Heat-tube composite liquid absorption core and preparation method for same

A liquid-absorbing core and heat pipe technology, applied in the field of heat pipes, can solve the problems of limited heat transfer area, limited capillary pressure effect, unfavorable boiling heat transfer enhancement, etc., to achieve increased heat transfer area, good capillary characteristics, and enhanced capillary flow transfer The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

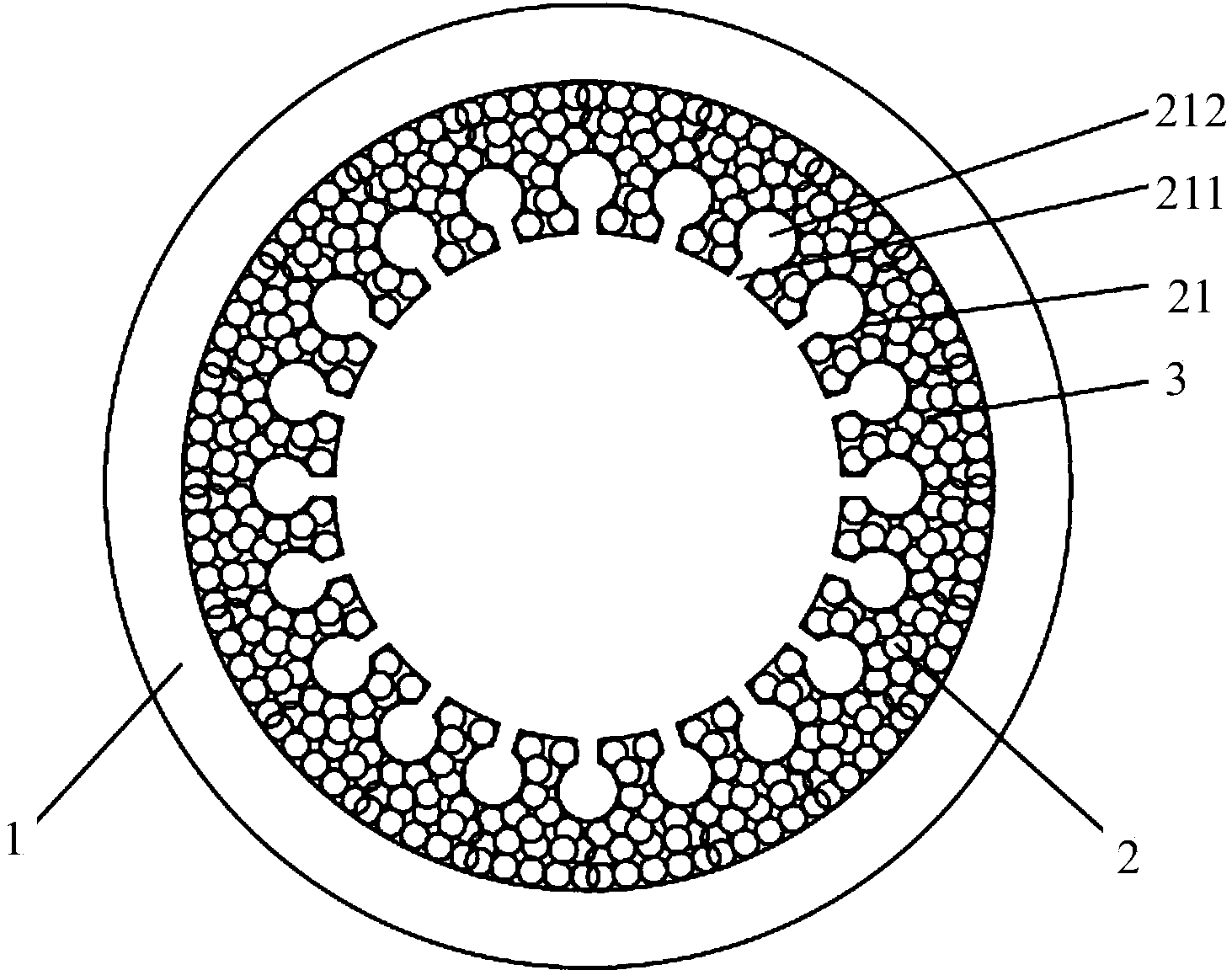

[0033] Such as figure 1 As shown, a heat pipe composite liquid-absorbing core is a tubular structure, including a metal outer casing 1 (preferably a copper outer casing) and a metal porous flow channel 2 arranged in the metal outer casing, and the outer wall of the metal porous flow channel 2 and The inner wall of the metal outer sleeve 1 is closely attached;

