Patents

Literature

225 results about "Waste combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combustion means the thermal treatment of solid waste in a device which uses elevated temperatures as the primary means to change the chemical, physical, or biological character or composition of the waste. Examples of combustion processes include incineration, pyrolysis and fluidized bed.

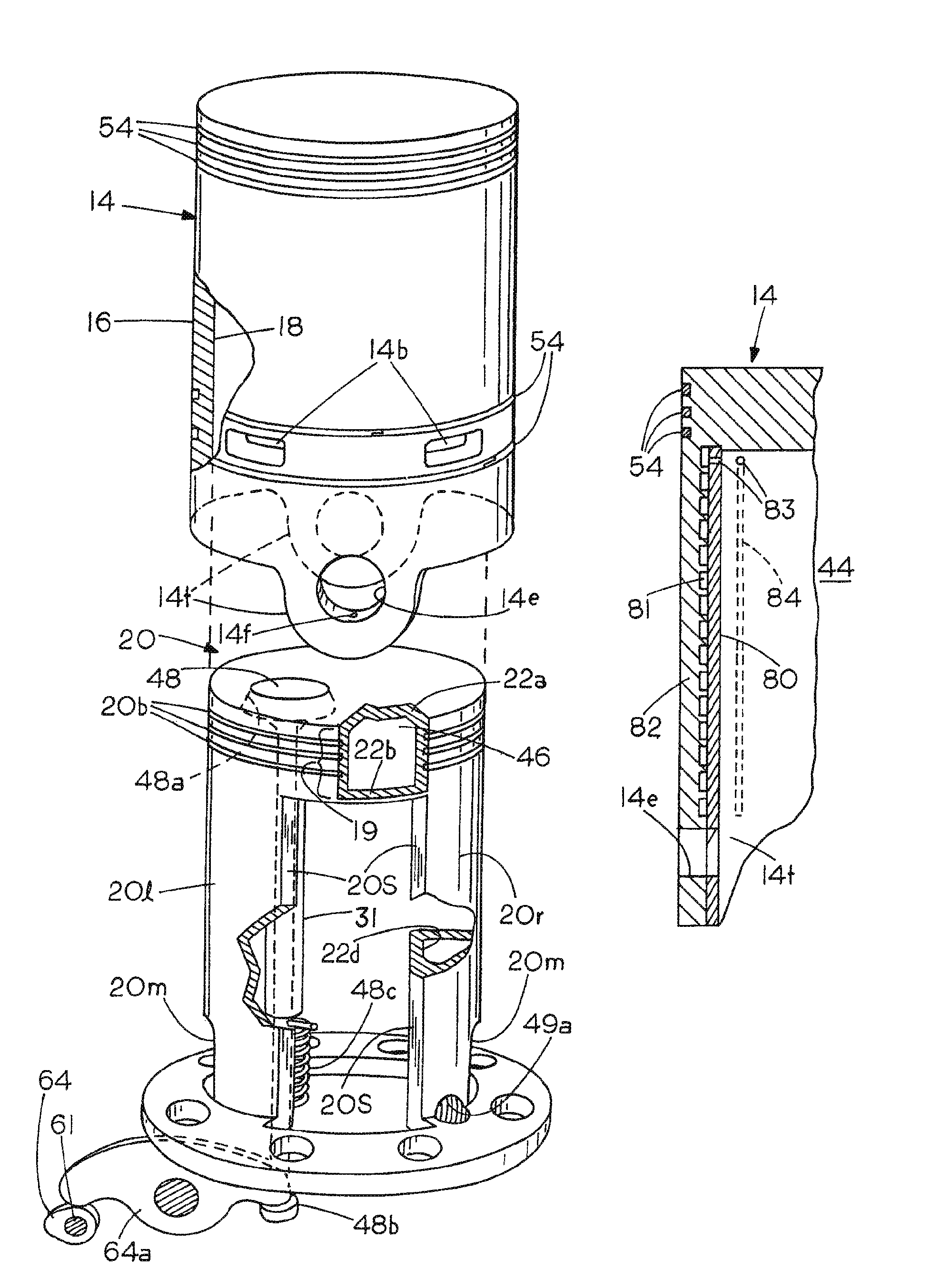

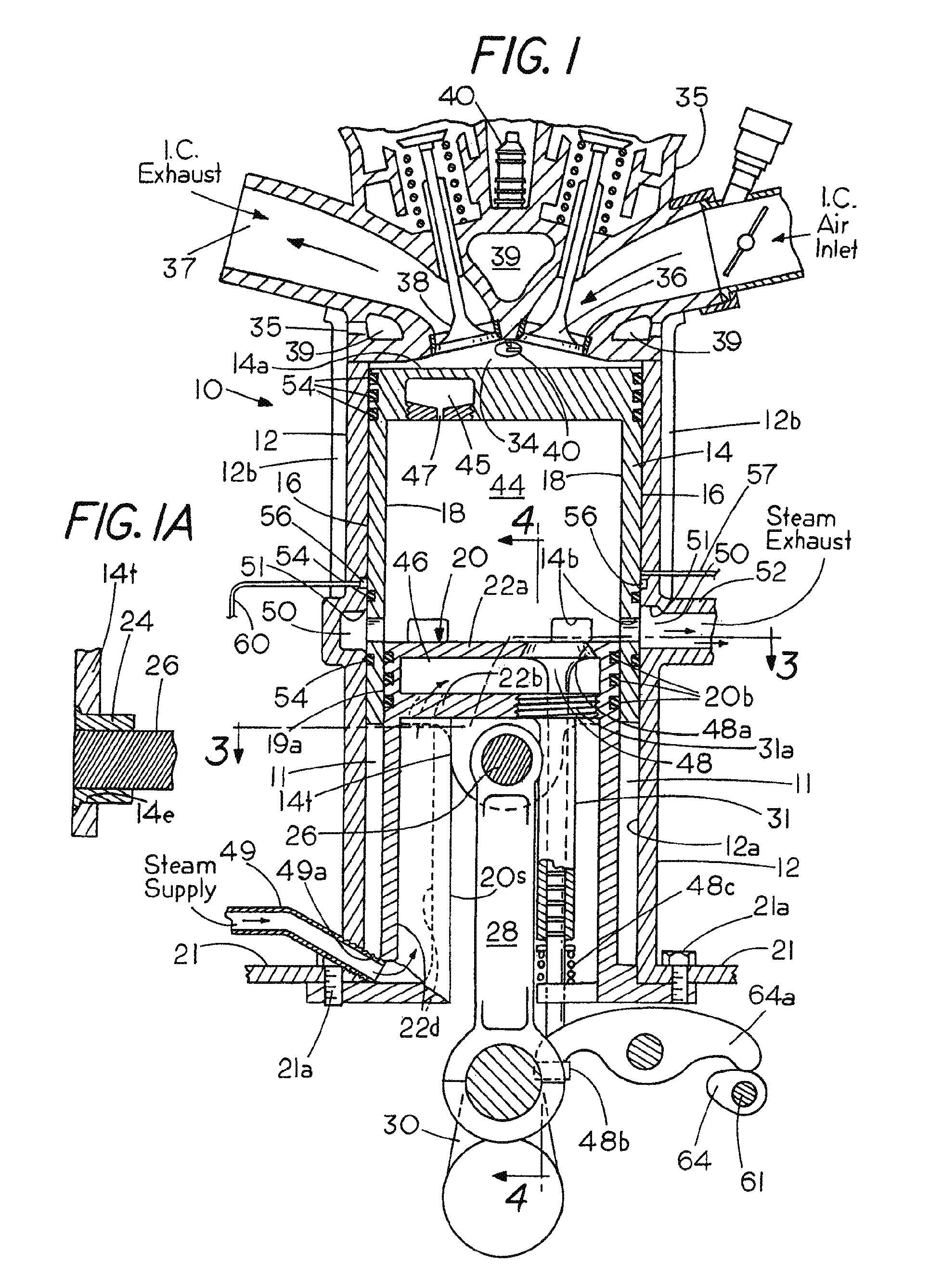

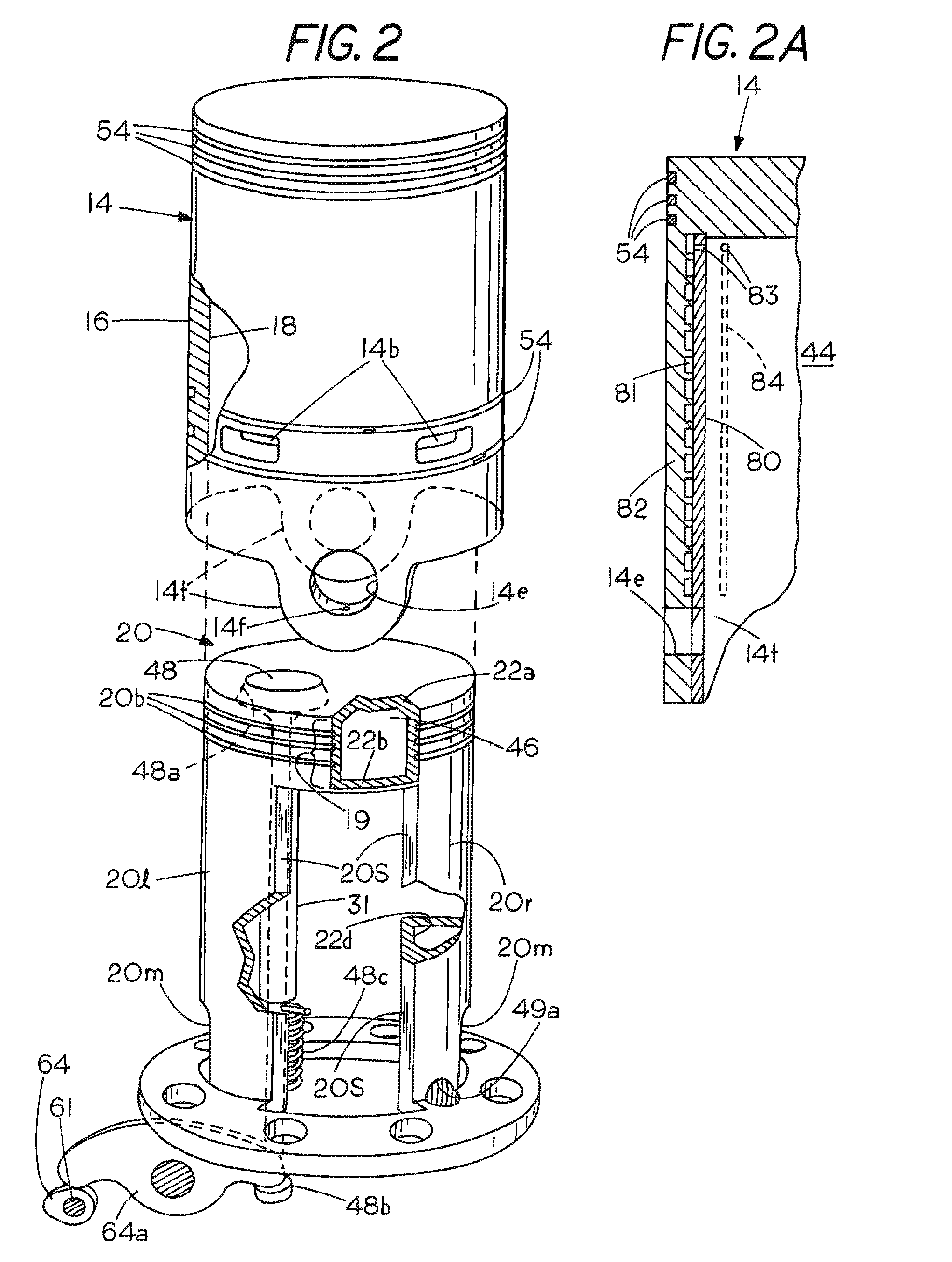

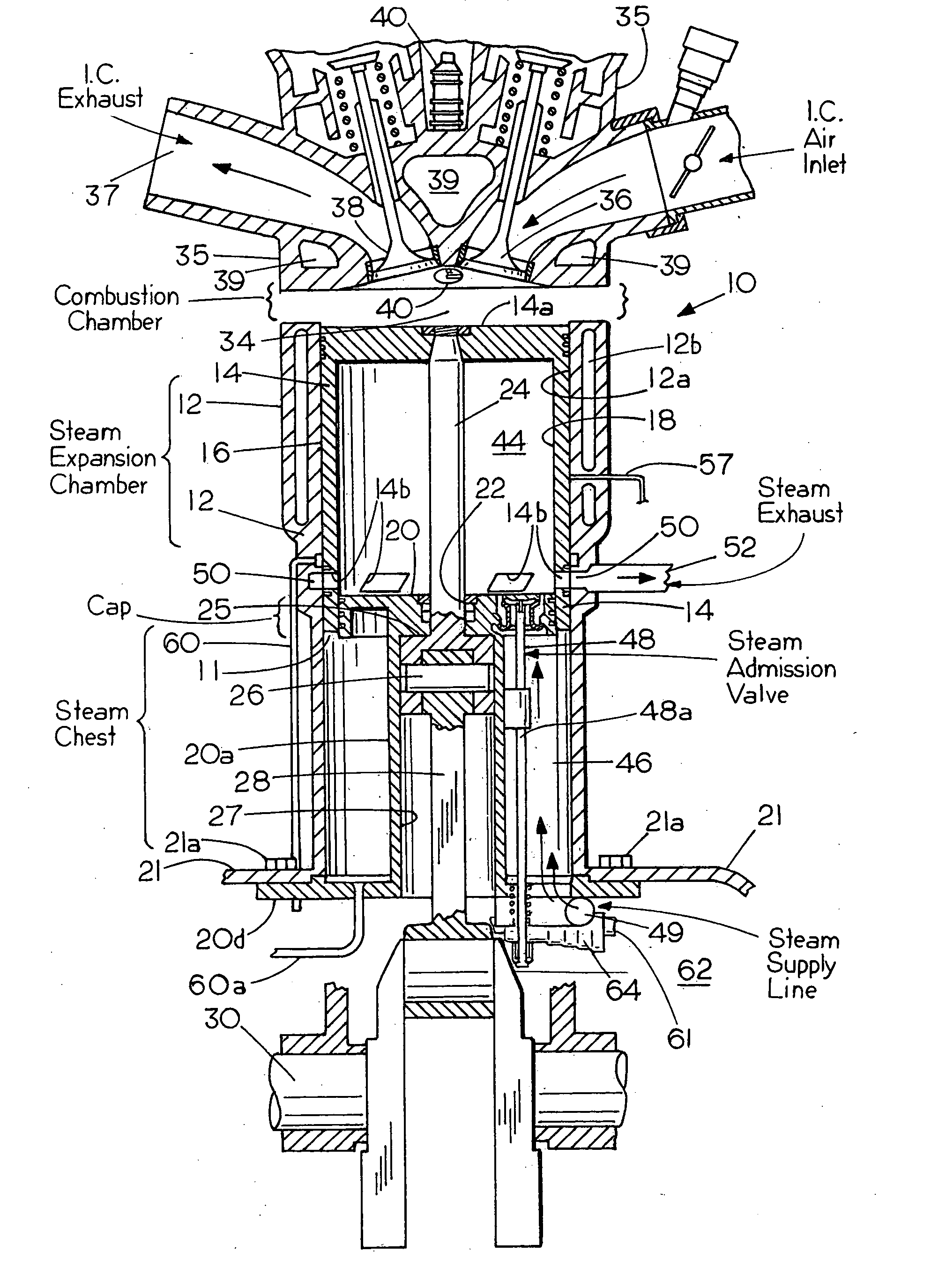

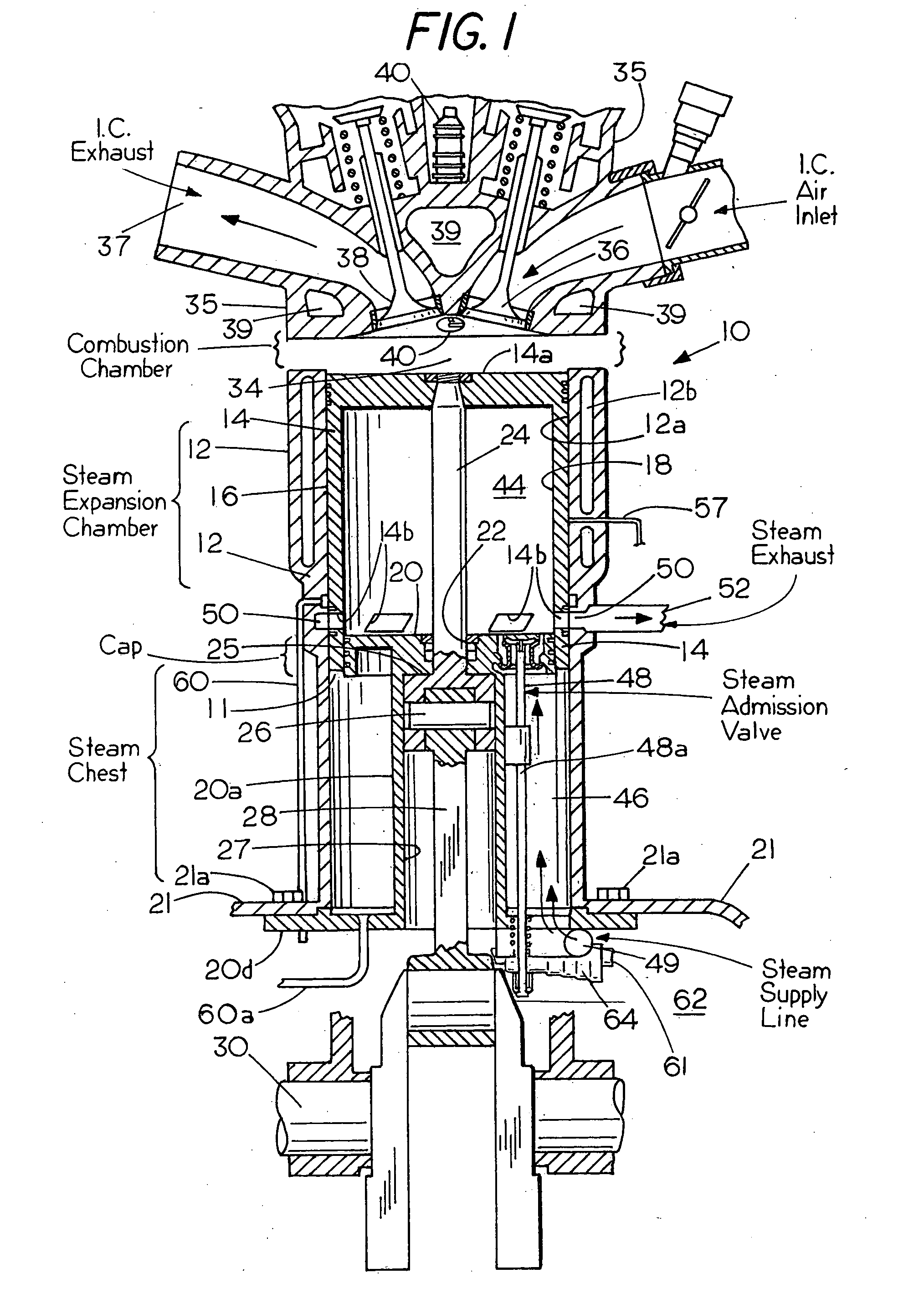

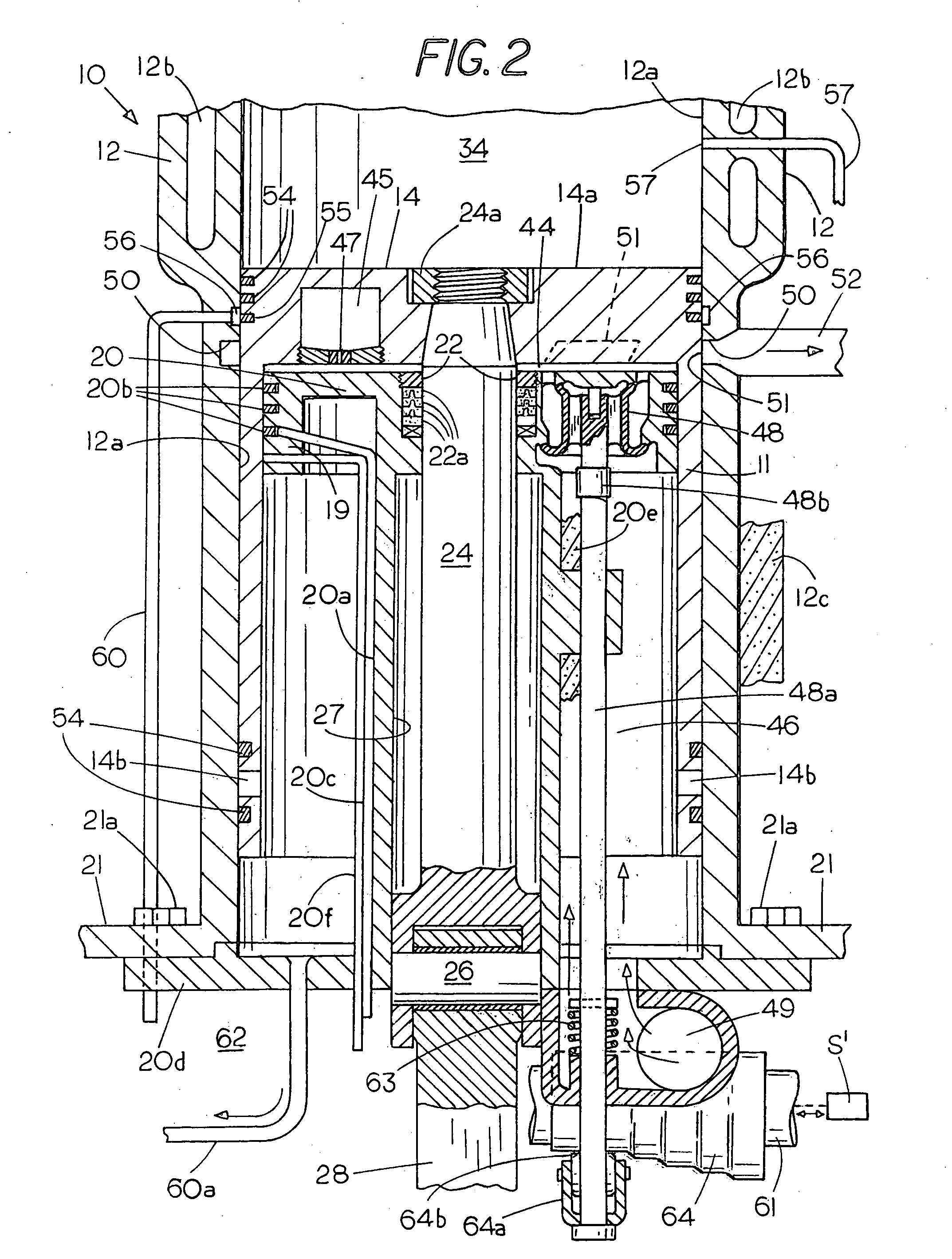

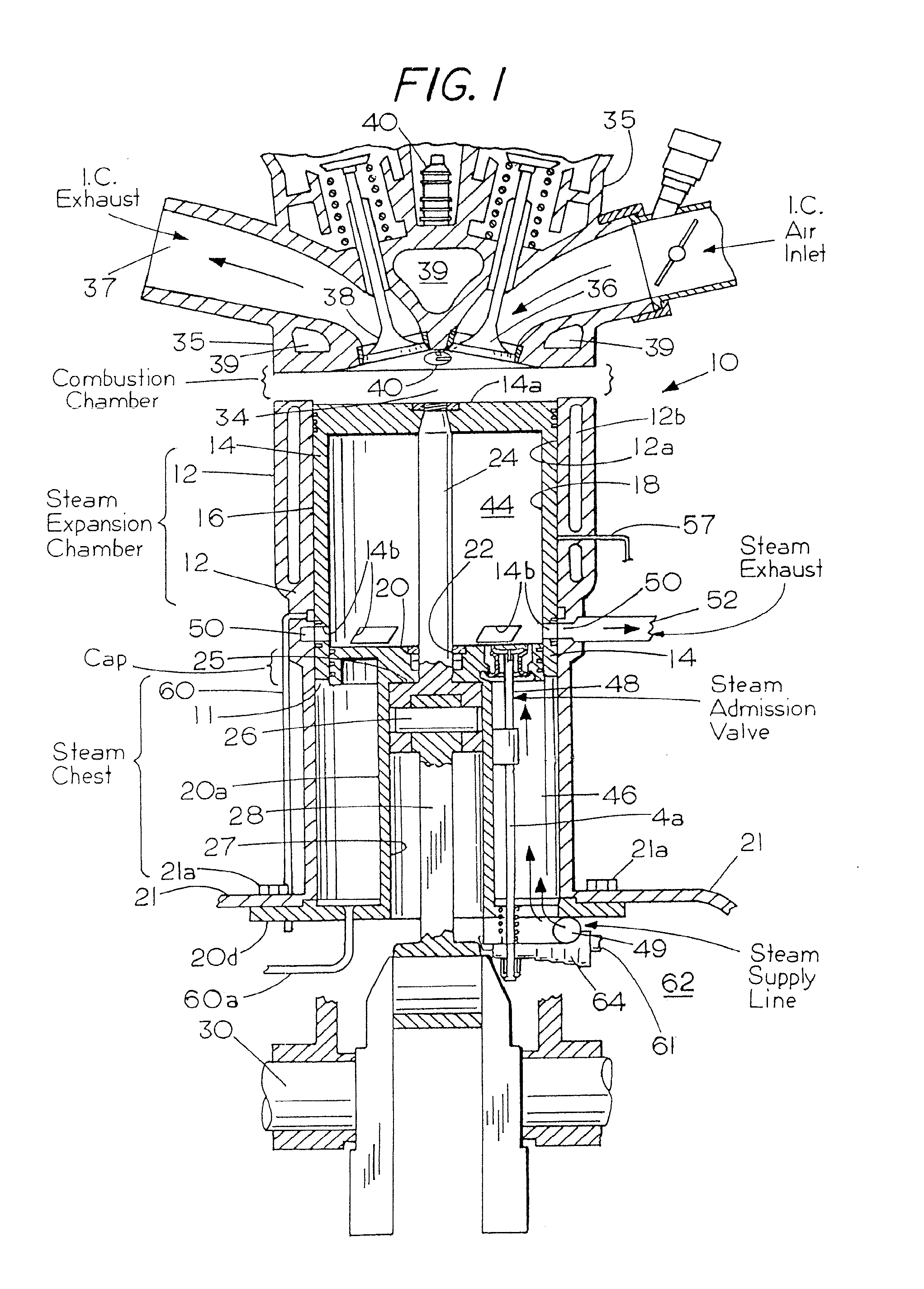

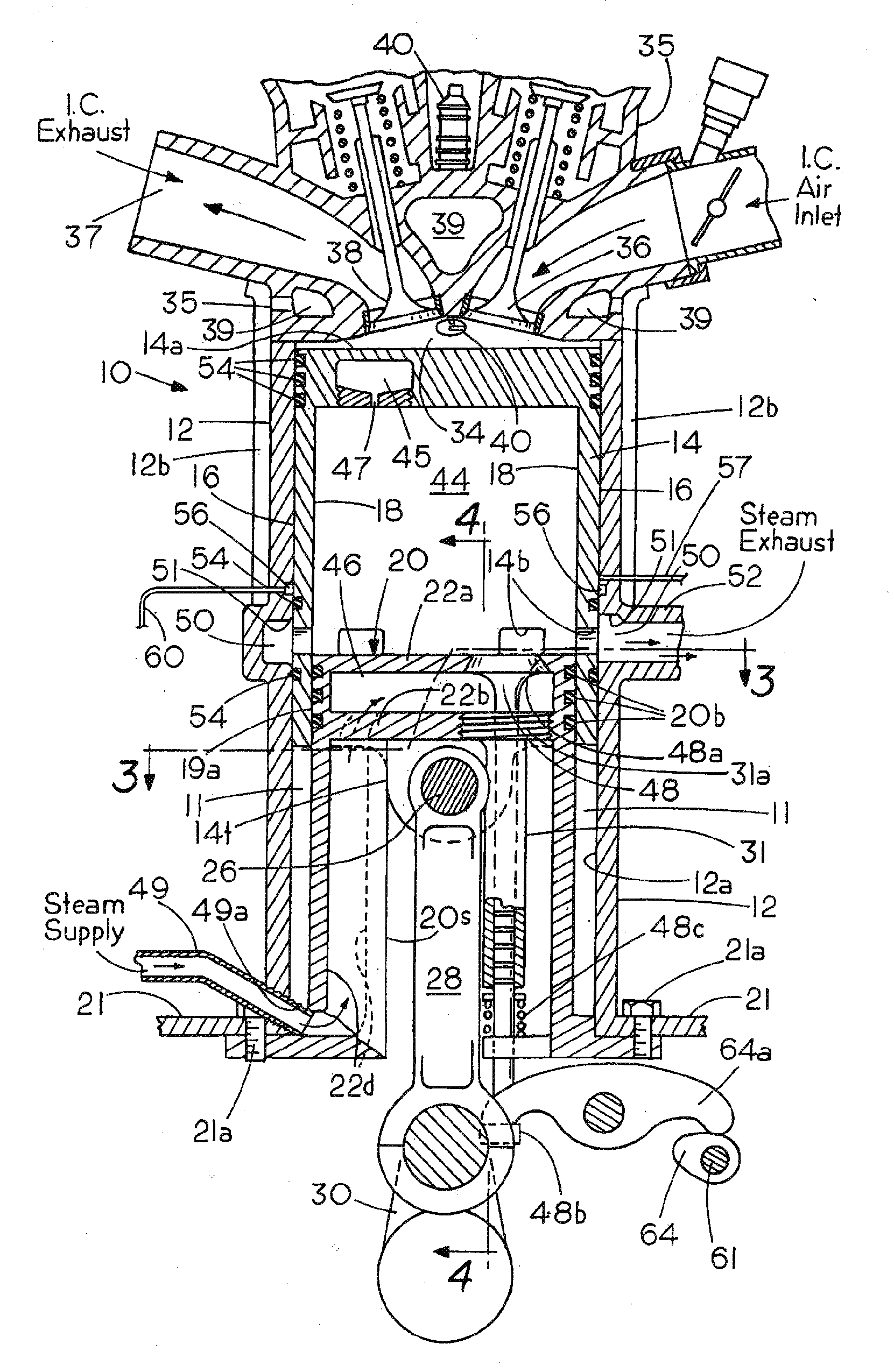

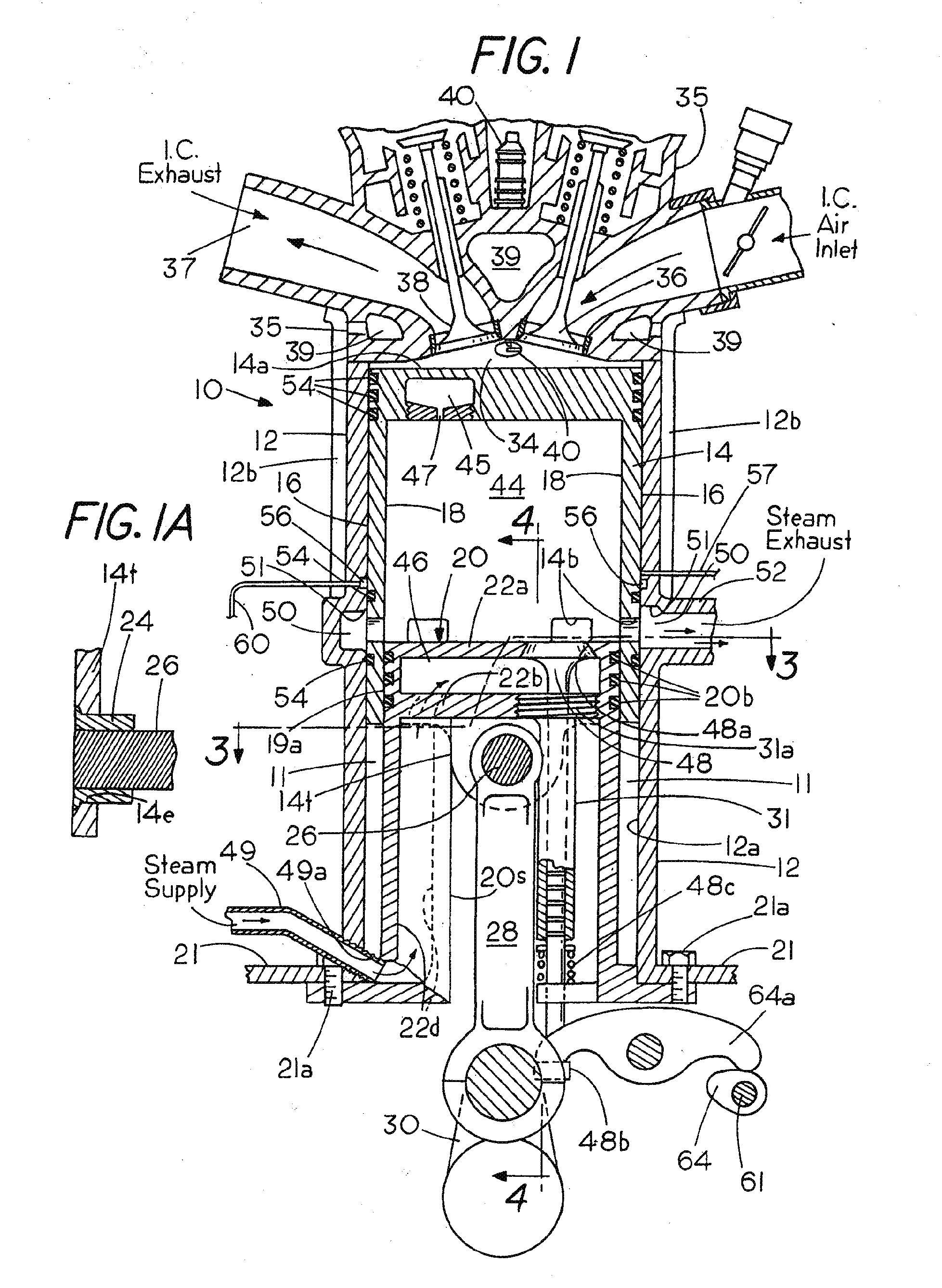

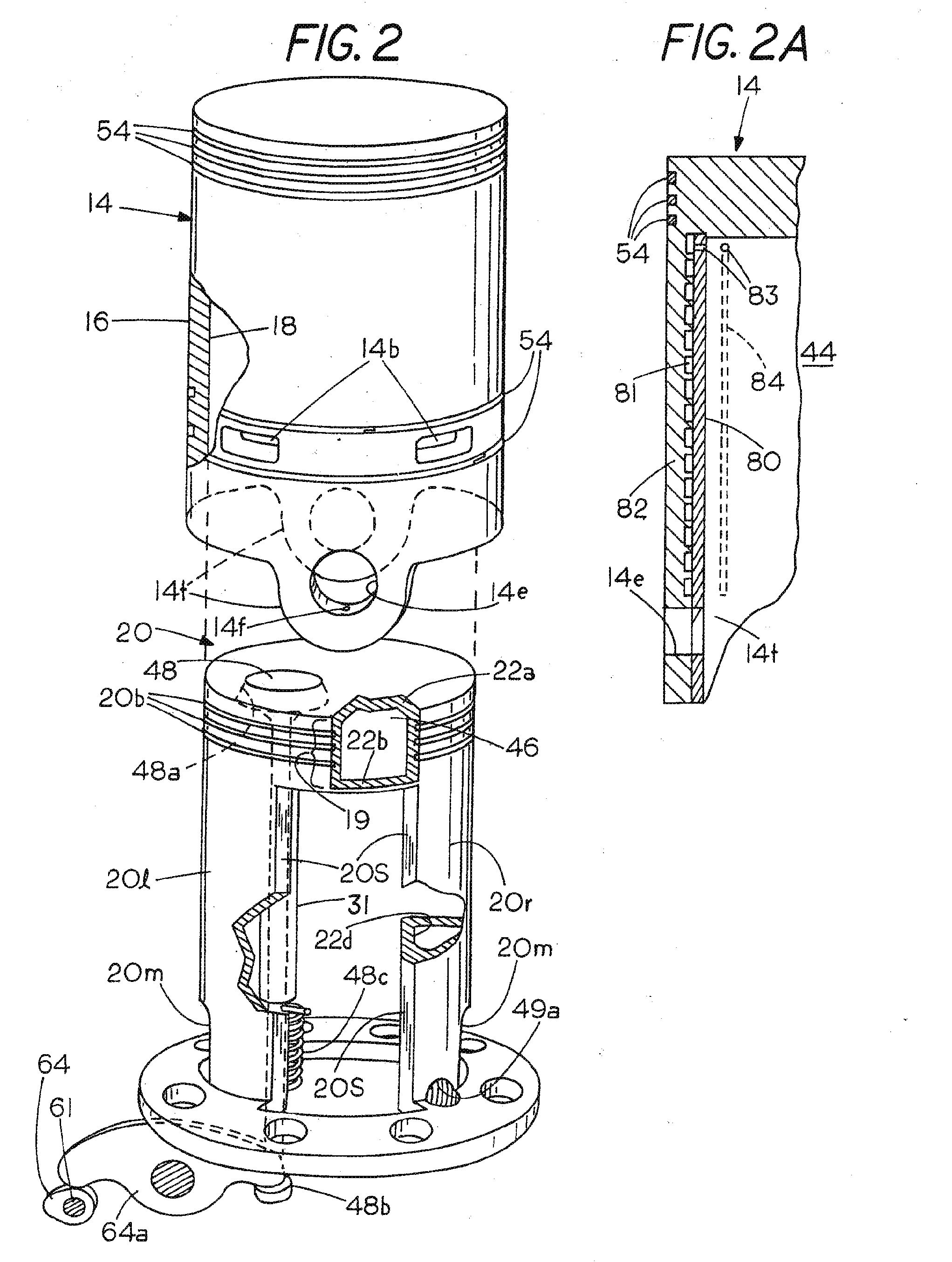

High efficiency multicycle internal combustion engine with waste heat recovery

ActiveUS8061140B2Effective recoveryIncrease enthalpyReciprocating combination enginesInternal combustion piston enginesCombustion chamberInlet valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder and a piston with an internal combustion chamber outward of the piston, a fixed cylinder cap and a steam expansion chamber inside the piston. The cylinder cap can be heated to reduce condensation of steam entering from a steam generator fired by waste combustion heat. Following exhaust, residual steam can be recompressed prior to admitting the next charge of steam. A wrist pin connected to an inner end of the piston skirt inwardly of the cylinder cap is coupled to a connecting rod secured to a crankshaft. One valve or a pair of steam inlet valves are connected to communicate in series within the cylinder cap inside the piston. The steam mass admitted is regulated to reduce fuel consumption. Coolant can be superheated in the combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

