Coffee and fresh fruit processing water recycling system and technological method

A process method and water circulation technology, applied in separation methods, green coffee processing, chemical instruments and methods, etc., can solve the problems of no solution, waste of water resources, high labor intensity, etc., to improve the integrity rate, save water, The effect of guaranteeing the quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

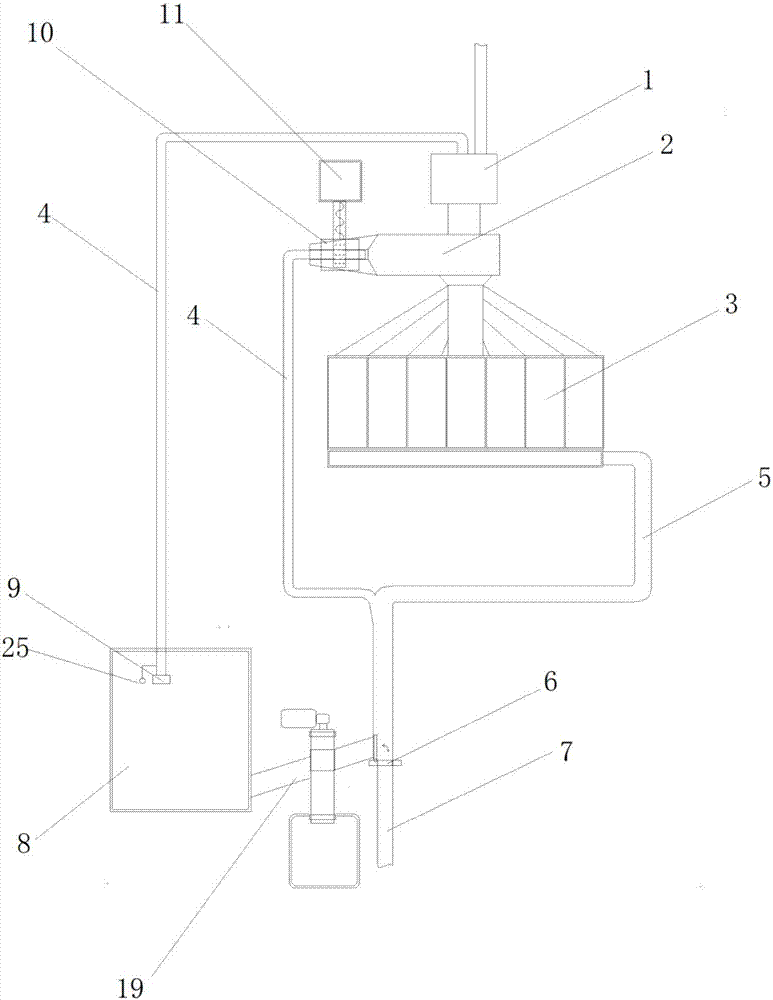

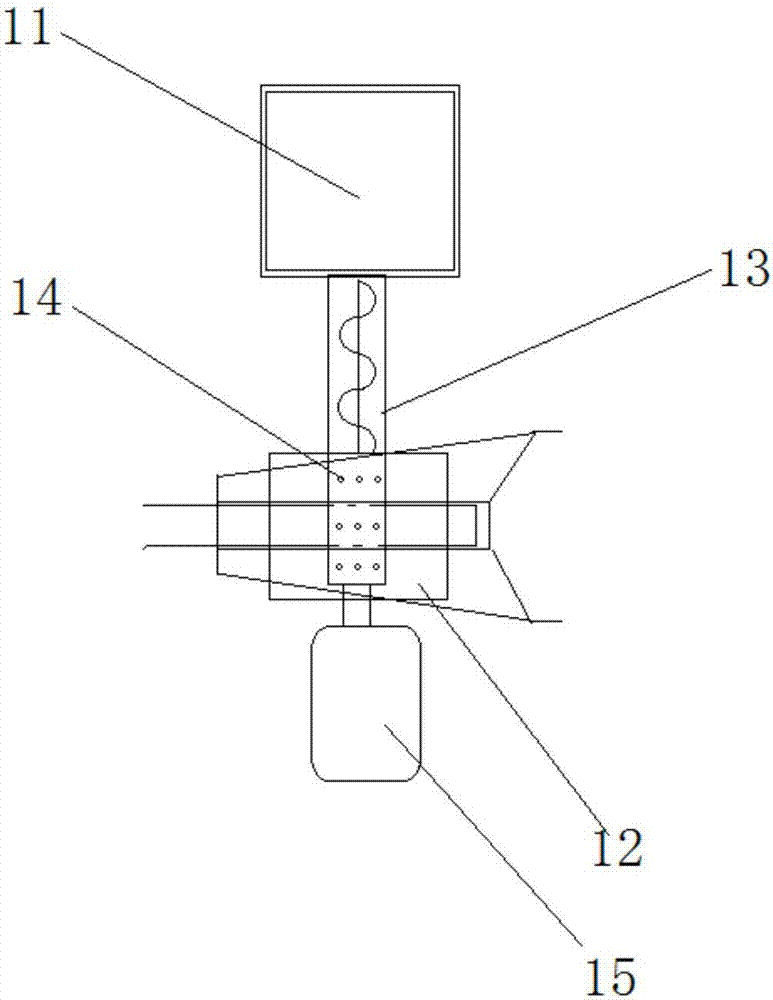

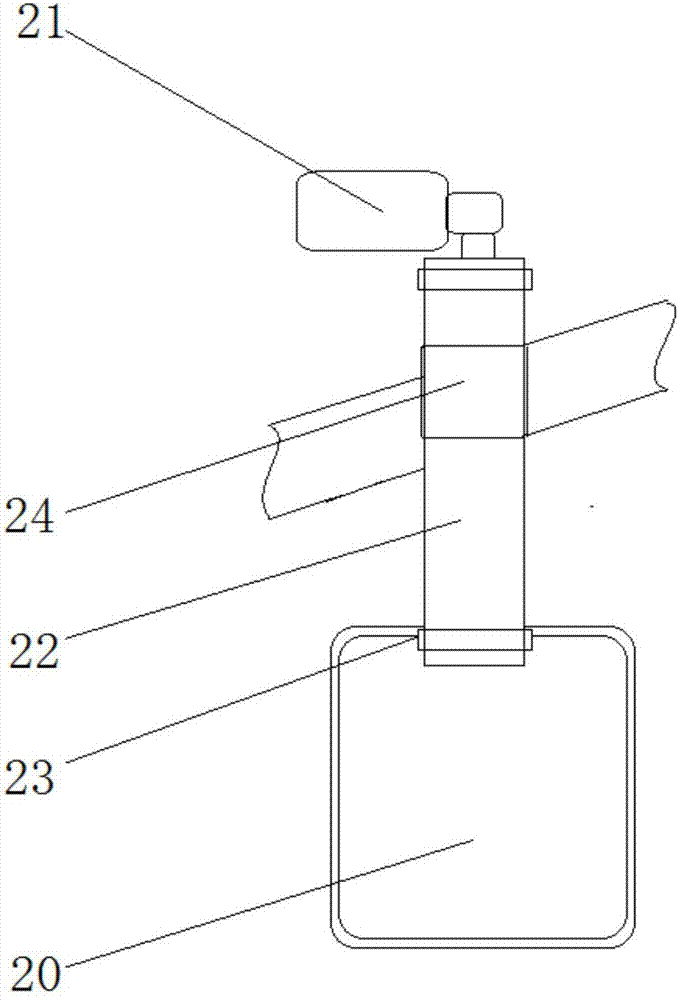

[0037] Embodiment 1: A water recycling system for fresh coffee fruit processing, comprising a cleaning water tank 1, a cleaning tank 2, a degumming fermentation tank 3, a water pipeline 4, and the cleaning tank 2 is connected to the degumming fermentation tank 3 through the water pipeline 4, and the water outlet of the degumming fermentation tank 3 The end is connected to the outlet channel 5 through the water pipe 4, and the outlet channel 5 is provided with an electronically controlled two-way valve 6. One end of the electronically controlled two-way valve 6 is connected to the drain pipe 7, and the other end is connected to the sedimentation tank 8, and the sedimentation tank 8 passes through the water pump. 9 and the water pipeline 4 are connected to the cleaning water tank 1, and a filter shell device 10 is installed in the cleaning tank 2, and the discharge end of the filter shell device 10 is connected to the fruit shell collection tank 11, and the other end is connected ...

Embodiment 2

