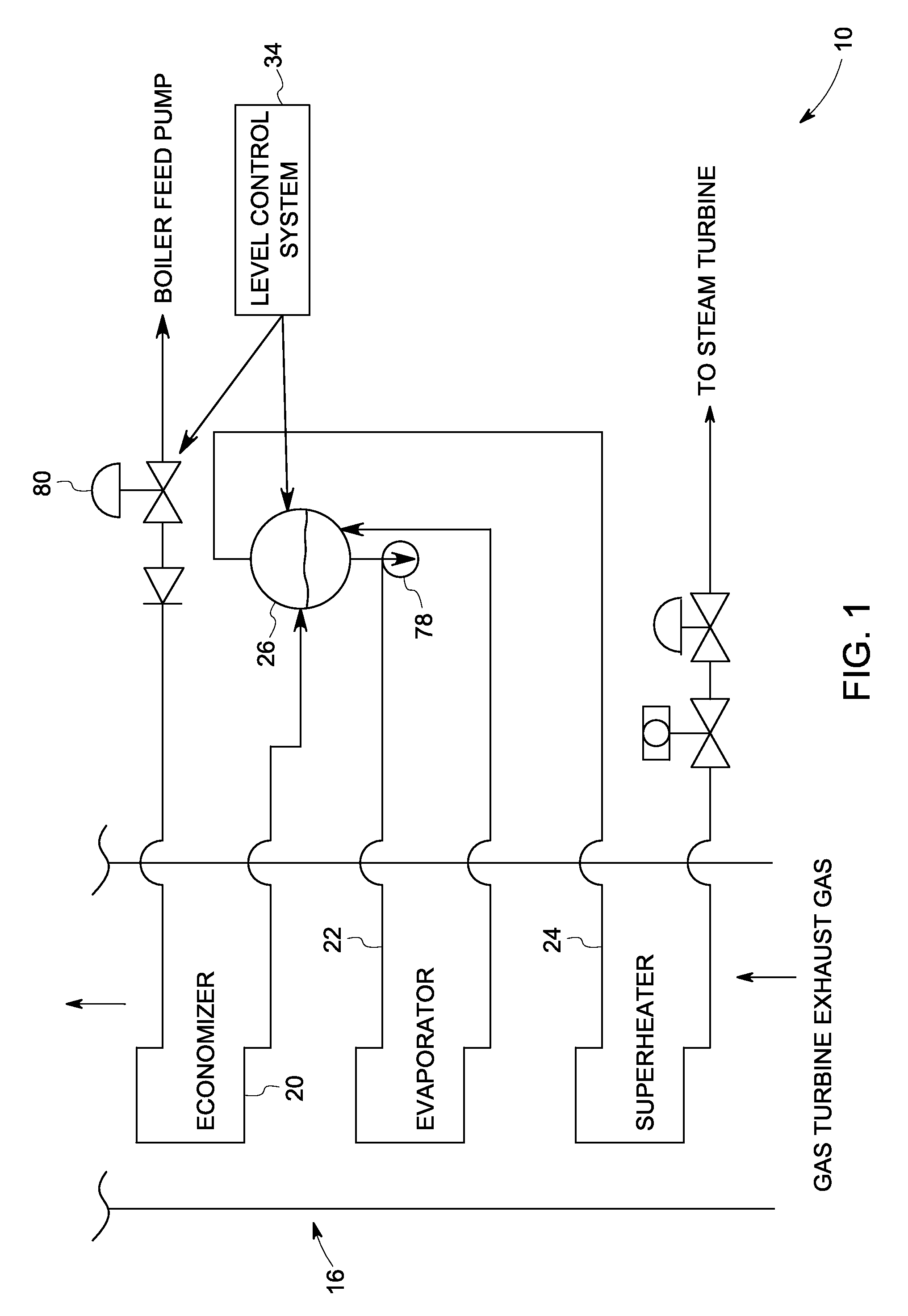

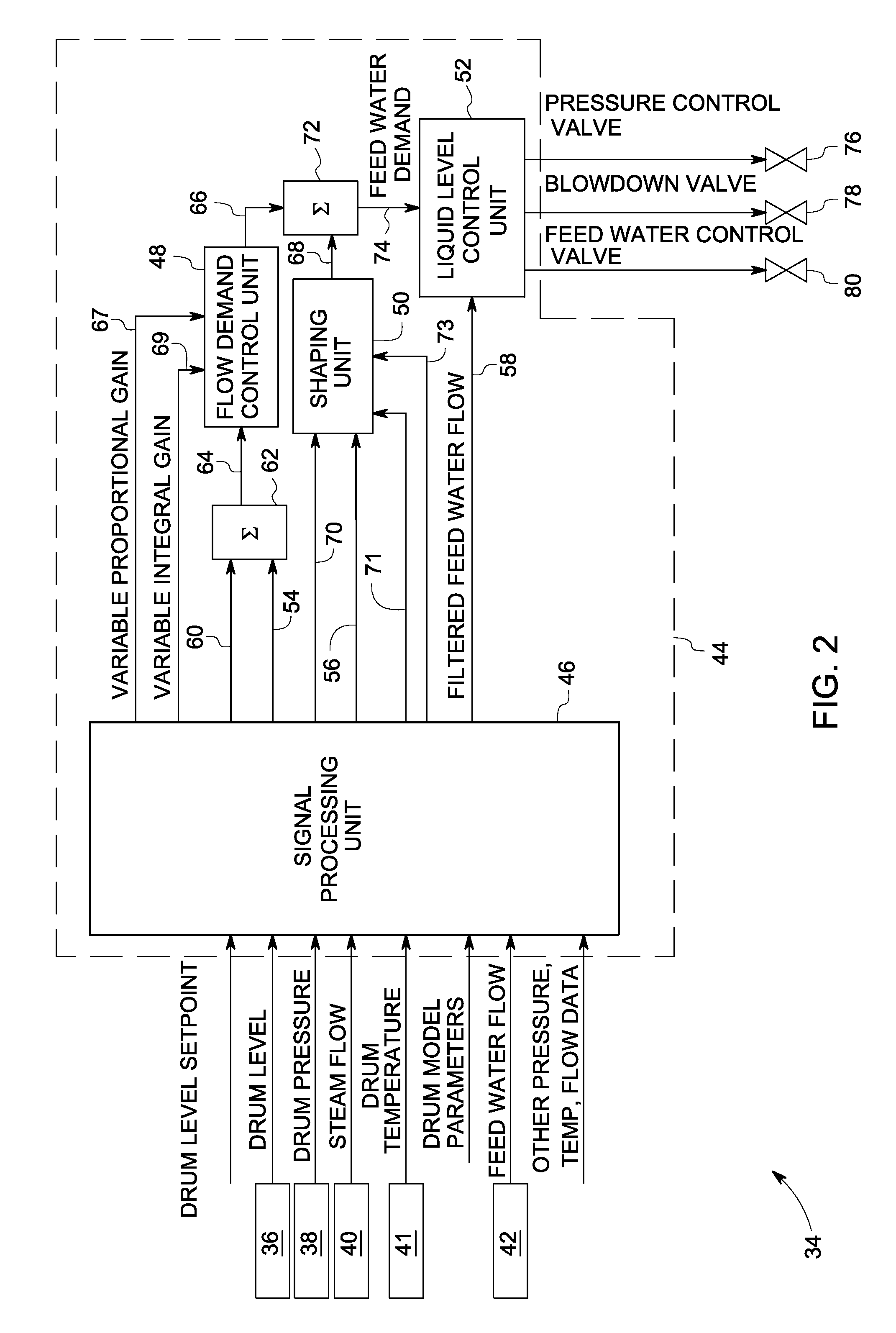

System and method for controlling liquid level in a vessel

ActiveUS20090159018A1Operating means/releasing devices for valvesPipeline systemsEngineeringSignal processing

A system includes sensors configured to measure parameters related to a vessel including liquid level, gas flow rate, pressure in the vessel, temperature of the vessel, and feed-liquid flow rate. A signal processing unit receives sensor output signals and generates a first filtered output signal representative of liquid level, a second filtered output signal representative of gas flow rate, a third filtered output signal representative of feed-liquid flow rate, a fourth filtered output signal representative of vessel pressure, and a fifth filtered output signal representative of vessel temperature. A flow demand control unit receives the first filtered output signal and generates an output signal representative of feed-liquid flow demand. A shaping unit receives the second, fourth, and fifth filtered output signal and generates an output signal representative of shaped gas flow rate as a function of pressure, temperature, or combination thereof in the vessel. A liquid level control unit controls the liquid level within predetermined limits by controlling one or more components based on the output signals from the flow demand control unit, the shaping unit, and the third filtered output signal.

Owner:GENERAL ELECTRIC CO

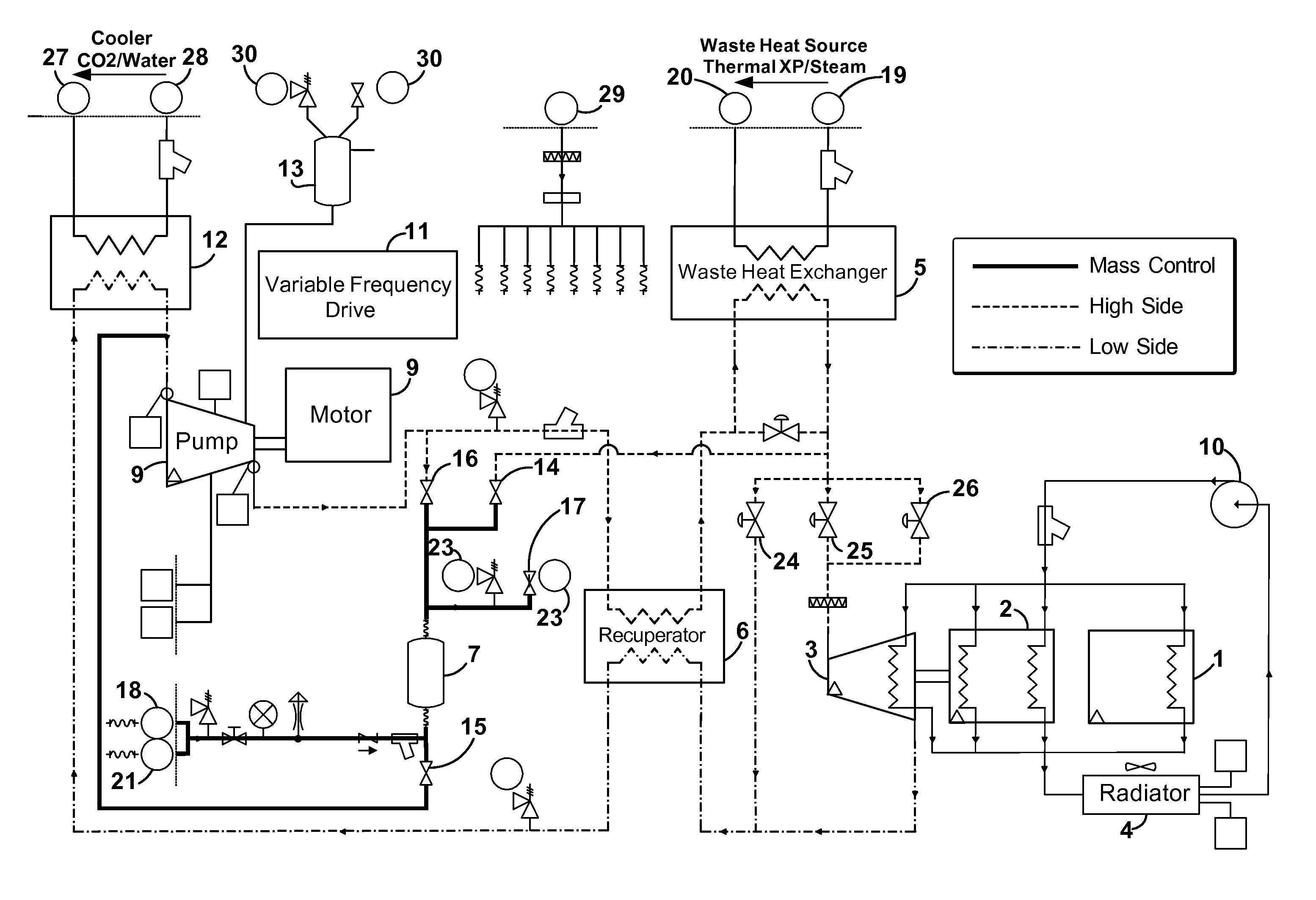

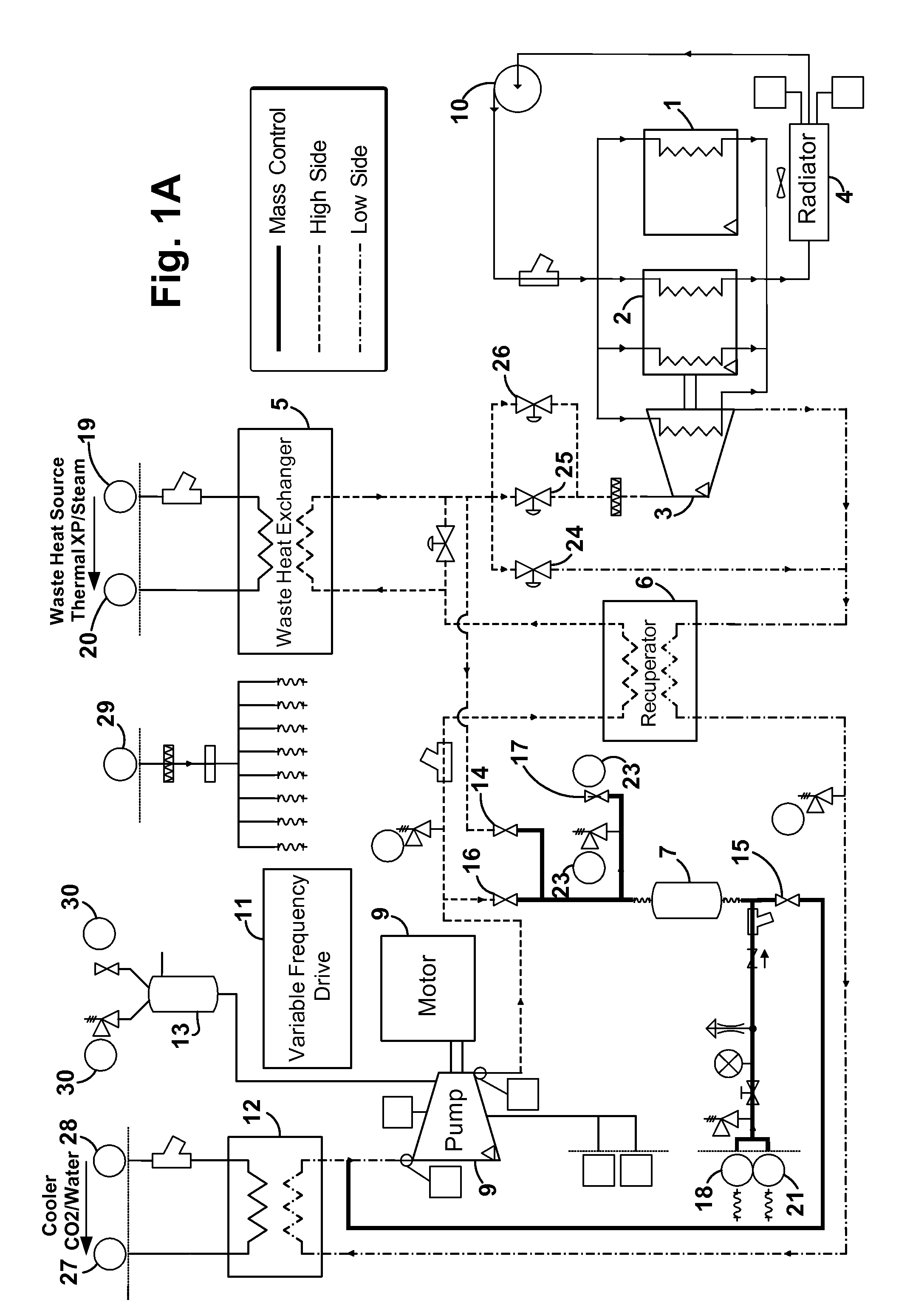

Thermal energy conversion method

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit.

Owner:ECHOGEN POWER SYST +1

Hybrid exhaust valve assembly

ActiveUS7401592B2Overcome bias forceReduce travel requirementsOperating means/releasing devices for valvesExhaust apparatusExhaust valveEngineering

An exhaust valve assembly includes a flapper valve fixed to a valve shaft where the flapper valve is movable between a closed position, an intermediate position, and an open position. A resilient member biases the flapper valve toward the closed position. An electric actuator actively moves the flapper valve at least from the closed position to the intermediate position. A coupling mechanism couples the valve shaft to an electric actuator shaft and allows the flapper valve to move to the open position in response to exhaust flow sufficient to overcome a biasing force of the resilient member without requiring input from the electric actuator.

