Methods and systems for forming concentrated consumable extracts

a consumable extract and concentrated technology, applied in the field of consumable aqueous extract production methods and systems, can solve the problems of poor flavor or fragrance characteristics of extracts, loss or degradation of desirable varietal flavor and fragrance components of ground, and inability to meet the needs of the market, and achieve the effects of reducing the loss of desirable flavor and fragrance characteristics, and being more concentrated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

One Pass Extraction Without Subsequent De-Watering

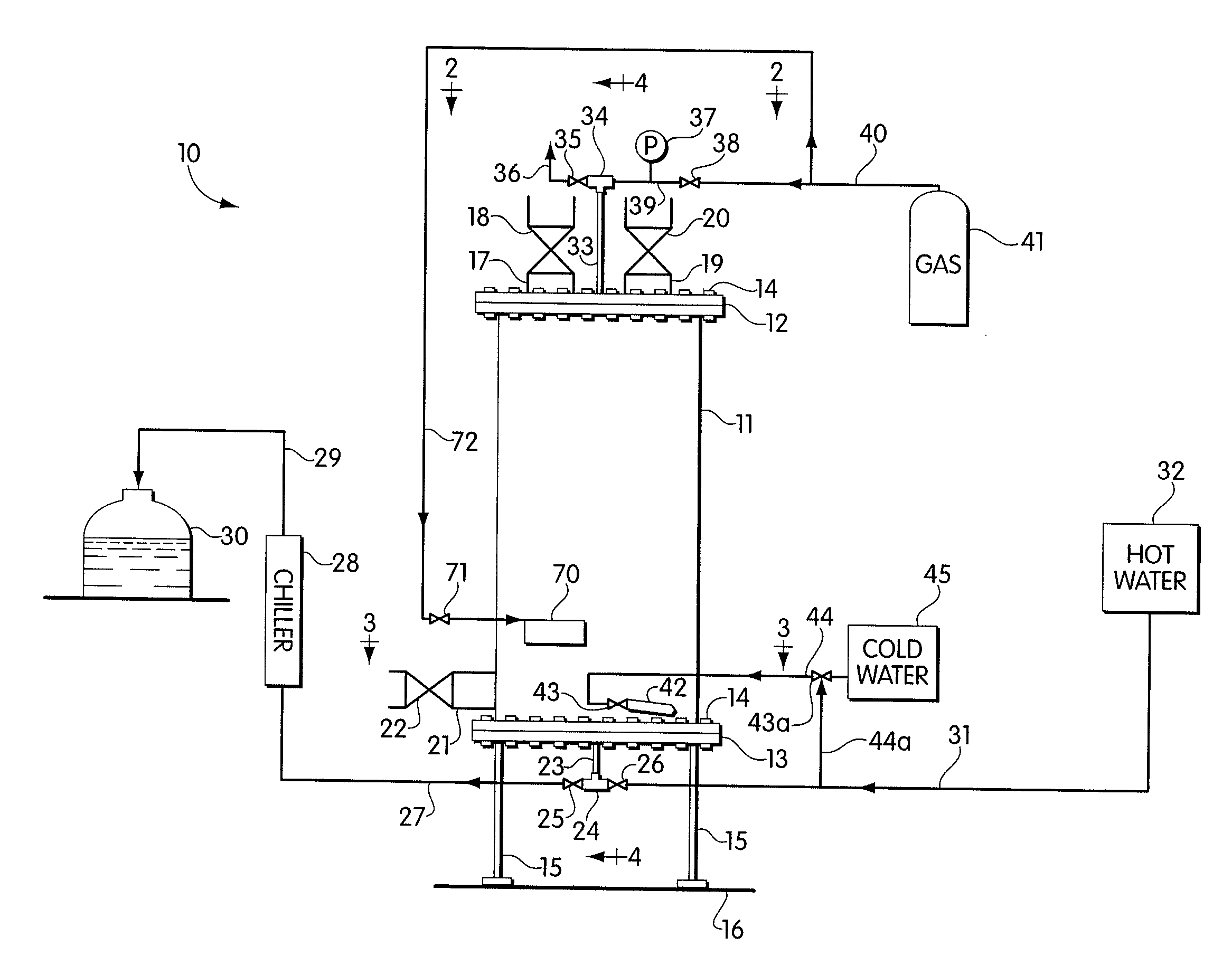

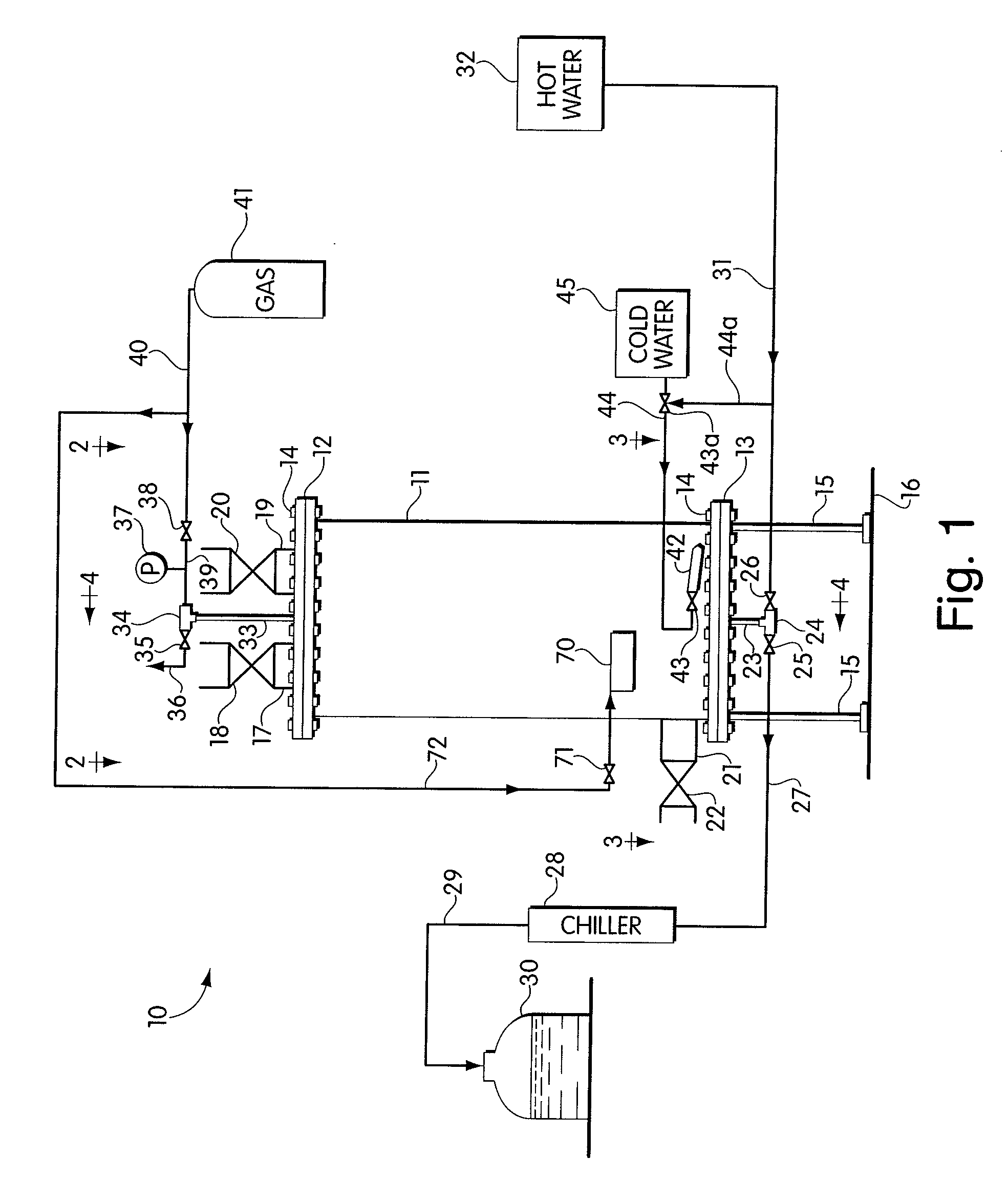

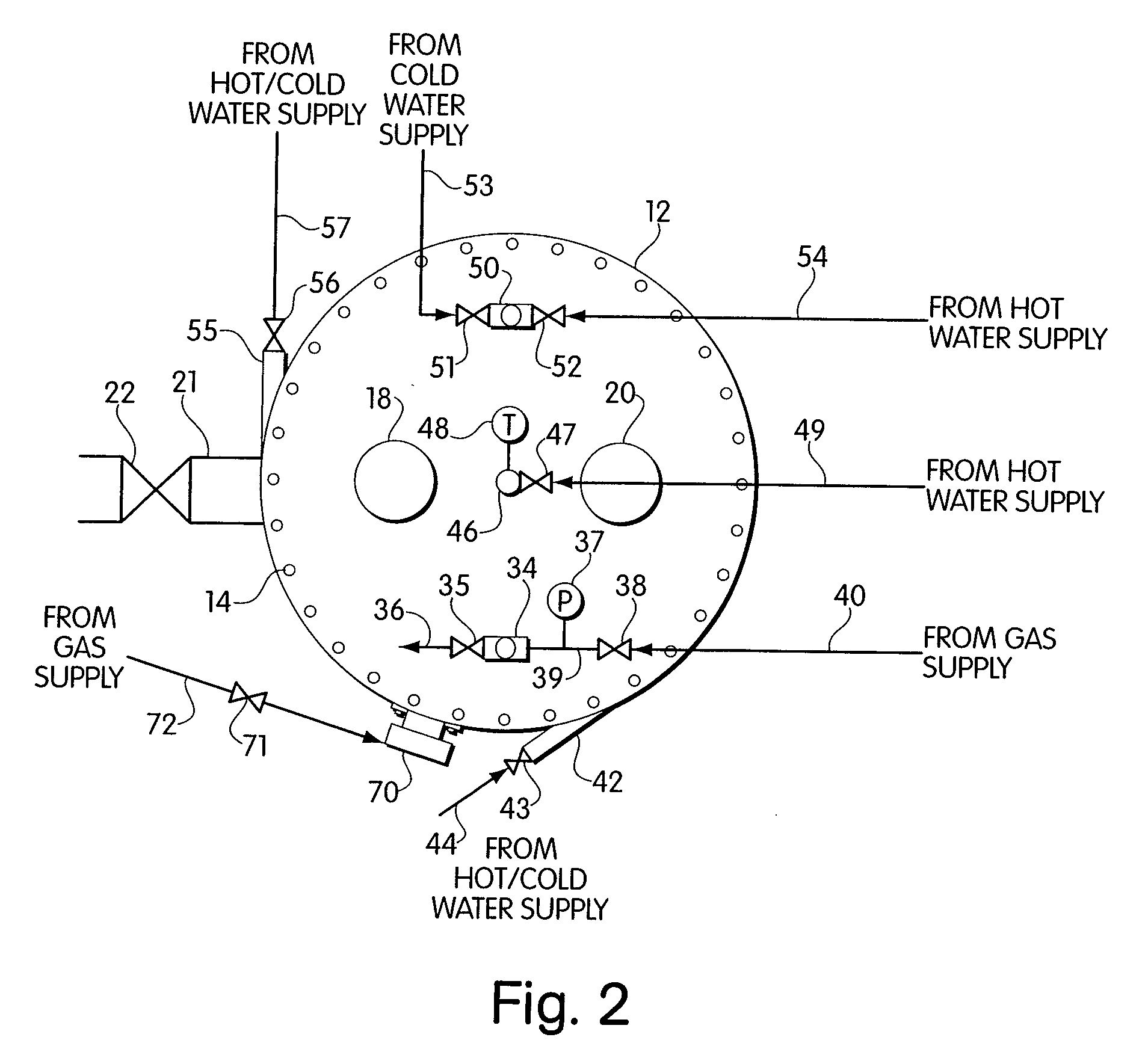

[0083]The industrial scale extractor described in connection with FIGS. 1-4 was used to produce a coffee extract using the methods described in the preceding sections with the modifications indicated below. Approximately 265 lbs. of a blend of Costa Rican, Colombian, and Sumatran coffee beans, roasted to a medium dark finish, were ground using a Bunn coffee grinder (HVG, Bunn-o-matic, Springfield, Ill.) on a setting of 4.0. A Rotap sieve analysis indicated an 80% retention in Tyler sieves 12, 16, and 18, with the remaining 20% distributed across sieves 20, 30, 40, 45, and the bottom tray.

