Patents

Literature

67results about How to "Reduce side load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

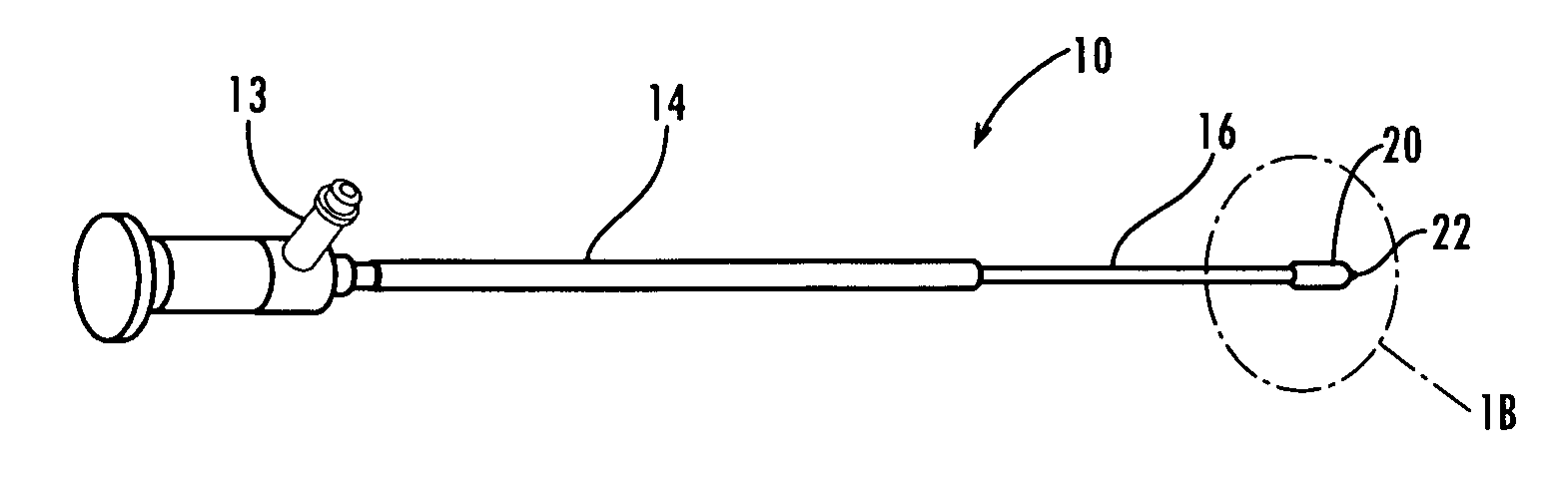

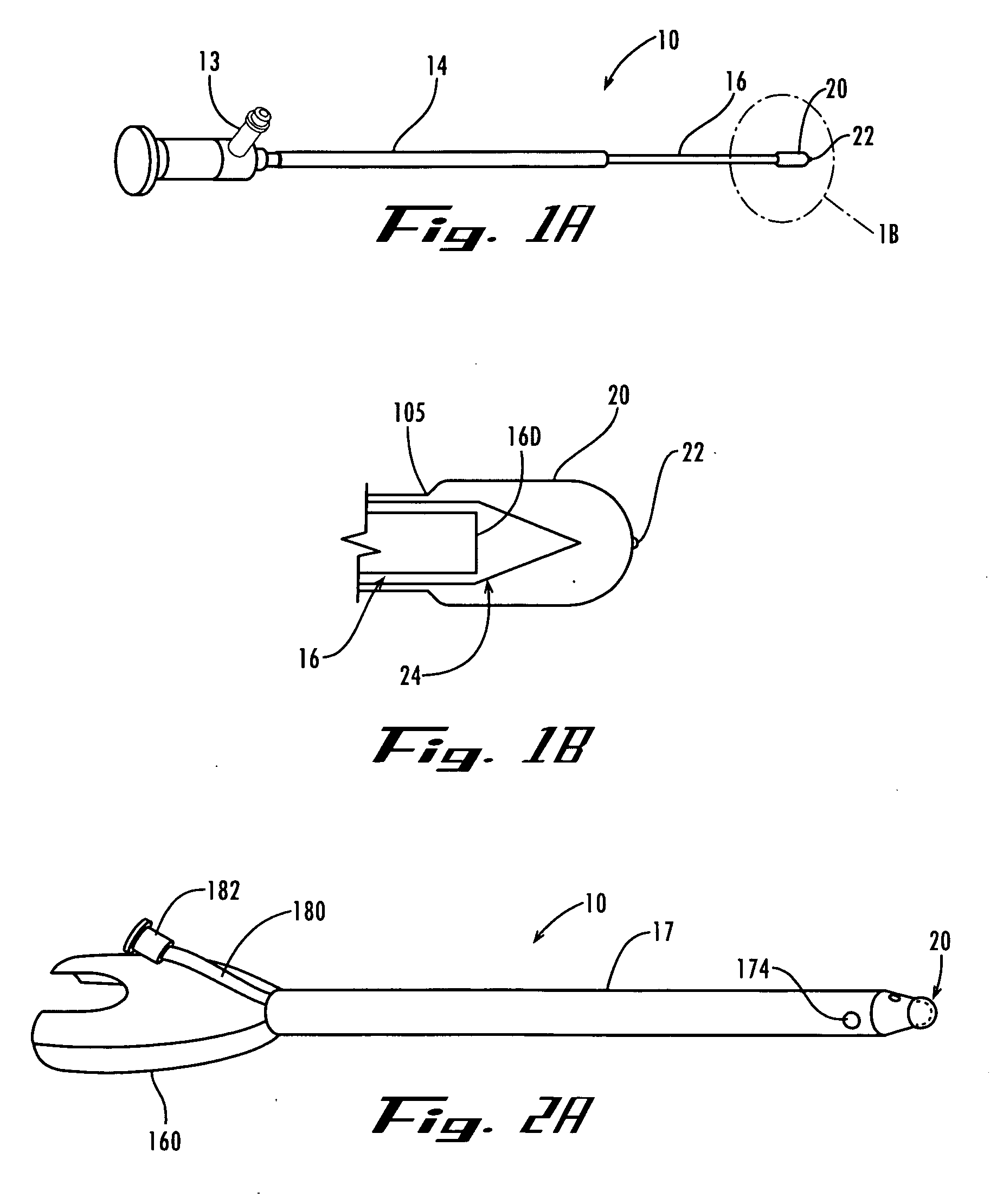

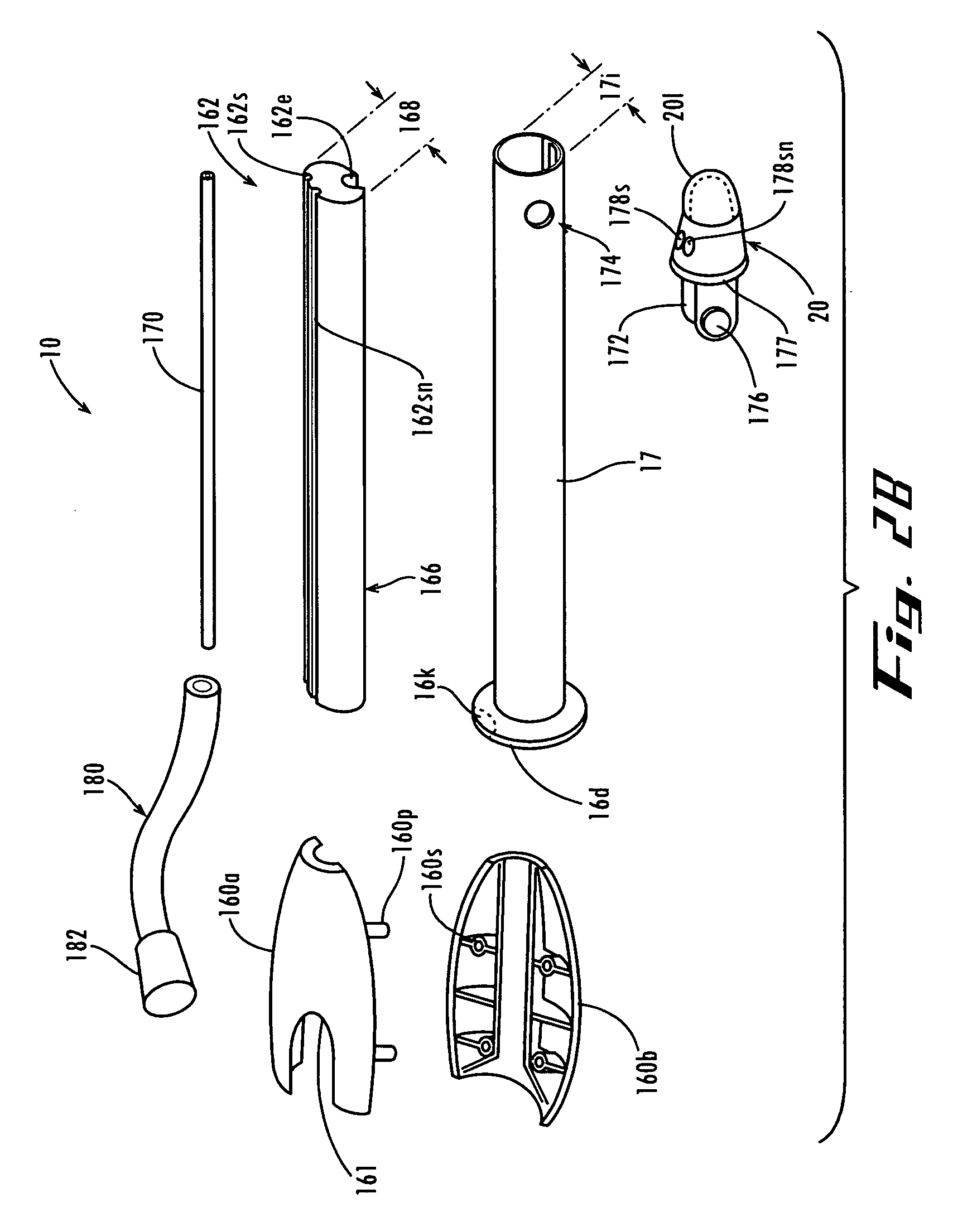

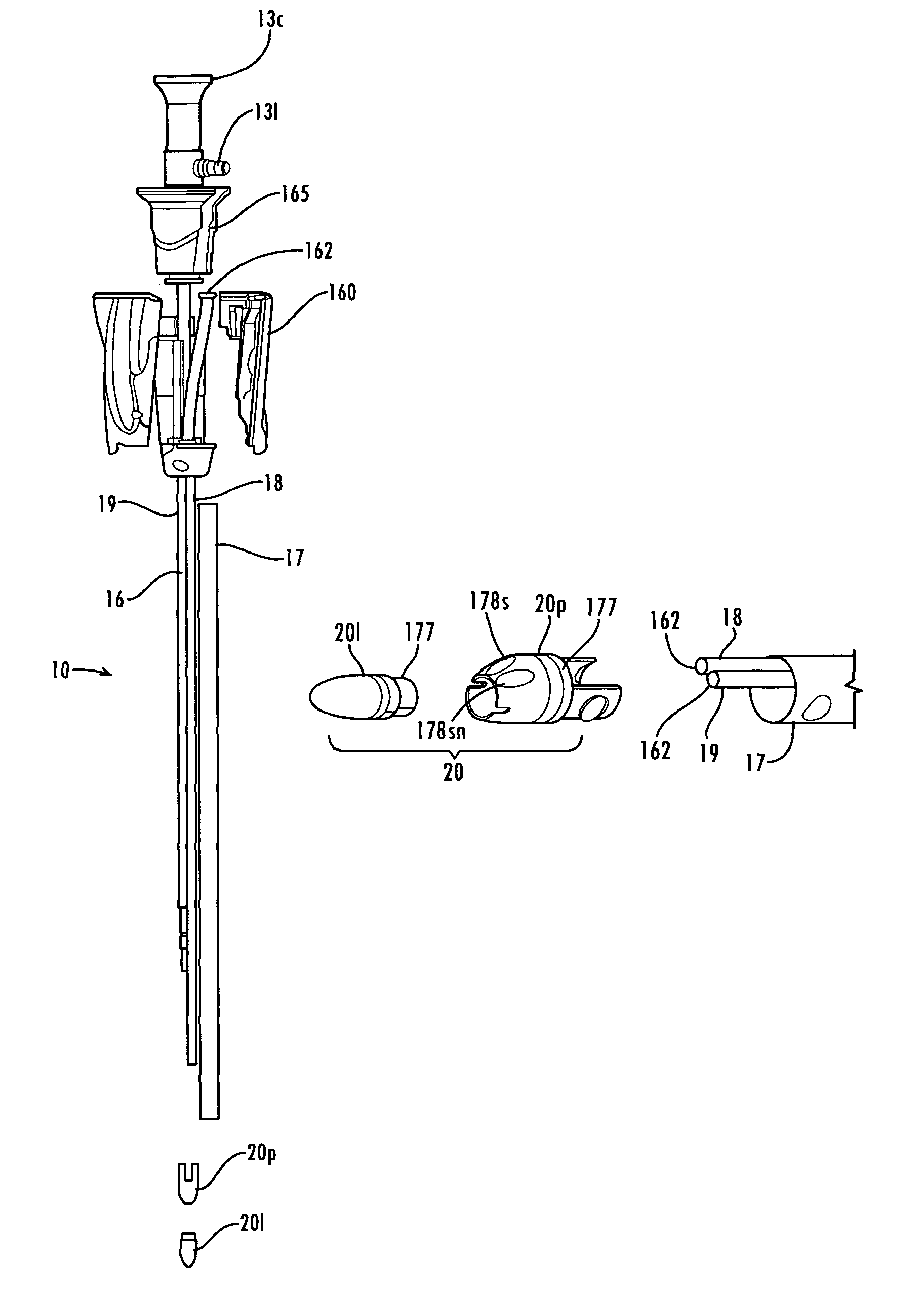

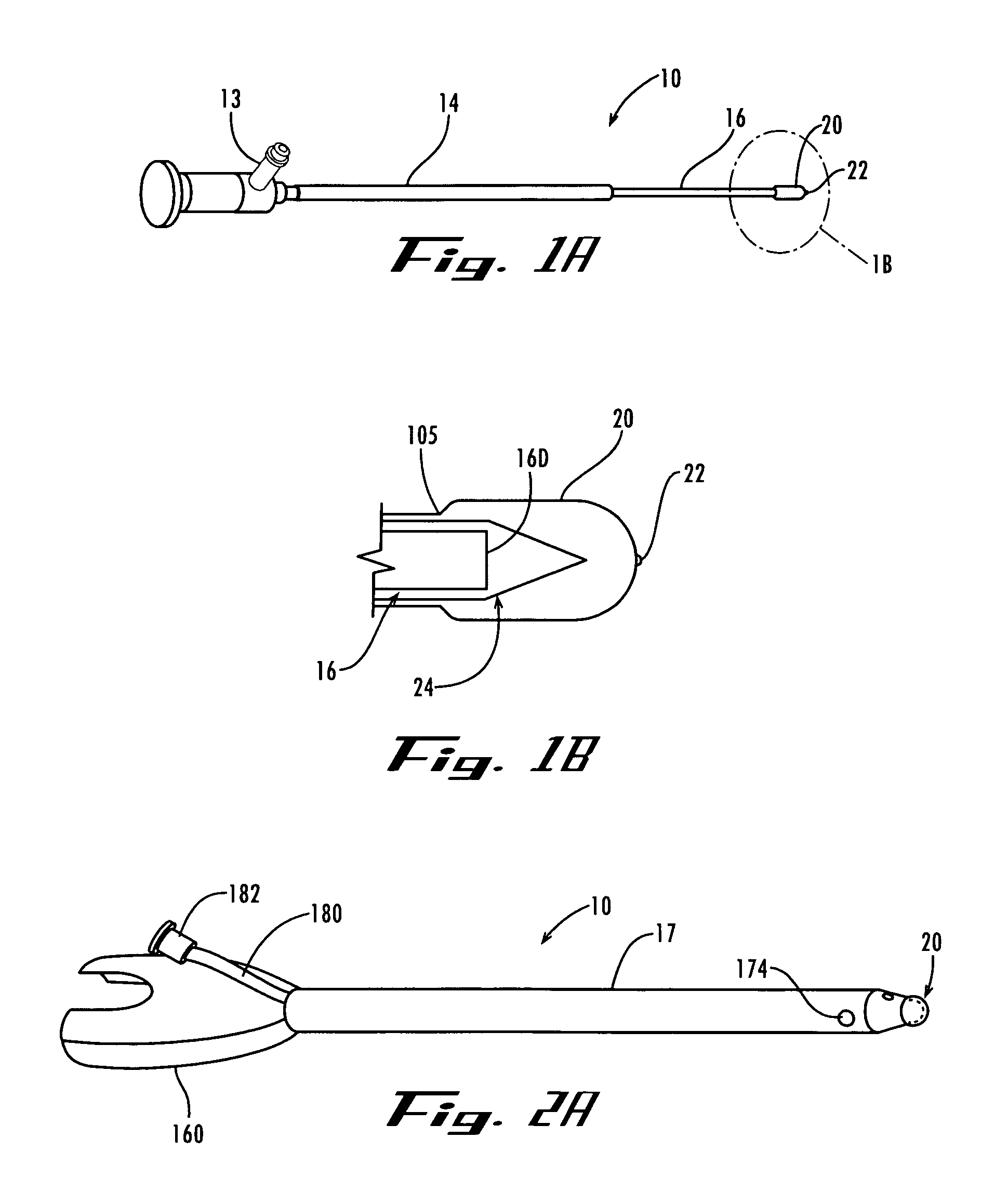

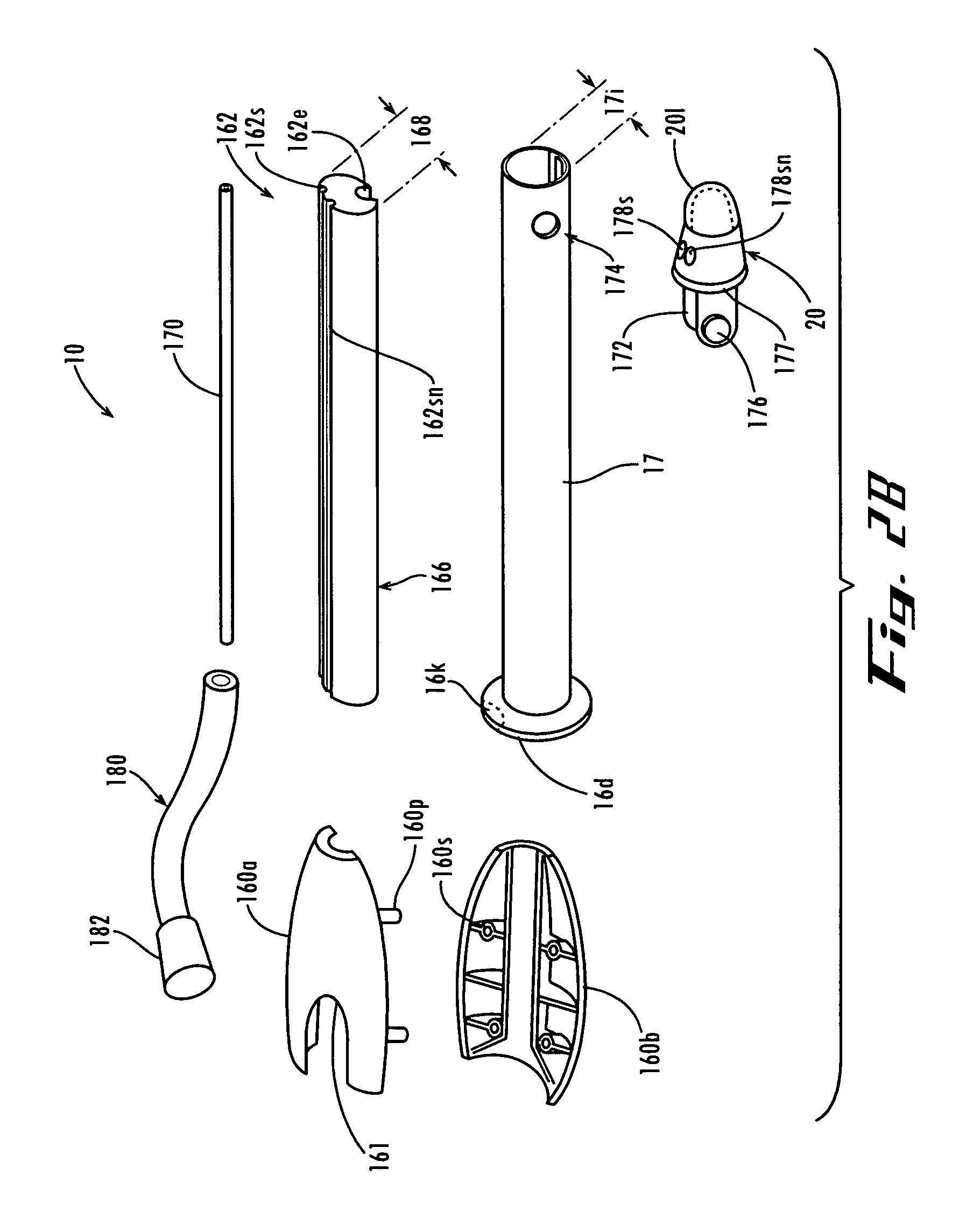

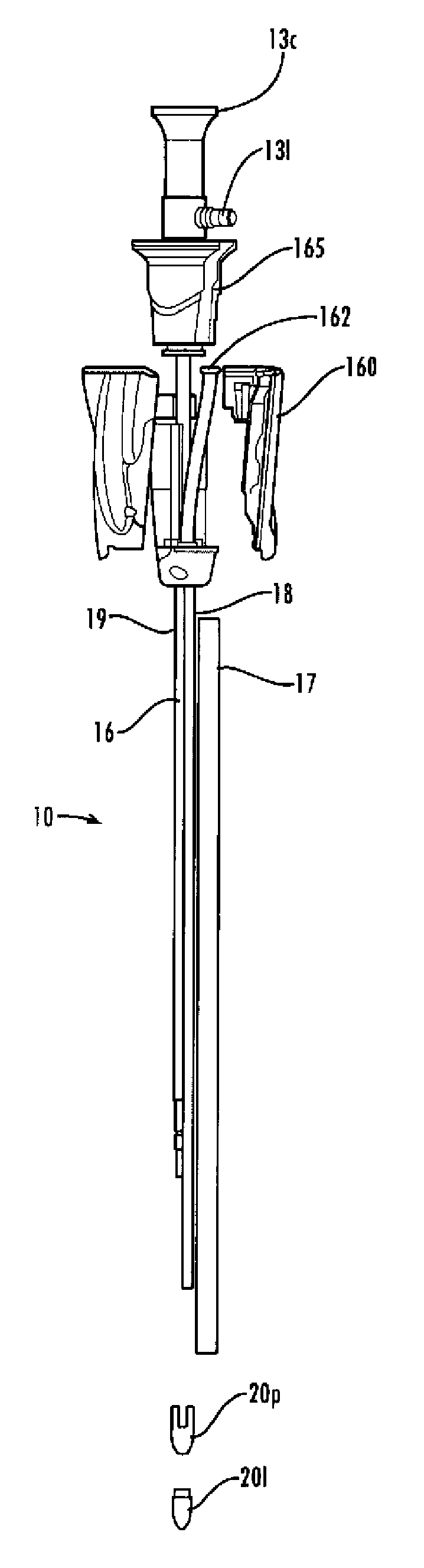

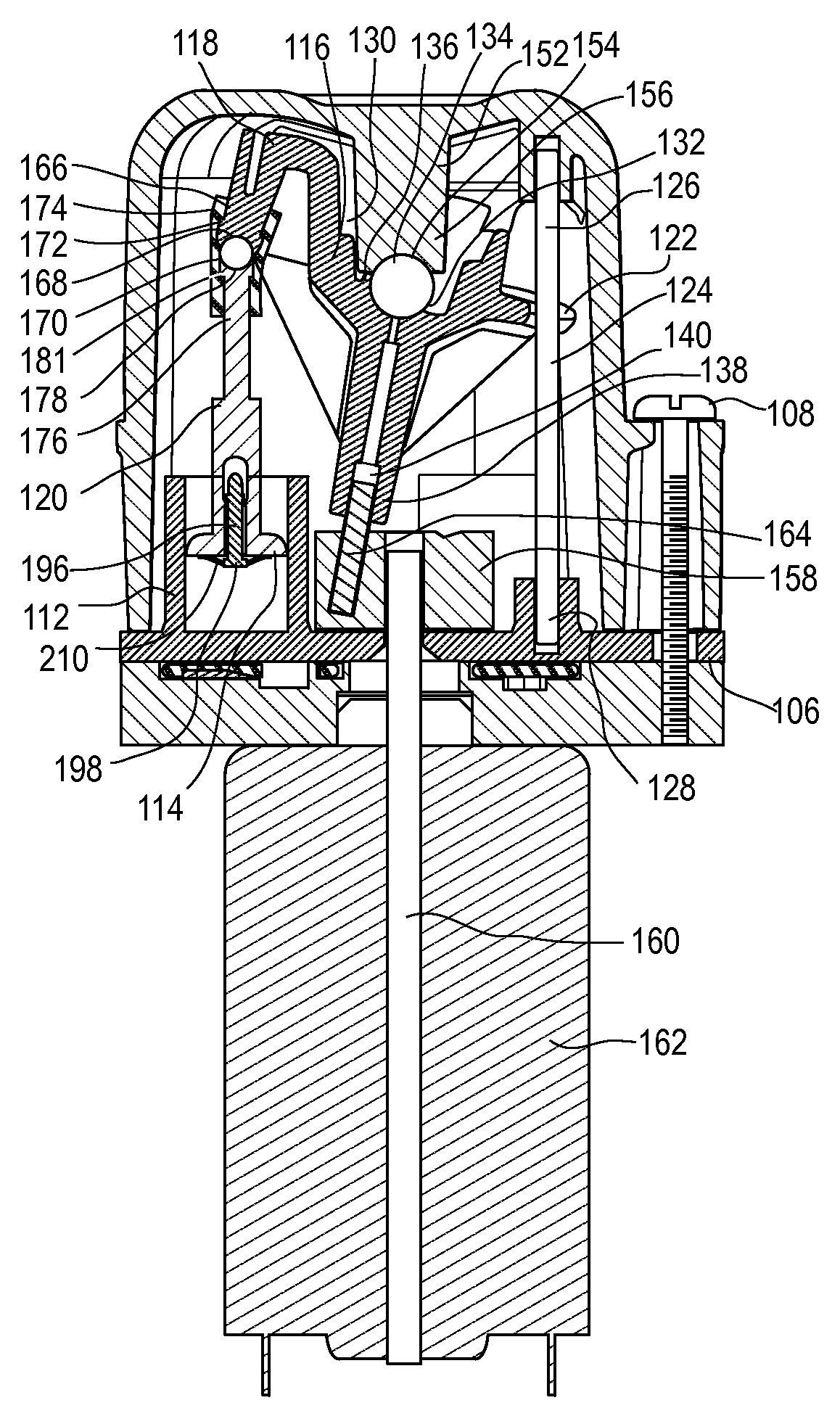

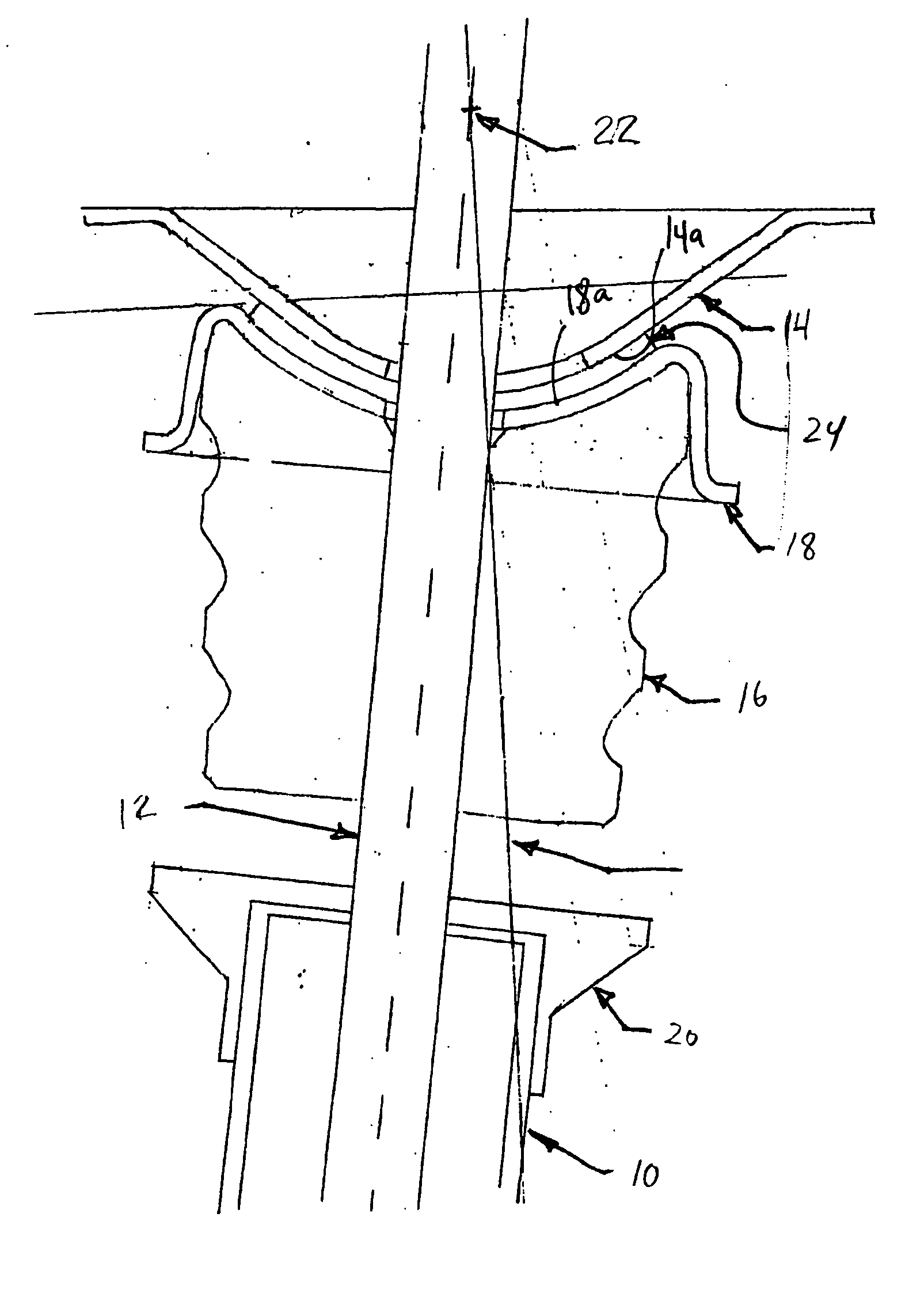

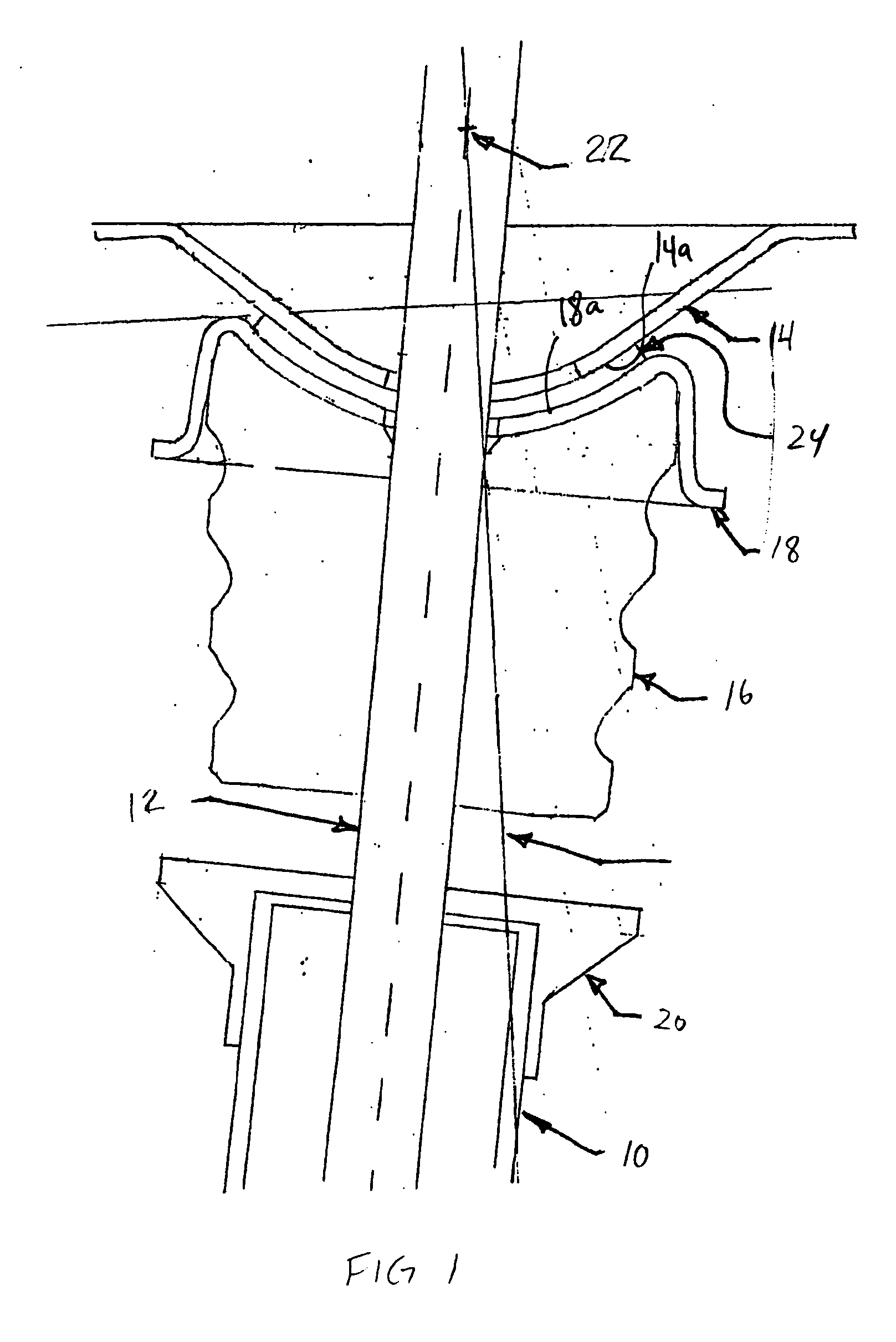

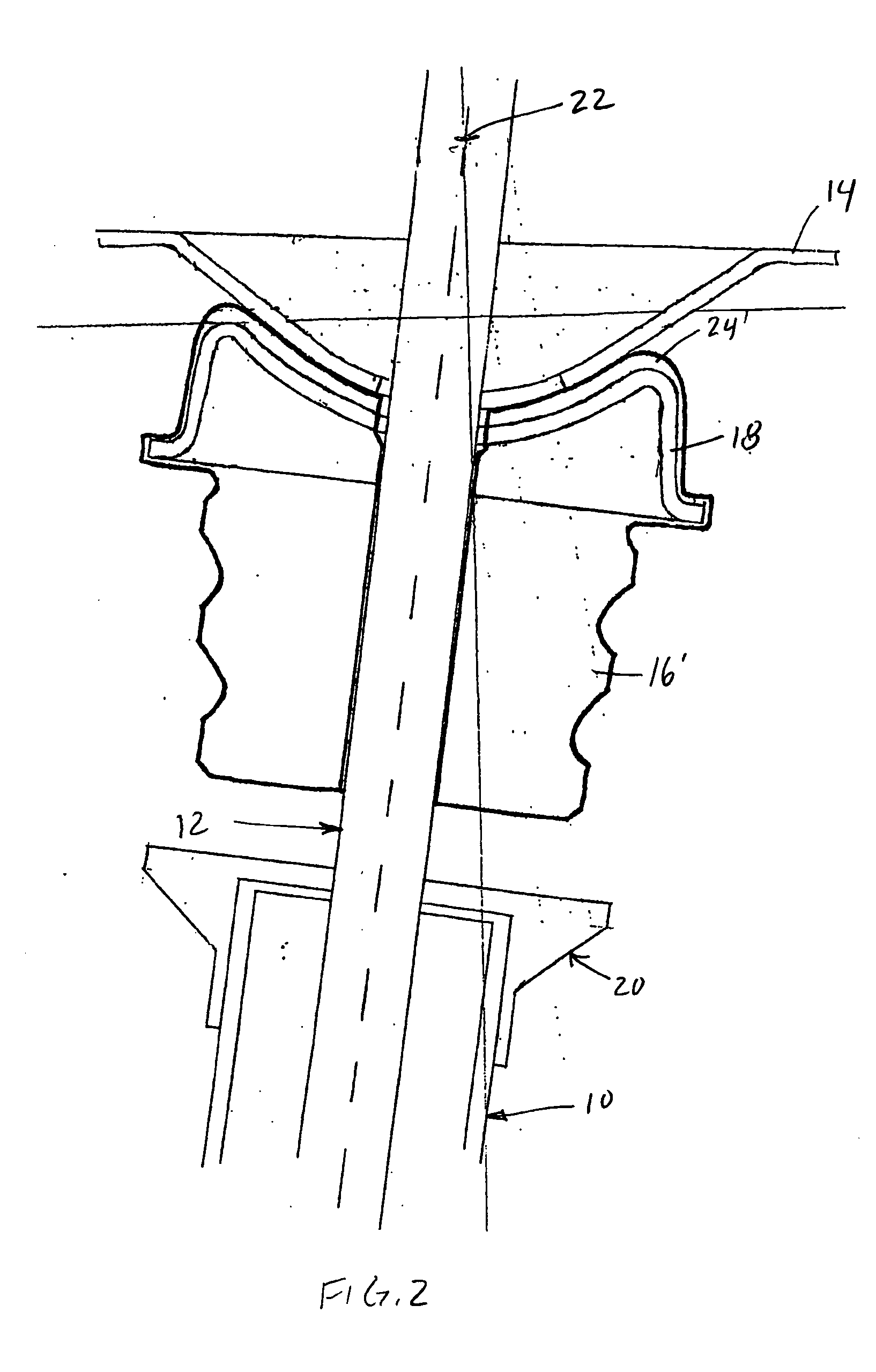

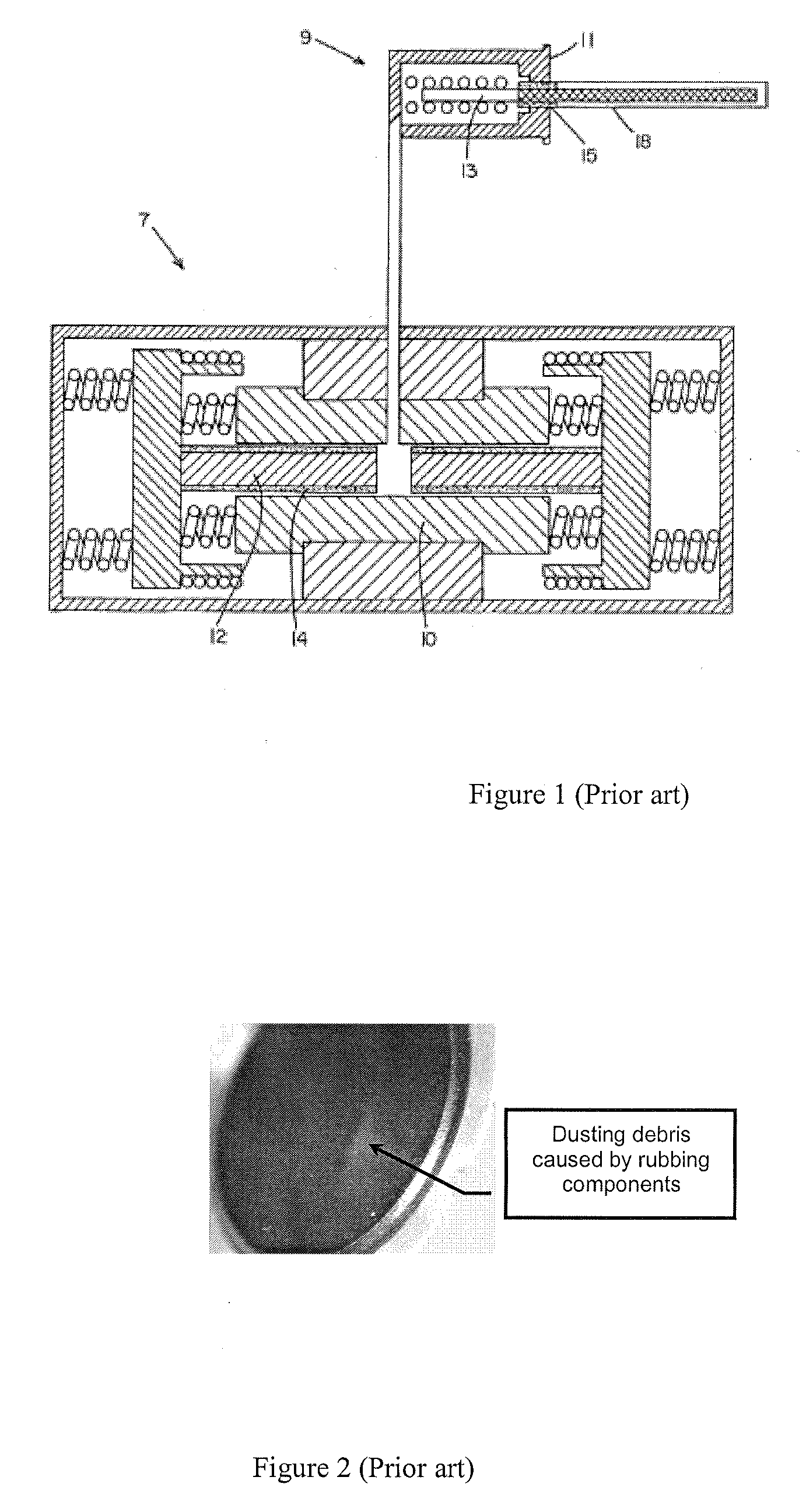

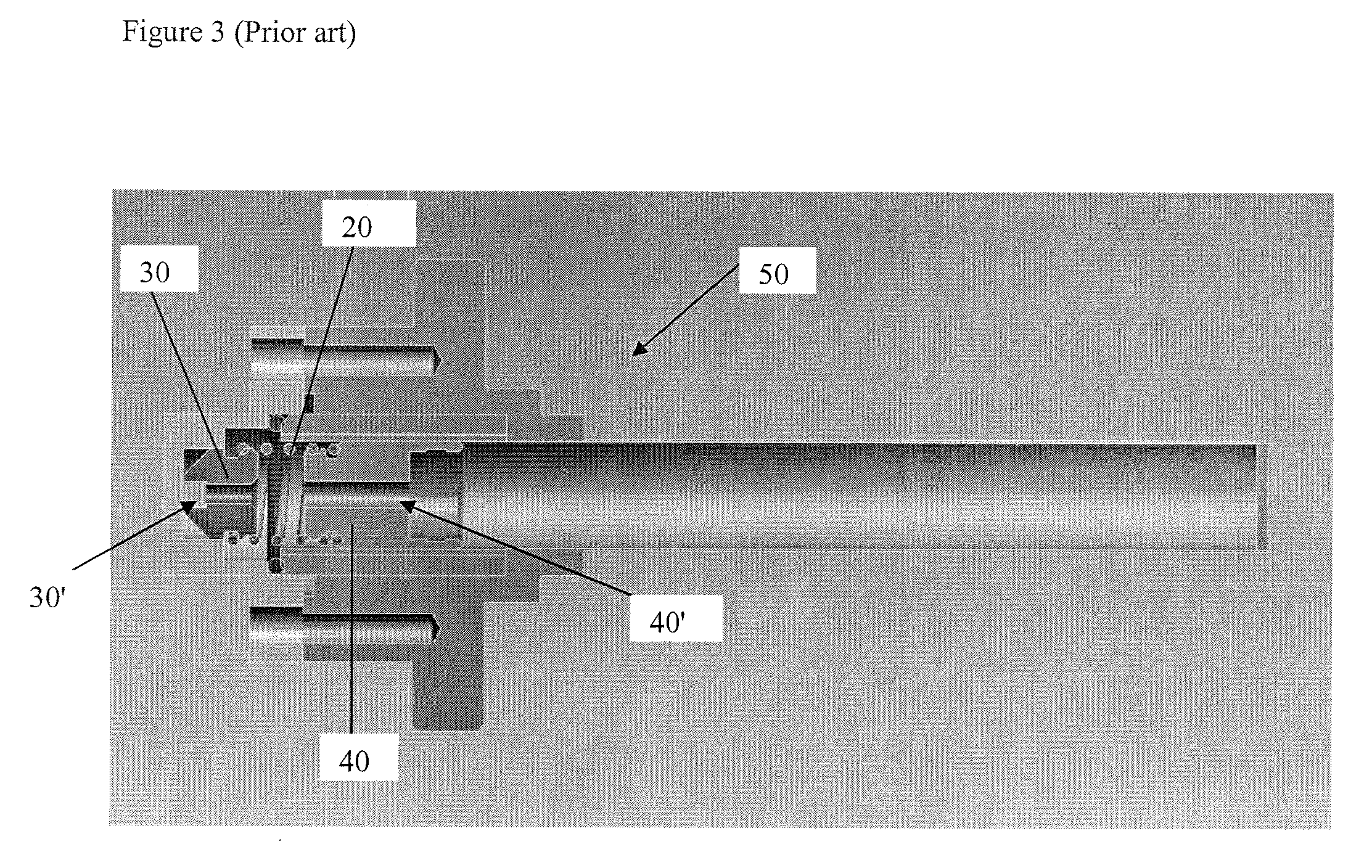

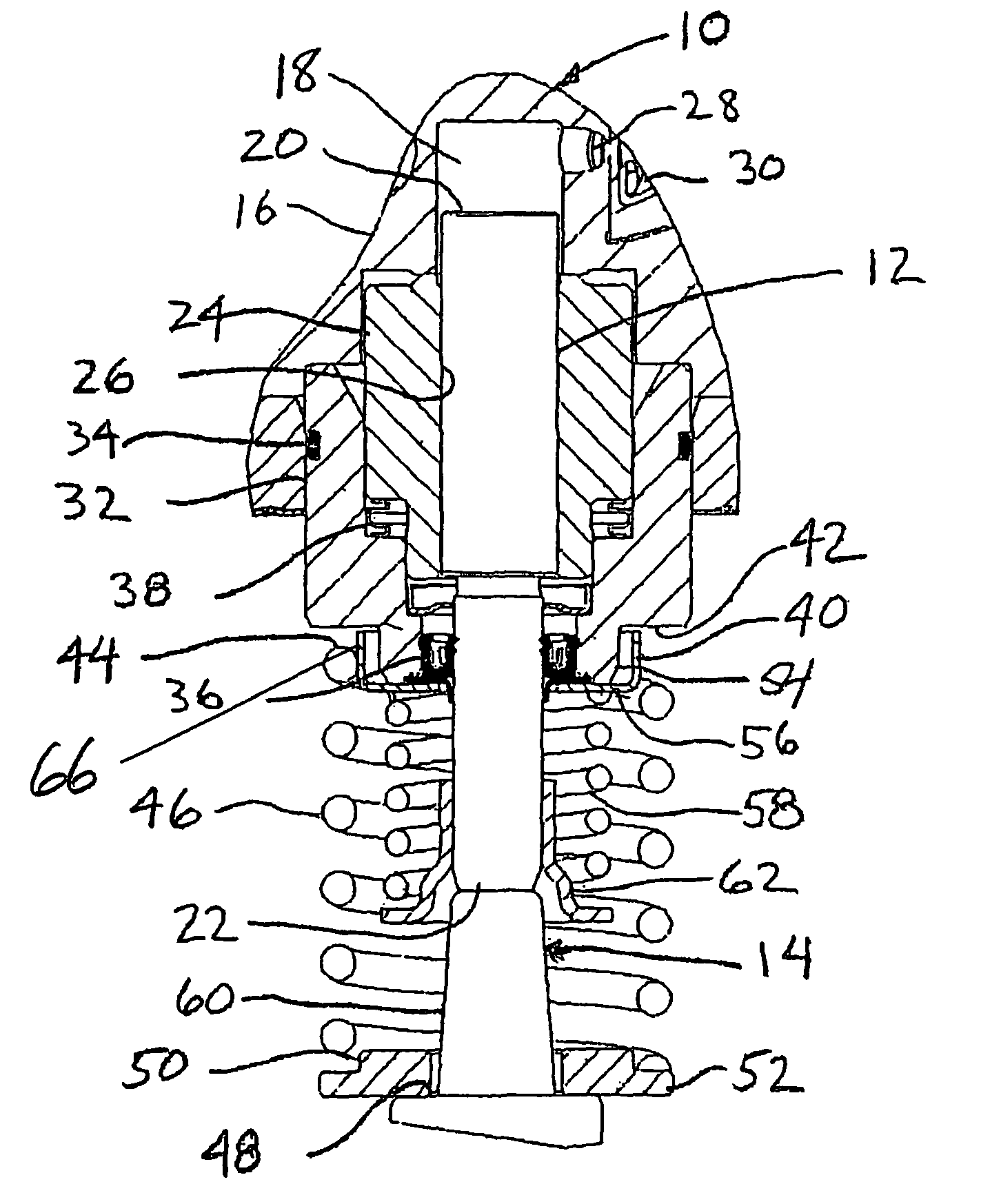

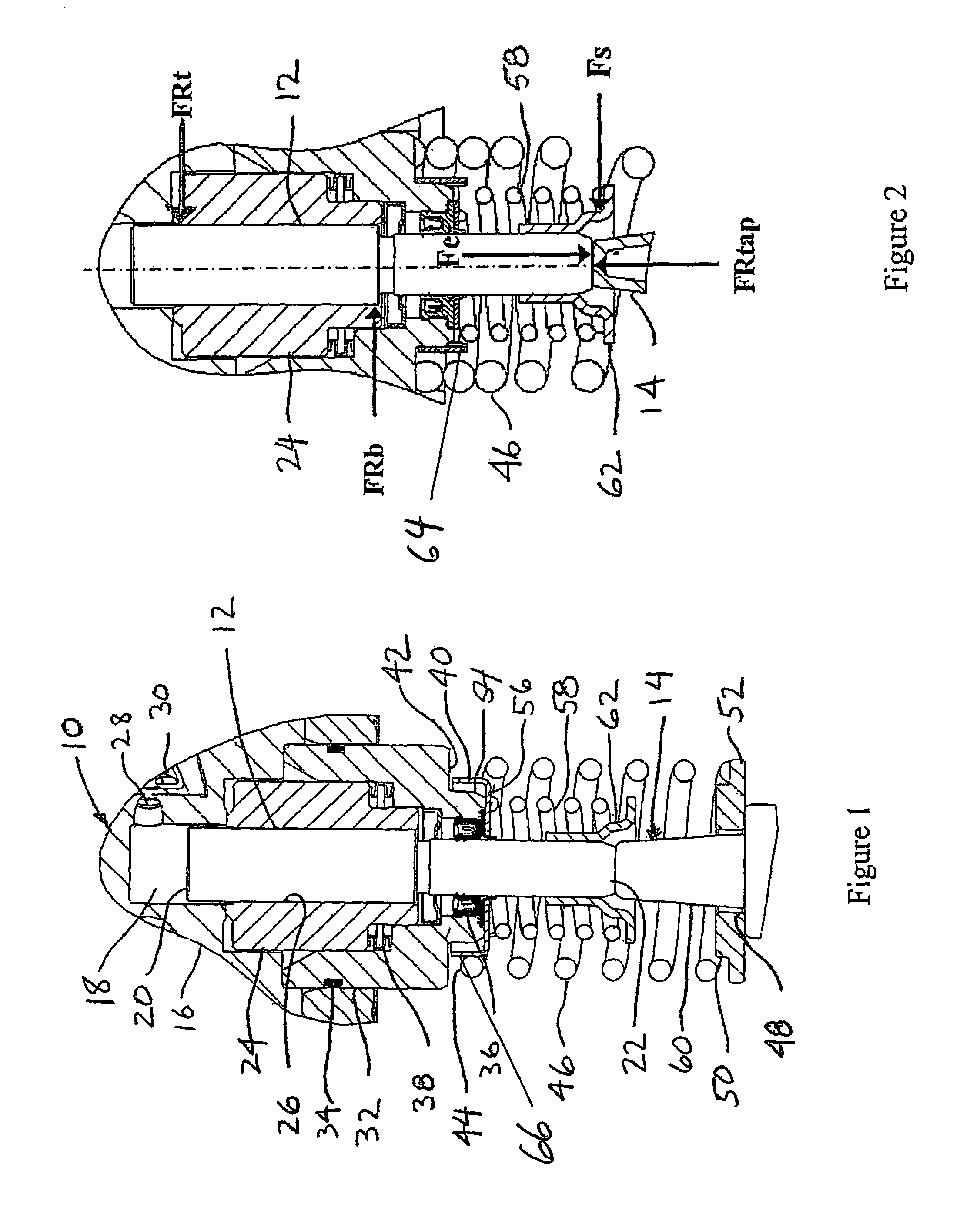

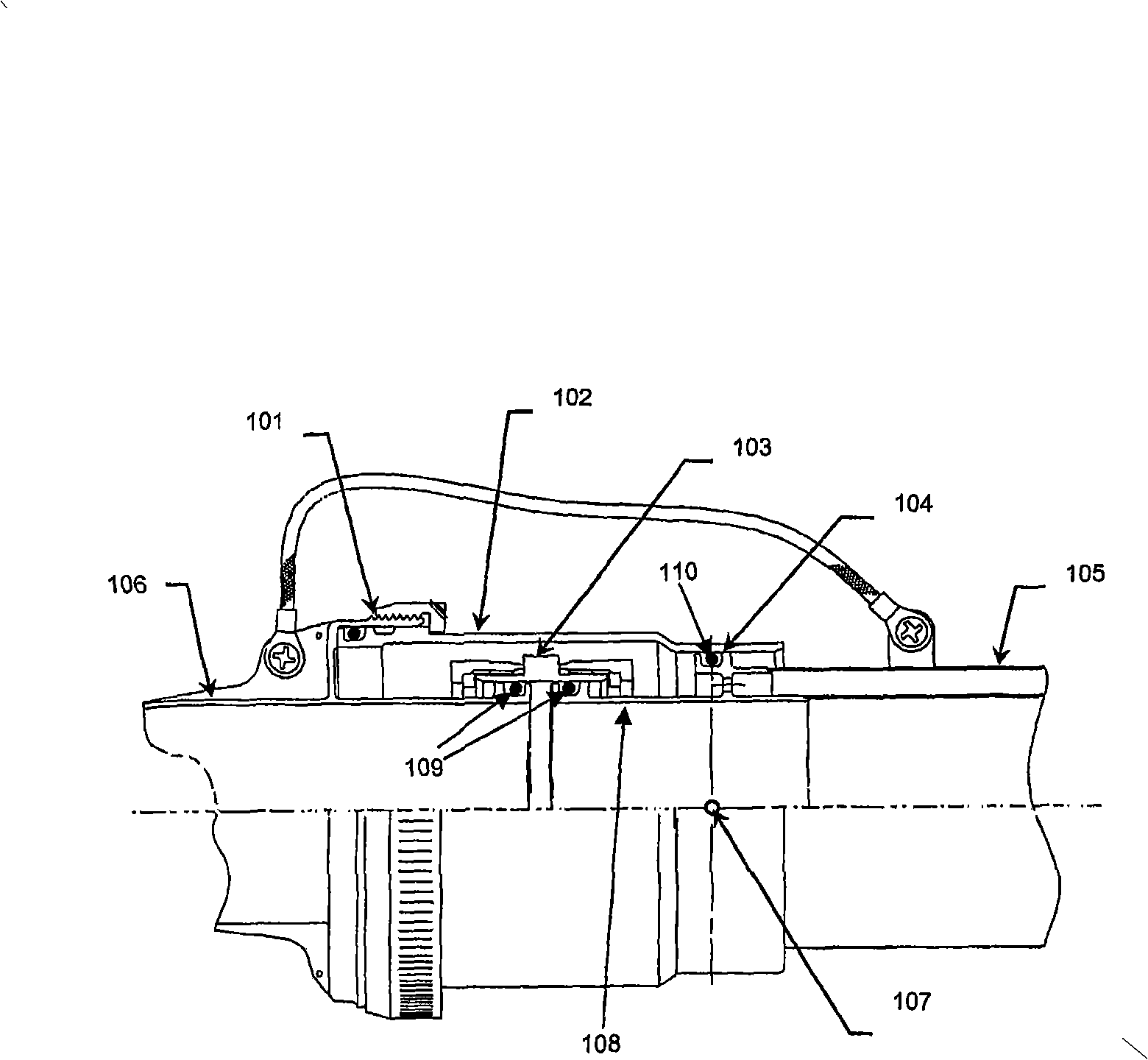

Apparatus and methods for performing minimally-invasive surgical procedures

ActiveUS20070129719A1Reduce side loadPrevent axial movementCannulasSurgical needlesSurgical departmentSurgical procedures

Devices, tools and methods for performing minimally invasive surgical procedures. Methods of performing minimally invasive ablation procedures. Methods of performing rapid exchange of tools in a device while the device remains in a reduced-access surgical space.

Owner:MAQUET CARDIOVASCULAR LLC

Apparatus and methods for performing minimally-invasive surgical procedures

ActiveUS8932208B2Prevent axial movementPrevent rotationCannulasSurgical needlesSurgical proceduresGeneral surgery

Devices, tools and methods for performing minimally invasive surgical procedures. Methods of performing minimally invasive ablation procedures. Methods of performing rapid exchange of tools in a device while the device remains in a reduced-access surgical space.

