Patents

Literature

70results about How to "Reduce backflow resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

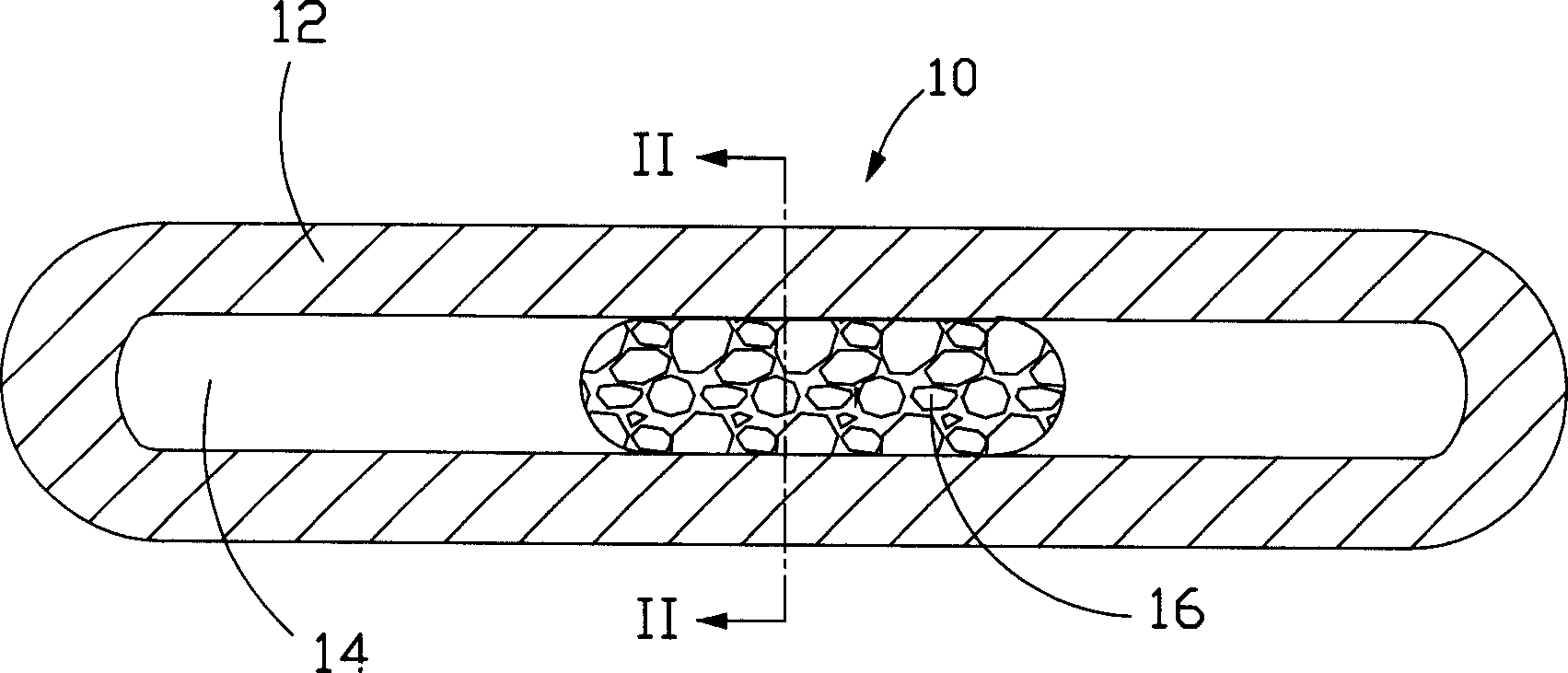

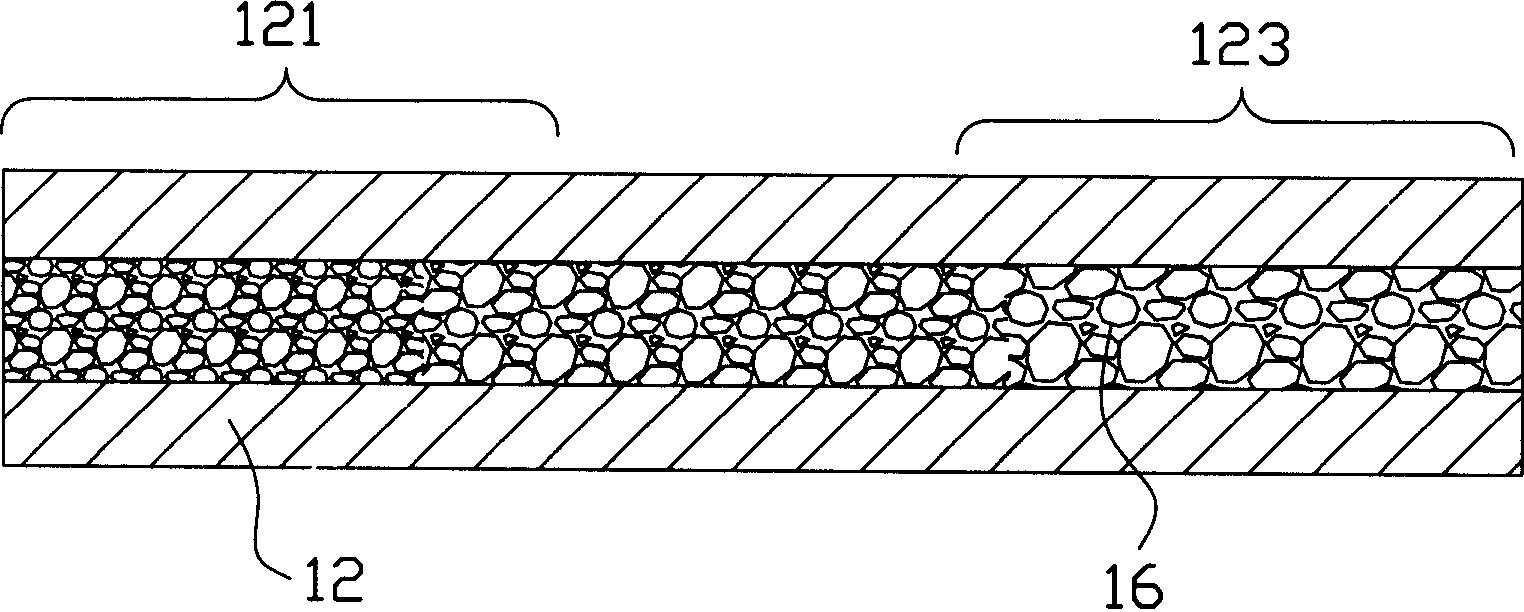

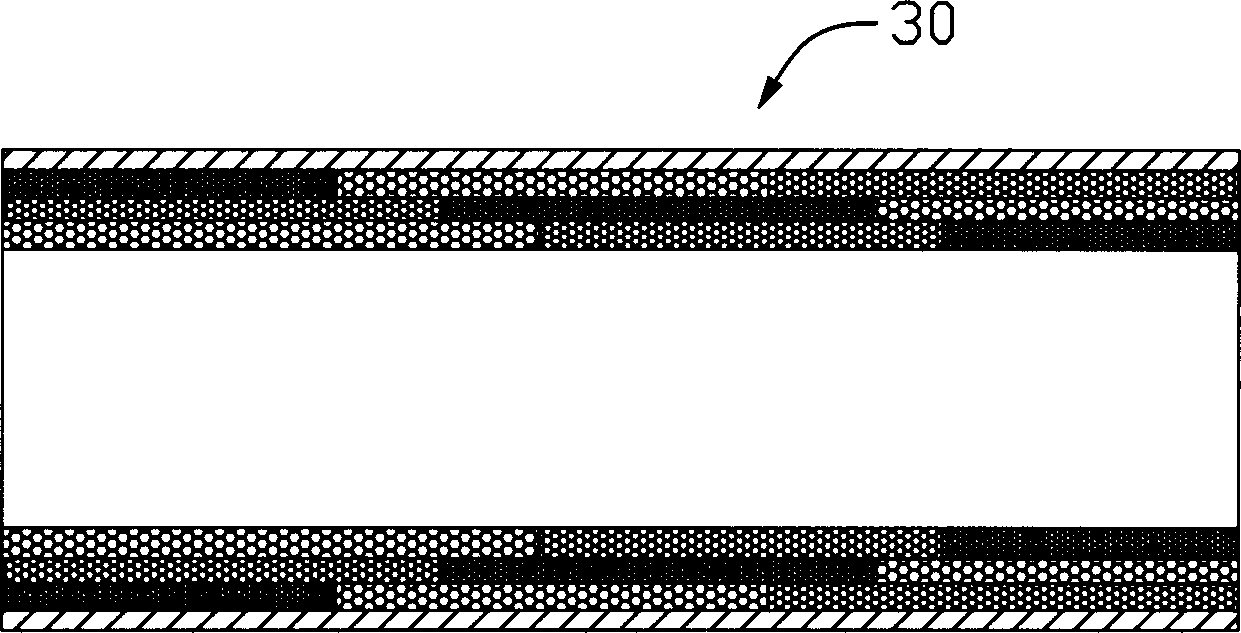

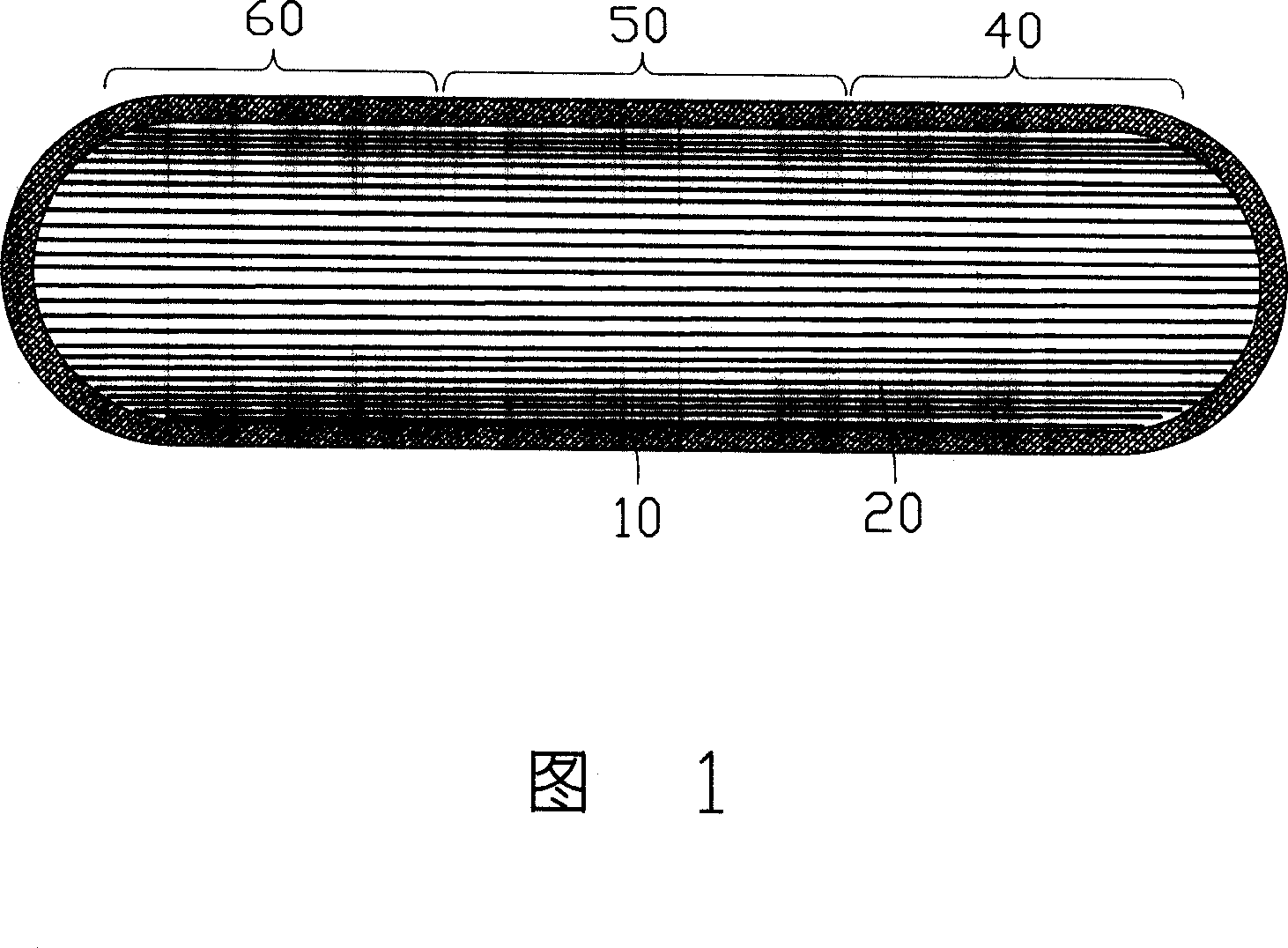

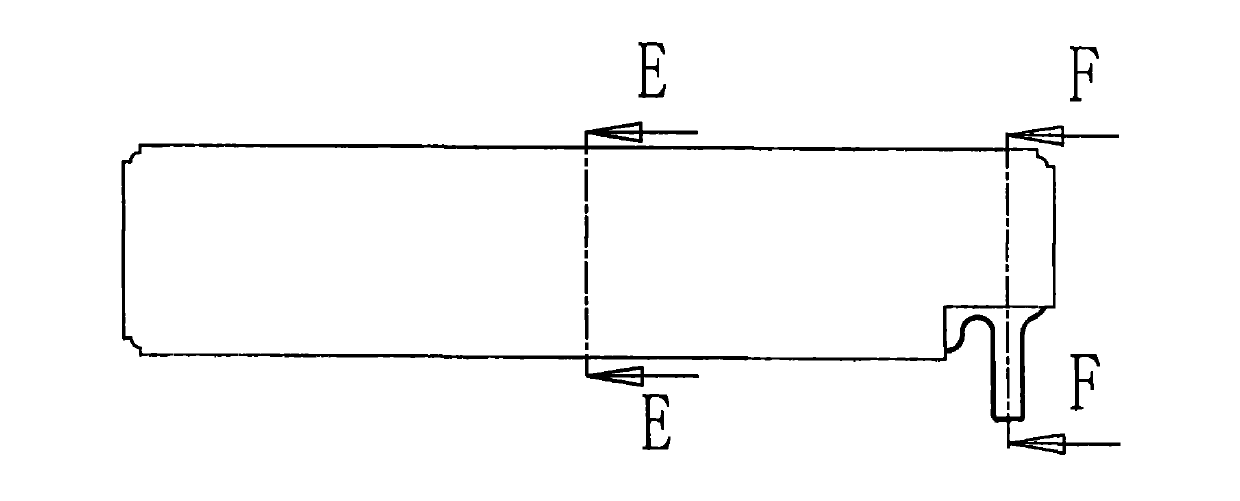

