Patents

Literature

78 results about "Coffee processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coffee production is the industrial process of converting the raw fruit of the coffee plant into the finished coffee. The coffee cherry has the fruit or pulp removed leaving the seed or bean which is then dried. While all green coffee is processed, the method that is used varies and can have a significant effect on the flavor of roasted and brewed coffee. Coffee production is a major source of income for 12.5 million households, most in developing countries. By adding value, processing the coffee locally, coffee farmers and countries can increase the revenue from coffee.

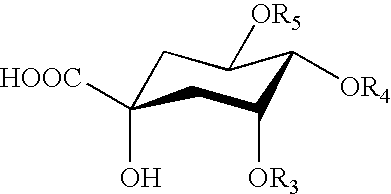

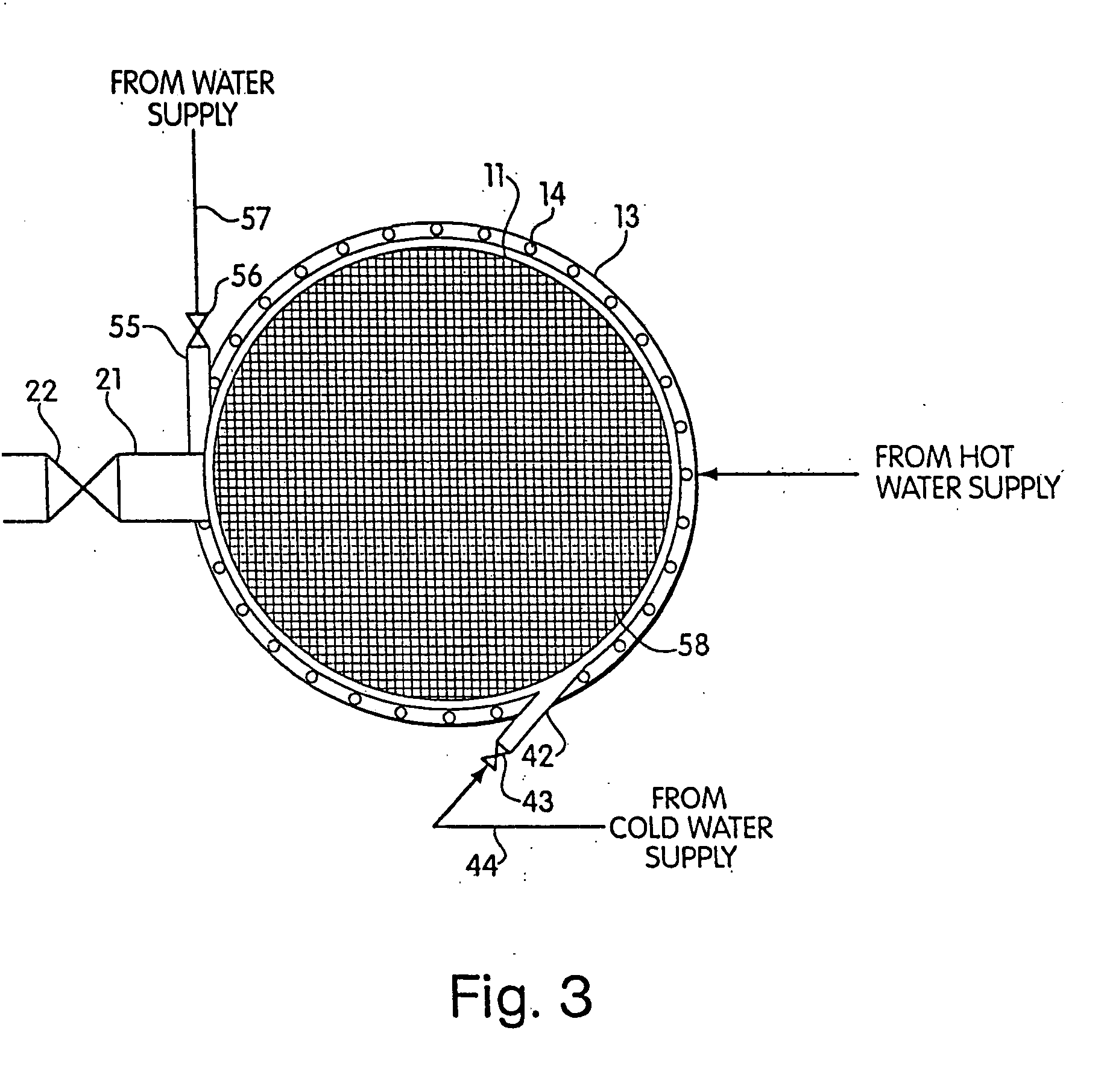

Methods and systems for forming concentrated consumable extracts

InactiveUS7419692B1Excellent and desirable and flavor and qualityExcellent and desirable and and fragrance qualitySemi-permeable membranesFiltration separationFiltrationCoffee processing

Typical known methods for producing large quantities of concentrated extracts from solid raw materials such as ground, roasted coffee are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides filtration methods for producing such high quality concentrated extracts from more dilute extracts via solvent removal. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial-scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances.

Owner:KERRY GROUP SERVICES

Methods and systems for forming concentrated consumable extracts

InactiveUS20080280023A1Fully understandSemi-permeable membranesSolid waste disposalHigh concentrationFiltration

Typical known methods for producing large quantities of concentrated extracts from solid raw materials such as ground, roasted coffee are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides filtration methods e.g. reverse osmosis or nanofiltration for producing such high quality concentrated extracts from more dilute extracts via solvent removal. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial—scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances. The solvent—reduced, concentrated extracts produced according to the inventive solvent removal methods can be advantageously used for applications where high quality coffee extracts, with a high concentration of soluble coffee solids, for example of at least 6 wt. %-40 wt. %, and a high level of retention of varietal flavor and fragrance characteristics are desired.