Owner:ARVIN TECH INC

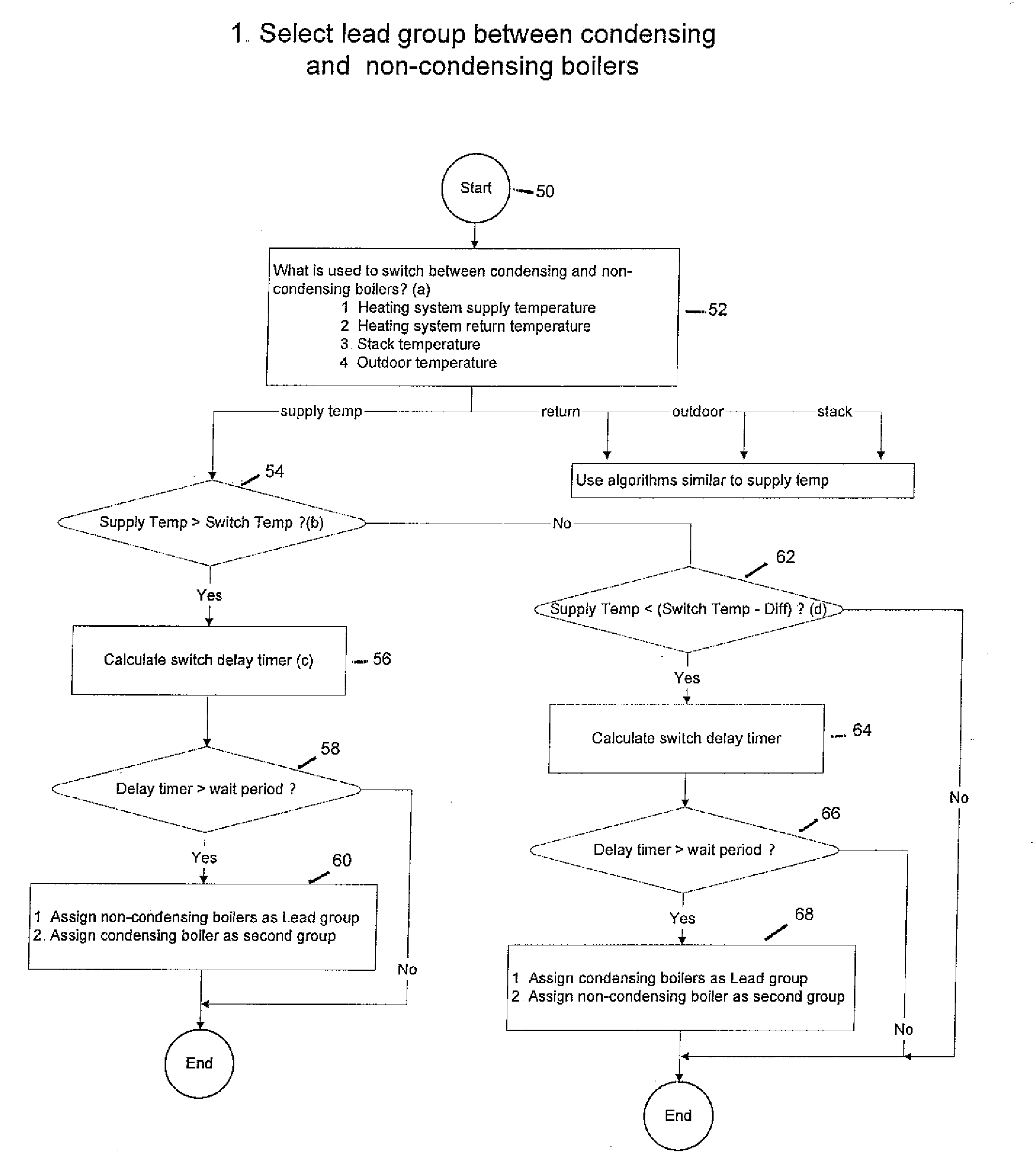

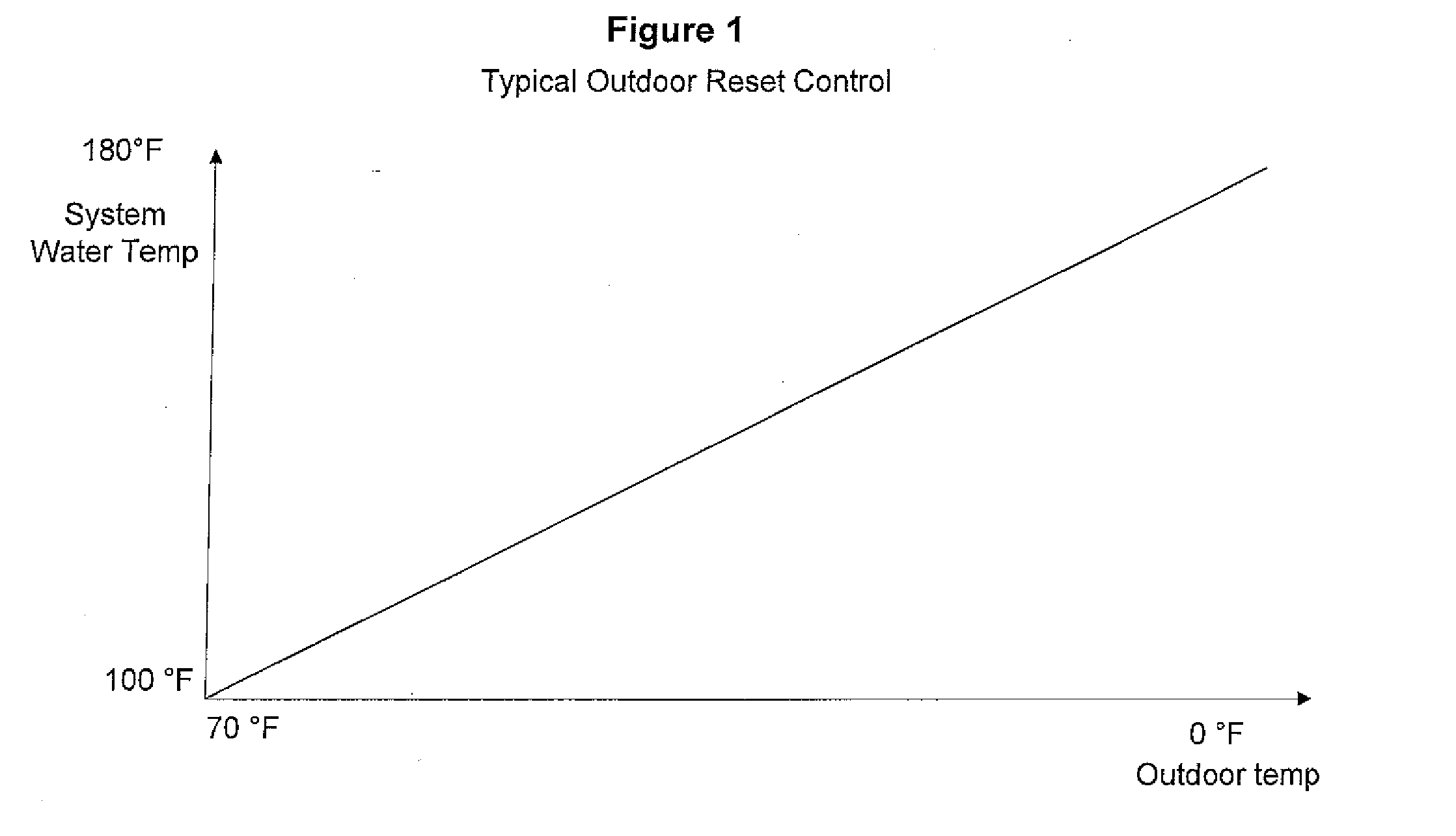

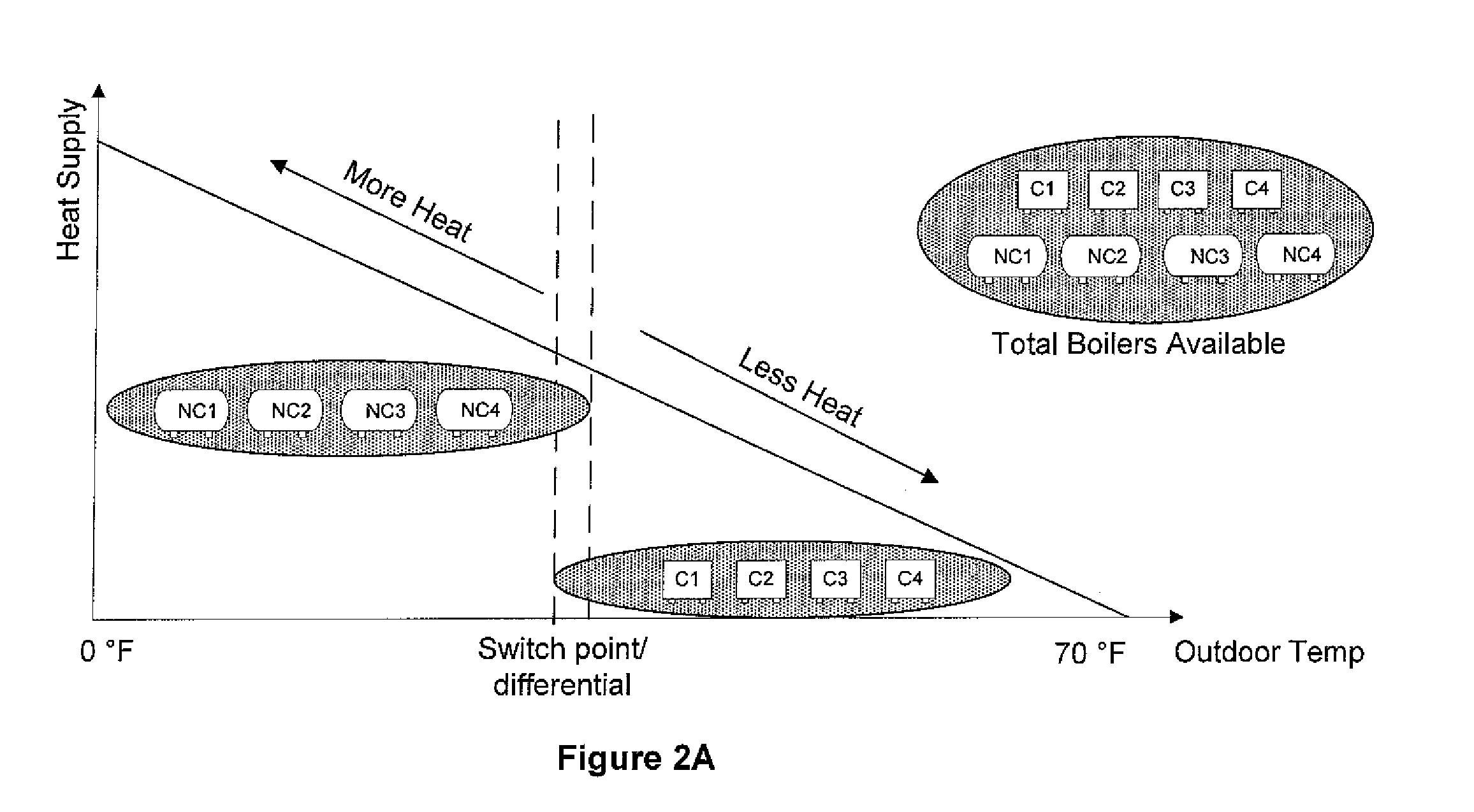

Optimizing multiple boiler plant systems with mixed condensing and non-condensing boilers

ActiveUS20100006042A1Maintaining overall heating plant efficiencyImprove efficiencyBoiler controlSteam generation plantsBoiler plantIndependent group

A system is provided to optimize multiple boiler plant systems having mixed condensing and non-condensing boiler groups. The system advantageously employs the independent groups of boilers depending on preset conditions under control of a system control unit. The preset conditions are checked against operating conditions of the boiler plant, and a system control unit controls which of the groups of boilers is the lead and which is secondary. In some instances, both groups of boilers may be utilized under heavy load. Further, effective switching between groups and within groups is also provided to minimize unnecessary repetitive boiler operation.

Owner:HEAT TIMER

Real time optimization and control of oxygen enhanced boilers

InactiveUS20040231332A1Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

Blowdown recovery system in a Kalina cycle power generation system

A method for capturing working fluid which includes a hazardous component and is discharged from a power generating system, includes directing the discharge to a container. There, the discharged working fluid is combined with a liquid in which the hazardous component is soluble to form a less hazardous mixture.

