Production process of low-salt oil-free fermented bean curd

A production process, fermented bean curd technology, applied in the field of low-salt oil-free fermented bean curd production process, can solve the problems of high labor intensity, high salt content of fermented bean curd, short production season, etc., to reduce labor intensity, speed up the fermentation process, and prevent miscellaneous bacteria pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

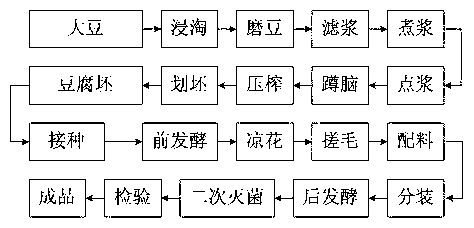

[0028] Such as figure 1 Shown, a kind of production technology of low-salt oil-free fermented bean curd, it comprises the following steps:

[0029] S1: Pretreatment before pulping: select 10kg of soybeans, leaching, and grinding the soybeans after leaching, filtering out impurities after grinding, and boiling the obtained filter pulp;

[0030] S2: Dispensing and squatting: after the pretreatment before dispensing, add 2% of the composite coagulant. After the dispensing is completed, perform the squatting operation. The composite coagulant is prepared from the following components and weight ratios : calcium sulfate 5, calcium acetate 2;

[0031] S3: Squeeze and scribing: after the brain squatting is completed, the pressing operation is performed to control the moisture content of the white slab to 75%.

[0032] S4: Inoculation: Inoculate the spore suspension of any one of Mucor racemosa, Mucor elegans, and Wutongqiao Mucor into the bean curd base at a ratio of 0.3%, and the ...

Embodiment 2

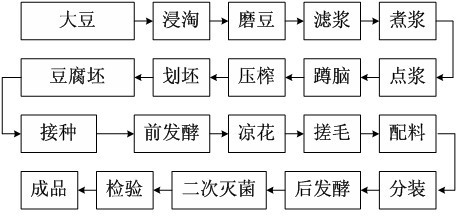

[0040] Such as figure 1 Shown, a kind of production technology of low-salt oil-free fermented bean curd, it comprises the following steps:

[0041] S1: Pretreatment before pulping: select 10kg of soybeans, leaching, and grinding the soybeans after leaching, filtering out impurities after grinding, and boiling the obtained filter pulp;

[0042] S2: Dispensing and squatting: After the pretreatment before dispensing, add 5% of the composite coagulant. After the dispensing is completed, perform squatting operation. The composite coagulant is prepared from the following components and weight ratio : calcium sulfate 4, calcium acetate 1;

[0043] S3: Squeeze and scribing: after the brain squatting is completed, the pressing operation is performed to control the moisture content of the white slab to 70%.

[0044] S4: Inoculation: inoculate the spore suspension of any one of Mucor racemosa, Mucor elegans, and Wutongqiao Mucor into the bean curd base at a ratio of 0.4%, and the inocu...

Embodiment 3

[0052] Such as figure 1 Shown, a kind of production technology of low-salt oil-free fermented bean curd, it comprises the following steps:

[0053] S1: Pretreatment before pulping: select 10kg of soybeans, leaching, and grinding the soybeans after leaching, filtering out impurities after grinding, and boiling the obtained filter pulp;

[0054] S2: Dispensing and squatting: After the pretreatment before dispensing, add 4% of the composite coagulant. After the dispensing is completed, perform the squatting operation. The composite coagulant is prepared from the following components and weight ratios : calcium sulfate 6, calcium acetate 3;

[0055] S3: Squeeze and scribing: after the brain squatting is completed, the pressing operation is performed to control the moisture content of the white slab to 72%.

[0056] S4: Inoculation: inoculate the spore suspension of any one of Mucor racemosa, Mucor elegans, and Wutongqiao Mucor into the bean curd base at a ratio of 0.35%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com