Patents

Literature

1172results about "Fruits/vegetable preservation by heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and apparatuses for thermal treatment of foods and other biomaterials, and products obtained thereby

InactiveUS20060151533A1Speed up heat exchangeImproved physical contactOpening closed containersBottle/container closureMedicineContinuous flow

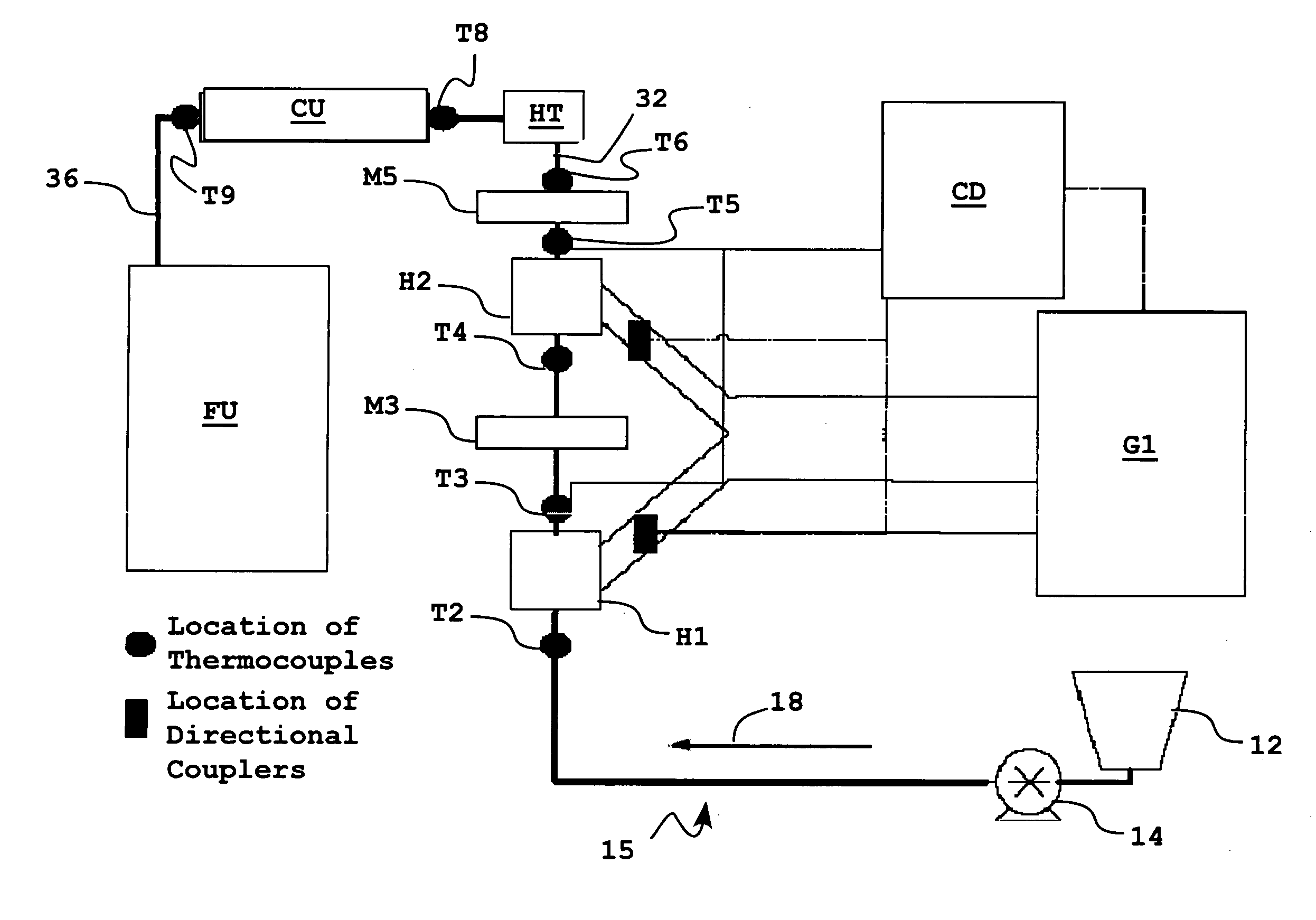

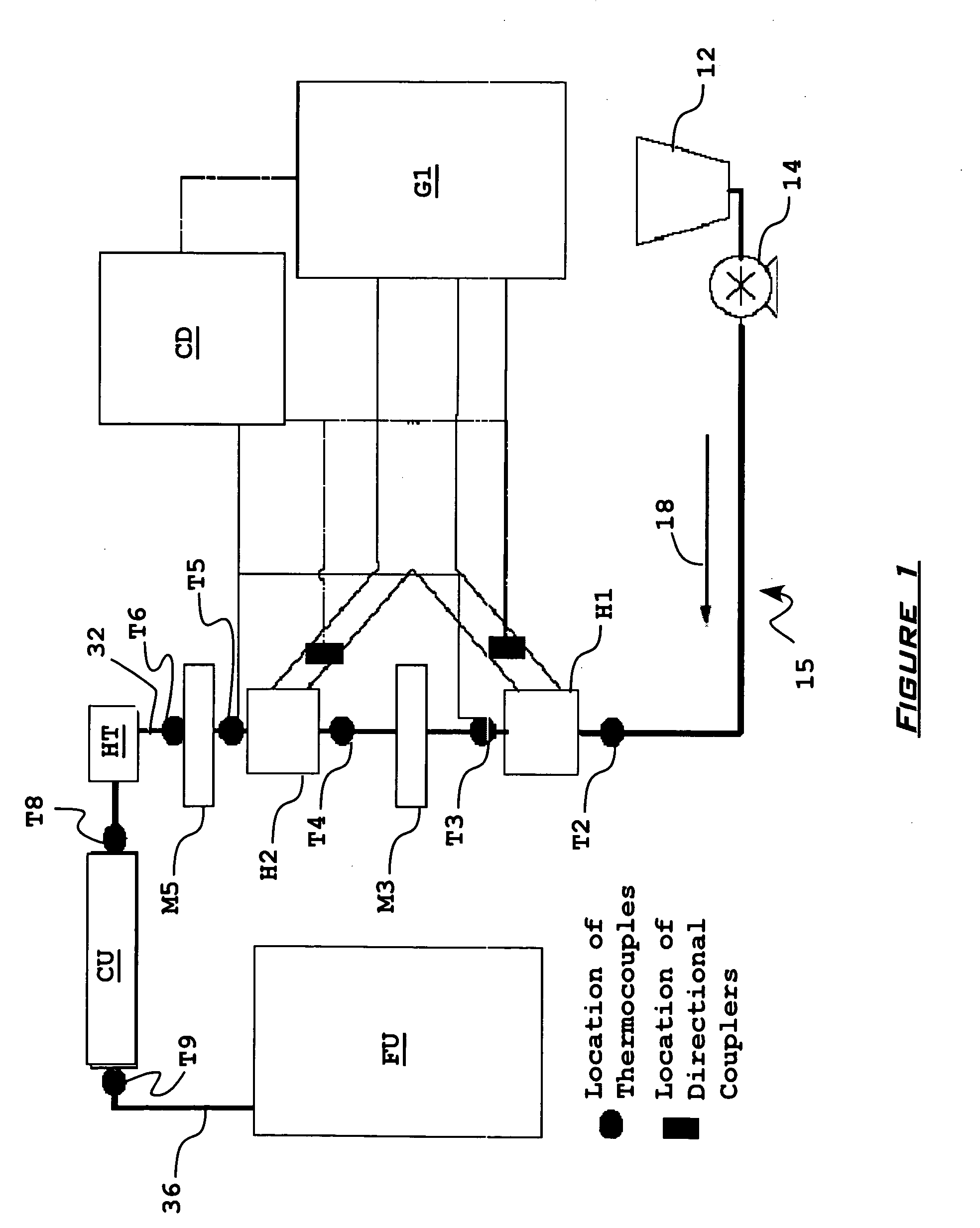

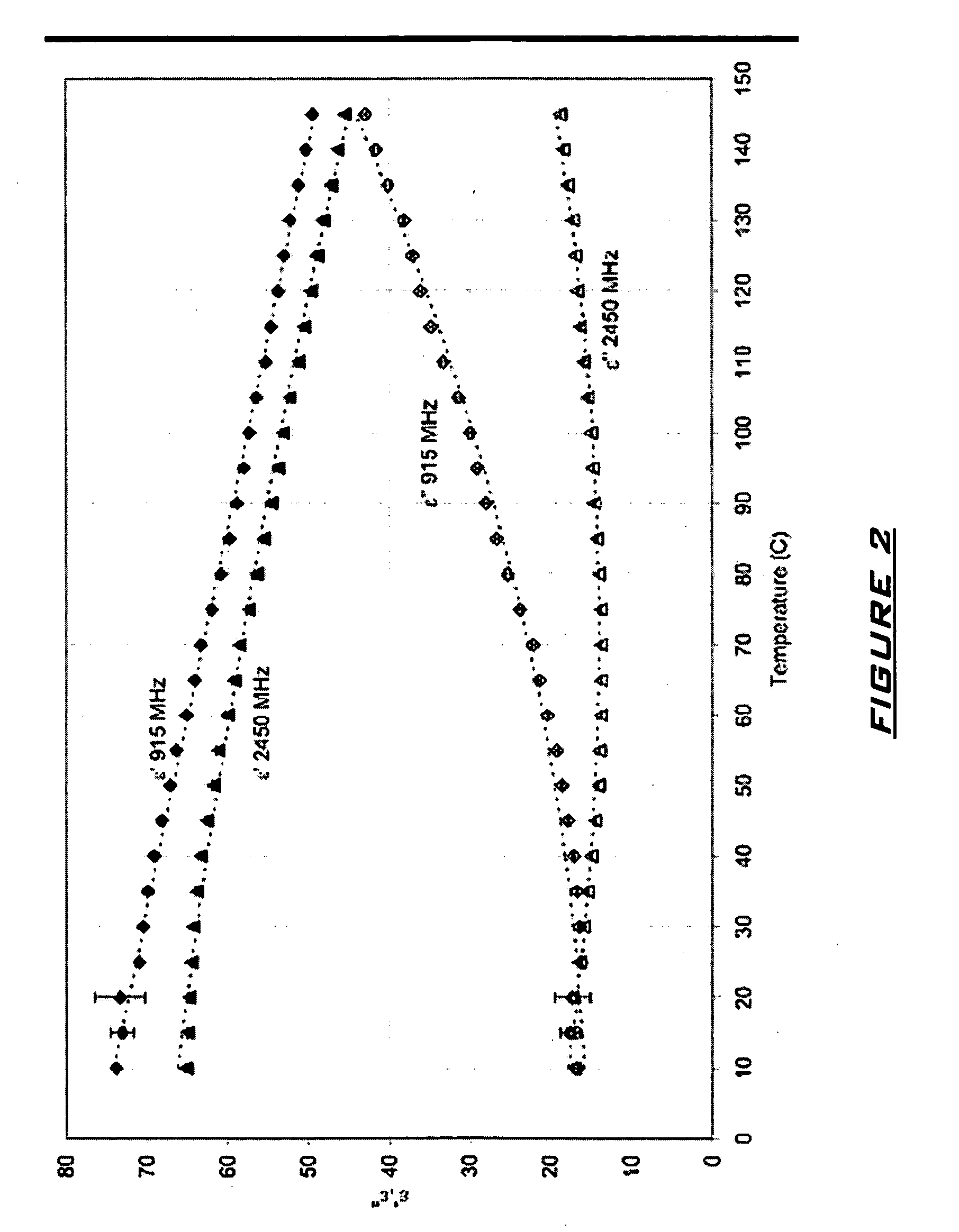

Methods and apparatuses for thermally treating flowable materials using electromagnetic radiation, and foods and materials obtained thereby. Also provided are methods of continuous flow thermal treatment of biomaterials, apparatuses for performing the same, and products prepared using the methods and / or apparatuses.

Owner:SIMUNOVIC JOSIP +6

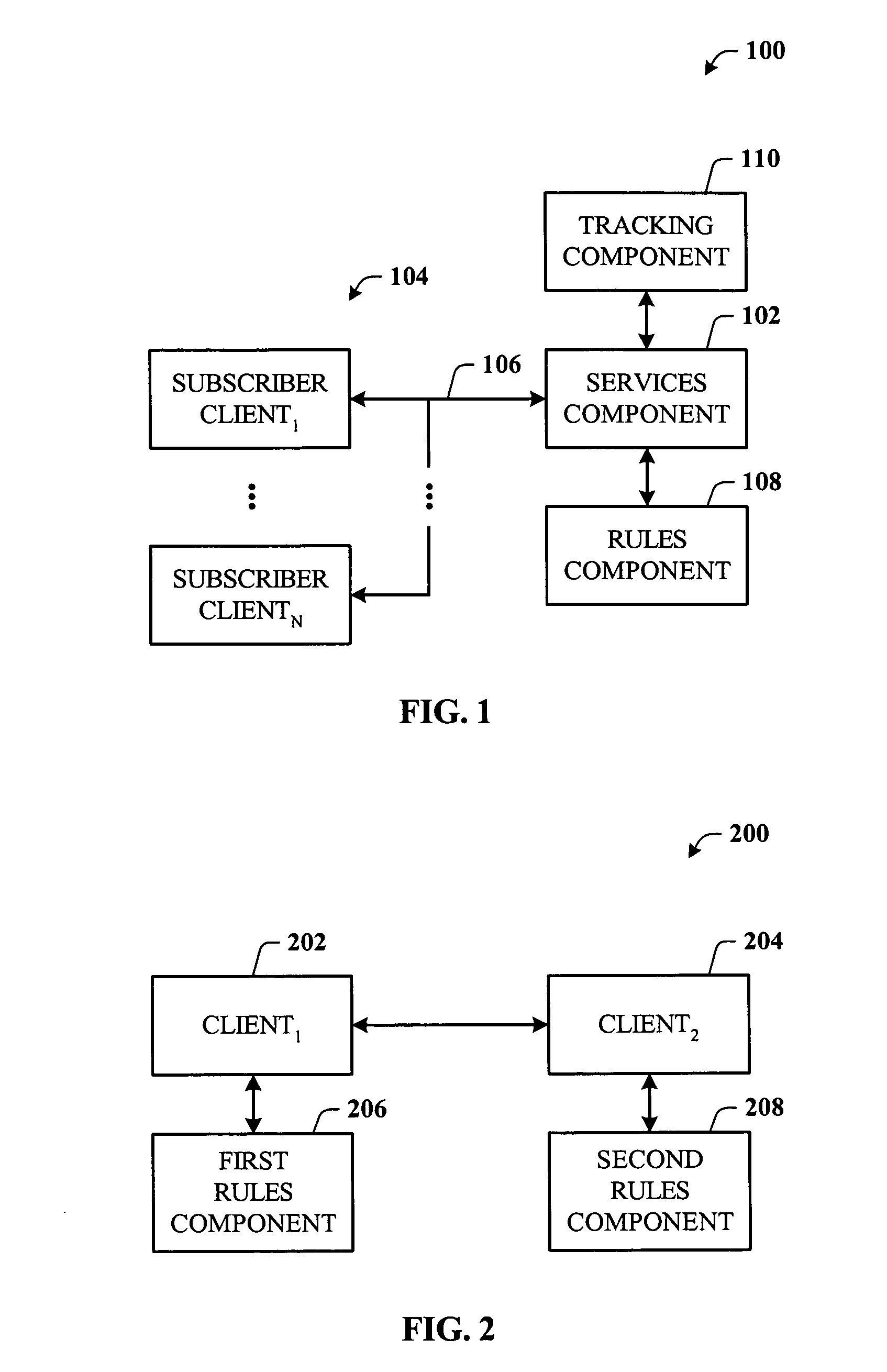

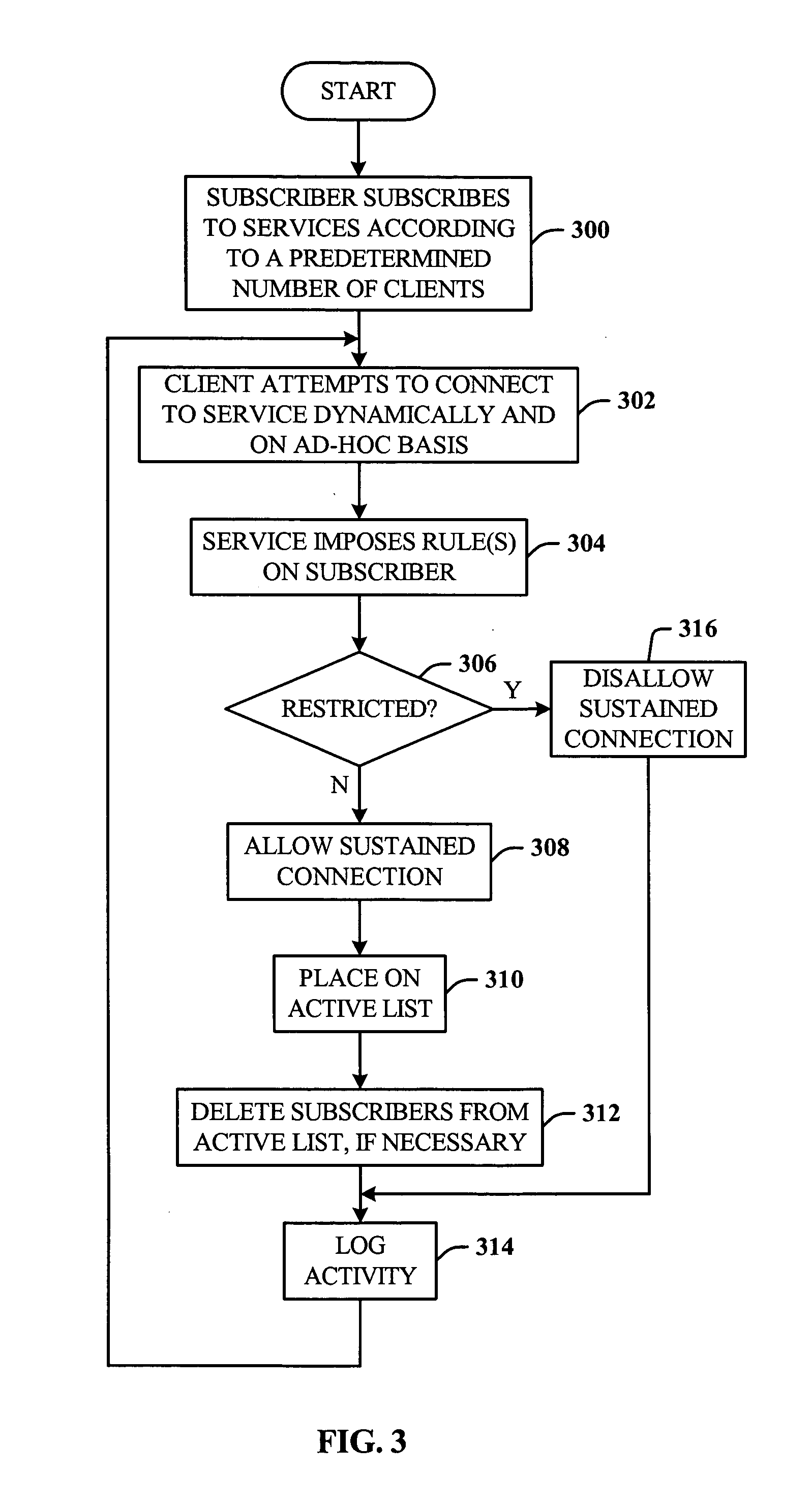

Architecture for controlling access to a service by concurrent clients

InactiveUS20050187957A1Metering/charging/biilling arrangementsDrying solid materials with heatClient-sideActive list

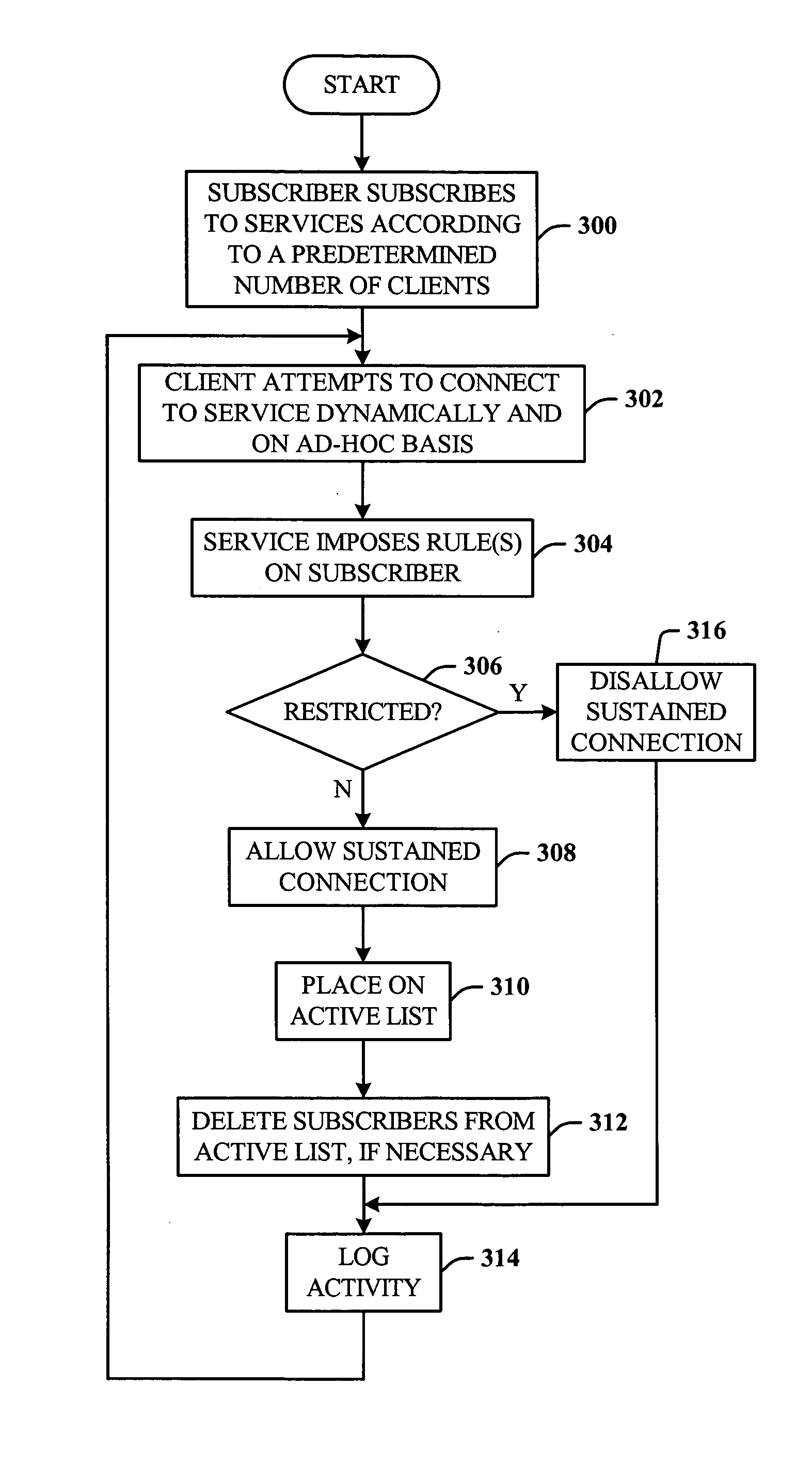

Architecture for controlling access to a service. The architecture allows denial of regular and periodic service to all but a selected number of concurrent clients associated with a subscriber, and without any manual administration at the server of a list of specific computers. Rather than require an administered list, the system discovers which clients are active, places the active clients on an active list, and excludes all client not on the active list. The system includes one or more rules the enforcement of which provide a mechanism for ensuring that the subscriber is not adding an unlimited number of clients or rotating clients in and out of the pool to effectively maintain service on a larger number of computers to which the subscriber is entitled.

