Patents

Literature

67results about How to "Less adjustment work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Burr-proof thermoplastic polyurethane elastic body conveying belt for food industry and manufacture method thereof

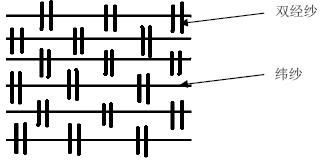

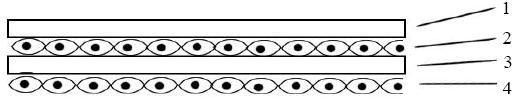

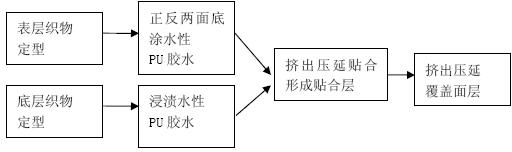

The invention relates to a burr-proof thermoplastic polyurethane elastic body conveying belt for food industry, which has the total thickness being 1.2 to 1.5mm and sequentially comprises a covering surface layer, surface layer fabrics, a pasting layer and bottom layer fabrics from top to bottom, wherein the fabrics are respectively formed by two warp yarns and one weft yarn through plain interweaving, in addition, the bottom layer fabrics are soaked with polyurethane (PU) glue water, and both the covering surface layer and the pasting layer are made of thermoplastic polyurethane (TPU). A manufacture method comprises the following steps that: the surface layer fabrics and the bottom layer fabrics are formed, so the fabric surface temperature reaches 180 to 190 DEG C, the front side and the back side of the surface layer fabrics are subject to prime coating by aqueous polyurethane glue water, and then, the surface layer fabrics are placed into a baking oven to be dried; the bottom layer fabrics are soaked into a soaking tank of the aqueous polyurethane glue water, are rolled by an anilox roller and are placed into the baking oven to be dried; the surface layer fabrics and the bottom layer fabrics are calendered and pasted; and a TPU covering surface layer is calendered on the surface of a semi-finished product. The burr-proof thermoplastic polyurethane elastic body conveying belt and the manufacture method have the advantages that periphery burrs are prevented from being mixed into food in the food conveying process, the food pollution is reduced, the burrs are reduced, the damage to two sides of the conveying belt is reduced, the post hemming tidying is not needed, and the production efficiency is improved.

Owner:SHANGHAI YONGLI BELTING +1

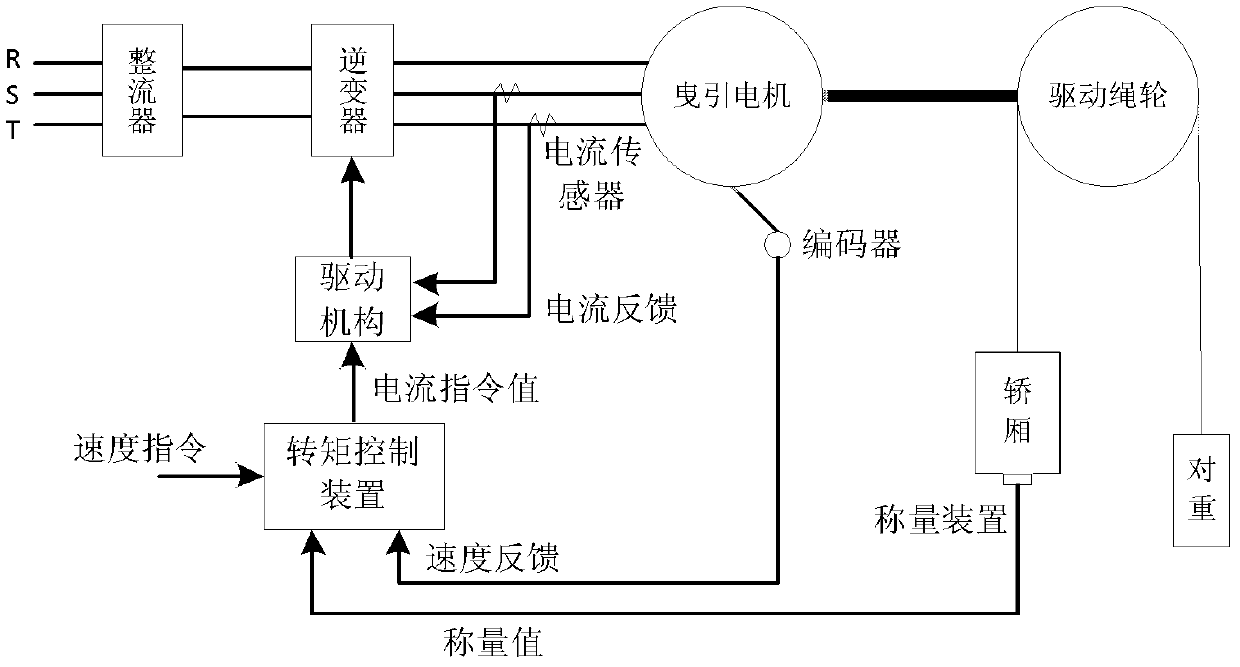

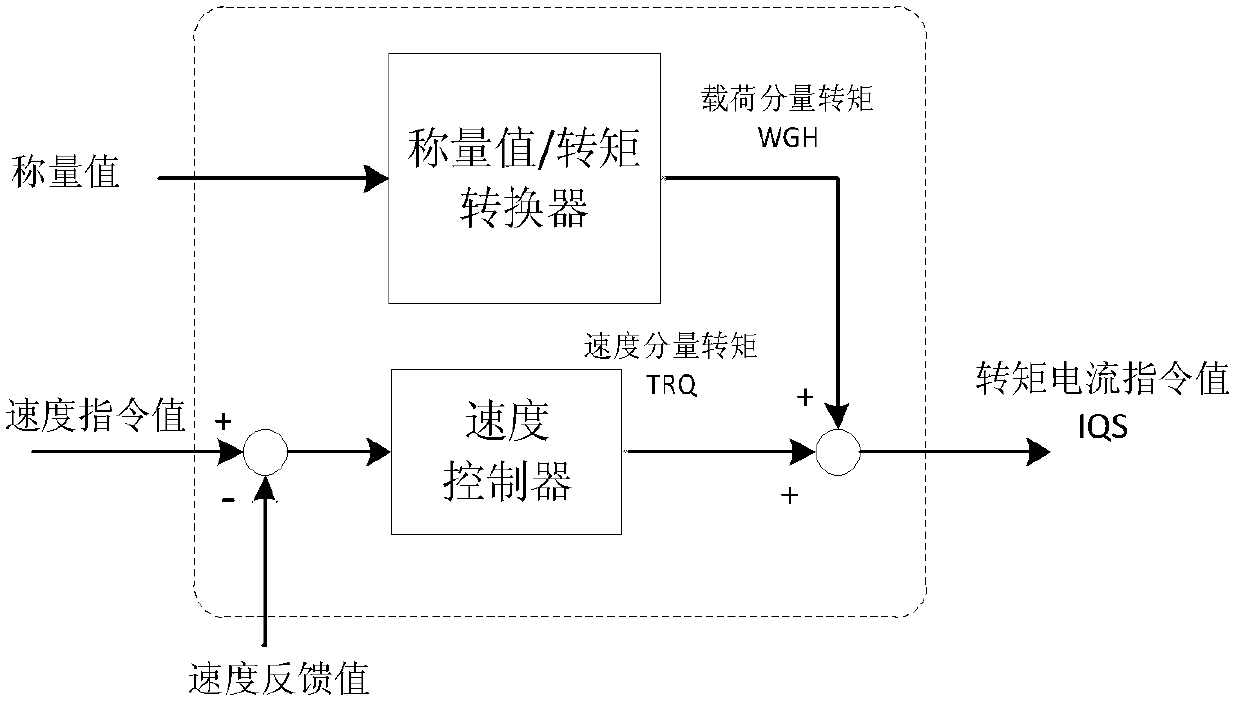

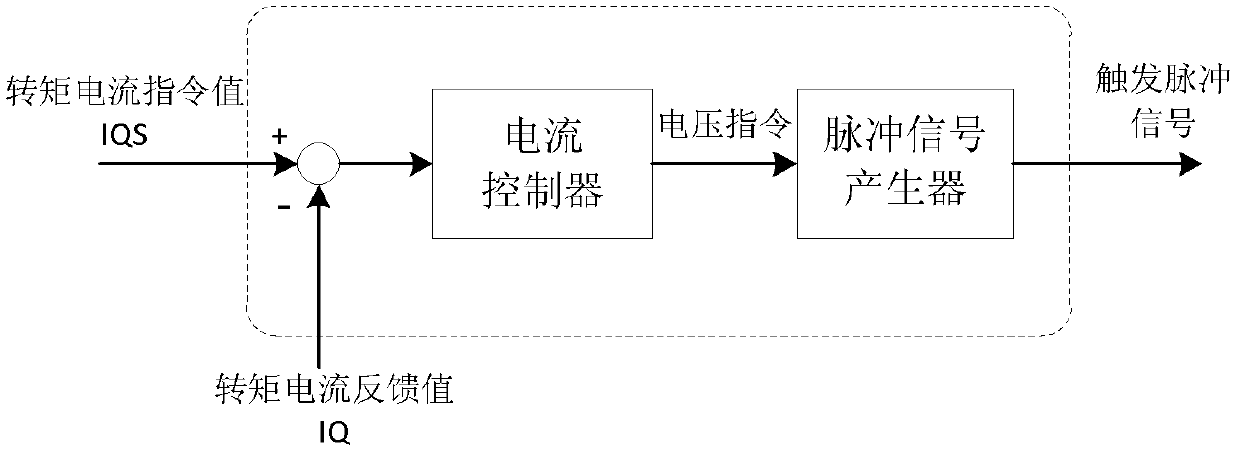

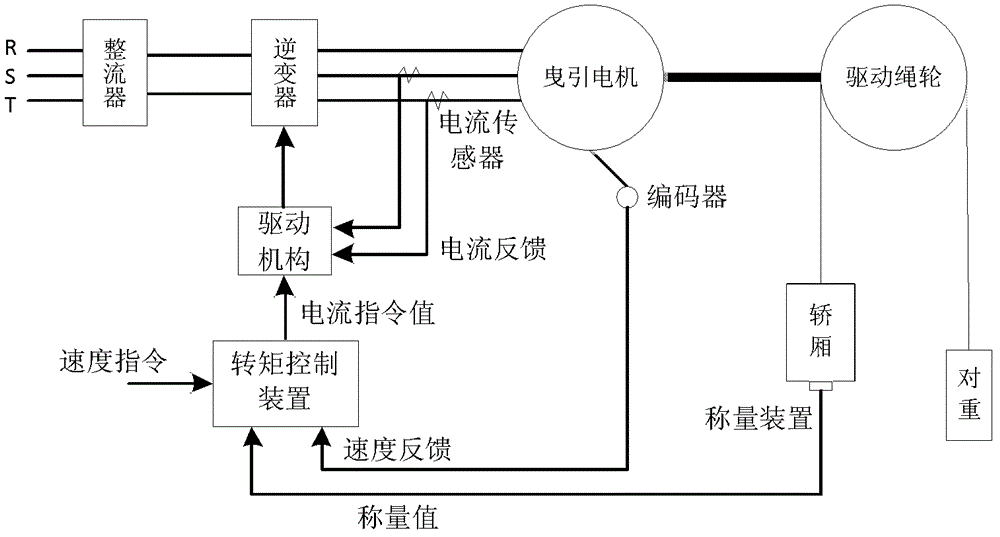

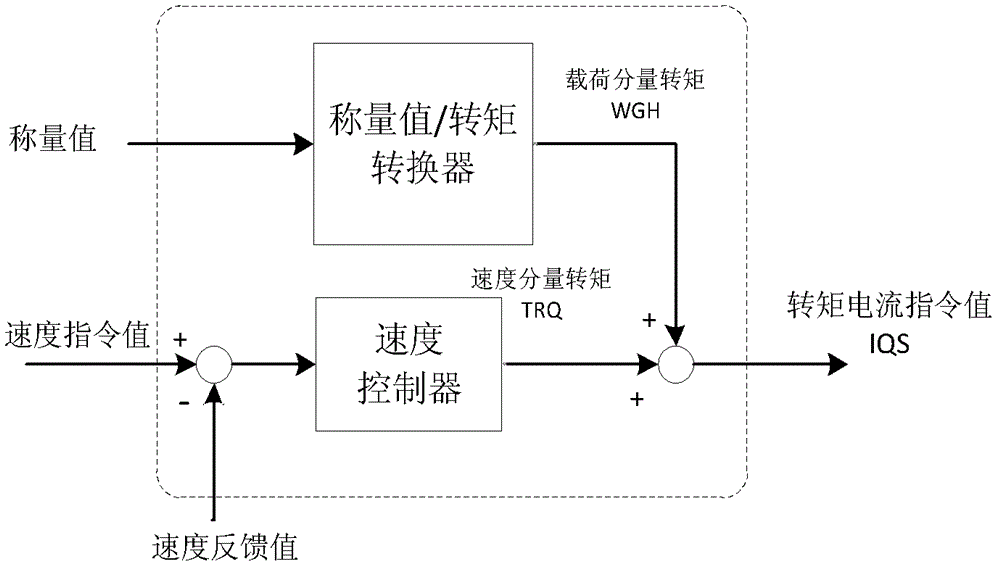

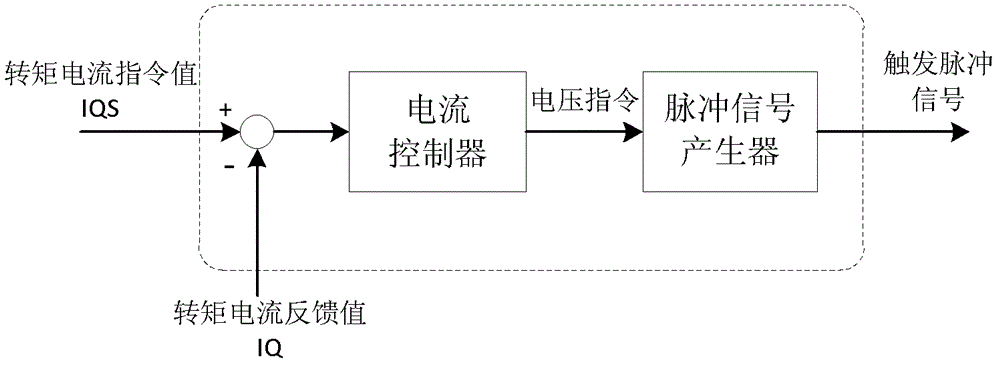

Elevator weighing value diagnosing and revising method

The invention discloses an elevator weighing value diagnosing and revising method. By means of the elevator weighing value diagnosing and revising method, parameters involved in torque calculation of sharing parts of load can be automatically revised according to weighing values and torque current values output by a weighing device when an elevator is started. After the parameters are revised, the elevator is started again, and torque of the sharing parts of the load can be calculated by a torque control device on the basis of the revised parameters, so that a drag motor can generate torques in advance to accurately compensate imbalanced moment between a lift car and a counter weight after a band-type brake is opened. By means of the elevator weighing value diagnosing and revising method, influence on torque calculation of the sharing parts of the load can be avoided when the weighing device, the drag motor and the like change, and starting performance of the elevator can be ensured when cost is not increased.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

