Patents

Literature

71results about How to "Reduce temperature fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

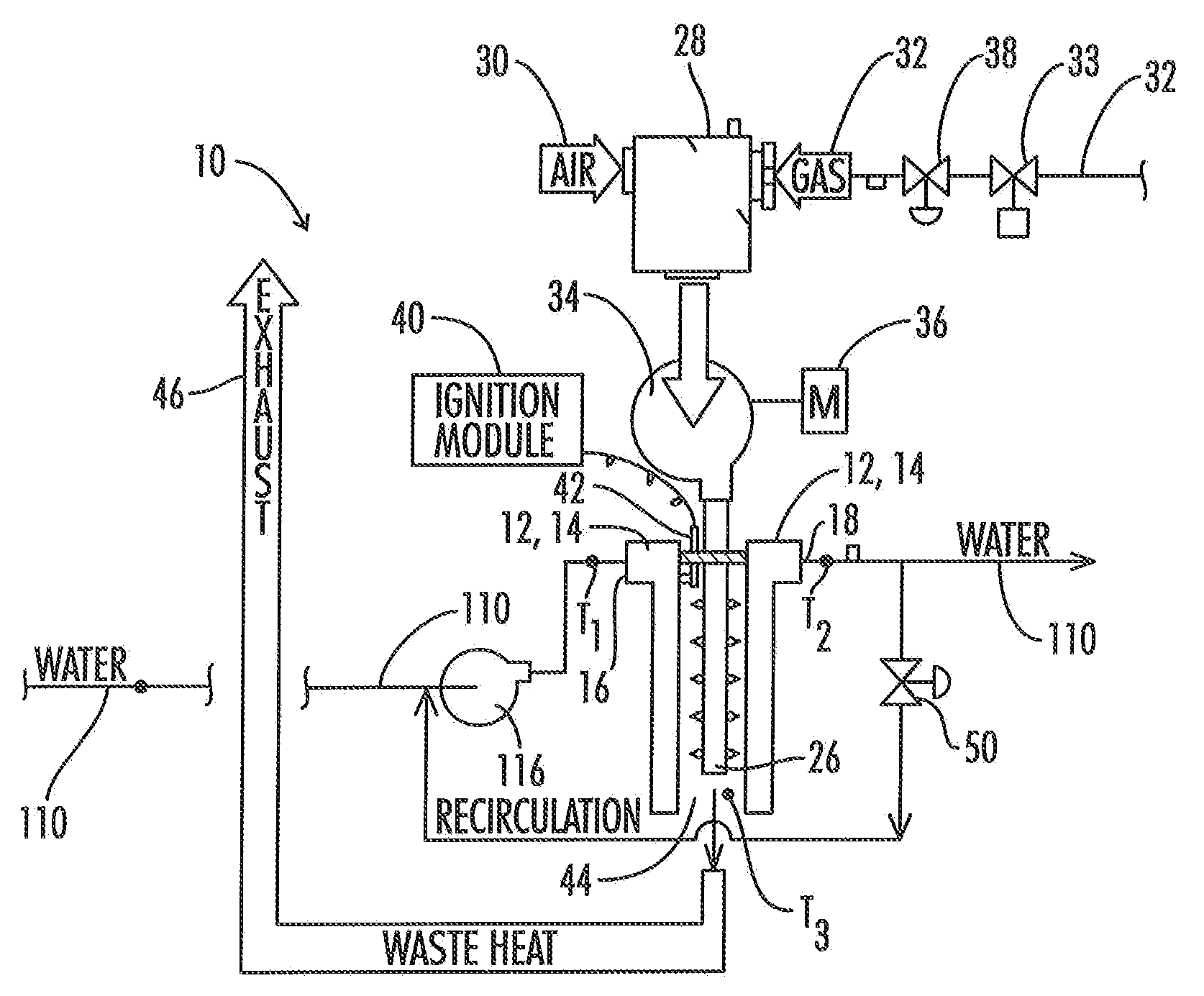

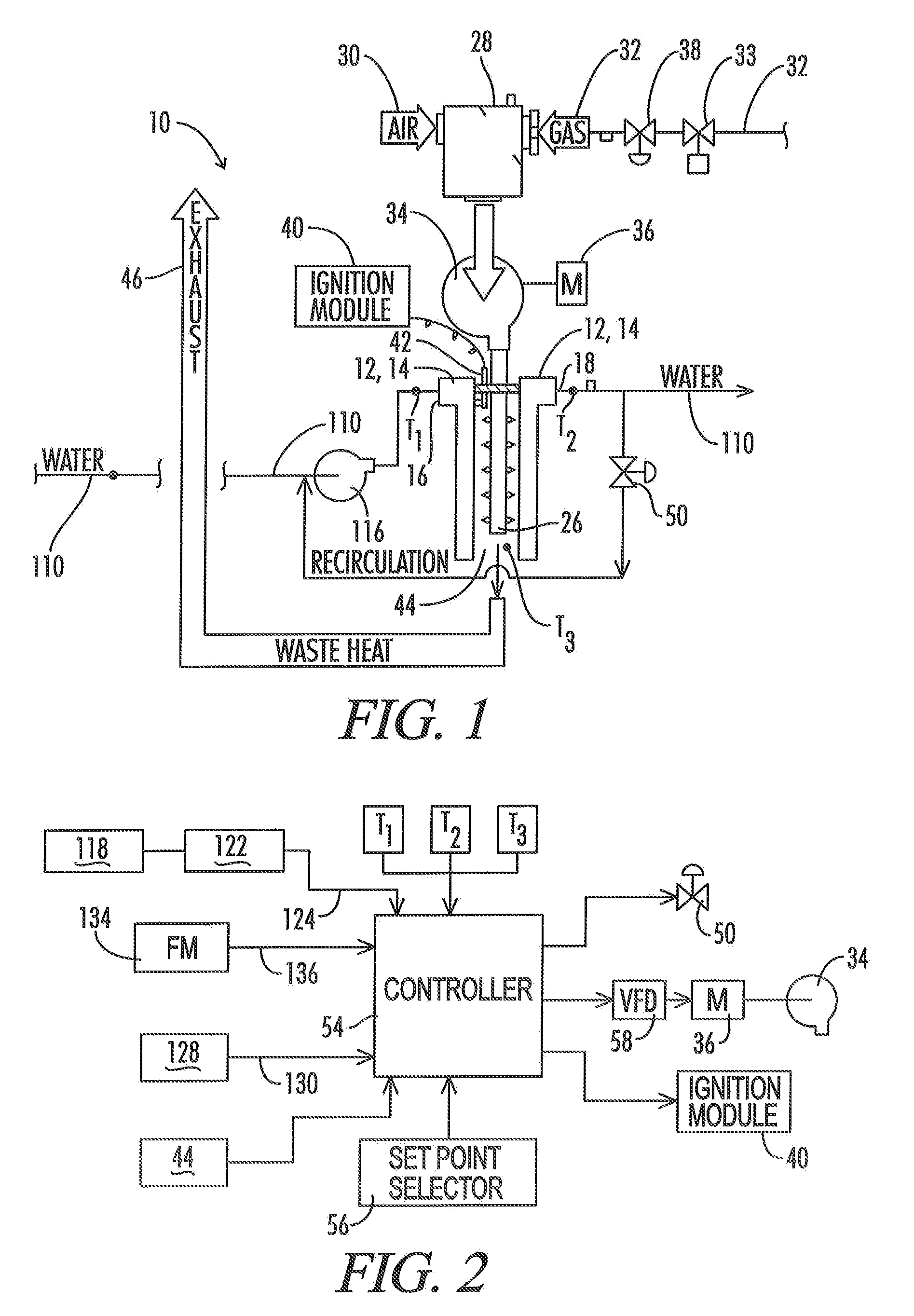

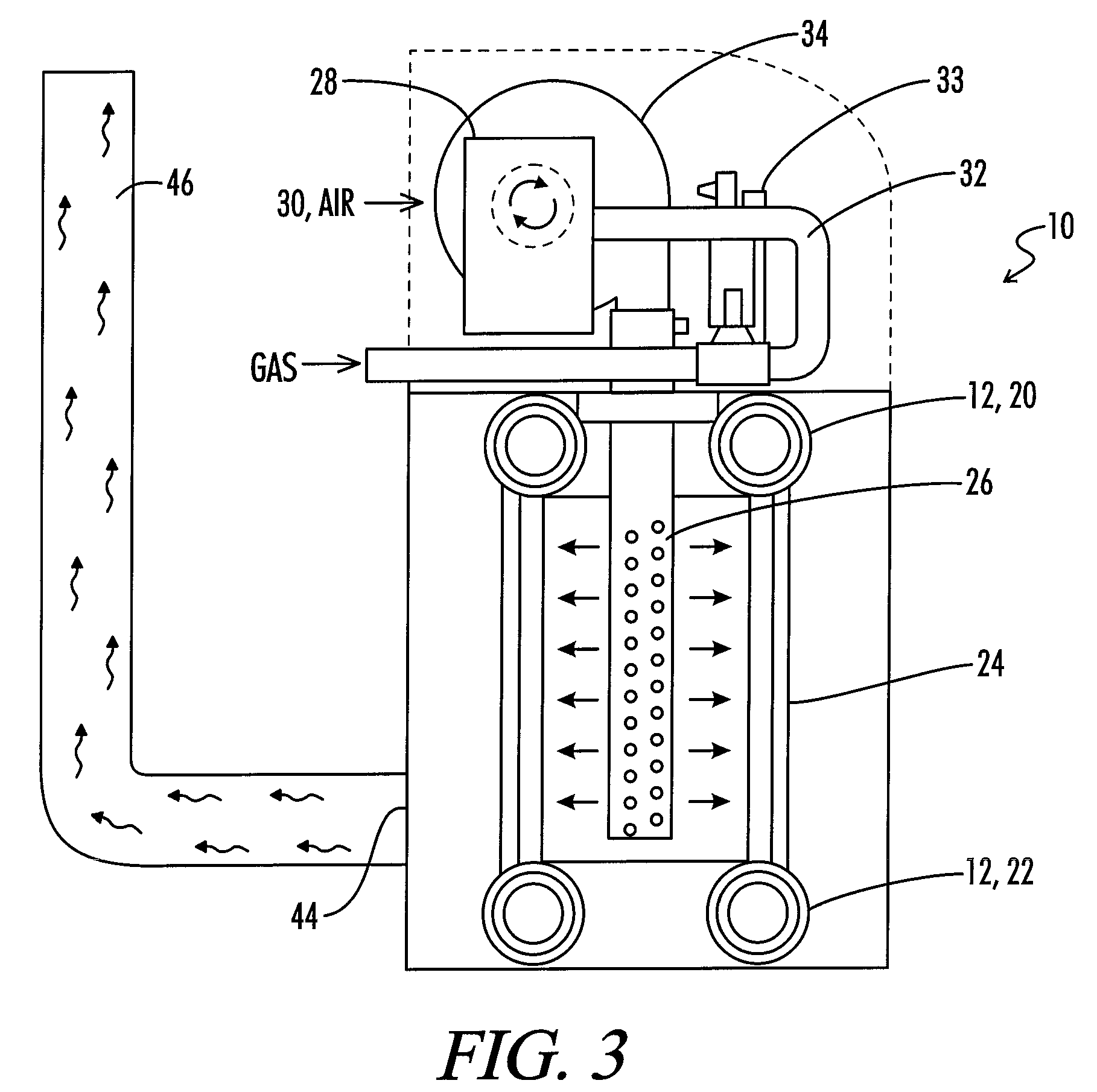

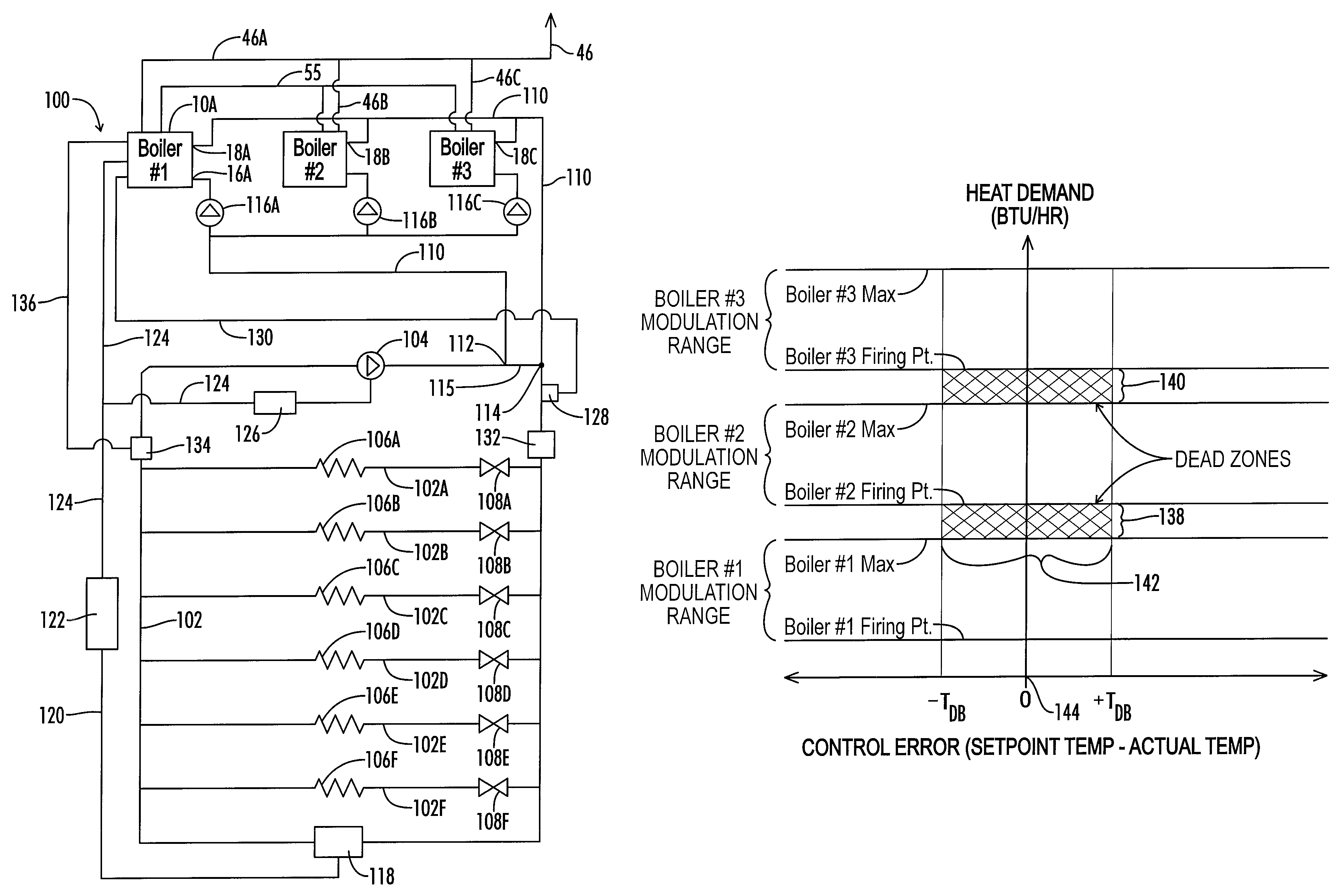

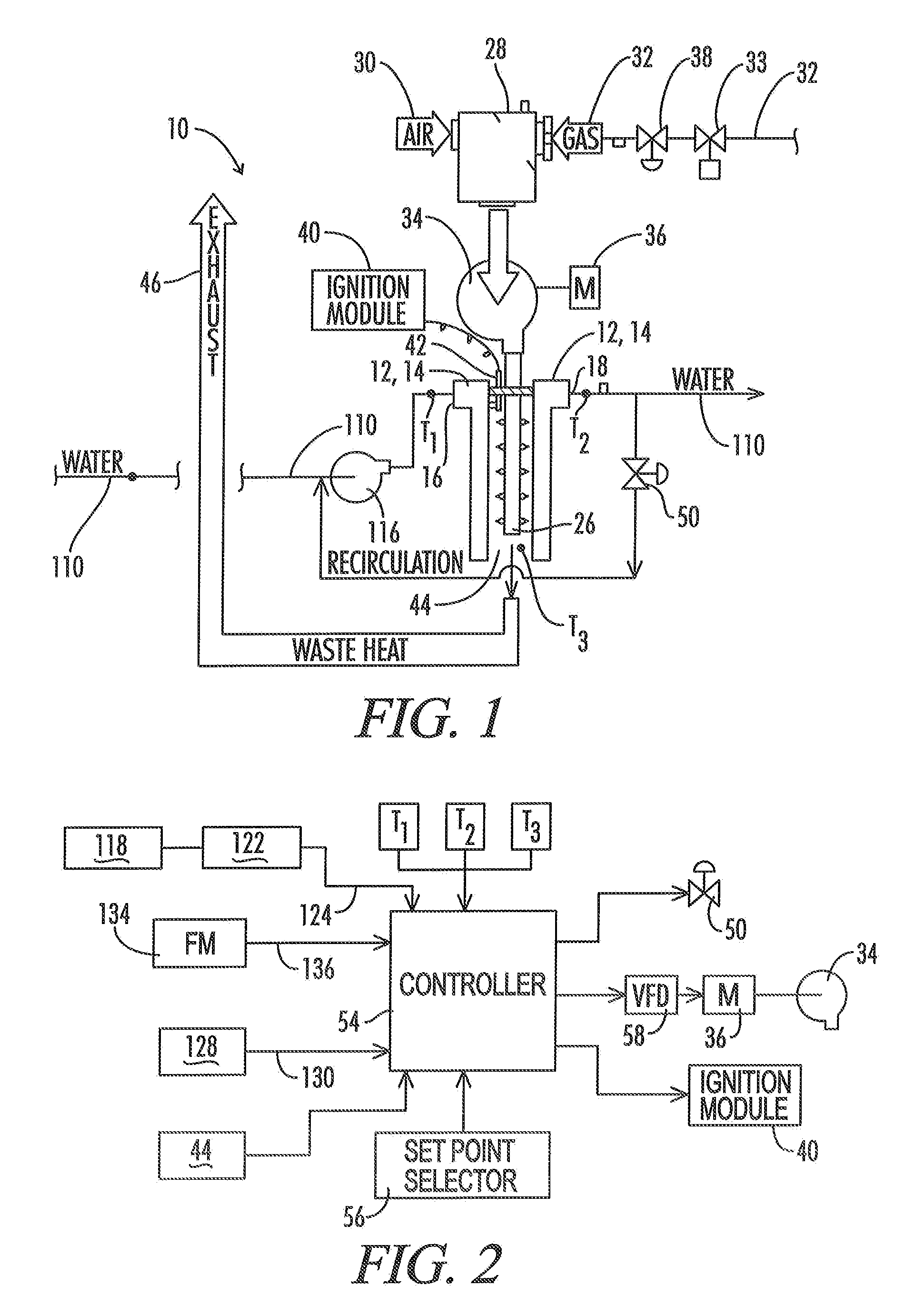

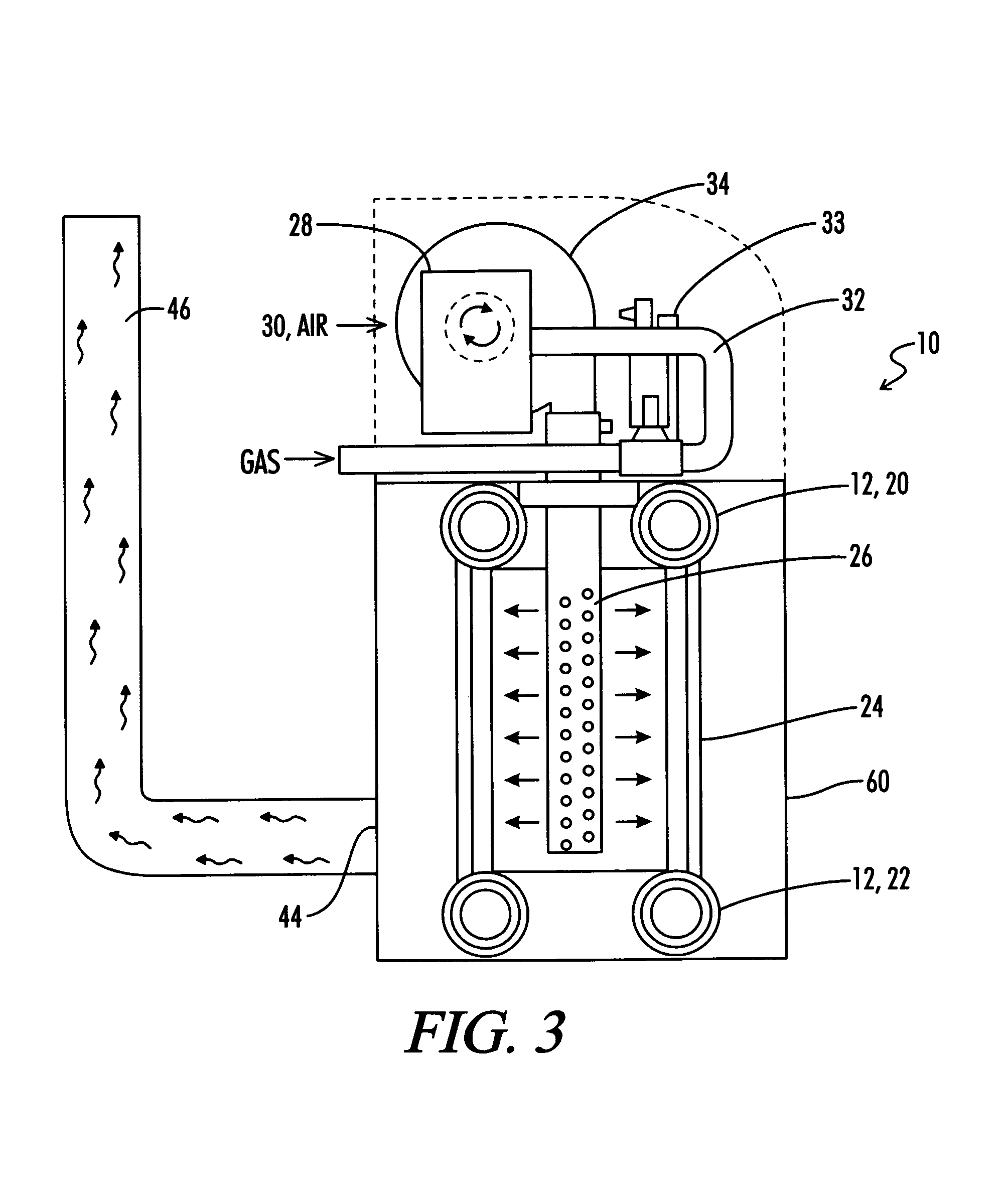

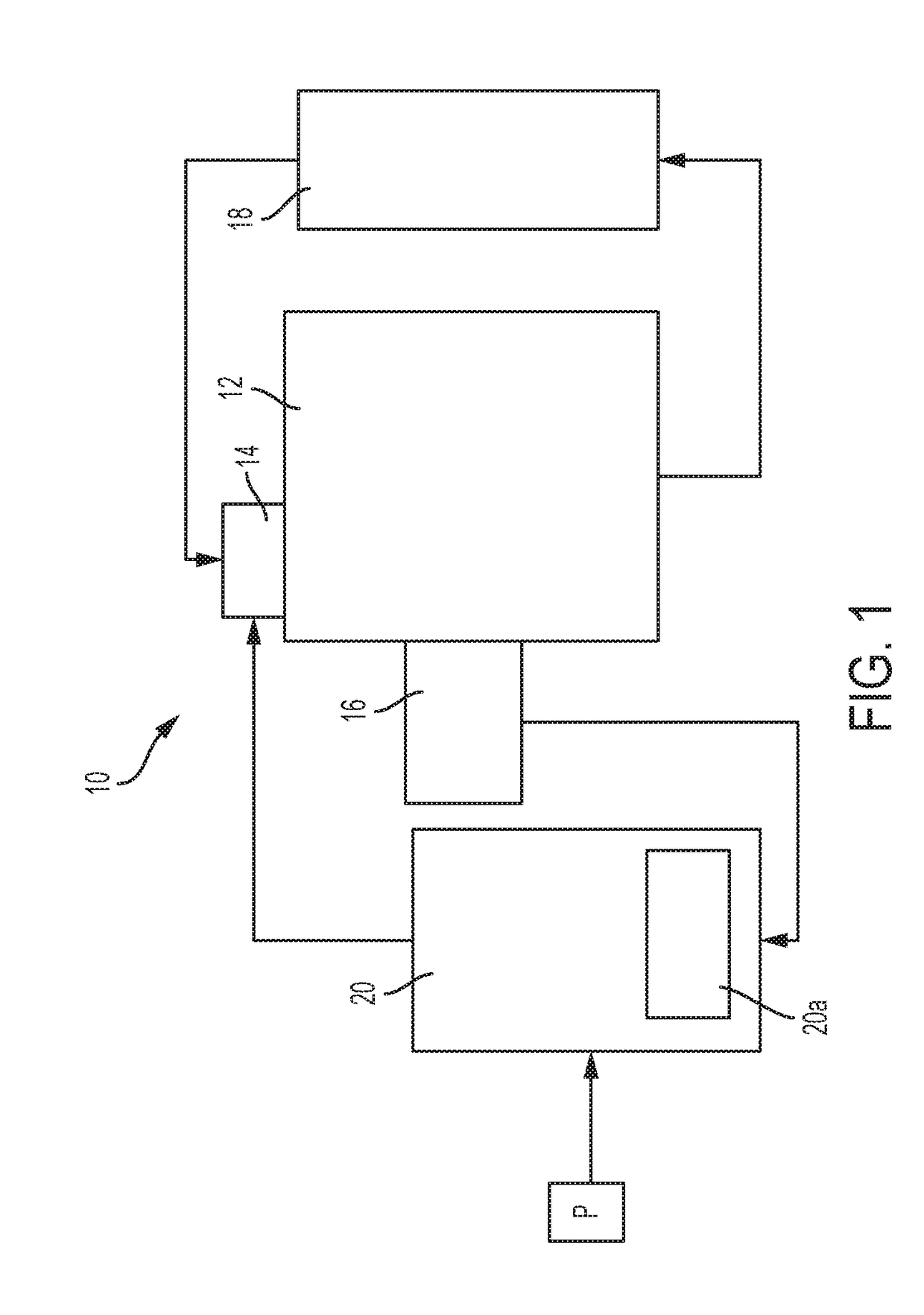

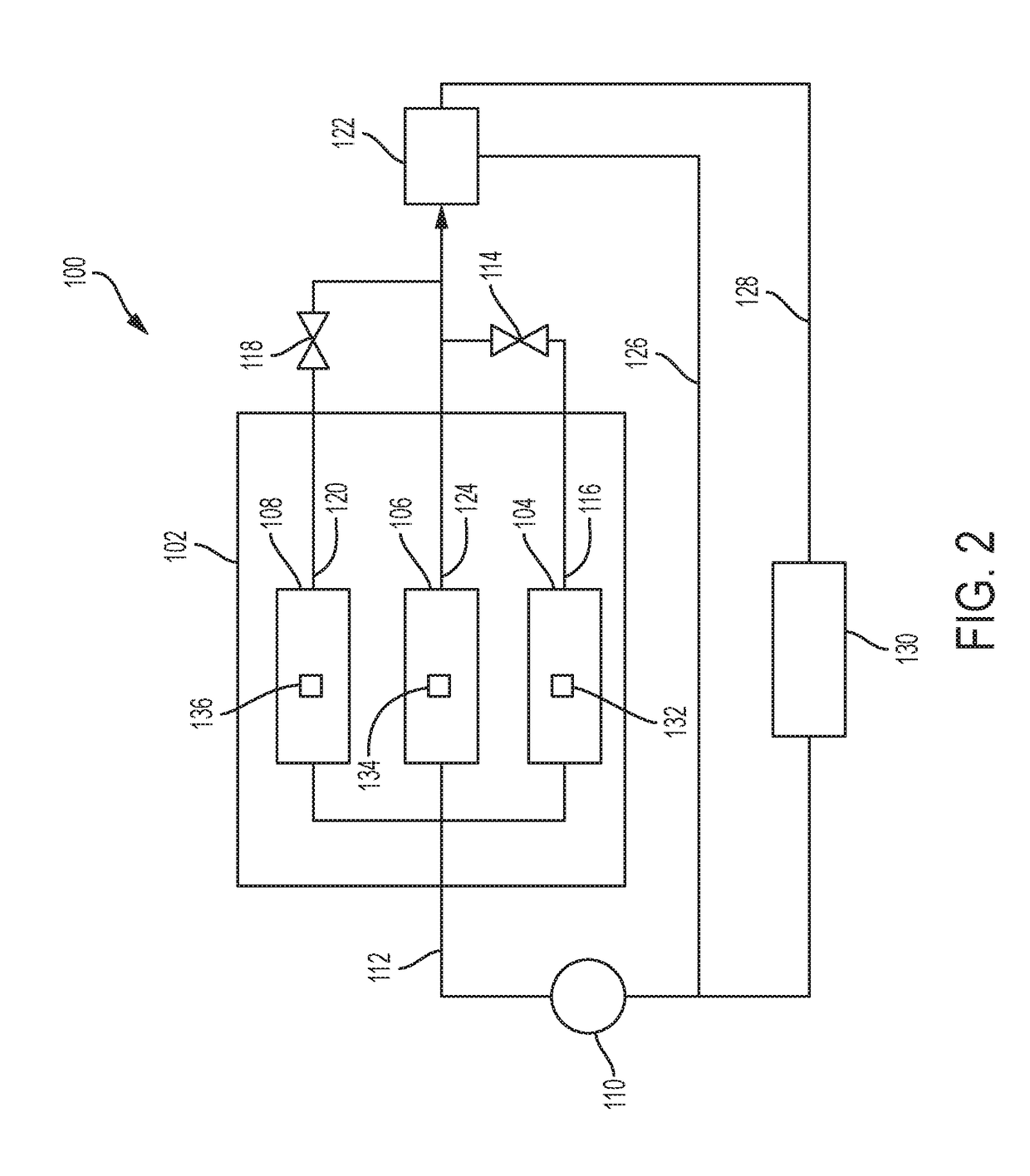

Control System For Modulating Water Heater

ActiveUS20080216771A1Shorten the overall cycleEarly detectionFluid heatersFuel supply regulationDeadbandHeating system

A control system is provided for a modulated heating system including a plurality of modulating water heaters, which may be modulating boilers. A deadband control scheme provides for reduced cycling of the modulating heater when total system heat demand falls between the maximum output of one heater and the sum of the maximum output of that one point and the minimum firing point of the next subsequent heater.

Owner:LOCHINVAR

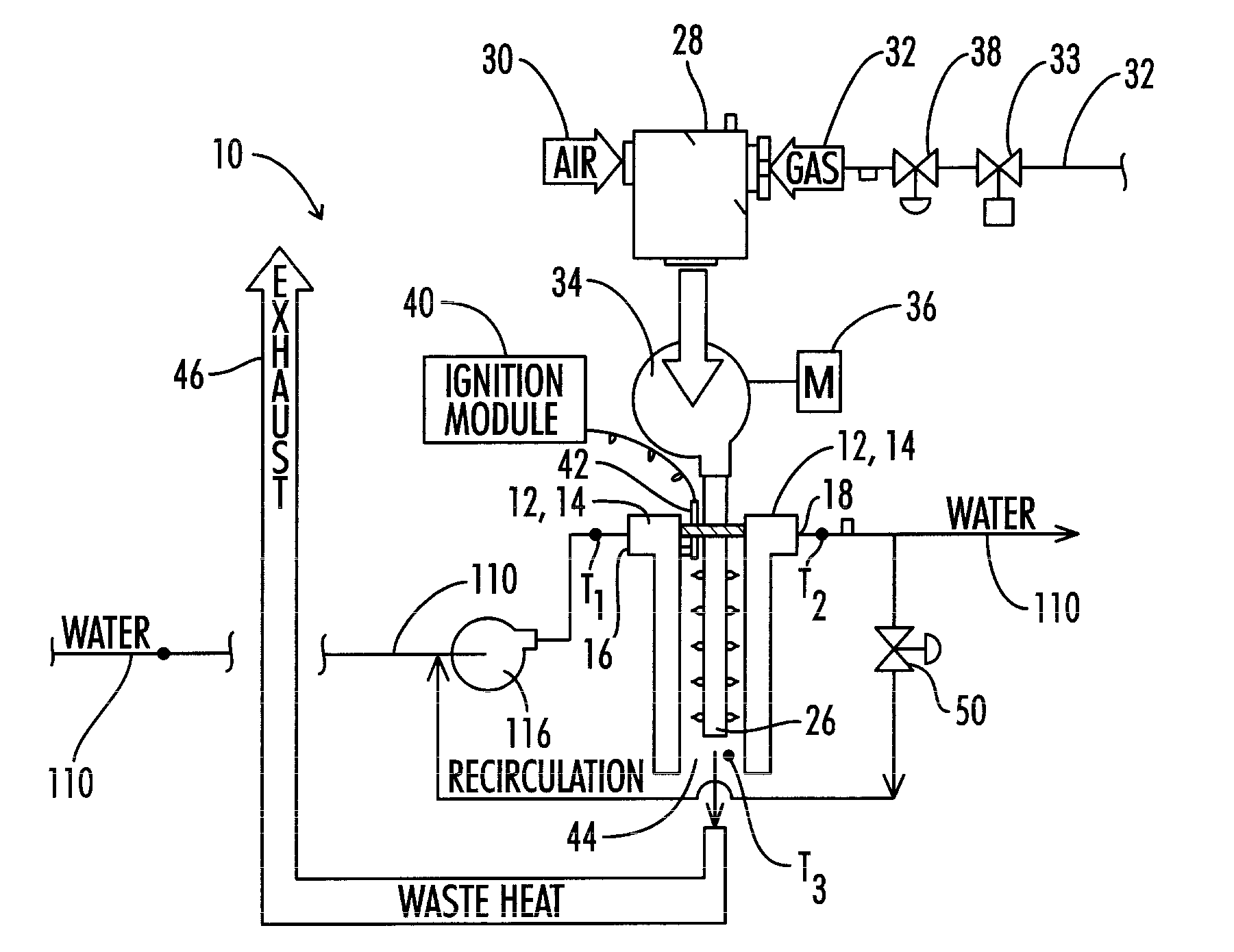

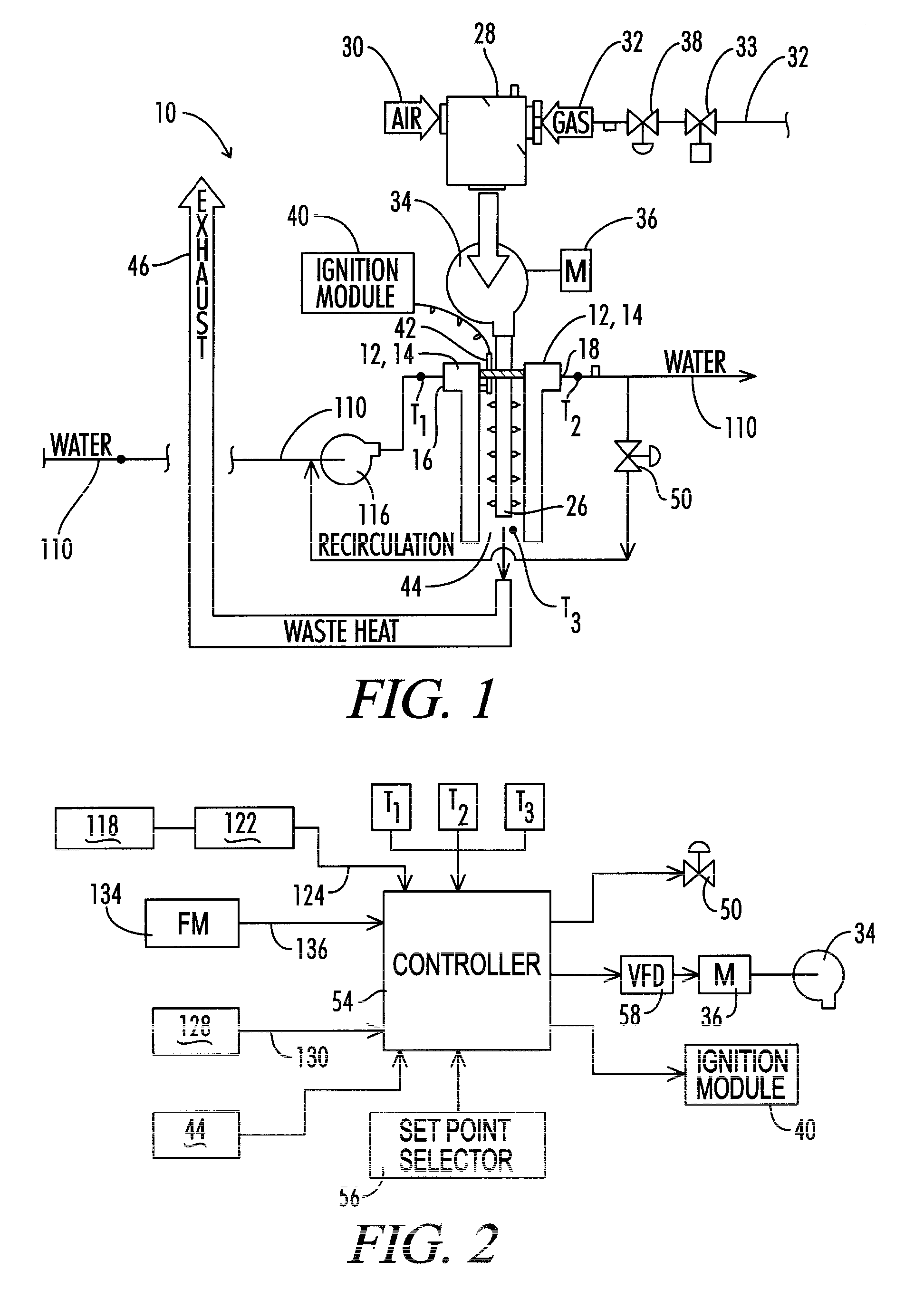

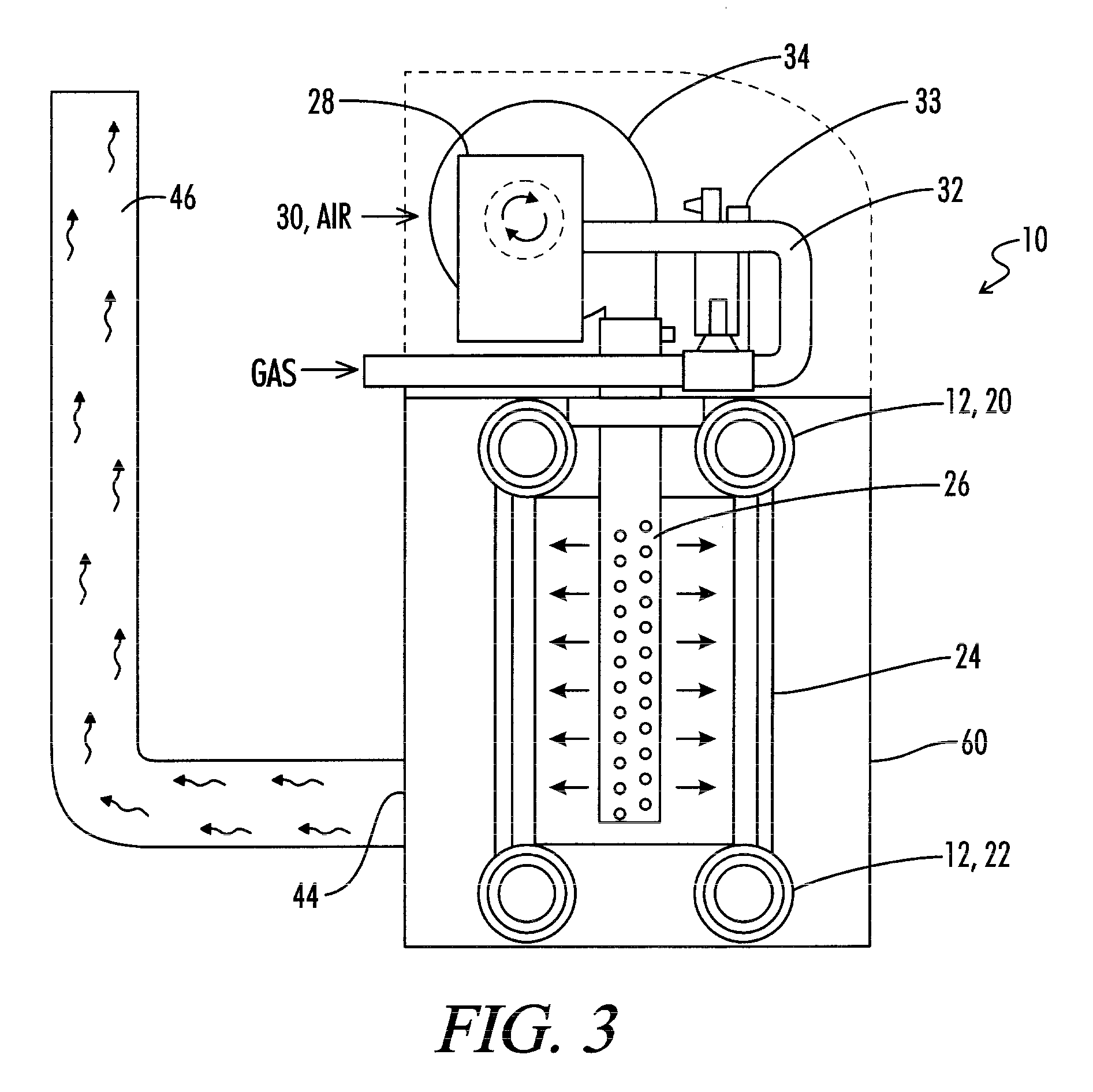

Control system for modulating water heater

ActiveUS7506617B2Reduce temperature fluctuationsReact much more quicklyMechanical apparatusTemperatue controlDeadbandHeating system

A control system is provided for a modulated heating system including a plurality of modulating water heaters, which may be modulating boilers. A deadband control scheme provides for reduced cycling of the modulating heater when total system heat demand falls between the maximum output of one heater and the sum of the maximum output of that one point and the minimum firing point of the next subsequent heater.

