Patents

Literature

295results about How to "Speed up the fermentation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

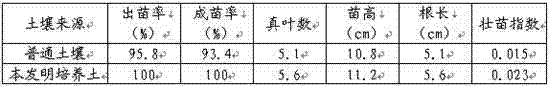

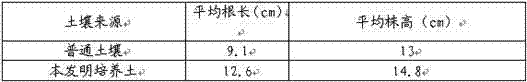

Seedling-cultivating substrate soil for micro agriculture

The invention relates to cultivation soil, in particular to seedling-cultivating substrate soil for micro agriculture. The seedling-cultivating substrate soil is formed by mixing a substrate with rural soil or clay and comprises the following components in weight percent: 25% to 45% of the substrate and 55% to 75% of the rural soil or clay; the substrate comprises 60% to 80% of organic matters in weight percent and includes 1% to 3% of nitrogen, 1.5% to 3.5% phosphorus, 2% to 4% of potassium, and 0.02% to 0.8% of trace elements including magnesium, calcium, iron, manganese and boron; the pH value of the substrate is 6.5 to 6.8; the organic matters comprise 1 to 4 parts of bamboo vinegar liquid, 1 to 3 parts of starch-acrylic acid graft copolymer, 15 to 40 parts of a straw decomposition agent, 15 to 40 parts of fermented human and animal excreta, 10 to 18 parts of edible fungus residue, 3 to 6 parts of waste bamboo, 2 to 5 parts of plant-charcoal powder, 5 to 10 parts of silt slag, 4 to 6 parts of bone meal and 4 to 9 parts of soybean meal. According to the invention, specific components and proportion are adopted to prepare the organic matters, and the organic matters are combined with inorganic matters to form the acidulous substrate, so that the seedling-cultivating substrate soil is high in nutritional ingredient and appropriate in proportion of trace elements, has an excellent odor removing effect, and avoids undesirable odors produced during planting of vegetables and other plants for urban families.

Owner:HUZHOU YIMENG CITY AGRI DEV

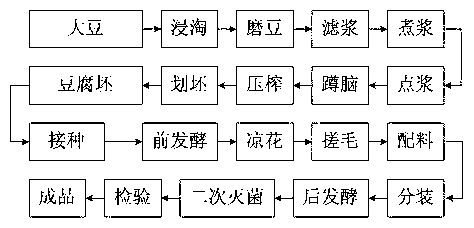

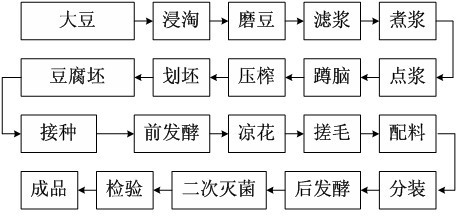

Production process of low-salt oil-free fermented bean curd

InactiveCN102696777APreserve the unique flavorGuarantee quality and safetyCheese manufactureFood scienceAlcoholHot peppers

The invention discloses a production process of low-salt oil-free fermented bean curd. The production process comprises the following steps: after performing the steps of immersing and washing soybean, grinding the soybean, filtering pulp, boiling the pulp, mixing pulp, concentrating, squeezing, dividing, inoculating, performing primary fermentation, cooling and mildewing, adding 8 to 10 percent of salt and 6 to 8 percent of alcohol; adding a proper amount of spice such as hot pepper powder, ginger powder, garlic powder and the like according to the traditional process; subpackaging into small bottles in one step; integrating fermenting, storing and finished product packaging materials; vacuumizing, so that the vacuum degree of the small bottle is 0.8 to 1.0; performing secondary fermentation for 1 to 2 months under the natural condition; performing secondary sterilization on the mature fermented bean curd, wherein the sterilization central temperature is 80 to 85 DEG C and the sterilization time is 25 to 35 minutes; and obtaining the finished products after passing inspection. The production process has the advantages that the unique flavor of the local traditional fermented bean curd is maintained; the characteristics of the times are achieved; the production process is fashionable and novel; the edible range is widened; the low-salt oil-free fermented bean curd has high nutritional value and preference, can realize industrial production and is safe and healthy; and quality safety of the oil-free fermented bean curd is effectively guaranteed.

Owner:WANYUAN LICHUAN FOOD COMPREHENSIVE DEV

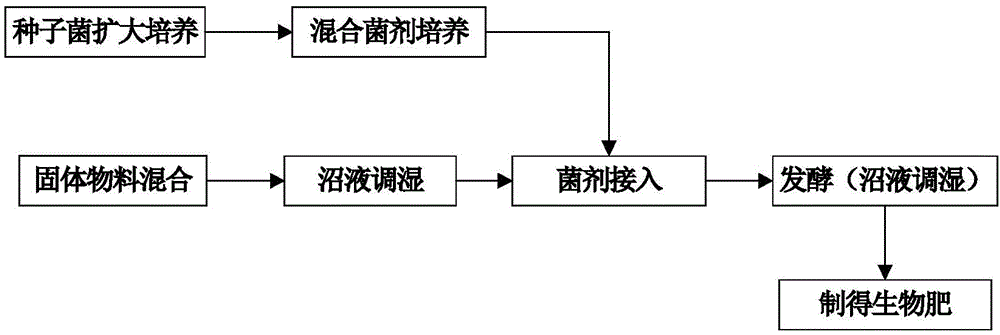

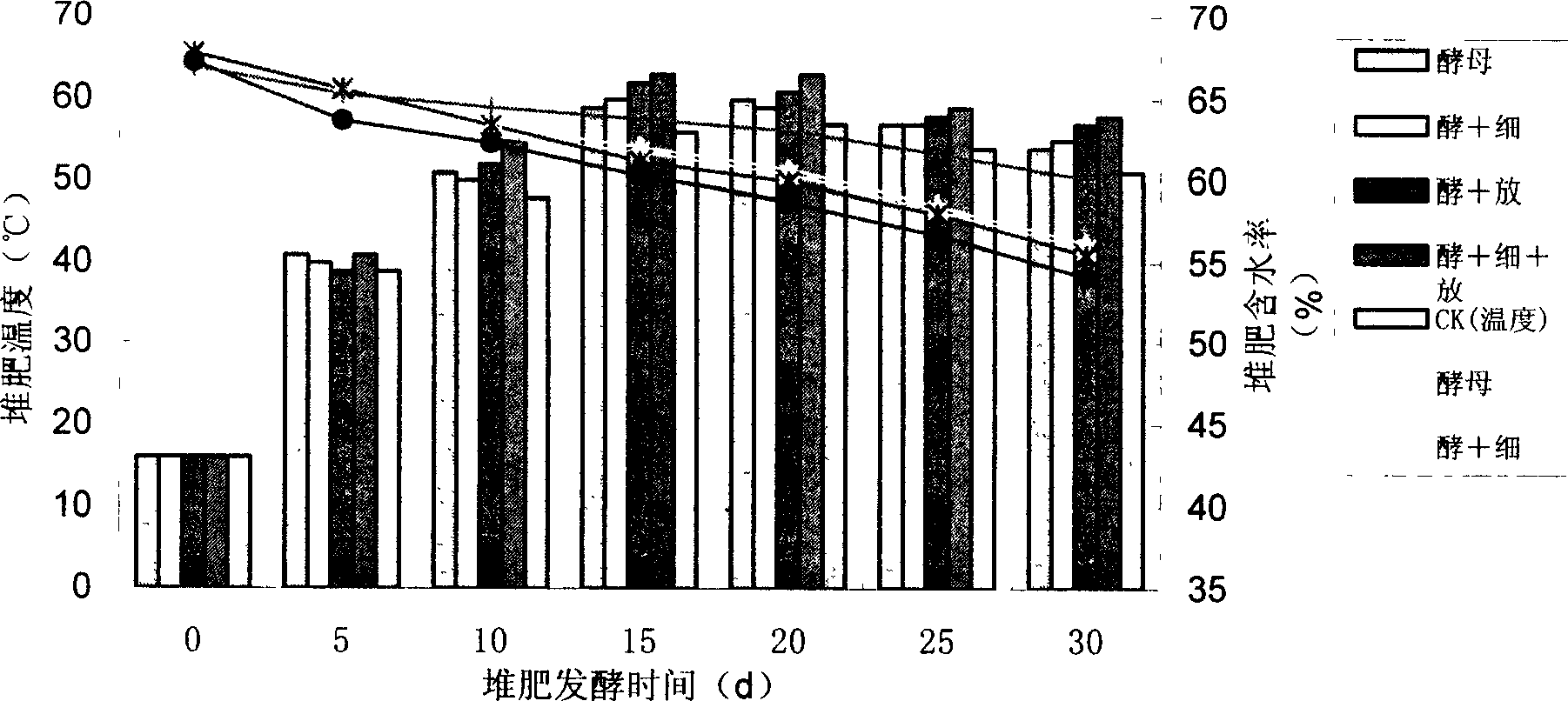

Bioorganic fertilizer using agricultural waste as raw materials and preparation method of bioorganic fertilizer

