Annular porous flow disturbing structure of gas flow adjusting device of solid rocket engine

A gas flow adjustment and flow adjustment device technology, which is applied to rocket engine devices, jet propulsion devices, machines/engines, etc., can solve the problem of uneven force on the spool of the flow adjustment device, structural damage of the flow adjustment device, and rocket engine thrust. Eccentricity and other problems can be achieved to reduce local erosion and ablation, simple structure, and reduce aerodynamic shock and side load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein.

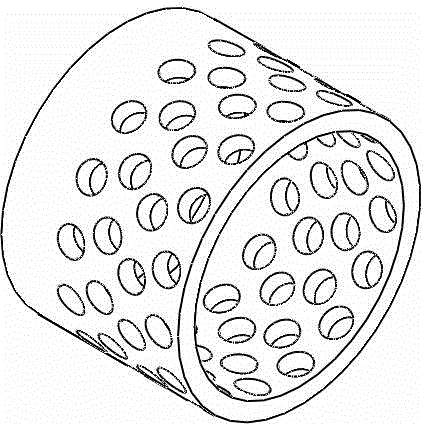

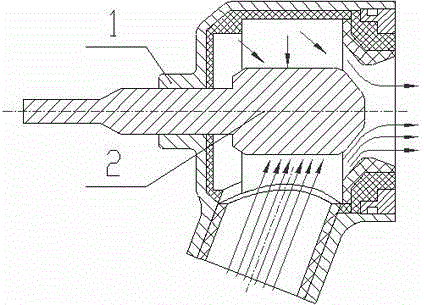

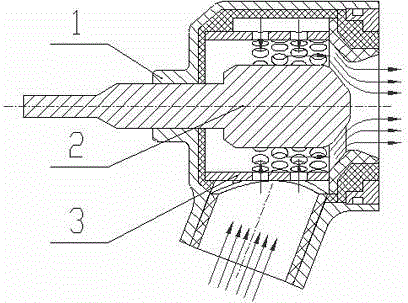

[0013] Such as figure 1 As shown, the annular porous spoiler structure of the solid rocket motor gas flow regulating device of the present invention is characterized by an annular porous structure. The spoiler structure can be made of high-temperature resistant alloy materials, composite materials or high-temperature structural ceramic materials. There are multiple (number ≥ 3) circular or other required shape ventilation holes. Multiple ventilation holes can be placed in the same circle or multiple circles. The ventilation holes can be arranged evenly in the circumferential direction, or they can be arranged in different positions according to the use requirements. place layout.

[0014] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com