Patents

Literature

1027results about How to "Speed up heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

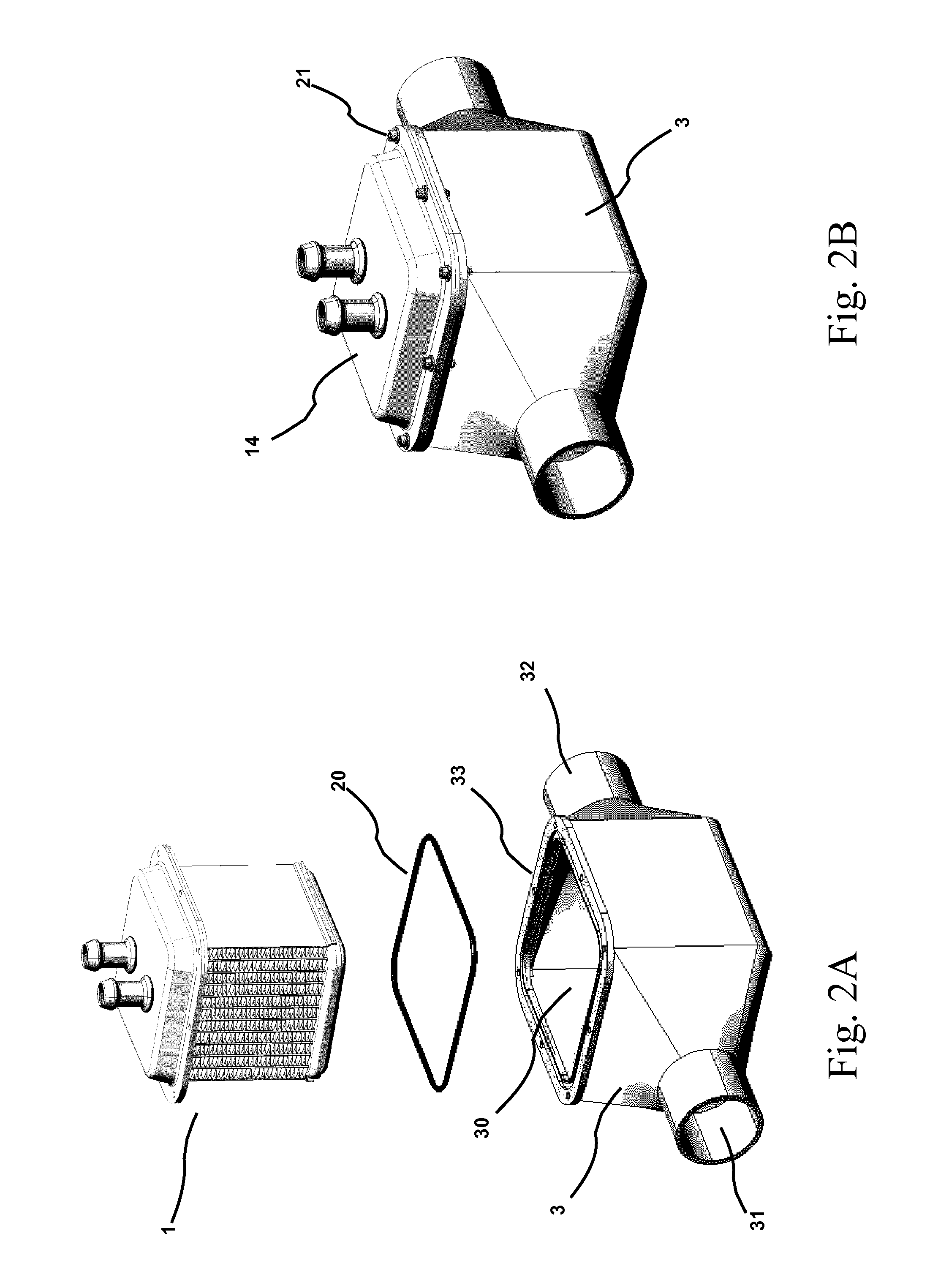

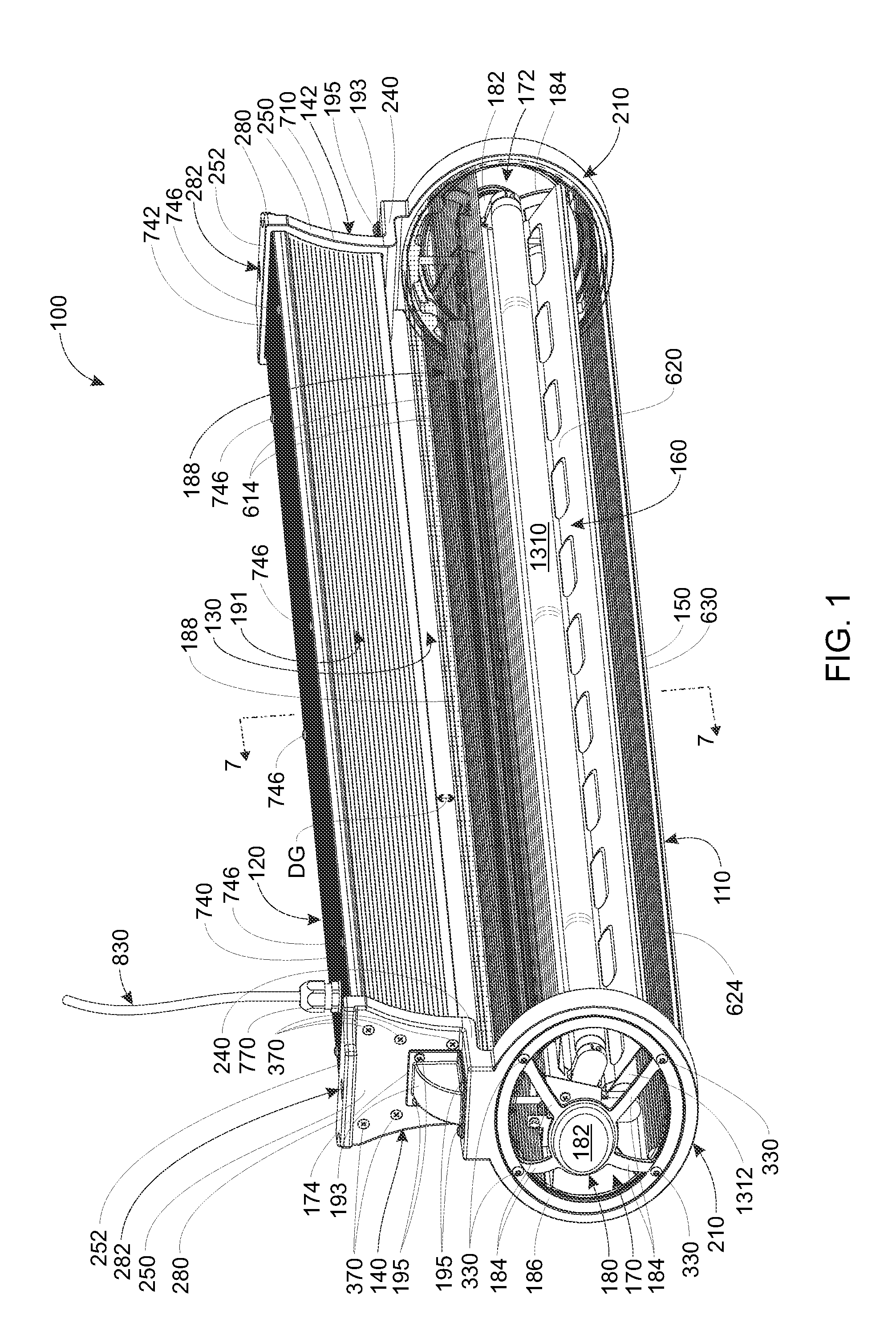

Devices, systems and methods for rapid endovascular cooling

ActiveUS20070043409A1Improve heat transfer efficiencySpeed up heat exchangeStentsBalloon catheterMedicineBlood flow

Devices and methods for warming or cooling blood flowing through the vasculature of a human or animal subject so as to alter or control the temperature of all or part of the subject's body. Heat exchangers are positioned within the subject's vasculature and heated or cooled heat exchange fluid is circulated through the heat exchanger. For certain therapeutic applications, the heat exchanger and associated elements of the system have sufficient power to lower the subject's body temperature by at least 3 degrees C. in less than 30 minutes.

Owner:ZOLL CIRCULATION

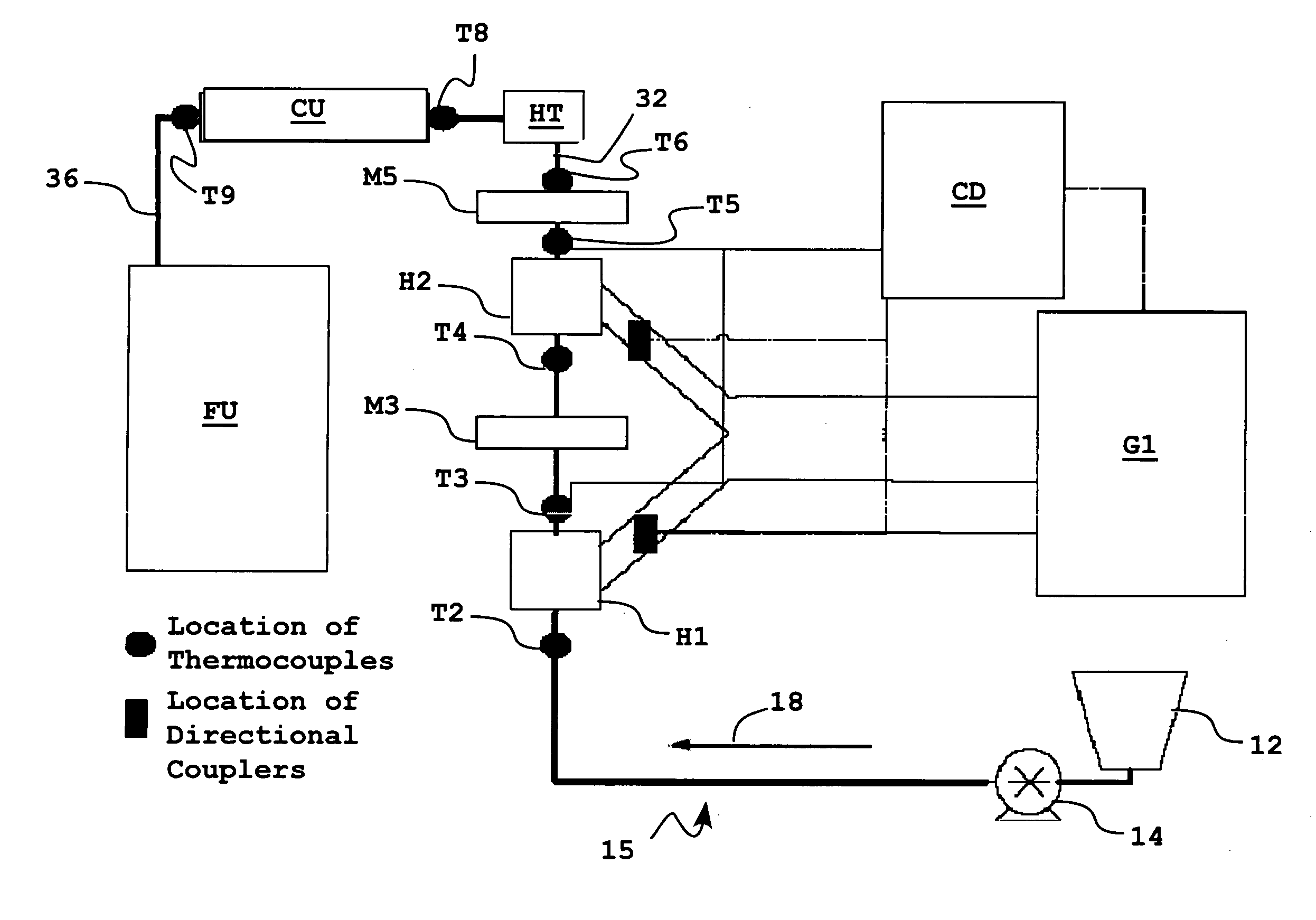

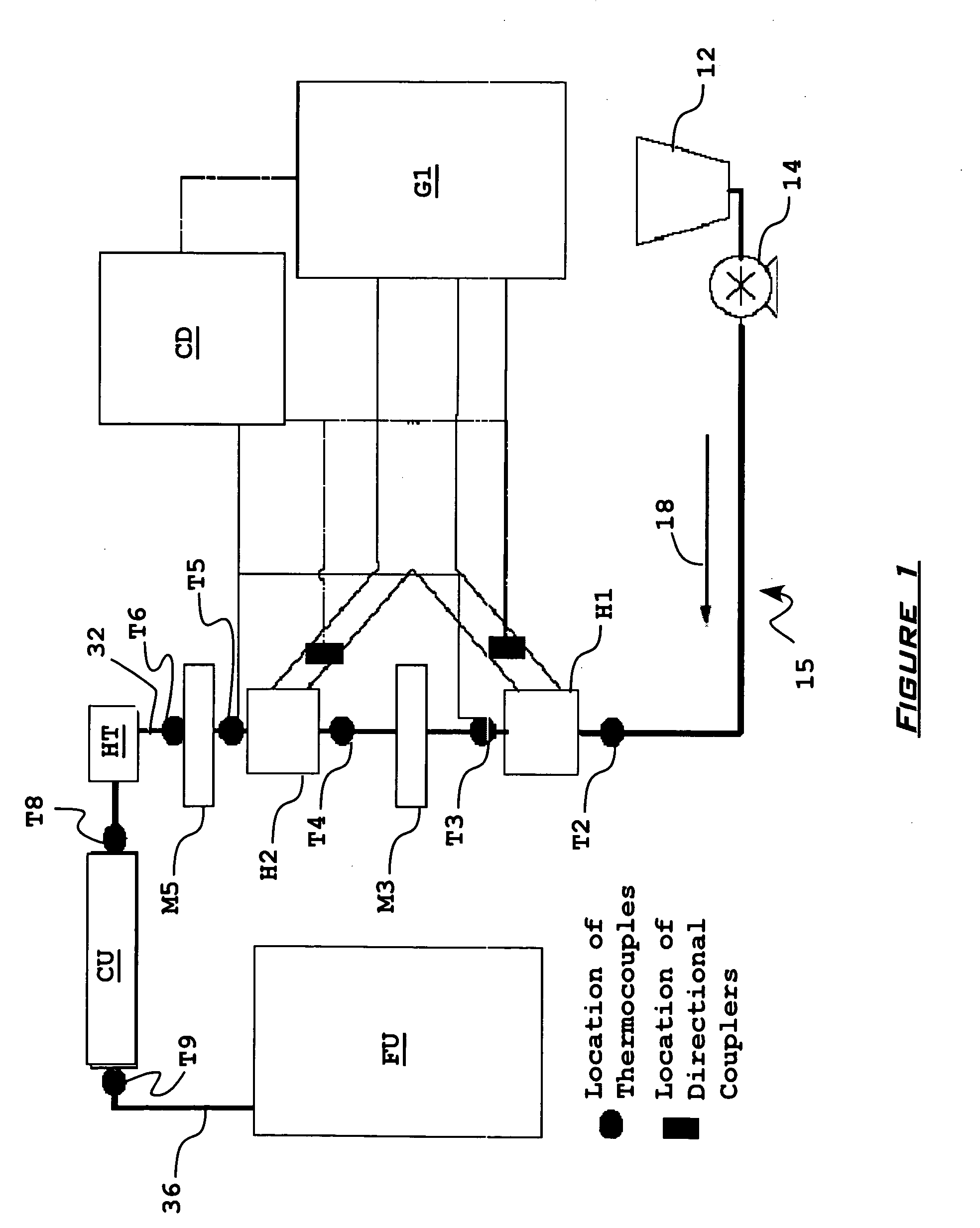

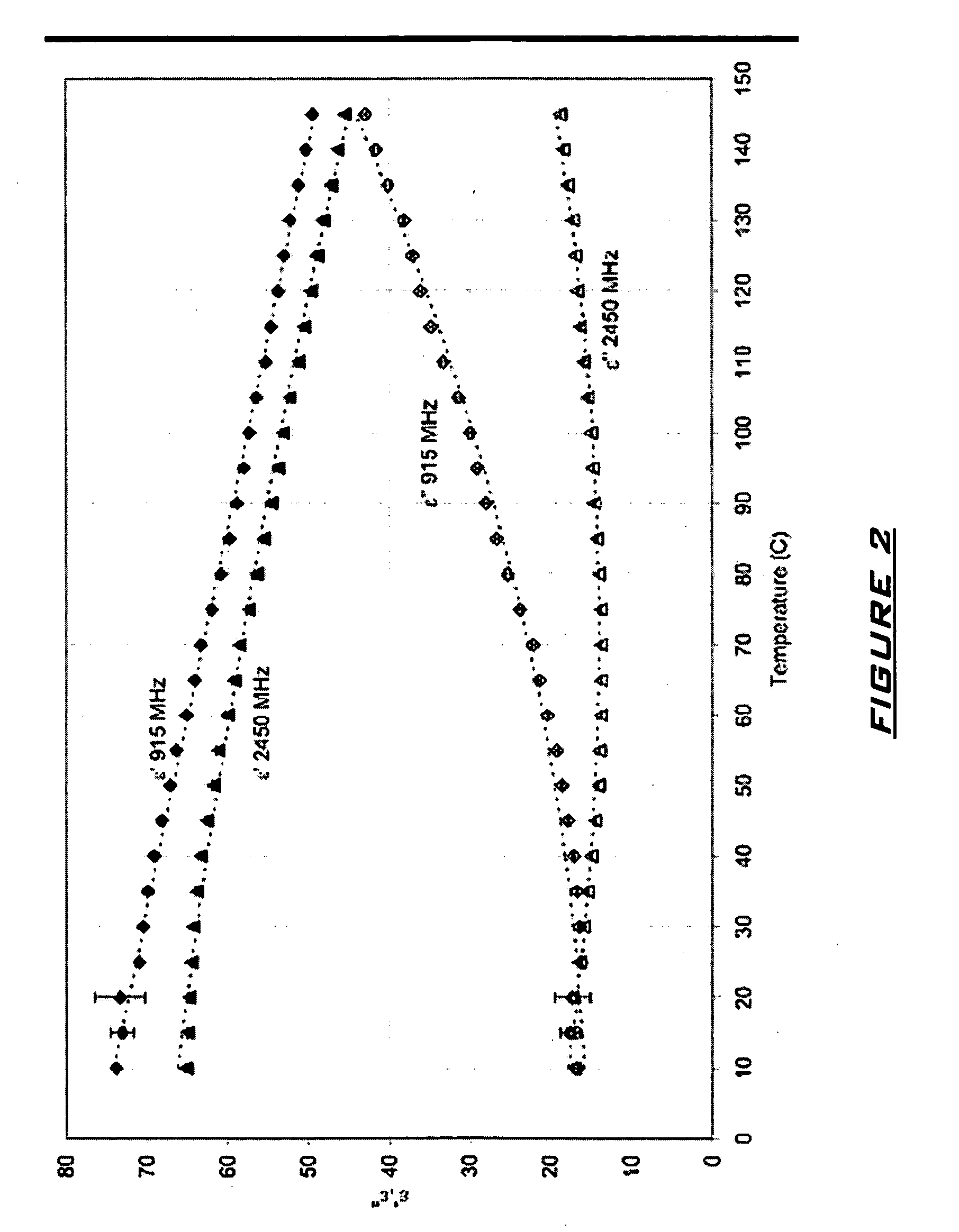

Methods and apparatuses for thermal treatment of foods and other biomaterials, and products obtained thereby

InactiveUS20060151533A1Speed up heat exchangeImproved physical contactOpening closed containersBottle/container closureMedicineContinuous flow

Methods and apparatuses for thermally treating flowable materials using electromagnetic radiation, and foods and materials obtained thereby. Also provided are methods of continuous flow thermal treatment of biomaterials, apparatuses for performing the same, and products prepared using the methods and / or apparatuses.