Owner:MICROSOFT TECH LICENSING LLC

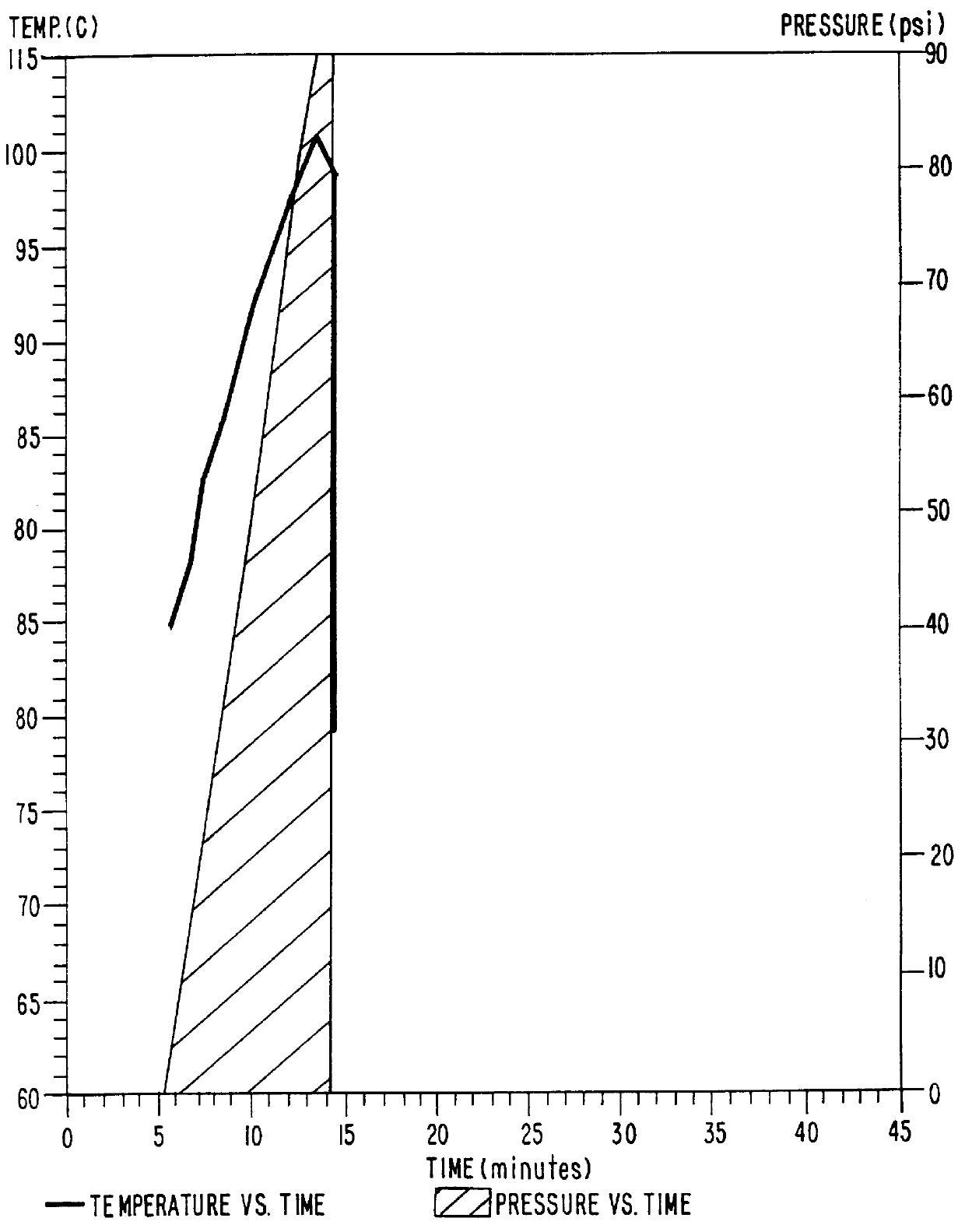

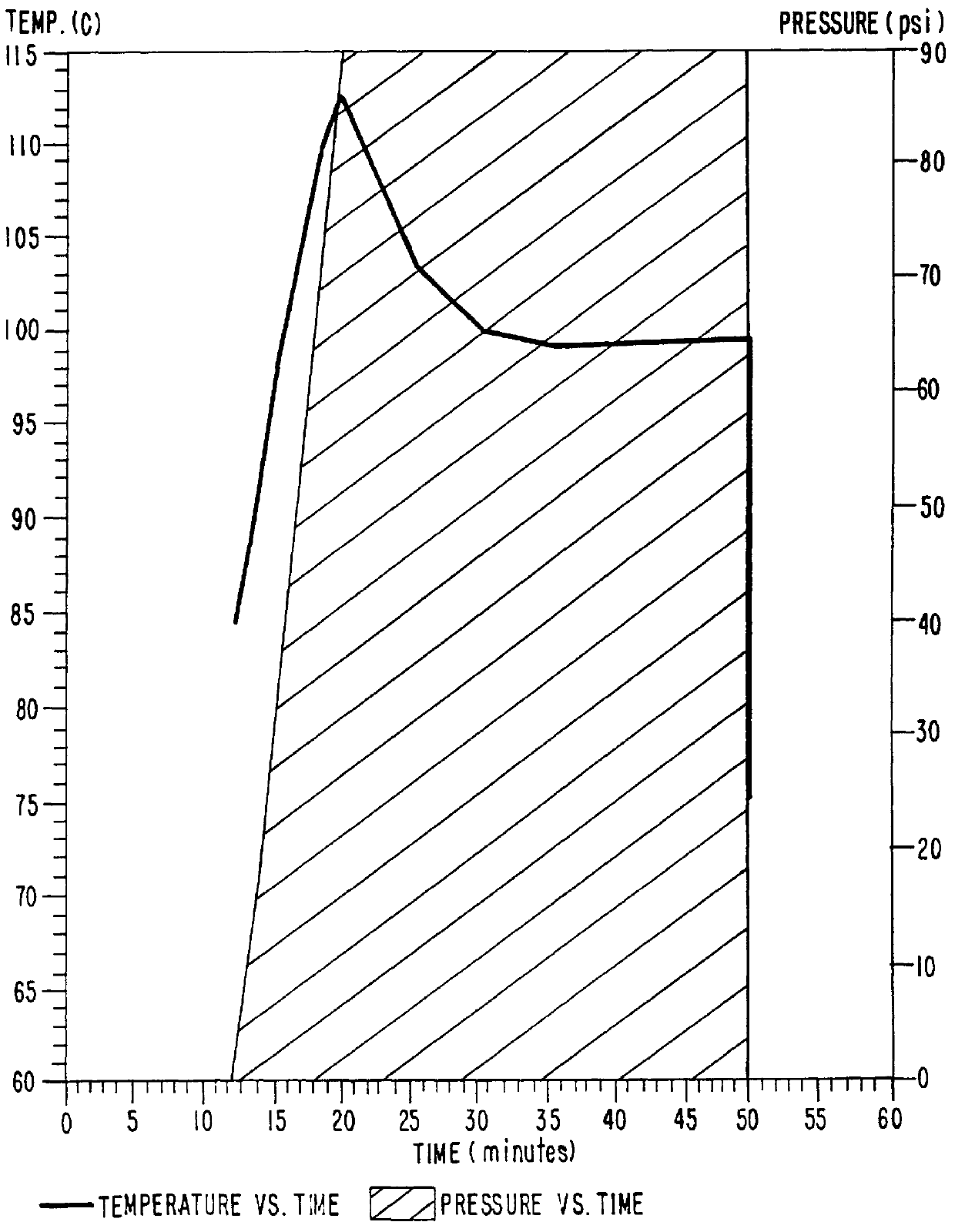

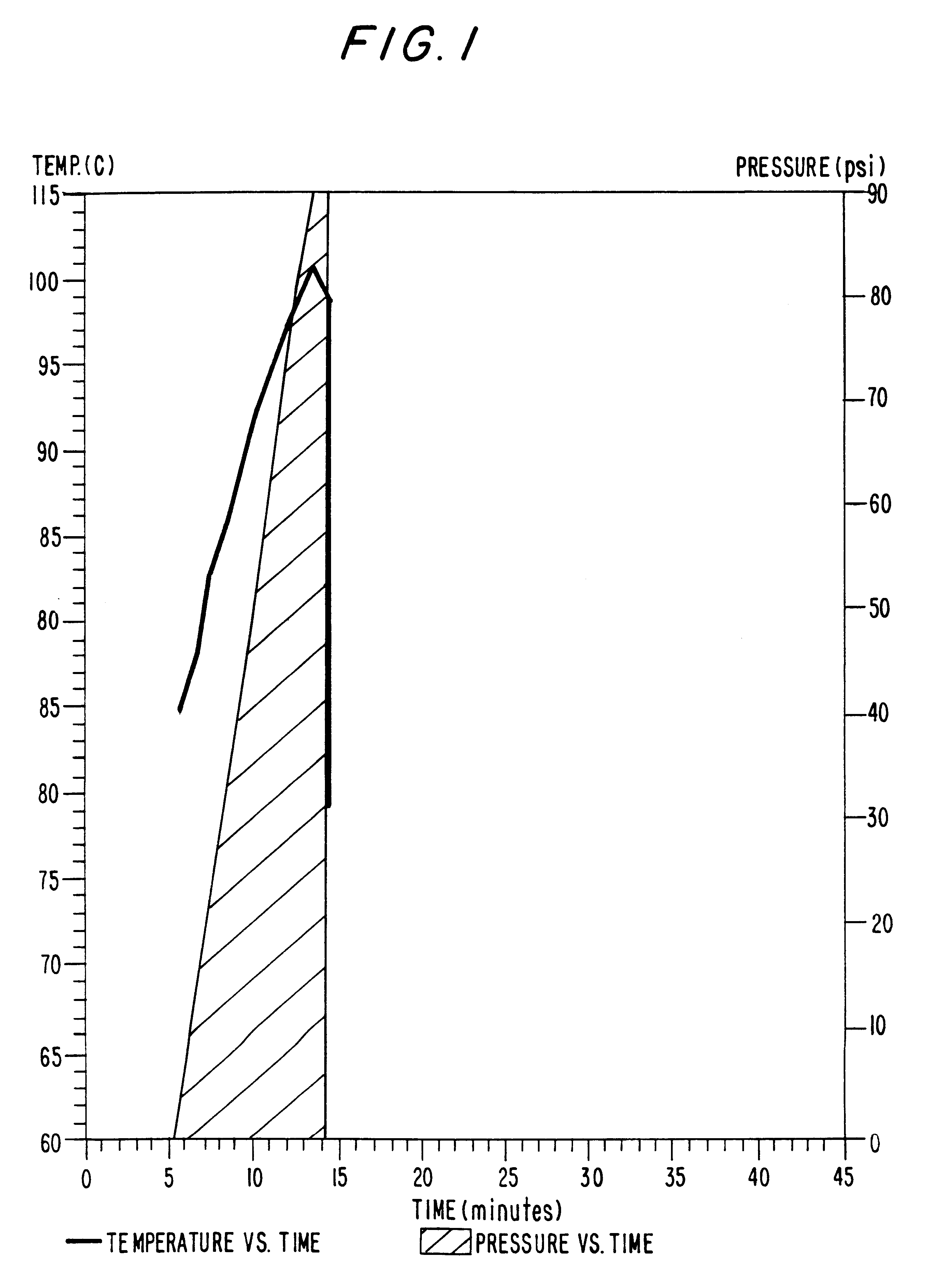

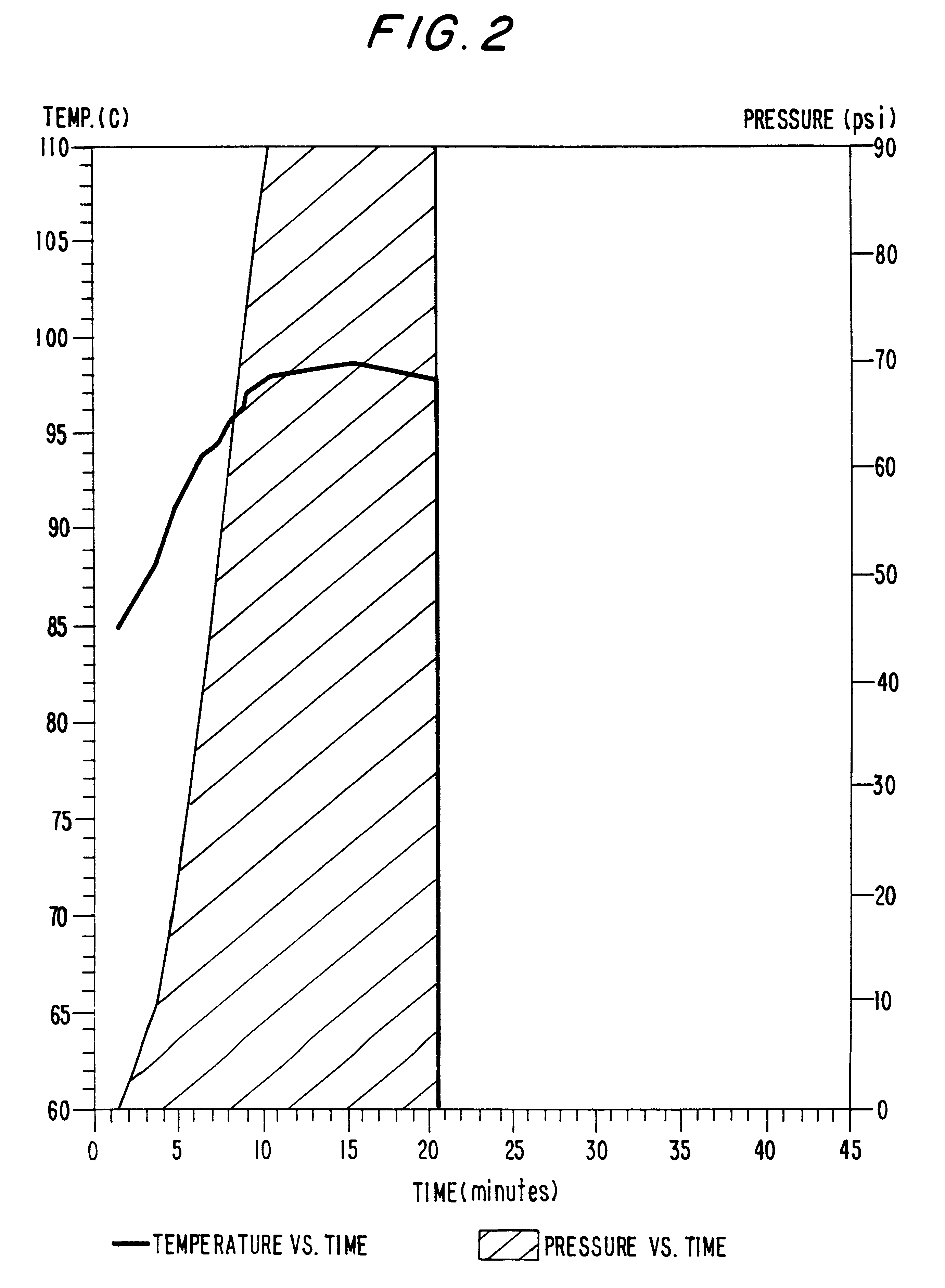

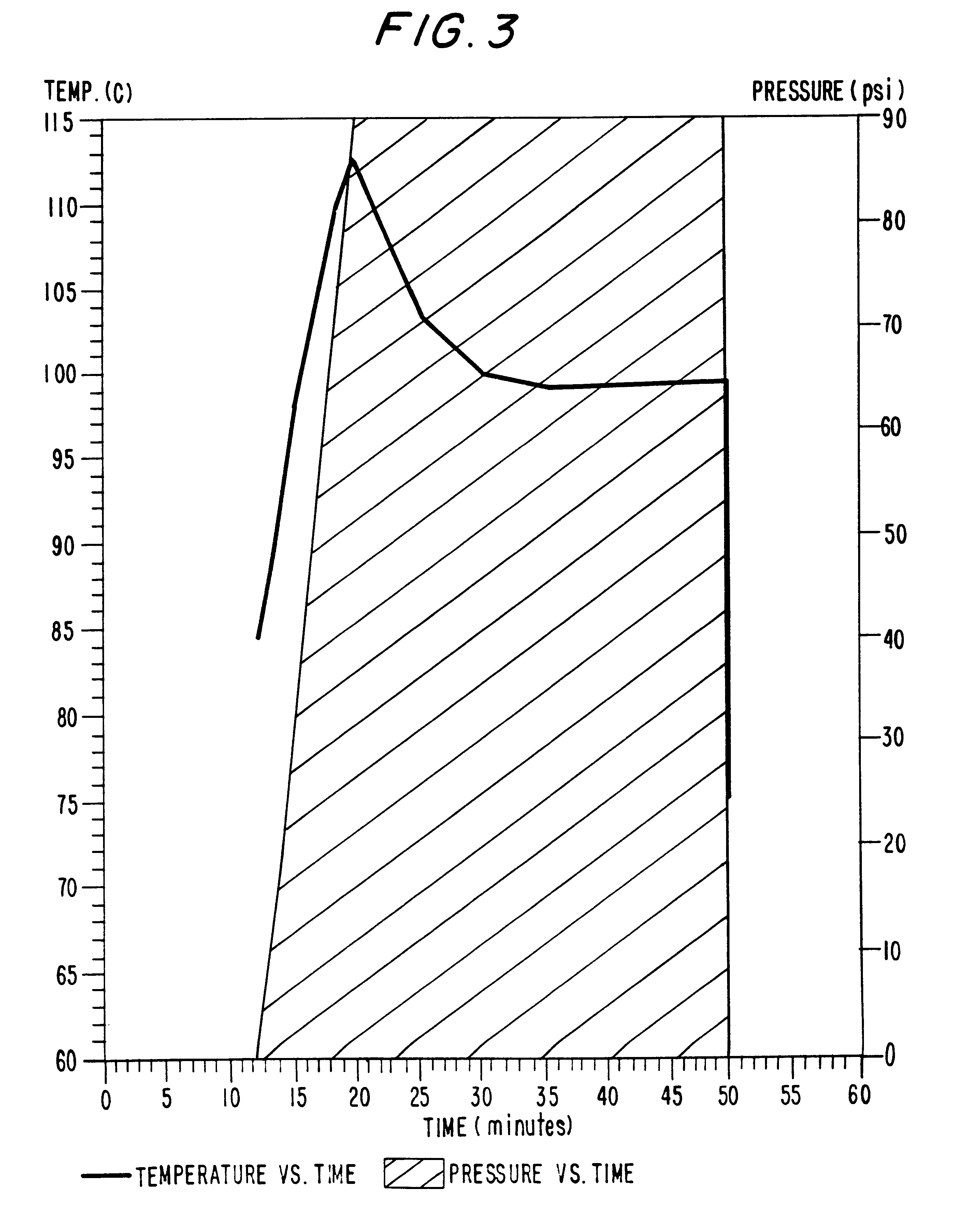

High temperature/ultra-high pressure sterilization of foods

InactiveUS6086936AImprove efficiencyFaster and more energy efficientMilk preservationMeat/fish preservation by heatingUltra high pressureProcess engineering

Method for sterilizing foods using both ultra-high pressures and high temperatures. The instantaneous temperature change that occurs when pressure is applied combines a high-temperature short-time process with ultra-high pressure to deliver a fast and therefore gentle thermal process to a pre-packaged product. The process involves heating a food to a pre-pressurized temperature, subjecting the food to ultra-high pressure, which instantaneously raises the temperature of the food, and then releasing the pressure so that the temperature returns to the original pre-pressurized temperature. The method leverages the adiabatic temperature rise which occurs when the food is hydrostatically pressurized, coupled with the lethality of the pressure, to achieve appropriate sterilization conditions.