Owner:ABB ALSTOM POWER INC

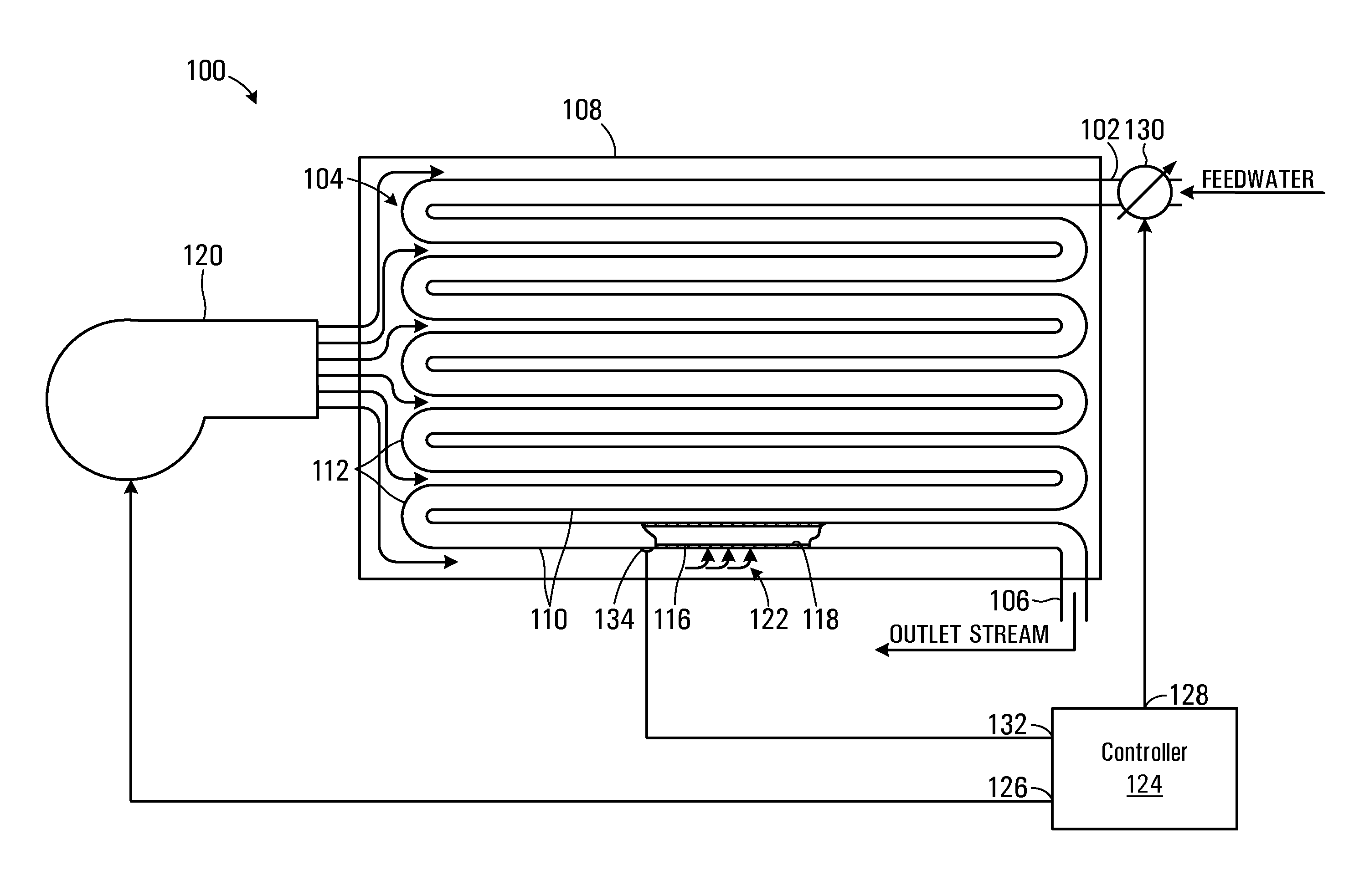

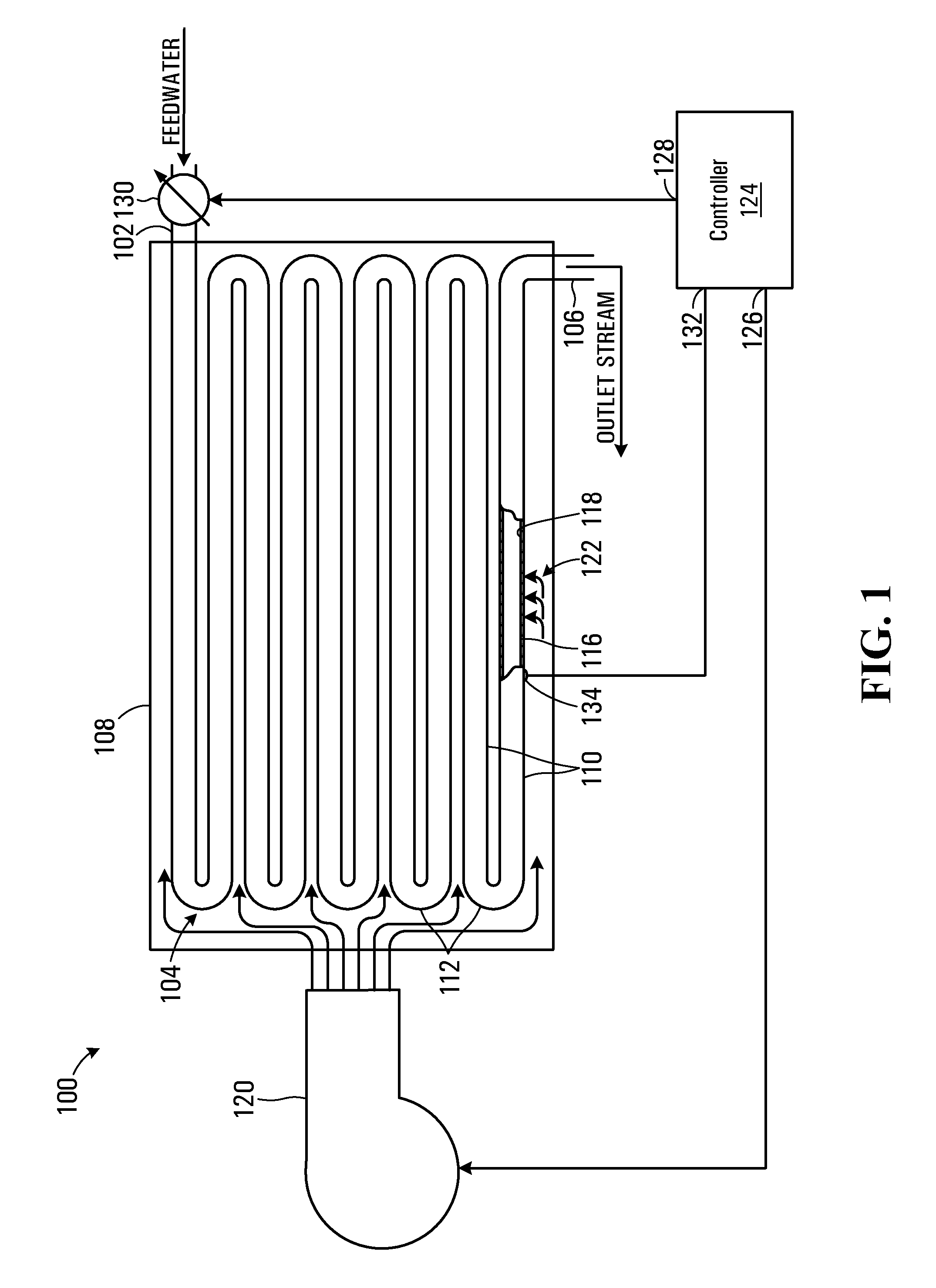

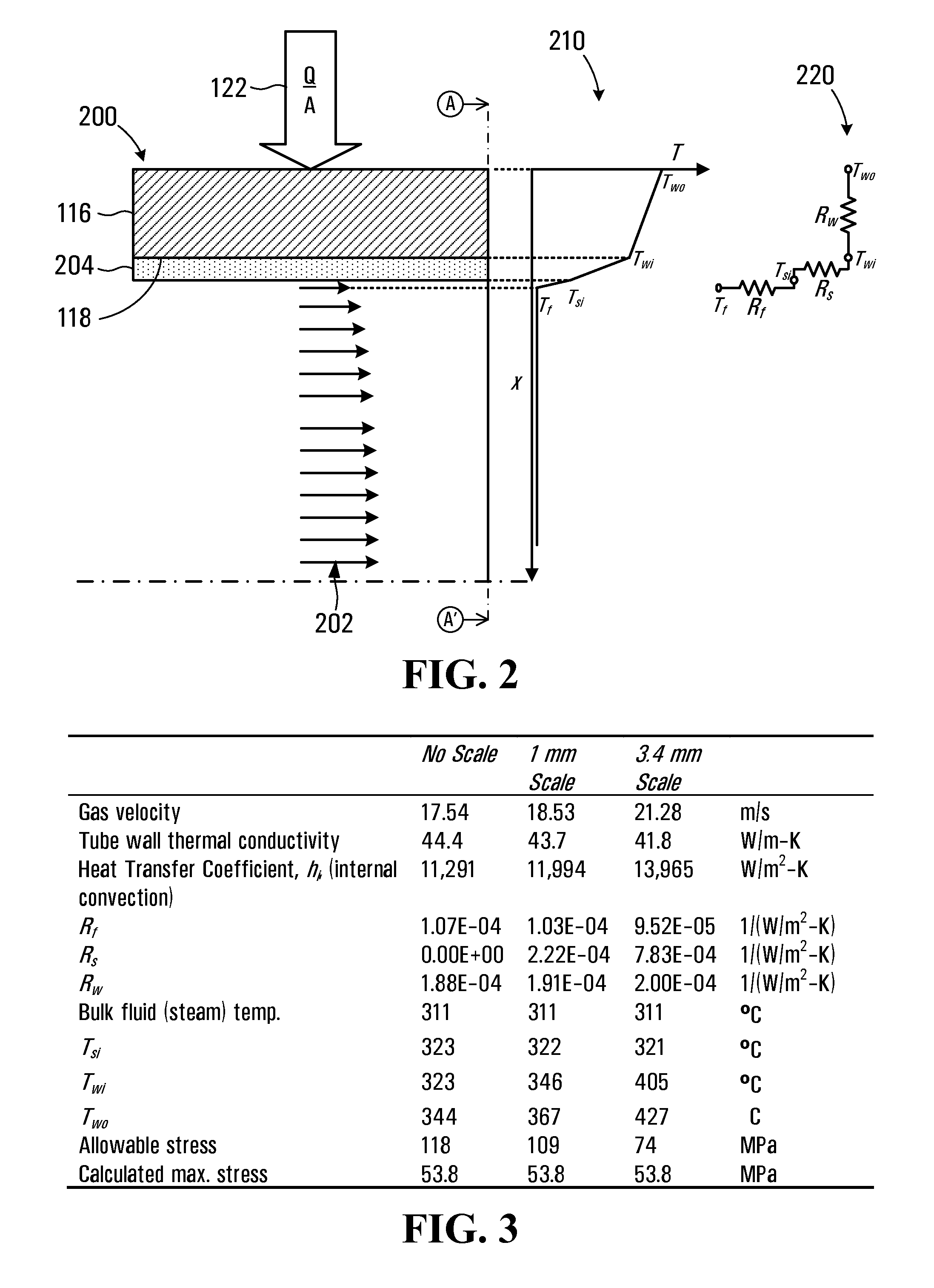

Steam generator and method for generating steam

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

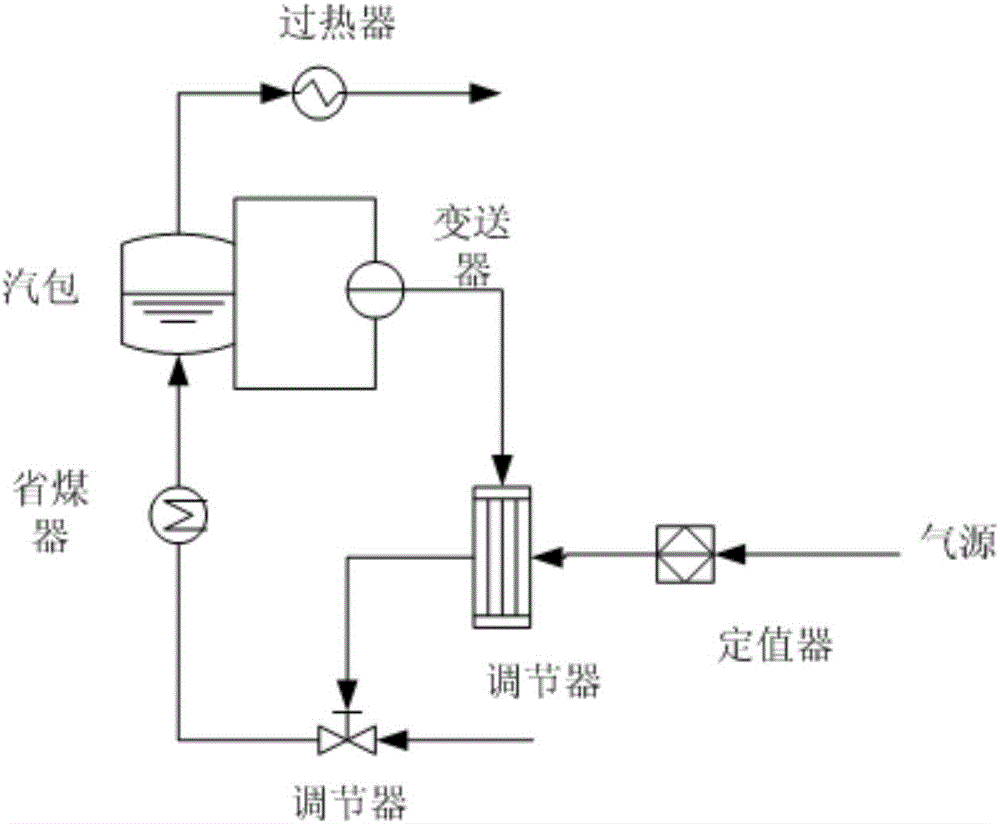

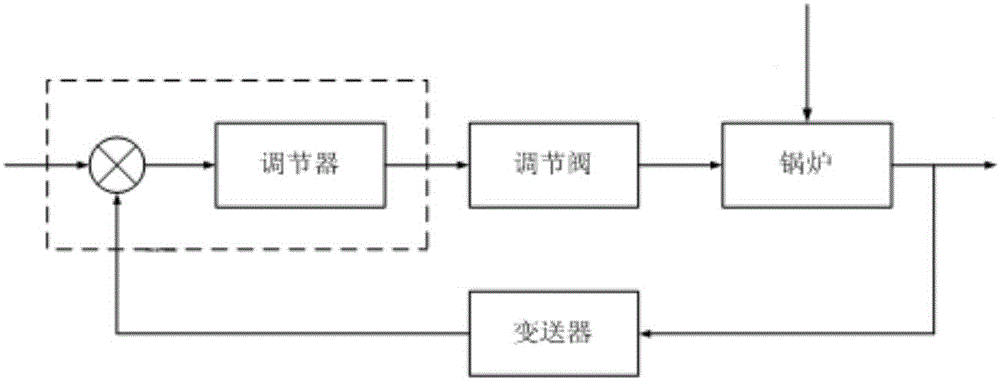

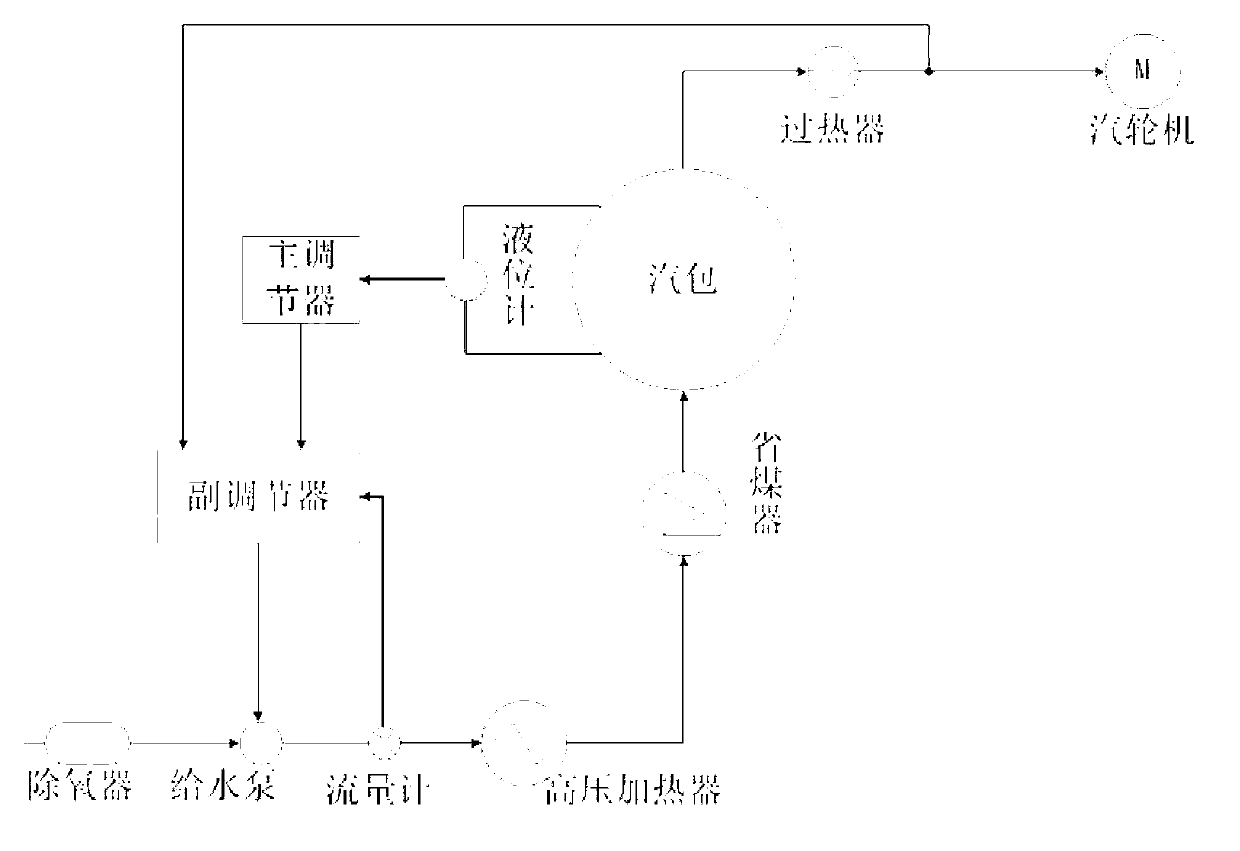

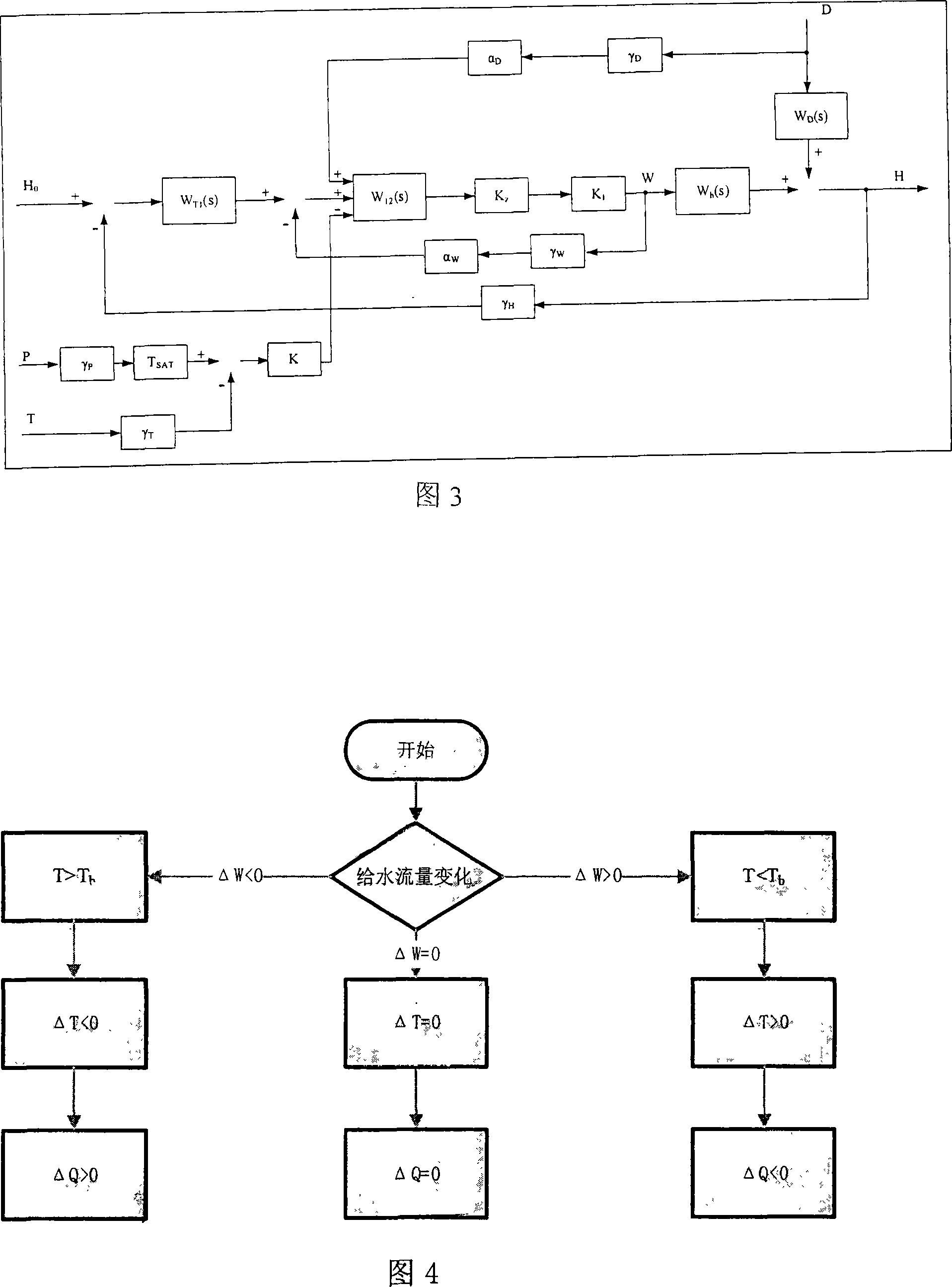

Liquid level control system and method of boiler

ActiveCN106642067AReal-time adjustment of running errorImprove adaptabilitySteam generation using hot heat carriersWater feed controlFuzzy control systemTime signal

The invention provides a liquid level control system and method of a boiler. The method comprises the steps that a real-time signal transmitted by a liquid level transmitter of the boiler is compared with a preset signal, and the operation errors of the boiler are determined; and the operation errors are subjected to repeated analog-digital conversion through a fuzzy controller so that the output quantity can be obtained, and the output quantity is used for controlling the opening degree of an adjusting valve so as to make sure that the liquid level of the boiler is within the preset range. Due to the fact that the real-time signal transmitted and detected by the transmitter is subjected to repeated fuzzy conversion through the fuzzy controller, the operation errors in the boilers can be adjusted in real time, the adaptability of the boiler control system to dynamic environment is improved, and the control effect of the boiler system is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