Owner:KERRY GROUP SERVICES

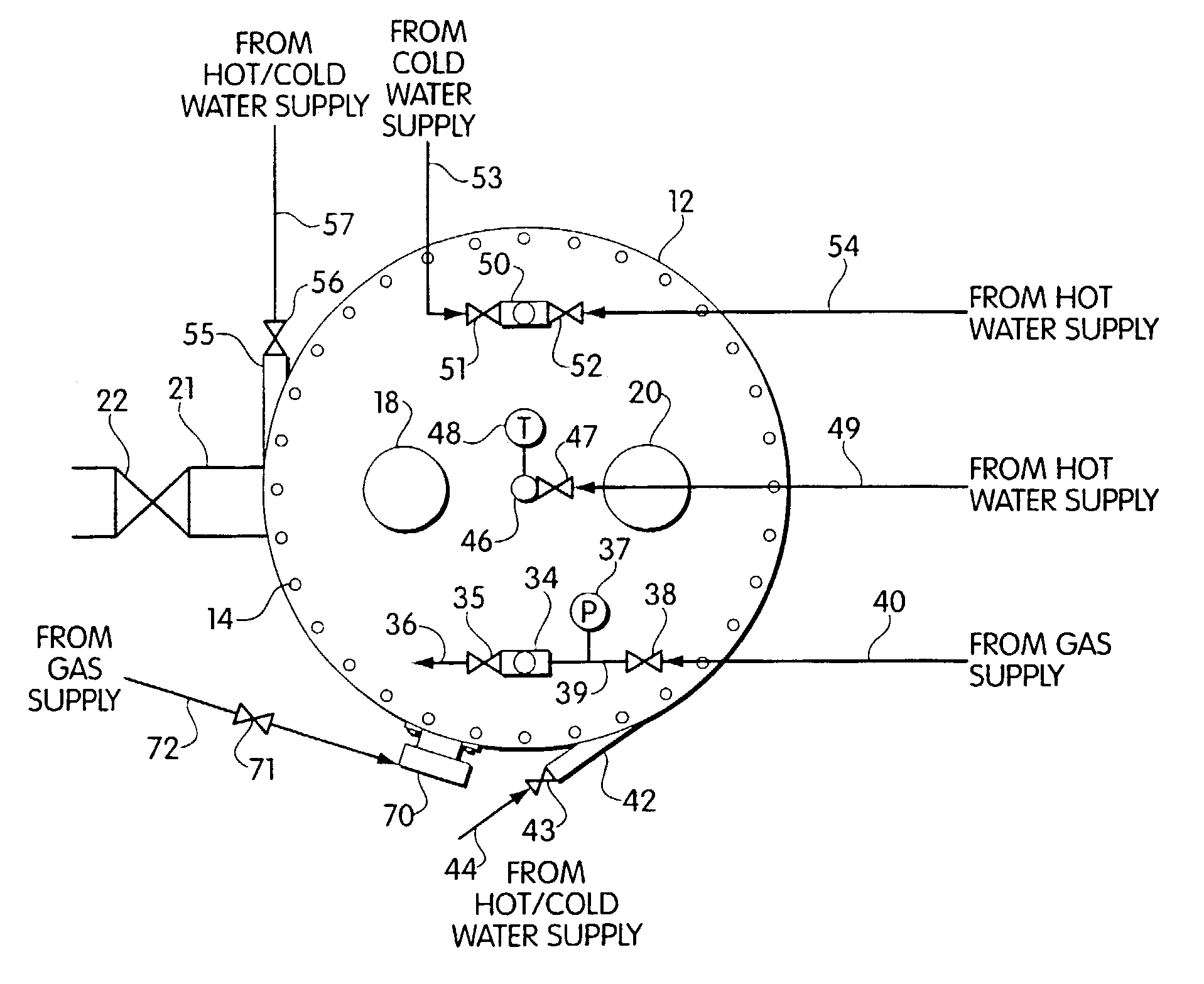

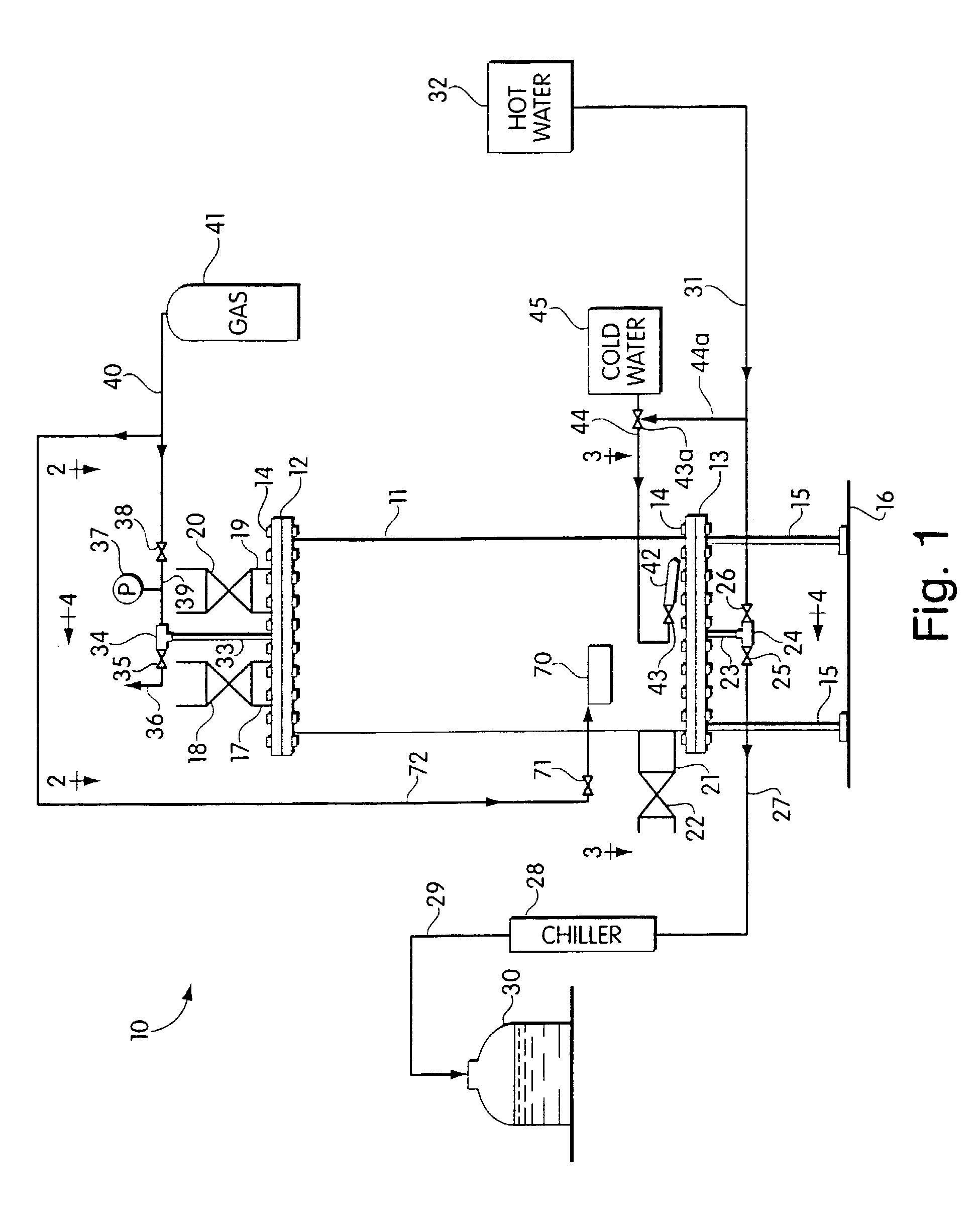

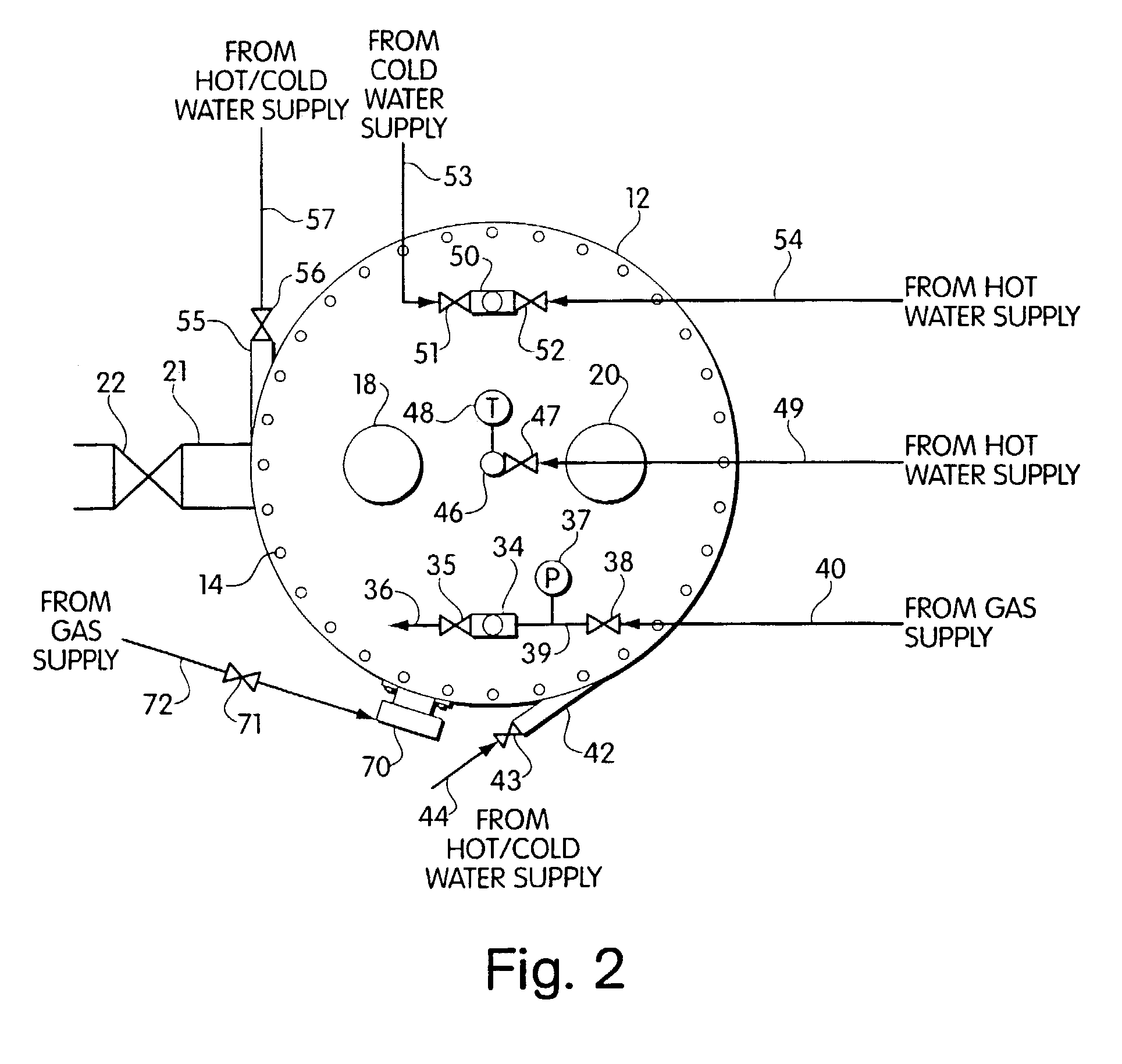

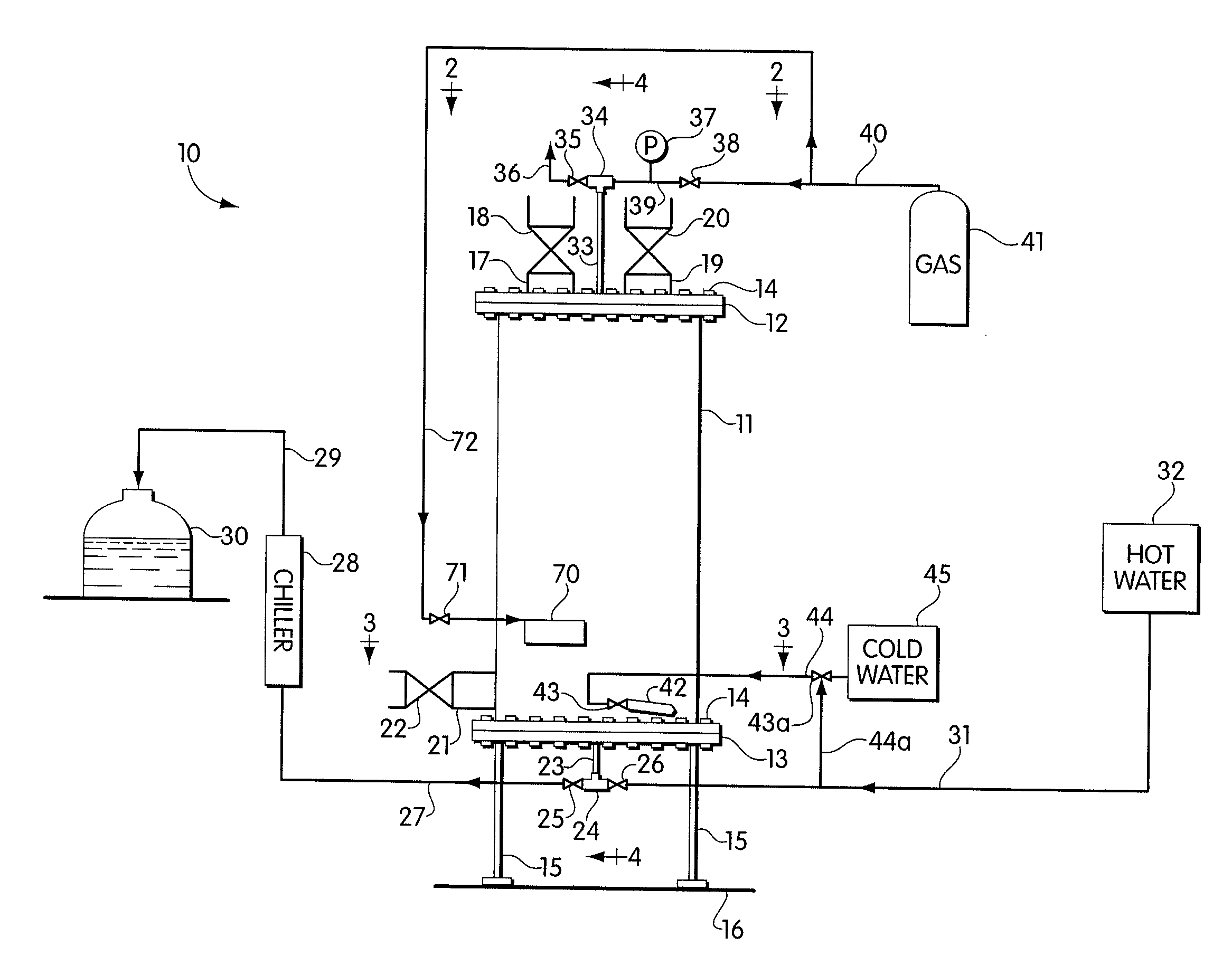

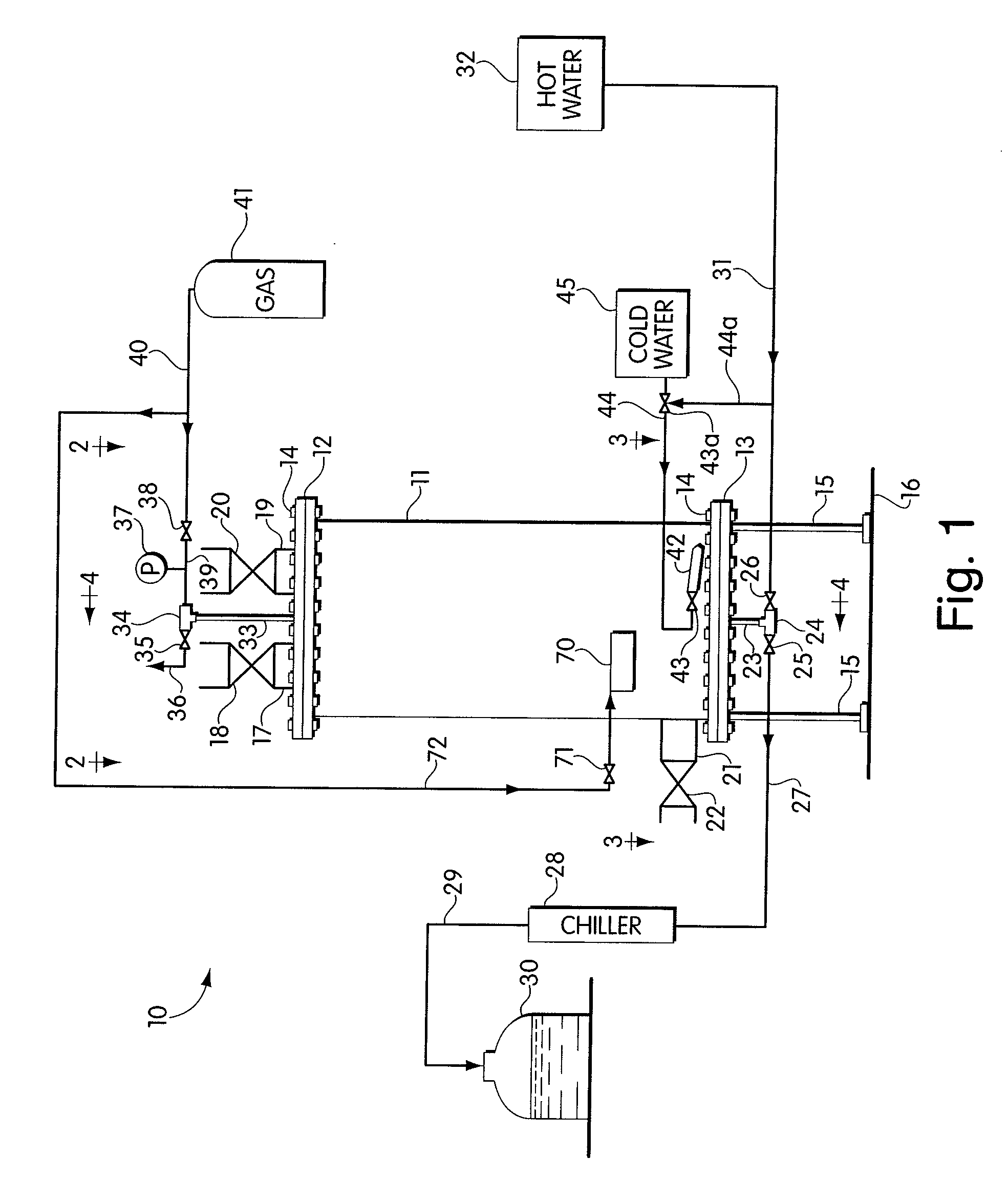

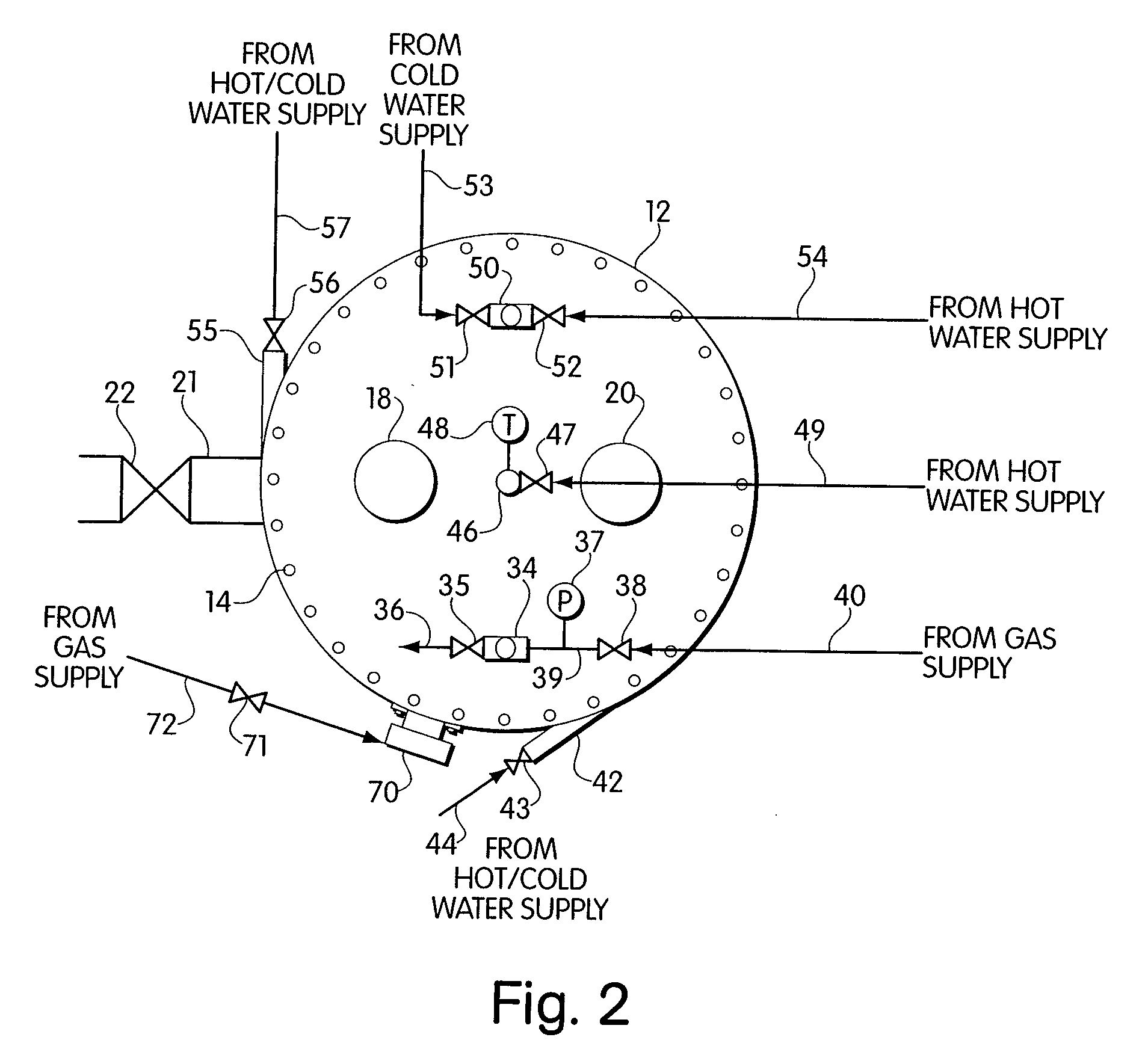

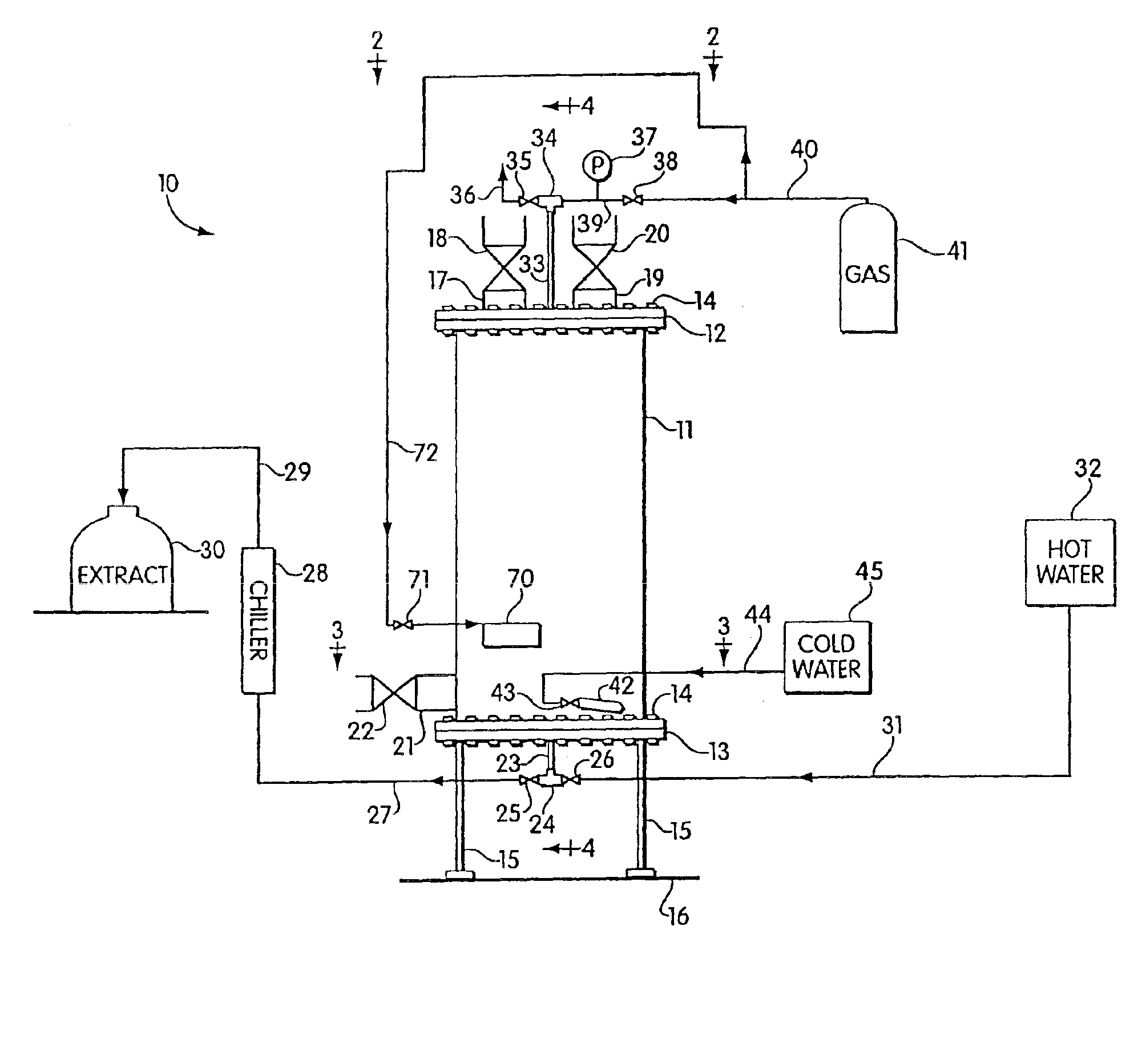

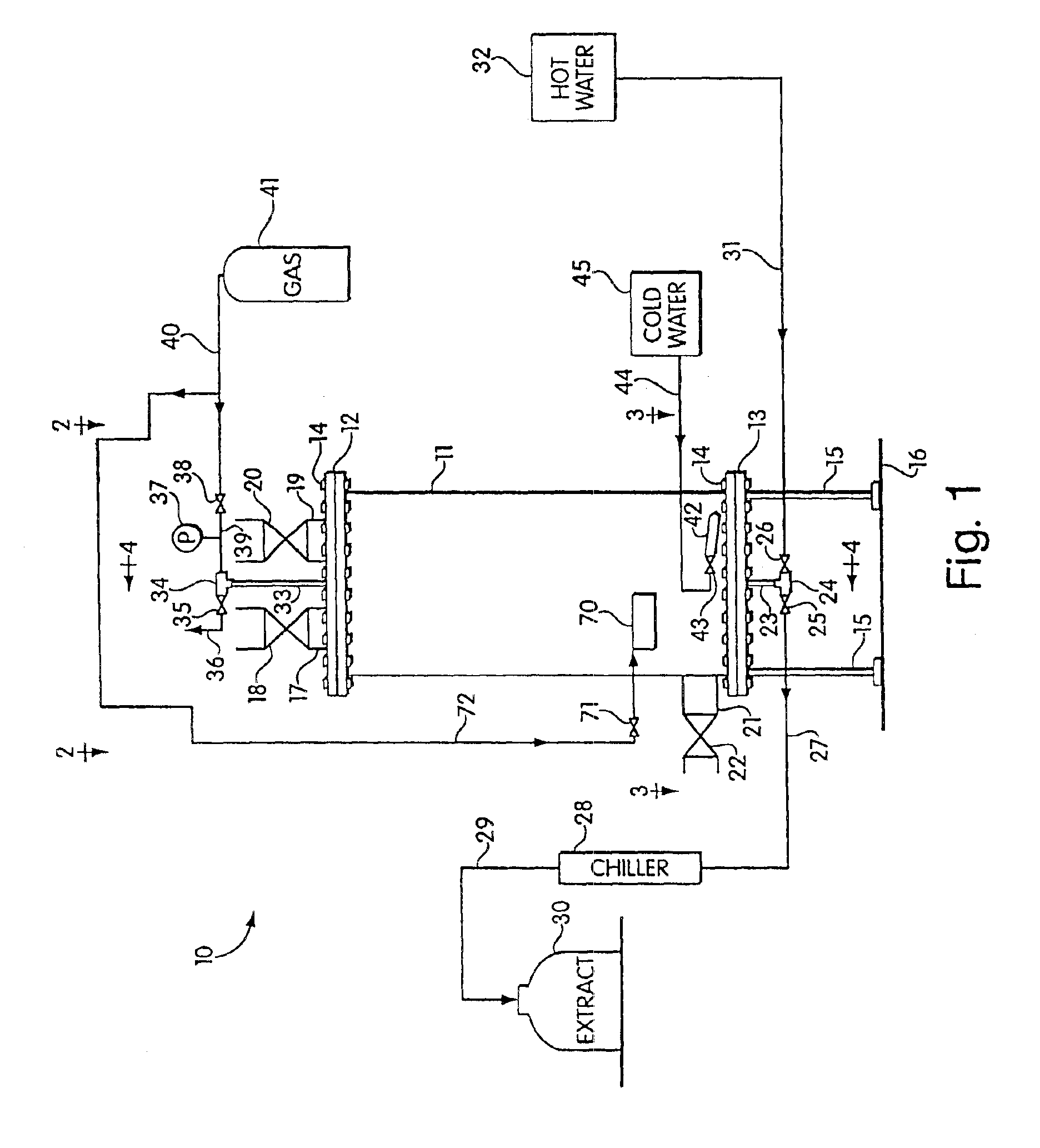

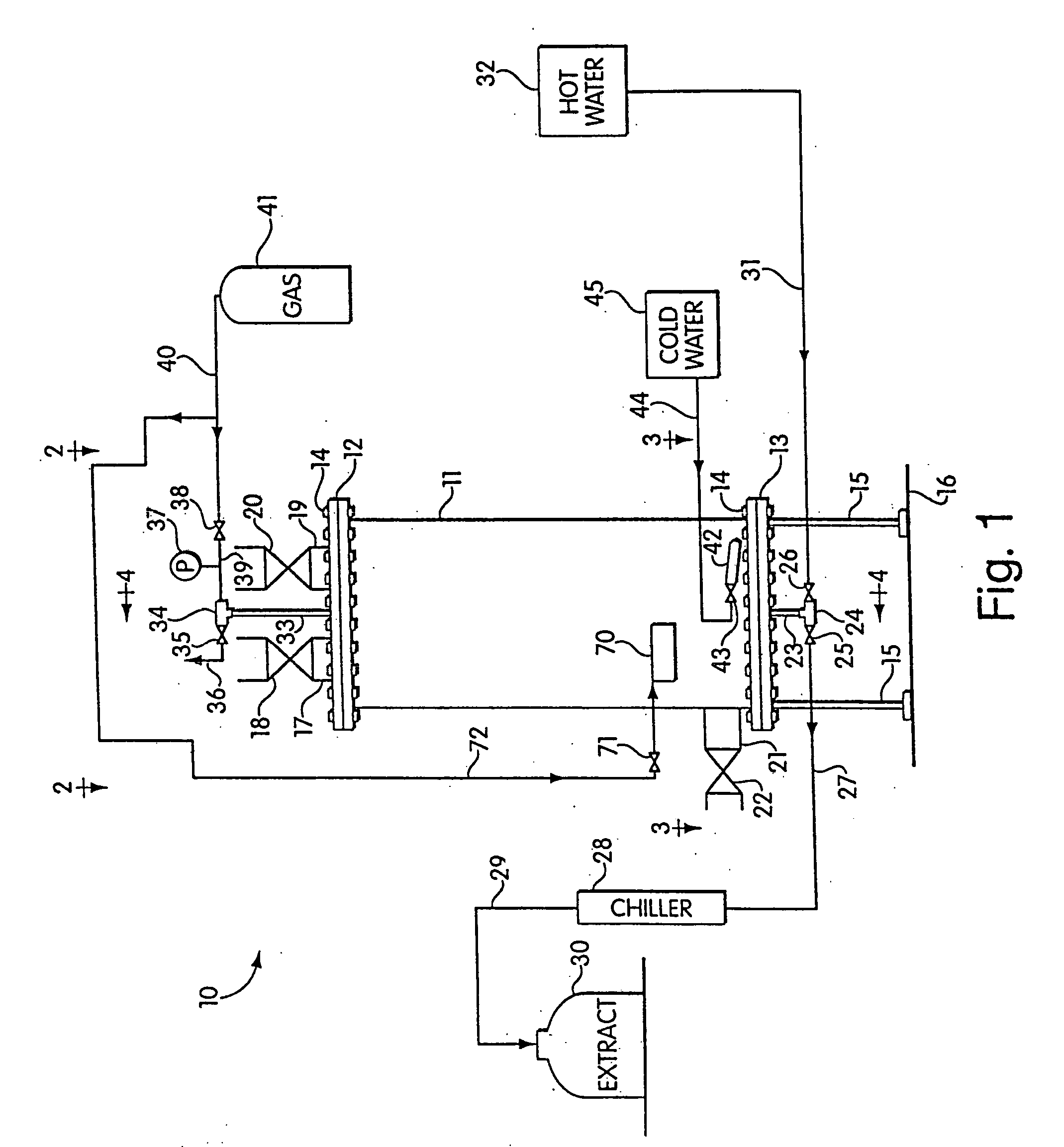

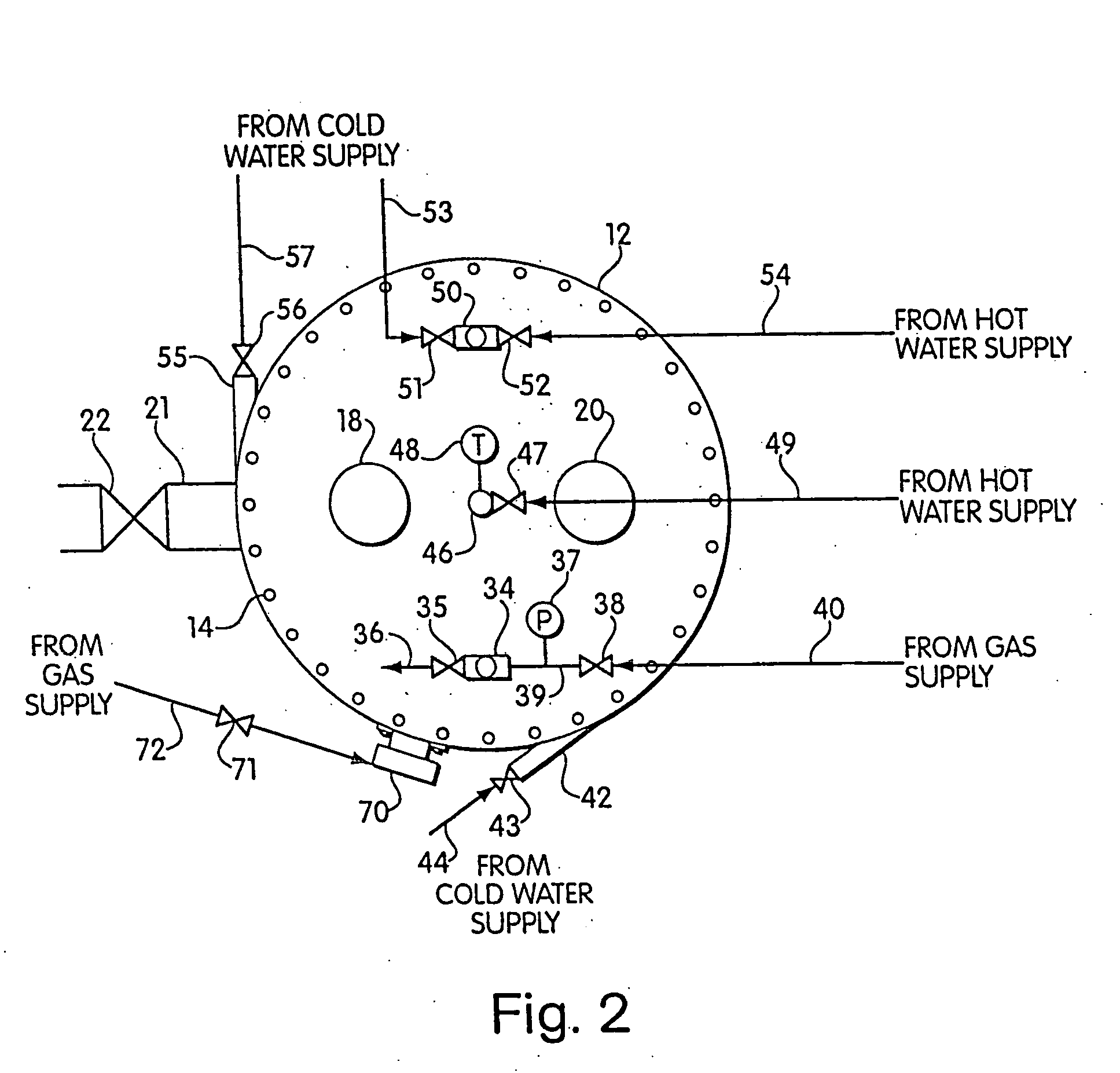

Coffee system

InactiveUS6887506B2Excellent and desirable and flavor and qualityExcellent and desirable and and fragrance qualityTea extractionTea substituesBeverage industryEngineering

Typical current methods for producing large quantities of extracts from solid raw materials such as ground, roasted coffee are designed for exhaustive extraction. Such methods are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides methods and apparatus for producing such high quality extracts. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial-scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances.

Owner:KERRY GROUP SERVICES

Liquid coffee product

InactiveUS6352736B2Lower ratioQuality improvementReady-for-oven doughsFruit and vegetables preservationCoffee processingGround coffee

A ready-to-serve coffee product which provides a refreshing beverage or topping. The product is a black, coffee containing liquid in an aseptically filled container. The liquid has a fresh, clean taste and may contain more than 2% by weight of soluble coffee solids. The liquid is produced by extracting coffee solids from roast and ground coffee at a draw-off ratio of less than about 3. The concentration of soluble coffee solids in the coffee extract is then adjusted to less than about 5% by weight under oxygen-reduced conditions.

Owner:NESTEC SA

Coffee Product

InactiveUS20080113077A1Improve the level ofIncrease aromaGreen coffee treatmentMeat/fish preservation by freezing/coolingChlorogenic acidCoffee processing

A coffee product comprises (i) a first portion consisting of unroasted coffee, in an amount of from 1 to 90% by weight based on the total weight of the ground coffee composition, and (ii) a second portion consisting of ground coffee which has been roasted to a higher degree of roast than said first portion, in an amount of from 99 to 10% by weight based on the total weight of the ground coffee composition in a weight ratio of (i) to (ii) is from 10:90 to 80:20 wherein the coffee product comprises at least 4 g of chlorogenic acids per 100 g of product.