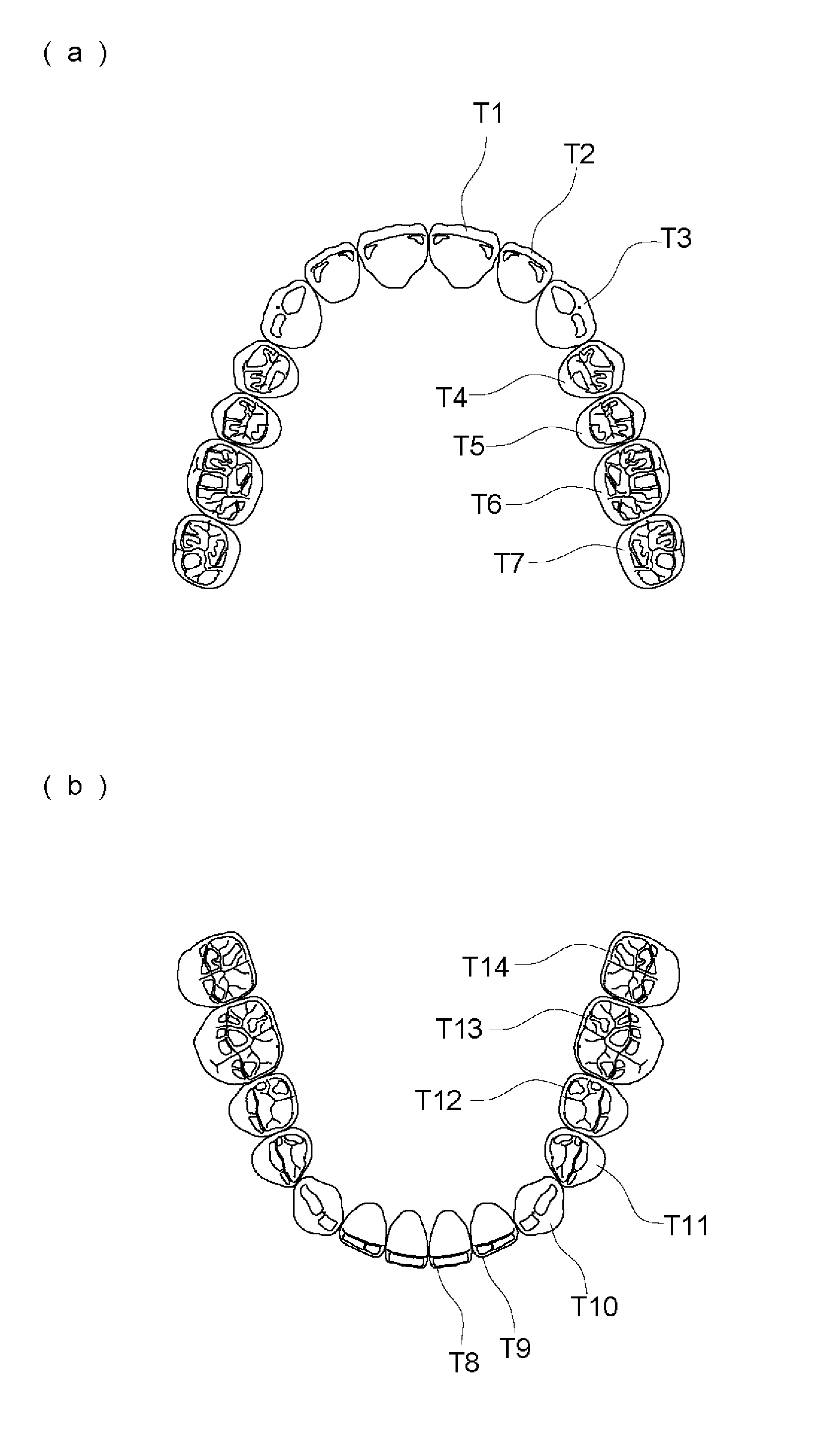

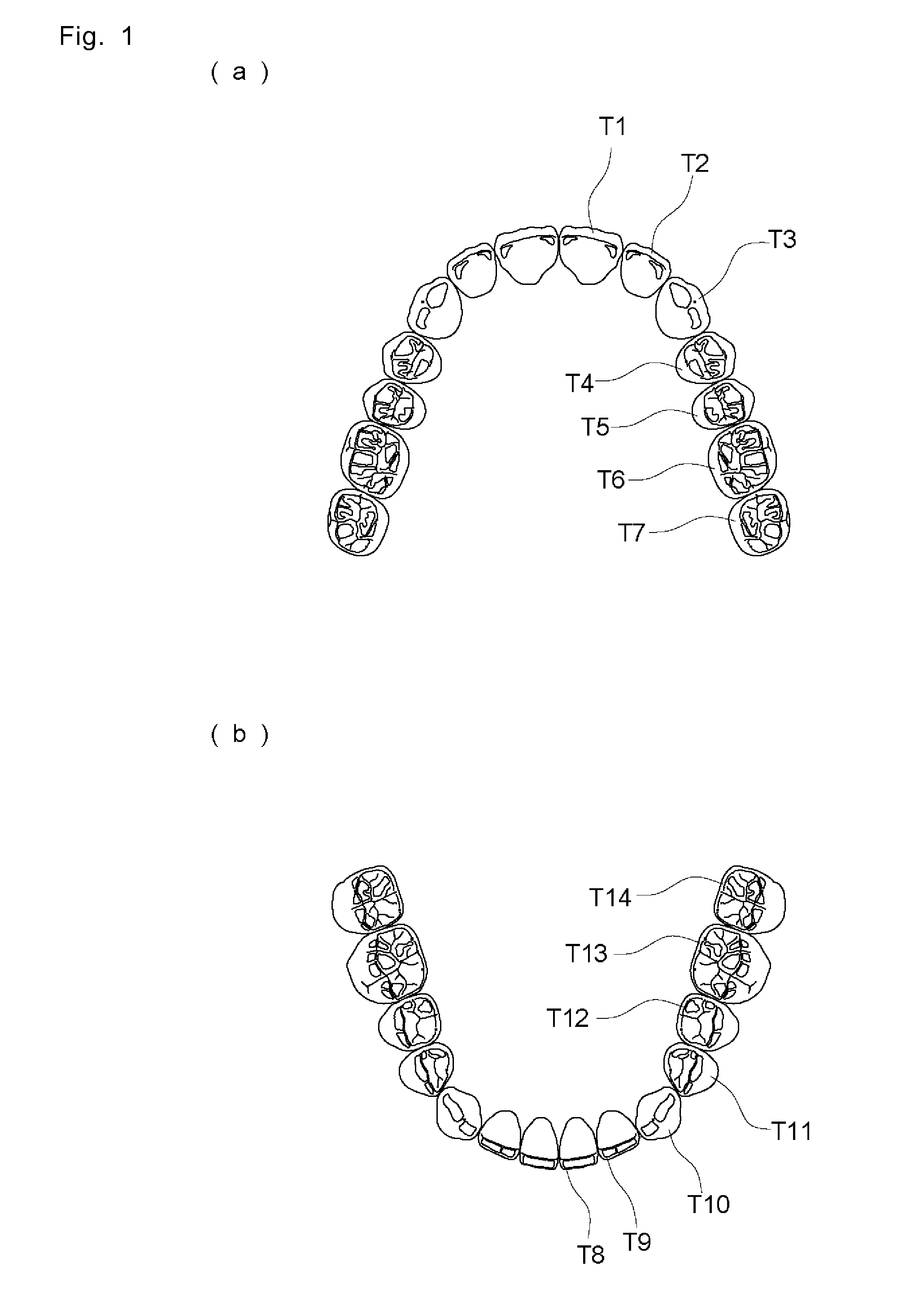

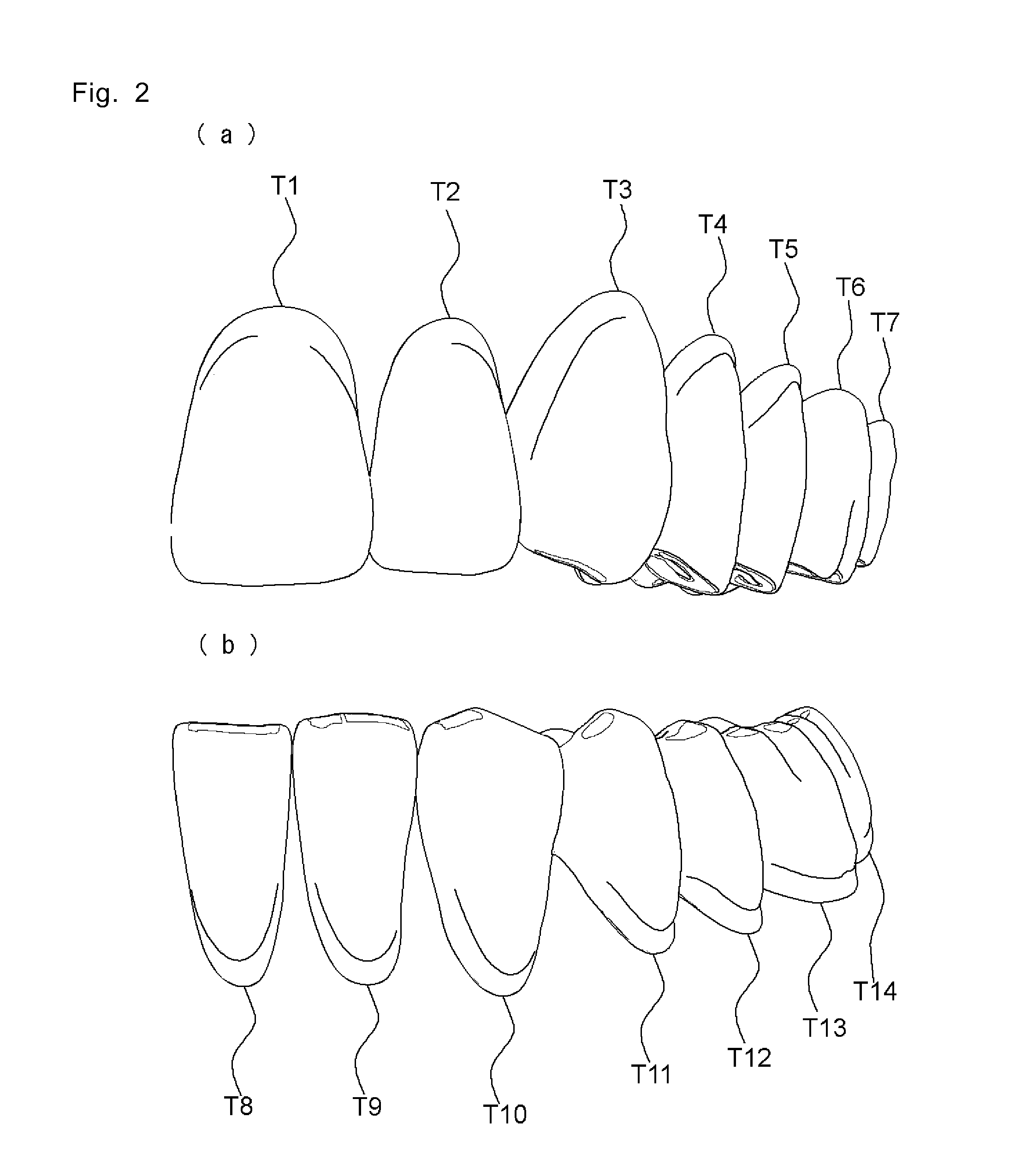

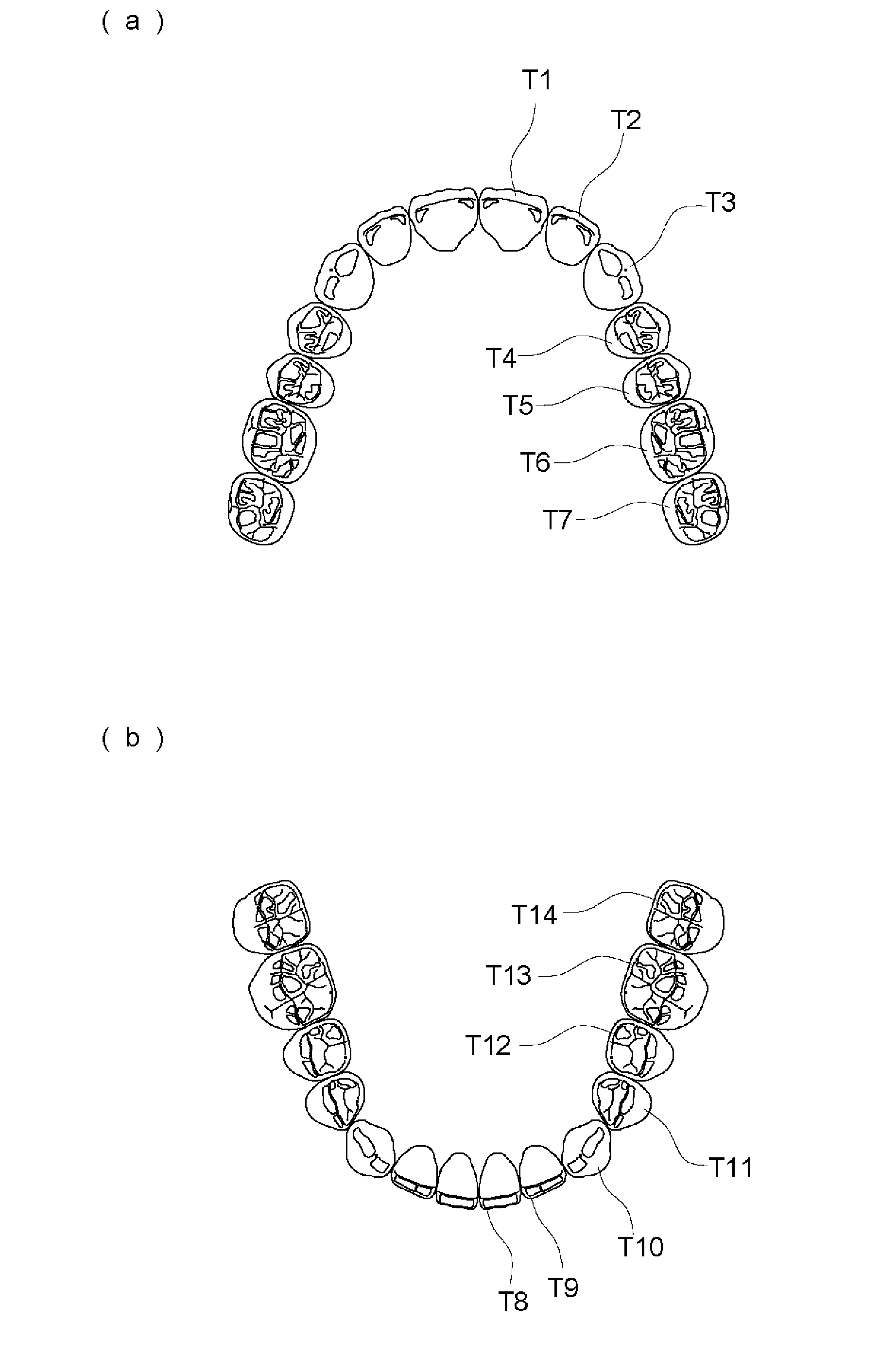

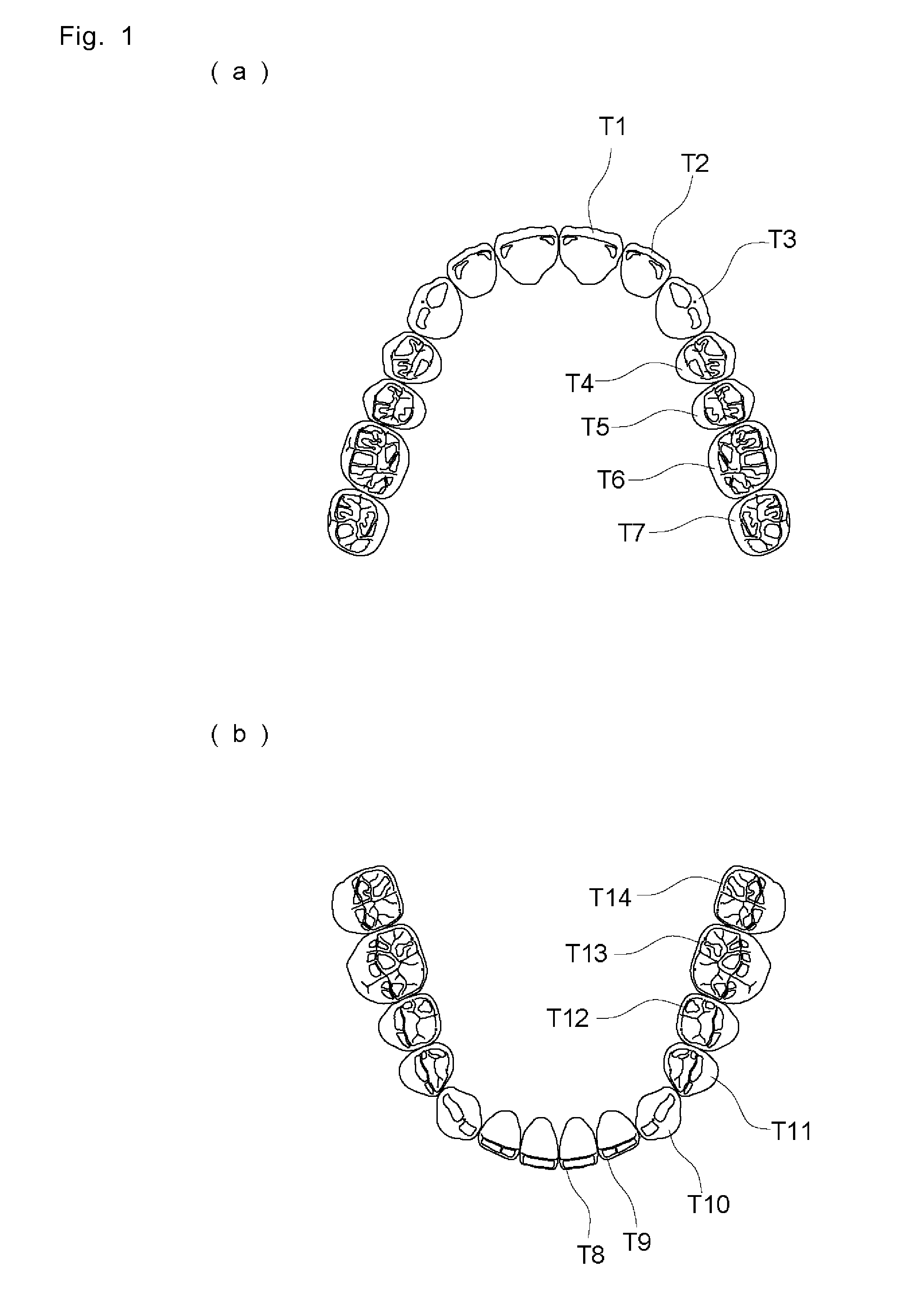

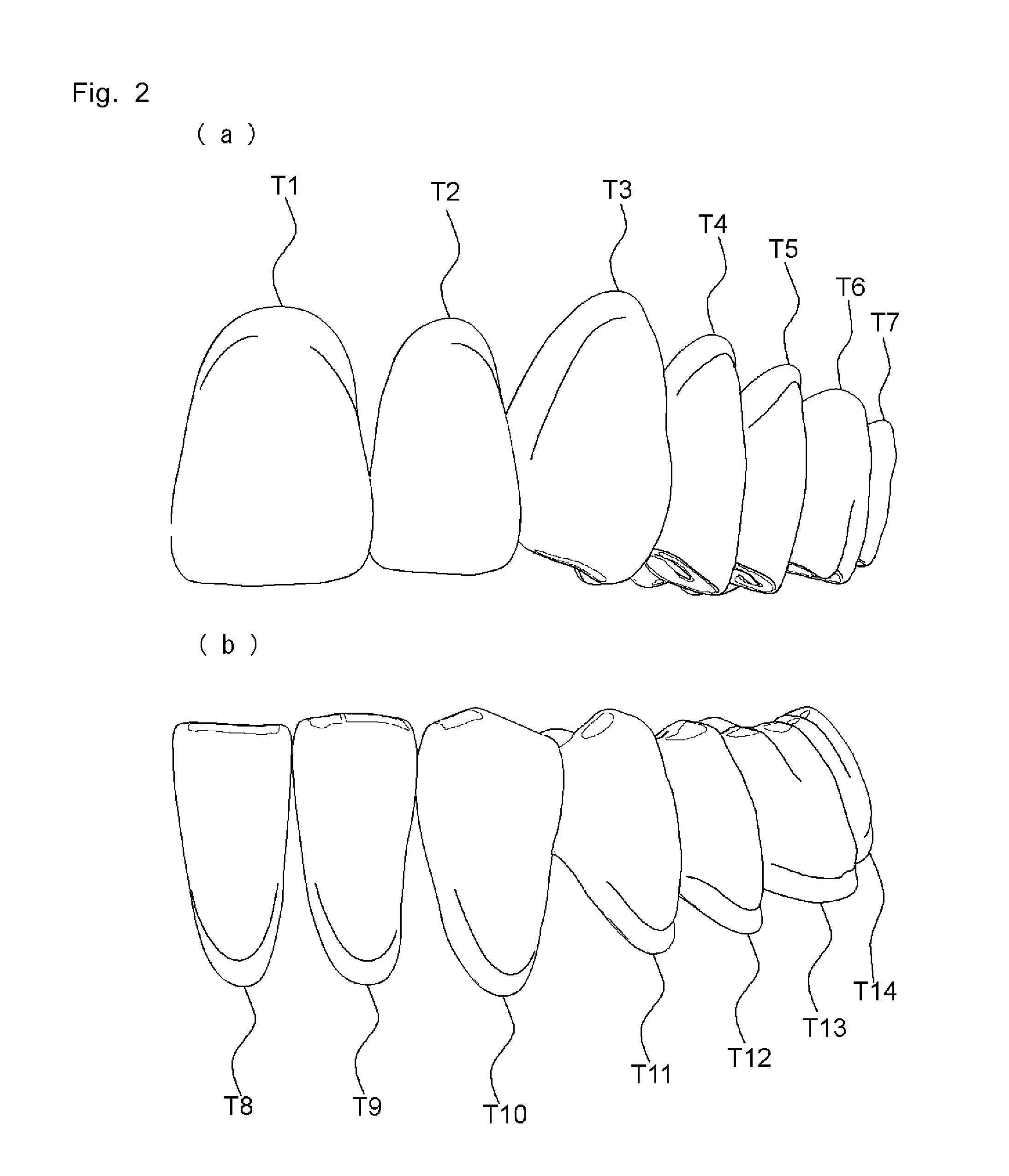

Artificial teeth easily enabling bilateral balanced occlusion

ActiveUS20100266988A1Less adjustment workBite firmlyTooth crownsArtificial teethSagittal planeCoronal plane

It is intended to provide artificial teeth designed to easily enable bilateral balanced occlusion with less grinding adjustment. According to the present invention, angles formed by occlusal facets of the artificial teeth with an occlusal plane are suitably set. An artificial tooth for maxillary central incisor, for example, has a protrusive facet and a retrusive facet on an incisal edge thereof. Of angles formed by the protrusive facet with the occlusal plane, the angle in cross section along a sagittal plane is 22.0° to 25.5°, and the angle in cross section along a coronal plane is 1.5° to 6.5°. Of angles formed by the retrusive facet with the occlusal plane, the angle in cross section along the sagittal plane is 20.5° to 23.0°, and the angle in cross section along the coronal plane is 1.5° to 6.5°.

Owner:SHOFU INC

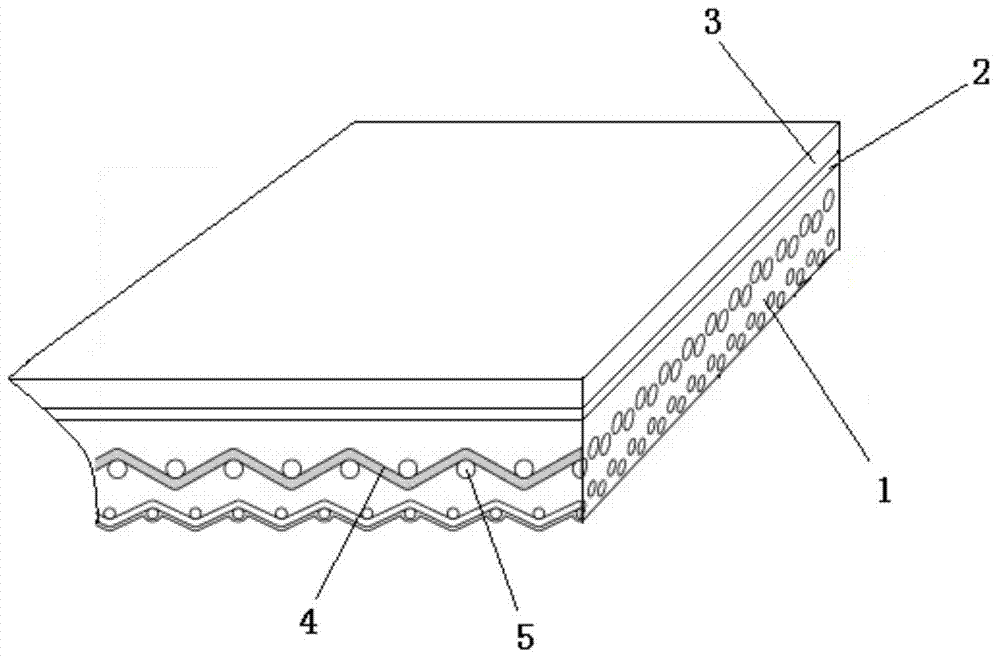

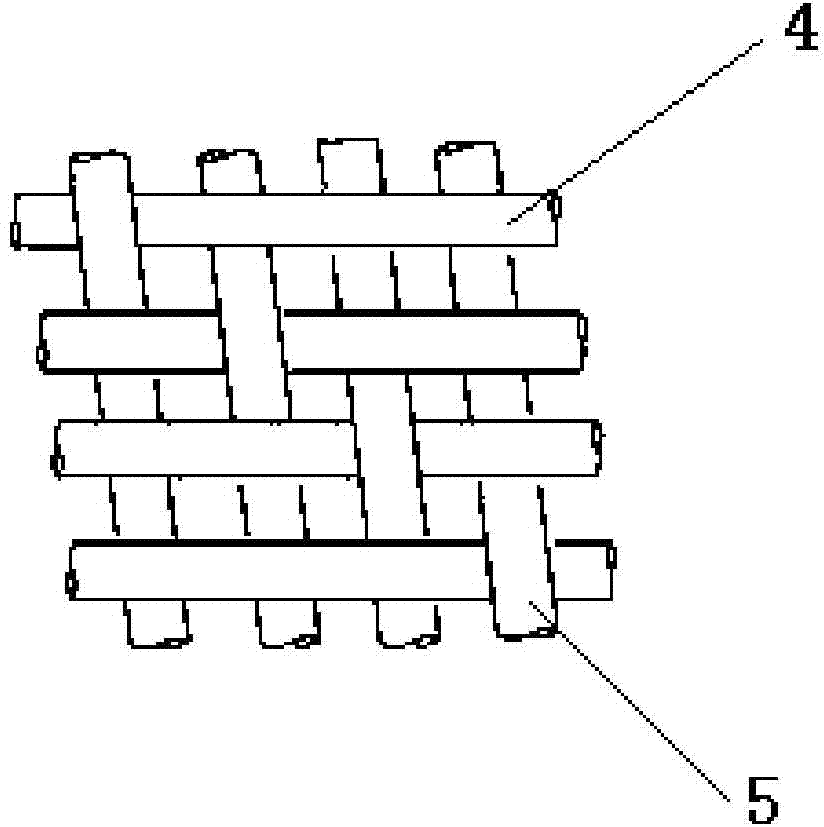

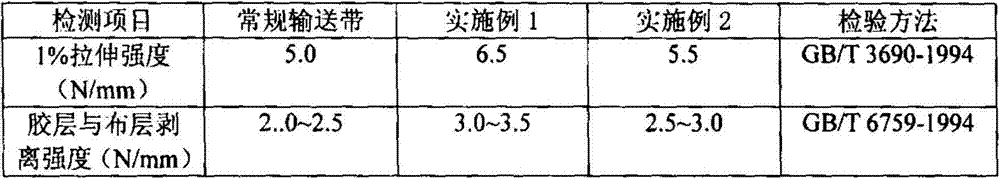

Conveying belt capable of reducing lateral side fuzz amount generation and preparing method of conveying belt

ActiveCN104326212AAvoid bumps or wavesPut an end to the big knife bend phenomenonConveyorsBeltsPre treatmentWear resistant

The invention relates to a conveying belt capable of reducing lateral side fuzz amount generation. The conveying belt comprises a framework layer, a pasting layer and a covering surface layer, wherein the framework layer is formed by single-layer or double-layer fabrics, the pasting layer is arranged between the framework layer and the covering surface layer, the pasting layer and the covering surface layer are respectively made of thermoplastic elastic bodies, the conveying belt is pretreated through immersing the fabrics of the framework layer by polyurethane glue water, then, a coating process is adopted for sequentially coating the pasting layer and the covering surface layer onto the framework layer, and then, the conveying belt is prepared through heat treatment, rolling pressing and edge cutting. Compared with the prior art, the conveying belt prepared by the invention has the advantages that the wear-resistant performance is good, in the use process, the abrasion damage to the two sides of the conveying belt can be obviously reduced, and the generation of lateral side fuzz is effectively prevented, so the pollution to carrying and conveying objects in the production process can be reduced, meanwhile, the prepared conveying belt does not need the later stage processing edge sealing process, the production efficiency can be greatly improved, and good application prospects are realized.