Owner:LOCHINVAR

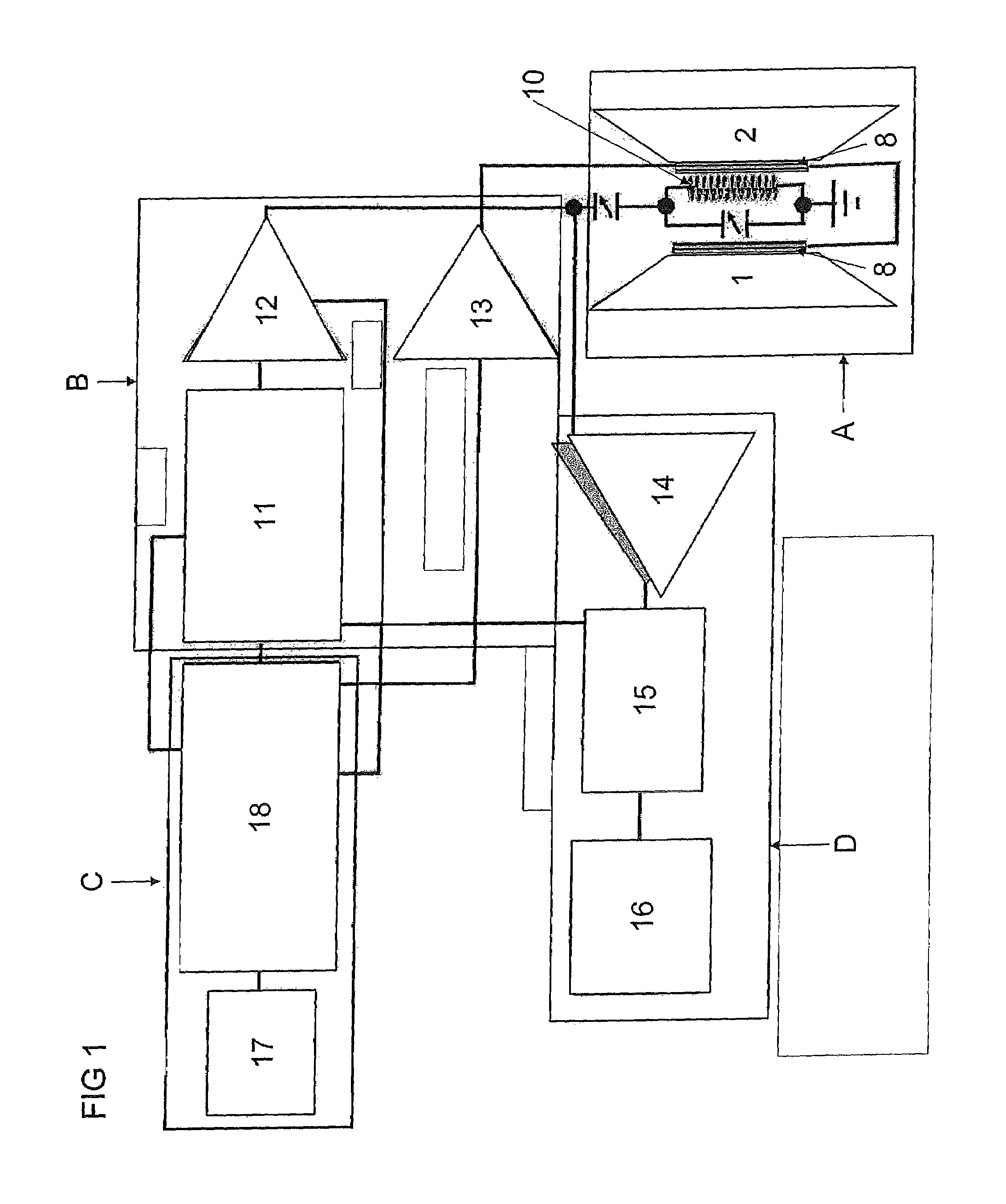

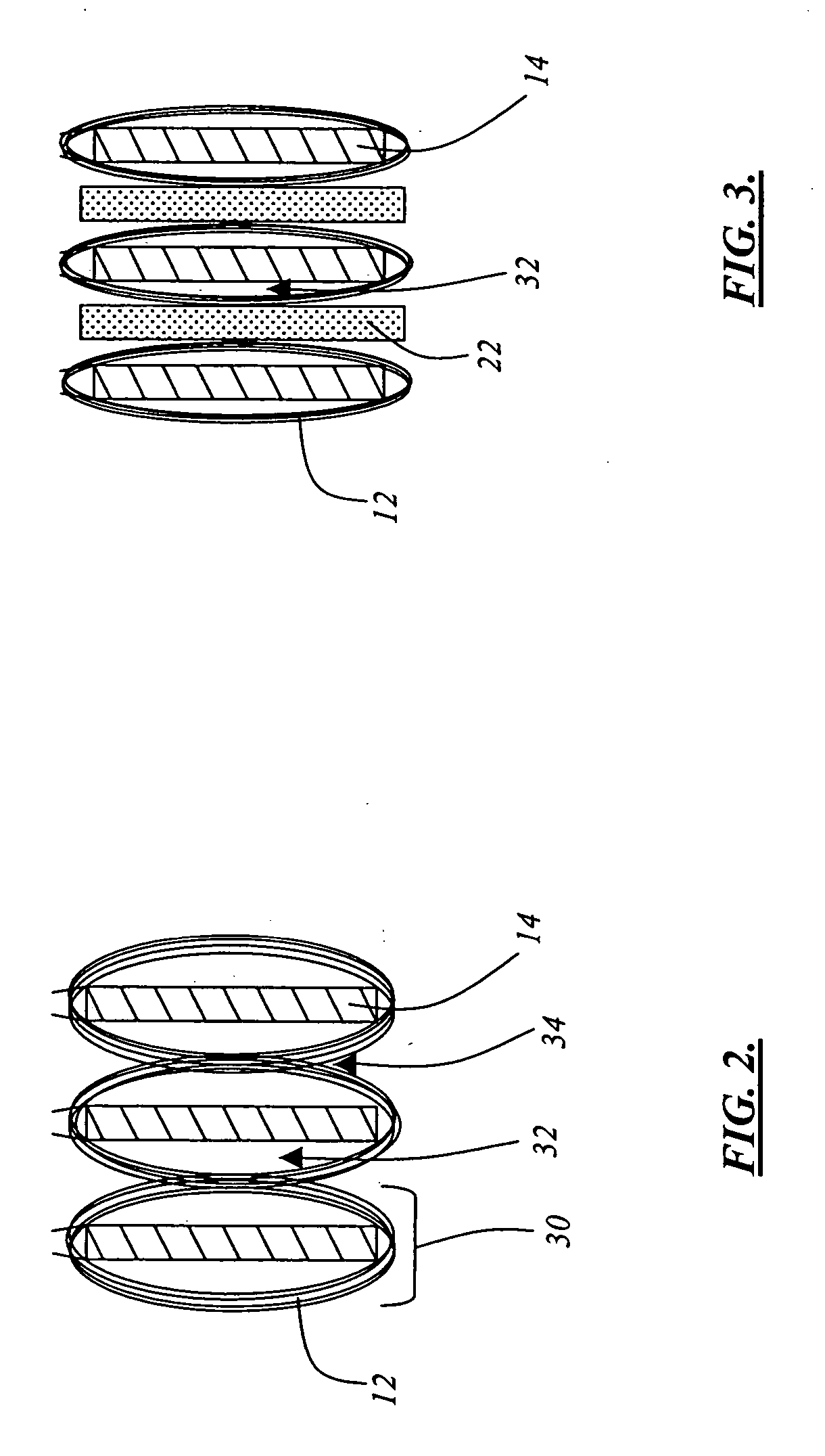

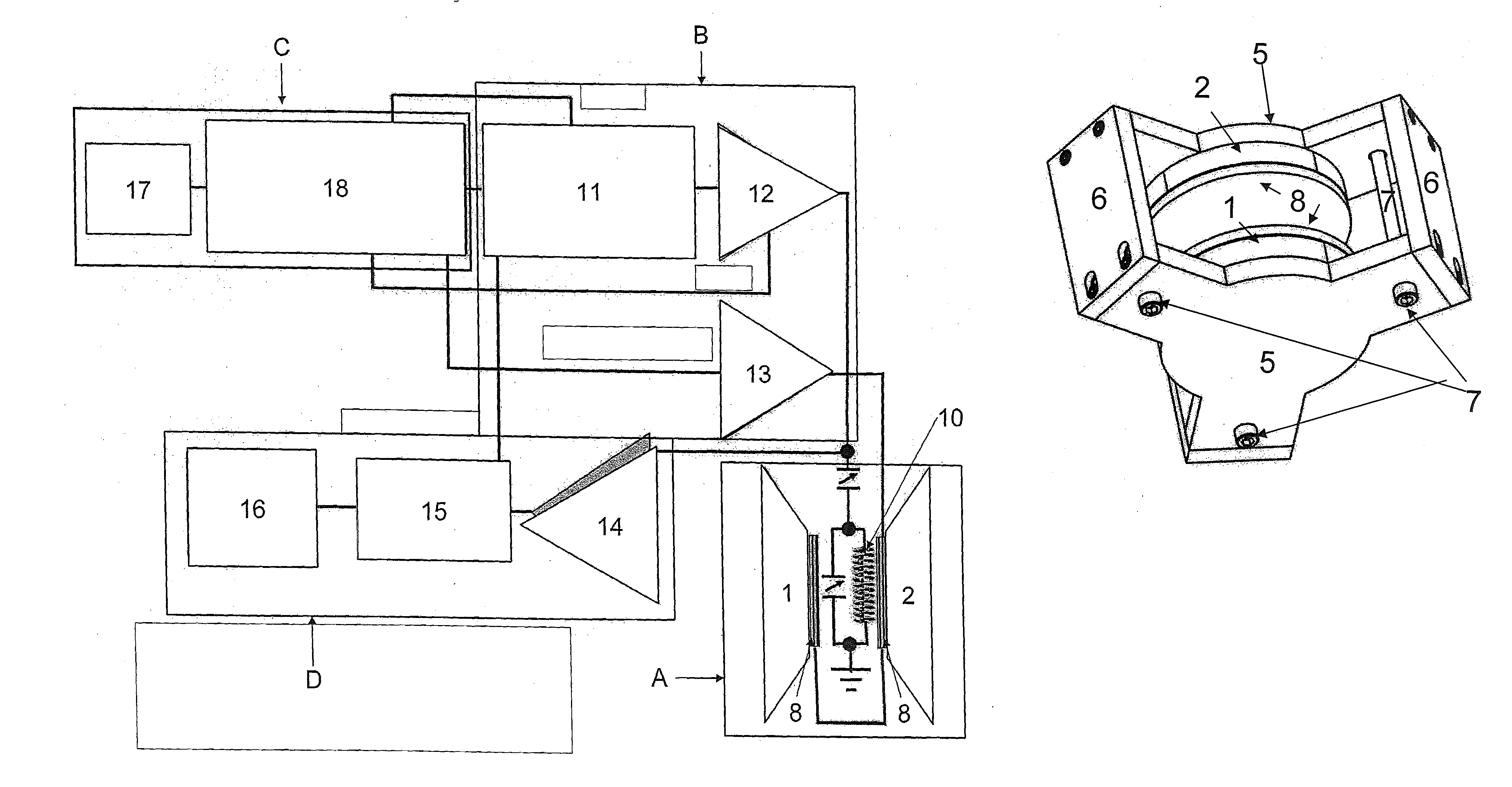

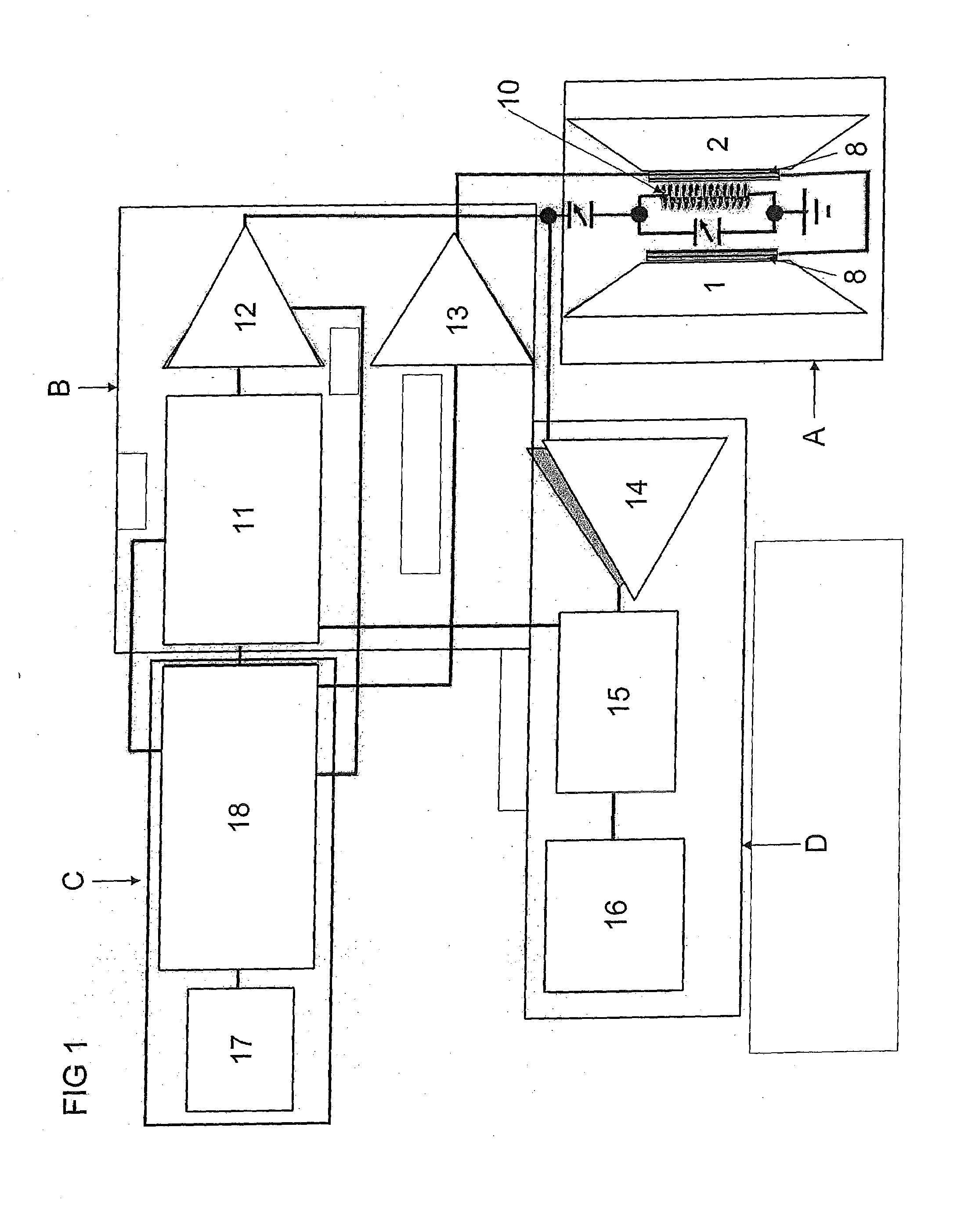

Compact and portable low-field pulsed NMR dispersion analyzer

ActiveUS7417426B2Small and portableLow costAnalysis using nuclear magnetic resonanceMeasurements using NMR imaging systemsMagnetic field gradientLiquid ratio

A compact and integrated portable device is provided for the analysis of dispersions by low-field pulsed NMR including: an NMR probe module, a means for generating radio frequency and magnetic field gradient pulses, a signal processor, and a master controller. Also provided are methods for using the device to measure one or more characteristics of phases or particles comprising a dispersion such as surface area, solid / liquid ratio, particle size, and elemental analysis.

Owner:XIGO NANOTOOLS

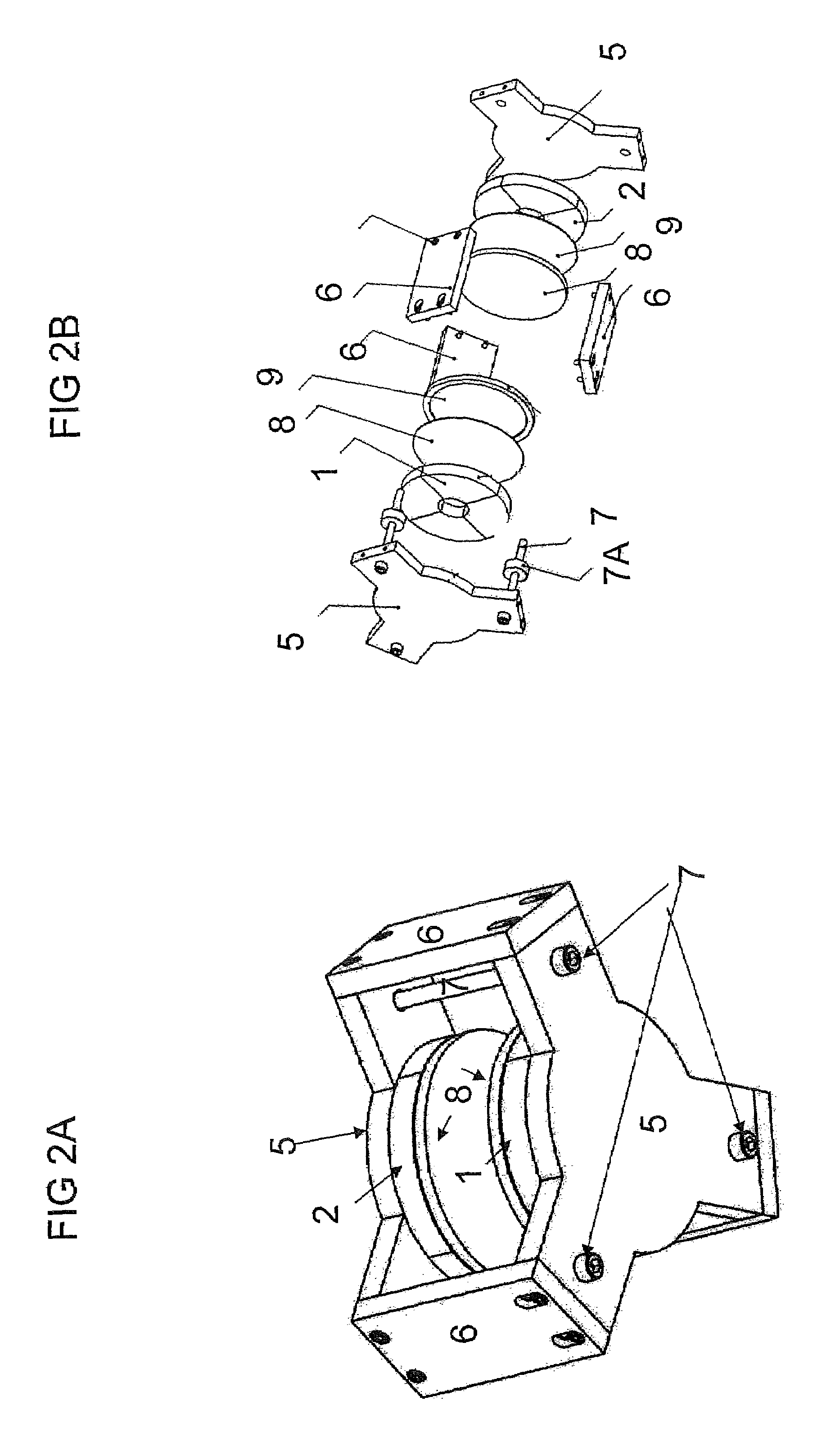

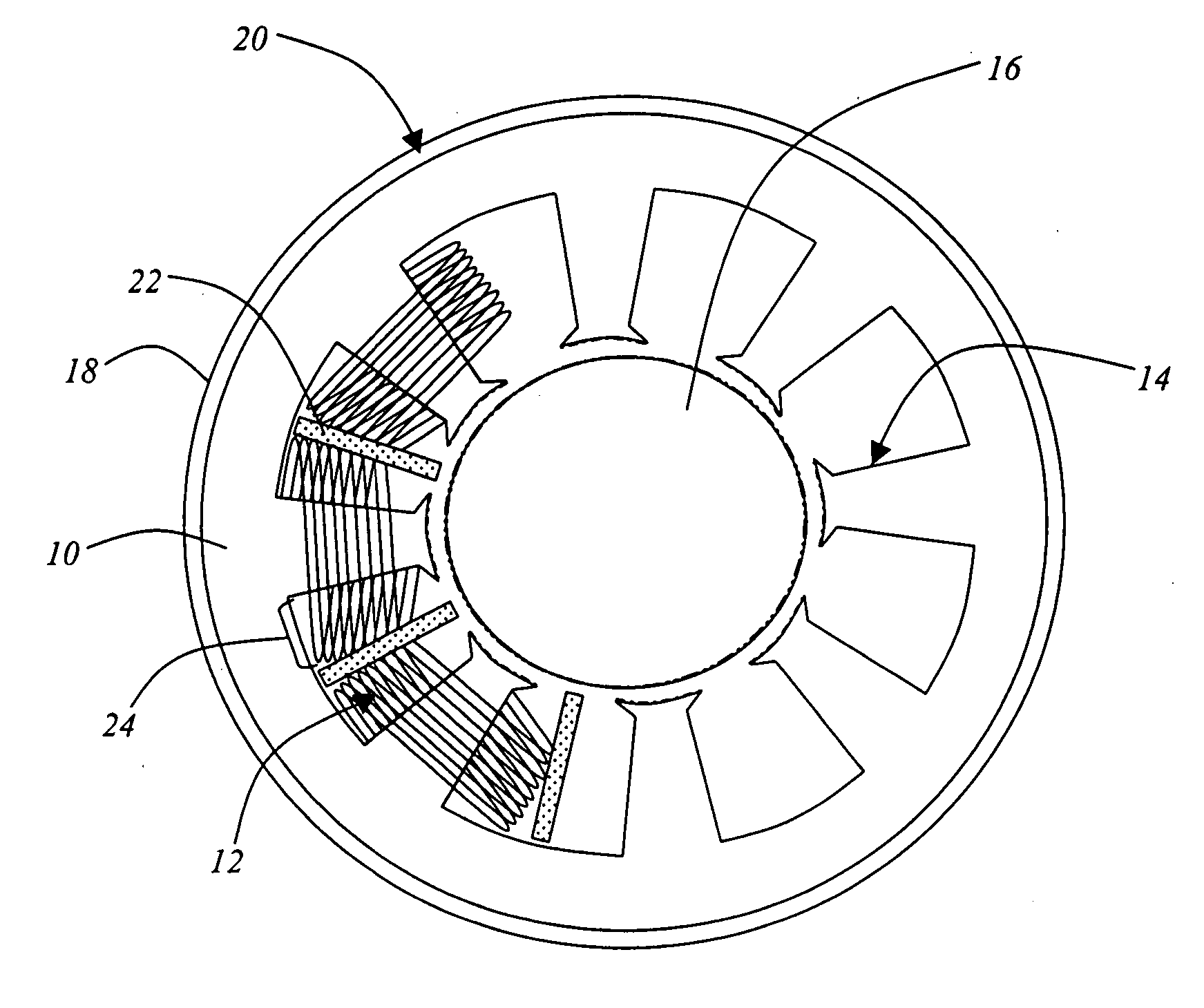

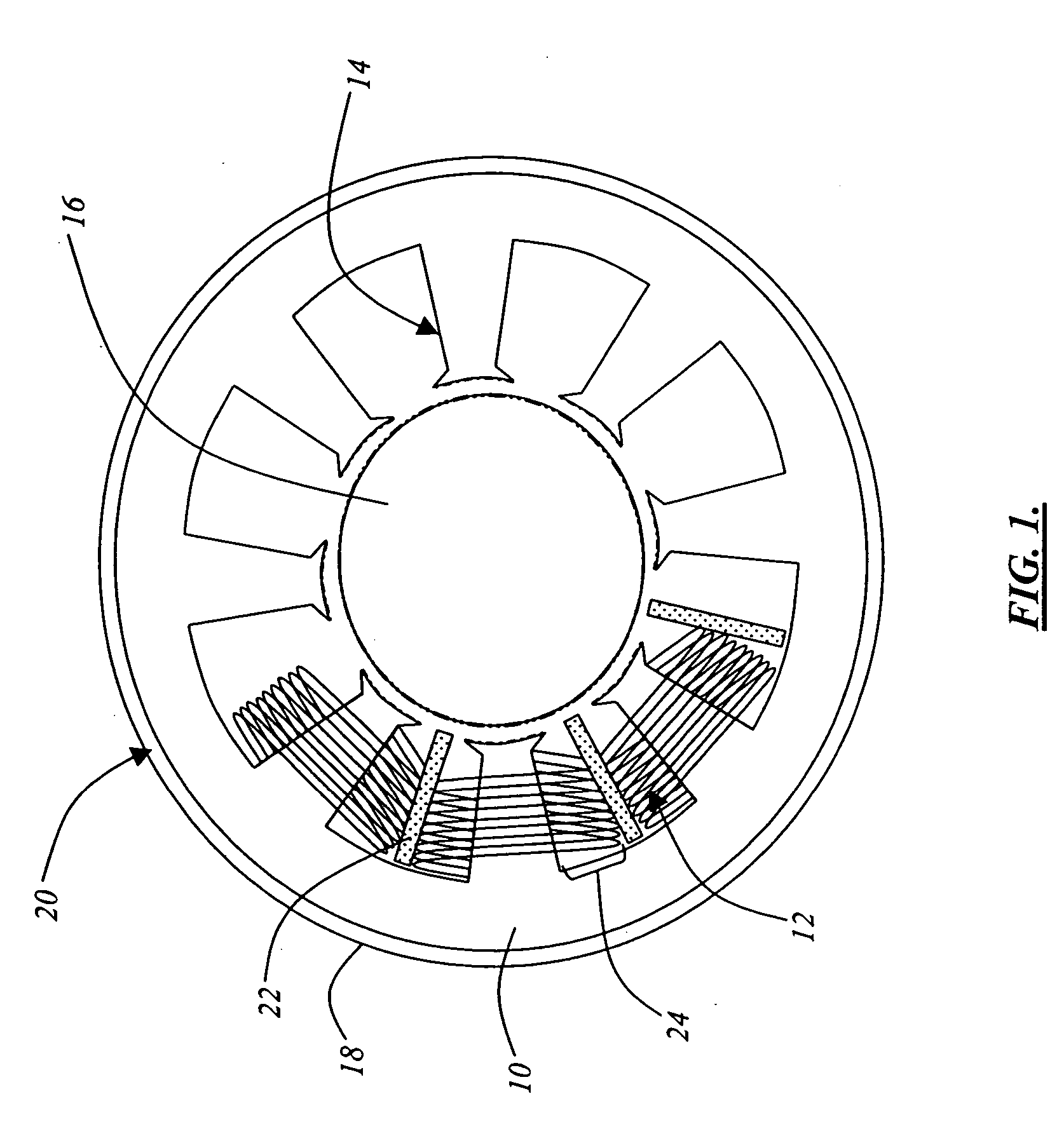

Methods and systems for electric machines having windings

InactiveUS20050057106A1Prevent movementInhibit deteriorationWindingsMagnetic circuit stationary partsElectrical and Electronics engineeringConductor Coil

Apparatus and method for cooling and preventing the deterioration of the windings of an electric machine. The apparatus includes an electrically insulative spacer wedgingly disposed between adjacent windings.

Owner:BALLARD POWER SYSTEMS

Compact and portable low-field pulsed NMR dispersion analyzer

ActiveUS20070210798A1Small and portableLow costAnalysis using nuclear magnetic resonanceMeasurements using NMR imaging systemsMagnetic field gradientLiquid ratio

A compact and integrated portable device is provided for the analysis of dispersions by low-field pulsed NMR including: an NMR probe module, a means for generating radio frequency and magnetic field gradient pulses, a signal processor, and a master controller. Also provided are methods for using the device to measure one or more characteristics of phases or particles comprising a dispersion such as surface area, solid / liquid ratio, particle size, and elemental analysis.