[0084]The vessel was filled with the dry ground coffee forming a bed and the system was wetted with hot water, from a supply maintained at 193 degrees F. and 90 psig, as described above. Valve 25 on the extract outlet line 23 was then closed and about 40 gallons of the hot water was added to the vessel via inlet line 46 yielding a final vessel pressu...

example 2

Two Pass Extraction with Subsequent De-Watering of the Second-Pass Extract and Formation of a Blended Coffee Extract

[0086]The industrial scale extractor described in connections with FIGS. 1-4 was used to produce a coffee extract using the methods described in the previous section with the modifications indicated below. Approximately 200 lbs. of Sumatran coffee beans were roasted and ground as described above in Example 1.

[0087]The extraction vessel was filled with the dry ground coffee and about 60 gallons of a first-pass coffee extract was produced as described previously for Example 1, except that in the present example pressurized nitrogen was utilized in place of the pressurized air in Example 1. Also, the step, in Example 1, of passing additional hot water through the bed of coffee performed immediately prior to the purging of residual extract from the bed with gas was omitted in the present example. The total yield of the first-pass extract was about 60 gallons from the 200 l...

example 3

One Pass Extraction with Subsequent De-Watering to Produce a Highly Concentrated Coffee Extract

[0091]An industrial scale extractor similar to that described in connection with FIGS. 1-4, except having a dome-shaped upper plate with a single, center-mounted raw material feed line and valve fed by a mechanical auger feed system. The industrial extractor utilized for the present example had an internal capacity of about 62.5 cubic feet, designed to extract about 1300 lbs. of ground, roasted coffee. About 1300 lbs. of the ground coffee described in example 2 was fed to the extractor, followed by closure of the valve on the raw material feed line.

[0092]The vessel was filled with the dry ground coffee forming a bed and the system was wetted with hot water, from a supply maintained at 193 degrees F. and 90 psig, as described above, except the first about 250 gallons of hot water added to the extractor were added through the bottom screen via line 23 and through tangential lines 42 and 55. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com