Owner:NESTEC SA

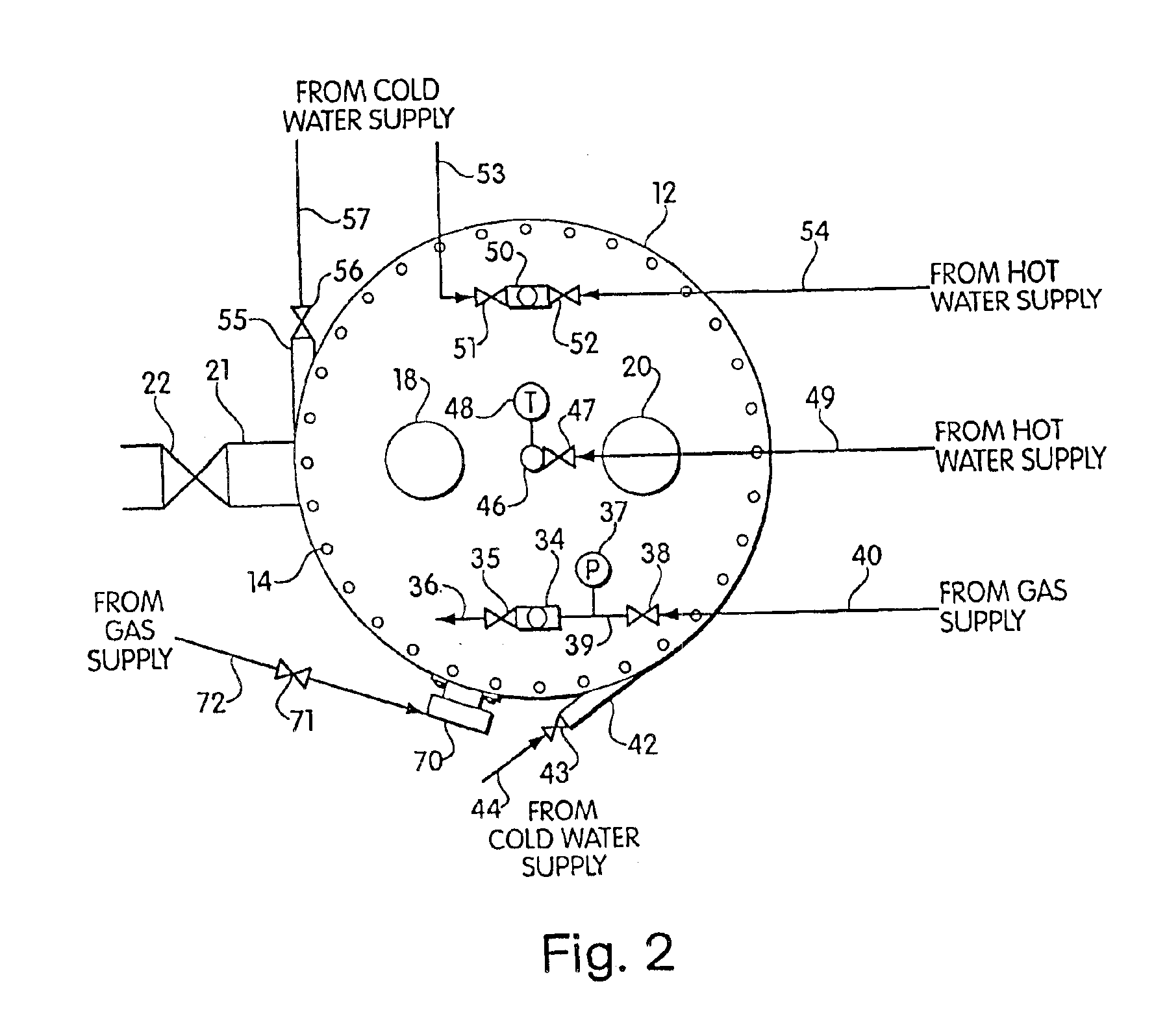

Coffee system

InactiveUS20050112253A1Excellent and desirable and flavorExcellent and desirable and and qualityTea extractionAlcoholic beverage preparationHigh concentrationEngineering

Typical current methods for producing large quantities of extracts from solid raw materials such as ground, roasted coffee are designed for exhaustive extraction. Such methods are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides methods and apparatus for producing such high quality extracts. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial-scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances. The inventive extraction methods, in some embodiments, involve subjecting roasted coffee to a static pressure treatment with pressurized solvent and / or removing extract from the bed of roasted coffee with a non-solvent gas as a final extraction step. The inventive methods can reduce the extent of extraction of the roasted coffee and the level of bitter, off-flavor components present in the coffee extracts. The extracts produced according to the invention can be advantageously used for applications where high quality coffee extracts, with a relatively high concentration of soluble coffee solids and a relatively high level of sweetness but without substantial amounts of bitter oils and acids, are desired.

Owner:KERRY GROUP SERVICES

Enzyme-Assisted Soluble Coffee Production

InactiveUS20080311245A1Reduce contentTea extractionAnimal feeding stuffParticulatesSemipermeable membrane

The invention relates to a coffee beverage composition being devoid of significant contents of oil and insoluble particulates, comprising(a) at least 15% based on the total weight of coffee solids of total mannose, wherein the free mannose content is less than 50% by weight of the total mannose content, and(b) less than 1,000 ppm on a total coffee solids basis of 5-hydroxymethyl furfural, and to a process for producing a soluble coffee extract, comprising the steps:(i) combining roast and ground coffee with water,(ii) adding hydrolase enzymes,(iii) wet-milling to a mean particle size of about 10 to about 250 μm,(iv) treating the reaction mixture by exposing it to a temperature in the range of about 20° C. to about 90° C., preferably about 50° C. to about 60° C., and(v) circulating the reaction mixture through a cross-flow semi-permeable membrane separation device where the soluble coffee extract is obtained as permeate.

