Peanut polypeptide liquid and peanut protein polypeptide beverage prepared from the peanut polypeptide liquid

A peanut protein polypeptide and a peanut polypeptide technology, applied in the food field, can solve the problems of low protein retention rate of peanut protein emulsion, limited application of peanut protein hydrolyzate, low degree of hydrolysis of peanut protein, etc., and achieves low cost, good market prospect, and high preparation efficiency. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] 1. Preparation of Peanut Polypeptide Solution

[0040] 1. Screening of raw material processing methods

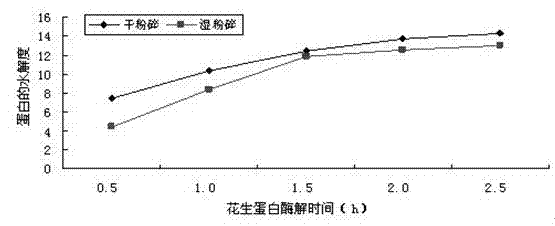

[0041] The present invention investigates the effects of different raw material processing methods (wet crushing and dry crushing) on the retention rate of peanut protein and the enzymatic hydrolysis speed of peanut compound protein.

[0042] Wet pulverization: dry the peanut kernels, remove the red coat, add water to soak at room temperature for 12 hours, drain, add water and use a colloid mill to refine the pulp twice, filter, collect the filtrate to obtain peanut protein liquid, and measure peanut protein Retention rate; then use peanut protein complex enzyme to enzymatically hydrolyze for 0.5, 1.0, 1.5, 2.0, 2.5 hours respectively under the recommended use conditions, and measure the degree of proteolysis under different enzymatic hydrolysis time.

[0043] Dry crushing: dry the peanut kernels, remove the red coat, and ultrafinely pulverize the peanut butter wi...

Embodiment 1

[0108] Embodiment 1, the preparation of peanut polypeptide liquid

[0109] After cleaning and removing impurities from the peanut kernels, bake them at a temperature of 145°C for 30 minutes, remove the red coat, and carry out ultrafine grinding with an ultrafine mill to obtain peanut butter; take 100g of peanut butter, add 1100g of hot water at 80°C to dissolve, Adjust the pH to 7.5, add 0.5 g of peanut compound protease, and perform enzymatic hydrolysis at 55°C for 2.5 hours; after the enzymatic hydrolysis, heat at 90°C for 15 minutes to inactivate the enzyme, and filter through a filter cloth to obtain peanut polypeptide liquid. It was determined that the degree of proteolysis was 15.13%, the content of peanut peptide was 39.02mg / mL, and the yield of peanut peptide was 98.03%.

Embodiment 2

[0110] Embodiment 2, preparation of peanut protein polypeptide beverage (small test)

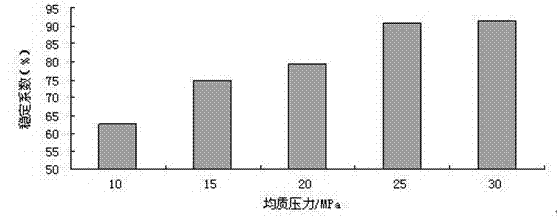

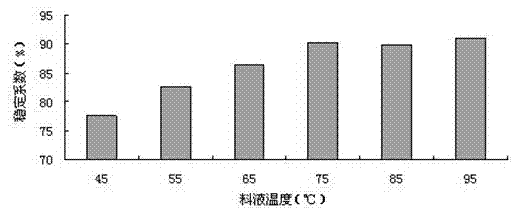

[0111] After cleaning and removing impurities from the peanut kernels, bake them at a temperature of 140°C for 35 minutes, remove the red coat, and perform ultrafine grinding with an ultrafine mill to obtain peanut butter; take 100g of peanut butter, add 2200g of hot water at 75°C to dissolve, Then cool to 55°C, adjust the pH to 7.5, add 0.5g of peanut compound protease, and incubate at 55°C for 2.5 hours for enzymolysis. After the enzymolysis is completed, heat at 90°C for 15 minutes to inactivate the enzyme, and filter through a filter cloth to obtain peanut polypeptide liquid; Take 100g of peanut butter, add 2200g of hot water at 75°C to dissolve it, and filter it with a filter cloth to obtain peanut protein liquid. Mix the obtained peanut polypeptide liquid with the peanut protein liquid, add 352g of white sugar and 11g of peanut milk emulsification stabilizer, homogenize at a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com