[0041] Embodiment 2: Further on the basis of Example 1, the fermentation tank is composed of several fermentation tanks 16 arranged in sequence in the longitudinal direction, and the bottom of the fermentation tank 16 is slope-shaped, and forms a high-short-short-slope on the slope according to the slope. A plurality of longitudinally arranged steps 17 are arranged next to each other, and the steps 17 have an upward inclination from the inside to the outer edge. The drainage gate 18 is arranged on the bottom side of the fermentation tank 16, and the drainage gate 18 is connected to the water outlet 5 . The fresh coffee fruit is washed into the fermentation tank with the water flow and then fermented. The traditional degumming fermentation tank 3 has a flat bottom surface, which is easy to cause the accumulation of fresh coffee fruit, resulting in uneven degumming and fermentation. At the same time, the size, weight, and whether it is good or bad of the fresh coffee fruit will de...

Embodiment 3

[0042] Embodiment 3: Utilize implementation 1 or 2 to carry out a kind of fresh coffee fruit processing water recycling process method of processing operation, comprise the fresh coffee fruit after cleaning shell and carry out fermentation degumming treatment to fresh coffee fruit, comprise the following steps:

[0043] s1. The fresh coffee fruit enters the cleaning tank for cleaning, the shell is filtered out, and the fresh fruit enters the fermentation tank along the water flow;

[0044] S2. Evenly distribute the fresh coffee fruit into the fermentation tank, and the cleaning water filtered out during cleaning is connected to the water outlet through the pipeline;

[0045] s3. The cleaning water enters the sedimentation tank through the outlet channel for effective sedimentation and purification treatment;

[0046] S4. After the settlement, the upper water body is pumped into the cleaning tank to clean the fresh coffee fruit just poured in, forming a cycle until the fresh co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com