Owner:KAL KAN FOODS

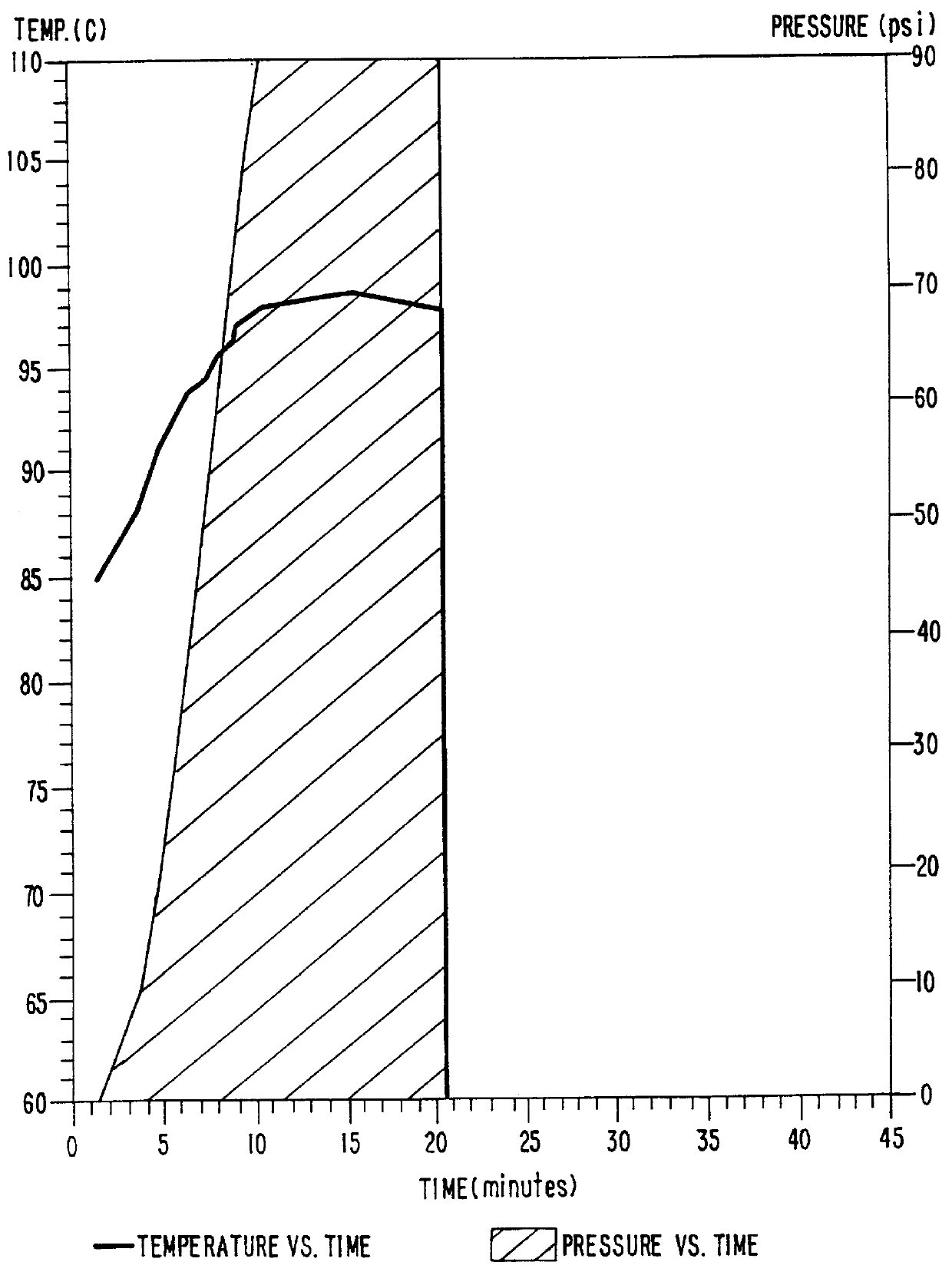

High temperature/ultra high pressure sterilization of foods

InactiveUS6207215B1Fresh lookAchieves commercial sterility of low acid food productsMilk preservationMeat/fish preservation by heatingUltra high pressureEngineering

Method for sterilizing foods using both ultra-high pressures and high temperatures. The instantaneous temperature change that occurs when pressure is applied combines a high-temperature short-time process with ultra-high pressure to deliver a fast and therefore gentle thermal process to a pre-packaged product. The process involves heating a food to a pre-pressurized temperature, subjecting the food to ultra-high pressure, which instantaneously raises the temperature of the food, and then releasing the pressure so that the temperature returns to the original pre-pressurized temperature. The method leverages the adiabatic temperature rise which occurs when the food is hydrostatically pressurized, coupled with the lethality of the pressure, to achieve appropriate sterilization conditions. The disclosure also includes foods which have been sterilized using both ultra-high pressures and high temperatures.

