Patents

Literature

858results about "Blast-producing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

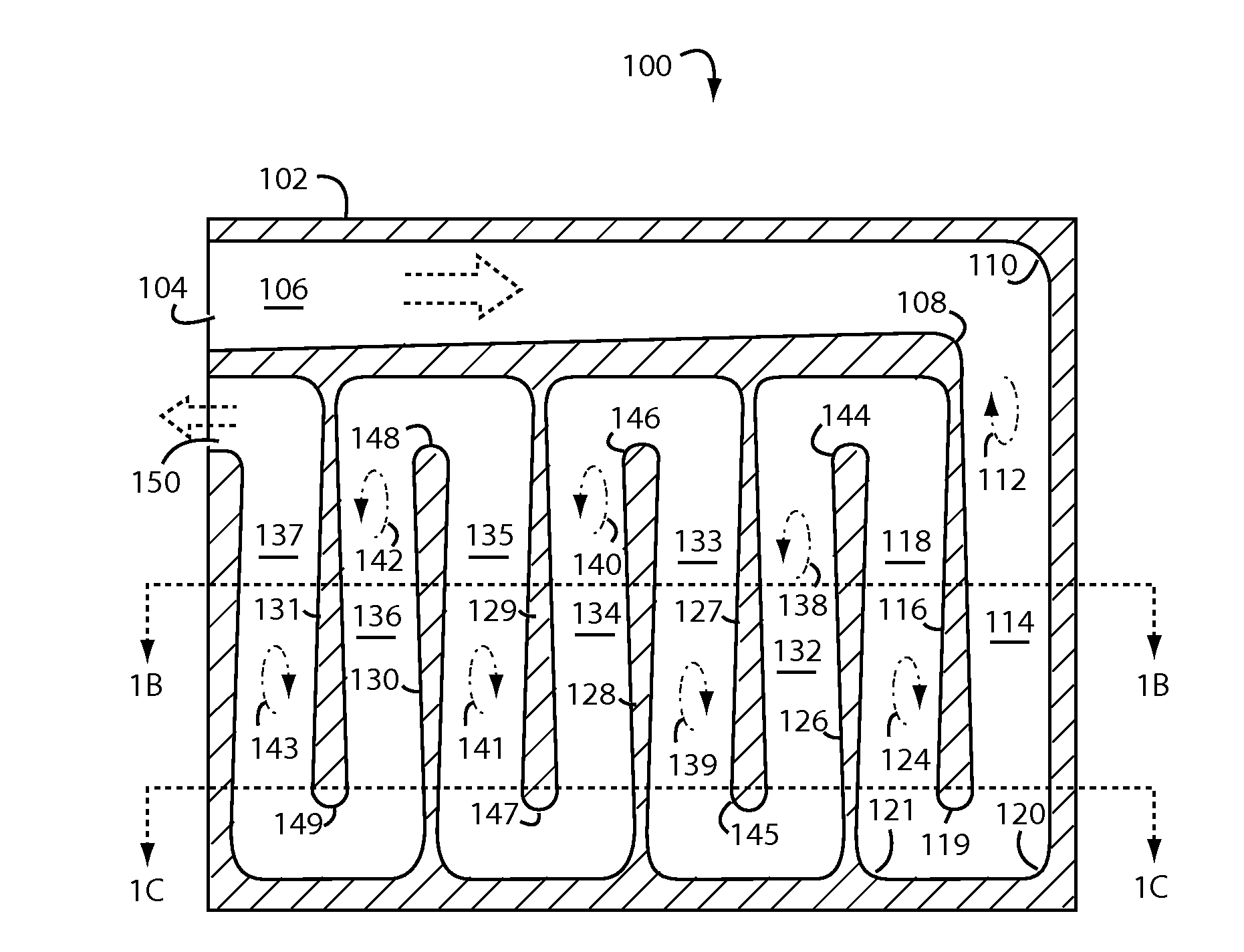

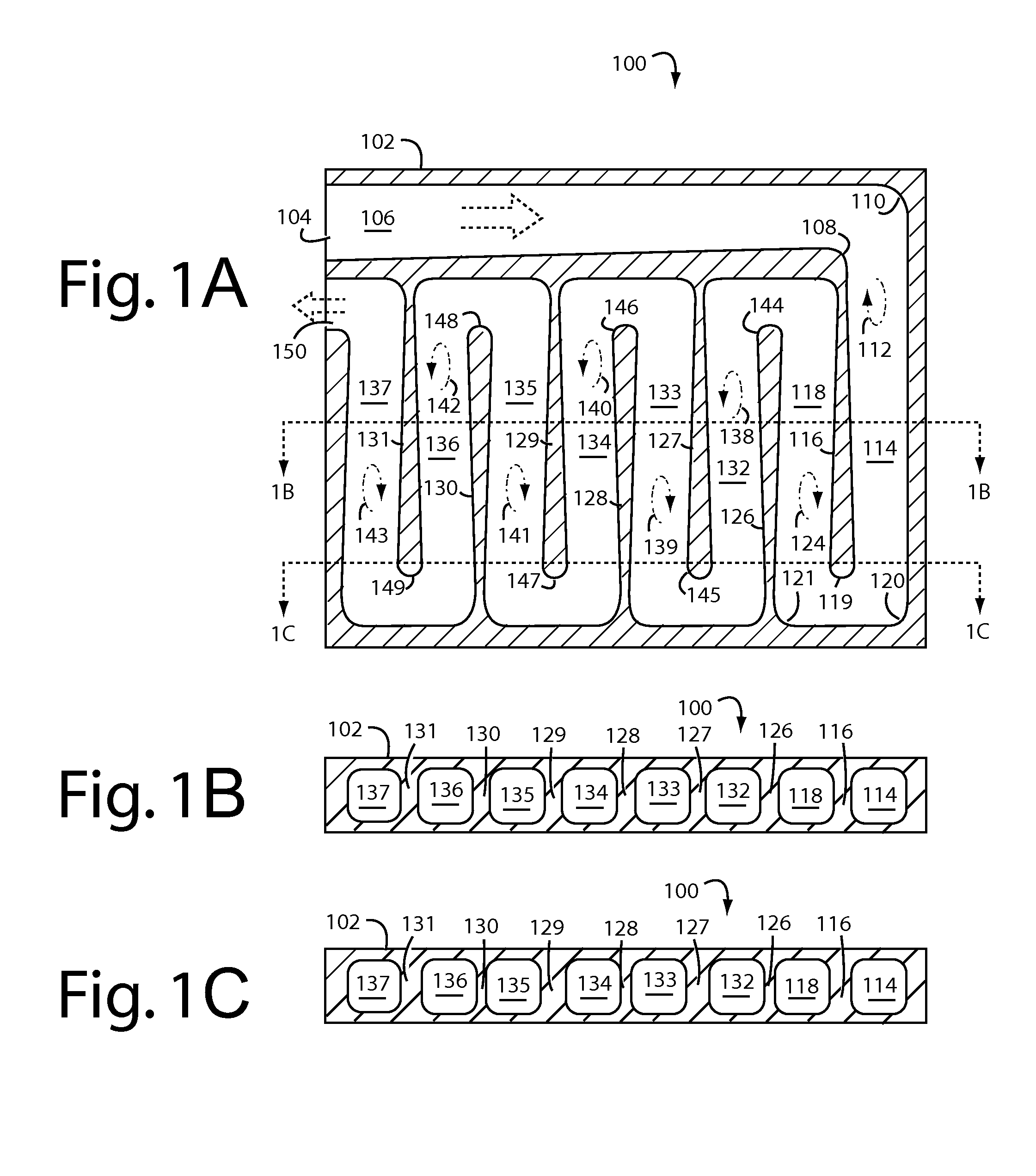

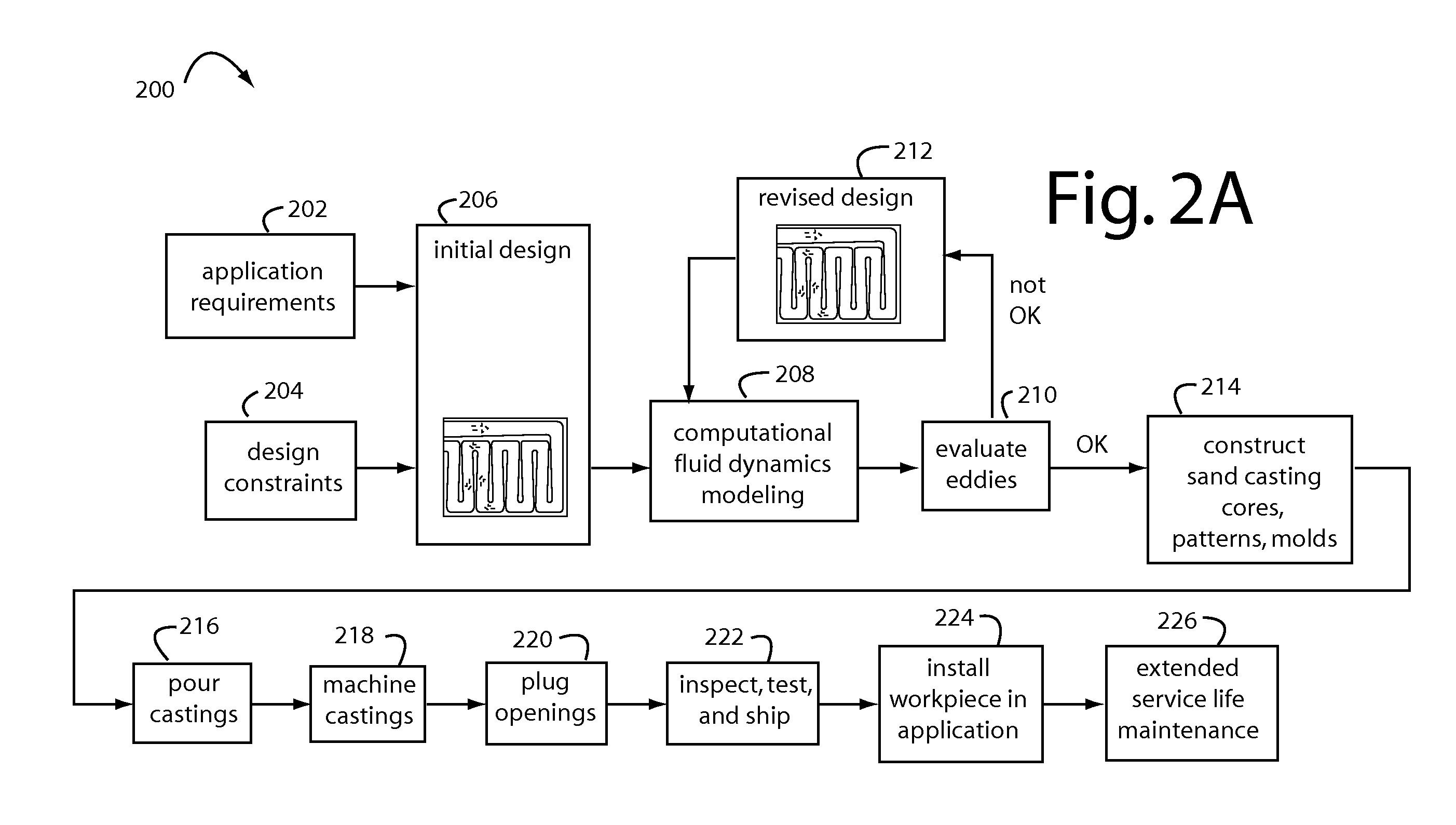

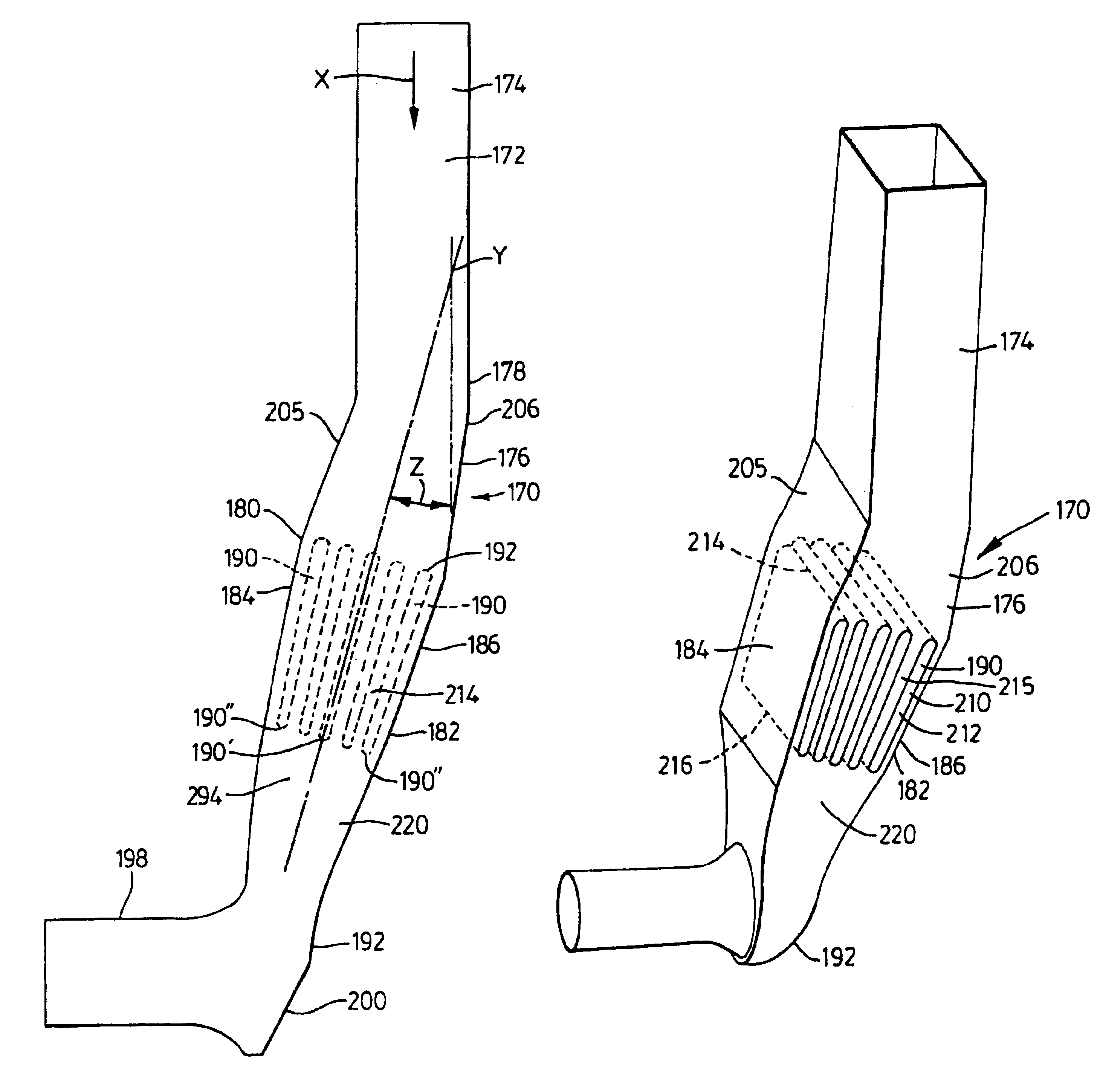

Eddy-free high velocity cooler

A cooling system comprises serpentine cooling fluid passages cast into a work piece with carefully controlled turning radii and profiles. Individual interdigitated baffles are contoured in the plane of coolant flow to have walls that thicken and then round off at their distal ends. The outside radii at these turns is similarly rounded and controlled such that the coolant flow will not be swirled into eddies.

Owner:MACRAE ALLAN J

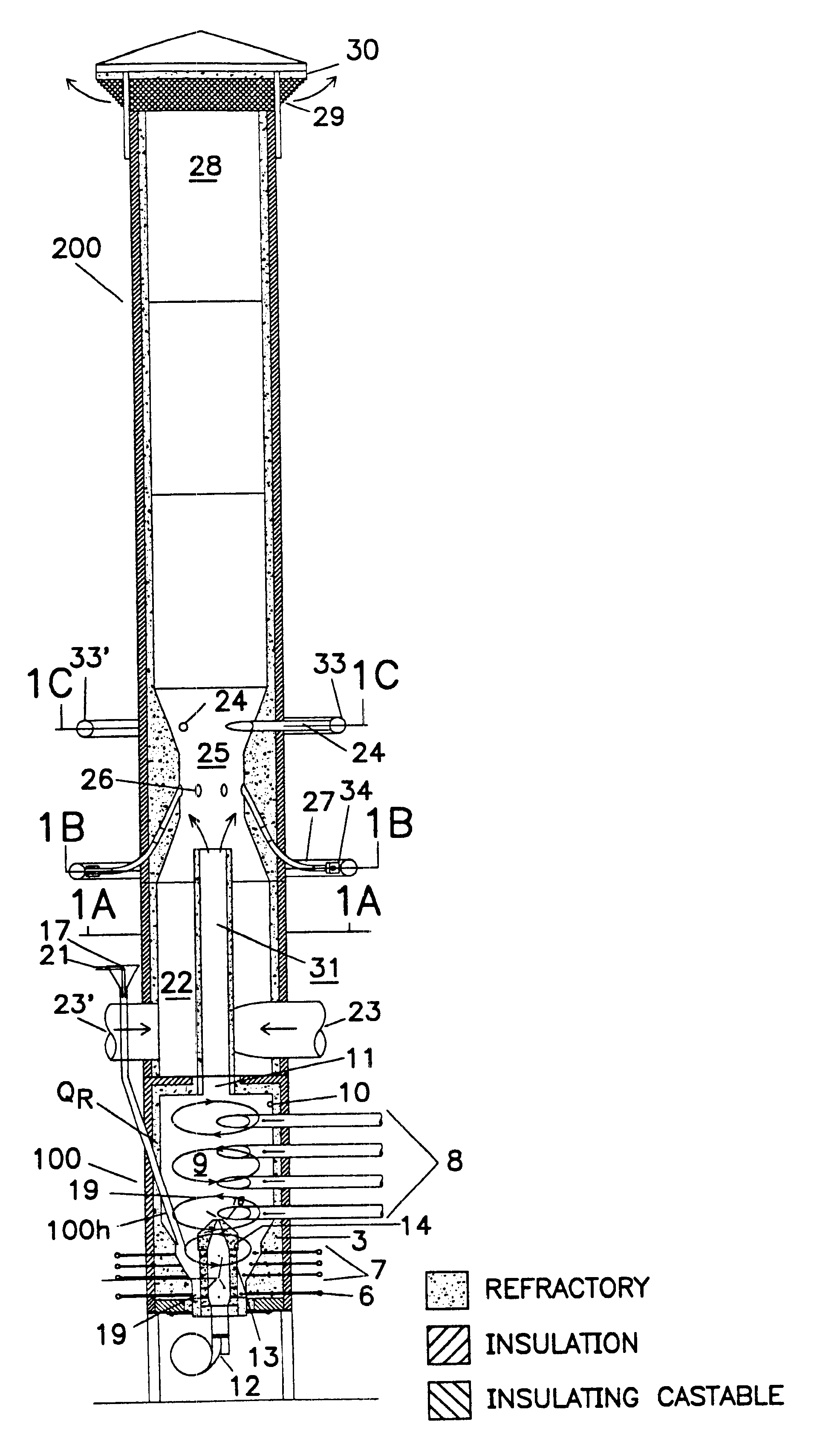

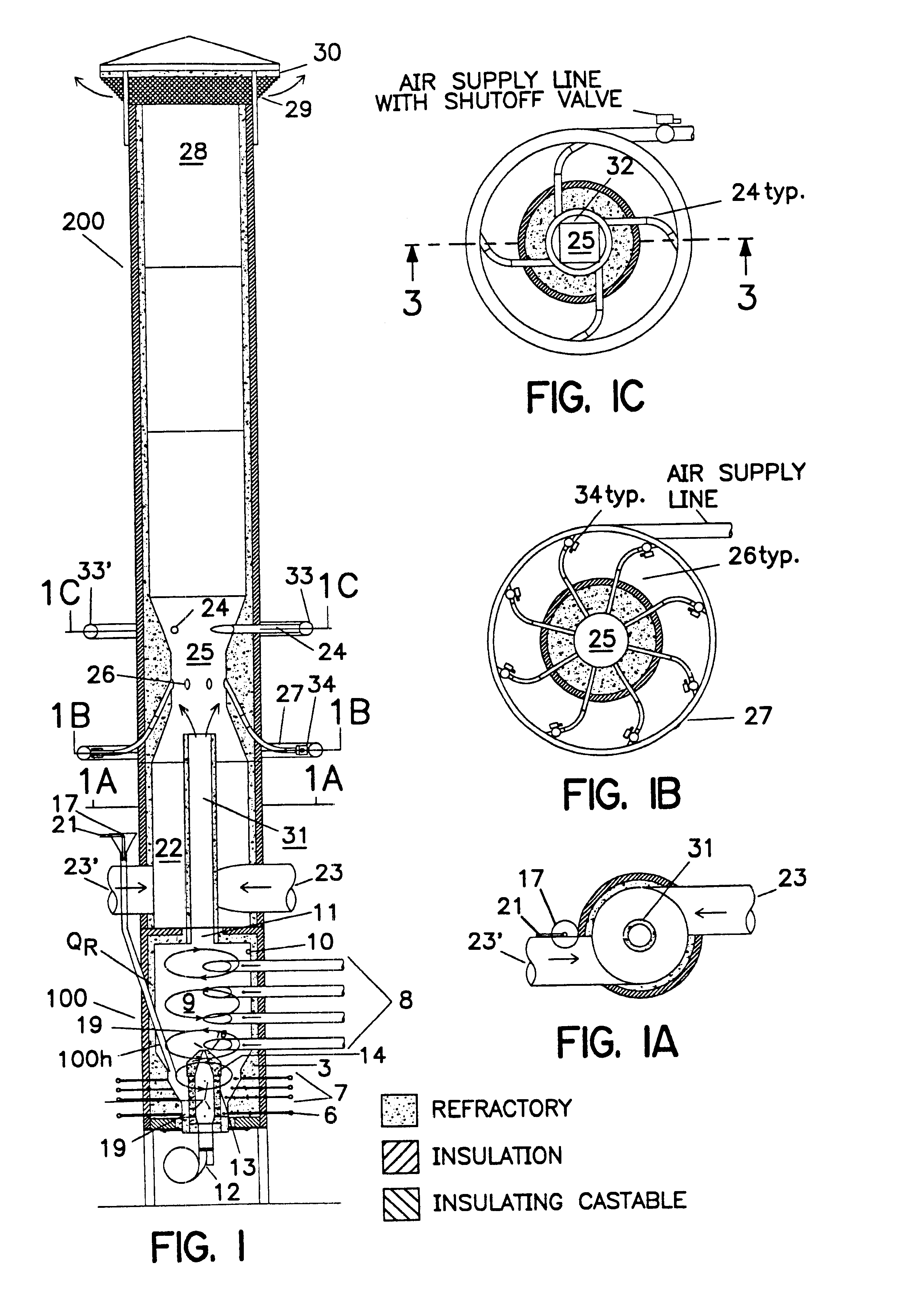

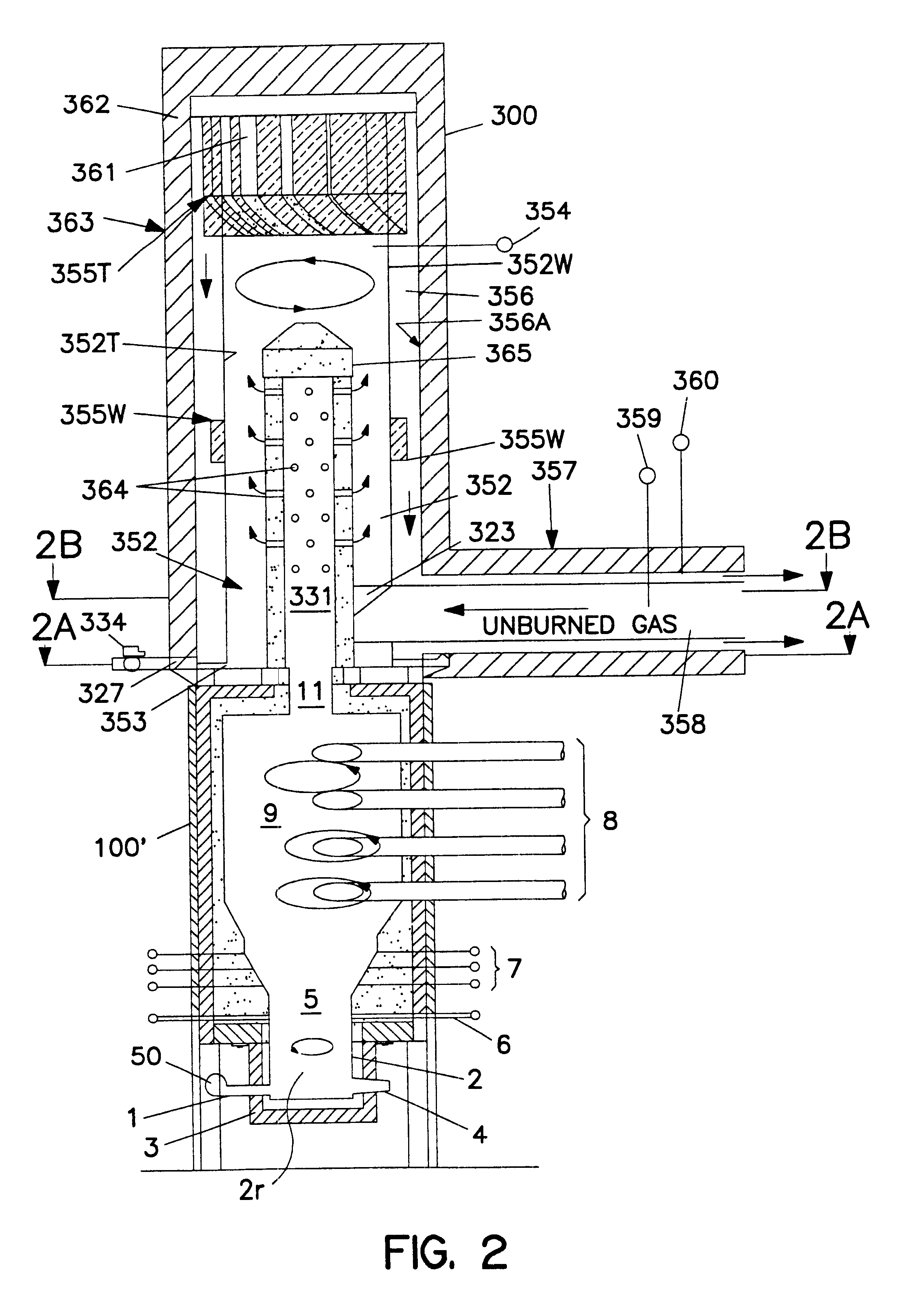

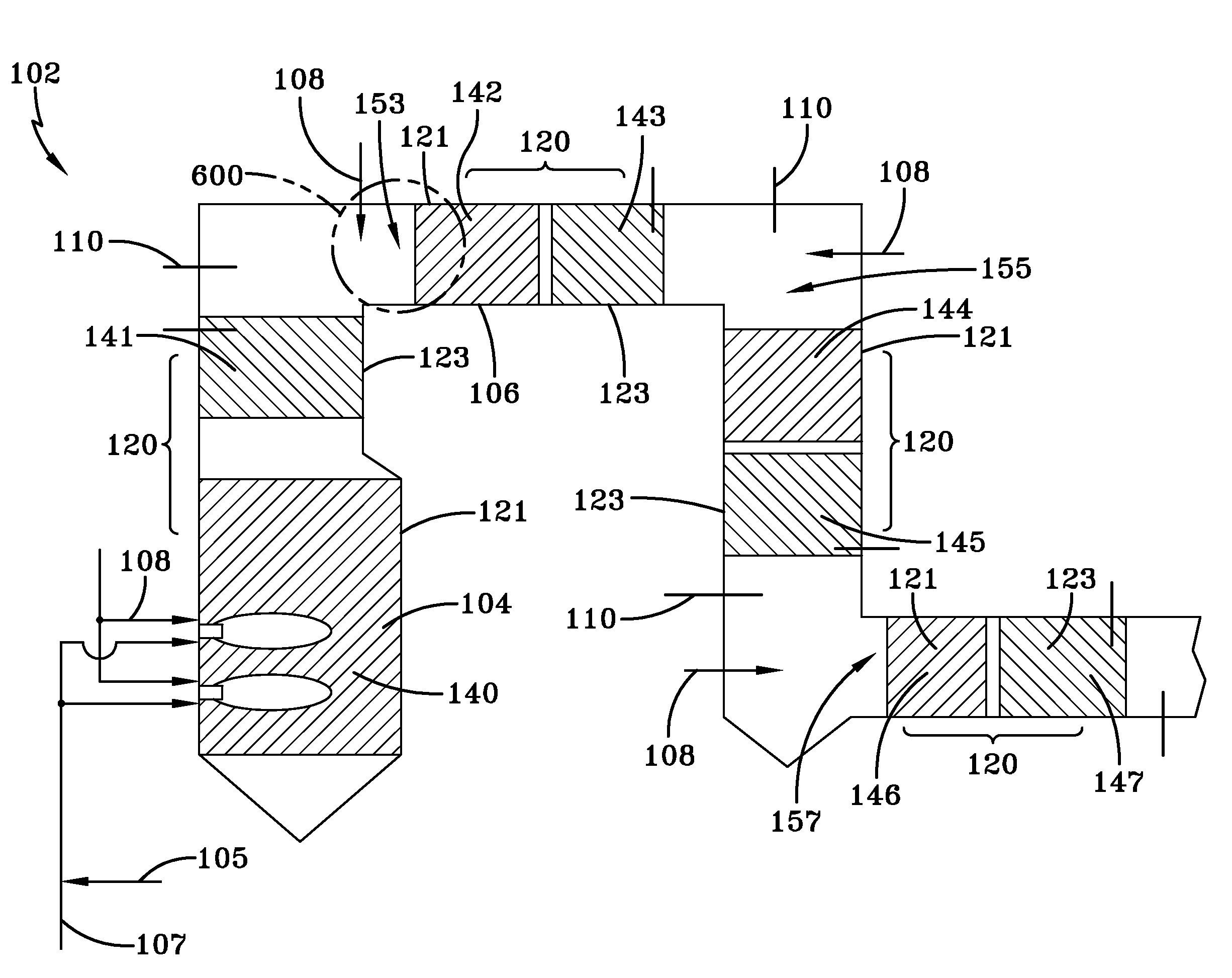

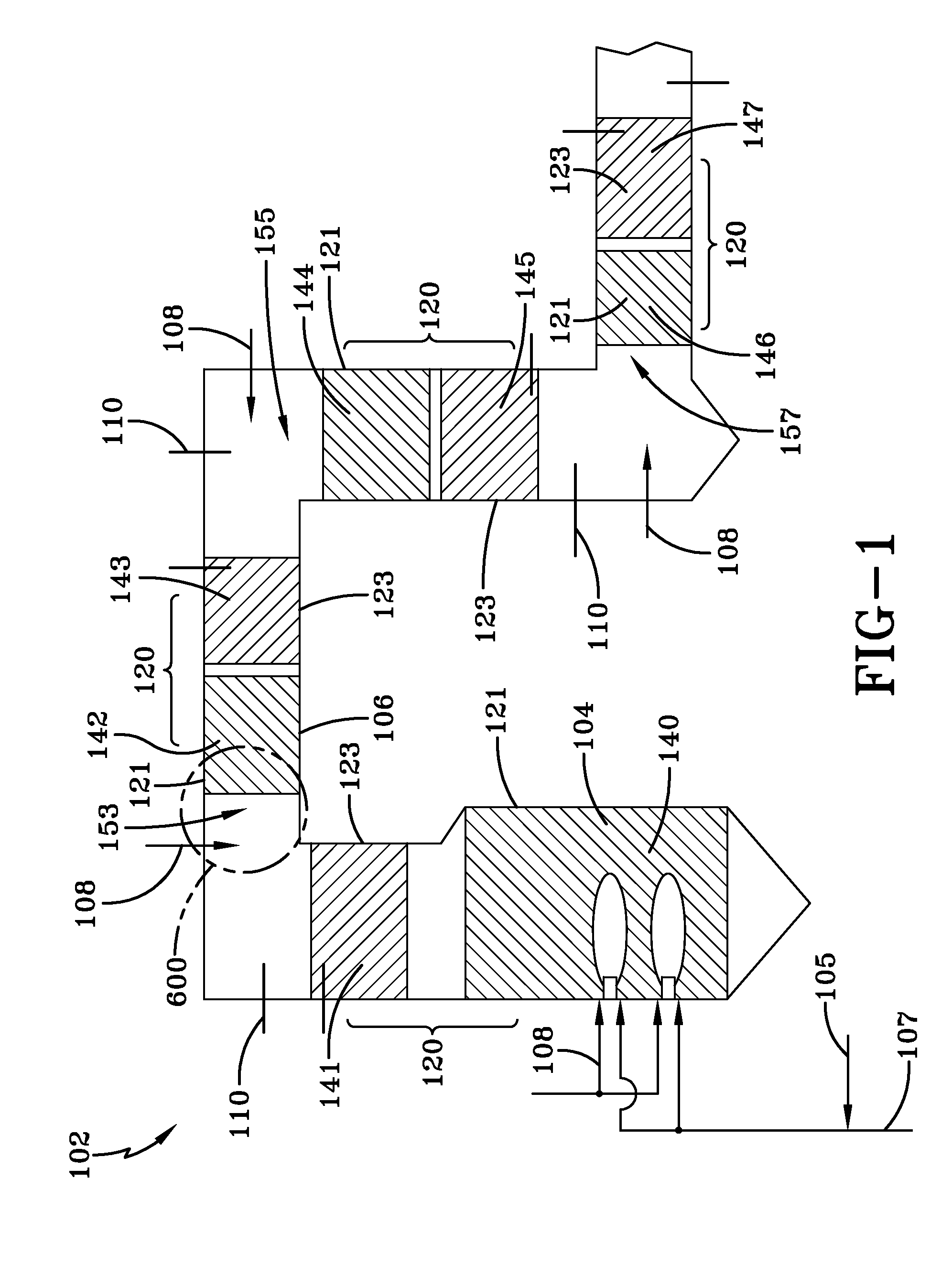

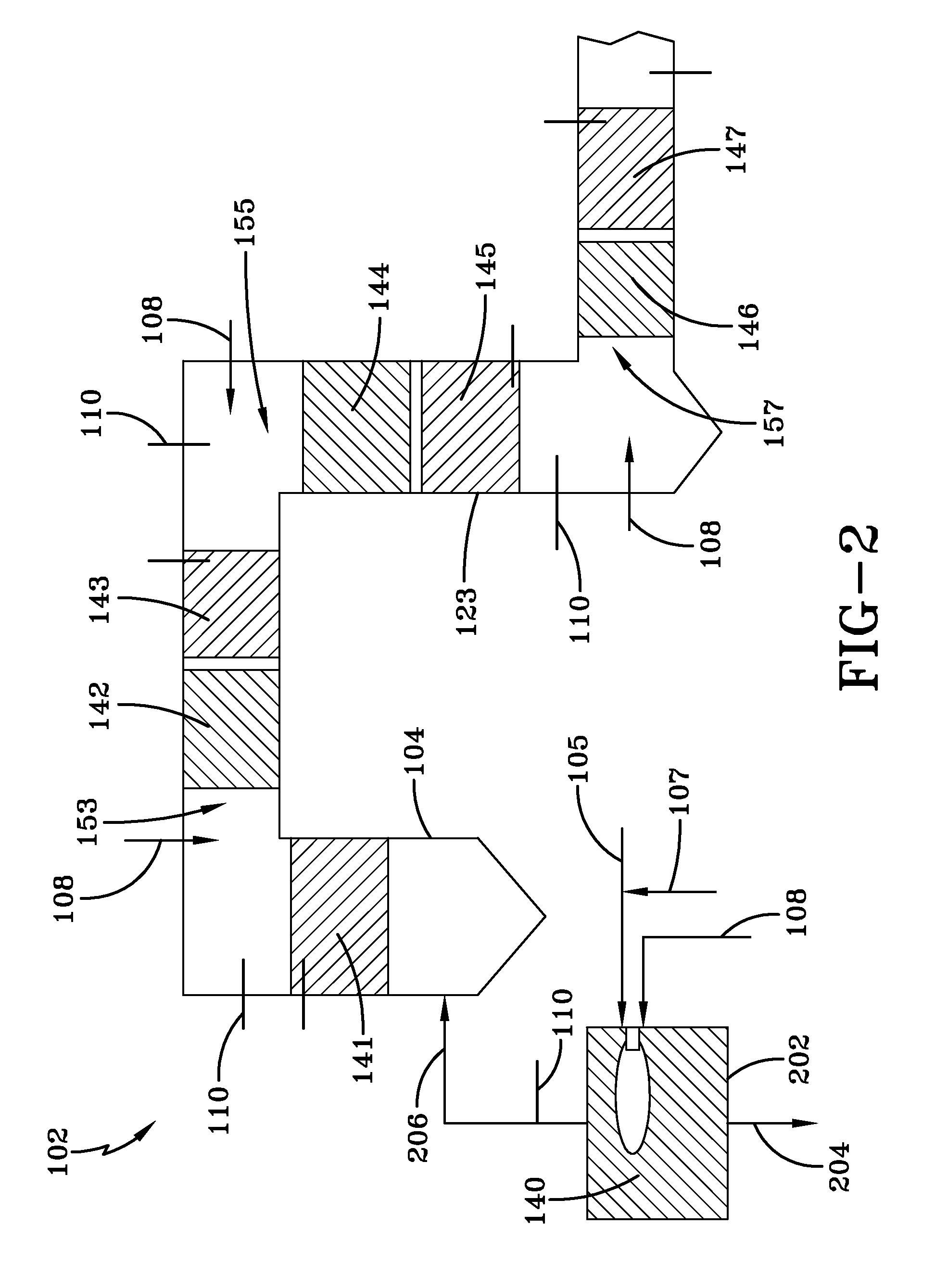

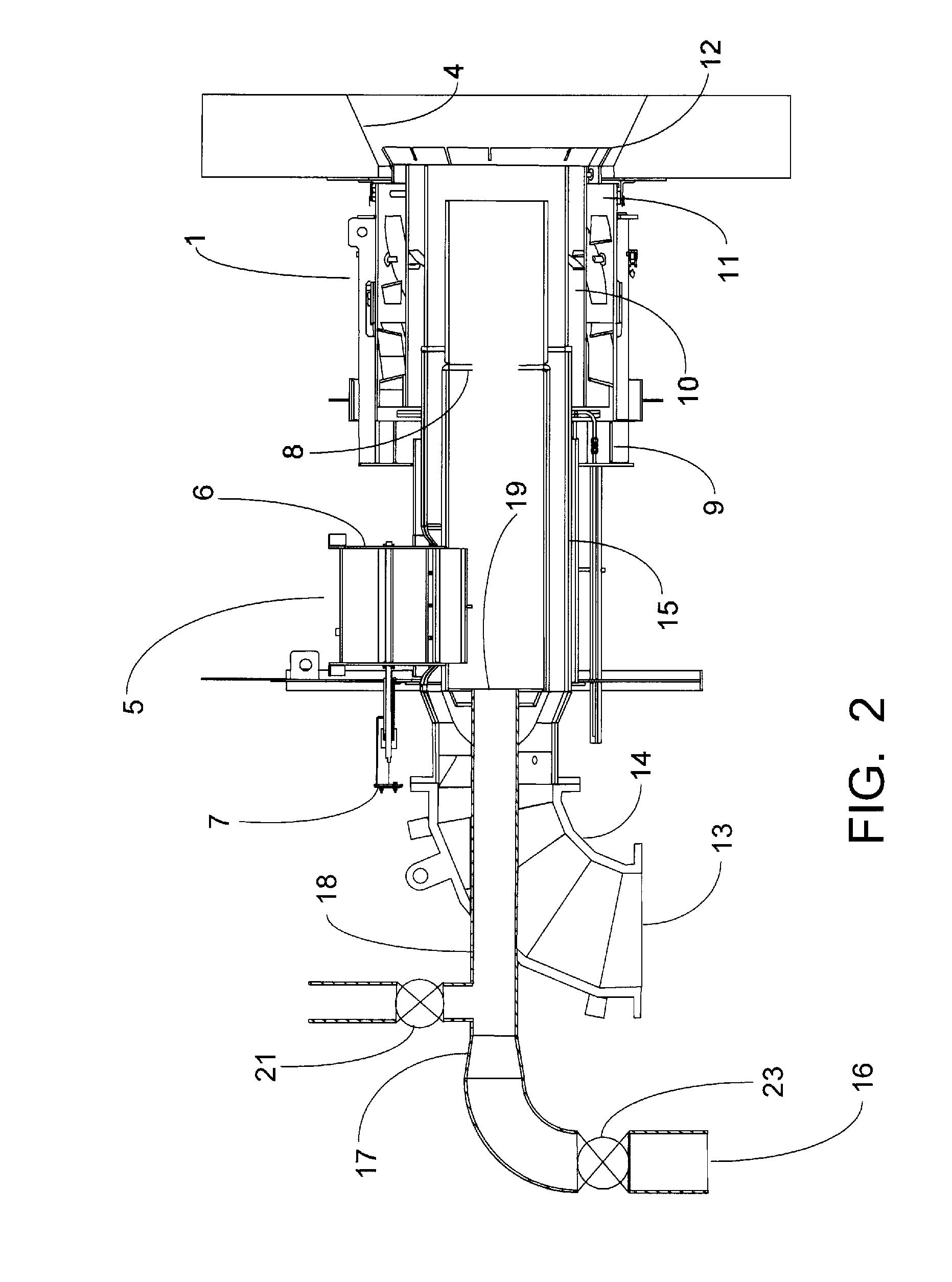

Combustors and burners with high turndown ratio

InactiveUS6363868B1Improve efficiencyIncrease flexibilityFuel supply regulationSolid waste disposalParticulatesCombustion chamber

Various smoke and combustible gas combustors (200, 300) are disclosed, and also disclosed are systems (100, 200) combining gas combustor with inventive burner. Such a burner (100 or 100') provides combustion of a particulate fuel such as sawdust, and many types of varying moisture content biomass fuels such as poultry litter. The combustors and burners exhibit a high turndown ratio ["TDR"].The smoke or combustible gas combustors (200, 300) are combined synergistically with such a burner (100, 100'), or combined with another suitable burner, so as to provide high temperature burner output gases to the combustor, which has coaxial inner and outer combustion chambers (352, 356) inlet tuyere(s) connected to the inner combustion chamber for introducing combustible smoke or other gases to be burned into the inner combustion chamber at one end thereof with cyclonic flow, and in which combustion air is mixed with combustible smoke or other gases to form a gas stream moving through the inner combustion chamber with cyclonic movement. A preheat tube (331) within the combustible gas heating chamber receives heated exhaust gases from the burner, and communicates with the inner combustion chamber exit through a plurality of apertures (364) for controlled flow of said heated exhaust gases into the gas stream and so heating same by mixing the exhaust gases with the stream of air and combustible gases.