Owner:XIGO NANOTOOLS

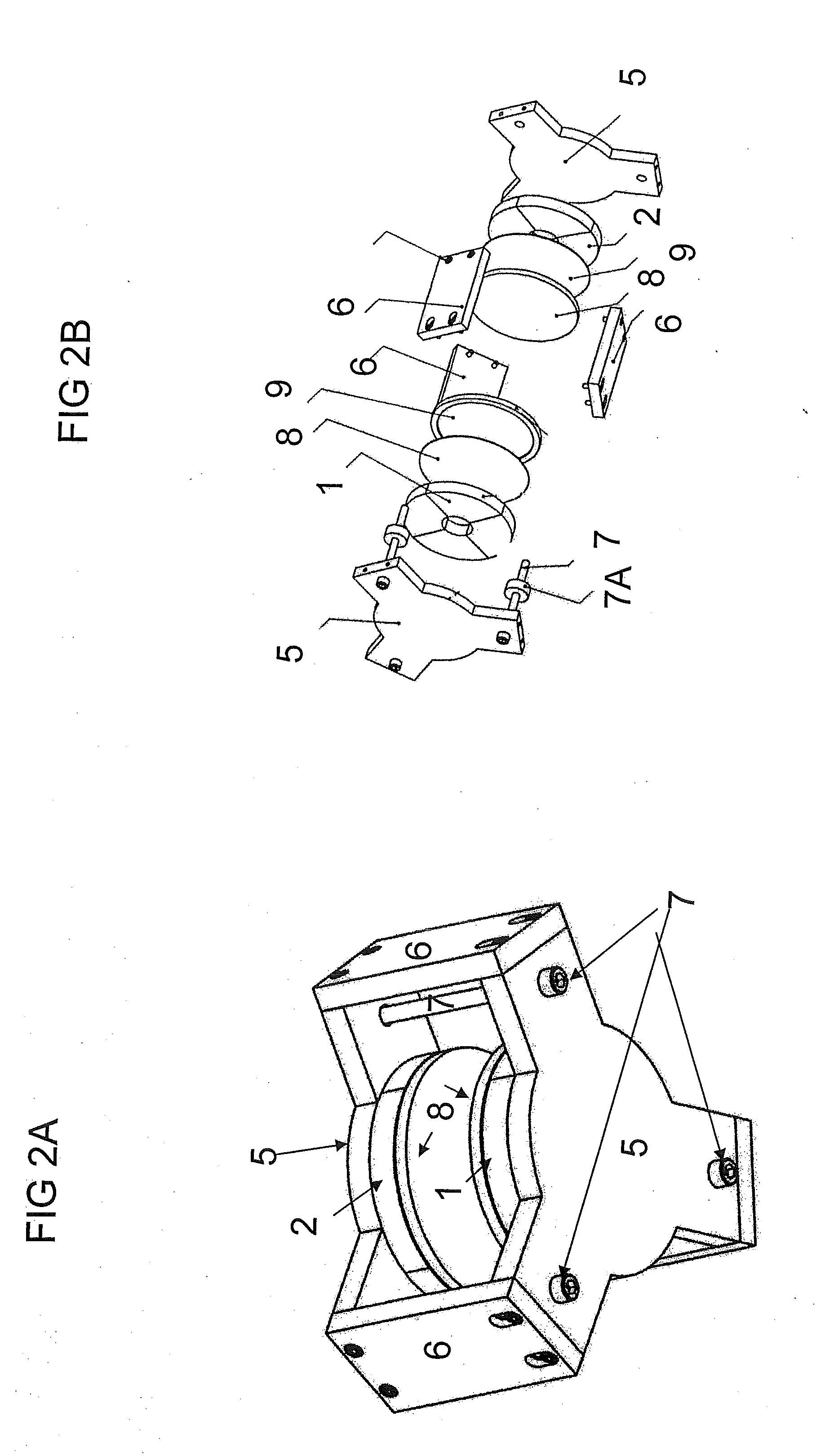

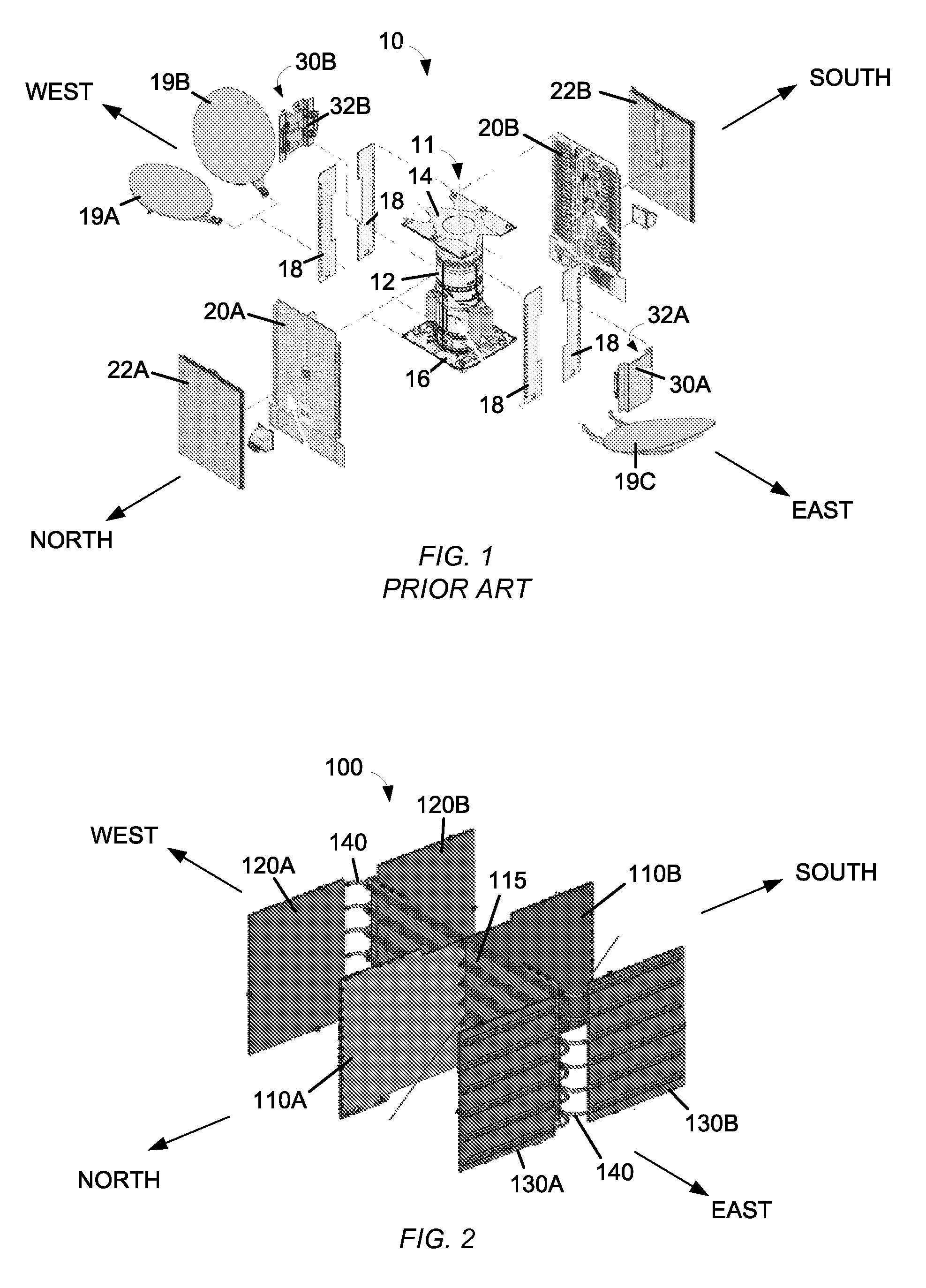

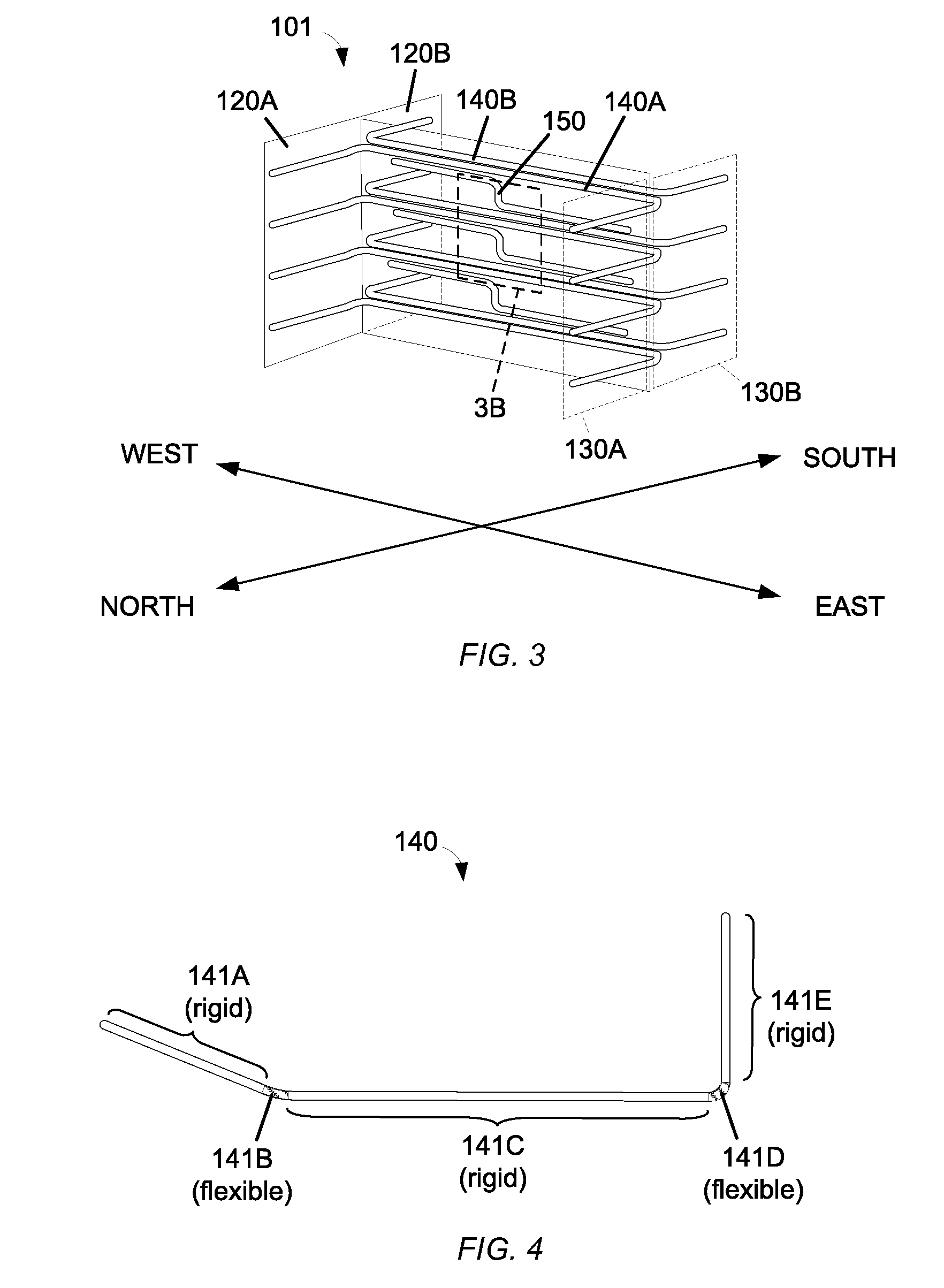

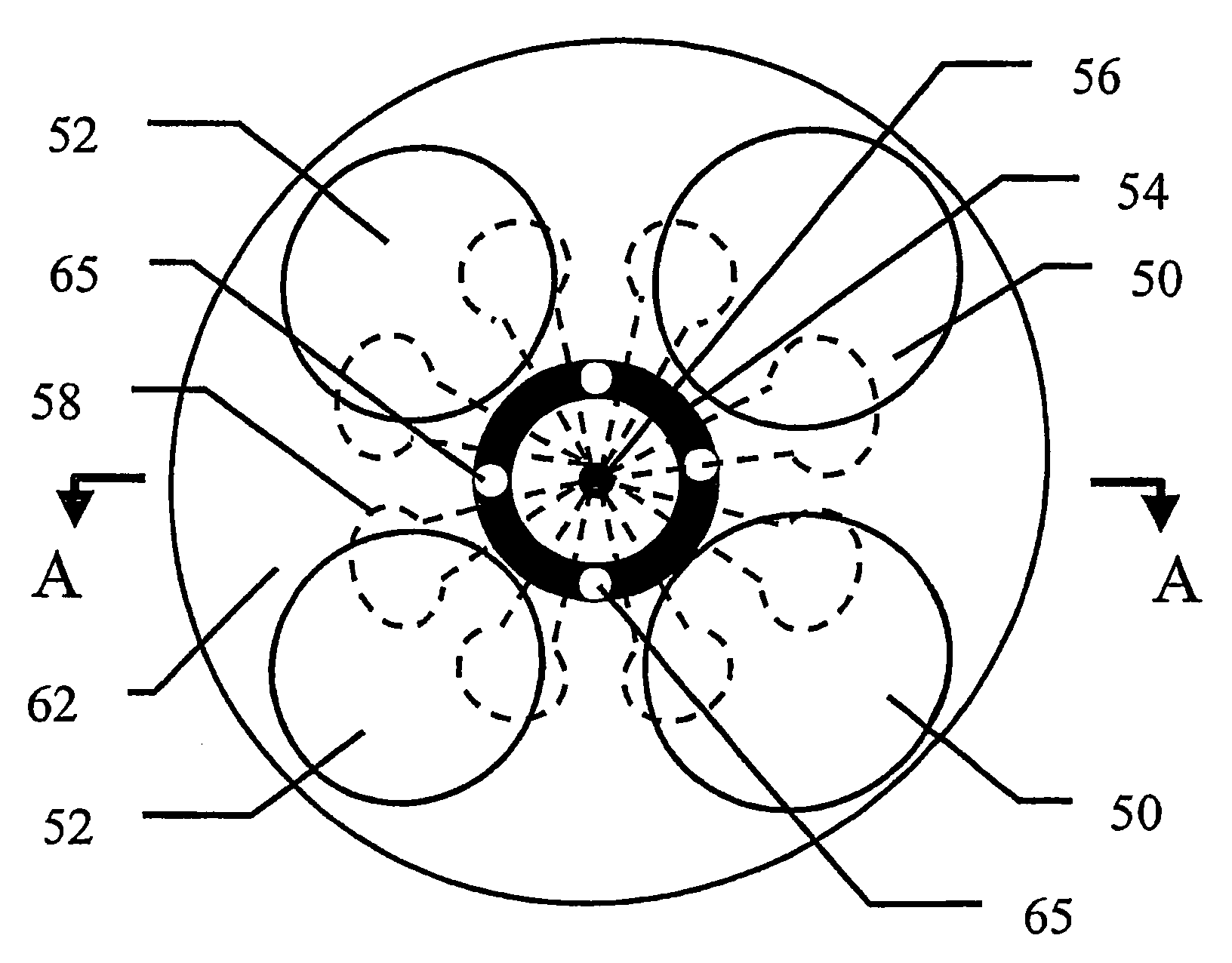

Spacecraft east-west radiator assembly

ActiveUS20140224939A1Reduce temperature fluctuationsEasy accessCosmonautic environmental control arrangementCosmonautic vehiclesComputer moduleThermal contact

A heat transfer assembly for a spacecraft is disclosed. The assembly includes an equipment panel having an east end and a west end. East and west radiator panels are coupled to the east and west ends, respectively, of the equipment panel. The assembly also includes a plurality of flexible heat pipes each having a first rigid tube thermally coupled to the east radiator panel, a second rigid tube coupled to the equipment panel, a third rigid tube thermally coupled to the west radiator panel, a first flexible tube sealingly coupled between the first and second rigid tubes, and a second flexible tube sealingly coupled between the second and third rigid tubes. The equipment panel is configured to retain one or more equipment modules in thermal contact with the second rigid tube of at least one of the plurality of flexible heat pipes.

Owner:LOCKHEED MARTIN CORP

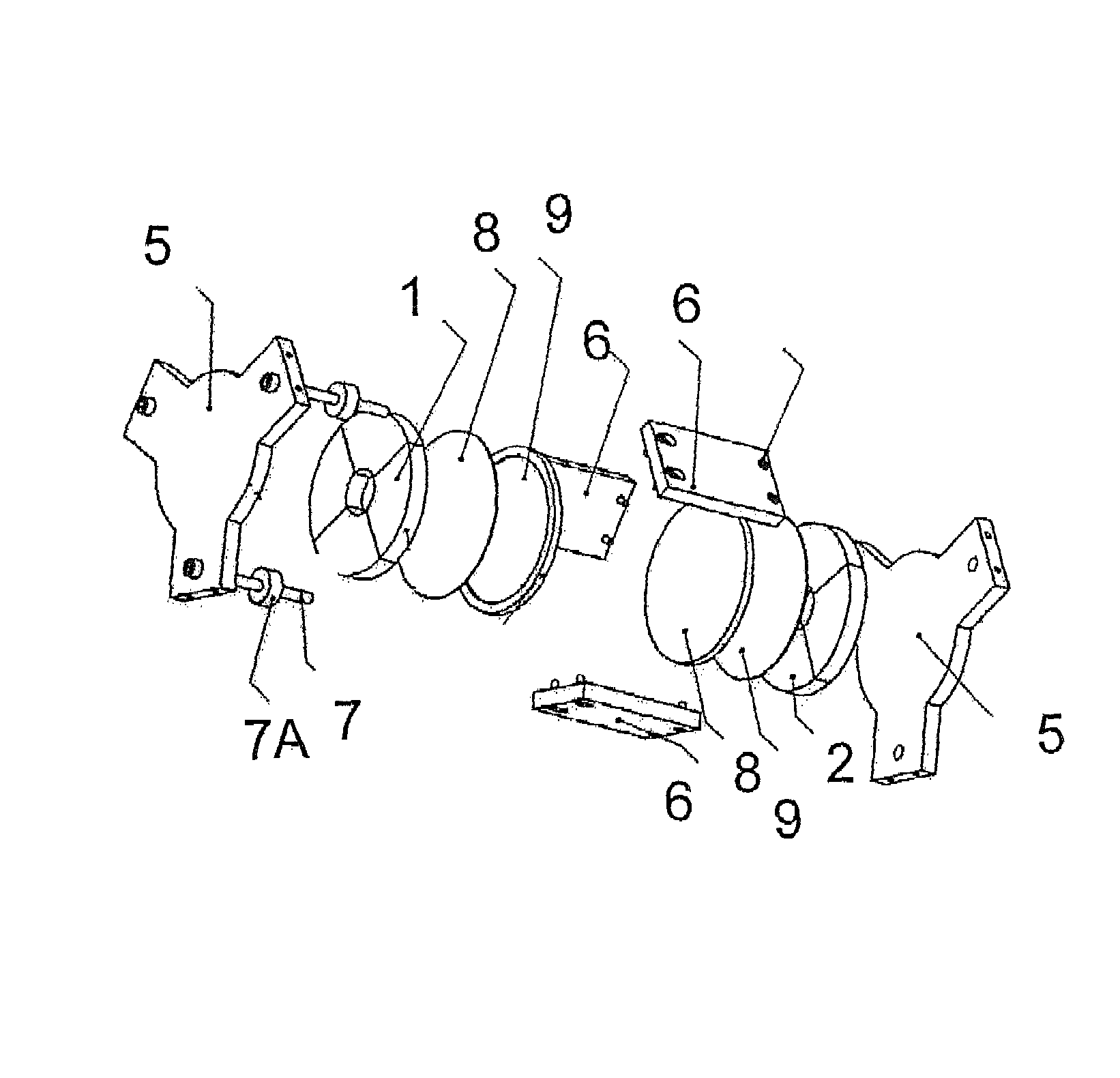

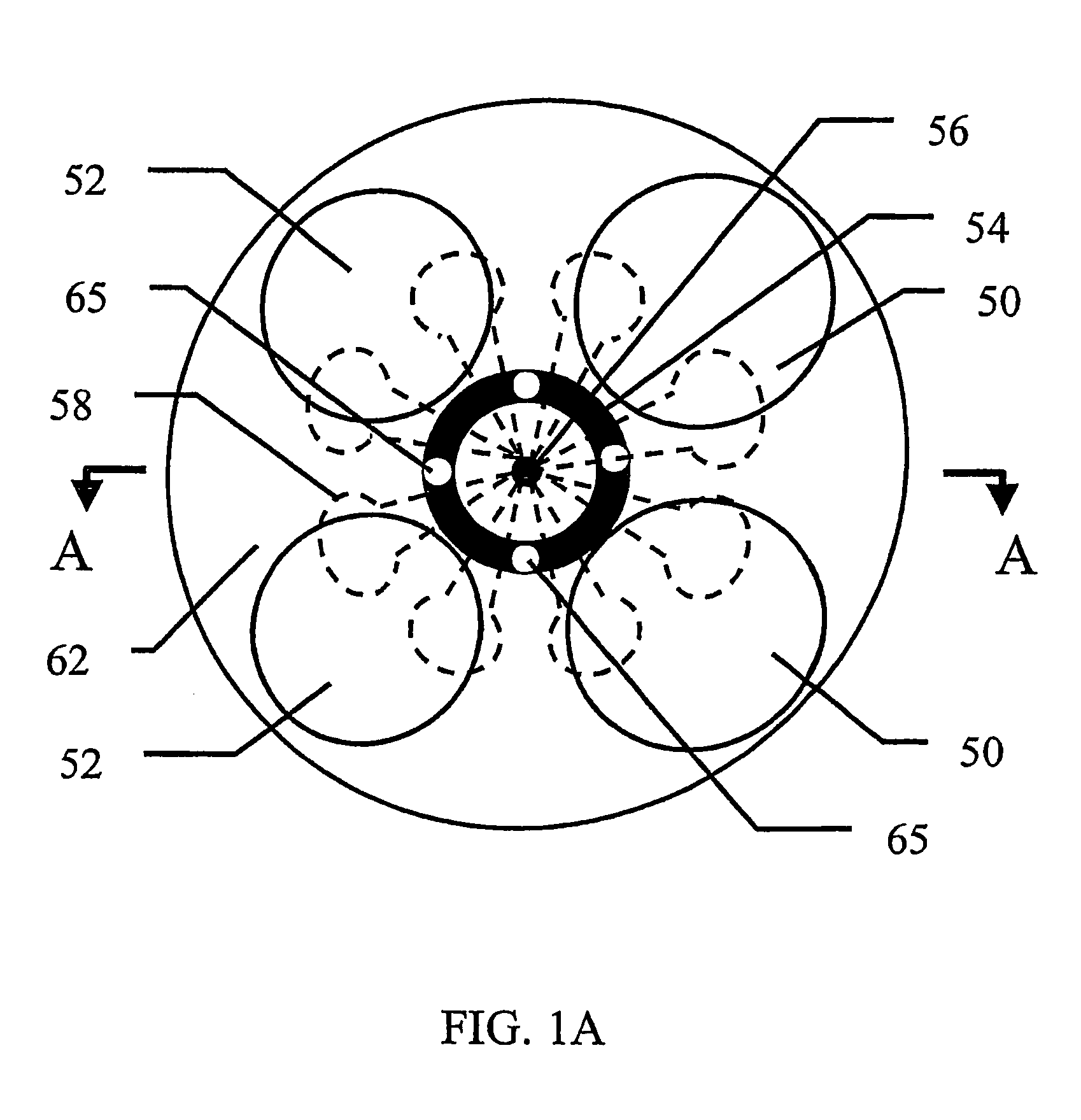

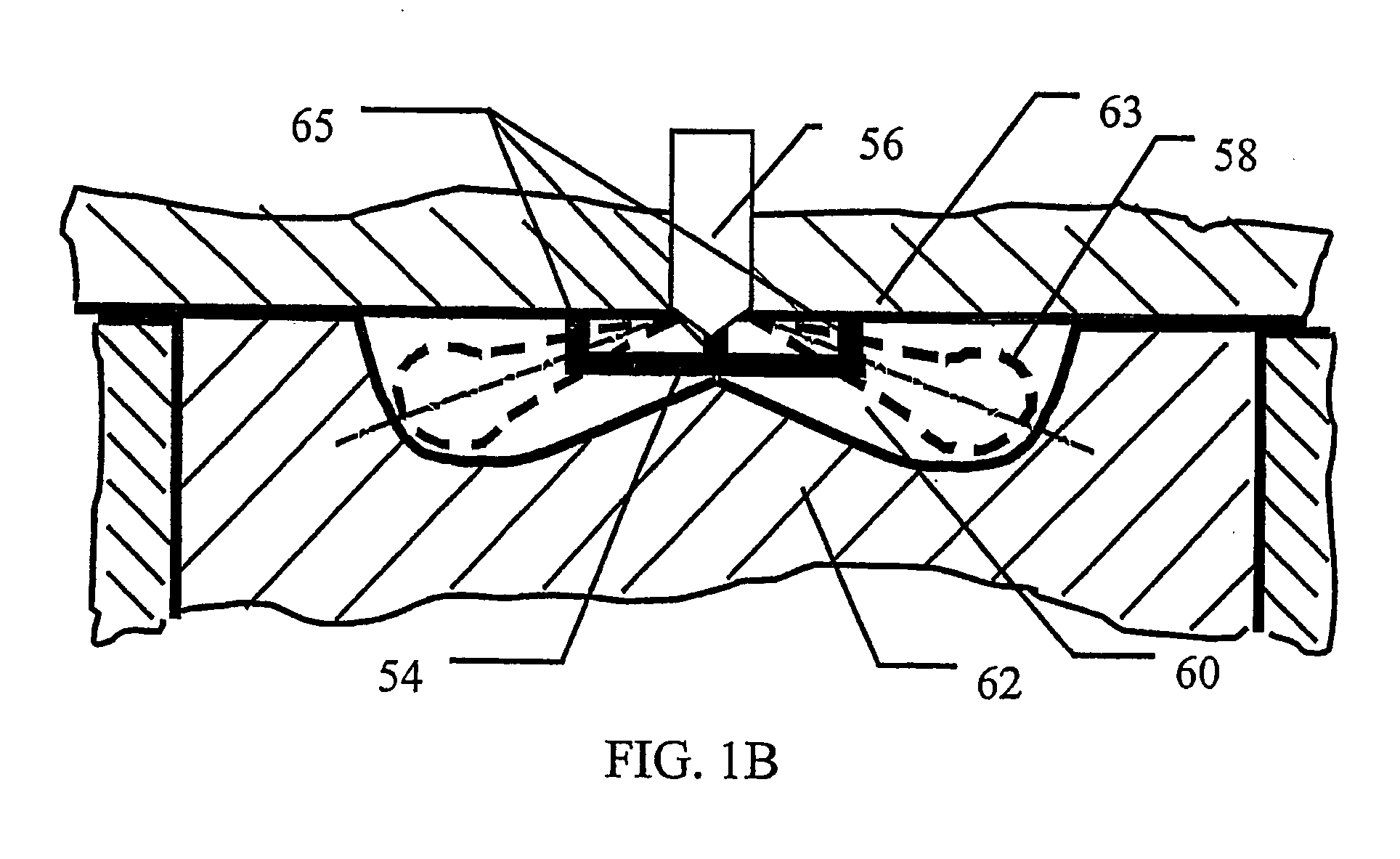

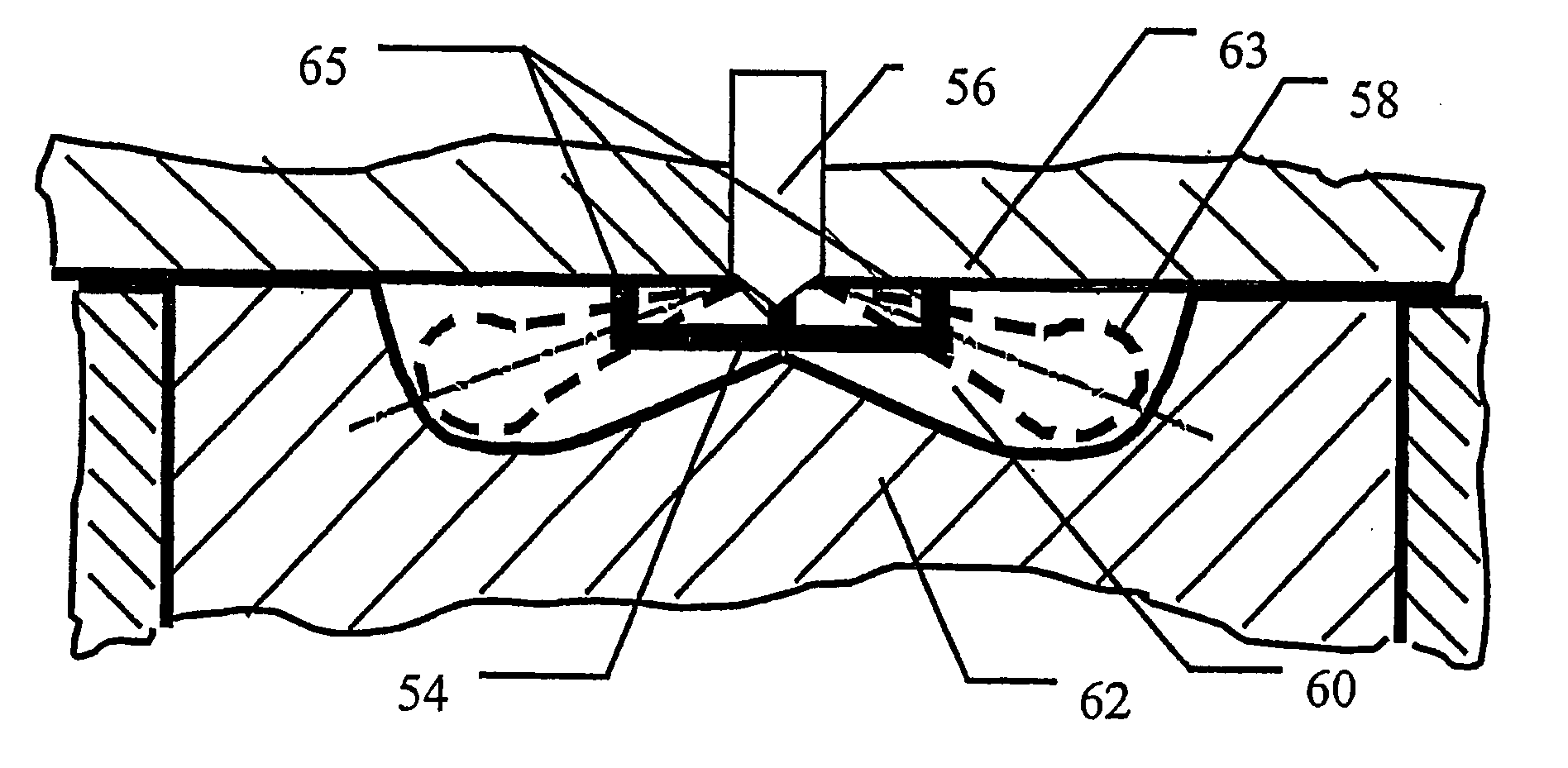

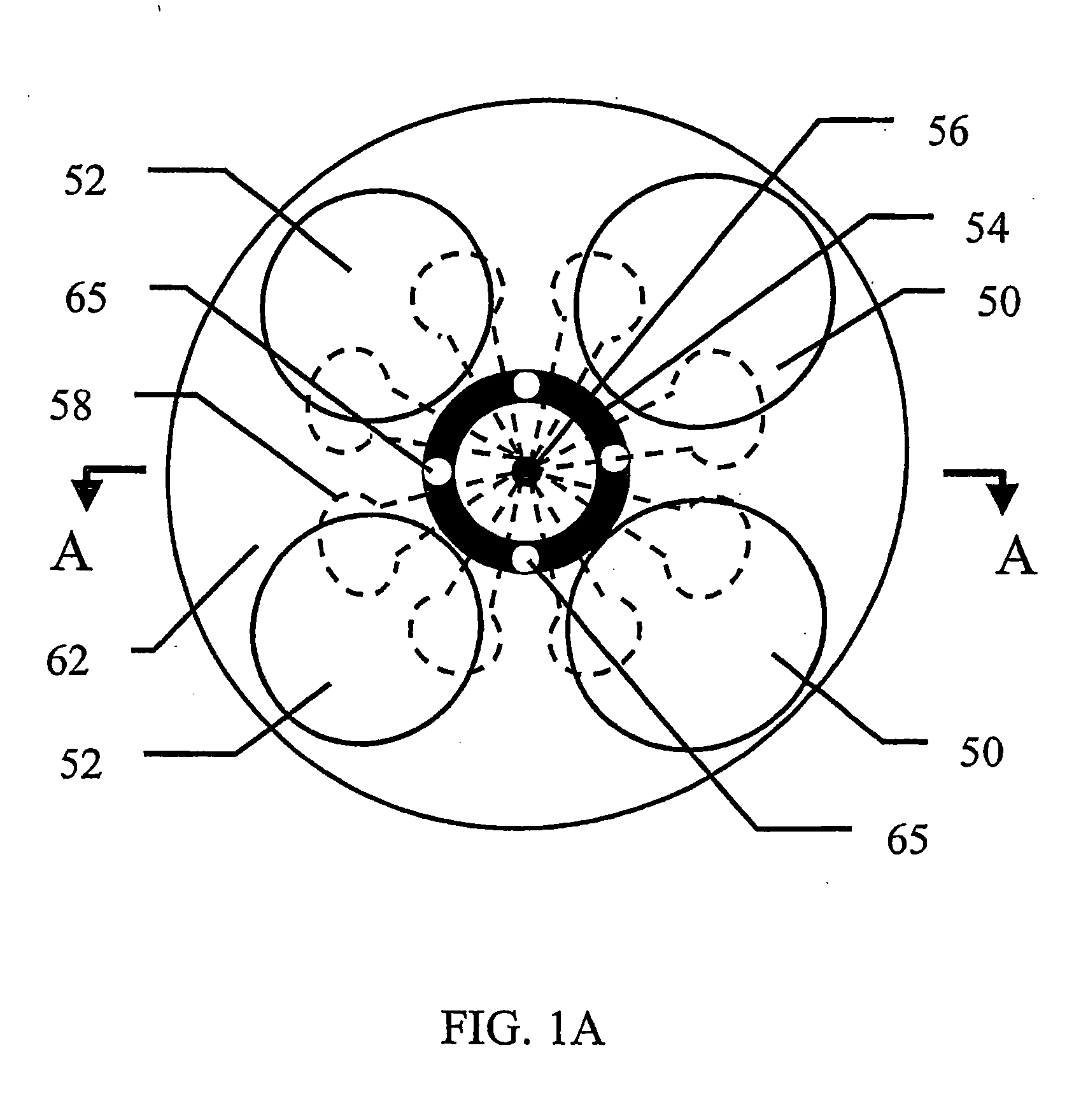

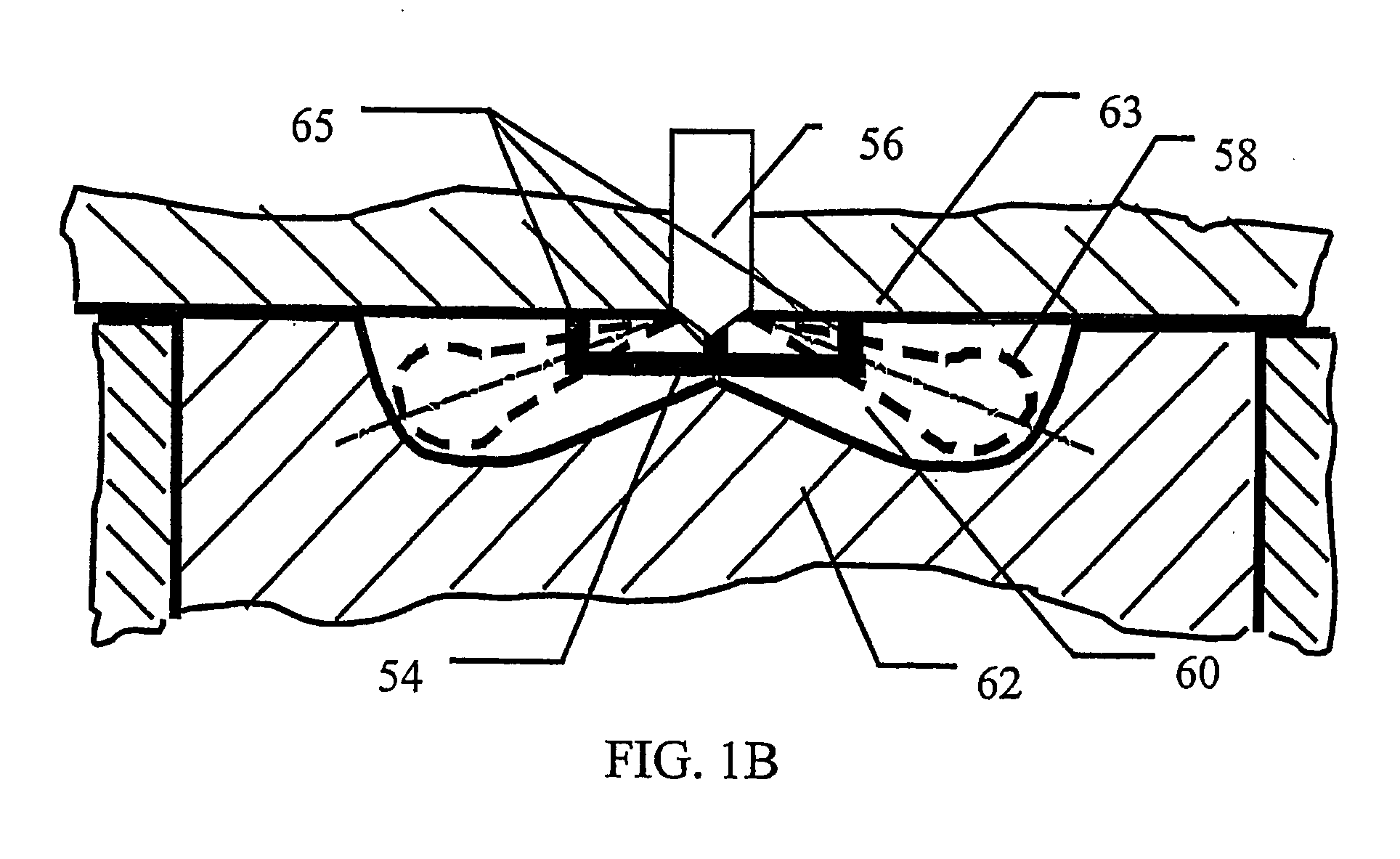

Glow ring ignition assist for internal combustion engine

InactiveUS7281514B2Increase temperatureAvoid less flexibilityElectrical controlInternal combustion piston enginesCombustion chamberPassive heating

A glow member, preferably in the shape of a ring, assists ignition and combustion of a fuel used in an internal combustion engine. A fuel injection valve injects a plurality of fuel jets directly into a combustion chamber during operation of the engine so that the fuel jets are aimed to the proximity of the glow member such that ignition of fuel in each fuel jet is assisted by the glow member. The glow member is made from high temperature materials and can include catalytic materials to further promote combustion. The glow member can be actively heated, for example by an electric current, in addition to being passively heated by the heat generated within the combustion chamber by the combustion of the fuel therein.

Owner:WESTPORT POWER

Control System For Modulating Water Heater

ActiveUS20090064944A1Reduce temperature fluctuationsReact much more quicklyHeating fuelFuel supply regulationImpact systemFlue gas

A control system is provided for a modulated heating system including at least one modulating water heater and a controller. A deadband control scheme provides for reduced cycling of the modulating heater when total system heat demand falls between the maximum output of one heater and the sum of the maximum output of that one point and the minimum firing point of the next subsequent heater. Condensation of flue gas products is prevented by monitoring flue exhaust temperature for each heater and controlling the modulation of each heater to maintain a minimum heater output sufficiently high to prevent condensation of flue gas products from that heater. Rapid reaction to changes in system heat demand is provided by sensing changes in flow rate in a primary loop of the system and anticipating resulting changes in temperature thus allowing for change in heater output prior to the time the change in flow rate has fully impacted system temperature.

Owner:LOCHINVAR

Glow ring ignition assist for internal combustion engine

InactiveUS20050217639A1High auto-ignition temperatureComplete combustionElectrical controlInternal combustion piston enginesCombustion chamberInternal combustion engine

A glow member, preferably in the shape of a ring, assists ignition and combustion of a fuel used in an internal combustion engine. A fuel injection valve injects a plurality of fuel jets directly into a combustion chamber during operation of the engine so that the fuel jets are aimed to the proximity of the glow member such that ignition of fuel in each fuel jet is assisted by the glow member. The glow member is made from high temperature materials and can include catalytic materials to further promote combustion. The glow member can be actively heated, for example by an electric current, in addition to being passively heated by the heat generated within the combustion chamber by the combustion of the fuel therein.