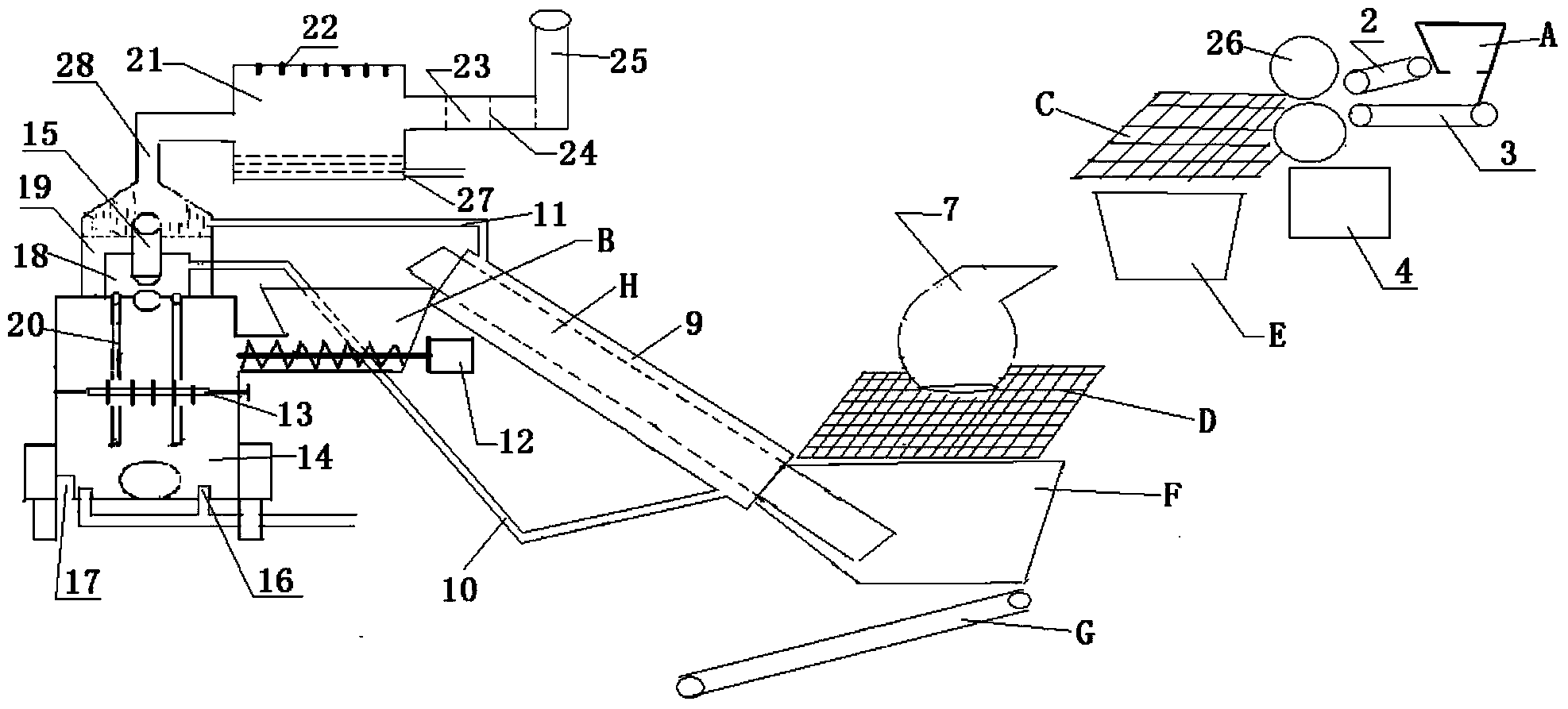

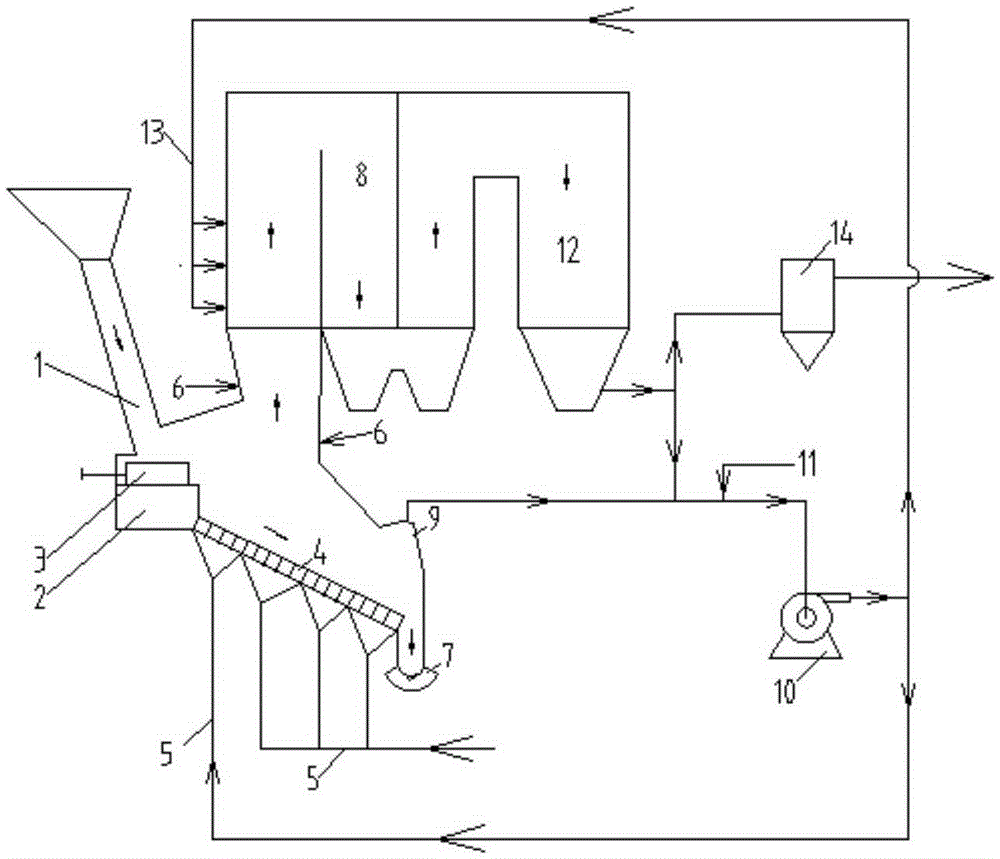

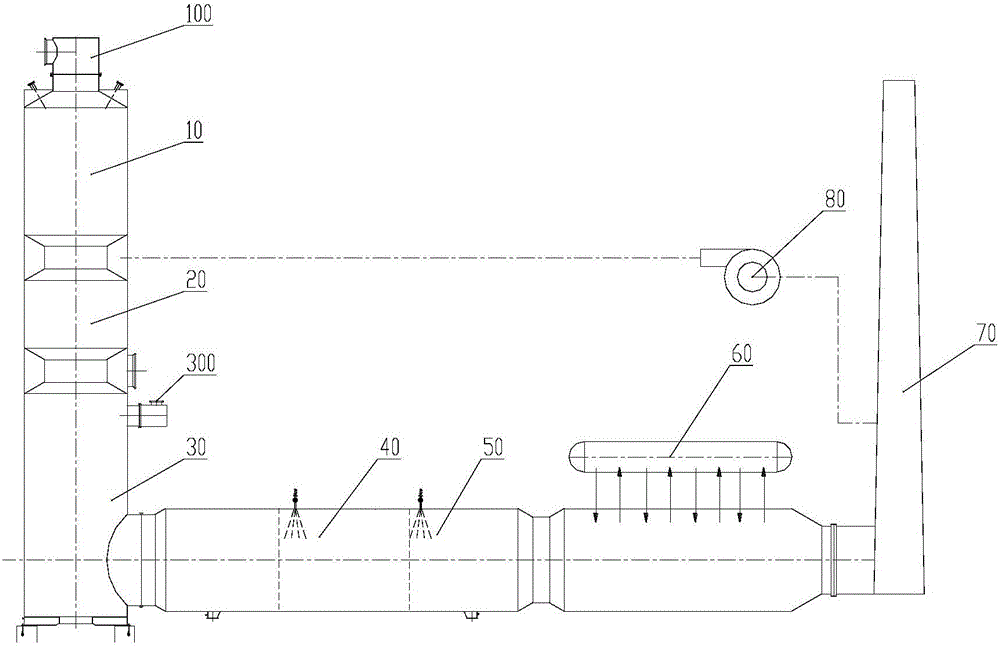

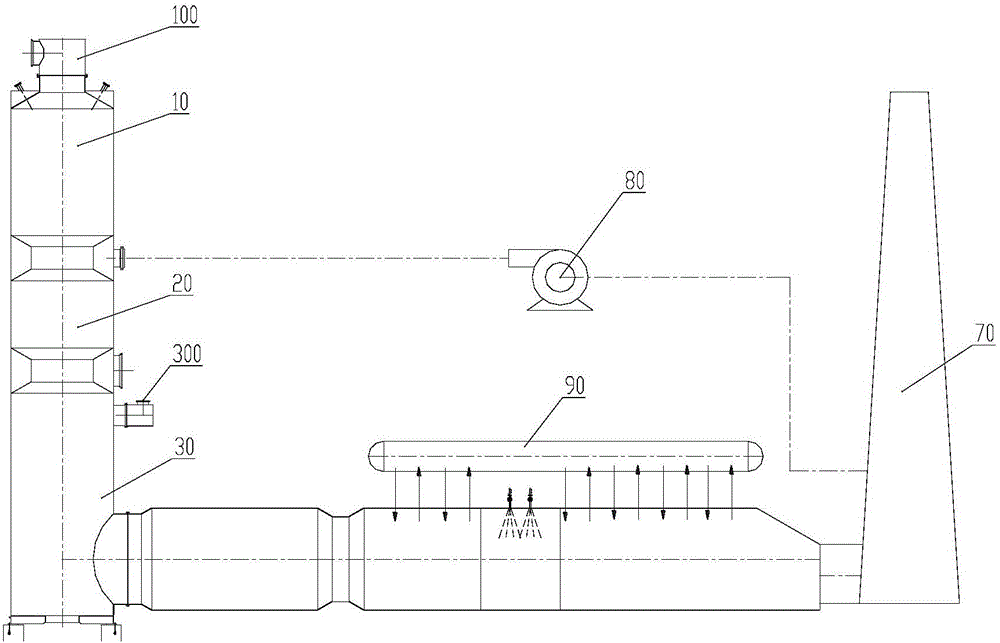

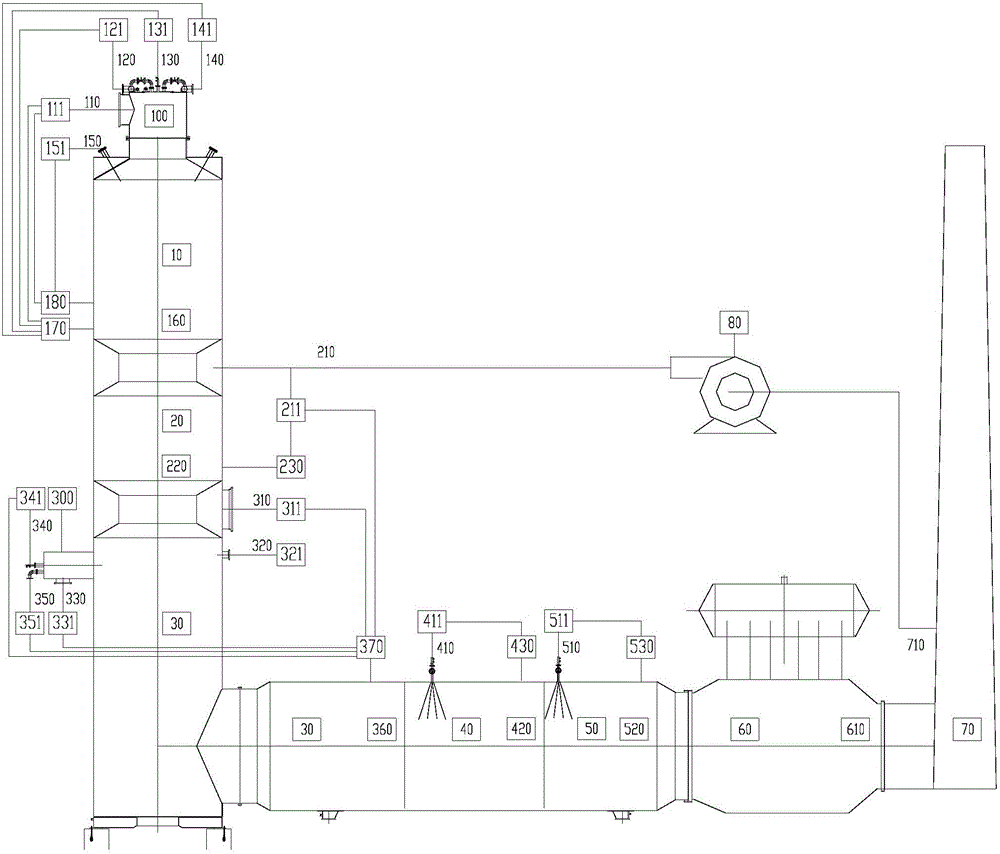

Solid waste combustion system

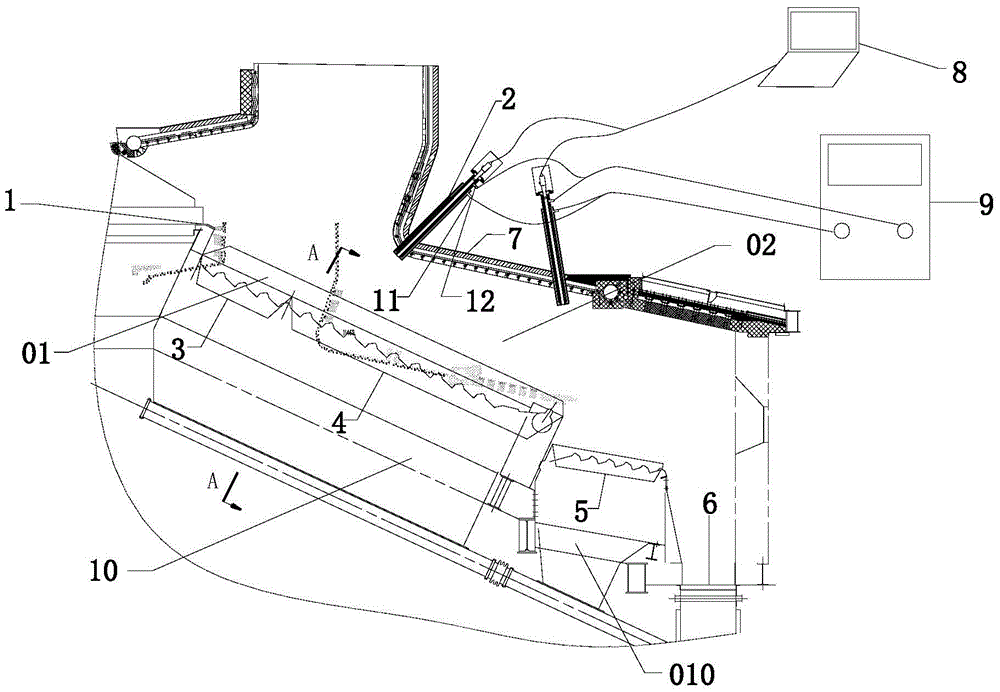

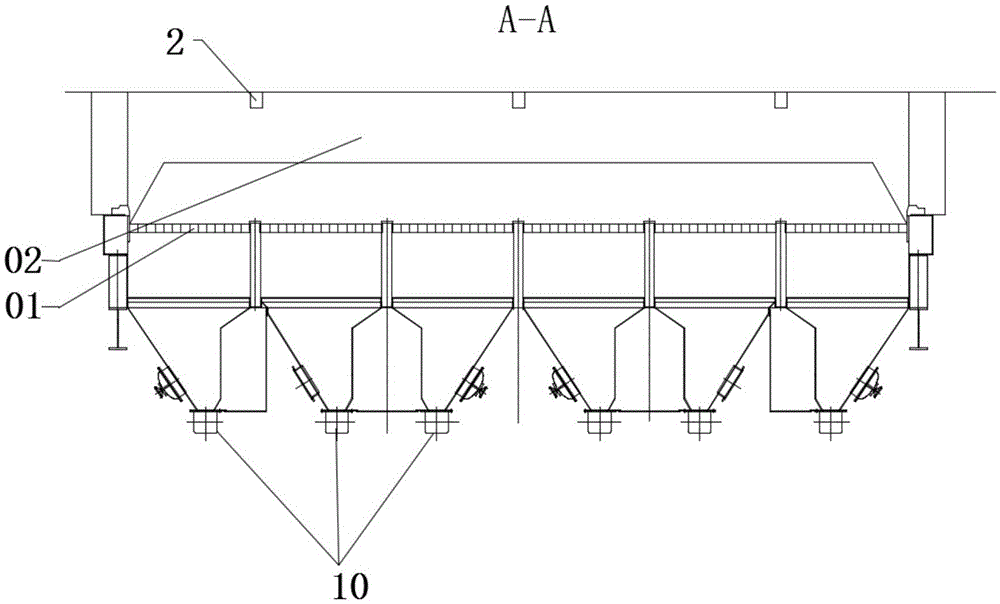

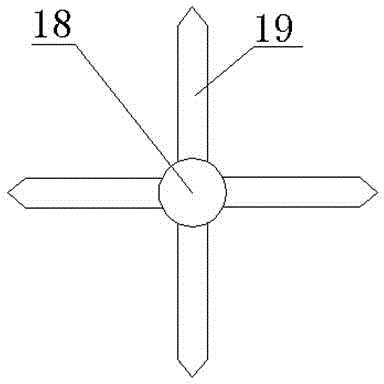

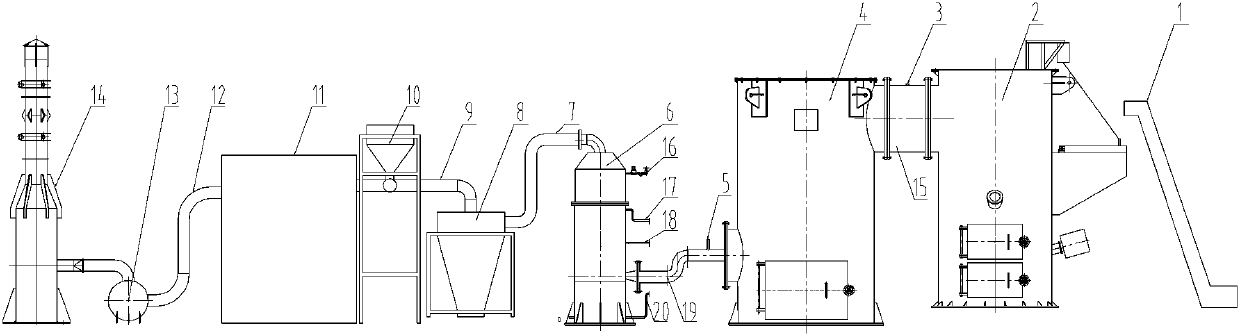

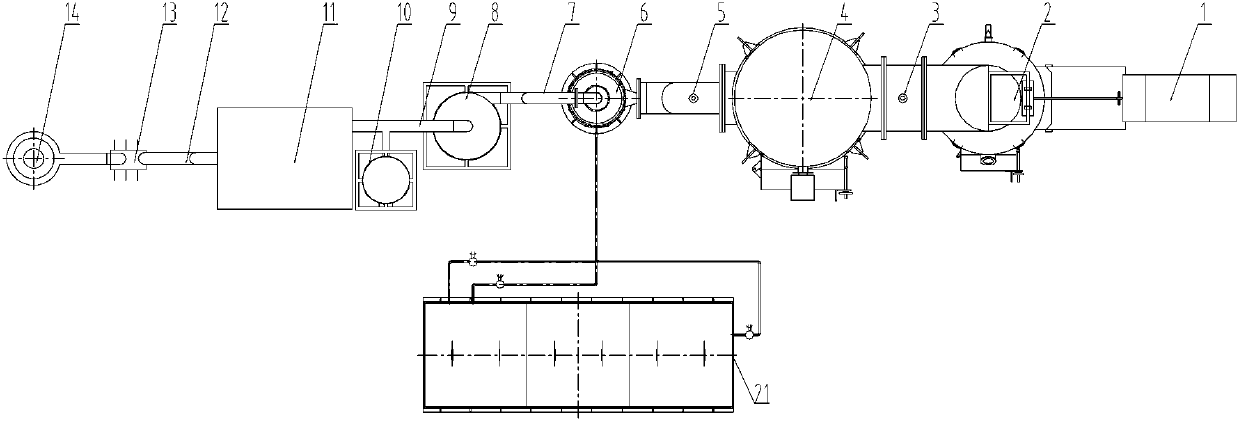

InactiveCN103398383AIncrease profitTake advantage ofIncinerator apparatusImpellerResource utilization

The invention provides a solid waste combustion system. The solid waste combustion system comprises a squeezing and water removing device, a screening device, a crushing device, a drying device, a combustion device and a smoke treating device, wherein the squeezing and water removing device comprises a waste feeding hopper; the feeding hopper is connected with a roller by a pressure conveying belt; the crushing device comprises a crusher and a shaking type screening net located on the bottom of the crusher; the combustion device comprises a hearth; the outer part of the hearth is connected with the feeding hopper and dried wastes are conveyed to the feeding hopper by a drying device conveying belt; a spiral conveying impeller is mounted on the connection part of the feeding hopper and the hearth; the hearth is internally provided with an agitation device; the smoke treating device is connected with the hearth; an opening is formed in the connection part of the hearth and the smoke treating device; the smoke treating device comprises a dust removing device and a desulfuration and deodorization device. The solid waste combustion system provided by the invention is high in combustion efficiency; the treated wastes can be utilized sufficiently so that the resource utilization rate is improved and a working process is environment-friendly and pollution-free.

