Patents

Literature

137 results about "Porous flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

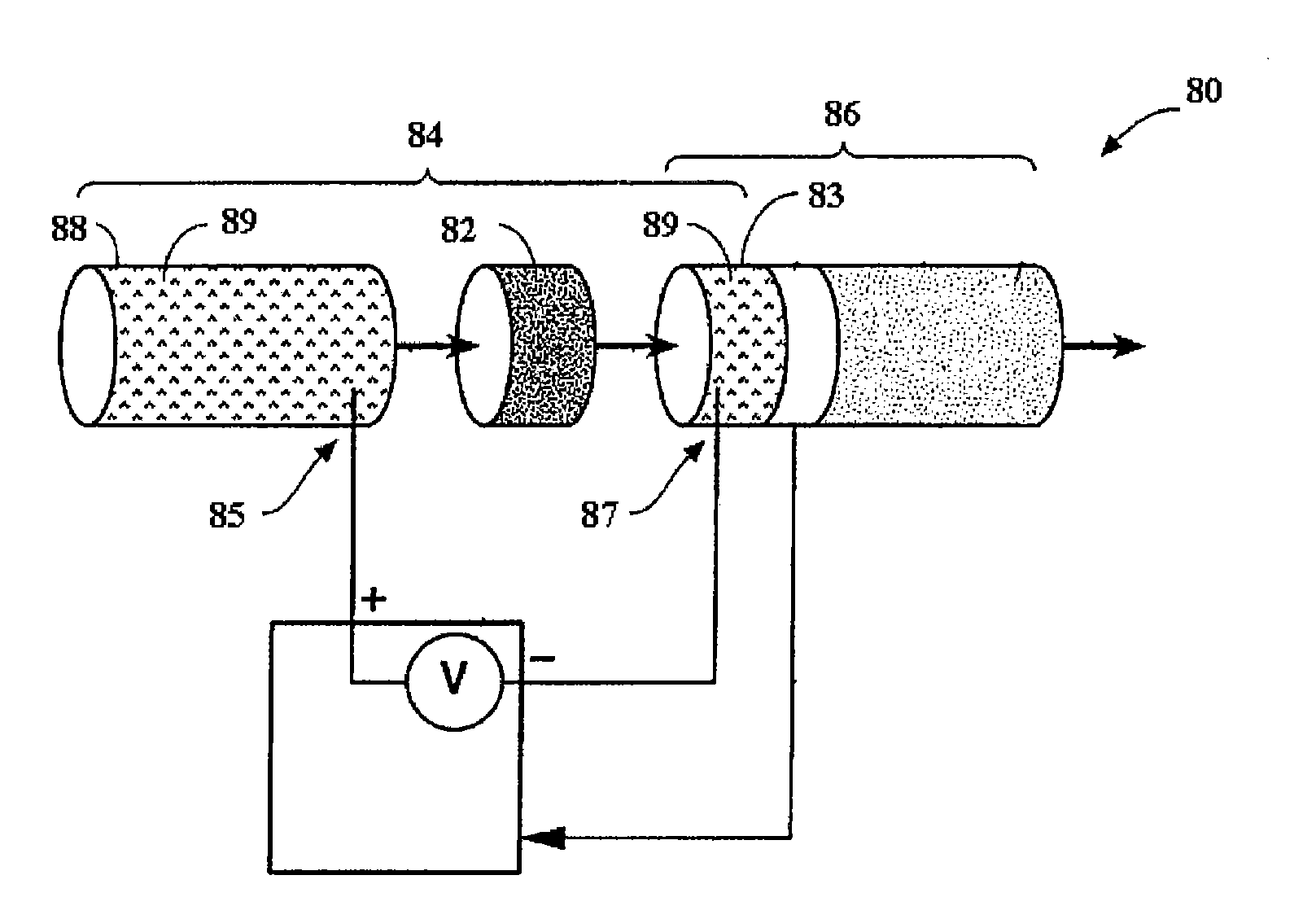

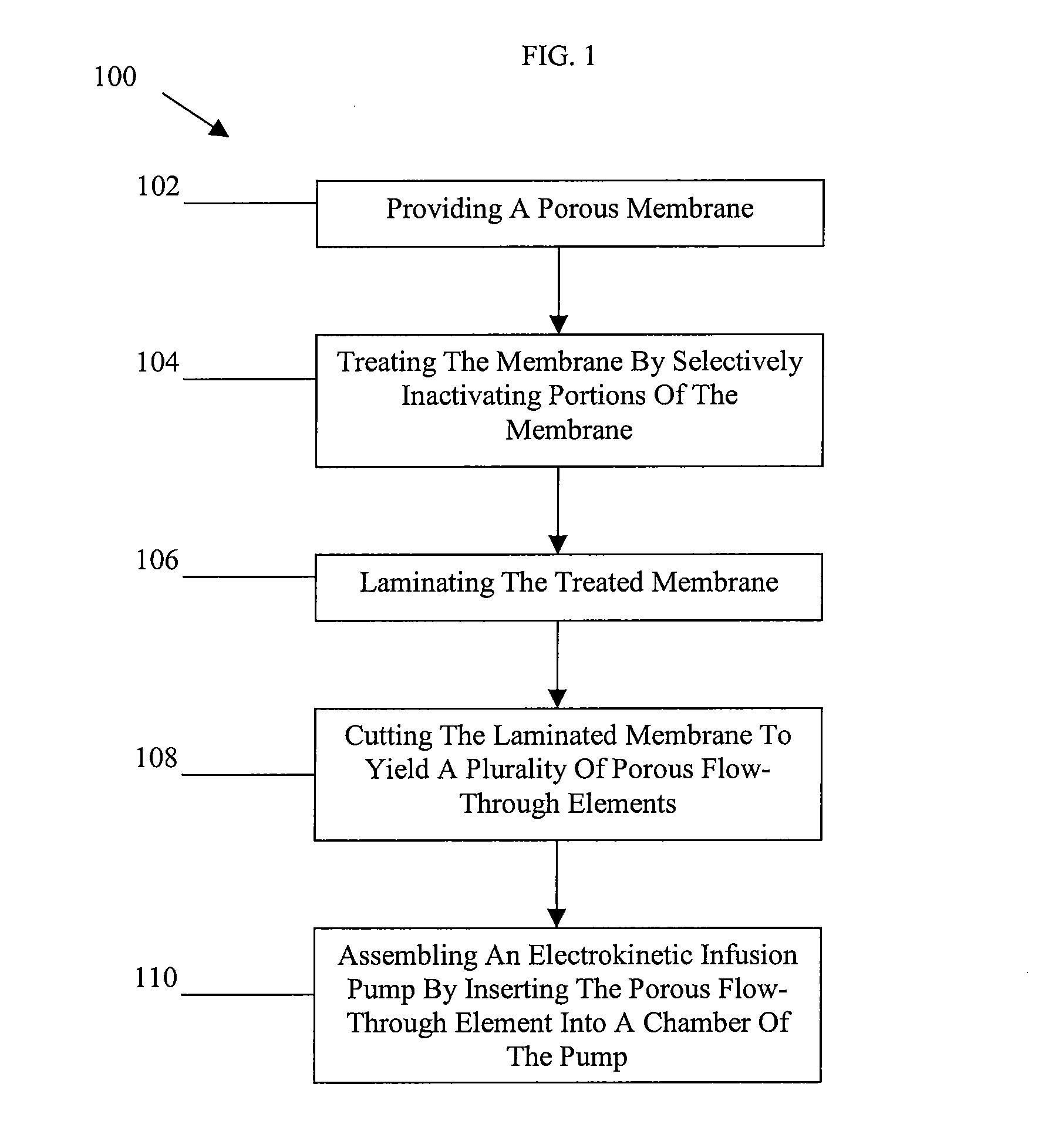

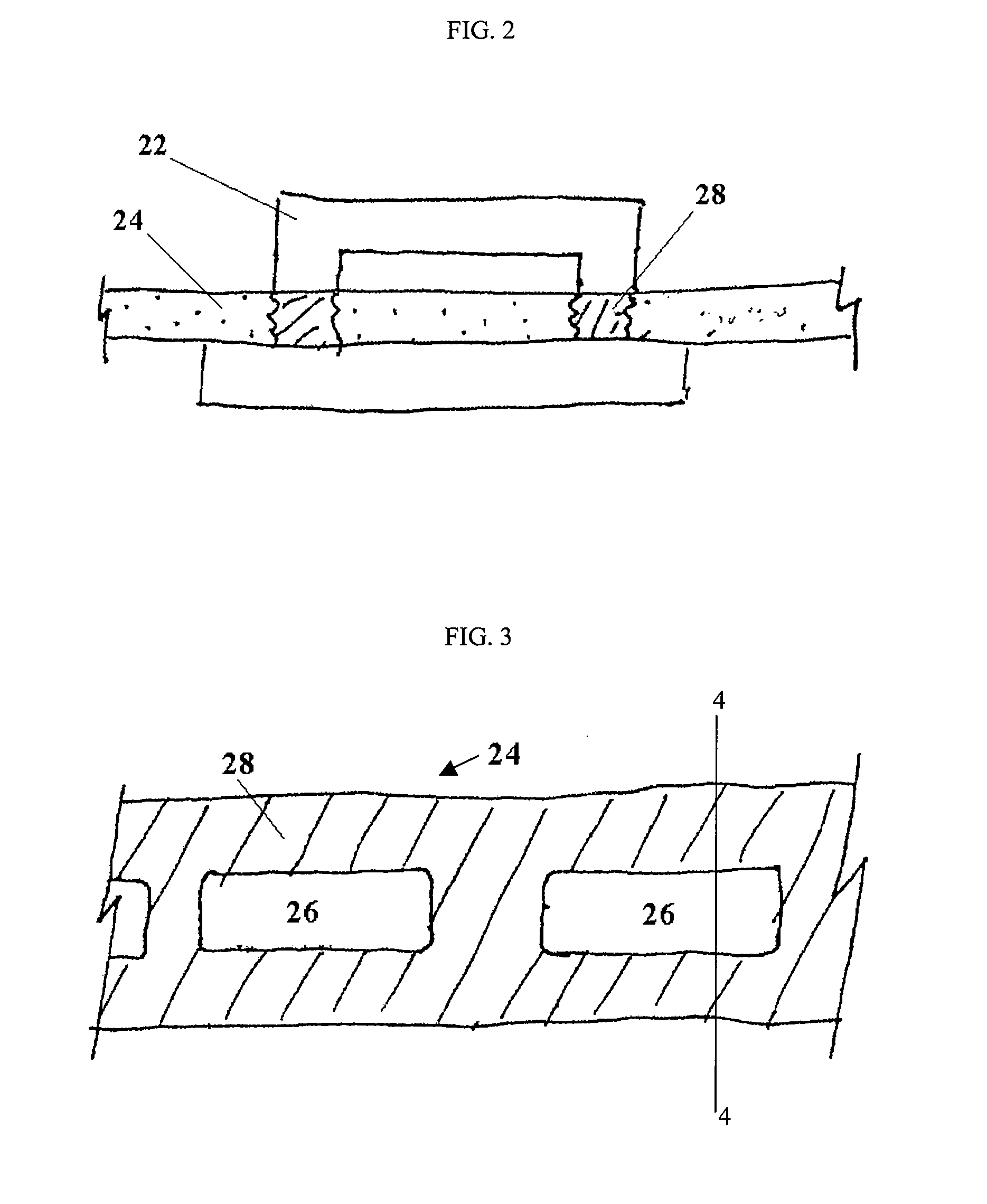

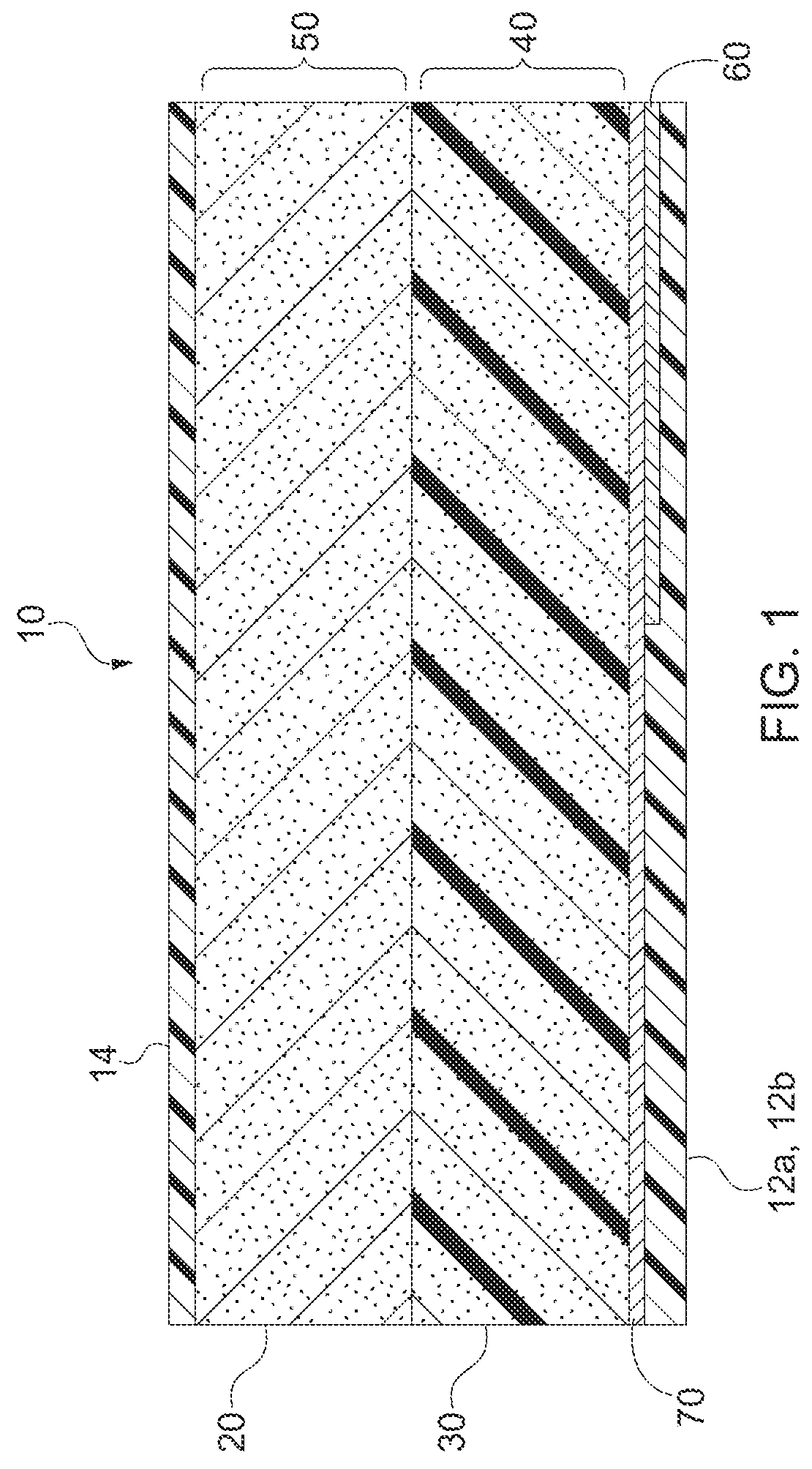

Method for manufacturing an electrokinetic infusion pump

InactiveUS20080149599A1Improve adhesionLamination ancillary operationsDecorative surface effectsPorous flowPorous membrane

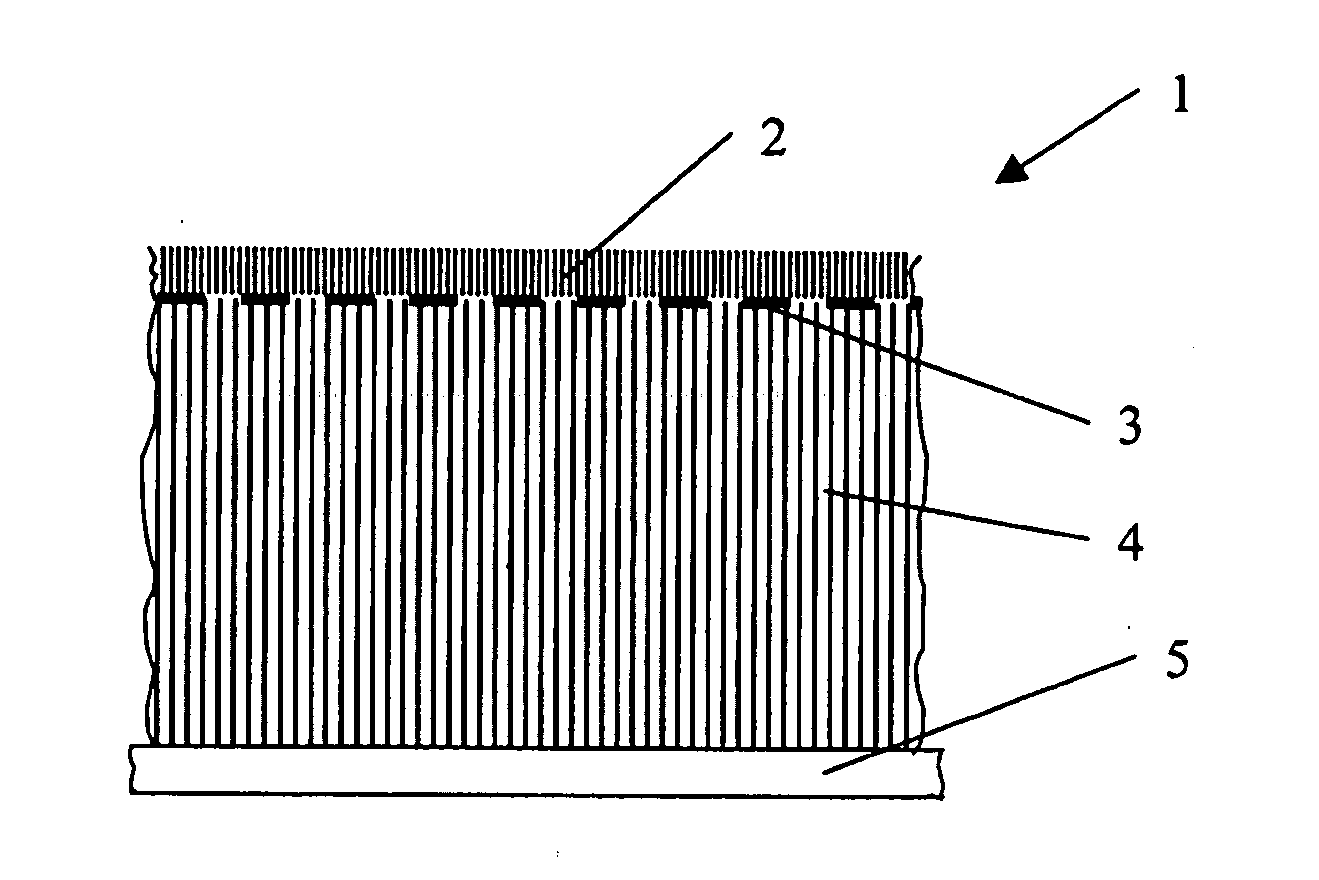

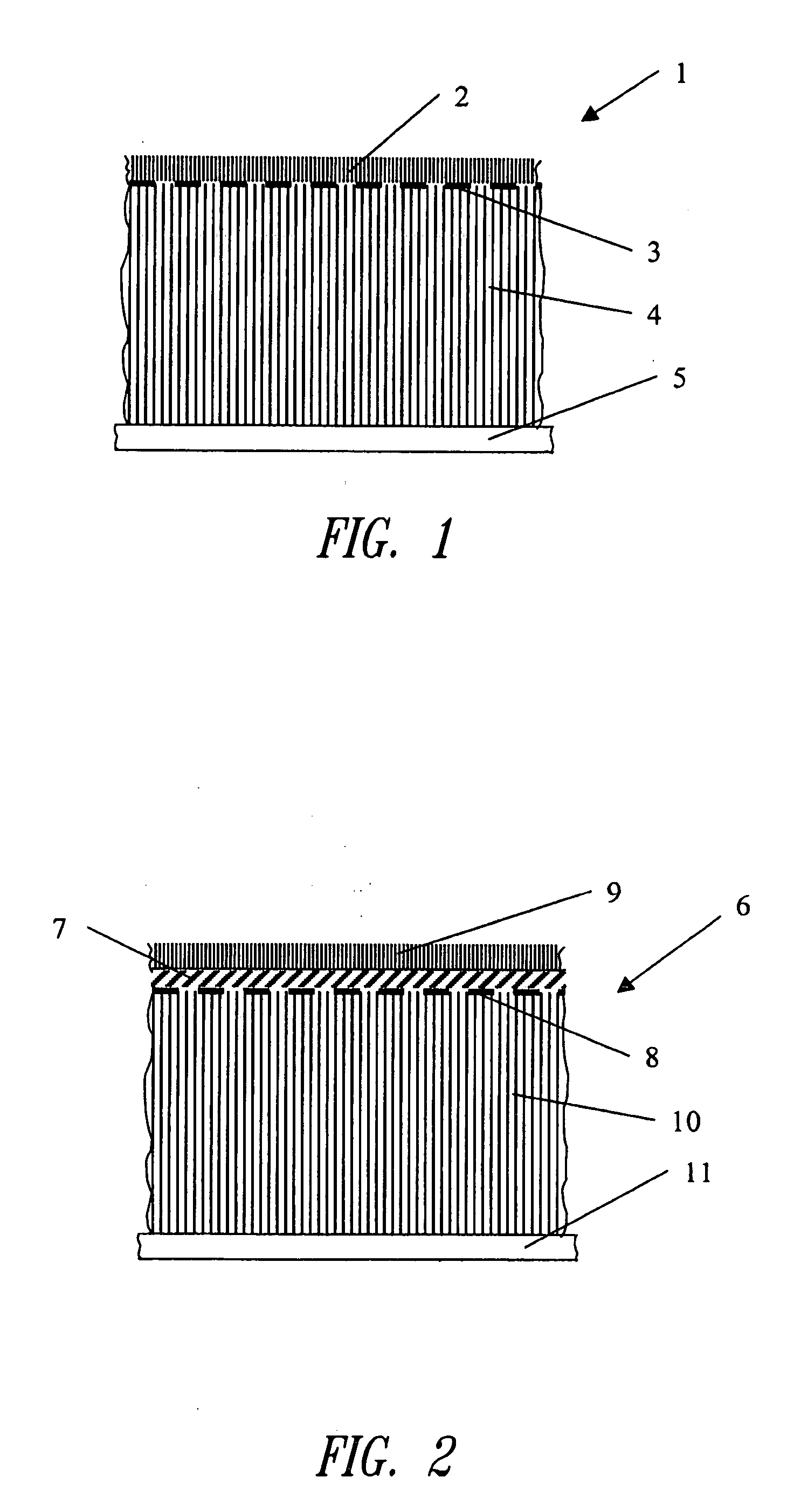

A method for producing a porous flow-through element for use in an electrokinetic infusion pump is provided and generally includes providing a porous membrane that is entirely porous along both its length and width, treating the membrane by selectively inactivating portions of the membrane in a desired pattern to define active regions that allow fluid flow therethrough and inactive regions that do not, and laminating the treated membrane. Various techniques can be used to treat the membrane including, for example, applying a heated embossing die to the membrane, contacting selected portions of the membrane with laser energy, applying a pore-penetrating chemical to the membrane, and cutting and removing selected portions of the membrane. The resulting treated membrane can be laminated between opposed films having one or more perforations therethrough with each perforation being aligned with an active region to define a fluid flow pathway therebetween.

Owner:LIFESCAN INC

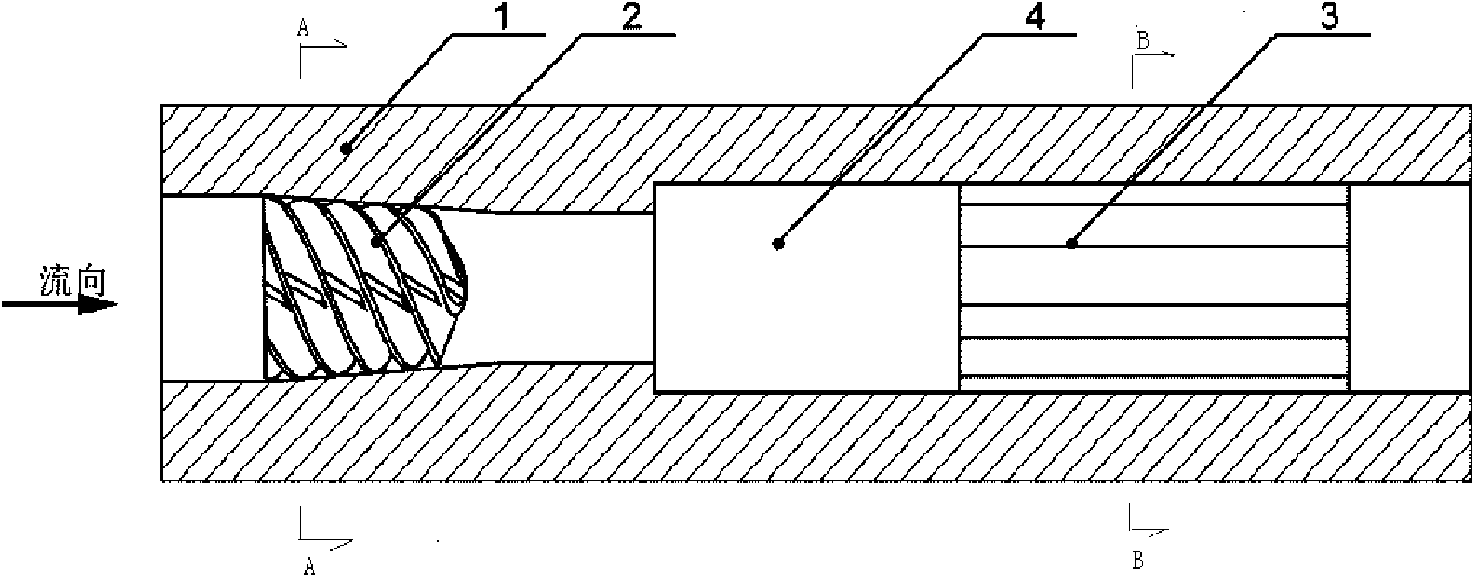

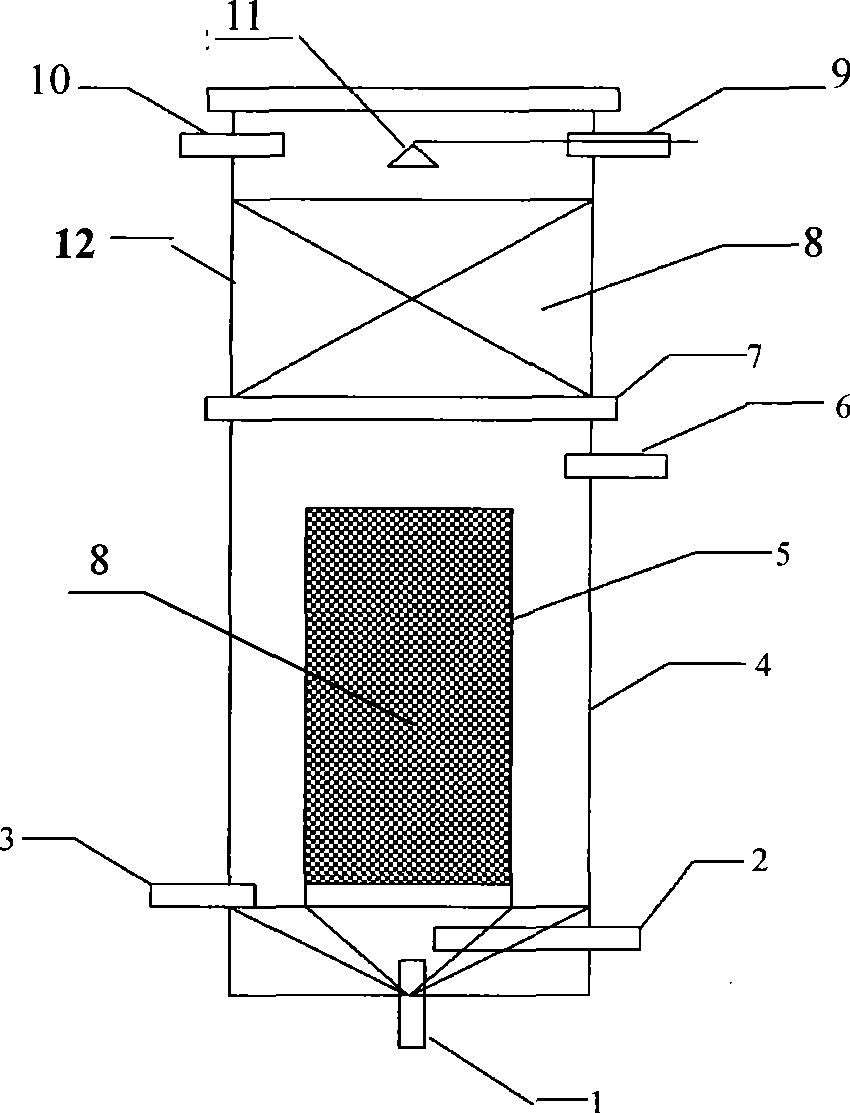

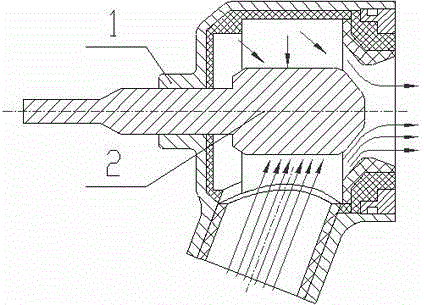

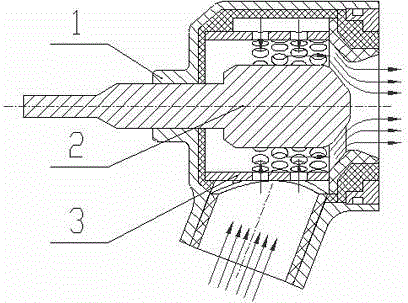

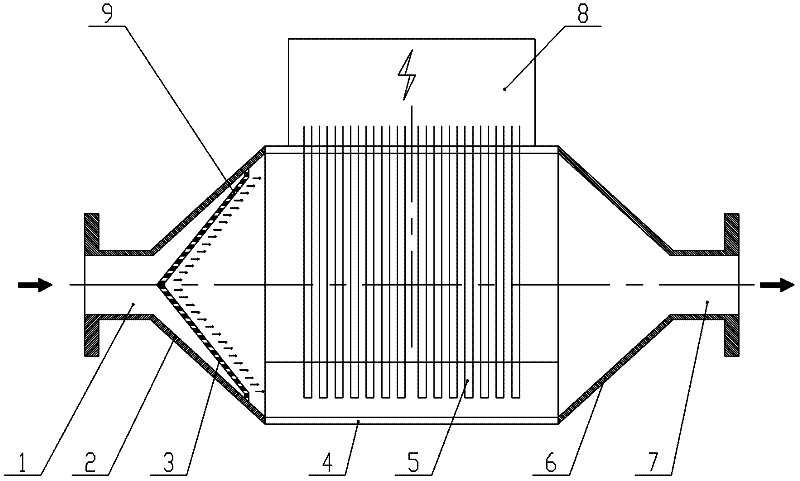

Multiphase flow rectifying device

InactiveCN101639374AConvenience to workHigh measurement accuracyVolume meteringPorous flowEngineering

The invention relates to a multiphase flow rectifying device which comprises a pipe connecter matched with a fluid pipeline, a spiral body and a flow adjustor, wherein the pipe connecter is provided with an upstream rectifying cavity and a downstream diffusion steady flow cavity; the spiral body is installed in the upstream rectifying cavity, and the flow adjustor is installed in the downstream diffusion steady flow cavity; and the upstream rectifying cavity of the pipe connecter has conicity matched with the spiral body. The fluid in two-phase flow or multiphase flow rotatably flows in the spiral direction and becomes the fluid with evenly distributed media and steady flow rate after being mixed and passing the porous flow adjustor. The invention has simple structure, simple and convenient installation and construction, less abrasion of the spiral body and the flow adjustor, favorable rectifying effect and high reliability and can not block the pipeline for long-term use, is particularly suitable for rectifying the fluid in the two-phase flow or the multiphase flow and can be matched with a flow meter to carry out the flow measurement of the two-phase flow or the multiphase flow.

