Patents

Literature

314 results about "Butter peanut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Peanut butter is served as a spread on bread, toast or crackers, and used to make sandwiches (notably the peanut butter and jelly sandwich).

Oxidative stabilization of omega-3 fatty acids in low linoleic acid-containing peanut butter

ActiveUS20050244564A1Raise the ratioOxidize slowlyFood preparationEdible oils/fats with aqeous phaseTriglyceridePhotodegradation

A food composition in which omega-3 fatty acids are stabilized against oxidation is disclosed. The food composition contains about 4 to about 100 weight percent of the composition in which triglycerides containing omega-3 fatty acids (and other fatty acids) are stabilized against oxidation in the absence of encapsulation. The fatty acid portion of the oil in the completed food composition includes less than about 10 percent by weight linoleic acid, at least 75 percent by weight of monounsaturated plus saturated fatty acids, and at least 3 percent by weight omega-3 fatty acids. The food composition can also contain comminuted peanuts, e.g., peanut butter, in which case the composition is also stabilized against photo-oxidation and the fatty acid portion of the oil portion of the food can contain less than about 15 percent by weight linoleic acid and at least 1 percent by weight omega-3 fatty acids. Methods of protecting a food composition from oxidation and photodegradation are also disclosed.

Owner:BOULDER BRANDS USA

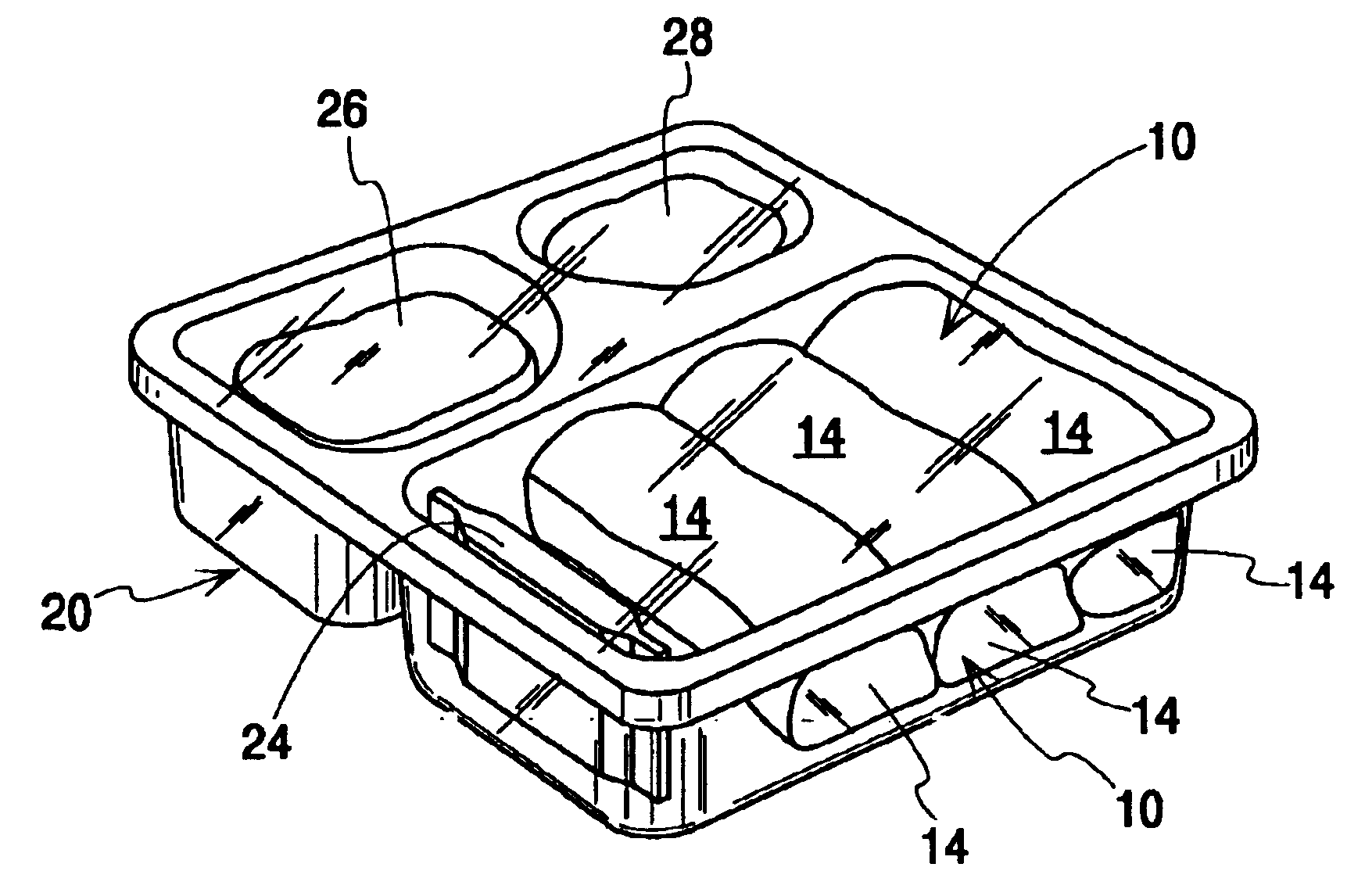

Soft, fully baked breadsticks

InactiveUS6919097B2Satisfactory textureSatisfactory chewability characteristicReady-for-oven doughsDough treatmentReady to eatAdditive ingredient

A fully baked, soft, breadstick product is provided having a water activity in the range of about 0.9 to 0.95. The breadstick product is ideally suited for use in a refrigerated, ready-to-eat kit. The breadstick products are of a convenient size and shape with perforations to allow the breadstick product to be separated into individual breadsticks. The breadstick product is especially adapted as a single serving or snack food product. Also provided is a kit containing the breadstick product with one or more additional food items. Such additional food items include, for example, cheese, cheese products, cheese sauces, tomato sauces, cream cheese, butter, margarine, jam, jelly, honey, peanut butter, olive oil, salad ingredients, salad dressings, and the like. Preferably, each component item is in a separate container sealed from the other food items to substantially retard or prevent flavor, moisture, and microbial migration from one food item to another. The breadstick products retain a soft, desirable texture throughout their anticipated shelf lives.

Owner:KRAFT FOODS INC

Maotai-flavor peanut thick chilli sauce and its preparation method

The invention discloses a peanut butter and its preparing process, wherein the raw materials include (by weight ratio) peanut 45-55 parts, dried soybean paste 15-25 parts, refined pork 30-50 parts, fermented soybean 35-45 parts, dried pepper 10-30 parts, soaked pepper 45-55 parts, chilli-paste with broad bean 45-55 parts, sesame 10-20 parts, catsup 25-35 parts, Chinese prickly ash 3-6 parts, white sugar 15-25 parts, green onion 10-20 parts, fresh ginger 10-20 parts, garlic 10-20 parts, cooking oil 80-120 parts, water or soup 200-300 parts.

Owner:安艳涛

Dried bean curd sandwiched with peanut butter and preparation method thereof

InactiveCN103444882AUnique flavorShorten the soaking timeCocoaCheese manufactureBiotechnologyAdditive ingredient

The invention discloses a dried bean curd sandwiched with peanut butter. The dried bean curd sandwiched with peanut butter is prepared from the following raw materials in parts by weight: 150-160 parts of soybean, 16-18 parts of peanut kernels, 4-5 parts of chocolate powder, 3-4 parts of honey, 3-4 parts of condensed milk, 2-3 parts of rose hip, 4-5 parts of blueberry, 2-3 parts of mulberry, 1-2 parts of pomegranate leaf, 1-2 parts of bay leaf, 1-2 parts of folium apocyni veneti, 2-3 parts of gynostemma pentaphylla, 1-2 parts of cistanche, 1-2 parts of Morinda officinalis, 1-2 parts of four-leaf clover, 1-2 parts of antirrhinum majus and 1-2 parts of salvia. According to the invention, the soybean is puffed firstly, and then is milled to enable the nutritional ingredients to be thoroughly integrated in the soybean milk, and the soaking time is shortened; the traditional Chinese medicines are pulverized and extracted by grape wine, and the traditional Chinese medicine ingredients are extracted completely, and are added in the soybean milk to prepare the dried bean curd with grape wine flavor; the peanut kernels are subjected to special processing and is prepared into peanut butter, and the peanut butter is sandwiched between the two dried bean curds to prepare the dried bean curd sandwiched with peanut butter, which is sweet and delicious and has special flavor.

Owner:JINCAIDI FOOD CO LTD

Beef peanut butter

InactiveCN103494173AThe production process is simple and environmentally friendlyHas the effect of nourishing the stomachFood ingredient functionsFood preparationIllicium verumFood material

The invention provides a beef peanut butter, comprising the following raw materials by weight: 100 to 110 parts of thick broad-bean sauce, 120 to 130 parts of beef, 80 to 100 parts of peanut, 70 to 80 parts of walnut, 40 to 50 parts of fermented soya bean, 4 to 5 parts of immature orange fruit, 5 to 6 parts of tulip, 5 to 6 parts of flos mume, 6 to 7 parts of spine date seed, 5 to 6 parts of rose, 4 to 5 parts of corn leaf, 4 to 5 parts of clover, 15 to 30 parts of star aniseed, 15 to 25 parts of cassia bark, 180 to 200 parts of honey, 30 to 40 parts of minced ginger, 10 to 50 parts of salt, 15 to 35 parts of soy, 10 to 35 parts of black vinegar, 15 to 25 parts of chilli powder, 30 to 40 parts of powdered pepper, 80 to 100 parts of sesame oil and a proper amount of water. According to the invention, a preparation process for the beef peanut butter is simple and environment-friendly; food materials rich in nutrients, e.g., walnut and fermented soya bean, are added; in particular, extracts of medicinal traditional Chinese medicinal materials like immature orange fruit and spine date seed with digestion helping and stomach strengthening effects are especially added in the process of preparation of the beef peanut butter, so the beef peanut butter has a certain stomach nourishing effect and is health care food beneficial for the stomach of people.

