Elevator weighing value diagnosing and revising method

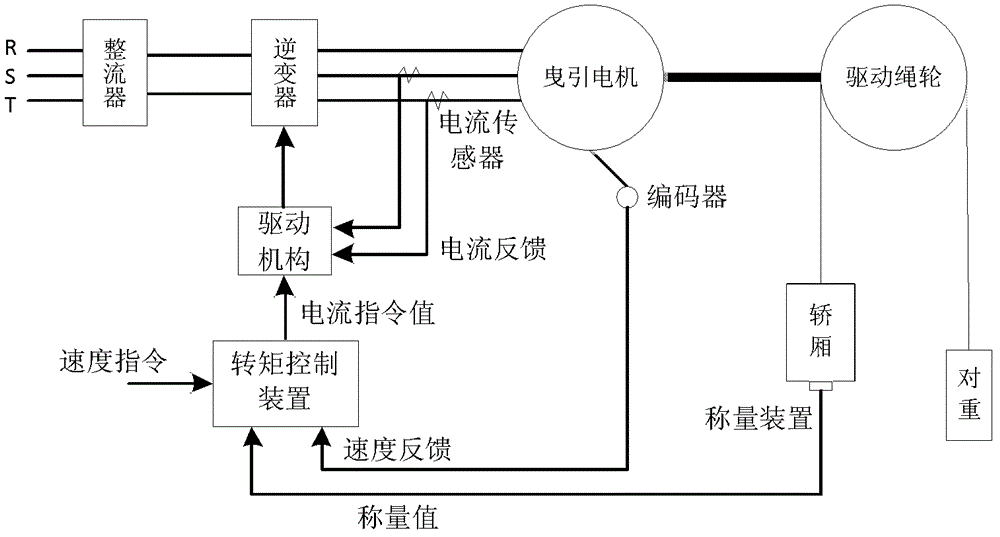

A weighing value, elevator technology, applied in the field of elevator control, can solve the problem of inaccurate torque compensation, achieve the effect of stable starting process, ensure starting performance, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

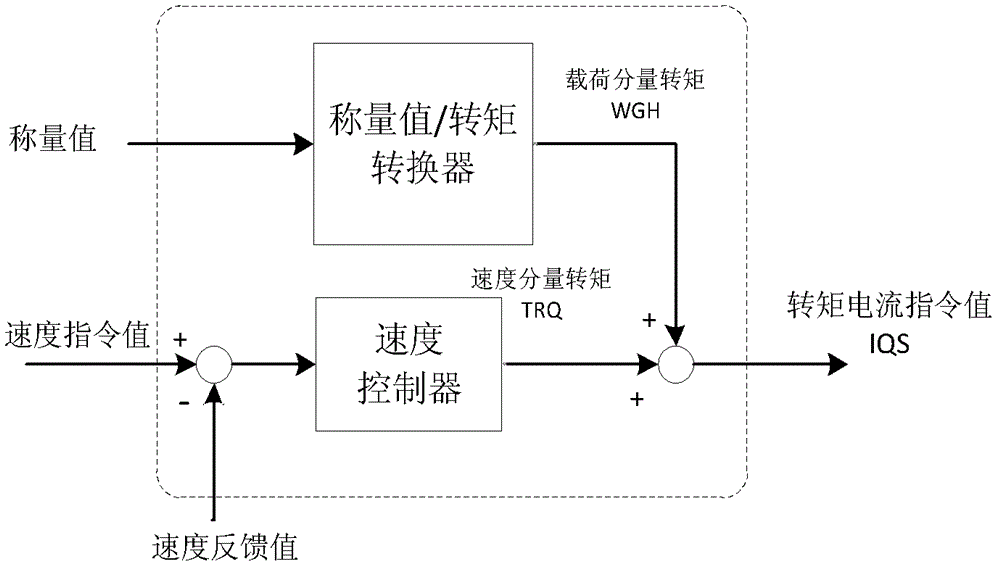

[0038] For the elevator whose no-load weighing value WN and half-load weighing value WB are written in the debugging stage, its torque control device can calculate the load component load according to formula 1. For the elevator whose no-load weighing value WN, half-load weighing value WB and full-load weighing value WF are written in the debugging stage, the load component load in the torque control device is calculated as follows:

[0039] UBLD=(W-WB)×CAP / (WB-WN) / 2, W

[0040] Or UBLD=(W-WB)×CAP / (WF-WB) / 2, W≥WB formula (4)

[0041] After calculating the load component load UBLD, calculate the load component torque WGH according to formula 2.

[0042] According to formula 2, the theoretical load component torque values at no-load, half-load and full load can be calculated:

[0043] IN=-CAP / 2×K+R at no load;

[0044] IB=R at half load;

[0045] IF=CAP / 2×K+R at full load.

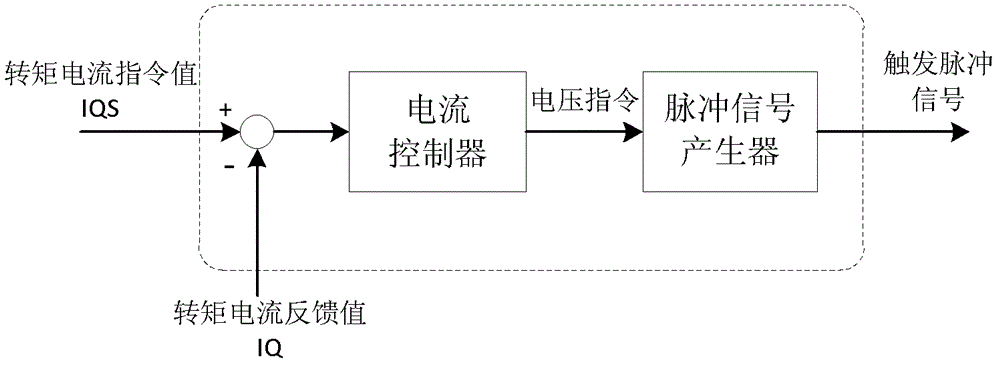

[0046] When the elevator is running normally, the elevator control system executes ...

Embodiment 1

[0057] In the weighing value diagnosis and correction action flow of Embodiment 1, the load condition of the elevator is judged according to the torque current command value IQS when the traction motor maintains zero speed during the elevator startup phase, and then the stored no-load, half-load and full-load scales are corrected. magnitude. In fact, it is rare for the load in the car to be half-loaded or fully loaded, which means that the cycle of weighing value correction is longer, and the elevator is likely to be in a state of poor starting performance for a long time.

[0058] In order to avoid the occurrence of the above situation, Embodiment 2 makes appropriate modifications to the action flow of weight value diagnosis and correction. When the elevator is running normally, the elevator control system executes repeatedly according to the specified calculation cycle Figure 6 The weighing value diagnosis correction action flow shown:

[0059] Determine which running sta...

Embodiment 3

[0067] In Embodiment 1 and Embodiment 2, it is necessary to manually write in the no-load weighing value WN, the half-load weighing value WB and the full-load weighing value WF by professionals in the elevator debugging stage. After that, the elevator control system according to Equations 1, 2, 3 and 4 calculate the load component load UBLD and the load component torque WGH.

[0068] In order to further reduce the workload in the elevator debugging stage, embodiment 3 cancels the weighing value writing step in the elevator debugging stage, and replaces the empty load, half-load and full-load weighing values written in the elevator debugging stage with the factory default. Load, half load and full load values. When the elevator starts to run normally, use the default no-load, half-load and full-load weighing values to carry out unbalanced load calculation and load component torque calculation for starting weighing action. At the same time, using the weighing value diagnosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com