Patents

Literature

169results about How to "Avoid surface cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

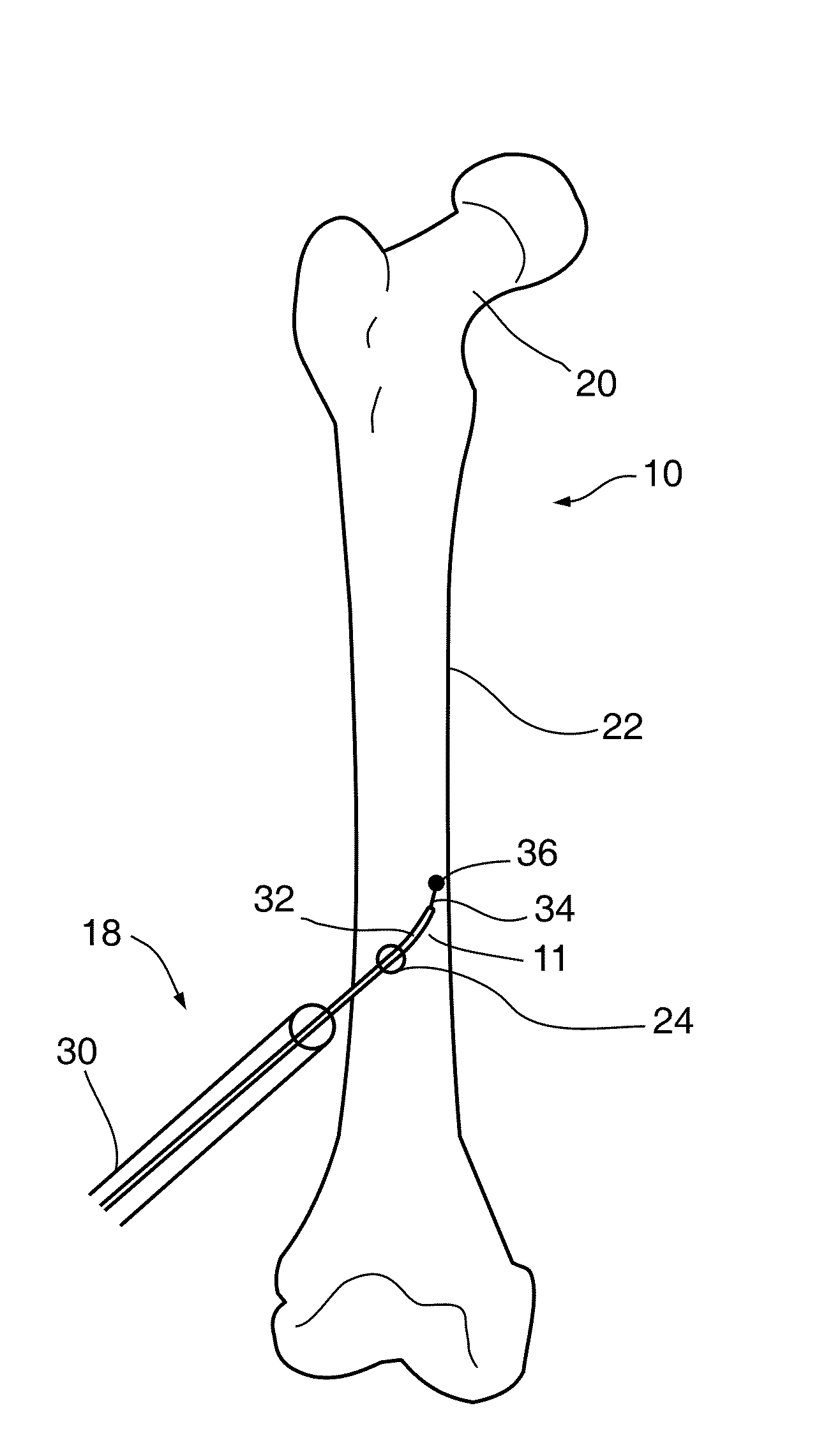

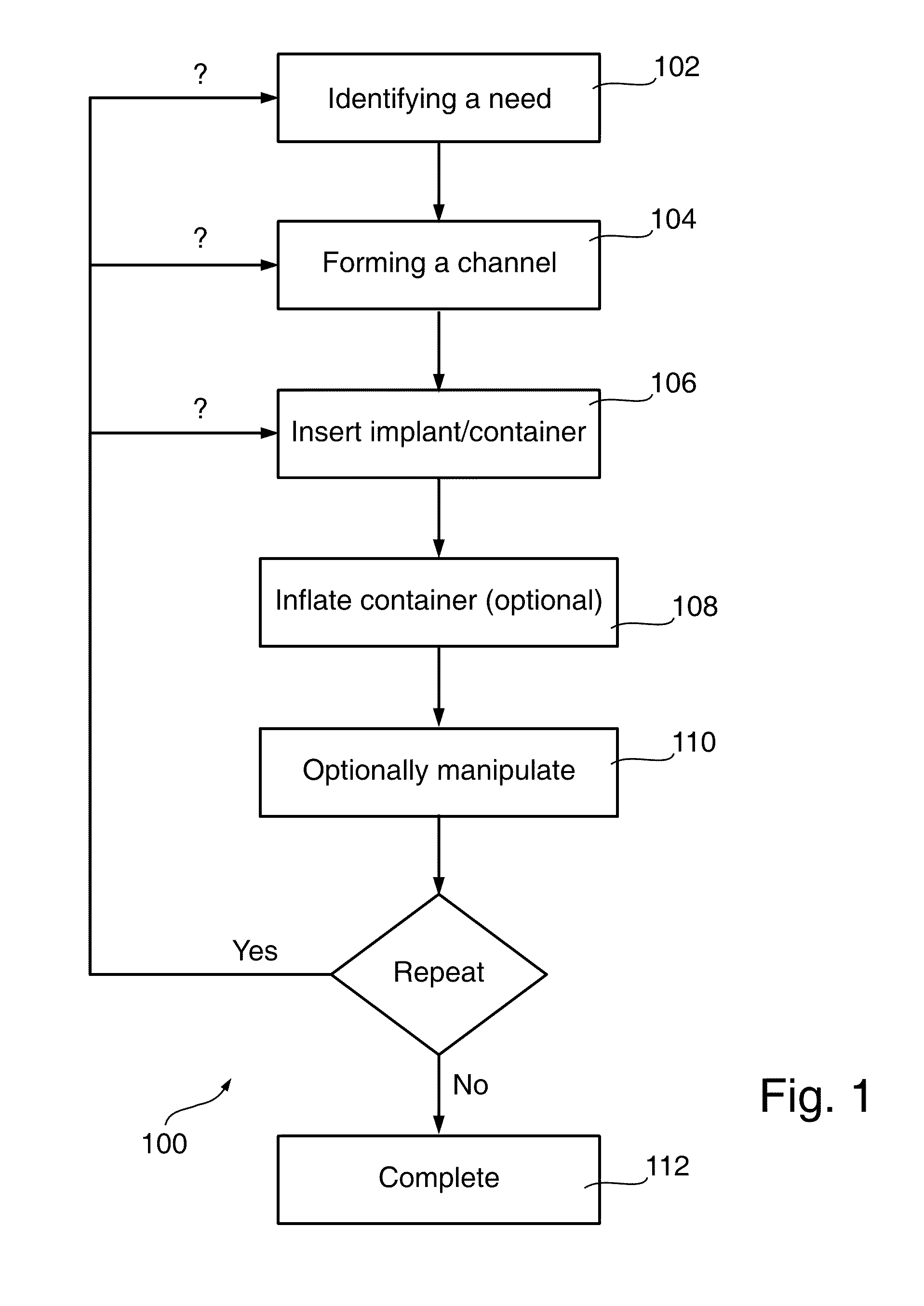

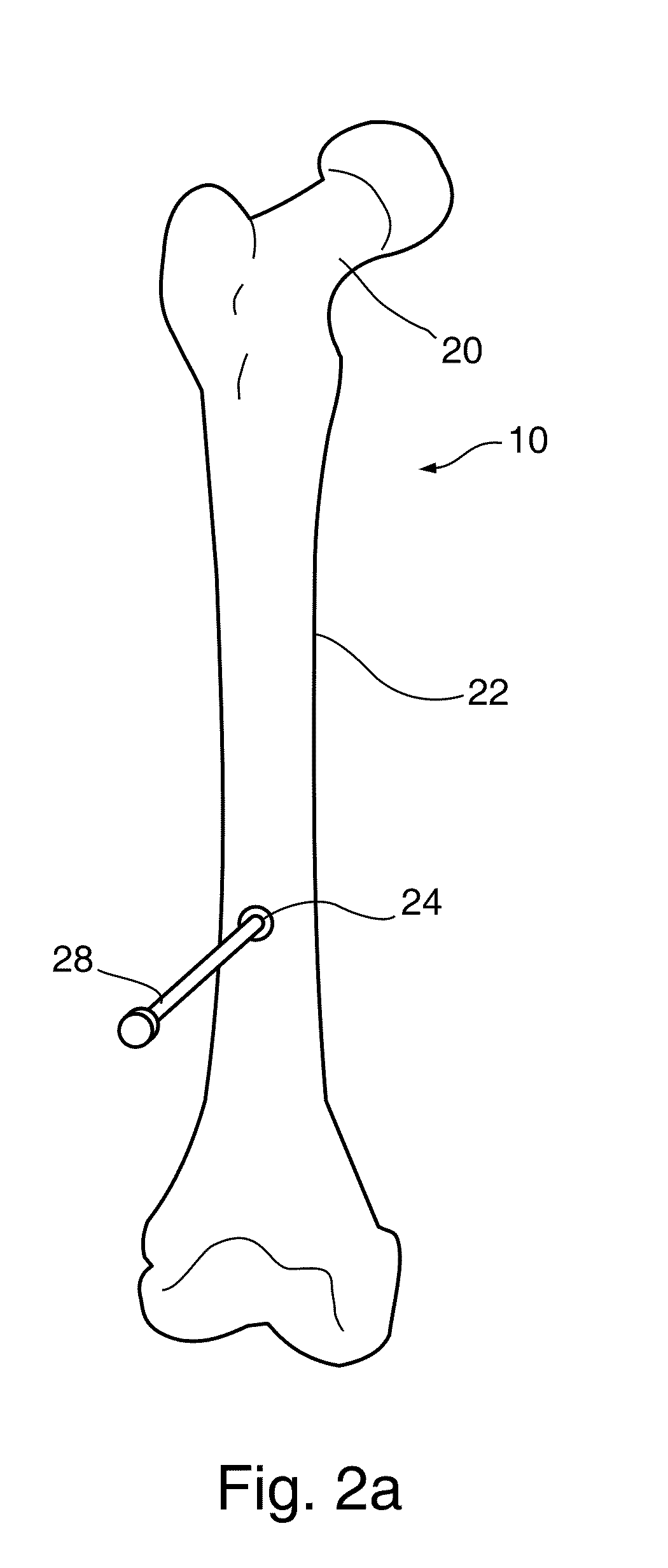

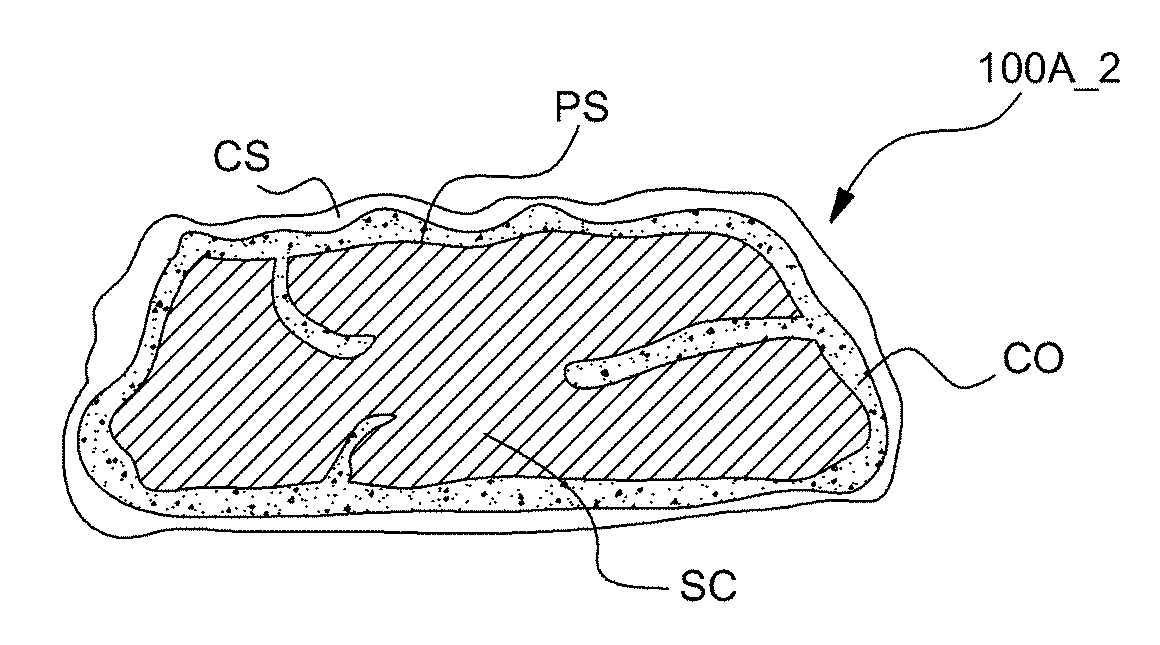

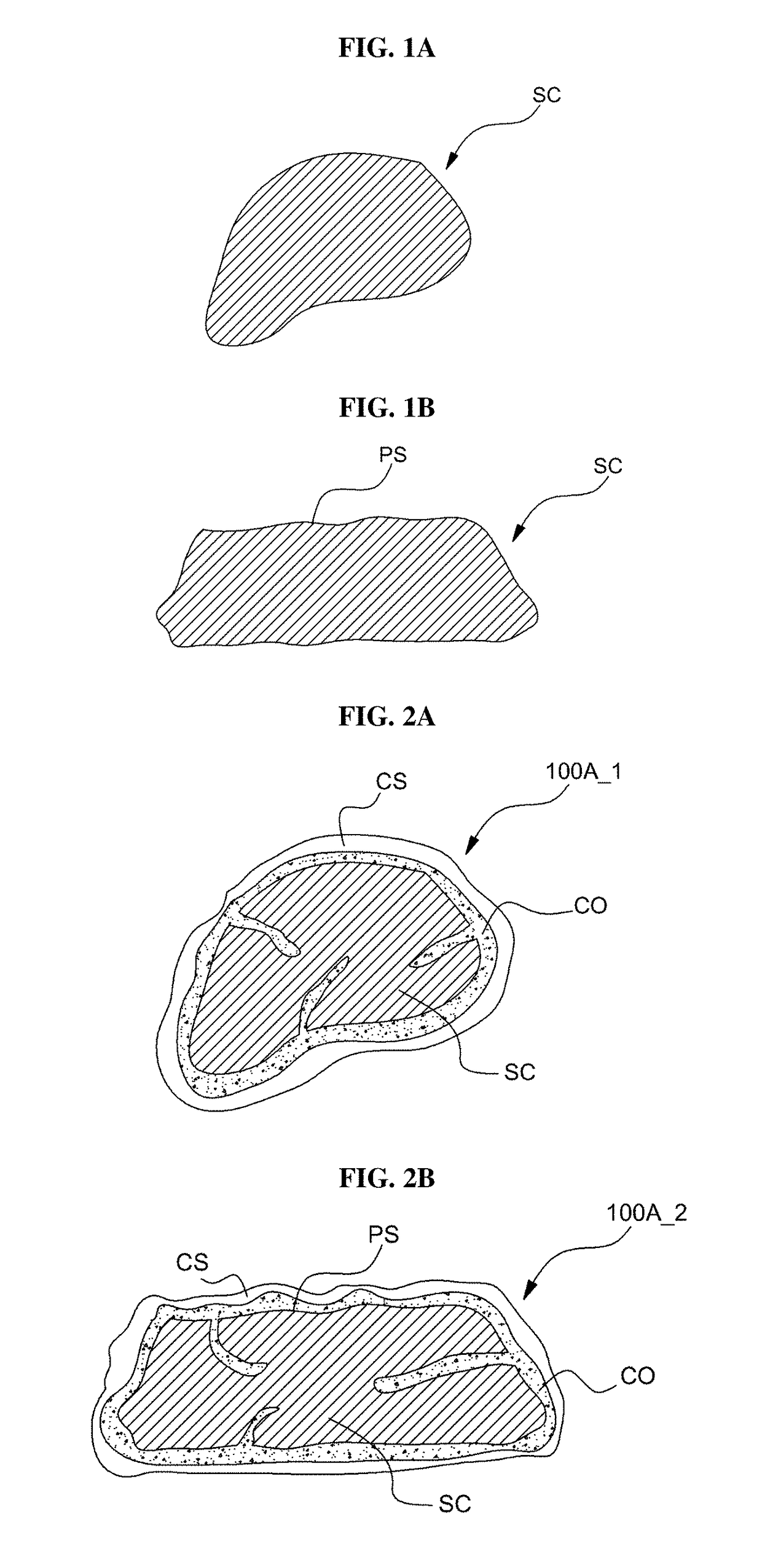

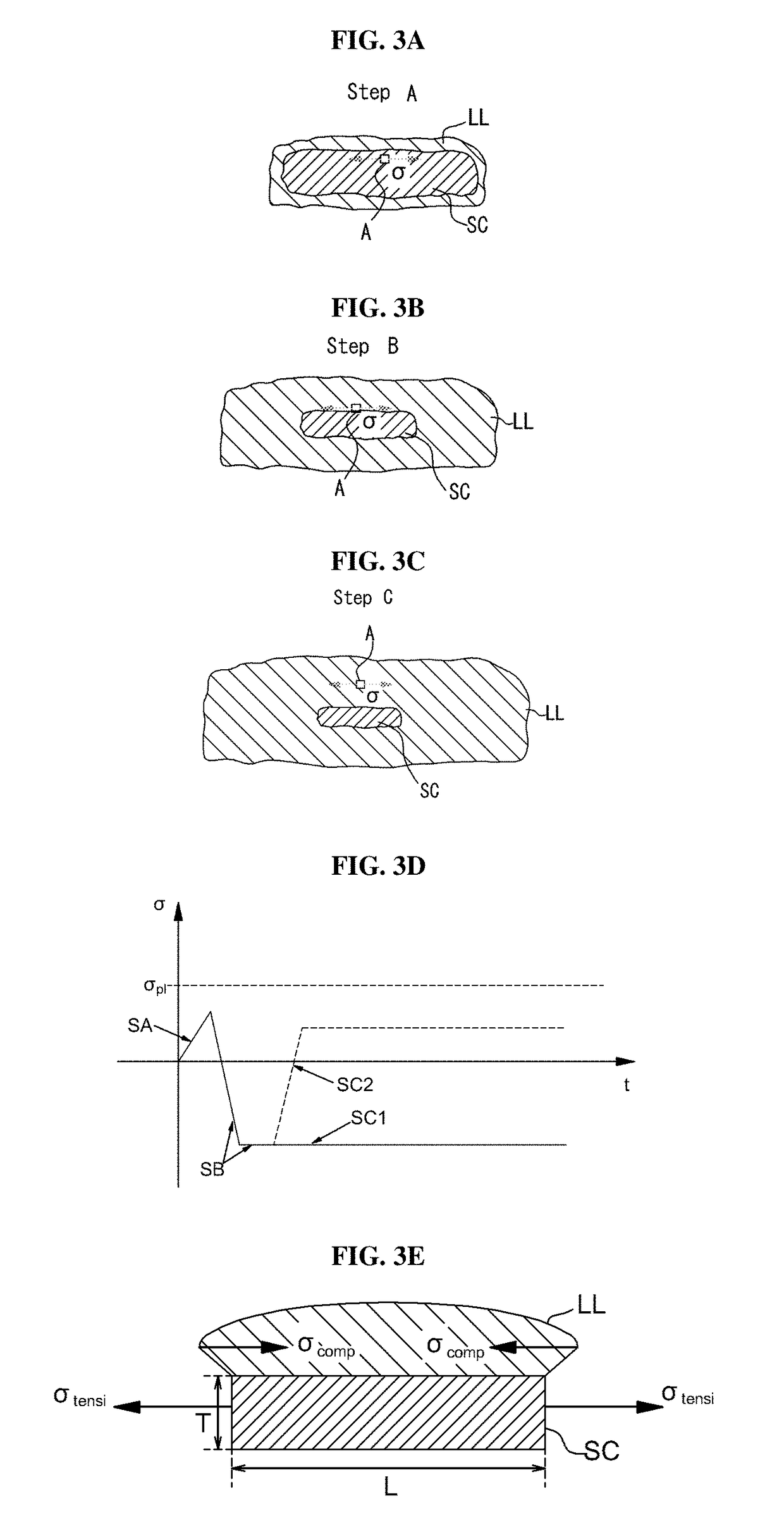

Bone implant

InactiveUS20100076503A1Minimize damageAvoid crackingInternal osteosythesisDiagnostic markersBone implantBiomedical engineering

A method of long bone strengthening and a composite implant for such strengthening. Also disclosed is a kit for building a composite implant in-situ in long bones. In an exemplary embodiment of the invention, the implant comprises a plurality of rigid tensile rods, in matrix of cement and surrounded by a partially porous bag.

Owner:N M B MEDICAL APPL

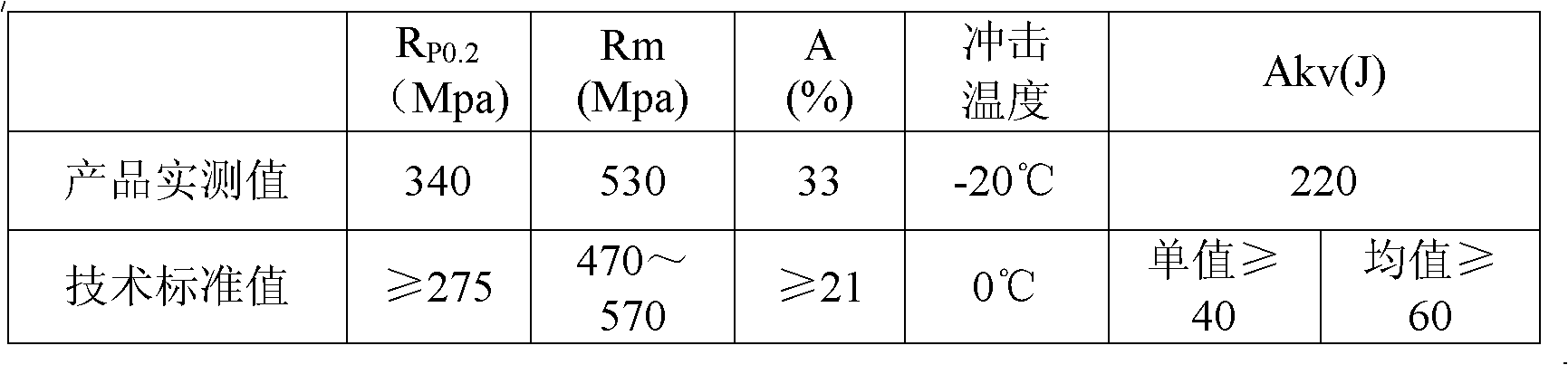

Steel for nuclear-island seamless steel tube and production method thereof

InactiveCN102021488AImprove low temperature impact toughnessAvoid internal cracksAlloy elementSteel tube

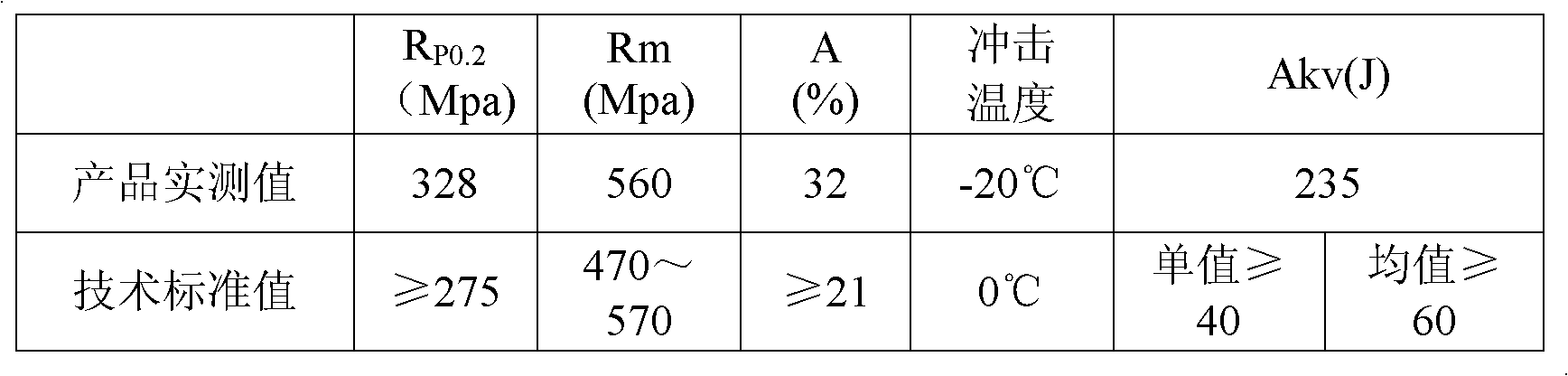

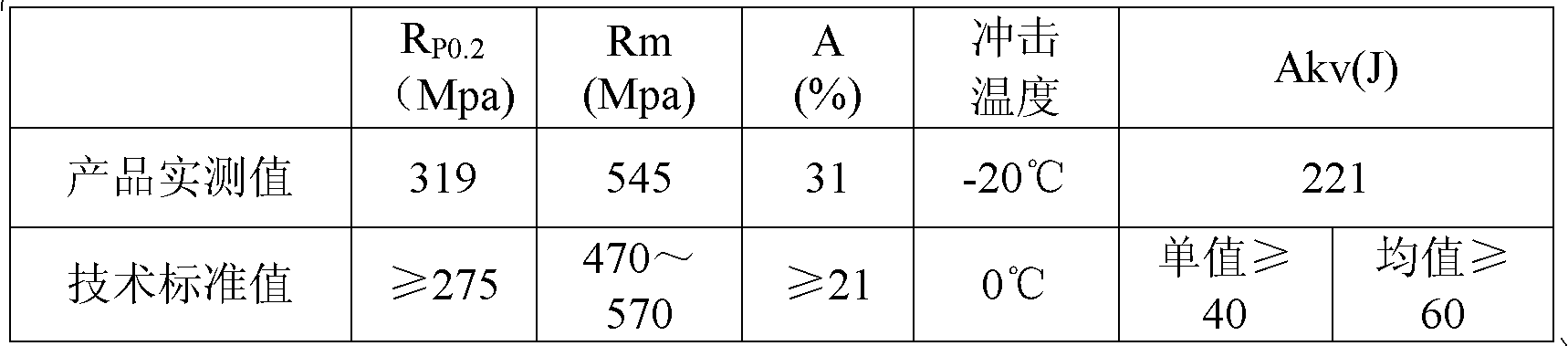

The invention belongs to the field of metallurgical technology, especially relating to steel for a nuclear-island seamless steel tube and a production method thereof. The steel in the invention comprises the following chemical components in percentage by weight: more than 0 and no more than 0.20 percent of C, no less than 0.10 and no more than 0.35 percent of Si, no less than 0.80 and no more than 1.60 percent of Mn, more than 0 and no more than 0.020 percent of P, more than 0 and no more than 0.015 percent of S, more than 0 and no more than 0.25 percent of Cr, more than 0 and no more than 0.50 percent of Ni, more than 0 and no more than 0.18 percent of Cu, more than 0 and no more than 0.10 percent of Mo, more than 0 and no more than 0.06 percent of V, no less than 0.020 and no more than 0.050 percent of Al, more than 0 and no more than 0.030 percent of Sn and the balance of Fe. The steel in the invention has the advantages of meeting the condition that the carbon equivalent is no more than 0.48 (Ceq = C + Mn / 6 + (Cr + Mo + V) / 5 + [(Ni +Cu)+ 15]<=0.48), controlling the contents of the main elements such as carbon and manganese in the steel, stabilizing the tensile property of the steel tube subjected to simulated destressing heat treatment, and simultaneously ensuring the tensile properties of the tube body and a sample subjected to the simulated destressing heat treatment to meet the technical standards. Because a residual element nickel as an alloy element is added, the low-temperature impact toughness of the steel in the invention is improved, and the impact toughness requirements for the steel at the temperatures of 0 DEG C and minus 20 DEG C are met.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Manufacturing process of forging stock of steel forging piece for oil extraction equipment in deep sea

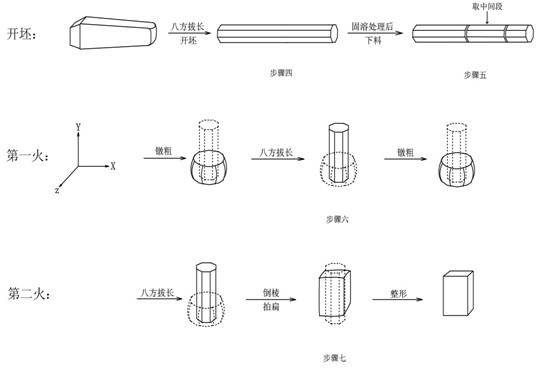

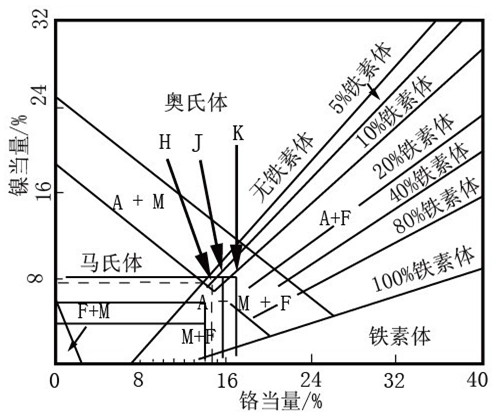