Owner:HEFEI FULAIDUO FOOD

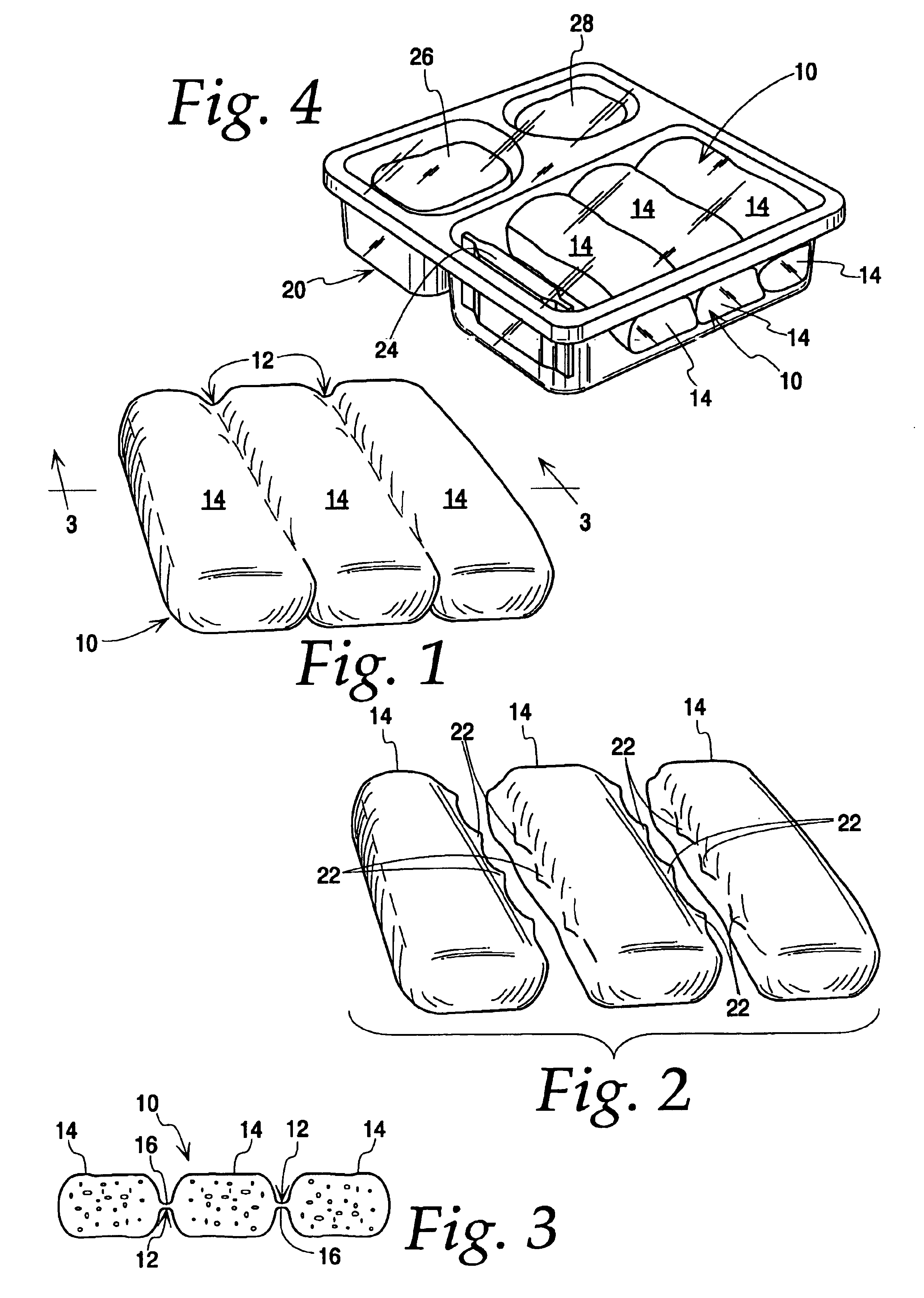

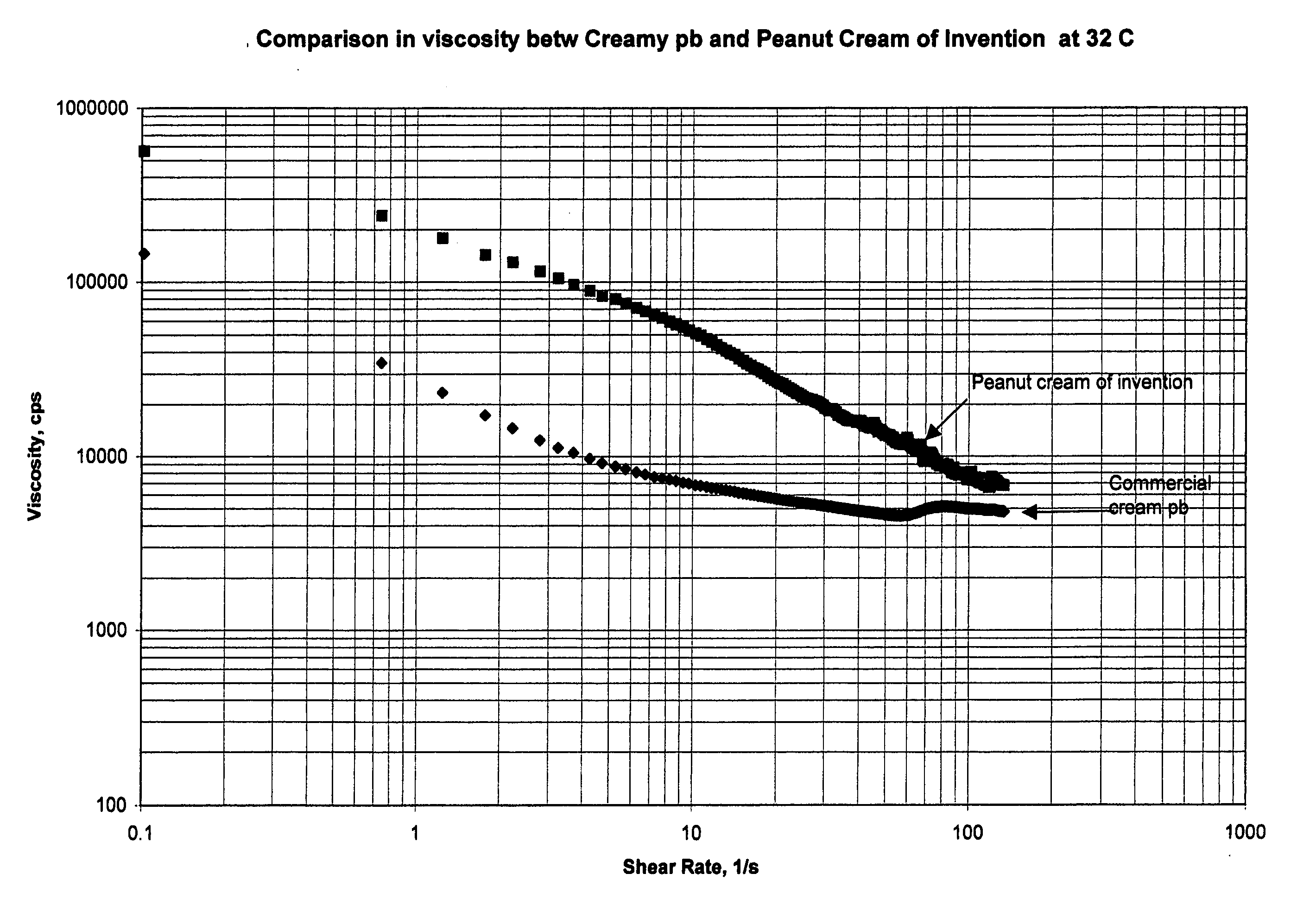

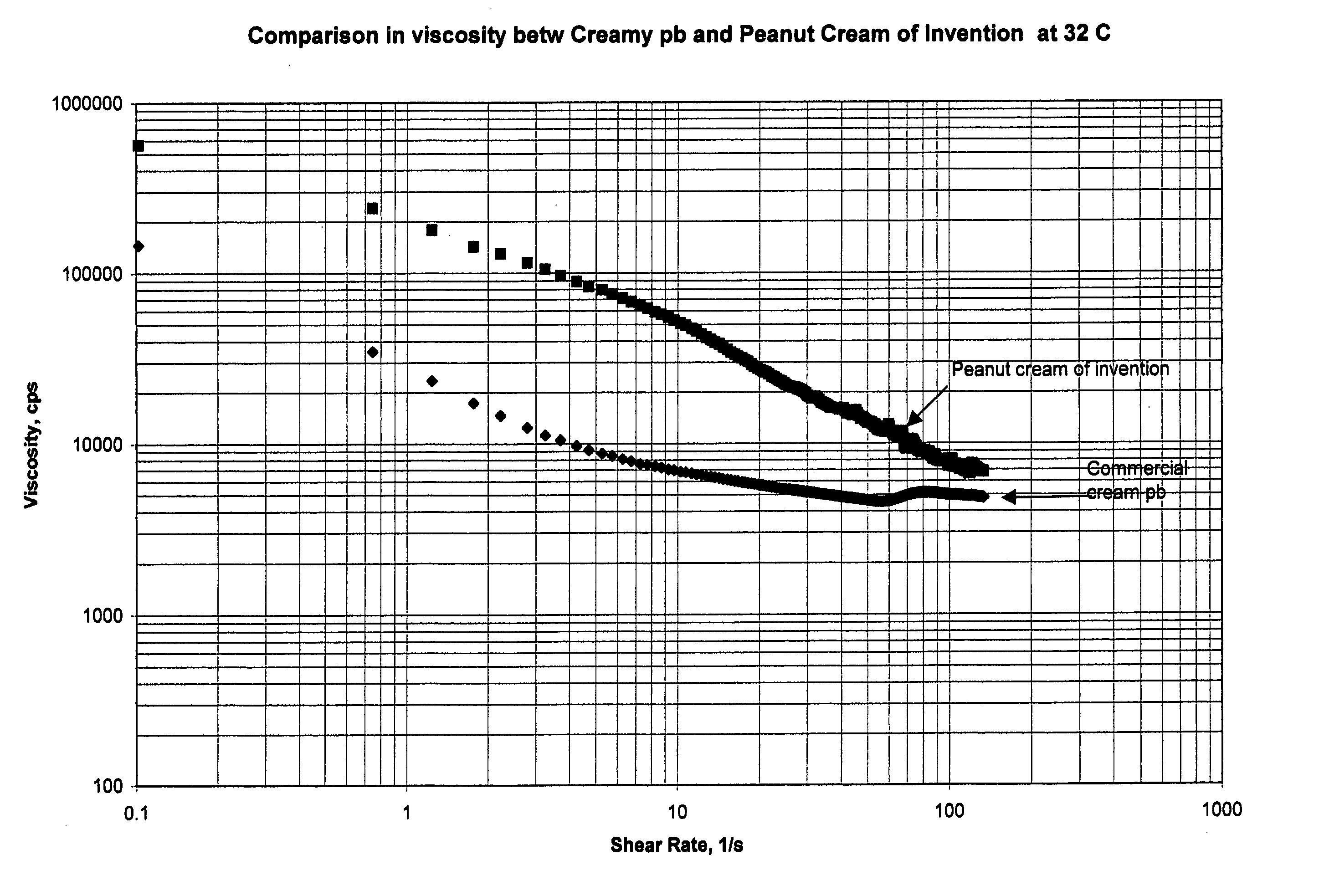

Nut creme

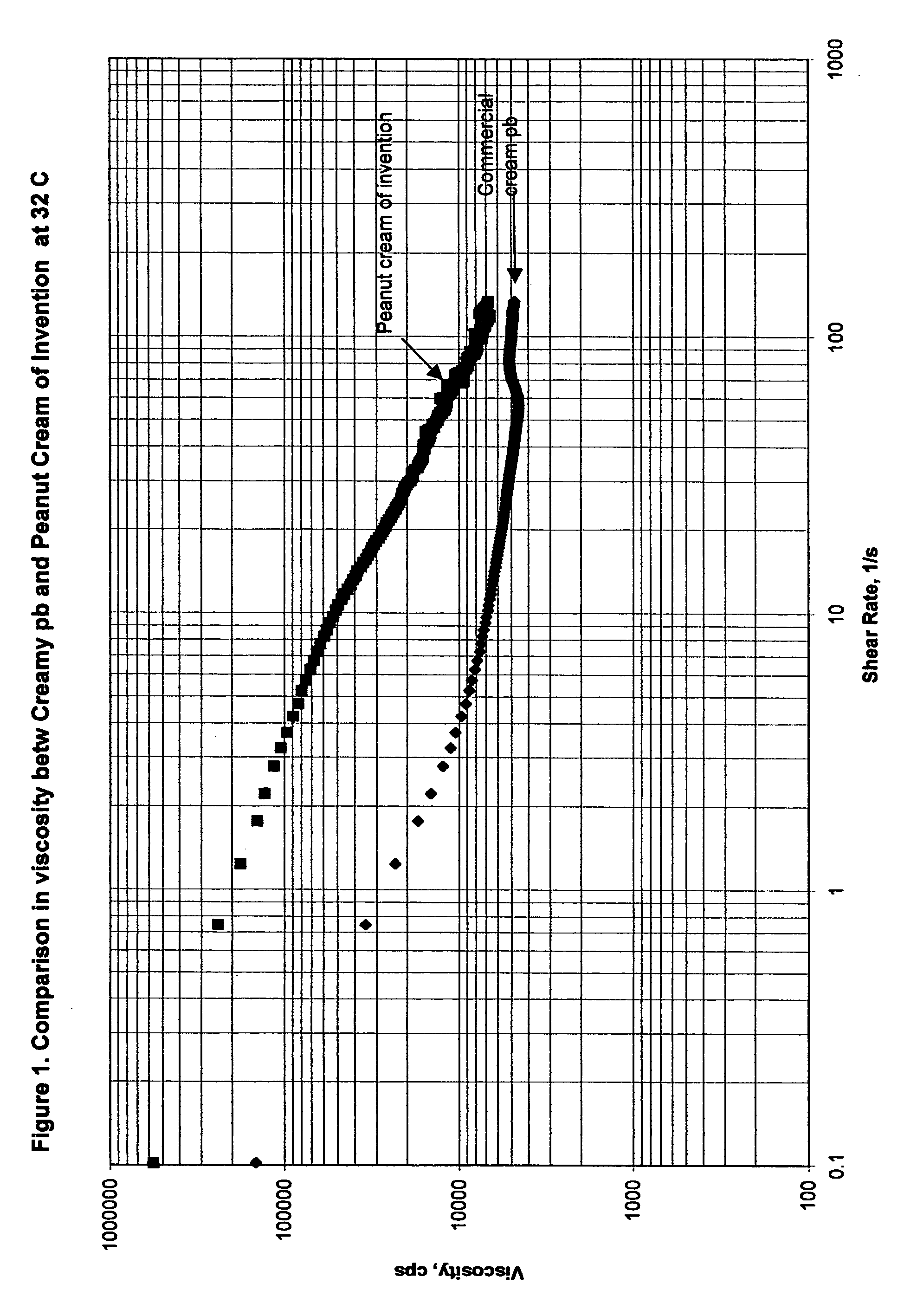

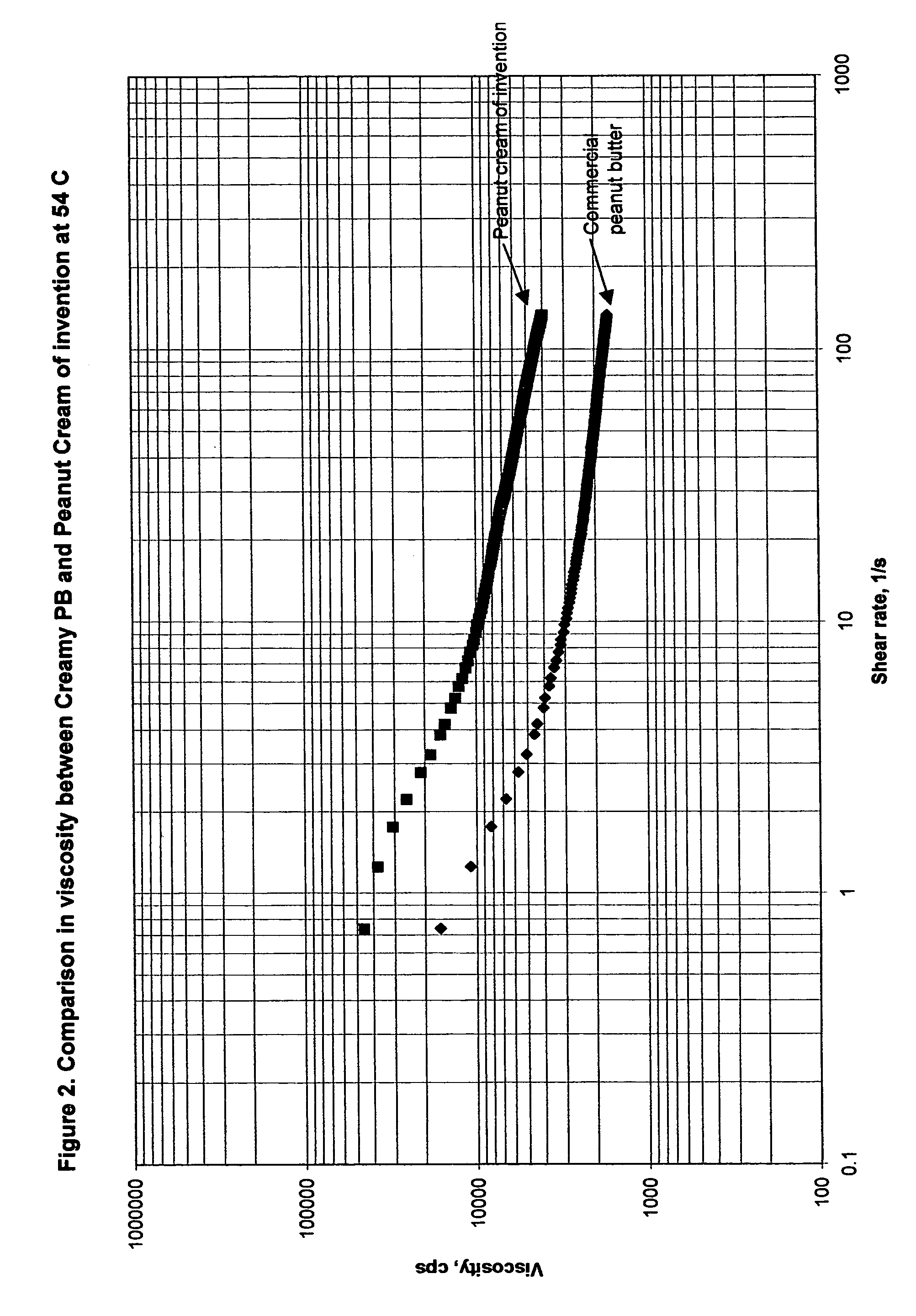

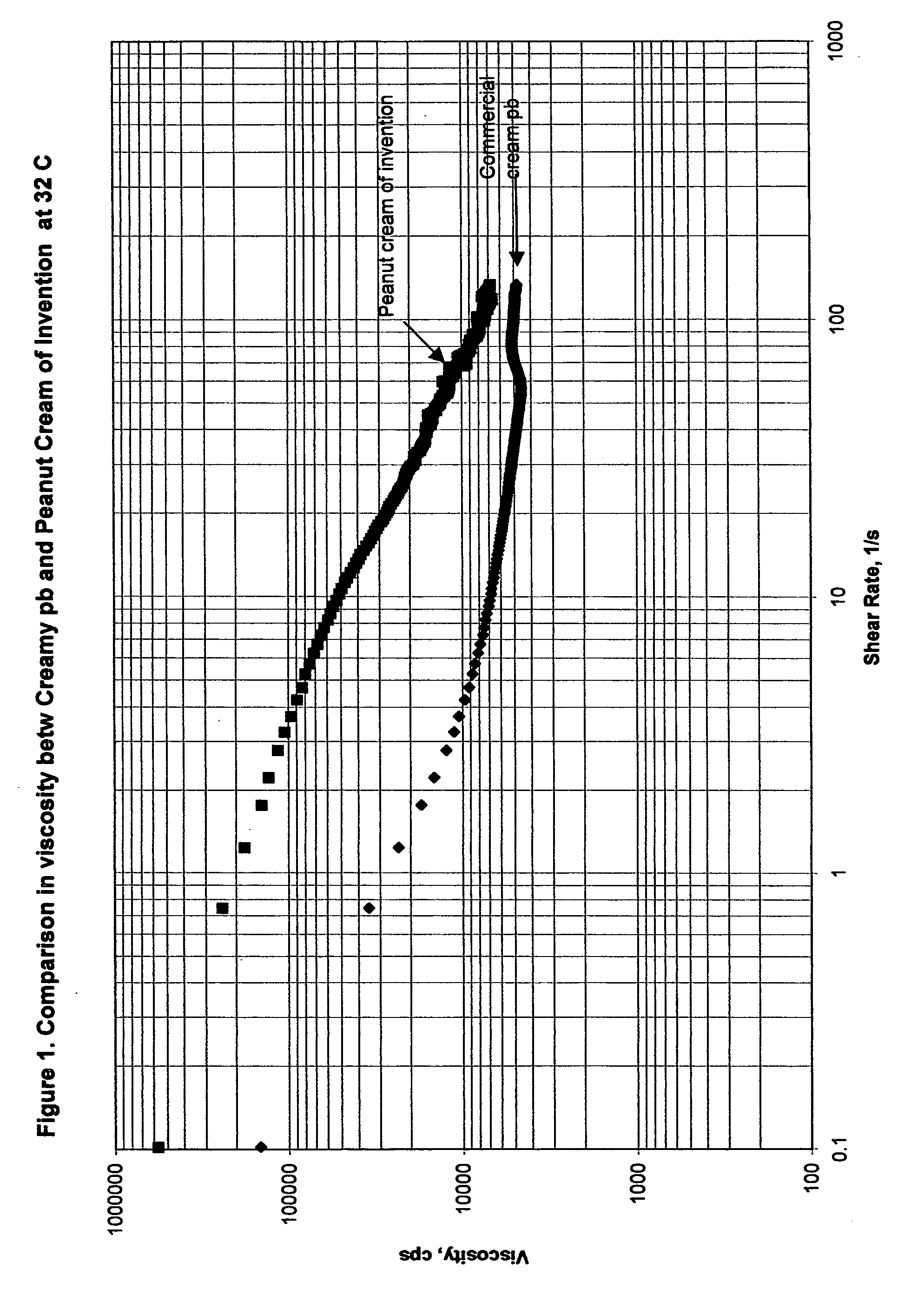

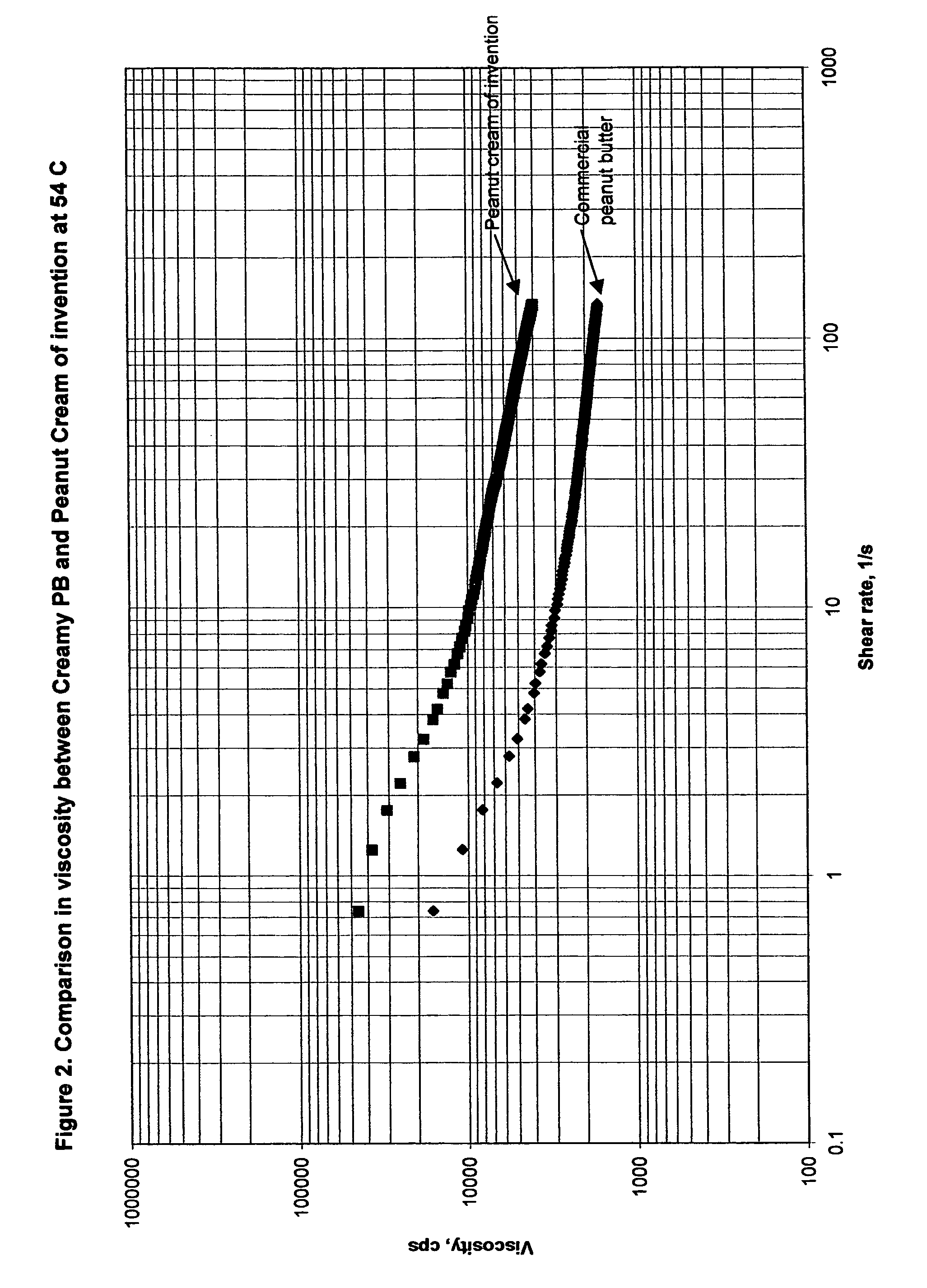

InactiveUS20060045938A1Easy to processDesirable creamy textureConfectionerySweetmeatsMolten stateOrganoleptic

A peanut crème which can be used to produce a snack or other food bar which includes at least two filling layers directly adjacent each other. When a layer of the peanut creme of the invention is deposited, it sets up quickly permitting the deposit of an additional layer thereon without impairing the texture of either layer. The result is a bar having a texture similar to that of peanut butter, in contrast to most previous bars which have lacked the organoleptic impact of peanut butter. The peanut creme is readily processable and physically stable. While the peanut creme layer sets up firmly when deposited in the molten state, it yields a desirable creamy texture in the final product.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