Owner:INDEPENDENT STAVE

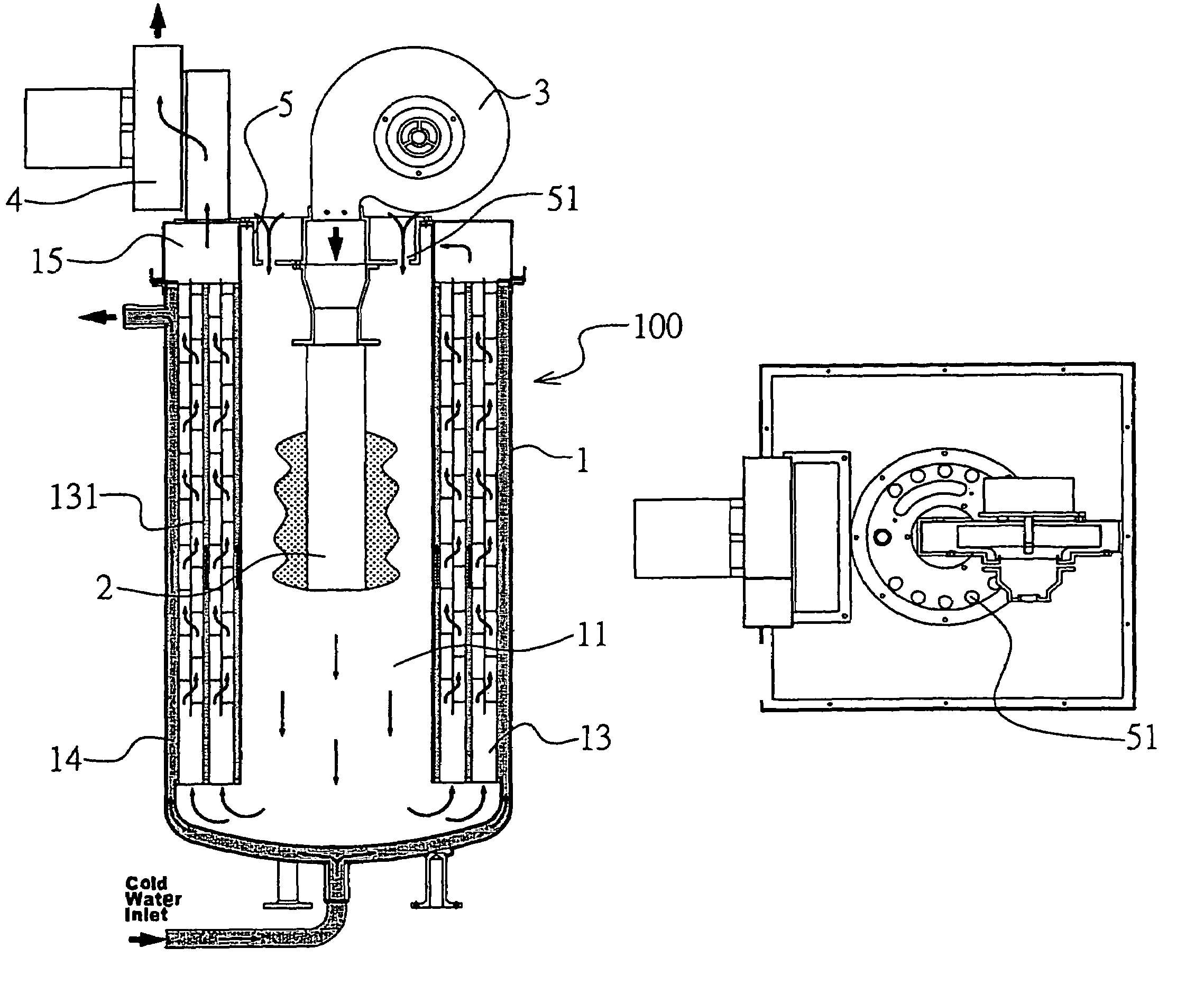

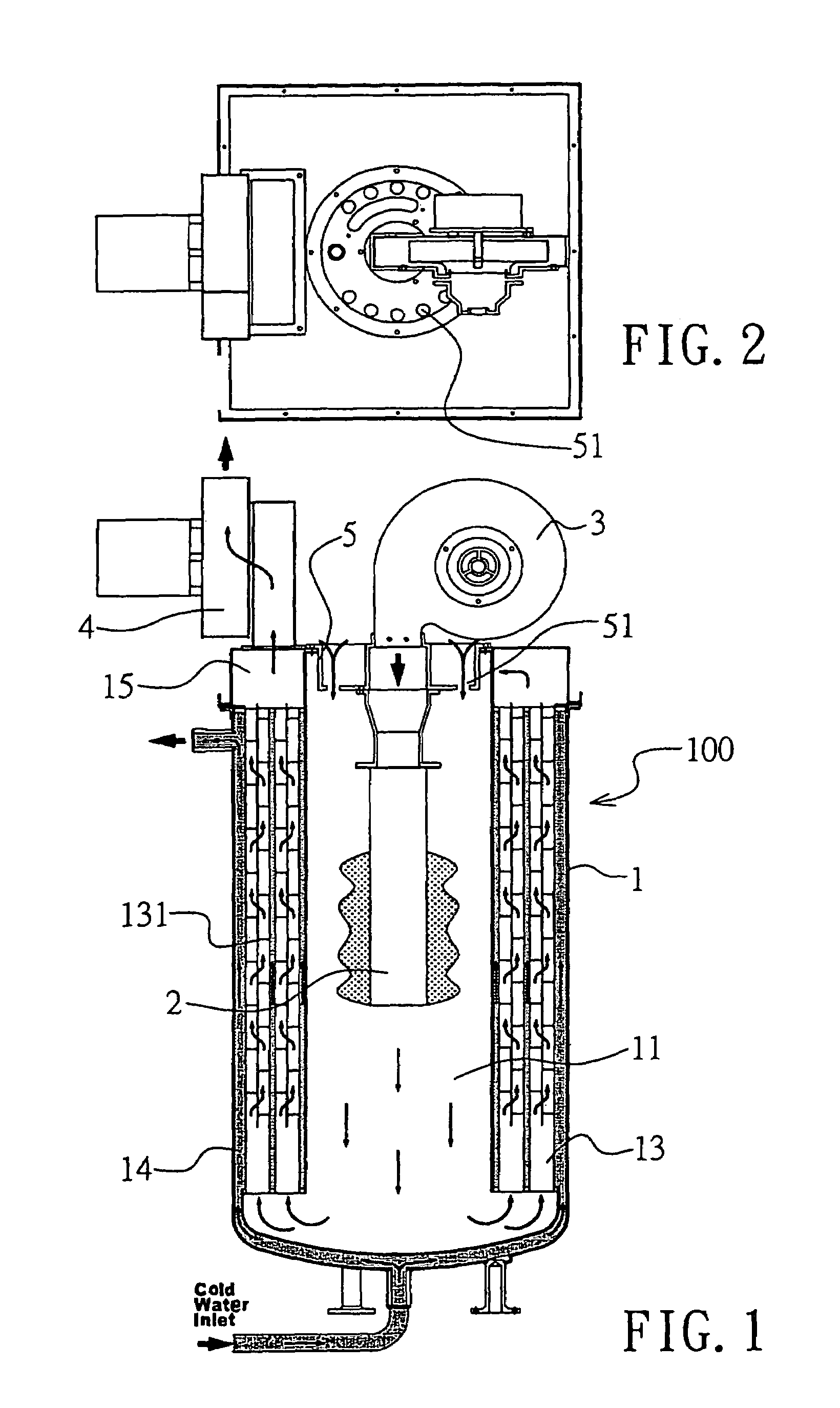

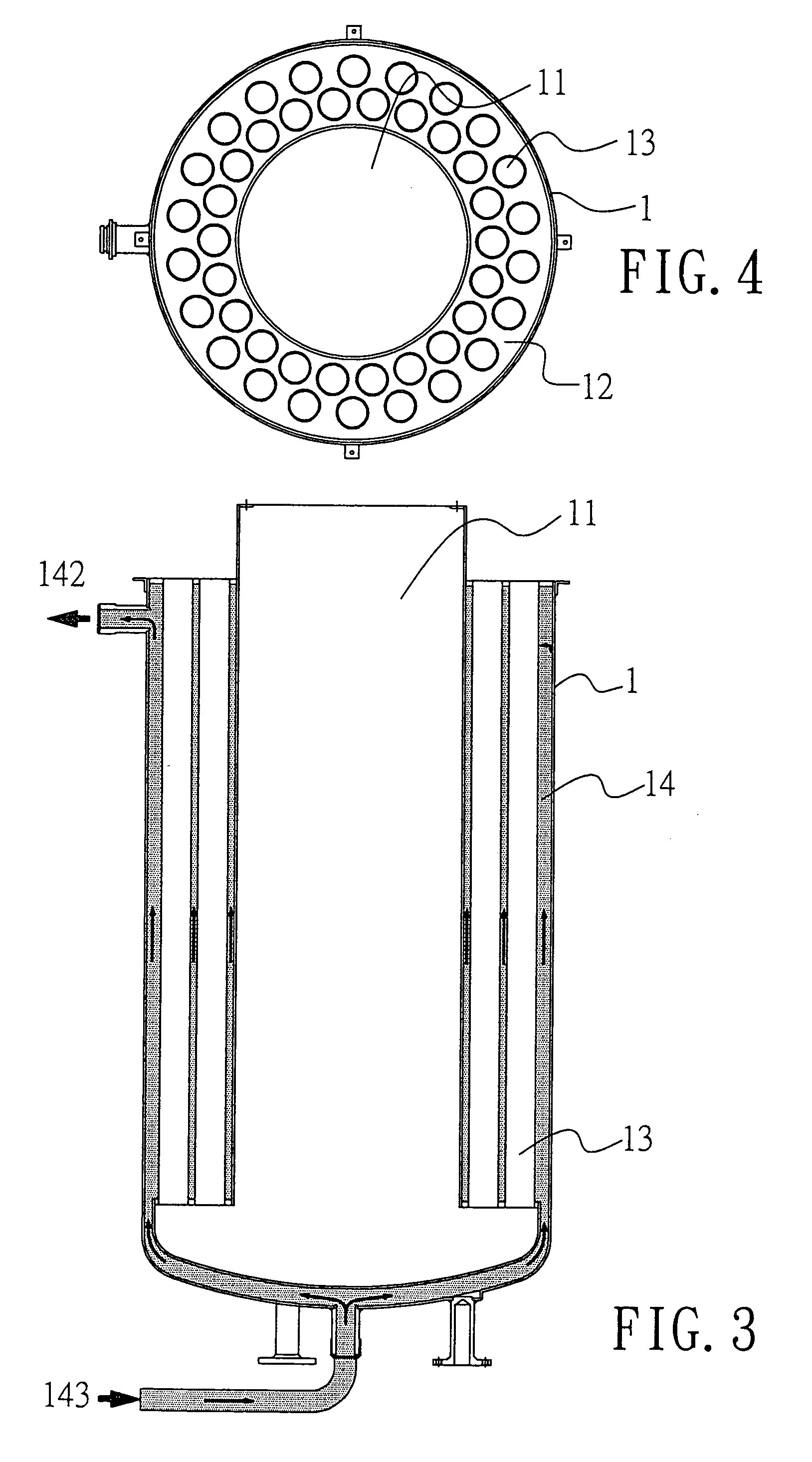

Water heater

InactiveUS6945197B2Improve efficiencyExtended service lifeSpace heating and ventilation detailsBlast-producing apparatusForced-airEngineering

A water heater which includes a heat exchanger having a first passage and a second passage connected with the first passage, a gas burner mounted within the first passage, a push blower having an outlet conmected with the gas burner for forcing air into the gas burner, and a water reservoir mounted surrounding the heat exchanger, whereby when the gas burner is turned on, the push blower will be turned on to force air into the gas burner thereby forcing combustion air generated from fire of the gas burner to move along the first passage and meanwhile the pull blower will be turned on to extract the hot air out of the second passage.

Owner:GRAND HALL ENTERPRISE COMPANY

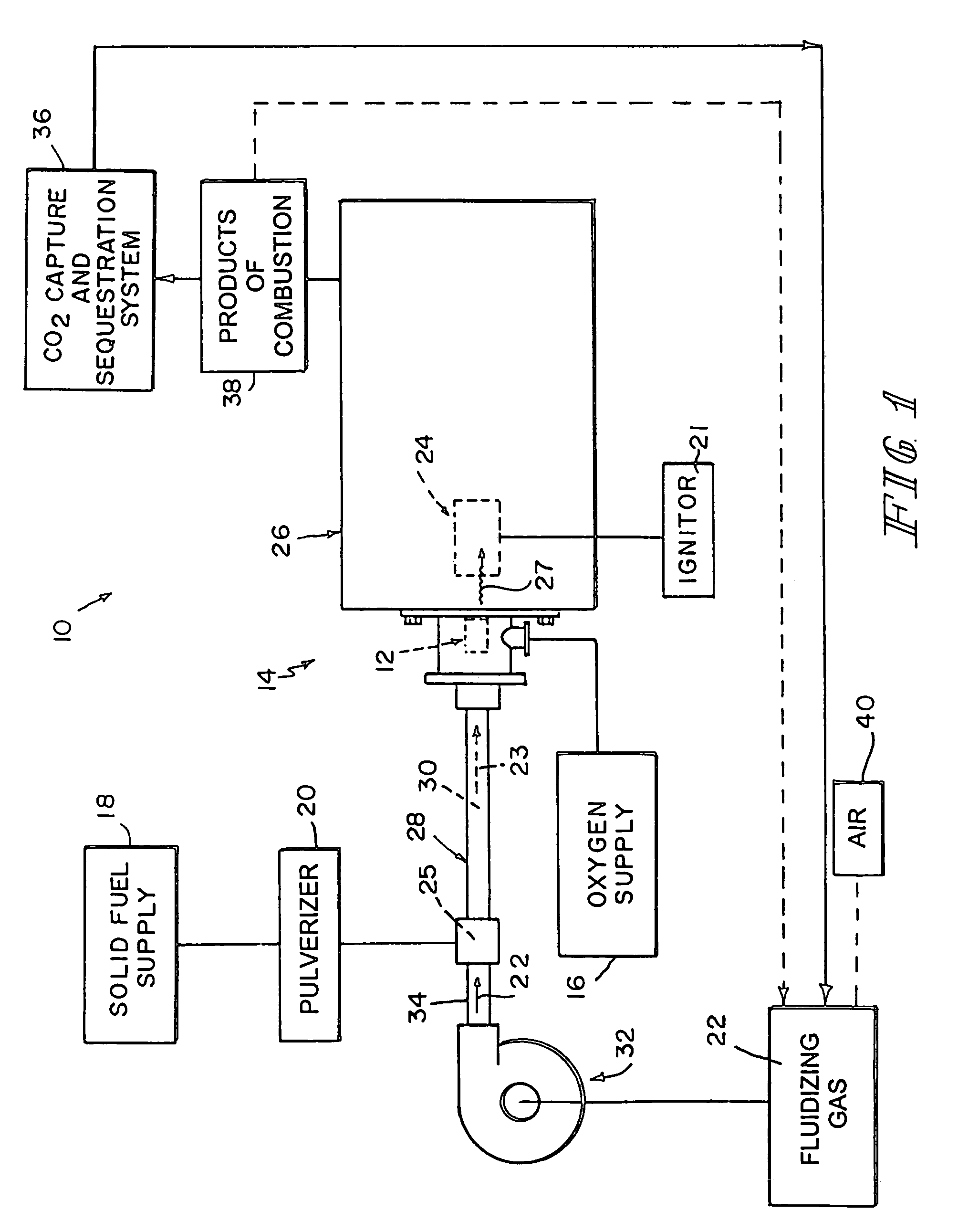

Oxy/fuel combustion system with minimized flue gas recirculation

InactiveUS20100077941A1Small sizeLow costAir supply regulationFluegas recirculationCombustion systemCombustion

This disclosure includes a system and method of controlling fuel combustion including providing a system, measuring a property, and providing oxygen and fuel in response to the property. The system includes a furnace arranged and disposed to receive fuel and oxygen and combust the fuel and the oxygen to form a combustion fluid, a plurality of heat exchanger sections arranged and disposed to receive heat from the combustion fluid, and a plurality of oxygen injectors arranged and disposed to controllably provide oxygen to the combustion fluid to adjust composition of the combustion fluid and temperature of the combustion fluid. The property measured is selected from the group consisting of temperature of the combustion fluid, composition of the combustion fluid, temperature of the heat exchanger sections, and combinations thereof and is performed in close proximity to the oxygen injectors.

Owner:AIR PROD & CHEM INC

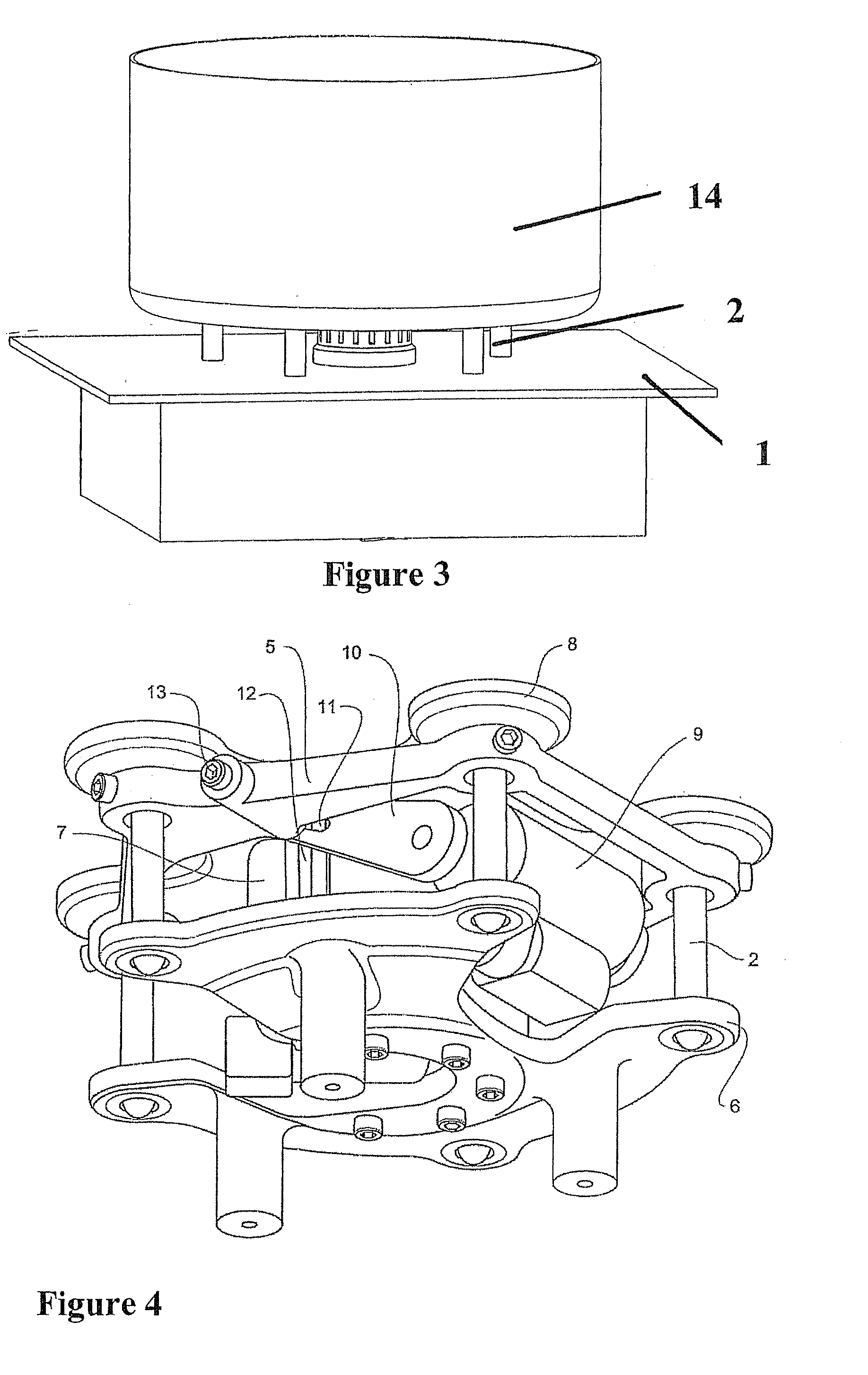

Cooking appliance

InactiveUS20070145032A1Easy to cleanVisually intuitiveDomestic stoves or rangesGearingThermodynamicsMedicine

In one aspect the invention discloses a gas cooktop which is relatively easy to clean and which is not visually complex. The gas cooktop surface is provided with a trivet having two operating conditions. In a first condition the trivet is retracted and is substantially flush with the cooktop surface. In a second condition the trivet is extended Lo support a cooking vessel above a gas burner. In another aspect the invention discloses an improved gas burner with a high turn-down ratio. The improved burner includes first and second gas flow passages, a flame front locator, in one of the passages and a burner head. Fuel gas is injected into an end of one of said passages and is ignited to establish a flame at the flame front locator. Secondary combustion air is provided through the other of the passages which on a high setting enables secondary combustion and on a low setting may mix with the hot gases and cool them resulting in a lower temperature at the cooking vessel.

Owner:FISHER & PAYKEL APPLIANCES LTD

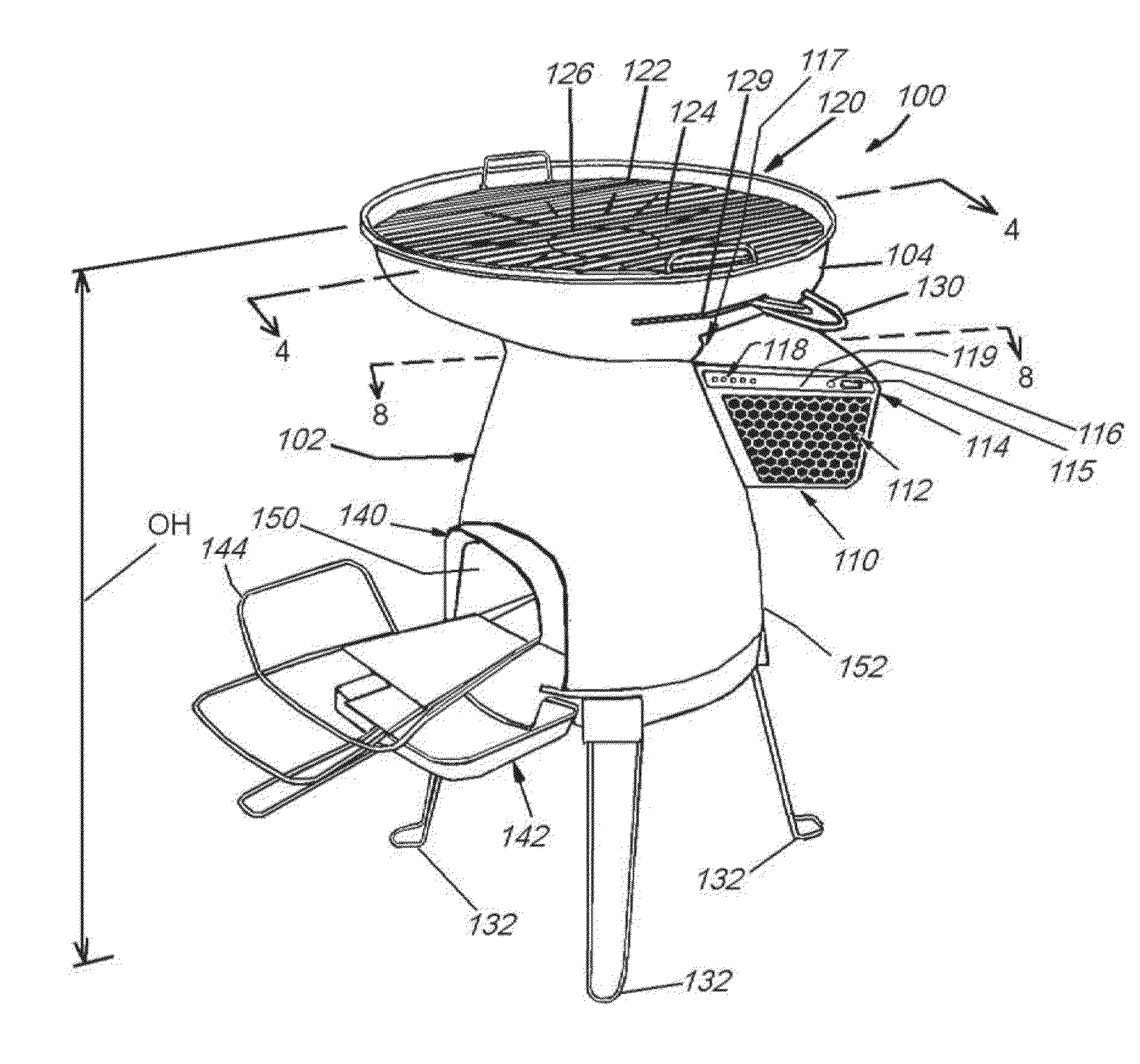

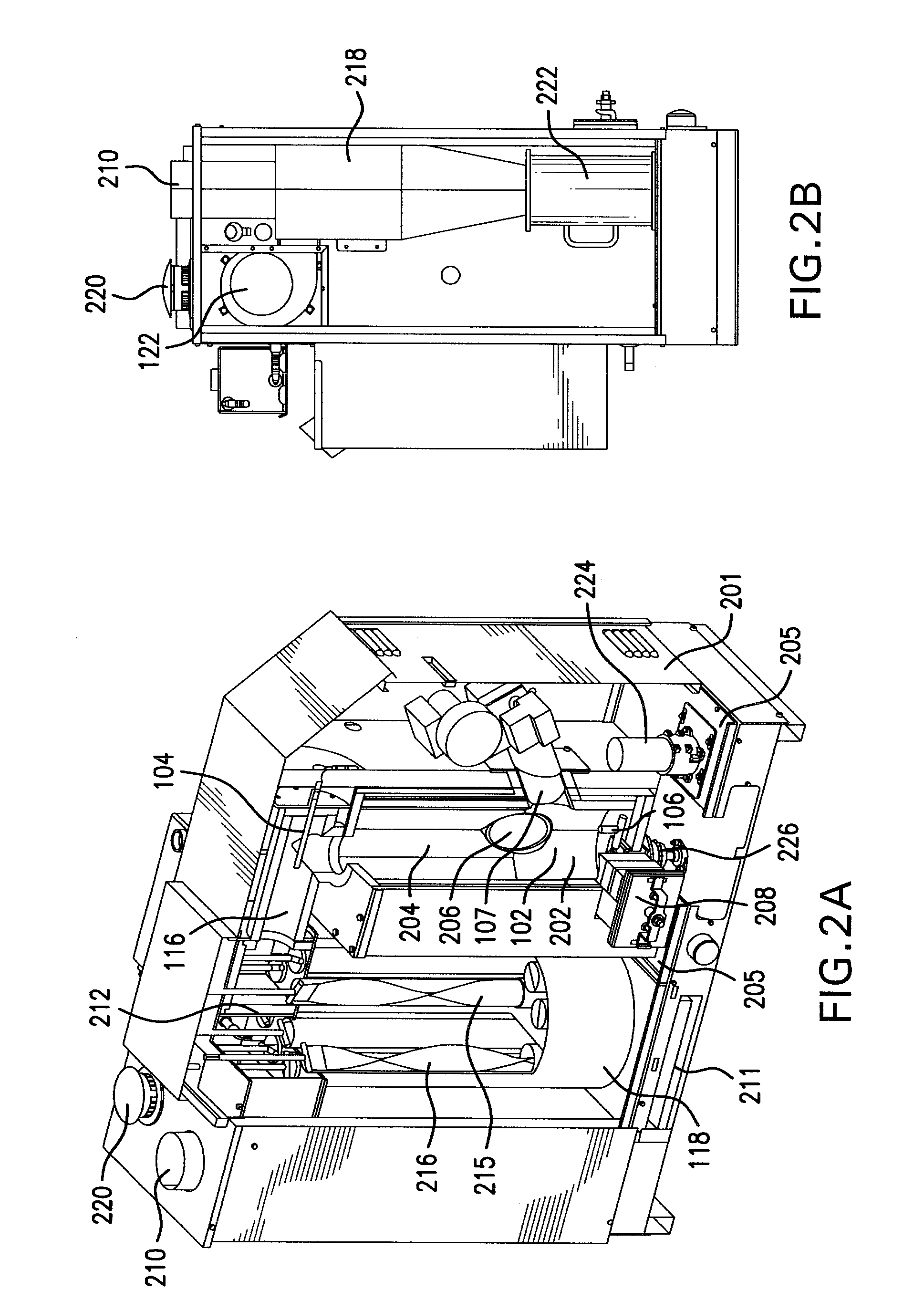

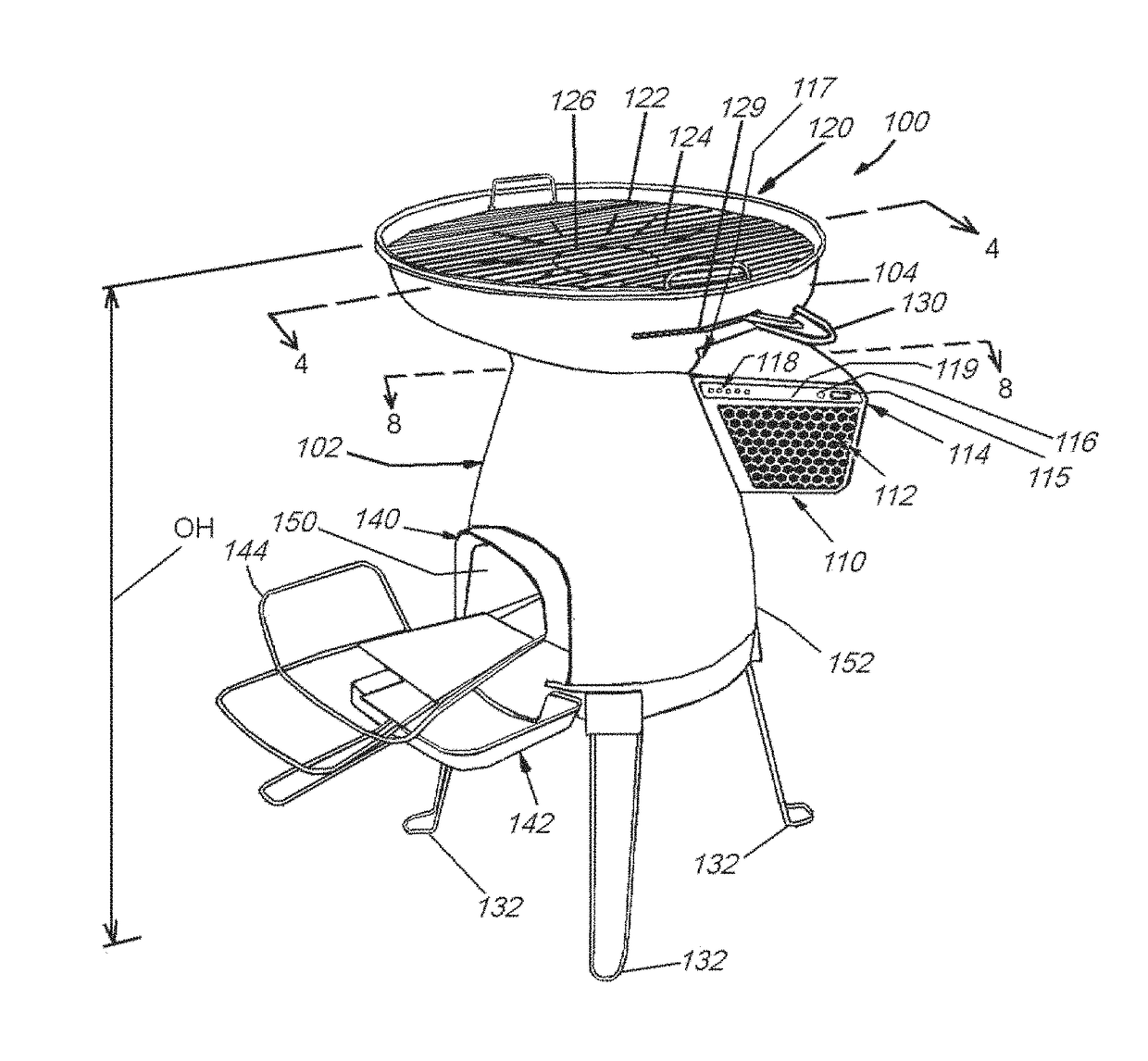

Portable combustion device utilizing thermoelectrical generation

ActiveUS20150201805A1Efficient combustionClean burningDomestic stoves or rangesBaking ovenCombustion chamberHeat conducting

This invention provides a portable combustion device that provides a cleaner combustion, provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids and provides a cooking surface that is a grill top. The combustion device has a combustion chamber into which the fuel source is placed for combustion. Mounted to the side of the combustion chamber is a housing that encloses the TEG, which generates an electrical output, based on a difference in temperature on opposing sides. Mounted onto the TEG housing and protruding into the combustion chamber through a small passageway is a heat-conducting probe and heat-conducting probe base unit.

Owner:BIOLITE INC

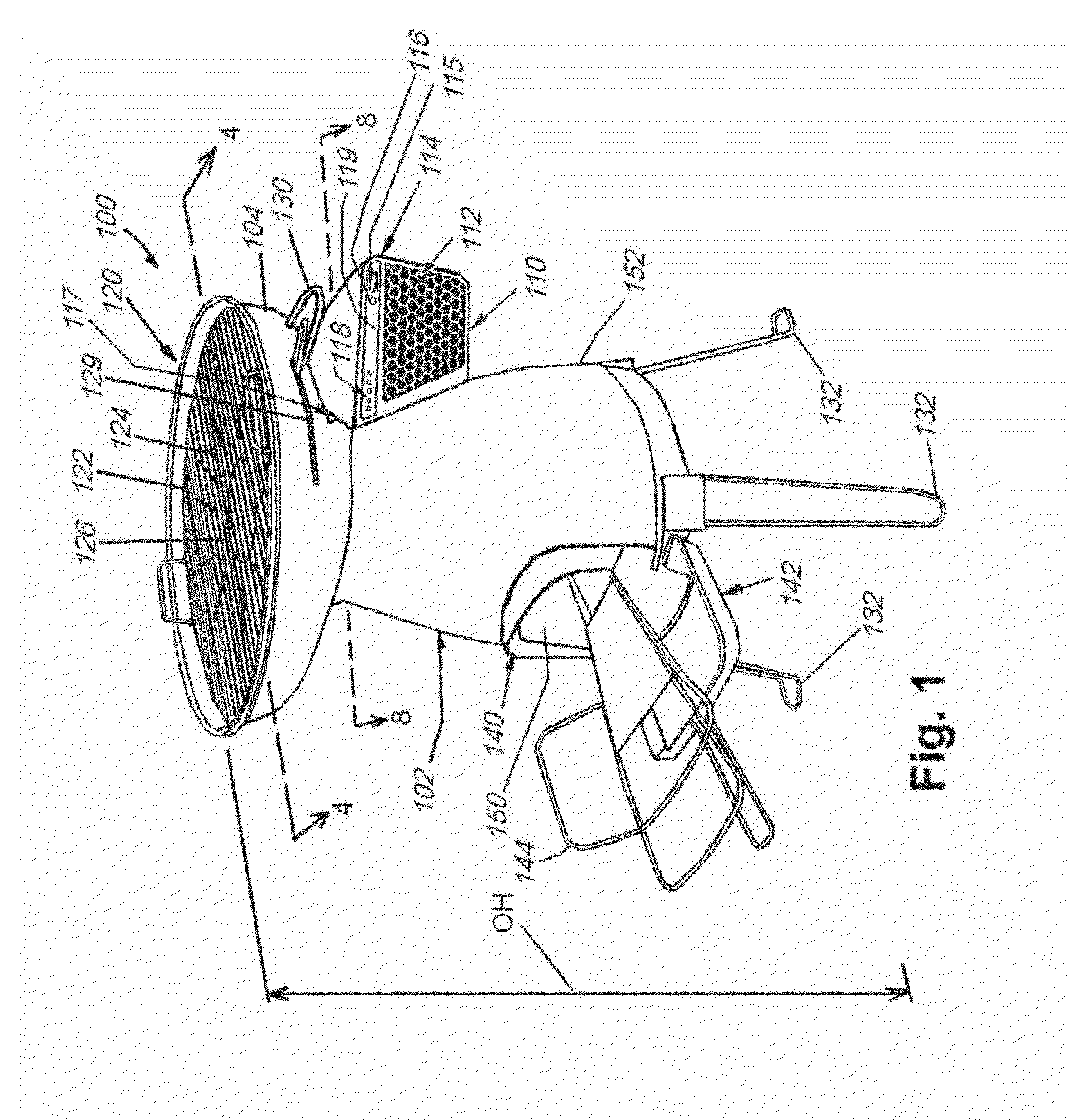

Fan for a gas burner system

A fan for a gas burner system where at the outflow side of the fan a combustion gas is fed in, in order to form a flammable mixture of gas and air, the fan comprising a spiral-shaped fan housing having a rotational axis and an air outlet; the air outlet of the fan housing widening like a snail shell towards the outflow side of the fan; an impeller that is arranged concentric to the rotational axis in the interior of the fan housing; and an electric motor for driving the impeller, which is integrated at the center of the impeller.