Owner:黎汉东

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS20090205338A1Operation efficiency can be improvedImprove efficiencyInternal combustion piston enginesSteam useCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder having a piston mounted for reciprocation therein with an internal combustion chamber outward of the piston, a fixed cylinder cap sealingly and slideably mounted within the piston and a steam expansion / recompression chamber inside the piston adjacent the cylinder cap. The cylinder cap can be unheated or heated externally to reduce condensation of steam entering the steam chamber from a steam generator fired by waste combustion heat. Steam remaining in the cylinder when a steam exhaust valve closes at the top center position is recompressed during an inward stroke of the piston up to admission pressure prior to admitting the next charge of steam. One valve or a pair of retractable steam inlet valves connected in series within the cylinder cap act in cooperation with steam recompression and clearance volume to achieve an effective zero steam chamber clearance and a gain in mean Rankine cycle temperature to maximize efficiency. The amount of steam admitted each outward stroke is continuously regulated, e.g. by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted during each cycle to reduce specific fuel consumption. Other valves balance steam displacement with the steam generator output to use steam more efficiently. Engine coolant can be evaporated in a combustion chamber cooling jacket to form steam which is then superheated in a combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

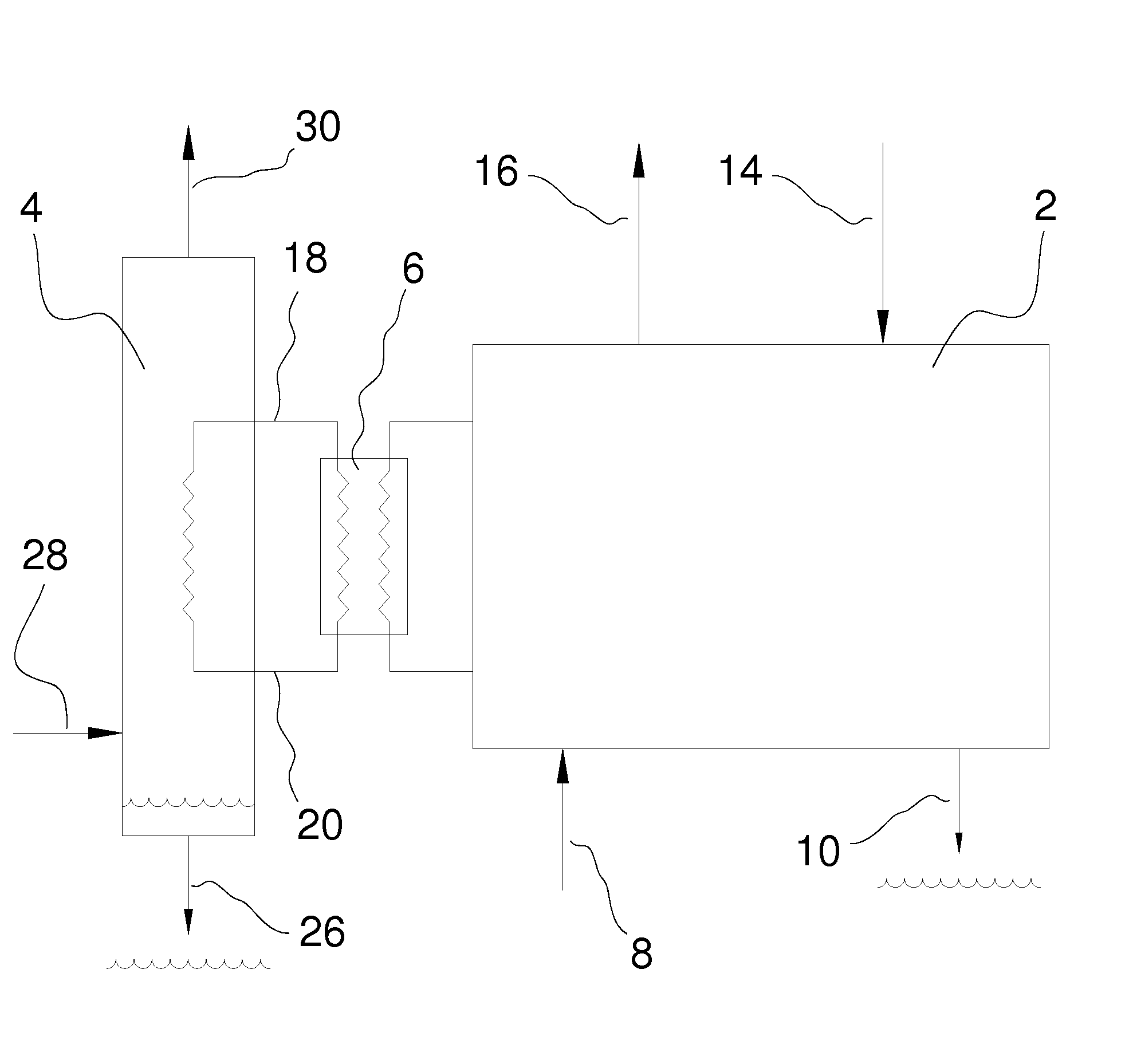

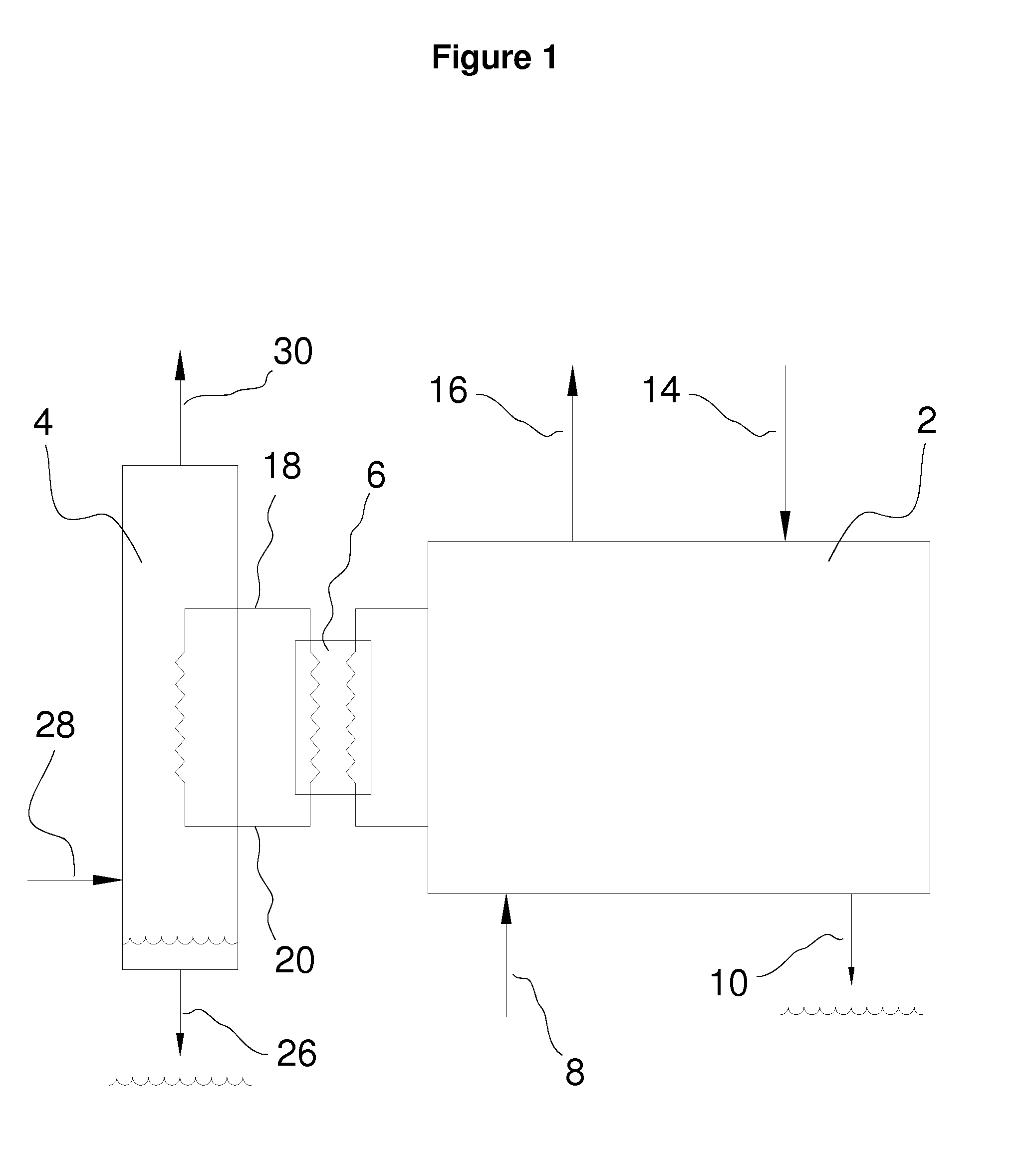

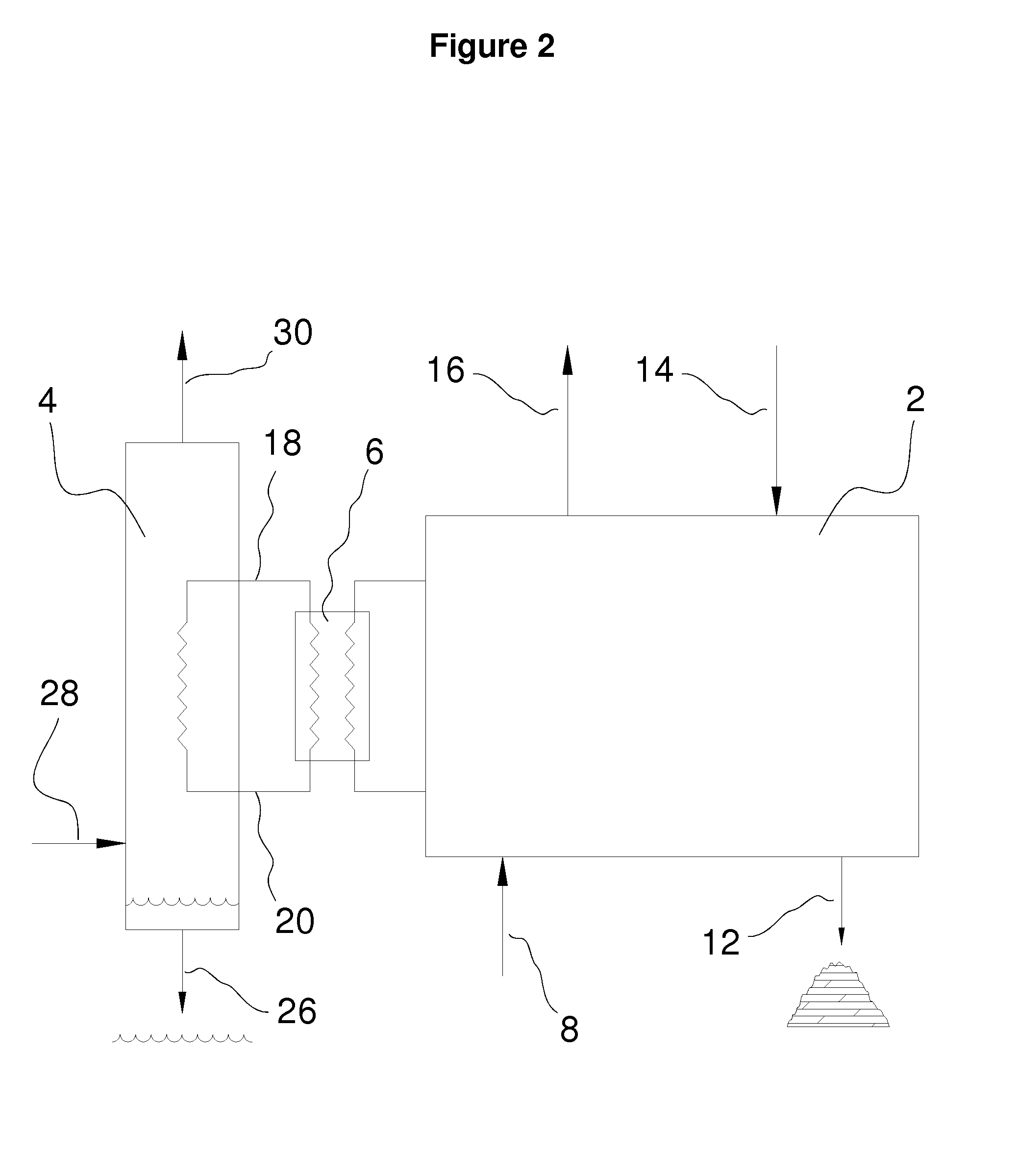

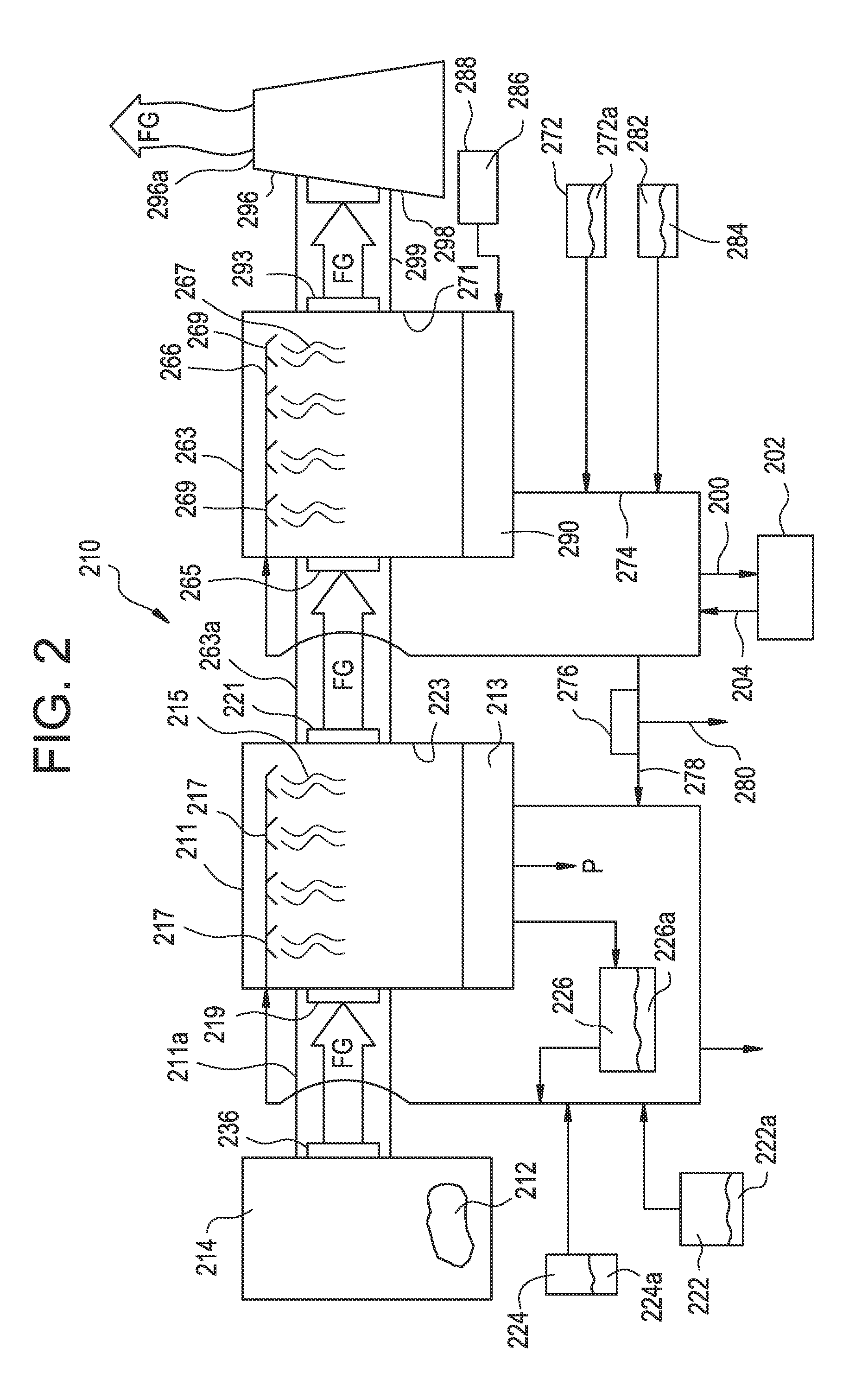

System and method for wastewater reduction and freshwater generation

InactiveUS20080277262A1Reduction of environmental liabilityImprove reliabilityBeehive ovensAuxillariesEvaporative coolerFresh water organism

A process whereby freshwater is generated and wastewater is eliminated through the employ of waste combustion gas; wherein combustion gas is cooled below dewpoint, via the effects of a wastewater fed evaporative cooler, resulting in the combined benefits of freshwater generation from the combustion gas and evaporative reduction of the wastewater.

Owner:LAYNE CHRISTENSEN COMPANY

Internal combustion engine with auxiliary steam power recovered from waste heat

ActiveUS7997080B2Effectively economizeImprove efficiencyInternal combustion piston enginesSteam regenerationExternal combustion engineEngineering