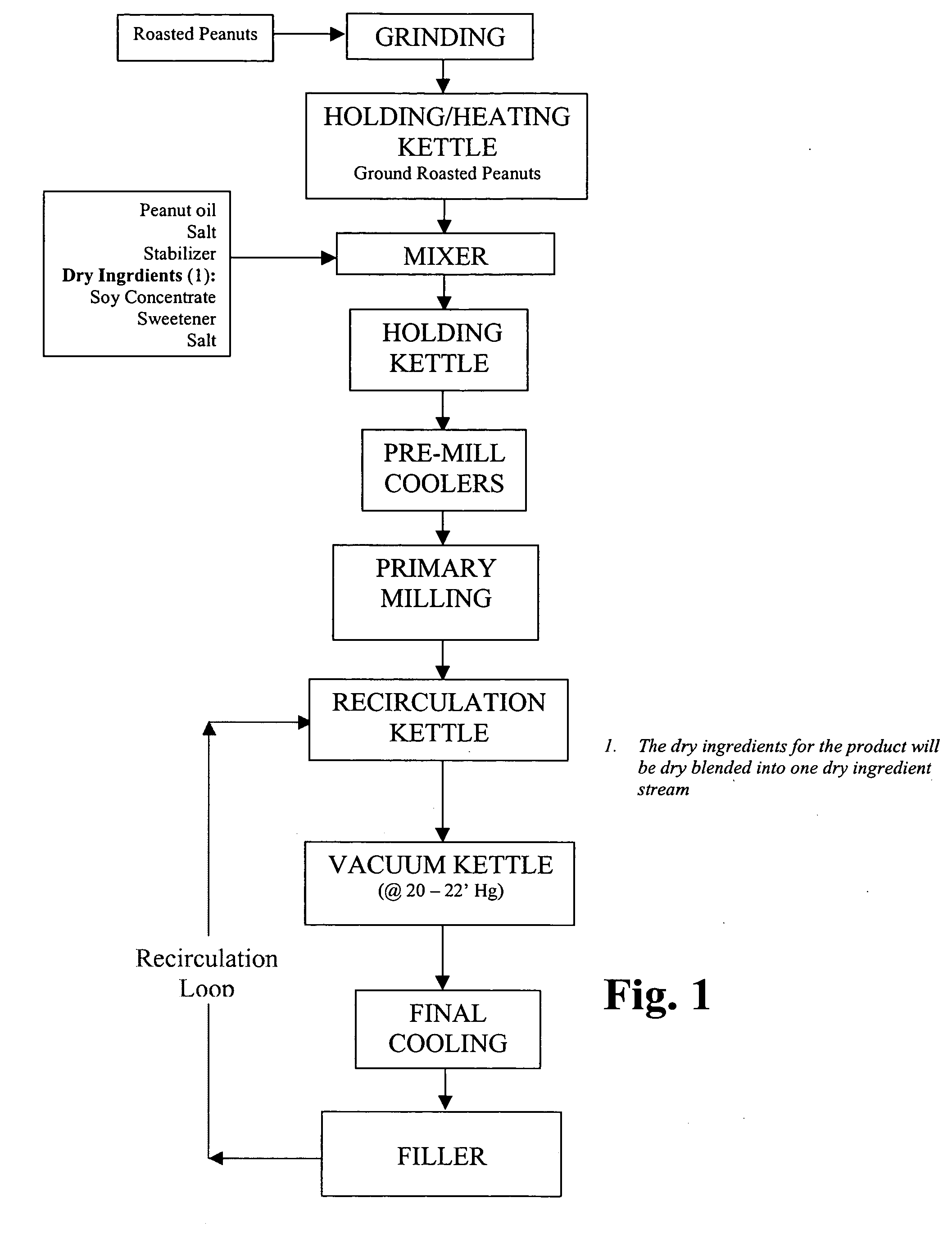

All natural omega enriched peanut butter

A peanut butter and / or peanut butter spread is disclosed which contains essentially all natural ingredients. The peanut butter and / or peanut butter spread includes peanut particles, peanut oil and a natural stabilizer. Preferred ingredients are described for making the natural stabilizer, and in one embodiment of the invention, the natural stabilizer comprises the Smart Balance product manufactured by GFA.Brands.

Owner:AYOUB VICTOR R

Hot pot flavoring capable of clearing fever and preparation method thereof

The invention discloses a hot pot flavoring capable of clearing fever, which comprises seasoning sauce and soup stock, wherein the soup stock comprises normal bone soup and chicken juice; the ratio of the seasoning sauce to the soup stock is 1: (8-10). The seasoning sauce is characterized by being prepared from the following components in percentage by weight: 10-15% of pepper, 15-18% of aniseed, 3-5% of netmeg, 3-8% of mulberry leaf, 5-8% of Foeniculum vulgare, 5-6% of chicken meal, 2-4% of lily, 2-4% of ginger powder, 0.5-1% of table salt, 2-3% of cinnamon, 2-4% of mother chrysanthemum, 2-4% of orange peel, 2-4% of radix ophiopogonis, 0.3-0.5% of white granulated sugar, 2-3% of sesame sauce, 2-5% of peanut butter, 2-3% of fish oil and the balance of edible essences. The hot pot flavoring has abundant nutritions and fresh and delicious taste and has the efficacies on appetizing, expelling cold and enhancing appetite after certain food materials capable of clearing the fever are added.

Owner:王爽

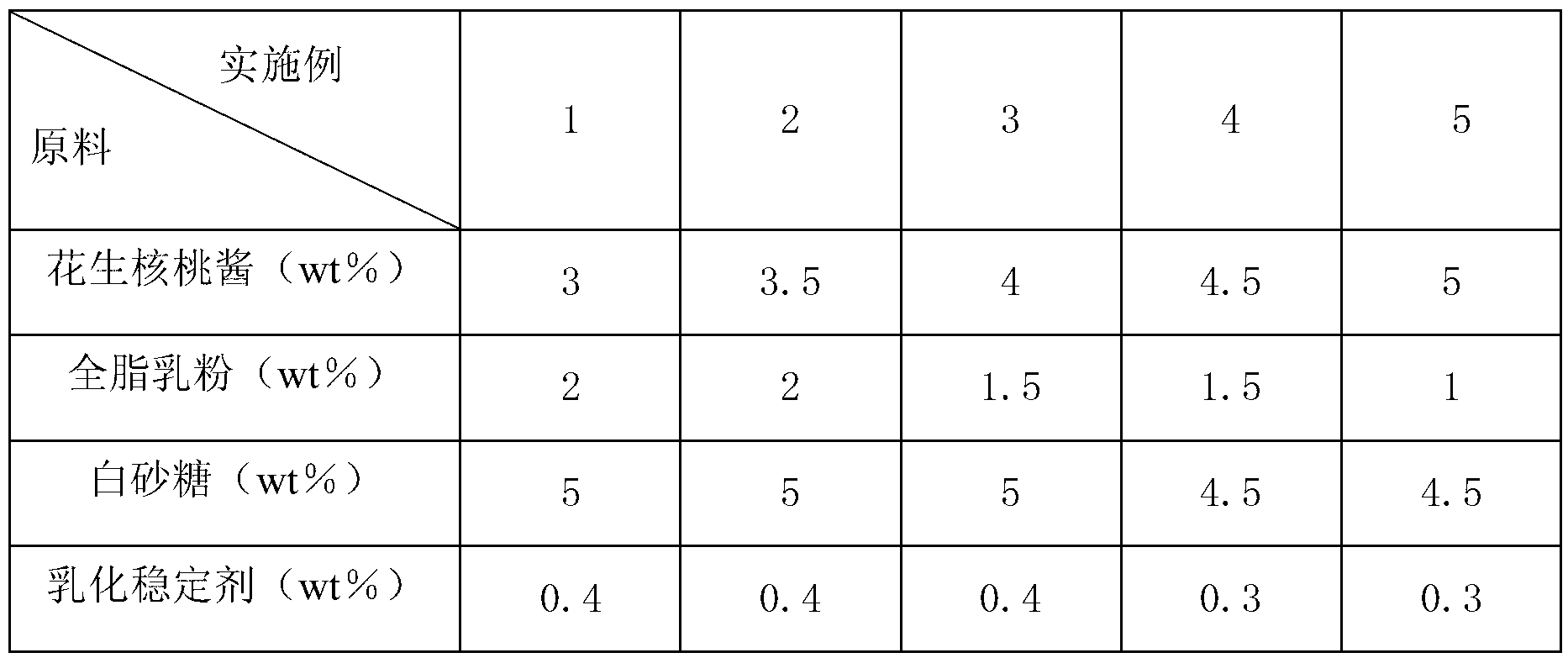

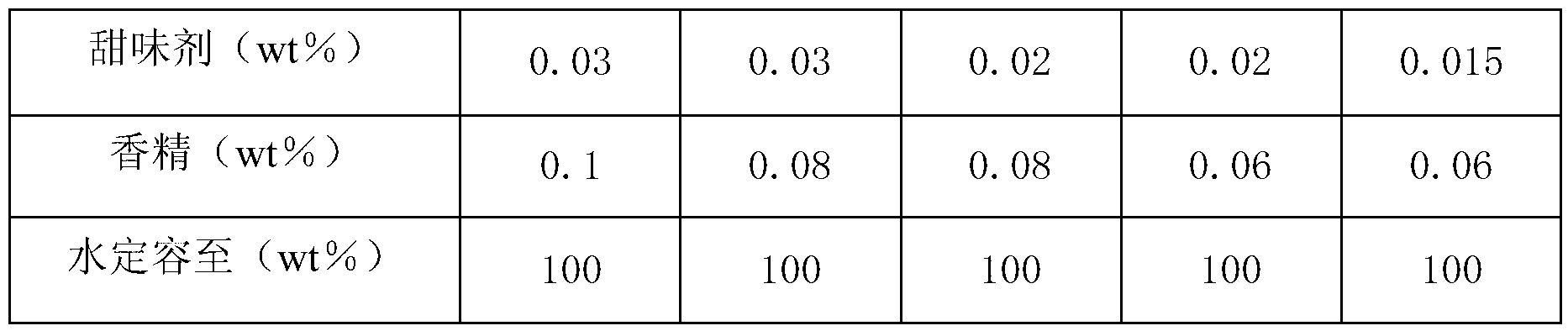

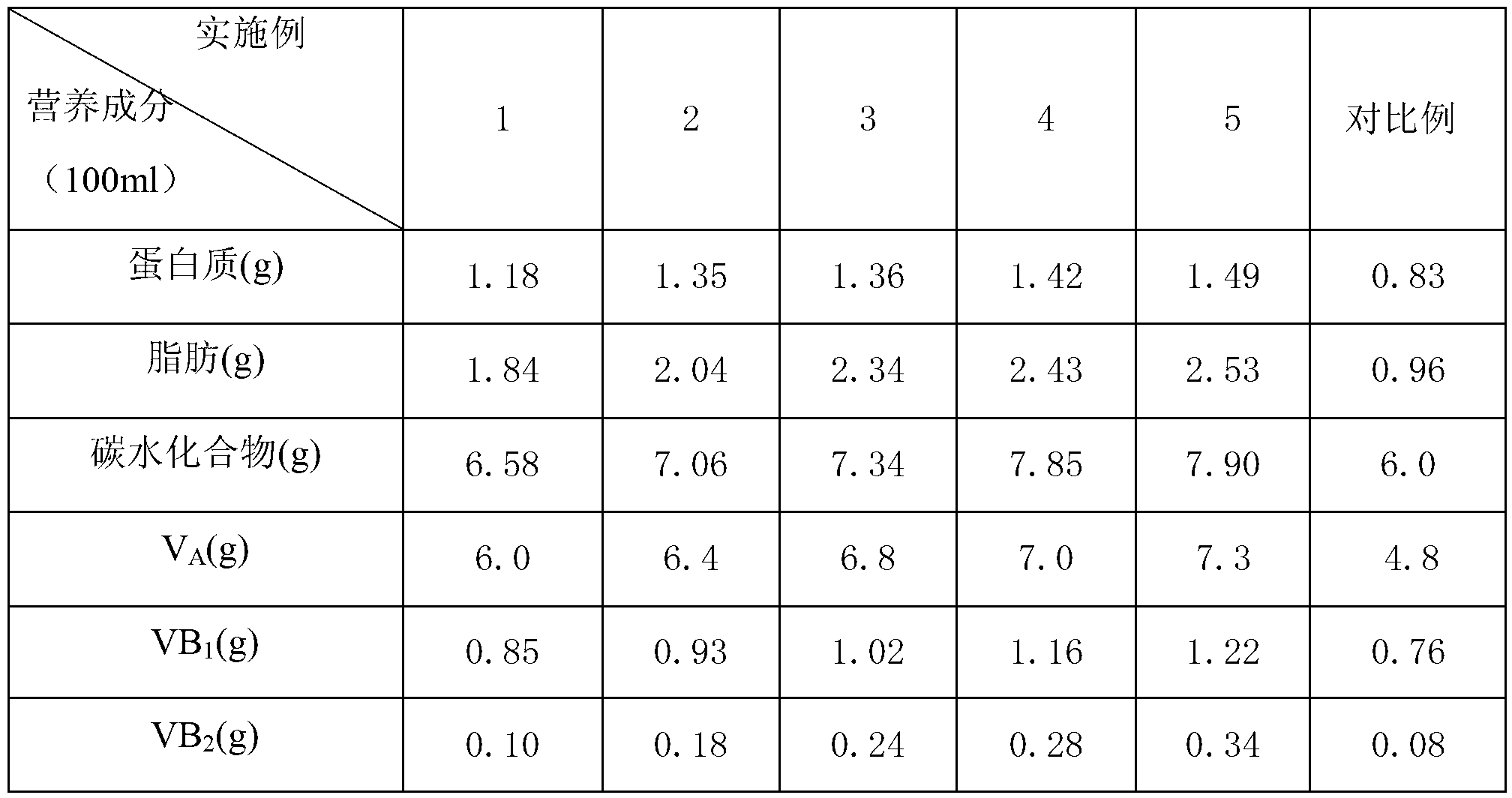

Compound protein milk beverage and preparation method thereof

The invention discloses a milk beverage and a preparation method thereof, and particularly relates to a compound protein milk beverage and a preparation method thereof. The compound protein milk beverage disclosed by the invention is prepared from the following raw materials in percentage by mass: 3-6% of a walnut-peanut butter, 0.5-2% of whole milk powder, 3-6% of white granulated sugar, 0.2-1% of emulsion stabilizer, 0.01-0.06% of sweetening agent, 0.02-0.1% of essence, and the balance of water. The preparation method comprises the following steps of: roasting, grinding, proportioning, homogenizing and sterilizing. The compound protein milk beverage disclosed by the invention combines the animal proteins of milk and the vegetable proteins of peanuts and walnuts, and retains the nutrient substances such as protein, fat, vitamins, trace elements and the like, thereby achieving an effect of nutrition complementation and improving the taste. According to the preparation method, the utilization rate of peanuts and walnuts is improved, the waste and the pollution are reduced, and the full-bodied flavors of walnuts and peanuts are kept to the maximum; and the energy consumption in the production process can be reduced to the maximum, the production time is shortened, and the stability of product quality is improved.

