Full-automatic tank type chemical plating equipment and chemical plating method

A fully automatic, chemical plating technology, used in liquid chemical plating, coatings, electrical components, etc., to achieve uniform circulation flow, uniform temperature of liquid medicine, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

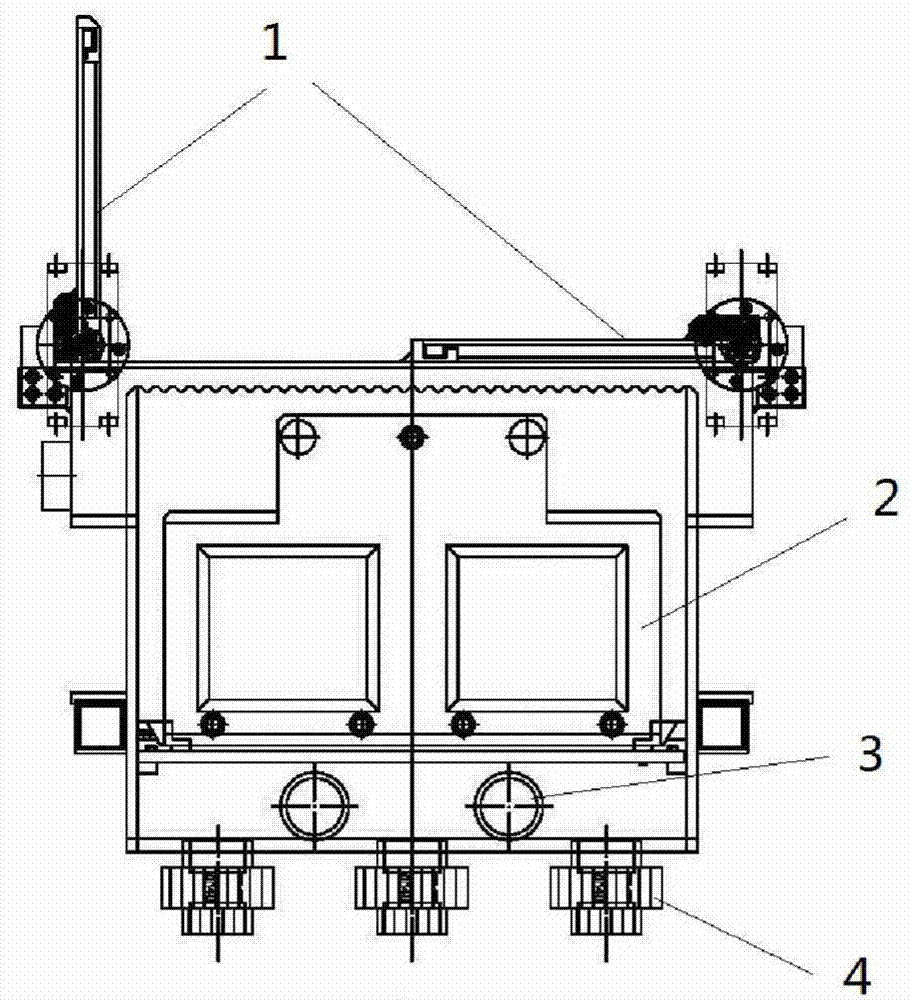

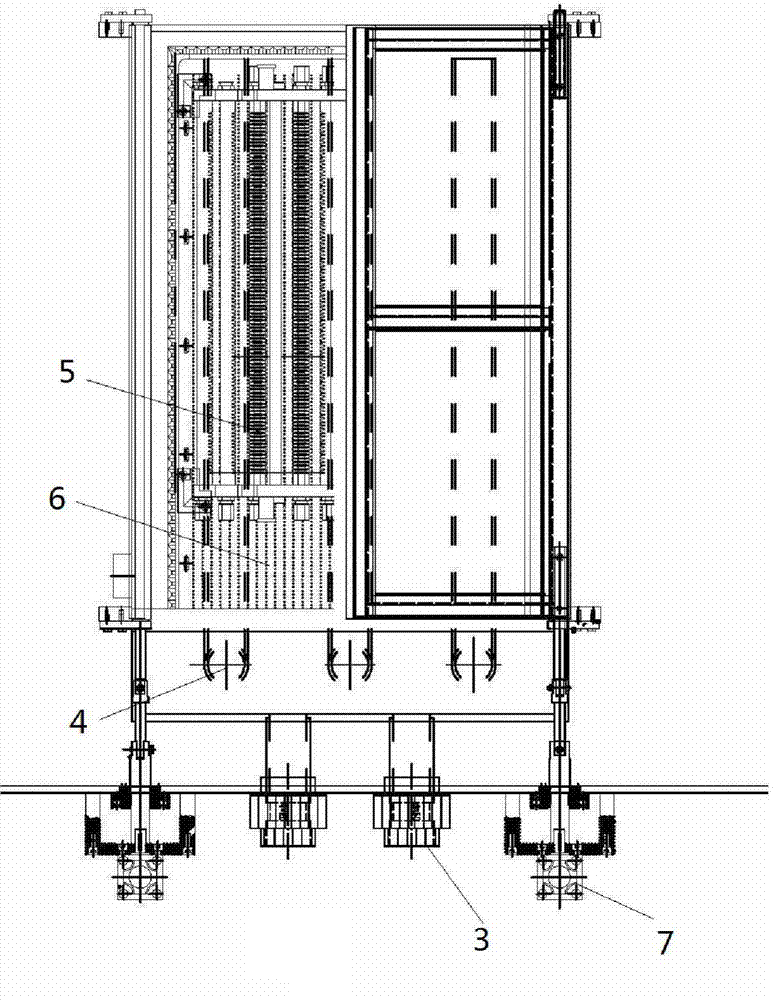

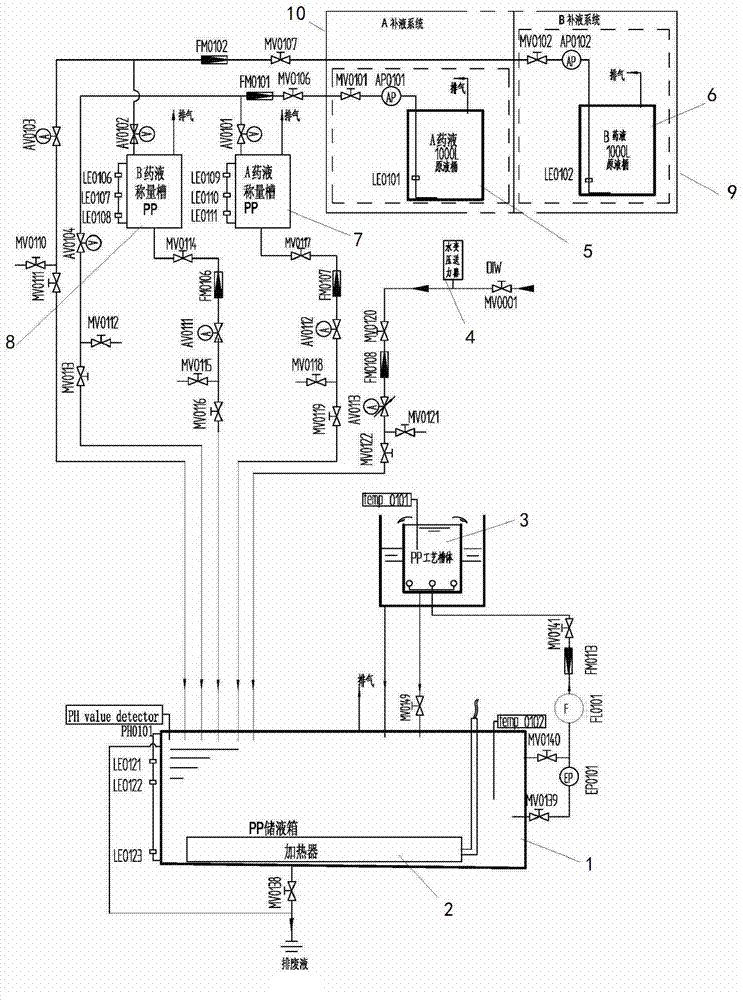

[0035] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, in order to adapt to the transformation of the manufacturing process of new crystalline silicon photovoltaic cells and realize new nickel and copper electrodes, the present invention provides a fully automatic tank-type electroless plating equipment applied to the production of crystalline silicon photovoltaic cells. Liquid circulation, uniform circulation flow, uniform liquid temperature, automatic supply of chemical liquid, crystal silicon battery dry in and dry out, stable chemical liquid, low equipment cost, easy maintenance and many other features.

[0036] An electroless plating equipment used in the production of crystalline silicon photovoltaic cells, equipped with a fully automatic manipulator and adopts a trough design;

[0037] The inside of the equipment has various functional tanks such as electroless plating, pickling, water washing, activation, and drying; the top of the chemical pl...

Embodiment 2

[0059] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 as shown,

[0060] An electroless plating equipment used in the production of crystalline silicon photovoltaic cells, equipped with a fully automatic manipulator and adopts a trough design;

