Patents

Literature

261 results about "Beverage industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

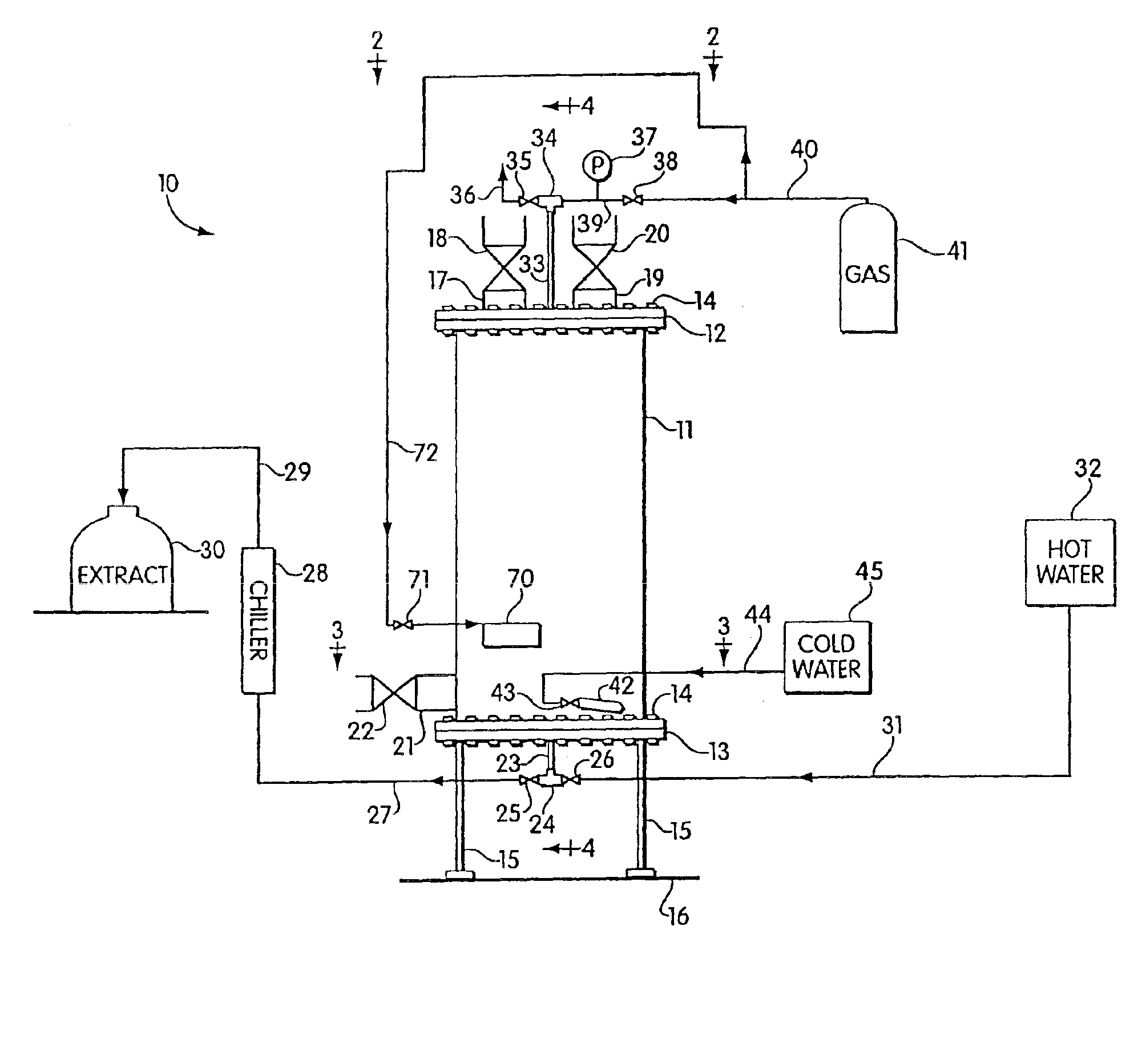

Methods and systems for forming concentrated consumable extracts

InactiveUS7419692B1Excellent and desirable and flavor and qualityExcellent and desirable and and fragrance qualitySemi-permeable membranesFiltration separationFiltrationCoffee processing

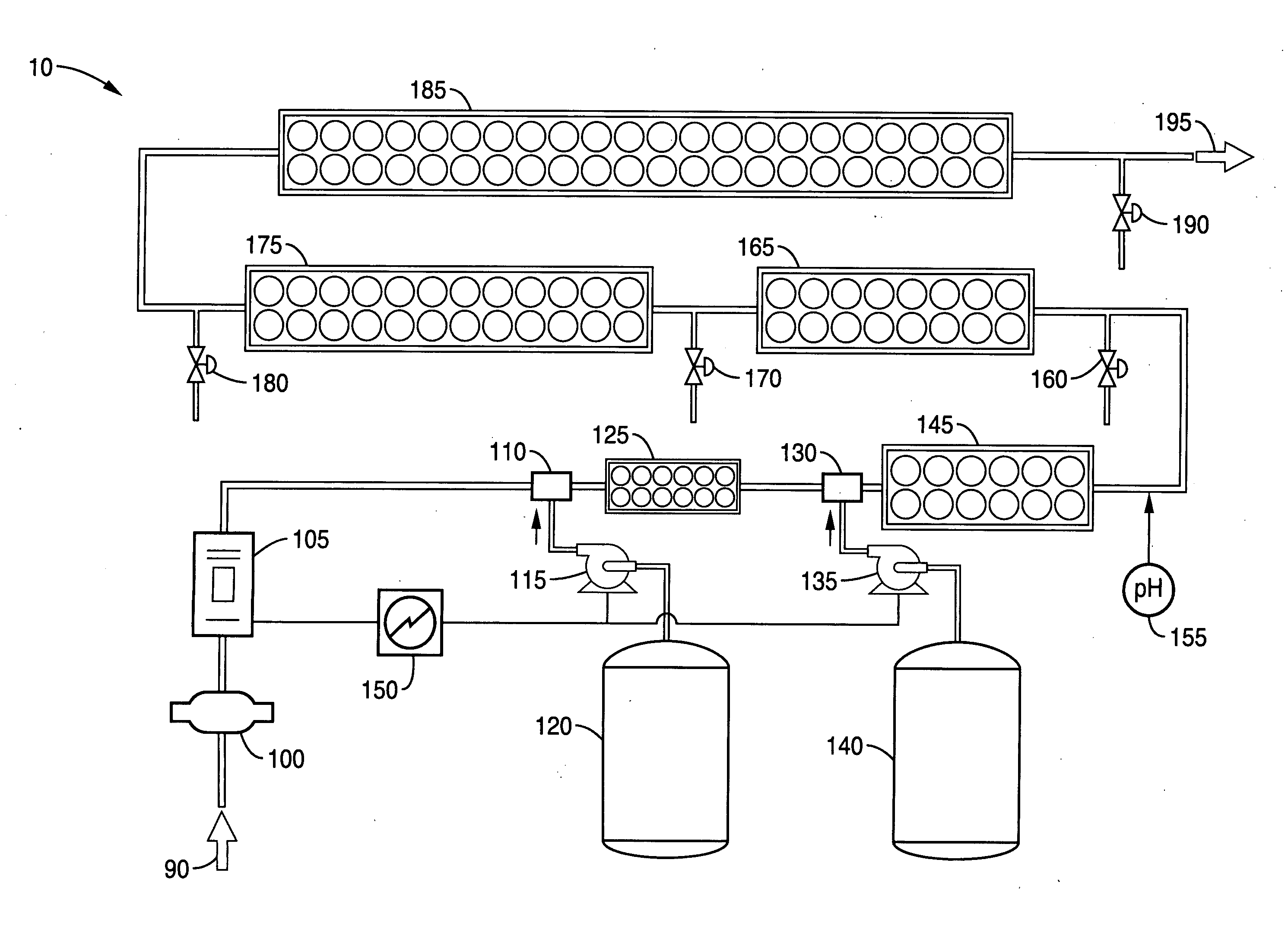

Typical known methods for producing large quantities of concentrated extracts from solid raw materials such as ground, roasted coffee are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides filtration methods for producing such high quality concentrated extracts from more dilute extracts via solvent removal. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial-scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances.

Owner:KERRY GROUP SERVICES

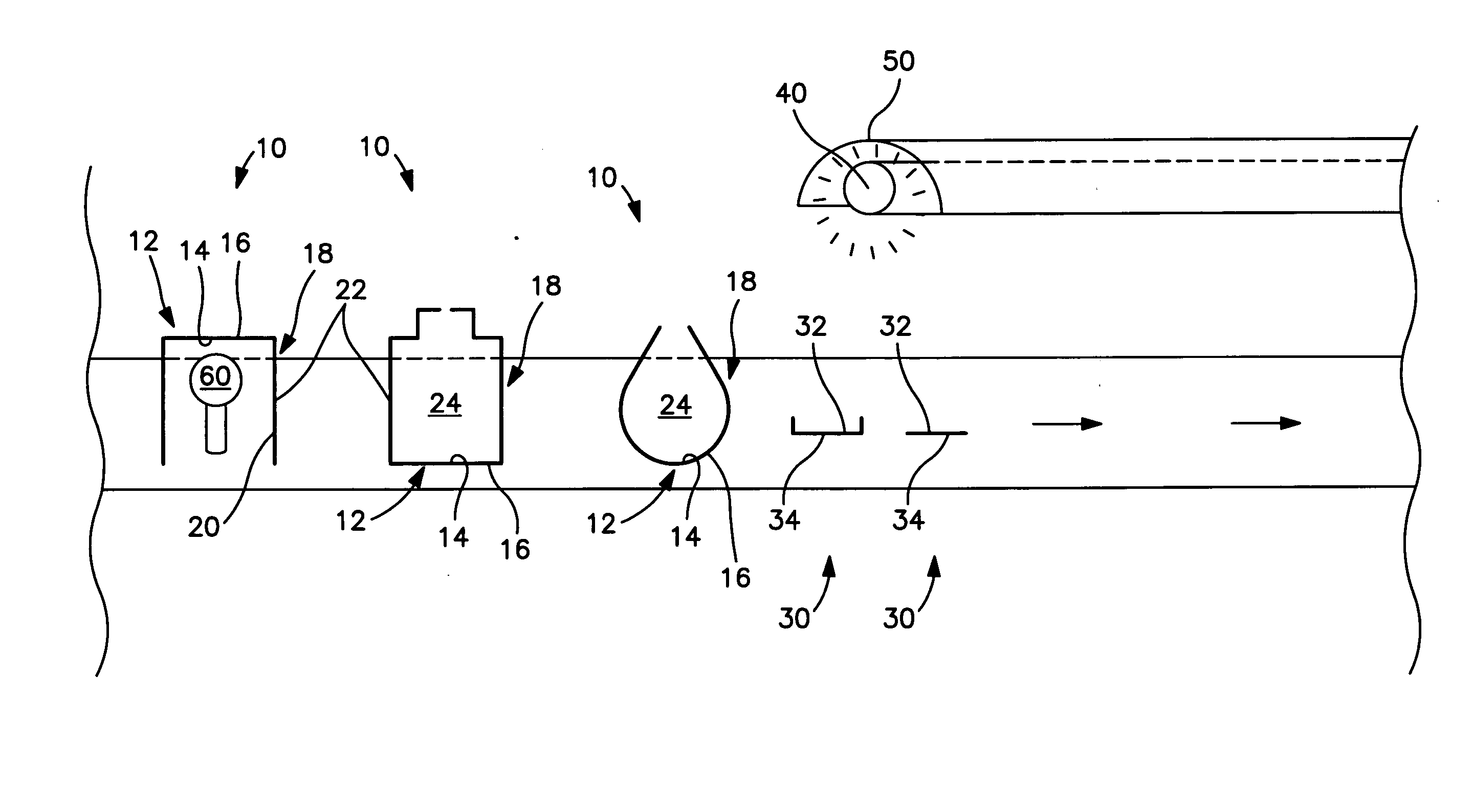

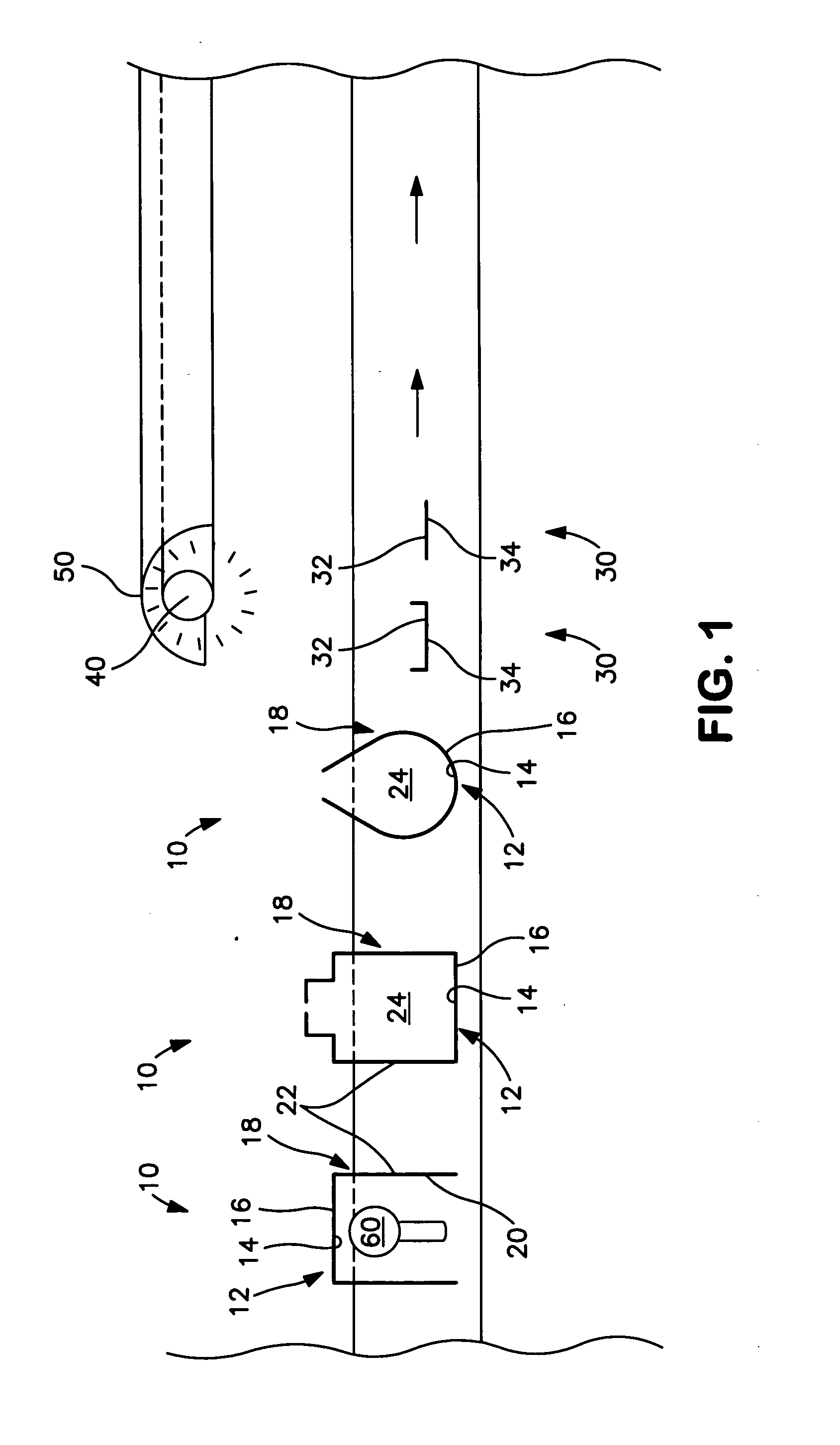

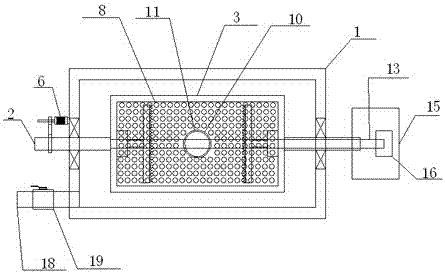

Method for sanitizing/sterilizing a container/enclosure via controlled exposure to electromagnetic radiation

ActiveUS20070258851A1Enhance sanitizationImprove the bactericidal effectPackage sterilisationLavatory sanitoryFood industryBeverage industry

A method for sanitizing / sterilizing a container / enclosure for use in the food industry or the beverage industry comprising the steps of: providing a container and / or enclosure; providing an electromagnetic radiation source; controllably exposing the container and / or enclosure to electromagnetic radiation from the electromagnetic radiation source for a period of time; and at least one of sanitizing and sterilizing at least a portion of the container and / or enclosure with the electromagnetic radiation.

Owner:FOGG FILLER CO LLC

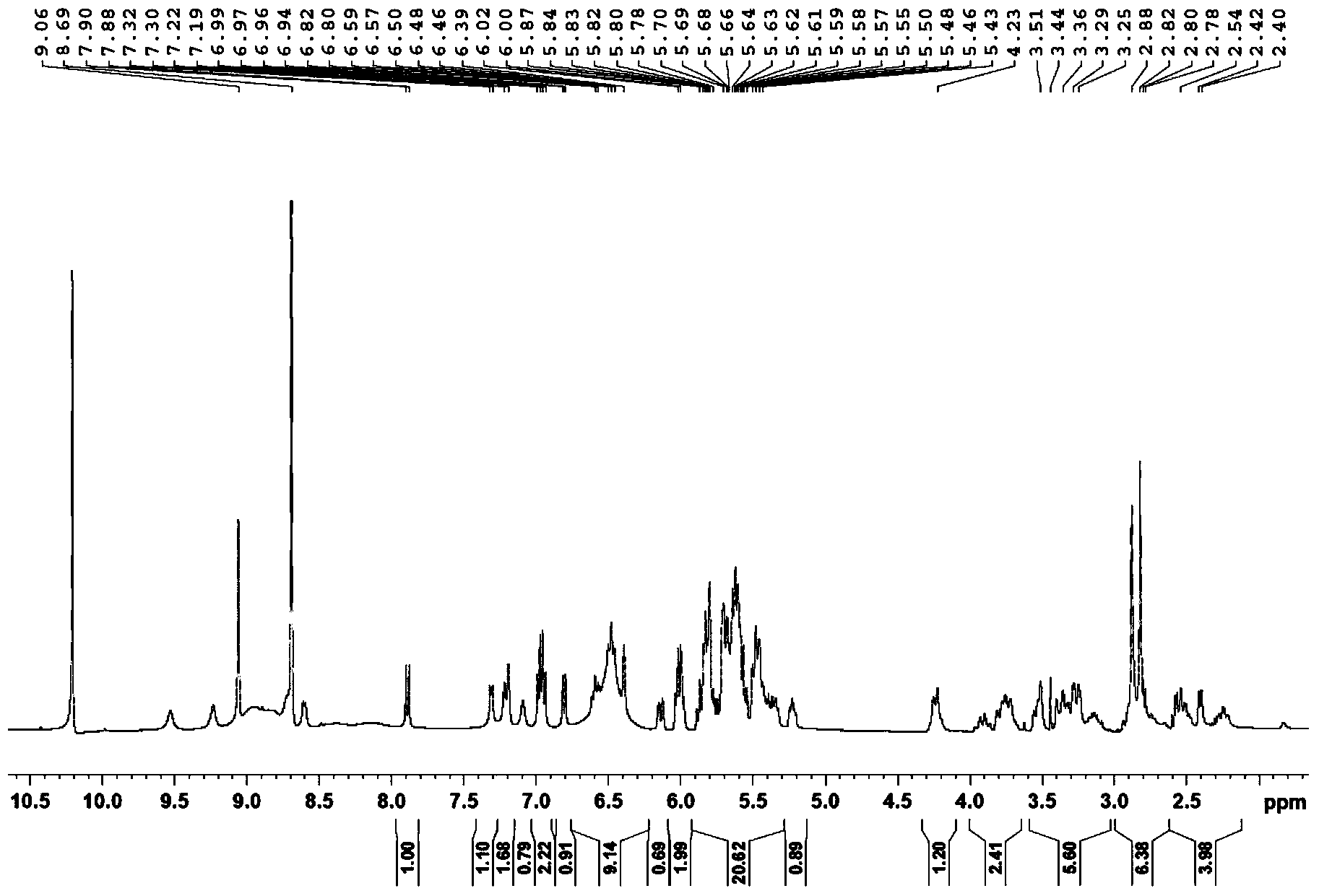

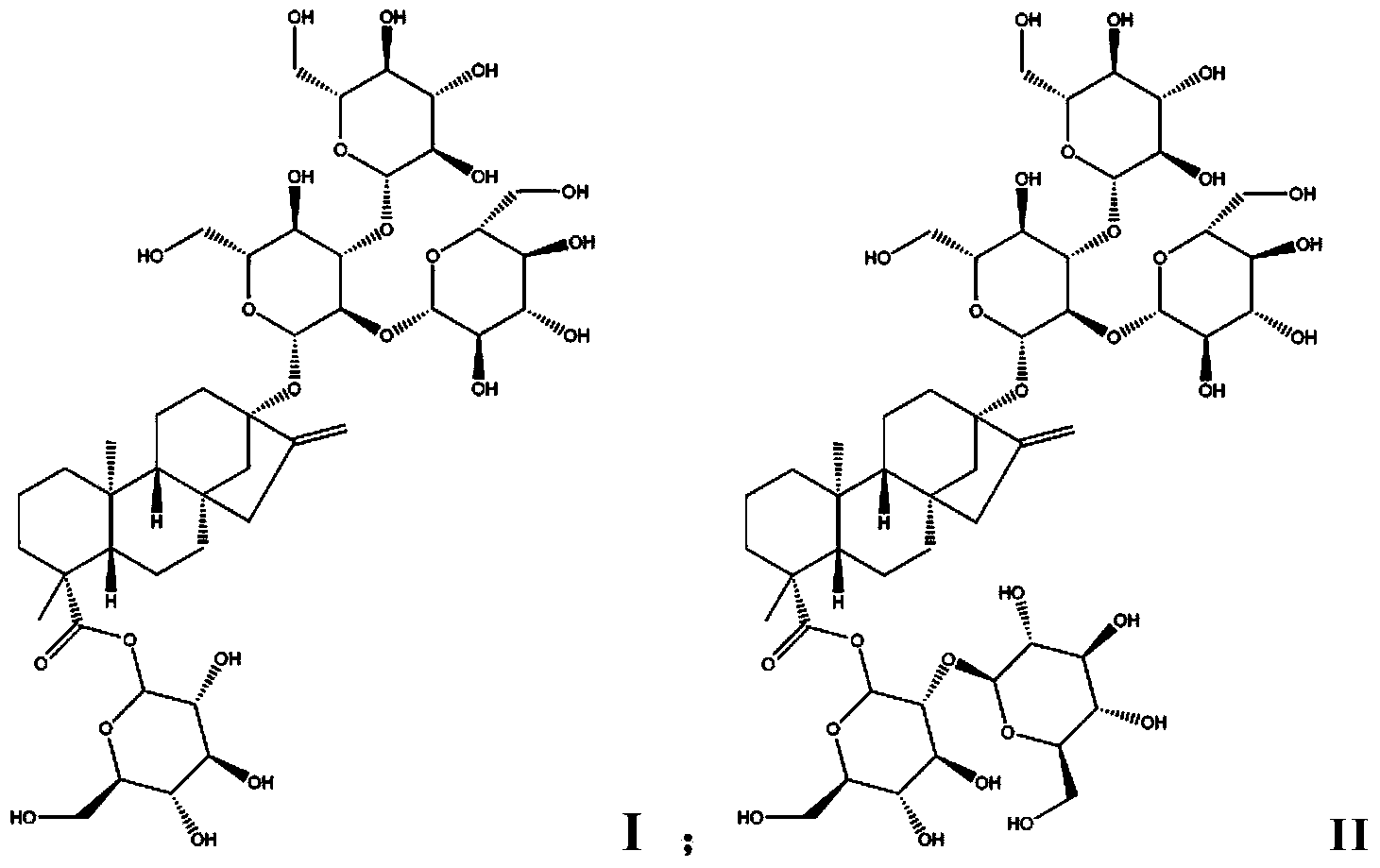

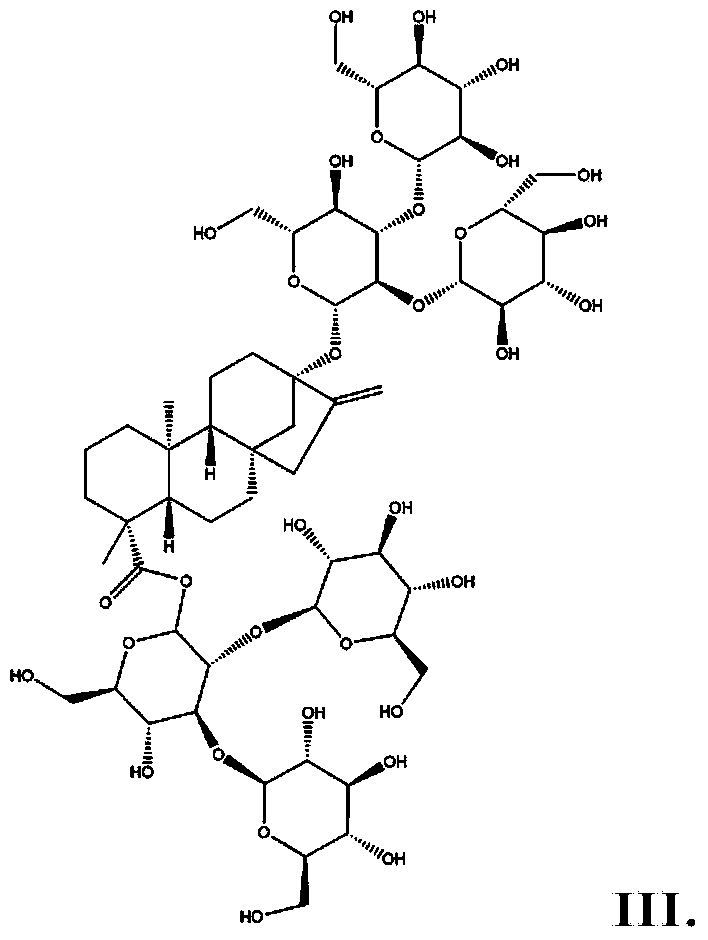

Method for preparing rebaudioside M through enzyme method

ActiveCN103757074AImprove conversion rateHigh purityFermentationSucrose synthetaseUdp glucosyltransferase

The invention relates to a method for preparing rebaudioside M through an enzyme method. According to the method, rebaudioside A or rebaudioside D is used as a substrate, and the substrate reacts to generate the rebaudioside M in the presence of sucrose and UDP under the catalytic action of a mixture of UDP-glucosyltransferase and sucrose synthetase or recombinant cells containing the UDP-glucosyltransferase and the sucrose synthetase, wherein the reaction is performed in a water-phase system having a pH value of 5.0-9.0 at 20-60 DEG C. The method for preparing rebaudioside M through an enzyme method has important application value; and compared with the existing technology of extracting rebaudioside M from stevia rebaudian leaves, the method provided by the invention obviously shortens the production cycle, improves the productivity and lowers the cost, and can provide products having higher purity. Thus, the method can be used in the food and beverage industry in a more economical manner.