Owner:姚贤卿

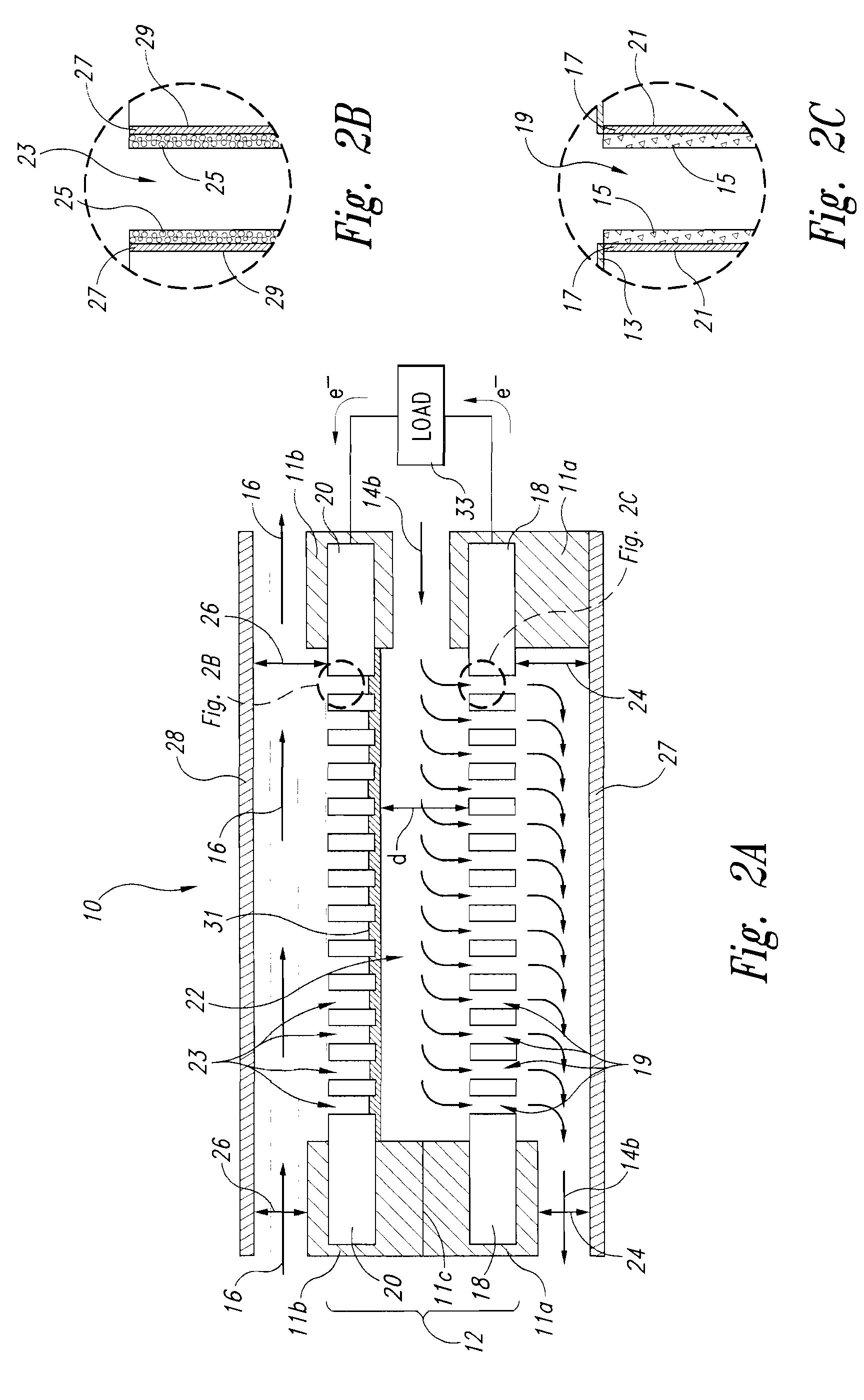

Electrochemical fuel cell component materials and methods of bonding electrochemical fuel cell components

A method of producing a porous flow field material for a bipolar separator plate is provided. The method includes bonding a single layer of wire mesh or bonding together at least two layers of wire mesh to form a porous flow field material, wherein the bonding is achieved by diffusion bonding, continuous resistance welding, continuous sintering, or a combination thereof. Such porous flow filed materials may function as, for example, fluid flow fields, current collectors, gas distribution layers, and / or coolant layers. A method of producing a bipolar separator plate including such porous flow field materials is also provided, wherein the component layers are bonded together by diffusion bonding, continuous resistance welding, continuous sintering, or a combination thereof, thereby forming a bipolar separator plate.

Owner:MARTIN KURZ & CO

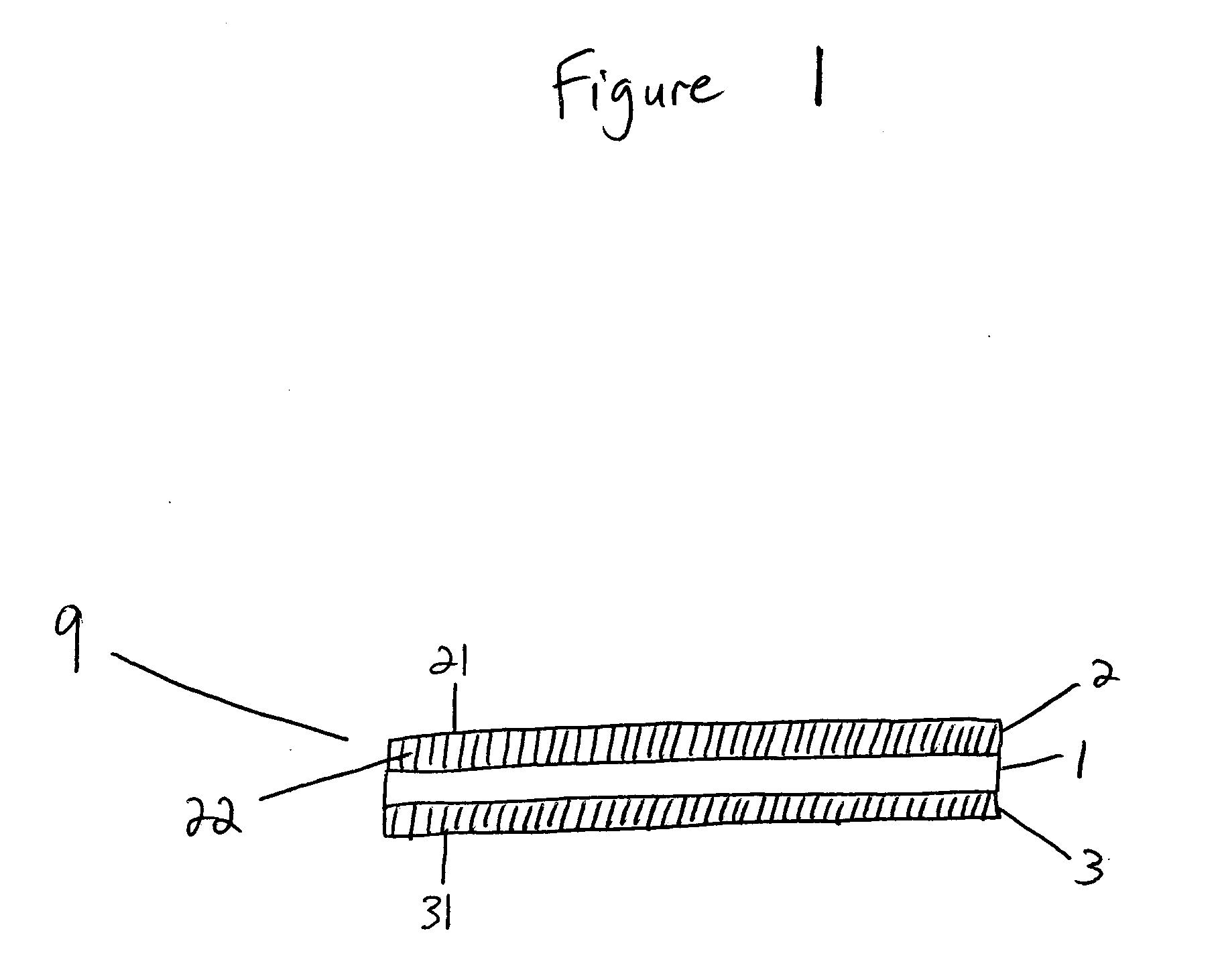

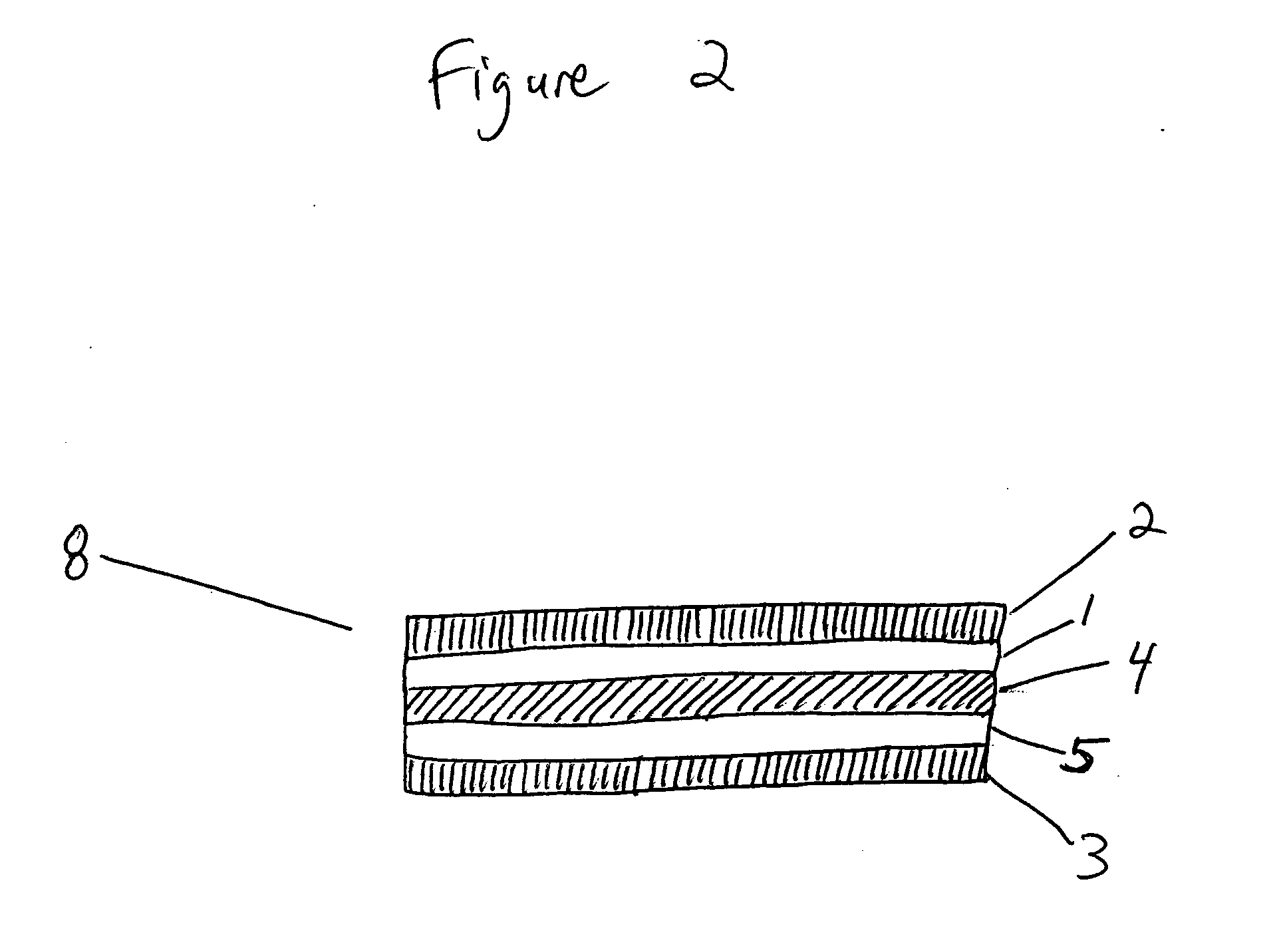

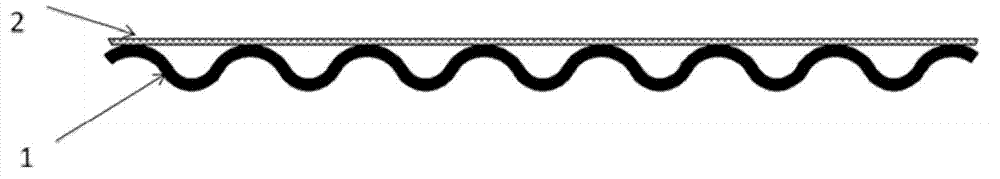

Thermoformable acoustic product

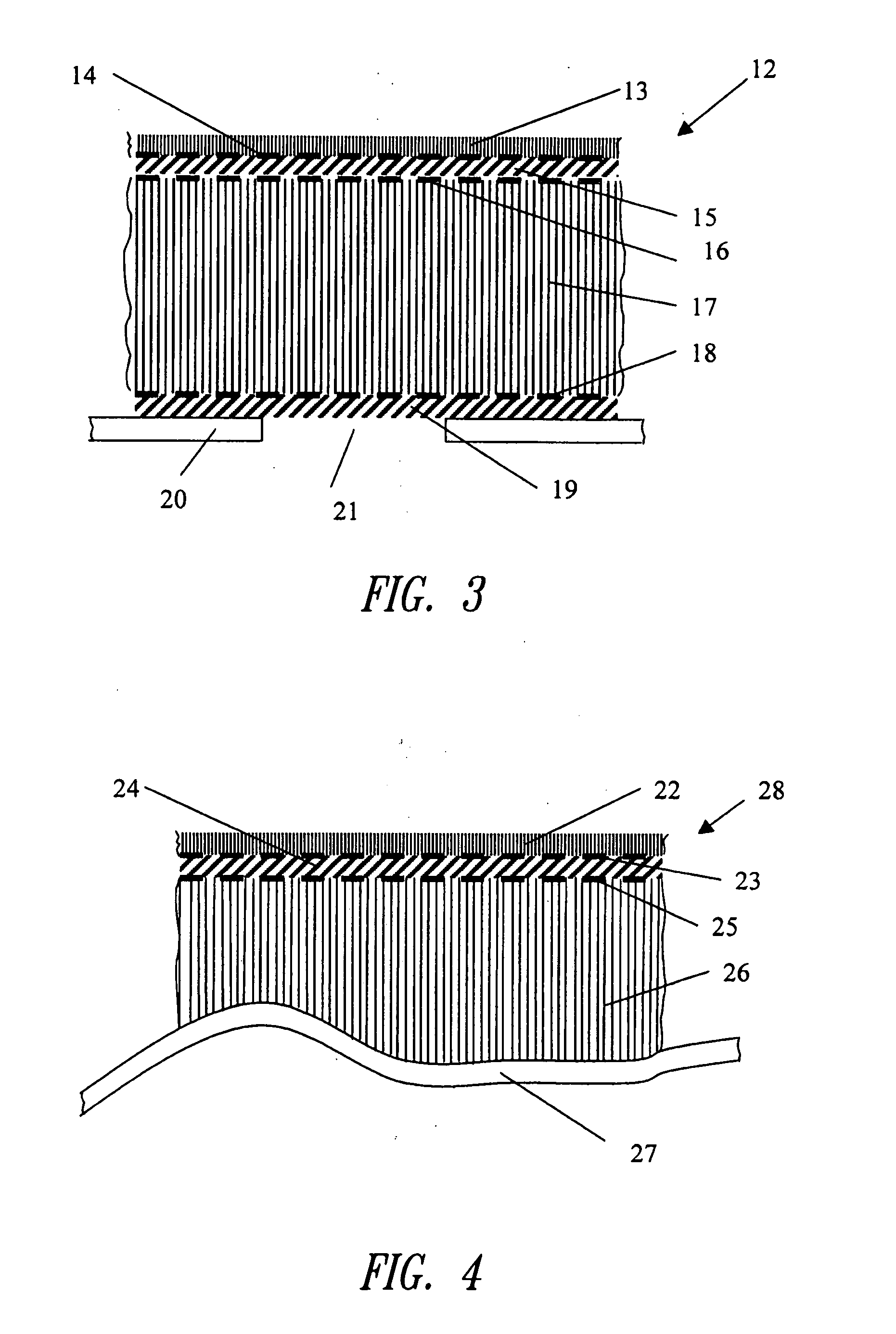

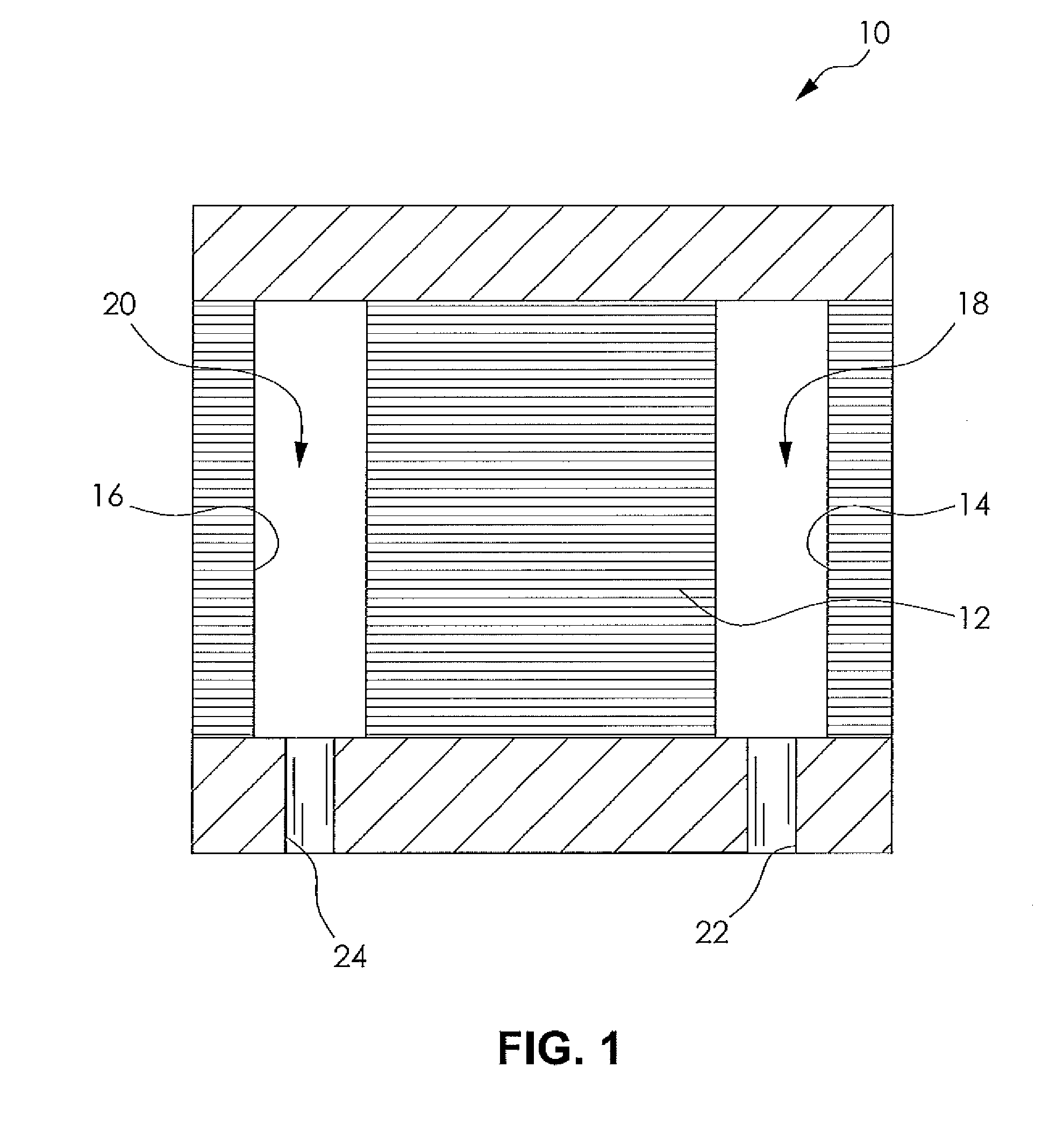

InactiveUS20060090958A1Improve aesthetic appearanceReduce resonanceWallsSound proofingFlow resistivityPorous flow

A thermo-formed acoustic product formed from an acoustic sheet with a relatively high flow resistance, and a layer of porous flow resistive spacer material attached to one side of the acoustic sheet and having a flow resistance substantially smaller than the acoustic sheet. The acoustic product has locally reactive acoustic behavior and an overall air flow resistance of between 2800 Rayls and 8000 Rayls. A decorative facing can be applied to the acoustic sheet.

Owner:ZEPHYROS INC

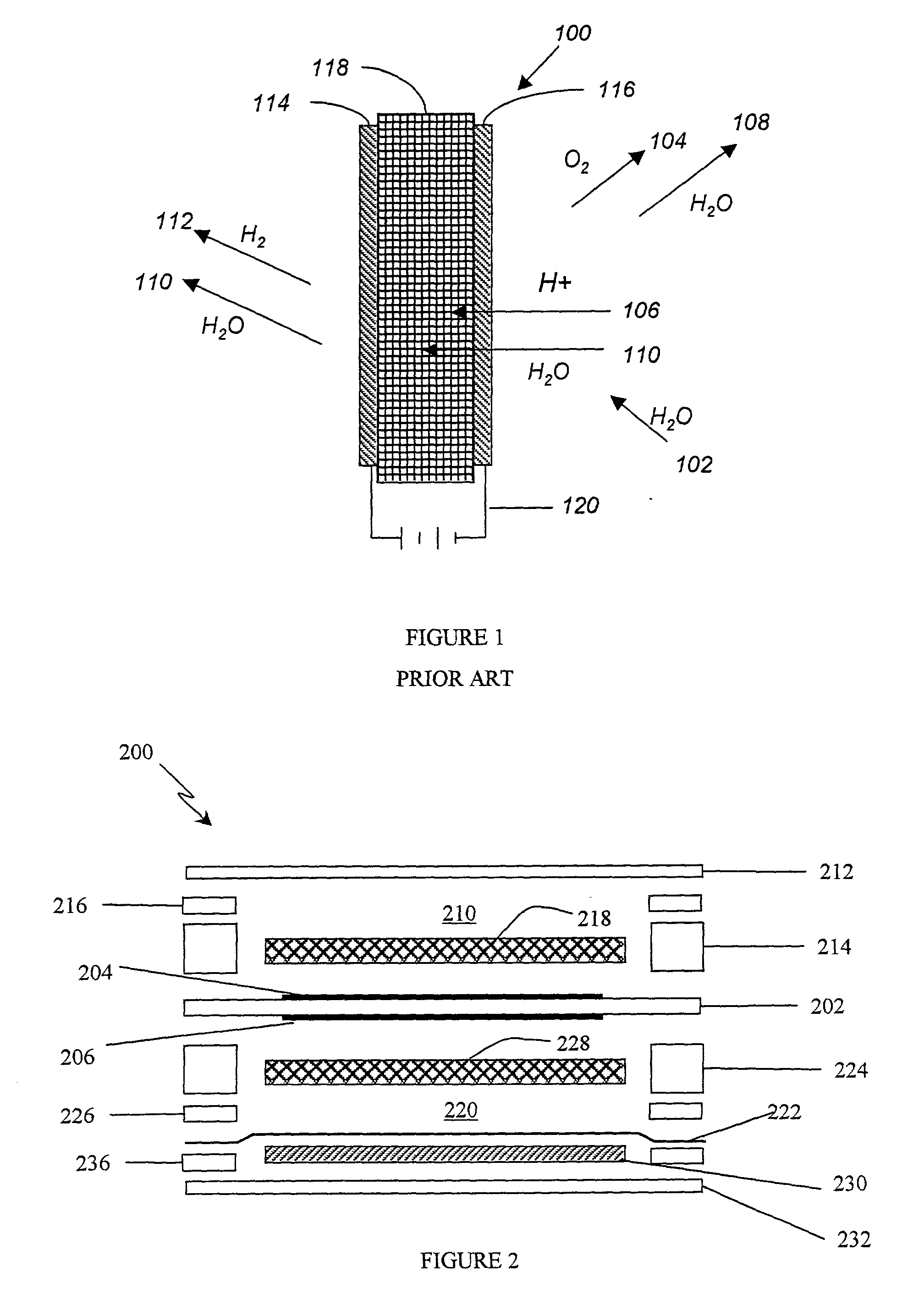

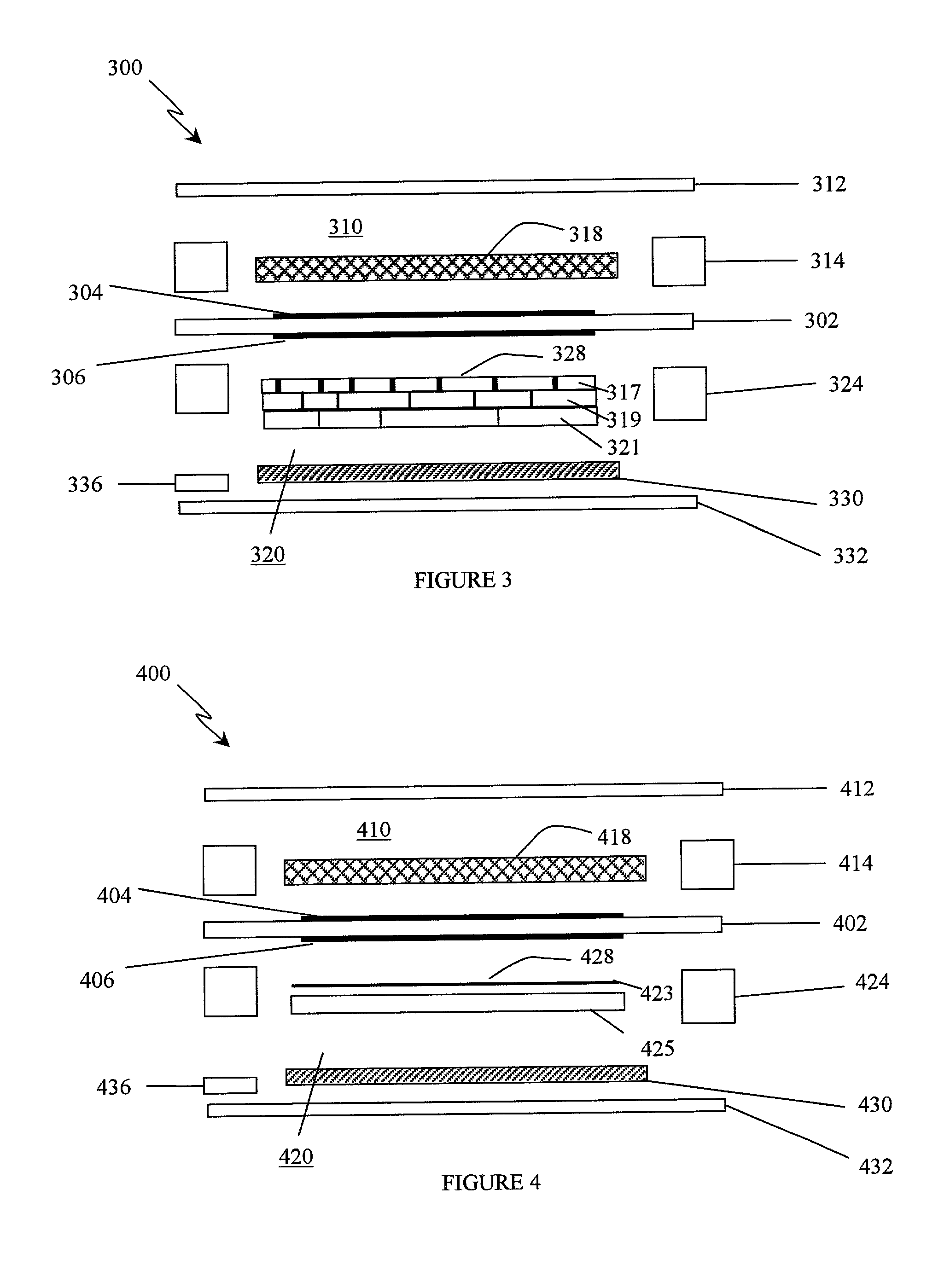

Method and apparatus for improved fluid flow within an electrochemical cell

Treated porous flow field members are used to support membranes in electrochemical cells and to enhance fluid flow to and from the membrane. The treated porous includes a support material having at least a portion thereof treated with a quantity of hydrophobic polymer, a quantity of hydrophilic polymer, or a quantity of a mixture of a hydrophobic polymer and a hydrophilic polymer. Depending on the type of treatment and the placement of the polymer-treated porous support, various fluid flow enhancements are attained.