Owner:WESTPORT POWER

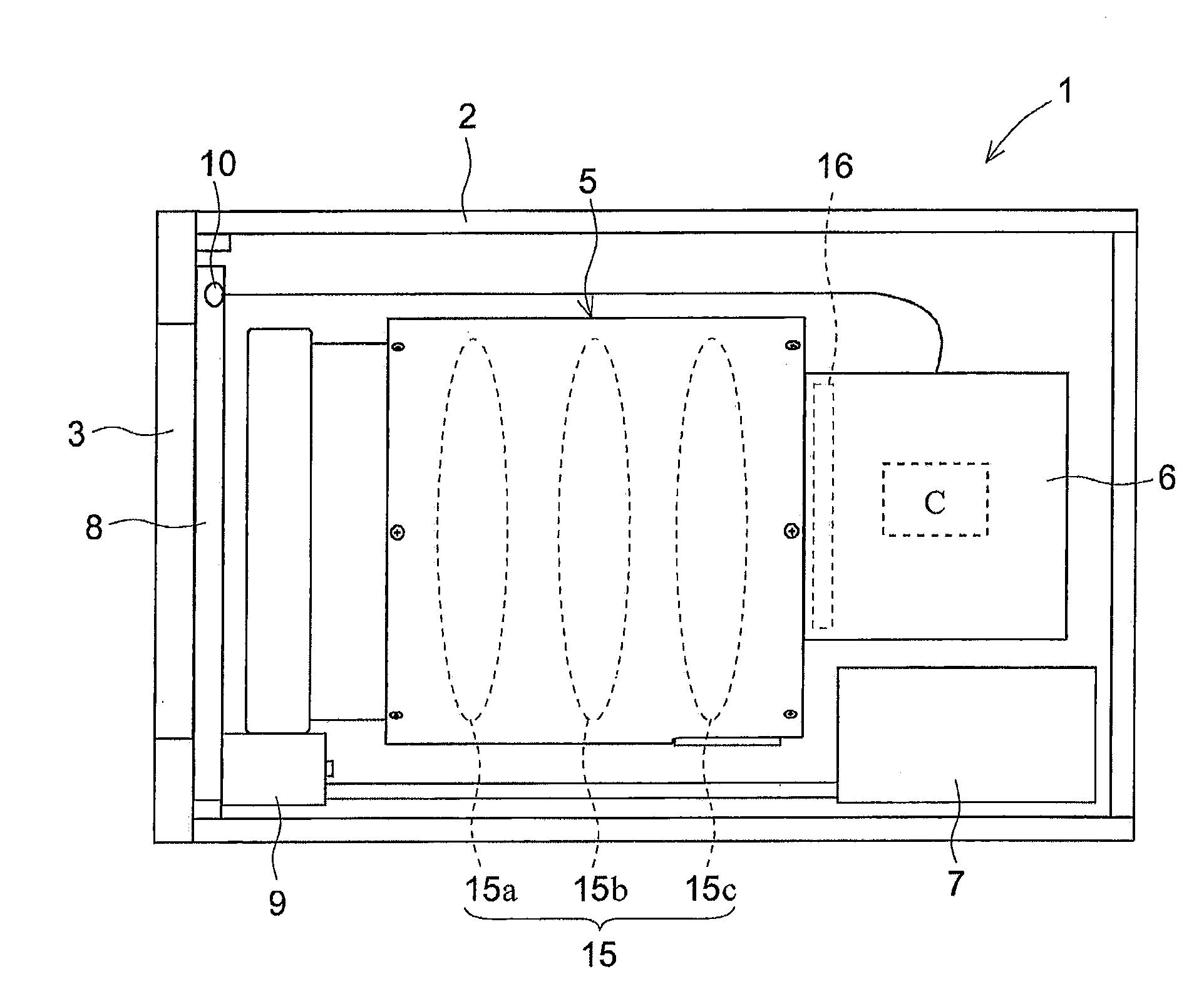

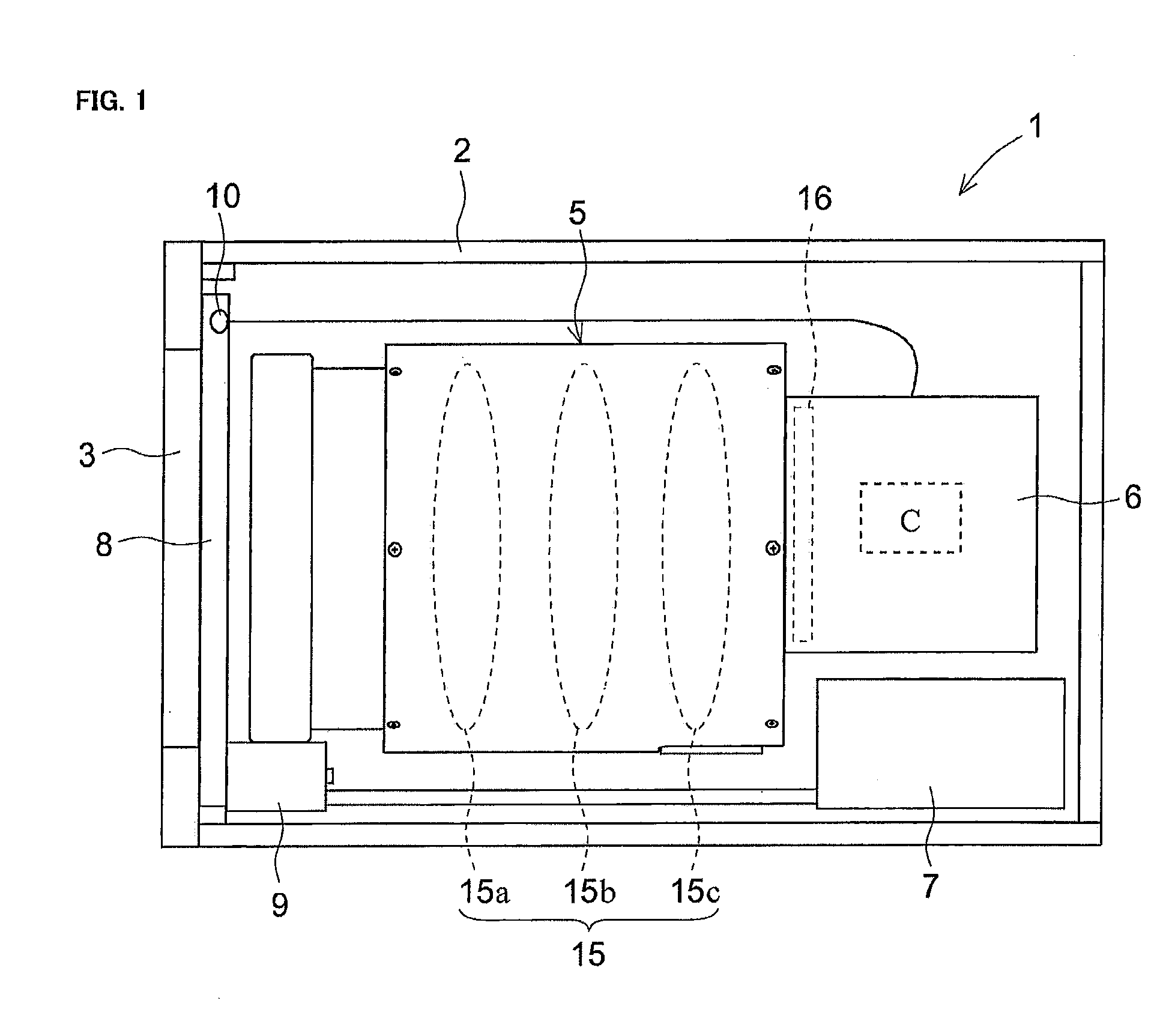

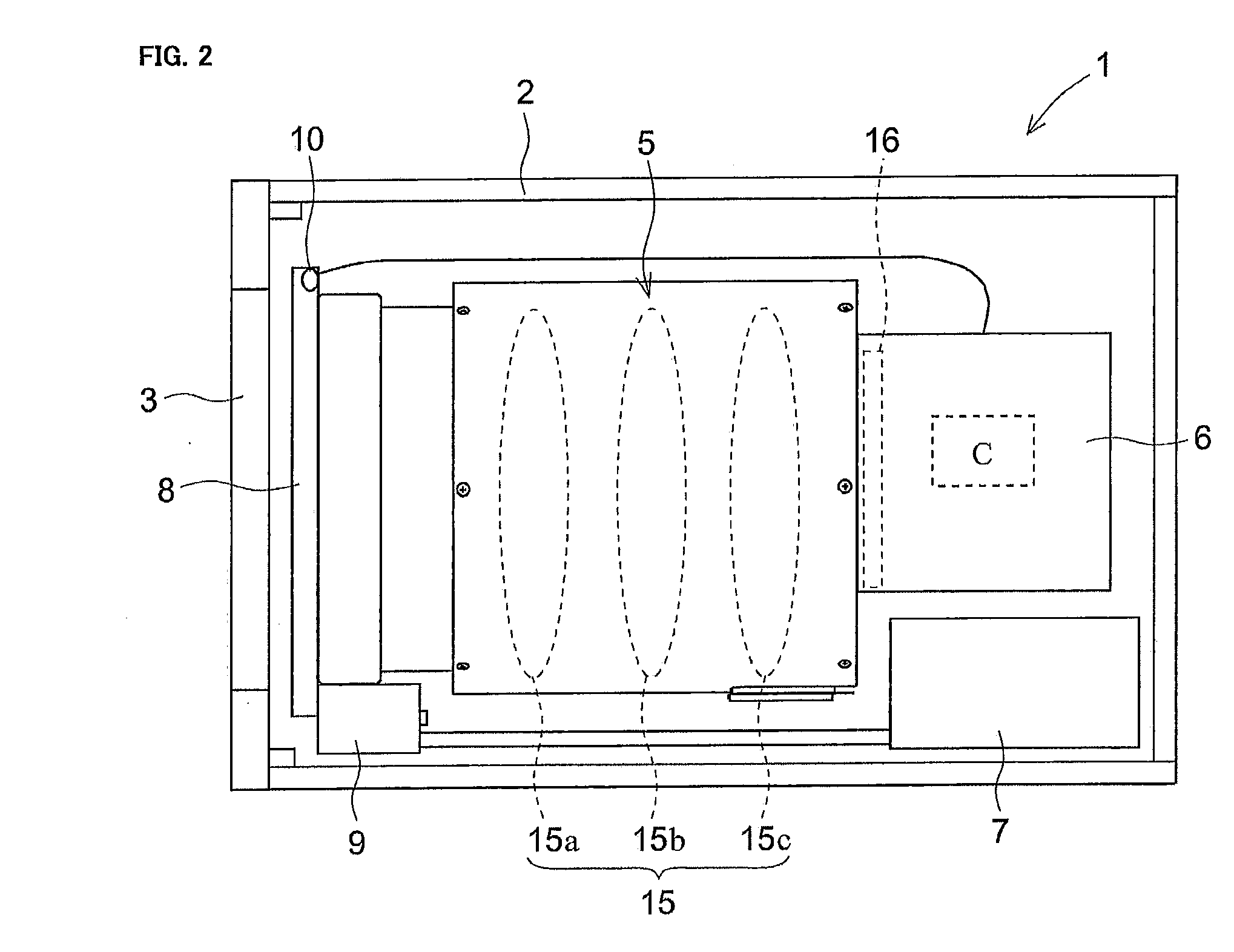

Infrared Camera

InactiveUS20130141590A1Enhance the imageReduce temperature fluctuationsTelevision system detailsColor television detailsInfrared image sensorsOptical path

An object of the present invention is to provide an infrared camera capable of shading correction with ease and an improved degree of accuracy and has good maintenance ability. To achieve the object, an infrared camera provided with an infrared lens group and an infrared image sensor located at an image focusing surface of the infrared lens group in a housing in which a window is formed at a portion facing the object side of the infrared lens group comprising: a controller correcting a captured image according to an output from the infrared image sensor and outputting the corrected image; a shutter arranged on an infrared light path in the housing from the window to the infrared lens group; and a temperature sensor detecting the temperature of the shutter is adopted.

Owner:TAMRON

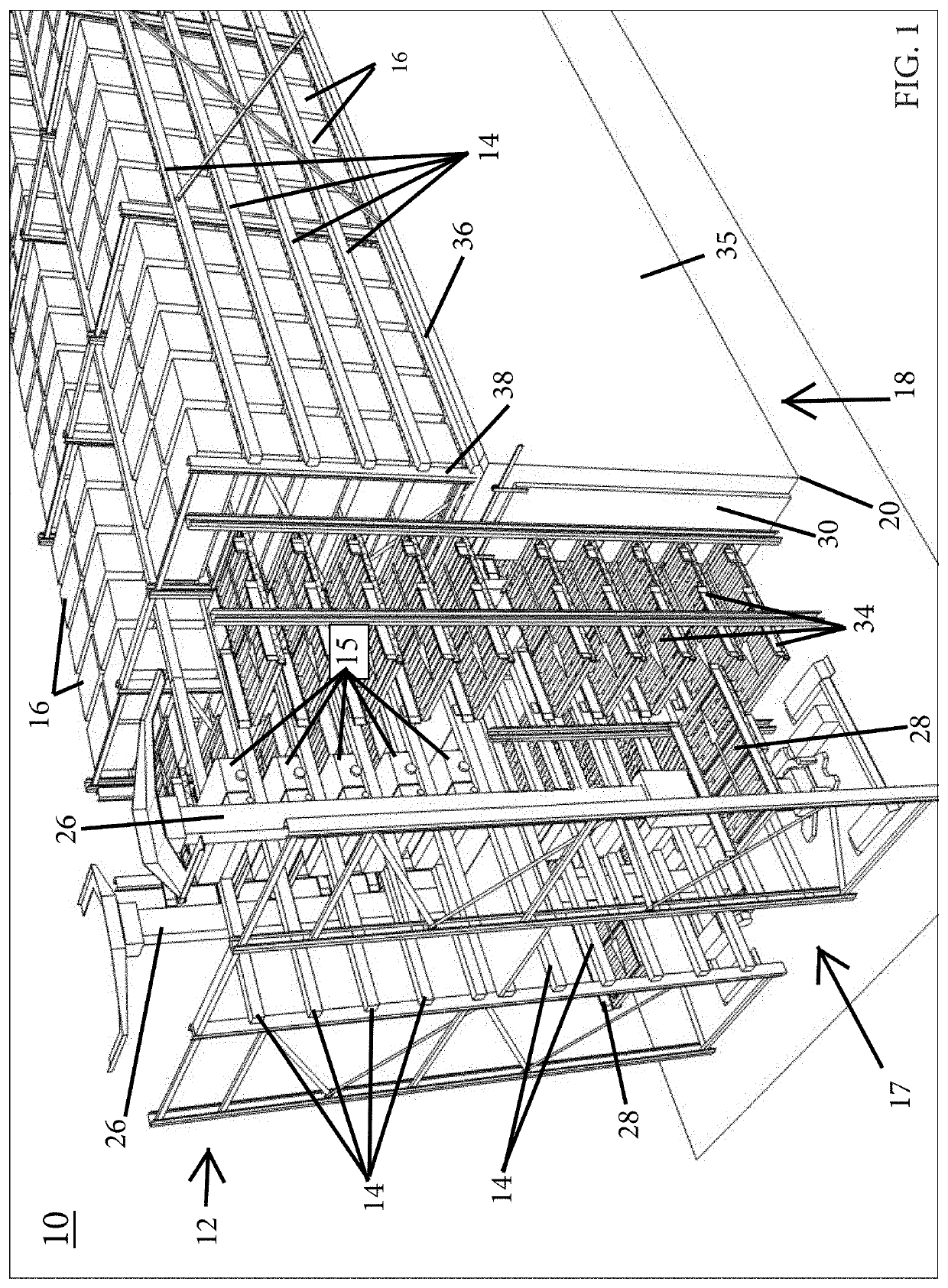

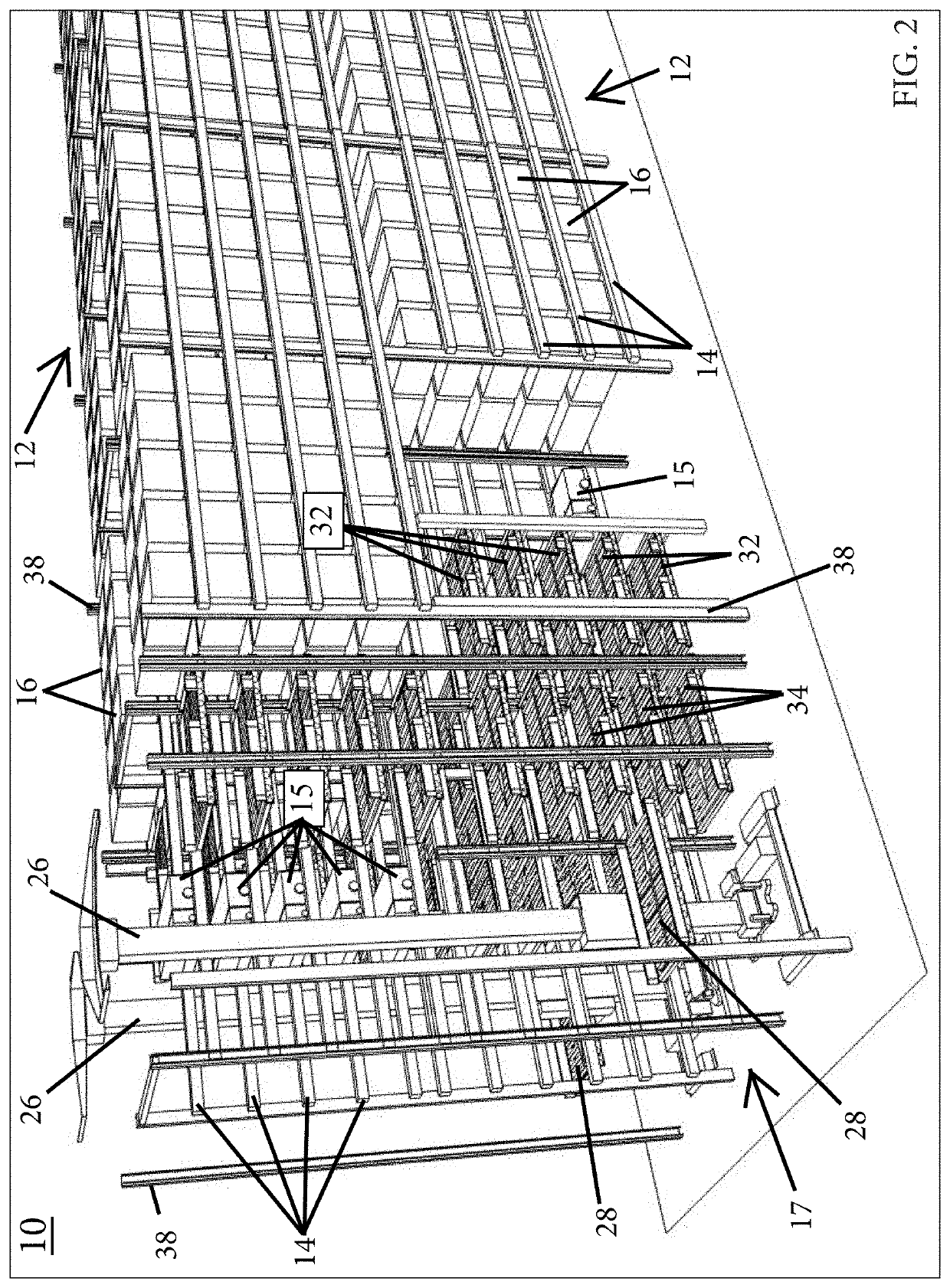

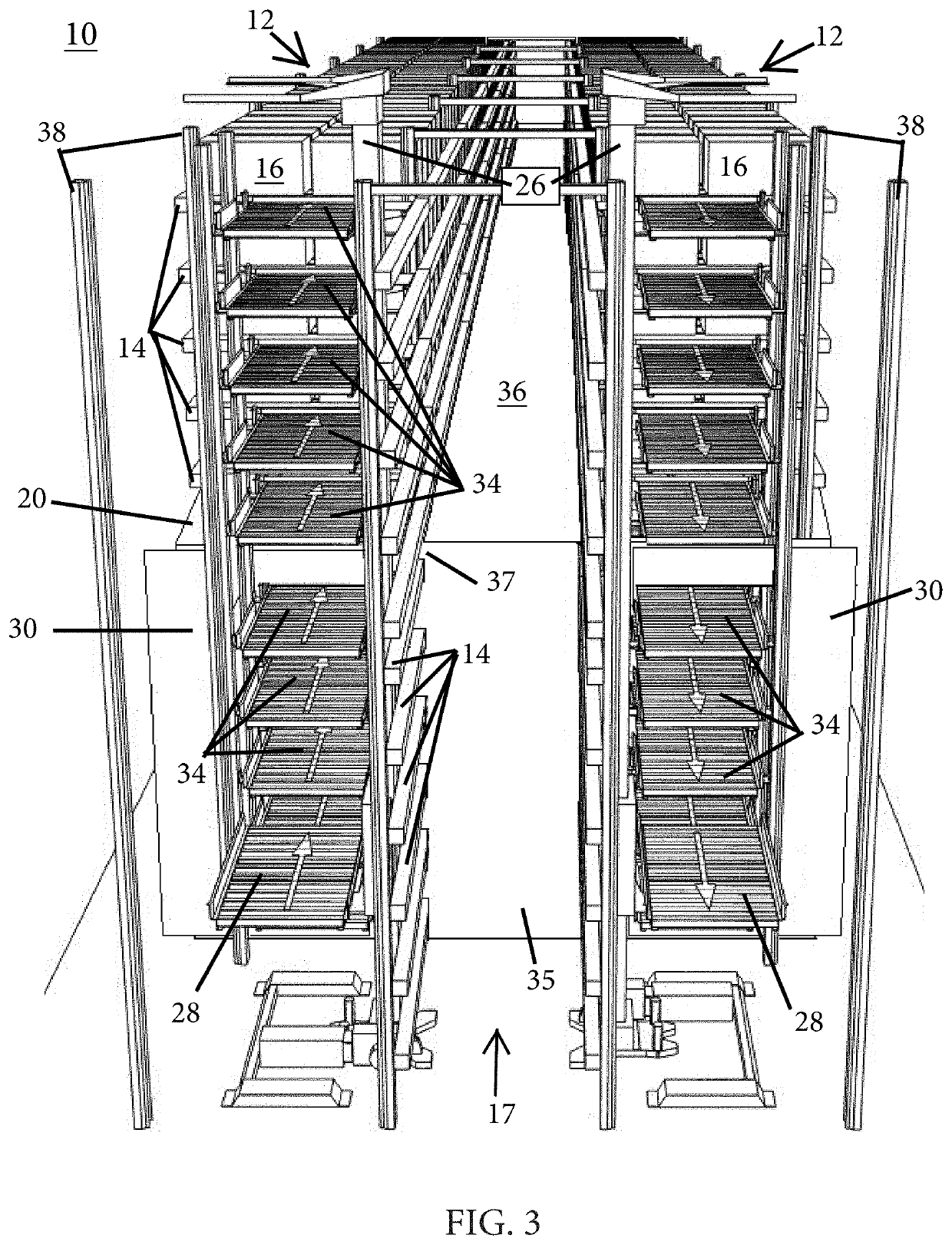

Multiple temperature automated storage system and method

ActiveUS20200166267A1Benefits in of efficiencyGuaranteed uptimeLighting and heating apparatusStationary refrigeration devicesThermodynamicsProcess engineering

A multiple temperature automated storage system includes a rack with multiple levels of shelves defining item storage positions, an aisle at each level, and a plurality of shuttles adapted to operate in the aisles for storing items to and retrieving items from the storage positions. A thermally insulated enclosure encloses some of the levels of the rack to define a low temperature zone with the remaining levels of the rack defining a higher temperature zone. A method of storing items at two different temperatures in a common automated storage system includes having a first portion of the automated storage system enclosed in a thermally insulated enclosure and a second portion of the automated storage system outside of the thermally insulated enclosure. A lift is provided in the second portion for supplying items to and retrieving items from both of the first and second portions, without entering the first portion.

Owner:DEMATIC

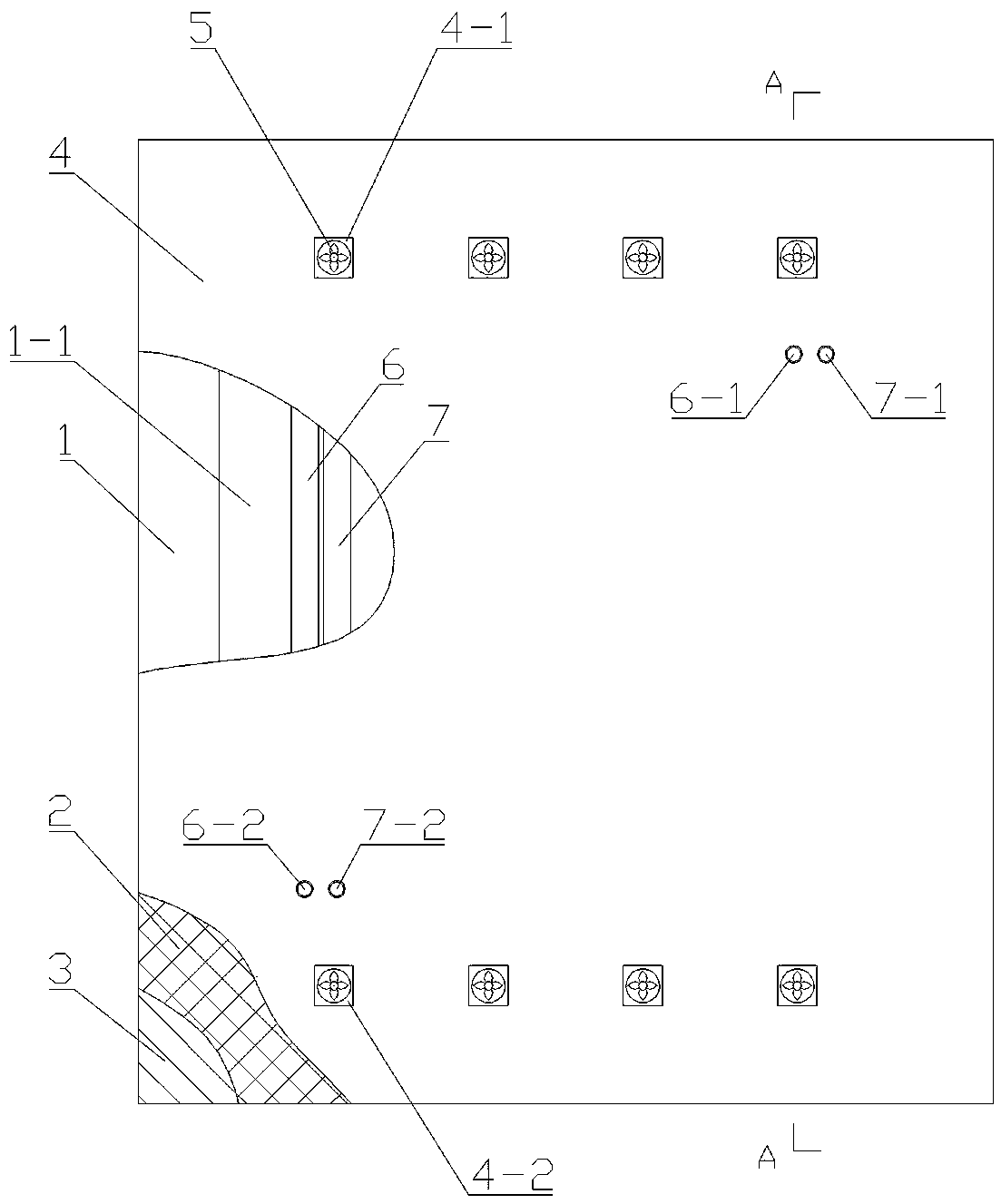

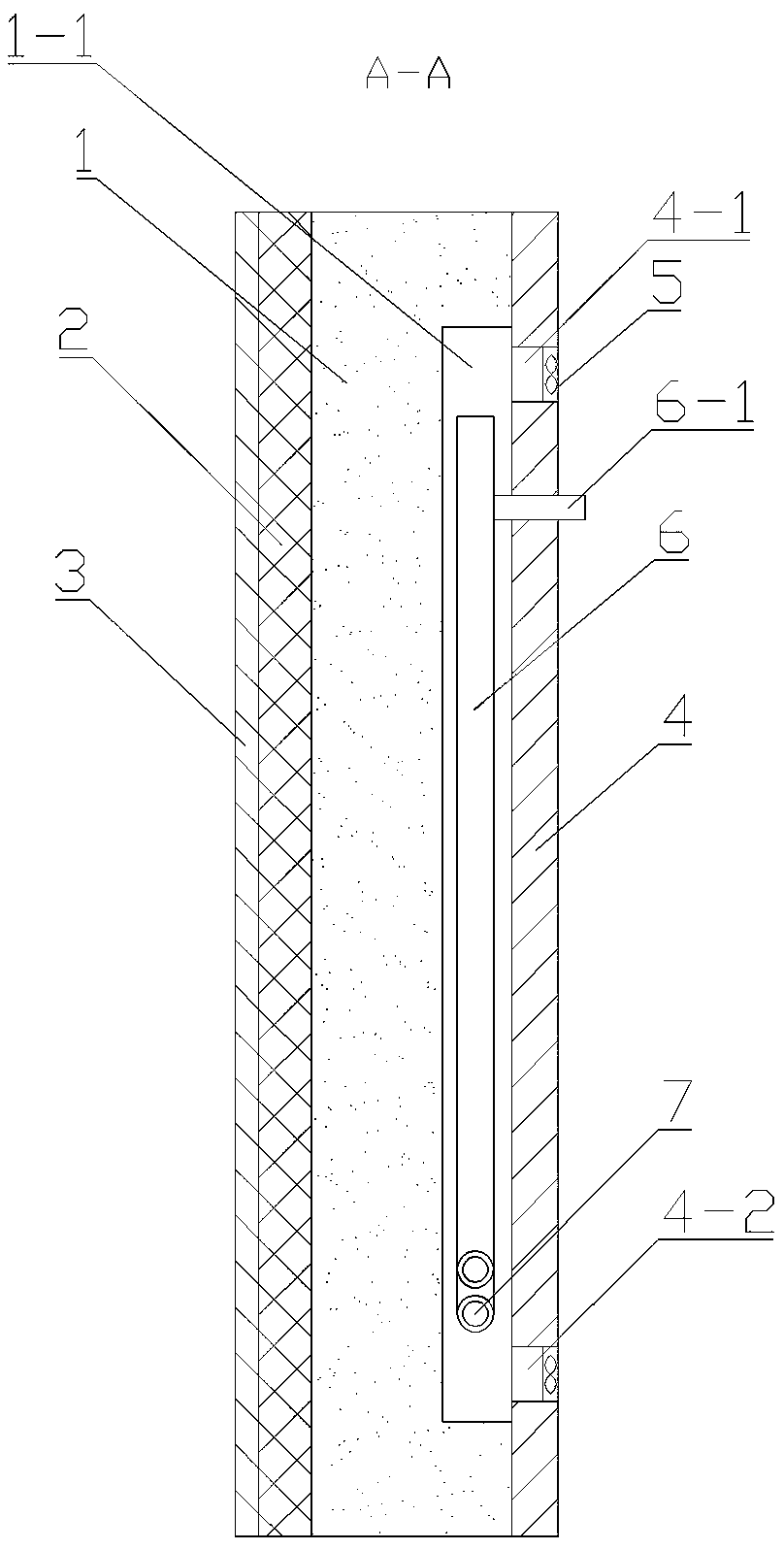

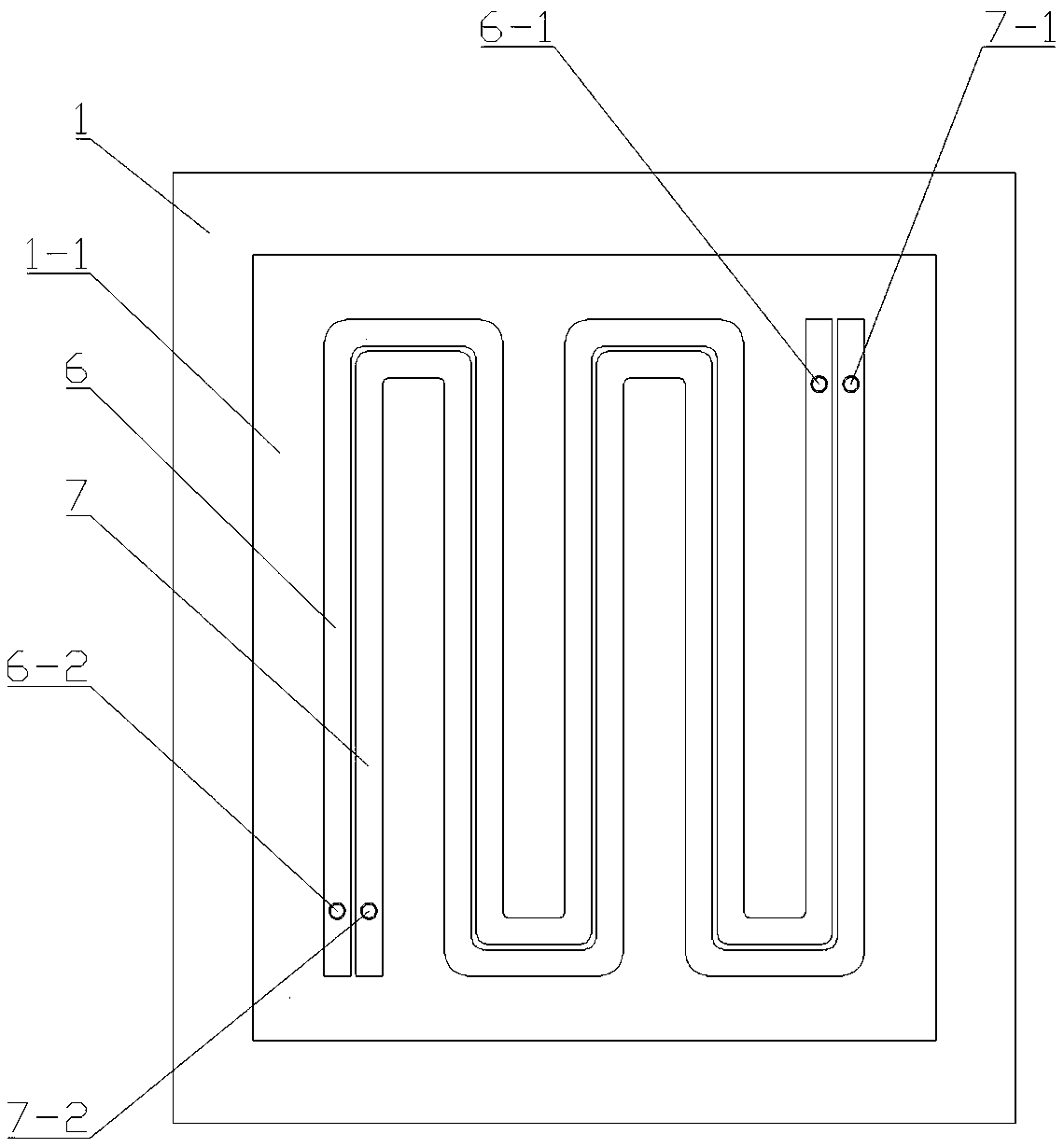

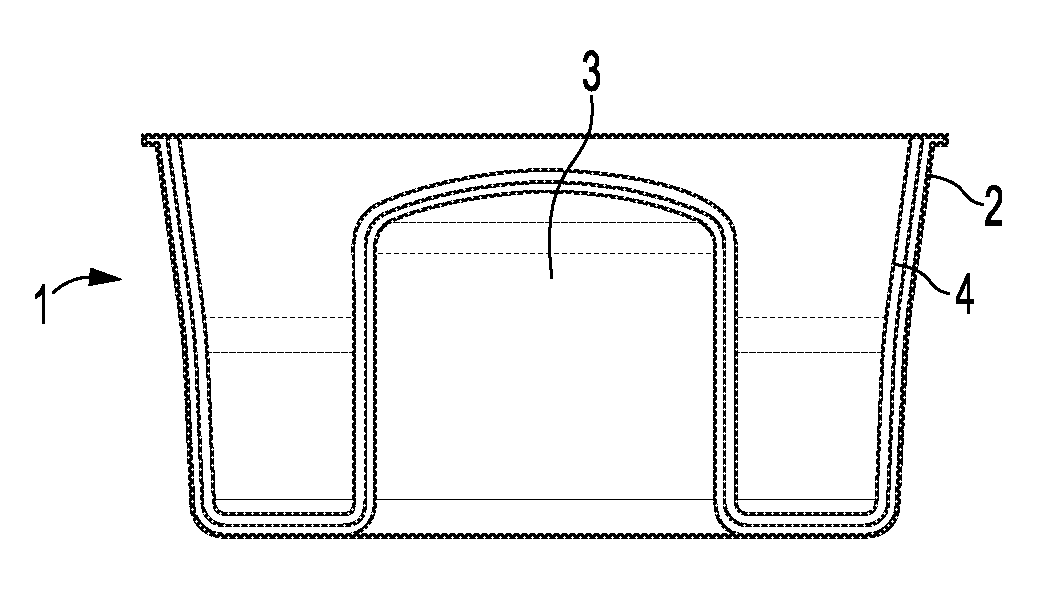

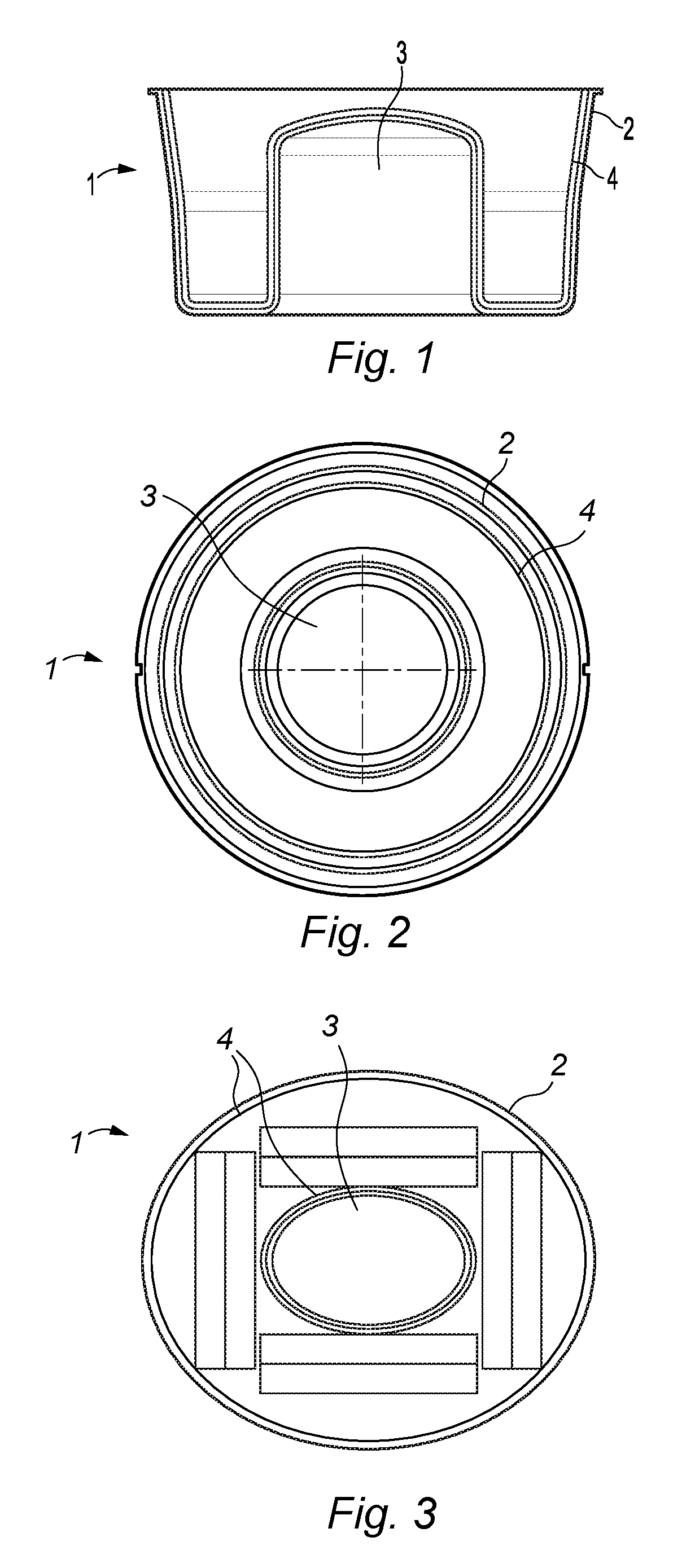

Multilayer wall embedded with phase change filling material and provided with cavity

PendingCN110344517AMitigate temperature fluctuationsImprove indoor comfortLighting and heating apparatusWallsFilling materialsPhase change

The invention discloses a multilayer wall embedded with a phase change filling material and provided with a cavity. The multilayer wall comprises a concrete wall, a thermal insulating layer, a reflecting layer, a facing layer, a draught fan, a high temperature phase change material water pipe and a low temperature phase change material water pipe, wherein the cavity is formed in the concrete wall;the thermal insulating layer and the reflecting layer are sequentially arranged on the outer side of the concrete wall; an upper tuyere and a lower tuyere communicating with the cavity are formed inthe two ends of the facing layer; the high temperature phase change material water pipe and the low temperature phase change material water pipe are arranged in the cavity; each of the high temperature phase change material water pipe and the low temperature phase change material water pipe comprises a concentric pipe, a water inlet pipe and a water outlet pipe; the concentric pipe comprises an outer pipe, an inner pipe, a circular ring passage and a temperature sensor; and the circular ring passage with the two ends sealed is filled with the phase change filling material. The phase change filling material is controlled to absorb and release heat at daytime and night of different seasons to adjust the temperature of the indoor air. The multilayer wall is simple in structure and convenientand fast to operate, can effectively alleviate the fluctuation of the indoor temperature to improve the indoor comfort level and realizes the purpose of building energy conservation all year round.