Owner:AA IND BELTING (SHANGHAI) CO LTD

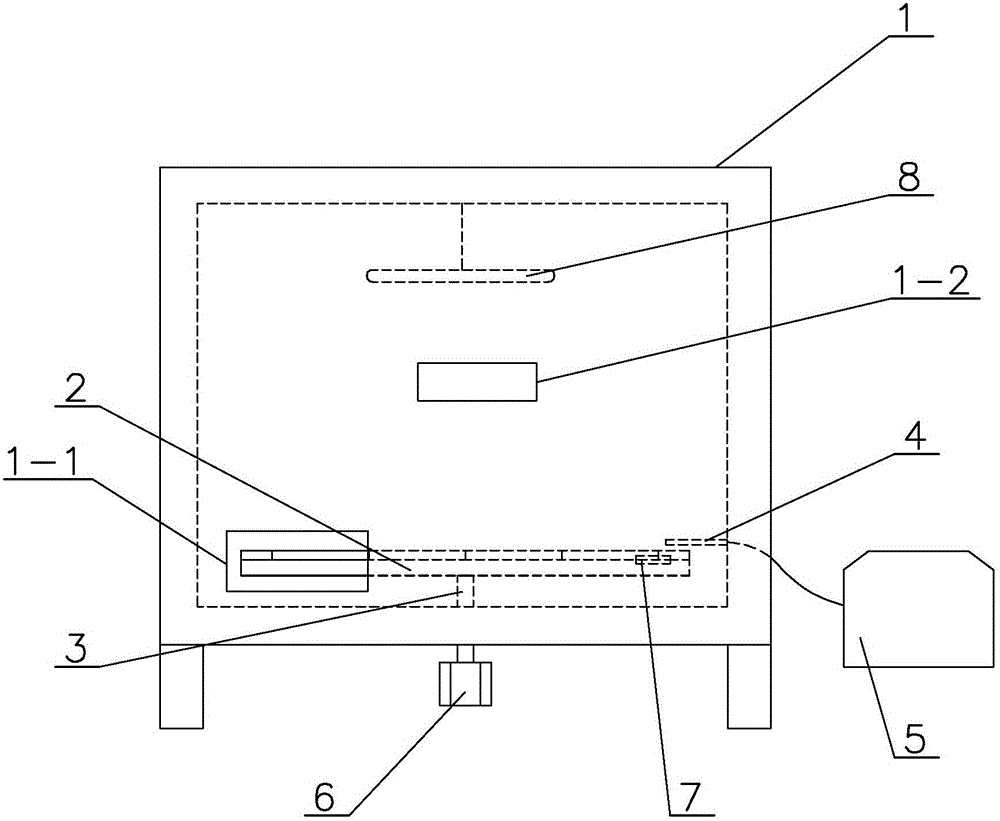

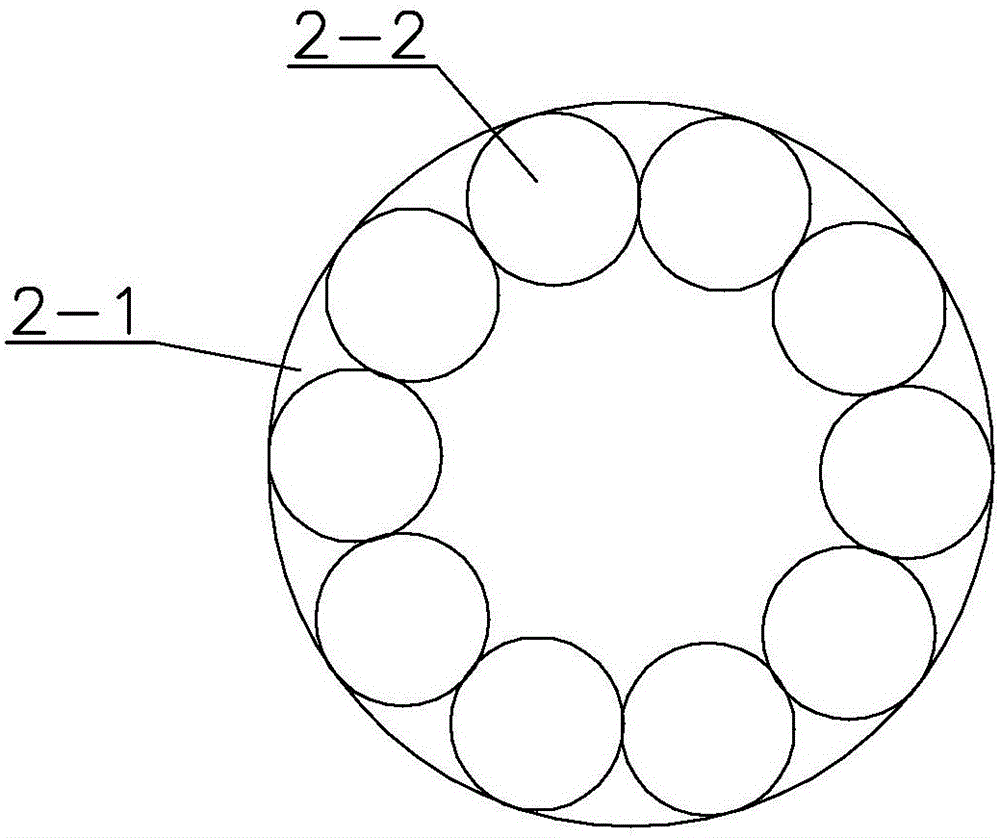

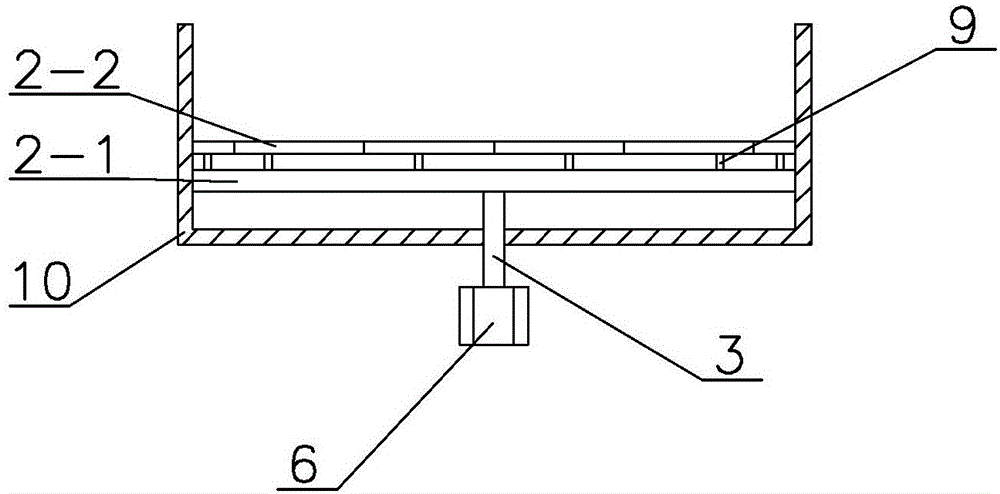

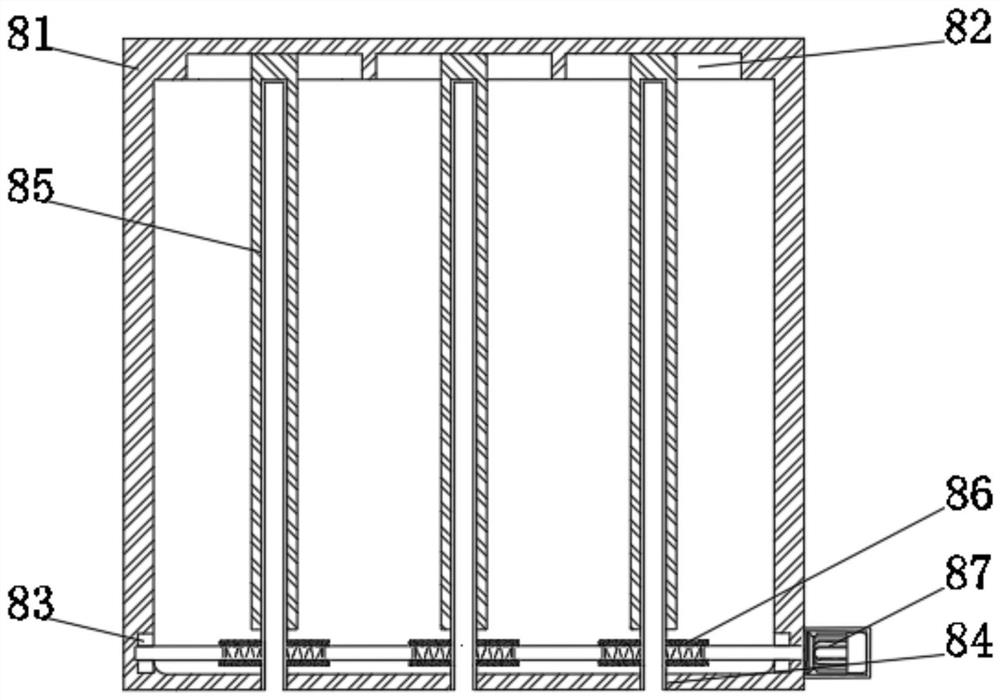

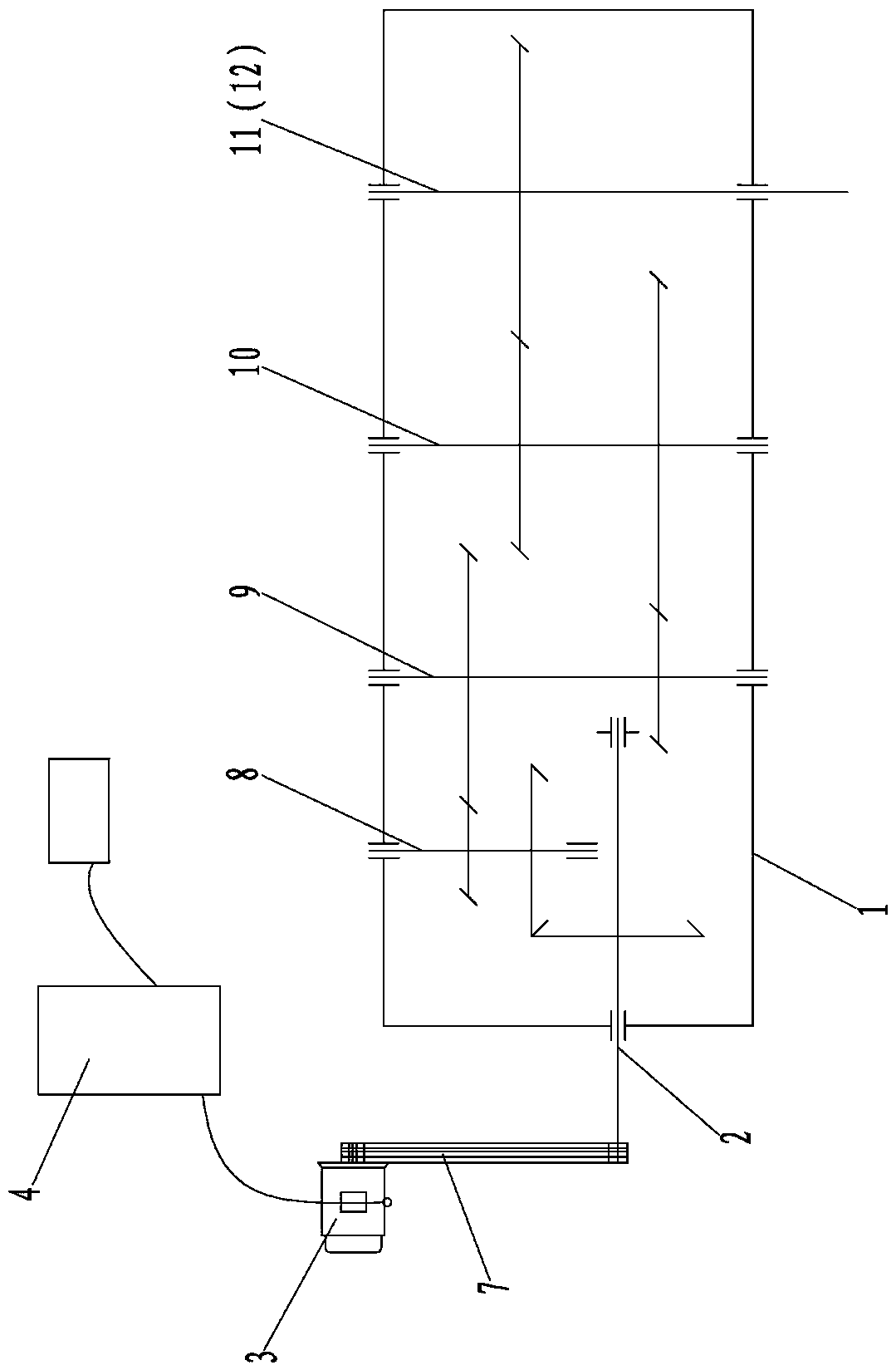

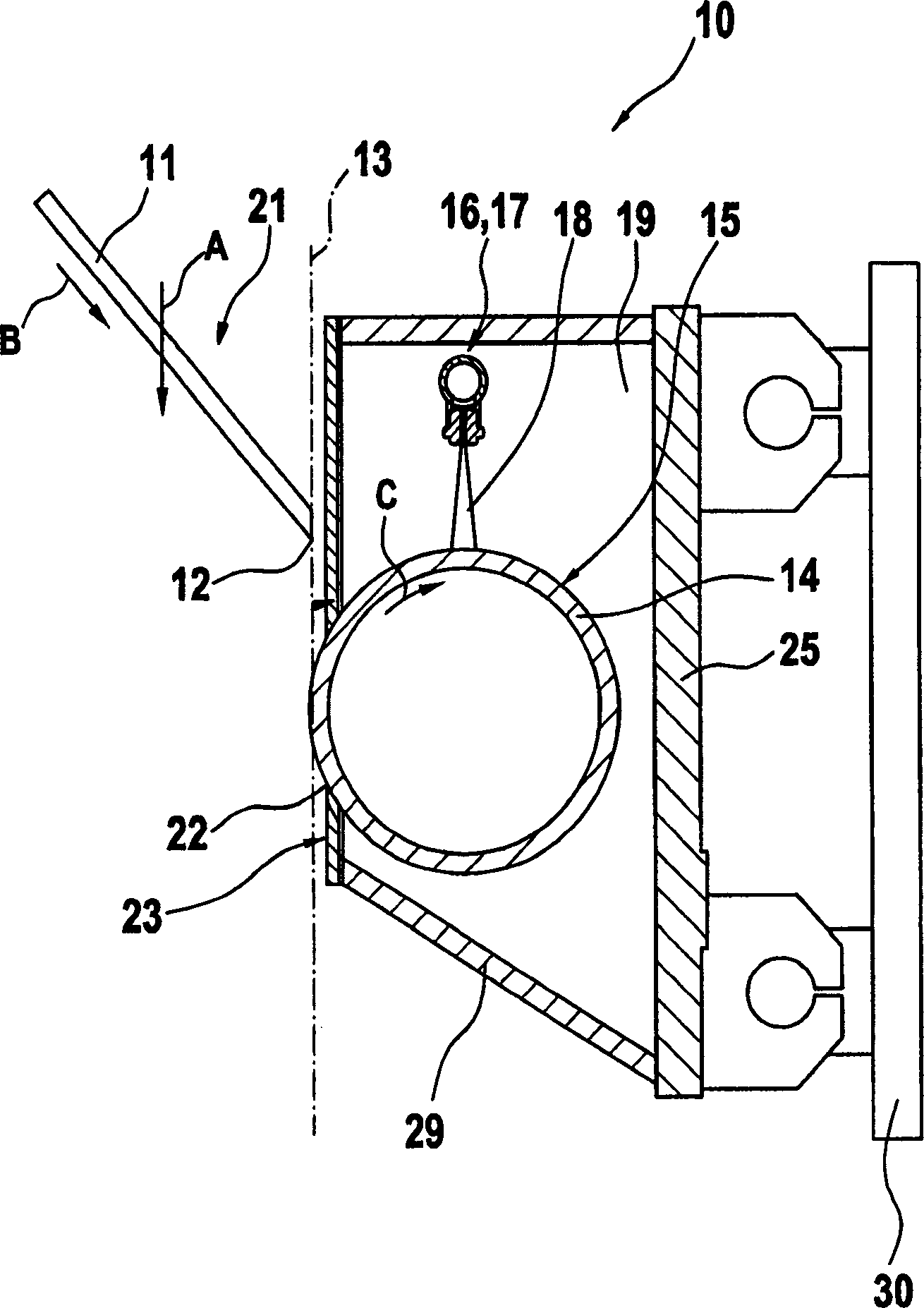

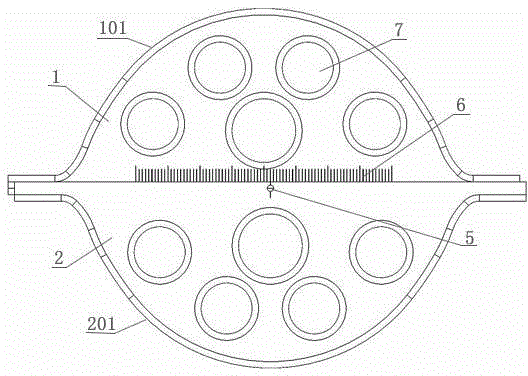

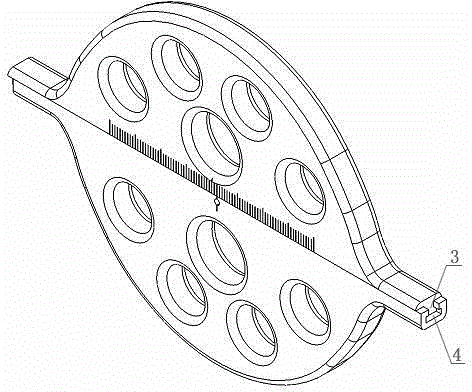

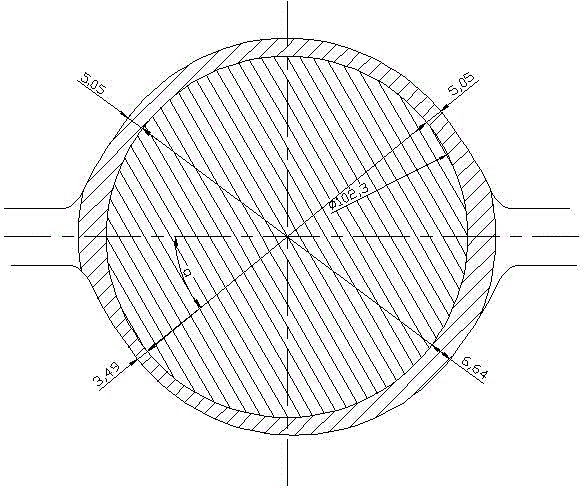

Test apparatus for ultraviolet aging acceleration of asphalt-based materials

ActiveCN105043964AAccurate temperature controlUniform photoagingWeather/light/corrosion resistanceThermal ageingUltraviolet lights

The invention provides a test apparatus for ultraviolet aging acceleration of asphalt-based materials and relates to a test apparatus. The invention solves the problems of tedious operation steps, uneven specimen aging, large thermal aging interference, failure in precise temperature control and accurate quantitative analysis of UV radiation energy in an asphalt specimen aging test. A complex rotating disk is set in an environment; complex rotating disk comprises a main rotating disk; at least one ultraviolet light source is disposed above the main rotating disk; the bottom of the main rotating disk is secured to one end of a drive shaft, and the other end drive shaft of the is connected to the output shaft of a drive motor; multiple asphalt specimens are placed on the main rotating disk; an ultraviolet probe of an ultraviolet radiation meter is arranged on the main rotating disk; the reading unit of the ultraviolet radiation meter is disposed outside the environment box; a temperature sensor is located in the environment and close to the main rotating disk; and a data acquisition and control system is set outside the environment box and is electrically connected to the temperature sensor. The invention is used for material ageing test.

Owner:HARBIN INST OF TECH

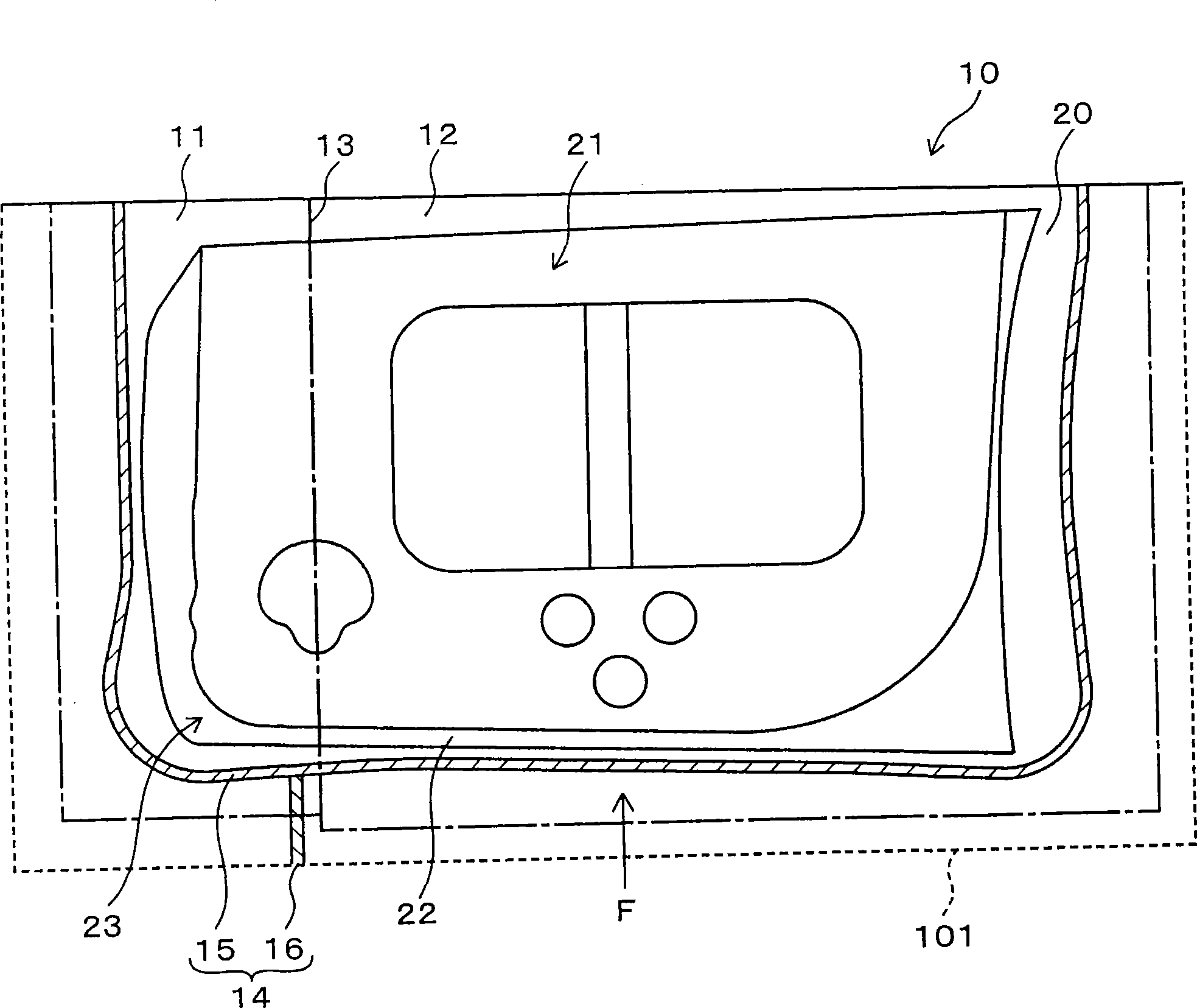

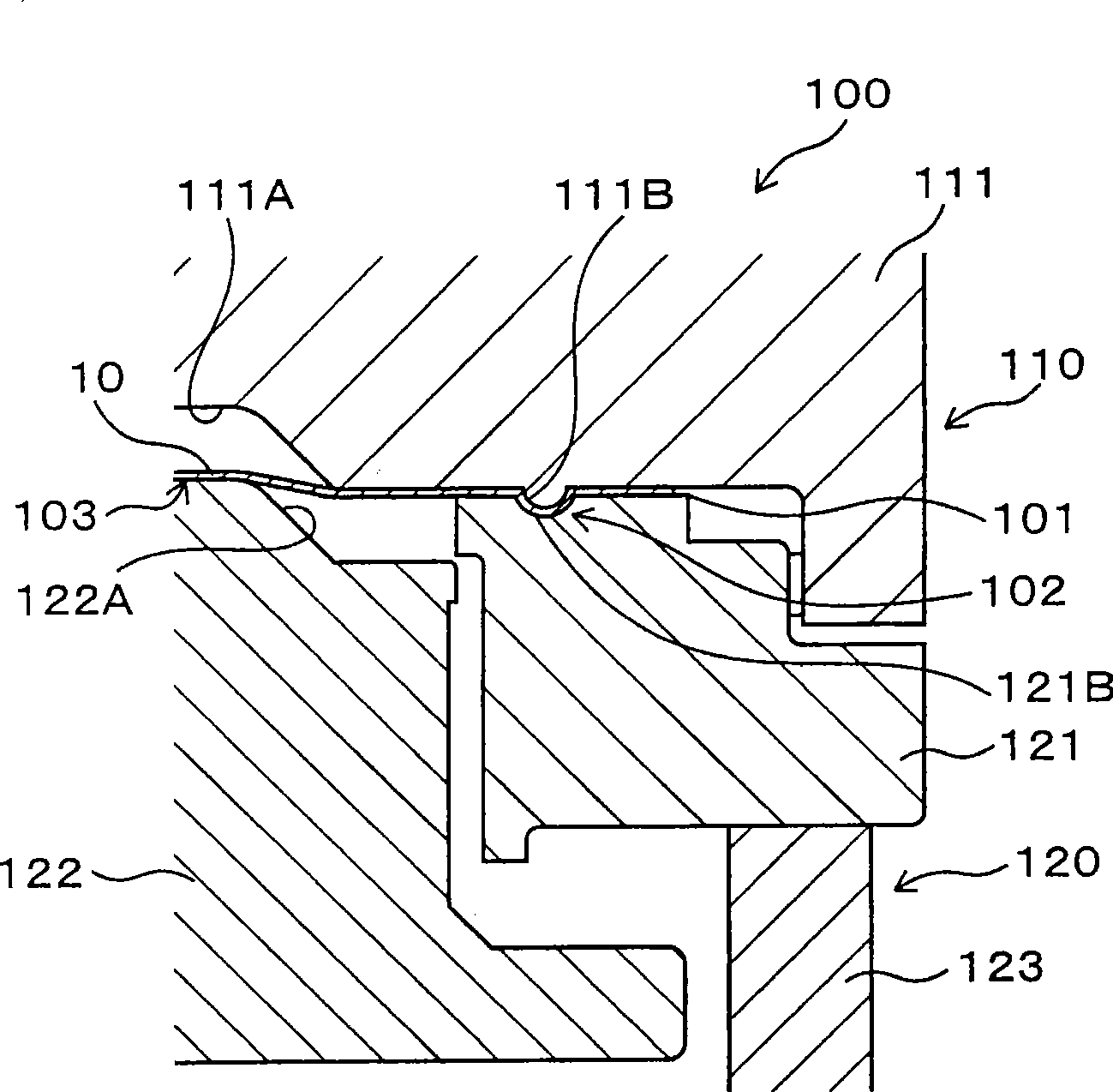

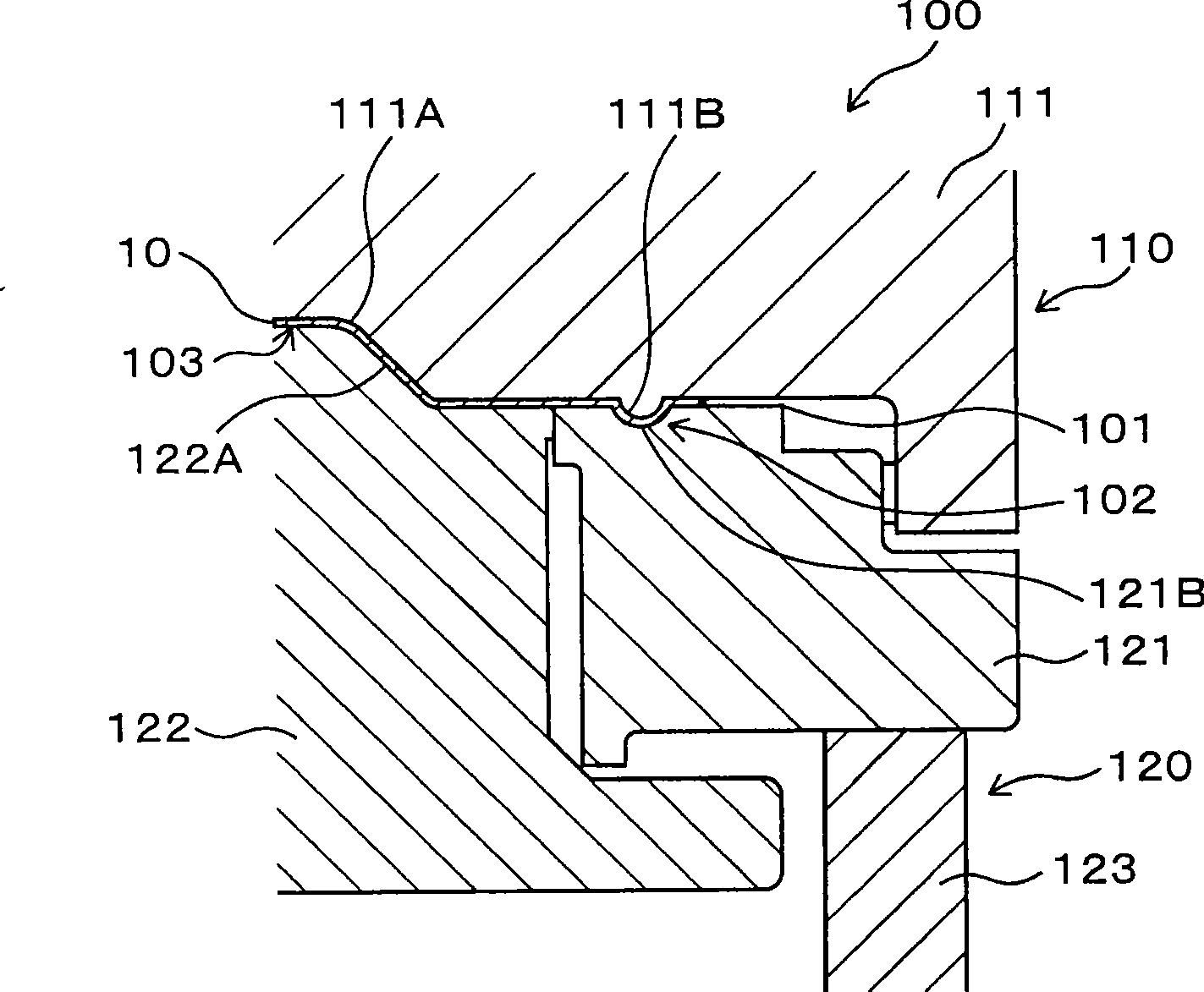

Press forming die assembly

The invention relates to a die for press forming, wherein a panel (20) of a blank material (10) is formed by the press forming die. The press forming die comprises draw beads for controlling the amount of the blank material flowing into a draw forming portion during the press forming. The draw heads comprises a conventional first draw bead (in accordance with a first bead (15)) and a second draw bead (in accordance with a second bead (16)) in a direction intersecting the first draw bead. The second draw bead is provided so that strain (fold) occurring at a thick sheet portion (11) in a shrink forming of a flange portion (23) is not transmitted to a thin sheet portion (12), thereby inhibiting the rotary of the thick sheet portion (11).

Owner:HONDA MOTOR CO LTD

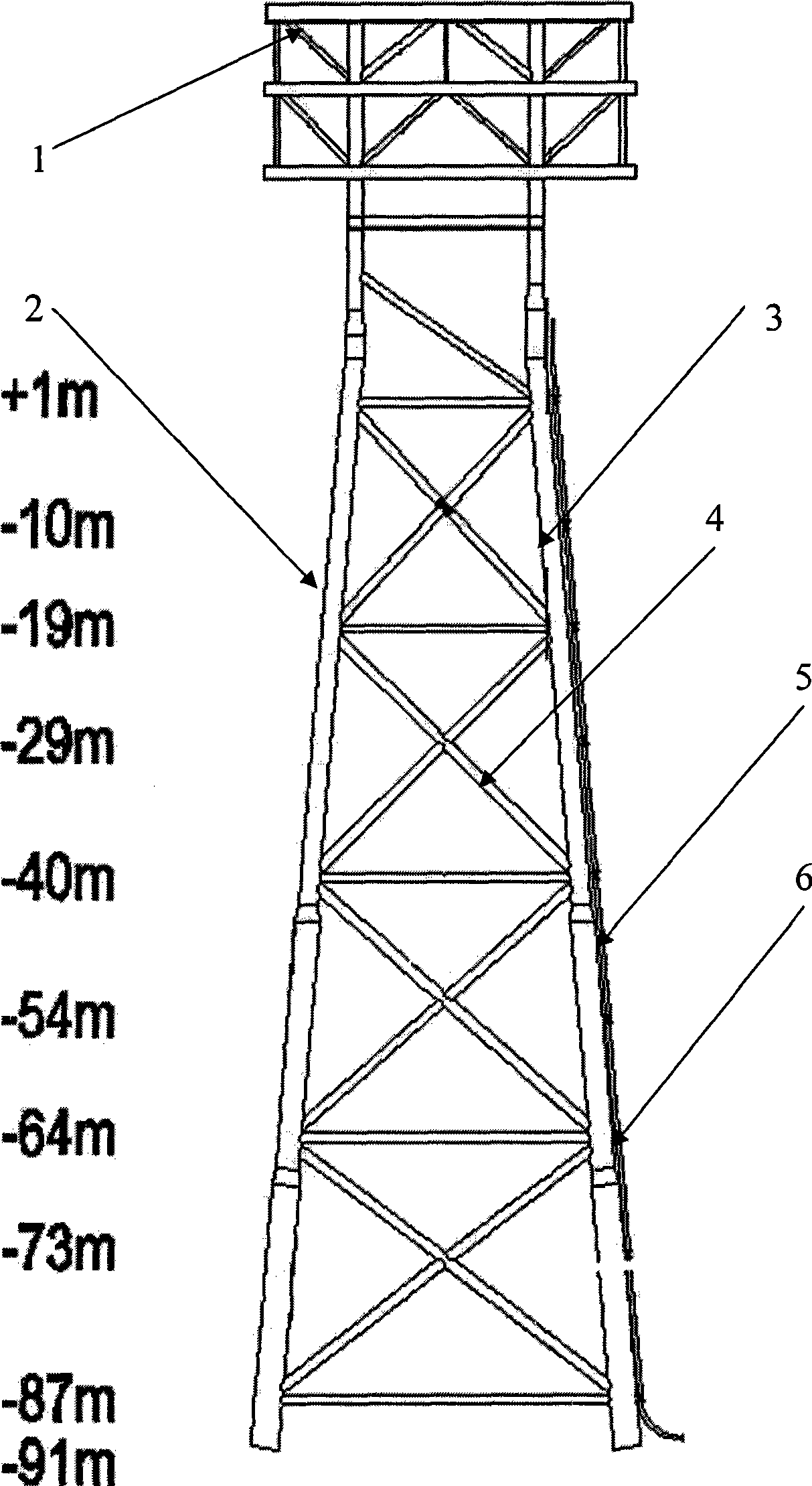

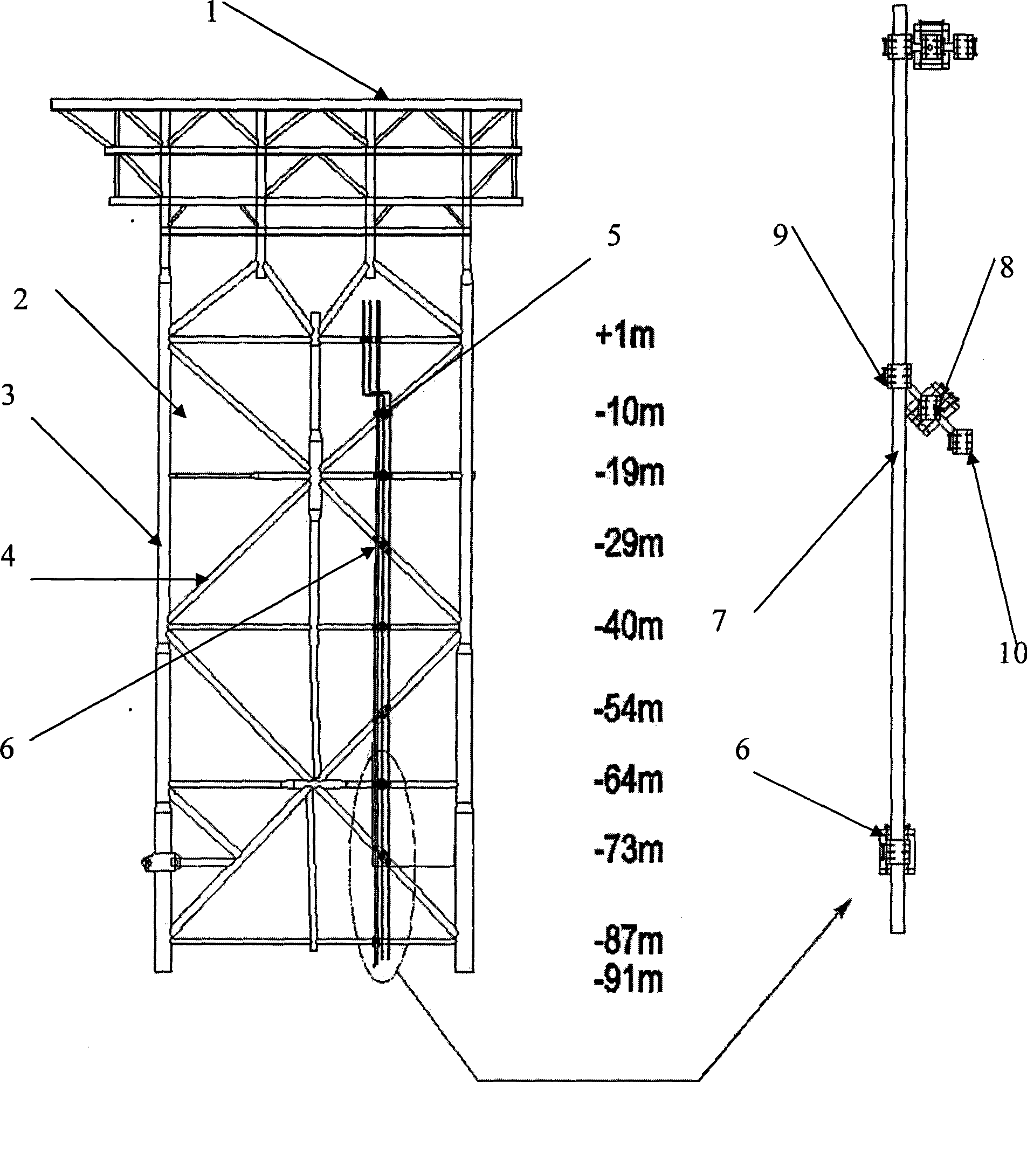

Installation method of riser clip on offshore jacket

InactiveCN101363218AImprove installation efficiencyEliminate coaxial adjustment workArtificial islandsUnderwater structuresLine tubingEngineering

