Patents

Literature

1055results about How to "Prevent axial movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

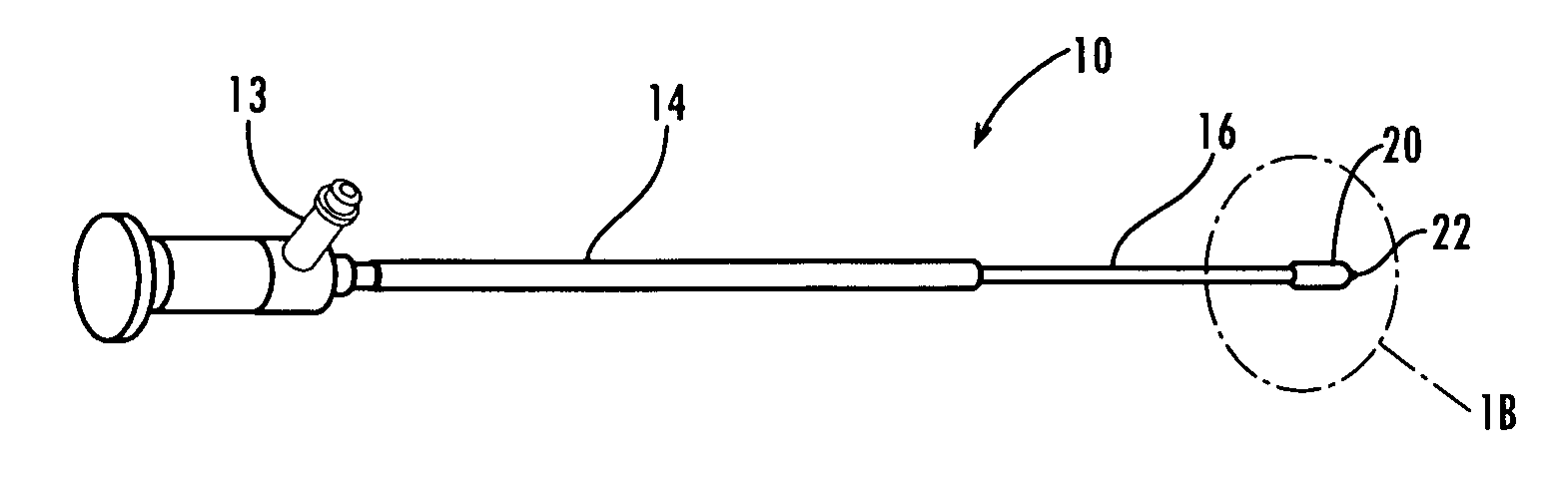

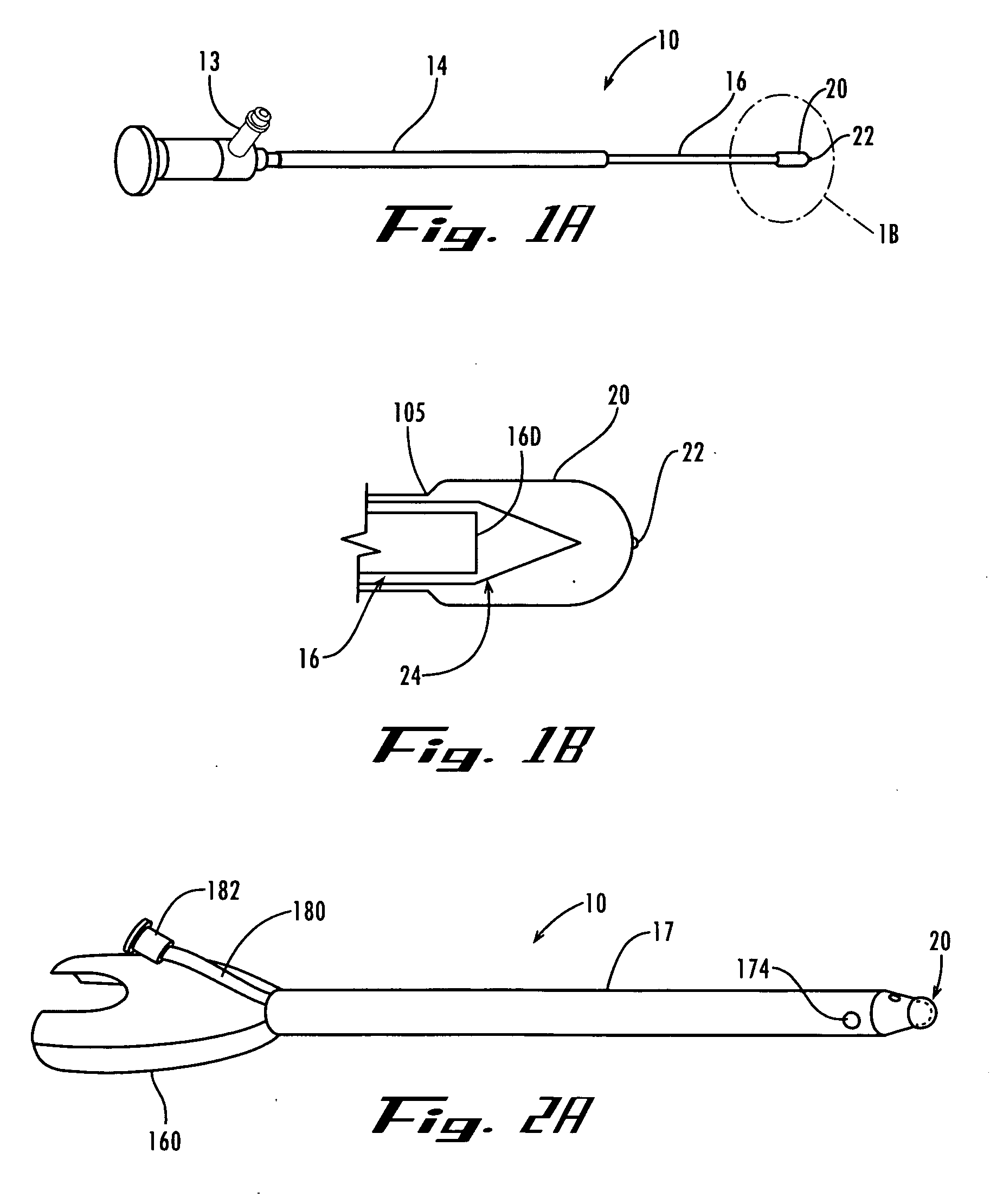

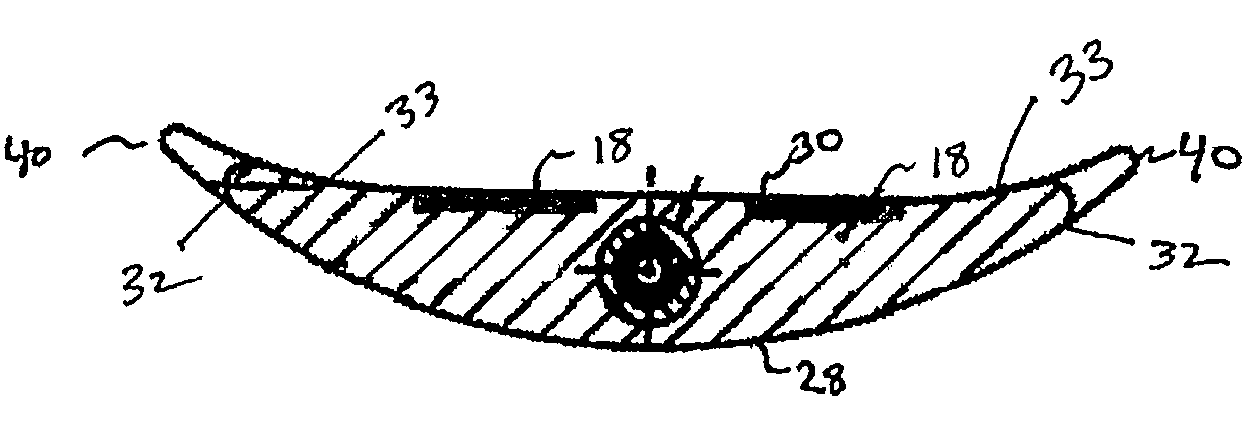

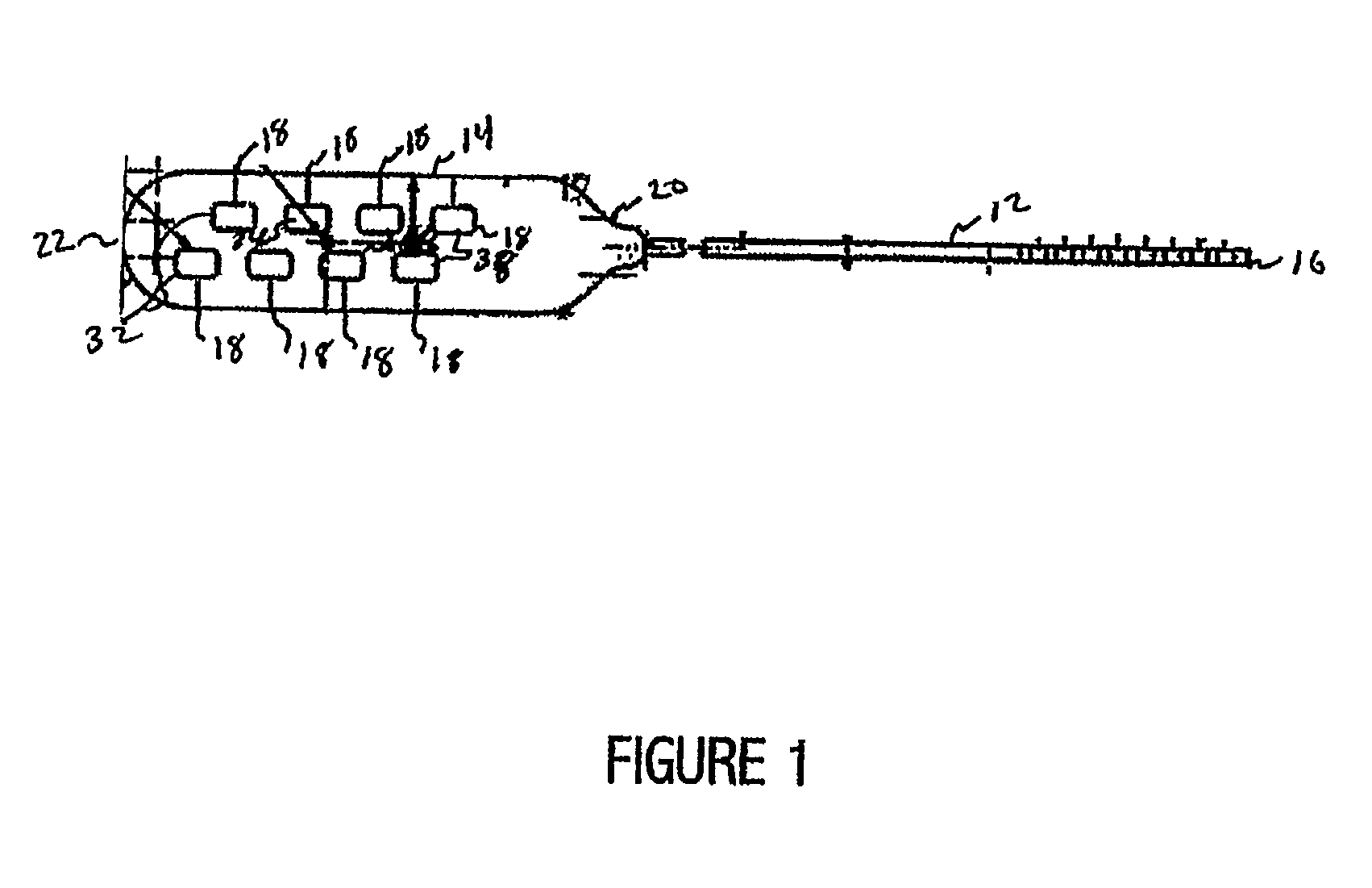

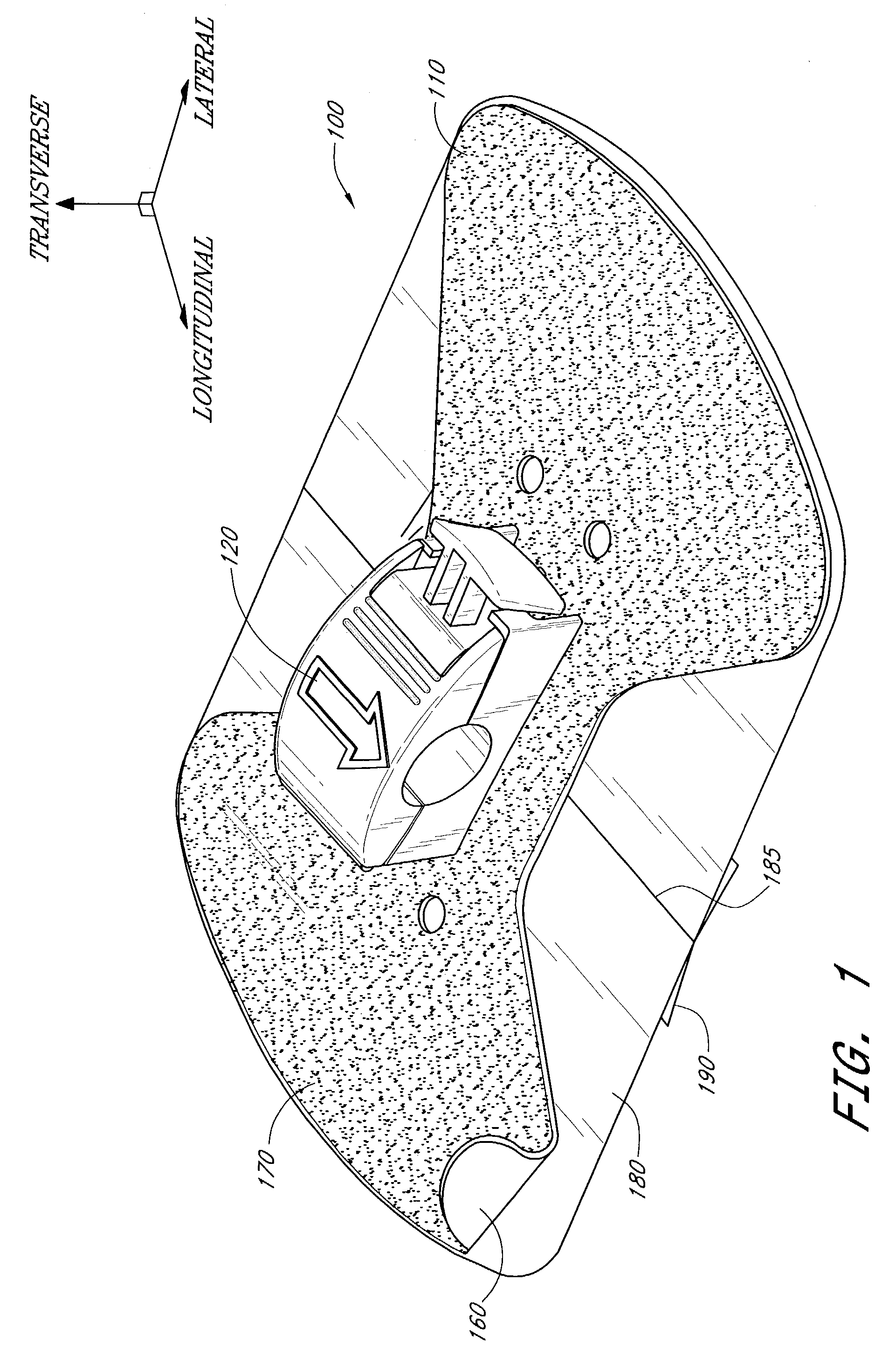

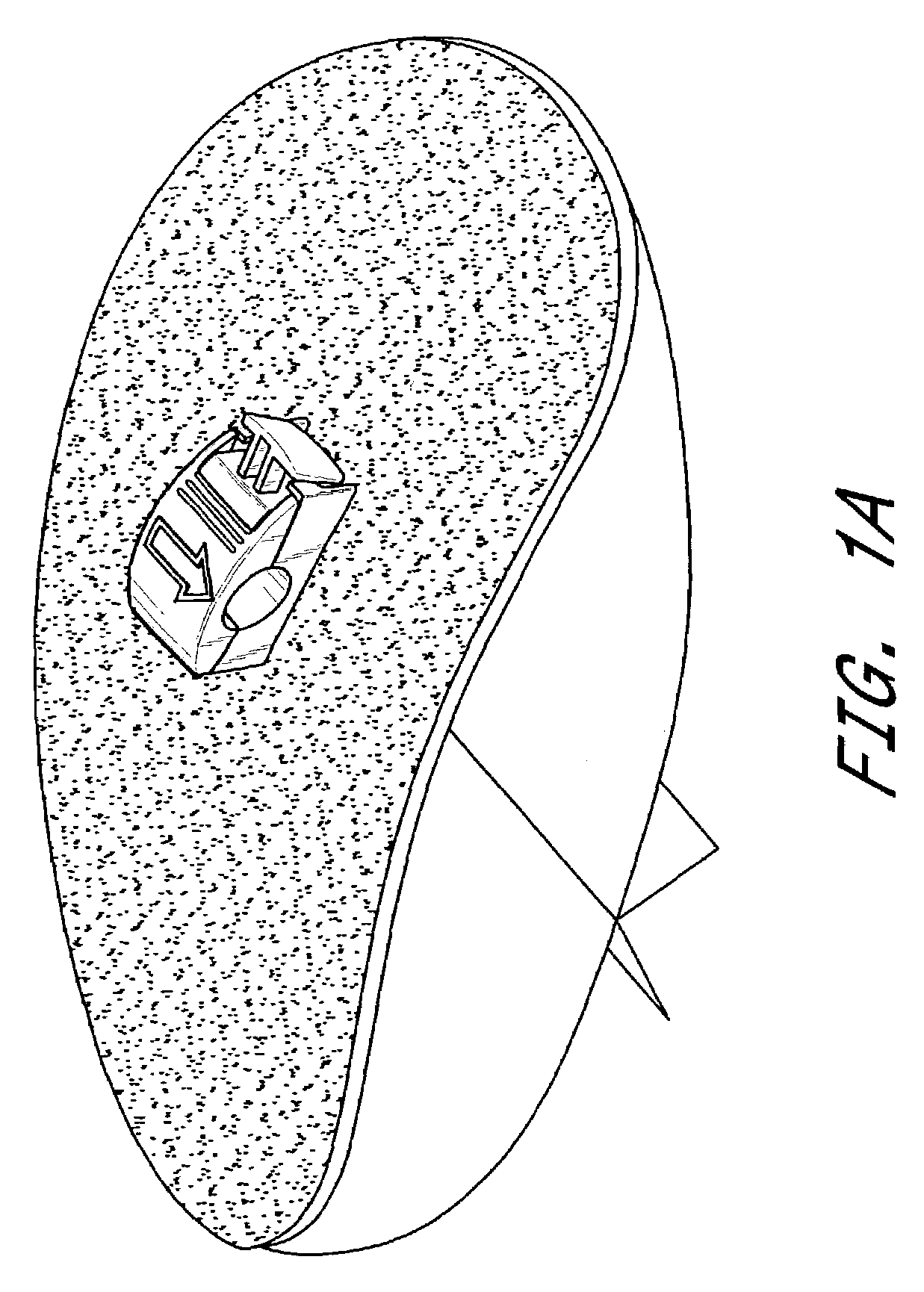

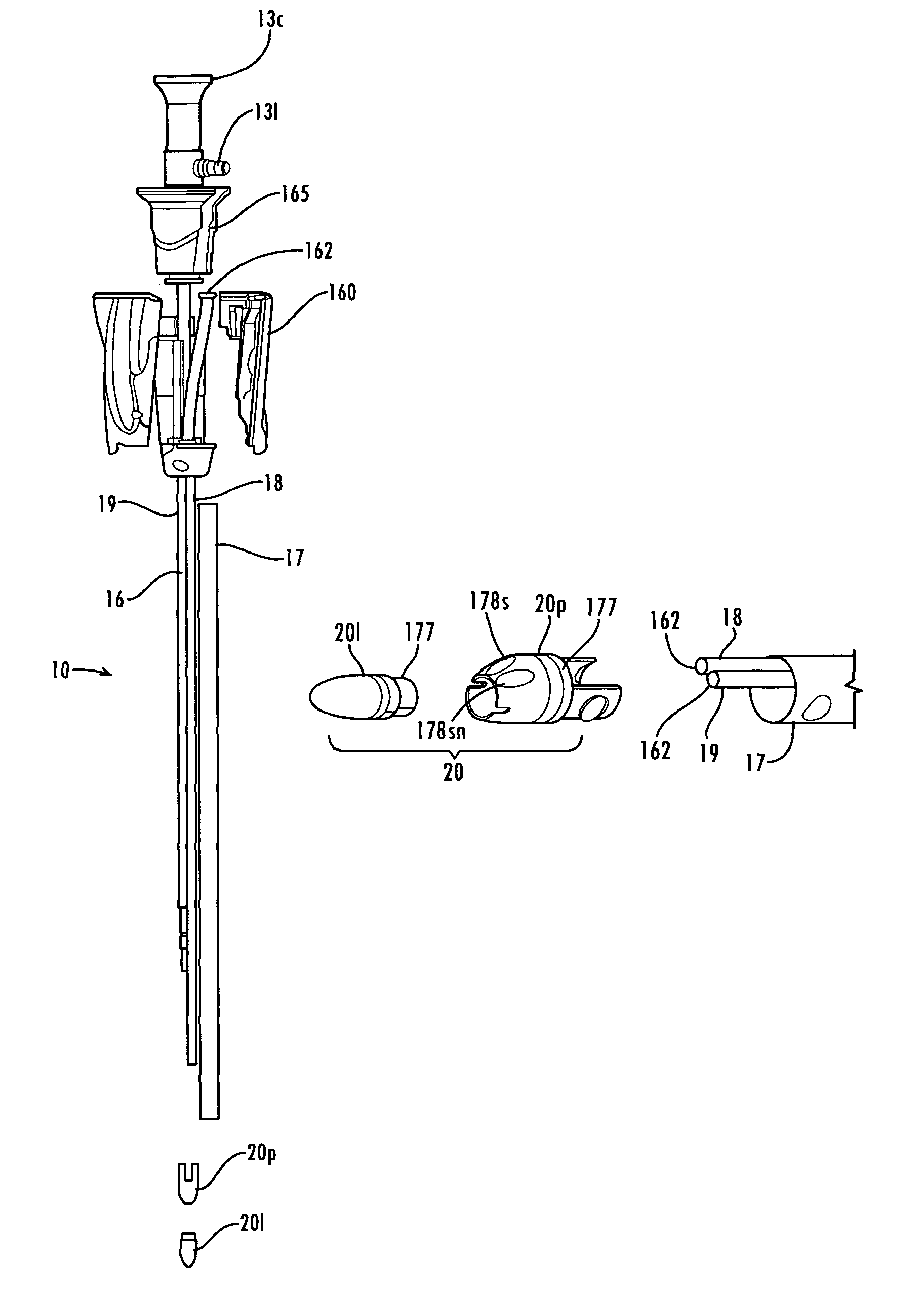

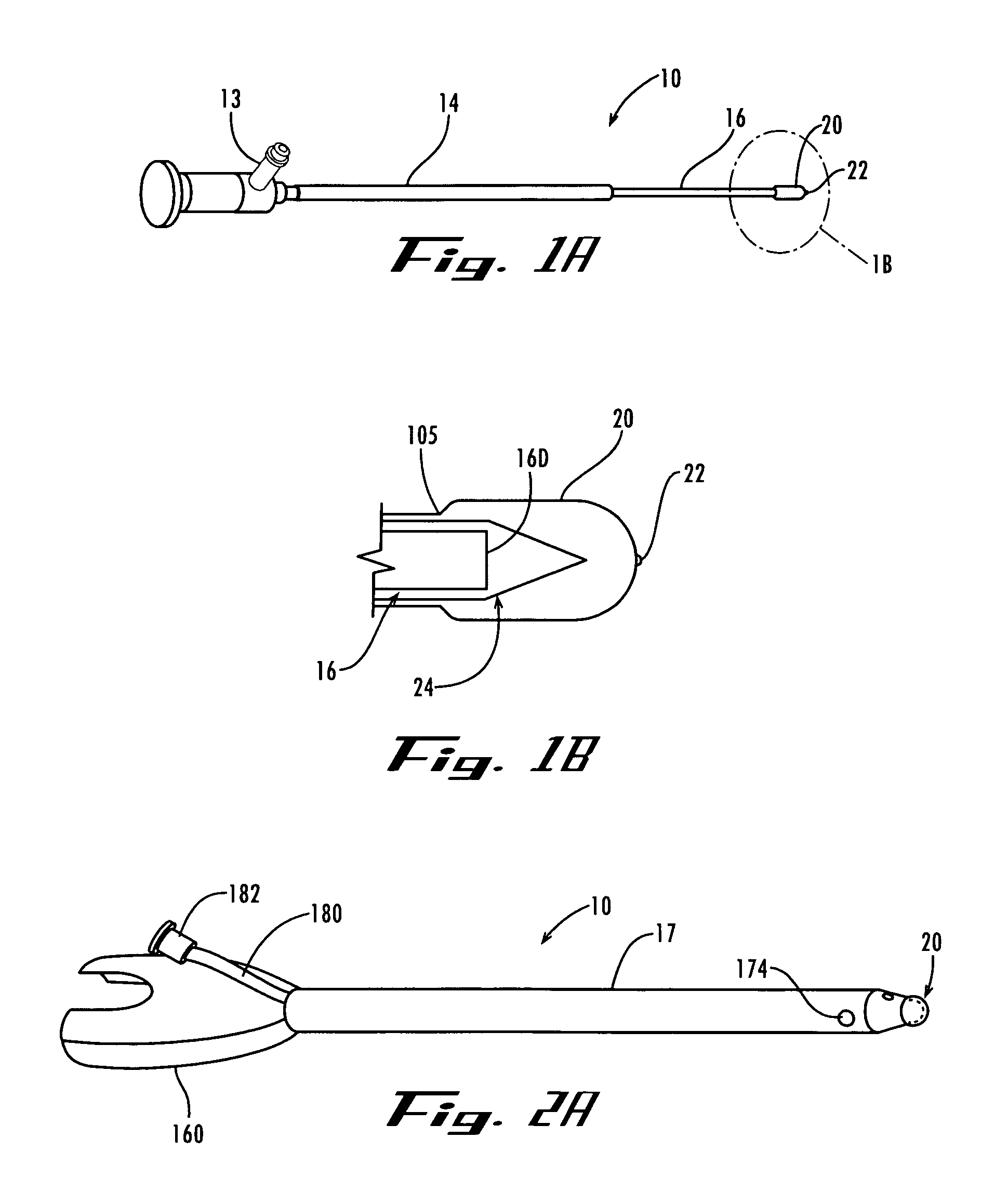

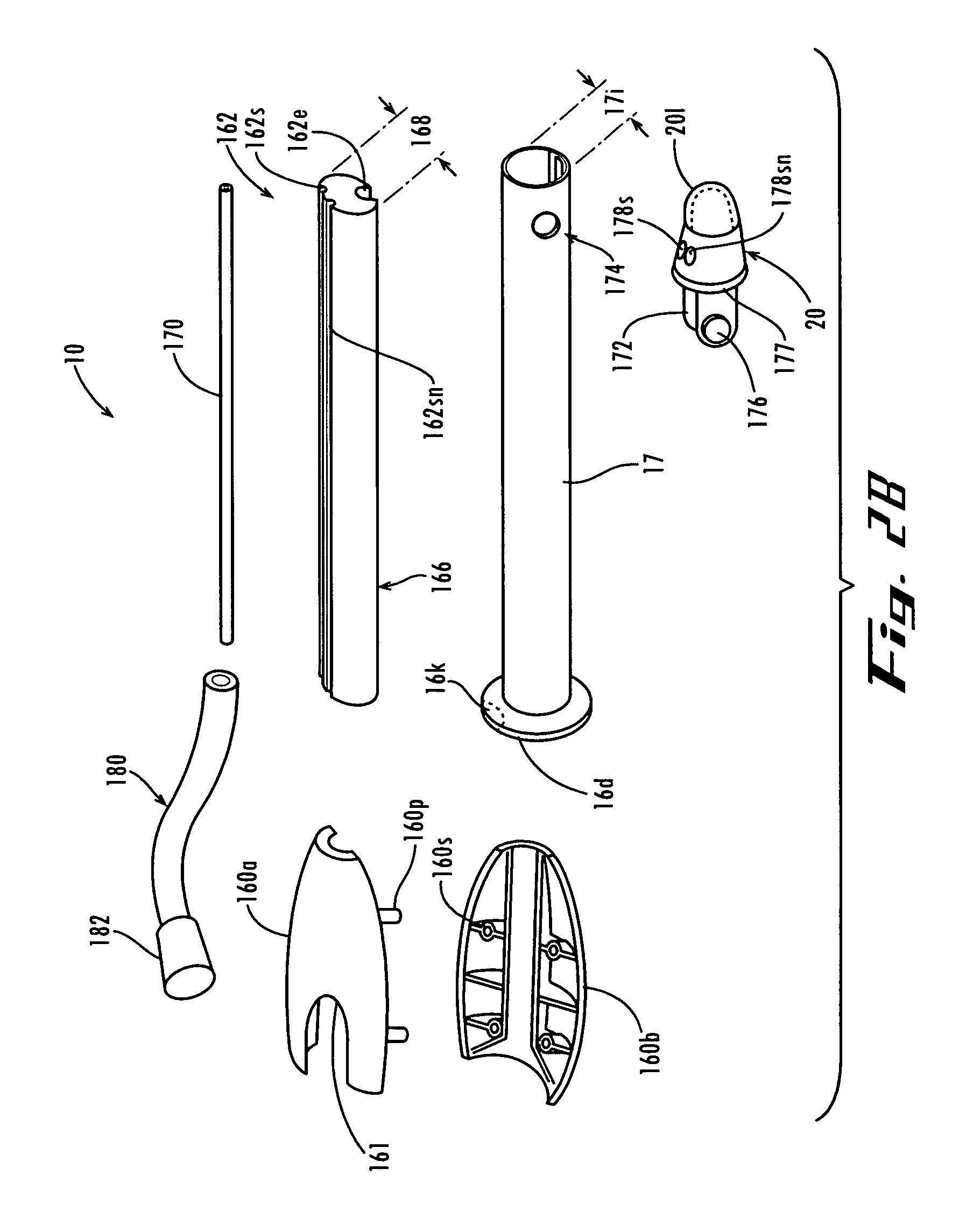

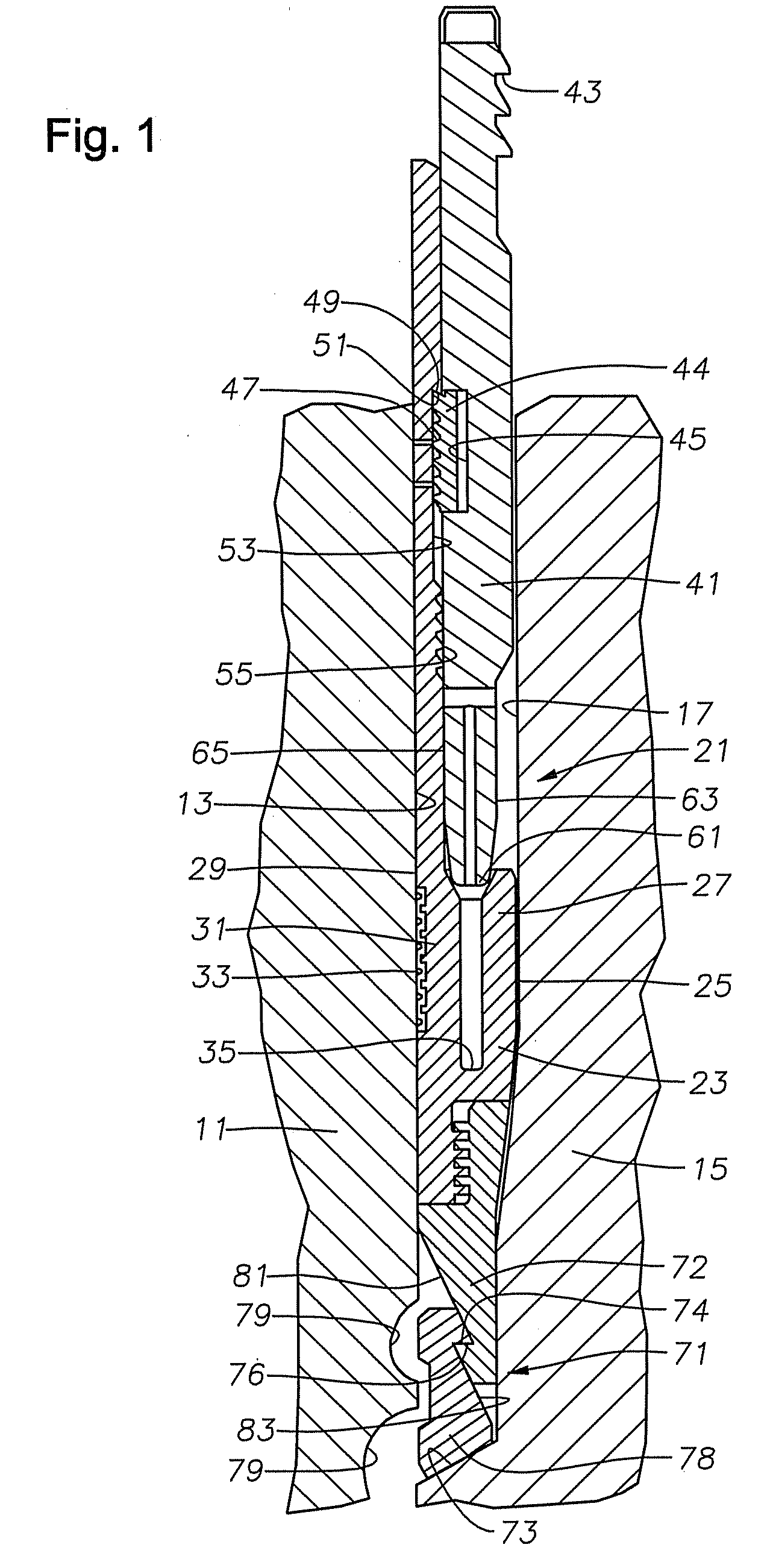

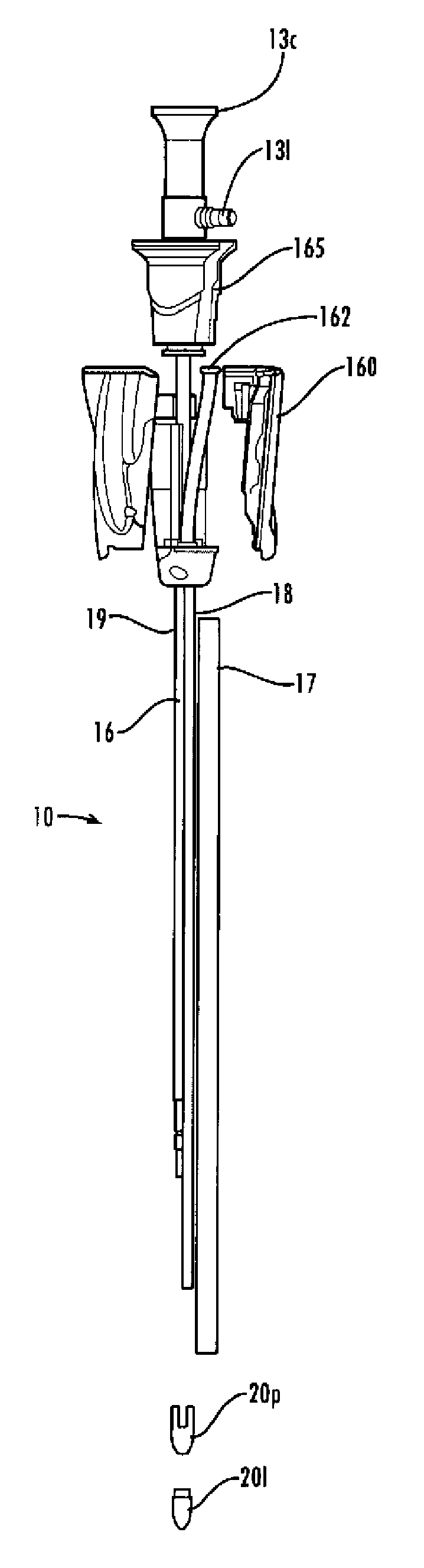

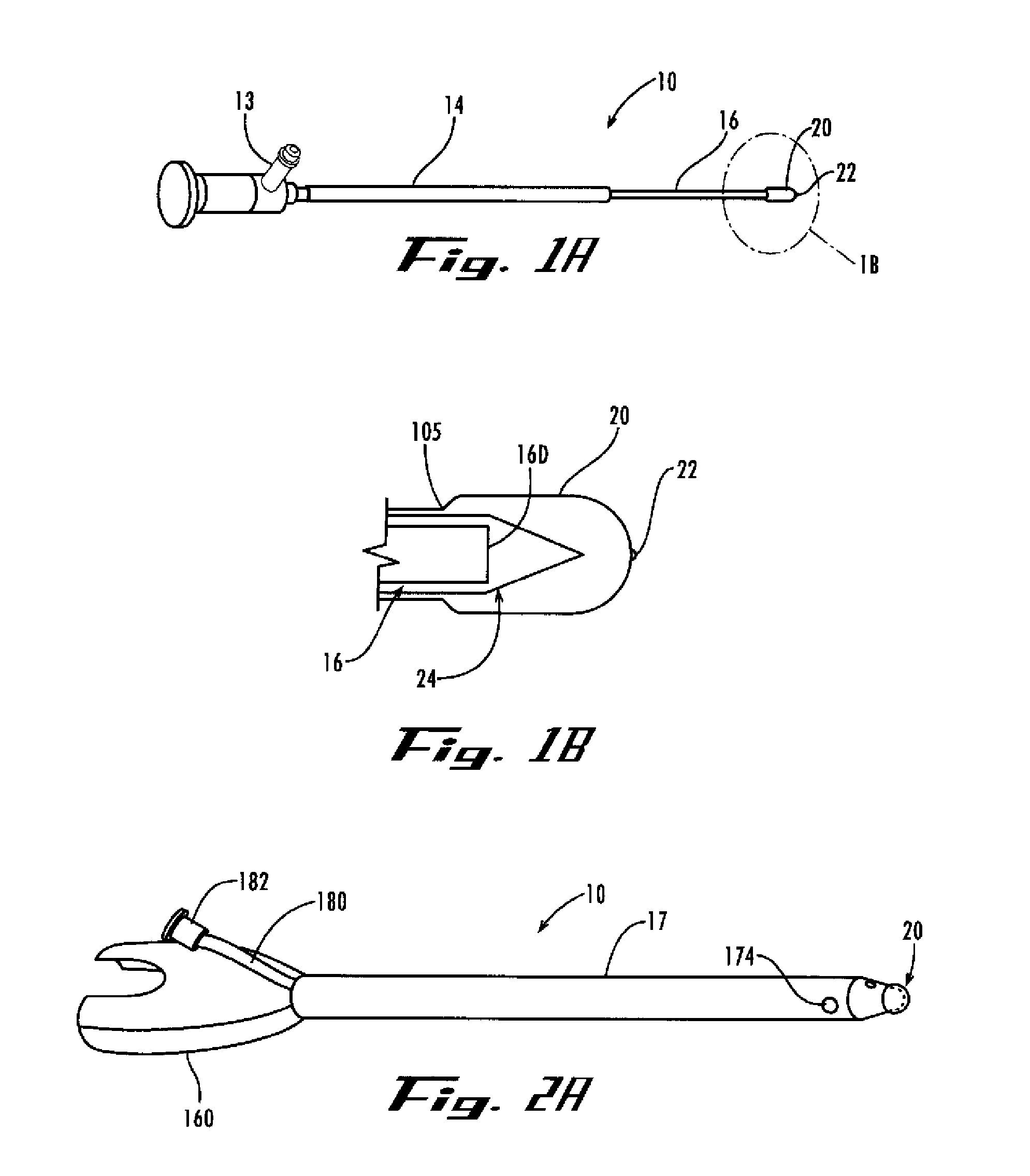

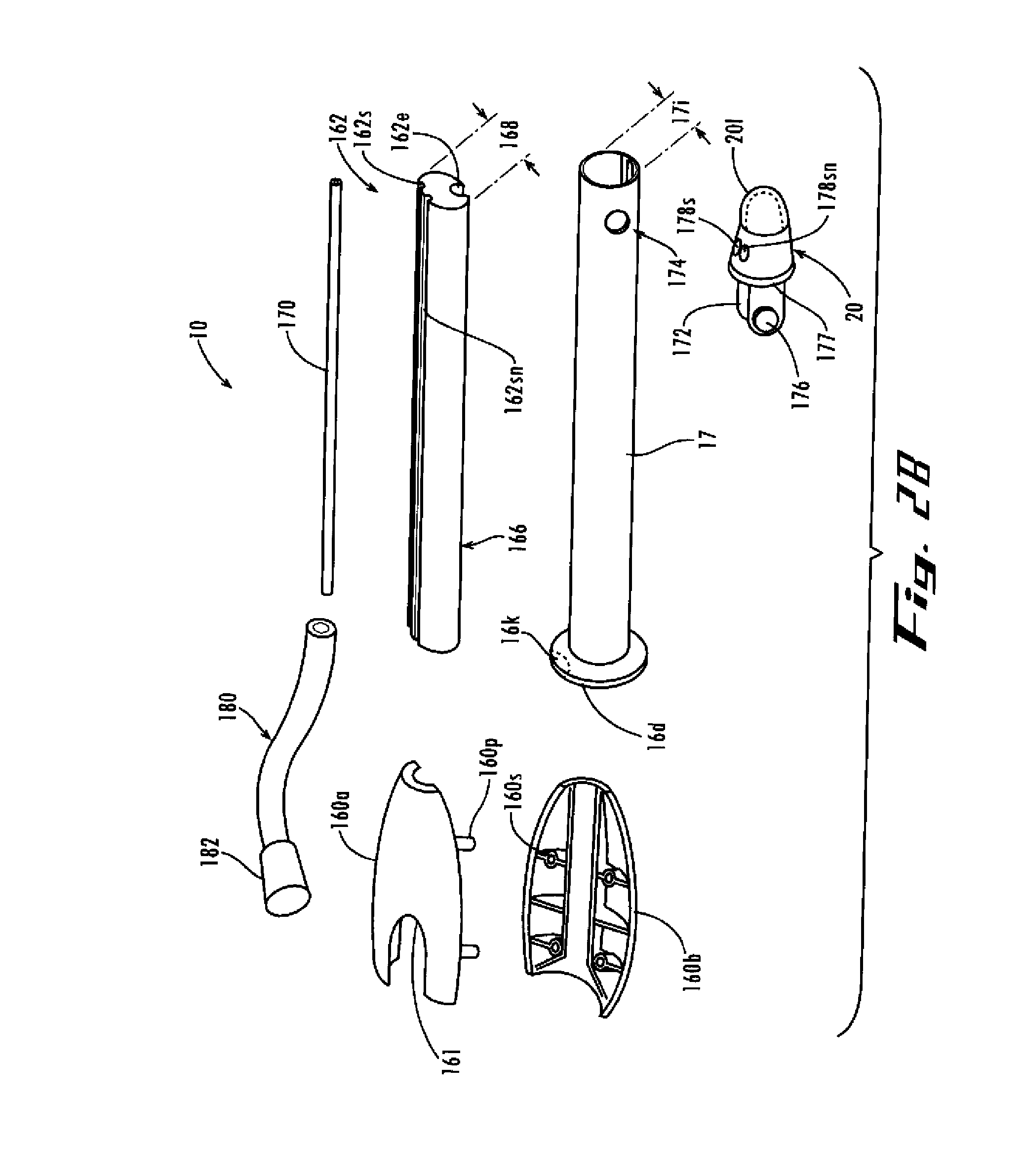

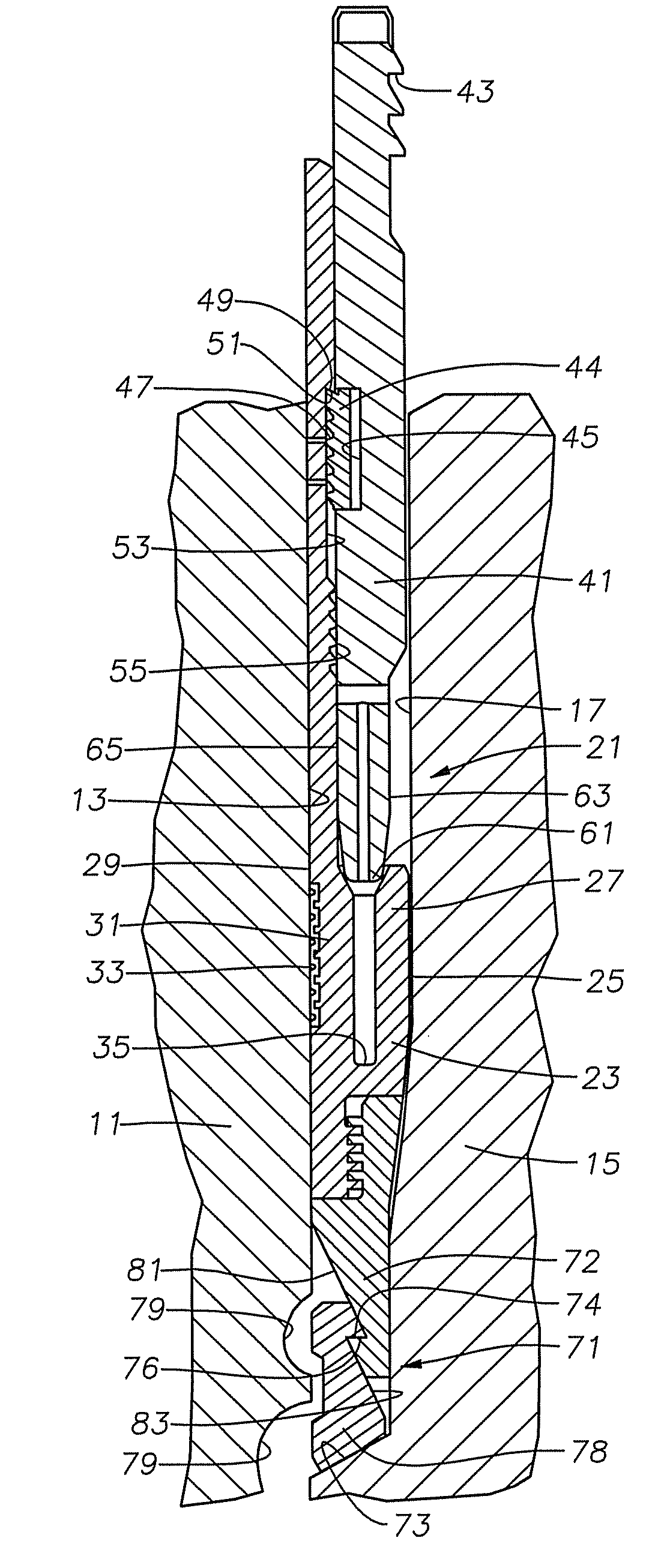