Owner:NANHUA UNIV

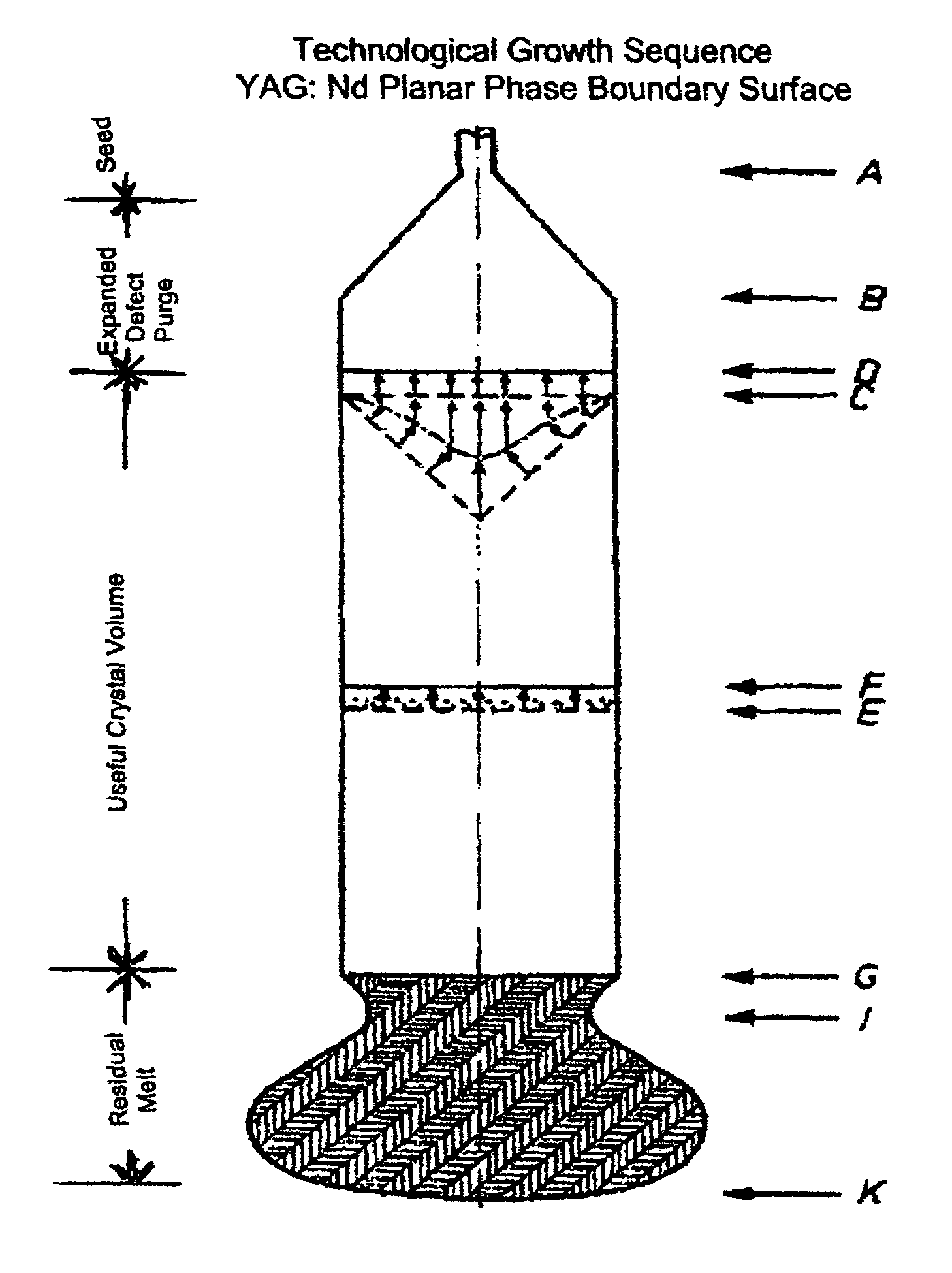

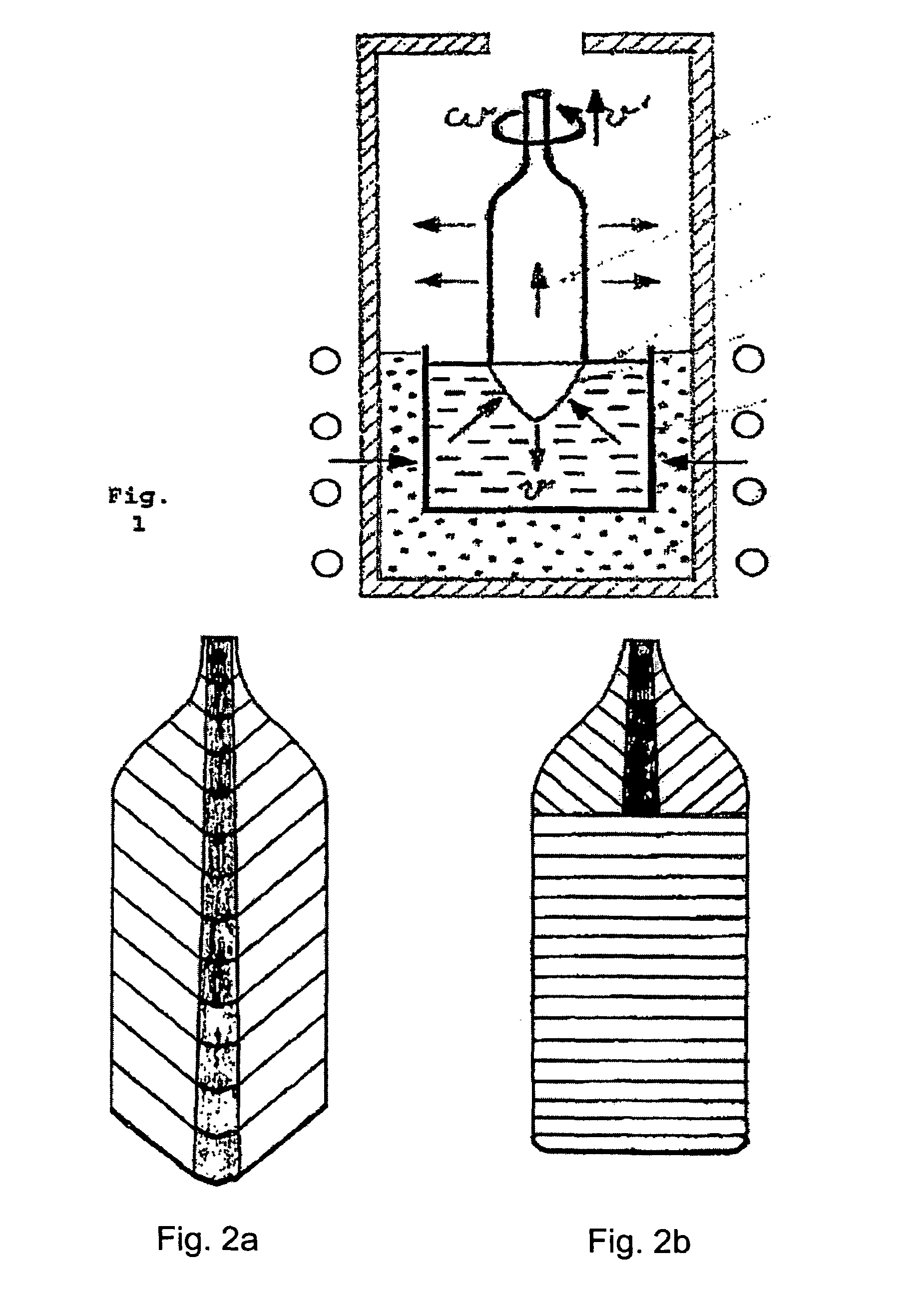

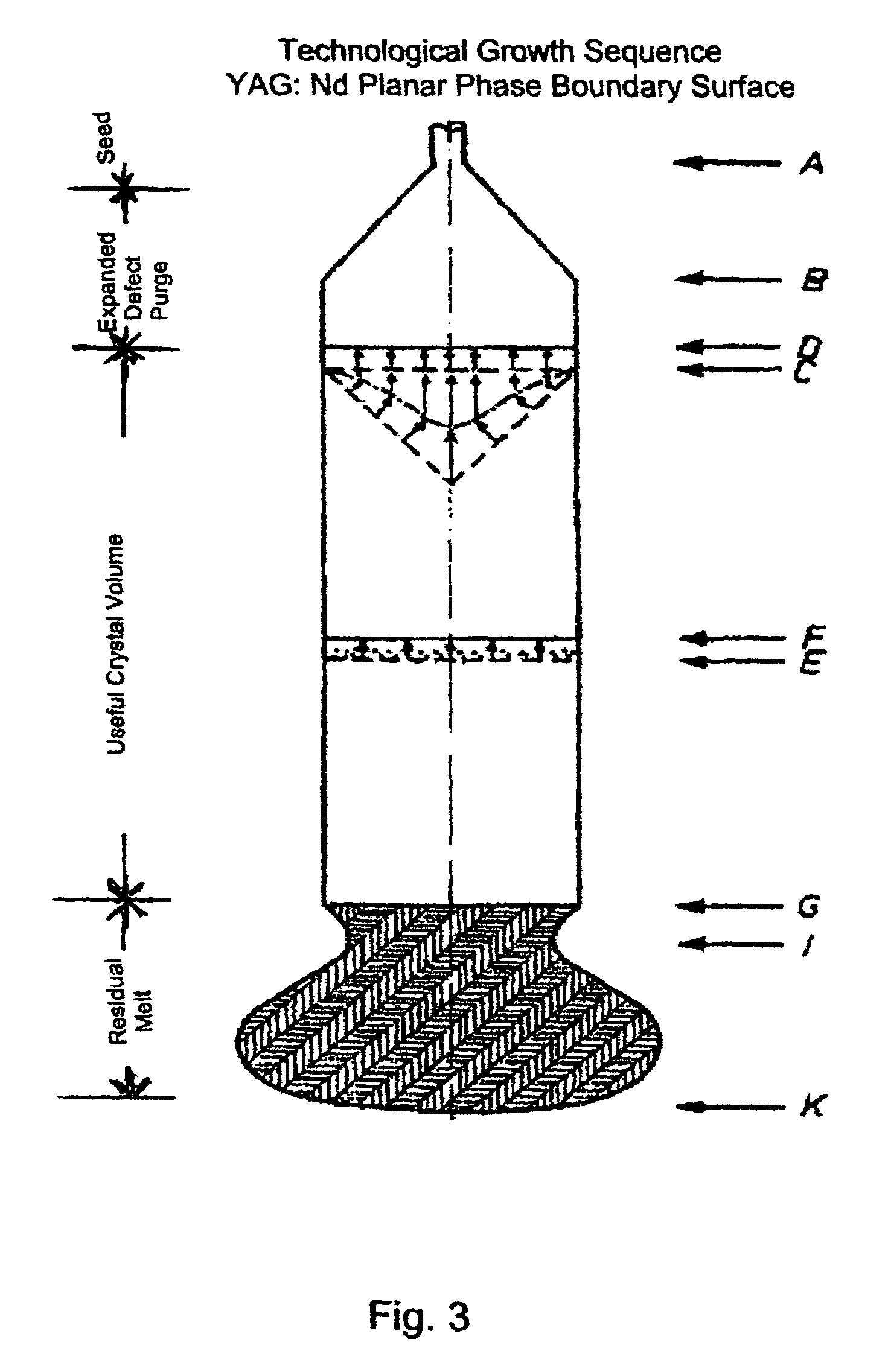

Method and apparatus for making a highly uniform low-stress single crystal by drawing from a melt and uses of said crystal

InactiveUS7476274B2Reduce heat lossMinimum radial and/or axial temperature gradientsPolycrystalline material growthBy pulling from meltCrucibleCrystal orientation

Owner:SCHOTT AG

Method for improving cleanliness of liquid steel in first ladle while casting

The invention belongs to the field of continuous casting processes in metallurgy and particularly relates to a method for improving the cleanliness of liquid steel in a first ladle while casting. The method is characterized by comprising two aspects, namely oxidizing liquid steel at a casting phase to increase impurities and causing falling by rapidly raising the temperature of a fireproof material; and aiming at the increase of the impurities caused by oxidizing the liquid steel at the casting phase, the method comprises the specific control steps of: (1) before casting, displacing an oxidized atmosphere in a tundish into an inert atmosphere; (2) sealing an submerged nozzle and preventing the air from entering the tundish; and (3) after the tundish is dried, reducing the air feeding amount. Aiming at the falling by rapidly raising the temperature of the fireproof material, the method comprises the specific control steps of: (1) sufficiently discharging water or a bonding agent in the fireproof material of the tundish; and (2) improving the drying temperature of the tundish to 1500 DEG C and lasting for 10-20 minutes. Compared with the prior art, the method disclosed by the invention has the beneficial effect that the cleanliness of the liquid steel in the first ladle can be controlled to the level of a normal pot.

Owner:ANGANG STEEL CO LTD

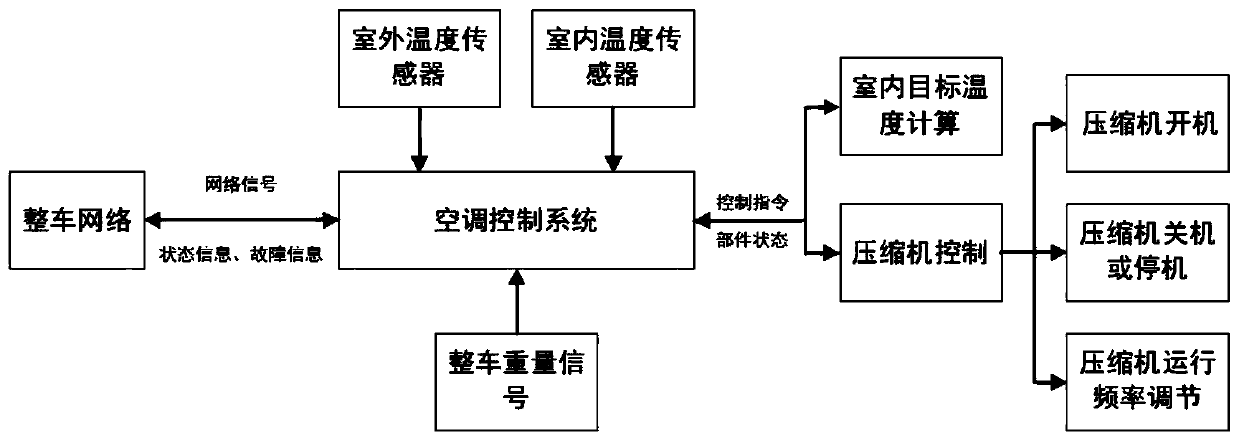

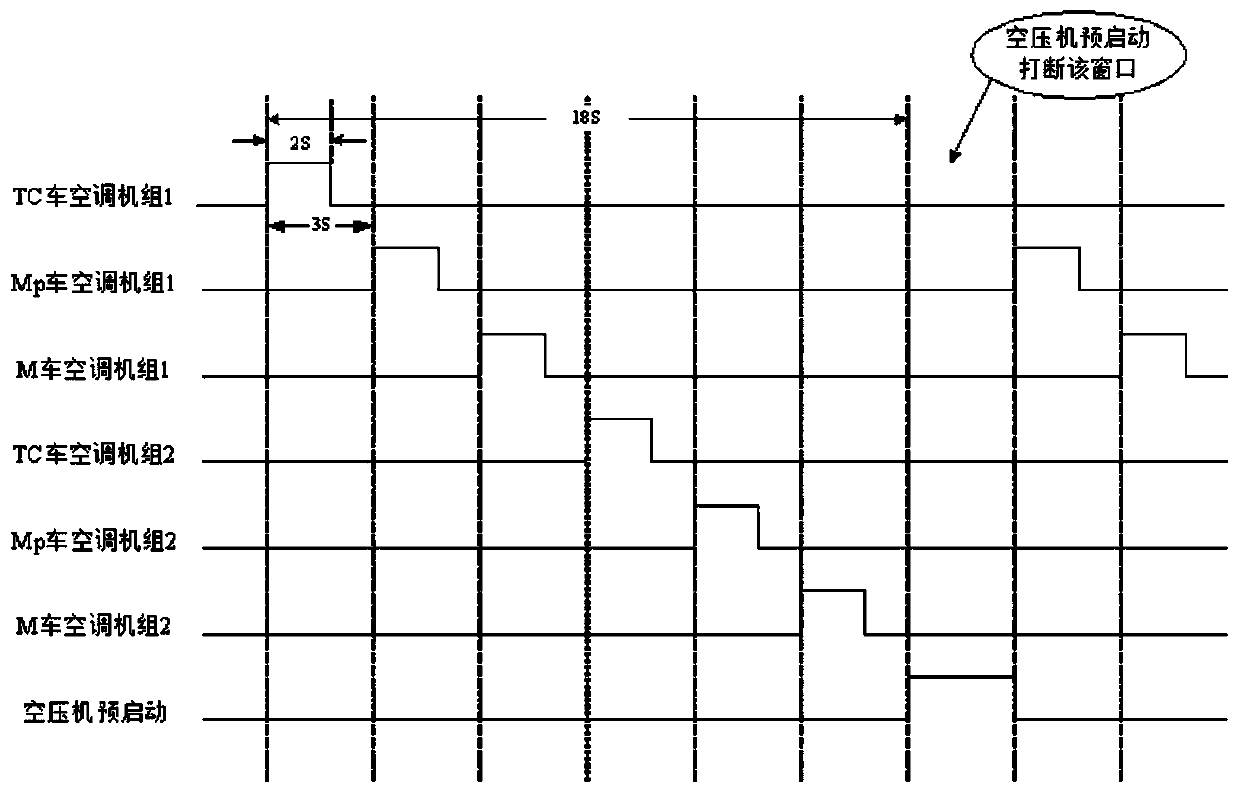

Compressor control method of rail vehicle variable-frequency air conditioner

ActiveCN111547091ALife-span-reducing effectsStrong output abilityRailway heating/coolingRailway transportControl theoryRunning time

The invention discloses a compressor control method of a variable frequency air conditioner of a railway vehicle. During startup and shutdown control, the temperature difference is used as a judgmentcondition, and the total running time or the continuous running time is added as a judgment condition, so that the compressor can be started immediately, capacity output can be performed quickly, thetarget temperature in the passenger room can be reached quickly, and matching of startup and shutdown of the compressor and actual requirements in the passenger room is realized; when the operation frequency is controlled, the duration time is also increased as a judgment condition; the operation frequency of the compressor is continuously adjusted according to the change of the heat load in the passenger room; the output capacity of the air conditioner is optimal; the actual temperature in the passenger room is always stabilized within the range of + / -1 DEG C of the indoor target temperature,so that the phenomenon of passenger room temperature fluctuation caused by frequent opening and closing of the compressor can be reduced, the passenger room is more comfortable and energy-saving, meanwhile, the operation frequency of the compressor is matched with the actual requirement in the passenger room, and the influence on the service life of the compressor is reduced.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

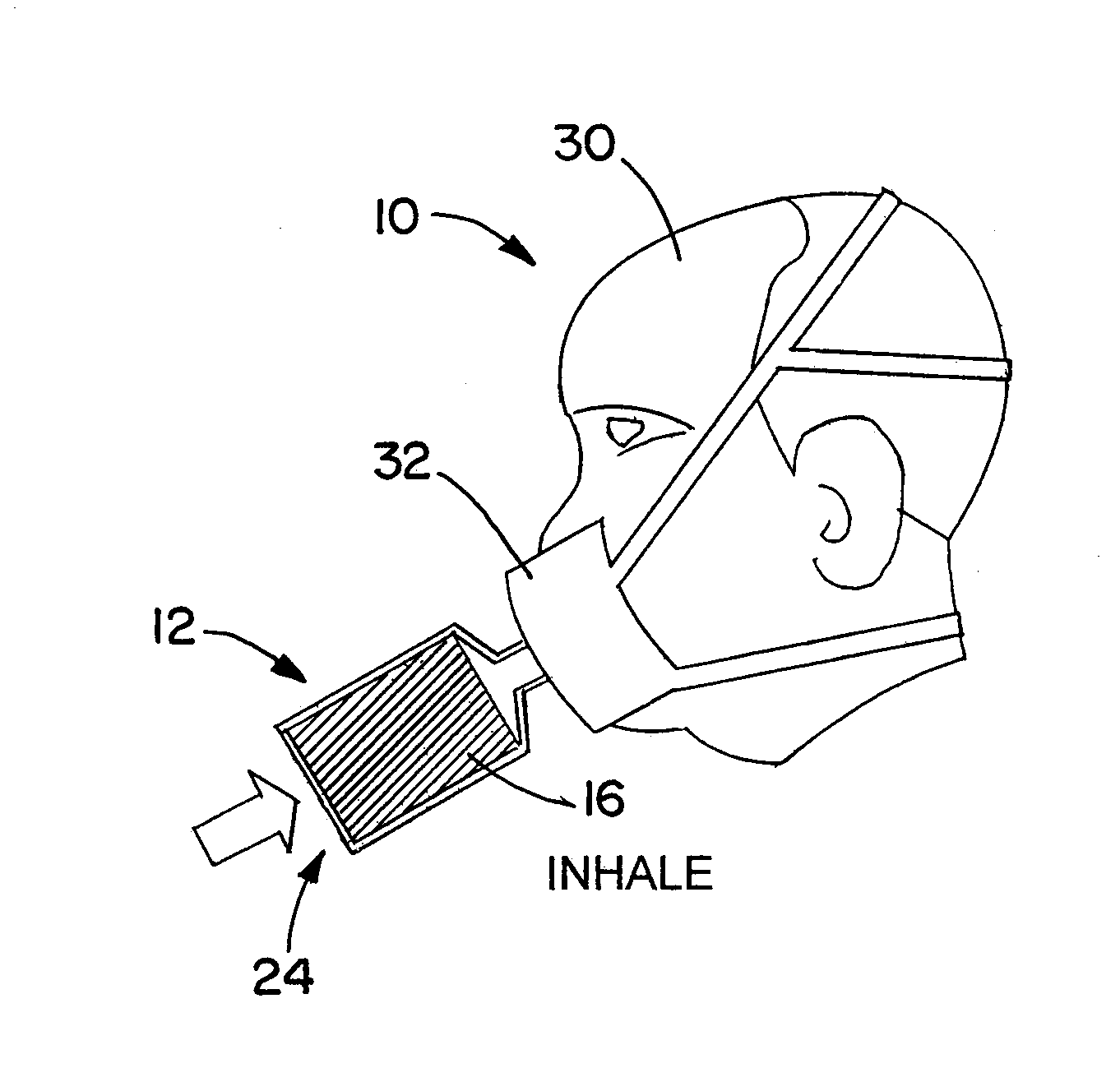

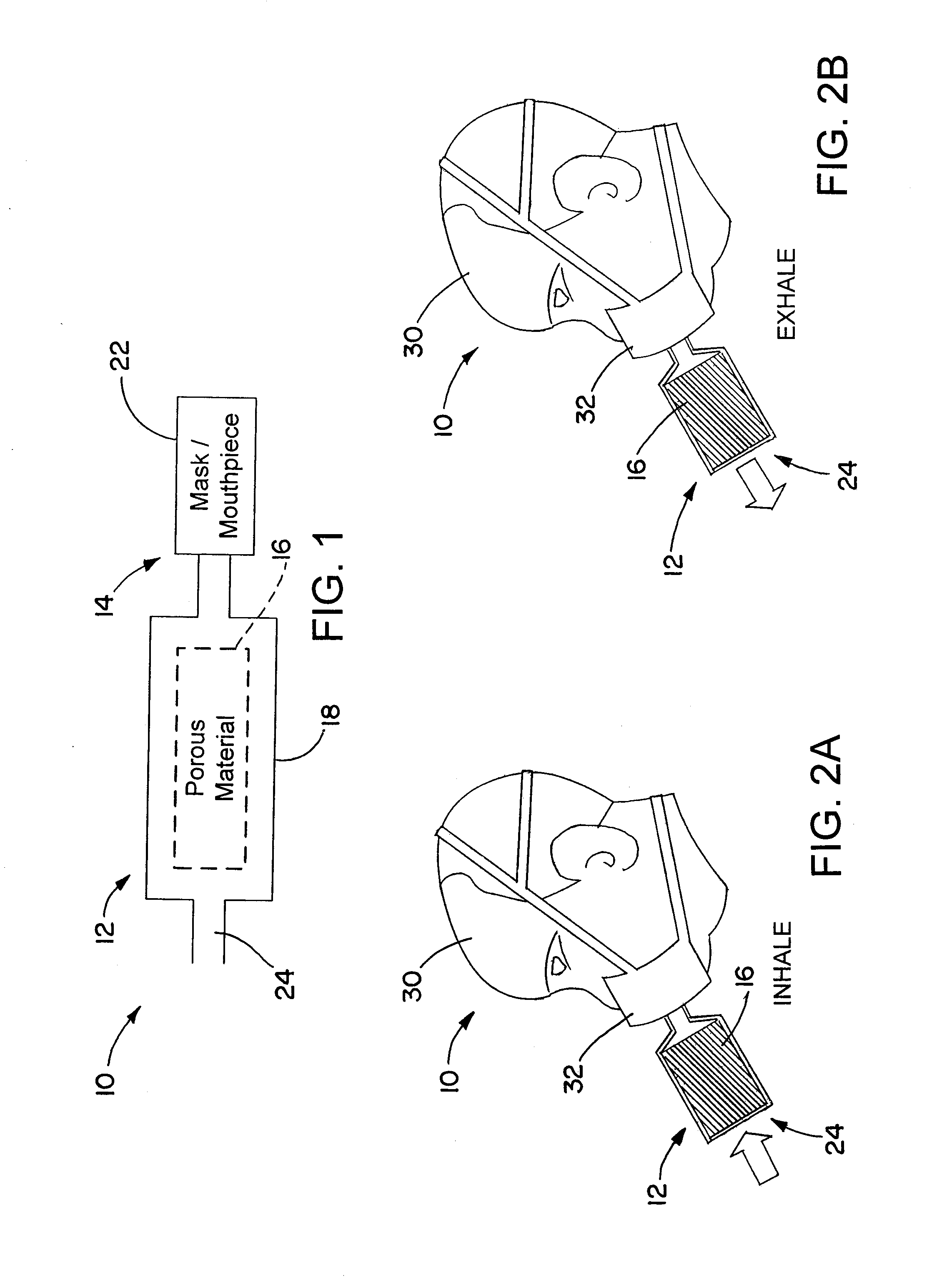

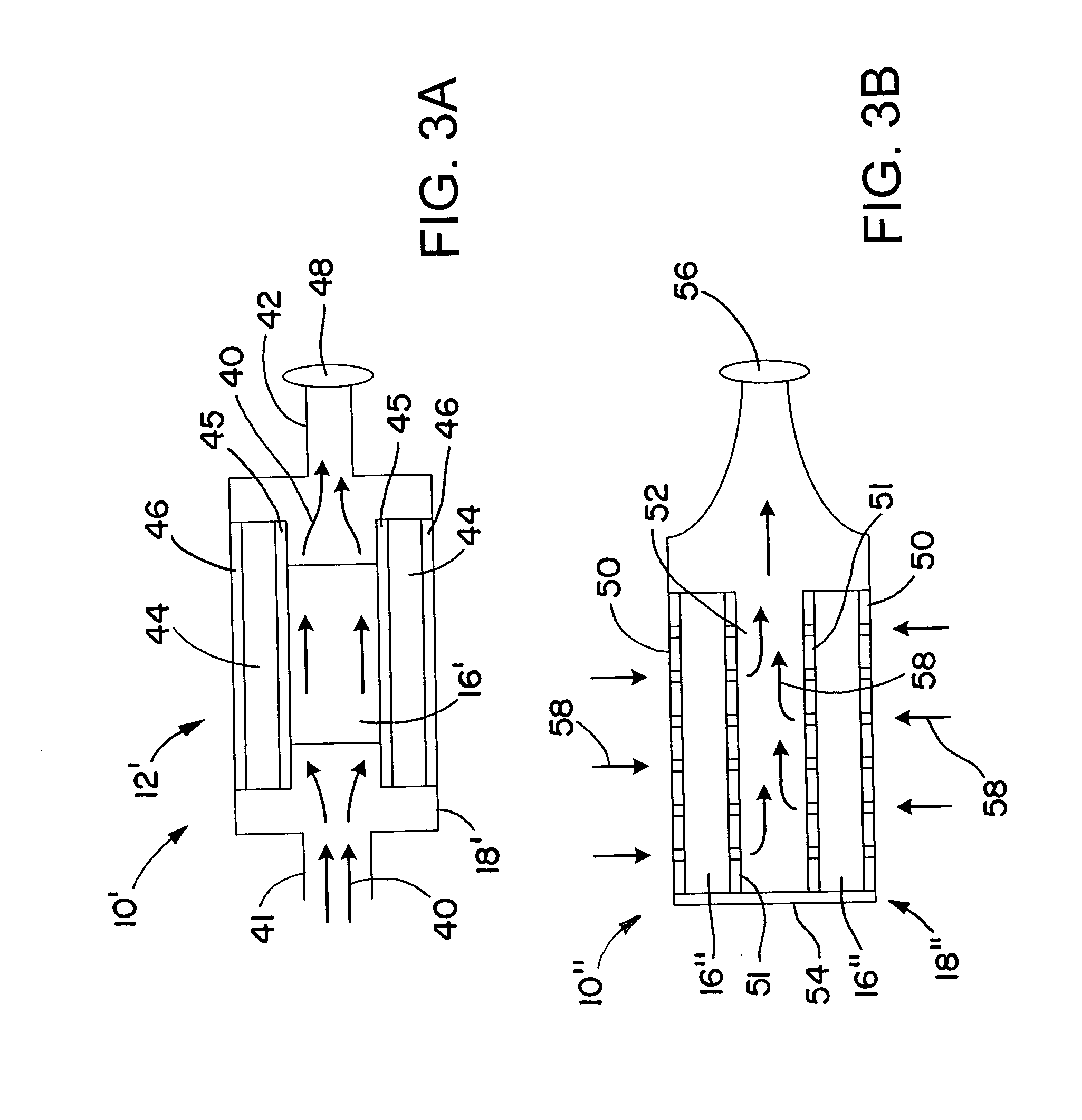

Breathing apparatus, and method for controlling temperature fluctuations

InactiveUS20140360500A1Reduce temperature fluctuationsRespiratorsLighting and heating apparatusEngineeringCause injury

A wearable breathing apparatus includes a thermal capacitor that a user inhales and exhales through. Inhaled air is cooled as it passes through the thermal capacitor, and exhaled air cools the material of the thermal capacitor for the next breathing cycle. The breathing apparatus may be used by a firefighter, for example, as a lightweight apparatus to enable the firefighter to safely breathe dangerously heated air, for example while in a fire shelter, that may otherwise cause injury to the user. The breathing apparatus advantageously does not require external power for cooling. The thermal capacitor may also be used as a part of a rebreather that uses a scrubber that removes carbon dioxide from exhaled air, for rebreathing. Further, the thermal capacitor may be used for other purposes, such as in recirculation of building air.