Owner:MINEBEAMITSUMI INC

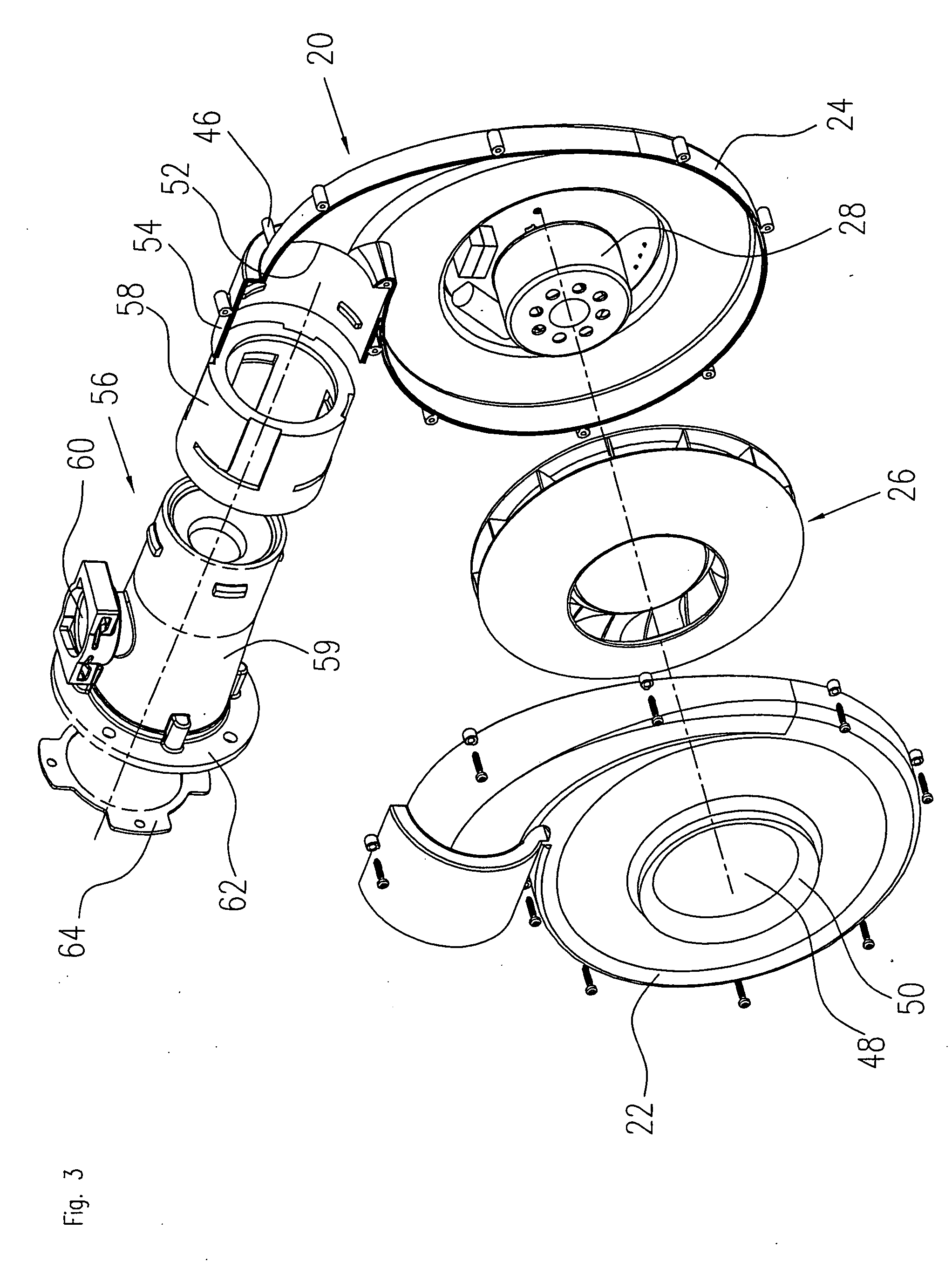

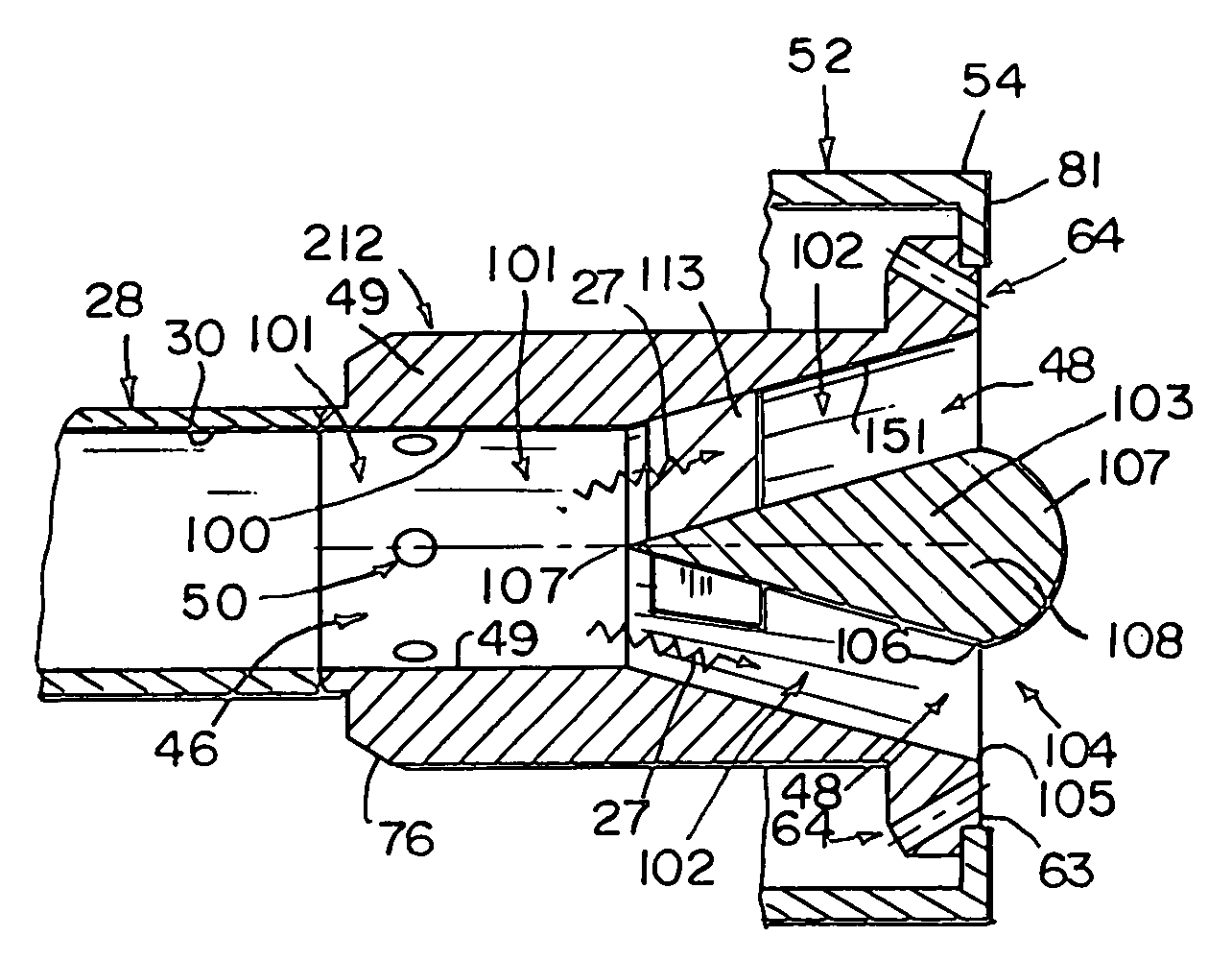

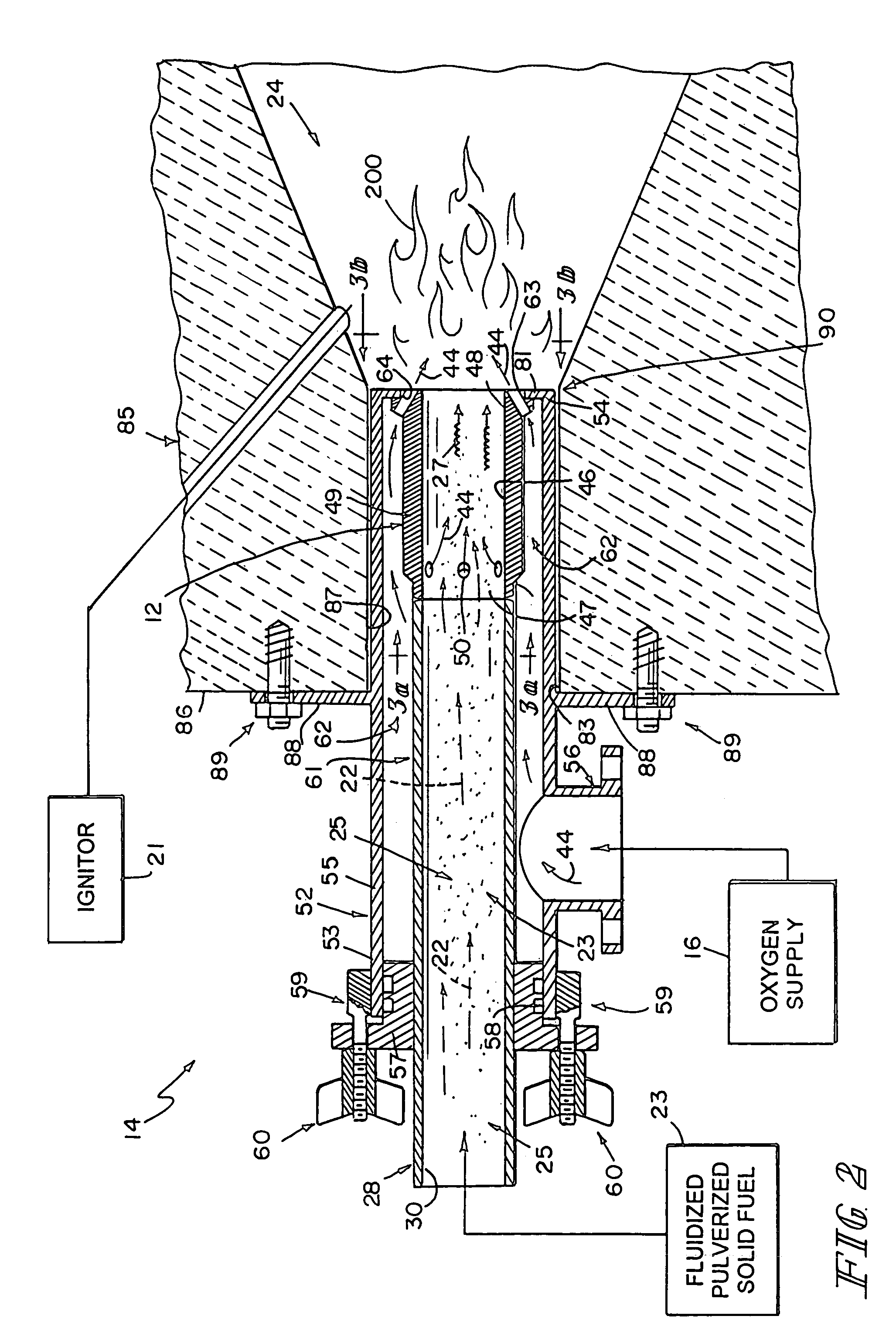

Apparatus for burning pulverized solid fuels with oxygen

InactiveUS7028622B2Reduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelDomestic stoves or rangesCombustorSolid fuel

A burner assembly combines oxygen and fuel to produce a flame. The burner assembly includes an oxygen supply tube adapted to receive a stream of oxygen and a fuel supply tube arranged to extend through the oxygen tube to convey a stream of fluidized, pulverized, solid fuel into a flame chamber. Oxygen flowing through the oxygen supply tube passes through oxygen-injection holes formed in the fuel supply tube and then mixes with fluidized, pulverized, solid fuel passing through the fuel supply tube to create an oxygen-fuel mixture in a downstream portion of the fuel supply tube. This mixture is discharged into the flame chamber and ignited in a flame chamber to produce a flame.

Owner:MAXON

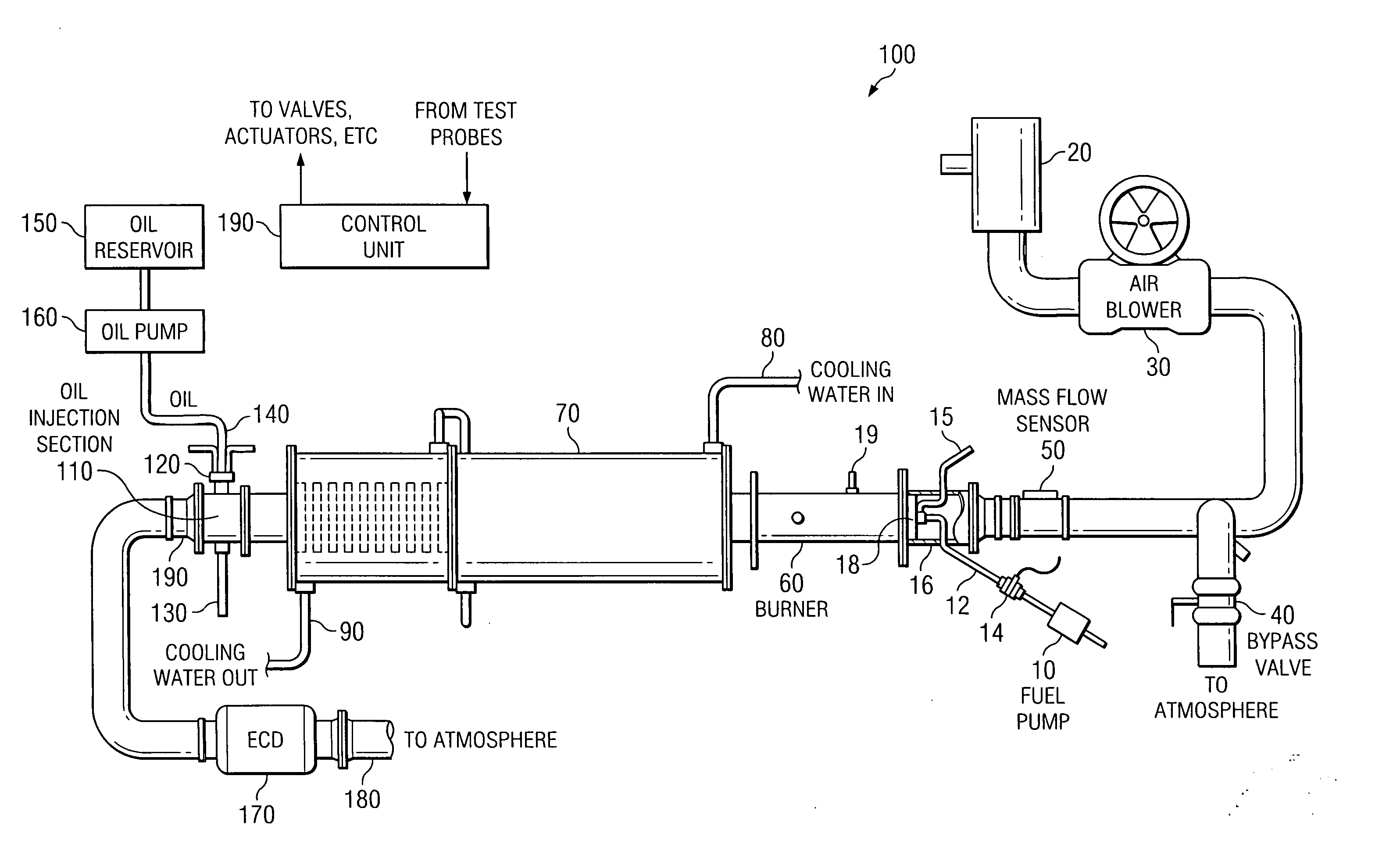

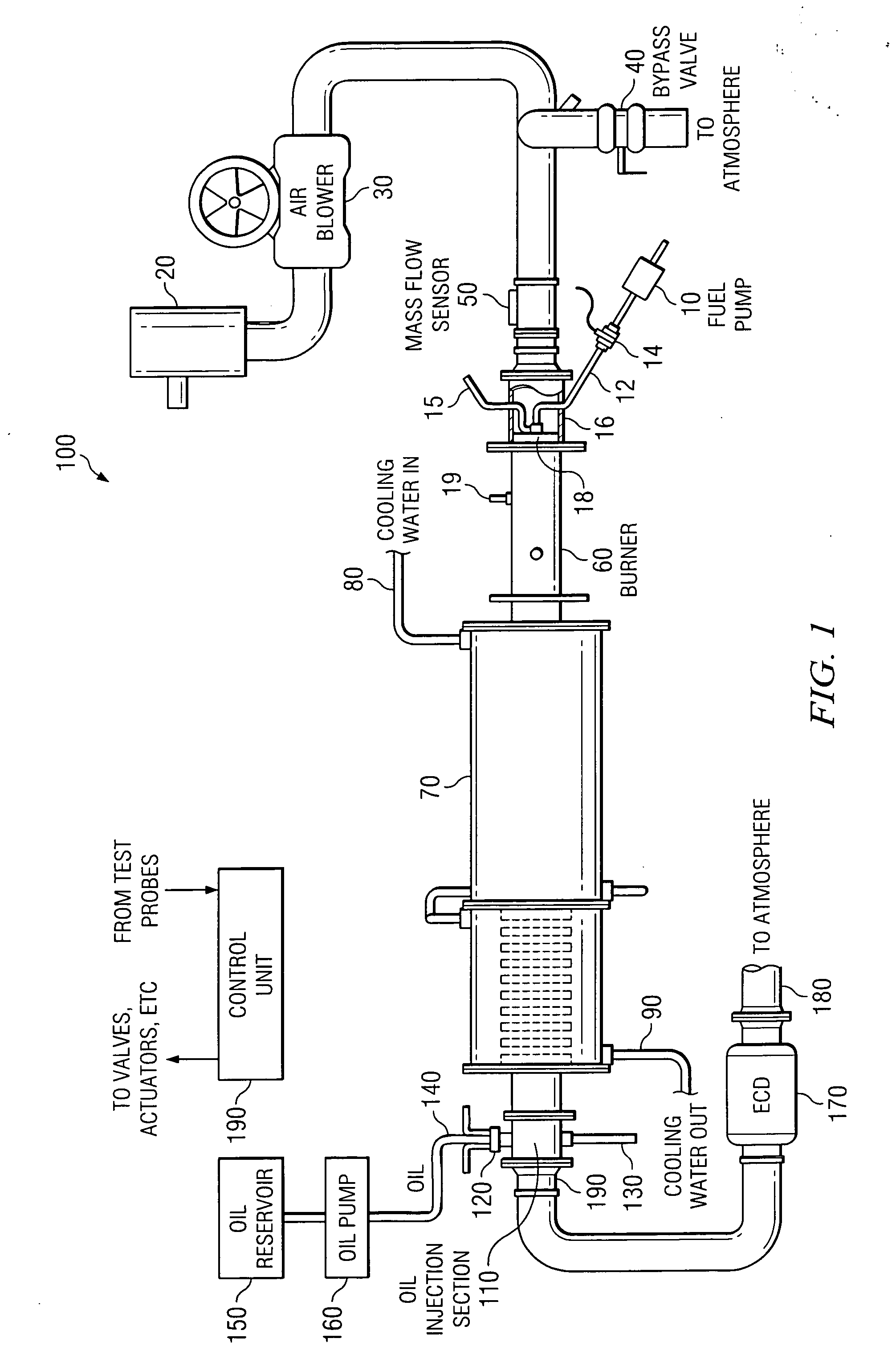

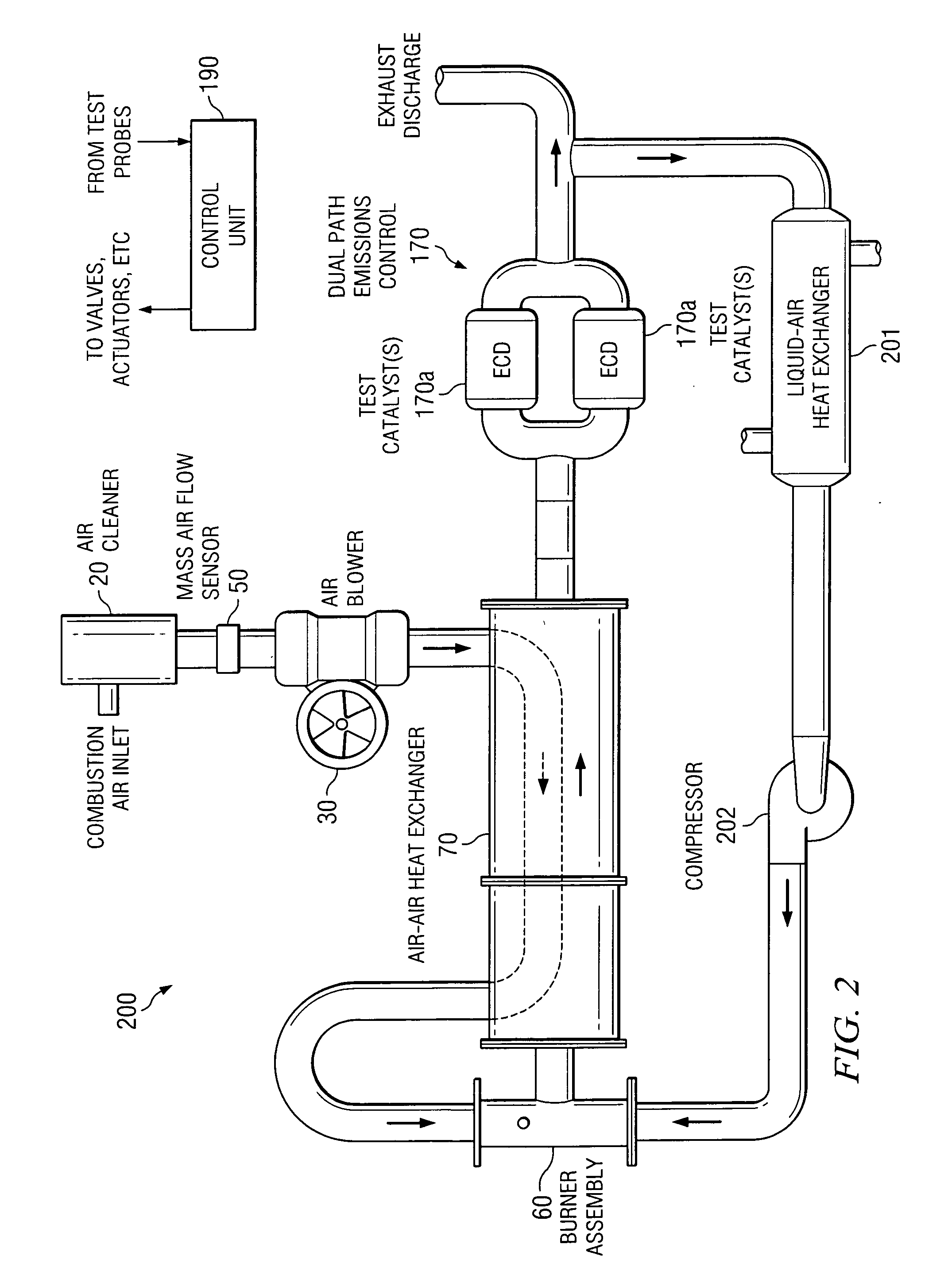

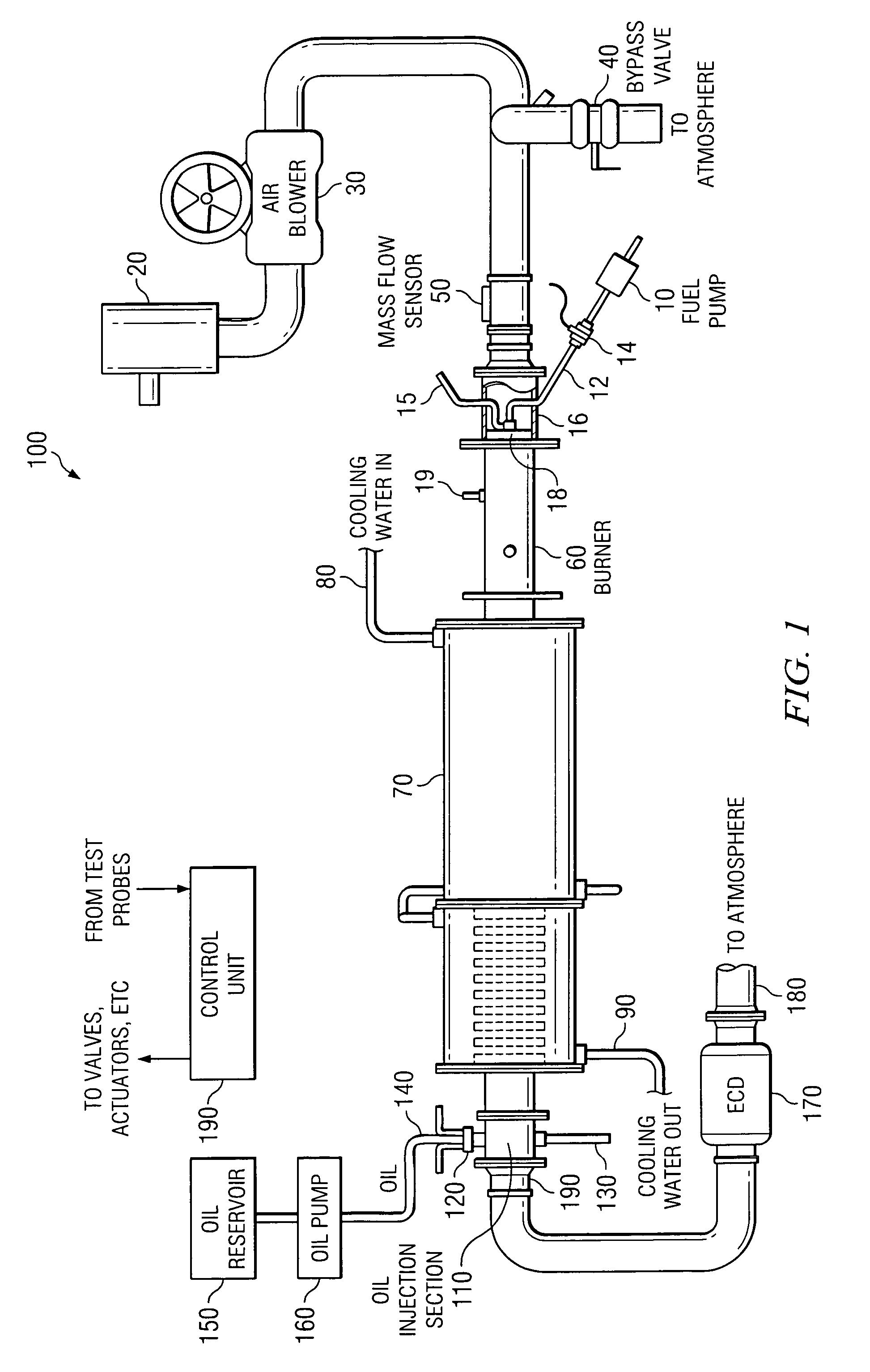

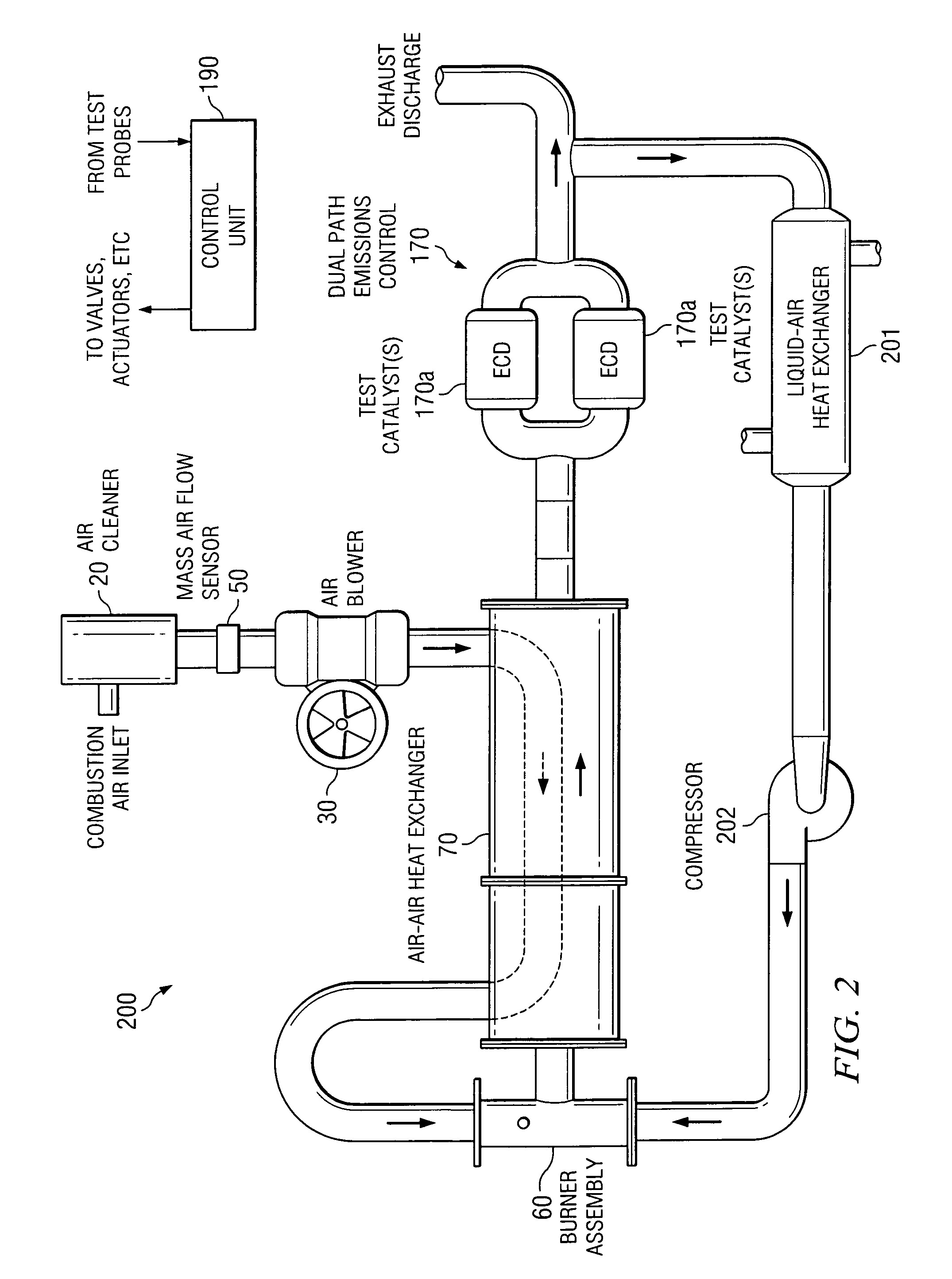

Use of recirculated exhaust gas in a burner-based exhaust generation system for reduced fuel consumption and for cooling

A burner-based exhaust gas generation system, for producing exhaust gas, typically for use in testing exhaust system devices. Post-burner exhaust gas is recirculated back to a main exhaust line, and used for purposes such as cooling or enhancing the burner output.

Owner:SOUTHWEST RES INST

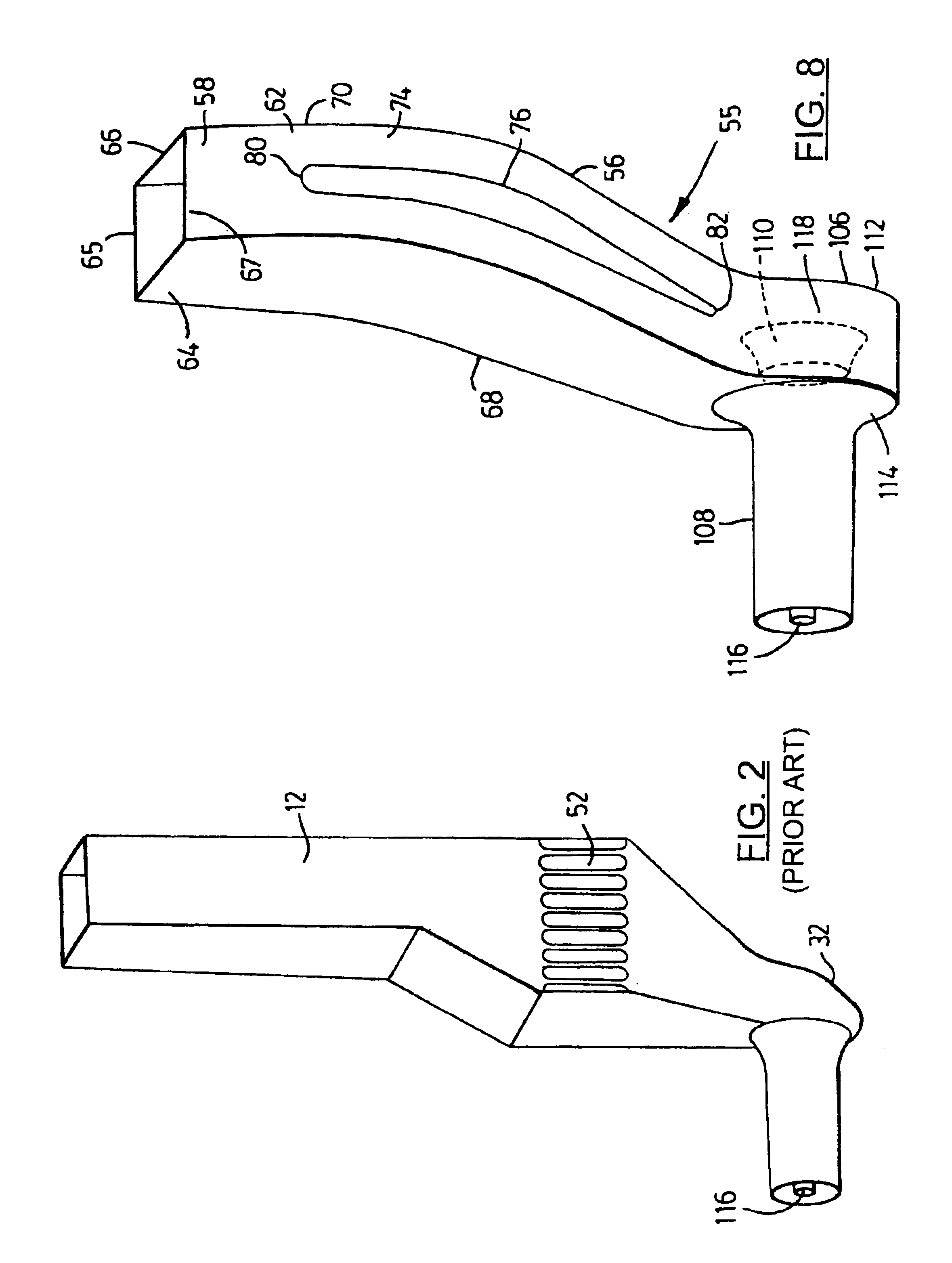

Inlet and outlet duct units for air supply fan

Duct units for delivery of air to an air supply fan and for connecting this fan to an air heater unit are disclosed. The duct unit for delivering air in one version has a narrow first section, a second, transition-type section and a wide sound attenuating, third section with these three sections extending generally vertically. Spaced apart splitters containing sound attenuating material and having side walls of perforated metal are mounted in the third section. The splitters include a central splitter and outer splitters with the latter converging inwardly towards a central axis of the third section. This duct unit also has an elbow-shaped duct section connected to the third section at its upstream end and connectible to the fan at its downstream end. In another version, the duct unit has a single, elongate splitter that extends longitudinally along at least a major portion of a second duct section and that bends through a smooth curve. The outlet duct apparatus has an elbow section of duct that bends through a smooth curve and an elongate second section connected to the elbow section. An elongate turning vane is mounted in the outlet duct and has a substantially curved first vane section and a second vane section that extends substantially upwardly.

Owner:M & I POWER TECH

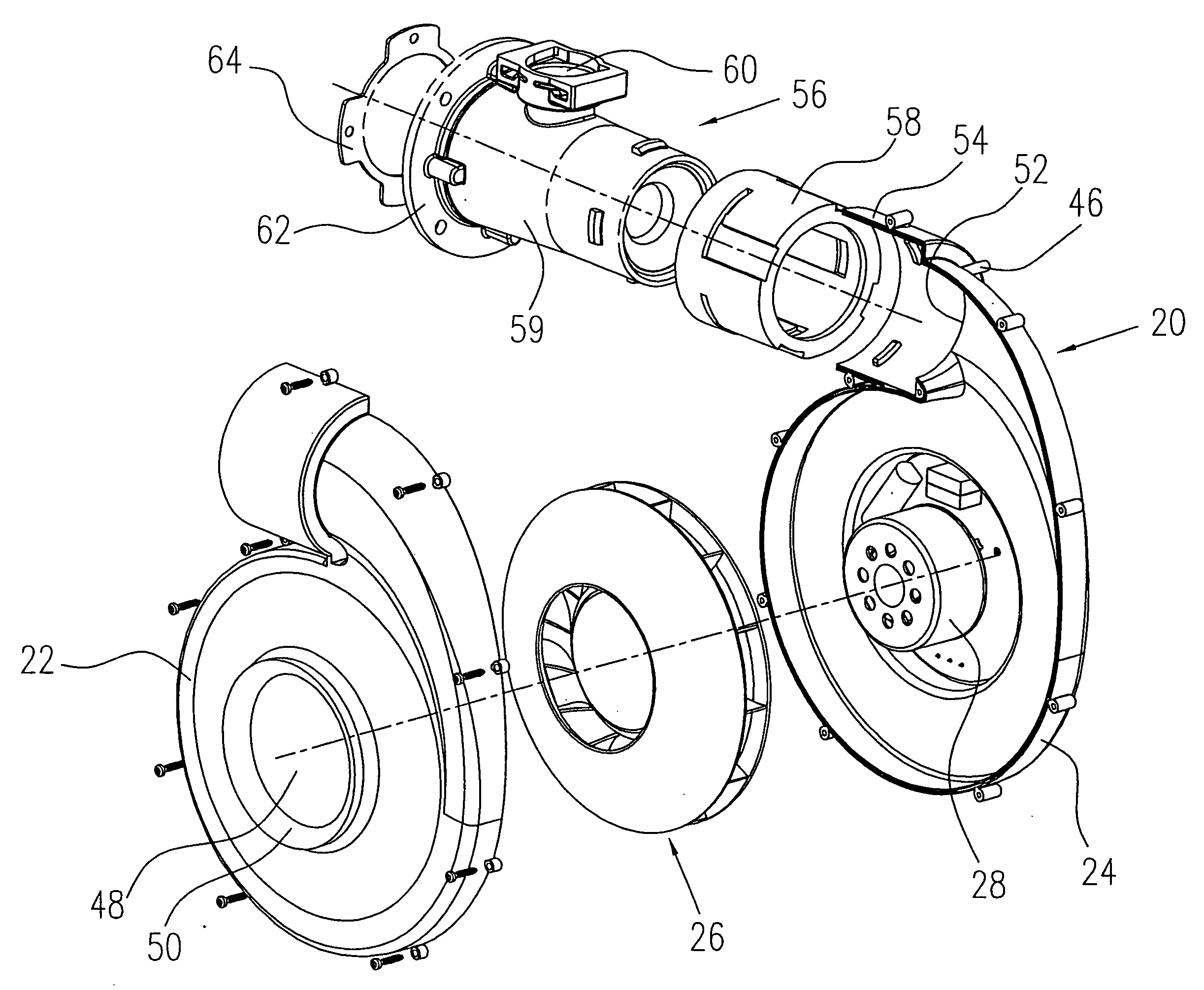

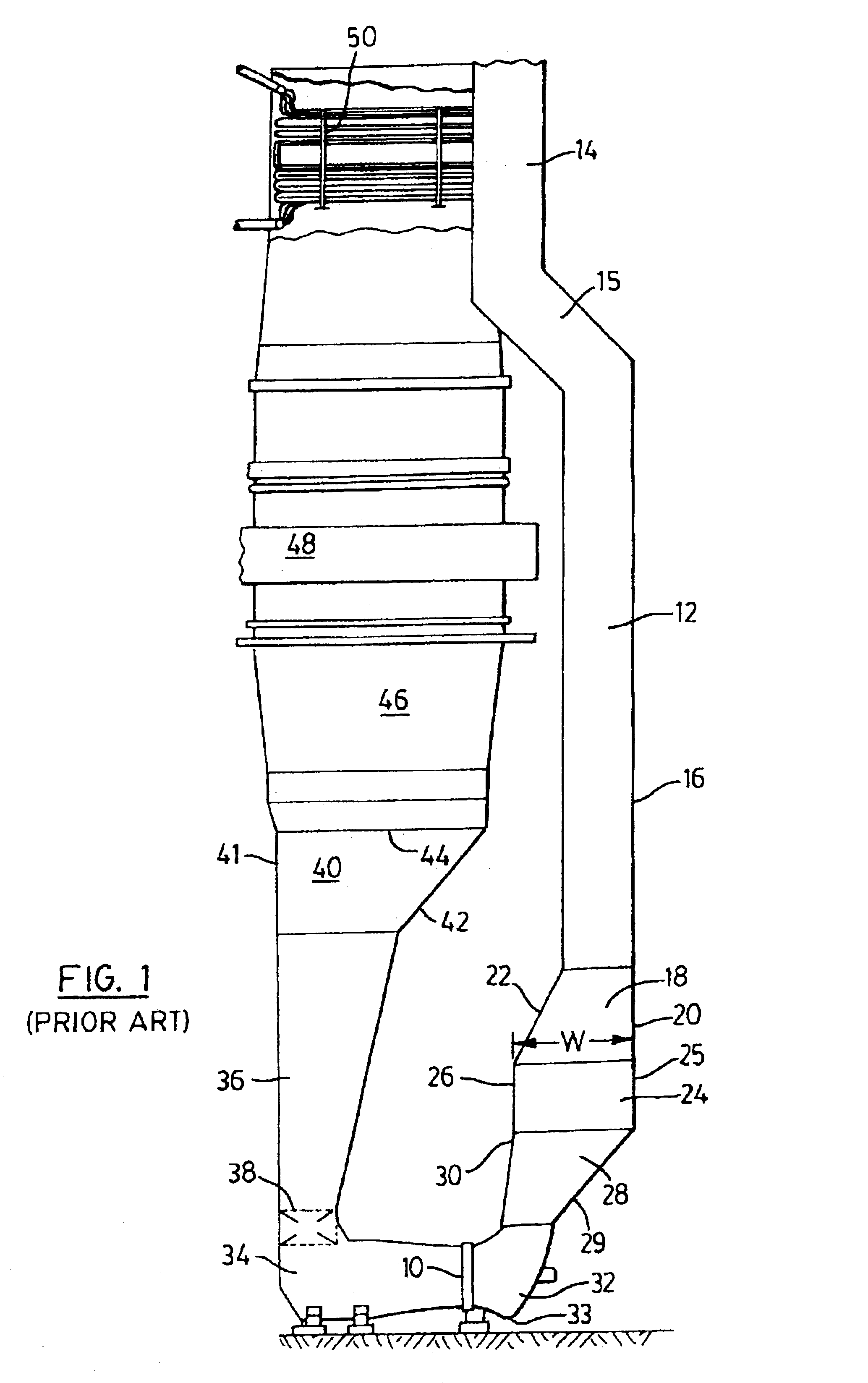

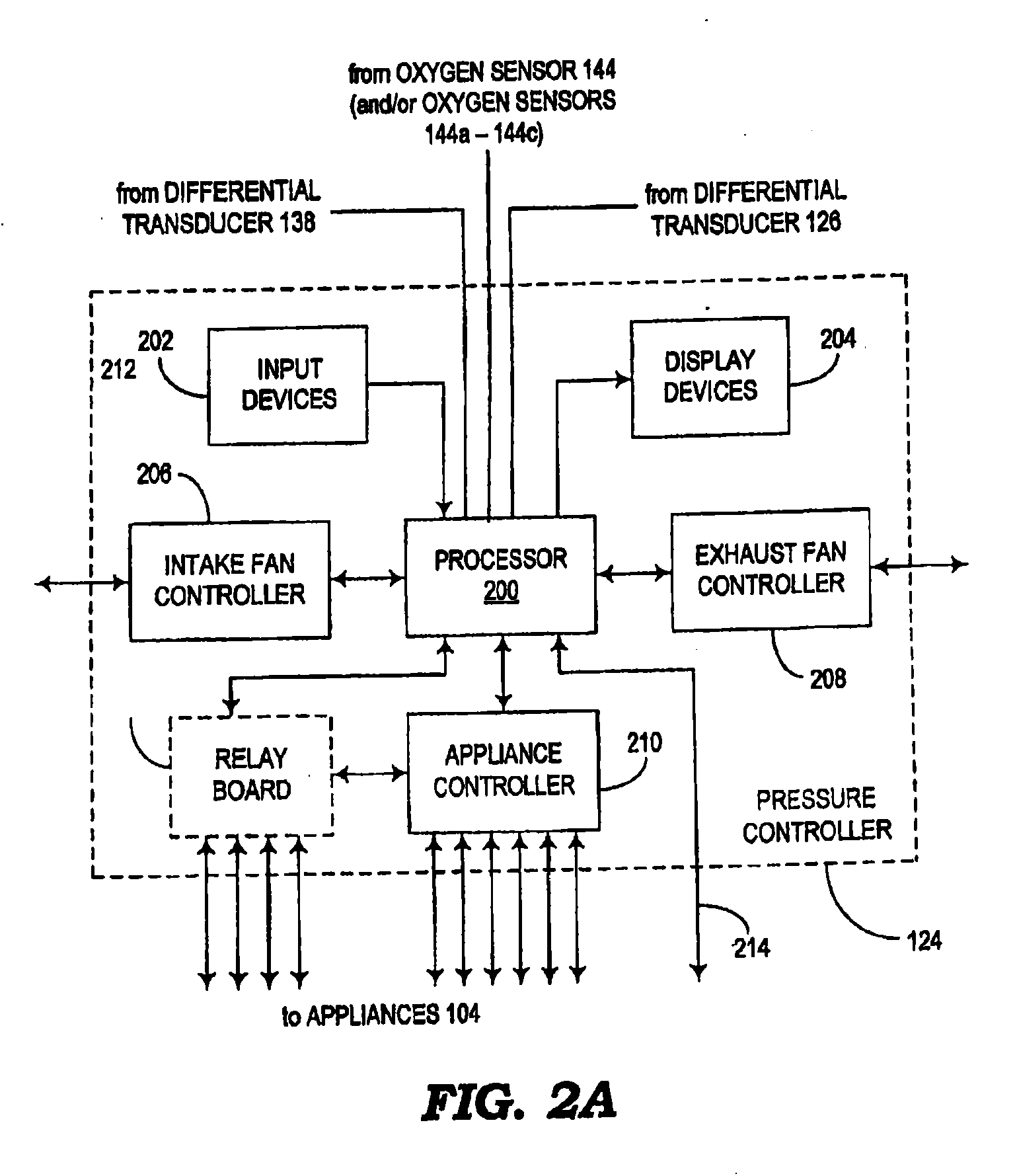

Mechanical draft systems

A representative mechanical draft system for drawing exhaust gasses from a chimney includes: an exhaust fan assembly having: a housing defining a chamber and having opposing openings, the opposing openings having a centerline extending therebetween, a first of the openings being operative to intake a flow of gasses, a second of the openings being operative to exhaust the flow of gasses from the chamber; and a centrifugal fan having a motor and an impeller, the motor being mounted external to the housing, the impeller being positioned within the chamber, a rotational axis of the impeller being inclined with respect to the centerline extending between the openings of the housing.