Owner:THERMAL POWER RECOVERY

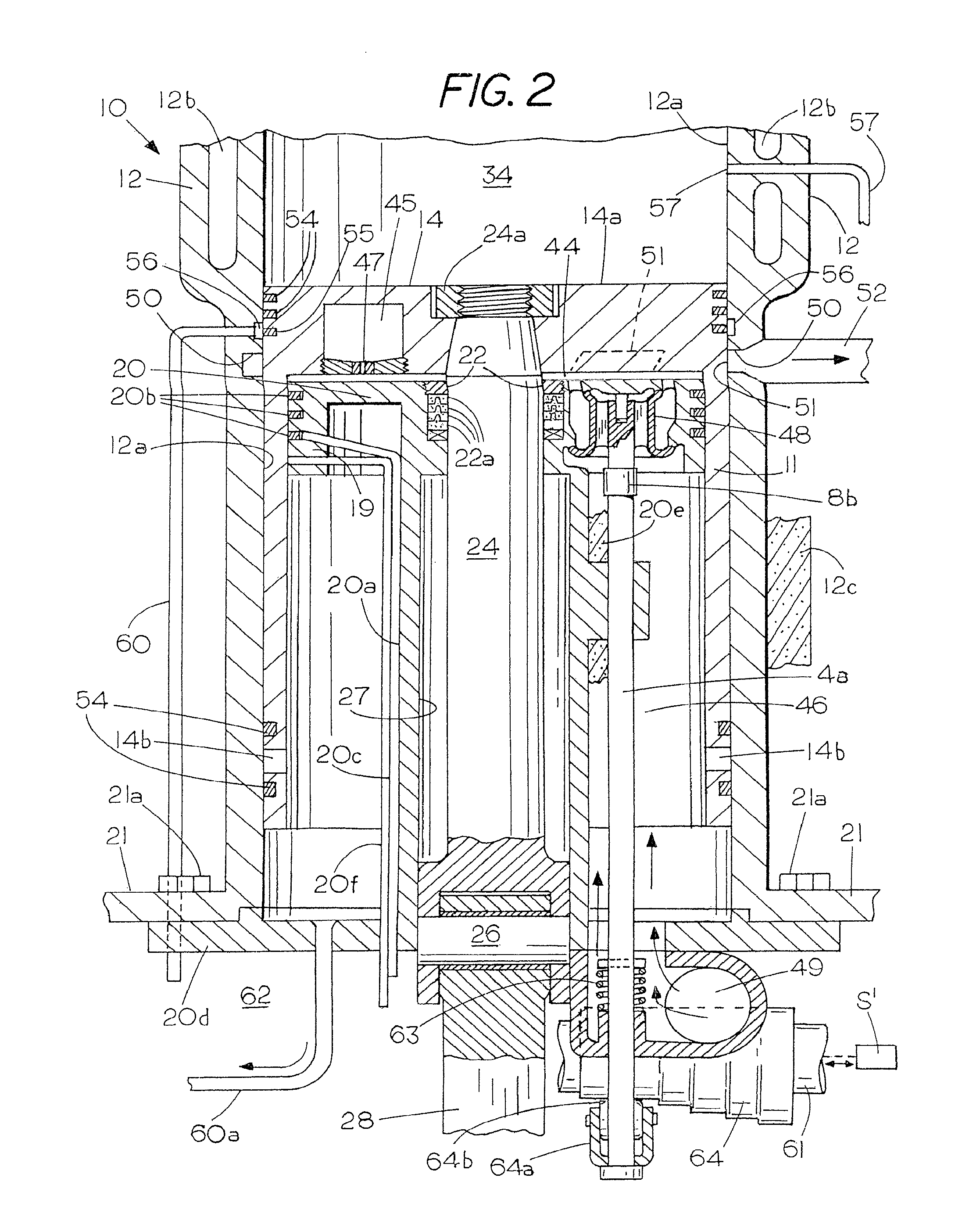

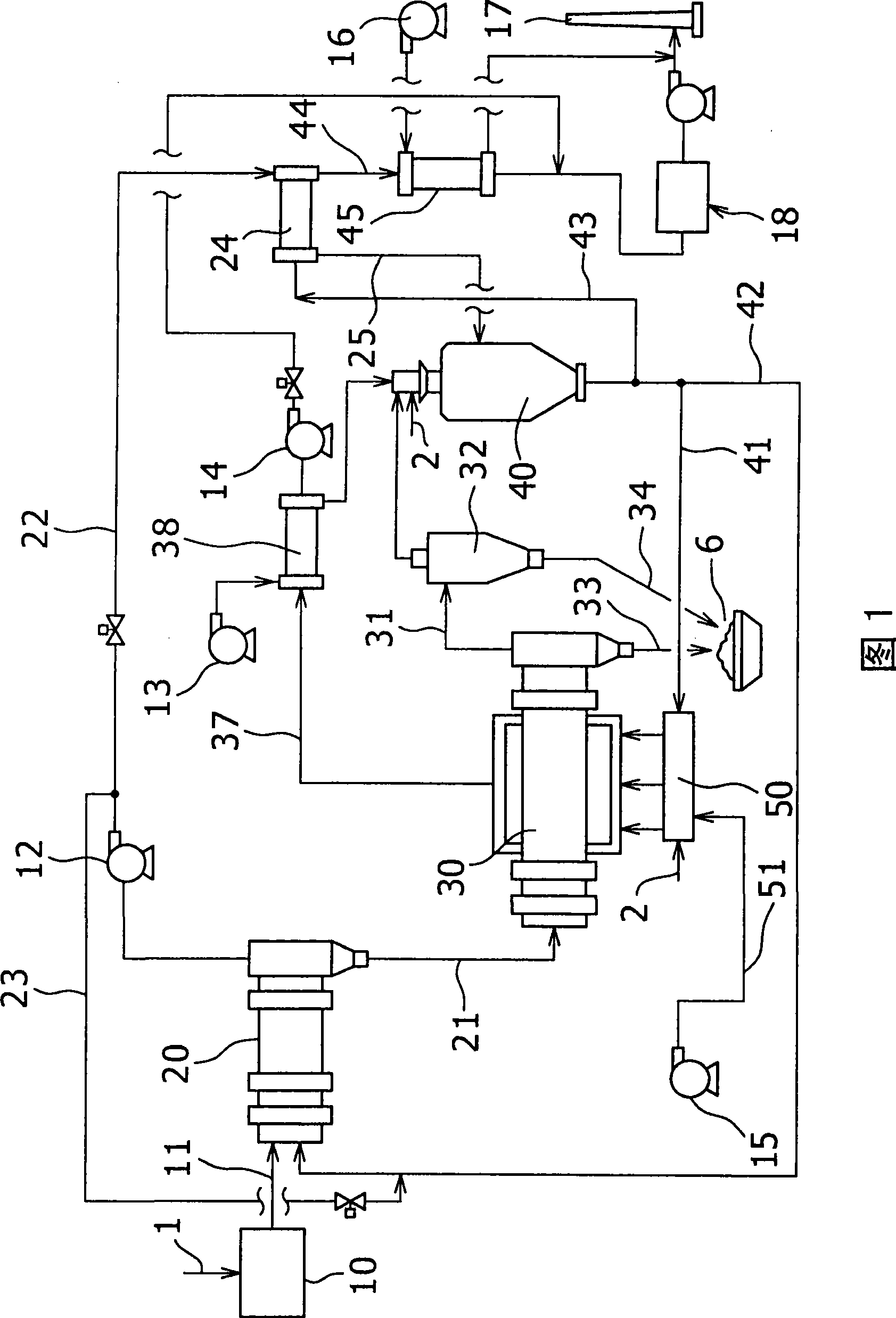

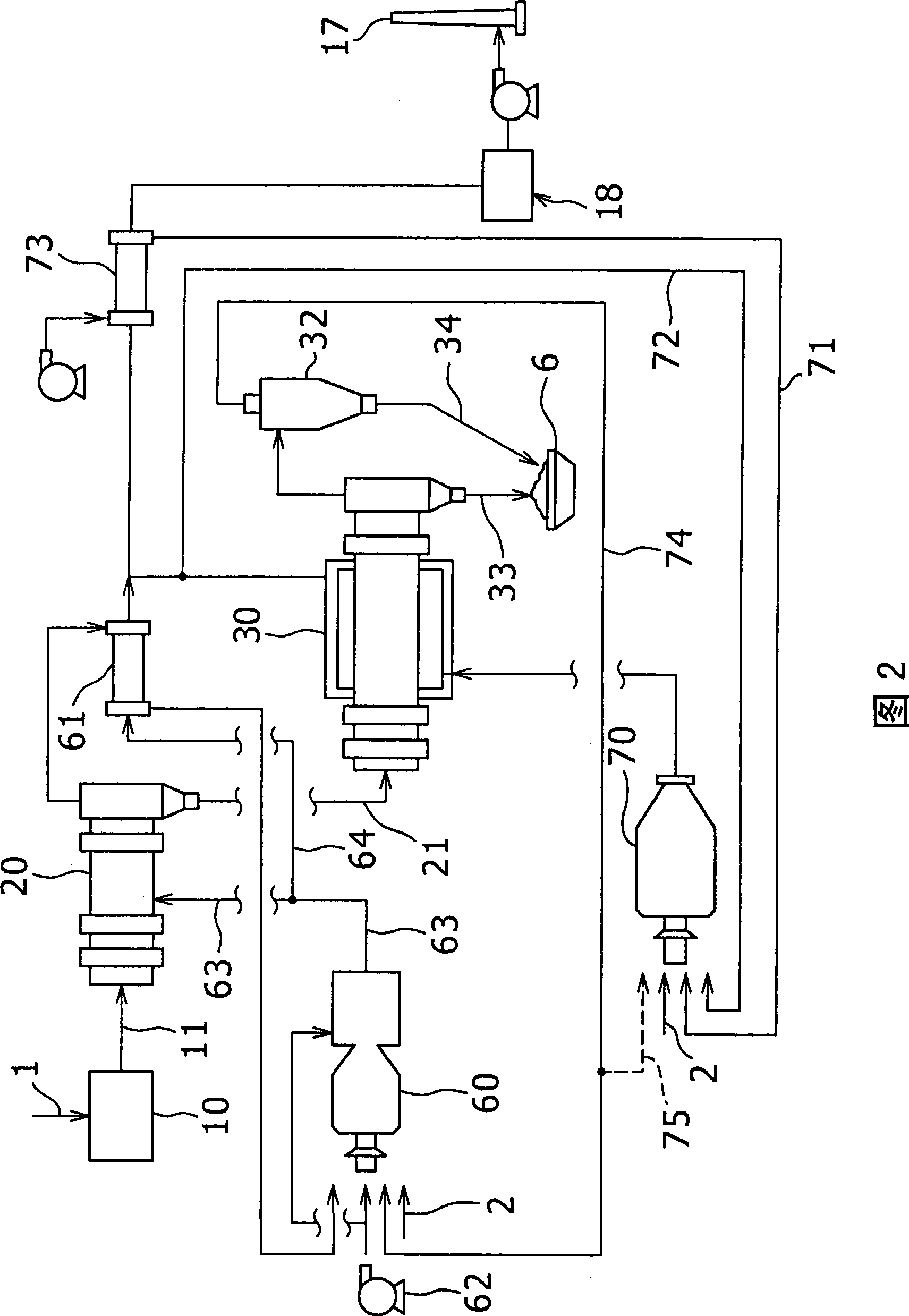

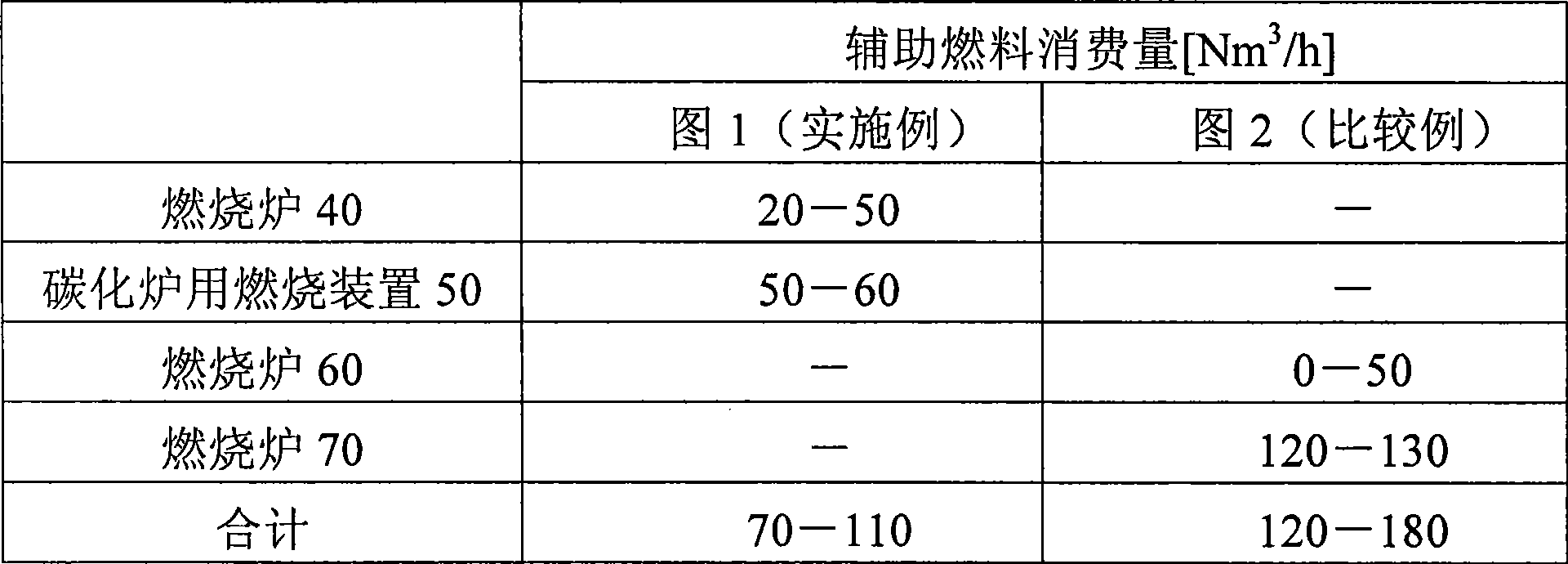

Carbonizing processing method and apparatus for high water-bearing organic

ActiveCN101376813AReduce consumptionStable quality controlSpecial form destructive distillationCarbideProduct gas

The invention aims at maintaining the quality of carbide and reducing the consumption of auxiliary fuels needed for obtaining the heat used for the carbonating of a carbide furnace as well as the heat used for the drying of a drying furnace during the carbonating of a high water-content organic substance. After the high water-content organic substance is dried by the drying furnace, carbonating is carried out in the carbonating furnace to obtain the carbide; besides, the dry distillation gases generated during the carbonating of the carbonating furnace are burnt in a combustion furnace by using the air used for combustion and the auxiliary fuels for maintaining the temperature of the waste combustion gas at the outlet of the combustion furnace between the temperature of the gas needed by the carbonating of the carbonating furnace and the temperature of the gas needed by the drying of the drying furnace; the branch of the waste combustion gas from the combustion furnace relates to at least two systems; a combustion device used for the carbonating furnace used for the waste combustion gas of the waste combustion gas pipeline of the first system is heated to the temperature of the gas needed by the carbonating; then the gas is supplied to the carbonating of the carbonating furnace; the waste combustion gas of the waste combustion gas pipeline of the second system is supplied to the drying of the drying furnace.

Owner:MITSUBISHI HEAVY IND LTD

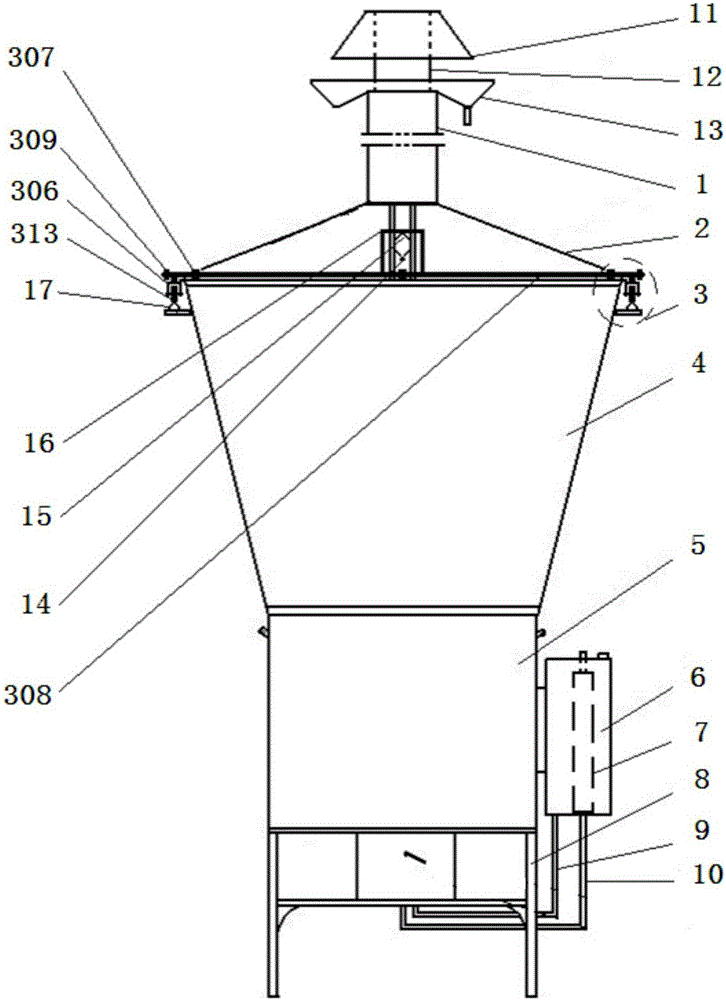

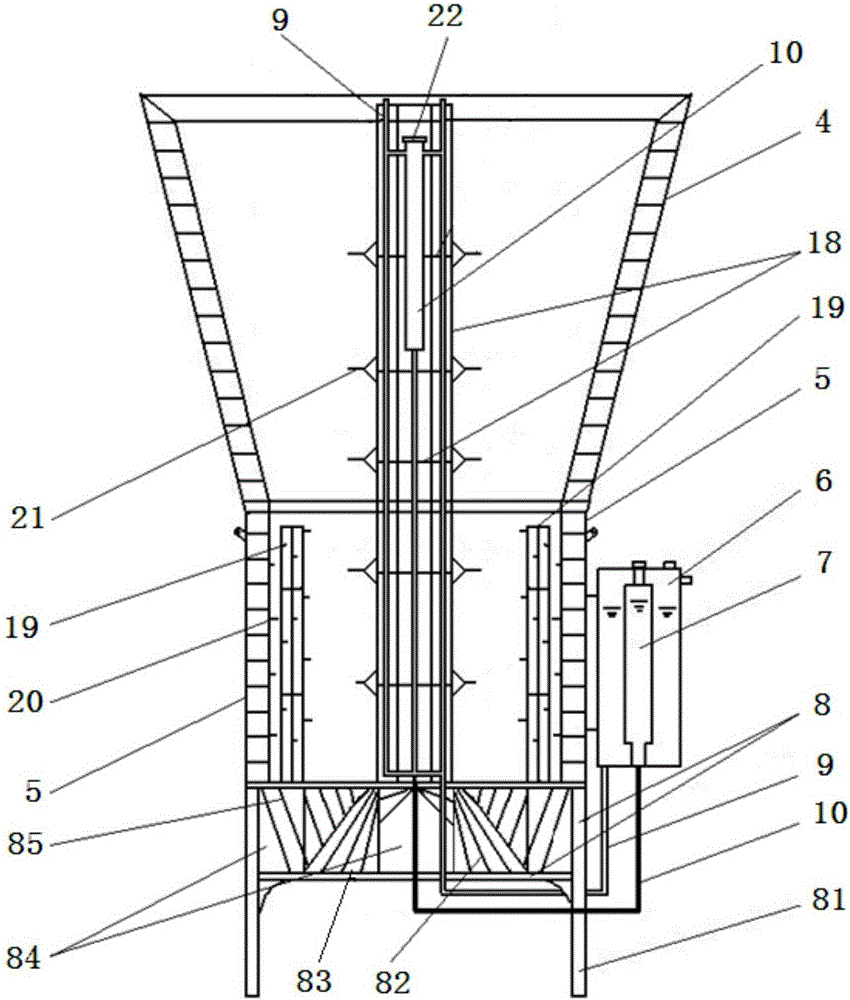

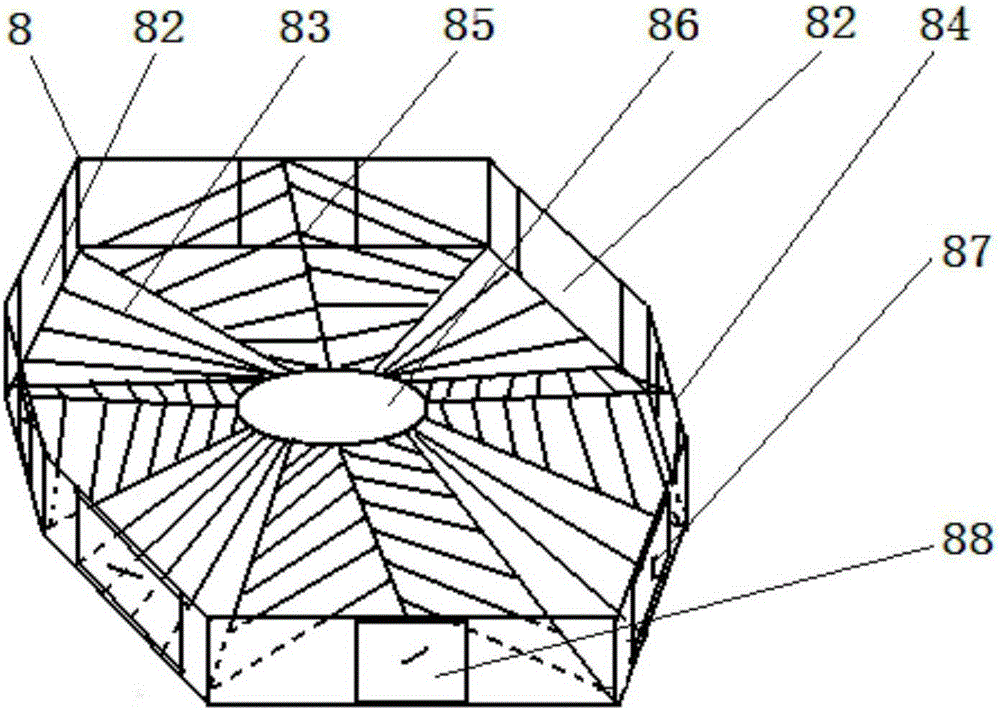

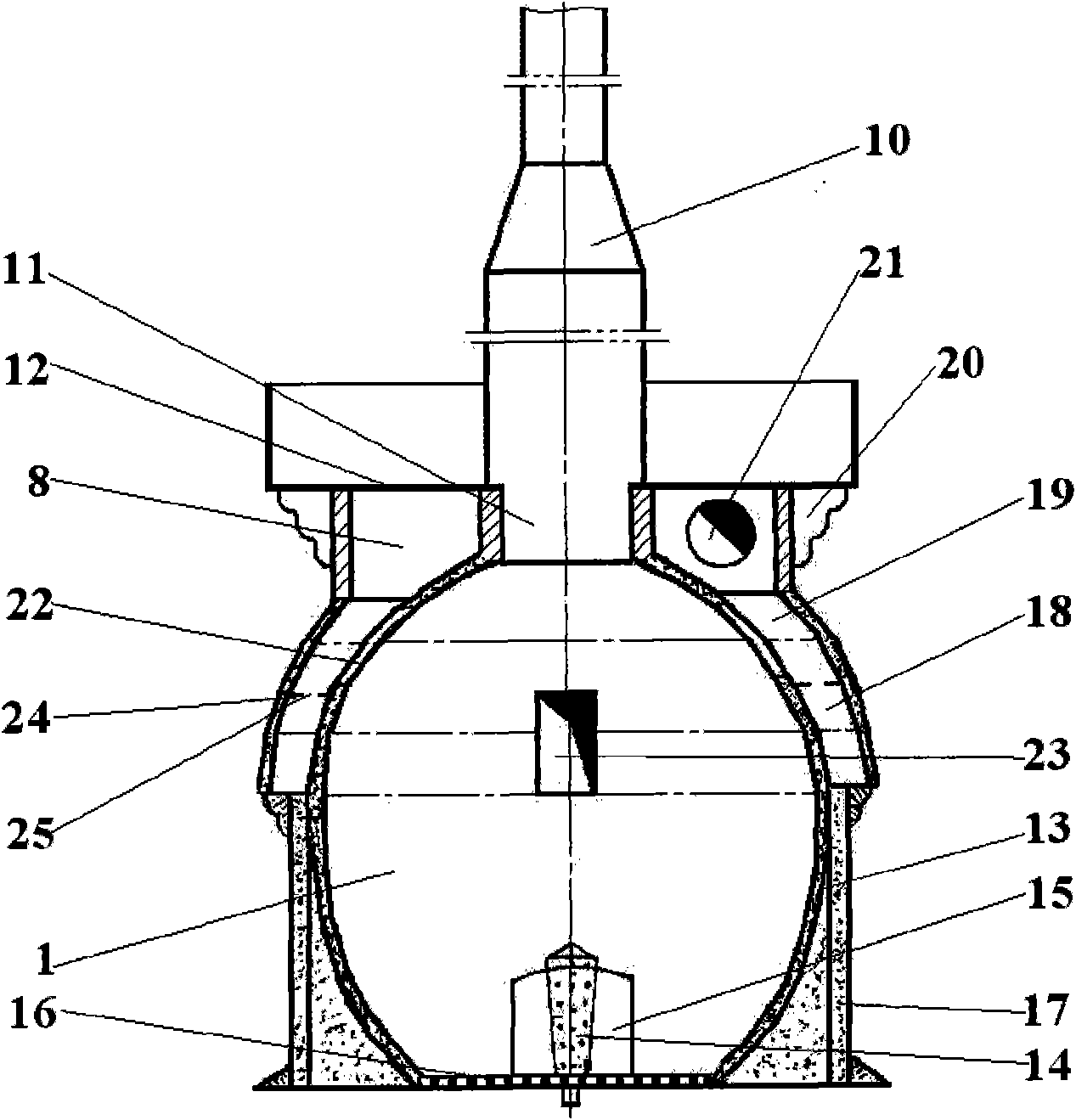

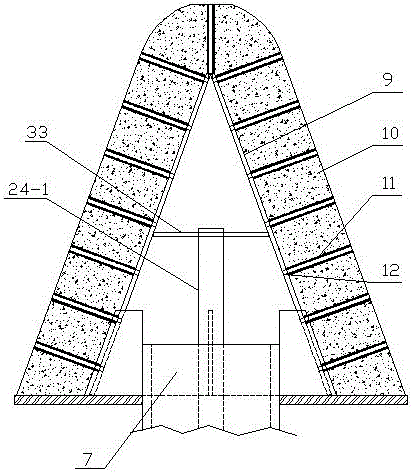

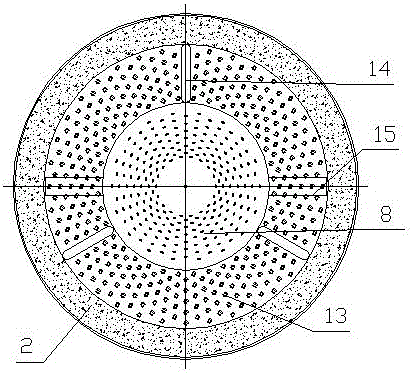

Environment-friendly efficient waste incinerator

The invention discloses an environment-friendly efficient waste incinerator. The environment-friendly efficient waste incinerator comprises a lower incinerator body part, an upper incinerator body part, an internal chimney, a base, an incinerator cover and an external chimney. The upper incinerator body part and the lower incinerator body part of an incinerator body are welded into a whole. The internal chimney is arranged in the middle of the lower incinerator body part and the middle of the upper incinerator body part. A combustion chamber is formed by the lower incinerator body part and the internal chimney. Refractory bricks are arranged on the periphery of the lower incinerator body part and the periphery of the upper incinerator body part. The bottom end of the lower incinerator body part is connected with the base. Both the upper surface and the lower surface of the base are open. The incinerator cover is arranged on the upper incinerator body part. The external chimney is arranged at the top of the incinerator cover in a connected mode. A water tank is arranged outside the lower incinerator body part. An oil tank is further arranged in the water tank. A water pipe and an oil pipe are arranged in the internal chimney. The water pipe is communicated with the water tank. The oil pipe is communicated with the oil tank. According to the environment-friendly efficient waste incinerator, oil in the oil pipe can be gasified by means of heat generated during waste combustion, so that waste on the upper portion of the incinerator body can be combusted for the second time, continuous waste combustion is achieved, incineration is thorough and rapid, and the incineration effect is good; pollution to the environment is small, and the environment-friendly efficient waste incinerator is suitable for waste treatment in village and town communities, schools and hospitals.

Owner:都安通达环保设备制造厂(普通合伙)