Owner:PROTON ENERGY SYST

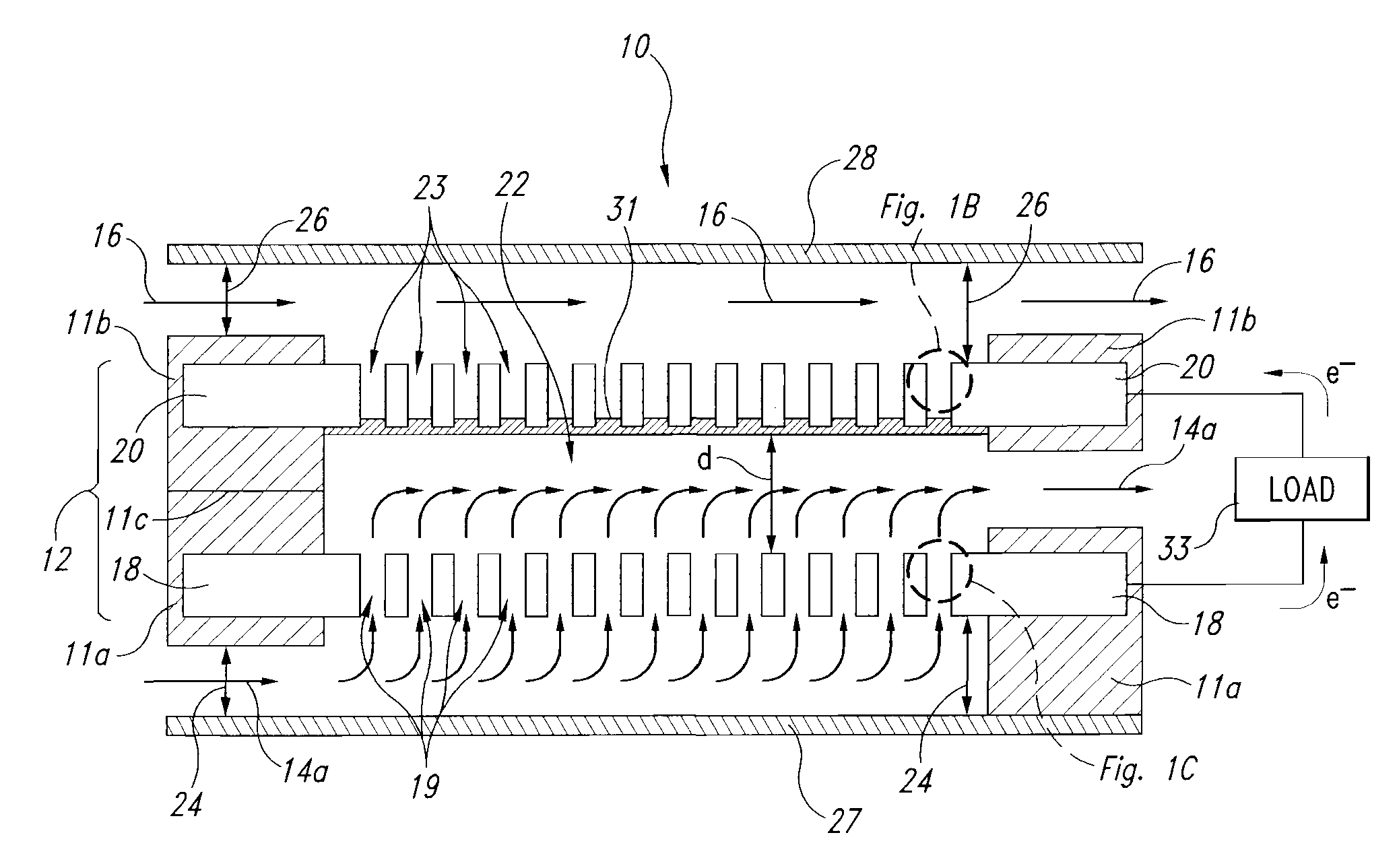

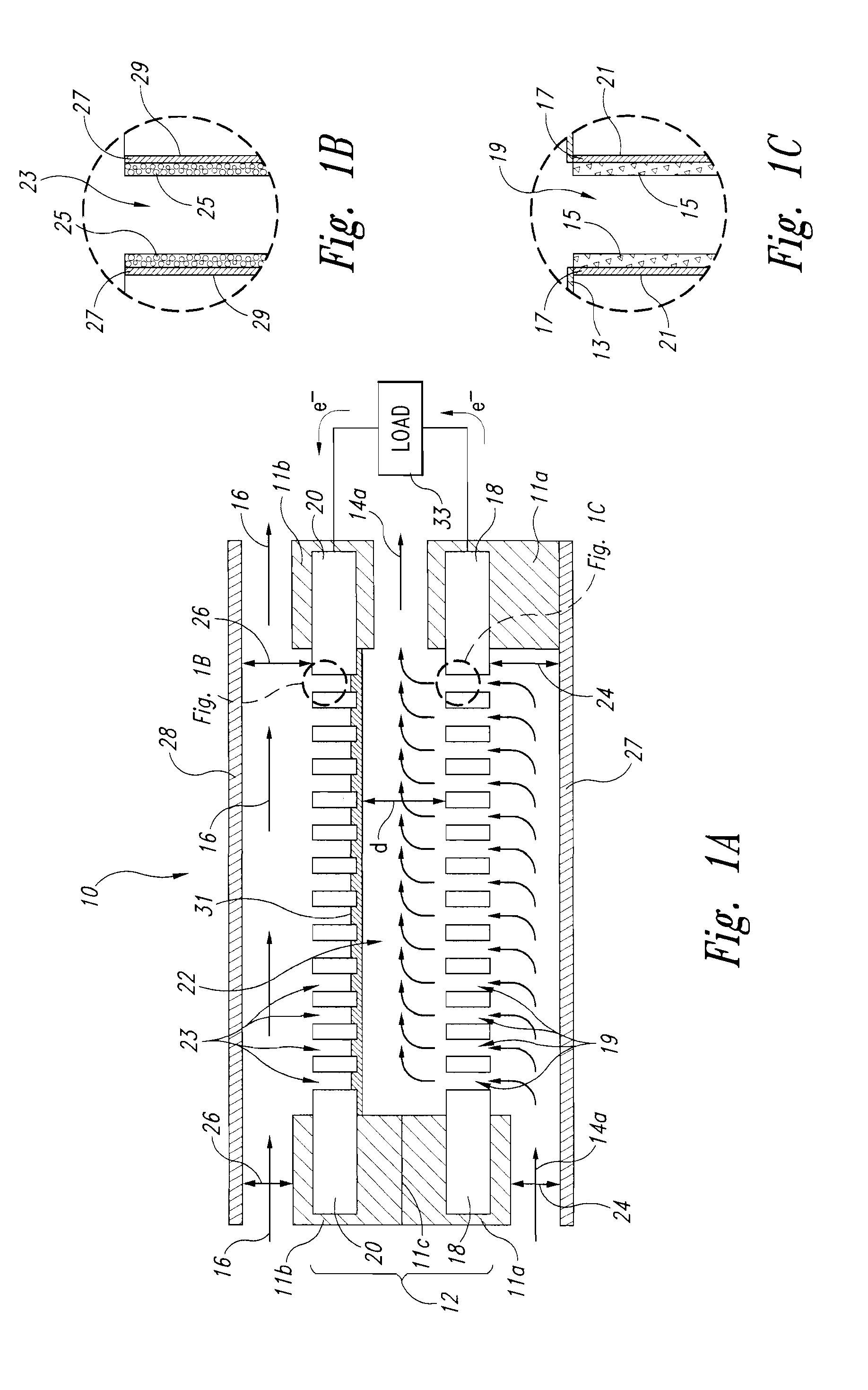

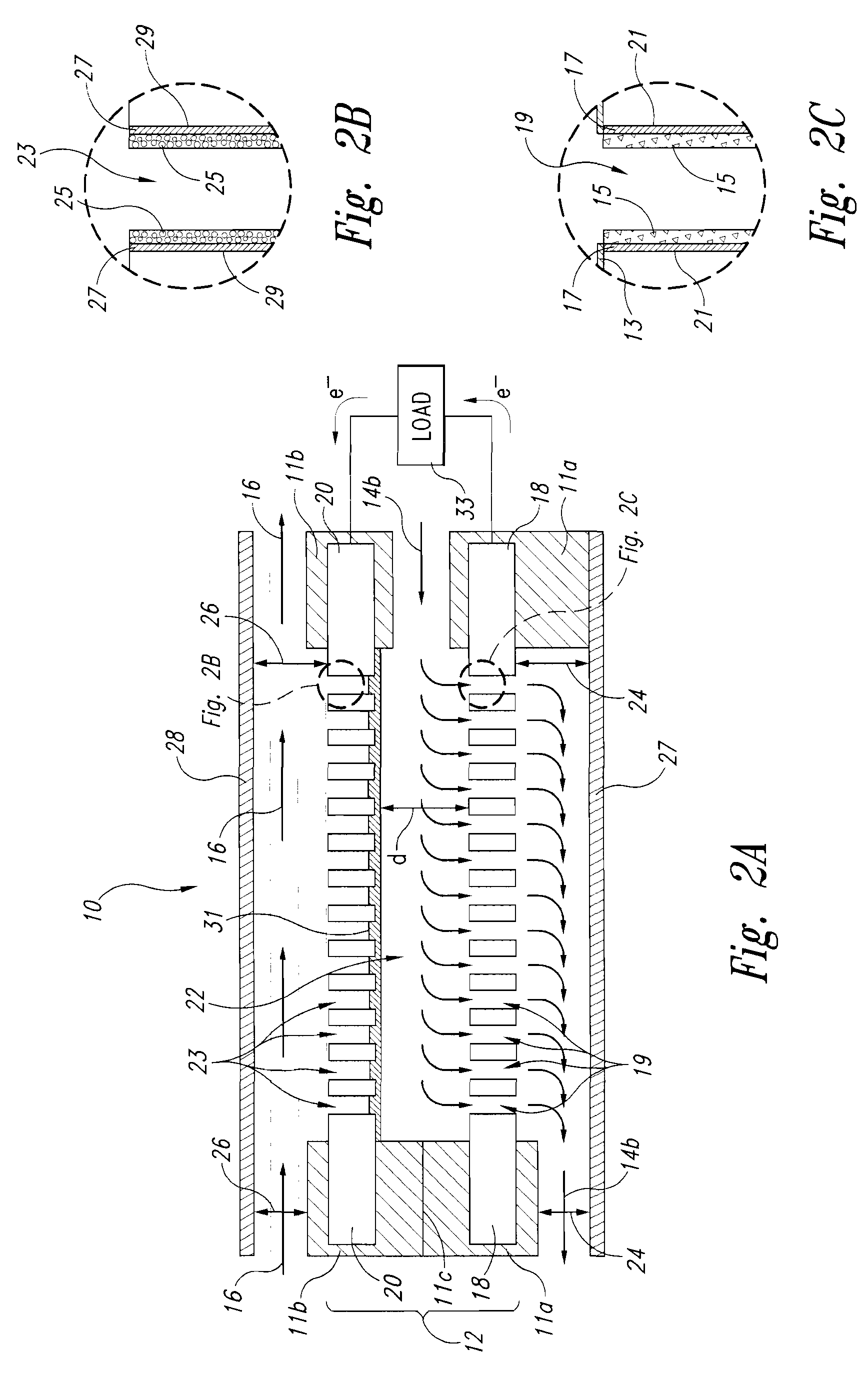

Continuous porous flow distributors for a fuel cell

InactiveUS20110039190A1Easy to transportMinimize the numberWater management in fuel cellsElectrode carriers/collectorsPorous flowFuel cells

A fuel cell plate for a fuel cell assembly is provided that includes a pair of unipolar plates including a flow field, an inlet flow distributor, and an outlet flow distributor, wherein the flow distributors are produced from a porous material to control liquid water throughout the reactant flow path.

Owner:GM GLOBAL TECH OPERATIONS LLC

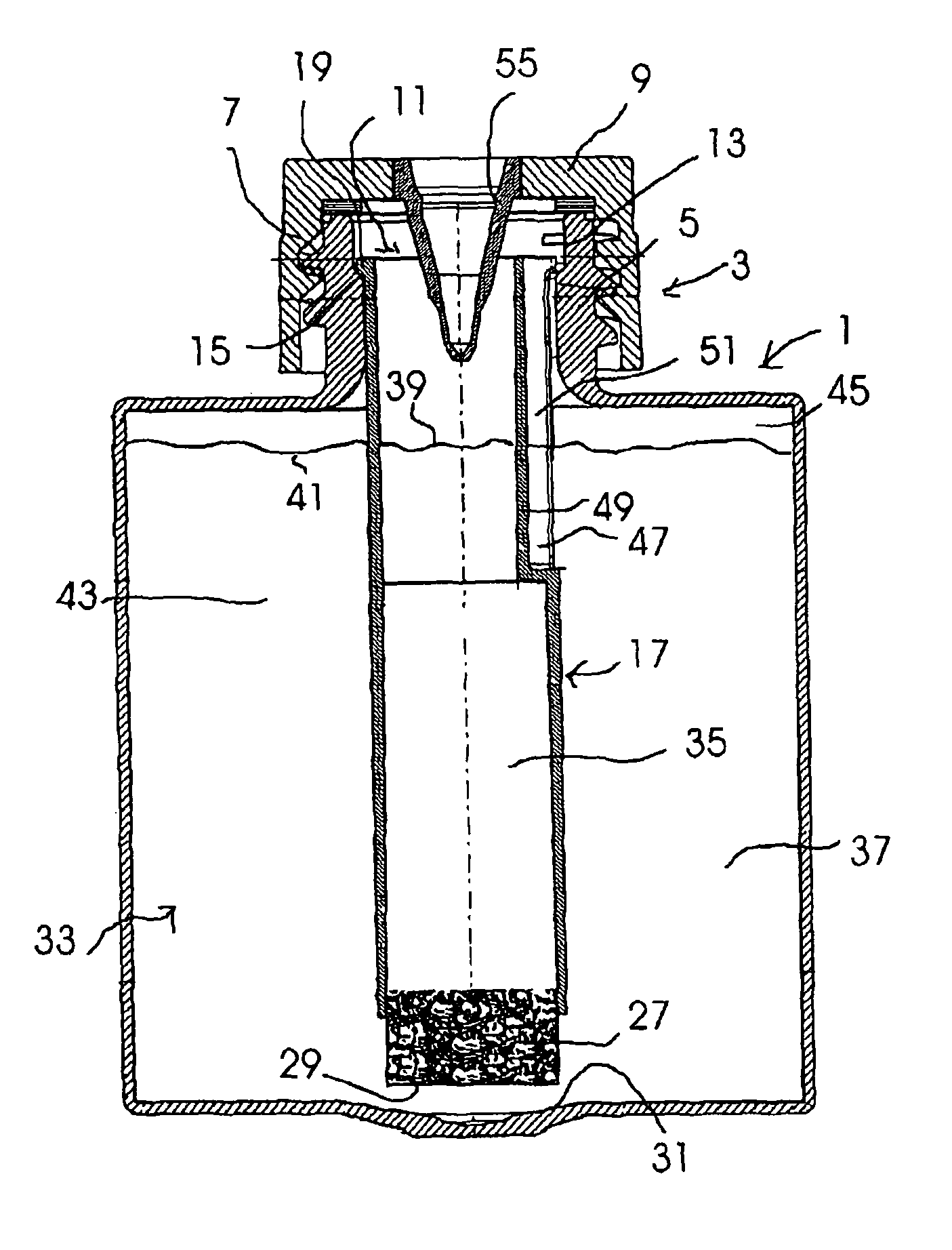

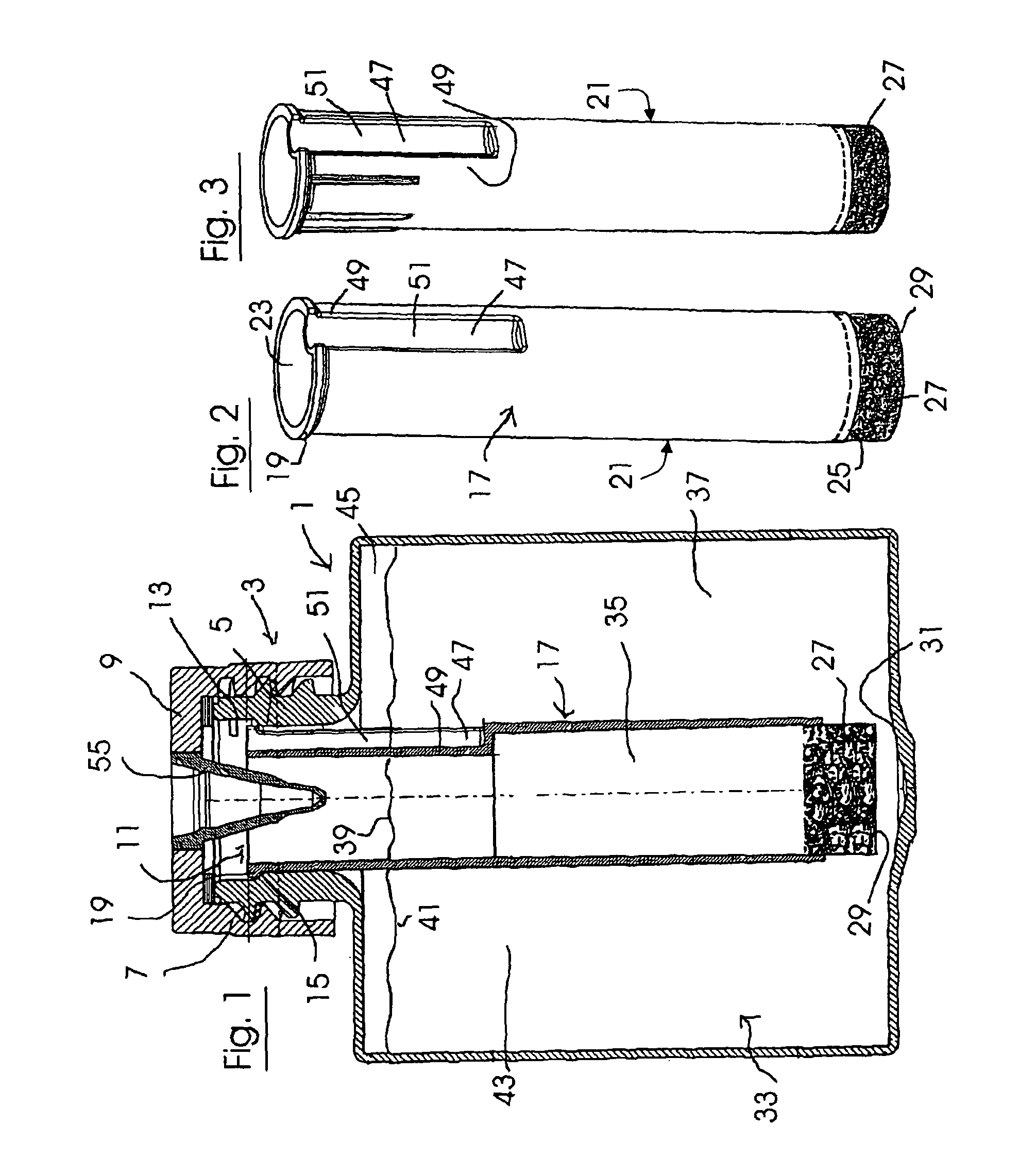

Liquid container with an extraction chimney

ActiveUS8206648B2Slow changeObstruct passageWater/sewage treatment by centrifugal separationMicrobiological testing/measurementInterior spacePorous flow

A liquid container with an upper opening and a tube-shaped withdrawal chimney is disclosed. The withdrawal chimney extends into the container through the upper opening which has a liquid-permeable zone in the form of a finely-porous flow resistance element in its lower end region such that liquid exchange can take place between the withdrawal chimney and the container inner space which surrounds it via the flow resistance element. A venting groove formed by a radial recess of the casing wall of the withdrawal chimney in its upper region may be provided to ensure adequate venting of the space above the liquid level.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

Composite electrode for flow battery

InactiveUS20160036060A1Less compressibleReduce feeding pressureCell electrodesRegenerative fuel cellsState of artComposite electrode

A composite electrode adapted for use in a flow battery stack system has a carbon felt stratum forming a semi-porous reaction zone and a carbon foam stratum forming a porous flow path zone. The composite electrode is less compressible than prior art electrodes having similar conductivity and specific surface areas. Flow battery stack systems employing the composite electrode operate with lower feed pressures, experiences a lower pressure drops across the electrodes, and realize improved electrical resistivity. Alternative embodiments provide electrical conductive elements and a current collector disposed on a surface of the composite electrode.

Owner:CONCURRENT TECH

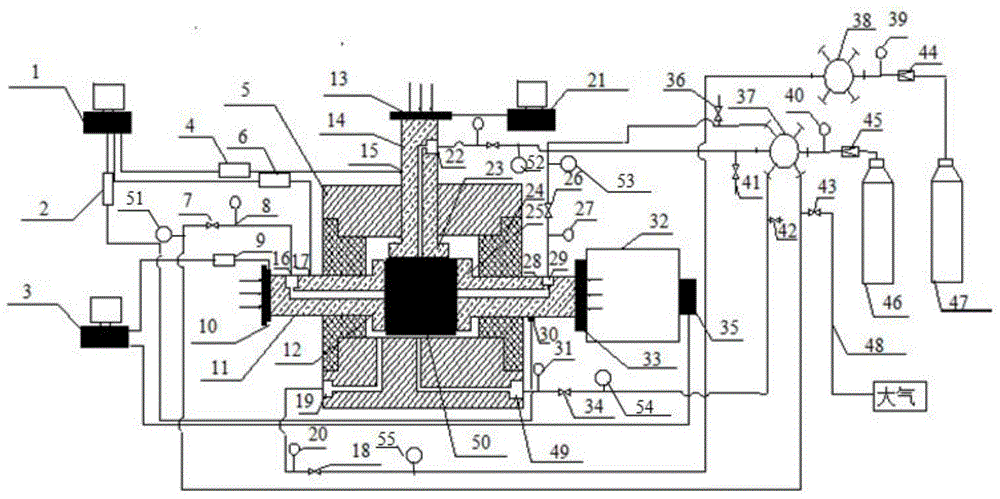

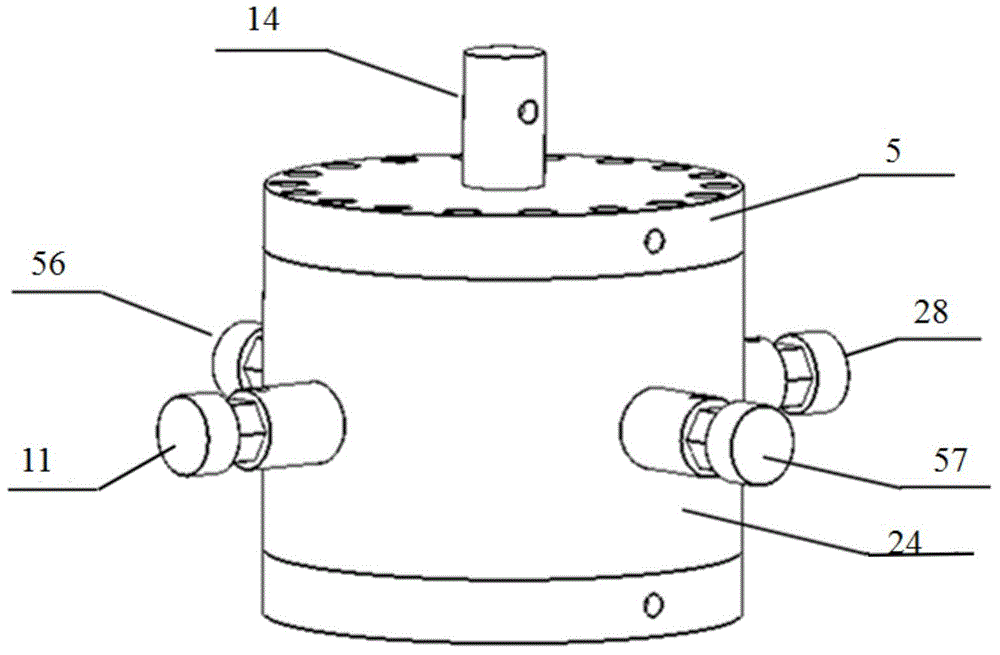

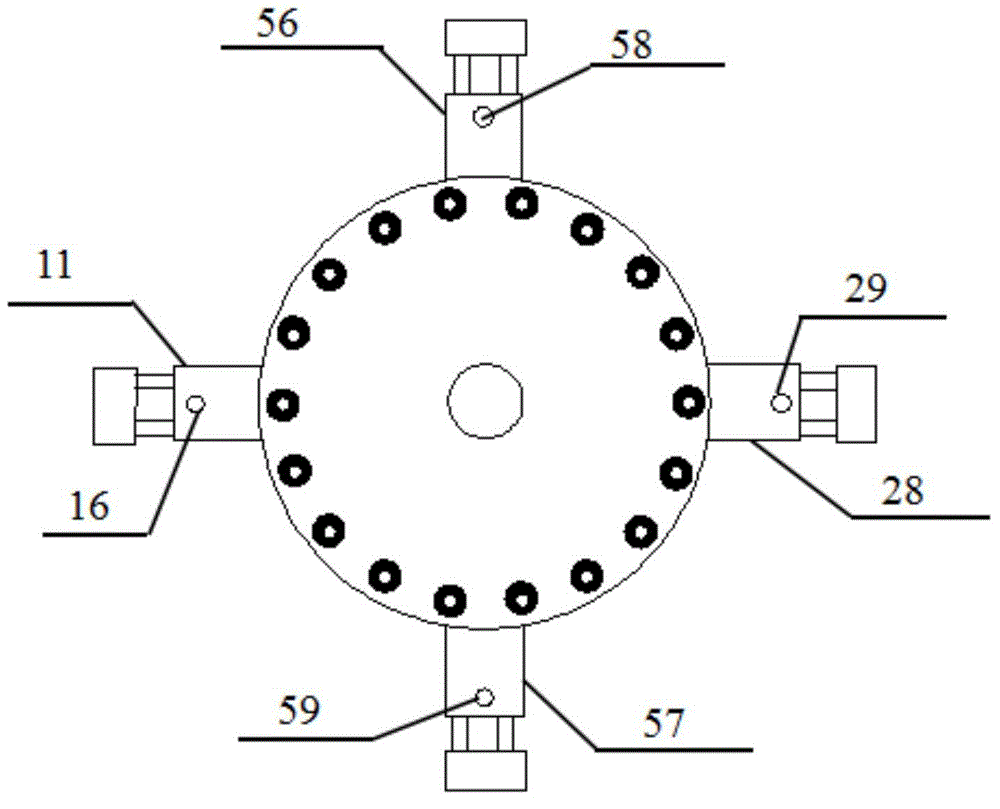

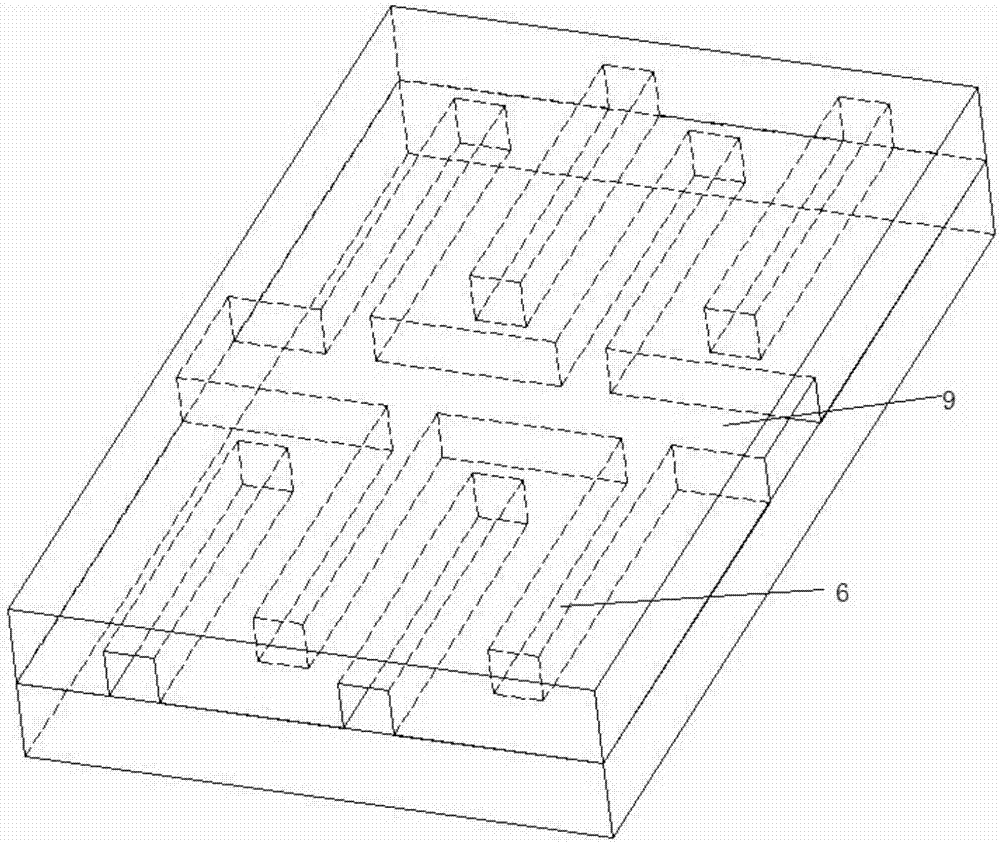

Multidimensional-loading and unloading multiphase porous media strong-coupling damage and porous flow experimental system and method

ActiveCN104596909AReal-time monitoring scalabilityReal-time damage monitoringMaterial strength using tensile/compressive forcesPermeability/surface area analysisGas solidPorous flow

The invention discloses a multidimensional-loading and unloading multiphase porous media strong-coupling damage and porous flow experimental system and a method. The system comprises an axial loading and unloading subsystem, a lateral loading and unloading subsystem, a confining pressure loading and unloading subsystem, a crack damage breaking monitoring subsystem, a central sealed cavity, an inflation subsystem and the like, and the experimental requirements of gas-solid-liquid porosity media mechanical deformation damage characteristic experiment, adsorption swelling deformation breaking porous flow experiment, loaded and unloaded gas-solid-liquid coupling porous flow experiment and gas / water pressure cracking experiment and the like can be met at the same time; the determination on porous flow spatial and temporary variability of the spatial and temporary variability media in X, Y and Z three-dimension direction can be realized, and the synchronous real-time monitoring to the crack expansion and damage during experiment can be performed.

