Refrigerator compressor motor rotor

A technology for refrigerator compressors and motor rotors, applied in electromechanical devices, electrical components, electric components, etc., can solve problems affecting motor startup performance and efficiency, axial movement of motor rotors, and slow motor startup response, etc., to achieve improved startup performance performance, reducing the stator-rotor air gap, and the effect of large starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

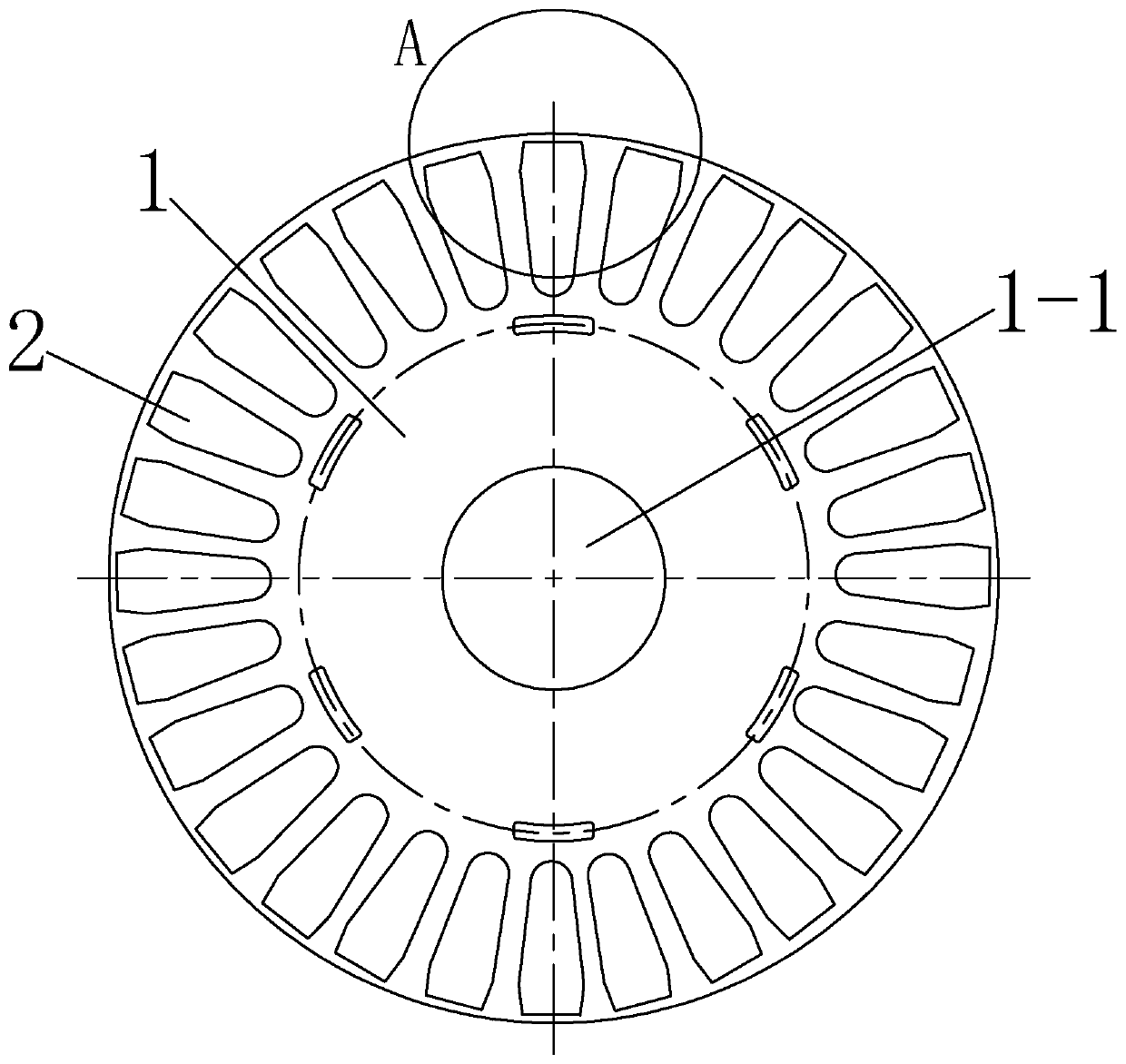

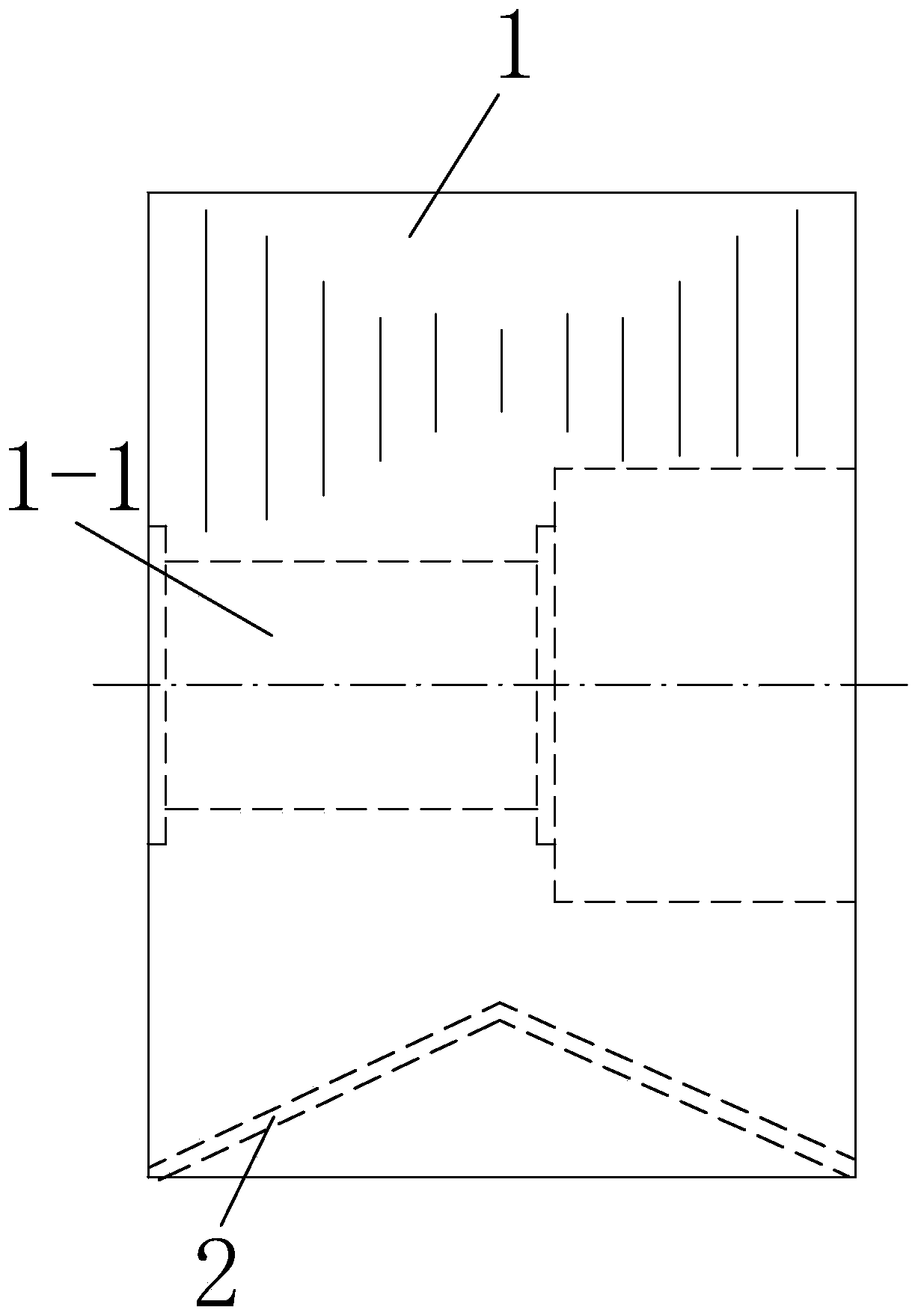

[0017] See Figure 1 to Figure 4 , The motor rotor of the refrigerator compressor in this embodiment includes a rotor body 1, the rotor body 1 is in the shape of a cylinder as a whole, and the center of the rotor body 1 is provided with a hollow shaft hole 1-1 along the axial direction.