Owner:KAL KAN FOODS

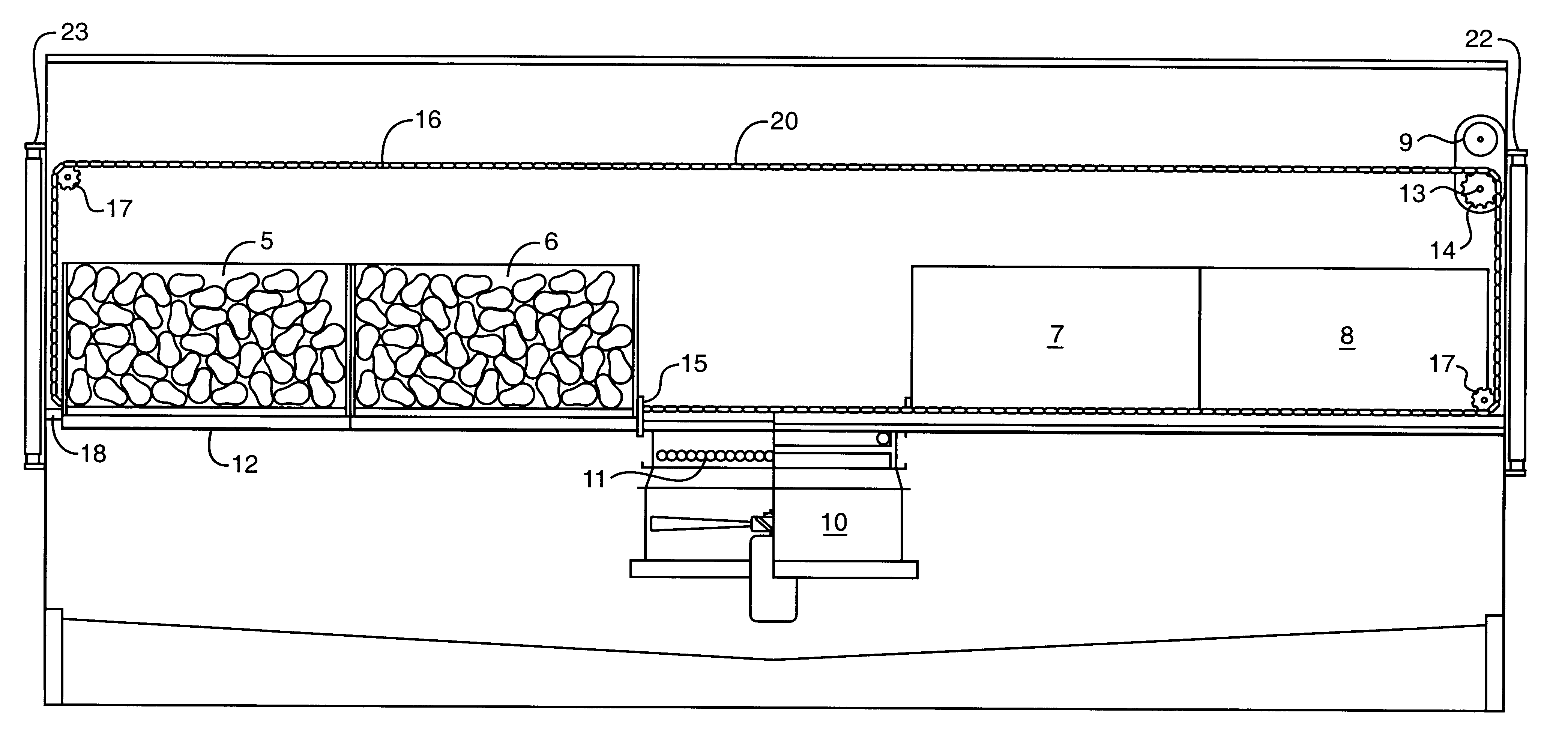

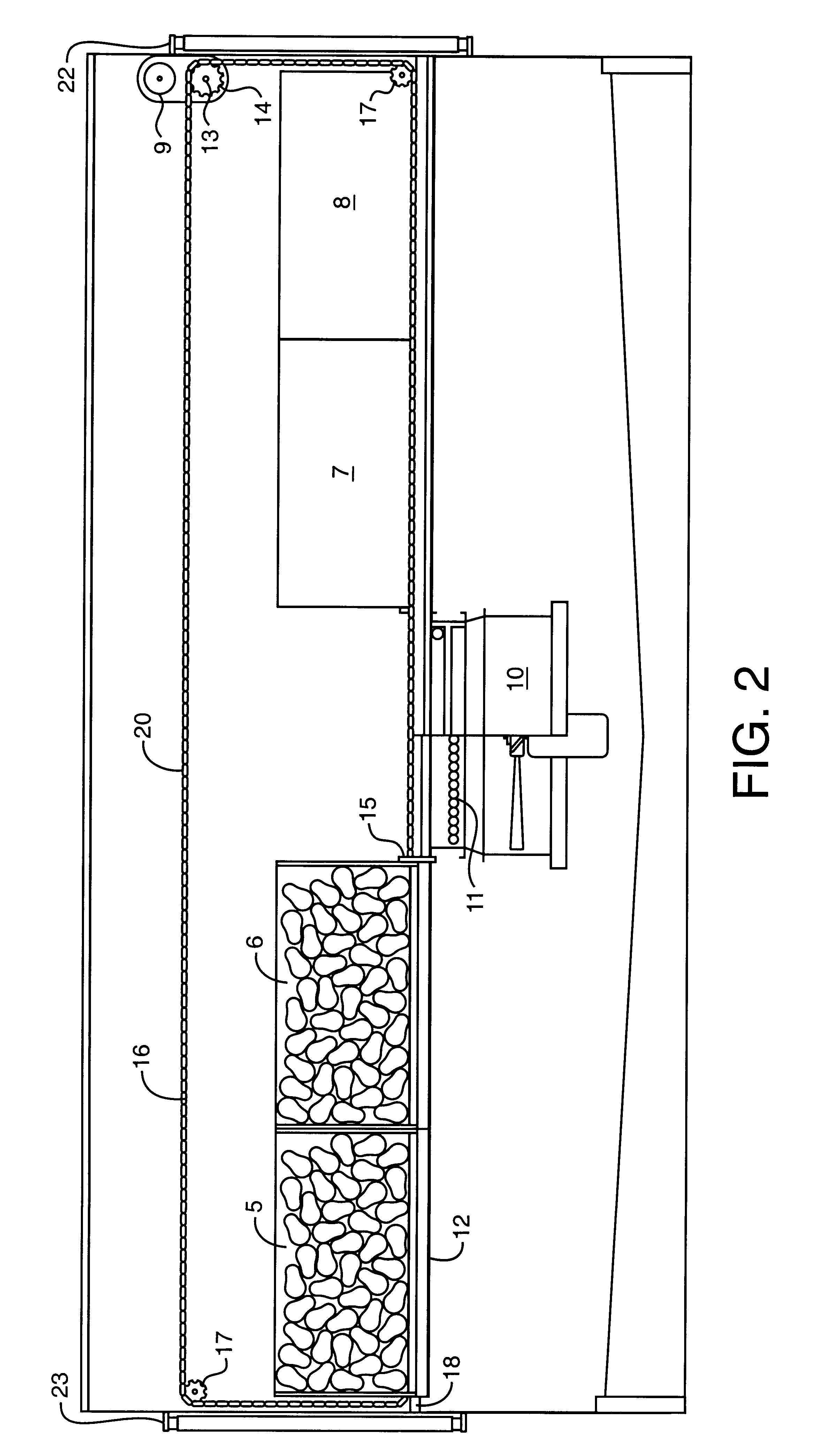

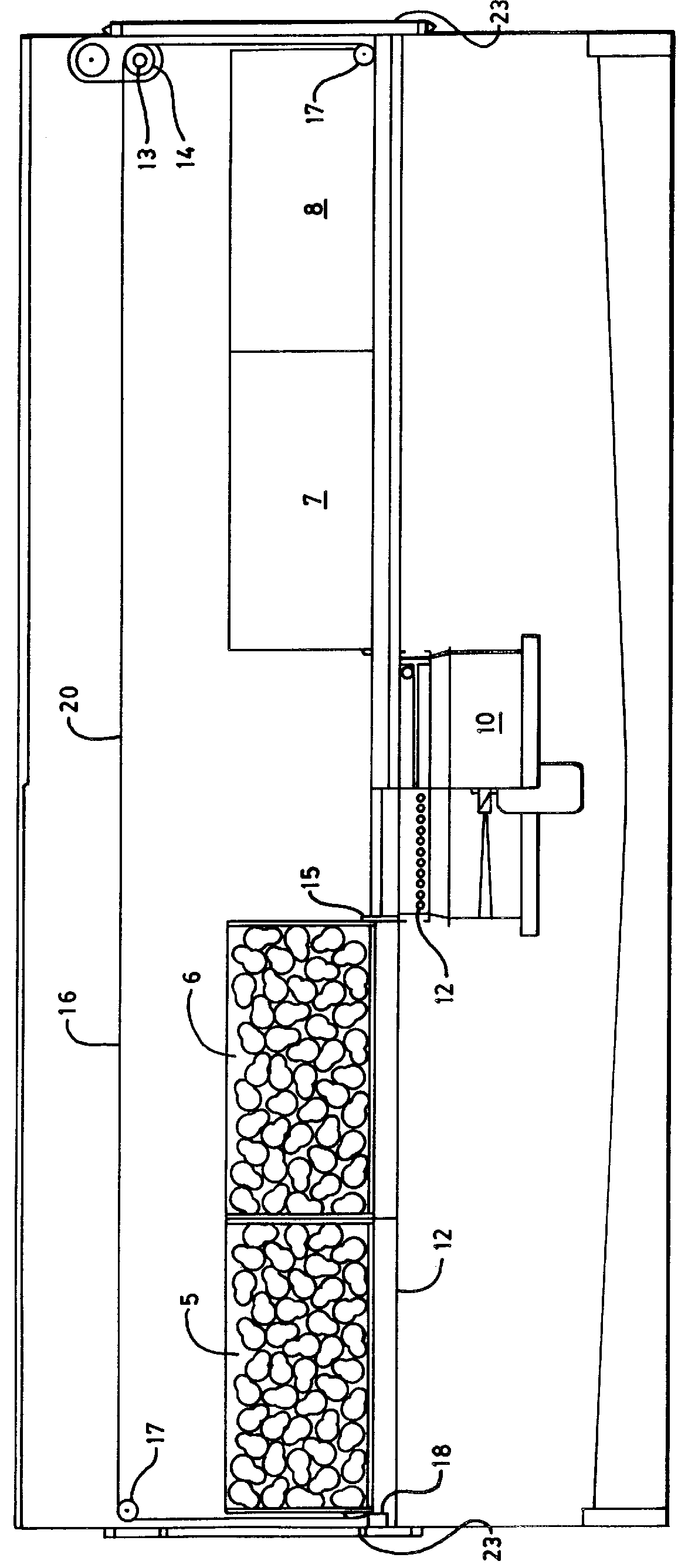

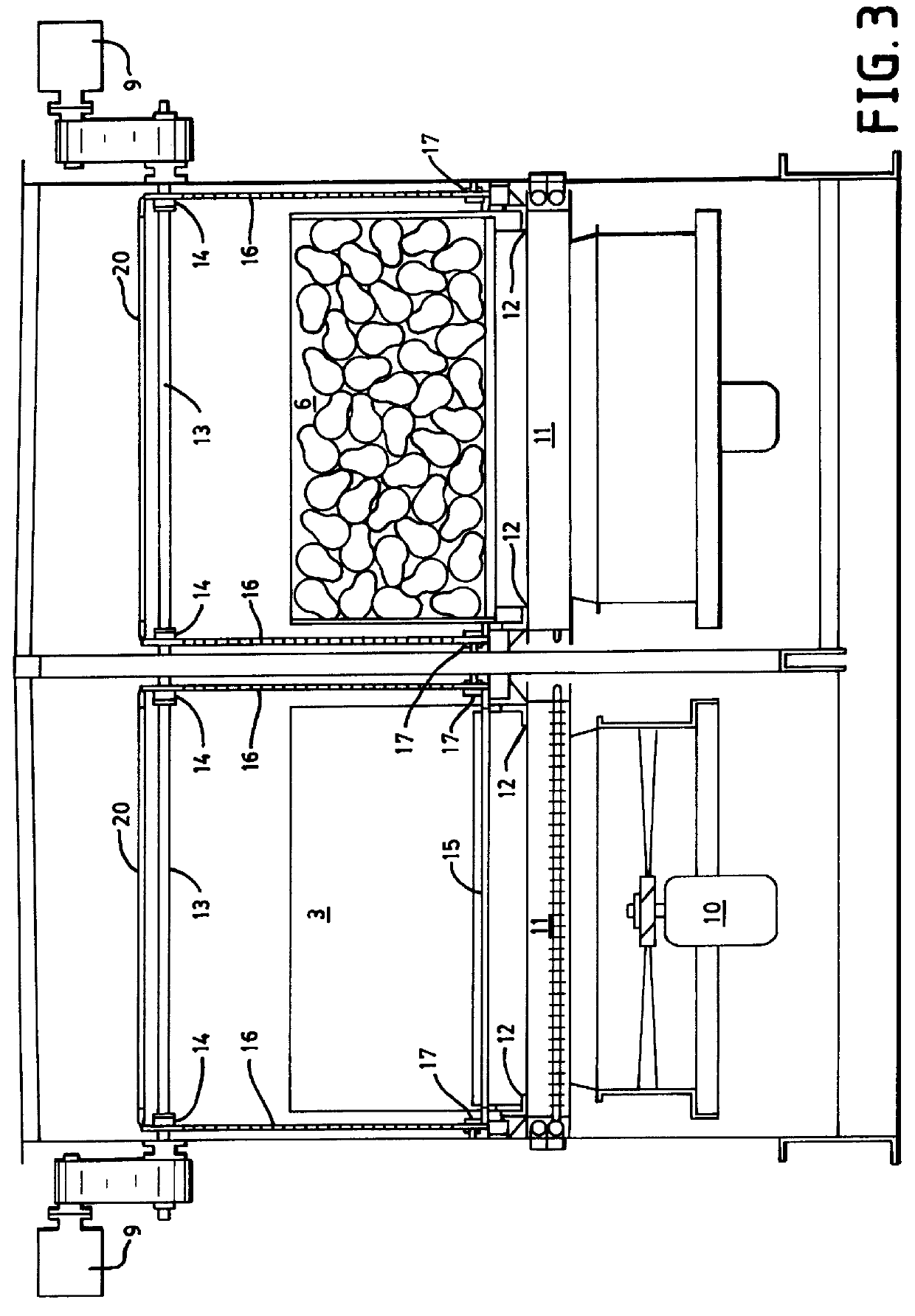

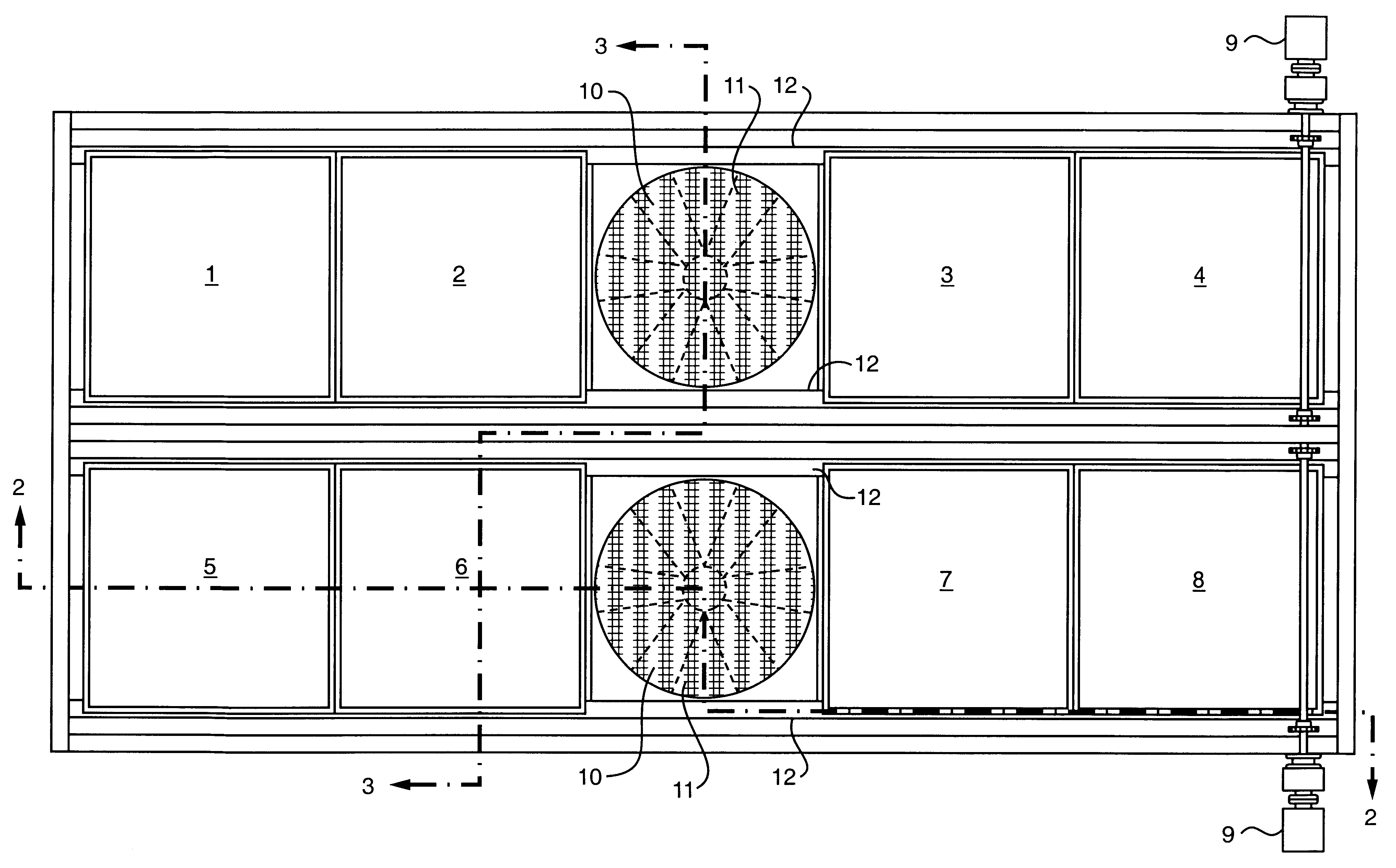

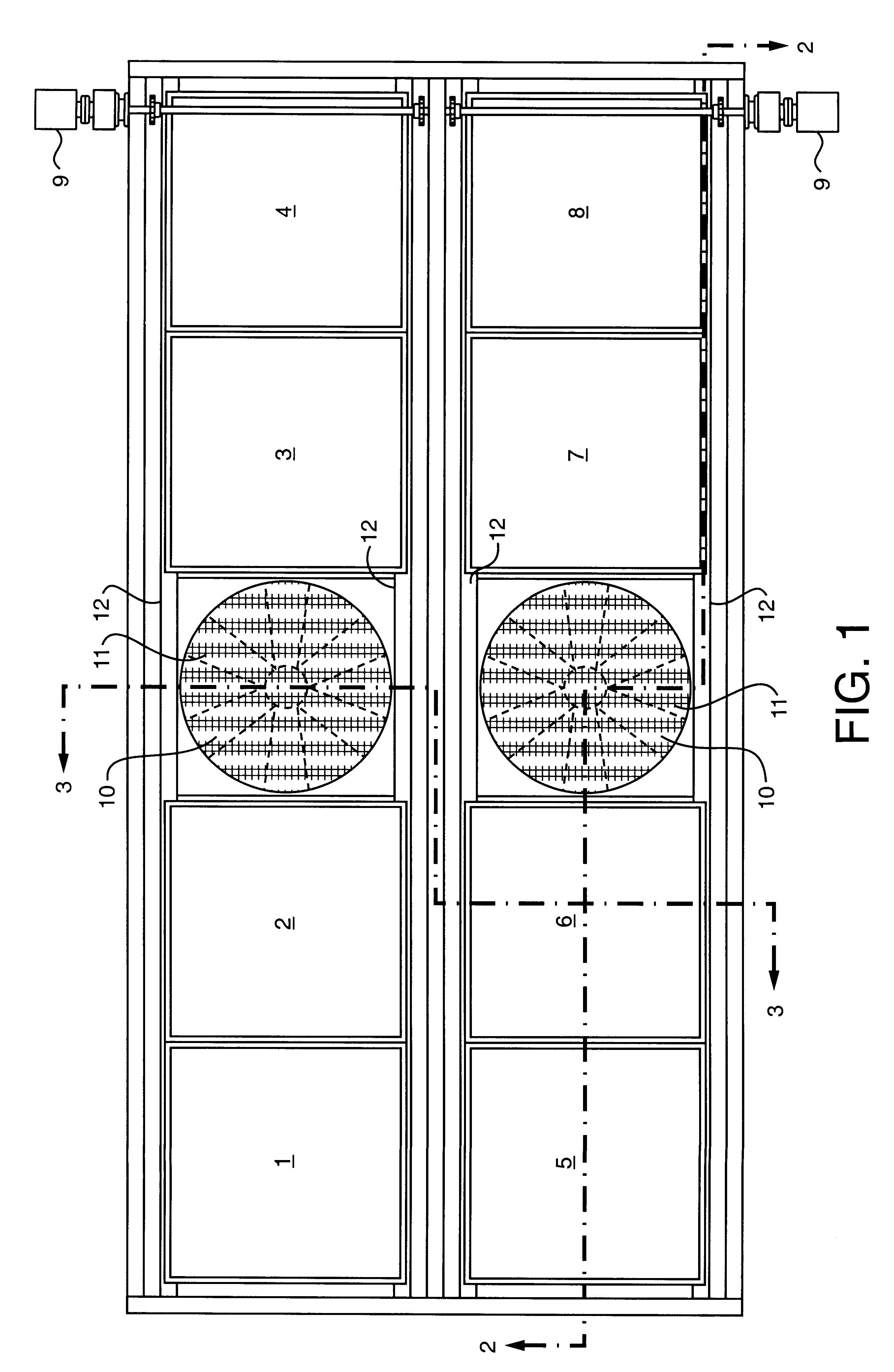

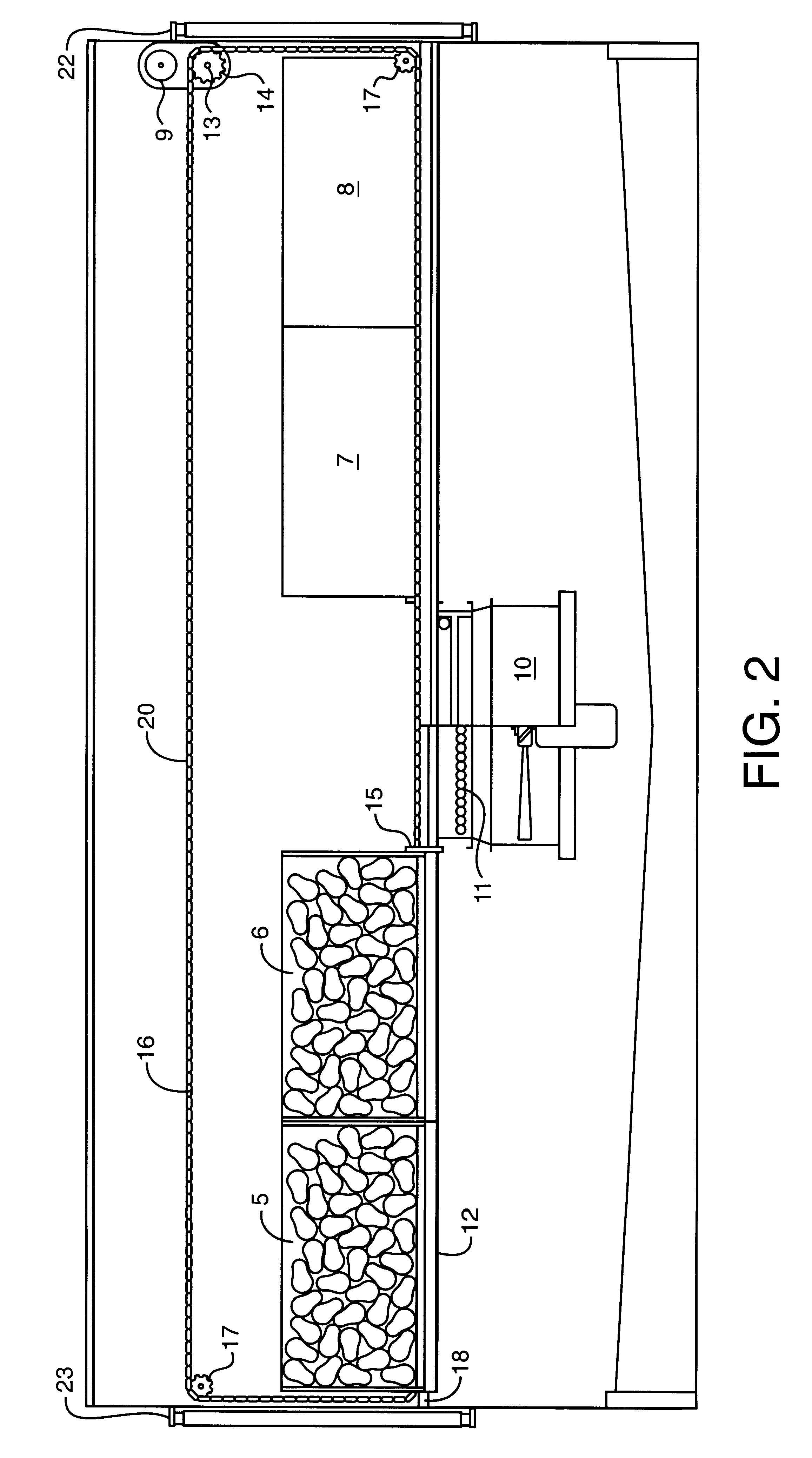

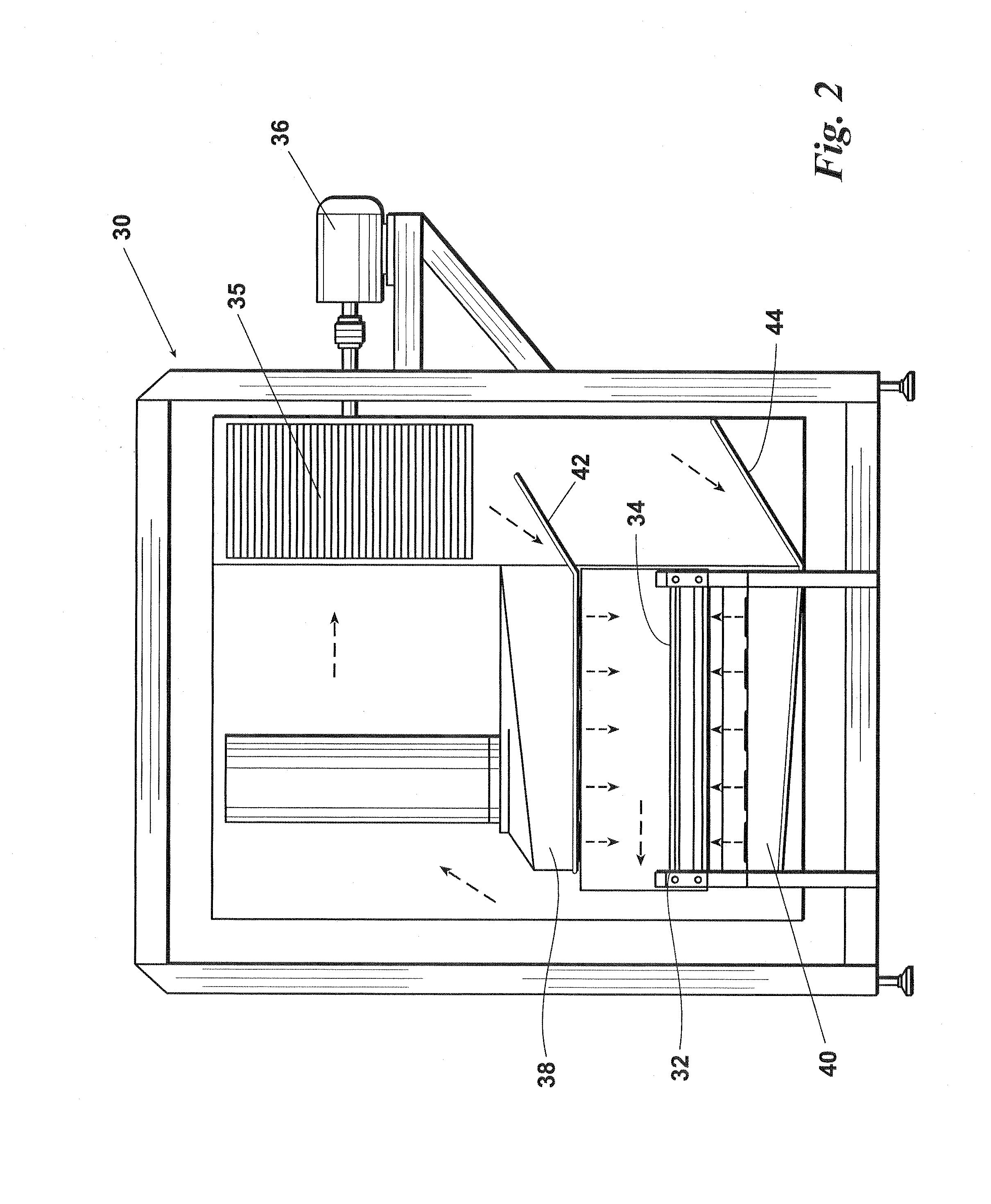

Mechanically loaded direct air circulation commodity disinfestation chamber

InactiveUS6171561B1Eliminate heat lossEliminates airflow inefficiencyFruits/vegetable preservation by heatingSeed preservation by heatingAir cycleAfter treatment

A disinfestation treatment chamber for treating fruit, flower and vegetable commodities subject to infestation by quarantine pests. The commodities are disinfested so as to meet quarantine restrictions without adversely affecting the quality of the commodity. The commodity is heated inside of the chamber in hot air having a relative humidity of 30-85% until the temperature of the commodity exceeds the thermal death point temperature of the target pest but is not so high as to adversely affect the quality of the commodity. The temperature of the commodity is held at this temperature until the pest is killed. The commodity is loaded into the treatment chamber in bins onto a low friction conveyor track system which transports the bins from one end of the chamber to the other. The commodities are treated while they are inside of the treatment chamber. After treatment of the commodities, the bins are unloaded using the low friction conveyor track system out of the opposite end of the treatment chamber. The chamber includes a fan / heat exchanger located inside the treatment chamber and positioned under the commodity bins. The space directly above the fan / heat exchanger is left unobstructed during treatment to enhance the airflow through the commodity bins.

Owner:WILLIAMSON MICHAEL R PH D

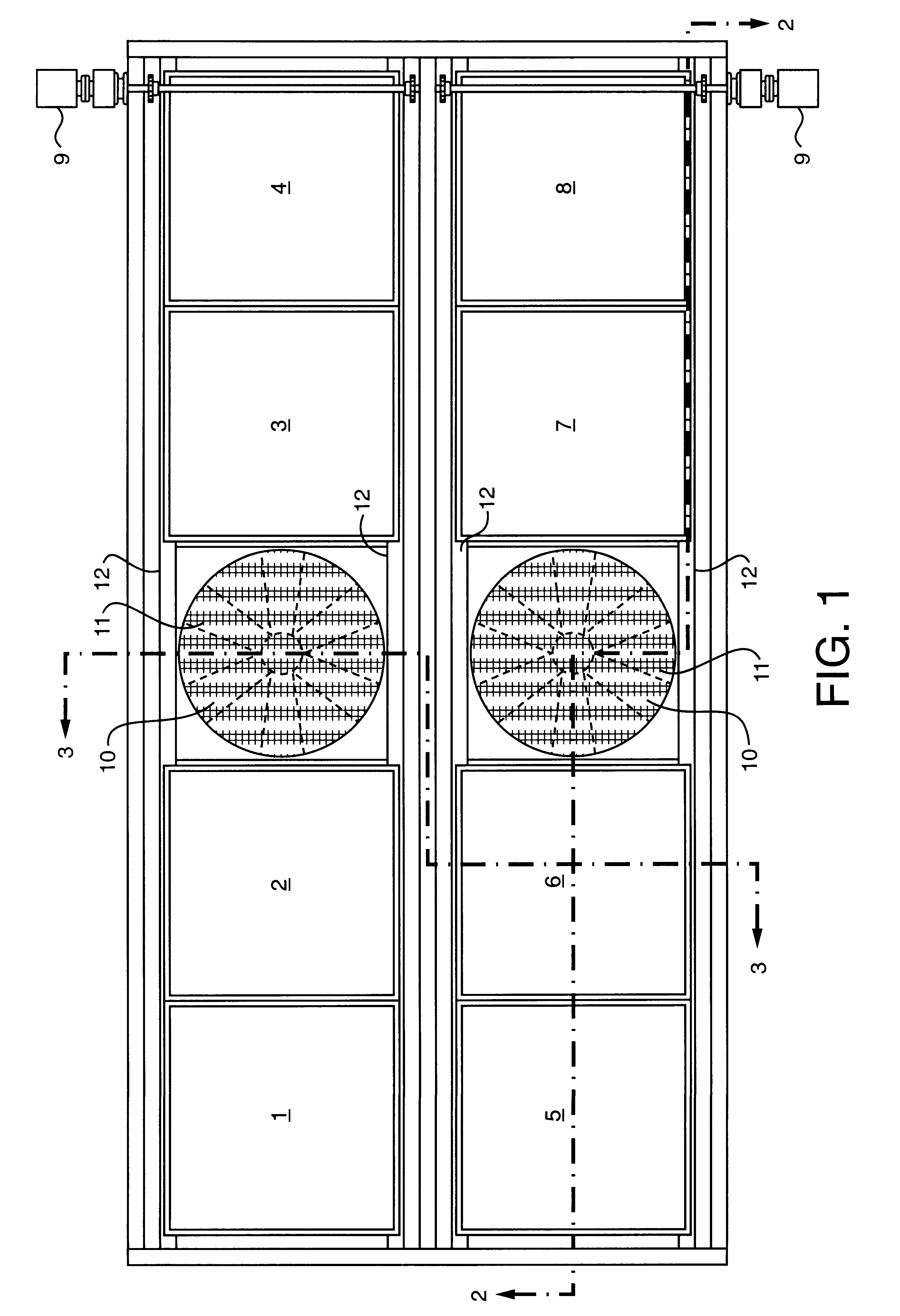

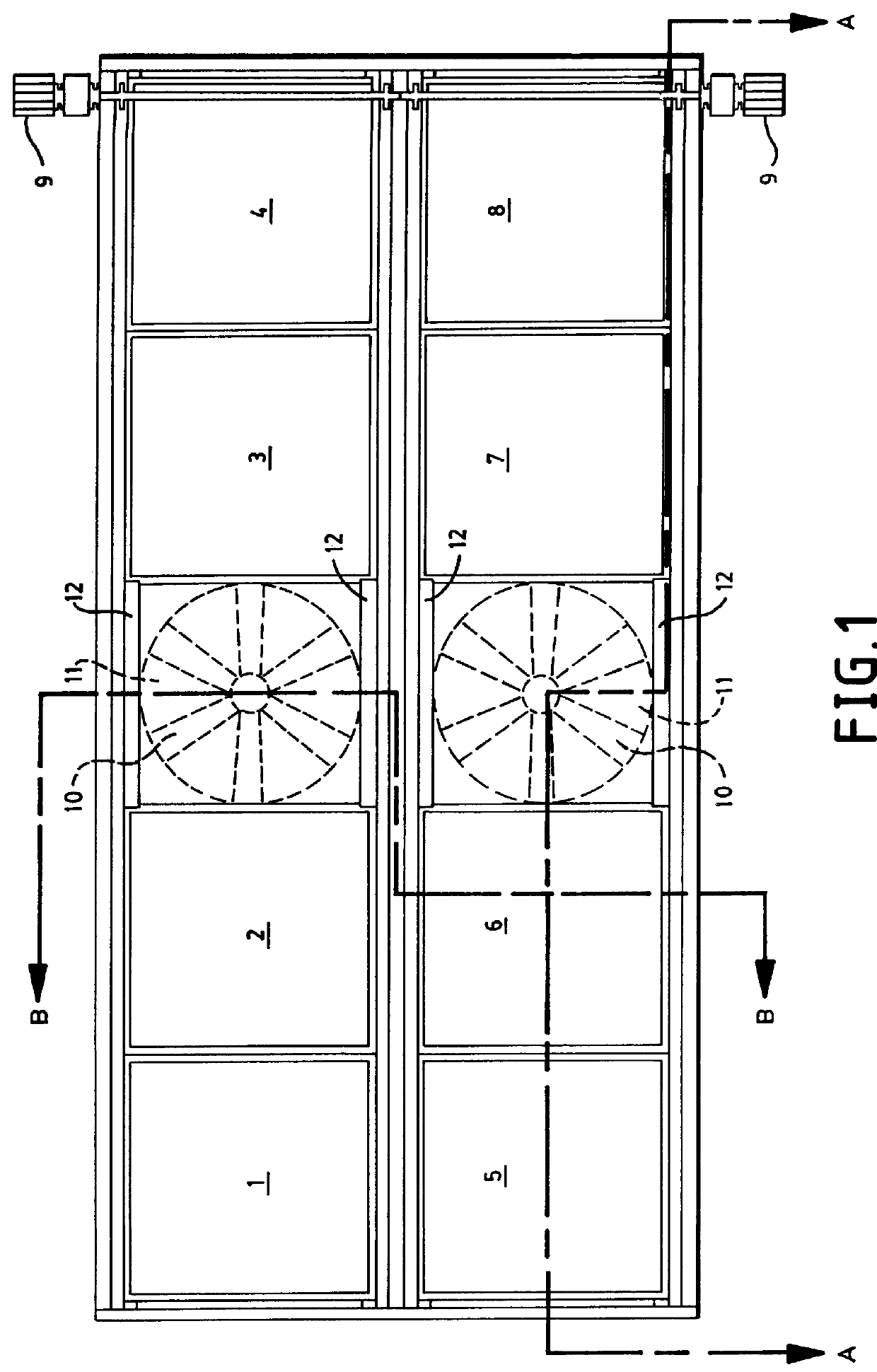

Wide body disinfestation chamber

InactiveUS6146600APrevent air leakageImprove distributionFruits/vegetable preservation by heatingSeed preservation by heatingEngineeringInfestation

A disinfestation treatment chamber for treating fruit, flower and vegetable commodities subject to infestation by quarantine pests. The commodities are disinfested so as to meet quarantine restrictions without adversely affecting the quality of the commodity. The commodity is loaded into the treatment chamber in bins onto a low friction conveyor track system which transports the bins from one end of the chamber to the other. The commodities are treated while they are inside of the treatment chamber.

Owner:WILLIAMSON MICHAEL R PH D

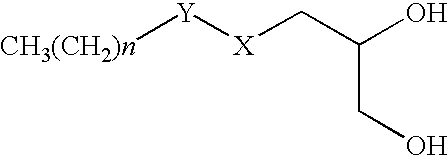

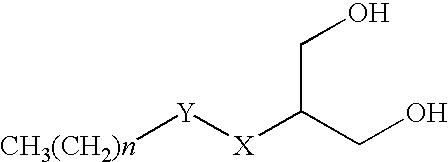

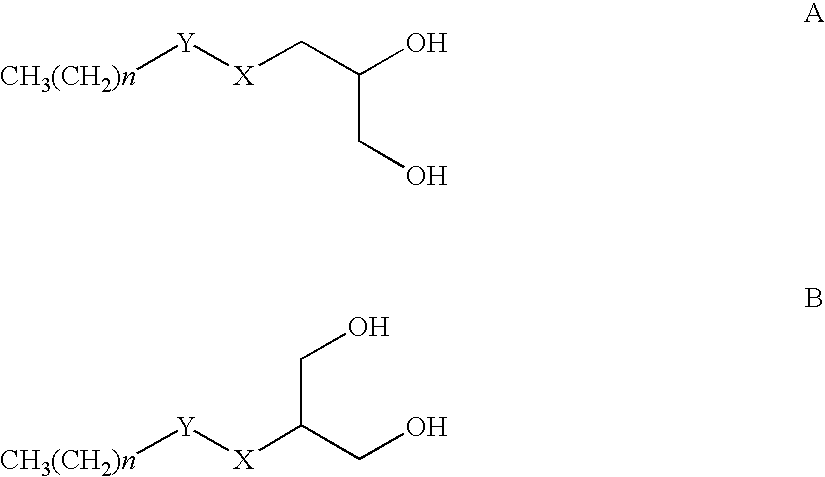

Thickened oil compositions of edible oil

InactiveUS20030099747A1Simple processAntibacterial agentsOrganic active ingredientsLong chain fatty acidChemical composition

Thickened, preferably thixotropic oil compositions are disclosed comprised of high proportions of edible oils, in particular unsaturated oils, and edible solidifying agents, in particular long chain fatty acids and / or long chain fatty alcohols, for use in the preparation of edible foods and medicinal / therapeutic products. Further disclosed are methods for the production of the thickened, thixotropic oil compositions, edible food and medicinal / therapeutic products containing same and methods of their production and consumption.