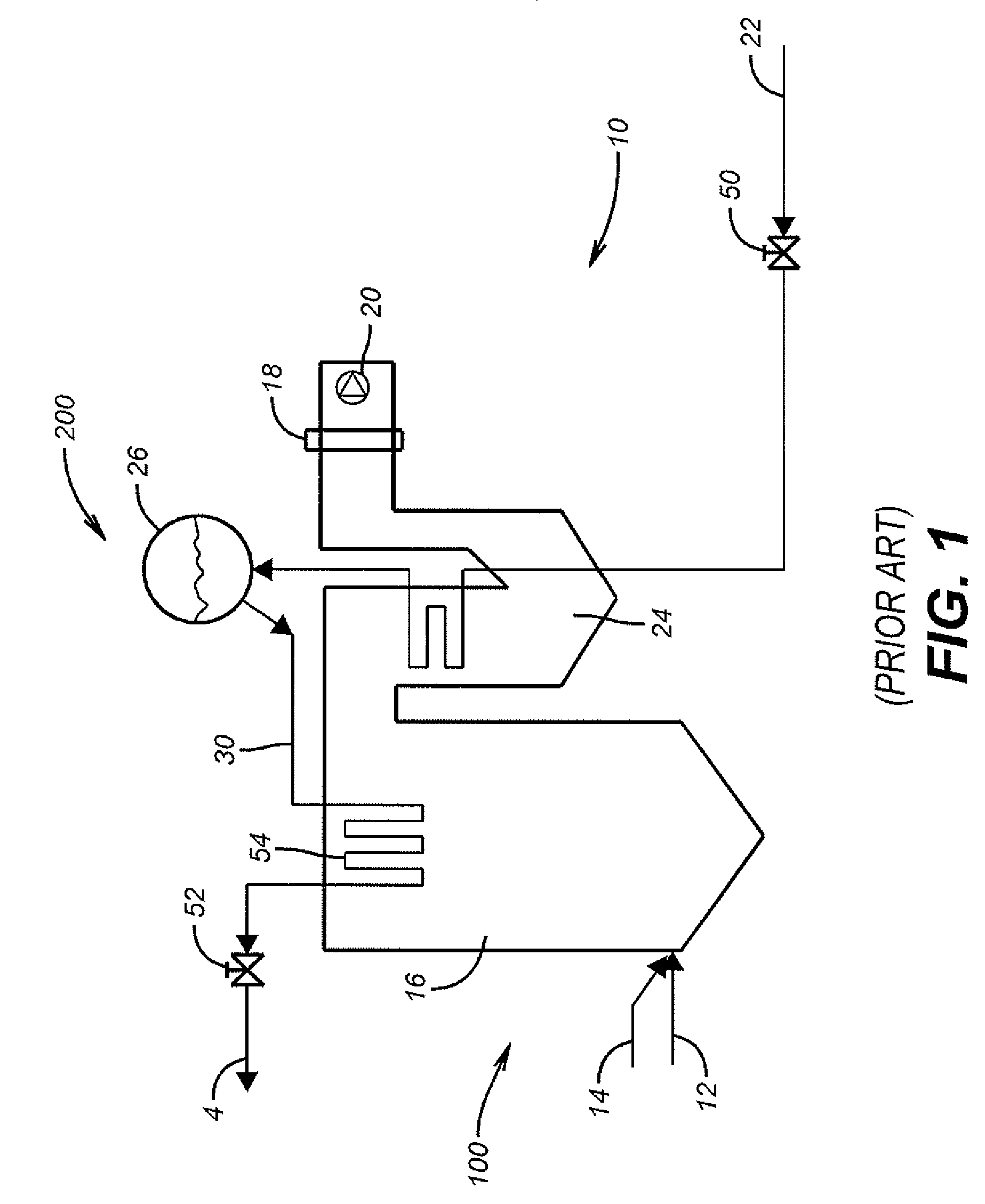

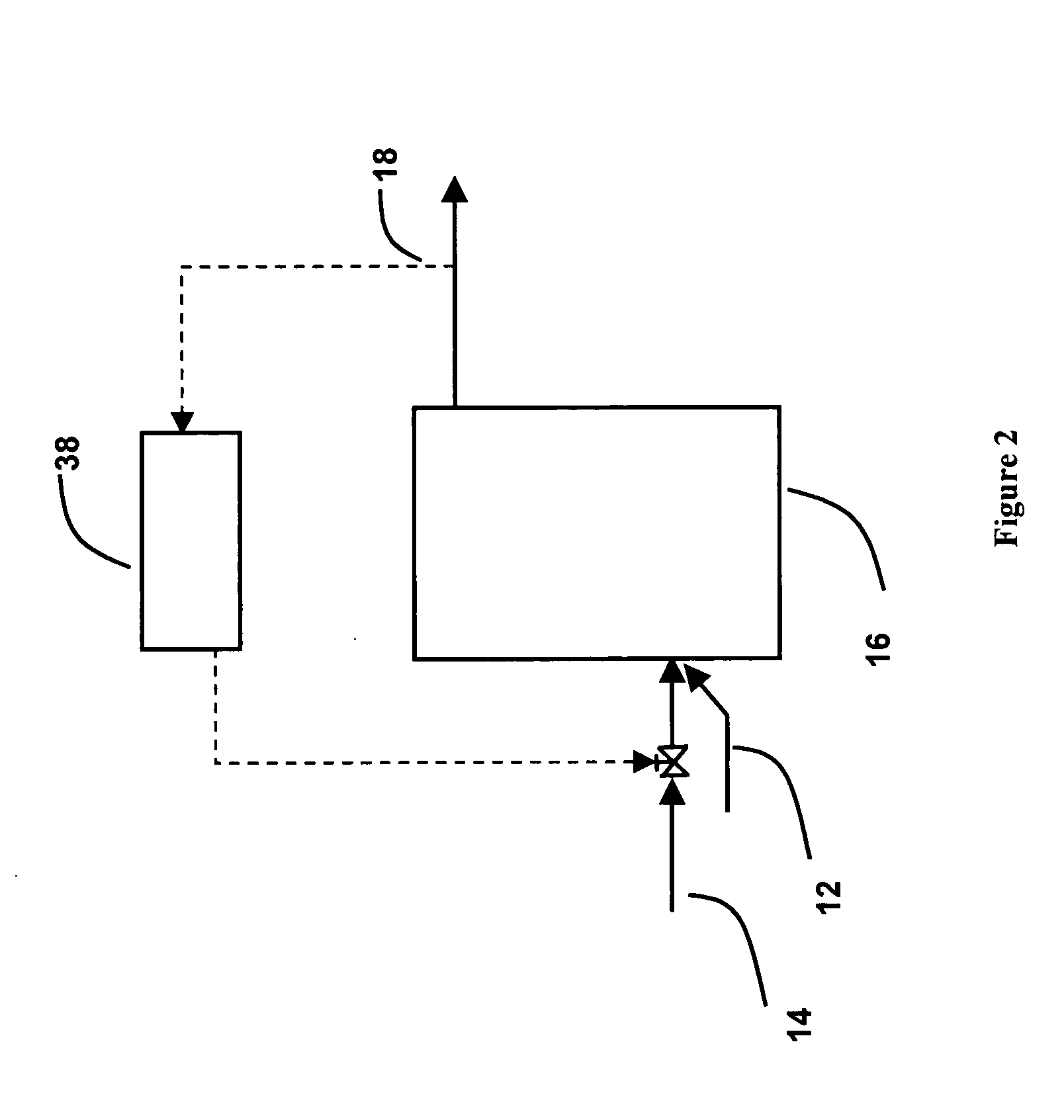

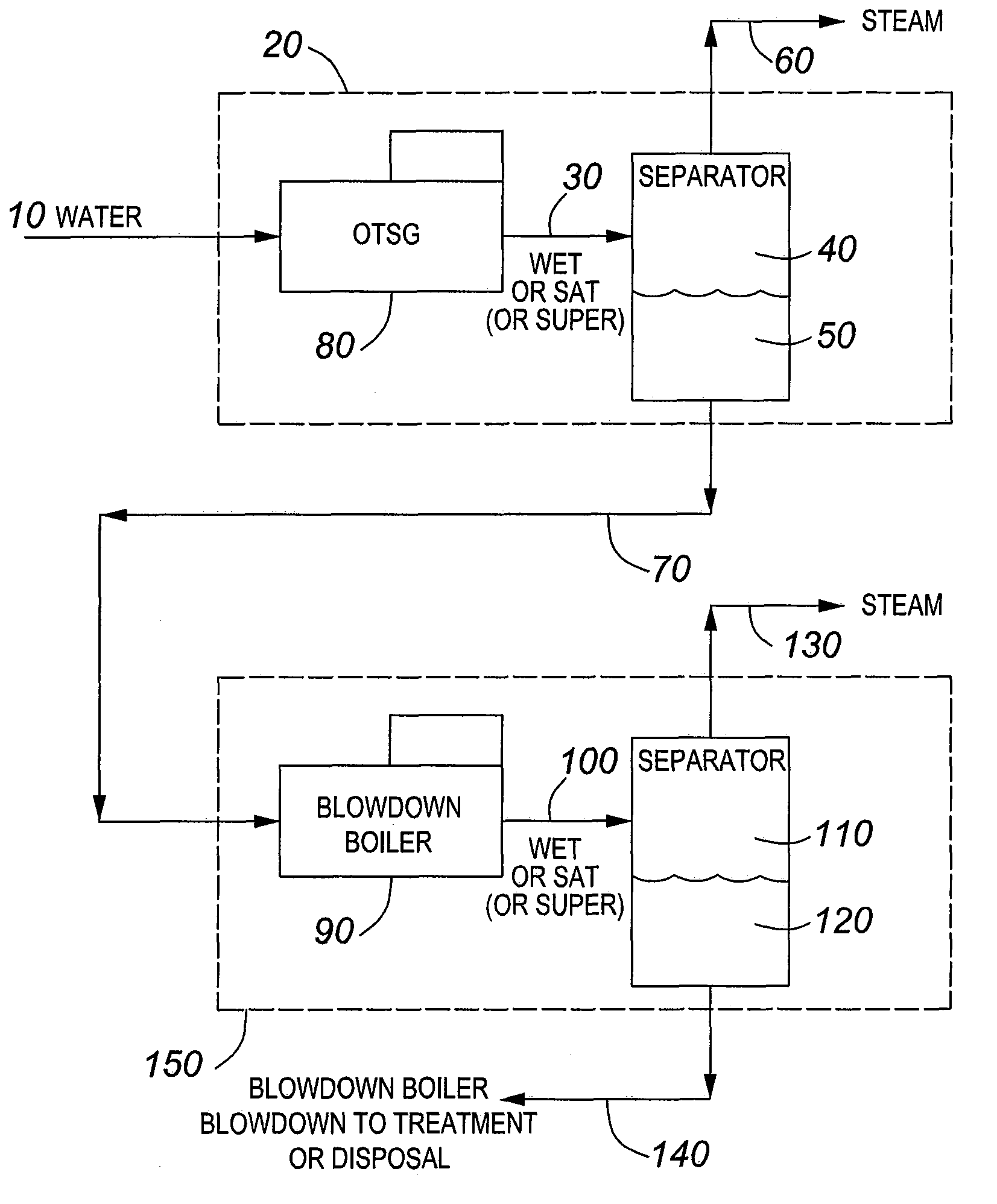

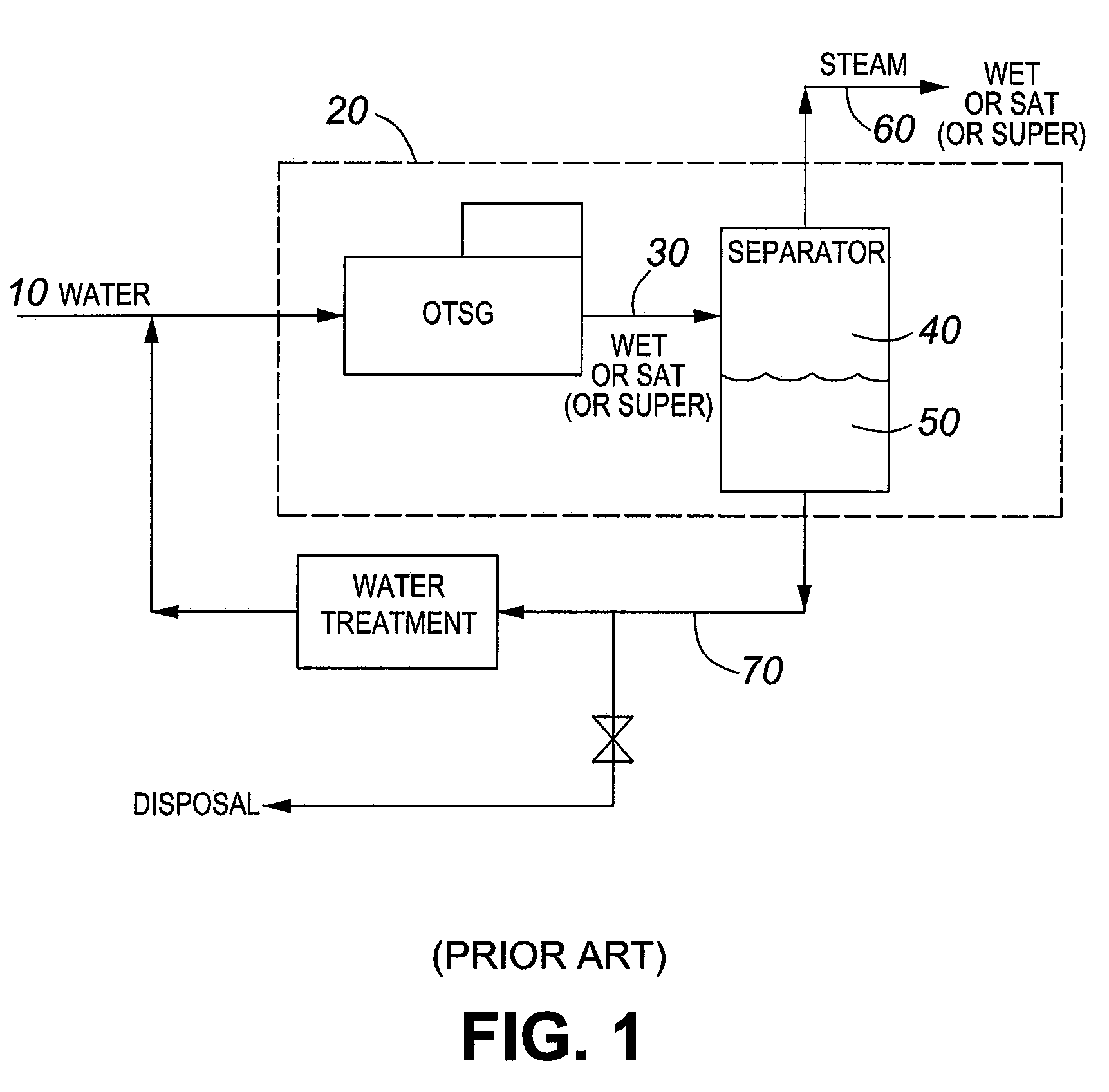

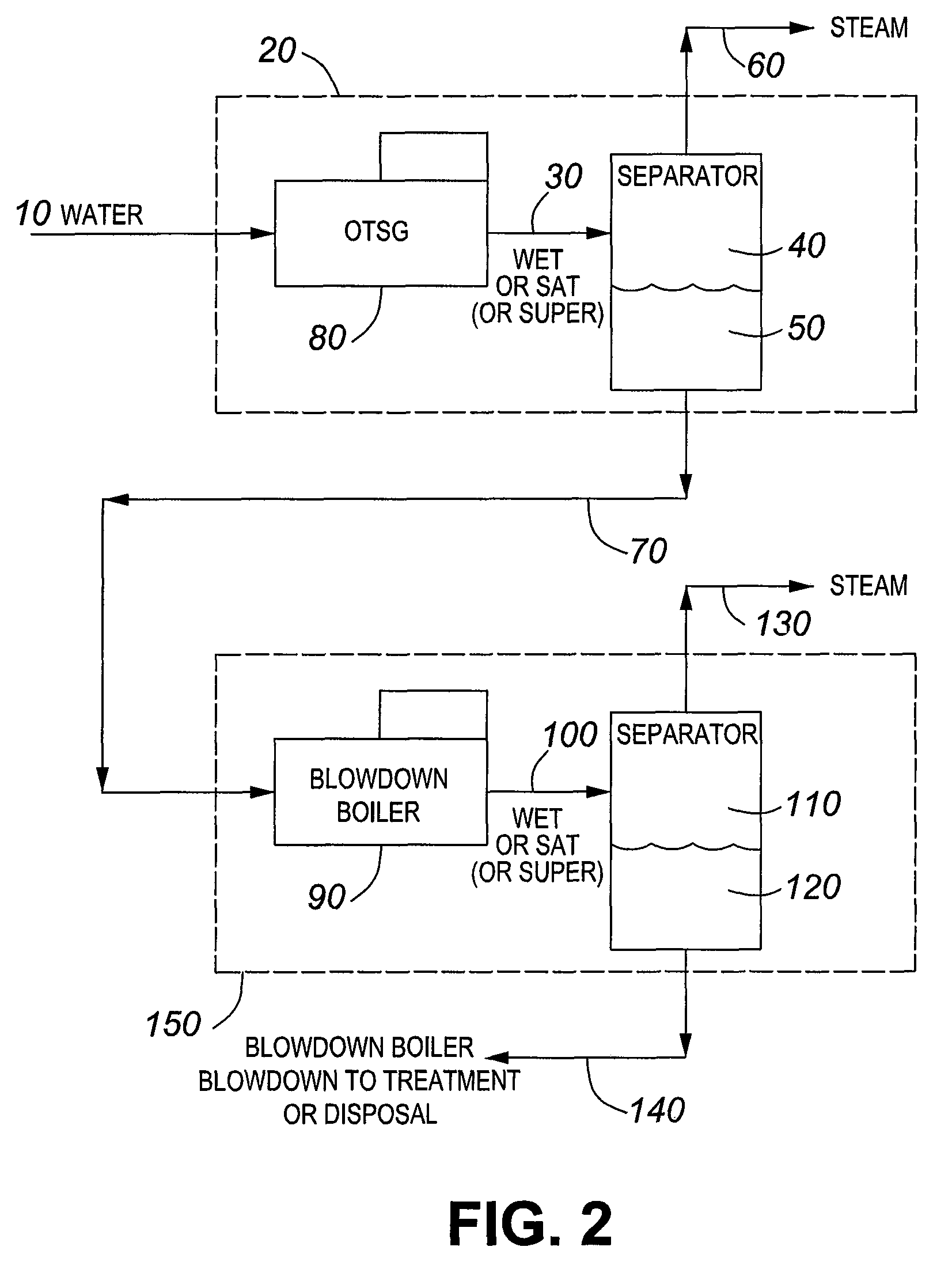

Method and apparatus for steam generation

ActiveUS8166925B2Reduce in quantityIncrease volumeWater circulationFuel injection apparatusBoiler blowdownHardness