Owner:PEPSICO INC

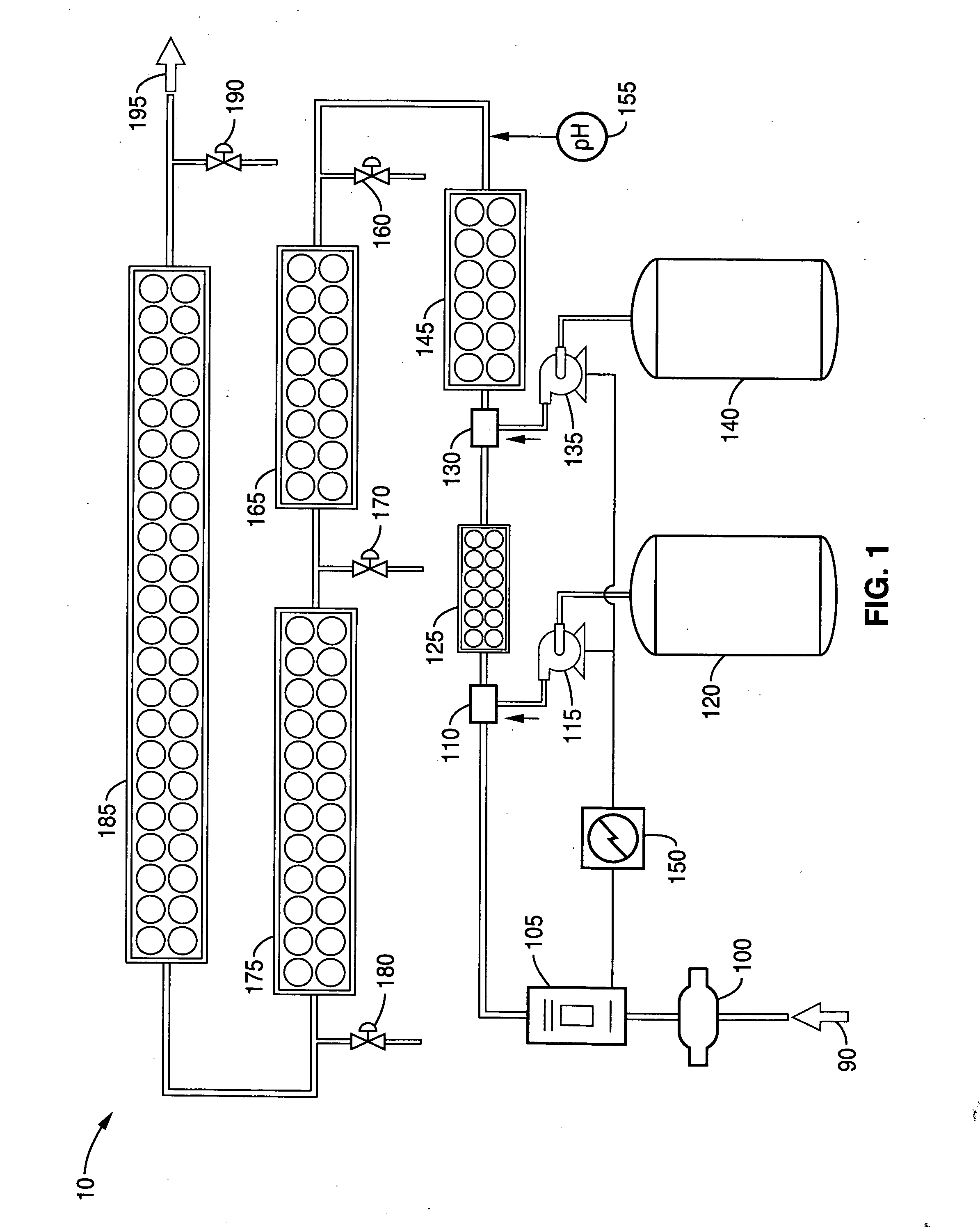

Methods and systems for forming concentrated consumable extracts

InactiveUS20080280023A1Fully understandSemi-permeable membranesSolid waste disposalHigh concentrationFiltration

Typical known methods for producing large quantities of concentrated extracts from solid raw materials such as ground, roasted coffee are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides filtration methods e.g. reverse osmosis or nanofiltration for producing such high quality concentrated extracts from more dilute extracts via solvent removal. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial—scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances. The solvent—reduced, concentrated extracts produced according to the inventive solvent removal methods can be advantageously used for applications where high quality coffee extracts, with a high concentration of soluble coffee solids, for example of at least 6 wt. %-40 wt. %, and a high level of retention of varietal flavor and fragrance characteristics are desired.