Owner:INTERCONTINENTAL GREAT BRANDS

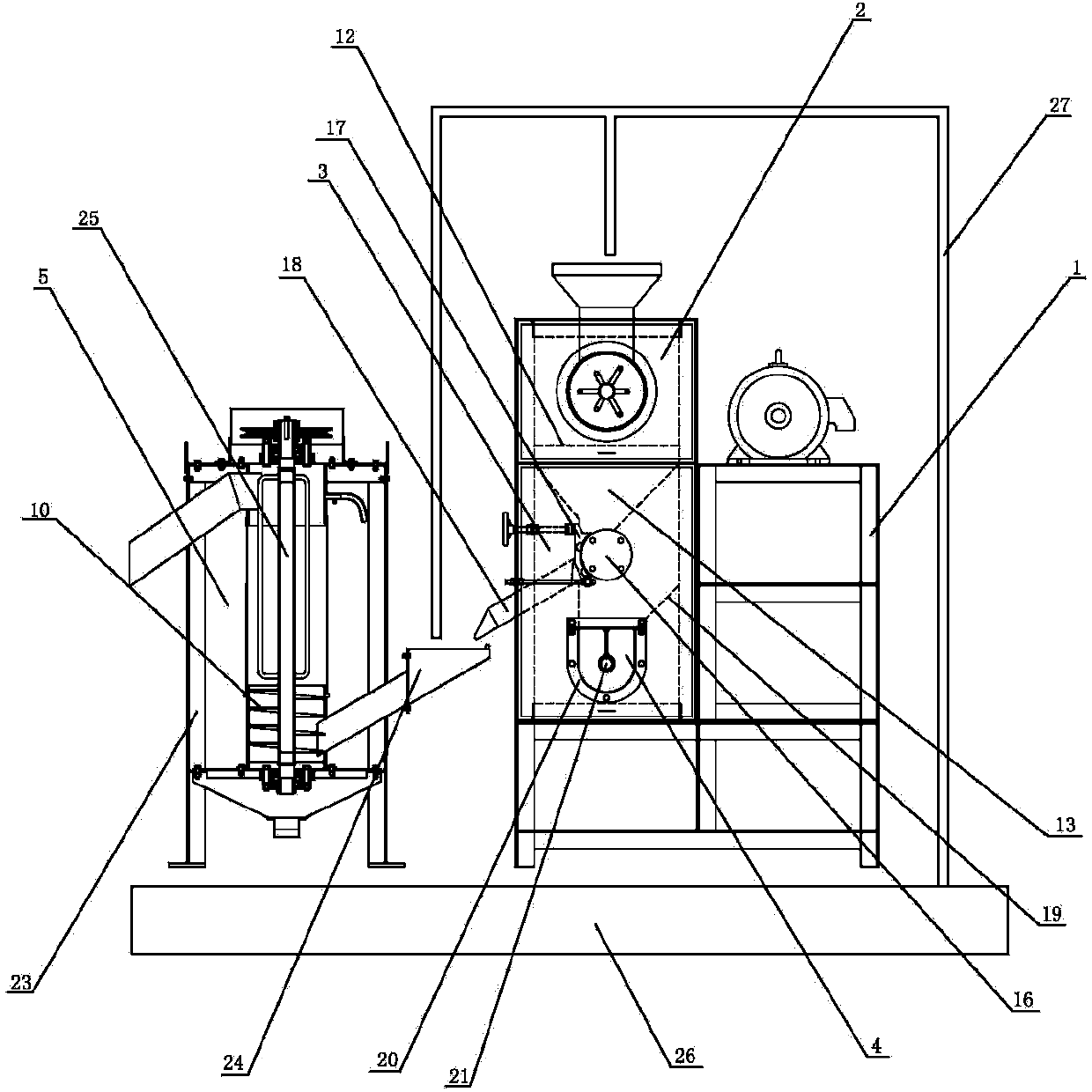

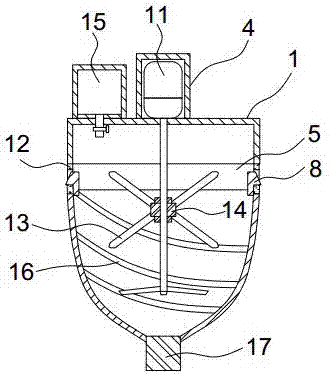

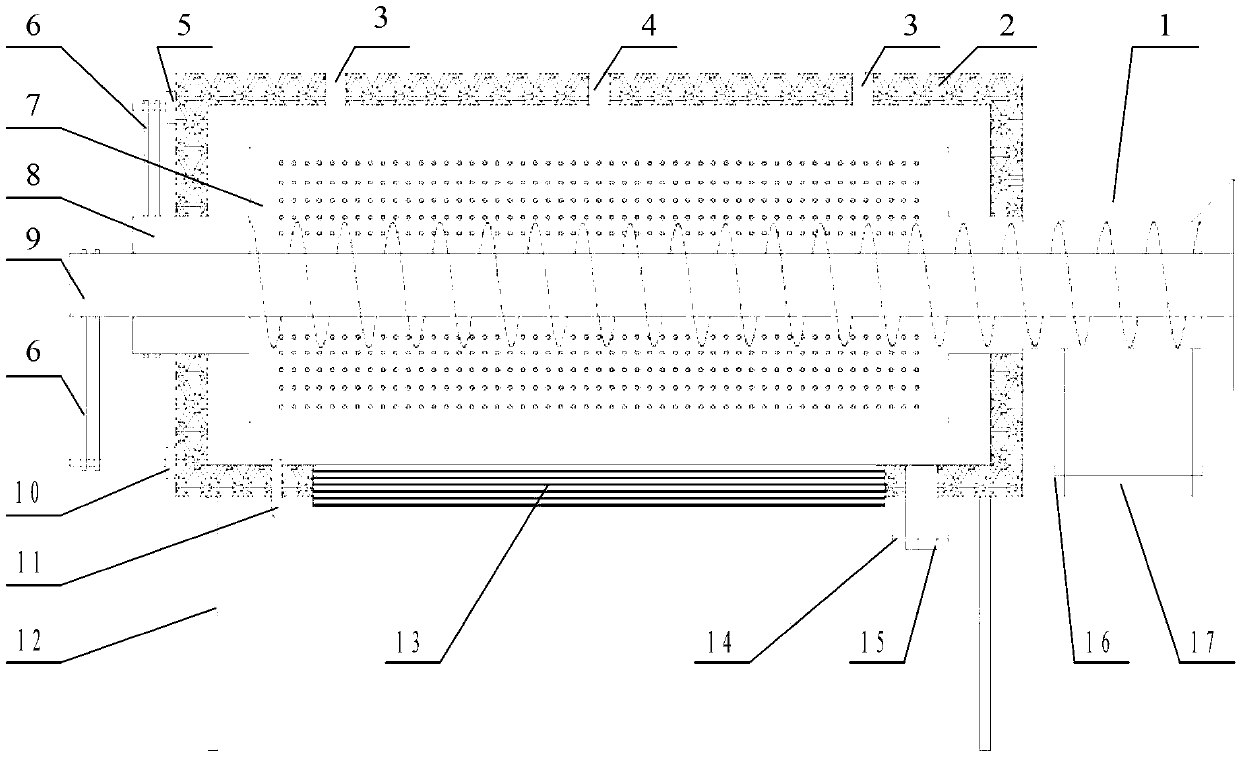

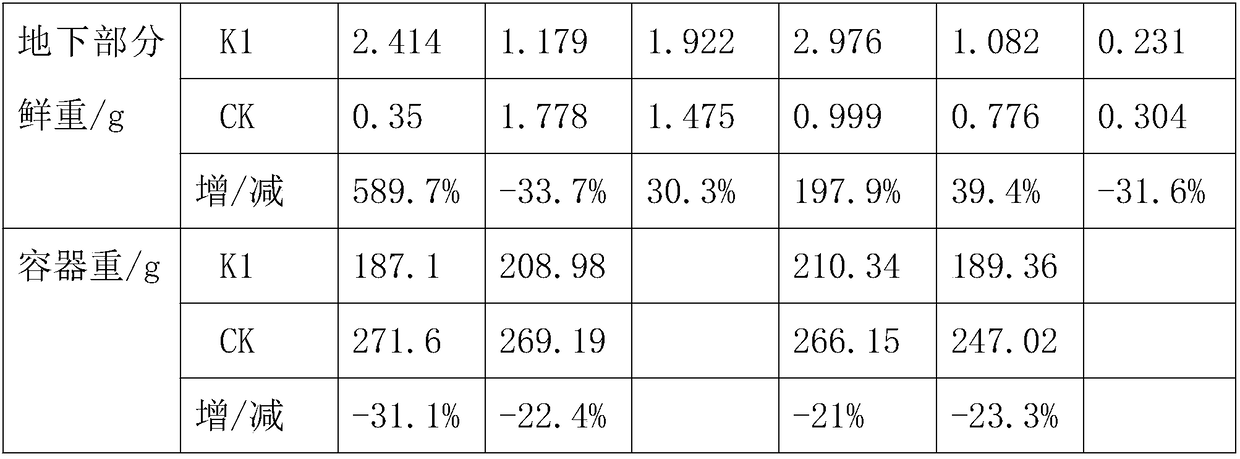

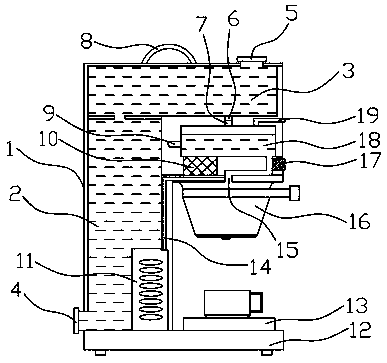

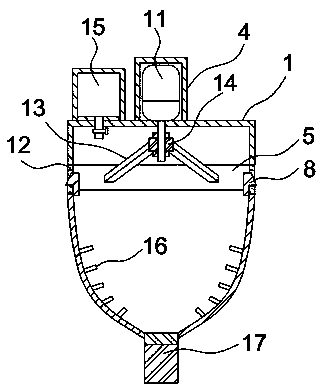

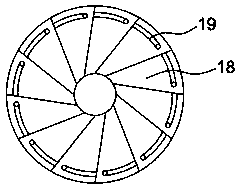

Coffee bean separating and rinsing device

ActiveCN103750513ASave waterSimple structureVegetable peelingFood treatmentWater circulationCoffee processing

The invention relates to a coffee processing device, in particular to a coffee bean separating and rinsing device integrating rapid sorting of unripe and ripe coffee cherries, separating of coffee beans and coffee peels and rinsing. The coffee bean separating and rinsing device is characterized by comprising a frame, an unripe and ripe coffee cheery separating device, a peel separating device, a drainage device, a degumming device and a cleaning water circulation device, wherein the unripe and ripe coffee cherry separating device, the peel separating device and the drainage device are arranged at the upper portion, in the middle and at the lower portion of the frame from top to bottom, the degumming device is arranged beside the frame and connected with the peel separating device, and the cleaning water circulation device is arranged at the bottom of the frame and connected with the drainage device and the unripe and ripe coffee cherry separating device. The coffee bean separating and rinsing device is simple in structure, reasonable in design, convenient to use and capable of saving resources, finishing procedures including unripe and ripe coffee cheery separating, peel removing, degumming and the like automatically, quickly and conveniently, reducing labor operation and increasing work efficiency.

Owner:YUNNAN PROV AGRI MACHINERY INST

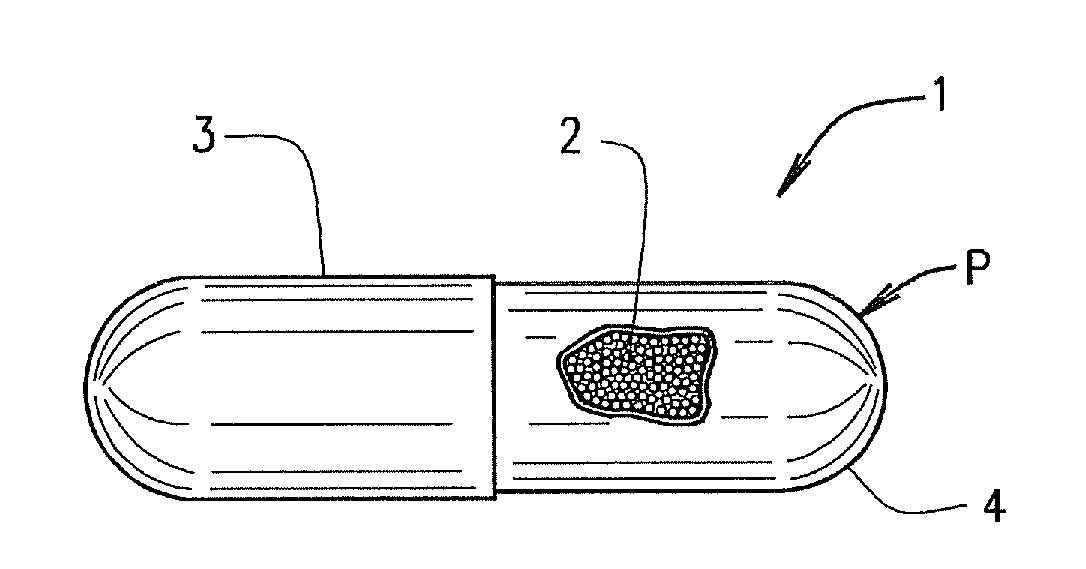

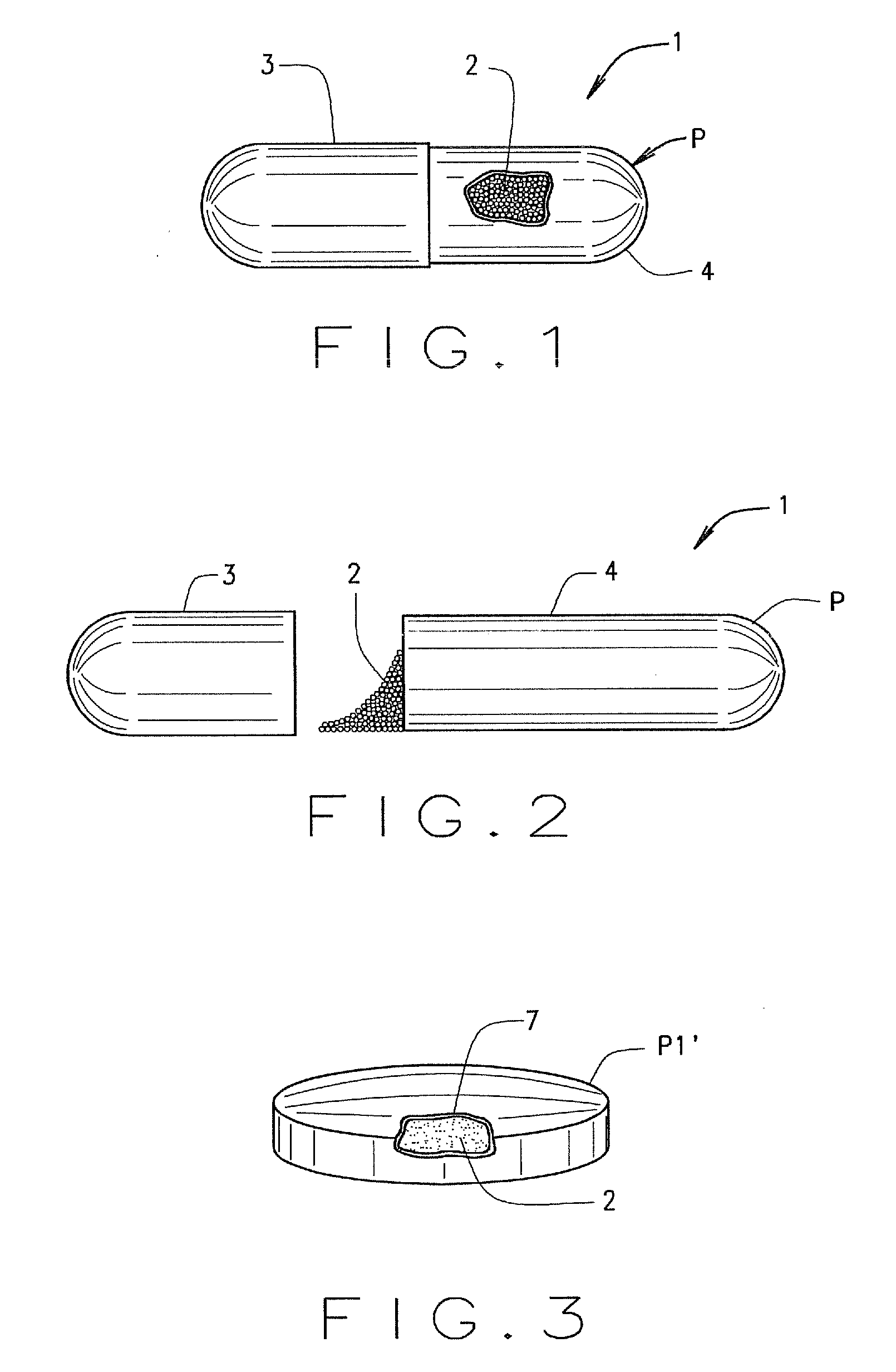

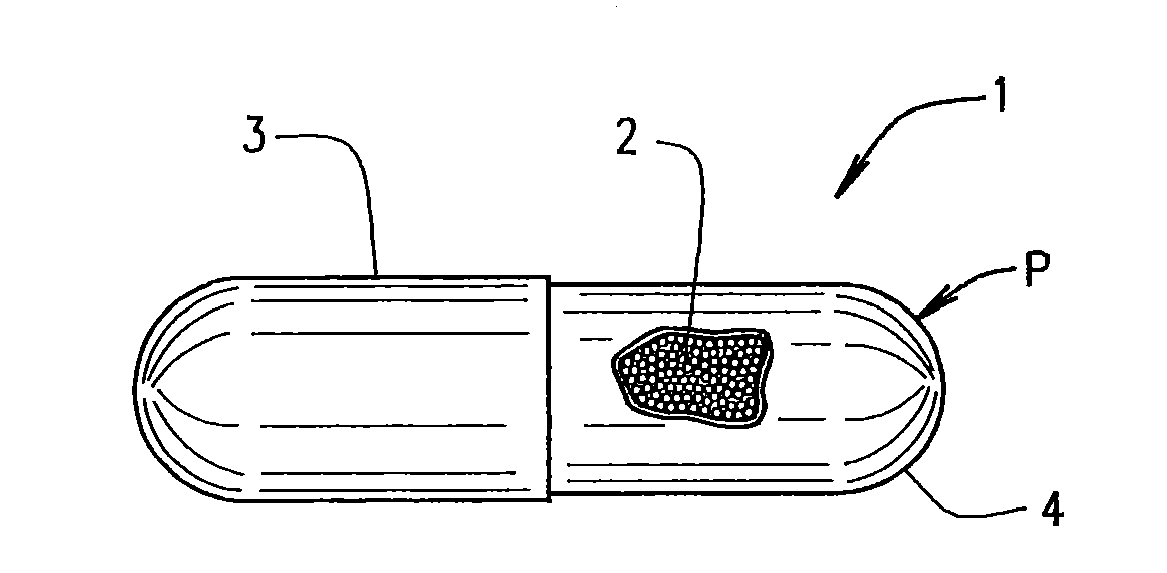

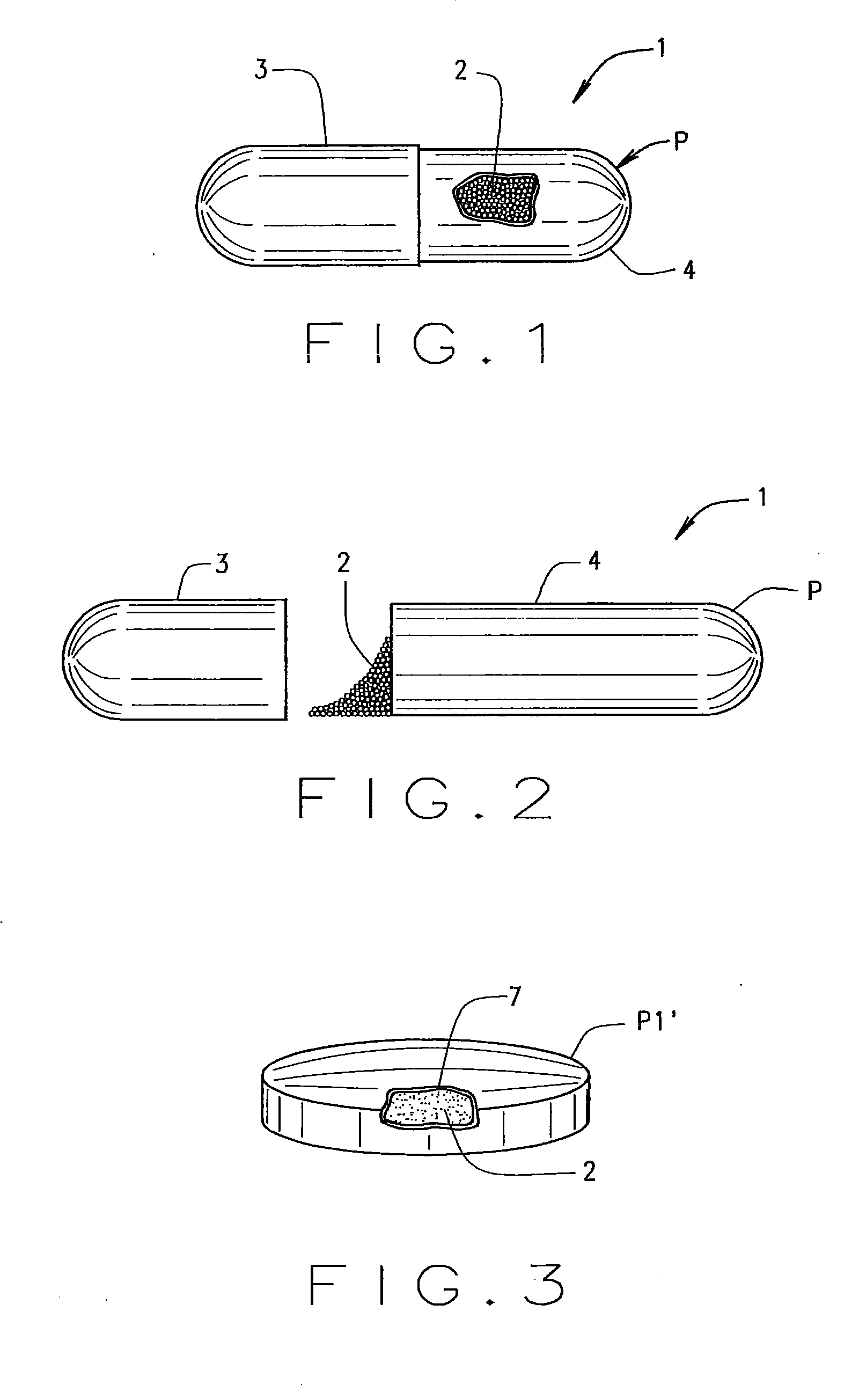

Coffee product and method

A coffee pill and method are provided. The coffee pill includes coffee encapsulated to prevent contact of the coffee product with the pallet during the initial stage of consumption by oral ingestion. Upon reaching the digestive tract, the encapsulant dissolves permitting the coffee product to be released from the pill.

Owner:EMPTY NEST IDEAS

Method and system for recovering aroma substances in production process of instant coffee

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Coffee product and method

InactiveUS20100239710A1Avoid the tasteConfectioneryAnimal feeding stuffDecaffeinated coffeeCoffee processing

A coffee pill and method are provided. The coffee pill includes decaffeinated coffee encapsulated to prevent contact of the coffee product with the pallet during the initial stage of consumption by oral ingestion. Upon reaching the digestive tract, the encapsulant dissolves permitting the decaffeinated coffee product to be released from the pill.

Owner:EMPTY NEST IDEAS

Brewable coffee product

InactiveUS20070160736A1Easy to moveReduce acidityRoasted coffee treatmentVanilla FlavorAdditive ingredient

A brewable coffee product usable to produce a coffee beverage. A first version coffee product includes ground roasted coffee, cocoa, a vanilla flavoring ingredient, and wheat, oats, corn, or barley flakes, or combinations thereof. One or more additional flavoring ingredients may be included such as mint, cinnamon, peppermint, or maple syrup. The coffee product may be individually packaged for single cup dipping. A second version of the coffee product includes ground roasted coffee and a plurality of elongate, non-toxic flow-facilitating members in the form of spaghetti, macaroni, noodles, or a combination thereof which facilitate flow of brewing water through the product during drip brewing. The pasta product also raises the pH of the coffee beverage brewed therewith to reduce acidity thereof.