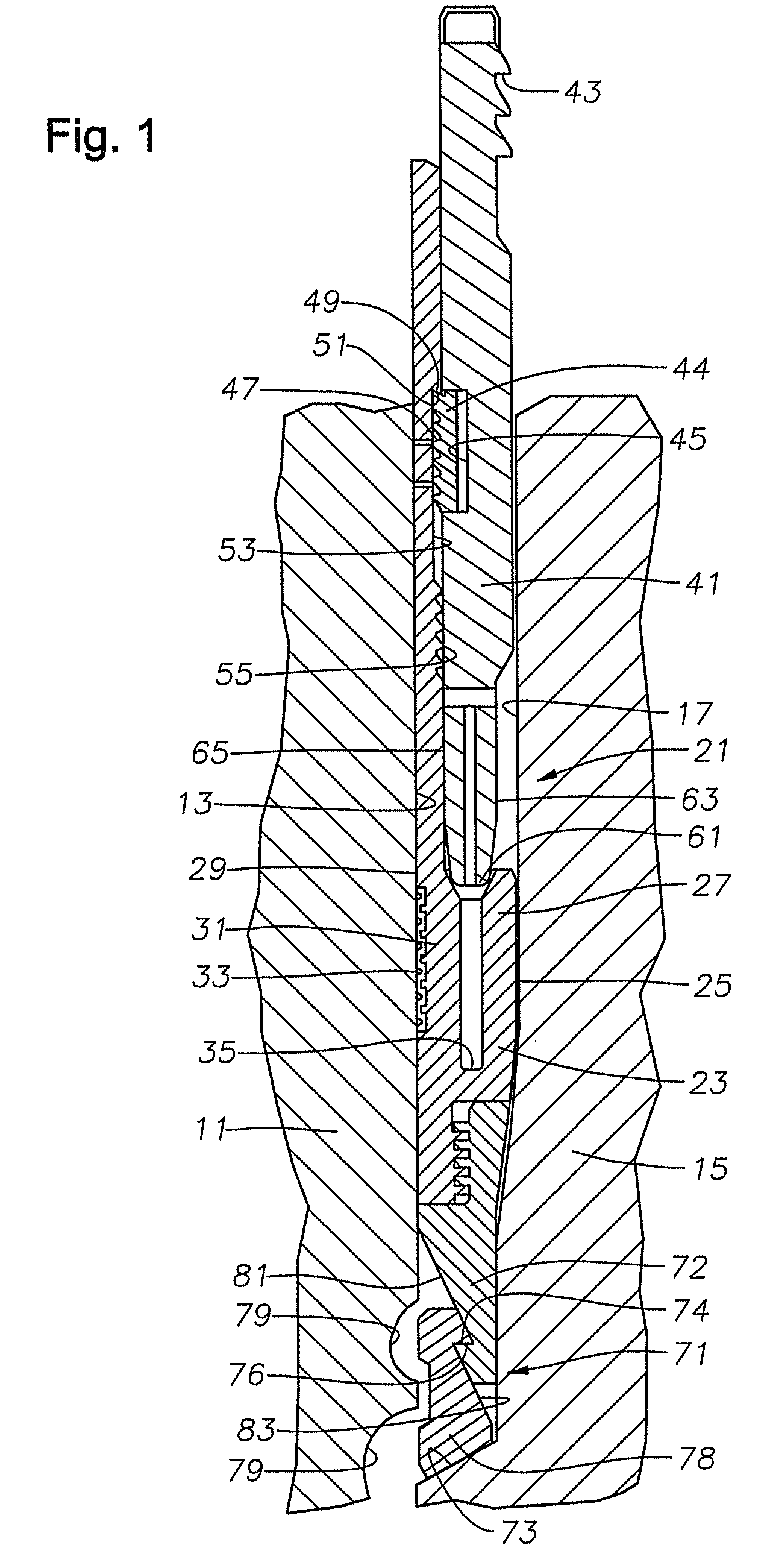

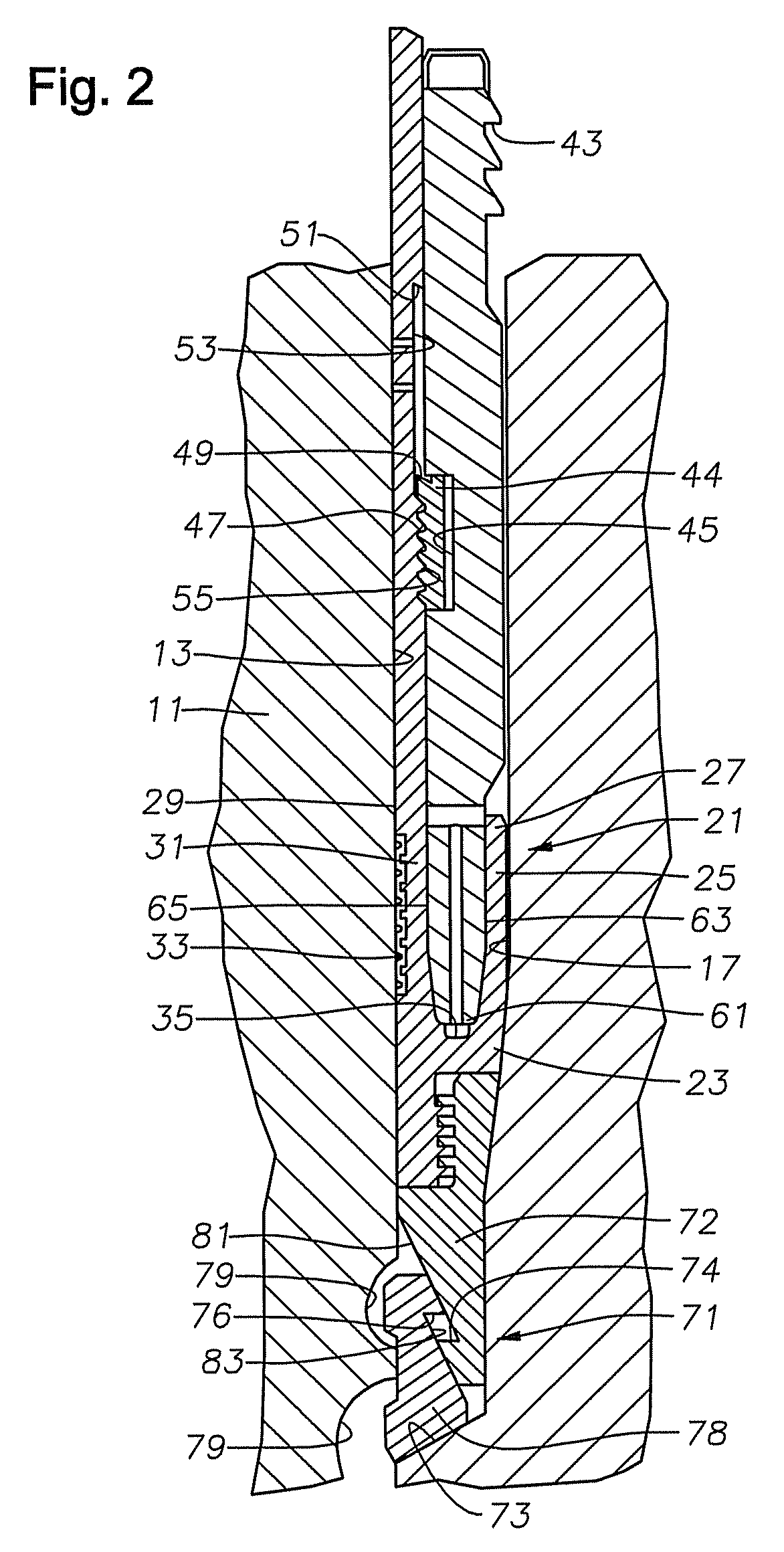

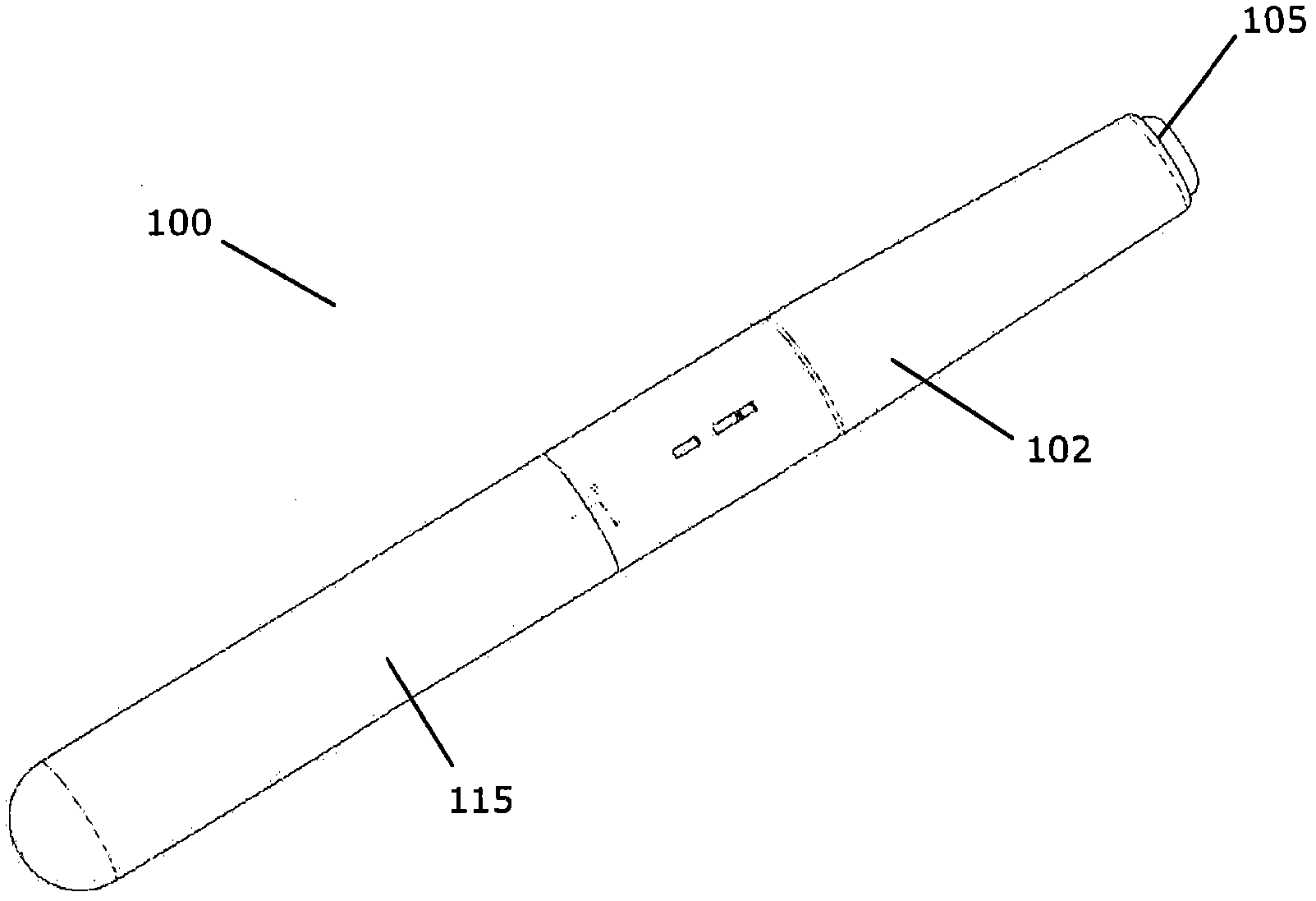

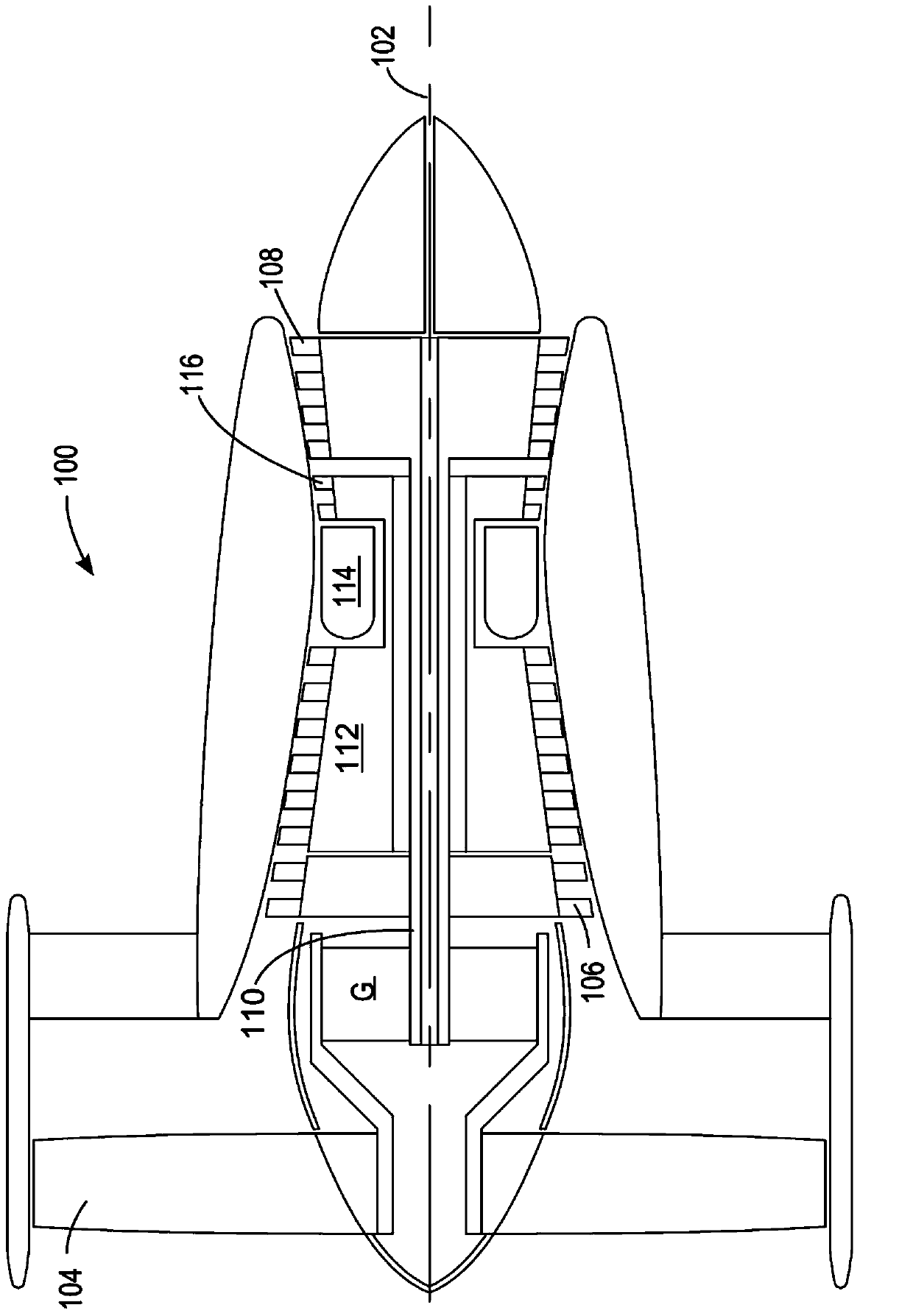

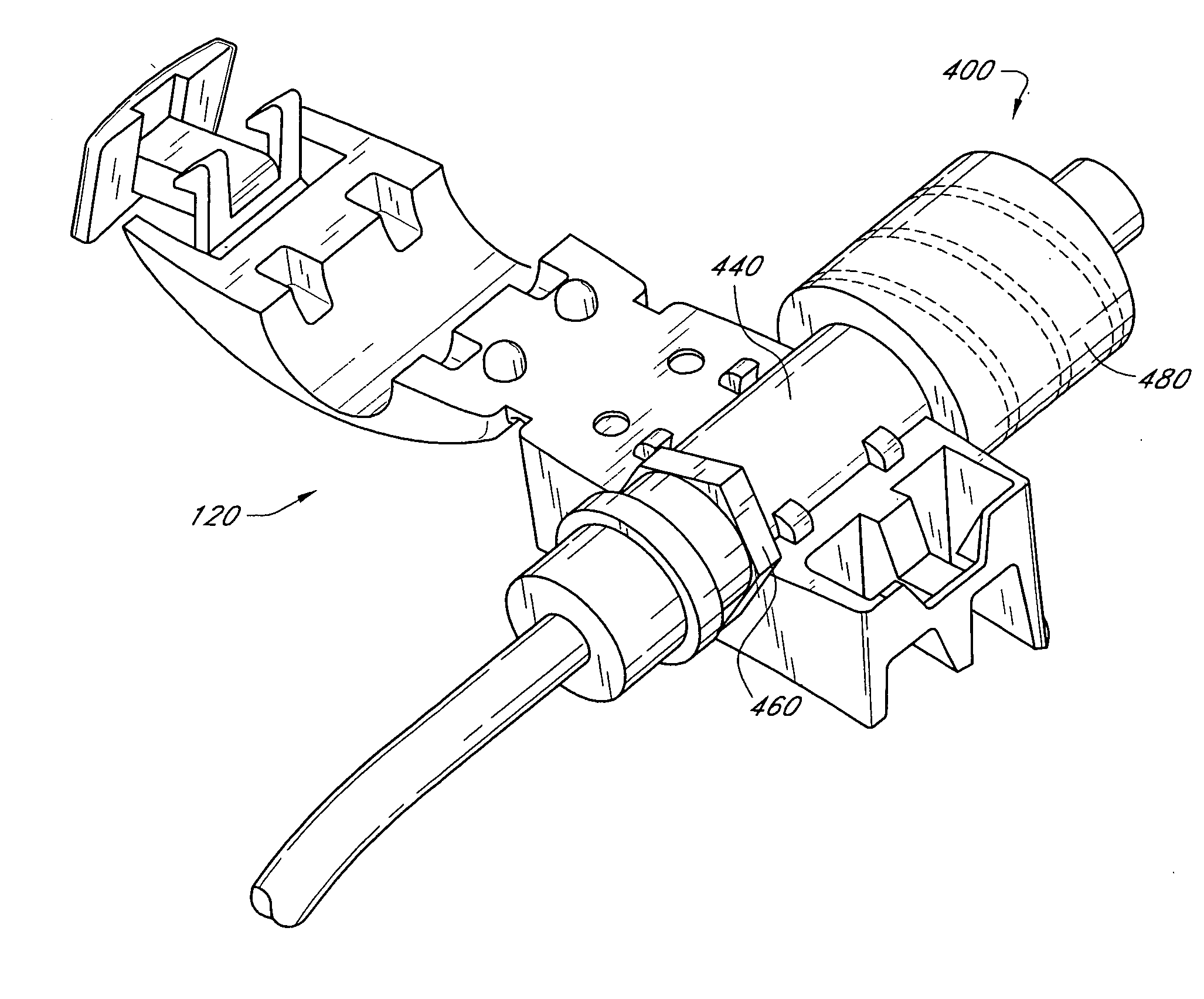

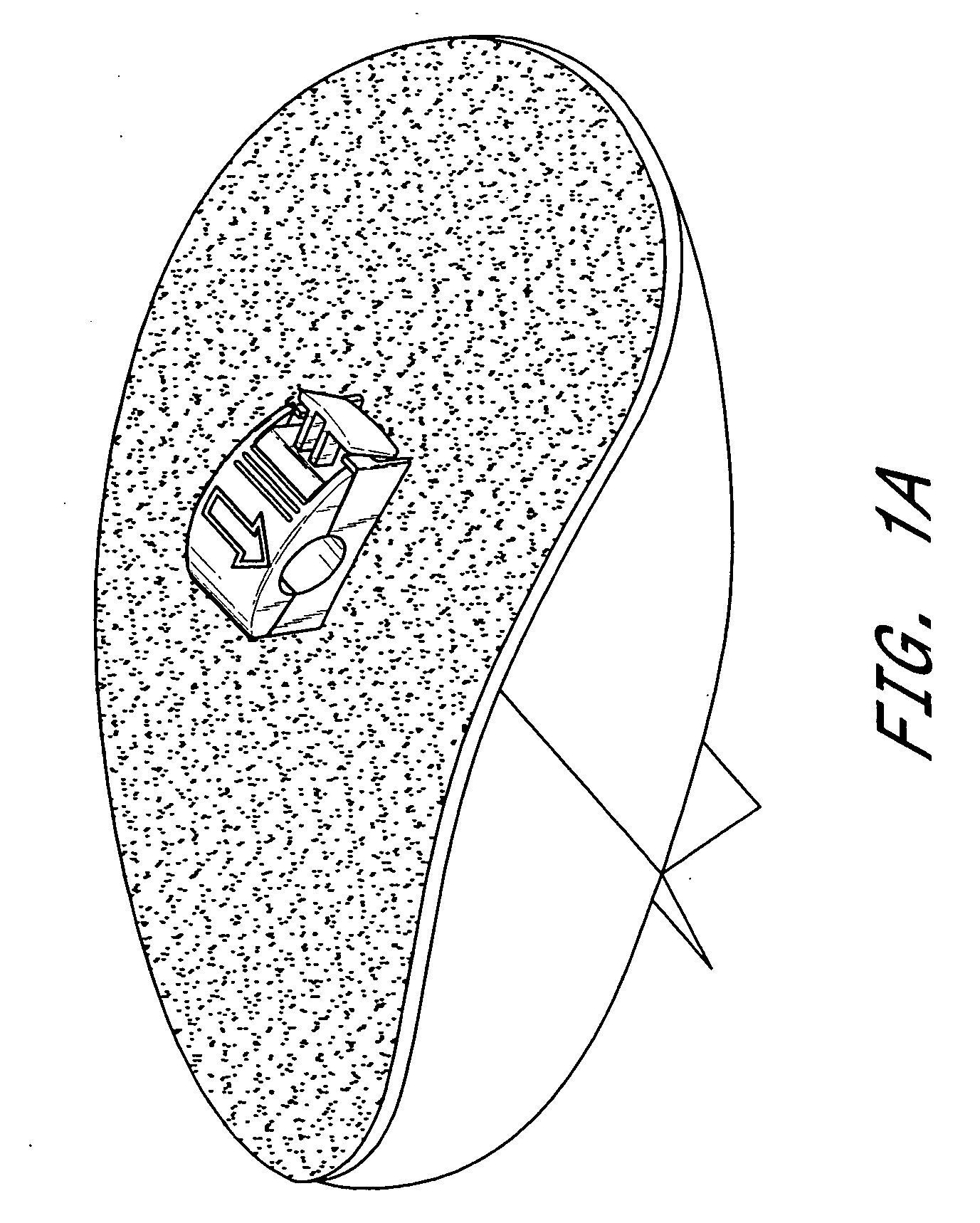

Apparatus and methods for performing minimally-invasive surgical procedures

ActiveUS20070129719A1Reduce side loadPrevent axial movementCannulasSurgical needlesSurgical departmentSurgical procedures

Devices, tools and methods for performing minimally invasive surgical procedures. Methods of performing minimally invasive ablation procedures. Methods of performing rapid exchange of tools in a device while the device remains in a reduced-access surgical space.