Owner:KERRY GROUP SERVICES

Coffee system

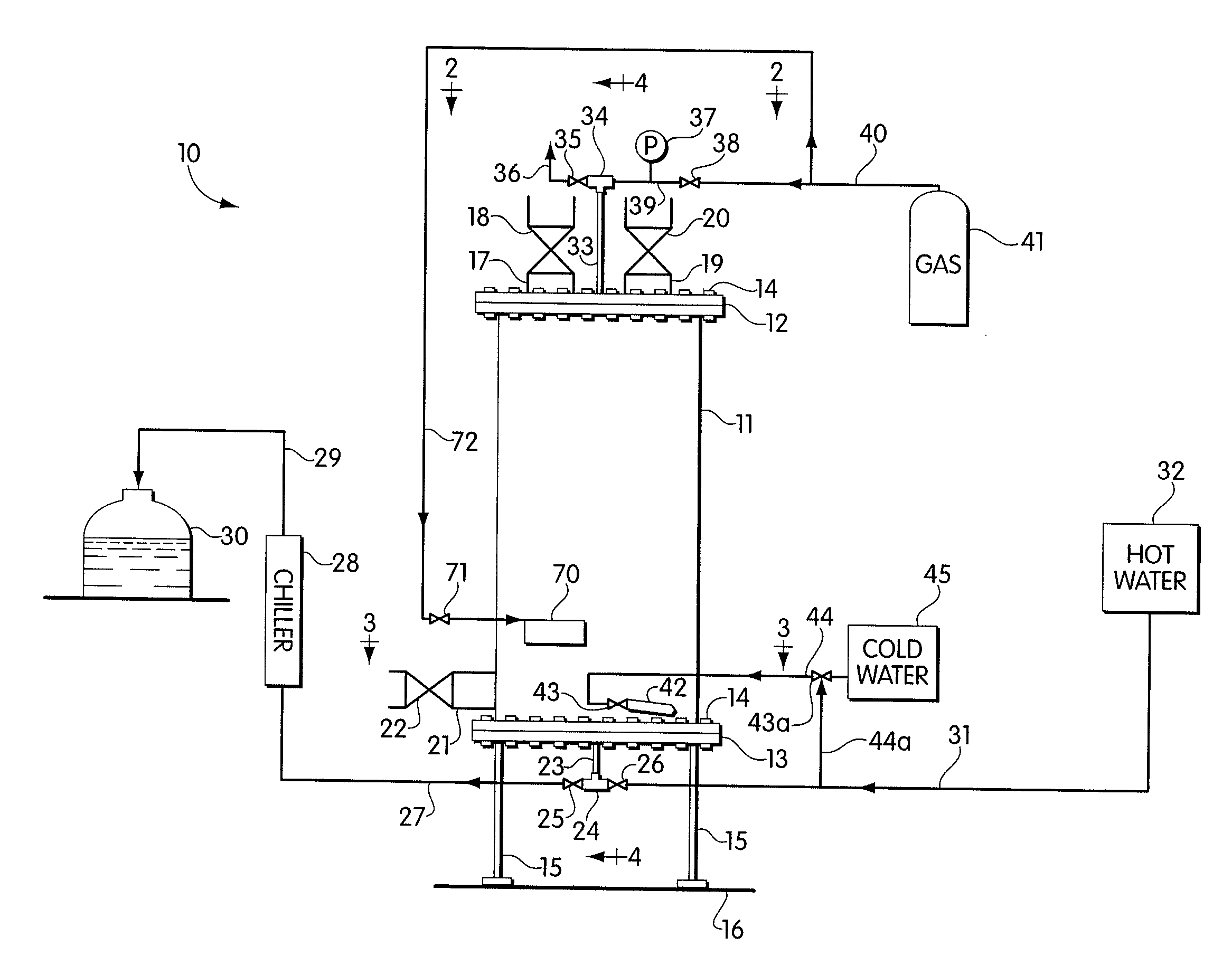

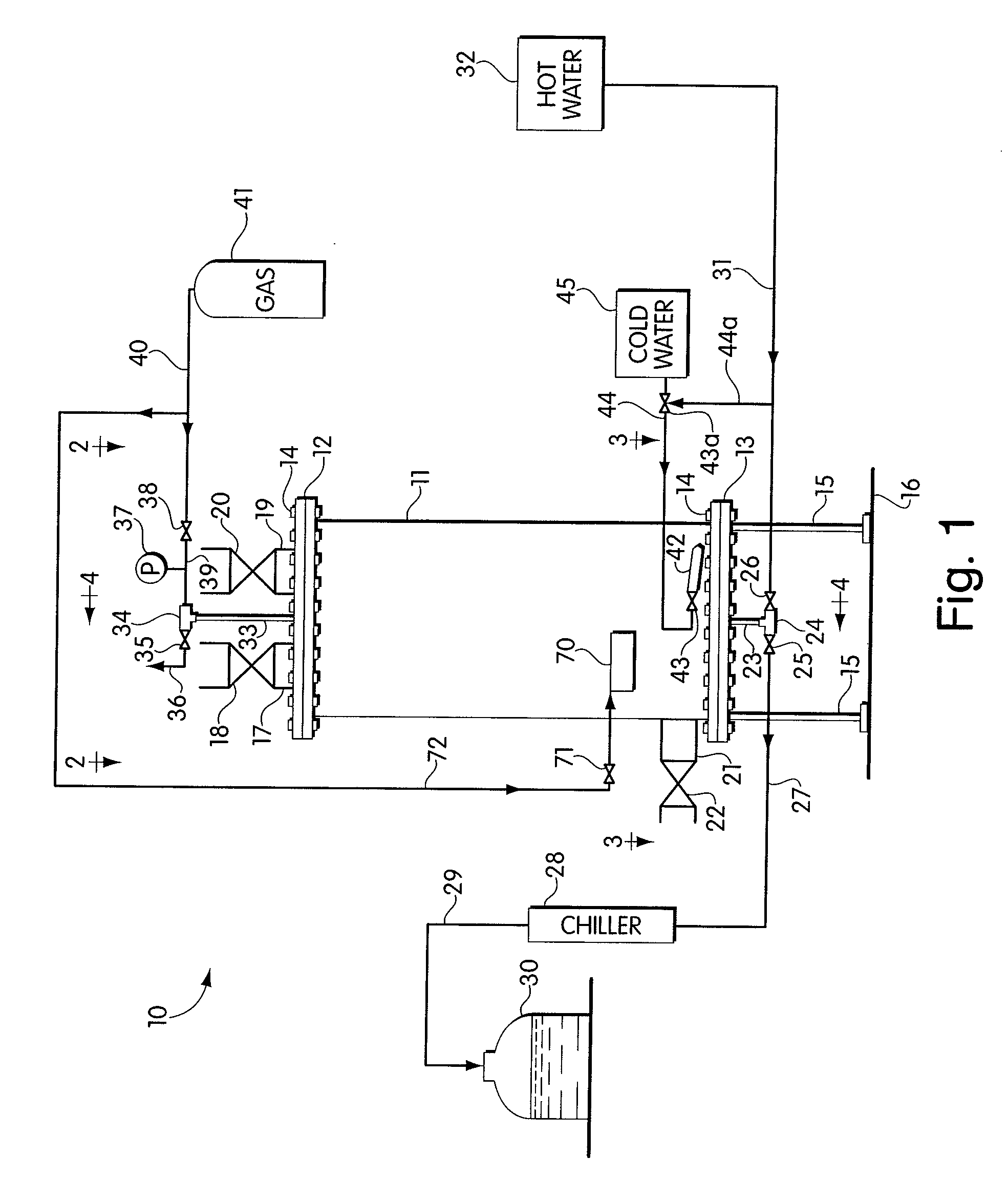

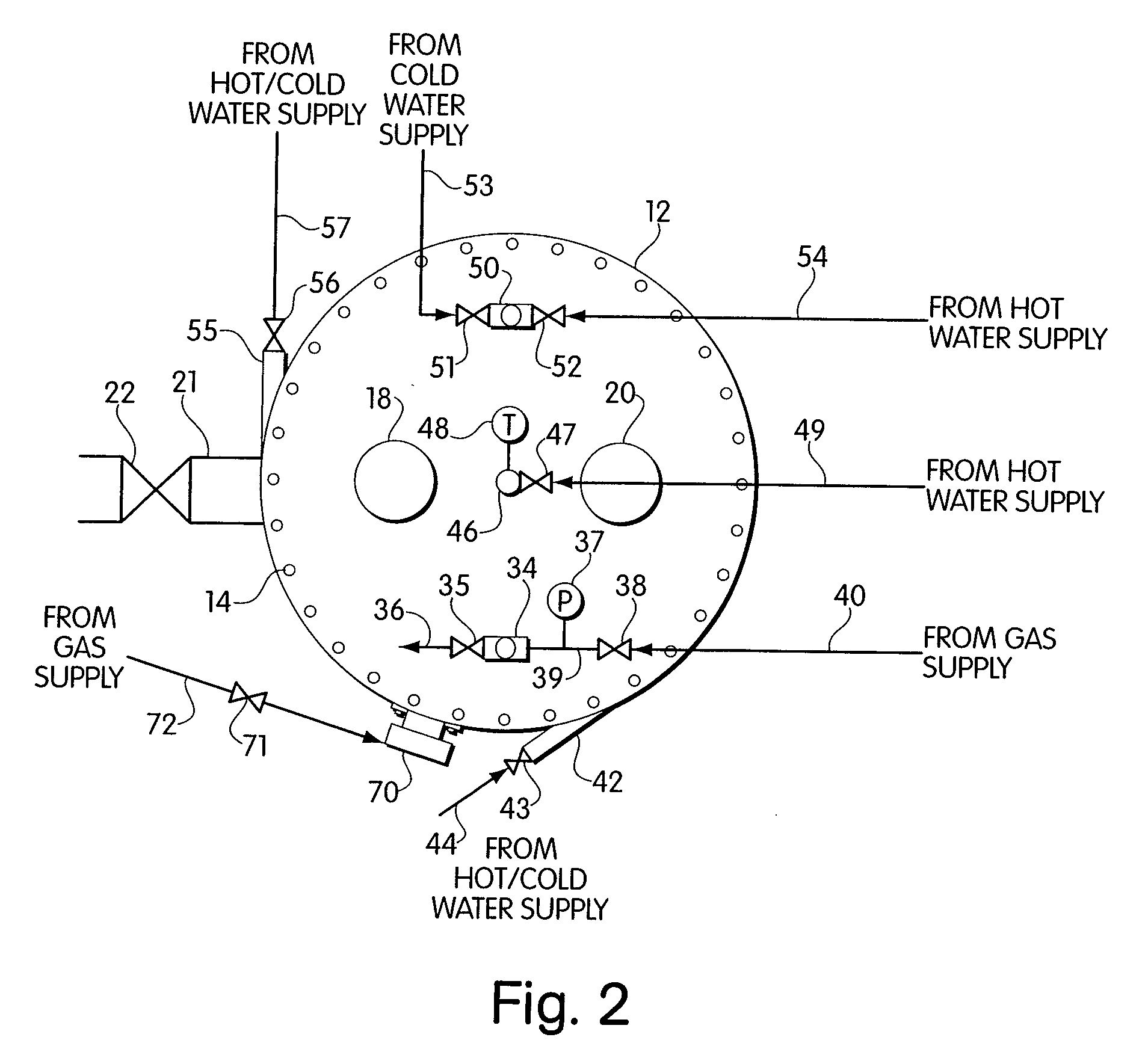

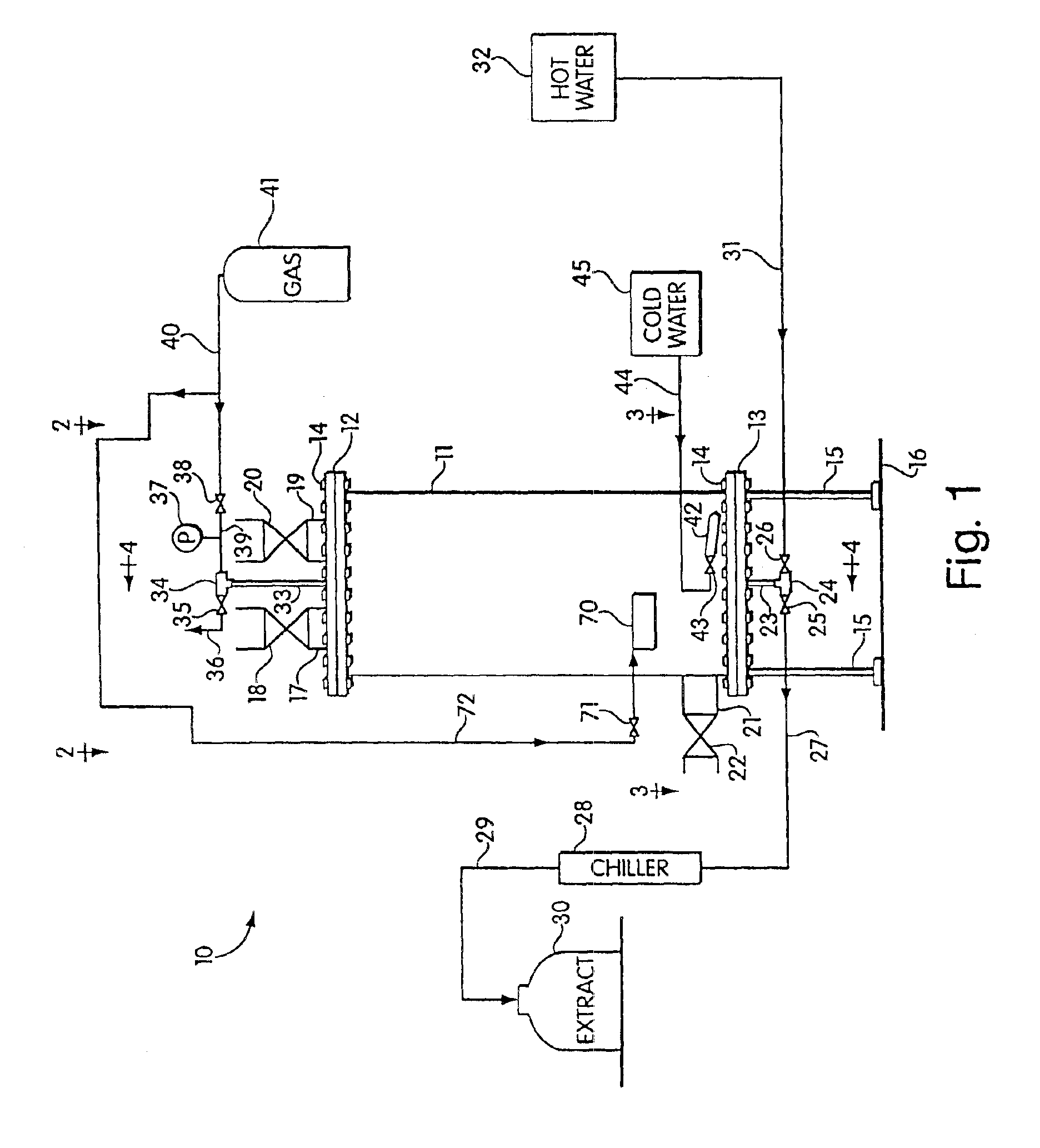

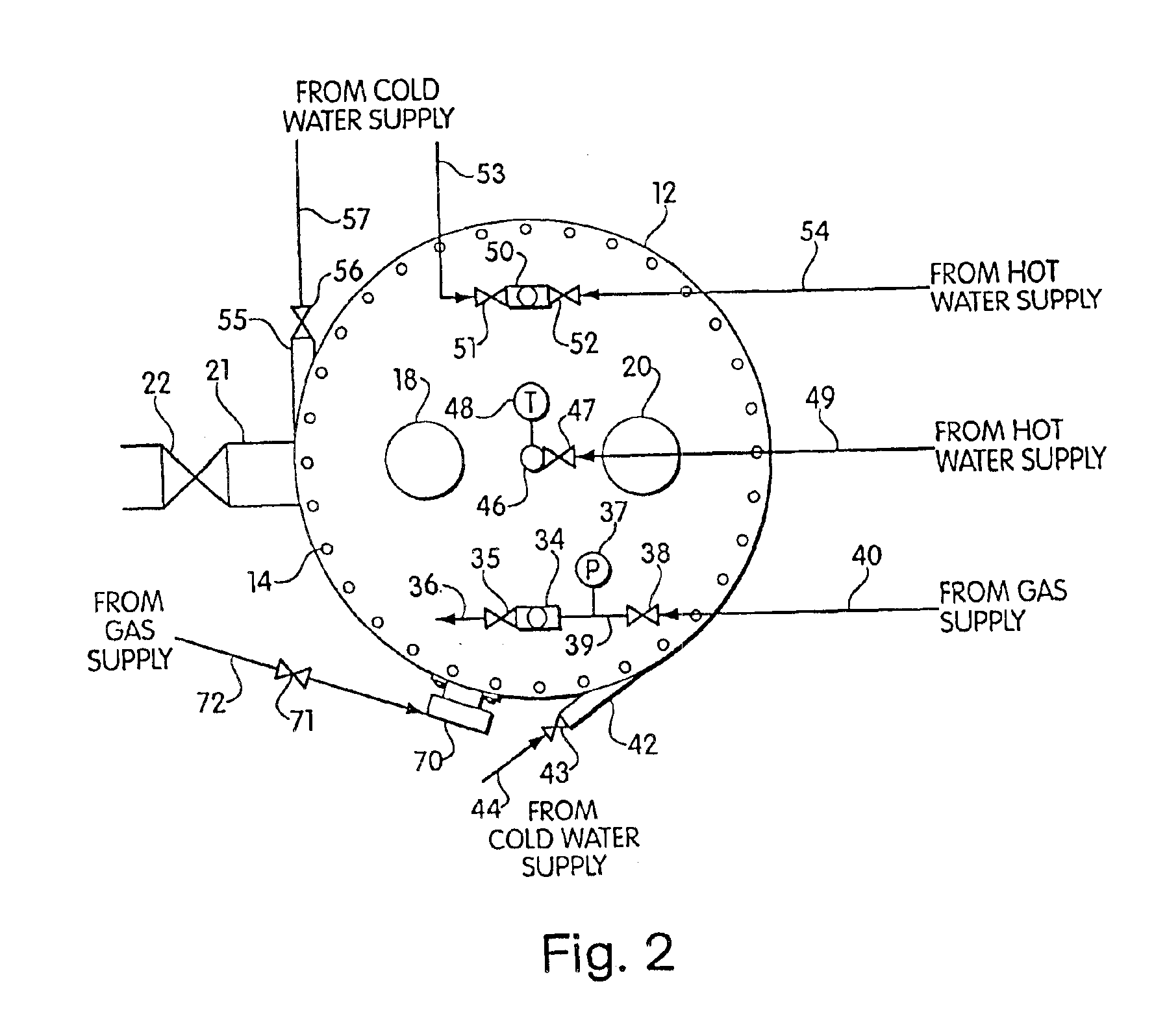

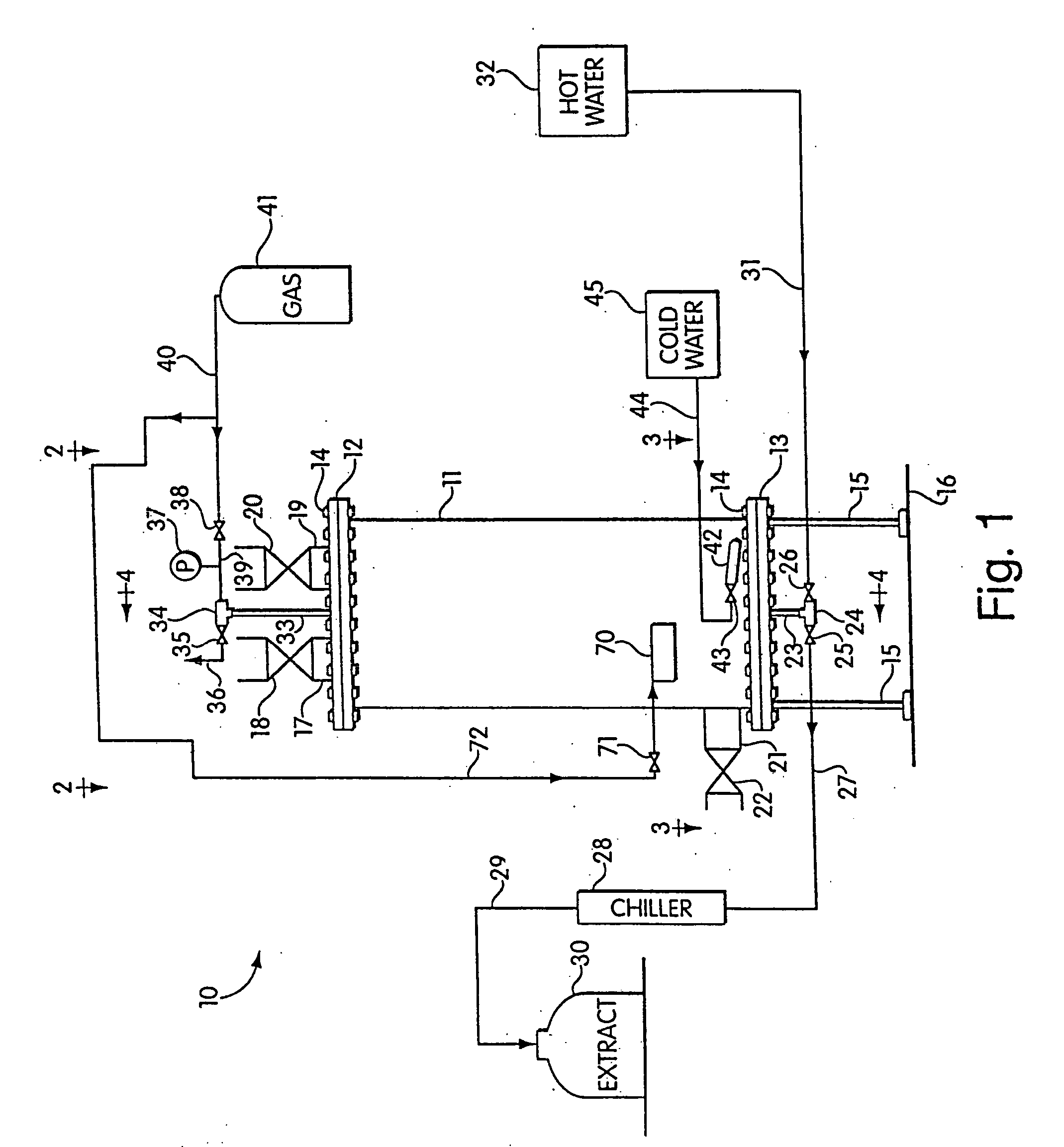

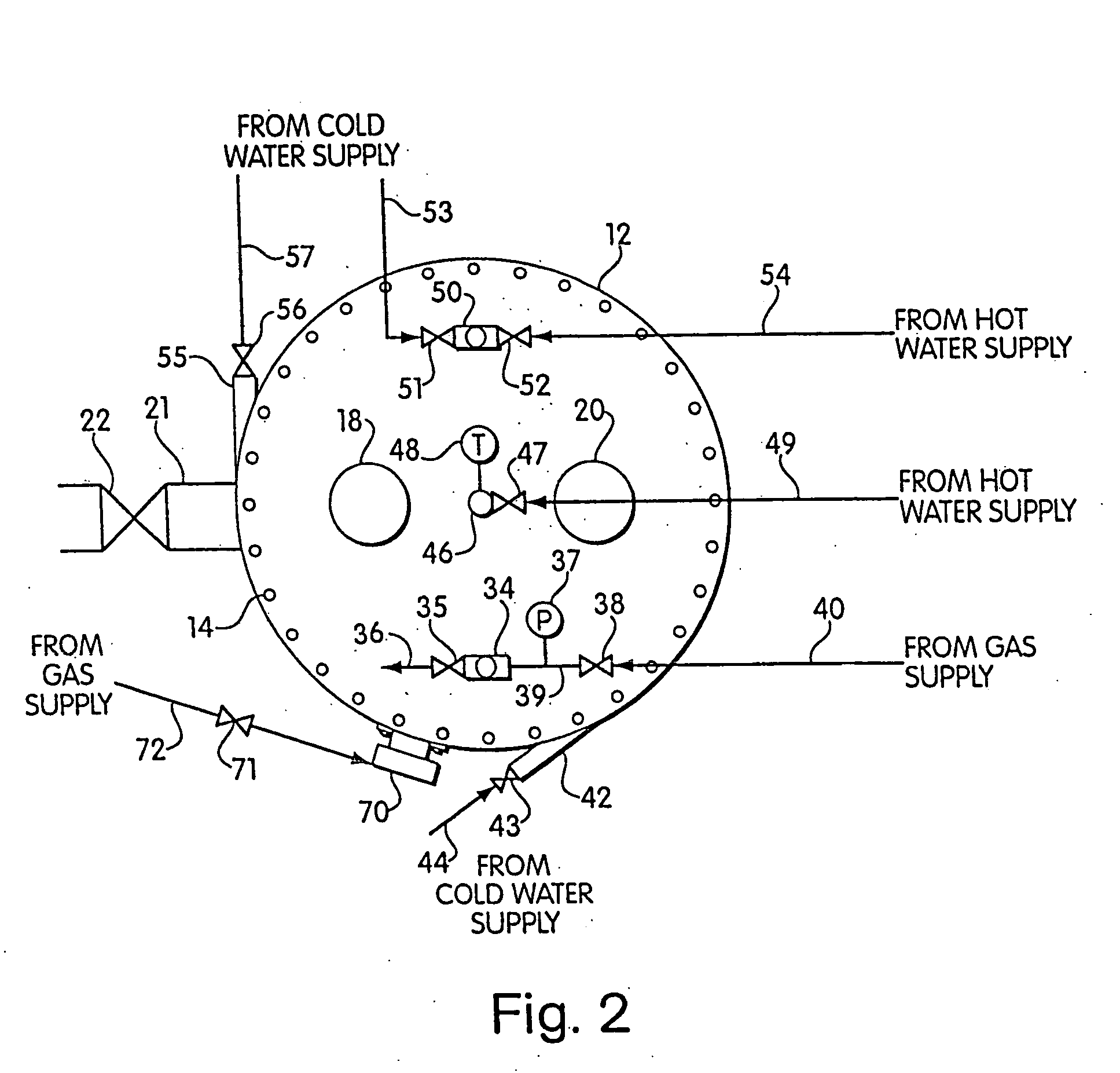

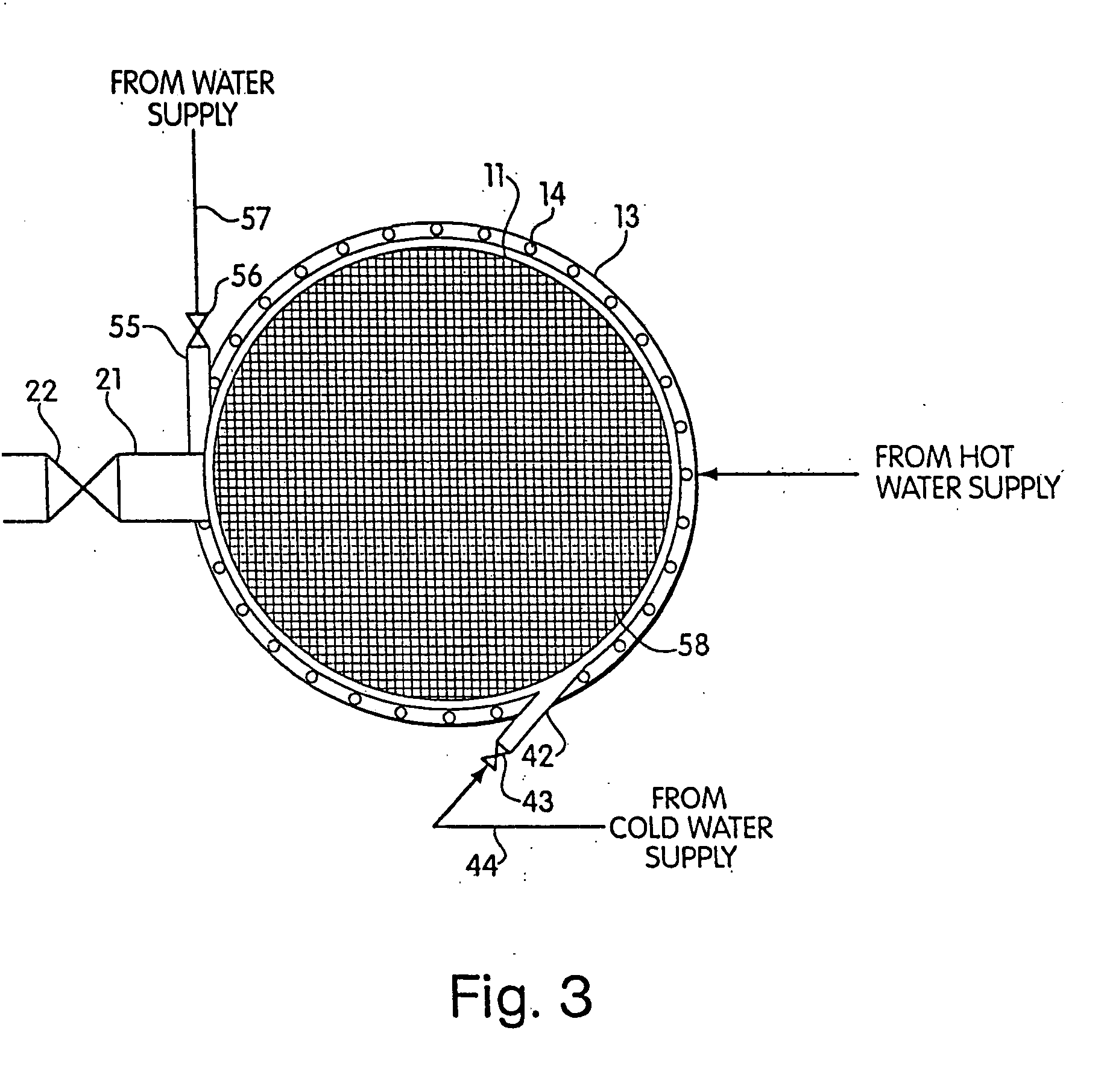

InactiveUS6887506B2Excellent and desirable and flavor and qualityExcellent and desirable and and fragrance qualityTea extractionTea substituesBeverage industryEngineering

Typical current methods for producing large quantities of extracts from solid raw materials such as ground, roasted coffee are designed for exhaustive extraction. Such methods are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides methods and apparatus for producing such high quality extracts. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial-scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances.

Owner:KERRY GROUP SERVICES

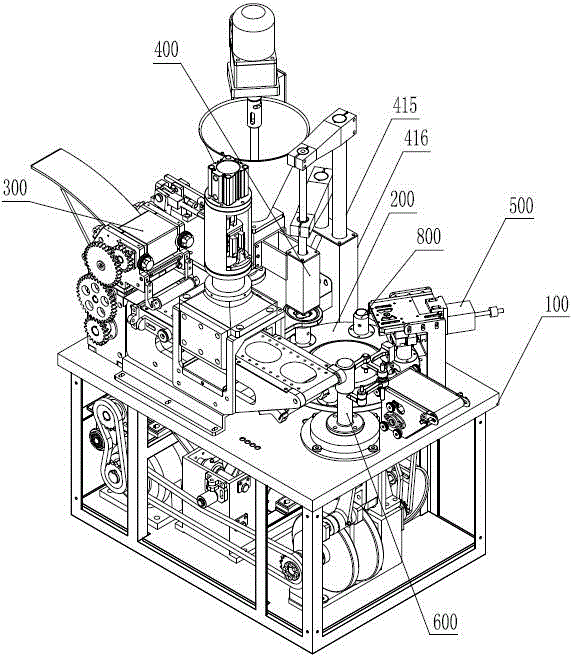

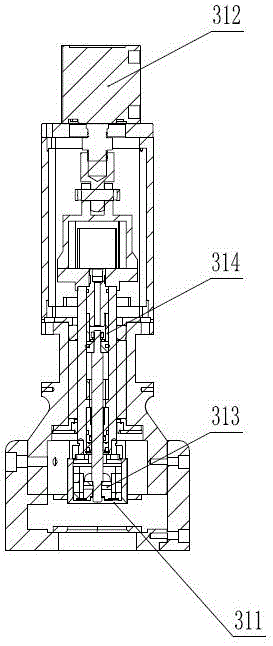

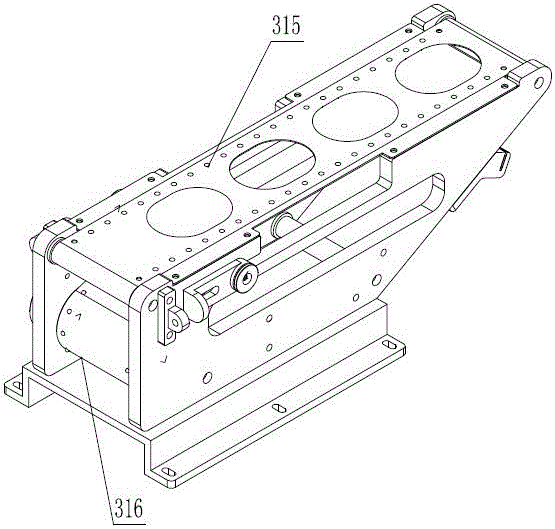

Compact stuffed food shaping machine

ActiveCN105724507AAchieve instant cookingReduce transportation and circulation linksDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationMolding machineProcess engineering

The invention belongs to the technical field of food processing and in particular relates to a compact stuffed food shaping machine. The shaping machine comprises a rack and a station turntable arranged on the rack, wherein a wrapper making device, a stuffing device, a laminating device and a discharge device are respectively arranged around the station turntable; a wrapper making station is arranged on the wrapper making device; a stuffing station is arranged on the stuffing device; a laminating station is arranged on the laminating device; a discharge station is arranged on the discharge device; a split shaping mold is also arranged on the rack and comprises a rotary wrapper receiving plate and mold cups, which are independent of each other. The compact stuffed food shaping machine can achieve immediate cooking of stuffed food and reduction of transport and circulation links, can avoid freezing, enables the taste of the stuffed food to be closer to the tastes of traditional hand-made dumplings and are applicable to the food and beverage industry, farmers' markets, dining halls of enterprises, organs and organizations, and the like.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Novel enhanced systems, processes and methodologies for producing clean water and products thereby

InactiveUS20080073200A1Low costFacilitates time and cost and efficient disposalAuxillariesGeneral water supply conservationIndustrial waste waterDistillation

Improved methods for carrier-gas humidification / dehumidification [HDH] or dewvaporization enable production of clean water, derived in part from models generated and tested with produced water from the oil and gas industries, which likewise address industrial waste water remediation and generally facilitate the time and cost efficient disposal of waste waters from a plurality of industries ranging from food, wine, and beverage production to novel enhanced efficiencies within the oil and gas industries themselves. High efficiency carrier gas HDH thermal distillation functions without membranes, at ambient or near ambient pressures with no required pre- or post-treatment, and economies of scale to leverage a plastics-based processing platform. Industrial waste water including that generated by the food, wine, and beverage industries, among others, is likewise ameliorated according to the instant teachings.

Owner:ALTELA

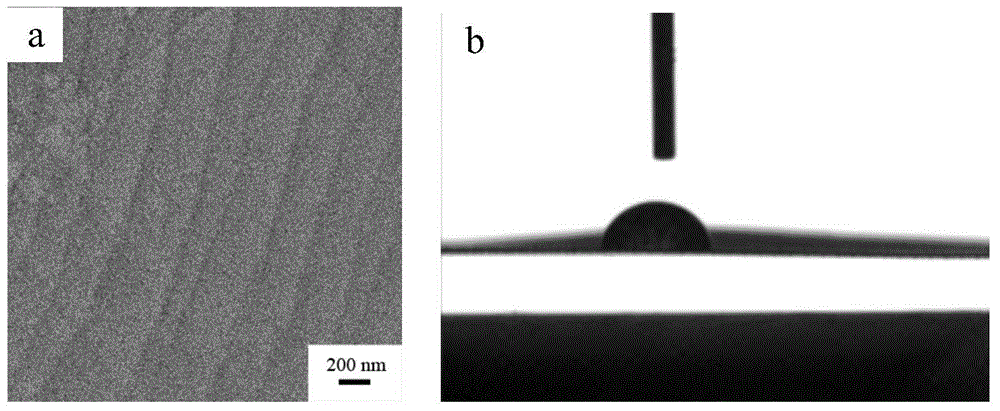

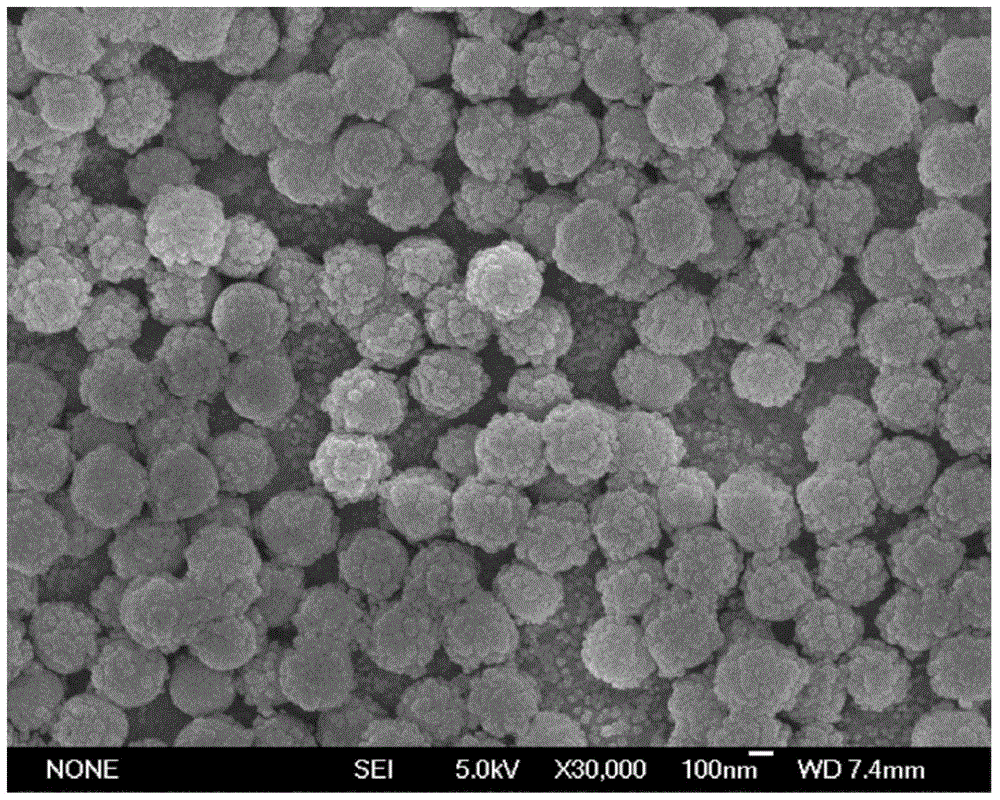

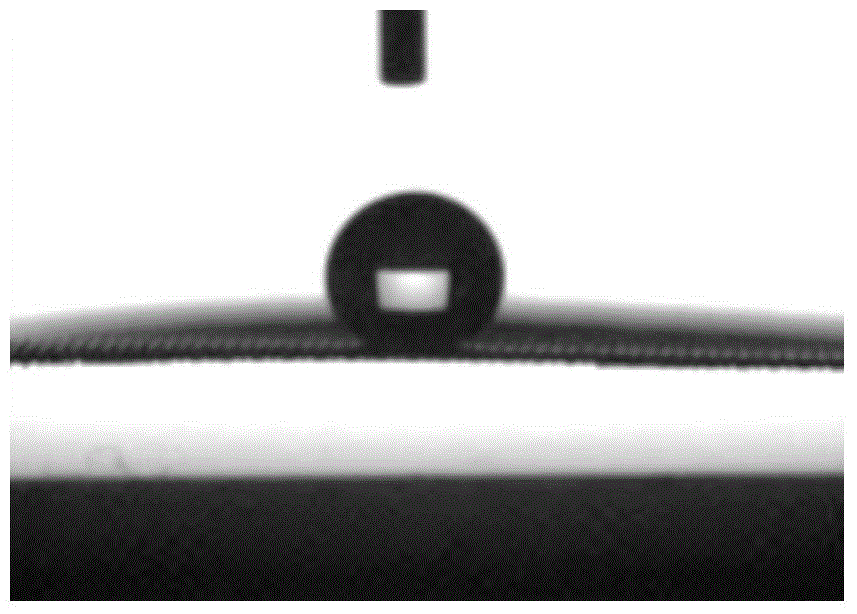

Super-hydrophobic coating layer used for oil-water separation and having hierarchical structure, super-hydrophobic material thereof, and preparation method of material

ActiveCN104802488AEasy to separateSimple processLayered productsCoatingsChemical industryOil water emulsion

The invention belongs to the technical field of preparation of nano-materials, and relates to a super-hydrophobic oil-water separation material containing a hierarchical structure coating layer. The hierarchical structure coating layer is formed by a layer of solid spherical SiO2 nano-particles with the particle size of 10-50nm and the particle size of 70-500nm, and the surface of the coating layer is provided with a layer of a low surface energy substance. The coating layer is obtained through layer-by-layer electrostatic in situ self-assembling, and can be used on stainless steel wire nets, stainless steel fiber sintered felts and other metal net products. The water contact angle of the stainless steel sintered nets coated with the hierarchical structure coating layer can exceed 150DEG. The material is simple to prepare, can be used to process filter core materials in coalescence separators, can be repeatedly used in oil-water separation, especially has a good separation effect on an oil-water emulsion, and can be widely used in oil-containing sewage treatment in the petroleum chemical industry, the metallurgy industry, the chemical engineering industry, the beverage industry, the food industry and the pharmacy industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