Owner:SIMUNOVIC JOSIP +6

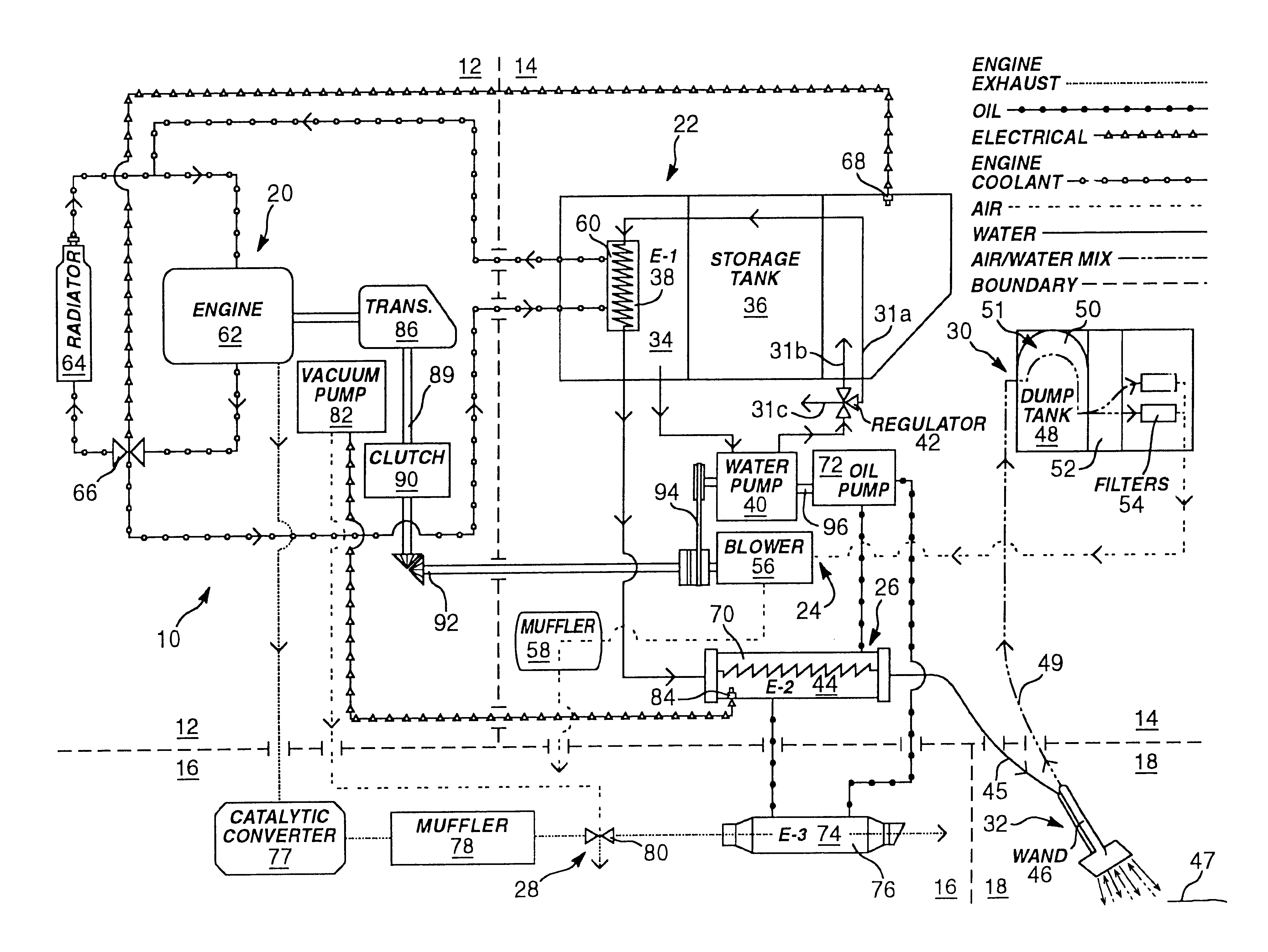

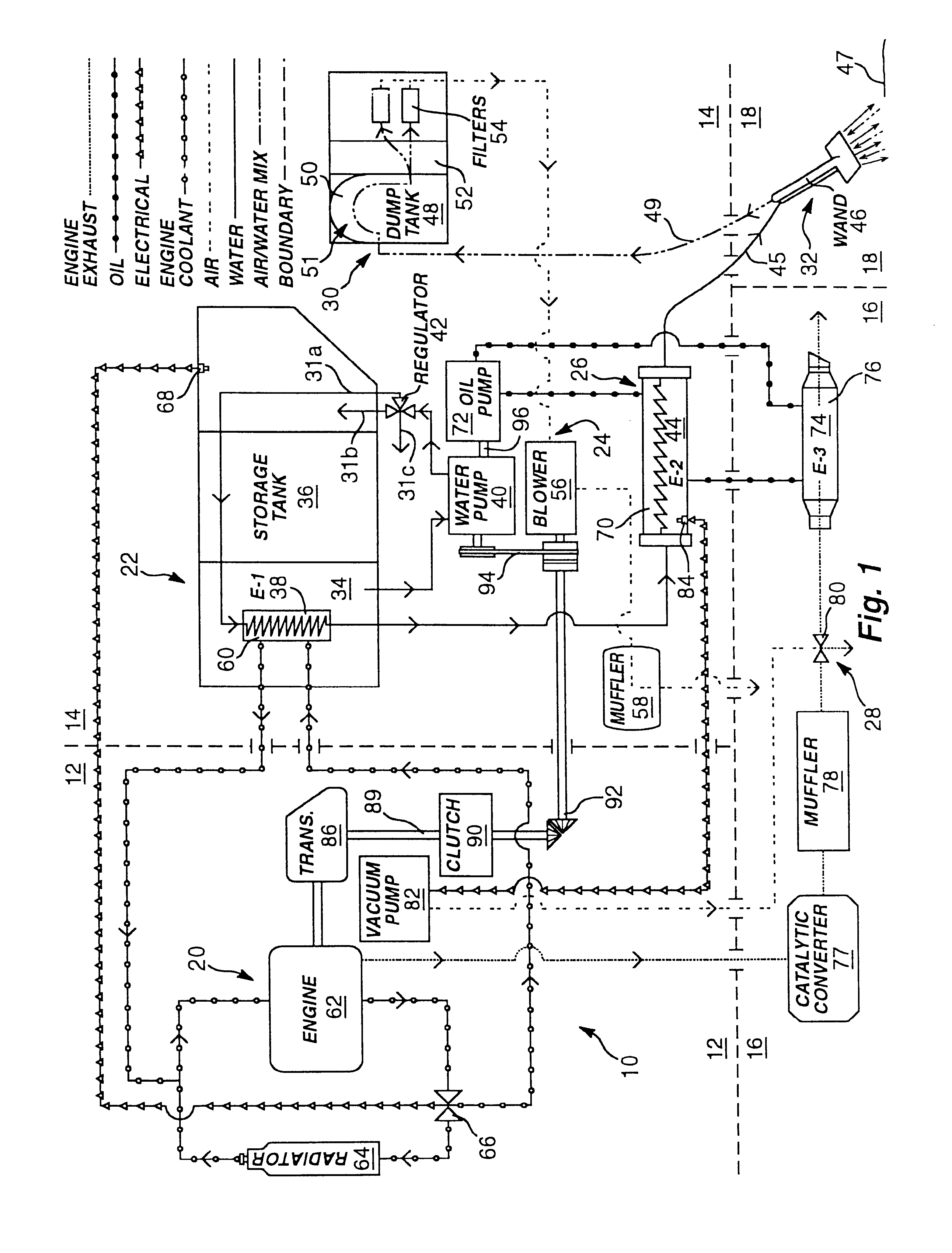

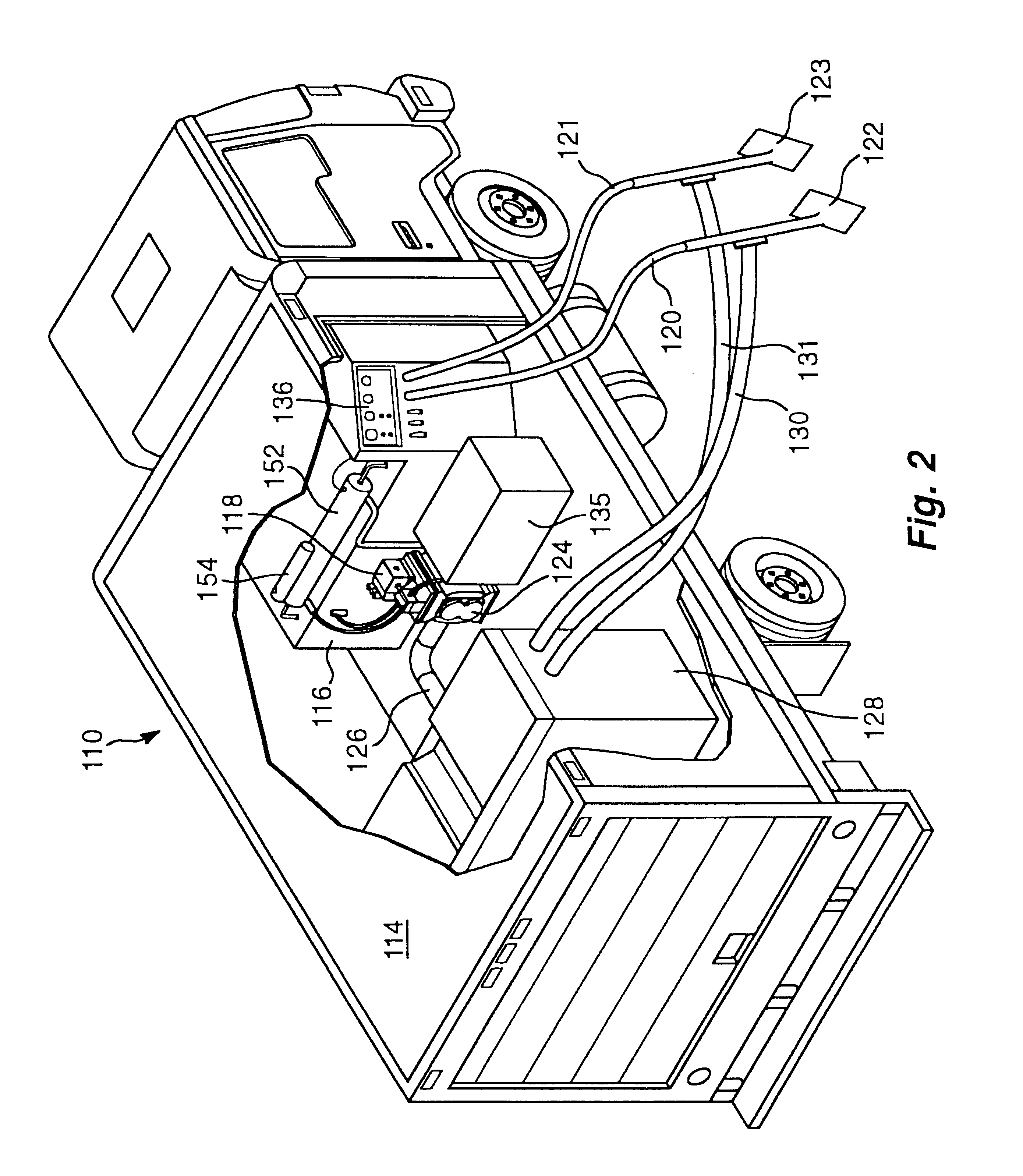

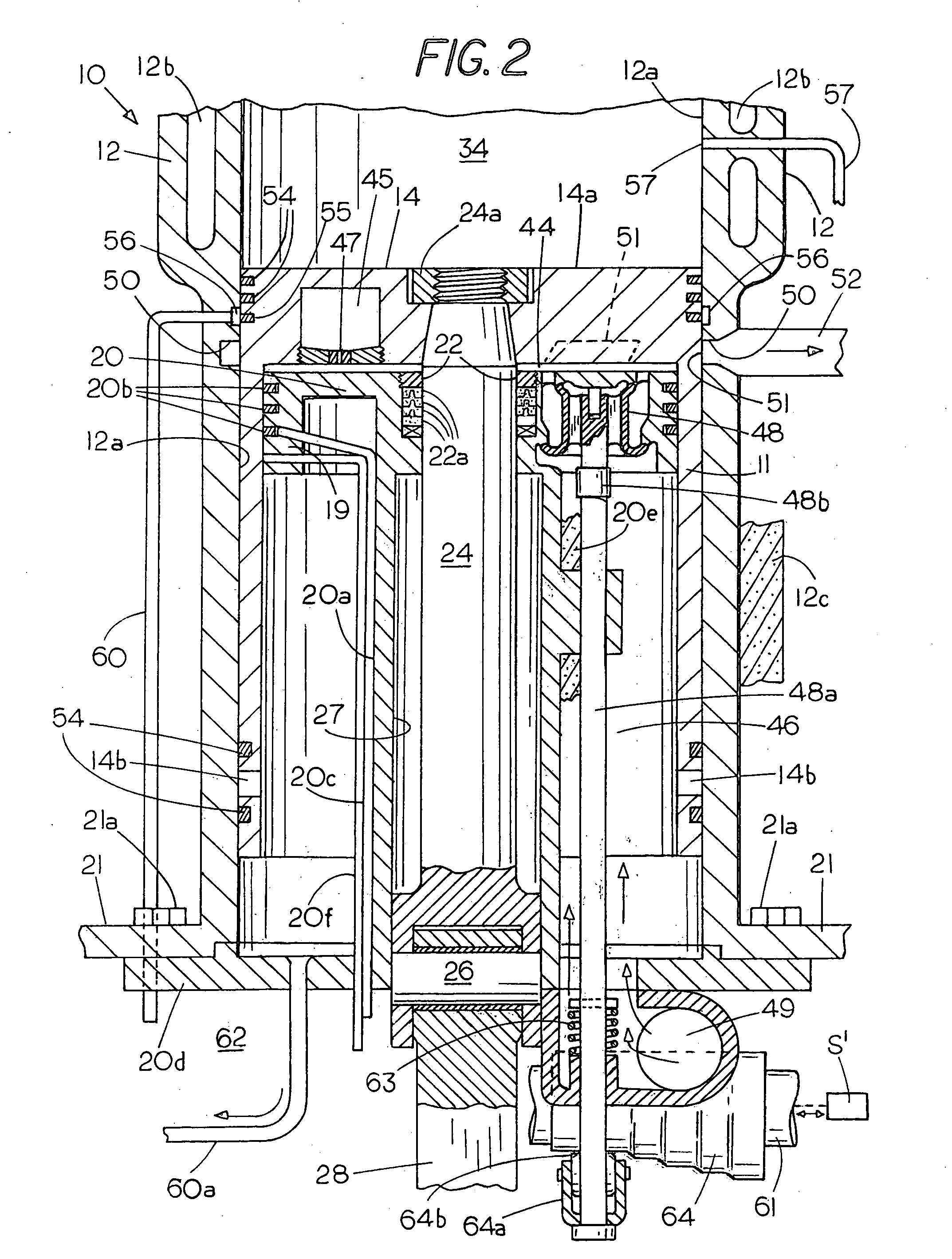

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

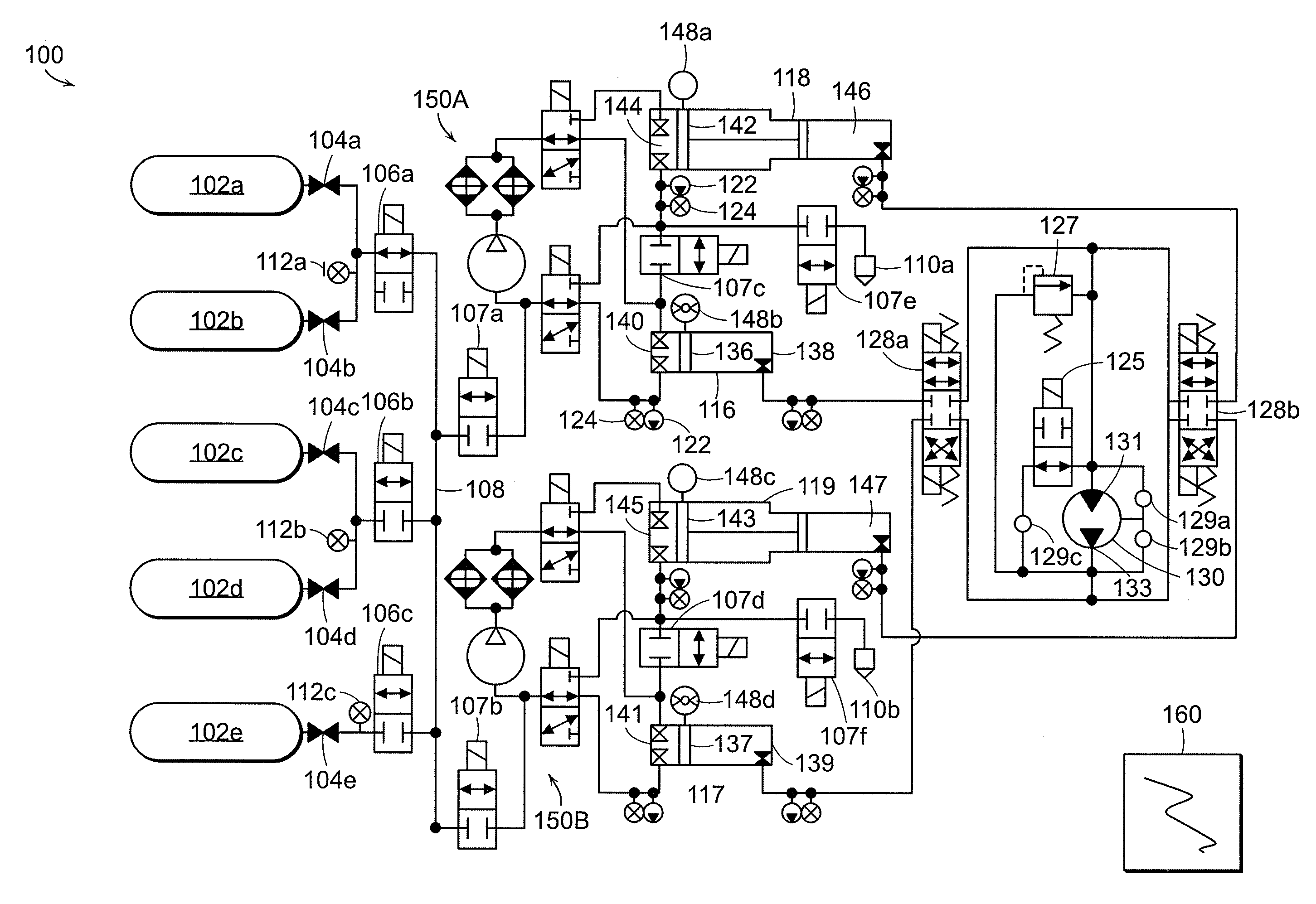

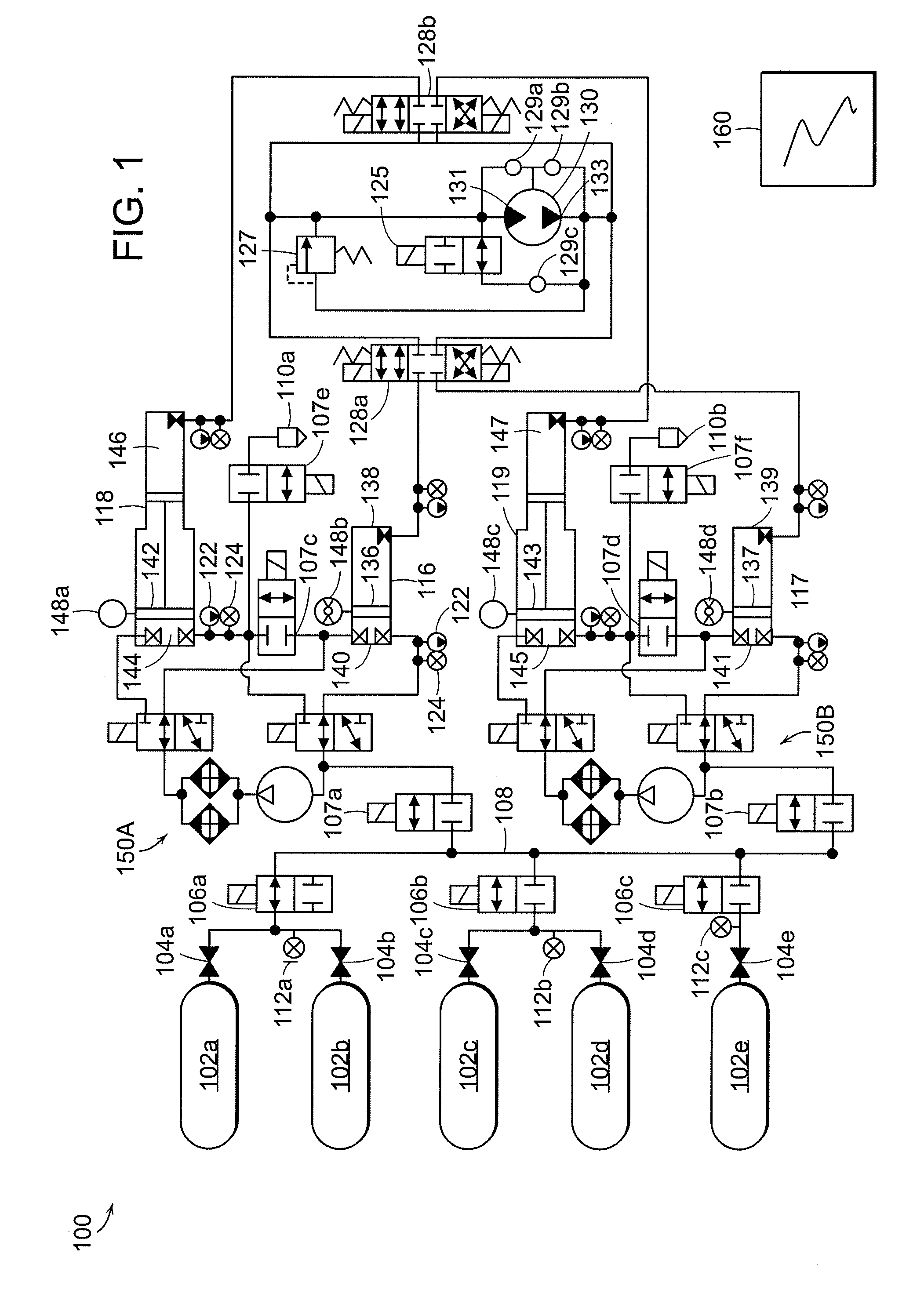

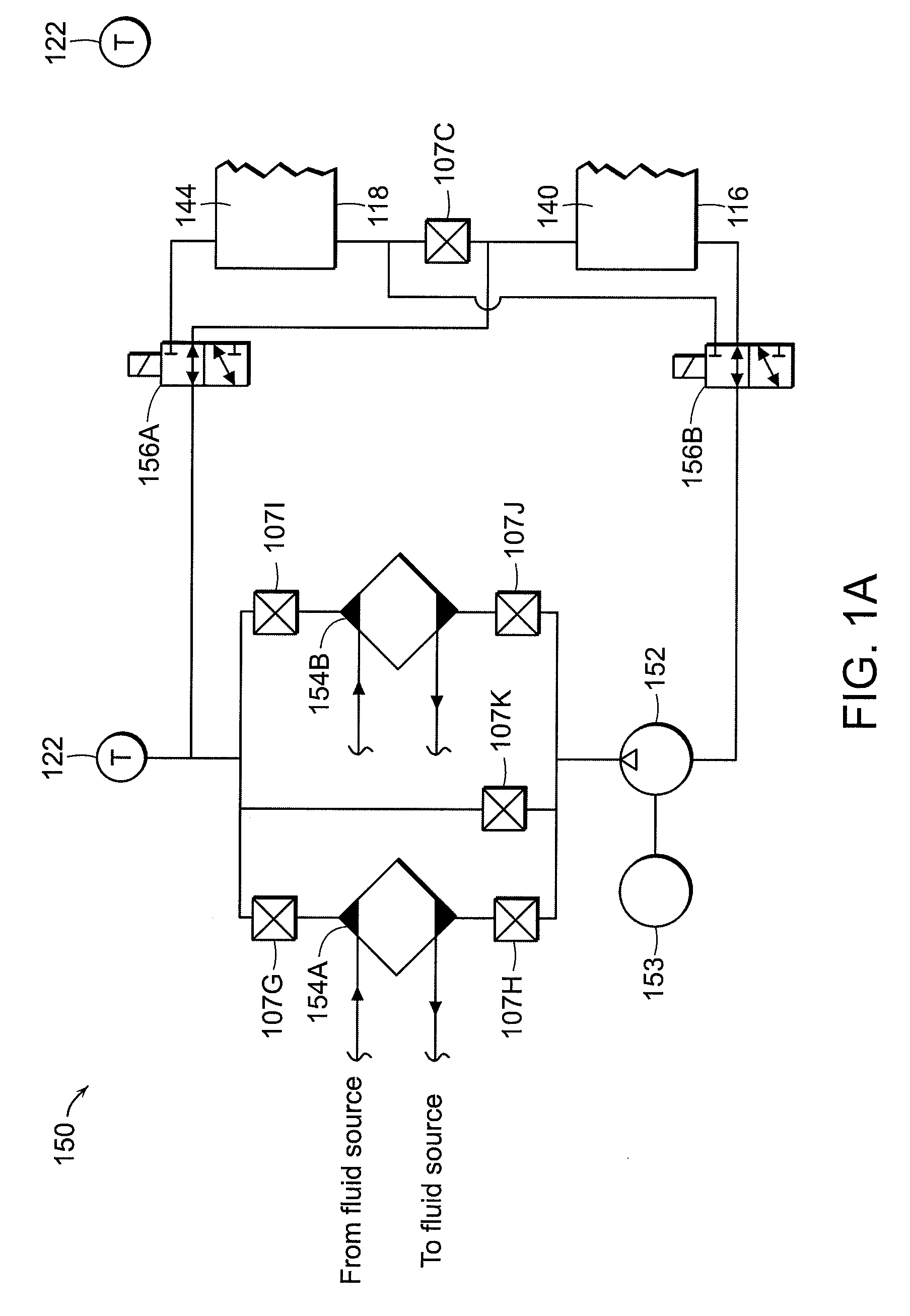

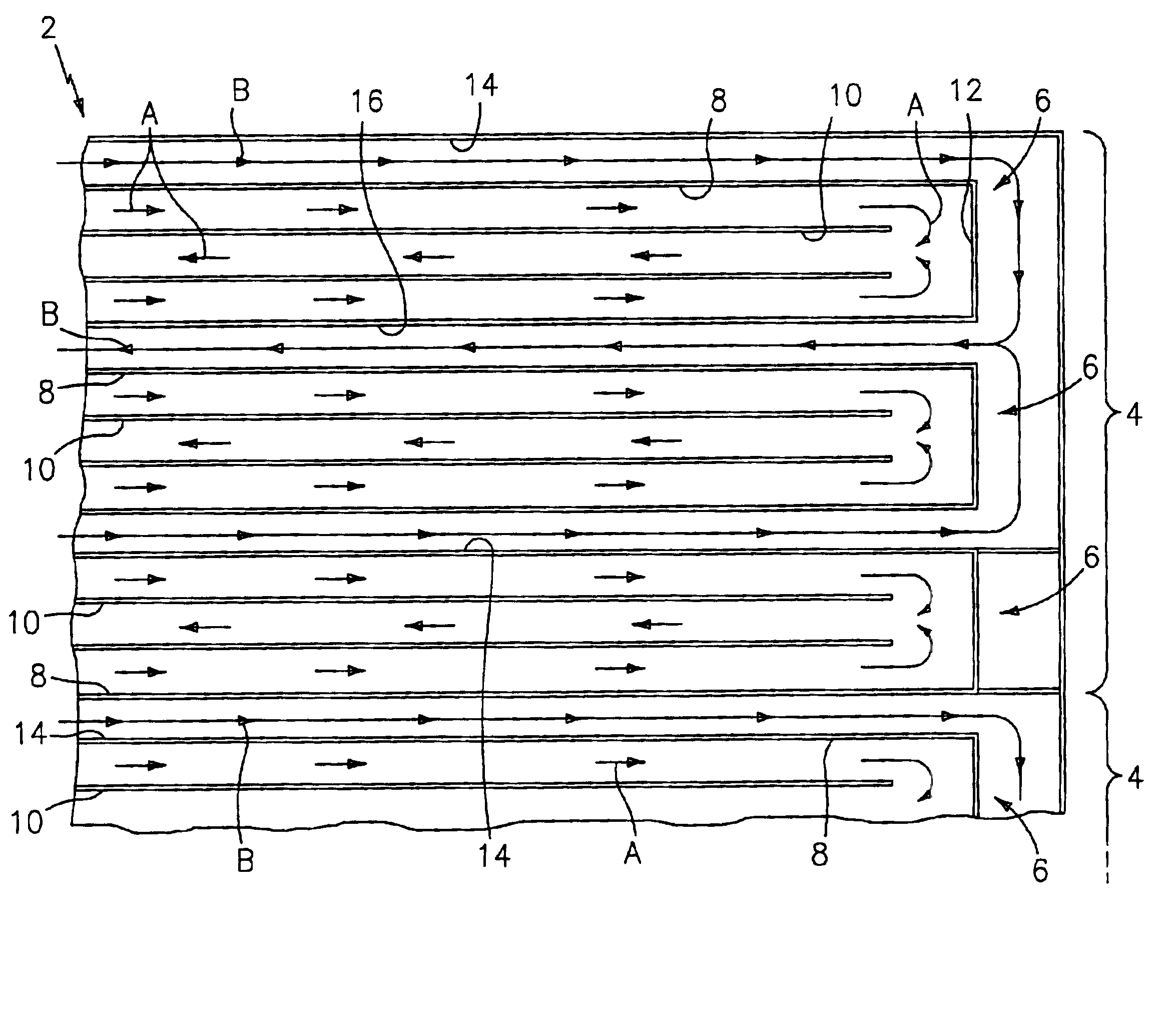

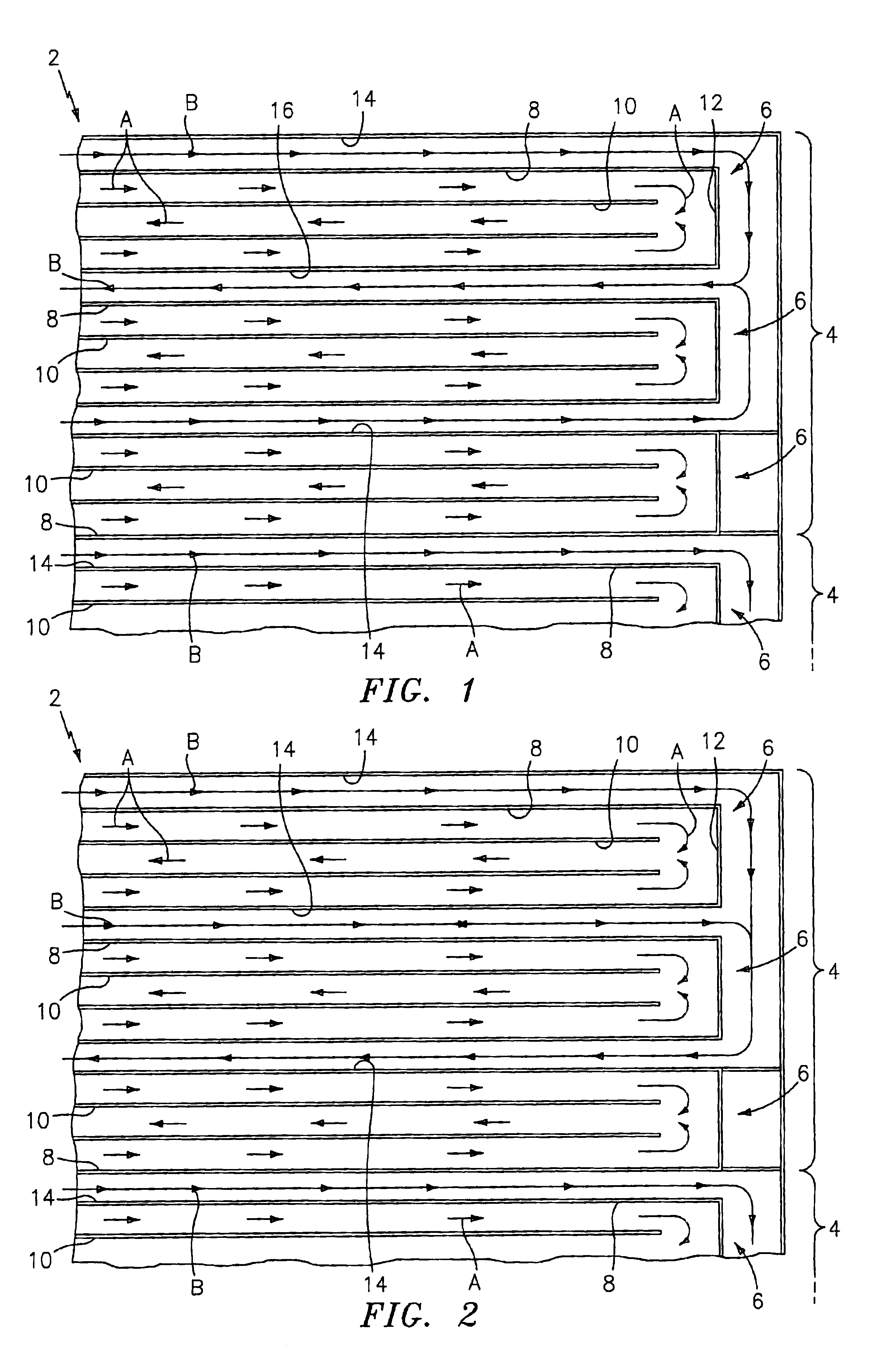

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

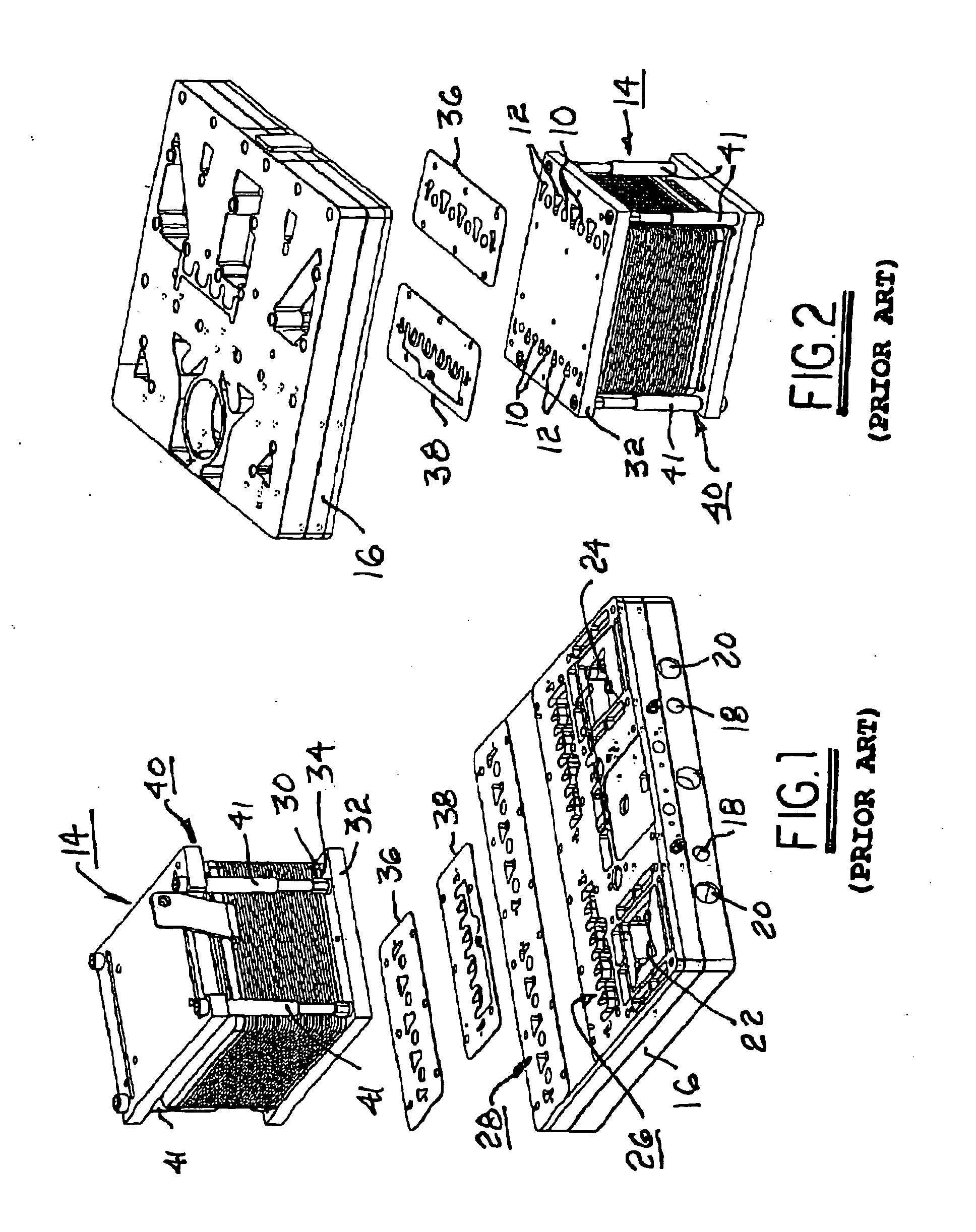

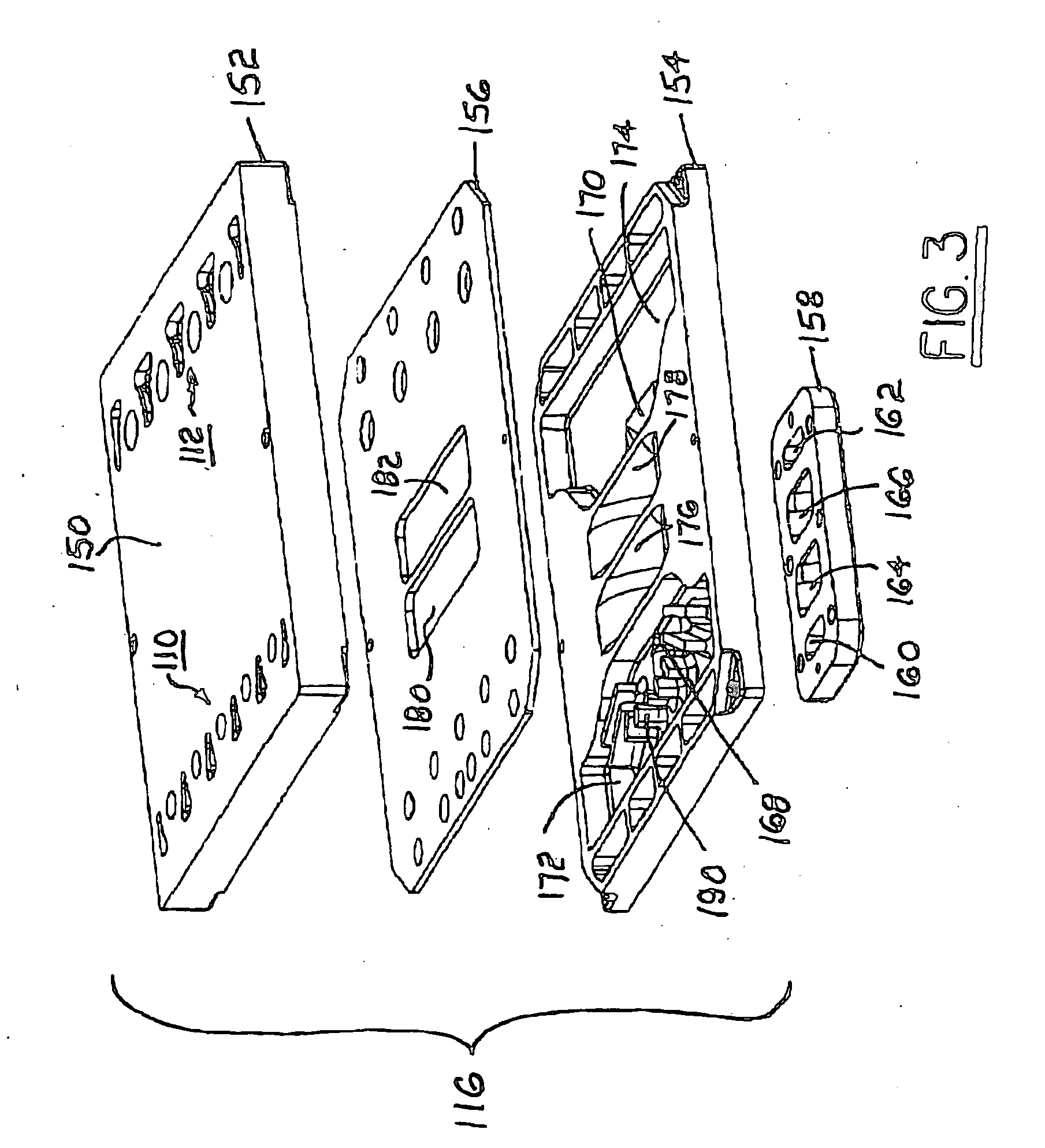

Compact fuel gas reformer assemblage

InactiveUS6773684B2Speed up heat exchangeSuitable for useHydrogenCarburetting by solid carbonaceous material pyrolysisCombustorFuel cells

Owner:INT FUEL CELLS

Reduction of fouling in heat exchangers

InactiveUS20080073063A1Reduce amountCost savingCorrosion preventionVibration cleaningCorrosionPetroleum

A method for reducing the formation of deposits on the inner walls of a tubular heat exchanger through which a petroleum-based liquid is flowing comprises applying one of fluid pressure pulsations to the liquid flowing through the tubes of the exchanger and vibration to the heat exchanger to effect a reduction of the viscous boundary layer adjacent the inner walls of the tubular heat exchange surfaces. Reduction of the viscous boundary layer at the tube walls not only reduces the incidence of fouling with its consequential beneficial effect on equipment life but it also has the desirable effect of promoting heat transfer from the tube wall to the liquid in the tubes. Fouling and corrosion are further reduced by the use of a coating on the inner wall surfaces of the exchanger tubes.

Owner:EXXON RES & ENG CO

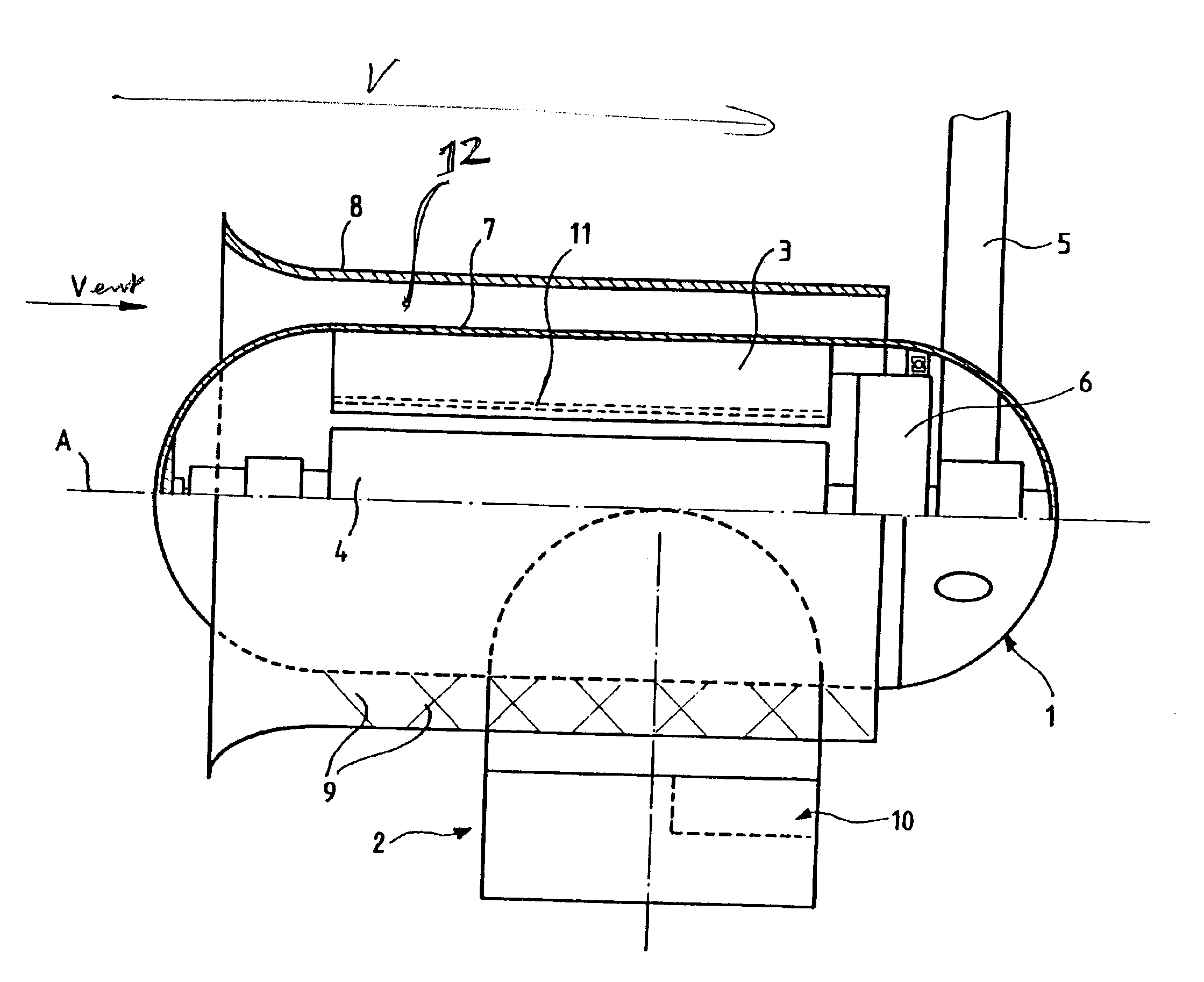

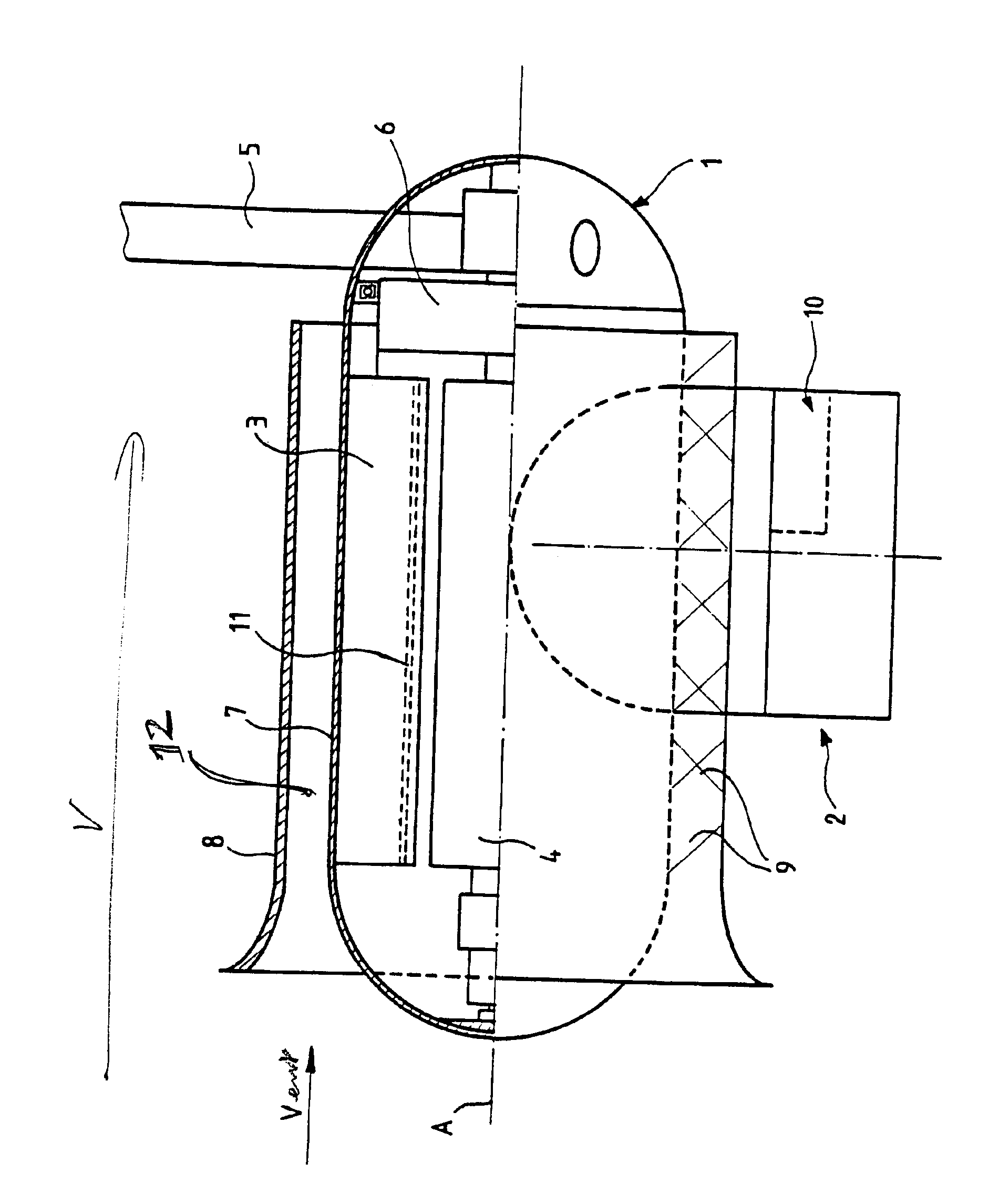

Wind-power generator pod constituted by the body of an electricity generator

InactiveUS6903466B1Reduce in quantitySimplifies installing the wind-power generatorEngine fuctionsWind motor supports/mountsPropellerWind driven

The pod of wind-powered generator is constituted by a rigid fairing in which at least one electricity generator for coupling to at least one wind-driven propeller is disposed. The rigid fairing of the pod is formed by the body of the generator in which there are mounted a stator and a rotor, thereby simplifying the structure of the pod.

Owner:ALSTOM SA

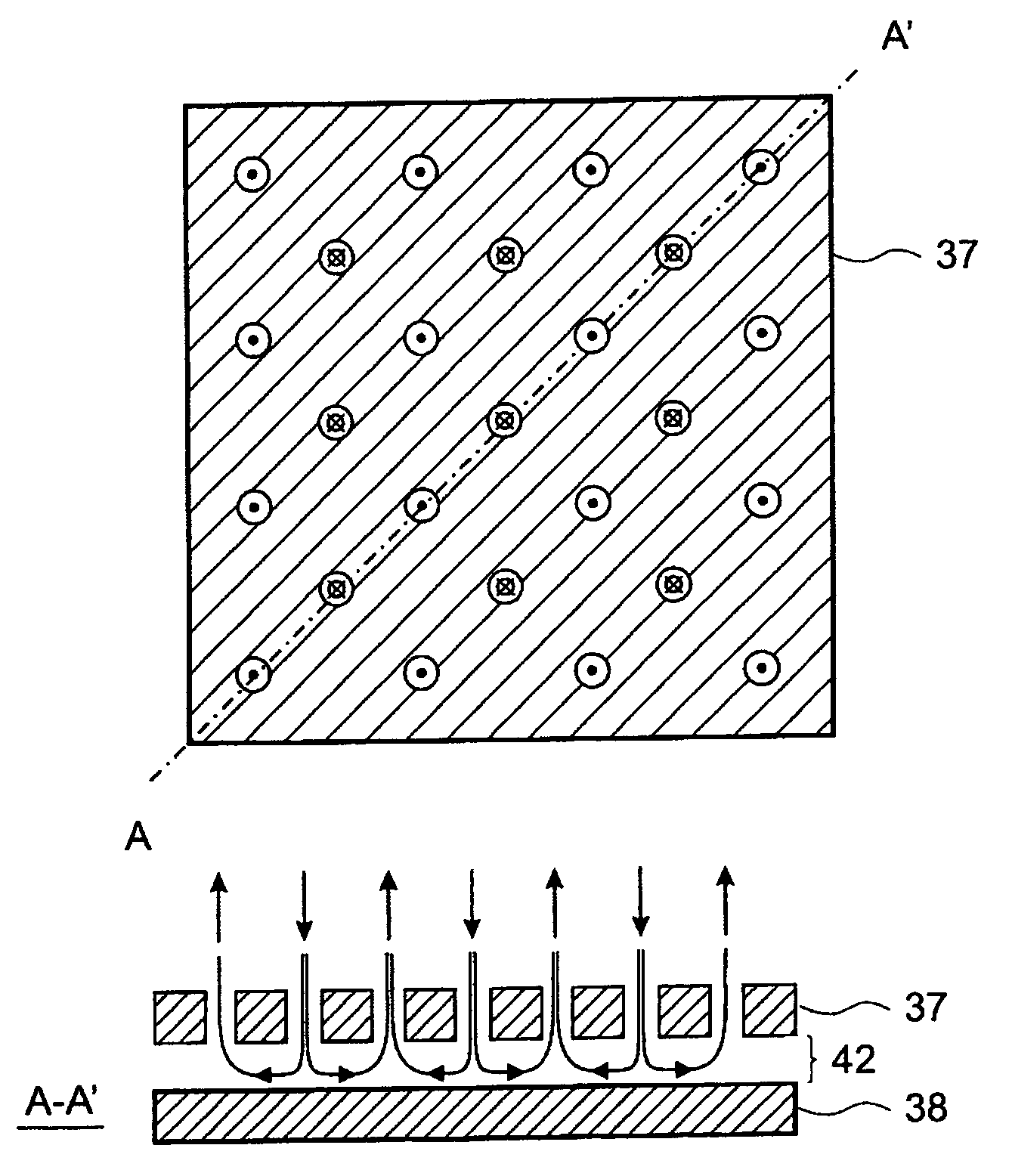

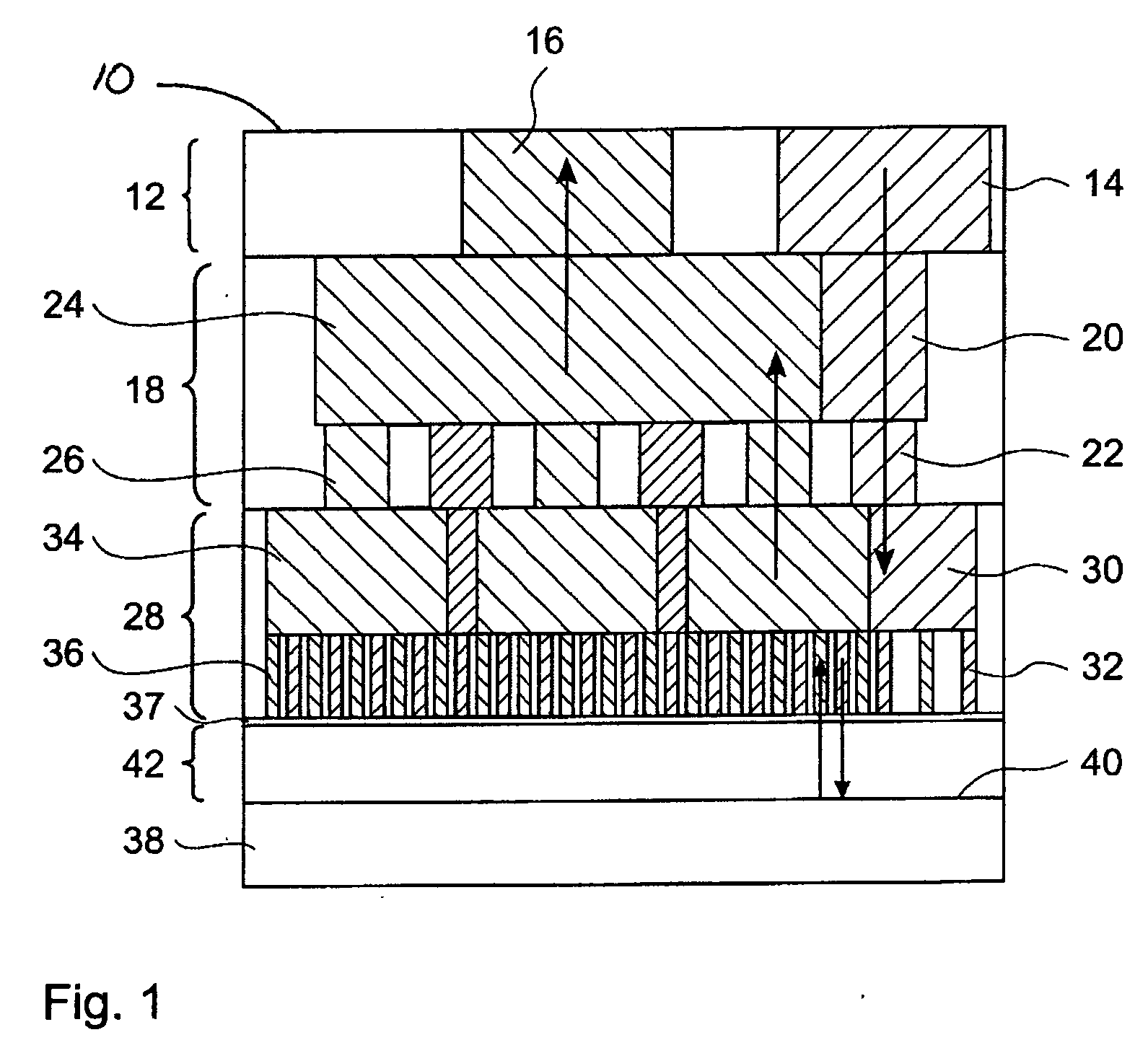

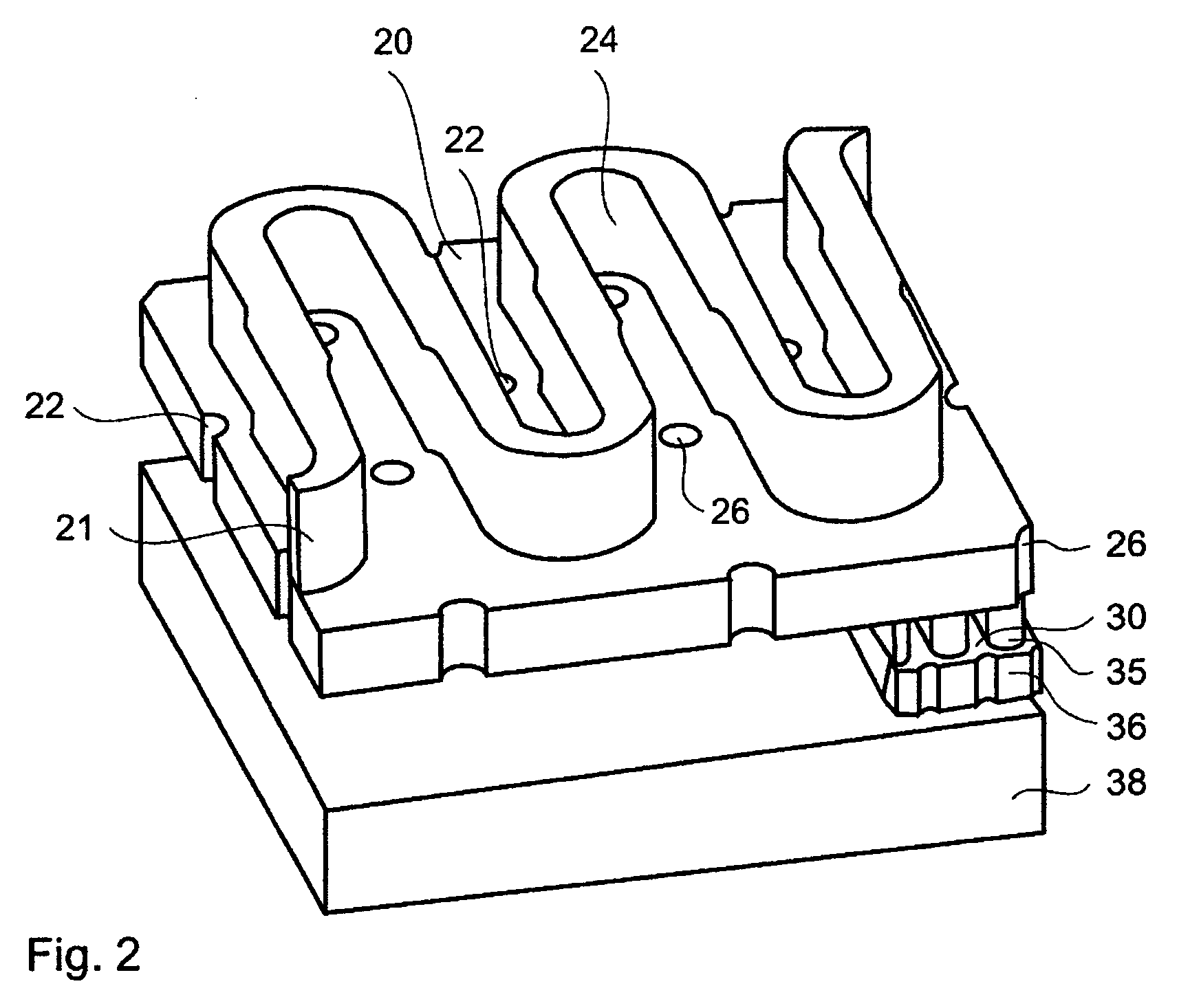

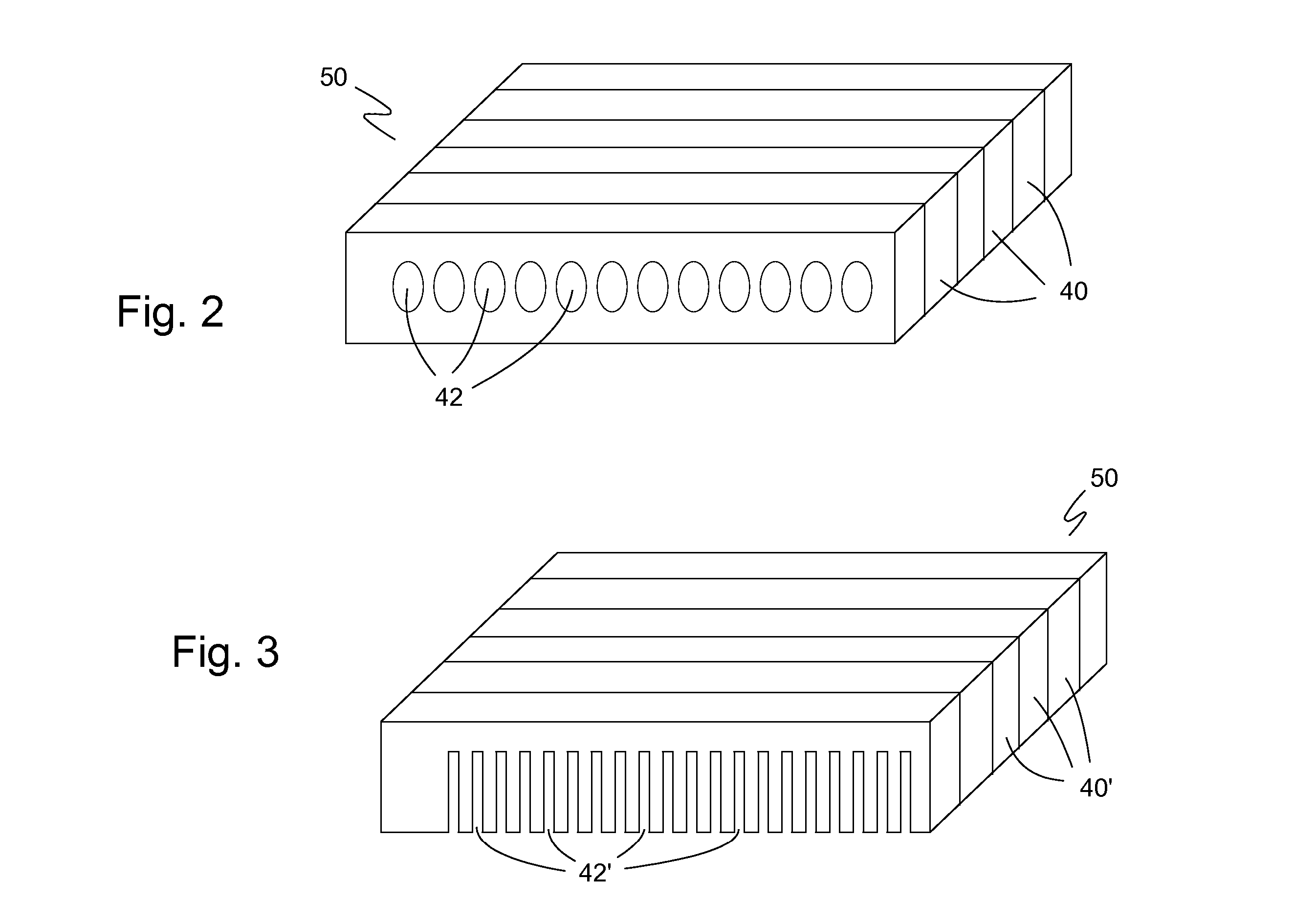

Cooling device

InactiveUS20070119565A1Minimal pressure dropMinimise pressure dropSemiconductor/solid-state device detailsSolid-state devicesEngineeringCoolant flow

A cooling device has a large number of closely spaced impinging jets, adjacent an impingement gap, with parallel return paths for supplying coolant flow for the impinging jets with the least possible pressure drop using an interdigitated, branched hierarchical manifold. Surface enhancement features spanning the impingement gap form U-shaped microchannels between single impinging jets and single outlets.