Owner:THIXO

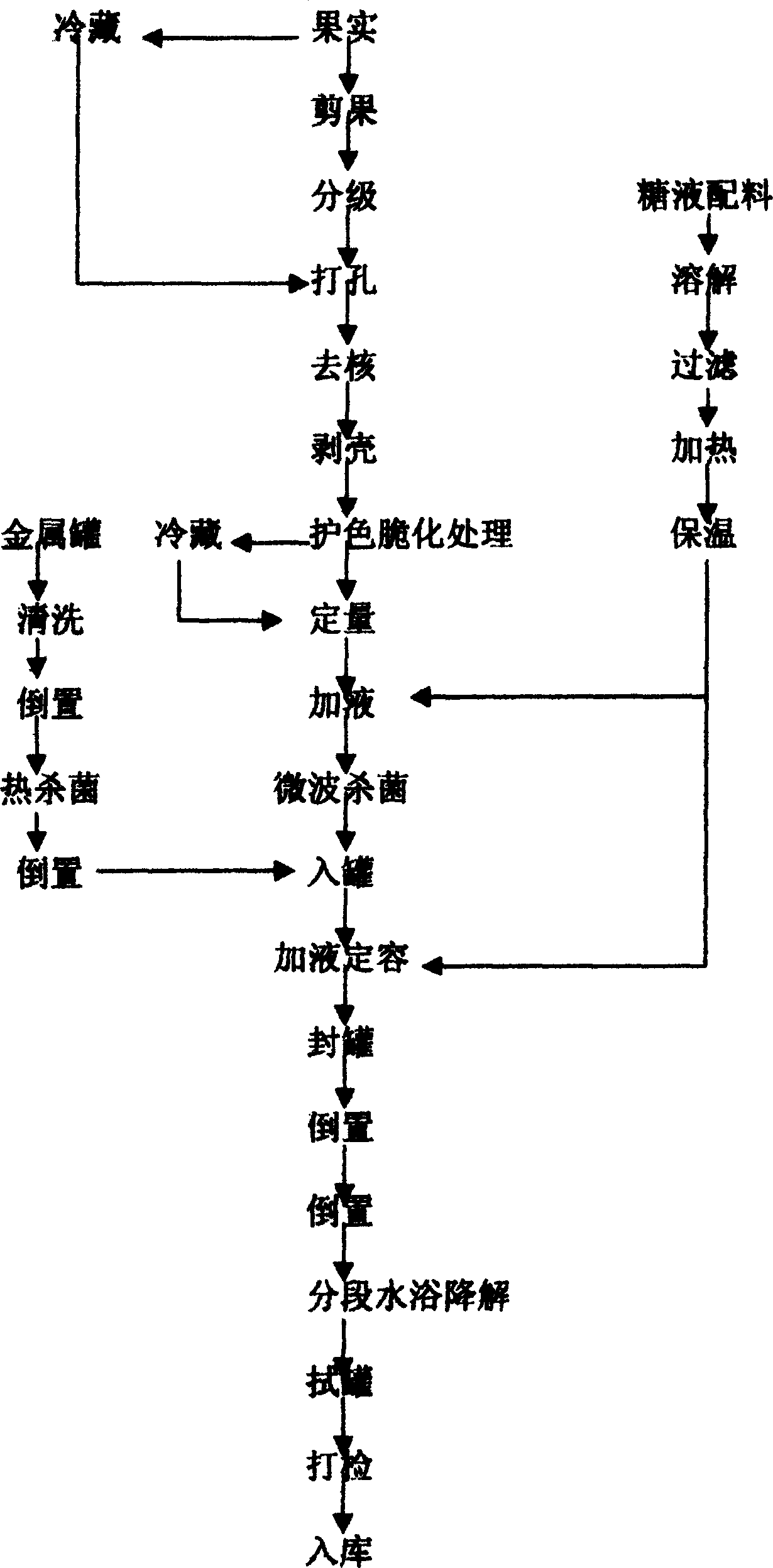

Tinned fruit production process

InactiveCN1478401AImprove completenessLess investmentFruits/vegetable preservation by heatingWater bathsTinning

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Mechanically loaded direct air circulation commodity disinfestation chamber

InactiveUS6447737B1Improve distributionAvoid lots of heatFruits/vegetable preservation by heatingSeed preservation by heatingAir cycleAgricultural science

A disinfestation treatment chamber for treating fruit, flower and vegetable commodities subject to infestation by quarantine pests. The commodities are disinfested so as to meet quarantine restrictions without adversely affecting the quality of the commodity. The commodity is heated inside of the chamber in hot air having a relative humidity of 30-85% until the temperature of the commodity exceeds the thermal death point temperature of the target pest but is not so high as to adversely affect the quality of the commodity. The temperature of the commodity is held at this temperature until the pest is killed. The commodity is loaded into the treatment chamber in bins onto a low friction conveyor track system which transports the bins from one end of the chamber to the other. The commodities are treated while they are inside of the treatment chamber. After treatment of the commodities, the bins are unloaded using the low friction conveyor track system out of the opposite end of the treatment chamber. The chamber includes a fan / heat exchanger located inside the treatment chamber and positioned under the commodity bins. The space directly above the fan / heat exchanger is left unobstructed during treatment to enhance the airflow through the commodity bins.

Owner:WILLIAMSON MICHAEL R PH D

Superheated steam blanching method for improving quality of quick freezing edible fungi

InactiveCN101513209APromote passivationComplete passivationFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingQuick FreezeBiotechnology

The invention provides a superheated steam blanching method for improving the quality of quick freezing edible fungi which belongs to the edible fungi processing technical field and relates to the quick freezing processing of the edible fungi. The invention provides the application of superheated steam technology in the quick freezing processing of the edible fungi. The key technology is to utilize superheated steam for the blanching of the edible fungi. The process comprises edible fungi raw material selecting, cleaning, grading, blanching, quick freezing, packaging and frozen storing. The superheated steam has the characteristics of high temperature, oxygen-free property and low water content. Therefore, the superheated steam can passivate enzyme contained in the edible fungi raw material rapidly and thoroughly and achieve the effect of proper dehydration through the regulation of technological parameters. Thus, the proper water content of quick freezing edible fungi products is maintained. The superheated steam blanching method has the advantages of convenient operation, reliable operation and high production efficiency. The whole process has no escape of nutrients and lowers the quality deterioration of the processing process to the maximum extent, thereby obviously improving the quality of the quick freezing edible fungi products to reach to the longer high quality shelf-life.

Owner:JIANGNAN UNIV

Method for protecting color of burdock and refreshing burdock

InactiveCN102150703AMaintain colorNo loss of nutritionFruits/vegetable preservation by heatingBrowning reactionRaw material

The invention relates to a method for simply protecting color of a burdock product and refreshing the burdock product. With burdock as a raw material, the better burdock product with better color-protecting and refreshing effects is obtained through steps of removing skins in water, hot-ironing, cutting, socking in color-protecting liquid, packaging and the like. Finally, bagged products keep better color and texture within 40 days, canned products can keep better color and texture within about 2 months; and industrialized production can be carried out. The invention has the advantages of simple operation conditions, reliable method and good color-protecting and refreshing effects, and can effectively inhibit browning reaction of the burdock, generated in the processing process.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Curable resin composition for sealing LED element

InactiveUS20060229408A1Improve adhesionExcellent level of heatDrying solid materials with heatMeat/fish preservation by heatingOptical transparencyHeat resistance

A curable resin composition for sealing an LED element is provided. The composition includes (i) an organopolysiloxane with a polystyrene equivalent weight average molecular weight of at least 5×103, (ii) a condensation catalyst, (iii) a solvent, and (iv) a finely powdered inorganic filler. It is suited to formation of a coating film or the like with excellent heat resistance, ultraviolet light resistance, optical transparency, toughness and adhesion, and is ideal for applications such as the sealing of LED elements.

Owner:SHIN ETSU CHEM IND CO LTD

Fresh-keeping method for lichee

InactiveCN1965660AHas antibacterial propertiesImprove ventilation and water permeabilityFruits/vegetable preservation by heatingFruits/vegetable preservation by coatingSulfurEngineering

The invention relates to an antiseptic method of leechee, wherein the invention uses antiseptic polypropylene non-woven cloth, to prepare different fresh-keeping bags, and packs dibutyl fumarate into common non-woven cloth to prepare the non-woven package, while the mass ratio between leechee and fresh agent is 10000:0.1-2; then putts leechee into the fresh-keeping bags, uses lines to tie the bag or uses thermal method to seal the bag, putts into ventilate package box, or putts packed leechee into bamboo frame to be put into fresh-keeping bag. The invention can store leechee at 0-5Deg. C for 30-35days. When the leechee is treated with sulfur, the leechee can be stored at 0-5Deg. C for 90-100day.

Owner:SOUTH CHINA UNIV OF TECH

Premium Quality Refrigerated Vegetable Products and Methods of Making Them

InactiveUS20130183420A1Obstruct passageIncrease storage spaceMilk preservationFruits/vegetable preservation by heatingMedicineAdditive ingredient

The disclosure relates to methods of treating whole, cut, or other processed botanical ingredient(s) in a manner that reduces the load of viable food-contaminating organisms (human or other animal pathogens and food spoilage organisms), preferably without substantially altering one or more of the organoleptic properties of the ingredient(s). The method includes subjecting a botanical foodstuff to a high pressure processing (HPP) treatment and to aseptically sealing the foodstuff within a package that contains a microbistat. Such treatments improve the storage stability of the foodstuff and preferably do not significantly alter one or more organoleptic properties of the botanical ingredient(s). Packaged foodstuffs treated as described herein exhibit beneficial properties, such as retention of taste, appearance, and texture and extended shelf life, relative to non-treated foodstuffs.

Owner:DEL MONTE FOODS

High fiber and ready-to-serve, ambient stable fruit-based composition

High fiber and ambient stable fruit-based compositions are described. The compositions are ready-to-eat, low in fat and suitable to be beverages, fillings, dips, sauces, spreads or dressings. The compositions have less than 20.0 ppm of extracellular terminal unsaturated ester.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

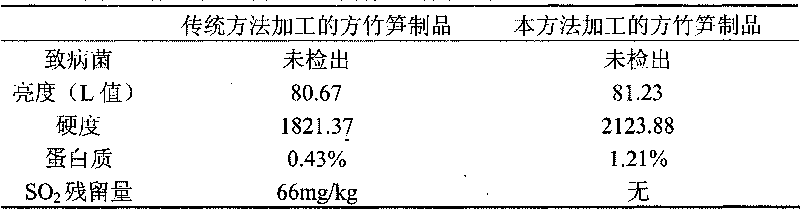

Processing method of flexible package fresh bamboo shoots

InactiveCN101731312APreserve the flavorRetain nutrientsFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingVitamin CEngineering

The invention belongs to the technical field of agricultural and sideline product processing, in particular to a processing method of flexible package fresh bamboo shoots, comprising the specific technological processes: sorting, cleaning / tidying, blanching (killing out), cooling, screening, adding preservative, vacuum packaging, sterilizing, cooling and obtaining finished products. Compared with the current processing method in the market, the invention has unique technology and adopts a sulphur-free formula; the prepared flexible package fresh bamboo shoot has the advantages of high quality, high safety, convenient eating, small loss of vitamin C, convenient storage and transportation, long quality guarantee period (12 months for refrigeration, and 6 months for normal temperature) and the like. The flexible package fresh bamboo shoot prepared with the invention improves the economy of bamboo shoots and is suitable for diversifying consumer demand at present.

Owner:JIANGNAN UNIV

Method for preparing dry day-lily buds

InactiveCN101911963AIncrease powerIncrease productionFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationFlavorFood additive

The invention discloses a method for preparing dry day-lily buds. The method comprises the following steps of: fixing day-lily buds; removing green from the day-lily buds, roasting and / or airing the day-lily buds; inspecting the dry day-lily buds; packaging the inspected dry day-lily buds; and putting the packaged dry day-lily buds in storage. The method is characterized in that: the fixing step comprises the following specific steps of: scattering picked fresh day-lily buds on a steaming sieve, wherein scattering thickness is between 150 and 200 millimeters; racking the steaming sieve; pushing the steaming sieve into a steam box; introducing steam into the steam box; controlling temperature in the steam box to be between 50 and 65 DEG C; steaming for 5 to 8 minutes; and opening the door of the steam box to take the steaming sieve out. Compared with the prior art, the method has the advantages that: 1) any food additive does not need to be added in a fixing process and the dry day-lily buds have a natural color, natural taste, natural flavor and sweet taste; 2) day-lily bud drying rate is increased by 2 percent by steam fixation and the growth rate of market prices is increased by 13 percent; and 3) the day-lily buds processed by the steam fixation are accordant with food quality standard, do not cause any pollution, are truly green food and are well appreciated by customers.

Owner:湖南吉祥食品有限公司

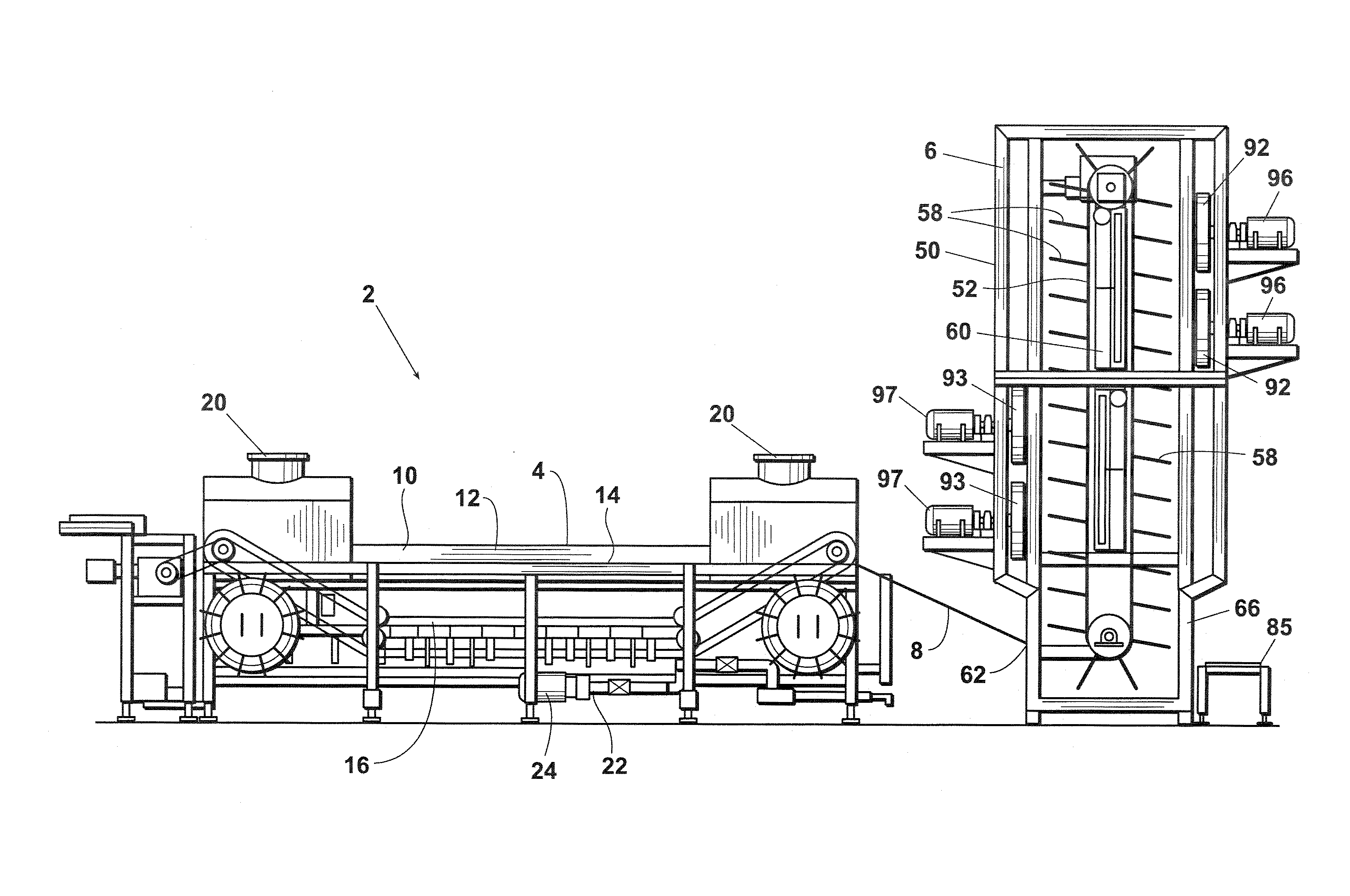

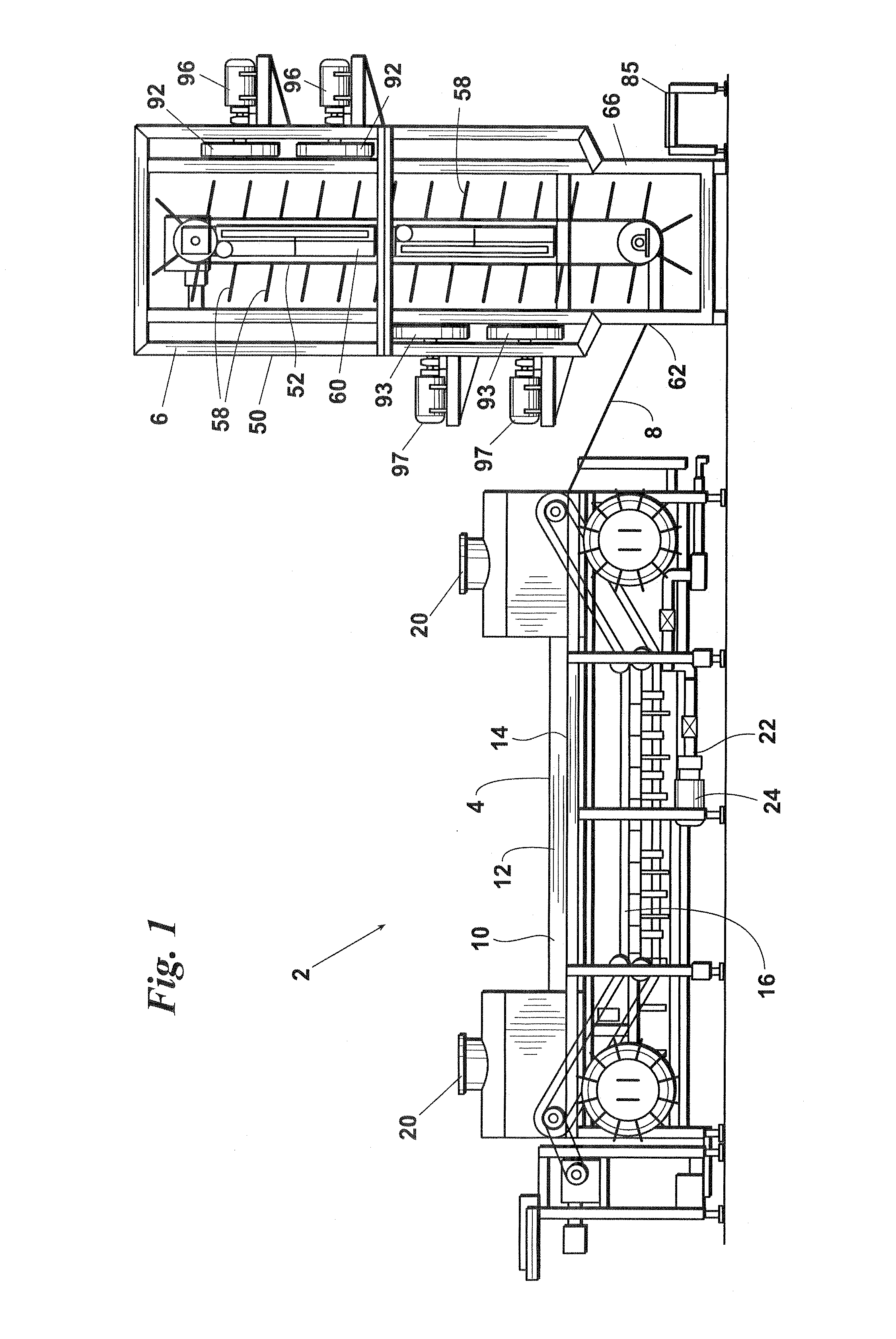

Surface pasteurization of cooked food products

InactiveUS7285299B1Satisfies needReduce decreaseReady-for-oven doughsMilk preservationProcess engineeringPasteurization

A method of surface pasteurizing precooked food products which are contained in packages. The method preferably comprises the steps of continuously heating the packages of the precooked food product such that the outer surfaces of the products contained within the packages are taken to an effective pasteurization temperature and then continuously cooling the packages of product. The heating and cooling steps are preferably conducted in a manner such that no more than a 10° temperature increase and preferably substantially no temperature increase occurs in the internal core of the product as a result of the heating step.