Owner:MAQUET CARDIOVASCULAR LLC

Apparatus and methods for performing minimally-invasive surgical procedures

InactiveUS20150142041A1Prevent axial movementPrevent rotationCannulasSurgical needlesSurgical departmentInvasive Procedure

Devices, tools and methods for performing minimally invasive surgical procedures. Methods of performing minimally invasive ablation procedures. Methods of performing rapid exchange of tools in a device while the device remains in a reduced-access surgical space.

Owner:MAQUET CARDIOVASCULAR LLC

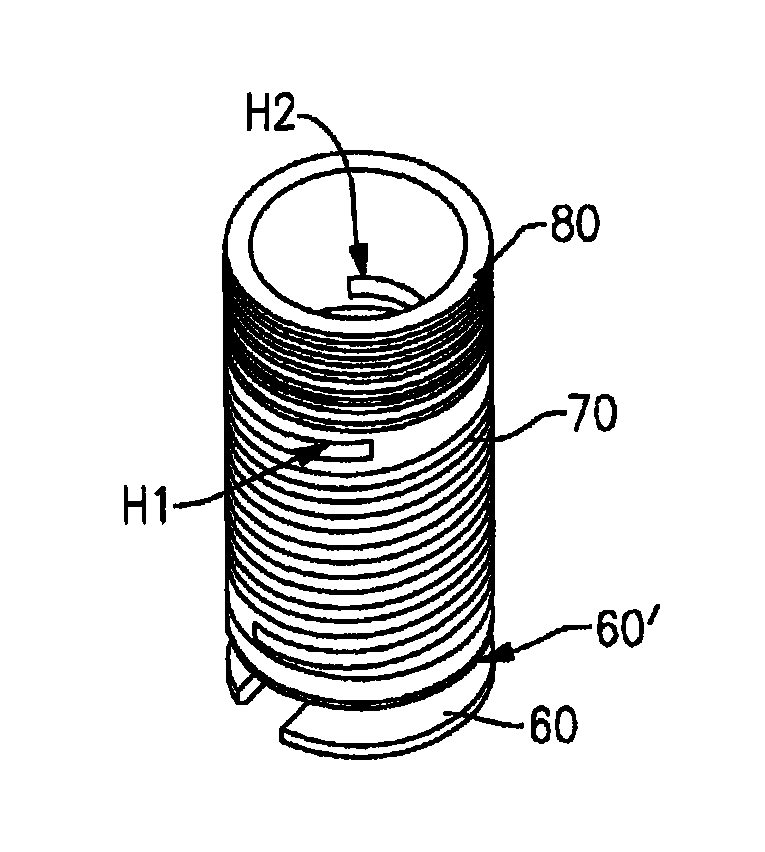

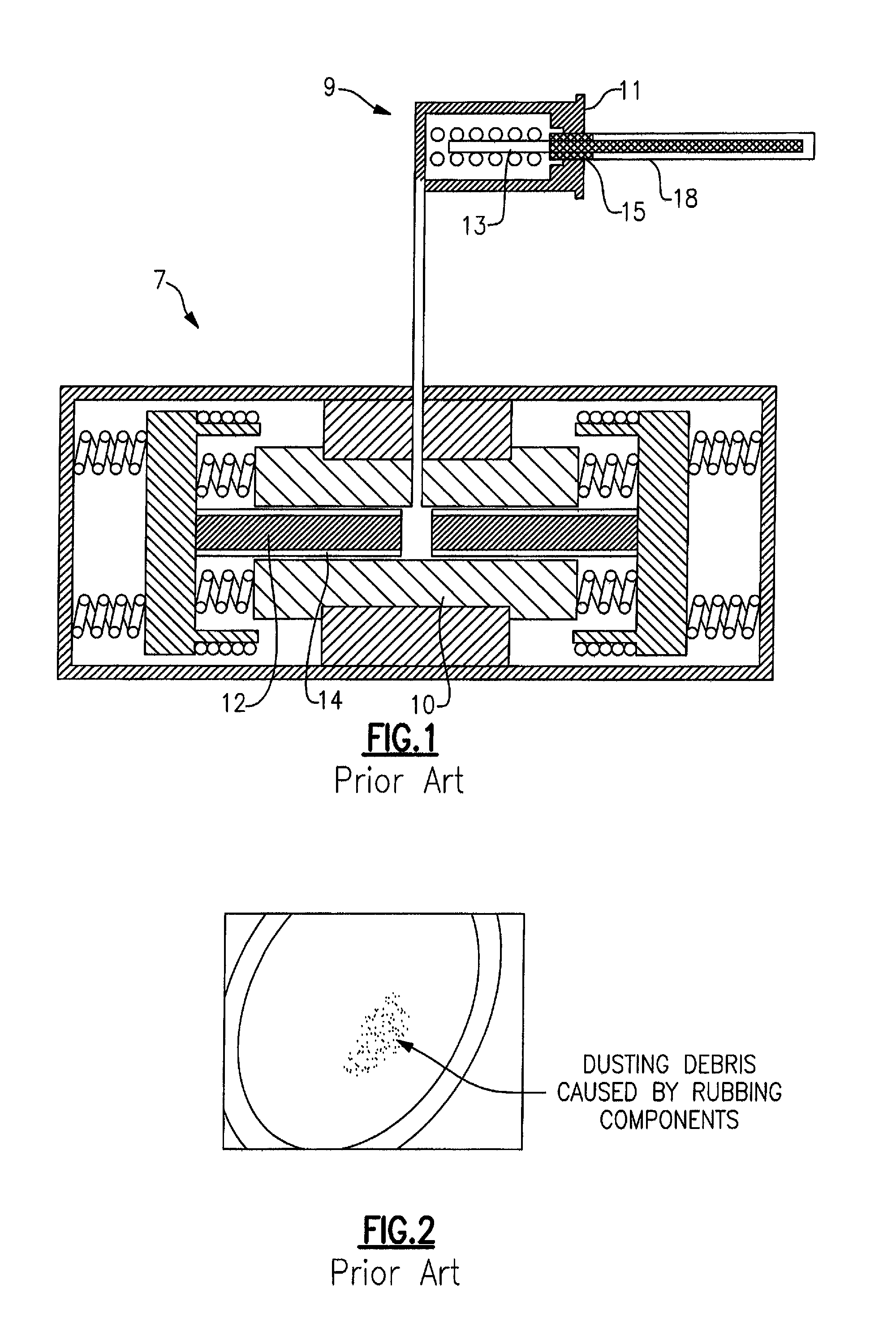

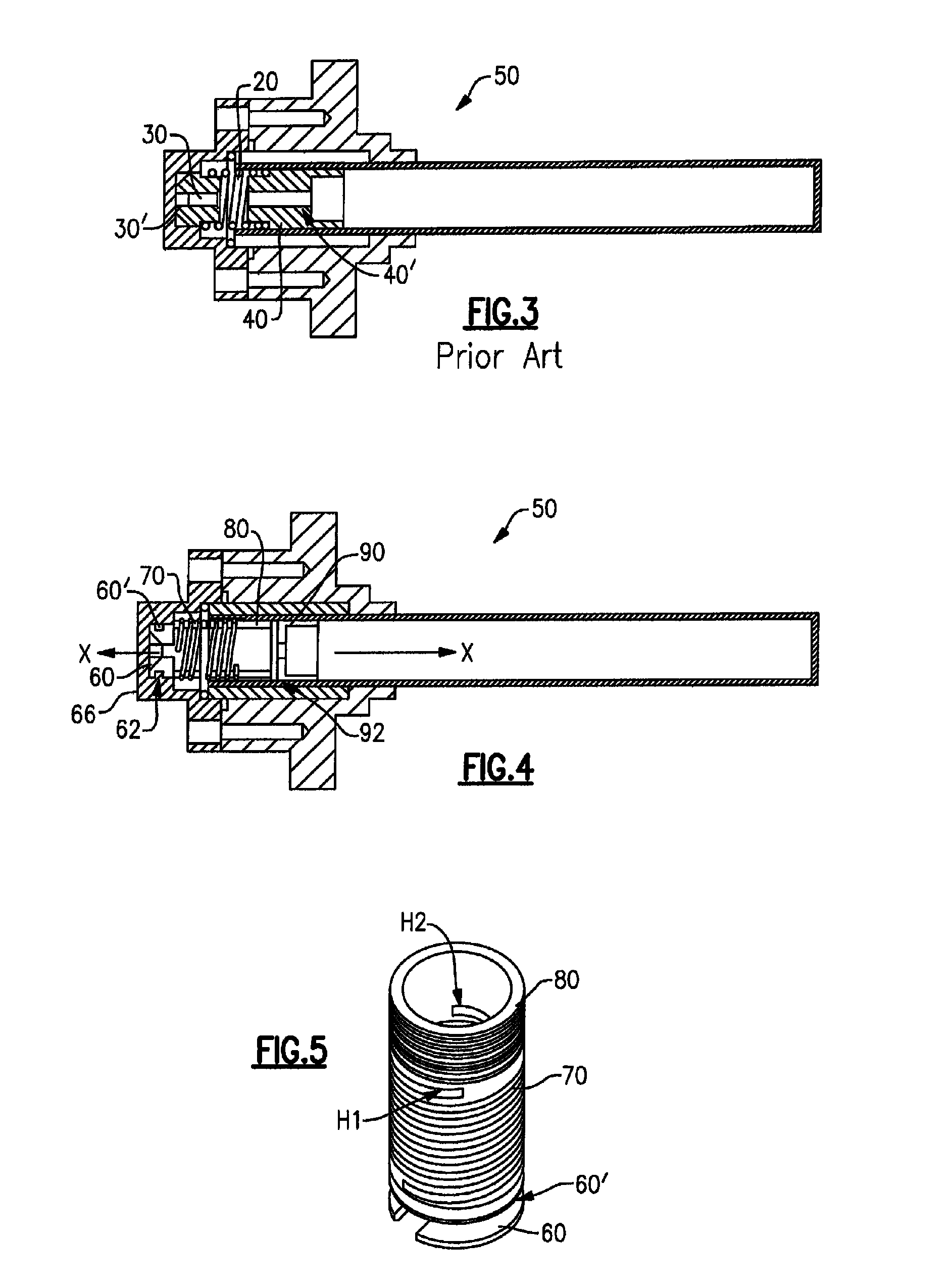

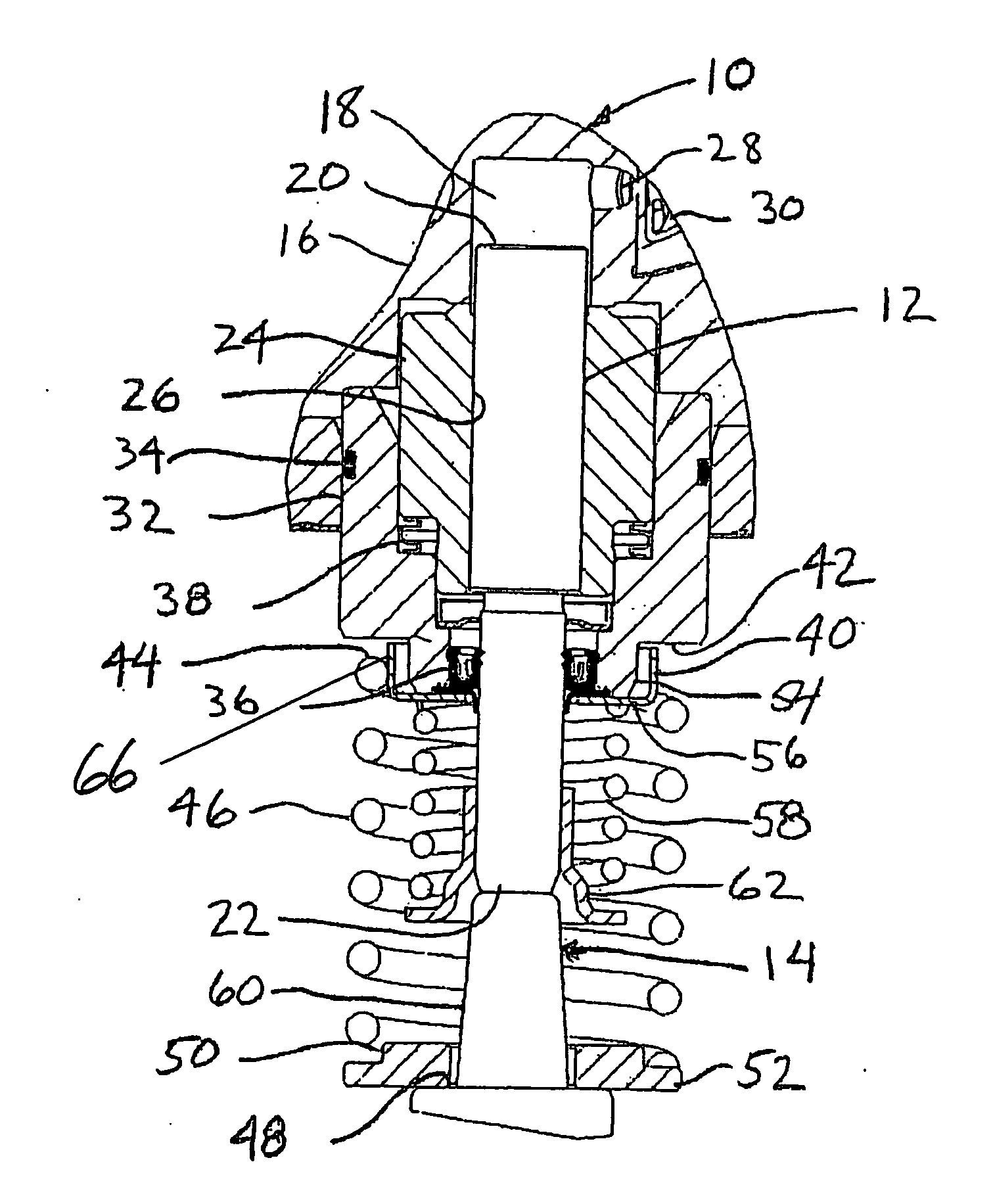

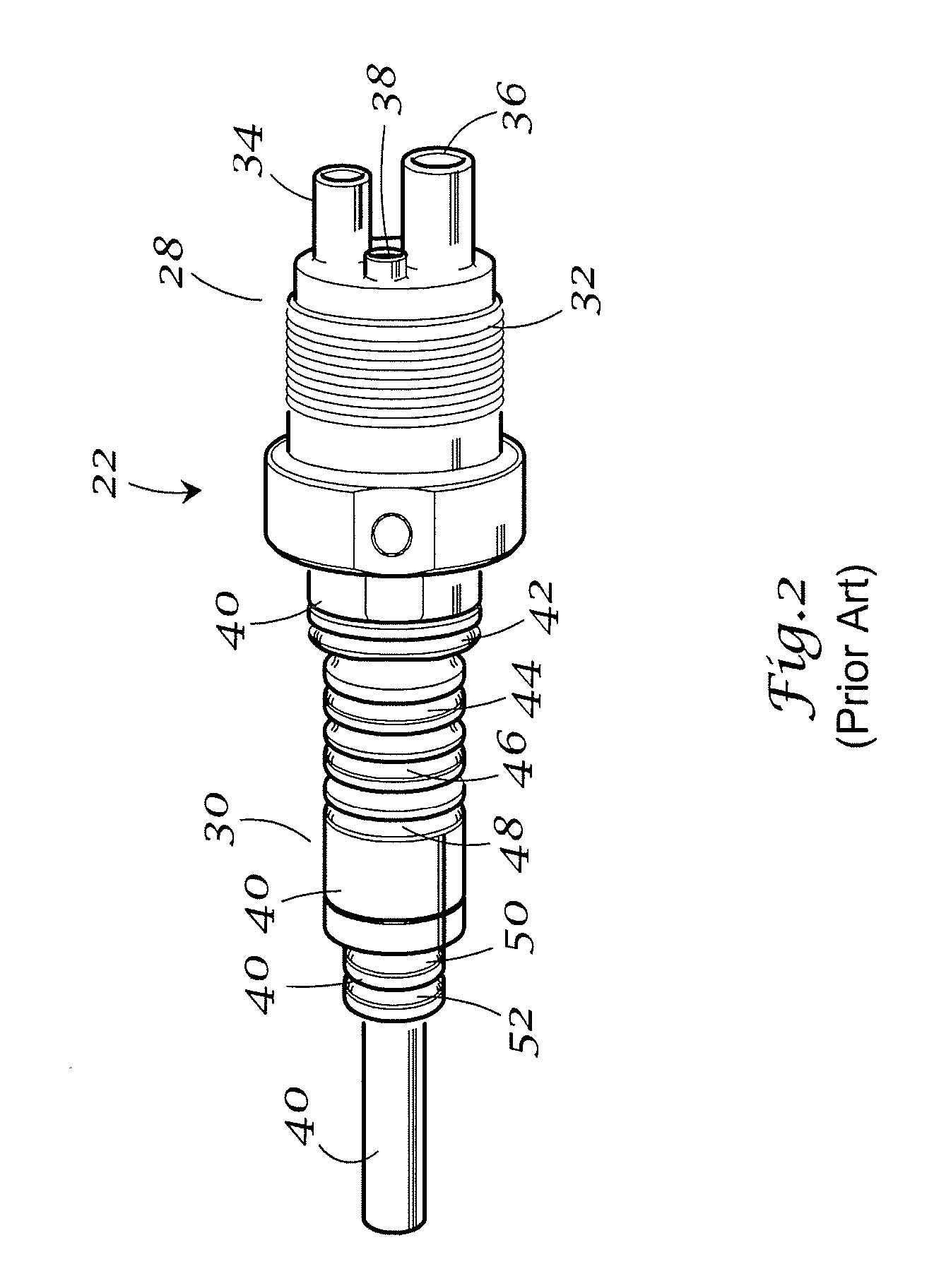

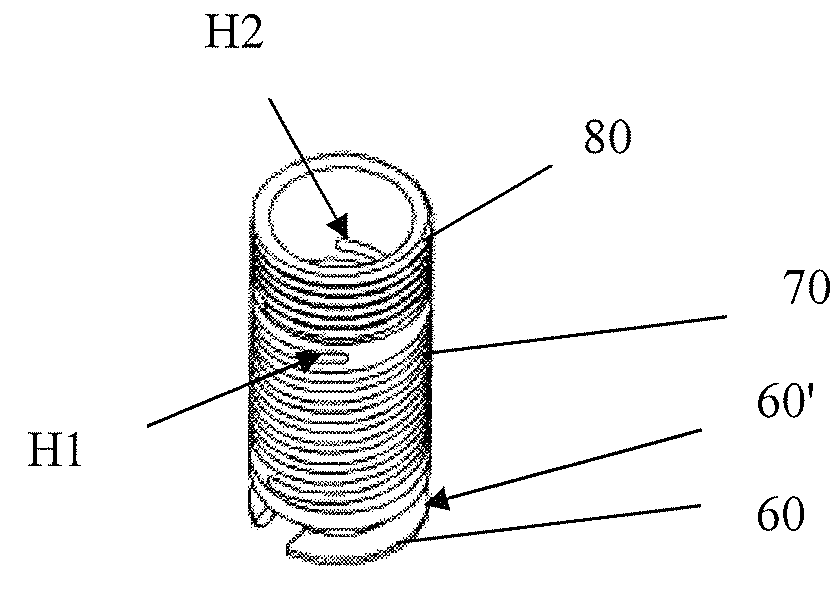

Machined spring with integral retainer for closed cycle cryogenic coolers

ActiveUS8127560B2Increased axial stabilityReduce debris generationSpringsCompression machinesEngineeringMechanical engineering

A retainer and spring with threaded end are machined from a single piece of material for threading to a piston in a closed cycle cryogenic cooler. Since the machined retainer and spring are a unitary part, they cannot rub against each other during operation of the piston which reduces debris generation. The spring is preferably formed as a double start helix which further increases axial stability and reduces side loading. The spring extends into an integrally formed, threaded end at the end thereof opposite the retainer.