[0018] A group of wire grooves 2 are evenly arranged on the outer periphery of the rotor body 1, and each wire groove 2 is arranged through the rotor body 1 from the front end surface to the rear end surface of the rotor body 1, and each wire groove 2 is arranged in a V shape in the rotor body 1 as a whole, And the apex of the V shape protrudes toward the direction of the shaft hole 1-1, such as figure 2 shown.

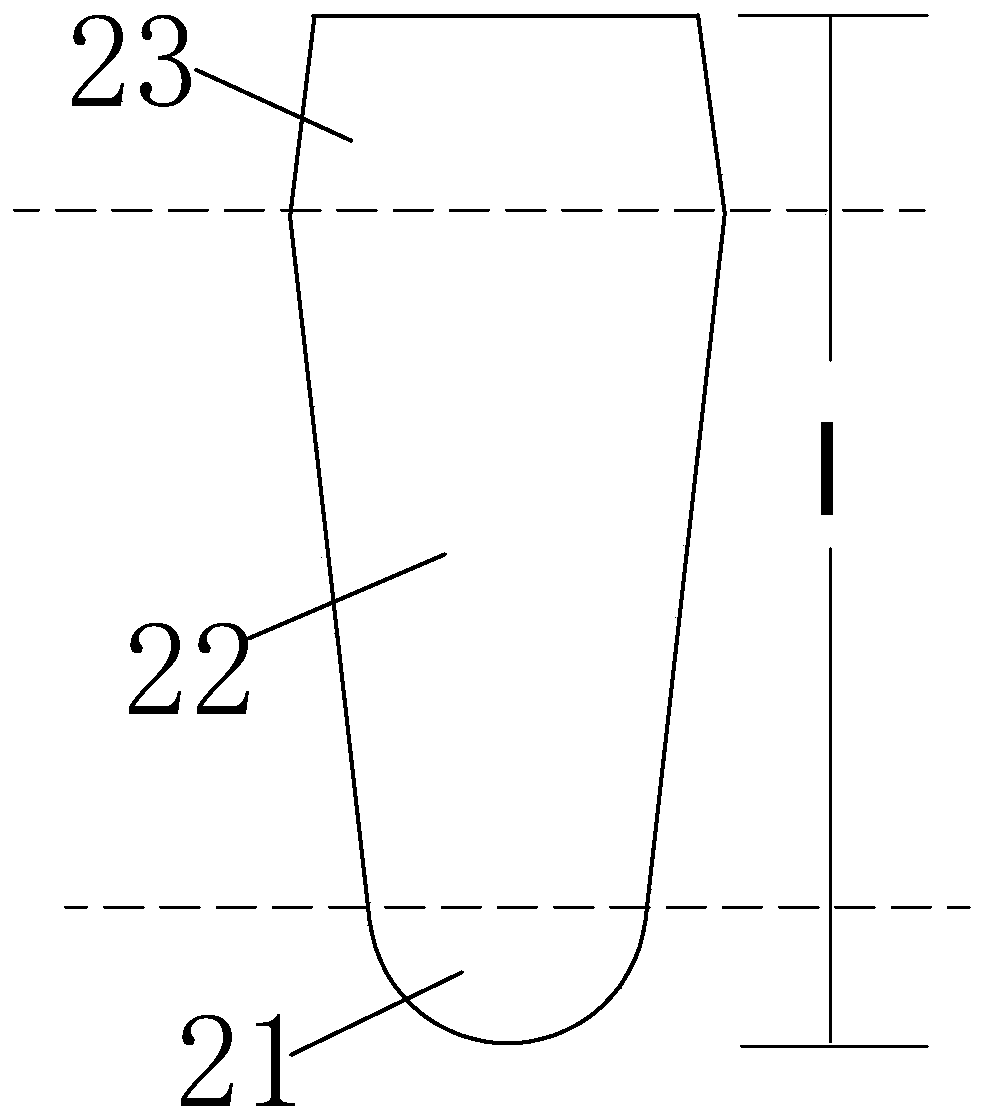

[0019] see image 3 with Figure 4 , The end surface (that is, the section) of the trunking 2 is composed of an inner end 21 , a main body 22 and an outer end 23 in one piece. Inner end 21 is a half ellipse, and main body 22 is a trapezoid that is narrow inside and wide outside;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com