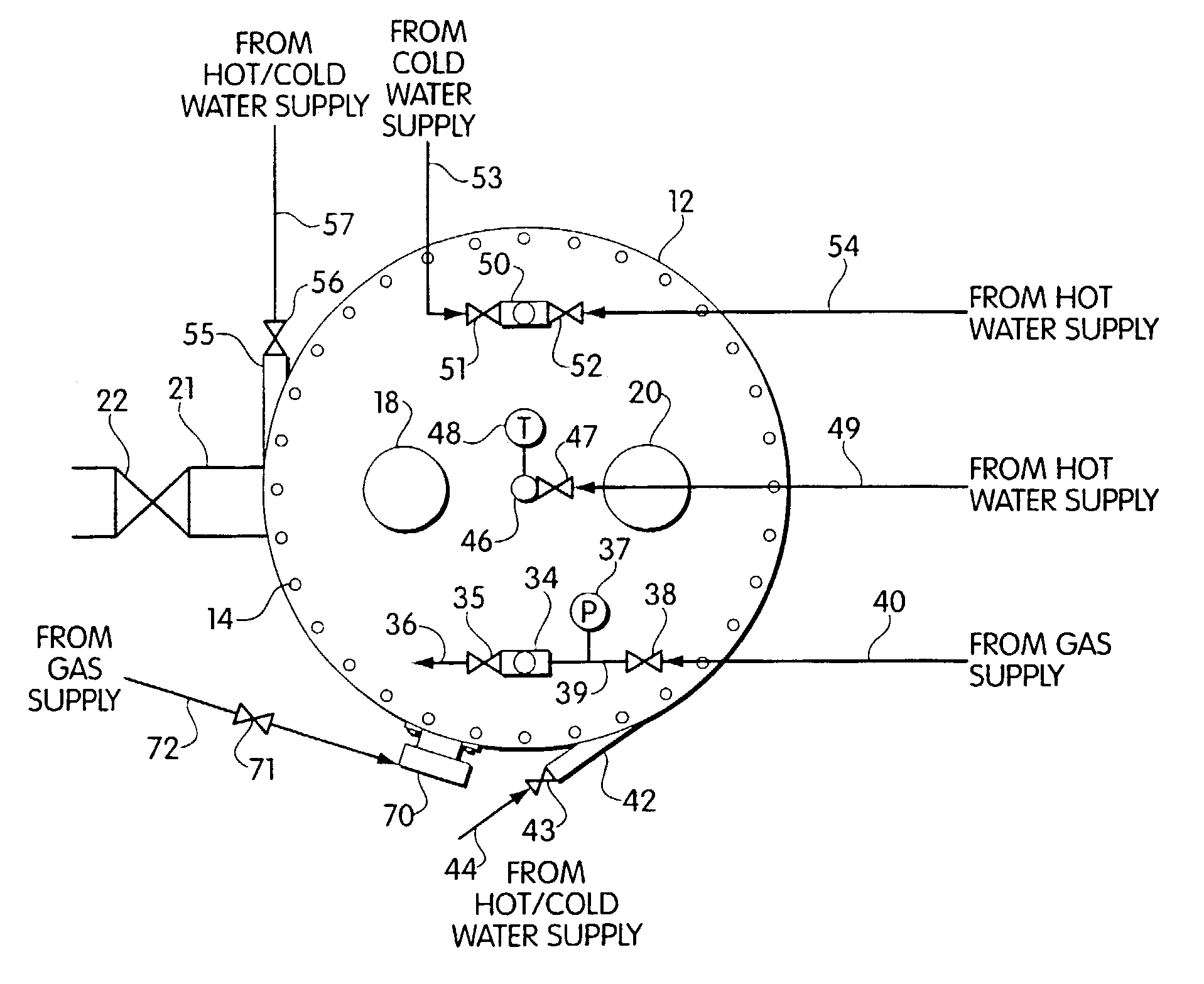

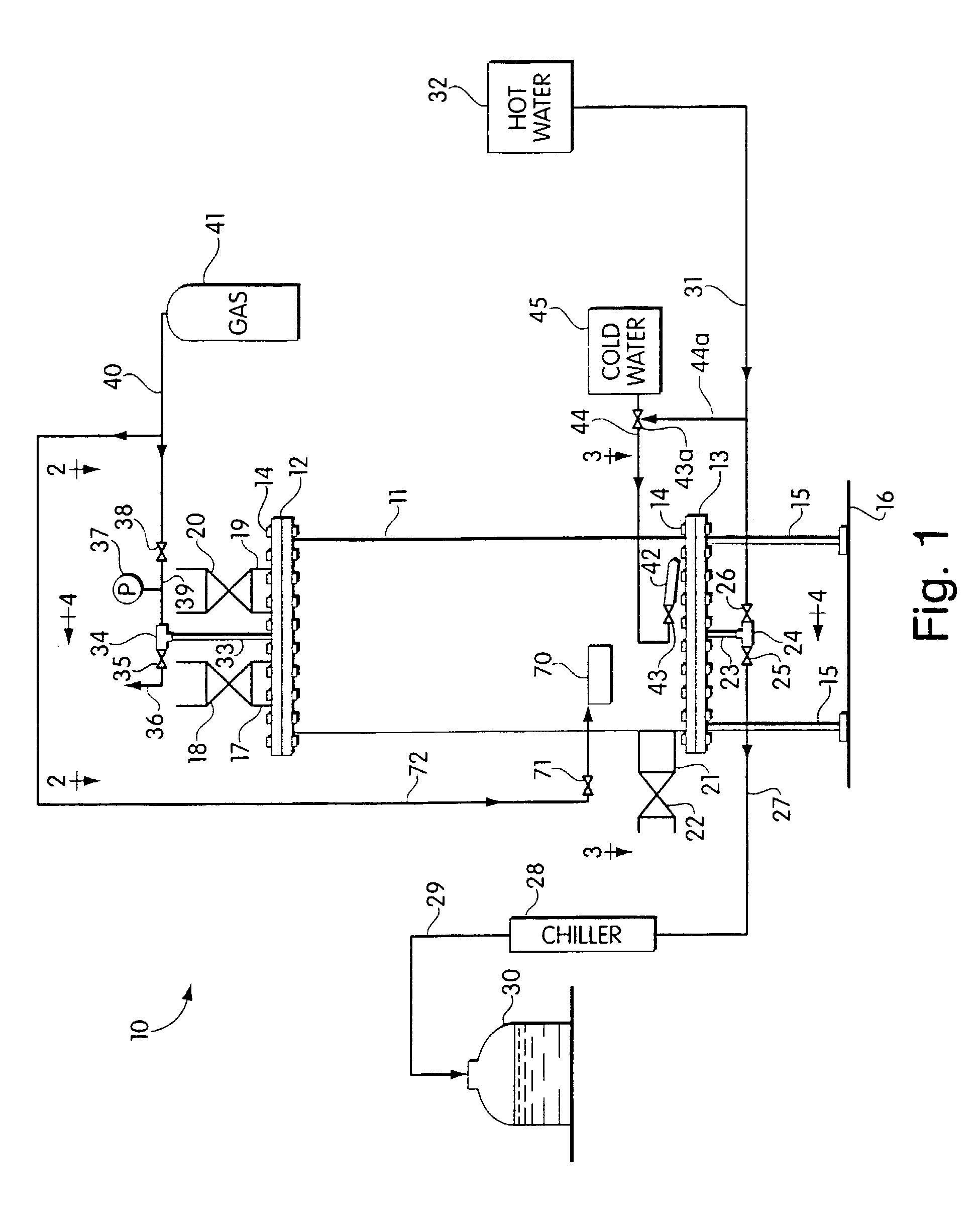

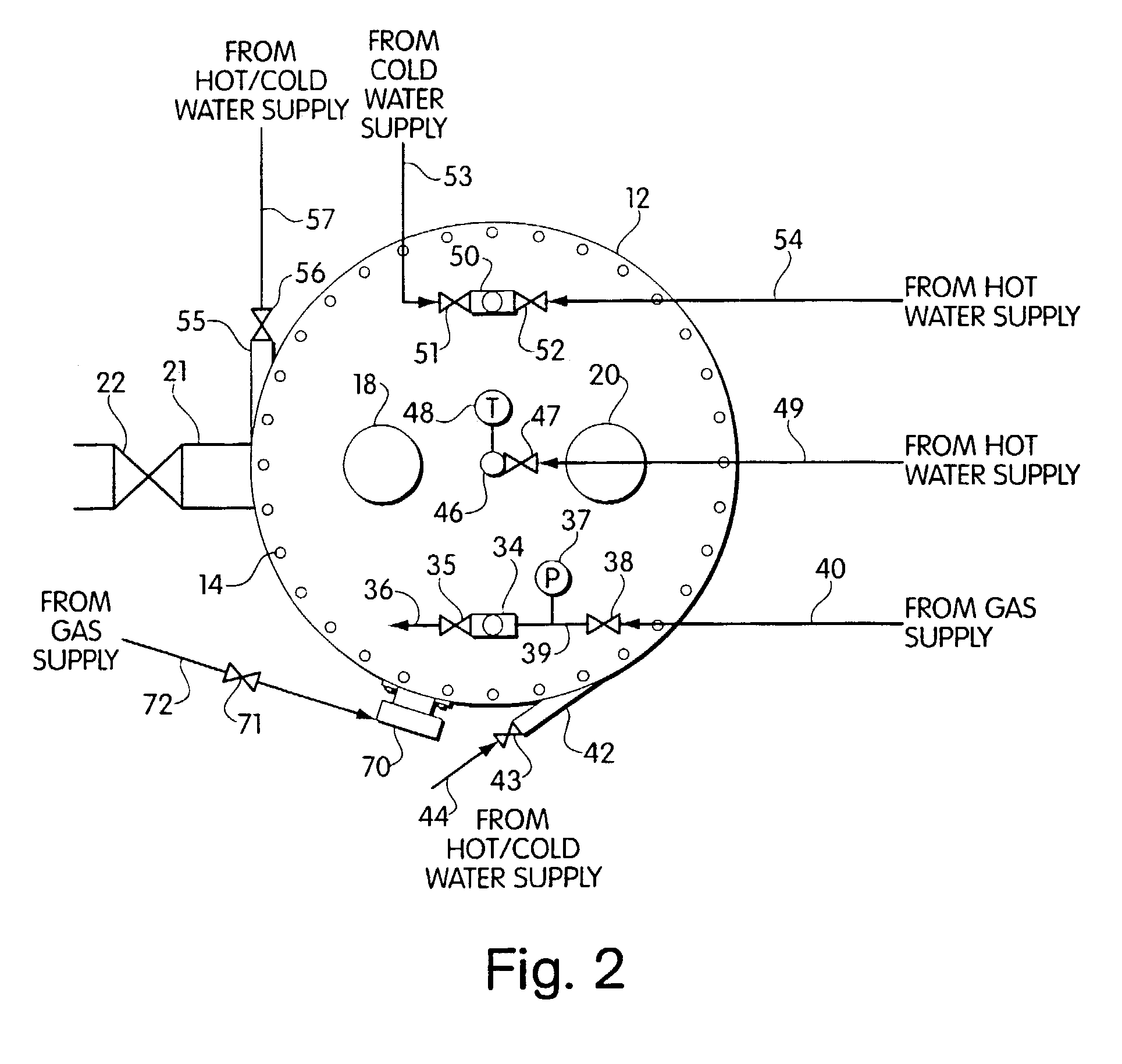

Coffee system

InactiveUS20050112253A1Excellent and desirable and flavorExcellent and desirable and and qualityTea extractionAlcoholic beverage preparationHigh concentrationEngineering

Typical current methods for producing large quantities of extracts from solid raw materials such as ground, roasted coffee are designed for exhaustive extraction. Such methods are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides methods and apparatus for producing such high quality extracts. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial-scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances. The inventive extraction methods, in some embodiments, involve subjecting roasted coffee to a static pressure treatment with pressurized solvent and / or removing extract from the bed of roasted coffee with a non-solvent gas as a final extraction step. The inventive methods can reduce the extent of extraction of the roasted coffee and the level of bitter, off-flavor components present in the coffee extracts. The extracts produced according to the invention can be advantageously used for applications where high quality coffee extracts, with a relatively high concentration of soluble coffee solids and a relatively high level of sweetness but without substantial amounts of bitter oils and acids, are desired.

Owner:KERRY GROUP SERVICES

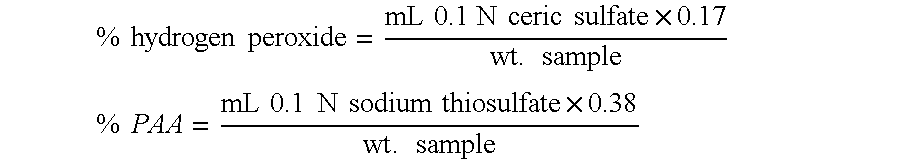

Methods and compositions for the generation of peracetic acid on site at the point-of-use

ActiveUS20120245228A1Easy to implementReduce operating costsBiocideDetergent mixture composition preparationAlkaline earth metalBleach

Methods and compositions for the generation of a peroxyacetic acid sanitizer in proximity to the point-of-use are disclosed. These methods comprise introducing a hydrogen peroxide-acetyl precursor solution to water, mixing, and then adding an aqueous source of a alkali metal or earth alkali metal hydroxide. Triacetin is a preferred acetyl precursor and is converted rapidly and with a high conversion rate into peracetic acid. These methods produce solutions with a high level of peracetic acid. Methods for preparing the hydrogen peroxide-acetyl precursor solution are also provided. Also disclosed are solid compositions comprising a liquid acetyl precursor, a water-soluble source of hydrogen peroxide, and a water-soluble source of alkalinity. The solid composition is a freely-flowable solid that is used as a bleaching agent and a stain remover for the treatment of articles such as fabrics, dentures, textile garments, and equipment used in the food and beverage industry.

Owner:ENVIRO TECH CHEM SERVICES

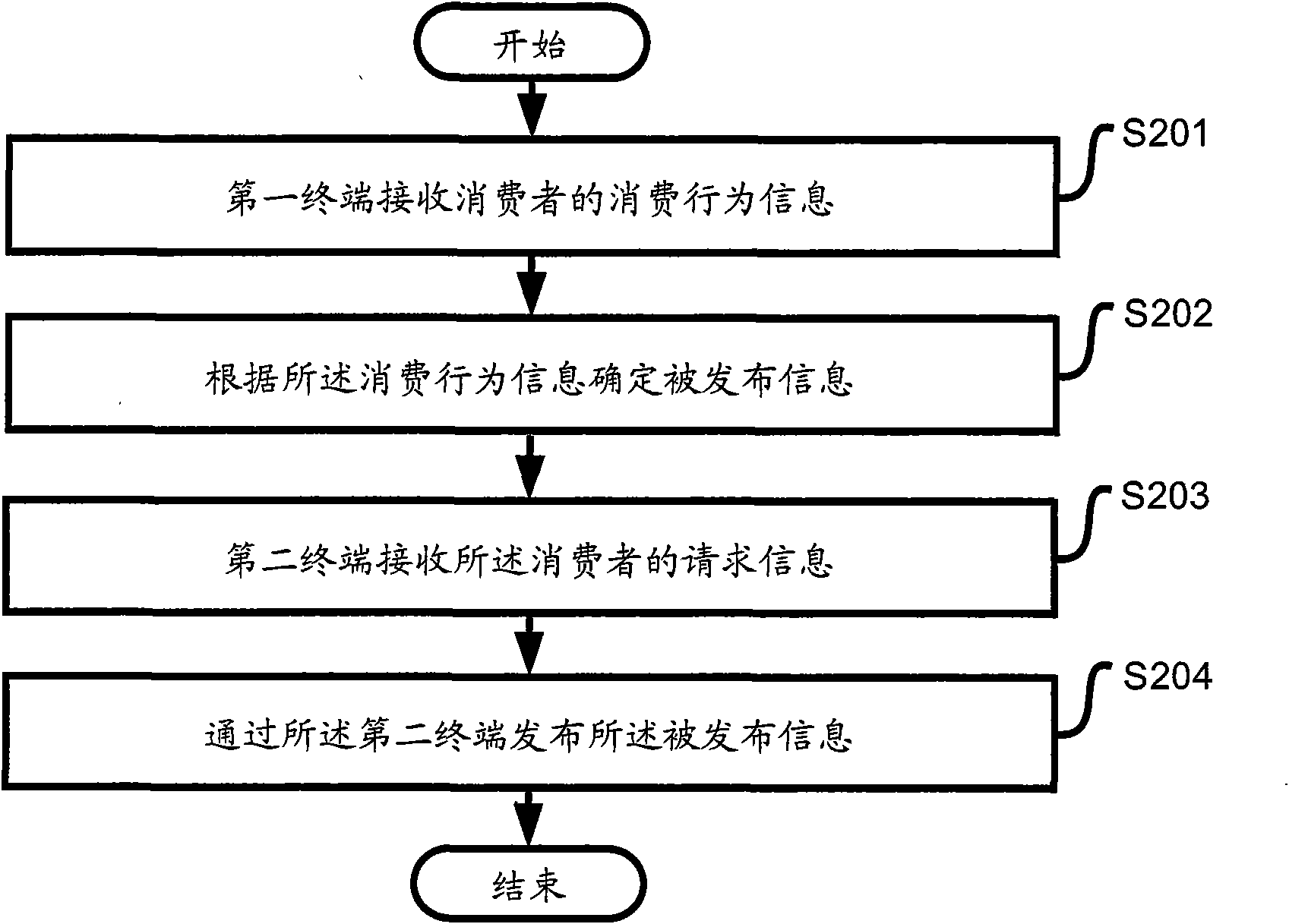

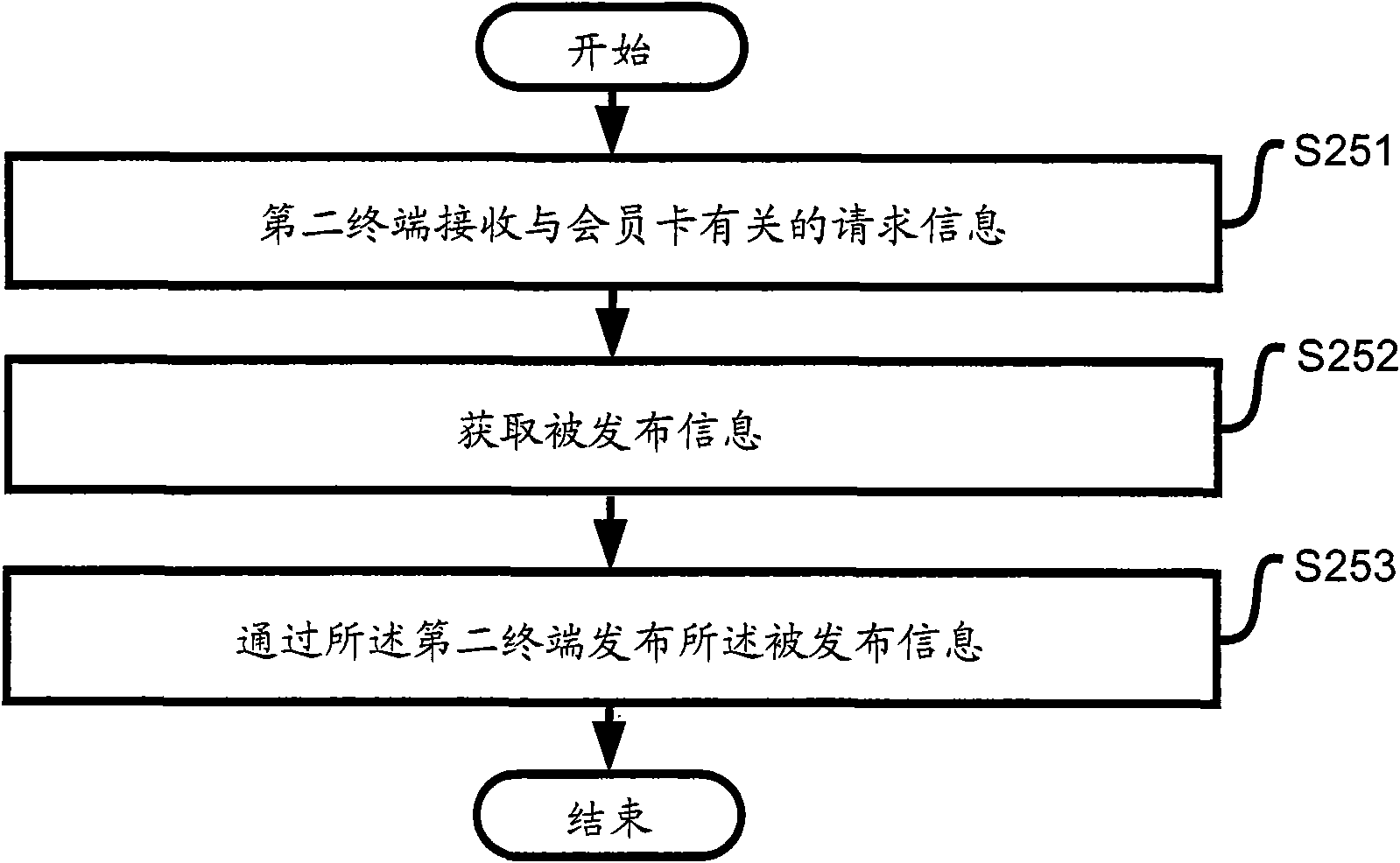

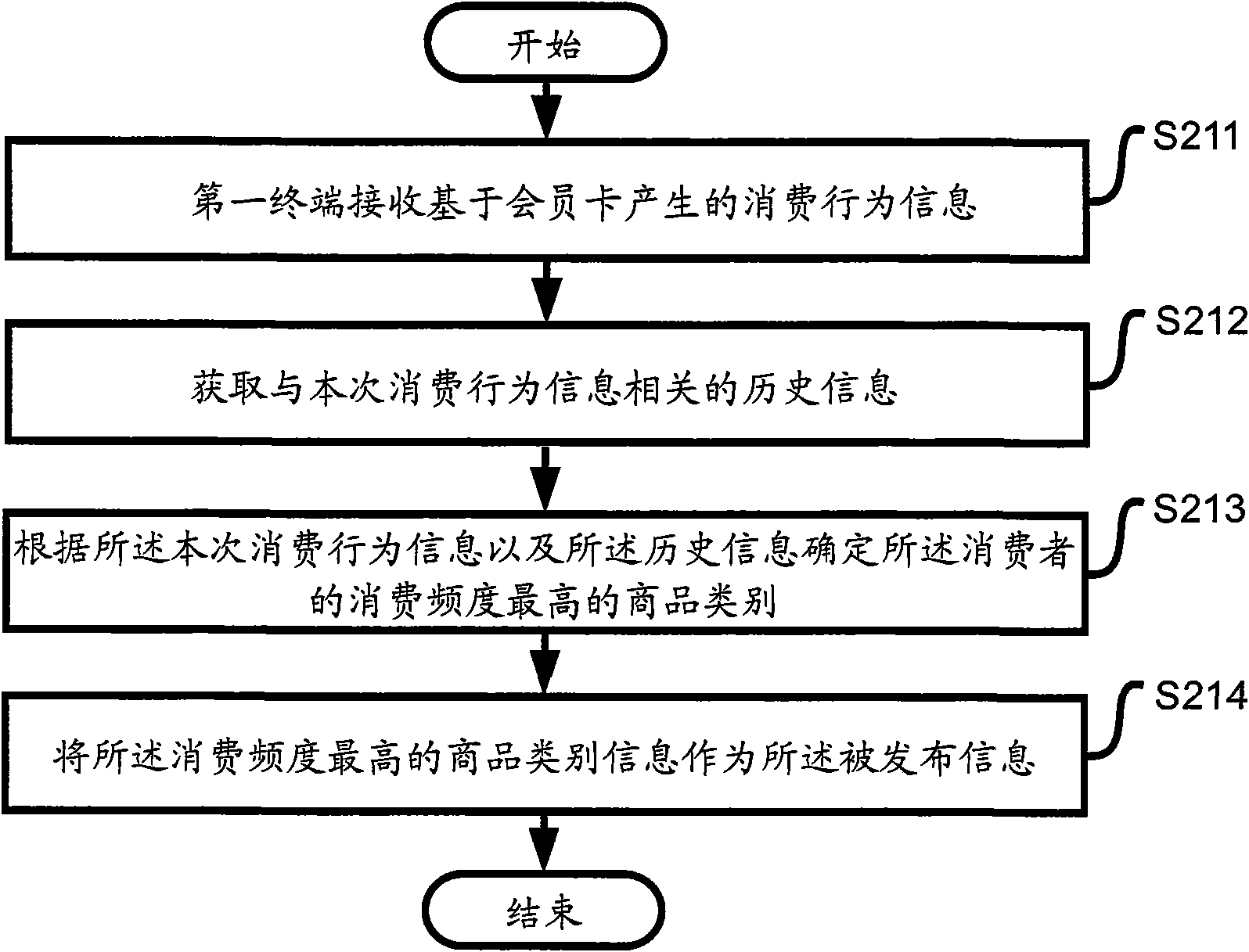

Control method and system for distributing information through multiple associated terminals

The invention provides a control method for distributing information through multiple associated terminals. The method comprises the following steps that: a, a first terminal receives consuming behaviour information of a consumer; b, distributed information is determined according to the consuming behaviour; c, a second terminal receives request information of the consumer; and d, the distributed information is distributed through the second terminal. The invention also provides a control system for distributing information through the multiple associated terminals. By associating a plurality of terminals serving as different parts, the process of distributing different information through different terminals is realized and the information has relevance, so that the same consumer or the same group of consumers acquire different information on different terminals, particularly more accurate information. More specifically, when the method and the system are applied in food and beverage industry, different information can be provided before and after the consumption of consumers, so that the subsequent consuming process of the consumer is guided with pertinence and best interest is provided to advertisers and advertising companies.

Owner:WEIPENG INFORMATION TECH SHANGHAI CO LTD

Method for fermenting fruit and vegetable pulp by adopting plant probiotics

PendingCN105995710AEfficient removalGuaranteed energy supply for growthFood scienceBiotechnologyOrganic acid

The invention provides a method for fermenting fruit and vegetable pulp by adopting plant probiotics, and is used for solving the problems that low-acid and acidic fruit and vegetable puree has shorter shelf life, the product flavor is not good, the processing cost is high and nutrition loss is serious during processing. The method is specifically completed by the steps of fruit and vegetable pretreatment, crushing, softening, fruit and vegetable pulping, mixing, primary sterilization and cooling, fermentation, centrifuging, degassing, homogenization, secondary sterilization and cooling and sterile filling. The method has the beneficial effects that the fruit and vegetable pulp with weaker acidity is fermented by different lactobacillus to generate plenty of organic acids, such as lactic acid, thus reducing the pH value of the fruit and vegetable pulp, generating better fermentation flavor at the same time, reducing the sterilization conditions and retaining the nutrients of fruit and vegetables and increasing the nutrients of the fermentation product while saving cost; meanwhile, the fermented fruit and vegetable puree is centrifuged by a horizontal spiral centrifuge to separate yeast mud, thus effectively improving the utilization stability of the fermented fruit and vegetable pulp in the beverage industry.

Owner:山西达明一派食品有限公司

Sanitizing and cleaning composition and its use for sanitizing and/or cleaning hard surfaces

ActiveUS7943565B2Low foamingReduce the smellInorganic/elemental detergent compounding agentsBiocideBiotechnologyOrganic acid

Owner:JOHNSONDIVERSEY INC

Conveyor lubricants for use in the food and beverage industries

InactiveUS20040167044A1Provide compatibilityAvoid formingOrganic chemistryLiquid carbonaceous fuelsCarboxylic saltEther

A lubricant concentrate comprising an effective lubricating amount of at least one ether carboxylate and at least one foam destabilizer, and methods of using the same. The lubricant concentrate may be diluted with water prior to use.