Owner:TDA RES

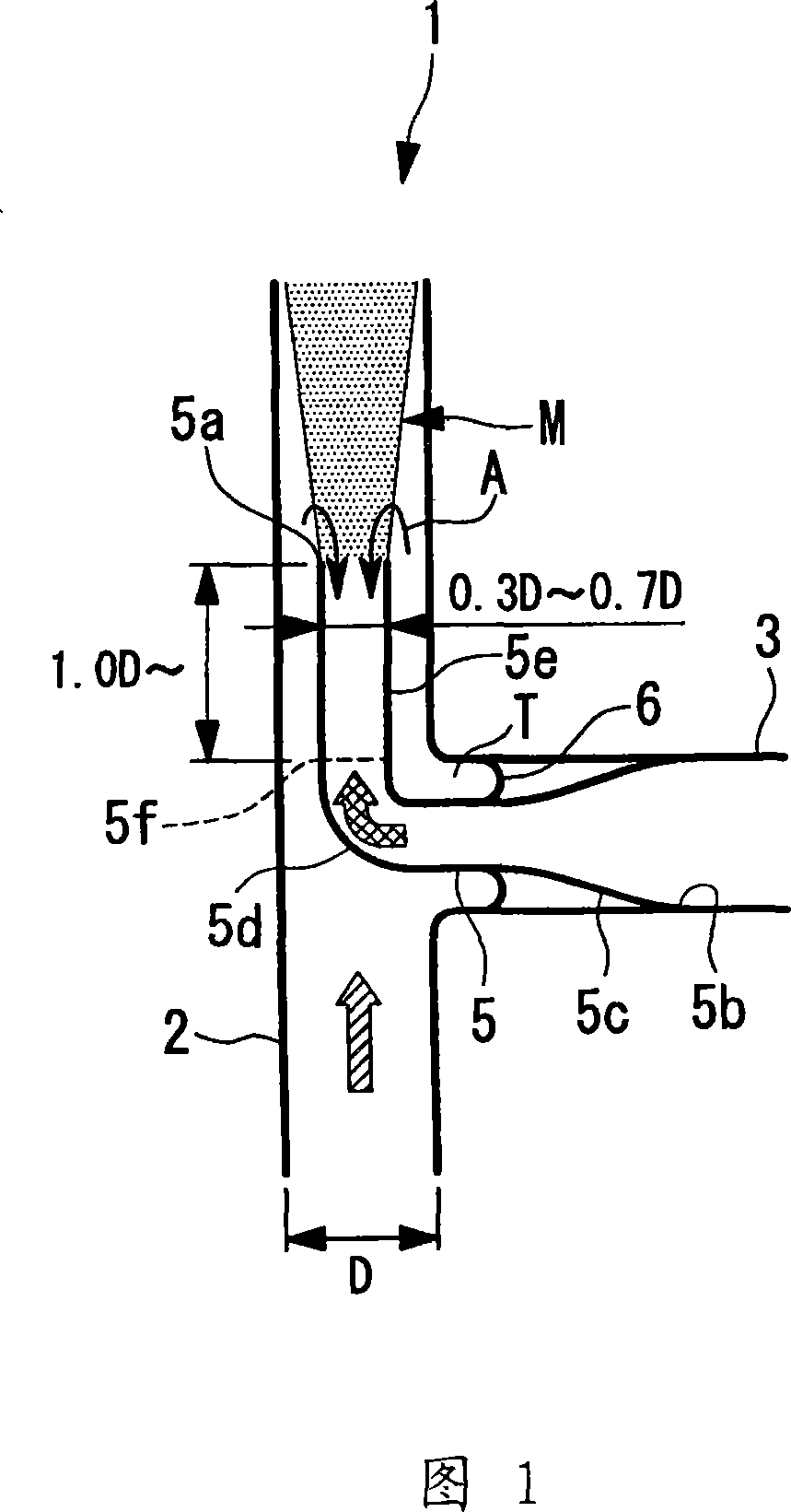

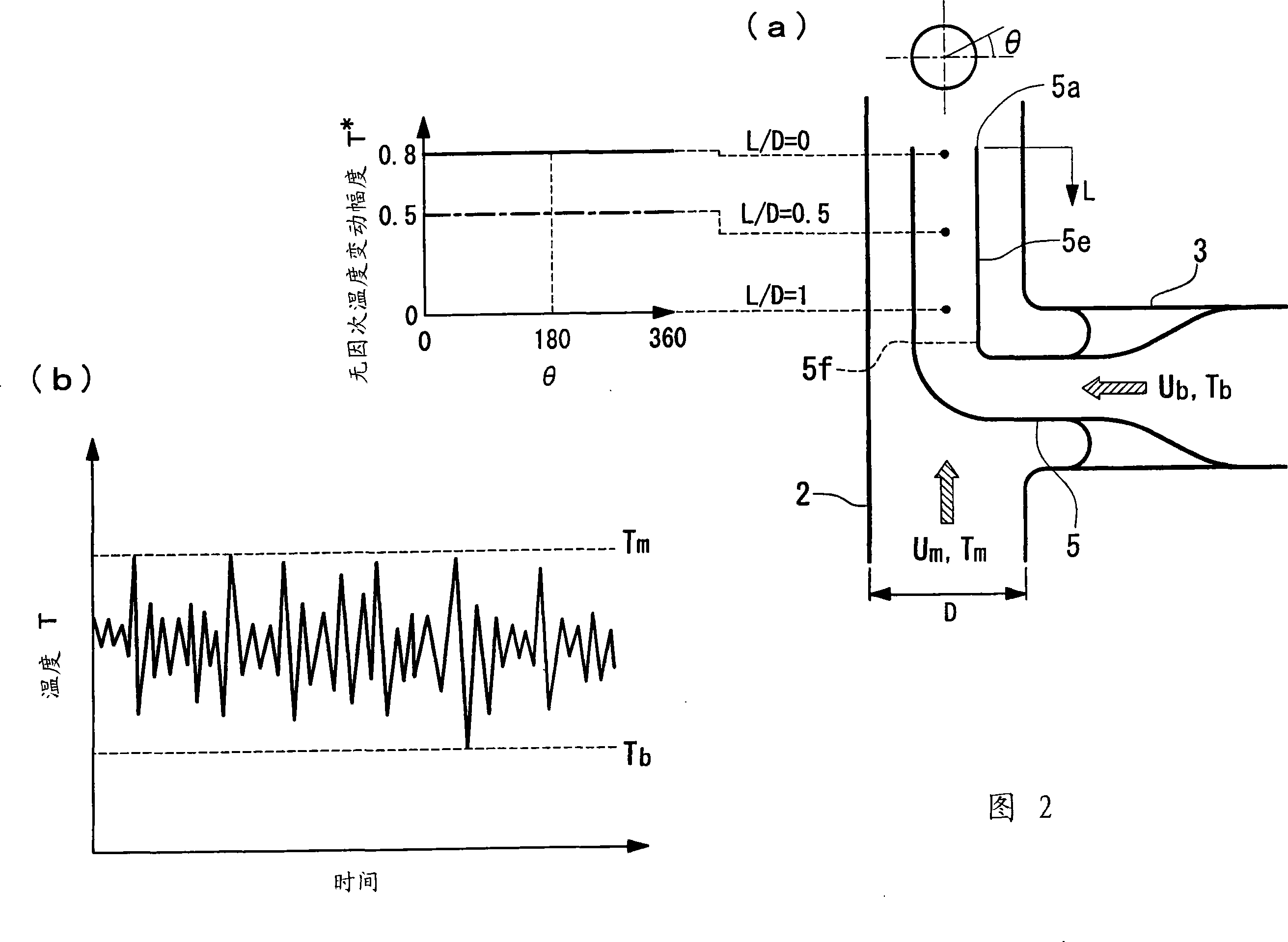

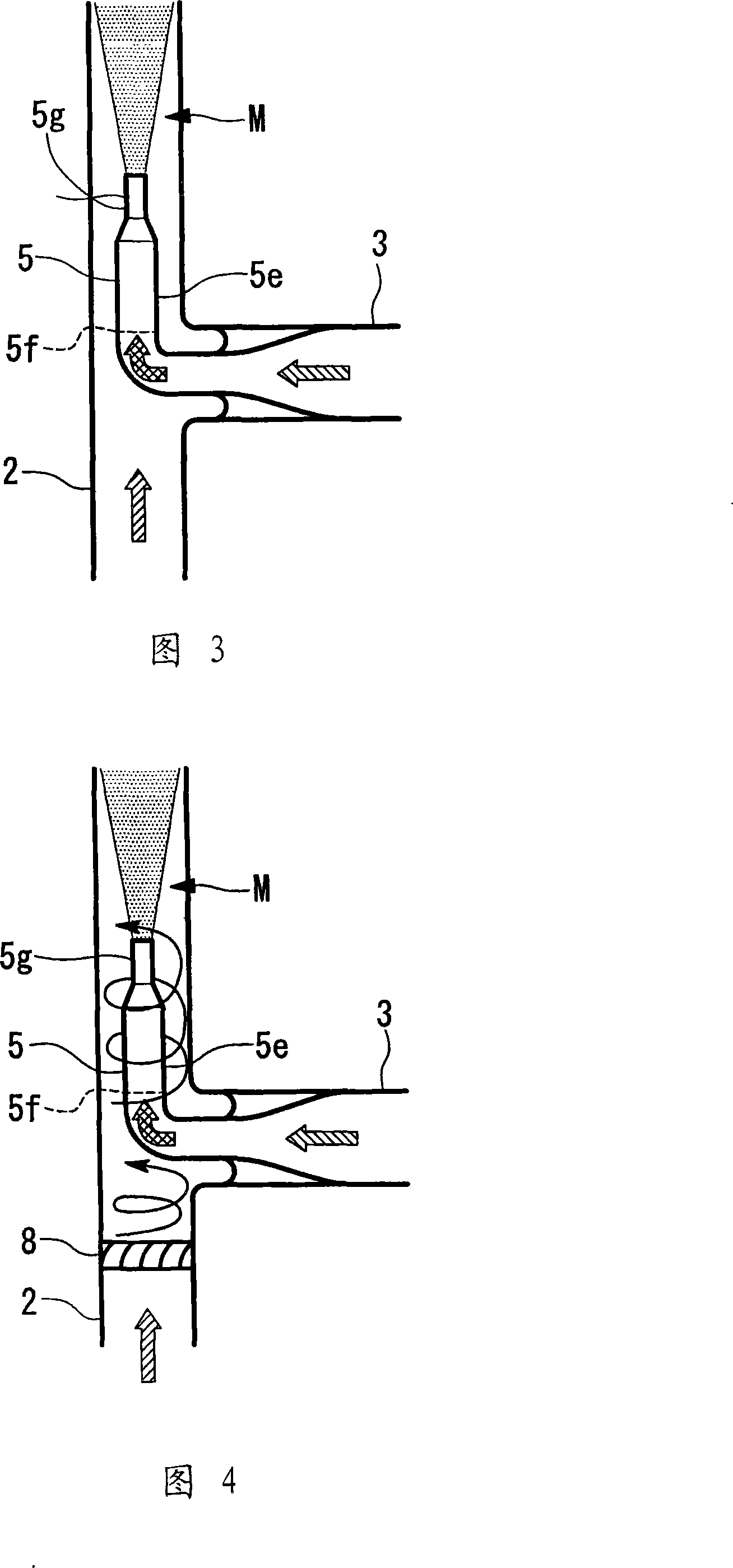

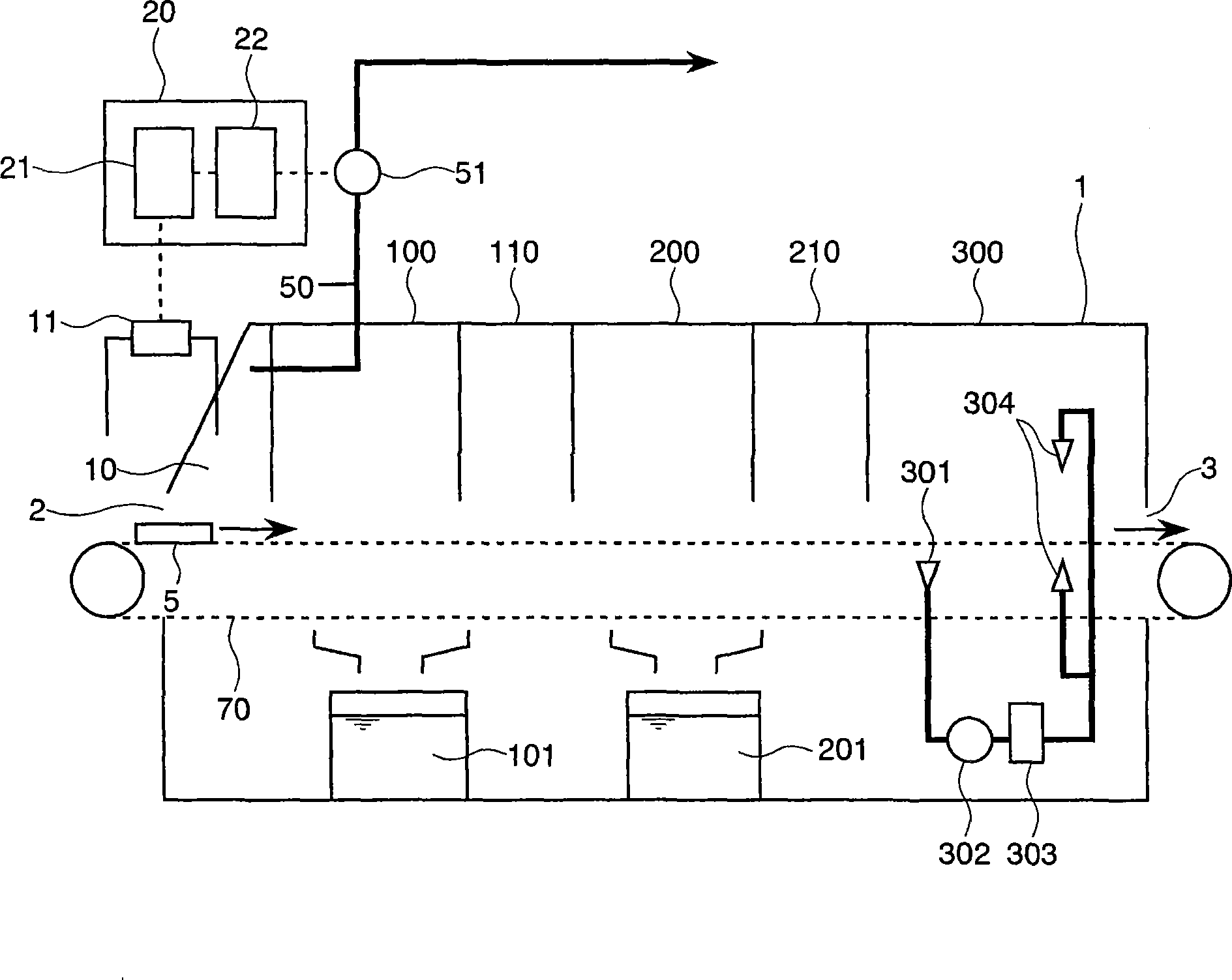

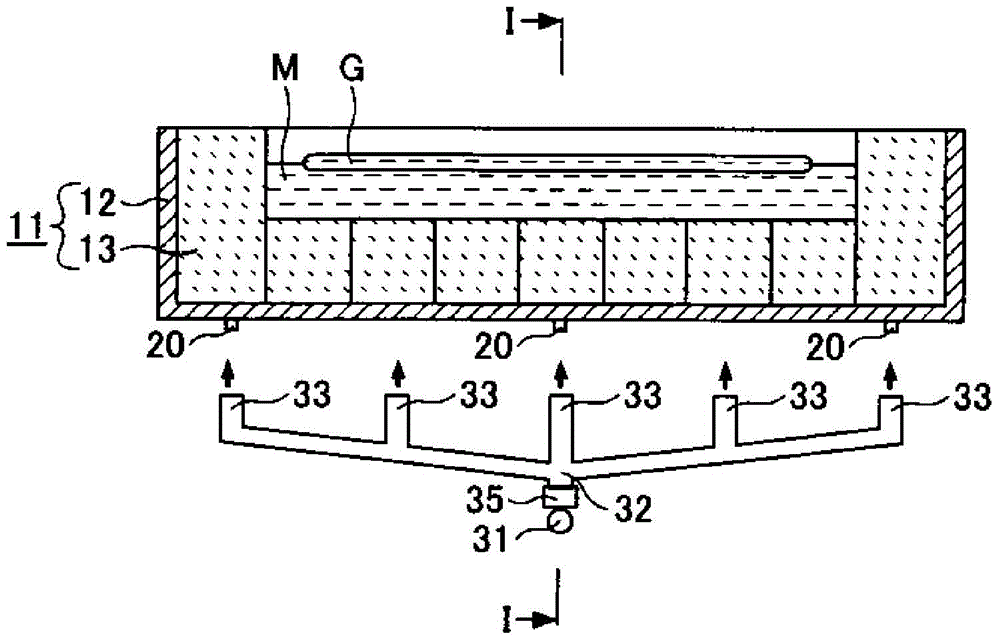

Piping with fluid mixing region

InactiveCN101233359AWell mixedReduce temperature fluctuationsFlow mixersTransportation and packagingThermal fatigueDistal portion

The present invention provides a pipe having a fluid mixing region where fluids of different temperatures are mixed, and an object of the present invention is to prevent thermal fatigue caused by fluctuations in the temperature interface. The pipe (1) of the present invention has a reducer (5) whose front end (5e) is arranged substantially on the central axis of the main pipe (2) and through which low-temperature water flows. The flowing high-temperature water has different temperatures, and the flow velocity is smaller than that of high-temperature water, and there is a fluid mixing area (M) for mixing high-temperature water and low-temperature water on the downstream side of the reducer (5). (5) A welded part (5f) connecting the front end part (5e) and the elbow part (5d) is formed on the top, and the distance between the welded part (5f) and the downstream end (5a) is the inner diameter (D) of the main pipe (2) above.

Owner:MITSUBISHI HEAVY IND LTD

Method for stabilizing semi-steel quality

The invention belongs to the technical field of metallurgy, and particularly relates to a method for stabilizing semi-steel quality after extracting vanadium from vanadium-containing molten steel. The method for stabilizing semi-steel quality comprises the following steps of: A, adding a recarburizer before a vanadium extracting end point according to carbon content and molten iron temperature in the vanadium-containing molten steel; and B, performing thermal compensation on semi-steel by adding ferrosilicon according to carbon content of semi-steel during tapping. The method has the advantage of stabilizing semi-steel quality.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

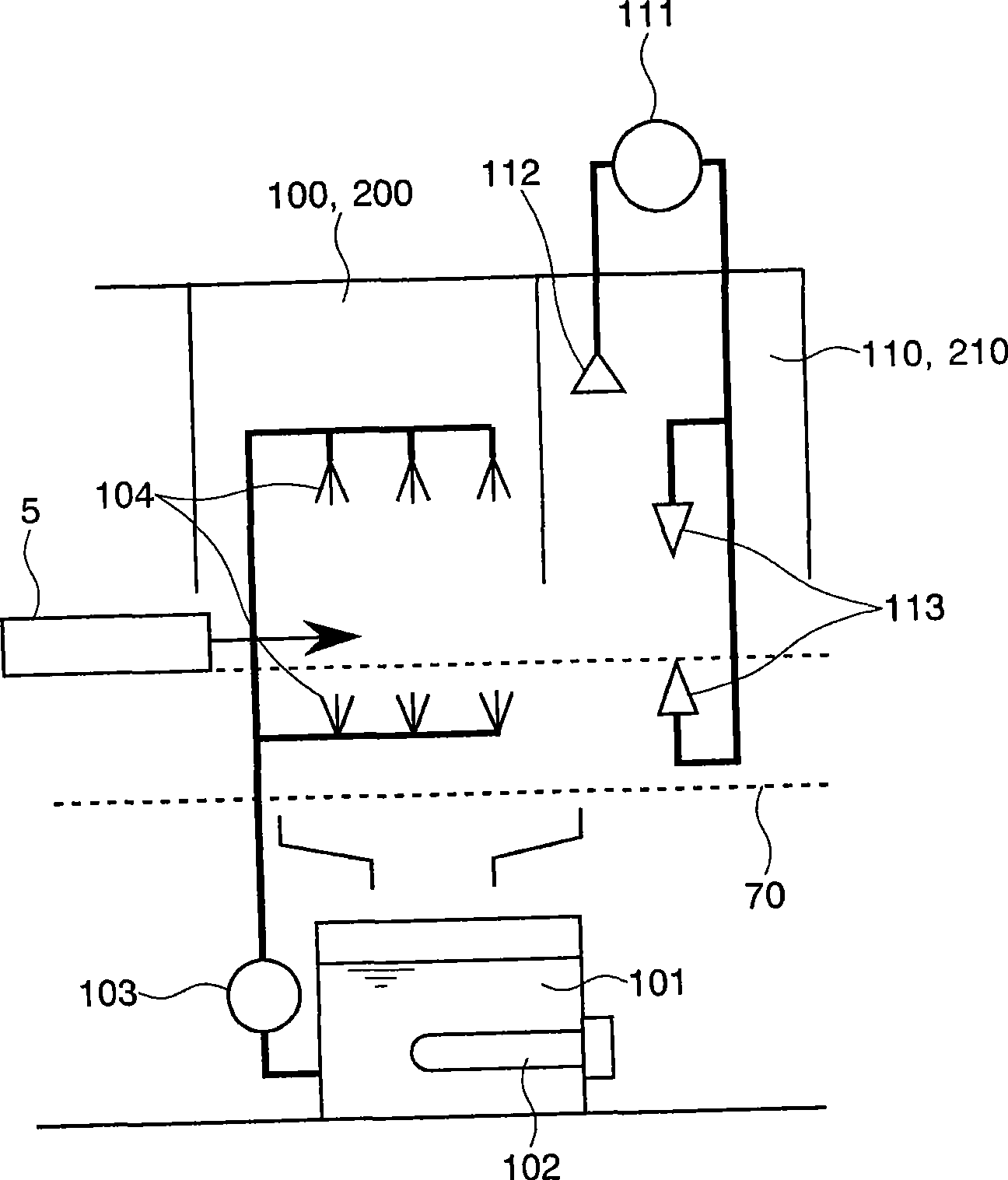

Cleaning device using water-based cleaning liquid

InactiveCN101374609AEasy temperature adjustmentReduce temperature fluctuationsCleaning heat-transfer devicesCleaning using gasesAir volumePneumatic pressure

The invention provides a cleaning device using a water-based cleaning A cleaning device (1) using a water-based cleaning liquid is filled up with steam produced when the liquid is heated to high temperature. Conventionally, heating or drying the cleaning liquid has caused steam leakage, resulting in a large loss of heat energy. To solve this problem, the cleaning device of the invention is provided with pressure difference measuring device (11) for measuring the pressure difference between the pressure in a gas discharge chamber (10) and the outside air pressure. The amount of discharge gas from the gas discharge chamber (10) is controlled in order that the pressure difference is a predetermined appropriate value, preventing a leakage of excessive steam and enabling the cleaning device to be always operated at an optimum exhaust air flow rate. A heat pump mechanism for recovering the heat of the discharge gas into the cleaning liquid in the cleaning device is installed to re-use the energy dissipated along with the exhaust air.

Owner:TAKAHASHI METAL INDS

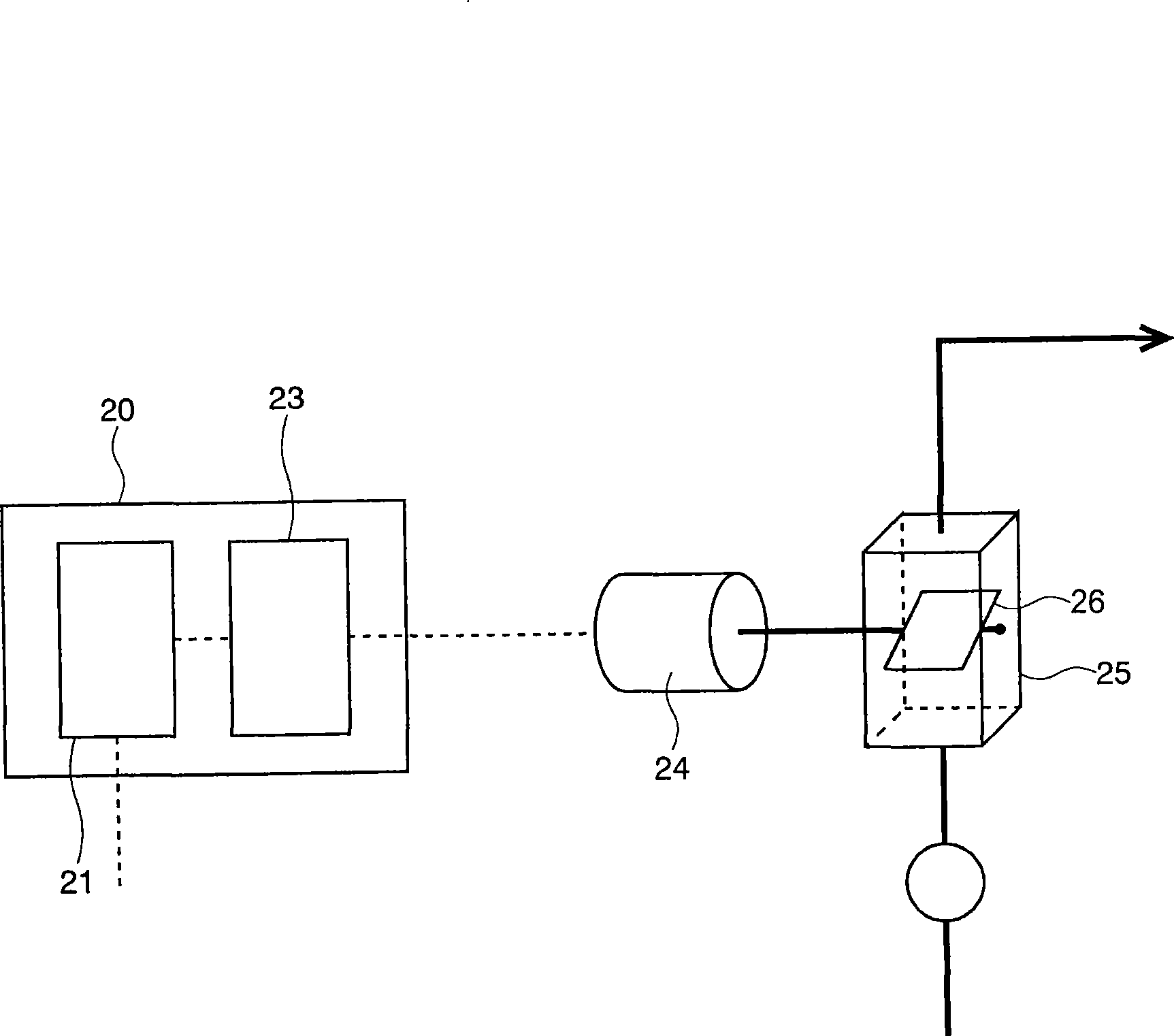

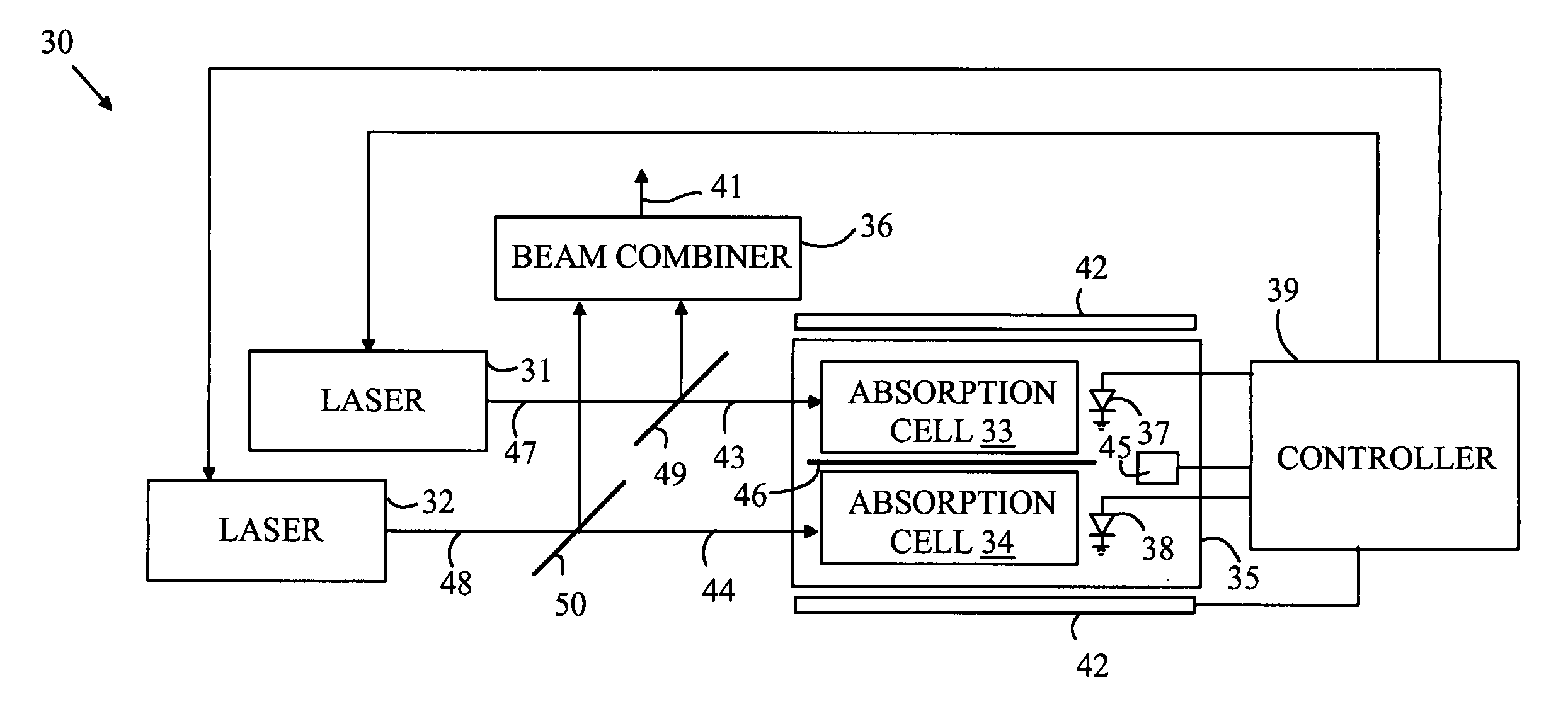

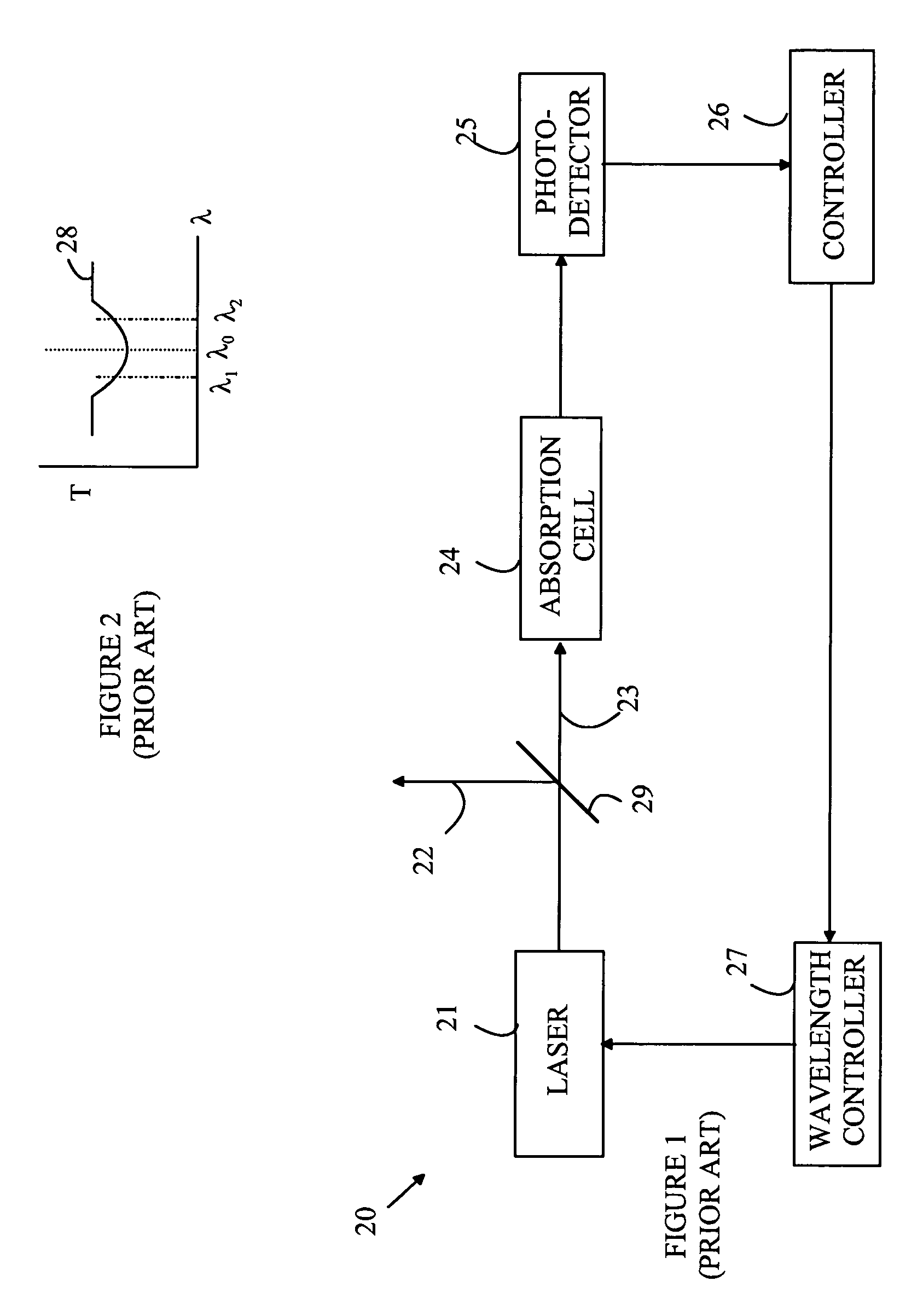

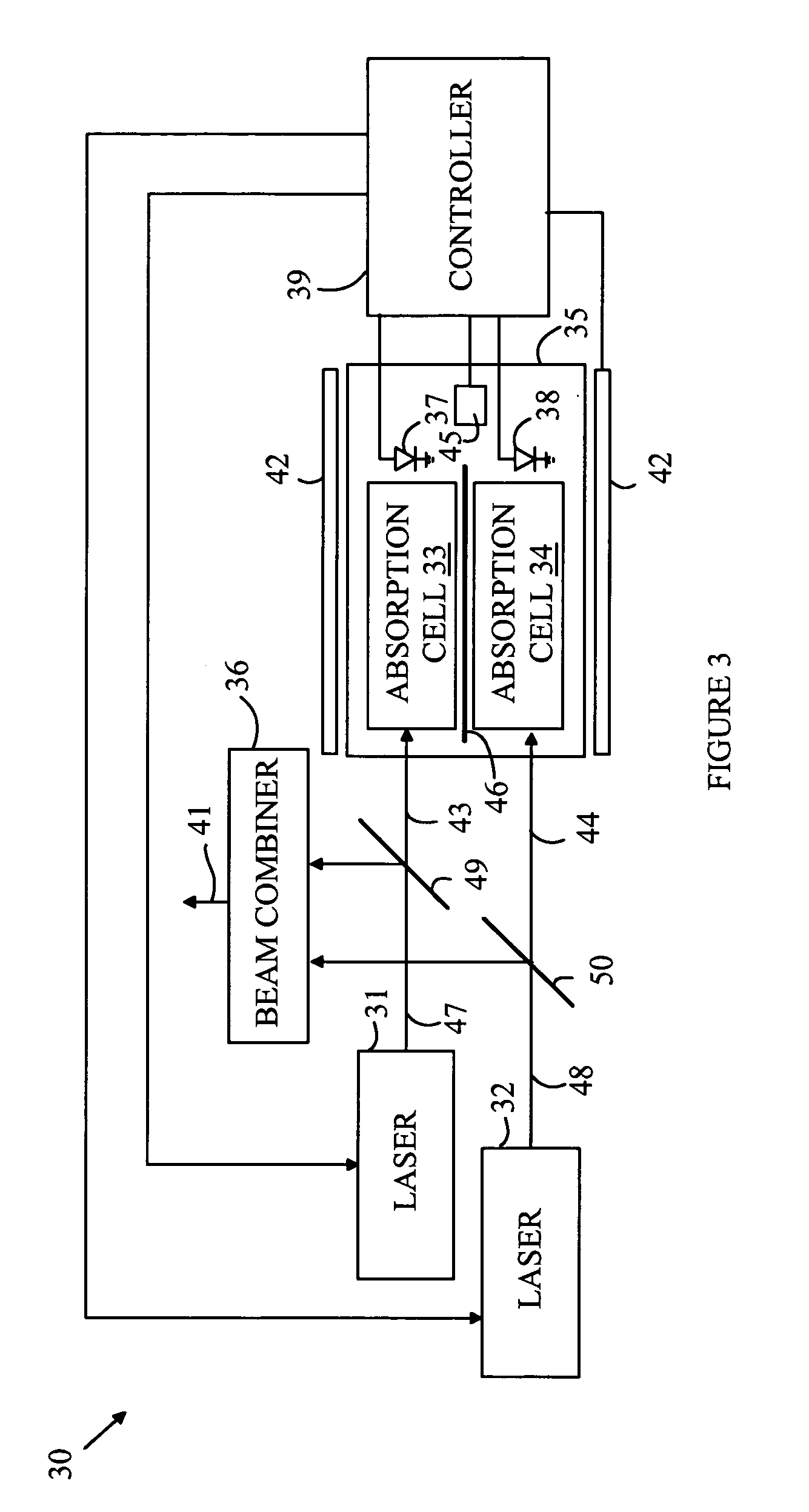

Light source that utilizes small footprint reference gas cells for multiple laser frequency stabilization

ActiveUS7843977B2Reduce diffuseReduce temperature fluctuationsSemiconductor laser optical deviceLaser cooling arrangementsAbsorption cellBeam splitter

A light source and the method for operating the same are disclosed. The light source includes first and second lasers, and first and second wavelength control assemblies. The lasers emit first and second light beams, respectively, at wavelengths that are determined by first and second wavelength control signals. First and second beam splitters split the first and second light beams, respectively, to create first and second sampling light beams. The first and second wavelength control assemblies receive sampling light beams and generate the first and second wavelength control signals such that the wavelengths of the first and second light beams differ by no more than a predetermined amount. The first and second wavelength control assemblies each include an absorption cell having a gas that has an optical absorption that varies with the wavelength of the first and second sampling light beams at wavelengths around the output wavelength of the light source.