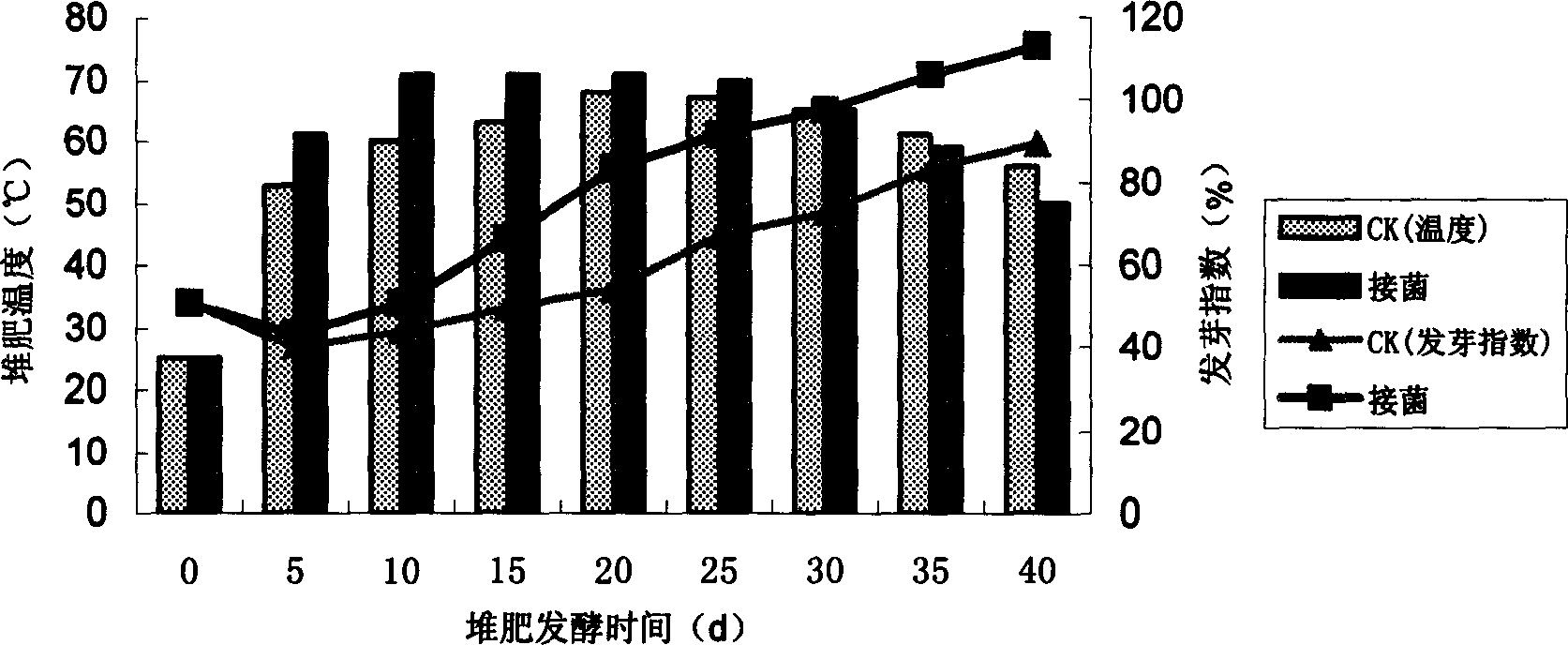

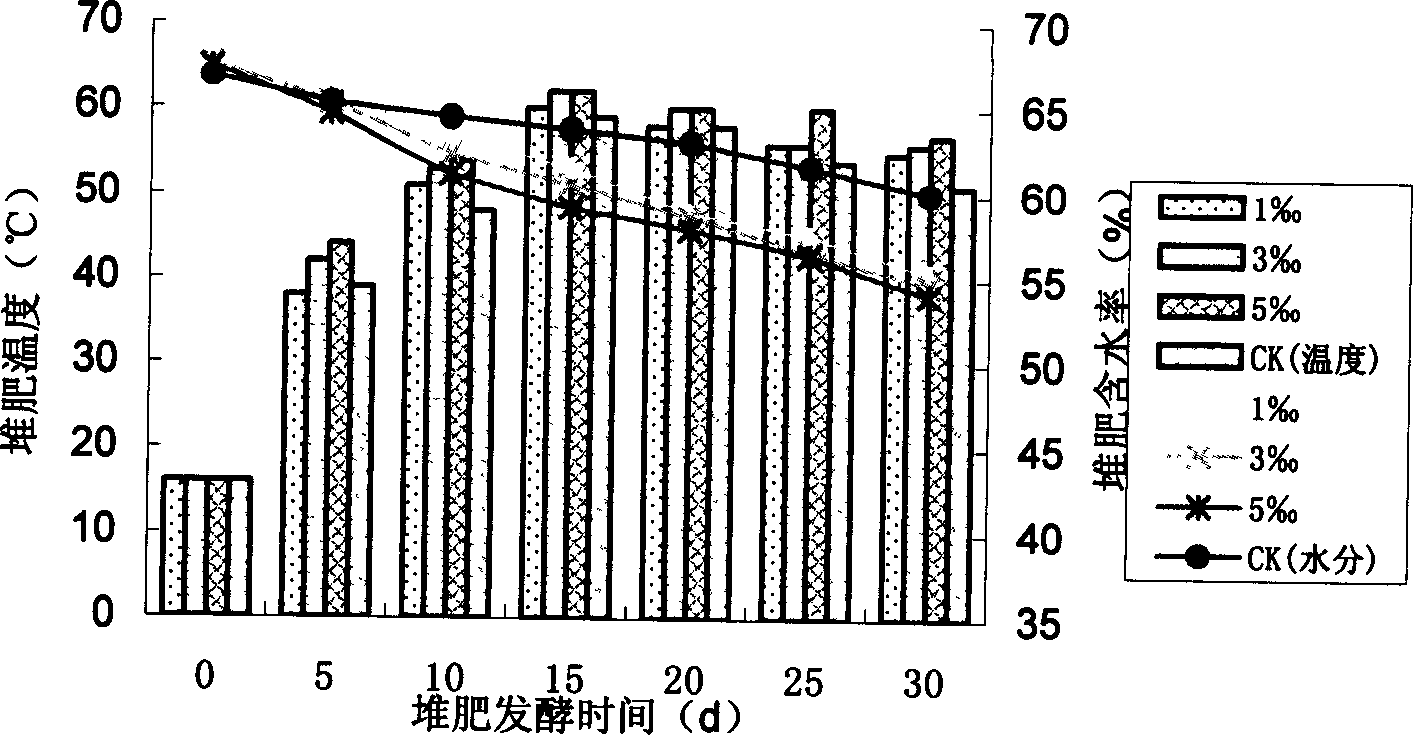

InactiveCN104671860AReduced ability to migrateShort cycleBio-organic fraction processingWaste based fuelFermentationLivestock

The invention discloses a bioorganic fertilizer using agricultural waste as raw materials, which comprises the following components in parts by weight: 40-50 parts of excrements of livestocks, 30-40 parts of biogas manure, 5-10 parts of mushroom residues, 5-10 parts of dregs, 3-5 parts of foots and 1-2 parts of fermentation strains. The preparation process of the bioorganic fertilizer comprises the steps of fungicide preparation, raw material preparation, inoculation and fermentation. The mositure content of materials in a pile is maintained to be 60%-80% through sprinkling of biogas manure. The fungicide culture is simple, and the operation is simple. The biogas manure is used as a fermentation substrate and a substrate humidity-controlling agent, and two purposes are achieved through one step. The fertilizer efficiency is high, the raw materials are easily available, and the applicability is high. The preparation period is short, and the conversion rate is high. The bioorganic fertilizer is first-choice fertilizer for producing organic agricultural prodcucts and high-quality agricultural products. The bioorganic fertilizer can be widely applied to various crops, fruit trees and vegetables.

Owner:新疆恒丰现代农业科技股份有限公司

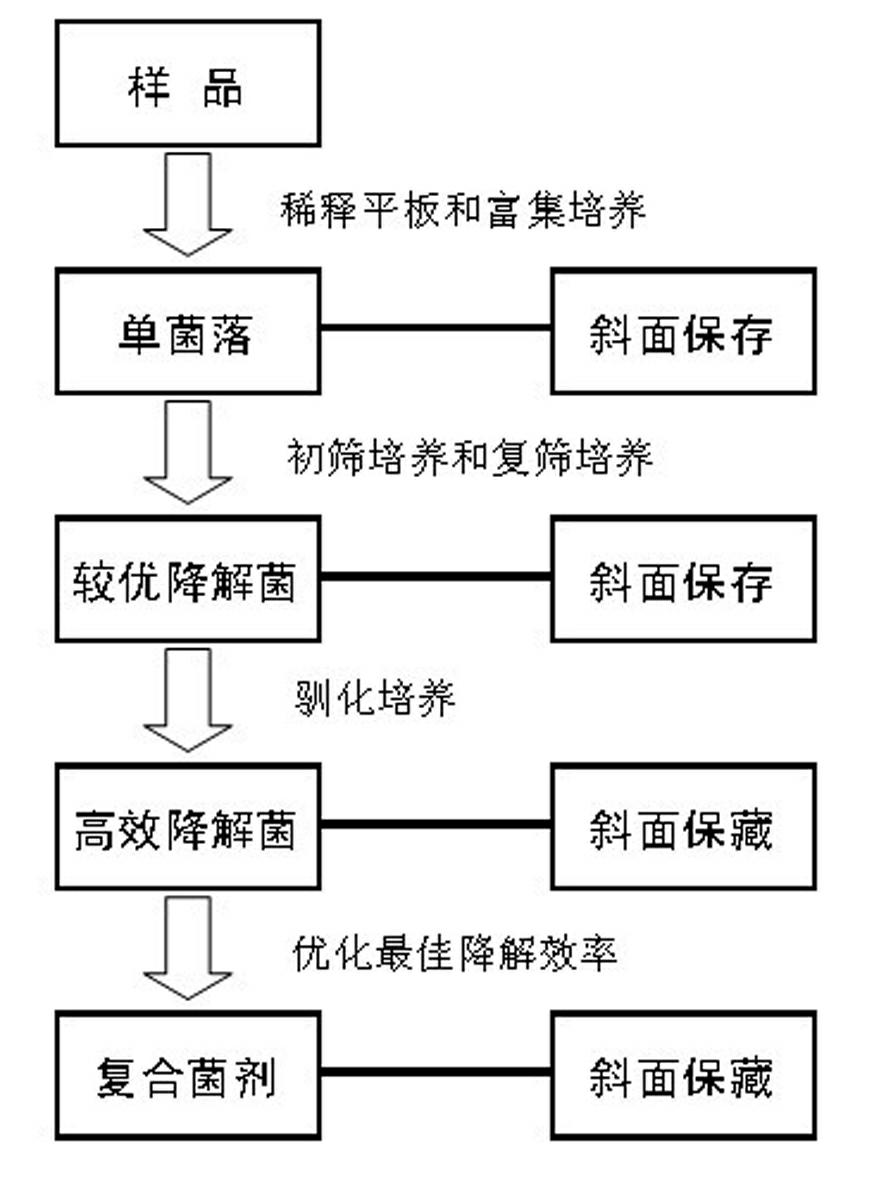

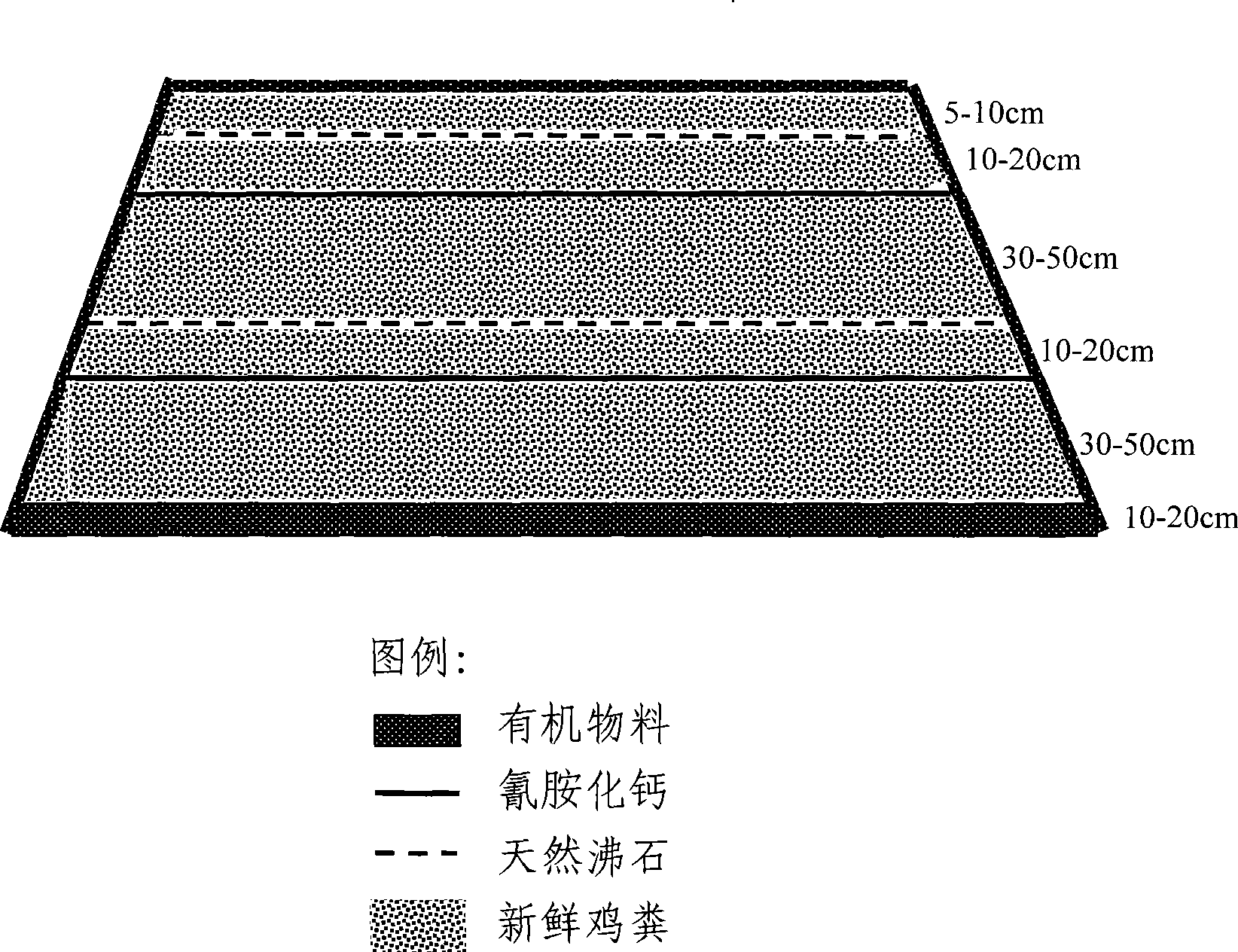

Composite bacterial agent for efficiently degrading kitchen garbage, and preparation method and application thereof

InactiveCN102533718ARich in nutrientsSolve the smell problemWaste based fuelOn/in organic carrierMicroorganismCellulose

The invention discloses a composite bacterial agent for efficiently degrading kitchen garbage, and a preparation method and application thereof. The efficiently degrading kitchen garbage, and preparation method and application thereof consists of a starch-degrading strain, an oil-degrading strain, a protein-degrading strain, a cellulose-degrading strain and a vector; and the preparation method comprises the following steps of: performing enrichment culture on each single strain, screening, and preparing the vector; and mixing a high-quality composite bacterial agent with the vector. The synergism of various microorganisms in the natural world is fully utilized, a microorganism-based control method is established, and the composite bacterial agent is utilized for coupled fermentation of the kitchen garbage to accelerate the biogas fermentation progress, improve the traditional fermentation process and improve the biogas yield.