Owner:ECOLAB USA INC

Trametes gallica, culture method and application thereof

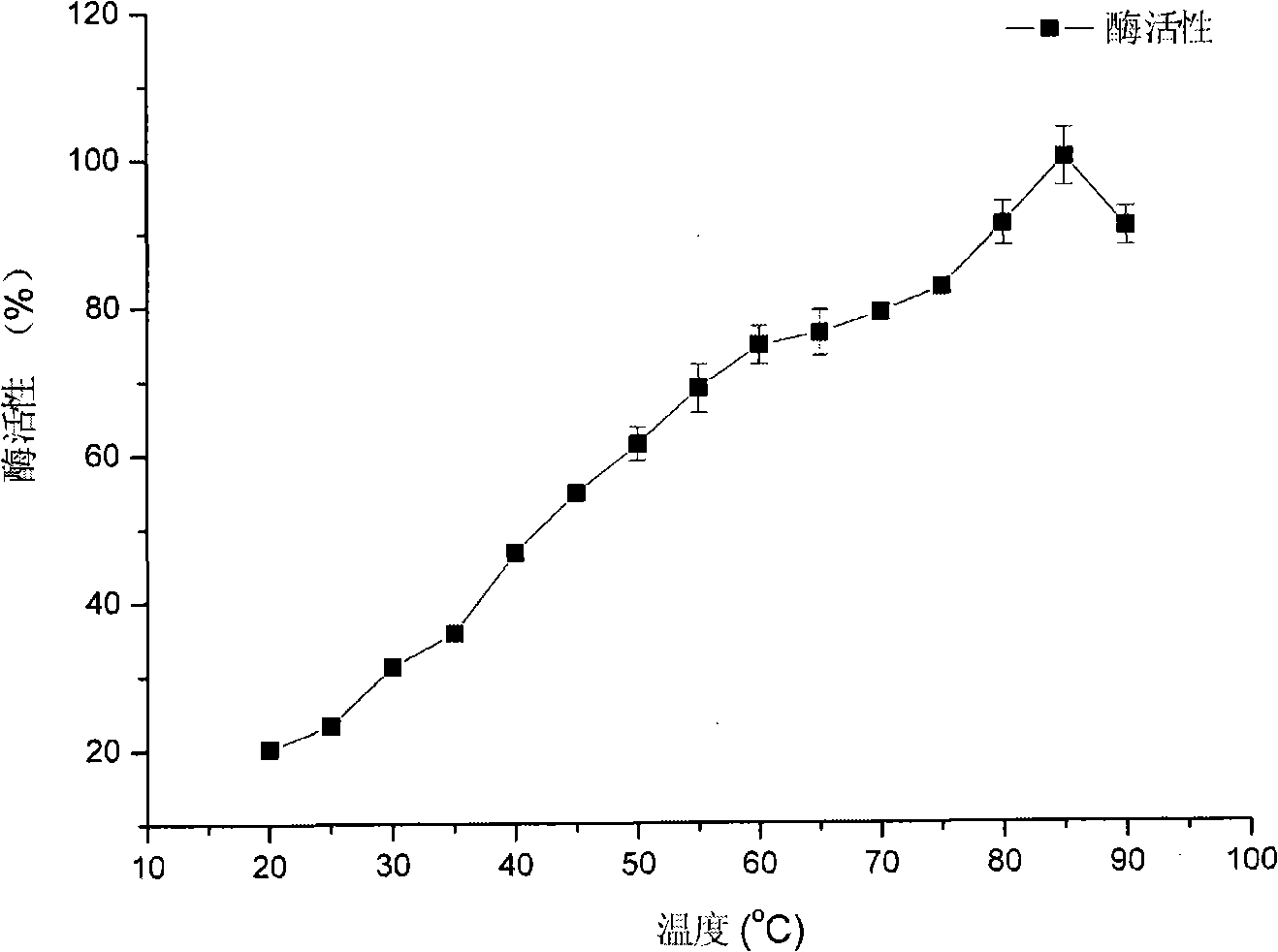

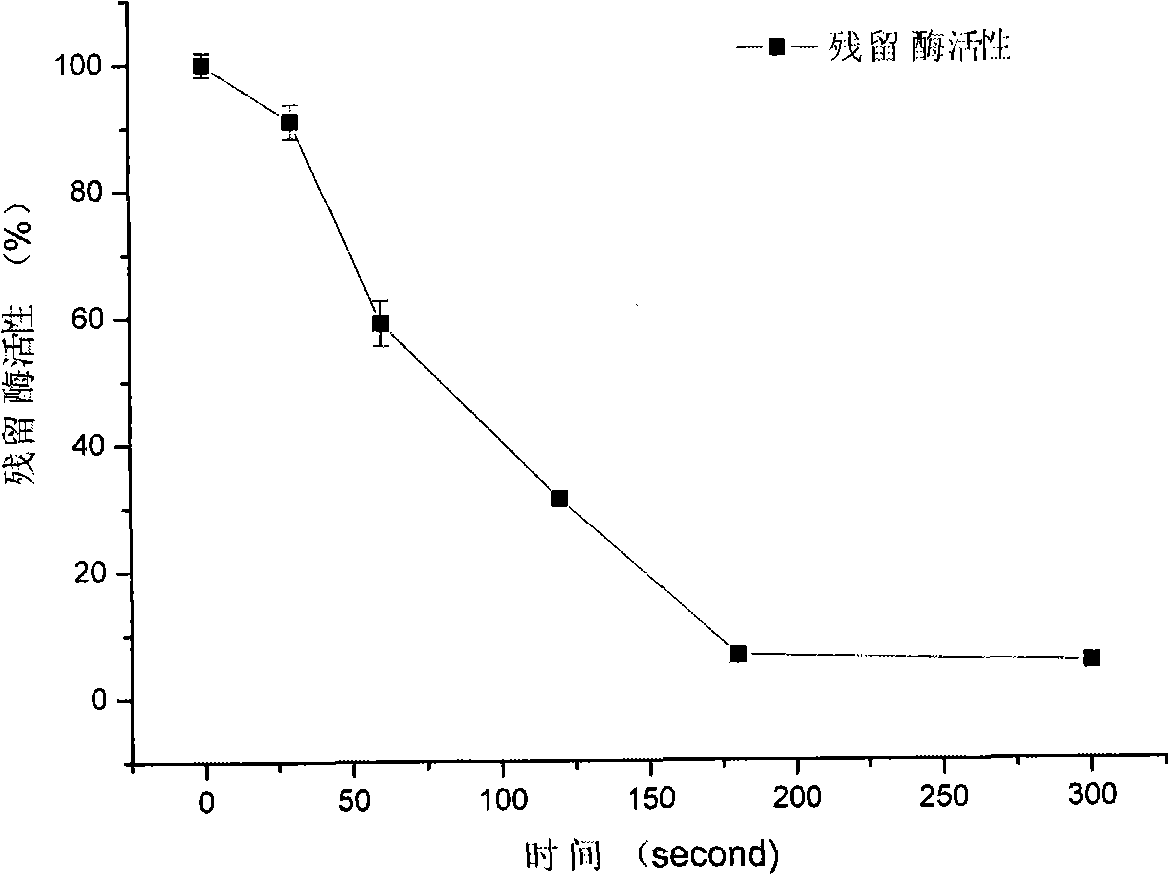

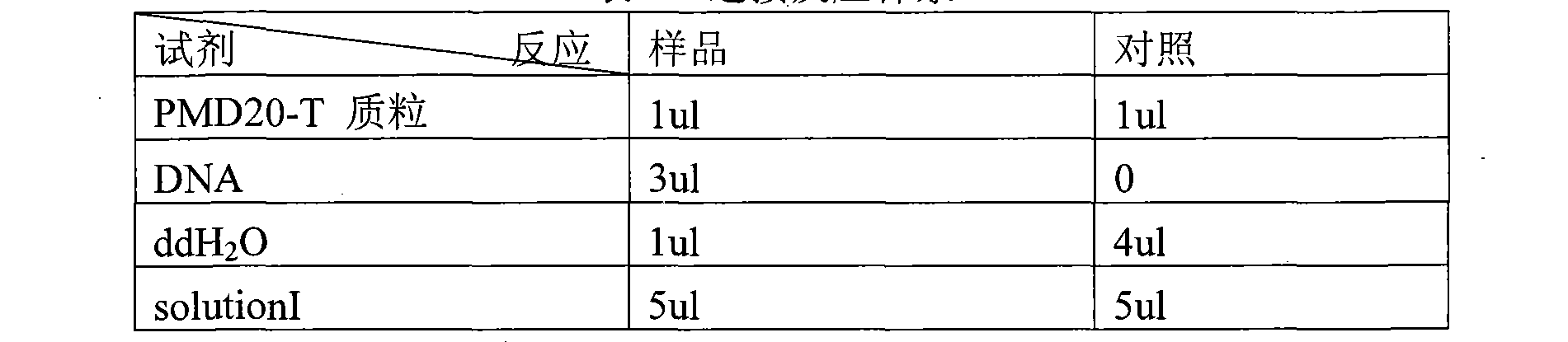

InactiveCN101280277AImprove thermal stabilityStrong temperature dependenceCellulosic pulp after-treatmentFungiOrganic synthesisPapermaking

The invention discloses bacterial strain trametes hirsuta 1g-9 produced by heat resistance laccase and a culturing method and the application thereof, which belongs to the technical field of the microorganism. The preservation number of the bacterial strain trametes hirsute 1g-9 is CGMCC No.2422; the bacterial strain trametes hirsute 1g-9 can be cultured through mill offal leach liquor slant culture or activated through PDA solid slant culture medium, to ferment the culture medium through the mill offal leach liquor to enlarge the culture; the bacterial strain trametes hirsuta 1g-9 can be applied to the industrial papermaking, the paper pulp modification, the papermaking sewage treatment, the dyeing and printing sewage treatment, the food industry, the beverage industry, the clothing industry and the organic synthesis industry.

Owner:SHANDONG UNIV

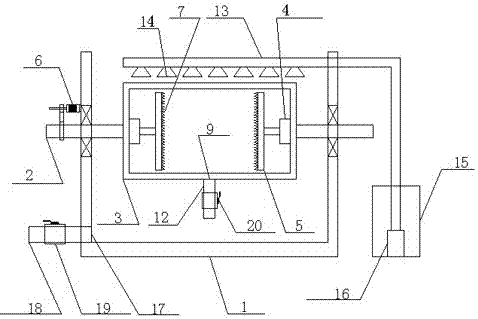

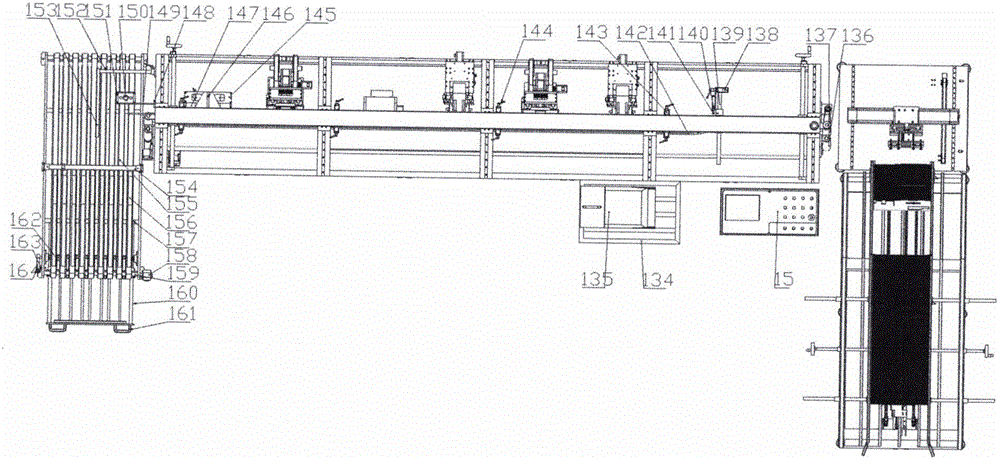

Drum-type fruit crushing device

InactiveCN107051629AEasily brokenImprove crushing efficiencySievingScreeningFruit juiceBeverage industry

The present invention relates to the technical field of mechanical equipment in the beverage industry, in particular to a drum-type fruit crushing device, which includes a juice collection tank with an open upper end, and a crushing mechanism arranged laterally in the juice collection tank, and the crushing mechanism includes The two rotating shafts arranged symmetrically through the bearings on the left and right side walls of the juice collection tank, the screen drum horizontally arranged between the two rotating shafts, the right end face of the left side cover of the screen drum and the left end face of the right side cover are symmetrical The two air cylinders provided, and the extruding plates installed on the moving ends of the air cylinders. The present invention has a simple structure and a reasonable design. Through the relative movement of two symmetrically arranged extrusion plates, the fruit is squeezed and crushed. At the same time, the motor is driven to drive the sieve cylinder to rotate, and the juice is thrown into the juice collection tank. After the fruit is broken, Through the nozzle on the water spray pipe, clean water is sprayed to clean the sieve cylinder and the juice collection tank, which greatly improves the work efficiency, simplifies the equipment and reduces the occupied area of the equipment.

Owner:JIYUAN YIHEYUAN BEVERAGE

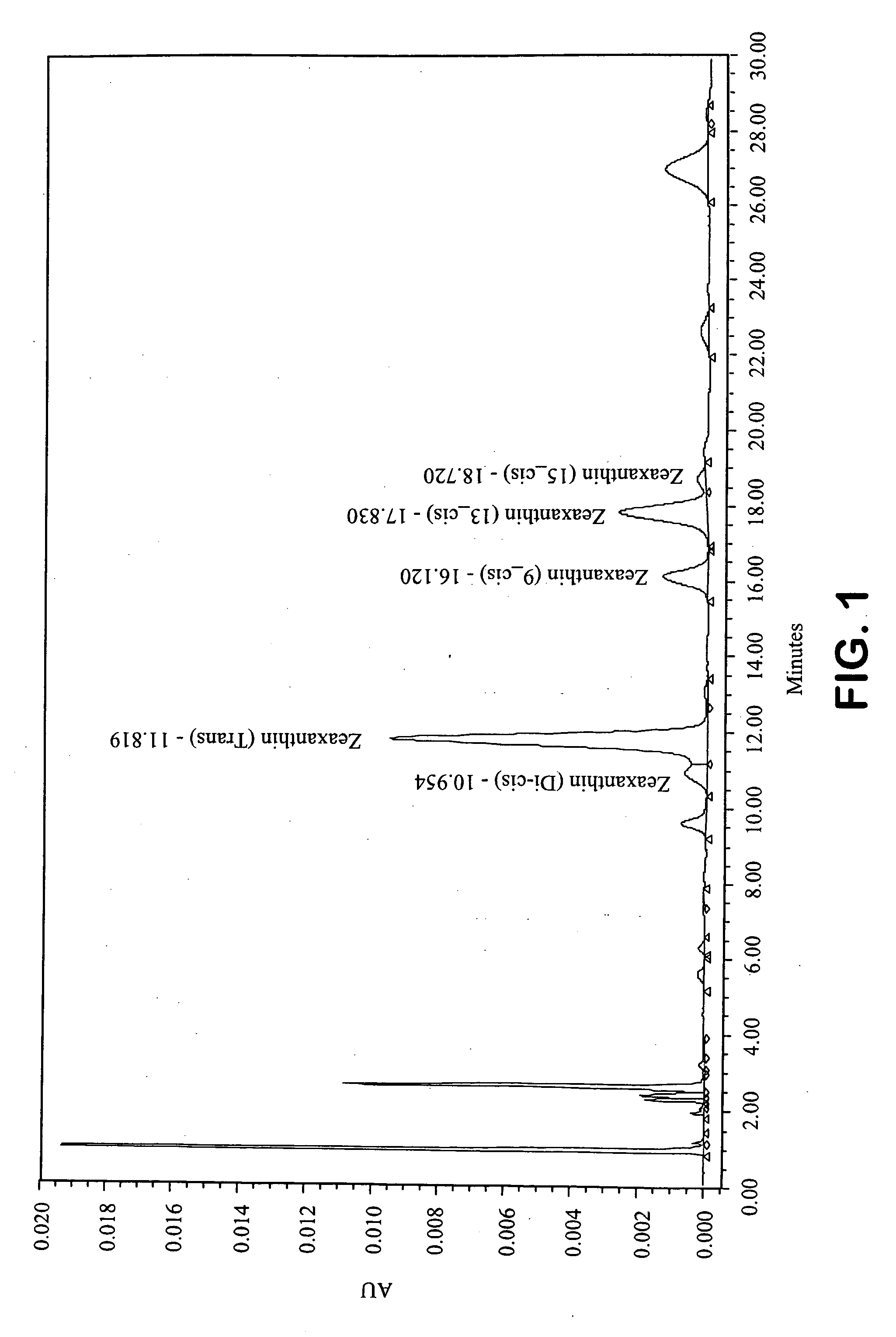

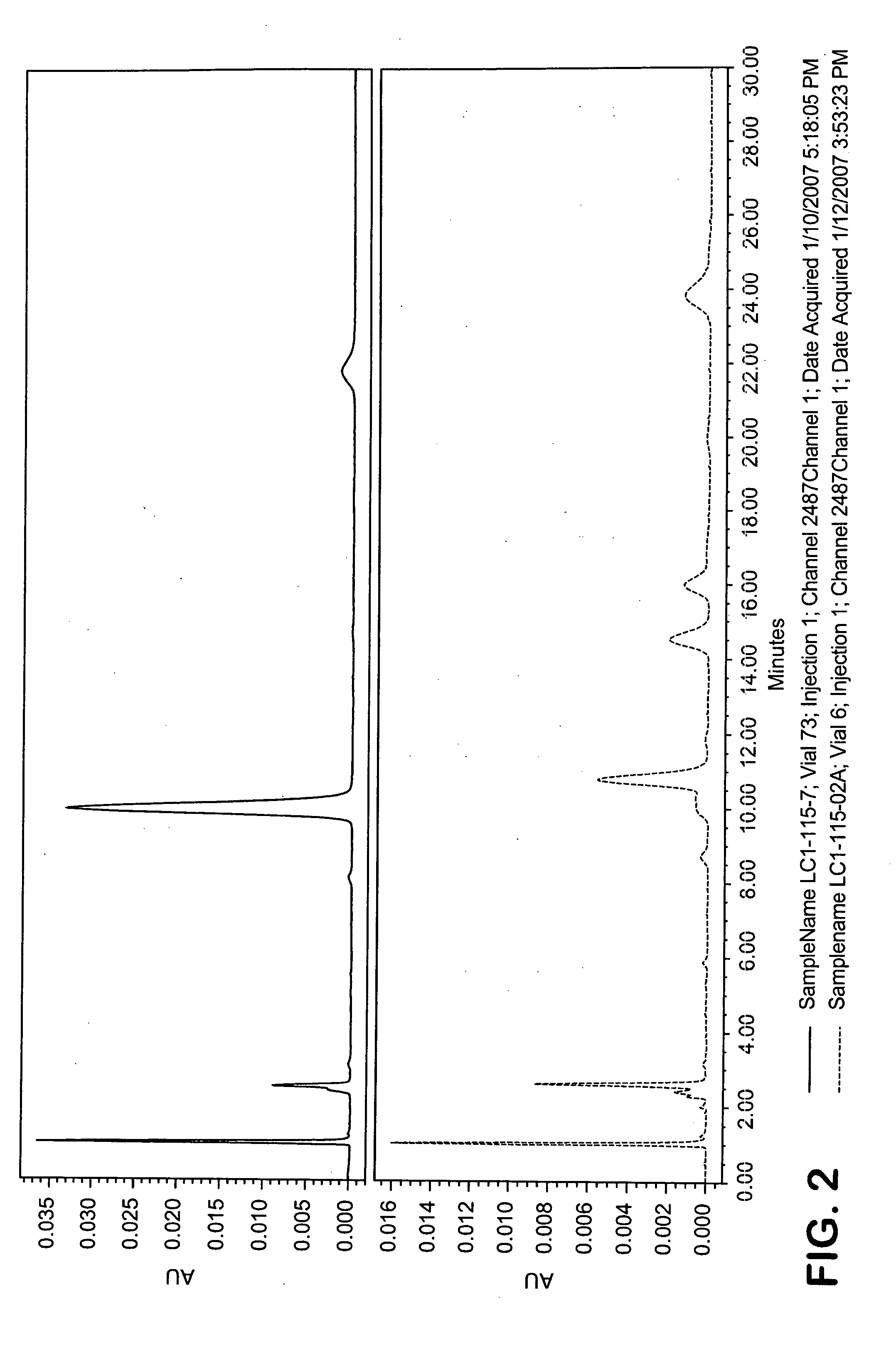

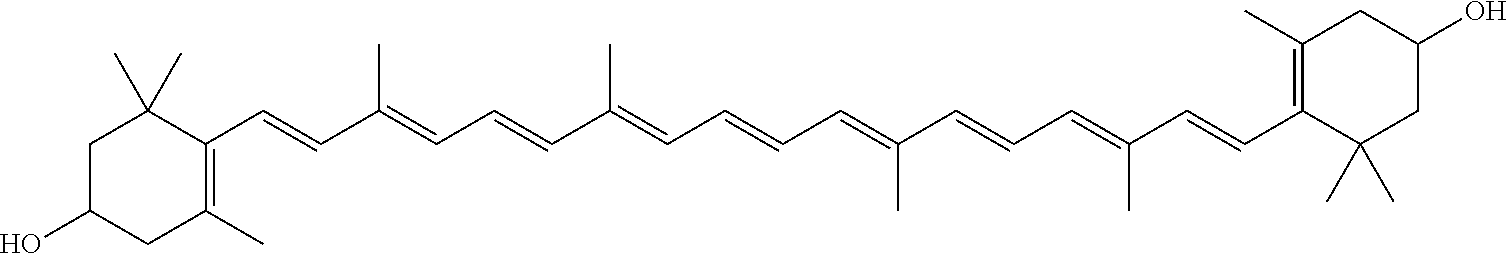

Process of converting esterified xanthophylls from capsicum to non-esterified xanthophlls in high yields and purities

ActiveUS20110282083A1High yieldHigh purityCosmetic preparationsOxygen-containing compound preparationBeverage industryPlant Sources

The present invention is concerned with a process to convert xanthophyll esters derived from Capsicum sources to their free (non-esterified) forms. The present invention is concerned with a process for obtaining Capsicum derived xanthophylls that meet the finished product needs for purity, yield, ease of use, industrial compatibility and cost that are required to make product suitable for the nutritional supplement, food and beverage industries. The present invention is concerned with a process which yields from 60 to 80%, of xanthophyll materials and nearly quantitative recovery of all input xanthophylls, which xanthophylls are of high purity. The present invention concerns a method to obtain xanthophyll esters present almost exclusively in the trans form when isolated from the natural plant sources. The present invention concerns a process to re-convert cis product back to the more desired trans form.

Owner:KALAMAZOO HLDG INC

Method for preparing nano-scale rice starch

InactiveCN101880332ADelicate and smooth tasteReduce pollutionPharmaceutical non-active ingredientsFood preparationSolubilityBeverage industry

The invention discloses a method for preparing nano-scale rice starch, which is characterized by comprising the following steps: (1) preparation of rice starch, (2) homogenizing treatment, (3) spray drying, (4) superfine crushing, (5) detection and (6) packing. The method has the advantages that: (1) the condition that the wet crushing is only widely applied in the beverage industry is changed by combining dry crushing and wet crushing; (2) the grain diameter of the rich starch prepared by the method can reach nano-scale; the rich starch has strong surface adsorption and affinity and good fragrance fixation, dispersibility and dissolubility, and is easily absorbed and digested in particular; the food prepared by using the nano-scale rice starch has smoother and more exquisite mouthfeel; the rich starch can be widely applied in the industries of medicaments, cosmetics and the like besides the food field; and (3) the method has simple production process, low cost and low environmental pollution, and is easy to realize industrialization.

Owner:NANCHANG UNIV

Systems, processes and methodologies for producing clean water

InactiveUS8444829B2Facilitates time and cost and efficient disposalImprove efficiencyAuxillariesGeneral water supply conservationIndustrial waste waterDistillation

Improved methods for carrier-gas humidification / dehumidification [HDH] or dewvaporization enable production of clean water, derived in part from models generated and tested with produced water from the oil and gas industries, which likewise address industrial waste water remediation and generally facilitate the time and cost efficient disposal of waste waters from a plurality of industries ranging from food, wine, and beverage production to novel enhanced efficiencies within the oil and gas industries themselves. High efficiency carrier gas HDH thermal distillation functions without membranes, at ambient or near ambient pressures with no required pre- or post-treatment, and economies of scale to leverage a plastics-based processing platform. Industrial waste water including that generated by the food, wine, and beverage industries, among others, is likewise ameliorated according to the instant teachings.