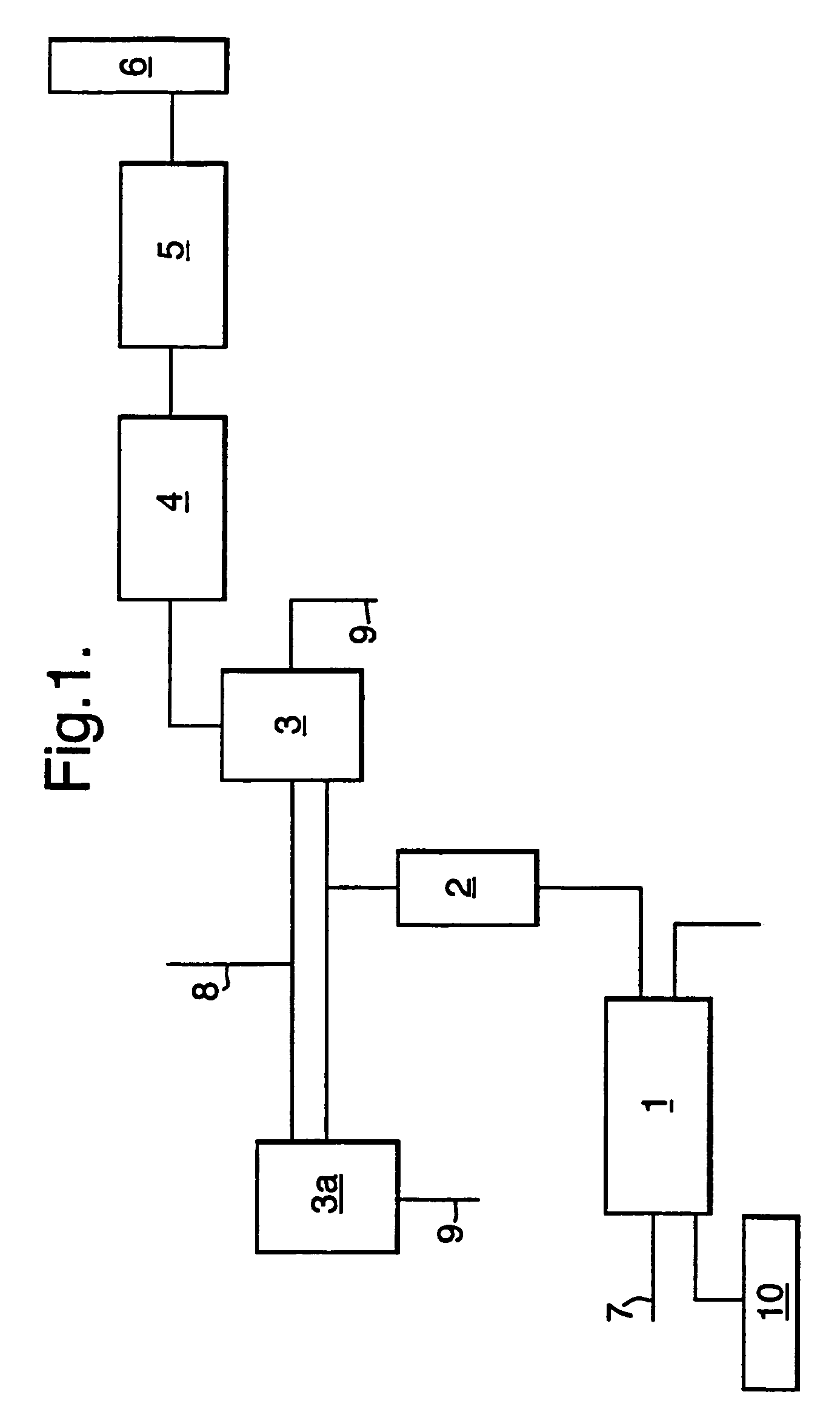

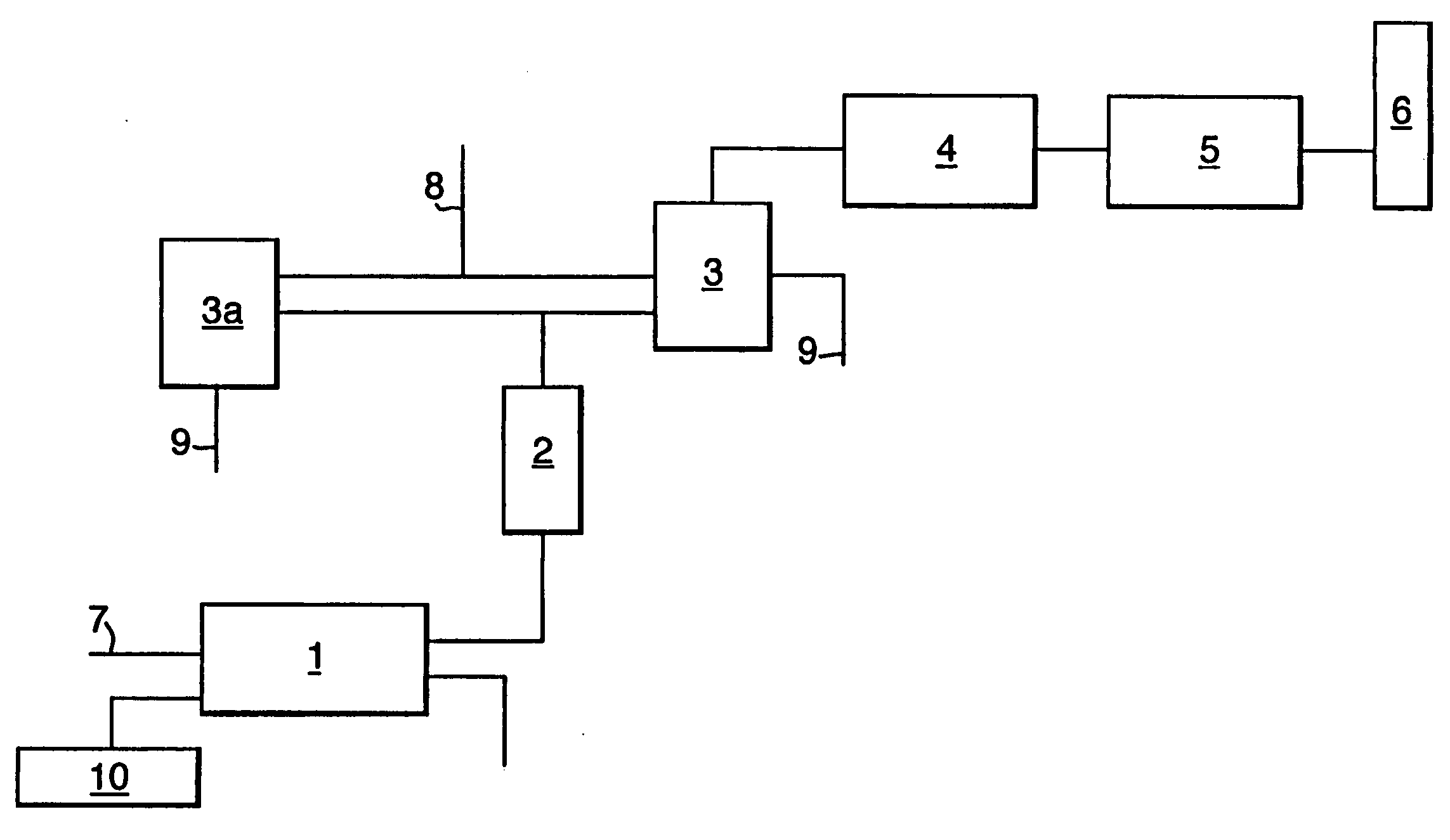

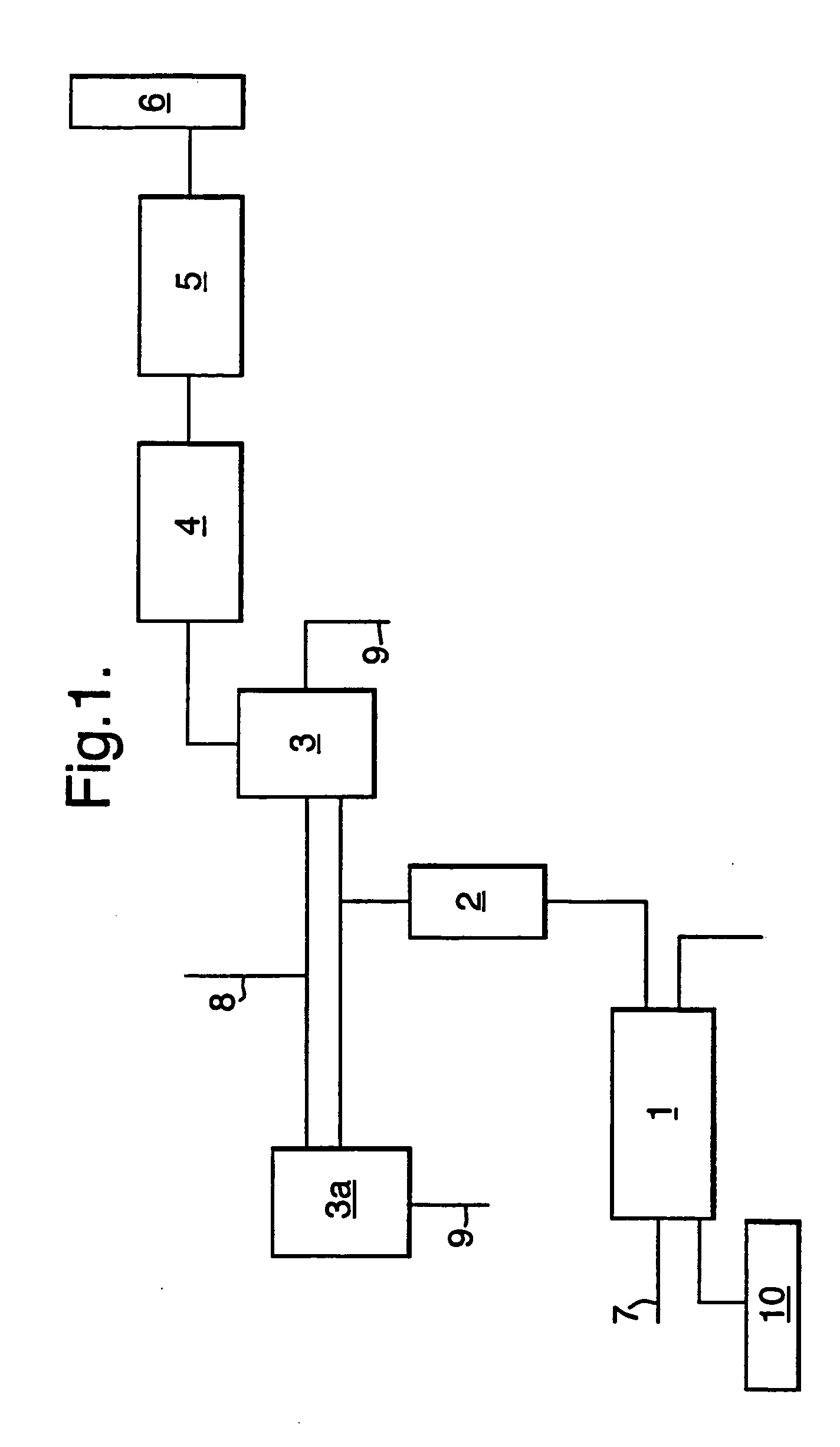

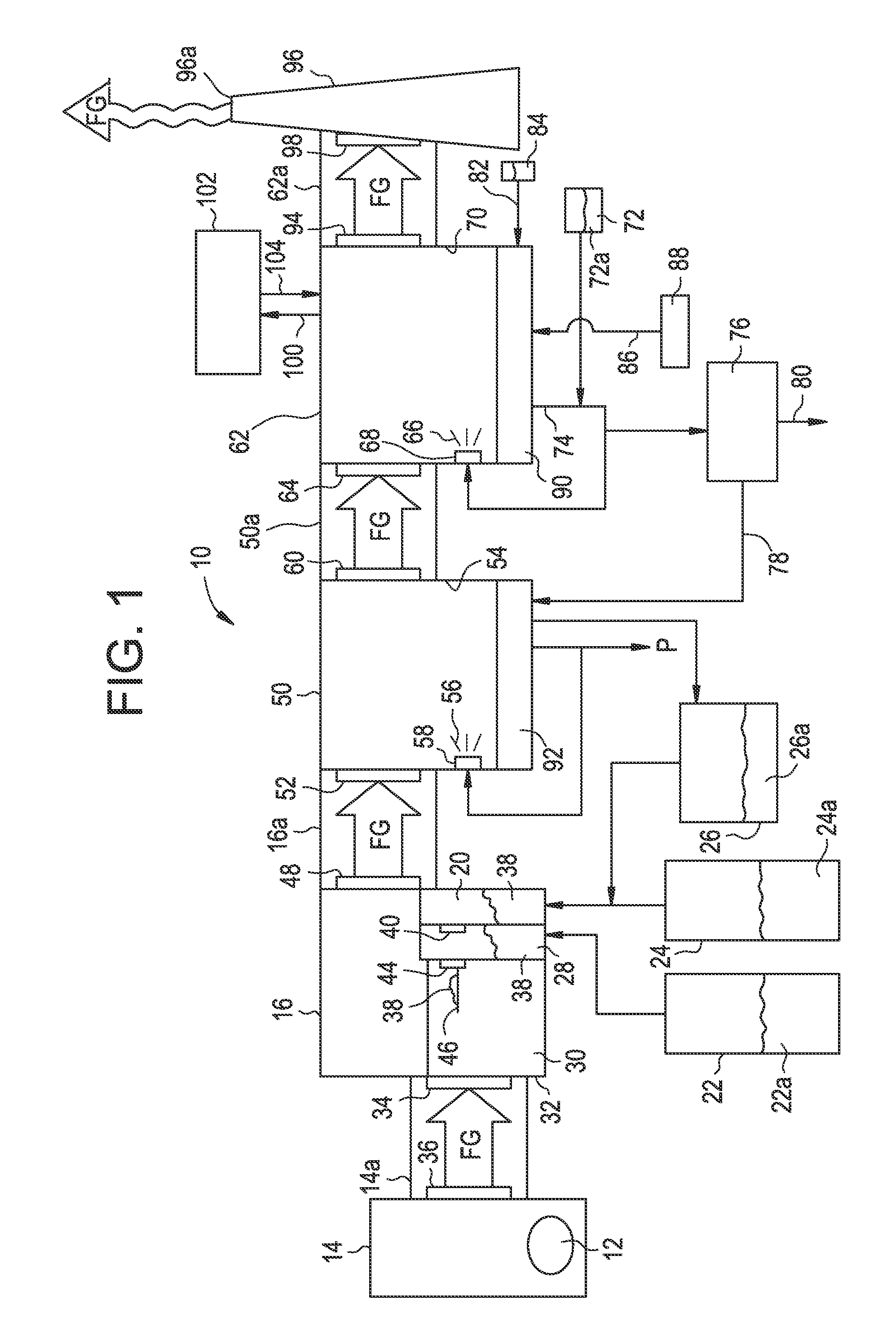

Method and process for co-combustion in a waste to-energy facility

InactiveUS7189074B2Reduce chanceImprove usabilityRotary drum furnacesCeramic production plantsCombustion chamberSlag

The co-combustion process may comprise the following unit operations: routing of hot gas (10) generated in the clinker cooling process to a rotary kiln (1); use of part of the rotary kiln exhaust gas to dry solid wastes in rotary dryers; leading the gases from both the dryer and the combustion kiln to the secondary combustion chamber (2); use of additional fuel to boost up the secondary combustion chamber reaction temperature to as high as 1200° C.; primary dry gas scrubbing in a precalciner or precalciners (3, 3a); heat recovery (4) and power generation; secondary gas scrubbing (5) in a semi-dry scrubber; bag filtering after activated carbon injection and returning of all the collected ash and used carbon into the waste kiln and / or a cement kiln. Detrimental materials for cement processing generated by waste combustion can be by-passed to a scrubbing system and a cement kiln. Residue slag from waste kilns can be treated and reused.

Owner:GREEN ISLAND ENVIRONMENTAL +1

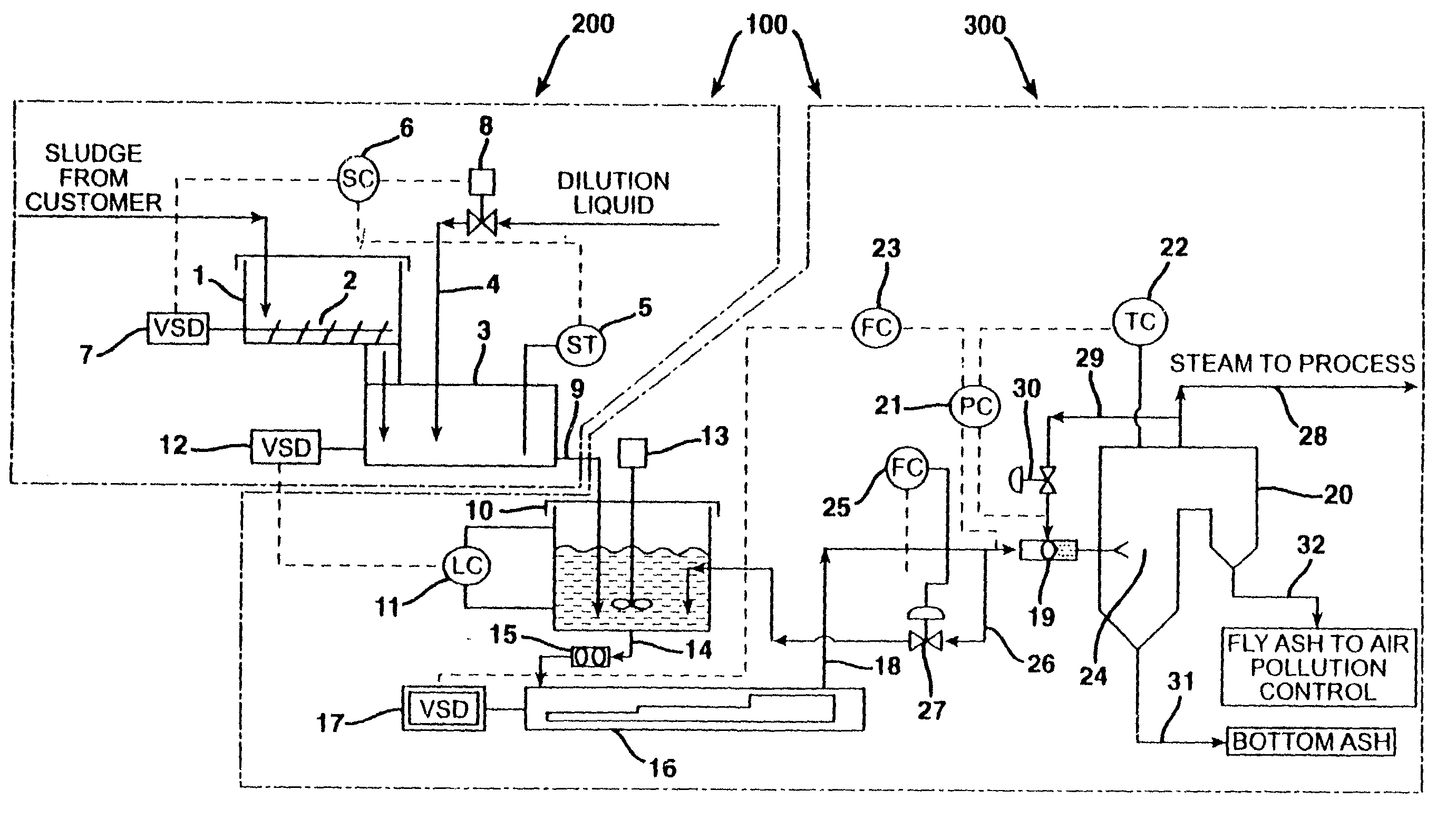

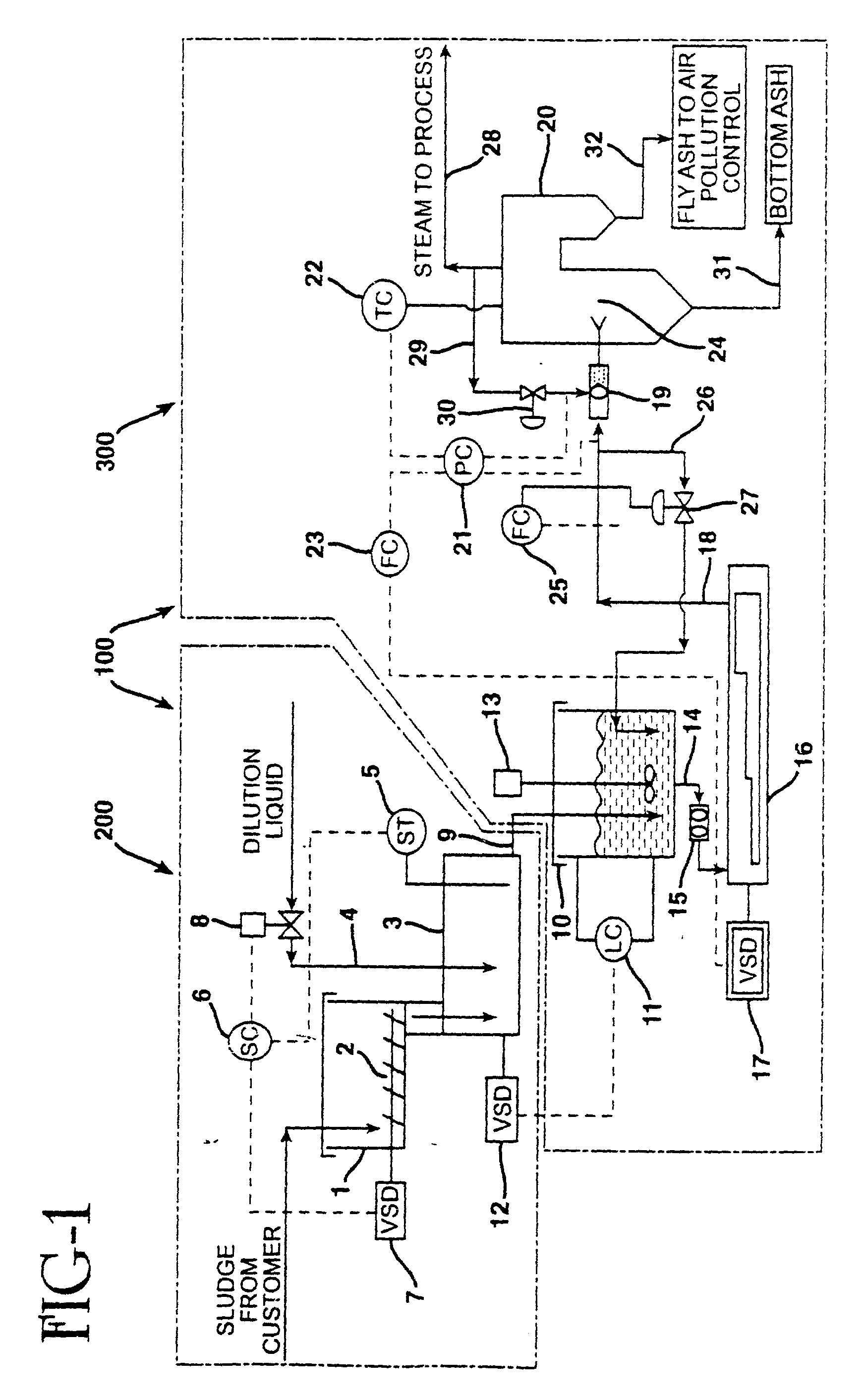

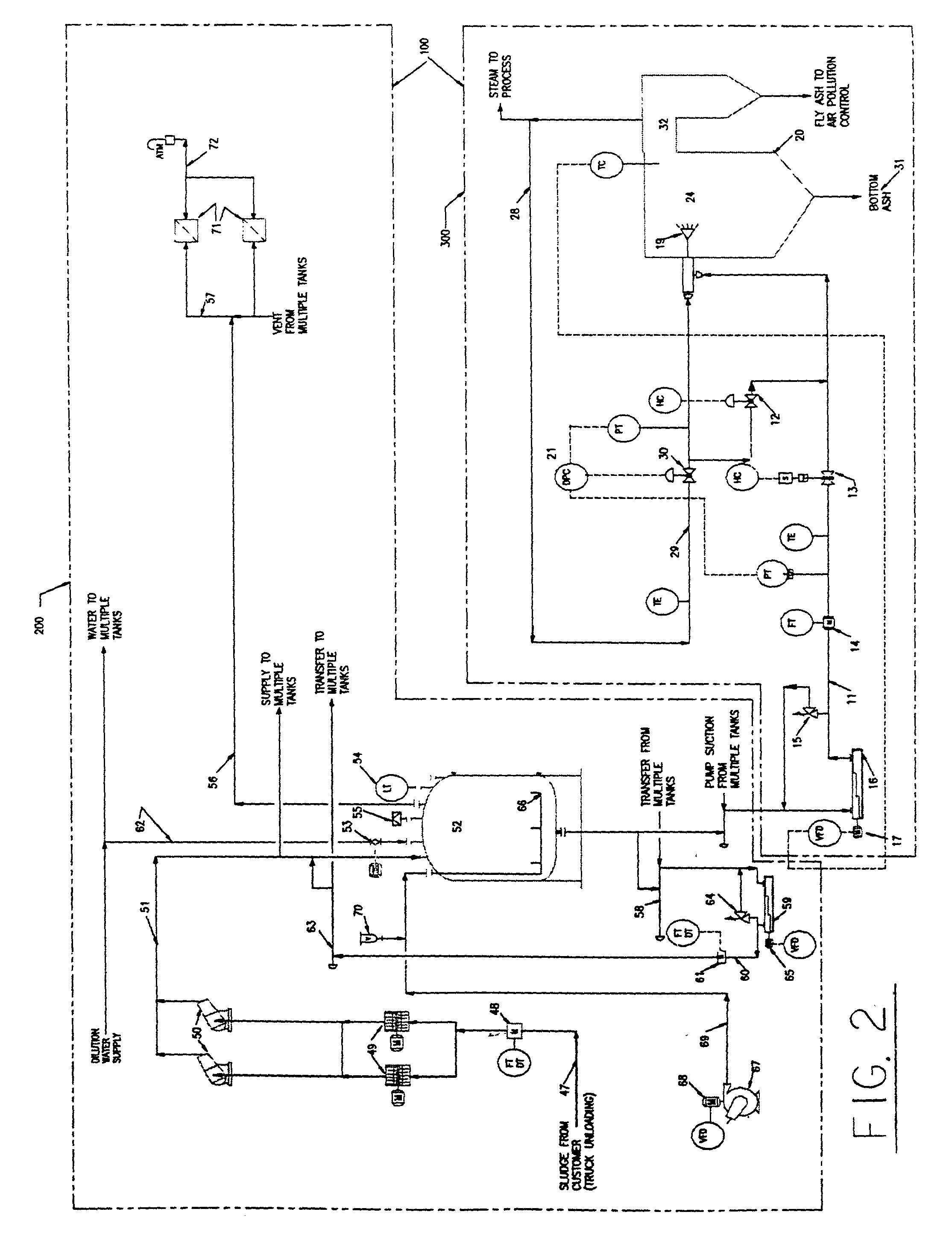

Co-combustion of waste sludge in municipal waste combustors and other furnaces

InactiveUS20020050236A1Maximize suspension burningEliminate needCremation furnacesSolid fuel combustionCombustorSludge

A system and method for treating, injecting and co-combusting sludge in a municipal waste or other solid fuel combustor. The system includes a sludge receiving and treatment module and a sludge injection and combustion module. The sludge is received and stored in one or more storage hoppers where its moisture content is monitored and varied to obtain a sludge having a desired moisture content. The treated sludge is then pumped to a furnace injection nozzle where it is preferably atomized with steam and sprayed into the combustion zone of the furnace. Improved odor control in sludge handling is also provided by a storage tank and a sludge tanker trailer each having an air diffuser for mixing and aerating the sludge and a filter system for filtering odors.

Owner:ECO TECH LLC

Chlorine fixing agent suitable for waste derived fuel, and preparation method and application thereof

The invention aims to provide a chlorine fixing agent suitable for reducing chloride emission in combustion gas of tail gas waste derived fuel. The chlorine fixing agent comprises the following components of acetylene sludge, fly ash and exciting agent in percentage of (60-80): (15-30): (3-10) by weight. With the adoption of the chlorine fixing agent, the purpose of treatment of wastes with processes of wastes against one another is realized; the waste is extruded into waste gas waste derived fuel at normal temperature under normal pressure, and the energy consumption is low; the volatilization rate of S-element and Cl-element are reduced greatly, so the chlorine fixing agent is beneficial for the waste combustion treatment; and the inflaming property of the waste is reduced. The waste derived fuel prepared by the preparation method has high compressive strength, and is suitable for the subsequent use of the waste derived fuel in combustion furnace and gasification furnace.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

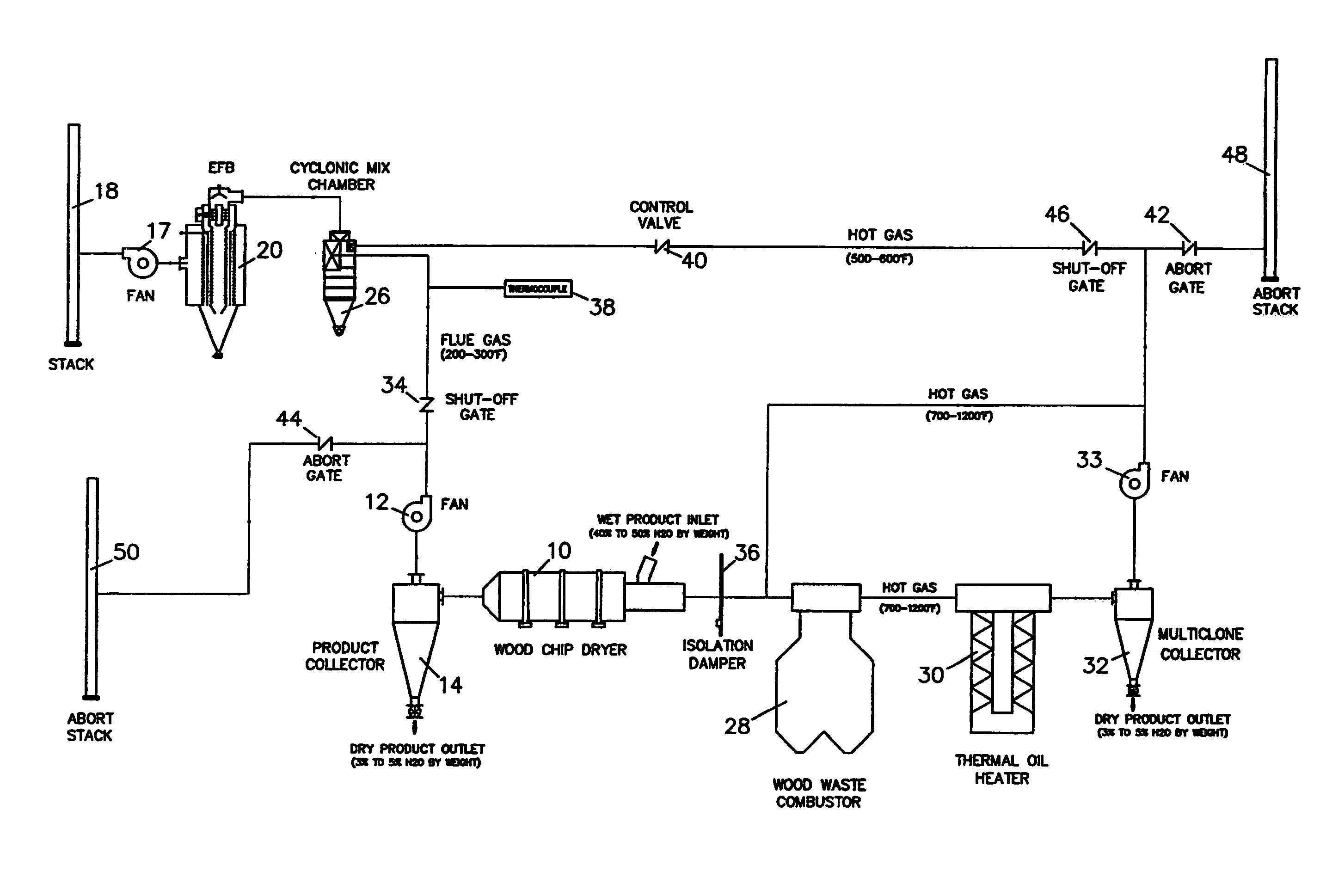

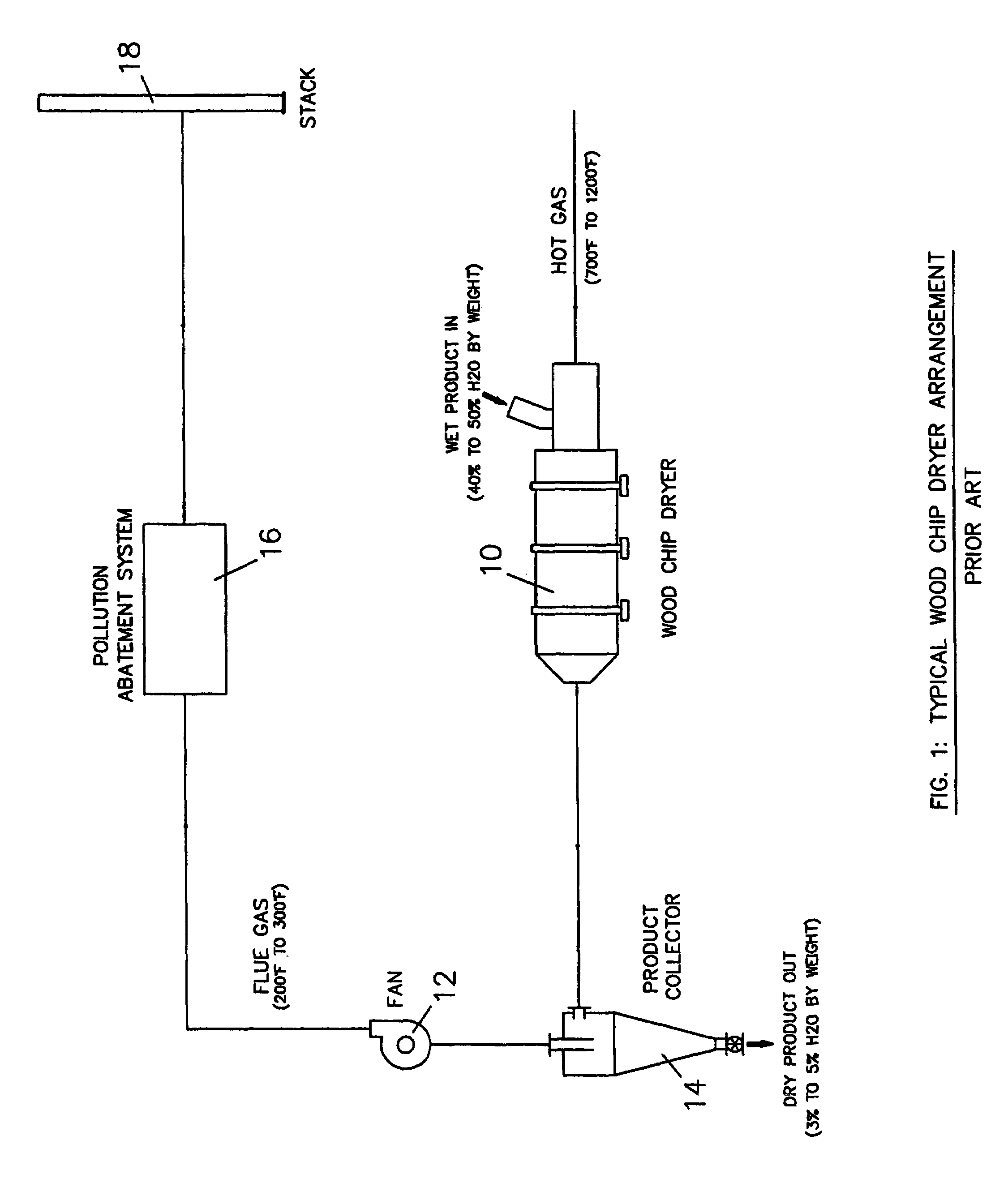

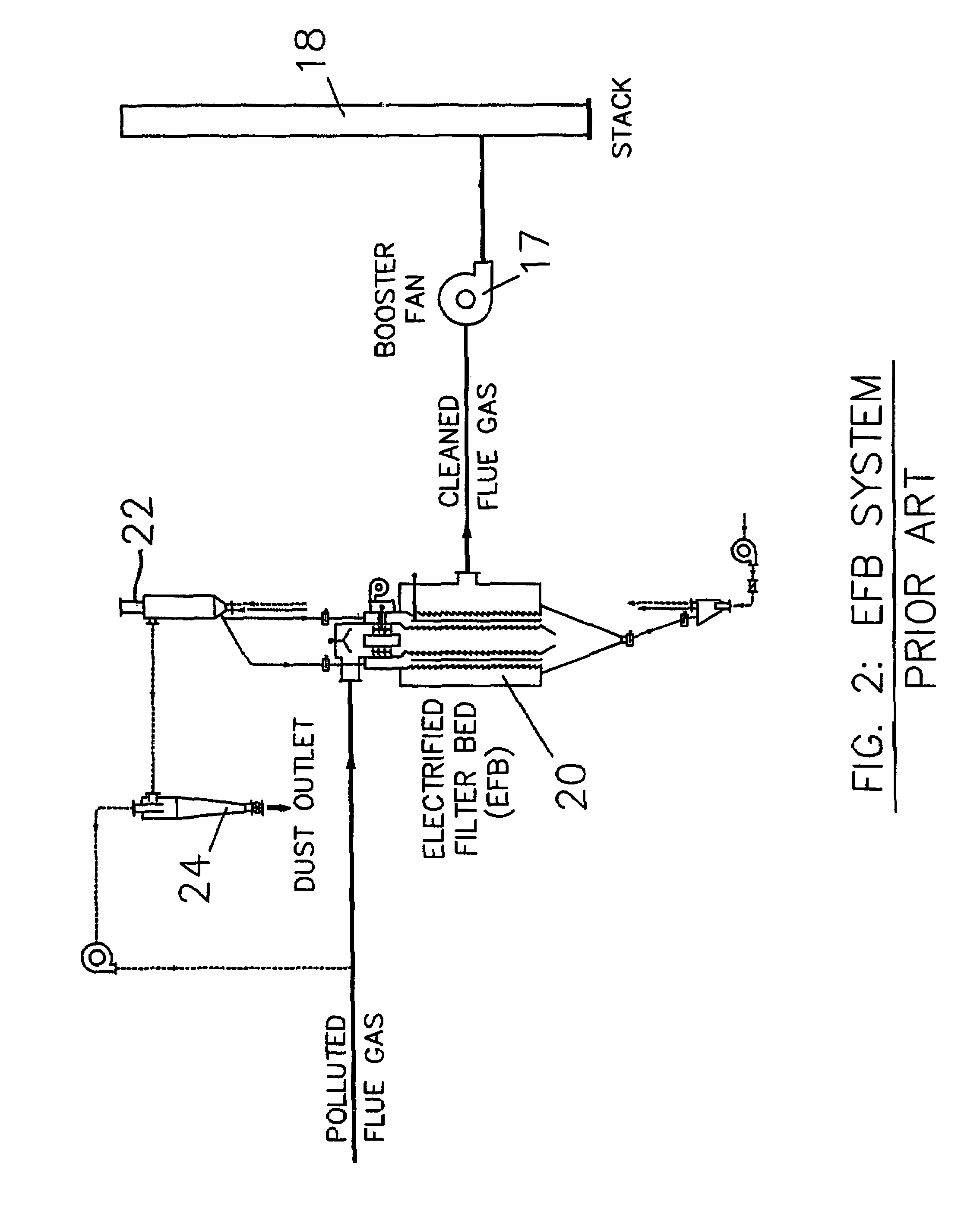

Apparatus and method using an electrified filter bed for removal of pollutants from a flue gas stream

InactiveUS7318288B2Free of materialRapidly preheatedDrying using combination processesDrying solid materials with heatWhirlwindPollution

Owner:EFB

Solid waste ceramic ecological brick

InactiveCN101172842ASolve pollutionRealize rational utilizationClimate change adaptationCeramic materials productionBrickEcological environment

The invention relates to a ceramic ecological brick produced by solid waste, and belongs to the solid waste utilizing and new material field. The product is made by using the graphite gangue as the main material and adding wedding agent with a certain rate and utilizes the heat energy generated by the burning of the flammable solid waste to realize the burning of the products. The invention solves the pollution problems of the solid waste and reduces the cost of the ceramic ecological brick by utilizing the solid waste to produce the ceramic ecological brick. The solid waste ceramic ecological brick has good permeability of water and can prevent the road seeper and improve the growth of the ground surface plant. With good moisture retention, the invention is useful for adjusting the temperature and the humidity of the city ground surface, reducing the thermal conductance and having significant meaning to the adjustment of the city atmosphere, the protection of the underground water material and the city environment.