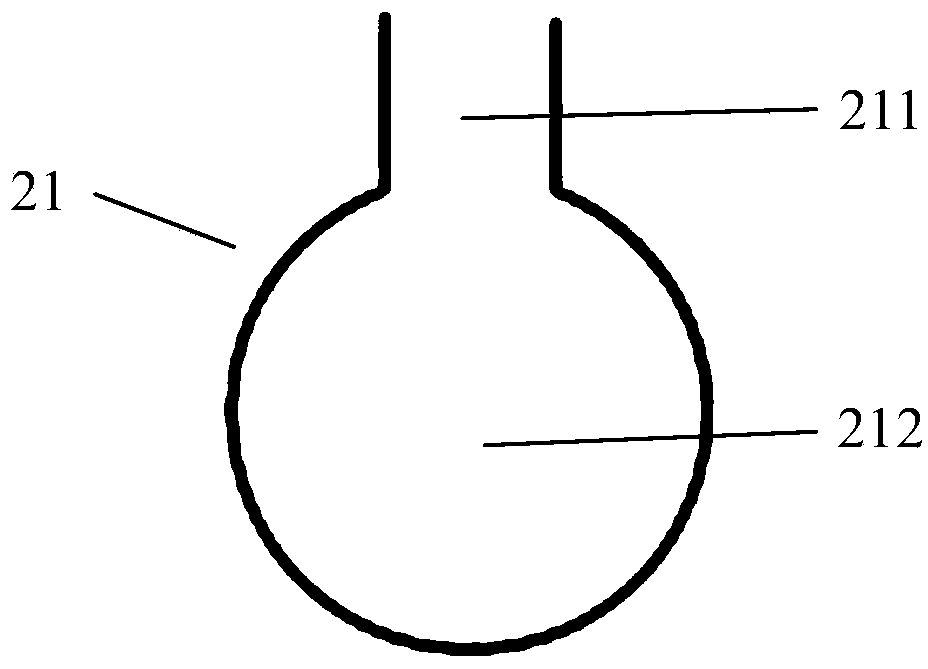

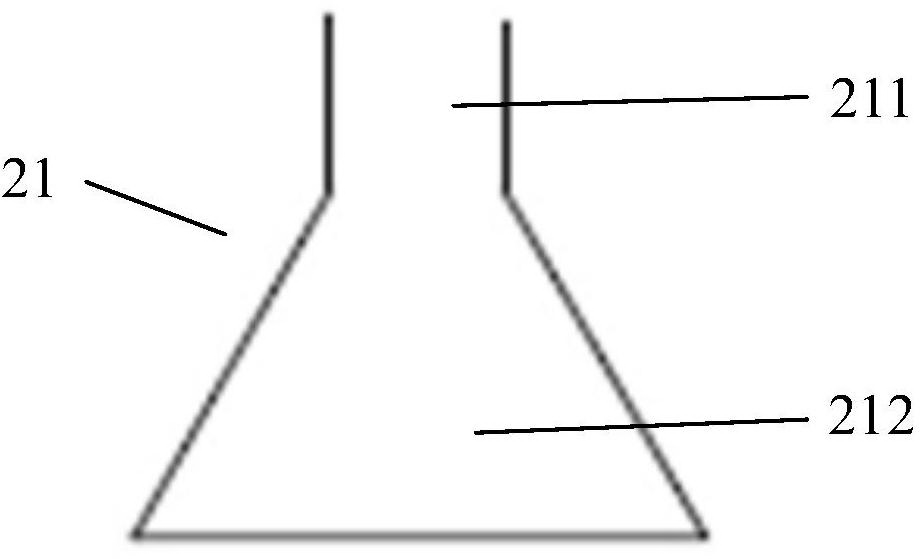

[0034] The metal porous flow channel 2 is formed by solid-phase sintering of metal powder particles 3 with a particle size of 40-180 μm (preferably 50-150 μm), and its surface and interior have a porous structure with an average pore size of 10-100 μm. There are 20-60 (preferably 20-40) liquid-absorbing grooves 21 with the same length as the axial length of the metal porous flow channel 2 evenly distributed along its circumferential directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com