Owner:NEW HOPE DAIRY HLDG

Oxidative stabilization of omega-3 fatty acids in low linoleic acid-containing peanut butter

ActiveUS7344747B2Raise the ratioOxidize slowlyFood preparationEdible oils/fats with aqeous phaseTriglycerideFood composition data

A food composition in which omega-3 fatty acids are stabilized against oxidation is disclosed. The food composition contains about 4 to about 100 weight percent of the composition in which triglycerides containing omega-3 fatty acids (and other fatty acids) are stabilized against oxidation in the absence of encapsulation. The fatty acid portion of the oil in the completed food composition includes less than about 10 percent by weight linoleic acid, at least 75 percent by weight of monounsaturated plus saturated fatty acids, and at least 3 percent by weight omega-3 fatty acids. The food composition can also contain comminuted peanuts, e.g., peanut butter, in which case the composition is also stabilized against photo-oxidation and the fatty acid portion of the oil portion of the food can contain less than about 15 percent by weight linoleic acid and at least 1 percent by weight omega-3 fatty acids. Methods of protecting a food composition from oxidation and photodegradation are also disclosed.

Owner:BOULDER BRANDS USA

Pork peanut butter with traditional Chinese medicine components

InactiveCN103355709AUnique flavorHas the health effect of clearing away heat and cooling bloodFood preparationBiotechnologyNutritive values

The invention discloses a pork peanut butter with traditional Chinese medicine components. The peanut butter is prepared by mixing and stirring the pork, a butter component and the traditional Chinese medicine components at a normal temperature. Although a plurality of traditional Chinese medicine components capable of clearing heat, cooling blood and removing toxicity are mixed and stirred and then added in the peanut butter group, the original flavor of the peanut butter not changed, and the compounded peanut butter has the health-care effects of clearing heat and cooling the blood, and has high nutritional value, unique flavor and delicate taste. The preparation process is simple and convenient, and is low in preparation cost and suitable for large-scale production.

Owner:XUZHOU HUAHONG FOOD

Nut butter compositions and methods related thereto

ActiveUS20080081092A1Superior “ oiling out ” resistanceProvide flexibilityDough treatmentConfectioneryAlcohol sugarsTriglyceride

In general terms, this invention provides nut butter compositions and methods for preparing the disclosed nut butter compositions. In preferred embodiments, the nut butter composition or method is a peanut butter. In another preferred embodiment, the present invention provides a method of preparing a gelled peanut butter composition comprising the steps of: blending peanut butter, emulsifier, sugar alcohol and triglyceride-based stabilizer so as to create a first blend; blending starch with the first blend to create a second blend; resting the second blend until a gel is formed, wherein the peanut butter is not more than 85 ° F. and 65-85%, the emulsifier is 0.15-0.5%, the sugar alcohol is 5-30%, the triglyceride-based stabilizer is 1-5%, and the starch is 1-5%.

Owner:KELLOGG CO

Ready-to-eat shrimp sauce and preparation method thereof

ActiveCN104055059AChange High Salt TasteModerately viscousFood ingredient as antioxidantFood ingredient as thickening agentBiotechnologyMicrobiology

The invention discloses a ready-to-eat shrimp sauce which is prepared from following components including, by mass, 10-20% of fermented soya bean sauce, 5-10% of peanut sauce, 5-10% of cooking wine, 3-5% of salad oil, 1-3% of salt, 5-10 of sugar, 0.5-1% of pepper powder, 1-3% of chilli powder, 1-3% of chicken essence powder, 3-5% of juice of green Chinese onion and ginger, 3-5% of a composite stabilizing agent and the balance shrimp paste. The shrimp sauce is oil-glossy and bright in color, is moderate in thickness, is fine and uniform in shape and form, is free of a layering phenomenon, is low in salinity and is good in color, mouthfeel and flavor. The invention also provides a preparation method of the ready-to-eat shrimp sauce. The preparation method includes following steps: (1) preparing the shrimp paste; (2) preparing a flavoring liquid; and (3) carrying out a flavoring and boiling process. The preparation method is simple in processing steps, is short in preparing period, is low in cost and is suitable for a large-scale industrial production. The shrimp sauce is not liable to be polluted during the preparation method and the preparation method is high in safety.

Owner:ZHEJIANG MARINE DEV RES INST

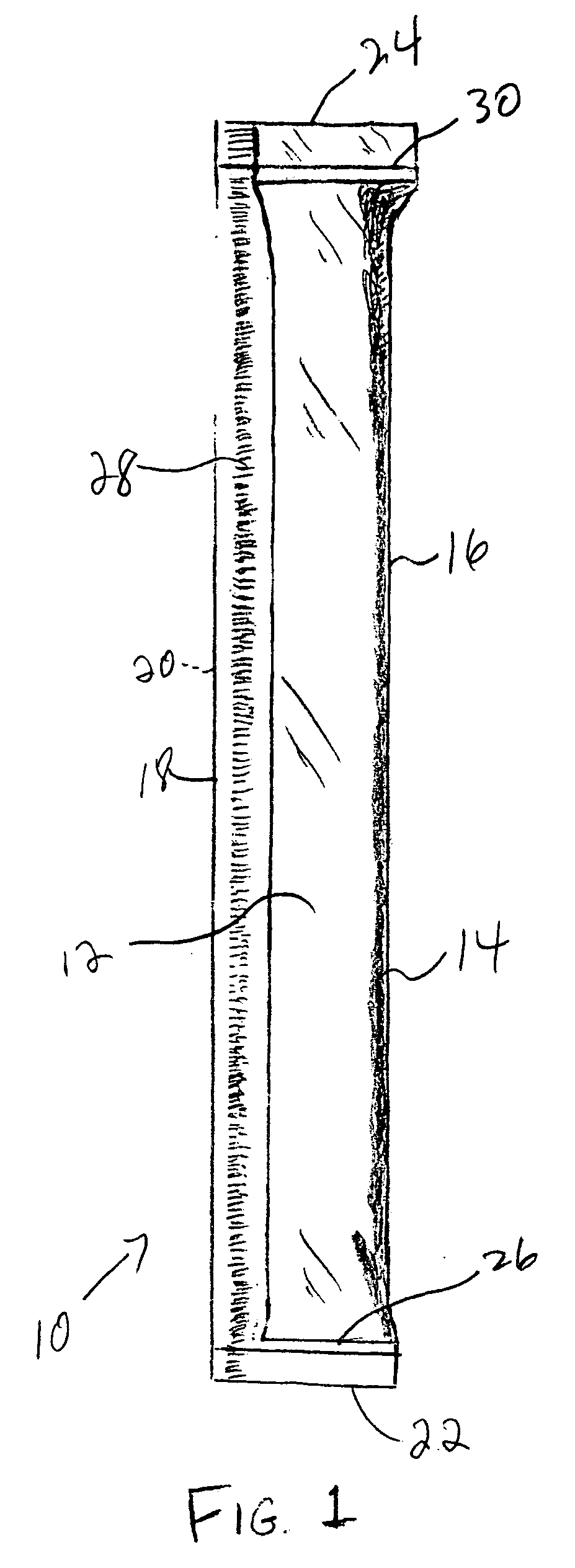

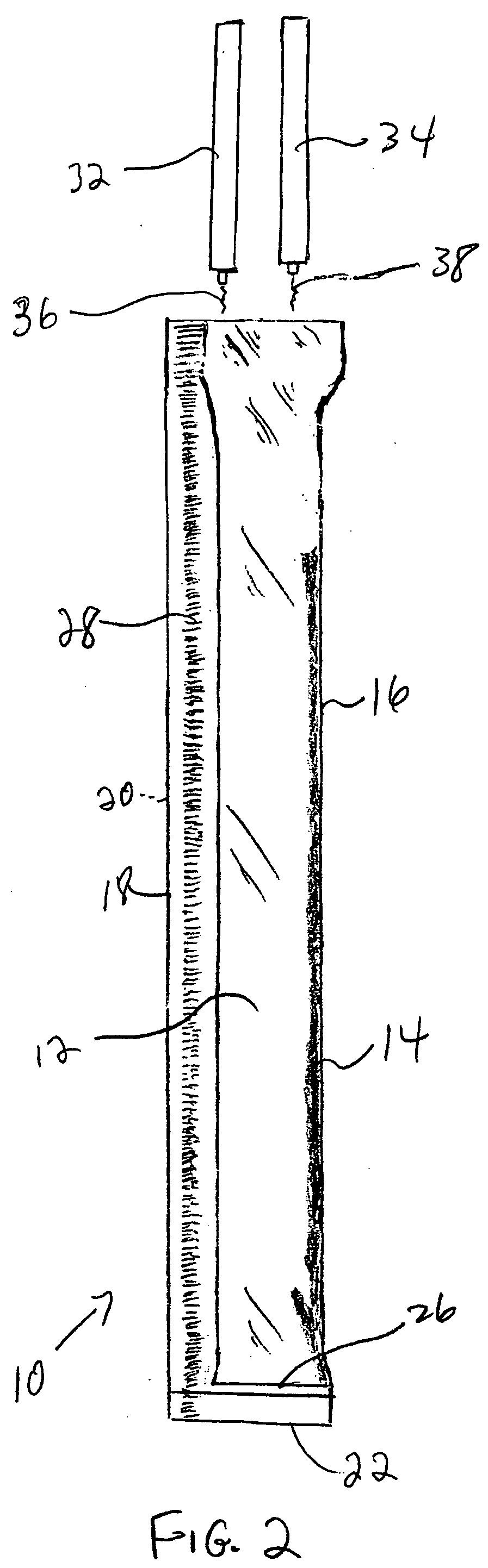

Food bar

InactiveUS20060045937A1Impairing textureEasy to processConfectionerySweetmeatsMolten stateEngineering

A snack or other food bar which includes at least two filling layers directly adjacent each other. Preferably one or more of the filling layers comprise a peanut creme specially adapted to the invention. When a layer of the peanut creme of the invention is deposited, it sets up quickly permitting the deposit of an additional layer thereon without impairing the texture of either layer. The result is a bar having a texture similar to that of peanut butter, in contrast to most previous bars which have lacked the organoleptic impact of peanut butter. The peanut creme is readily processable and physically stable. While the peanut creme layer sets up firmly when deposited in the molten state, it yields a desirable creamy texture in the final product

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

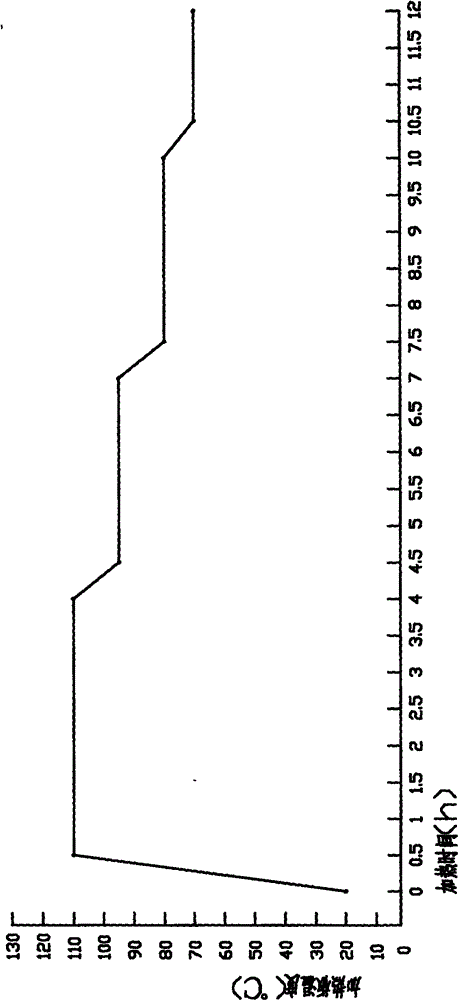

Production technology of peanut butter

The invention discloses a production technology of a peanut butter, which belongs to the field of food processing. The production technology comprises the following steps of: baking: baking and heating peanuts to 160 DEG C, maintaining for 45-55 minutes till the inner color and outer color of peanut kernels are consistent, and selecting the peanuts without burnt taste for standby; removing peels and screening: timely discharging the baked peanut kernels, spreading for cooling or blowing cold wind for cooling, and cooling the peanut kernels and removing the peels by using a peeling machine and screening to separate seed leaves and embryos; milling to obtain the butter: putting the separated seed leaves in a grinding machine for milling to obtain the butter; canning and sterilizing: filling cans with the peanut butter, carrying out microwave sterilization on the peanut butter in the cans, and simultaneously cooling the tans by flowing water till the water level is in the range of one half to three quarters of the cans, wherein the whole process lasts for 10 minutes; and freezing: to standing the cans at the condition of -3 DEG C to -1 DEG C, and storing after completing whole crystallization. The production technology has the beneficial effects of being safe and sanitary, good in sterilization effect and simultaneously being capable of maintaining the original taste of the peanut butter.