The invention discloses a manufacturing process of a forging stock of a steel forging piece for oil extracting equipment in a deep sea, which comprises the following steps of: with martensite precipitation hardening type stainless steel as a steel forging piece material, selecting a square ingot, heating to 1180DEG C, cogging along the length direction of the steel ingot to obtain an octagonal section steel billet, wherein the forging ratio is 2.0-2.2; heating the octagonal section steel billet to 1040DEG C and preserving heat for 360 minutes; carrying out oil cooling below 32DEG C; taking an intermediate section as a billet; axially upsetting the billet from the initial forging temperature of 1150DEG C to the final forging temperature of 990DEG C; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; axially upsetting when the billet is drawn to the length of the original billet; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; when axially forging and shaping the billet when the billet is upset to half of the height of the original billet, enabling the total forging ratio to be 5.5 and obtaining a rectangular forging piece; and air cooling to be 340-360DEG C, carrying out furnace insulating for 120 minutes and then carrying out furnace cooling to the room temperature.

Owner:NANJING DEV ADVANCED MFG

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

High-alkalinity mould flux used for niobium/vanadium/titanium-containing low alloy wide and heavy plate blank and manufacturing method thereof

The invention discloses a high-alkalinity mould flux used for niobium / vanadium / titanium-containing low alloy wide and heavy plate blanks and a manufacturing method thereof. The high-alkalinity mould flux is made from the following raw materials in percentage by weight: 35 to 45 percent of pre-melting materials, 11 to 14 percent of fluorite, 28 to 30 percent of wollastonite, 3 to 6 percent of flint clay, 3 to 6 percent of limestone, 2 to 4 percent of sodium carbonate, 1 to 3 percent of lithium carbonate, 1 to 3 percent of manganese carbonate, 2 to 4 percent of magnesium oxide, 2 to 4 percent of carbon black, 4 to 7 percent of graphite and 1 to 3 percent of binders. The mould flux has a good capability of absorbing Al (s), V, Ti, Nb and other metals and metal oxides or carbides thereof and nitride inclusions in molten steel, and remains unchanged after molten steel purification. Therefore, not only are the performances of the mould flux stable, but also the internal quality of casting blanks is improved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Adhesive Resin Composition, Its Cured Product And Adhesive Film

InactiveCN102559113AHard to reduce adhesionDifficult to reduce insulationNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesion forceEpoxy

The present invention provides an adhesive resin composition which has high heat conductivity and no easy adhesion force and insulation reduction. The adhesive resin composition comprises the following components: epoxy resin (which comprises epoxy resin of which the mass is above 50wt% relative to total mass of the epoxy resin and epoxide equivalent is 150-220), curing agent which is composed of imidazolium compound, phenoxy resin and aluminum oxide powder, wherein ammonium ion in the cured object is less than 50wtppm. Maximal diameter of the aluminum oxide powder is less than 120 mu m, and the proportion of crystal spherical aluminum oxide in total aluminum oxide powder is above 90wt%. The diameter arrangement of the crystal spherical aluminum oxide satisfies the following conditions: i) the particles of which the average diameter D50 is 35-50 mu m and the ratio (volume average diameter) / (number average diameter) is 1.2-2.0 account for 30-50wt%; ii) the particles of which the average diameter is 5-15 mu m and the ratio (volume average diameter) / (number average diameter) is 2.0-3.5 account for 30-50wt%; and iii) the particles of which the average diameter D50 is 0.1-2 mu m account for 10-30wt%.