Owner:MAQUET CARDIOVASCULAR LLC

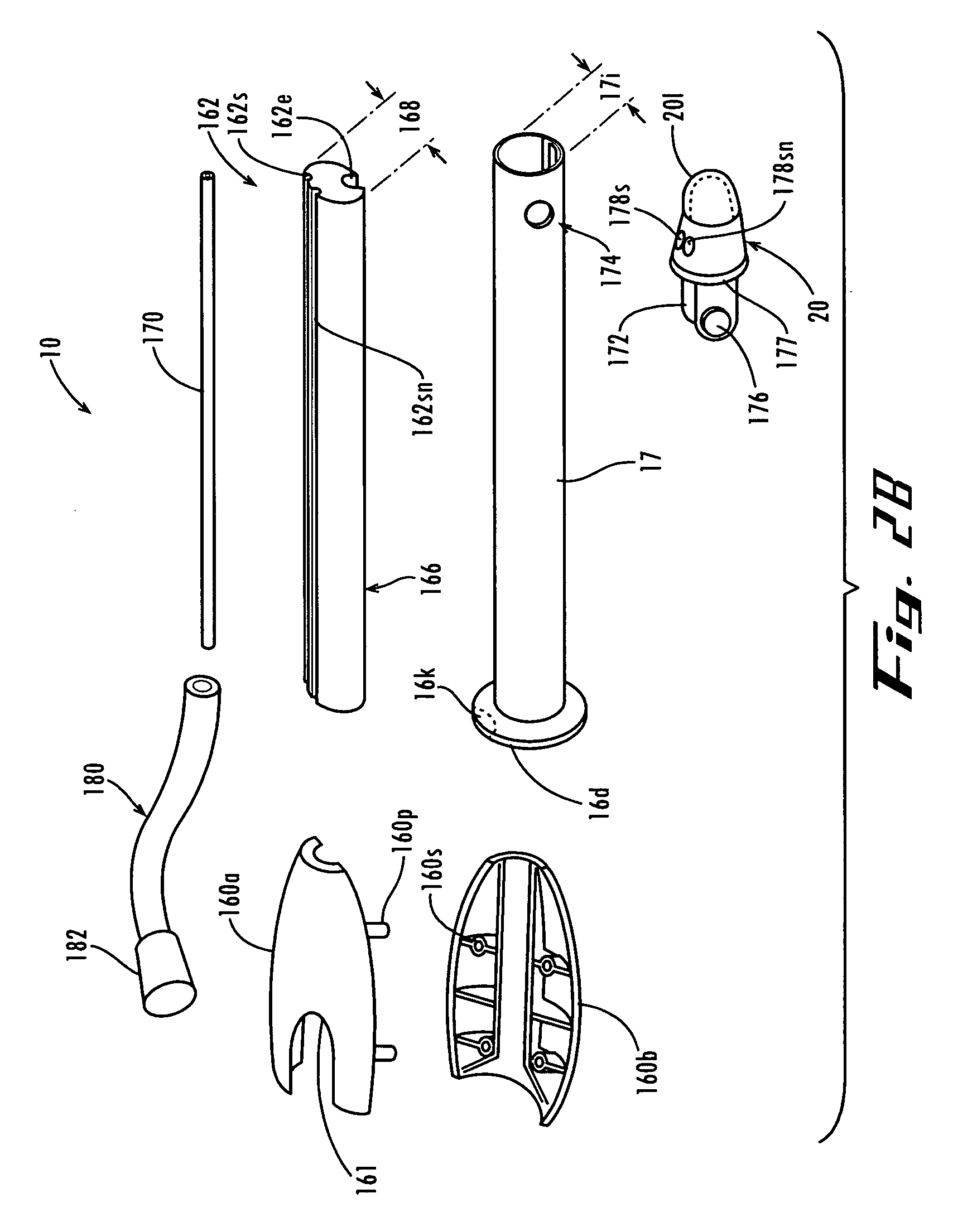

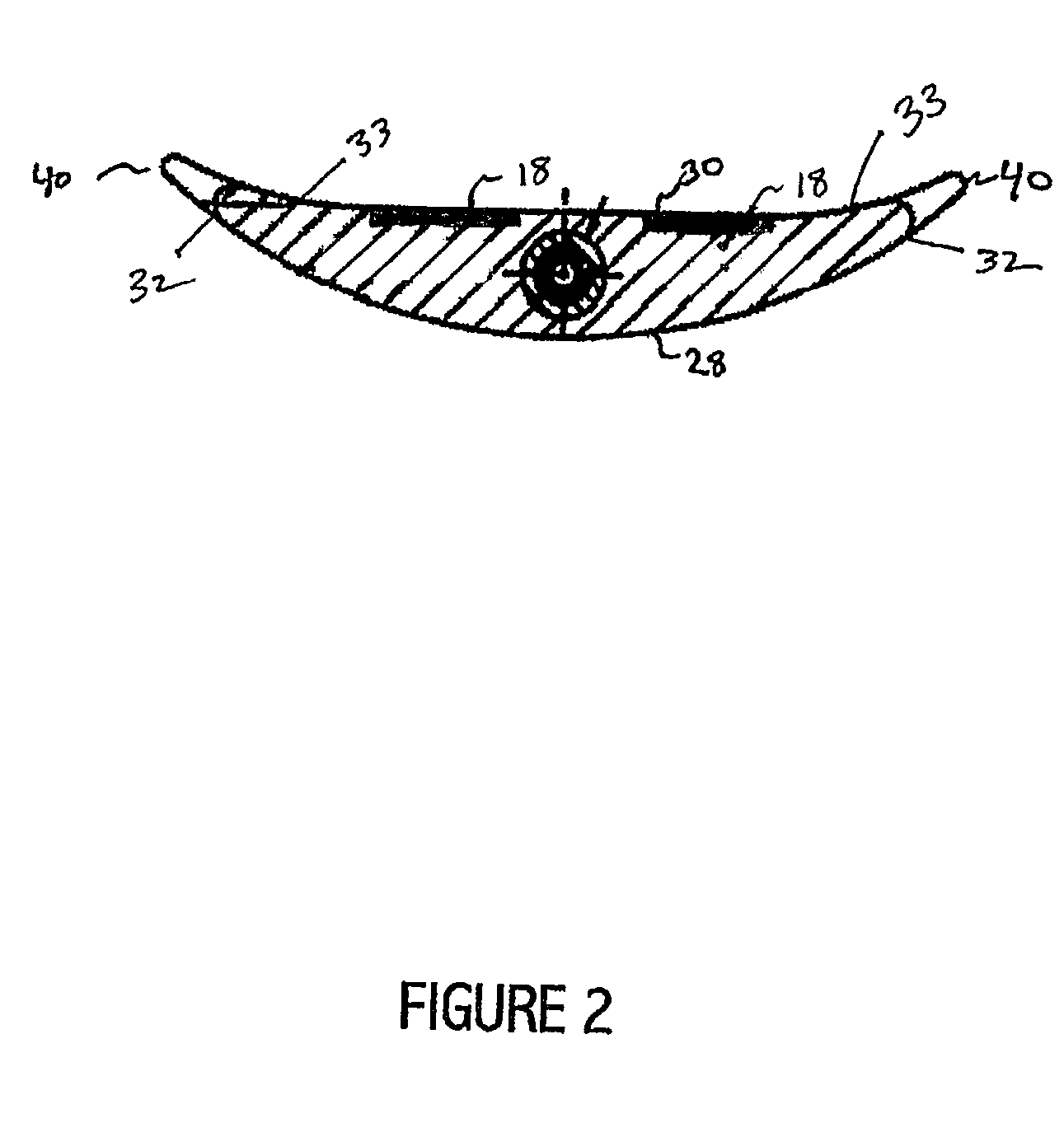

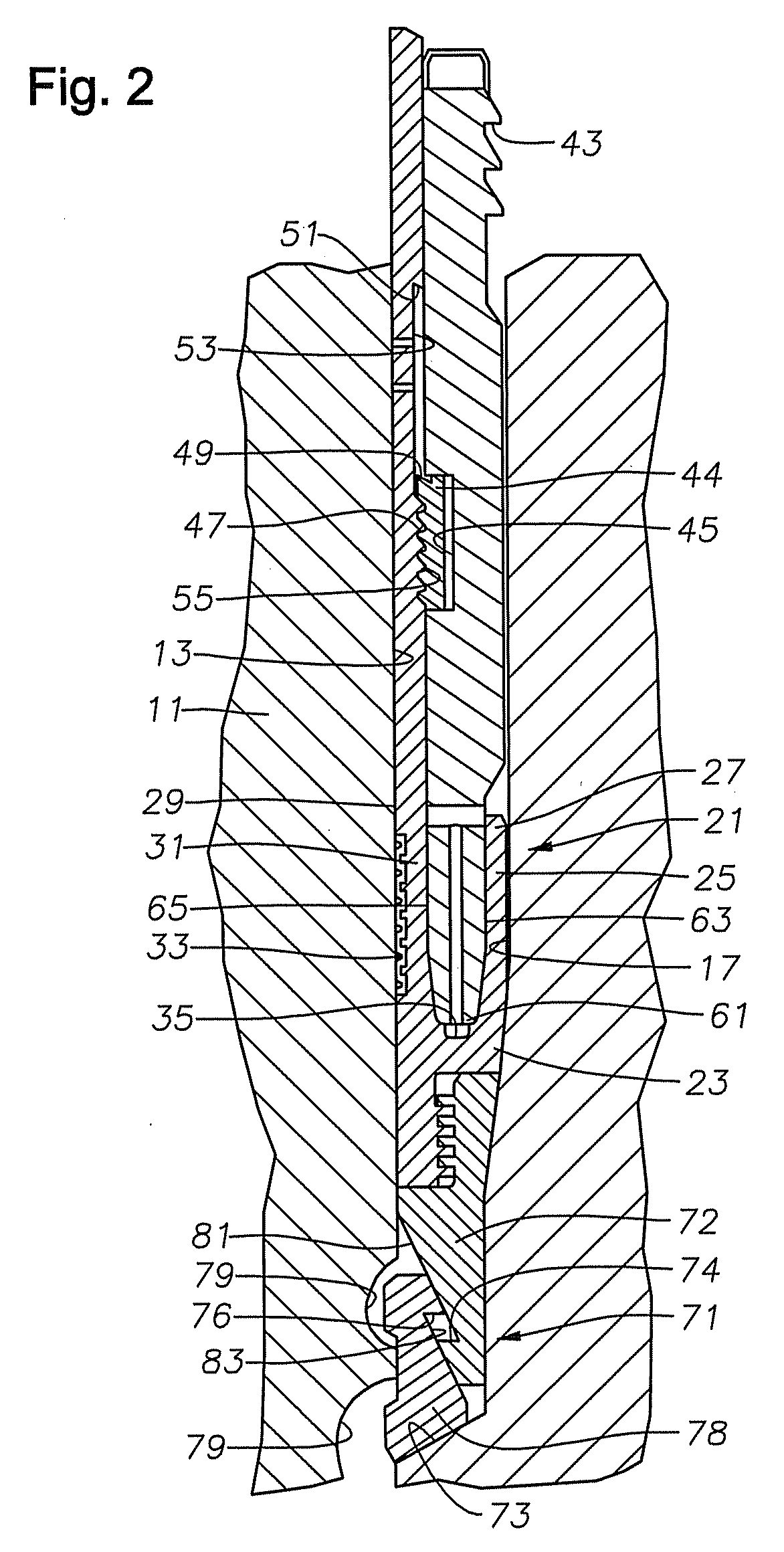

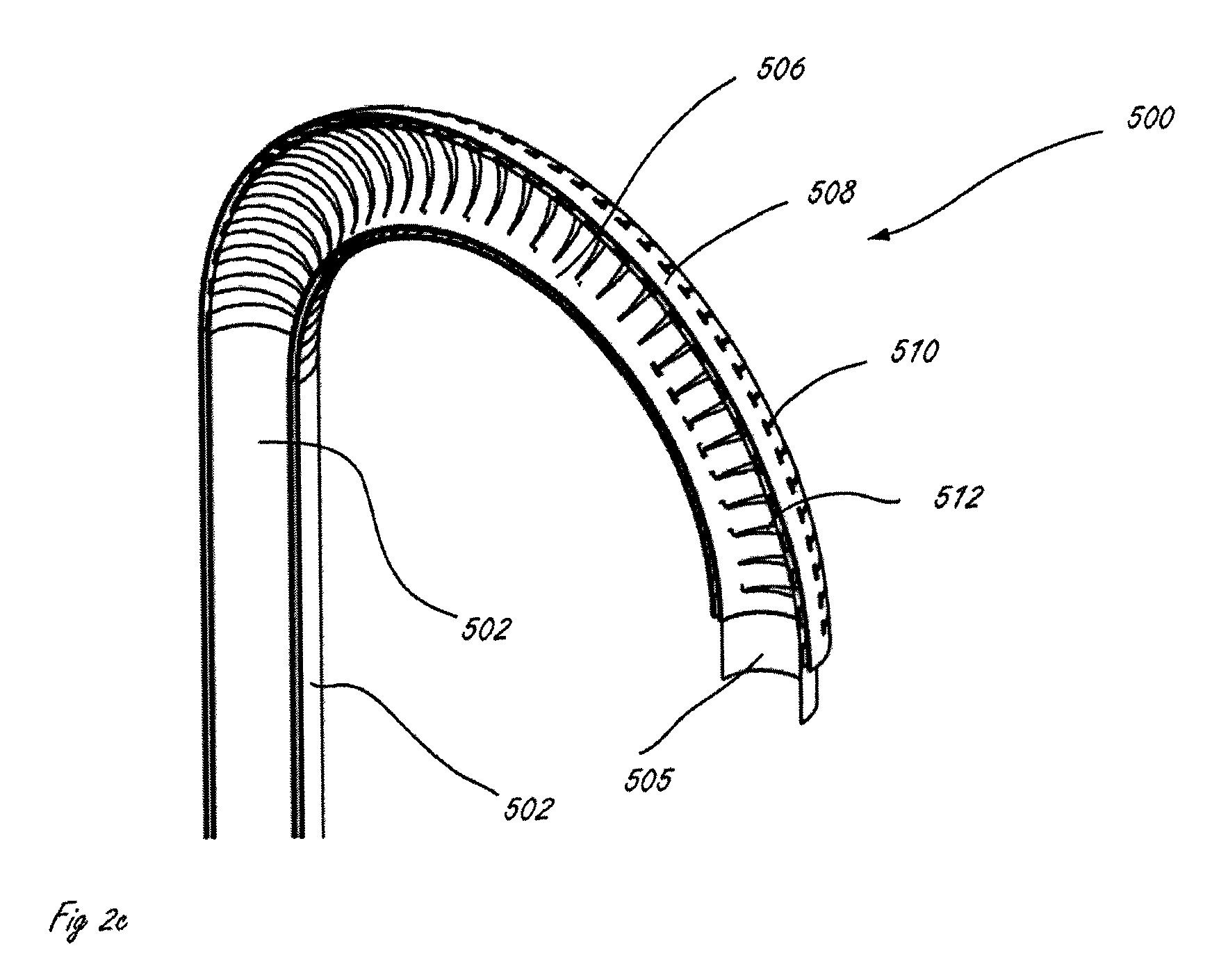

Winged electrode body for spinal cord stimulation

ActiveUS6999820B2Prevent axial movementOptimize couplingSpinal electrodesExternal electrodesSpinal cord stimulationTarget fibers

An implantable stimulation system including epidural lead for spinal cord stimulation that includes a paddle having a curved proximal end and lateral winged tips and an array of electrodes coupled to conductors within a lead body. The conductors couple to a pulse generator or other stimulation device. The curved and winged paddle provides more complete electrical stimulation coverage to targeted human tissue by minimizing the potential gap between electrodes and targeted fibers.

Owner:ADVANCED NEUROMODULATION SYST INC

High-temperature resistant vibration tool for horizontal well

ActiveCN104234651AHigh working reliabilityImprove high temperature resistanceVibration devicesUpper jointTemperature resistance

The invention relates to a high-temperature resistant vibration tool for a horizontal well. The high-temperature resistant vibration tool for the horizontal well comprises a shell assembly and a vibration assembly arranged in the shell assembly and is characterized in that the shell assembly comprises an upper joint, an upper joint sleeve, a connection sleeve, a cover and a lower joint which sleeve from top to bottom in sequence; the vibration assembly comprises an upper end turbine, an eccentric shaft and a lower end turbine which are connected in sequence from top to bottom; the vibration assembly is arranged in the shell assembly by an upper end bearing and a lower end bearing; the upper end bearing and the lower end bearing respectively sleeve two end shafts of the eccentric shaft; an upper thrust ring and a lower thrust ring are respectively arranged at two ends of the vibration assembly and are respectively arranged in the upper joint sleeve and the lower joint; a channel for allowing fluid to flow is arranged in each of the shell assembly and the vibration assembly. The high-temperature resistant vibration tool for the horizontal well has the beneficial effects that the work reliability and high temperature resistance of the tool are improved, the deepening depth is increased, and enough drilling and pressing effects are applied.

Owner:JEREH ENERGY SERVICES

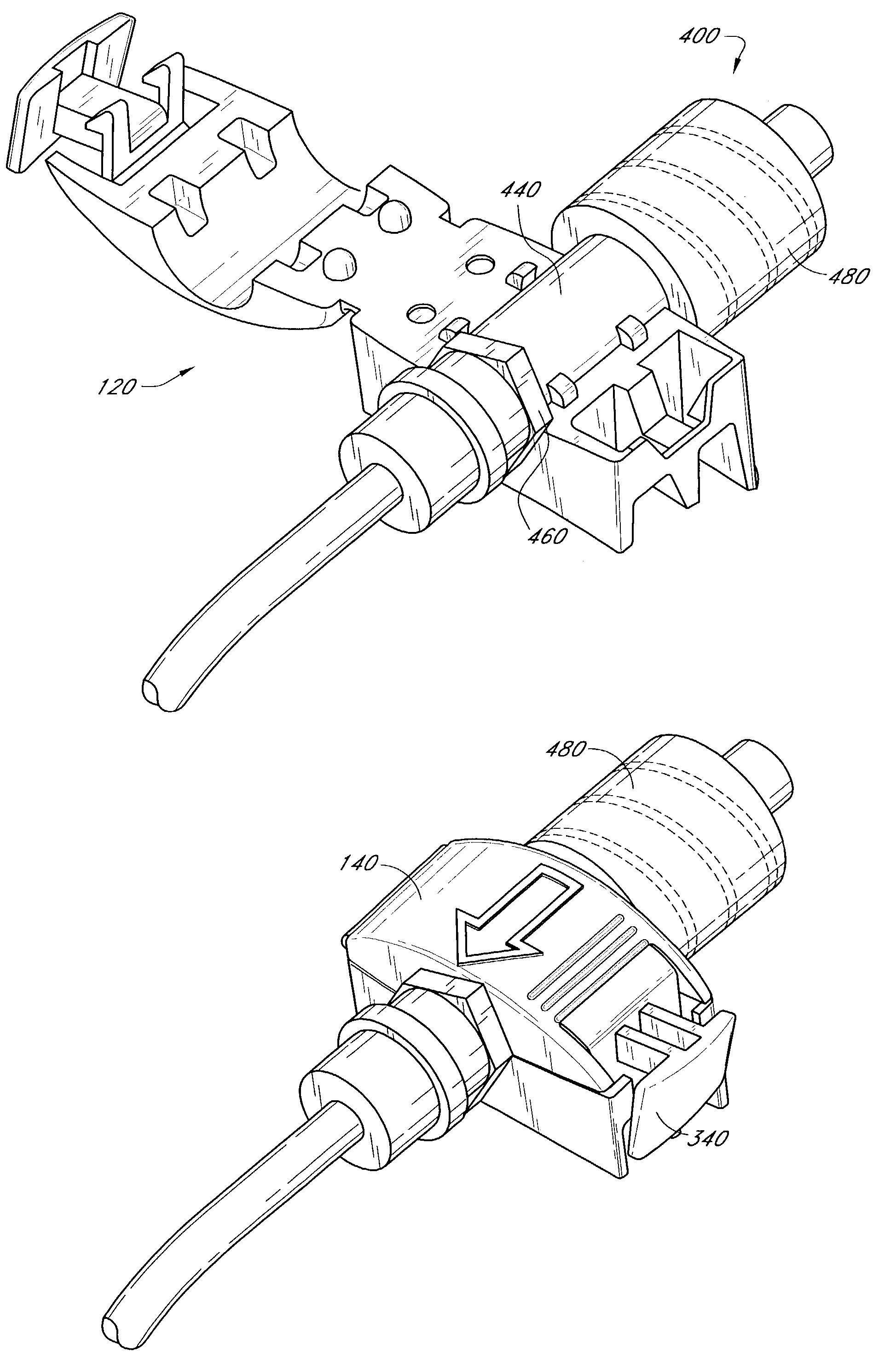

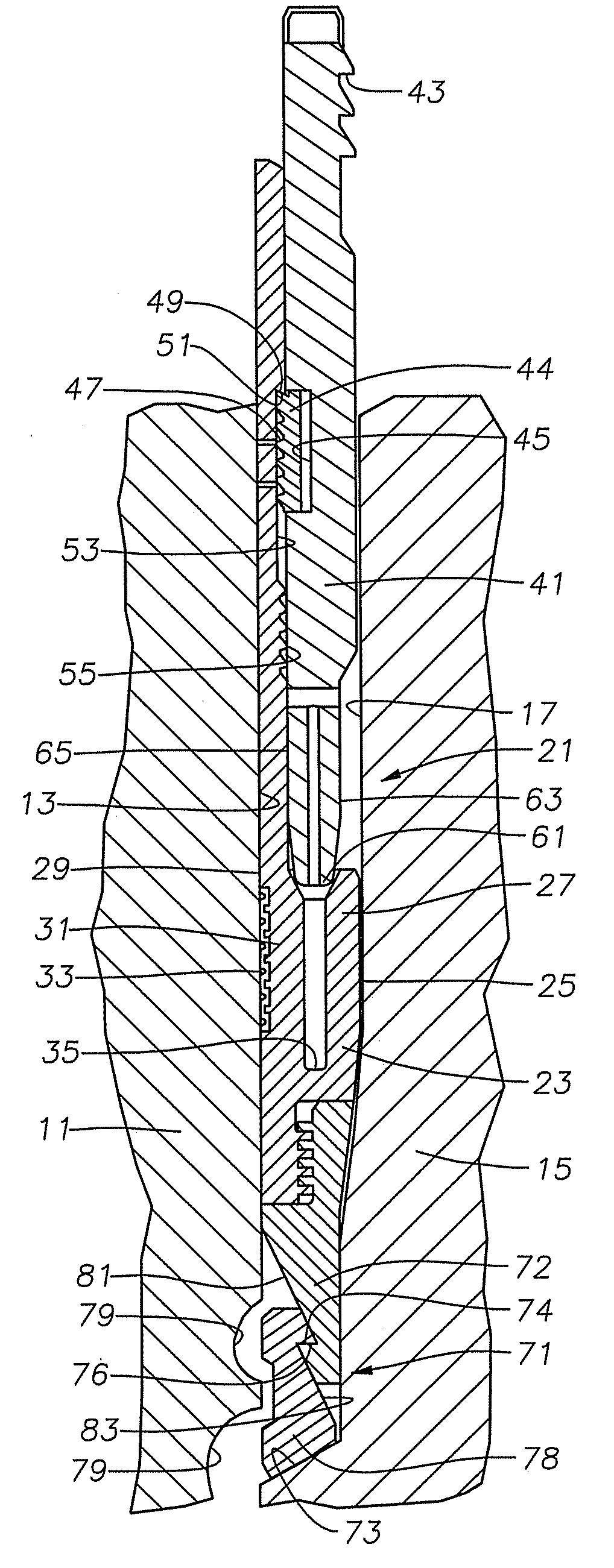

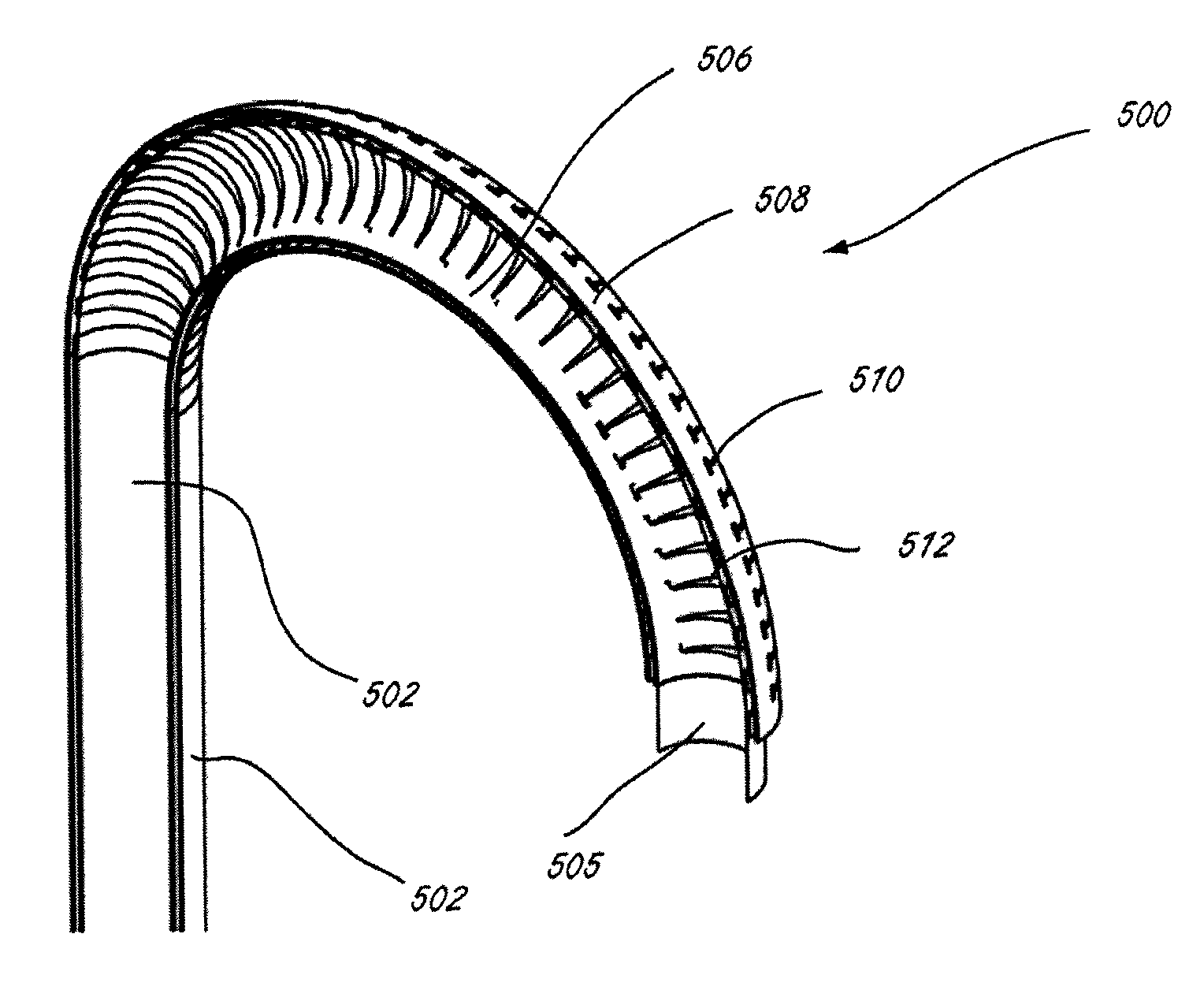

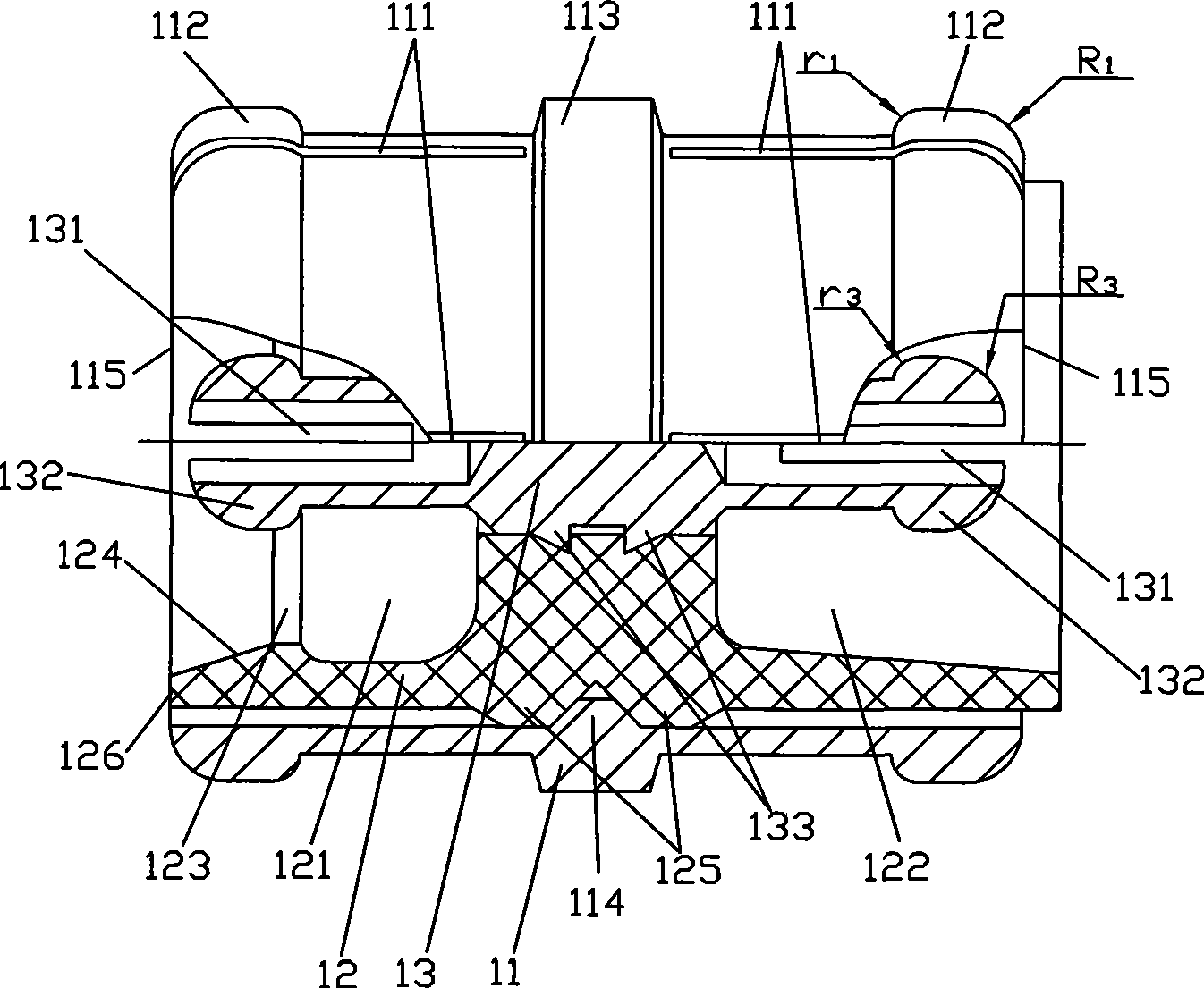

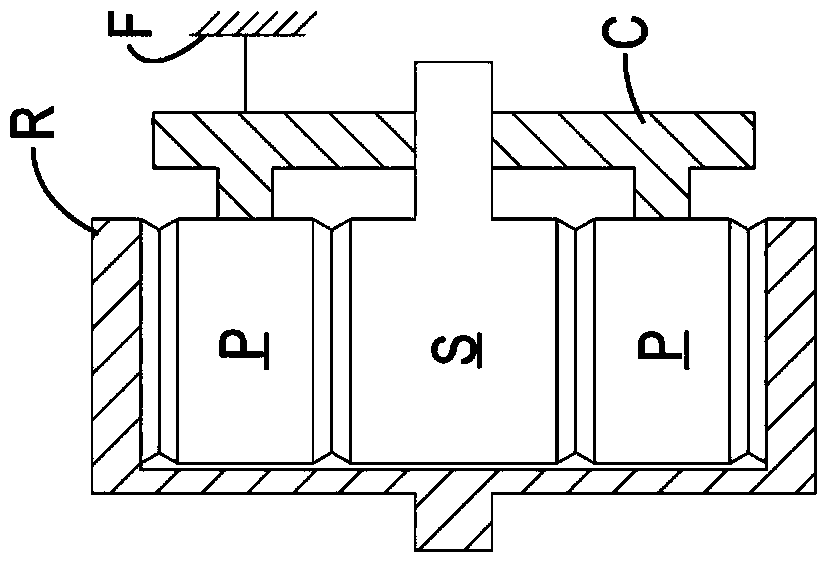

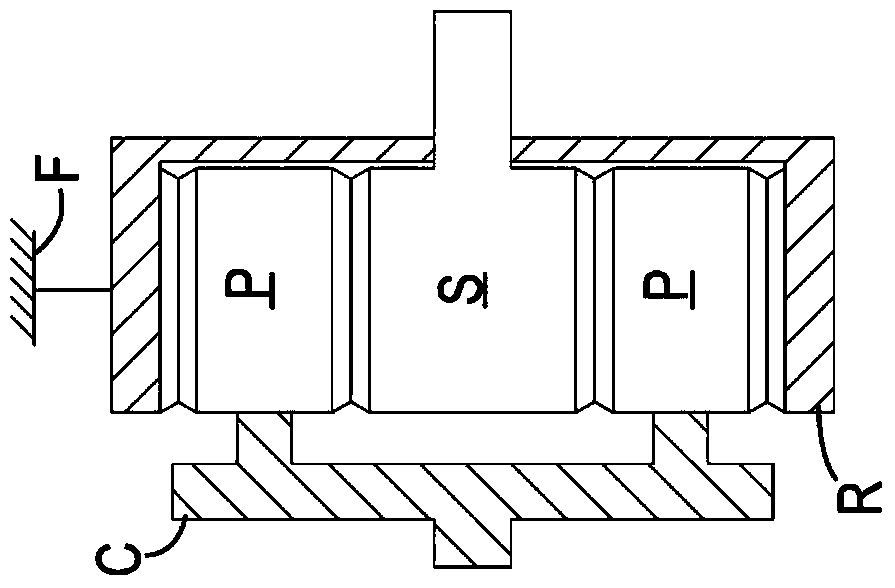

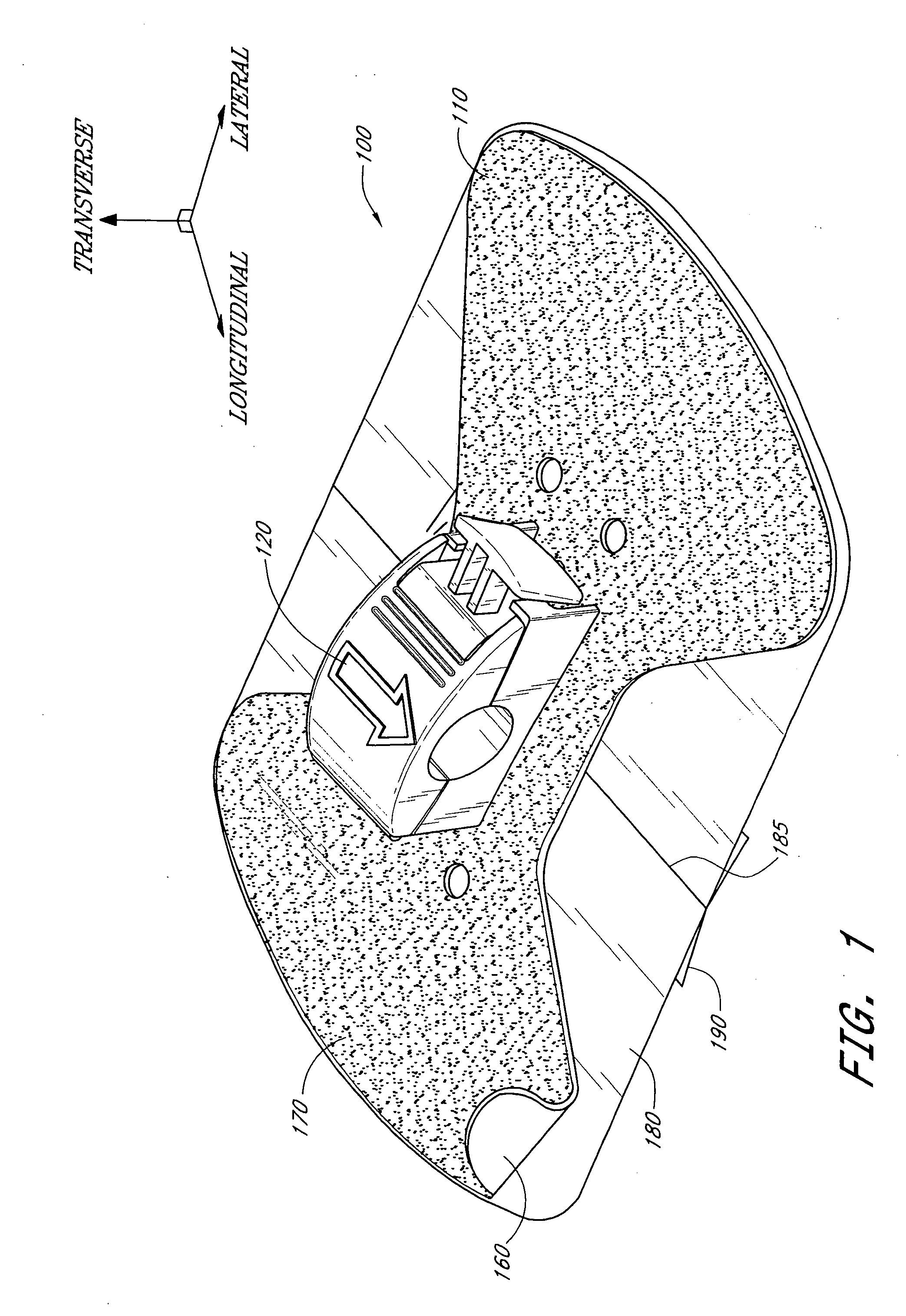

Medical line securement device

ActiveUS7223256B2Prevent axial movementCatheterInfusion needlesCATHETER ADAPTERBiomedical engineering

A medical line securement device holds a medical article such as a connector fitting for a catheter or a catheter adaptor in position upon the body of a patient and inhibits axial motion of the medical article. The securement device includes a retainer with a base and a cover. The cover is hinged to the base such that it may be moved between an open and closed position. The base and cover each have a groove which cooperate when the cover is in the closed position to form a channel through the retainer. The medical article includes an elongated body which is received within the groove of the retainer, the elongated body lying between at least a pair of regions of larger radius of the medical article. By receiving the portion of the elongated body of the medical article between the regions of larger radius, axial motion of the medical article through the groove is inhibited. The retainer may also include one or more slots to receive any radial projections of the medical article within the retainer.