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

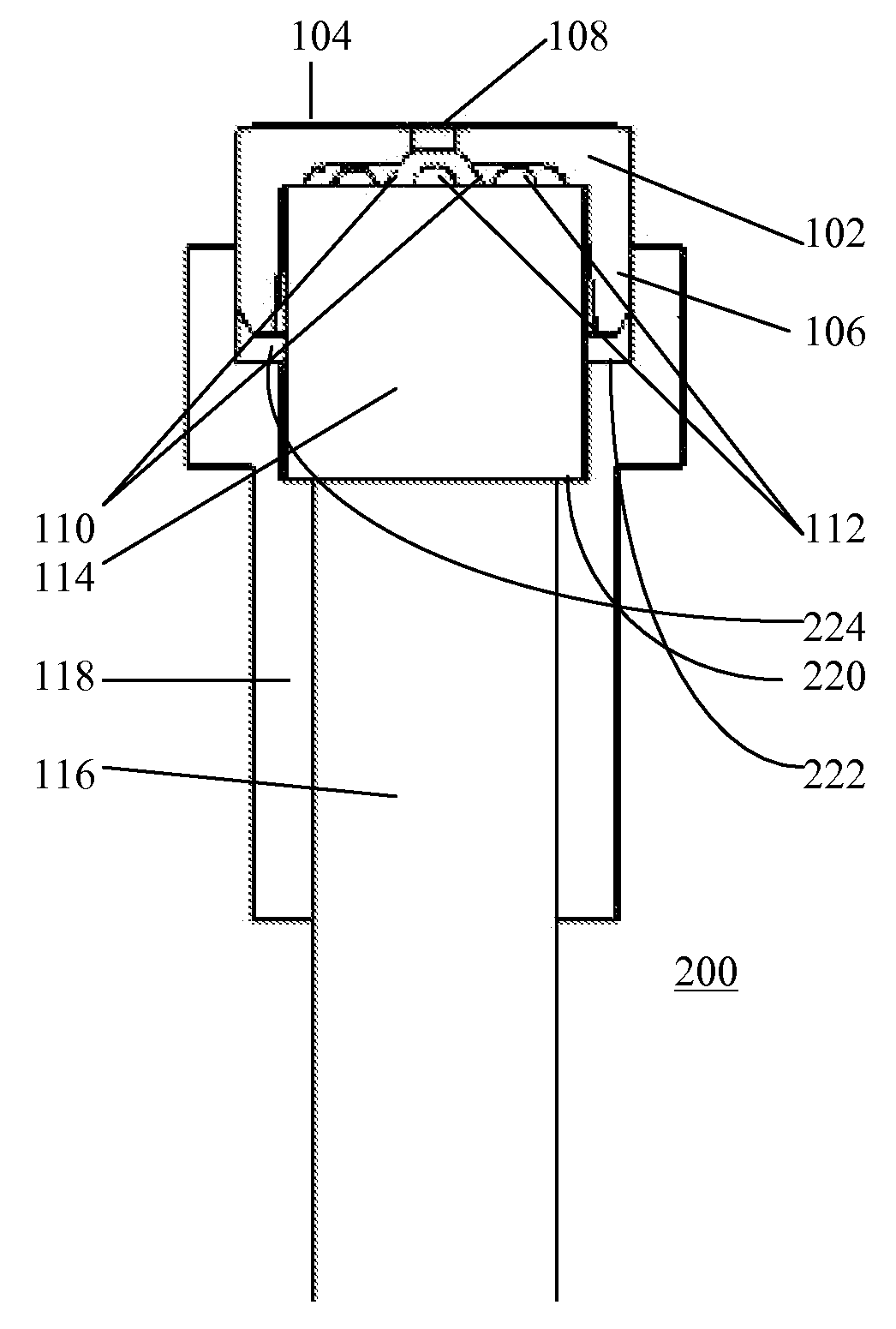

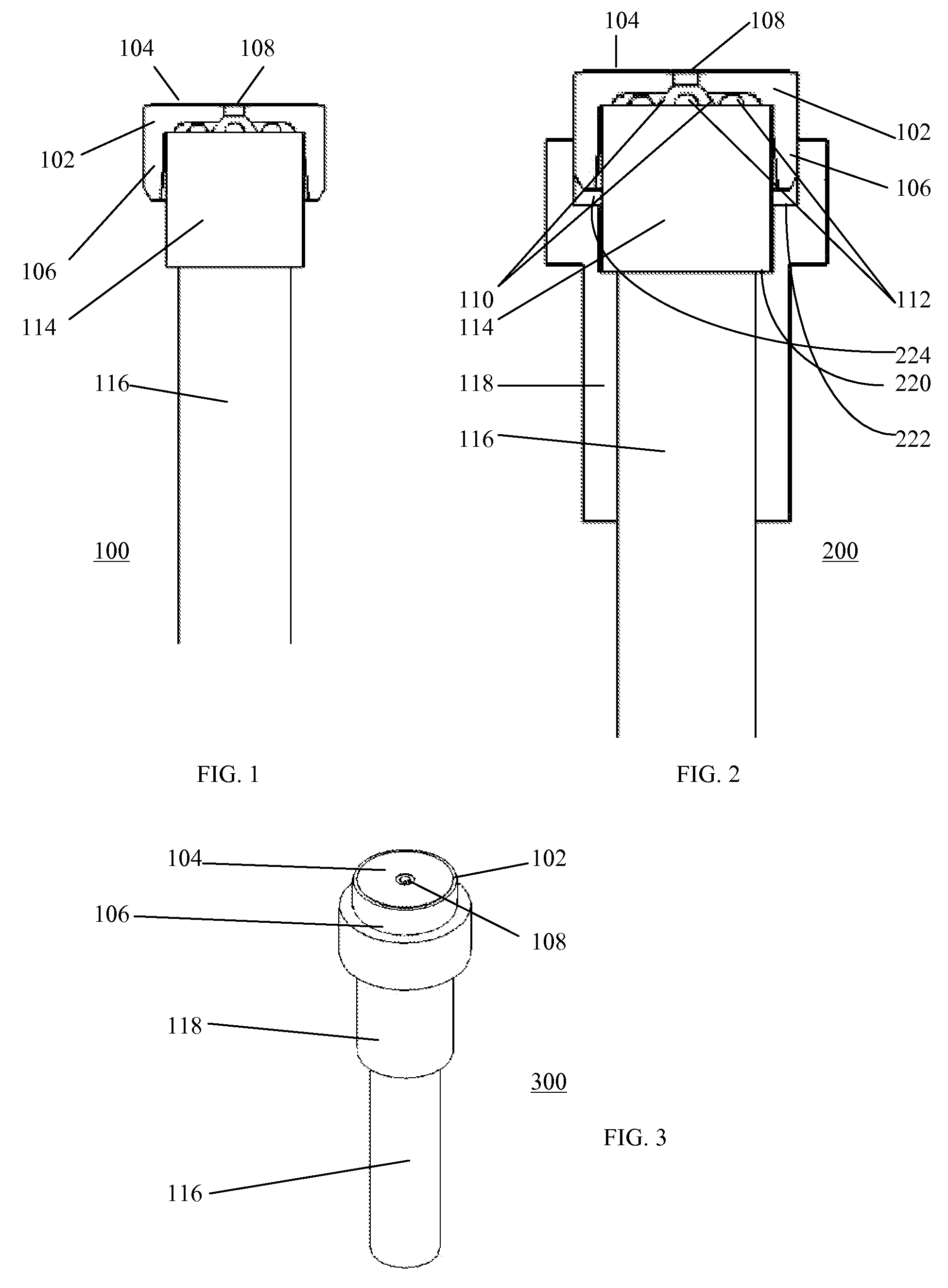

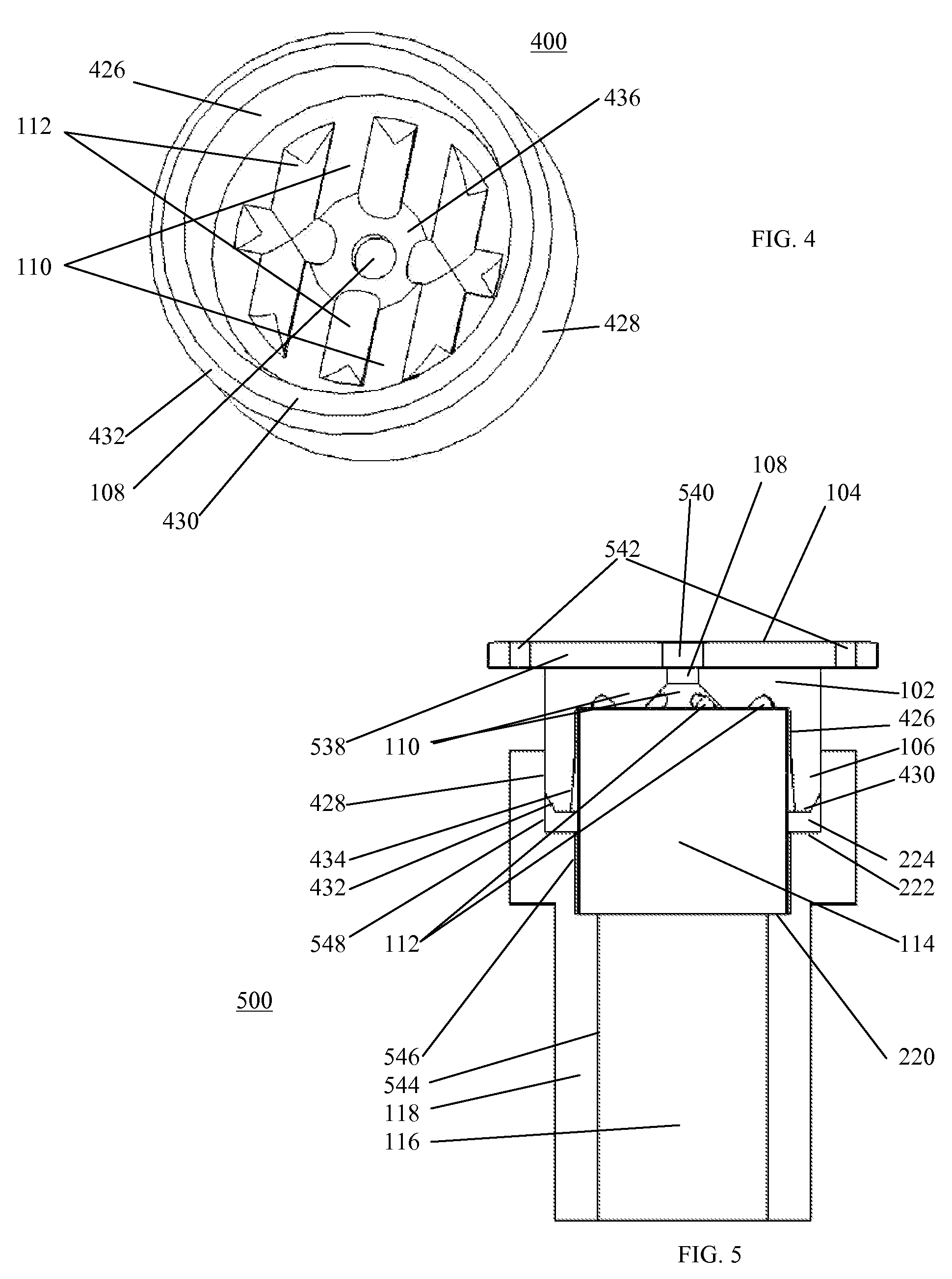

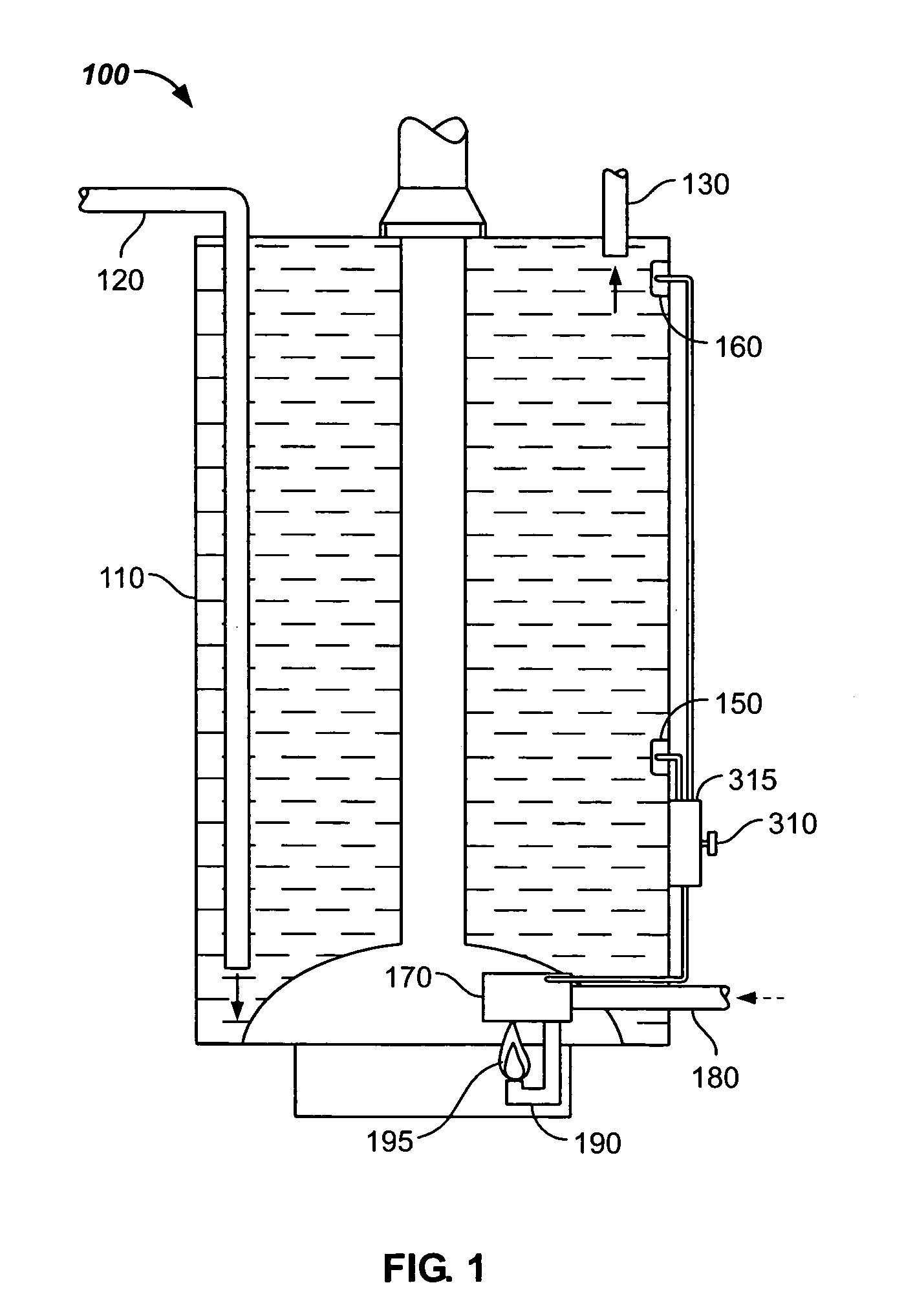

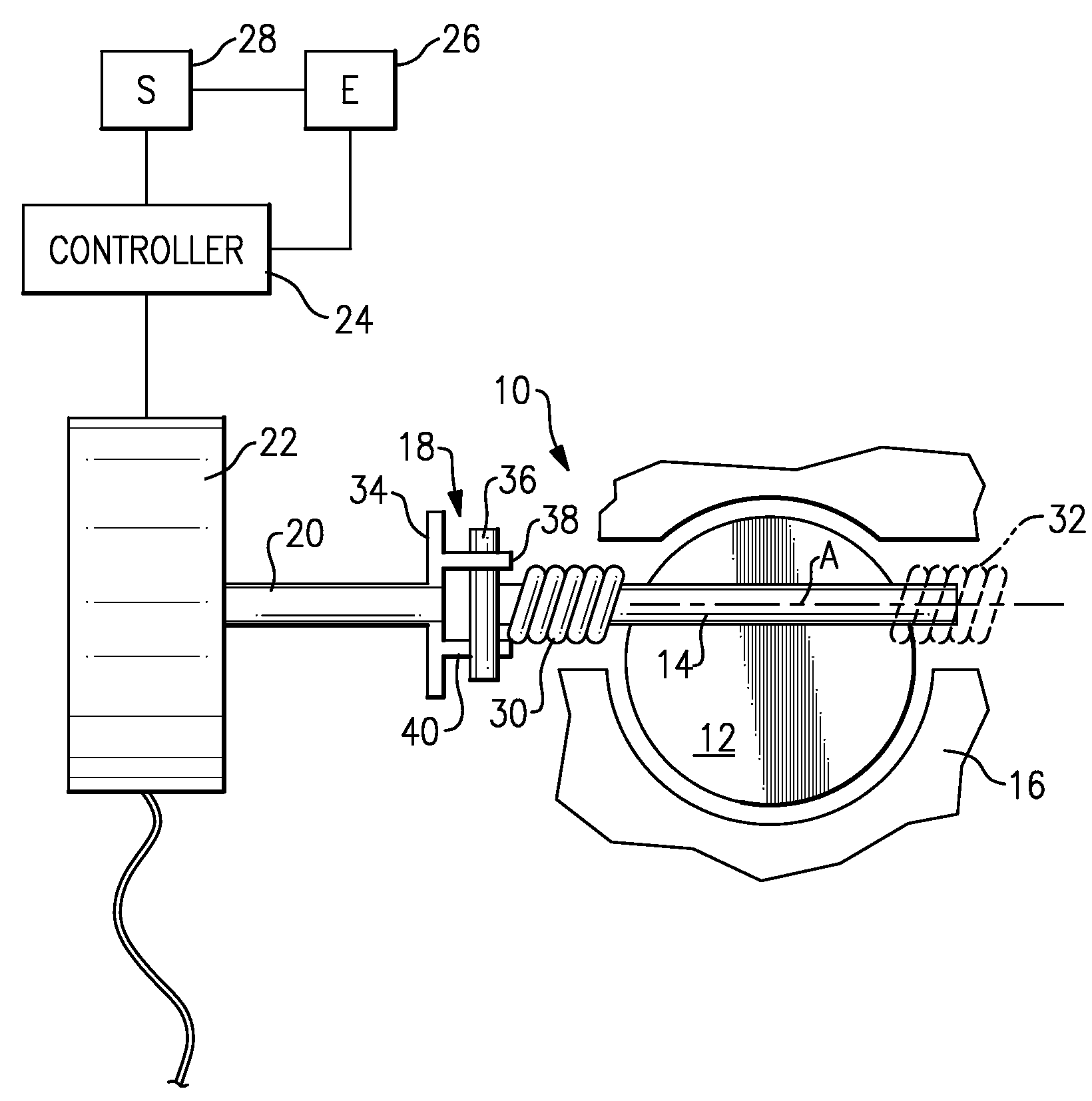

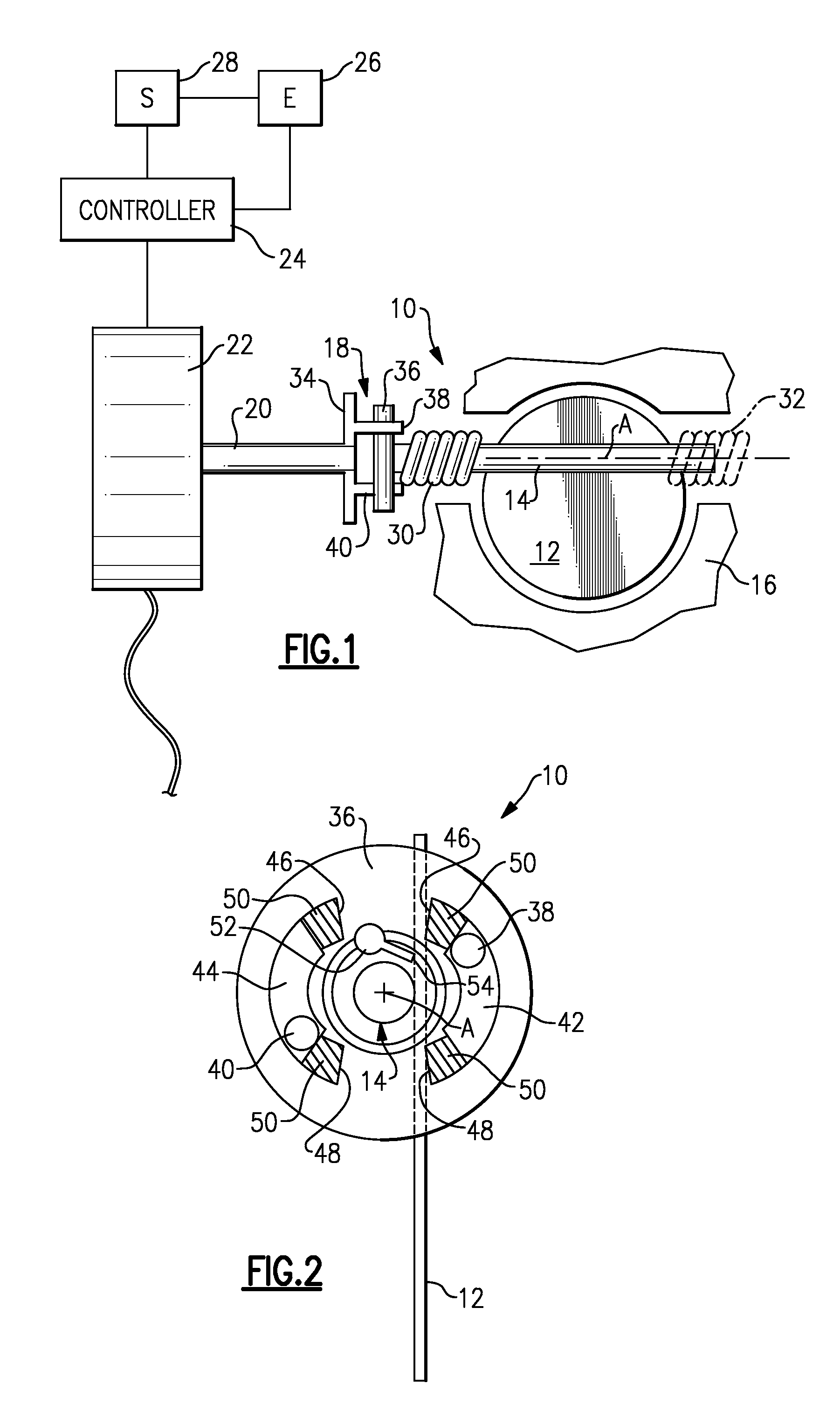

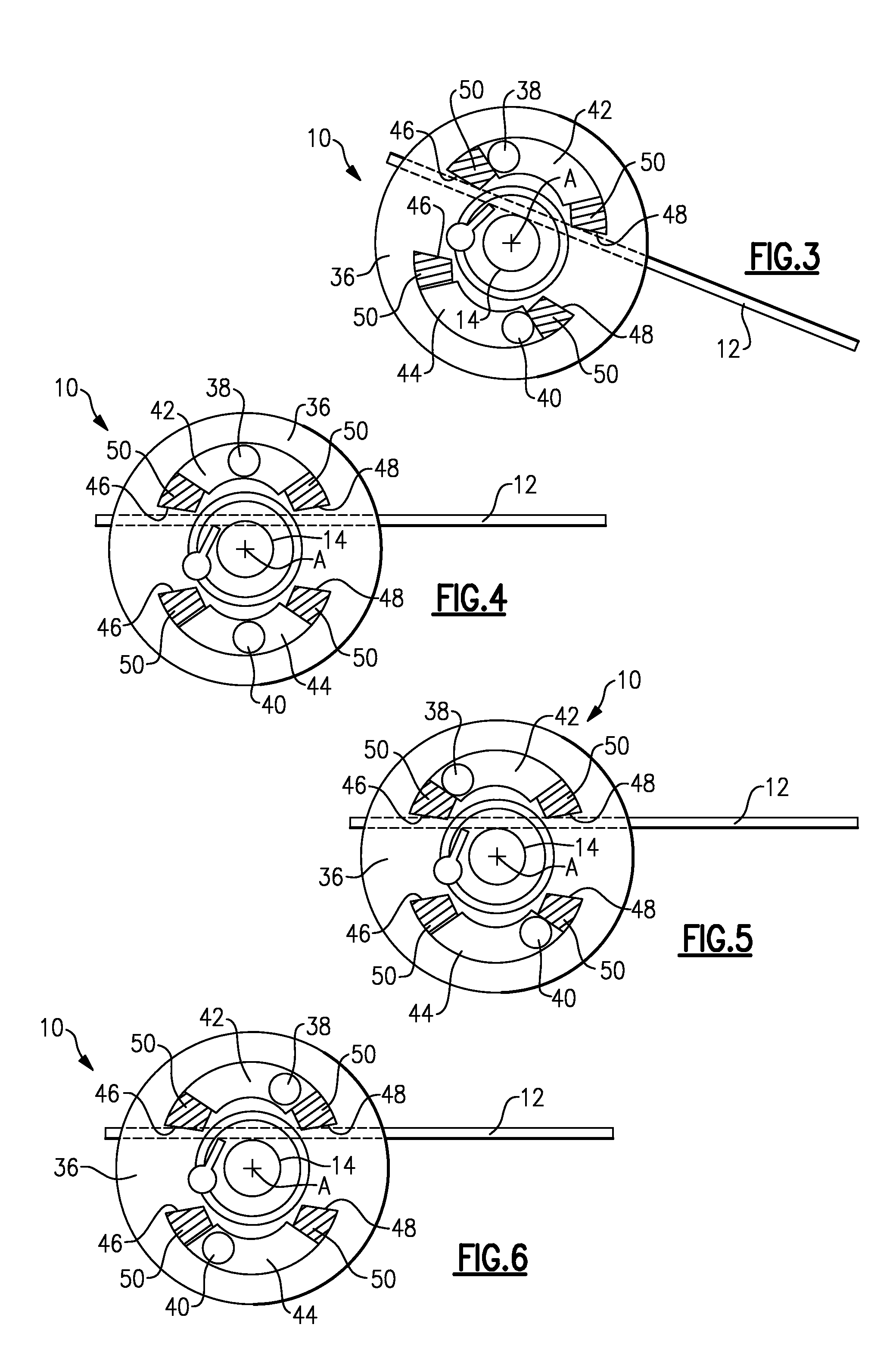

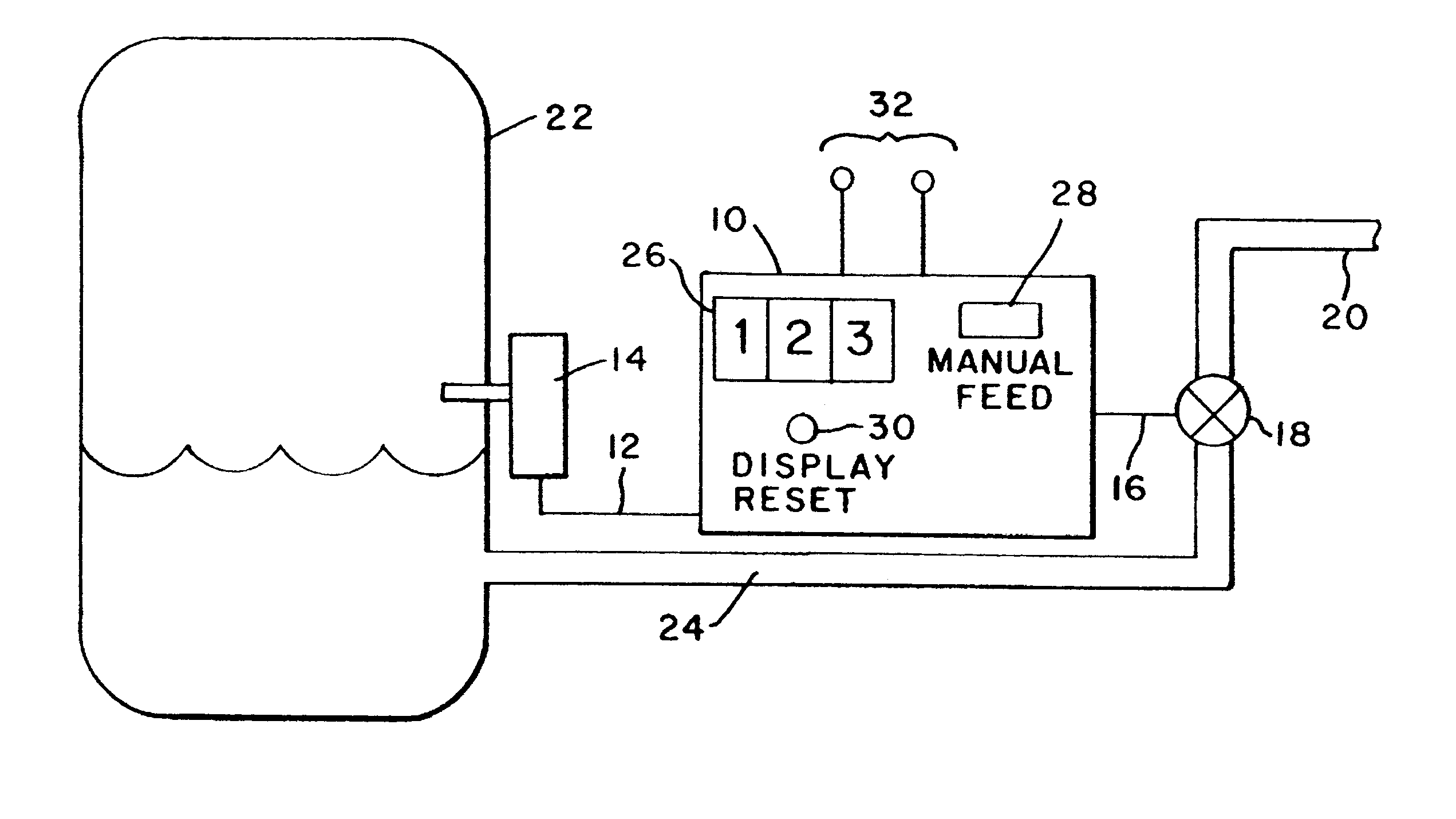

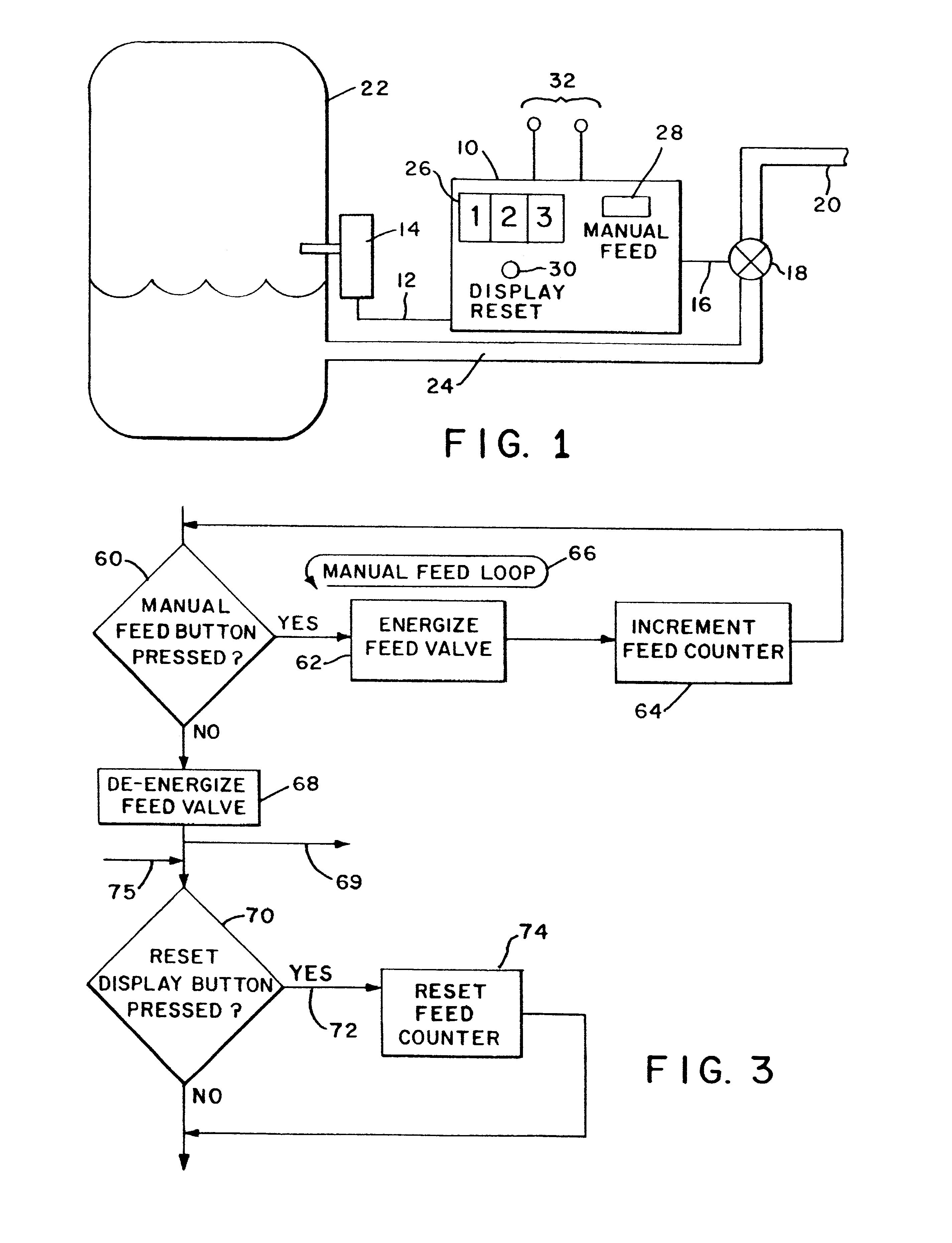

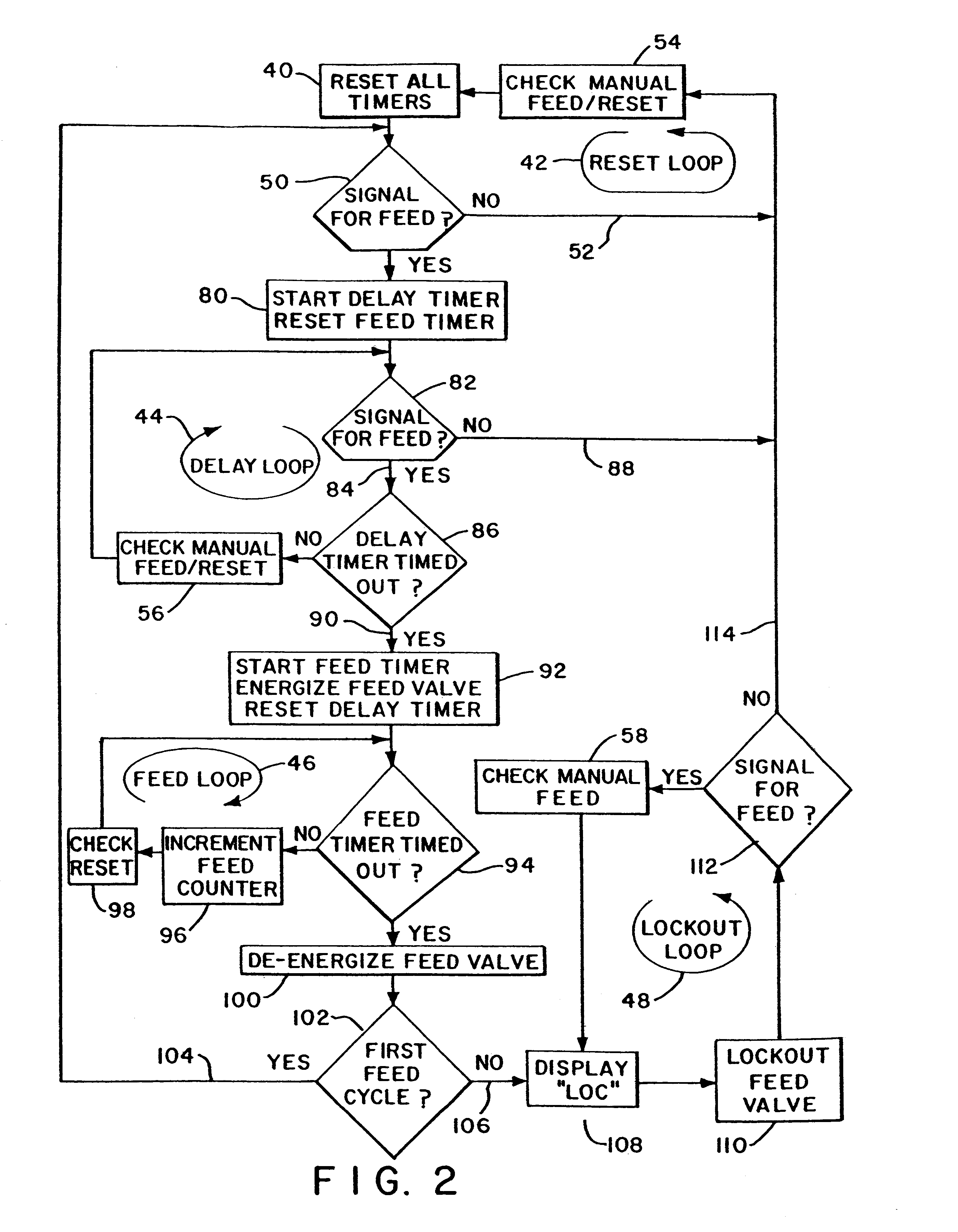

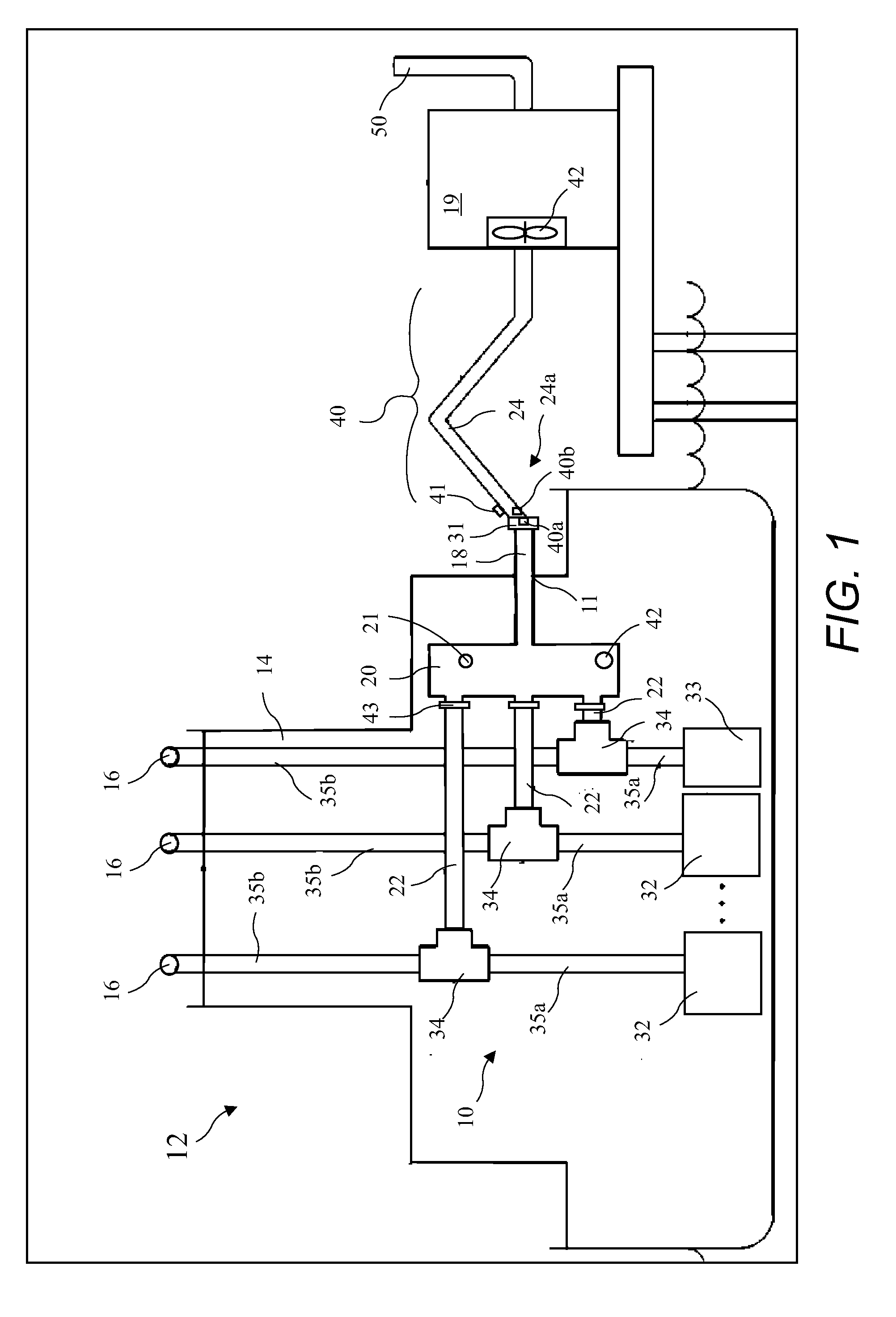

Water feeder controller for boiler

A water feeder controller for a boiler monitors a low water cutoff sensor in a boiler and uses a feed timer to feed water to the boiler for a predetermined feed period of time. The feed timer brings the water level in the boiler well above the low water cutoff sensor. The feed timer supplies water to the boiler only if the low water cutoff sensor continues to indicate a low water level for a delay period of time measured by a delay timer. A resettable display indicates the quantity of water supplied by the water feeder to the boiler based on a feed counter incremented during water feeding. A manual feed button