Owner:IBM CORP

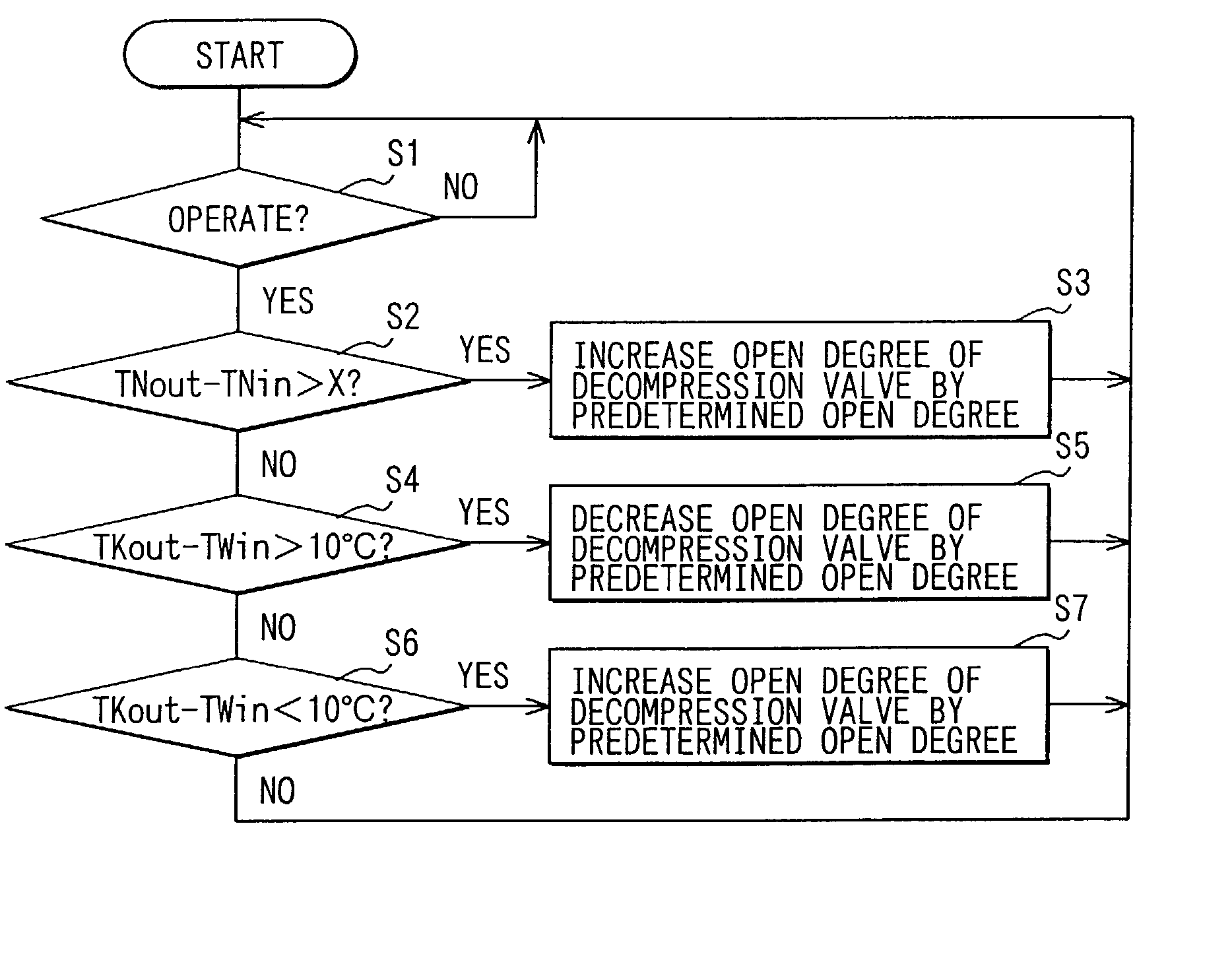

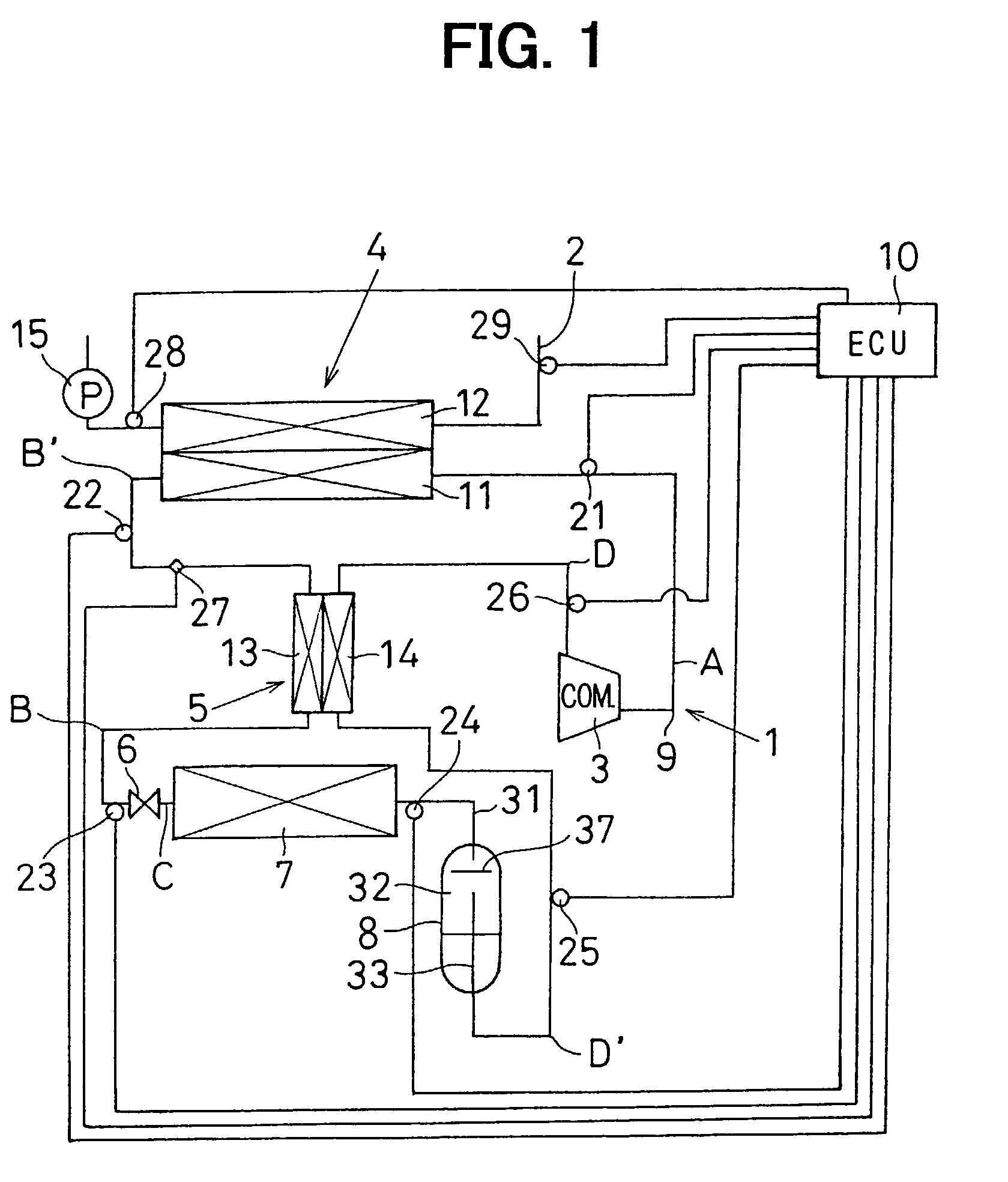

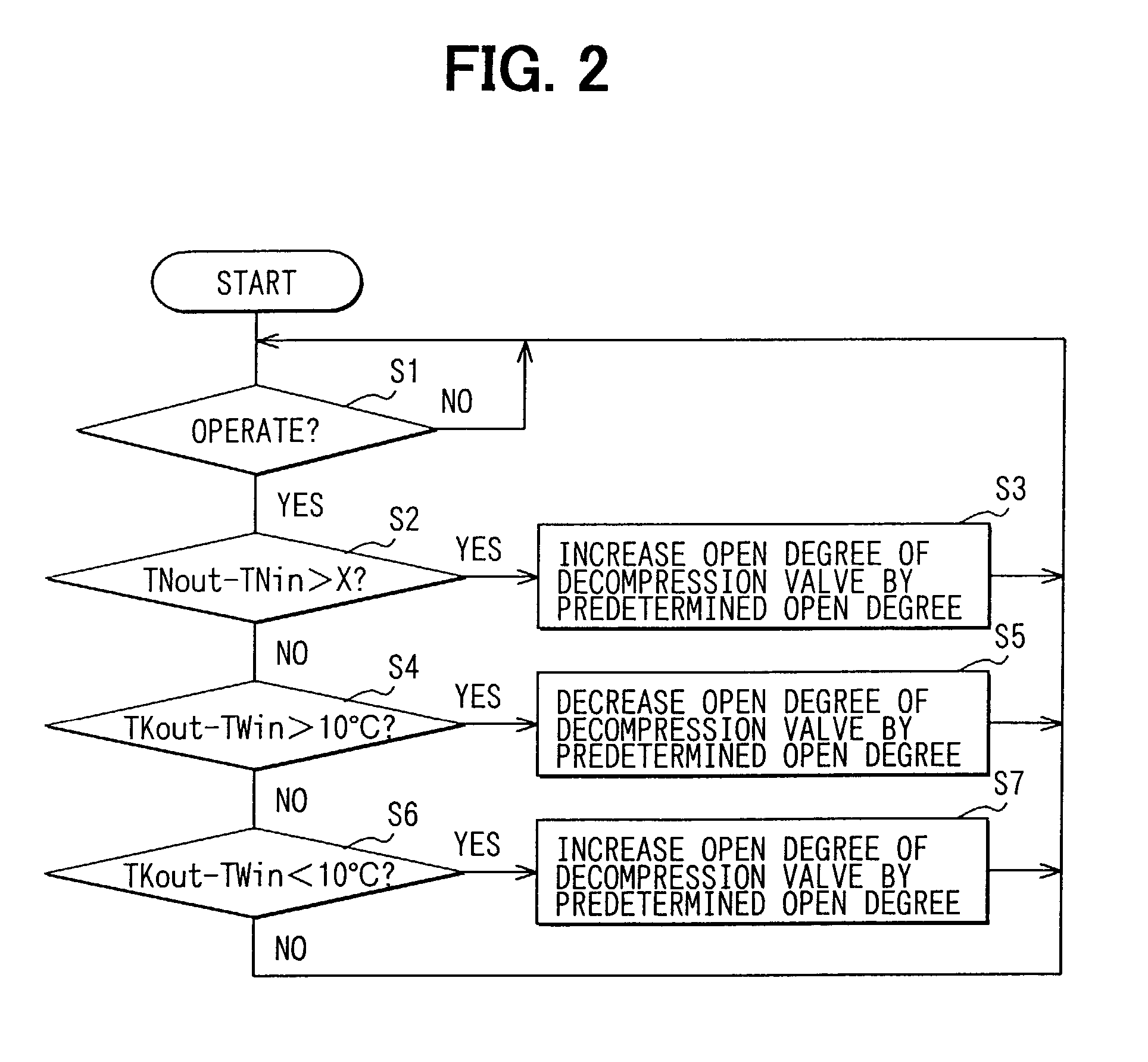

Super-critical refrigerant cycle system and water heater using the same

InactiveUS20030061827A1Speed up heat exchangeIncrease heightCompressorHeat pumpsWater flowEngineering

In a heat-pump water heater with a super-critical refrigerant cycle, a valve open degree of a decompression valve is controlled to control a pressure of high-pressure side refrigerant so that a temperature difference between refrigerant flowing out from the water-refrigerant heat exchanger and water flowing into a water-refrigerant heat exchanger is set in a predetermined temperature range. Thus, the pressure of high-pressure side refrigerant in the super-critical refrigerant cycle can be controlled, thereby suitably adjusting heat-exchange performance of an internal heat exchanger, and restricting the temperature of refrigerant discharged from the refrigerant compressor from being uselessly increased.

Owner:DENSO CORP

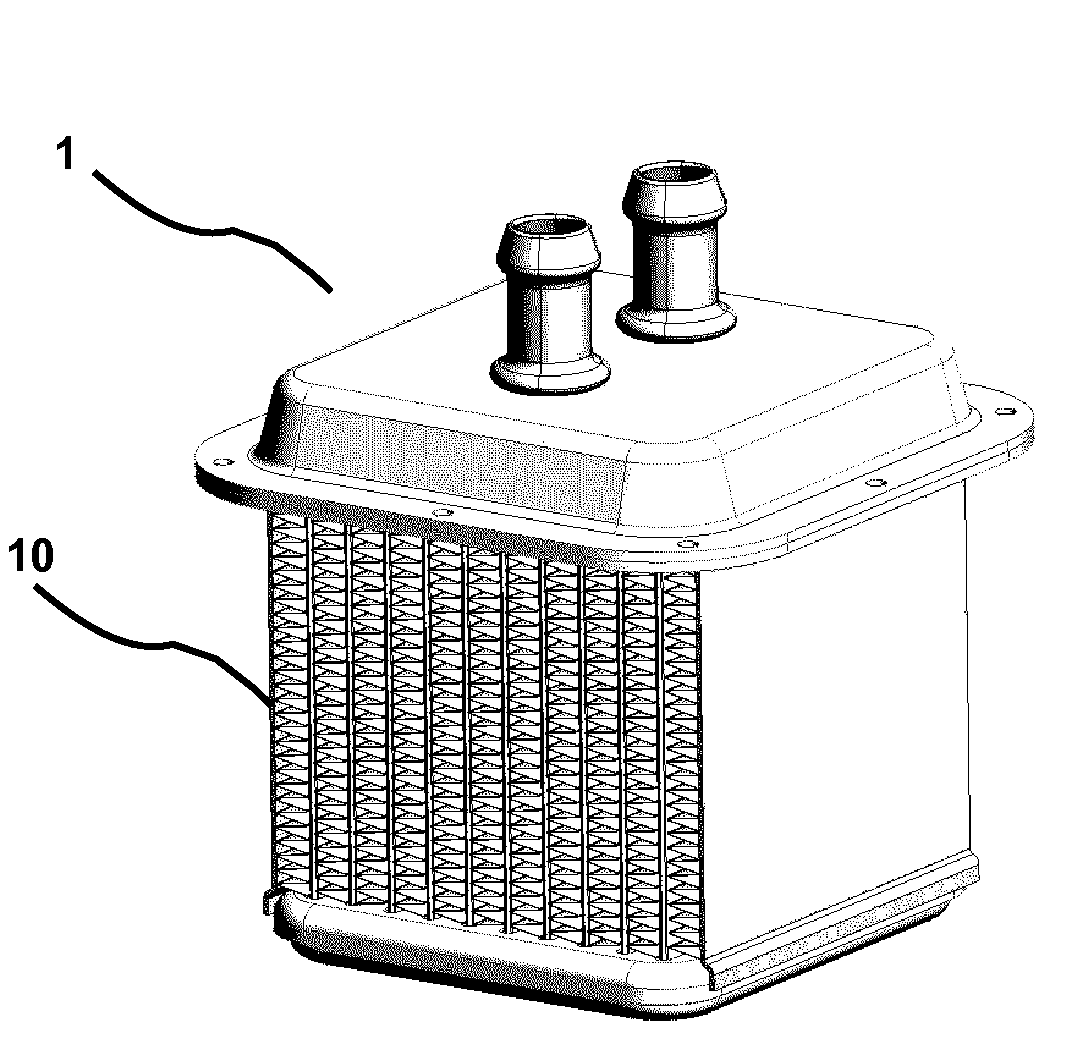

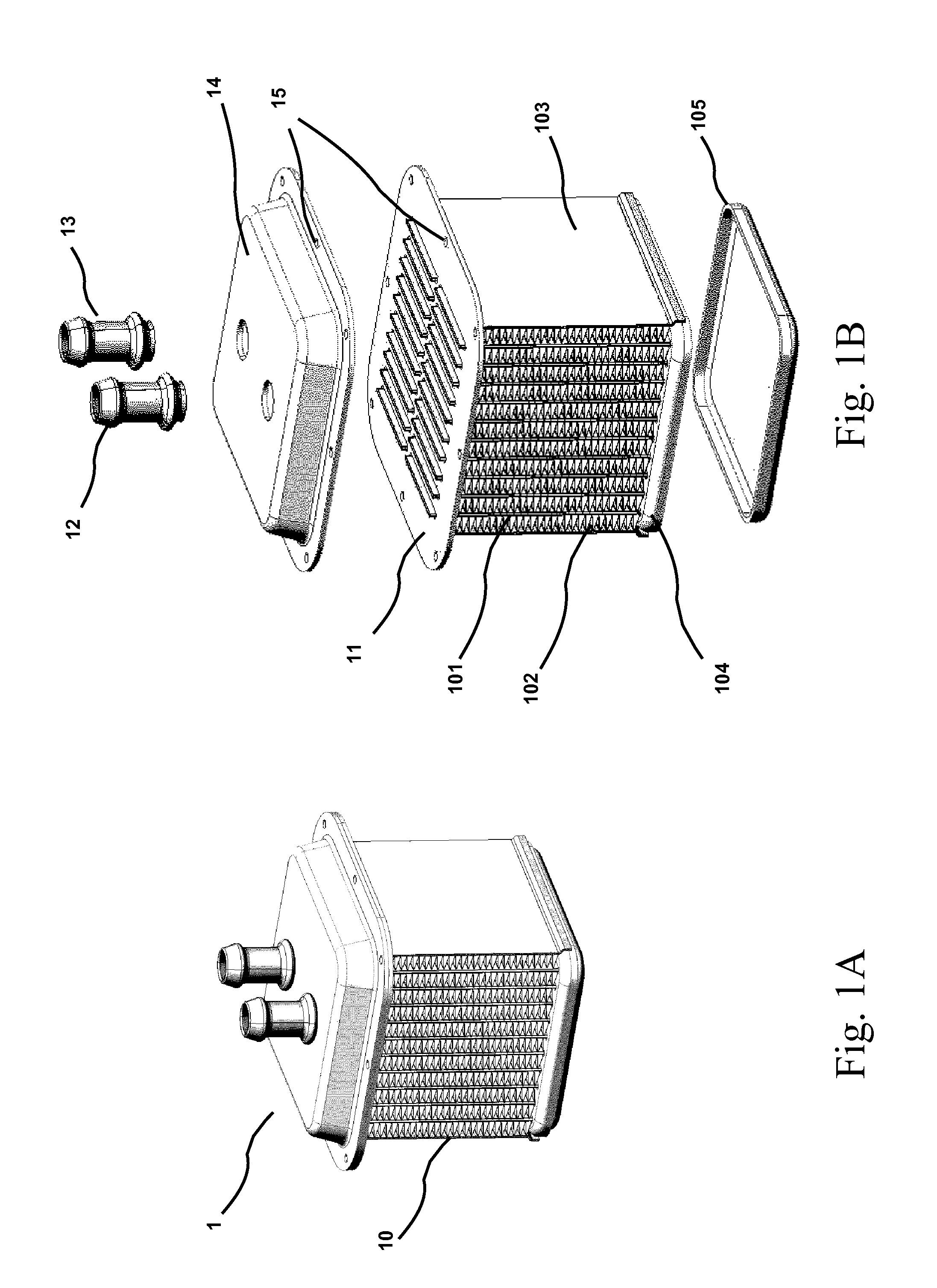

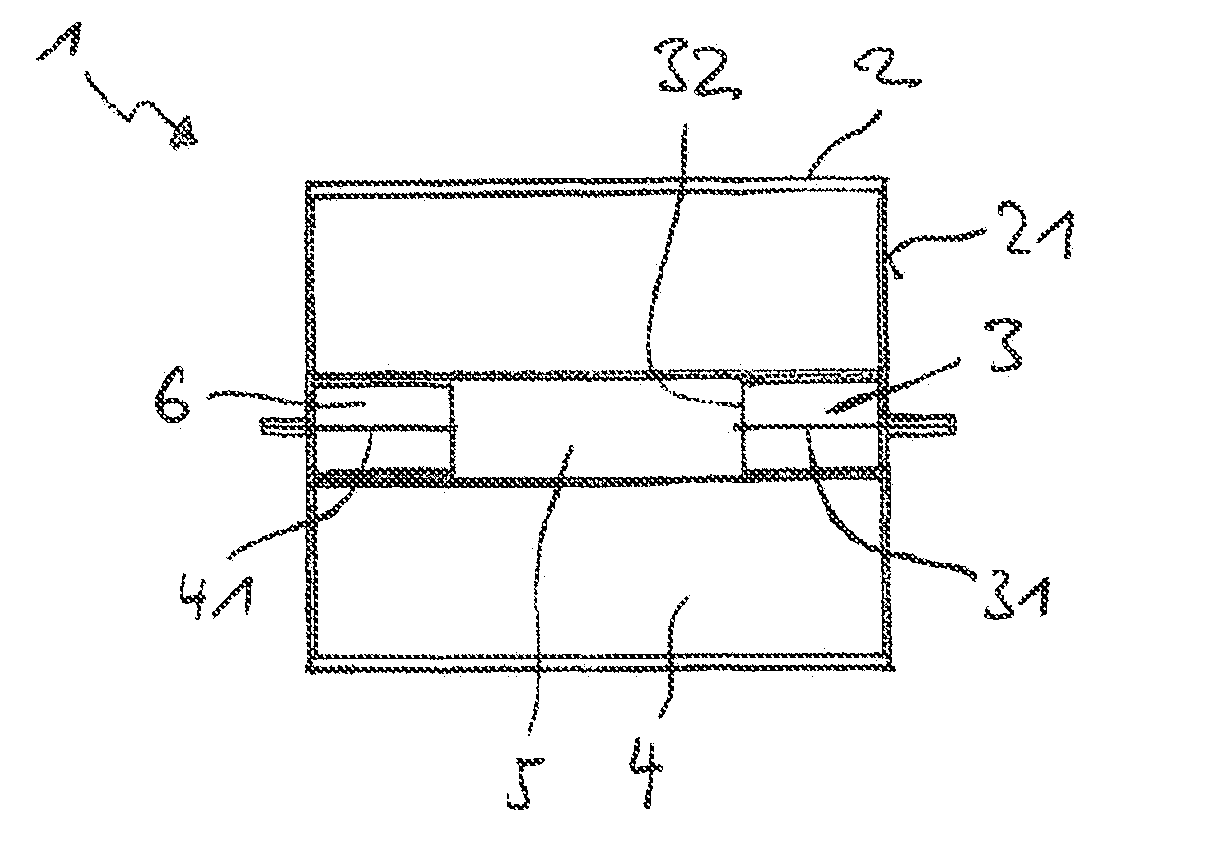

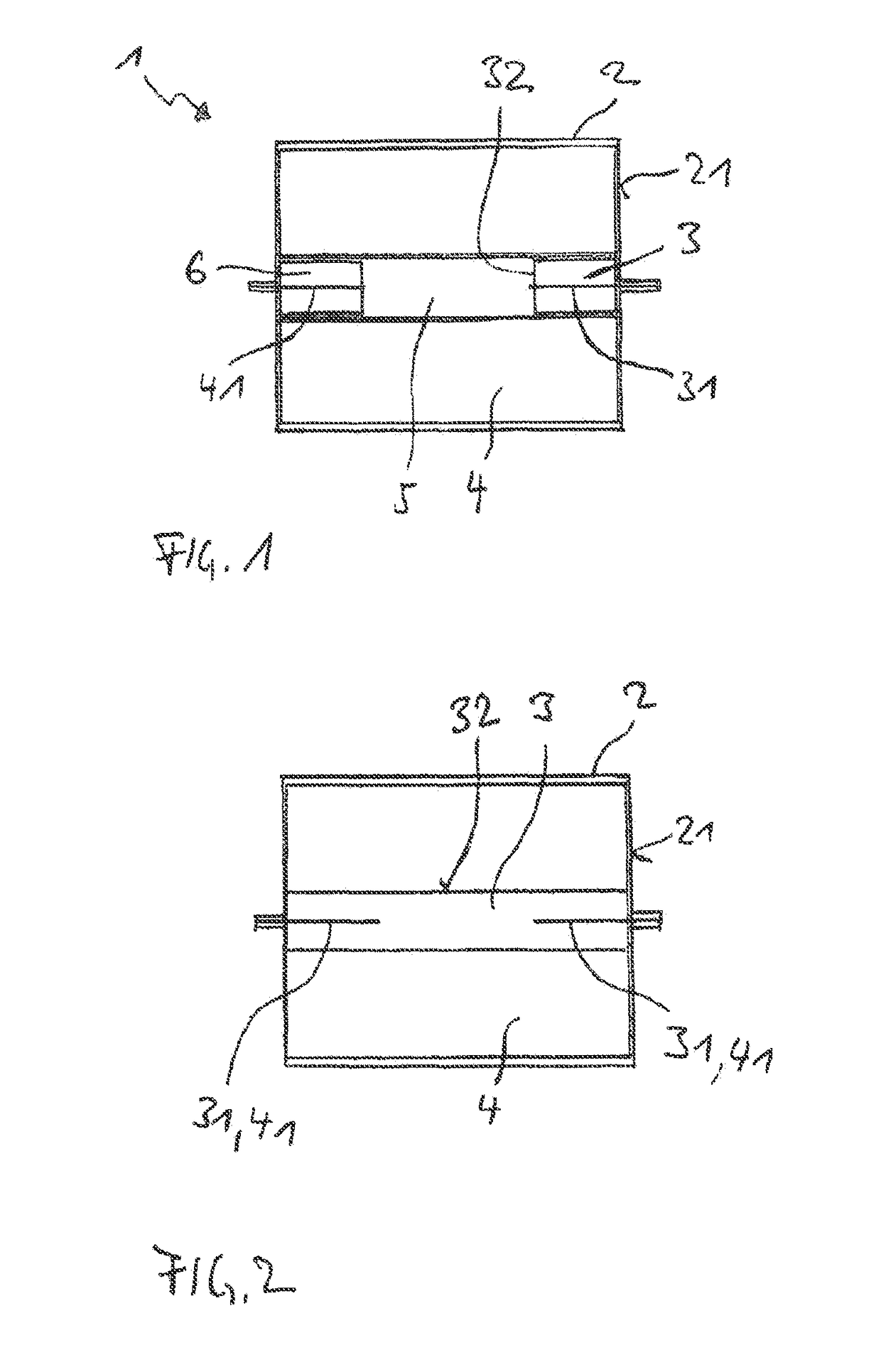

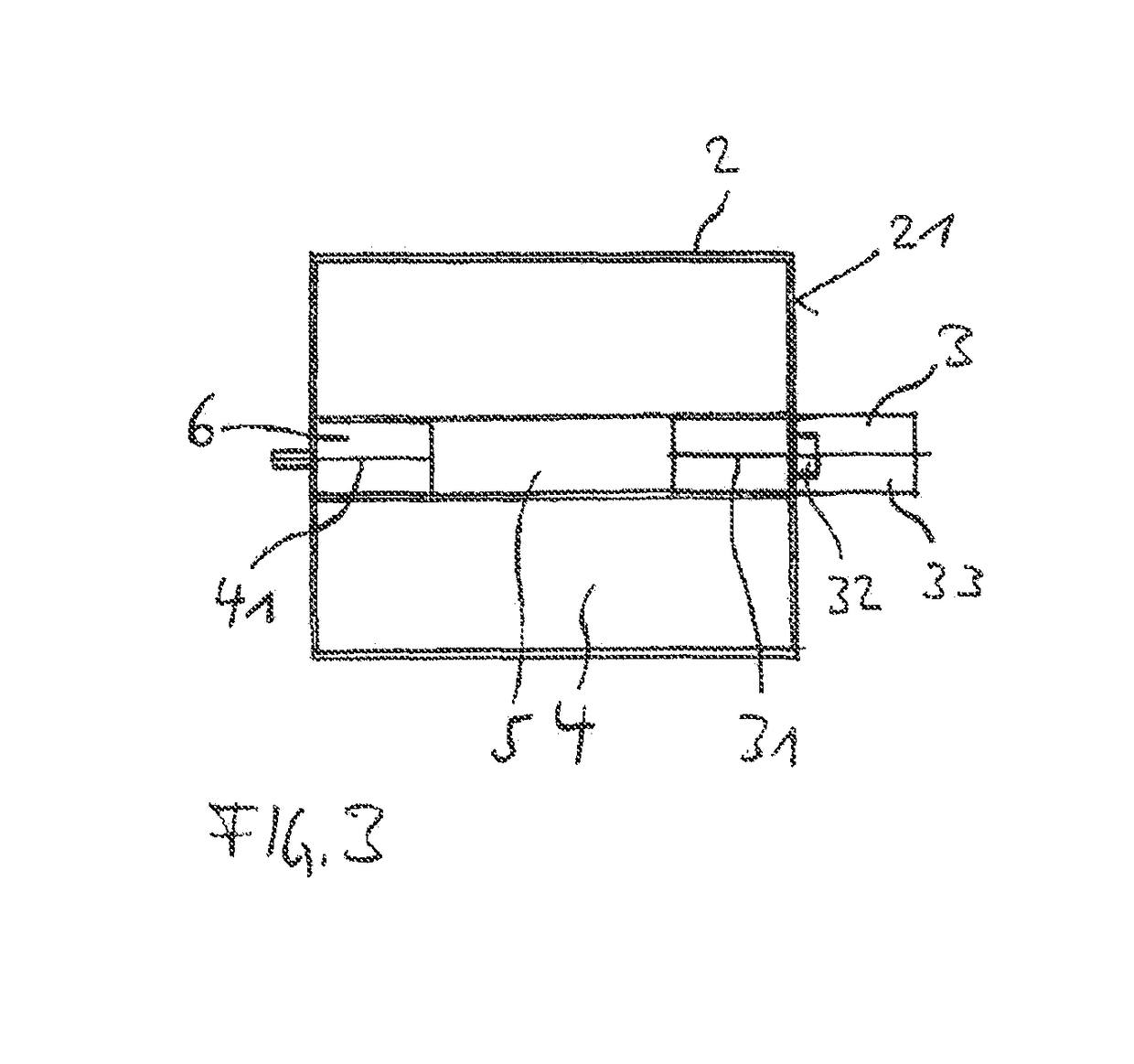

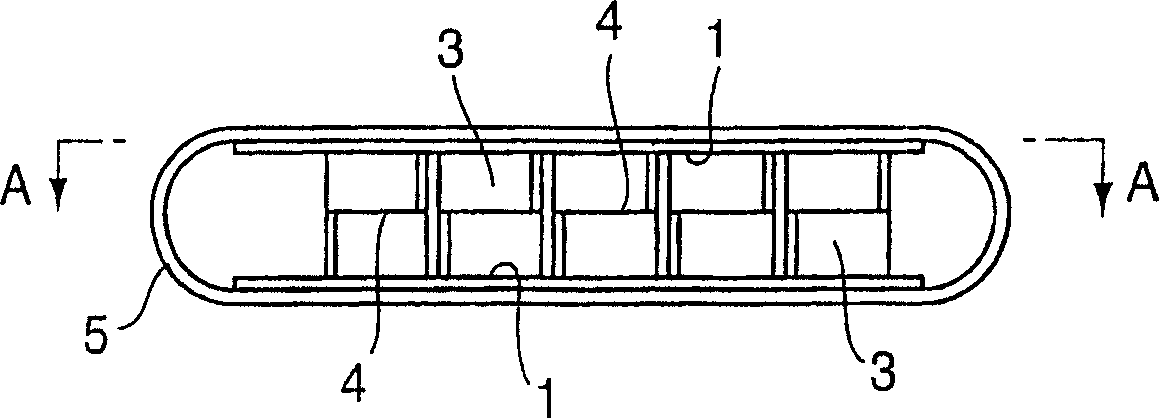

Heat exchanger arrangement

InactiveUS20090014153A1Satisfactory responseSpeed up heat exchangeInternal combustion piston enginesStationary conduit assembliesNuclear engineeringChiller

A heat exchanger arrangement comprising a charge cooler and a housing. The charge cooler comprises a charge cooler core, a header plate, a coolant entry duct and a coolant exit duct. Specifically, the charge cooler core comprises hallow heat-transfer elements through which a coolant can flow. The housing is in the form of a chamber with a single aperture for receiving the cooler core and comprises an air entry duct, an air exit duct and a flange. The cooler core is fixed inside the housing by fixing the header plate of the charge cooler to the flange of the housing. Additionally, the header plate of the charge cooler closes the single aperture for receiving the cooler core.

Owner:JOO DE DEUS & FILHOS

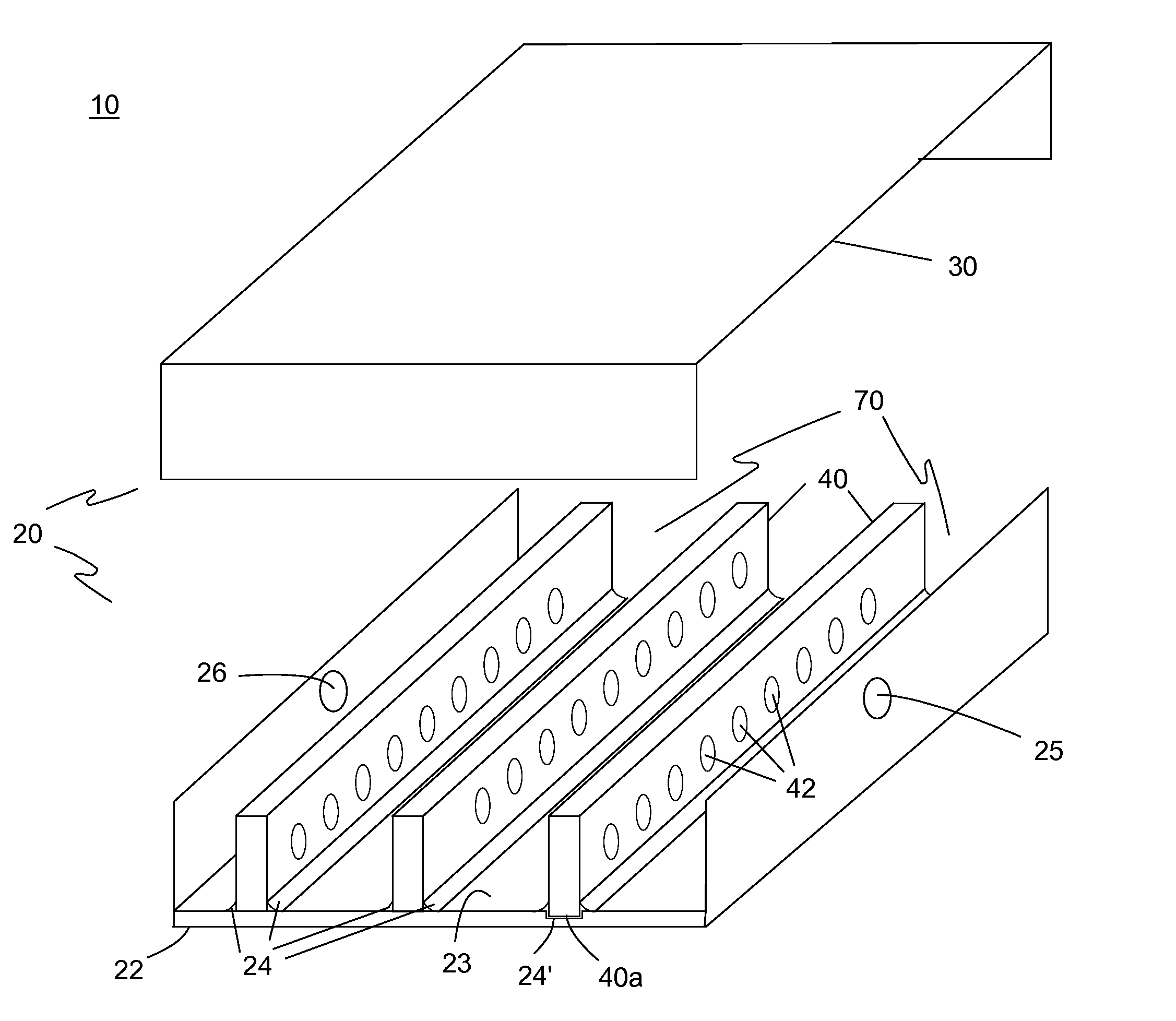

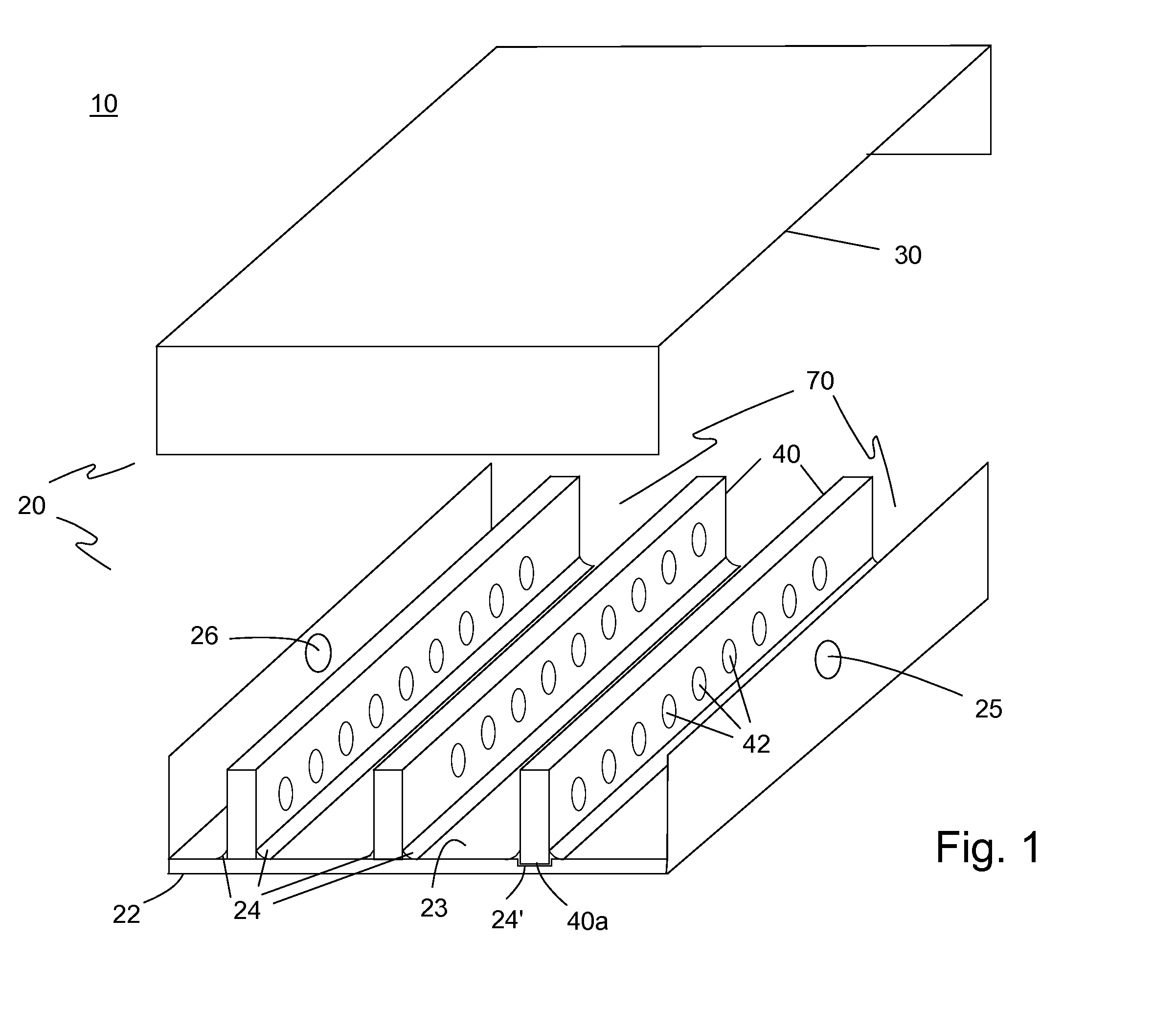

High Efficiency Fluid Heat Exchanger and Method of Manufacture

InactiveUS20060237166A1Good thermally conductive bondIncrease surface areaMetal-working apparatusHeat exhanger finsEngineeringHeat exchanger

A fluid heat exchanger has a housing having a thermally conductive base, a plurality of fin members connected to the base in a parallel, spaced relationship, a heat exchanger fluid inlet on one side of the plurality of fin members, and a heat exchanger fluid outlet on the opposite side of the plurality of fin members. The plurality of fin members each have a plurality of passageways and are arranged in the housing so that the passageways of one fin member are offset from the passageways of adjacent fin members.