Owner:无锡丰陆环保科技有限公司

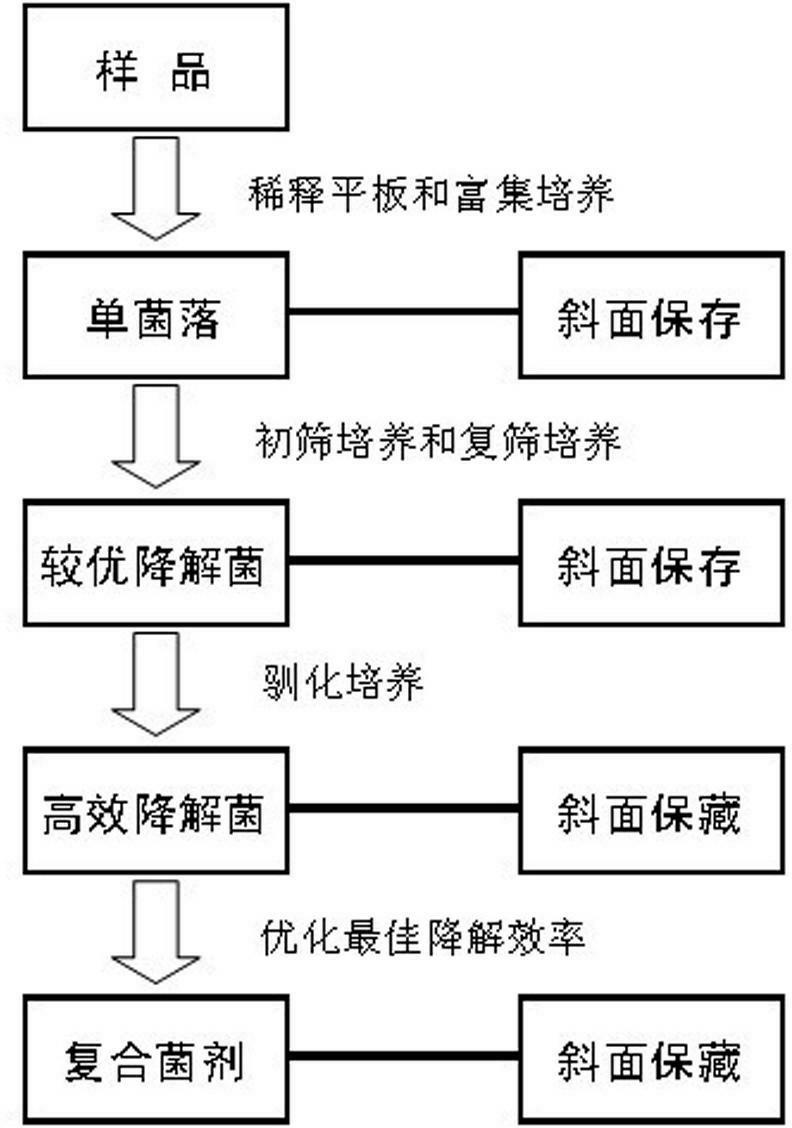

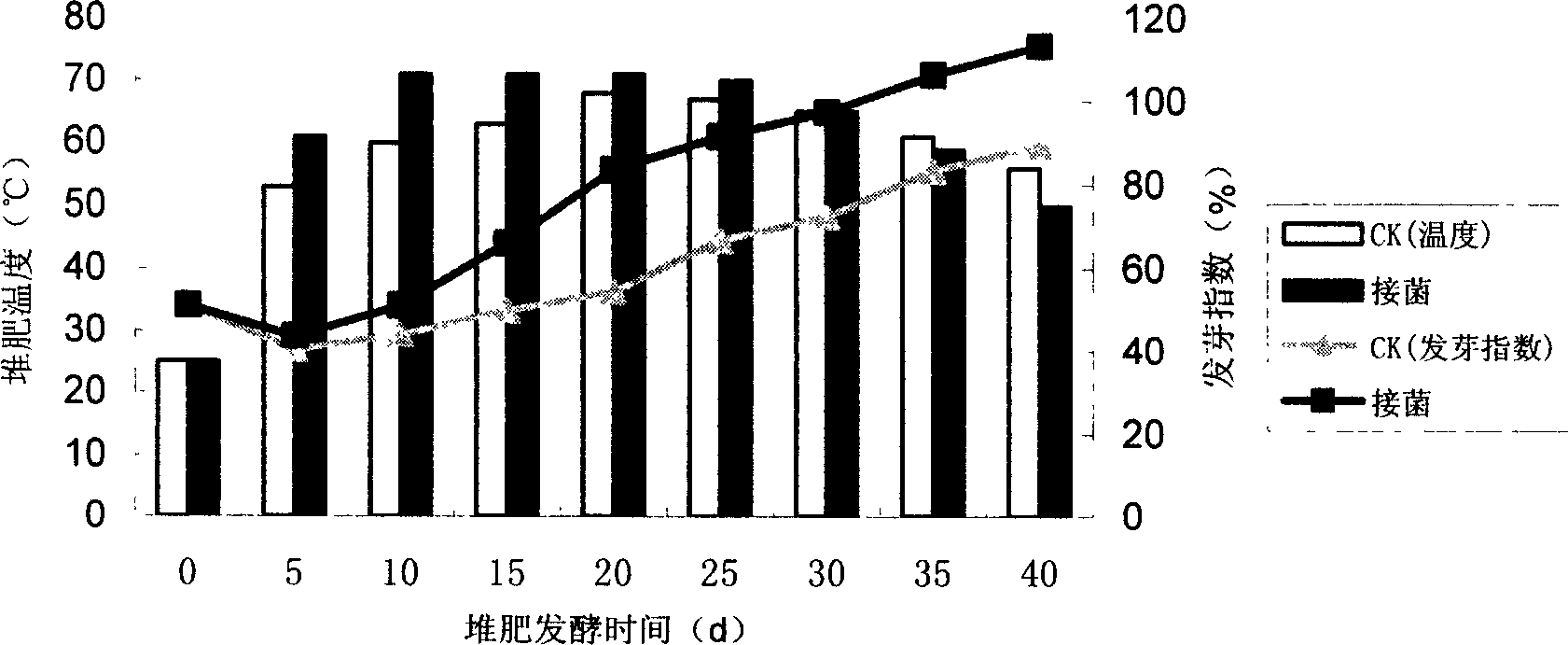

Livestock carcase harmless disposal technology and biological organic fertilizer processing method

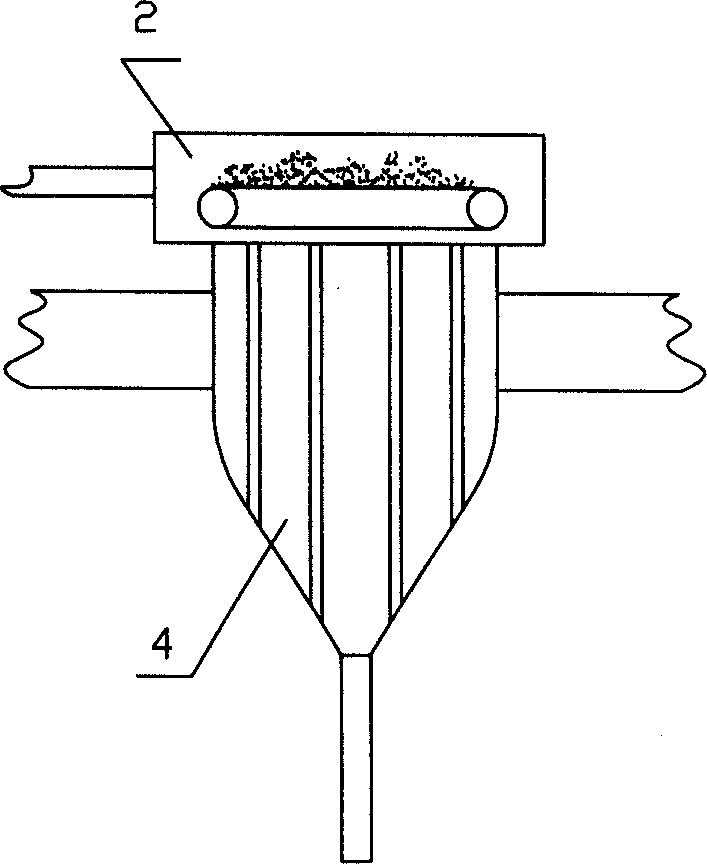

InactiveCN105016797AIncrease contact areaSpeed up the fermentation processBio-organic fraction processingOrganic fertiliser preparationChemistryDual effect

The invention relates to a method for conducting harmless disposal on various livestock carcases through a method of comprehensively utilizing and combining the physical technology, the chemical technology and the biological technology, and processing the livestock carcases into biological organic fertilizer. The livestock carcases can be processed into biological organic fertilizer rick in nitrogen, phosphorus, potassium and various microelements by further conducting enzymolysis through protease, lipase and the like and conducting compost thermophilic fermentation and drying after conducting sterilization, deordorization and gelatinization through a high-temperature and high-pressure steam explosion technology with the livestock carcases as main raw materials and with crop straw as adsorption carriers and filler. The biological organic fertilizer has the beneficial effects of being capable of holding water and fertilizer and being released slowly, durable, and the like. The biological organic fertilizer can be safely and trustingly used for organic vegetables, fruit and other products due to the fact that the detection shows that the biological organic fertilizer is free of pathogenic bacteria and antibiotic drug residues. No emission of sewage or germs or drug residues or poisonous gas is caused in the whole process, and the dual effects of protecting the environment and utilizing resources to the maximum extent are achieved.

Owner:霍英军

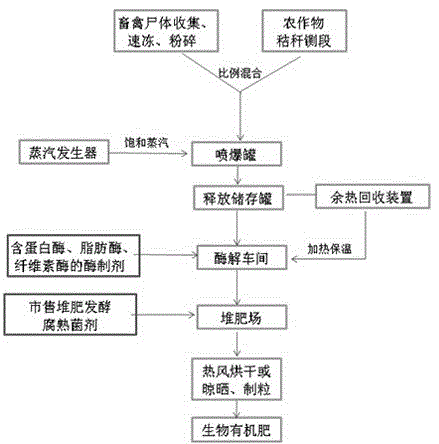

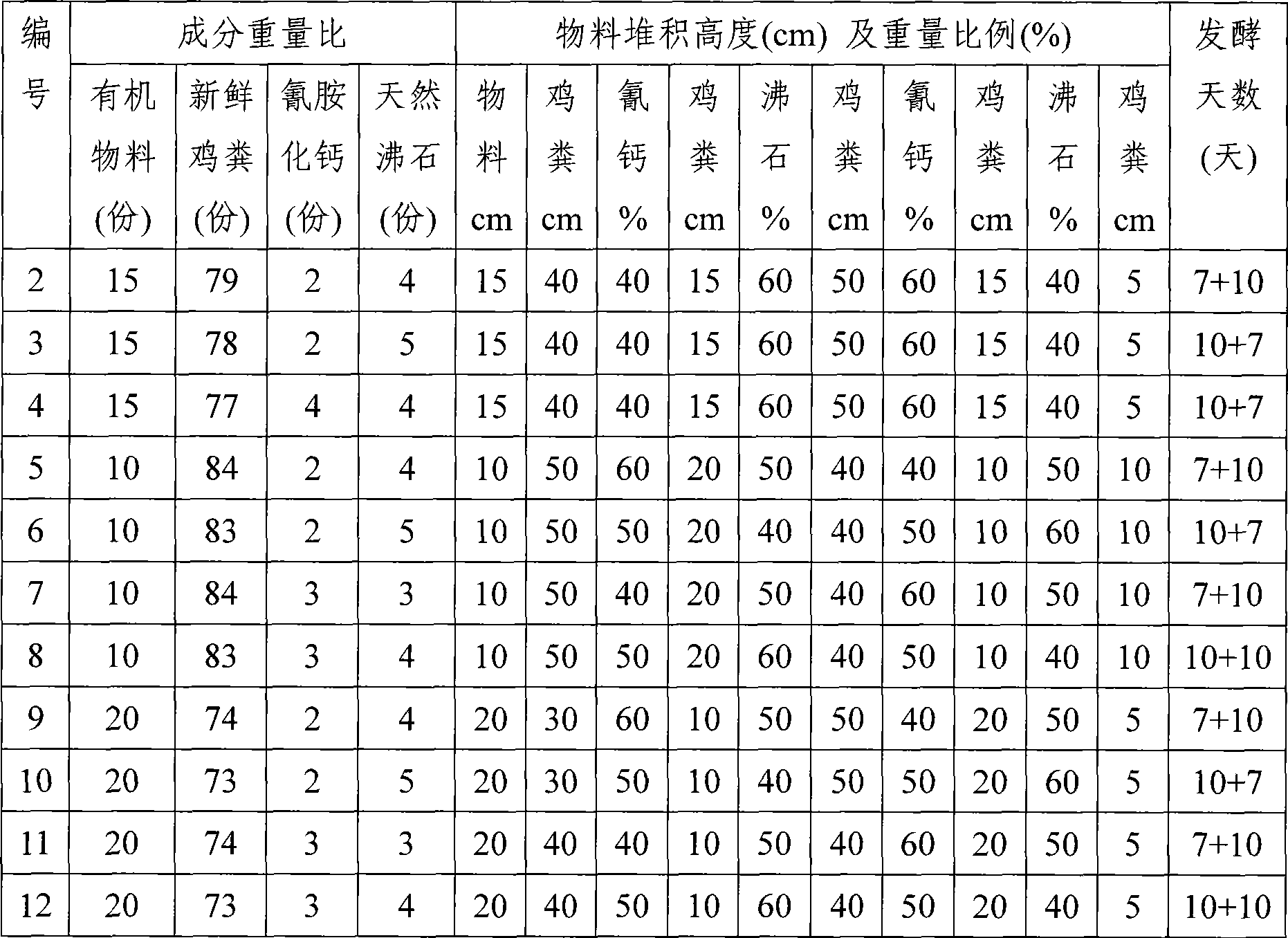

Chicken manure deodorant ammonia-fixing fertilizer and preparation thereof

InactiveCN101372426AReduce lossesImprove microbial activityBio-organic fraction processingClimate change adaptationFermentationPollution