Owner:UNITHERM FOOD SYST LLC

Color protection preservation method of poached green leaf vegetable instant product

InactiveCN102919338AMaintain colorInhibit enzyme activityFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingSucrosePotato starch

The invention discloses a color protection preservation method of a poached green leaf vegetable instant product, belonging to the field of fruit / vegetable food processing. The method mainly comprises the following steps of: performing pretreatment, blanching for enzyme deactivation and vacuum infiltration soaking with a color protection and crisp protection agent (sodium alginate, calcium chloride, potato starch and zinc gluconate) of the green leaf vegetable; and performing secondary color protection preservation soaking by use of the color protection preservation liquid consisting of table salt, edible glycerin, sodium carboxymethylcellulose and sucrose ester. The method reduces the color protection preservation cost, and improves the color of the poached green leaf vegetable product stored in normal-temperature condition. The nano ZnO antibacterial liquid (in which a sodium hexametaphosphate dispersion protector with concentration of 0.015% is added) is subjected to vacuum packing and low-frequency (915MHz) microwave uniform sterilization. The storage temperature is normal temperature. Through the invention, good color and fresh degree of the poached green leaf vegetable instant product are kept in the normal-temperature storage period.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

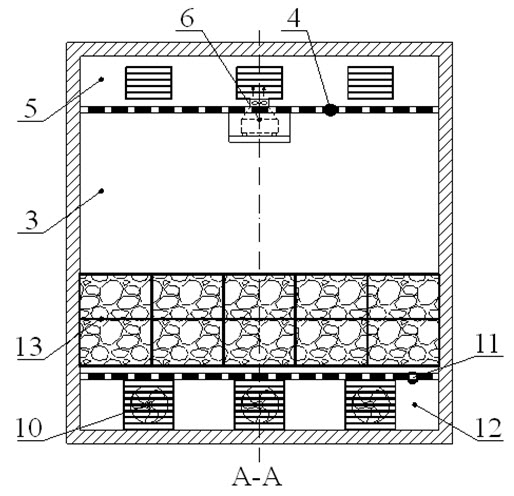

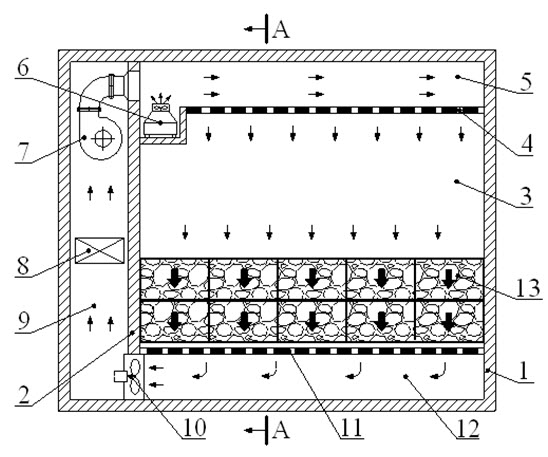

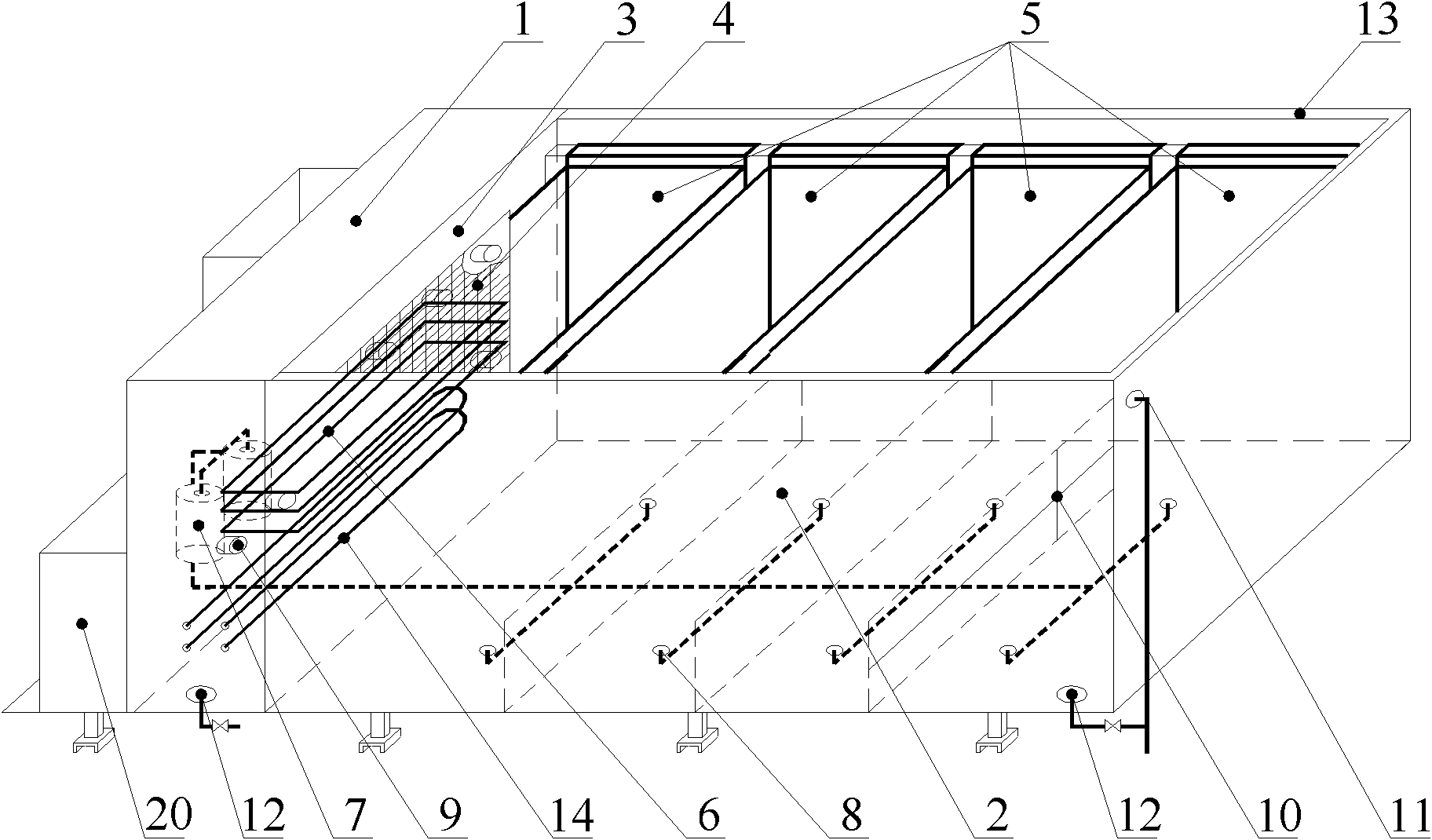

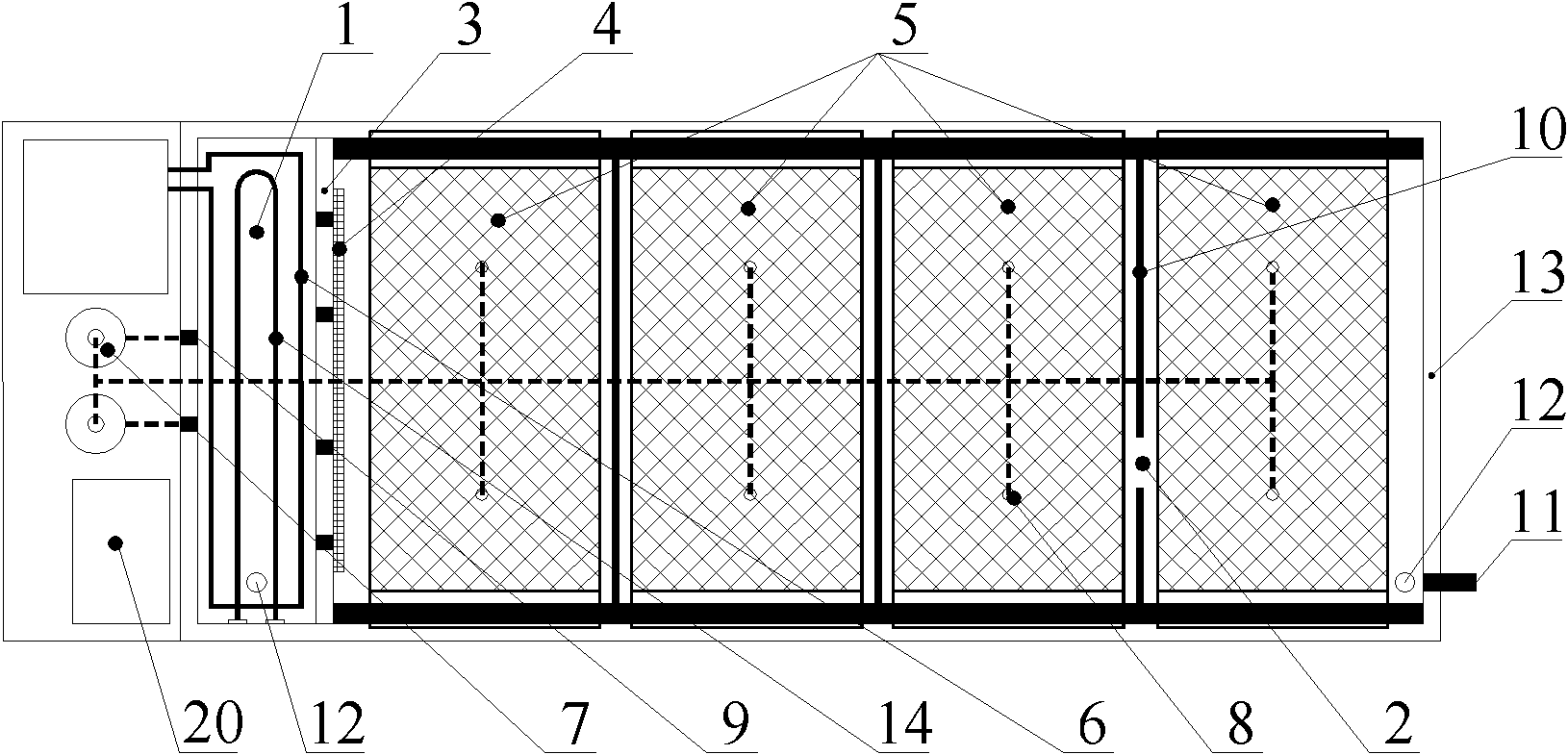

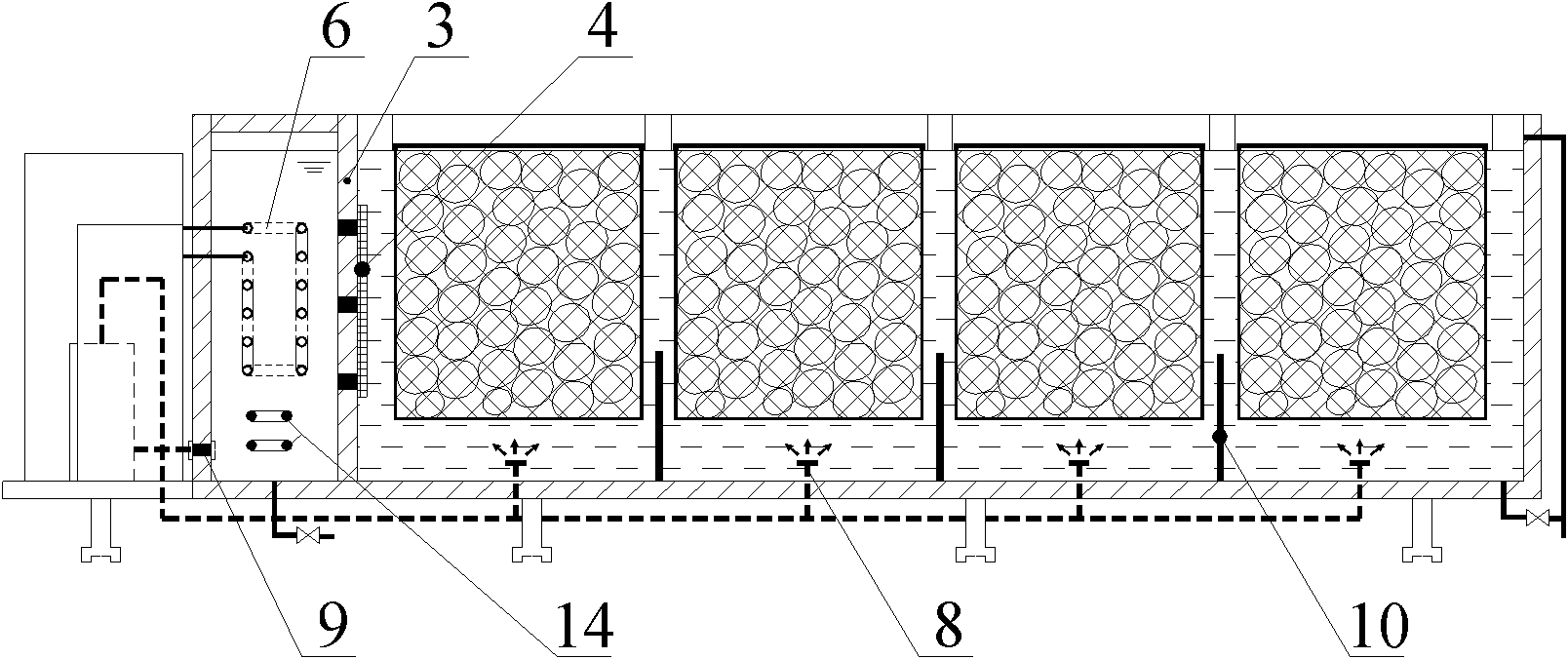

Heat pump type pressure gradient fruit vegetable heat treatment library

ActiveCN101919436AReduce heat treatment energy consumptionShorten the timeFood processingFruits/vegetable preservation by heatingThermodynamicsAir treatment

The invention discloses a heat pump type pressure gradient fruit vegetable heat treatment library. The library is composed of a library entry, a heat pump system, a circulation air system and a humidifying system, the library entry is divided into four parts of air treatment, air supply plenum, fruit vegetable heat treatment and return air plenum. The upper end and the lower end of the clapboard are respectively provided with three centrifugal fans and three pressure gradient fans, an air supply homogenizing plate and a return air floor plate are respectively arranged at the upper part and the lower part in the library, and a fruit vegetable heat treatment chamber is formed between the two plates. An air supply plenum chamber is formed between the air supply homogenizing plate and the upper top wall of the library entry, and a return air plenum chamber is formed between the return air floor plate and the lower bottom of the library entry. The condenser of the heat pump system is arranged in an air treatment chamber, a centrifugal humidifier is arranged above the right side of the clapboard, and the return air floor plate is placed with a fruit vegetable box. Pressure gradient air supply is adopted, so that treatment time can be reduced. The invention adopts heat pump heat source, the heat pump can supply 3-5 units of heat into the library while a compressor consumes every 1 unit electricity; compared with the electric heating method, fruit vegetable heat treatment energy consumption can be obviously reduced, and energy conservation effect of the system is obvious.

Owner:TIANJIN UNIV

Method for pickling leaf mustard

InactiveCN100998395AQuality improvementSuitable for saltyFruits/vegetable preservation by heatingFood preparationWater contentLactobacillus plantarum

A method for salting leaf-type mustard with short period decreased from 2-3 months to 12 days or less includes such steps as dewatering fresh mustard, proportionally adding edible salt, kneading, adding the liquid containing lactobacillus plantarum and cheese lactobacillus, mixing, and laying aside.

Owner:熊新安

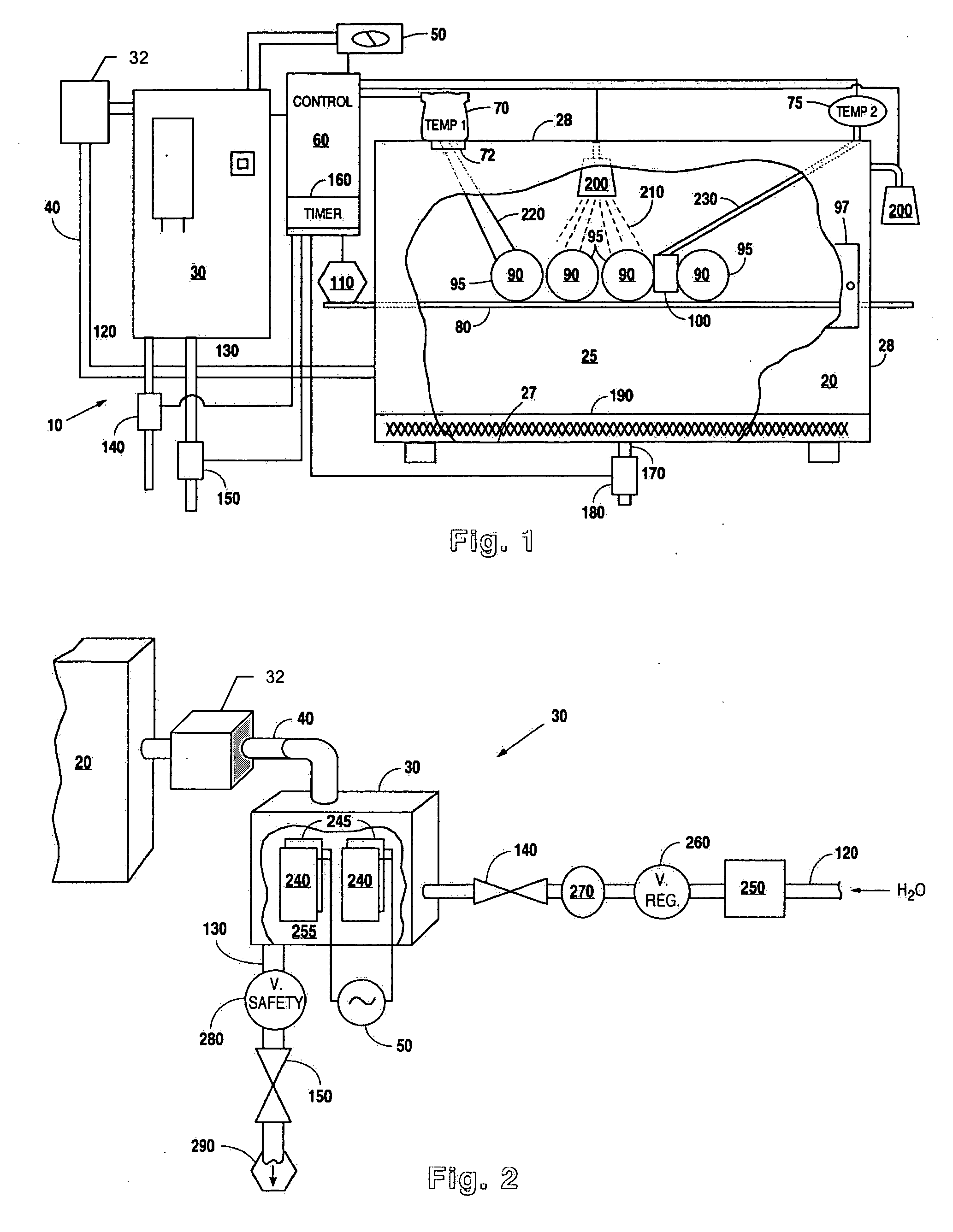

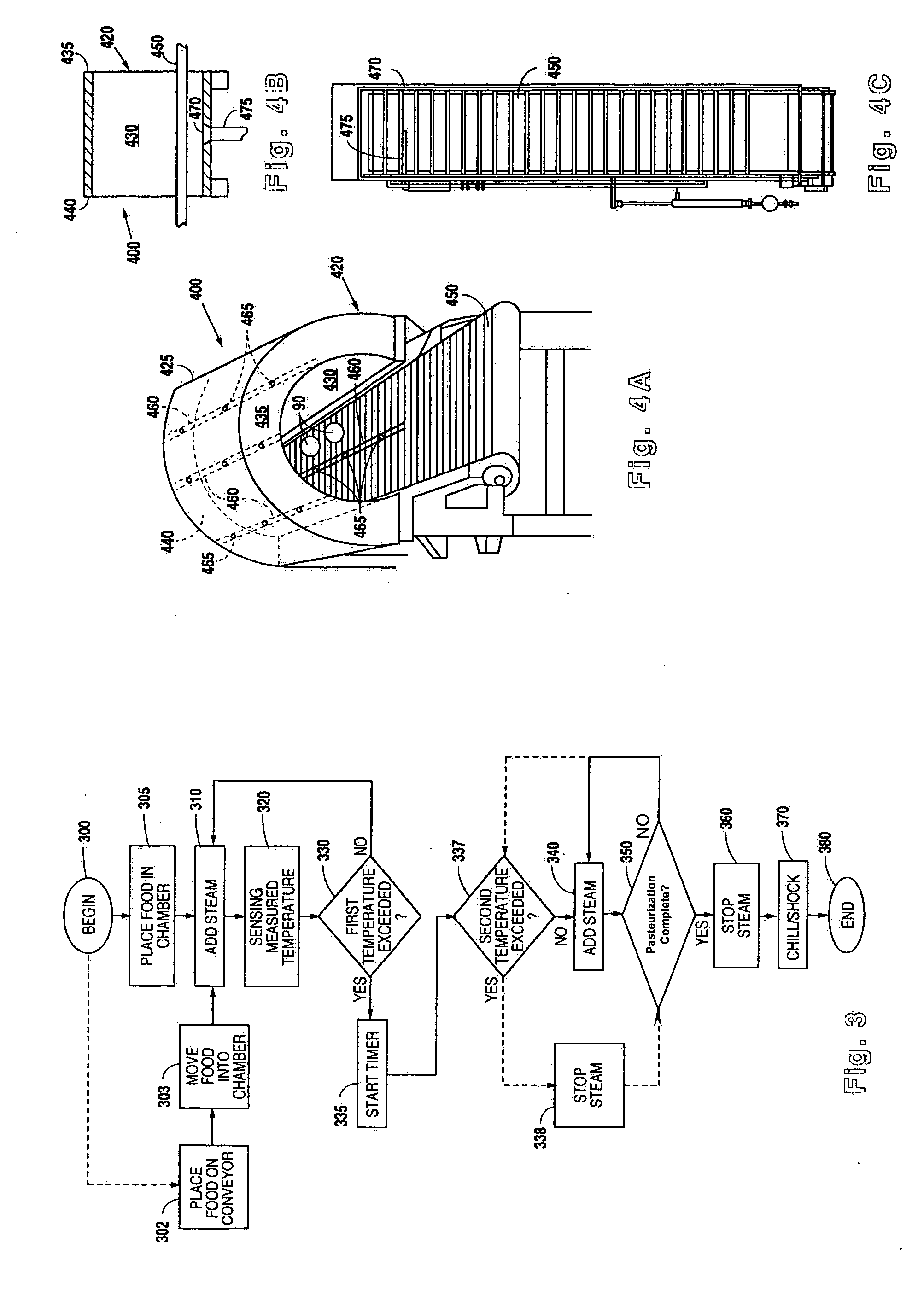

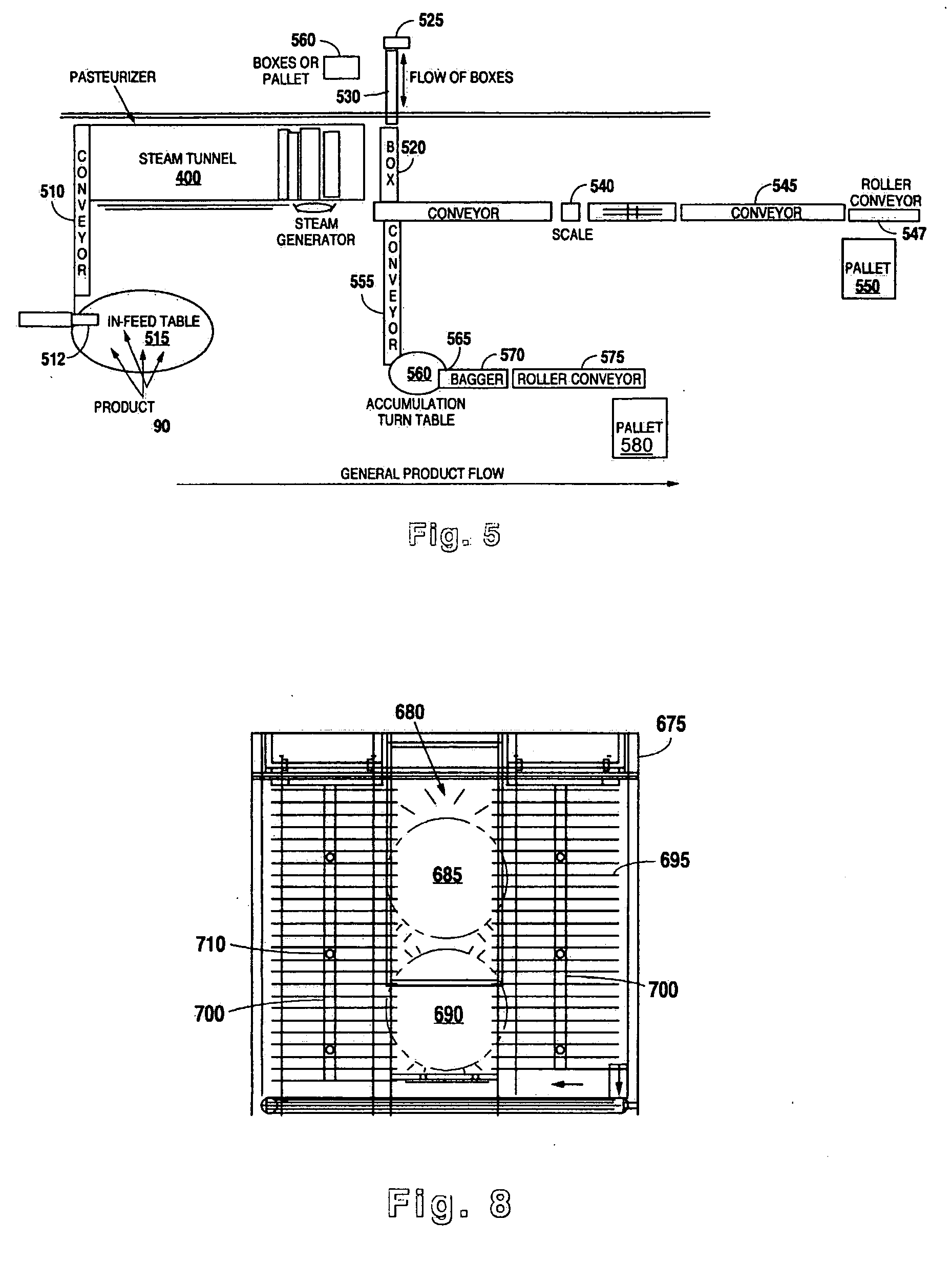

Apparatus and method for microbial intervention and pasteurization of food and equipment

InactiveUS20050112255A1Reduce exposure timeLess time to cookMeat/fish preservation by heatingFruits/vegetable preservation by heatingEngineeringSuperheater

The present invention discloses an apparatus and method for microbial intervention and pasteurization of food or equipment comprising a chamber, steam generator, superheater, controller, timer, power source, and temperature sensor. The temperature sensor and timer control exposure of the food or equipment to the superheated steam. After steam application, the food or equipment may be bathed by a chilled water source. The method for microbial intervention and pasteurization of the food and / or equipment surface includes: placing food or equipment in the chamber, adding superheated steam to the chamber until the surface temperature of the food or equipment is greater than a first preselected temperature, and maintaining the surface temperature by the continued application of superheated steam until the surface temperature is greater than a second preselected temperature.