Owner:DAY JON

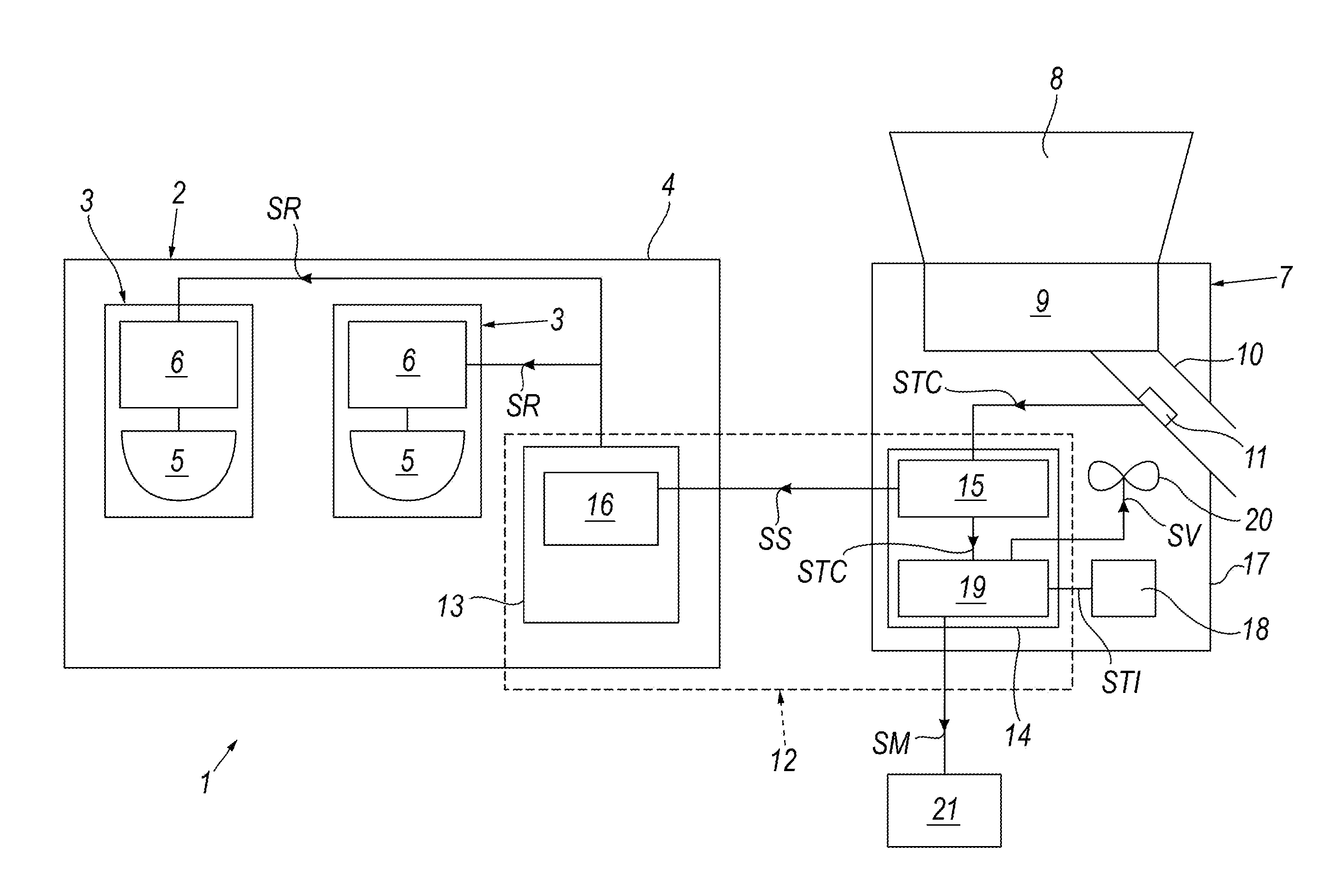

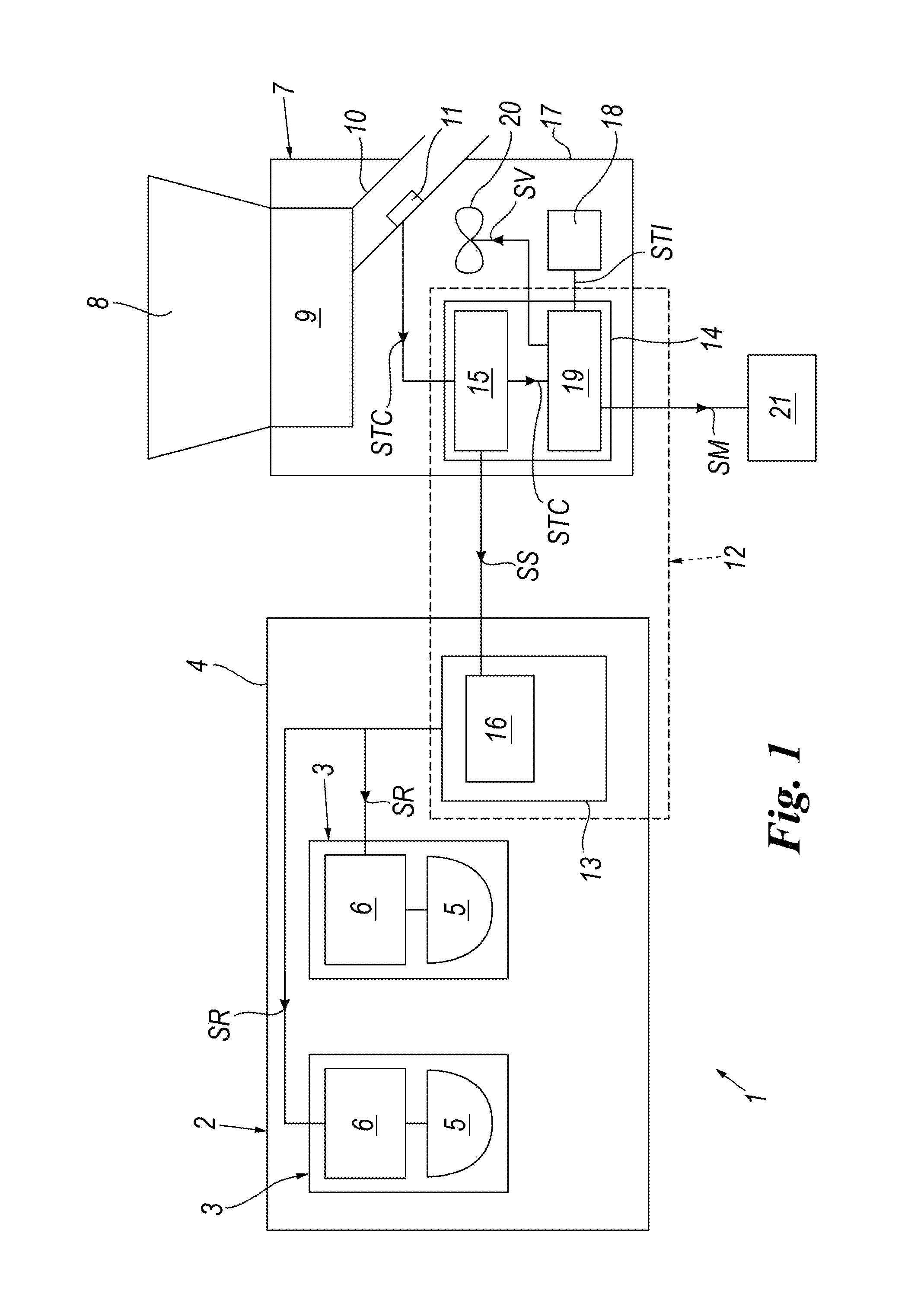

Espresso coffee dispensing system and method

InactiveUS20130302481A1High and constant qualityBeverage vesselsAvicultureElectronic controllerEspresso coffee

An espresso coffee dispensing system including at least one espresso coffee production machine including at least one espresso coffee dispensing unit, the unit comprising a filter for containing ground coffee powder and hot water feeder; a coffee grinder having an exit port for coffee powder and a temperature sensor disposed in proximity to the exit port to measure the temperature value of the ground coffee powder leaving the port; electronic controller associated with the coffee grinder to determine the water temperature value.

Owner:DALLA CORTE PAOLO

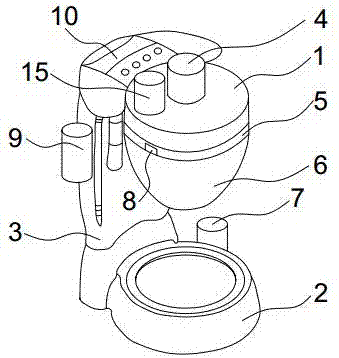

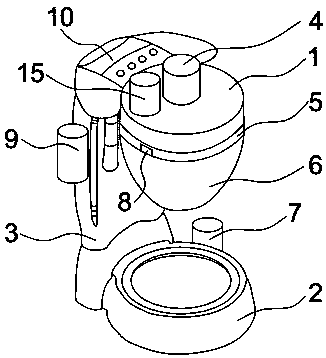

Efficient and flexible coffee maker

The invention provides an efficient and flexible coffee maker, and belongs to the technical field of coffee processing. The coffee maker includes a coffee maker body, a boiling box and a base; the base is connected to the lower end of the coffee maker body, the boiling box is connected to the upper end of the coffee maker body, a control panel is connected to the top face of the coffee maker body,a garbage box is connected to the side face of the coffee maker body, a rotation belt is arranged at the upper end of the boiling box, a rotation box is connected to the rotation belt, a rotation mechanism is connected to the inner side of the rotation belt, and an outlet column is connected to the bottom of the boiling box. The control panel can control the working conditions of the coffee maker, regulation and control are convenient, and the usage flexibility of the coffee maker is improved; the garbage box is used for placing temporary garbage produced in a coffee boiling process, it is convenient to maintain the grinding environment clean and tidy, the situation is avoided that bacteria and viruses are brought in a coffee grinding process, and the edible value of coffee is improved. The efficient and flexible coffee maker can completely boil the coffee, so that the coffee has good mouthfeel.

Owner:兰溪市拜瑞珂科技服务有限公司

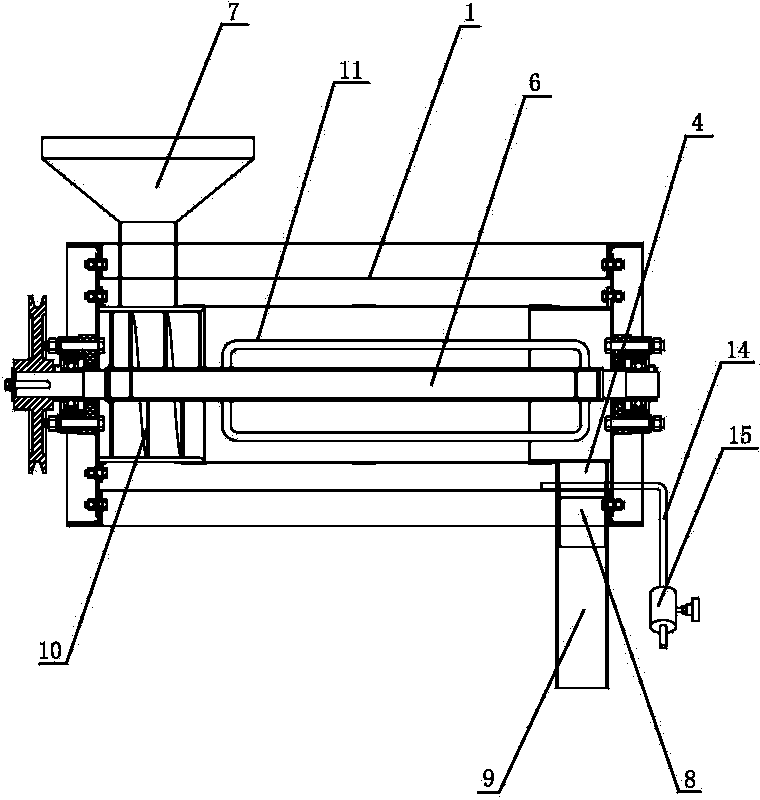

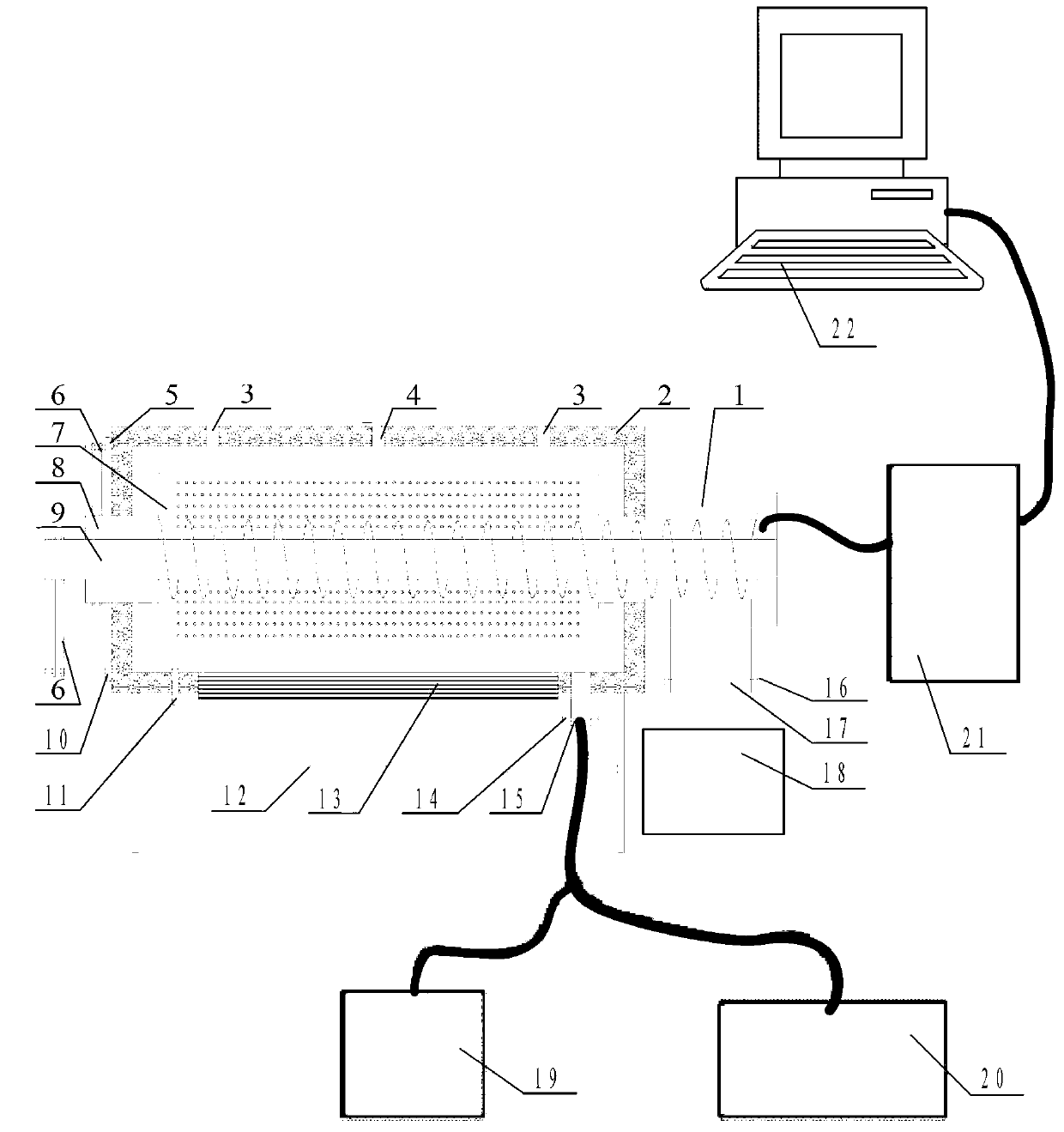

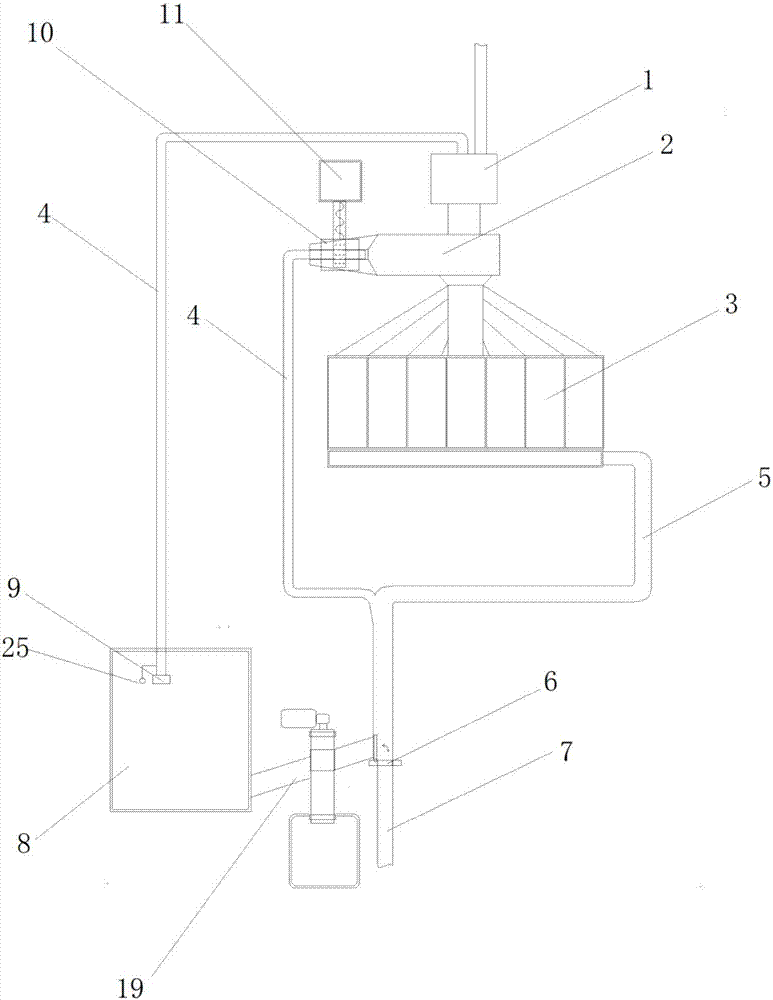

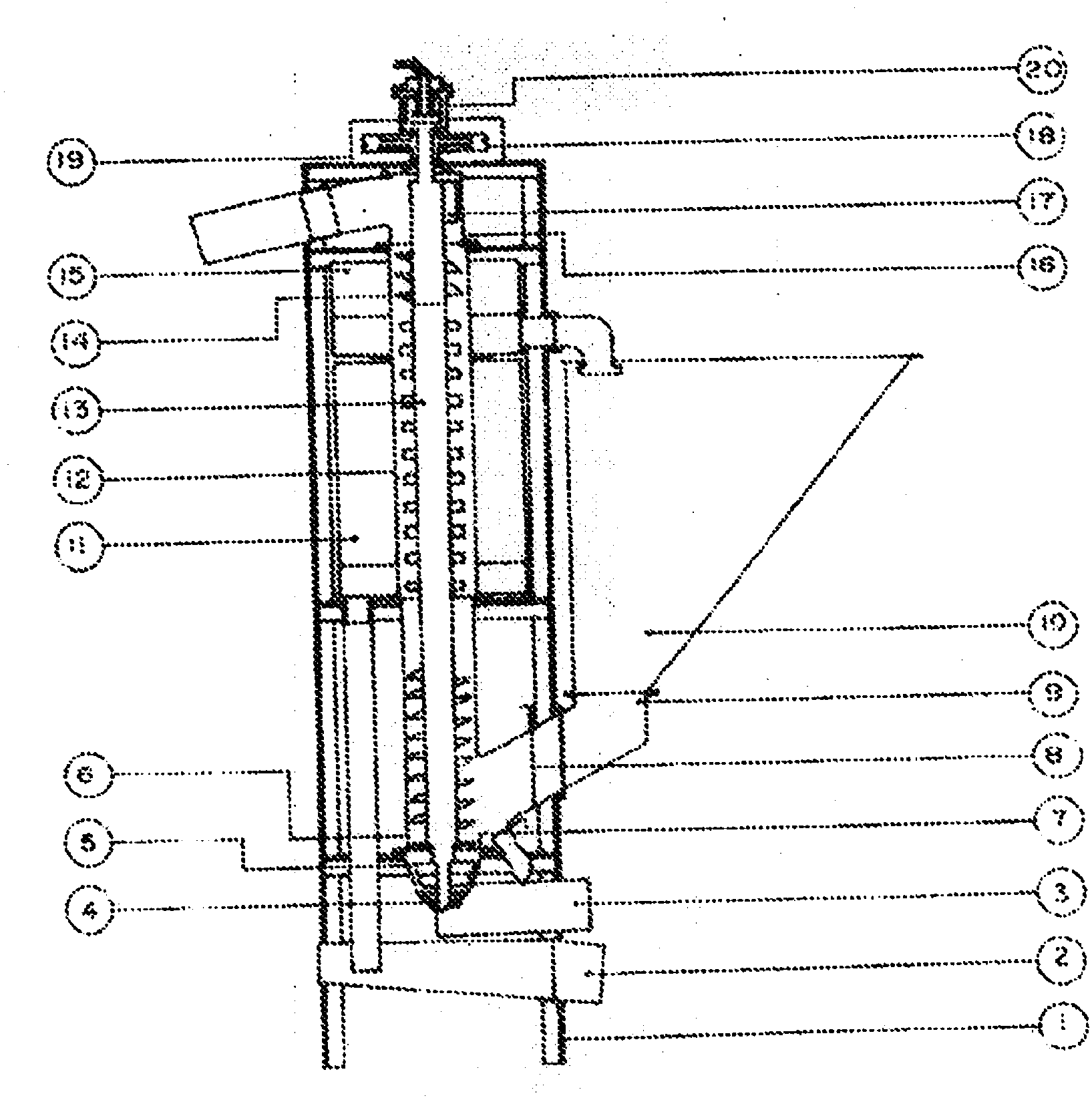

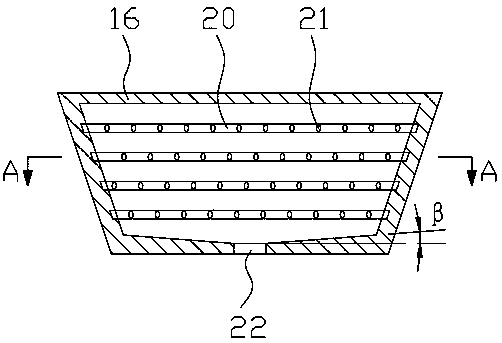

Fermentation and cleaning integrated machine of coffee and fresh fruits

ActiveCN103120355AImprove qualityAvoid residueGreen coffee treatmentFood treatmentAgricultural engineeringCoffee processing