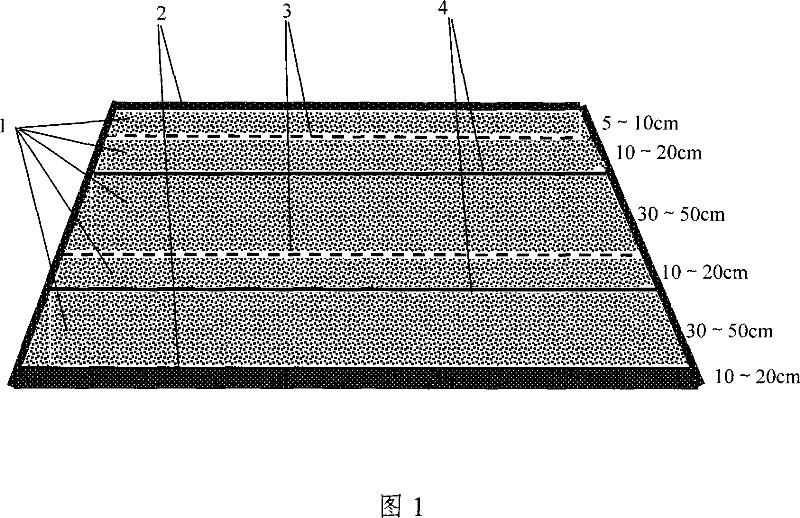

The invention relates to an organic fertilizer, in particular to a chicken manure deodorizing and nitrogen preserving organic fertilizer and a preparation method thereof. Calcium cyanamide, natural zeolite, organic materials are taken as additive materials added to fresh chicken manure for stacking and fermentation treatment so as to prepare the organic fertilizer. The preparation method is characterized by simple process and low cost, and solves the problems of loss of nitrogen nutrients in wastes and environmental pollution in raising chicken. The components of the organic fertilizer based on weight ratio are 10-20% of the organic materials, 2-3% of the calcium cyanamide, 3-5% of the natural zeolite, and 73-84% of the chicken manure on dry basis. The preparation method is as follows: the organic materials, the chicken manure, the calcium cyanamide and the natural zeolite are stacked in layers according to a certain proportion; the outer layer is sprinkled with the organic materials, after 7-10 days of fermentation sealed by plastic cloth, turnover is done mechanically or artificially, then the sealed fermentation is carried out for another 7-10 days by the plastic cloth, and the organic fertilizer is obtained after being dried in the sun. The organic fertilizer has the advantages of reasonable formula, good nitrogen preserving and deodorizing effects, and easy application, thus being suitable for being used as a fertilizer for producing pollution-free agricultural products.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

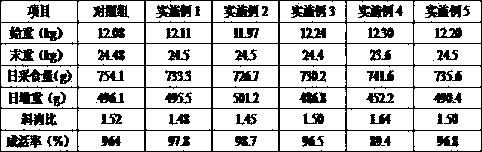

Simple and efficient fermented soybean meal production technology and application thereof

ActiveCN103385360AFacilitated releaseImprove efficiencyFood processingAnimal feeding stuffBiotechnologyGinkgo biloba

The invention relates to a simple and efficient fermented soybean meal production technology and an application thereof. The preparation method comprises the following steps of: mixing soybean meal with a Chinese herbal medicine mixture of liquorice, wild chrysanthemum, folium ginkgo and pericarpium citri reticulatae viride at a ratio of 100:(1-2), adding composite zymocyte consisting of succinic acid generating bacillus filiformis, bacteroides ruminicola, bacillus subtilis natto and lactic acid bacteria, and performing mixed anaerobic fermentation. The release and absorption of active substances of the Chinese herbal medicine can be promoted, and the fermentation efficiency of the fermented soybean meal can be improved. Through low-temperature drying, the fermented soybean meal can be used for completely or partially replacing fish meal and for completely or partially replacing antibiotics in pig feed production, and can effectively improve the food intake of live pigs and the utilization rate of feed, promote the growth of live pigs, improve the immunity, enhance the disease resistance and improve the pork quality.

Owner:廉江双胞胎饲料有限公司

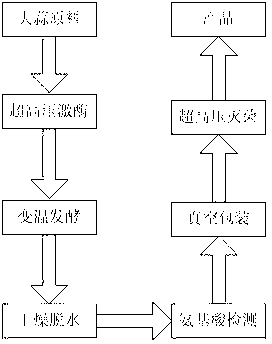

Production method for black garlic with high amino acid content

ActiveCN103053960ASpeed up the fermentation processHighly effective therapeuticFood preparationBiotechnologyAmino acid content

The invention provides a production process for black garlic with high amino acid content and specifically relates to a method for producing black garlic with high amino acid content by adopting ultrahigh pressure for promoting the combination of enzymatic reaction and temperature shift fermentation. The method comprises the following steps: garlic is processed in an ultrahigh pressure cavity after being subjected to vacuum package, wherein the pressure of the ultrahigh voltage cavity is 100-400Mpa, and the processing time is 30s-15min; the garlic processed by the ultrahigh pressure is subjected to temperature shift fermentation; and finally, the garlic is dried and dewatered. According to the method, the allinase in the garlic can be activated by adopting ultrahigh pressure process; the fermentation process of the black garlic is accelerated; and the black garlic can be generated within 3-8 days through combining with step fermentation. In the whole production process, no additive is added and low-temperature pretreatment is not needed, so that the fermentation time is shortened greatly, the production cost is lowered and the energy is saved. The S-allyl-L-cysteine content in the black garlic produced by the invention is higher than the black garlic fermented by the common fermentation process by more than 50%.

Owner:山东软黑金农业发展有限公司

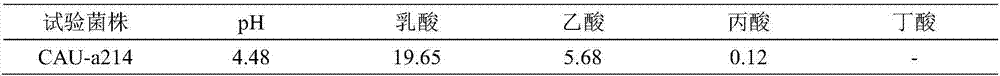

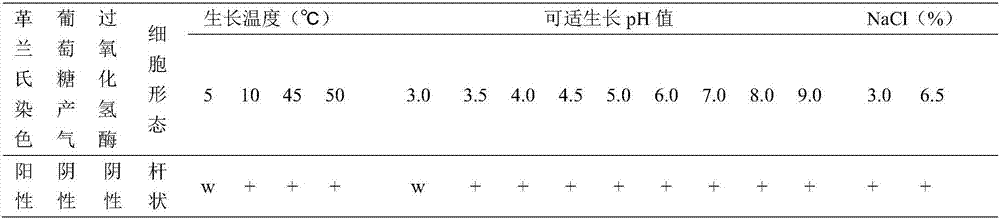

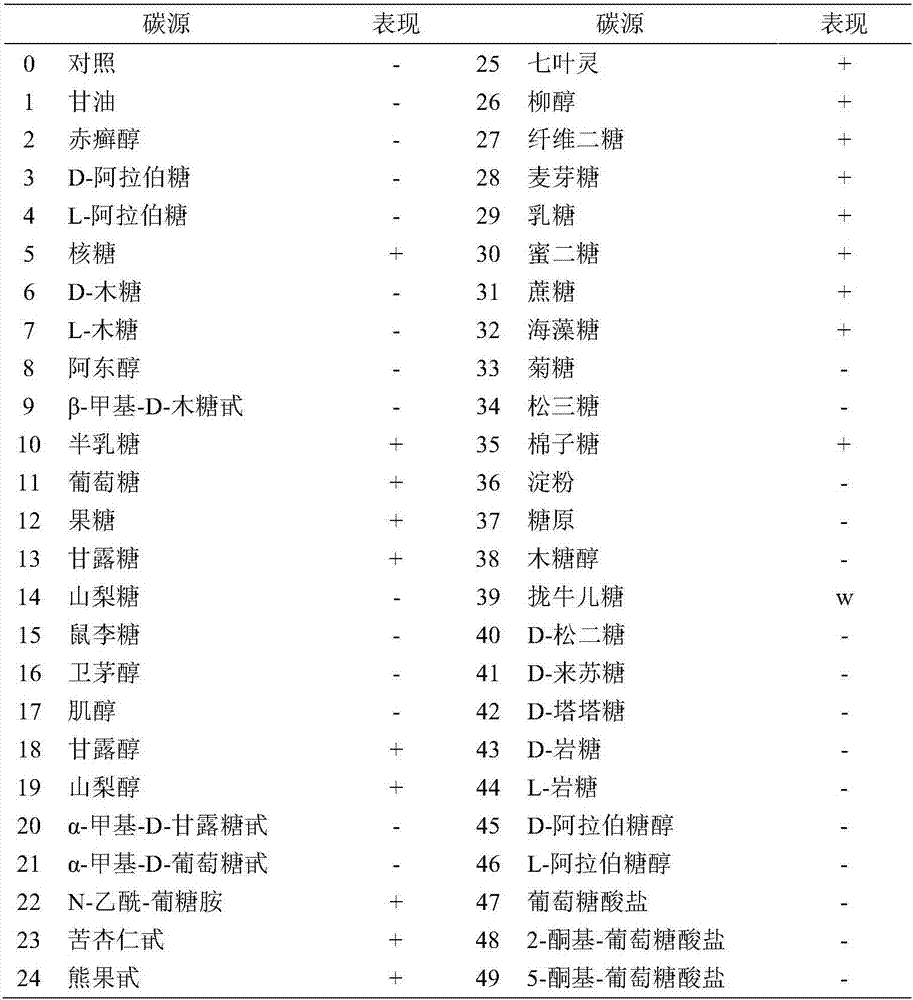

Lactobacillus plantarum and application thereof to silage preparation

InactiveCN107047978AImprove silage qualityCan inhibit reproductionAnimal fodder preservationMicroorganismMicrobiology

The invention belongs to the field of microorganism application and feed compounding and processing and discloses a strain of lactobacillus plantarum and application thereof to silage preparation. A preservation number of lactobacillus plantarum CAU-a214 is CGMCC NO.13609 and can be used for preparation of silage especially alfalfa silage. The lactobacillus plantarum CAU-a214 has advantages that quickness in pH value decrease, acceleration of fermentation process and increase of ensiling rate can be realized; propagation of undesirable microorganisms can be inhibited so as to improve alfalfa silage quality, alfalfa nutrients can be better preserved, silage in-vitro digestibility is improved, and the problem of difficulty in silage fermentation is solved. Compared with existing lactobacillus additives on the market, additives prepared from lactobacillus plantarum CAU-a214 have advantages of excellent effects, low cost, safety and easiness in use.

Owner:CHINA AGRI UNIV

Fertilizer additive for improving acidified soil

InactiveCN105061042AImprove pHEnhance disease resistance/resilienceBio-organic fraction processingOrganic fertiliser preparationMicrobial agentChemistry

The present invention discloses a fertilizer additive for improving acidified soil. The fertilizer additive is prepared from the following raw materials by weight: 3-5 parts of smectite powder, 1-2 parts of peat soil, 1-3 parts of peat soil, 3-6 parts of silt, 5-10 parts of smashed deciduous leaf, 6-15 parts of pomegranate rind, 0.3-0.5 part of dicyandiamide, 0.1-0.2 part of thiourea, 10-12 parts of activated carbon, 40-45 parts of pomace, 3-5 parts of shell powder, 3-5 parts of calcium silicon powder, 1-2 parts of lignin, 0.1-0.2 part of an EM microbial agent, 0.1-0.2 part of Bacillus subtilis microbial agent, and 2-4 parts of a complex deodorant.

Owner:MAANSHAN KEBANG ECO FERTILIZER

Quinoa cookie and preparation method for same

InactiveCN105815414AFull of nutritionPromote value-addedDough treatmentBakery productsNutrientFlavor

A quinoa cookie is prepared by the ingredients including 90-100 parts by weight of quinoa powder, 1-8 parts by weight of dried skim milk, 5-10 parts by weight of eggs, 1-1.5 parts by weight of baking soda, 15-25 parts by weight of olive oil, 13-15 parts by weight of kudzu vine roots, 5-10 parts by weight of carrots, 5-8 parts by weight of kiwi fruits, 3-4 parts by weight of cranberries, 2-3 parts by weight of hawthorns, 0.4-0.5 part by weight of white vinegar, 0.03 part by weight of pectinase, 0.8 part by weight of artificial yeast, 15-25 parts by weight of saccharose, 9-10 parts by weight of raffinose oligose and 80-150 parts by weight of water. According to the invention, highly nutrient quinoa is taken as the principal ingredient to prepare the quinoa cookie which has abundant nutrition, a unique flavor and outstanding health care treatment effects through unique preparation and processing technologies, so that edible values of the quinoa are enhanced.