Owner:VENETEC INT INC

Apparatus and methods for performing minimally-invasive surgical procedures

ActiveUS8932208B2Prevent axial movementPrevent rotationCannulasSurgical needlesSurgical proceduresGeneral surgery

Devices, tools and methods for performing minimally invasive surgical procedures. Methods of performing minimally invasive ablation procedures. Methods of performing rapid exchange of tools in a device while the device remains in a reduced-access surgical space.

Owner:MAQUET CARDIOVASCULAR LLC

Metal Annulus Seal

ActiveUS20100116489A1Prevent axial movementWithout riskDrilling rodsConstructionsWellheadEngineering

A wellhead seal assembly forms a metal-to-metal seal between inner and outer wellhead members. A metal seal ring has inner and outer walls separated by a slot. An energizing ring has a C-ring captured on its outer surface. When the energizing ring is moved farther into the slot, the C-ring is forced from its pocket and engages a profile on the seal ring, locking the energizing ring to the seal assembly.

Owner:VETCO GRAY

Steerable medical delivery devices and methods of use

ActiveUS8323241B2Prevent axial movementMedical devicesCatheterBiomedical engineeringMedical treatment

Owner:SHIFAMED HLDG

Apparatus and methods for performing minimally-invasive surgical procedures

InactiveUS20150142041A1Prevent axial movementPrevent rotationCannulasSurgical needlesSurgical departmentInvasive Procedure

Devices, tools and methods for performing minimally invasive surgical procedures. Methods of performing minimally invasive ablation procedures. Methods of performing rapid exchange of tools in a device while the device remains in a reduced-access surgical space.

Owner:MAQUET CARDIOVASCULAR LLC

Metal annulus seal

ActiveUS7762319B2Prevent axial movementWithout riskDrilling rodsConstructionsEngineeringMechanical engineering

A wellhead seal assembly forms a metal-to-metal seal between inner and outer wellhead members. A metal seal ring has inner and outer walls separated by a slot. An energizing ring has a C-ring captured on its outer surface. When the energizing ring is moved further into the slot, the C-ring is forced from its pocket and engages a profile on the seal ring, locking the energizing ring to the seal assembly.

Owner:VETCO GRAY

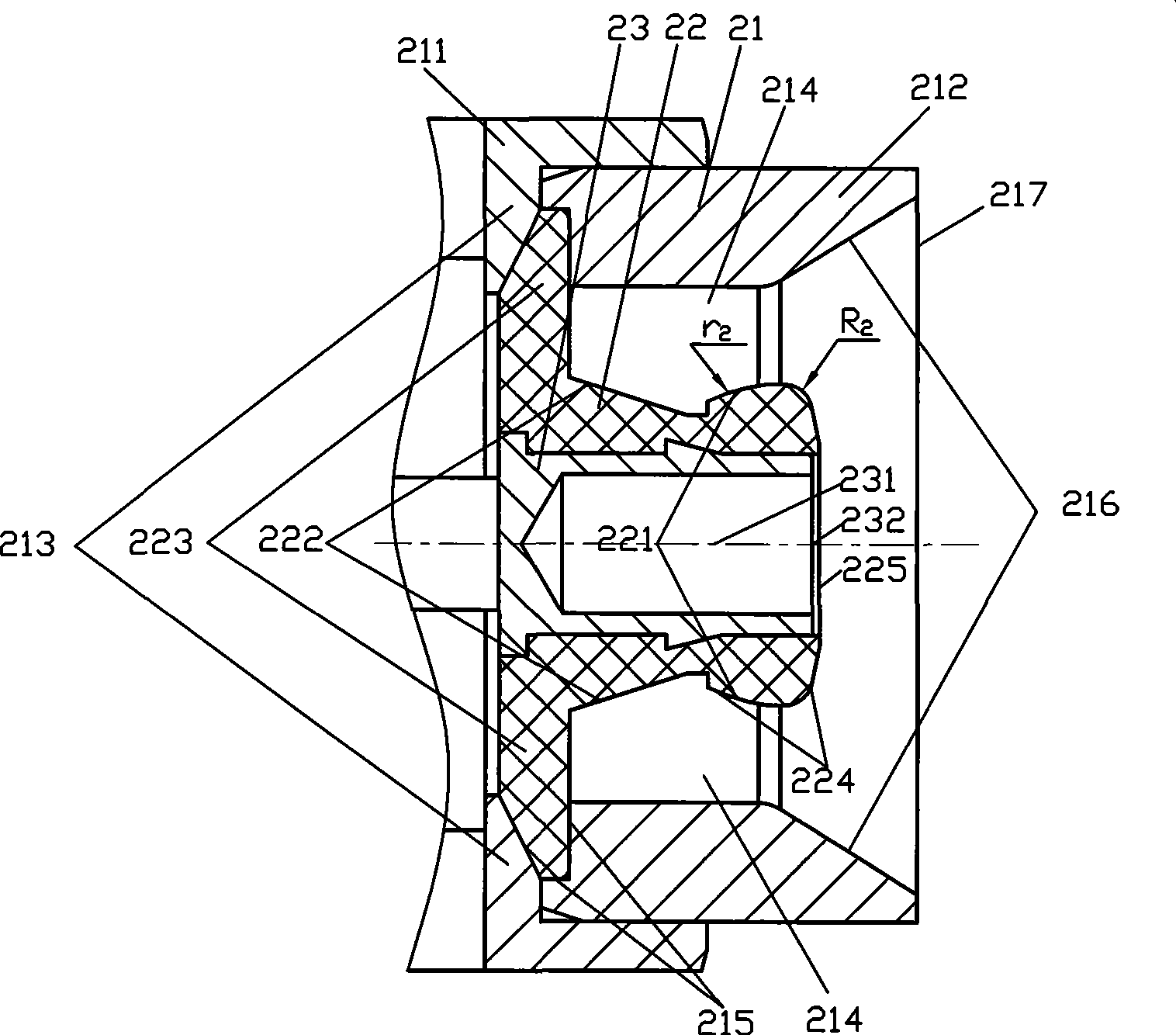

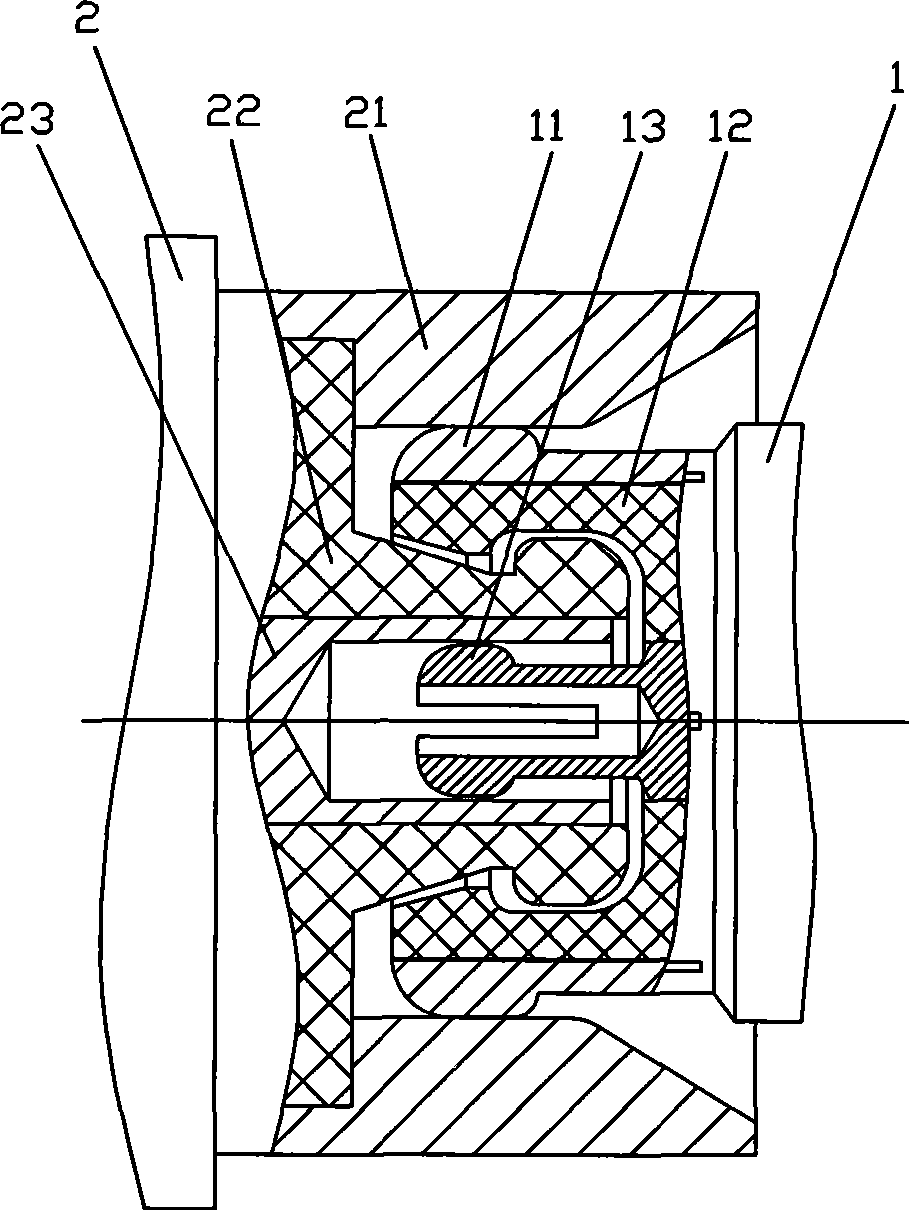

RF coaxial connector capable of slight bias insertion

InactiveCN101459304AEasy extractionStable structureCoupling device detailsTwo-part coupling devicesElectrical conductorRadio frequency

The invention provides a radio frequency coaxial connector which can be a little deflected, comprising a plug and a socket, the plug is inserted in the socket, an inner conductor and an outer conductor of the plug are all equipped with symmetrical expansion gaps along two sides of the axial line direction, outer peripheral faces of head portions of two ends of the inner conductor and the outer conductor of the plug are all equipped with small and large flanges of which end faces are radiused, one end of an insulating body of the plug is equipped with a ball socket cavity, the other end is equipped with a tapered hole, the ball socket cavity has an inlet, and the outside of the inlet is flared. An outer peripheral face of the head portion of the insulator of the socket is equipped with a ball end engaged with the ball socket cavity, and an inner conductor and an outer conductor of the socket are equipped with a cylindrical cavity respectively. When the plug is inserted in the socket with a little axis deviation, the outer conductor of the plug slides in the cylindrical cavity along a flare opening of the socket, the ball socket cavity of the plug can be simultaneously inserted with the ball end of the socket with a certain deflection, and the inner conductor of the plug can be simultaneously inserted in the cylindrical cavity of the inner conductor of the socket. The invention generates deflection relatively to axis deviation, and is convenient in installation, reliable in connection and simple in structure.

Owner:JIANGSU UNIV OF SCI & TECH

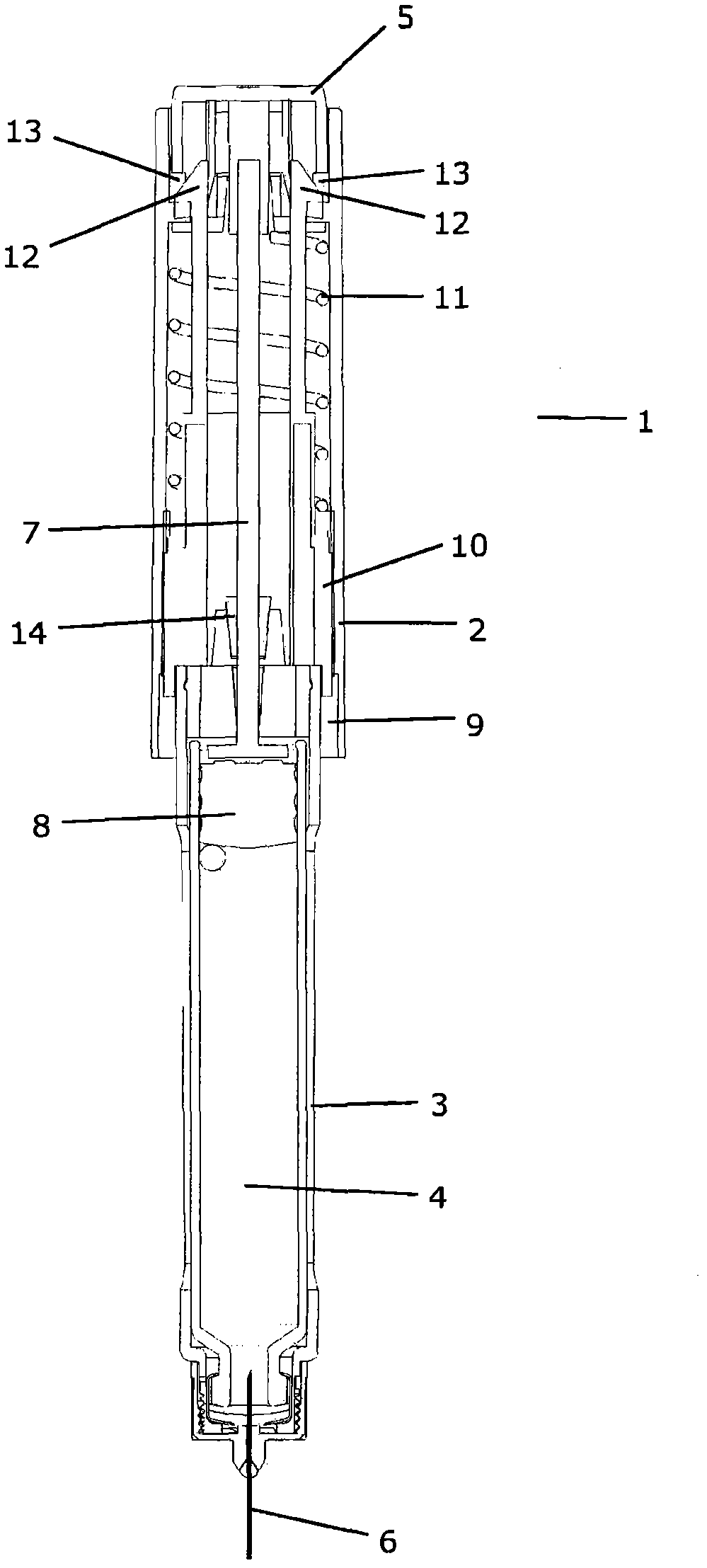

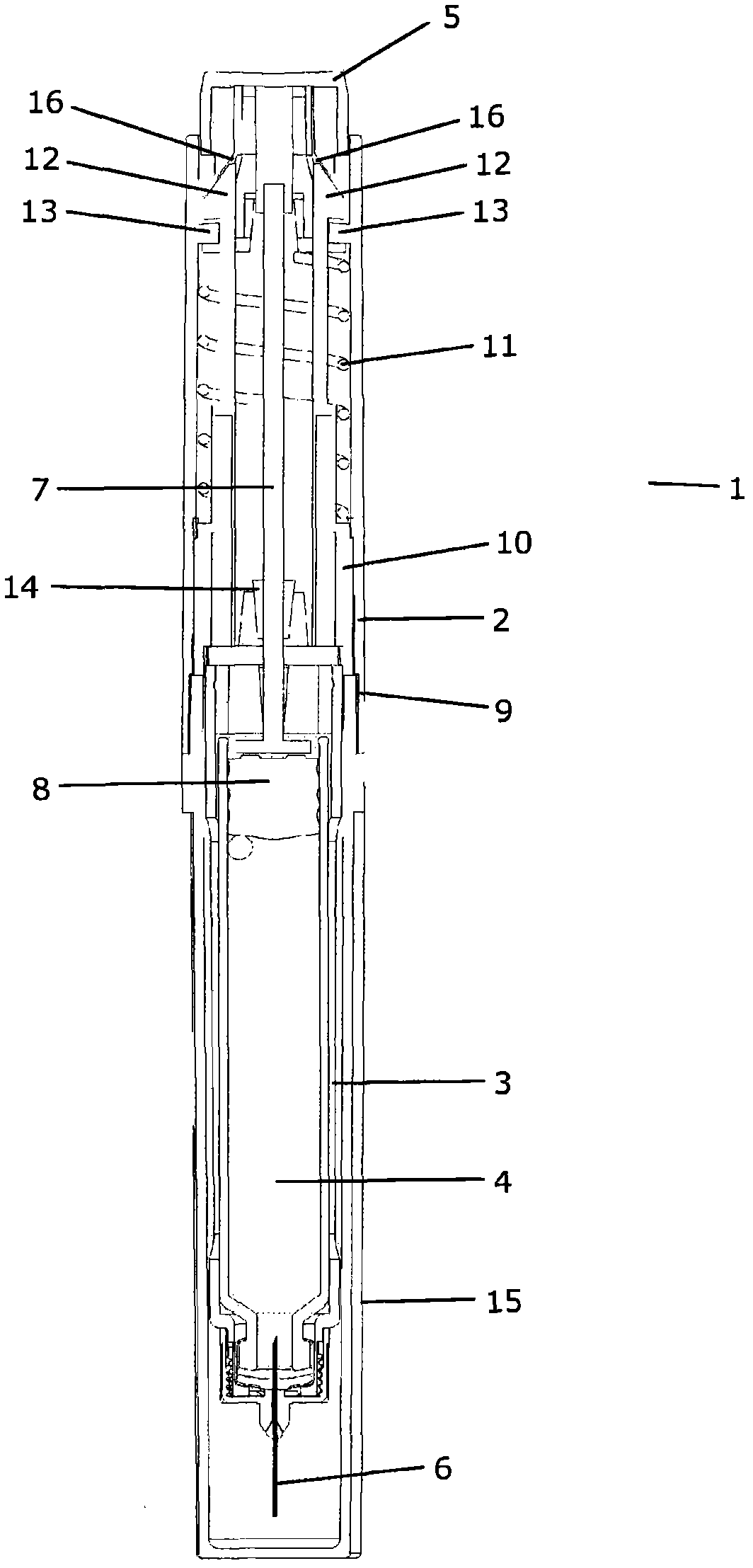

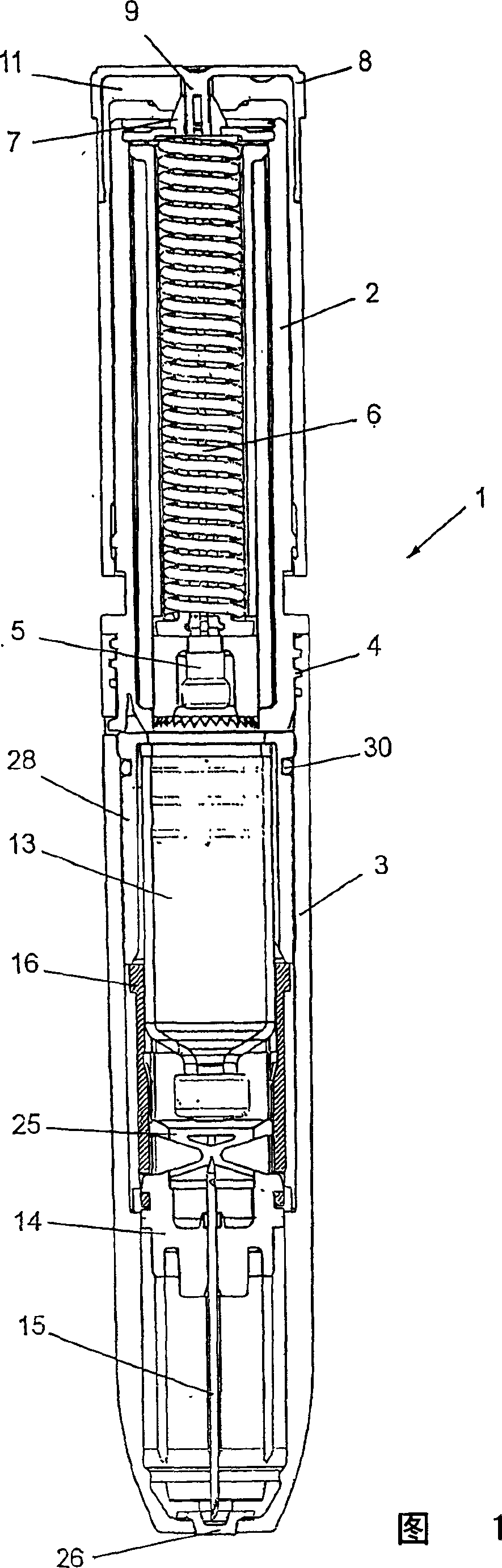

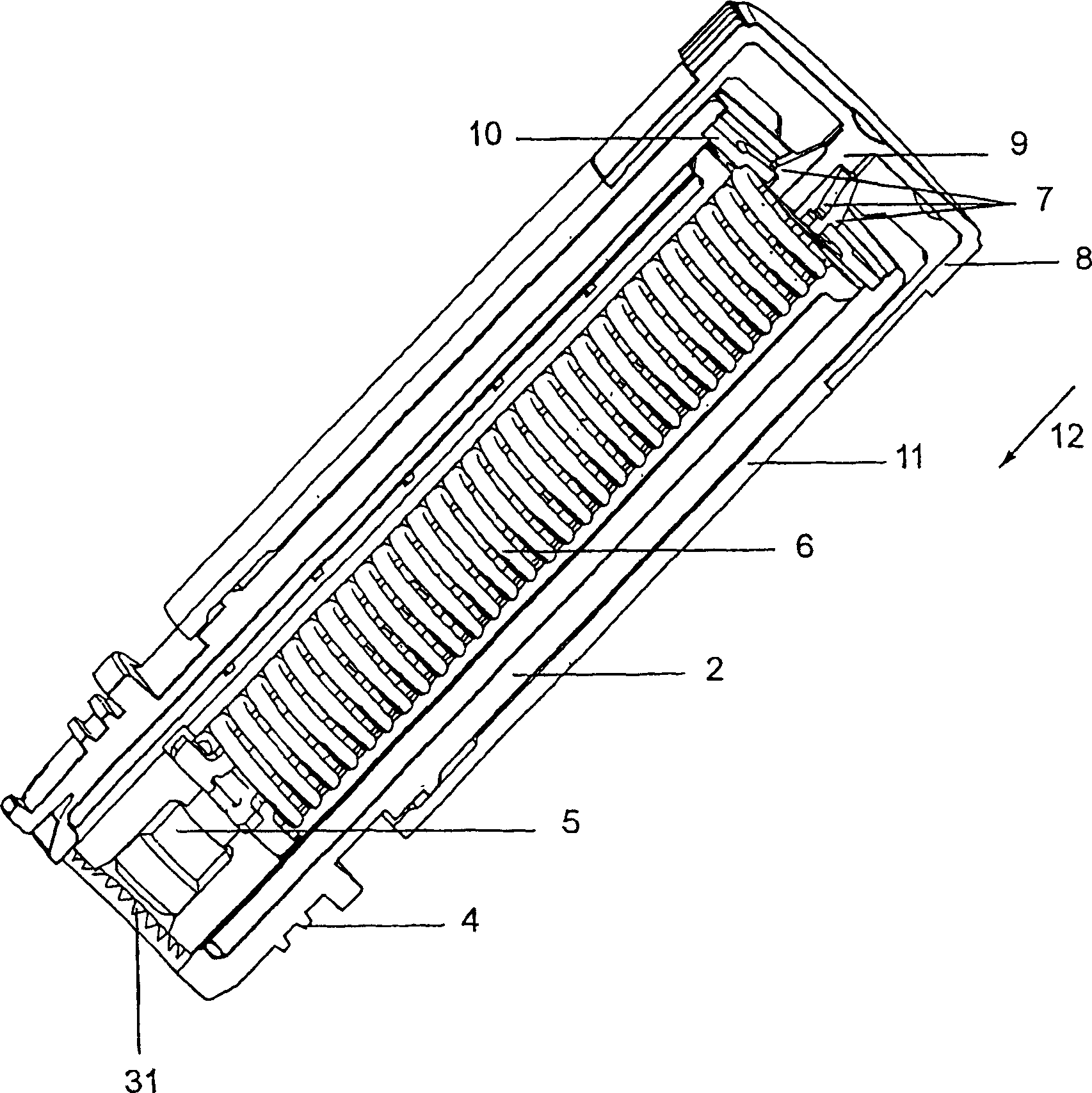

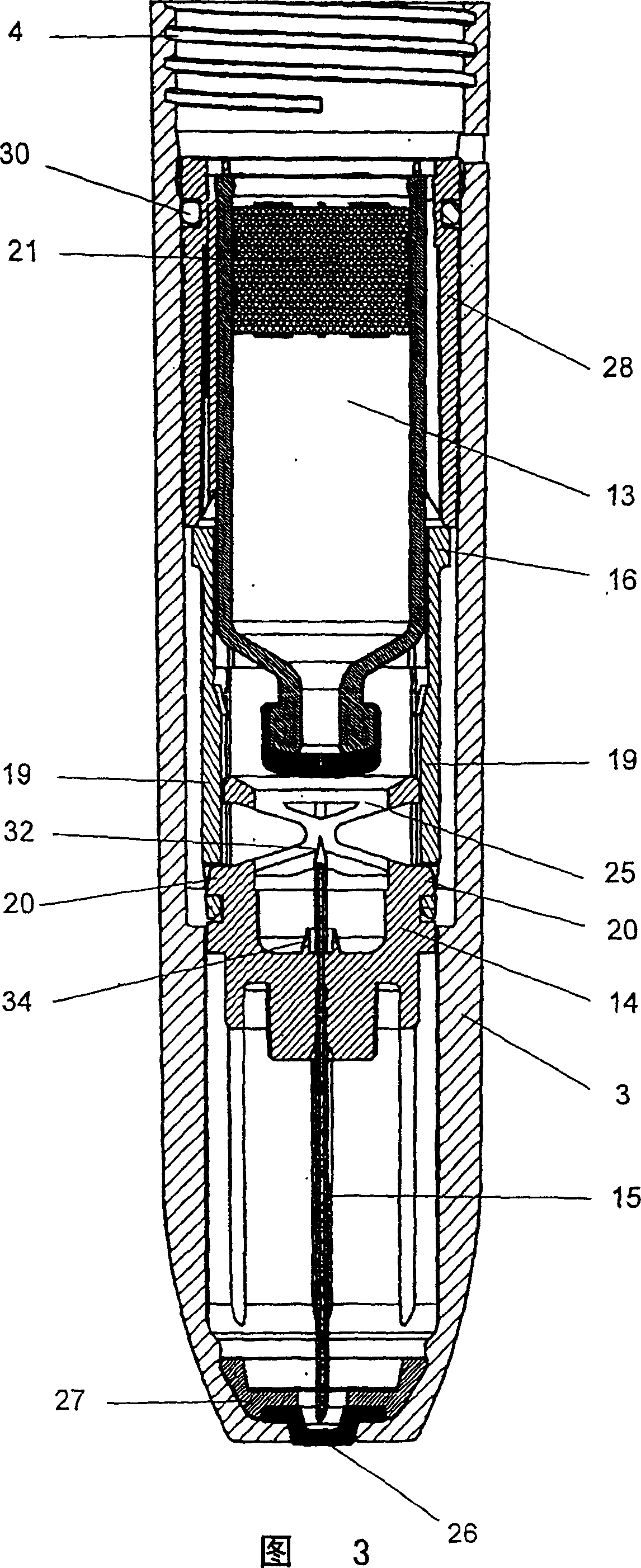

Device for injecting apportioned doses of liquid drug

InactiveCN101912650APrevent axial movementAmpoule syringesAutomatic syringesInjection equipmentDrug doses

A mechanical injection device (1) for injecting apportioned doses of liquid drug. The injection device (1) comprises a dose setting means, an injection means, a removable cap (15) and a cap receiving part (9) adapted to abut or engage with the cap (15) when the cap (15) is mounted on the injection device (1). The dose setting means is operatively coupled to the cap receiving part (9) in such a manner that mounting and / or dismounting of the cap (15) on / from the injection device (1) causes the dose setting means to set a dose. Thereby a correct dose of drug is automatically set during a cap on / cap off cycle. Since such a cycle is normally performed between two subsequent injections, the number of steps required to be performed by the user is reduced.

