Method for improving peanut butter rheological characteristics by wheat fibers and composite emulsifier

A compound emulsifier and wheat fiber technology, applied in the direction of bacteria, application, streptococcus/lactococcus used in food preparation, etc., can solve the problems of poor health, poor spreadability, poor stability, etc., to reduce fat content and avoid large amounts Add and solve the effect of oil stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The production process of the product is as follows:

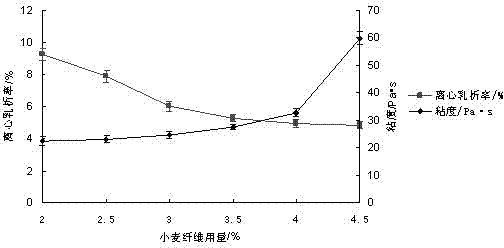

[0026] Peanut puree, add wheat fiber, stir well and let it stand; add monoglyceride dissolved in hot peanut oil and sucrose ester dissolved in warm water, emulsify evenly, add sucrose, salt, potassium sorbate, nisin and The remaining water is evenly stirred, homogenized, packed and sealed, sterilized, cooled, and the finished product is obtained.

[0027] (1) Determination of the ratio of water to peanut puree

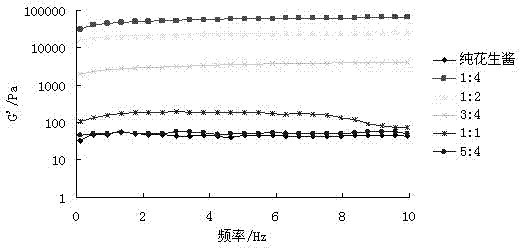

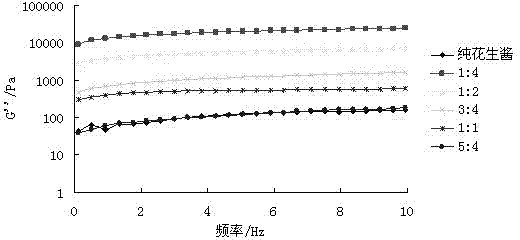

[0028] Since peanut puree has a water-in-oil structure, when water is added, the structure will be gradually destroyed until the emulsion is broken. When water is continuously added, the oil-in-water structure will replace the original water-in-oil structure and re-form, so that Peanut butter has different rheological properties at different water distribution ratios. Since the peanut butter we want to produce has similar rheological properties to peanut puree, we must first determine the mass ratio of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com