Owner:HENAN UNIV OF SCI & TECH

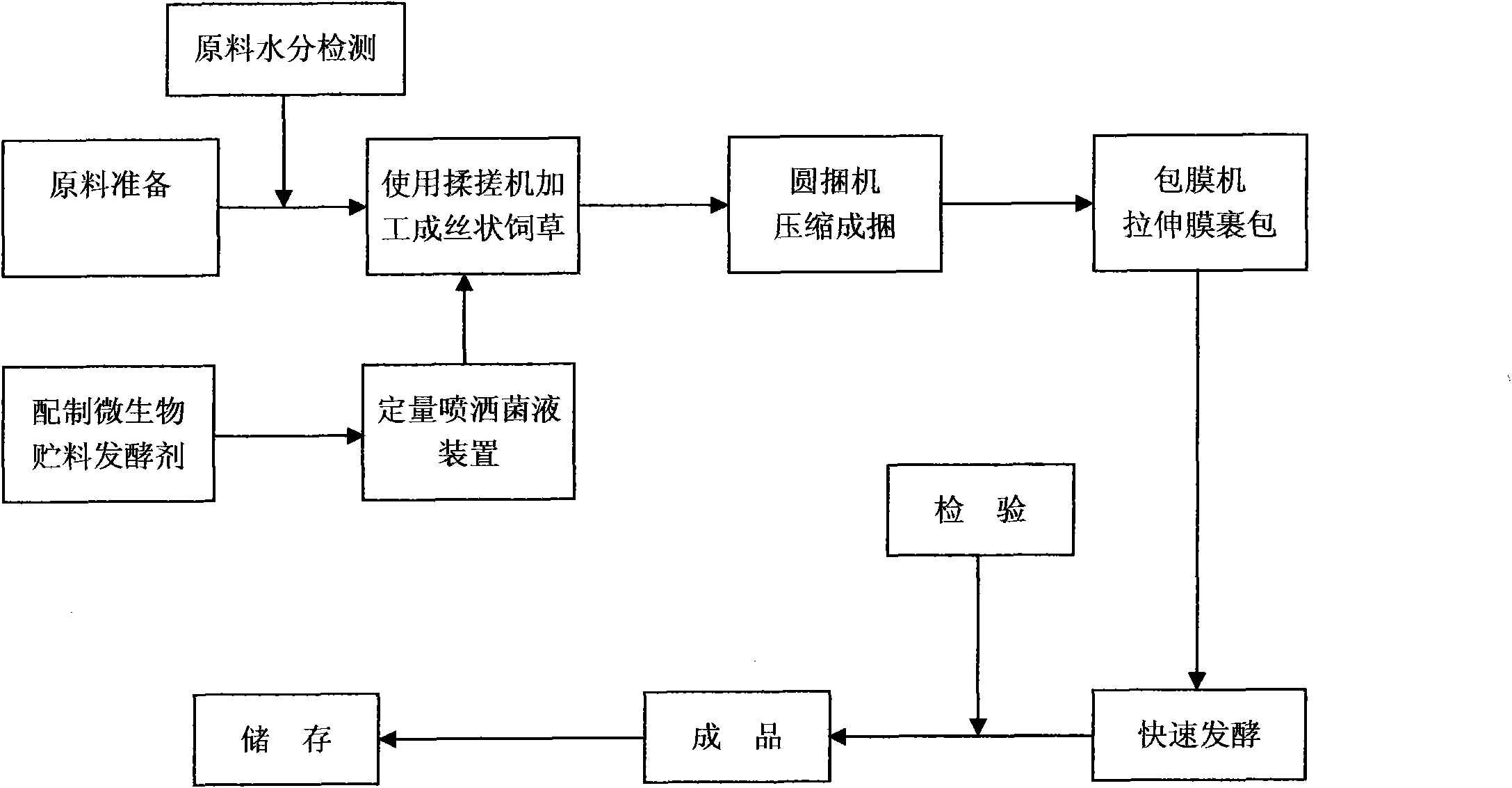

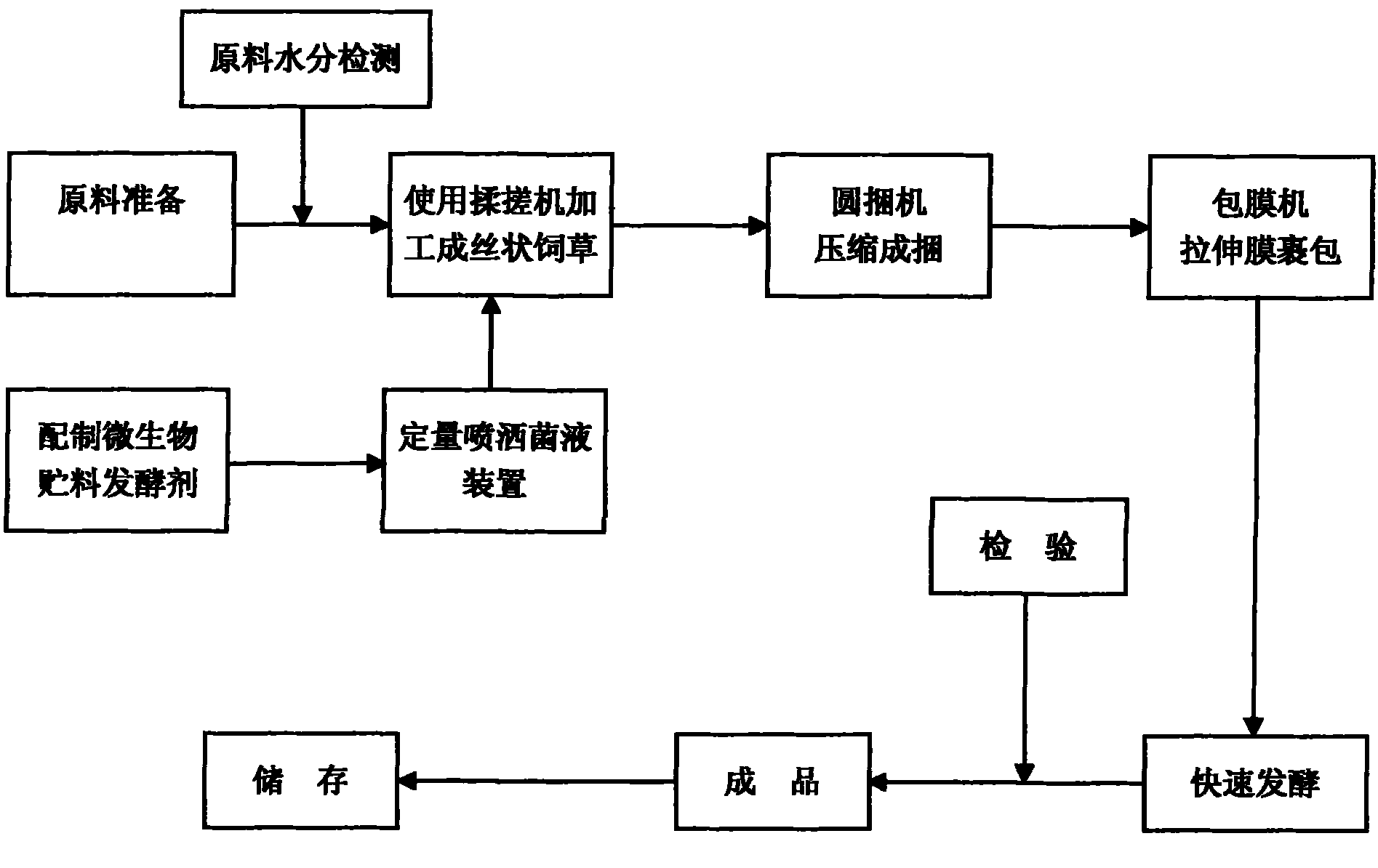

Wrapped low-moisture rapid-orientation fermented straw nutrition forage grass

ActiveCN101849610AHigh nutrient concentrationImprove feeding effectFungiBacteriaBiological storageAnimal Foraging

The invention relates to a wrapped low-moisture rapid-orientation fermented straw nutrition forage grass which is a livestock forage grass that takes straws of crops as raw materials and is prepared from the following process step of: machining corn straws as main materials with the moisture content of 15-50 percent into 3-8 cm filaments by a straw rubbing machine. The wrapped low-moisture rapid-orientation fermented straw nutrition forage grass is characterized in that a straw biological-storage preparation agent is prepared from the following steps of: respectively obtaining three dried thalluses of small-sized filamentous fungi, bacillus subtilis and lactobacillus acidophilus by adopting a solid fermentation culture method and a liquid fermentation culture method, and evenly mixing the three dried thalluses according to the weight ratio of 2:1:1, wherein the amount of straws and the thalluses of the straw biological storage preparation agent is 1000:1 to 1.5. The invention has the beneficial effects that: 1. the nutrition concentration of the forage grass is high; 2. the moisture content is low, and the economic value of the forage grass is improved; 3. the thallus design is more reasonable, the treated and prepared straw is converted into the straw fermentation forage grass which has good palatability, high intake rate and easy digestion; and 4. the invention is suitable for professional and industrial production.

Owner:王明堂

Method for producing edible fungus with high yield by carrying out enzymolysis on crop straws with enzymatic microorganisms

InactiveCN102550282AExtensive sources of raw materialsSimplify the cultivation process of edible fungiBio-organic fraction processingOrganic fertiliser preparationCompostCarbon nitrogen

The invention provides a method for producing edible fungus with high yield by carrying out enzymolysis on crop straws with enzymatic microorganisms. The method comprises the following steps of: (1) cutting the crop straws into sections of between 2 and 3cm, mixing with rice hulls, adding water which accounts for 60 to 70 percent of the weight of the mixture, adding 95-105g of enzymatic microorganisms, uniformly mixing, stacking to 1-1.5m, sealing for 24 hours, overturning when the mixture is heated to 60 DEG C, and spreading and cooling; and (2) preparing and uniformly stirring 50 to 75 parts of straws and rice hulls subjected to enzymolysis of the enzymatic microorganisms, 15 to 30 parts of organic auxiliary materials, and 1 to 5 parts of inorganic auxiliary materials in parts by weight, inoculating the edible fungus strain in a disinfect and sterilized environment or a fungus room . According to the method, the crop straws are utilized to replace traditional corn cobs, sawdust and other raw materials to serve as composts of the edible fungus, and the raw materials have wide sources, the bio-transformation rate of the edible fungus is increased, the carbon nitrogen ratio is increased, and the production yield of the edible fungus is improved.

Owner:武汉楚天绿色科技开发有限公司

Grape wine added with procyanidin B2 and preparation method

InactiveCN101633873AReduce green smellIncrease aromaMicroorganism based processesWine preparationProcyanidin B2Vitis vinifera

The invention relates to the field of grape wine, in particular to grape wine added with procyanidin B2 and a preparation method. The invention is characterized in that the addition quantity of a grape pip extract in the wine is 0.01-20mg / mL, the content of the procyanidin B2 in the extract is 20-98%, the addition quantity of the procyanidin B2 in the wine is ensured to reach 0.002-19.6mg / mL, the addition quantity of sucrose in the wine is 20-200mg / mL, and the addition quantity of zymosan in the wine is 0.2-0.3mg / mL. After the husks of grape raw materials are broken, the peduncles of the grape raw materials are removed and the grape raw materials are pulped, the grape pip extract, the sucrose and the zymosan are added into the grape pulp according to the above addition quantity, and the grape wine is prepared by fermentation, deposit, filtration, filling and aging. The invention enhances the content of the procyanidin B2 in the grape wine, reinforces the health-care function of the grape wine, improves the production technique procedures simultaneously and improves a product in various aspects of the appearance, the colour, the fragrance, the mouth feel, the aftertaste and the like.