Owner:CHINA UNIV OF MINING & TECH

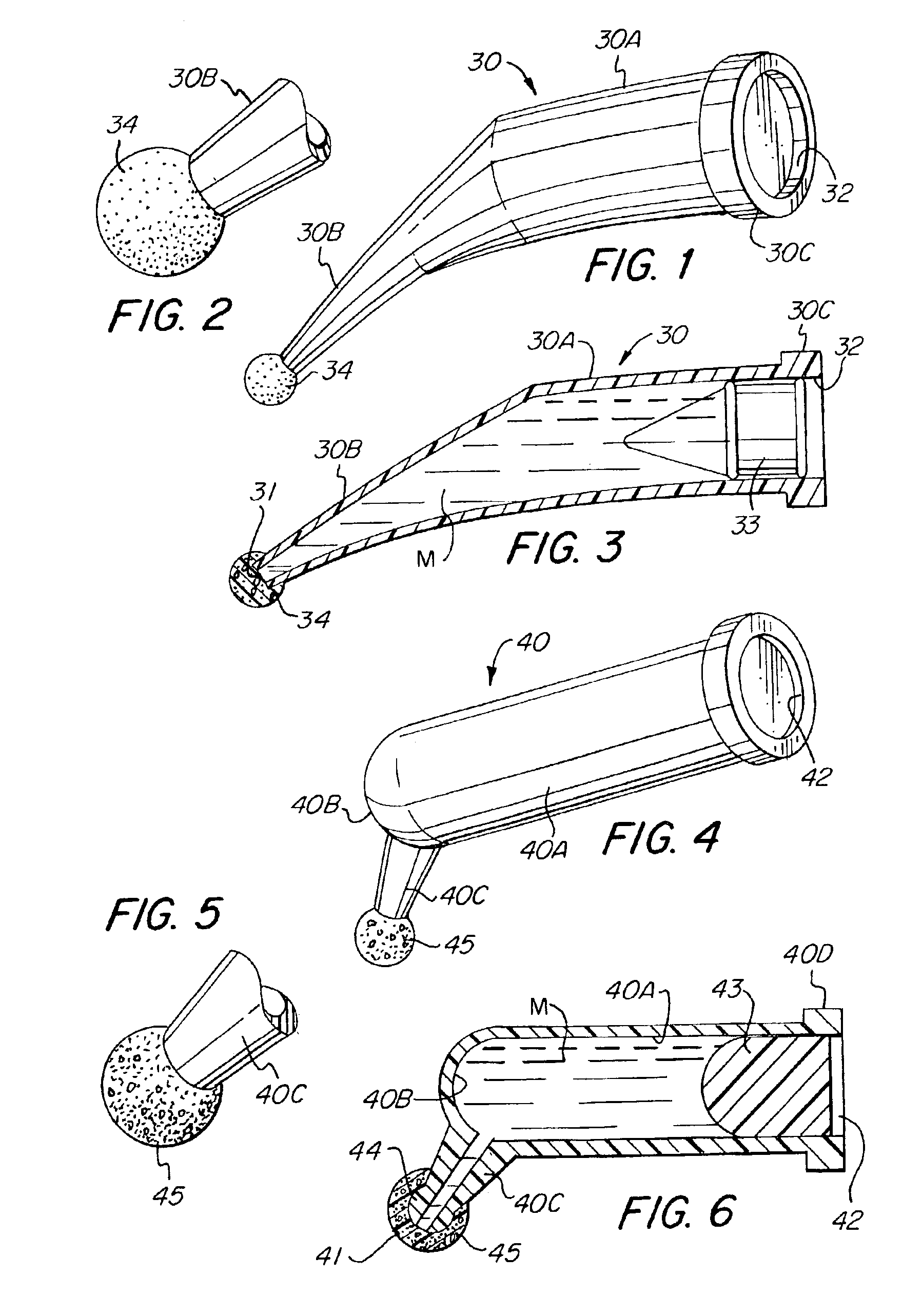

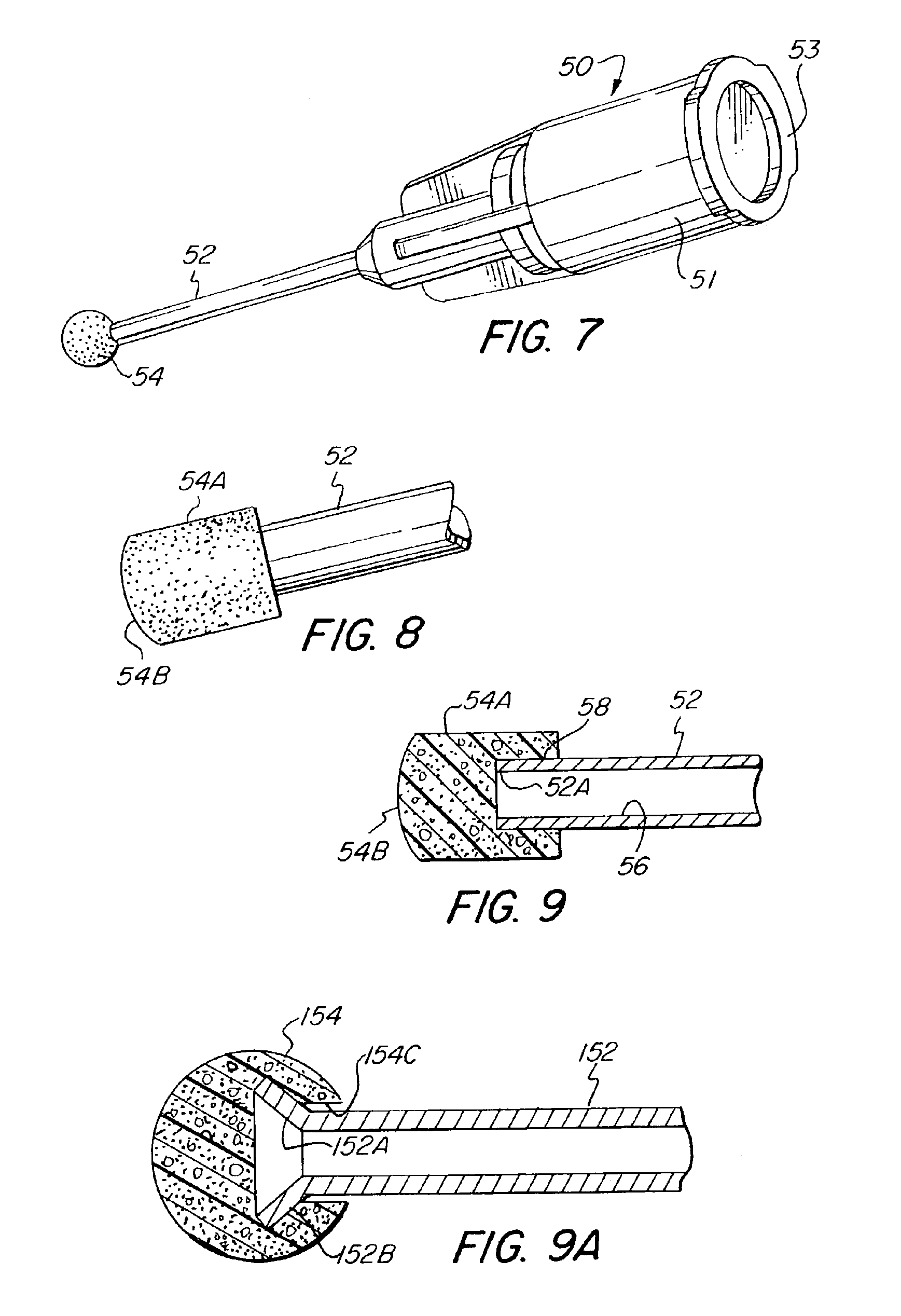

Dental material container with porous flow through applicator

A dental nozzle, cartridge, capsule or container having a porous or foam flow through applicator connected at the discharge end thereof; and having a body portion containing or receiving a low viscosity dental material. In one form, a displaceable plunger or piston is disposed within the body portion to extrude the dental material through the discharge orifice and attached flow through applicator. The foam or porous applicator may be connected to the discharge end at the time of manufacture as by molding, or by mechanically connecting or by adhering the same to the discharge orifice as part of the assembly process. The flow through applicator may be made in a variety of shapes to provide improved and controlled application of a low viscosity dental material to a dental site. Additionally, the porosity of the porous or foam material may be matched to the viscosity of the dental material to control the flow of dental material therethrough.

Owner:CENTRIX

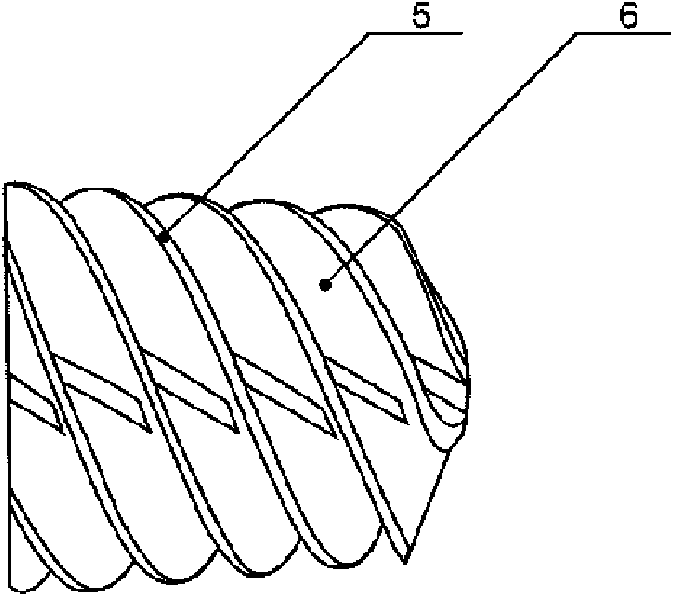

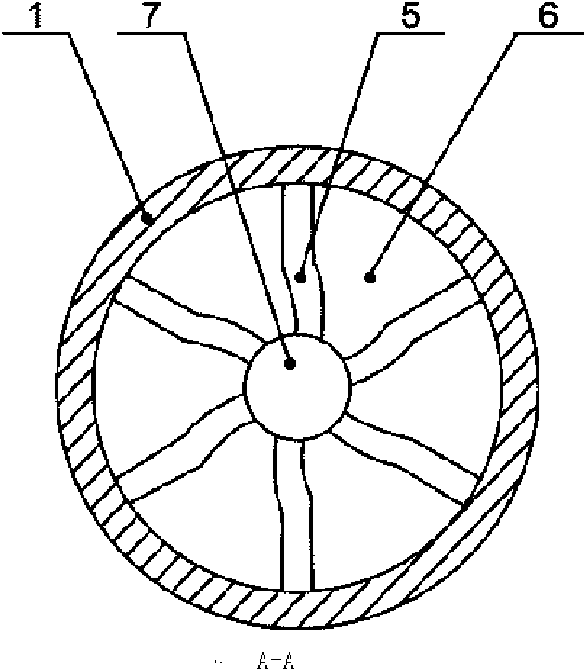

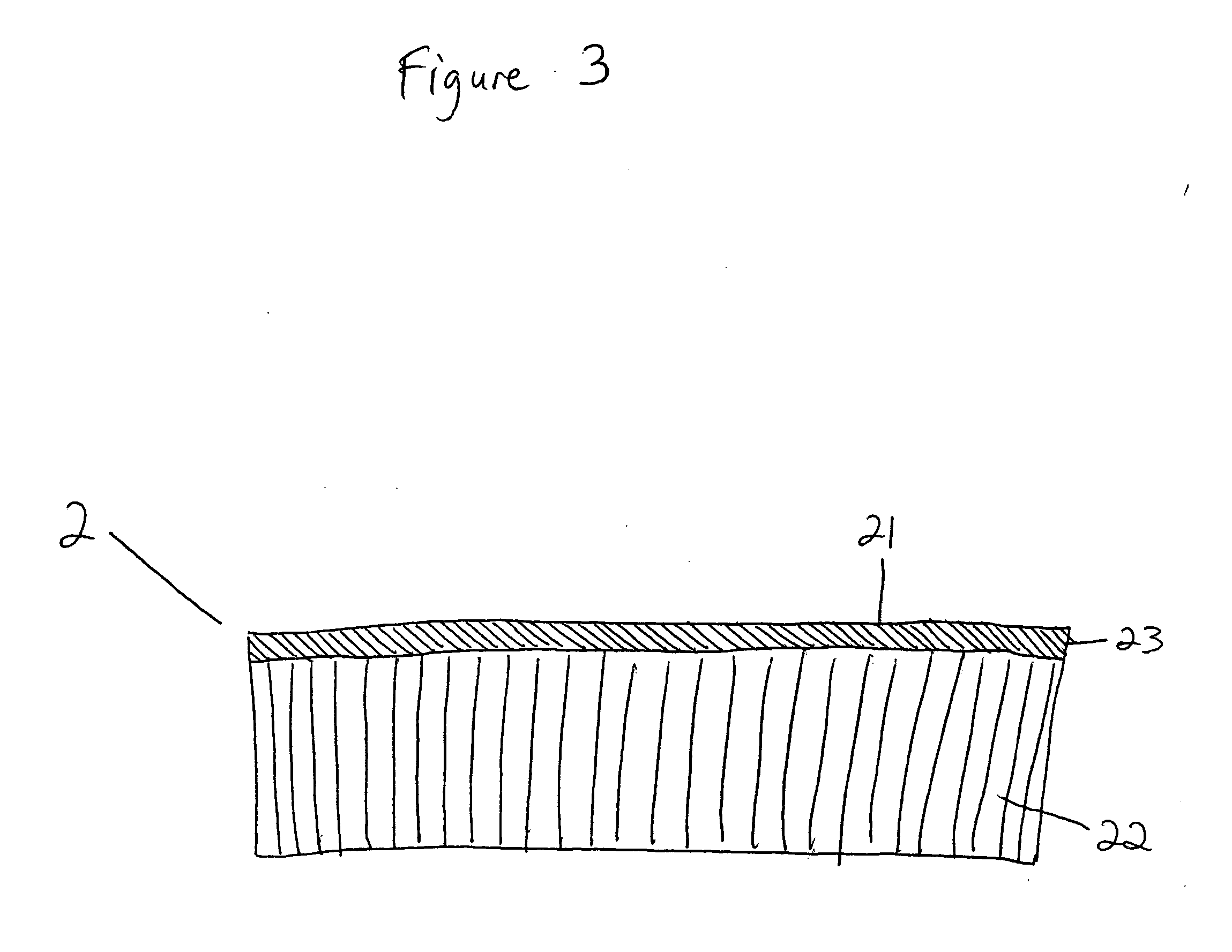

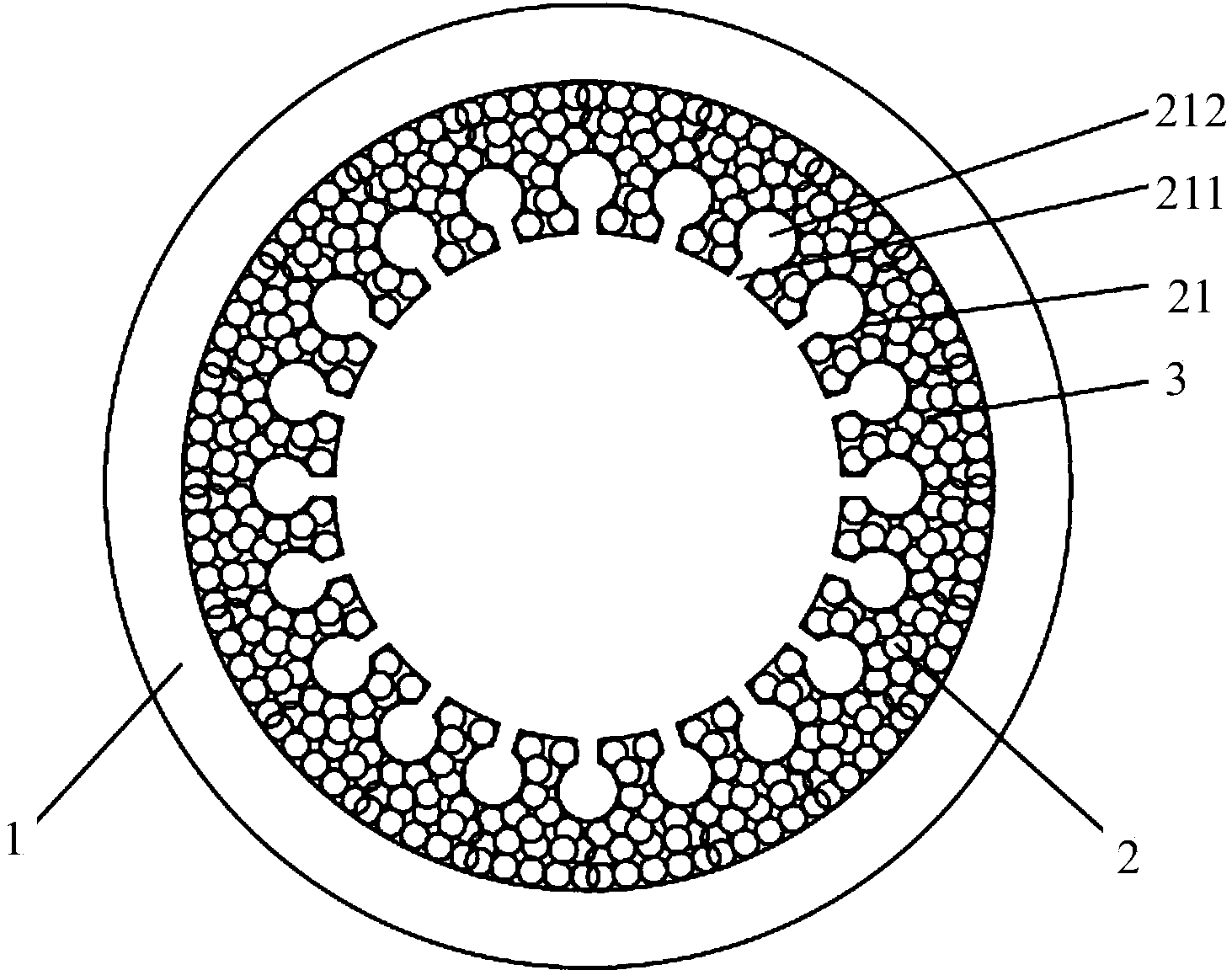

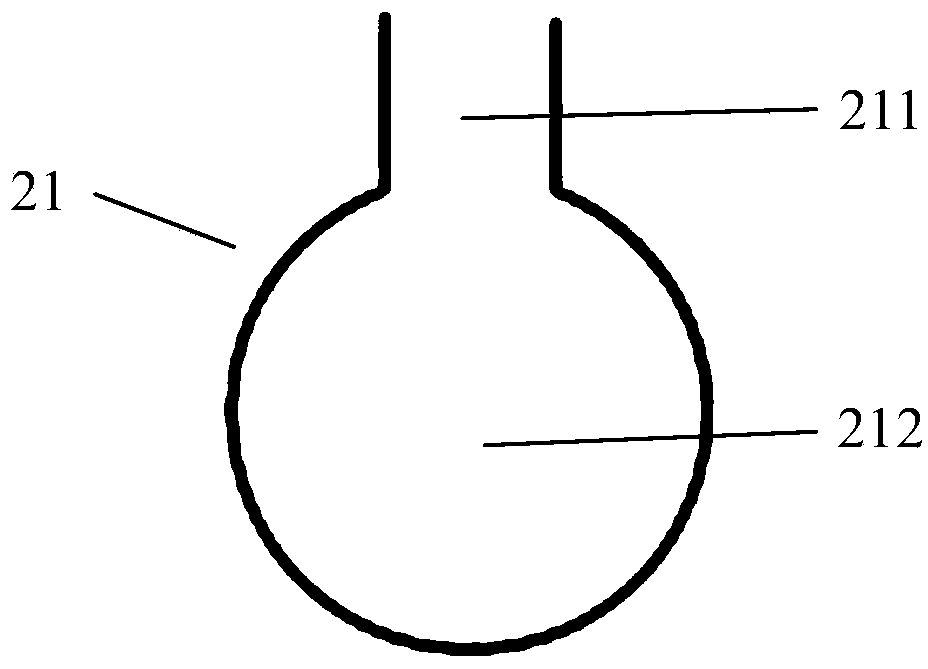

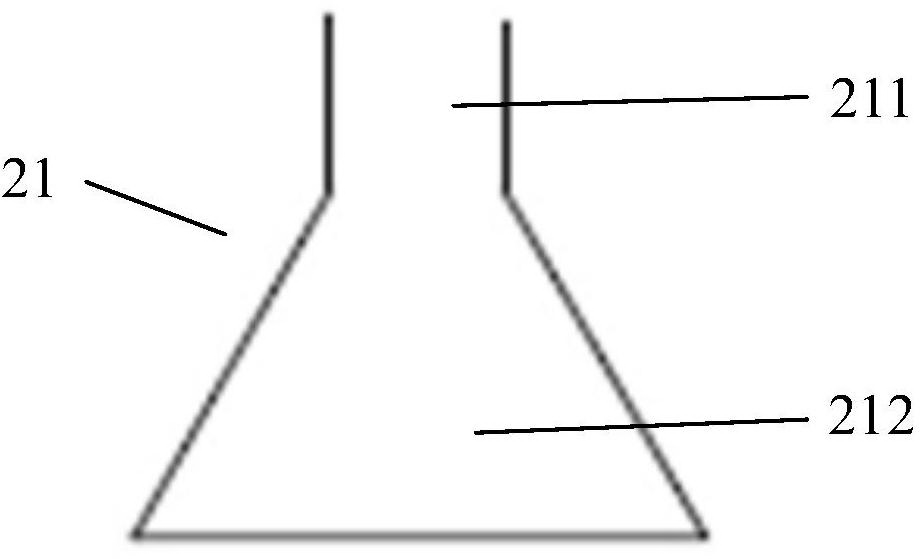

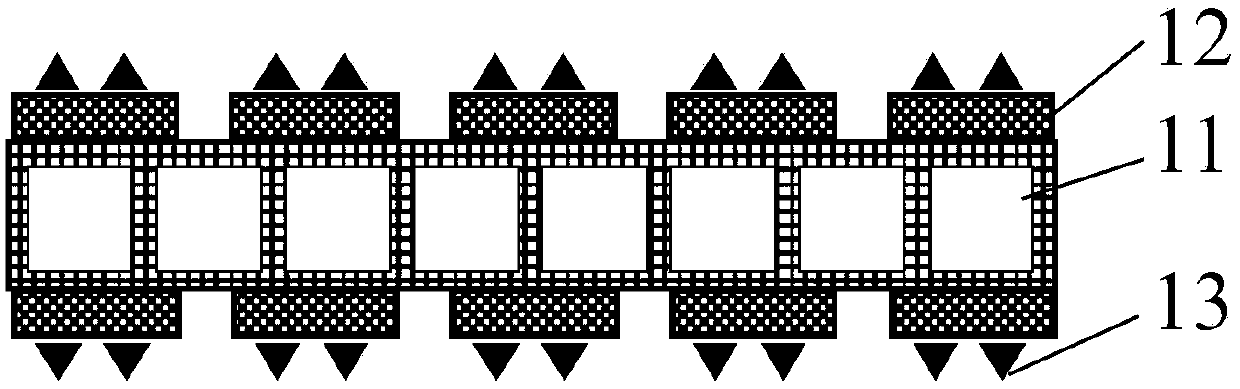

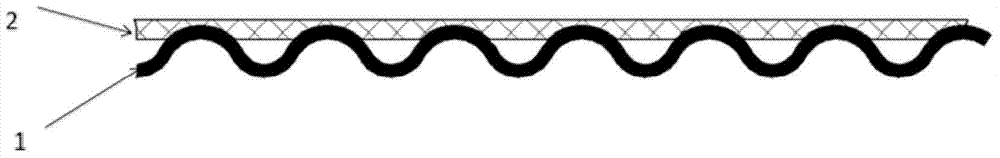

Heat-tube composite liquid absorption core and preparation method for same

ActiveCN104075603AImprove heat transfer performanceReduce backflow resistanceIndirect heat exchangersPorous flowCapillary pressure

The invention discloses a heat-tube composite liquid absorption core and a preparation method for the same. The heat-tube composite liquid absorption core is of a tubular structure, and comprises a metal outer sleeve and a metal porous flow channel, wherein the outer wall of the metal porous flow channel is in close fit with the inner wall of the metal outer sleeve; the metal porous flow channel is formed by carrying out solid-phase sintering on metal powder particles with particle sizes of 40-180 microns, the surface and the interior of the metal porous flow channel are provided with porous pore structures with an average pore diameter of 10-100 microns, and the inner wall surface of the metal porous flow channel is uniformly distributed with 20-60 liquid absorption grooves with lengths which are the same as the axial length of the metal porous flow channel along the peripheral direction thereof; each of the liquid absorption grooves comprises an embedded groove body and a slit, and the embedded groove body is communicated with the cavity of the metal porous flow channel through the slit. The heat-tube composite liquid absorption core disclosed by the invention is simple in manufacturing process and low in production cost, and capable of effectively making up the defects of a single groove or a sintering liquid absorption core, increasing a capillary pressure, reducing a liquid backflow resistance and increasing a permeability; meanwhile, the liquid absorption grooves are capable of effectively weakening the reverse shearing of steam flowing for liquid flowing, thus greatly improving the heat transfer performance of a heat tube.