The invention provides a fermentation and cleaning integrated machine of coffee and fresh fruits, and belongs to the coffee processing equipment field. The fermentation and cleaning integrated machine of the coffee and the fresh fruits aims at solving the problems that coffee bean quality is affected due to different degrees of fermentation caused by natural fermentation inside a fermentation pool of common wet method processing in the prior art, and coffee bean quality and flavor are affected due to mechanized degumming and cleaning directly through friction in machinery wet method processing. The fermentation and cleaning integrated machine of the coffee and the fresh fruits comprises a control system, a fermentation barrel, an inner barrel, a spiral shaft and a heating plate. The spiral shaft penetrates through the inner barrel, the inner barrel is arranged inside the fermentation barrel, two sides of an inner barrel shaft of the inner barrel penetrate through the two sides of the fermentation barrel, the inner barrel and the spiral shaft are respectively driven to rotate by a dynamo, the heating plate is used for heating the fermentation barrel, and the control system is used for controlling temperature of the heating plate and rotating speed of the dynamo. The fermentation and cleaning integrated machine of the coffee and the fresh fruits combines fermentation and cleaning into one, the whole fermentation process is realized according to set temperature, humidity and time, automatic cleaning is completed, and pectin and coffee beans are separated.

Owner:CHANGCHUN UNIV OF SCI & TECH +1

Enzyme-Assisted Soluble Coffee Production

Owner:INTERCONTINENTAL GREAT BRANDS LLC

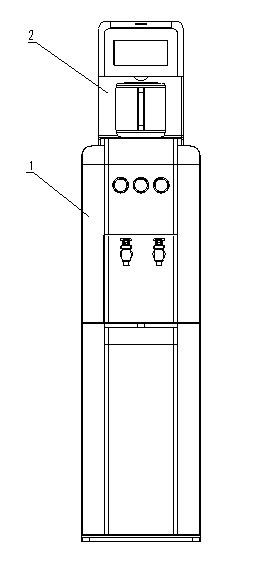

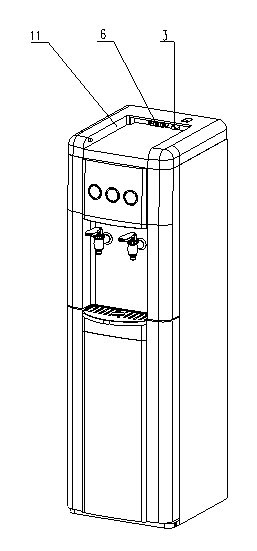

Drinking water machine with coffee function

InactiveCN102151086AMeet the needs of making fresh coffeeEasy to assembleBeverage vesselsLiquid transferring devicesComputer moduleEngineering

The invention discloses a drinking water machine with a coffee function. The machine comprises a drinking water machine, a coffee module and a control circuit, wherein a first water path port and a first circuit port are formed on the drinking water machine; a second water path port and a second circuit port are formed on the coffee module; the first water path port and the first circuit port of the drinking water machine are connected and combined with the second water path port and the second circuit port respectively; and the coffee module is movably arranged on the drinking water machine. The machine can make coffee by utilizing coffee beans, adopts butting assembly, is convenient to operate, can move the coffee machine to clean at any time, has a simple and reliable structure, is easy to assemble, and saves placement space.

Owner:MIDEA GRP CO LTD +1

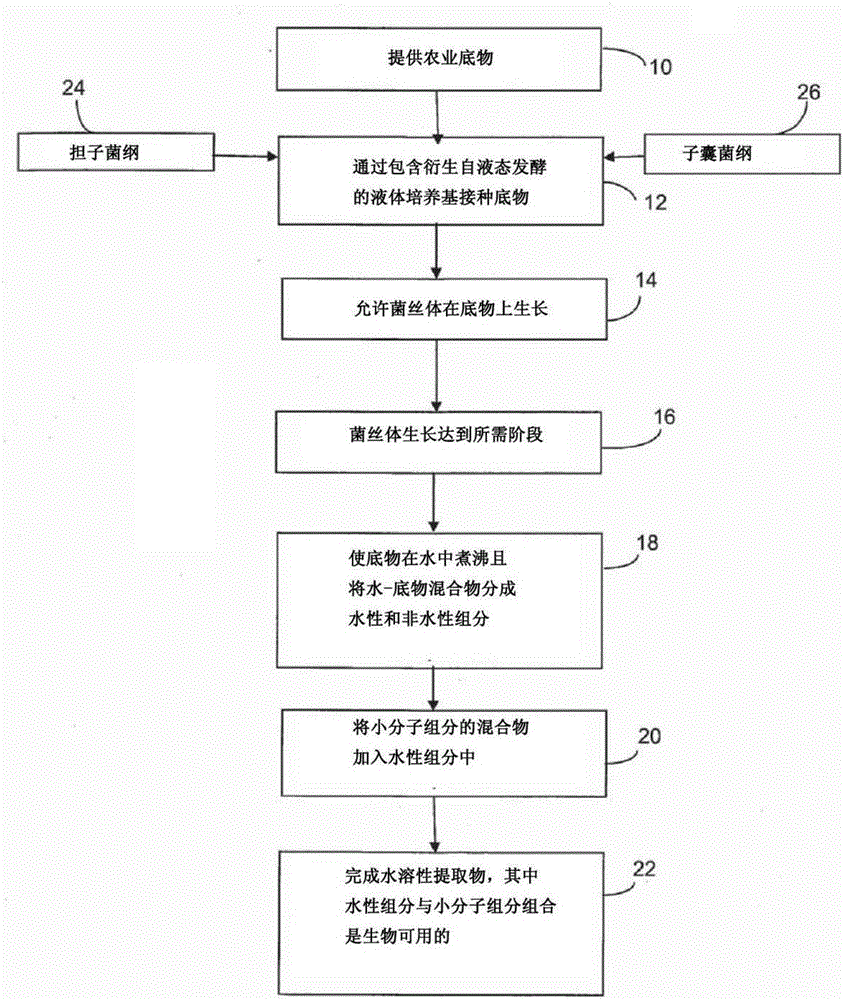

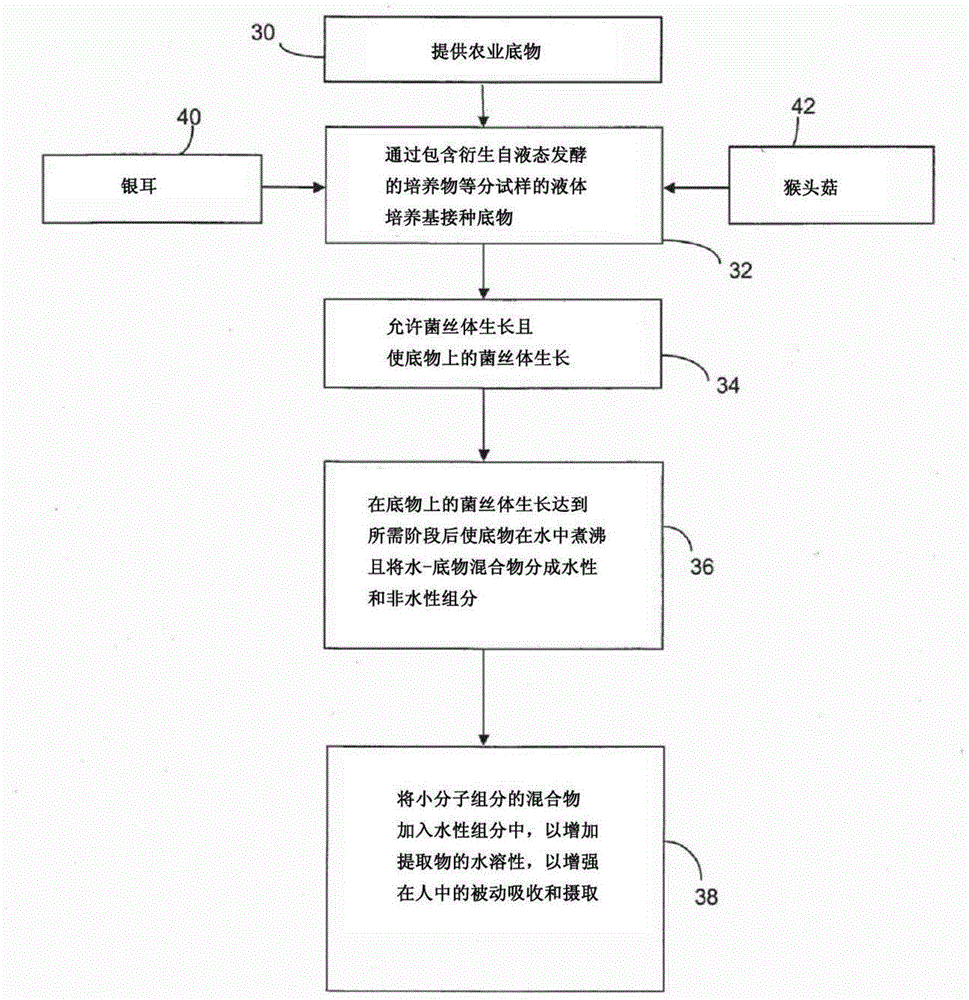

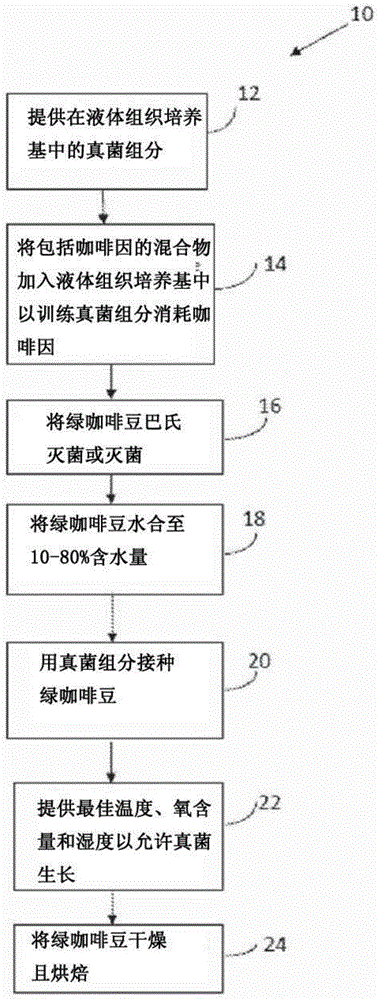

Myceliated coffee products and methods for making

InactiveCN105228462AReduced taste componentsImprove the level ofFruit and vegetables preservationCocoaBiotechnologyChlorogenic acid

The present invention provides a method for the preparation of a myceliated coffee product. This method providing green coffee beans and sterilizing the green coffee beans to provide prepared green coffee beans, and a step of inoculating the prepared green coffee beans with a prepared fungal component and culturing the inoculum to prepare the myceliated coffee product. The methods of the instant invention result in prepared green coffee beans and myceliated coffee products having reduced levels of undesirable taste components, such as chlorogenic acids, and increased levels of myceliation products, such as beta glucans and polysaccharides, relative to starting green coffee beans.

Owner:MYCOTECH

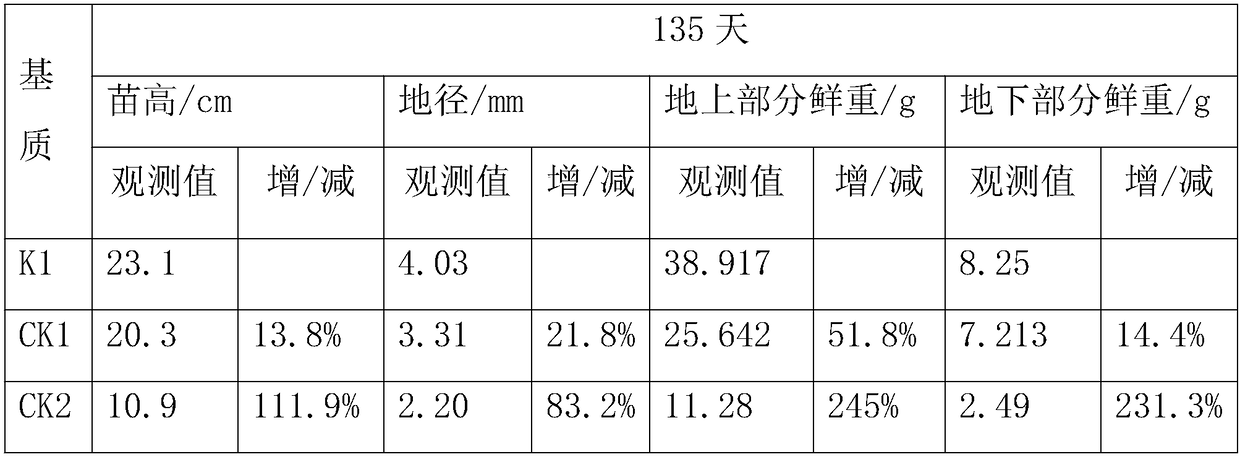

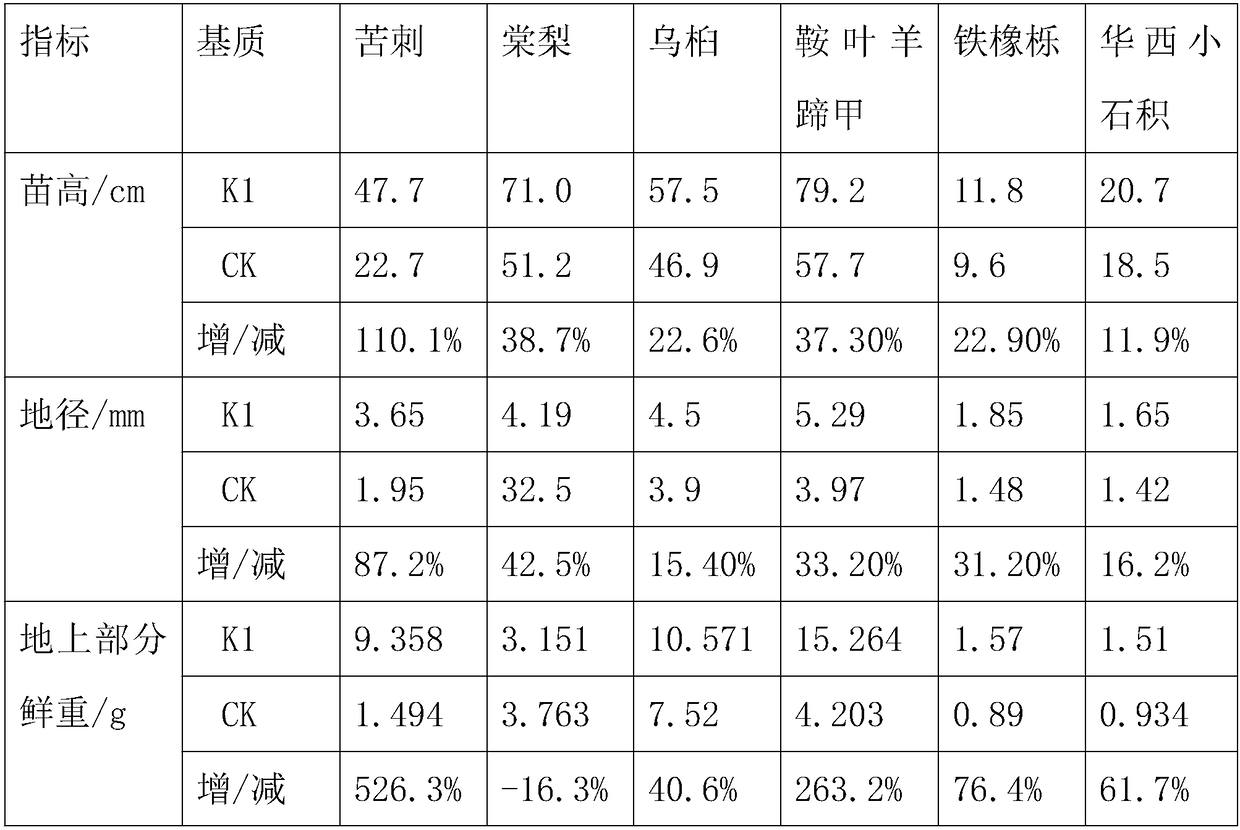

Seedling substrate using coffee processing residues as raw material and preparation method thereof

InactiveCN108235912AReduce manufacturing costLow production costGrowth substratesCulture mediaPorosityWater holding

The invention relates to the technical field of substrate preparation, and specifically discloses a seedling substrate using coffee processing residues as a raw material and a preparation method thereof. The seedling substrate consists of the following components in percentages by volume: 30%-34% of the coffee processing residues, 7.5%-8.5% of cow dung, 22.5%-25.5% of puffed perlite and 22.5%-25.5% of vermiculite; and the pH of the seedling substrate is 6.5-6.9, the total porosity is 71%-75%, and the water holding porosity is 49%-51%. The seedling substrate is prepared through three steps of raw material collection and pretreatment, fermentation and seedling substrate preparation. The seedling substrate prepared by using the coffee processing residues as the raw material has the advantagesthat the raw materials are easy to obtain, the formula is reasonable, nutrition is balanced, the seedling substrate is soft and breathable, and the operation technology is easy to grasp, so that theseedling substrate can effectively promote the growth and development of aboveground and underground parts of seedlings, therefore, the seedling cost is reduced, and the seedling cycle is shortened.