The invention discloses an installation method of the vertical pipe clamp of a jacket, which comprises the following steps: marking, clamp installation, swinging, initial installation, continued installation and wiring, wherein, in the step of the marking, a diver sets an underwater mapping and installation location; in the step of the clamp installation, in accordance with the measured sizes, a plurality of small clamps are fixed on the pipe at intervals, lifting points are provided on the pipe and large clamps are opened; in the step of the swinging, the pipes are lifted to the installation location and the driver is responsible for the underwater command that a windlass straighten the location of the pipe on a platform; in the step of the initial installation, the large clamps are fixed on a lacing pipe from bottom to top, the small clamps are opened and the pipes are lifted to the platform; in the step of the continued installation, the clamps at the higher installation position are installed in sequence by circularly carrying out clamp installation, swinging and initial installation; and in the step of the wiring, the pipelines are arranged into the small clamps.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Method for manufacturing steel wire hydraulic knitted rubber hose containing formaldehyde modified lignin

ActiveCN102173066AGood dispersionGood physical and mechanical propertiesTubular articlesDispersityEngineering

The invention relates to a method for manufacturing a steel wire hydraulic knitted rubber hose containing formaldehyde modified lignin, belonging to the technical field of the methods for manufacturing rubber products. Mixing rubber produced by utilizing a mixing process serves as a rubber hose and used for producing the high-performance steel wire knitted hydraulic rubber hose for an inner liner. The technical scheme of the method comprises the following steps of: a sizing material mixing process: adopting a two-stage mixing method, that is, mixing and producing one-stage rubber by utilizingan internal mixer, placing the rubber for 8-24 hours and then carrying out second-stage sulfur adding in an open mill, wherein a reverse-order mixing method and variable-speed mixing are utilized in the one-stage mixing in the internal mixer and the heat treatment is carried out on the sizing material during the two-stage mixing in the open mill; extruding the inner liner of the steel wire hydraulic knitted rubber hose by utilizing the mixing rubber; and manufacturing the steel wire hydraulic knitted rubber hose via a knitted steel wire enhancing layer and an extrusion external coating and through cladding, setting and vulcanizing. By utilizing the mixing process, the dispersity of the lignin is greatly improved; the physical and mechanical properties of the steel wire hydraulic knitted rubber hose are good; and compared with nitrile rubber separately using carbon black as a reinforcing agent, the steel wire hydraulic knitted rubber hose containing the formaldehyde modified lignin hasobvious advantages of rigidity, aging resistance and oil resistance at a normal temperature.

Owner:GUANGZHOU TIANHE HOSE PRODS

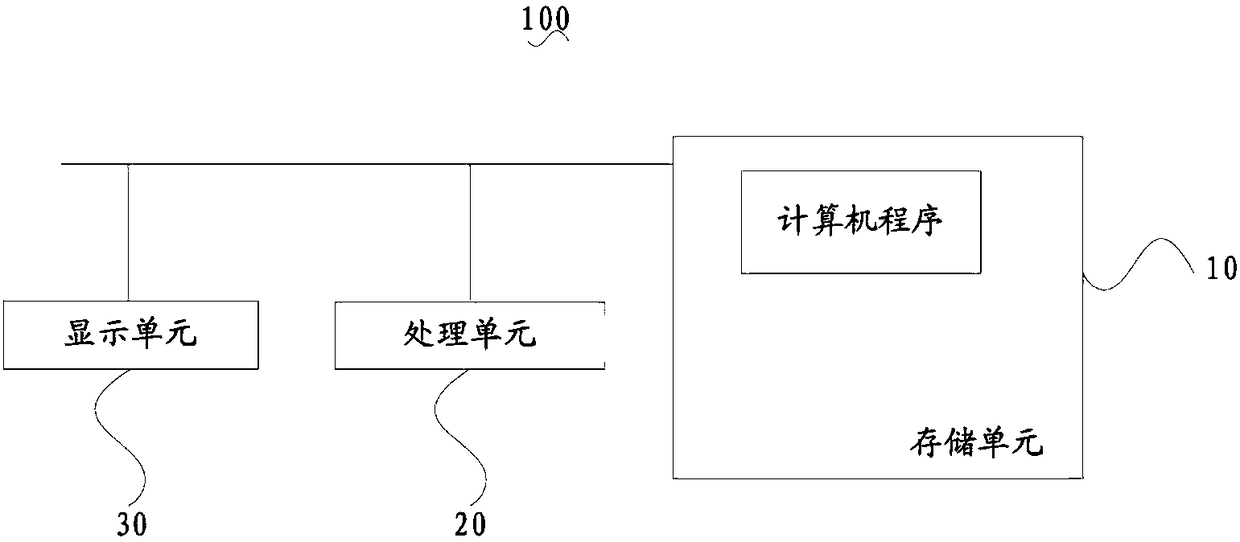

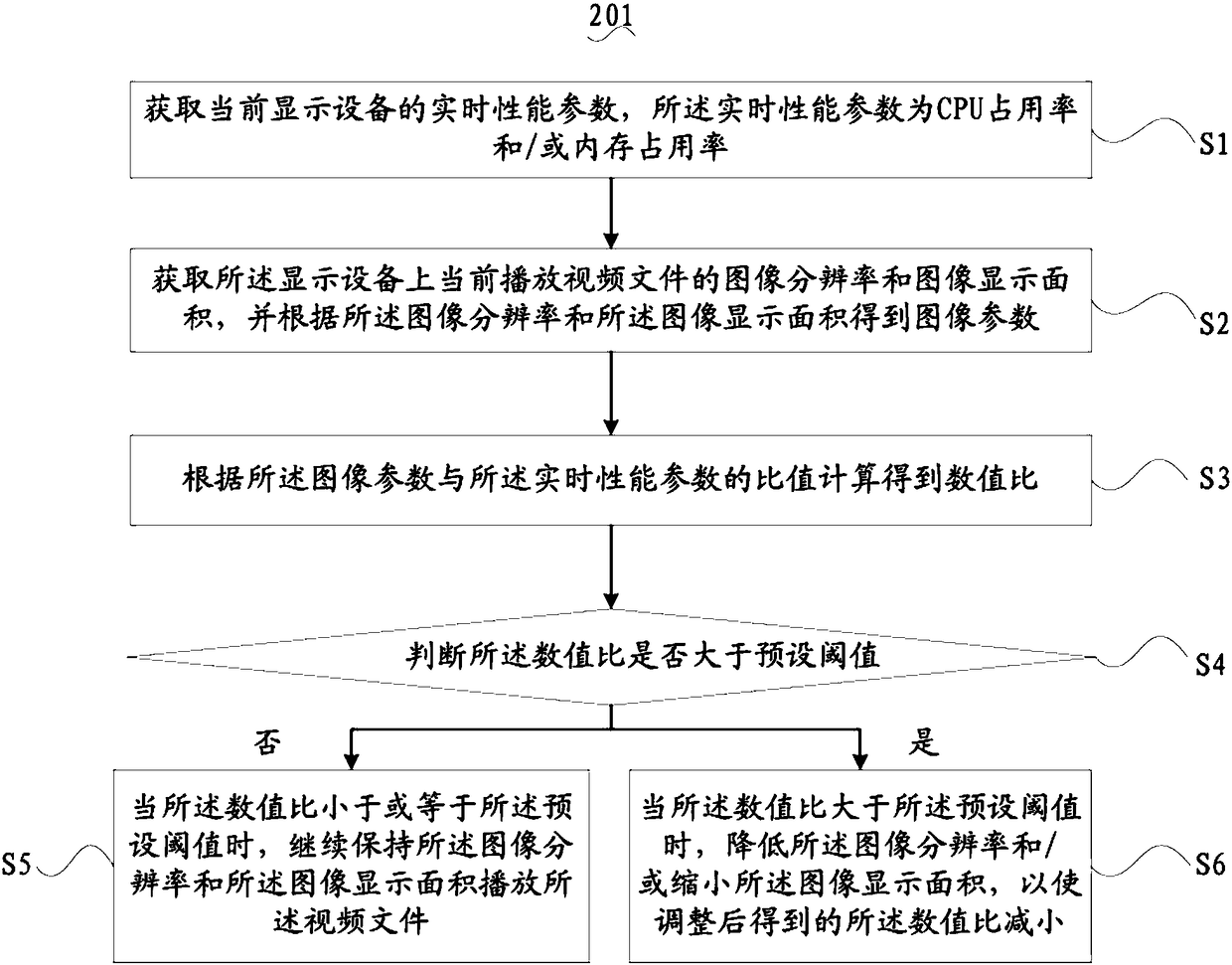

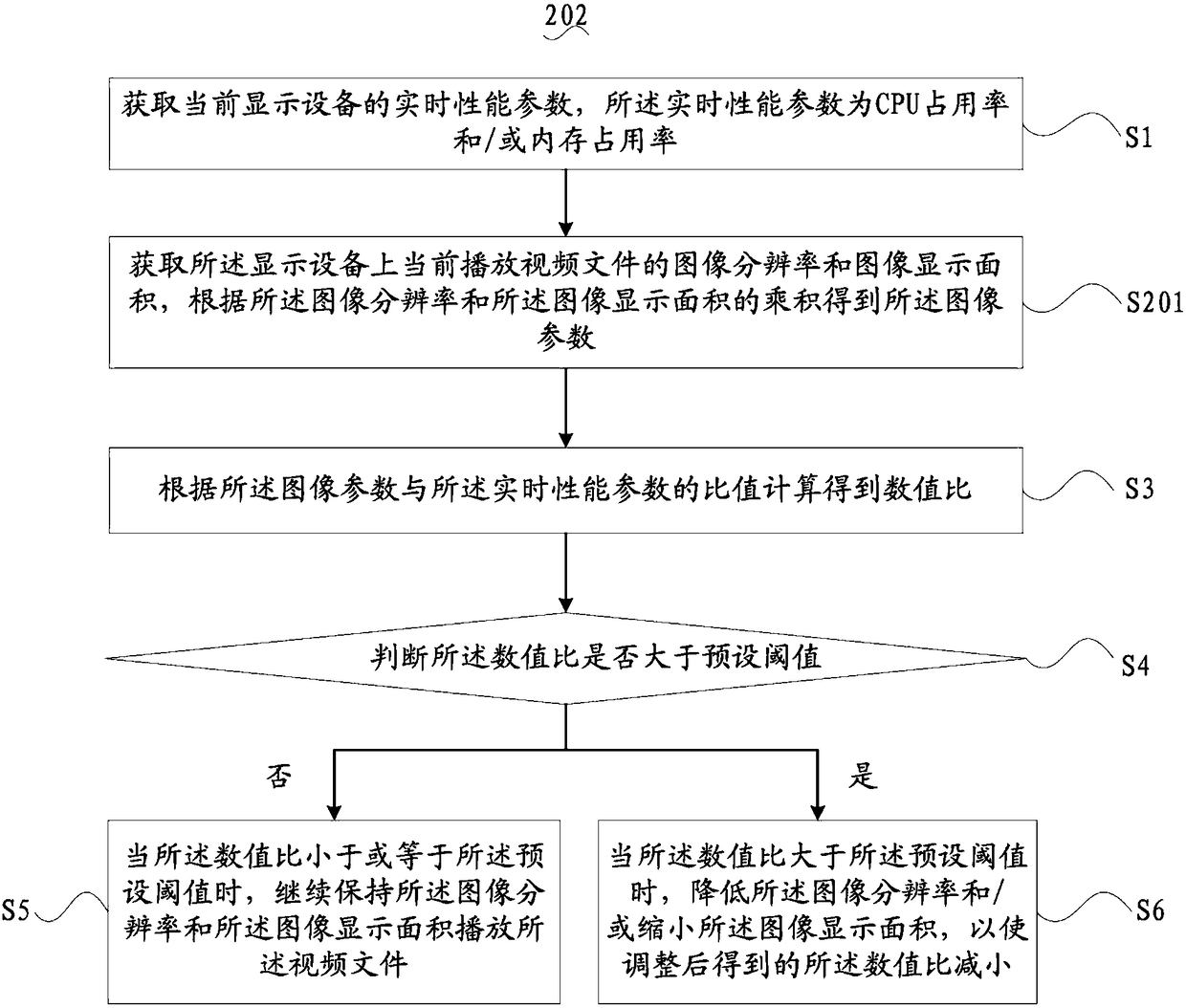

Video playing method, display device and computer readable storage medium

ActiveCN108377421AReduce real-time performance parametersSolve CatonSelective content distributionImage resolutionOccupancy rate

The invention discloses a video playing method. The method comprises the following steps: obtaining a real-time performance parameter of a current display device, wherein the real-time performance parameter is a CPU occupancy rate and / or a memory occupancy rate; obtaining an image resolution and an image display area of a currently played video file on the display device, and obtaining an image parameter according to the image resolution and the image display area; performing calculation according to the image parameter and the performance parameter to obtain a numerical value ratio; when thenumerical value ratio is smaller than or equal to a preset threshold, continuing to keep the image resolution and the image display area to play the video file; and when the numerical value ratio is greater than the preset threshold, reducing the image resolution and / or reducing the image display area. The invention further discloses a display device and a computer readable storage medium. By adoption of the technical scheme provided by the invention, the blockage phenomenon during the video playing can be reduced.

Owner:SHENZHEN TCL DIGITAL TECH CO LTD

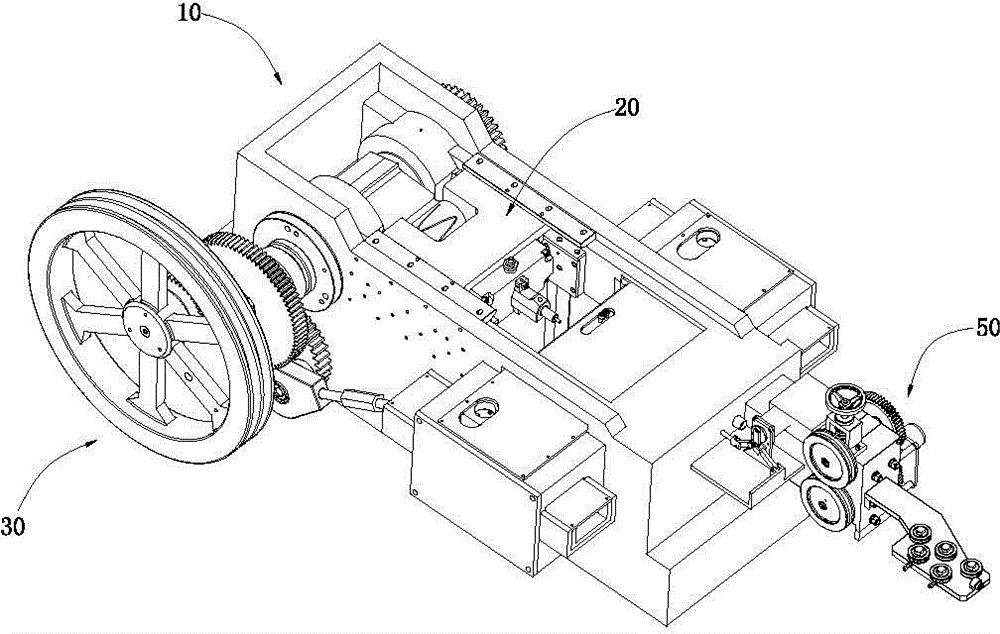

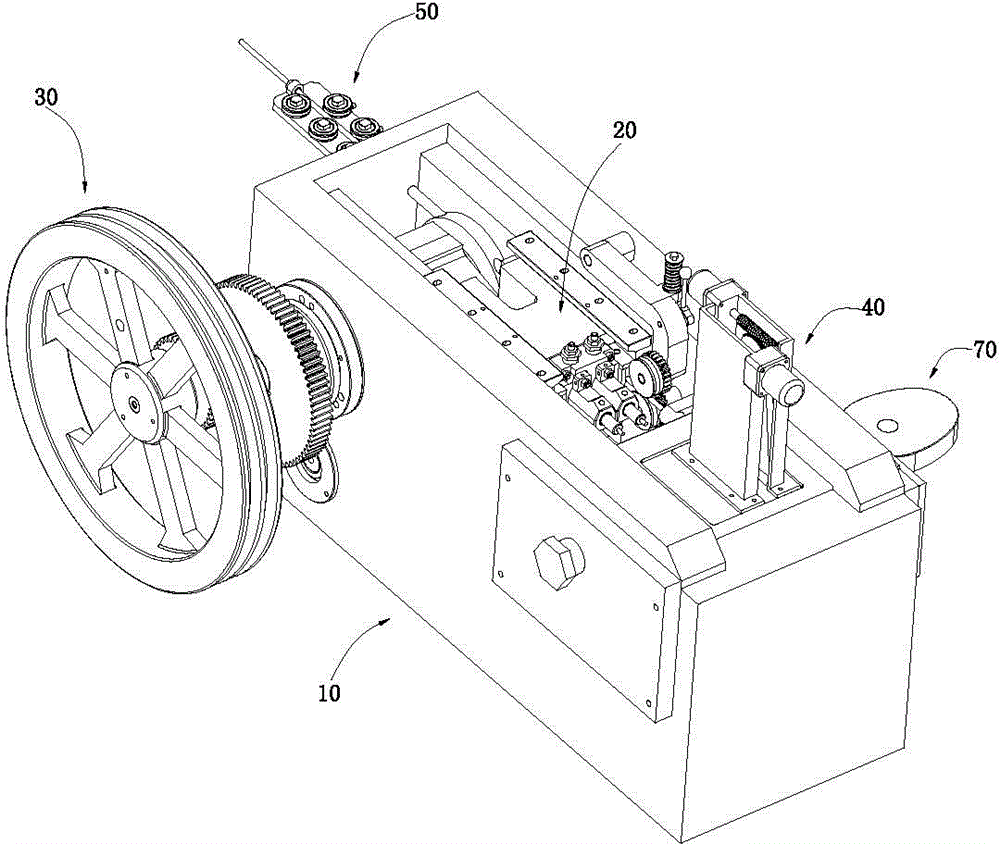

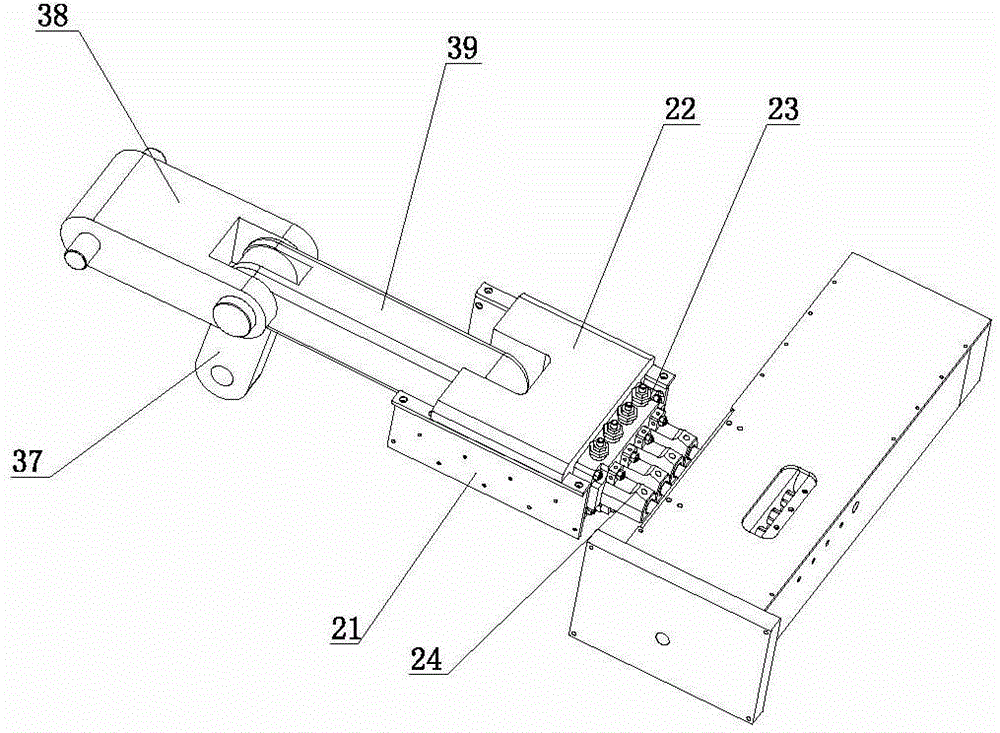

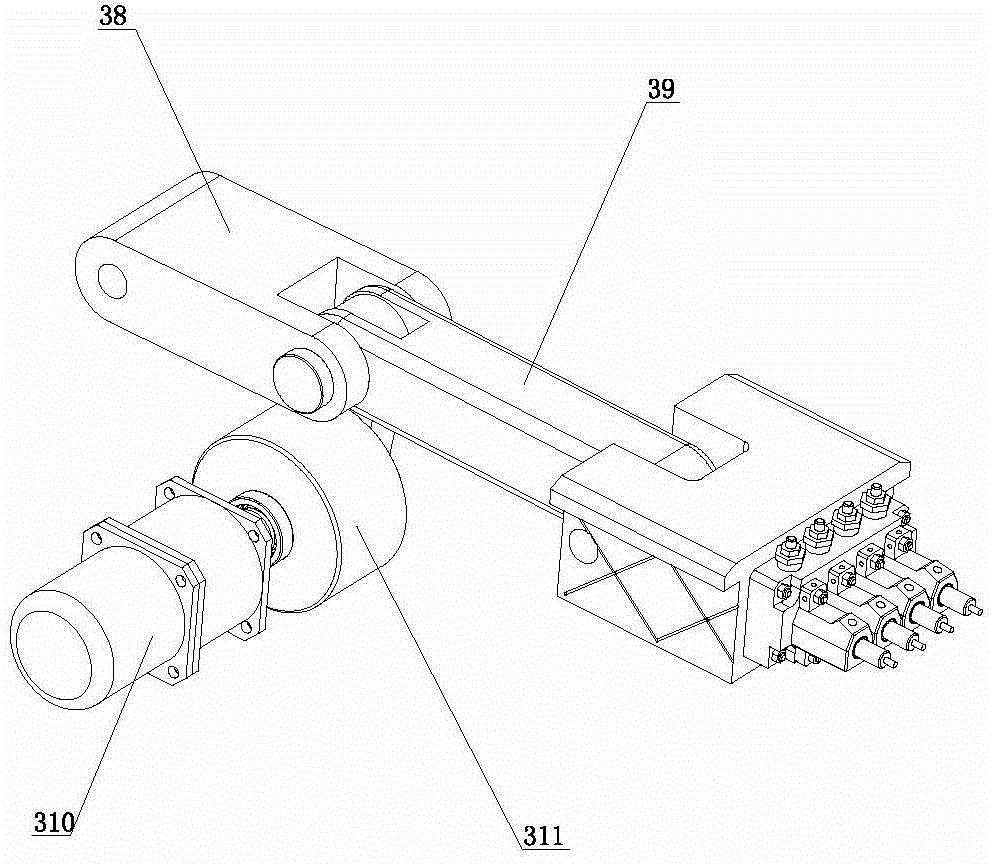

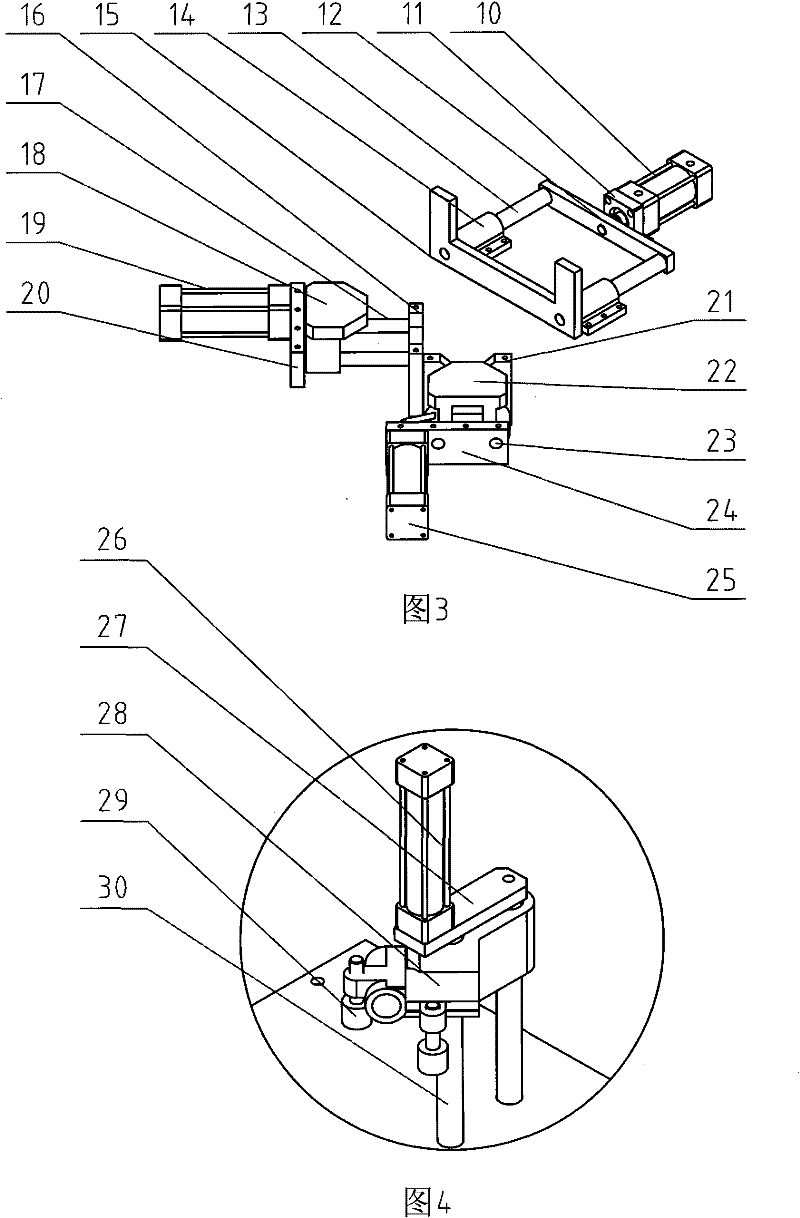

A die closing upsetter and a working method

InactiveCN106031941ASimple structureImprove upsetting efficiencyUpsetting pressesSwagging pressesMechanical engineering

The invention provides a die closing upsetter and a working method. The die closing upsetter comprises a machine body, a punch assembly, a punch assembly driving mechanism, a feeding mechanism and a material cutting sleeve; the machine body is provided with a die closing assembly which comprises a first die closing base and a second die closing base; the side surface, close to the second die closing base, of the first die closing base is provided with a first installing groove; the side surface, close to the first die closing base, of the second die closing base is provided with a second installing groove. A first die closing driving mechanism driving the first die closing base to translate and a second die closing driving mechanism driving the second die closing base to translate are also arranged. The working method comprises the steps of feeding materials, realizing displacement full-circle material cutting through the translation of the die closing assembly, and performing upsetting. The working method requires no independent material cutting mechanism and material clamping and blank delivering mechanism, realizes die closing material cutting and die closing upsetting and achieves the effect of a clamp.