Owner:FERROTEC USA CORP

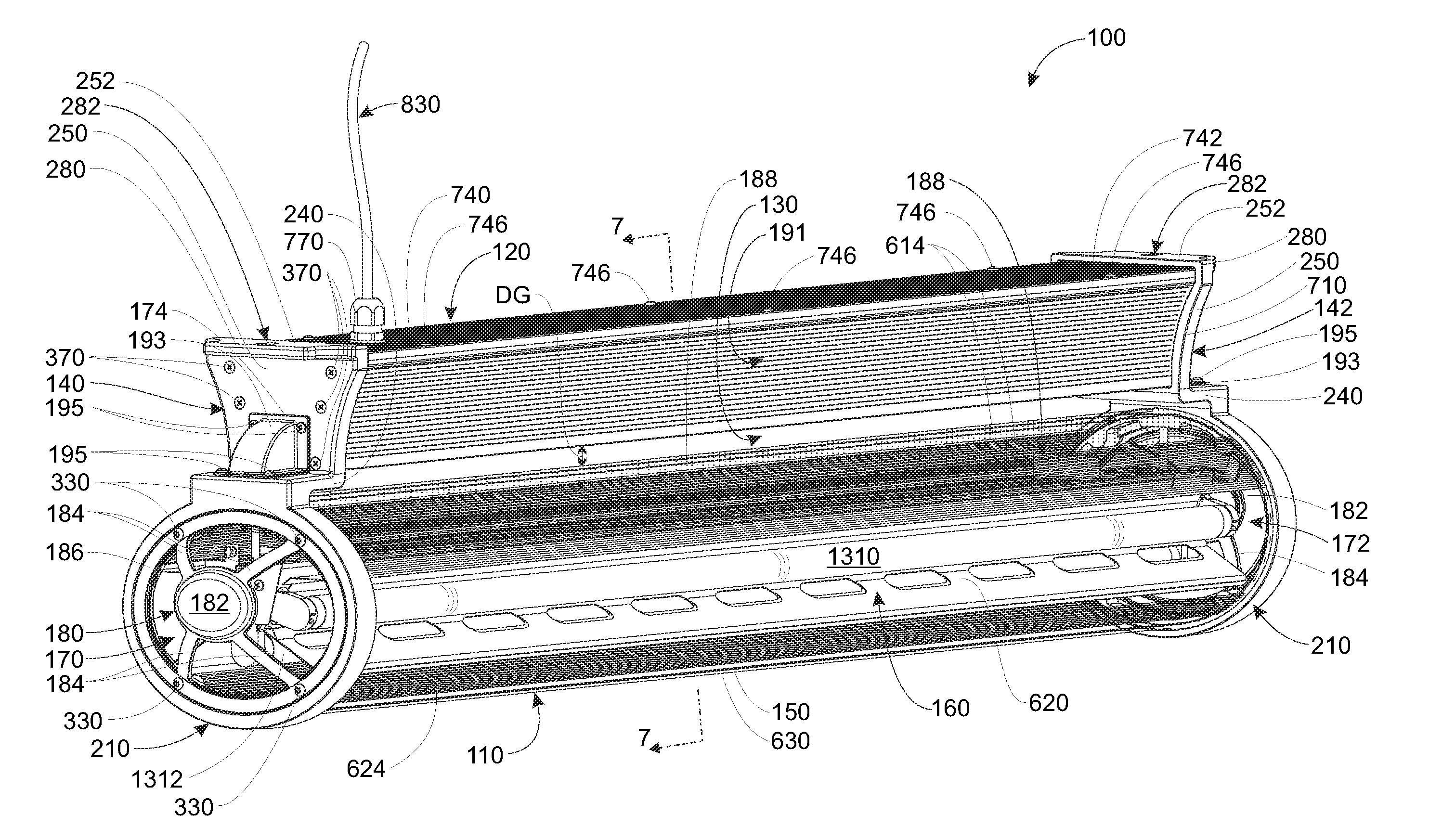

Adjustable snow making tower

InactiveUS6161769AIncrease flexibilityOptimize quantityLiquid surface applicatorsStands/trestlesBlock and tackleEngineering

Method and apparatus for making snow by generating water spray from a triple array of multiple nozzle sub-boom branch-pipes transversely protruding from the upper end of a main boom of a pivotably adjustable snow making pipe tower. Three air jet streams, one for each branch pipe, are simultaneously discharged under high pressure into and sequentially through the throats of each associated multiple stack of water sprays issuing from each set of branch pipe nozzles to thereby form multiple spray plumes of atomized and seeded water all directed forwardly from the upper end of the tower pipe. The water pipe may be an elliptical aluminum extrusion with two interior air tubes respectively controllably feeding large and small diameter air jet arrays to thereby provide a range of air jet water spray interaction. The pipe tower may be pivotally raised and lowered by a block-and-tackle or chain fall type drive mechanism that may be recoupled to the tops of a lifting pole and tower pipe for bodily raising the entire tower pipe and its support pipe telescopically on a ground support pole. Spreader-supported guy wires may be used to brace the tower pipe and also provide an electrical deicing circuit. Air jet control, blow-out valving and water drain conduit arrangements are disclosed, and also universally adjustable ground support systems for the pipe tower, including an underground-fed combined telescopic hydraulic ram forming air and water conduits.

Owner:BOYNE USA +1

Vapor-tight lighting fixture

InactiveUS20120229025A1Readily and individually accessible for service and replacementReadily removableLight source combinationsPoint-like light sourcePenetronLed array

This invention provides a vapor-tight luminaire that maintains a moisture-proof, sealed lower housing for the light-producing lamps (fluorescent lights, LED arrays, etc.) while isolating the electronic components in a separate, upper housing that is spaced apart from, and largely thermally isolated from, the lamps. The lamp housing comprises a unitary non-penetrated tubular lens with one or more removable end caps, sealed by gaskets. The lamp assembly is slidably mounted within the lower housing so that it is readily removable and replaceable with another assembly of the same or different type. The electronics in the upper housing is readily accessible and replaceable by removing a top cover that encloses a three sided channel member. The upper housing is metal and desirably enhances heat exchange with the environment. The two housings are held together by a pair of opposing end cap structures that include a housing end and a removable end cap. The housing end includes an upper plate that is fastened against an adjacent end of the upper housing's channel member. This compresses gaskets that stand between the respective ends of the lens and a lower ring on each housing end. The electronics of the upper housing is interconnected via a wiring harness connector to an end connector in on the lamp assembly. The wiring harness passes between the two housings free of penetration of the lens.

Owner:GREENDOT TECH

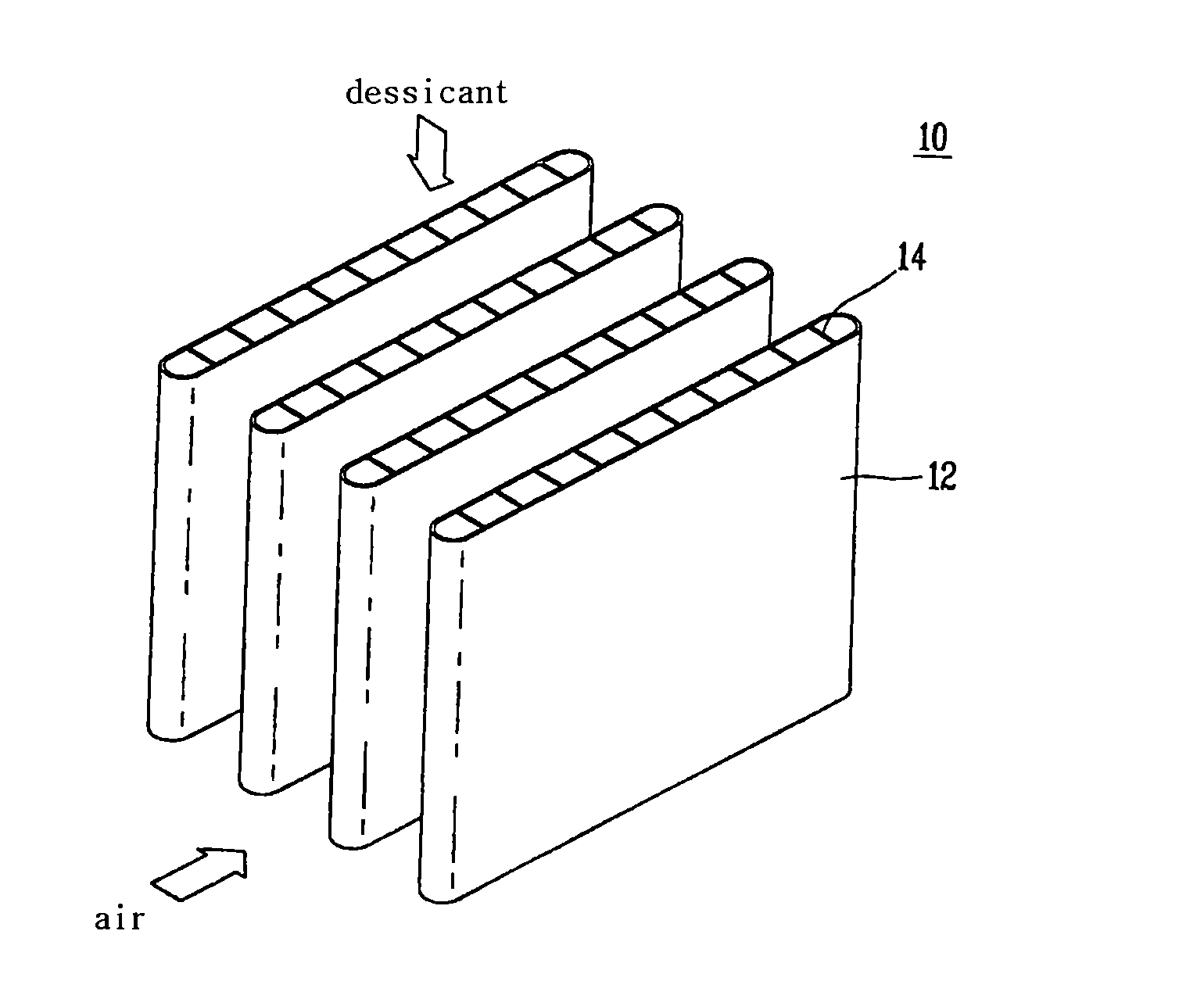

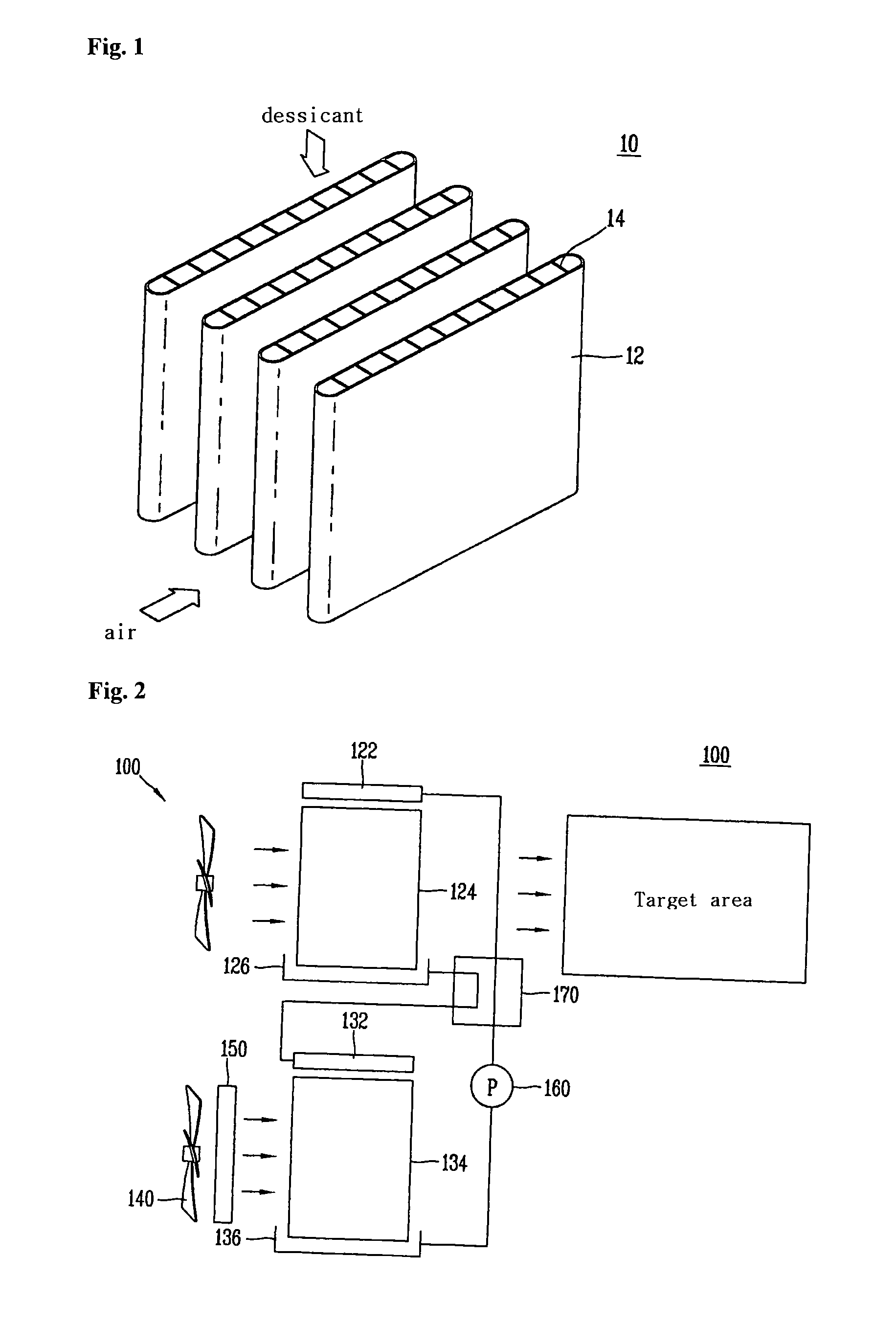

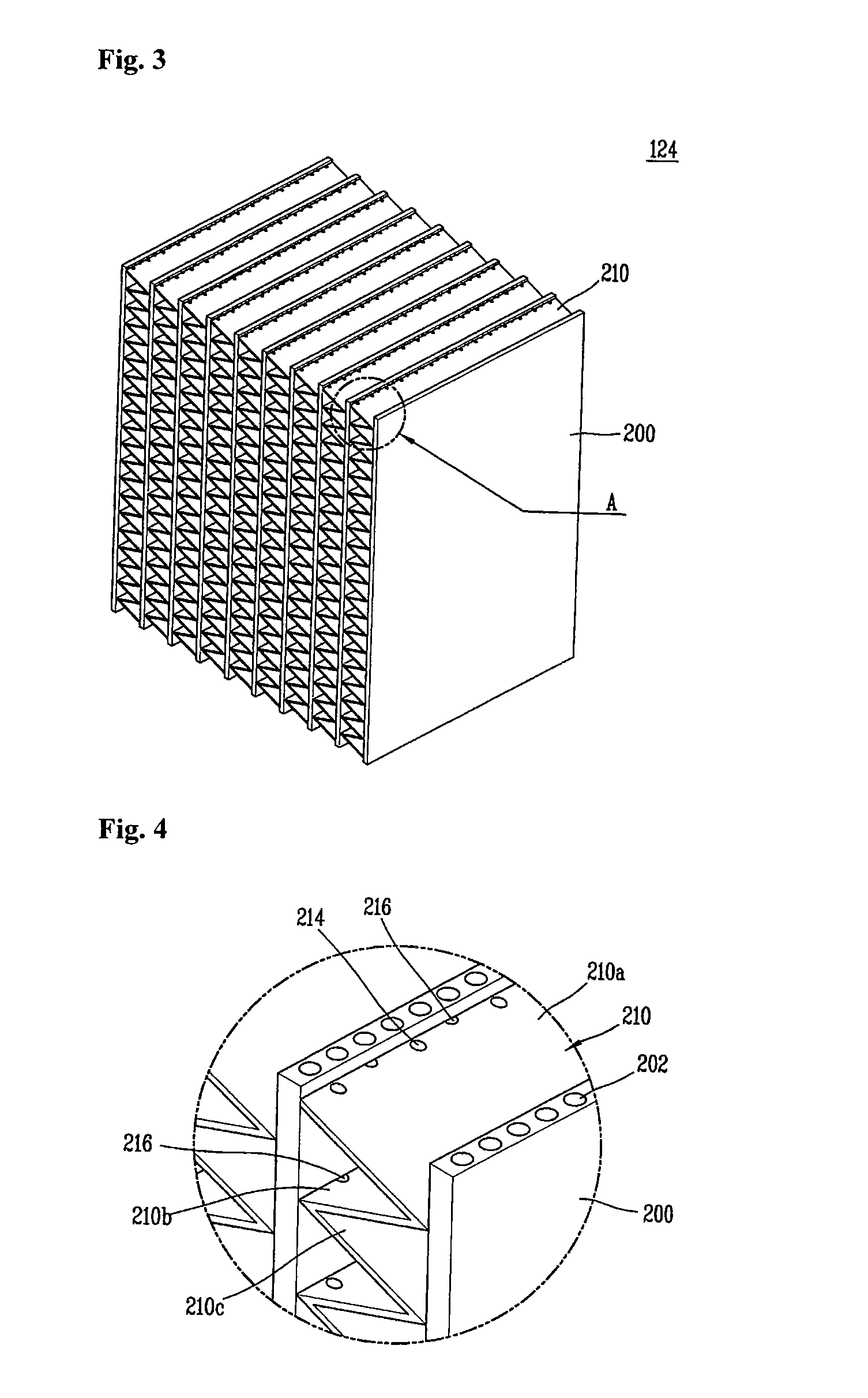

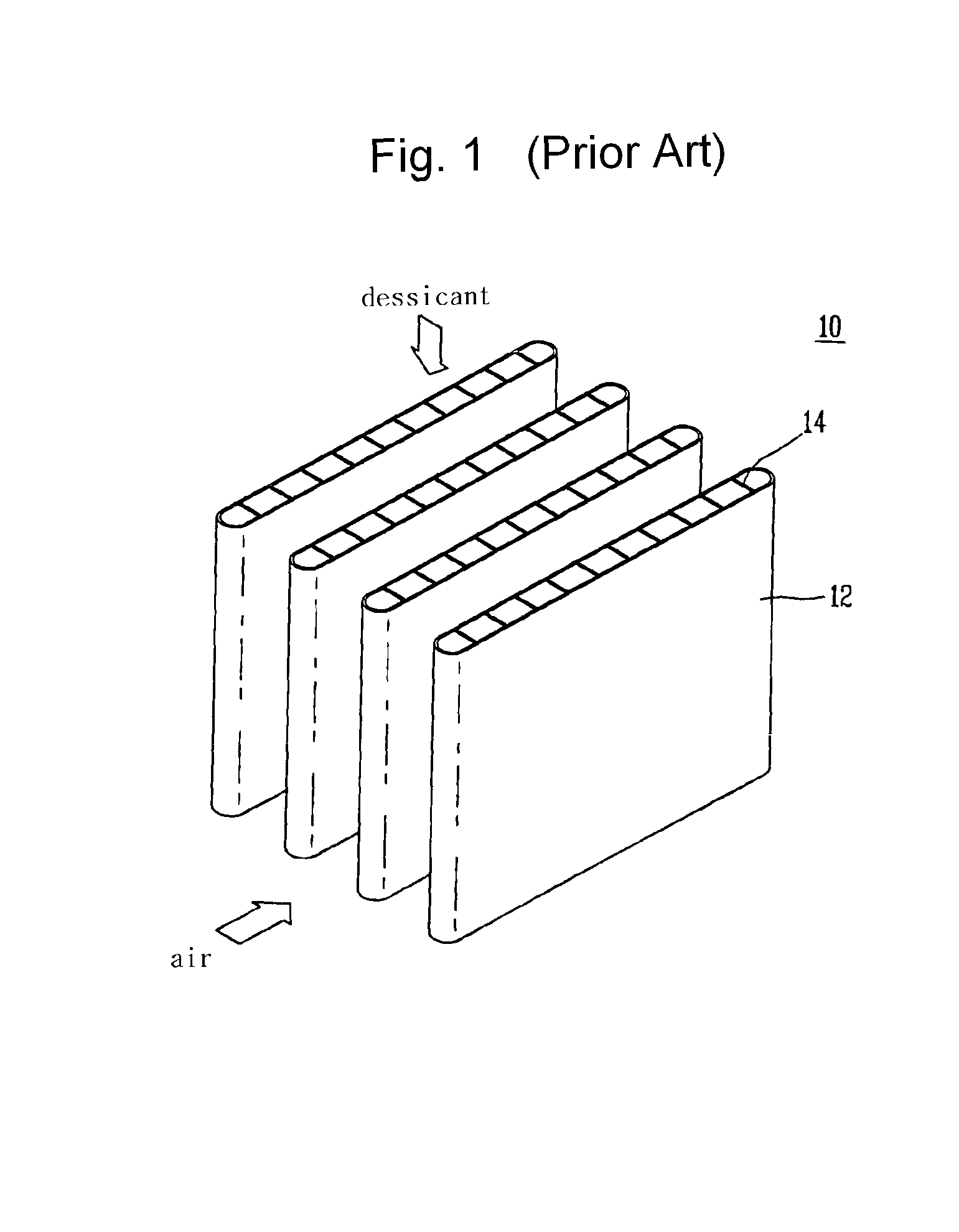

Heat exchanger for dehumidifier using liquid desiccant and dehumidifier using liquid desiccant having the same

InactiveUS20110073290A1Small sizeIncrease heat transfer efficiencyGas treatmentDispersed particle separationEngineeringLiquid desiccant

Disclosed are a heat exchanger for a dehumidifier using a liquid desiccant and a dehumidifier using a liquid desiccant having the same. The heat exchanger for a dehumidifier using a liquid desiccant, comprises: a plurality of plate-type heat exchanger bodies to which a heat transfer medium flows through flow paths formed therein; and a plurality of plates extending between the respective heat exchanger bodies, and inclined with respect to the surfaces of the heat exchanger bodies.

Owner:KOREA INST OF SCI & TECH

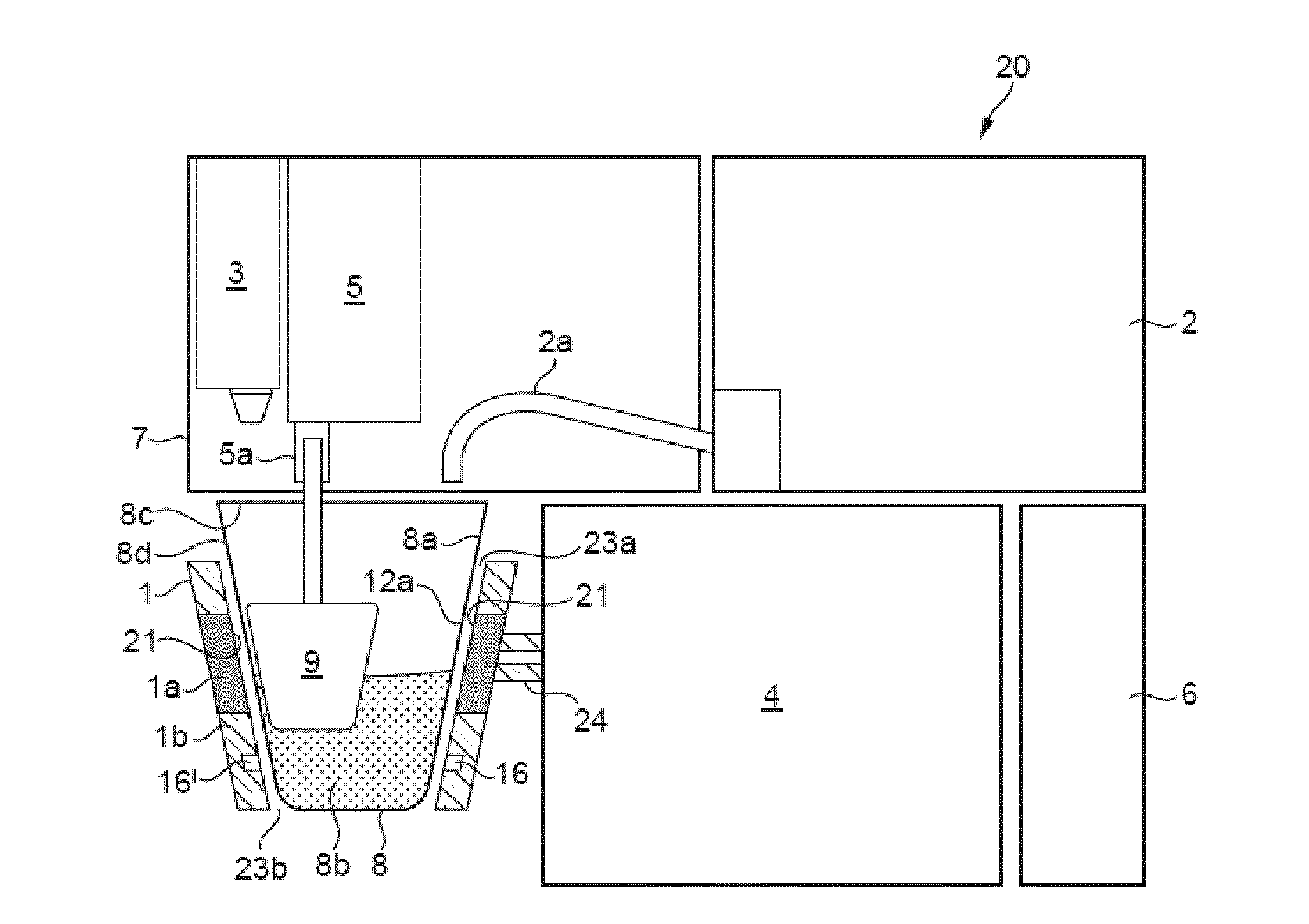

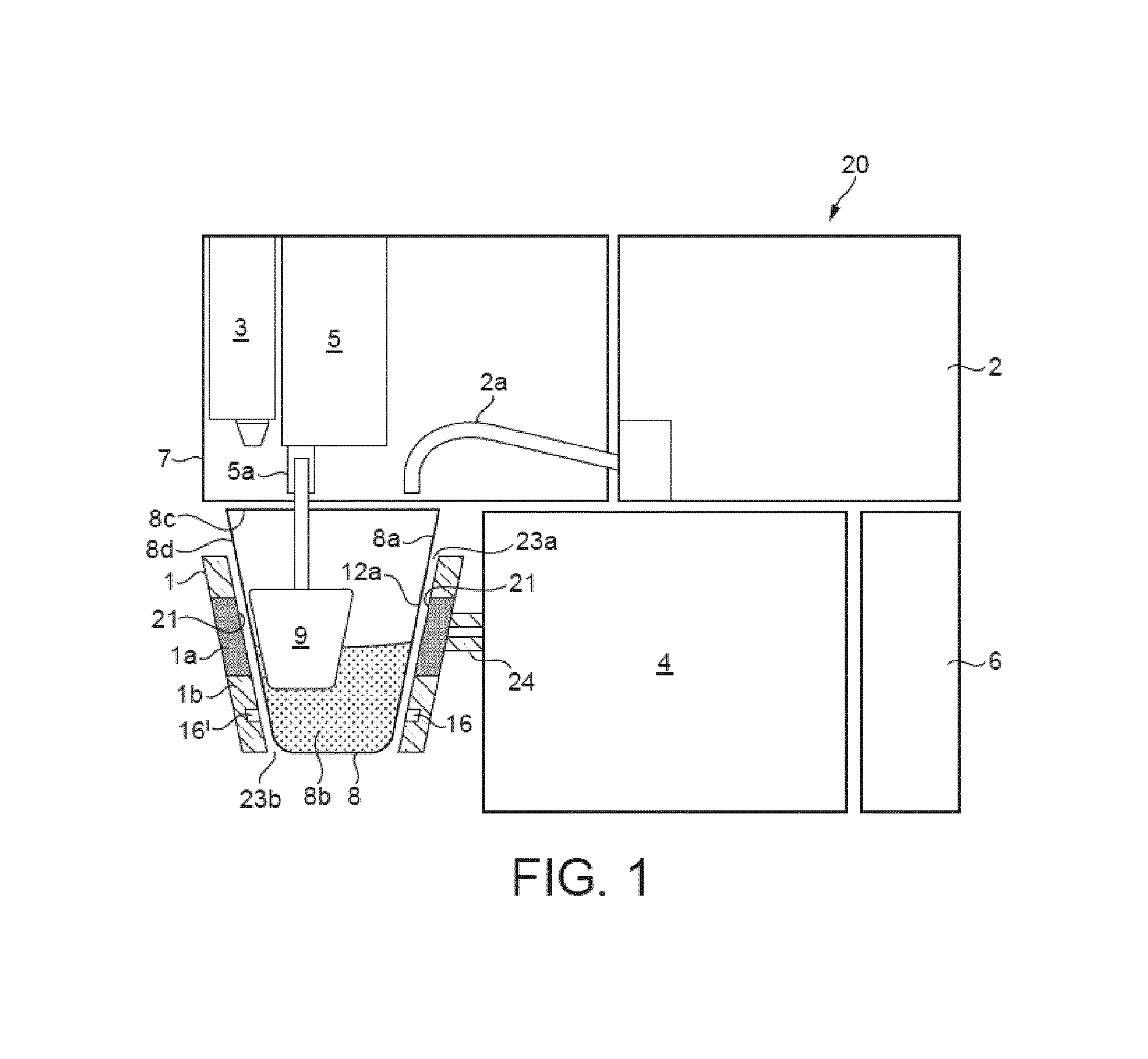

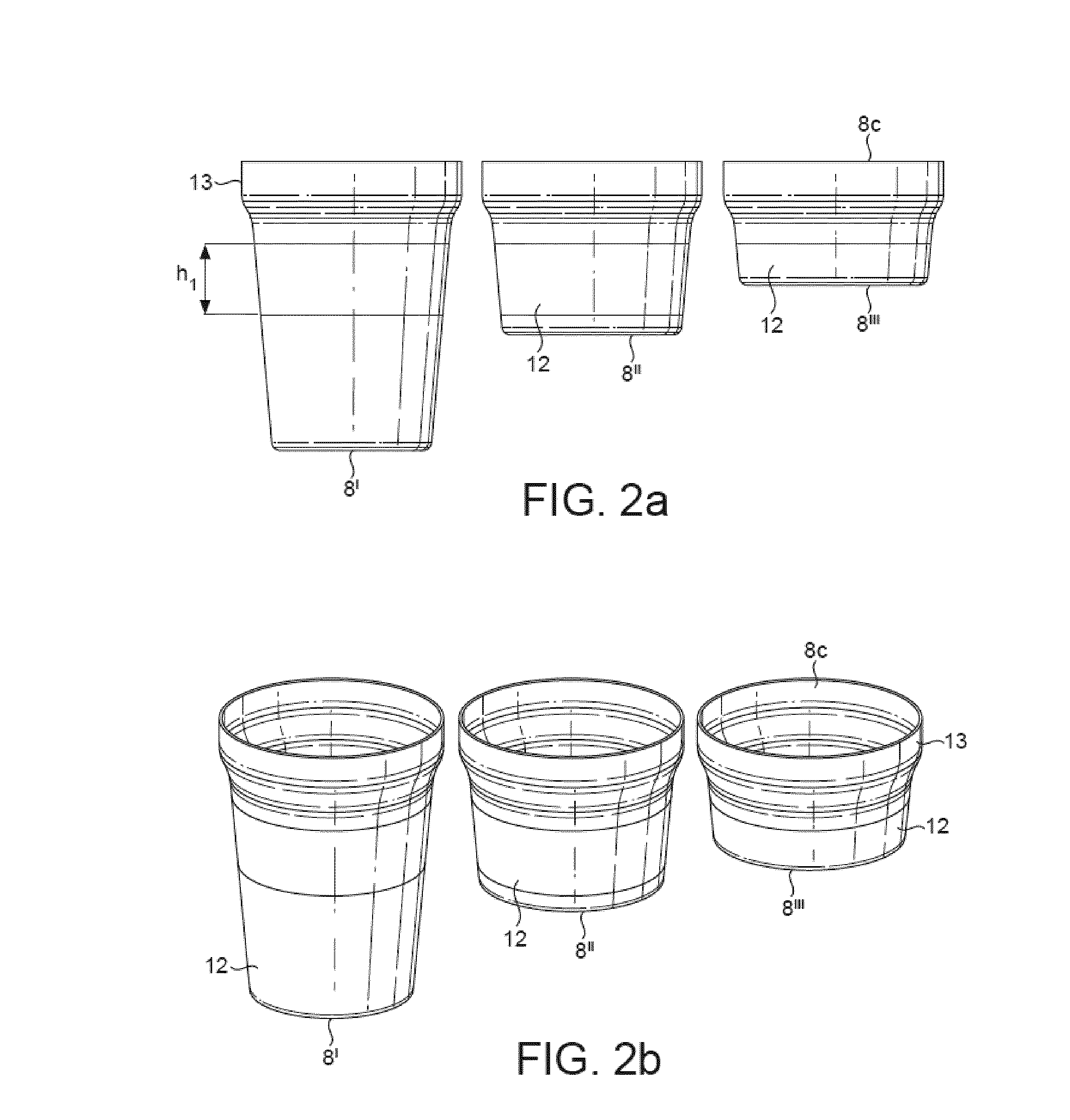

Machine, system and method for preparing a cooled confectionery product with aerated texture

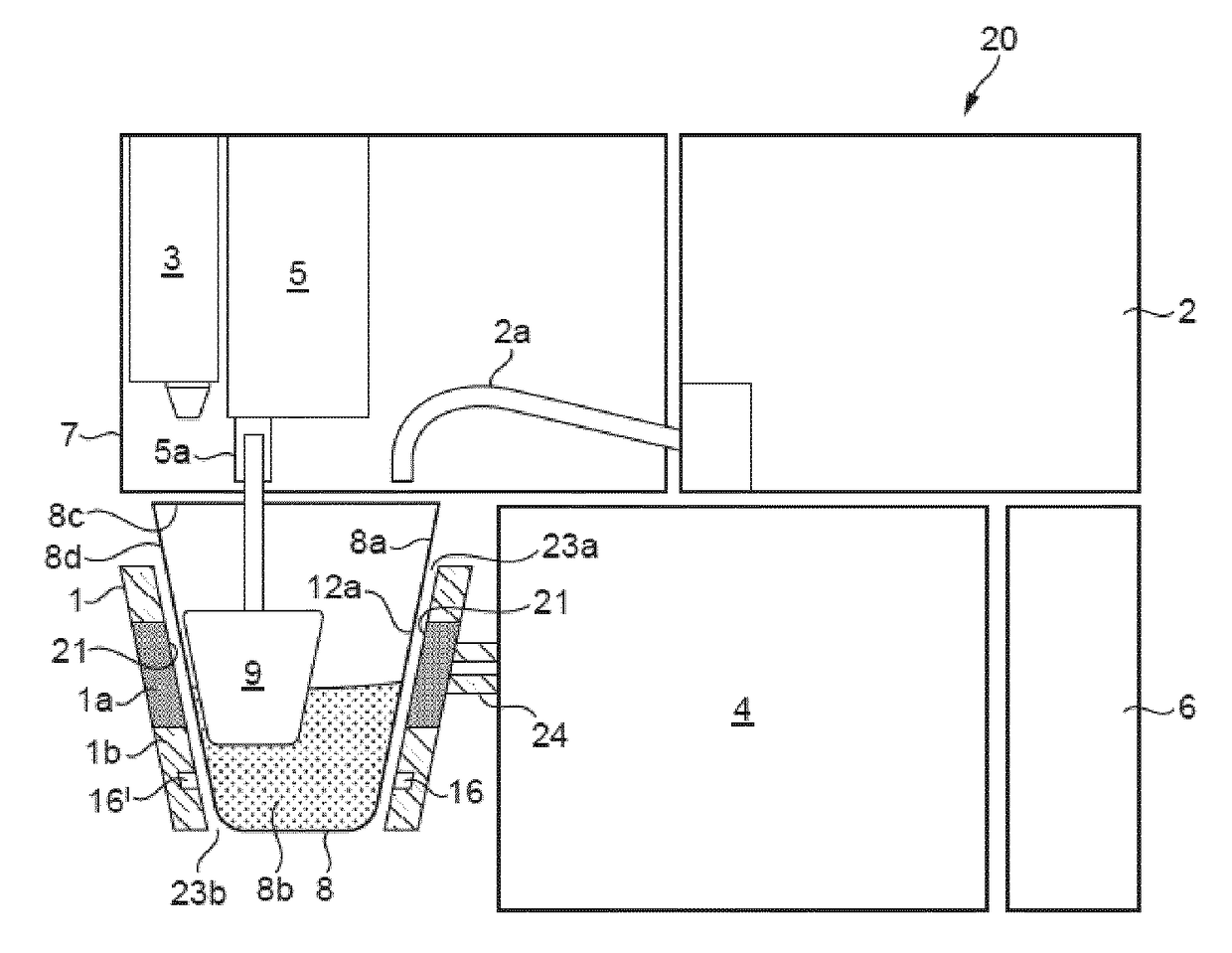

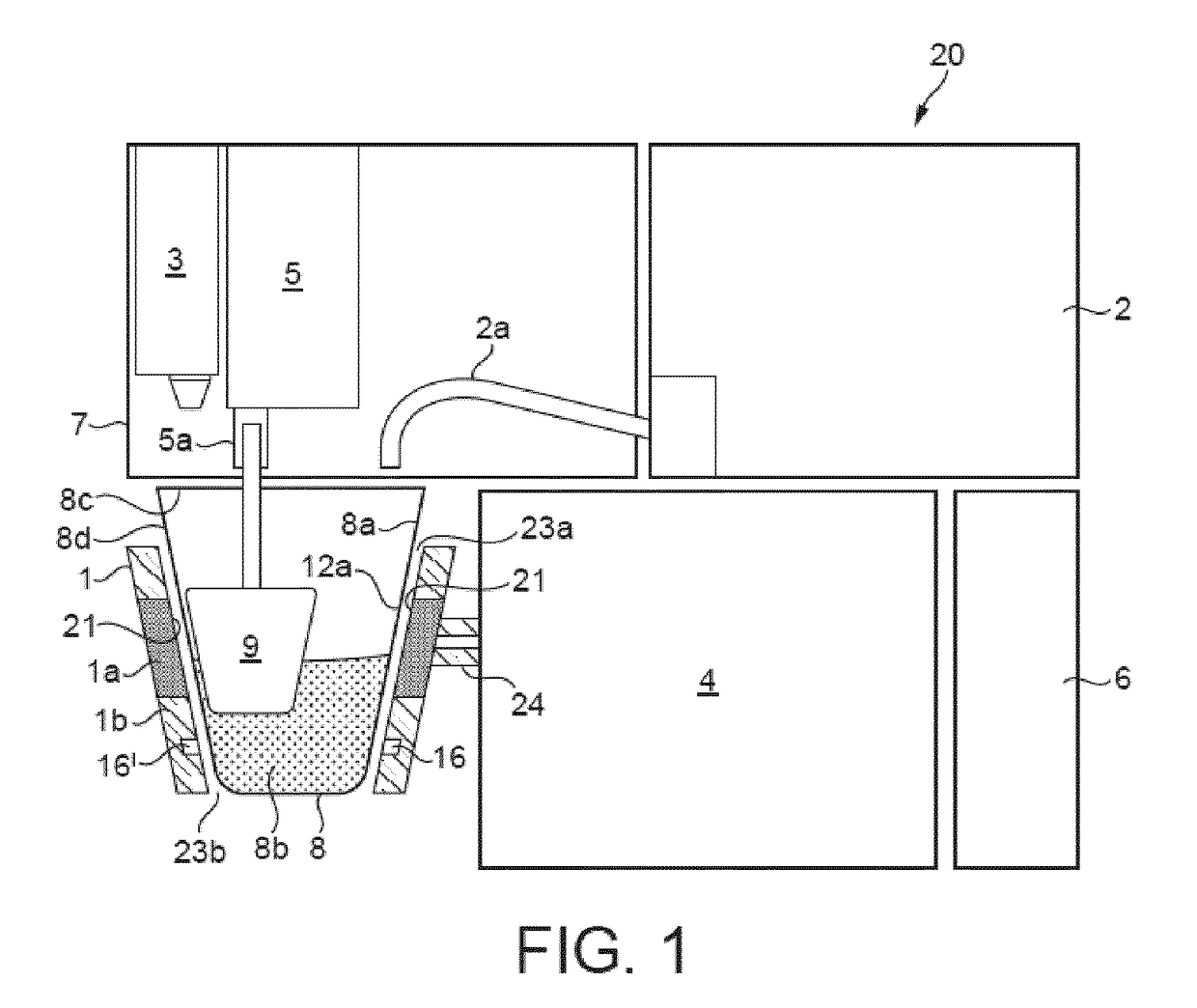

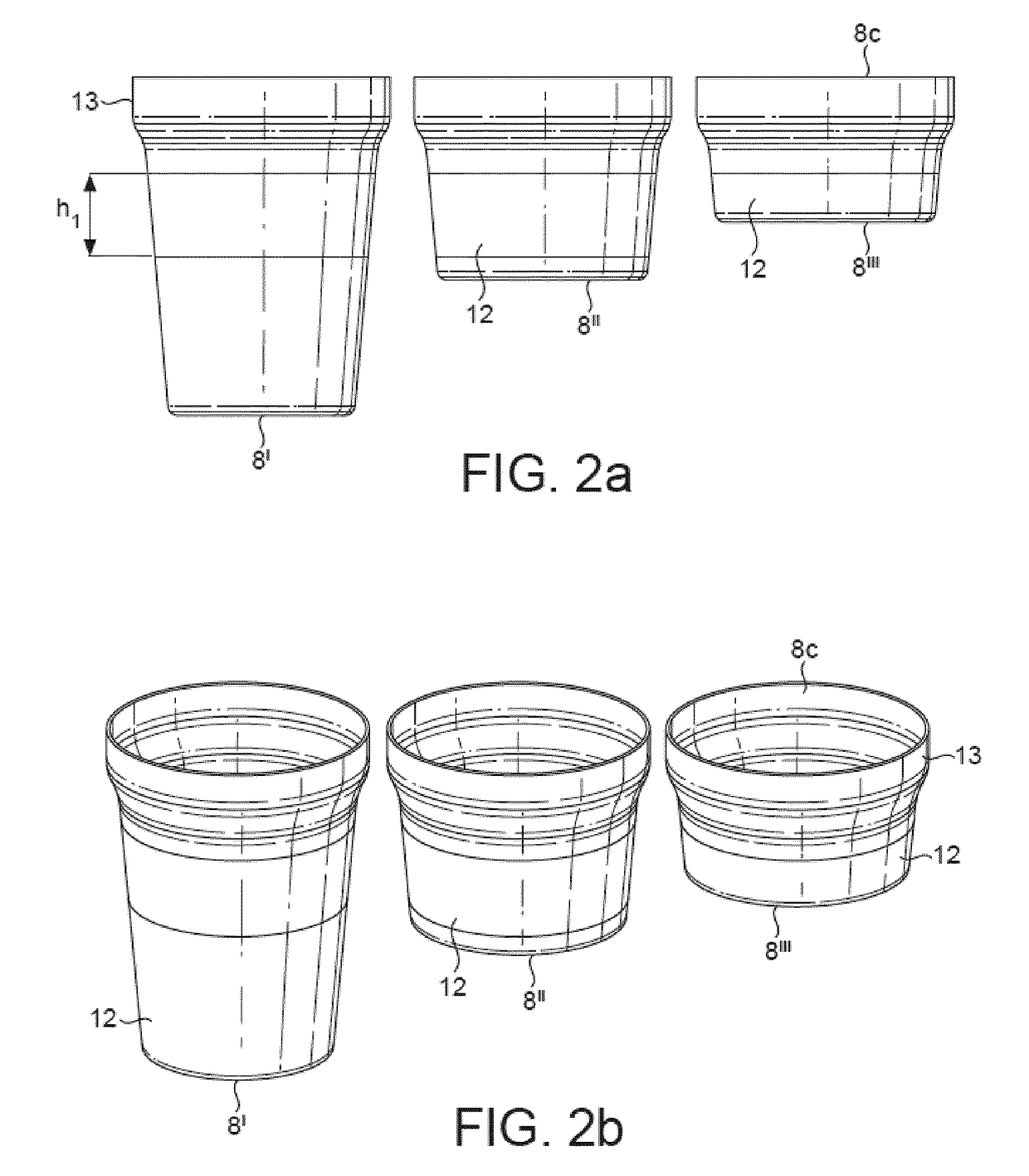

ActiveUS20160255858A1Reduce cooling powerReduced possible foamabilityFrozen sweetsEngineeringMechanical engineering

The invention relates to a machine for preparing a cooled food product, comprising: a receiving seat (1), for accommodating an essentially cup-shaped container, comprising a heat exchange element (1a) having a heat exchange contact surface (21) arranged to be in contact with an outer surface of a side wall (8d) of the container when the container is placed in the machine, and a stirring unit (5) connectable to a stirring member (9) and arranged for driving the stirring member (9) according to a combination of movements, wherein at least one of the combination of movements has a component directed towards the interior of the container when placed in the receiving seat (1). The method further relates to a system comprising the machine and a container and a method of preparation.