Owner:XIAMEN UNIV

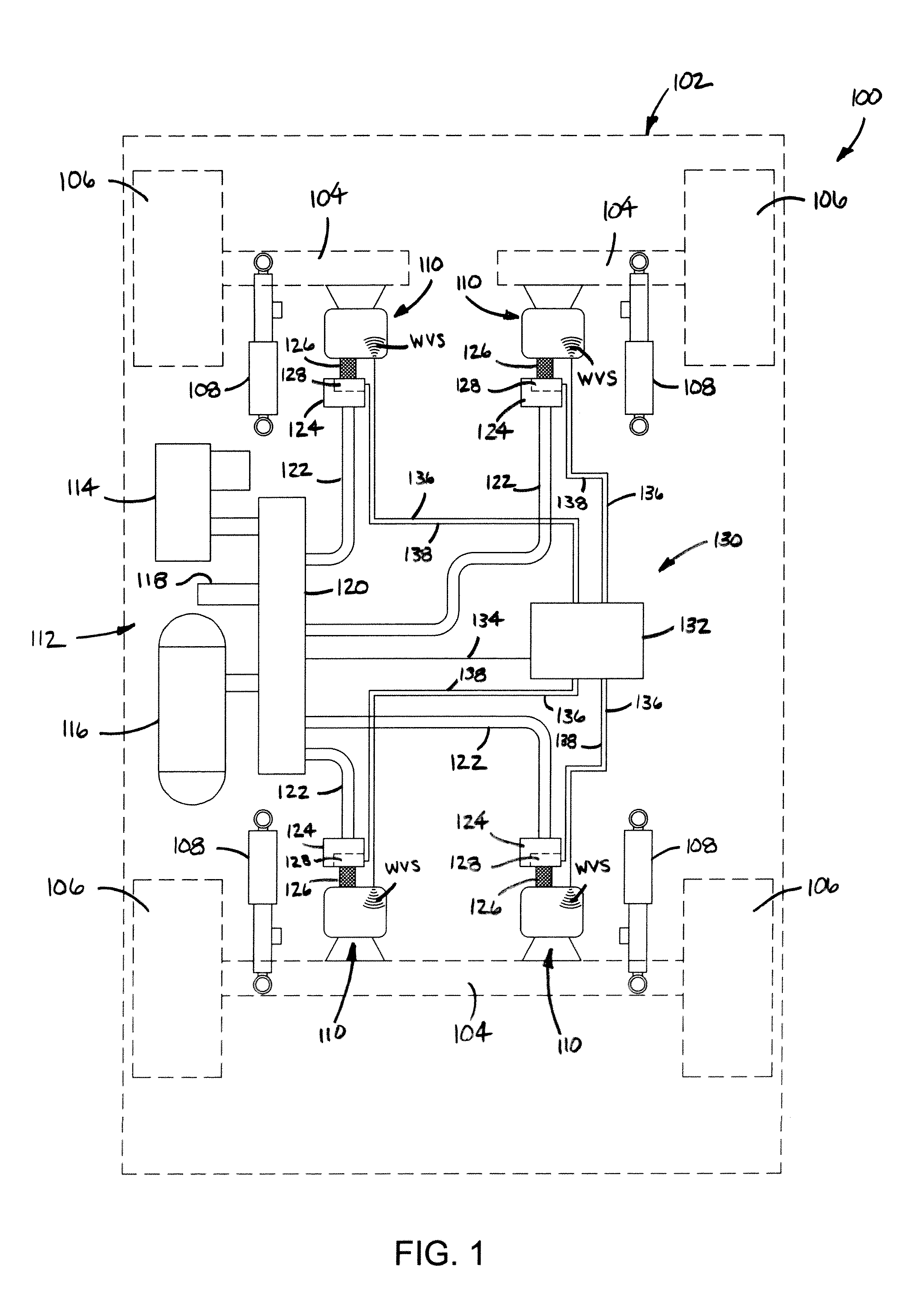

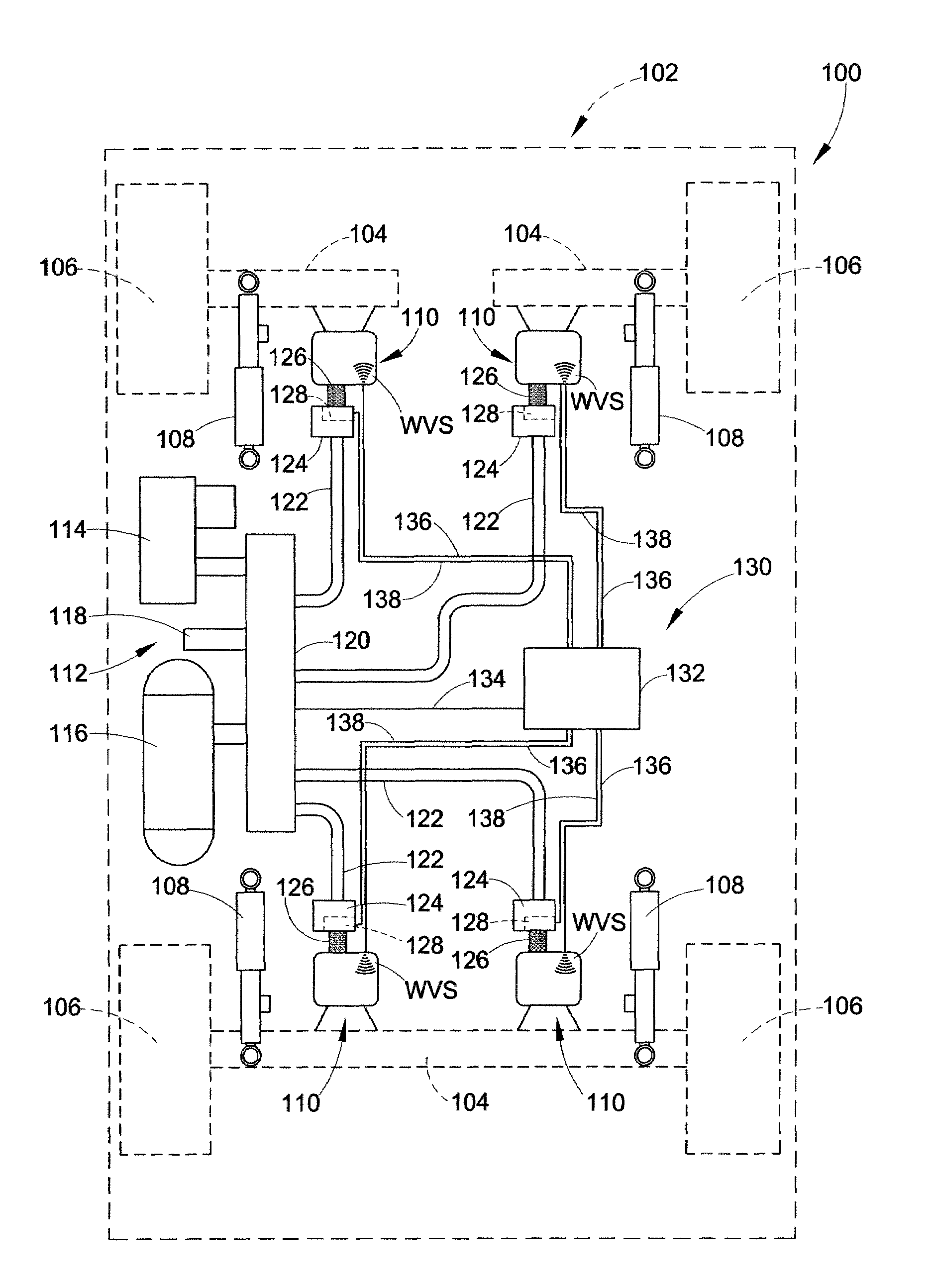

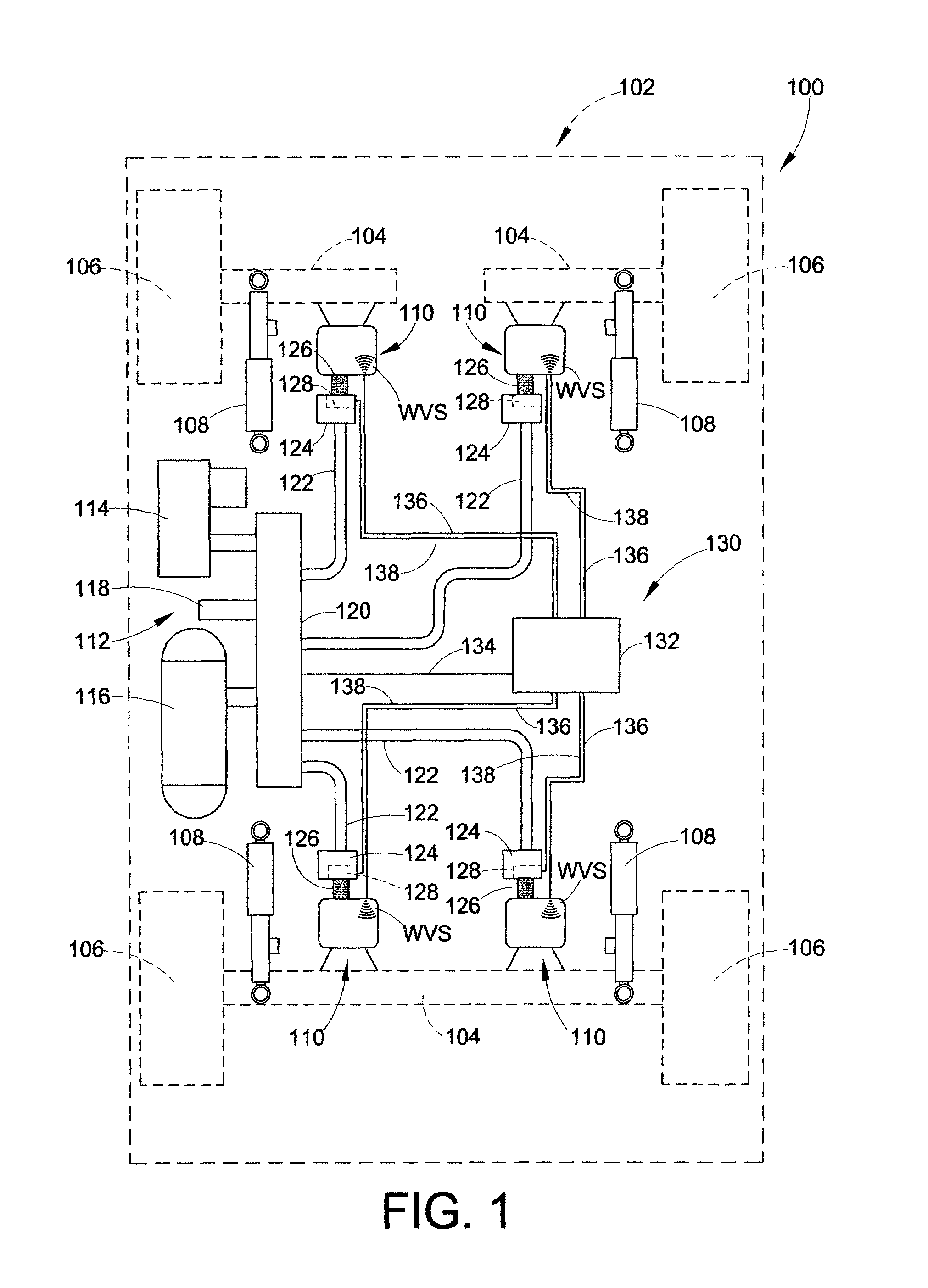

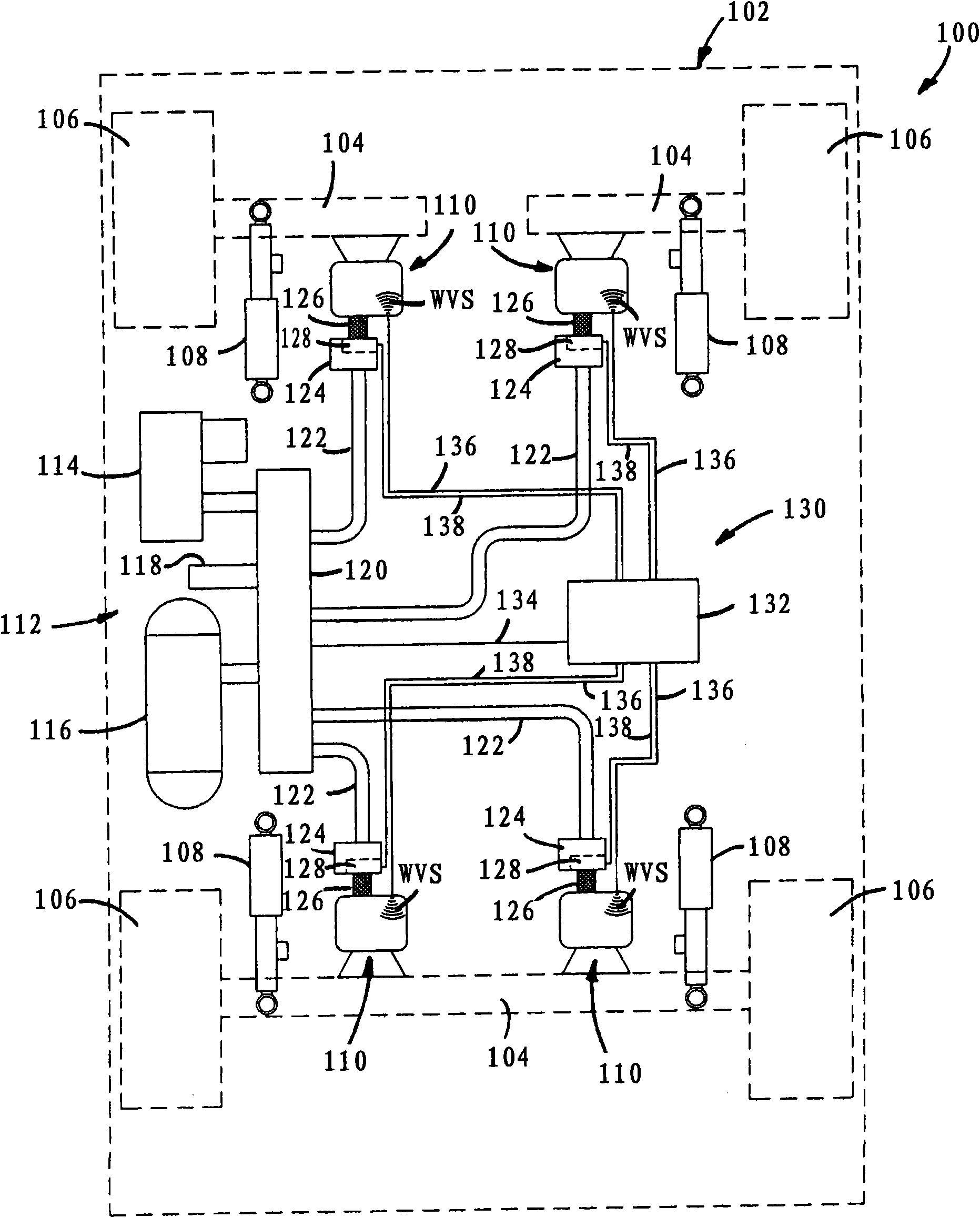

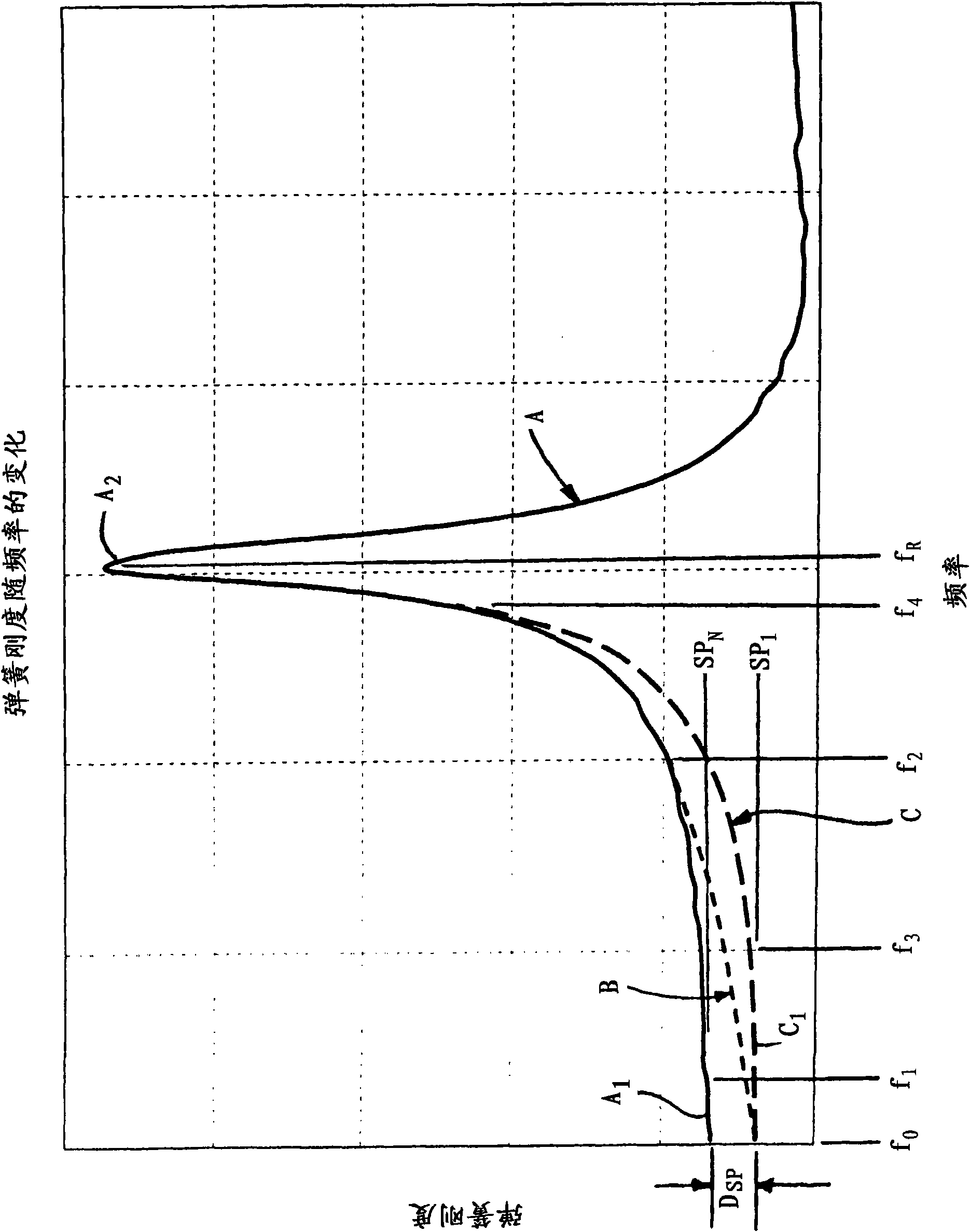

Gas spring assembly

InactiveUS20080284072A1Dissipate kinetic energyLiquid springsResilient suspensionsPorous flowGas spring

A gas spring assembly that is suitable for use on a vehicle suspension system includes a first end member and a second end member that is spaced from the first end member. A flexible wall is secured between the first and second end members and at least partially defines a first gas chamber therebetween. A confinement at least partially forms a second gas chamber that is in communication with the first gas chamber. A porous flow restrictor is operatively disposed between the gas chambers. A suspension system including such a gas spring assembly as well as a method is also included.

Owner:FIRESTONE IND PROD COMPANY

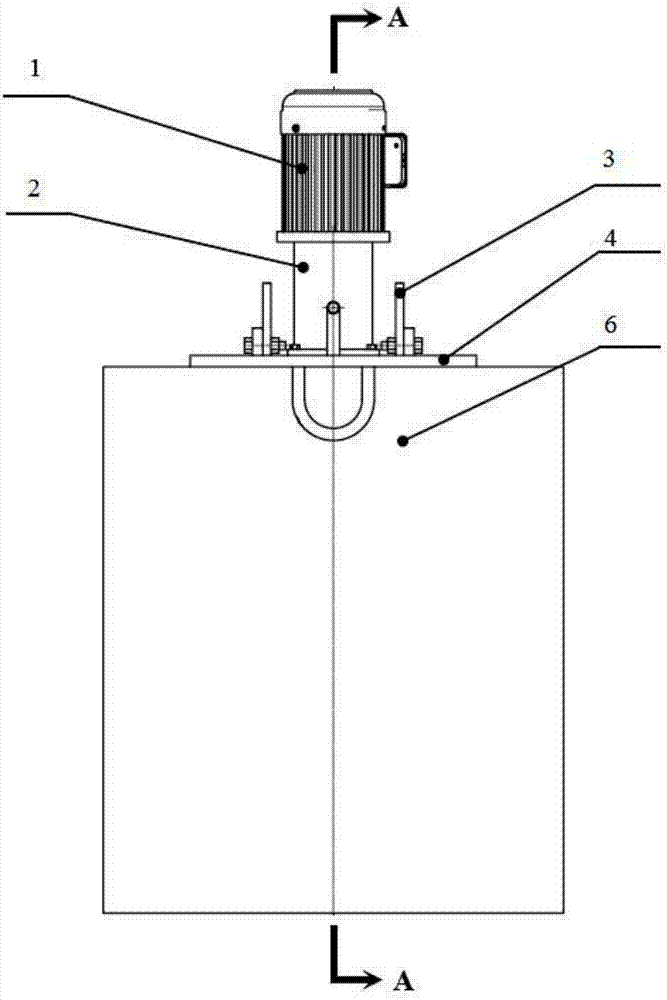

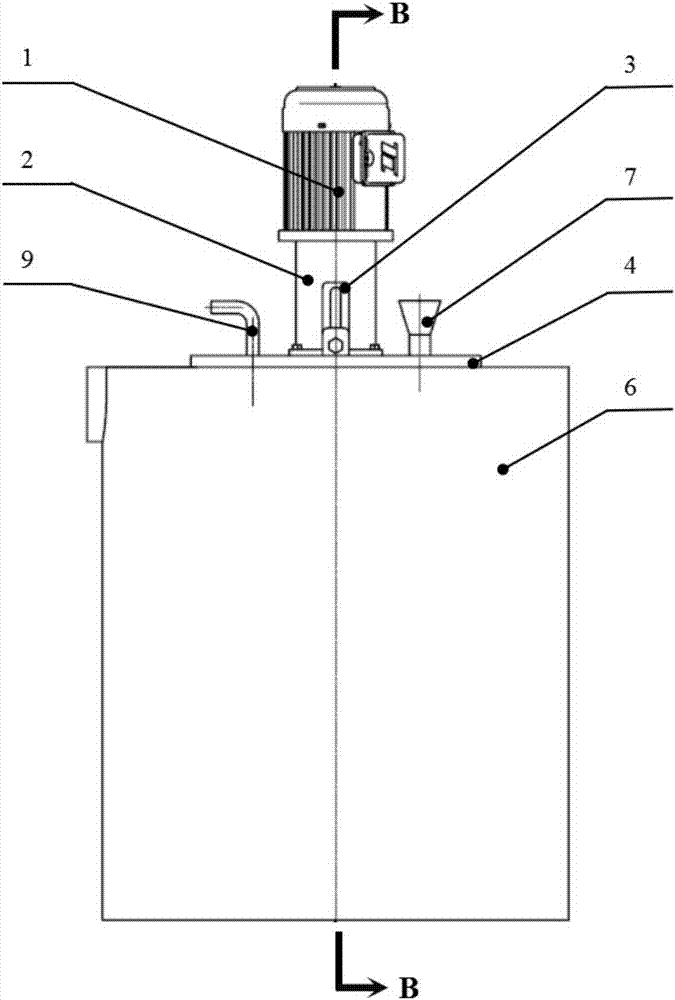

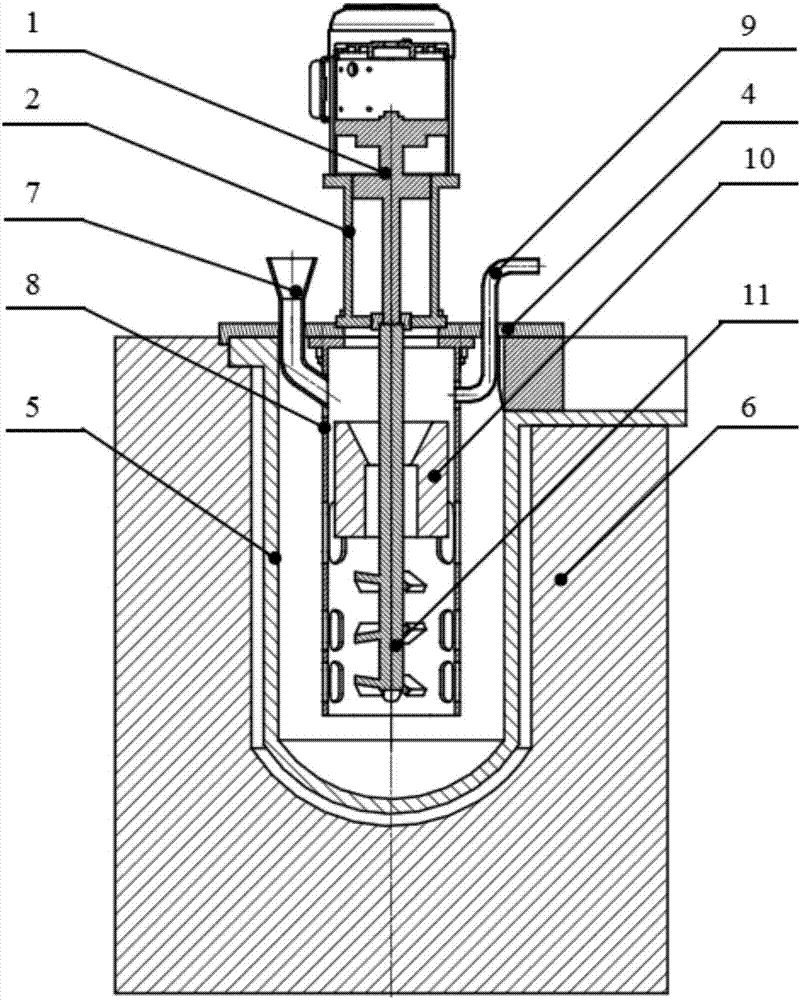

Device and method for efficiently preparing SiC-particle-reinforced aluminum-based composite material with high quality

ActiveCN107385263AEvenly distributedImprove wettabilityTransportation and packagingRotary stirring mixersPorous flowCrucible

The invention provides a device and method for efficiently preparing a SiC-particle-reinforced aluminum-based composite material with high quality. The device comprises a stirring device, a crucible, a resistance furnace, a feeding device and an argon gas delivery pipe. The stirring device comprises a stepless speed regulating electromotor, a connection base, lifting blocks, a crucible cover, a porous flow equalizer, a through-connection flow smoothing device and a stirring paddle. The stirring paddle is connected with the stepless speed regulating electromotor, and the stepless speed regulating electromotor is fixed to the connection base. The connection base, the lifting blocks and the porous flow equalizer are connected with the crucible cover correspondingly, the porous flow equalizer and the through-connection flow smoothing device are both of a hollow structure, and the through-connection flow smoothing device and the stirring paddle are both located in the porous flow equalizer. The through-connection flow smoothing device is internally of a funnel-shaped structure, the rod portion of the stirring paddle penetrates through the through-connection flow smoothing device, and the through-connection flow smoothing device is fixed to the lifting blocks. One end of the feeding device and one end of the argon gas delivery pipe both communicate with the porous flow equalizer, and the other end of the feeding device and the other end of the argon gas delivery pipe penetrate through the crucible cover to be exposed in the air. The crucible is located in the resistance furnace, and the crucible cover is tightly covered to the position between the crucible and the resistance furnace.

Owner:沈阳铸研科技有限公司

Biological treatment apparatus and method for wastewater containing volatile organic matter

InactiveCN101481171AEasy to transport and installSimple process daily operationDispersed particle separationSustainable biological treatmentWater dischargeAtmospheric air

The invention relates to a device and a method for the biological processing of waste water containing volatile organic substances. The main part of the device comprises a liquid-phase biological fluidized bed and a gas-phase biological dripping filtration bed which are coupled, a porous flow guiding cylinder is arranged in the liquid-phase biological fluidized bed, a compound magnetic polyurethane foam carrier is filled in the porous flow guiding cylinder, and the bottom of the porous flow guiding cylinder is provided with a micropore aeration system to provide sufficient oxygen for biological oxidizing reaction. A compound magnetic polyurethane foam carrier is filled in the gas-phase biological dripping filtration bed to further degrade the volatile organic chemical compound generated in the biochemical process to thoroughly degrade the volatile organic substances. The device has high sewage processing efficiency, ensures the water quality of processed water reaches the national first-grade waste water discharge standard, and eliminates the atmosphere pollution by the volatile organic compound in the biochemical process. The device of the invention has simple structure, small occupied land, low investment, high waste water processing efficiency and low energy consumption, and is suitable for the processing and the recovery of the waste water containing volatile organic substances.

Owner:深圳市中拓天达环保科技有限公司

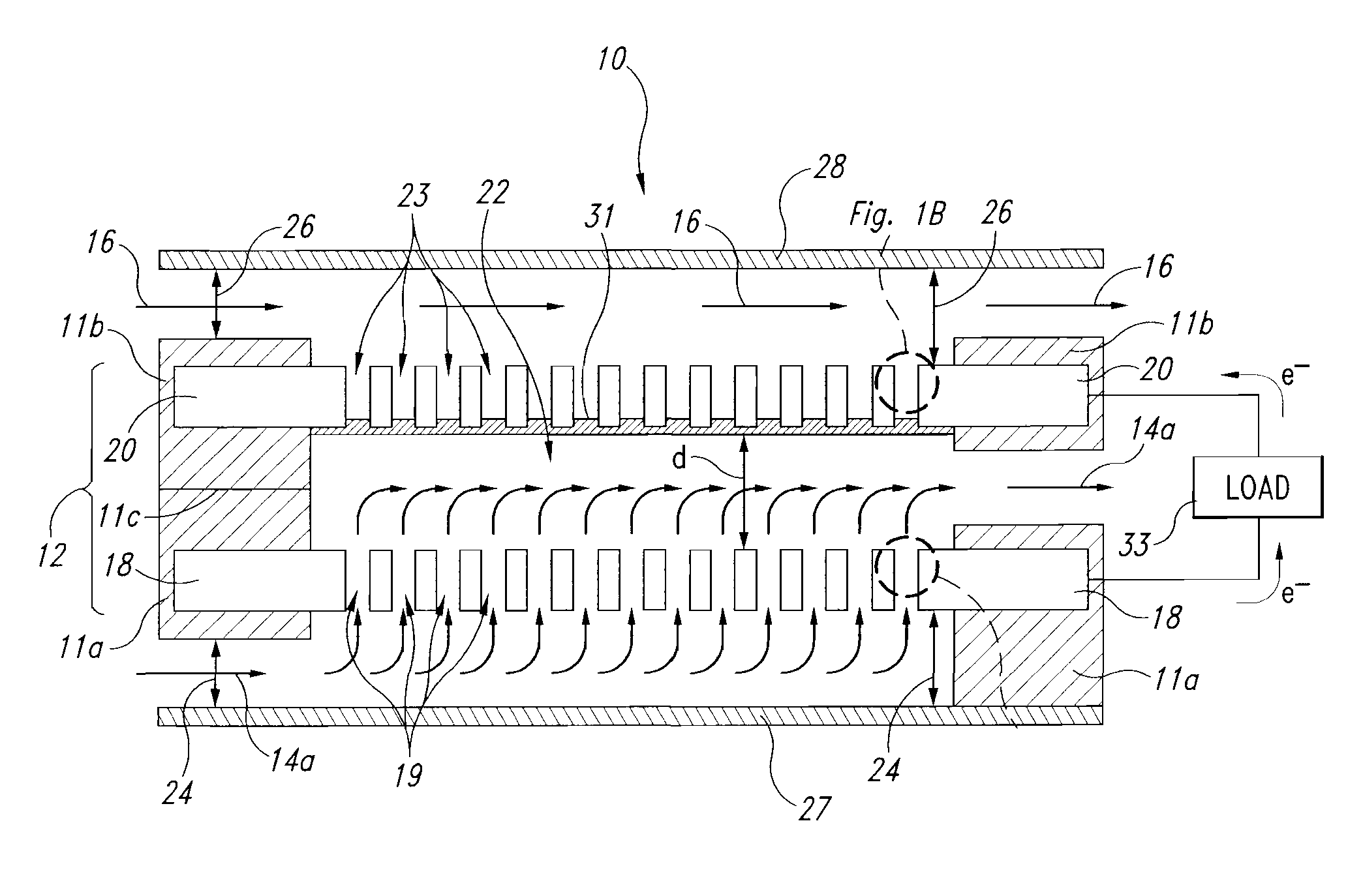

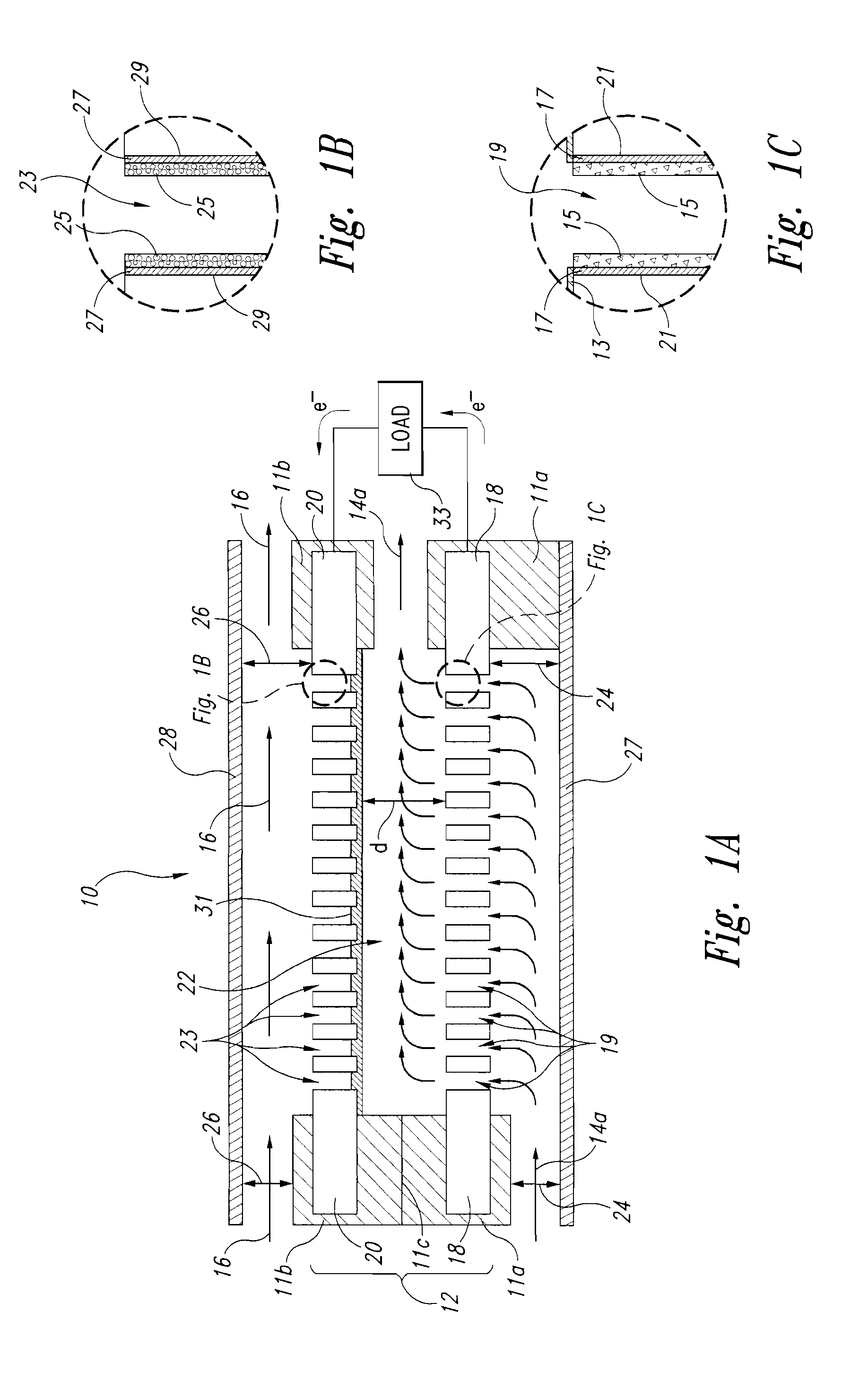

Liquid-liquid fuel cell systems having flow-through anodes and flow-by cathodes

The invention disclosed herein relates to fuel cell electrode pair assemblies, not having interposing proton exchange membranes, configured to receive and react with liquid anolyte and liquid catholyte microfluidic flowstreams. In one embodiment, the present invention is directed to a fuel cell electrode pair assembly, not having an interposing proton exchange membrane, configured to receive and react with a liquid microfluidic anolyte flowstream (e.g., laminarly flowing methanol solution) and a liquid microfluidic catholyte flowstream (e.g., laminarly flowing nitric acid solution), wherein the fuel cell electrode pair assembly comprises: a porous flow-through anode; a porous flow-by cathode confronting and spaced apart from the anode; and a central plenum interposed between and connected to the anode and the cathode.

Owner:EPD INVESTMENT CO

Gas spring assembly

Owner:FIRESTONE IND PROD COMPANY

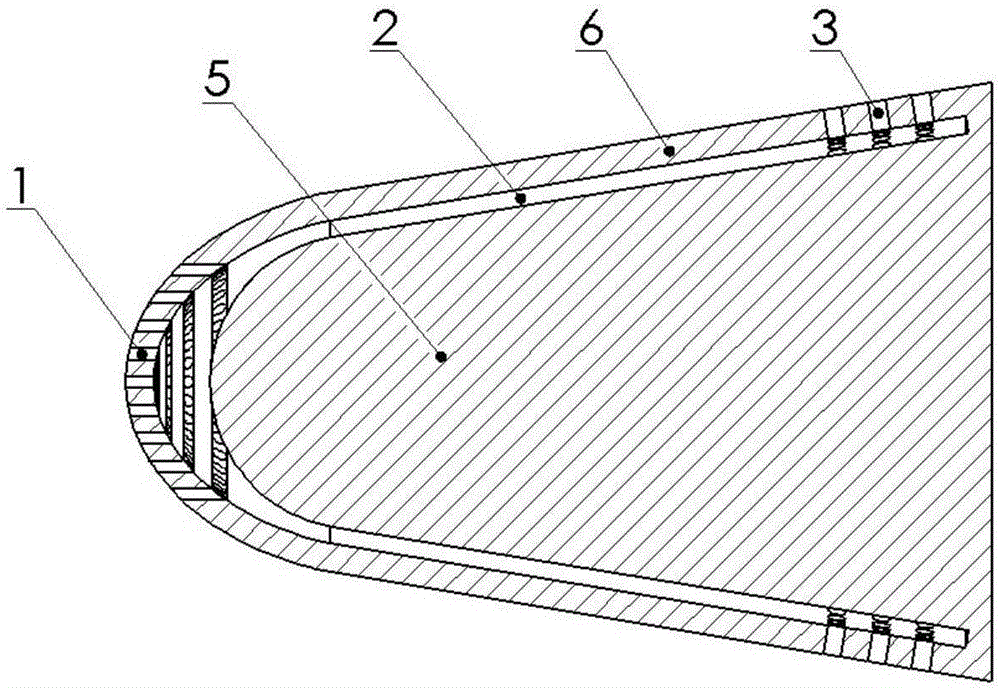

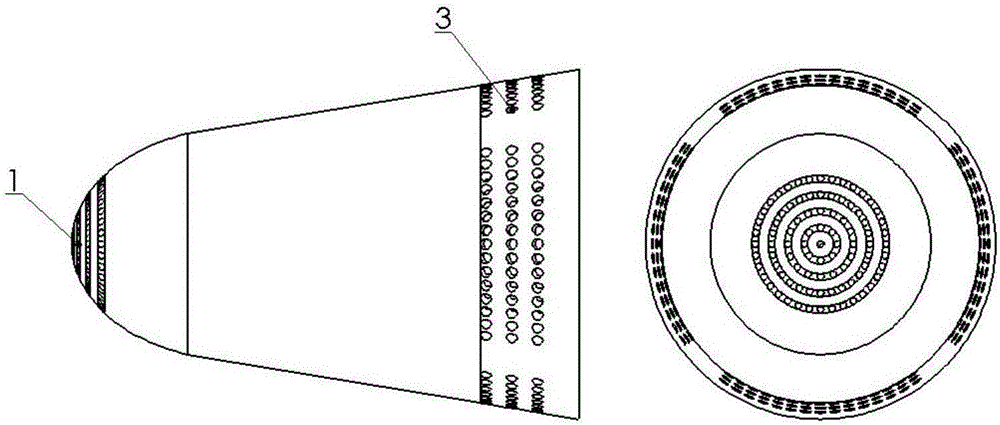

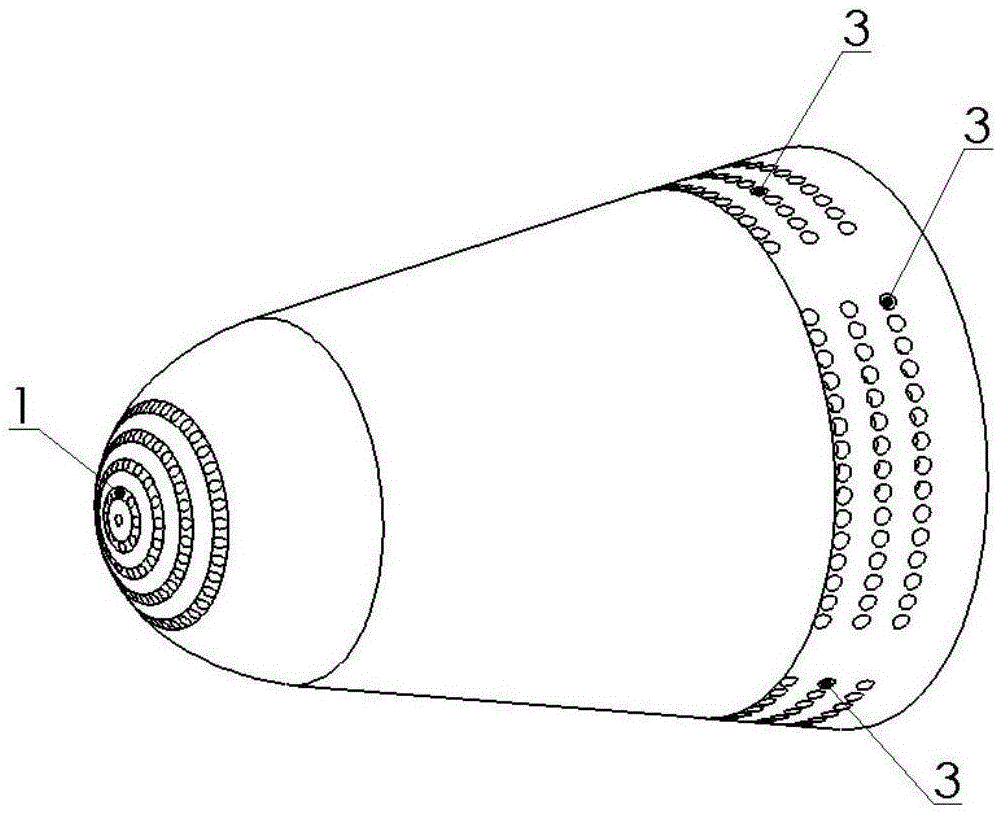

Porous flow-control device applied in hypersonic maneuverable reentry vehicle

ActiveCN106184719APrevent sprayingTo achieve the purpose of adjusting torqueAir-flow influencersPorous flowFlight vehicle

The invention provides a porous flow-control device applied in a hypersonic maneuverable reentry vehicle. The porous flow-control device realizes the purpose of adjusting the torque of the vehicle by a non-movable part. The porous flow-control device comprises an air inlet hole arranged at the head part of the vehicle and an exhausting hole arranged at the tail part of the vehicle, wherein the air inlet hole and the exhausting hole are communicated by a duct arranged in the vehicle. The porous flow-control device provided by the invention has the advantages that high-pressure air behind bow shock wave at the head part of the vehicle is introduced into the internal duct, and the high-pressure air of the internal duct is sprayed out from the tail part of the vehicle as an air source of porous jet flow, so that the carry of redundant jet working medium is avoided.