Owner:NIPPON STEEL CHEMICAL CO LTD

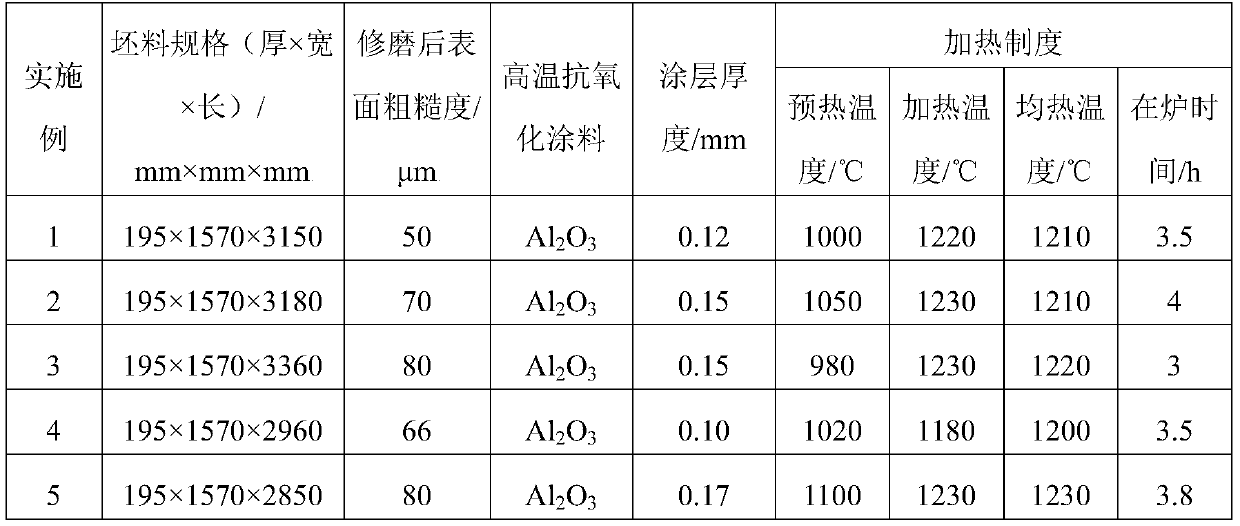

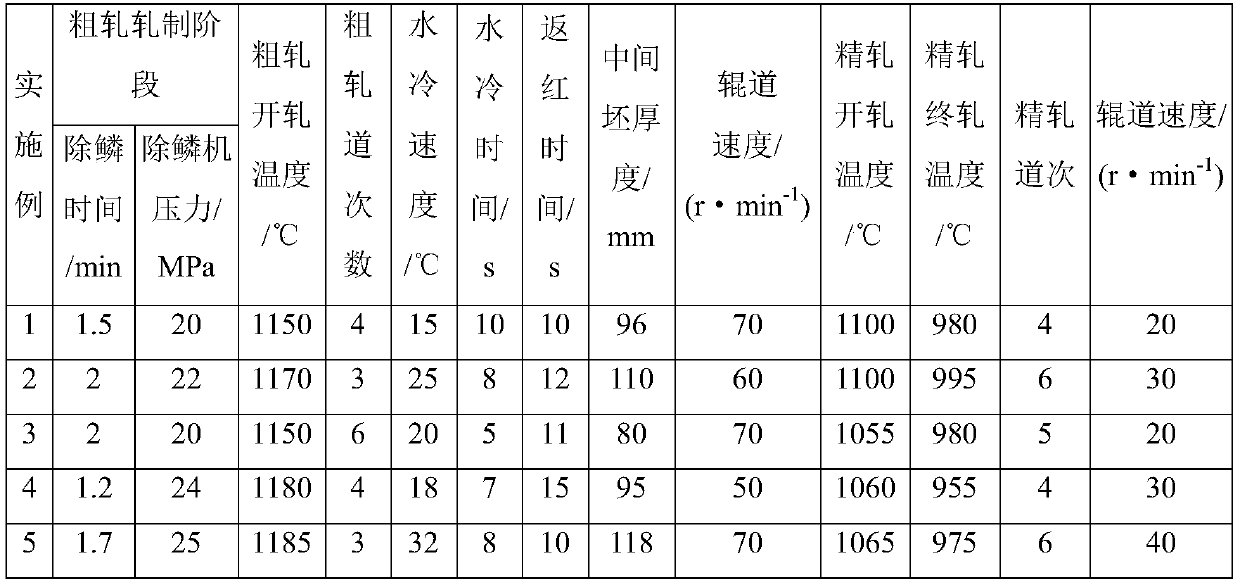

Excellent-performance high-N austenitic stainless steel medium-thick plate and manufacturing method thereof

ActiveCN110499448AIncrease the axial grain rateQuality improvementProcess efficiency improvementReduction rateThick plate

The invention discloses an excellent-performance high-N austenitic stainless steel medium-thick plate and a manufacturing method thereof. The continuous casting slab medium axialite ratio is higher than or equal to 80%; the casting blank surface roughness is smaller than or equal to 100 microns; the casting blank preheating section temperature is 980 DEG C to 1100 DEG C, the heating section temperature is 1160 DEG C to 1230 DEG C, the soaking section temperature is 1200 DEG C to 1230 DEG C, and the in-furnace time is 3 h-4 h; the rough rolling starting temperature is higher than or equal to 1150 DEG C, the first-two gate rolling reduction rate is higher than or equal to 20%, the rough rolling follow-up gate reduction rate is smaller than or equal to 15%, and the intermediate blank thickness is 80 mm to 120 mm; the finish rolling start temperature is higher than or equal to 1050 DEG C, the final rolling temperature is higher than or equal to 950 DEG C, and the rolling reduction rate issmaller than or equal to 20%; and the solution temperature is 980 DEG C to 1050 DEG C, and the in-furnace time is 2 min / mm to 5 min / mm. The product width is 2200 mm to 4000 mm, and the product thickness is 30 mm to 60 mm. The -196 DEG C yield strength is larger than or equal to 350 MPa, the tensile strength is larger than or equal to 1250 MPa, the elongation is larger than or equal to 40%, and thesurface crack rejection rate drops from more than 15% to less than 5%.

Owner:ANGANG STEEL CO LTD

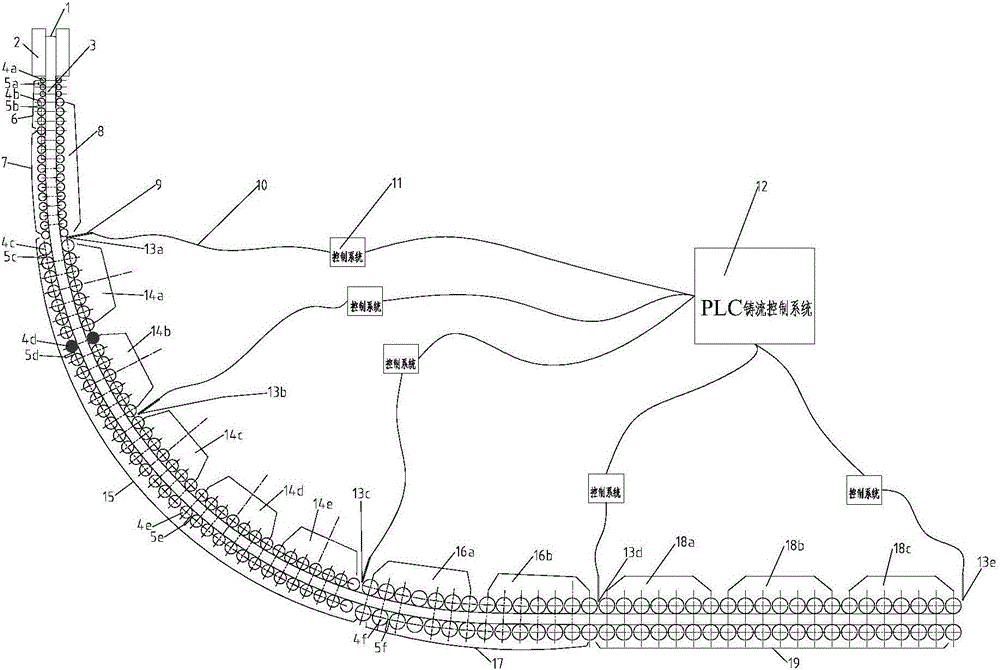

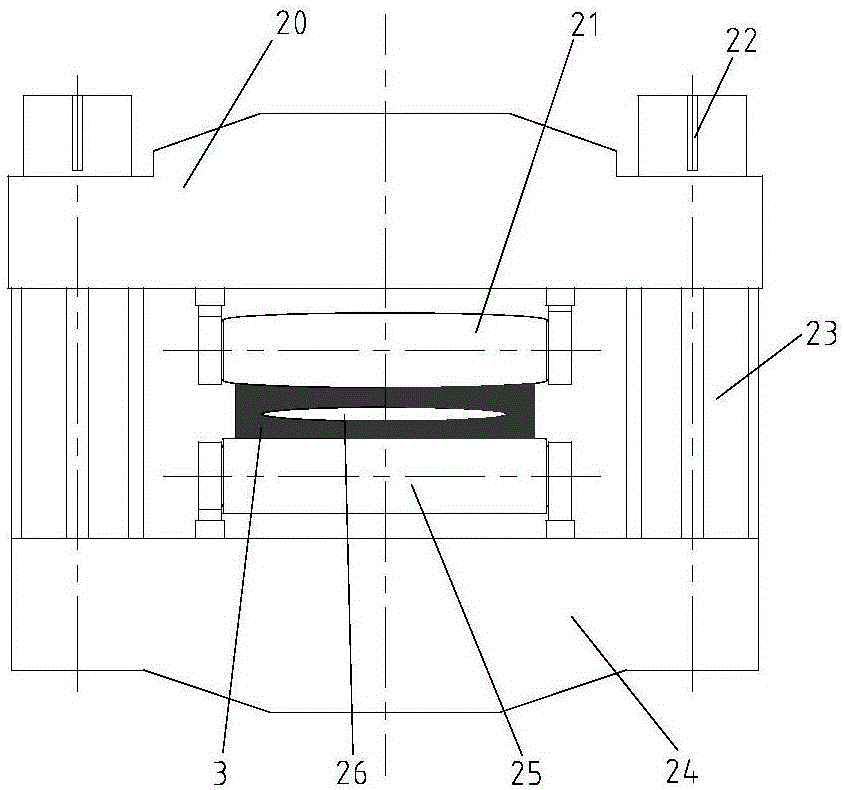

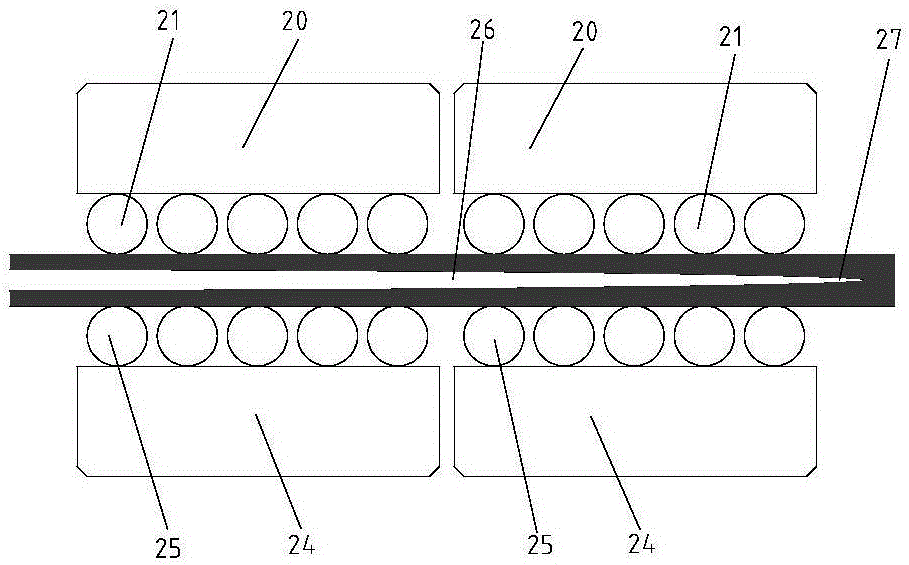

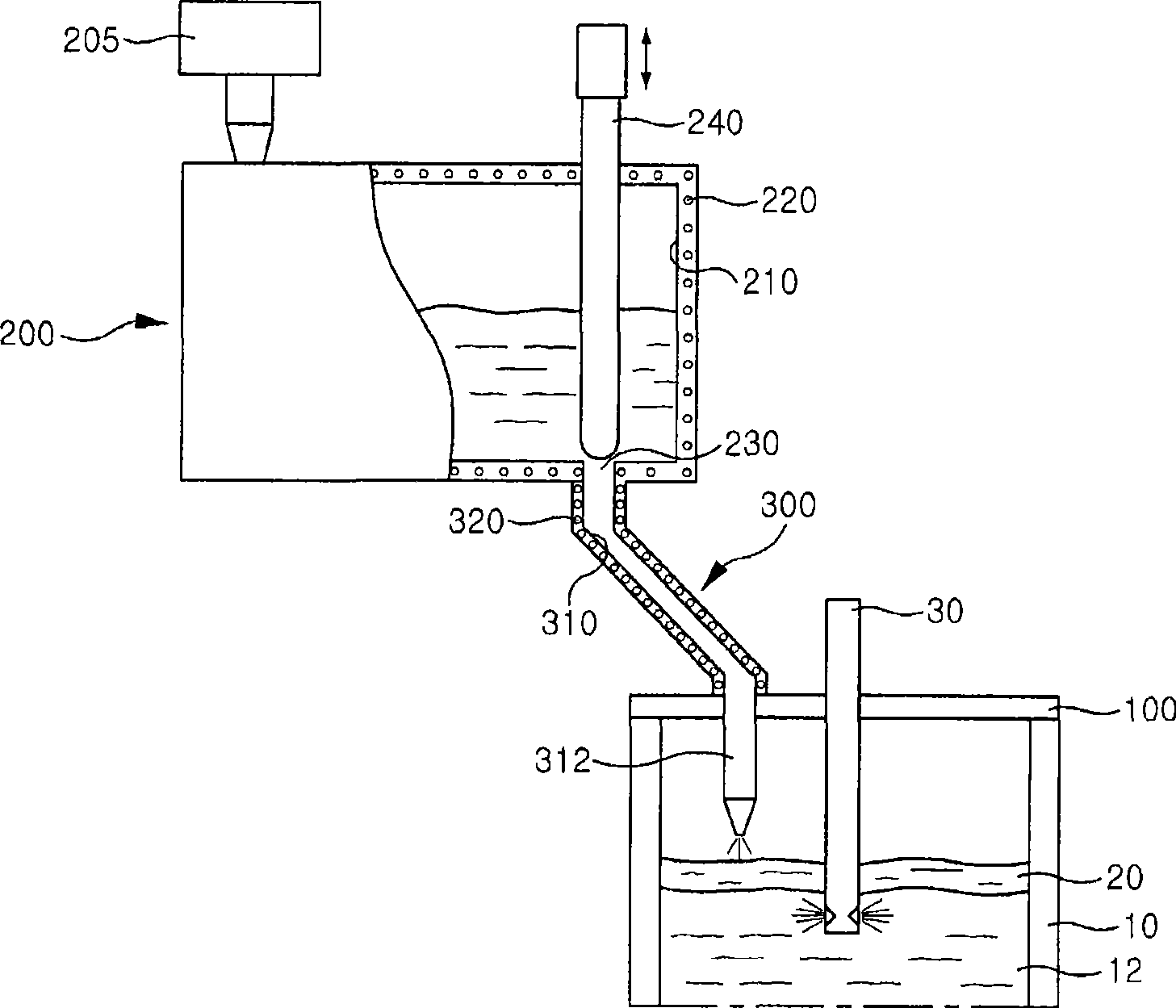

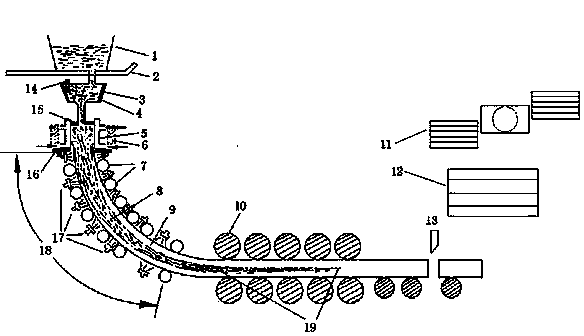

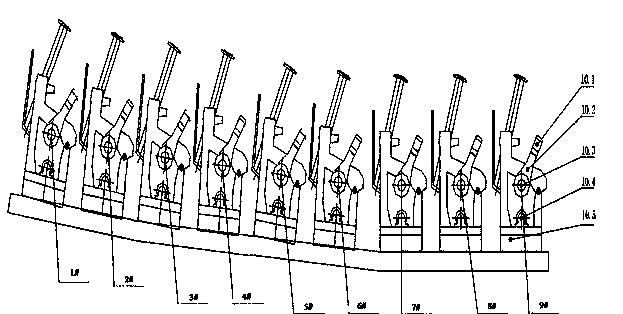

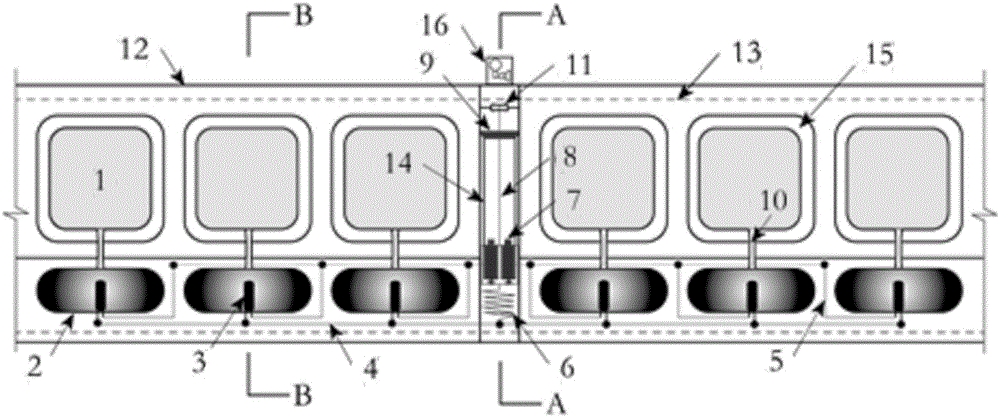

Device and method for improving casting blank quality of continuous casting production