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

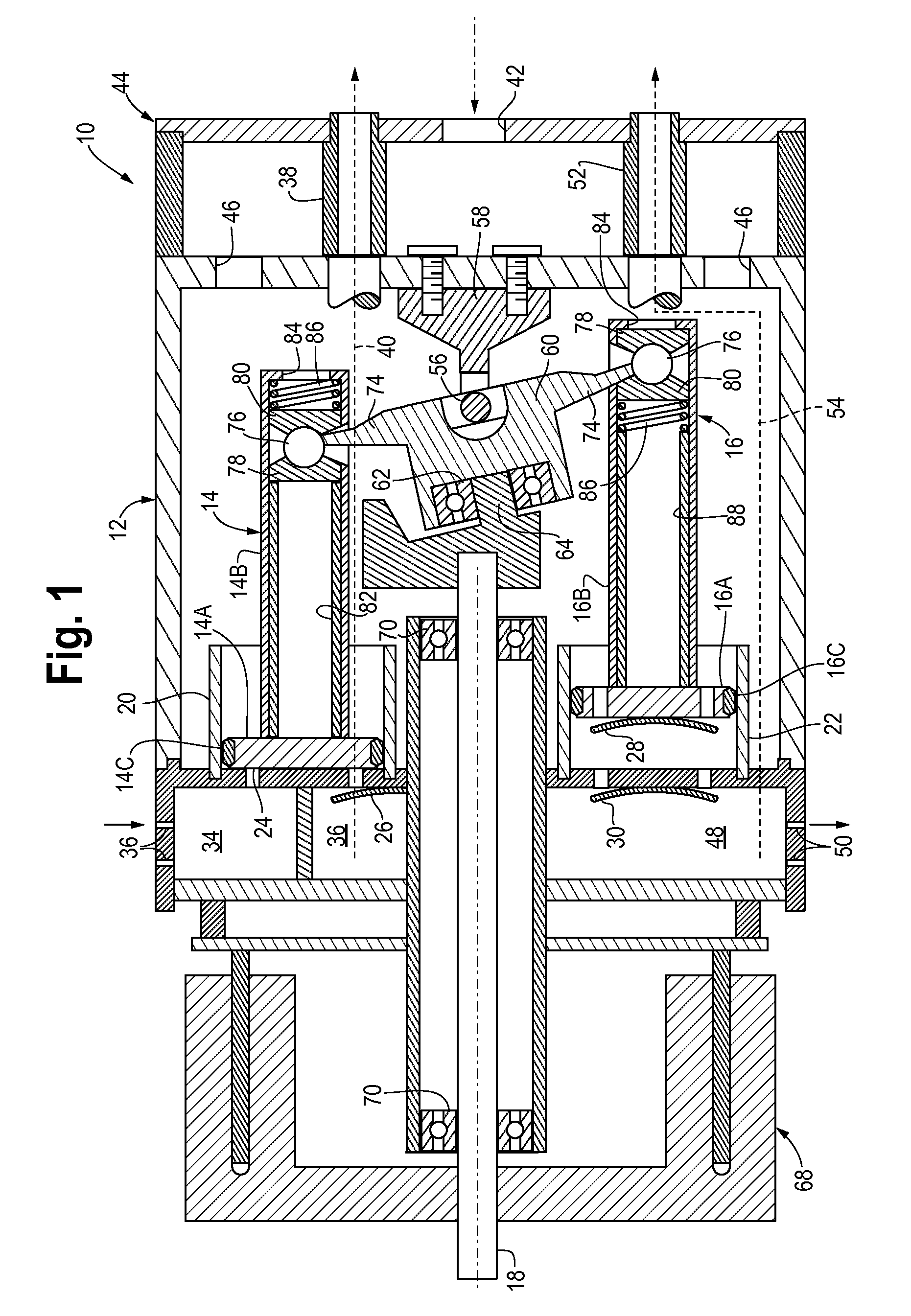

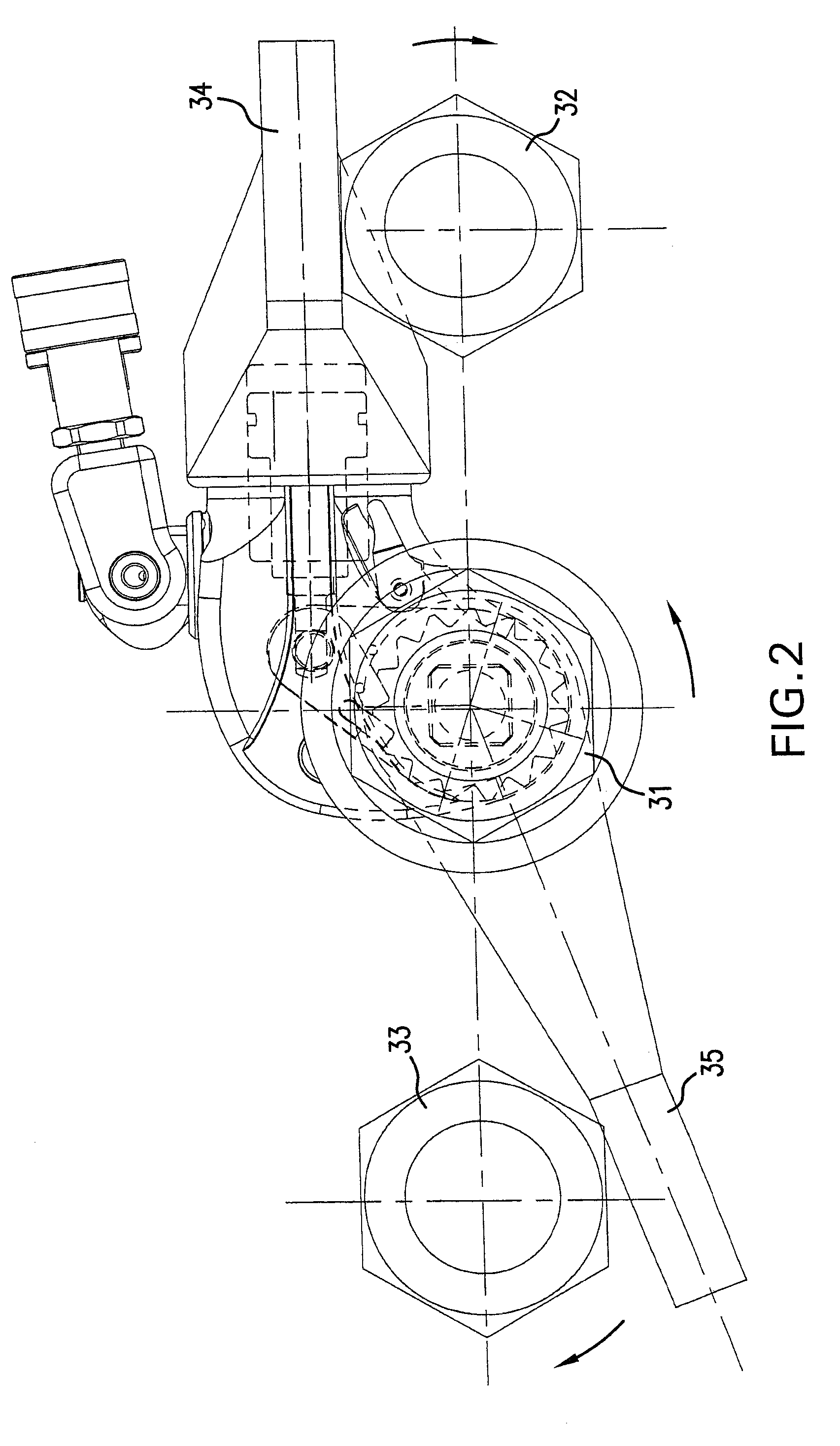

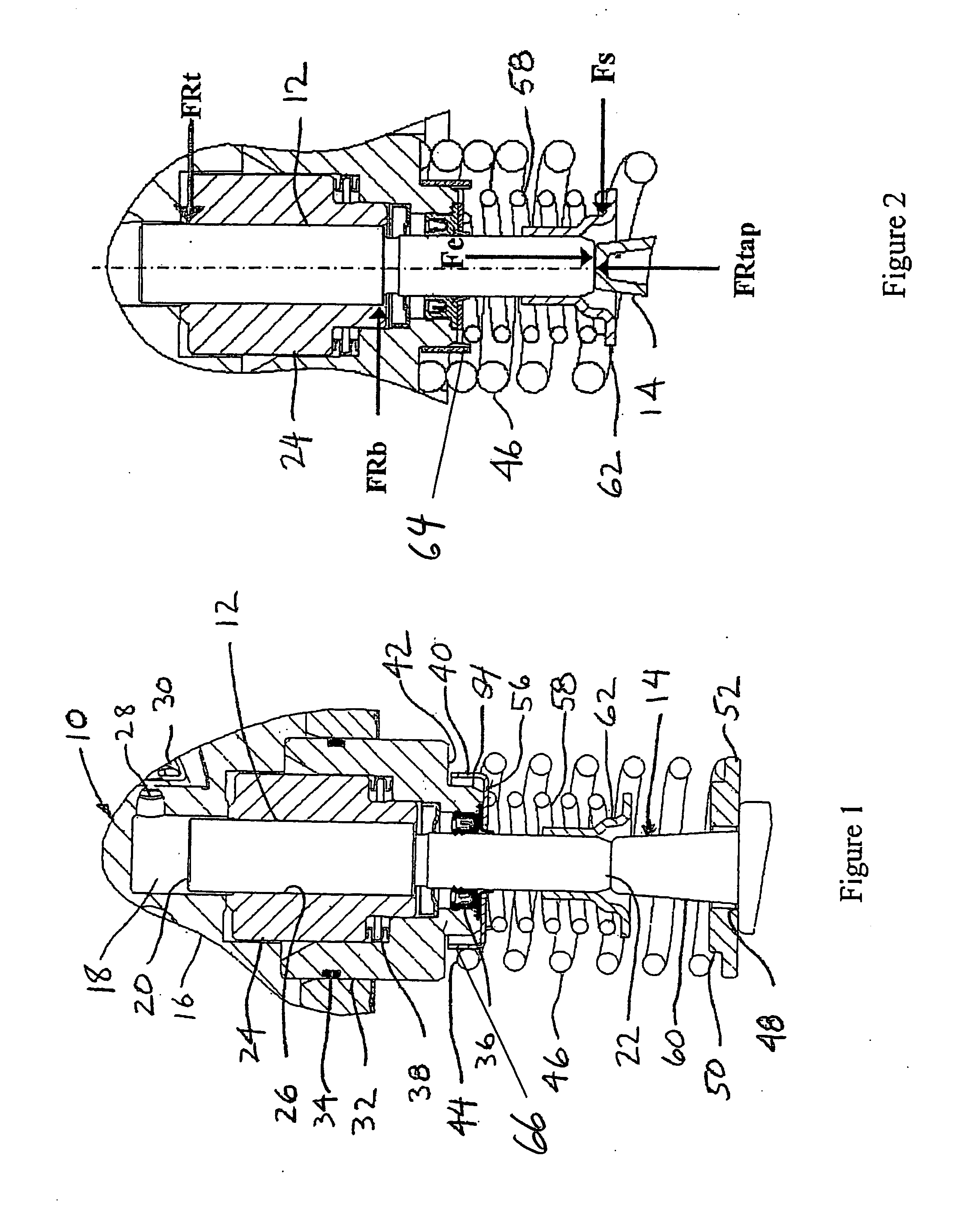

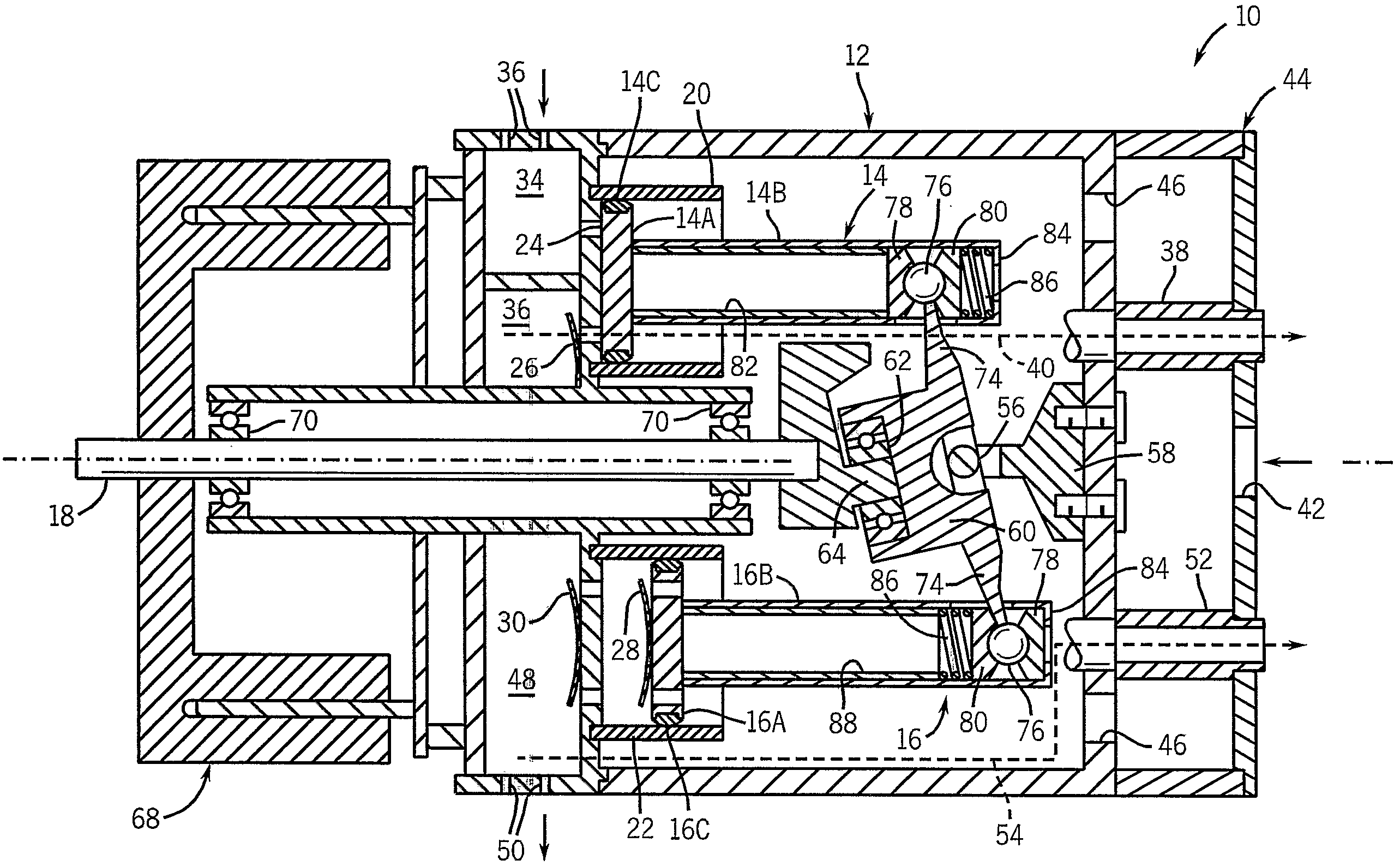

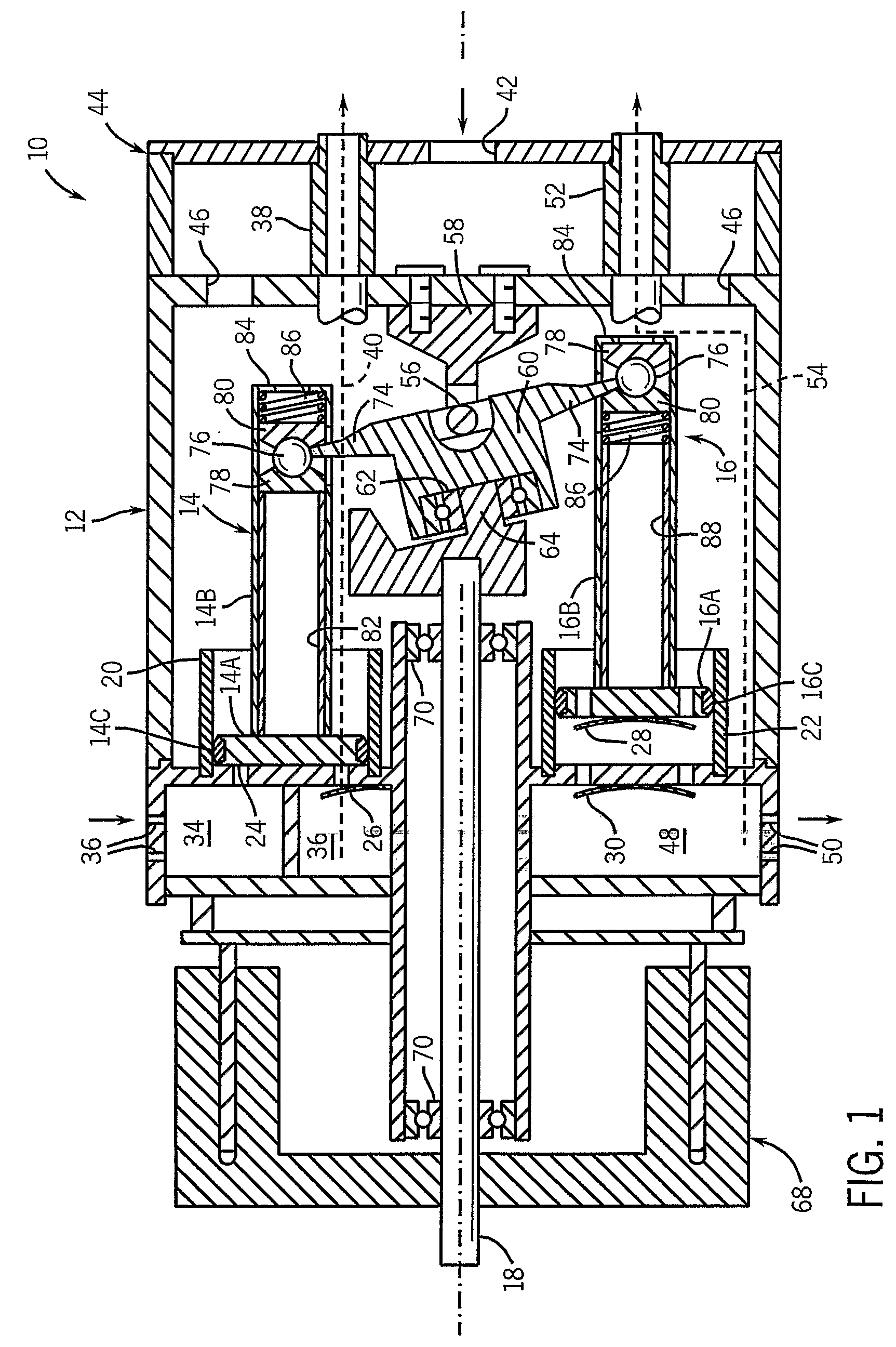

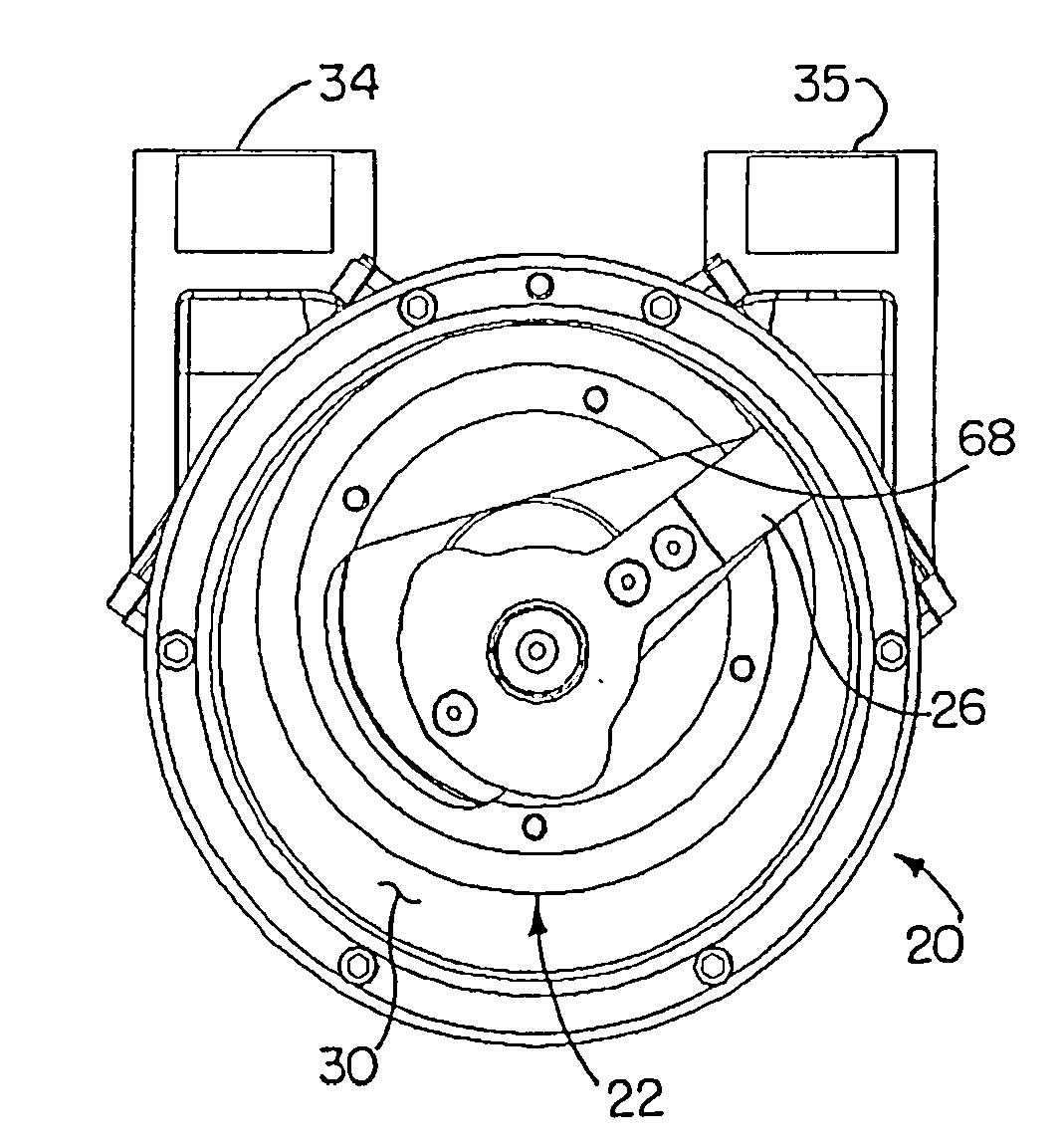

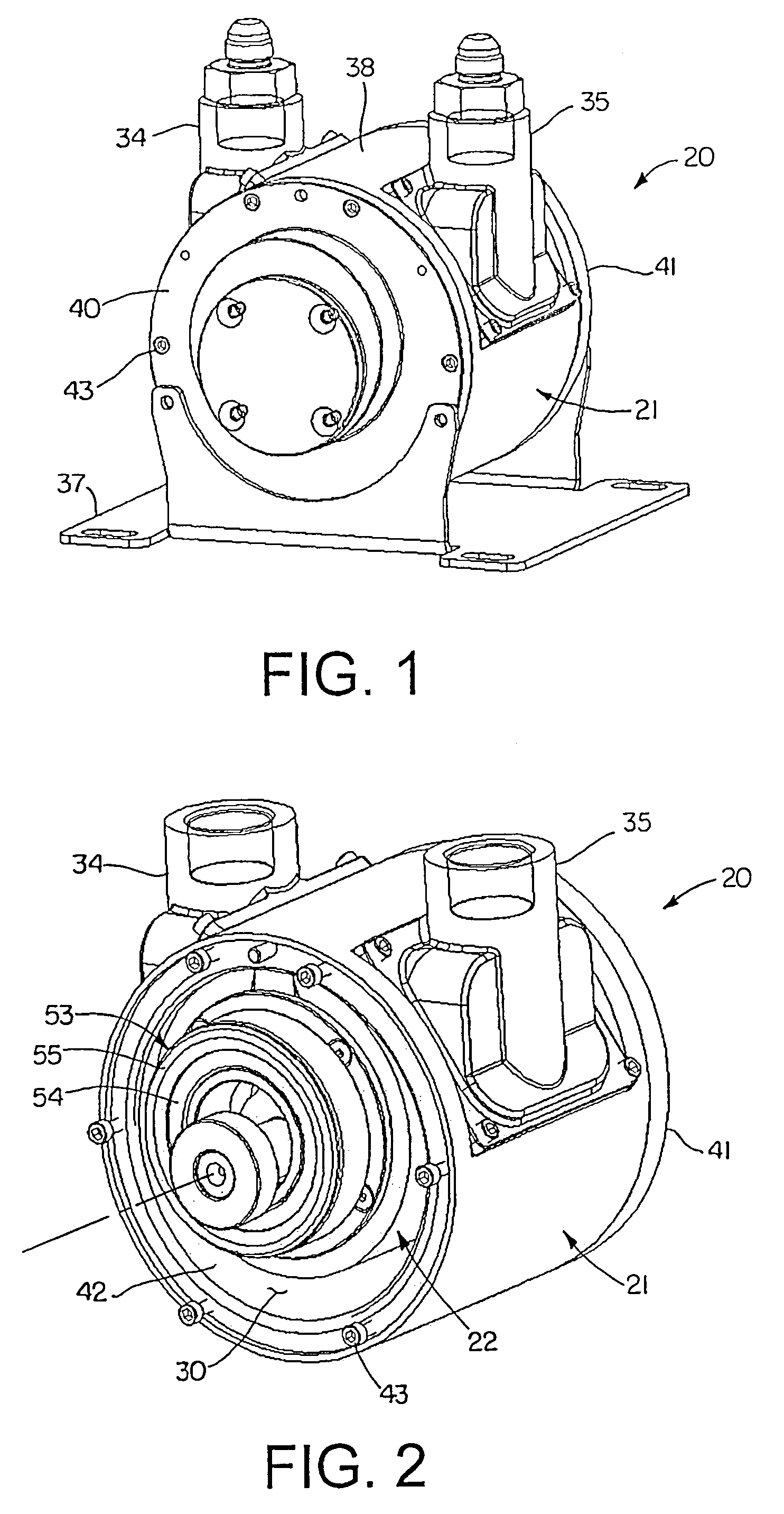

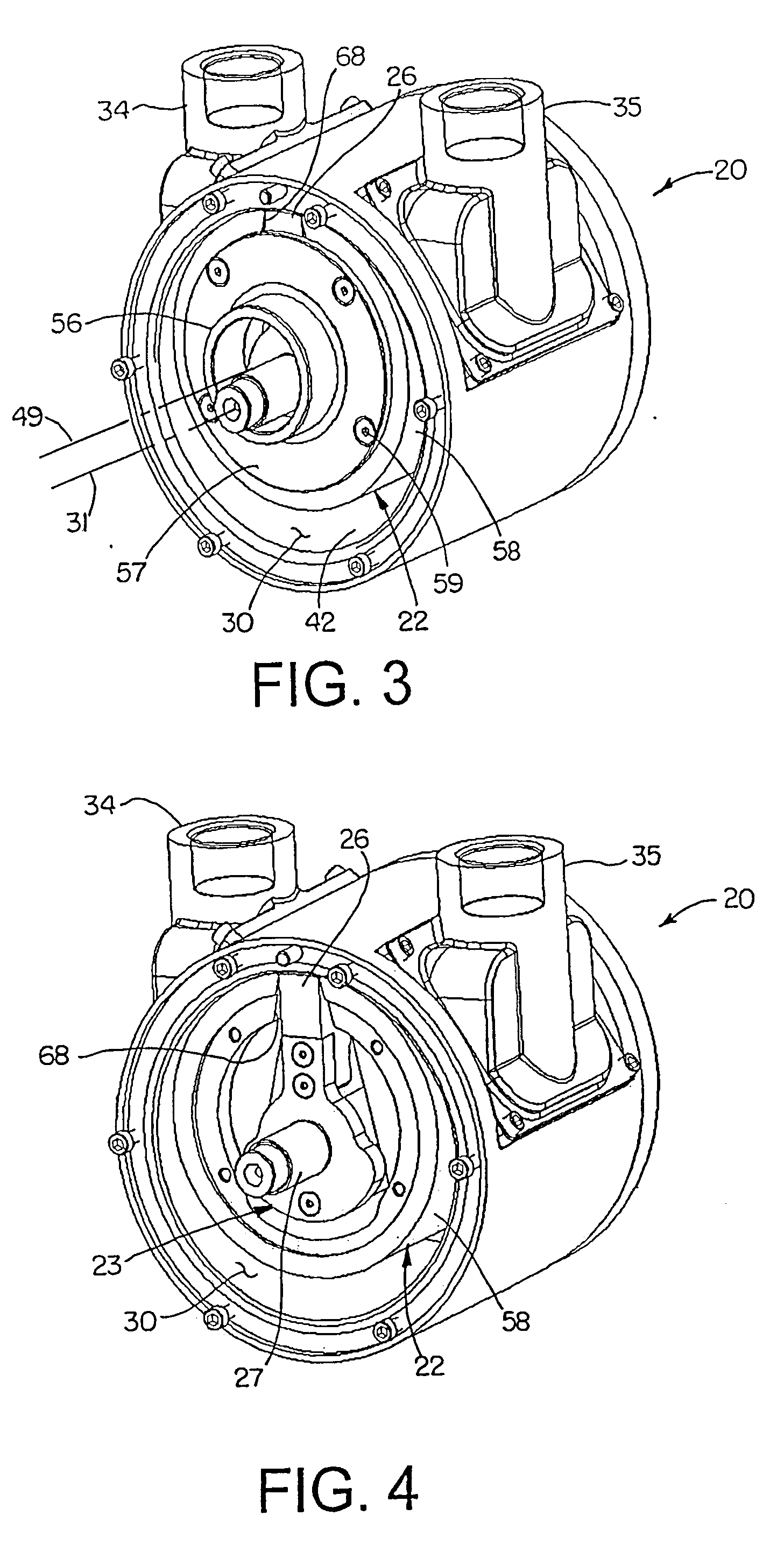

Hybrid nutating pump

InactiveUS7451687B2Eliminate connectionMinimize wobble motionPositive displacement pump componentsPressure pumpsReciprocating motionDrive shaft

A nutating pump for creating pressure or a vacuum. The nutating pump includes a housing with a center support positioned within said housing. The center support includes a semi-spherical recess. The pump also includes a drive shaft adapted to be connected to an electric motor and an eccentric adapted to be connected to the drive shaft. The pump further includes a ball adapted to form a ball joint and is adapted to be positioned within the semi-spherical recess of said center support. In addition the pump includes a nutating yoke positioned within the housing. The yoke includes a semi-spherical recess adapted to accept said pivot ball. The nutating yoke is adapted to be connected to the eccentric, such that rotation of the eccentric causes the yoke to move about the ball. The pump also includes a connecting rod connected to the yoke, a piston connected to the connecting rod and a cylinder adapted to accept the piston, wherein the movement of the yoke about the ball causes the piston to reciprocate within the cylinder.