Owner:NAT UNIV OF DEFENSE TECH

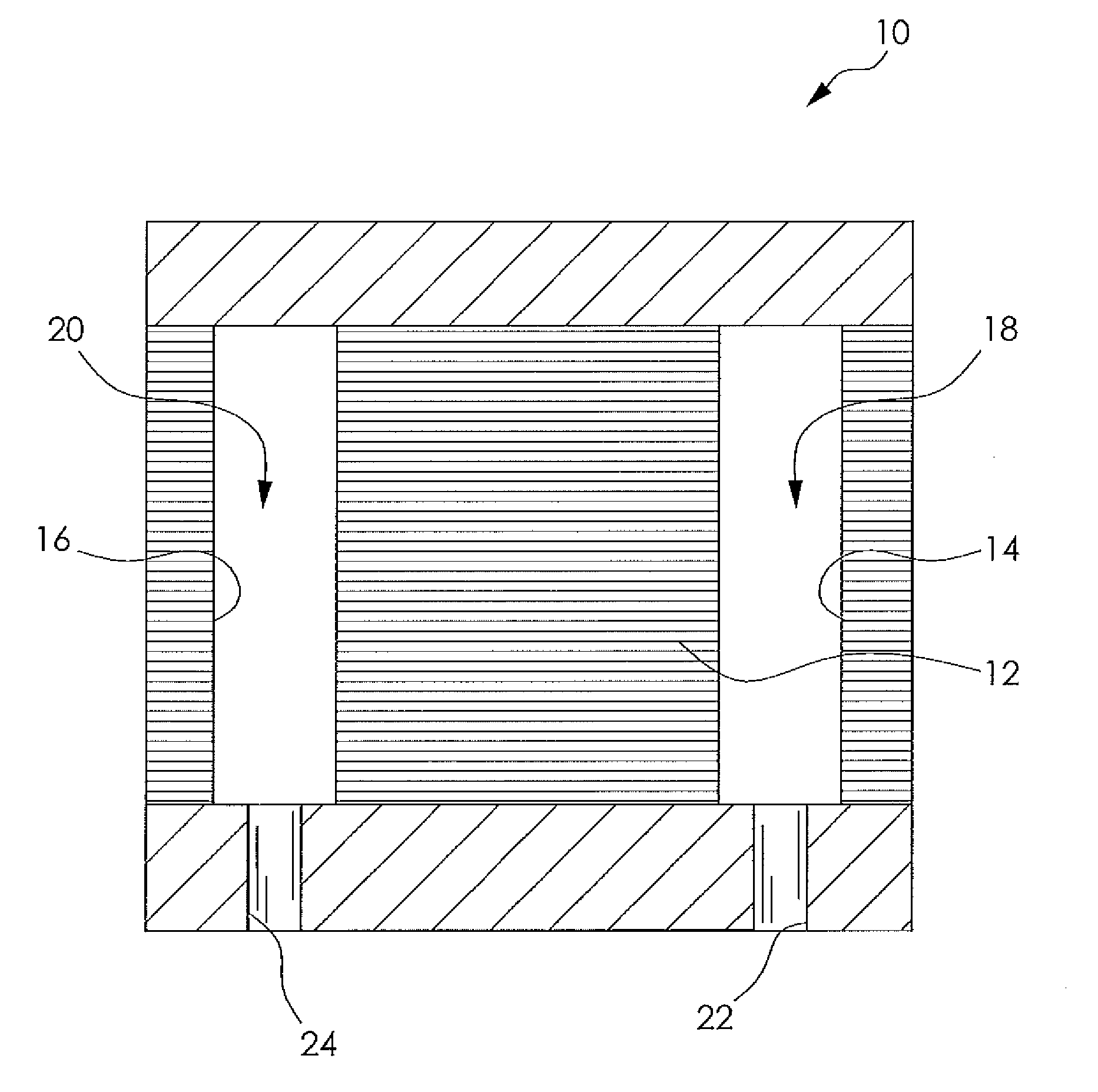

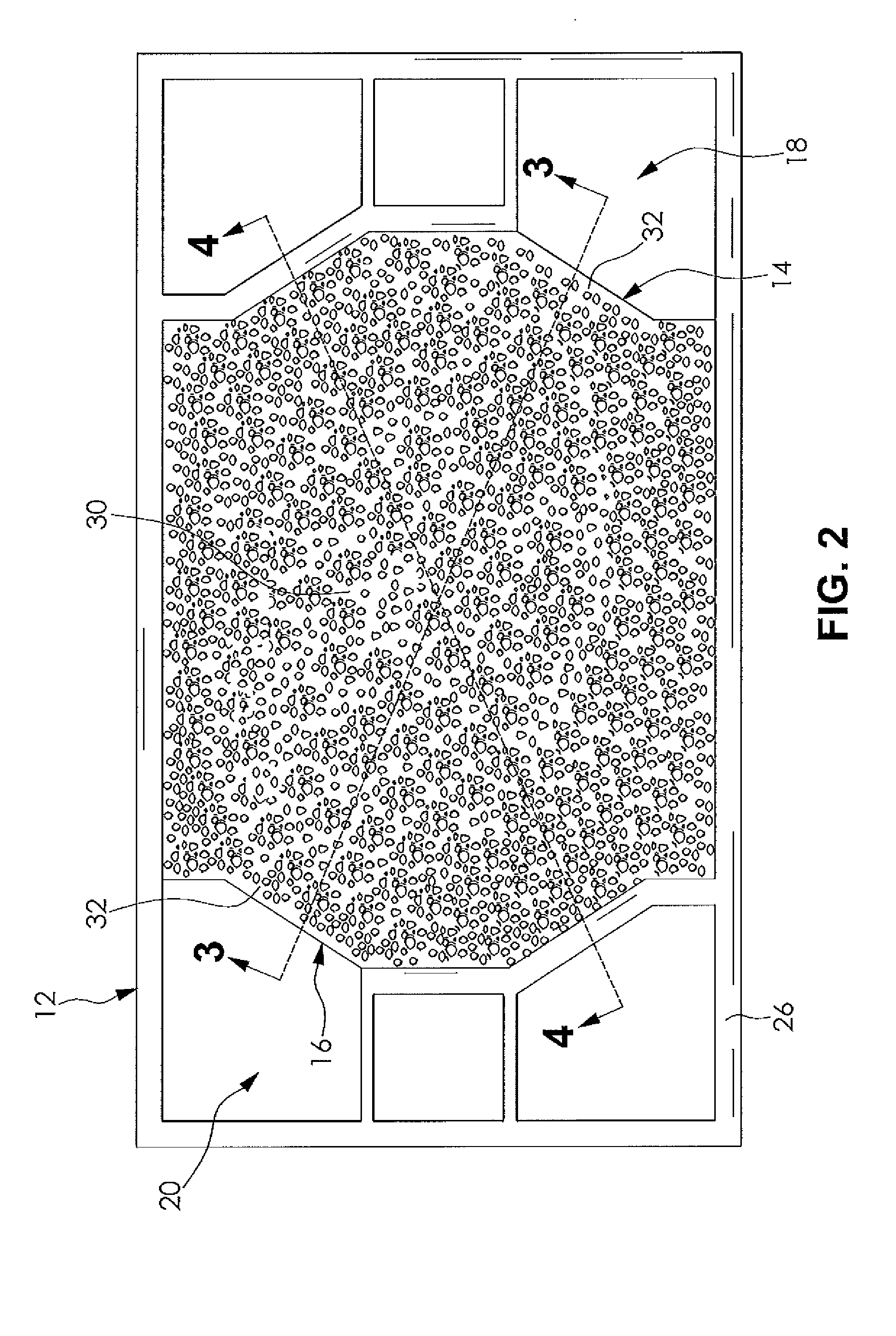

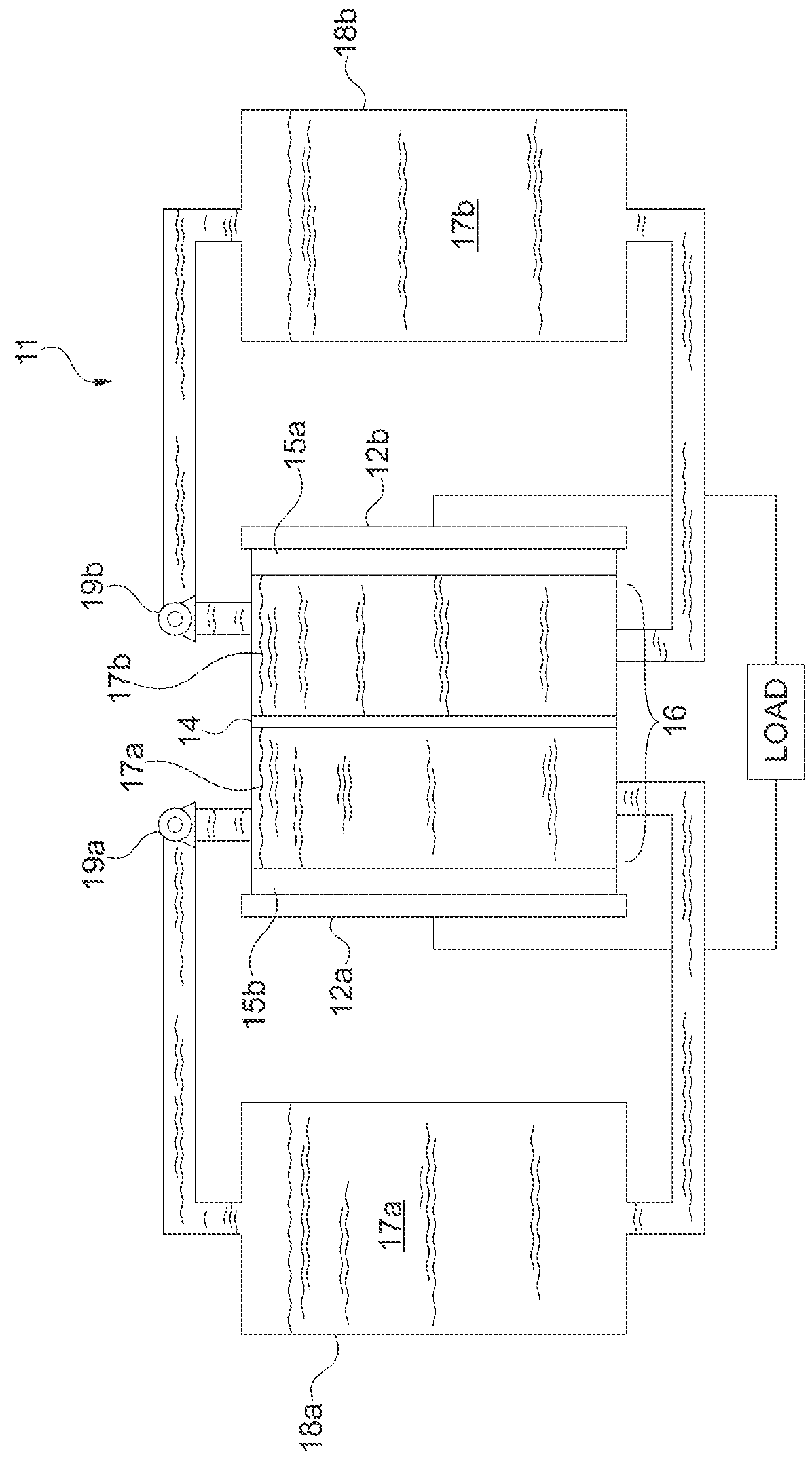

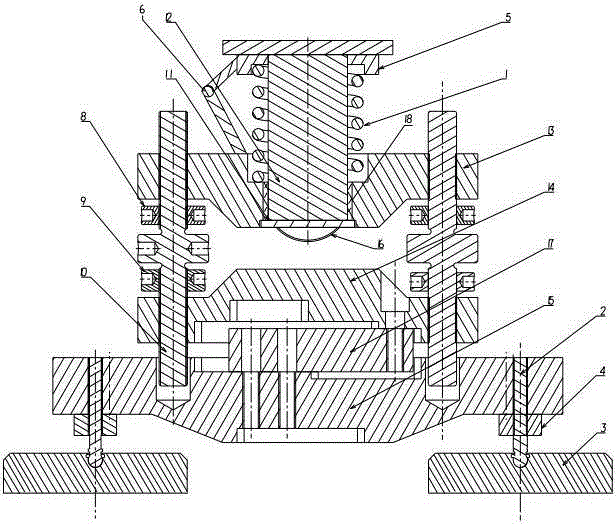

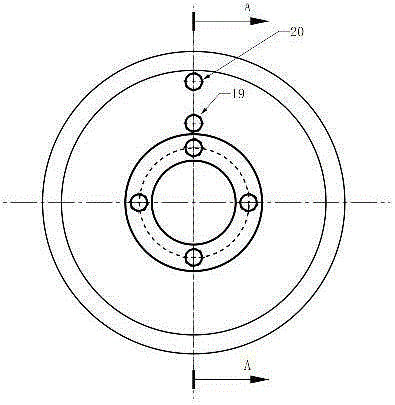

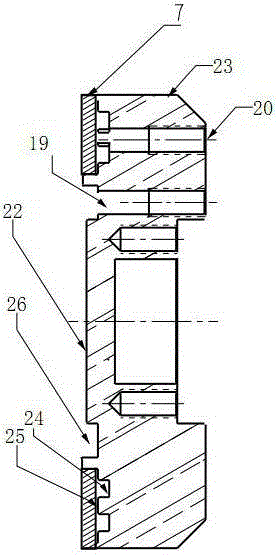

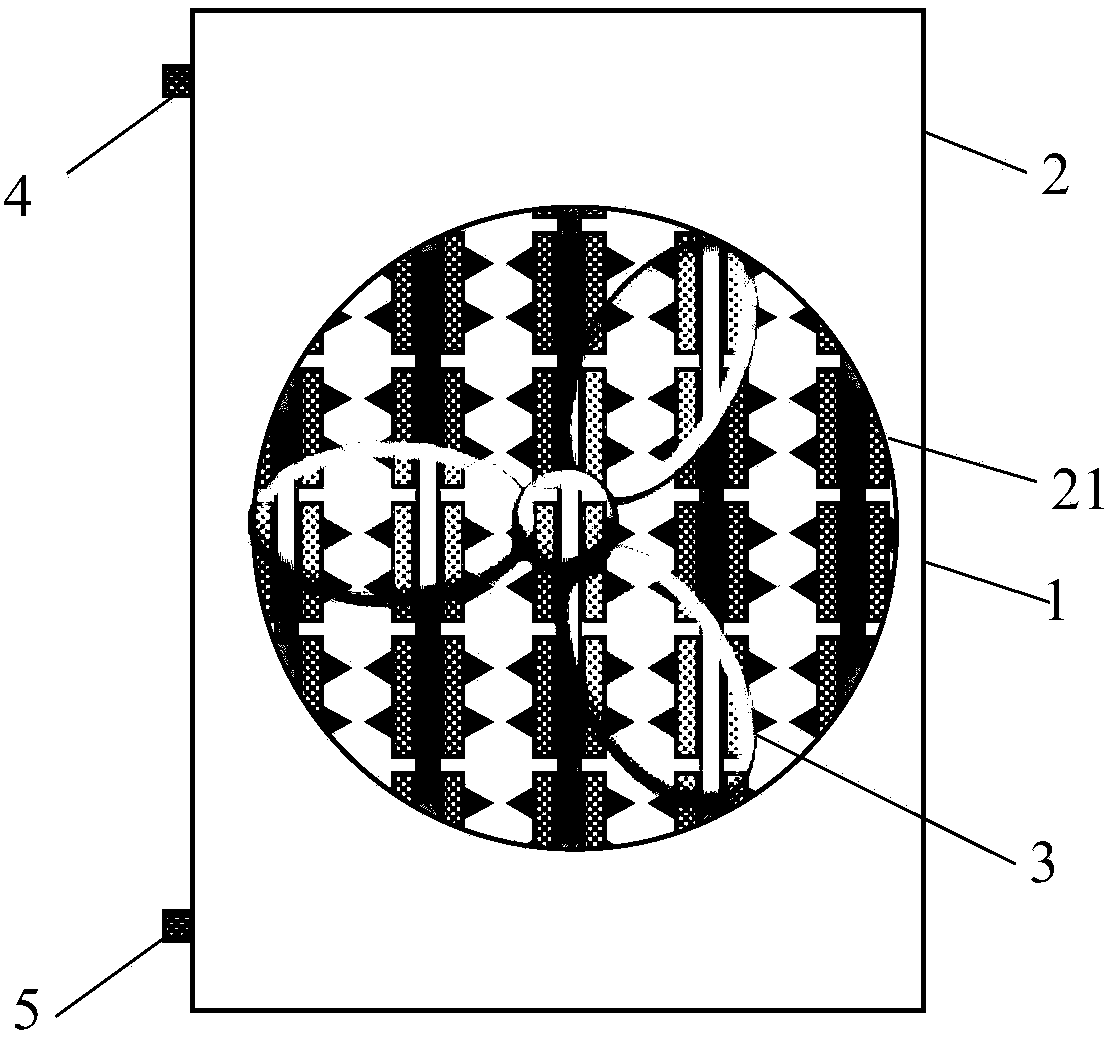

Porous air-suspending supporting system applied to full physical simulation

The invention relates to a porous air-suspending supporting system applied to full physical simulation. According to the air-suspending supporting system, a vacuum pre-load with volume reduction hills is adopted for being combined with a porous flow controller; and the porous air-suspending supporting system mainly comprises a vertical guide mechanism, an adjustable supporting transverse beam, a bearing sensor (17) and an air-suspending supporting mechanism (3), wherein the air-suspending supporting mechanism (3) is formed by an air-suspending supporting shell (23), air nozzles (19 and 20) and the porous flow controller (7). The air-suspending supporting shell (23) is formed by air-suspending pressure-sharing structures (7, 22, 24, 25 and 26), a negative pressure vacuum cavity (26) and the volume reduction hills (22). According to the porous air-suspending supporting system applied to full physical simulation, the anti-dumping force is increased so that the system can be more stable; and the system stability is further improved.

Owner:北京太和科技有限公司 +1

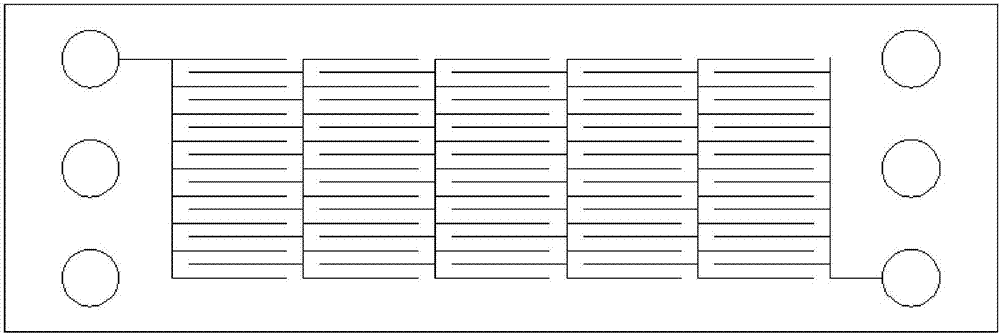

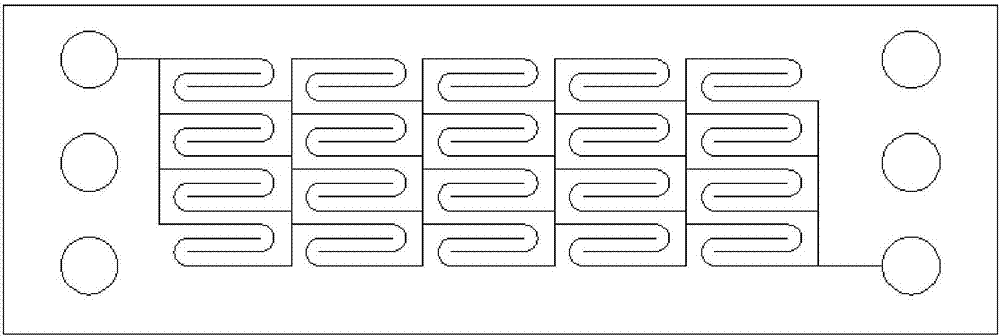

Fluid flow assembly and fuel cell electric pile comprising same

The invention relates to a fluid flow assembly and a fuel cell electric pile comprising the same. The fluid flow assembly is used for gas and fluid flow of a reversible fuel cell for hydrogen production power generation, and also applicable to a power generation fuel cell or a hydrogen production electrolysis apparatus with a single function; the fluid flow assembly comprises distribution flow guiding plates used for drainage of the fluid and porous fluid flowing layers used as fluid main flowing channels in a combination manner; a fuel cell pile or an electrolysis apparatus comprising the fluid flow assembly comprises a plurality of single cell assemblies in an overlaid manner; each single cell comprises one fluid flow assembly used as a negative electrode and the other fluid flow assembly used as a positive electrode; and a conventional air permeating layer is arranged in an MEA membrane electrode which only includes a proton exchange membrane and a catalytic layer. Compared with the prior art, the fluid flow assembly and the fuel cell electric pile comprising the same have the advantages of capabilities of rapidly and effectively discharging product fluids, more uniformed fluid distribution, stable power generation performance of the fuel cell due to graded setting of drainage grooves, and the like.

Owner:QINGDAO HANHE HYDROGEN ENERGY EQUIP TECH CO LTD

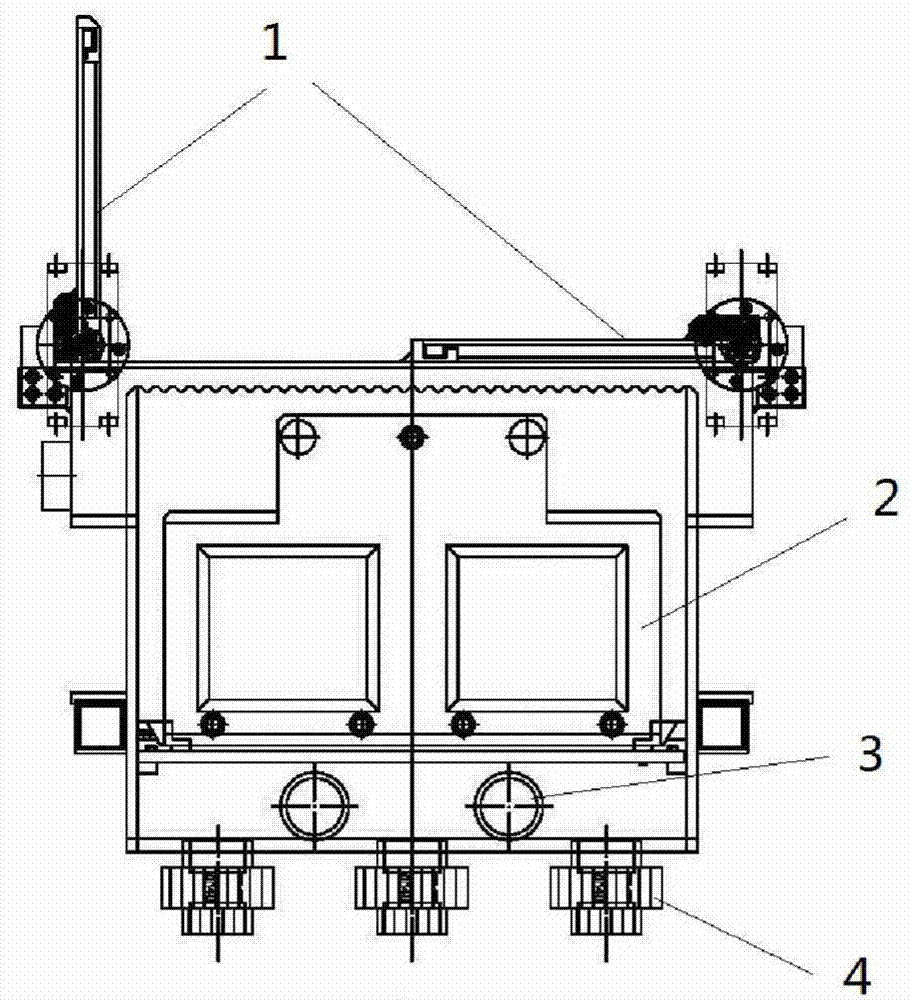

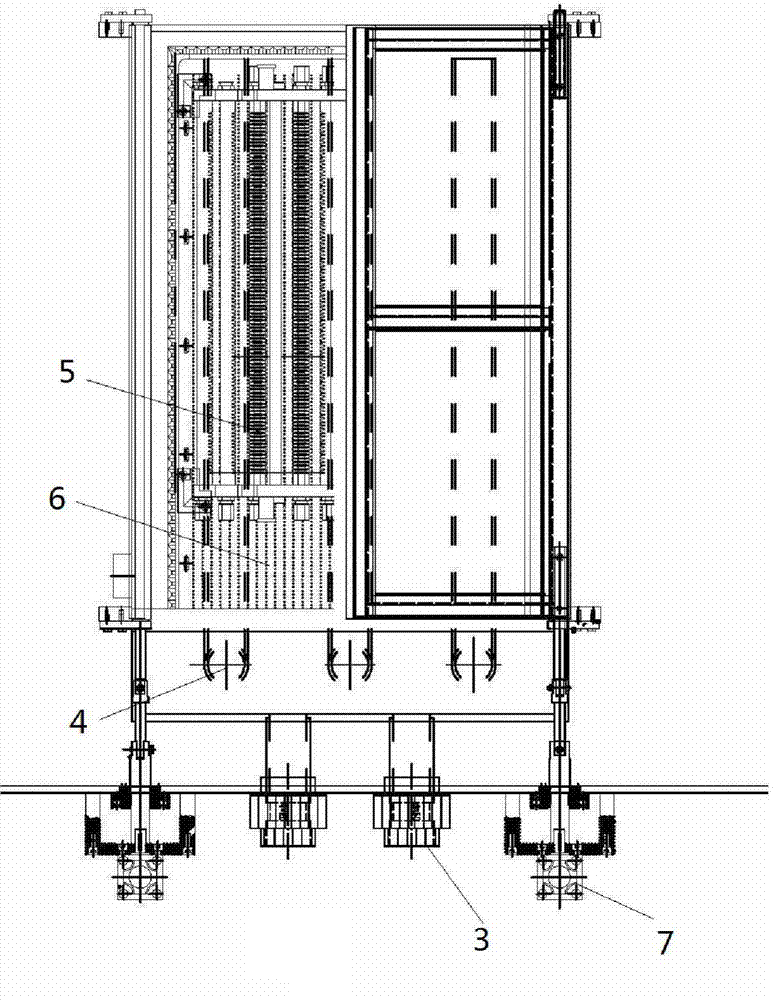

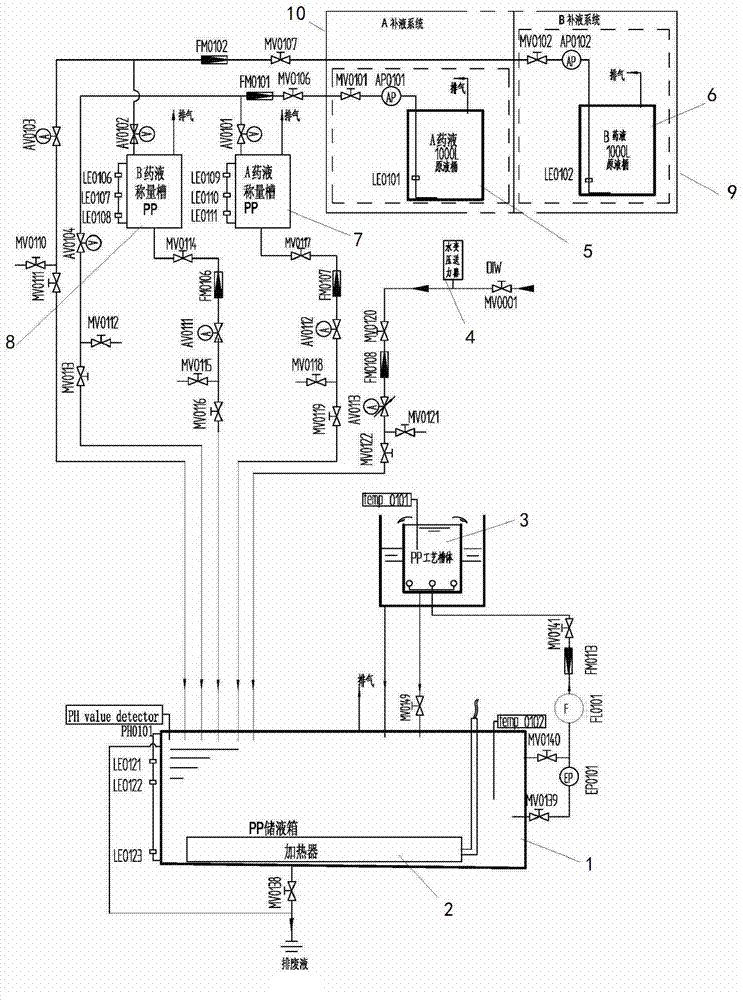

Full-automatic tank type chemical plating equipment and chemical plating method

InactiveCN103498134AWith cycleWith automatic replenishmentFinal product manufactureLiquid/solution decomposition chemical coatingChemical platingPorous flow

The invention relates to full-automatic tank type chemical plating equipment applied to crystalline silicon photovoltaic cell production and belongs to technical field of chemical plating equipment for crystalline silicon photovoltaic cell production. A chemical plating method and a tank type design scheme are used. A process tank of the equipment is provided with a circulating system, a heating system and a filtering system. The heating system is disposed in a liquid storage tank independent of the process tank. The process tank provided with a porous flow uniformizing board adopts multi-pipe liquid intaking. The equipment is provided with a full-automatic chemical liquor feed system. A slow-lifting drying device is disposed at an outlet end of the equipment. All parts contact with process chemical liquor is made of engineering plastics. Automatic feed, discharge and intermediate transferring are performed through a full-automatic mechanical arm. The full-automatic tank type chemical plating equipment has the advantages that the equipment is full-automatic, of the tank type, easy to maintain, uniform in chemical liquor circulating flow, uniform in process temperature, stable in chemical liquor property, and capable of achieve dry-in and dry-out of crystalline silicon cells, and the like.