[0061] The sequence of basic process tank arrangement is as follows: alkali cleaning step; water washing step; activation step; nickel plating step; water washing step; nickel plating step; water washing step; copper plating step; drying step; nickel (or silver plating) step; ;

[0062] The crystalline silicon photovoltaic cell is placed in the standard flower basket 5, and in order to improve the production capacity of the equipment, the equipment provides the flower basket 2, and each flower basket can hold 4 standard flower baskets.

[0063] The fully automatic manipulator 11 takes the flower basket 2 from the feeding station 8, puts it into the corresponding tank body 9 according to the requirements of the contro...

Embodiment 3

[0078] Embodiment 3: as figure 1 , figure 2 , image 3 , Figure 4 as shown,

[0079] An electroless plating equipment used in the production of crystalline silicon photovoltaic cells, equipped with a fully automatic manipulator and adopts a trough design;

[0080] The sequence of basic process tank arrangement is as follows: activation step; nickel plating step; washing step; pickling step; washing step; nickel plating step; washing step; copper plating step; drying step; nickel (or silver plating) step; drying ;

[0081] The crystalline silicon photovoltaic cell is placed in the standard flower basket 5, and in order to improve the production capacity of the equipment, the equipment provides the flower basket 2, and each flower basket can hold 4 standard flower baskets.

[0082] The fully automatic manipulator 11 takes the flower basket 2 from the feeding station 8, puts it into the corresponding tank body 9 according to the requirements of the control program, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com