Owner:NOVO NORDISK AS

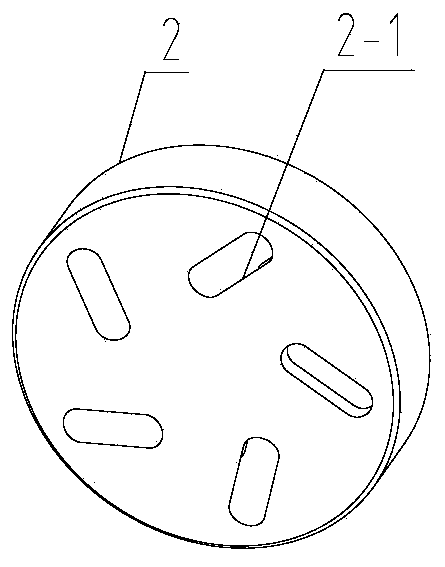

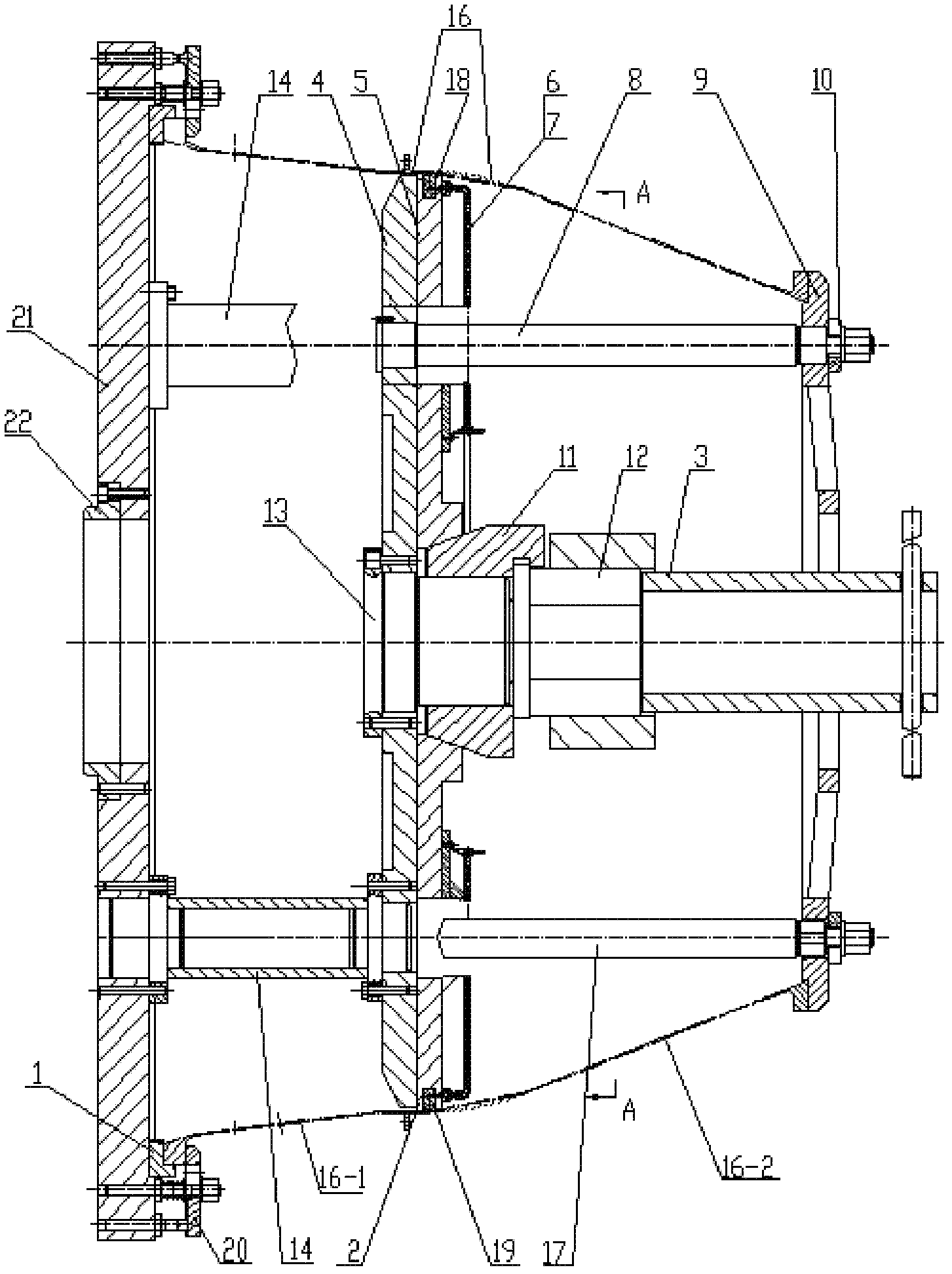

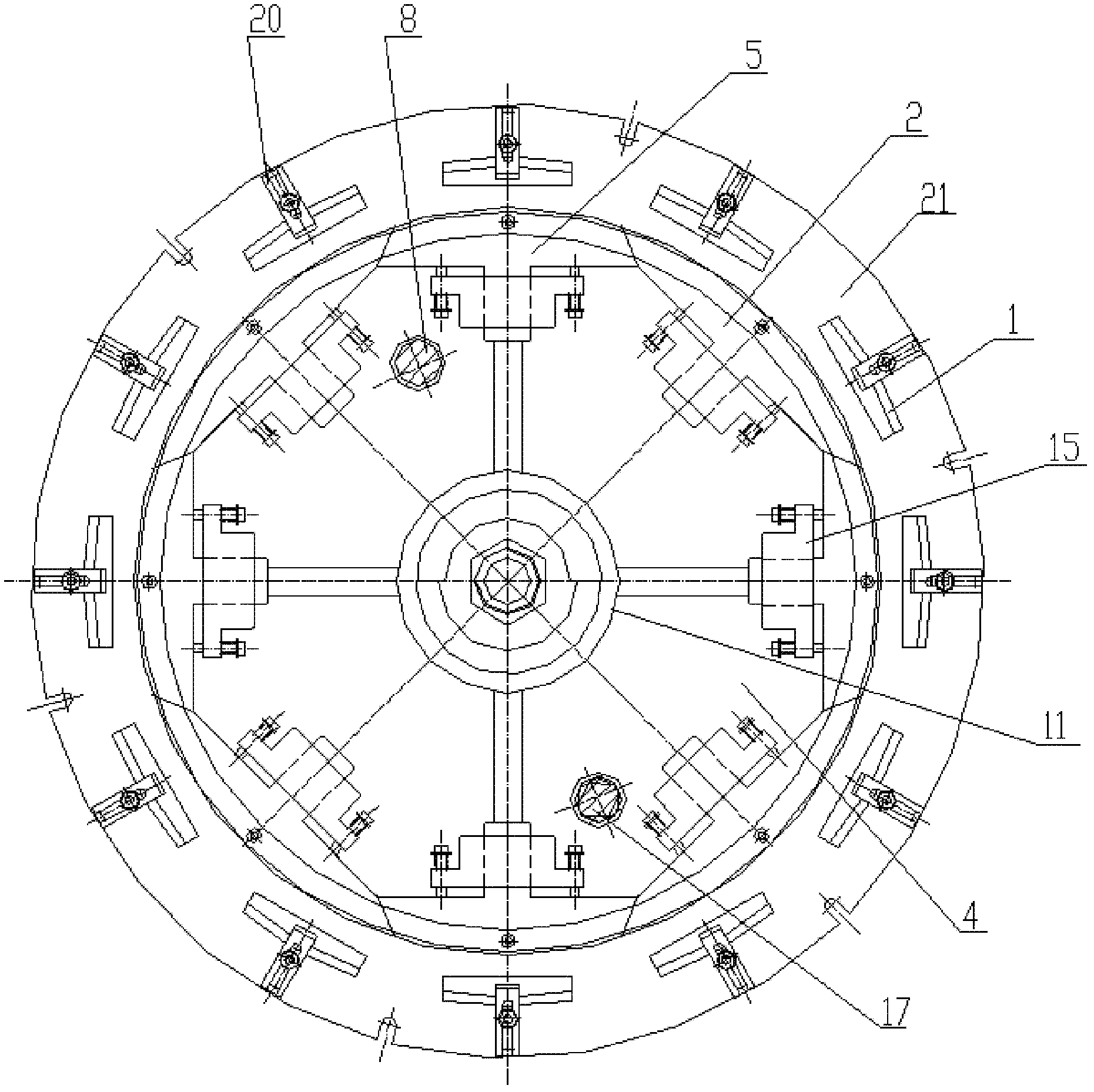

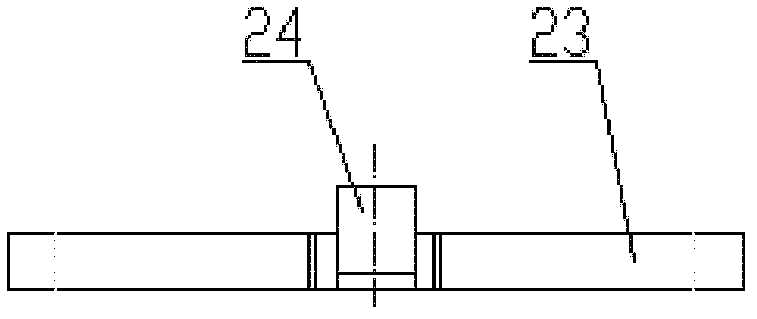

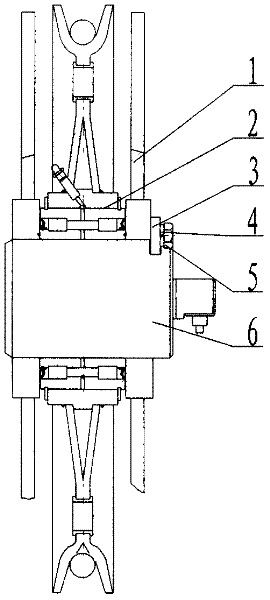

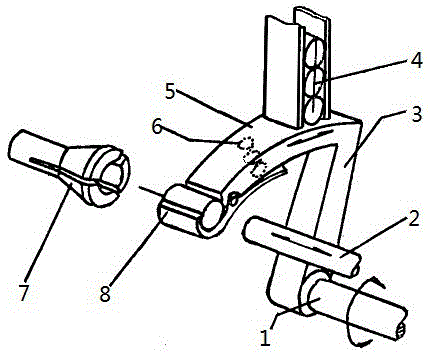

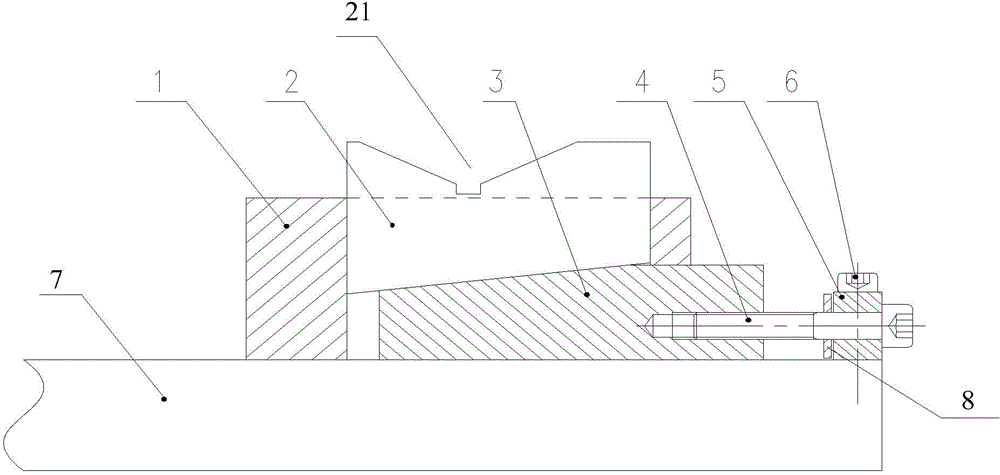

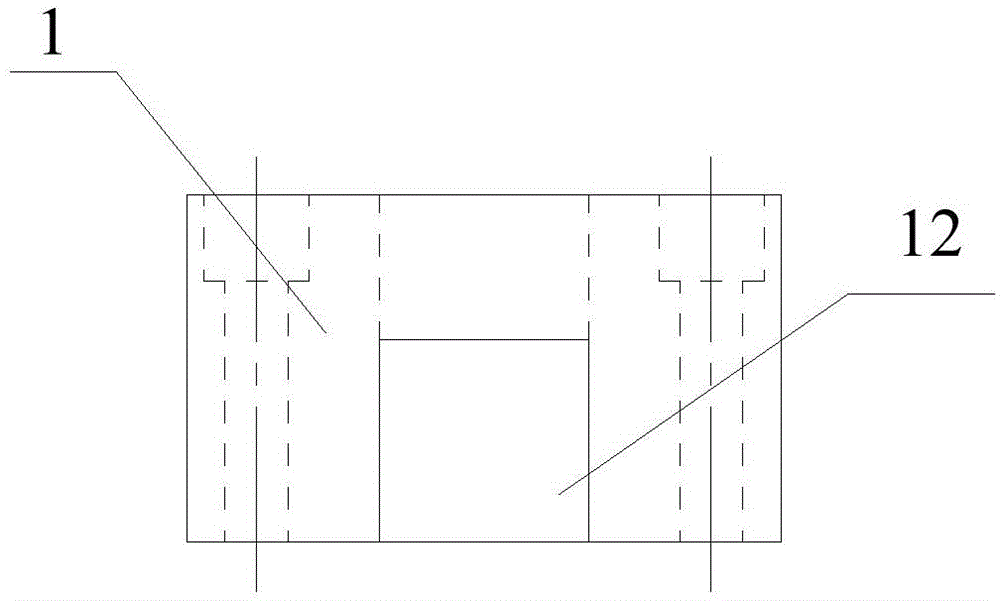

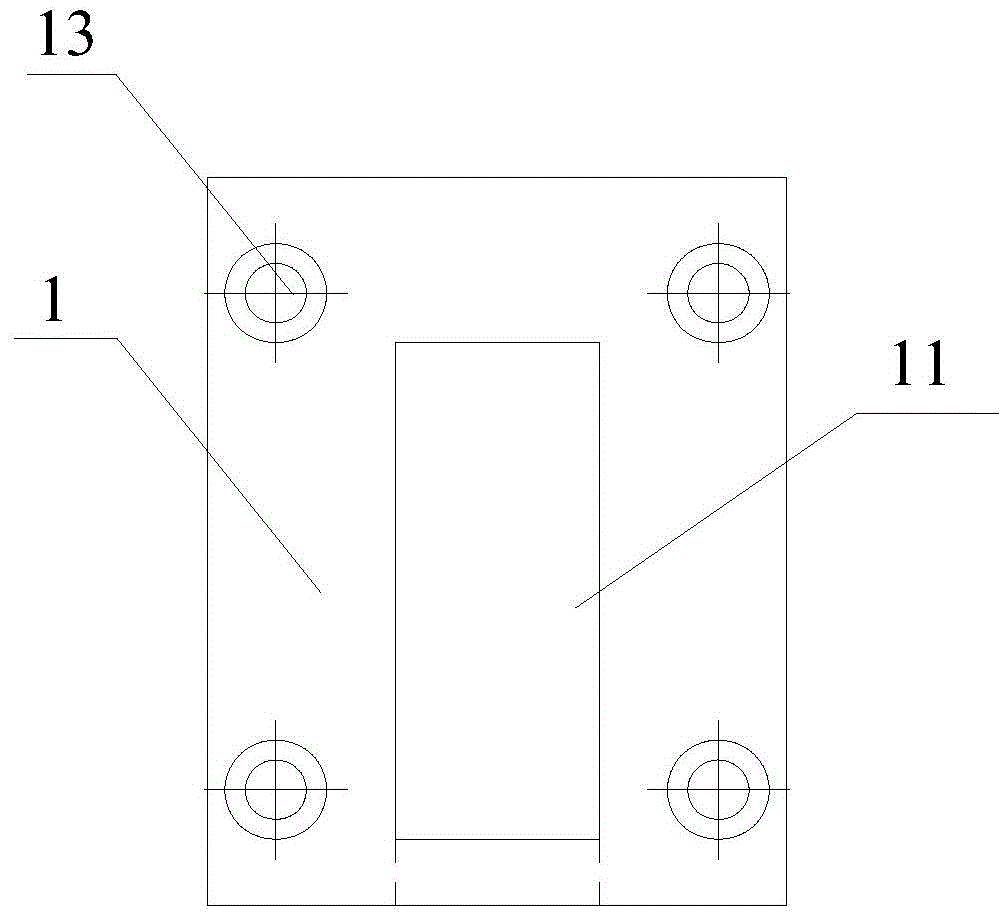

Welding fixture for thin-wall part

ActiveCN102248269AGuaranteed adjustabilityPrecise positioningWelding accessoriesEngineeringThin walled

The invention relates to a welding fixture for a thin-wall part. In the welding fixture for the thin-wall part, a pedestal is connected with a supporting plate through a connecting shaft; a pressing plate is used for fixing the welded part; a mandrel is fixed in a central hole of the pedestal; the number of positioning blocks is at least four; each positioning block is arranged on the same circumference of the pedestal; the number of pressing blocks is as same as that of the positioning blocks; the pressing blocks are used for fixing the welded part; one end of a positioning shaft is fixed inthe central hole of the supporting plate; a wedge block is arranged on the positioning shaft; a dowel nut is arranged at the thread section of the positioning shaft and is connected with the wedge block; the number of driving parts is at least three; the number of driven parts is as same as that of the driving parts; the number of guide parts is equal to the sum of the number of the driving partsand the driven parts; each driving part and each driven part are placed on the supporting plate along the circumference of the supporting plate at intervals; each guide part corresponding to one driving part or one driven part is fixed on the supporting plate; a first insert is arranged on one driving part; a second insert is arranged on one driven part; and an air tap jack and a vent hole communicated with the air tap jack are formed on each insert.

Owner:SICHUAN FST MACHINING MFG

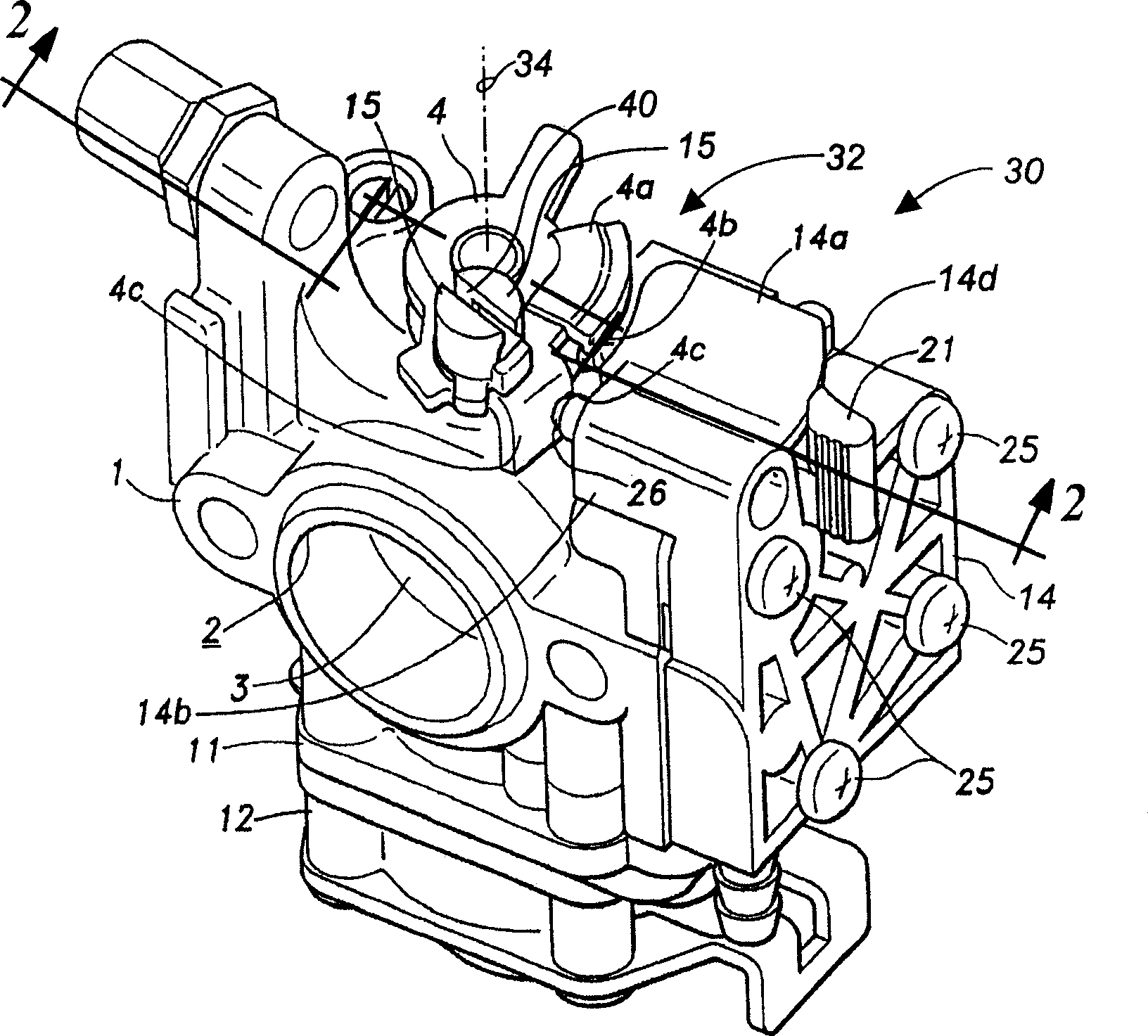

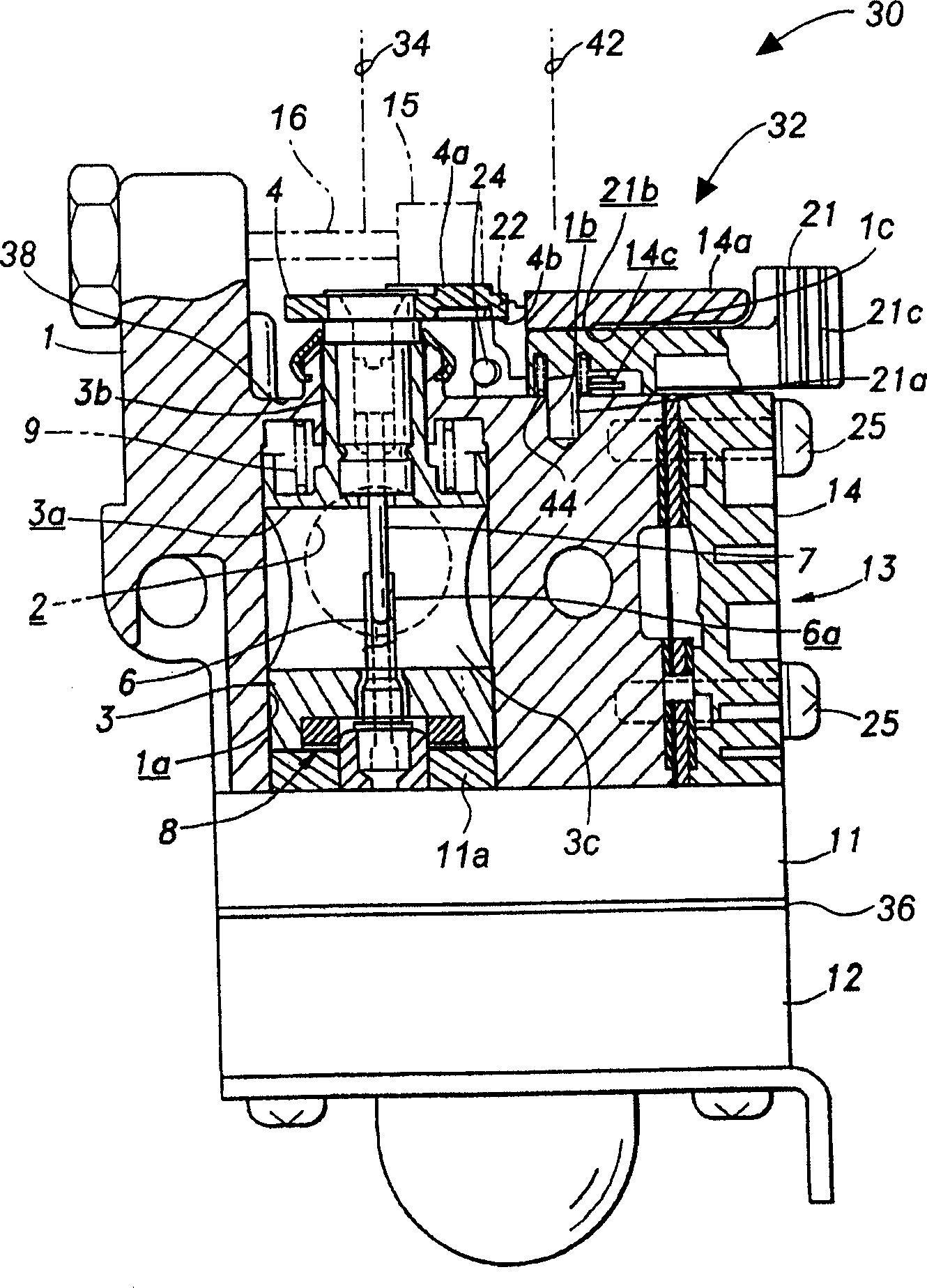

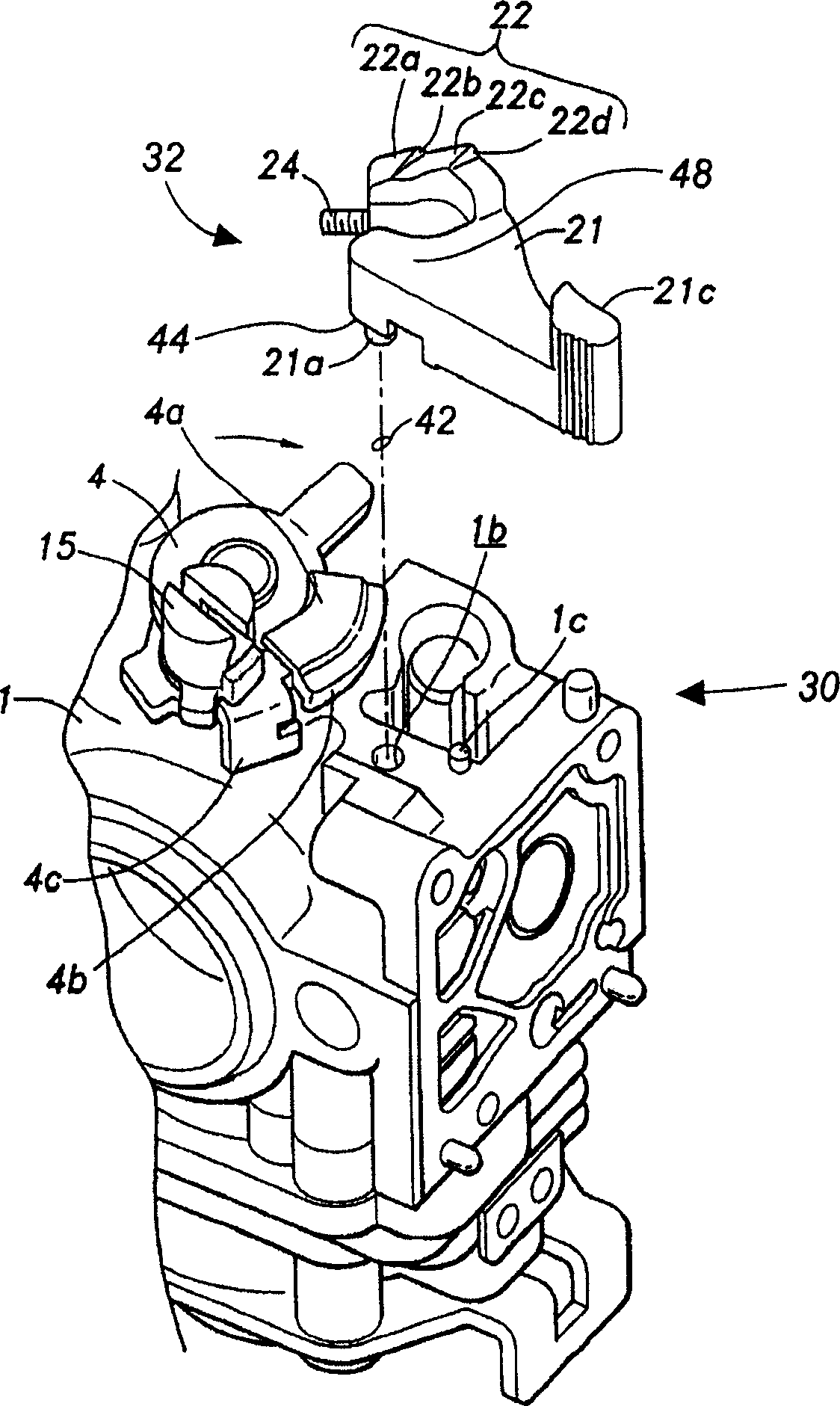

Engine start device of a rotary valve carburetor

InactiveCN1869425AIncrease concentrationPrevent axial movementMachines/enginesCarburettorsCombustionRotary valve

A compact engine start device of a combustion engine rotary-type carburetor overrides normal operation of a rotary throttle valve to provide a richer mixture of fuel-and-air to start a cold engine. Rotation of a start lever of the start device activates a releasable camming interface coupler causing the throttle lever to rotate about a rotary axis and axially lift partially out of the carburetor at prescribed angular and axial distances. This provides the engine, through a fuel-and-air mixing passage, with a controlled and enriched ratio and volume of a fuel-and-air mixture. Preferably, the start lever has a projecting rod that inserts into a hole in the carburetor body for rotation about an axis orientated substantially parallel to the rotary axis. An outward surface of the start lever is in rotational sliding contact with a low-profile, preferably cantilevered, retention arm preferably formed unitarily to a metering fuel pump cover engaged removably to the body of the carburetor, thus allowing rotational movement but preventing axial movement of the start lever. Because the start lever does not move axially to displace the rotary throttle valve, the height of the start lever is favorably minimized. Moreover, the start lever preferably has a knob for user interface at a distal end of the lever that conforms generally about the retention arm thus maximizing knob size yet not contributing to an increase in carburetor size.

Owner:WALBRO ENGINE MANAGEMENT

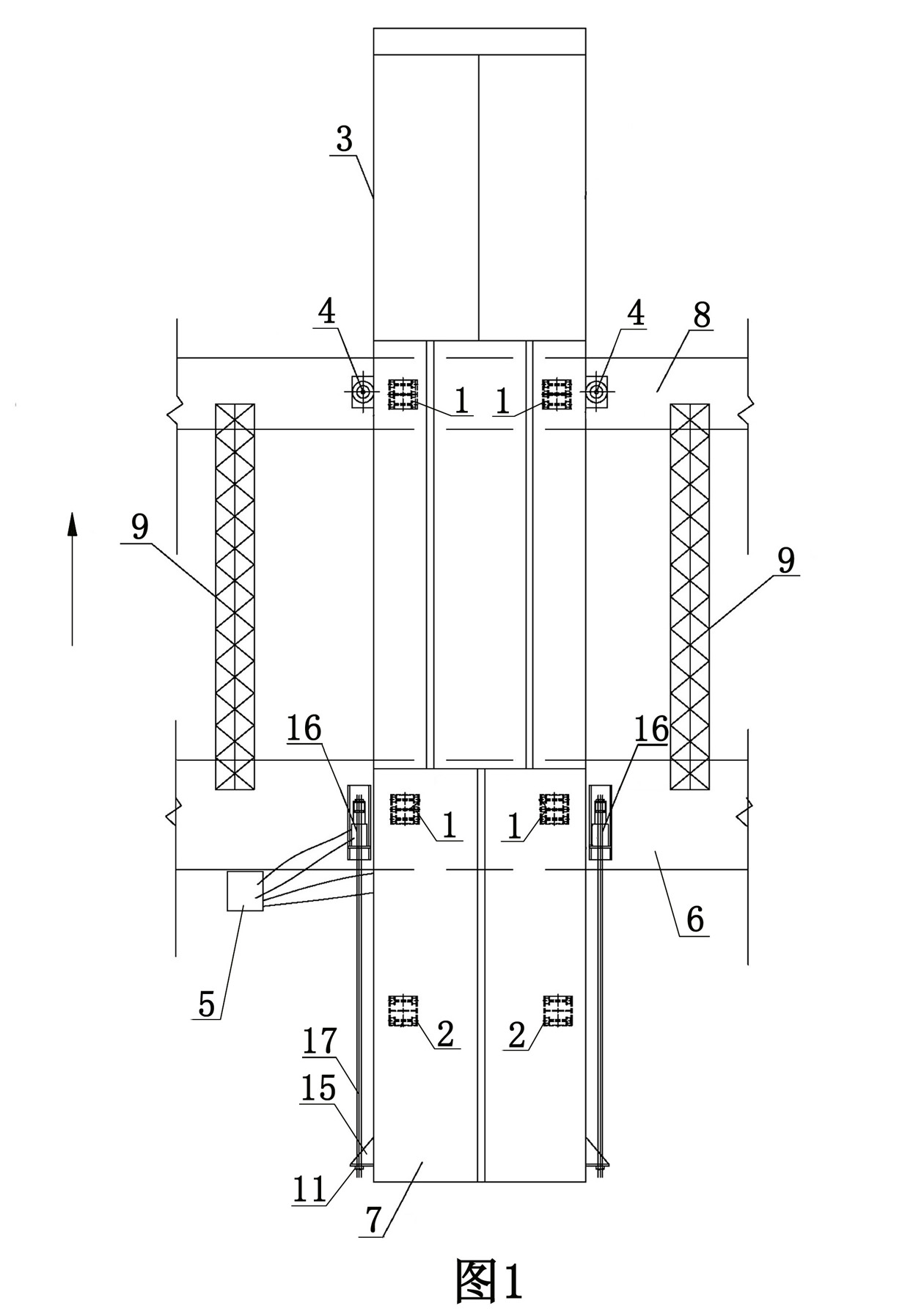

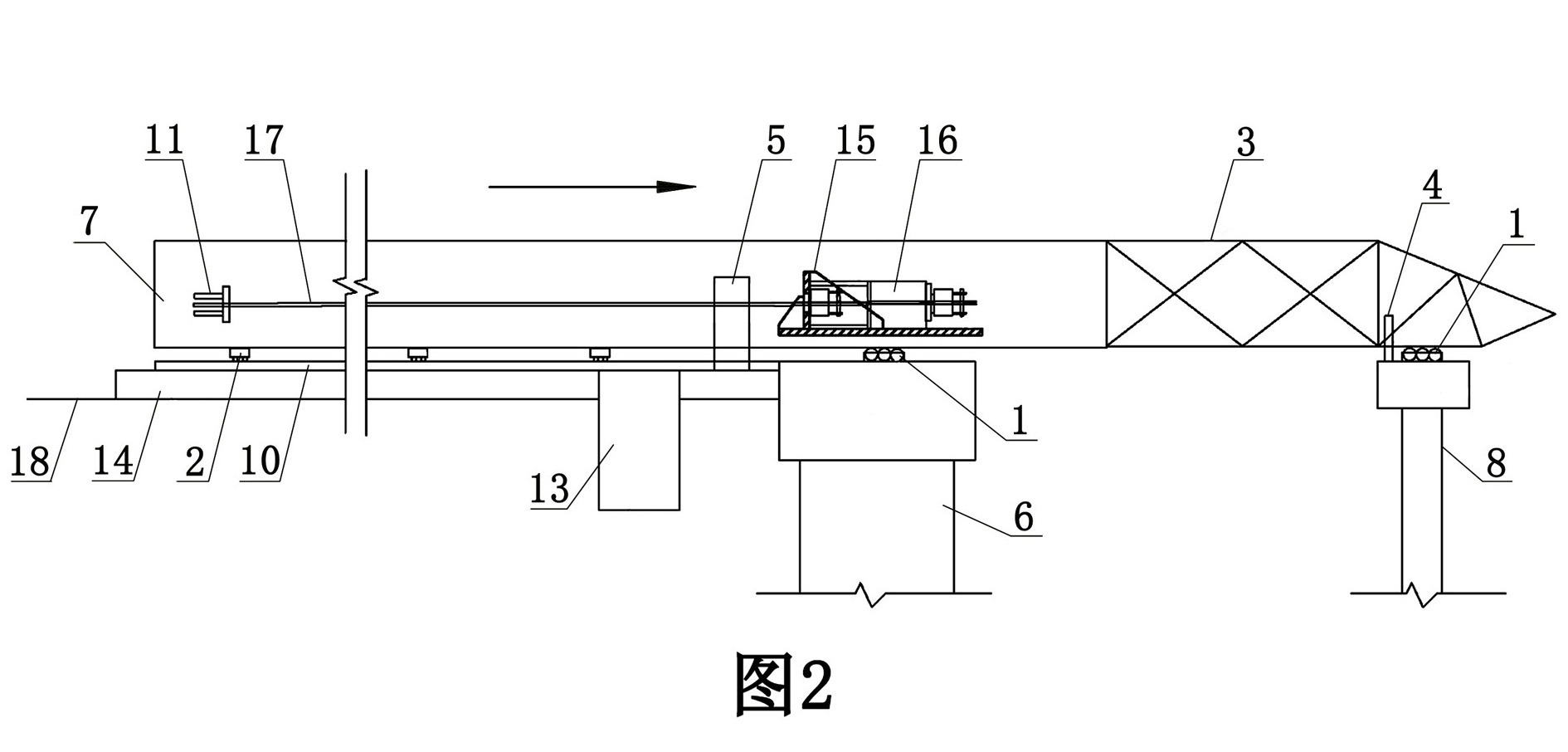

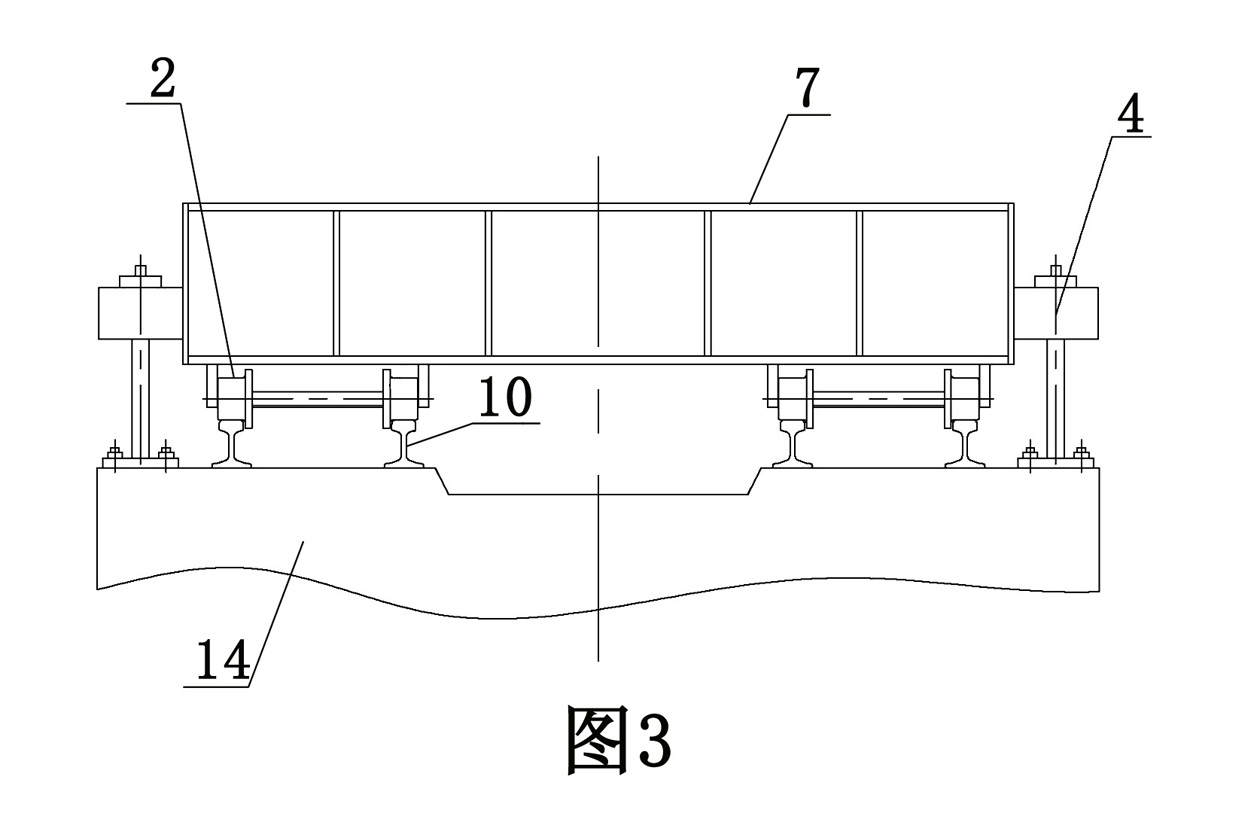

Device for performing incremental launching construction on bridge by using multi-roller sliding ways and construction method thereof