Owner:GARDNER DENVER THOMAS

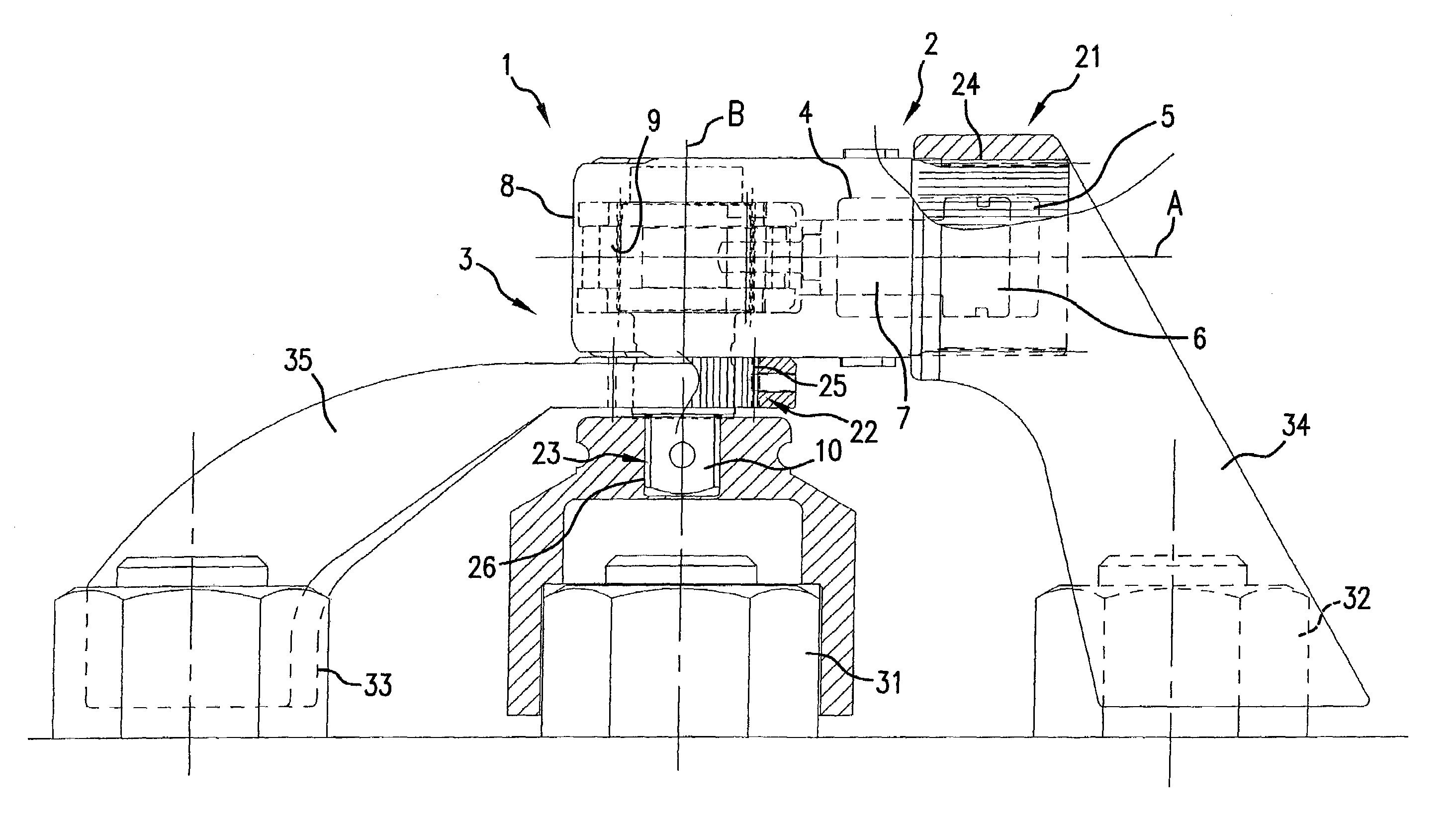

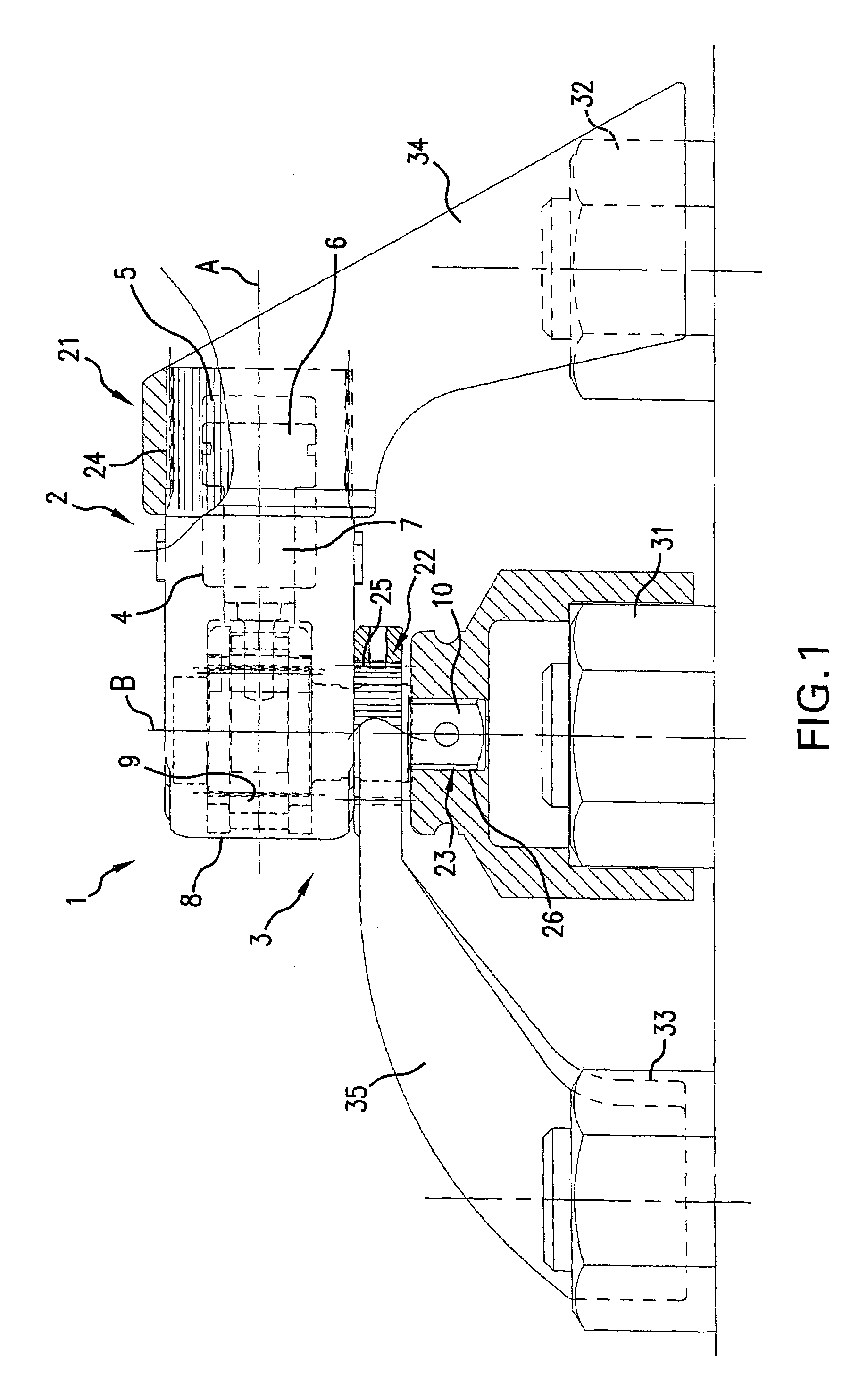

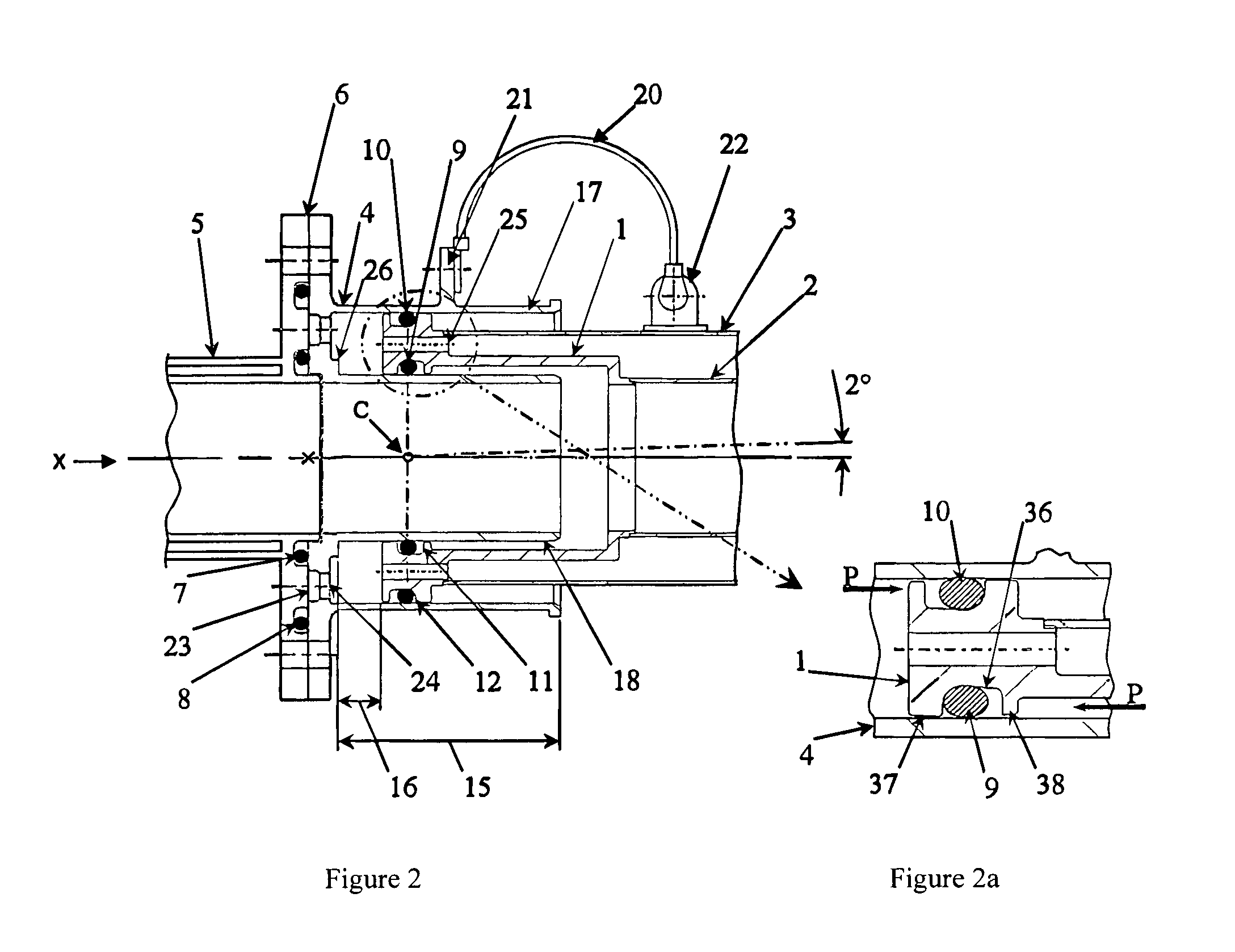

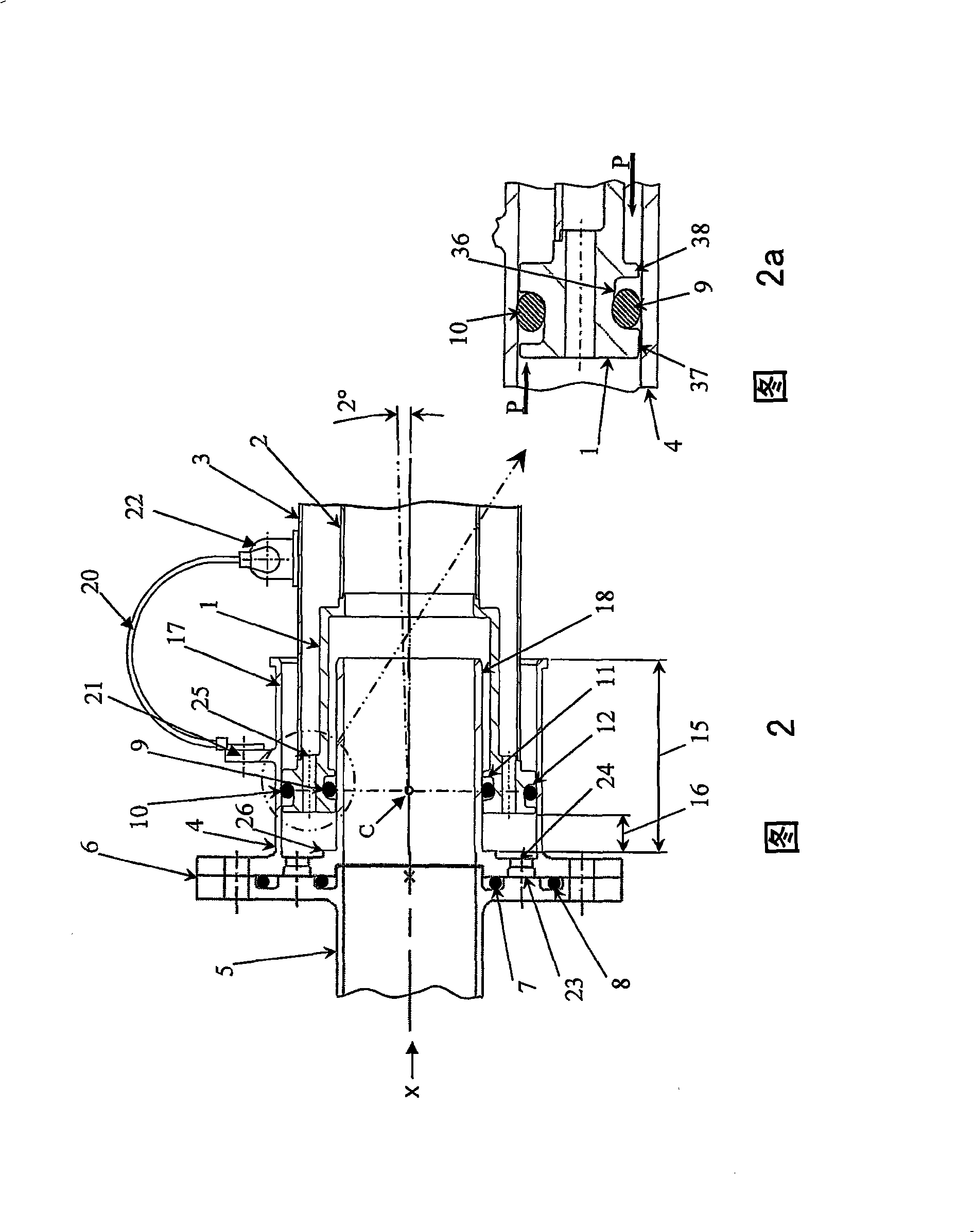

Fluid-operated torque wrench for and method of tightening or loosening fasteners

InactiveUS7765895B2Reduce frictionImproved Torque AccuracySpannersWrenchesEngineeringStationary object

A fluid-operated torque wrench for tightening or loosening a fastener has a housing having two housing portions including a cylinder portion and a driving portion, cylinder-piston means arranged in the cylinder portion and movable along a first axis, a lever-type ratchet mechanism arranged in the driving portion and connected to the cylinder-piston means to be driven by the later, the lever-type ratchet mechanism having a ratchet turnable about a second axis which is perpendicular to the first axis, at least three connecting elements including first and second connecting elements receiving a given turning force acting in one direction during operation of the wrench, and a third connecting element receiving a turning force in an opposite direction during operation of the wrench and being equal to the given turning force acting in the one direction, so that one of the turning forces turns a fastener to be tightened or loosened while another of the turning forces is transferred to a stationary object.

Owner:HYTORC DIV UNEX CORP

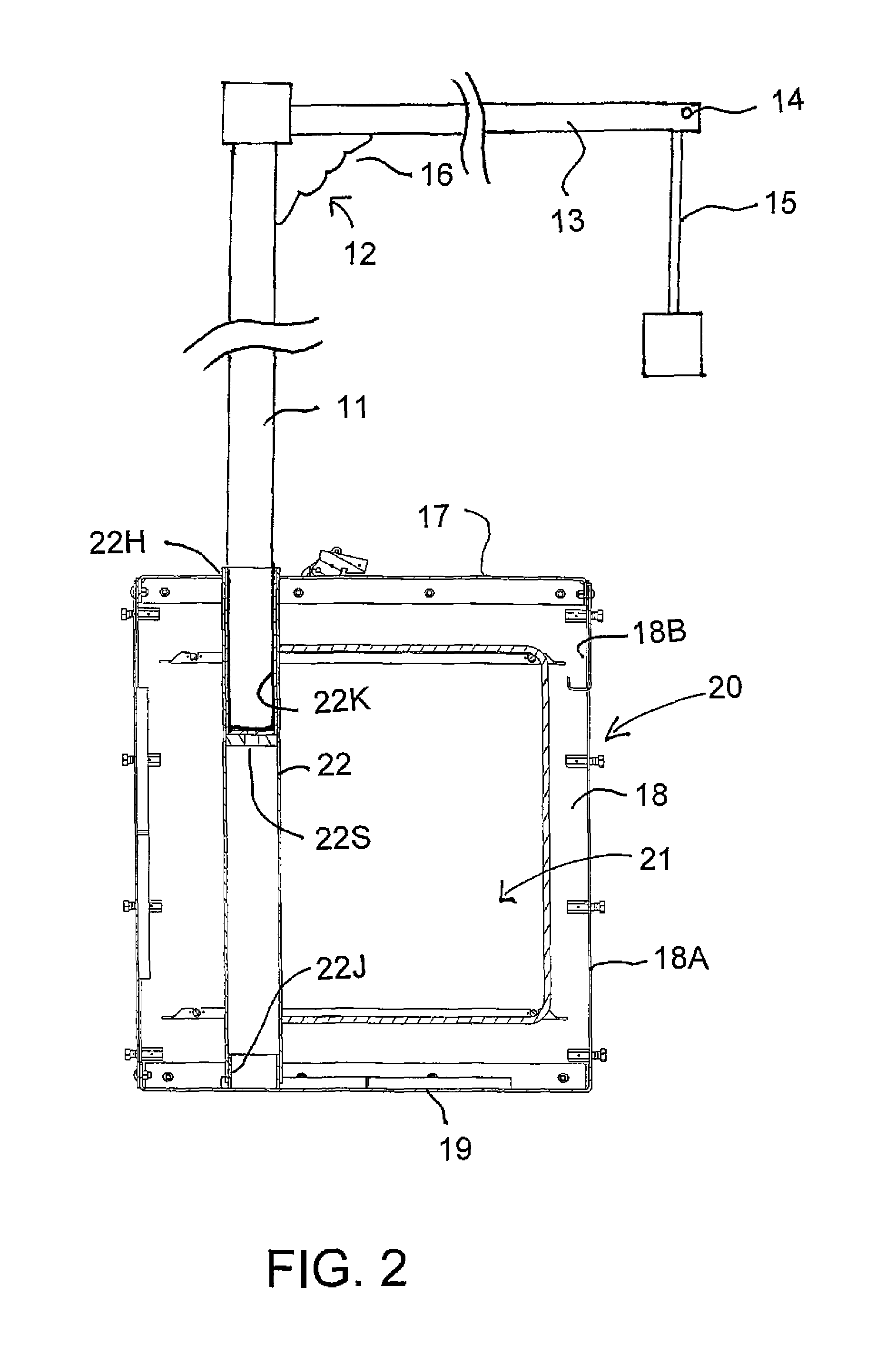

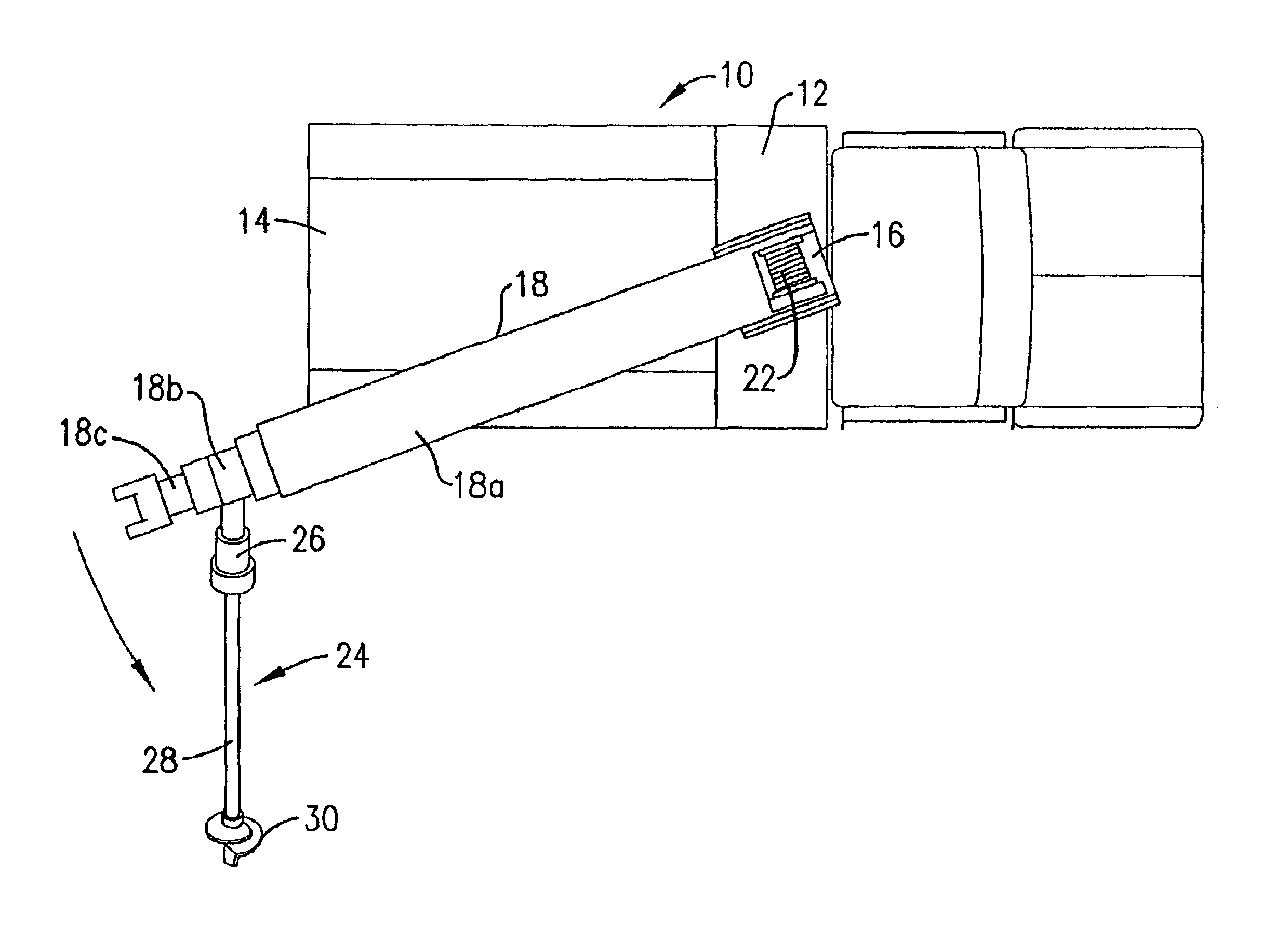

Base for supporting an upstanding mast

Owner:TUFFBUILT PRODS

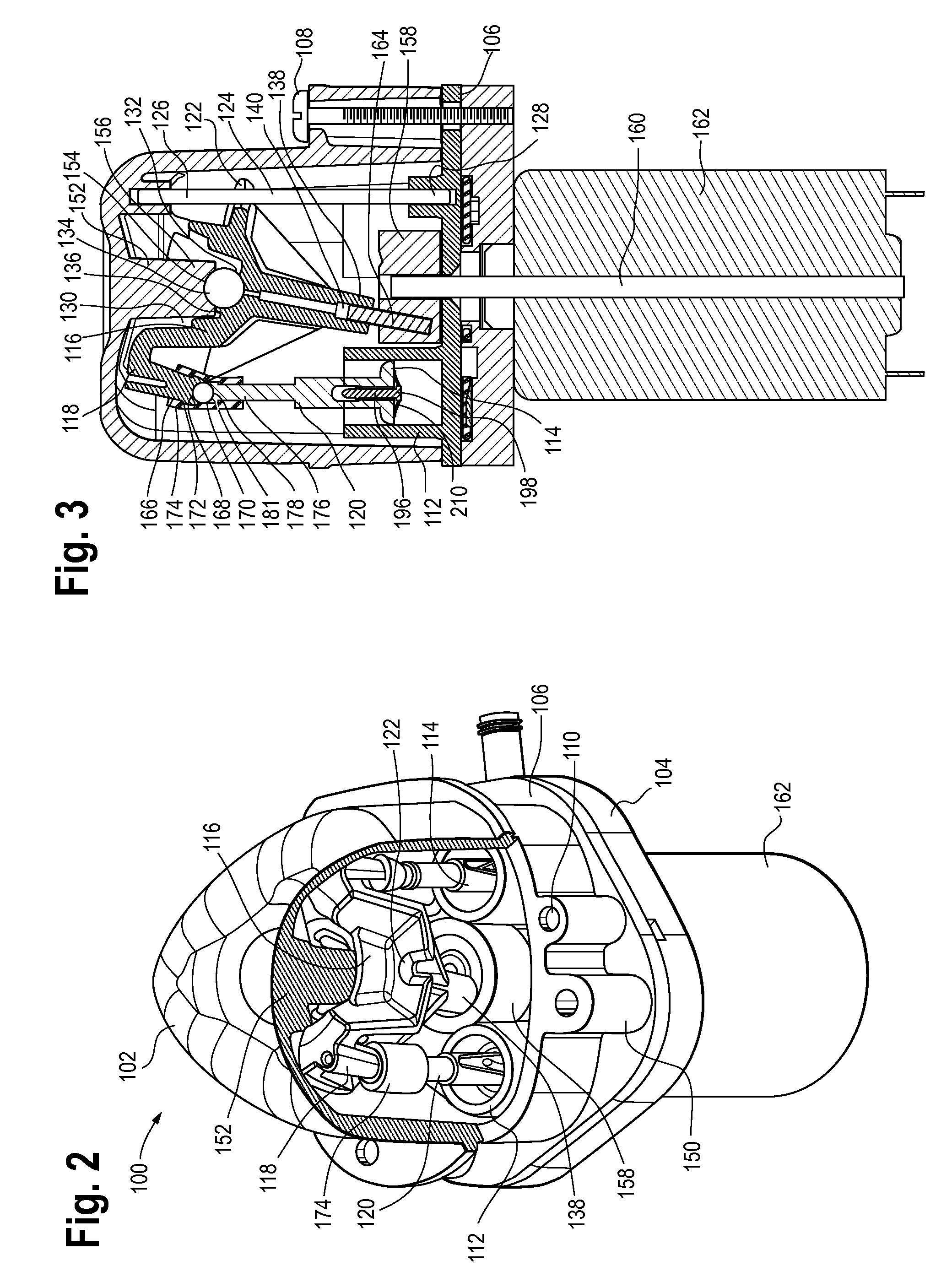

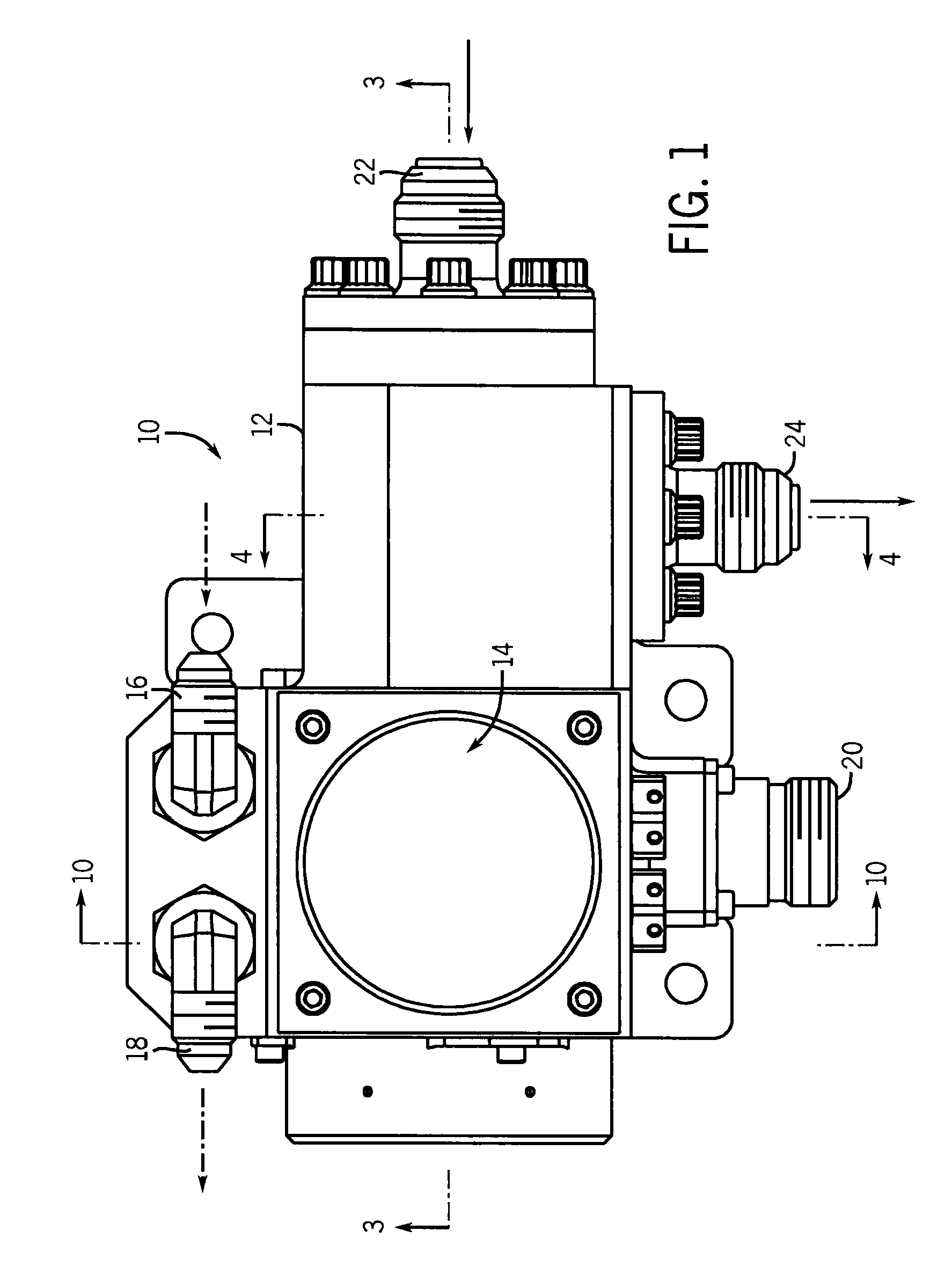

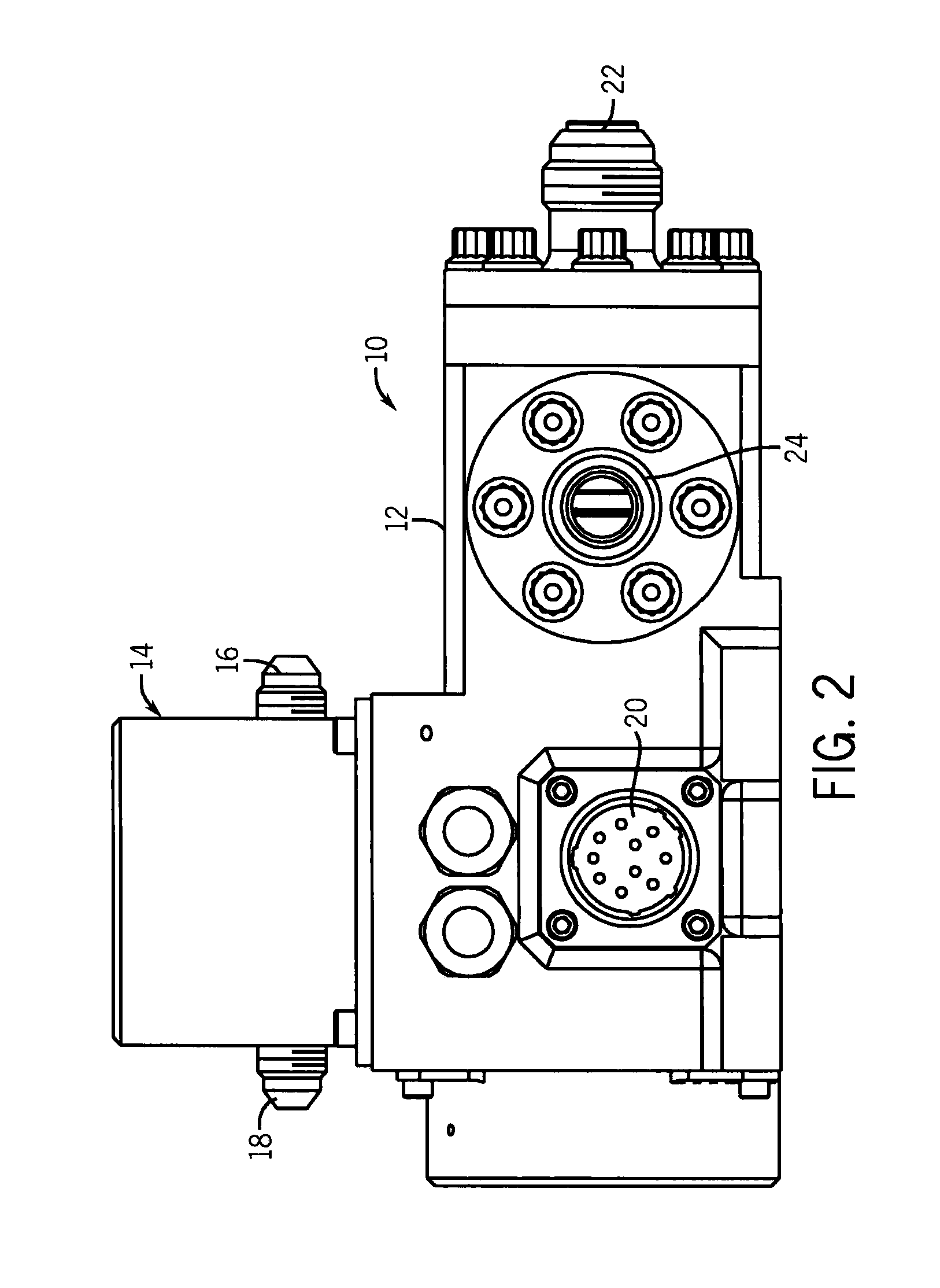

Single piston pump with dual return springs

ActiveUS20110303195A1Eliminate pump piston seizuresSpring force can be minimizedPositive displacement pump componentsFuel injecting pumpsReturn functionSpring force

Pump piston seizures caused by excessive side loads produced by the uneven loading of a large piston return spring are prevented by separating the tappet return function from the piston return function, thereby minimizing the spring force acting on the piston. Separate and distinct biasing means perform the respective functions. Preferably, a stronger, heavier load outer spring is mounted between the pump body and the tappet, such that it imparts no load and therefore no side loads to the pumping piston. A weaker, lighter load inner spring imparts less side load to the pumping piston than a conventional piston return spring, because the inner spring need not carry any tappet load. During both the pumping and charging strokes of the piston, the piston return spring can assist the tappet return spring, but the tappet return spring does not assist the piston return spring.

Owner:STANADYNE OPERATING CO LLC (

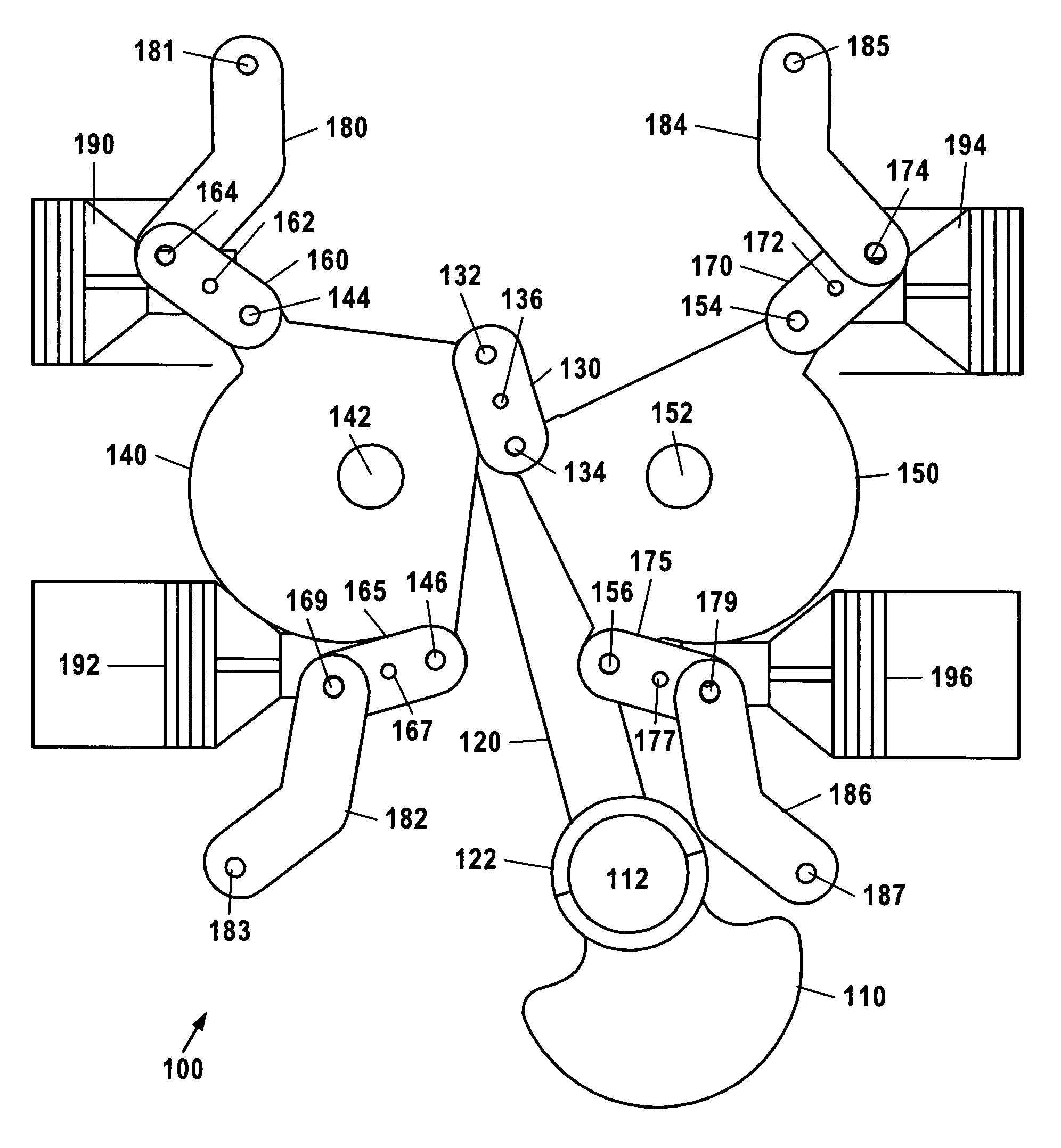

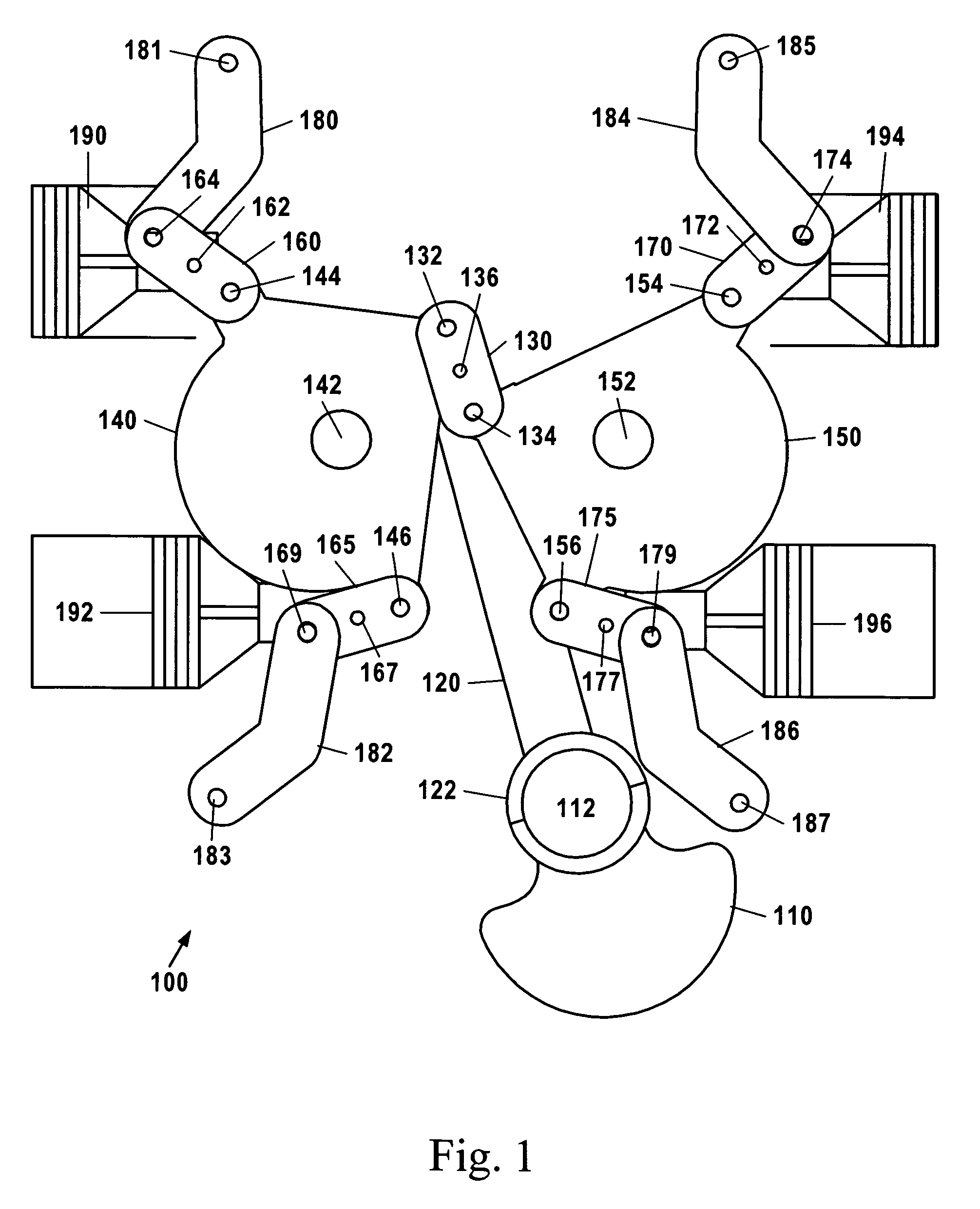

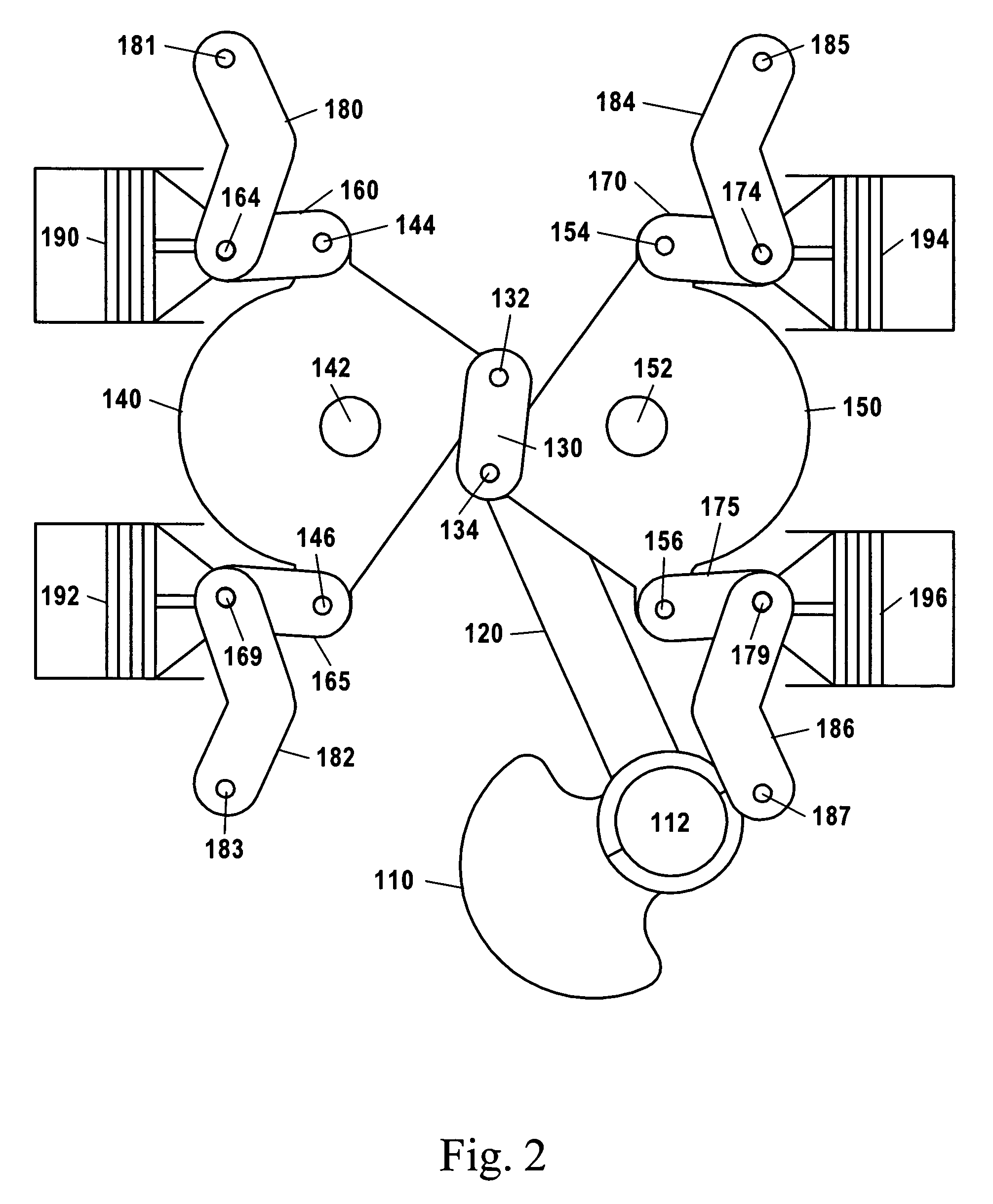

Force transfer mechanism for an engine

ActiveUS7219647B1Reduce side loadShorten the lengthConnecting rodsReciprocating piston enginesPistonTransfer mechanism

A multiple watt-linkage force transfer mechanism is provided for an internal-combustion engine. The force transfer mechanism comprises two “bell cranks” that are used to drive a single crankshaft through a watt linkage mechanism. Each bell crank, in turn, is driven by two pistons through corresponding watt linkage mechanisms. The watt linkages connected to the pistons enable the connection ends of the pistons to travel along substantially straight paths, significantly reducing side loads against the piston walls. Also, all four pistons preferably drive a single connecting rod. This changes the role of the crankshaft—and the corresponding strength and rigidity requirements for the crankshaft—by reducing the necessary number of rod journals and main journals on the crankshaft.