The invention discloses a device and method for improving casting blank quality of continuous casting production. The device comprises a plurality of casting-rolling mill racks arranged in the casting strand direction, an electromagnetic linear period symmetric stirring unit and a drive adjustment type secondary cooling water control unit. The casting-rolling mill racks are used for artificially and forcibly forming solidification tail ends and arranged on a casting strand horizontal area. The electromagnetic linear period symmetric stirring unit is arranged on a casting strand arc area. The drive adjustment type secondary cooling water control unit is used for conducting stepless water spraying cooling on the surfaces of casting blanks based on real-time measuring. The liquid core large-rolling-reduction casting-rolling device and technology used for artificially and forcibly forming the solidification tail ends form the large rolling reduction in the thickness direction of the casting blanks, so that the solidification tail ends are artificially and forcibly formed inside the casting blanks, conditions for forming defects in the natural solidification process of the casting blanks are terminated, flowing of solute element molten steel enriched in the casting blanks is prevented, and the effects of homogenizing and density inside the casting blanks are improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Mold flux and continuous casting method using the same

InactiveCN101472693APrevent surface curingControl heat transferMelt-holding vesselsMolten metal pouring equipmentsPolymer chemistryContinuous casting

A mold flux including 20 to 50 wt% of CaO, 20 to 50 wt% of SiO2, 20 wt% or less of Al2O3, 20 wt% or less of Na2O, 10 wt% or less of Li2O, 20 wt% or less of B2O3, and 10 wt% or less of MgO, and a continuous casting method using the mold flux. The quality of products can be improved, since the occurrence of surface cracks of cast pieces is suppressed. Further, since the occurrence of break-out is prevented, it is possible to improve the process stability.

Owner:POHANG IRON & STEEL CO LTD

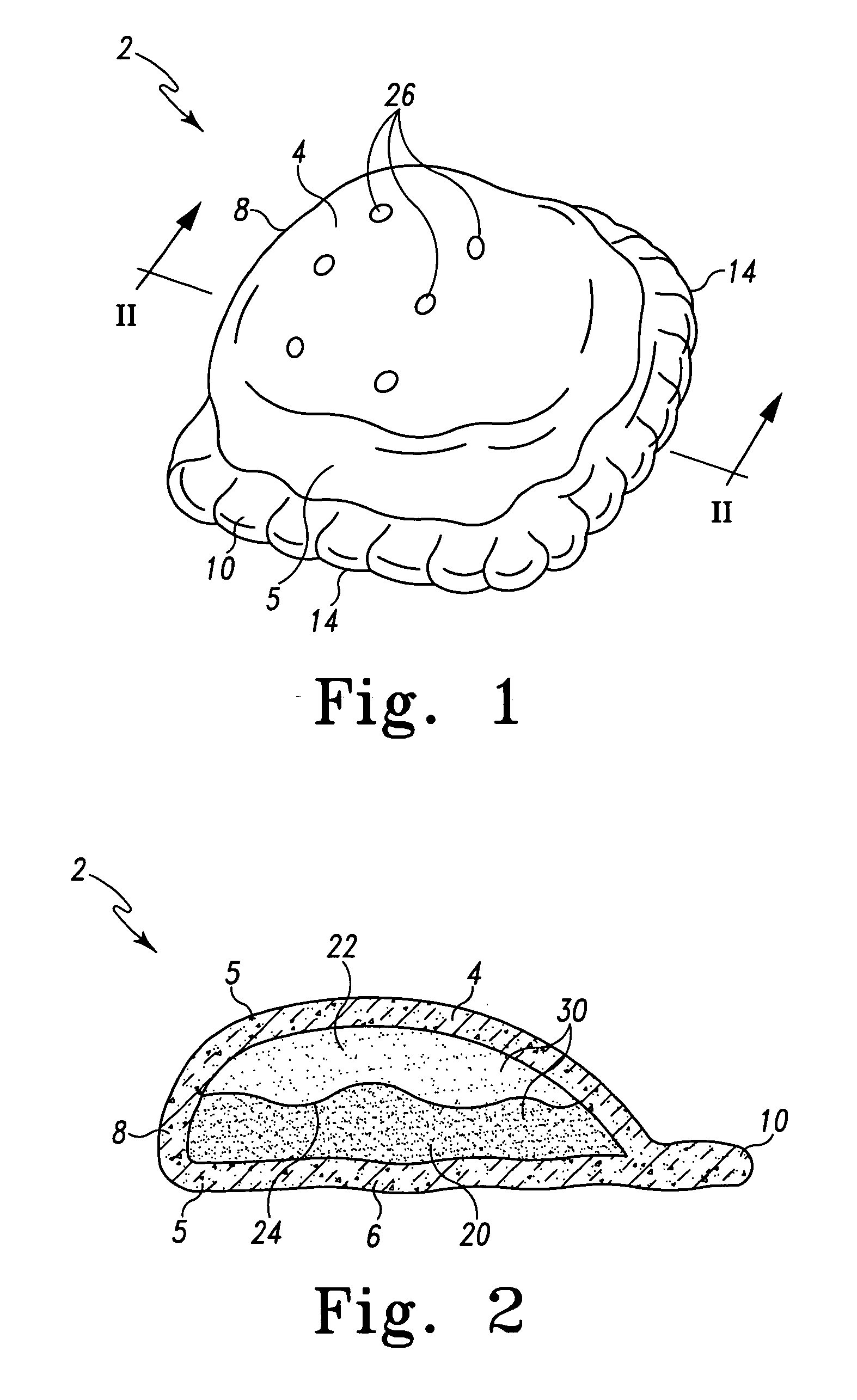

Peanut butter pastry product

InactiveUS20050175740A1Avoid surface crackingLess fillingConfectionerySweetmeatsEngineeringButter peanut

Methods and compositions are provided for a nut butter-filled pastry comprising a pastry exterior, and a filling substantially enclosed in the pastry exterior, the filling comprising a nut butter. In illustrative embodiments, the nut butter is peanut butter.

Owner:MCWATTERS SUSAN KAY HALL +4

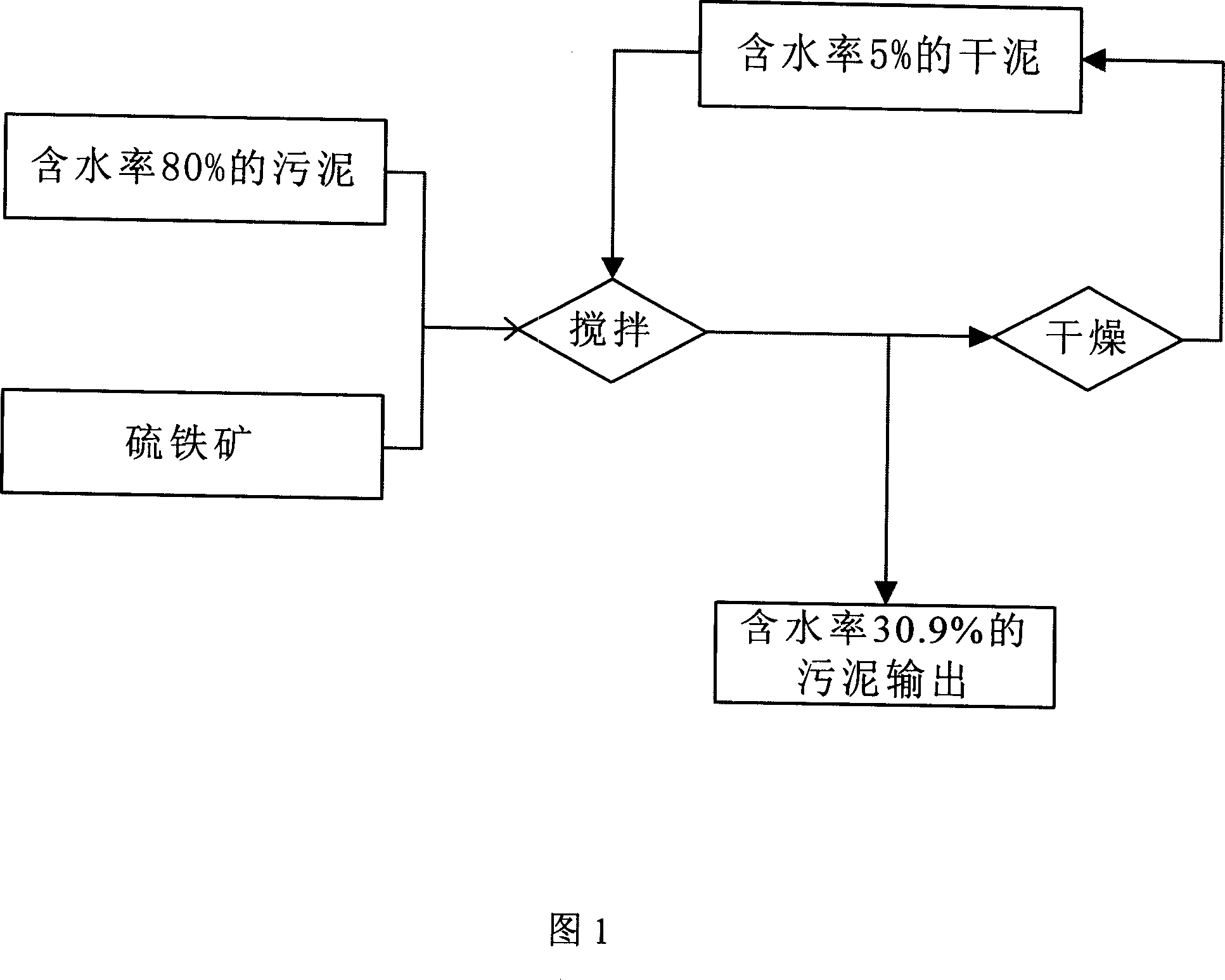

Modified tempering method in sludge treatment process and application thereof

ActiveCN101012097ALoose textureWell-developed poresSludge treatment by de-watering/drying/thickeningSolid waste managementBrickPyrite

The invention discloses a modifying tempering method in the sludge disposing course, which comprises the following steps: doping 1-50% pyrite or coal ash into sludge with water content at 70-80%; transmitting the mixture into stirrer; adding dried sludge with water content at 5-8%; adjusting the water content of sludge at 30-35%; drying the sludge; discharging.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

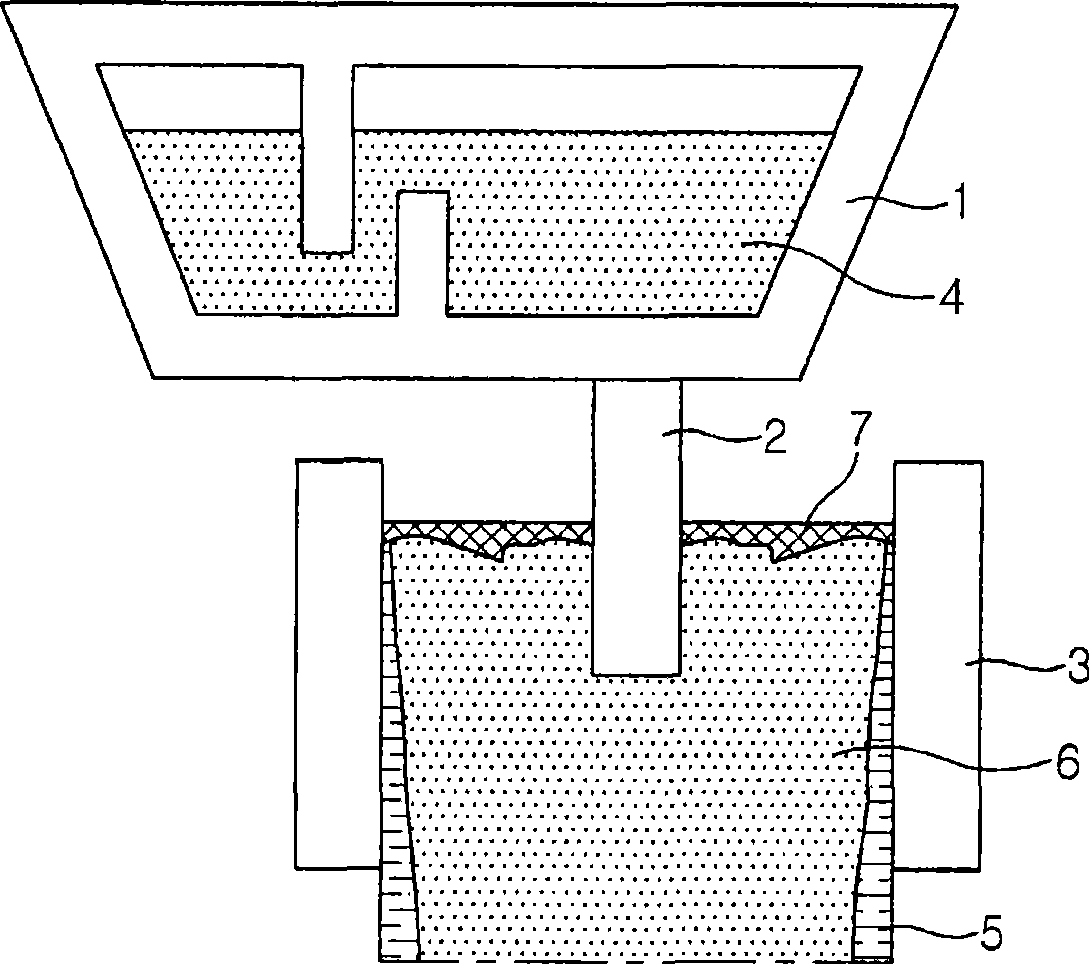

Method for improving self-feeding capacity of high and thick large-cross section casting blank

ActiveCN102161090AAchieving radial self-feedingImprove the interface heat transfer coefficientState of artDiameter ratio

The invention relates to the field of casting blank manufacturing, in particular to a method for improving the self-feeding capacity of a high and thick large-cross section casting blank, and can solve the problems that the center quality of the thick large-cross section casting blank is poor, cracks are generated on the surface of the thick large-cross section casting blank, and the rejection rate is high in the prior art. The method comprises the following steps of: controlling external cooling conditions of different solidification stages of the casting blank to quickly solidify the outer surface of the casting blank to form a shell, establish strength and prevent surface cracks from being generated; performing heat preservation and slow cooling on the surface of the casting blank to keep a large area of a core part in a pasty area, wherein a solidification layer on the outer surface of the casting blank is kept at a higher temperature so that plastic deformation is realized; and performing simultaneous solidification and solid-phase movement in the subsequent solidifying and shrinking process of the casting blank to fulfill the aim of radial self-feeding of a deformable metal at a high temperature so as to eliminate the internal shrinkage cavities and surface cracks of the casting blank and obviously improve the looseness until the internal looseness of the casting blank is eliminated. The method is applicable to the high and thick large-cross section casting blank, particularly to a thick large-cross section casting round blank and a thick large-cross section casting square blank of which the height-diameter ratio is high and the axial looseness cannot be improved through riser feeding.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing silicon-based active material particles for secondary battery and silicon-based active material particles

ActiveUS20170214042A1Prevent over-boostingExtended service lifeSiliconCell electrodesShear stressSolvent

The present invention relates to a method for preparing silicon-based active material particles for a secondary battery and silicon-based active material particles. The method for preparing silicon-based active material particles according to an embodiment of the present invention comprises the steps of: providing silicon powder; dispersing the silicon powder into an oxidant solvent to provide a mixture prior to grinding; fine-graining the silicon powder by applying mechanical compression and shear stress to the silicon powder in the mixture prior to grinding to produce silicon particles; producing a layer of chemical oxidation on the fine-grained silicon particles with the oxidant solvent while applying mechanical compression and shear stress to produce silicon-based active material particles; and drying the resulting product comprising the silicon-based active material particles to yield silicon-based active material particles.