Owner:天津市壹杯红生物技术有限公司

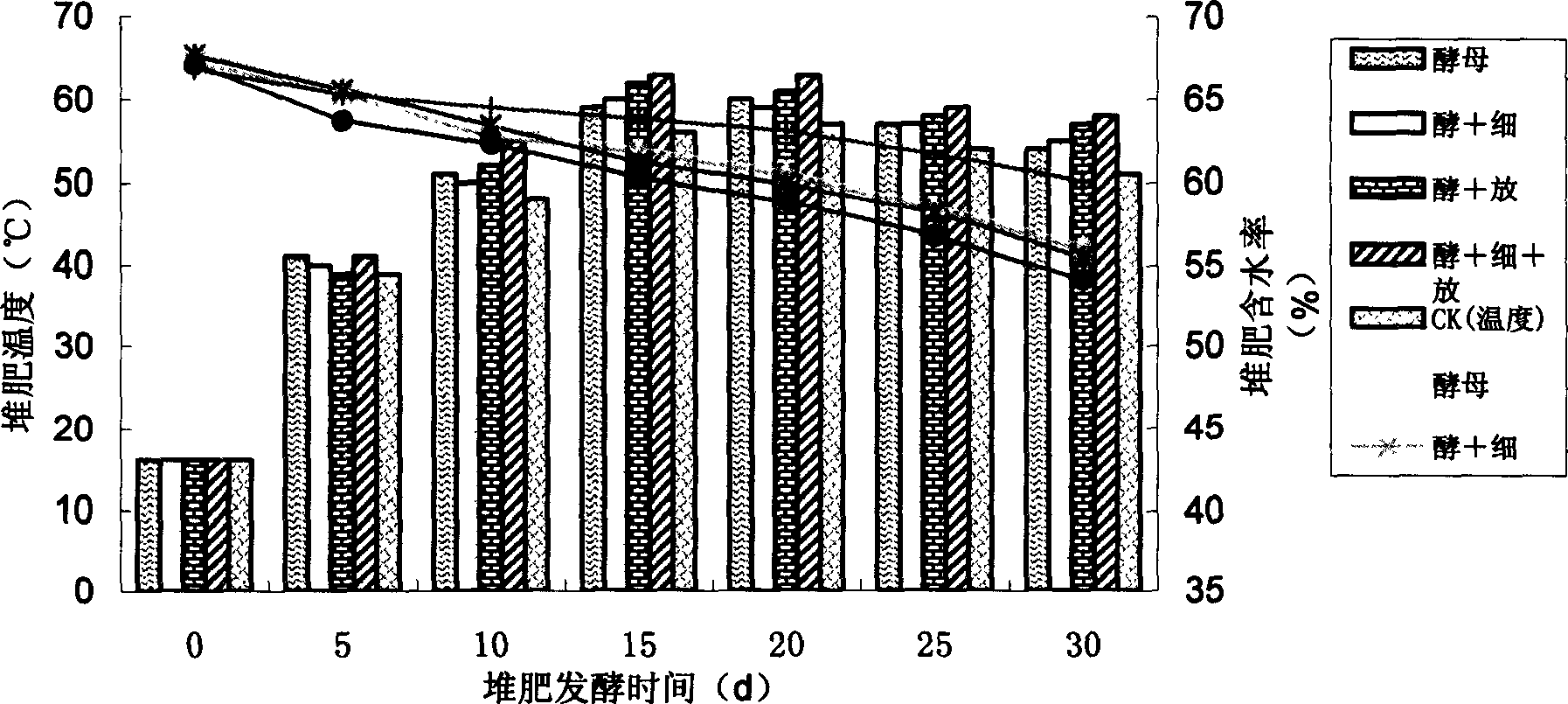

Zymogen agent for treating agricultural wastes and preparation method

A formentation bacterial agent for processing agricultural waste is composite or single bacterial agent prepared by cultivating and fermenting three bacterial agents of retaining cupsule film spoyeast ZJY2, griseolutein W, and cerecin ME1-2. The application process includes controlling water content rate of waste to be 55-56%, adding and mixing the agent, stirring the mixer for ventilation at setting time for 20-30 days and achieving the aim of making the waste nonhazardous and resources.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

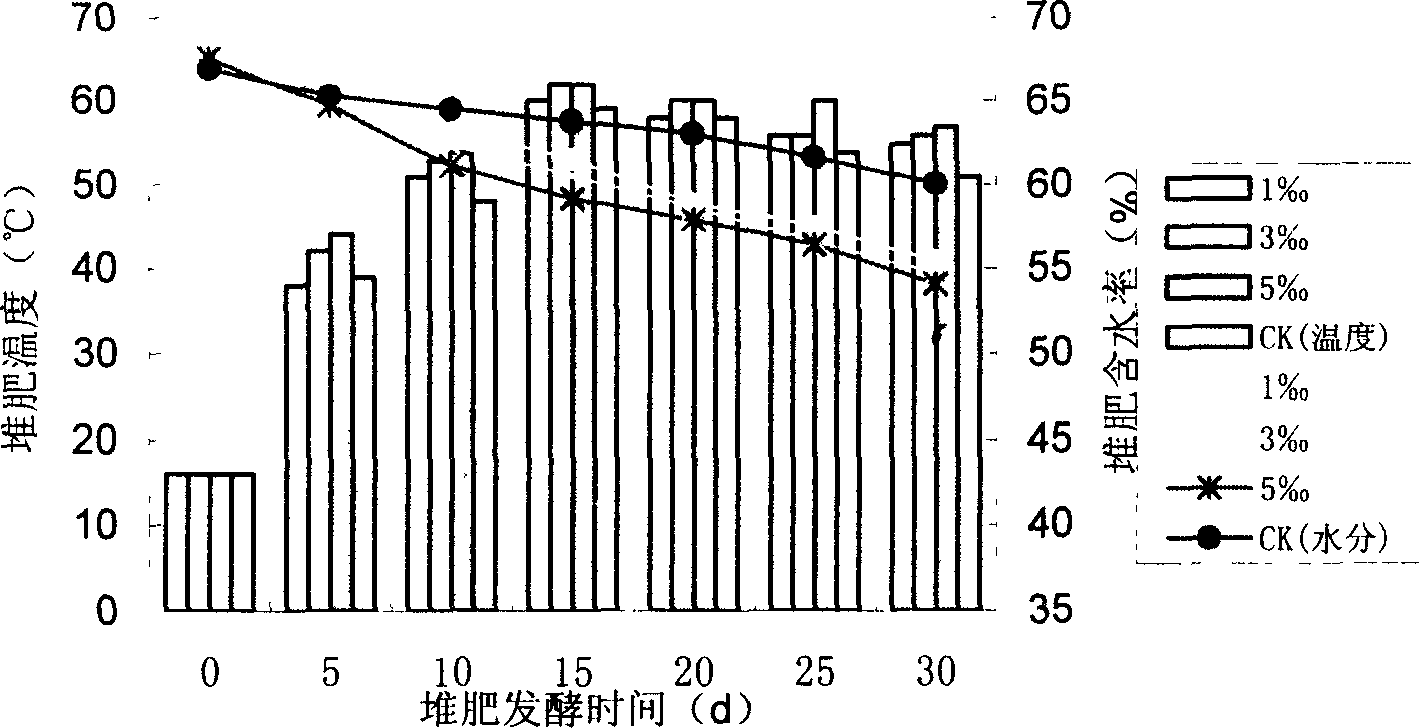

Vinegar residue fermented complex micro organism fungicide and preparation method thereof