Owner:YUNNAN ACAD OF FORESTRY

Natural new material for filter rod composition and application thereof

InactiveCN103340478AImprove adsorption capacitySave resourcesTobacco smoke filtersCellulose acetateClub shaped

The invention relates to a new material for filter rod composition and application of the new material and belongs to the technical field of cigarette filter rod materials. The natural new material can be obtained through the following steps that fresh coffee shells which are stripped out and discarded are gotten from a coffee production base when coffee is harvested, the fresh coffee shells are dried in the air till the moisture content is below 30%; the dried coffee shells are put into a baking device and baked at a lower temperature of about 60 DEG C till the moisture content is 9-12%; the baked coffee shells are cut into filaments or particles, and the coffee shells are rolled into club-shaped composite new material after humectant and tobacco extracting solution are added or are not added.. The natural composite new material and cellulose acetate fibroin are composited be used as material for manufacturing binary composite filter rods. The natural new material for filter rod composition has the advantages of being low in cost, good in environment friendliness, safe, good, natural, capable of playing a role in filtering and absorbing large-particle aerosol substances in smoke, and remarkable in economic benefit and social benefit.

Owner:YUNNAN RES INST OF TOBACCO SCI

Method for retaining aroma of roasted coffee by utilizing fixative

The invention discloses a method for retaining aroma of roasted coffee by utilizing fixative and belongs to the field of roasted coffee processing in food processing. By adding specified fixative of specified proportion during the roasting process of green coffee beans, the aroma of roasted coffee becomes stronger and the taste becomes mellower under the condition that the production cost is not increased or slightly increased. The method is characterized in that butter is added as the fixative during the roasting process of the green coffee beans when the whole green coffee beans become orange to light coffee; other matters needing attention are the same as those of the common roasting methods of coffee; and the adding proportion is calculated by the weight and particularly the adding proportion is 2% of the green coffee beans.

Owner:保山锦庆热作科技有限公司

Method for extraction of oily components from coffee beans and/or of residual materials of coffee production

InactiveCN106998728AImprove dissolution efficiencyFatty-oils/fats refiningFatty-oils/fats productionCoffee processingSolvent

The invention relates to a method for wet extraction of oily components from coffee beans and / or of residual materials of coffee production, wherein the coffee beans and / or the residual materials are extracted with a residual moisture content of 10 to 95 mass%, measured relative to the total weight of the coffee beans and / or residual materials of coffee production, using an extraction agent mixture that consists of at least one polar and one non-polar solvent each.

Owner:GCR GLOBAL COMMODITY RESOURCES UG HAFTUNGSBESCHRANKT

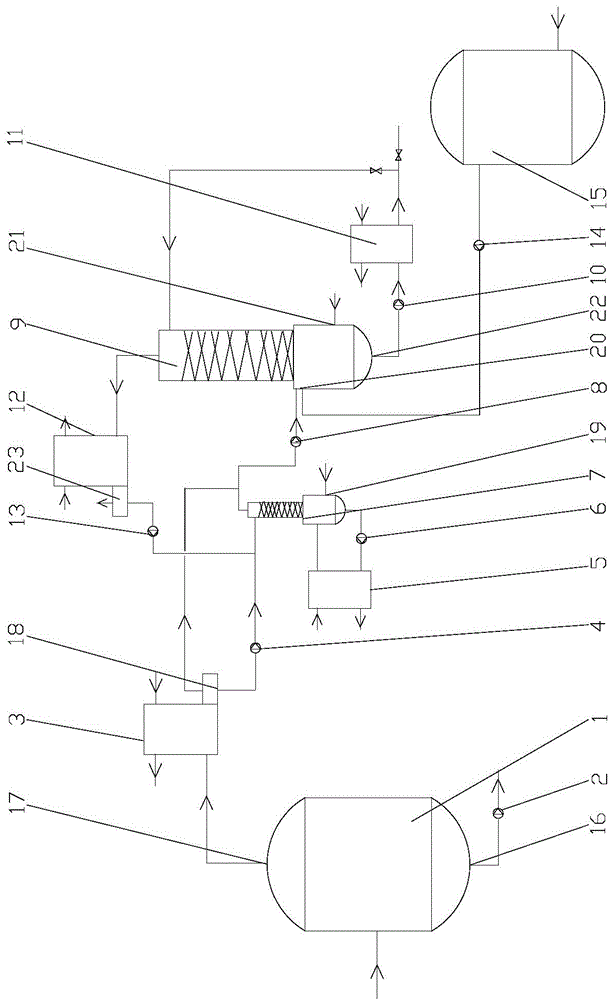

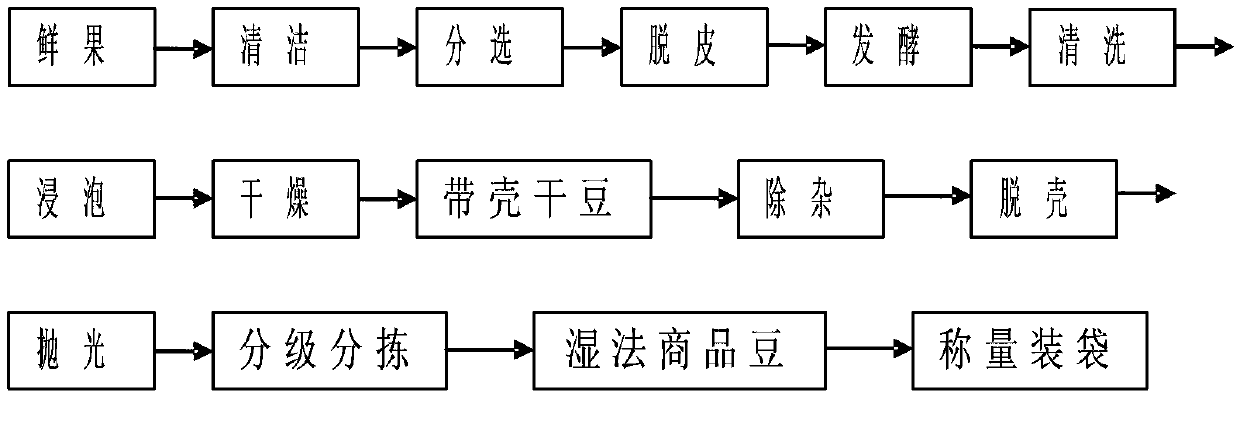

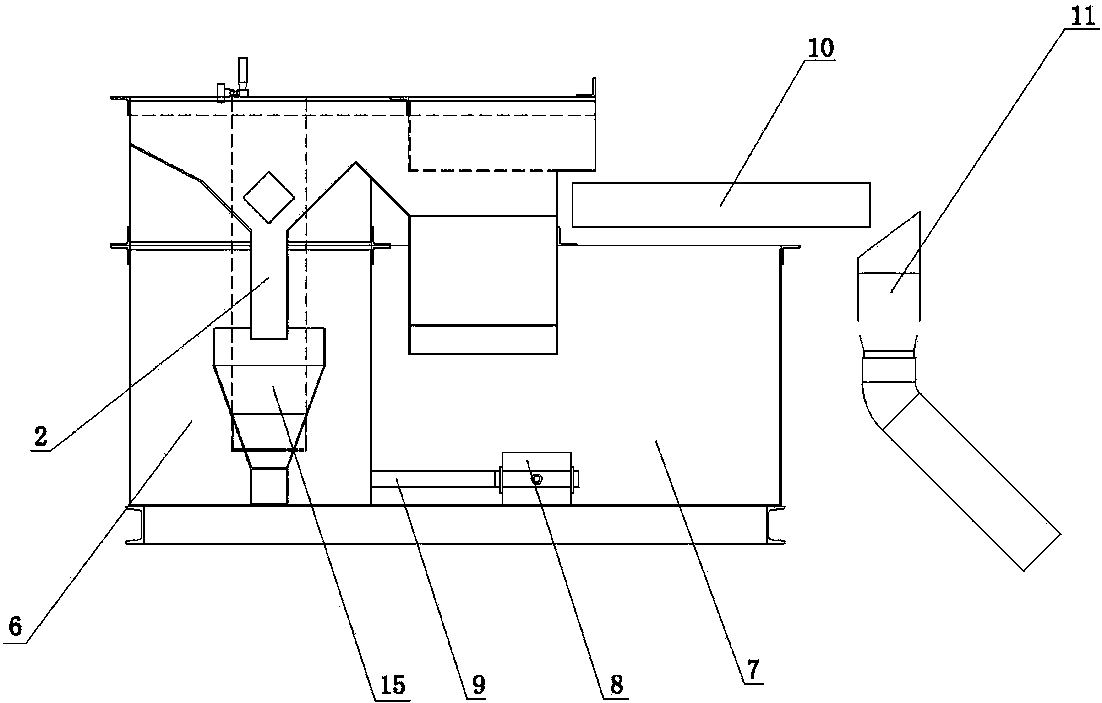

Coffee and fresh fruit processing water recycling system and technological method

ActiveCN107183284AGuaranteed quality rateImprove filtration efficiencyClimate change adaptationGreen coffee treatmentWater cyclingWater resources

The invention provides a coffee and fresh fruit processing water recycling system and a technological method. The system comprises a washing water tank, a washing groove, a degumming and fermentation pool and a water pipeline; the washing groove is connected with the degumming and fermentation pool through the water pipeline; the water outlet end of the degumming and fermentation pool is connected to a water outlet duct through the pipeline; the water outlet duct is provided with an electronic control two-way valve; one end of the electronic control two-way valve is connected with a drainage pipe; the other end of the electronic control two-way valve is connected with a sedimentation pool; the sedimentation pool is connected to the washing water tank through a water pump and the water pipeline; a nutshell filter device is installed in the washing groove; the discharge end of the filter shell device is connected with a nutshell collection groove; and the other end of the filter shell device is connected to the water outlet duct through the water pipeline. By adopting the system and a processing fermentation method using the system, the water for coffee processing can be saved, waste of water resources can be effectively solved, the content change of circulating water can be ingeniously utilized to improve the fermentation efficiency, and the quality of coffees and fresh fruits are improved.

Owner:澜沧瑞峰茶叶咖啡有限公司

Modular system for wet coffee processing without water pollution

The instant invention discloses a coffee washing machine wherein the coffee mucilage has previously been degraded by means of natural fermentation or by the addition of pectinolytic enzymes, wherein the degradation process minimizes the coffee's environmental impact together with the washing process. The method disclosed in the instant invention comprises: i) depulping coffee berries; ii) conveying coffee to a screening system in order to remove berries not depulped and the vast majority of the pulp; iii) conveying depulped berries to a tank, iv) storing the depulped berries in tanks allowing for mucilage degradation either through natural fermentation or by use of pectinolytic enzymes; v) conveying coffee from the fermentation tank towards the mechanical washer; vi) removing the degraded mucilage, allowing for washed coffee ready to initiate the drying phase.

Owner:FEDERACION NACIONAL DE CAFETEROS DE COLOMBIA

Coffee brewing equipment capable of automatically adjusting temperature

InactiveCN110150984ASpeed up brewingImprove uniformityBeverage vesselsAgricultural engineeringCoffee processing

The invention provides coffee brewing equipment capable of automatically adjusting the temperature, and belongs to the technical field of coffee processing. The equipment comprises a shell, a base connected to the bottom of the shell and a brewing box in matched connection with the shell, a brewing outlet is formed in the bottom of the brewing box, at least one concave ring is arranged on the inner wall of the brewing box, air outlets are uniformly distributed in the inner walls of the concave rings and are correspondingly connected with steam branch pipes, and the steam branch pipes are connected with a boiling device arranged at the lower end of the shell through steam guide pipes. The equipment is large in brewing temperature adjusting amplitude, the brewing speed is high, different requirements can be met, coffee brewing is uniform, and obtained coffee has strong coffee fragrance and soft and smooth mouth feel.

Owner:金华市坤麦科技有限公司

Processing technology capable of improving coffee processing efficiency and coffee beans processed thereby

The invention relates to a processing technology capable of improving coffee processing efficiency and coffee beans processed thereby, and belongs to the field of food processing. The processing technology capable of improving coffee processing efficiency comprises the following steps of performing flotation on coffee fruits, removing pectin from peeled selected coffee fruits by performing biological enzyme degumming, dying the pectin-removed coffee beans, removing shell, carrying out polishing, and carrying out post-treatment. The biological enzyme degumming is performed by using pectinase and cellulase. The processing technology capable of improving coffee processing efficiency is simple in processing process, good in condition controllability; moreover, the degumming process of the coffee beans is improved so that coffee yield is stabilized with coffee bean quality improved, and thus, the processing technology is suitable for industrial production. Coffee beans prepared by adoptingthe processing technology are small in water-soluble substance loss, relatively low in bean breakage rate, and relatively high in yield.

Owner:中国咖啡工程研究中心

Multifunctional coffee maker

InactiveCN108552951AGreat tasteHigh working reliabilityBeverage vesselsBoiling processPulp and paper industry

The invention provides a multifunctional coffee machine, and belongs to the technical field of coffee processing. The coffee machine comprises a machine body, a boiling box and a base; the base is connected to the lower end of the machine body, the boiling box is connected to the upper end of the machine body, a control panel is connected to the top face of the machine body, a rotation band is arranged at the upper end of the boiling box, a rotation box is connected to the rotation band, a rotation mechanism is connected to the inner side of the rotation band, and an outlet column is connectedto the bottom of the boiling box. According to the coffee machine, coffee can be fully boiled, so that the coffee has the good taste; a feeding box can achieve the purpose that automatic feeding canbe conducted in the coffee boiling process, the operation that after the coffee is boiled, sugar needs to be added for stirring is omitted, and then the coffee machine is used more conveniently; a steam outlet is used for exhausting steam or boiling water, stirring can be conducted in the coffee boiling process, coffee powder can be pressed, and the coffee taste and nutritional value are significantly improved.