Owner:NEXEON LTD

H13 round steel continuous casting and continuous rolling manufacturing process

ActiveCN109158558AAvoid crackingAvoid surface crackingWork heating devicesMetal rolling arrangementsHot workingContinuous rolling

The invention relates to a continuous casting and continuous rolling manufacturing process of H13 round steel for hot working molds with specifications of phi 50 mm to phi 150 mm; the alloy content ofthe steel is 9%; arc billet continuous casting machines with sections above 300*400 mm are used for continuous casting; and a 850 reversible and continuous casting unit is used for rolling. As the alloy content of the steel is higher, the bad segregation, middle cracks and center cracks are easily generated in the solidification process, the deformation resistance in the continuous casting process is high, the surface rolling defects are easily generated, the welding is difficult in the rolling process due to internal looseness, the cracking phenomenon is easily generated through air coolingafter rolling, and the quality of rolled materials and final products is badly influenced. A continuous casting electromagnetic stirring technology, a light pressing technology and an ultraweak cold technology are applied, and such processes as high-temperature dispersion and belt temperature annealing are combined to effectively control the grade of belt structures, to prevent center cracks and surface cracks of continuous-cast blanks and cooling stress cracks of the rolled materials and to improve the ultrasonic flaw detection pass percent of the rolled materials and the pass percentage of the belt structures.

Owner:NANJING IRON & STEEL CO LTD

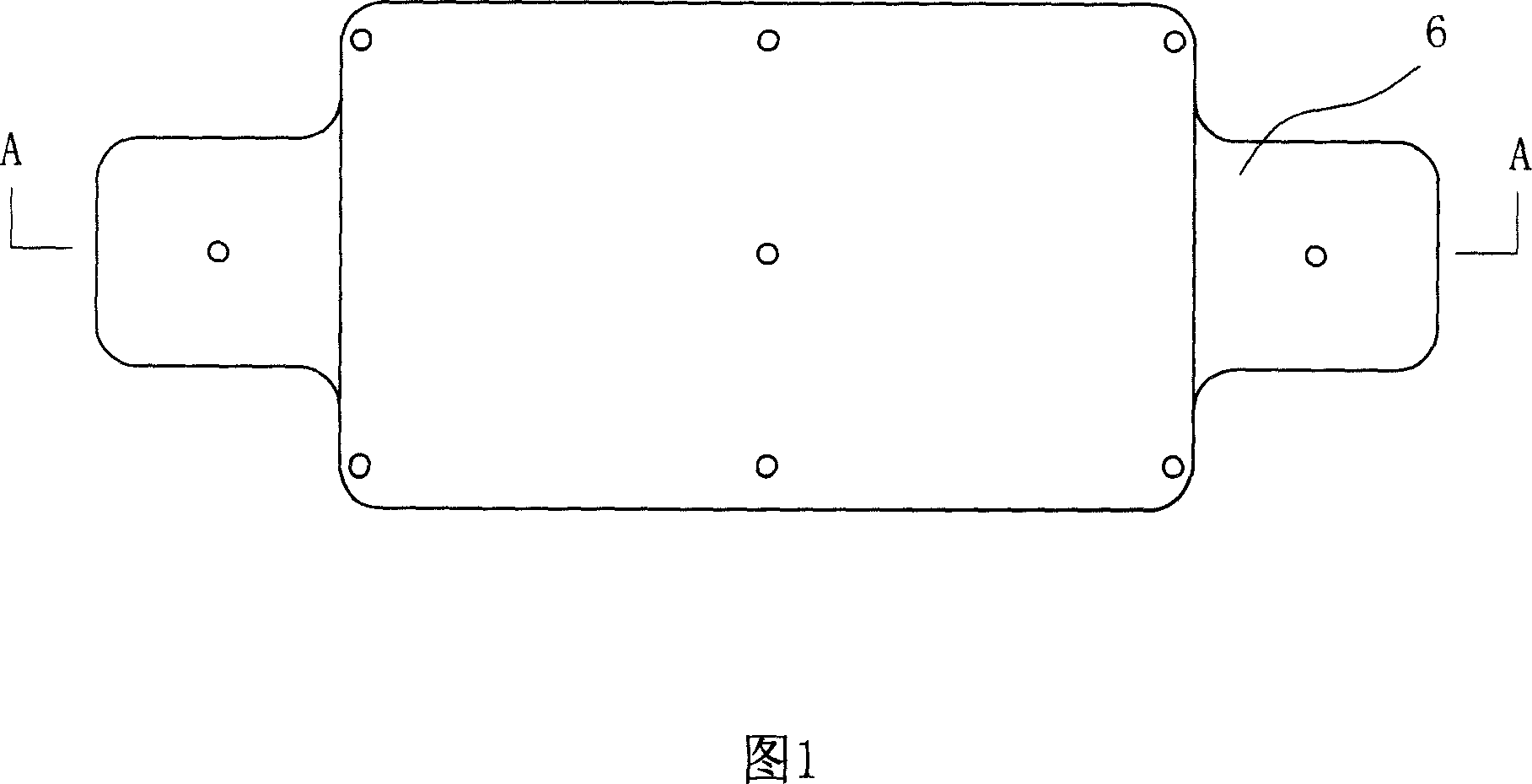

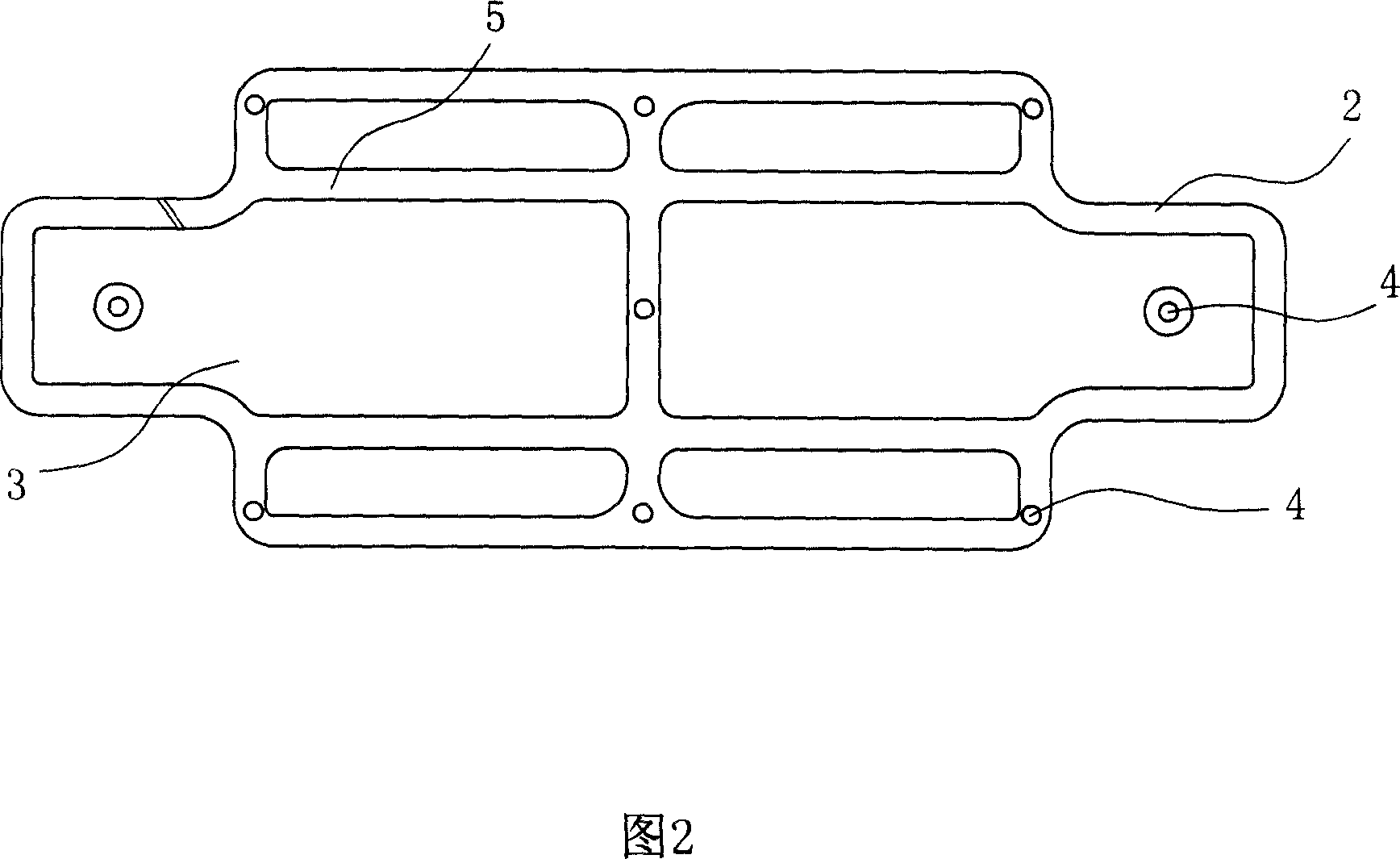

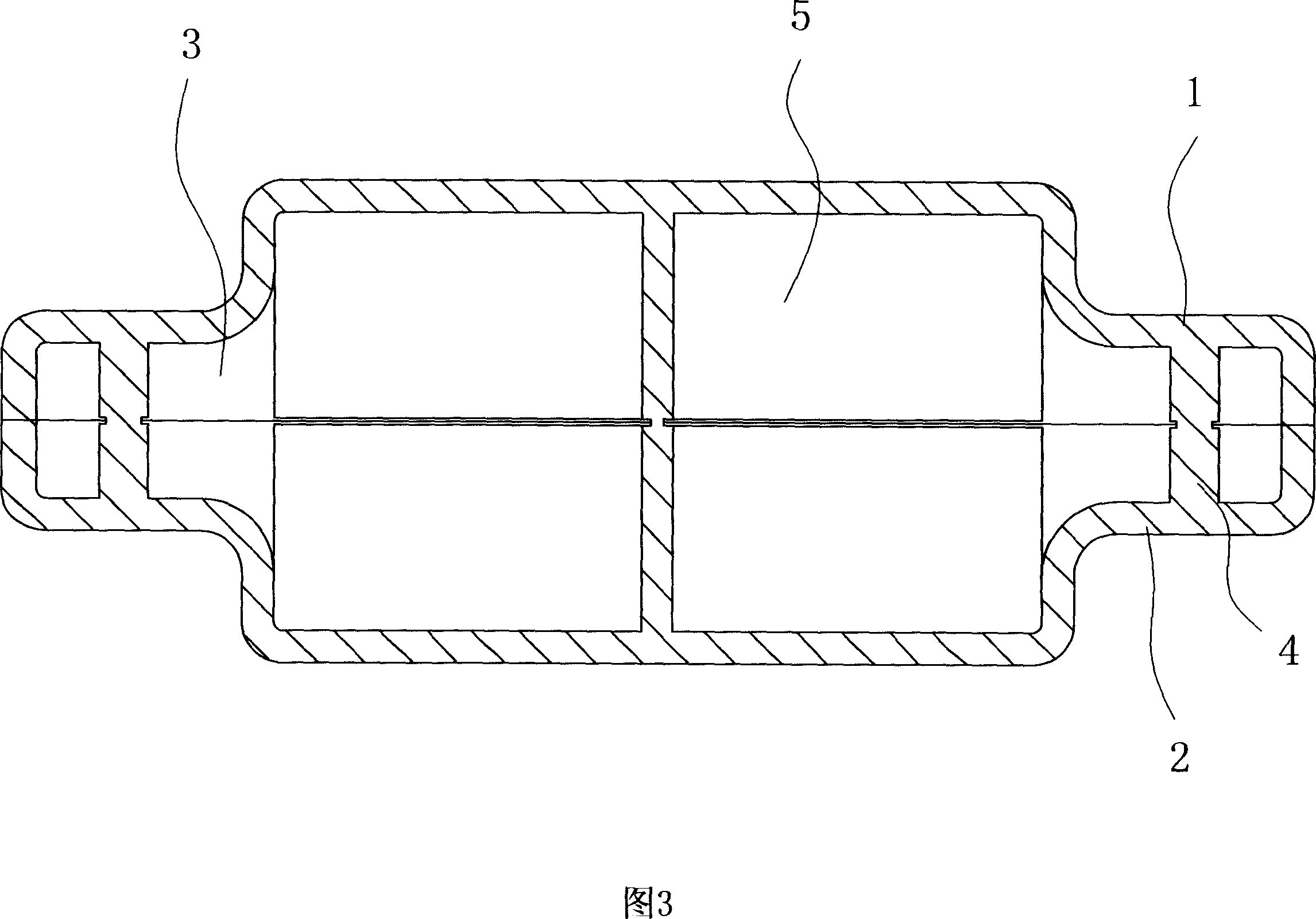

Cold core

Owner:SUZHOU MINGZHI TECH

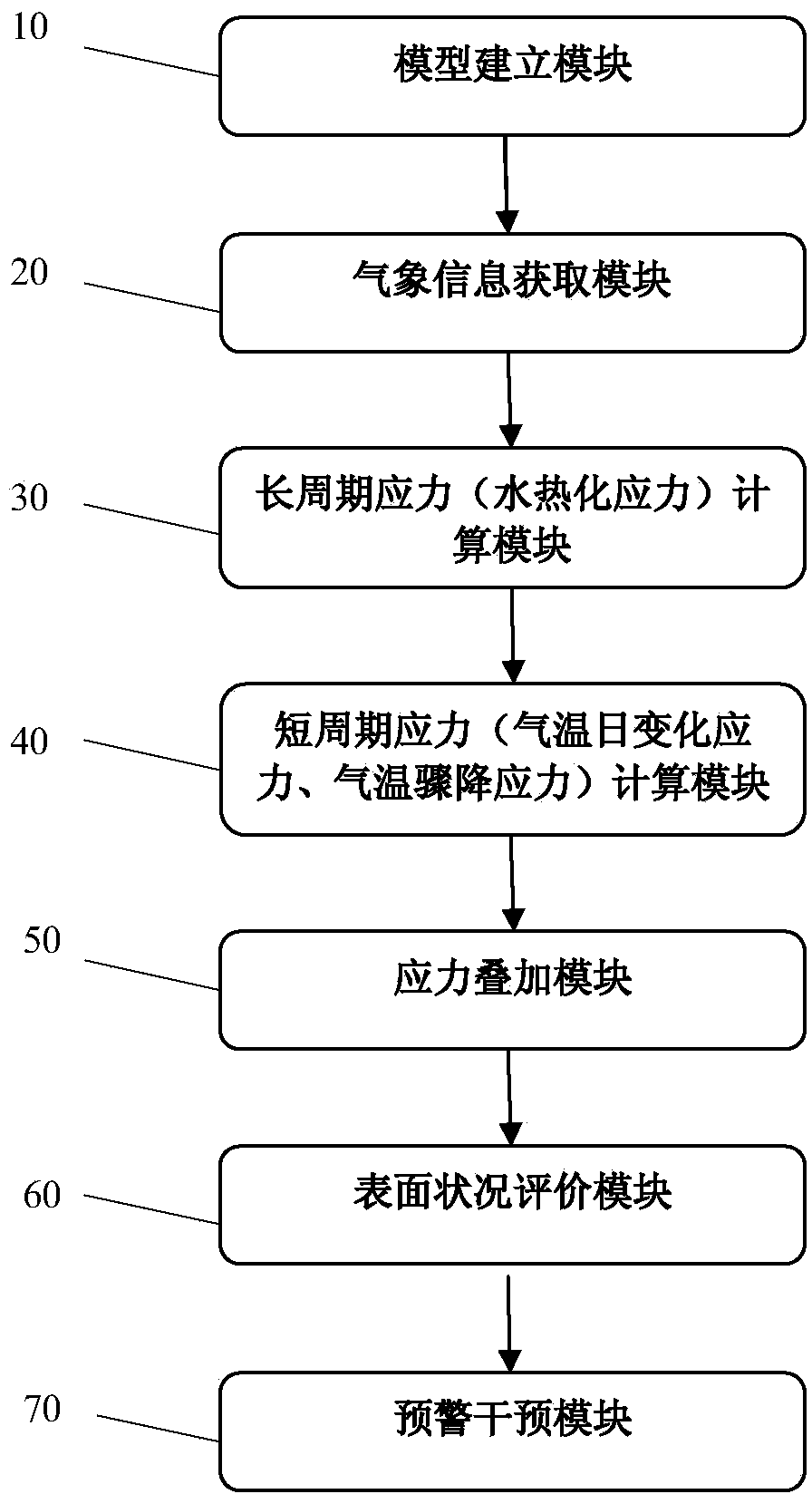

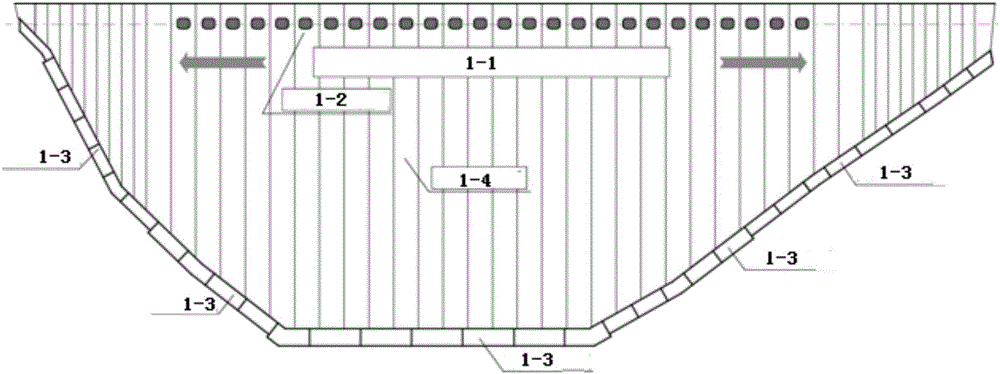

Mass concrete surface cracking risk early warning, intervening and decision-making system