Owner:CHINA UNITED CLEANING TECH BEIJING

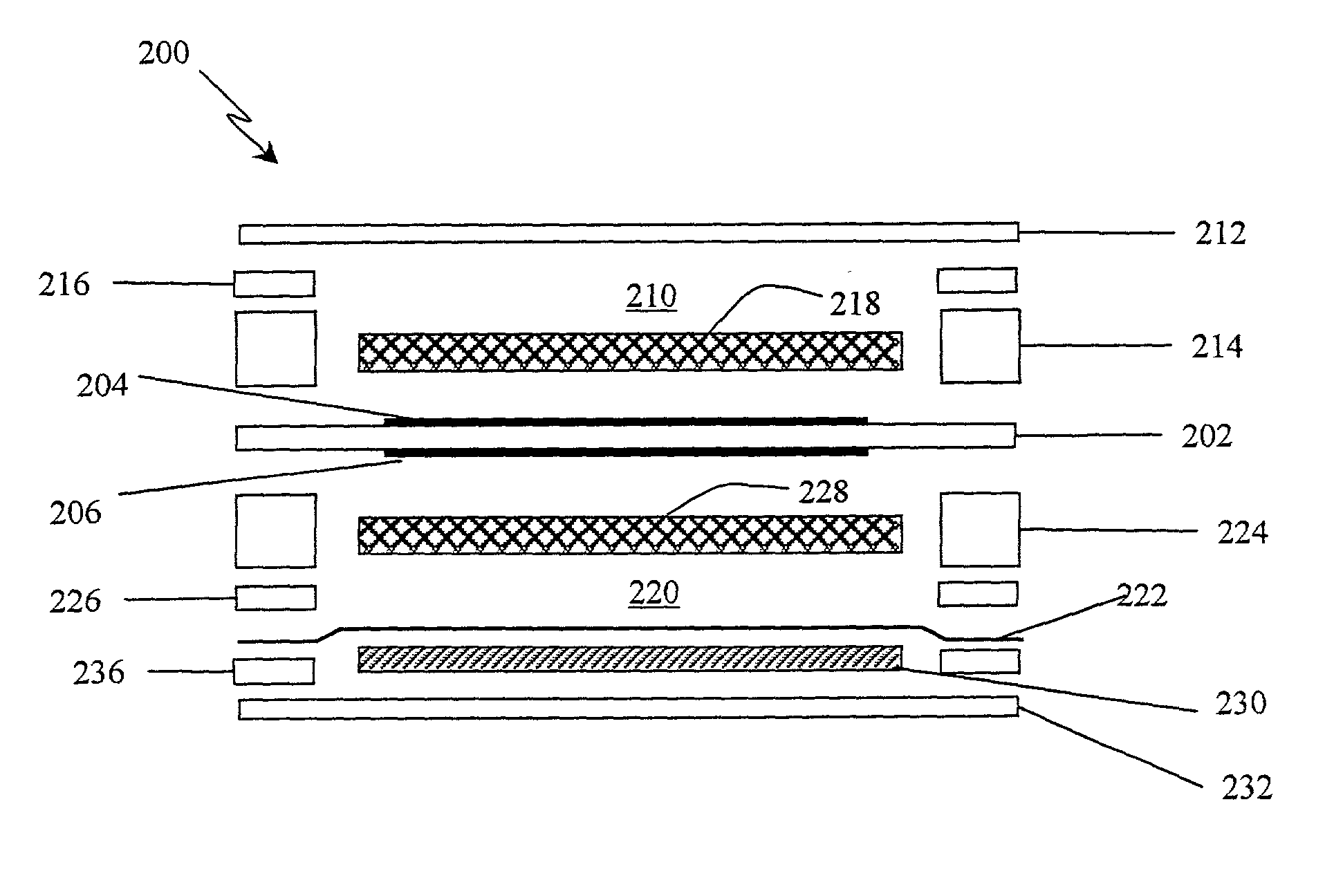

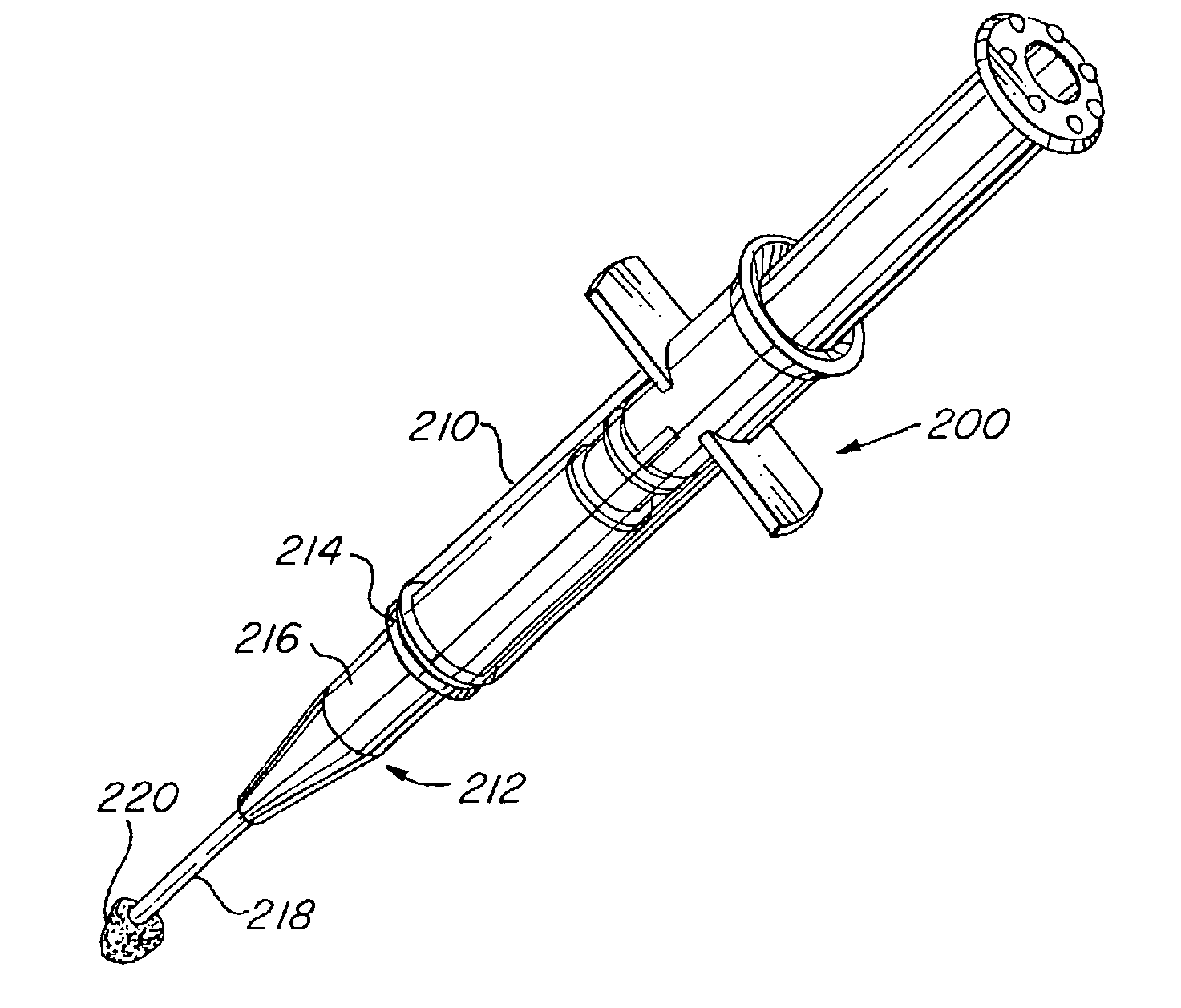

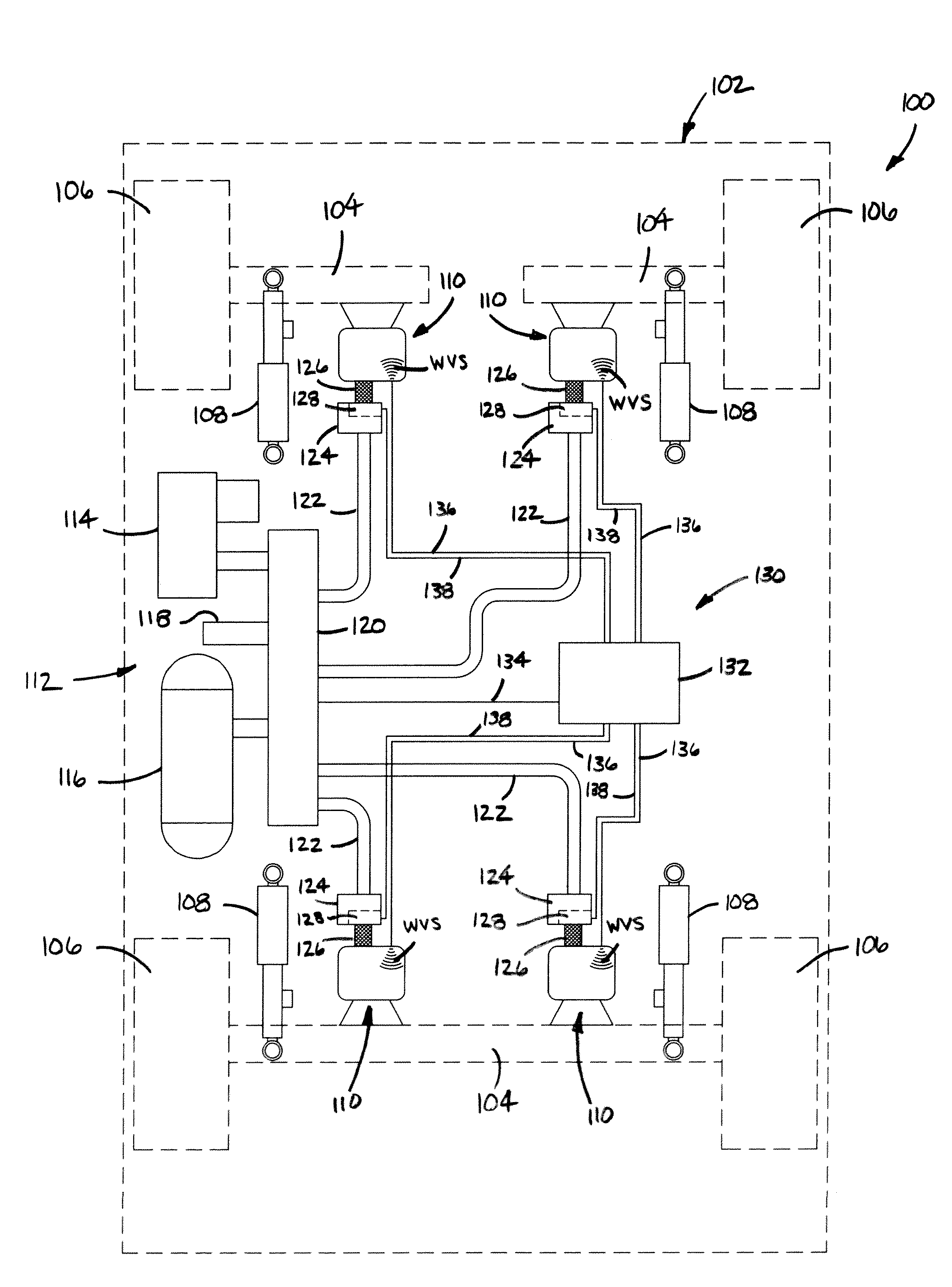

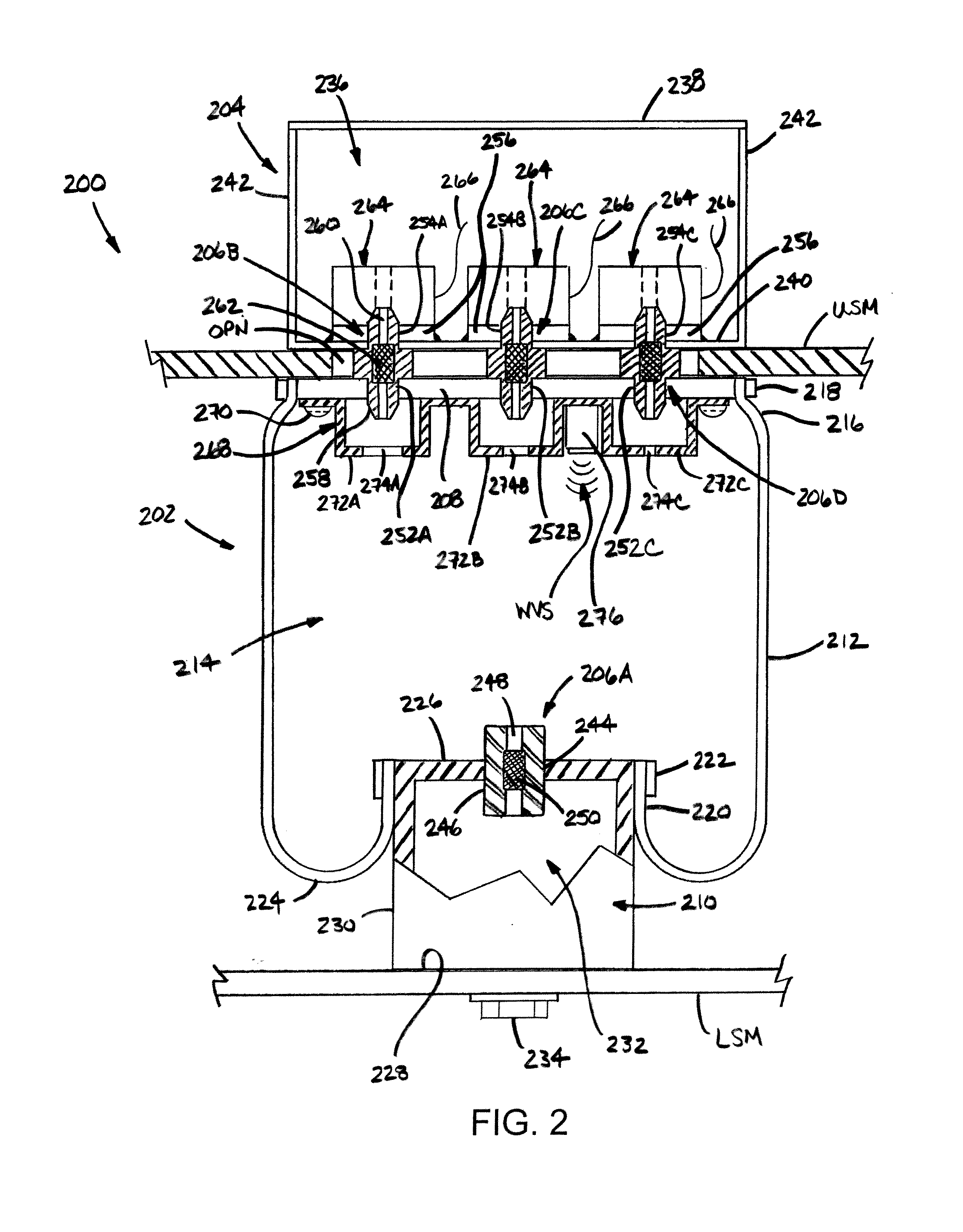

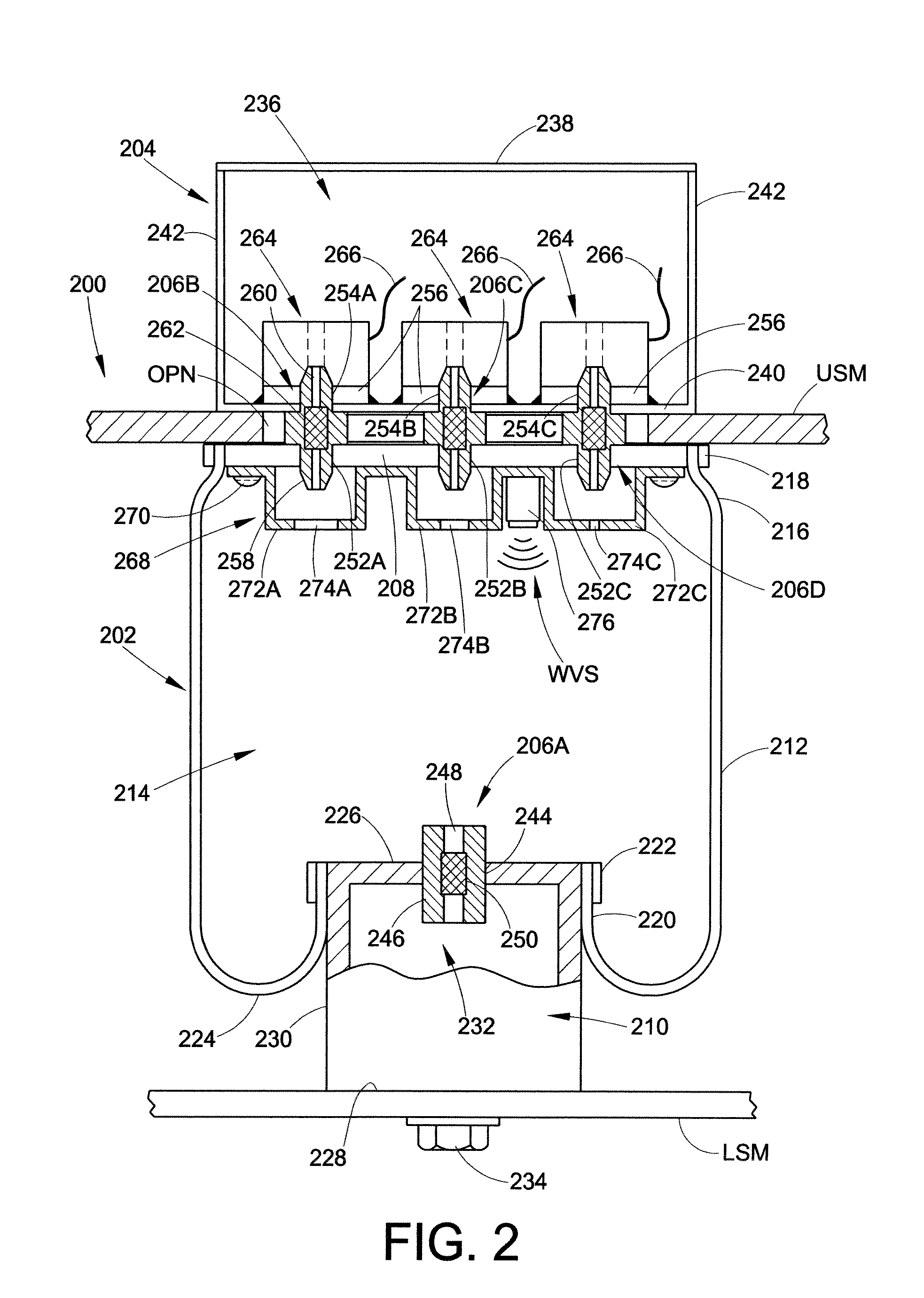

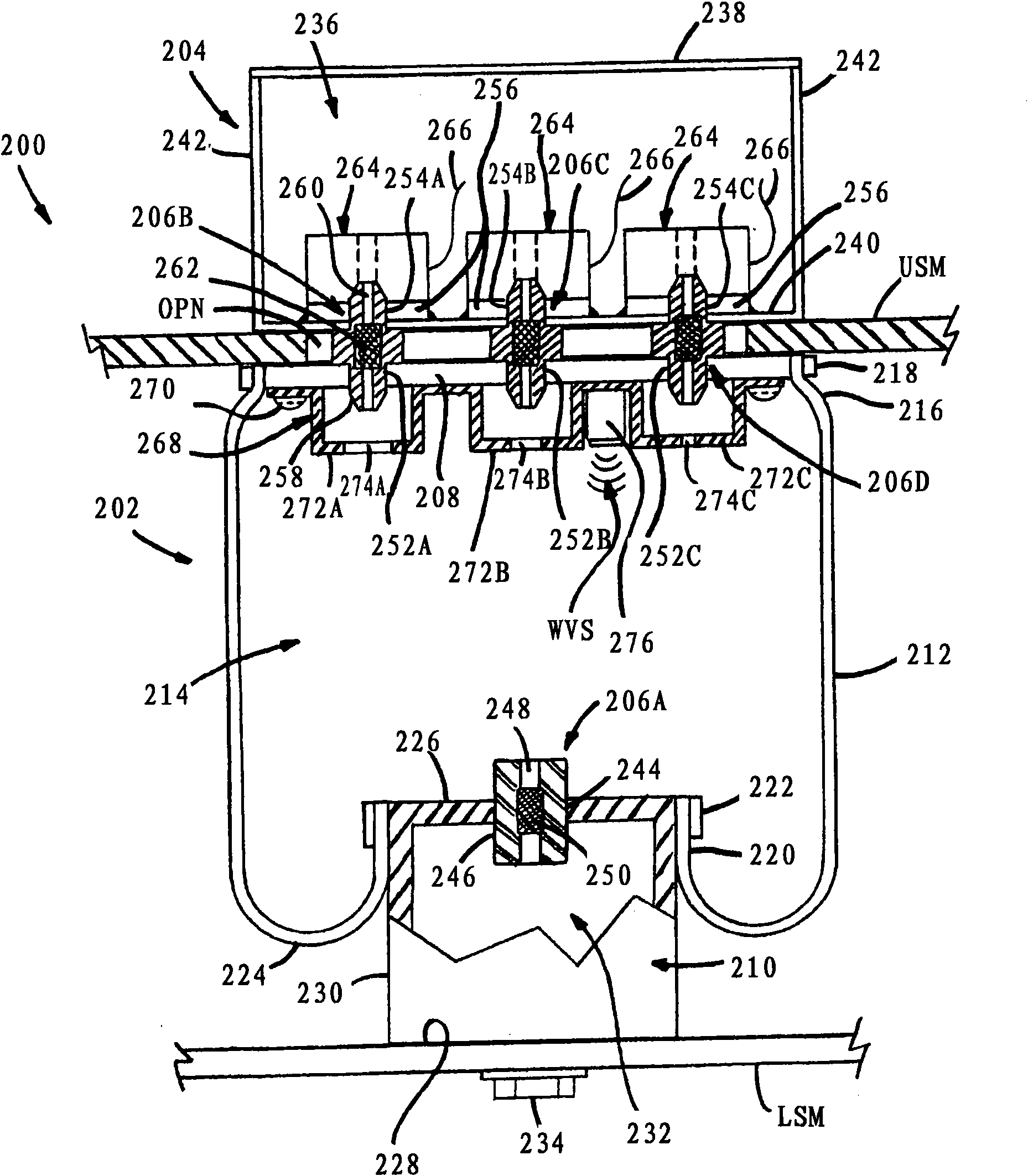

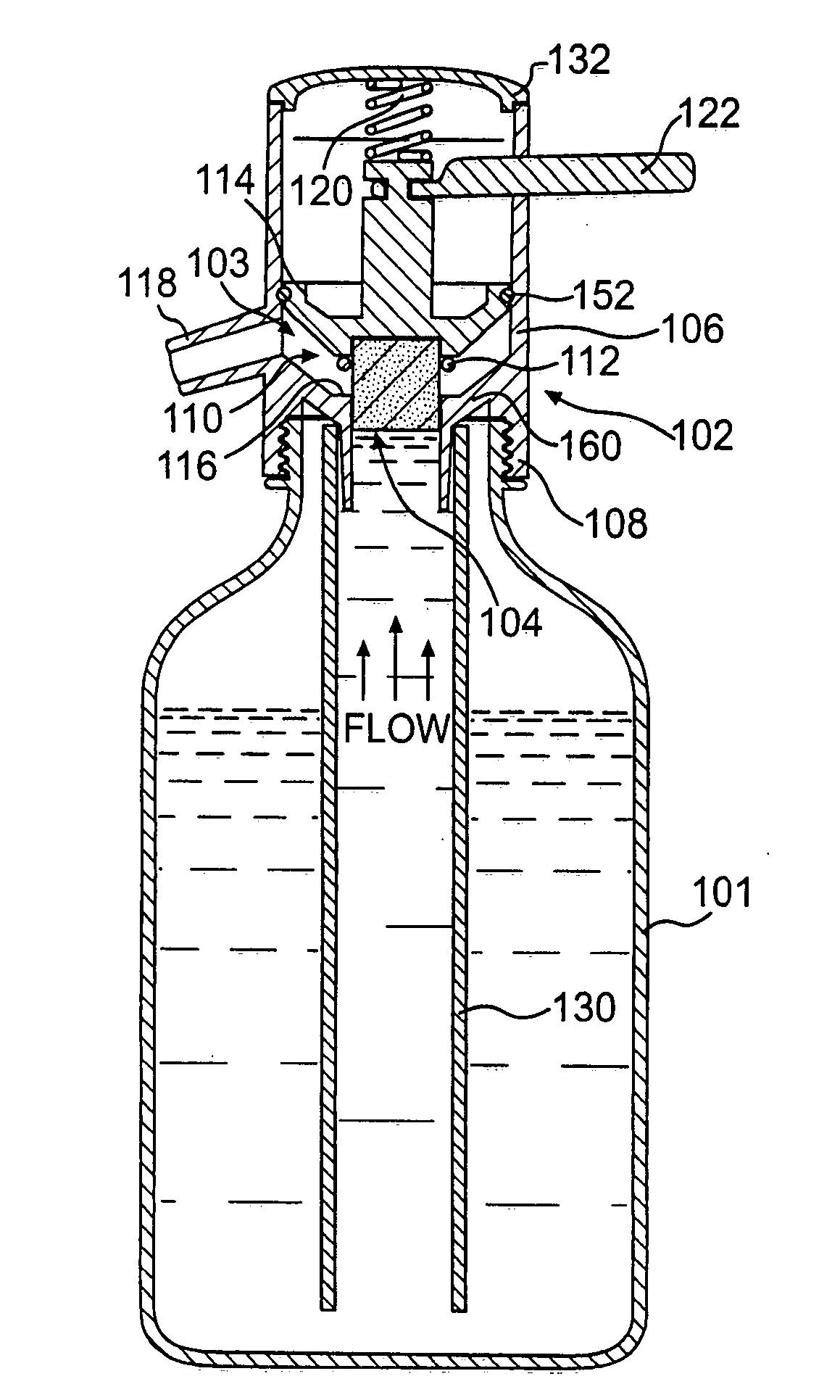

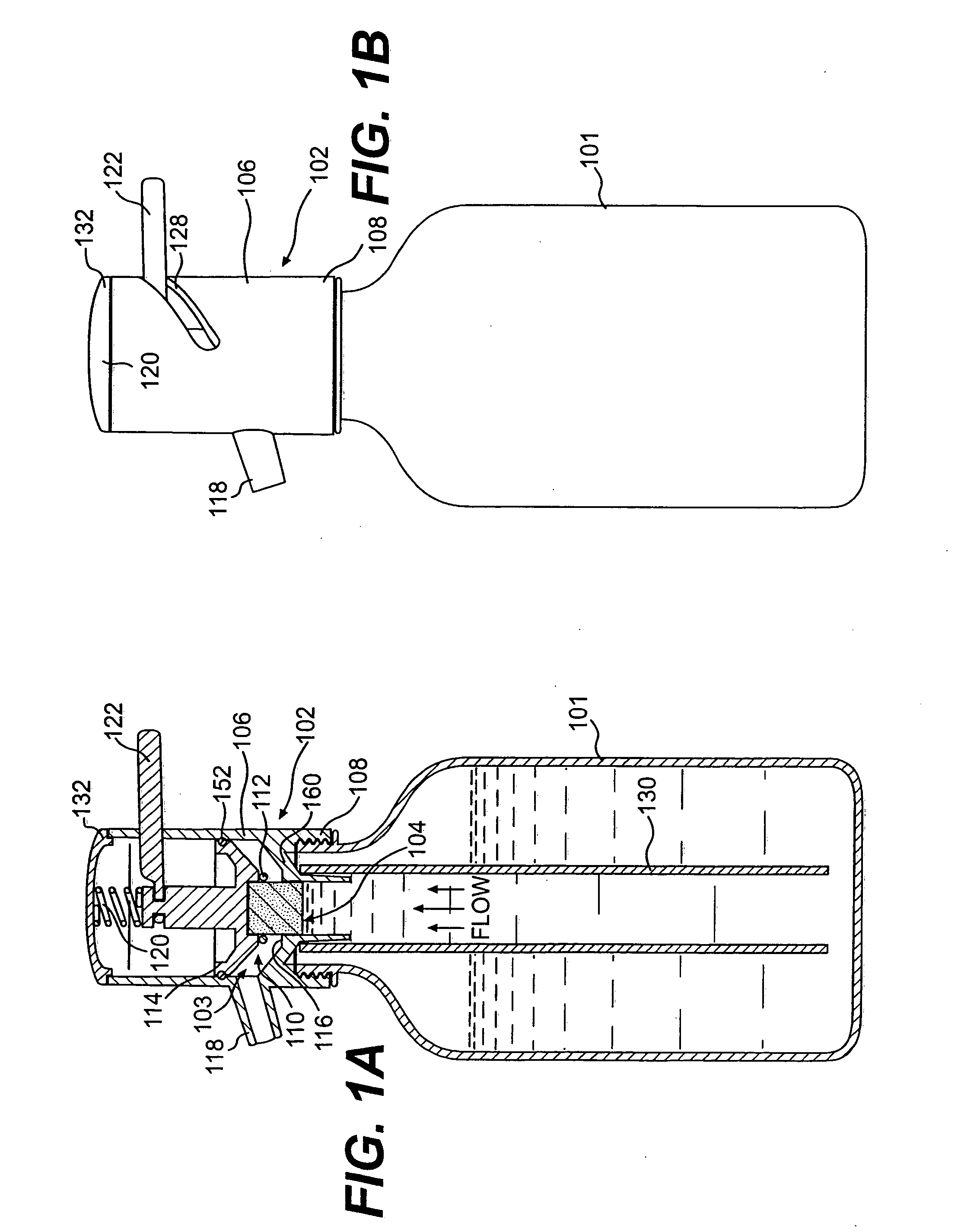

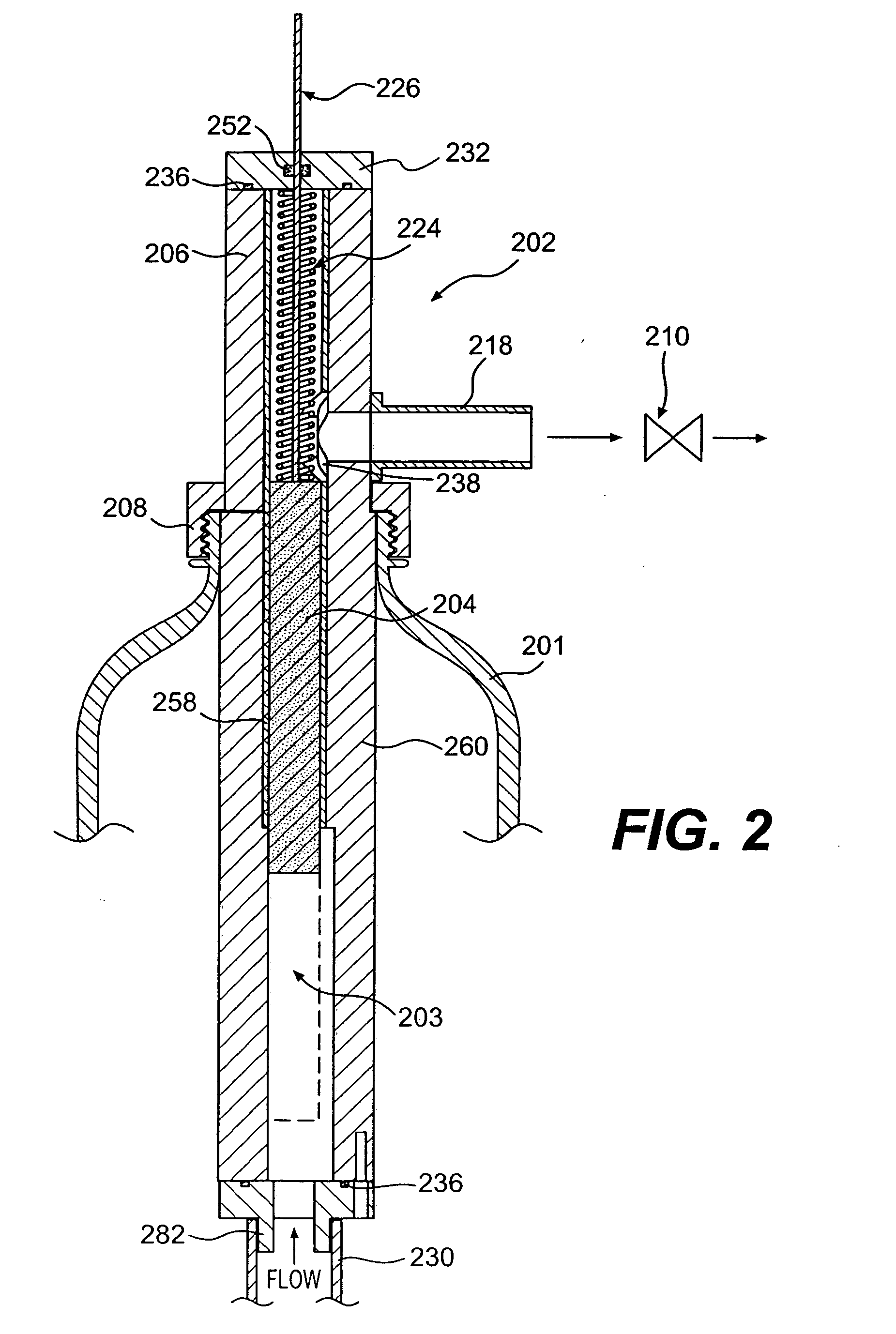

Gas spring assembly

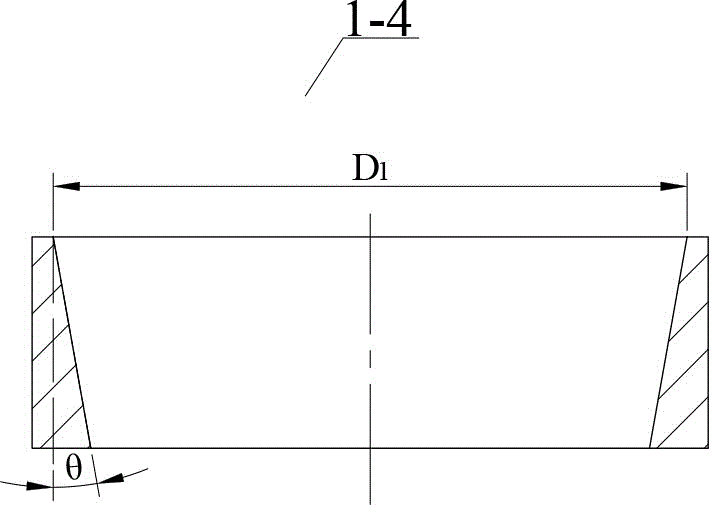

A gas spring assembly (200) that is suitable for use on a vehicle suspension system includes a first end member (208) and a second end member (210) that is spaced from the first end member. A flexiblewall (212) is secured between the first and second end members and at least partially defines a first gas chamber (214) therebetween. A confinement (204) at least partially forms a second gas chamber(232, 236) that is in communication with the first gas chamber. A porous flow restrictor (206A-D) is operatively disposed between the gas chambers. A suspension system including such a gas spring assembly as well as a method is also included.

Owner:BFS DIVERSIFIED PRODS

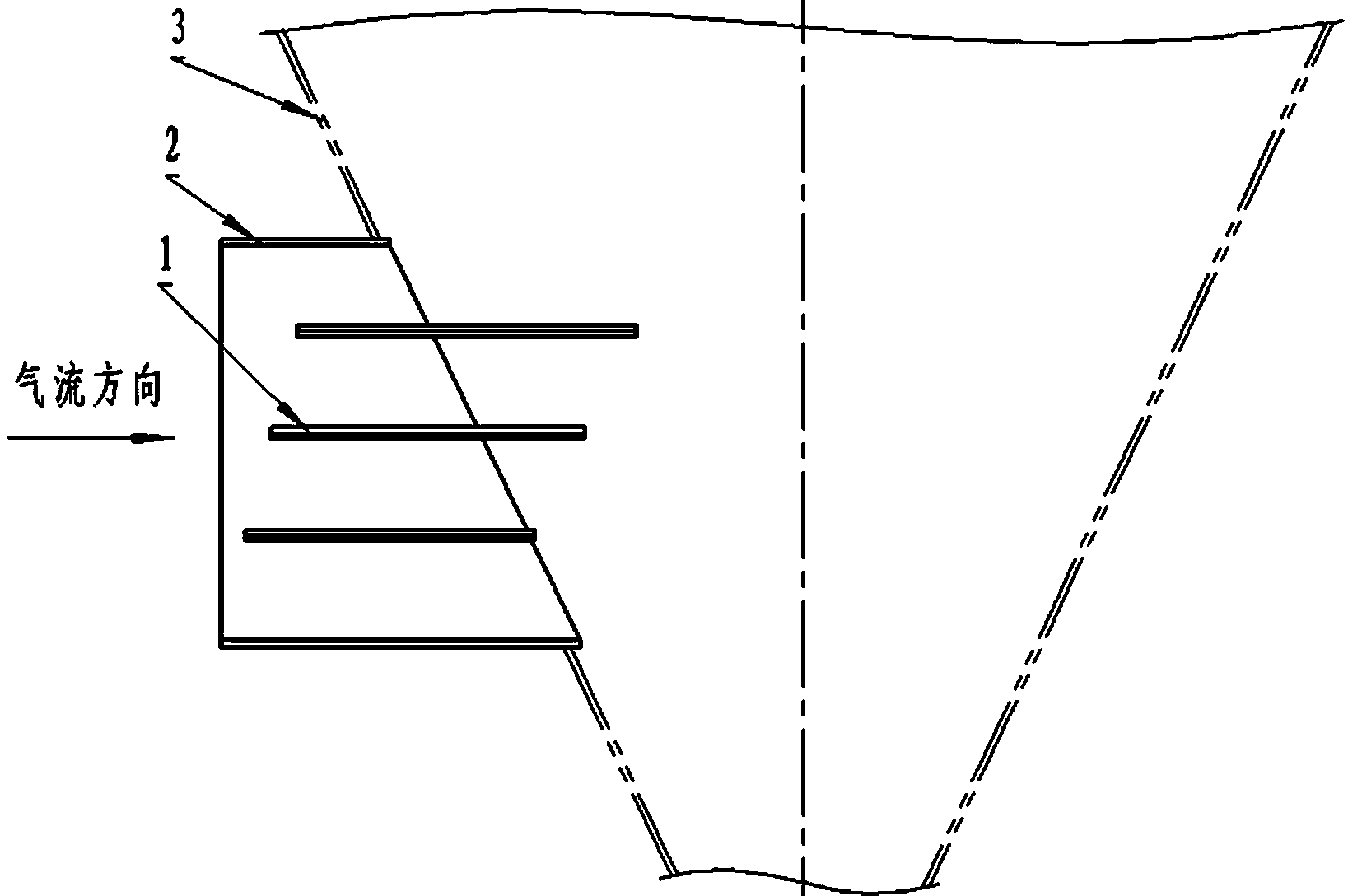

Air inlet flow rectifier for bag-type dust collector

InactiveCN103845976AGood dust removalSmall running resistanceDispersed particle filtrationPorous flowFiltration

The invention discloses an air inlet flow rectifier for a bag-type dust collector. The air inlet flow rectifier comprises an air inlet pipe arranged on the side face of an ash hopper of the dust collector, wherein the air inlet pipe is internally provided with a plurality of porous flow equalization boards in the ladder-shaped distribution. The porous flow equalization boards of the air inlet pipe are designed to be ladder-shaped, and thus the airflow velocity of a filter bag chamber is quickly reduced, and the airflow direction is changed so that airflow is uniformly distributed and dusty air is uniformly guided in the ash hopper; the airflow is prevented from directly washing filter bags, so that the service life of each filter bag is prolonged, and the running resistance of the bag-type dust collector is reduced; the inertial setting volume of dust in the dust hopper is increased, the absorbing capacity of the dust on each filter bag is reduced, and same filtering loading is achieved for each filter bag; the filtration resistance of the filter bags and the emission of dusty gas concentration at an outlet are reduced, and the service life of each filter bag is prolonged.

Owner:湖南益天环保科技有限公司

Thermoelectric generation module based on flat plate heat pipes and heat pipe circulation waste heat thermoelectric generation system formed by thermoelectric generation module based on flat plate heat pipes

The invention discloses a thermoelectric generation module based on flat plate heat pipes and a heat pipe circulation waste heat thermoelectric generation system formed by the thermoelectric generation module based on the flat plate heat pipes. The thermoelectric generation module based on the flat plate heat pipes comprises a thermoelectric generation unit, a shell and a fan. Multiple groups of porous parallel flow flat pipes are arranged in the thermoelectric generation unit in parallel. The left and right sides of the porous parallel flow flat pipes are closely provided with thermoelectricgeneration pieces and heat radiation fins in turn. The upper and lower ends of the porous parallel flow flat pipes are inserted into a gas collection pipe and a liquid collection pipe so as to form the integrated thermoelectric generation module. Multiple groups of thermoelectric generation modules and a waste heat pipeline internal heat exchanger, a gas pipeline and a liquid pipeline can form theheat pipe circulation waste heat thermoelectric generation system, and the waste heat in the pipeline can be efficiently transmitted to all the thermoelectric generation modules for power supply through gravity heat pipe circulation. The scheme has the advantages of high generation efficiency, stable voltage, flexible and convenient to design and install and high in expansibility, and standardization, modularization and productization of the thermoelectric generation device can be facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

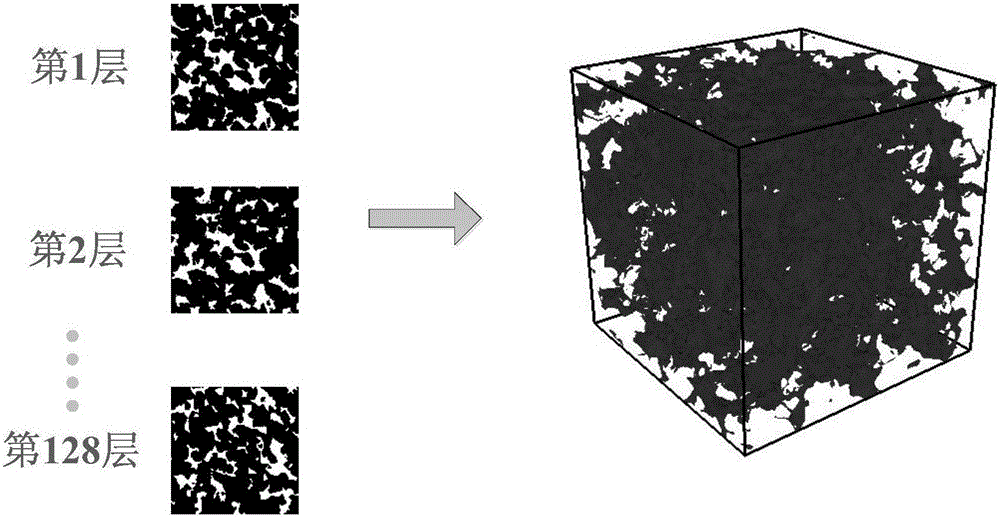

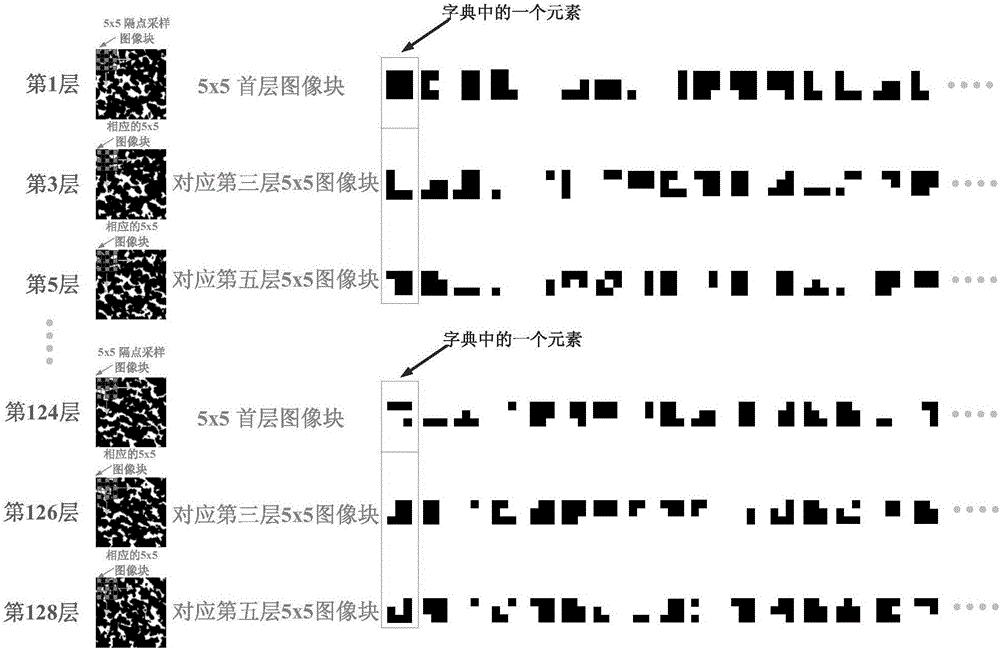

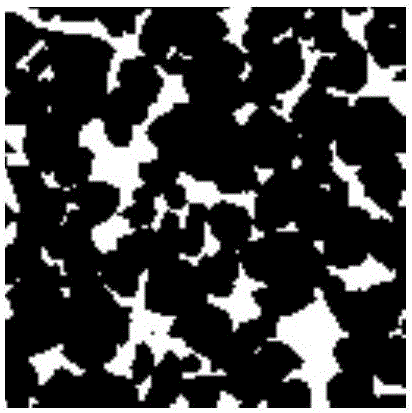

Porous medium super dimensional reconstruction method based on learning

ActiveCN105957003AHas practical valueGeometric image transformationThree dimensional ctThree dimensional microstructure

The invention relates to a porous medium super dimensional reconstruction method based on learning. Based on a three-dimensional modeling problem of a porous medium two-dimensional image, a learning method in super resolution reconstruction is introduced in porous medium three-dimensional reconstruction by the porous medium super dimensional reconstruction method, and a dictionary from a single image to a three-dimensional structure is established, and then a super dimensional concept is proposed. The porous medium super dimensional reconstruction method is characterized in that an original CT image sequence is selected, and is used as a training set; the super dimensional reconstruction method is used to establish the dictionary from every two-dimensional image layer of the original three-dimensional CT sequence to the three-dimensional structure of the corresponding positions of five CT image layers including the above mentioned layer by using the super dimensional reconstruction method. Based on the original reference image, a matched three-dimensional structure is searched in the established training set, and the super dimensional reconstruction is realized. A good explanation is provided for a real porous medium microstructure by the reconstructed three-dimensional microstructure, which can be used for the researching of the porous medium microstructure electrical characteristics and the porous flow characteristic, and has the practical value.

Owner:SICHUAN UNIV

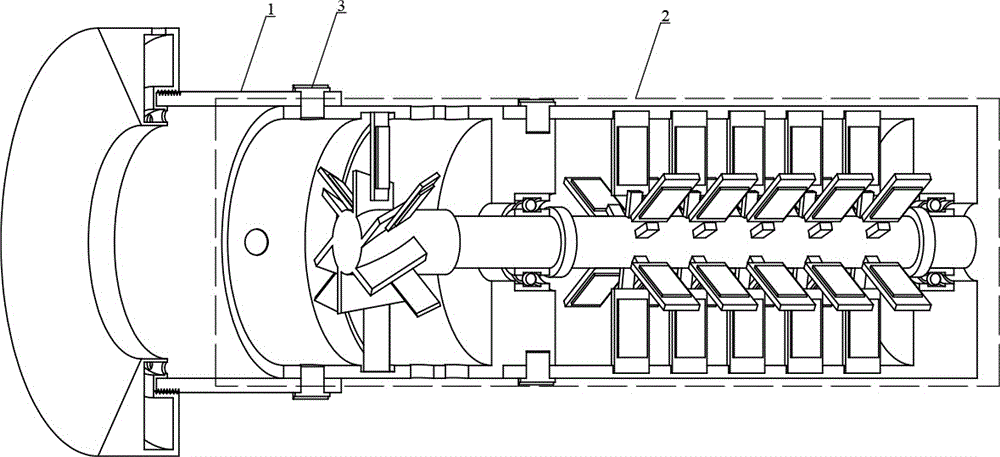

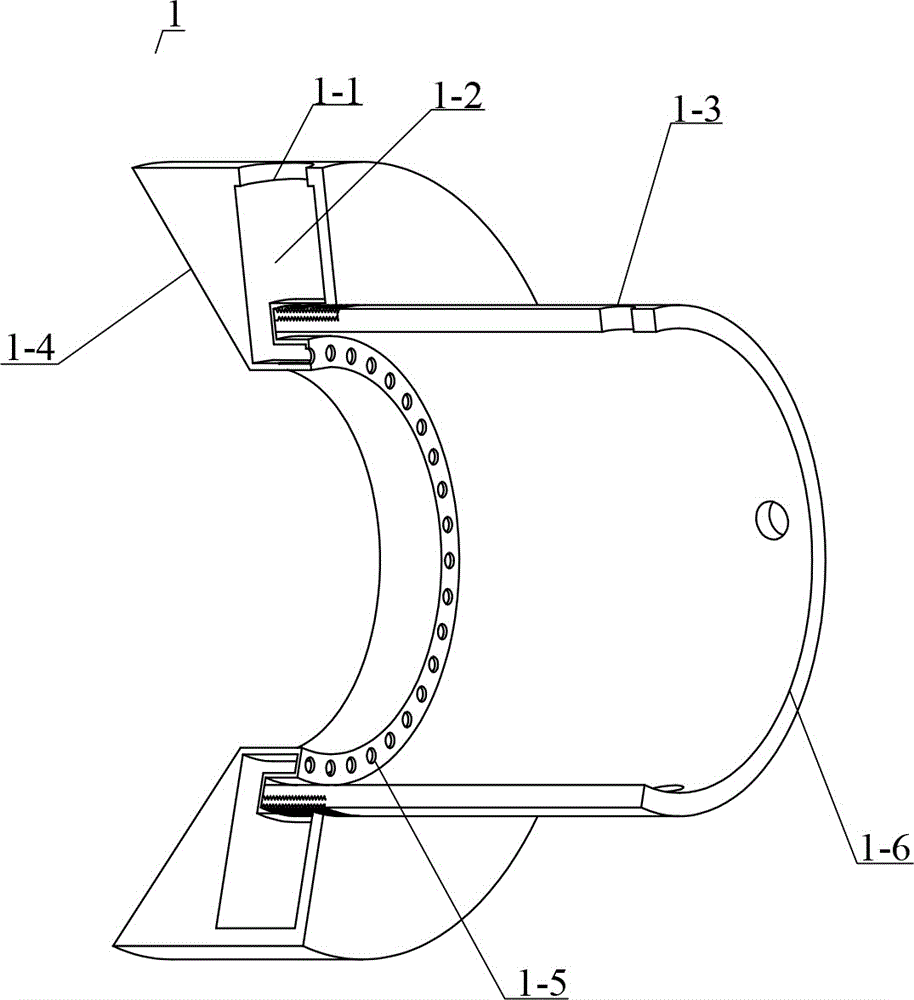

Porous flow-increasing type rotary piezoelectric generator

ActiveCN106230317AImprove energy conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric generatorHigh pressure