Owner:SOC DES PROD NESTLE SA

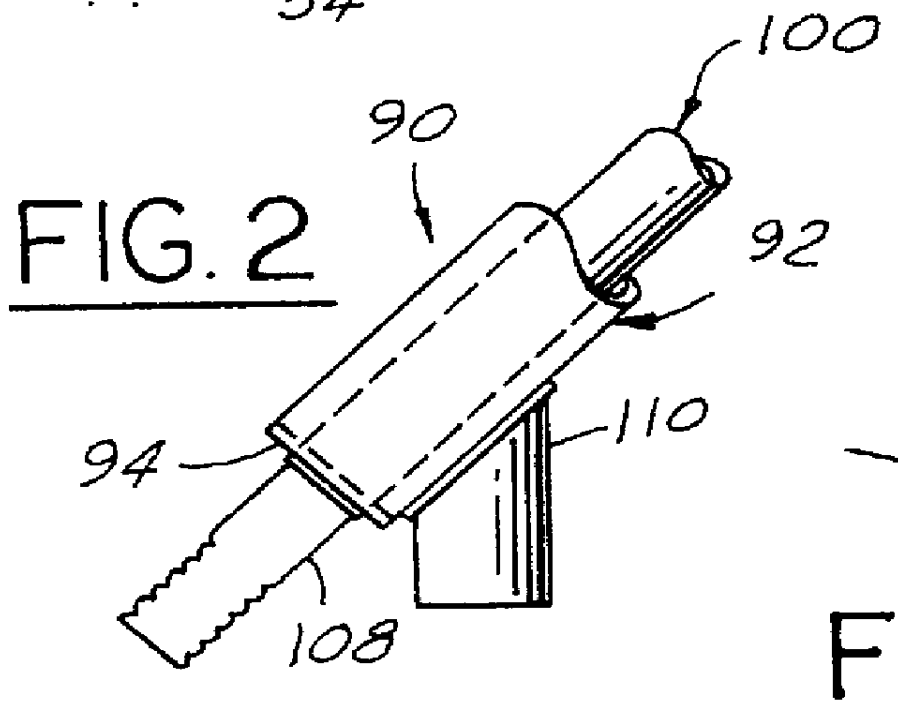

Machine, system and method for preparing a cooled confectionery product with aerated texture

ActiveUS10111447B2Reduced possible foamabilitySpeed up heat exchangeLighting and heating apparatusIce productionEngineeringMechanical engineering

A machine for preparing a cooled food product includes a receiving seat, for accommodating an essentially cup-shaped container, including a heat exchange element having a heat exchange contact surface arranged to be in contact with an outer surface of a side wall of the container when the container is placed in the machine, and a stirring unit connectable to a stirring member and arranged for driving the stirring member according to a combination of movements, wherein at least one of the combination of movements has a component directed towards the interior of the container when placed in the receiving seat. Also disclosed is a system including the machine, a container, and a method of preparation.

Owner:SOC DES PROD NESTLE SA

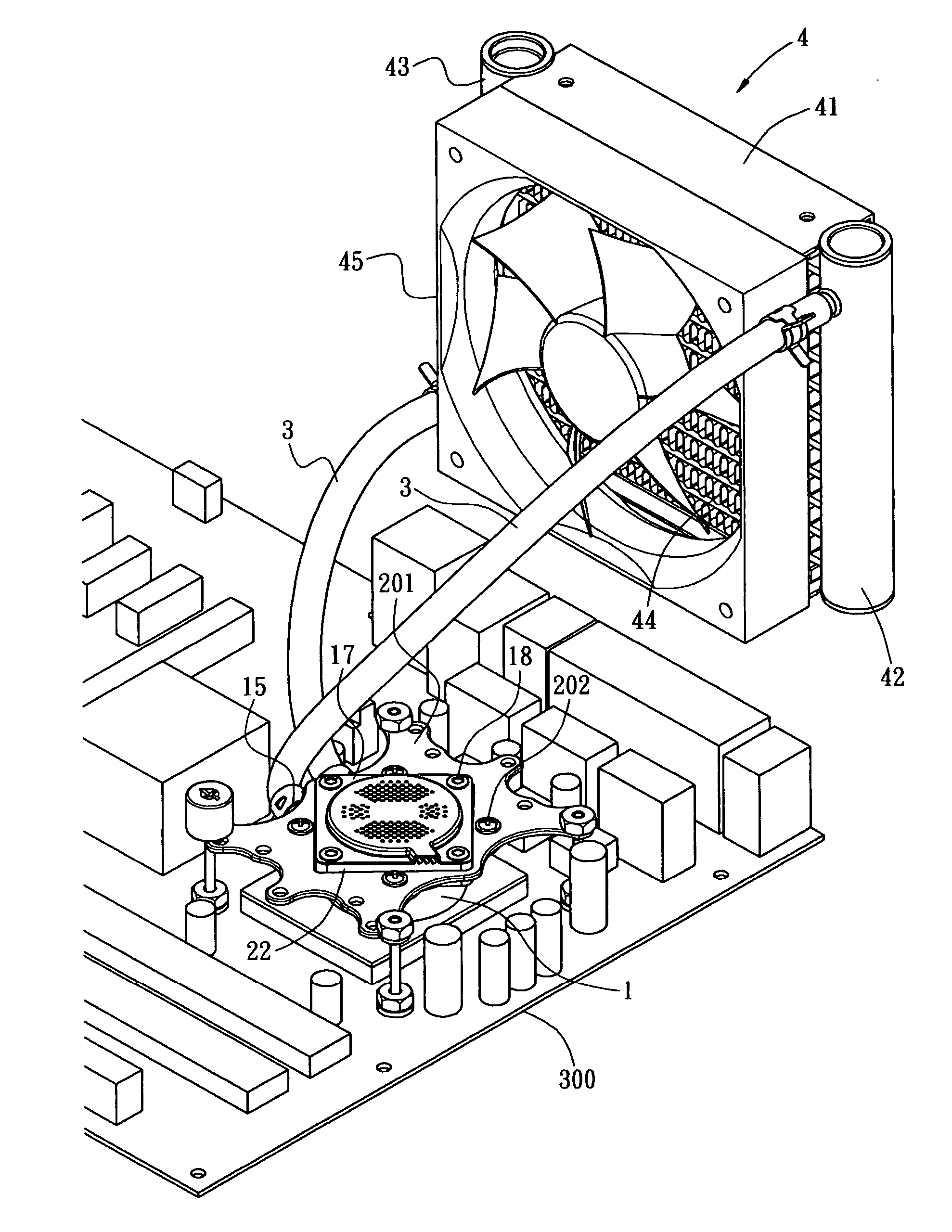

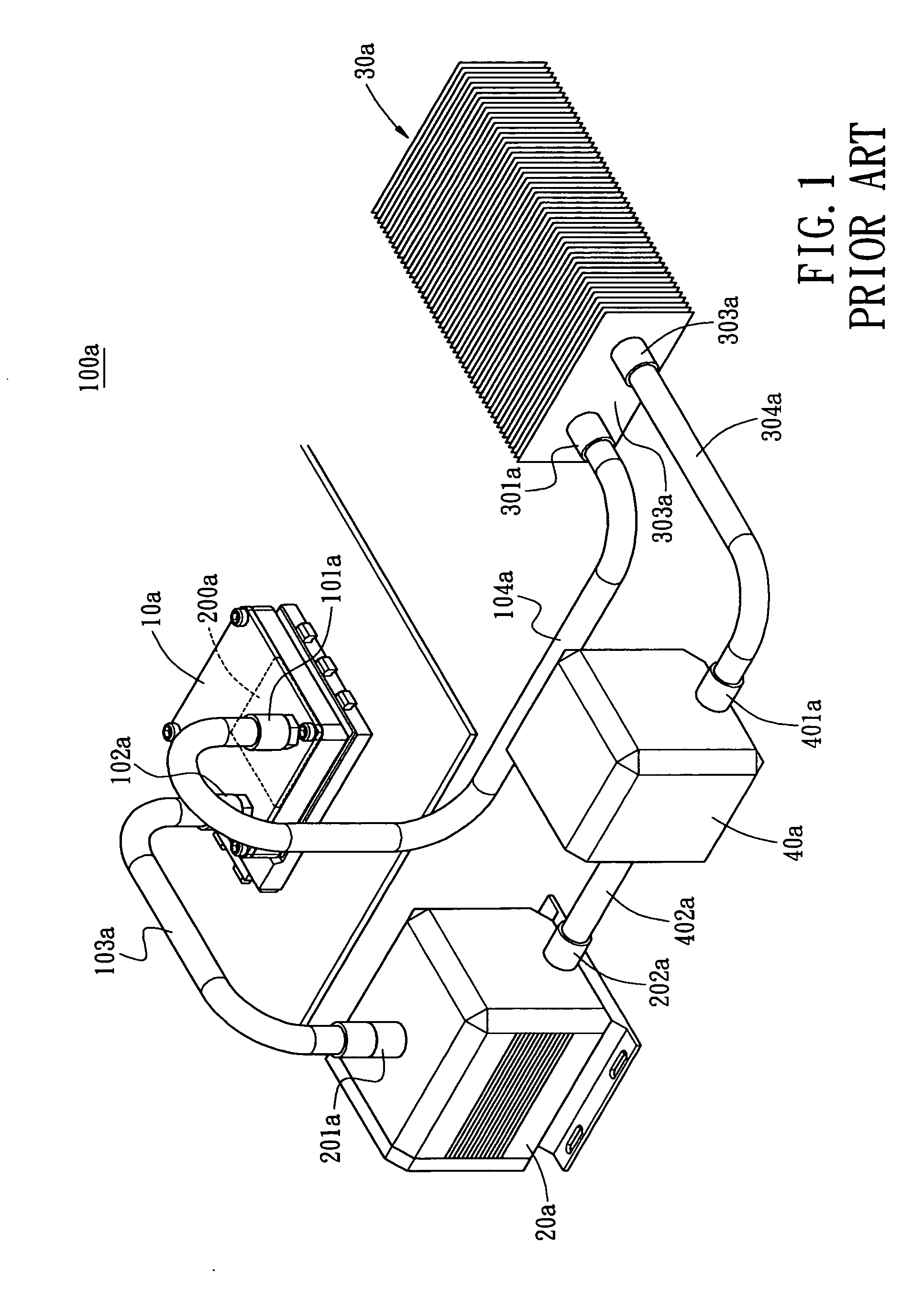

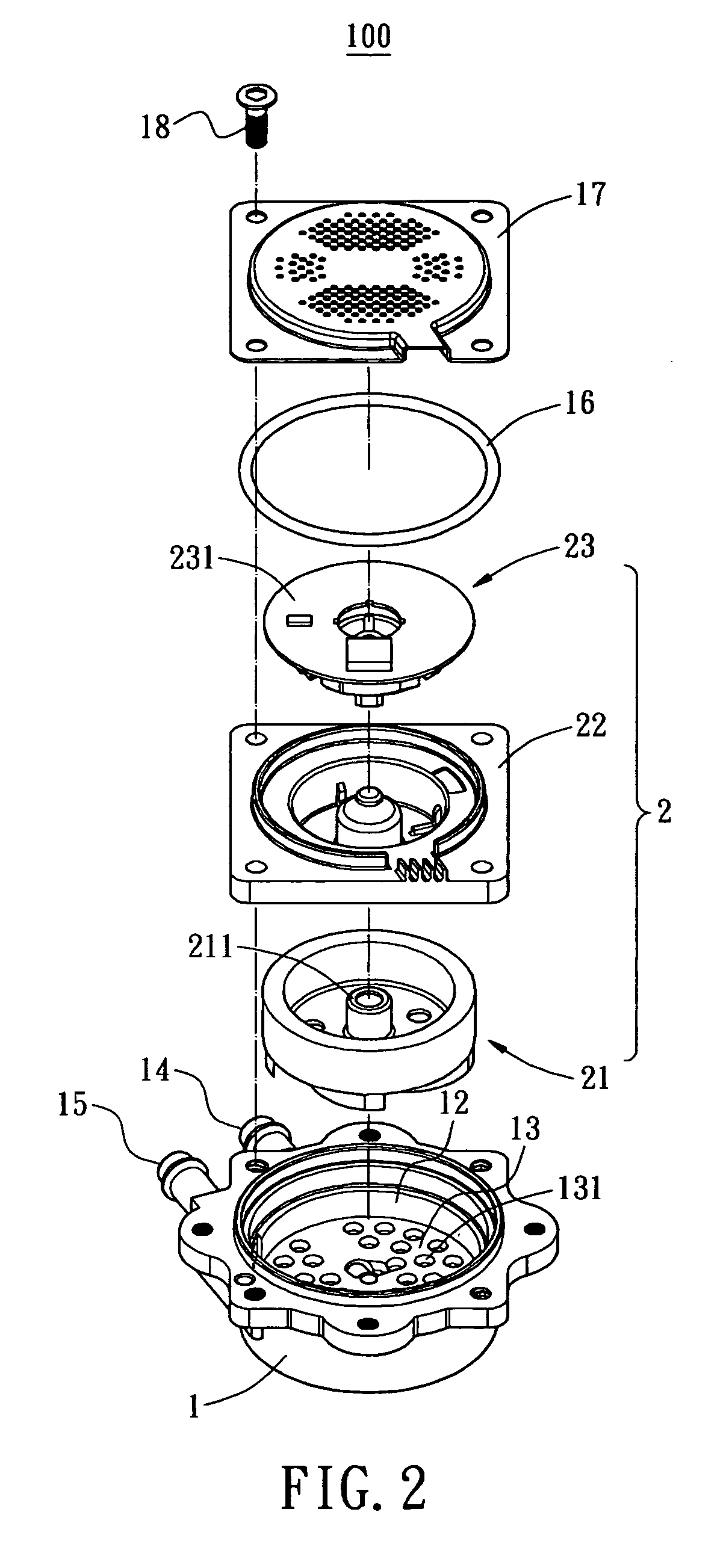

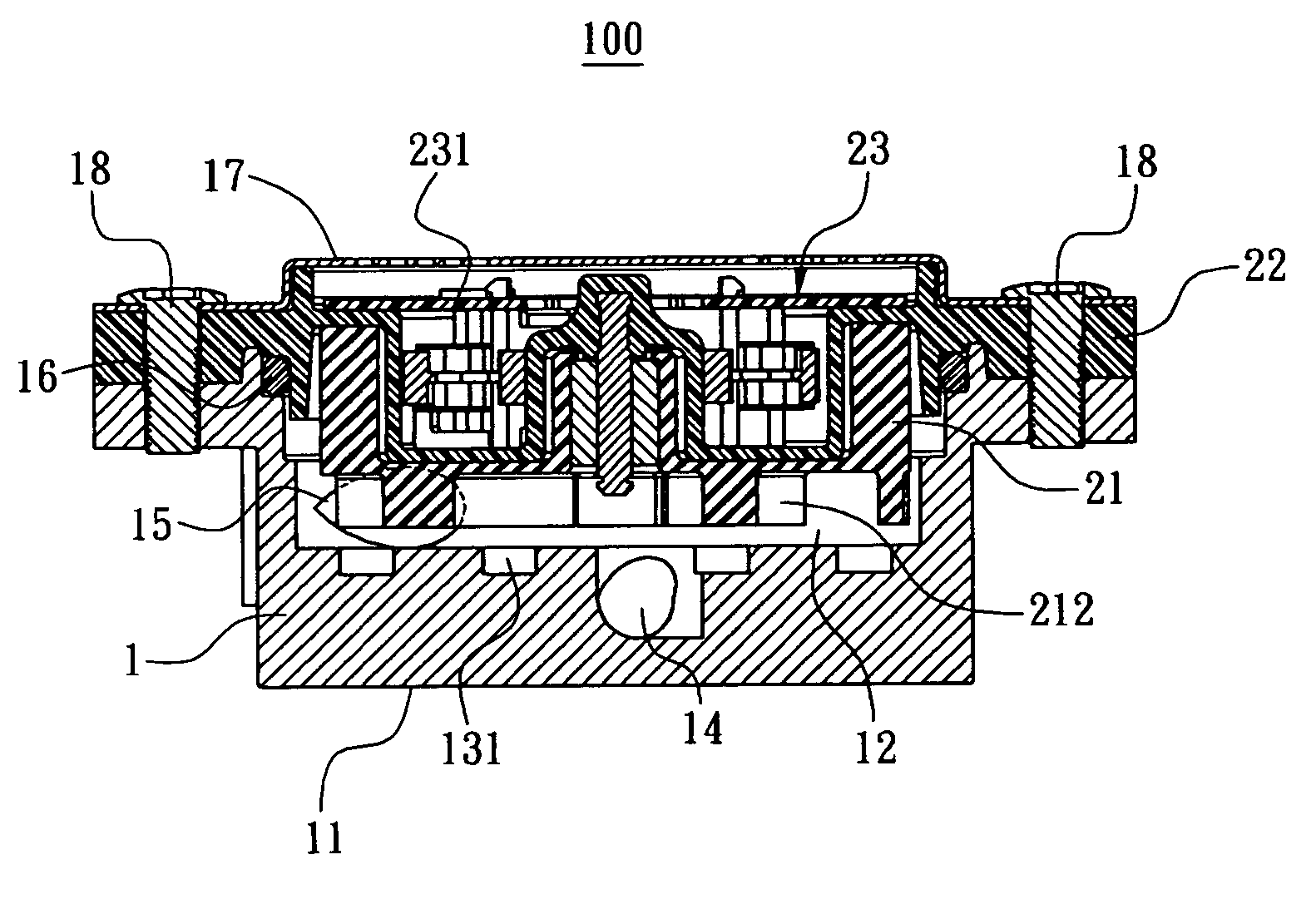

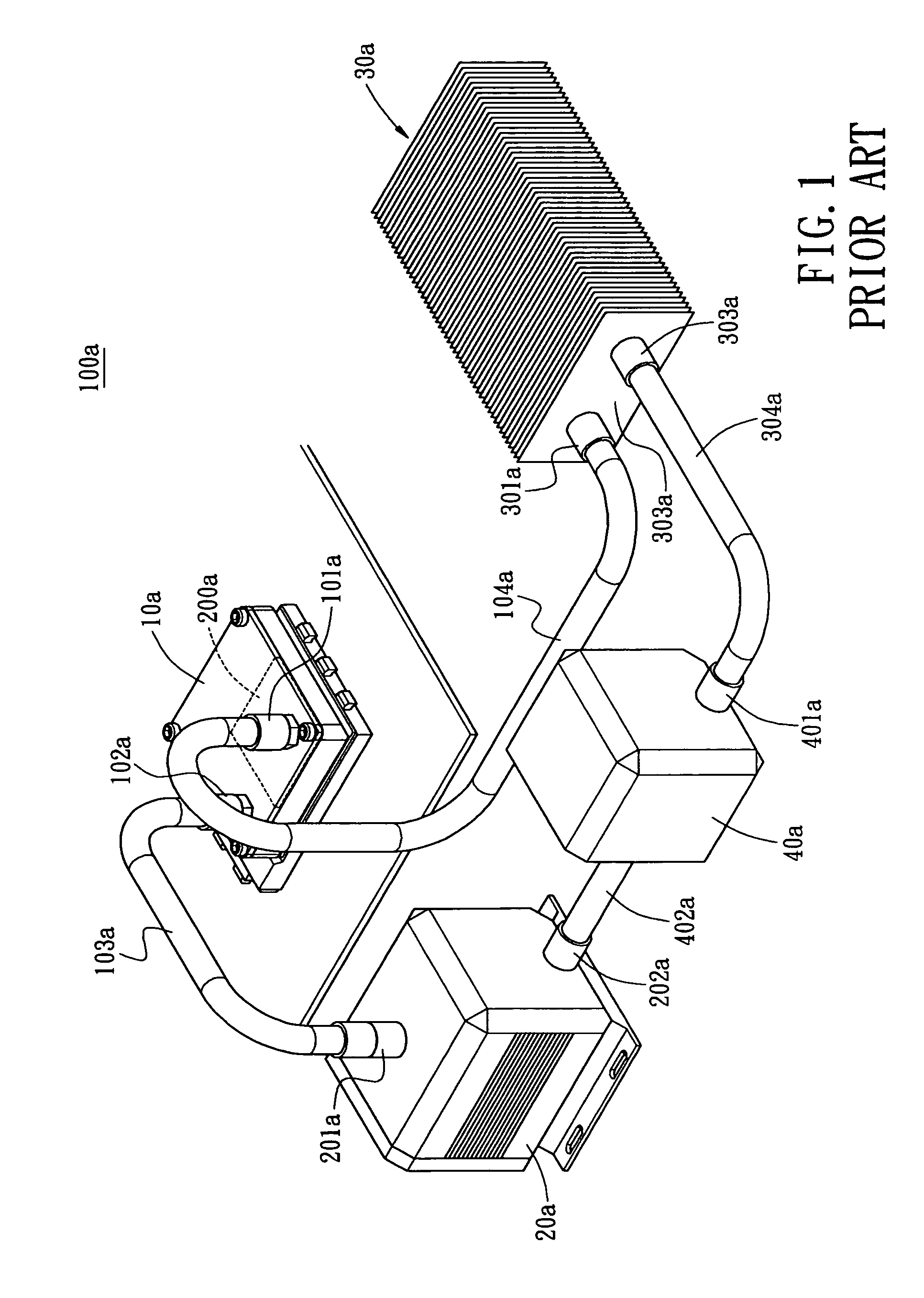

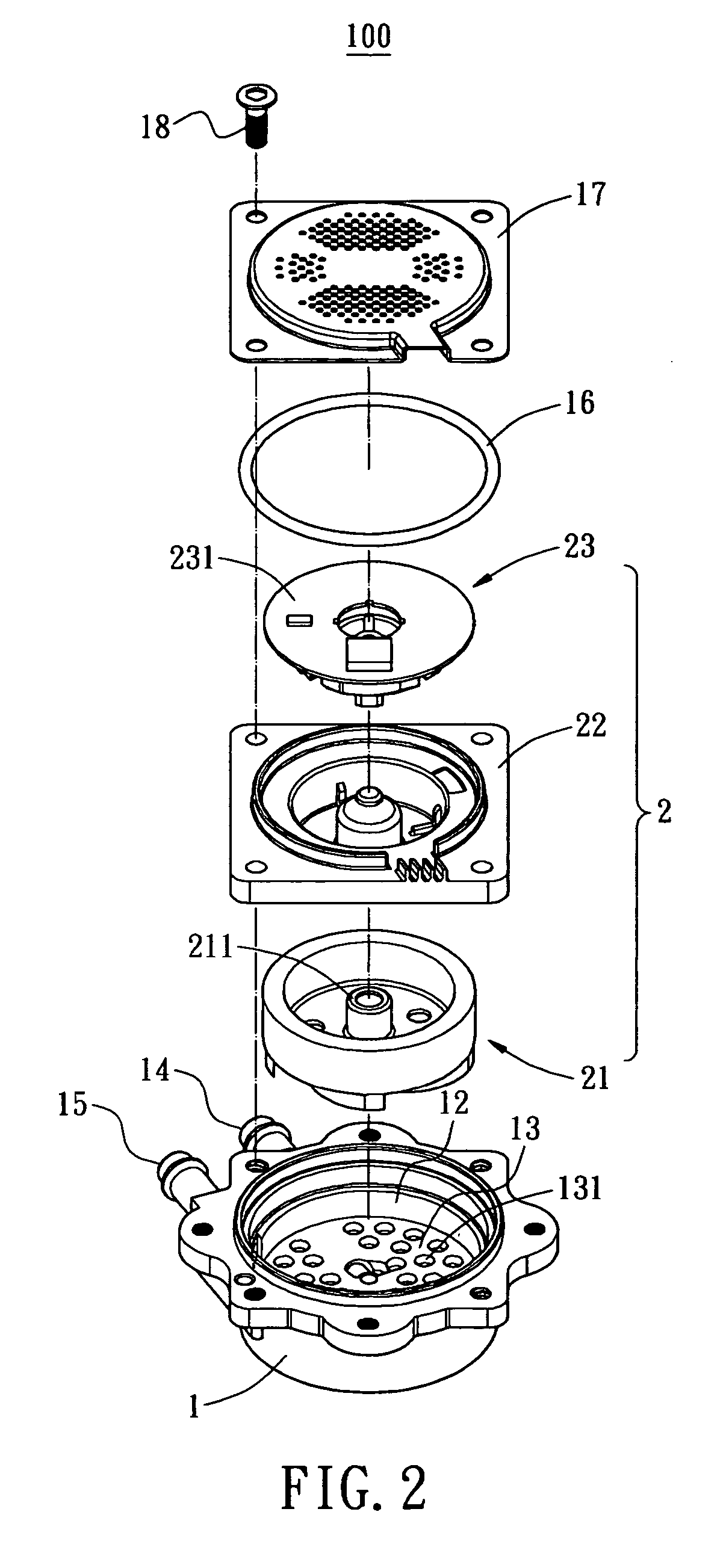

Water-cooling heat dissipation device

ActiveUS20070029069A1Increase the heat exchange areaImprove heat transfer efficiencyDigital data processing detailsSemiconductor/solid-state device detailsNuclear engineeringCooling fluid

A heat dissipation system includes a housing, a circulator and a cooler. The housing has at least one surface made of heat-conductive metal to contact with a heat source. The housing includes a recess with a passage formed on the bottom to contain cooling liquid and an inlet and an outlet connected to the recess. Two pipes are provided to connected between the inlet and the outlet and the cooler, respectively. The circulator is installed in the recess to circulate the flowing of the cooling liquid. As such, heat generated from the heat source is directly conducted to the housing and takes away by the cooling liquid circulated by the circulator to the cooler.

Owner:CHEMTRON RES

Water-cooling heat dissipation device

ActiveUS7249625B2Compact structureLow costDigital data processing detailsSemiconductor/solid-state device detailsNuclear engineeringCooling fluid

Owner:CHEMTRON RES

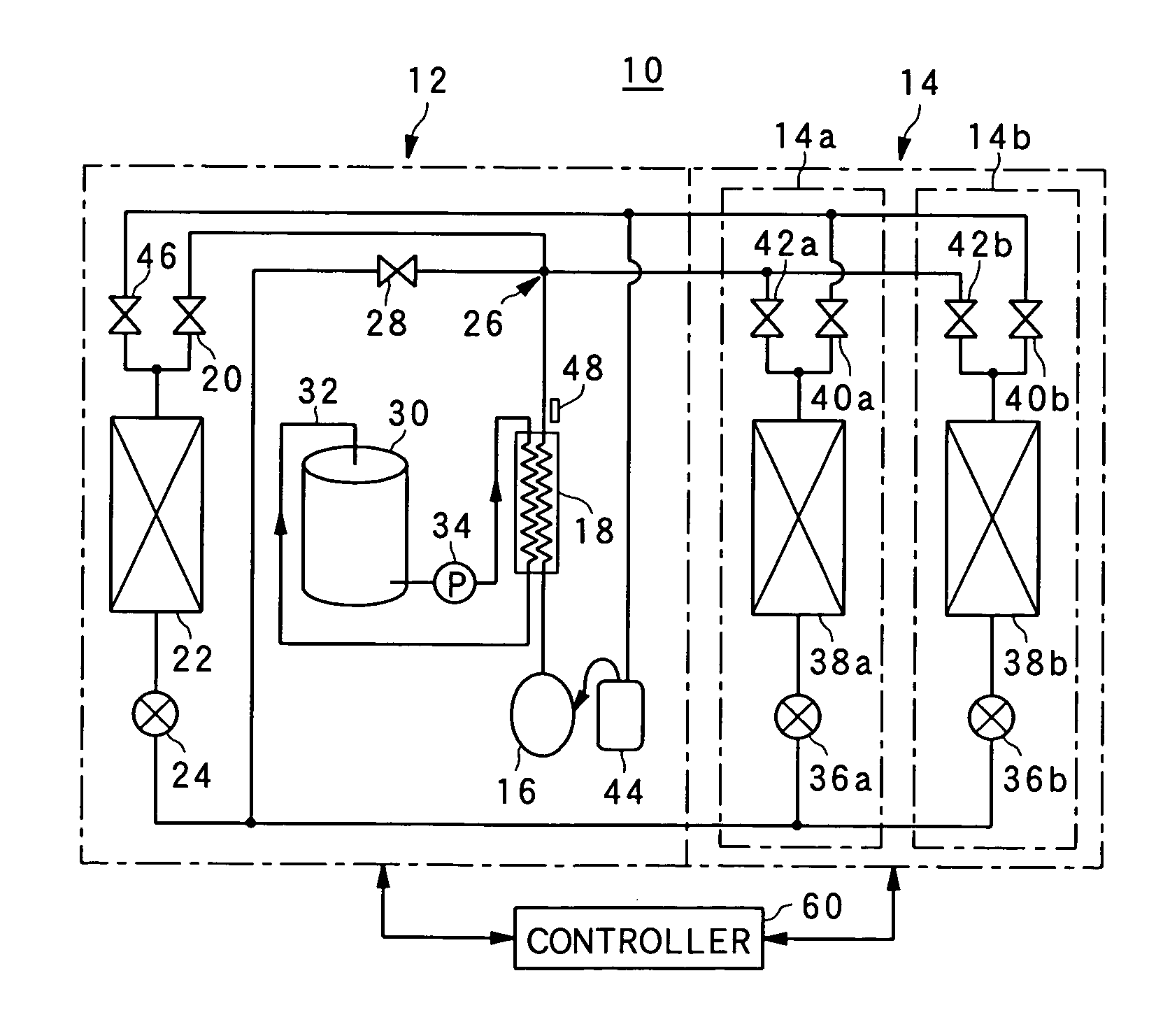

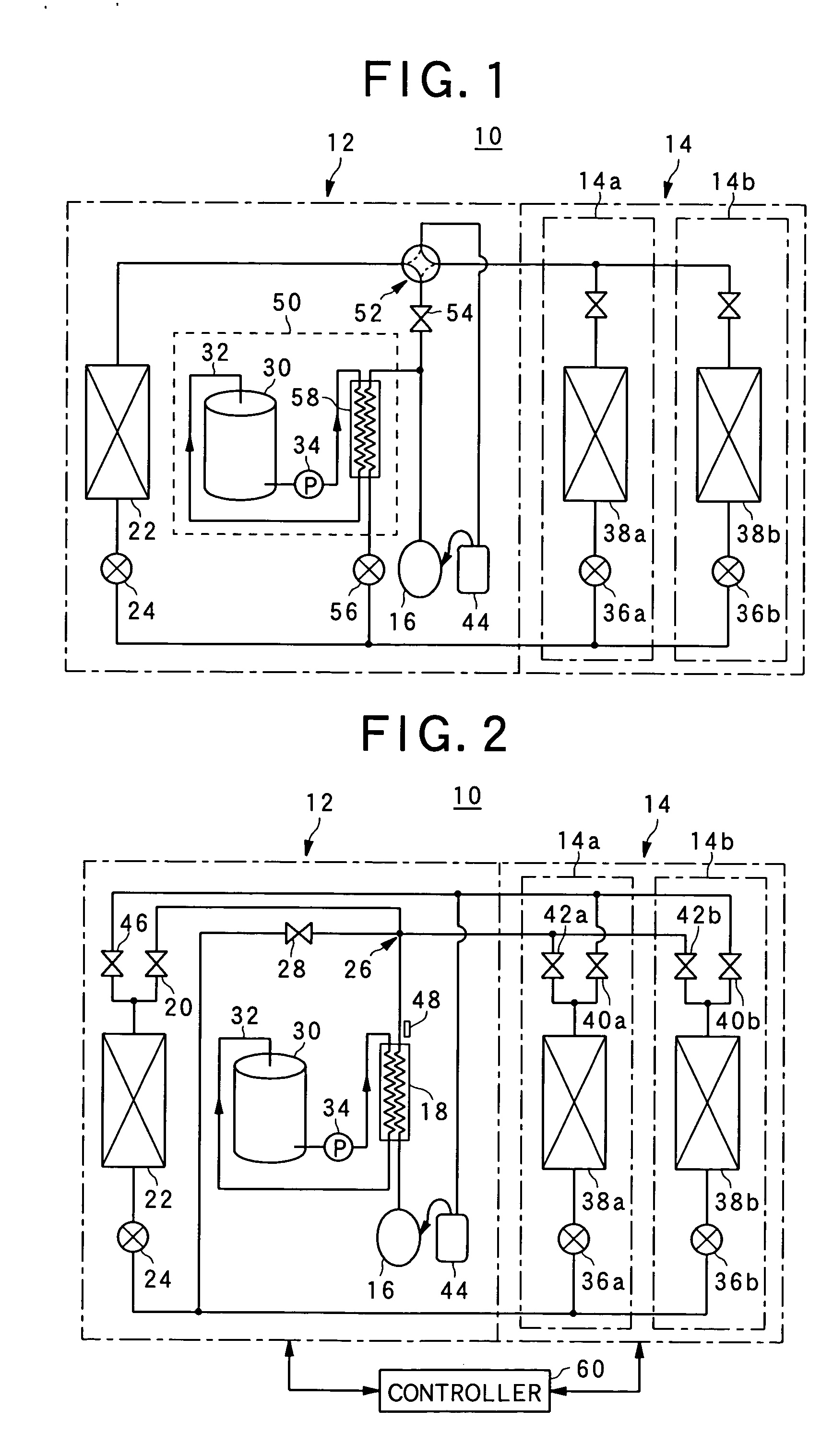

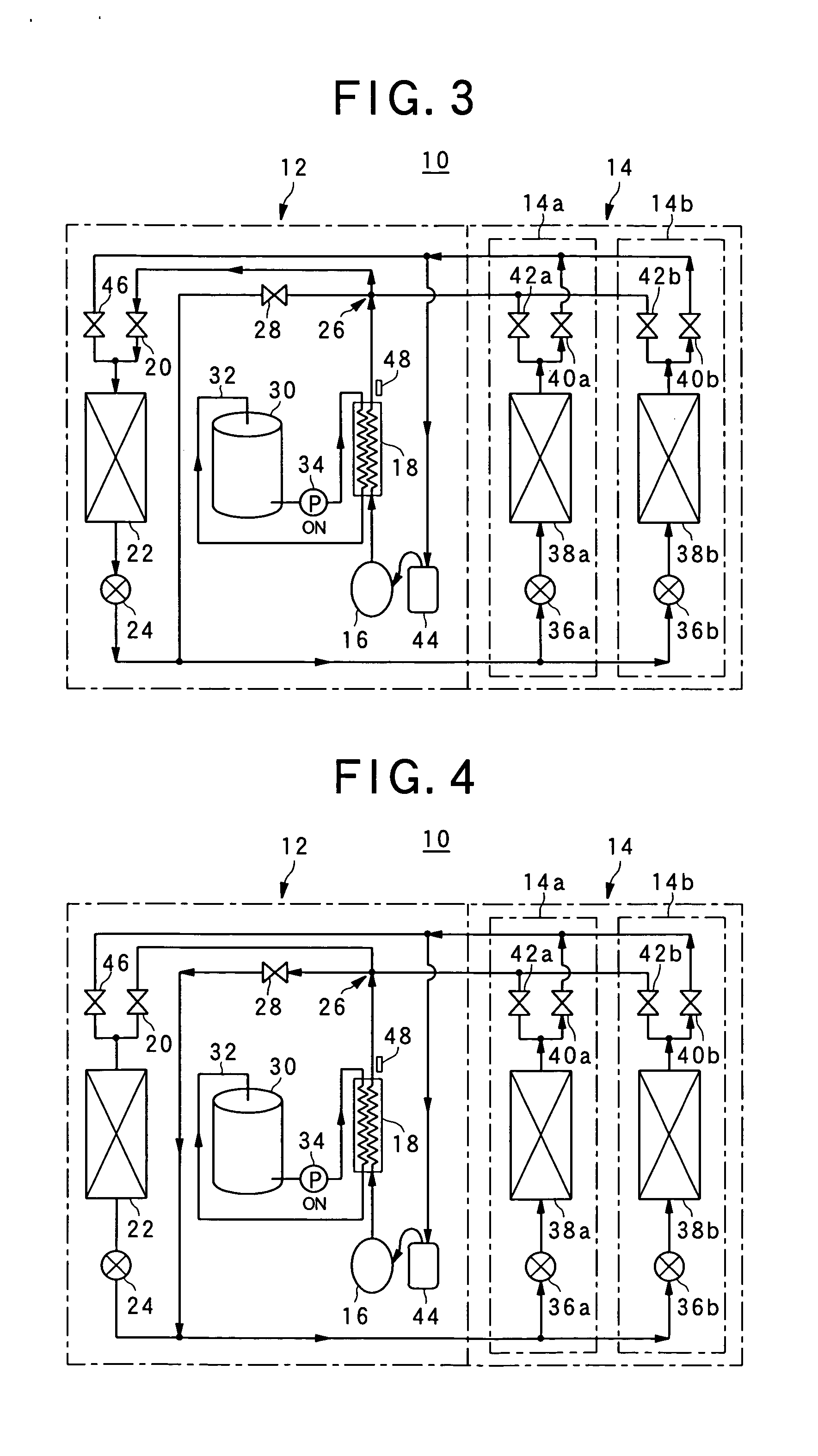

Refrigerant circuit and heat pump type hot water supply apparatus

InactiveUS20050066678A1Cutting costsInferior cycle efficiencyHeat pumpsCompression machines with non-reversible cycleEngineeringRefrigerant

In a heat pump type hot water supply apparatus having a compressor (16), an outdoor heat exchanger (22), an expansion valve (24) and at least one indoor heat exchangers, and a water heat exchanger (18) for heat-exchanging refrigerant and water to achieve hot water, the water heat exchanger (18) is equipped in the refrigerant circuit so as to be connected to the outdoor heat exchanger (22) in series in the refrigerant circuit.