Owner:QINGDAO UNIV OF SCI & TECH

Method and process for co-combustion in a waste to-energy facility

InactiveUS20050039638A1High degreeReduce chanceRotary drum furnacesCeramic production plantsCombustion chamberSlag

The co-combustion process may comprise the following unit operations: routing of hot gas (10) generated in the clinker cooling process to a rotary kiln (1); use of part of the rotary kiln exhaust gas to dry solid wastes in rotary dryers; leading the gases from both the dryer and the combustion kiln to the secondary combustion chamber (2); use of additional fuel to boost up the secondary combustion chamber reaction temperature to as high as 1200° C.; primary dry gas scrubbing in a precalciner or precalciners (3, 3a); heat recovery (4) and power generation; secondary gas scrubbing (5) in a semi-dry scrubber, bag filtering after activated carbon injection and returning of all the collected ash and used carbon into the waste kiln and / or a cement kiln. Detrimental materials for cement processing generated by waste combustion can be by-passed to a scrubbing system and a cement kiln. Residue slag from waste kilns can be treated and reused.

Owner:GREEN ISLAND ENVIRONMENTAL +1

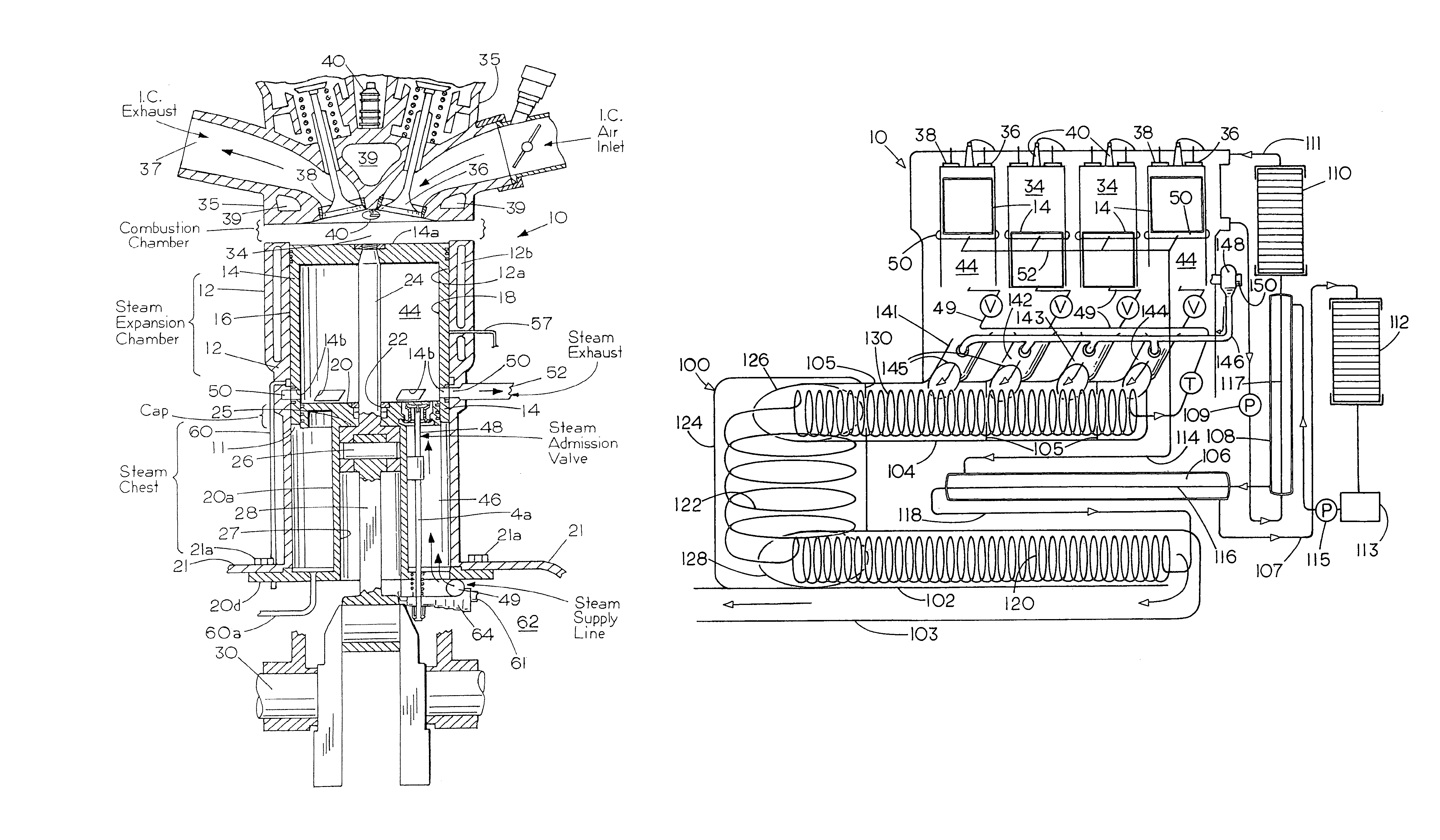

High Efficiency Multicycle Internal Combustion Engine With Waste Heat Recovery

ActiveUS20090293480A1Operation efficiency can be improvedReduce specific fuel consumptionReciprocating combination enginesInternal combustion piston enginesCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder having a piston mounted for reciprocation therein with an internal combustion chamber outward of the piston, a fixed cylinder cap sealingly and slidably mounted within the piston and a steam expansion and recompression chamber inside the piston adjacent the cylinder cap. The cylinder cap can be unheated or heated externally to reduce condensation of steam entering the steam chamber from a steam generator fired by waste combustion heat. After a steam exhaust valve closes at the top center position, residual steam is recompressed during an inward stroke of the piston up to admission pressure prior to admitting the next charge of steam. A wrist pin that is connected to an inner part of the skirt of the piston and located inwardly of the cylinder cap is coupled to a connecting rod that is secured at its inner end to a crankshaft. One valve or a pair of retractable steam inlet valves connected in series within the cylinder cap inside the piston act in cooperation with steam recompression and a variable clearance volume to achieve an effective zero steam chamber clearance and a gain in mean Rankine cycle temperature to maximize efficiency. The amount of steam admitted each outward stroke is continuously regulated to reduce fuel consumption. Engine coolant can be evaporated in an engine cooling jacket to form steam that is superheated in a combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

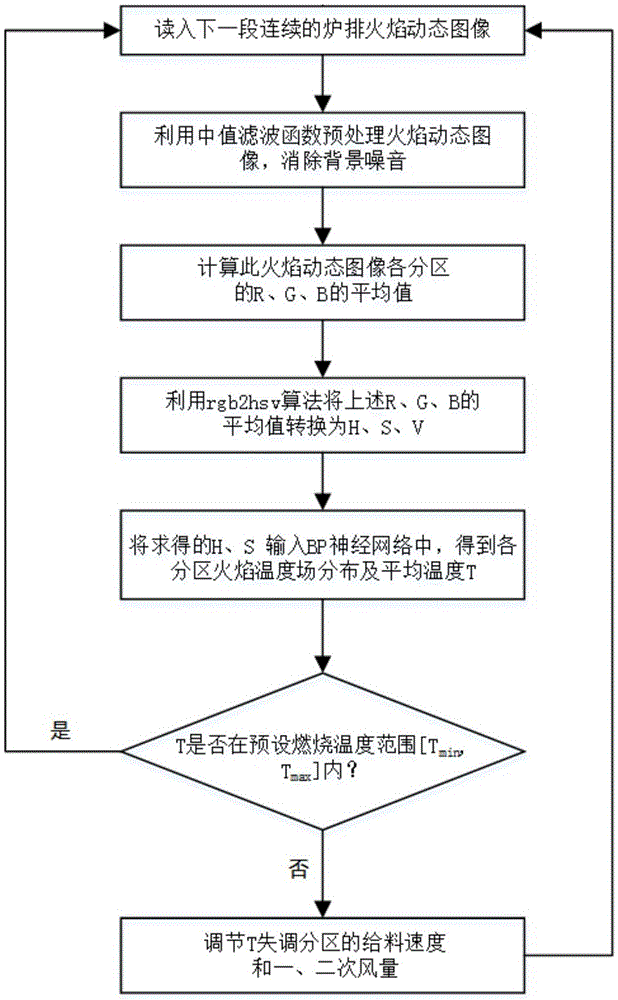

Control optimization method and device used for fire grate incinerator and based on flame radiation images

InactiveCN105627329APrecise control of combustion operating parametersLarge imaging rangeIncinerator apparatusAir volumeTime optimal

The invention discloses a control optimization method used for a fire grate incinerator and based on flame radiation images. The control optimization method comprises the following steps that the waste combustion conditions of all subareas are shot in real time, and image noise is eliminated; the multiple flame images are acquired, and the average values of R, G and B of the obtained images are calculated; the average values of the R, the G and the B are input into a trained BP neural network, and temperature field distribution and the average temperature T of all fire grate combustion areas are obtained; and the obtained flame average temperature T of all the combustion areas and a preset temperature range are compared and judged, and accordingly the feeding speed of all the combustion areas, the primary air volume and the secondary air volume are adjusted correspondingly. The invention further discloses a control optimization device used for the fire grate incinerator and based on the flame radiation images. According to the control optimization method used for the fire grate incinerator and based on the flame radiation images, temperature fields of waste flame on all subarea fire grates can be quickly rebuilt in real time; by adjusting the combustion parameters of all the subarea fire grates correspondingly, real-time optimal control over waste burning uniformity and efficiency is achieved.

Owner:ZHEJIANG UNIV

Waste incineration treatment apparatus and treatment method thereof

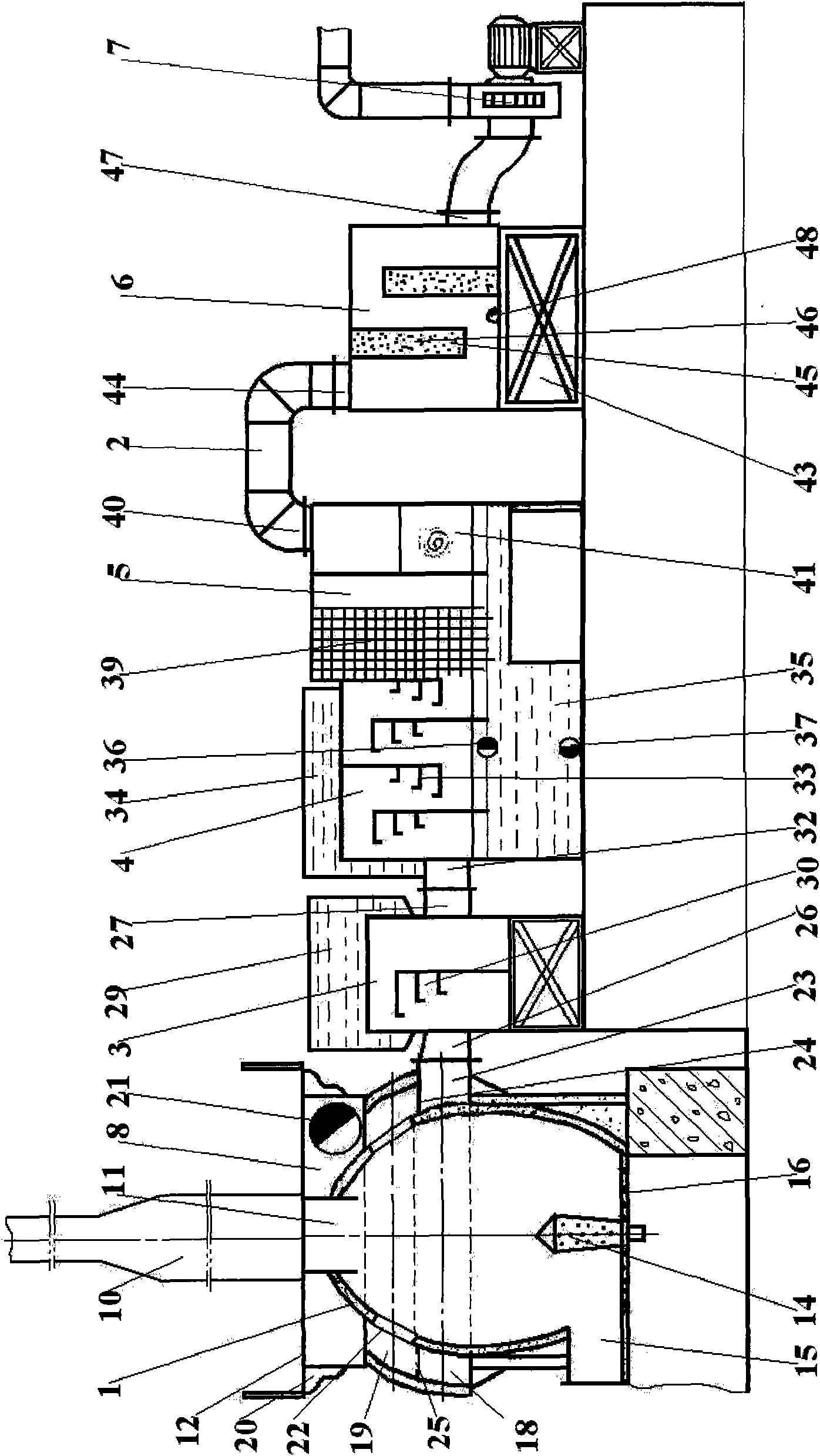

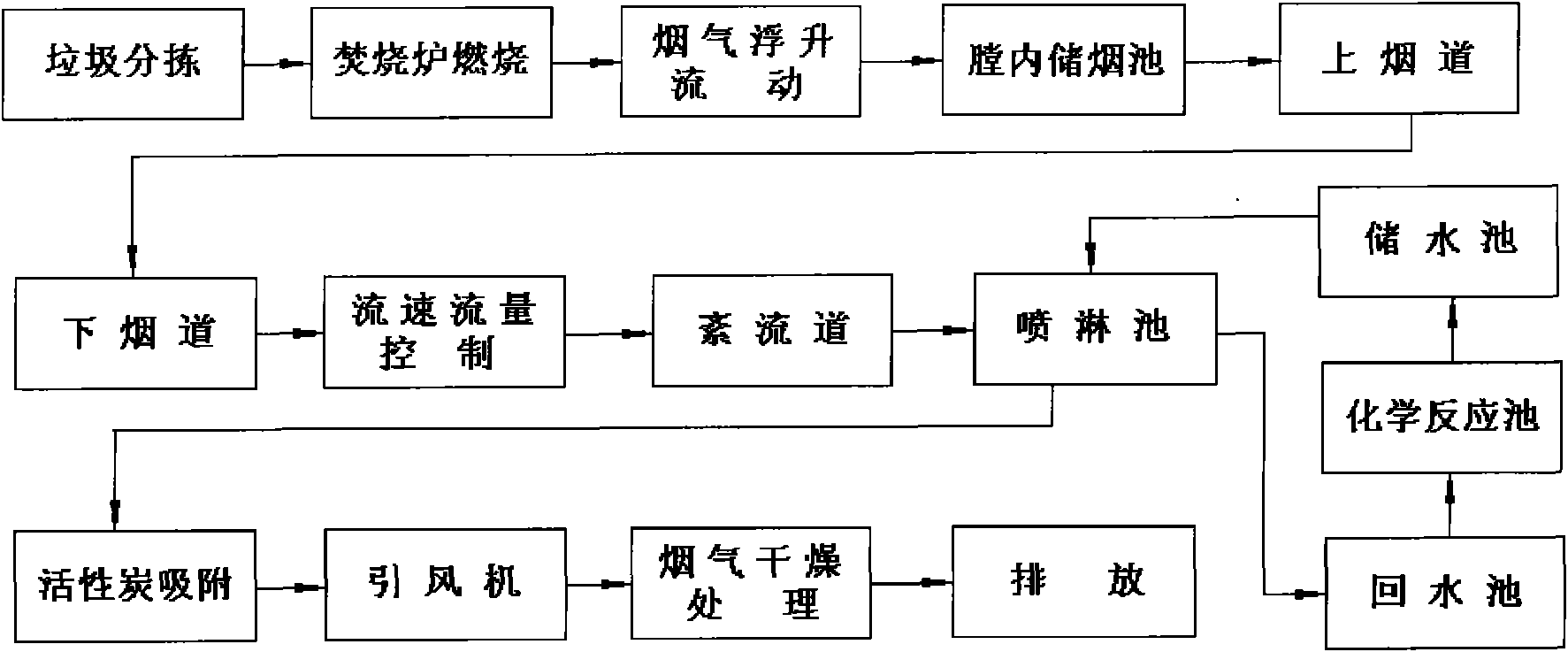

InactiveCN101876439ABurn fullyImprove combustion efficiencyUsing liquid separation agentIncinerator apparatusActivated carbonEngineering

The invention discloses a waste incineration treatment apparatus which is characterized in that an active carbon absorption chamber is internally provided with a smoke inlet of the active carbon chamber, which is communicated with a smoke exhaust pipeline of a high-pressure spraying dust-removal pool, and a smoke outlet of the active carbon chamber, which is communicated with a smoke intake pipeline of a draught fan; the active carbon absorption chamber is internally provided with a plurality of active carbon holding frames which are provided with small holes arranged densely; the frame is internally filled with active carbon; the active carbon holding frames are staggered with each other and fixedly connected with an inner wall of the active carbon absorption chamber, so that a flowing passage of the smoke in the active carbon absorption chamber is an S-shaped twisted passage. In addition, the invention further discloses a corresponding treatment method adopted by the treatment apparatus. By adopting the technical scheme, the efficiency of waste combustion is improved; the furnace has higher insulation performance and makes the waste combustion more efficient; the dust-removal and drying effect of the smoke is better, the finally discharged smoke and ashes are clearer, and the hazard-free treatment of the smoke is realized.

Owner:SHE COUNTY LVYUAN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Oxidation system and method for cleaning waste combustion flue gas

InactiveUS20140241971A1Efficient and cost-effective captureRemoval in wet scrubbers and condensers is facilitatedCombination devicesGas treatmentFlue gasEnvironmental engineering

Methods and systems for the removal of SO2 from waste combustion flue gas are described herein. The subject methods and systems entail one step, two steps or three steps to produce cleaned flue gas for release to the atmosphere.

Owner:GENERAL ELECTRIC TECH GMBH

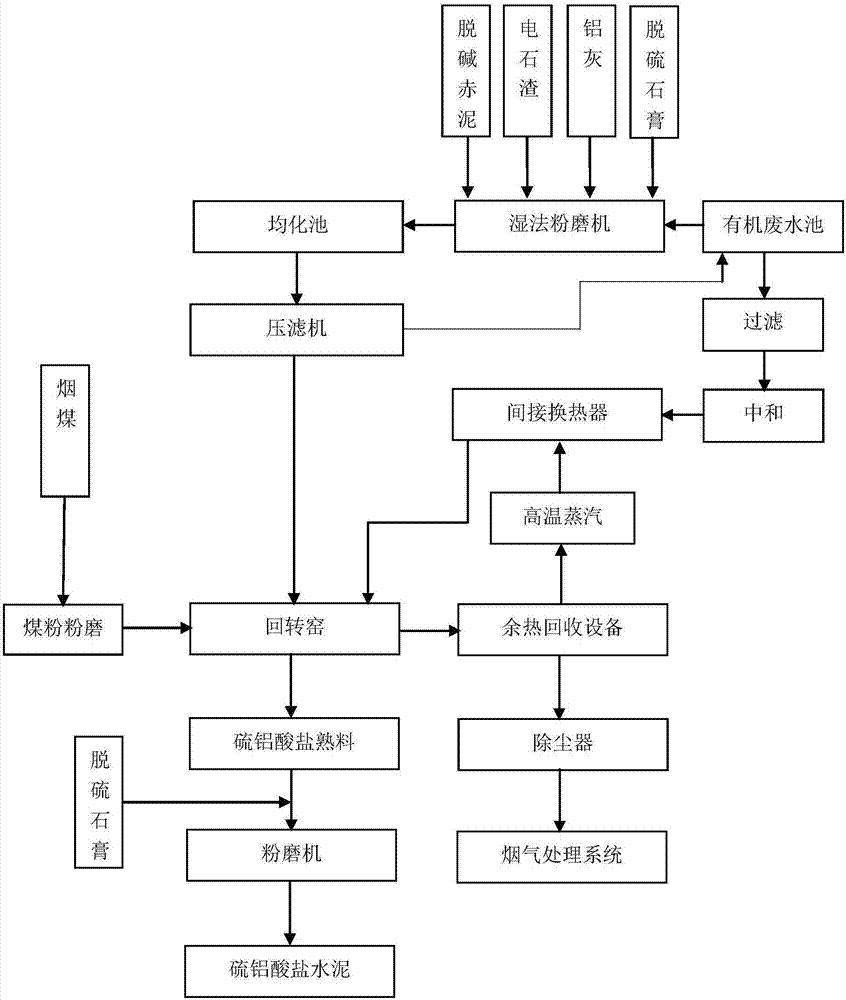

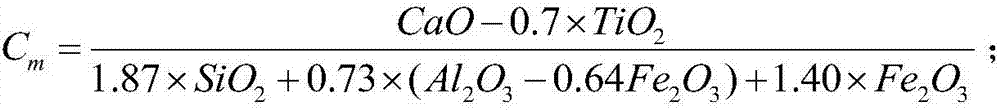

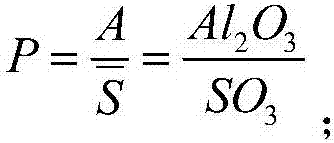

System and method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste

ActiveCN106866006ASolve the shortcomings of productionSolve the problem of difficult utilization of solid wasteClinker productionFiltrationRed mud

The invention discloses a system and a method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste. The system consists of an organic wastewater pool, a homogenizing pool, a wet powder mill, a pressure filter, a rotary kiln and an indirect heat exchanger. The method includes: mixing dealkalized red mud, carbide slag, aluminum ash, desulfurized gypsum and a part of organic wastewater to obtain a mixed solution, which has a water content of 60%-70% (mass), then conducting wet pulverizing on the mixed solution, and subjecting the wet pulverized material to homogenizing treatment so as to obtain a slurry, and performing mechanical pressure filtration dehydration to obtain a slurry, concentrating another part of organic wastewater, then sending the concentrated organic wastewater and the slurry into the rotary kiln and performing high-temperature calcination to obtain a sulphoaluminate clinker, and spraying pulverized coal into the rotary kiln during high-temperature calcination to combust organic waste in the pulverized coal and slurry and organic waste in the concentrated wastewater. The system and method realize comprehensive utilization of industrial solid waste and organic wastewater and zero-pollution emission.