Owner:ENERVEX

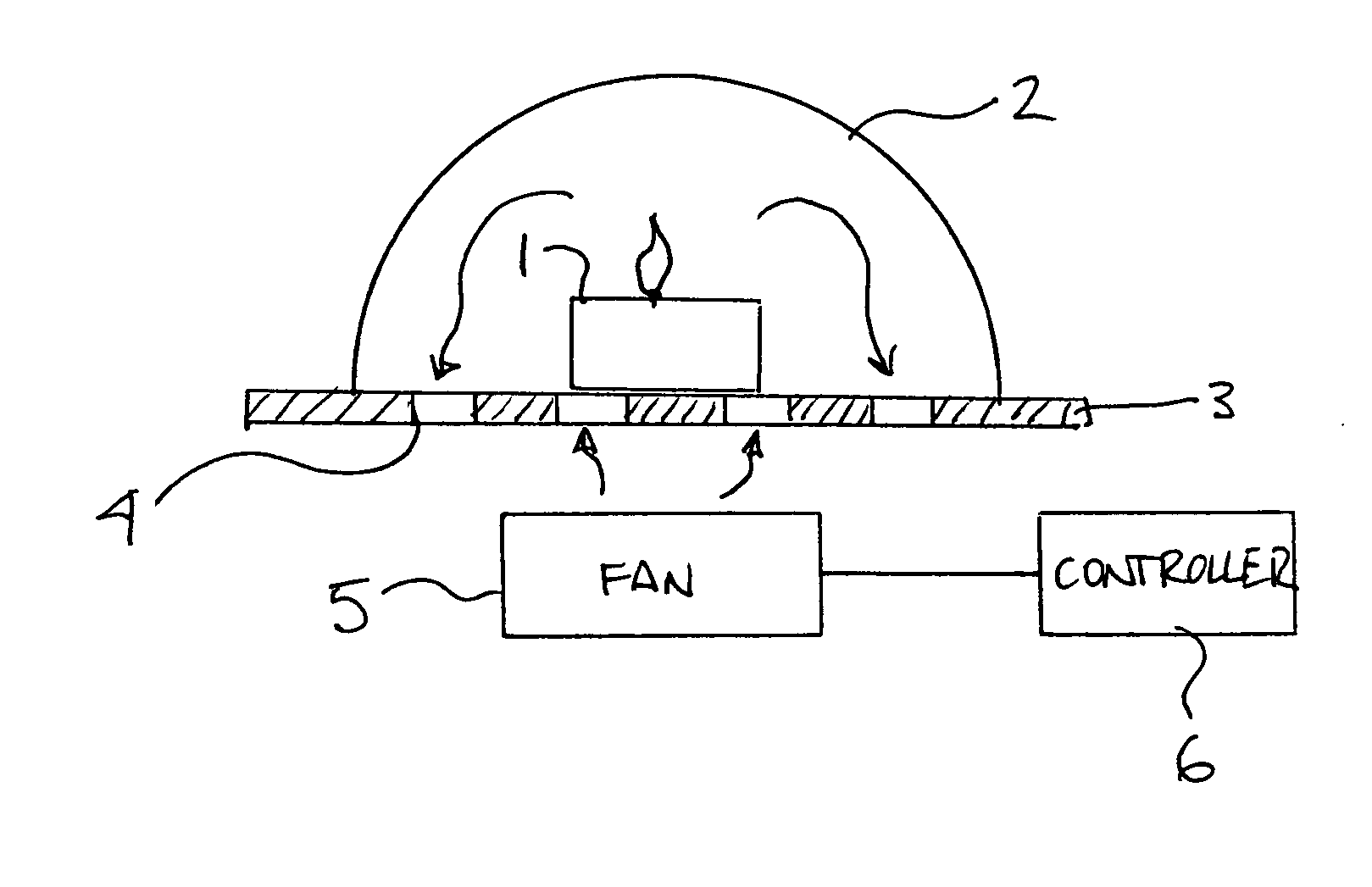

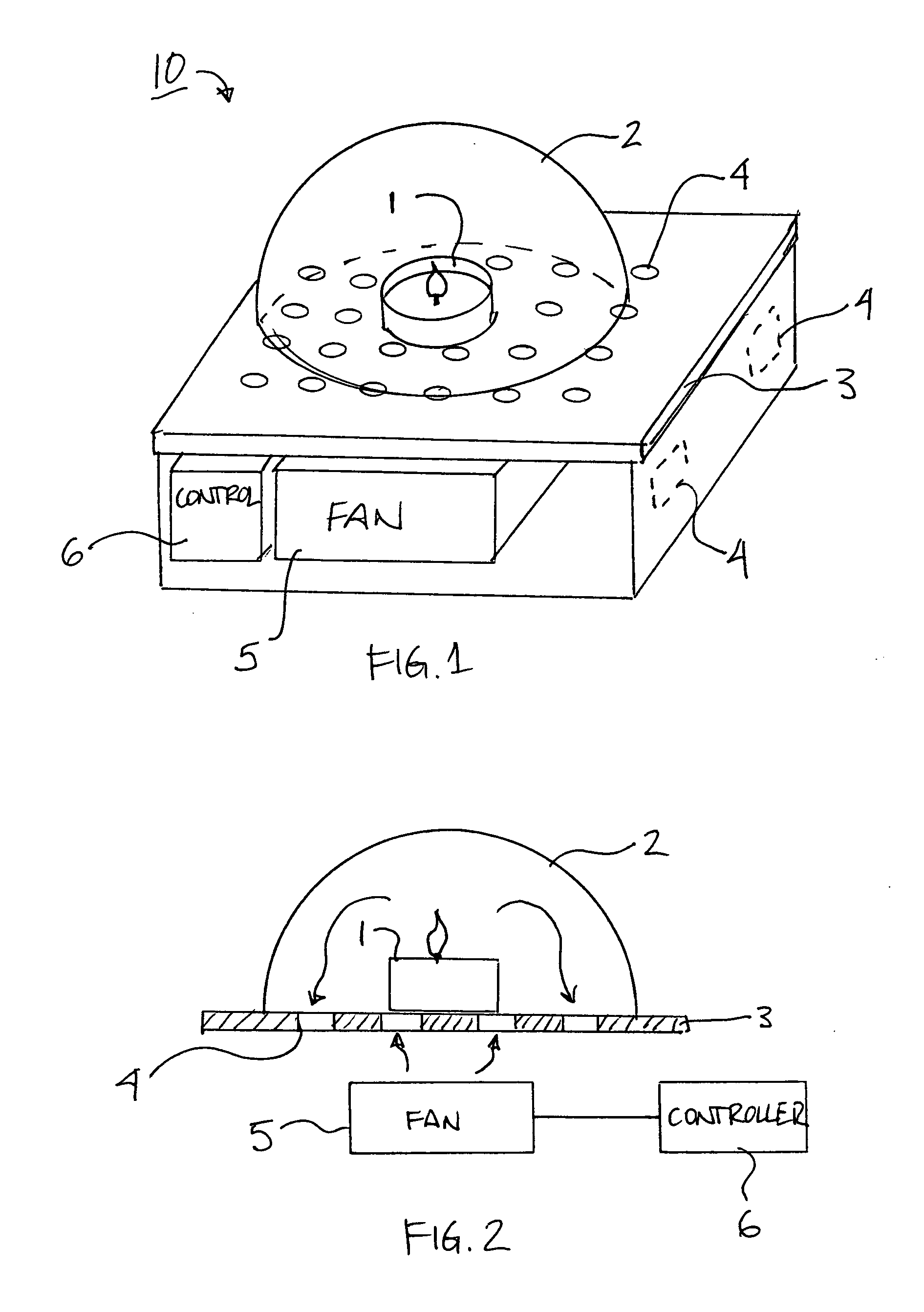

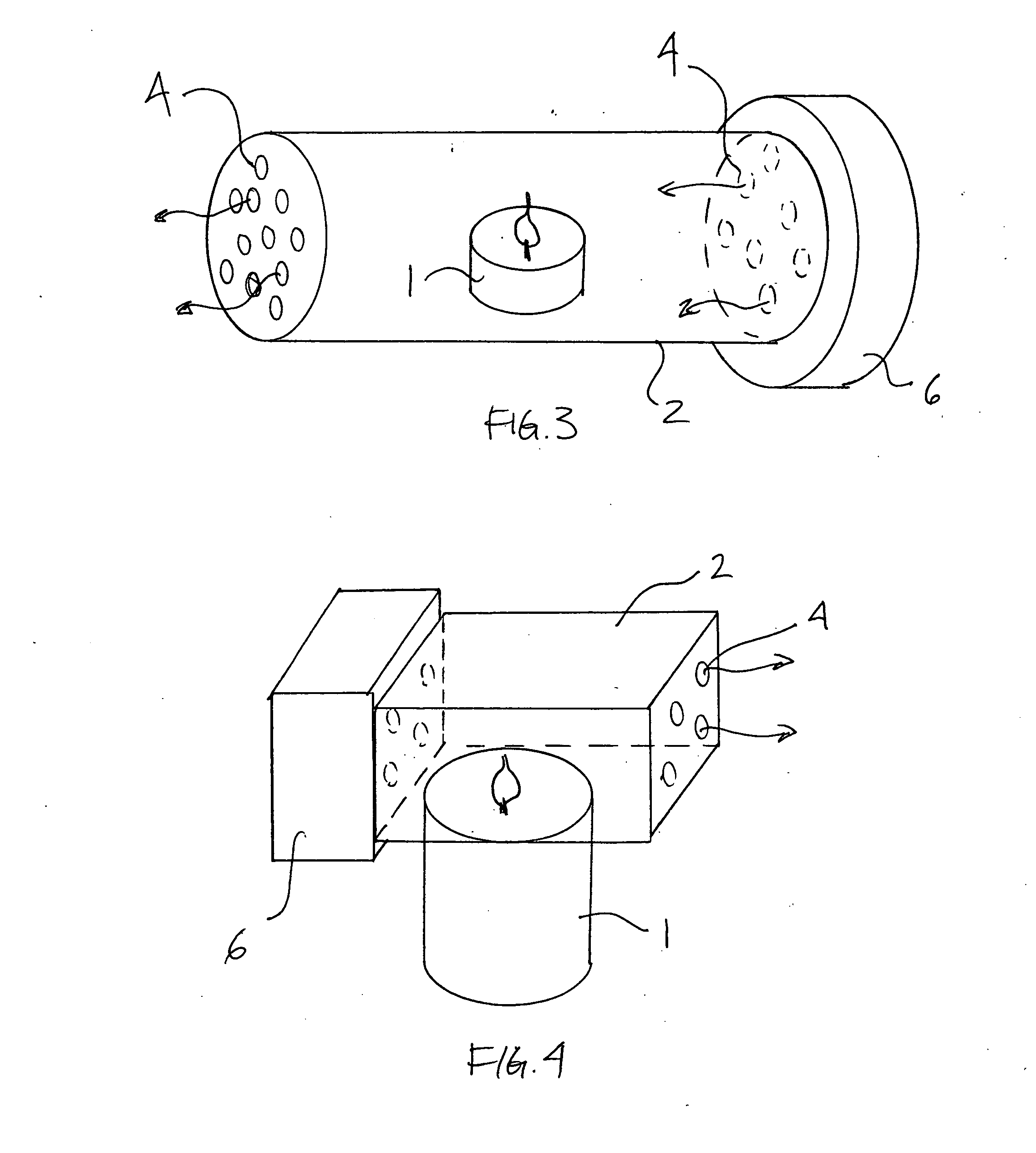

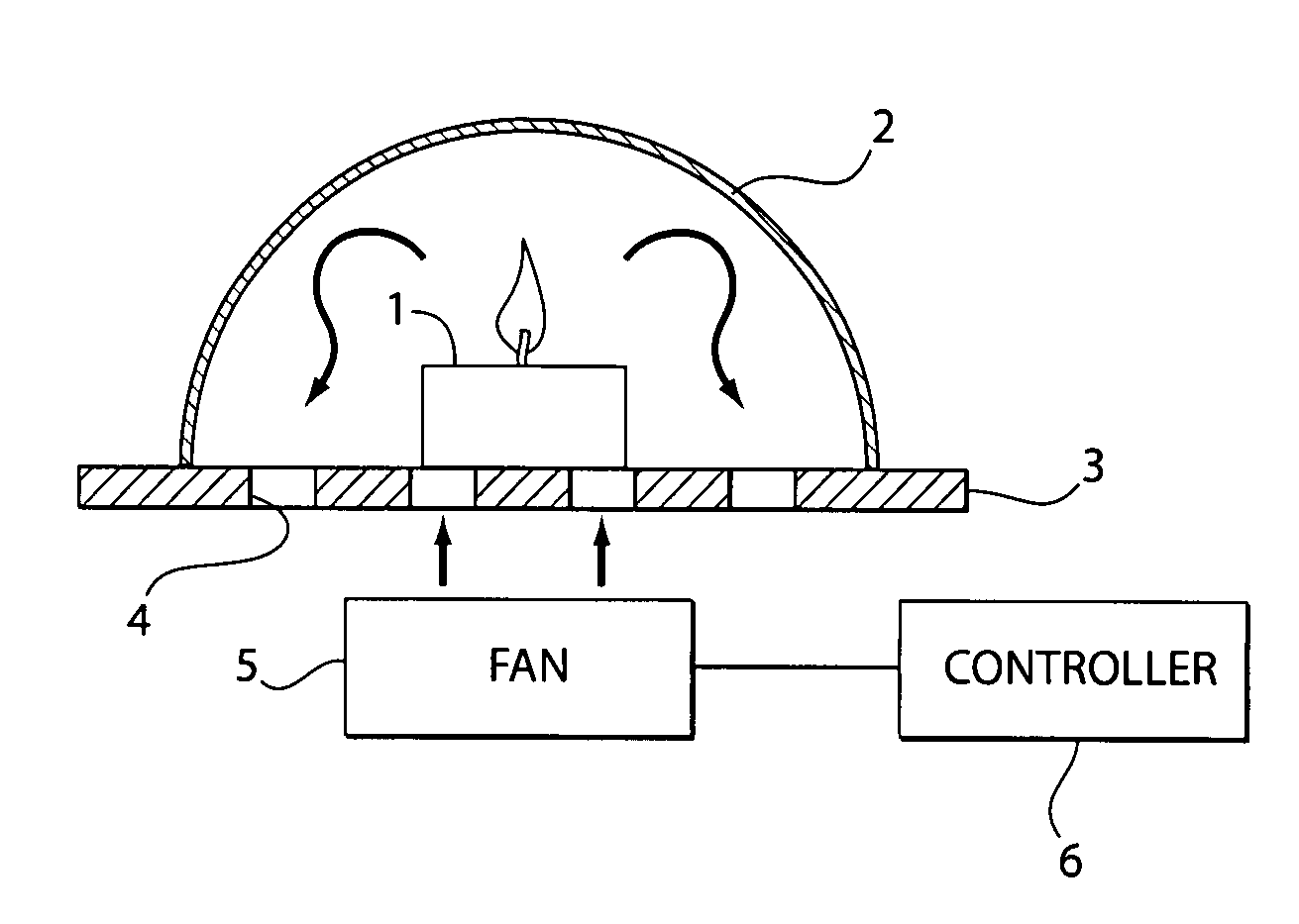

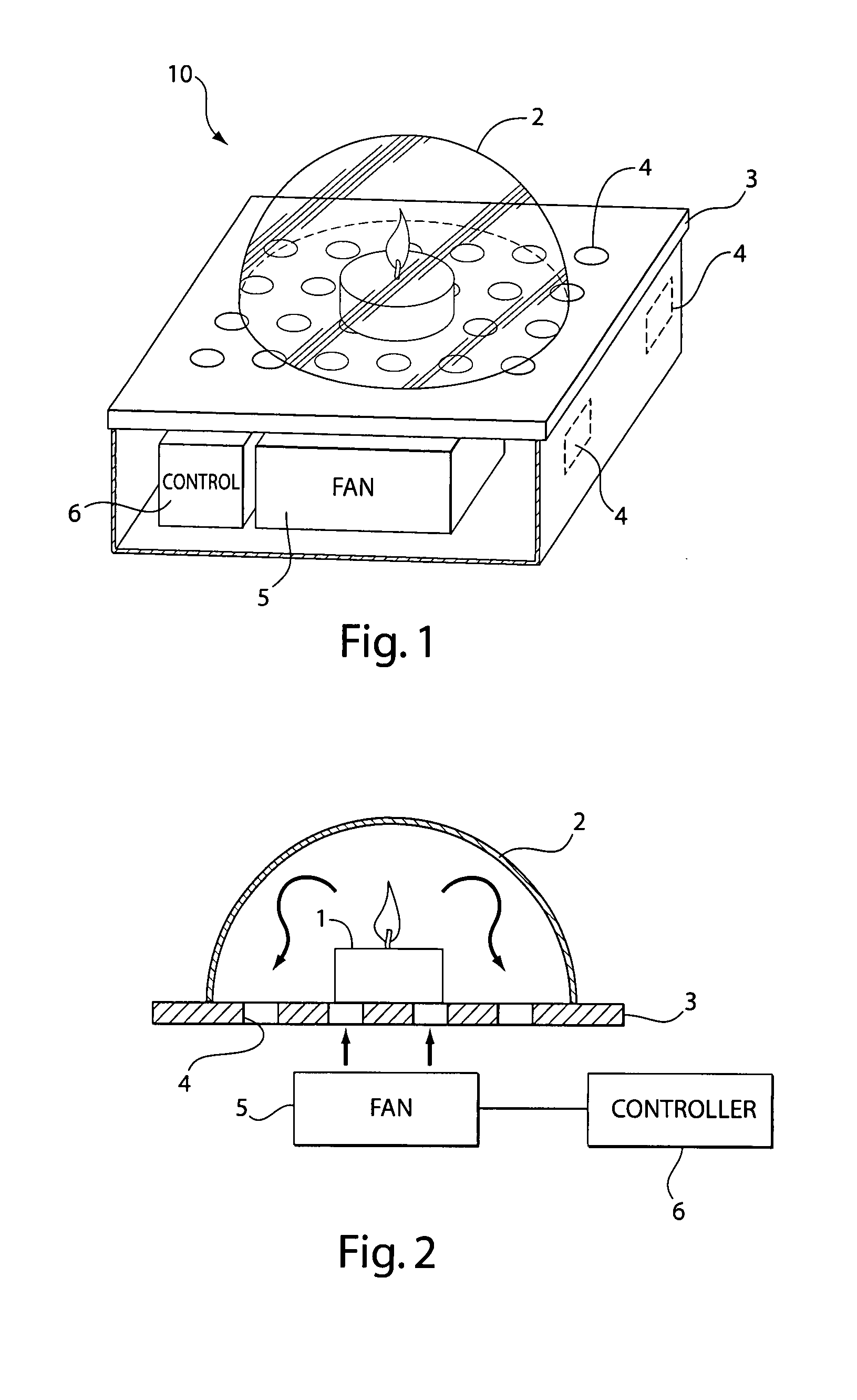

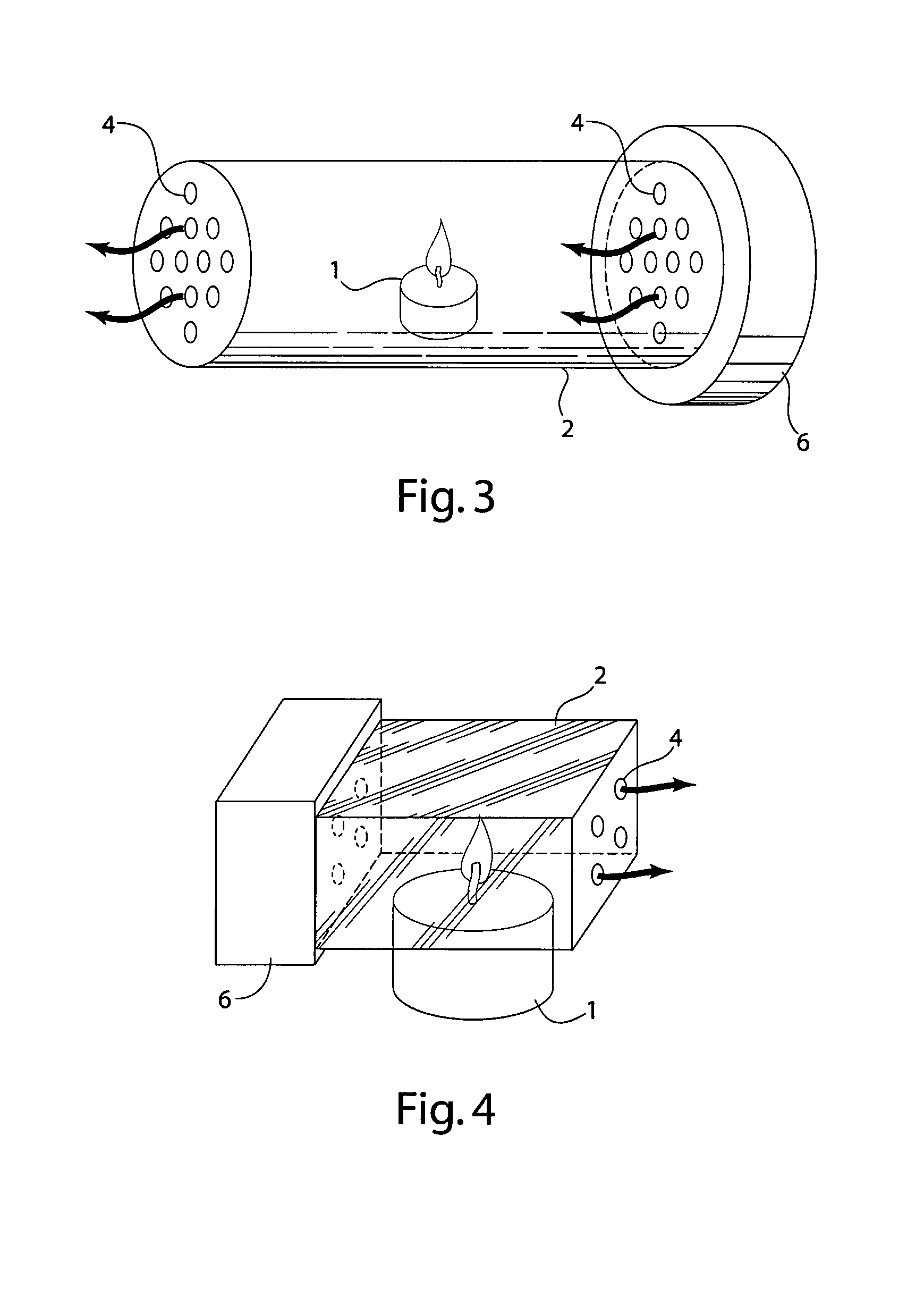

Method and apparatus for controlling a burning flame

ActiveUS20060099540A1Reduce the possibilityNon-electric lightingCapillary burnersAir movementEngineering

A method and apparatus for controlling a candle flame. A candle flame may be provided in a controllable environment, e.g., an enclosed area formed at least in part by an air-tight cover. Air may be forced into the enclosed area by an air movement device (e.g., a fan) to keep the flame burning. The flame may be extinguished by reducing (e.g., stopping) air flow into the enclosed area.

Owner:AVELAR VICTOR

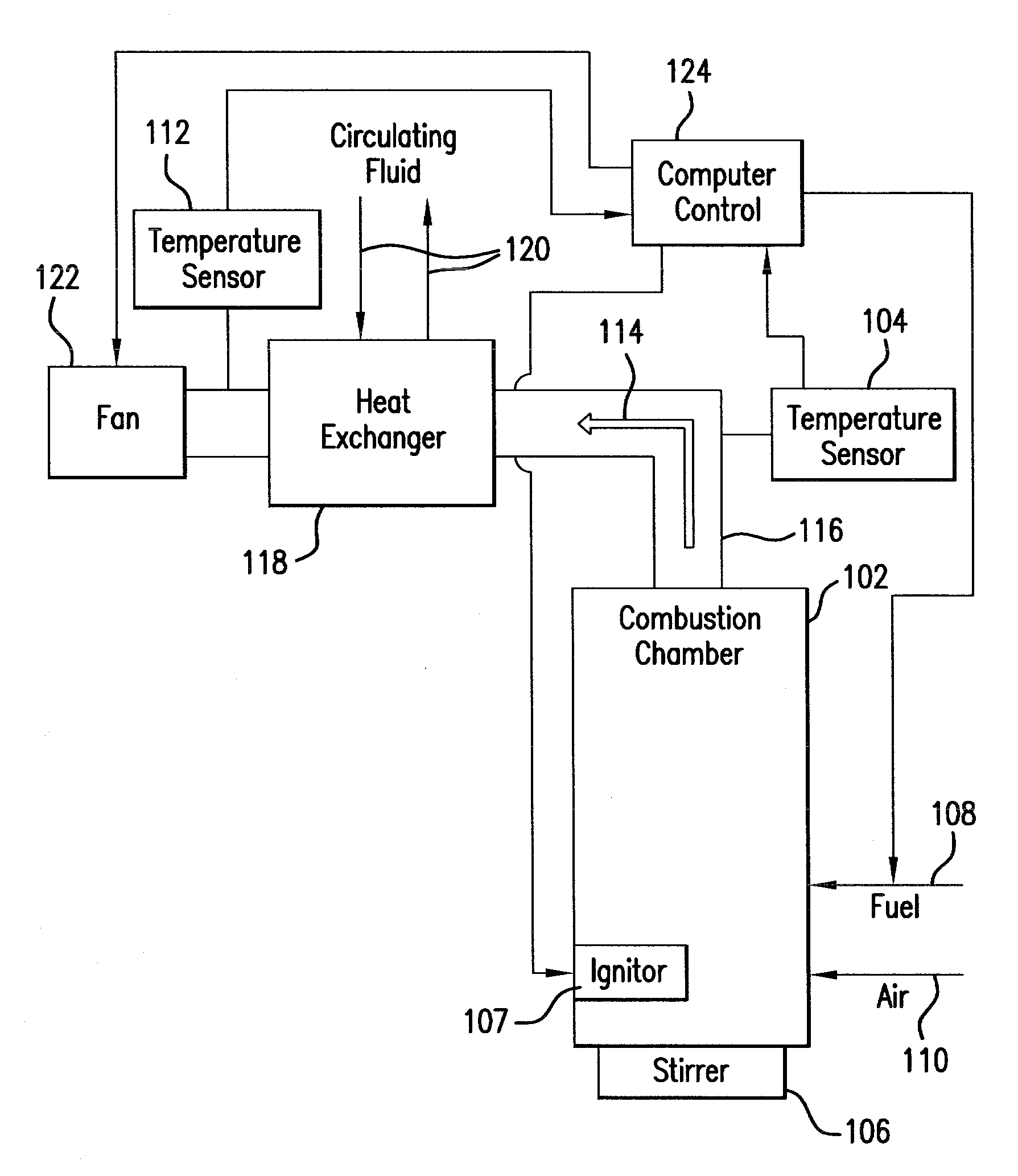

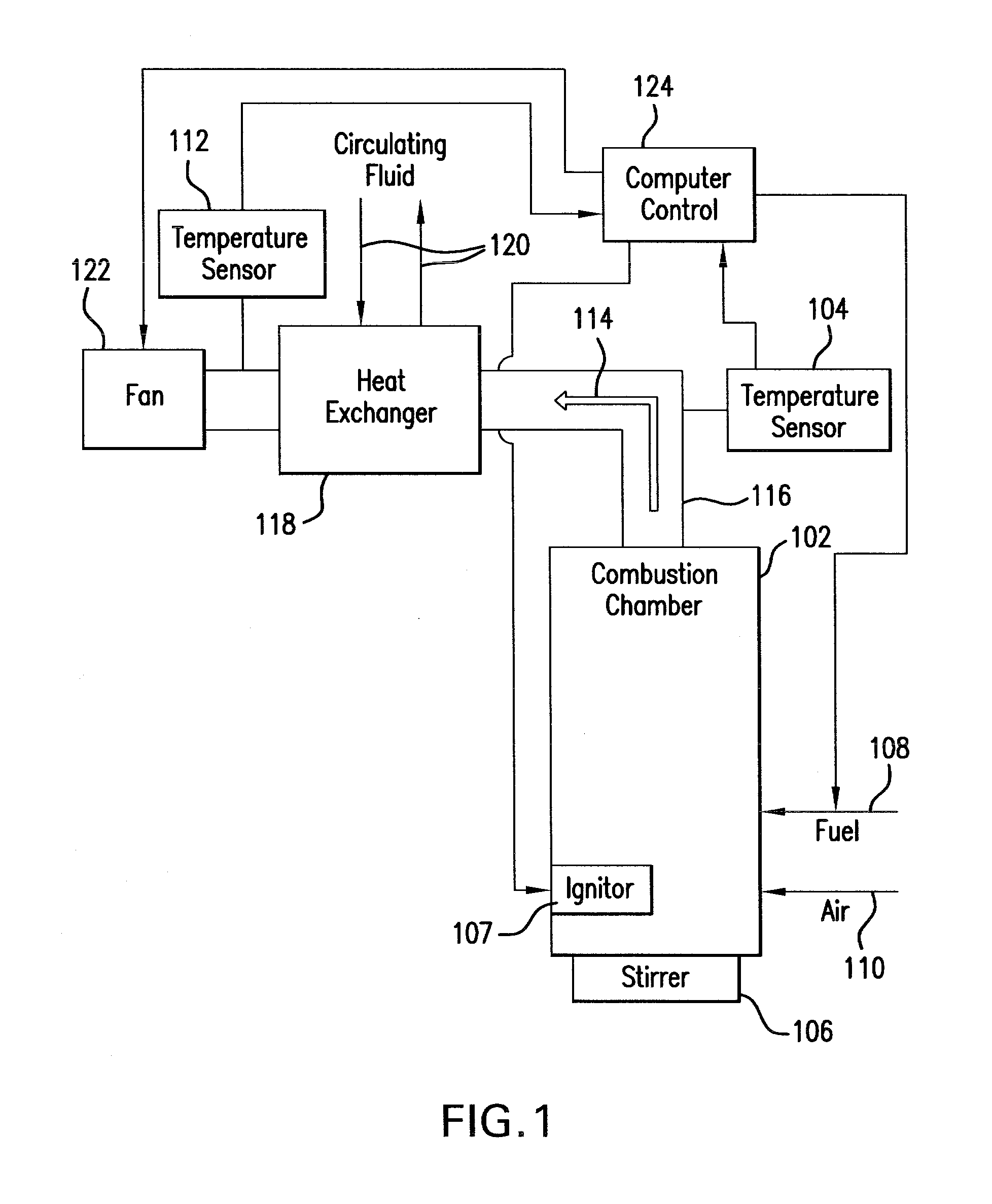

Non-catalytic biomass fuel burner and method

The present invention relates to a non-catalytic biomass burner that may be used to burn a variety of fuel types at high efficiencies. The burner may include a cylindrical combustion chamber with an auxiliary igniter to heat the fuel in the combustion chamber until desirable combustion temperatures are reached. Fuel may be added to the chamber via a fuel feed assembly, and the rate of fuel addition to the chamber by the fuel feed assembly may be controlled by a computer. A fan located on the distal side of a flue pipe from the chamber may also be provided that pulls air into the chamber through one or more air inlets that are designed to encourage cyclonic air and exhaust flow in the chamber. Methods are further provided for controlling the manner of operation of the burner by a computer that may be instructed by a computer program code.