Owner:BRICKLEY MICHAEL DENNIS

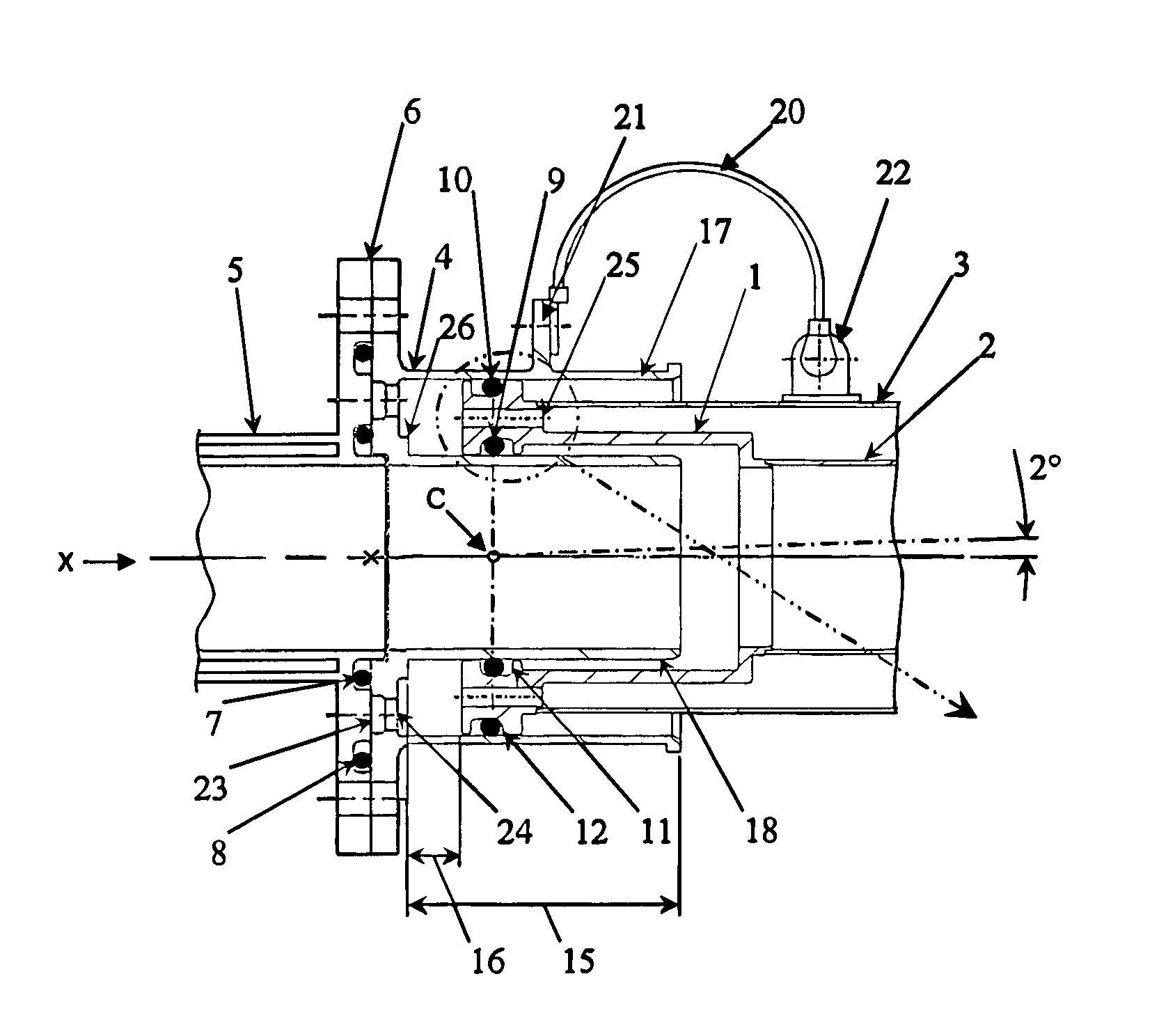

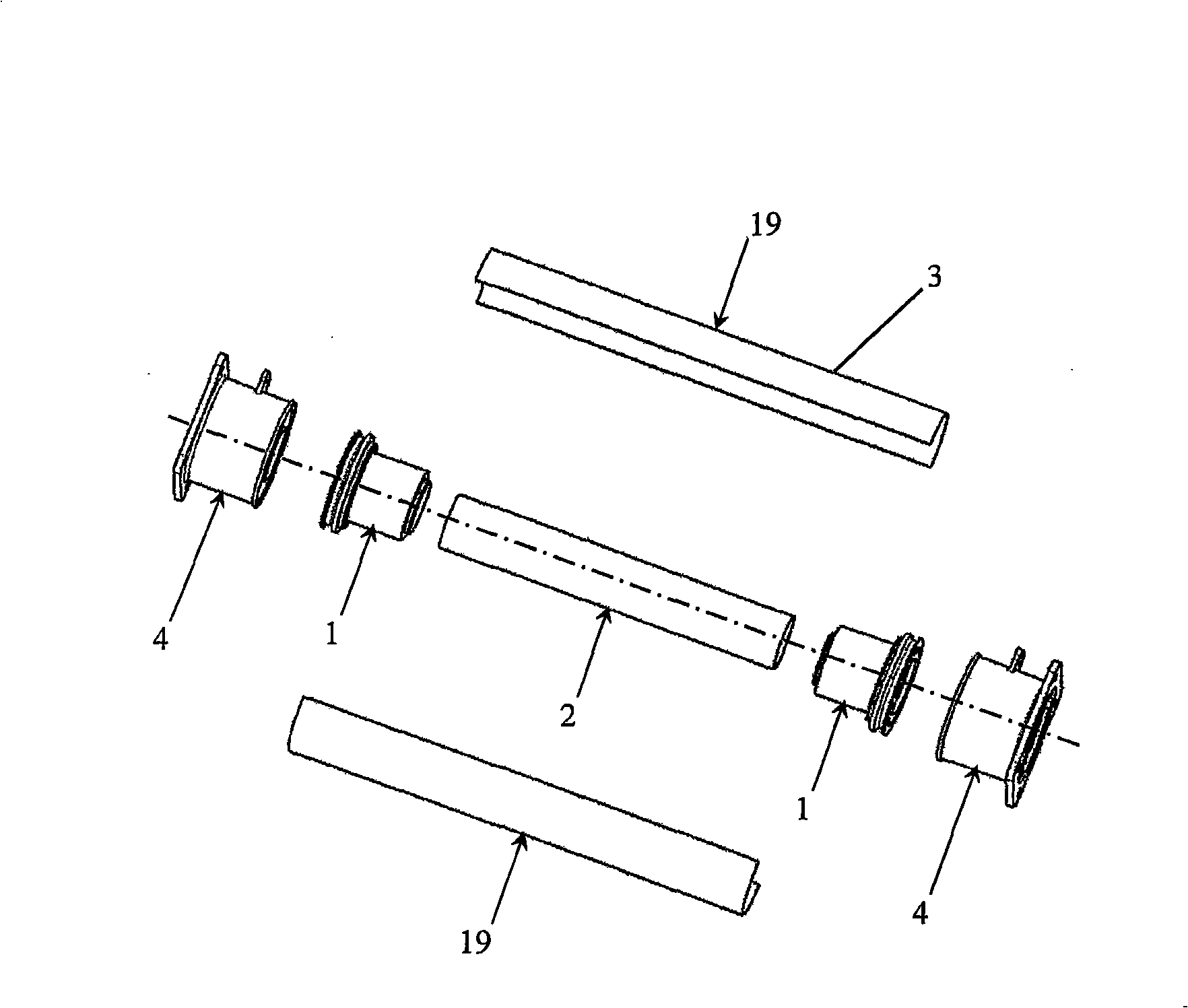

Aircraft fuel pipe coupling

A coupling for fuel pipe includes a pipe end fitting, which includes a male outer surface including a groove and a female inner surface including a groove. The coupling includes a double-walled socket including a female outer socket and a male inner shaft. The pipe end fitting is accommodated in the region between the female outer socket and the male inner shaft. A first seal ring seals between the female inner surface and the male inner shaft. A second seal ring, which may be substantially coplanar with the first, seals between the male outer surface and the female outer socket of the double-walled socket. The coupling may be so arranged that the pipe end fitting and the double-walled socket are able to pivot relative to each other by up to at least ±2 degrees and are able to slide both towards and apart from each other.