Owner:磐安海璞食品科技有限公司

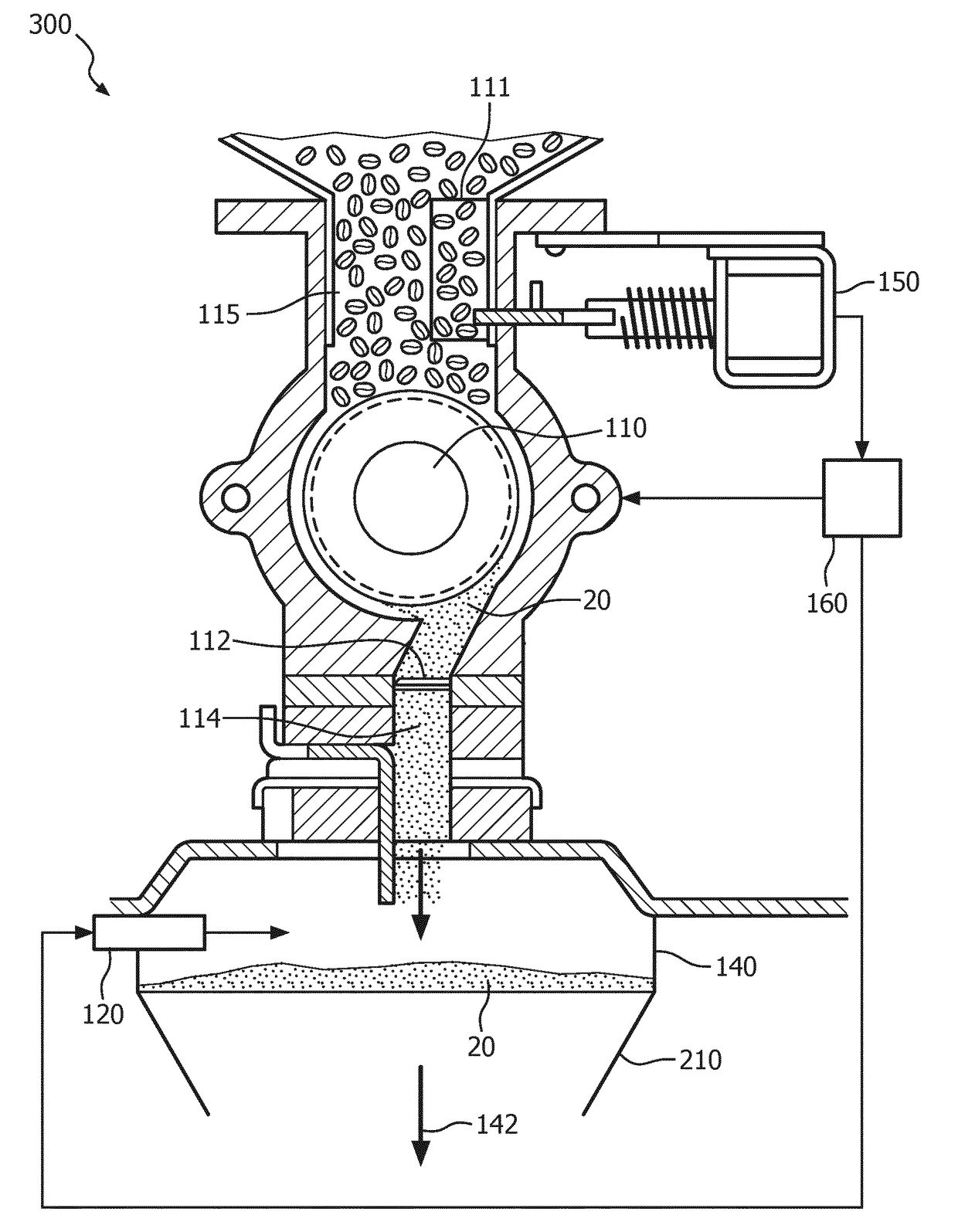

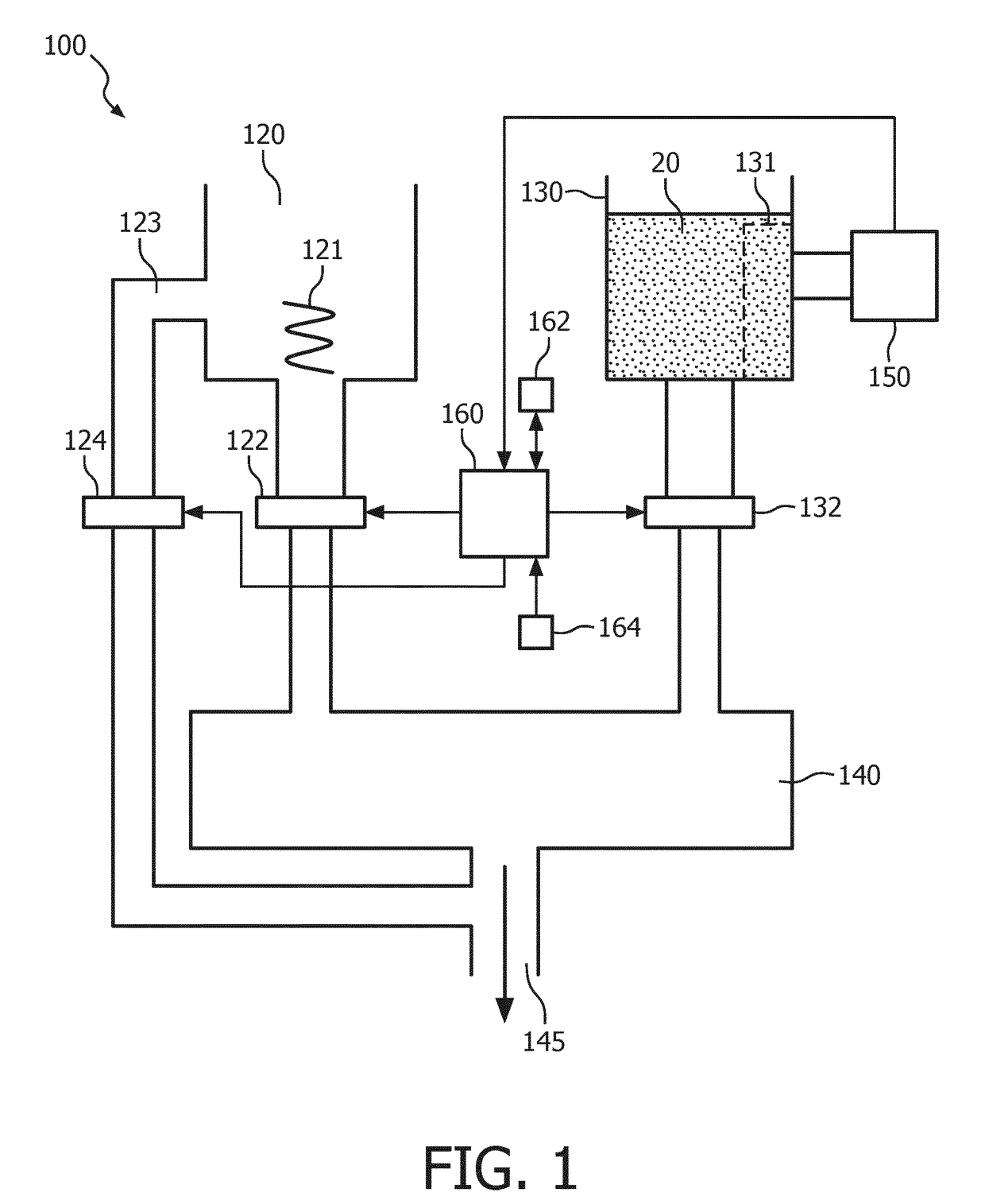

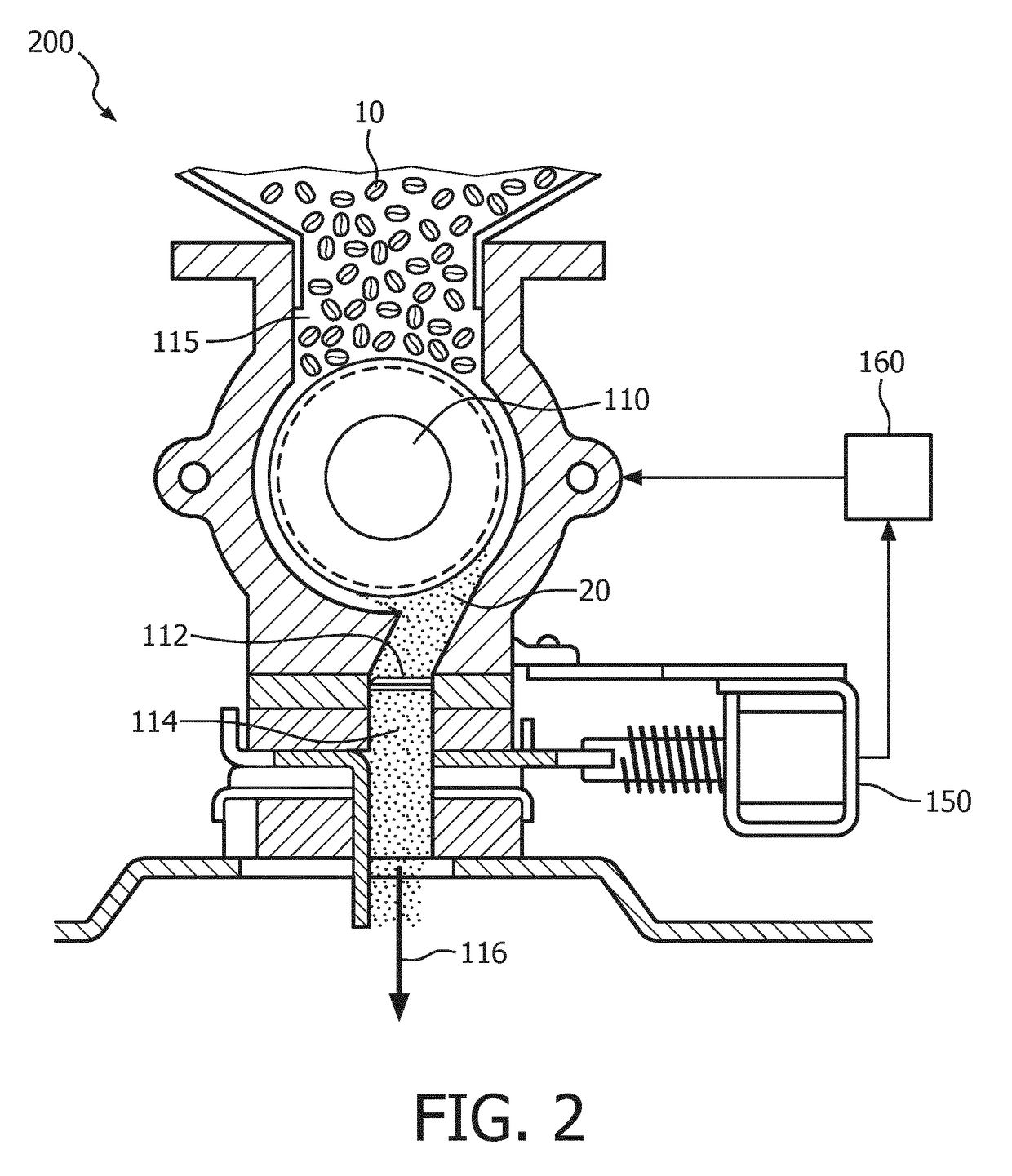

Coffee processing apparatus and method

ActiveUS20170303731A1Compensation effectBeverage vesselsCoffee grinding methodsCoffee processingGround coffee

A coffee processing apparatus (100, 200, 300) is disclosed that comprises at least one of a grinding stage (110) for grinding coffee beans (10) into ground coffee beans (20); and a brewing stage (140) for brewing coffee from ground coffee beans; the coffee processing apparatus further comprising a sensor (150) arranged to sense a total concentration of volatile organic compounds released by said coffee beans or ground coffee beans; and a controller (160) responsive to said sensor and arranged to control said grinding stage and / or said brewing stage as a function of said total concentration. Methods of controlling such a coffee processing apparatus are also disclosed.

Owner:VERSUNI HLDG BV

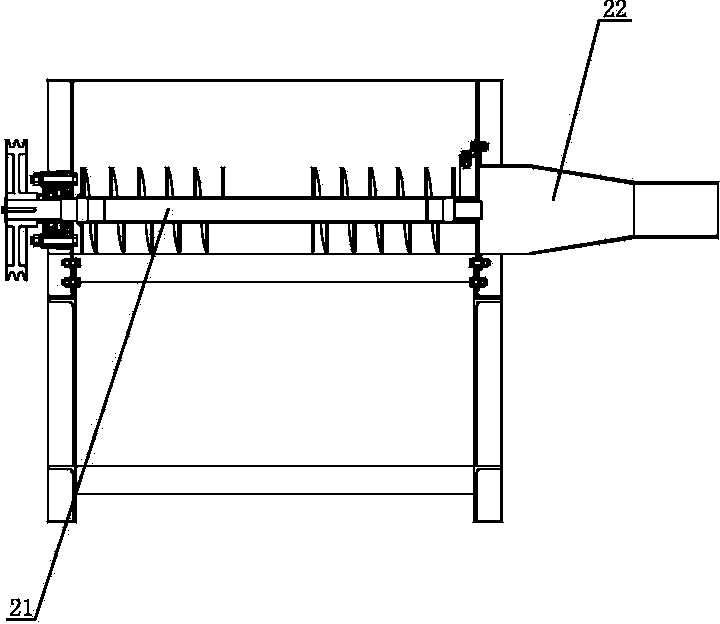

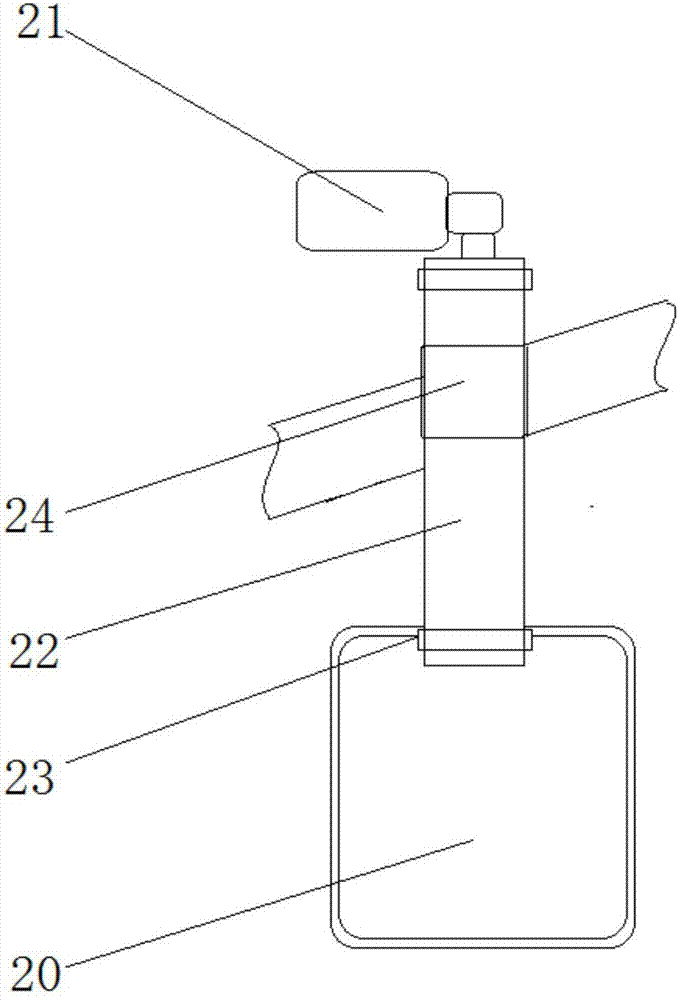

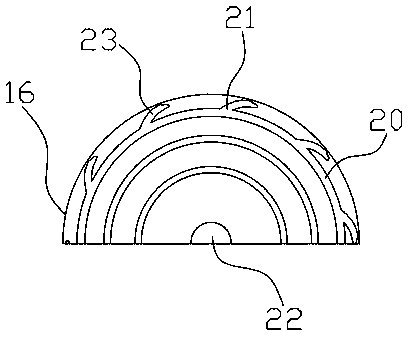

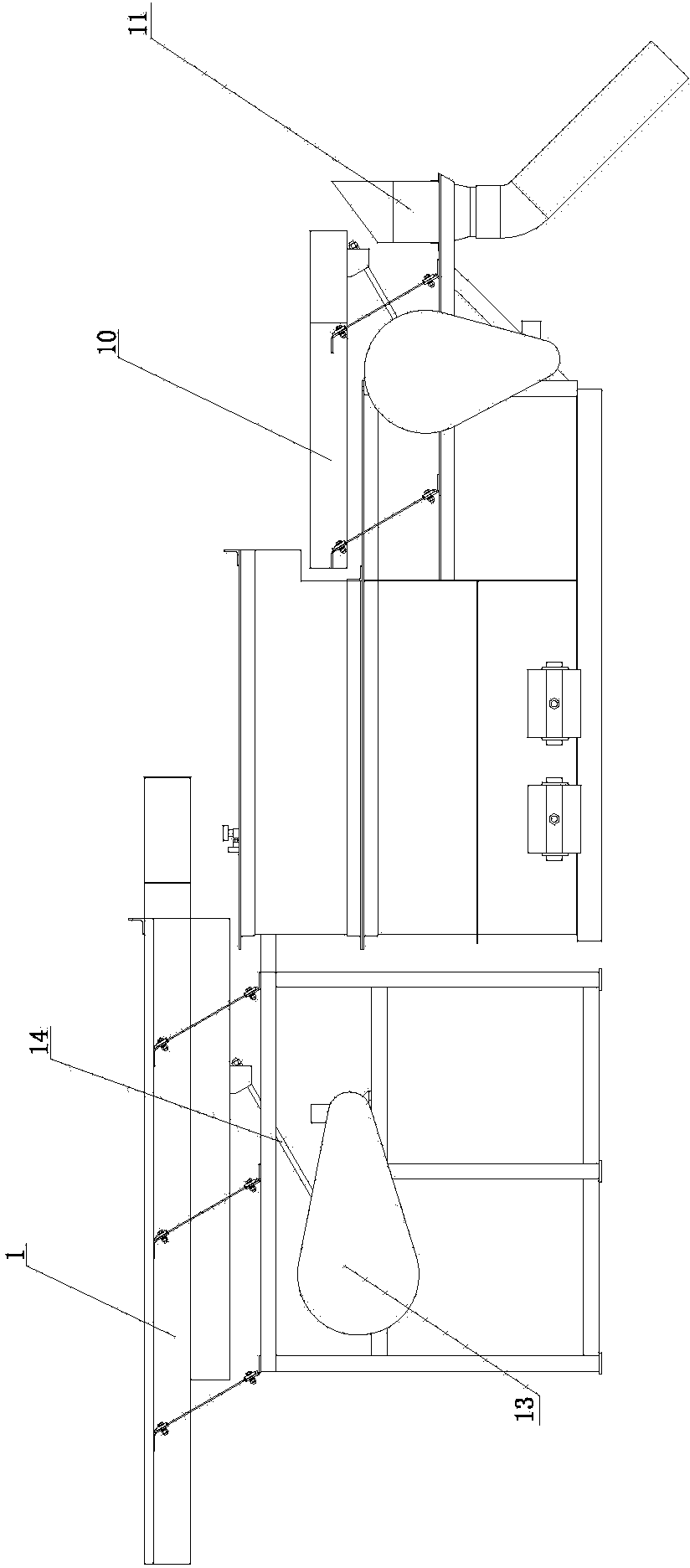

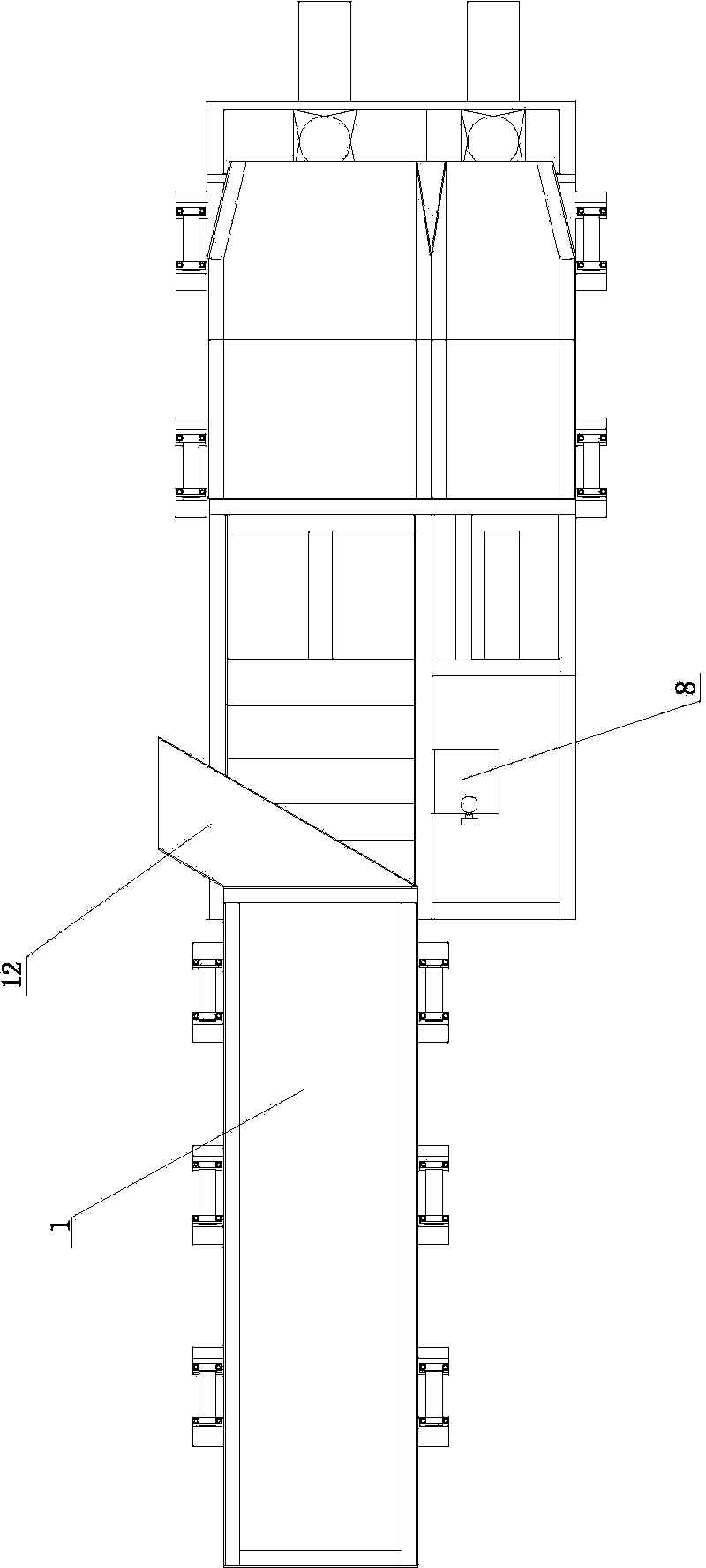

Mechanical siphon machine for fresh coffee fruits

ActiveCN104055201AStructural listDesign scienceFood treatmentWater storage tankAgricultural engineering

The invention provides a mechanical siphon machine for fresh coffee fruits, and relates to a preliminary coffee processing device, in particular to a material homogenizing and separating device used for evenly feeding, and separating tree branches, tree leaves, floating fruits, non-floating fruits, stones, iron nails and the like in preliminary coffee processing. The mechanical siphon machine for fresh coffee fruits comprises a machine frame and a vibrating screen, and the vibrating screen is used for even feeding. The mechanical siphon machine is characterized in that the siphon machine further comprises a separation screening box and a sorting and collecting device, the vibrating screen, the separation screening box and the sorting and collecting device are sequentially mounted on the machine frame, an outlet of the vibration screen is located above the separation screening box, the sorting and collecting device is located under the separation screening box, the separation screening box comprises a water storage tank and a siphon screening device, and the siphon screening device is fixed in the water storage tank. The mechanical siphon machine for fresh coffee fruits is simple in structure, scientific in design and convenient to use, and through the siphon principle, sundries in fresh coffee fruits are quickly separated and screened, and the process is quick and convenient.

Owner:YUNNAN PROV AGRI MACHINERY INST

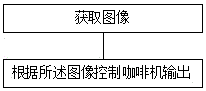

Creative coffee processing method for intelligent coffee machine

InactiveCN105147108AImprove targetingFlexible outputBeverage vesselsProcess engineeringCoffee processing

The invention provides a creative coffee processing method for an intelligent coffee machine. The method comprises an obtaining procedure and an outputting procedure, wherein the obtaining procedure comprises the step of obtaining an image, and the outputting procedure comprises the step of controlling the coffee machine to conduct outputting according to the image. By the adoption of the scheme, the image is obtained, and the coffee machine is controlled to conduct outputting according to the image, so that the coffee machine does not output monotonous coffee any more, neither hidebound and stylized patterns such as tree leaves, flowers or plants, and the pertinence of the coffee machine relative to the image is greatly improved.

Owner:XUCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com