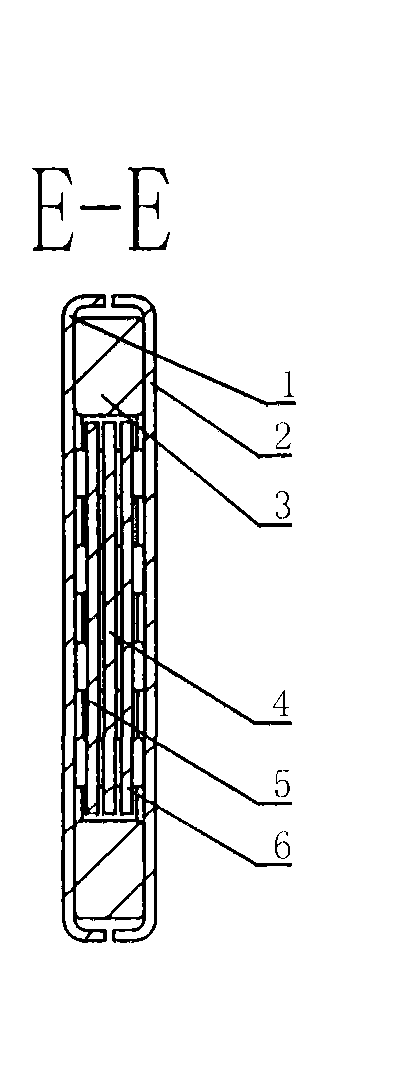

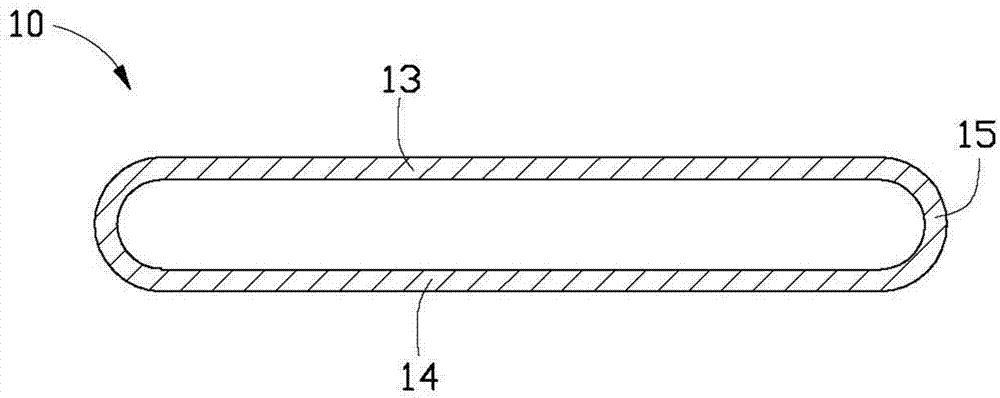

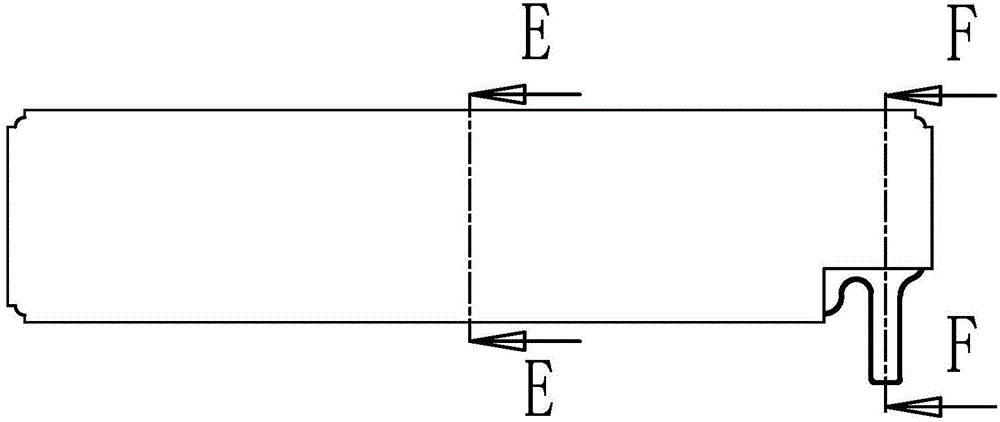

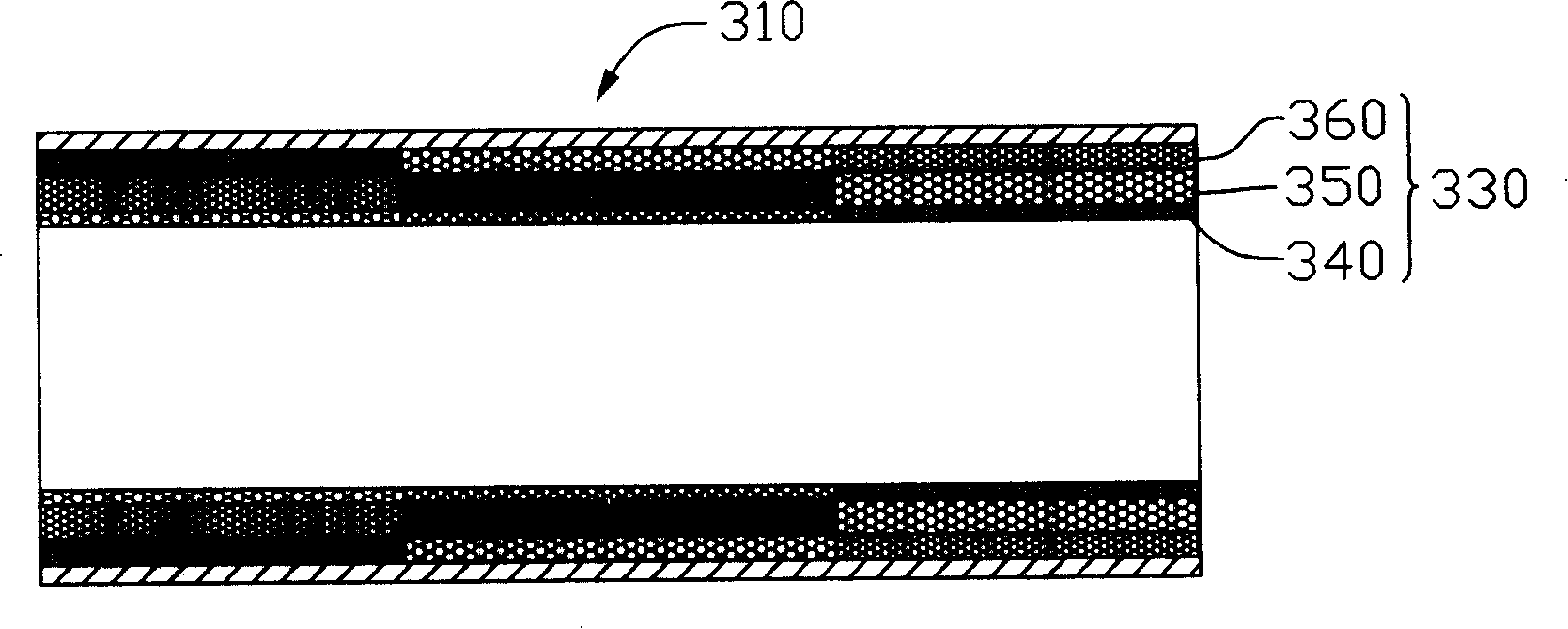

Flat type heat-pipe

InactiveCN1892165AIncrease backflow resistanceLarge to small return resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