Owner:KEYSIGHT TECH

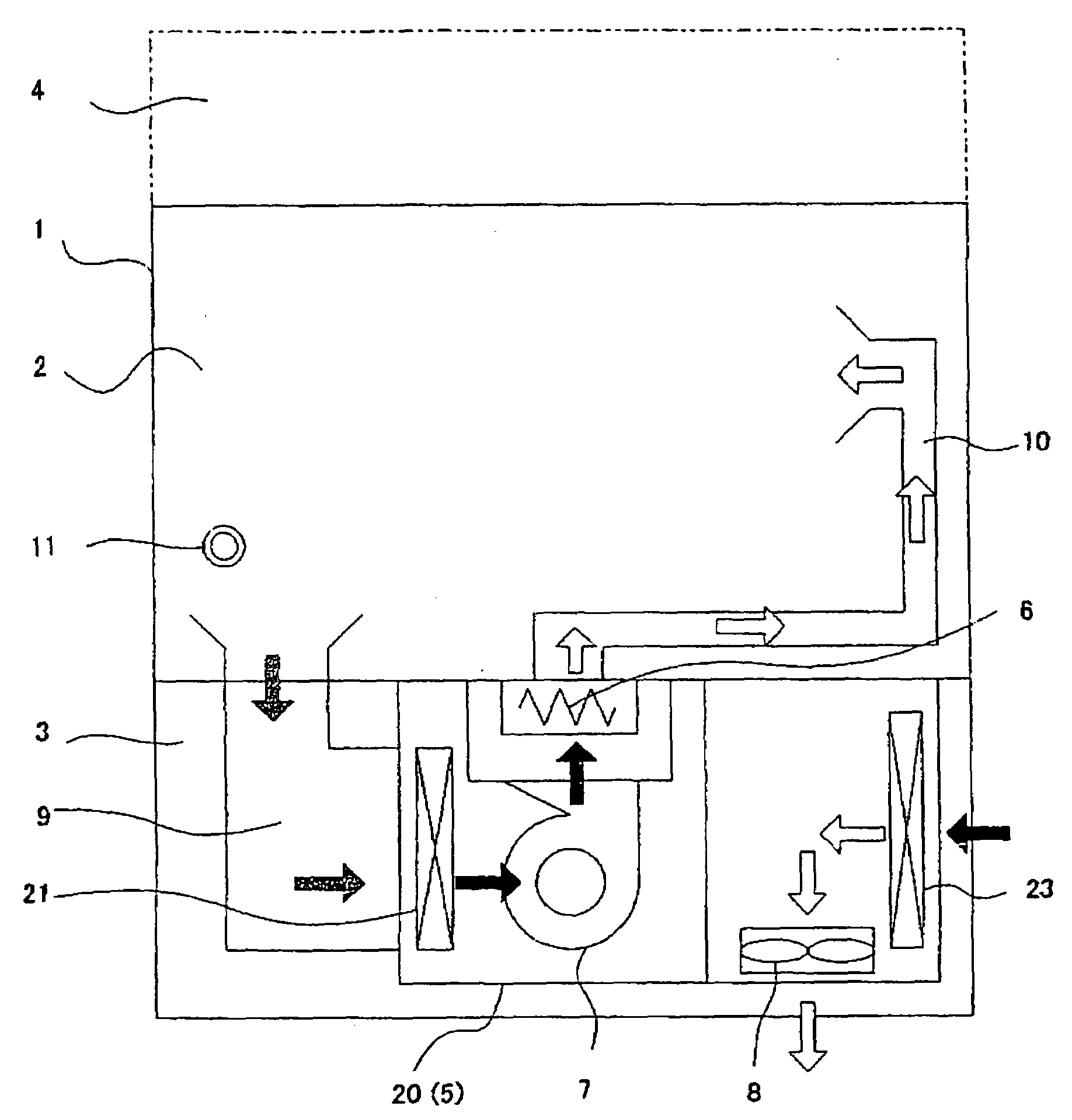

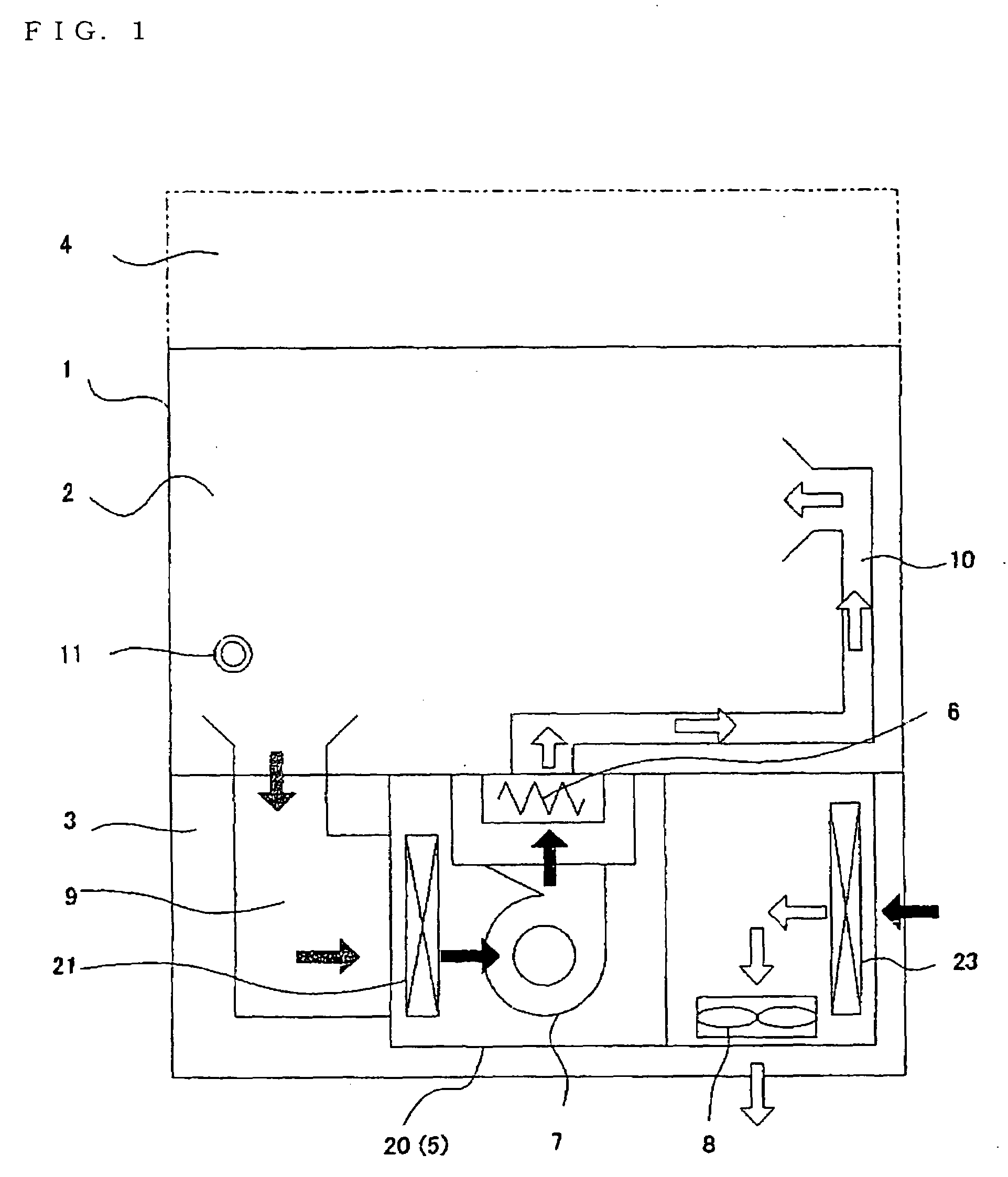

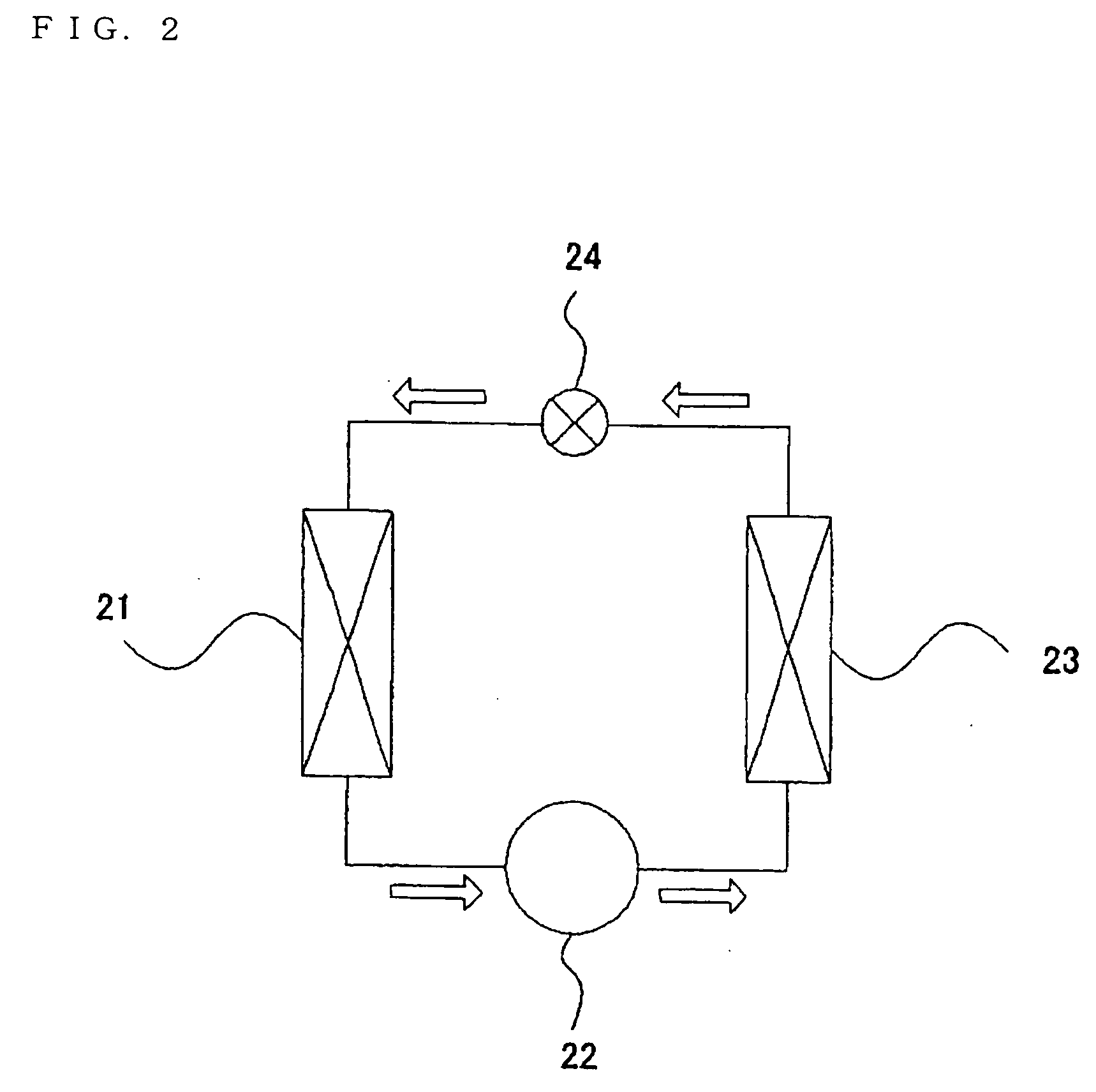

Vehicle air-conditioning system

InactiveUS20090159256A1Reduce temperature fluctuationsSuppressing immediate fluctuationAir-treating devicesVehicle heating/cooling devicesProcess engineeringAir conditioning

To propose a vehicle air-conditioning system capable of further reducing a temperature fluctuation of blowing-out air when temperature-conditioned air is supplied to an in-car space.The vehicle air-conditioning system including a cooling apparatus 5 capable of changing an amount of withdrawn heat in a stepwise manner, heaters 6A, 6B, and 6C, each having different heat release capability, which constitutes a heating apparatus 6 capable of changing an amount of generated heat in a stepwise manner, and a control device 30 including a supplying amount of heat calculating portion 30A for calculating a supplying amount of heat to an in-car space 2 and an amount of generated and withdrawn heat setting portion 30B for setting amounts of withdrawn and generated heat of the cooling apparatus 5 and the heating apparatus 6 on the basis of the supplying amount of heat calculated by means of the supplying amount of heat calculating portion 30A.

Owner:MITSUBISHI ELECTRIC CORP

Method and system for coolant flow control for a prime mover in a vehicle propulsion system

InactiveUS20190085752A1Improve fuel economyImprove efficiencyLiquid coolingCoolant flow controlControl theoryStreamflow

A vehicle propulsion system includes a prime mover having a coolant inlet and coolant outlet, a coolant flow controller having a flow control inlet in communication with the prime mover coolant outlet, and a flow control outlet in communication with the prime mover coolant inlet, and a controller that determines a coefficient based upon a power of the prime mover, and that provides a coolant flow command signal to the coolant flow controller based upon the power of the prime mover.

Owner:GM GLOBAL TECH OPERATIONS LLC

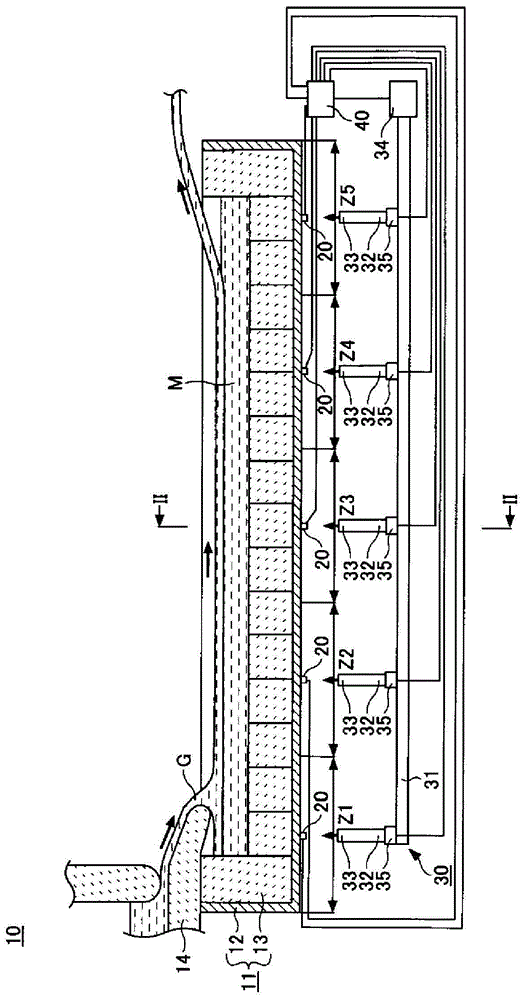

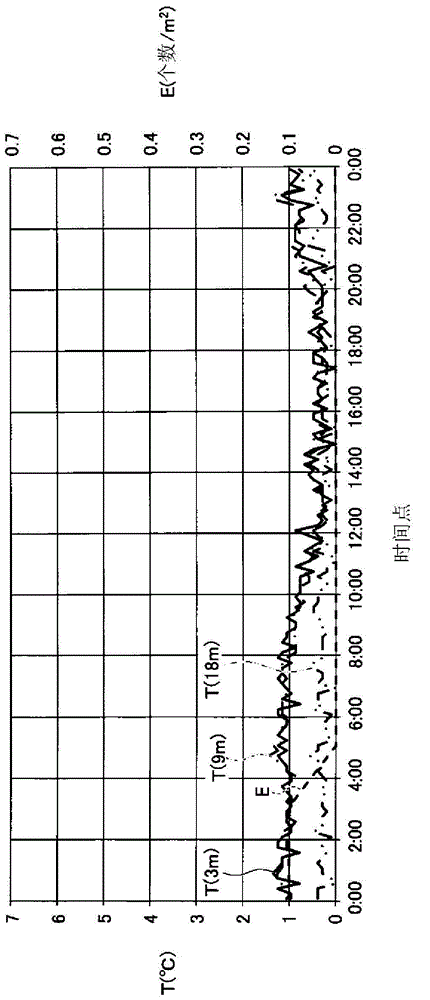

Method for producing float glass and apparatus for producing float glass

The invention provides a method for producing float glass and an apparatus for producing the float glass. The method for producing the float glass comprises a molding step that molten glass flows on a molten metal in a bath groove to form a plate-shaped glass tape. In the molding step, a lower wall part of the bath groove is cooled by means of a main pipe, branch pipes and nozzles to blow and send a fluid to the lower surface of the bath groove, midways of the various branch pipes are provided with flow adjusting parts for adjusting flow of the fluid, the lower wall part is provide with a plurality of temperature adjusting areas which independently adjust temperature by utilizing the flow adjusting parts, and at least one temperature sensor is disposed in each of the temperature adjusting area. In the molding step, the flow adjusting parts are controlled according to measuring temperature of the at least one temperature sensor disposed in the corresponding temperature adjusting area.

Owner:ASAHI GLASS CO LTD

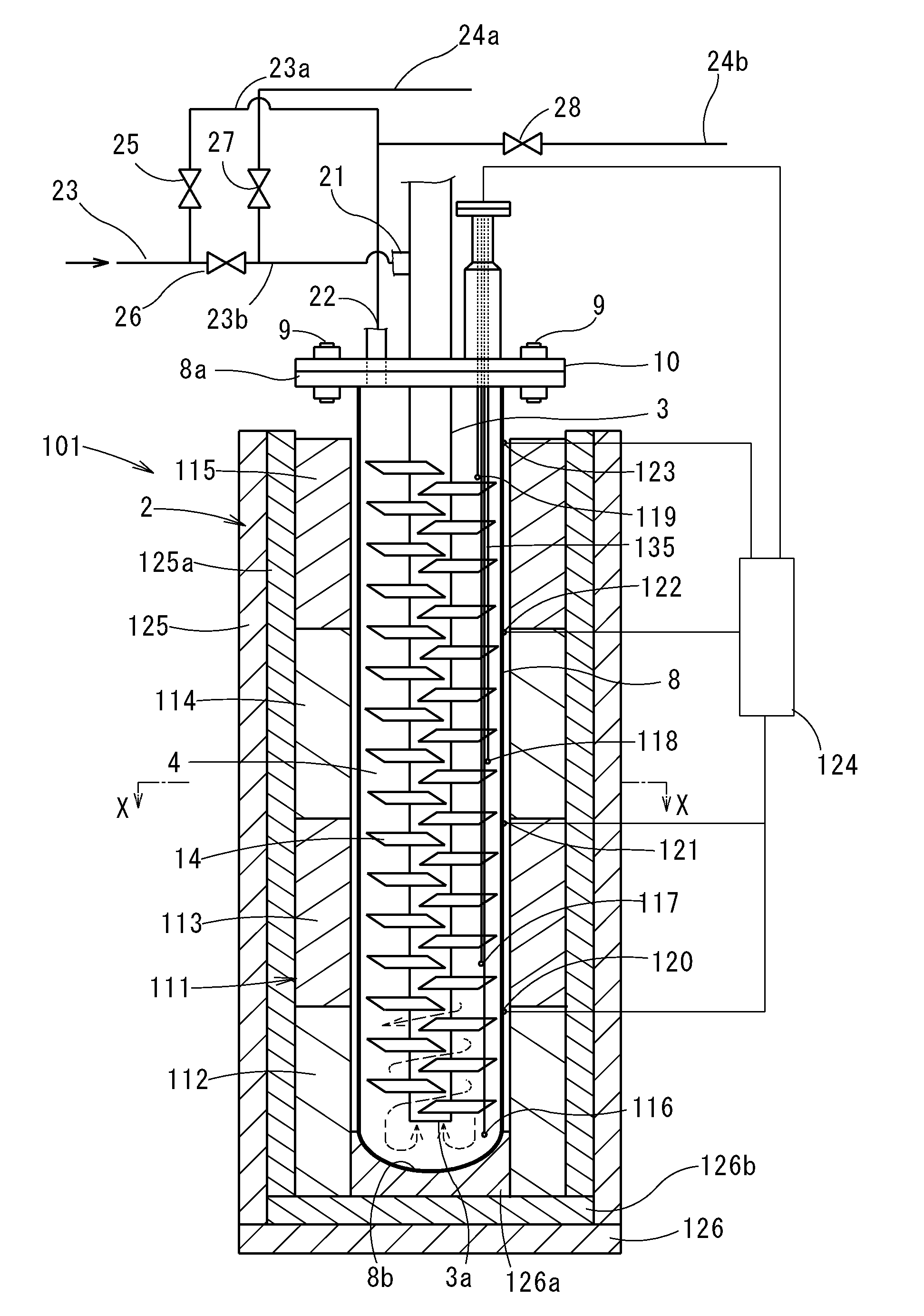

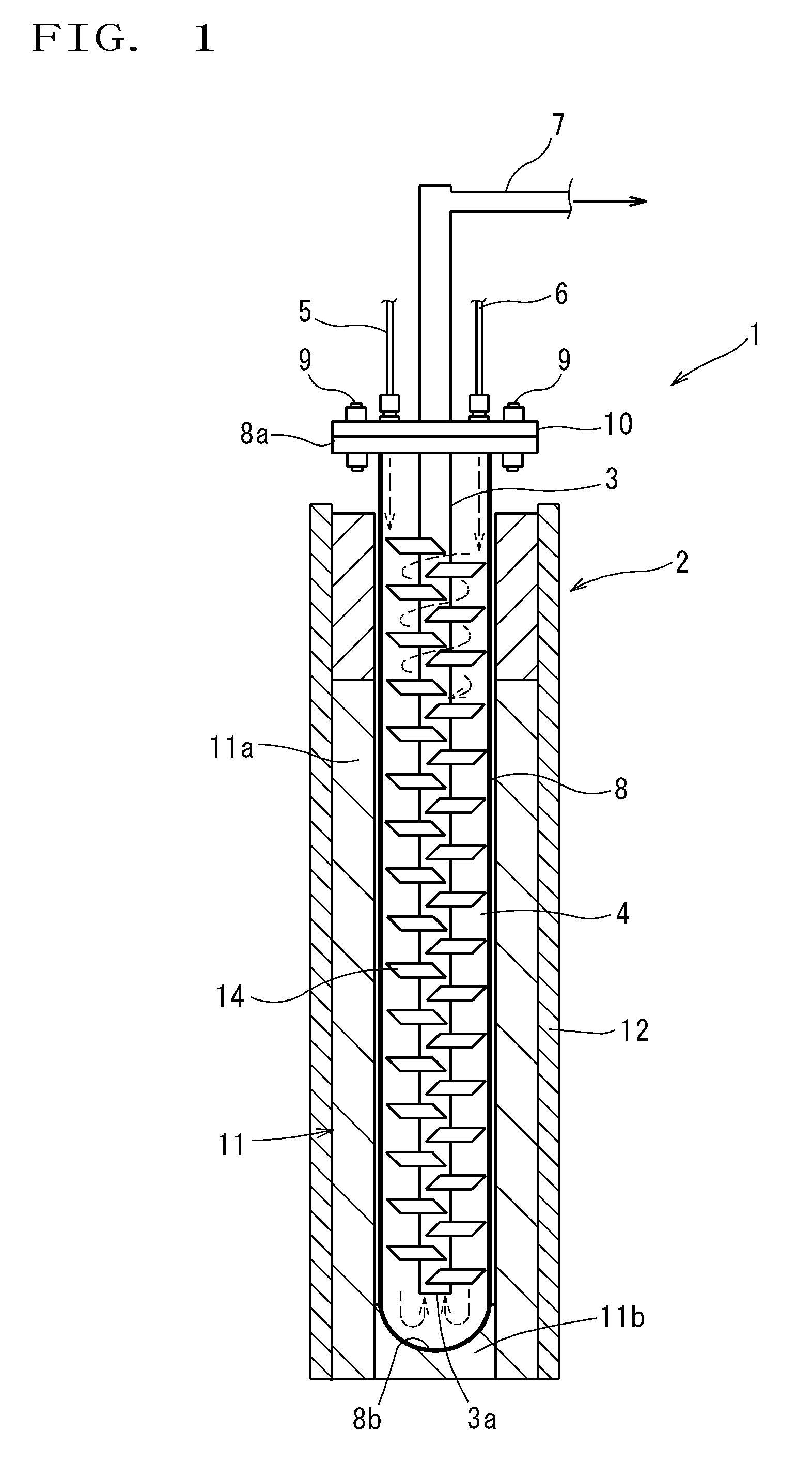

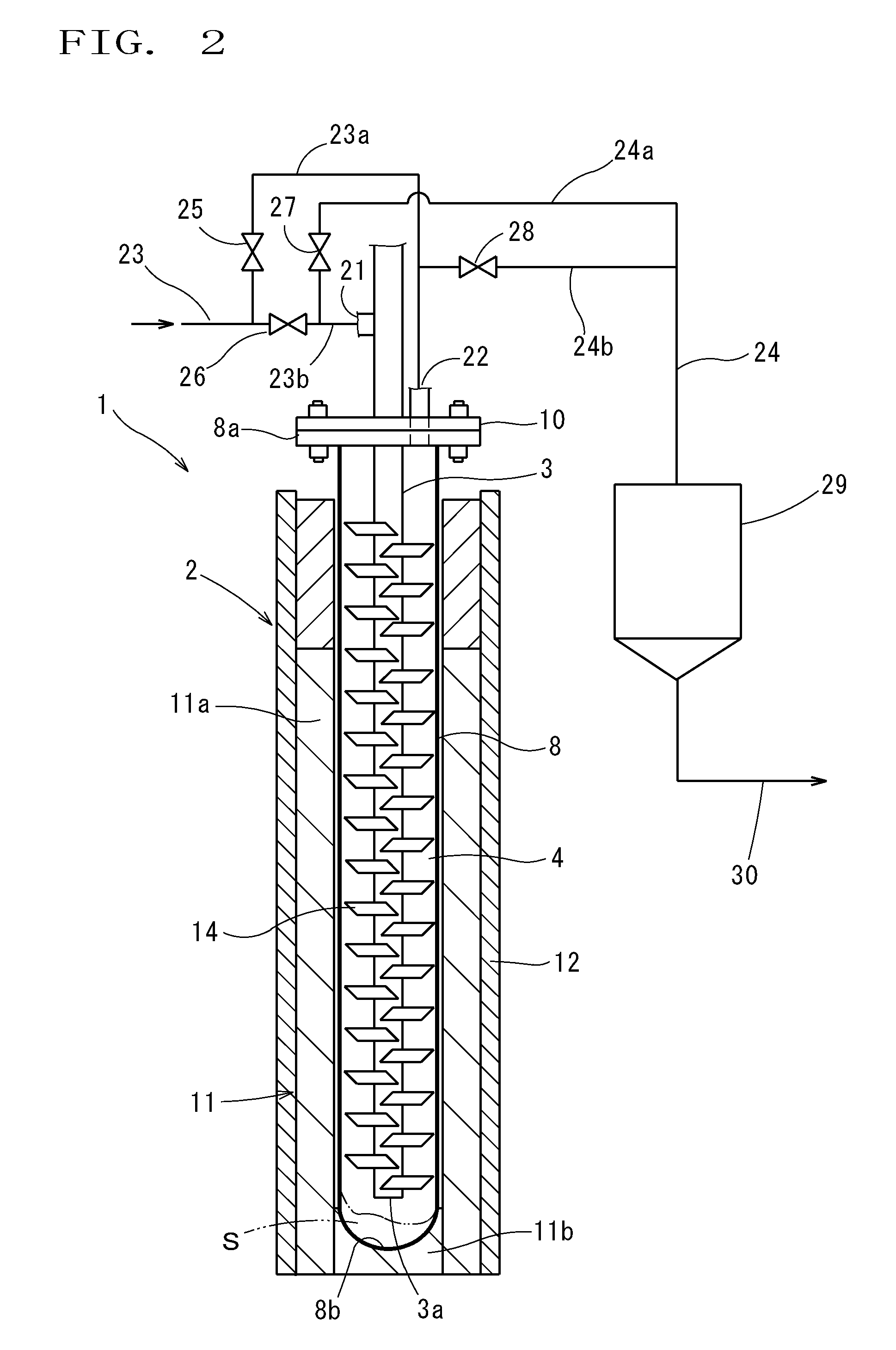

Method for manufacturing trichlorosilane

InactiveUS20120213687A1Reduce loadImprove consumption efficiencyChemical/physical/physico-chemical reactor detailsHalogenated silanesDecompositionBoiling point

A method for manufacturing trichlorosilane in which hydrogen chloride and polymers including high-boiling chlorosilanes generated in a polycrystalline silicon manufacture process, a trichlorosilane manufacture process, or a conversion process are introduced into a decomposition furnace and are decomposition reacted at a high temperature, the method including: heating the decomposition furnace and a fin provided in the decomposition furnace; supplying the polymers and the hydrogen chloride to the decomposition furnace from an upper portion thereof so as to react the polymers and the hydrogen chloride by leading to an inner-bottom portion of the decomposition furnace while heating and stirring; and discharging a reacted gas from the inner-bottom portion upwardly above the decomposition furnace through a center of the decomposition furnace.

Owner:MITSUBISHI MATERIALS CORP

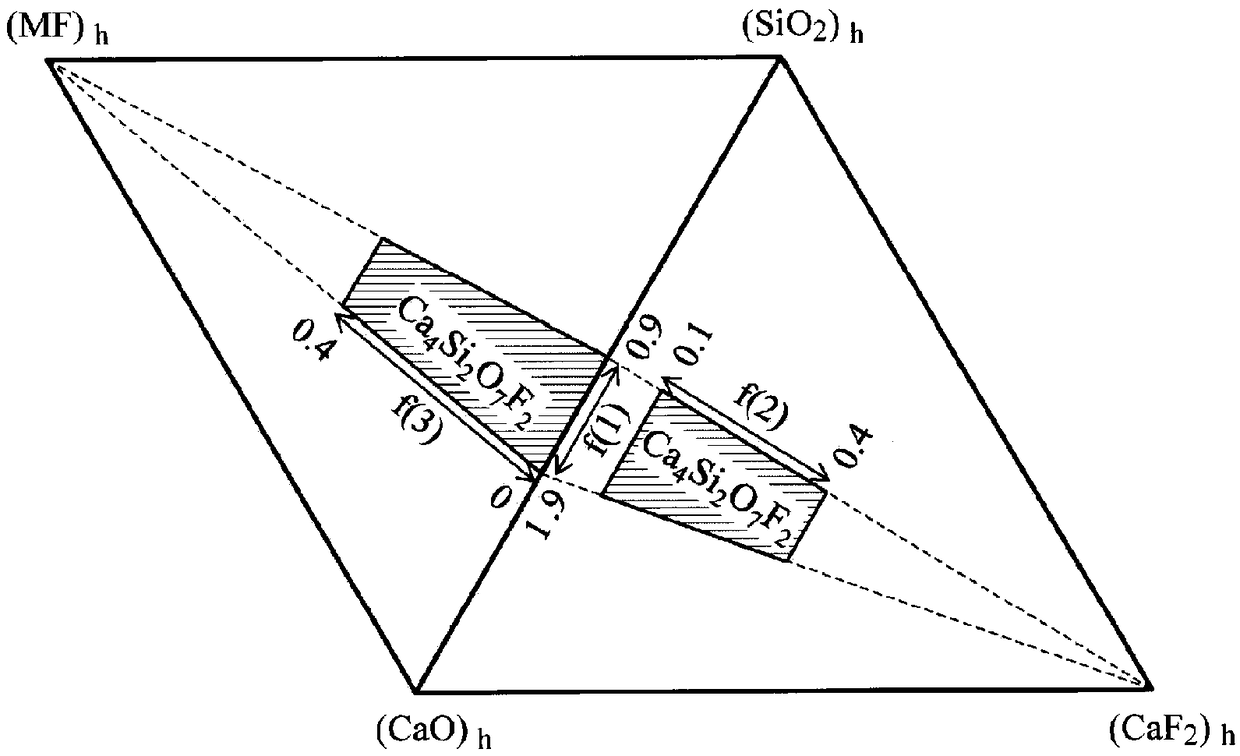

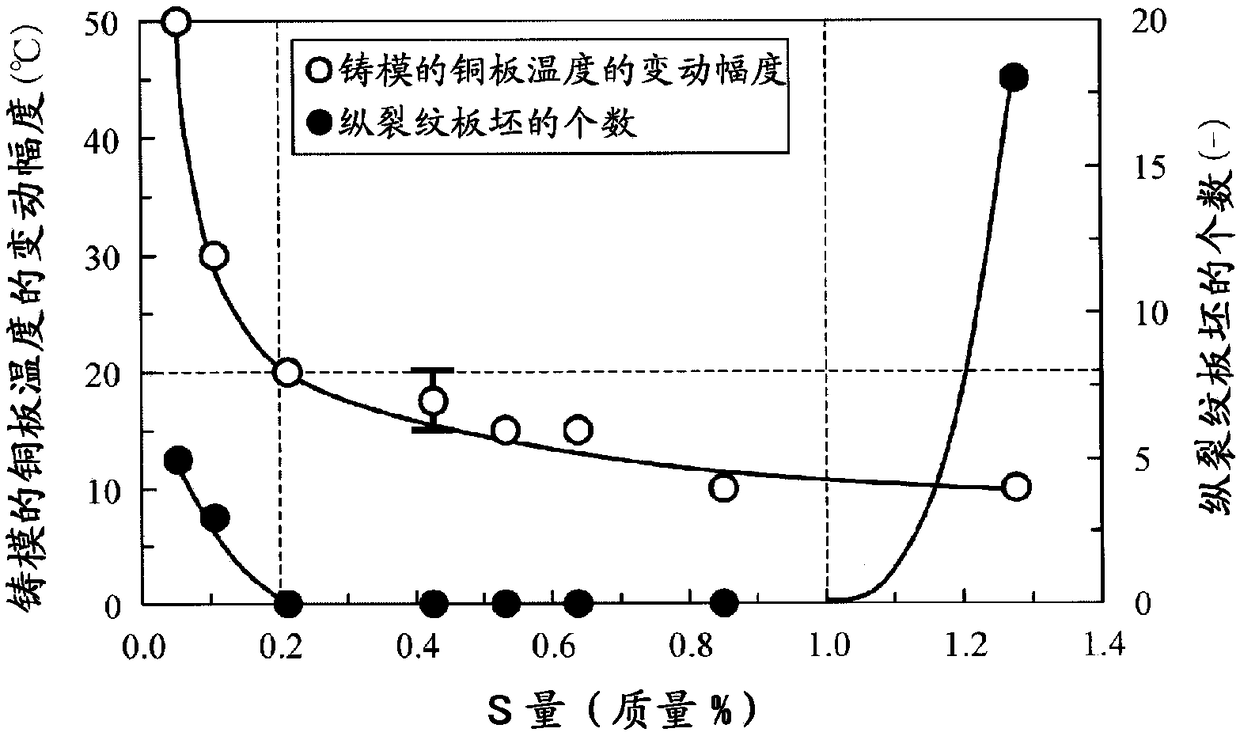

Mold flux for continuous casting and continuous casting method

ActiveCN108348992AReduce temperature fluctuationsAvoid surface crackingProcess efficiency improvementMetallurgyContinuous casting

The mold flux for continuous casting has a base material composition containing 25-60% by mass of CaO, 15-45% by mass of SiO2, 5-25% by mass of F, 0.2-1.0% by mass of S and 0-20% by mass of Li2O, Na2Oand K2O in total. With respect to the base material composition, f(1) is 0.90-1.90, f(2) is 0.10-0.40, f(3) is 0-0.40, and the total of CaO, SiO2, F, S, Li2O, Na2O and K2O is 90-100% by mass.