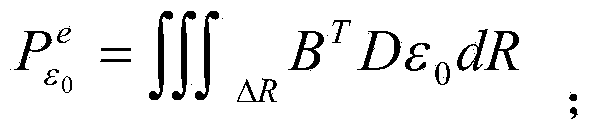

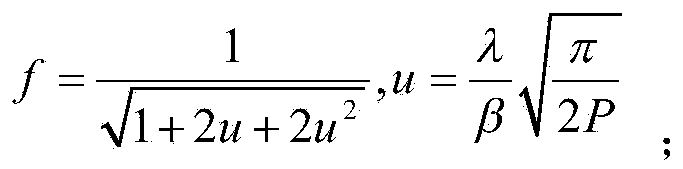

InactiveCN103556597AAvoid surface crackingFully automatedMeasurement devicesHydraulic engineering apparatusSoftware systemSurface conditions

The invention provides a mass concrete surface cracking risk early warning, intervening and decision-making system which comprises a model establishing module (10), a weather information obtaining module (20), a long-period stress calculating module (30), a short-period stress calculating module (30), a stress superposition module (50), a surface condition evaluating module (60) and an early-warning and intervening module (70). The system performs early warning and intervention on concrete surface cracking through an automatic software system, achieves early-warning automation and intervention intellectualization and effectively prevents the concrete surface cracking.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

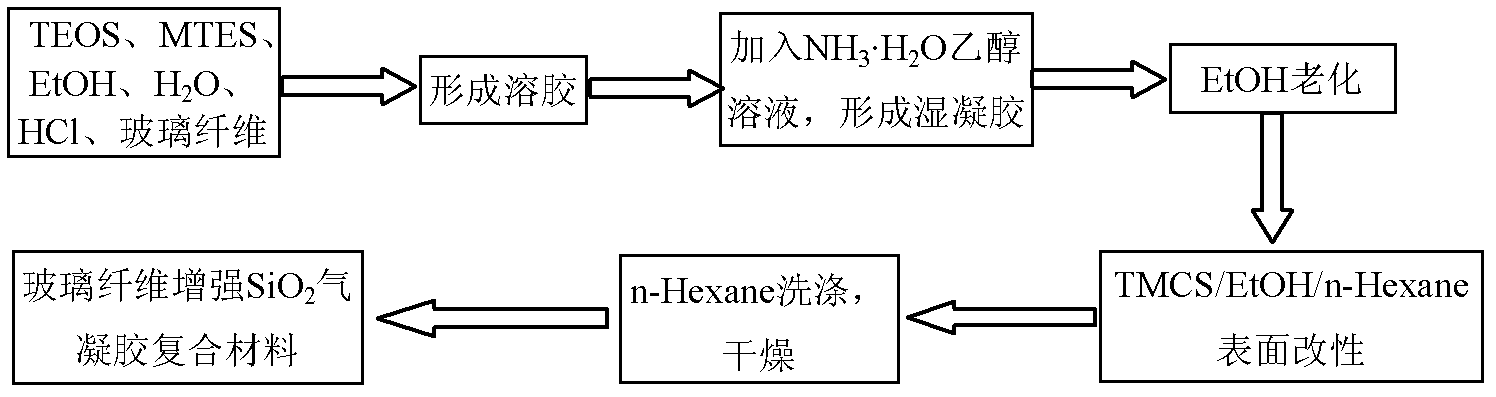

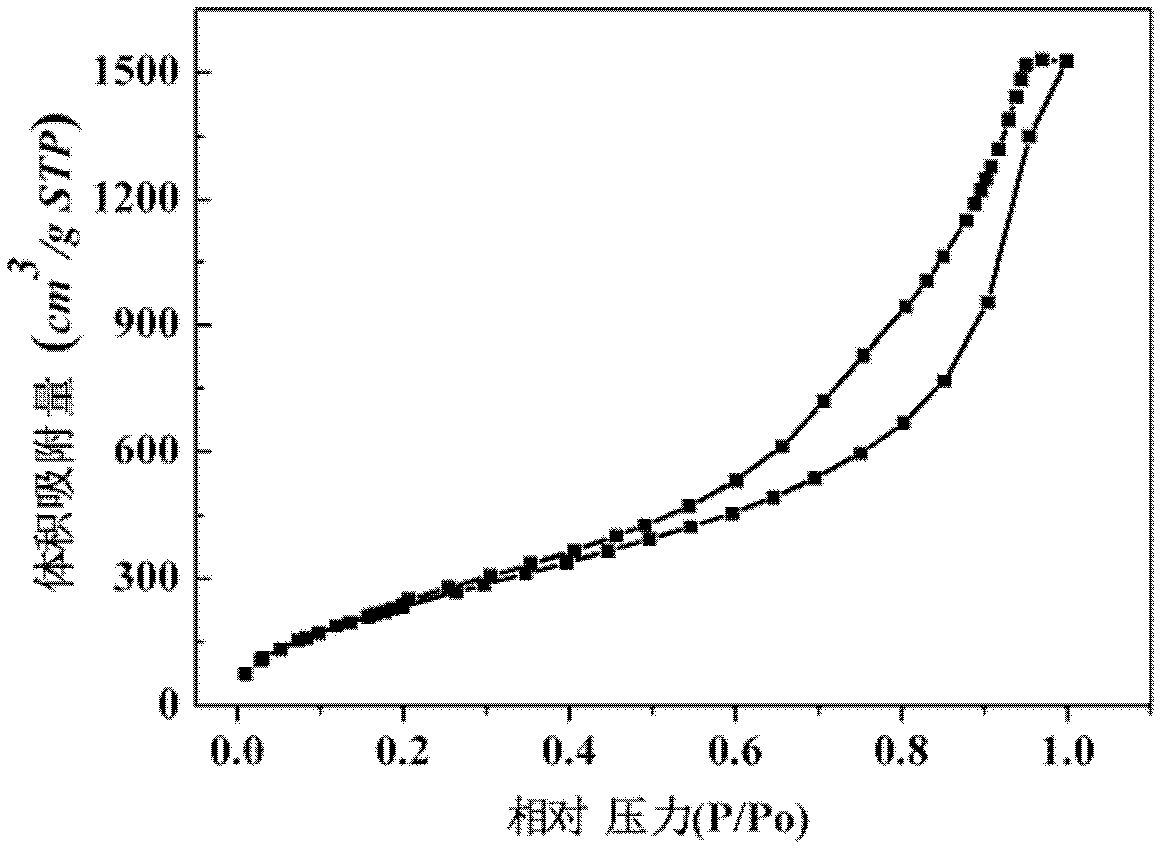

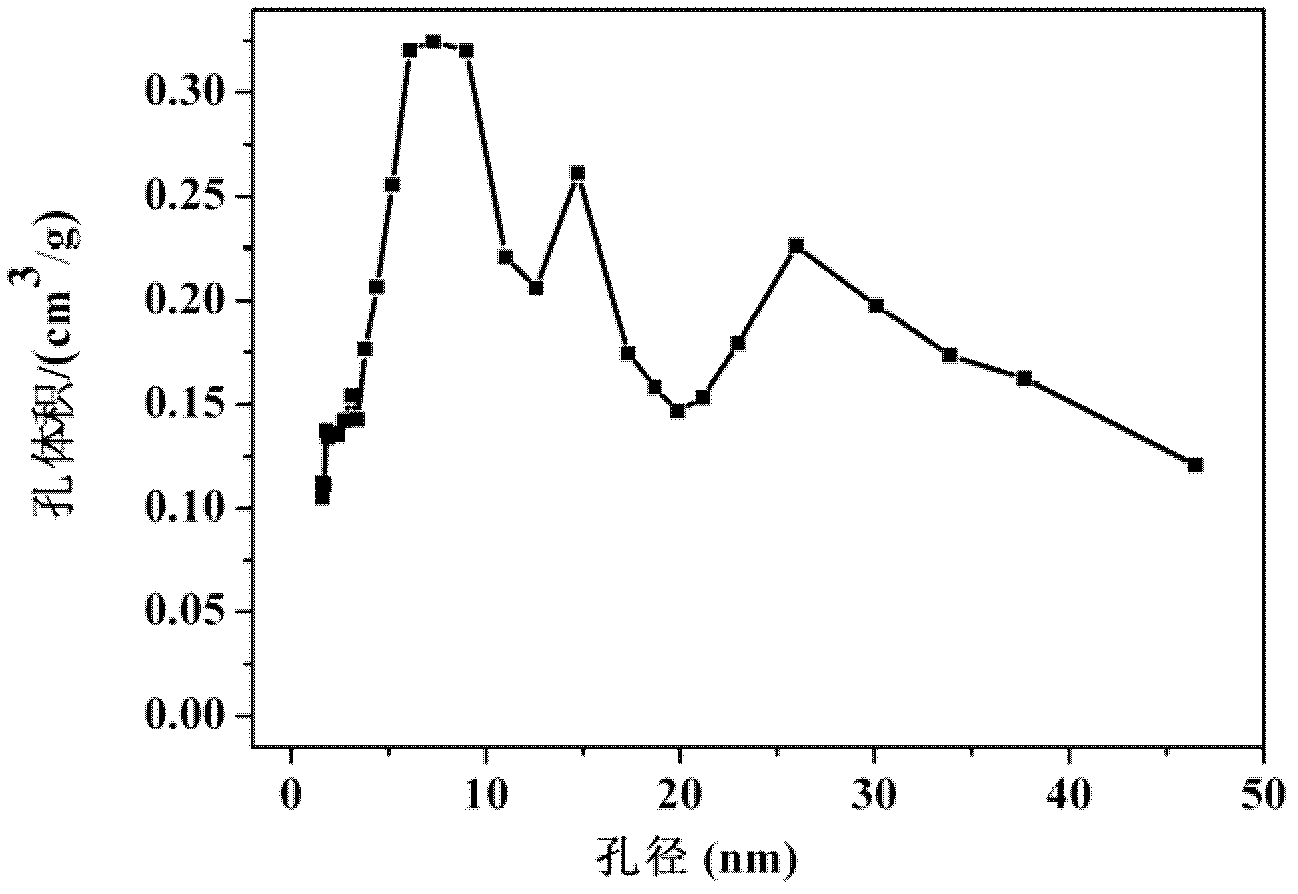

Preparation method of silicon dioxide aerogel composite material

The invention relates to preparation and a method of a silicon dioxide aerogel composite material. The silicon dioxide aerogel composite material takes tetraethyl orthosilicate as a silicon source and industrially-produced glass fibers or fiber cotton materials as a reinforcing body. Firstly, composite wet gel is prepared by adopting a fiber surface acid treatment process or an acid treatment and coupling agent crosslinking common treatment process and a sol-gel method, then, the composite wet gel is aged, solvent-replaced and modified, and finally, the silicon dioxide aerogel composite material is prepared under the normal-pressure drying. The prepared silicon dioxide aerogel composite material has the characteristics of high porosity, high specific surface area, low density, low dielectric constant, low thermal conductivity and the like and also has good formability, and functional materials with different properties and structures can be prepared as required. The preparation and the method have the advantages of simple synthesis process, low raw material cost and low equipment requirements; and the prepared composite aerogel has a certain mechanical property, is enlarged in the application field and can be taken as building heat-insulation and sound-insulation materials, transportation pipeline energy conservation and environmental protection material and fire protection and heat insulation materials.

Owner:厦门纳美特新材料科技有限公司

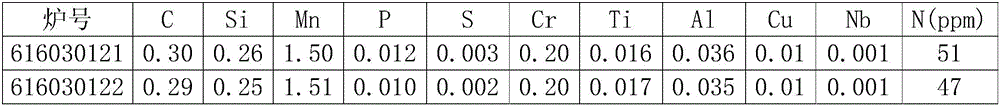

Production process for effectively preventing marine anchor chain round steel from generating cracks

InactiveCN106086595ASolve the problem of nozzle nodulationReduce inclusion contentProcess efficiency improvementElectric furnaceChemical compositionSlag

The invention relates to a production process for effectively preventing marine anchor chain round steel from generating cracks. A preparation method includes the steps of an electric furnace smelting procedure, a refining procedure outside an LF, a square billet continuous casting procedure and a rolling procedure. Chemical components are reasonably designed, the carbon equivalent is controlled, Ti microalloy reinforcement is added, the content of P and S is controlled to be smaller than or equal to 0.015%, the content of N is controlled to be smaller than or equal to 70 ppm, the content of residual elements of Cu, Nb and the like is reasonably controlled, the LF is well sealed, the soft blowing flow of argon is reasonably controlled, molten steel is prevented from absorbing nitrogen, aluminum deoxidation is enhanced, the soft blowing time of the argon is properly prolonged, whole-process protective casting is adopted for the continuous casting, the pulling speed and the superheat degree are low, proper protective slag is selected, the straightening temperature is raised, continuously cast billet enters a pit to be slowly cooled, the tapping interval is well controlled in a rolling manner, the compression ratio is increased, and a reasonable heat treatment process is selected. The marine anchor chain round steel produced through the method is simple in procedure and low in cost, vacuum treatment is not needed, and the technical problems that marine anchor chain round steel produced at present is bad in surface quality, high in crack occurrence ratio, not stable in quality and the like are solved.

Owner:ZENITH STEEL GROUP CORP

Light heat insulating sound proofing wall partition board and its production method

InactiveCN1785887ALight in massHigh strengthCeramic shaping apparatusSurface strengthMaterials science

The present invention relates to a light heat-insulating sound-proof partition wall board and its production method. It is made up by using cement, light asbestos wool, light stone granules and polypropylene fibre through a certain production process. Besides, said invention also provides the concrete steps of said production process.

Owner:杨立峰

Continuous casting process for boiler pipe steel resistant to sulphuric acid dew point corrosion

The invention relates to a continuous casting process for boiler pipe steel resistant to sulphuric acid dew point corrosion. A full-protecting pouring mode is adopted during continuous casting. A long nozzle argon sealing protecting casting mode is adopted from a steel ladle to a tundish. An integrated built-in submersed nozzle protecting casting mode is adopted from the tundish to a crystallizer. Molten steel in the tundish uses molten steel covering agents. Continuous temperature measurement is carried out on the tundish. Full-automatic liquid surface detection is carried out on the liquid surface of the crystallizer in the continuous casting process. The continuous casting pulling rate is automatically controlled according to the superheat degree of the tundish. Automatic water distribution is carried out for the crystallizer and secondary cooling. The crystallizer uses special casting powder for the boiler pipe steel resistant to sulphuric acid dew point corrosion in the casting process. By means of the continuous casting process for the boiler pipe steel resistant to sulphuric acid dew point corrosion, the surface cracks of rolled metal can be largely reduced, and the flaw detection rate and yield are greatly increased.