Owner:DONGGUAN SHIXI INTELLIGENT MACHINE MFG

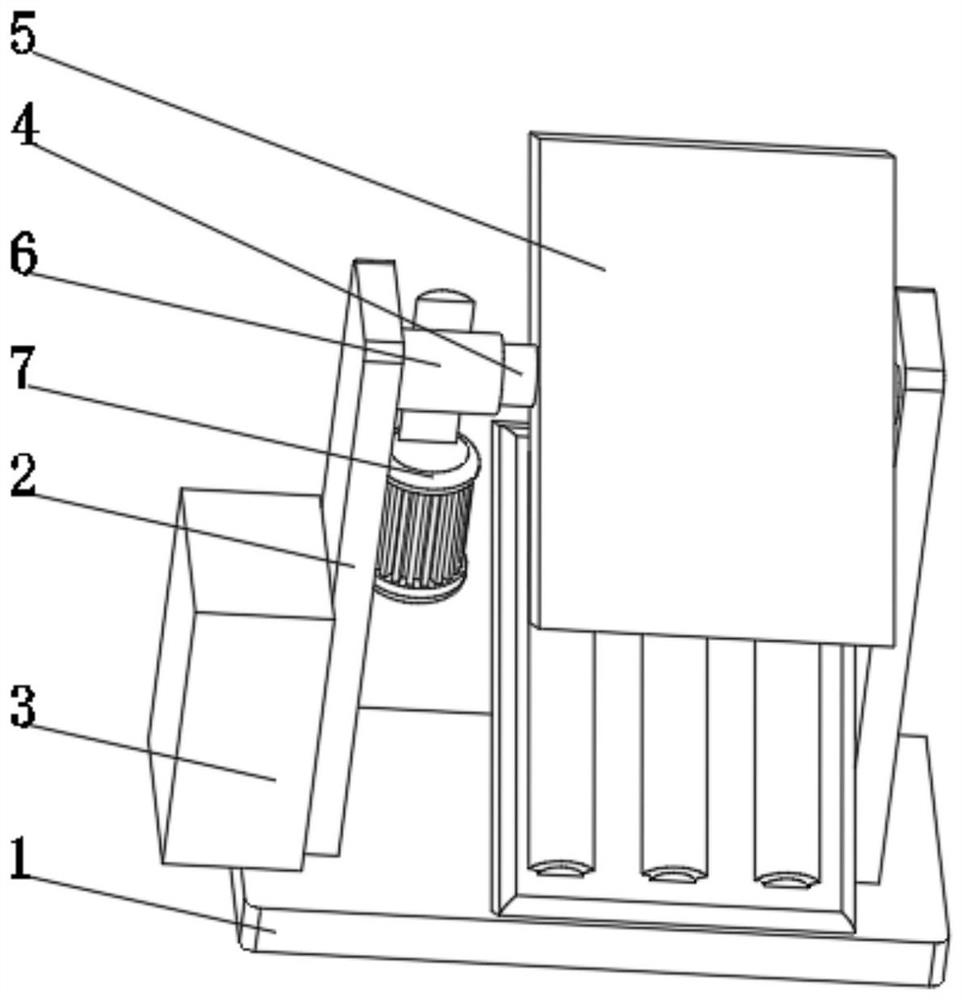

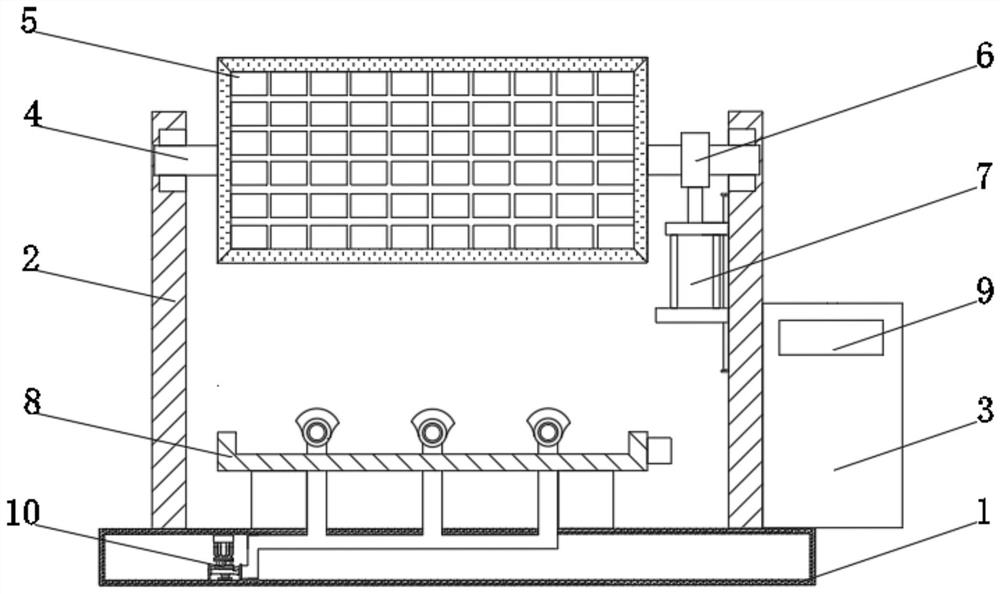

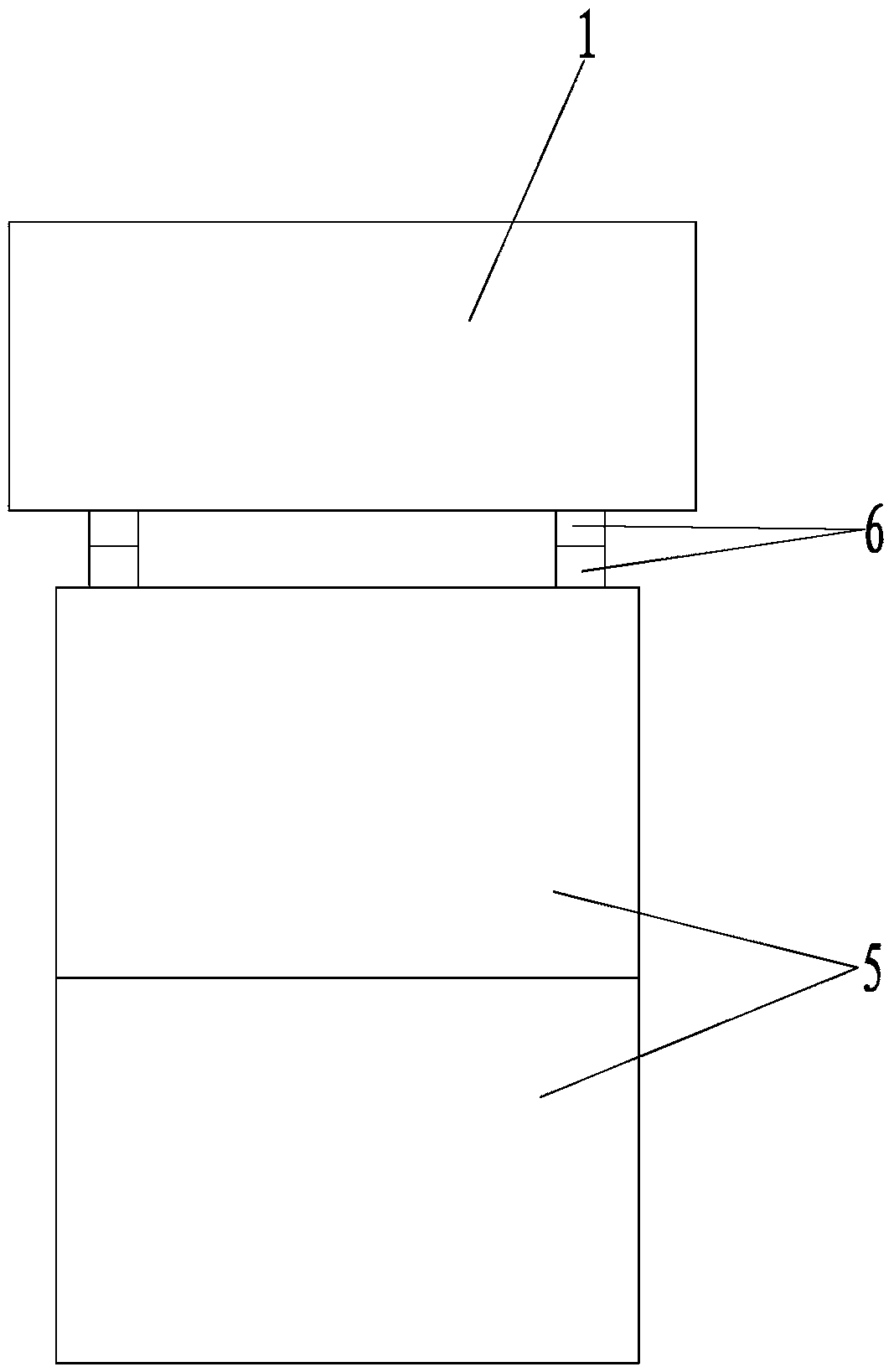

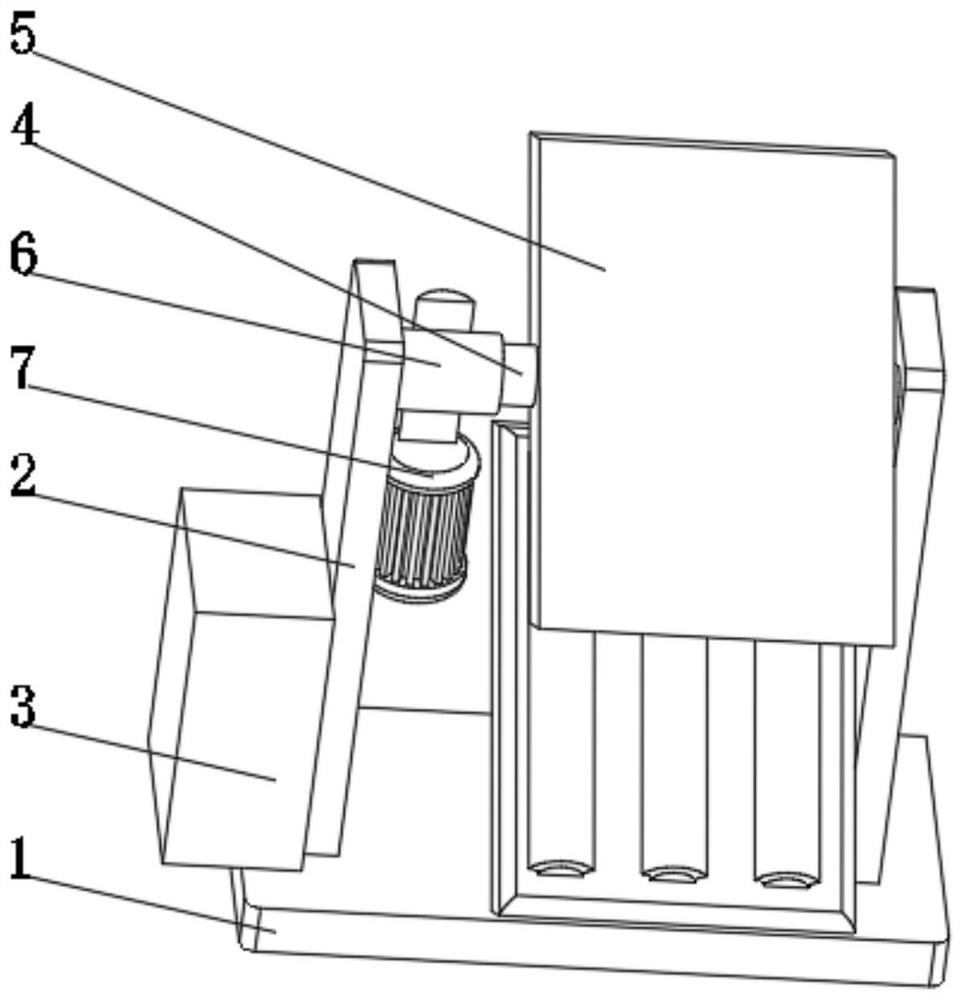

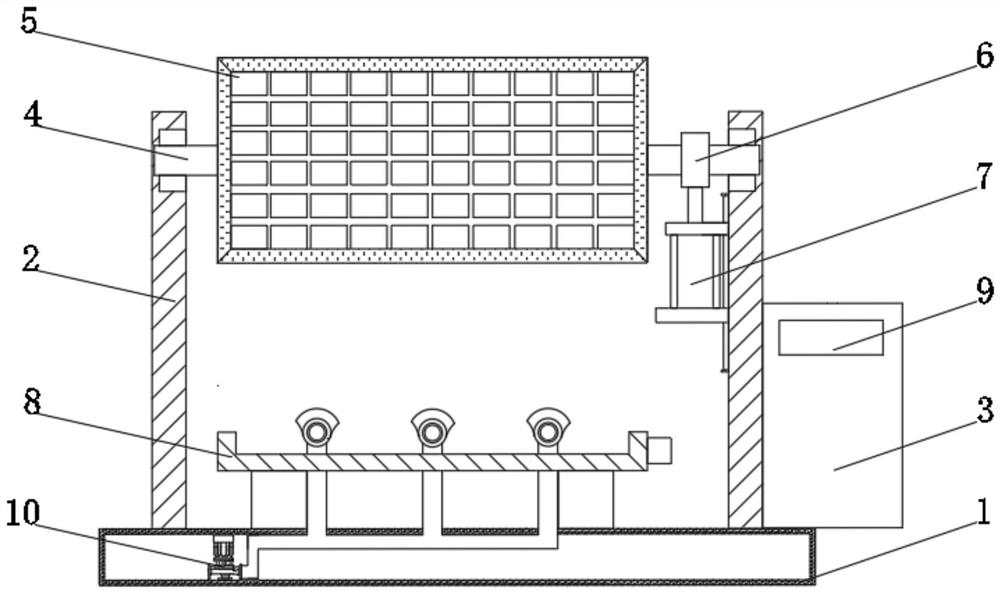

Self-cleaning solar power generation panel

ActiveCN112821860AWill not affect normal workIncrease resistancePhotovoltaic supportsSolar heating energyPhysicsSolar power

The present invention discloses a self-cleaning solar power generation panel. A fixing support is fixed to the top of a water storage base, one side of the fixing support is fixedly connected with a control electric appliance cabinet, the inner side of the fixing support is rotationally connected with a rotating shaft through a bearing, and the side face of the rotating shaft is fixedly connected with a solar power generation panel and a rotating connecting base. A lifting device is fixedly connected to one side of the rotating connecting base, one side of the lifting device is slidably connected with the fixing support through a sliding block and a sliding rail, a cleaning mechanism is arranged below the solar power generation panel, and the side, away from the solar power generation panel, of the cleaning mechanism is fixedly connected with the water storage base through a telescopic device; a thermal induction resistor is arranged on one side of the control electric appliance cabinet, and a water pump is arranged in the water storage base. According to the self-cleaning solar power generation panel, the normal work of the solar power generation panel is not influenced, and the situation that the equipment is damaged and the equipment cost is increased due to the explosion of the solar power generation panel caused by temperature difference is prevented.