Owner:SANYO ELECTRIC CO LTD

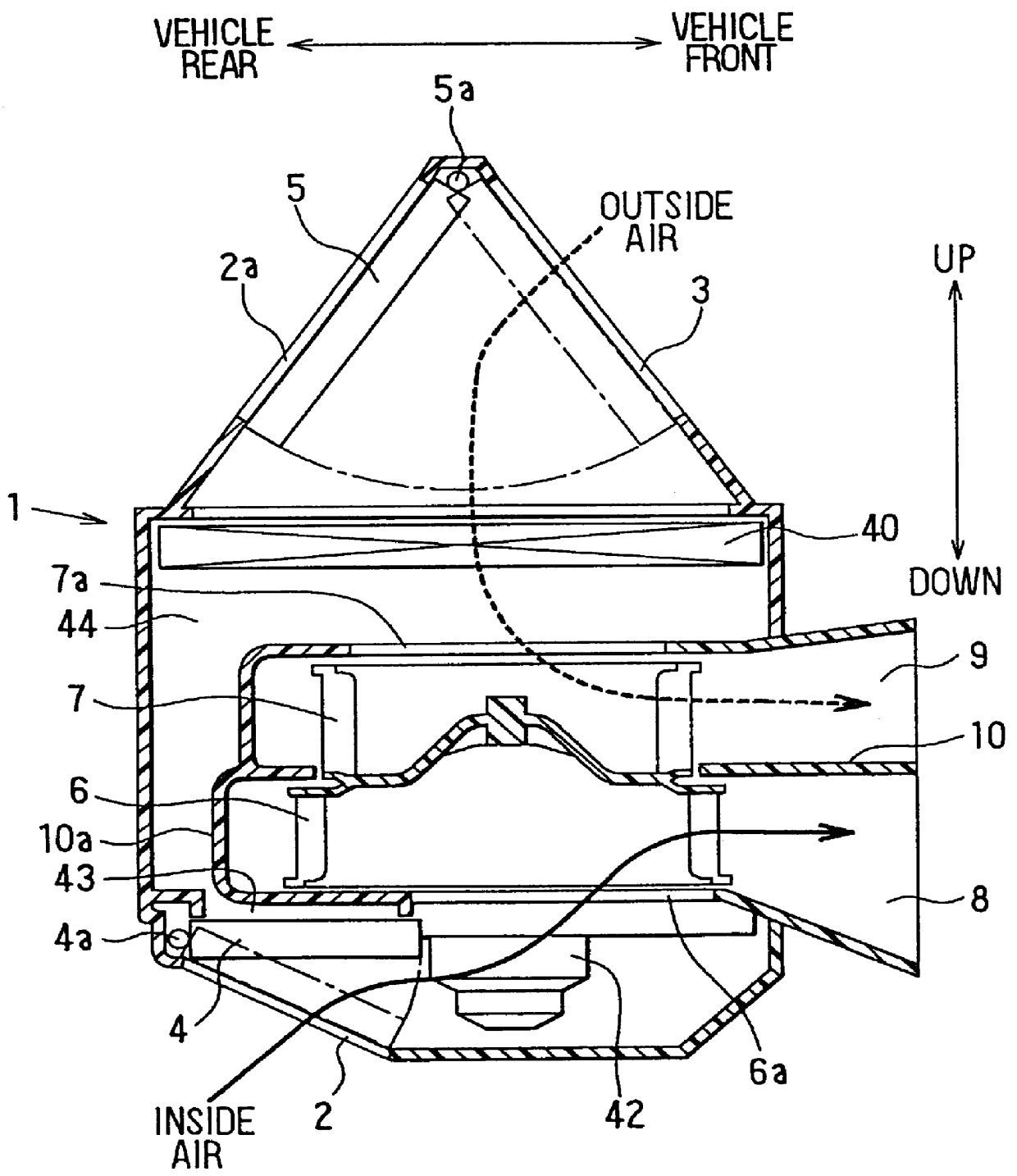

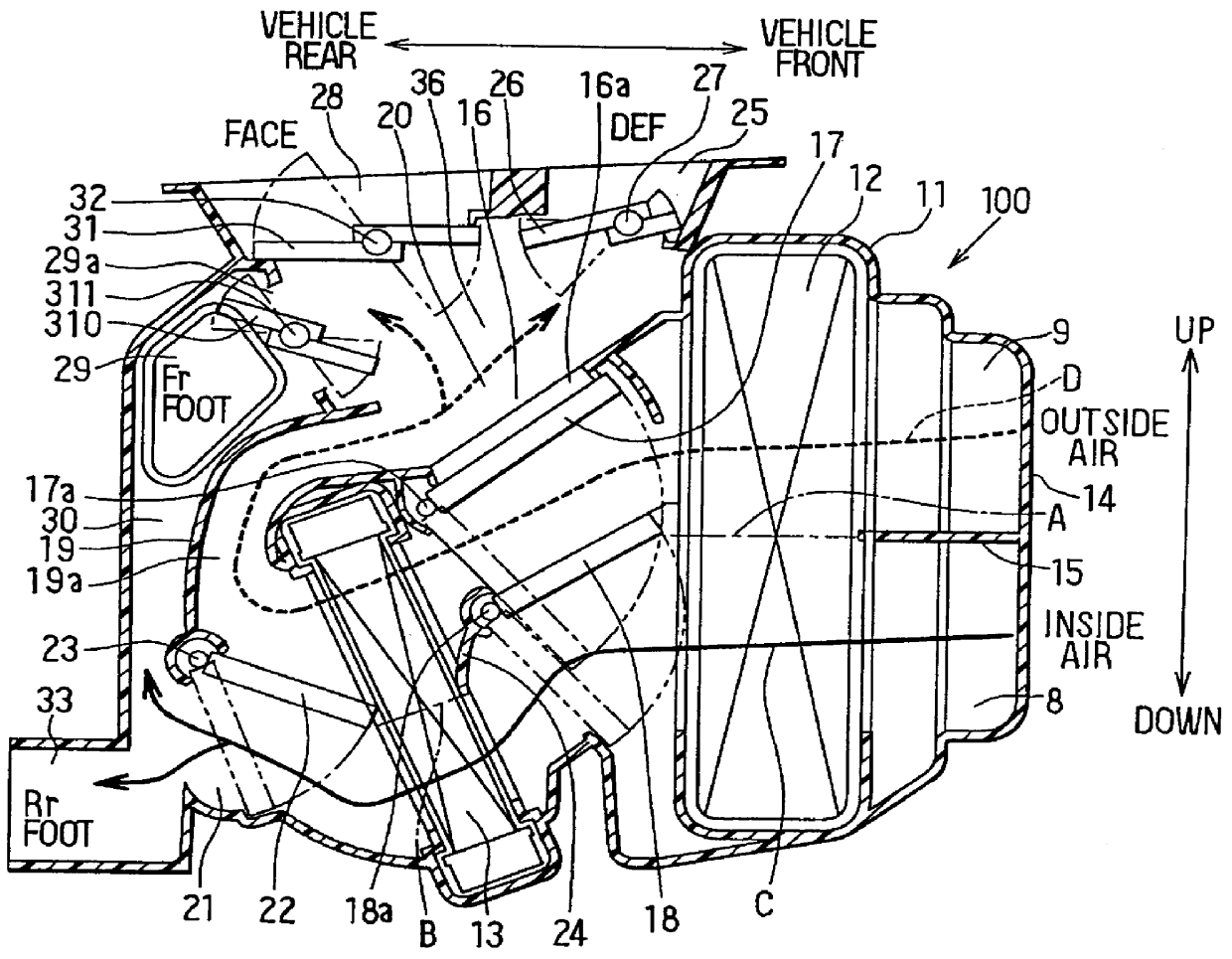

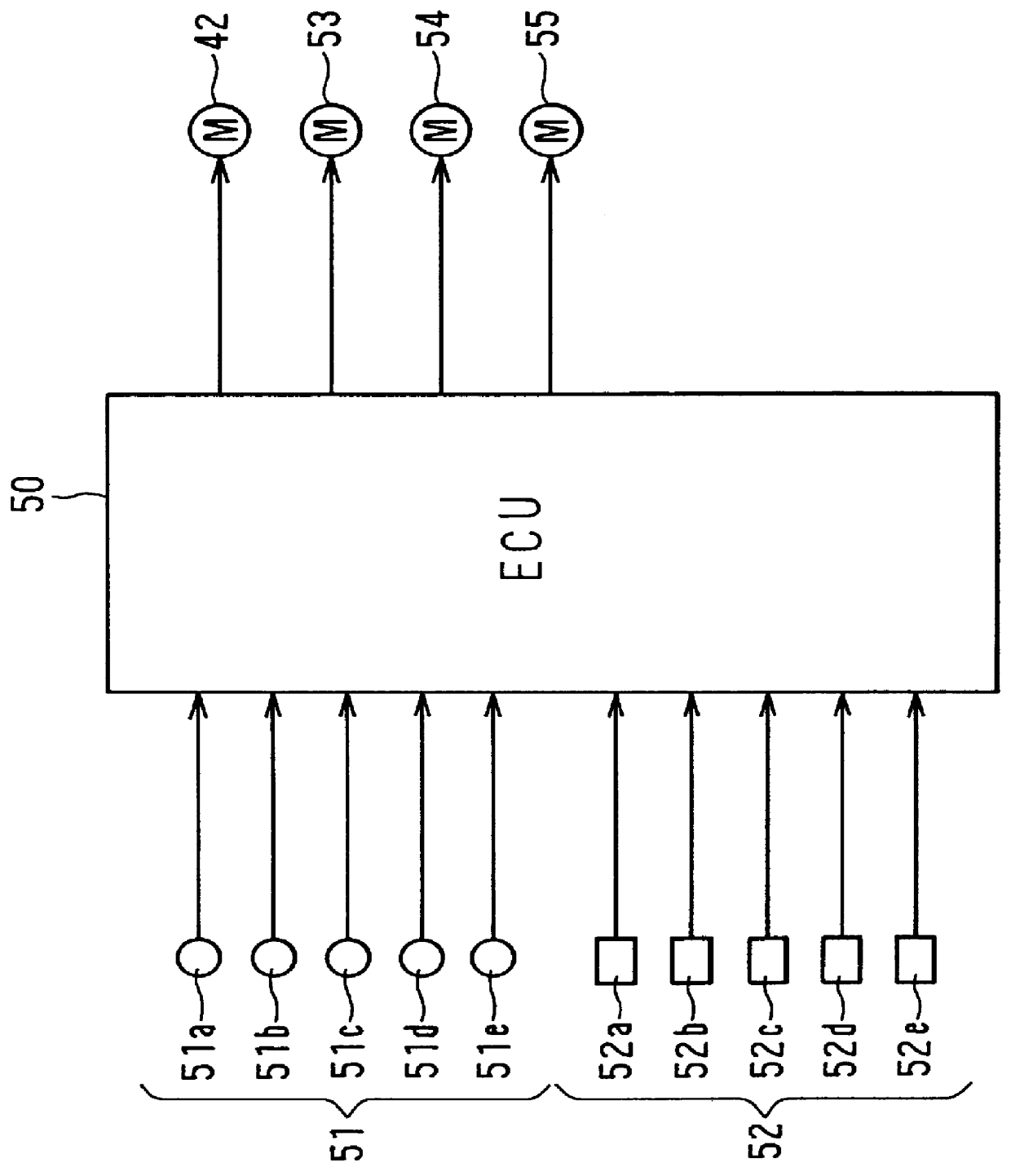

Air conditioning apparatus for vehicle with double layer flow mode

InactiveUS6135201AIncrease air volumeReduce air volumeAir-treating devicesRailway heating/coolingAir conditioningEngineering

In an air conditioning apparatus for a vehicle, a double layer flow mode is set when the maximum heating state is set during an air outlet mode where both a foot opening portion and a defroster opening portion are opened. During the double layer flow mode, an air passage of an air conditioning case is partitioned into a first air passage through which inside air flows and a second air passage through which outside air flows, in such a manner that the first air passage communicates with the foot opening portion and the second air passage communicates with the defroster opening portion. When the double layer flow mode is set, the maximum rotation speed of a blower for blowing air is reduced by a predetermined level as compared with an entire outside air mode or an entire inside air mode. Thus, heating capacity for a passenger compartment of the vehicle can be improved.