Owner:NIPPON STEEL CORP

Method for preparing double-sealed-end glycol ether

ActiveUS20170334818A1Long single-pass lifespanHigh selectivityMolecular sieve catalystsChemical recyclingMolecular sieveAlcohol

Disclosed is a method for preparing a double end capped glycol ether, the method comprising: introducing into a reactor a raw material comprising a glycol monoether and a monohydric alcohol ether, and enabling the raw material to contact and react with an acidic molecular sieve catalyst to generate a double end capped glycol ether, a reaction temperature being 50-300° C., a reaction pressure being 0.1-15 MPa, a WHSV of the glycol monoether in the raw material being 0.01-15.0 h−1, and a mole ratio of the monohydric alcohol ether to the glycol monoether in the raw material being 1-100:1. The method of the present invention enables a long single-pass lifespan of the catalyst and repeated regeneration, has a high yield and selectivity of a target product, low energy consumption during separation of the product, a high economic value of a by-product, and is flexible in production scale and application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

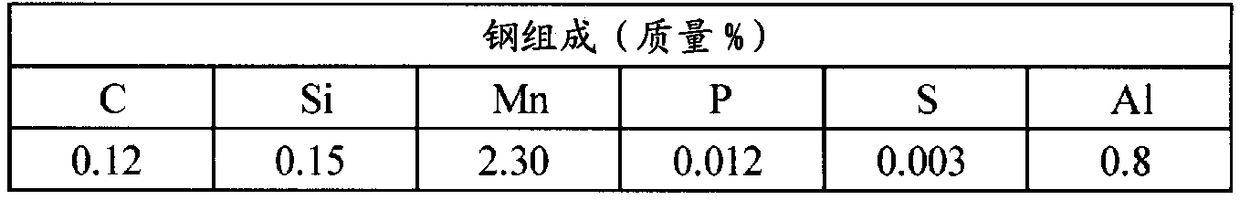

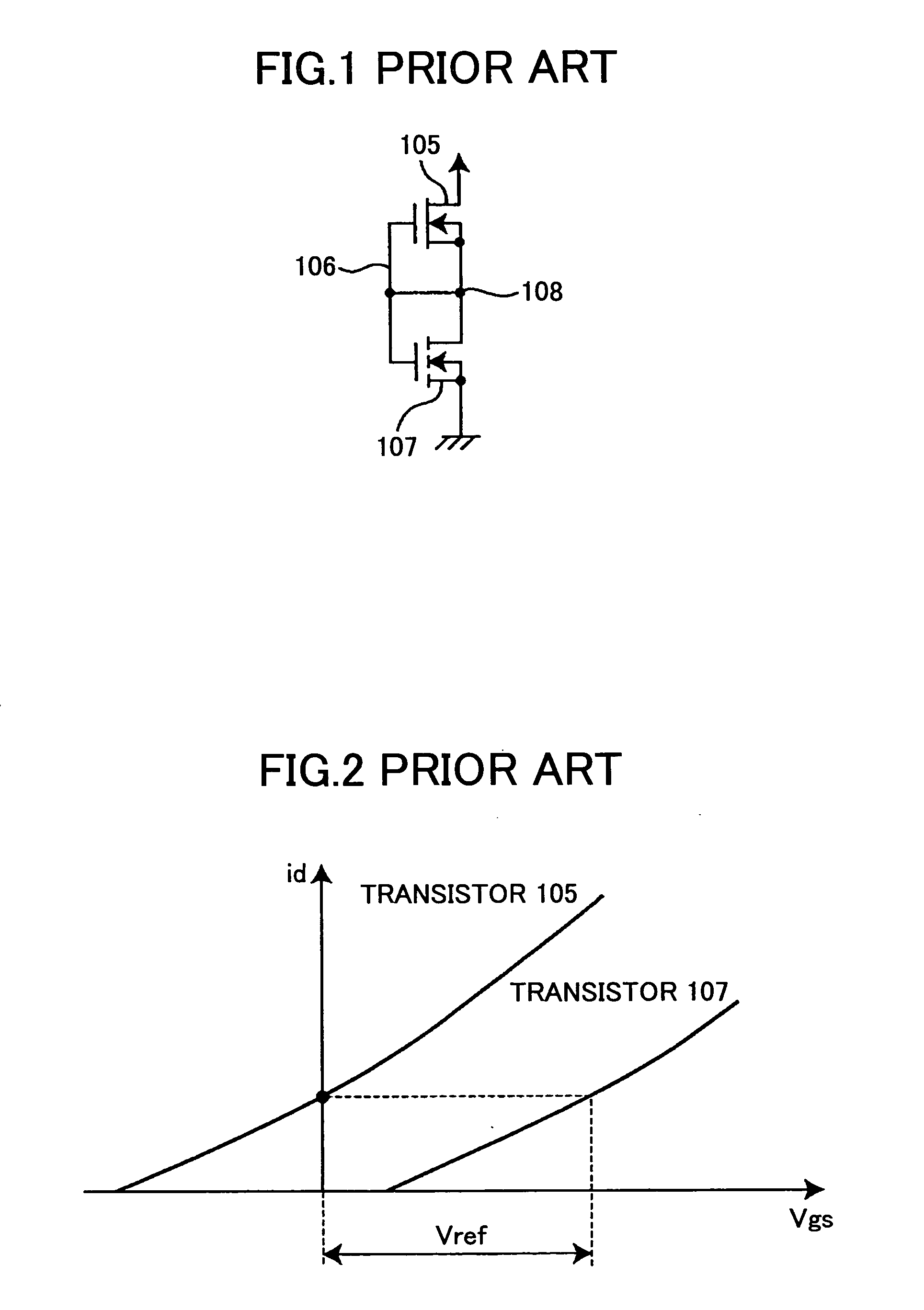

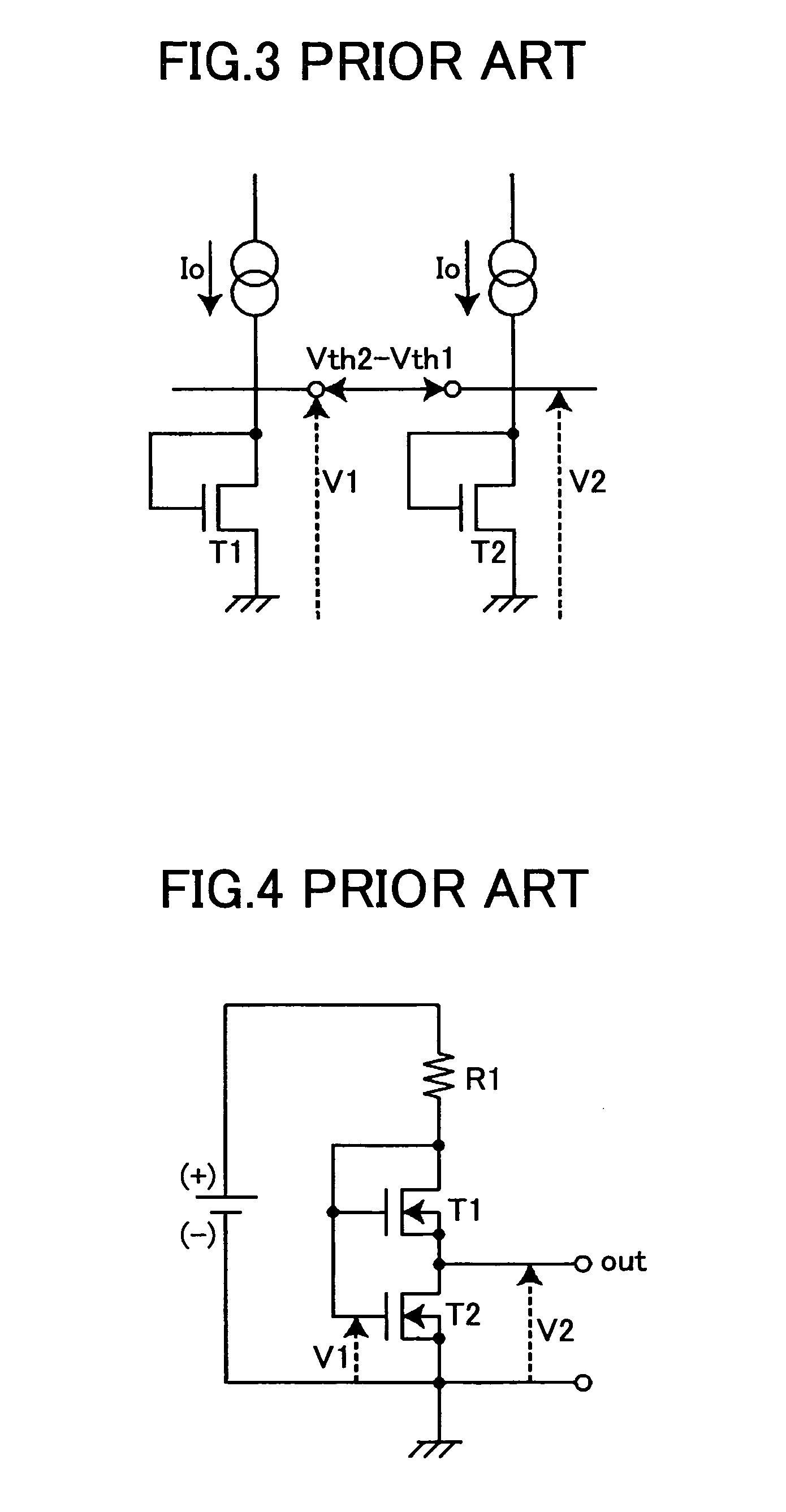

Reference voltage generation circuit, and constant voltage circuit using the reference voltage generation circuit

InactiveUS20070057291A1Reduce power sourceReduce temperature fluctuationsStatic storageElectric variable regulationEngineeringVoltage reference

A reference voltage generation circuit includes: a first field-effect transistor that is an n channel-type field-effect transistor of a depletion-type, wherein one terminal of the first field-effect transistor is connected to a predetermined power source voltage; a second field-effect transistor including a concentrated n-type gate, wherein one terminal of the second field-effect transistor is connected to another terminal of the first field-effect transistor; and a third field-effect transistor including a concentrated p-type gate, wherein one terminal of the third field-effect transistor is connected to another terminal of the second field-effect transistor; wherein a gate of the first field-effect transistor is connected to a part where the first and the second field-effect transistors are connected, each substrate gate of the first and the third field-effect transistors is connected to a ground voltage, a gate and a substrate gate of the second field-effect transistor and a gate of the third field-effect transistor are connected to a connecting part where the second and the third field-effect transistors are connected, and a reference voltage is output from the connecting part.

Owner:RICOH ELECTRONIC DEVICES CO LTD

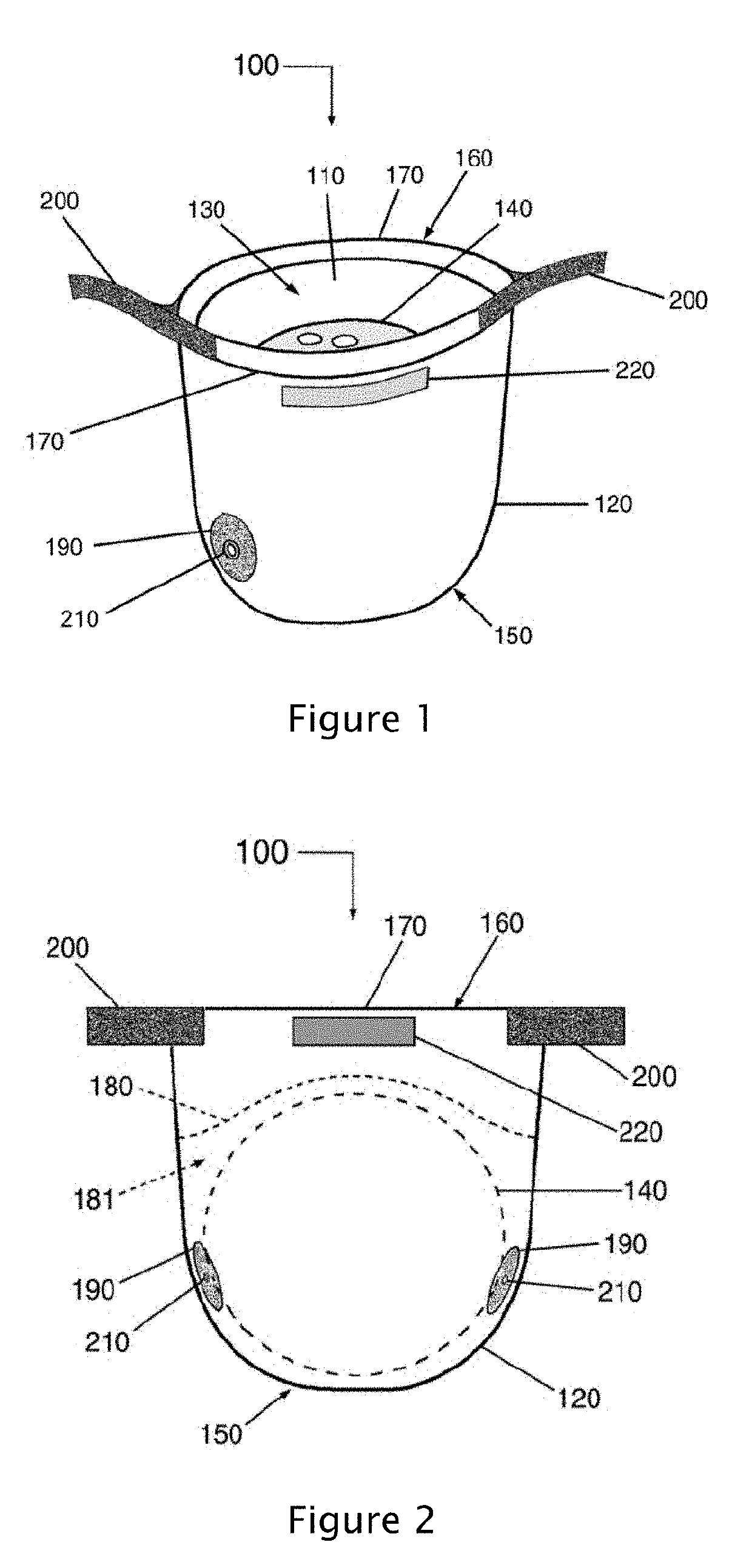

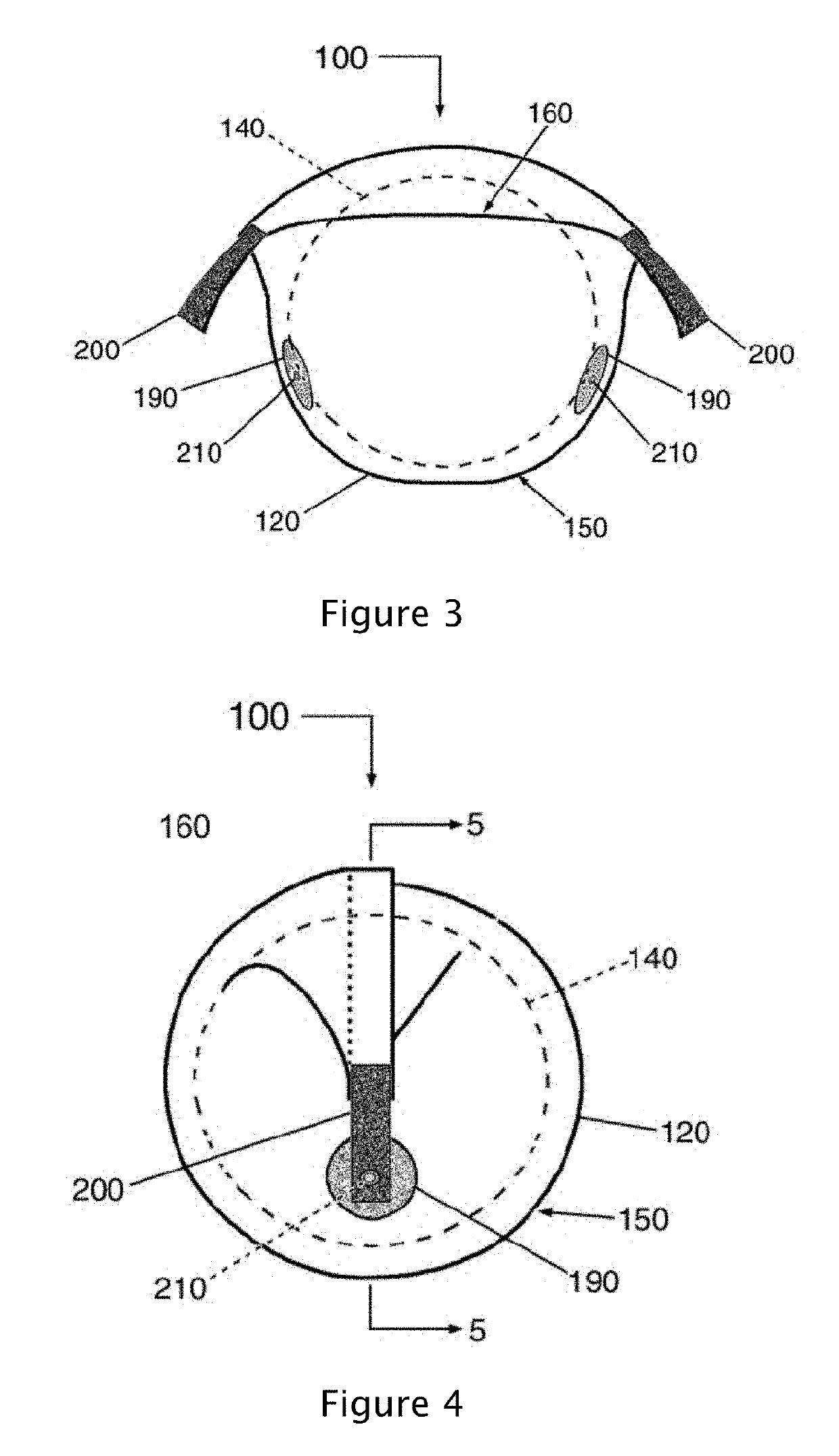

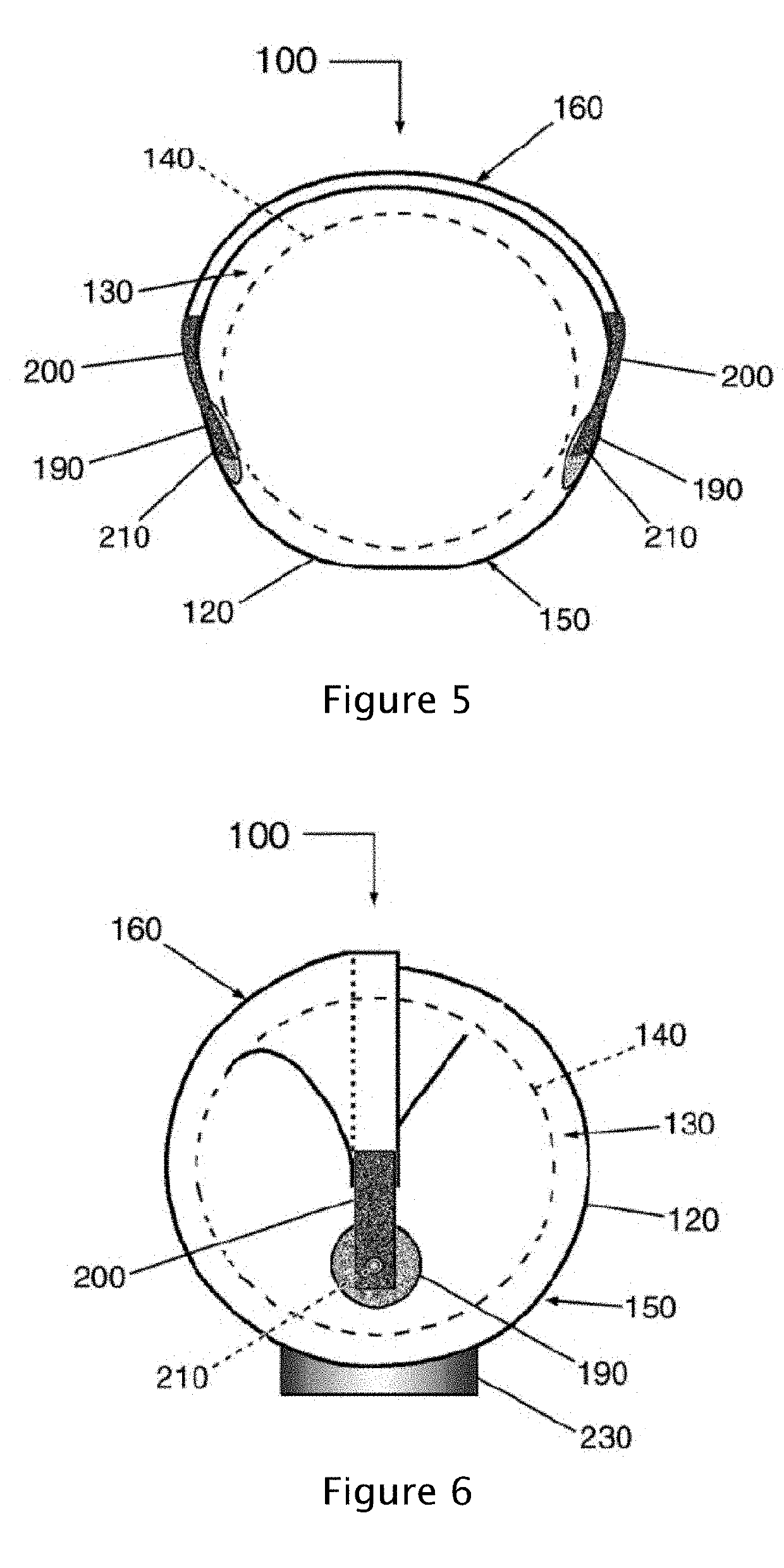

Preservation system for a bowling ball

ActiveUS20190314687A1Strong marketing advantageIncrease vapor pressureBall sportsHand carts with one axisVapor barrierEngineering

A method and a bowling ball enclosure are provided for encasing and reducing temperature fluctuations of and within a bowling ball. The bowling ball enclosure includes a flexible inner vapor barrier layer and a flexible outer layer that are made of a polymer material, the inner layer forming an interior region that receives the bowling ball. The bowling ball enclosure also includes a bottom portion and a top portion, wherein the top portion is positionable from a first position to a second position to encapsulate the bowling ball. In the first position, the top portion being in an open position to receive the bowling ball into the interior region. In the second position, the top portion being in a closed position to encapsulate the bowling bowl. A bowling ball bag includes a vapor ball layer to reducing the emission of volatiles from a retained bowling ball.

Owner:MAGNUM SHIELDING

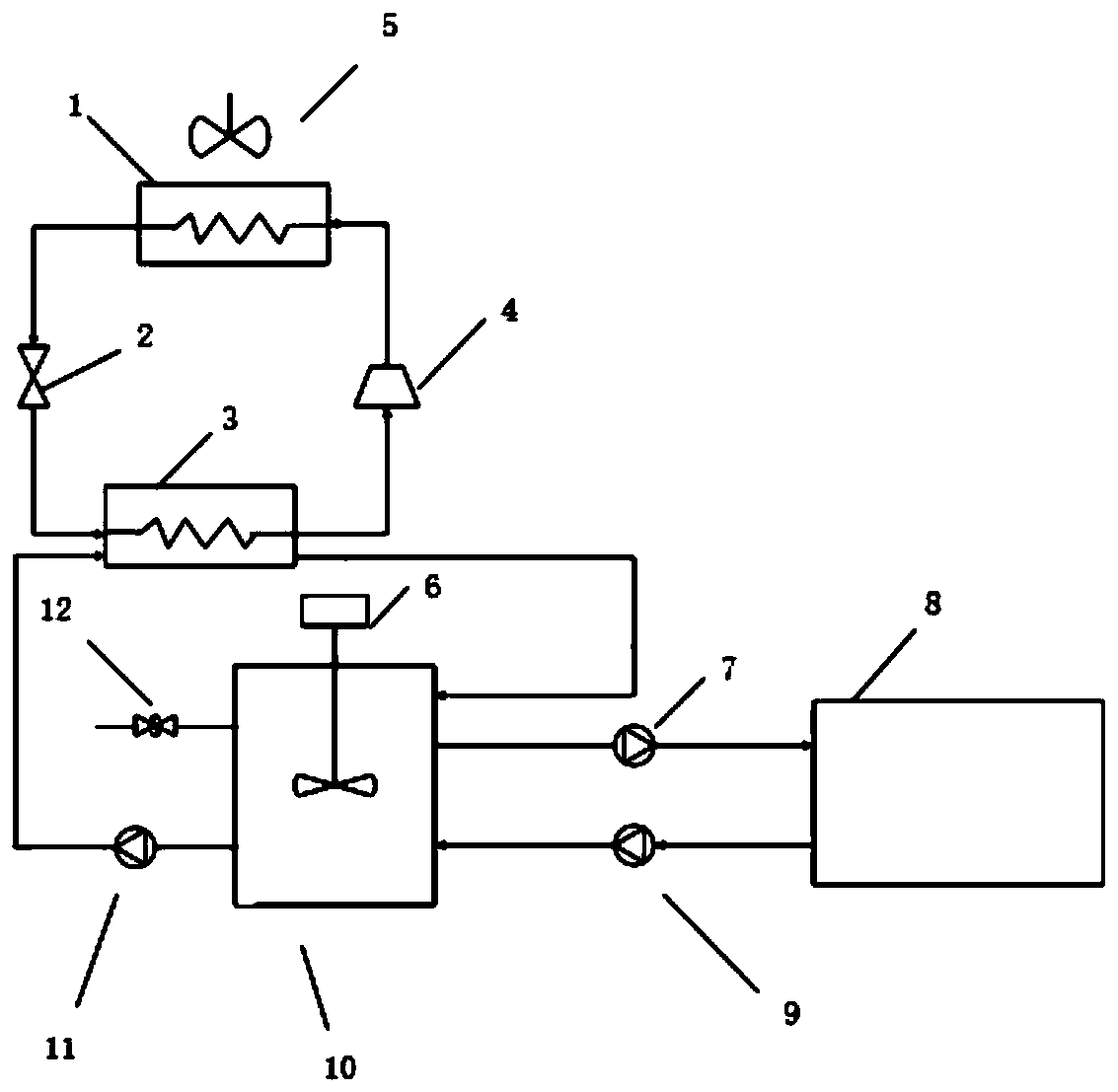

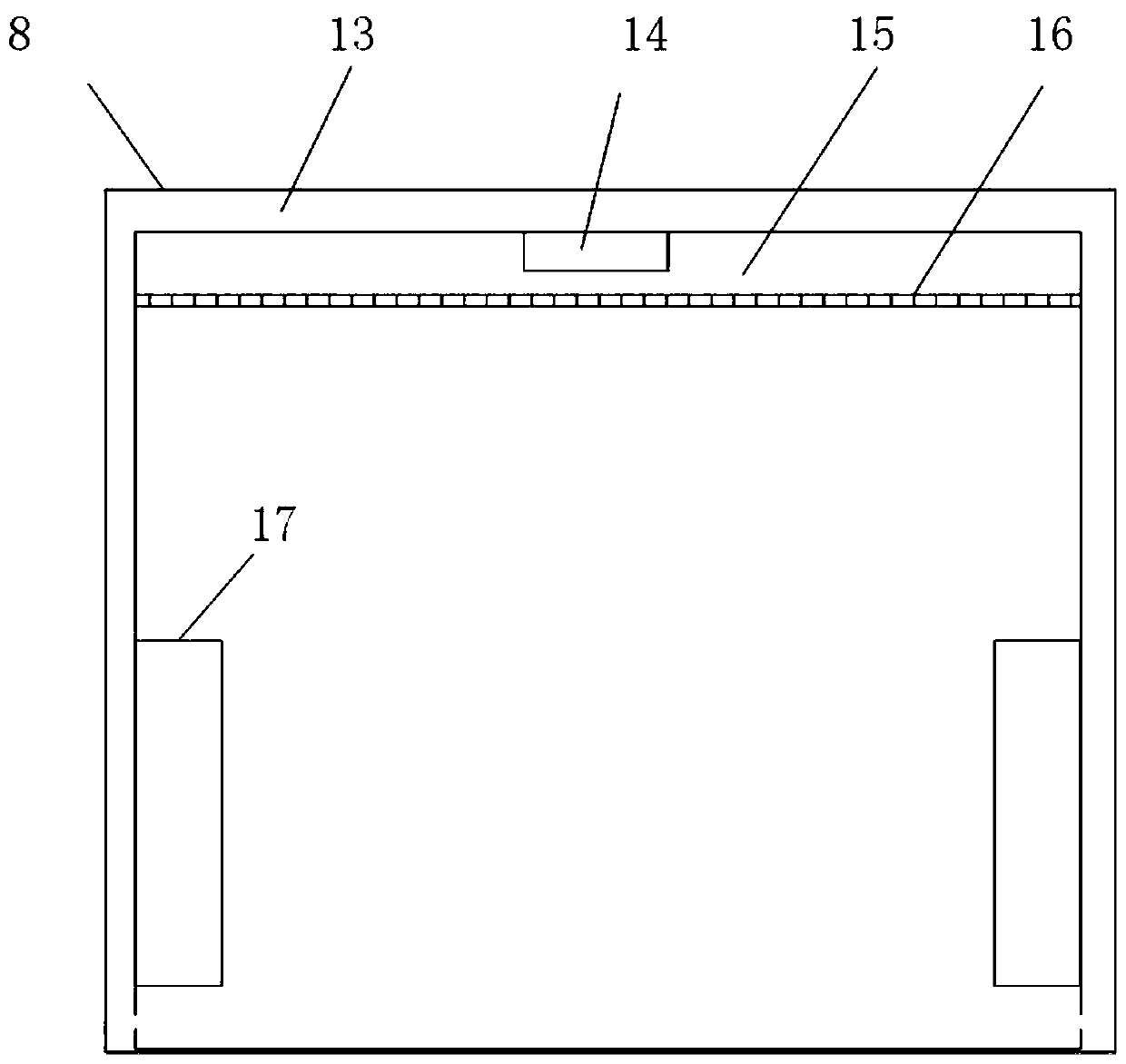

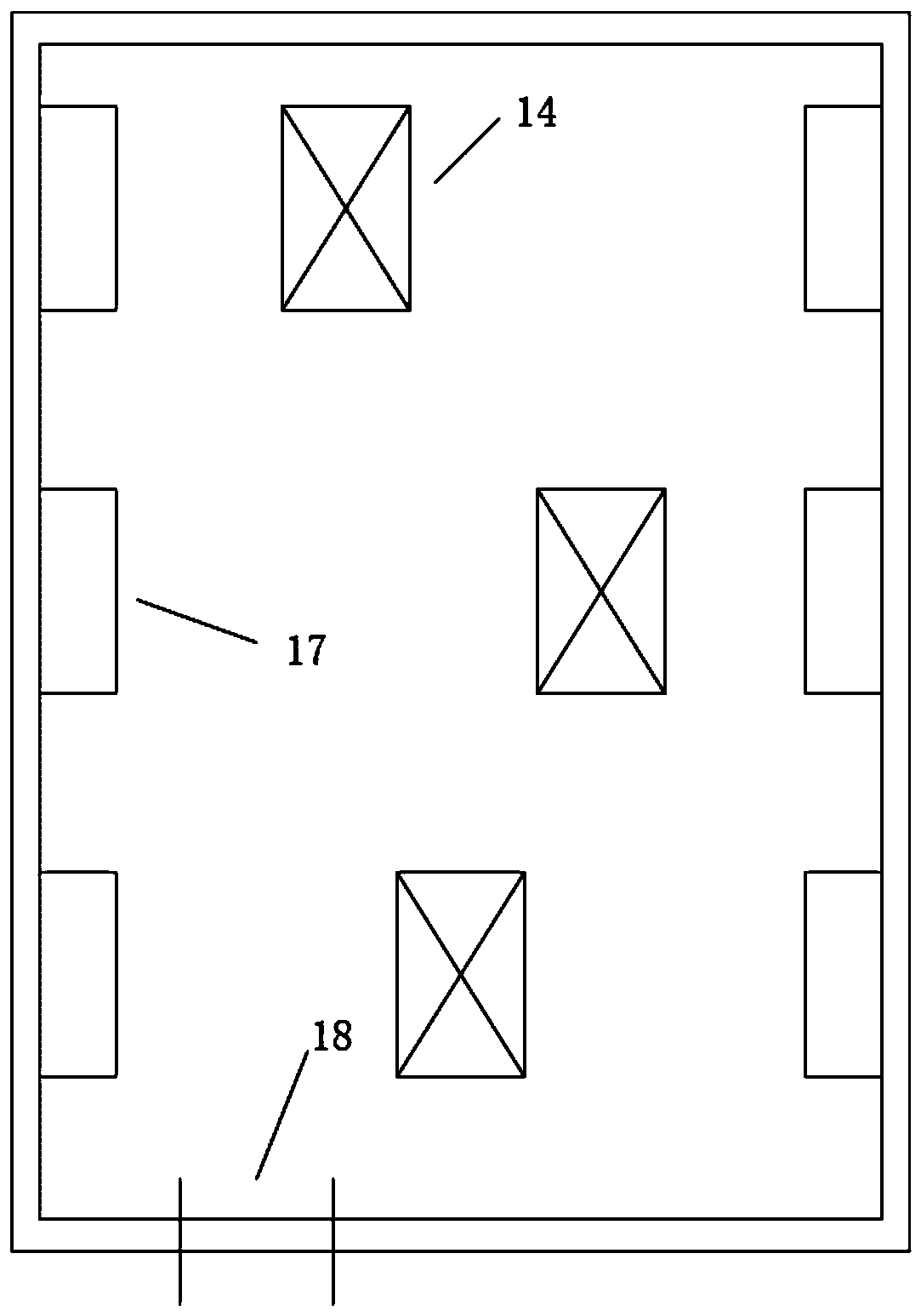

Ice-temperature library with ice slurry heat exchangers

InactiveCN109708381AReduce temperature fluctuationsStable temperatureLighting and heating apparatusIce productionSlurryEngineering

The invention discloses an ice-temperature library with ice slurry heat exchangers, and belongs to the field of fruits and vegetables storage, and the ice-temperature library with the ice slurry heatexchangers aims to solve the problem of large temperature fluctuations in an existing ice temperature library. The ice slurry heat exchangers are uniformly arranged on the sidewall of the ice-temperature library; and fins are arranged on each heat exchanger to enhance heat transfer. Cooling of the ice-temperature library is achieved by heat exchange between the gas and an ice slurry device; at thesame time, the ice crystal particles in the ice slurry absorb the heat to be melted while the overall temperature of the ice slurry is constant, so that the temperature fluctuation caused by the sudden rise of the temperature during storage in the ice-temperature library is eliminated, and the storage quality of fruits and vegetables is improved. The ice-temperature library is applicable to the field of fruits and vegetables storage, so that economic losses caused by improper storage are reduced, and the quality of storage is improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

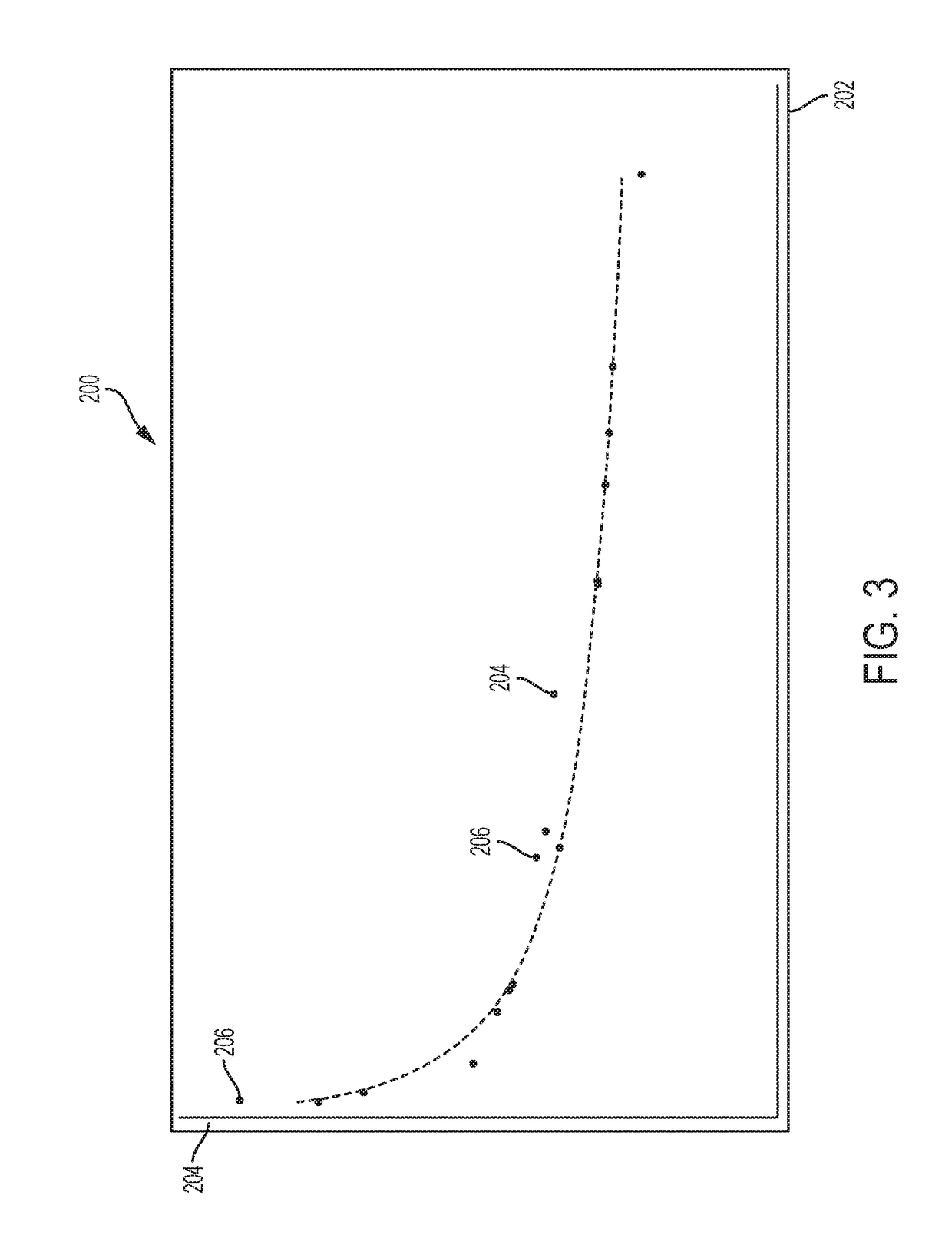

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com