Owner:NINGBO OUTLUX ELECTRICAL CO LTD

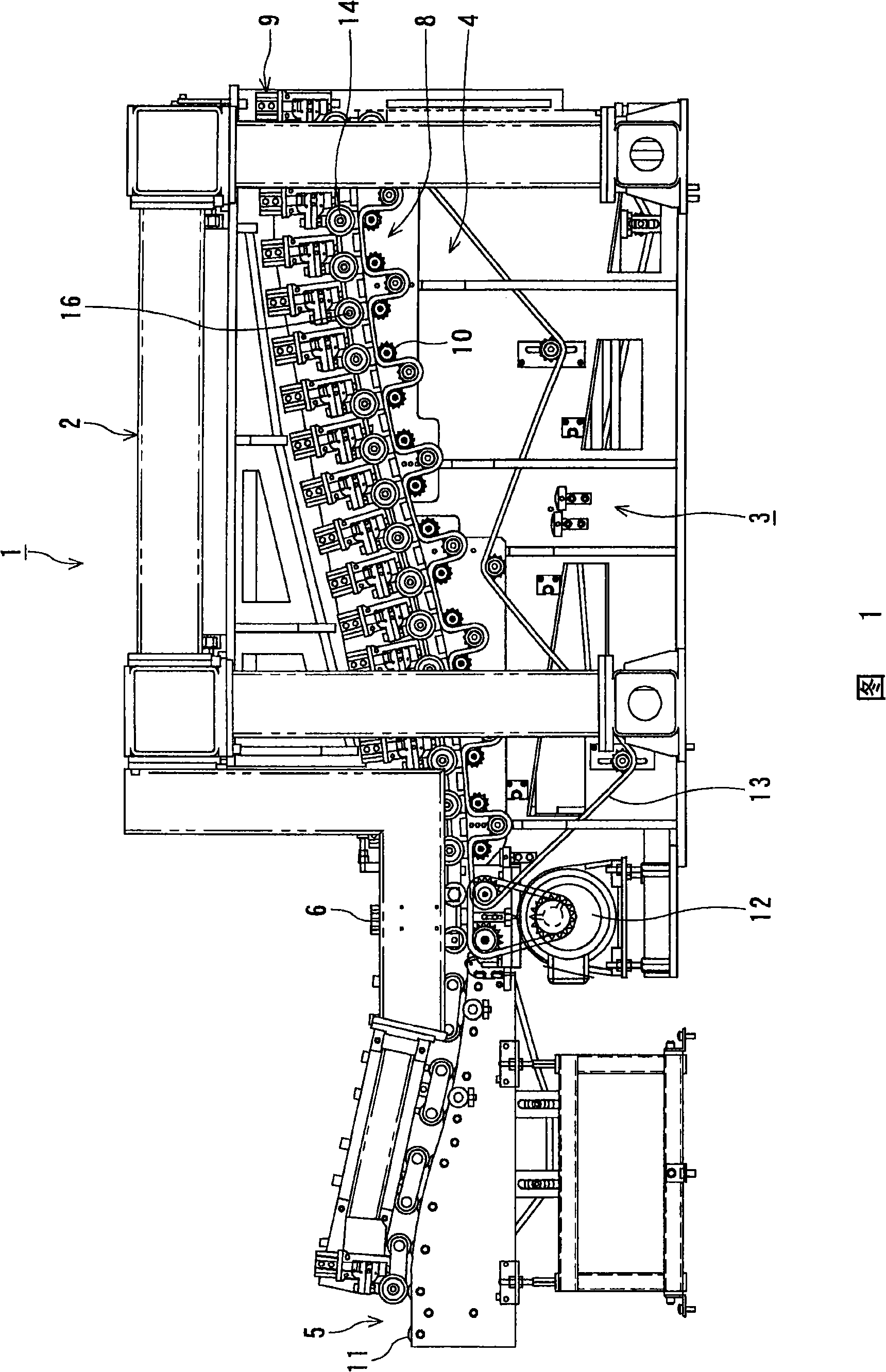

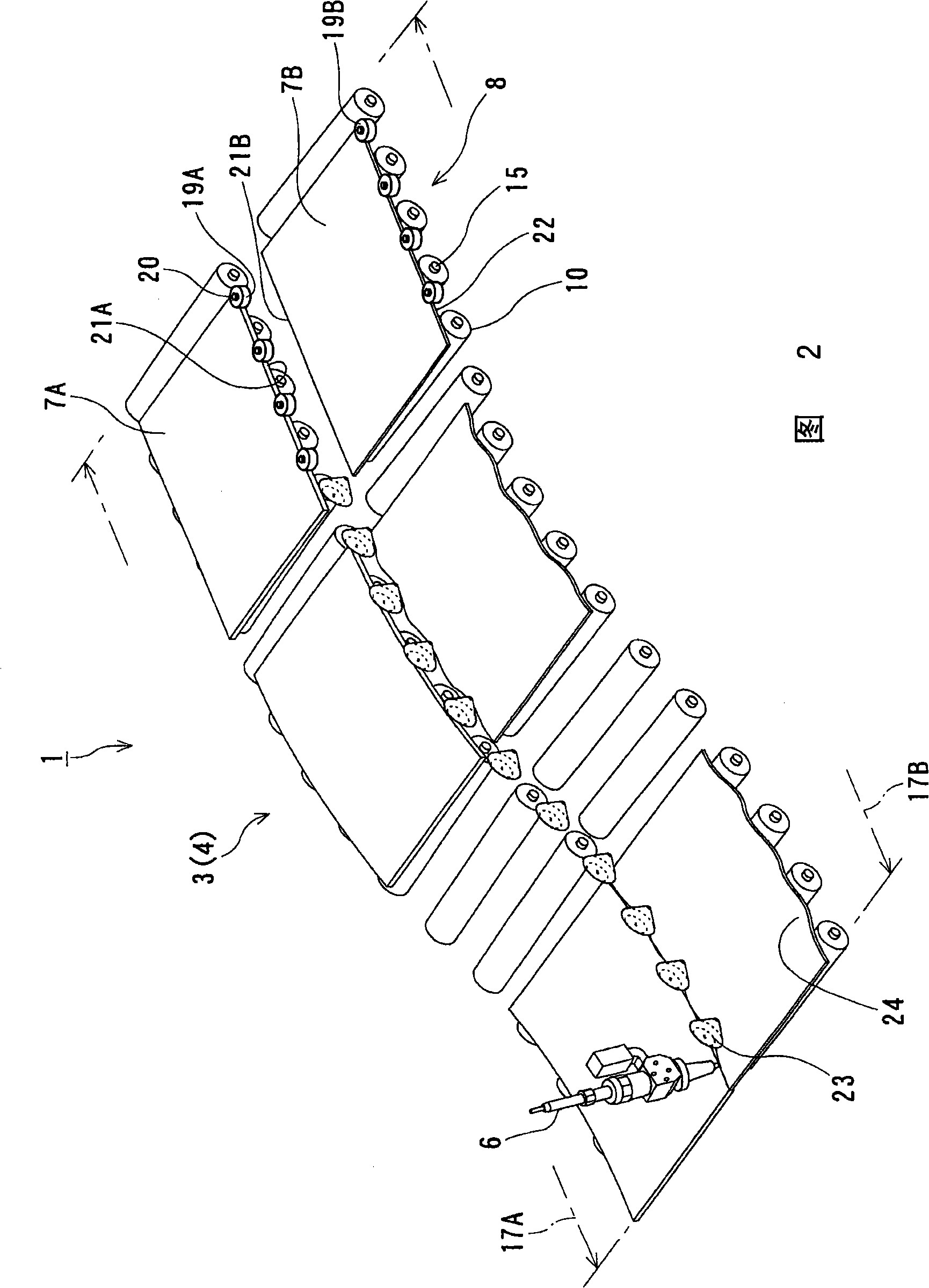

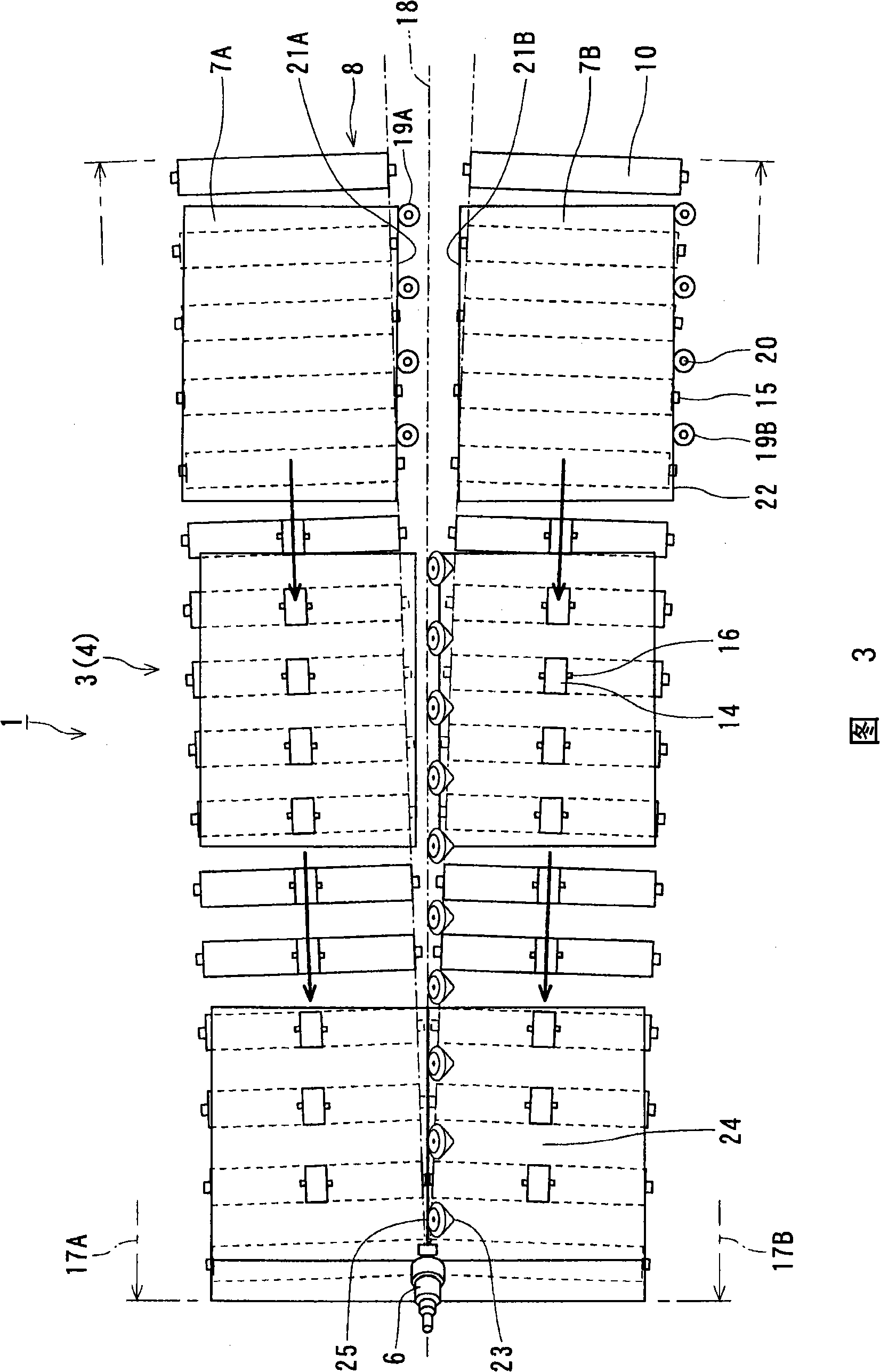

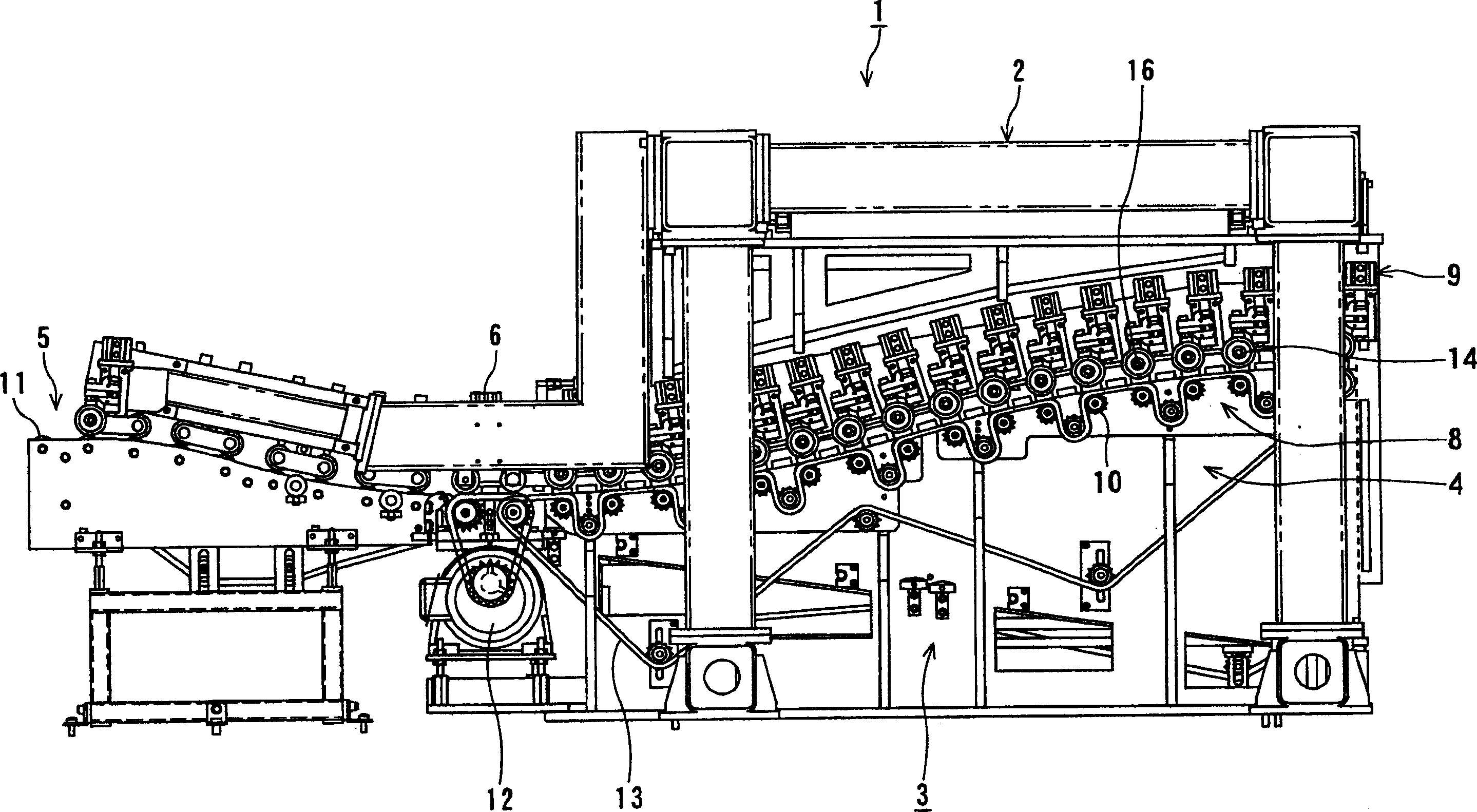

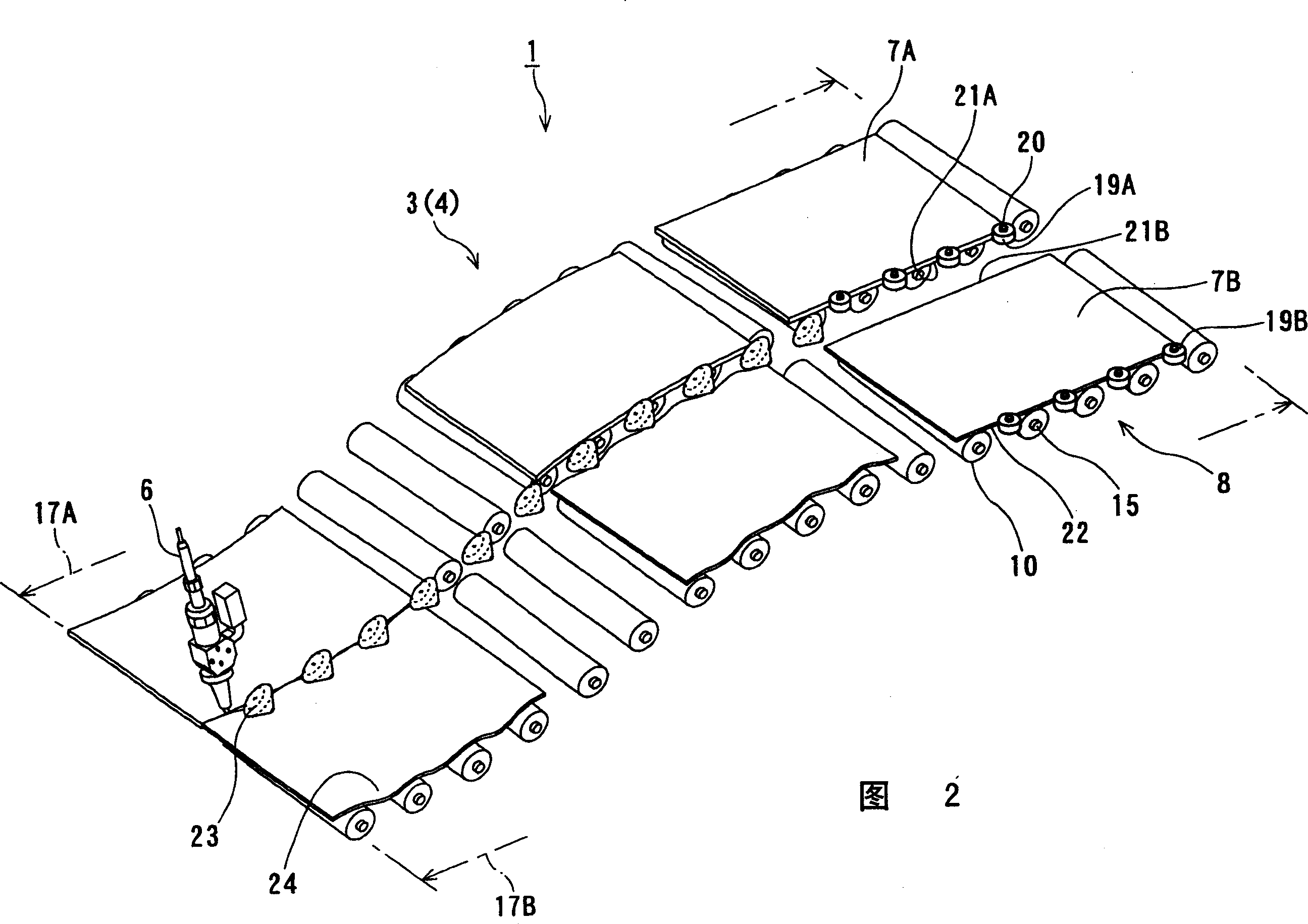

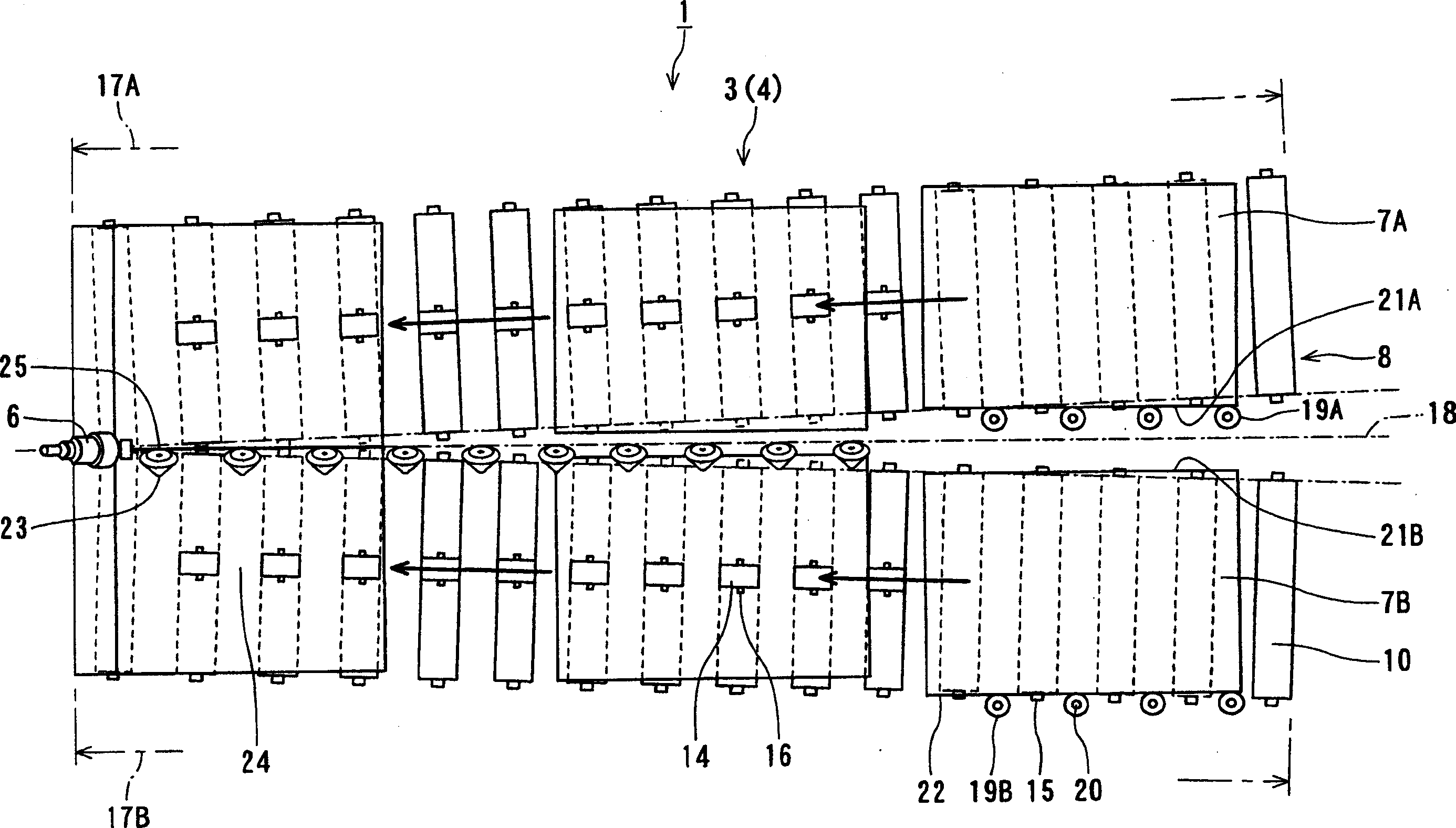

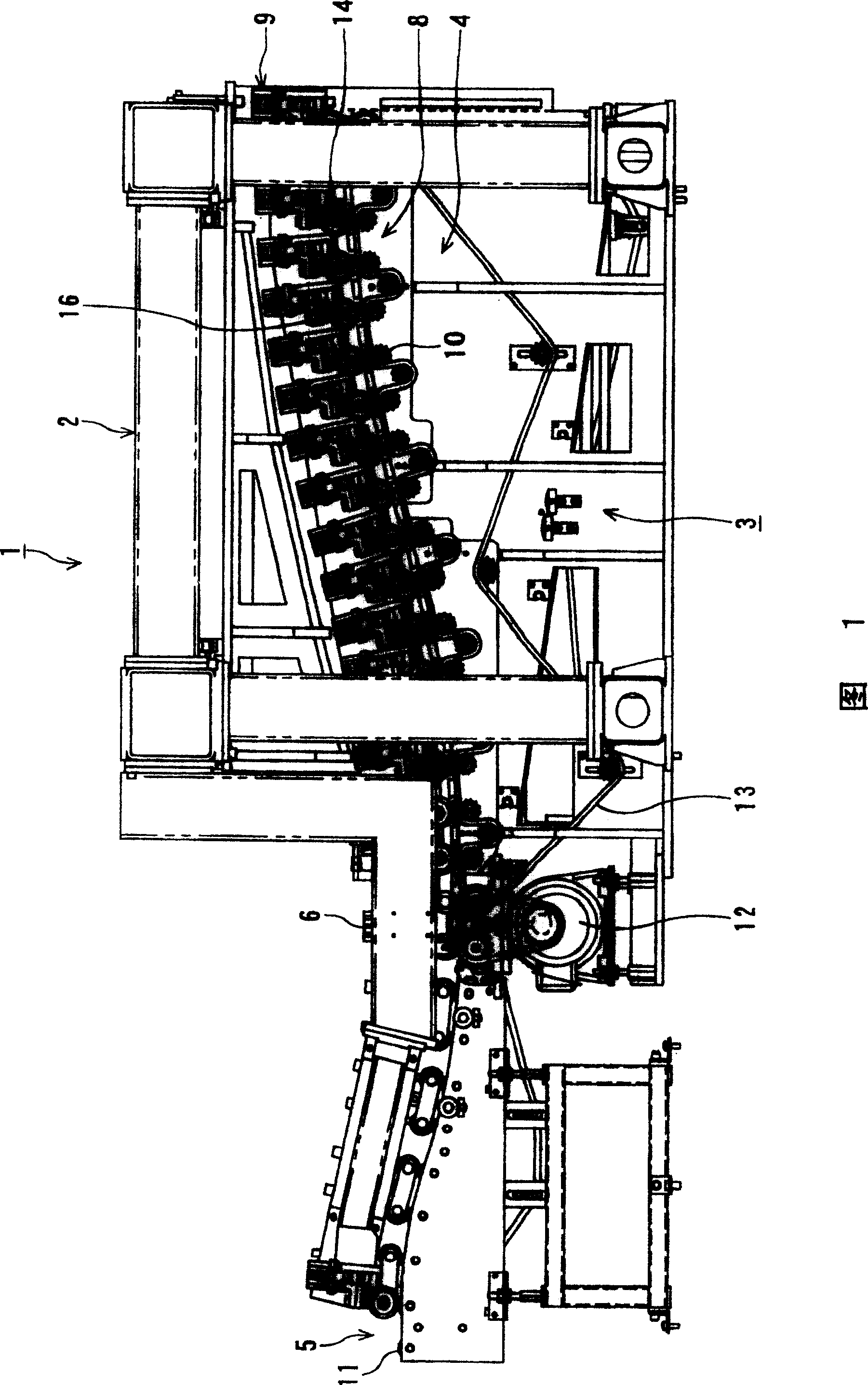

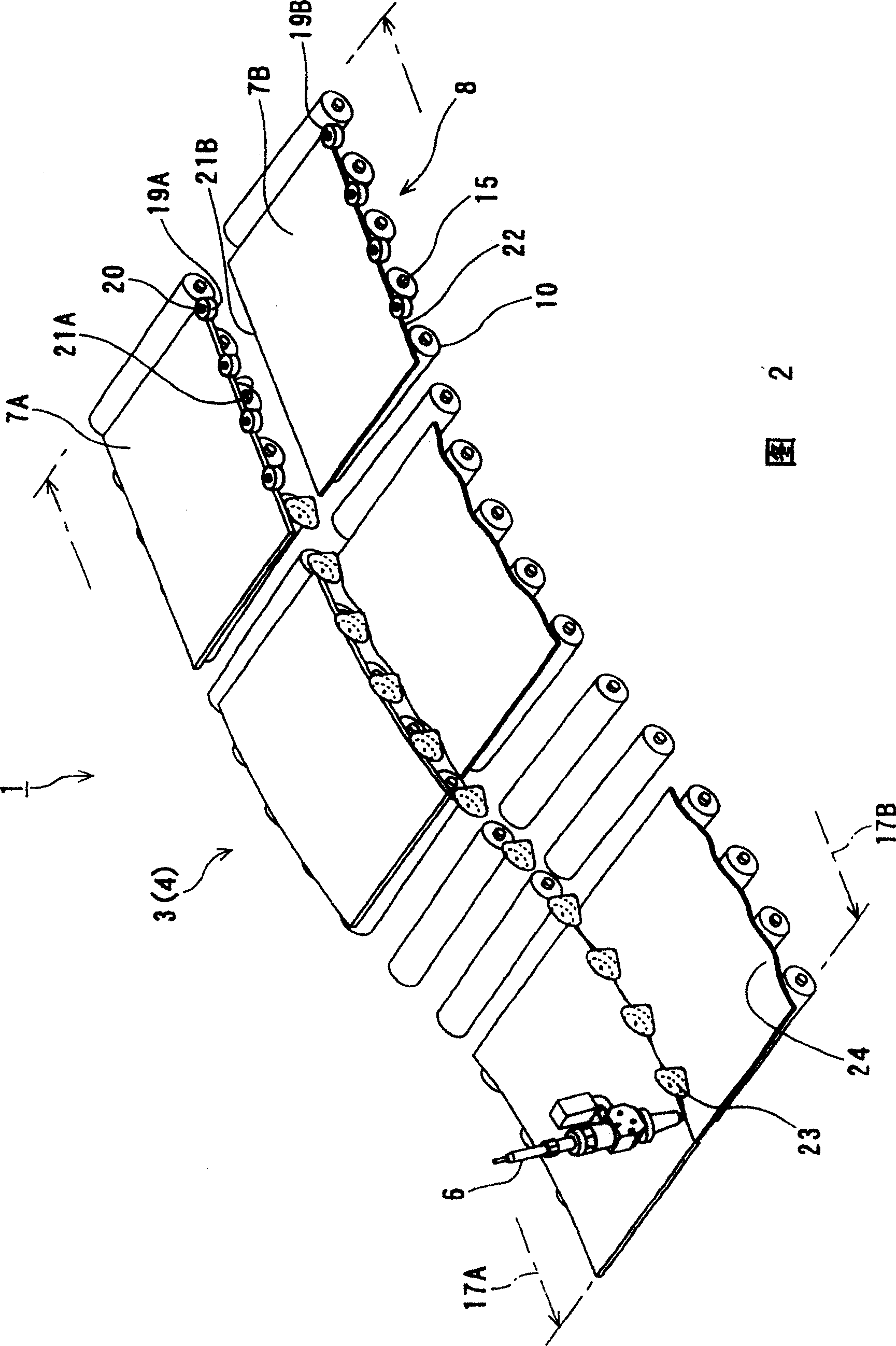

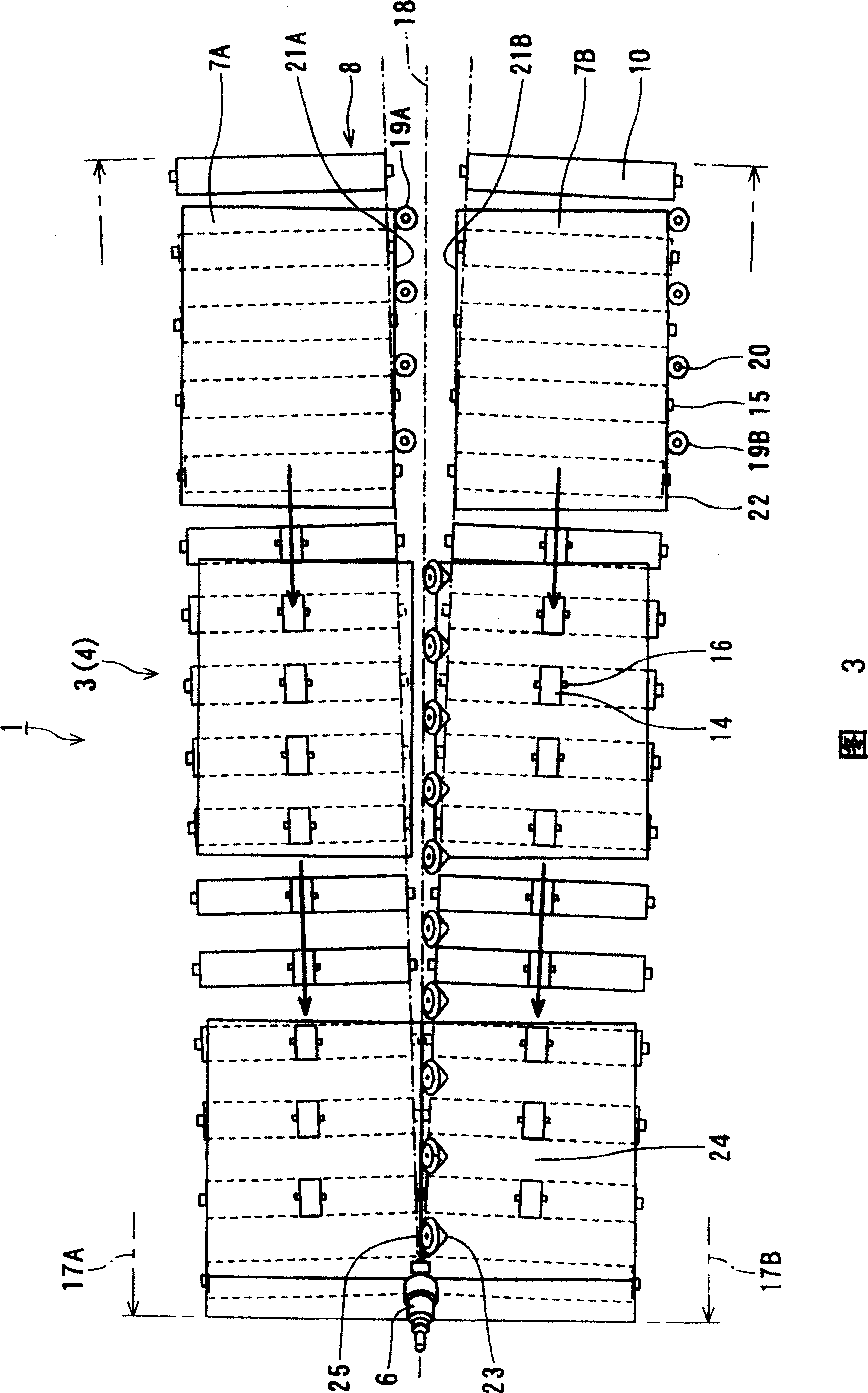

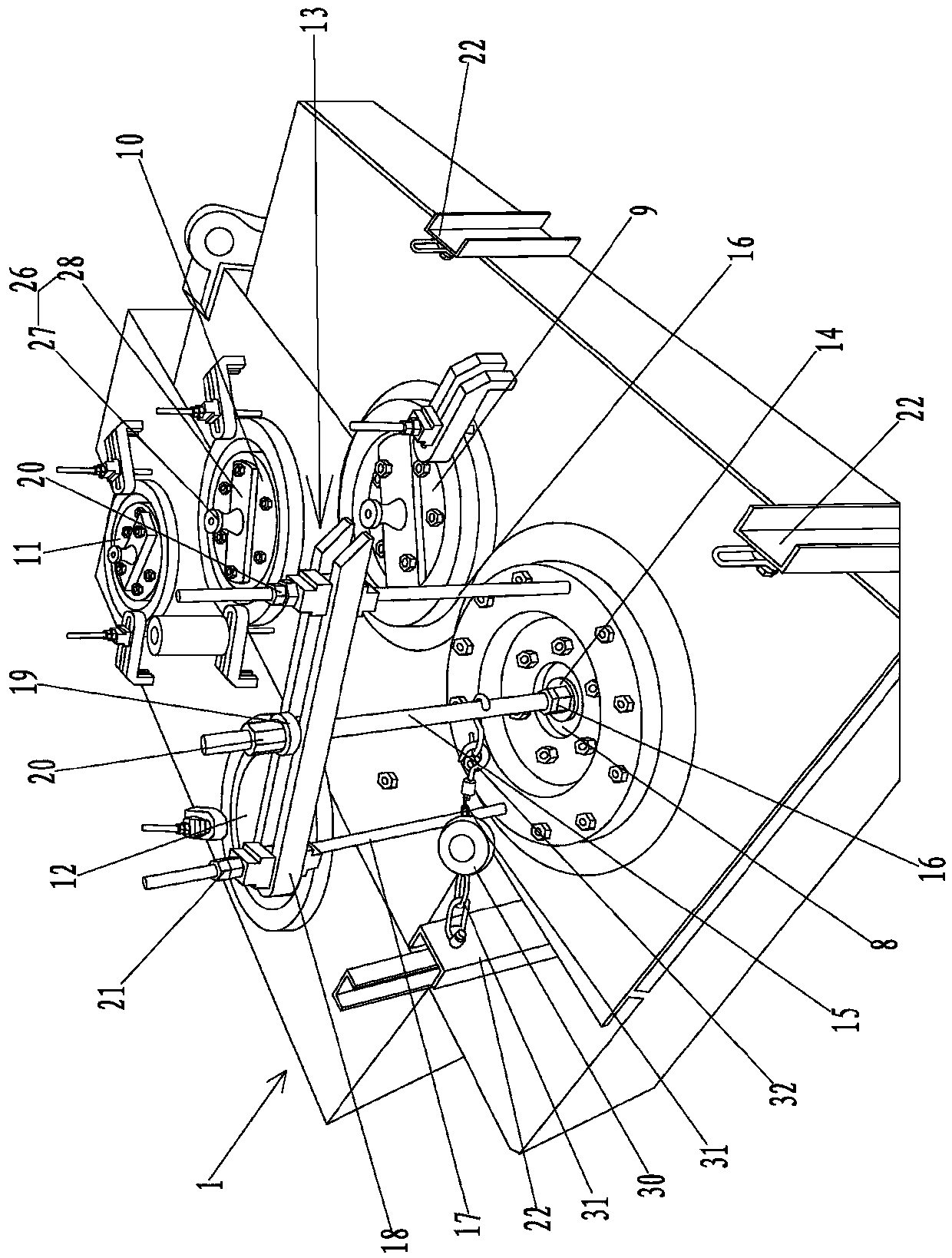

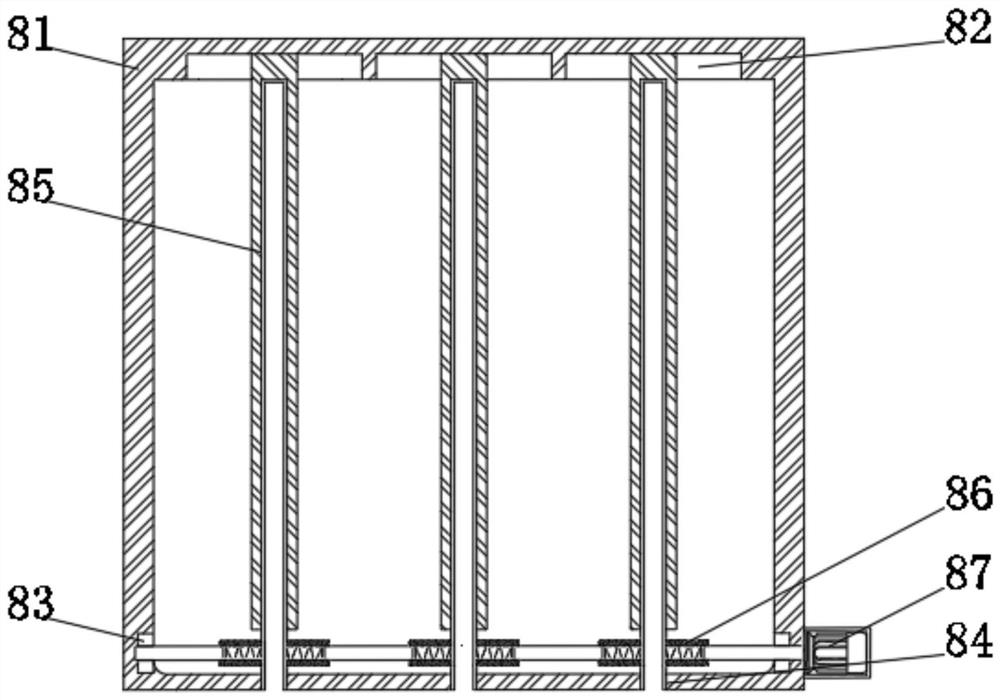

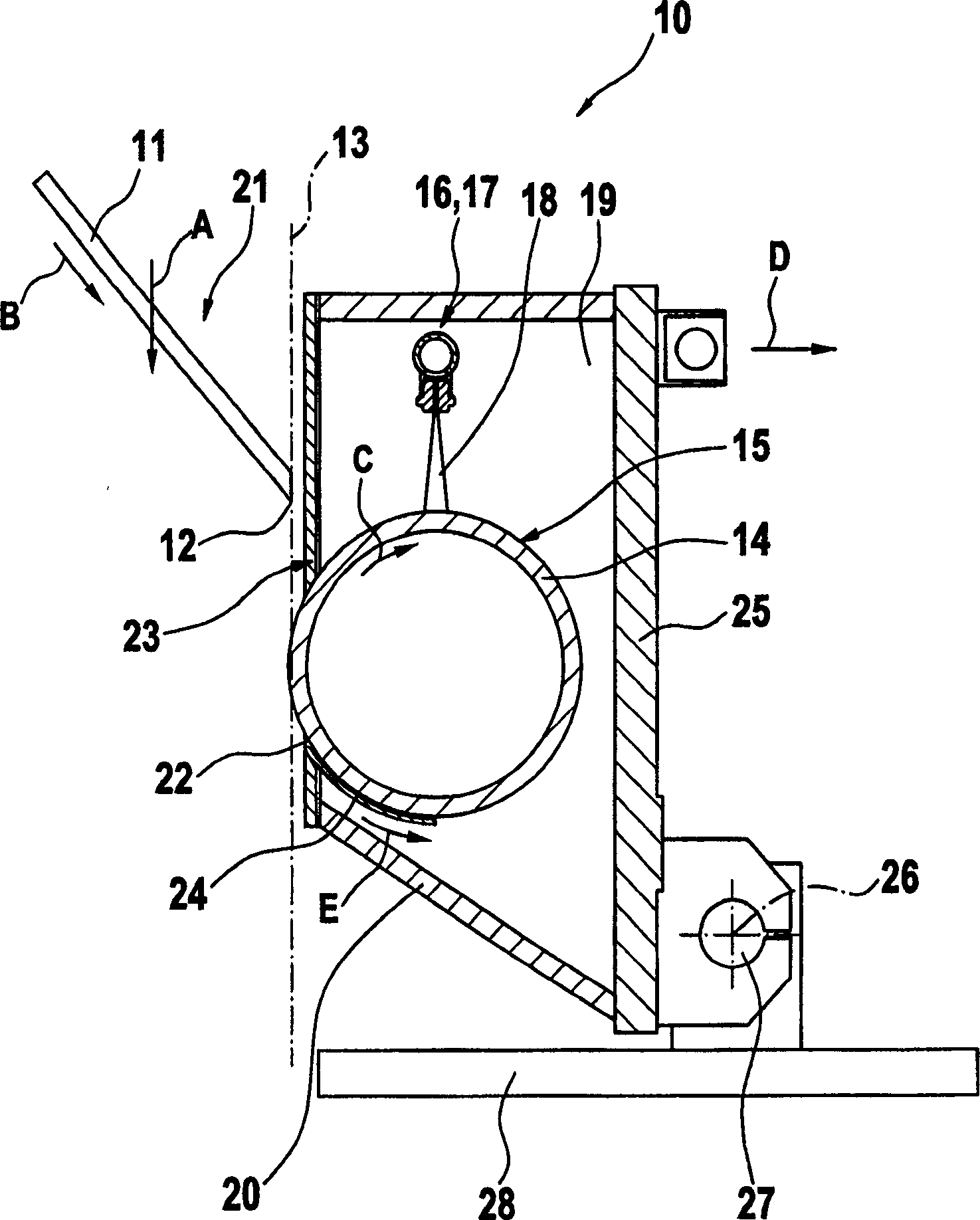

Conveyor for sheet-shaped thin plate and method of conveying same

InactiveCN101357427ALess adjustment workImproved butt weld performanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A conveyor for guiding and conveying a plurality of sheet-shaped thin plates in rows arranged side by side to a welding position at which ends of the adjacent thin plates are butted and welded to each other, includes a plurality of conveying paths, which are adjacent to each other, having different conveying surfaces which are placed on a same horizontal plane, and a guide unit disposed between the adjacent two conveying paths for guiding the thin plates on one of the conveying paths with respect to another one thereof toward the welding position. Each of the conveying paths is composed of a plurality conveying rollers, and the guide unit includes guide rollers each having a guide surface for guiding the thin plate on the one of the conveying paths in a state that the thin plate on the one conveying path is partially depressed with respect to the another one of the conveying path.

Owner:SUZUKI MOTOR CORP

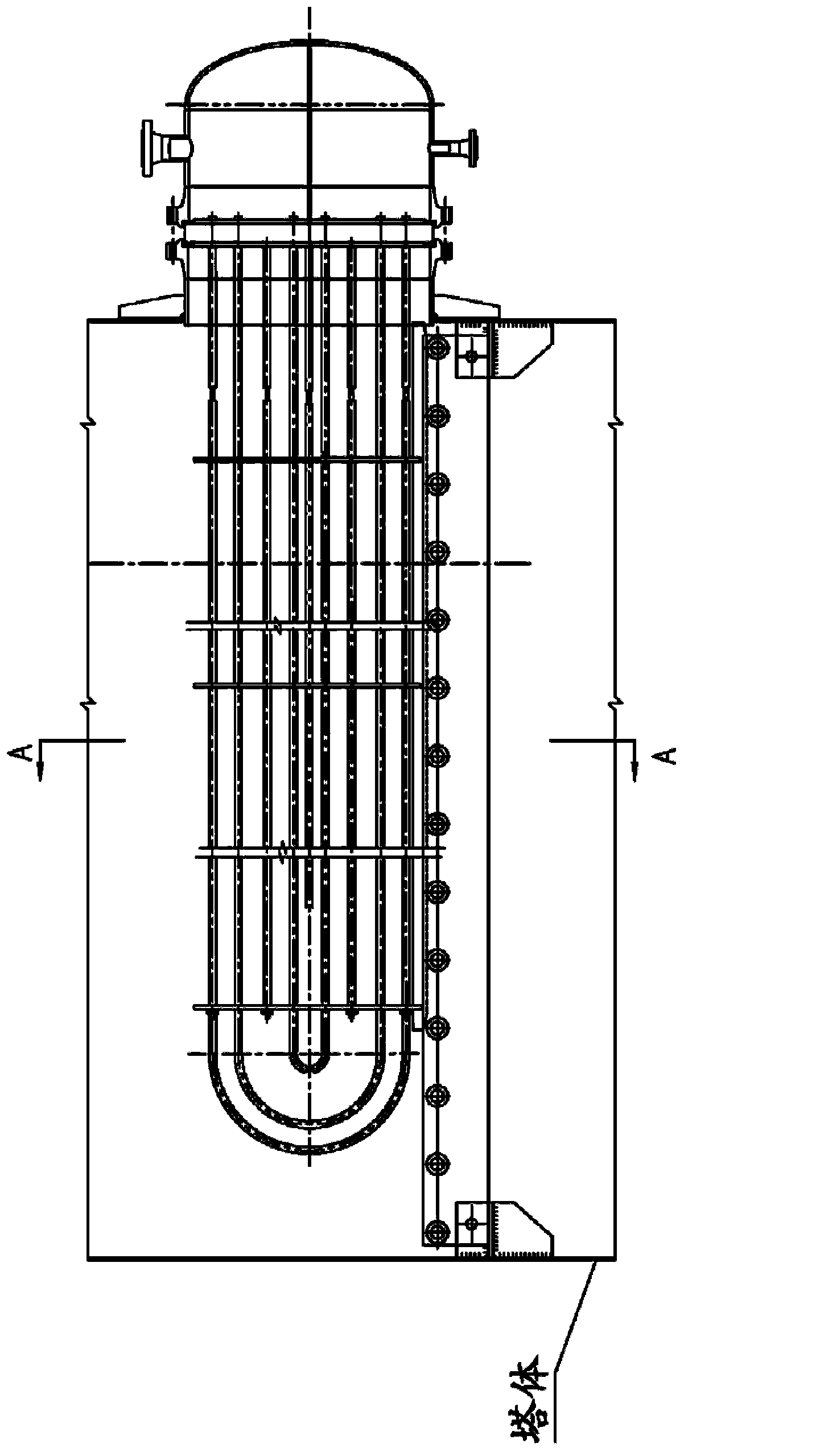

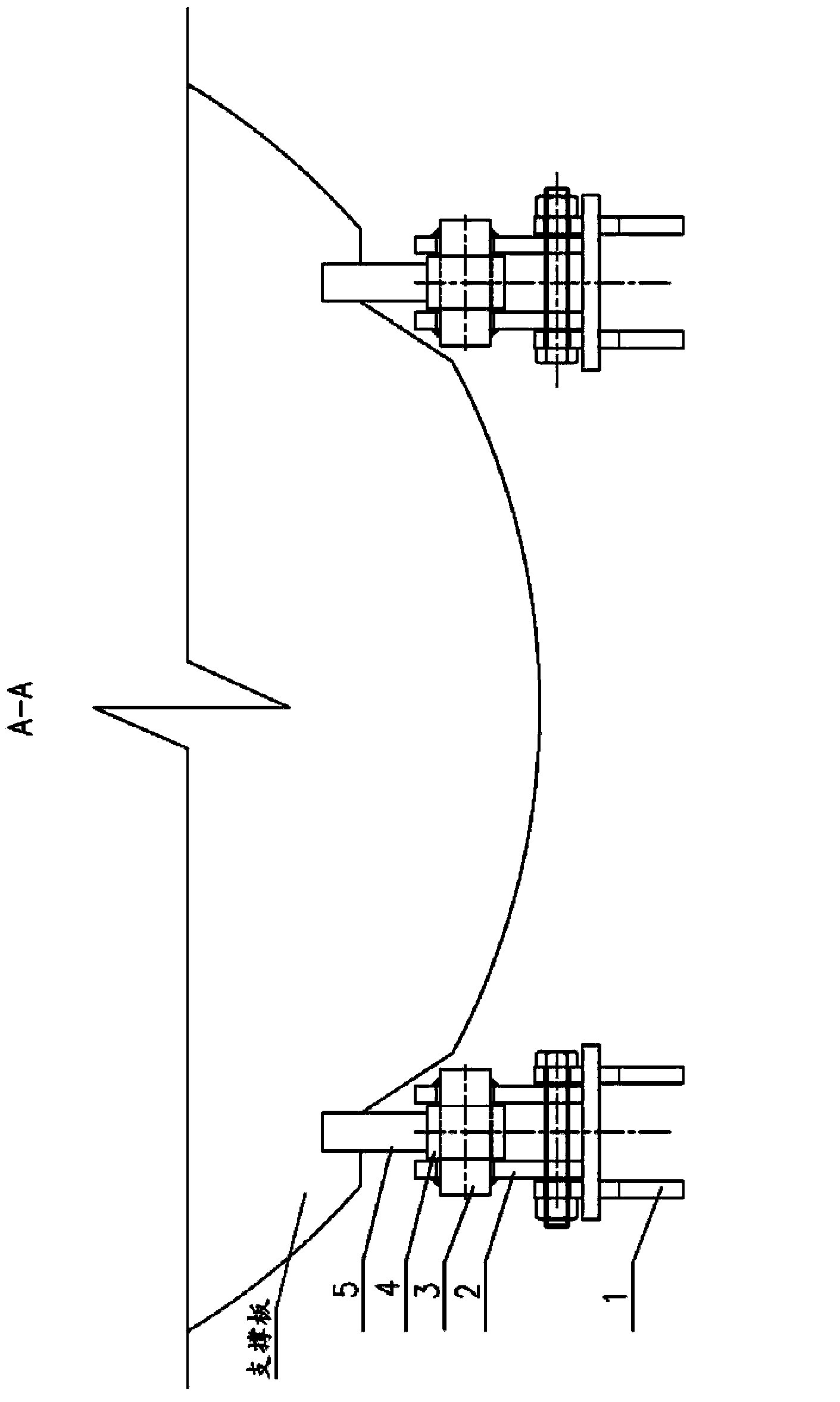

Installing slide way for inserted heat exchanger on tower

The invention relates to an installing slide way for an inserted heat exchanger on a tower. The installing slide way comprises two supporting seats, two track plates, a fixing shaft and idler wheels, wherein the two supporting seats are welded to the inner wall of a tower body; the two ends of each track plate are fixed to the corresponding supporting seat through bolts, and drilled holes are evenly distributed in the track plates in the same horizontal plane in the length direction; the fixing shaft penetrates from one drilled hole in the track plate on one side to one drilled hole in the other track plate on the other side, and the fixing shaft and the outer sides of the track plates on the two sides are welded together; the fixing shaft penetrates through the idler wheels. Through the installing slide way, the installing difficulty of the heat exchanger can be reduced, and installing accuracy of the heat exchanger is improved.

Owner:LUOYANG RUIZE PETROCHEM ENG

Conveyor for sheet-shaped thin plate and method of conveying same