ActiveCN101818481AMeet the needs of climbingReduced longitudinal stiffness requirementsBridge erection/assemblyEngineeringSteel box girder

The invention discloses a device for performing incremental launching construction on a bridge by using multi-roller sliding ways and a construction method thereof. The device comprises a drawing part and a sliding part, wherein the drawing part comprises jack reaction supports, centre hole jacks, steel stranded wires, fixed end clampers, steel box girder reaction seats and an oil pump; the jack reaction supports are fixed on two sides at a predetermined position of a steel box girder of a structural pier; the centre hole jacks are arranged on the jack reaction supports; one end of each steel stranded wire is fixed with corresponding centre hole jack, while the other end is fixed on the corresponding steel box girder reaction seat through the corresponding fixed end clamper; and the sliding part comprises the multi-roller sliding ways fixed on the structural pier and a temporary pier in pairs, and further comprises a railway foundation and a steel guide way which are paved on a platform foundation, and a girder-transporting track run on the steel guide way. The device utilizes the mechanical characteristics of a roller structure so as to reduce requirements on the longitudinal rigidity of the temporary pier, satisfying needs on the climbing of vertical curves in the incremental launching process and greatly accelerating the incremental launching construction process.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP +1

Device for automatically injecting liquids to be injected

ActiveCN1874810APrevent axial movementWon't let goAmpoule syringesAutomatic syringesAxial displacementEngineering

The invention relates to an automatic injection device (1) comprising a housing that is sub-divided in the axial direction, the parts of said housing being interconnectable. An axially displaceable stud (5) is guided in a first part (2) of the housing, and an injection canula (15) blocked in a canula guiding mechanism (14) is mounted, with an ampule (13), in the second part (3) of the housing in such a way that they can be displaced in relation to each other. According to the invention, the injection canula (15) is embodied as a puncturing part (32) for the ampule (13), on the side thereof facing the ampule (13), and the end of the ampule (13) facing the injection canula (15) is plunged into a sleeve (16) blocked in the second part (3) of the housing, the inner diameter of the sleeve essentially corresponding to the outer diameter of the ampule (13). Radially inwardly protruding projections (17) are formed on the inner circumference of the sleeve (16), and the sleeve (16) comprises locking elements which co-operate with locking elements (20) of the canula guiding mechanism (14). An axial displacement of the ampule (13) in the direction of the canula guiding mechanism (14), overcoming the displacement resistance exerted by the projections (17), causes the release of the locking elements (20) and the axial displaceability of the canula guiding mechanism (14).

Owner:药品咨询有限责任两合公司

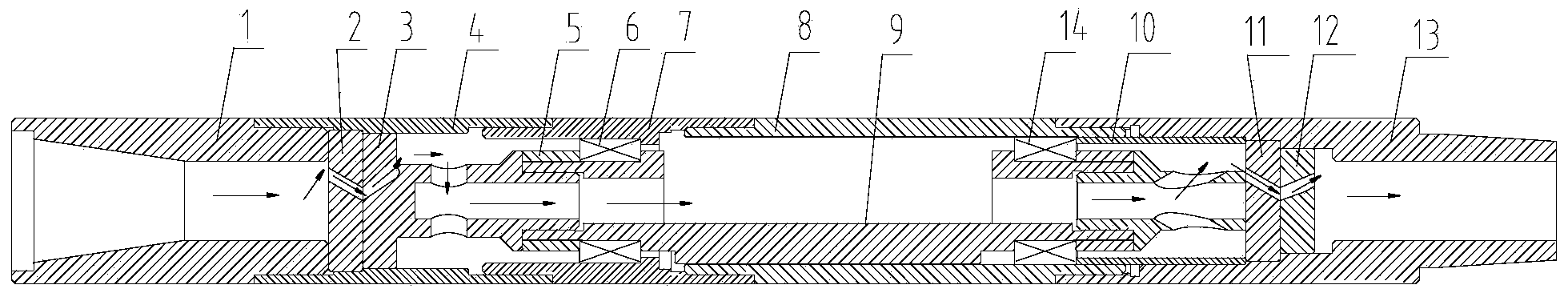

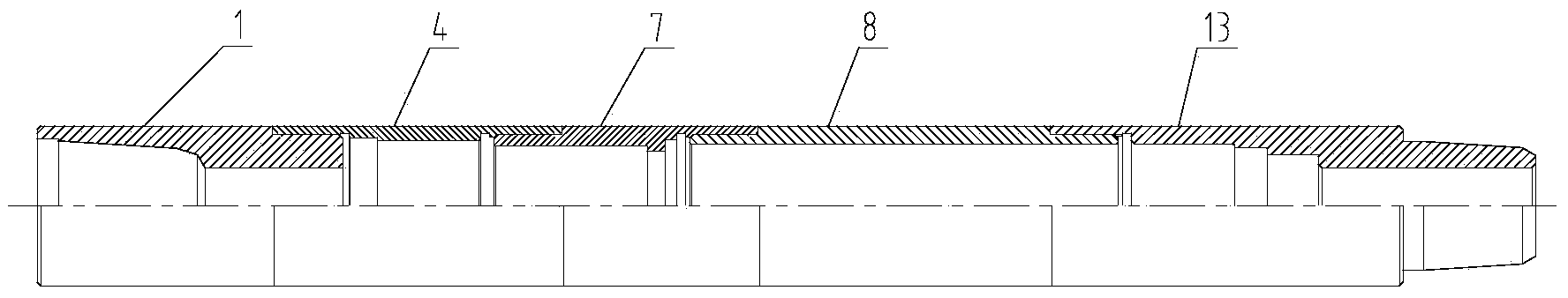

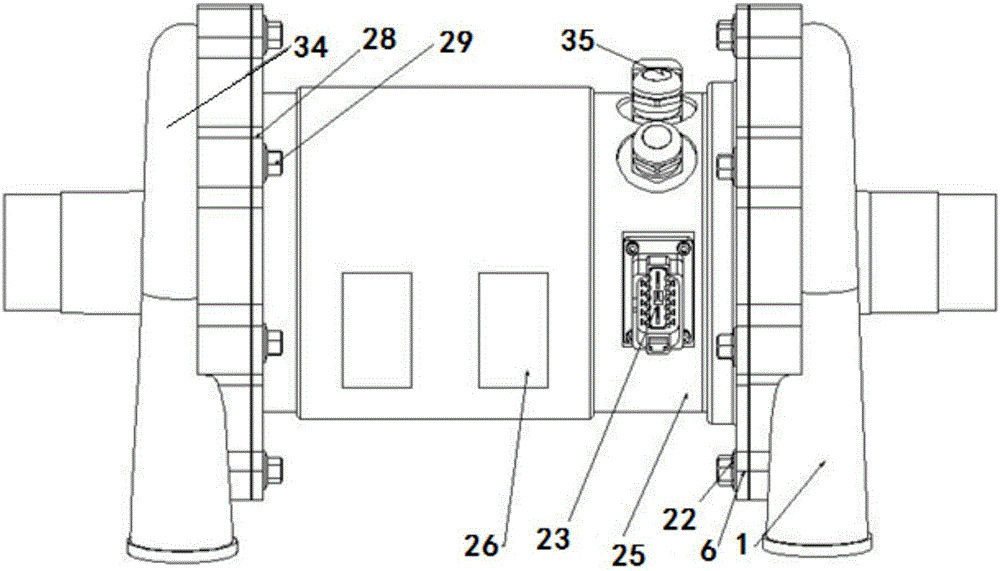

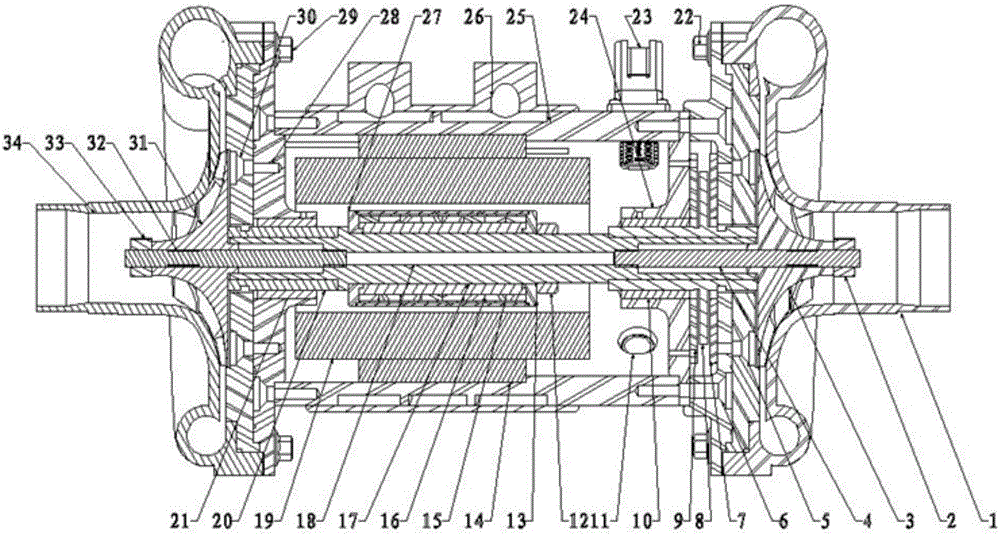

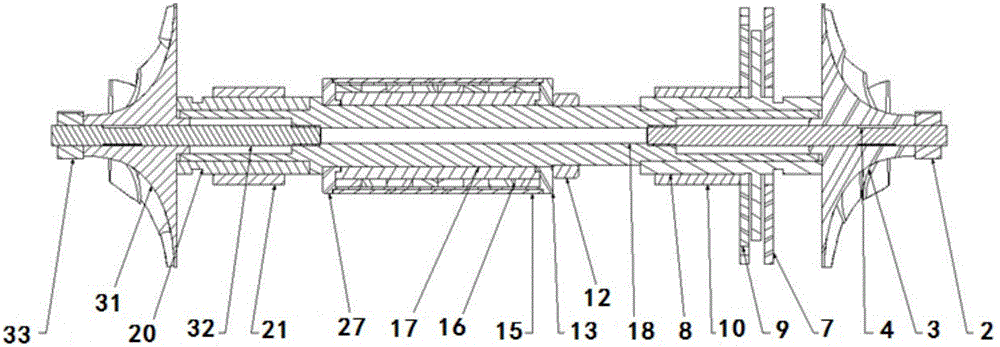

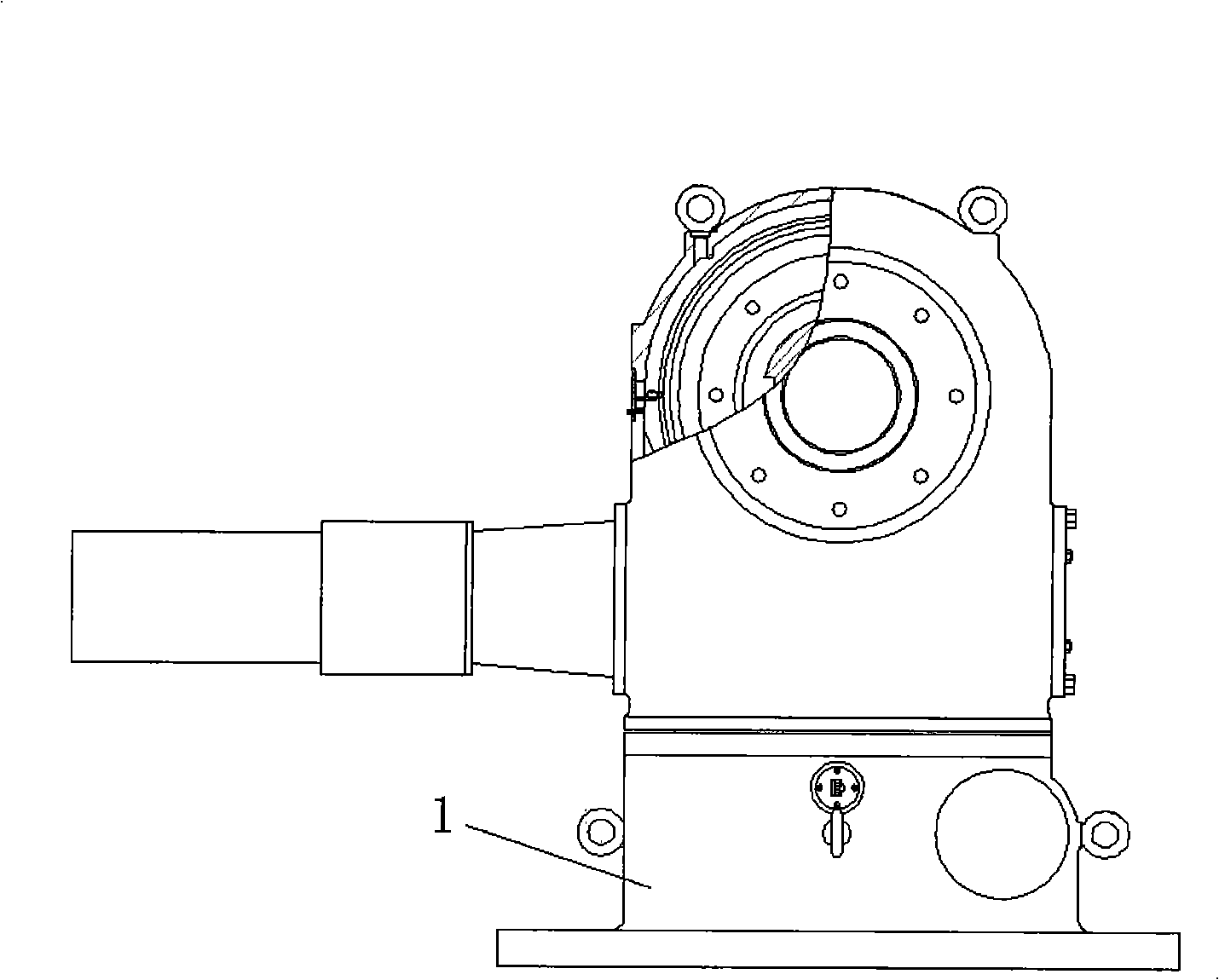

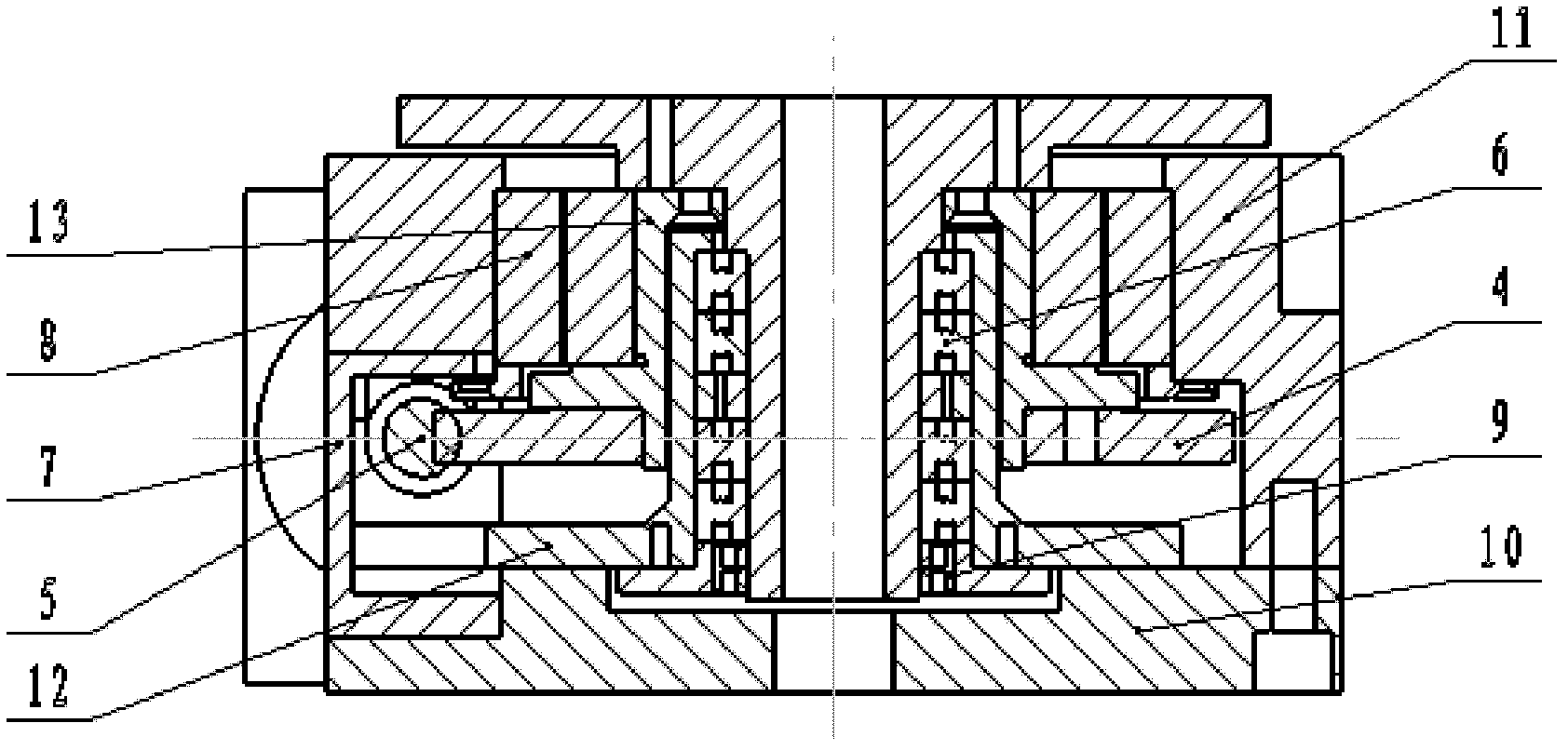

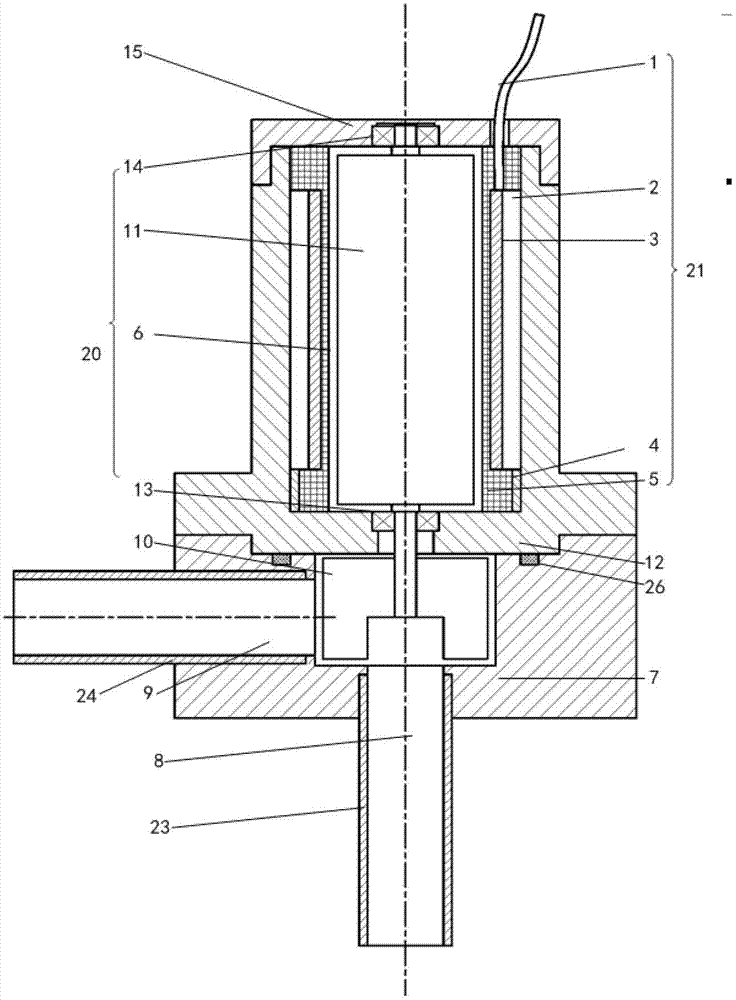

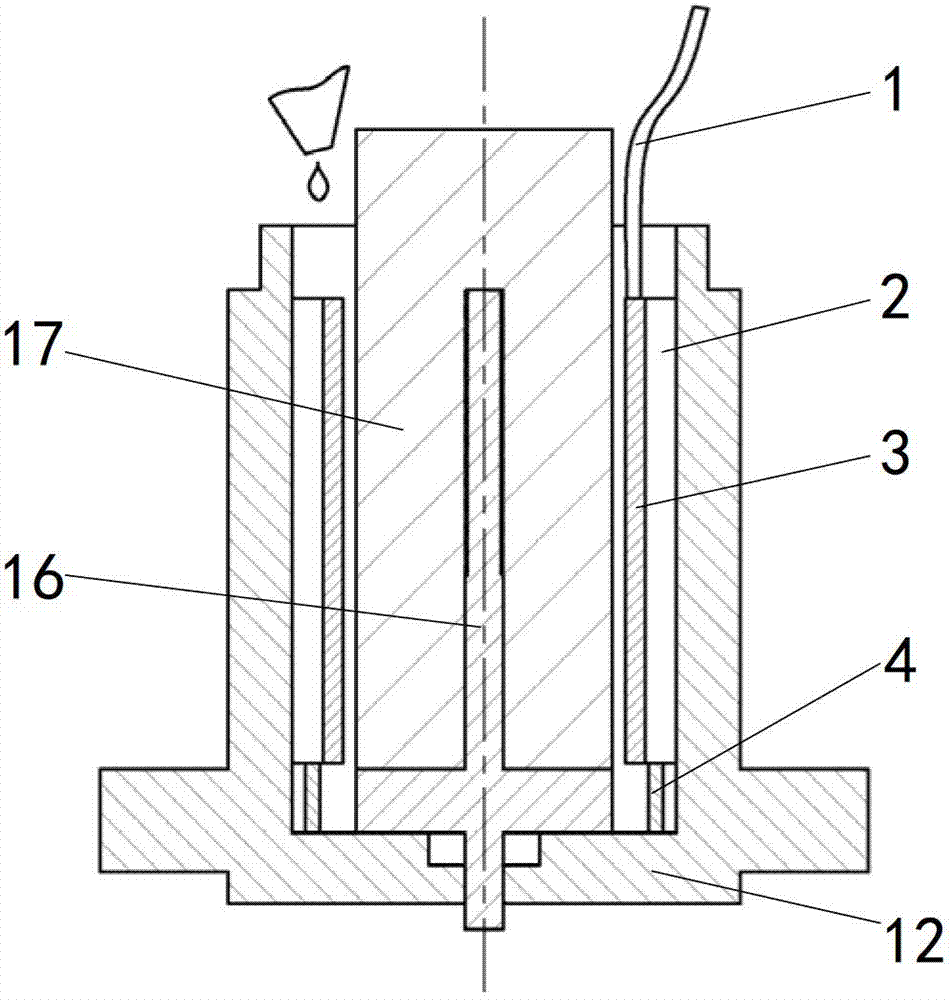

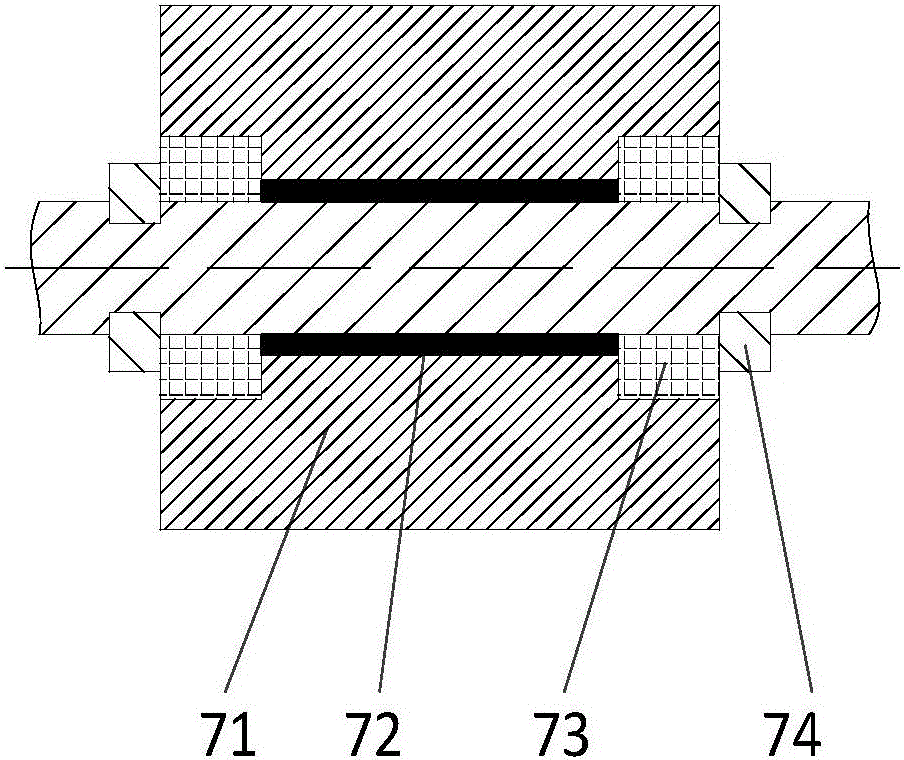

Two-stage series pressurization direct-driven centrifugal air compressor of fuel cell engine

ActiveCN105889096AImprove reliabilityReduce volumeMagnetic circuit rotating partsPump componentsImpellerStator

The invention relates to a two-stage series pressurization direct-driven centrifugal air compressor of a fuel cell engine. The two-stage series pressurization direct-driven centrifugal air compressor comprises end covers, a spindle, volutes, impellers, a rotor, a stator and a driver. The spindle is supported by a left-end radial supporting air foil bearing, a left-end radial supporting air foil bearing bush, an air foil axial thrust bearing and a right-end radial supporting air foil bearing, wherein the left-end radial supporting air foil bearing and the left-end radial supporting air foil bearing bush are arranged on the left side, and the air foil axial thrust bearing and the right-end radial supporting air foil bearing are arranged on the right side of the spindle. The left-end radial supporting air foil bearing bush is arranged on the outer side of the spindle in a surrounding manner. The left-end radial supporting air foil bearing is fixed to the outer side of the left-end radial supporting air foil bearing bush. The air foil axial thrust bearing is fixed to the outer side of the spindle in a bush form. The right-end radial supporting air foil bearing is fixed to the outer side of the air foil axial thrust bearing. Compared with the prior art, the two-stage series pressurization direct-driven centrifugal air compressor is more suitable for the air inlet pressurization scene of the fuel cell engine with the high oilless air inlet requirement, and the durability and reliability of the air compressor of the fuel cell engine can be improved.

Owner:TONGJI UNIV

Gearbox and turbine engine with geared fan

A gearbox (10) includes: a carrier (16) having a central axis and forward and aft walls with respective forward an aft coaxial bores; a pin received in the bores, and secured against axial movement; an inner race mounted on the pin between the forward and aft ends, and secured against axial movement relative to the carrier (16); a planet gear mounted for rotation about the pin, wherein a cylindrical interior surface of the planet gear defines an outer race surrounding the rollers, wherein either the inner race or the interior surface of the planet gear defines at least two axially-spaced apart annular raceways; a plurality of generally cylindrical rollers made of a ceramic material disposed in each of the raceways, between the inner and outer races; a sun gear mounted for rotation about the central axis and engaged with the planet gear; and a ring gear engaged with the planet gear.