allows water to be manually fed to the boiler. The quantity of water manually supplied to the boiler is also shown on the display. The feed timer and delay timer are preferably implemented in software in a microcontroller in the water feeder controller. A lockout loop in the software prevents overfeeding of water to the boiler in the event of a failure of the low water cutoff sensor.

Owner:COWLES OPERATING CO

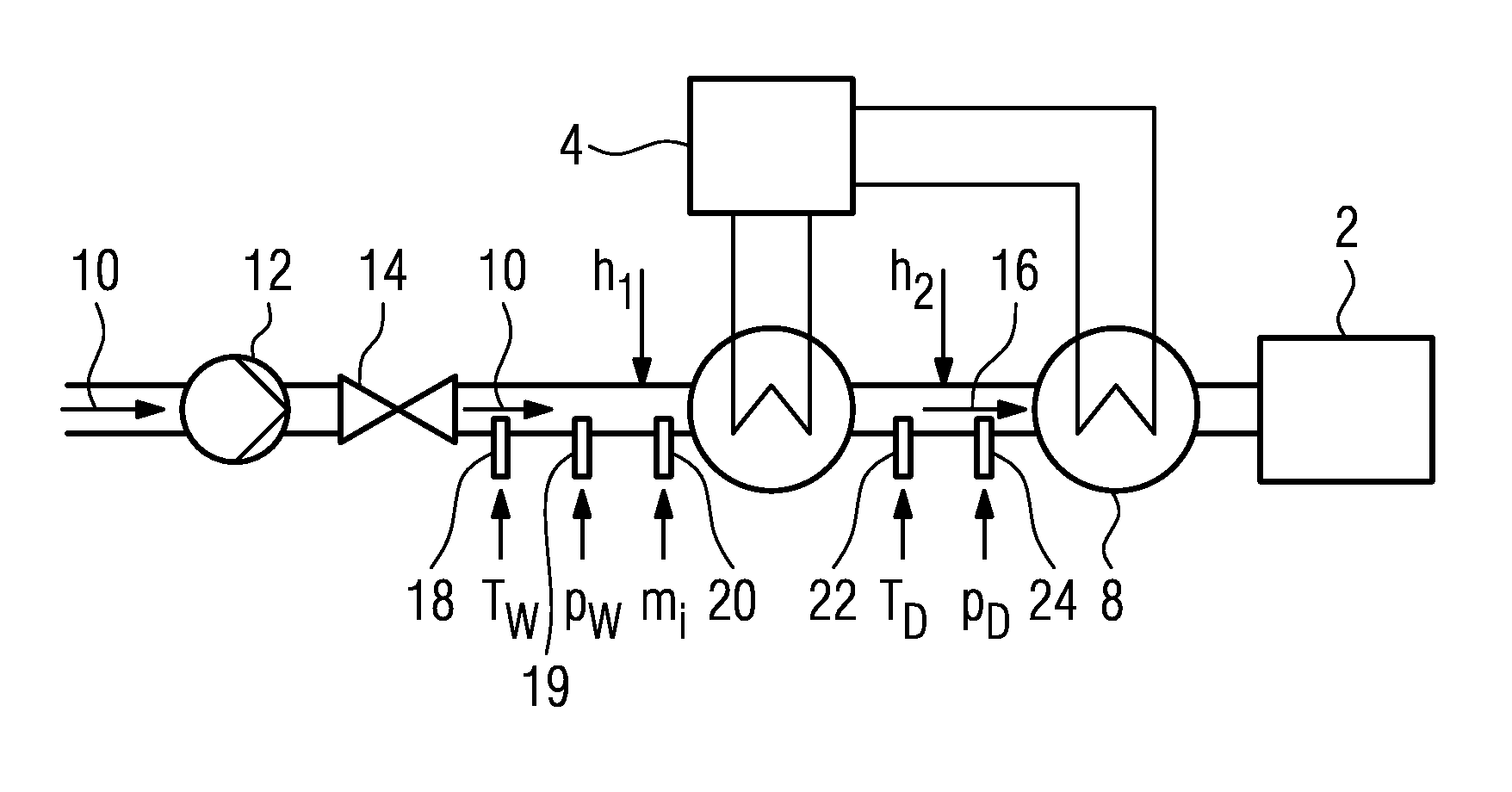

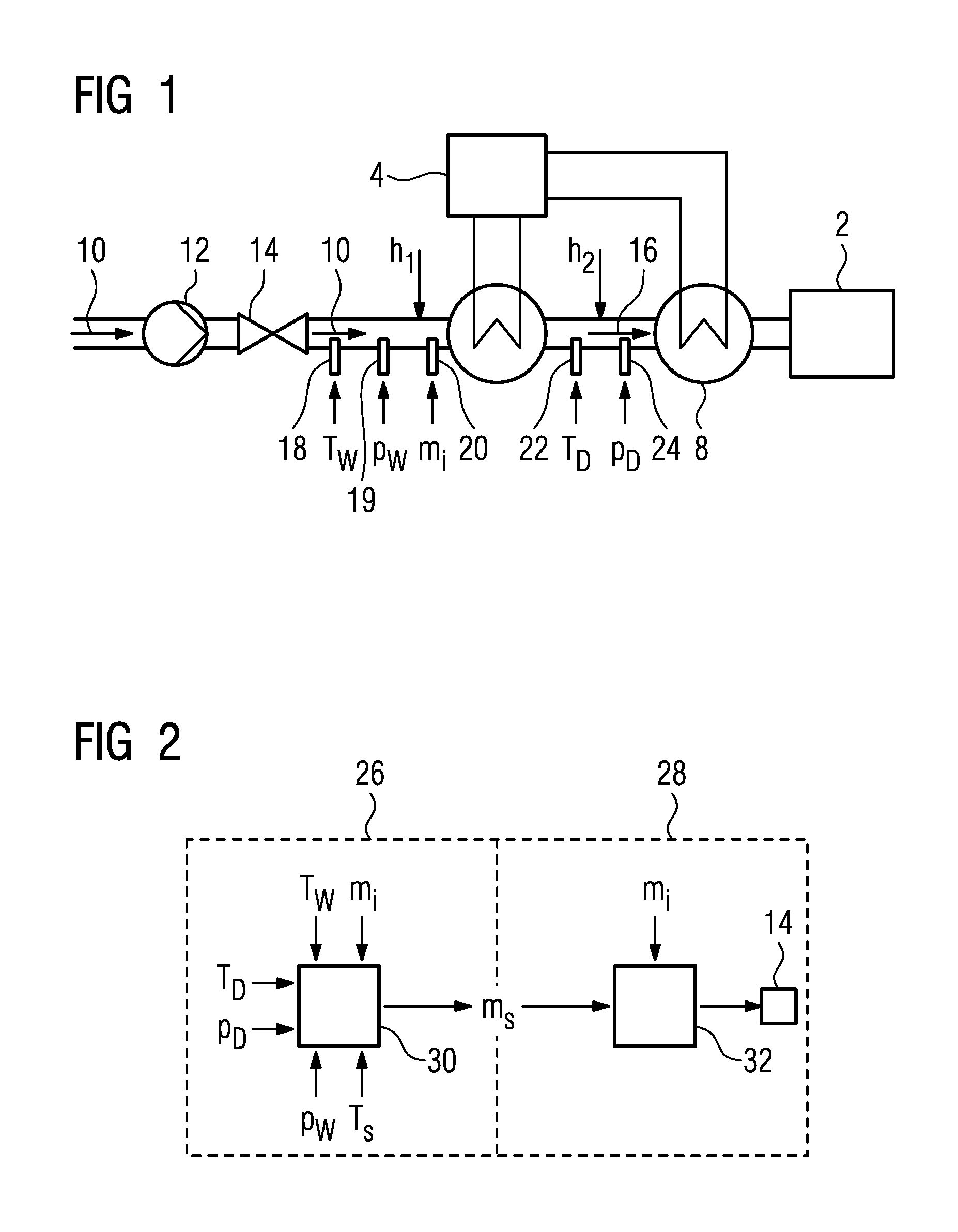

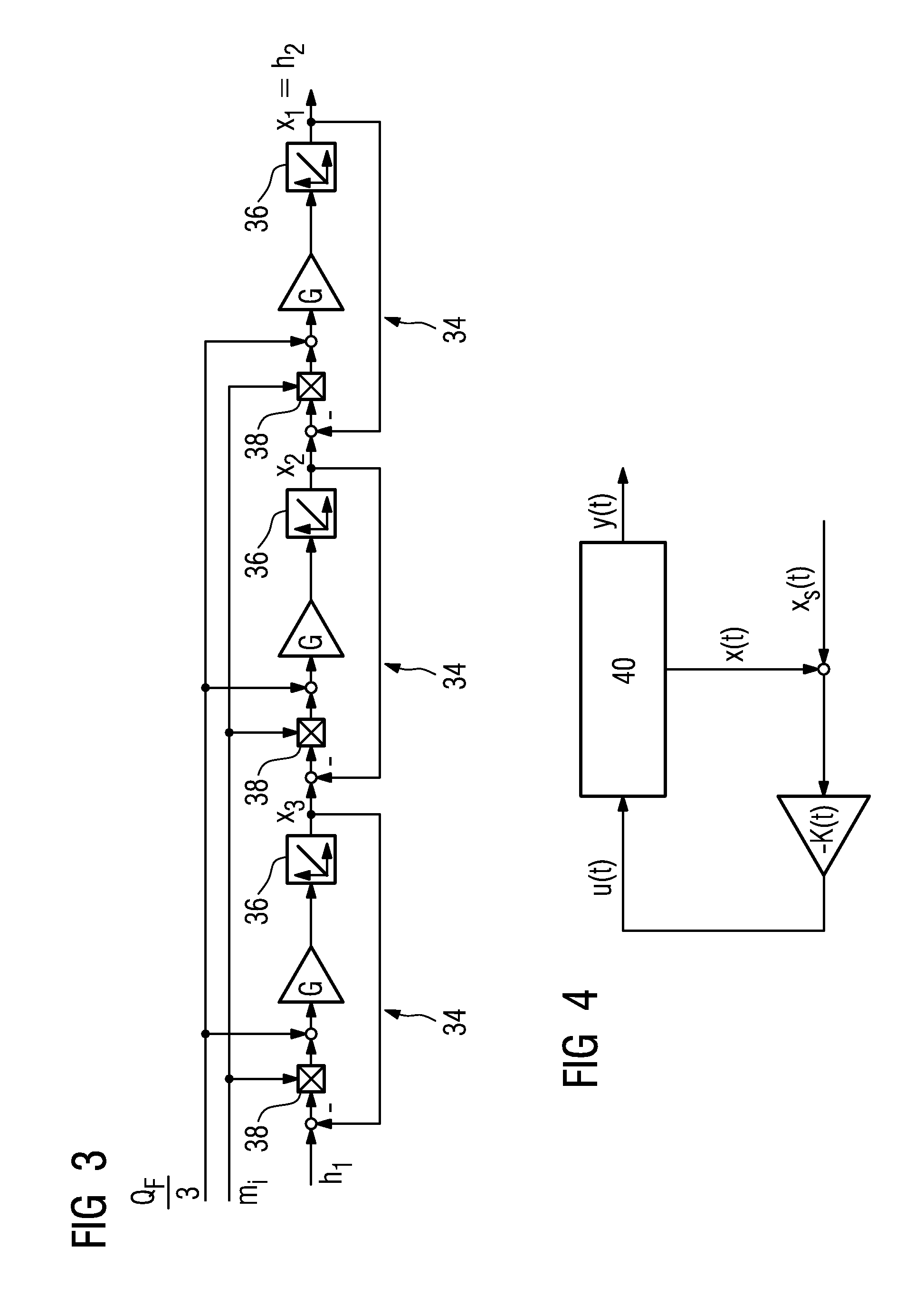

Method and device for regulating the production of steam in a steam plant

InactiveUS20130133751A1Precise and stable controlBoiler controlPipeline systemsEngineeringSteam generation

A method for regulating the production of steam from feed water in an evaporator of a steam plant is provided. A state regulator calculates a plurality of states of a medium in the evaporator by means of an observer and, on the basis thereof, determines a feed water mass flow rate as a regulating variable. In order to obtain a stable and precise regulation of the temperature of the steam, the state regulator is a linear-quadratic regulator.