Owner:AIRBUS OPERATIONS LTD

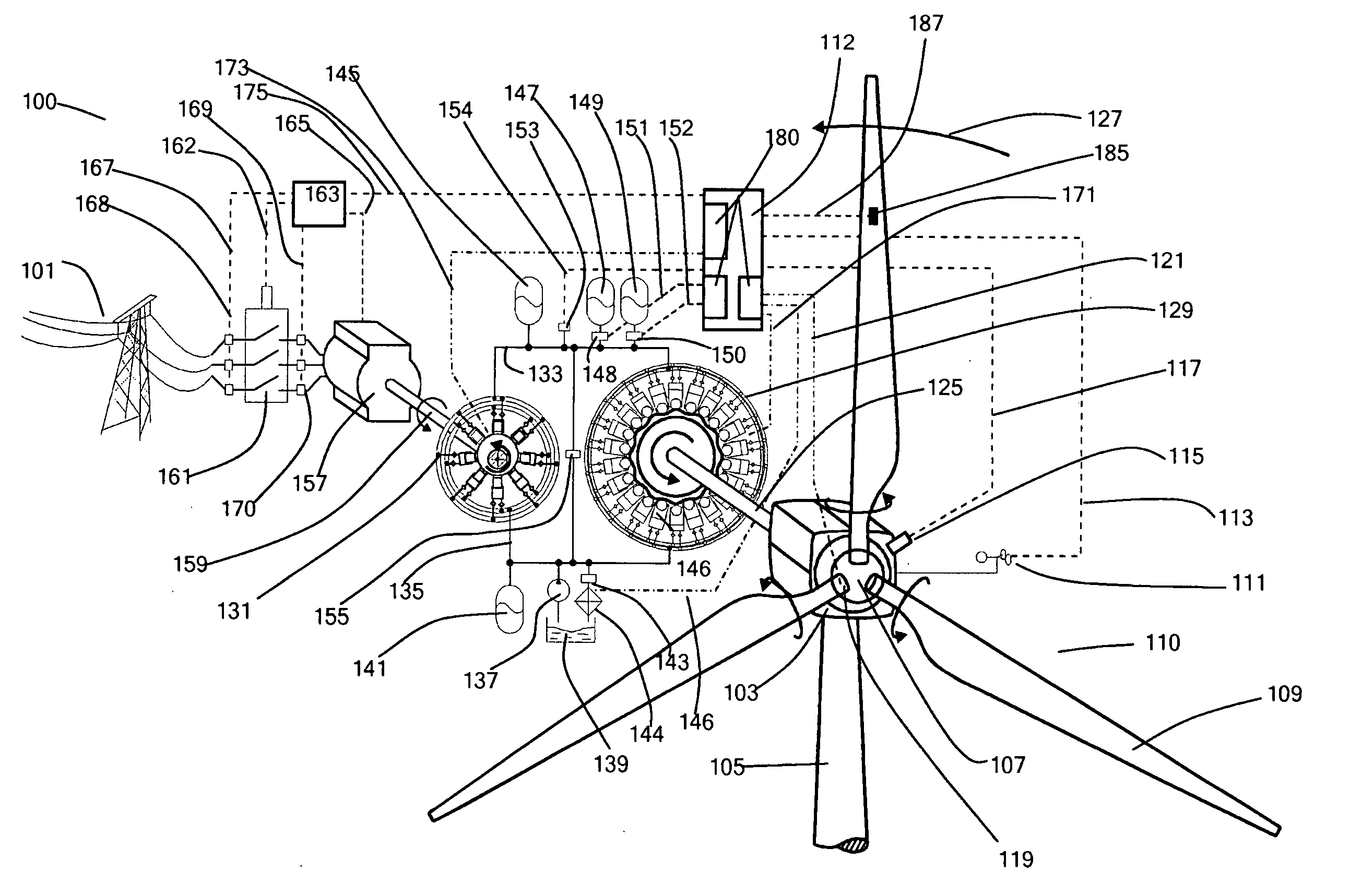

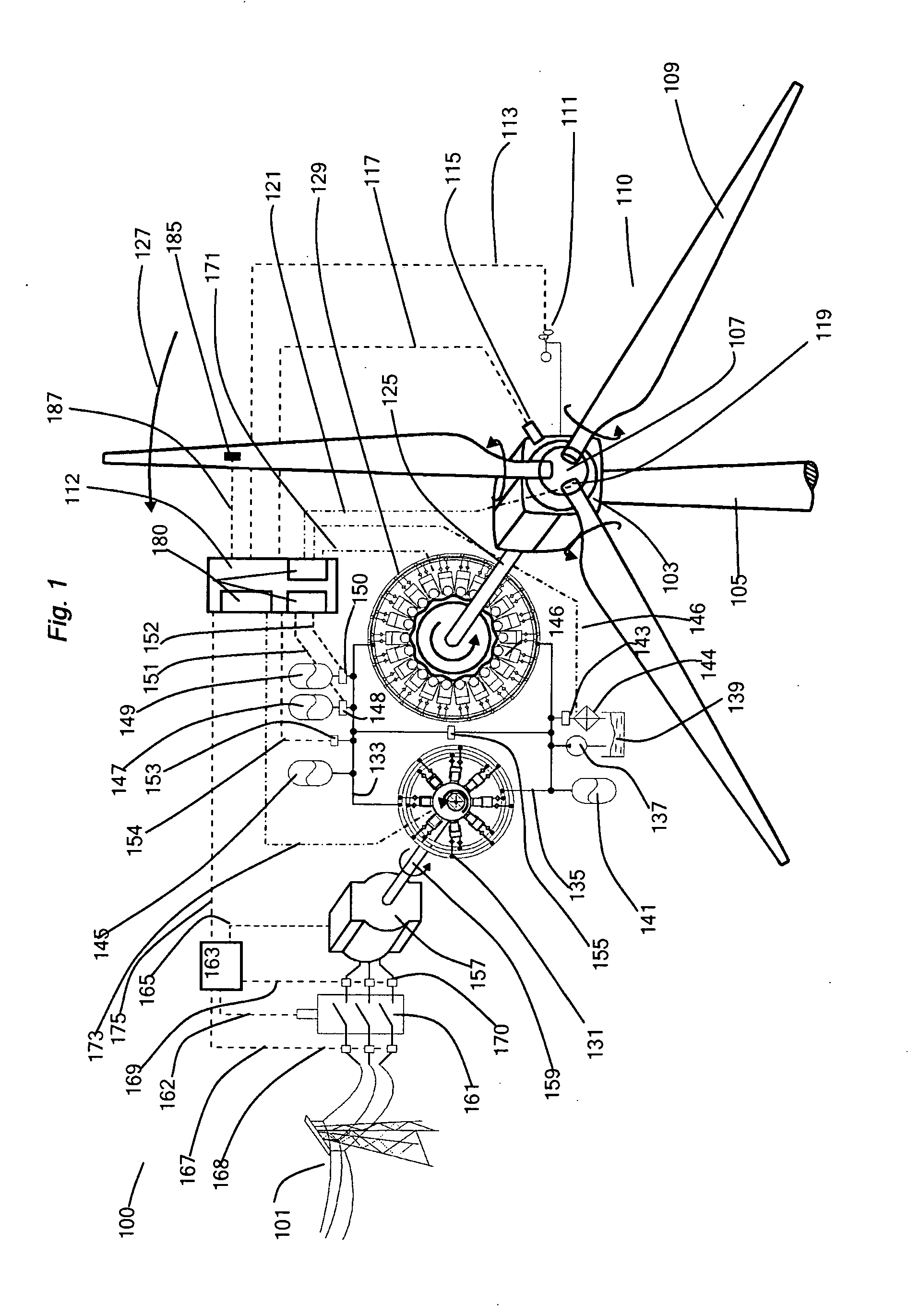

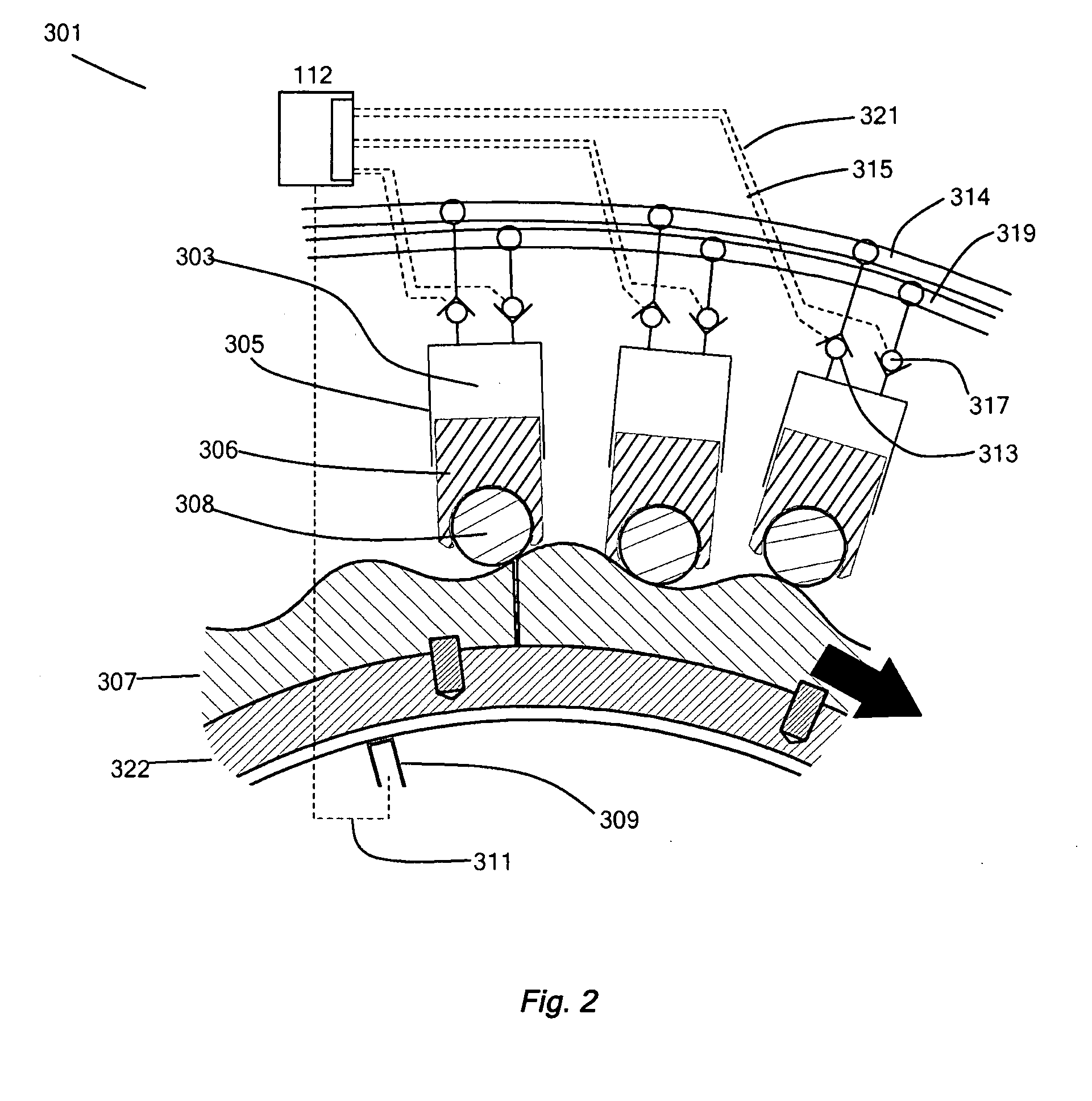

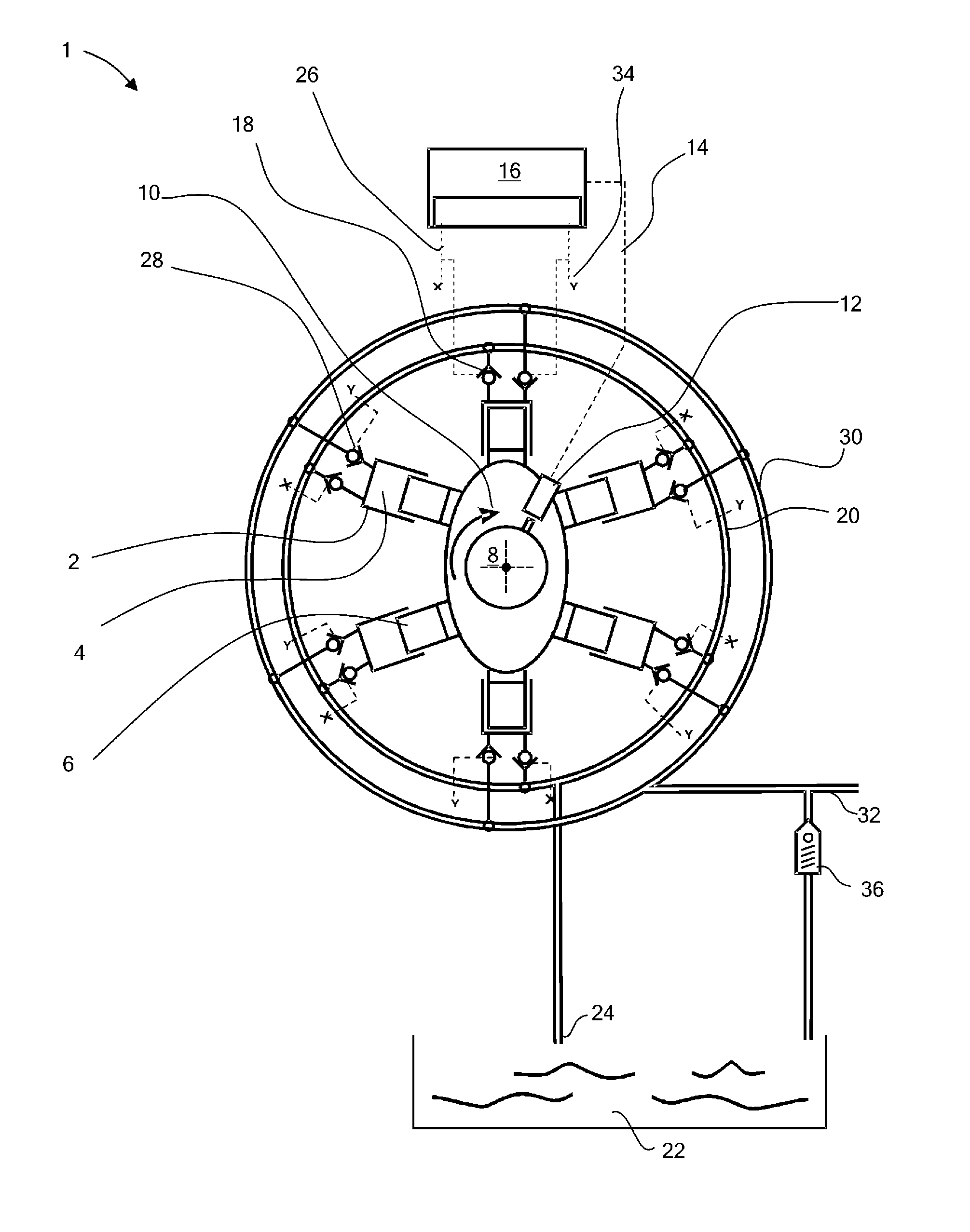

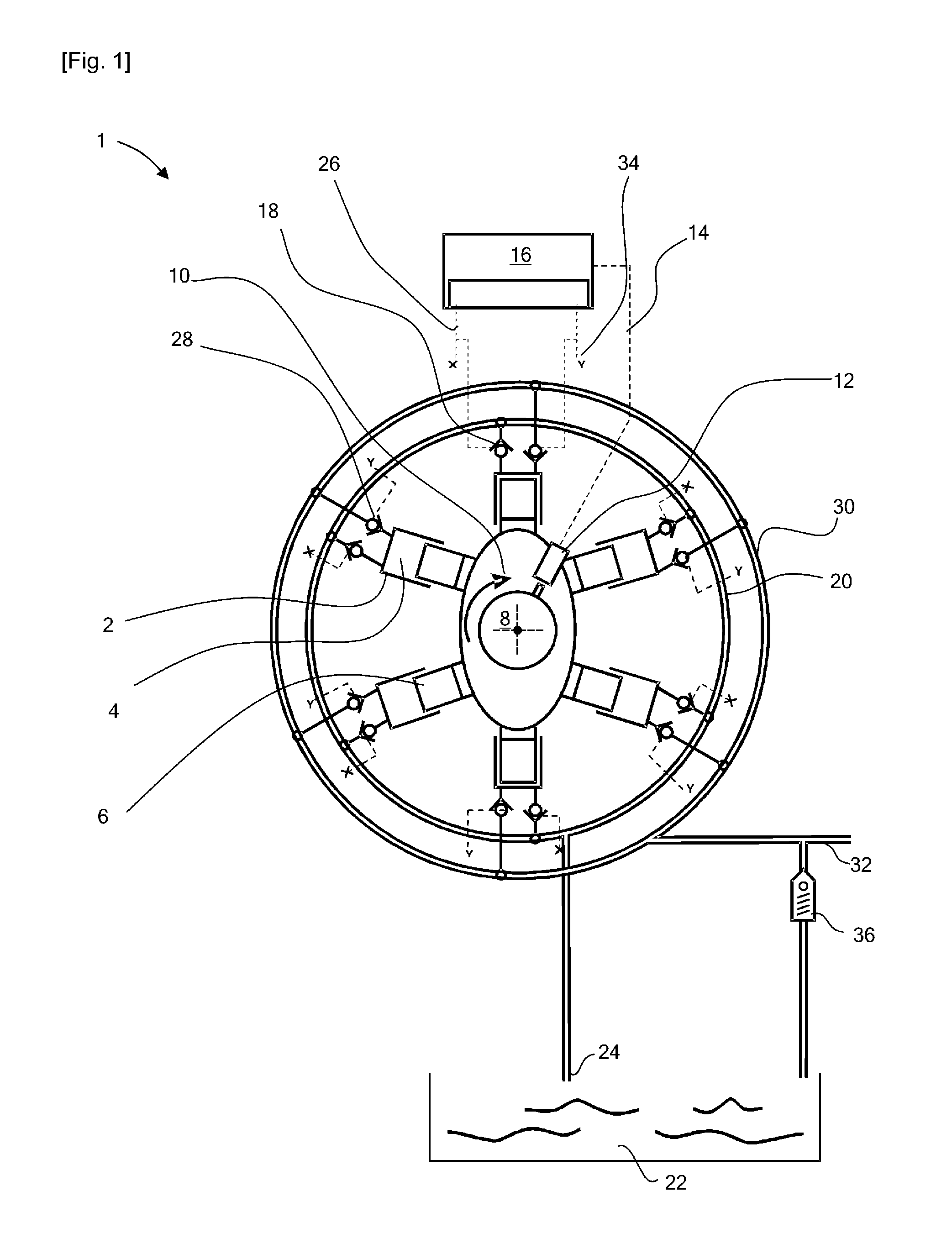

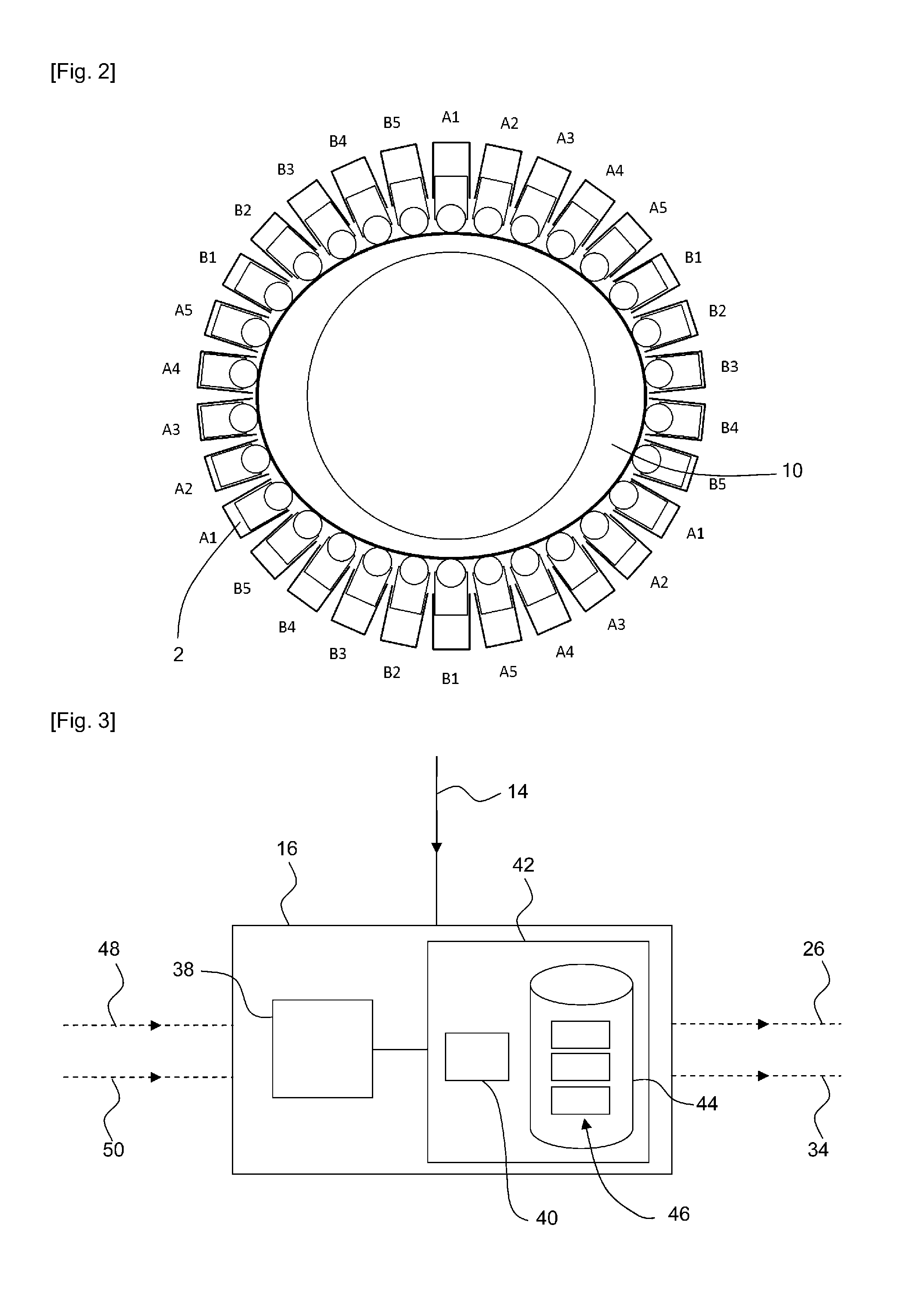

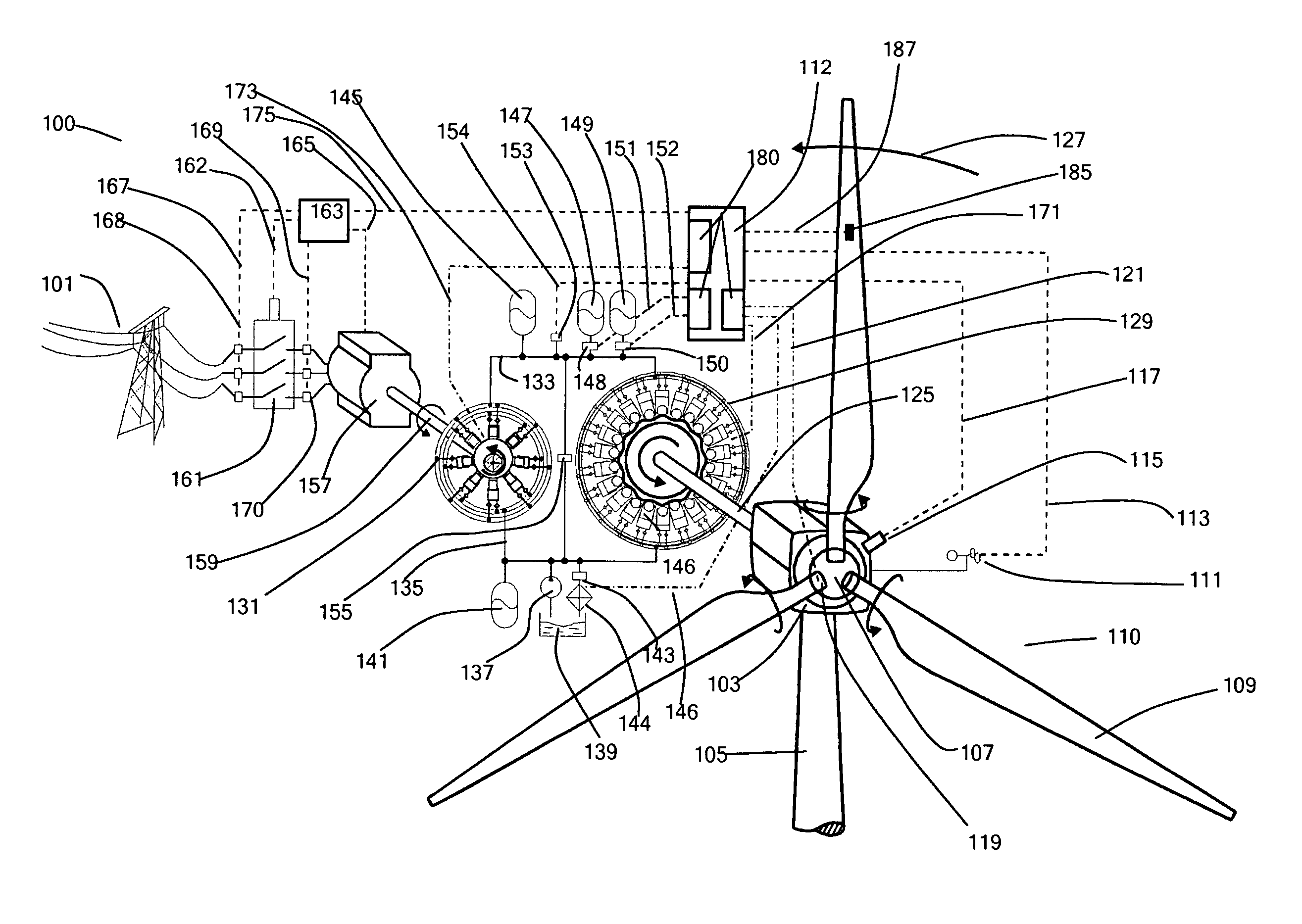

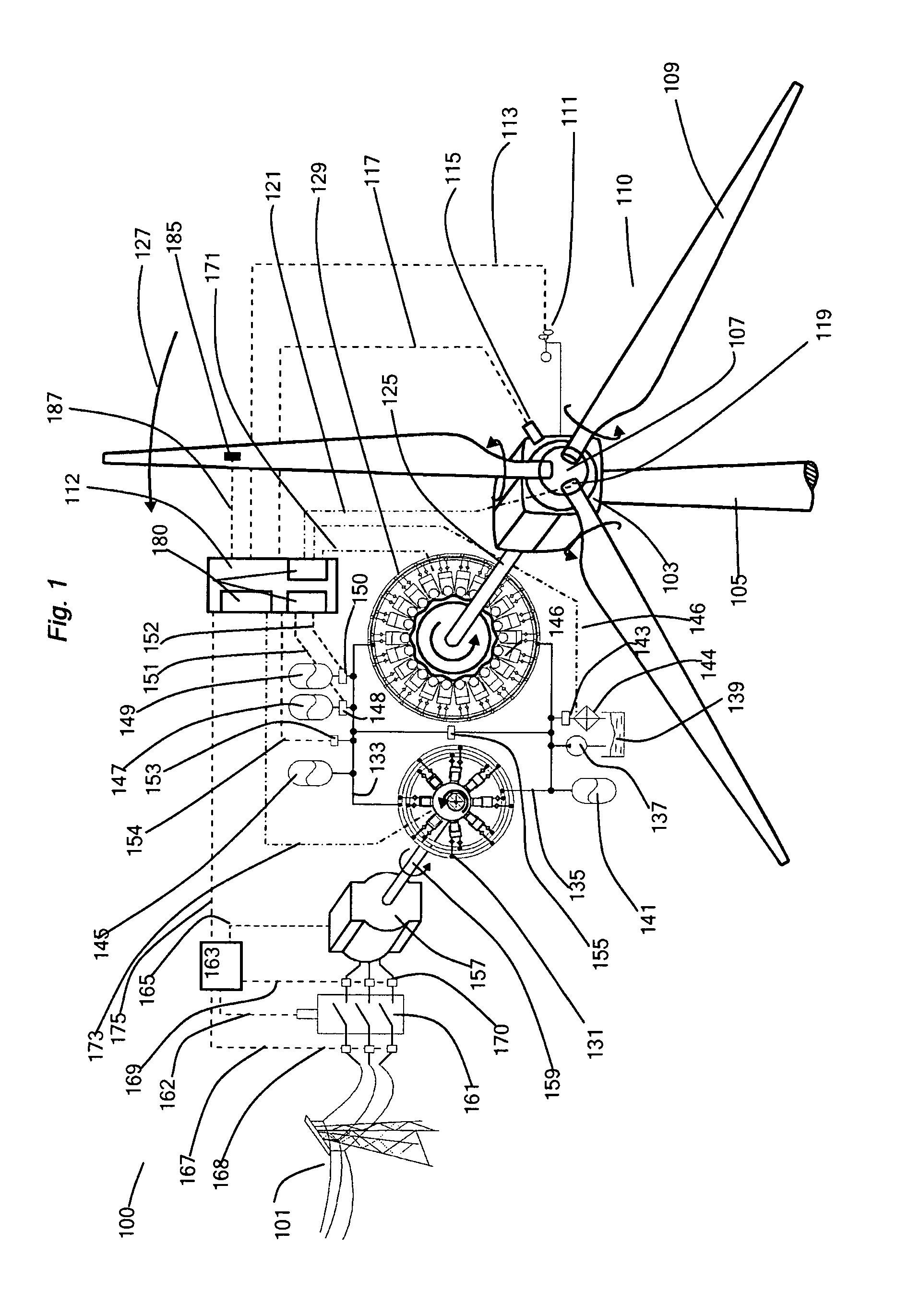

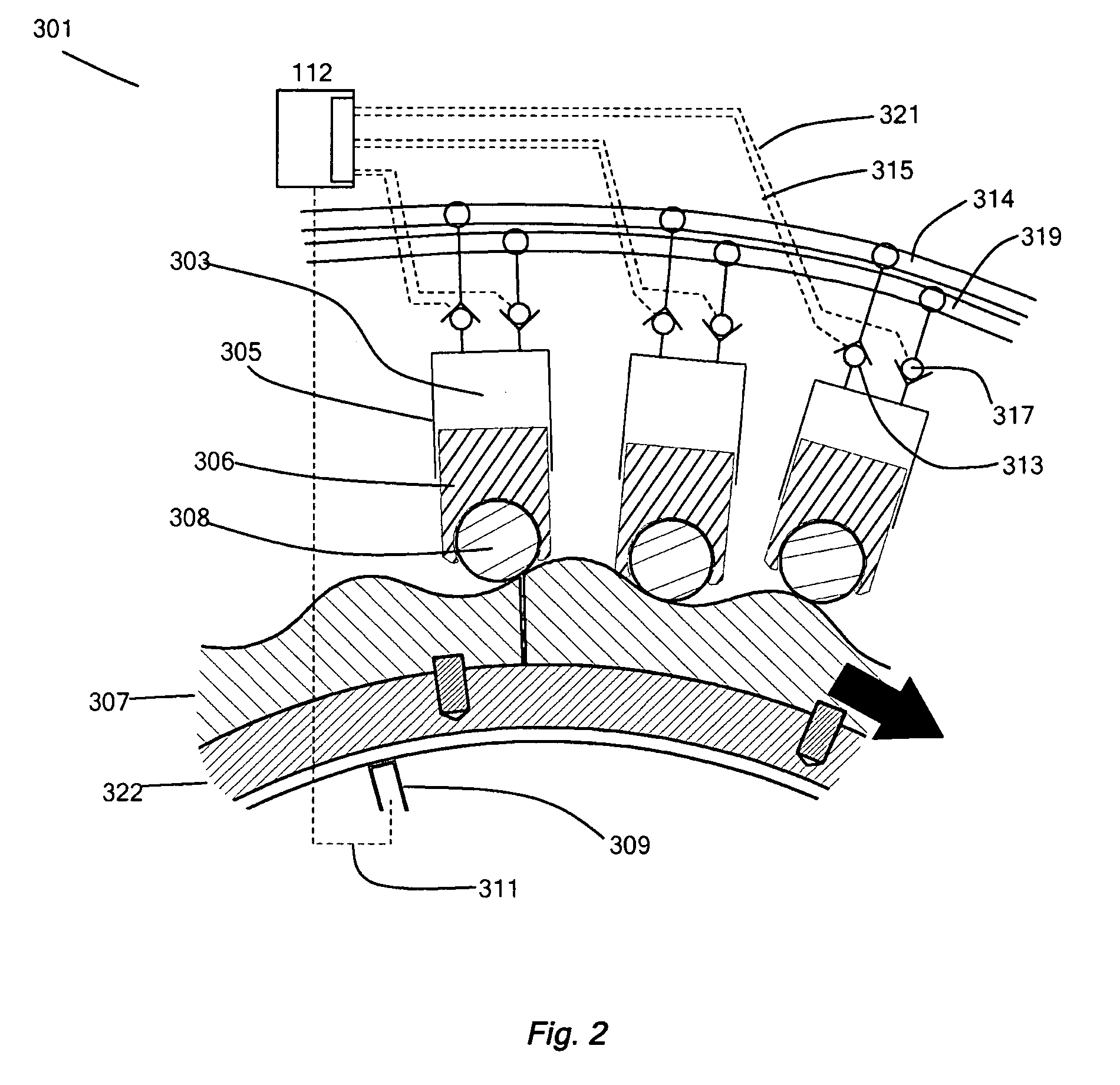

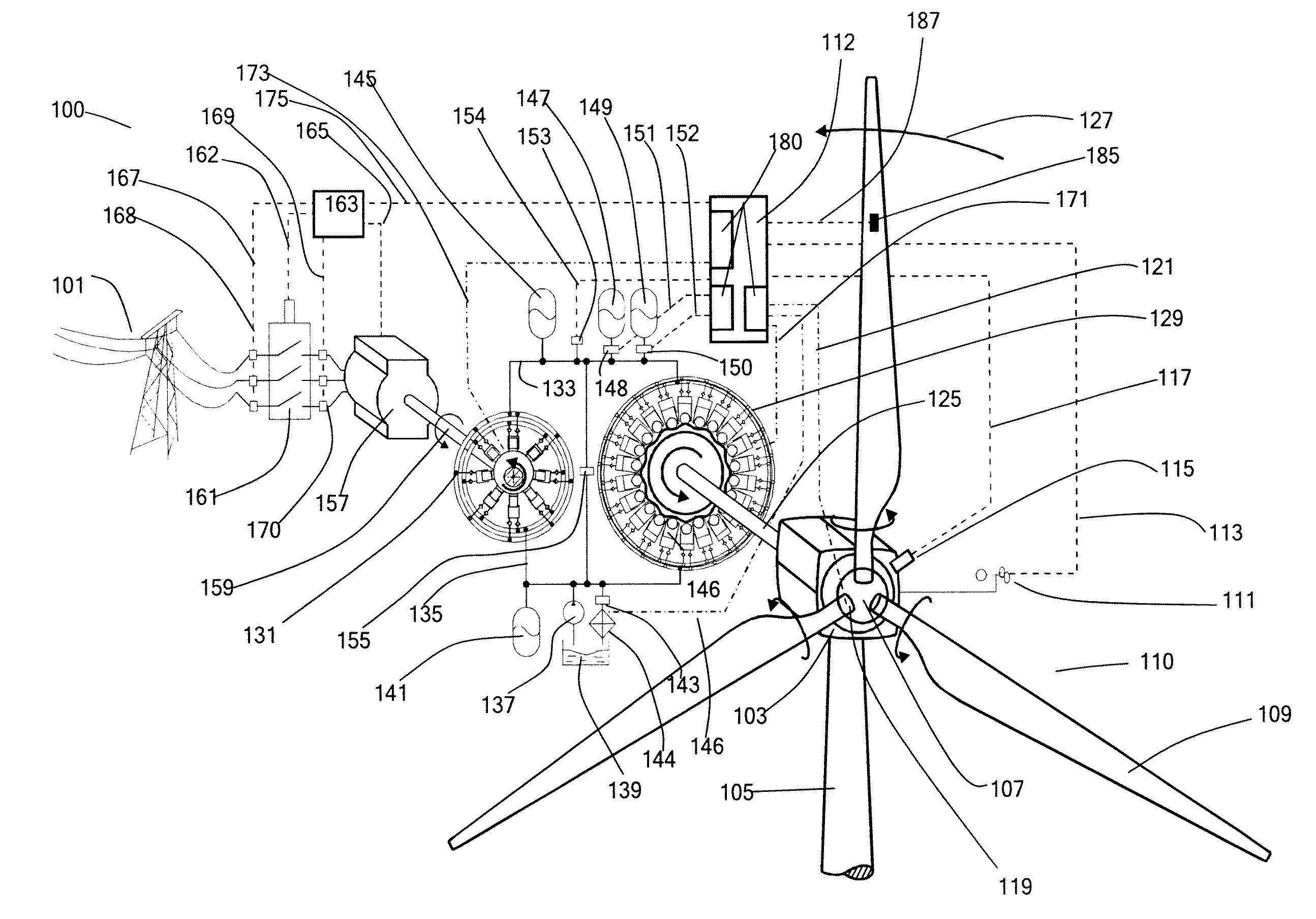

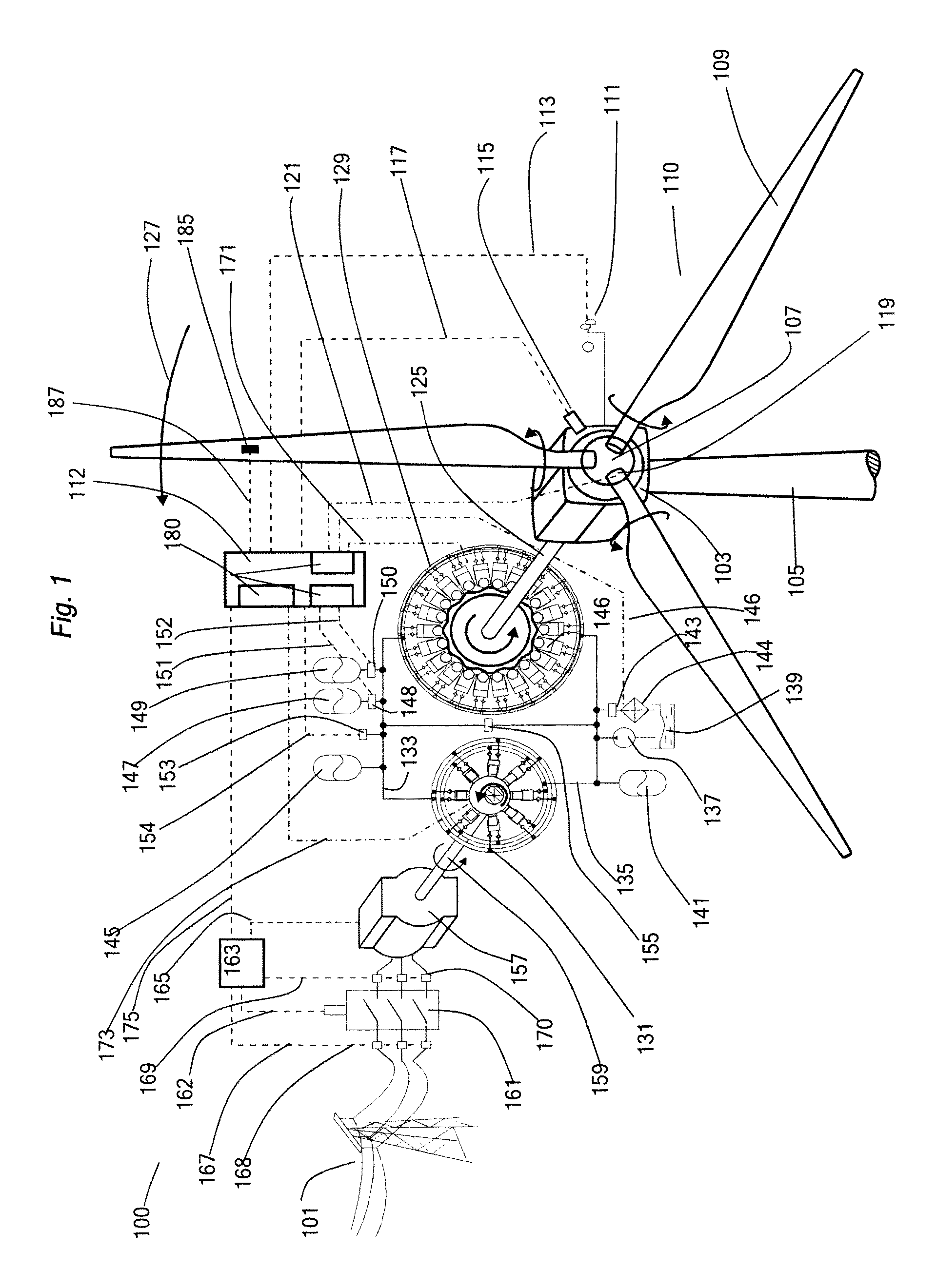

Fluid-working machine with multi-lobe ring cam

ActiveUS20130149171A1Minimum energy lossFlow on effectRotary/oscillating piston combinations for elastic fluidsEngine fuctionsEngineeringCam

A fluid-working machine for a renewable energy generation device, the fluid-working machine comprising a ring cam and a plurality of working chambers, the ring cam having an annular working surface extending around an axis of rotation of the ring cam, the annular working surface defining a plurality of waves, each working chamber having a piston, each piston in operative engagement with the ring cam working surface, the ring cam and working chambers being mounted to rotate relative to each other, cycles of working chamber volume being thereby coupled to rotation of the ring cam relative to the working chambers, characterised in that the individual waves of the ring cam working surface have an asymmetric profile.

Owner:MITSUBISHI HEAVY IND LTD

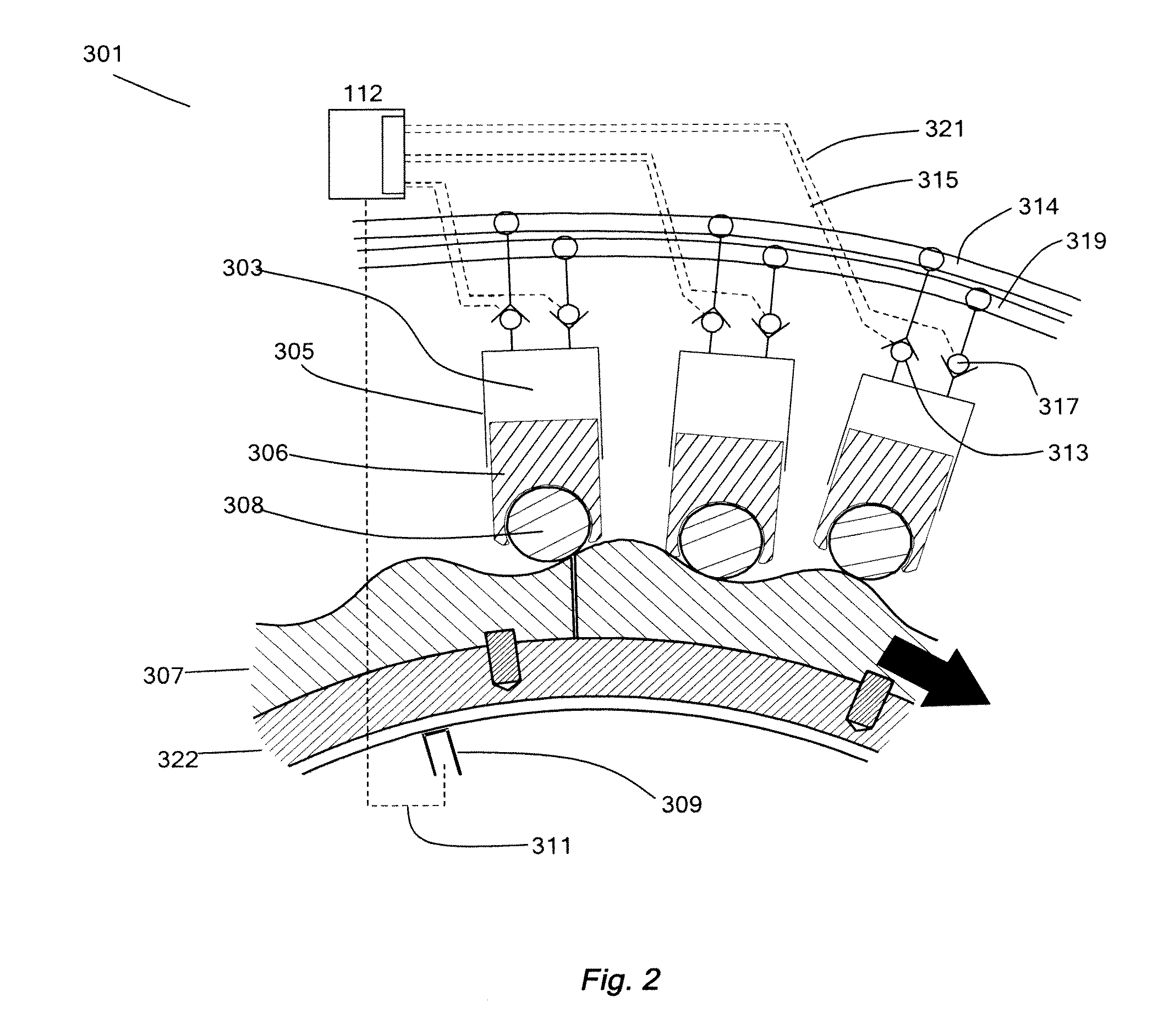

Method of controlling hydraulic machine to reduce torque ripple and/or bearing side load

InactiveUS20130205763A1Little changeSure easyPositive displacement pump componentsRotary clutchesWorking fluidEngineering

A hydraulic machine in which the volume of working fluid displaced by each cylinder is selectable on each cycle of working chamber volume by active control of one or more electronic valves has a controller configured to select specified groups of cylinders to repetitively carry out active cycles until a change in selection is made. The groups are selected to reduce torque ripple and / or bearing side load. The cam profile may be varied to further reduce torque ripple.

Owner:MITSUBISHI HEAVY IND LTD

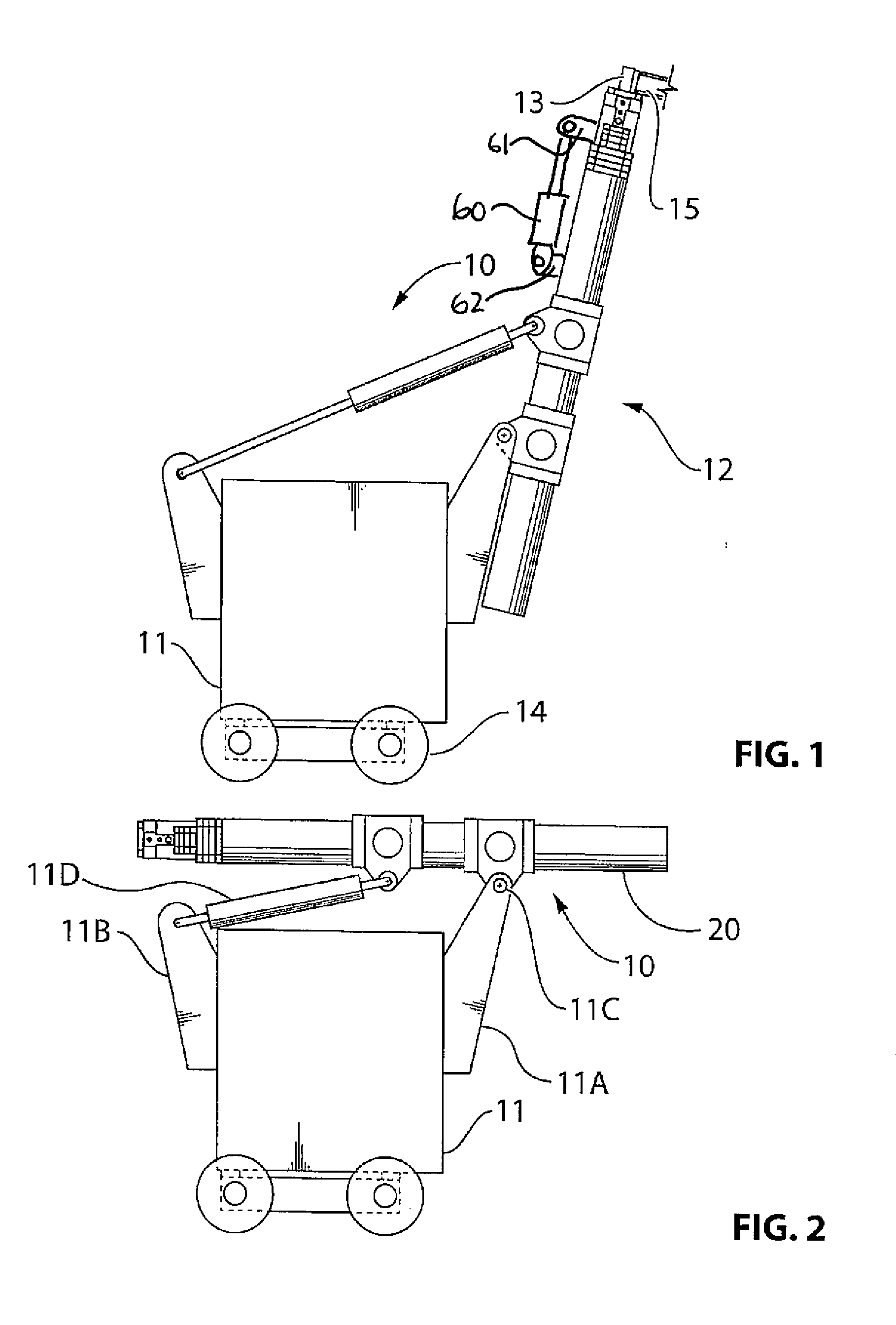

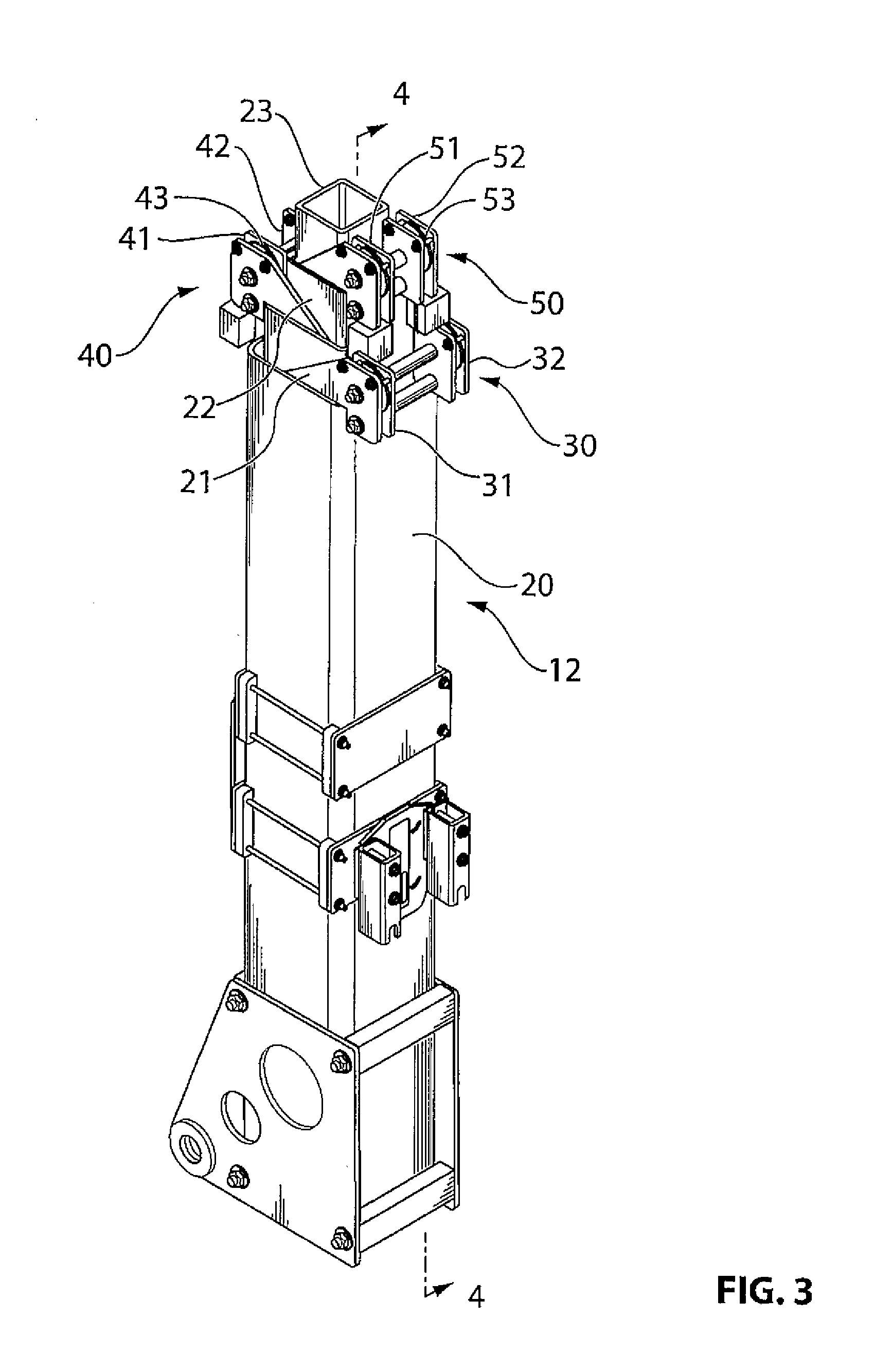

Rotational float for rotating equipment

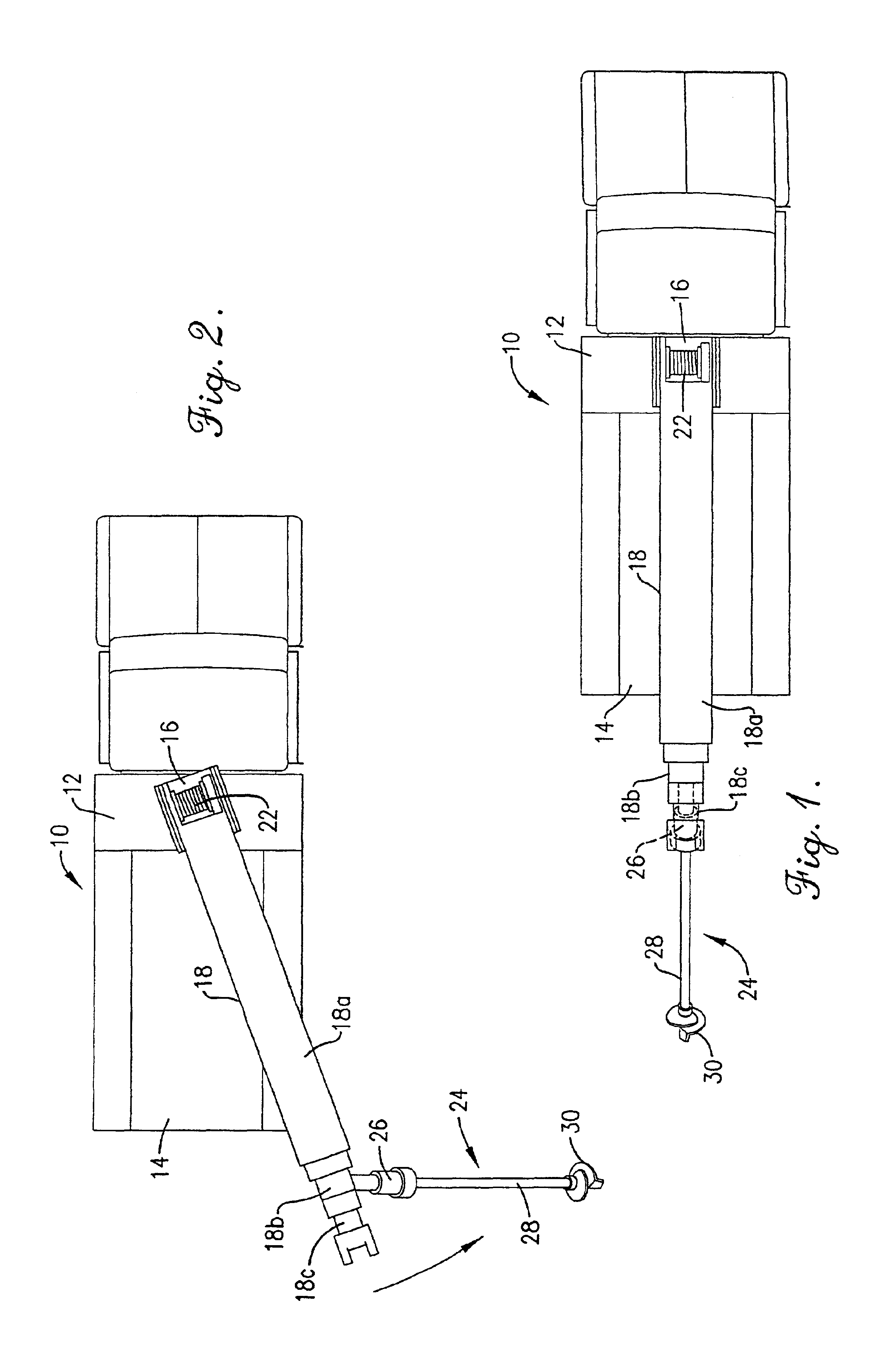

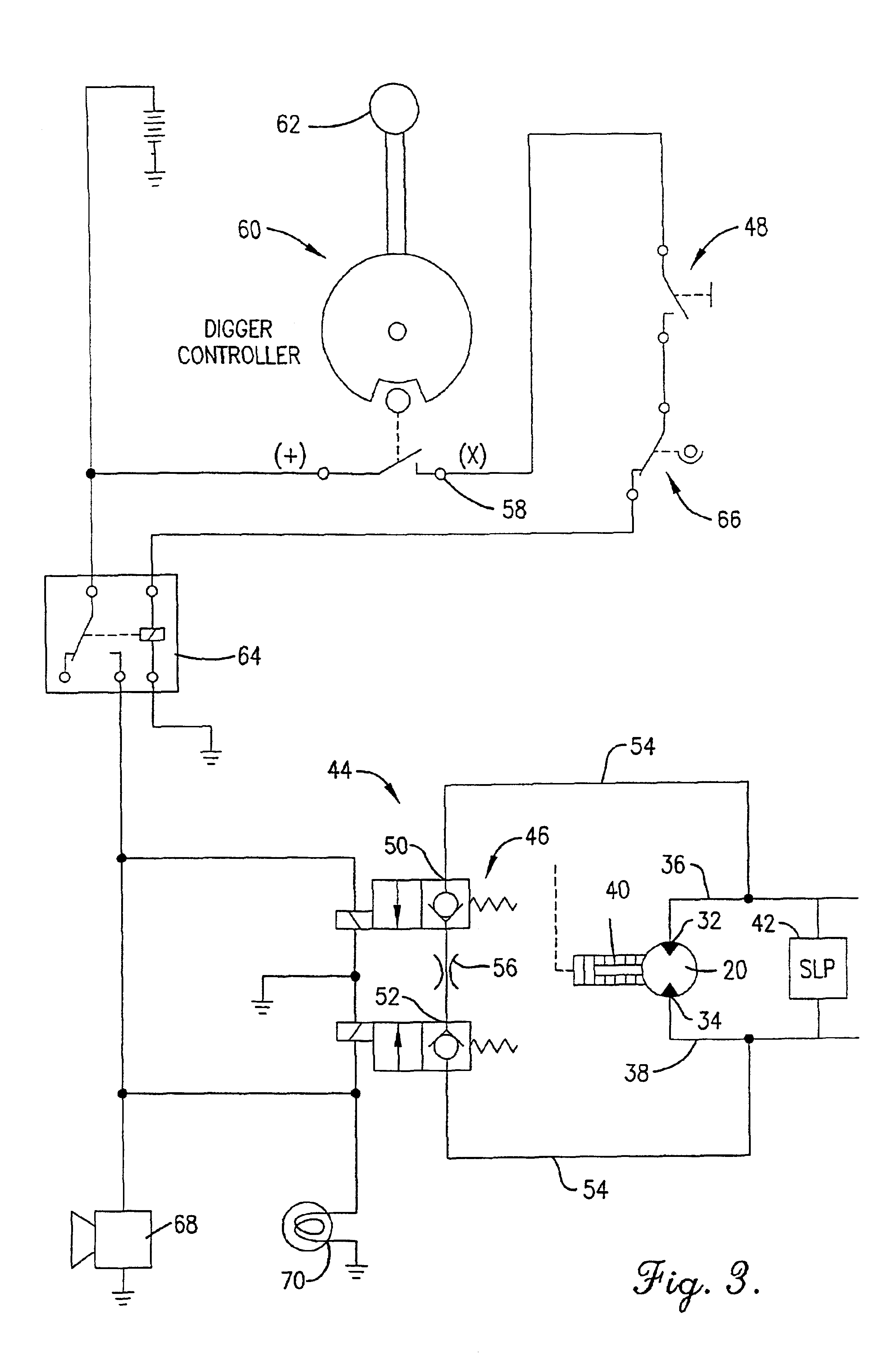

InactiveUS6871710B1Ease of operationPrevent be damageDerricks/mastsSoil-shifting machines/dredgersEngineeringMechanical engineering

A rotational float system (44) that is meant to be used with existing side load protection systems and that may be selectively operated to permit a digger derrick rotation motor (20) or other rotatable equipment to freely rotate toward a side load to ease operation of and prevent damage to the digger derrick (10) and to assist in the correct installation of screw anchors. The rotational float system (44) includes valve structure (46) interposed between the ports (32, 34) of a hydraulic rotation motor (20) and a control mechanism (48) for selectively opening and closing the valve structure (46). The valve structure (46) is normally biased to a closed position and the control mechanism (48) is normally open. When the control mechanism (48) is operated, it opens the valve structure (46) to connect the ports (32, 34) of the rotation motor (20) to one another. This allows the pressure of the hydraulic fluid present at each of the ports (32, 34) to equalize so that the rotation motor (20) may float or rotate toward any external side loads.