Owner:LASKOWSKI SCOTT +3

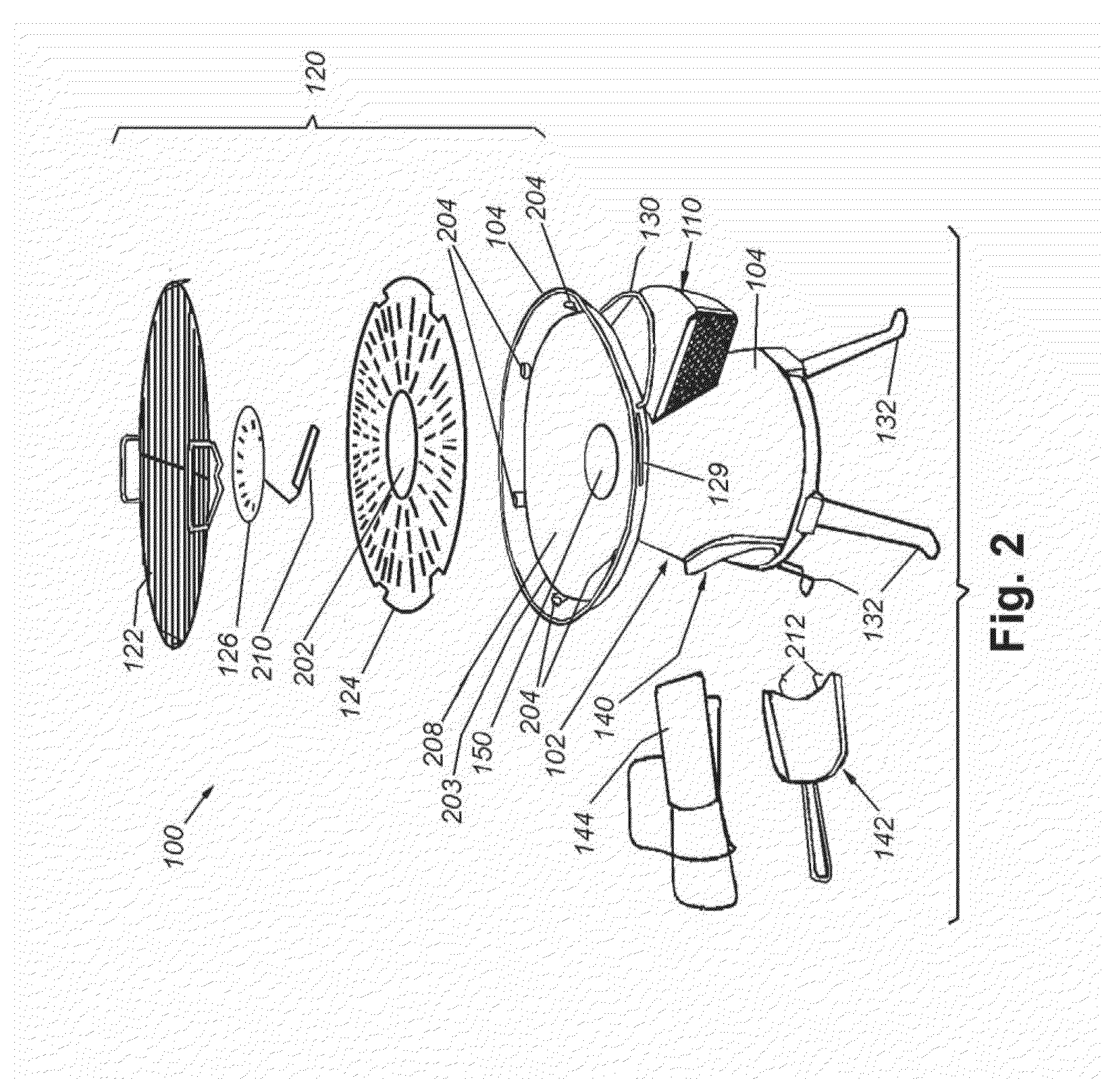

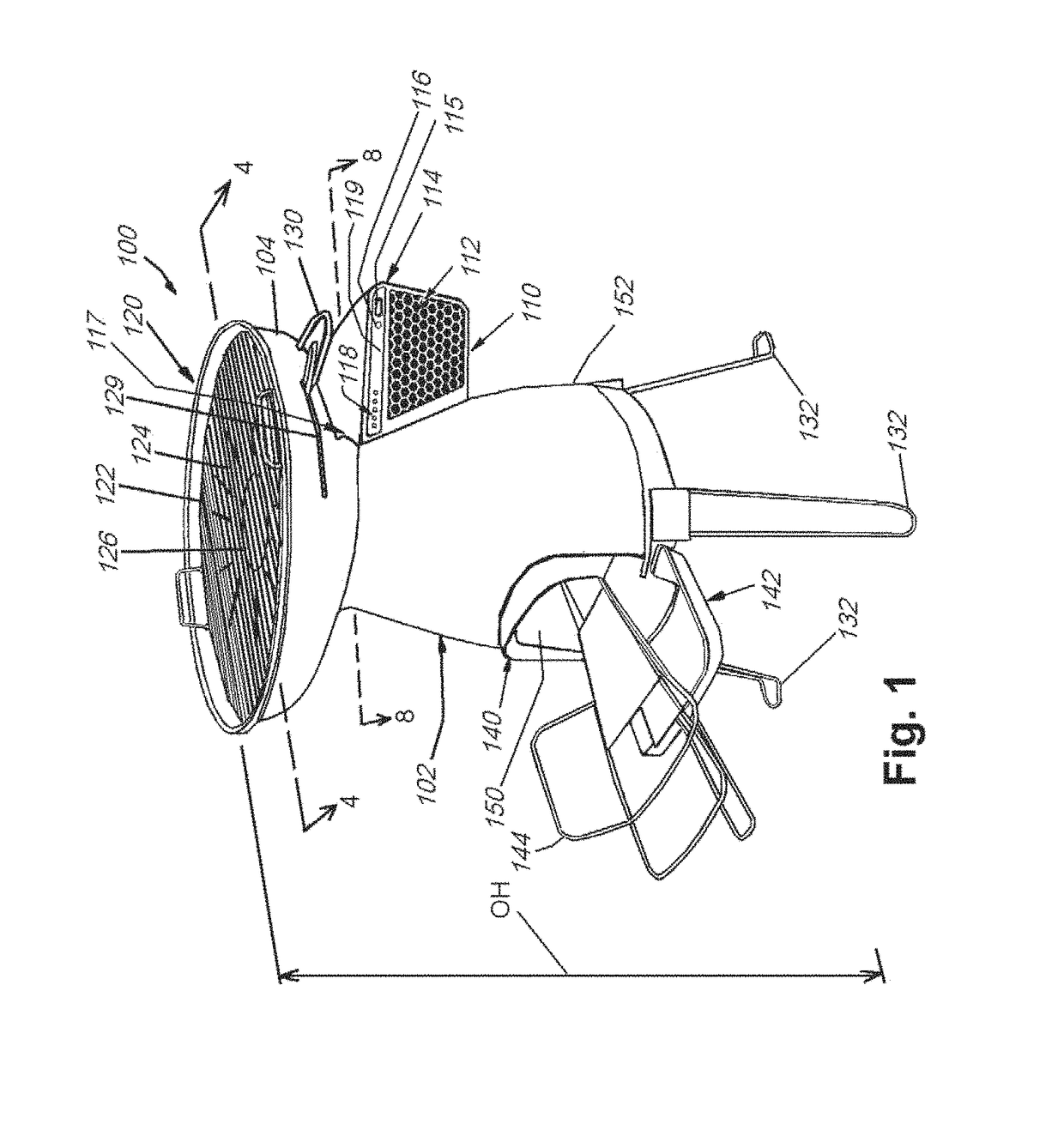

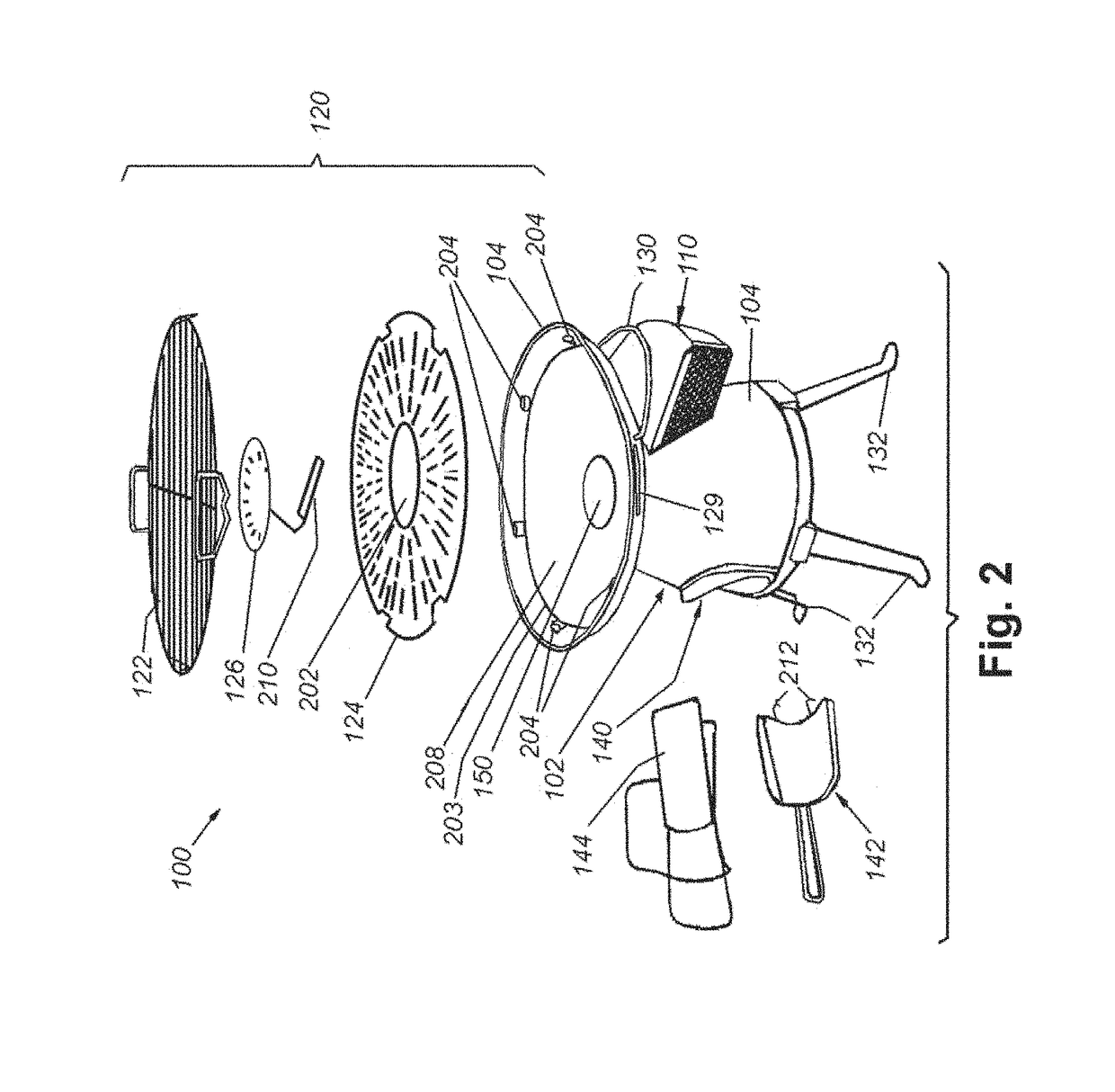

Portable combustion device utilizing thermoelectrical generation

ActiveUS9844300B2Increase heatEfficient transferDomestic stoves or rangesSolid fuel combustionCelluloseCombustion chamber

This invention provides a portable combustion device that provides a cleaner combustion, provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids and provides a cooking surface that is a grill top. The combustion device has a combustion chamber into which the fuel source is placed for combustion. Mounted to the side of the combustion chamber is a housing that encloses the TEG, which generates an electrical output, based on a difference in temperature on opposing sides. Mounted onto the TEG housing and protruding into the combustion chamber through a small passageway is a heat-conducting probe and heat-conducting probe base unit.

Owner:BIOLITE INC

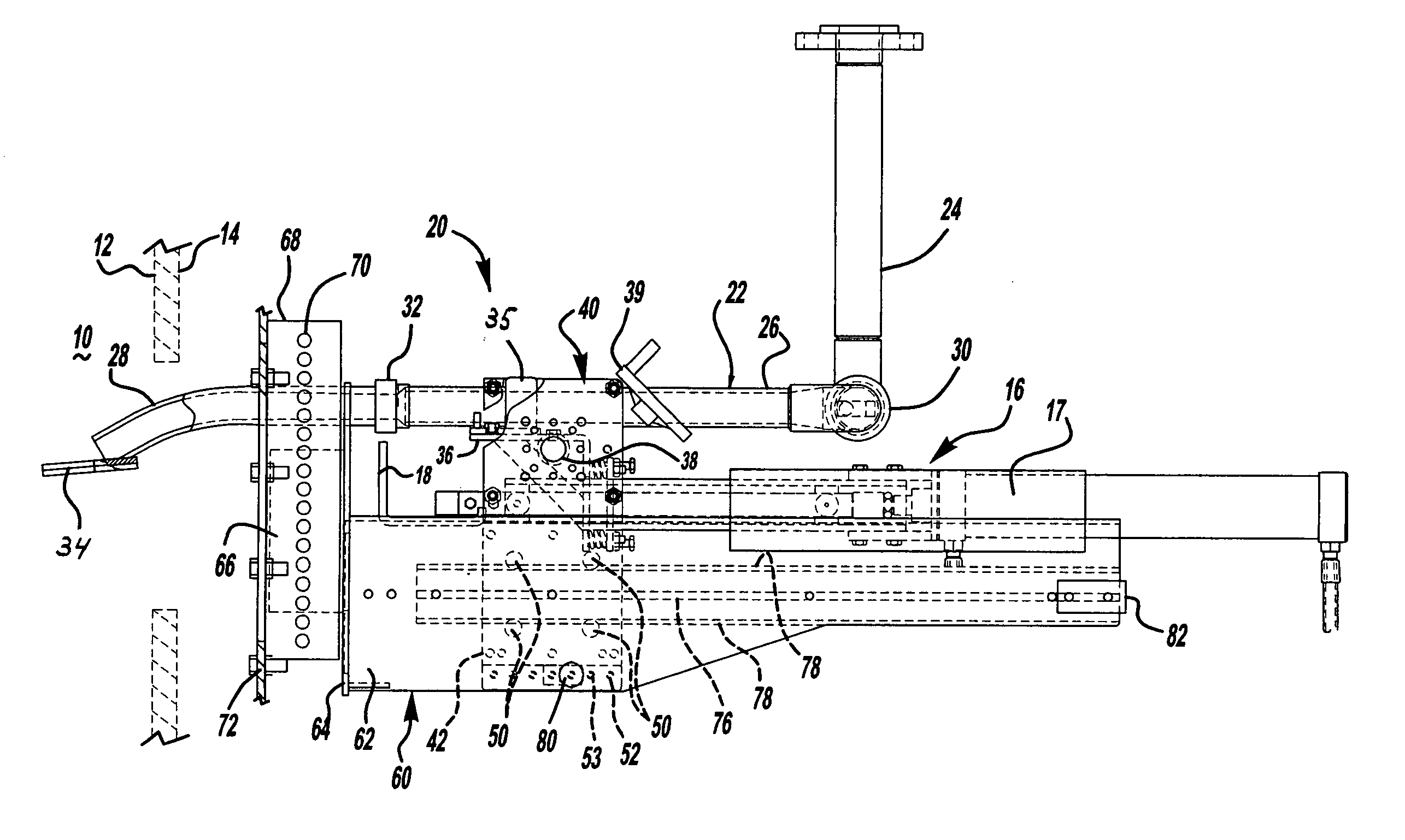

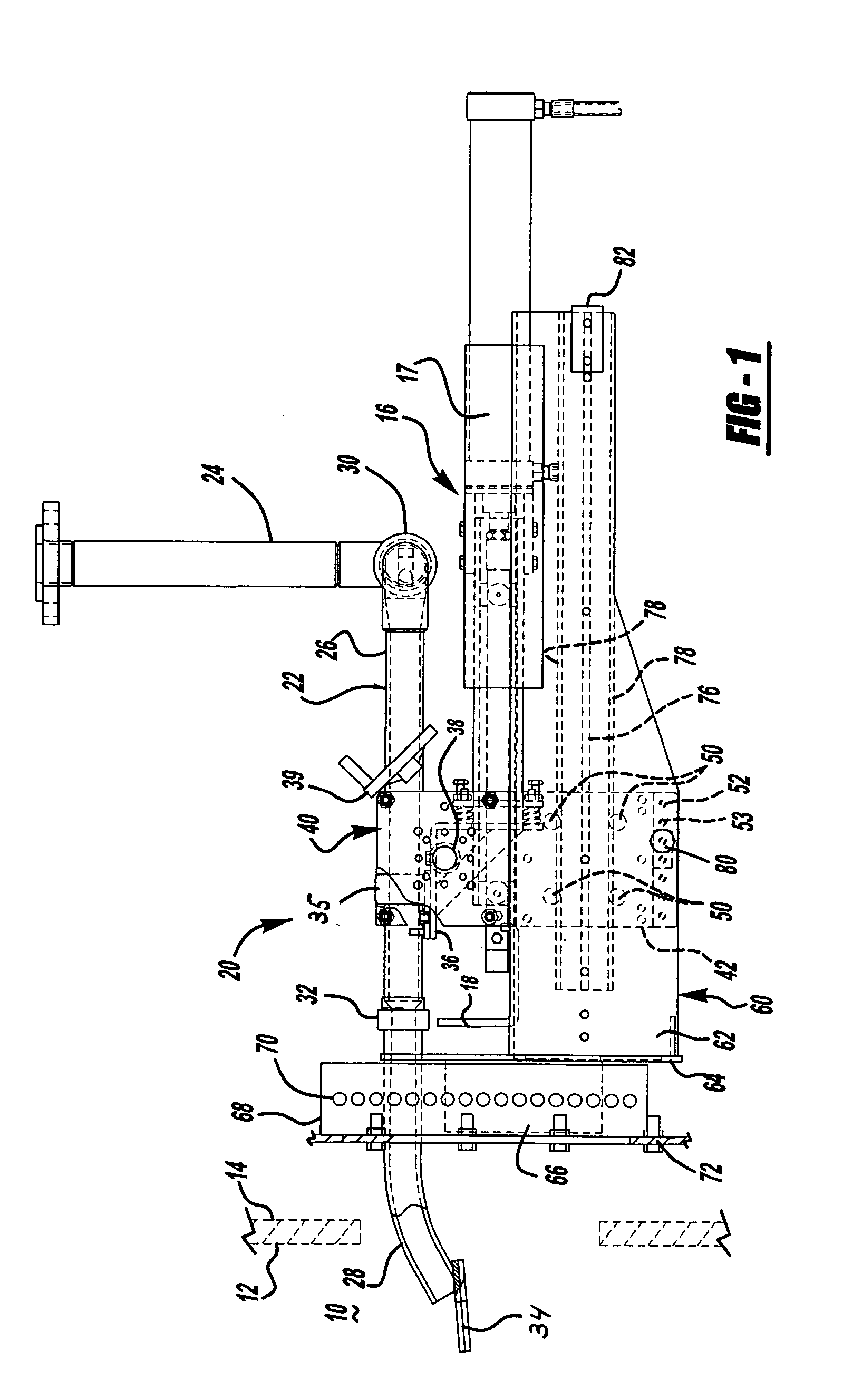

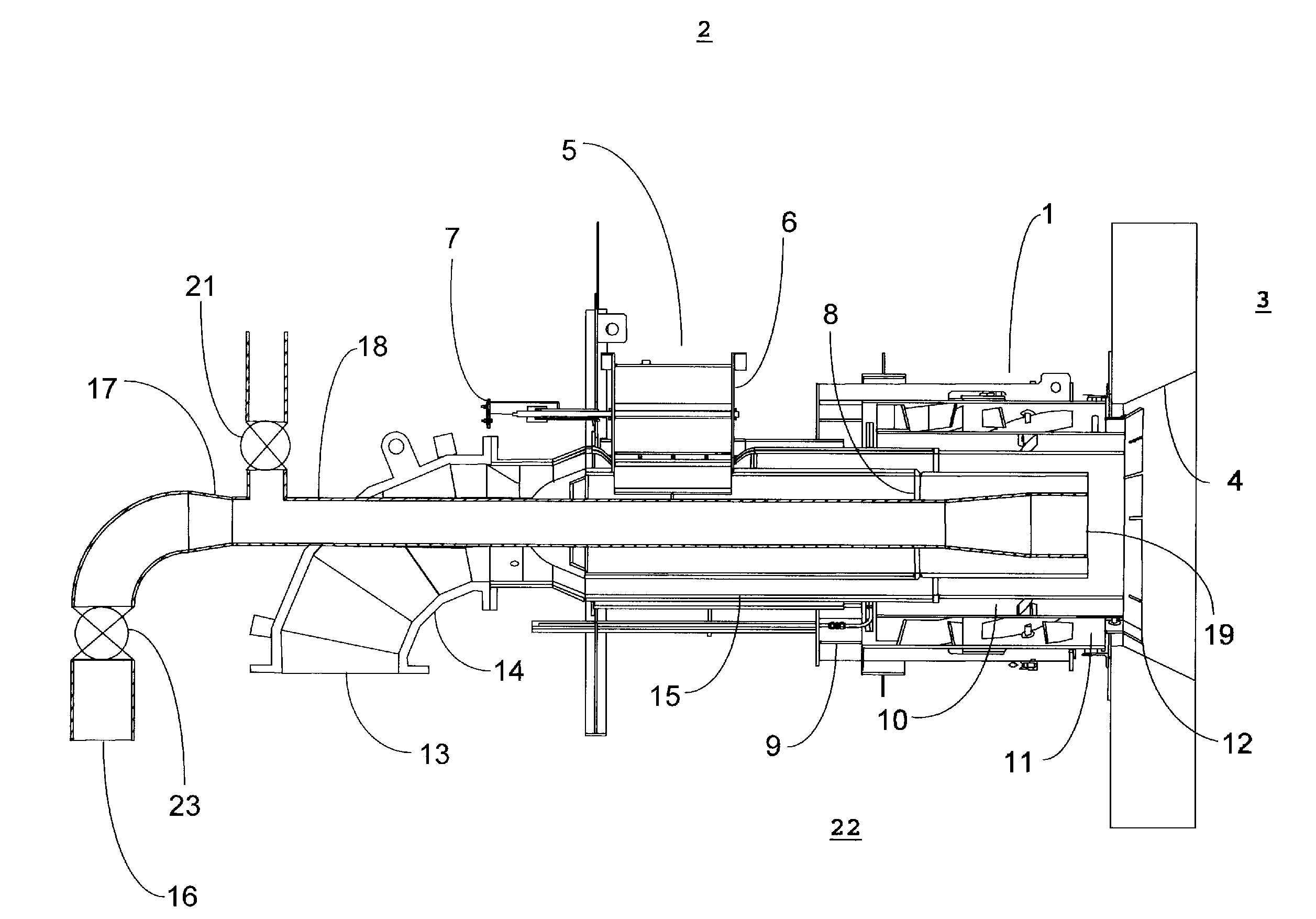

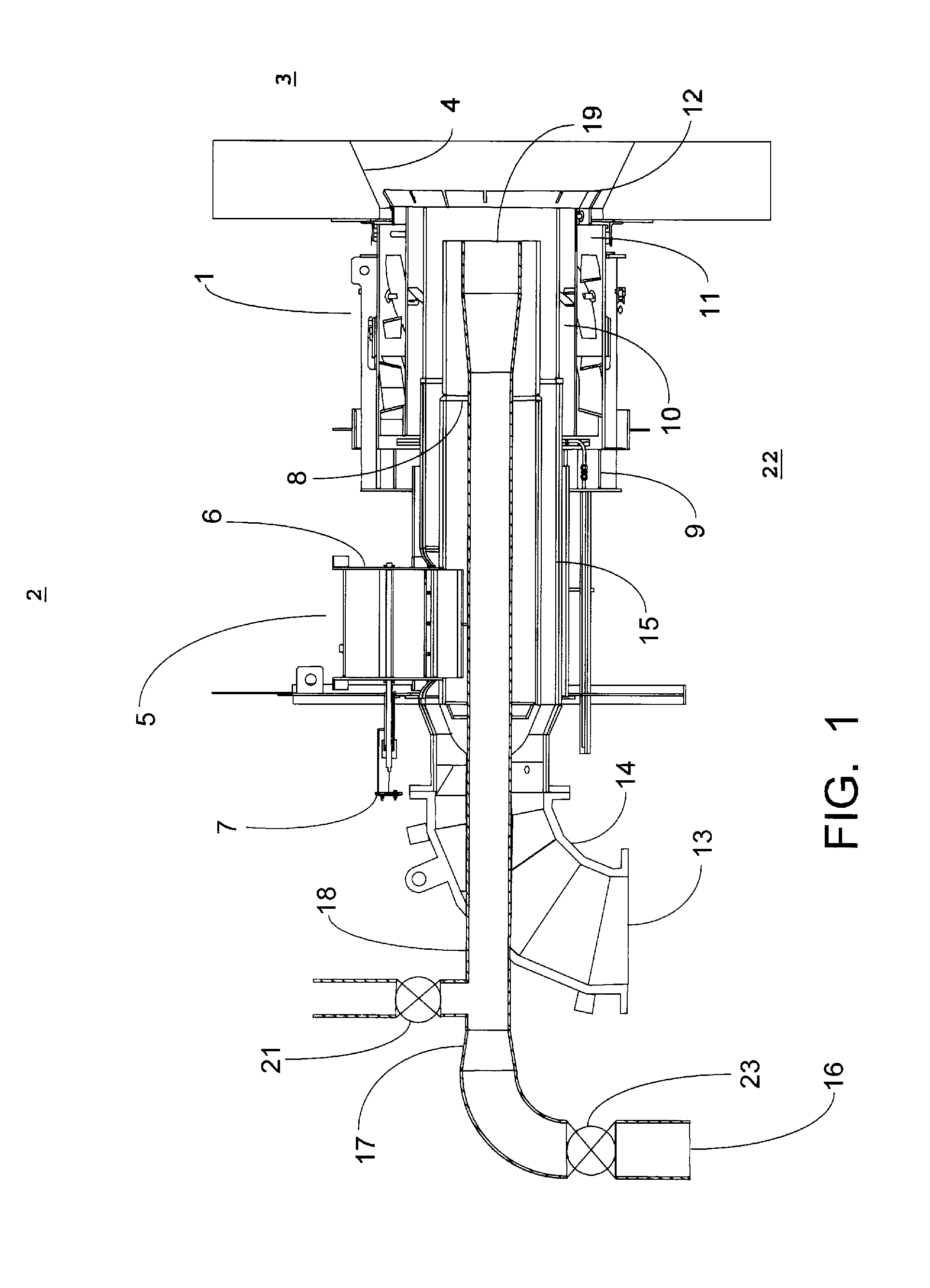

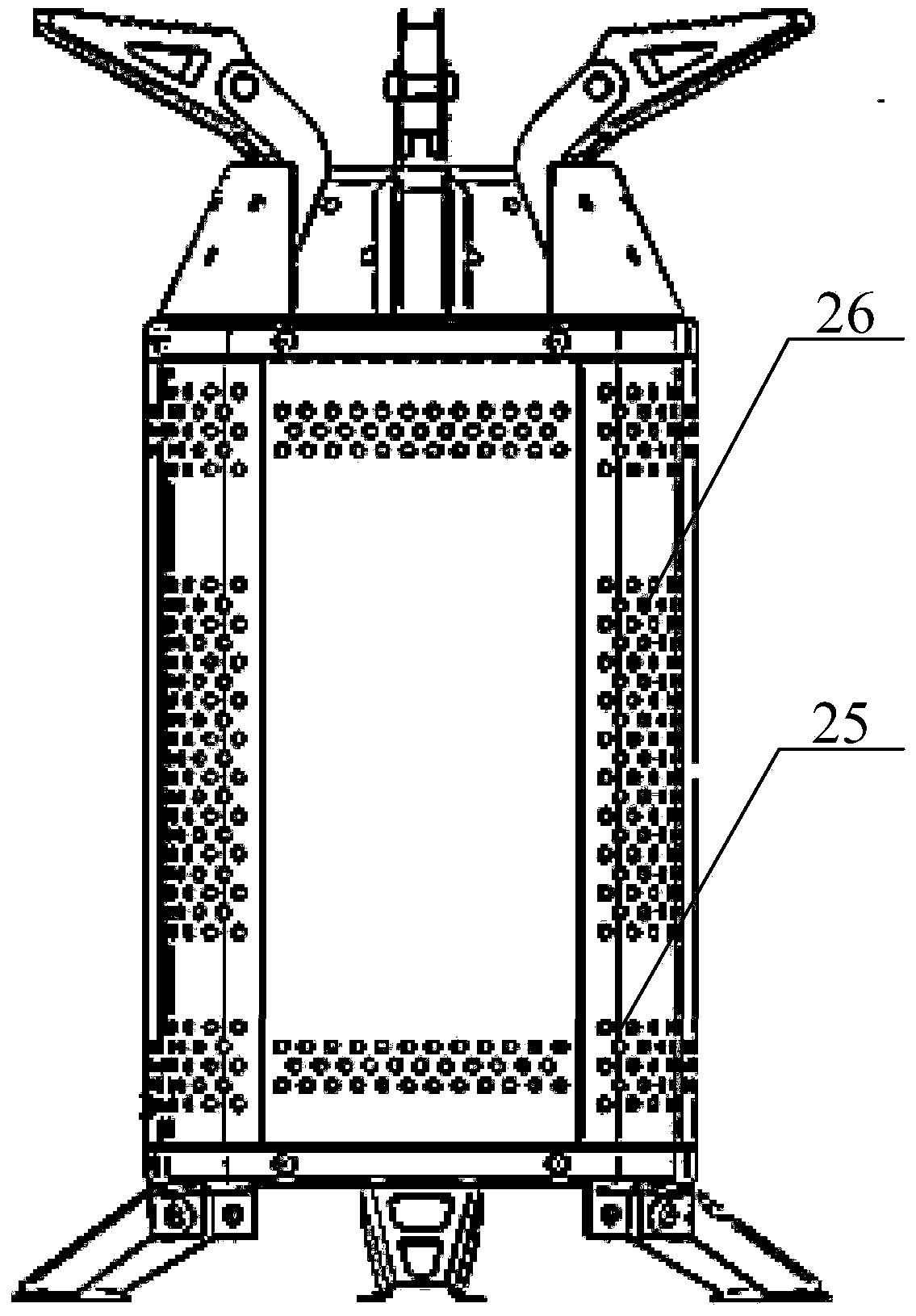

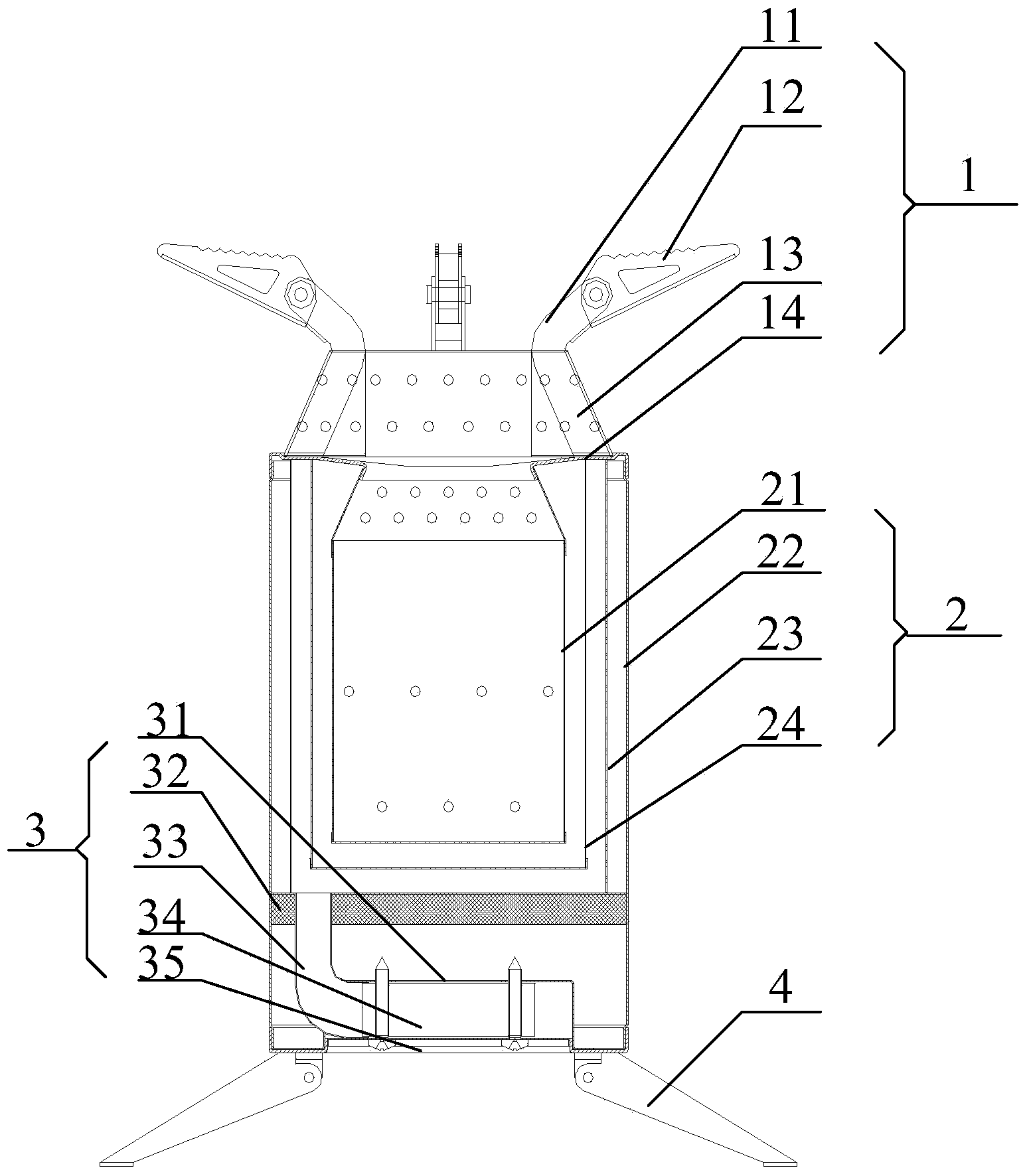

Retractable liquor gun holder for a recovery furnace

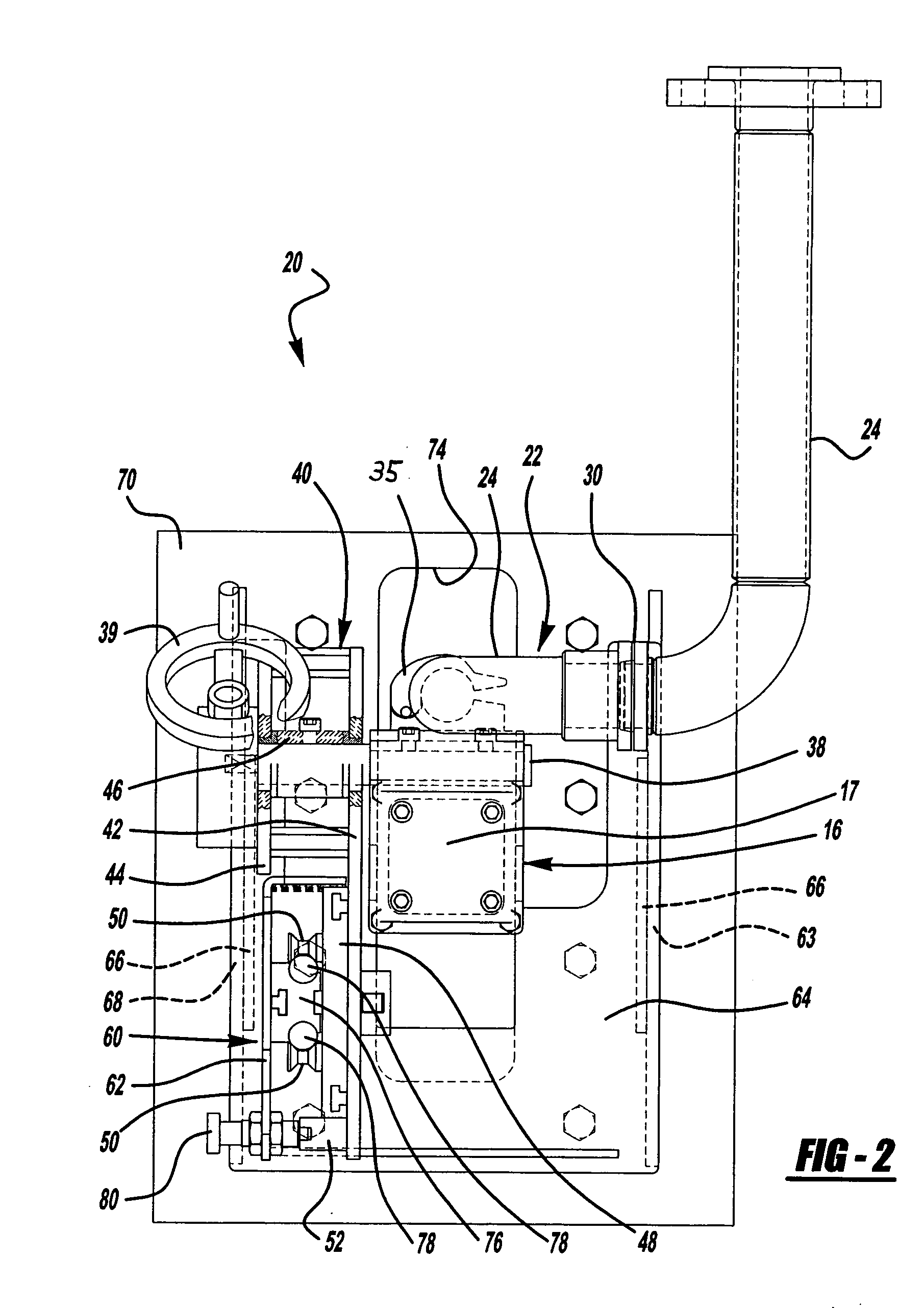

A liquor gun holder for a recovery furnace includes a rail assembly, a carriage assembly moveably mounted onto the rail assembly such that the carriage assembly is moveable longitudinally along the rail assembly, a pivot pin supported by a bearing and extending laterally from the carriage assembly, and a cleaning assembly pivotally mounted onto the pivot pin such that the cleaning assembly is rotatable about a horizontal axis extending longitudinally through the pivot pin and is positioned laterally from the carriage assembly and the rail assembly, the cleaning assembly including a clamp adapted to secure a liquor gun thereon such that the liquor gun is rotatable with the cleaning assembly and is positioned laterally from the carriage assembly.

Owner:DIAMOND POWER INT

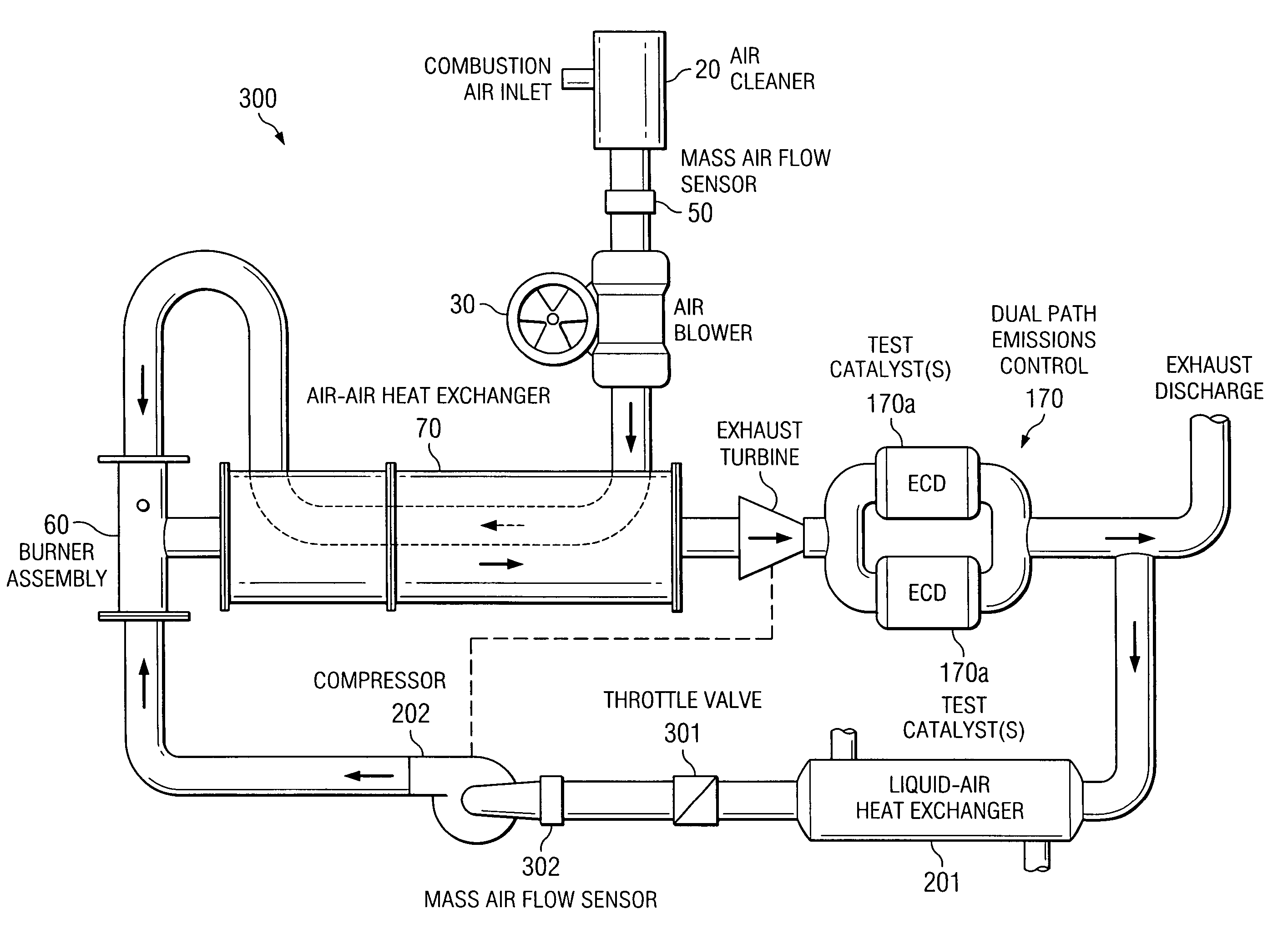

Use of recirculated exhaust gas in a burner-based exhaust generation system for reduced fuel consumption and for cooling

A burner-based exhaust gas generation system, for producing exhaust gas, typically for use in testing exhaust system devices. Post-burner exhaust gas is recirculated back to a main exhaust line, and used for purposes such as cooling or enhancing the burner output.

Owner:SOUTHWEST RES INST

Direct fired outdoor heater and heating method

InactiveUS6138666AReduced service lifeIncrease temperatureDomestic stoves or rangesBoiler water tubesCombustionEngineering

A heater includes a housing having an angled top, a fan having a discharge disposed parallel to the angled top of the housing, and a baffle for laminarizing airflow through the heater. The heater may also create airflow through a cover, across a housing, a heat sensitive component, and / or a raceway, and into a housing inlet. The heater may include a manifold having at least one coupling member that slidingly engages and disengages a burner. Methods for propelling combustion air through a heater, laminarizing combustion airflow in a heater, improving the efficiency of a heater, and converting a heater to make it compatible with a different fuel are also disclosed.

Owner:ZODIAC POOL SYST

Harmless treatment environment-friendly device for crop straws

InactiveCN107816722ADelicate handlingSolve the blockageBlast-producing apparatusIncinerator apparatusSlagWater storage tank

The invention provides a harmless treatment environment-friendly device for crop straws, and belongs to the technical field of crop straw environment-friendly treatment. The harmless treatment environment-friendly device comprises a treatment machine body, a primary crushing chamber, a secondary crushing chamber, a waste gas treatment chamber, a waste gas purifying chamber and a water storage tank. According to the harmless treatment environment-friendly device, in the actual working process, after being put into the primary crushing chamber, the large number of crop straws can fall on a cutting blade of a cutting rotating roller for primary cutting crushing treatment, materials after primary treatment fall into the secondary crushing chamber for deep secondary crushing treatment under theaction of gravity, so that the large straws are treated more exquisitely, and favorable conditions are provided for subsequent incineration treatment; and in the treatment process, an electric telescopic rod is adjusted to make an opening and closing side baffle to conduct inlet plugging, not only can be the plugging problem caused by too fast falling of the large bulk materials solved, but alsosplashing broken slag materials in the treatment process can be blocked very well, so that the harm to surrounding people due to the fact that the broken slag materials splash to the exterior of the device is prevented.