Owner:NANJING IRON & STEEL CO LTD

Preparation method of medical biodegradable zinc alloy capillary wire material

The invention provides a preparation method of a medical biodegradable zinc alloy capillary wire material. A medical biodegradable zinc alloy is sequentially subjected to vacuum melting and homogenizing treatment to obtain a zinc alloy cast ingot, then the zinc alloy cast ingot is sequentially subjected to skin turning and extrusion, a zinc alloy coarse bar is obtained and sequentially subjected to rotary swaging and annealing, a fine bar is obtained, the surface of the obtained fine bar is coated with a graphite lubricant coating, then the fine bar is subjected to cold drawing for wire drawing, and the medical biodegradable zinc alloy capillary wire material is obtained, wherein the diameter of the capillary wire material is smaller than 0.1 mm. The preparation method is a compound machining method comprising vacuum melting, thermal extrusion forming, rotary swaging and cold drawing for wire drawing, the purposes of enhancing the material performance and plastification can be achieved through surface lubrication and proper thermal treatment of the special procedures, the microstructure grain fragmentation can reach the nanoscale, the comprehensive mechanical performance is excellent, the surface quality is good, and corrosion resistance, degradation uniformity and degradation speed all meet the clinical application requirements.

Owner:XIAN ADVANCED MEDICAL TECH

Continuous casting system and process producing large-specification elliptical billets

The invention relates to a continuous casting system producing large-specification elliptical billets. The continuous casting system comprises a tundish, a crystallizer, an aftercooling area and a straightening mechanism, a continuous temperature measuring device matched with an inductive heating device is arranged in the tundish, an electromagnetic stirring device stirring molten steel is arranged in the crystallizer, the aftercooling area comprises an arc-shaped guide section and atomizing water nozzles arranged on two sides of the arc-shaped guide section, the straightening mechanism comprises a plurality of straighteners capable of continuously straightening the elliptical billets, and the straighteners are distributed along the progressing direction of the elliptical billets on a declining curve, and a cutting machine, a burial pit and a shot blasting machine are sequentially arranged at the tail end of the straighteners. The invention further provides a continuous casting process on the basis of the continuous casting system. The continuous casting process has the advantages of short procedures and low cost, the elliptical billets have excellent surface quality, macro quality of the cross section reaches the primary standard of the country, and yield of the elliptical billets is up to 96% which is at least 10% higher than a die casting process.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Powder ash air-entrained concrete processing technology

The invention discloses a powder ash air-entrained concrete processing technology. The formula of the powder ash air-entrained concrete comprises the following components: 6-10 parts of cement, 3-8 parts of gypsum, 5-9 parts of quick lime, 15-20 parts of powdered ash, 1-2 parts of a grinding aid, 3-5 parts of waterborne polymer resin, 2-4 parts of an antifoaming agent, 3-5 parts of a thickening agent, 6-8 parts of a preservative and 2-4 parts of a stabilizer, wherein a ratio of water to material is 4:7. The formula disclosed by the invention is simple and reasonable in structural design, convenient to operate, short in production period, low in processing cost, capable of realizing recycling, reducing waste and improving quality and applicable performance of the powder ash air-entrained concrete, safe and stable and contributes to wide promotion and popularization.

Owner:福建国强新型环保建材有限公司

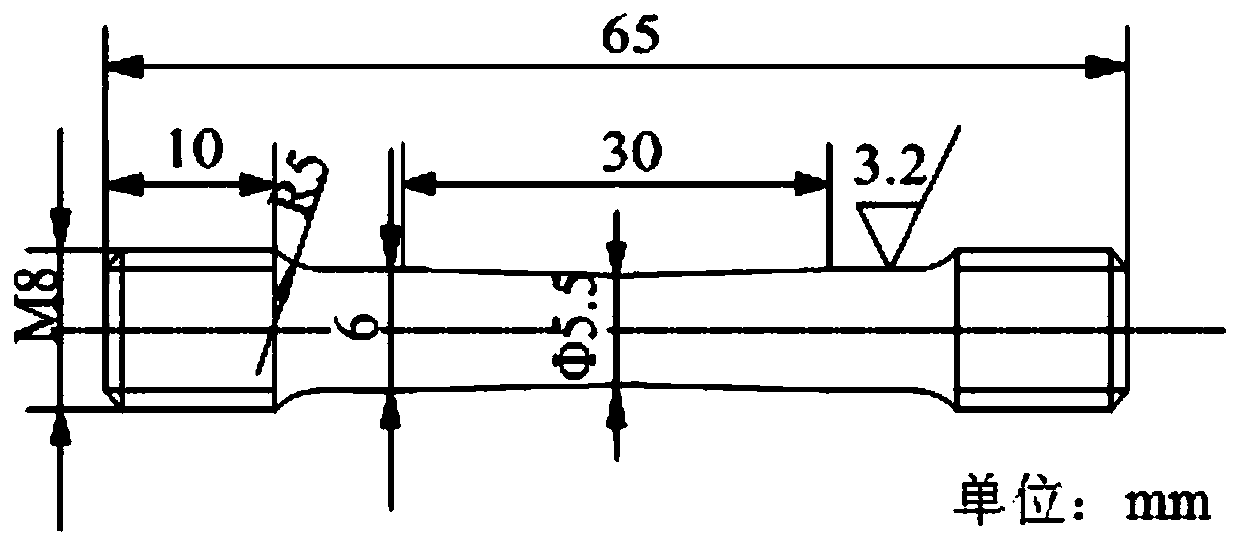

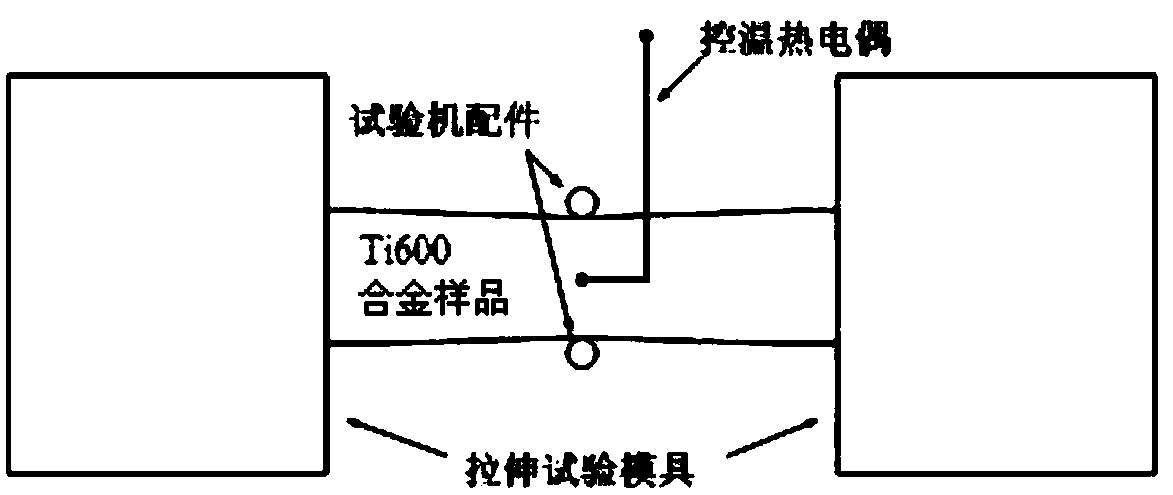

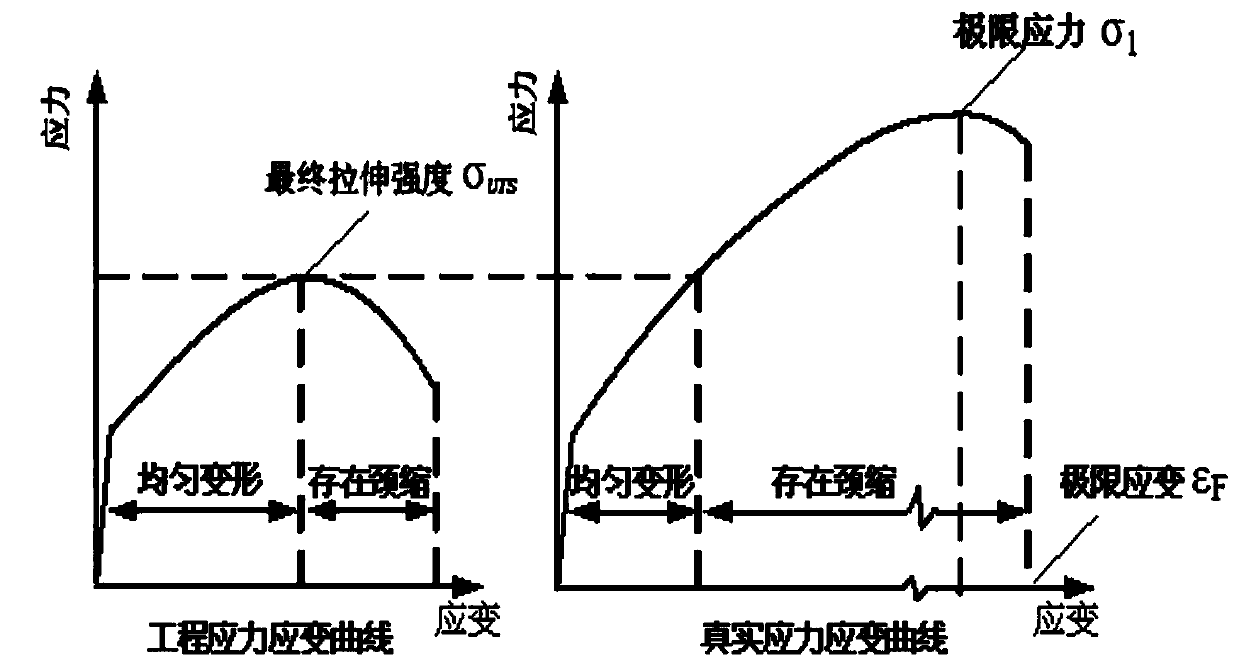

Physical experiment and numerical simulation combined method for predicting metal extrusion forming cracking

InactiveCN108920871AReliable critical damage valueQuality improvementDesign optimisation/simulationSpecial data processing applicationsElement modelMaterials science

The invention discloses a physical experiment and numerical simulation combined method for predicting metal extrusion forming cracking. The method comprises the steps that first, a hot-stretch test isperformed on metal, and then a Normalized Cockcroft&Latham damage model is selected for calculation to obtain a critical damage value of the metal; second, simulated verification is performed on thecritical damage value of the metal; and third, the critical damage value of the metal after simulated verification is embedded into a metal extrusion finite element model, and the cracking phenomenonin the metal extrusion forming process is predicted. According to the method, a physical experiment and simulated verification are combined to acquire the reliable critical damage value of the metal,then the positions and shapes of metal surface and internal cracks generated in multiple extrusion forming processes are predicted through numerical simulation of the extrusion processes, an error caused by a test mistake is avoided, prediction precision is improved, the prediction range is expanded, therefore, crack generation is avoided, and the quality of metal extrusion pieces is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

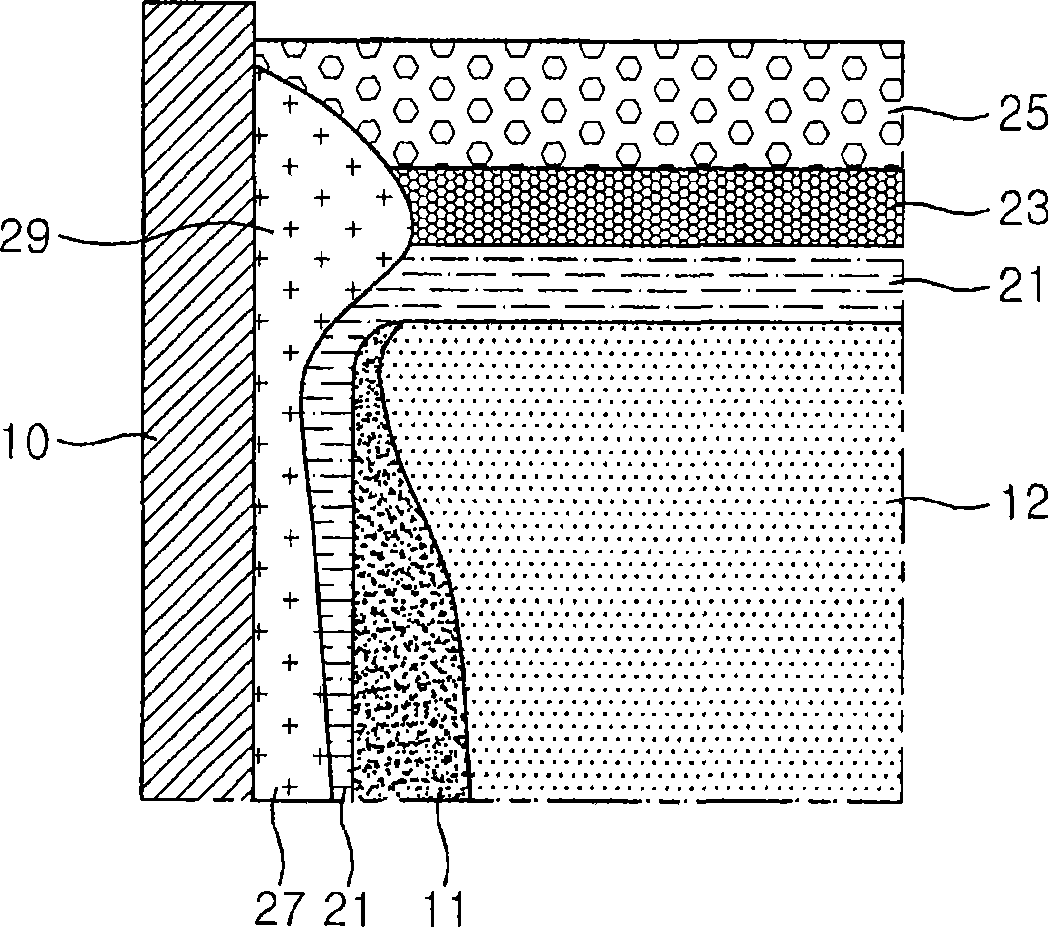

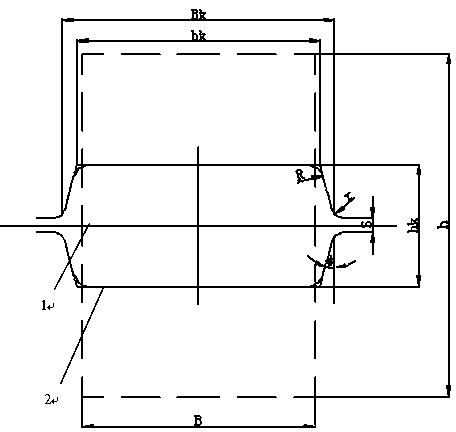

Pass system and roughing process for avoiding cracks on surface of large-size round steel

ActiveCN104209318AImprove chance of formationAvoid surface crackingTemperature control deviceMetal rolling arrangementsLarge sizeMaterials science

The invention discloses a pass system and a roughing process for avoiding cracks on the surface of large-size round steel. The bottom width size b(i)k( / i) of a channel for roughing a first pass to the (n-1)th pass and the width B of an incoming material entering the passes at the first time meet the following relation that b(i)k( / i) / B is equal to 1.030-1.045; the bottom width size b(i)k( / i) of a channel for roughing the nth pass and the width B of the incoming material meets the following relation that B minus b(i)k( / i) is equal to 0-3mm; the width B(i)k(i) of the pass channel opening, a maximum value b of a rolled piece outputted from the pass and broadening allowance delta meet the following relation that the B(i)k(i) is equal to b plus delta; the start rolling temperature of the roughing process is controlled to be 1,100-1,200DEG C; the finish rolling temperature is controlled to be 1,000-1,100 DEG C. According to the pass system and the roughing process disclosed by the invention, rolling cracks on the surface of the large-size round steel are effectively eliminated, and the yield of products is remarkably improved.