InactiveCN1803384AAvoid vertical overlapAvoid overlappingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A conveyor for guiding and conveying a plurality of sheet-shaped thin plates in rows arranged side by side to a welding position at which ends of the adjacent thin plates are butted and welded to each other, includes a plurality of conveying paths, which are adjacent to each other, having different conveying surfaces which are placed on a same horizontal plane, and a guide unit disposed between the adjacent two conveying paths for guiding the thin plates on one of the conveying paths with respect to another one thereof toward the welding position. Each of the conveying paths is composed of a plurality conveying rollers, and the guide unit includes guide rollers each having a guide surface for guiding the thin plate on the one of the conveying paths in a state that the thin plate on the one conveying path is partially depressed with respect to the another one of the conveying path.

Owner:SUZUKI MOTOR CORP

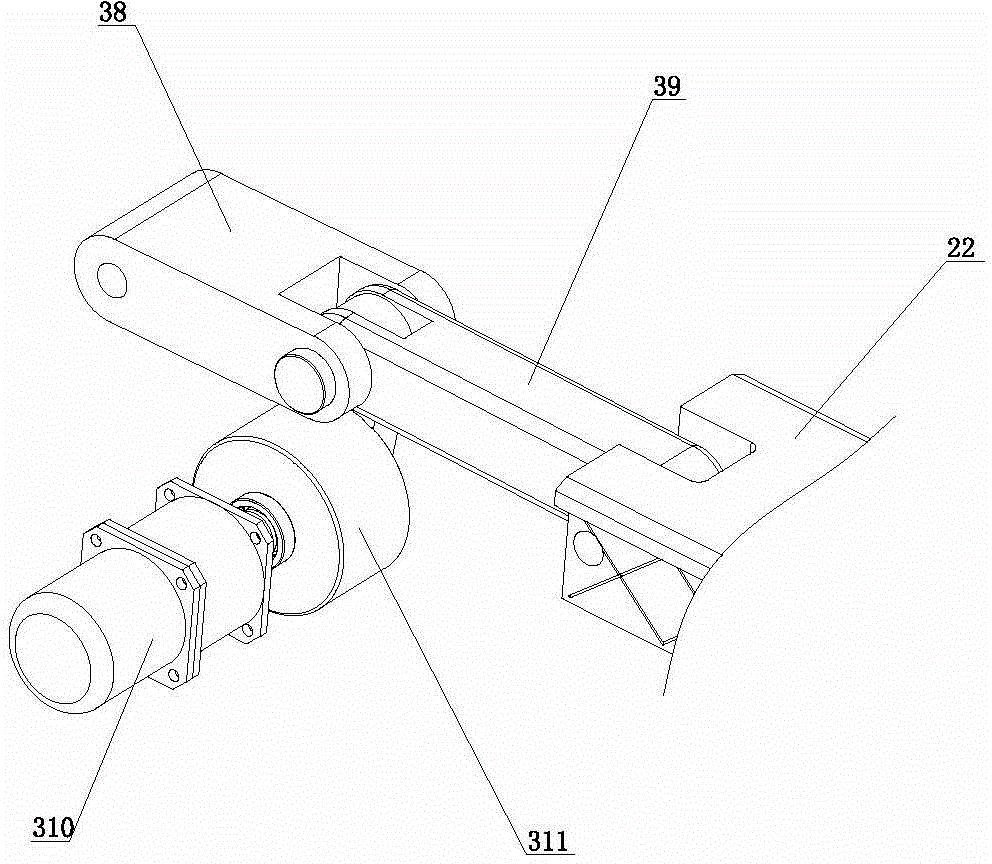

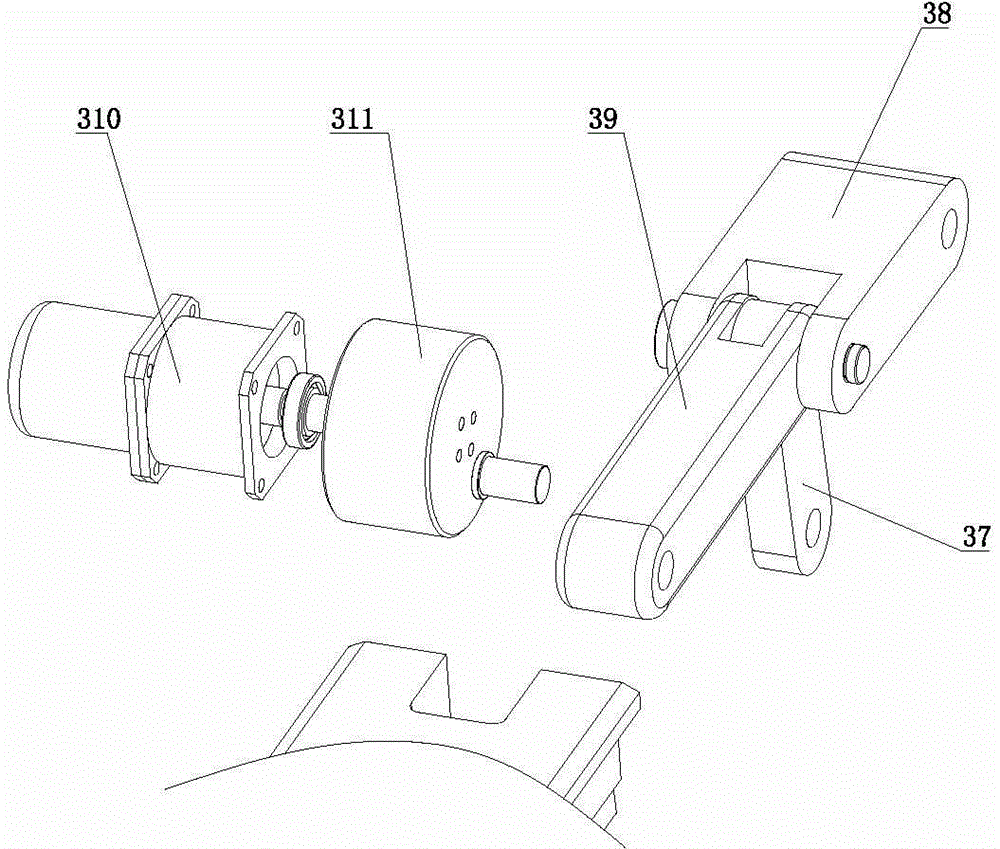

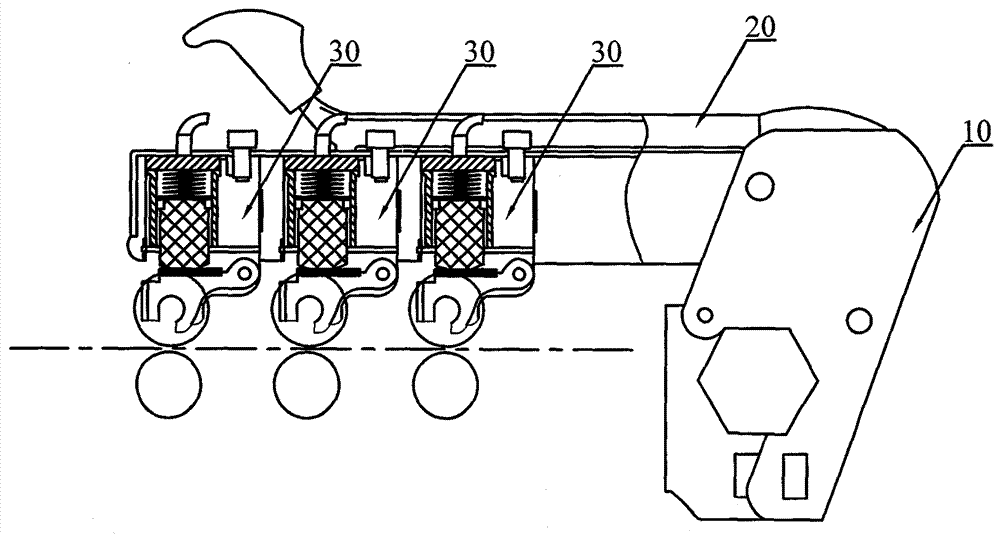

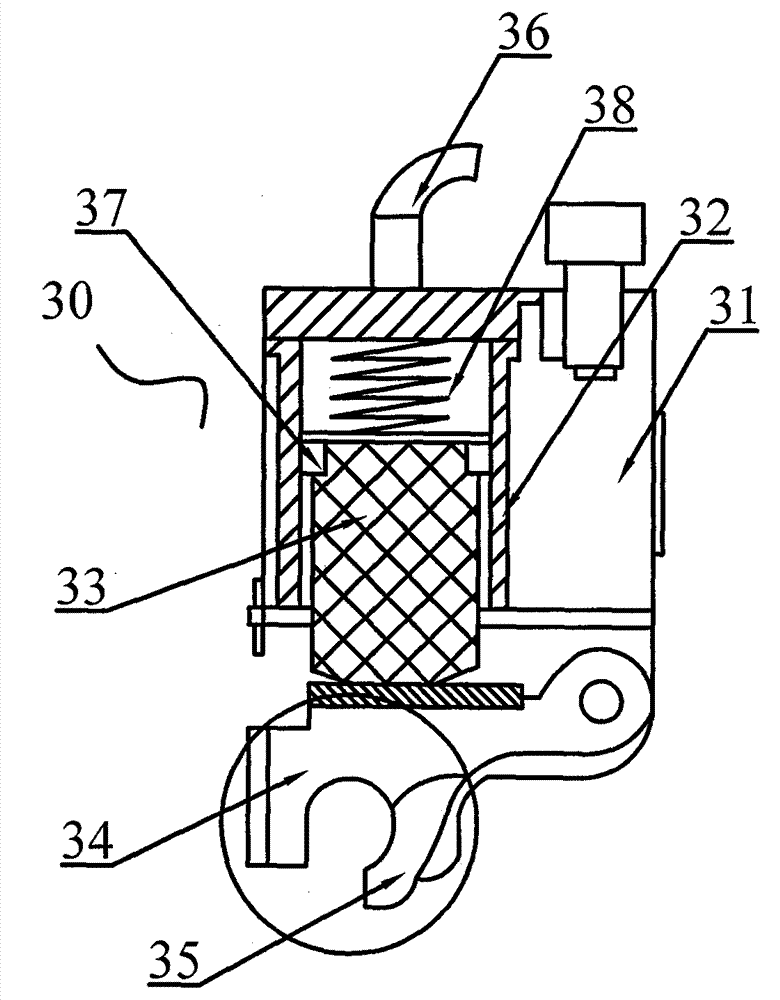

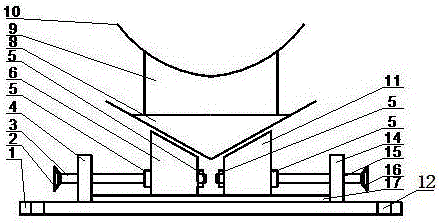

Pressurized rocking frame of ring spinning frame drafting system

InactiveCN104120518AReduce stepless voltage regulation functionWith stepless pressure regulation functionDrafting machinesEngineeringMechanical engineering

The invention relates to a pressurized rocking frame of a ring spinning frame drafting system. The pressurized rocking frame comprises a rocking frame base and a rocking frame body, wherein the rocking frame body is arranged on the rocking frame base. The pressurized rocking frame further comprises multiple air cylinder pressurizing devices, wherein the multiple air cylinder pressurizing devices are arranged and installed on the rocking frame body and comprise assembling supports, air cylinders, pistons with rods, pressurizing rods and holding jaws. The assembling supports are fixed on the rocking frame body through bolts, the air cylinders are fixed on the assembling supports, the piston ends of the pistons with the rods are arranged in the air cylinders, the other end of each of the pistons with the rods are arranged above the pressurizing rods, the pressurizing rods are located under the air cylinder, the holding jaws are arranged on the pressurizing rods, and the air cylinders of the air cylinder pressurizing devices are respectively provided with an independent air pressure source connecting end. By adopting the pressurized rocking frame, the consistency of pressurized pressure of each rocking frame set is improved, unified pressure regulation and stepless pressure regulation of the same pressurized positions of all of rocking frames of a whole machine can be achieved, and the spinning quality is improved. In addition, the production efficiency is effectively improved, and the labor intensity is reduced.