Owner:ALTELA

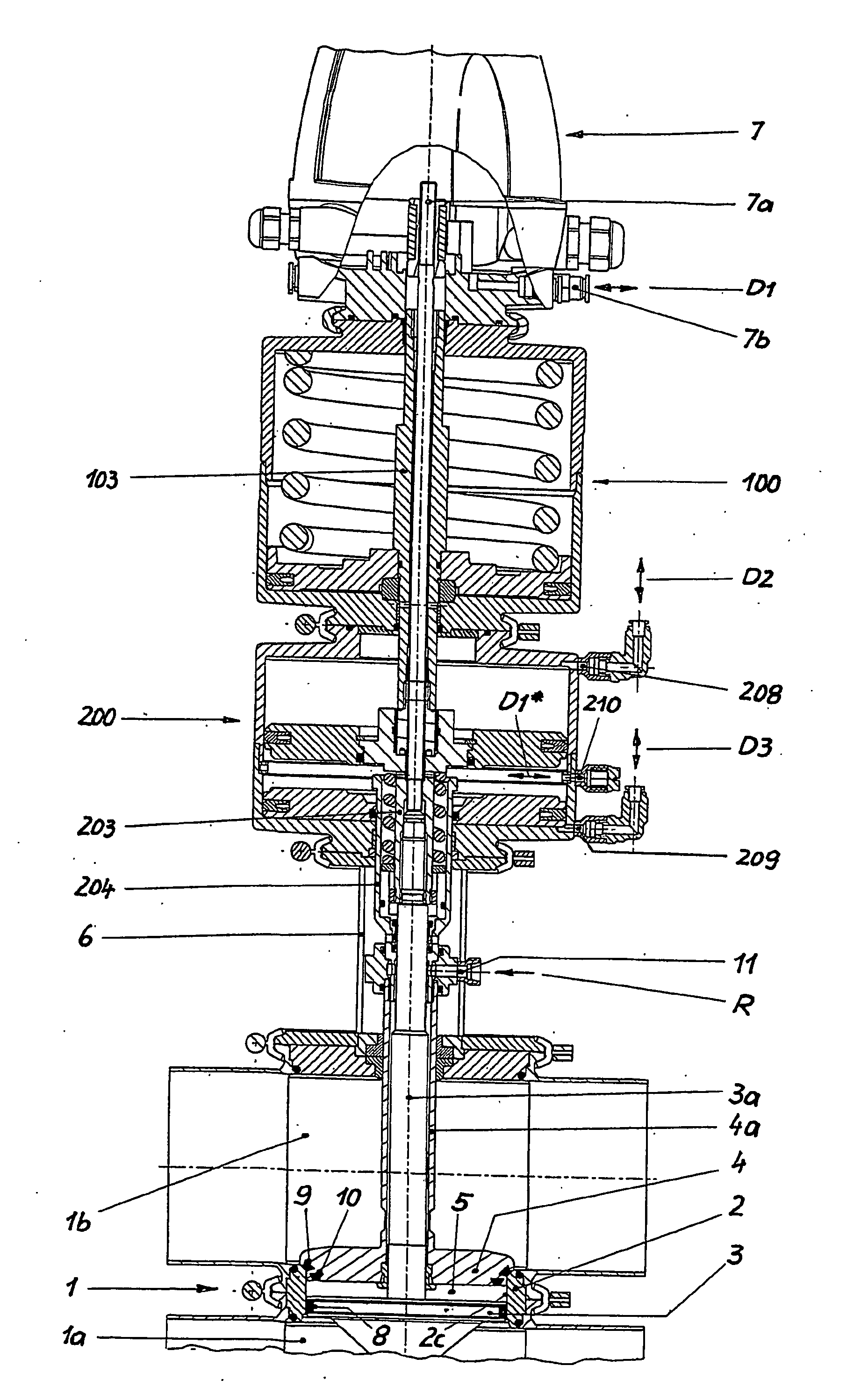

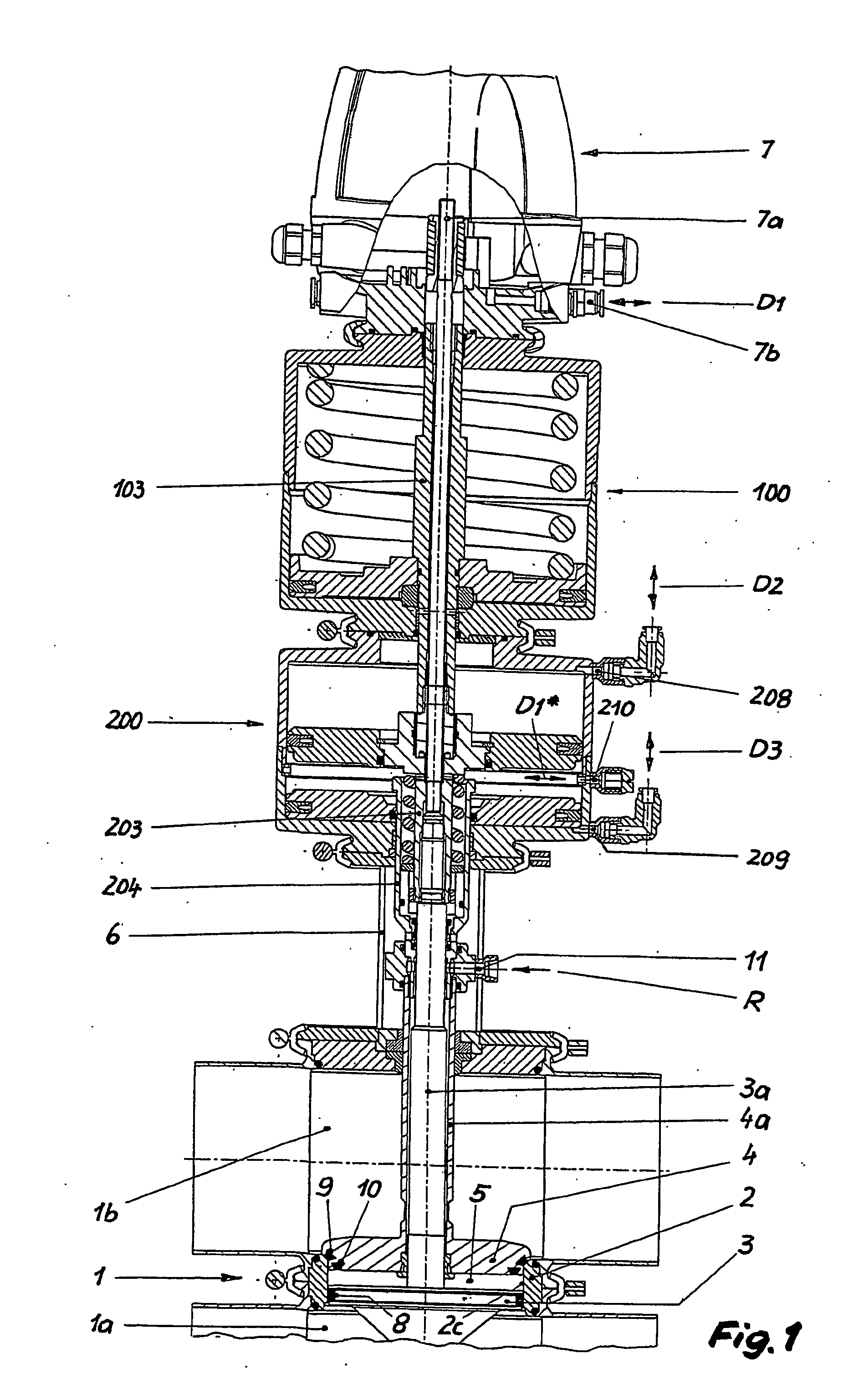

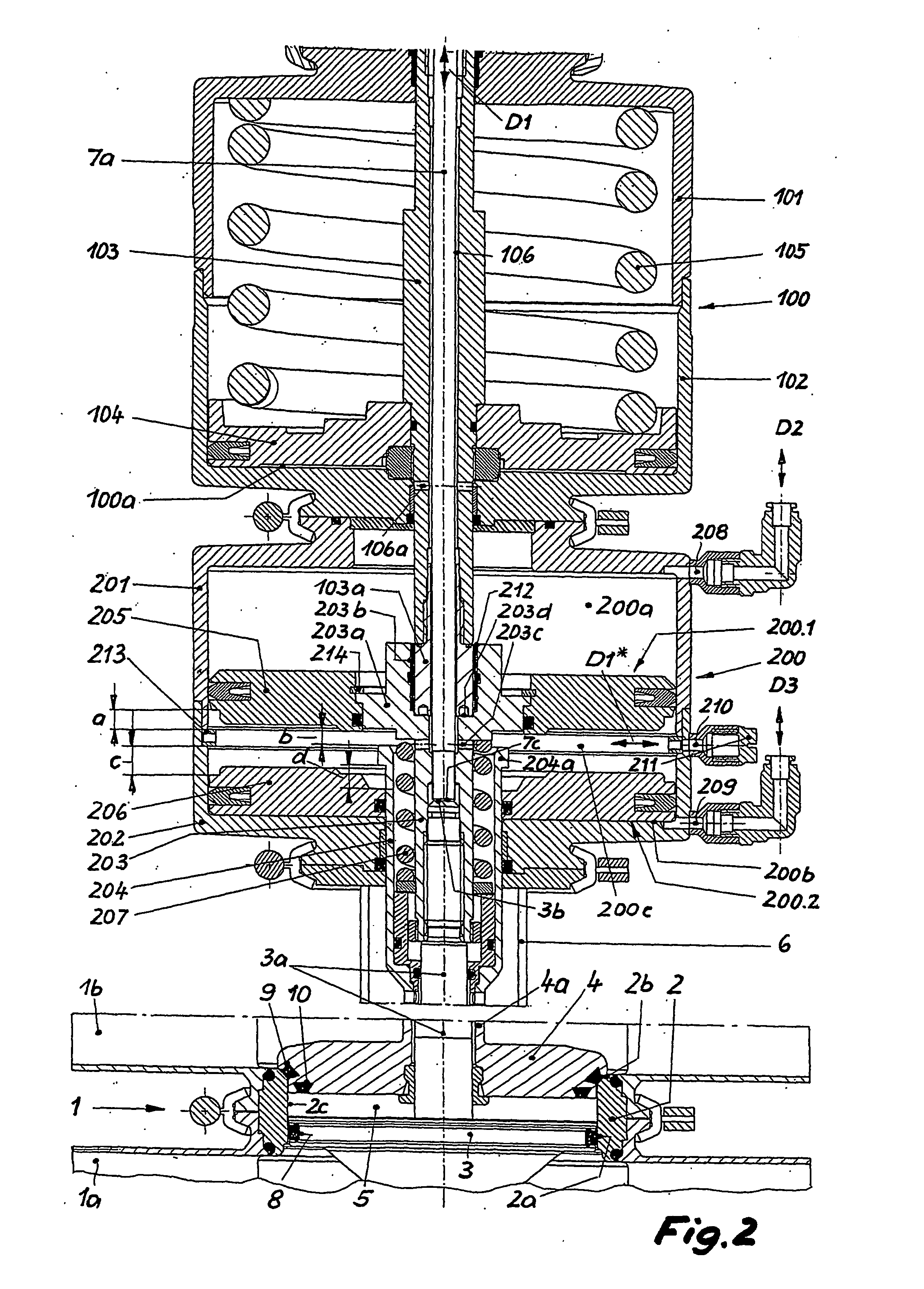

Device for actuating double seat valves

InactiveUS20060108550A1Reduce diameter sizeLow costPlug valvesOperating means/releasing devices for valvesEngineeringBeverage industry

The invention relates to a device for actuating double seat valves, which are especially suitable for the food and beverage industry and which have an independently actuated first closing element (3), which is designed as a sliding piston and a fully dependent on this actuated second closing element (4), which is designed as a seat disc, whereby the actuator (100, 200) produces at all times using a main adjustment device (100) for the fully open position (H) as well as, for the case of maximum requirements, the respective individual adjustment devices (200; 200.1, 200.2) which are assigned to the closing elements (3, 4) for generation of the partially open positions (T1, T2) acting in opposite directions for the seat cleaning of the closing elements (3, 4). The object of the invention is to design a device according to this generic type in such a manner that it is constructed as simply as possible and is easily and economically adjustable to the various requirements which are put onto a double seat valve of the type in discussion (only full opening stroke or full opening stroke as well as seat cleaning partial strokes). This is thus achieved in that the individual adjustment devices (200; 200.1, 200.2) are designed stand-alone and are additively inserted between the main adjustment device (100) and a valve housing (1), that the third working piston (206;206 / 206.1) is positioned able to be moved axially on the second control rod (4a, 204) which is designed as a hollow rod, and encloses the first control rod (3a, 203) and is able to be brought in the direction of the second partially open position (T2) in a clamped connection, that the second actuating piston (205) is tightly connected on one side with the first control rod (3a, 203) which adjusts the first closing element (3), that it is otherwise directly or indirectly positioned able to be moved axially on a first actuator stem (103) of the main adjustment device (100) and is able to be brought with this in the direction of the fully open position (H) in a clamping connection, and that it is able to be loaded with pressurizing medium on each of its two piston surfaces (FIG. 2).

Owner:TUCHENHAGEN GMBH

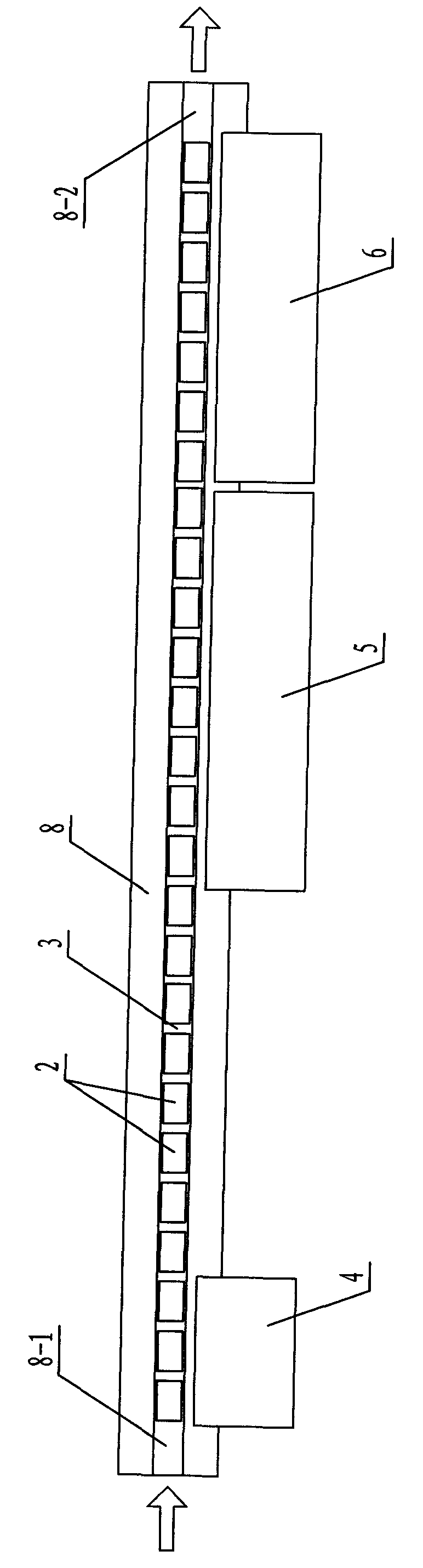

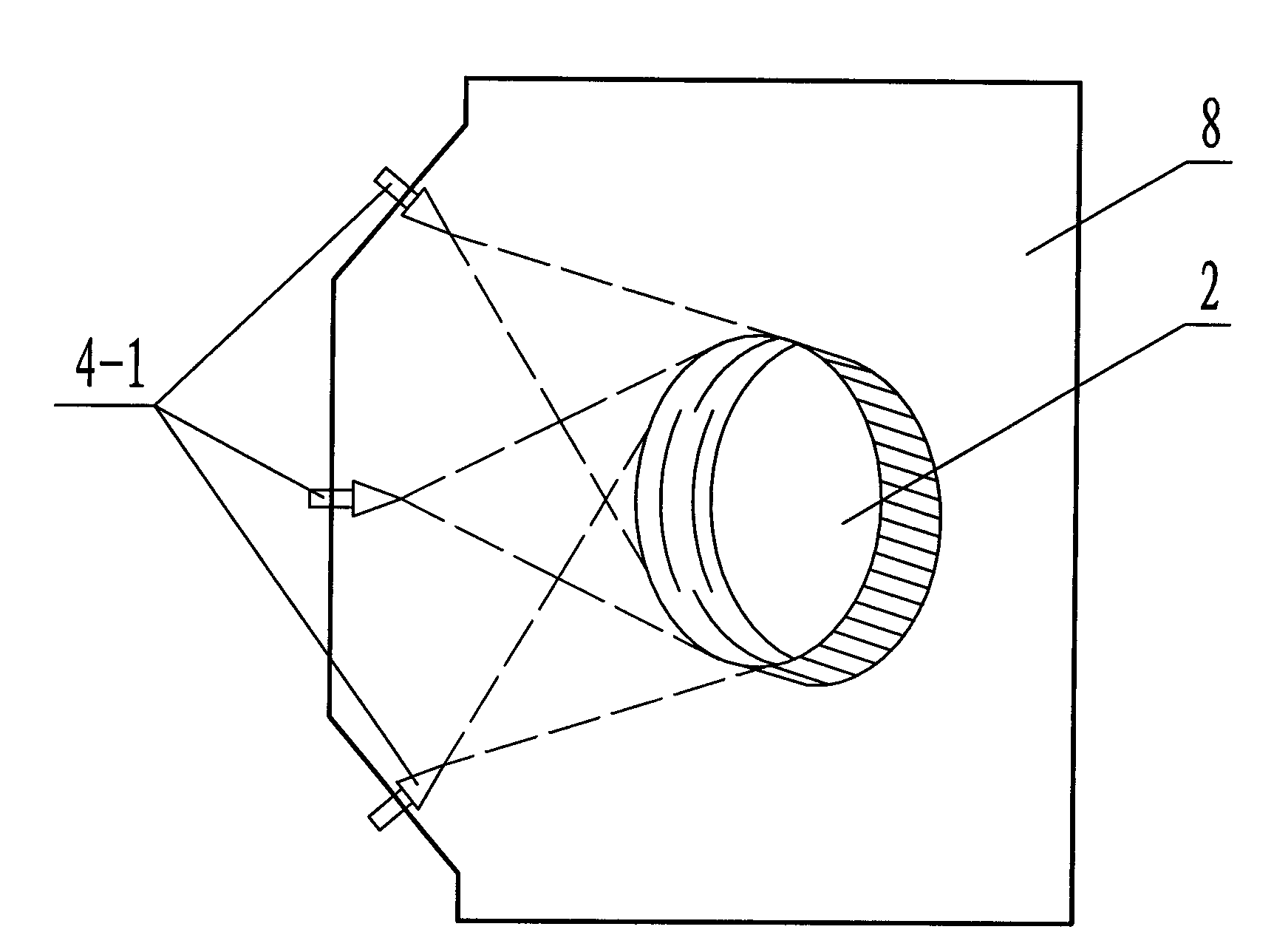

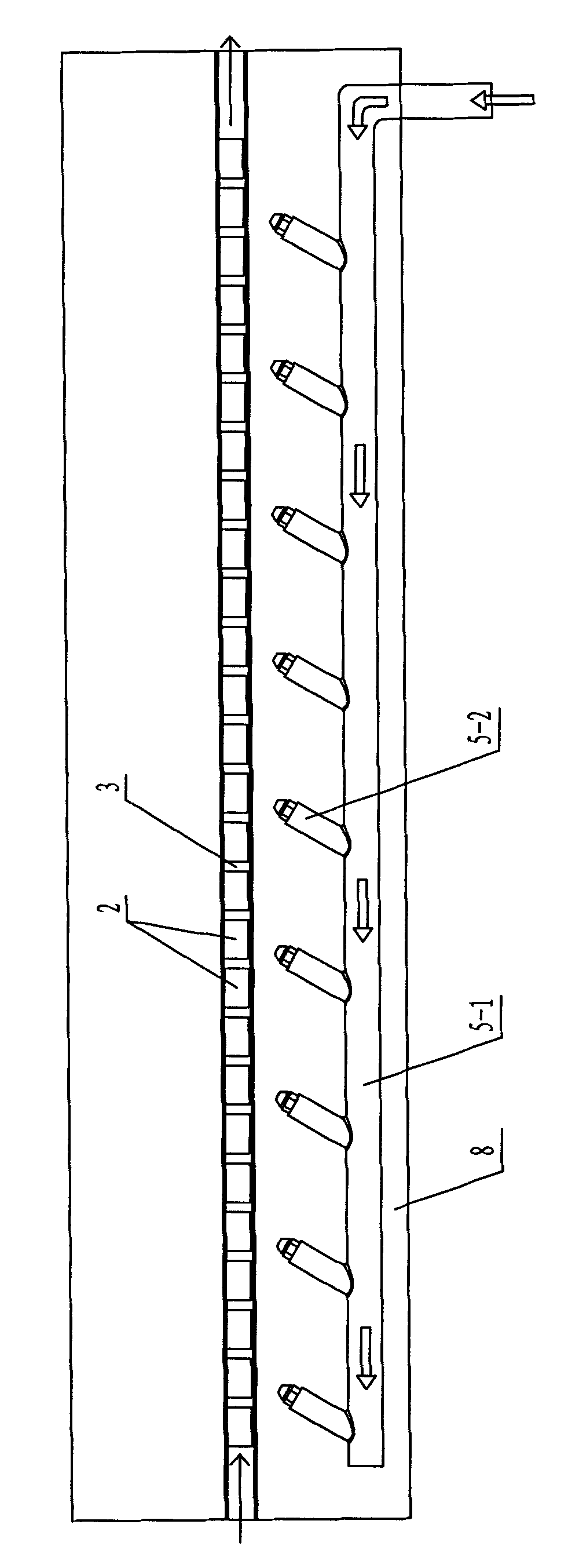

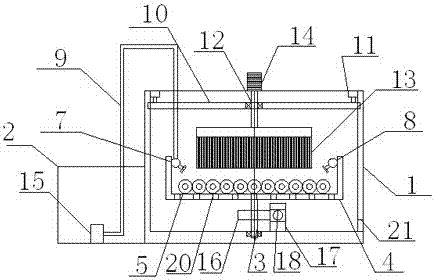

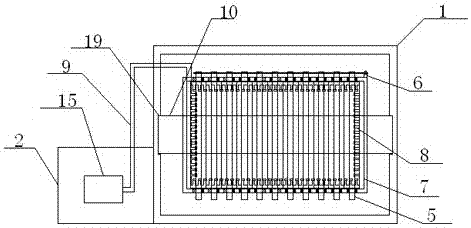

Bottle cap sterilization method and device

InactiveCN102145186APromote decompositionEliminate Hydrogen Peroxide ResiduePackage sterilisationChemicalsUltravioletBeverage industry

The invention relates to a bottle cap sterilization method and a bottle cap sterilization device. In order to solve the technical problems, the invention provides the bottle cap sterilization method and the bottle cap sterilization device with thorough sterilization, no sterilization dead angle and little residue. The invention adopts the technical scheme that the bottle cap sterilization method is characterized by comprising the following steps of: a, atomizing hydrogen peroxide solution, spraying the atomized hydrogen peroxide solution on a bottle cap to perform sterilization, and ensuring that the acting time of the solution is 5 to 12 seconds; b, blowing sterile hot air to the bottle cap, wherein the temperature of the sterile hot air is 80 to 90 DEG C and the acting time is 3 to 5 seconds; and c, irradiating the bottle cap by adopting ultraviolet with wavelength of 250 to 260 nanometers, and ensuring that the radiation quantity is 333 to 600W.s / m<2>. The method and the device are mainly applied to bottle cap sterilization before filling in the food and beverage industries.