Owner:徐州市子房商业公司

Peanut Spread

InactiveUS20130078359A1Improve stabilityPreventing oil separationCocoaFood preparationButter cocoaFatty acid

Nut spreads having a stabilizer which is a blend of certain palm oil fraction stabilizers with certain cocoa butters and / or cocoa butter equivalents and / or replacers and / or substitutes and / or extenders (with similar fatty acid profile to cocoa butter). When these fats are used in combination, particularly at ratios preferred herein, they impart a smooth creamy texture to the final nut butter or nut butter based products and more importantly provide enhanced stability during storage, preventing oil separation in the final product during prolonged storage. The texture and spreadability of the final nut spread based product achieved by using this blend is also superior to the texture and spreadability obtained by using conventional palm oil alone. Preferably the cocoa butters, -equivalents, replacers and substitutes are not hydrogenated.

Owner:HORMEL FOODS

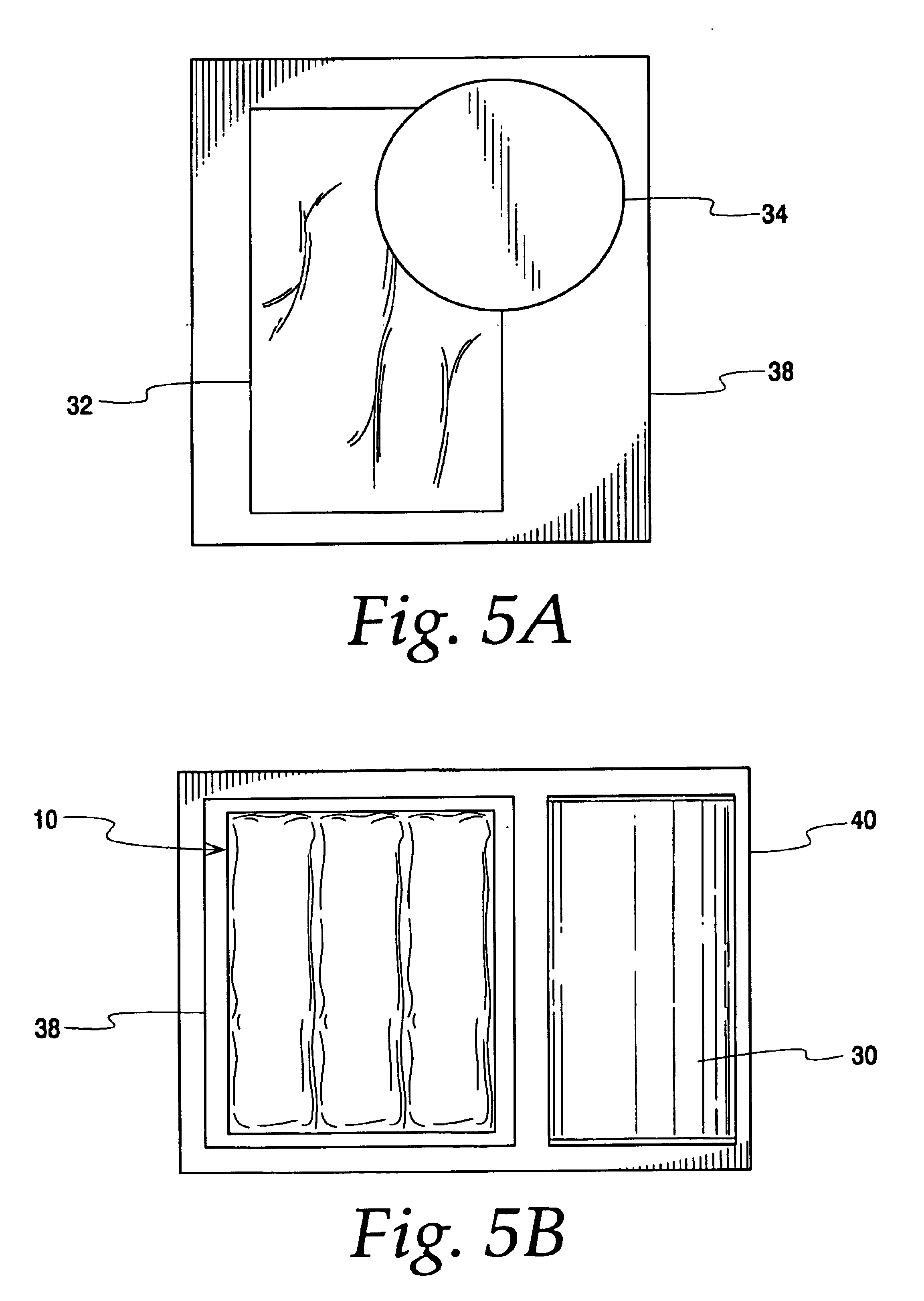

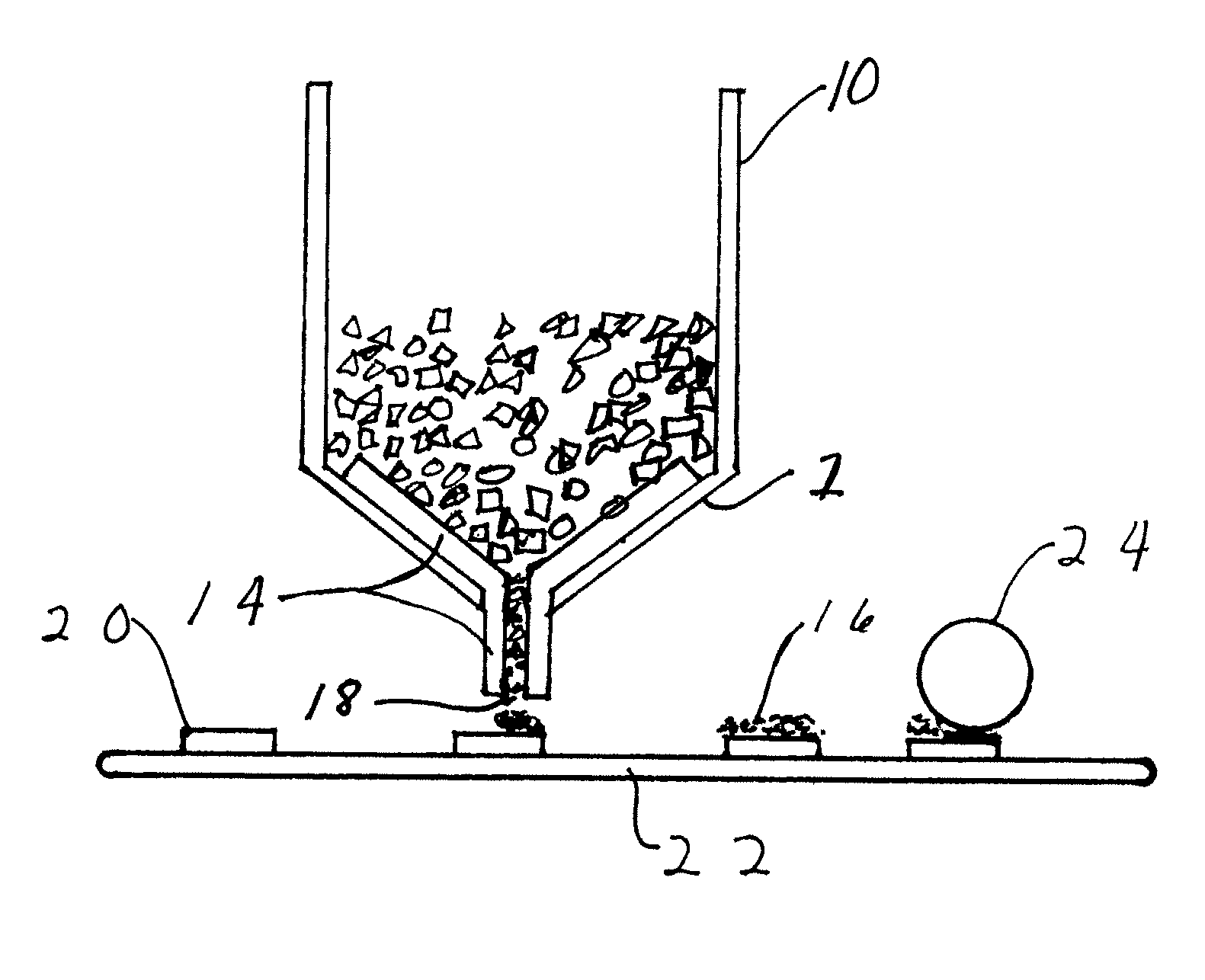

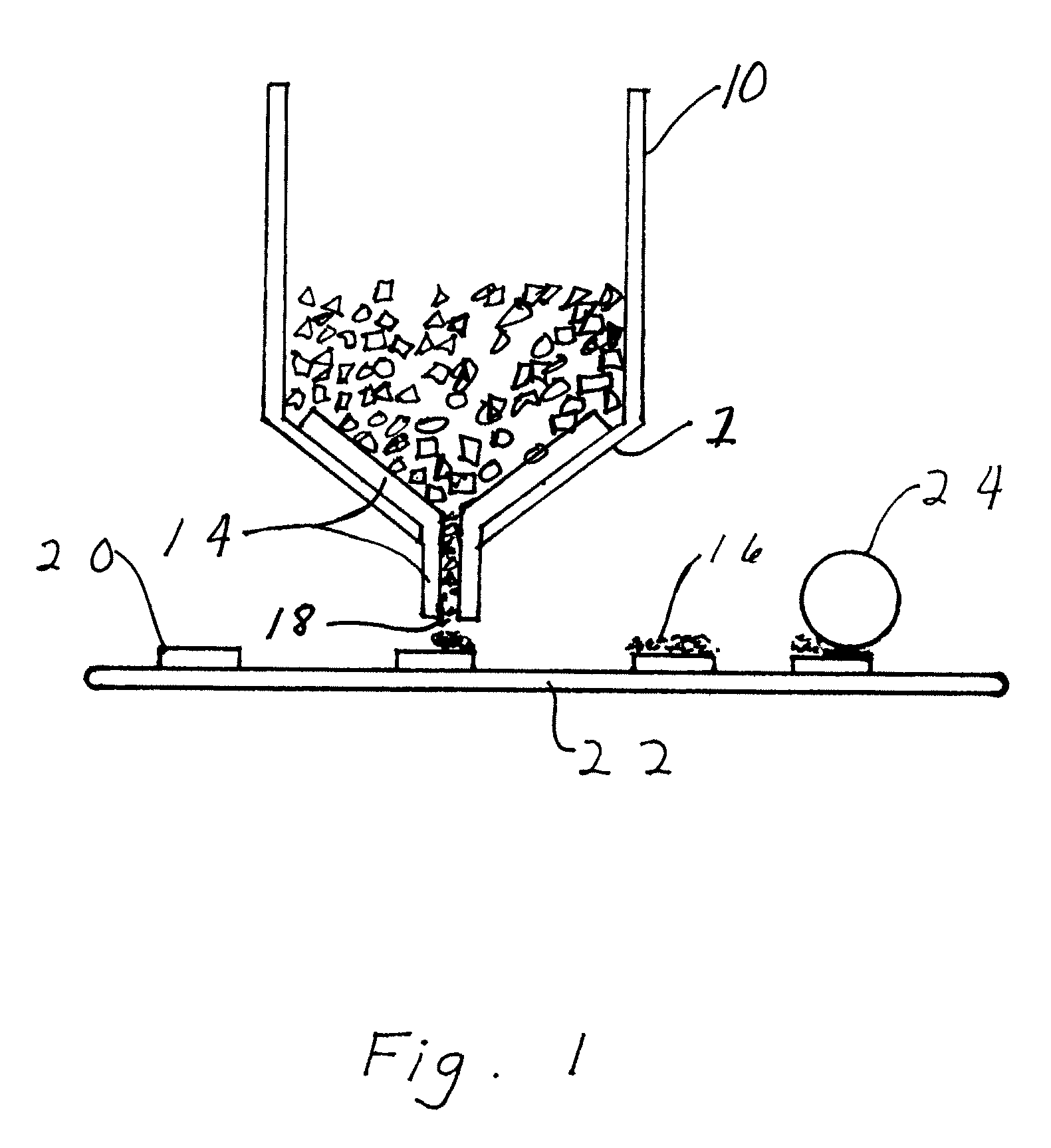

Nut butter variegate and process for preparing

InactiveUS20060093727A1Convenient to enjoyFacilitate their formulationReady-for-oven doughsFood preservationHuskEngineering