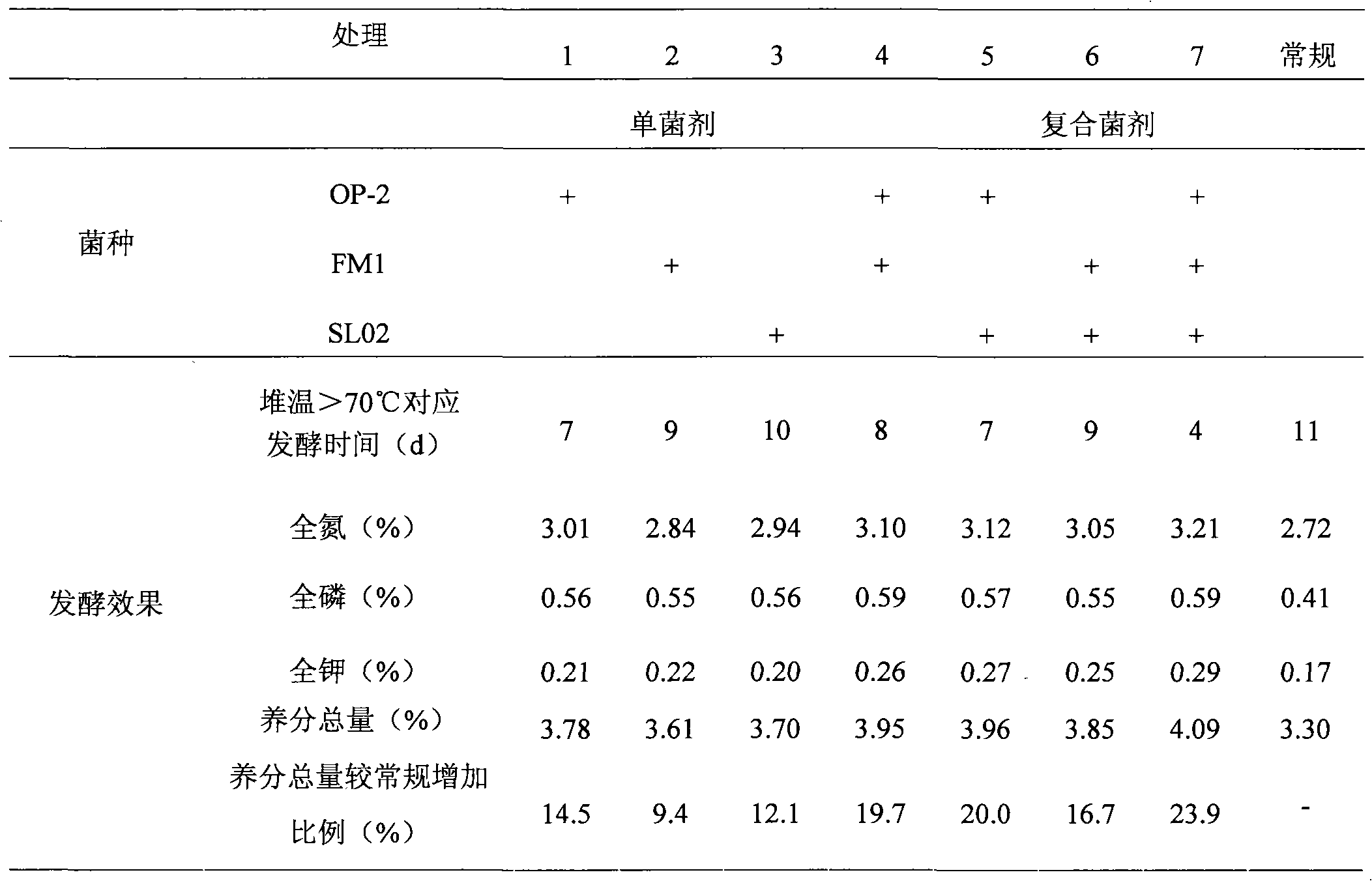

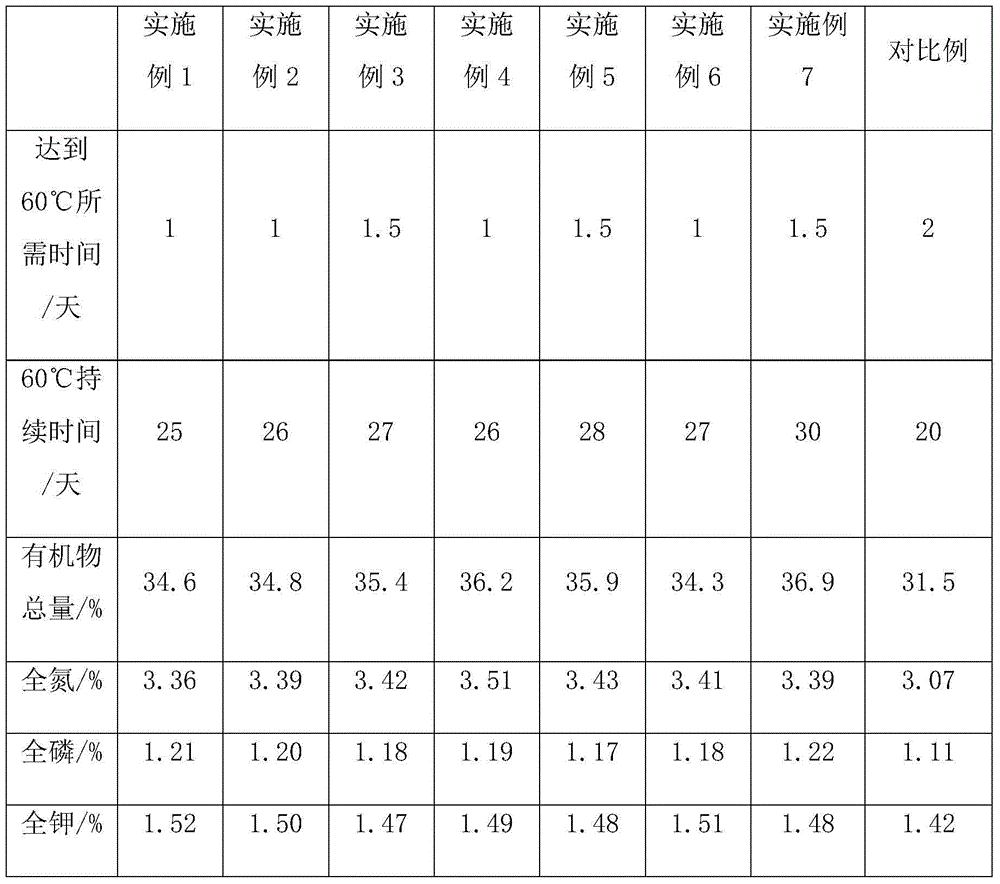

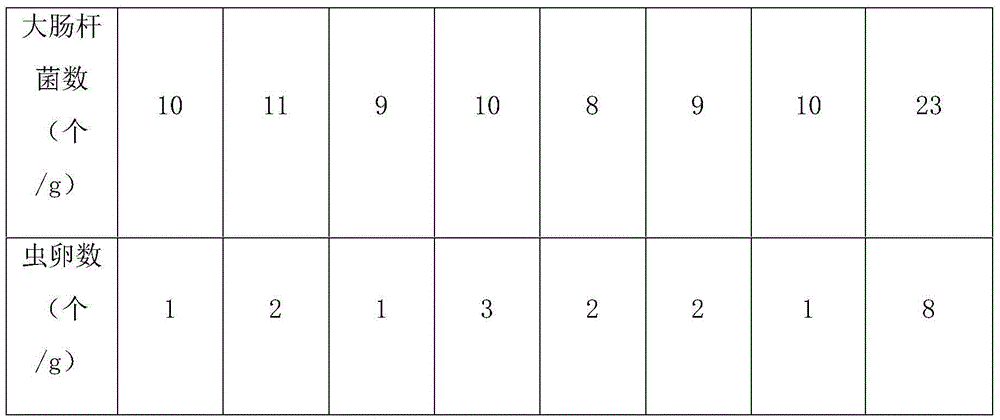

InactiveCN101805697ARaise the fermentation temperatureSpeed up the fermentation processBio-organic fraction processingFungiPotassiumMixed materials

The invention discloses a preparation method of vinegar residue fermented complex micro organism fungicide. The fungicide is formed by single strain fungicides of bacillusacidocaldarius., rhizopus stolonifer and trichoderma viride by weight ratio of 1:1:1, wherein firstly stock seeds of the single strain fungicides are respectively multiplied by a primary test tube and are respectively subject to secondary liquid culture to obtain bacteria; then 50-60% of rice bran and 50-40% of wheat bran are mixed by weight percent and stirring to be uniform is carried out to obtain mixed material, the cultured bacteria are respectively inoculated according to the volume weight ratio of bacterium and mixed material, thus obtaining single strain fungicide. The complex micro organism fungicide provided by the method can increase fermentation temperature of vinegar residue compost and speed up fermentation, and fermentation finished product thereof has high content of full dose nutrients (nitrogen, phosphorous and potassium) and good nutrition.

Owner:JIANGSU UNIV

Method for preparing novel chicken manure organic fertilizer

InactiveCN104649749AIncrease contentReproduce fastBio-organic fraction processingExcrement fertilisersHuskOrganic fertilizer

The invention provides a method for preparing a novel chicken manure organic fertilizer, comprising the following steps: (1) constructing a fermentation tank, forming vents in the bottom of the fermentation tank, and arranging a rainproof device on the top of the fermentation tank; (2) dehydrating chicken manure till the water content is 45-50%, mixing uniformly with straws, rice husk, humic acid, peanut shell, melon seed shell and bran to obtain a mixture, and uniformly spraying a compound fermentation agent to the mixture to obtain a fermented raw material; (3) transferring the fermented raw material obtained in step (2) to the fermentation tank constructed in step (1), piling up, and forming a plurality of vents penetrating through the pile by using a stick; and (4) turning over the fermented raw material once every day when the temperature of the pile reaches 35 DEG C or above and twice every day when the temperature of the pile reaches 60 DEG C or above, and curing, drying and crushing the pile when the temperature of the pile is lowered to 40 DEG C or below to obtain the chicken manure organic fertilizer.

Owner:SUZHOU AORAN COMMODITY

Golden camellia dark tea and processing technology thereof

ActiveCN106720556AReduce moisture lossPromote conversionPre-extraction tea treatmentChemistryFermented tea

The invention discloses golden camellia dark tea and a processing technology thereof. The golden camellia dark tea is prepared from, by weight, 30-80% of fresh leaves of golden camellia tea and 20-70% of loose tea of finished dark tea products. The processing technology comprises the steps of preparation, fixation, rolling, mixture storage, moisture regaining, fermentation, drying, aroma increasing and filling. The golden camellia dark tea is organic integration of ingredients, beneficial to the human body, in the golden camellia tea and the dark tea, compared with the golden camellia tea and the dark tea, the golden camellia dark tea is higher in health care efficacy, the cold nature of golden camellia tea leaves is eliminated, the taste is improved, and consumer groups are expanded.

Owner:广西国茗金花茶科技有限公司

Actinobacillus and method for producing succinic acid

InactiveCN101845407AIncrease productionMeet the needs of fermentation productionBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologySuccinic acid fermentation

The invention provides actinobacillus and a method for producing succinic acid. The Actinobacillus succinogenes CGMCC2560 for producing the succinic acid by fermenting saccharine materials can produce the succinic acid through fermentation, or joint production is performed through succinic acid fermentation and cellulosic ethanol fermentation. Under the anaerobic condition of introducing CO2 and / or N2 and in the environment that pH is maintained 5.5-7.5, 10-110g / L of succinic acid can be produced from 10-100g / L of saccharine materials by anaerobic fermentation. In the joint production method, CO2 generated in the cellulosic ethanol fermentation process is used for the fermentation production of the succinic acid so as to improve the yield of the succinic acid and the cellulosic ethanol and realize zero emission of the CO2. In the joint production, the yield of the succinic acid can reach 92g / L, and the yield of the cellulosic ethanol reaches 108g / L.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

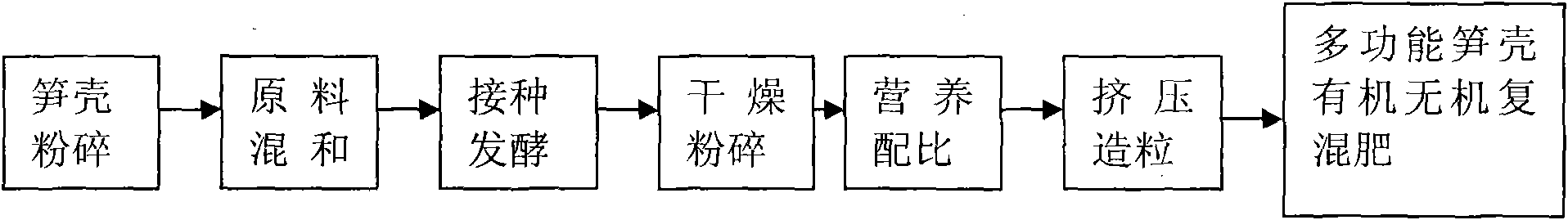

Preparation process of multifunctional bamboo-shell organic-inorganic composite fertilizer

InactiveCN101851127AImprove qualityPromote degradationBio-organic fraction processingOrganic fertiliser preparationCelluloseBiotechnology

The invention relates to a preparation process of multifunctional bamboo-shell organic-inorganic composite fertilizer, which comprises 60 to 70 parts of bamboo shell, 30 to 40 parts of manure and 0.5 to 1 part of micro-organism microbial inoculum (consisting of 40 to 50 parts of cellulose-decomposing bacteria, 30 to 40 parts of yeast and 10 to 20 parts of mesophile), and is characterized in that the above raw materials are fermented for 15 to 30 days, bamboo-shell organic fermentation materials are proportioned with conventional N, P and K inorganic fertilizer and middle-micro element fertilizer according to the nutrition required for different crops and different growth periods after being dried and crushed, the bamboo-shell resource can be transformed to the special organic-inorganic composite fertilizer with 20 to 40 percent of organic substance and 15 to 25 percent of nitrogen, phosphorous and potassium through pelleting, so the recycling of bamboo-shell waste is realized, and remarkable economic, social and ecological benefits can be created.

Owner:ZHEJIANG UNIV

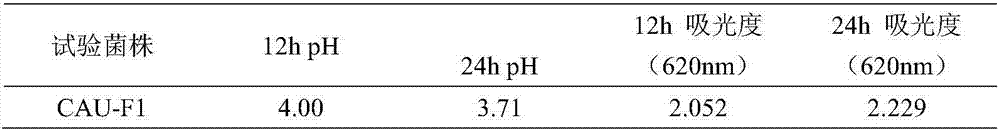

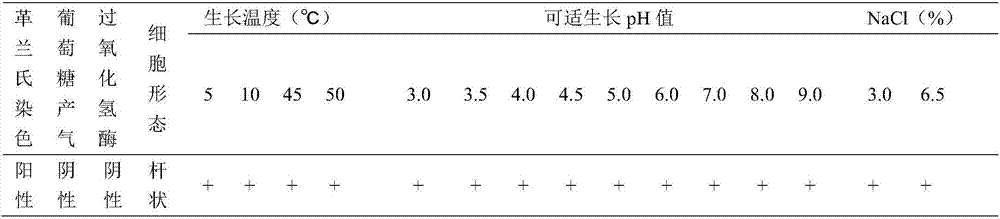

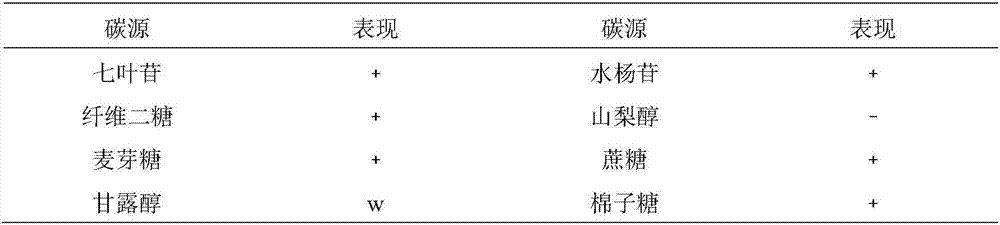

Lactobacillus plantarum and its application

InactiveCN107034156ASpeed up the fermentation processIncrease silage rateBacteriaLactobacillusLactobacillus plantarumReproduction

The invention discloses Lactobacillus plantarum and its application, and belongs to the field of silage preparation and processing. The Lactobacillus plantarum CAU-F1, with collection number of CGMCC No. 13610, is used for preparing silage, in particular to lucerne silage. The Lactobacillus plantarum CAU-F1 can rapidly decrease a pH value of silage, accelerate the fermenting process and improve the ensiling rate; besides, the Lactobacillus plantarum can inhibit reproduction of undesirable microorganisms, improve the lucerne ensiling quality, well store the lucerne nutrition, overcome the problem of difficulty in lucerne fermentation, and increase the in-vitro digestibility coefficient of the silage. The ensiling effect of the additive prepared by the Lactobacillus plantarum CAU-F1 is better than that of the marketed lactobacillus additive; moreover, the Lactobacillus plantarum is low in cost, safe and easy to use.

Owner:CHINA AGRI UNIV

Rhizome substrate soil for micro agriculture

The invention relates to cultivation soil, in particular to rhizome substrate soil for micro agriculture. The rhizome substrate soil is formed by mixing a substrate with rural soil or clay and comprises the following components in weight percent: 25% to 45% of the substrate and 55% to 75% of the rural soil or clay; the substrate comprises 60% to 80% of organic matters in weight percent and includes 1% to 3% of nitrogen, 1.5% to 3.5% phosphorus, 2% to 4% of potassium, and 0.02% to 0.08% of trace elements including magnesium, calcium, iron, manganese and boron; the pH value of the substrate is 6.5 to 6.8, the electric conductivity of the substrate is 1.5 to 3.5S, and the cation exchange capacity of the substrate is larger than or equal to 100; the organic matters comprise 2 to 5 part of bamboo vinegar liquid, 0.5 to 2 parts of crystallization mother liquid containing 15% to 25% of abamectin, 4 to 8 parts of nucleotide salt, 3 to 8 parts of chitosan oligosaccharide, 1 to 3 parts of starch-acrylic acid graft copolymer, 15 to 40 parts of a straw decomposition agent, 15 to 40 parts of fermented human and animal excreta, 10 to 18 parts of edible fungus residue, 3 to 6 parts of waste bamboo, 2 to 5 parts of plant-charcoal powder, 5 to 10 parts of silt slag, 4 to 6 parts of bone meal and 4 to 9 parts of soybean meal. According to the invention, specific components and proportion are adopted to prepare the organic matters, and the organic matters are combined with inorganic matters to form the acidulous substrate, so that the rhizome substrate soil is high in nutritional ingredient and appropriate in proportion of trace elements, has an excellent odor removing effect, and is clean and nvironment-friendly.