Owner:BACKI CHRISTOPH +5

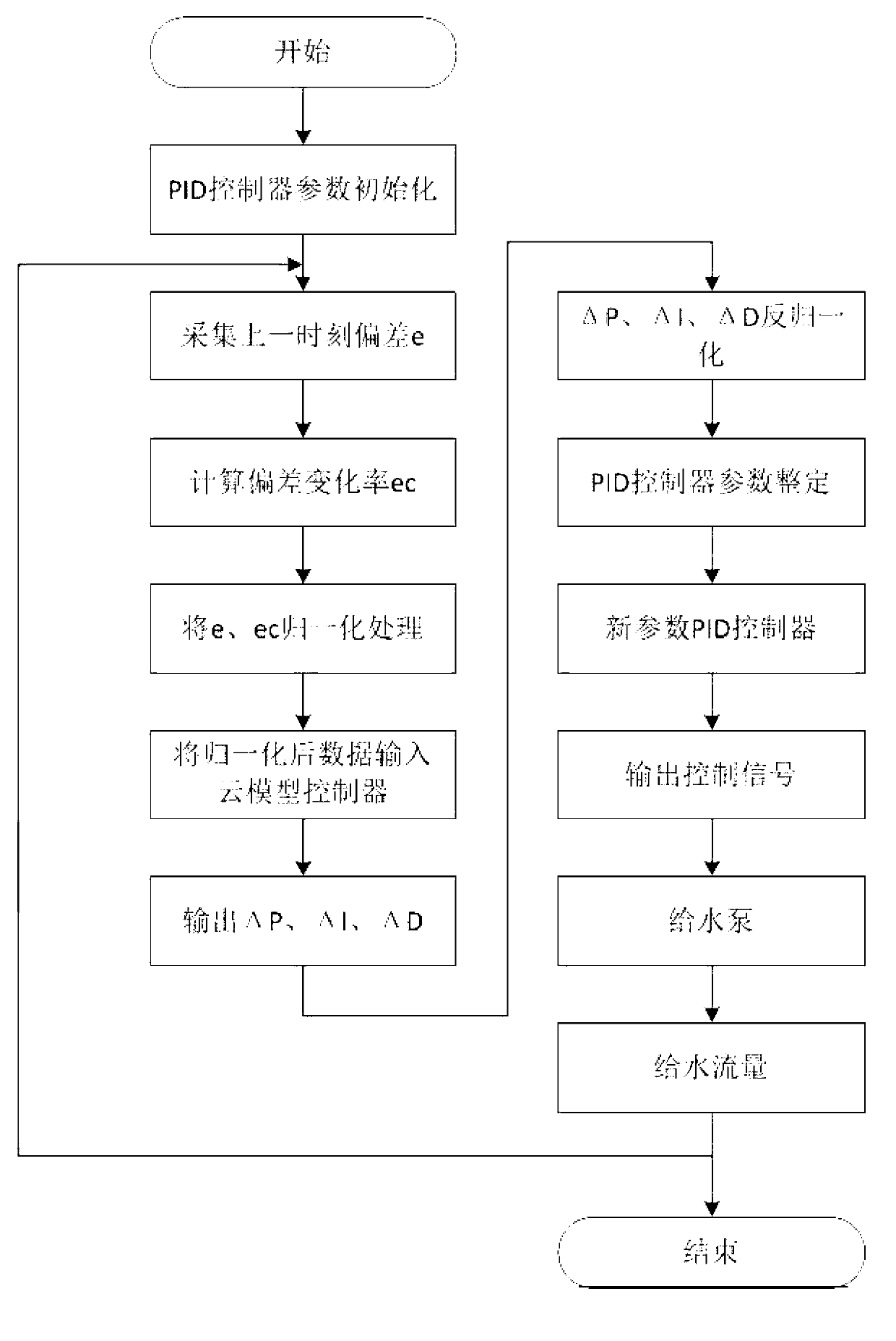

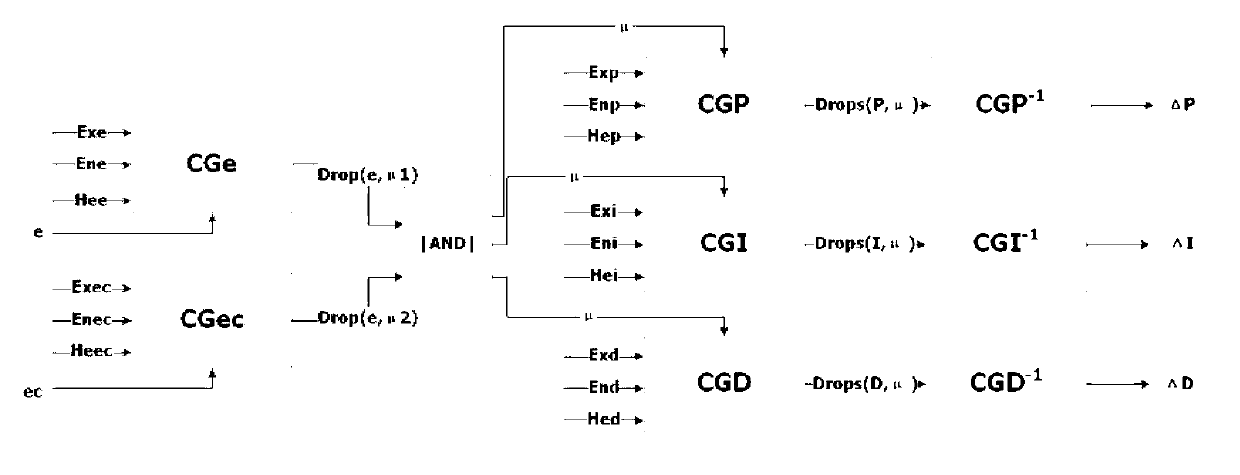

Boiler drum water level self-adaptation PID (proportion integration differentiation) control method

InactiveCN102997222AImprove control qualityWater feed controlProportion integration differentiationControl system

The invention discloses a boiler drum water level self-adaptation PID (proportion integration differentiation) control method in the technical field of electric control. According to the technical scheme, the method comprises the steps of: establishing a two-dimensional dual-input three-output cloud model controller; collecting and controlling system deviation variable quantity e, and calculating the deviation variable rate ec; establishing PID controller setting values delta P, delta I and delta D; substituting the system deviation variable quantity e and the deviation variable rate ec into the two-dimensional dual-input three-output cloud model controller; outputting the setting values delta P, delta I and delta D through seasoning; carrying out linear calculation with a conventional PID controller again, wherein the PID controller which generates novel parameters after setting determines the system output quantity. The boiler drum water level self-adaptation PID control method provided by the invention improves the stability of a boiler drum water level control system, accelerates the system response speed, and intensifies the anti-interference capability on disturbing signals.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

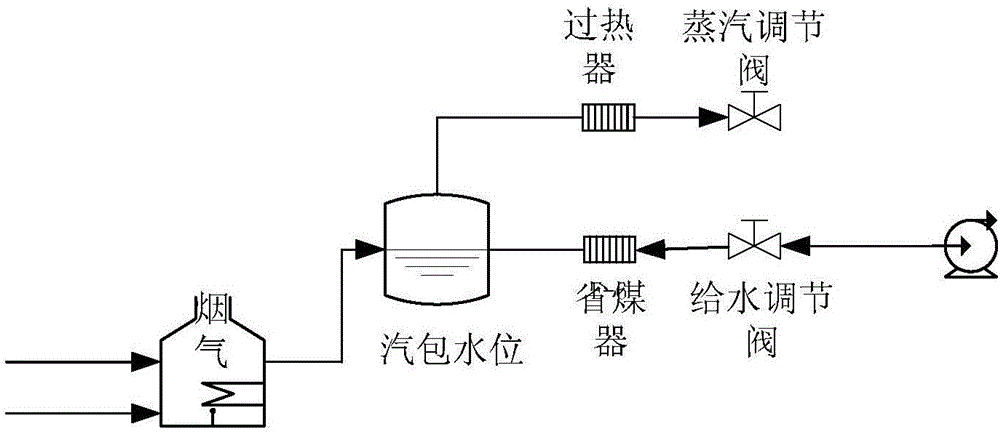

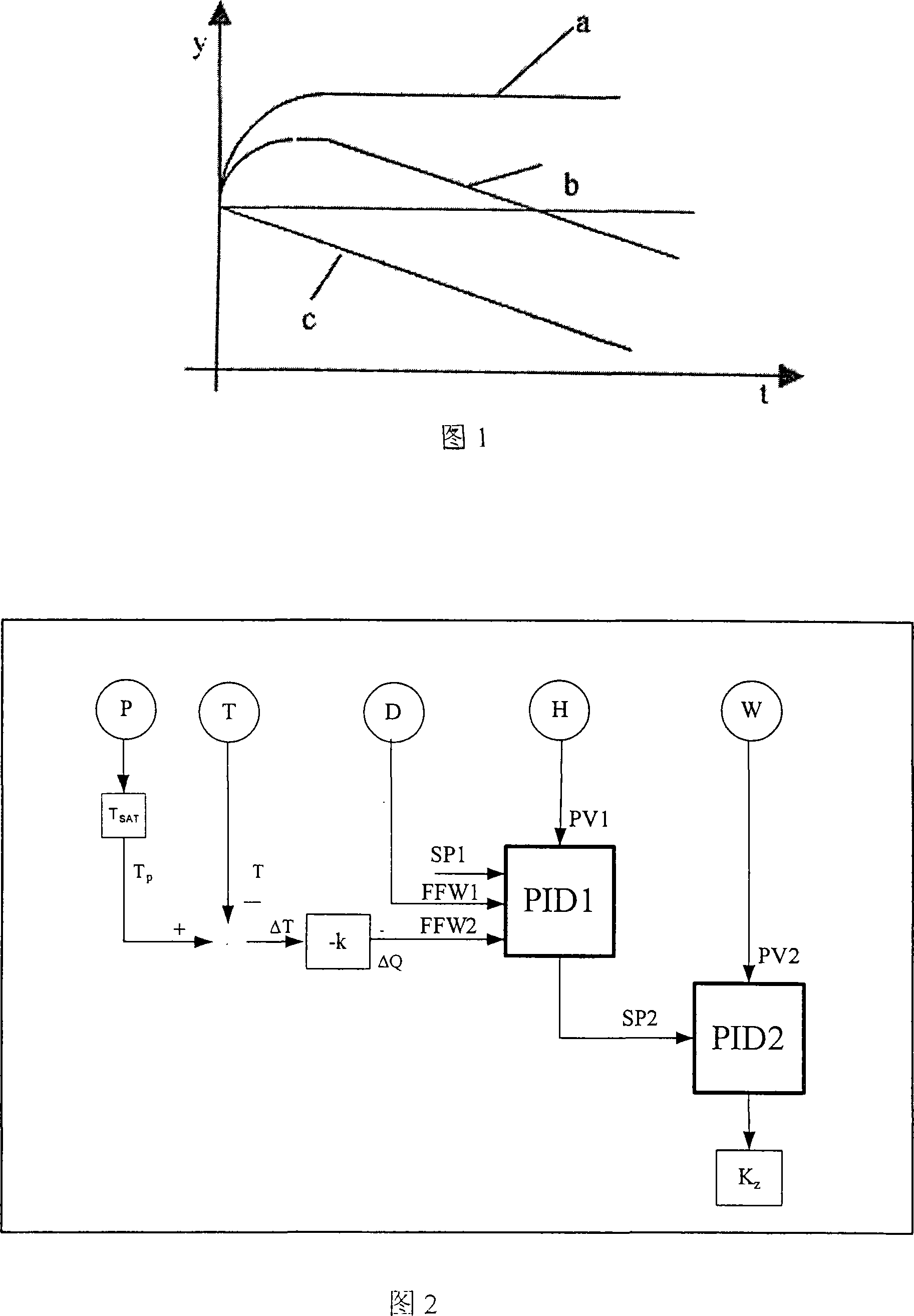

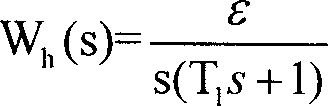

Method for correcting water level of steam drum based on temperature and pressure

ActiveCN101135438AImprove dynamic qualityGuaranteed uptimeSteam separation arrangementsWater feed controlEngineeringLinearity

This invention relates to a correctional method of water level in the steam drum based on the temperature and pressure that belongs to the heat process control field including the following steps: the temperature difference DeltaT is linear to the water supply flow increment in small range, DeltaQ=-kDeltaT, theDeltaQ is used as the feedforward value in the main circuit of the cascade control of the water level in the steam drum, to eliminate the adverse effect of 'false water level' on the water supply control. When the load increases,DeltaQ>0, and the steam drum working condition is nearly stable, the correctional value is 0; when the load decreases, the controlled water supply is suppressed, DeltaQ<0; when the water flow increases, the temperature T of the steam drum decreases and the water supply flow increment DeltaQ<0; when the water supply flow is nearly constant, the correctional value is 0; when the water supply flow decreases, the controlled supply flow increases, DeltaQ>0. This method introduces the effect of steam drum pressure and water temperature on the steam bubble in the steam drum water to correct the water level control, which suppresses the overshoot phenomenon and ensures the steady operation of the boiler.

Owner:CHINA ELECTRIC POWER RES INST +1

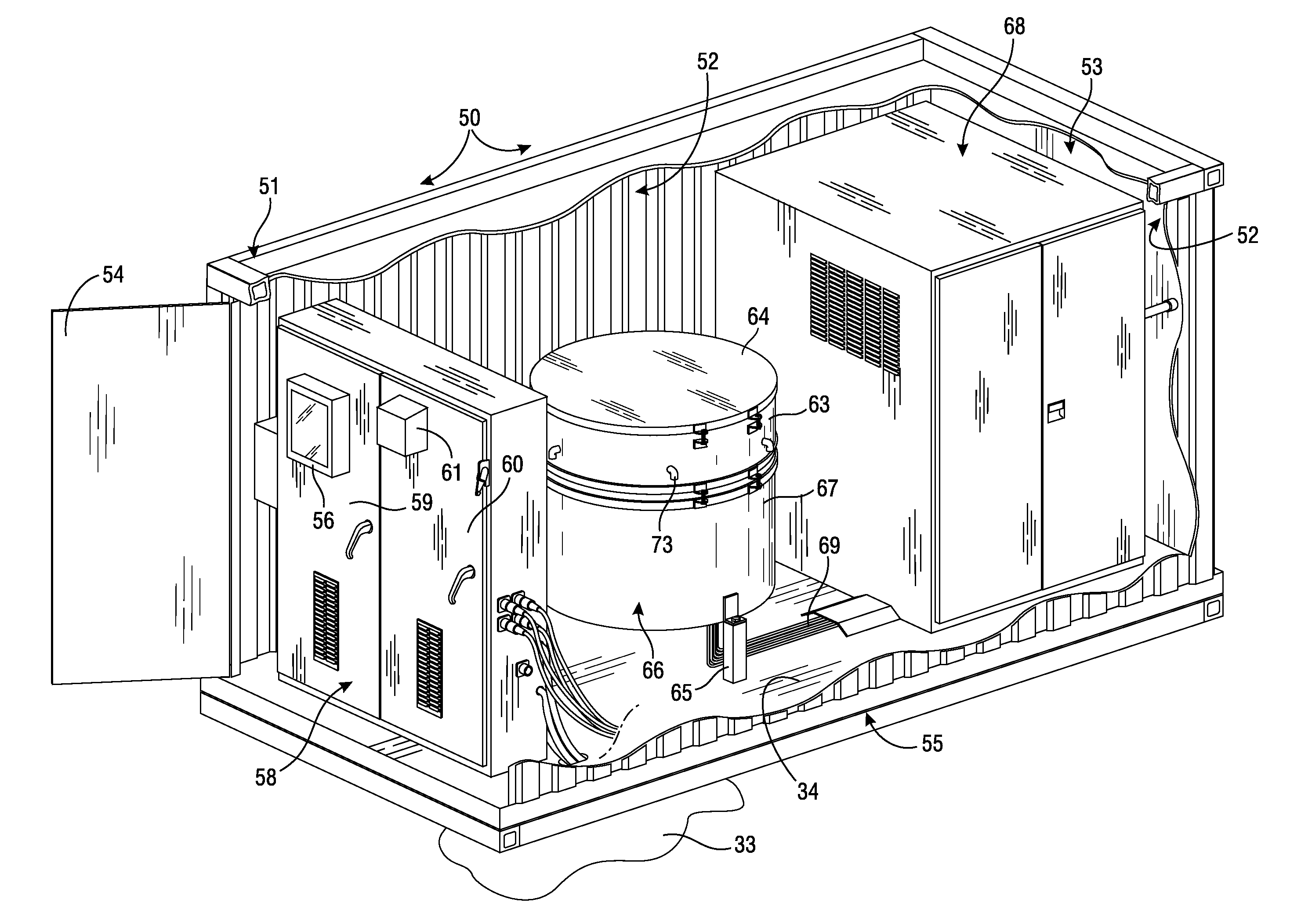

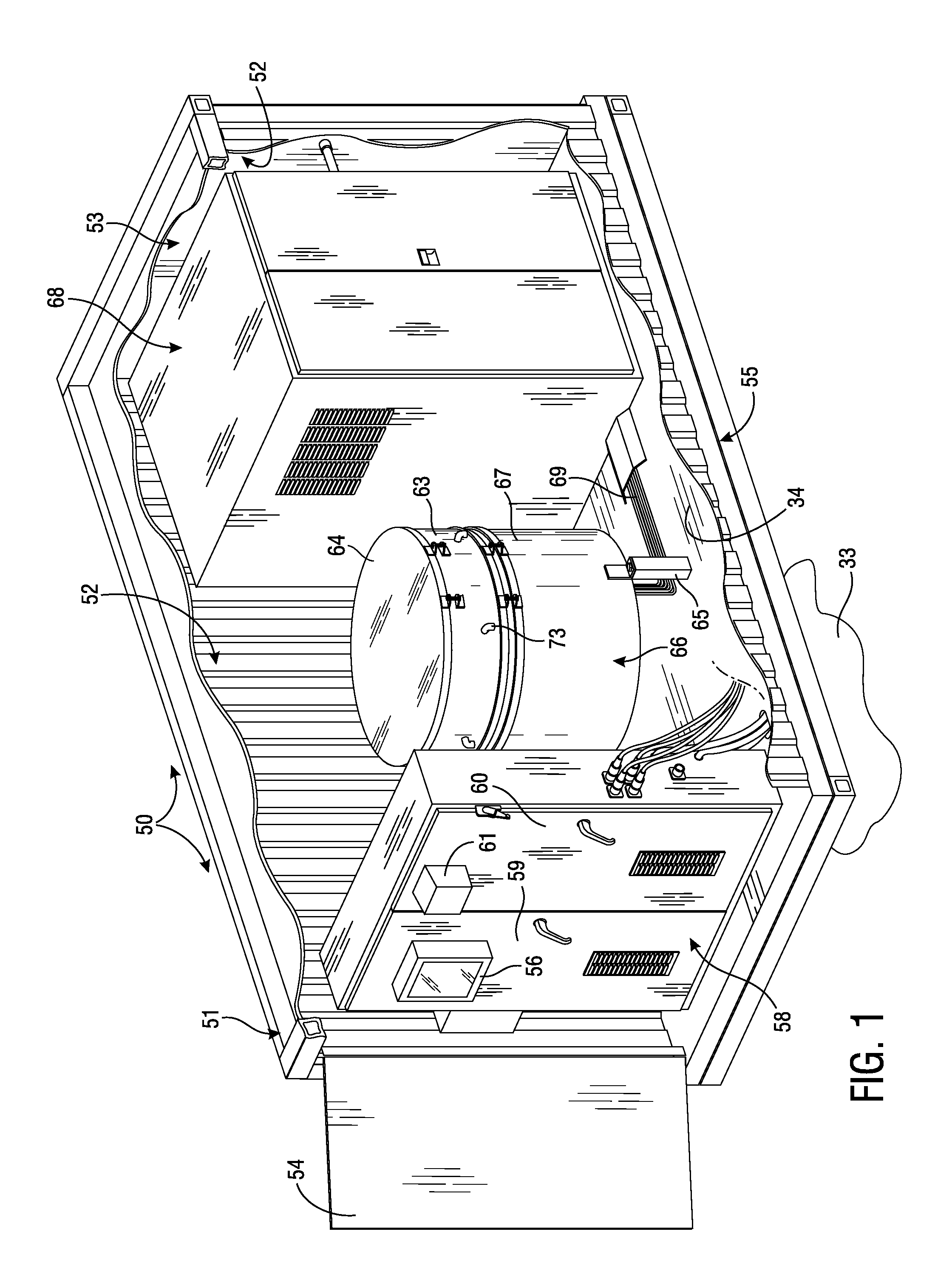

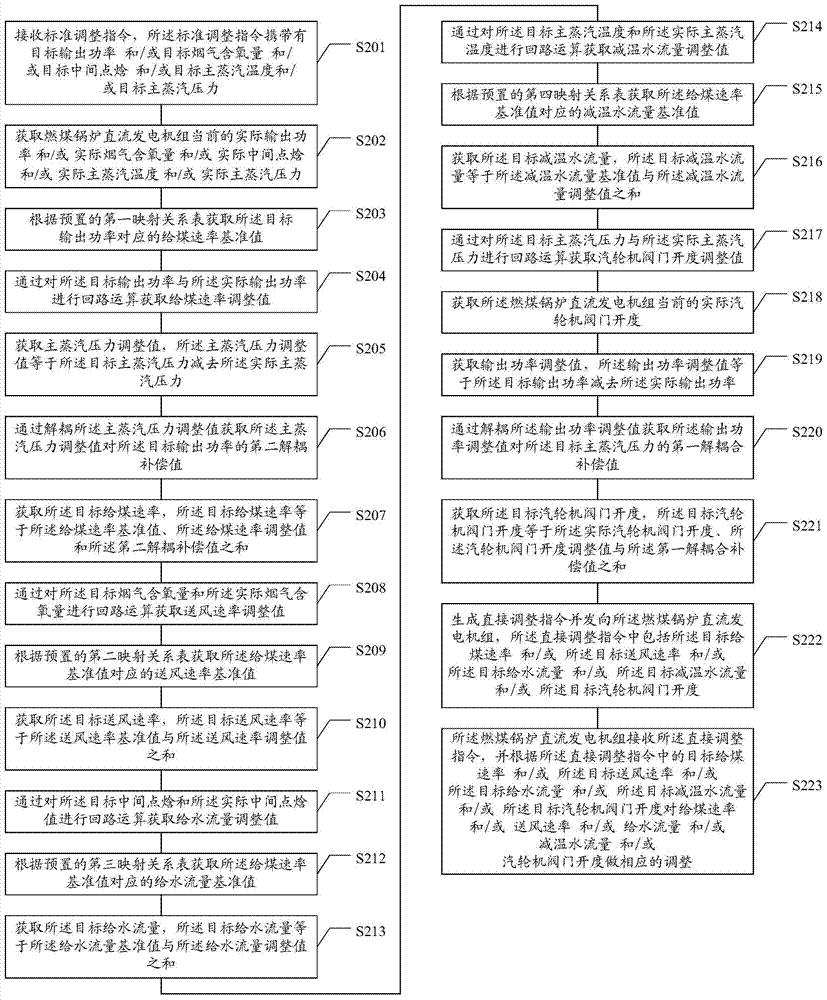

Methods for Super Heated Steam Generation

InactiveUS20130136435A1Increase superheatAccurate monitoringMachines/enginesFlash steam boilersEngineeringSuperheated steam

Modularized, superheated steam generators comprise a steam module (46), a thermocouple module (41), and an electrode module (45) assembled within a containment enclosure (66). The multi-stage steam module (46) comprises a plurality of first stage pressure vessels (77) surrounding and feeding a second stage pressure vessel (78). The steam module (46) is coaxially surrounded by insulation (48) disposed within a cylindrical shroud (72). The electrode module (45) radiantly heats the steam module with resistive heating elements (119). The thermocouple module (41) includes thermocouples monitoring first stage temperatures within and between pressure vessels (77). PLC computer SCADA software (600) operates the generators. Thermocouple data is analyzed to control heater temperatures, the water feeding system (340), and outputted steam temperature. PLC software (600) provides operating logic (602) establishing a start up subroutine (602), a ramp up subroutine (603), a steady state subroutine (605), and a shut down subroutine (606).