Owner:GENERAL ELECTRIC CO

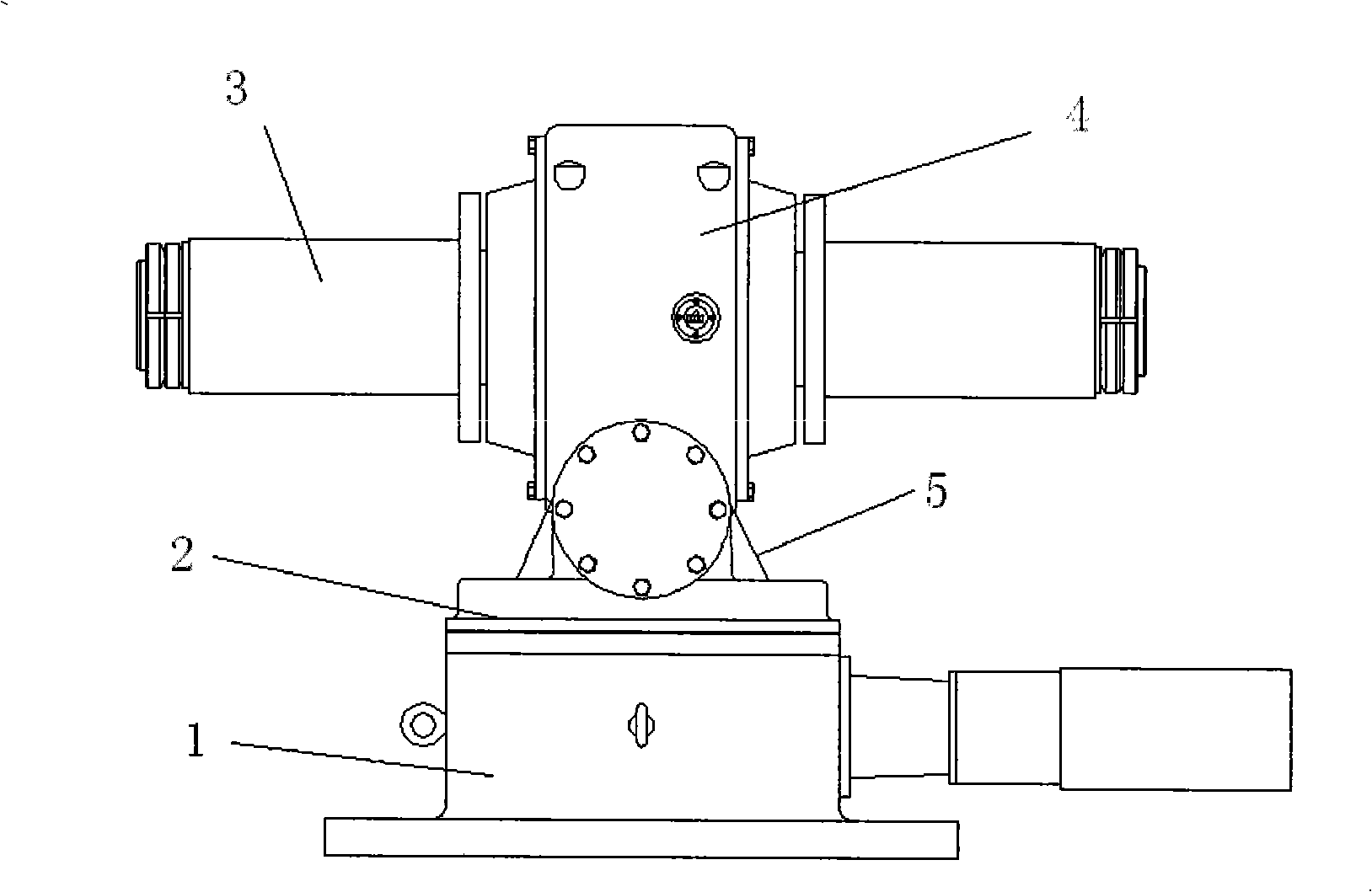

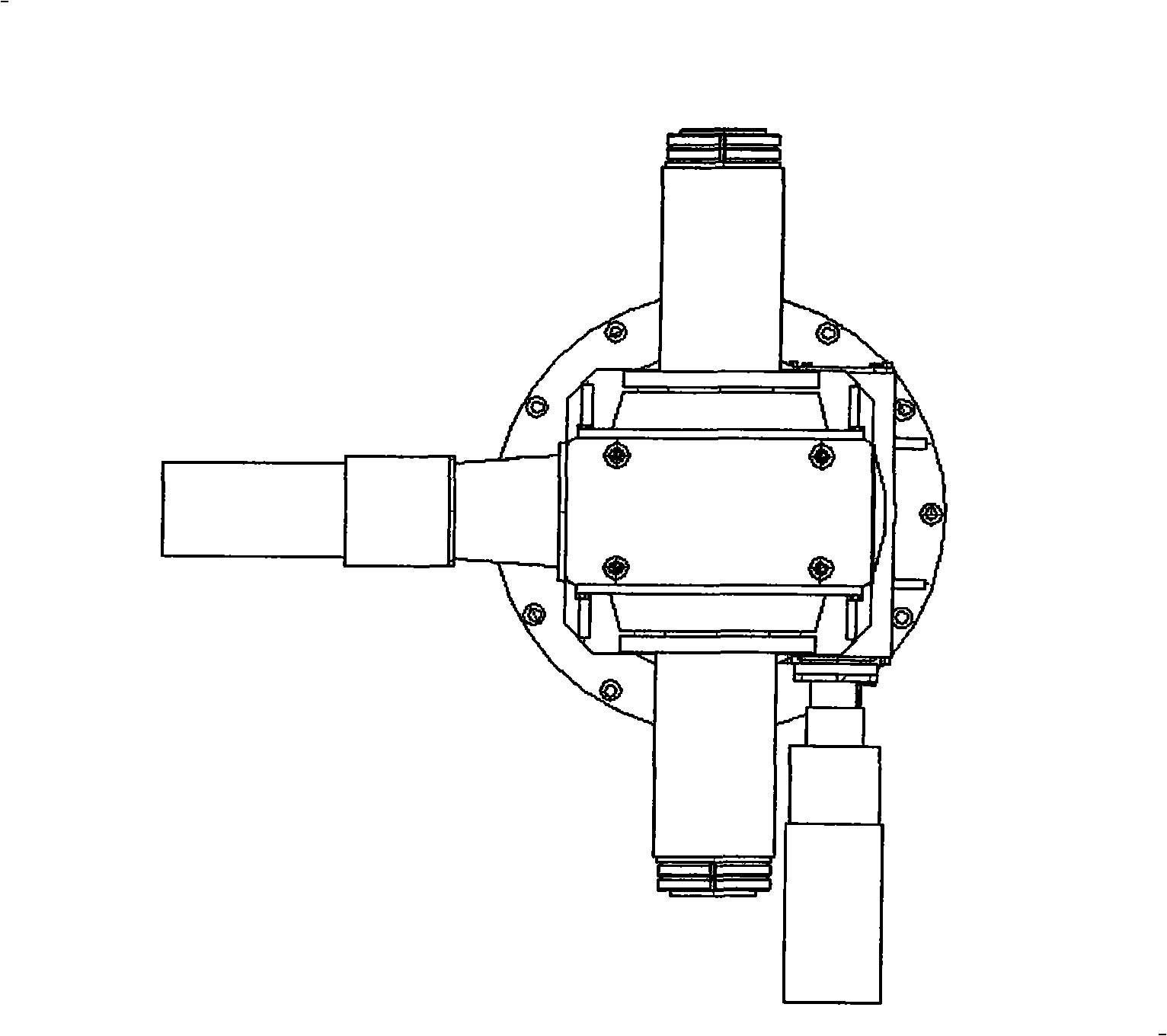

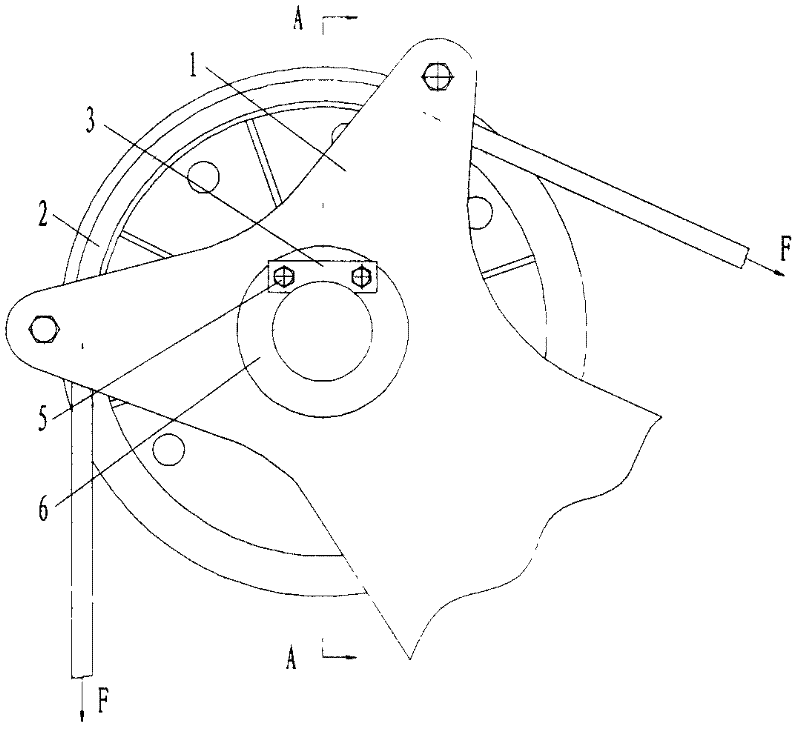

Solar energy heliostat gearing device

InactiveCN101261046APrevent axial movementSufficient horizontal stiffnessSolar heating energySolar heat collector controllersHeliostatScrew thread

The invention relates to a solar heliostat transmission gear, which comprises an upper box body component, a lower box body component and a rotary mechanism which connects the upper box body component and the lower box body component into a whole, wherein, the rotary mechanism comprises a spline groove which is matched and connected with a lower worm wheel shaft in the lower box body component and is arranged in the center of an upper box body bottom surface of the upper box body component, and the lower worm wheel shaft drives the upper box body component to move through the spline groove. Moreover, a gap fine adjustment structure is respectively arranged on both shaft ends of an upper worm wheel shaft in the upper box body component and the lower worm wheel shaft in the lower box body component and comprises an end bearing, a transparent cover and a threaded sleeve, wherein, the end bearing is arranged on the end part of the upper worm wheel shaft or the lower worm wheel shaft; the transparent cover is fixed together with an upper box body or a lower box body, and an inner ring of the transparent cover is provided with threads; and the threaded sleeve is arranged inside the transparent cover and externally provided with threads which are matched with the threads of the inner ring of the transparent cover, and tightly presses on the end bearing. The solar heliostat transmission gear not only has simple transmission form, high transmission efficiency and good maintainability, but also has long service life and low manufacturing and maintenance costs.

Owner:BEIHANG UNIV

Medical line securement device

InactiveUS20070088329A1Prevent axial movementCatheterTube connectorsCATHETER ADAPTERBiomedical engineering

A medical line securement device holds a medical article such as a connector fitting for a catheter or a catheter adaptor in position upon the body of a patient and inhibits axial motion of the medical article. The securement device includes a retainer with a base and a cover. The cover is hinged to the base such that it may be moved between an open and closed position. The base and cover each have a groove which cooperate when the cover is in the closed position to form a channel through the retainer. The medical article includes an elongated body which is received within the groove of the retainer, the elongated body lying between at least a pair of regions of larger radius of the medical article. By receiving the portion of the elongated body of the medical article between the regions of larger radius, axial motion of the medical article through the groove is inhibited. The retainer may also include one or more slots to receive any radial projections of the medical article within the retainer.

Owner:VENETEC INT INC

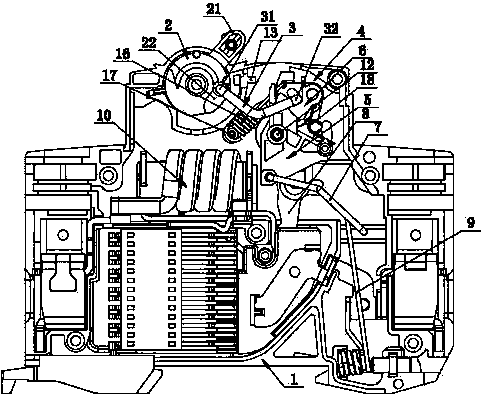

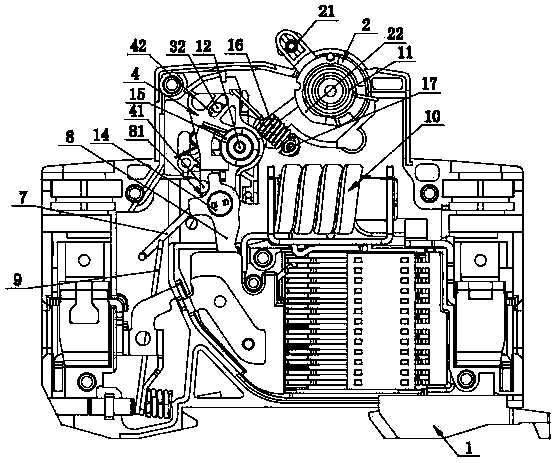

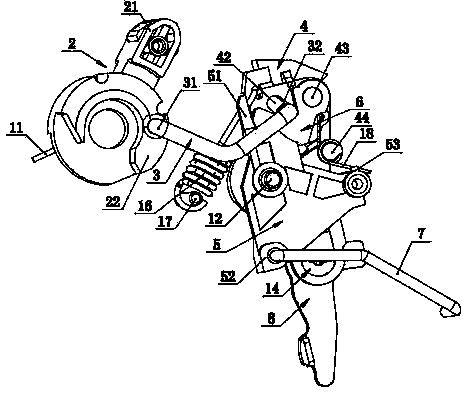

Operation mechanism of small-size breaker

ActiveCN103745892ALinkage guaranteeReduced chance of slippingProtective switch operating/release mechanismsMetal sheetEngineering

The invention discloses an operation mechanism of a small-size breaker. The operation mechanism comprises a shell, a handle, a U-shaped connection rod, a contact support, a jumping pin, a lock catch, a pull rod, a movable contact, a metal sheet and an electromagnetic device; a rotary shaft is inserted in the shell; the middle of the contact support is hinged onto the rotary shaft; a downwards-inclined long slot hole is formed in the upper end of the contact support; one end of the U-shaped connection rod is hinged to and fixed with the inner end of the handle; the other end of the U-shaped connection rod slides in the long slot hole; a V-shaped slot capable of forming touch abutting with the end, sliding in the long slot hole, of the U-shaped connection rod is correspondingly formed in the upper end surface of the lock catch, so the linkage with the lock catch can be realized by the sliding of the U-shaped connection rod in the long slot hole; the end, linked with the lock catch, of the U-shaped connection rod is changed to be the movable end, so the separating probability of the breaker in the fast switching on process is greatly reduced, the switching off action of the breaker is faster and the operation is more stable and more reliable.

Owner:ZHEJIANG CHUANGQI ELECTRICAL CO LTD

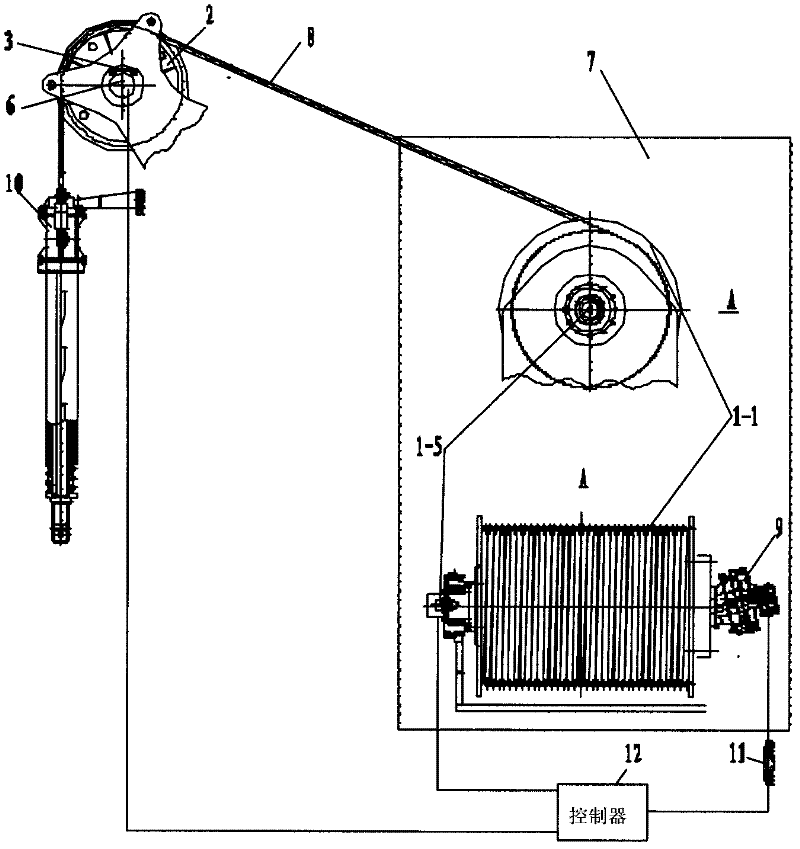

Rod carrying monitoring system for drill rod of rotary drilling machine

InactiveCN102359366AEffective monitoringTroubleshoot severe damageAutomatic control for drillingSolenoid valveMonitoring system

The invention relates to a rod carrying monitoring system for a drill rod of a rotary drilling machine, belonging to monitoring systems of engineering machinery. The monitoring system comprises a pin shaft sensor, a sounding coder, a controller, a pilot solenoid valve and a main winding system, wherein the pin shaft sensor is connected to the center of the main winding pulley, the sounding coder is connected with a rotating shaft at one side of a main winding drum, the output ends of the pin shaft sensor and the sounding coder are both connected with the input end of the controller, the output end of the controller is connected with the pilot solenoid valve, the pilot solenoid valve is connected with a main winding motor of the main winding system, the controller is arranged in an electric control box, the pilot solenoid valve is installed on the drilling machine car body, the main winding system and the main winding motor are connected with the winding drum, the main winding drum is connected with the drill rod through a steel wire rope, the steel wire rope pass through a main winding pulley groove, a main winding pulley is installed on a main winding pulley bracket. The rod carrying monitoring system has the advantages of simple structure, capability of effectively monitoring the rod carrying condition of the drill rod and judging whether the rod carrying of the drill rod happens or not without depending on the experience of operators, and good reliability and practical applicability.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

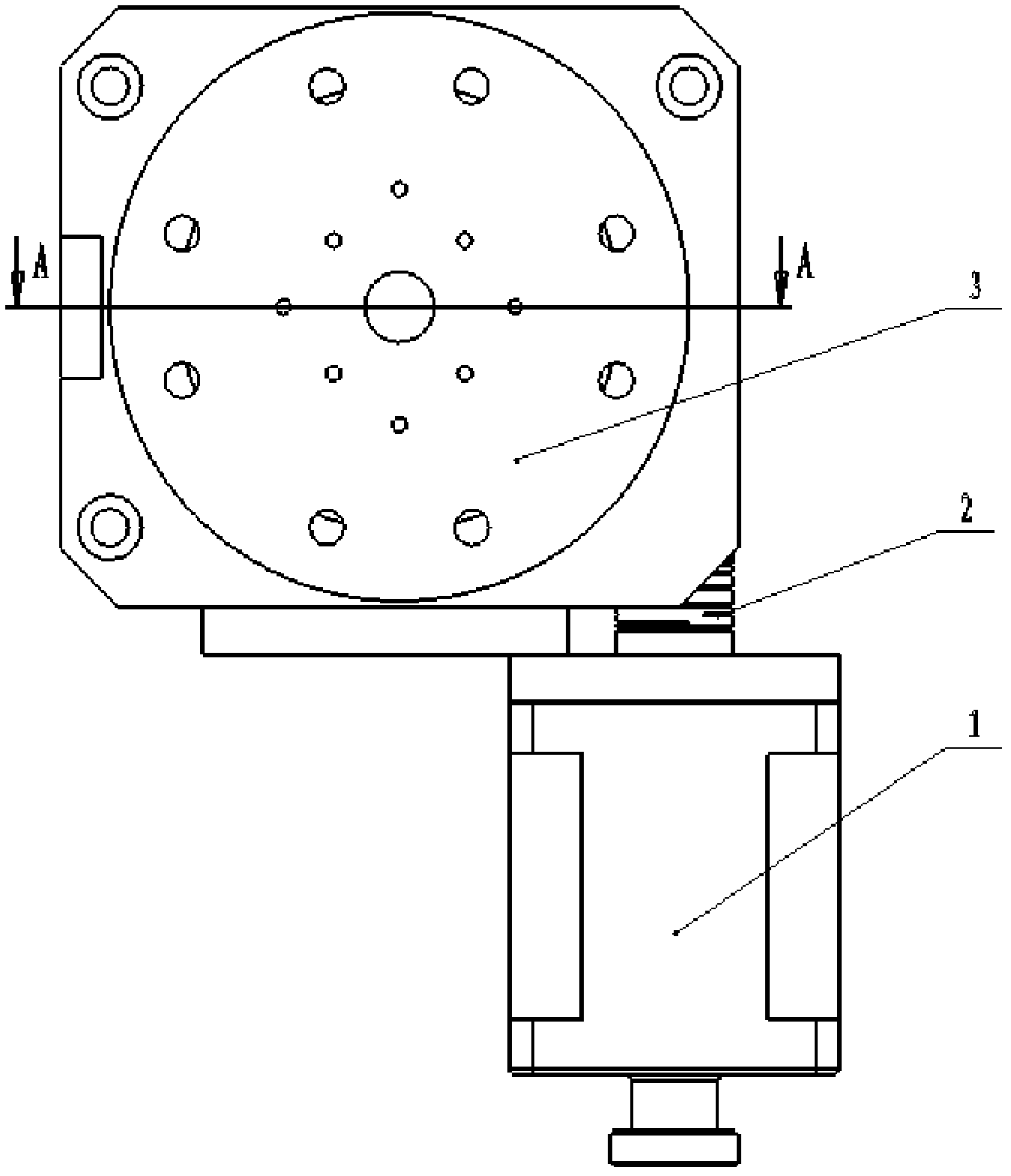

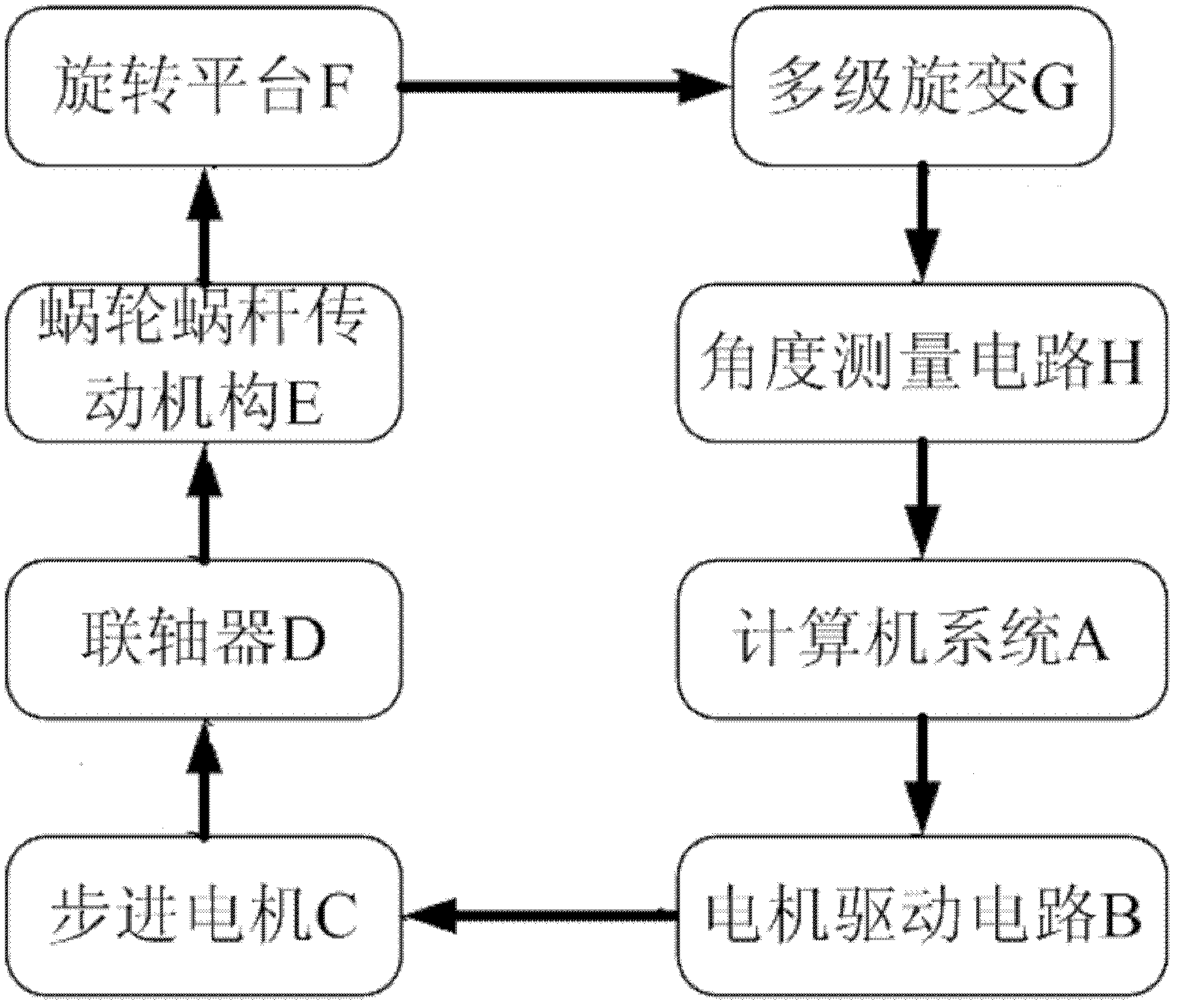

Electric control rotating platform and position measuring method for inertial navigation instrument

InactiveCN102589547AWith transmission self-locking functionRealize precise rotation angle positioningNavigation by speed/acceleration measurementsCouplingEngineering

The invention provides an electric control rotating platform and a position measuring method for an inertial navigation instrument. The lower platform body of the rotating platform is directly connected with a measurement carrier; a support bracket, the outer platform body of the rotating platform and an outer adjusting bracket are fixedly connected to the lower platform body of the rotating platform; the support bracket is contacted with the outer ring of an angular contact bearing for positioning; a hollow shaft is connected with the inner ring of the angular contact bearing; the inner rings of two pairs of angular contact bearings are positioned by two tightening nuts; a positioning bracket is fixedly connected with the hollow shaft and a plurality of stages of spirally variable rotors are positioned at the same time; a plurality of stages of spirally variable stators are fixedly connected with the outer platform body of the rotating platform; a worm wheel is fixedly connected to the positioning bracket; a worm is connected with the outer adjusting bracket through double-end bearing support; and the output shaft of a stepping motor is connected with the input shaft of the worm by a coupling. The electric control rotating platform is small in error and high in precision, provides a solution for the precise rotation and the position measurement of the inertial navigation instrument, and simultaneously provides the guarantee for the accurate and reliable measurement of the inertial navigation instrument.

Owner:HARBIN ENG UNIV

Automatic loading mechanism of pin shaft

The invention discloses an automatic loading mechanism of a pin shaft to solve the problem of low manual loading efficiency in the prior art. The mechanism comprises a swing rod arranged below a bin, wherein an outlet of the bin is arched; the swing rod comprises a first support rod and a second support rod formed to an L shape and integrally molded; the first support rod is driven through power to perform the reciprocating rotation; the upper part of the second support rod is a convex arched slide table; the convex arched slide table and the outlet have the same curvature; the convex arched slide table can slide along the outlet when the first support rod swings; a groove is formed in the end part of the second support rod at the side of the convex arched slide table, and can swing below the outlet; a push rod capable of performing reciprocating linear motion is arranged at one side of the swing rod; the other side of the swing rod is a spring chuck; and the axles of the spring chuck, the groove and the push rod are on one straight line.

Owner:CHONGQING GANGQIAN MACHINERY

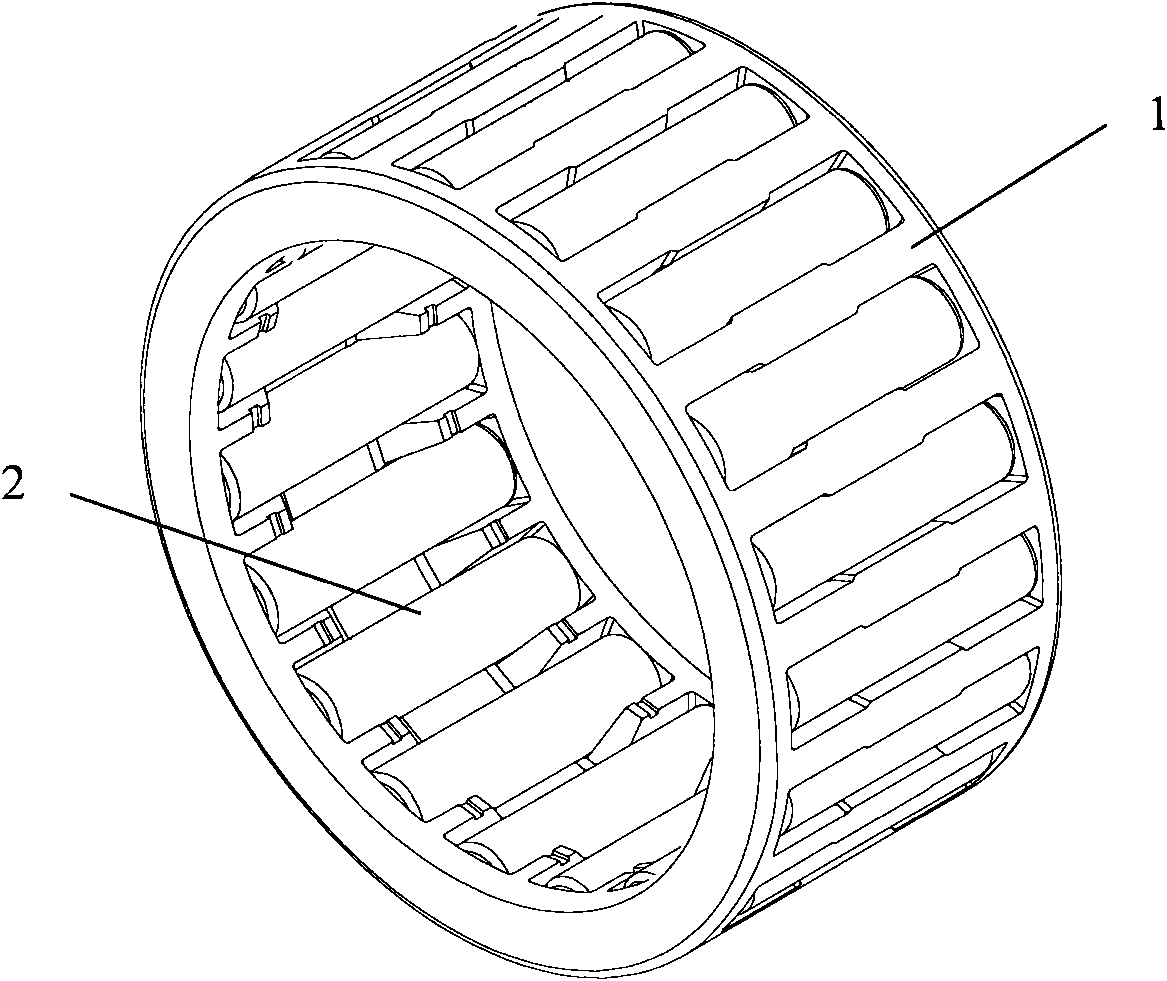

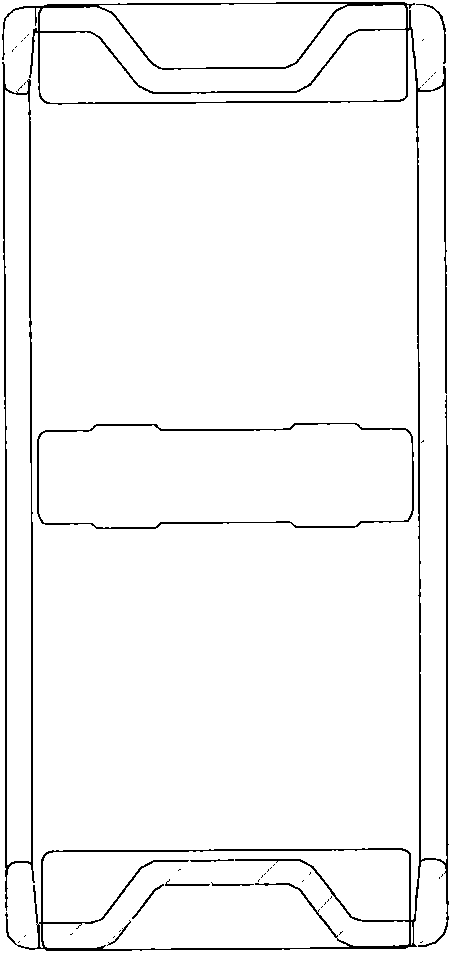

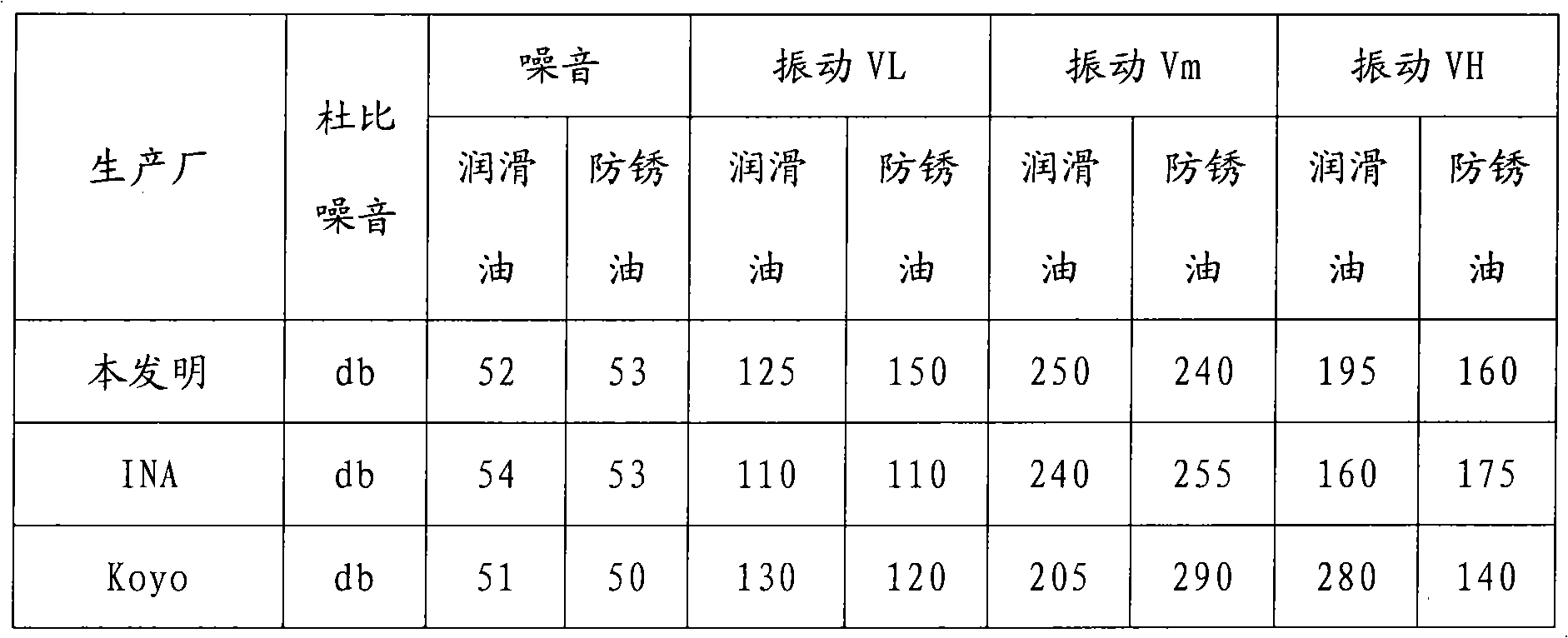

Method for manufacturing needle bearing

InactiveCN101642866AEffective axial unloadingPrevent axial movementGrinding machinesPistonNeedle roller bearing

The invention relates to a method for manufacturing a needle bearing, in particular to a method for manufacturing a bearing of a piston link mechanism in cylinder equipment. The invention mainly aimsto provide the method for manufacturing the low-noise and low-vibration needle bearing in order to solve the problems in the needle bearing manufacturing industry at present. At present, a low-noise and low-vibration needle bearing product does not exist at home and a standard of low noise of the needle bearing also does not exist in the nation and in the industry. The method for manufacturing theproduct comprises the following steps of: a) processing a ringed retainer blank; b) fixing the ringed retainer blank on a lathe and cutting grooves on inner and outer sides of the retainer to form M-shaped sections; c) on a punch press, processing a needle groove parallel with the central axis of the bearing along the circumferential direction of the retainer; d), processing a cylindrical rollingneedle and processing symmetrical correcting curved surfaces at two ends of the cylindrical rolling needle; and e) assembling the rolling needle and the retainer into the bearing product.