Owner:TOTTENHAM DENNIS E +1

Production method of instant black fungus

InactiveCN101396043APositive and pronounced flavorDeliciousFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingFlavorAdditive ingredient

The invention provides a preparation method used for instant auricularia auricula, comprising the steps as follows: auricularia auricula is washed; subsequently, the washed auricularia auricula is dried and sterilized in drying and sterilizing equipment so as to lead the weight of water attached to the auricularia auricula to be reduced to below 15% of total weight of the auricularia auricula; subsequently, the auricularia auricula and edible condiment juice are filled in a packaging bag; finally, a vacuum sealing method is used to seal the auricularia auricula and the edible condiment juice in the packaging bag; in the packaging bag, the auricularia auricula is pickled in the edible condiment juice for at least 1-10 hours. The instant auricularia auricula prepared by the preparation method has fresh flavor and good taste; the instant auricularia auricula can be convenient to be eaten by opening the bag and can keep natural taste and nutrient composition.

Owner:吕冰洁

Color protection fresh keeping method of fresh cut tuber

InactiveCN101518279AGood color protectionLow costFruits/vegetable preservation by heatingFood preparationSugarPlant Tubers

The invention discloses a color protection fresh keeping method of fresh cut tubers, which belongs to the technical field of fruit and vegetable fresh keeping. After being peeled, sliced, soaked by color protecting liquid, blanched, soaked by sugar, drained and packed, sampled fresh or stored tuber raw materials are refrigerated without suffering from browning reaction. The invention is easy to operate, has short period and can be widely used for keeping fresh cut vegetable fresh, such as potatoes, sweet potatoes, yams, and the like which are prone to browning reaction and provides a new thought for increasing the edible safety of clean tuber vegetables and extending the shelf life of products.

Owner:CHINA AGRI UNIV

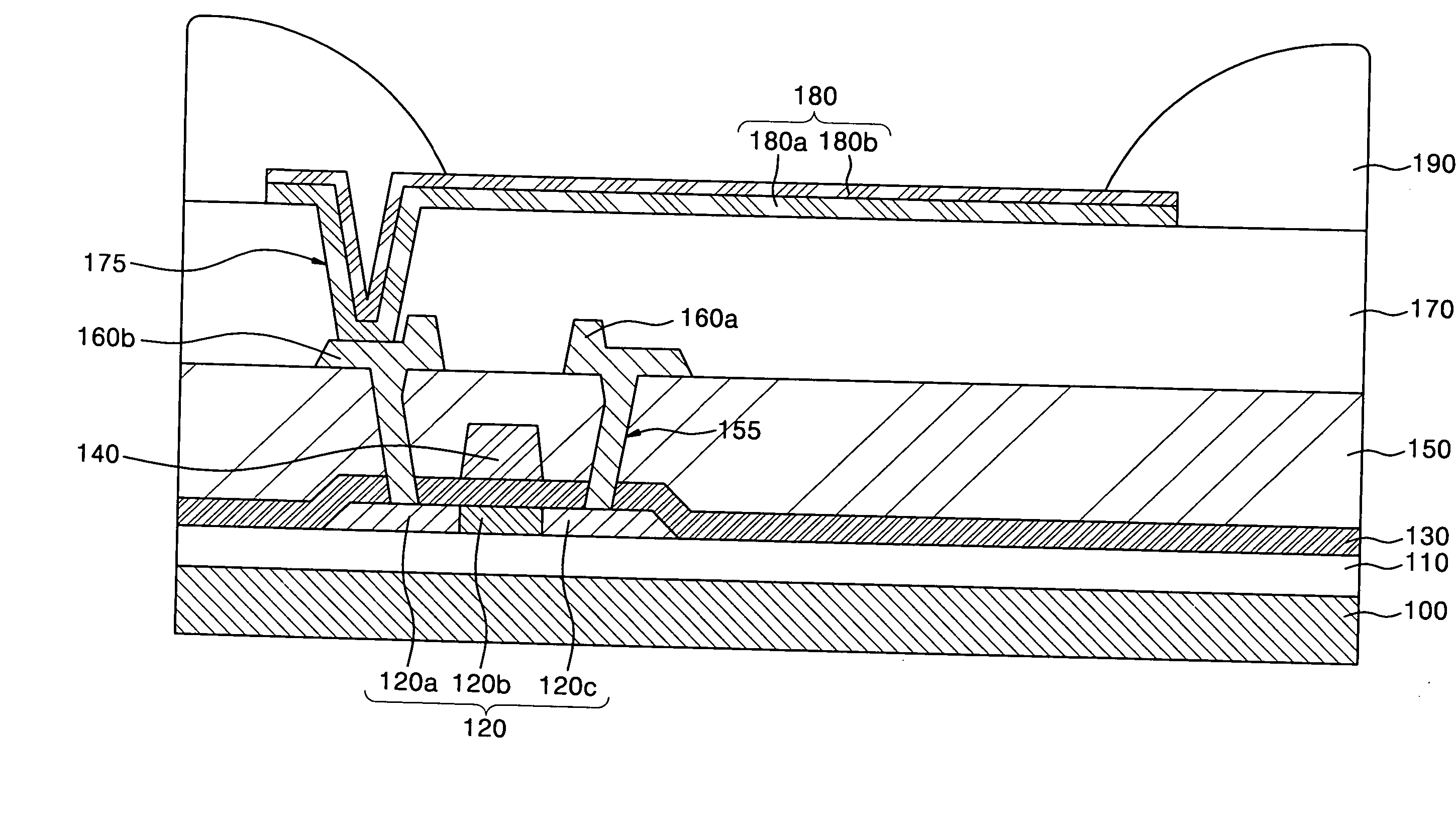

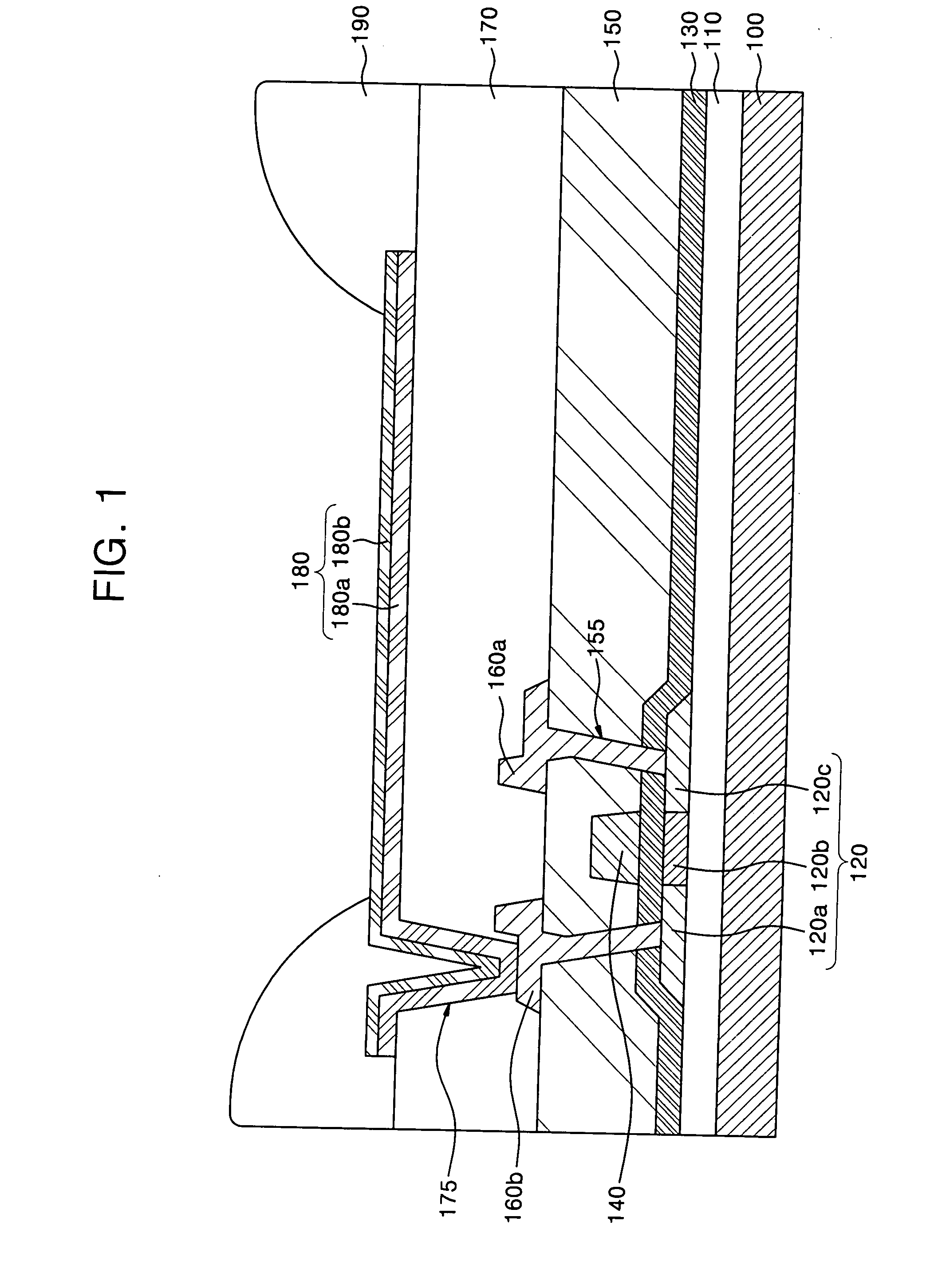

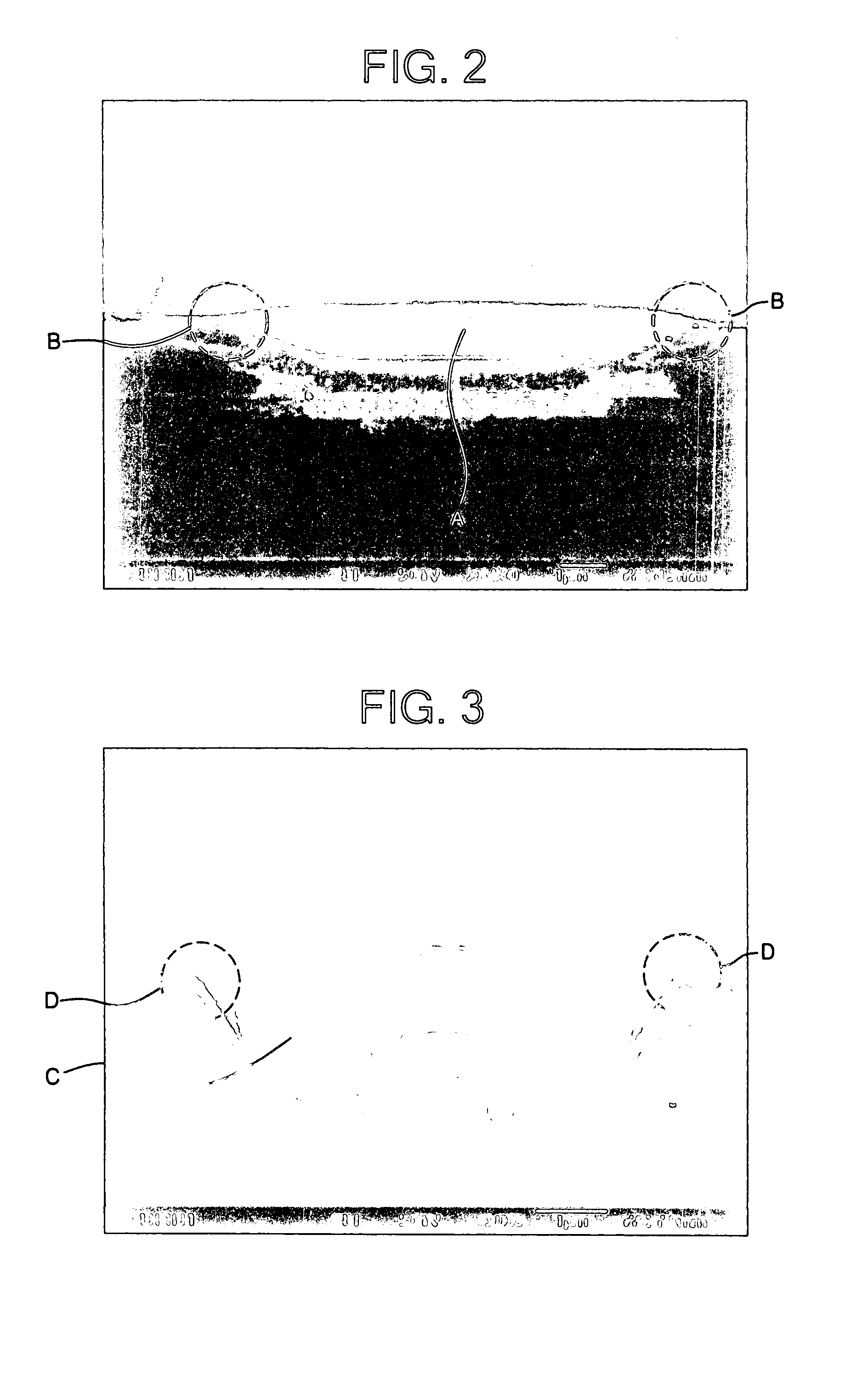

Organic light emitting display device and method of fabricating the same

ActiveUS20070257253A1Increase (or maximize) transfer efficiencyImprove transmission efficiencyMeat/fish preservation by heatingFruits/vegetable preservation by heatingDisplay deviceOrganic layer

An organic light emitting display device and a method of fabricating the same are provided. A trench is formed in a planarization layer, and then a first electrode is formed to have opposite ends in the trench, thereby reducing a height difference between the planarization layer and the first electrode. That is, the thickness of a pixel defining layer formed on the first electrode may be reduced by reducing or minimizing protrusion of the first electrode with respect to the planarization layer. Thus, transfer efficiency can be increased when an organic layer is formed by a laser induced thermal imaging method, and reliability of a device can be improved by reducing or preventing thermal damage of the organic layer and open defects.