Owner:HANGZHOU WAHAHA GROUP

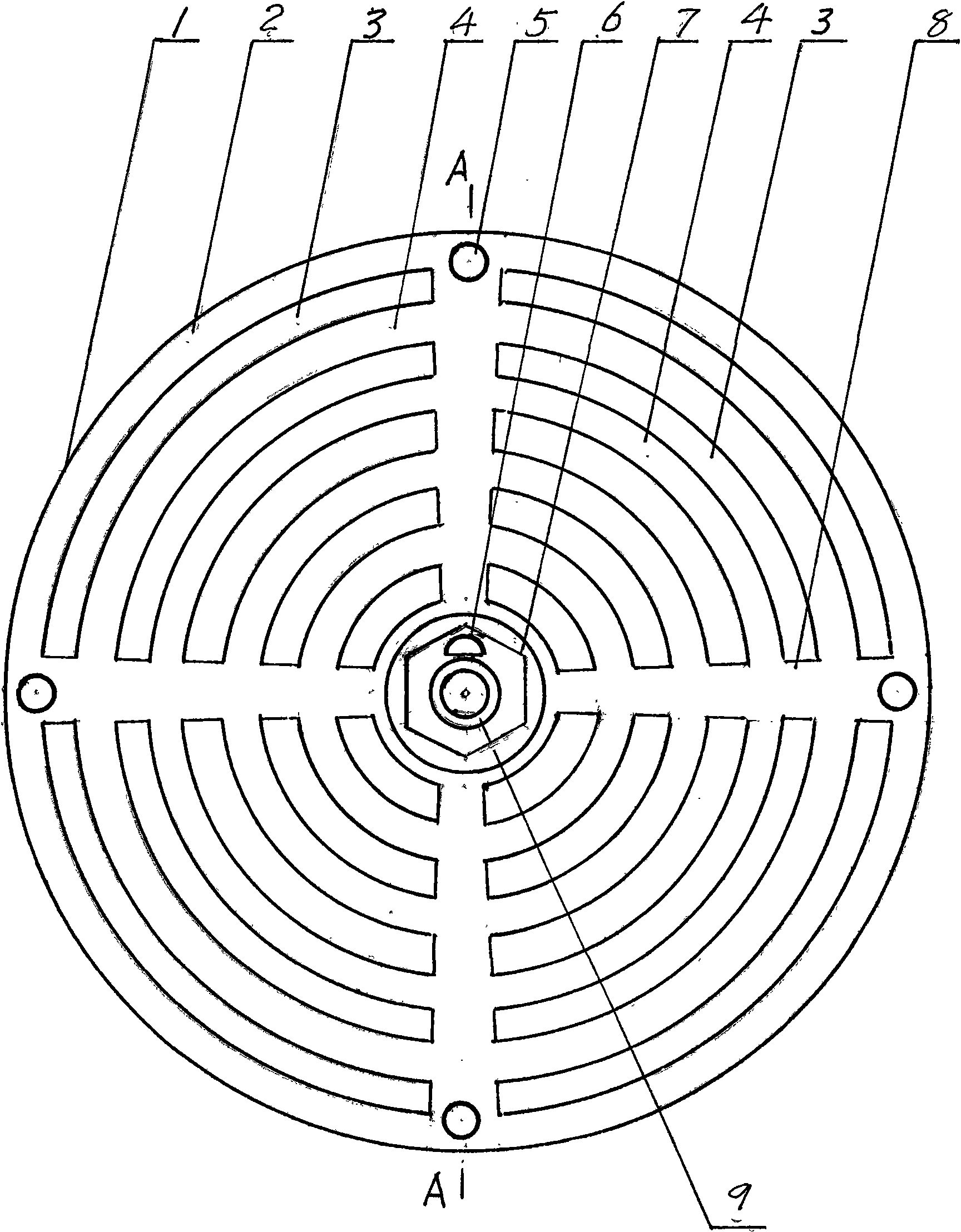

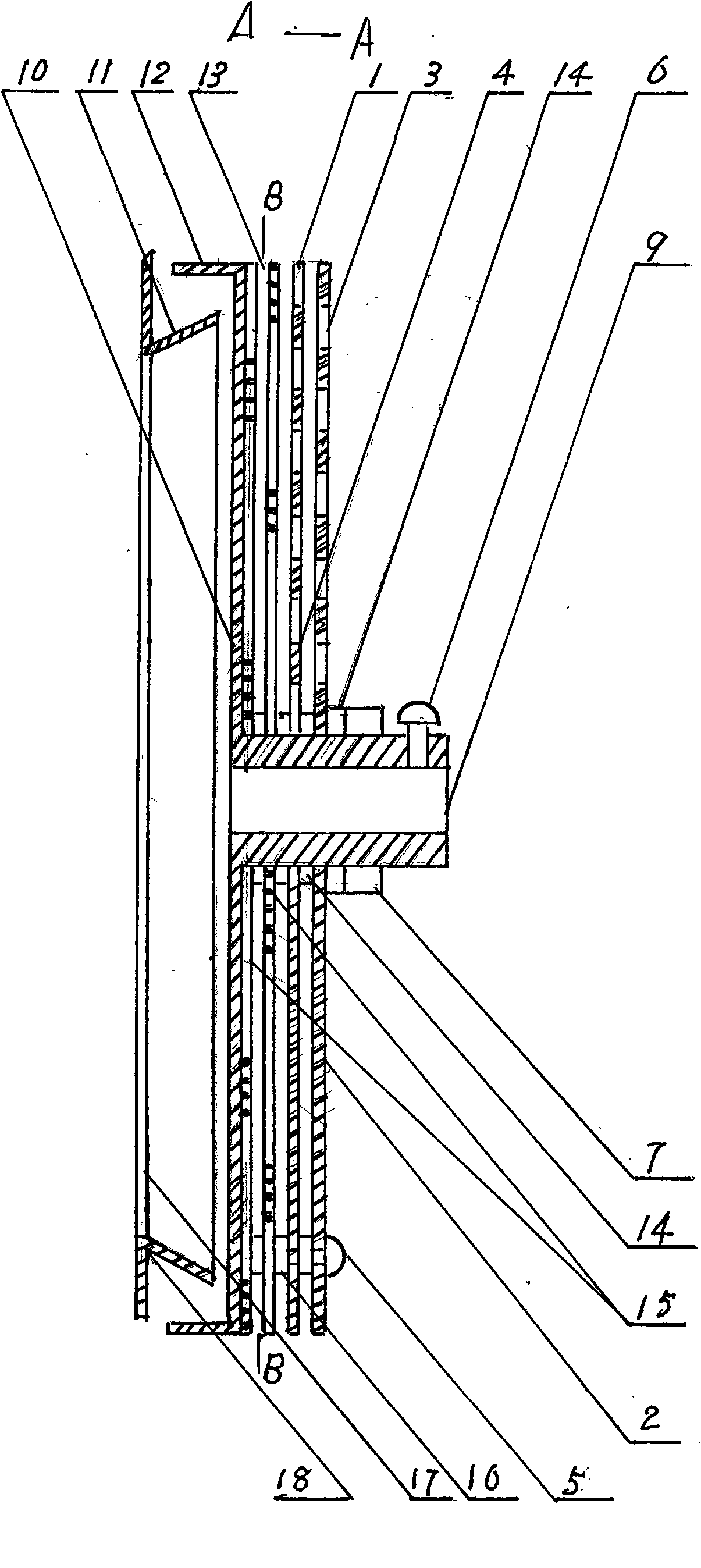

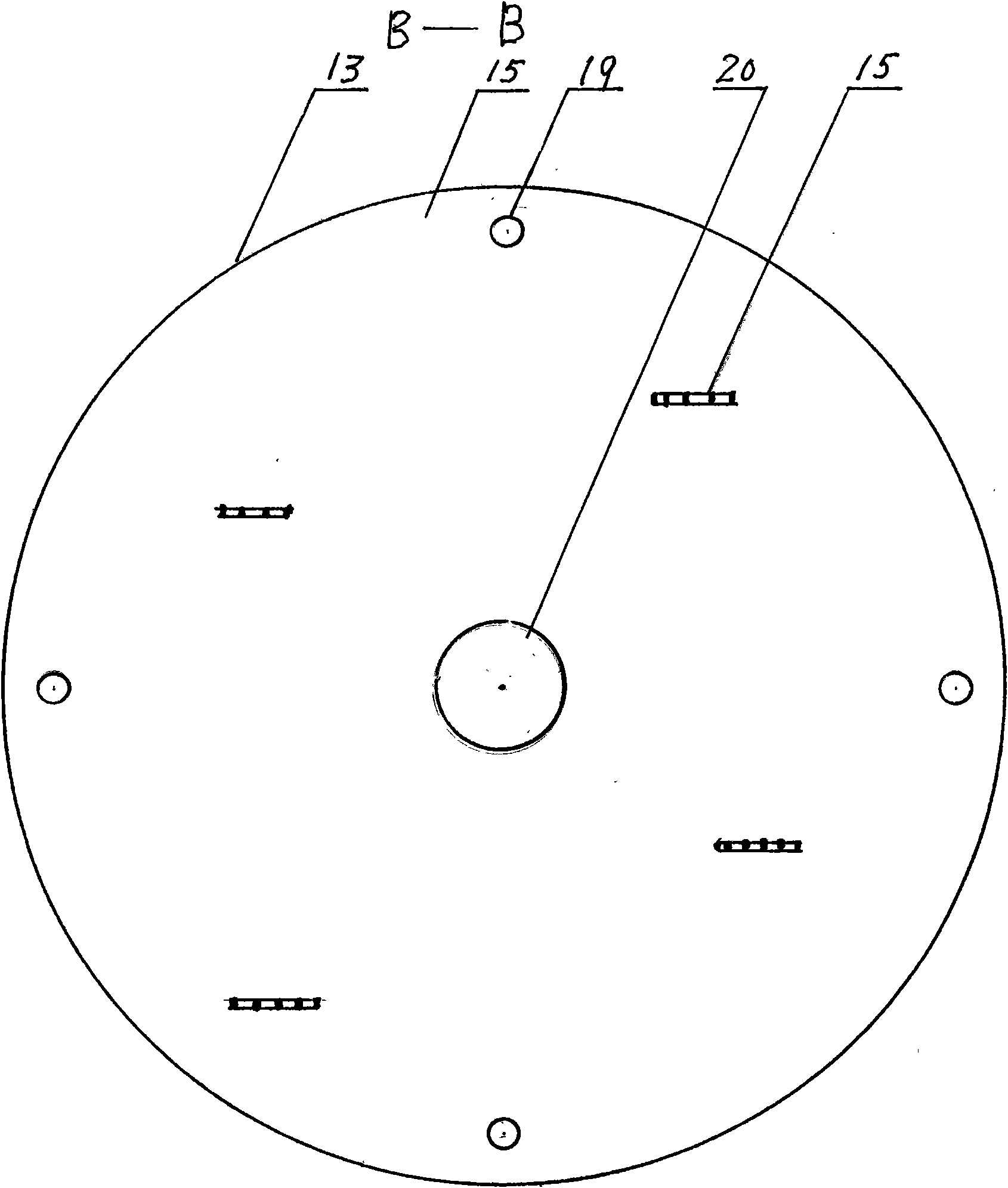

Rotary oil smoke purifier

InactiveCN101865482AImprove purification effectDomestic stoves or rangesLighting and heating apparatusImpellerWhole body

The invention discloses a rotary oil smoke purifier. An oil removing body 1 and an oil filtering body 13 are arranged at the front side of a circular support frame 21, an oil baffle body 10 is arranged at the back side of the circular support frame 21, and the oil removing body 1, the oil filtering body 13 and the oil baffle body 10 are connected into a whole body through screw nuts 7, a circular plate pad 14, screws 5 and a plat pad 16. The rotary oil smoke purifier is suitable for being installed on air exhaust equipment of families and food and beverage industry. When a motor is started for work, oil smoke firstly enters a two-layer round oil removing sheet 2 of the oil removing body 1 for carrying out oil removal and purification treatment and then enters the oil filtering body 13, a two-layer filtering screen 15 operates for purification, the smoke gas enters air absorption holes from the space in order to make oil dirt thrown to the periphery fall down, the oil baffle body 10 is designed on the rotary oil smoke purifier, and consists of a round oil baffle ring 12 and a conical oil baffle ring 11, the conical oil baffle ring 11 is shielded and sheathed in the round oil baffle ring 12, and the bottom edge 17 is welded and fixed to the edge part of the air absorption holes of the air exhaust equipment for forming an oil flowing groove 18 with an outwards inclined angle between 15 and 75 degrees, so the oil dirt can fall back and can sequentially slide down to a groove of the oil flowing groove 18 to flow into an oil collection box. The rotary oil smoke purifier provided by the invention has the advantages of simple structure, reliable performance, strong applicability and good oil smoke purification effect, and really realizes the dismounting washing avoidance of an impeller, an air passage and a motor, and exhausted gas is environment-protection clean gas.

Owner:张惠生

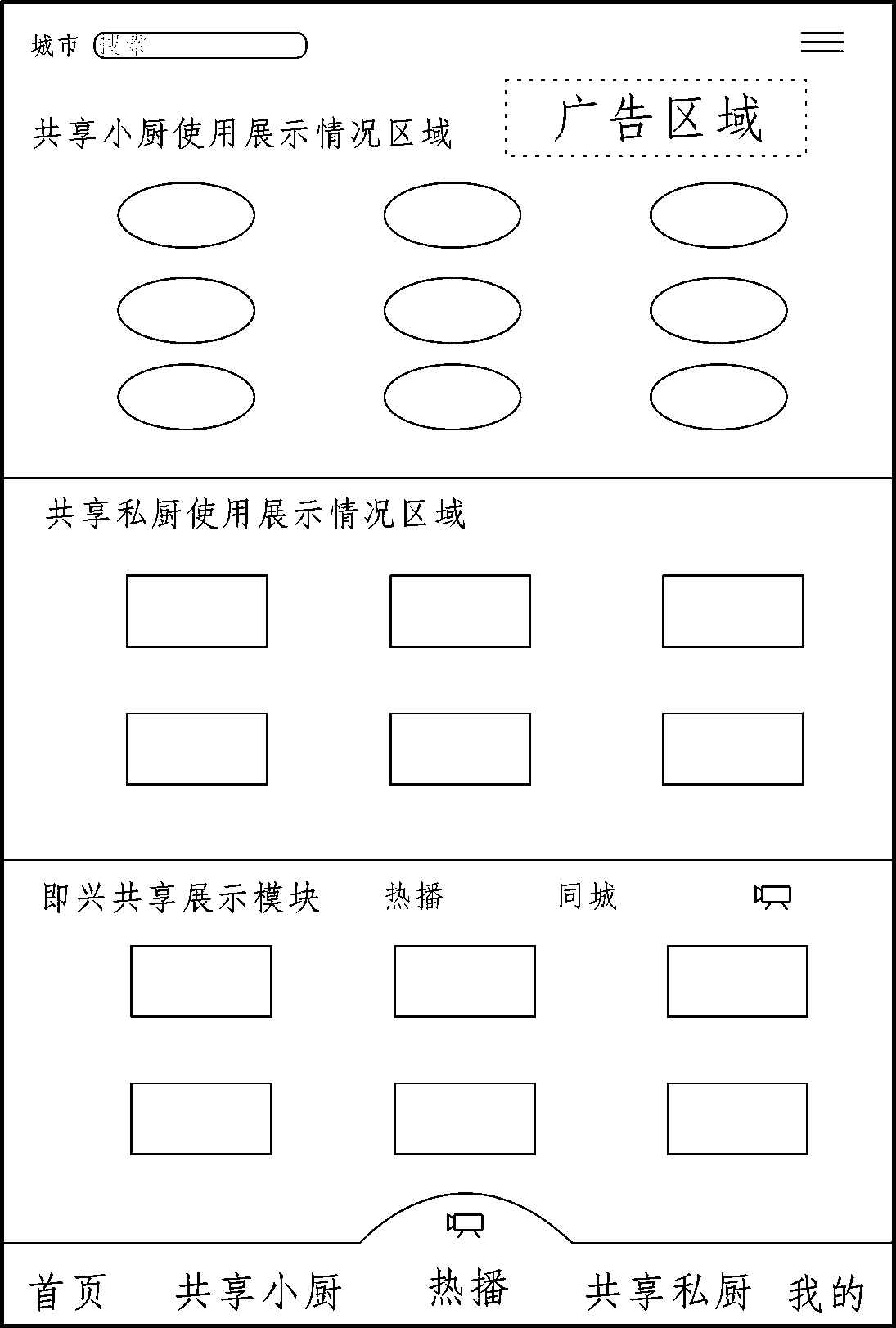

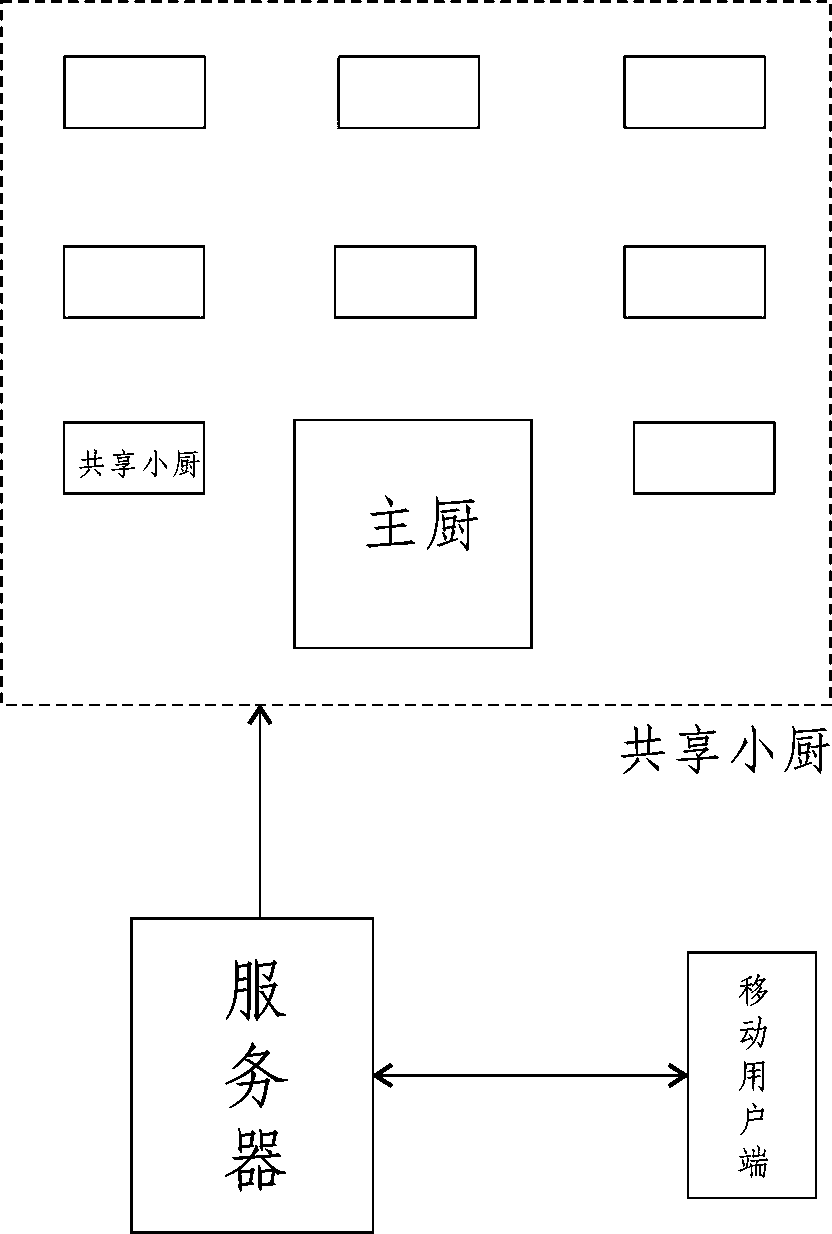

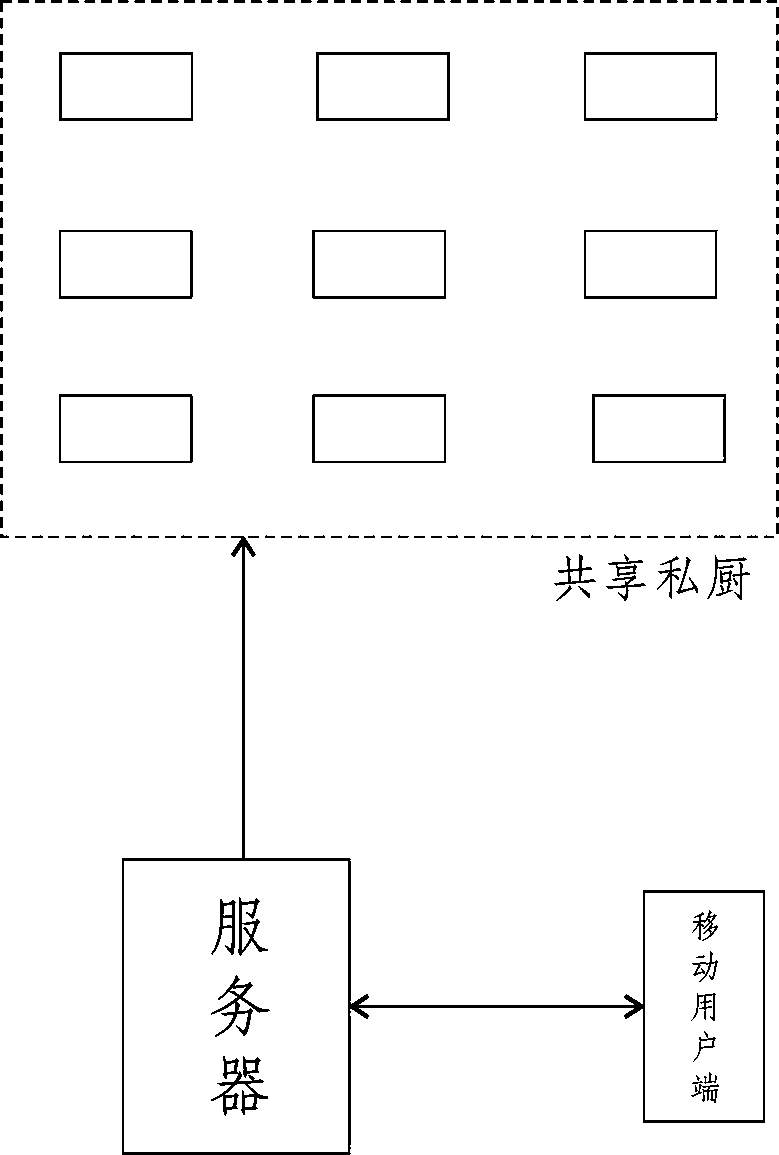

Shared kitchen system and sharing method

InactiveCN107679953ASave resourcesSave time and costApparatus for meter-controlled dispensingBuying/selling/leasing transactionsAdditive ingredientFinancial transaction

The present invention provides a shared kitchen system and a sharing method. The sharing method of the kitchen includes the following steps that: (1) a user downloads and installs the application (APP) of the shared kitchen system at first; (2) the user registers user information on the APP to obtain a use permission; (3) the user logs in and completes online uploading of kitchen cooking ingredient and dish information or kitchen operation information; (4) a consumer performs selection according to the ingredient and dish information of the kitchen of the user and places an orders or sets up ademand order; (5) the user cooks dishes according to the order information; and (6) the consumer signs for the dishes, and a transaction is completed. With the shared kitchen system and the sharing method of the invention adopted, people' stereotypes for dirty, unhealthy and disordered kitchens can be changed; the consumer can eat food without worries; a great deal of time and resources can be saved; the consumer can cook at any time to demonstration his or her skills in cooking; the user' experience involving the consumer and interaction between the user and the consumer can be enhanced; theconsumer can eat the food happily; and food consumption can be redefined; and the consumption upgrade of the food and beverage industry can be realized.