Owner:DENSO CORP

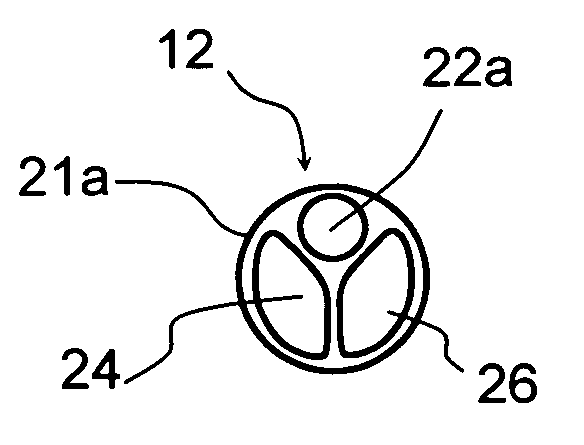

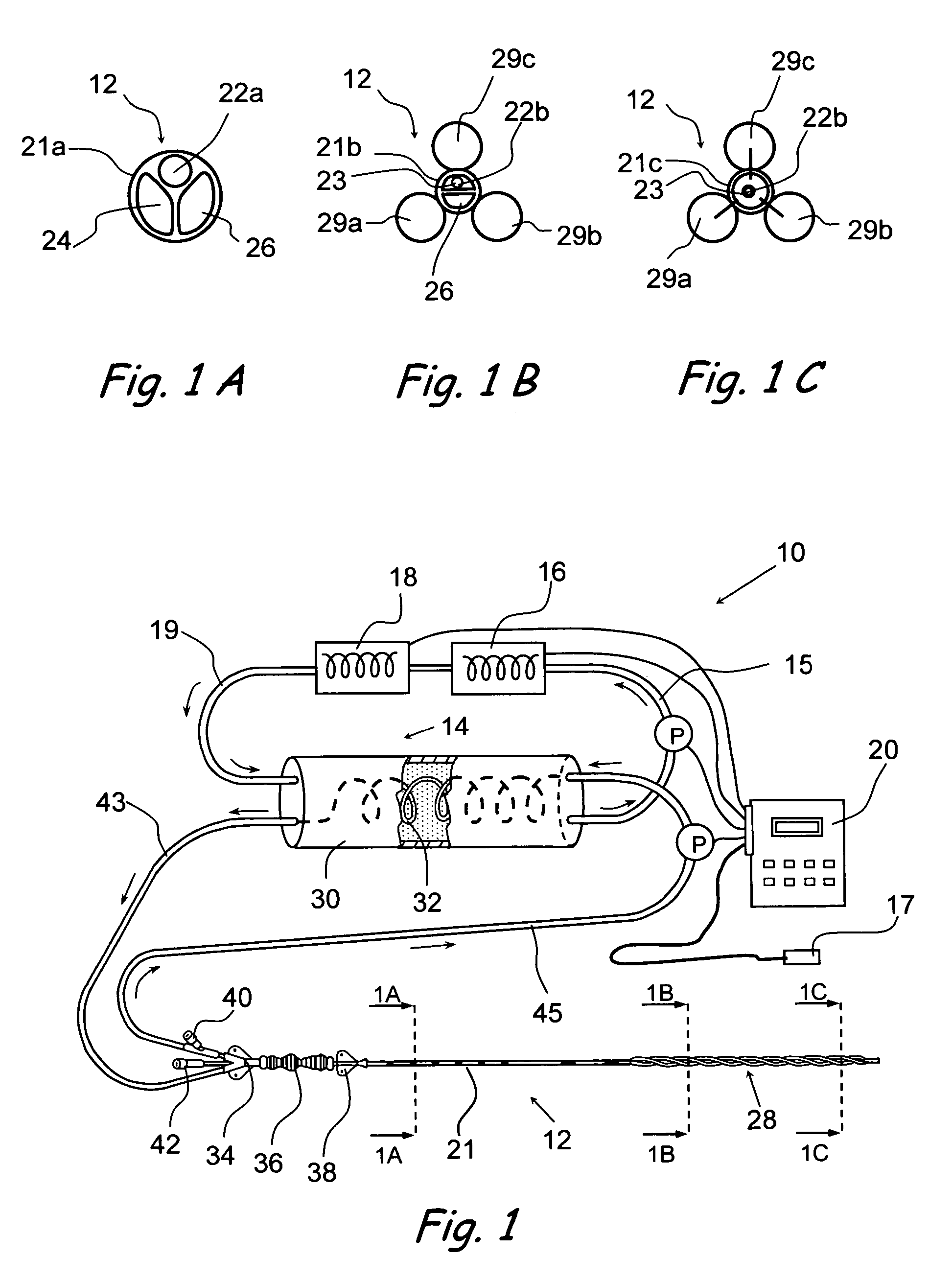

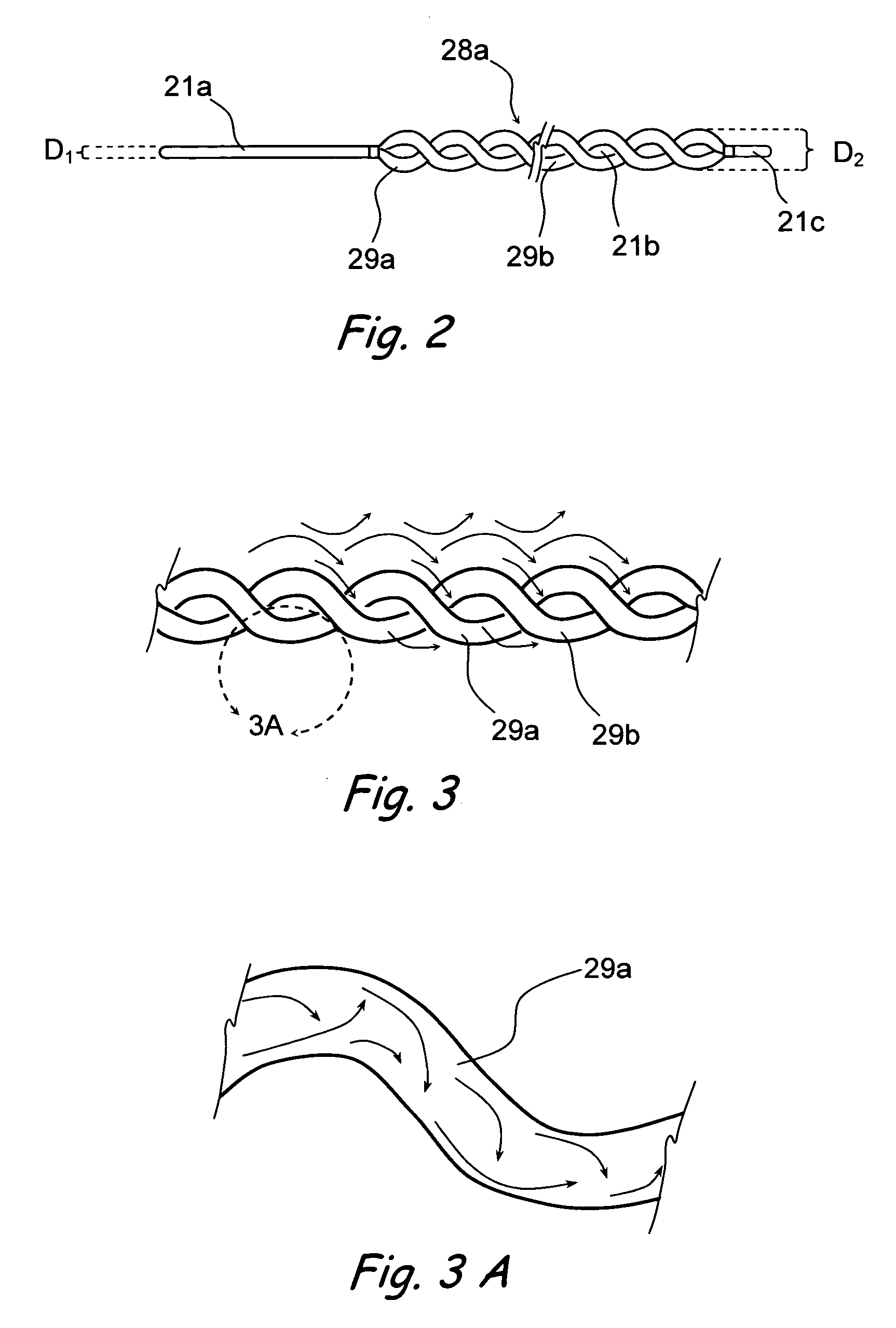

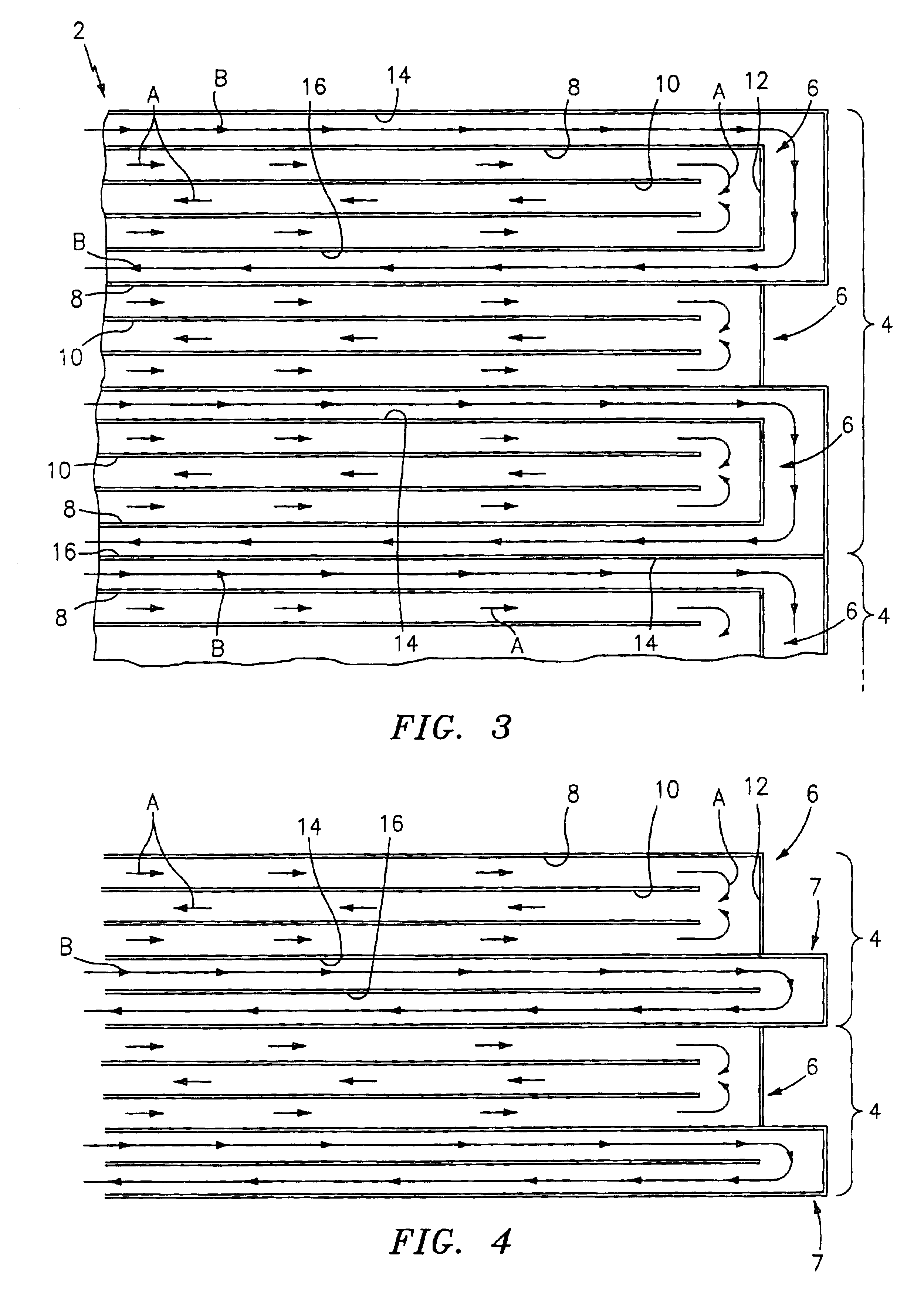

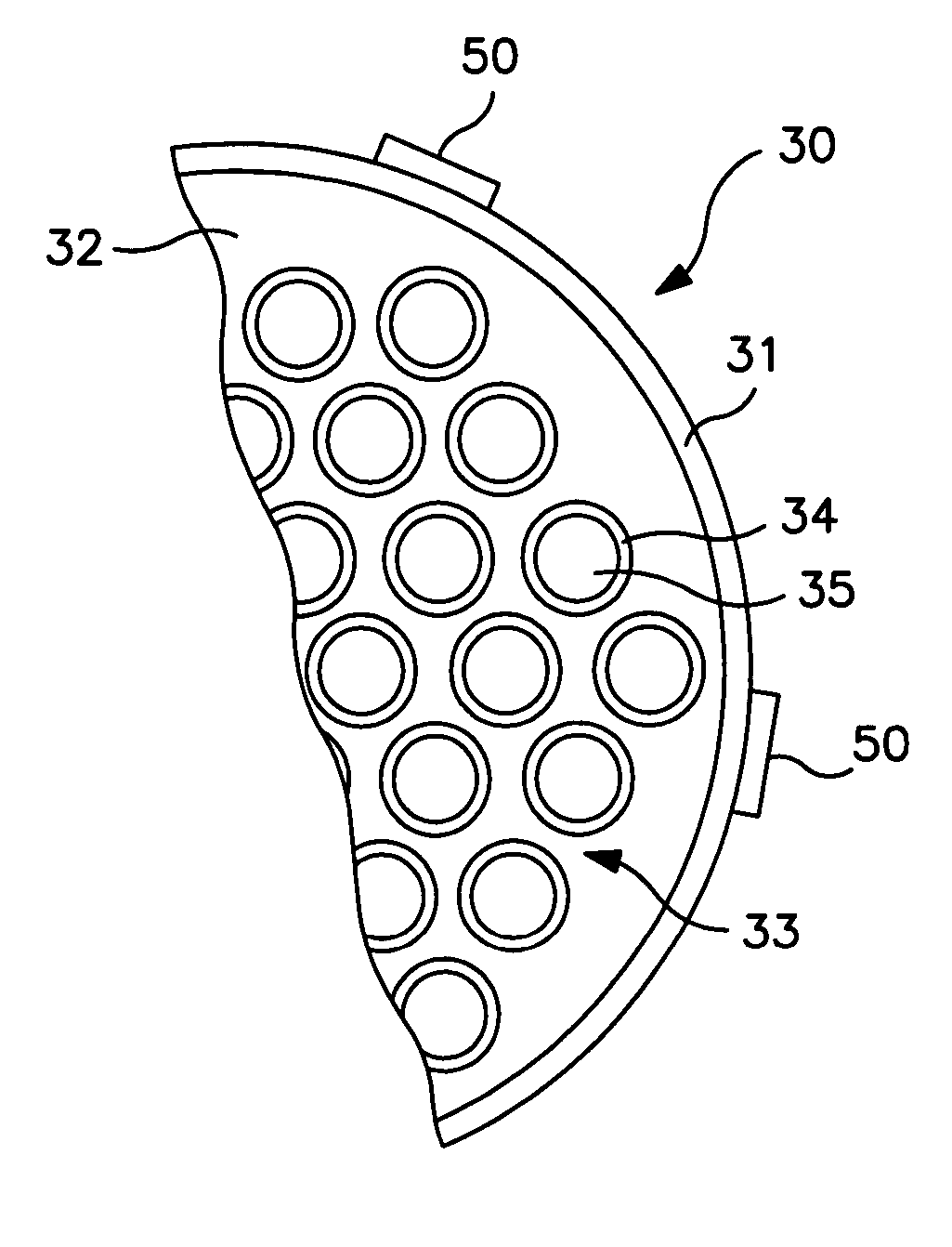

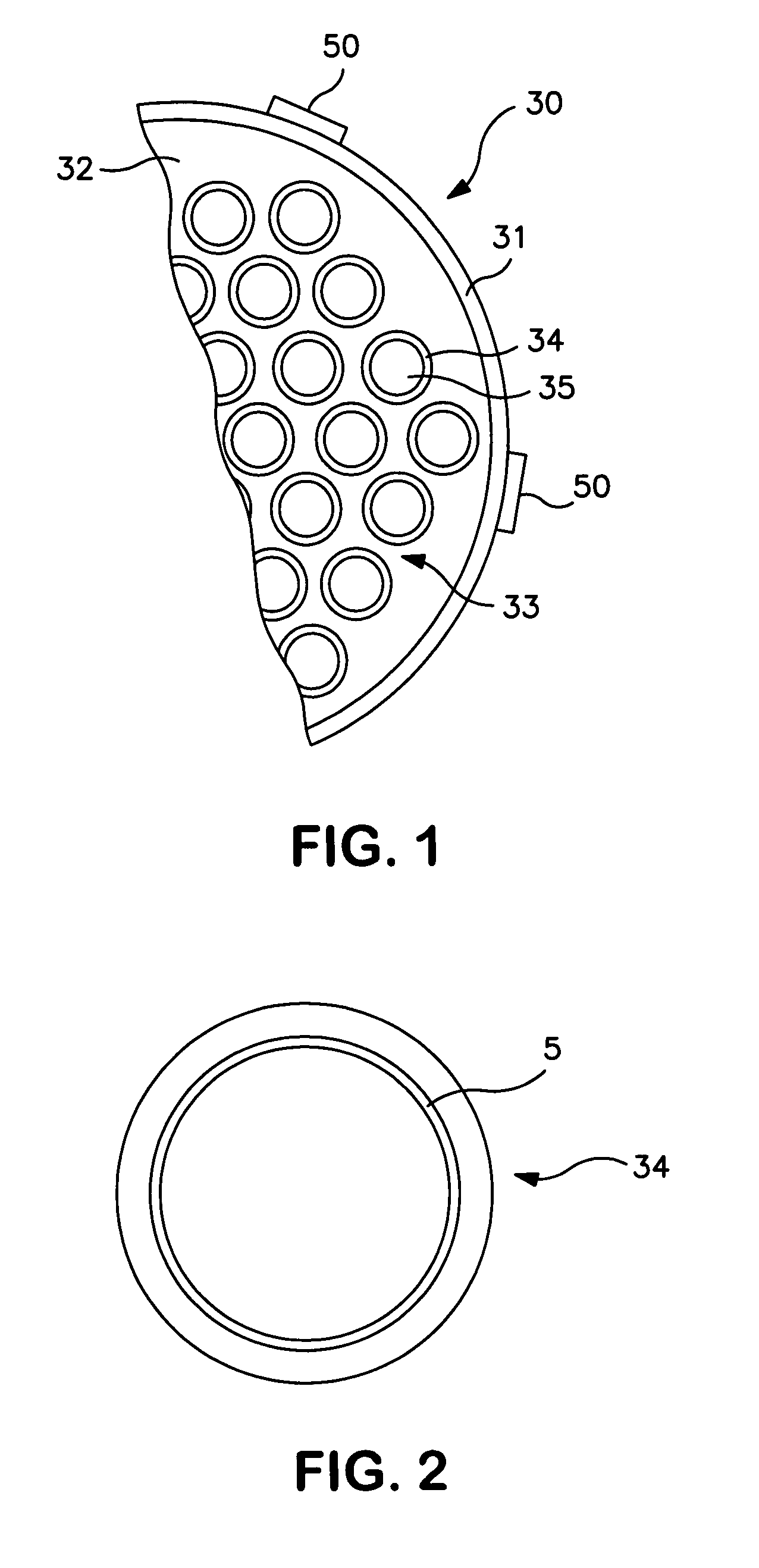

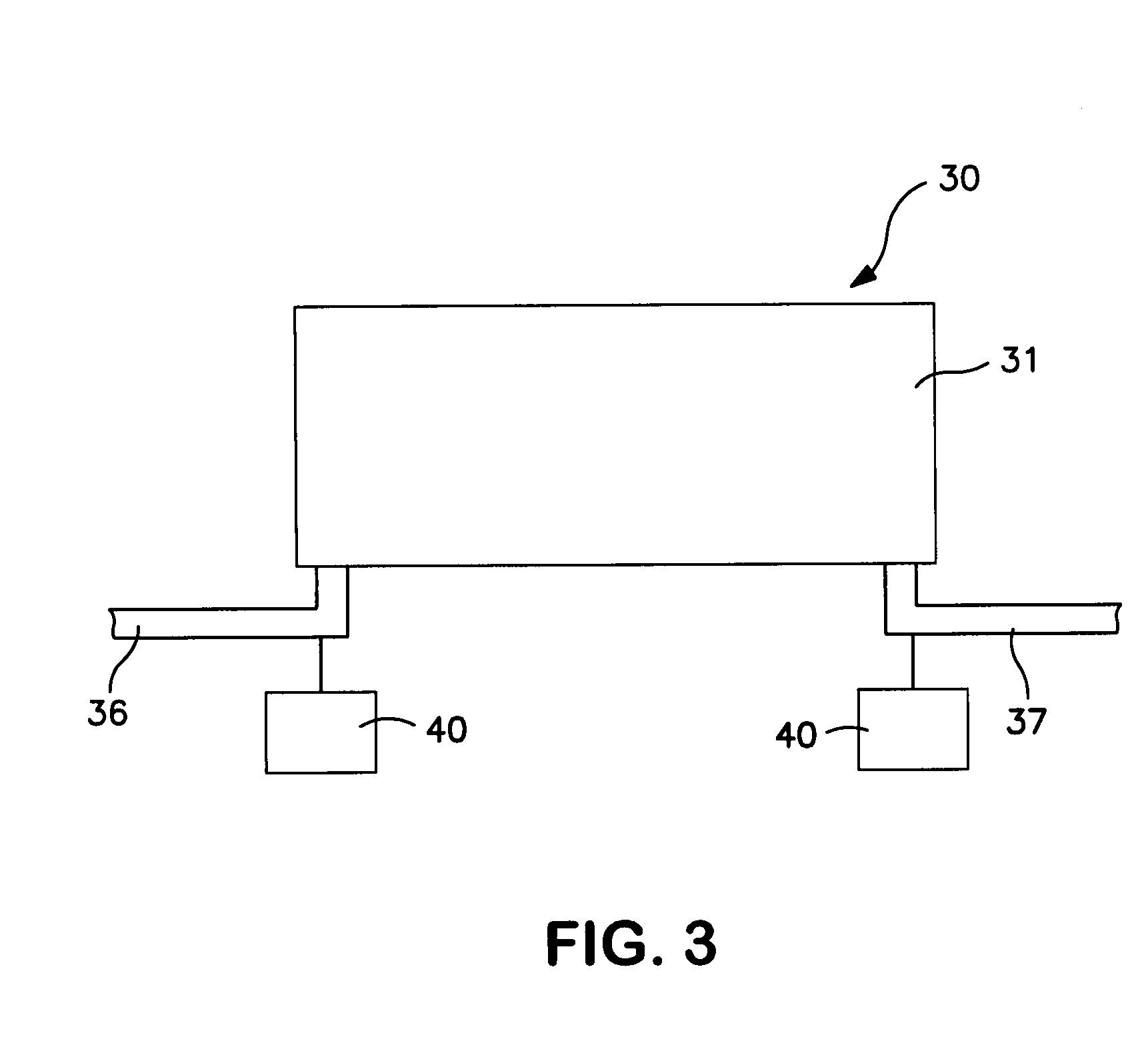

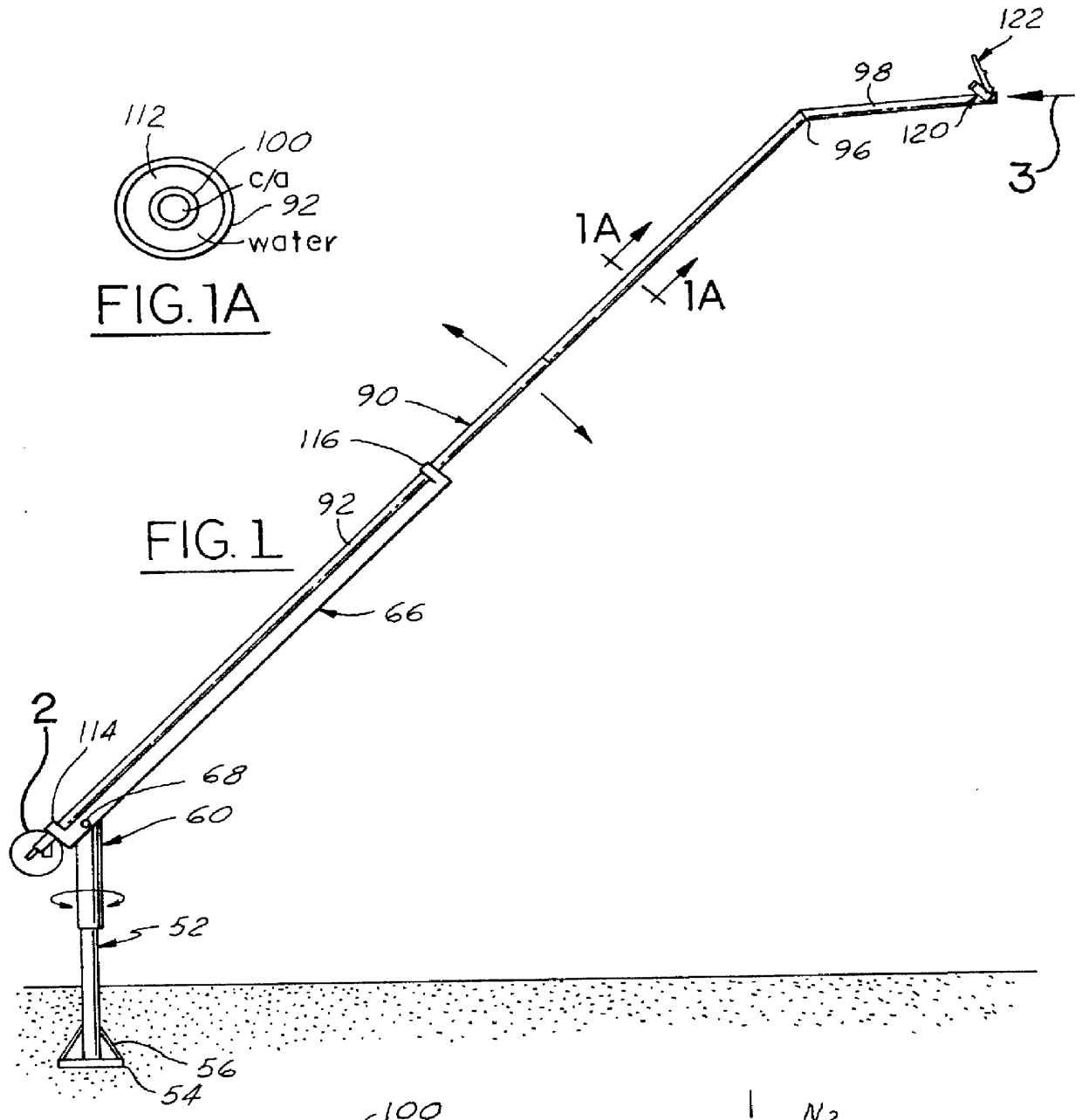

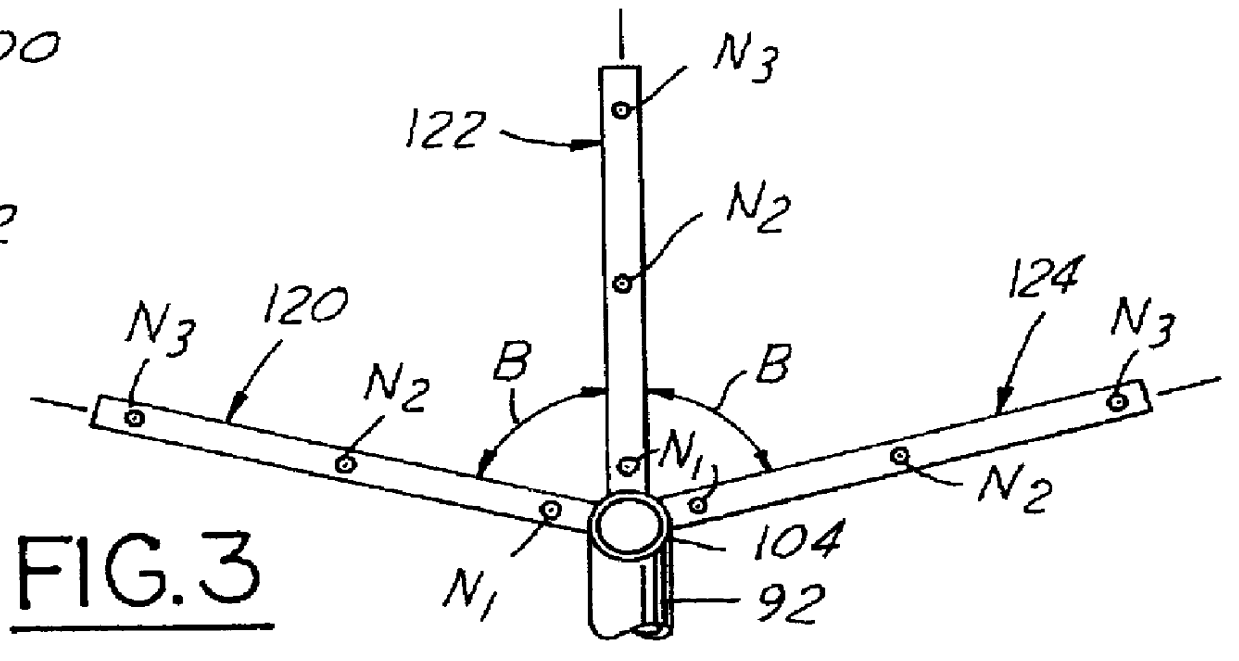

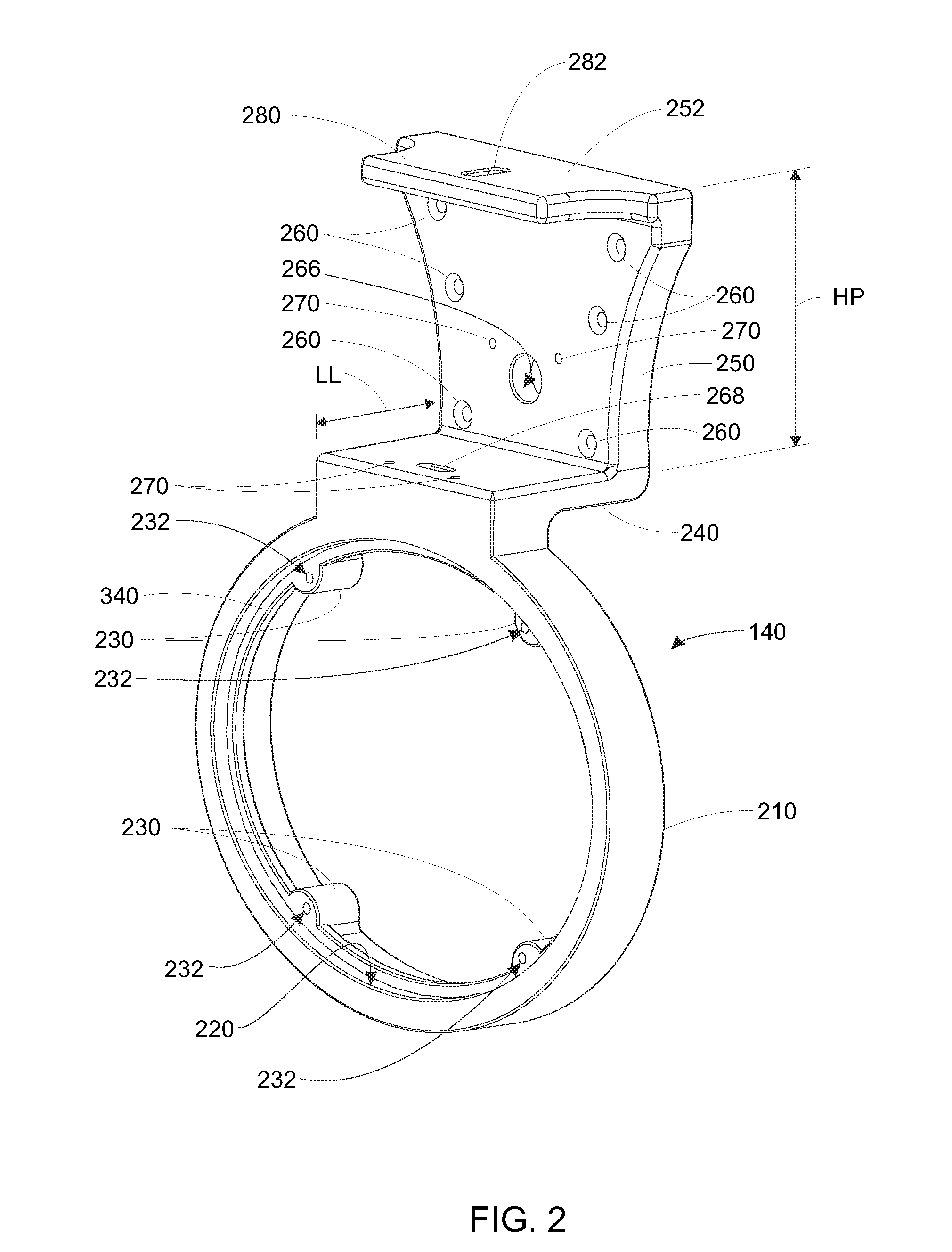

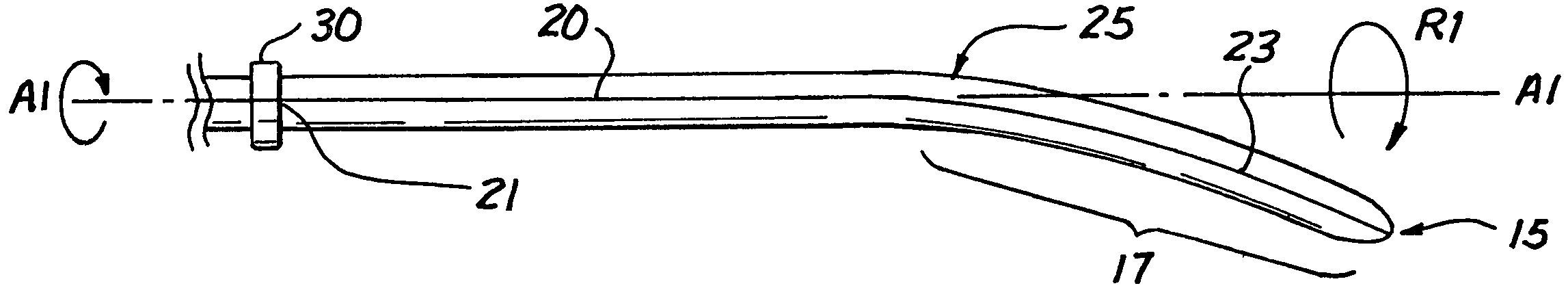

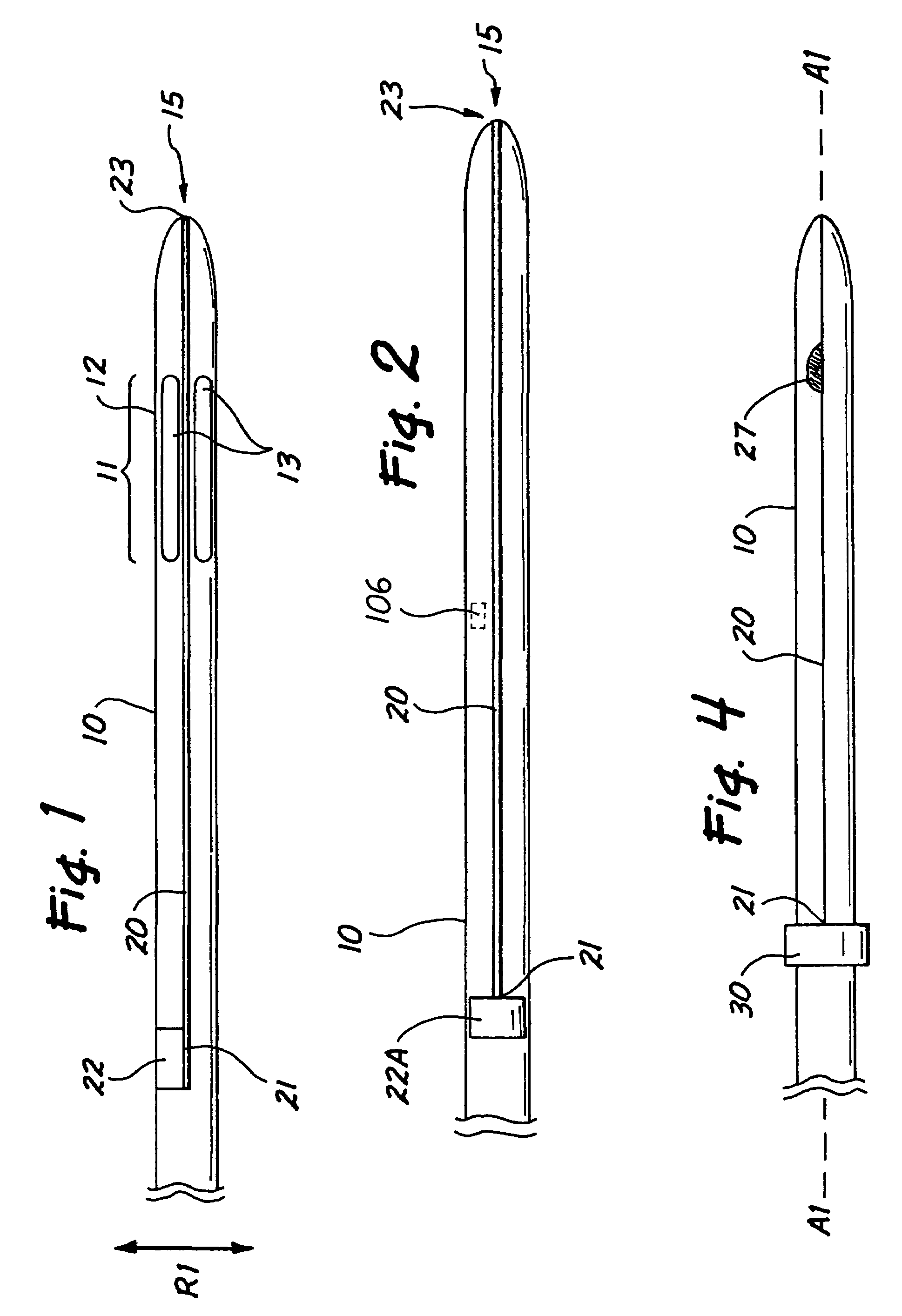

Moving heat exchange catheter system

A catheter system for controlling the body temperature of a patient by modifying the temperature of blood flowing within a blood vessel of the patient. The catheter system comprises a catheter body having a heat exchange region in contact with the blood; and a mechanism for moving the heat exchange surface, thereby increasing heat exchange between the heat exchange surface and blood flowing past the heat exchange surface. Various methods of moving the heat exchange surface are disclosed.

Owner:ZOLL CIRCULATION

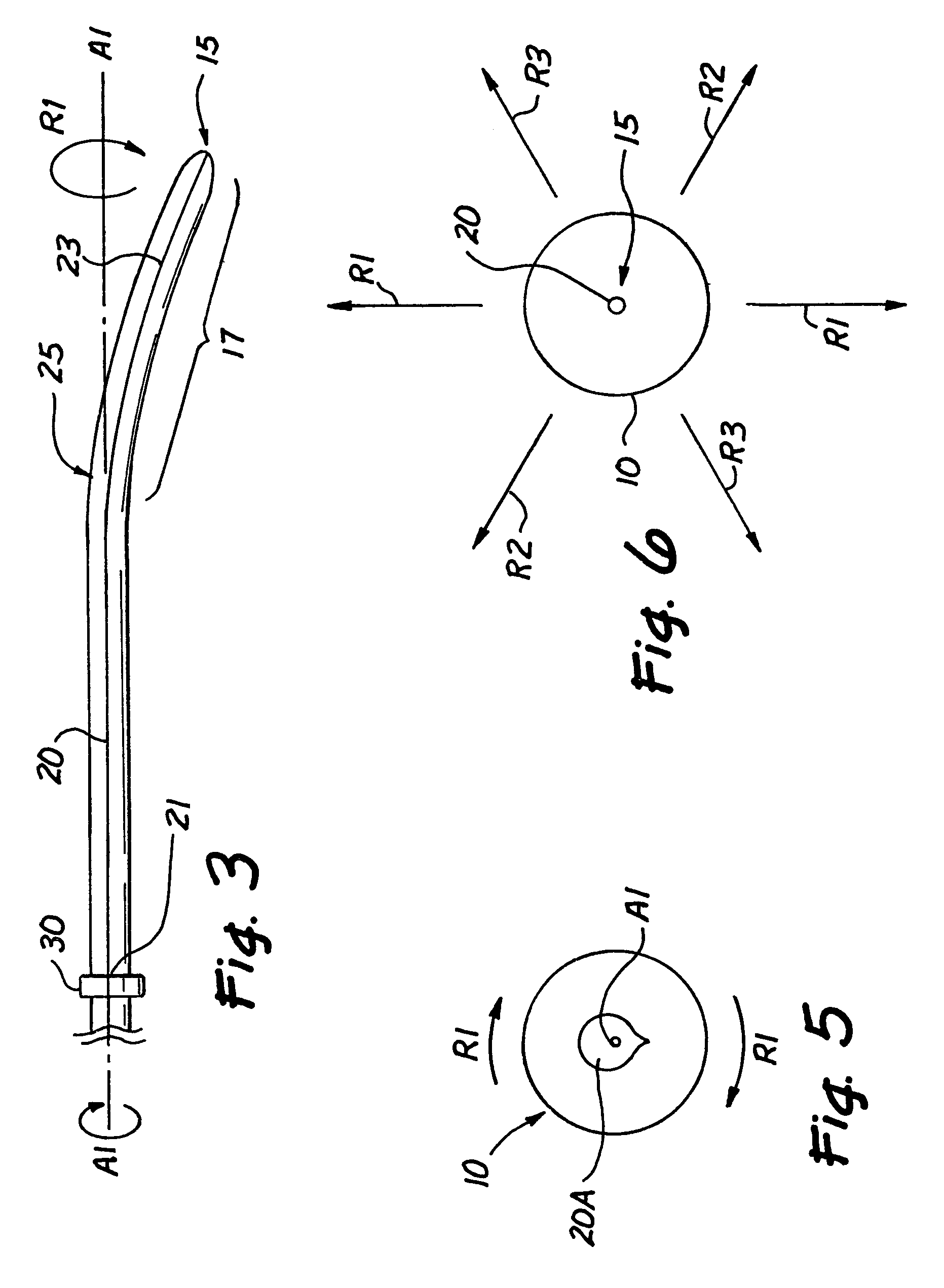

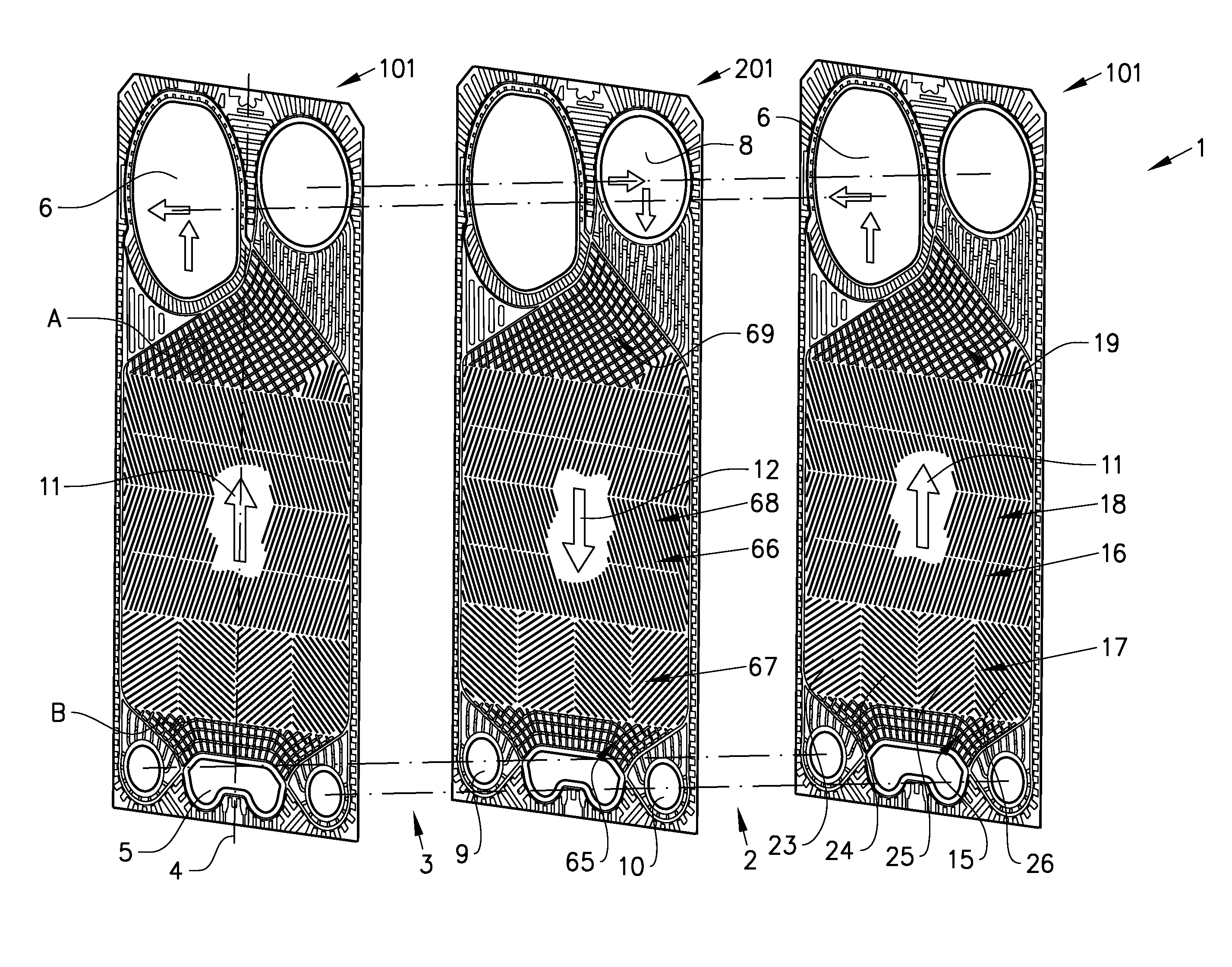

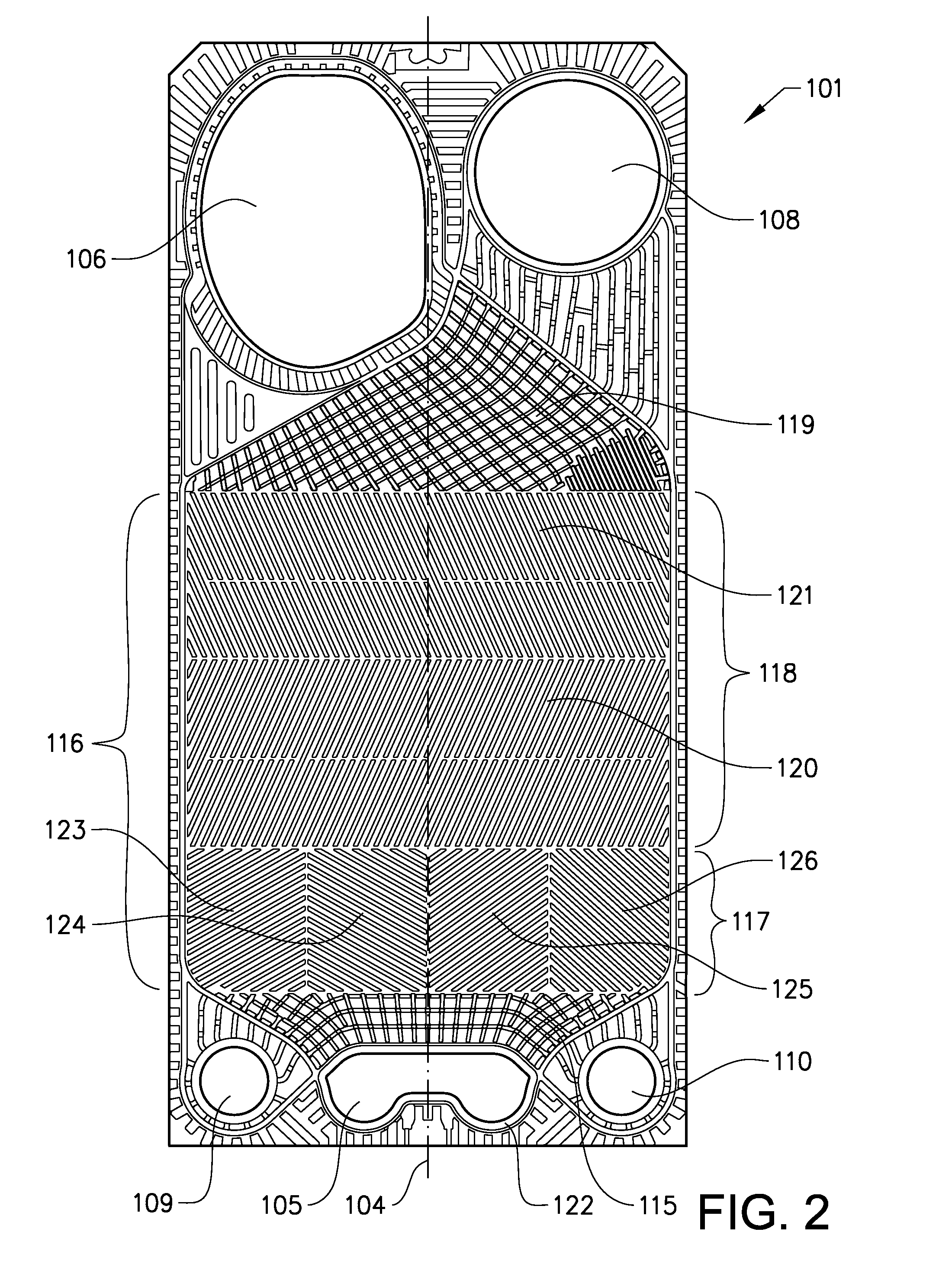

Heat Exchanger

ActiveUS20110139419A1Increase flow resistanceLow flow resistanceHeat exhanger finsHeat transfer modificationEvaporationEngineering

The invention refers to a plate heat exchanger where the heat exchanger comprises a first flow channel between a first plate and a second plate, and where the flow channel comprises a first distribution passage, a heat transfer passage and a second distribution passage, where the heat transfer passage is vertically divided in a lower and an upper heat transfer passage and where the lower heat transfer passage is horizontally divided in a plurality of adjacent heat transfer zones, where the intermediate angle between the ridges and grooves in any of the heat transfer zones of the lower heat transfer passage is at least 30° larger than the intermediate angle of the upper heat transfer passage. The advantage of the invention is that an improved heat exchanger is provided, having an increased thermal performance and an improved evaporation capacity.

Owner:ALFA LAVAL CORP AB

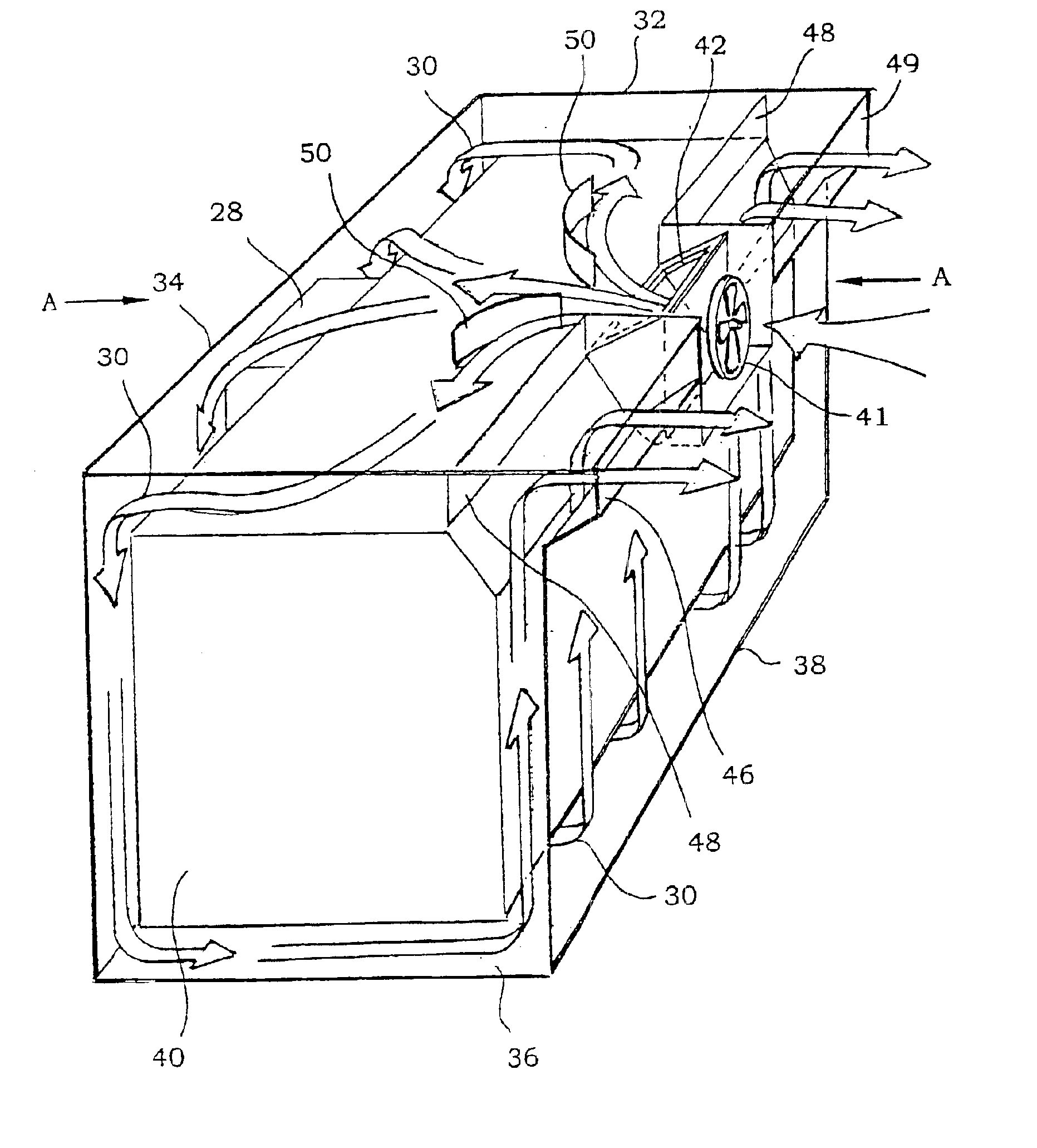

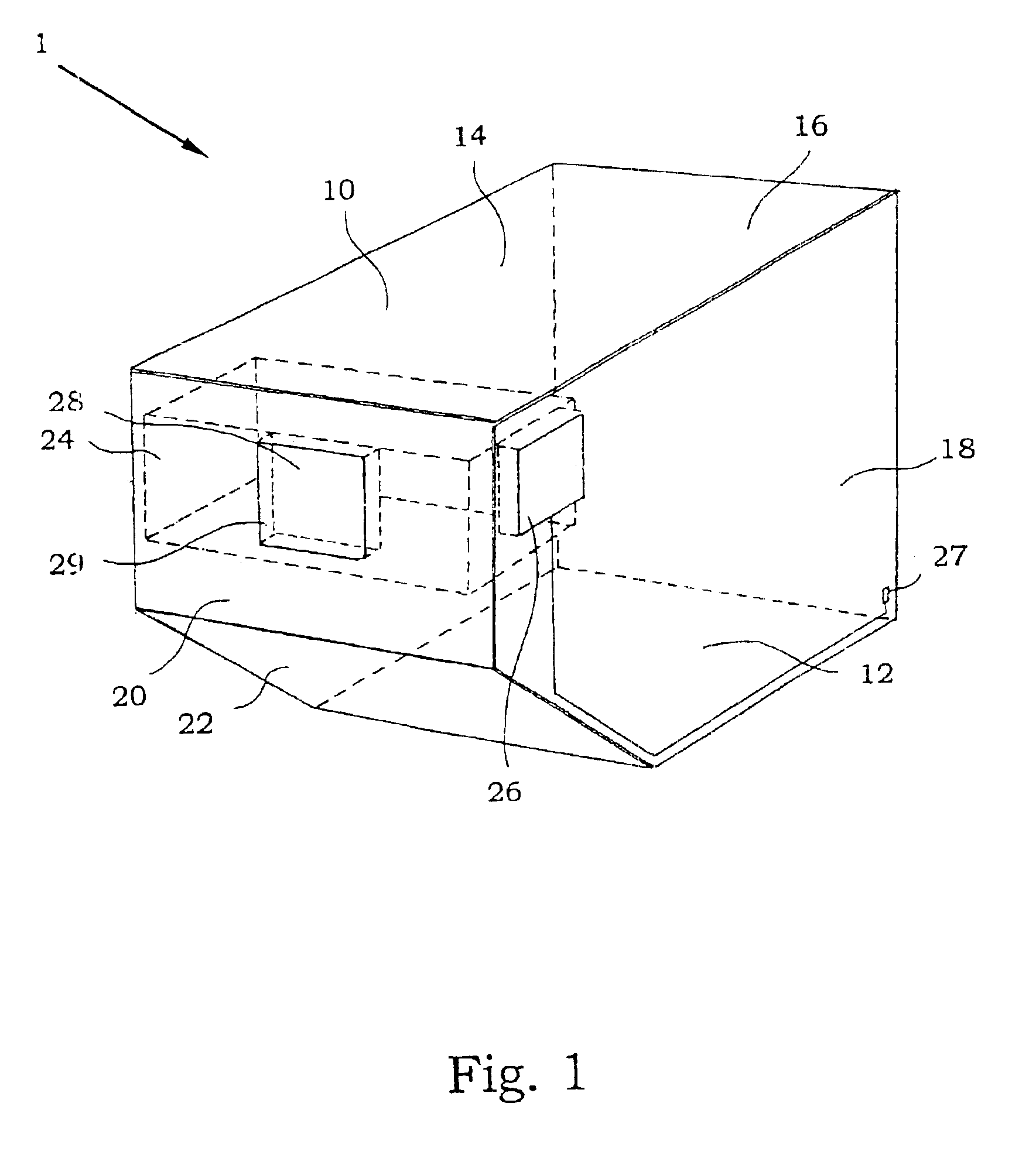

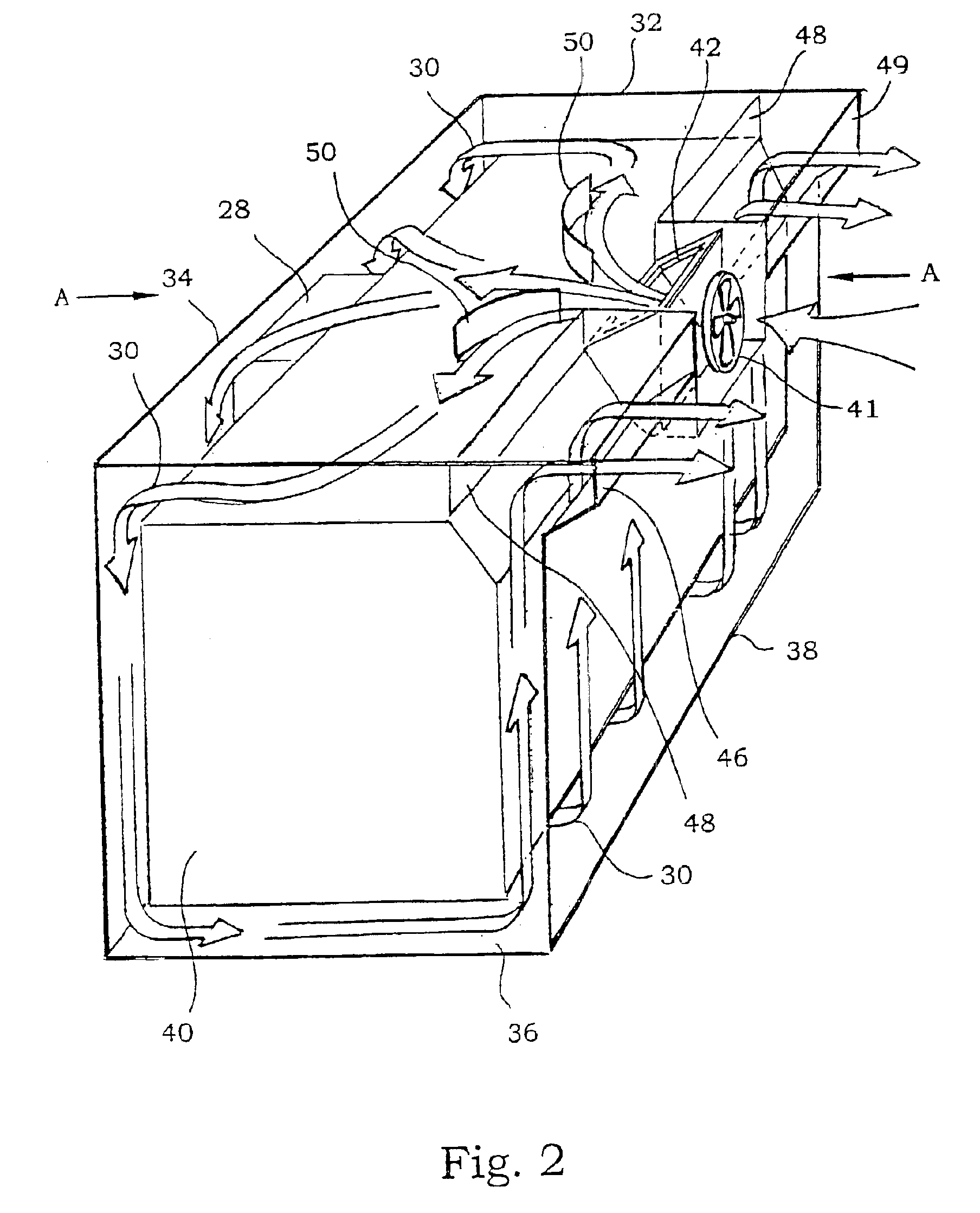

Air-cargo container, a refrigerator unit for an air-cargo container and a manufacturing method of an air-cargo container

InactiveUS6860115B2Simple wayEasy maintenanceLighting and heating apparatusDomestic refrigeratorsModular unitAir cargo

An air-cargo container is equipped with a modular refrigerating unit, which is attachable into the container shell in substantially one piece. Preferably, a control unit for the modular refrigerating unit is also provided as one single module. The refrigerating unit comprises the entire enclosure of an airflow path around an icebox, and is preferably mounted at a small distance from the wall and ceiling of the container. Simple positioning elements facilitate the actual positioning and mounting procedure. The refrigerating unit preferably comprises sealing flanges which during mounting by the positioning elements automatically are fitted into elements at the container wall. A manufacturing method is also disclosed, which comprises mounting of modular units into a shell of an air-cargo container. The mounting is preferably performed by using positioning elements, which guides the modular units into the proper positions.

Owner:ENVIROTAINER ENG

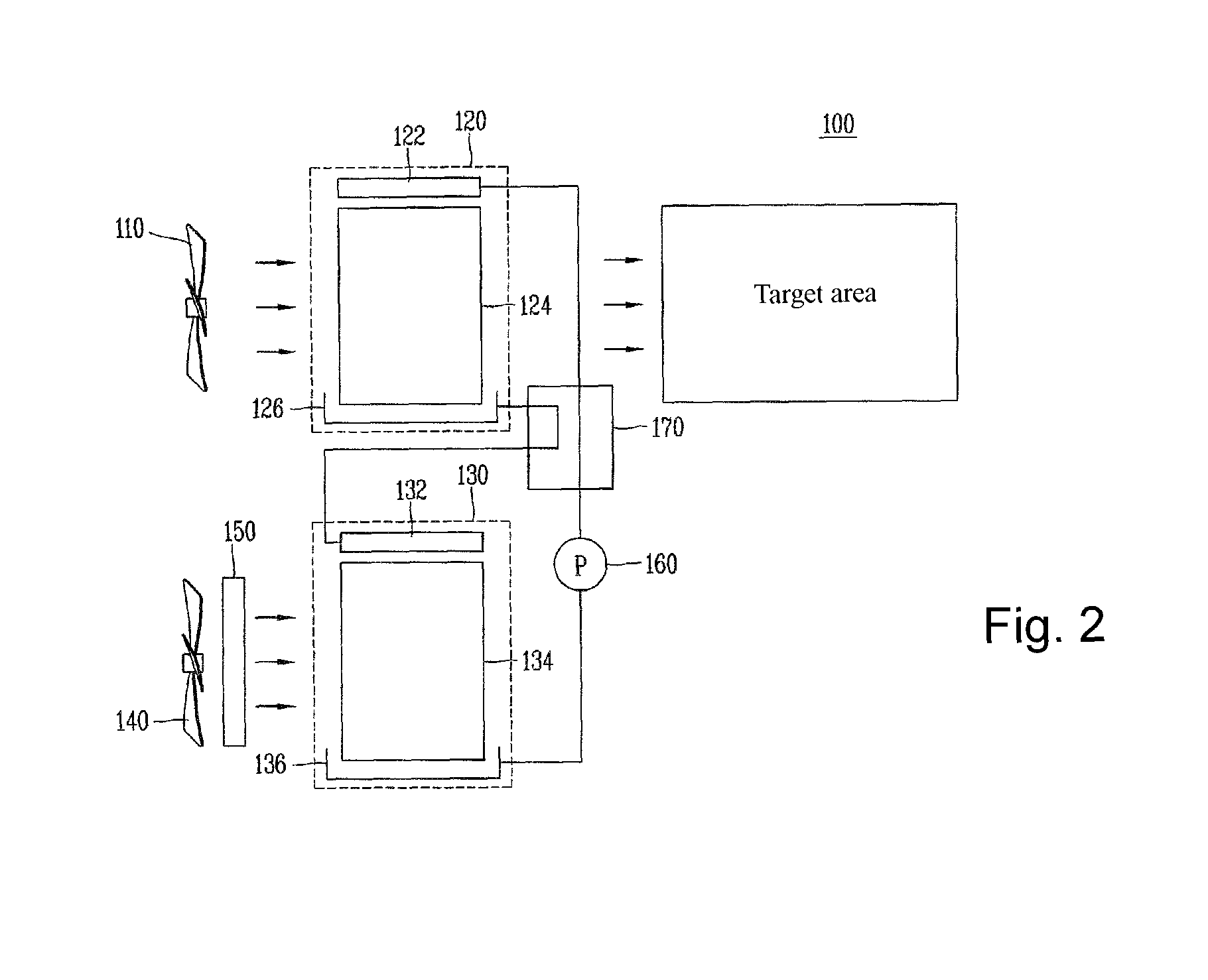

Rotary Heat Exchanger Device

InactiveUS20170328649A1Speed up heat exchangeLower assembly costsEnergy recovery in ventilation and heatingAir treatment detailsEngineeringDrive motor

A rotary heat exchanger device is disclosed. In an embodiment the rotary heat exchanger includes a rotary heat exchanger having a rotary heat exchanger axis of rotation, a drive motor having a stator and a rotor including a rotor axis of rotation and a housing into which the rotary heat exchanger is installed and in which the latter rotates, wherein the rotor axis of rotation and the heat exchanger axis of rotation extend coaxially and the rotor is rigidly connected to the rotary heat exchanger.

Owner:TBM

Heat exchanger for dehumidifier using liquid desiccant and dehumidifier using liquid desiccant having the same

InactiveUS8696805B2Small sizeImprove heat transfer efficiencyUsing liquid separation agentMachines/enginesEngineeringLiquid desiccant

Disclosed are a heat exchanger for a dehumidifier using a liquid desiccant and a dehumidifier using a liquid desiccant having the same. The heat exchanger for a dehumidifier using a liquid desiccant, comprises: a plurality of plate-type heat exchanger bodies to which a heat transfer medium flows through flow paths formed therein; and a plurality of plates extending between the respective heat exchanger bodies, and inclined with respect to the surfaces of the heat exchanger bodies.