Owner:CHANGZHOU WUJIN CHANGJIANG NEEDLE BEARING

High-reliability miniature mechanical pump

ActiveCN102788022AImprove potting effectImprove operational conveniencePump componentsPump installationsMotor protectionImpeller

The invention discloses a high-reliability miniature mechanical pump which comprises a pump body, pump chambers, a fluid inlet, a fluid outlet, an impeller and a brushless motor, wherein the pump body is formed in such a manner that a volute, a motor protection housing and a motor cover plate are connected with one another, and the pump chamber for accommodating the impeller and the pump chamber for accommodating the brushless motor are formed. The fluid inlet and the fluid outlet are formed in the volute and communicated with the pump chambers. The brushless motor is arranged in the pump chamber in the motor protection housing and the motor cover, an output shaft of the brushless motor is connected with a spindle of the impeller, and the brushless motor comprises a permanent magnet rotor assembly and a winding coil stator assembly, wherein a metal sleeve is arranged between the rotor assembly and the stator assembly, and a waterproof sealant layer is formed on the surface of a stator coil to wrap and seal the stator coil. The invention further discloses other structural adjustment. With the adoption of the high-reliability miniature mechanical pump, the water tightness of the motor can be achieved, the heat dissipation performance of the motor can be improved, the spare part structure of the pump can be further simplified and compact, the effective seal of the pump chambers and the precise concentric positioning of the impeller can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

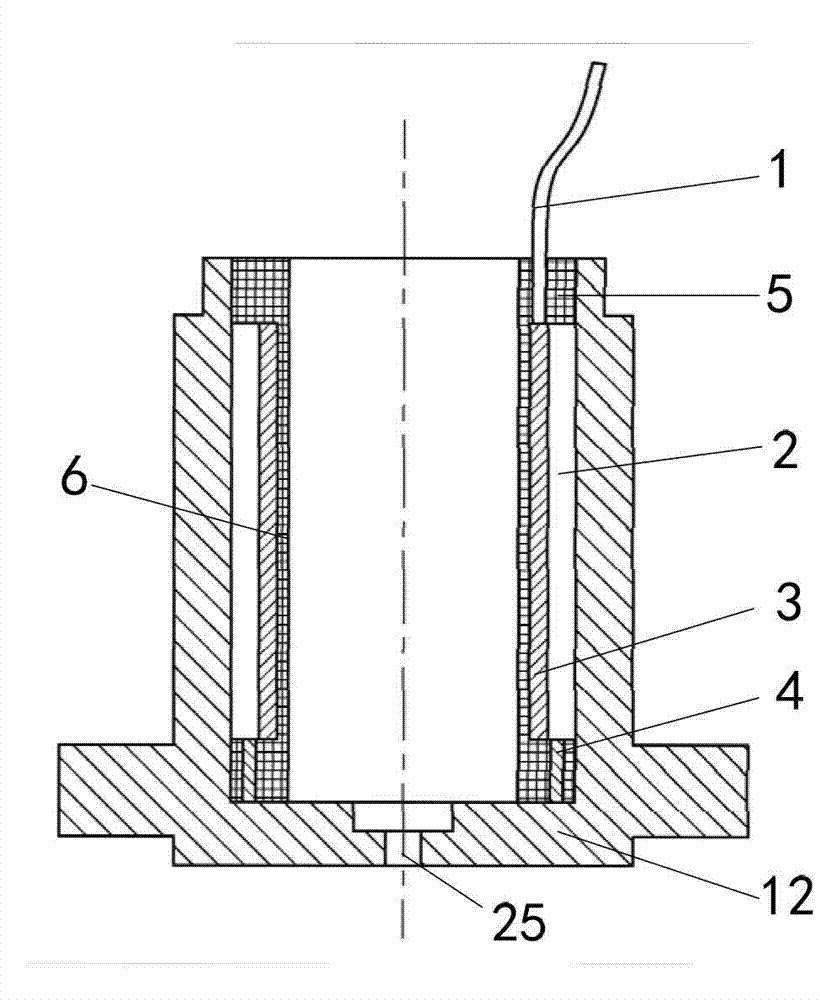

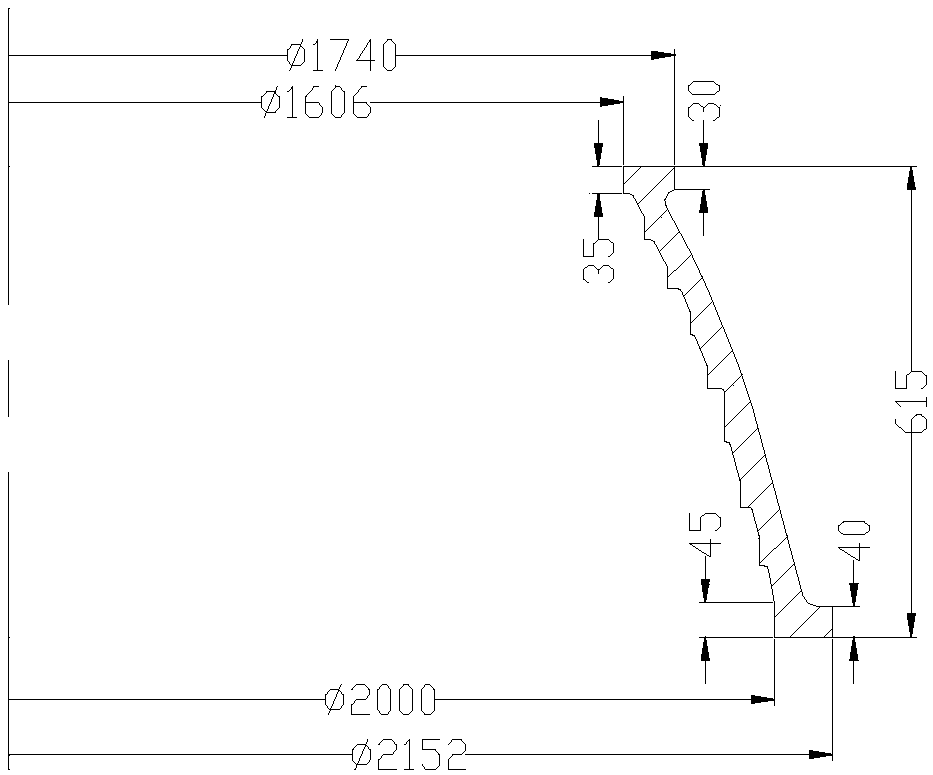

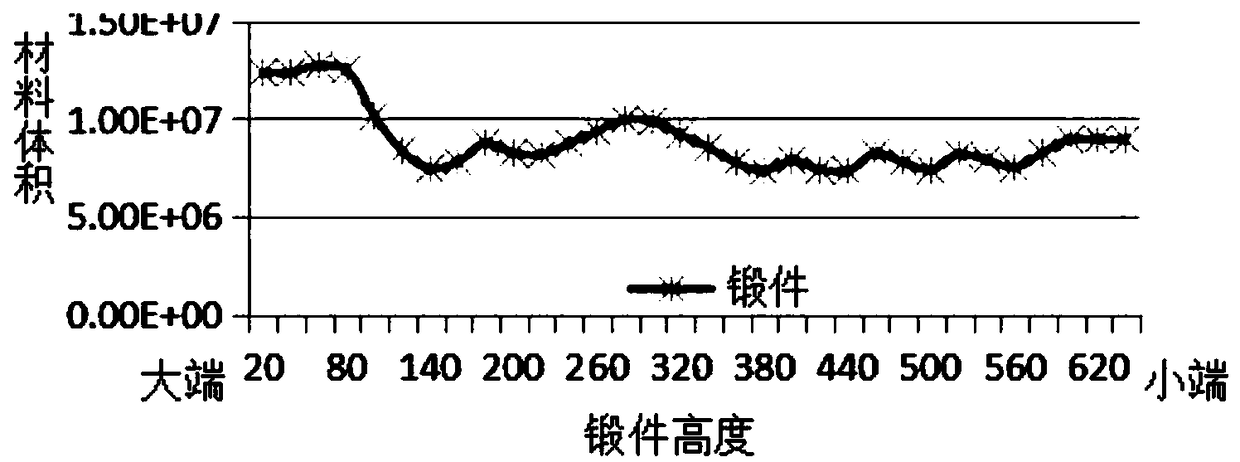

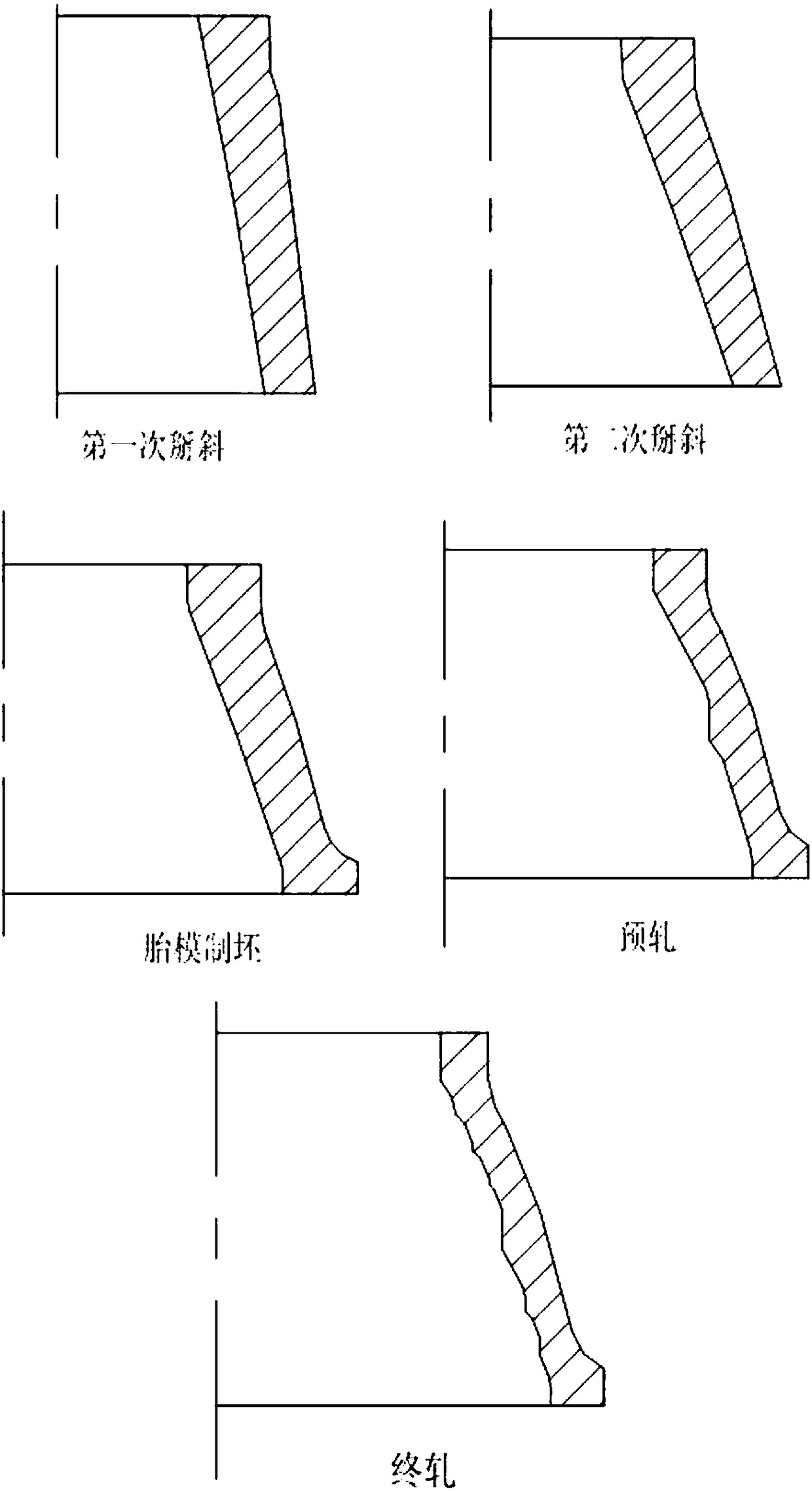

Manufacturing method of multi-step large-diameter casing ring forged piece

ActiveCN108246937AStable rolling processPrevent axial movementMetal rollingAbnormal shapedCrystallite

The invention relates to the technical field of special-shaped forged piece manufacturing technologies, in particular to a multi-step large-diameter casing ring forged piece and a manufacturing methodthereof. According to the multi-step large-diameter casing ring forged piece and the manufacturing method thereof, the casing ring forged piece is manufactured through processes of discharging, upsetting, punching, mandrel supporter reaming, inclining through breaking-off, forming die blanking, pre-rolling and rolling forming; the size distribution characteristic of a blank in the height direction meets the final forming requirements through upsetting, punching, mandrel supporter reaming, and forming die blanking; the large end of the blank is made to face downwards through a special structure, and rolling of the blank is ensured to be stable by loading from the position above a core roller die; the blank makes tight contact with the die by adjusting the size of the ring billet, and axialmoving of the blank is prevented; grains are refined by using high-temperature large deformation at the earlier stage, and the grains are kept to be unchanged by adopting low-temperature small deformation in the follow-up special-shaped blanking and forming process, so that the grains are fully refined; and finally, according to the manufacturing method of the multi-step large-diameter casing ring forged piece, rolling is stable, and the rolling precision of the forged piece can be well ensured.

Owner:GUIZHOU AVIATION TECHN DEV

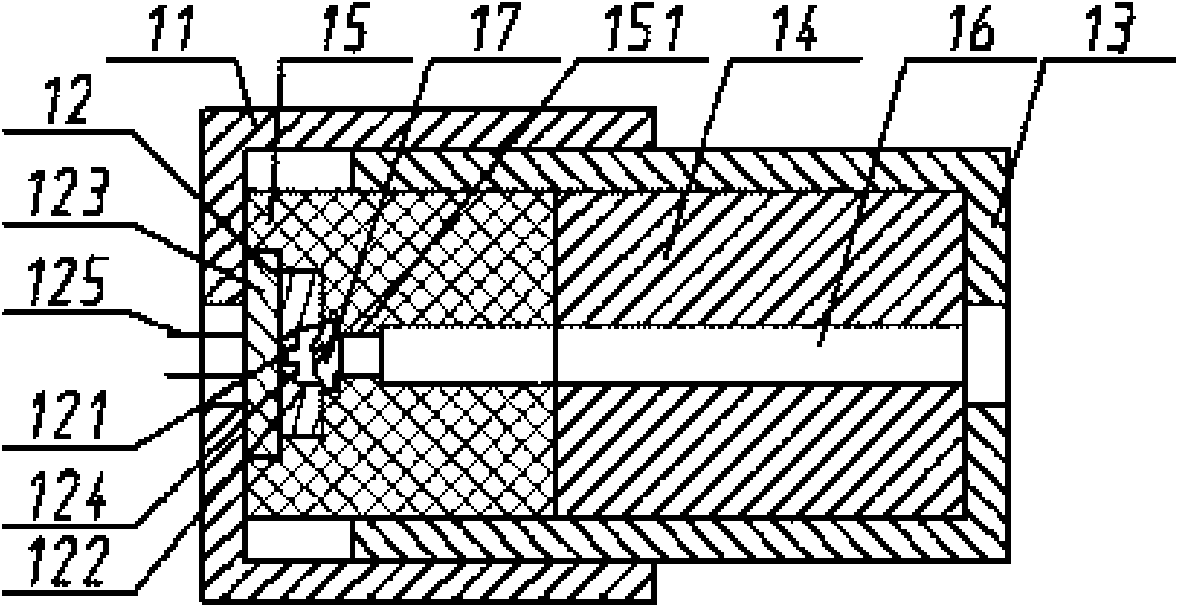

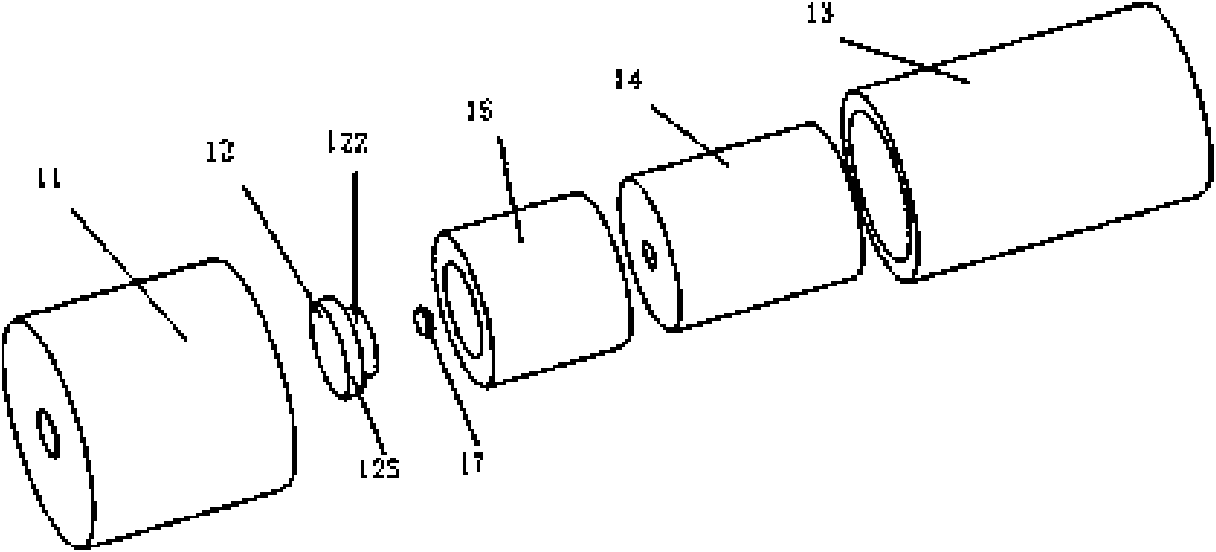

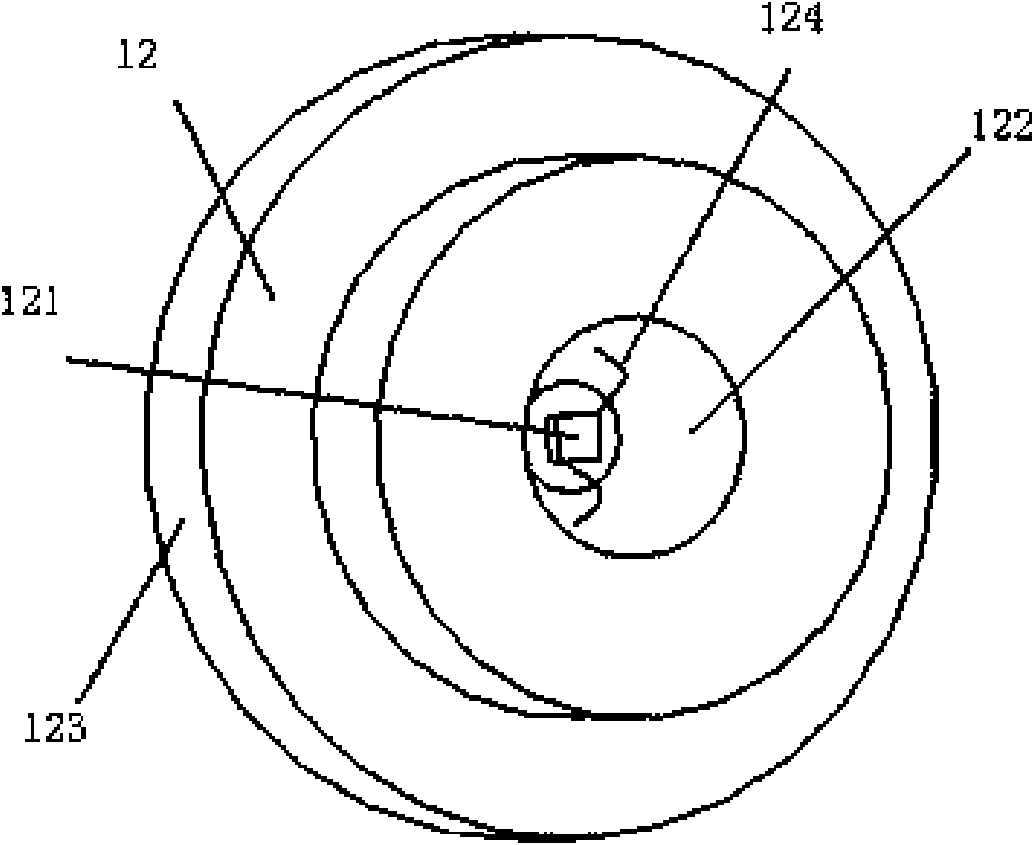

Optical fibre-LED coaxial connector

InactiveCN101629700ASmall light emitting surfaceReduce adverse effectsMechanical apparatusPoint-like light sourceEngineeringMetallic Lead

The invention provides an optical fibre-LED coaxial connector comprising a front-end outer sleeve and a rear-end sleeve matched with each other to form a cavity; an LED base is arranged in the front-end outer sleeve; a condensing lens is mounted between the LED base and an optical fibre end portion; an optical fibre fixer is mounted in the cavity for fixing the LED base, the condensing lens and the optical fibre; the optical fibre fixer comprises a centering ring and a clamping ring; the LED is used as input of the condensing lens and the optical fibre is used as a conductor for outputting light rays; an LED chip, a radiator, a chip lead, an electrode lead and a reflecting bowl are packaged on the LED base; the reflecting bowl outputs light to the LED for alignment; the condensing lens focuses light rays into the optical fibre; the centering ring and the LED base are processed accurately to ensure the optical fibre and the LED chip coaxial, thereby effectively improving the coupling efficiency; in addition, the connector has simple and compact mechanical connection structure, and simple and convenient installation and disassembly.

Owner:HUAZHONG UNIV OF SCI & TECH

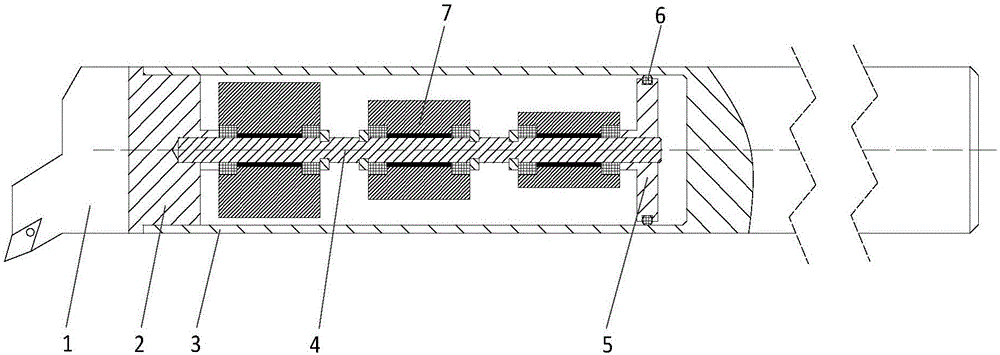

Dynamic vibration attenuation boring tool

InactiveCN106363198AGood vibration reduction effectPrevent axial movementTurning toolsRubber ringVibration attenuation

The invention discloses a dynamic vibration attenuation boring tool which comprises a tool bit, a tool bar, a tool bit end cover, a connection rod and a tool tail end cover, wherein the connection rod is arranged in the tool bar; two ends of the connection rod are respectively connected with the tool bit end cover and the tool tail end cover; the tool bit end cover is also connected with the tool bar; the tool bit is arranged on the tool bit end cover; the tool tail end cover is connected with the inner wall of the tool bar through an O-shaped ring; at least two vibration attenuation modules are arranged on the connection rod, and are axially fixed on the connection rod through clamping springs; the vibration attenuation modules comprise vibration cores, damping oil and rubber rings; the vibration cores are suspended on the connection rod through the rubber rings; and the damping oil is filled between the vibration cores and the connection rod. According to the dynamic vibration attenuation boring tool, the diameters of the vibration cores of different vibration attenuation modules are different, so that differentiated vibration attenuation can be performed on different positions of the tool bar, vibration generated during part machining can be attenuated, and the quality of a machined surface is improved.

Owner:SOUTHEAST UNIV

Double boring bottom cylinder supporting tool

InactiveCN104551755AEasy to operateClamping saves time and effortLarge fixed membersPositioning apparatusRelative displacementEngineering

The invention provides a double boring bottom cylinder supporting tool. The double boring bottom cylinder supporting tool comprises a pedestal, and a positioning base, a slide block and an adjusting supporting base which are arranged on the pedestal, wherein a chute is formed along the vertical direction in the positioning base; a supporting block is arranged in the chute; an adjusting bolt is horizontally arranged on the adjusting supporting base and is connected with the slide block; the slide block is arranged below the supporting block; the bolt is connected with the slide block; the slide block is arranged below the supporting block; the matched surface between the upper surface of the slide block and the lower end of the supporting block is an inclined surface; a workpiece supporting opening is formed in the upper end of the supporting block. The angle of the combination surface between the supporting block and the slide block is reasonably used, the telescopic height of the tool is adjusted by relative displacement between the supporting block and the slide block, replacement of the tool during machining is avoided, the structure is convenient to operate, the double boring bottom cylinder supporting tool can be suitable for clamping bottom cylinders or cylindrical workpieces with different diameters, time and labor are saved during clamping, convenience is improved for workers, the production efficiency is improved, and the cost is reduced.

Owner:CHONGQING YAOYONG SHOCK ABSORBER

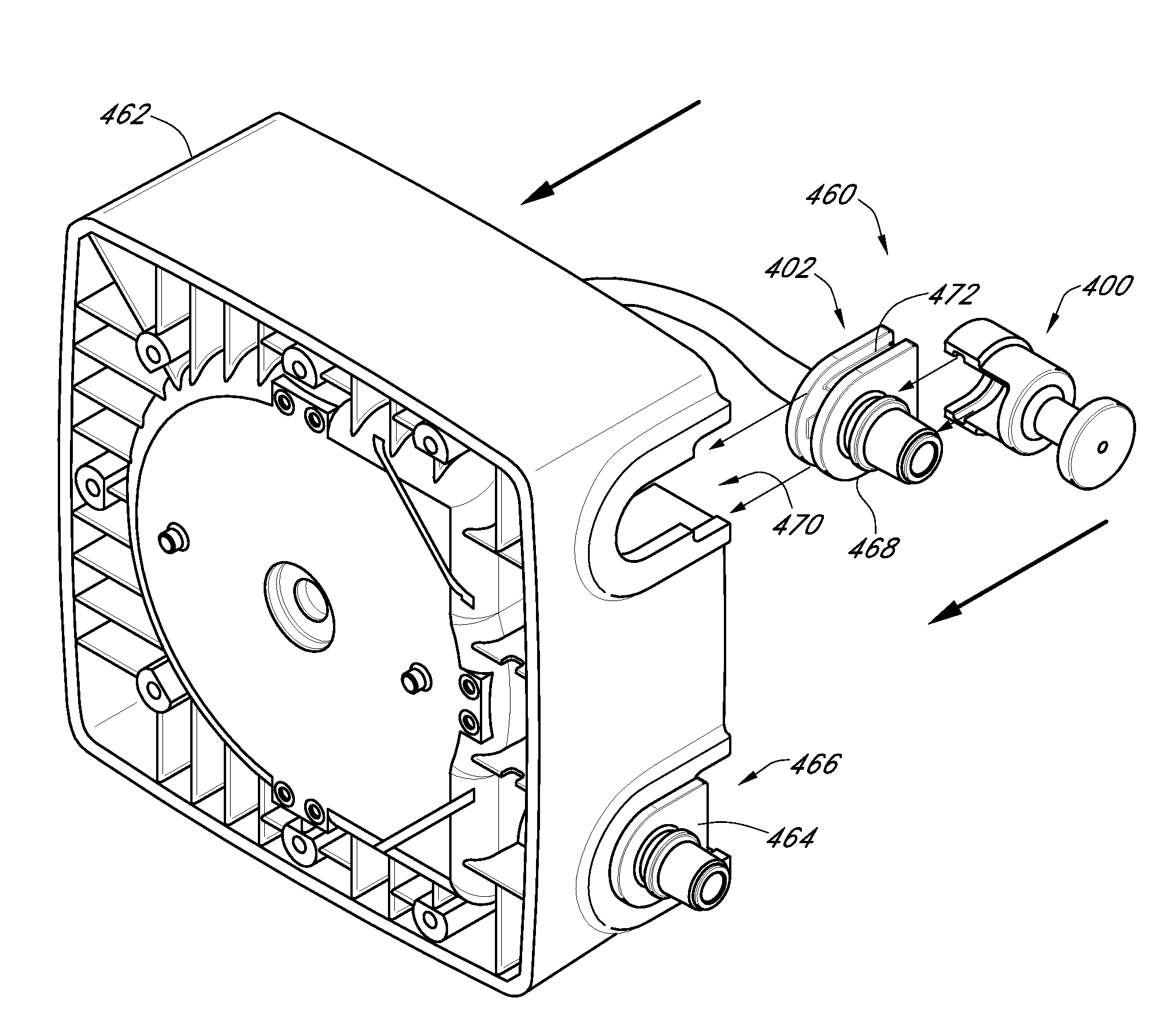

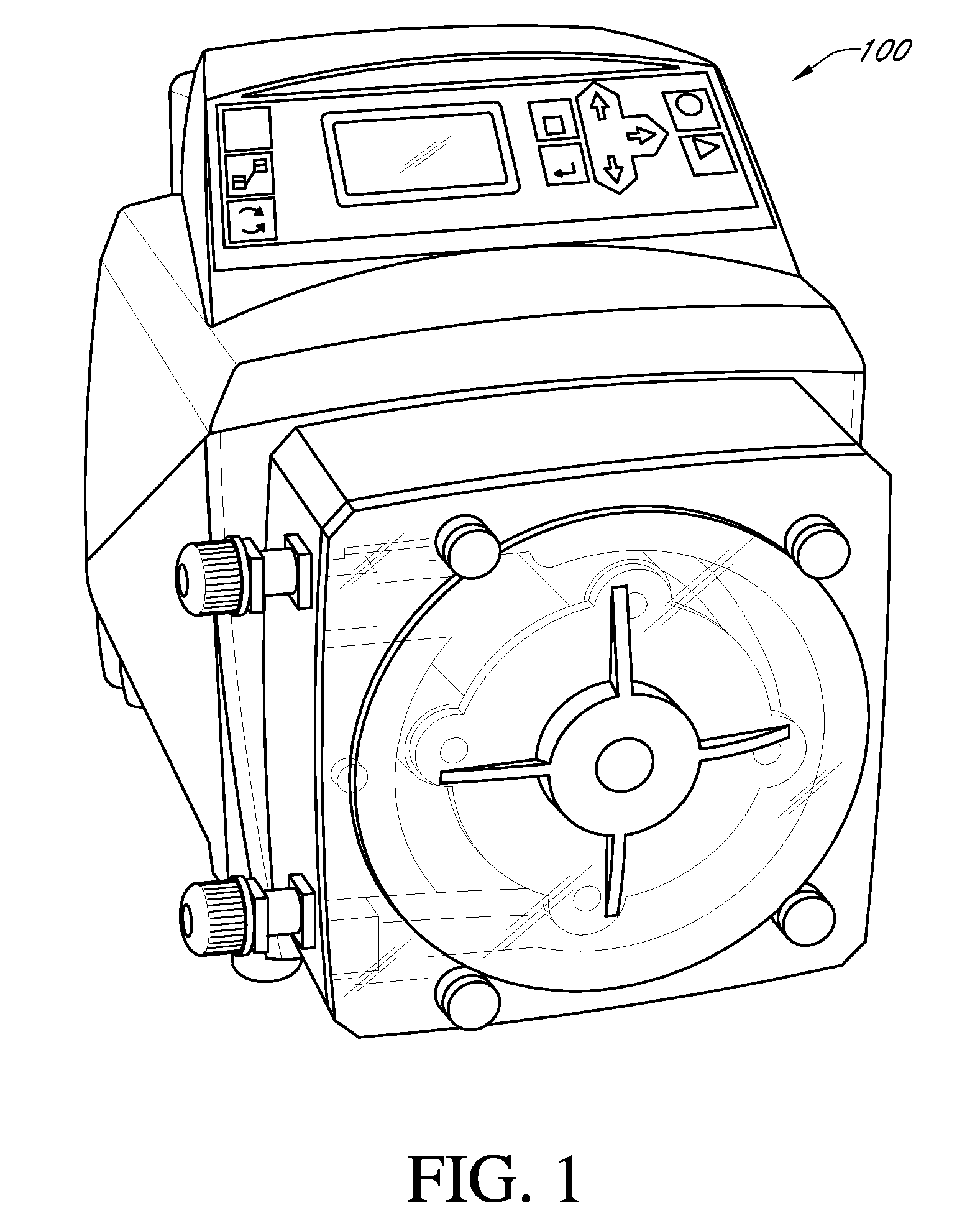

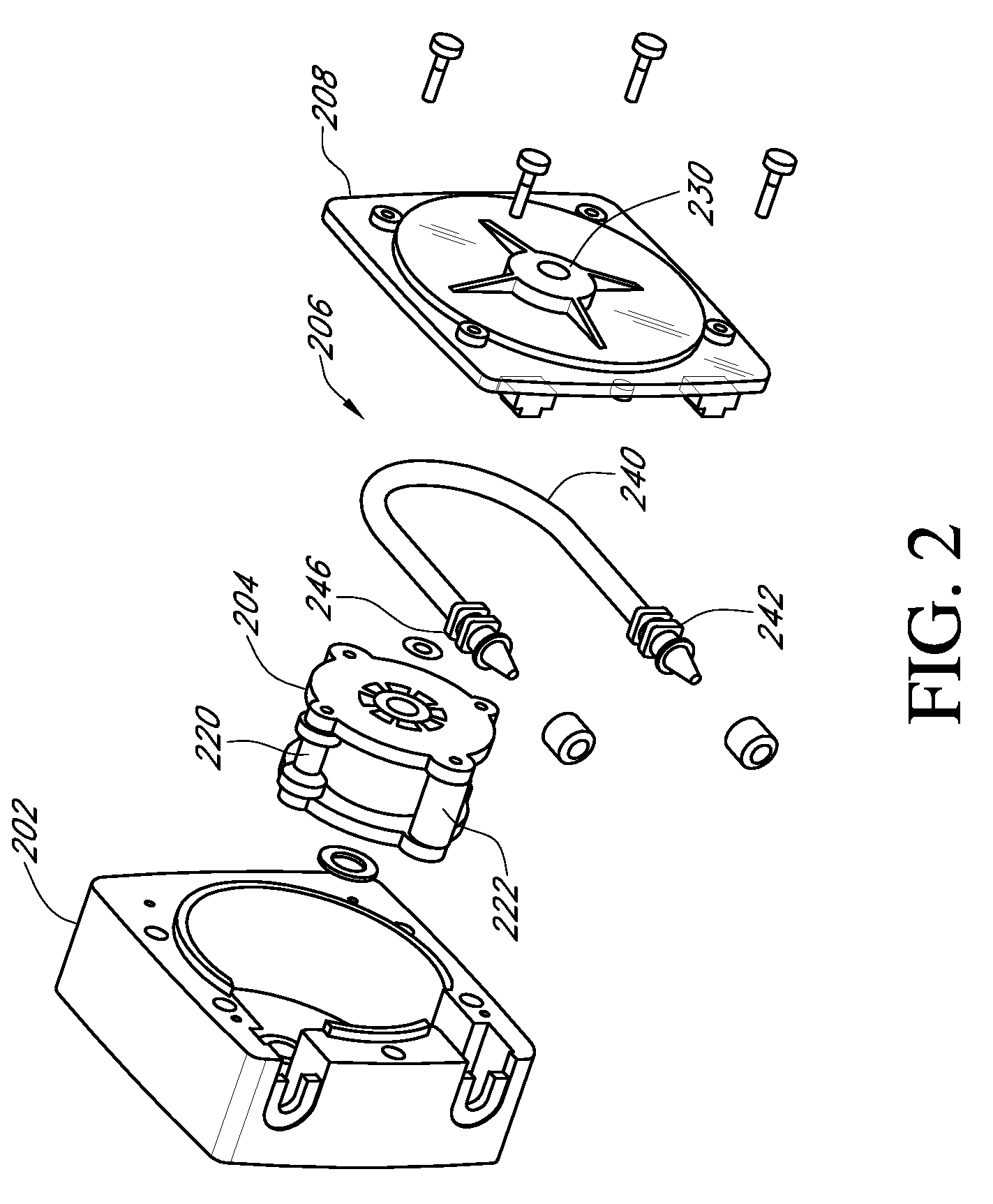

Tubing installation tool for a peristaltic pump and methods of use

InactiveUS20100005655A1Prevent axial movementEasy to installMetal-working apparatusEngine componentsPeristaltic pumpBiomedical engineering

A peristaltic pump is provided that can comprise a safety switch in order to control an operational parameter of the pump in response to a state of the pump. Additionally, methods are provided for maintaining and replacing tubing of the pump. A tubing installation tool is also provided for handling industrial tubing during installation or removal of the tubing from a pump.

Owner:BLUE WHITE INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com