Owner:SHANDONG UNIV

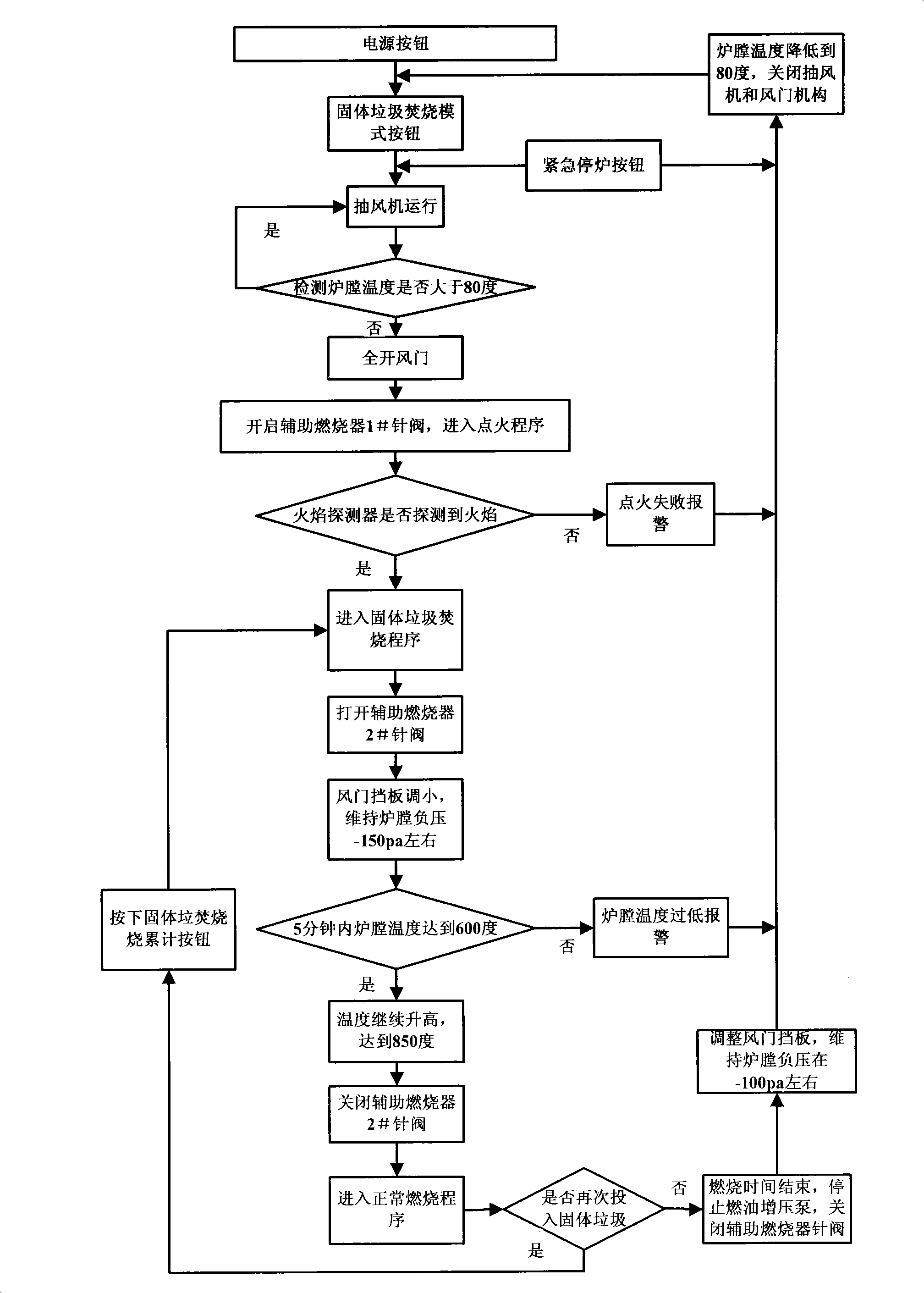

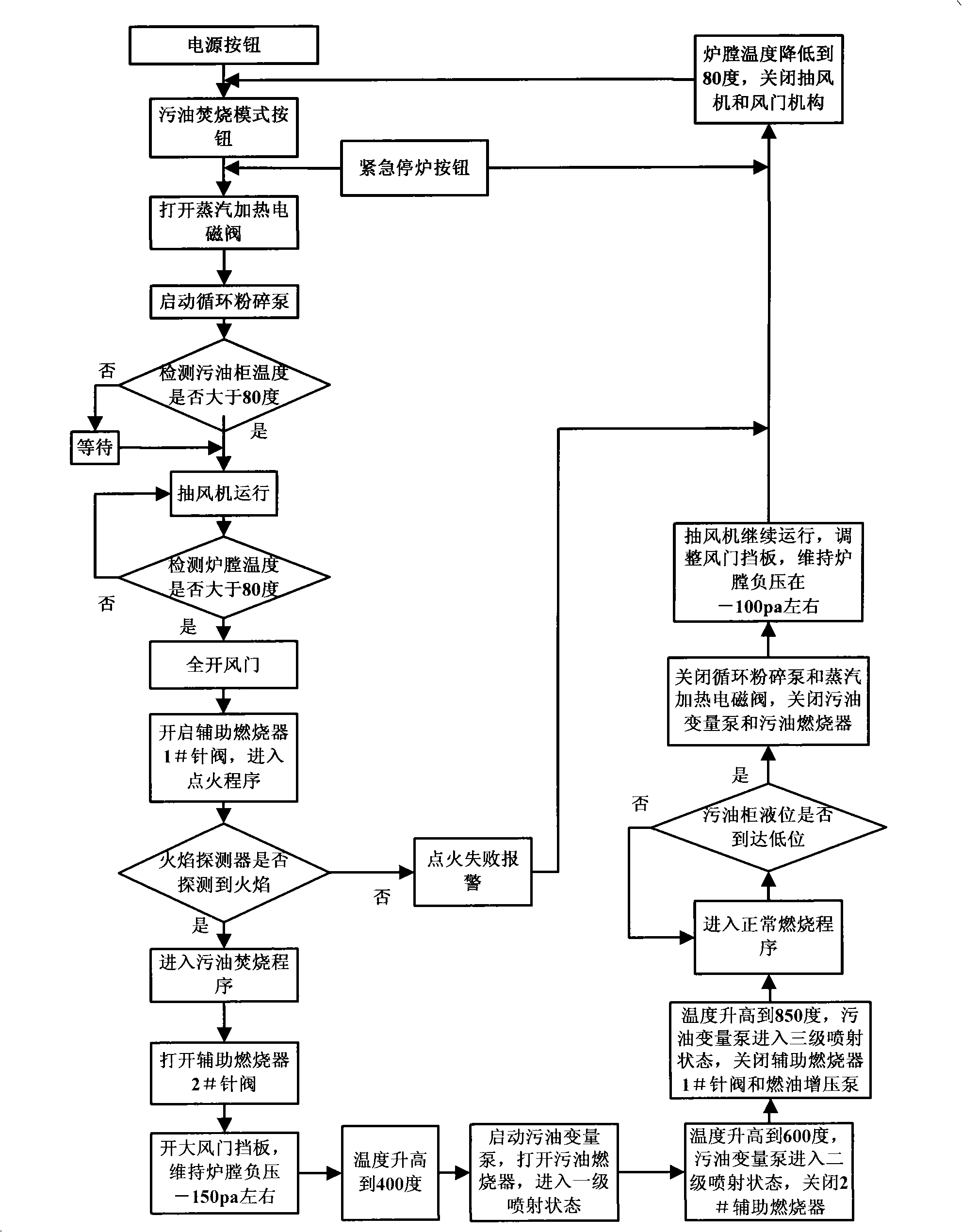

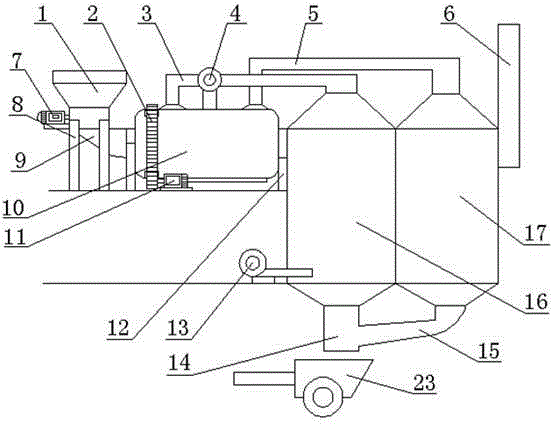

Control method of incineration furnace for vessel

InactiveCN101344253AFix stability issuesSolve uncontrollable problemsIncinerator apparatusFlue gasEngineering

The invention discloses a control method of a marine incinerator, which belongs to the field of combustion technology, shipboard automation technology and environment technology. The control method is applicable to three combustion modes, namely, solid waste combustion, sump oil combustion, and solid waste combustion and sump oil combustion, is simple and easy to be realized, and utilizes sensor technology and programmable control technology to control the whole working process of the incinerator. Considering the working parameter of the marine incinerator under various working condition completely, the automation, high efficiency, stabilization and reliable operation of the marine incinerator can be realized on the basis of accuracy control of the incinerator hearth temperature, hearth pressure and releasing temperature of flue gases. The invention completes the influence of continuous changing of various parameters to the whole combustion process during the spraying burning process, leads the waste and sump oil to be burnt fully, improves the burning efficiency, and reduces the dusty gas emission greatly.

Owner:SHANGHAI JIAO TONG UNIV

Environment-friendly waste incineration equipment for paper making factory and work method

The invention provides environment-friendly waste incineration equipment for a paper making factory. The environment-friendly waste incineration equipment comprises a waste feeding tank, a waste feeding pipe, a sorting rotary motor, a sorting rotary shaft, a sorting plate, a feeding pipe support, a preheating sealing tank, a tank support, a combustion furnace, a combustion draught fan, a smoke conveying pipe, a smoke exhaust fan, a smoke exhaust pipe, a tail gas treatment tank, a smoke outlet tank, a combustion furnace slag outlet pipe, a tail gas tank slag outlet pipe and a control valve. The environment-friendly waste incineration equipment for the paper making factory utilizes smoke generated in the combustion furnace for even preheating, water in waste is effectively reduced, the waste combustion efficiency and effect can be improved, and energy losses can be reduced. The sorting plate is arranged at the front end of the equipment for sorting, so that subsequent combustion efficiency is increased, and the collecting efficiency of ash and the combustion efficiency of the waste can be increased through the combustion furnace. The subsequent tail gas treating tank reduces pollutions to surroundings.

Owner:ZHEJIANG HUACHUAN IND GRP

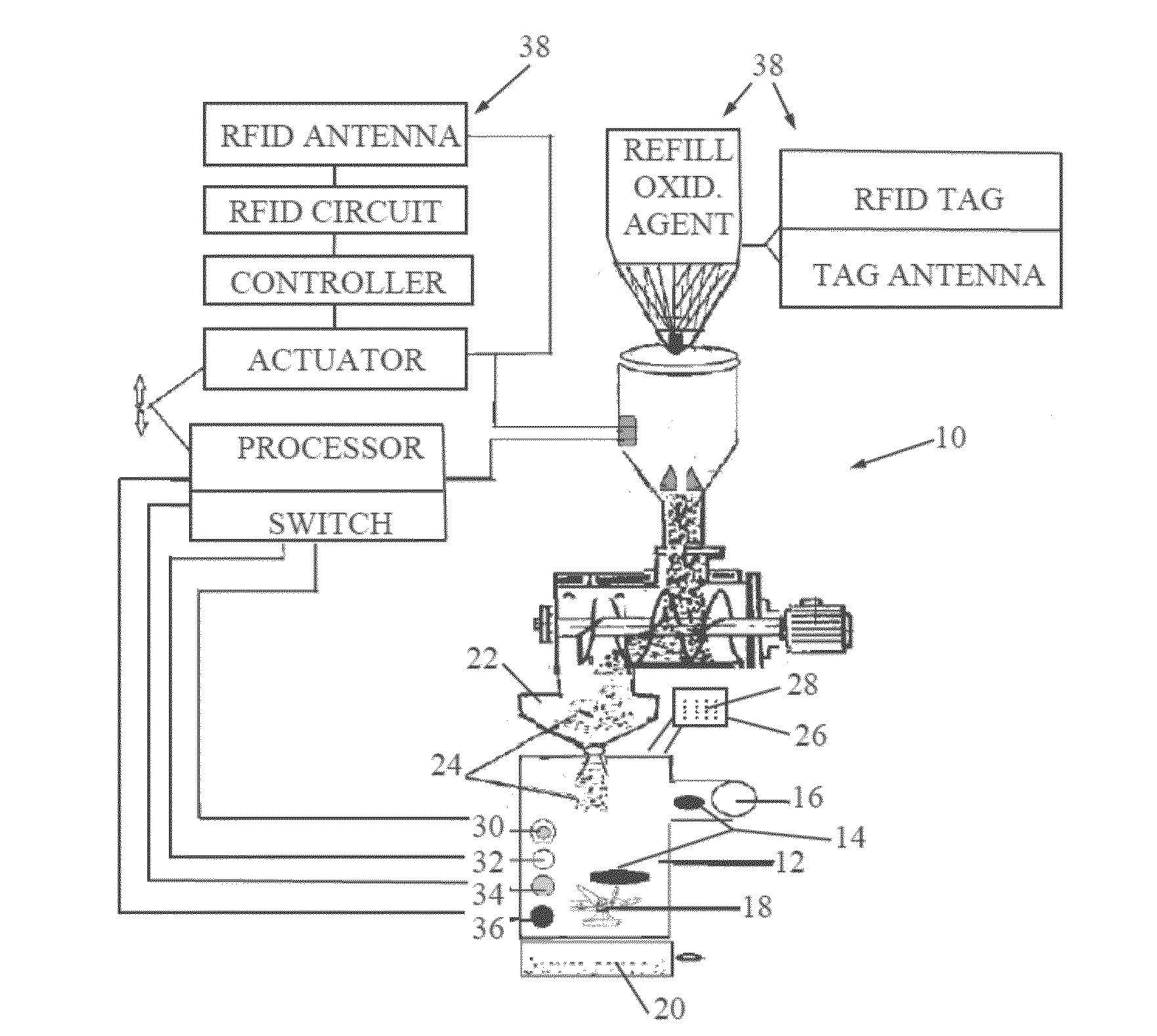

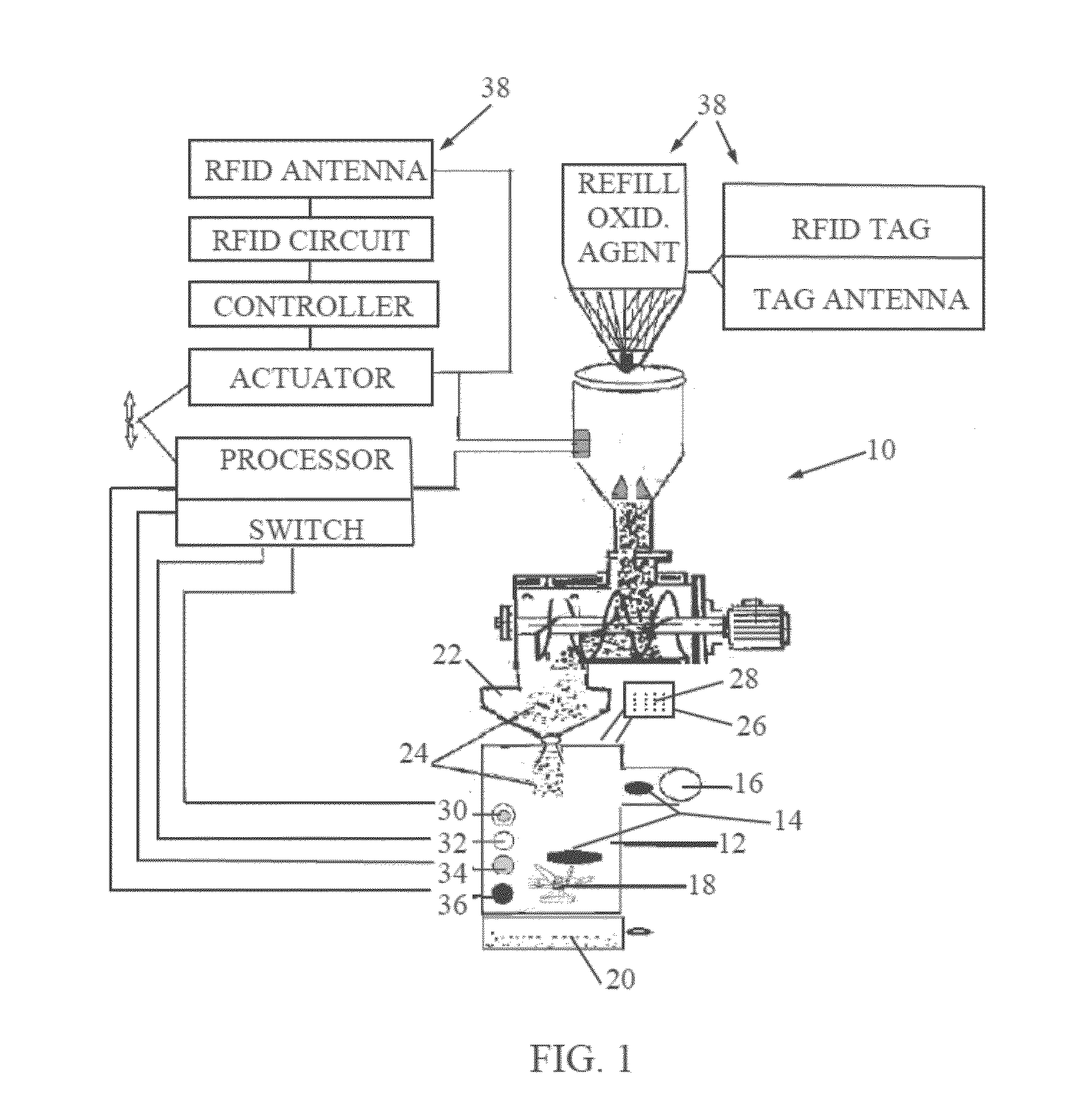

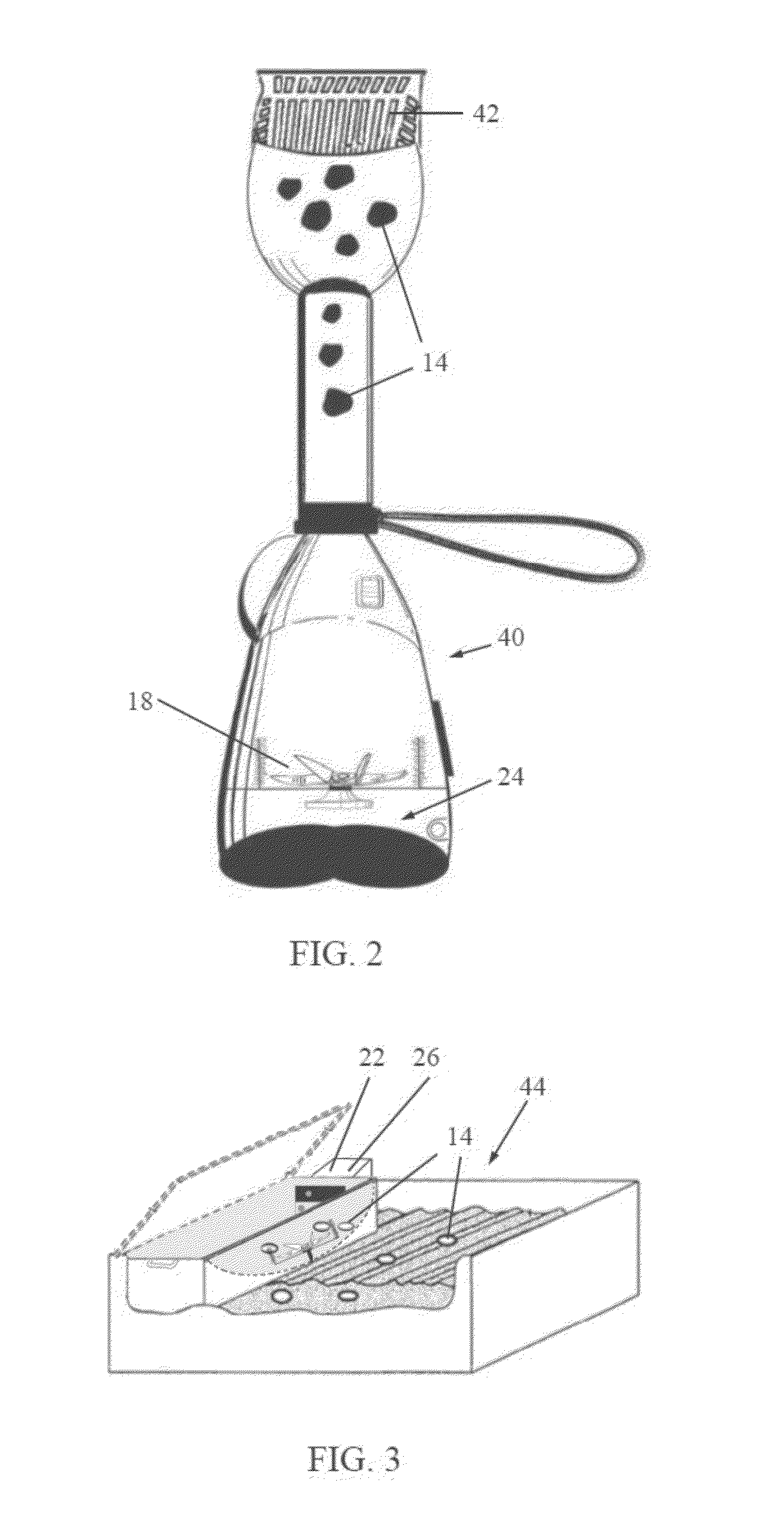

Disposal of organic waste

InactiveUS20130146513A1Reduce moistureCost-effective disposingSludge treatment by oxidationIon-exchanger regenerationOxidizing agentExothermic reaction

Apparatus including a receptacle for holding therein organic waste, a first dispenser operative to dispense an oxidizing agent to the organic waste so as to cause an exothermic reaction that results in combustion of the organic waste, and a second dispenser operative to dispense a reducing agent that neutralizes a residual amount of the oxidizing agent that remains after the exothermic reaction.

Owner:PAULEE CLEANTEC

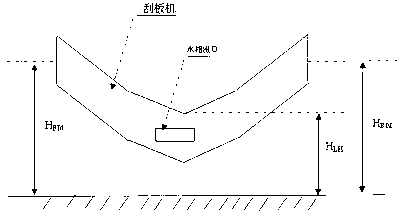

Treatment method of high concentration waste alkali solution

ActiveCN102877351AOvercome the explosionLower emission ratePulp liquors combustionHigh concentrationCyclohexanone

The invention relates to a treatment method of a high concentration waste alkali solution. The method includes: spraying waste alkali into an alkali recovery furnace, using a fuel to support combustion, combusting the waste alkali in the presence of an oxygen-containing gas to generate steam as a by-product, conducting electric precipitation to recover dry alkali ash, and making a molten material formed in combustion flow out of a chute at the furnace bottom. The method is characterized by: using a nozzle to jet one or several bundles of high-speed fluids so as to impact, cool and break the molten material from the chute into granular or powdered coarse alkali; bringing the granular or powdered coarse alkali into a cylindrical pipeline, and making the coarse alkali enter solid-liquid separation equipment selected from a scraper or a screw conveyor under the driving of a water flow, and separating a solid phase so as to obtain moisture-containing coarse alkali; and bringing the water phase separated by the solid-liquid separation equipment into a trough, a water tank or other intermediate containers, and then performing pressurization to circulate the water phase to the cylindrical pipeline and the nozzle. The method provided in the invention has the advantages of being able to completely recover the molten material generated by waste alkali combustion and generating no wastewater, thus being able to be used for cyclohexanone and other chemical industrial production and having good environmental protection significance and economic benefits.

Owner:CHINA PETROCHEMICAL CORP

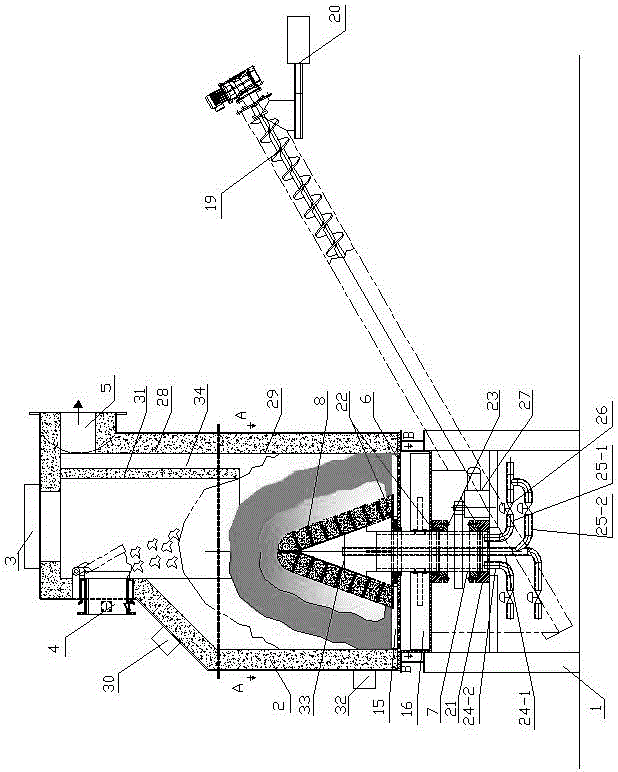

Modified grate furnace waste incineration device

ActiveCN105351944AAdjust the temperature reasonablyReasonable adjustment of oxygen contentIncinerator apparatusThermal energyFlue gas

The invention discloses a modified grate furnace waste incineration device. An air vent is formed in the rear arch of a hearth of a waste incineration furnace, is connected with the air chamber of a fire grate at the drying section of an incinerator through a pipeline, and is also connected with an outlet flue of the hearth of the incinerator through the pipeline; the coal economizer outlet of a waste heat boiler joins the pipeline connected with the air vent of the rear arch of the hearth through the pipeline; a circulating fan is further arranged on the pipeline; an air conditioning bypass is arranged at the inlet of the circulating fan. According to the invention, partial hot smoke containing certain content of oxygen at the tail part of the hearth and the partial hot smoke at the outlet of the coal economizer are recycled, so that drying and preheating of waste and disturbance and combustion support of smoke are met, the fed combustion air amount and the total smoke amount can be effectively reduced, the oxygen content of a combustion area is reasonably controlled, improvement of the waste combustion quality is facilitated, improvement of the utilization efficiency of combustion thermal energy is also facilitated, and the content of pollutants in the discharged flue gas is decreased.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

Chemical incinerator for conveniently treating combustion waste gas and waste slag

InactiveCN107883382AEasy to collect and arrangeReasonable structureEmission preventionBlast-producing apparatusCombustion chamberSlag

The invention relates to a chemical incinerator which is convenient for treating combustion waste gas and waste slag. It includes a furnace body which is divided into a combustion chamber, a slag collection chamber, a waste gas recirculation chamber and a waste gas treatment chamber by a partition inside. The waste gas reflow chamber is respectively connected with the slag collection chamber and The exhaust gas treatment chamber is connected through the air holes on the corresponding partitions. The exhaust gas return chamber is equipped with a first exhaust fan, and the bottom of the exhaust gas treatment chamber is equipped with a second exhaust fan. The air inlet of the first exhaust fan is located in the combustion chamber, and the outlet of the second exhaust fan is The tuyere is connected with the outside; the bottom of the combustion chamber is connected with the slag collection chamber, and the bottom of the combustion chamber is provided with a downward-sloping deflector. There are first and second filter screens, and the mesh holes of the first filter screen are larger than the mesh holes of the second filter screen. The invention can process the harmful flue gas generated in the incineration process on the basis of fully incinerating the waste, prevent the gas from leaking out as much as possible, and also easily collect and discharge the waste slag generated by the combustion.