Owner:周梅阳

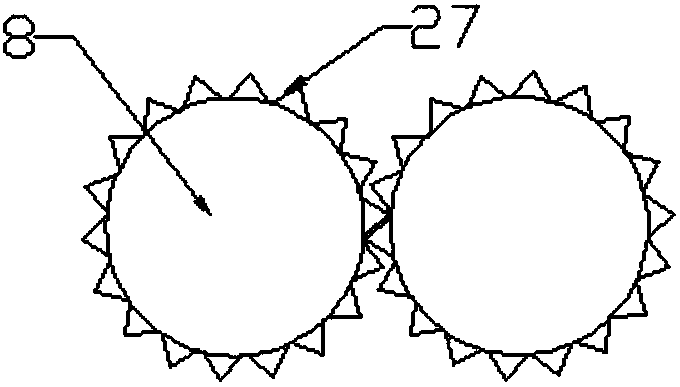

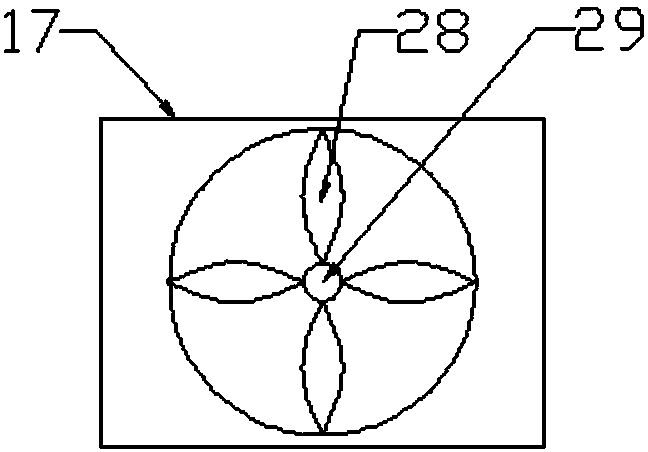

Biomass center air jet burner

InactiveUS20100275824A1Promote combustionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorInjection air

A combustion apparatus capable of firing biomass fuel including a burner assembly which includes a biomass nozzle concentrically surrounded by a core air zone and extending axially along the length of the core air zone, the burner assembly residing within a windbox, the windbox being attached to a furnace of a boiler, and the burner assembly being connected to the furnace by a burner throat, through which air and fuel supplied to the burner assembly are emitted into the furnace.

Owner:BABCOCK & WILCOX POWER GENERATION GRP INC

Gas mixture ratio control apparatus and method implementing low-nitrogen combustion by oxygen-deficient CO2-rich gas

InactiveCN104501203AControl air volumeIndirect carbon-dioxide mitigationBlast-producing apparatusAir preheaterLow nitrogen

The invention provides a gas mixture ratio control apparatus and method implementing low-nitrogen combustion by oxygen-deficient CO2-rich gas. The apparatus comprises an air preheater, a mixed gas tank, a blower, a boiler flue gas reflow pipe, a fresh air pipe and a blower air pipe; one end of a flue gas incoming chamber of the air preheater is communicated with a flue gas outlet of a boiler and communicated with the mixed gas tank through the boiler flue gas reflow pipe; a fresh air outlet of the fresh air preheater is communicated with the mixed gas tank through the fresh air pipe; the mixed gas tank is communicated with an air inlet of the blower; the blower is communicated with a primary air chamber inlet of the boiler. The blower extracts boiler flue gas and fresh air through the boiler flue gas reflow pipe and the fresh air pipe, respectively; the boiler flue gas and the fresh air are mixed well in the mixed gas tank; mixed gas is blown into the boiler by the blower; various gases engage in oxidation-reduction reactions in a hearth of the boiler; thus, oxygen nitride is eliminated or largely decreased.

Owner:深圳市山水乐环保科技有限公司

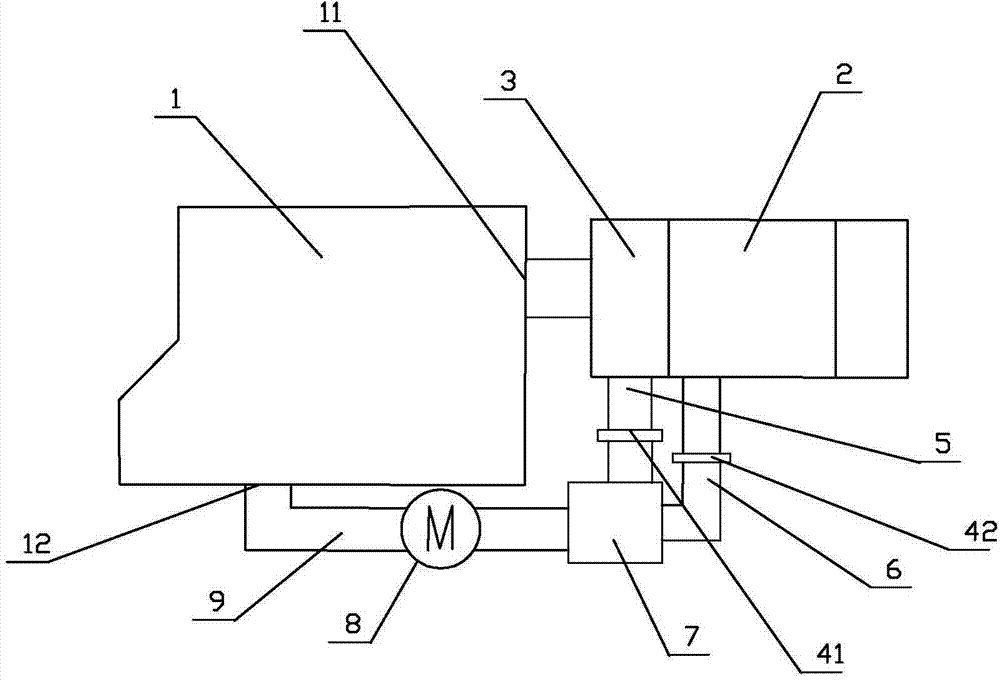

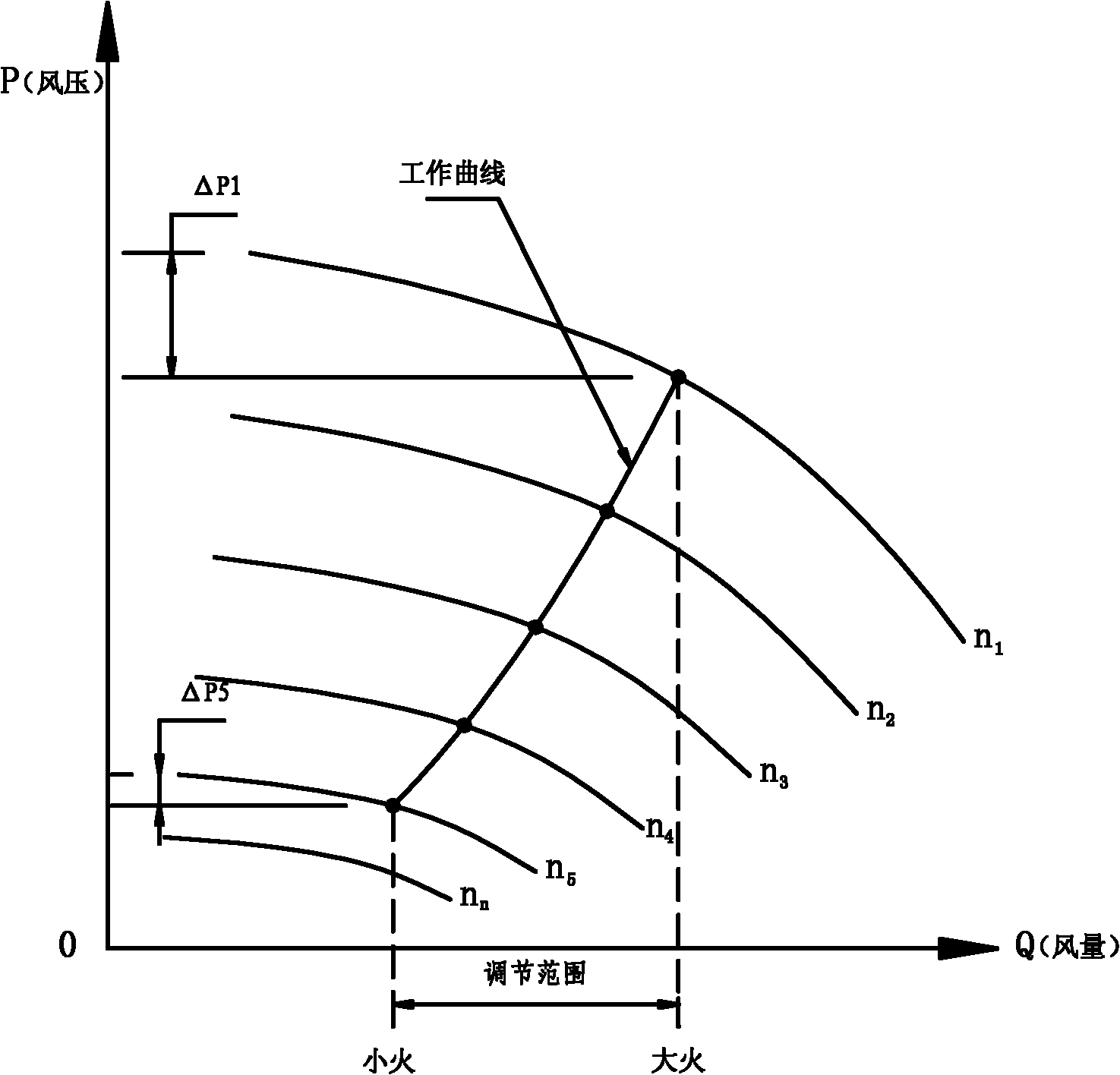

Combustor

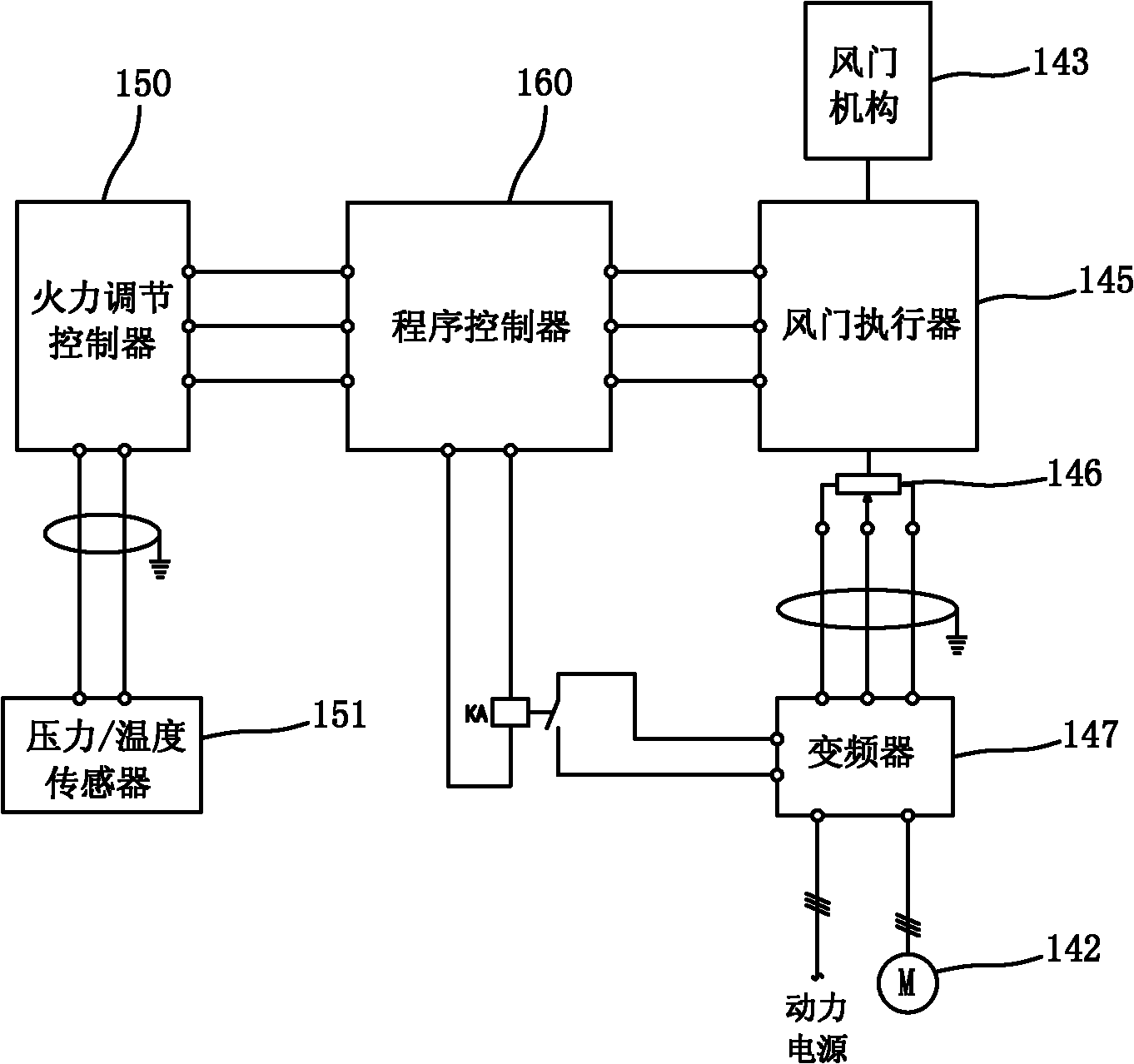

InactiveCN102072489AWiden the firepower adjustment ratio rangeControl speedFuel supply regulationAir supply regulationFrequency changerCombustor

The invention discloses a combustor, which comprises a combustion head, an ignitor, a fuel conveying / regulating device, a combustion air conveying / regulating device, a safe operation monitoring device and an electric control device, wherein the combustion air conveying / regulating device is provided with an air door mechanism controlled by an air door actuator and a frequency converter for controlling the rotate speed of an air blast motor and is provided with a displacement sensor which is linked with the air door actuator to control the output frequency of the frequency converter; a programming controller of the electric control device instructs the air door actuator to control the switching value of the air door mechanism according to the requirement of fuel loads; and the frequency converter adjusts the frequency output of the frequency converter to the air blast motor according to a switching value signal, which is detected by the displacement sensor, of the air door mechanism so as to control the rotate speed of the air blast motor. Thus, the firepower regulating ratio range of the combustor can be widened by the combination of frequency control and air door regulation.

Owner:HERMEN ENTERPRISES

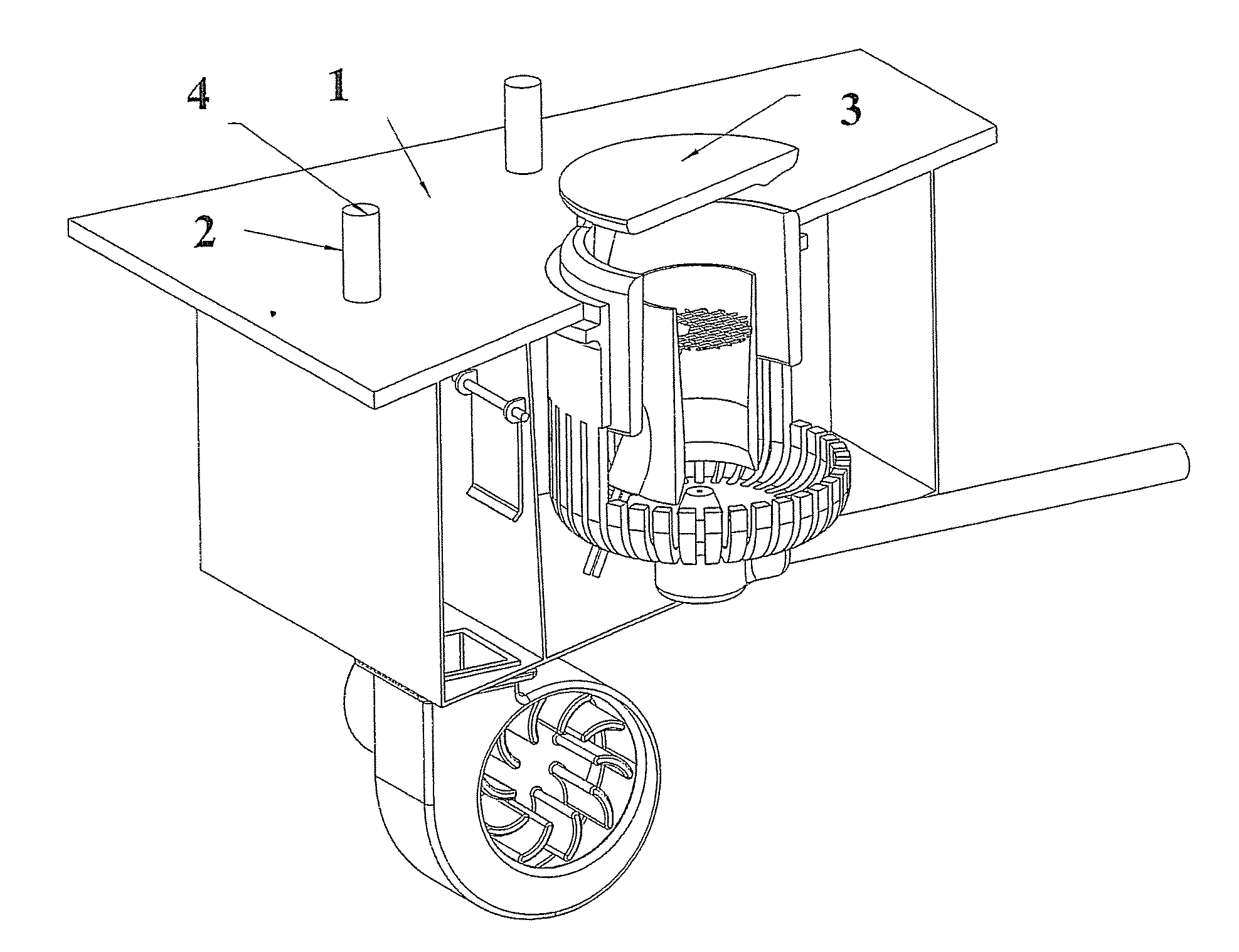

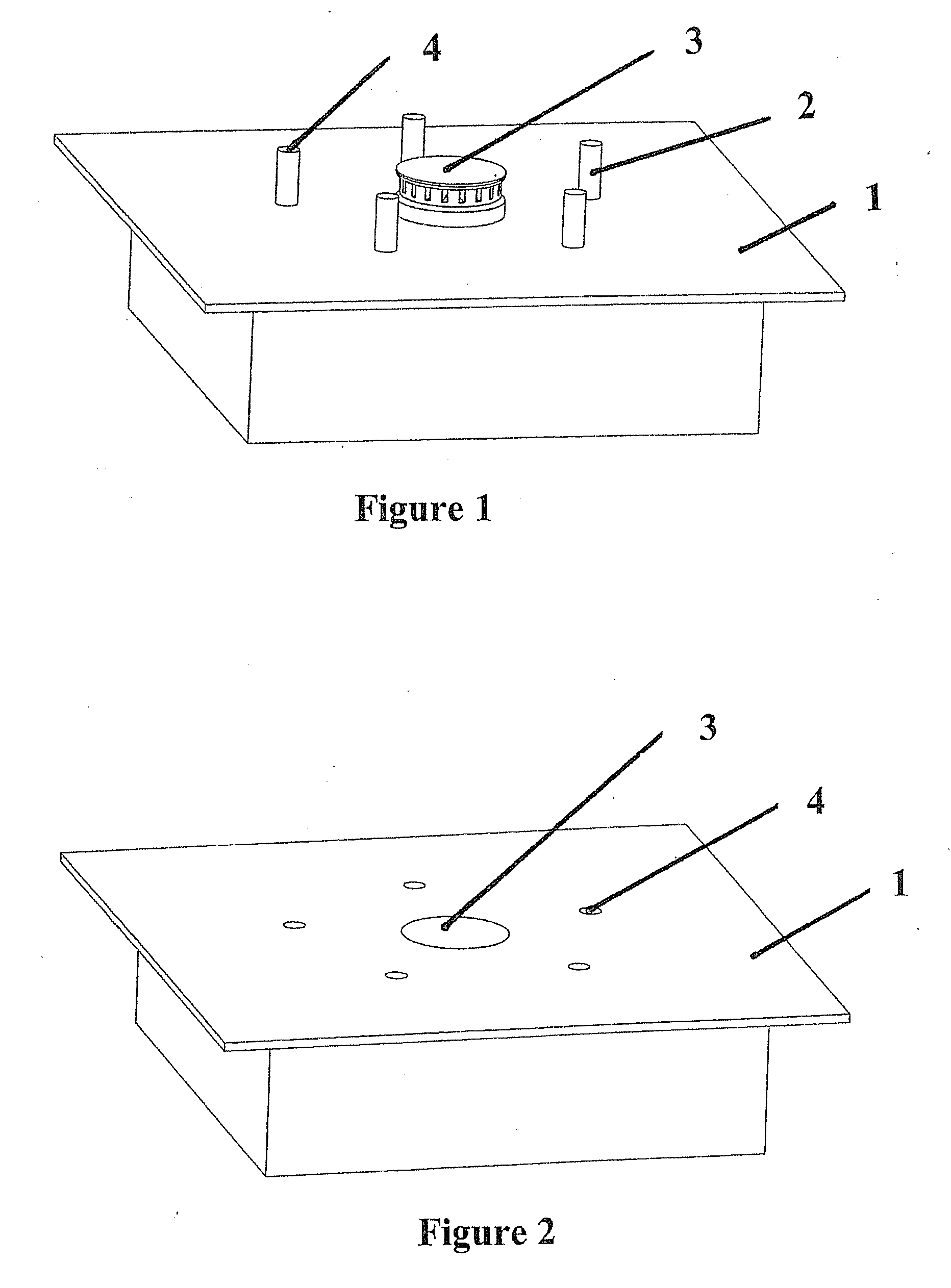

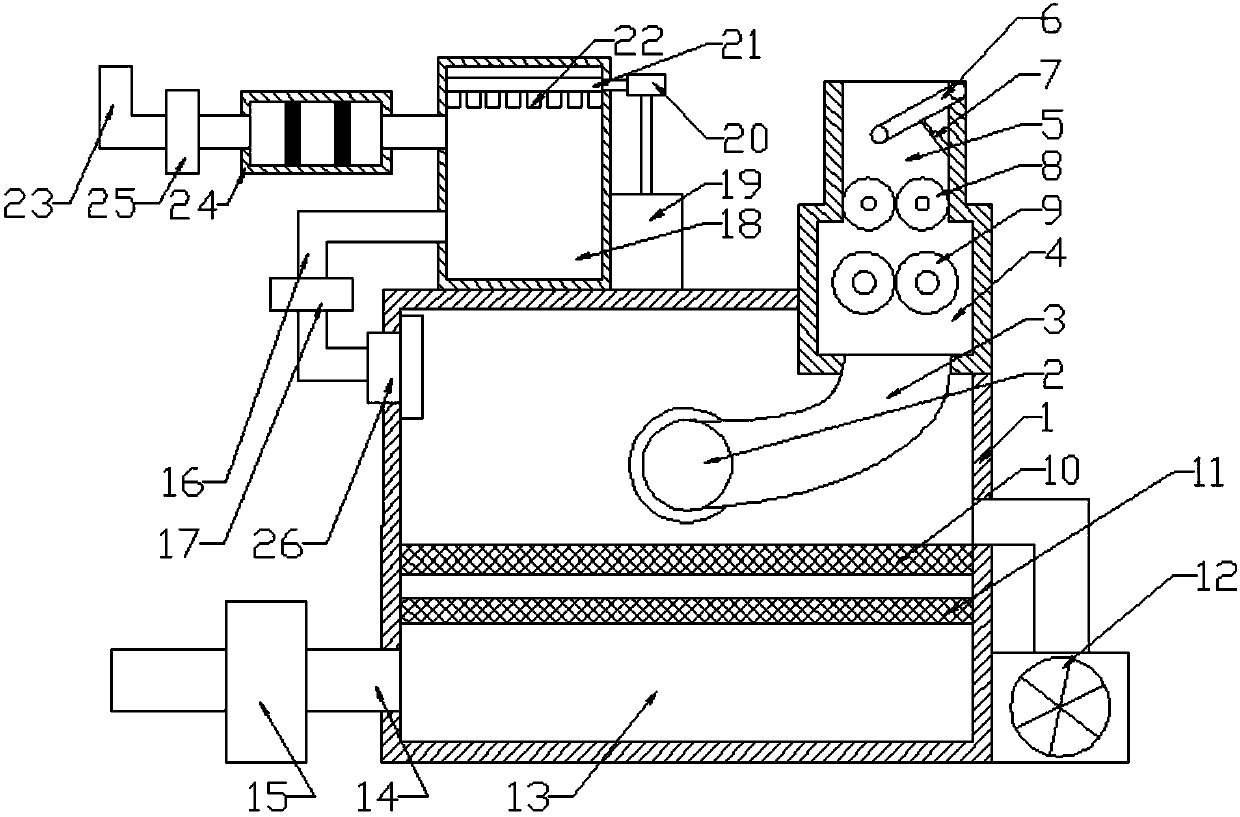

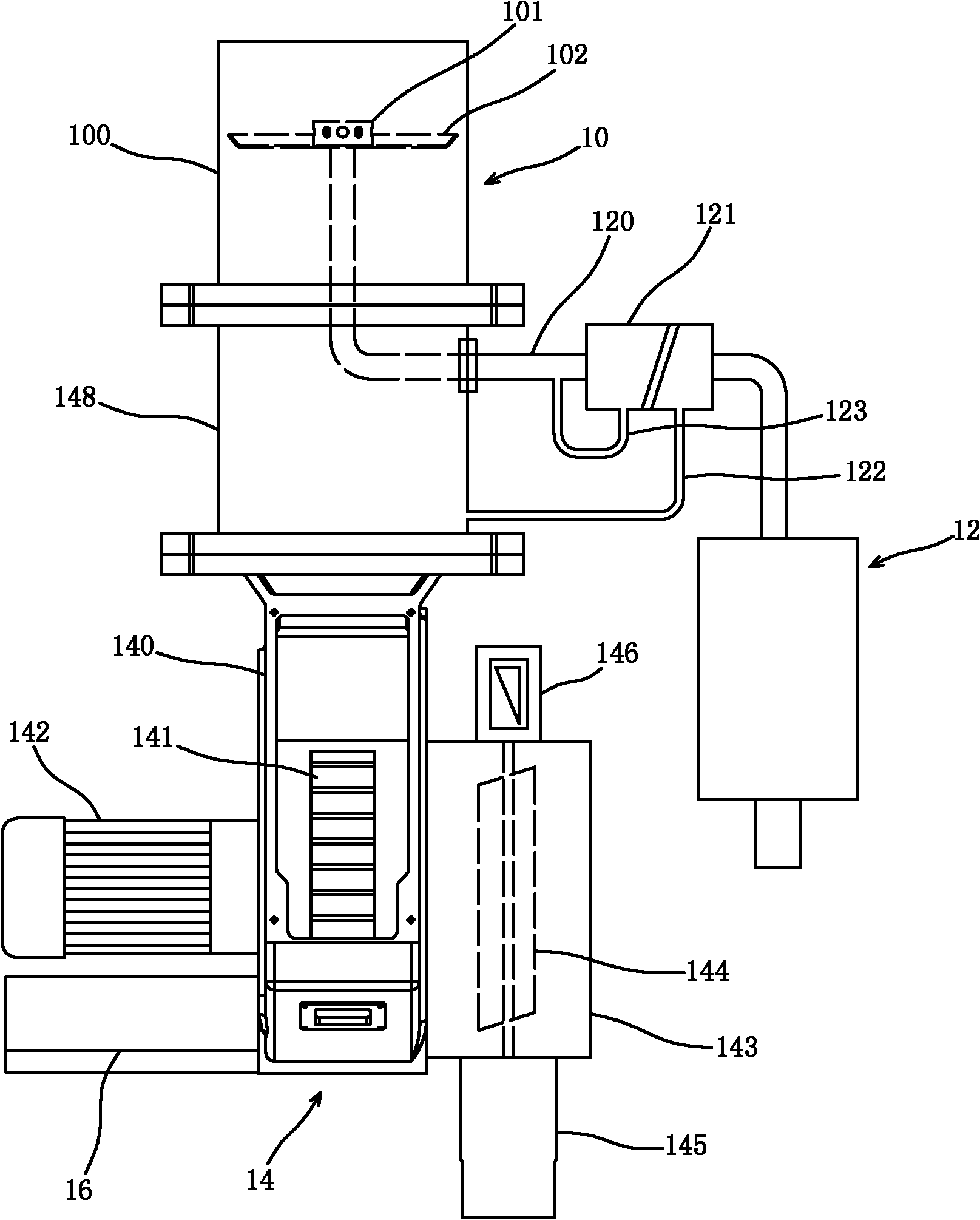

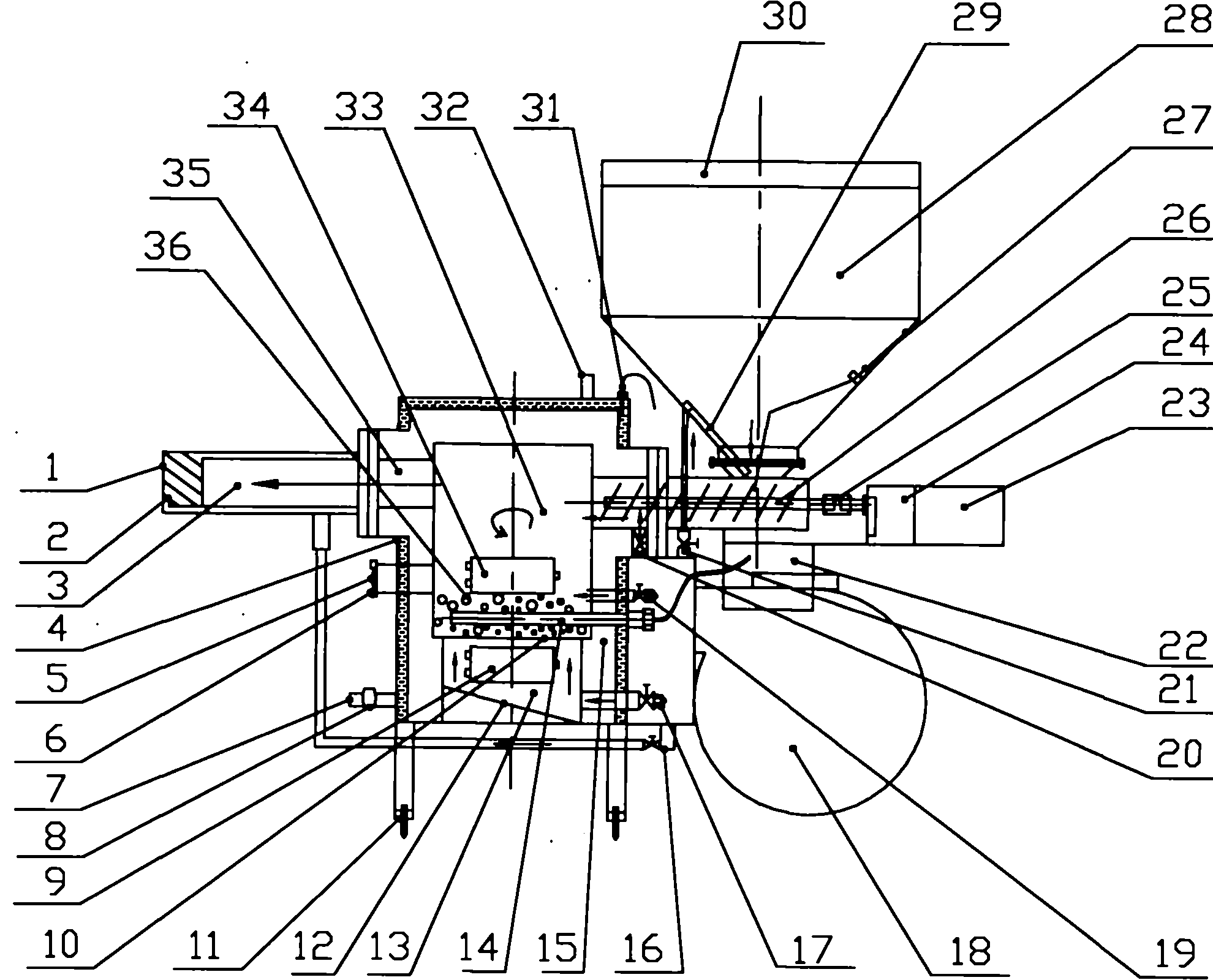

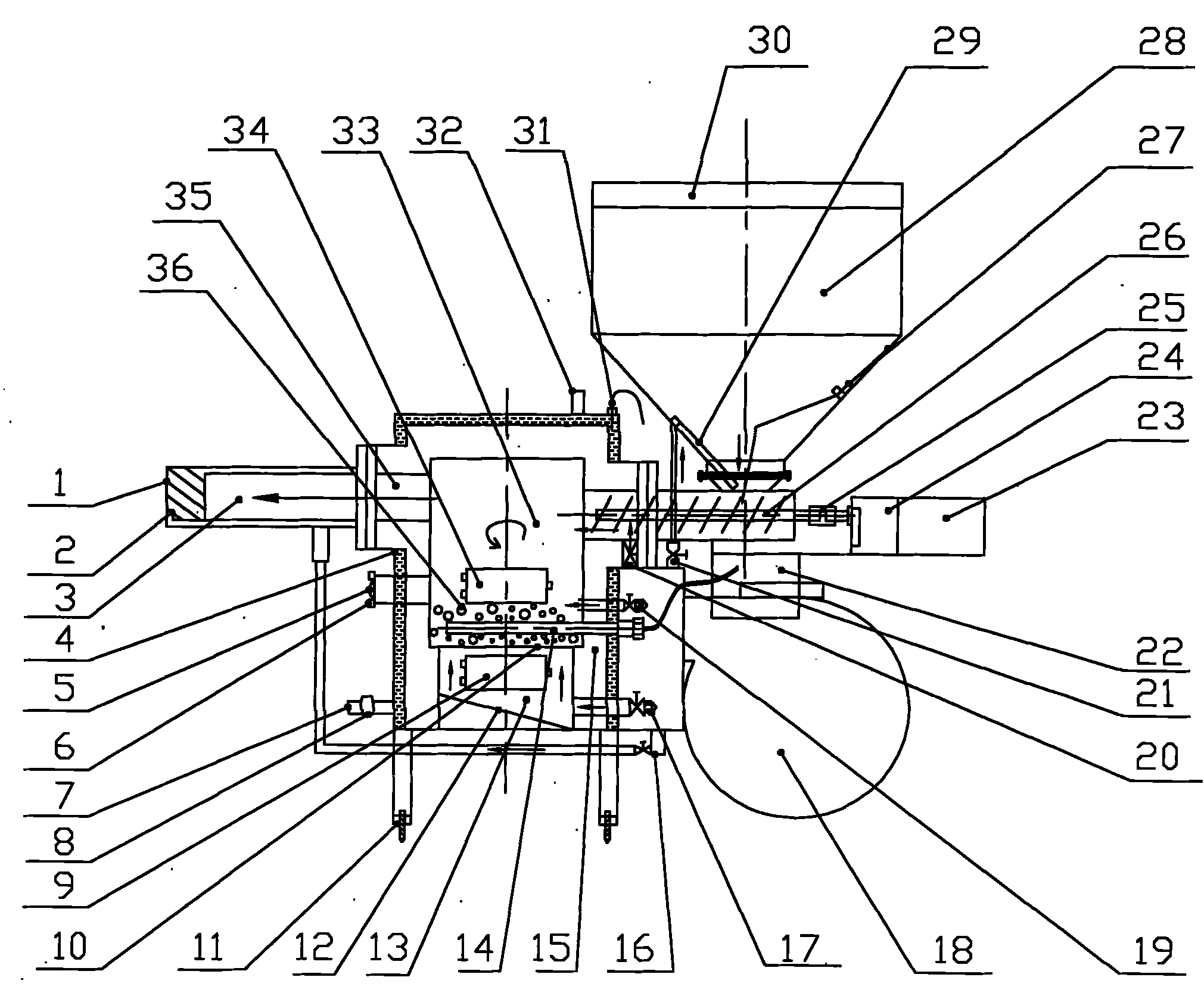

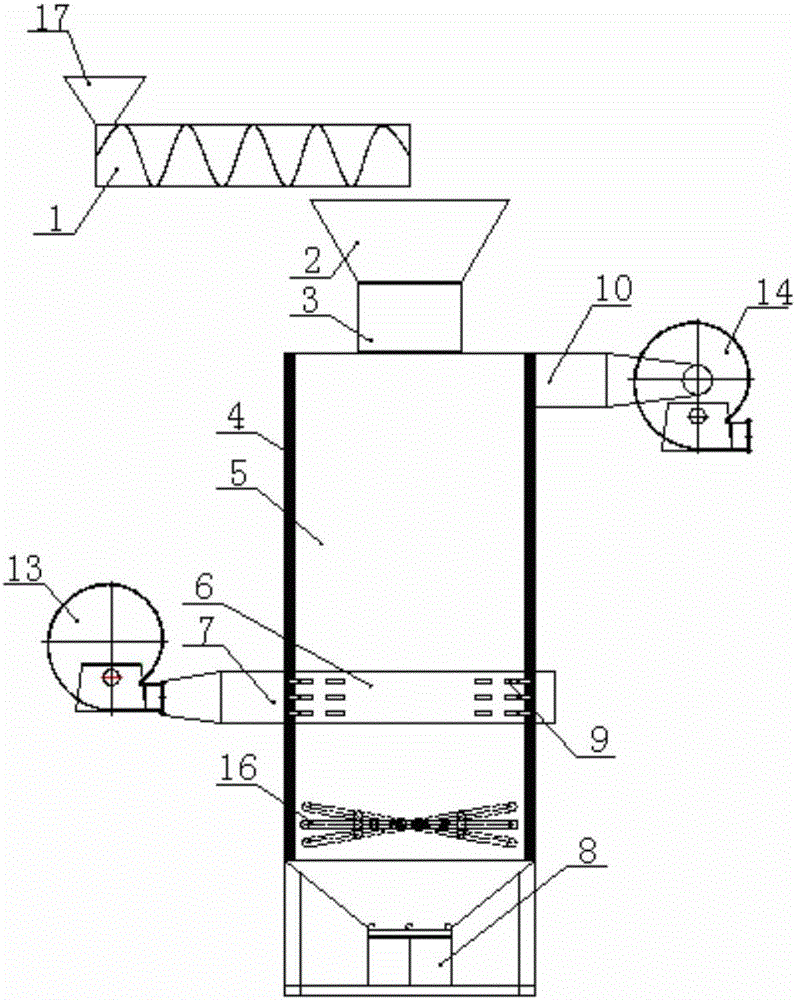

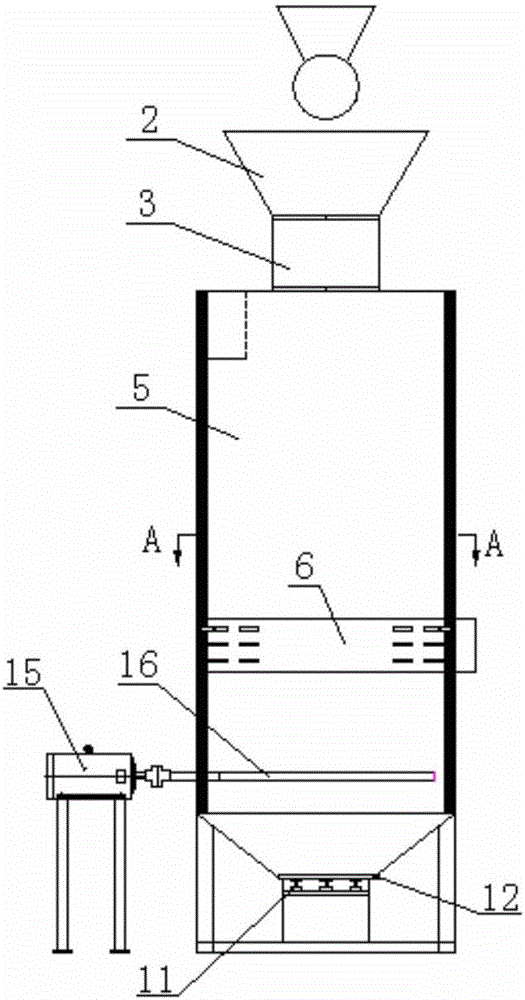

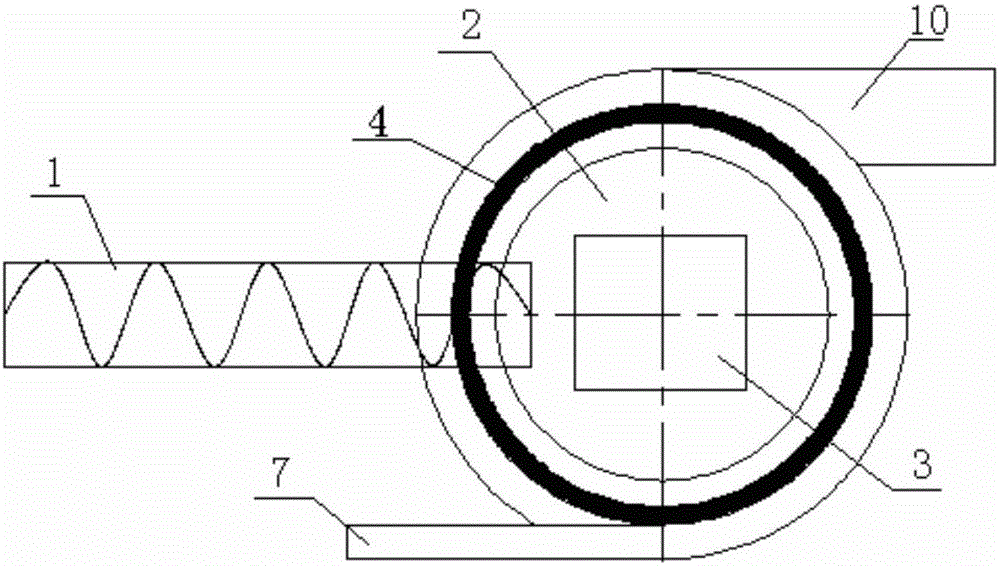

Biomass semi-gasification automatic control combustion engine

ActiveCN101893233AReduce pollutionLow costSolid fuel combustionBlast-producing apparatusAutomatic controlCombustion chamber

The invention discloses a biomass semi-gasification automatic control combustion engine. The combustion engine mainly comprises an engine base, a semi-gasification combustion chamber, a fire hole and a fire cylinder, wherein the semi-gasification combustion chamber is formed in the inner part of the engine base; the fire hole is formed on the engine base and communicated with the semi-gasification combustion chamber; and the fire cylinder is communicated with the fire hole. The combustion engine is characterized in that: the outer part of the engine base is provided with a feeding device connected with the semi-gasification combustion chamber; the inner part of the semi-gasification combustion chamber is provided with a fire grate which divides the inner part of the semi-gasification combustion chamber into a combustion cavity and an ash removing cavity; the fire hole is communicated with the combustion cavity; an ignition device extending into the inner part of the combustion cavity is also arranged on the engine base; and simultaneously the out part of the engine base is provided with a blower device which is connected with the combustion cavity, the ash removing cavity, the fire cylinder and the feeding device respectively. The biomass semi-gasification automatic control combustion engine can greatly reduce environmental pollution, reduce carbon emission and sulfur emission by 99 percent and 100 percent respectively compared with that of coal combustion, lower the cost by 40 to 60 percent compared with that of oil use, and simultaneously reduce the carbon emission and the sulfur emission by 60 percent and 99 percent respectively.