Owner:HUNAN SHENGKAIRUI MACHINERY CO LTD

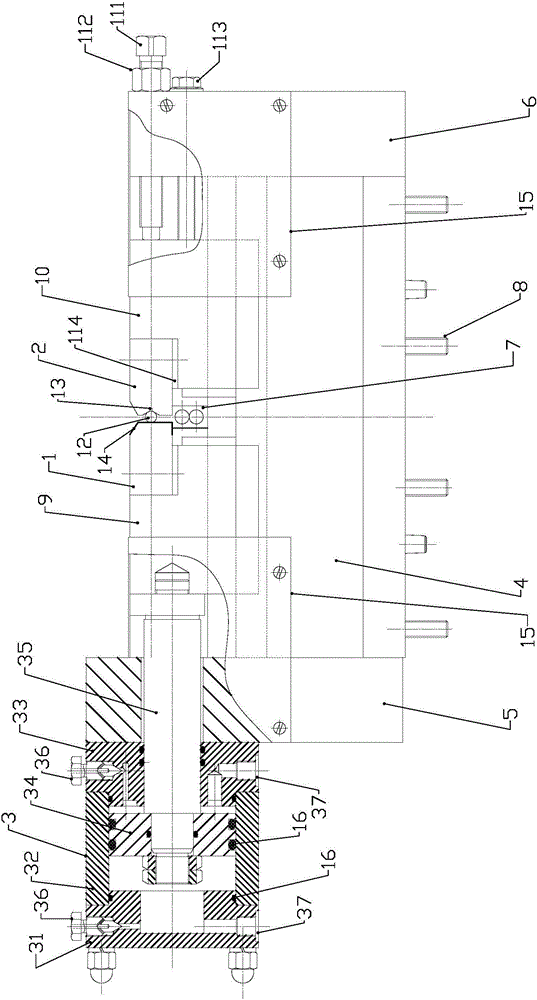

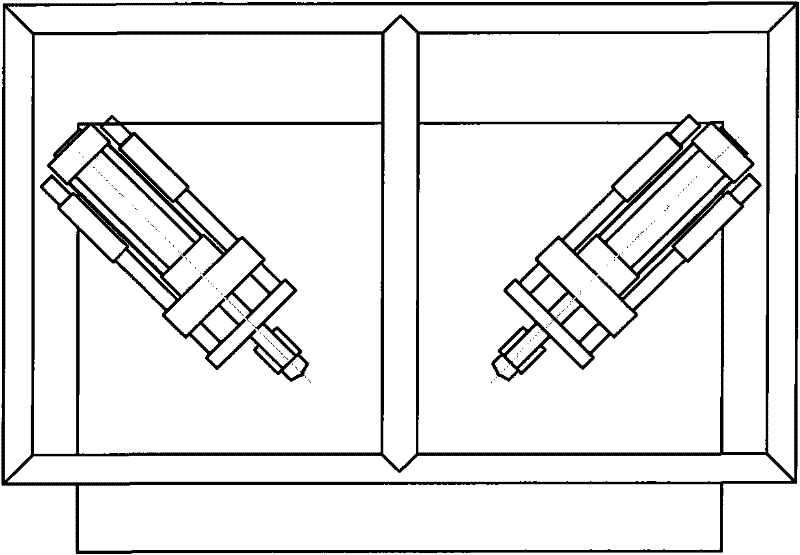

Clamping device of friction welding machine

InactiveCN106513982ALess adjustment workImprove stabilityNon-electric welding apparatusFriction weldingVertical plane

The invention discloses a clamping device of a friction welding machine and belongs to an auxiliary tool of a friction welding machine. The clamping device structurally comprises a moving clamp and a fixed clamp; the moving clamp is connected with a clamping cylinder; the right end surface of the moving clamp is a vertical plane; the section of the left end surface of the fixed clamp is V-shaped; the left and right ends of a clamp body are provided with a left end plate and a right end plate correspondingly; a material supporting plate is arranged on the middle position of the upper part of the clamp body, and the lower part of the clamp body is provided with a linear guide rail; the moving clamp is arranged on a left slide block; the fixed clamp is arranged on a right slide block; the fixed clamp is connected with a fixed clamp regulating device through the right slide block; the moving clamp is connected with the clamping cylinder through the left slide block; a to-be-welded bar material is clamped between the moving clamp and the fixed clamp; and the rear of the to-be-welded bar material is in contact with a main cylinder located on a bed body. The clamping device of the friction welding machine, disclosed by the invention, has the characteristic that the defects of clamping instability of the clamps, complex worker regulation processes and the like in a daily friction welding production process are overcome.

Owner:济南沃德汽车零部件有限公司

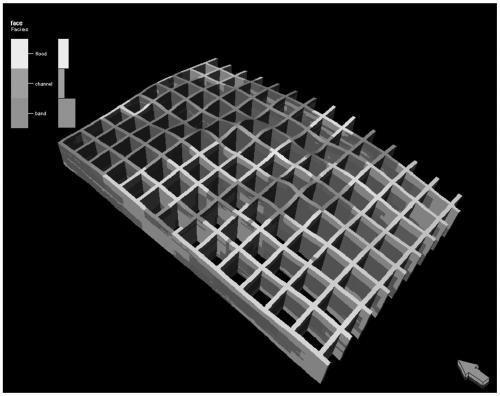

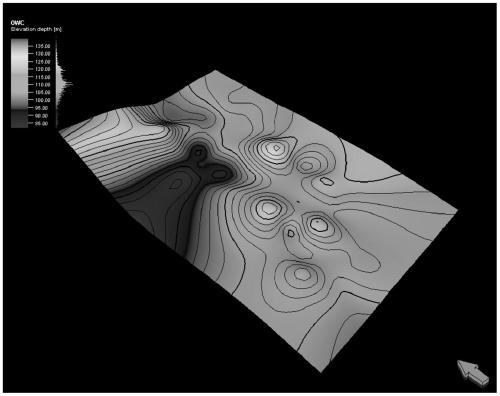

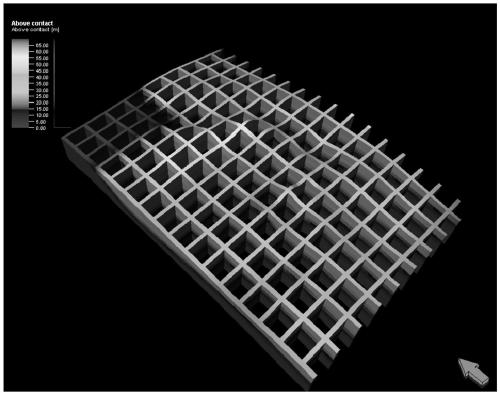

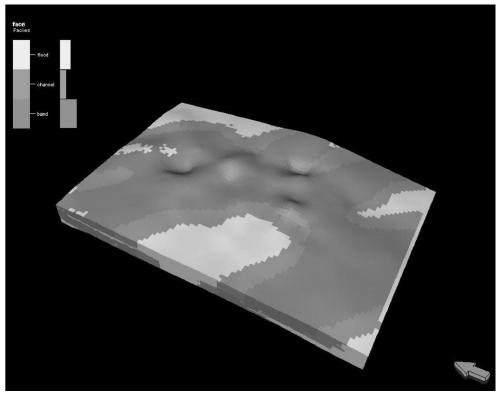

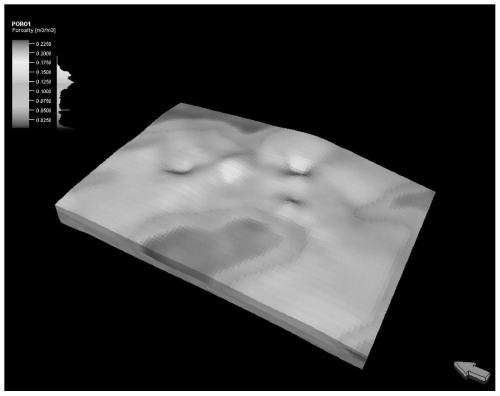

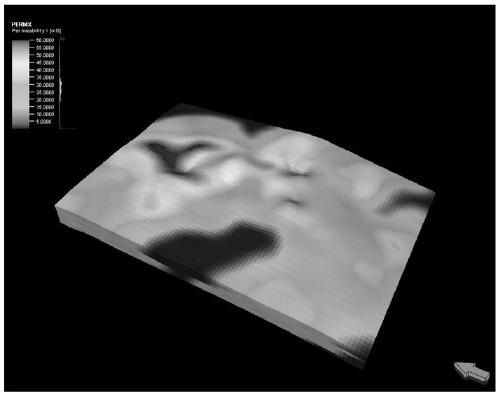

Saturation modeling method based on oil-containing boundary and oil-water transition zone constraint

ActiveCN111274694AReduce flow rateReduce Geological Reserve ErrorsDesign optimisation/simulationConstraint-based CADThermodynamicsSoil science

The invention discloses a saturation modeling method based on oil-containing boundary and oil-water transition zone constraint. The method comprises the following steps: (1) establishing a target workarea construction model and a sedimentary microfacies model; (2) establishing an oil-bearing boundary model of a target work area according to a geological oil reservoir research result; (3) establishing an oil-water interface and a height model above the oil-water interface according to an oil-water interpretation result of the logging curve; (4) generating a height logging curve above an oil-water interface, and establishing a cross plot with a water saturation logging interpretation result; (5) establishing a nonlinear fitting function according to the cross plot, and establishing a watersaturation model by utilizing an attribute calculation function; and (6) performing interactive calculation on the model and an oil-containing boundary model to obtain a final oil saturation model ofthe work area. According to the method, the oil saturation model conforming to the underground oil-water distribution rule is established, the repeatability is high, the operability is high, and laterhistorical fitting, scheme prediction and remaining oil research are facilitated.

Owner:PETROCHINA CO LTD

Conveyor for sheet-shaped thin plate

InactiveCN100471614CLess adjustment workImproved butt weld performanceWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringThin sheet

A conveyor for guiding and conveying a plurality of sheet-shaped thin plates in rows arranged side by side to a welding position at which ends of the adjacent thin plates are butted and welded to each other, includes a plurality of conveying paths, which are adjacent to each other, having different conveying surfaces which are placed on a same horizontal plane, and a guide unit disposed between the adjacent two conveying paths for guiding the thin plates on one of the conveying paths with respect to another one thereof toward the welding position. Each of the conveying paths is composed of a plurality conveying rollers, and the guide unit includes guide rollers each having a guide surface for guiding the thin plate on the one of the conveying paths in a state that the thin plate on the one conveying path is partially depressed with respect to the another one of the conveying path.

Owner:SUZUKI MOTOR CORP

Artificial teeth easily enabling bilateral balanced occlusion

ActiveUS8128404B2Less adjustment workBite firmlyTooth crownsArtificial teethCoronal planeSagittal plane

It is intended to provide artificial teeth designed to easily enable bilateral balanced occlusion with less grinding adjustment. According to the present invention, angles formed by occlusal facets of the artificial teeth with an occlusal plane are suitably set. An artificial tooth for maxillary central incisor, for example, has a protrusive facet and a retrusive facet on an incisal edge thereof. Of angles formed by the protrusive facet with the occlusal plane, the angle in cross section along a sagittal plane is 22.0° to 25.5°, and the angle in cross section along a coronal plane is 1.5° to 6.5°. Of angles formed by the retrusive facet with the occlusal plane, the angle in cross section along the sagittal plane is 20.5° to 23.0°, and the angle in cross section along the coronal plane is 1.5° to 6.5°.

Owner:SHOFU INC

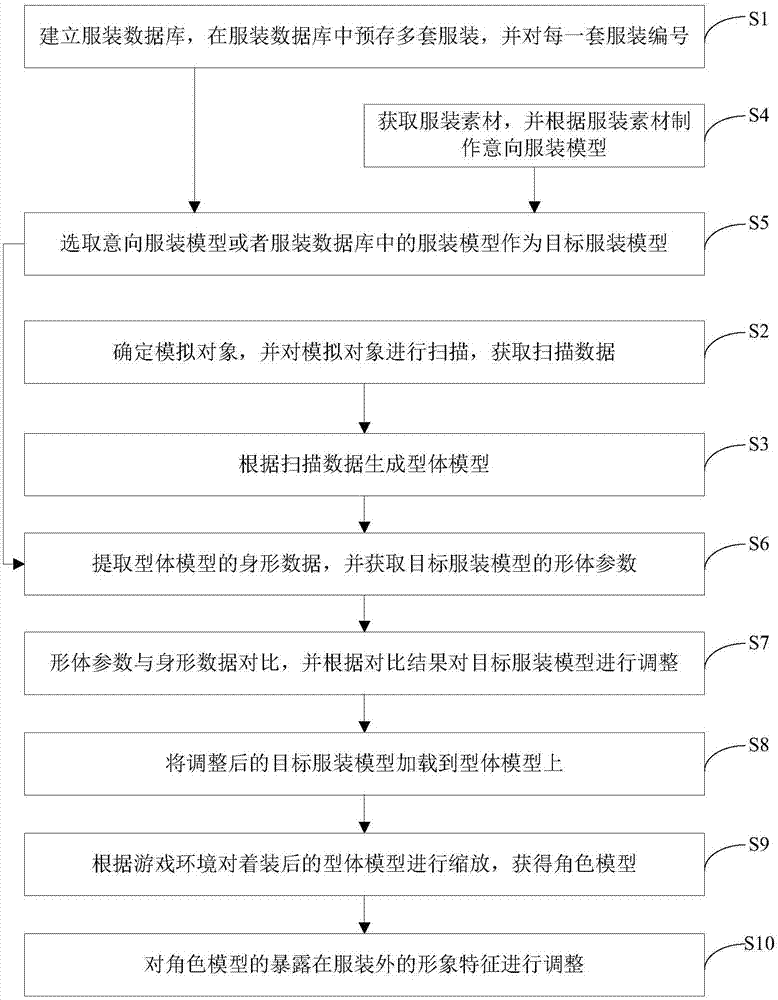

Method used for imitating synthetic game character

InactiveCN107123165ASimplify modification workSimplify workSpecial data processing applicationsImage generationHuman–computer interactionComputer science

The invention discloses a method used for imitating a synthetic game character. The steps S2 and S3 are combined. By imitating a simulation object, a game user can make a game character model based on the self-intention, by simulating an idol or the like, which satisfies the user experience of a game and enriches images in the game. The game world is more rich and varied.

Owner:合肥视尔文化创意有限公司

Elevator weighing value diagnosing and revising method

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Tooth engagement adjustment method and adjustment system for eccentric bushing type gearbox of heavy multi-stage vertical shaft

PendingCN111059264AIngenious structural designReduce workloadGearing detailsGear wheelControl engineering

The invention relates to a tooth engagement adjustment method and adjustment system for an eccentric bushing type gearbox of a heavy multi-stage vertical shaft. The adjustment method comprises the following steps of adjusting the gearbox to a preset height by a box body positioning assembly; adjusting the axial position of each to-be-adjusted gear to a preset position through each axial positioning device; starting a driving device on an input shaft to apply a radial load force to the to-be-adjusted gear shaft through a load device connected to the to-be-adjusted gear shaft adjacent to the input shaft; stopping the driving device working for a preset time to detect the tooth engaging condition of each to-be-adjusted gear; and when the tooth generation is not qualified, adjusting an eccentric bushing on each to-be-adjusted gear and repeating the previous step; when the tooth engagement is qualified, adjusting the tooth engaging condition of each adjacent to-be-adjusted gear successivelyaccording to the steps, and when the tooth engagement is not qualified, repeating the previous step till adjusting all the to-be-adjusted gears. The method can improve the adjustment accuracy, optimize an operating process and reduce the adjustment workload properly, and the adjustment system is simple and skillful in structural design.

Owner:西马克工程(中国)有限公司

Saturation modeling method with equivalent J function constraint

ActiveCN111550238ALess adjustment workFast modelingDesign optimisation/simulationBorehole/well accessoriesWell loggingOil water

The invention discloses a saturation modeling method with equivalent J function constraint. The saturation modeling method with the equivalent J function constraint comprises the following steps of 1)establishing a sedimentary microfacies model, a porosity model and a permeability model of a target work area; 2) establishing a height model above an oil-water interface according to the oil-water interface; 3) establishing an equivalent J function model; 4) generating a height logging curve above the oil-water interface of each single well in the target working area; 5) generating an equivalentvariable curve of different sedimentary facies; 6) establishing an intersection graph of the equivalent variable curve and a logging water saturation curve under different sedimentary facies conditions, and establishing a linear fitting distribution function; 7) converting the equivalent J function model generated in the step 3) into a fitted water saturation geological model; 8) establishing anoil-containing boundary model; and 9) obtaining a water saturation model after boundary constraint, further obtaining an oil saturation model of the target work area, and obtaining a geological modelof the original oil saturation of the oil reservoir.

Owner:PETROCHINA CO LTD

Upsetting forging press and operating method

The invention discloses an upsetting forging press and an operating method. Material ejection servo motors are adopted for driving a material ejection mechanism of the upsetting forging press, and the material ejection mechanism is installed in an integral main die assembly. The integral main die assembly comprises a main die base. A material shearing die installation hole and an upsetting female die installation hole are formed in the main die base. The operating method comprises the steps that feeding is conducted, and displacement all-round material shearing is achieved through horizontal movement of the integral main die assembly; and then upsetting is conducted, and blanks or formed members are ejected out through the material ejection mechanism. According to the operating method, an independent material shearing mechanism is omitted and meanwhile parts in the integral main die assembly can be replaced and adjusted outside a machine body, so that the upsetting efficiency is improved, and the stroke and position of the material ejection mechanism can be adjusted conveniently and flexibly.

Owner:西大(常熟)研究院有限公司

A self-cleaning solar panel

ActiveCN112821860BWill not affect normal workIncrease resistancePhotovoltaic supportsSolar heating energyWater storageEngineering

The invention discloses a self-cleaning solar power generation panel. The top of the water storage base is fixed with a support. One side of the fixed support is fixedly connected with a control electrical cabinet. The inner side of the fixed support is rotatably connected with a rotating shaft through a bearing. It is connected with a solar power generation panel and a rotating connection seat. One side of the rotating connection seat is fixedly connected with a lifting device. One side of the lifting device is slidably connected with the fixed bracket through a slider and a slide rail. The side of the mechanism far away from the solar power generation panel is fixedly connected to the water storage base through a telescopic device, the side of the control electrical cabinet is provided with a thermal induction resistor, and a water pump is provided inside the water storage base. The invention relates to the technical field of solar power generation panel self-cleaning. The self-cleaning solar power generation panel does not affect the normal operation of the solar power generation panel, and prevents the temperature difference from causing the solar power generation panel to explode, causing equipment damage and increasing equipment costs.

Owner:NINGBO OUTLUX ELECTRICAL CO LTD

Method for cleaning a grinding body coated with cubi boron nitride and apparatus for performing said method

InactiveCN1550289AExtended service lifeEliminates expensive constructionAbrasive surface conditioning devicesCleaning using gasesBoron nitrideEngineering

The cleaning-off device is used in the process of cleaning boron nitride off a grindstone. The grindstone (14) is in the region of a separating element, and liquid or gas (16) is applied in the region of the grindstone by means of a jet element (17), which applies a cleaning jet (18) of liquid or gas to the grindstone parallel to the separation line.

Owner:HAUNI MASCHINENBAU AG

A fixed pipe support

The invention provides a technical scheme of a stationary pipeline support. According to the scheme, the stationary pipeline support comprises a bottom plate, wherein a sliding groove is formed in the bottom plate, and a left sliding block and a right sliding block are arranged in the sliding groove and connected with a horizontal moving driving mechanism; a V-shaped bracket is erected on the upper surfaces of the left sliding block and the right sliding block, and the upper surfaces of the left sliding block and the right sliding block are wedge-shaped surfaces matched with the bottom surface of the V-shaped bracket; a tube bracket is fixed at the upper part of the V-shaped bracket. As the sliding groove is arranged and the left sliding block and the right sliding block are arranged in the sliding groove and matched with the V-shaped bracket for use, the relative distance between the left sliding block and the right sliding block and the positions of the left sliding block and the right sliding block in the sliding groove are adjusted so as to drive the position of the V-shaped bracket on the left sliding block and the right sliding block in horizontal and vertical directions, and finally the adjustment effect of a pipeline in the horizontal and vertical directions is realized.

Owner:JIGANG GRP

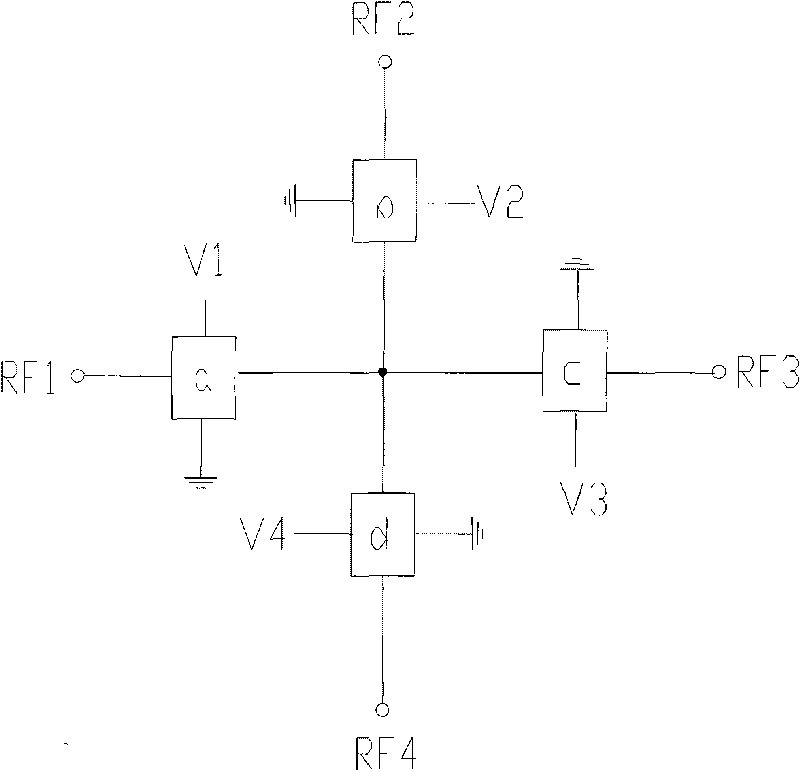

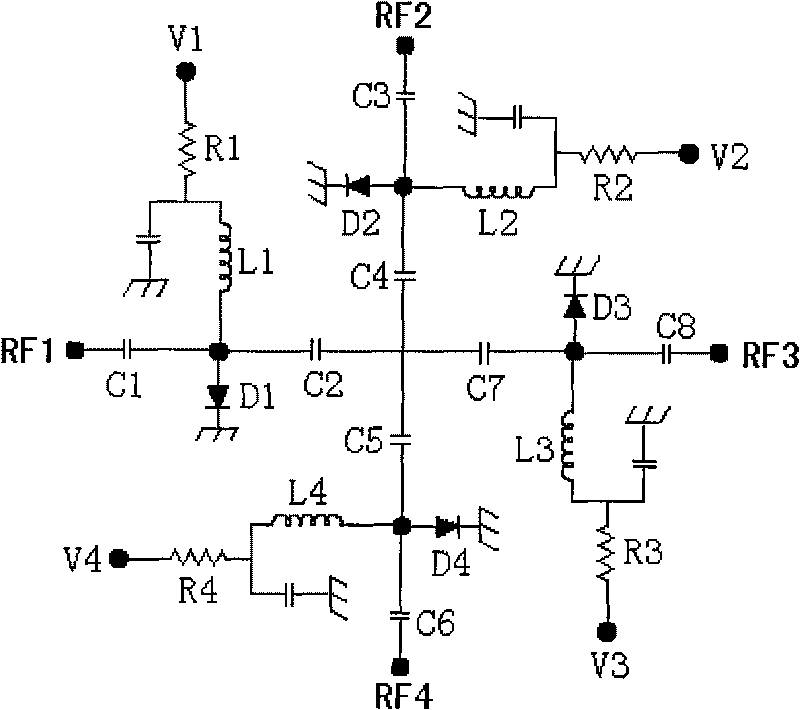

Millimeter-wave double-pole double-throw switch circuit

ActiveCN101692511AEliminate the effects ofAvoid reliability problemsWaveguide type devicesLogic circuit coupling/interface arrangementsEngineeringInput/output

The invention relates to a millimeter-wave double-pole double-throw switch circuit comprising four input-output ports and four gating control circuits matched with the four input-output ports. The nillimeter-wave double-pole double-throw switch circuit is characterized in that branched circuits connected with the four input-output ports are connected in the cross shape; the first input-output port and the third input-output port on two ends of the same branched circuit and form symmetric branched circuit structures taking the crossing point as the center with the second input-output port and the fourth input-output port on two ends of another branched circuit; and the four input-output ports of all the branched circuits are connected to the crossing point through the gating control circuits. The millimeter -wave double-pole double-throw switch circuit controls the passageway of the millimeter-wave signal through the gating control circuits, thereby eliminating the phase errors generated by different chips, having improved reliability and consistence, reducing the use amount of the precious metal and lowering the cost. In addition, the millimeter-wave double-pole double-throw switch circuit uses one chip to realize the function of two chips, thereby reducing the assembling and debugging load and improving the efficiency of the system.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

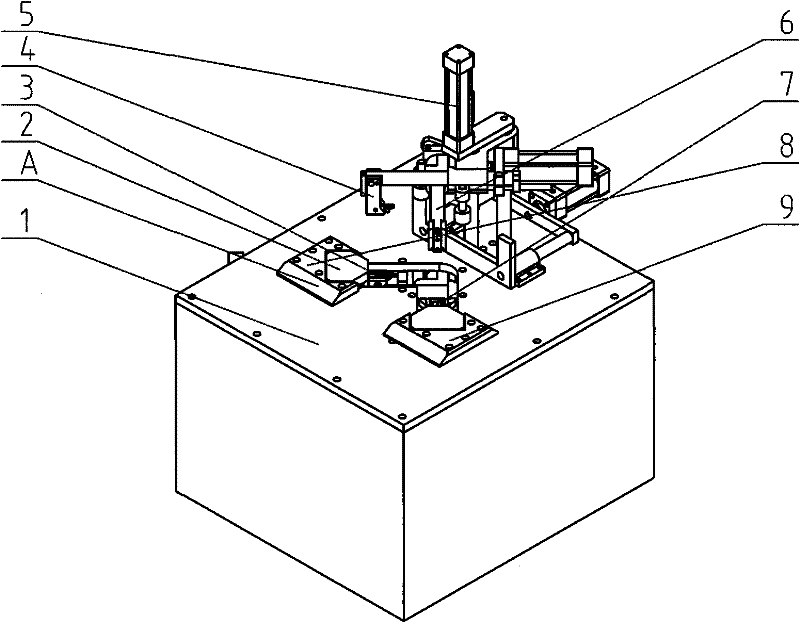

Online continuous roller hole pattern misplacement detection instrument and method

InactiveCN104690095ASimple structureThe detection method is simple and reliableMeasuring devicesMetal rolling arrangementsEngineeringNumeric Value

The invention relates to an online continuous roller hole pattern misplacement detection instrument and method. The online continuous roller hole pattern misplacement detection instrument comprises an upper hole pattern template and a lower hole pattern template which are provided with part cambered surfaces corresponding to continuous roller hole patterns and jointly form the continuous roller hole patterns. The instrument is characterized in that contact faces of the upper hole pattern template and the lower hole pattern template adopt a form that a slider is matched with a slideway, a zero position mark is arranged at the center of one of the hole pattern templates, the other hole pattern template is provided with a reference graduated ruler mark corresponding to the zero position mark, and multiple through holes convenient for hand-holding are distributed in faces of the upper hole pattern template and the lower hole pattern template. The instrument is simple in structure, reliable in use and simple to operate; hole pattern misplacement is adjusted and eliminated according to measured misplacement numeric value, so that the problem that existing continuous roller hole pattern misplacement is less prone to being timely found and dealt is solved, wall thickness accuracy of continuously rolled steel pipes is improved greatly, defective product rate is lowered remarkably, and production cost is saved.

Owner:辽宁天丰特殊工具制造股份有限公司

V-shaped angle seam cleaner for plastic doors and windows and cleaning method thereof

The invention discloses a V-shaped angle seam cleaner for plastic doors and windows and a cleaning method thereof, which comprises a stander and a broaching device. The broaching device comprises an upper broaching device and a lower broaching device, wherein the upper broaching device is provided with a left upper broaching device and a right upper broaching device; the lower broaching device isprovided with a left lower broaching device and a right lower broaching device; each broaching device is provided with a broaching shaft, a broaching tool and a gas cylinder; the broaching shafts of the left upper broaching device and the right upper broaching device are mutually vertical and the bottom plane of the broaching tool and a worktable have same distances; the broaching shafts of the left lower broaching device and the right lower broaching device are mutually vertical and the upper plane of the broaching tool and the worktable have same distance; and the moving directions of the left upper broaching device and the left lower broaching device are same and the moving directions of the left upper broaching device and the right lower broaching device are same. The invention can save the labor intensity of operators, has simple operation process and few working procedures and improves the working efficiency.

Owner:JINAN DECA MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com