Owner:TRIMETEOR OIL & GAS CORP

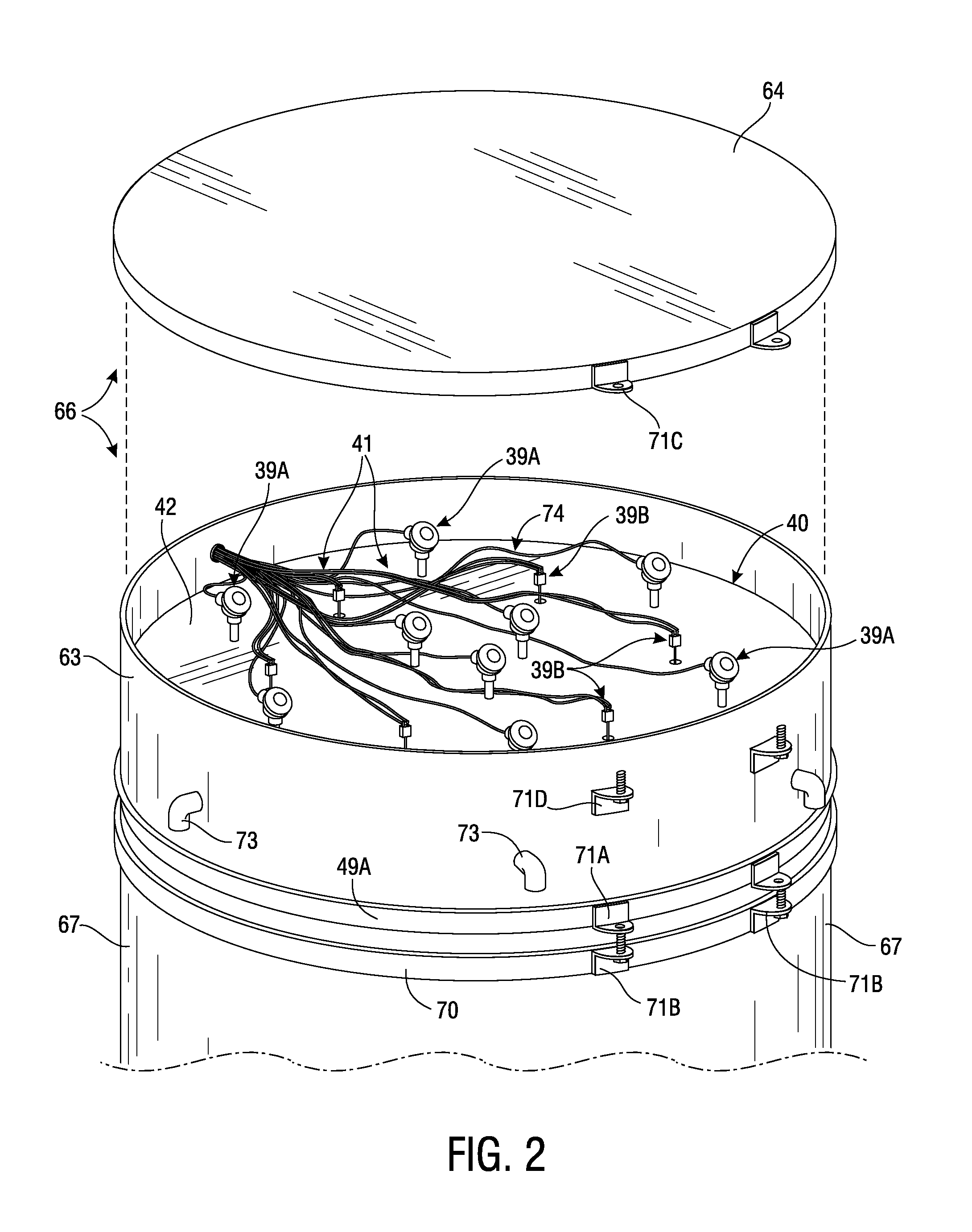

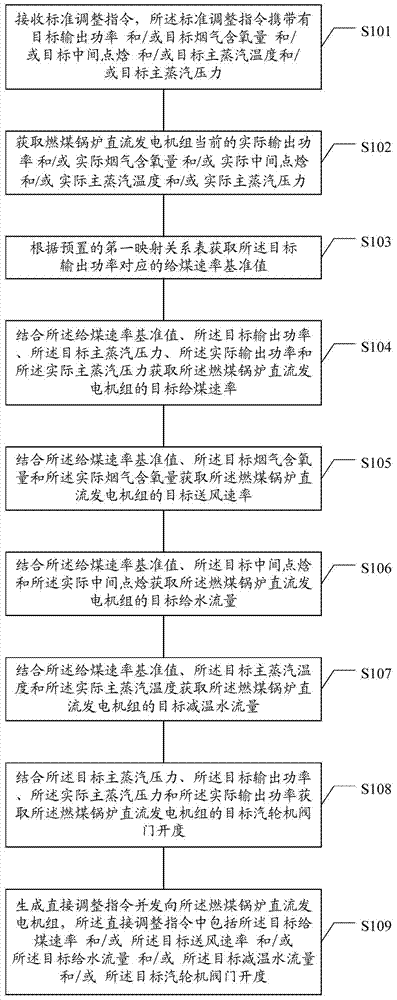

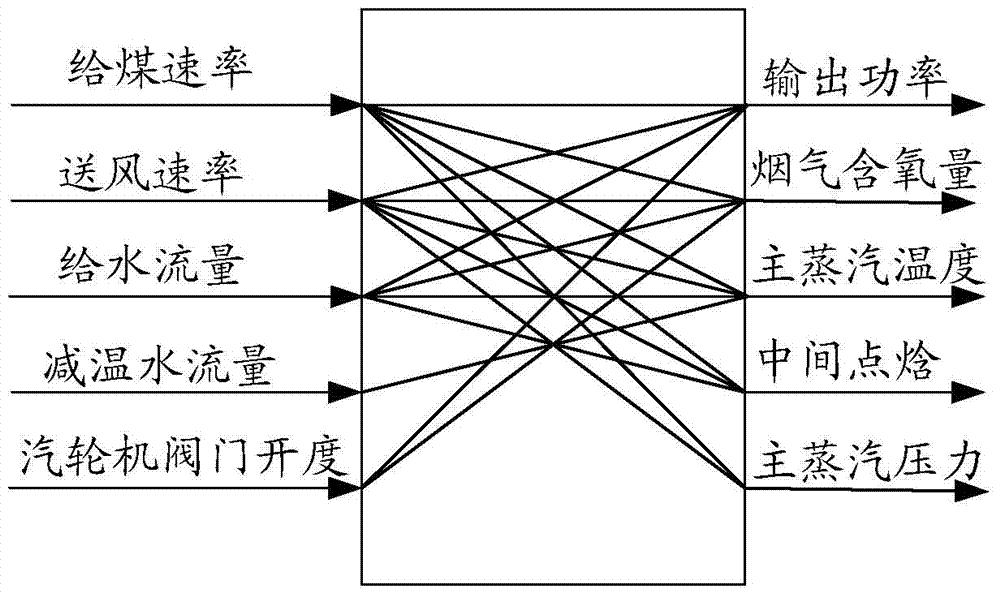

Method and device for controlling direct-current generator set of coal-fired boiler

ActiveCN103697454ADegree of reductionShorten the timeBoiler controlMachines/enginesWater flowProcess engineering

The invention discloses a method for controlling a direct-current generator set of a coal-fired boiler, and belongs to the technical field of generator set control. The method comprises the following steps of receiving a standard adjustment instruction; acquiring the current actual output power and the like of the direct-current generator set of the coal-fired boiler; acquiring a coal supply rate reference value corresponding to a target output power; acquiring a target coal supply rate; acquiring a target air supply rate; acquiring target water supply flow; acquiring target attemperation water flow; acquiring target turbine valve opening; generating a direct adjustment instruction and sending the direct adjustment instruction to the direct-current generator set of the coal-fired boiler. The output power of the direct-current generator set of the coal-fired boiler is adjusted by simultaneously adjusting the coal supply rate and the like which have influence on the output power of the direct-current generator set of the coal-fired boiler, the fluctuation degree of the output power can be reduced, and the fluctuation time of the output power can be shortened.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Exhaust Gas Diverter and Collection System For Ocean Going Vessels

ActiveUS20140090379A1Conveniently routedDispersed particle filtrationExhaust apparatusWater basedAtmospheric air

An exhaust gas collection system for capturing the exhaust gas emitted by auxiliary engines, auxiliary boilers and other sources on an Ocean Going Vessel (OGV) while at berth or at anchor, so that these gases may be carried to an emissions treatment system for removal of air pollutants and greenhouse gases. The exhaust gas collection system includes a diverter to redirect the exhaust gas normally carried by exhaust pipes to the OGV's stack for release to the atmosphere, to an exhaust gas treatment system. The emissions treatment system may be land-based, water-based, or on the OGV. When the emissions treatment system is land-based, water-based, the exhaust gas is carried to a connection location that accessible by a ducting system to carry the exhaust gas to the emissions treatment system. The exhaust gas collection system preferably includes parallel-flow ducts and a manifold to combine the parallel-flows into a single duct for more convenient routing through the vessel.

Owner:ADVANCED CLEANUP TECH +1

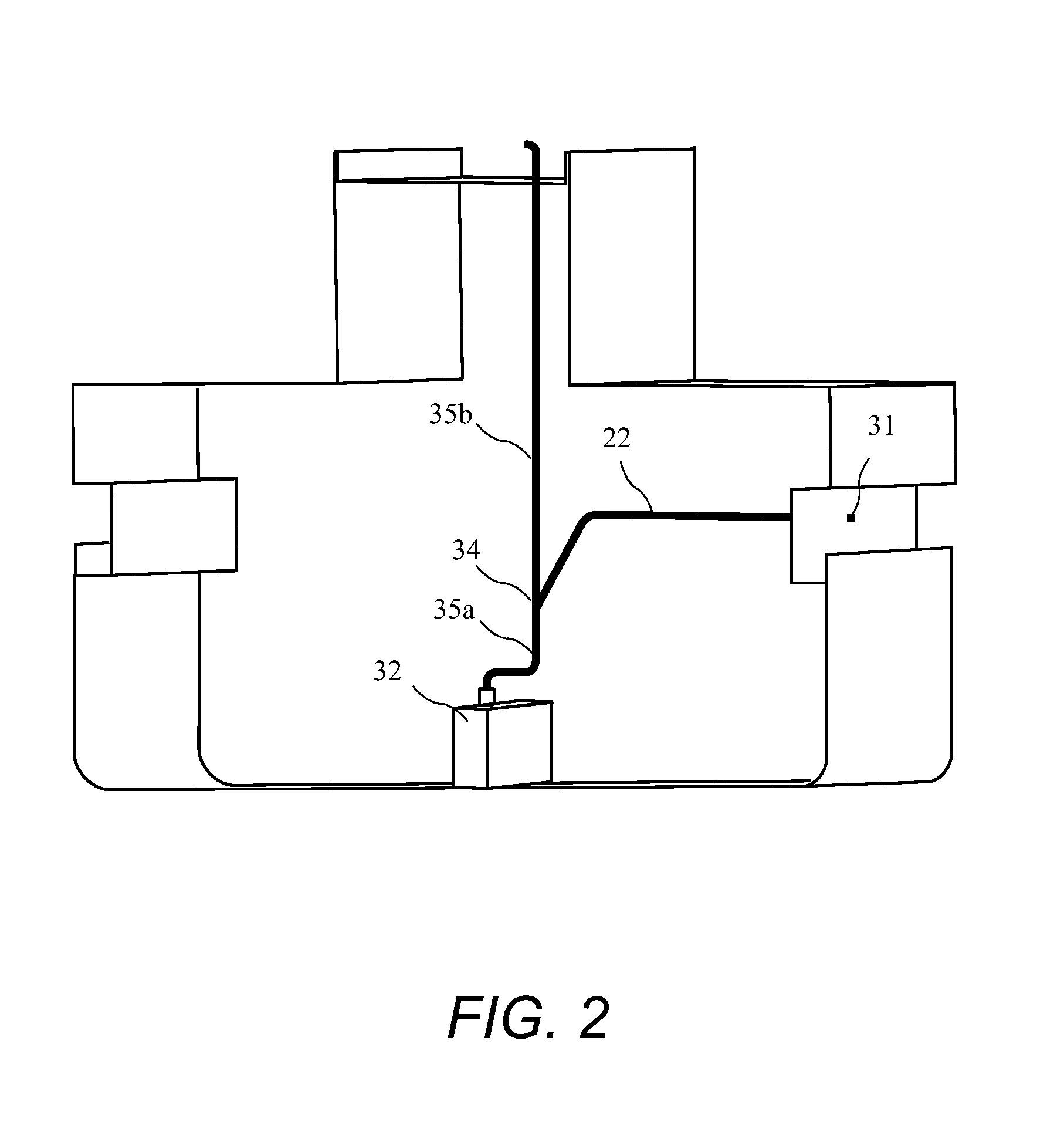

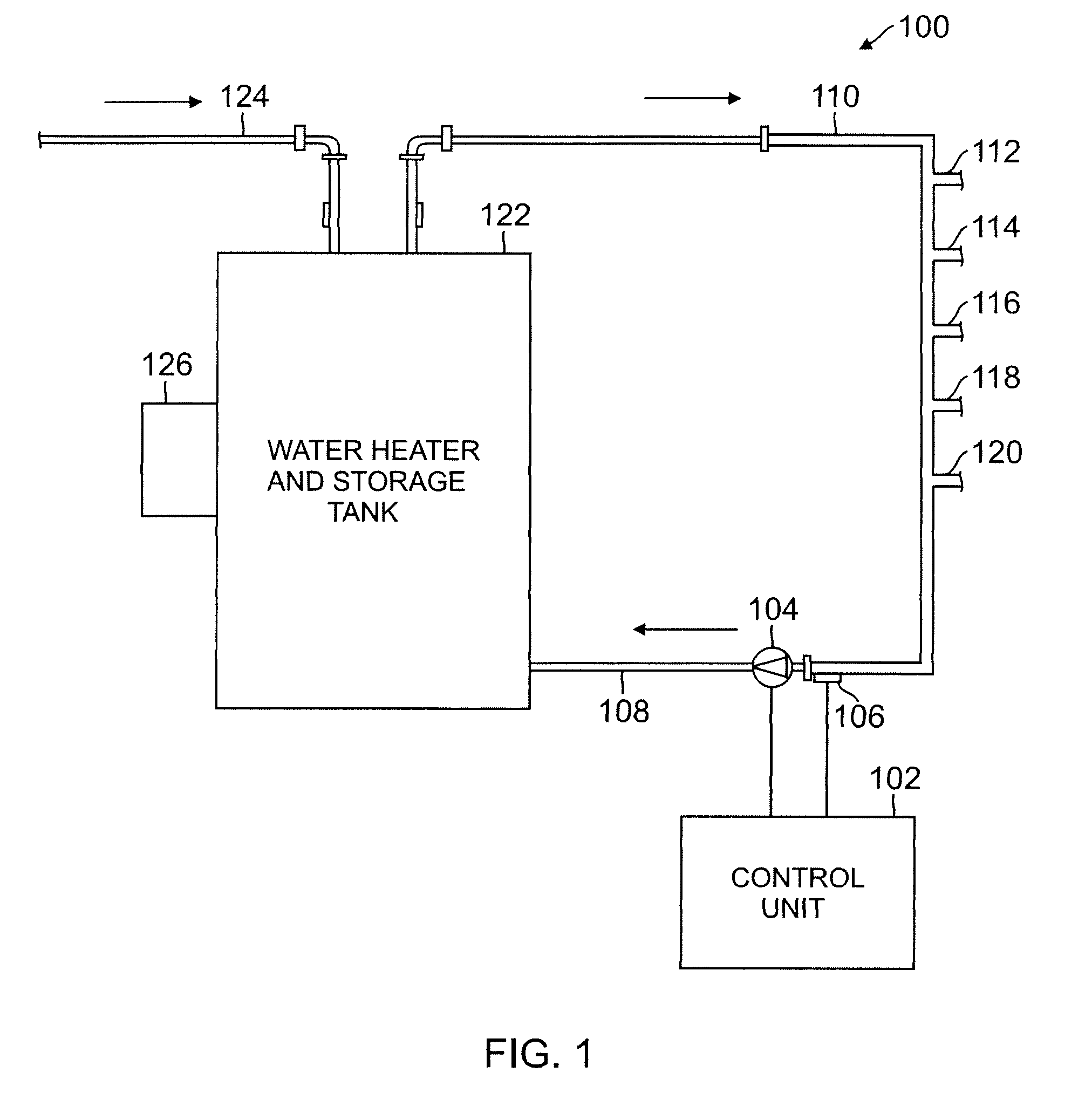

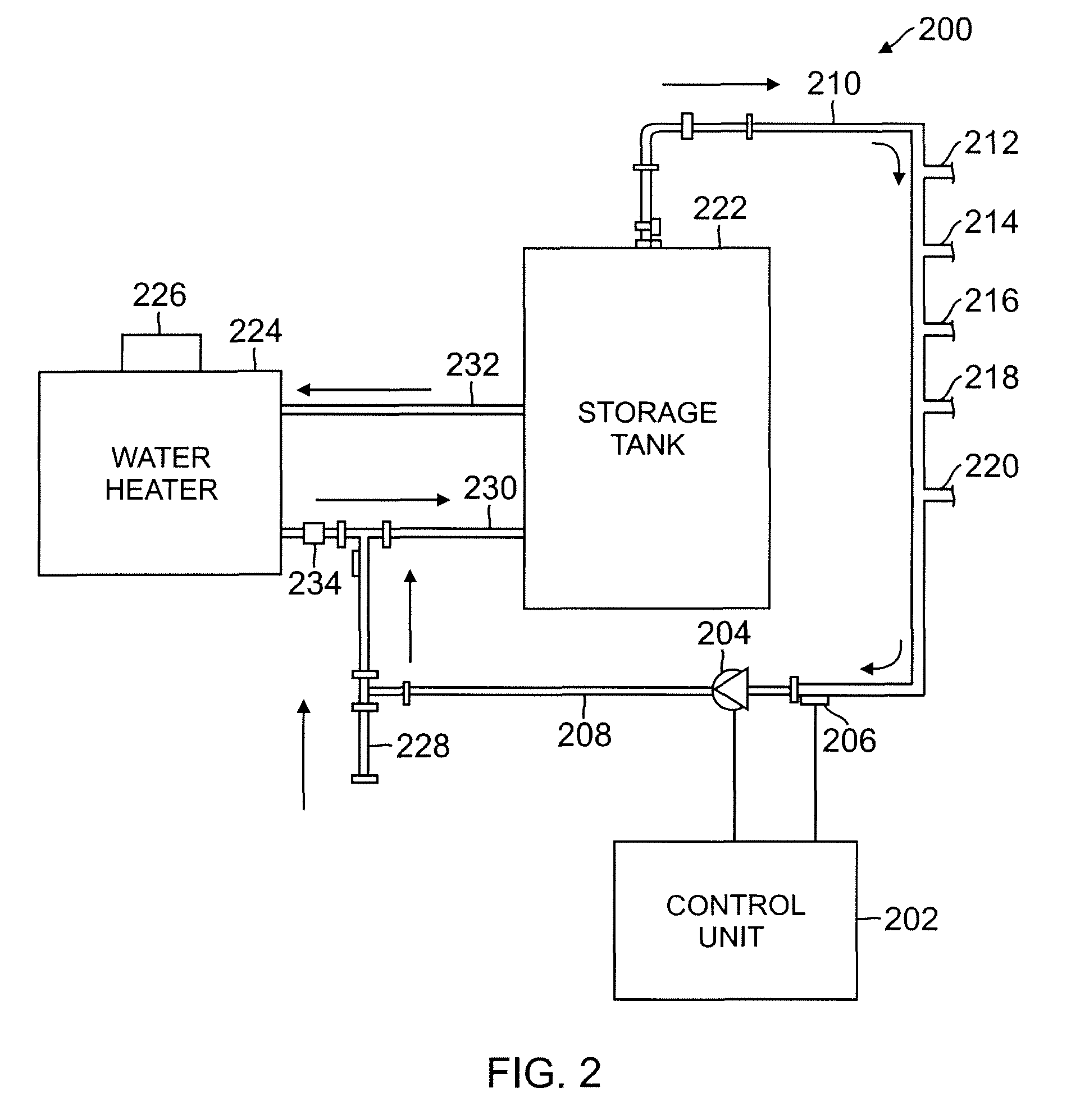

System and method for controlling a pump in a recirculating hot water system

InactiveUS8191513B2Efficient regulation technologiesMachines/enginesTemperature controlWater cycling

A system and a method for controlling a pump in a recirculating hot water system is provided. In one embodiment, the invention relates to a method for controlling a temperature of water in a recirculating hot water system including a storage tank for storing heated water, a recirculation conduit including a supply conduit for supplying the heated water to users via a plurality of outlets having a first outlet and a last outlet and a return conduit for returning an unused portion the heated water to the storage tank, a pump for circulating the heated water, the pump disposed along the return conduit, the method including measuring, at a point along the recirculation conduit, a temperature of the heated water provided from the storage tank, and controlling a speed of the pump, disposed along the return conduit, based on the measured temperature.

Owner:TDK FAMILY PARTNERSHIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com