Owner:朱春华

Method and apparatus for controlling a burning flame

ActiveUS7226284B2Reduce the possibilityNon-electric lightingCapillary burnersAir movementEngineering

A method and apparatus for controlling a candle flame. A candle flame may be provided in a controllable environment, e.g., an enclosed area formed at least in part by an air-tight cover. Air may be forced into the enclosed area by an air movement device (e.g., a fan) to keep the flame burning. The flame may be extinguished by reducing (e.g., stopping) air flow into the enclosed area.

Owner:AVELAR VICTOR

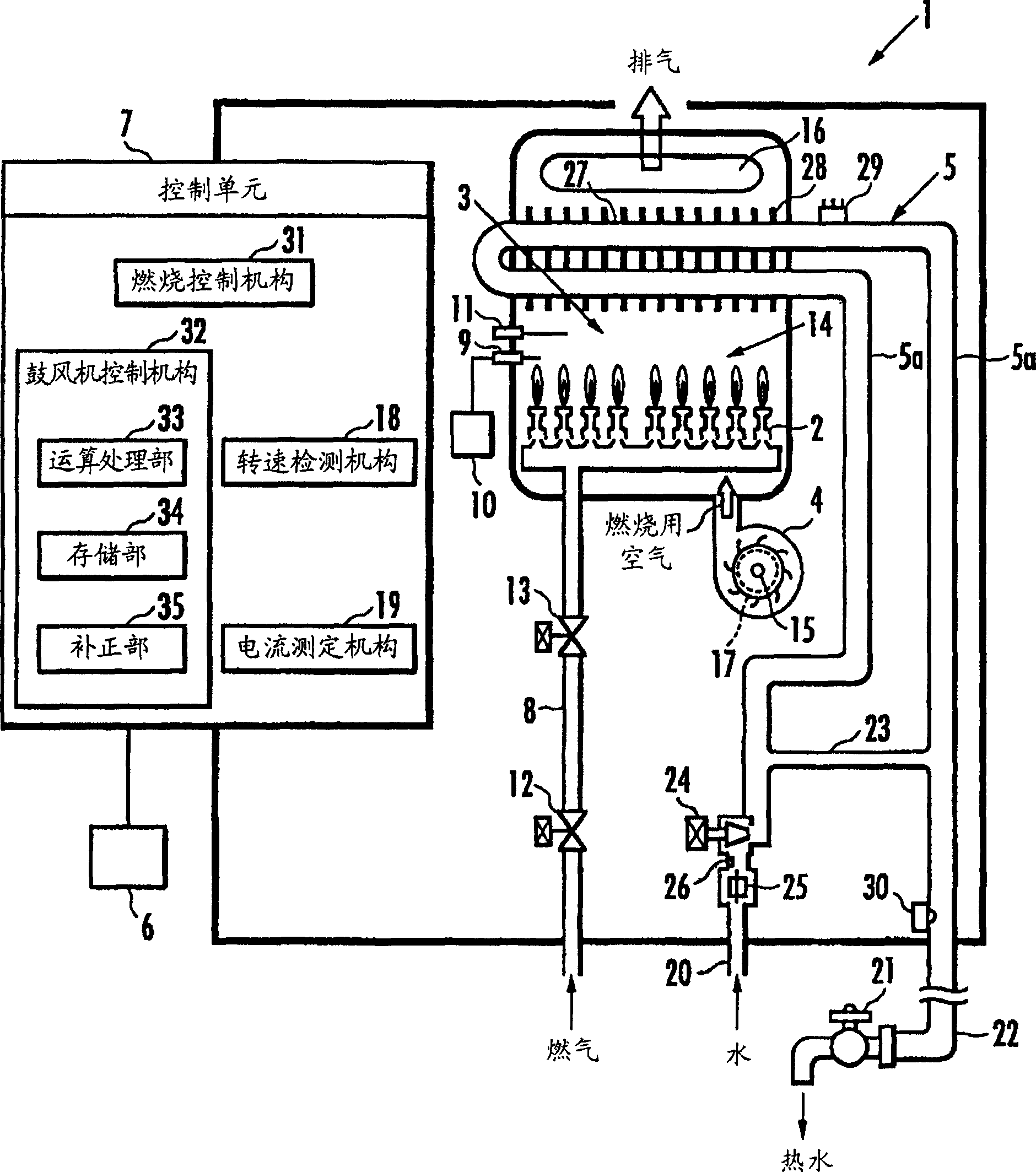

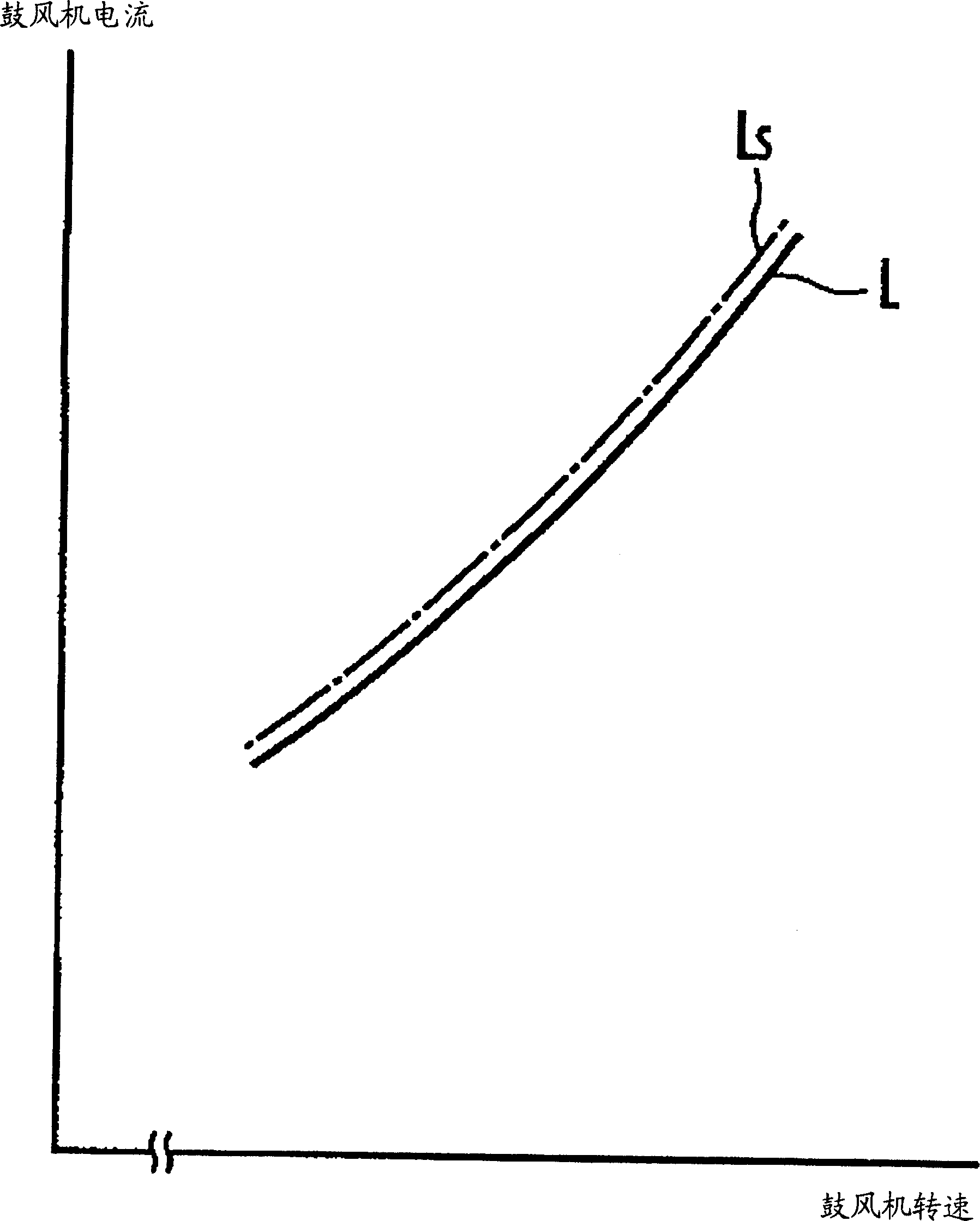

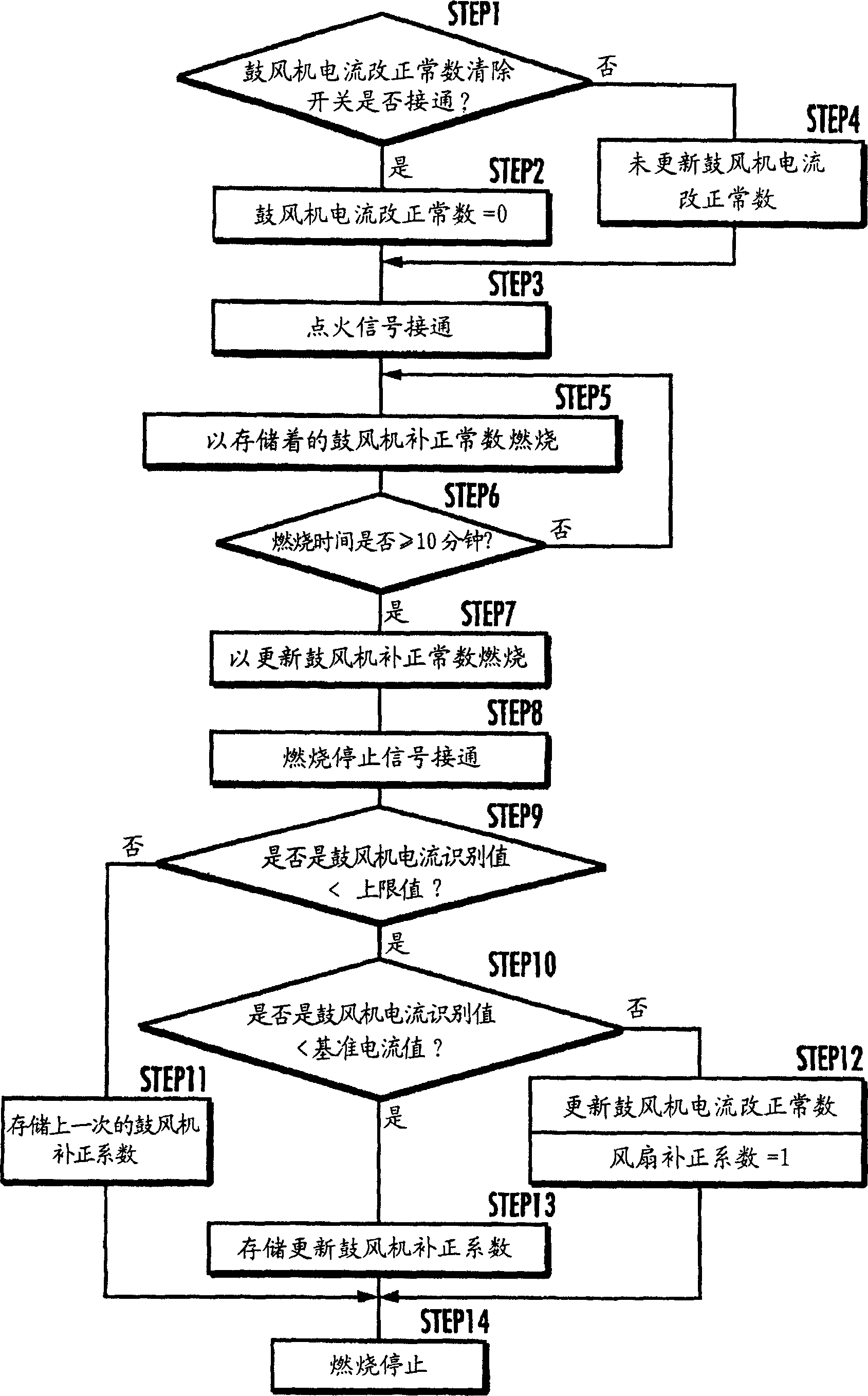

Burner

ActiveCN1752523ALess adjustment workAir volume correctionAir supply regulationElectric motor controlLower limitCombustor

To provide combustion equipment. This combustion equipment is provided with a fan control means which controls a fan for supplying a burner with combustion air. The fan control means is equipped with a first operation means which computes the revised value of a fan current from the difference between a detected current value and a reference current value on the basis of fan revolution - fan current properties that are predetermined corresponding to the fan revolution - fan current properties that show the lower limit of the dispersion of the current of the fan, a second operation means which computes the fan current recognized value being the difference between the detected current value and the fan current revised value, a third operation means which computes a fan correction value based on the fan current recognized value, a memory means which stores the reference current value, the fan current revised value, the fan current recognized value, and the fan correction, and a correction means which corrects the quantity of air of the fan based on the fan correction value.

Owner:RINNAI CORP

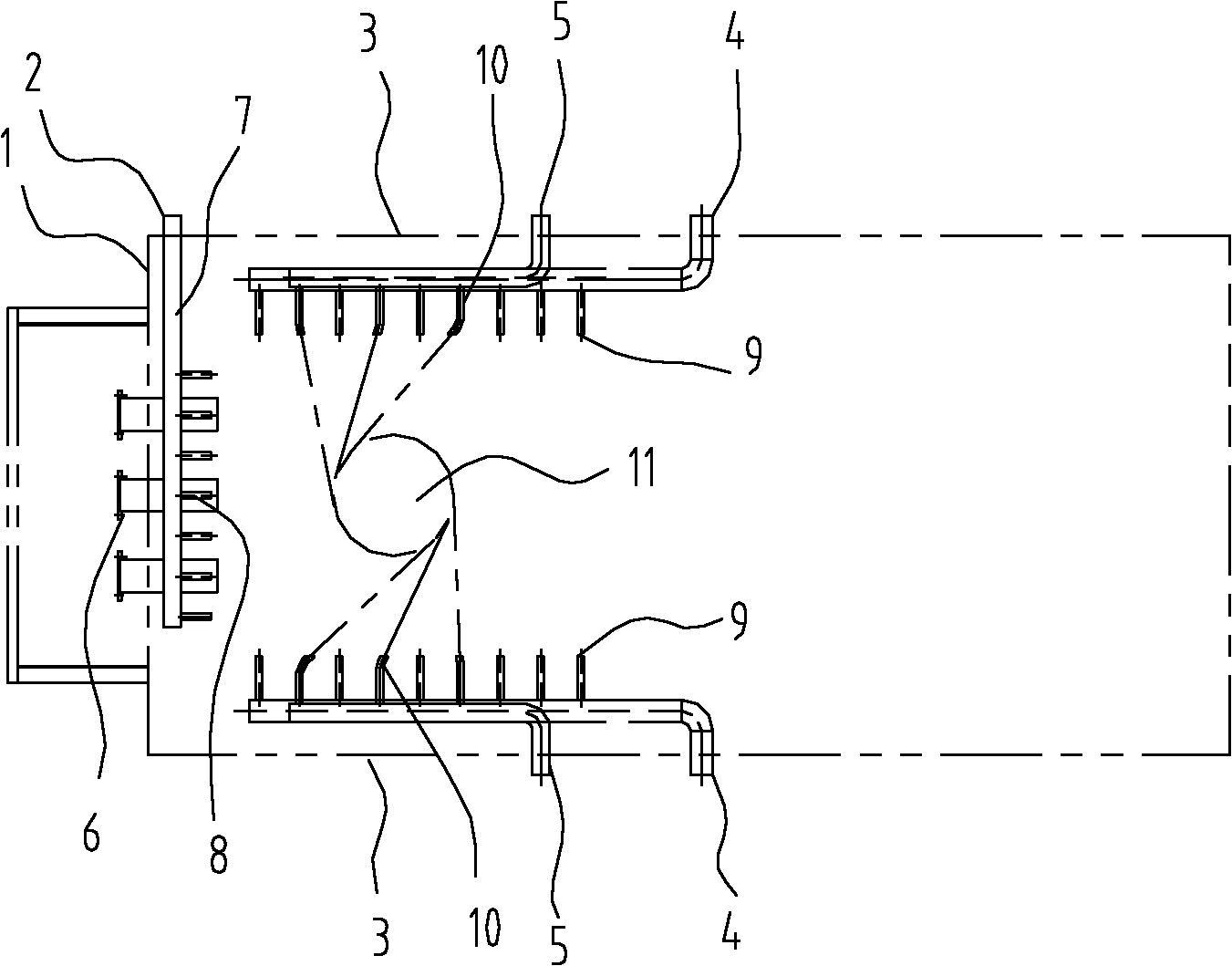

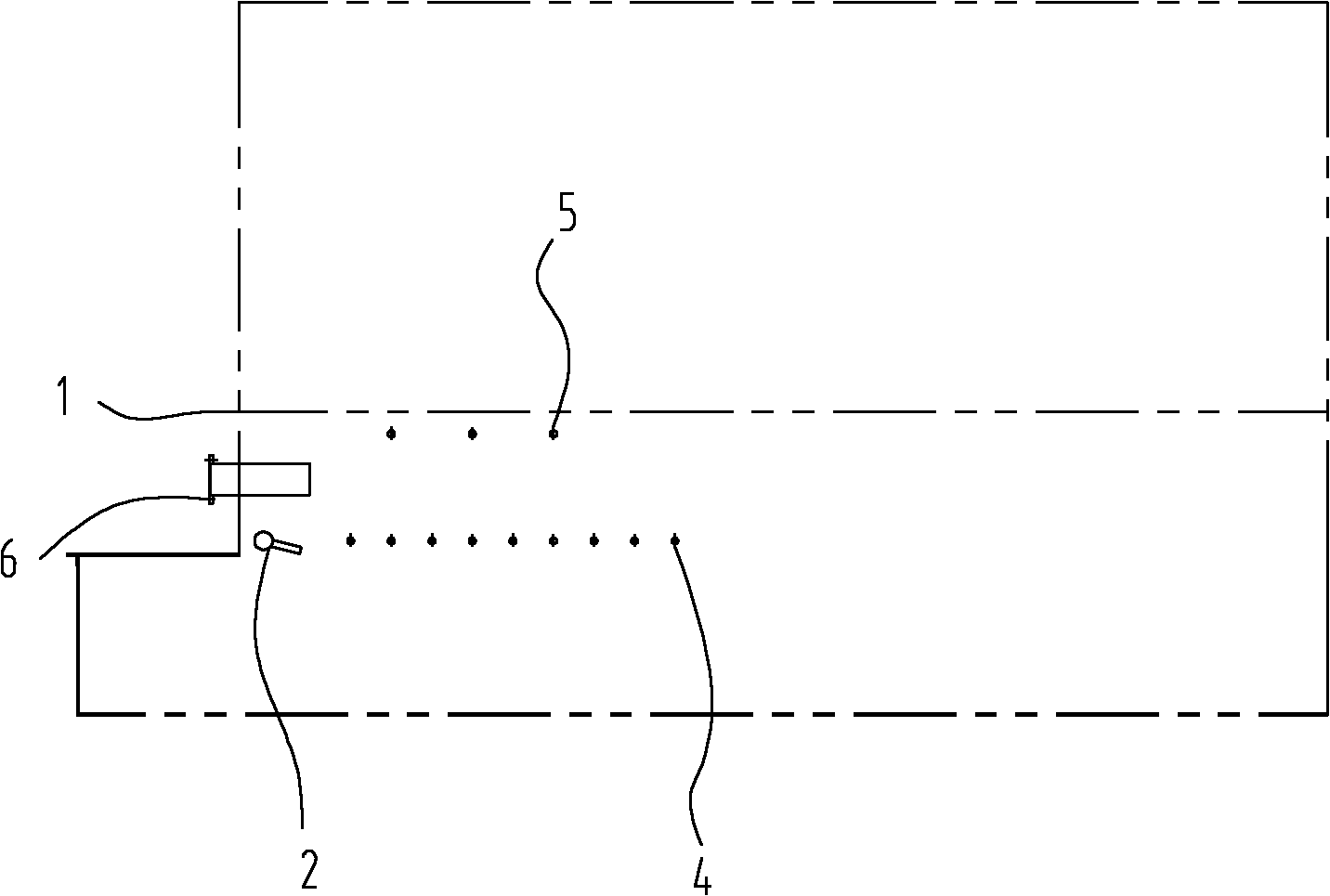

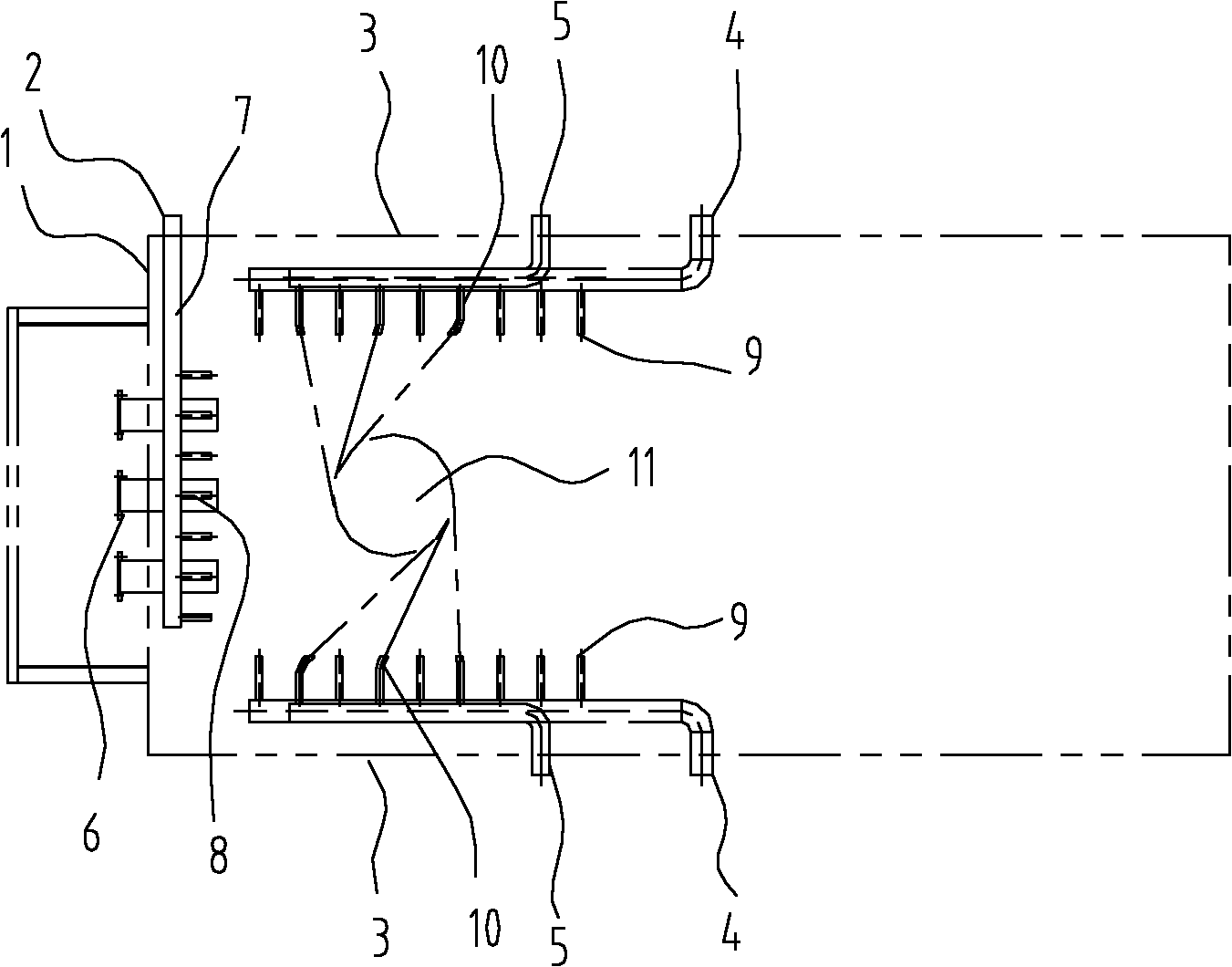

Air distribution system of biomass moulding fuel boiler

InactiveCN102012038APromote combustionBurn fullyBlast-producing apparatusAir volumeDistribution system

The invention discloses an air distribution system of a biomass moulding fuel boiler, comprising a stokehole air pipe arranged on the front wall of the boiler, a bottom air pipe arranged on the side wall of the boiler, and a cyclone air pipe arranged above the bottom air pipe. In the invention, the stokehole air pipe is additionally arranged to ensure that biomass moulding fuel entering the boiler from a feed port of the boiler is rapidly dried and subjected to volatile matter separation so as to further burn rapidly; the biomass moulding fuel sufficiently burns under the condition of air compensation by the bottom air pipe at the side wall of the boiler; and the cyclone air pipe arranged above the bottom air pipe ensures the BMF (Biomass Moulding Fuel) to further burn sufficiently on one hand and ensures that powdery ash residues fall on a fire grate under the cyclone action so as to reduce the content of the powdery ash residues entering a radiation area along with high-temperature gas fume.

Owner:GUANGZHOU DEVOTION THERMAL TECH

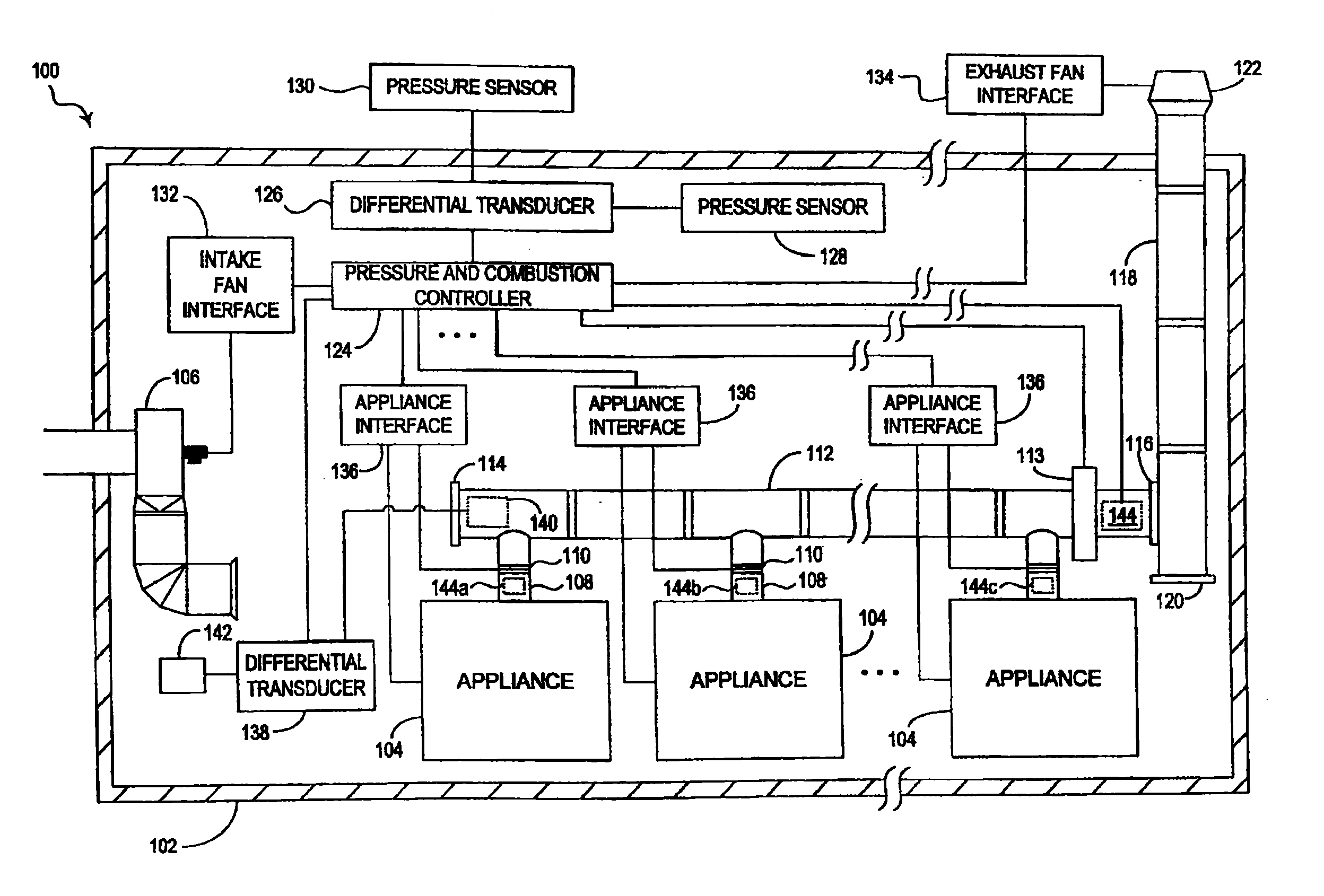

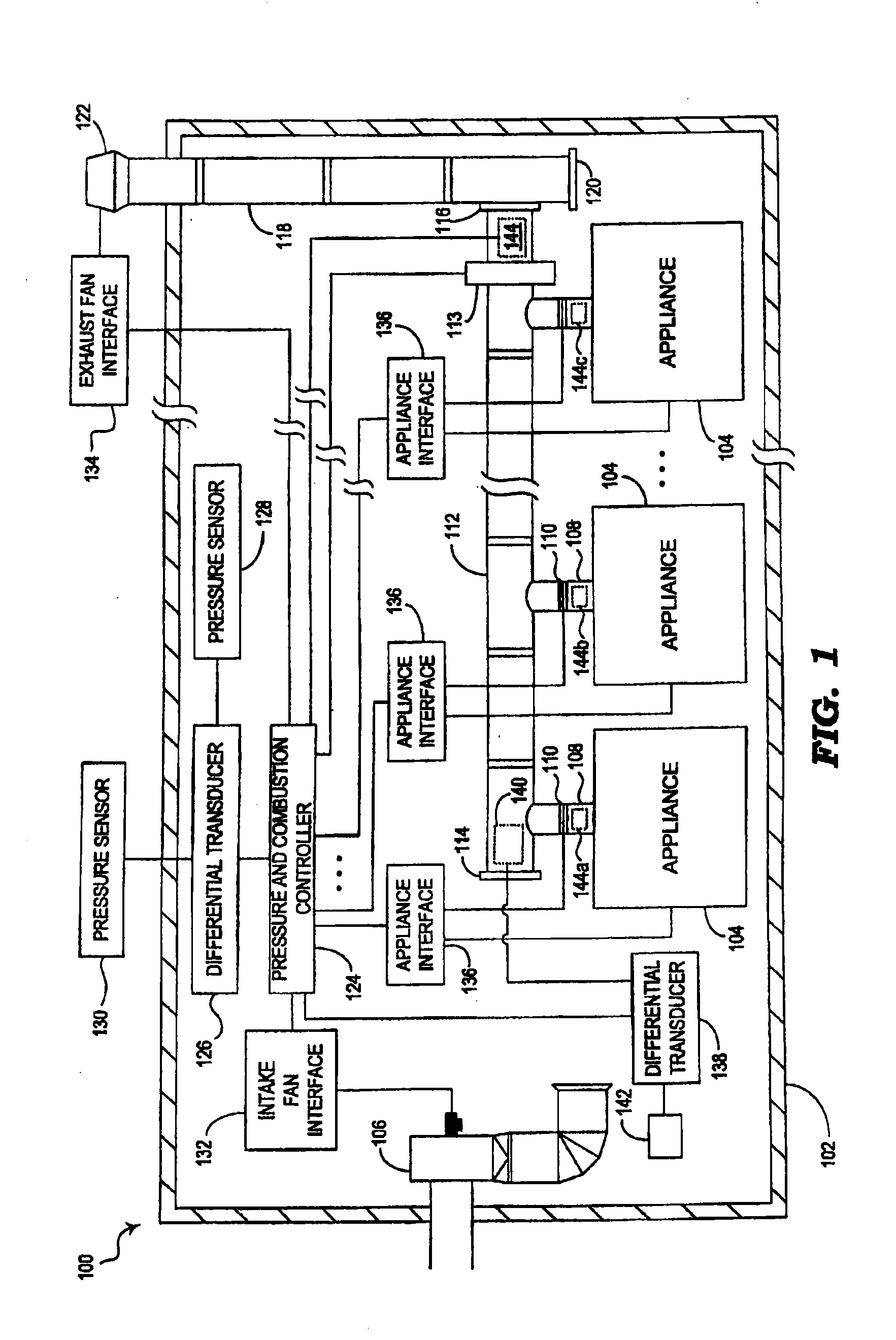

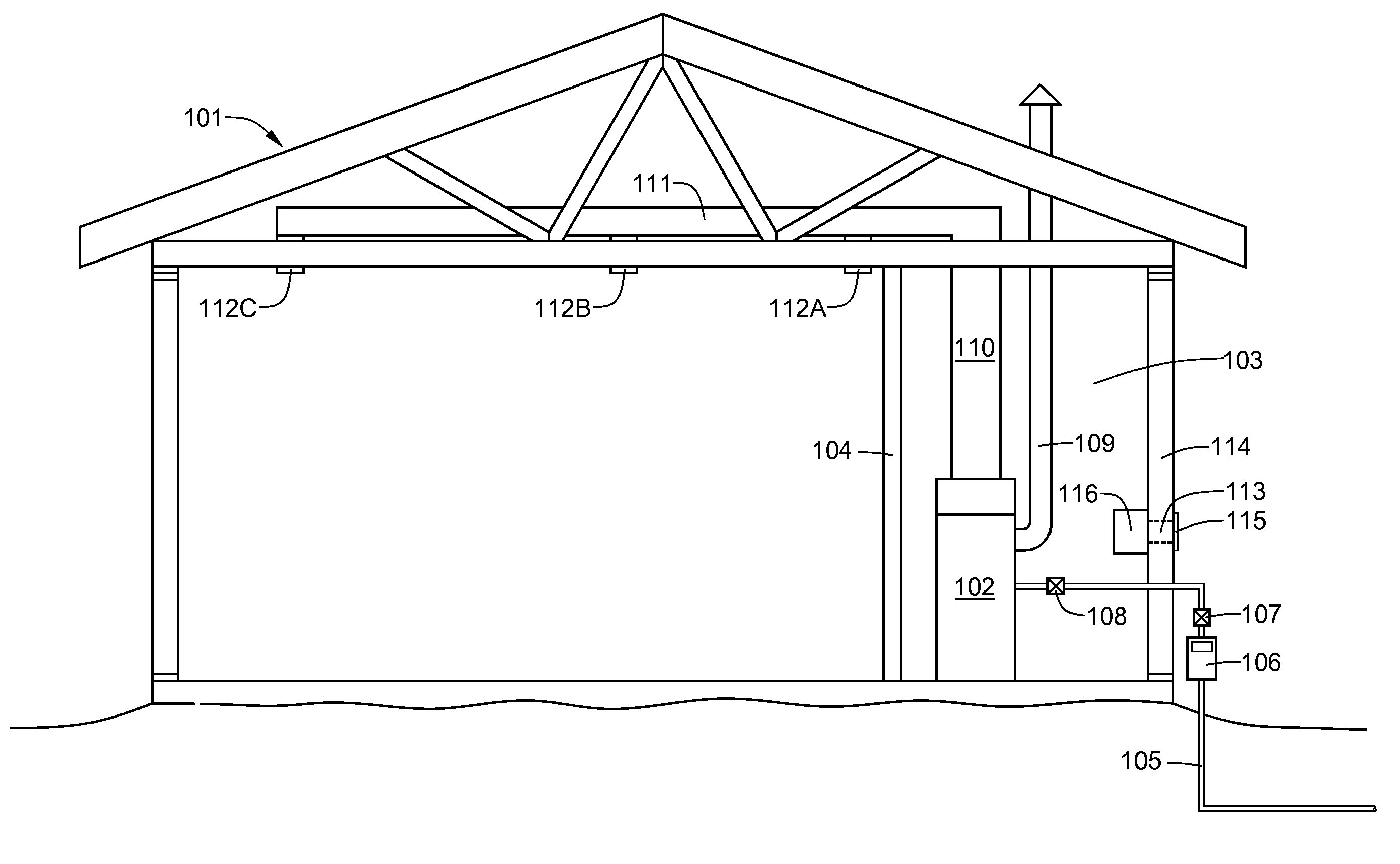

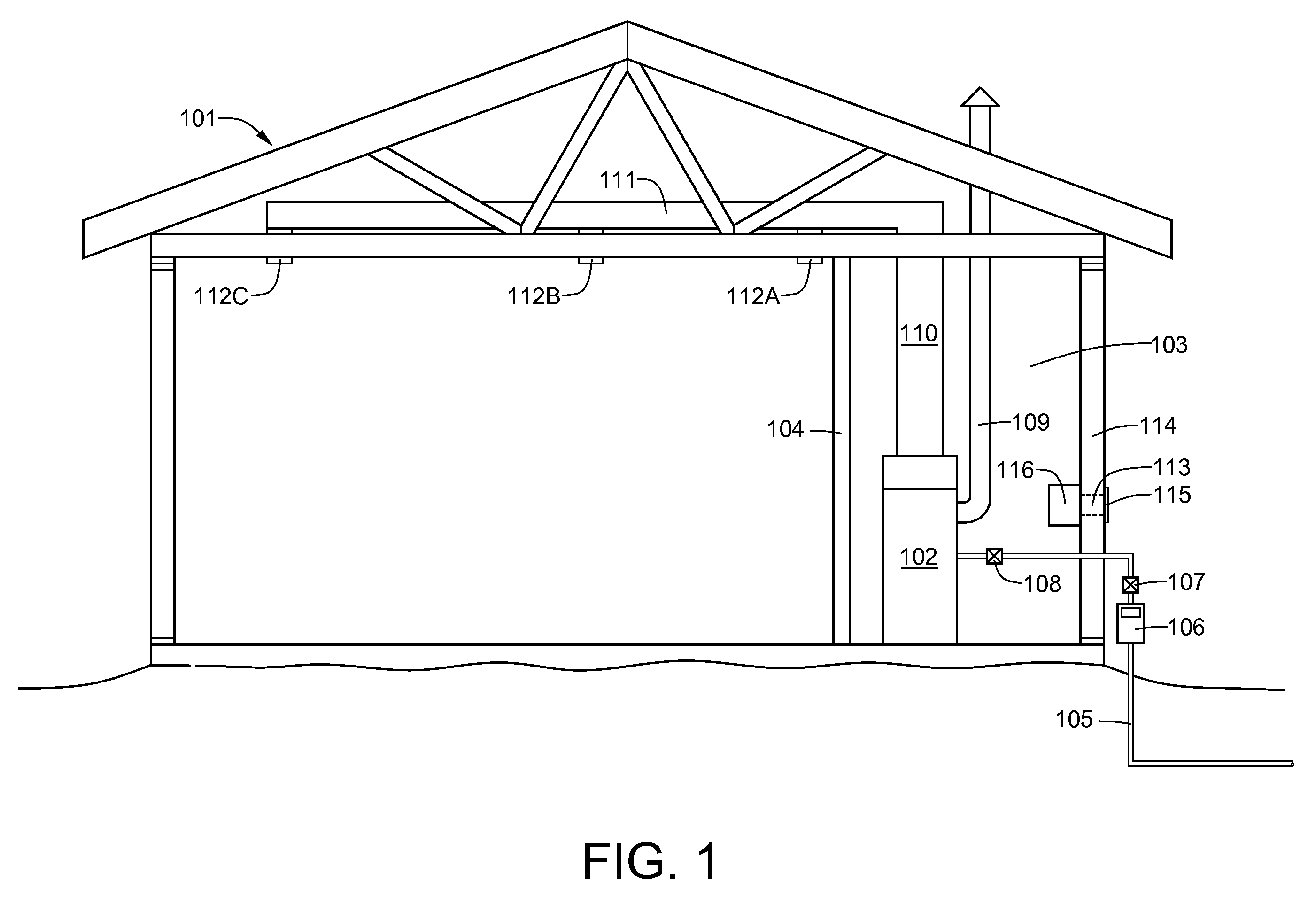

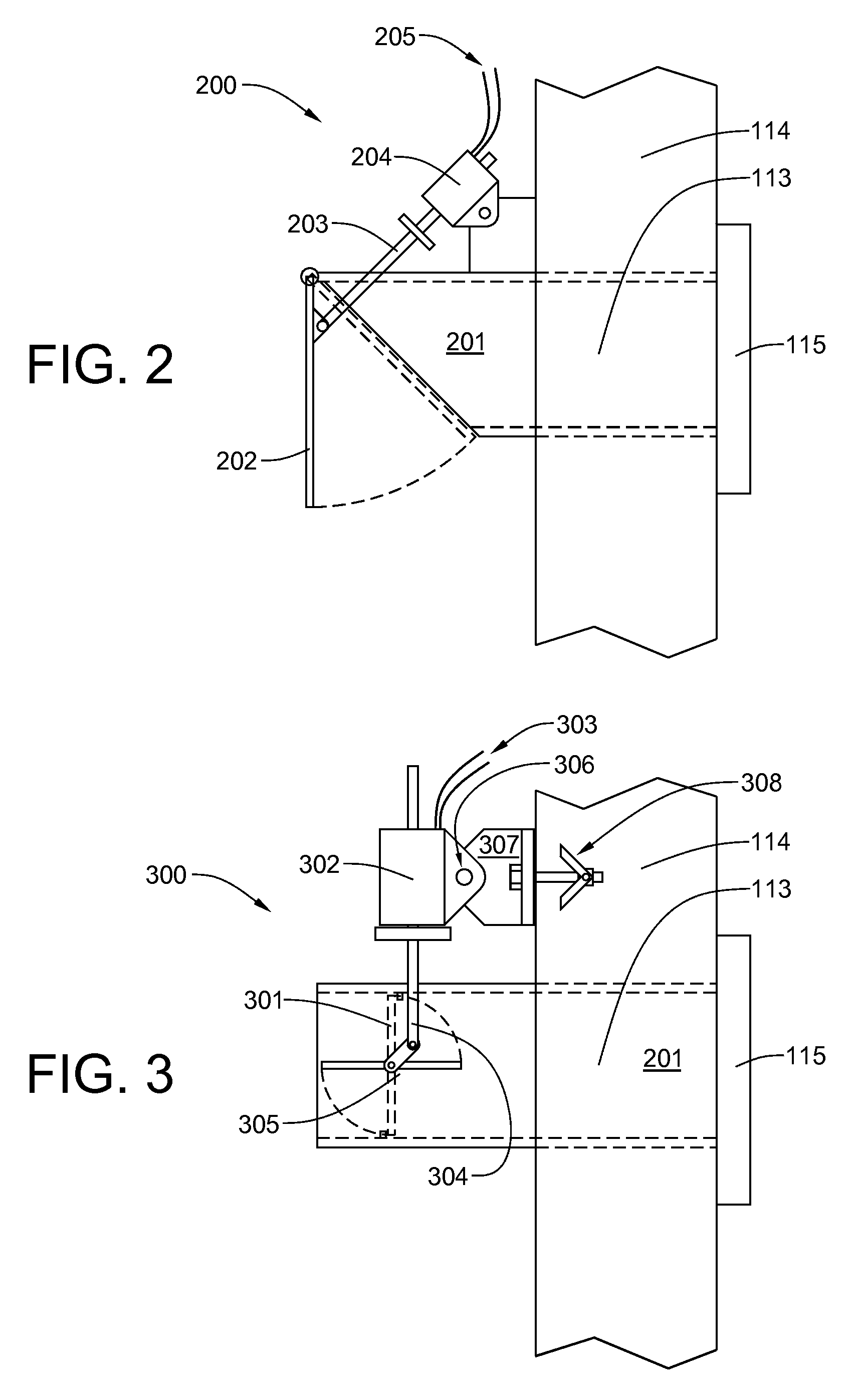

Combustion air vent control for furnaces

InactiveUS20070204862A1Prevent air leakageKeep for a long timeAir supply regulationDomestic stoves or rangesCombustionAir pump

Various apparatus are disclosed for controlling the combustion air vent of fuel-fired furnaces. For a first embodiment of the invention, a furnace-controlled air valve is placed in the combustion air duct. When the furnace begins a heating cycle, the valve is opened. When the heating cycle ends, the valve is closed and remains closed until the beginning of the next heating cycle. For a second embodiment of the invention, a positive-displacement air pump is placed in the combustion air duct. The air pump pumps air from the exterior into the mechanical room at a controlled rate during each heating cycle of the furnace. The air valve or the air pump is controlled directly or indirectly by the furnace thermostat.