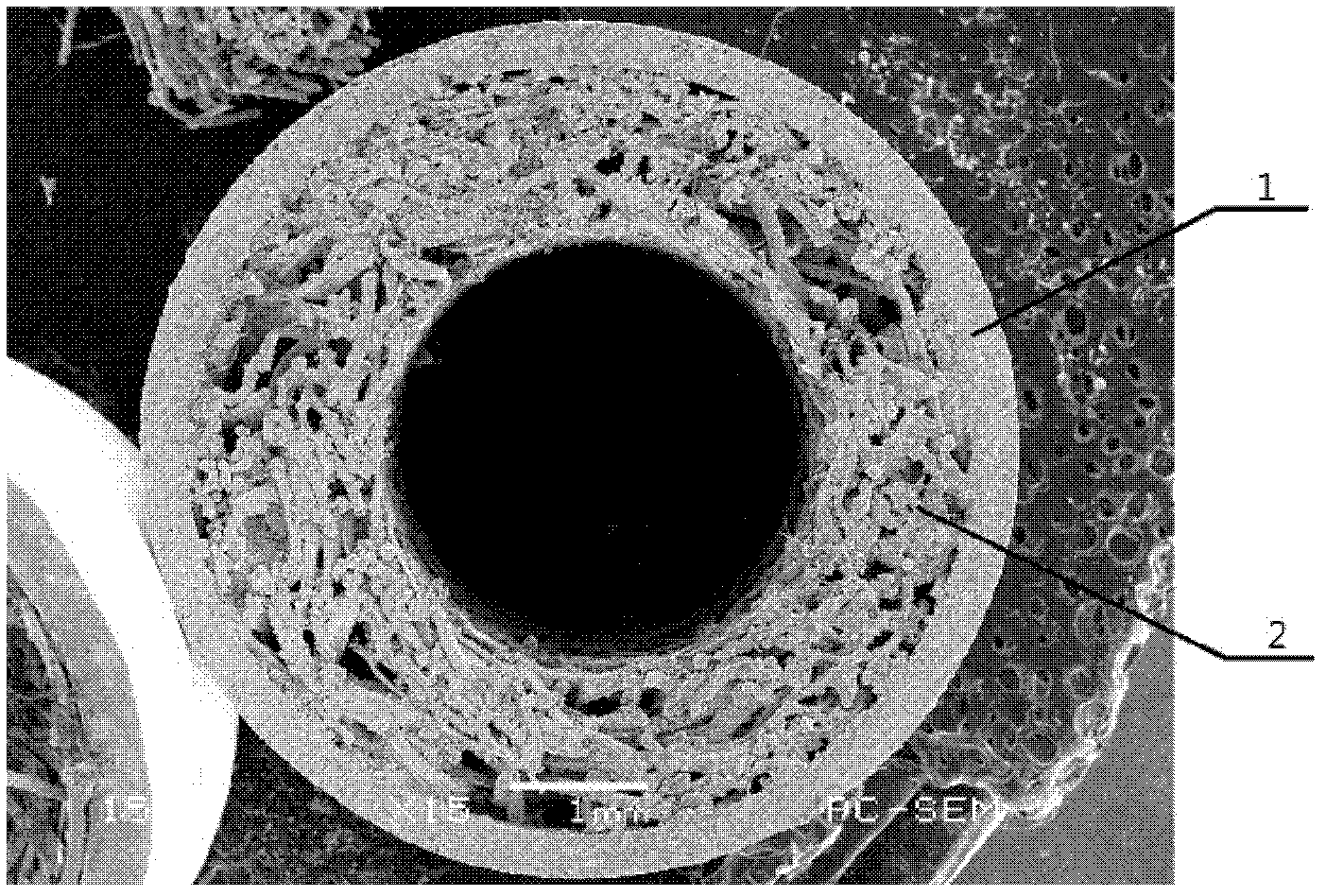

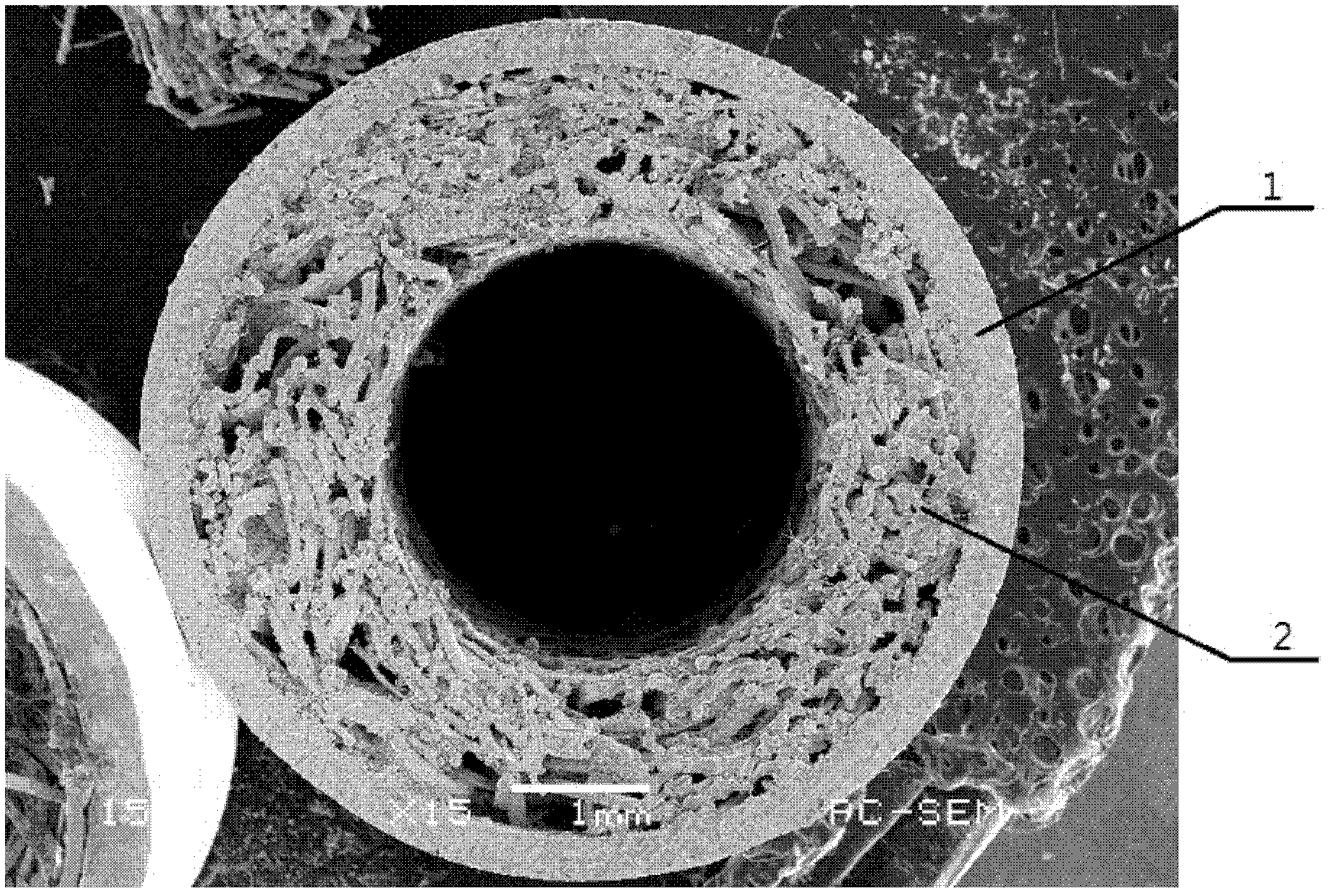

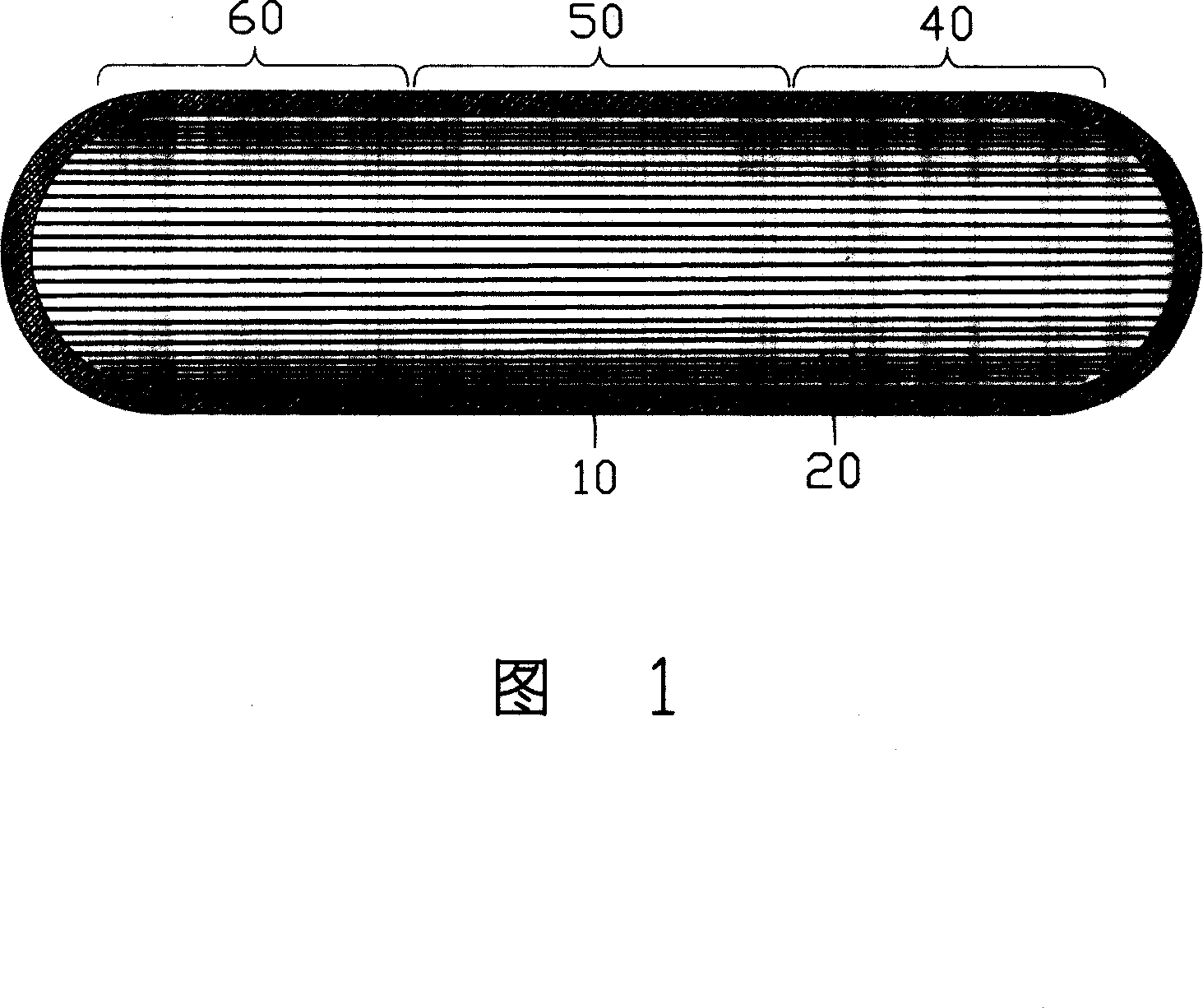

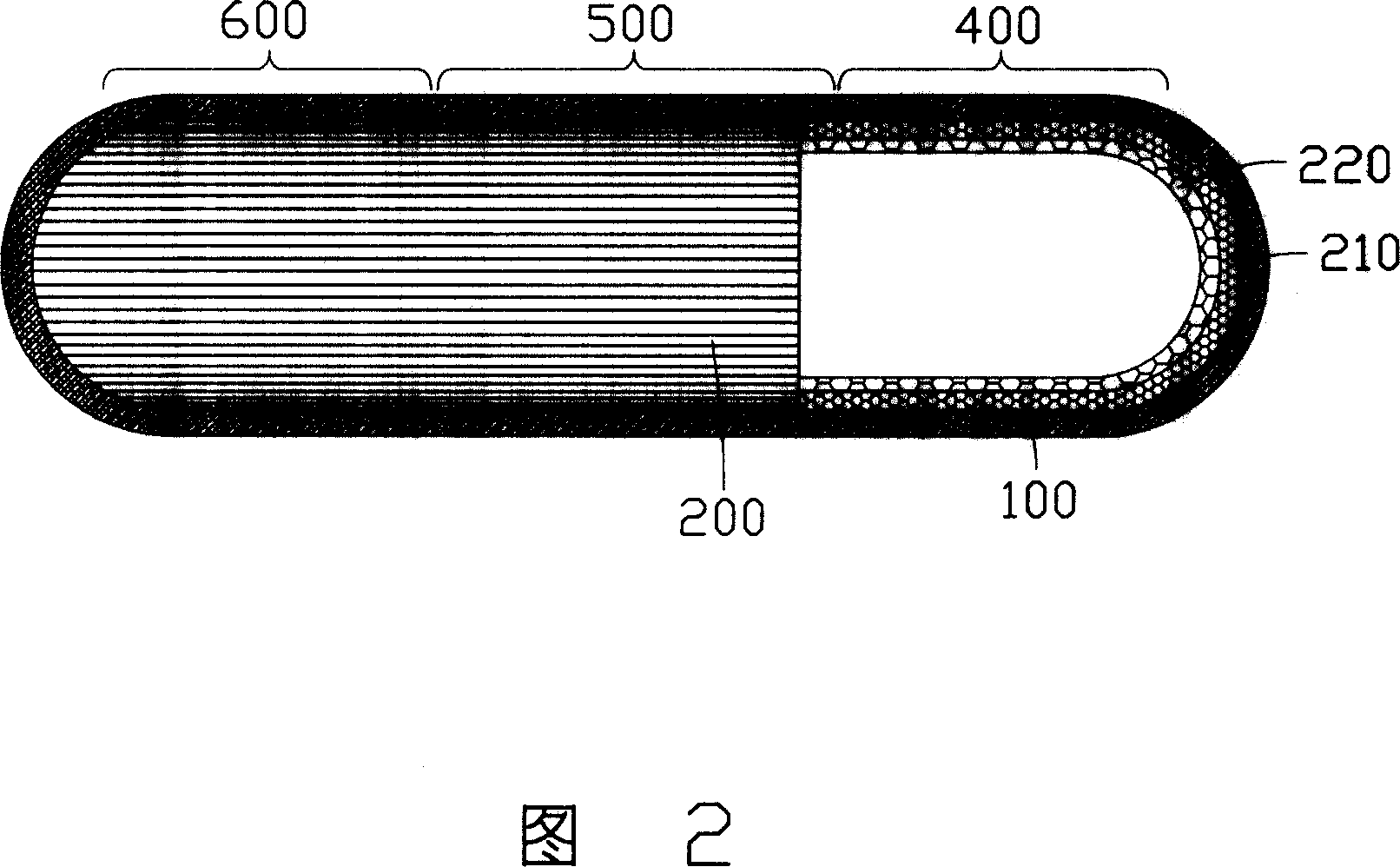

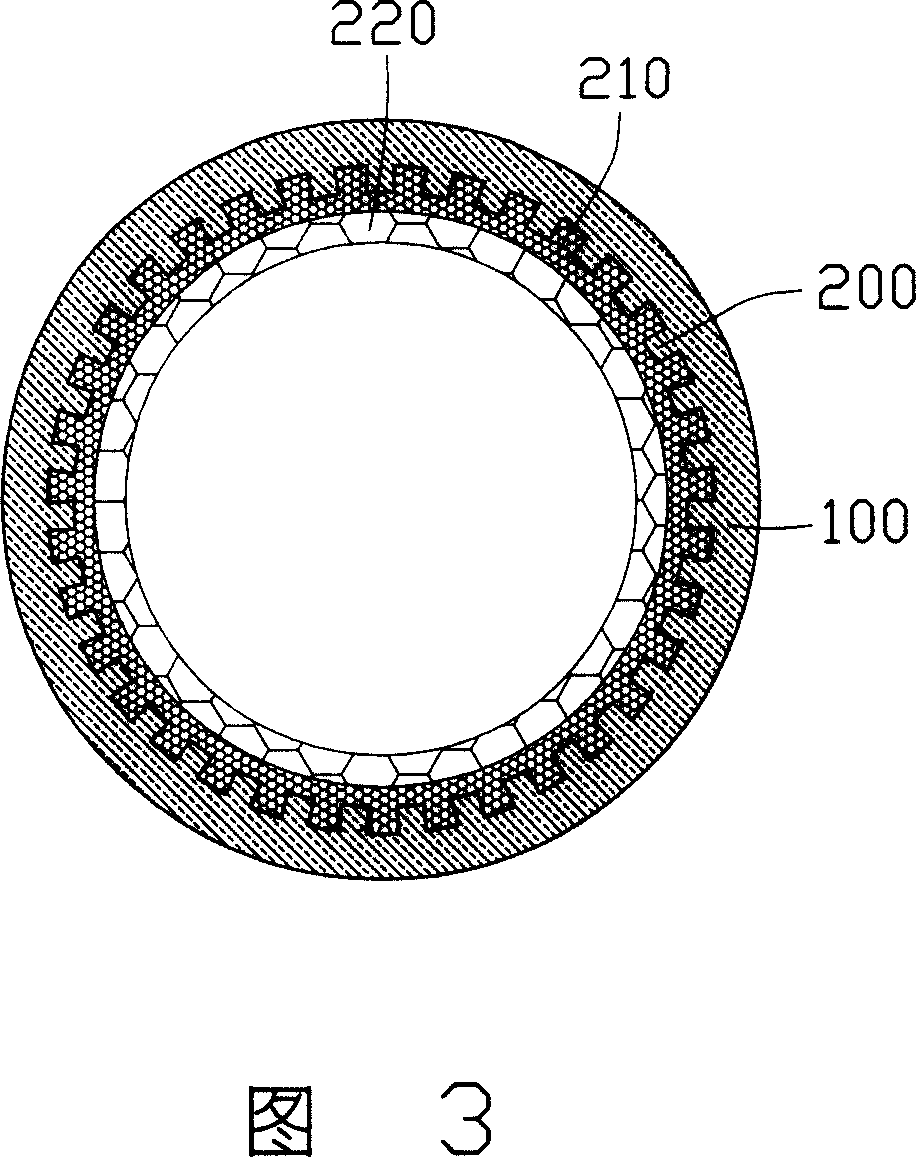

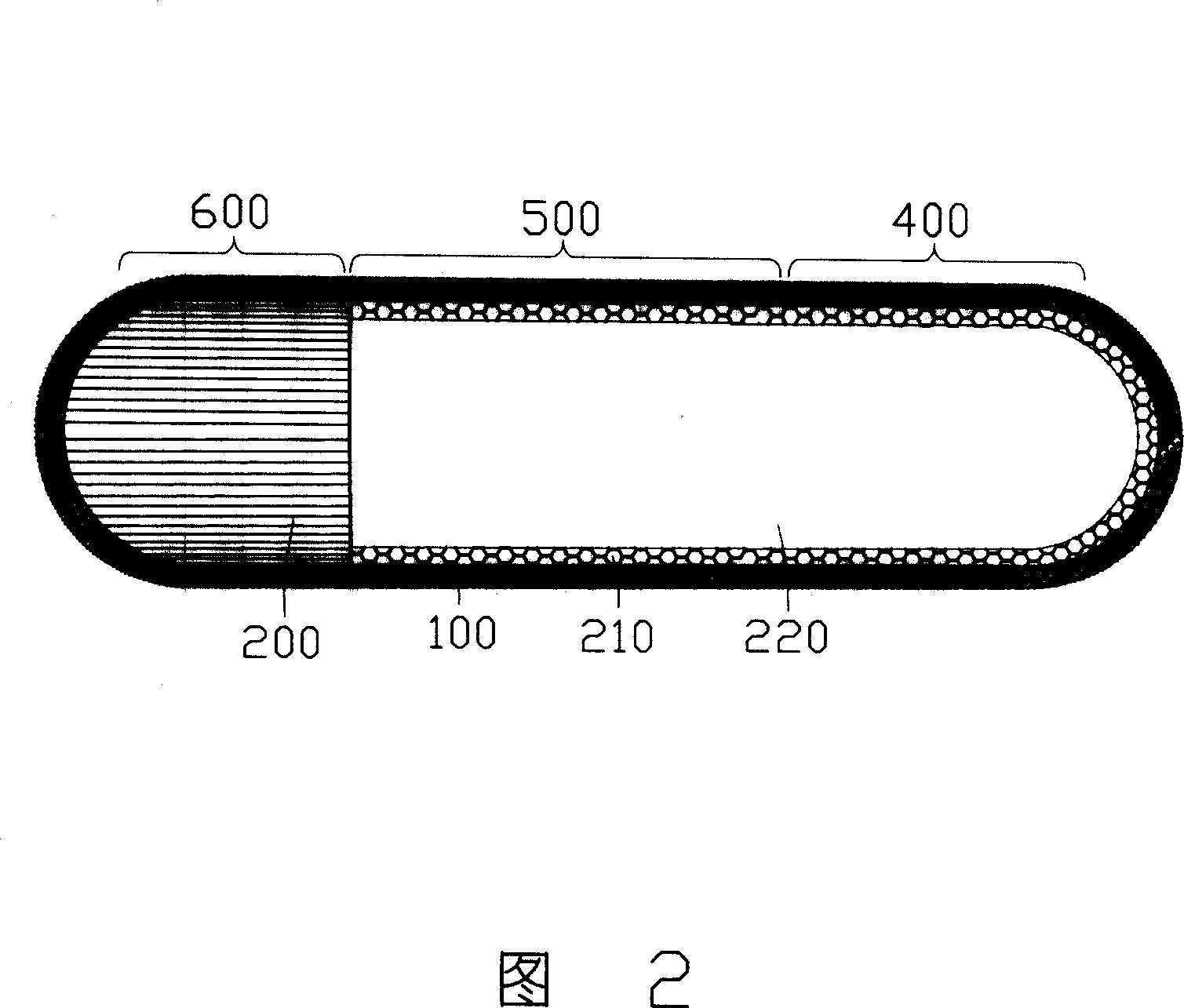

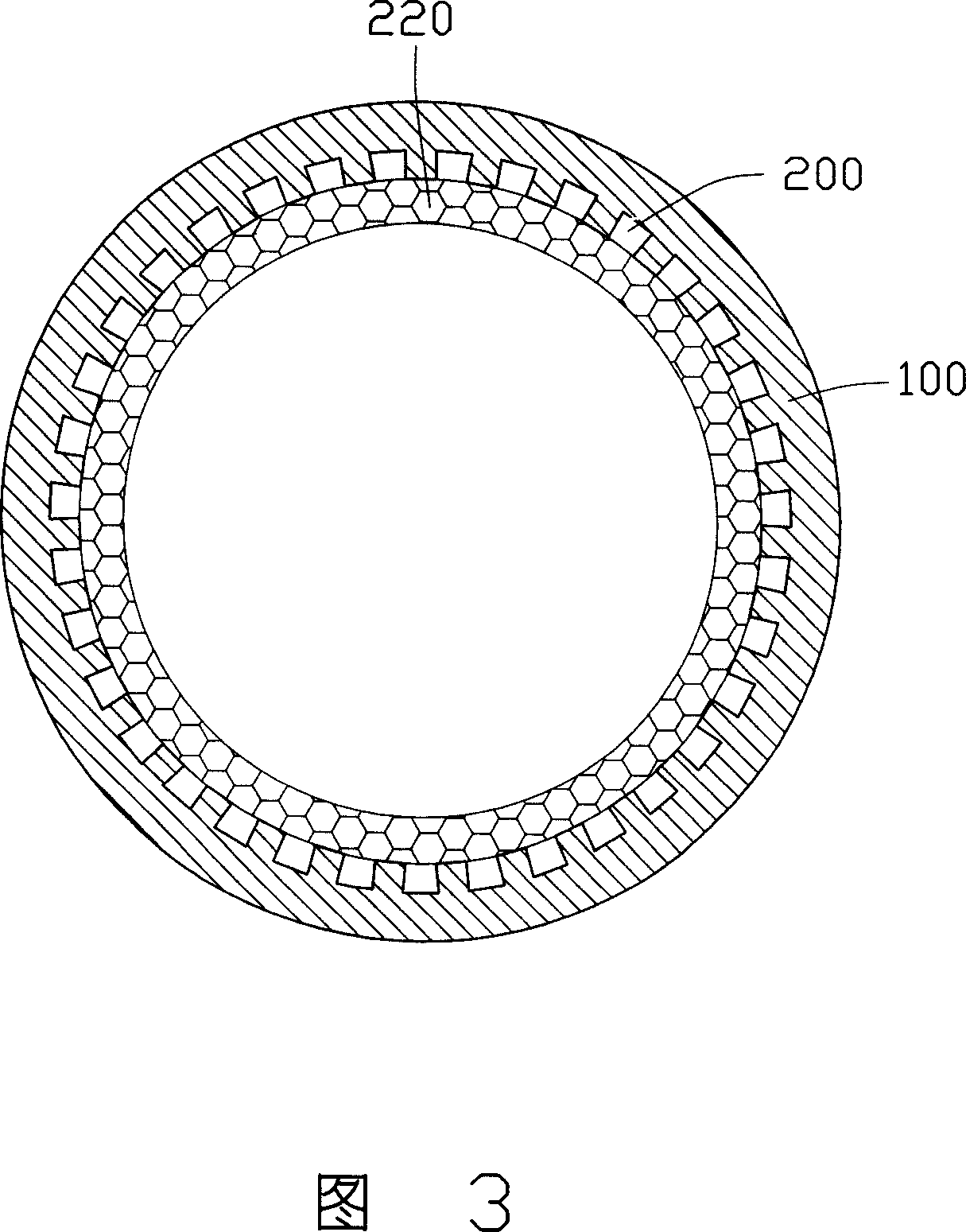

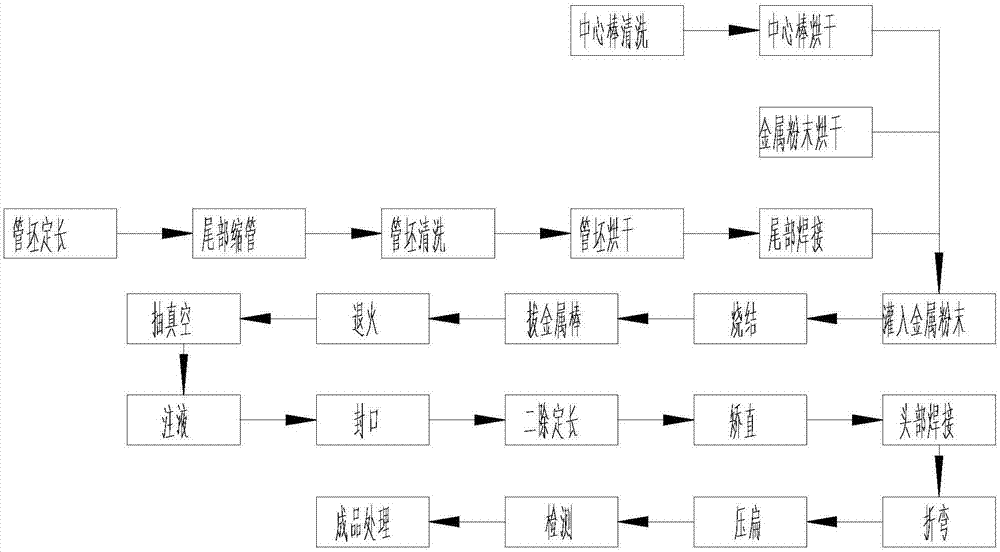

Fiber sintering type micro heat pipe and manufacturing method thereof

InactiveCN102305564ARich multi/microscale surface structuresIncrease contact areaIndirect heat exchangersPorosityMetal fiber

The invention discloses a fiber sintering type micro heat pipe and a manufacturing method thereof. The fiber sintering type micro heat pipe consists of a base pipe, a liquid suction core and a liquid working medium, wherein the liquid suction core is formed by solid-phase sintering for metal fibers. The manufacturing method for the fiber sintering type micro heat pipe mainly comprises four steps, namely preparation for the base pipe, processing of the metal fibers, manufacturing of the liquid suction core and precise encapsulation for the liquid suction core. After the metal fibers are sintered, metallurgical bonding is realized among the fibers and a large quantity of multi-scale pore structures are formed. The fiber sintering type micro heat pipe manufactured by using the method has the advantages of simple process, low cost, high porosity and controllability of the liquid suction core, high permeability, small liquid reflux resistance, large specific surface area of a metal fiber sintering layer, high capillary force and the like, and a stable three-dimensional meshed porous structure is formed among the fibers, so the fiber sintering type micro heat pipe is difficult to damage.