In a first embodiment, the invention is directed to a process for making a variegated nut spread comprising (a) forming an enclosure from a film, b) pumping a nut spread into the enclosure; and (c) before, during, or after step (b), pumping in a separate stream of an inclusion to form a variegated nut spread; and (d) sealing the enclosure to form a container without homogenizing the nut spread and inclusions. The inclusion is generally another food component which is desirably eaten with peanut butter, such as fruit filling variegate, banana, marshmallow filling, chocolate, bacon bits, etc. The invention is also directed to a nut spread, comprising discrete inclusions selected from the group consisting of chocolate syrup, fruit and mixtures thereof. The inclusions in the nut butter of the inventions are discrete so that consumers can experience simultaneously organoleptic properties both of the inclusions and the nut butter.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

Hot spicy sauce and preparation method thereof

The invention relates to hot spicy sauce and a preparation method thereof. A formula comprises the materials by the weight part: 5 to 15 of soybean sauce, 0.25 to 0.75 of mashed garlic, 0.4 to 1.2 of round onion, 0.5 to 1.5 of scallion, 0.5 to 1.5 of beef, 0.5 to 1.5 of shrimp meat, 0.5 to 1.5 of peanut chip, 0.4 to 1.2 of sesame chip, 0.3 to 0.9 of peanut butter, 0.3 to 0.9 of sesame butter, 1 to 3 of hot pepper, 0.3 to 0.9 of thin soy sauce, 0. 05 to 0.1 of yellow rice wine, 0.2 to 0.4 of gourmet powder and 0.2 to 0.4 of white sugar. The method adopts the new formula and the reasonable processing technology, the prepared hot spicy sauce has proper sharp taste, and the delicate flavor of the hot spicy sauce is increased to satisfy popular taste.

Owner:荆先东

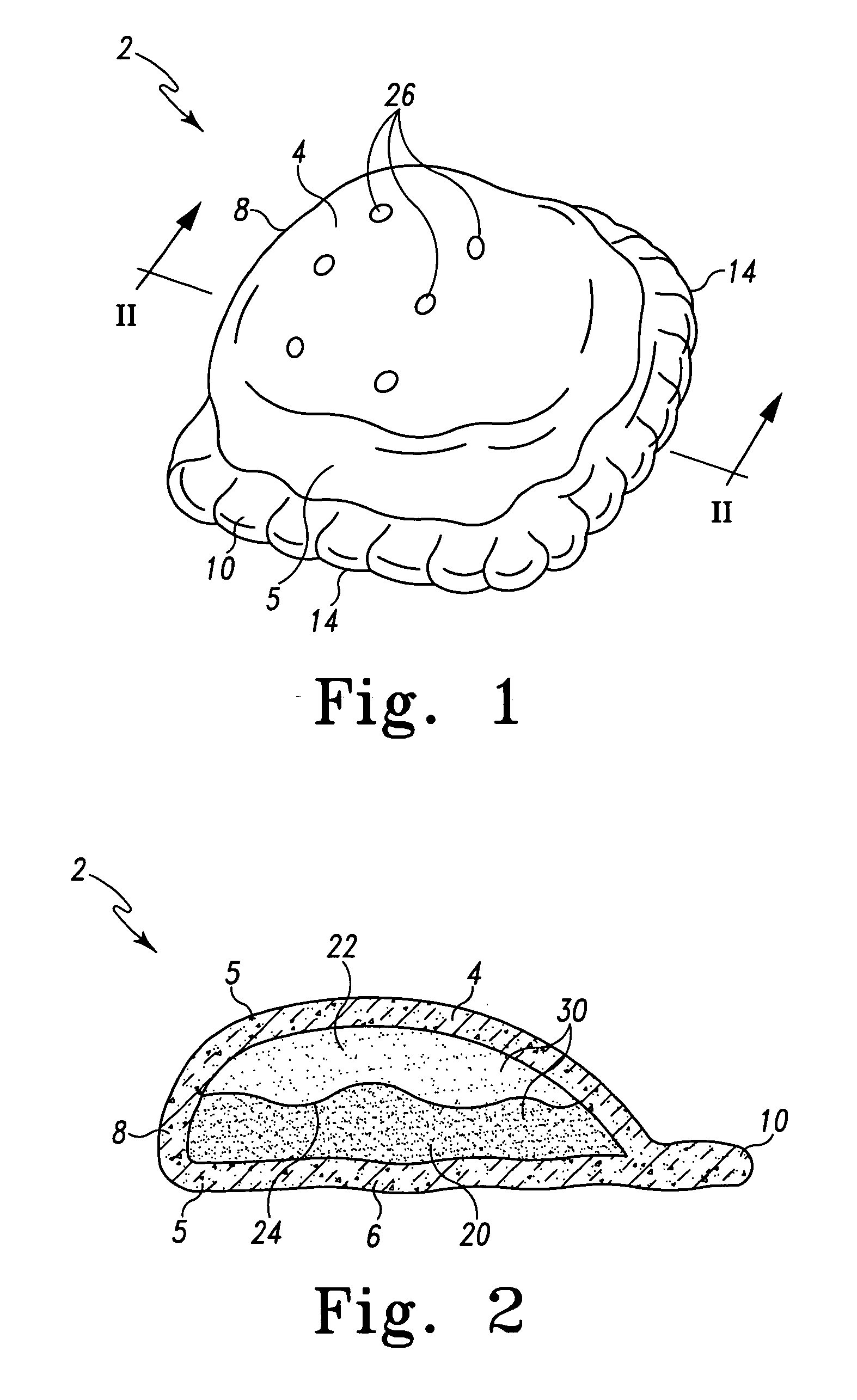

Peanut butter pastry product

InactiveUS20050175740A1Avoid surface crackingLess fillingConfectionerySweetmeatsEngineeringButter peanut

Methods and compositions are provided for a nut butter-filled pastry comprising a pastry exterior, and a filling substantially enclosed in the pastry exterior, the filling comprising a nut butter. In illustrative embodiments, the nut butter is peanut butter.

Owner:MCWATTERS SUSAN KAY HALL +4

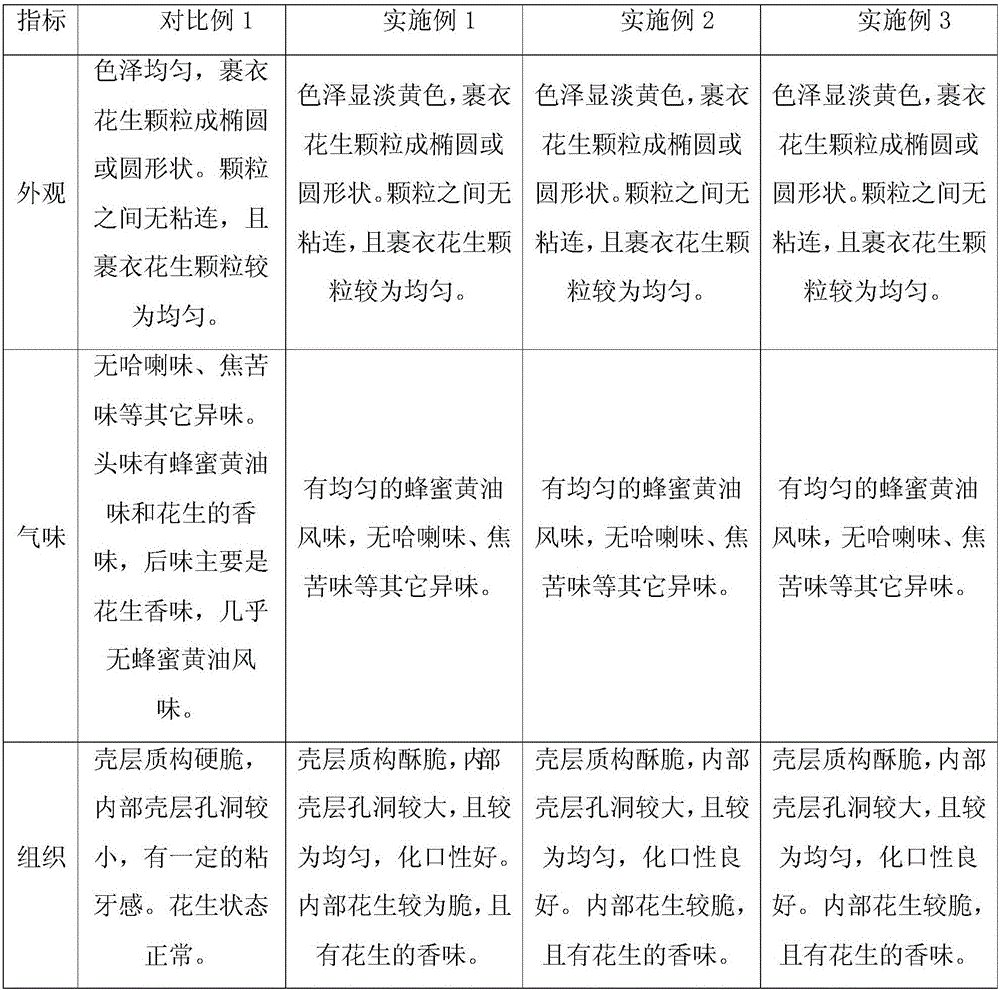

Coating formula, honey and butter coating peanuts and peanut preparation method

InactiveCN106578285AImprove crispnessControl stickinessConfectionerySweetmeatsFood flavorProduct processing

The invention discloses a coating formula, honey and butter coating peanuts and a peanut preparation method, and belongs to the technical field of food processing. The coating formula consists of coating liquid and coating powder, wherein the honey and butter coating peanuts made by the coating formula are obtained through the following steps of (1) preparing the coating liquid; (2) preparing the coating powder; (3) performing coating shaping; (4) performing baking; and (5) performing seasoning. The qualified honey and butter peanuts are obtained through the five steps, and the honey and butter coating peanuts prepared by the method disclosed by the invention have good crisp feel and good honey and butter flavor, the technological design is scientific and reasonable, not only is rich flavor of products guaranteed, but also the industrial processing feasibility of the products is guaranteed, the nutrition of the peanut products is strengthened, the application range of the peanuts is widened, and the comprehensive utilization value of nut resources is increased.

Owner:无锡赞匠生物科技有限公司

Peanut spread

InactiveUS20050142276A1Reduce eliminate needHigh strengthFood preparationHigh intensityVegetable Proteins

A peanut or other nut spread with reduced levels of adjusted carbohydrates. The spread preferably includes peanuts, added peanut oil, added vegetable protein such as soy protein, and a stabilizer. An high intensity sweetener may also be included.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

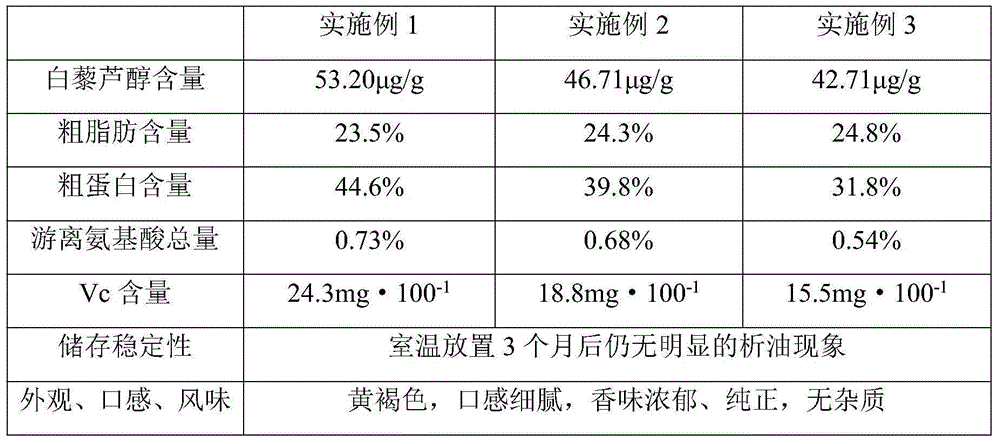

Peanut butter with low fat content and high resveratrol content and preparation method of peanut butter

The invention discloses peanut butter with a low fat content and a high resveratrol content and a preparation method of the peanut butter, and belongs to the technical field of food processing. According to the peanut butter disclosed by the invention, sprouted peanuts are used for replacing traditional common peanut kernels as raw materials, molecular distillation monostearin, sucrose ester and xanthan gum are in combined utilization as additives, and radio frequency sterilization is adopted for replacing traditional heat sterilization, so that the nutrition of the peanut butter is improved, besides, the problems that the stability is insufficient and bottom sedimentation is easy to cause existing in traditional peanut butter are solved. According to the peanut butter obtained by the preparation method disclosed by the invention, the resveratrol content is increased to 53.20 mu g / g from the original 0.01-4.50 mu g / g, the content of crude protein, the content of free amino acid and the content of vitamin C are remarkably increased, and the content of the crude fat is remarkably reduced. The peanut butter disclosed by the invention is high in stability, and cannot cause obvious oil precipitation phenomena after being left standing for 3 months at a room temperature.

