Method for producing float glass and apparatus for producing float glass

A float glass and a manufacturing method technology, which are applied in the fields of float glass manufacturing and float glass manufacturing devices, can solve problems such as difficulty in reducing the temperature fluctuation range, and achieve the effect of reducing the temperature fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

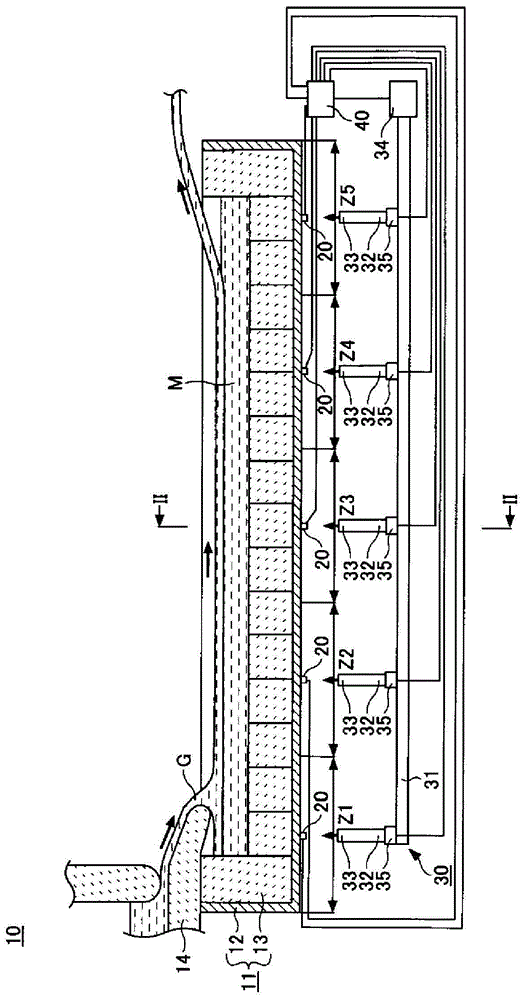

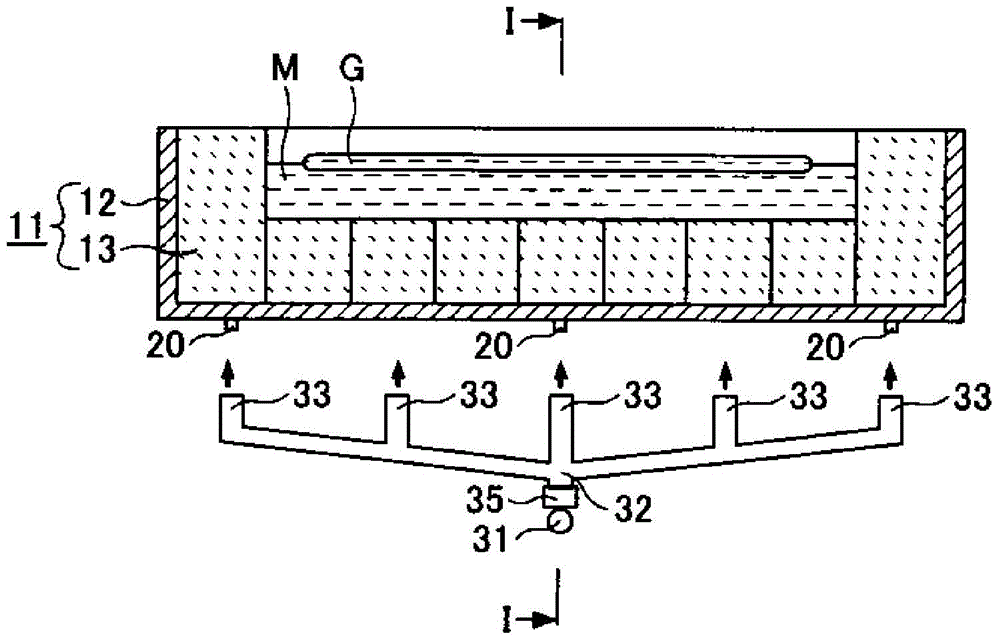

[0068] In Example 1, using figure 1 and figure 2 The float glass manufacturing apparatus 10 shown manufactures the float glass of an alkali-free glass. Air is used as the fluid, an air fan is used as the fluid supply part 34 , and an opposed blade damper is used as the flow rate adjustment part 35 . The rotation speed of the air fan and the rotation angle of the rotation shaft of each opposing blade damper are controlled so that the deviation between the temperature measured by the predetermined temperature sensor and the set temperature becomes zero.

[0069] On the other hand, in Comparative Example 1, float glass was produced in the same manner as in Example 1 except that the rotation angle of the rotation shaft of each opposing vane damper was constant. That is, in order to make the deviation between the temperature measured by the predetermined temperature sensor and the set temperature zero, only the rotation speed of the air fan is controlled.

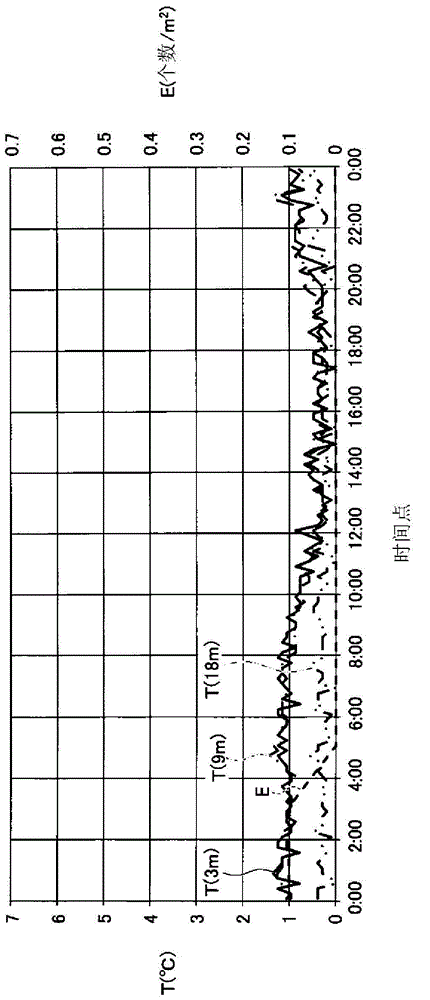

[0070] image 3 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com