Owner:SOUTH CHINA UNIV OF TECH

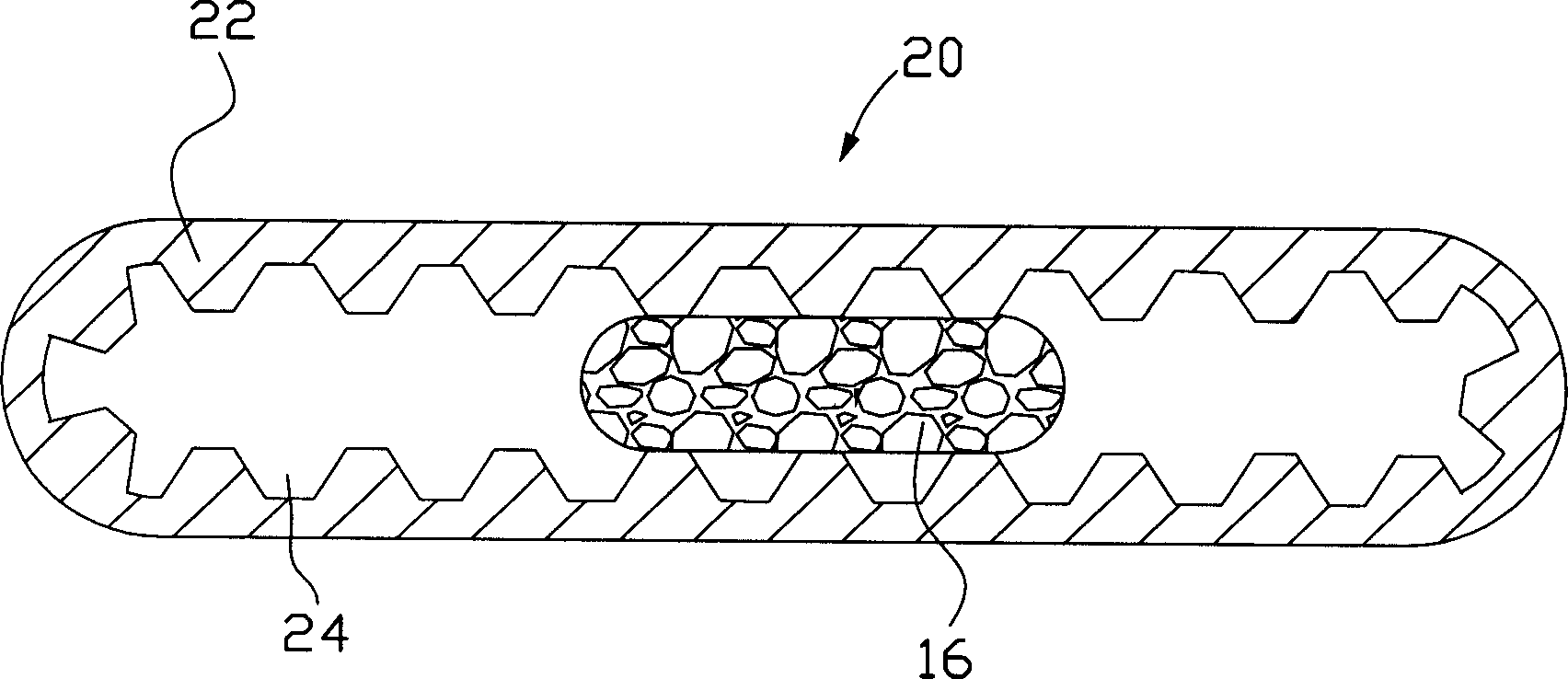

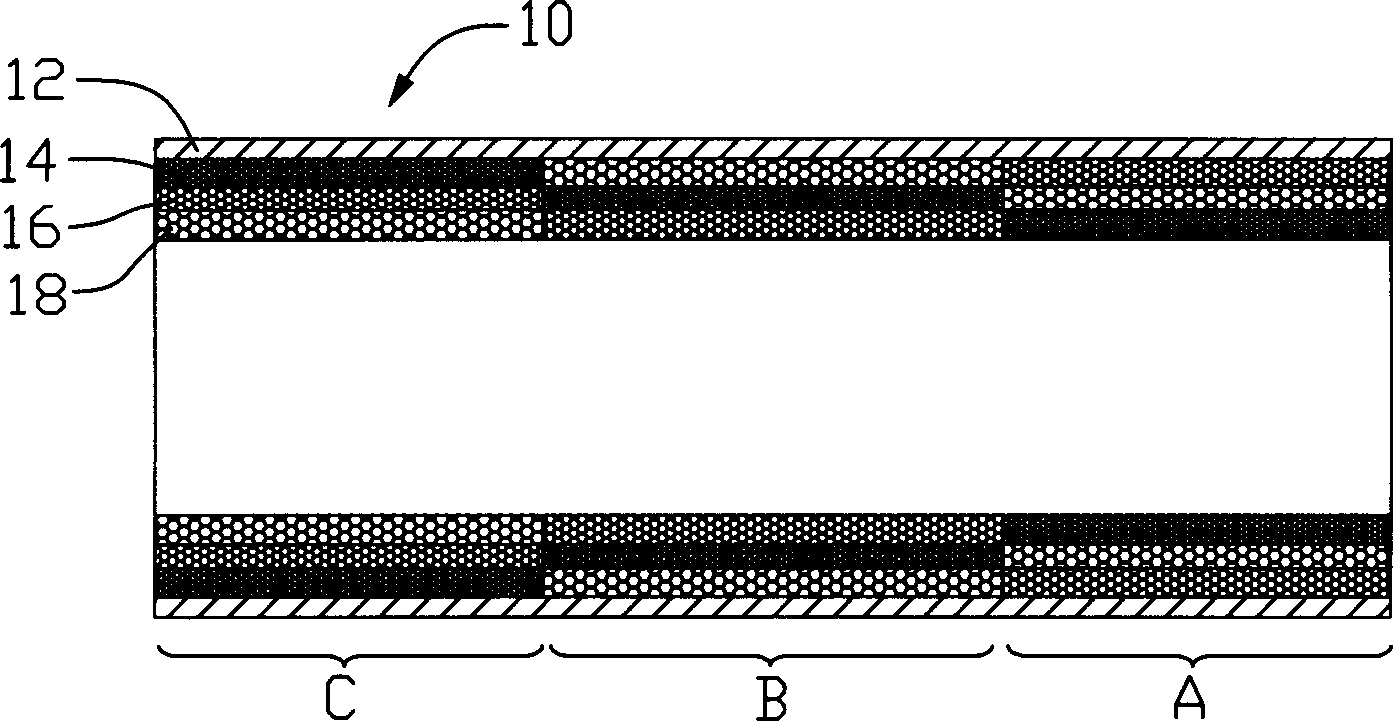

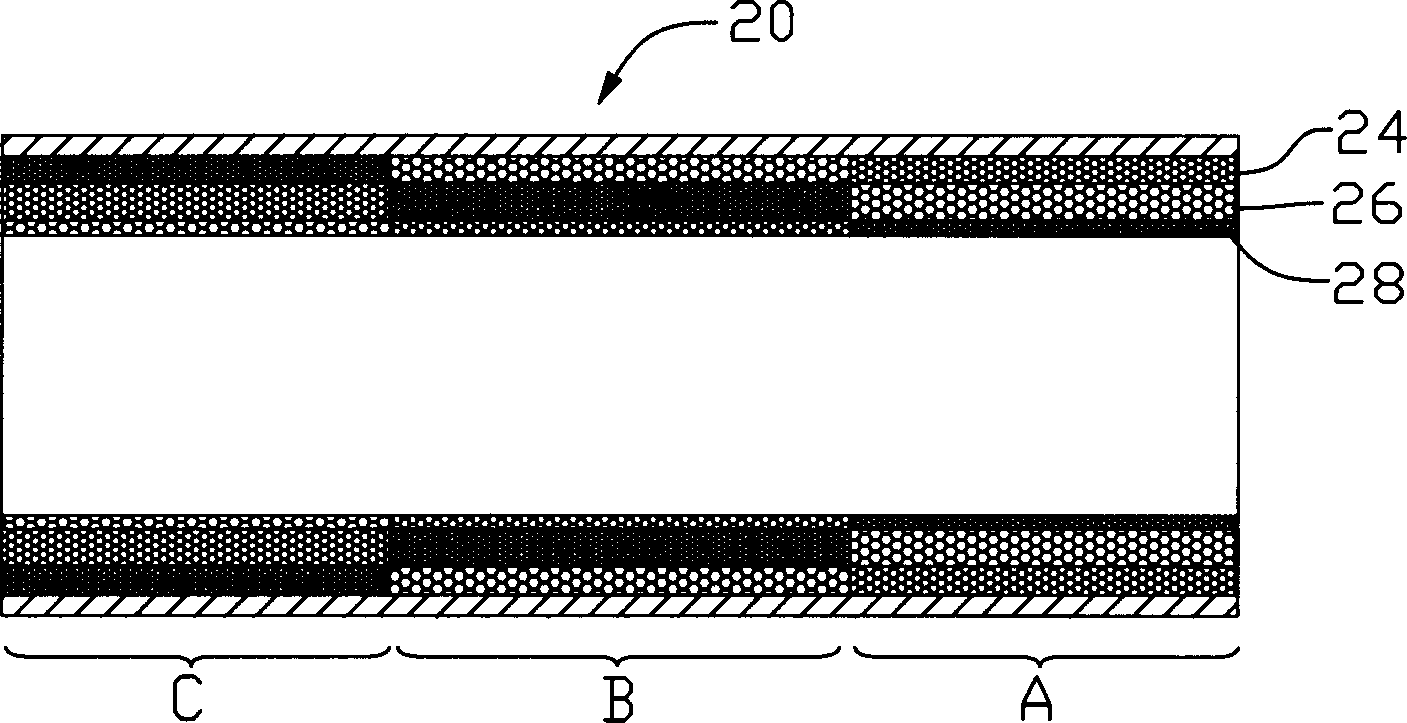

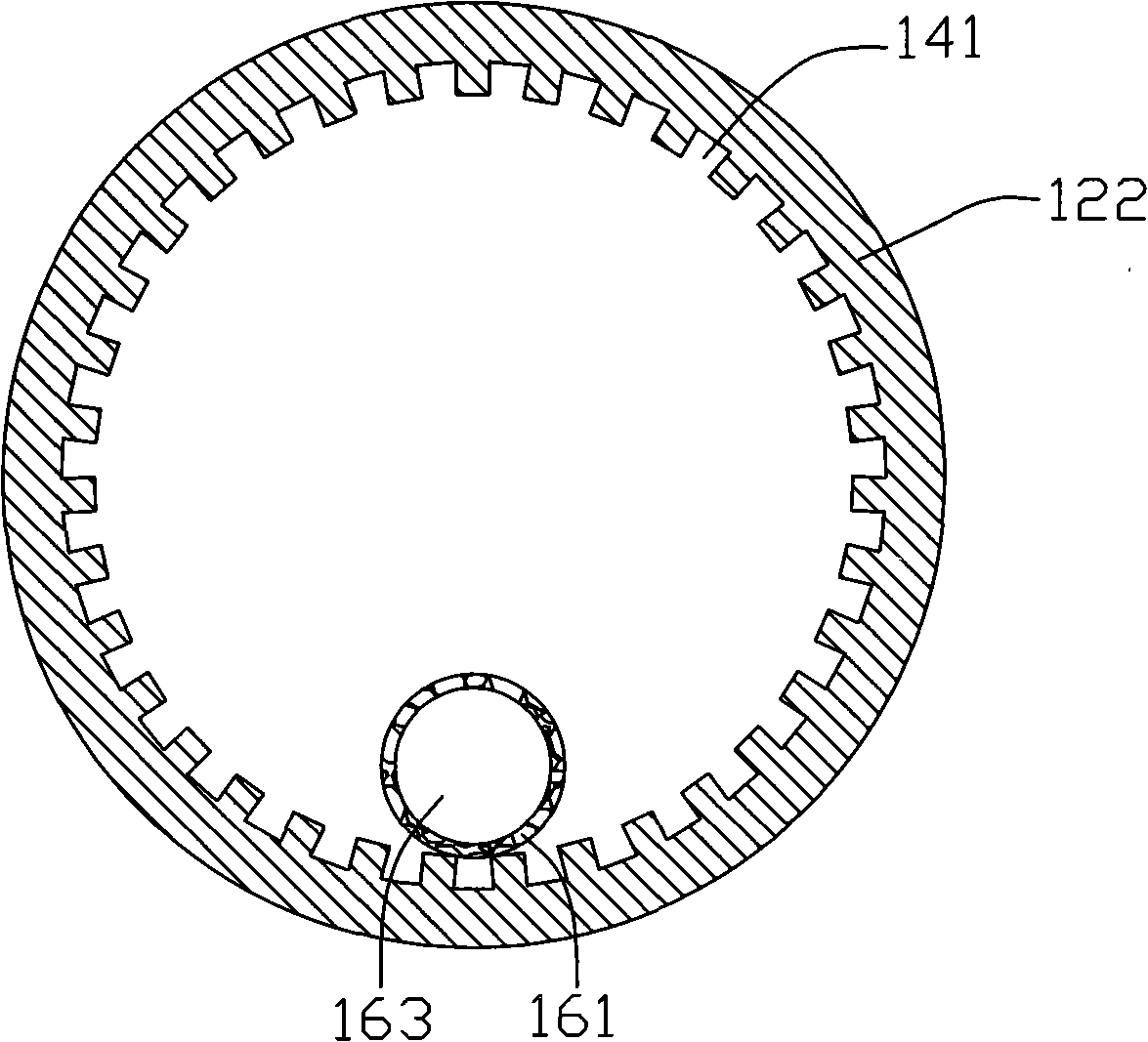

Sintering type heat pipe and manufacturing method thereof

InactiveCN1844833AImprove performanceReduce resistanceIndirect heat exchangersCapillary actionHeat pipe

The invention relates to a sintered heat tube, which comprises a metallic tube. Wherein, the inner wall of tube has porous capillary structure formed by sinter powder; the porous capillary structure has several layers along the radius of heat tube, while each layer has several sections along the axle of heat tube; said capillary structure is formed by embedding different powder particles into the tube, using core rod as the control of thickness to be sintered on the inner wall. Said porous capillary structure can realize variable three-dimensional grade porous size and supply lower reflux resistance and improved capillary function, to improve the property of heat tube.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Heat pipe

InactiveCN101055153AImprove heat transfer efficiencyReduce backflow resistanceIndirect heat exchangersEvaporationEngineering