Owner:曾庆松

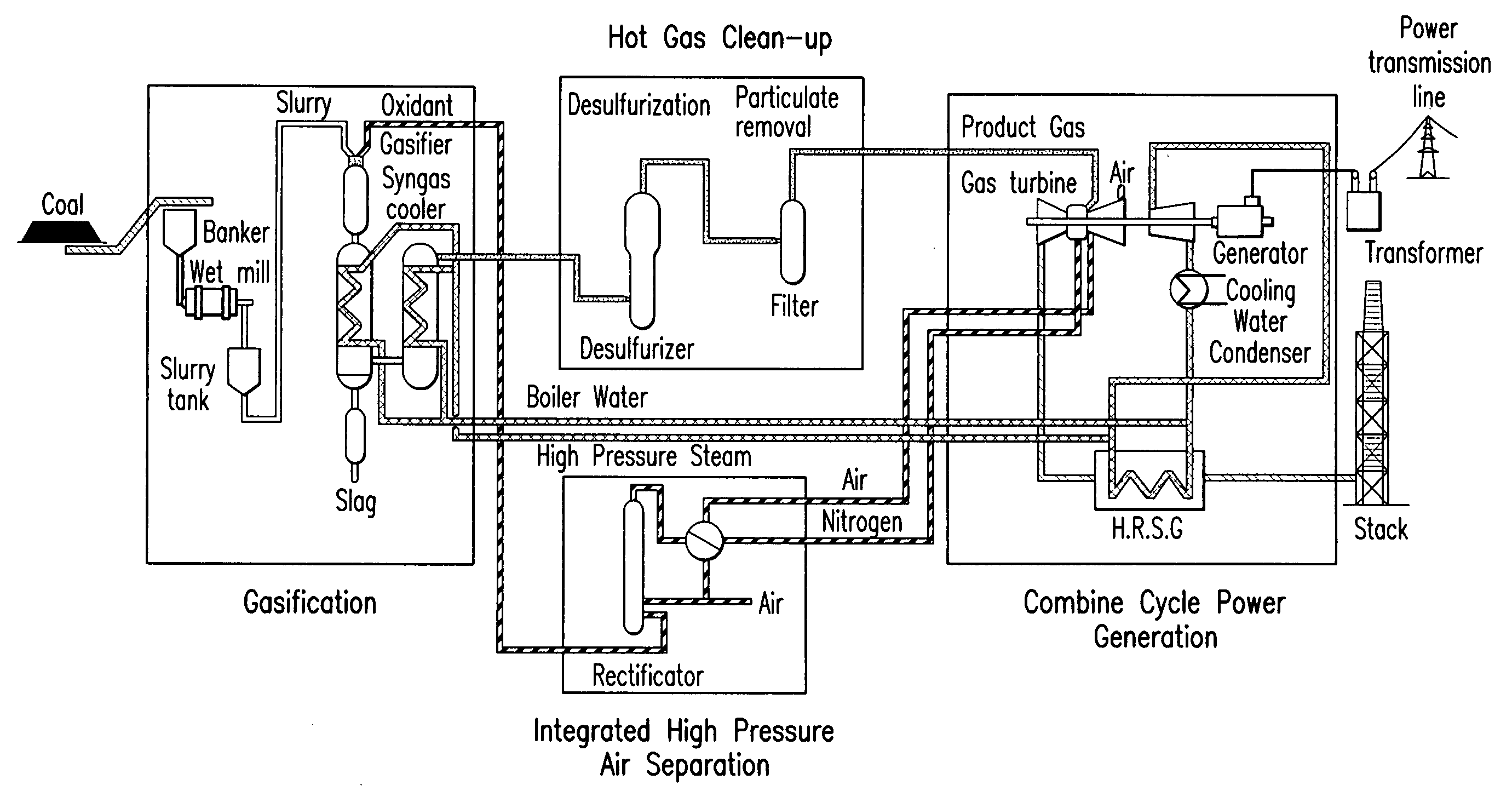

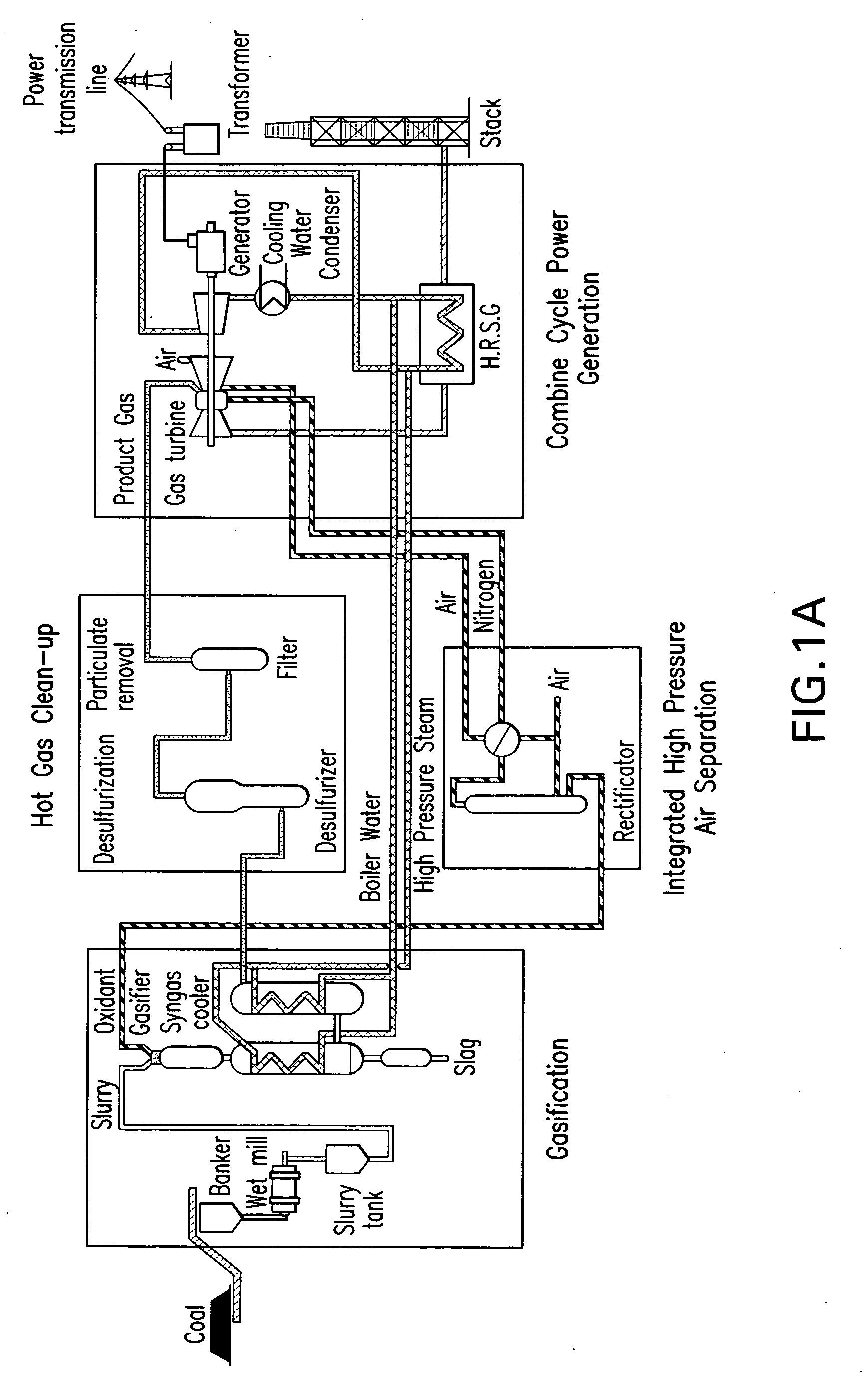

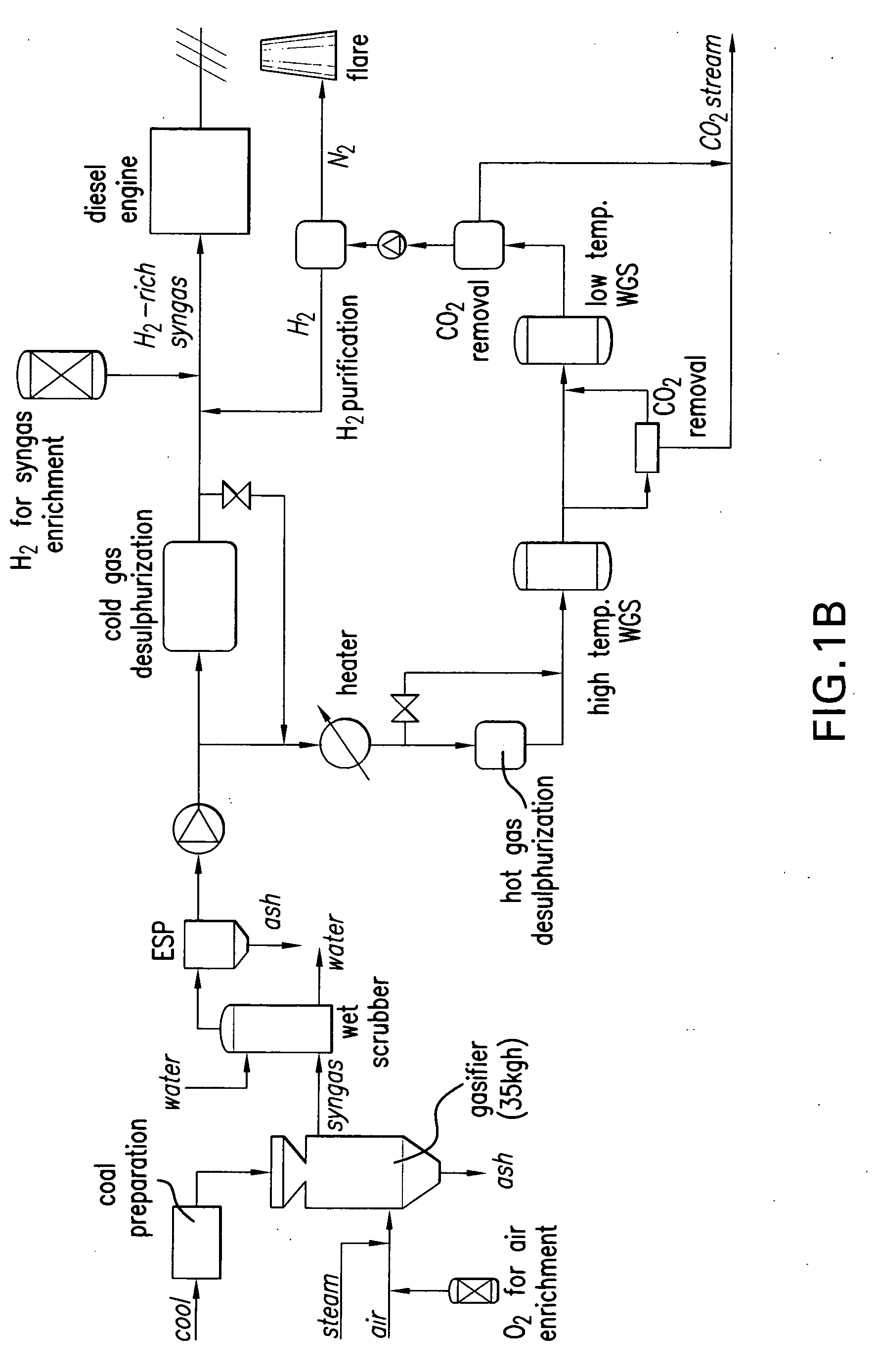

Method and apparatus for removing carbon dioxide gas from coal combustion power plants

InactiveUS20090205364A1Improve efficiencyHigh trafficSolidificationGas treatmentPower stationCombustion

The invention relates to a method and apparatus for removing CO2 gas emissions from a coal combustion power plant, comprising a means for physically removing the CO2 gas from the coal, and then using a turbo compressor and turbo expander device to produce super chilled air, which can then be mixed with the CO2 gas to form frozen CO2 crystals which can agglomerate together to form dry ice blocks, wherein the ice blocks can be easily transported and stored, and / or used for commercial purposes (such as for the beverage industry). The heating (compression) and cooling (expansion) processes preferably generate additional energy which can then be used to offset the substantial costs associated with separating the CO2 gas from the coal.

Owner:ENIS BEN M +1

[high caustic contact cleaner]

InactiveUS20040254085A1Easy to cleanMaintain levelInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBeverage industryMechanical engineering

A cleaning formulation especially suited for cleaning a substantially vertical or inclined surfaces which is soiled by components used in the food or beverage industry. The cleaning formulation has foam characteristics as well as long cling times. Yet, it is easily rinsed from the surface.

Owner:JOHNSONDIVERSEY INC

Preparation method of low-viscosity cured buckwheat flour

The invention discloses a preparation method of low-viscosity cured buckwheat flour. The preparation method comprises the following steps: (1), extruded buckwheat flour is prepared from raw buckwheat materials with a traditional extrusion and expansion technology; (2), amylase and water are uniformly mixed and then blended with the expanded buckwheat flour, and an obtained wet mixture is extruded, expanded, dried and finally milled into fine flour. The buckwheat is taken as the raw material, buckwheat starch is pasted through primary extrusion and expansion and assisted by the amylase on the basis of secondary extrusion and expansion, the buckwheat starch can be subjected to complete enzymolysis, and the low-viscosity cured buckwheat flour is prepared. The preparation method is simple to operate, energy-saving and environment-friendly, a product has low viscosity, and the problem about application of the buckwheat flour in the liquid beverage industry is solved.

Owner:BEIJING SHUOFANG SCI & TECH DEV CO LTD

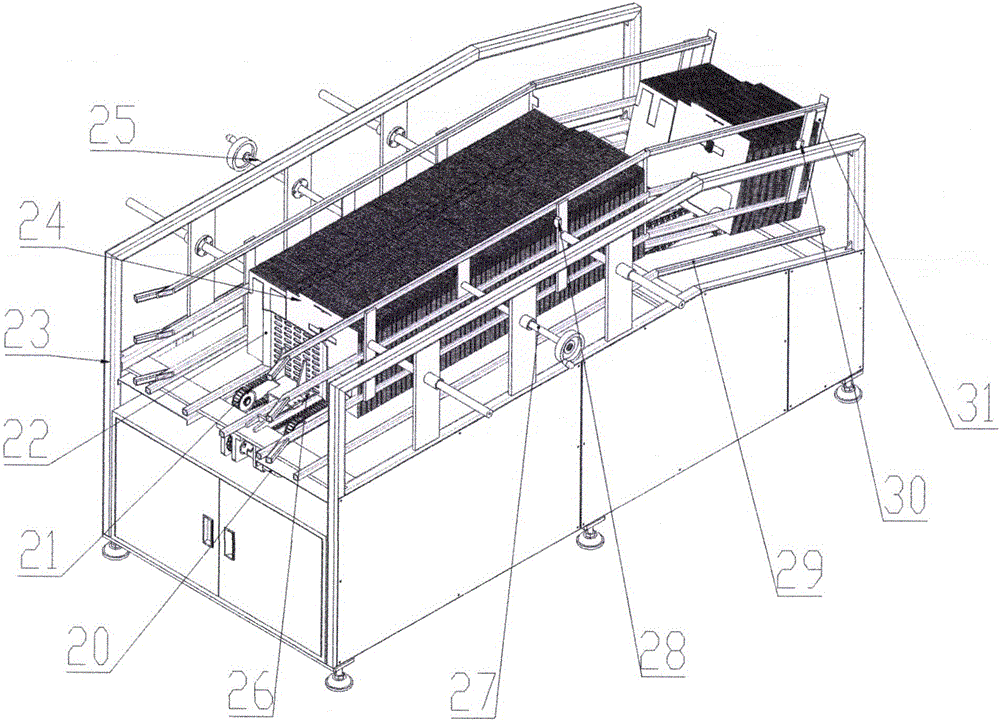

Cleaning machine for fruits

The invention relates to the technical field of mechanism equipment in the beverage industry, in particular to a cleaning machine for fruits. The cleaning machine comprises a cleaning pool and a water tank arranged on the left side of the cleaning pool, a box, a first cleaning device, a second cleaning device, a first driving device and a second driving motor are arranged on the cleaning pool. An opening is formed in the upper end of the box, the first cleaning device is installed inside the box, the second cleaning device is installed vertically in a sliding mode, the first driving device drives the first cleaning device, and the second driving motor drives the second cleaning device. The cleaning machine is simple in structure and reasonable in design, manual operation is not needed during cleaning, labor is saved, the cleaning effect and efficiency of the cleaning machine are greatly improved, the cleanness and sanitation of the fruits are guaranteed, meanwhile, water resources are saved, and the using cost is lowered.

Owner:JIYUAN YIHEYUAN BEVERAGE

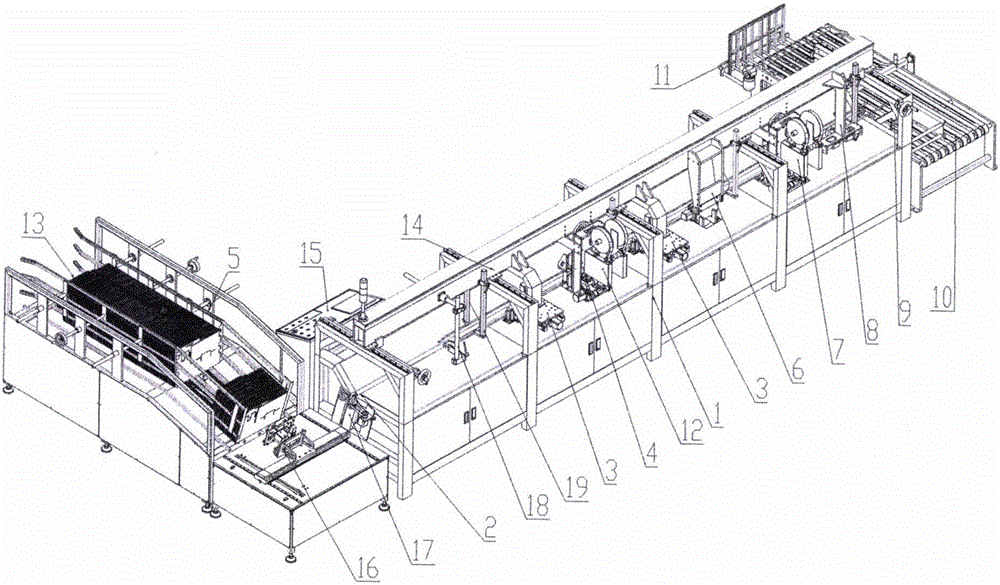

Machine equipment for online mounting of lifting ribbon

ActiveCN106393792AIncrease productivityReduce management costsBox making operationsPaper-makingUltrasonic weldingControl system

The invention discloses machine equipment for online mounting of a lifting ribbon. The machine equipment comprises a main body conveying rack, a carton conveying chain device, an adhesive coating device, a reinforcing band mounting device, a stock bin device, a lifting ribbon mounting device, an ultrasonic welding device, an automatic detecting device, an automatic rejecting device, a collecting plate conveying device, a collecting plate stacking device, an automatic unwinding device, an upper plate width adjusting component, a main body station translation cross beam, a transfer control system, a separate plate conveying device, a carton inputting compression roller component, a flip guiding device and a pressing plate guide rod component. The invention also discloses a process flow of the equipment. According to the machine equipment and the process flow thereof disclosed by the invention, mechanical automatic mounting is realized, the production efficiency is high, and the uncontrollability of offline sampling inspection for the quality of a product is overcome; by adoption of an automatic detection technology and an automatic rejection technology, the qualification rate of the quality of the product is 90 to 99 percent, the mounting of lifting handles of gift boxes with various sizes can be finished, labor force for mounting the lifting handles of packing boxes in the milk beverage industry is greatly reduced, and the production cost is reduced.

Owner:江苏力奥智能装备有限公司

Preparation method of wheat germ polypeptide beverage

ActiveCN104256828AProcess stabilitySimple and fast operationVegetable proteins working-upNatural extract food ingredientsWheat germBeverage industry

The invention provides a preparation method of a wheat germ polypeptide beverage. The preparation method is characterized by comprising the following steps: 1, protein extraction, extracting protein in wheat germ with water and separating solid from liquid; 2, compound enzymolysis, performing compound enzymolysis to the protein extract obtained in step 1 and separating solid from liquid; 3, concentration and enzyme deactivation, concentrating supernatant fluid obtained in step 2, deactivating enzyme and separating solid from liquid; 4, compounding and sterilization, compounding supernatant fluid obtained in step 3 and obtaining a polypeptide product after sterilization. Through the method, the variety and the content of biological active peptides can be increased and the nutritional values can be improved. The technology is simple in operation process, easy to control and suitable for amplification, can fully utilize wheat germ resource and provides a new beverage for the beverage industry.

Owner:HEBEI ZIFENG BIOTECH

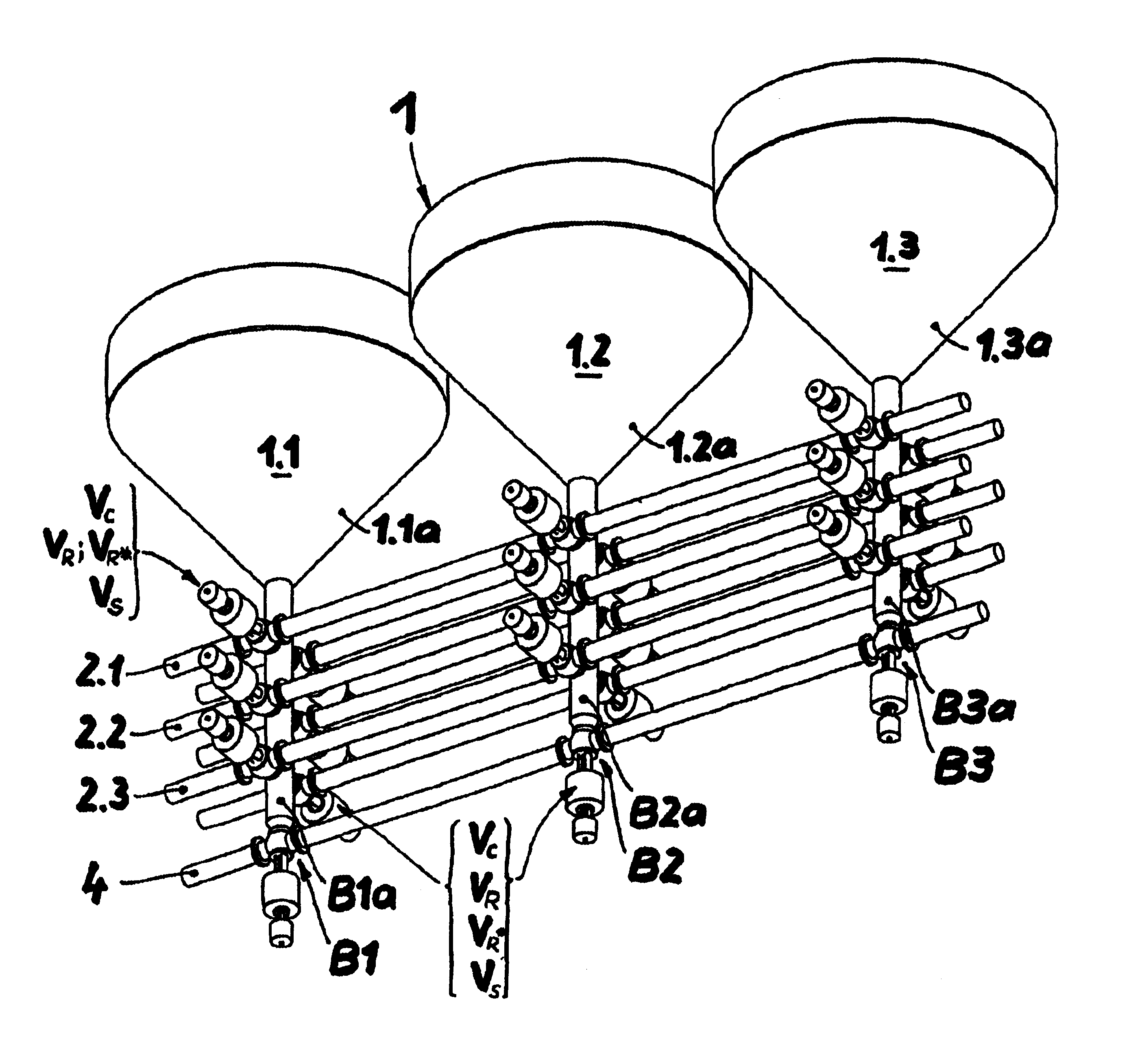

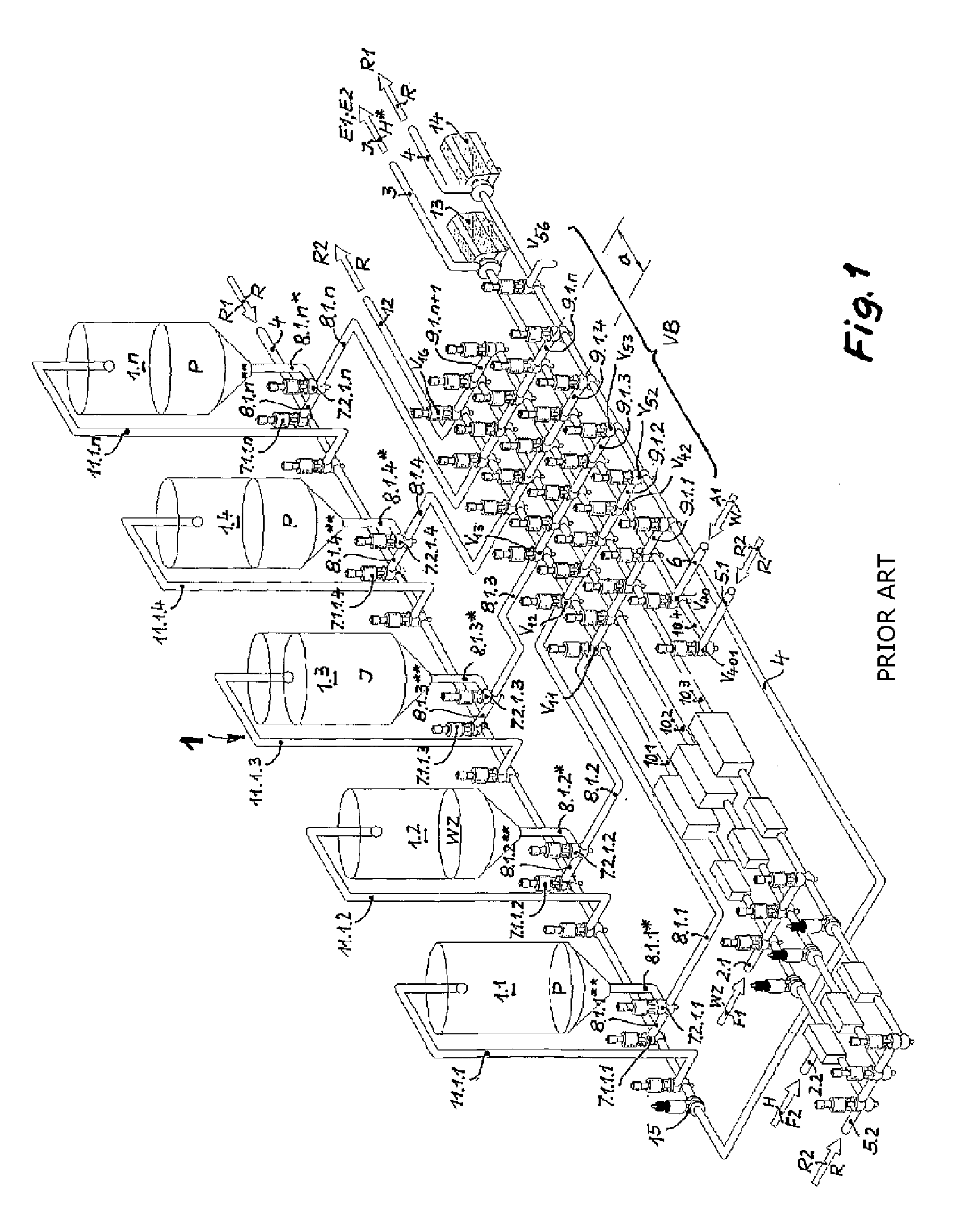

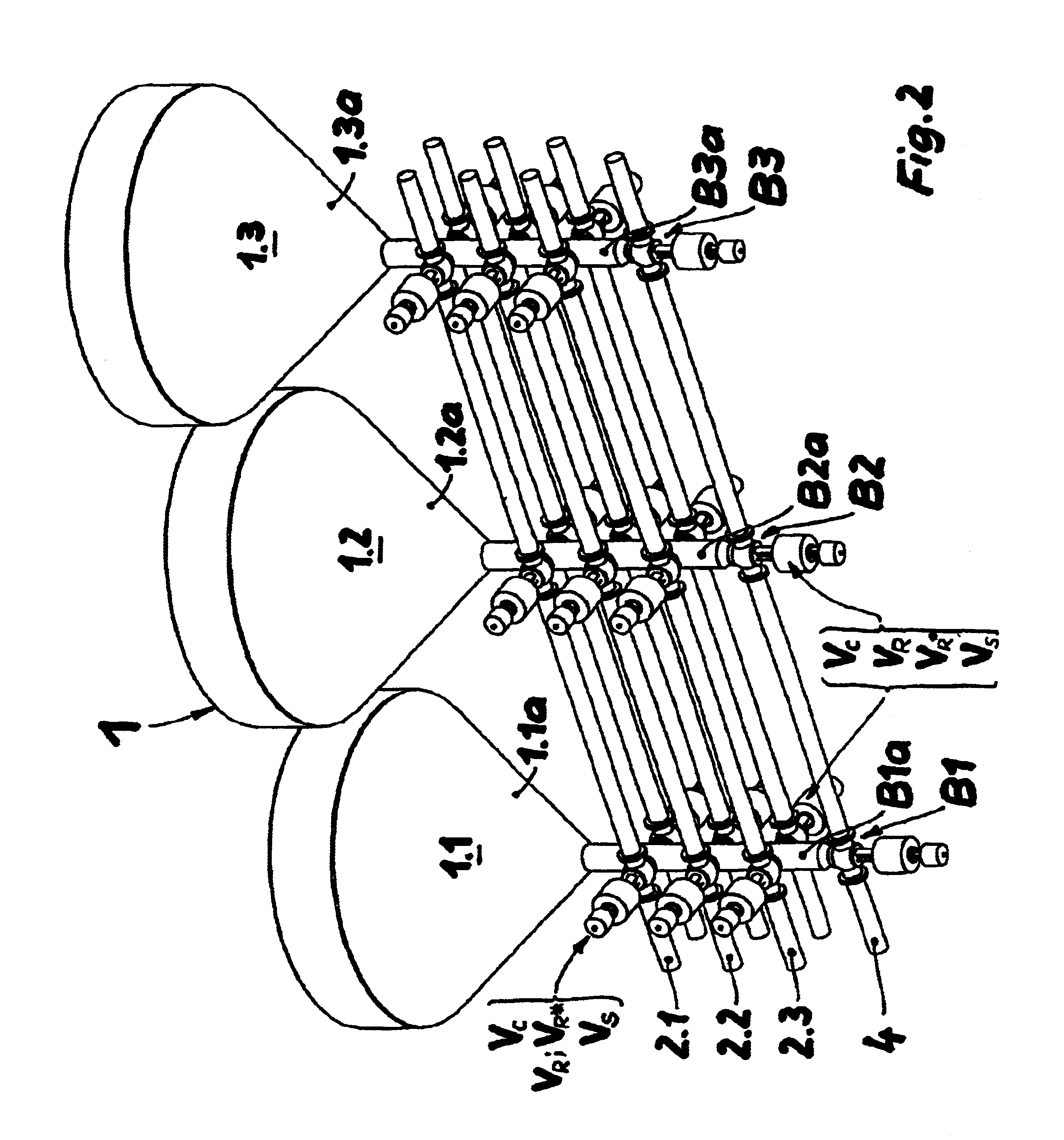

Method and device for operating tank farm systems which are interconnected with pipes in a fixed manner and which have pipe systems for liquids

ActiveUS7302958B2Improve quality requirementsOptimizationBeer fermentationOther washing machinesPharmaceutical industryBeverage industry

The invention relates to a method for operating tank farm systems, which are interconnected with pipes in a fixed manner and which have pipe systems for liquids, particularly for use in systems which are subject to high microbiological quality requirements and which are used for processing and transferring products in the foodstuffs and beverage industry, pharmaceutical industry, and biotech industry. The invention provides that the supply and discharge of liquids into and out of the respective tank ensues from underneath, and that the liquids that are being supplied or discharged flow through a space which is directly connected to the respective tank contents and which is situated underneath the respective tank in a switchable manner, and in a manner that ensures mixing, from the pipes of the pipe system that lead to this space.

Owner:GEA BREWERY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com