Owner:ALTEC INDS

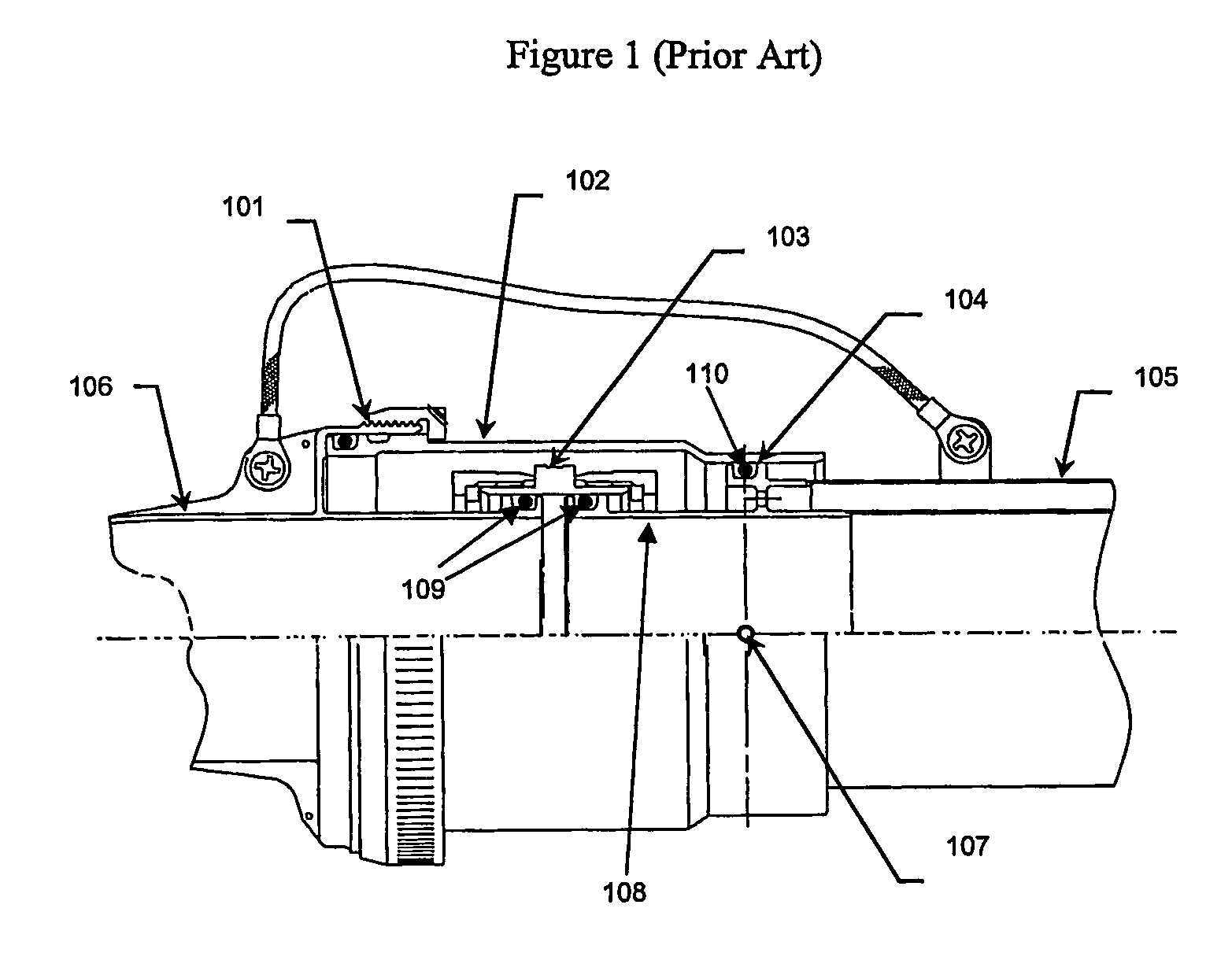

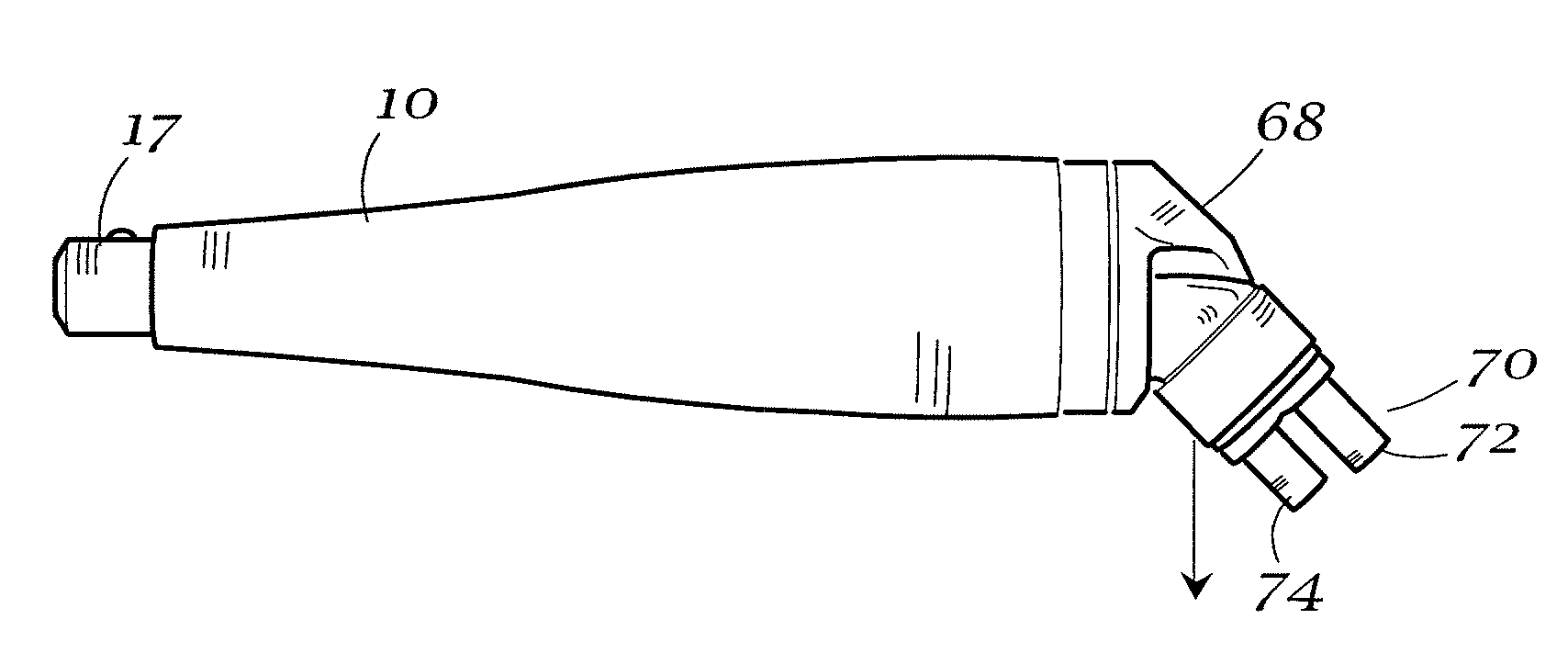

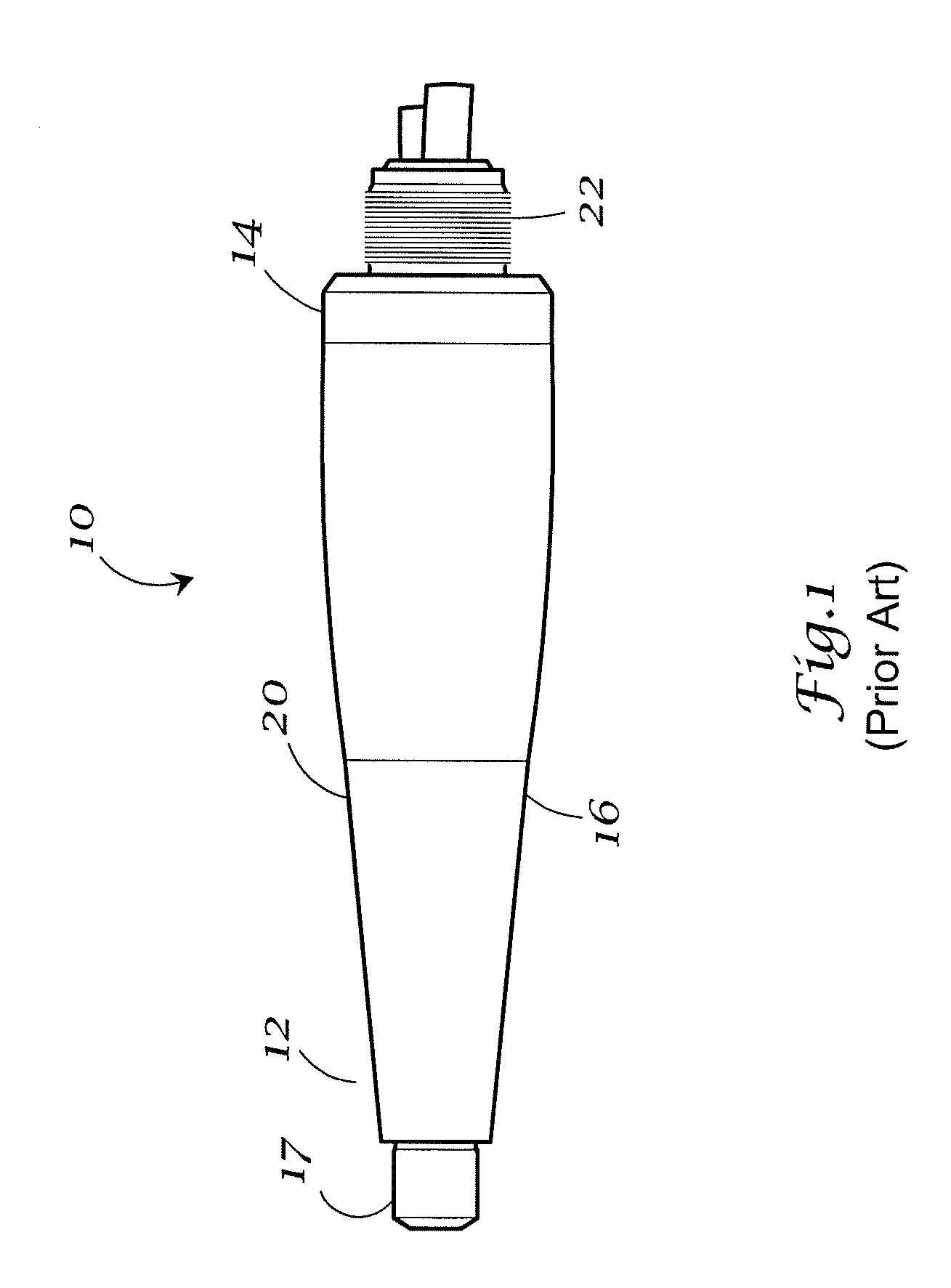

Angled hose connection for dental handpiece

A dental handpiece having a distal end including an attachment for assembly of a removable workpiece and a handpiece body intermediate a proximal end and the distal end. The handpiece extends in a substantially axial direction. A coupler is included having a cylinder portion and a supply-end portion, the cylinder portion being assembled into the handpiece extending in the axial direction toward the distal end. The cylinder portion includes at least one seal that interfaces with an interior of the body so as to isolate a portion of the body interior into at least one distinct chamber. The supply-end portion of the coupler extends from the proximal end of the handpiece body at an angle from the axis. The supply-end portion also includes a plurality of outlets, the at least one distinct chamber in fluid communication with one of the outlets of the plurality of outlets.

Owner:DENTSPLY SIRONA INC

Jounce bumper, rate cup, and strut mount bottom plate

InactiveUS20060272911A1Large angular travelLow stress levelSpringsResilient suspensionsJounceMechanical engineering

A strut and jounce bumper assembly is provided including a rate cup and jounce bumper that are capable of moving with the strut rod wherein the rate cup is provided with a concave spherical upper surface that engages a convex spherical surface of a strut mount bottom plate. The design allows use of a larger jounce bumper and striker in applications where the strut rod has large angular travel.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Machined Spring With Integral Retainer For Closed Cycle Cryogenic Coolers

ActiveUS20080295523A1Increased axial stabilityReduce debris generationSpringsCompression machinesEngineeringMaterials processing

A retainer and spring with threaded end are machined from a single piece of material for threading to a piston in a closed cycle cryogenic cooler. Since the machined retainer and spring are a unitary part, they cannot rub against each other during operation of the piston which reduces debris generation. The spring is preferably formed as a double start helix which further increases axial stability and reduces side loading. The spring extends into an integrally formed, threaded end at the end thereof opposite the retainer. The spring is therefore solidly connected to its adjoining parts which greatly reduces tilting and off-axis movements inherent in the prior art, wound spring designs.

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

Fluid-working machine with multi-lobe ring cam

ActiveUS9328720B2Reduce side loadRotary/oscillating piston combinations for elastic fluidsEngine fuctionsCamMechanical engineering

A fluid-working machine for a renewable energy generation device, the fluid-working machine comprising a ring cam and a plurality of working chambers, the ring cam having an annular working surface extending around an axis of rotation of the ring cam, the annular working surface defining a plurality of waves, each working chamber having a piston, each piston in operative engagement with the ring cam working surface, the ring cam and working chambers being mounted to rotate relative to each other, cycles of working chamber volume being thereby coupled to rotation of the ring cam relative to the working chambers, characterized in that the individual waves of the ring cam working surface have an asymmetric profile.

Owner:MITSUBISHI HEAVY IND LTD

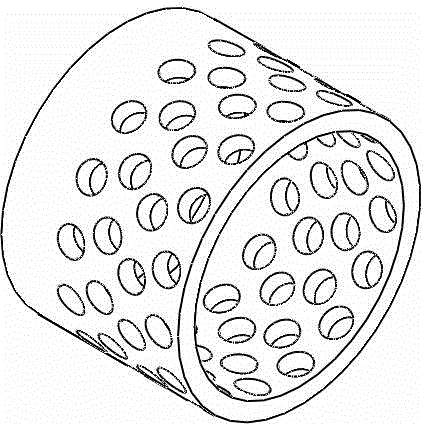

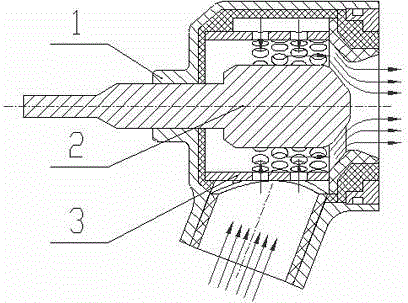

Annular porous flow disturbing structure of gas flow adjusting device of solid rocket engine

The invention proposes an annular porous gas turbulence structure of a solid rocket motor gas flow regulating device, which premixes and evenly distributes the high-temperature and high-speed incoming gas, reduces the uneven erosion and aerodynamic impact of the gas on the valve core of the flow regulating device, and can also be used To filter some of the bulky debris entrained in solid rocket motor gases. The annular porous gas turbulence structure can process multiple air holes on the annular turbulence structure according to the incoming flow direction. The shape and number of air holes can be adjusted according to the area of the gas inlet and nozzle outlet. The periphery of the spool of the regulating device is fixed between the gas inlet and the spool of the flow regulating device through mechanical and adhesive means. The invention not only has the characteristics of simple structure, compactness, easy molding, convenient assembly, high temperature resistance, reliable operation, etc.; it also plays the role of premixed gas flow, uniform distribution of gas, and reduces local erosion and ablation of high-temperature and high-speed gas on the gas flow adjustment device. .

Owner:SHANGHAI XINLI POWER EQUIP RES INST

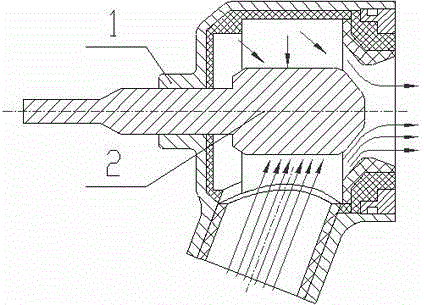

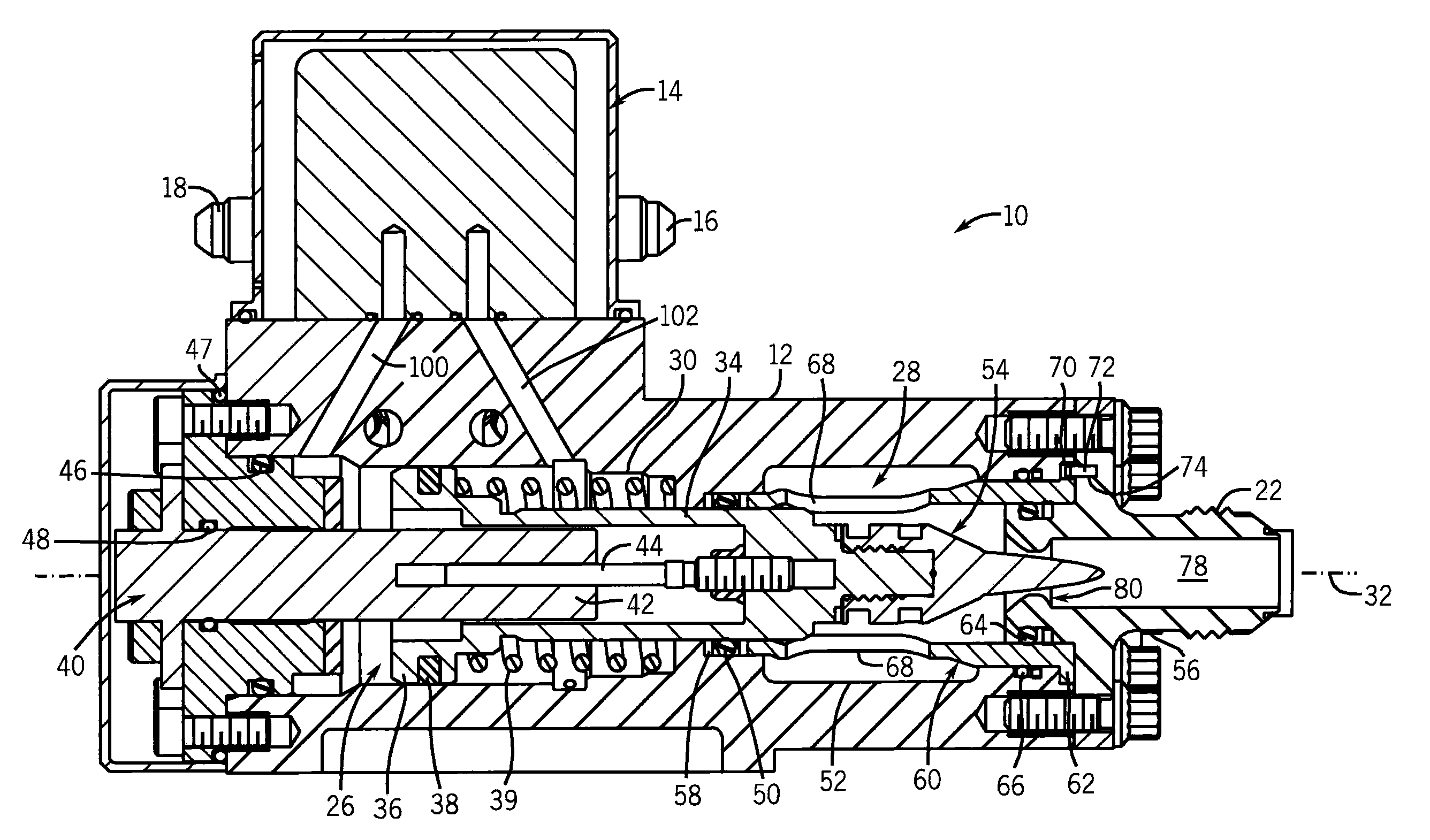

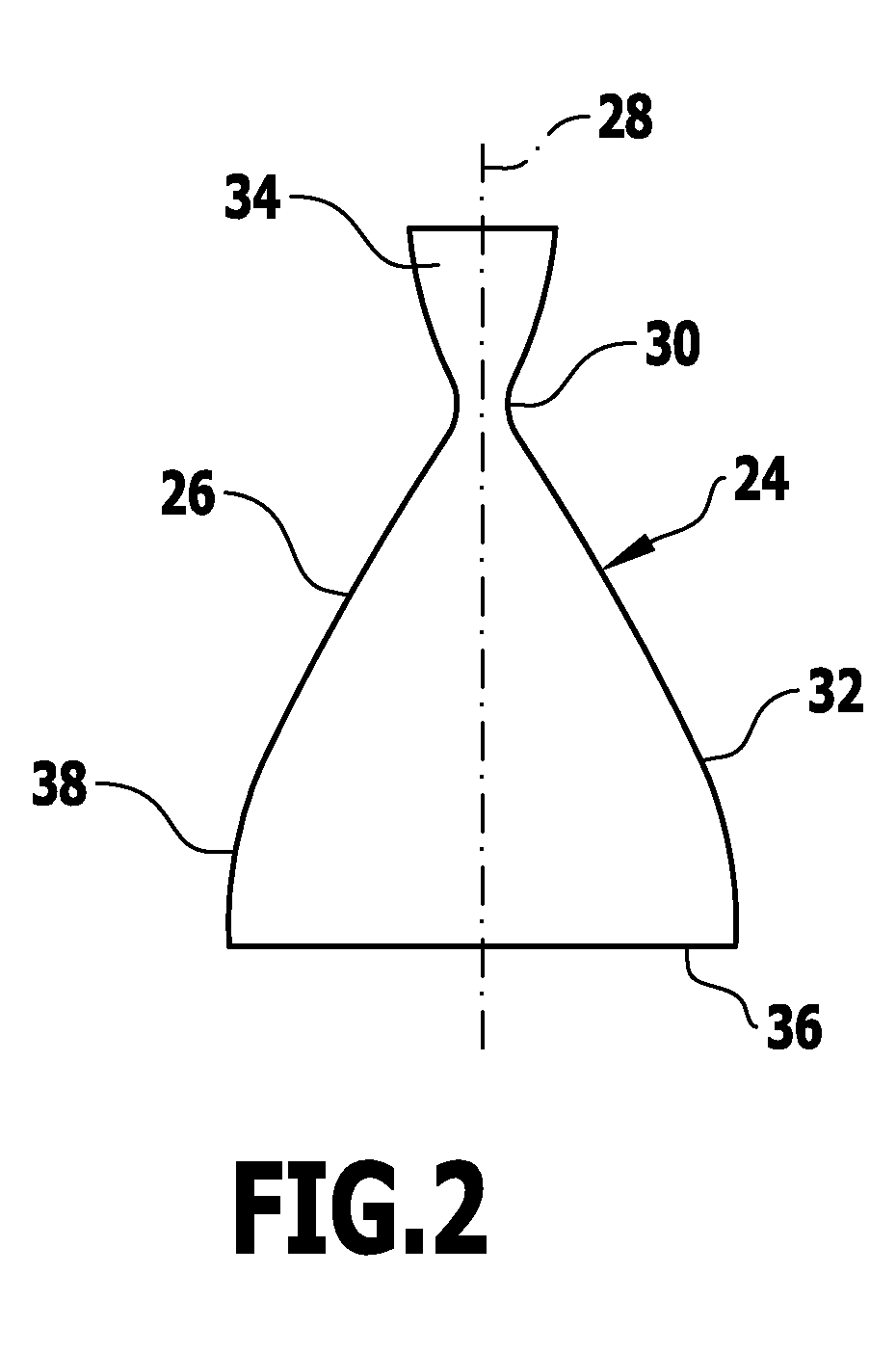

Reverse flow fueldraulic valve

ActiveUS7913973B1Reduce side loadMeter high pressure media accurately and reliablyOperating means/releasing devices for valvesValve members for absorbing fluid energyCombustionFlight vehicle

A reverse flow valve for metering high pressure gaseous media, such as ignition media to the injectors of a scramjet engine in a hyerpsonic flight vehicle, has a metering member that moves parallel to the flow direction of the metered media and throttles the valve in a direction counter to the flow direction. This reduces side loading on the metering member and permits the use of a lighter and smaller actuating mechanism. The metering member can be a pintle having a uniquely configured pintle seat providing bubble tight shut off of the inlet flow without effecting the critical flow contour of the media. The pintle can be driven by a piston that is responsive to push-pull forces of pressurized drive fluid under servo control. The drive fluid is isolated from the gaseous media by a primary seal, which can be seated on the piston without deformation by a seal retainer. The drive fluid can be fuel diverted from the sustained combustion fuel system of the vehicle so that a separate hydraulic system is not required.

Owner:VALEO SCHALTER & SENSOREN +1

Single piston pump with dual return springs

ActiveUS8495987B2Eliminate pump piston seizuresSpring force can be minimizedPositive displacement pump componentsFuel injecting pumpsReturn functionSpring force

Pump piston seizures caused by excessive side loads produced by the uneven loading of a large piston return spring are prevented by separating the tappet return function from the piston return function, thereby minimizing the spring force acting on the piston. Preferably, a stronger, heavier load outer spring is mounted between the pump body and the tappet, such that it imparts no load and therefore no side loads to the pumping piston. A weaker, lighter load inner spring imparts less side load to the pumping piston than a conventional piston return spring, because the inner spring need not carry any tappet load. During both the pumping and charging strokes of the piston, the piston return spring can assist the tappet return spring, but the tappet return spring does not assist the piston return spring.

Owner:STANADYNE OPERATING CO LLC

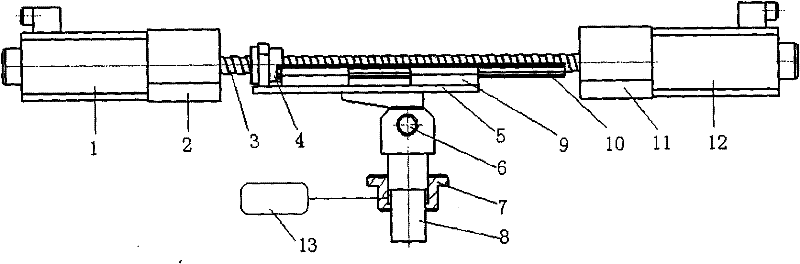

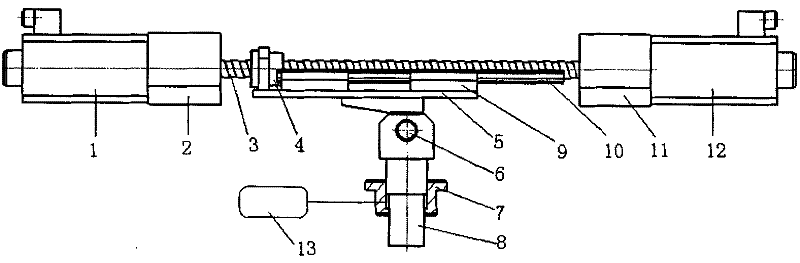

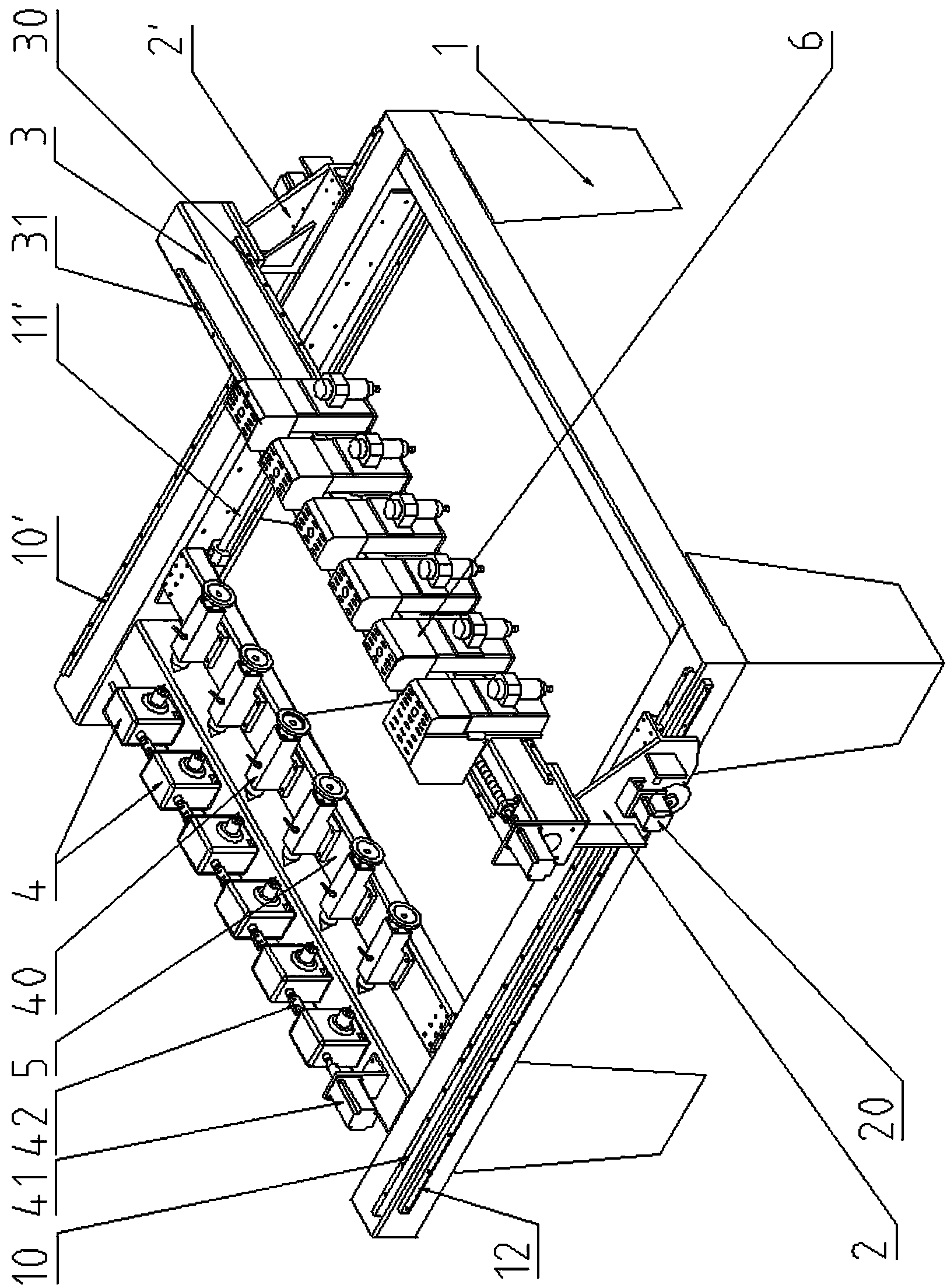

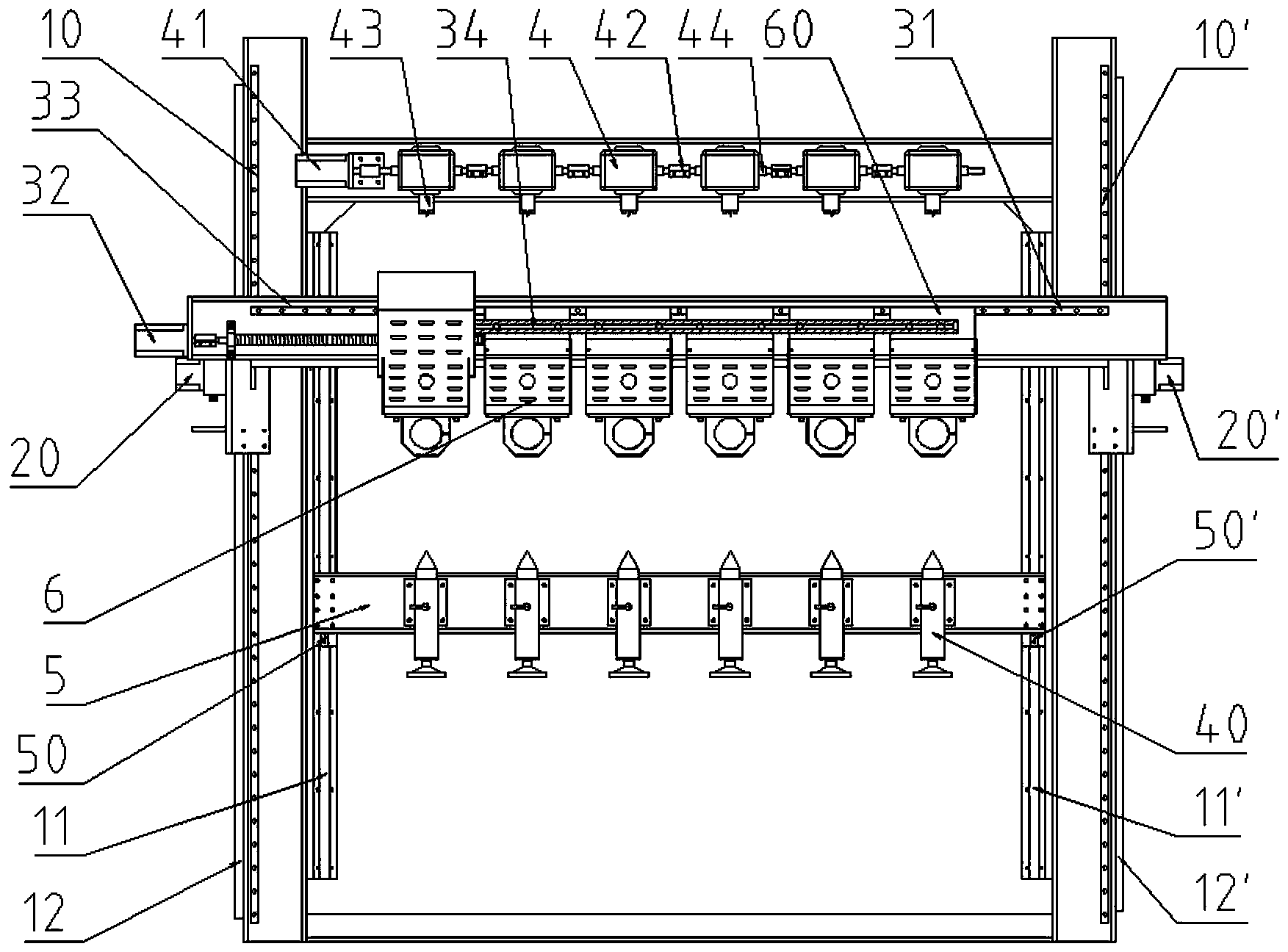

Main transmission mechanism of servo numerical control rotary head press

The invention relates to a main transmission mechanism of a servo numerical control rotary head press, wherein two electrical motors with middle torque and small inertia are connected to a precise ball screw with large lead by a safety coupler mounted in a bracket and with a pulse unloading function; a small angle rolling wedge driving mechanism, a screw nut and a ball guide rail slider are fixed together; a ball guide rail and a rack are fixed; a wedge drives a roller and a punch to move up and down; and the two electrical motors are controlled by a synchronous driving method. The mechanism related by the invention can be used for improving the rigidity, transmission precision, fatigue life, abrasive resistance and high-speed servo impact carrying capacity of the main transmission overall mechanism, and reducing the friction of the transmission system and the lateral load of the punch; by using the two electrical motors with middle torque and small inertia, the requirements of carrying and high dynamic response are satisfied synchronously; the key performance for accelerated reciprocating movement of the system can be ensured; the selection difficulty of the servo driving electrical motor and the manufacture cost of the whole machine are reduced; and the plurality of electrical motors are driven synchronously, so that the feasibility for realizing large-tonnage drive systems is improved.

Owner:JIANGSU YAWEI MACHINE TOOL

Aircraft fuel pipe coupling

InactiveCN101313167AReduce weightReduced occupied volumePower plant fuel tanksPipe couplingsCouplingDouble wall

A coupling for connecting double-walled fuel comprises a pipe end fitting (1), which includes a male outer surface for example including a groove (12) and a female inner surface for example including a groove (11). The coupling also includes a double-walled socket (4), which includes a female outer socket (17) and a male inner shaft (18). The pipe end fitting is partially accommodated in the region between the female outer socket and the male inner shaft of the double-walled socket. A first seal ring (9) seals between the female inner surface of the pipe end fitting (1) and the male inner shaft (18) of the double-walled socket (4). A second seal ring (10) which may be substantially coplanar with the first, seals between the male outer surface of the pipe end fitting (1) and the female outer socket (17) of the double-walled socket (4).

Owner:AIRBUS OPERATIONS LTD

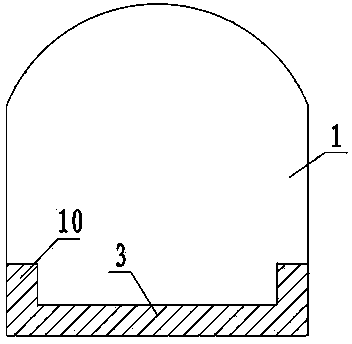

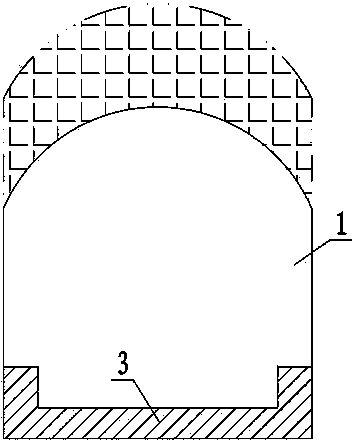

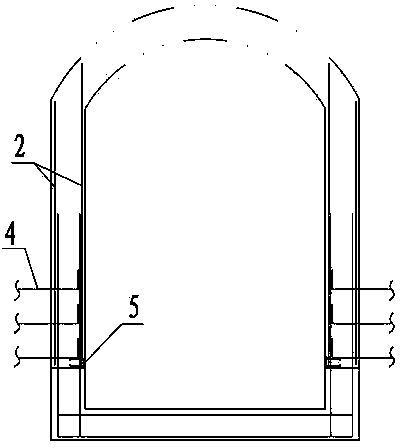

Method for rebuilding diversion tunnel body into flood discharging tunnel body

ActiveCN103388322AReduce demolitionGuaranteed functional requirementsBarrages/weirsReinforced concreteRebar

The invention discloses a method for rebuilding a diversion tunnel body into a flood discharging tunnel body. The method comprises the steps of 1, excavating the section of the original diversion tunnel body to the designed expanding excavation section of the flood discharging tunnel in an expanding mode; 2, mounting vertical reinforcing steel bars at tunnel edge walls; 3 pouring tunnel edge wall and tunnel top arch concrete according to construction demands; and 4, after the diversion is finished, pouring bottom plate concrete on an original diversion tunnel bottom plate, wherein the bottom plate concrete is poured in two layers from bottom to top, the pouring elevation of the lower concrete is higher than that of embedded steel plates; after the pouring of the lower layer concrete is finished, the upper layer concrete is poured after the reinforcing steel bars needed to be mounted in the upper layer concrete are welded with the embedded steel plates; the top face elevation of the upper layer concrete is the bottom plate elevation of the flood discharging tunnel after rebuilding; the strength level of the lower layer concrete is lower than that of the upper layer concrete. The method for rebuilding the diversion tunnel body into the flood discharging tunnel body has the main advantages of omitting the demolishing of poured reinforcing steel bar concrete in the built diversion tunnel, and ensuring the function demands on the tunnel in different periods.

Owner:YELLOW RIVER ENG CONSULTING

Hybrid nutating pump

InactiveUS7302883B2Eliminate connectionMinimize wobble motionMulti-stage pumpsWobble plate gearingsUniversal jointEngineering

A nutating pump has a cross-type universal joint connecting a nutating member to a pump housing, ball joints connecting the nutating member to piston rods, and the piston rods fixed to piston heads so that the piston heads wobble in pump cylinders.

Owner:LYNN WILLIAM HARRY +1

Driven Vane Compressor

InactiveUS20080279709A1Reduce side loadLess power consumptionOscillating piston enginesSealing arrangement for pumpsPump chamberEngineering

Owner:PARKER HANNIFIN CORP

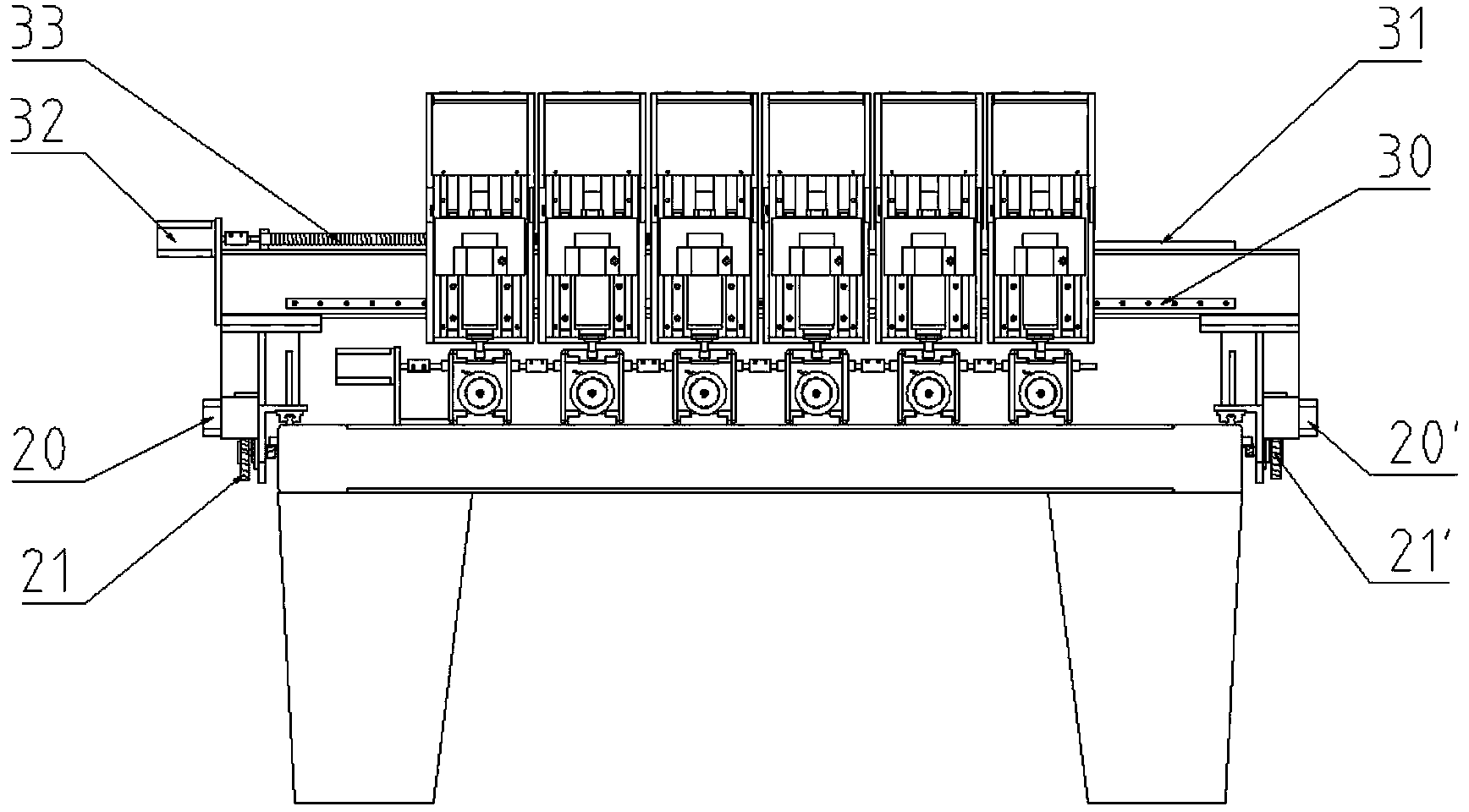

Y-direction assembly of numerical control carving machine

The invention provides a Y-direction assembly of a numerical control carving machine. The Y-direction assembly comprises a left guide rail and a right guide rail which are arranged on the two sides of a tool body and a left Y-direction rack and a right Y-direction rack which are arranged on the tool body. A left column and a right column are movably connected onto the tool body through the left guide rail and the right guide rail. A left Y-direction drive motor and a right Y-direction drive motor are arranged on the left guide rail and the right guide rail respectively, left and right Y-direction drive motor spindle gears are arranged on spindles of the left and right Y-direction drive motors respectively, and left and right Y-direction large gears and left and right Y-direction small gears are arranged on the left column and the right column respectively. The left and right Y-direction large gears are connected with the left and right Y-direction small gears through transmission shafts respectively, the left and right Y-direction drive motor spindle gears are meshed with the left and right Y-direction large gears respectively, and the left and right Y-direction small gears are meshed with the left and right Y-direction racks respectively. The Y-direction assembly is flexible in walking, easy to control and capable of improving the carving accuracy and the service life effectively.