The invention discloses a porous flow-increasing type rotary piezoelectric generator. The invention aims to solve the problem of low energy exchange efficiency of the present piezoelectric generator for converting the gas energy under industrial environment. The porous flow-increasing type rotary piezoelectric generator is composed of a porous array type flow-increasing device, a rotary stirring type generator component and a fastening bolt, wherein the porous array type flow-increasing device and the rotary stirring type generator component are fastened with each other through the fastening bolt. The porous array type flow-increasing device can be used for amplifying the flow of high-pressure small flow gas, acts on a piezoelectric component for realizing energy capture and is capable of increasing the electric energy generation efficiency of the piezoelectric generator by above 3 times. An energy management circuit is used for rectifying the generated electric energy; the low-power consumption electronic devices including nodes of Internet of Things can be continuously and effectively supplied with power; the porous flow-increasing type rotary piezoelectric generator has wide application prospect in the technical field of low-power consumption electronic equipment, nodes of Internet of Things and low-power consumption sensor.

Owner:CHANGCHUN UNIV OF TECH

Dispenser assembly having a porous flow control member

ActiveUS20050242123A1Reduce wasteEconomically beneficialClosuresLiquid flow controllersPorous flowVALVE PORT

A dispenser assembly that can be used as a dispenser on a container includes a dispenser body having a flow passage, and a porous flow control member positioned in the flow passage such that the liquid must pass through at least a portion of the porous flow control member before being dispensed. The porous flow control member is operable to vary a resistance to flow of the liquid through the dispenser assembly during dispensing. A valve is provided and is movable between an open position that allows the liquid to be dispensed and a closed position that prevents the liquid from being dispensed. A discharge spout directs the flow of liquid discharged from the container. A dip tube is attached to the dispenser body and extends inside the container to supply the liquid to be discharged to the dispenser body. An attachment portion is provided to attach the dispenser assembly to the container.

Owner:PEPSICO INC

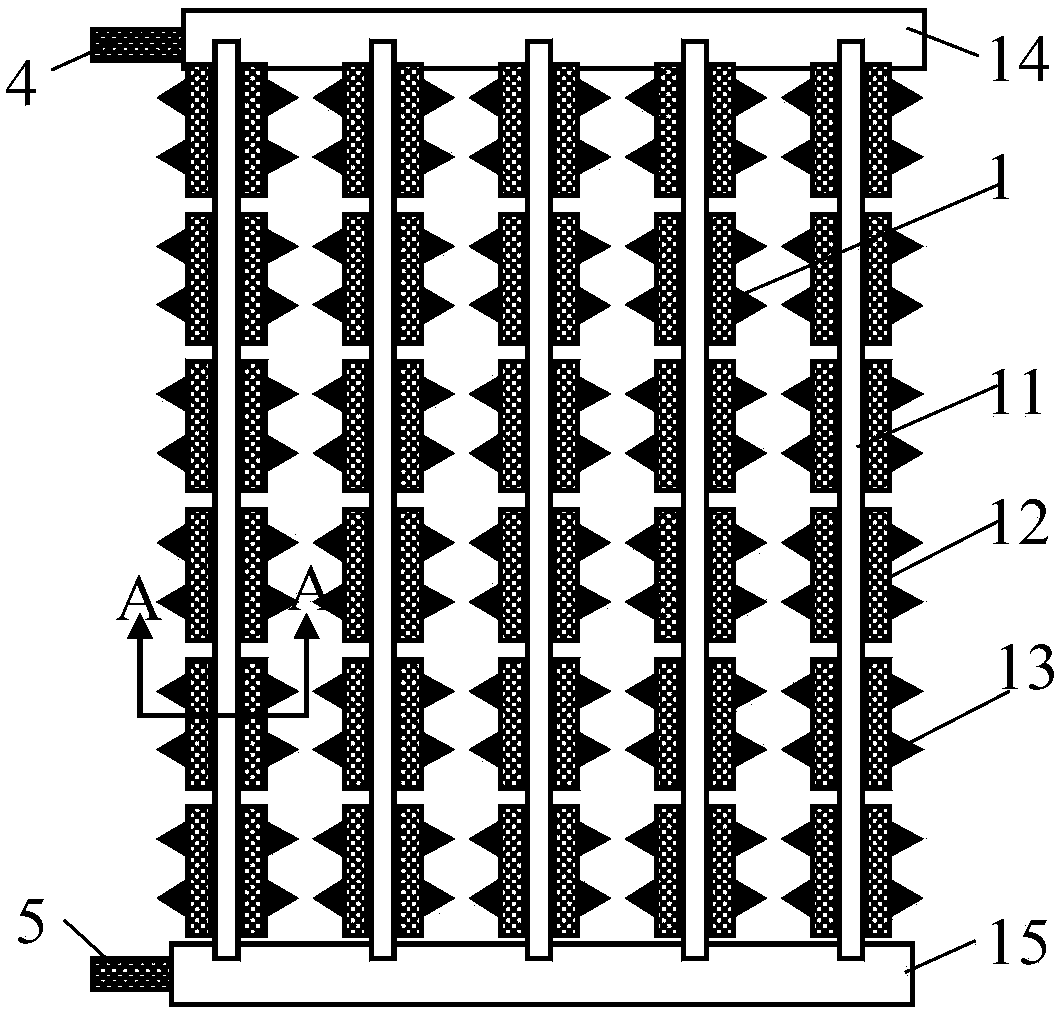

High-integration-level fuel cell bipolar plate for optimizing distribution of reaction gas

InactiveCN103618091ARaise the concentration of the reactant gasIncrease output powerFinal product manufactureCell electrodesEngineeringFluid field

The invention provides a high-integration-level fuel cell bipolar plate for optimizing the distribution of reaction gas. According to the high-integration-level fuel cell bipolar plate, the bipolar plate is in a two-layer structure; a lower layer is a metal plate punched with a runner and an upper layer is a net-shaped porous flow field plate; the net-shaped porous flow field plate is a flat plate; the net-shaped porous flow field plate is arranged on the metal plate punched with the runner to form an anode plate or a cathode plate. The high-integration-level fuel cell bipolar plate for optimizing the distribution of the reaction gas has the beneficial effects that the concentration of the reaction gas of a membrane electrode opposite to a convex part of the flow field under a galvanic pile assembling condition can be improved obviously; the effective area of an electrode in a galvanic pile operation process is improved greatly; the output power and the specific power density of a galvanic pile are improved greatly; transition is formed between a microcosmic size pore of electrode carbon paper and the macroscopic size runner of the metal plate by the porous flow field plat, so that the discharging of liquid-state water generated by a reaction is facilitated and the water management of a fuel cell is simplified; materials are simple and novel materials do not need to be explored; the structure is simple and only a conventional structure of an existing fuel cell needs to be improved simply; great influences on the assembling and the structure of the galvanic pile are avoided.

Owner:SUNRISE POWER CO LTD

Annular porous flow disturbing structure of gas flow adjusting device of solid rocket engine

The invention proposes an annular porous gas turbulence structure of a solid rocket motor gas flow regulating device, which premixes and evenly distributes the high-temperature and high-speed incoming gas, reduces the uneven erosion and aerodynamic impact of the gas on the valve core of the flow regulating device, and can also be used To filter some of the bulky debris entrained in solid rocket motor gases. The annular porous gas turbulence structure can process multiple air holes on the annular turbulence structure according to the incoming flow direction. The shape and number of air holes can be adjusted according to the area of the gas inlet and nozzle outlet. The periphery of the spool of the regulating device is fixed between the gas inlet and the spool of the flow regulating device through mechanical and adhesive means. The invention not only has the characteristics of simple structure, compactness, easy molding, convenient assembly, high temperature resistance, reliable operation, etc.; it also plays the role of premixed gas flow, uniform distribution of gas, and reduces local erosion and ablation of high-temperature and high-speed gas on the gas flow adjustment device. .

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Liquid-liquid fuel cell systems having flow-through anodes and flow-by cathodes

The invention disclosed herein relates to fuel cell electrode pair assemblies, not having interposing proton exchange membranes, configured to receive and react with liquid anolyte and liquid catholyte microfluidic flowstreams. In one embodiment, the present invention is directed to a fuel cell electrode pair assembly, not having an interposing proton exchange membrane, configured to receive and react with a liquid microfluidic anolyte flowstream (e.g., laminarly flowing methanol solution) and a liquid microfluidic catholyte flowstream (e.g., laminarly flowing nitric acid solution), wherein the fuel cell electrode pair assembly comprises: a porous flow-through anode; a porous flow-by cathode confronting and spaced apart from the anode; and a central plenum interposed between and connected to the anode and the cathode.

Owner:EPD INVESTMENT CO

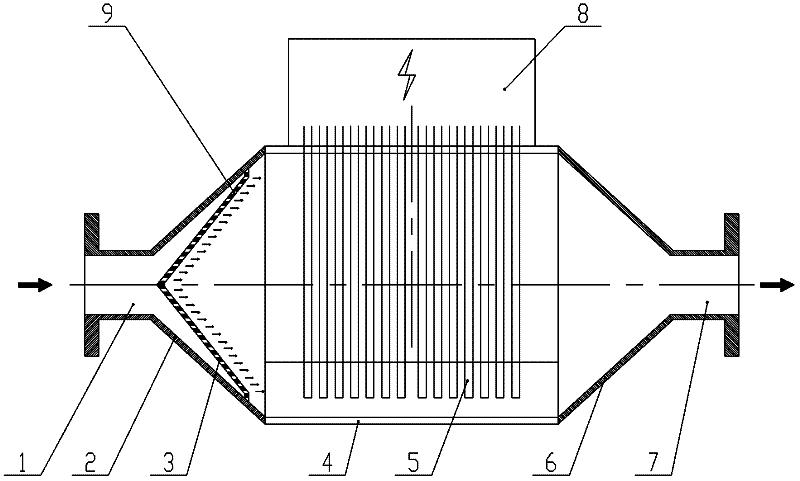

Flow equalization device for air electric heater

InactiveCN102331088AReduce energy consumptionExtended service lifeFluid heatersPorous flowEngineering

The invention relates to a flow equalization device for an air electric heater. Two ends of a heater cylinder are provided with an inlet cone and an outlet cone; the inlet cone and the outlet cone are provided with an air inlet and an air outlet respectively; an electric heating tube nest is arranged in the heater cylinder; and a conical flow equalizer which is provided with flow equalization holes is fixed in the inlet cone. The conical and porous flow equalizer is arranged in the inlet cone of the heater, so that the flow field of the air is equalized and then the air enters the electric heater which efficiently exchanges heat with heated air; therefore, the energy consumption of the heater can be reduced and the service life of the whole heater can be prolonged simultaneously.

Owner:WUXI BEYOND AOK ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com