Owner:SAMSUNG DISPLAY CO LTD

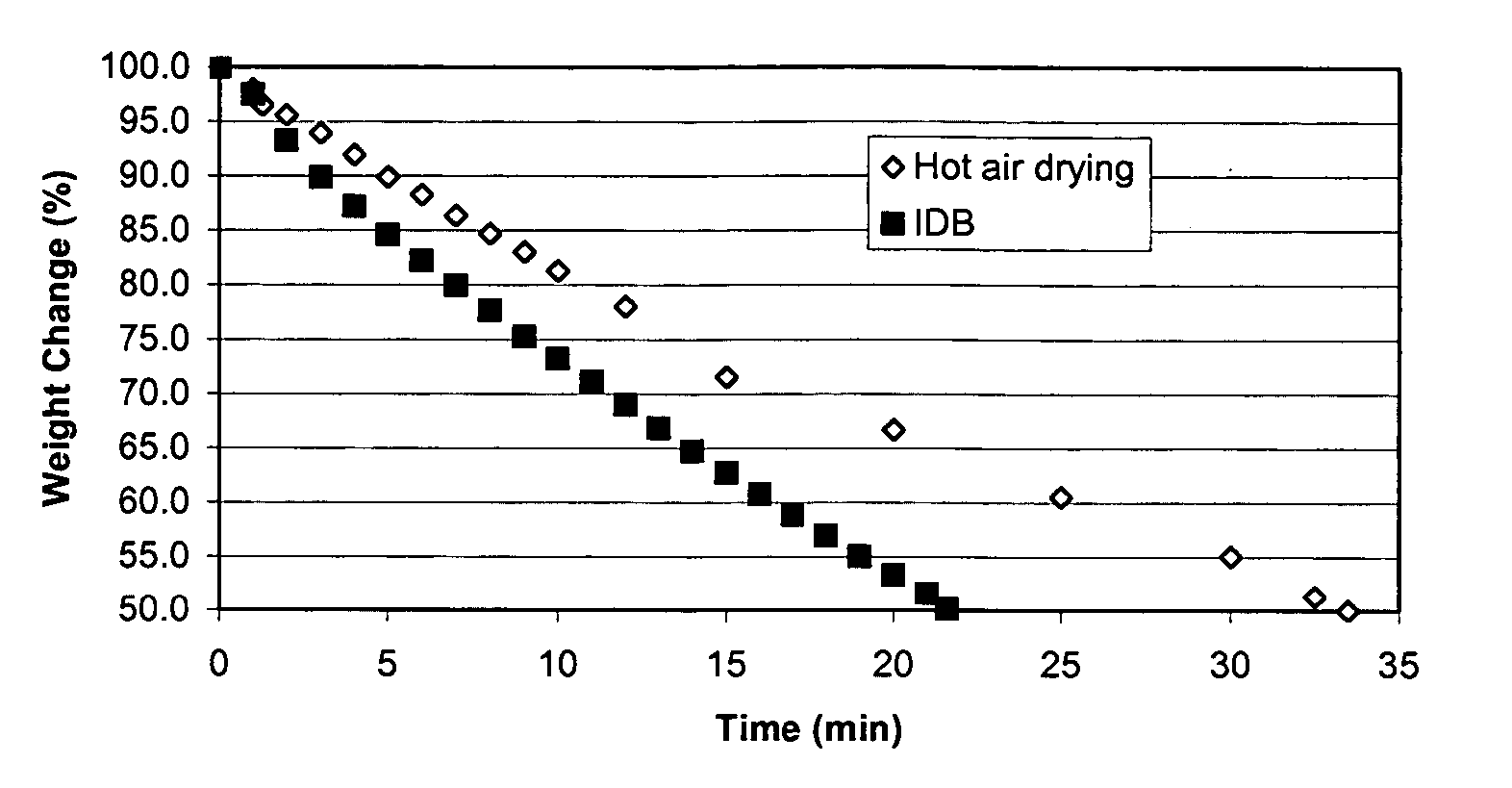

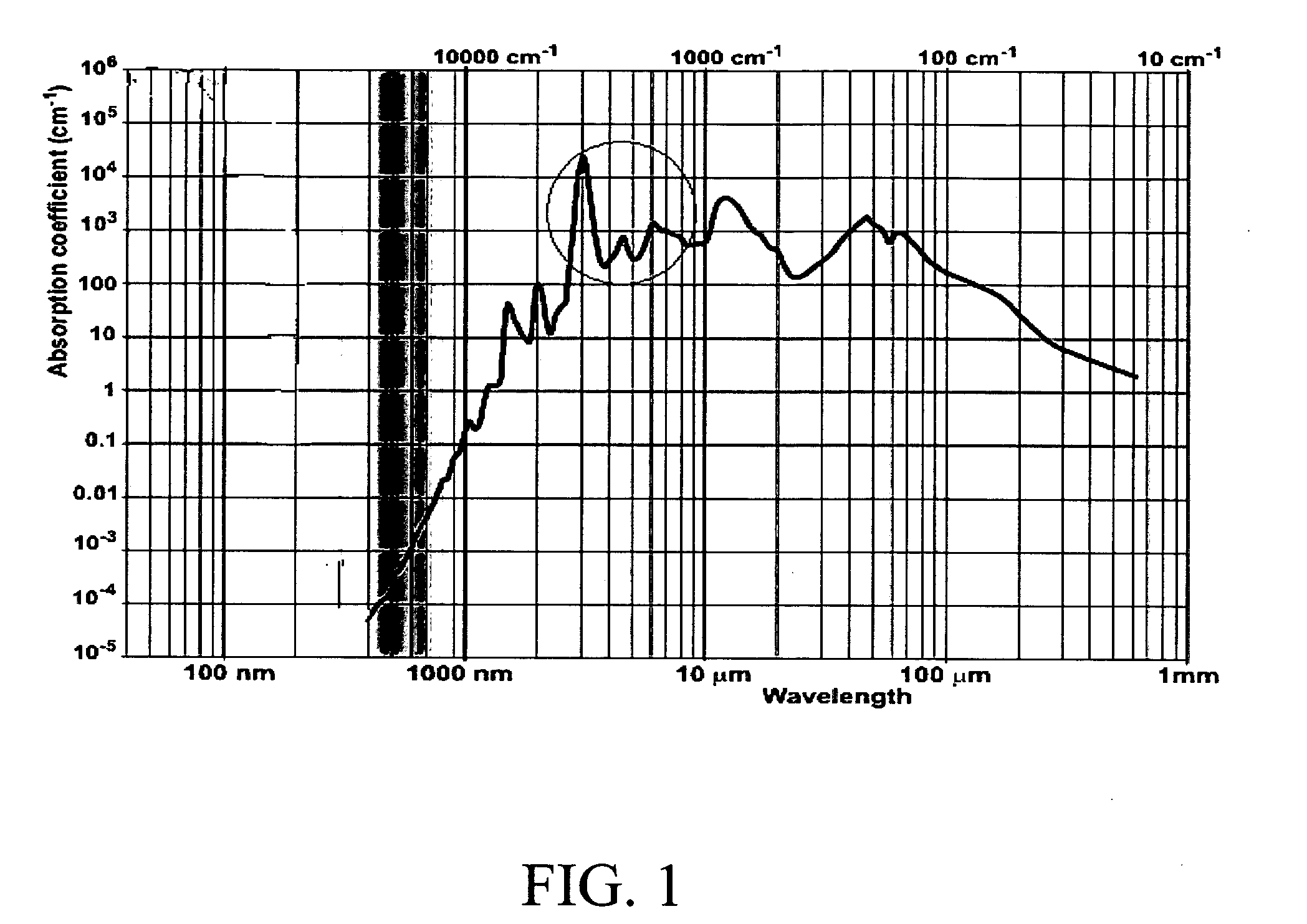

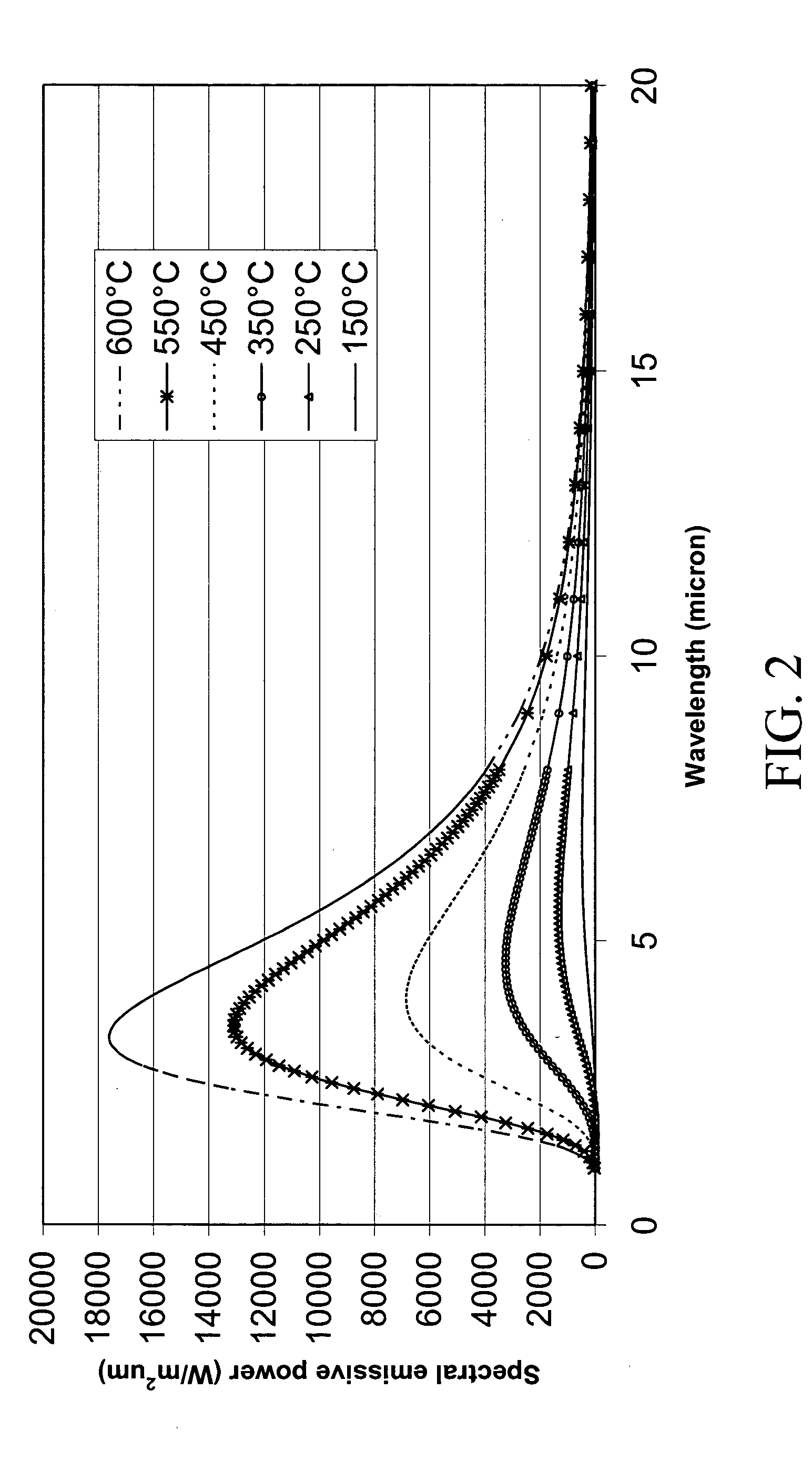

Novel infrared dry blanching (IDB), infrared blanching, and infrared drying technologies for food processing

InactiveUS20060034981A1Simple processShorten the timeMilk preservationDough treatmentSide effectVolumetric Mass Density

This invention relates to food processing and, in particular, blanching and dehydration of foods. Conventional blanching and dehydration requires use of steam and forced hot air. This invention is the first to effectively use infrared radiation energy to perform simultaneous blanching and dehydration of fruits and vegetables. Since this technology does not involve the addition of steam or water in the process of blanching, it has been named “infrared dry-blanching” (IDB) technology. IDB is intended to be a replacement for current steam, water and / or microwave blanching methods. It can be used to produce many kinds of value-added dried, refrigerated, frozen and dehydrofrozen foods such as fruit and vegetable products. In general, the advantages of IDB include (1) uniform heating which enhances energy efficiency and limits damage from over-heating, (2) capability of zone heating to address differential density, (3) ability to treat large or small lots with the same piece of equipment, (4) portability, since equipment can be built on wheels, and (5) a safe, non-toxic process with no harmful side-effects to humans or the environment.

Owner:UNITED STATES OF AMERICA +1

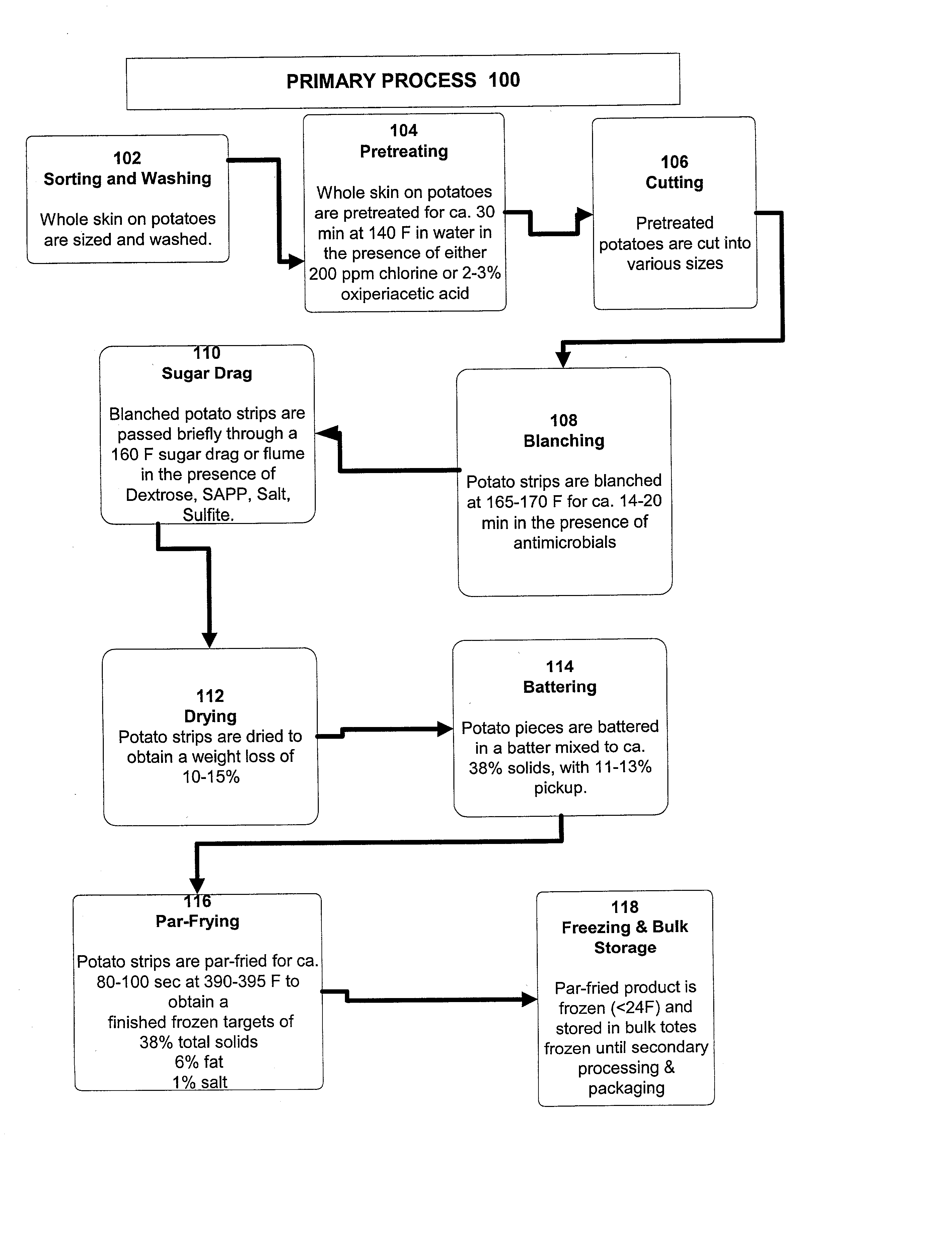

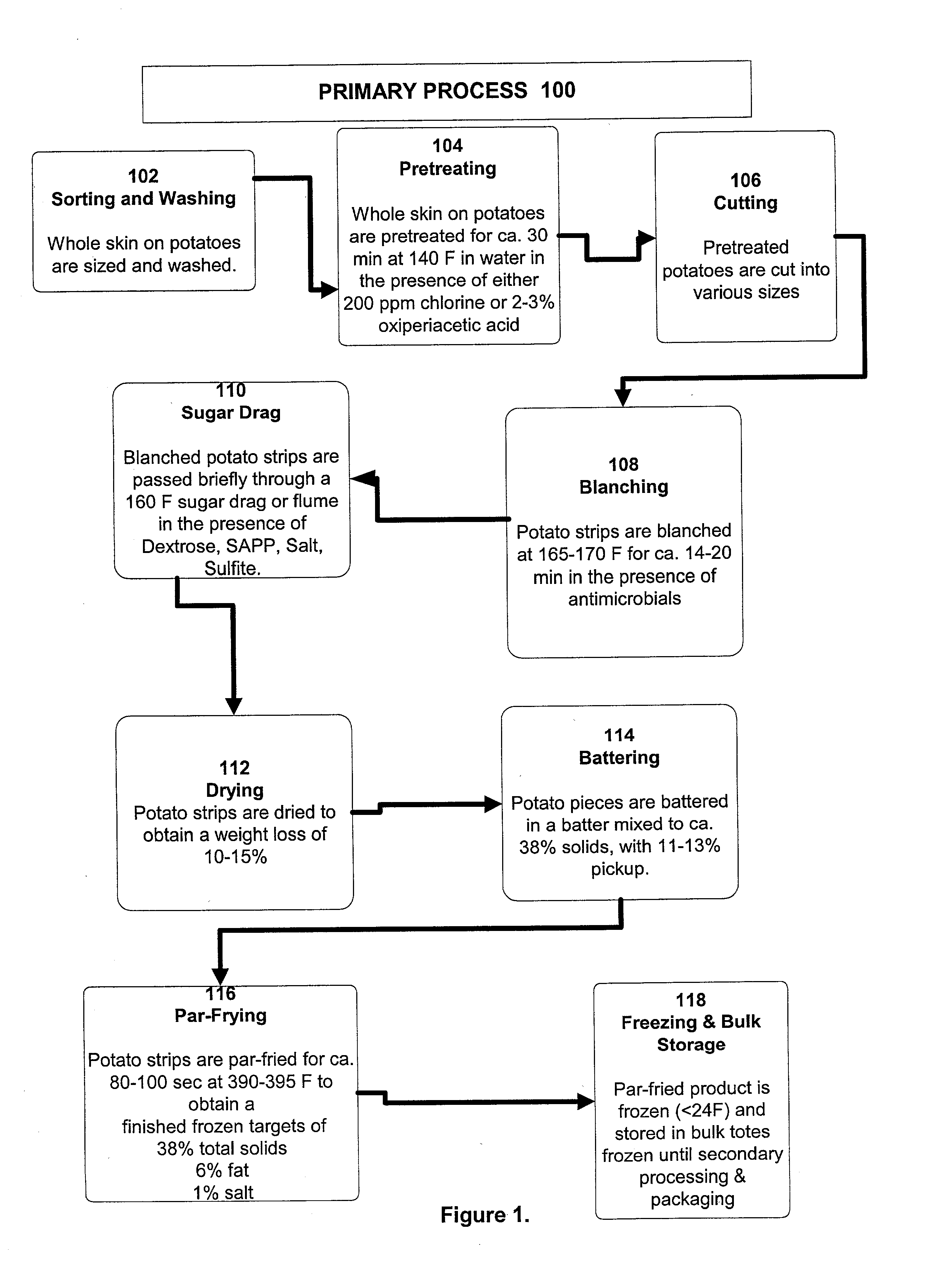

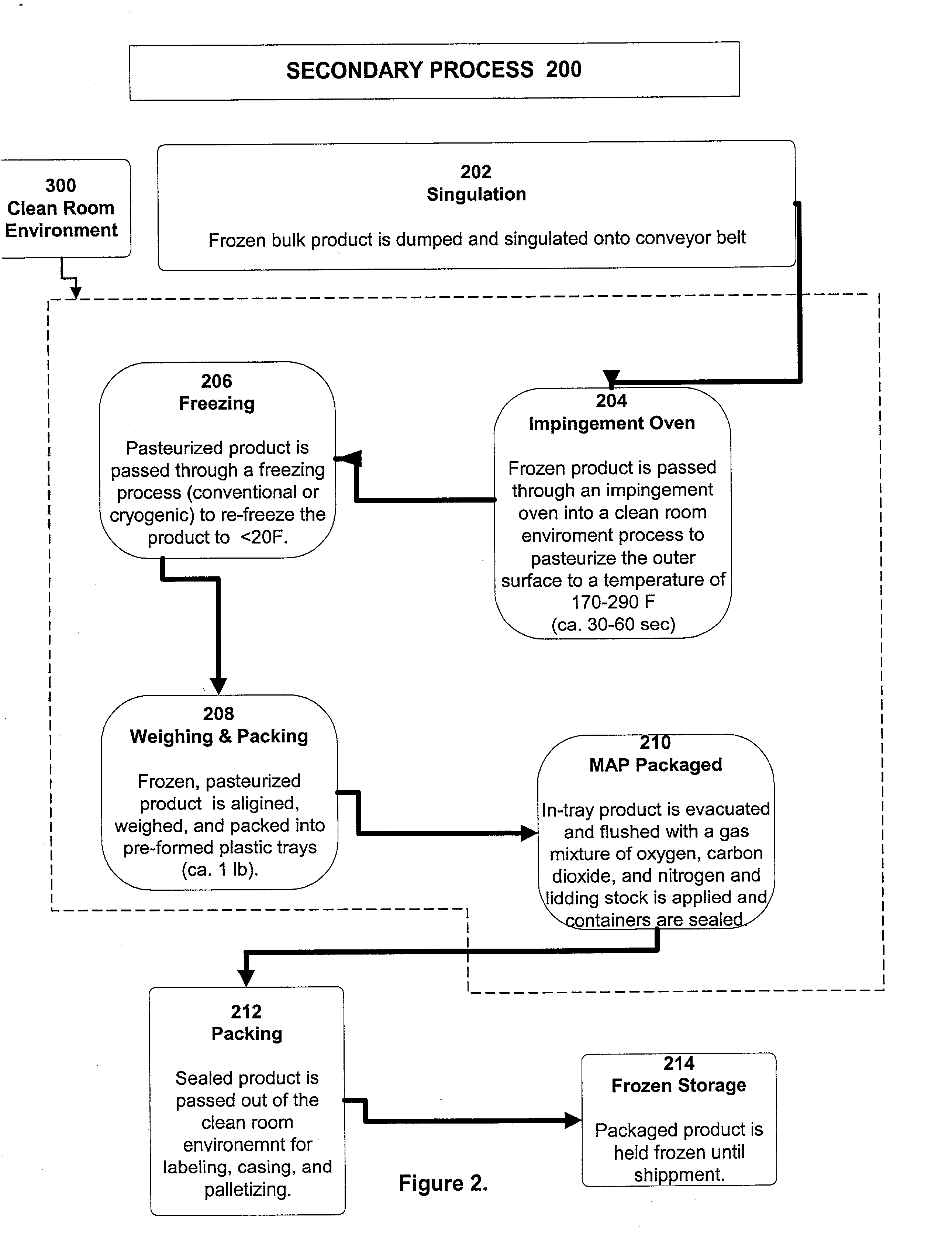

Process for preparing french fried potatoes having an extended shelf life at refrigerated temperatures and a reduced reconstitution time

InactiveUS20020127315A1Meat/fish preservationFruits/vegetable preservation by heatingRadurizationUltraviolet

Potato pieces are processed after a primary process by passing the potato products, preferably frozen or chilled, through a pasteurization process. The pasteurization process includes passing the potato products through an impingement oven, a steam tunnel, an ultra violet (UV) light exposure tunnel, radurization equipment, or combinations thereof, for thermal and / or non-thermal pasteurizing, in a clean room, to reduce or eliminate microbial load on the potato pieces.

Owner:HEINZ

A dewatering processing method of pickled cabbage

InactiveCN101156624AGood colorImprove qualityFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingForeign matterThree stage

The invention provides a dehydration processing method for the cabbage, and includes the following procedures: selecting materials; spraying and rinsing by flowing spray salt water; cutting off the root; cutting out the white leaf in the inner core of the cabbage and the exceptional rotted leaf, the exceptional yellow core, and the exceptional withered core; cutting off the core-cut cabbage, and selecting the big blocks, the hard stem, and the foreign bodies out; winnowing by a fan, and removing the leftover bits and pieces and the foreign bodies; placing the winnowed cabbage in the clean water for bubble rinsing again, sterilizing and killing enzyme by blanching and scalding; placing the cooled cabbage in a centrifuge for centrifugal drying; drying in three stages; seeking the foreign bodied out; and sealing, packing and loading in a storeroom. The invention conducts effective protective processes during the process course, and the dehydrated cabbage has high quality.

Owner:慈溪市蔬菜开发有限公司

Energy-saving multifunctional cold-heat pretreatment device for fruits and vegetables before storage

InactiveCN101843276AInhibit dry consumptionHas a cleaning effectFood processingFruits/vegetable preservation by heatingEngineeringCold injury

The invention discloses an energy-saving multifunctional cold-heat pretreatment device for fruits and vegetables before storage. A water temperature treatment chamber is connected with a fruit and vegetable pretreatment chamber to form an integral water tank, and a partition board with through holes and a filter screen are arranged between the two chambers. A fruit and vegetable basket is placed in the pretreatment chamber, a spiral tubular heat exchanger is placed in the water temperature treatment chamber, and circulating cold water or hot water enters the fruit and vegetable pretreatment chamber from the lower part in a parallel mode through a water pump. The return water is subjected to heat re-exchange through the filter screen, the partition board and the spiral tubular heat exchanger and then returns to the water pump. The device integrates pre-cooling, cold shock and hot shock treatment of the fruits and the vegetables, and saves running energy consumption when the treatment of the fruits and the vegetables is finished; and compared with air, the water serving as a treatment medium has high heat exchange efficiency, can inhibit drying loss during the pretreatment of the fruits and the vegetables, and has cleaning effects on the fruits and the vegetables. A control system can timely adjust the running parameters of the system according to the change of working conditions so as to avoid cold injury of the fruits and the vegetables caused by over-low water temperature and hot injury of the fruits and the vegetables caused by over-high water temperature.

Owner:TIANJIN UNIV

Technique for quick-frozen gingers

ActiveCN102696746AGuaranteed qualityKeep the original tasteFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingIce waterRefrigeration temperature

A technique for quick-frozen gingers includes the processes of ginger selection, desulfurization, sterilization and quick-freezing. The process of ginger selection includes three steps, i.e. material selection, material trimming and winnowing; the process of desulfurization includes three steps, i.e. soaking for desulfurization, cleaning in clean water and sorting; the process of sterilization includes three steps, i.e. sterilization in medical solution, blanching for sterilization and cleaning in normal-temperature water; the process of quick-freezing includes three steps, i.e. cooling in ice water, quick-freezing and making of ice rinds; the gingers are quick-frozen under less than 25 DEG C below and within 15 minutes; in the steps of cooling in ice water and quick-freezing, water temperature is chosen according to the temperature of the quick-freezing tunnel of a fluidized quick-freezing machine, an ice water pond needs to be refrigerated if the temperature of the quick-freezing tunnel is higher than 30 DEG C below, the refrigeration temperature is controlled at 0 DEG C to 5 DEG C, and if the temperature of the quick-freezing tunnel is lower than 30 DEG C below, the ice water pond uses normal-temperature water; in the step of making of ice rinds, the gingers discharged out of the discharge outlet of the quick-freezing tunnel are directly put into a container containing ice water with temperature lower than 4 DEG C for 1 to 3 seconds; and after being packaged, the gingers are stored under the low-temperature condition of less than 18 DEG C below and transported to a point of consumption.

Owner:罗平县阳洋黄姜有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com