Owner:FU ZHUN PRECISION IND SHENZHEN +1

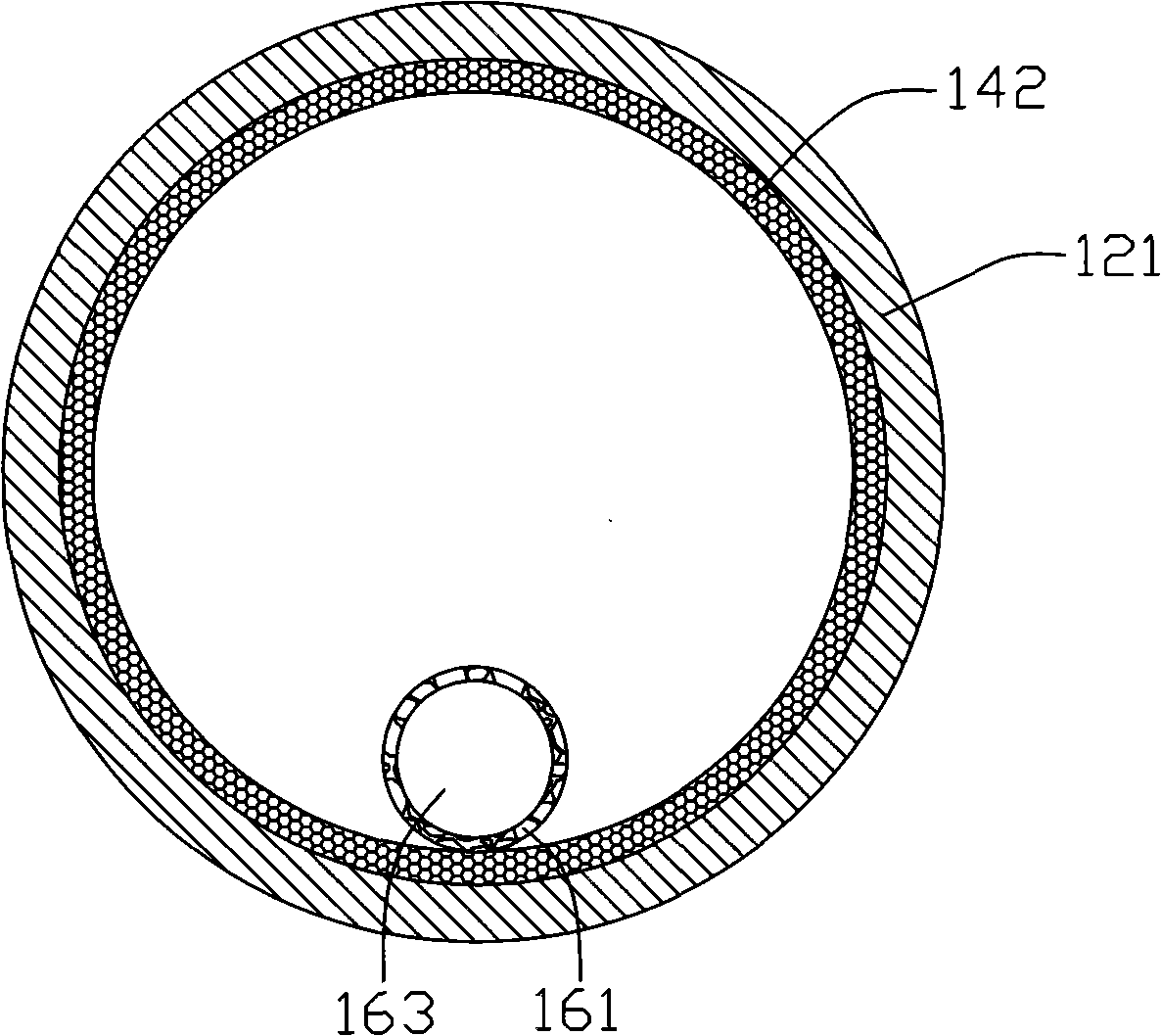

Hot pipe

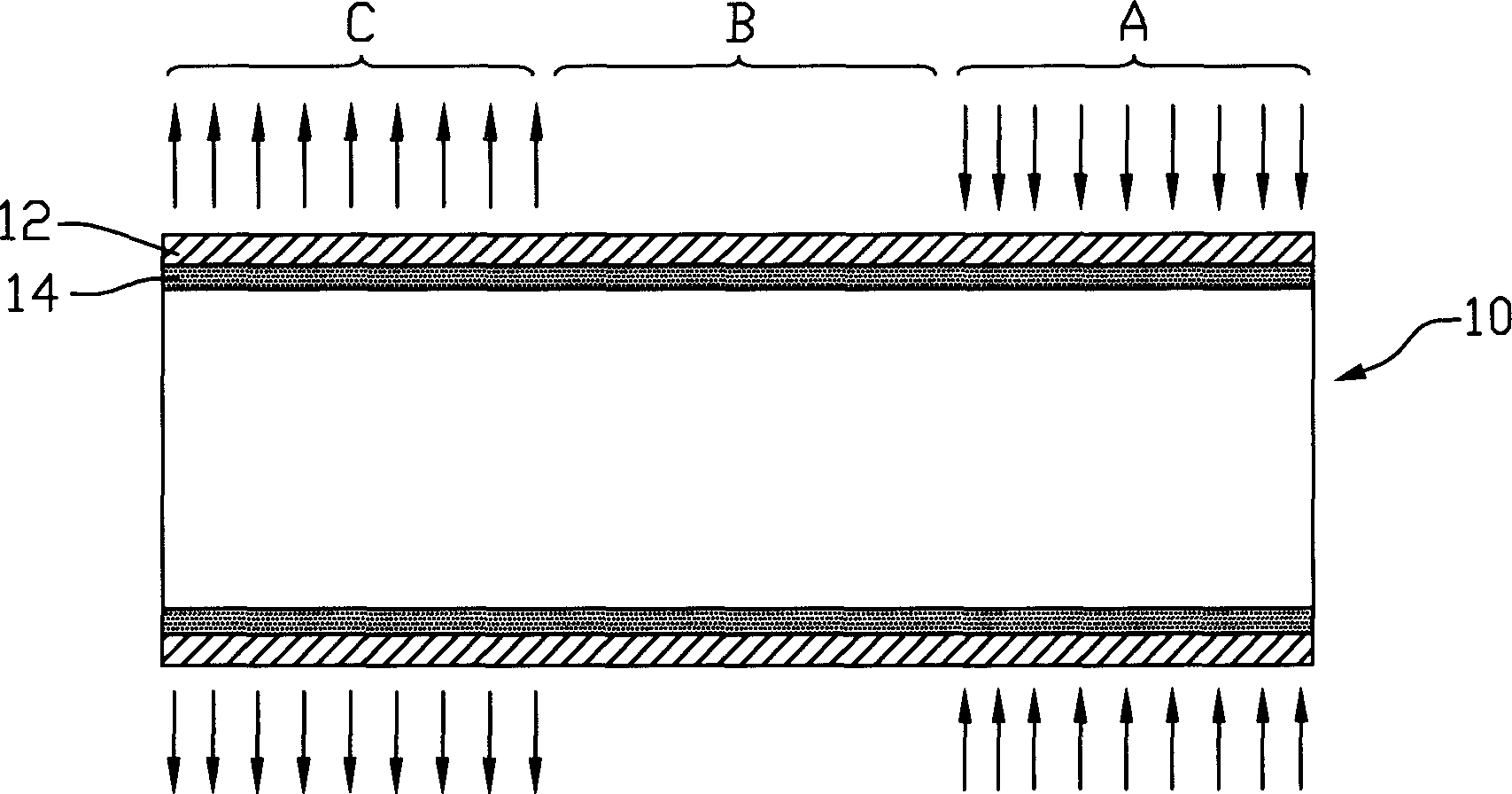

InactiveCN101349519AImprove heat transfer performanceSmall apertureIndirect heat exchangersWorking fluidEngineering

A heat pipe comprises a pipe body, a capillary structure in the pipe body and working fluid which is filled in the pipe body, wherein the heat pipe comprises an evaporating section and a condensing section along the pipe body direction, the capillary structure comprises a main capillary structure and an auxiliary capillary structure, wherein the main capillary structure is attached on the inner walls of the pipe body, the main capillary structure of the evaporating section has stronger capillary force than the main capillary structure of the condensing section, the auxiliary capillary structure comprises at least a haemal tube in hollow tube structure, wherein the haemal tube is extended between the evaporating section and the condensing section, a plurality of tiny pores are formed on the walls of the haemal tube, and one side of the haemal tube is contacted with the main capillary structure, thereby facilitating the capillary structure of the heat pipe to provide stronger capillary acting force and to have small liquid reflux resistance, and increasing the heat transfer property of the heat pipe.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

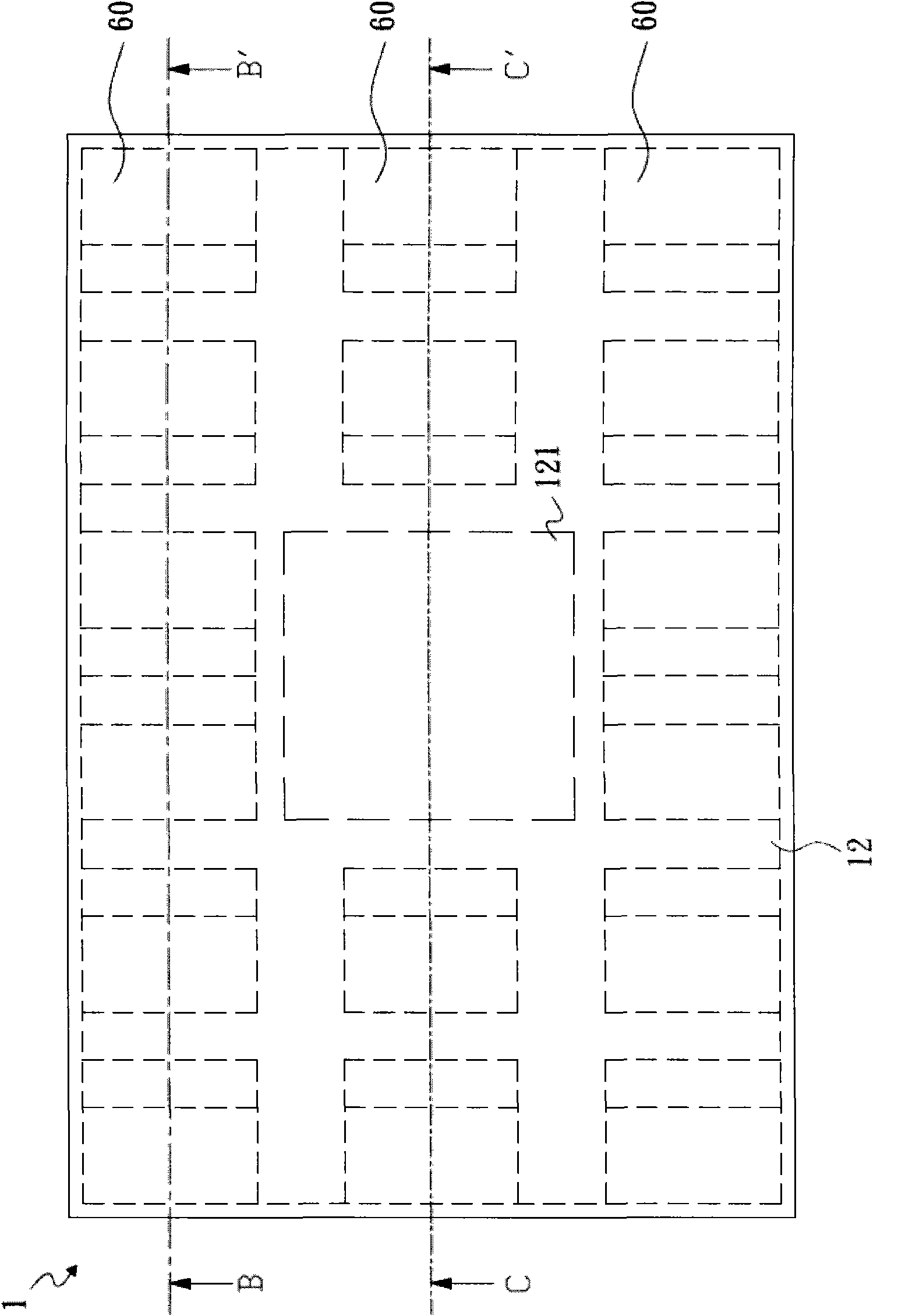

Micro-crack flat heat pipe and manufacturing method thereof

ActiveCN102829659AImprove permeabilityReduce backflow resistanceIndirect heat exchangersRoom temperaturePhase change

The invention discloses a micro-crack flat heat pipe and a manufacturing method thereof. The micro-crack flat heat pipe comprises a pipe body and a porous capillary layer attached to an inner wall of the pipe body, wherein a plurality of slots are arranged on the surface of the porous capillary layer and are uniformly distributed along the circumference of the inner wall of the pipe body. The manufacturing method comprises the following steps: placing a sintered core bar on the middle part in the pipe body and arranging a clearance between the pipe body and the sintered core bar; contracting the tail at one end of the pipe body and then performing de-rusting and de-oiling treatment on the pipe body and the sintered core bar; filling metal powder into the clearance between the pipe body and the sintered core bar and placing the metal powder together with the pipe body into a high-temperature sintering furnace for sintering; after sintering, taking out the pipe body, cooling to room temperature and then taking out the sintered core bar; vacuumizing, filling a working medium and sealing at the other end of the pipe body; and flattening and shaping the pipe body. A phase-change flattening technology is adopted by the invention; a continuous and big enough porous capillary layer, namely, a micro-crack channel space, is obtained according to a sintered core bar inducing method; a steam channel is supplied; and the heat transfer and mass transfer properties of the flat heat pipe are obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

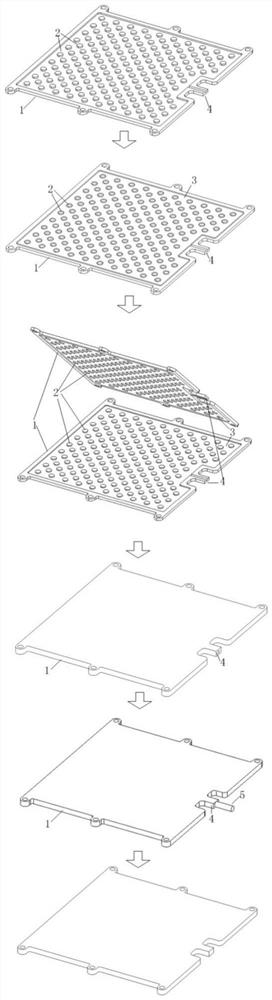

Flat heat pipe liquid suction core provided with fins and embedded grooves and manufacturing method thereof

InactiveCN104864755AIncrease disturbanceIncrease the heat exchange areaIndirect heat exchangersCapillary pressureMarine engineering

The invention discloses a flat heat pipe liquid suction core provided with fins and embedded grooves and a manufacturing method thereof. The flat heat pipe liquid suction core comprises a metal evaporation plate, wherein multiple first embedded grooves and multiple second embedded grooves which are arranged at intervals and distributed in a staggered mode in the first direction and the second direction and multiple fins distributed in an array mode are arranged on the evaporation face of the metal evaporation plate, and each first embedded groove and each second embedded groove respectively comprises a groove body forming a groove cavity and a vertical gap forming a groove opening. Each fin comprises a fin body and a supporting boss and is formed by the gaps and internal groove bodies of the corresponding first embedded groove and the corresponding second embedded groove in a staggered mode. The liquid suction core can increase heat exchange area, promote boiling for nucleus formation, enhance boiling heat transfer, improve capillary pressure and reduce backflow resistance. During manufacture, a ball-end milling cutter is utilized to mill the embedded grooves in the first direction, and a base plate is turned to mill the embedded grooves in the second direction and meanwhile form a fin structure. The flat heat pipe liquid suction core is simple in manufacturing process and low in machining cost and can remarkably strengthen heat transfer.