Owner:JIANGNAN UNIV

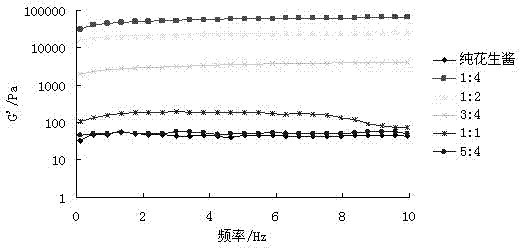

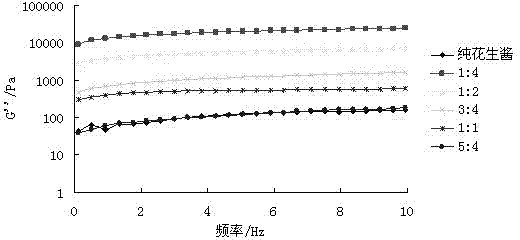

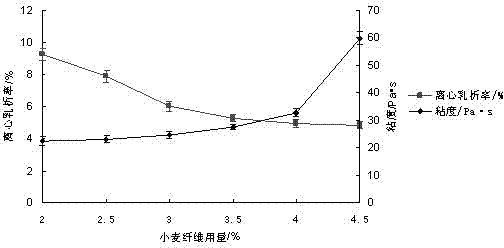

Method for improving peanut butter rheological characteristics by wheat fibers and composite emulsifier

InactiveCN103829292AEvenly distributedOptimize the best parametersFood ingredient as clouding agentFood preparationDeep processingOrganoleptic

The invention discloses a method for improving peanut butter rheological characteristics by wheat fibers and a composite emulsifier and belongs to the technical field of peanut product deep-processing. Water is added into raw peanut pulp as a raw materials so that the peanut butter is transformed into a stable oil-in-water structure and has rheological characteristic similar to that of pure peanut butter; and through combination of adsorption of free grease in the raw peanut pulp by wheat fibers and emulsification effects produced by the composite emulsifier, a peanut butter product which has long-term stability, is uniform, is not layered and has good rheological characteristics is produced. The peanut butter product has a centrifuged milk precipitation rate of 4.23% reduced by 57.5% than the centrifuged milk precipitation rate of the pure peanut butter and has good rheological characteristics, smearing characteristics and sensory quality. The peanut butter product satisfies current requirements on peanut butter stability and smearing characteristics and reduces damage caused by trans-fatty acids in the peanut butter on the health.

Owner:JIANGNAN UNIV

Vacuum freeze-drying processing method for compound fruit and vegetable peanut butter granules

The invention discloses a vacuum freeze-drying processing method for compound fruit and vegetable peanut butter granules. The processing method comprises the following steps of: (a), selecting materials, wherein the compound fruit and vegetable peanut butter granules are prepared from the following ingredients in part by weight: 60 to 80 parts of peanut butter, 6 to 8 parts of apple, 6 to 8 parts of banana, 2 to 4 parts of green bean, 2 to 4 parts of carrot, 2 to 4 parts of sweet potato, 2 to 4 parts of broccoli, 0.3 to 0.6 part of potato starch, 0.2 to 0.4 part of sucrose fatty acid ester and 1 to 2 parts of pectin; (b), mashing; (c), gelatinizing; (d), preprocessing fruit and vegetable ingredients; (e), mixing; (f), traying and quick-freezing; (g), cutting; (h), traying and quick-freezing; (i), performing vacuum freeze-drying; (j), sorting; (k), metal-detecting; and (l), packaging. The method has the advantages that the ingredients are selected through elaborate research and are high in palatability; and after fruit and vegetables are added, peanut butter has unique flavor and taste, does not have other undesirable abnormal taste, has long quality guarantee period and can be directly eaten.

Owner:HUBEI XINMEIXIANG FOODS

Puffed chocolate products and preparation method thereof

The invention relates to the technical filed of food processing, and especially relates to puffed chocolate products and a preparation method thereof. The puffed chocolate products are prepared from the following ingredients: cocoa masses, peanut butter with peanut kernel grains, sesame paste, skimmed milk powder, chocolate powder, puffed chocolate corn rings, puffed chocolate corn balls, chocolate essence, cocoa powder, beta-cyclodextrin, hydroxypropyl modified starch, oxidized starch, and pullulan; and the puffed chocolate corn rings are prepared from the following raw materials: corn starch, rice flour, oat flour, wheat flour, white granulated sugar, swelling agent, edible salt, stevioside, water, fructose syrup, maltose syrup, white granulated sugar, edible salt, vegetable oil, butter, monoglyceride, phospholipid, collagen protein, hydroxypropyl modified starch, beta-cyclodextrin, pullulan, chocolate essence, chocolate powder, milk powder, and cocoa powder. The chocolate layers of the puffed chocolate products disclosed by the invention are fine, smooth and refreshing in taste; and the puffed products are crispy in taste. The puffed chocolate products have good heat-resistant stability and moisture resistance.

Owner:ZHENGZHOU RONGLIDA BIOLOGICAL TECH CO LTD

Peanut butter and preparing method thereof

The invention belongs to the technical field of food processing, and in particular relate to peanut butter and a preparing method thereof. The peanut butter comprises the following main ingredients in parts by weight: 5-20 parts of peanut kernel, 20-60 parts of peanut protein powder, and 100-300 parts of water; and the peanut butter comprises accessory materials in parts by weight: 2-8 parts salt, 1-8 parts of dextrin, 1-5 parts of a sweetening agent, 5-10 parts of peanut oil, red kojic rice with the weight accounting for 0.1-0.4% of the weight of the peanut protein powder, 1-3 parts of white spirit, 8-12 parts of white sesame seed, 2-8 parts of garlic, 2-8 parts o fginger, and 1-4 parts of paprika powder. According to the peanut butter and a preparing method, the peanut protein powder is taken as the raw material, and the peanut oil and the roasted peanut kernel are taken as the accessory materials and added into the peanut butter in various forms, so that the peanut butter has a pure flavor, and an enhanced mouthfeel; and in addition, the preparing method disclosed by the invention adopts the method, in which the peanut protein powder is dried to be used for directly preparing the peanut butter, which is different from the traditional method in which the peanut kernel is dried and then grinded. The peanut butter and the preparing method provided by the invention have the advantage that the peanut protein powder is dried completely, so that the flavor completely emits out, and the peanut butter has delicate and pure mouthfeel.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

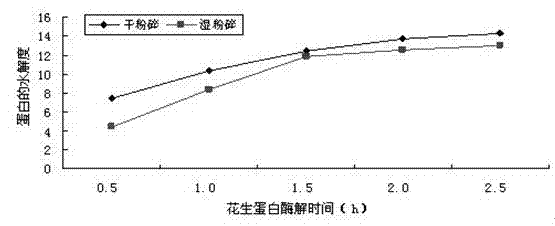

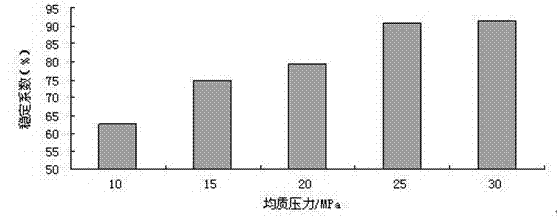

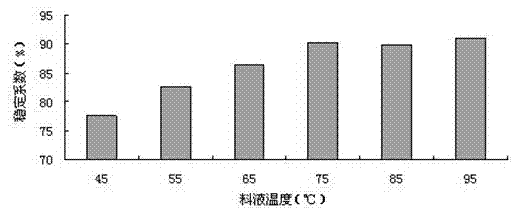

Peanut polypeptide liquid and peanut protein polypeptide beverage prepared from the peanut polypeptide liquid

The invention discloses peanut polypeptide liquid and a peanut protein polypeptide beverage prepared from the peanut polypeptide liquid. A preparation method of the peanut polypeptide liquid comprises the following steps of drying peanut kernels by an oven, removing red skin, carrying out ultra-fine crushing to obtain peanut butter, adding the peanut butter into hot water having a temperature above 75 DEG C for dissolution according to a weight ratio of 1: (7 to 27), adjusting a pH value to of the peanut butter solution to a pH value of 7.0 to 8.5, based on the weight of the peanut butter, adding 0.3 to 0.9 wt% of peanut composite protease into the peanut butter solution, carrying out enzymolysis at a temperature of 45 to 65 DEG C for 0.5 to 2.5 hours, deactivating the peanut composite protease, and filtering to obtain the peanut polypeptide liquid. The preparation method of the peanut polypeptide liquid is simple, saves time and has a low cost. Dry ultra-fine crushing is utilized in raw material treatment so that a peanut protein retention ratio is high and an enzymolysis speed is fast. The peanut composite protease is utilized in proteolysis so that a degree of hydrolysis, the concentration of a trichloroacetic acid soluble protein, and a polypeptide yield are high. The peanut protein polypeptide beverage prepared from the peanut polypeptide liquid, white sugar and peanut protein liquid prepared from peanut butter which is subjected to dry ultra-fine crushing and is dissolved in water has the advantages of rich nutrient, specific fragrance belonging to peanut, smooth andfine mouthfeel, and no bitter taste.

Owner:SOUTHWEST UNIVERSITY +1

Method for producing low fat peanut paste using degreased peanut powder

Disclosed is a method to produce low-fat peanut butter from defatted peanut flour. The production method includes the following steps: baking: baking the defatted peanut flour in a tunneling-based microwave dryer for 100-400 seconds and then cooling through strong wind until reaching room temperature; aromatizing: adding aromatizing agent water solution into the baked peanut flour based on weight ratio of 2.2:1 and mixing to be even; seasoning: adding pure peanut oil into aromatized peanut butter based on weight ration of 3-10:100 and mixing to be even; emulsifying: bathing the peanut butter in water with temperature of 60-80 EDG C to enable the interior and the exterior of the peanut butter to be heated evenly, inserting the probe of an ultrasonic cell disruptor into the peanut butter and conducting emulsification treatment for 20-30 minutes per 50kg under the conditions of harmony indicator output of 50, dutyfactor of 60, temperature of 60-80 DEG C; cooling: speedily stirring the emulsified butter and cooling to 20-50 DEG C through air to avoid the accumulation of the heat of the butter, which leads to the precipitation of the fat; store maturity: putting the cooled peanut butter into a packing container and keeping still for 48h to make the butter totally steady and fixed.

Owner:BOHAI UNIV

Marshmallow

An improved marshmallow, consisting of an existing or new marshmallow item or shape, which has been infused with, co-extruded with, molded with or injected with a flavored filling, at the time of manufacture or at a later date. In addition, marshmallow could be drop formed over or onto said flavored filling. Said flavored filling could be a simple chocolate or jelly, or a more complex combination of ingredients, that impart the taste of an easily recognizable popular brand name confection such as, Reese's(TM) peanut butter cups, Milky Ways(TM) or Snickers(TM) candies to name a few. Or said flavored filling could impart the taste of a popular liquor such as Ballies Irish cream(TM), Amaretto(TM), or Sambooka(TM). Said flavored filling could also be a combination of ingredients that create a new flavor or taste, be fortified with vitamins and or minerals to make the product more nutritious, or contain a pharmaceutical and thus be used as a delivery medium for a medicine, medication, antibiotic or vaccine, therefore making it much easer to administer to a child, or much more pleasant for an adult.

Owner:LONG JASON

Pet biscuit containing animal liver and preparation method thereof

InactiveCN103053864AIncrease elasticityChange mobilityAnimal feeding stuffAnimal scienceSodium ascorbate

The invention relates to a pet biscuit containing animal livers and a preparation method thereof, particularly relates to a pet biscuit prepared of animal livers and plants, and belongs to the field of pet food processing. The pet biscuit containing animal livers is characterized by comprising the following raw components in parts by weight: 60-73 parts of flour, 5-7 pars of bean flour, 3-6 parts of white sugar, 12-15 parts of palm oil, 8-10 parts of (braked) animal liver, 0.6-0.9 part of peanut butter, 2-5 parts of egg, 0.25-0.4 part of granulesten, 0.15-0.4 part of fructo-oligose, 0.45-0.60 part of flaxseed powder, 0.02-0.05 part of sodium ascorbate, 2-5 parts of flavouring agent, 0.0100.04 part of composite vitamin for animals, and 16-20 parts of water. The high-grade pet biscuit containing animal liver, provided by the invention, has balanced nutrition and high palatability. The invention also provides the preparation method of the animal liver biscuit.

Owner:江苏贝甜宠物食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com