Owner:HUZHOU YIMENG CITY AGRI DEV

Agricultural waste fermenting bacterial prepn and its prepn process

InactiveCN1772880AIncrease profitSpeed up evaporationBacteriaMicroorganism based processesTectorial membraneYeast

The present invention discloses fermented bacteria preparation for agricultural waste treatment and its preparation process. The present invention separates and breeds three kinds of bacteria with fast growth and high heat resistance, including two strains of tectorial membrane yeast ZJY2 and Strreptomyces griseus W1 and one known strain Bacillus cereus ME1-2. These three kinds of spawn are cultured and fermentation produced separately and further produced into compound bacteria preparation in certain ratio or single bacteria preparation. When the bacteria preparation is used in treating agricultural waste, the waste is added with regulator to control the water content in 55-65 wt% and the bacteria preparation in 0.1-0.5 wt% is added through stirring, and the mixture is aerobic high temperature fermented for 20-30 days to reduce amount, reduce harm and become useful resource.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

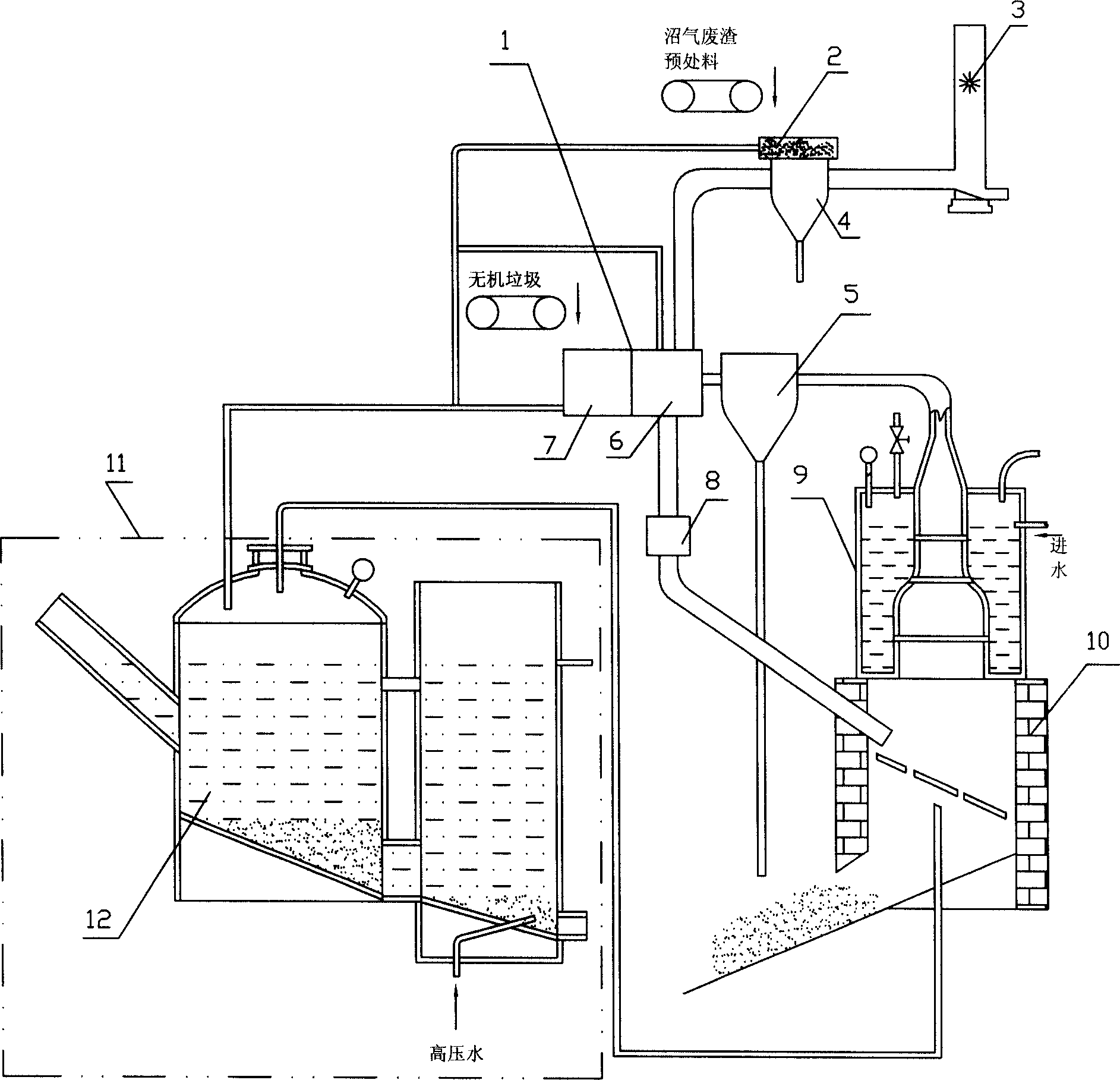

Method for treatment of urban garbage

A method for treating city garbage includes such steps as classifying the garbage into the garbage A able to be biologically decomposed and the combustible garbage B, loading the garbage A in marsh gas pool to generate marsh gas, using the marsh gas to burn the garbage B in incinerator and installing the duster in the chimney of incinerator to remove the dust from fume.

Owner:张四灿

Composite inoculant for promoting decomposing of cellulose organic wastes, and preparation method thereof

ActiveCN103320369APromote decompositionGood synergyFungiBio-organic fraction processingCelluloseChrysosporium species

The invention discloses a composite inoculant for promoting the decomposing of cellulose organic wastes, and a preparation method thereof. The active components of the inoculant for promoting the decomposing of cellulose organic wastes comprise Sporotrichum thermophile, Trichoderma konigii, Phanerochaete chrysosporium, Aspergillus niger, Saccharomyces cerevisiae, Bacillus subtilis and Streptomyces ambofaciens. Experiments in the invention prove that the composite inoculant for promoting the decomposing of cellulose organic wastes can effectively improve the decomposing speed of the organic wastes, and can be used for producing biological organic fertilizers.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Vegetable waste organic fertilizer and preparation method thereof

InactiveCN101514117BSimple processEasy to implementBio-organic fraction processingOrganic fertiliser preparationCalcium cyanamideResource utilization

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

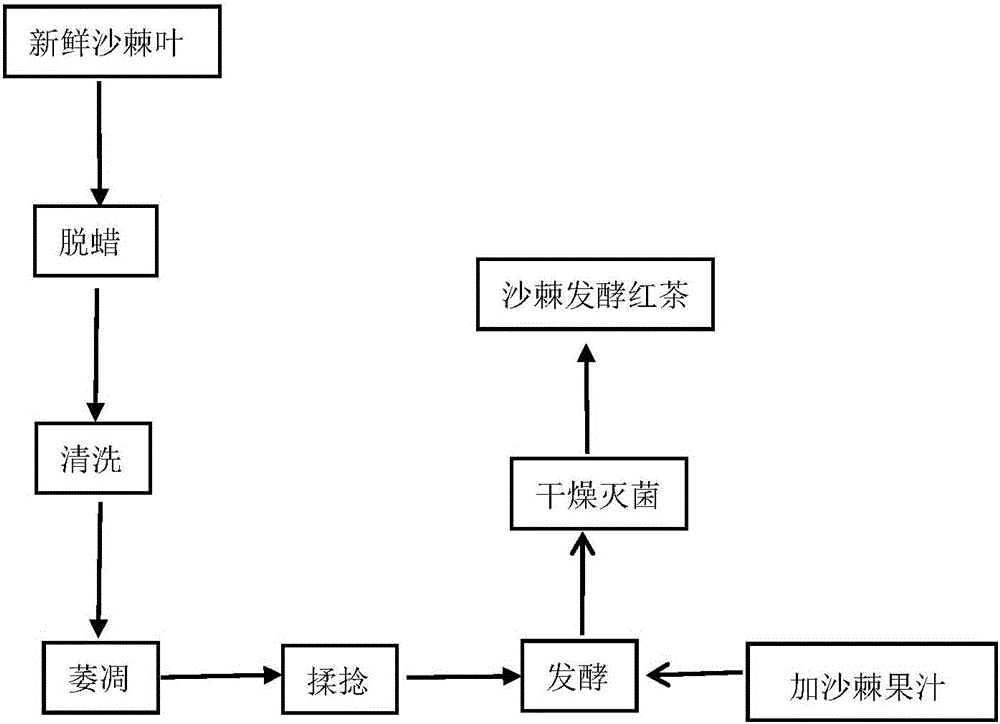

Hippophae rhamnoides black tea and preparation method thereof

The invention discloses a preparation method of hippophae rhamnoides black tea. The preparation method comprises the following steps of (1) picking hippophae rhamnoides leaves; (2) performing dewaxing treatment on the pickled hippophae rhamnoides leaves, wherein dewaxing means removing tissue having protection effects on surfaces of the hippophae rhamnoides leaves through a specific reagent; (3) performing withering; (4) performing rolling; (5) performing fermentation; and (6) performing drying and sterilization. The black tea not only has color, aroma and taste of tea and pleasure sense when the black tea is drunk, but also has certain health-care functions.

Owner:内蒙古宇航人高技术产业有限责任公司

Preparation method of organic fertilizer

InactiveCN108892581AAvoid pollutionPromote growthCalcareous fertilisersAnimal corpse fertilisersPassion fruitFermentation

The invention discloses a preparation method of an organic fertilizer, and relates to the technical field of organic fertilizers. The preparation method of the organic fertilizer comprises the following steps that 1, cow dung, chicken manure, pig manure, quicklime, pond mud, yellow bean pods, corn distillers' grains, compound zymophyte, corn straw powder, humic acid, bagasse, wheat bran, peanut cake powder, silkworm excrement, furnace slag, pitaya stems, banana peel, pineapple peel, grape pomace, passion fruit peel, bean curd, expired yogurt, durian peel, coffee residues, rice washing swill, earthworm manure, egg shells, bones, rotten vegetable leaves, shrimp shells, waste tea leaves, spoiled milk powder and trace elements are obtained by weight; 2, the cow dung, the chicken manure, the pig manure and the quicklime are mixed, dried and crushed to obtain excrement powder; 3, the excrement powder is mixed with the rest materials, and fermentation is conducted to obtain the organic fertilizer. According to the preparation method of the organic fertilizer, the fermentation process of the organic fertilizer can be accelerated, the fermentation time can be shortened, the fertility of theorganic fertilizer can be improved, and the disease resistance of plants is improved.

Owner:广西乐业康辉生态养殖专业合作社

Processing technology of bead-shaped black tea

InactiveCN105360370AImprove uniformityGood surface smoothnessPre-extraction tea treatmentBead shapeBlack tea

The invention discloses a processing technology of bead-shaped black tea in order to solve the problem that bead-shaped black tea does not exist in the market because tea leaves without fixation are crisp, and the tea leaves are difficult to roll and shape. The processing technology comprises the following steps of withering tea leaves for 5-8 hours; rolling the withered tea leaves for 45-80 minutes according to different freshness of the tea leaves; performing fermentation for 3-5 hours; performing dehydration until the water content is 40%-50%; performing resurgence: putting the tea leaves after the resurgence in a double-pan roasting machine, frying semi-finished products, combining the fried semi-finished products in pans for the first time and for the second time, and shaping the fried tea leaves to form granular tea leaves; drying the tea leaves at two stages of a gross fire and a complete fire; and finally performing flavor distilling on the dried tea leaves. The bead-shaped black tea made by the technical scheme of the invention is high in uniformity, good in surface smoothness, rich and long in fragrance, red and bright in soup color, mellow in mouth feel and long in aftertaste; besides, the double-pan roasting machine is adopted, so that the disposable yield of the tea leaves is high, and the cost of consumed human resources is also low.

Owner:贵州湄潭盛兴茶业有限公司

Facility cultivation technique for crop rotation of stropharia rugosoannulata and rice

InactiveCN108990697AUniform fruitingThe fruiting rate is stableCultivating equipmentsPlant protectionNutrientHyphomycetes

The invention discloses a facility cultivation technique for crop rotation of stropharia rugosoannulata and rice, and belongs to the technical field of edible mushroom cultivation. The facility cultivation technique includes the steps of fermentation of a culture material, construction of a mushroom shed, construction of a ridged bed, seeding, mycelium management and protection, mushroom cultivation and harvesting, and rice planting and harvesting. After the components of the culture material are subjected to composting and fermentation separately, layered laying is adopted, so that nutrient and oxygen supply in the development process of mycelia and fruiting bodies is ensured, the whole fruiting is uniform, the fruiting rate is stable, the total yield is high, the quality is good, the planting cycle is short, and the continuous cropping obstacles can be solved by crop rotation of the stropharia rugosoannulata and rice.

Owner:湖北省曙骧生态农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com