Owner:KOREA INST OF SCI & TECH

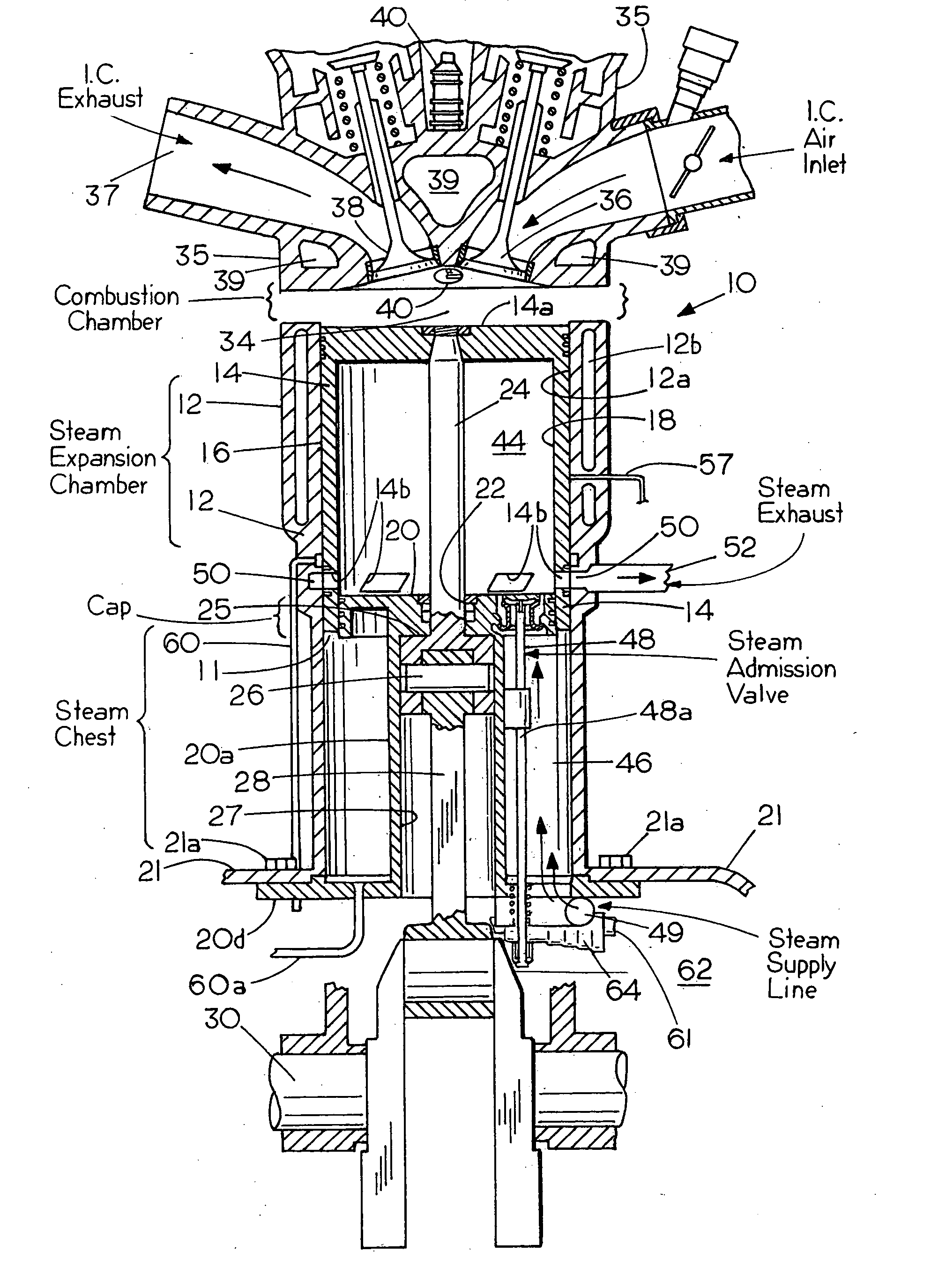

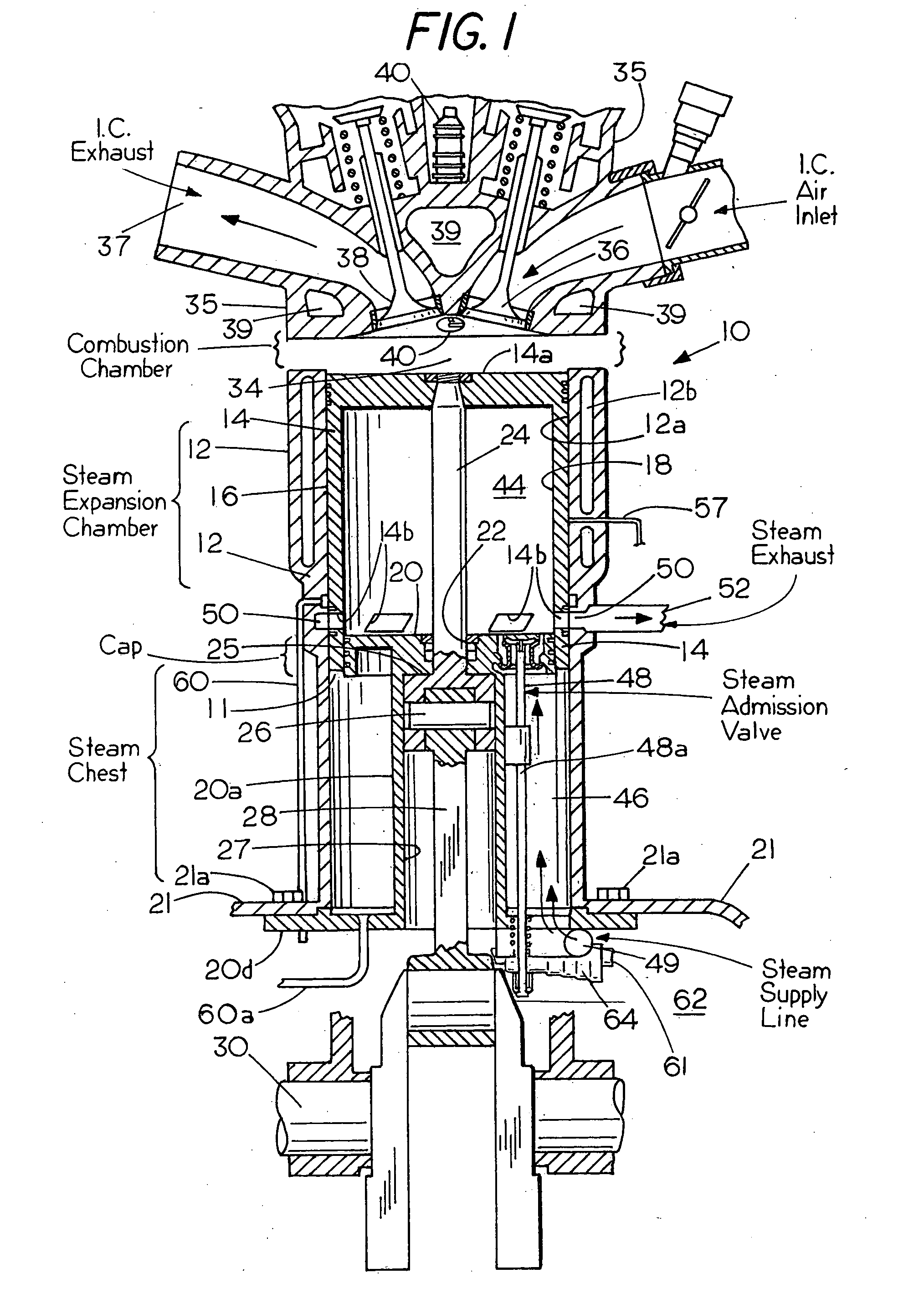

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS20090205338A1Operation efficiency can be improvedImprove efficiencyInternal combustion piston enginesSteam useCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder having a piston mounted for reciprocation therein with an internal combustion chamber outward of the piston, a fixed cylinder cap sealingly and slideably mounted within the piston and a steam expansion / recompression chamber inside the piston adjacent the cylinder cap. The cylinder cap can be unheated or heated externally to reduce condensation of steam entering the steam chamber from a steam generator fired by waste combustion heat. Steam remaining in the cylinder when a steam exhaust valve closes at the top center position is recompressed during an inward stroke of the piston up to admission pressure prior to admitting the next charge of steam. One valve or a pair of retractable steam inlet valves connected in series within the cylinder cap act in cooperation with steam recompression and clearance volume to achieve an effective zero steam chamber clearance and a gain in mean Rankine cycle temperature to maximize efficiency. The amount of steam admitted each outward stroke is continuously regulated, e.g. by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted during each cycle to reduce specific fuel consumption. Other valves balance steam displacement with the steam generator output to use steam more efficiently. Engine coolant can be evaporated in a combustion chamber cooling jacket to form steam which is then superheated in a combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

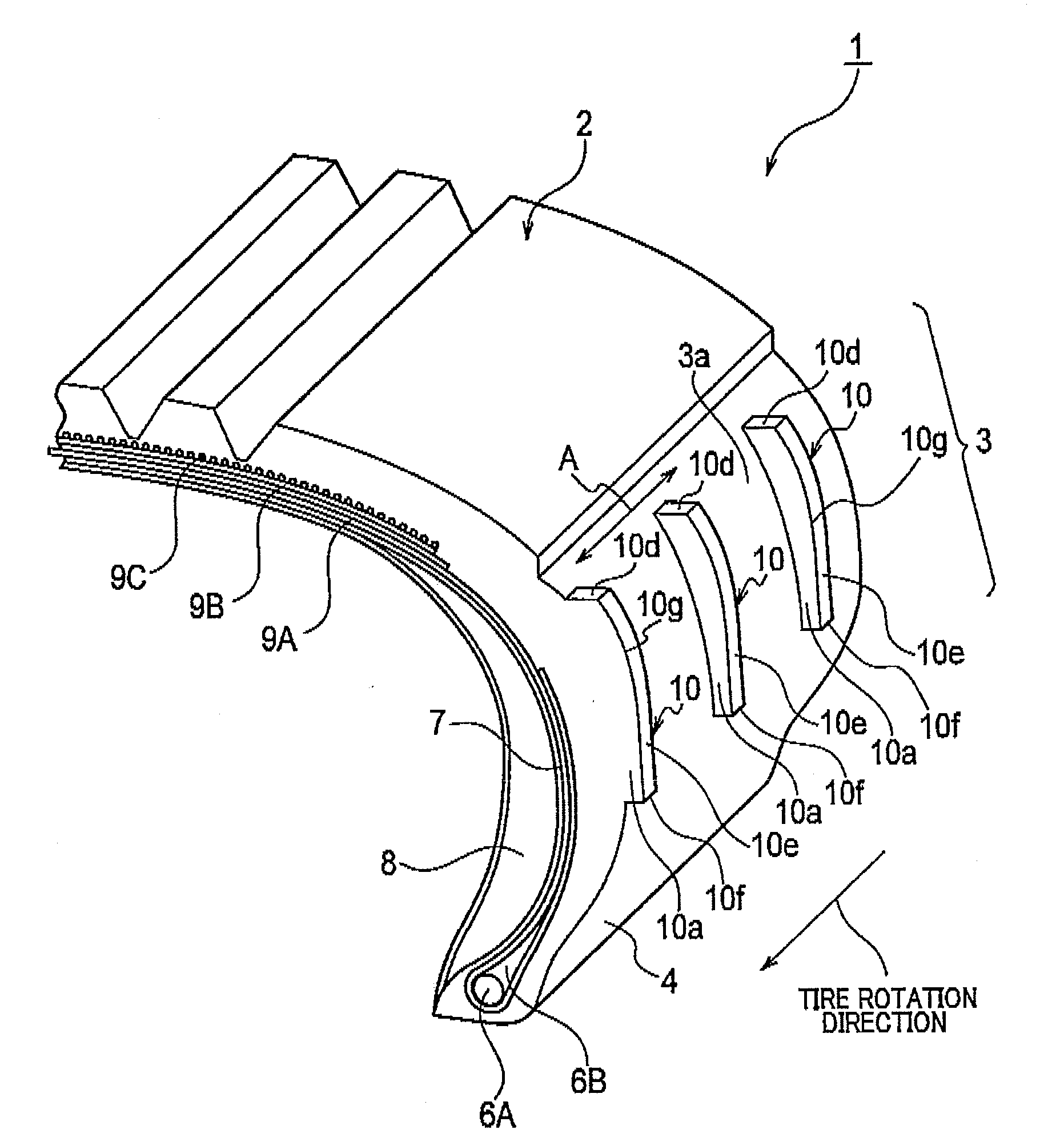

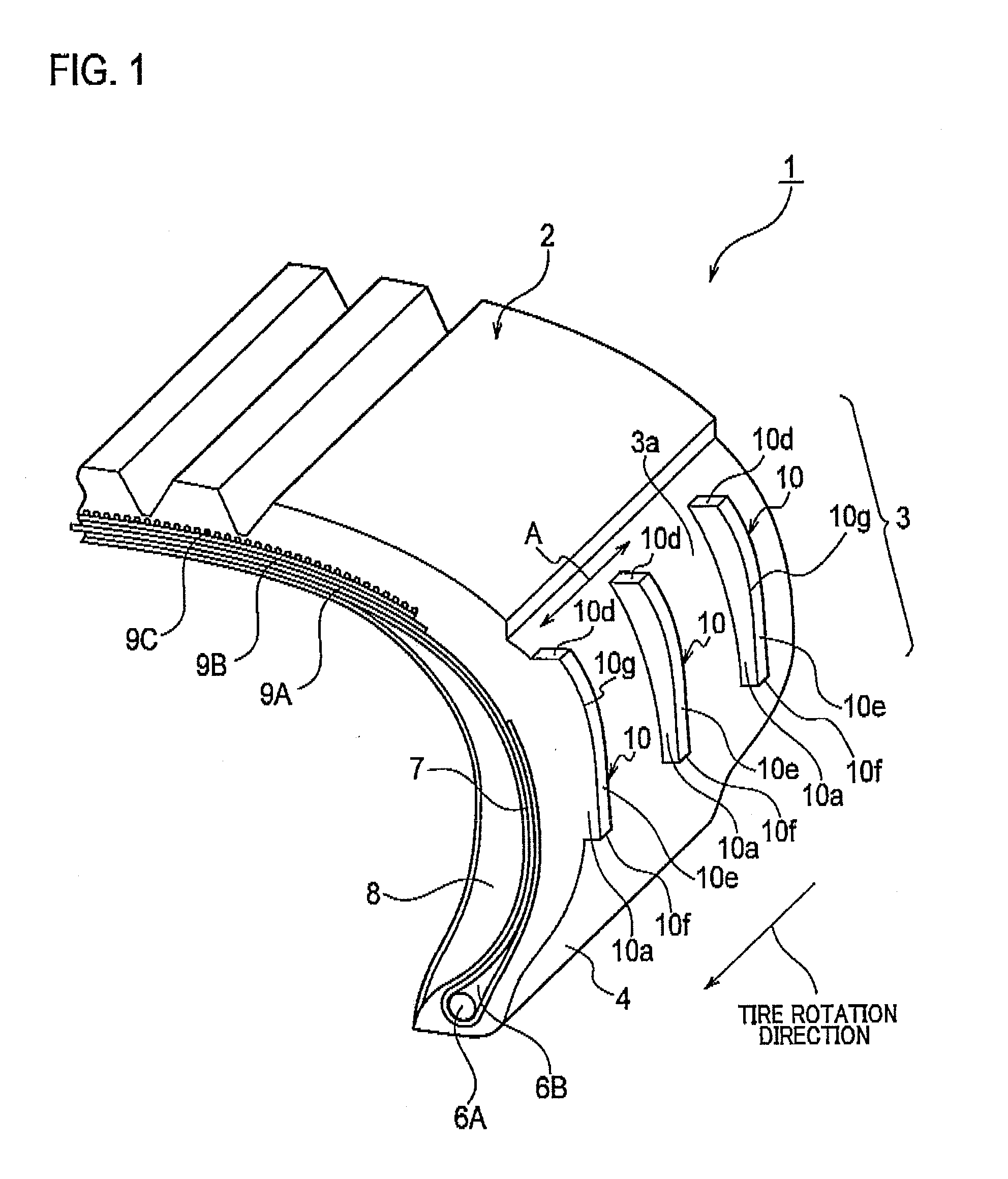

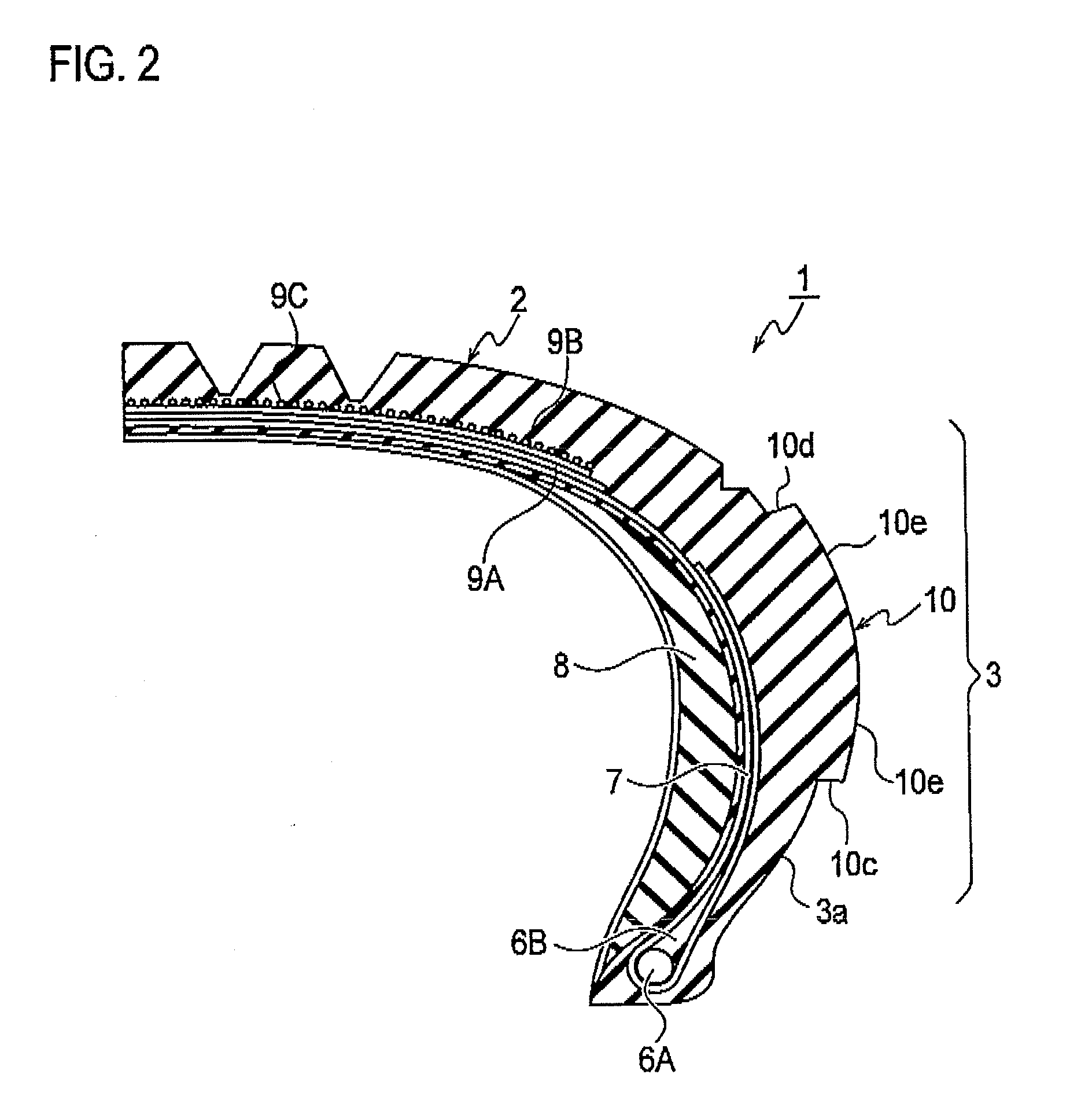

Pneumatic tire

ActiveUS20100038001A1Speed up heat exchangeEasy to separateTyre measurementsTyre tread bands/patternsEngineeringAirflow

The present invention relates to a pneumatic tire 1 in which turbulent-flow generating projections 10 each extending from an inner circumference side to an outer circumference side are provided on a outer circumferential face 3a which is tire surface of tire side portion 3 at intervals in a tire circumferential direction. Each of the turbulent-flow generating projections 10 includes an edge portion 10g when being viewed in a cross-sectional shape taken along a direction perpendicular to an extending direction thereof, and a front wall angle θ formed between a front wall face 10a of each turbulent-flow generating projection 10 and the tire surface (outer circumferential face 3a) is set in the range of 70° to 110°, the front wall face being hit by an airflow.

Owner:BRIDGESTONE CORP

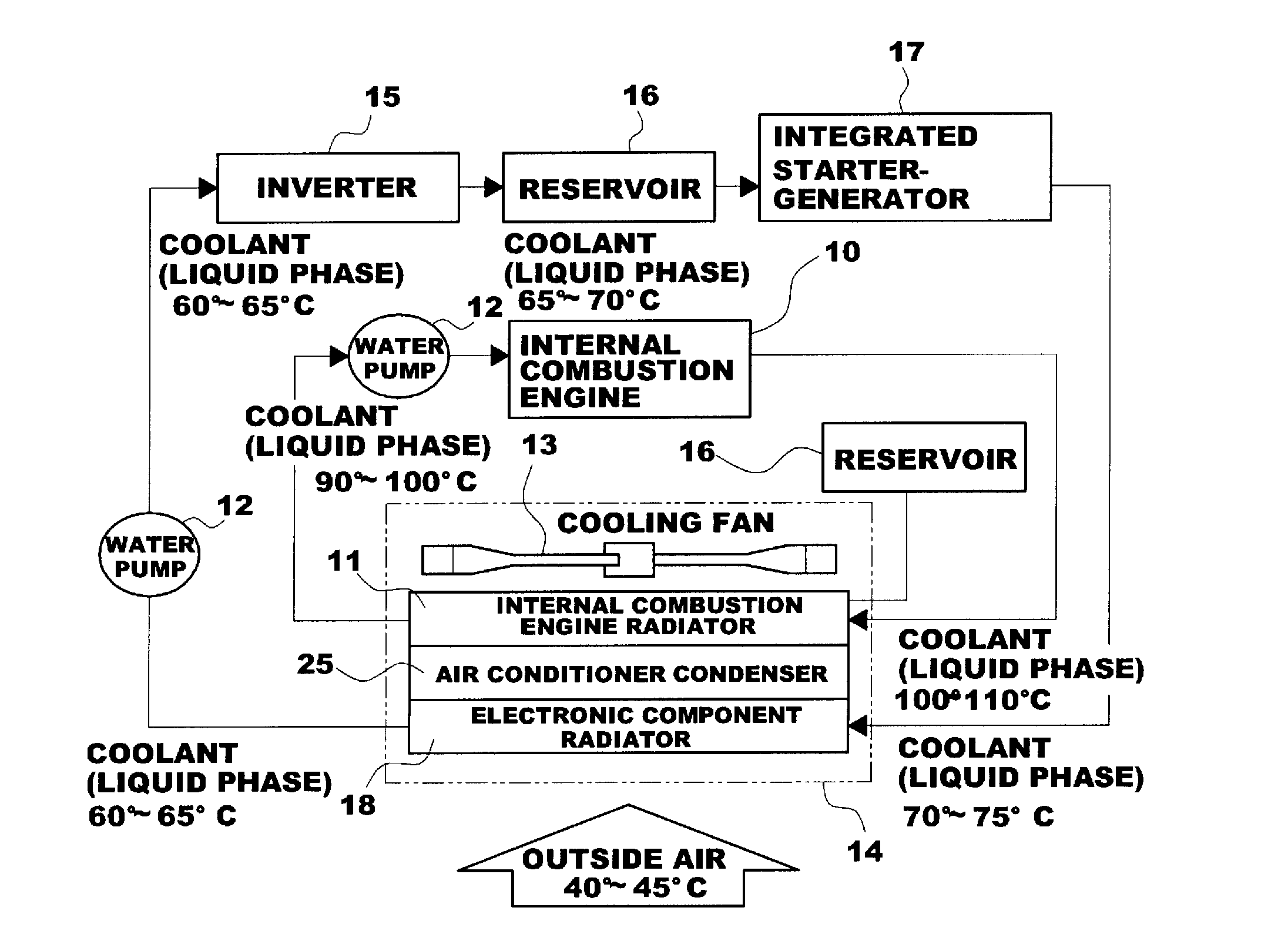

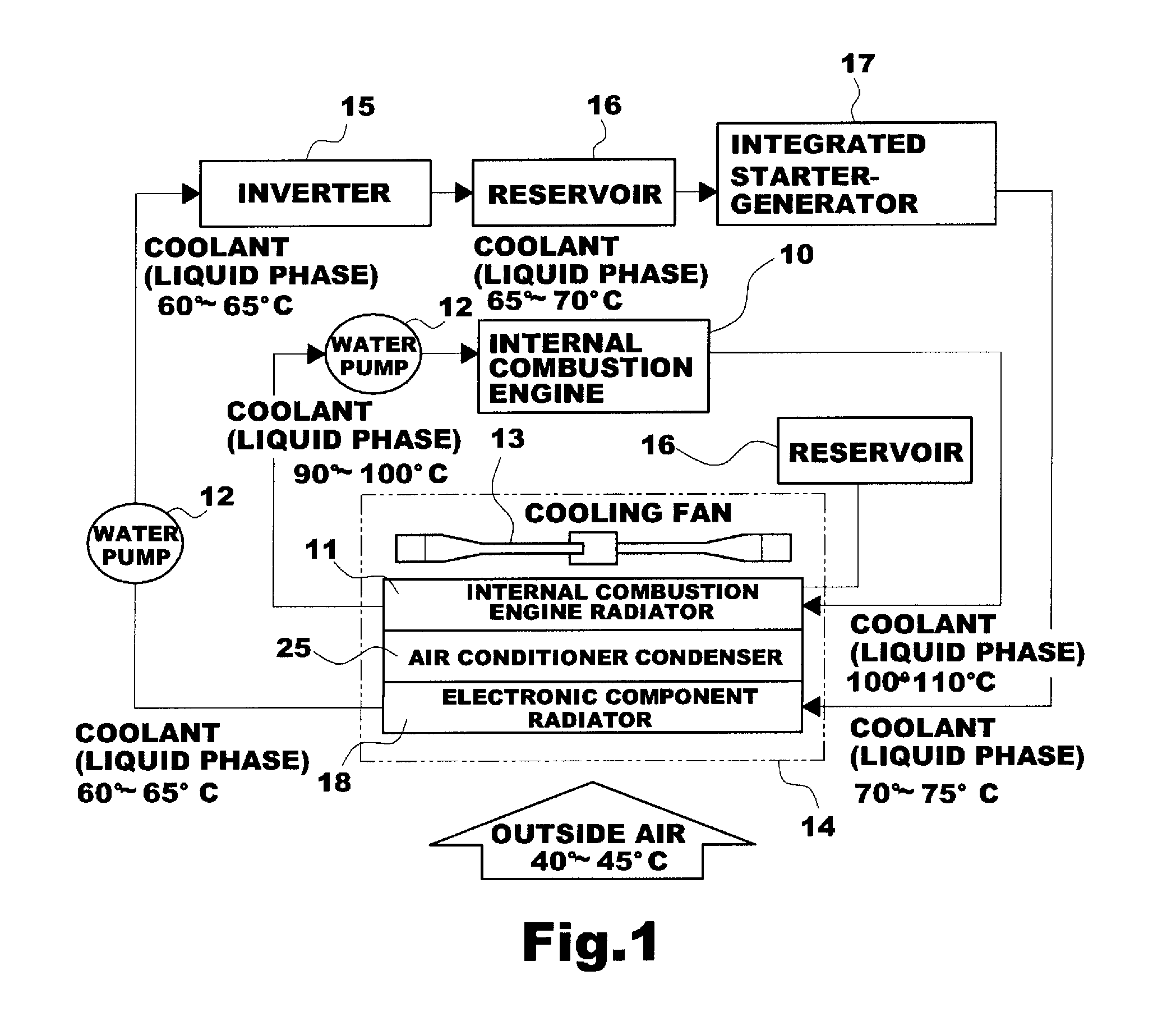

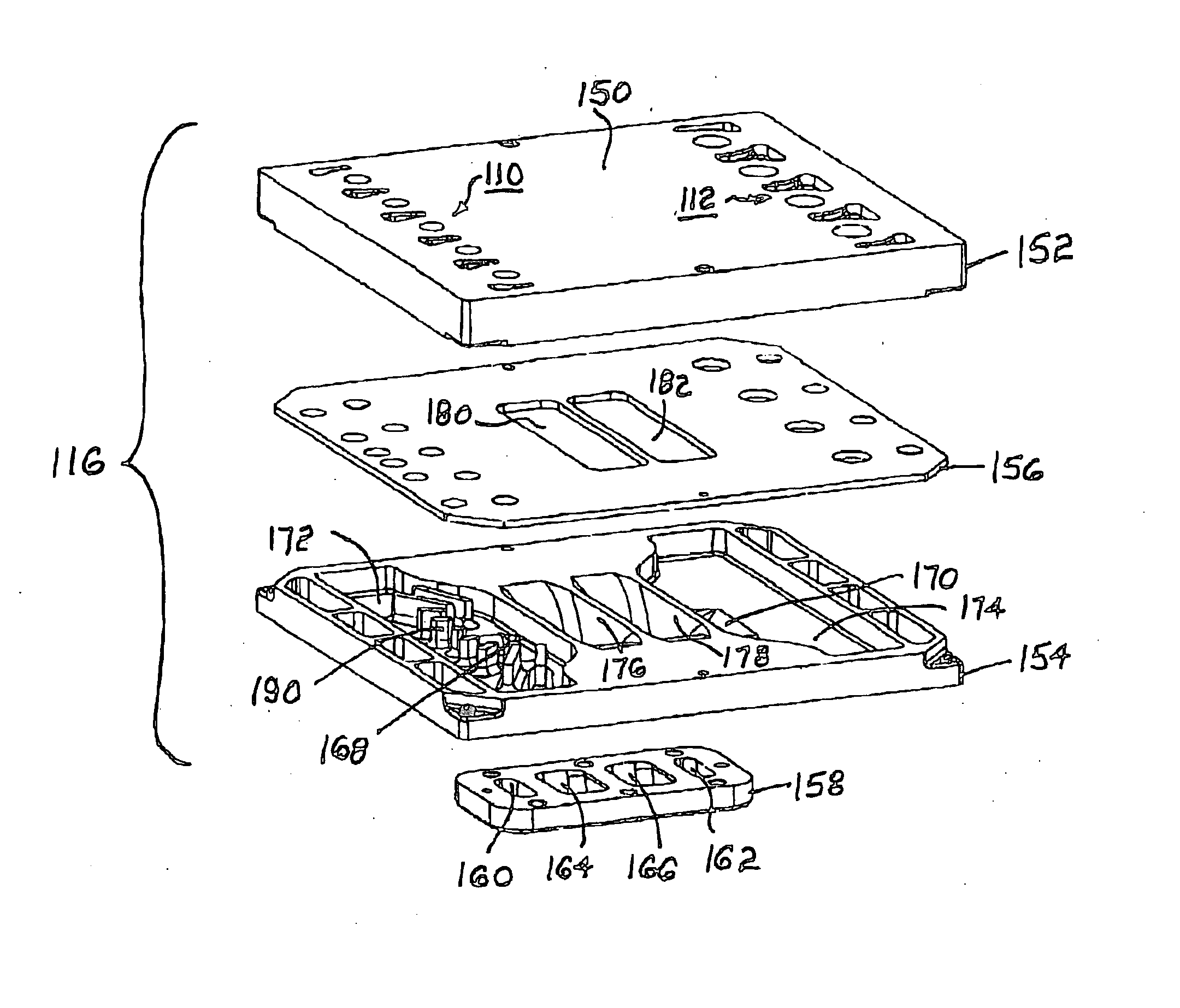

Evaporation Cycle Heat Exchange System for Vehicle

ActiveUS20100126438A1Easy to evaporateImprove fuel efficiencyLiquid coolingElectric propulsion mountingWorking fluidTurbocharger

An evaporation cycle heat exchange system for a vehicle is provided. The evaporation cycle heat exchange system is a new type of cooling system that cools vehicle electronic components, a fuel cell stack, an internal combustion engine, an automatic transmission, a turbocharger, etc. using an evaporative heat exchanger, thus improving cooling efficiency and reducing the size of components such as a radiator. The evaporation cycle heat exchange system cools coolant circulating through a vehicle cooling system by employing an evaporative heat exchanger in which a working fluid flows by a pressure difference caused by volume expansion and capillary phenomenon. Accordingly, it is possible to improve the cooling efficiency of the entire cooling system, reduce the size of components to comply with pedestrian protection regulations, improve fuel efficiency, and ensure the stability of the system. Moreover, the present invention provides an evaporation cycle heat exchange system for a vehicle, in which a product-integrated or line-integrated evaporative heat exchanger capable of being mounted in various vehicle components such as an inverter, a fuel cell stack, an oil fan of an internal combustion engine, a turbocharger, an automatic transmission oil fan, etc. is employed. Accordingly, it is possible to easily apply the evaporative heat exchanger to various vehicle components and various vehicle models, and thus it is possible to increase the degree of freedom of the design of the cooling system.

Owner:HYUNDAI MOTOR CO LTD

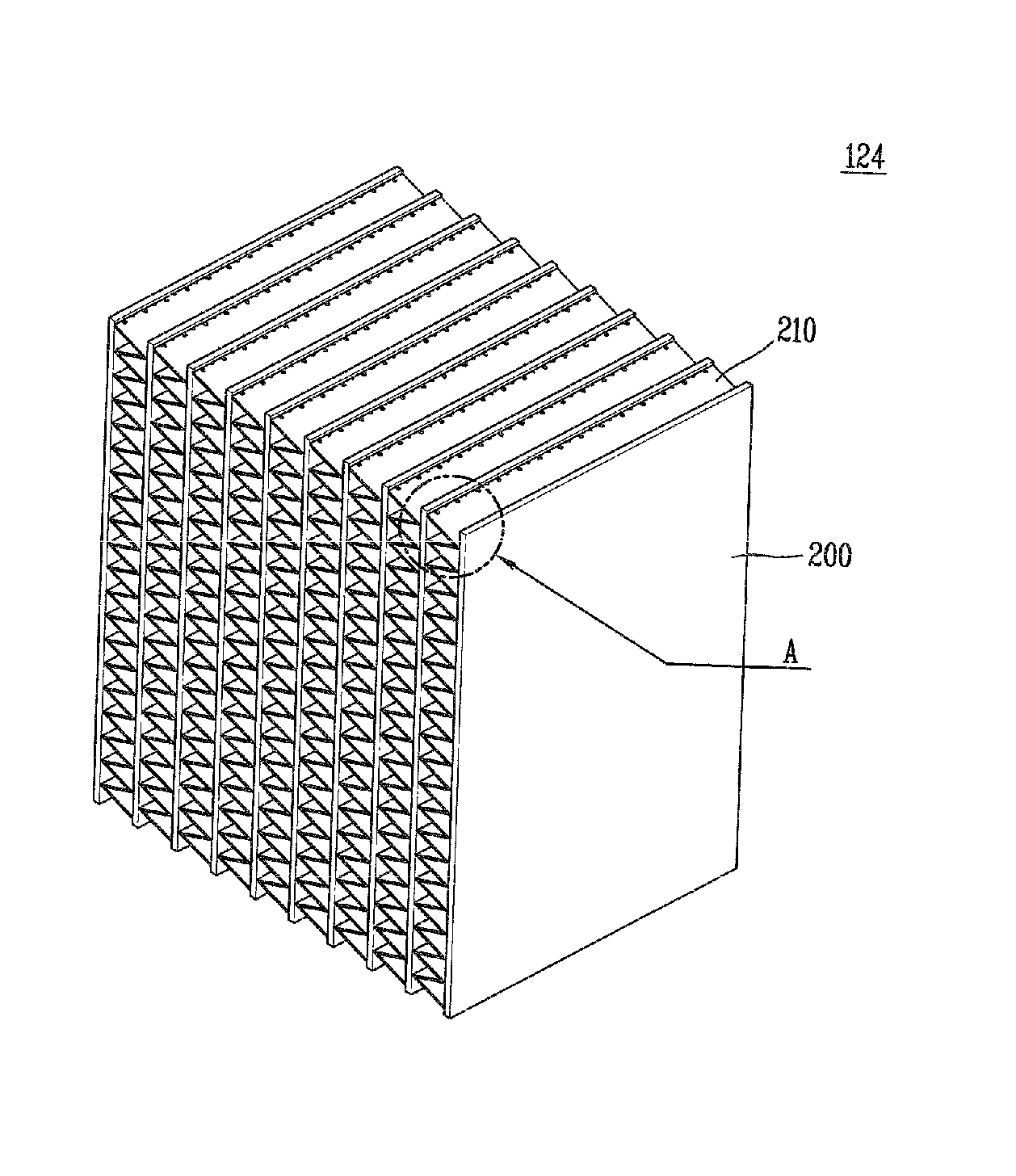

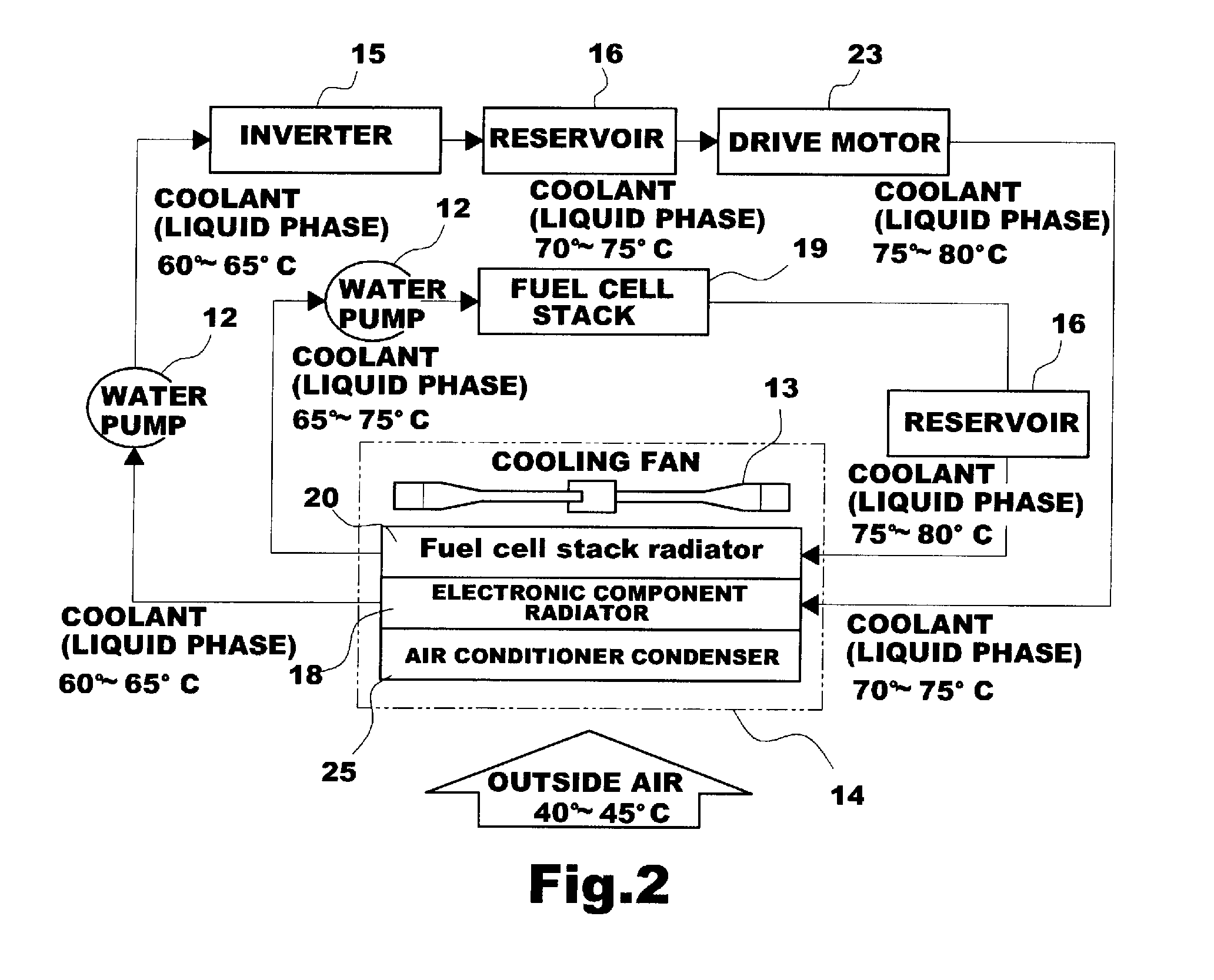

Solid oxide fuel cell stack having an integral gas distribution manifold

ActiveUS20070248868A1Increased durabilityImprove reliabilityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

An SOFC stack module including an integral individual stack manifold containing all of the gas pathways necessary for supply and exhaust of fuel gas and cathode air to and from the stack chimneys. The stack is mounted and hermetically joined directly to the manifold without an intermediate base plate. Flanges at the inlet and outlet ports couple to system distributary manifolds via high temperature sealing joints. The manifold preferably is fabricated of a ferritic stainless steel, and may be formed in a one-piece casting, a combination of multiple castings and stamped plates metallurgically joined (brazed or welded together), or stamped from sheet metal stock. Preferably, the manifold includes fin structures extending into adjacent fuel gas and cathode air chambers to enhance balancing of temperatures by heat exchange therebetween. Heat exchange may be further improved by configuring the manifold to have a plurality of interleaved anode and cathode gas supply chambers.

Owner:BATTELLE MEMORIAL INST +1

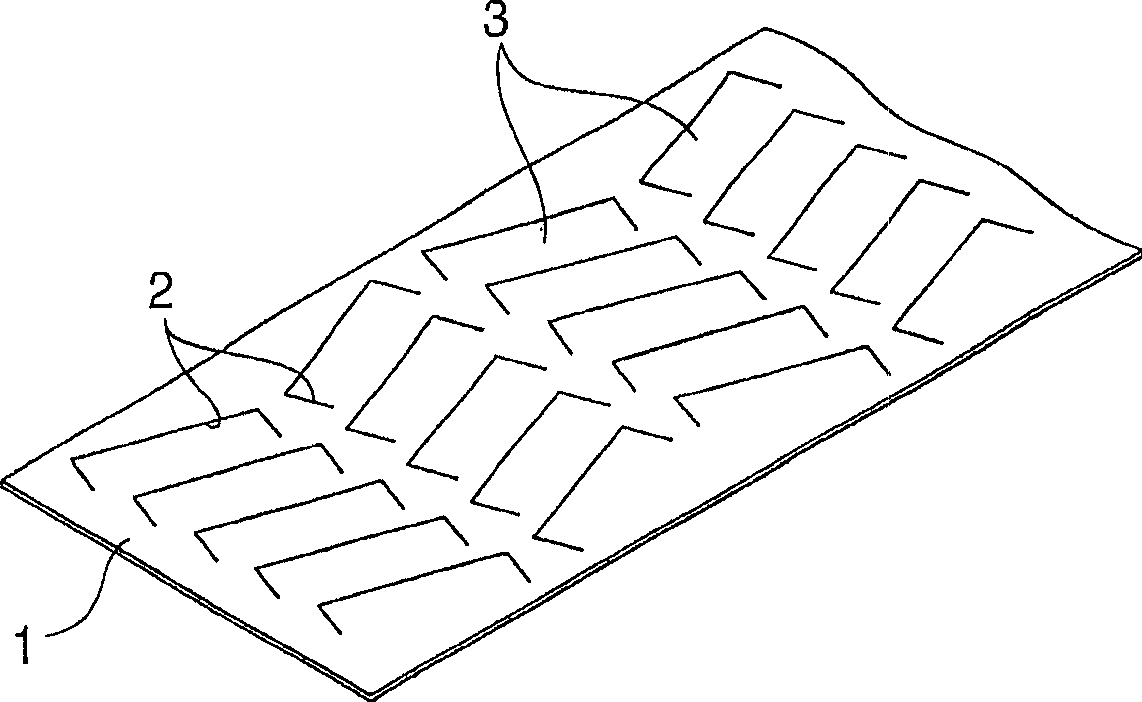

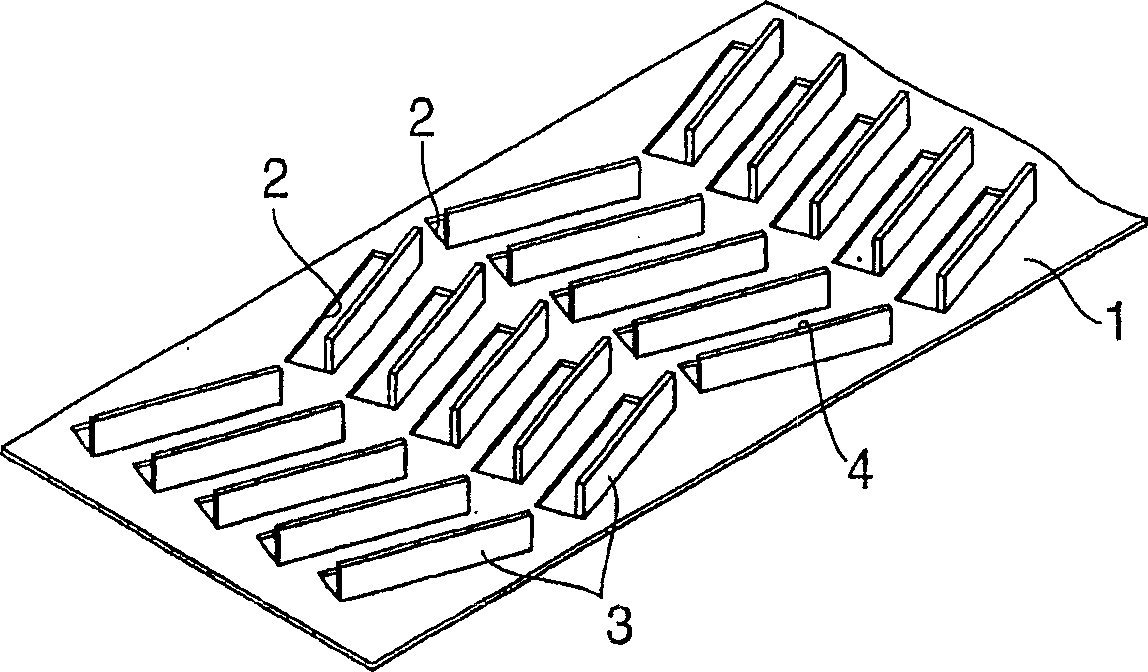

Fin, method of fabricating the same and heat exchanger tube, heat exchanger and gas cooling apparatus

InactiveCN1755316ASpeed up heat exchangeImprove cooling efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelShell and tube heat exchangerEngineering

The invention relates to a shell and tube heat exchanger used as a coolant mechanism. The shell and tube heat exchanger comprises a plate-fin arranged inside or outside a heat exchanger tube, and at least one heat exchanger tube internally provided with the plate-fin. Through the heat exchanger has simple structure and easy manufacture, the heat exchanger can still limberly process fluid bodies with different shapes, promote the effective heat exchanging action of the fluid bodies, obtain good cooling efficiency, and can process a plurality of fluid bodies. The plate-fin that the invention relates to is the plate-fin for stirring liquid; the plate-fin is arranged inside or outside the heat exchanger tube to lead the fluid bodies which is composed of cooled medium or refrigeration medium to flow inside or outside the heat exchanger tube, thus impingiment flow or vortex flow with stirring action are generated; the plate-fin is arranged inside or outside the heat exchanger tube, and thus the blade edges of the plate-fin are butted and jointed up and down to enable the blade edges opposite to each other, and each butted and jointed blade edges are crossed with each other. The invention also relates to a method for manufacturing the plate-fin as well as the heat exchanger tube internally provided with the plate-fin, and the heat exchanger or an EGR gas cooling device provided with at least one heat exchanger tube.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com