Methods and apparatuses for thermal treatment of foods and other biomaterials, and products obtained thereby

a technology of thermal treatment and foods, applied in the directions of liquid handling, transportation and packaging, bottle/container closure, etc., can solve the problems of limited treatment options, large investment in frozen puree distribution and storage, long and poorly controlled, etc., to reduce temperature distribution variability and increase physical contact and heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Sweetpotato Puree (SPP)

[0231] Beauregard cultivar sweetpotatoes were prepared in the Fruit and Vegetable Pilot Plant, Department of Food Science, North Carolina State University (Raleigh, N.C., United States of America), for testing in a 5 kW microwave unit, color, and rheological analyses, and measurement of dielectric properties. The roots were cured at 30° C. at 85-90% relative humidity for seven days stored at 13-16° C. and 80-90% relative humidity, and the puree was prepared as previously described (Truong et al. 1994). Roots were washed, lye-peeled in boiling solution (104° C.) of 5.5% NaOH for 4 minutes, and thoroughly washed in a rotary-reel sprayed washer to remove separated tissue and lye residue. Peeled roots were hand-trimmed and cut into approximately 0.95 cm thick slices using a commercial slicer (Louis Allis Co. Slicer, Milwaukee, Wis., United States of America). The slices were steam-cooked for 20 minutes in a thermoscrew cooker (Rietz Manufacturing C...

example 2

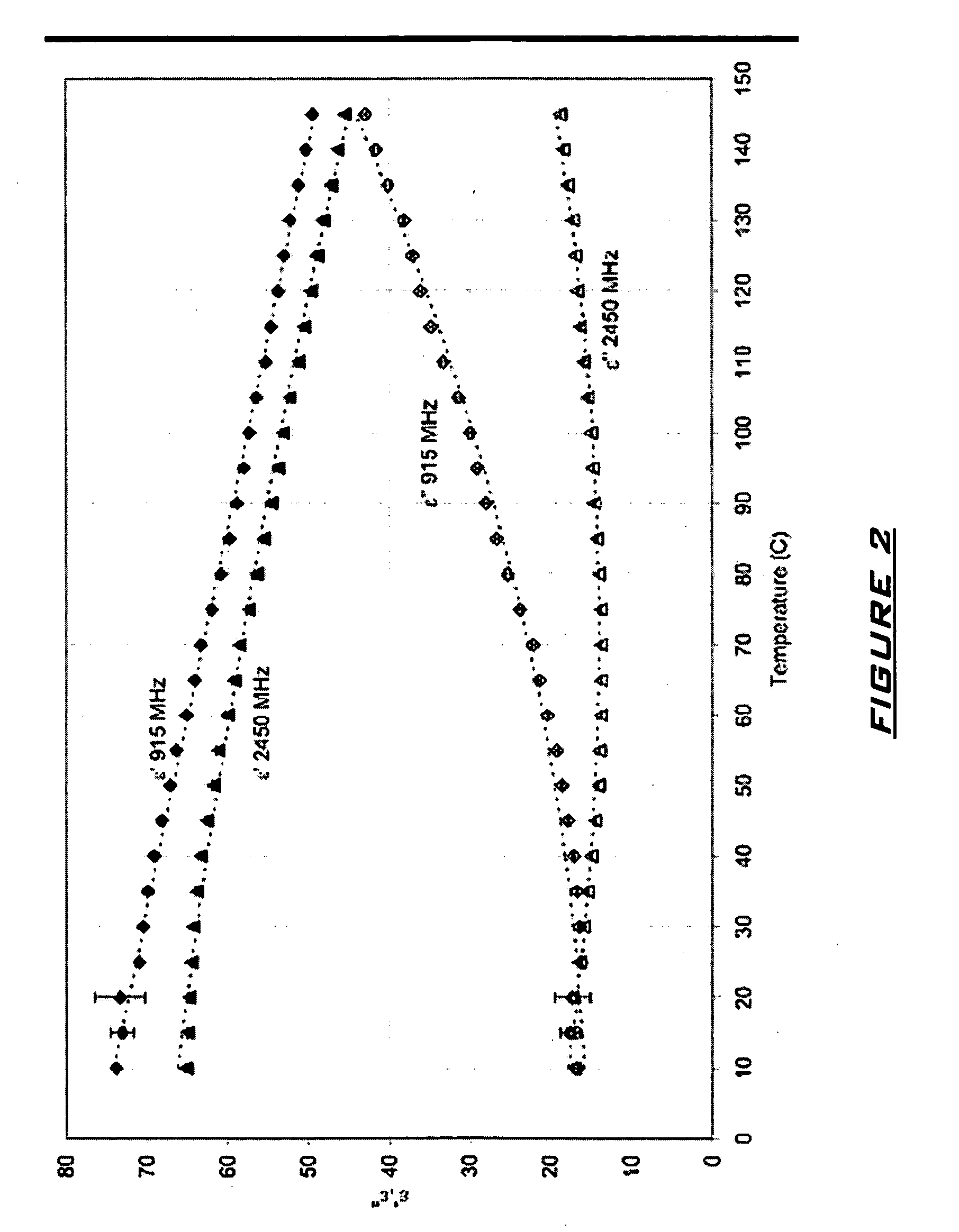

Measurement of Dielectric Properties

[0233] An open coaxial dielectric probe (HP 85070B; Agilent Technologies, Palo Alto, Calif., United States of America) was used with an automated network analyzer (HP 8753C; Agilent Technologies) to measure the dielectric properties of the SPP samples. The dielectric properties were measured in the 300 to 3000 MHz frequency range, with 541 intermediate frequencies. The system was calibrated using the calibration sequence following the instruction manual provided by the manufacturer (Agilent 1998). The samples (<100 g) were heated in a water bath (Model RTE111, Neslab Instruments Inc, Newington, N.H., United States of America) until the desired temperatures (10° C. to 145° C. in 5° C. intervals) were attained, the samples were then placed in an insulating block to measure the dielectric properties. The temperature was measured again after the dielectric properties were read to ensure that the temperature was within 2° C. of the set point. Three re...

example 3

Rheological Tests

[0234] Constant rate measurement of sweetpotato puree viscosity as a function of shear rate was performed at 25° C. with a StressTech rheometer (Reologica Instruments AB, Lund, Sweden) using a cone and plate geometry (C40 4). Apparent viscosity was recorded as shear rates were ramped from 0.1 / s to 300 / s. Two repeated measurements were performed on each of the duplicated samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com