Owner:COWAN SCOTT DAVID

Household garbage incinerator

ActiveCN106122975AUniform temperature distributionIncrease temperatureTravelling grateBlast-producing apparatusCombustionSlag

The invention discloses a household garbage incinerator. A furnace door is arranged at the top of a furnace cavity of the incinerator. Materials are put into the furnace cavity through a feeding system. At least two rows of fire grates used for carrying garbage are arranged in the furnace cavity. The garbage entering the furnace cavity is dried and combusted on the fire grates. A slag discharging and dust removing door is arranged at the bottom of the furnace cavity. A plurality of injection pipes are arranged on the side wall of the furnace cavity. The injection pipes are connected with an air blower and used for injecting air to the interior of the furnace cavity. An exhaust port is formed in the top of the furnace cavity, arranged in the tangential direction of the furnace cavity, connected with an induced draft fan and used for pumping smoke in the furnace cavity. According to the household garbage incinerator, the movable fire grates are adopted, layered combustion is achieved, the garbage is evenly distributed, and the purpose of controlling the combustion condition in the incinerator can be achieved by controlling the induced air amount and air blowing amount. Through the arrangement of the injection pipes, the smoke temperature in the incinerator can be distributed more evenly, the retention time of the smoke is greatly prolonged, harmful matter such as dioxin can be completely decomposed, and sufficient combustion of the garbage is achieved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Camping stove

InactiveCN103644578AFierce firepowerDomestic stoves or rangesSolid fuel combustionEngineeringForced-air

The invention relates to a camping stove. The camping stove comprises a stove head, a stove body and a supporting frame, wherein the stove body comprises an outer drum and a burning drum arranged in the outer drum; the outer drum is a sealed type outer drum sheathed at the outer part of the burning drum; the bottom part of the outer drum is also provided with a forced air-supply assembly communicated with an inner cavity of the outer drum. The camping stove has the advantages that since the burning drum is arranged in the closed inner cavity defined by the outer drum, and the forced air-supply assembly is communicated with the closed inner cavity, even though the camping stove is used at a high-altitude oxygen-poor region, the forced air-supply system also can convey enough oxygen into the burning drum to support burning of fuel in the burning drum, so that powerful fire is provided for the camping stove.

Owner:CHENGDU FLENDA SCI & TECH

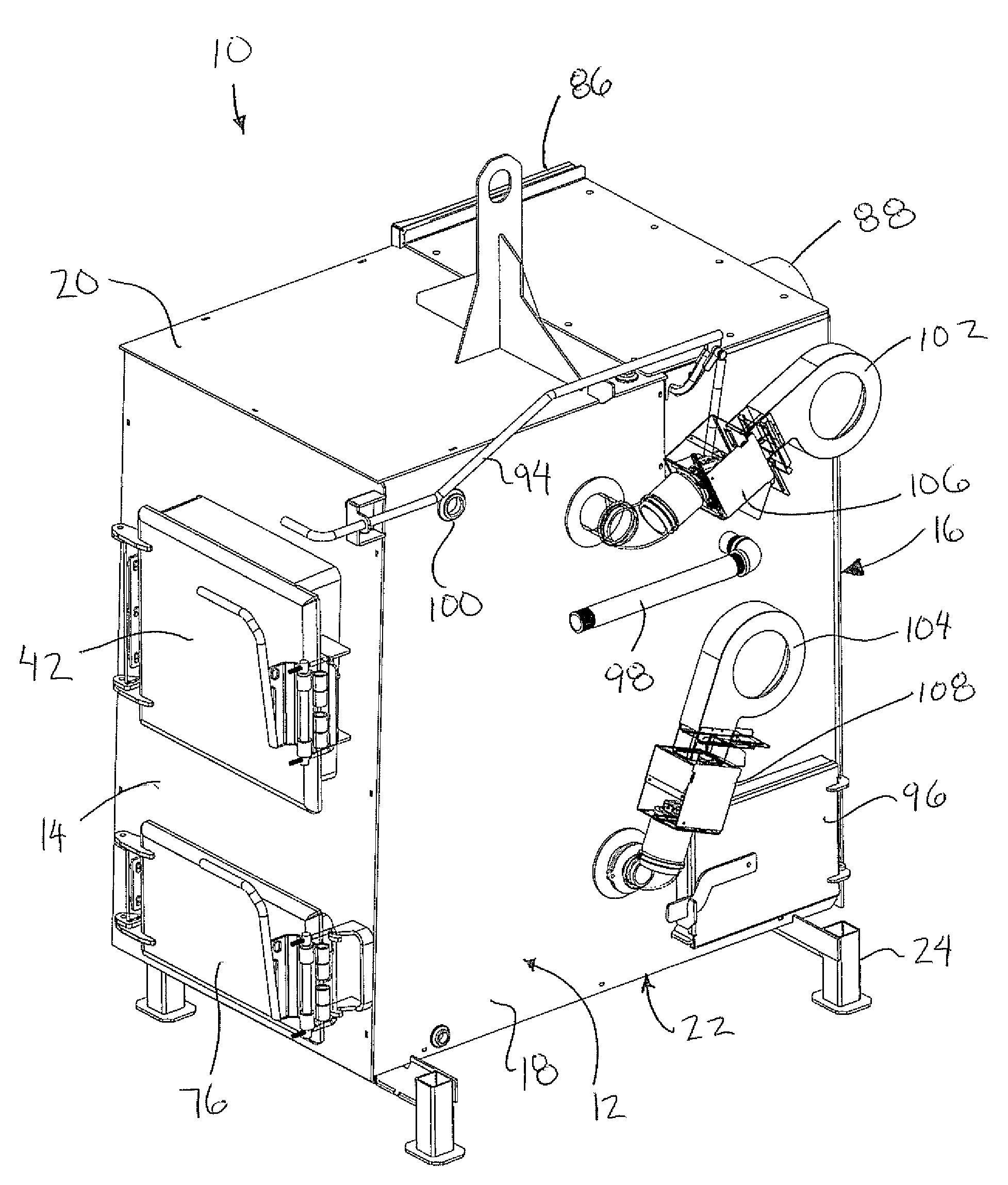

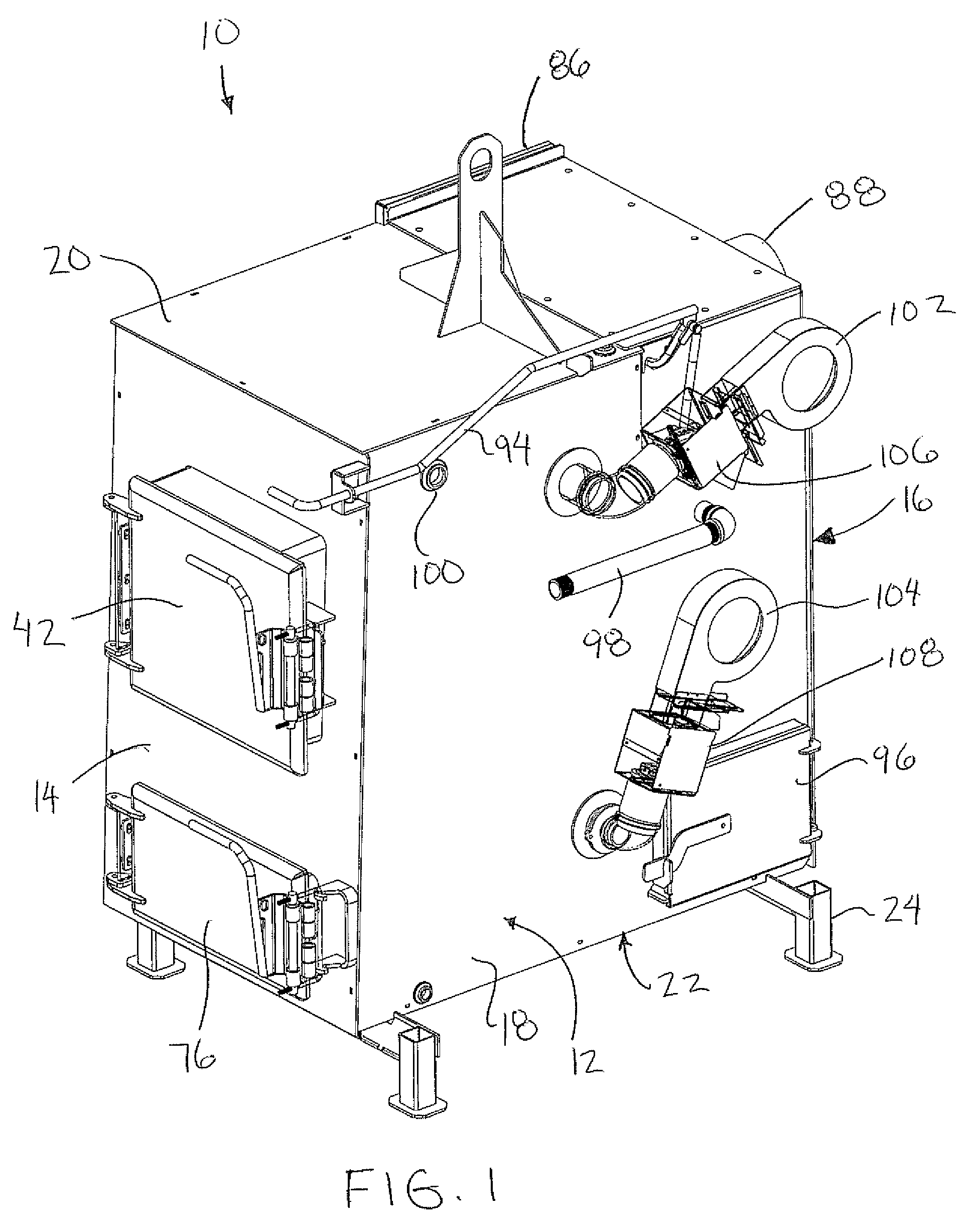

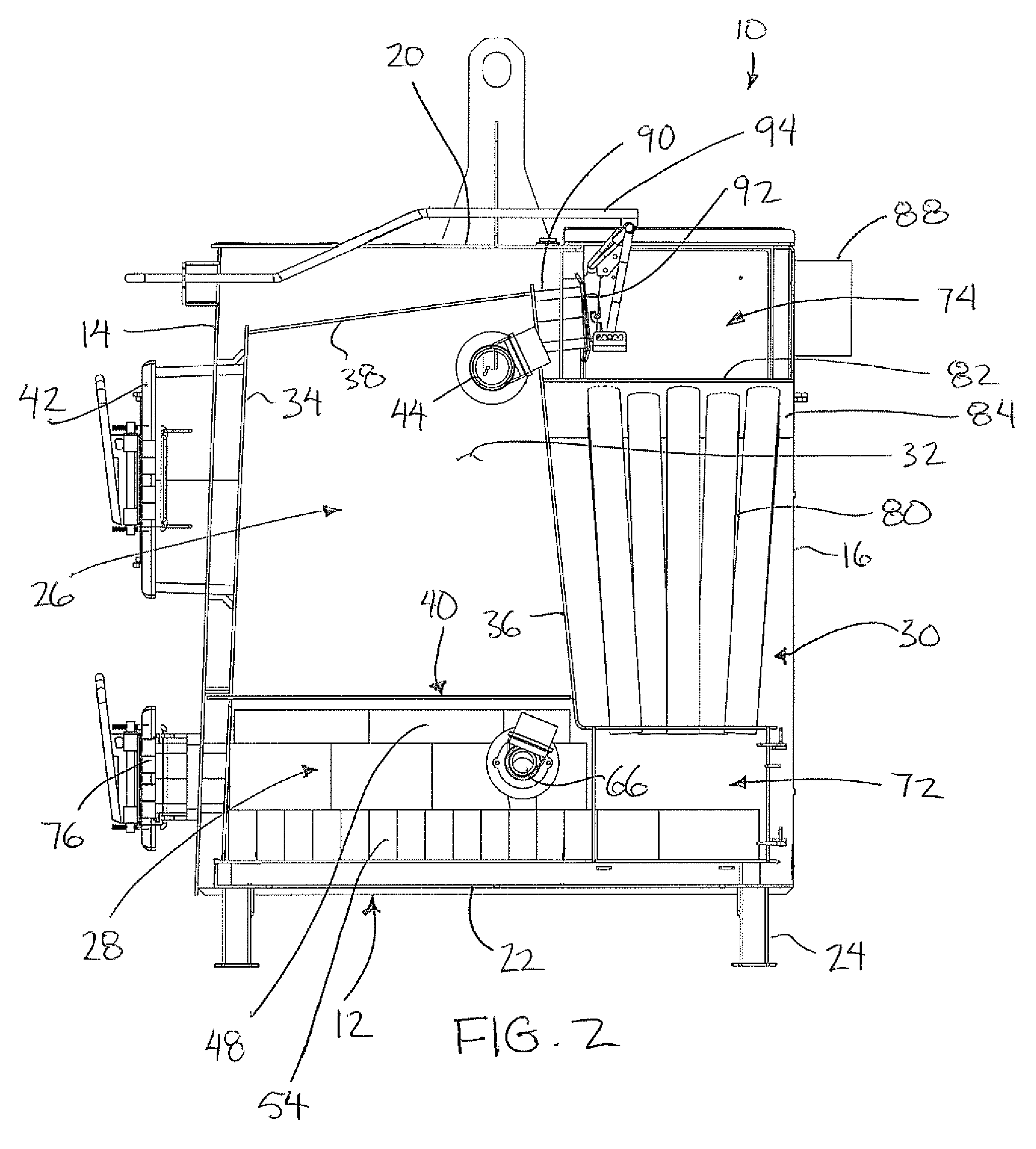

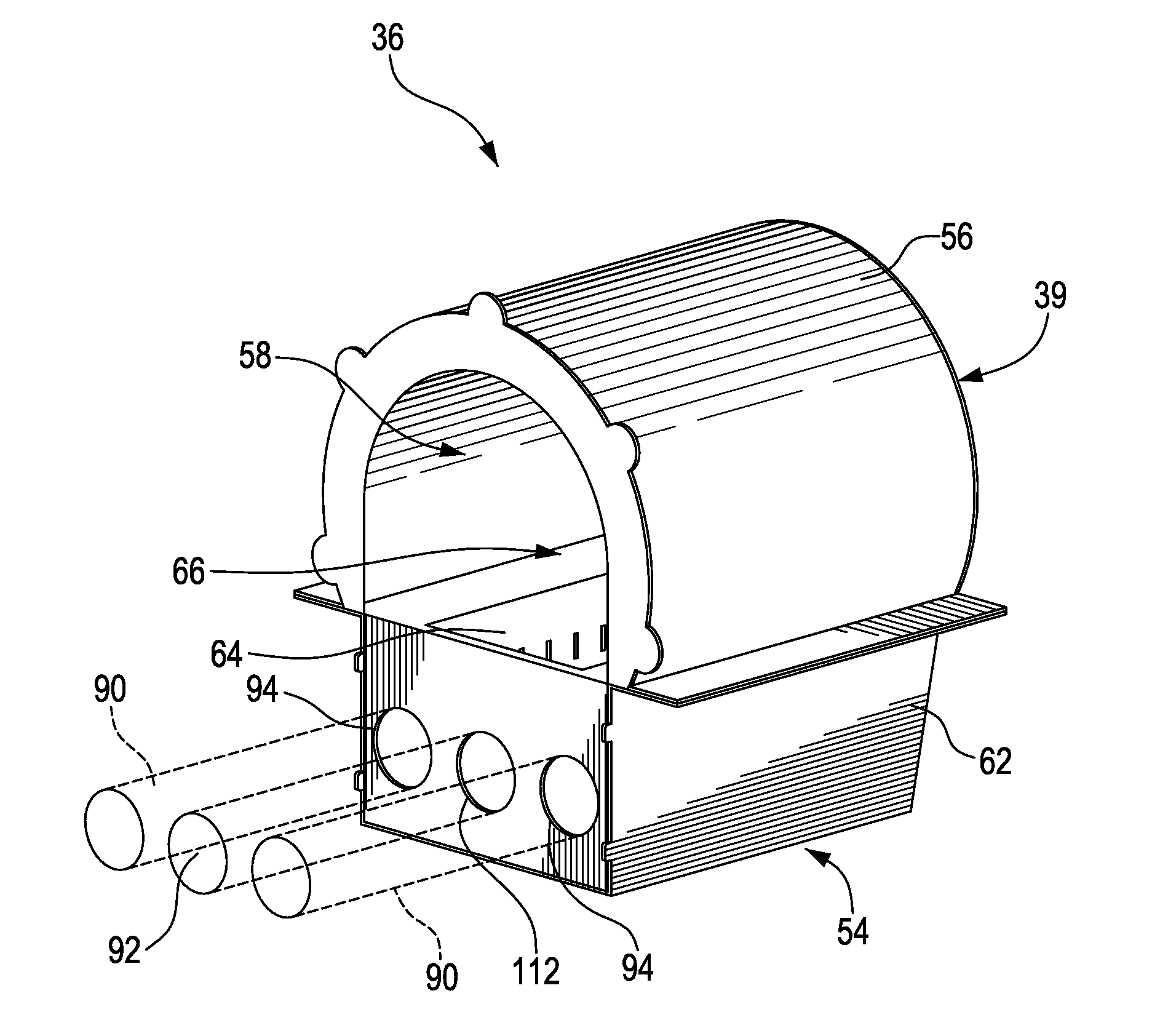

Solid Fuel Boiler Assembly

InactiveUS20100083883A1Prevent air flowImprove sealingAir supply regulationBoiler controlCombustion chamberSolid fuel

A boiler assembly including primary and secondary combustion chambers includes primary and secondary air controls for controlling combustion air to the chambers respectively. The air controls are operable between open positions to allow combustion in the chambers and a closed position in which the combustion air passages are fully sealed to fully interrupt combustion responsive to heating demands. The air controls are supported externally on the main housing of the boiler assembly so as to be modular and readily releasable from the main housing and the respective combustion air passages. The primary combustion chamber communicates with the secondary combustion chamber at a location partway in between introduction of the secondary combustion air and the exhaust passage.

Owner:HOFER NEIL +1

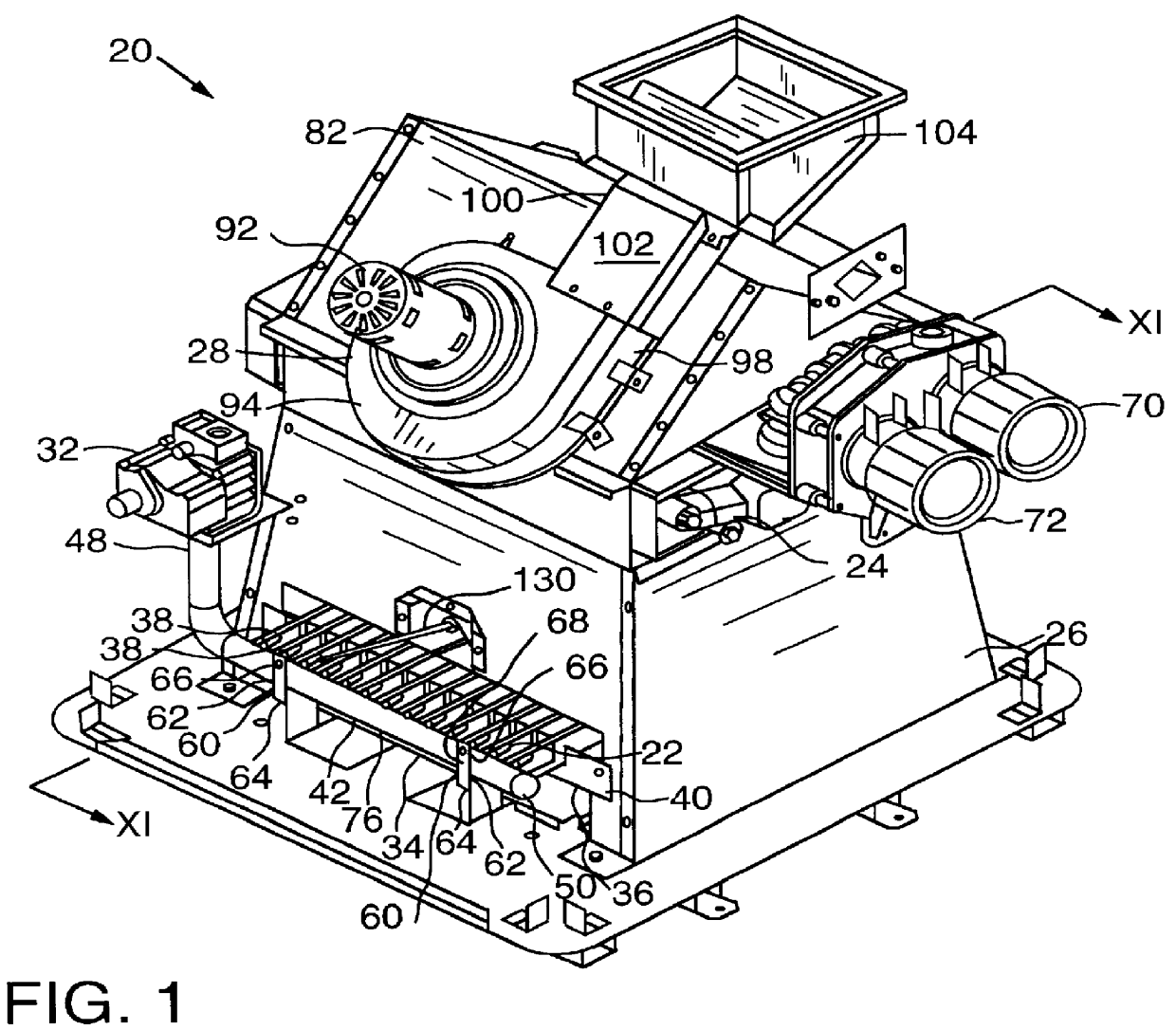

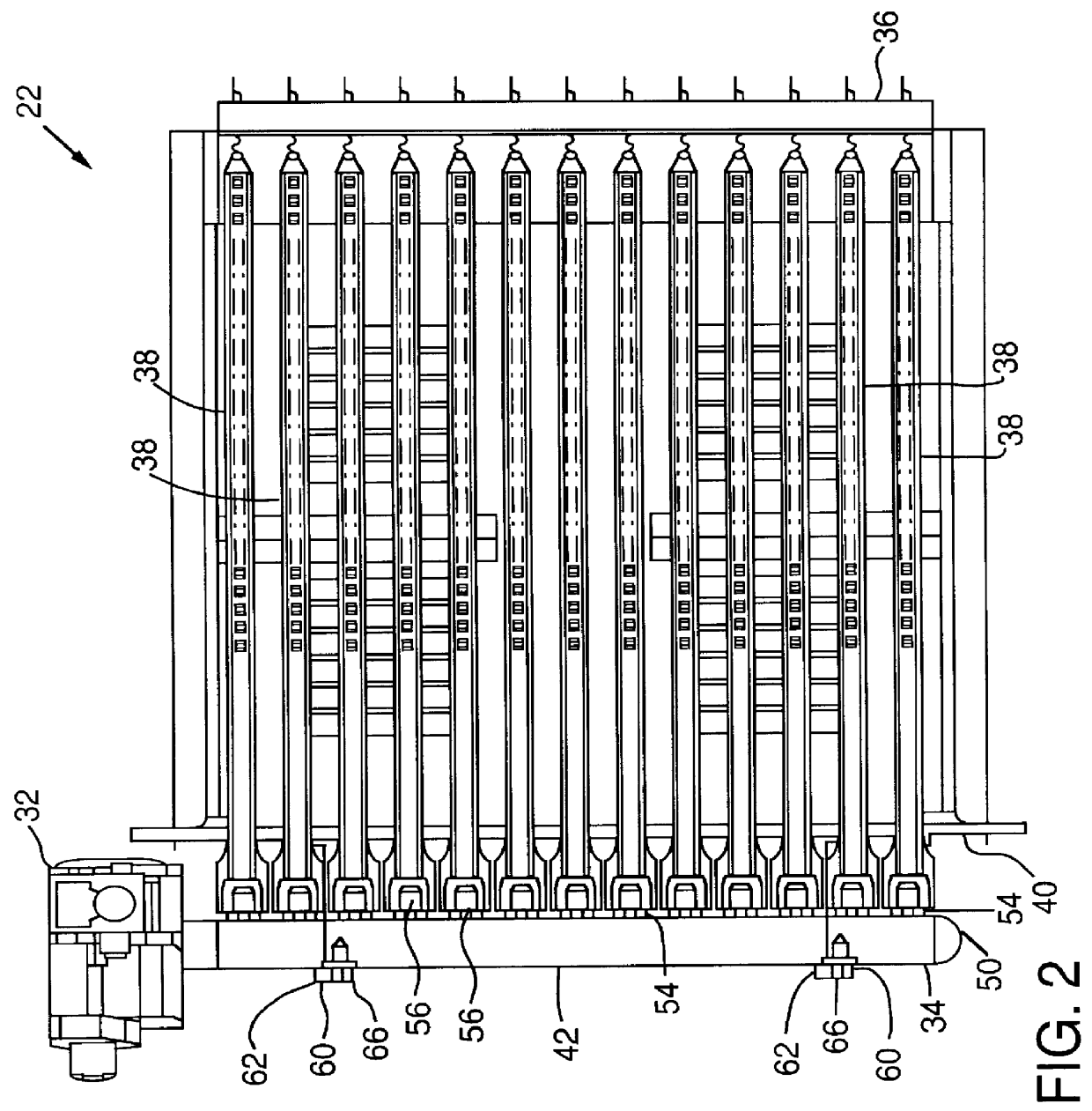

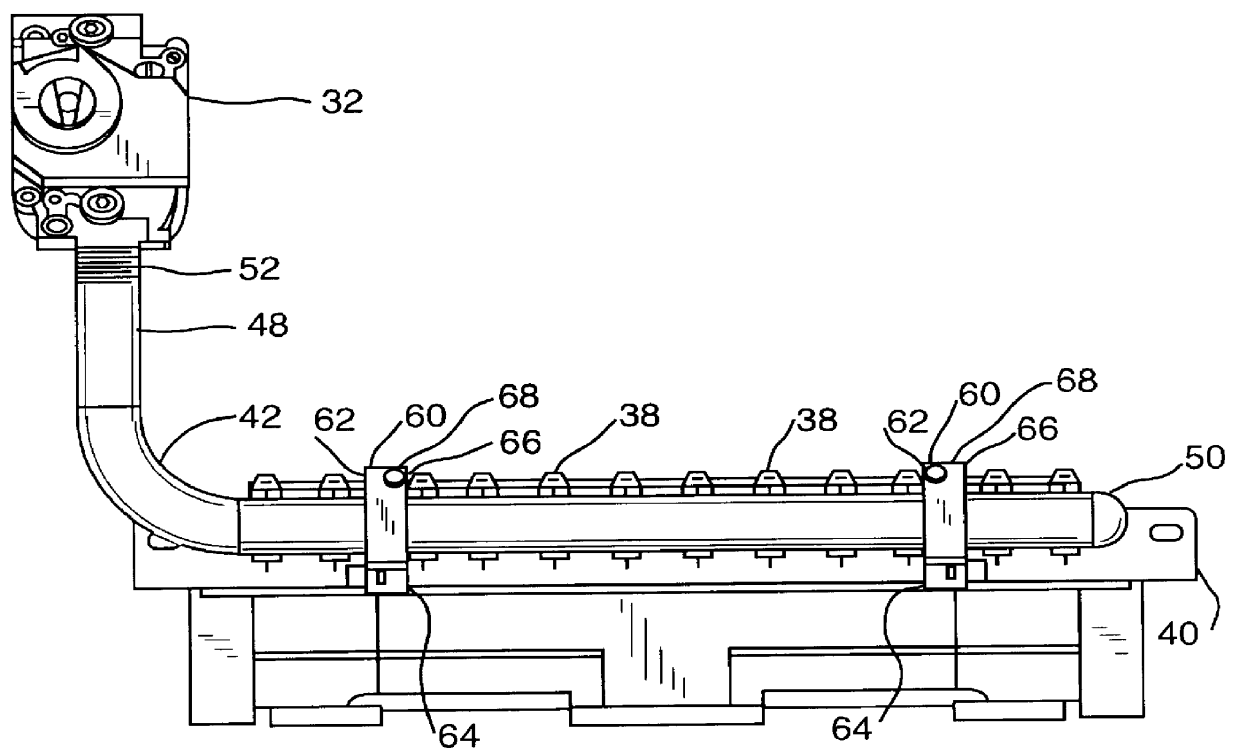

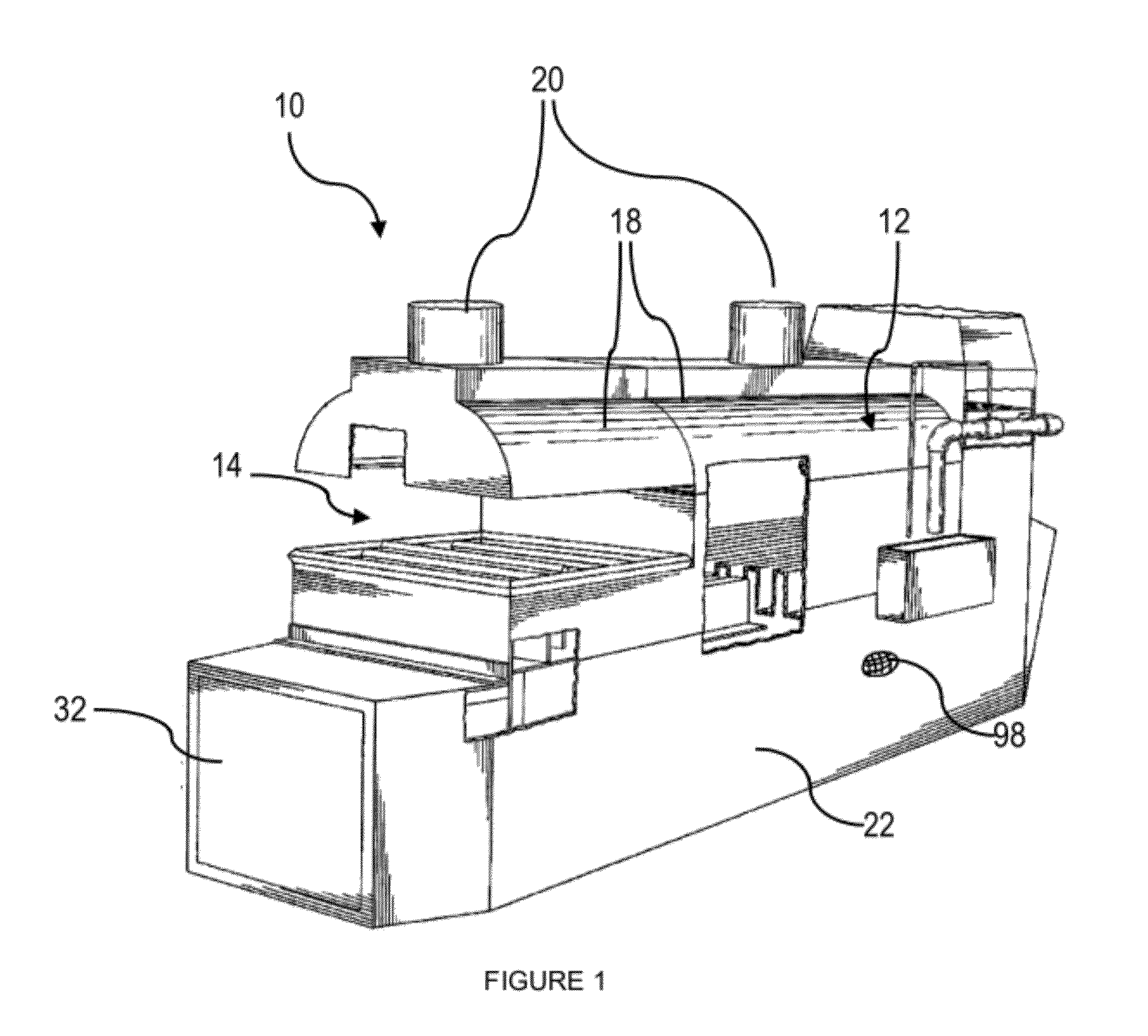

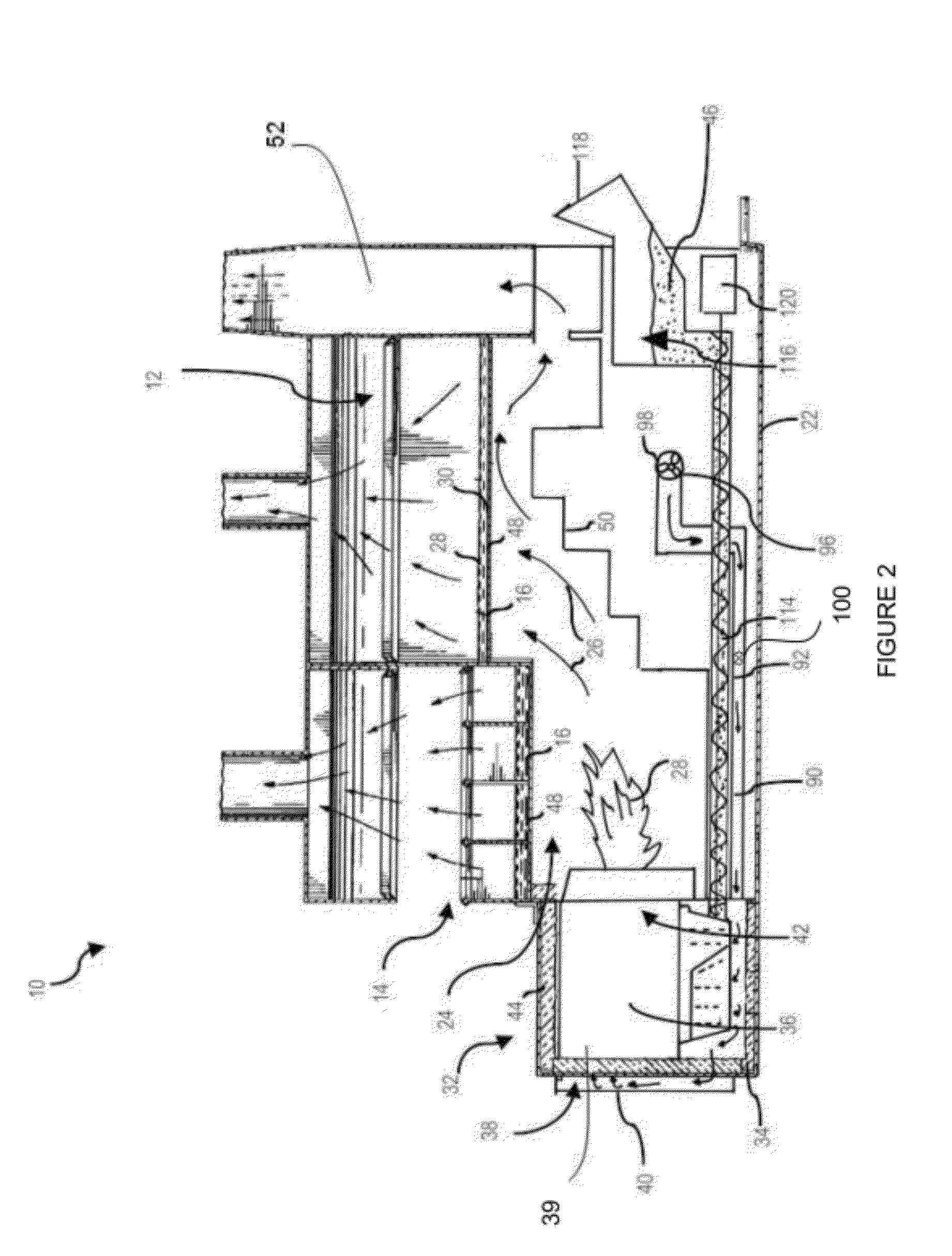

Maple syrup evaporator with biomass burner

A burner using biomass combustibles, namely pellet fuel, for a maple syrup evaporator. Compared to wood or oil burning heat sources, pellet fuel is less costly, burns more efficiently and generates the heat necessary to properly evaporate maple sap. The burner includes a burn pit defining a plurality of holes for allowing air to communicate between a combustion chamber and a primary air plenum formed between a base and an underside of the burn pit. An air supply conduit supplies air supply to the primary air plenum. A fuel conduit in communication with the combustion chamber supplies the pellet fuel for combustion within said burn pit. A secondary plenum in pneumatic communication with the primary air plenum receives and cools a portion of the primary air supply. A plurality of injectors in communication with the secondary plenum inject the cooled air into the combustion chamber.

Owner:LES EQUIPS DERABLIERE CDL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com