Owner:NANJING IRON & STEEL CO LTD +1

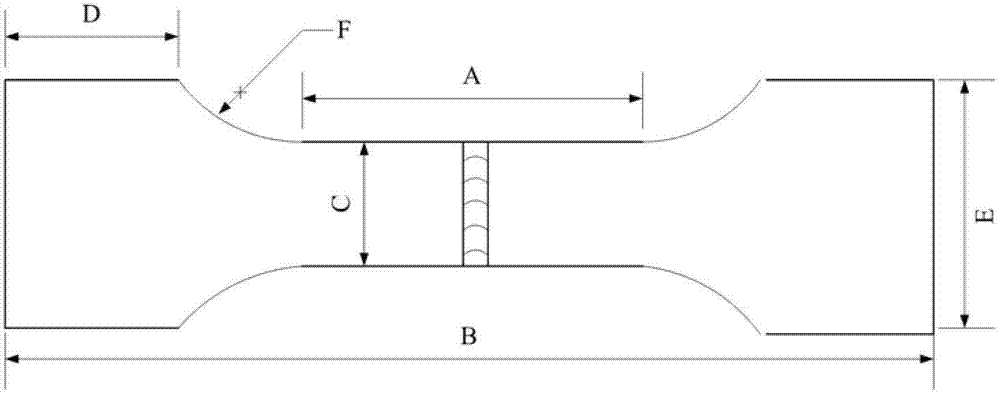

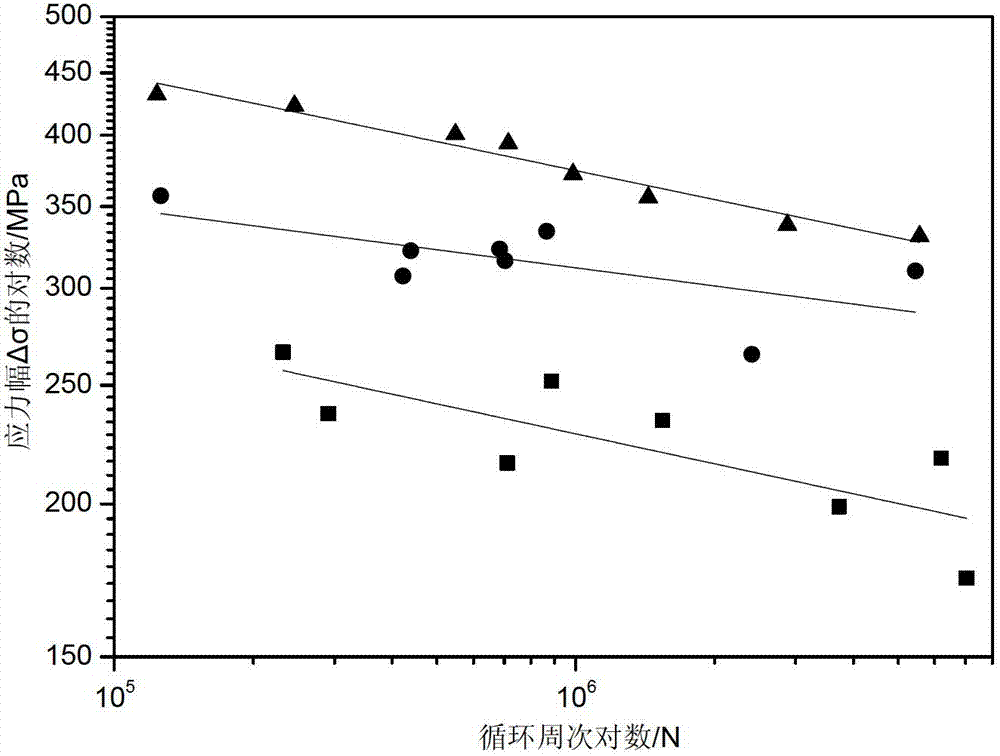

Pretreatment process for reducing defects of surface of ultrasonic impact test piece

The invention discloses a pretreatment process for reducing the defects of a surface of an ultrasonic impact test piece. The process comprises the following steps of carrying out degreasing and decontamination and then carrying out mechanical polishing. Through surface treatment, grease contaminations on the surface are removed, and residual slag and sharp parts on the surface of the test piece are polished off, so that higher surface quality is achieved. The surface conditions of the ultrasonic impact test piece are improved, and the sharpness of the surface is reduced, so that the crack initiation sources are reduced.

Owner:TIANJIN UNIV

Immersion non-woven fabrics and method for producing artificial boards by coating films

InactiveCN101591862AGuarantee product qualityTemperature heat conduction balanceWood veneer joiningTextiles and paperPolyurethane adhesiveWear resistant

The invention relates to immersion non-woven fabrics and a method for producing artificial boards by coating films on the immersion non-woven fabrics. The ration of the non-woven fabrics is between 50 and 500 g / m and the thickness is between 0.5 and 5 mm; and a resin adhesive is a phenolic resin adhesive, a melamine resin adhesive or a polyurethane adhesive. The resin content of the immersion non-woven fabrics is between 28 and 36 percent, the volatile content is between 8 and 9 percent, and the pre-cure degree is between 30 and 55 percent. The method for producing the artificial boards by coating films on the immersion non-woven fabrics comprises the following steps: immersing the non-woven fabrics in the resin adhesive, and drying; and coating the films on the surfaces of the artificial boards through hot pressing, wherein the hot-pressing temperature is between 85 and 150 DEG C, the time is between 5 and 10 min, and the pressure is between 0.5 and 1 Mpa. The artificial boards produced by the method are wear-resistant, fire-retardant, neat, rich in color, low in cost, and environment-friendly.

Owner:邱天祥

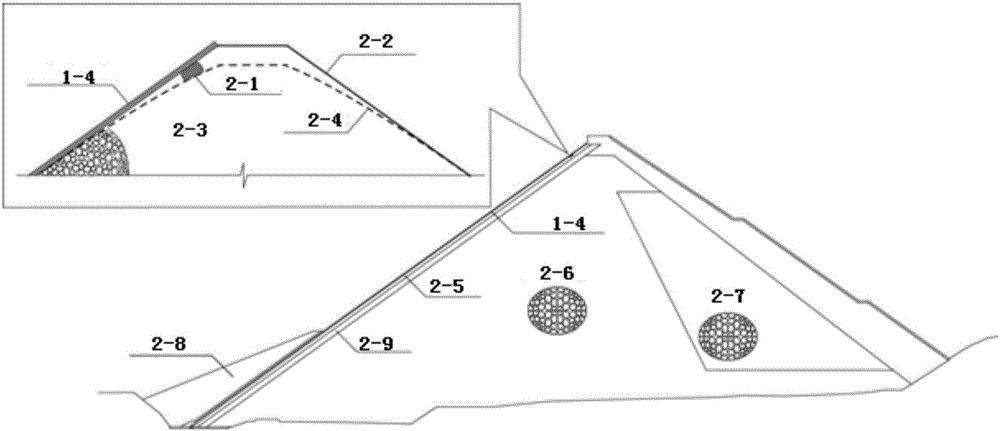

Airbag type automatic protection device for rock-fill dam panel disengagement and design method of device

ActiveCN106812119AImprove the state of stressAvoid surface crackingEarth-fill damsRock-fill damsEngineeringStressed state

An airbag type automatic protection device for concrete panel rock-fill dam panel disengagement is arranged in an extrusion side wall under a concrete panel rock-fill dam panel. The automatic protection device is characterized in that the automatic protection device is composed of a protection airbag, an air generator and an automatic triggering device; the protection airbag is installed on the portion, close to the dam crest part, in a precast concrete extrusion side wall; the air generator is connected with the protection airbag through a breather pipe; the automatic triggering device is internally provided with a disengagement quantity detector electric ignition mechanism, and the electric ignition mechanism is connected with the air generator and controls starting of the air generator. According to the airbag type automatic protection device, the blank in the prior art is filled up, when disengagement occurs between the panel and cushion materials and the disengagement amount reaches the quantity value harming the concrete panel safety, the airbag type protection device is automatically started, the inflatable airbag supports the panel, the stress state of the concrete panel is improved, and secondary diseases such as surface cracks, slab staggering and the like are prevented.

Owner:NANJING HYDRAULIC RES INST

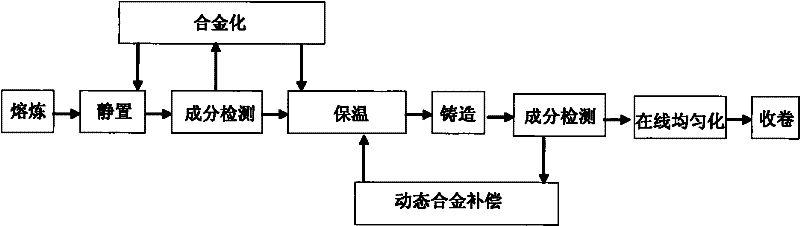

Non-vacuum production method for CuCrZr alloy wire rod

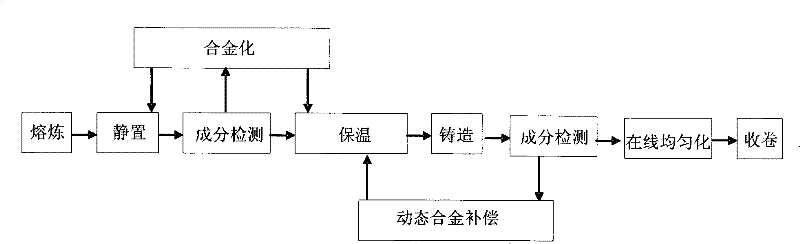

The invention relates to a non-vacuum production method of a CuCrZr alloy wire rod. The method comprises the following steps of: putting a raw material of an alloy substrate in a melting furnace, heating up the raw material to the temperature of between 1,250 and 1,350 DEG C, and after the raw materials in the furnace are melted, removing gas and making slag; after the melt stands, adding primaryalloy elements in the melt for the primary alloying; performing composition detection by on-line sampling, transferring the melt to a thermal preservation furnace after the composition detection is passed, adding secondary alloy elements in the melt in the thermal preservation furnace for the secondary alloying; after the melt stands, starting to cast at a casting temperature of between 1,200 and1,300 DEG C and at a casting speed of between 0.1 and 0.50 mm / m, performing the composition detection by the on-line sampling every 20 to 30 minutes in the casting process, monitoring the compositionfluctuation, and when the fluctuation of the alloy elements is close to the composition lower limit, adding the secondary alloy elements in the melt for the dynamic alloying compensation; and performing on-line homogenization thermal preservation treatment on the obtained casting blank, hardening and collecting raw materials, rolling the wire rod of which the line diameter is less than or equal to phi 30 mm, cutting a bar blank of which the line diameter is more than phi 30 mm and performing the fixed size raw material collection. The method realizes the non-vacuum and continuous production of the heavy coil CuCrZr alloy wire rod.

Owner:苏州中色华人铜业有限公司

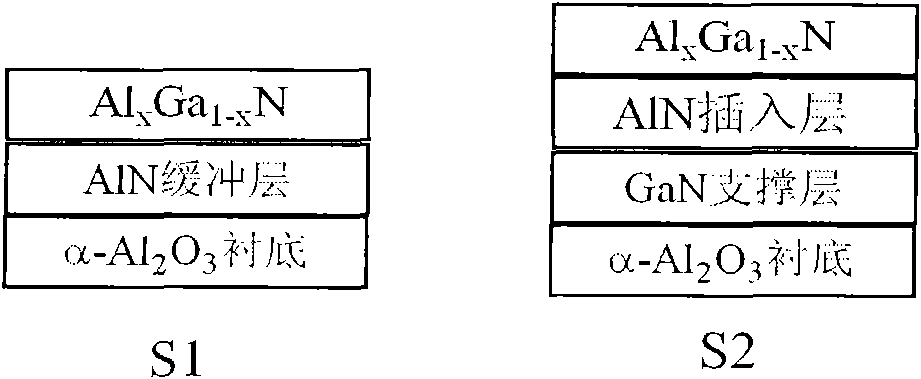

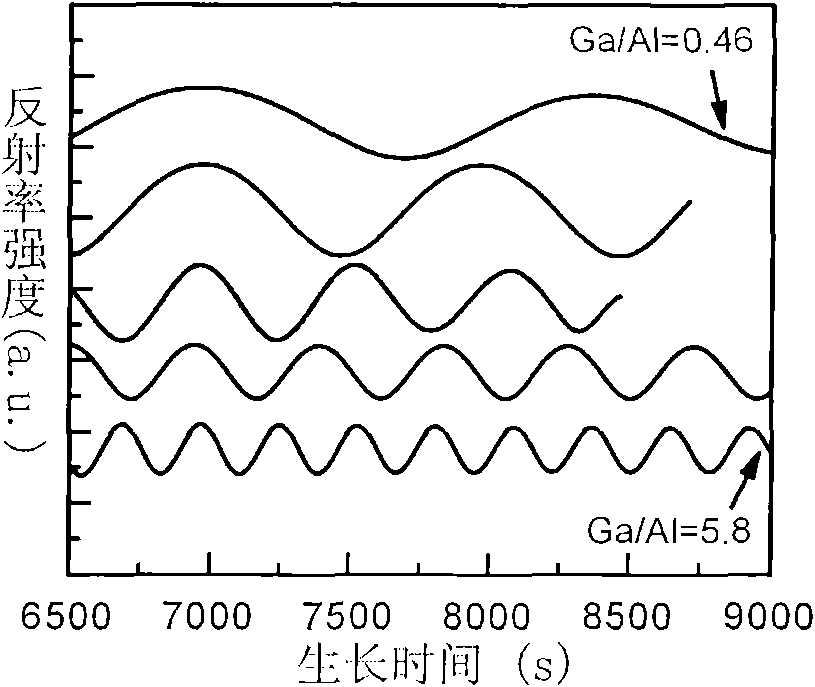

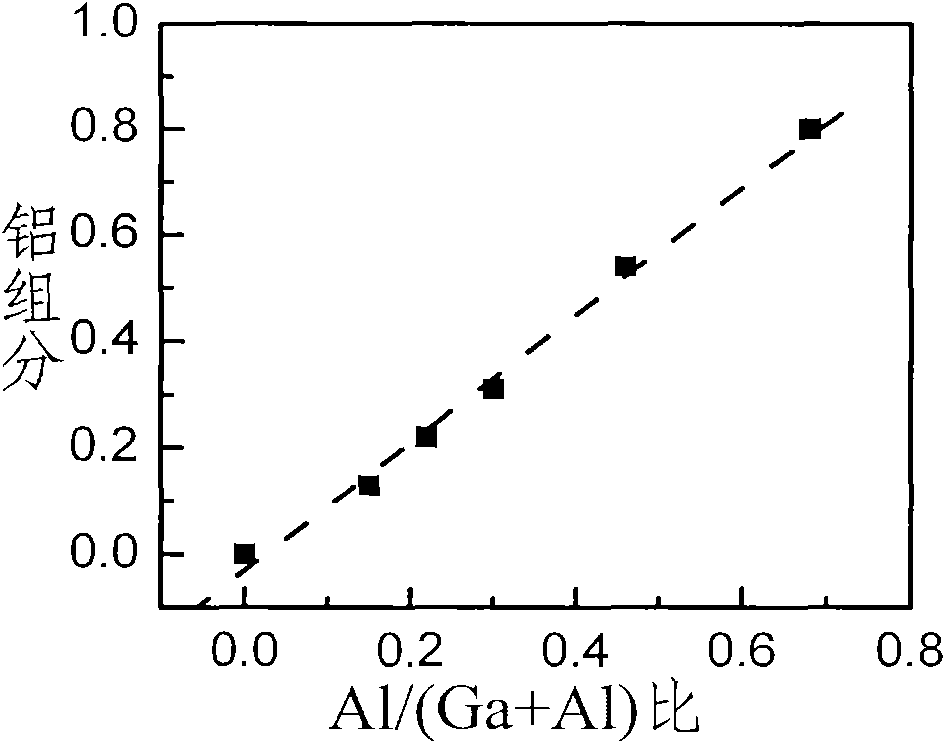

Growth method for obtaining high aluminium component Al-Ga-N alloys by improving aluminium doping efficiency

InactiveCN101777488AInhibit surface cracksGood qualitySemiconductor/solid-state device manufacturingSemiconductor devicesAluminiumCathodoluminescence

A growth method for obtaining high aluminium component Al-Ga-N alloys by improving aluminium doping efficiency is characterized by adopting MOCVD to epitaxially grow an AlxGa1-xN film alloy layer on the alpha-Al2O3 substrate, adopting an AlN buffer layer or insert layer to prevent crack on the film layer and realizing adjustment of the Al component in AlxGa1-xN by controlling the mole ratio of Al / Ga, wherein the number x of Al atoms is not less than 0 and not more than 0.8, and the control method of the Al component is as follows: keeping certain molar weight of the injected Al and reducing the mole ratio of Ga to Al from 5.8 to 0.46. The method has the following advantages: the AlxGa1-xN alloy can be obtained, the number x of Al atoms in the alloy is as high as 0.8, and the Al doping efficiency is improved by 9%; the Al-Ga-N film has excellent quality, the full-width at haft-maximum (FWHM) of the typical X-ray rocking curve of AlxGa1-xN (0002) is less than 300 seconds of arc; the luminescent property is excellent and the cathodoluminescence spectra show remarkably strong band-edge luminescence peaks; and the surface is smooth and flat and the typical roughness (RMS) is less than 0.8nm.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com