Owner:登封市绿奥农林科技有限公司

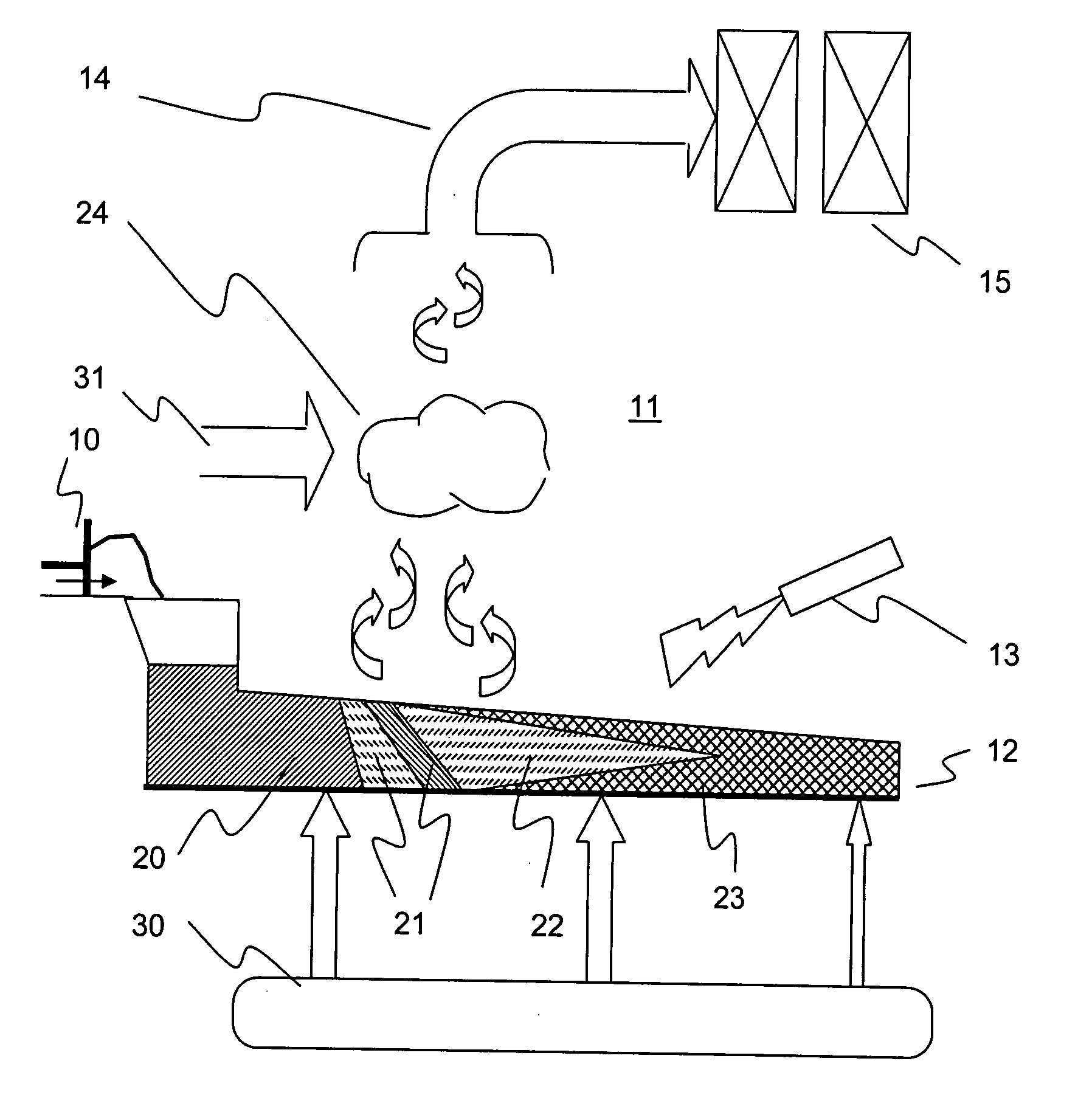

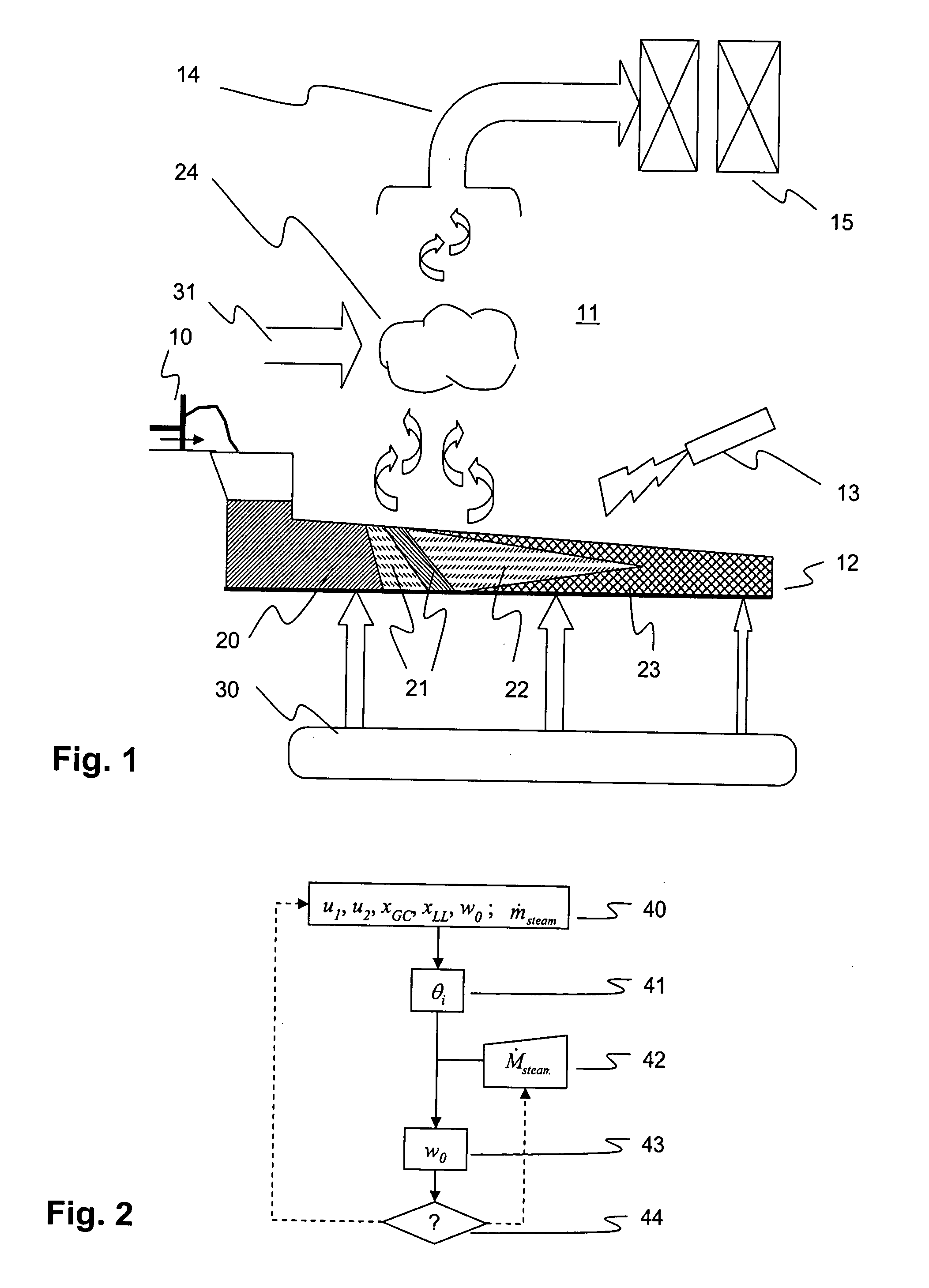

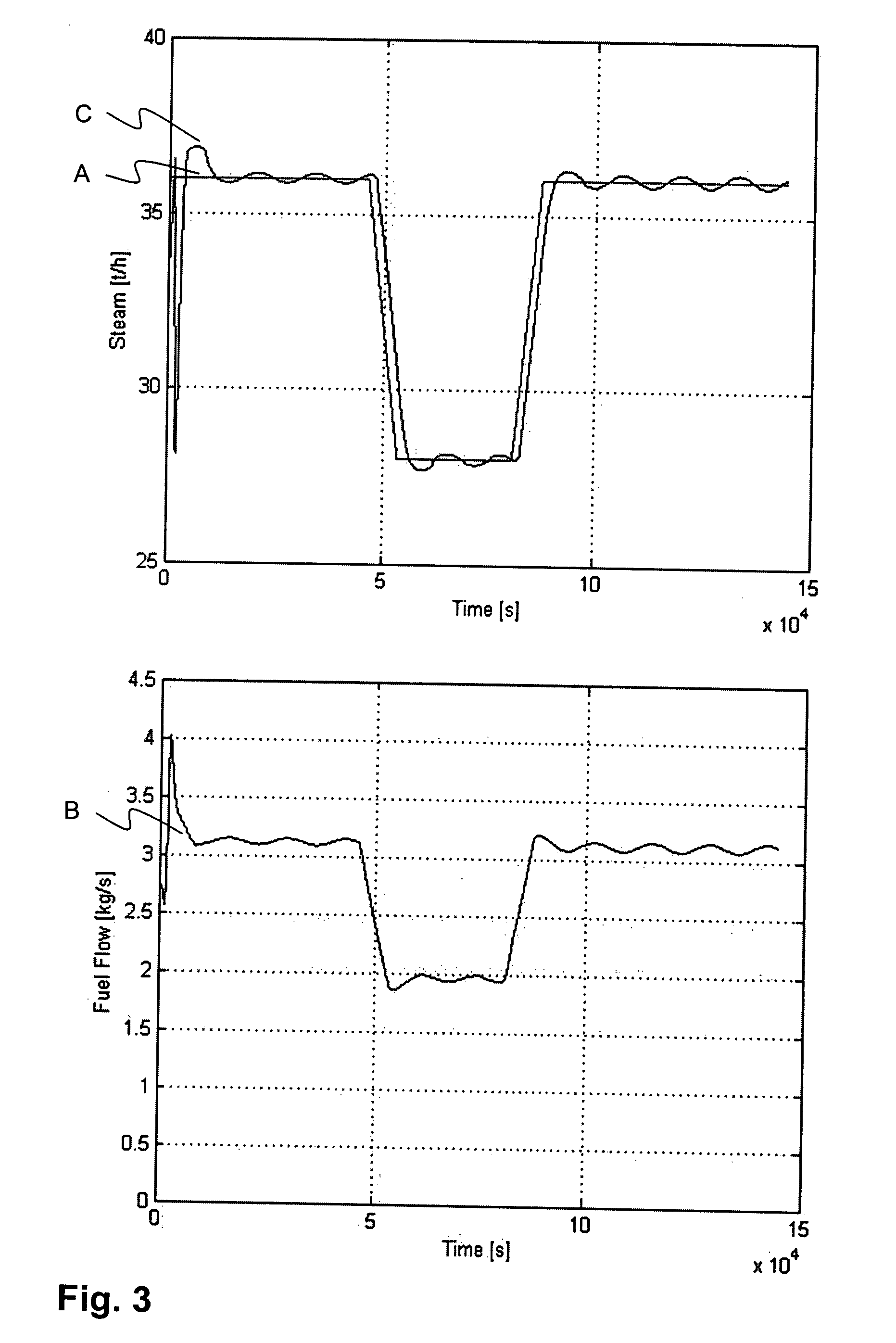

Controlling a waste combustion process

InactiveUS20080053348A1Sampled-variable control systemsFuel supply regulationProcess engineeringActuator

The present invention is concerned with a method of controlling on-line the steam output of a waste incineration plant that is fed with waste of varying composition. Process or system quantities (u2, u3, xGC, xLL, w0) are measured repeatedly, at different times during operation of the plant, and a relation with linear parameters (θi) as coefficients of non-linear expressions (φi) of the process quantities is established by evaluating said measurements. From this relation, an optimal waste feed rate to obtain a desired steam output ({dot over (M)}steam) is determined and applied to a waste feed actuator of the waste incineration plant.

Owner:ABB TECH AG

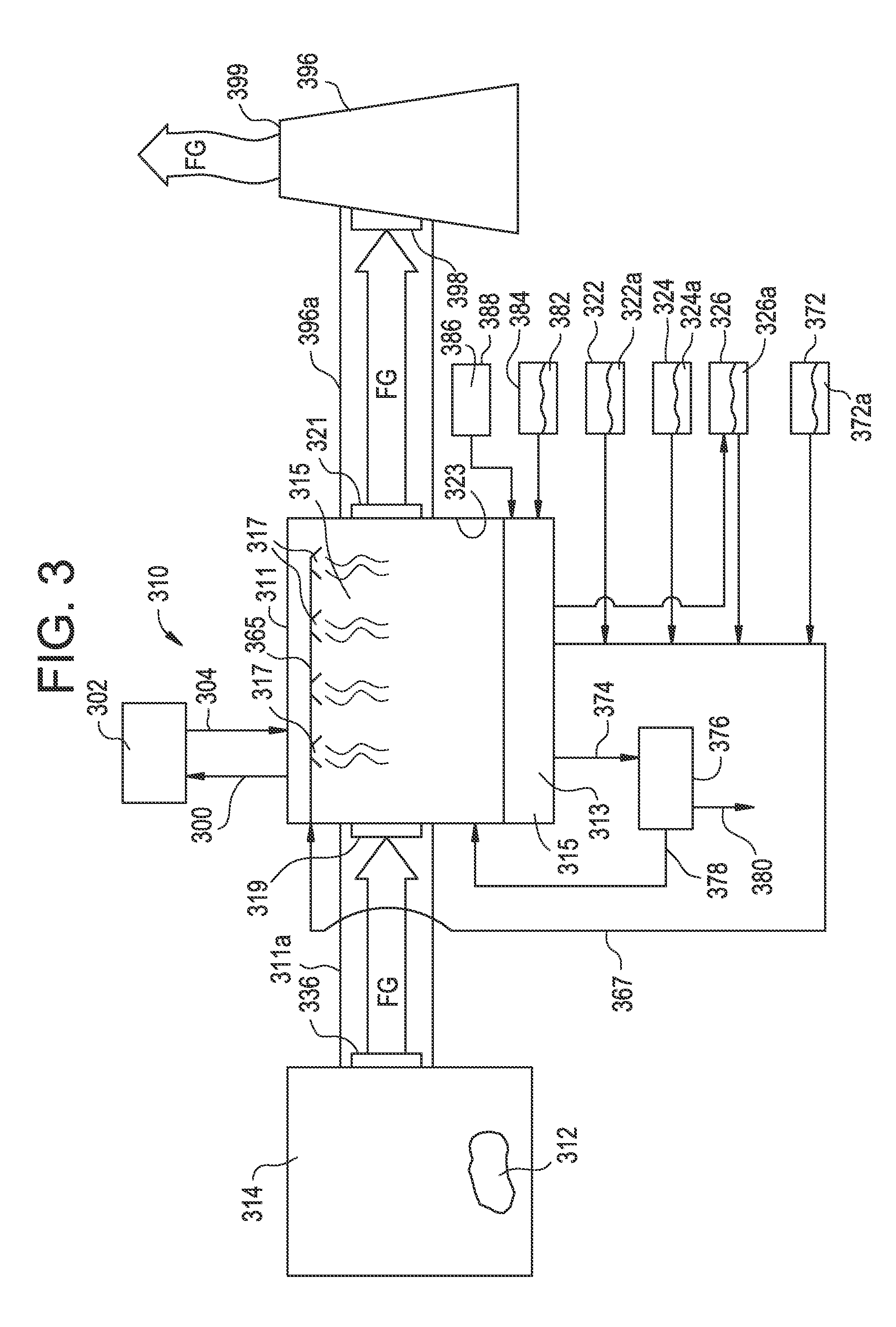

Low nitrogen oxide incinerating device used for treatment of nitrogen containing waste gas and nitrogen containing waste liquid and low nitrogen oxide incinerating method used for treatment of nitrogen containing waste gas and nitrogen containing waste liquid

InactiveCN105937766AControl generationSuppress generationIncinerator apparatusNitrogen oxidesLow nitrogen

The invention provides a low nitrogen oxide incinerating device used for a treatment of nitrogen containing waste gas and nitrogen containing waste liquid and a low nitrogen oxide incinerating method used for the treatment of the nitrogen containing waste gas and the nitrogen containing waste liquid. The device comprises an oxygen debt reducing section, a primary quenching section, an oxidizing section, a secondary quenching section, SNCR denitrating section and a waste heat boiler. The method comprises the following steps: (1) oxygen debt incinerating; (2) primary quenching; (3) oxygen excess incinerating; (4) secondary quenching; (5) SNCR denitrating; (6) waste heat recovery. According to the device and the method, the technology of combining the staged combustion of the air over a furnace, the flue gas recycling and the SNCR denitrating is utilized, and a whole set of incinerating device, incinerating method and controlling philosophy are provided, so that the generating of the nitrogen oxide during the combustion of the waste such as nitrogen containing waste gas, nitrogen containing waste liquid and like can be effectively controlled, particularly the generating of the fuel type nitrogen oxide can be inhibited significantly and the transformation rate that the nitrogen generates the nitrogen oxide in the fuel composition can be lowered.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

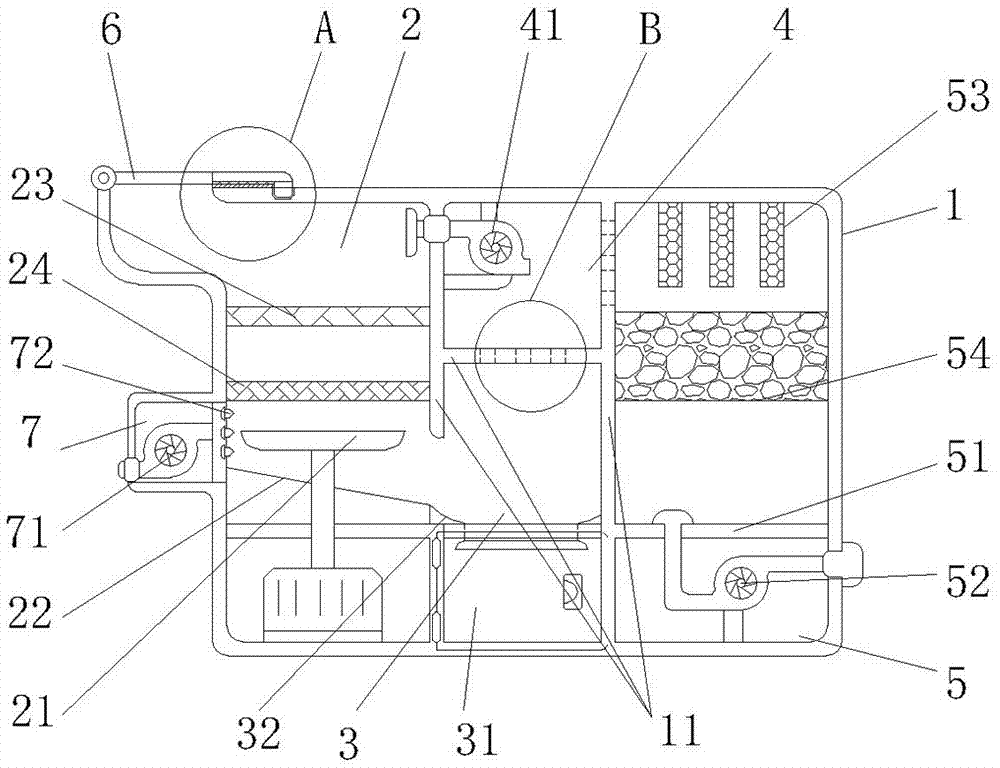

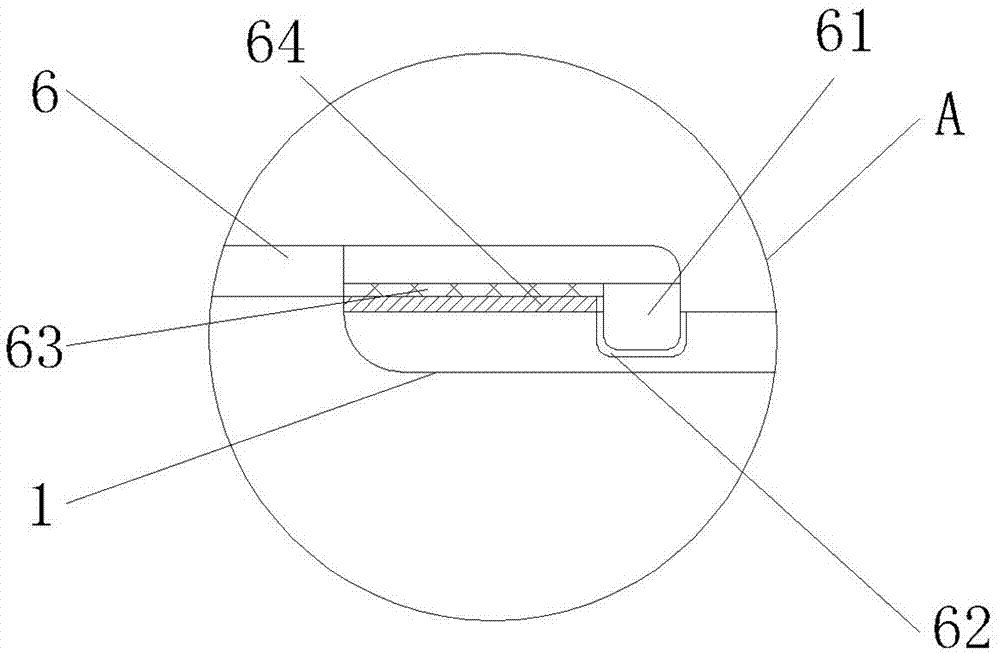

Multifunctional integrated gasification furnace with rotary furnace core air supply and simple scraper dust removal

ActiveCN106190323AIncreased operating lifeUniform air supplyGasification processes detailsGasification apparatus detailsRefractorySpray nozzle

The invention provides a multifunctional integrated gasification furnace with rotary furnace core air supply and simple scraper dust removal, relating to the technical field of environment friendliness. The gasification furnace is characterized by adopting the rotary air supply furnace core, and the waste combustion gasification interface is a refractory material layer formed by embedding ceramic air supply nozzles in the rotary furnace core cone surface instead of on the metal furnace chassis, thereby greatly prolonging the service life of the metal furnace chassis. A dust scraper is arranged on the furnace chassis, the lower part of the furnace chassis is provided with a dust receiver, one side of the dust receiver is provided with a closed dust falling tank, and the bottom of the dust falling tank is provided with a screw conveyer which can convey the collected furnace dust to the inlet of the incinerator dust feeder, thereby enhancing the environment friendliness of facility operation and improving the working environment.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Waste incineration system and high-efficiency incineration control method

PendingCN110878943AQuality assuranceGuaranteed effectIncinerator apparatusCombustion chamberEmission standard

The invention provides a waste incineration system and a high-efficiency incineration control method. The waste incineration system comprises a primary combustion chamber used for primary waste combustion. An exhaust gas outlet of the primary combustion chamber communicates with an exhaust gas inlet of a secondary combustion chamber through a first flue. An exhaust gas outlet of the secondary combustion chamber is connected with a spray tower used for spraying treatment on exhaust gas through a second flue. An outlet of the top end of the spray tower is connected with an exhaust gas purifyingsystem through a third flue. The waste incineration system can effectively control the waste incineration temperature, make use of flammable gas generated from incineration, meanwhile, controls the exhaust gas combustion temperature and the exhaust gas cooling rate to decompose dioxin and prevents resynthesis of dioxin to meet the treated waste emission standard. The high-efficiency incineration control method is high in intelligence degree, advanced, high in working efficiency, safe, reliable, energy-saving and friendly to environment.

Owner:YICHANG JIANGXIA MARINE MACHINERY +1

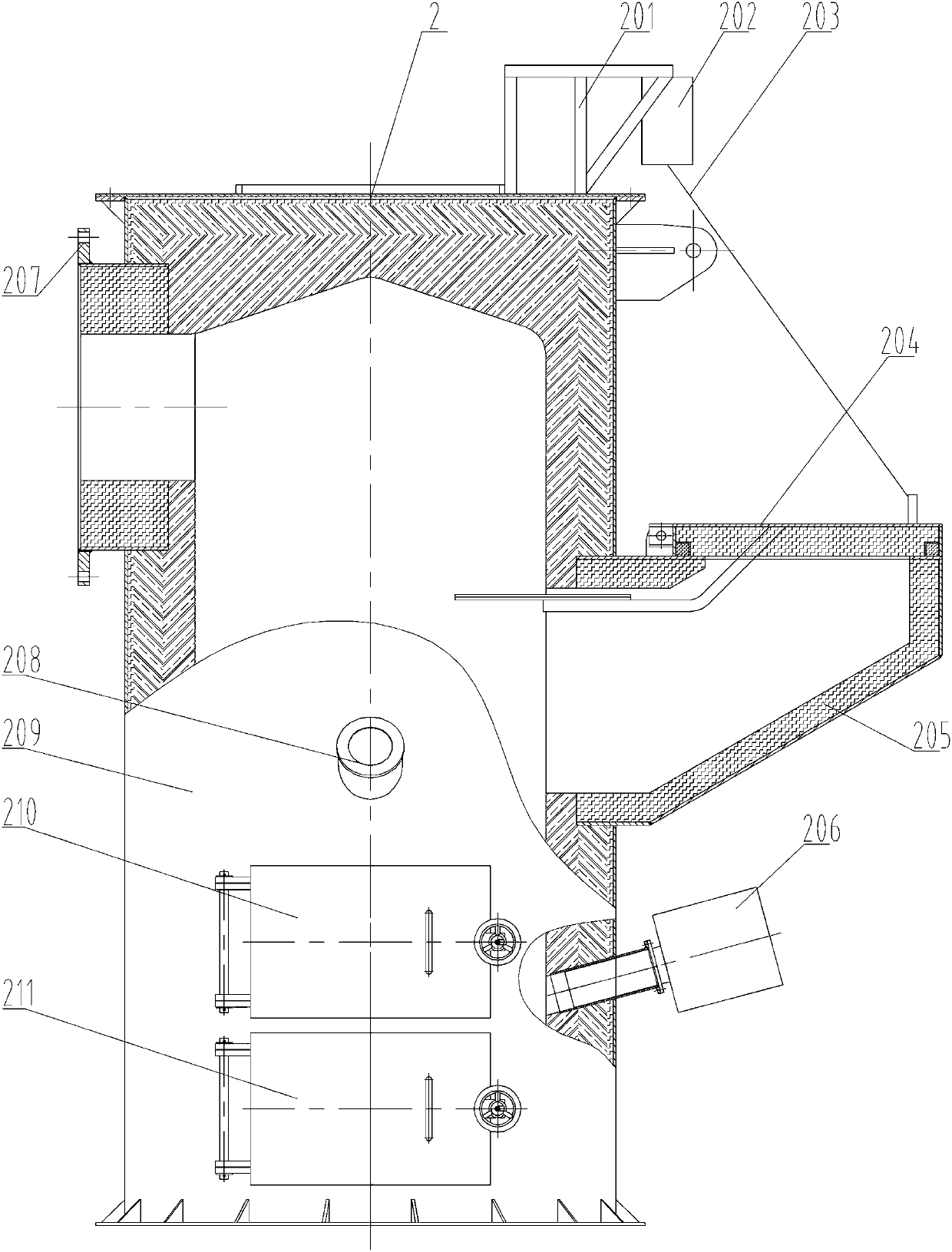

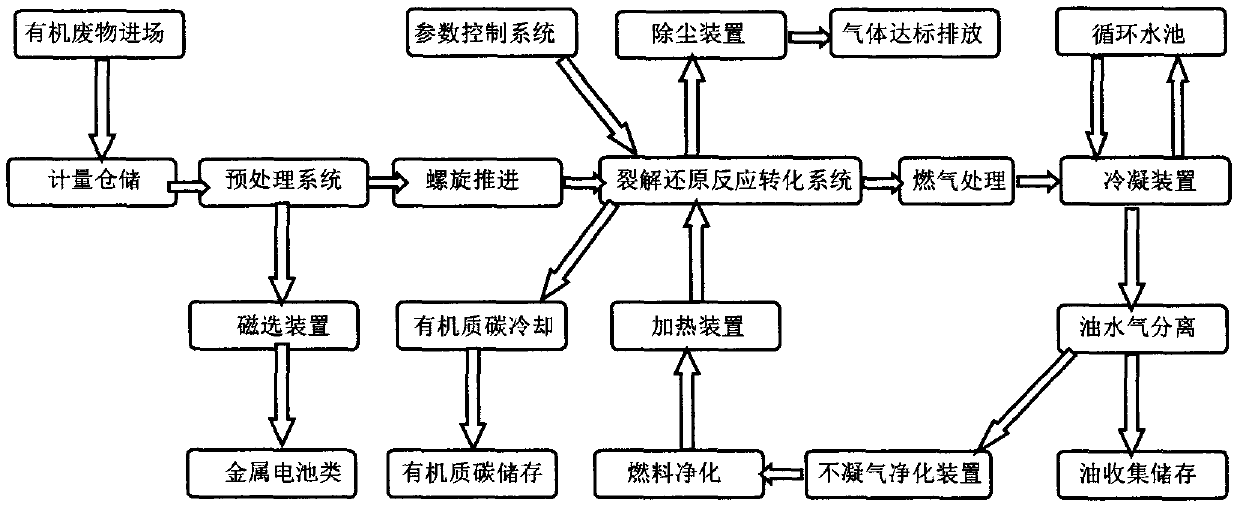

Domestic organic waste splitting decomposition reductive transformation reaction processing process

InactiveCN107626726AHigh calorific valueEnsure continuous and efficient operationSolid waste disposalIndirect heating destructive distillationDecompositionAdditive ingredient

The invention relates to a domestic organic waste splitting decomposition reductive transformation reaction processing process, and belongs to the technical field of environmental protection. Along with rapid growth of population, cities and towns are enlarged continuously, the yield of domestic organic waste is increased day and day, environments of the cities and towns and the surroundings are seriously polluted, and bodies of surrounding residents can be seriously harmed. At present, the main domestic organic waste processing methods in China are power generation by waste combustion, pyrolysis gasification and landfill. As organic waste of the cities and towns in China is complex in ingredient and low in calorific value, auxiliary fuel needs to be added during power generation by wastecombustion and pyrolysis gasification, and therefore the processing cost is increased, hazardous substance like Dioxin is generated during running of power generation by waste combustion due to the factors of technologies, operation and the like, a large amount of land is occupied by landfill treatment, and meanwhile the atmosphere and the underground water source are seriously polluted. The domestic organic waste splitting decomposition reductive transformation reaction processing process is low in cost, harmless, minimized and recycle, the domestic organic waste is environment-friendly and high in efficiency and becomes resource matter.

Owner:董平年

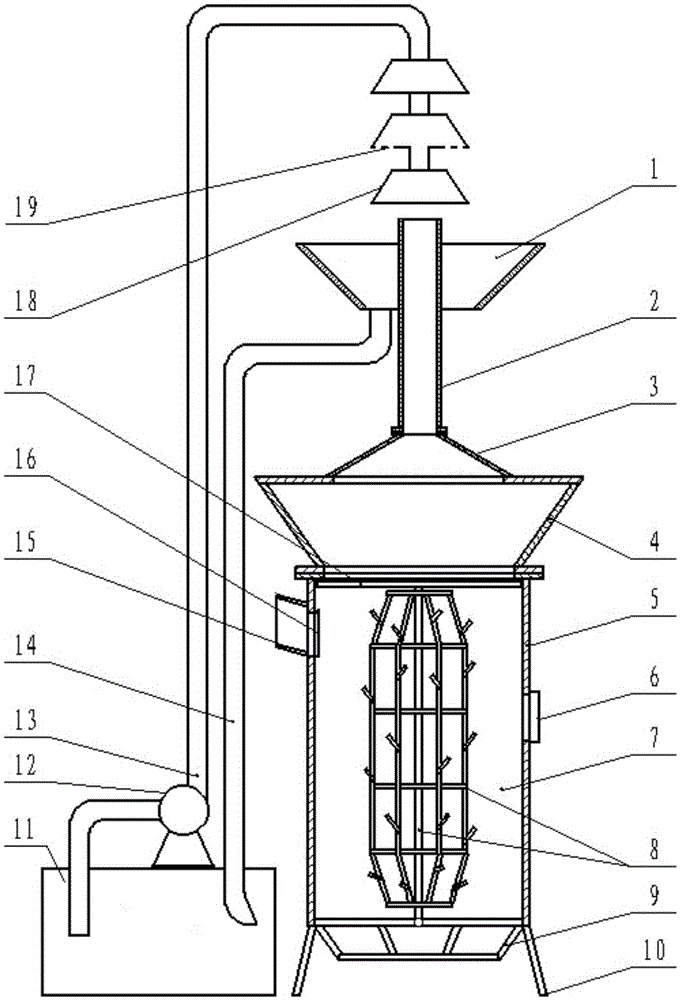

Environment-friendly waste incinerator

ActiveCN105258126AIncrease temperatureStable heat sourceIncinerator apparatusBrickCombustion chamber

The invention discloses an environment-friendly waste incinerator. The environment-friendly waste incinerator comprises an incinerator body, a combustion chamber, a high-position feed inlet, an incinerator grate and incinerator legs. Refractory bricks are arranged on the inner wall of the incinerator body. The incinerator body is hollow, so that the combustion chamber is formed. The high-position feed inlet is formed in the upper portion of the incinerator body. The incinerator grate is arranged at the bottom of the incinerator body. The bottom end of the incinerator body is open, so that an ash outlet is formed. The incinerator legs are arranged at the bottom end of the incinerator body. The environment-friendly waste incinerator further comprises a dust hopper, a chimney, a water collection tank, a water pool, a water pump, a water inlet pipe and a water outlet pipe. The lower end of the dust hopper is connected with the upper end of the incinerator body through a flange. The upper end of the dust hopper is welded to a reversed hopper. The chimney is connected with the reversed hopper through a flange. The water collection tank is fixed to the upper portion of the chimney in a surrounding mode. The water pool is arranged at one side of the incinerator body. The water pump is installed above the water pool. One end of the water inlet pipe is connected with the water pump. The other end of the water inlet pipe is arranged above the chimney. One end of the water outlet pipe is connected into the water pool, and the other end of the water outlet pie is installed at the bottom of the water collection tank. According to the environment-friendly waste incinerator, smoke generated after waste combustion can be cleaned, emission of harmful smoke is reduced, and pollution to air caused by waste combustion is reduced.

Owner:都安瑶族自治县计量检定测试所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com