Owner:安庆市宏大涛业精啄数控科技有限公司

Fluid-Working Machine with Multi-Lobe Ring Cam

A fluid-working machine for a renewable energy generation device, the fluid-working machine comprising a ring cam and a plurality of working chambers, the ring cam having an annular working surface extending around an axis of rotation of the ring cam, the annular working surface defining a plurality of waves, each working chamber having a piston, each piston in operative engagement with the ring cam working surface, the ring cam and working chambers being mounted to rotate relative to each other, cycles of working chamber volume being thereby coupled to rotation of the ring cam relative to the working chambers, characterised in that the individual waves of the ring cam working surface have an asymmetric profile.

Owner:ARTEMIS INTELLIGENT POWER

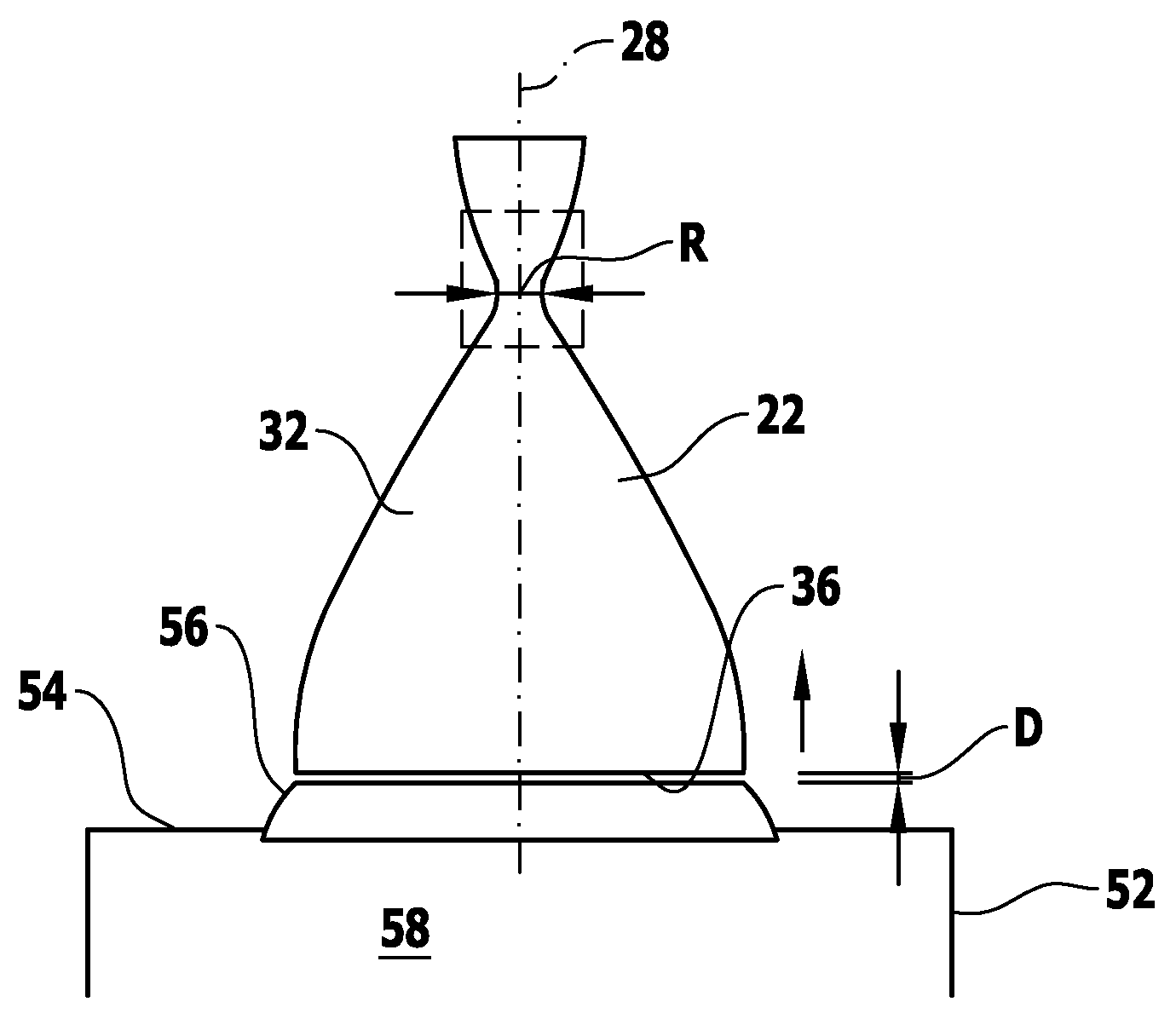

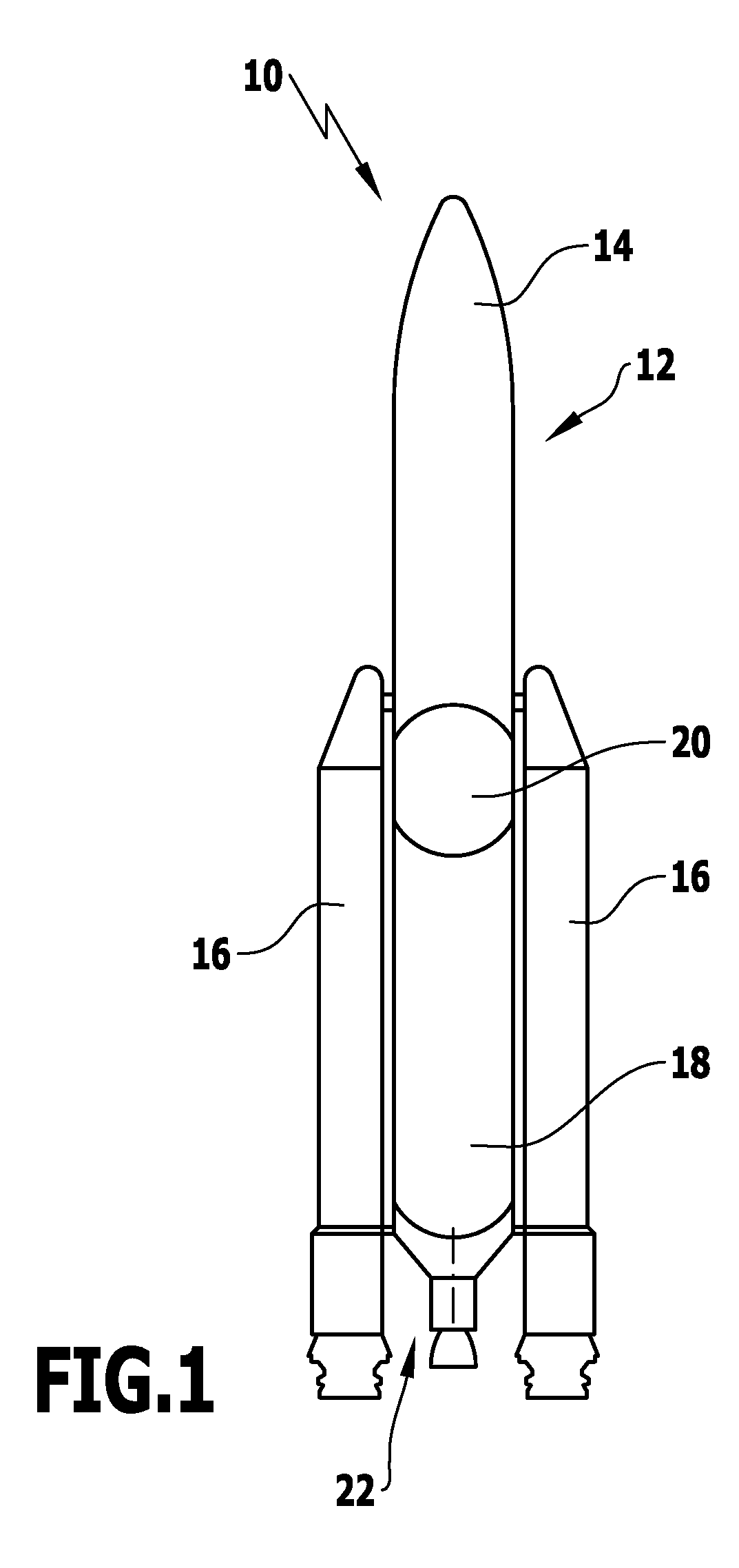

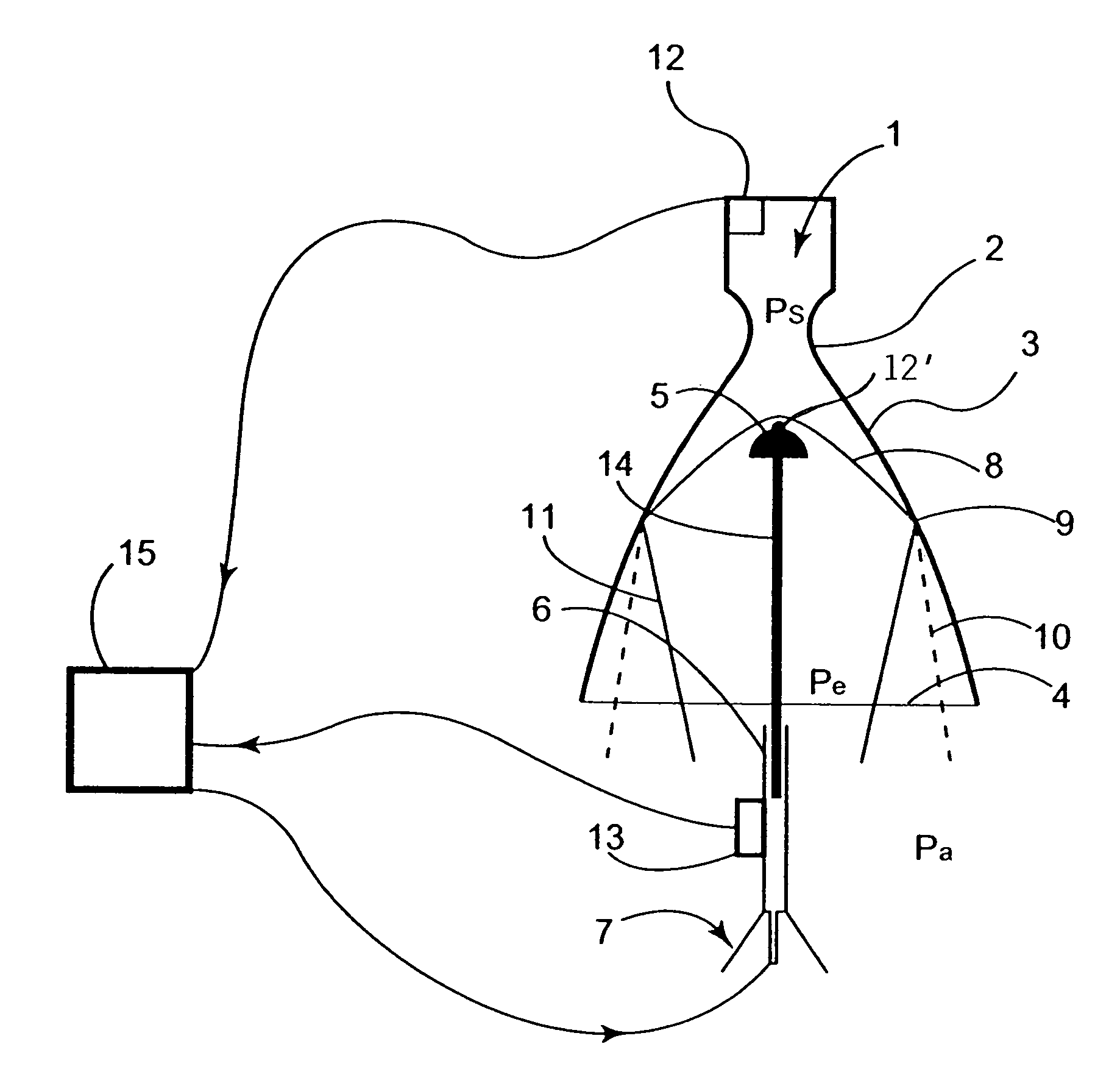

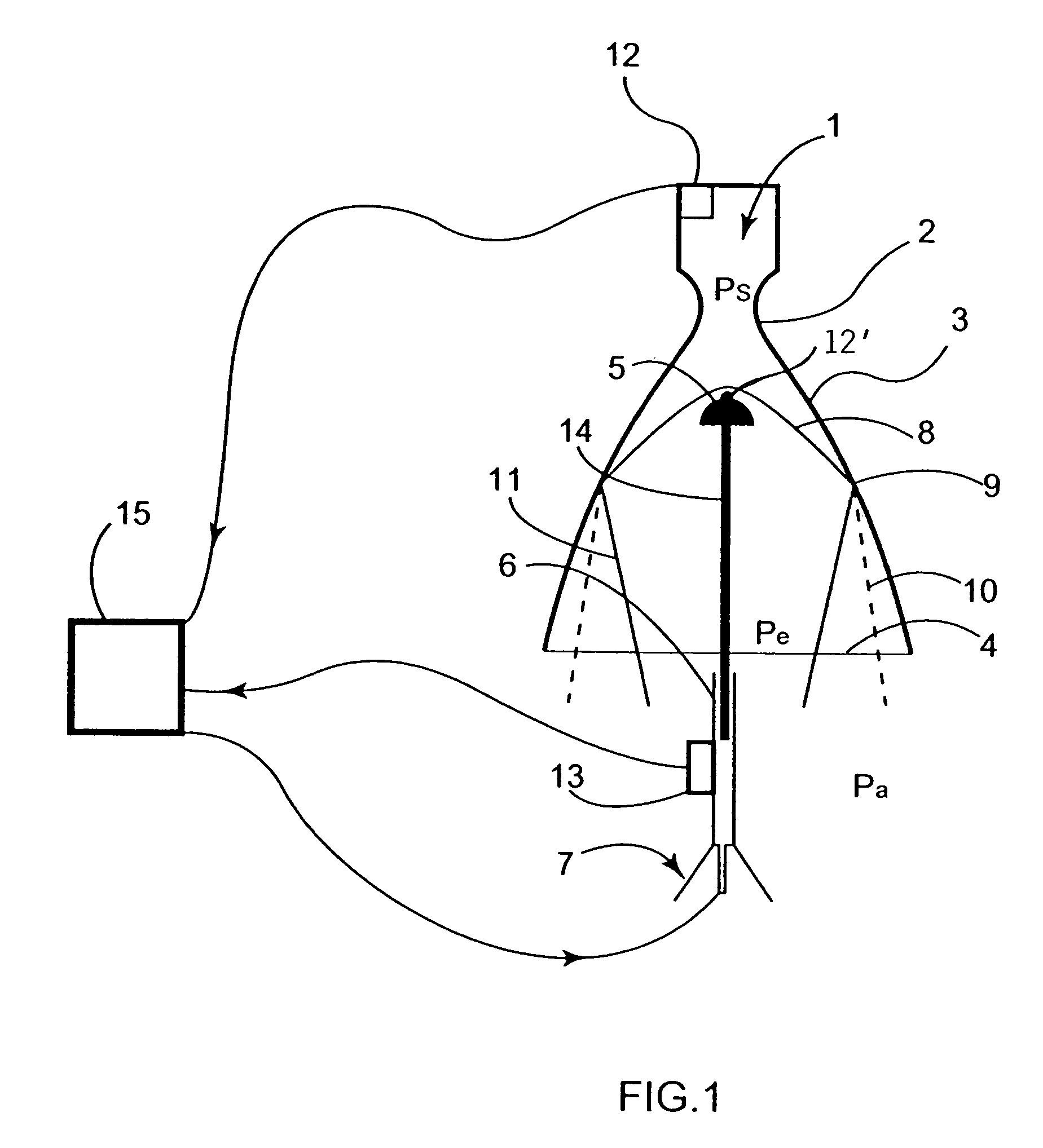

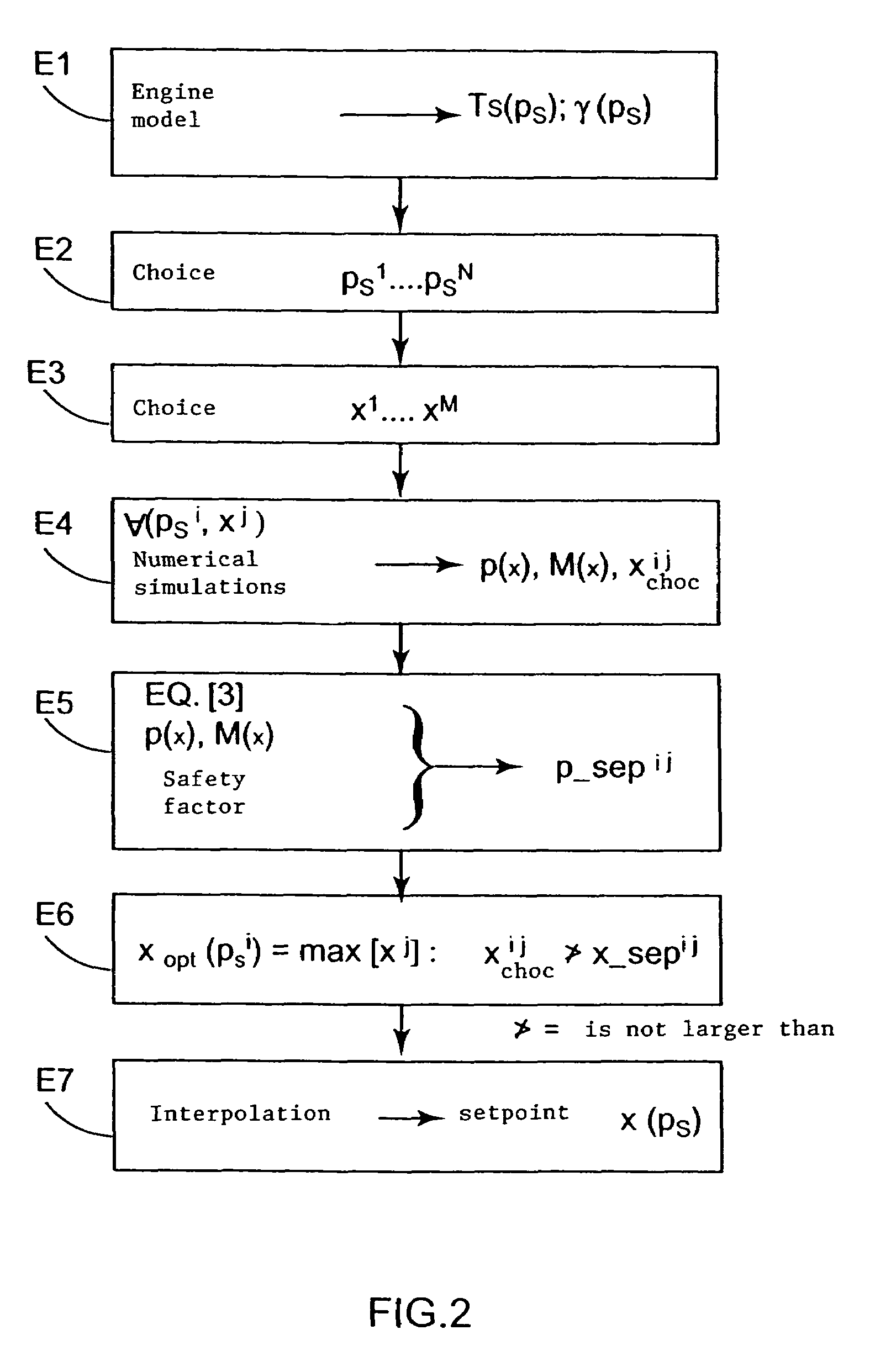

Engine apparatus and method for reducing a side load on a flying object

InactiveUS8938972B2Reduce side loadLarge air volumeTurbine/propulsion fuel supply systemsPower plant exhaust arrangementsCombustion chamberAcute angle

An engine apparatus is provided for a flying object, the engine apparatus including a combustion chamber having a throat region and a nozzle region, the nozzle region having a nozzle wall, wherein the nozzle region expands from the throat region towards an exit end relative to a combustion chamber axis, wherein the nozzle region has associated therewith a skirt having a skirt wall, the skirt being positioned downstream relative to the exit end and surrounding the exit end of the nozzle region, and wherein the skirt wall is at an acute angle away from the combustion chamber axis with respect to the nozzle wall, at least at the exit end of the nozzle region.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

Method for reducing the nonsteady side loads acting on a nozzle of a rocket engine

InactiveUS7603842B2Easy to controlReduce nonsteady loadAircraft navigation controlCosmonautic vehiclesShock waveCombustion chamber

Owner:EUROPEAN SPACE AGENCY

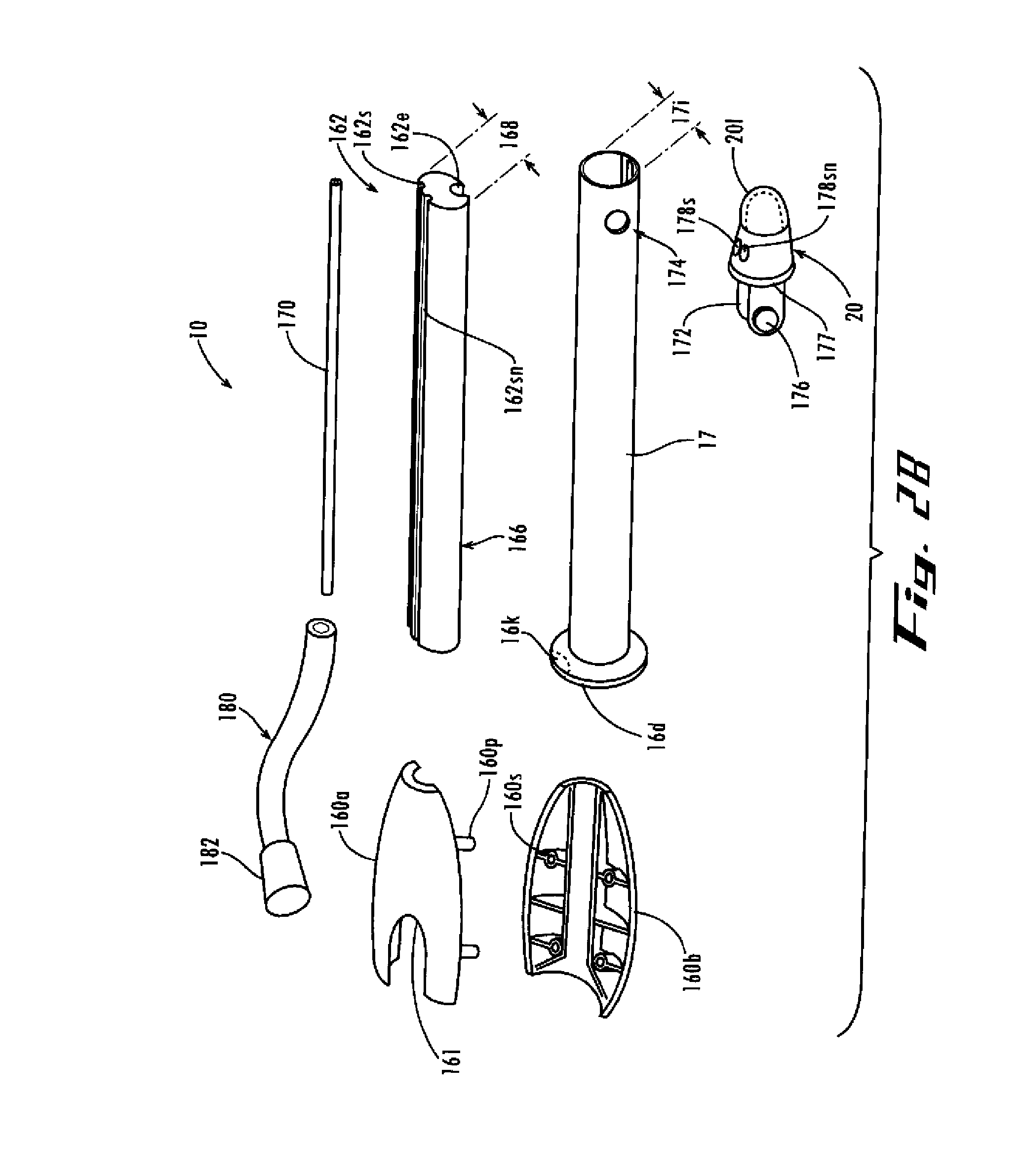

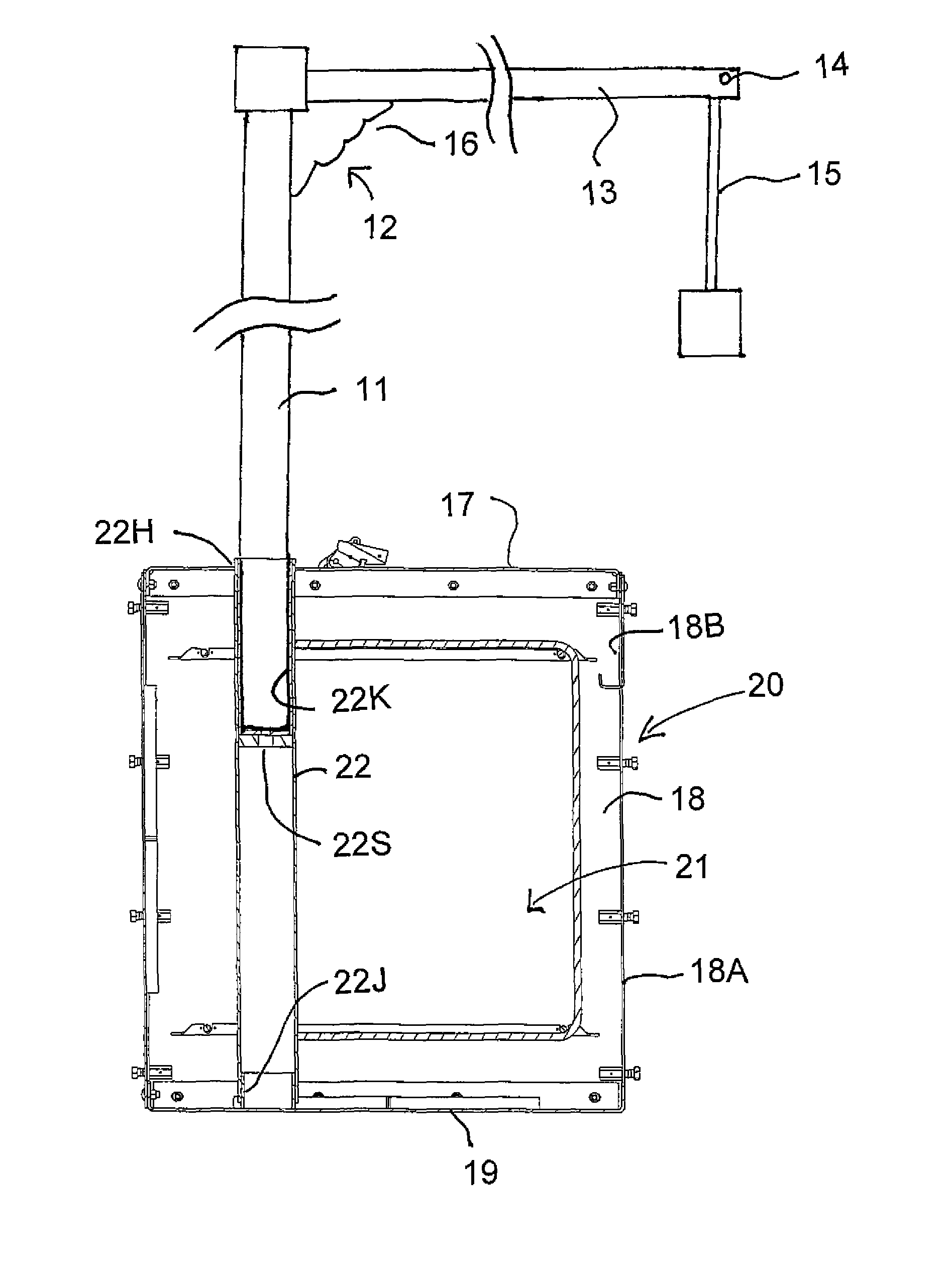

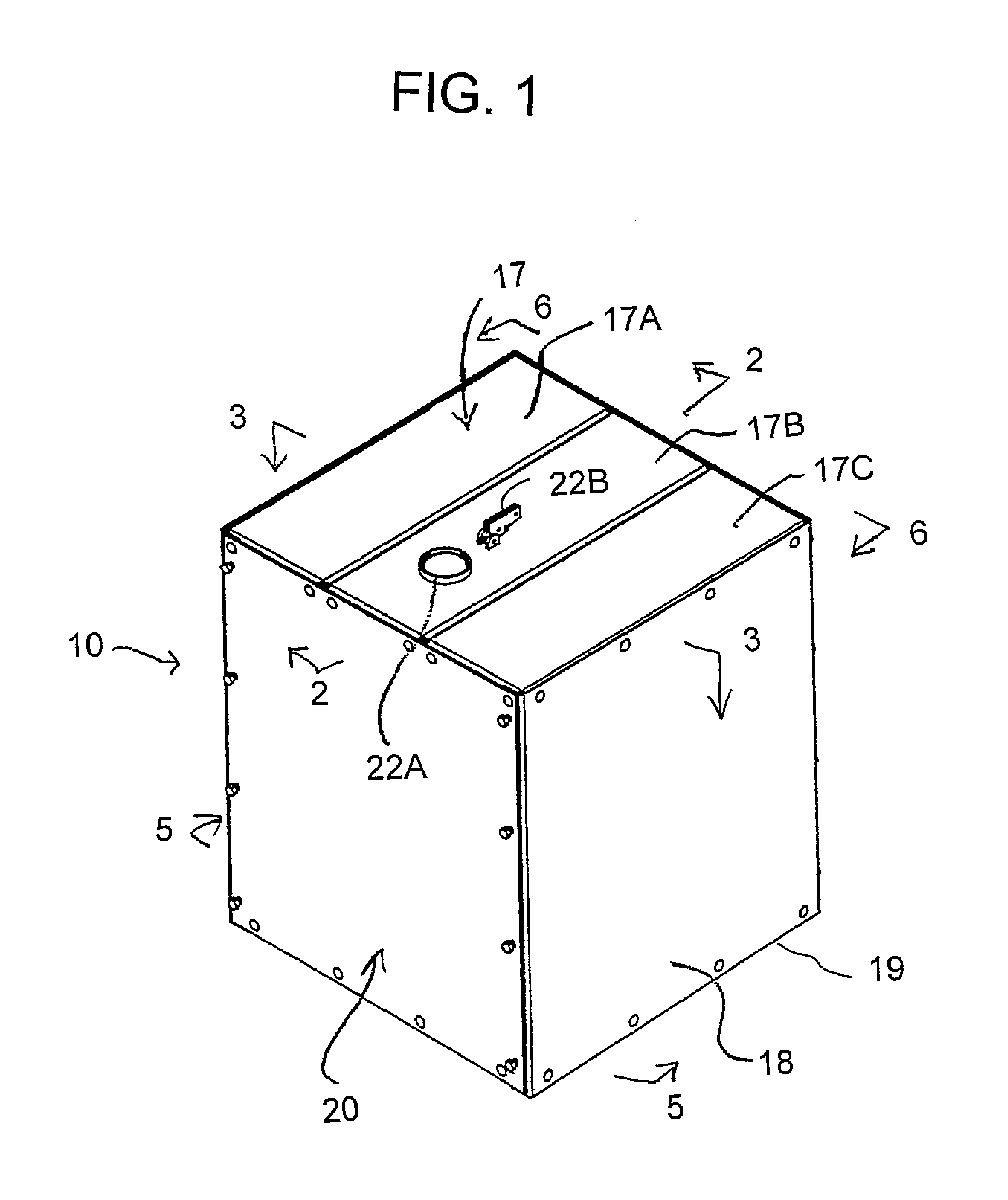

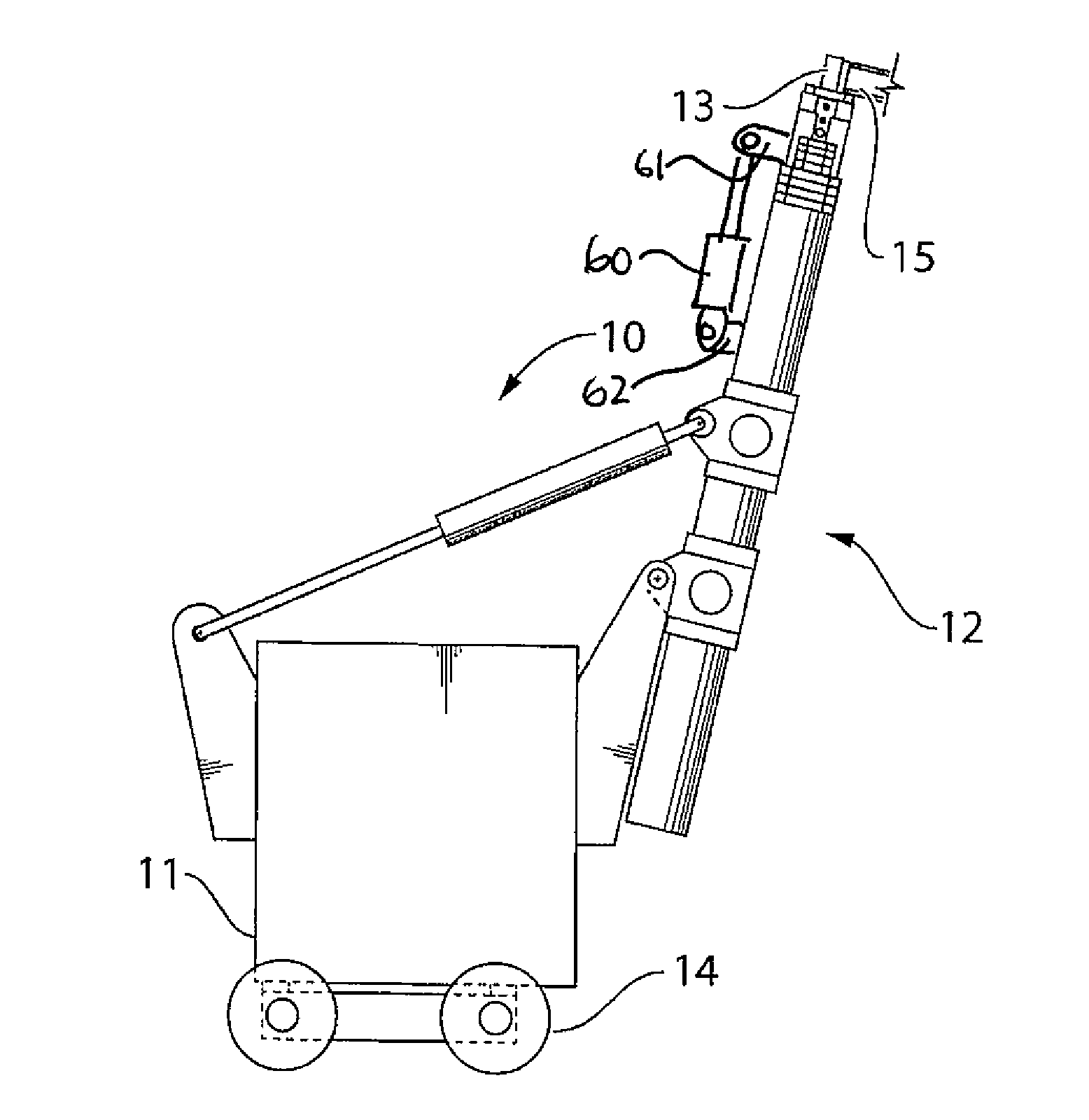

Fall Protection Apparatus with a Mast and a Boom

ActiveUS20160375281A1Maintain continuityGuaranteed to continue to useSafety beltsStands/trestlesFall protectionEngineering

A fall protection apparatus includes a heavy support base with a pivotal mast having a top member for rotation around the axis of the mast carrying a series of booms pivotal about respective vertical axes, each having an end coupling member for receiving a fall restraint harness. Each boom is formed by a tube which fractures on a fall and an elongate stainless steel strap inside the tube which bends without fracturing. The mast includes a series of telescopic rectangular mast sections with a winch driven cable and pulley arrangement for extending the first section which acts to pull the second inner section to the extended position as the first inner section moves out of the outer section. Each section includes first and second pulleys mounted at the same face of the section with the cable located between the face of the section and the face of the next section.

Owner:TUFFBUILT PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com