Owner:XIAMEN UNIV

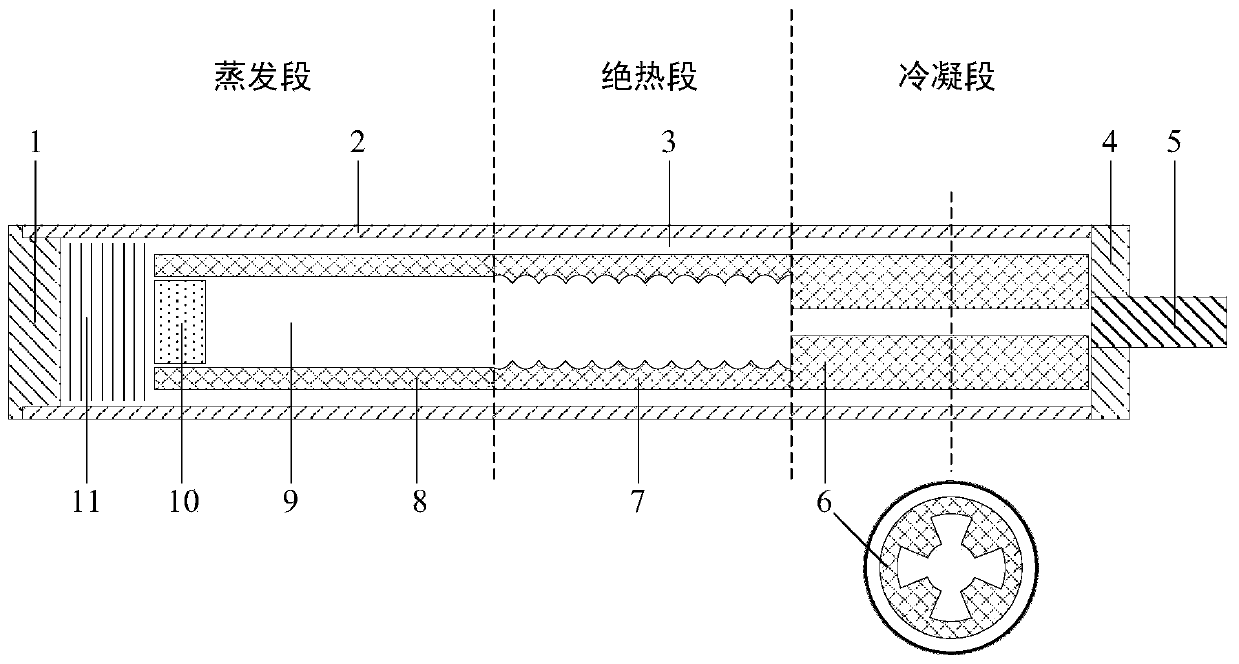

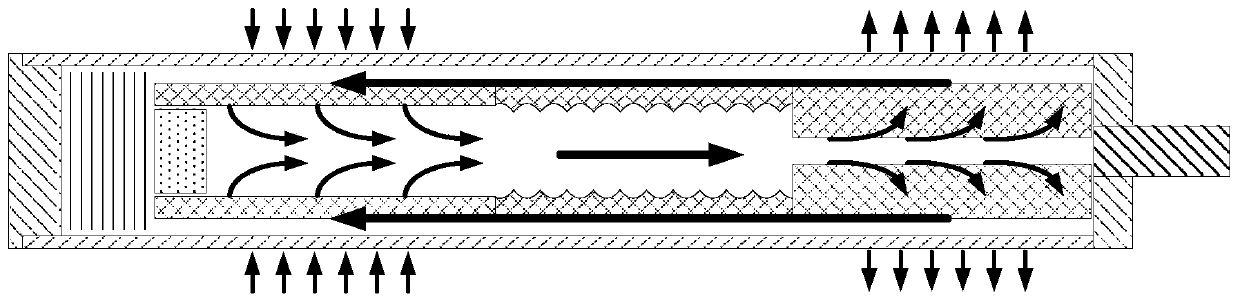

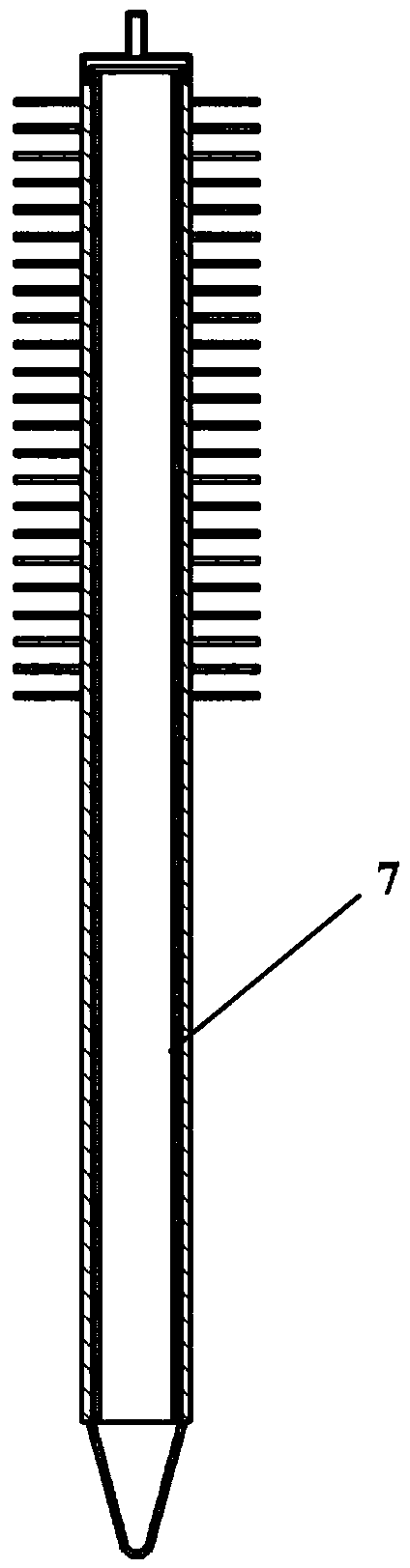

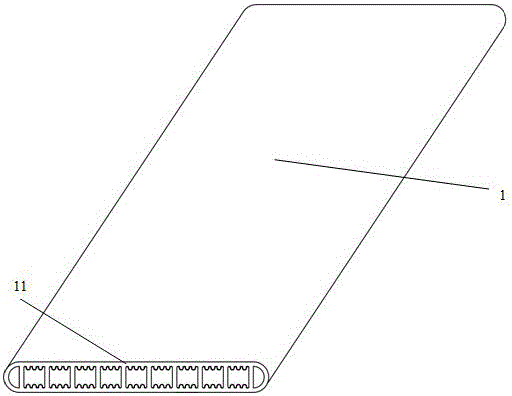

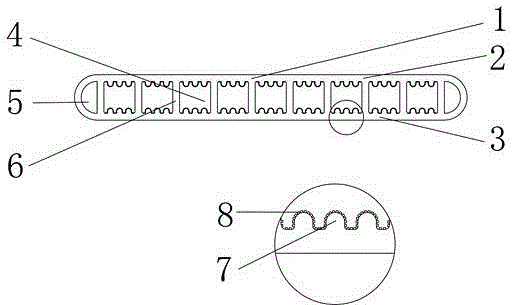

Hot metal high-temperature heat pipe

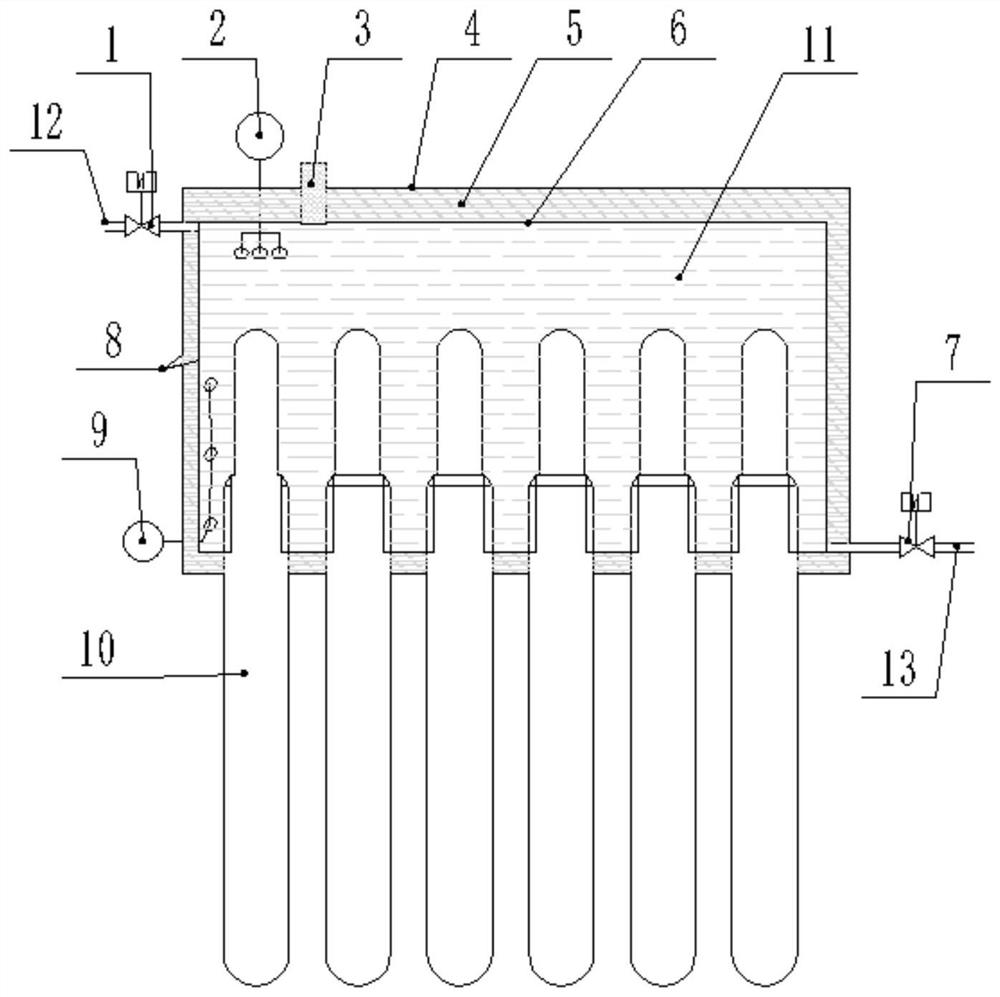

ActiveCN111473669AReduce backflow resistanceSpeed up condensationIndirect heat exchangersHeat exchange apparatusSteam condensationLiquid state

The invention discloses a hot metal high-temperature heat pipe. The hot metal high-temperature heat pipe comprises a liquid filling pipe, a top end cover, a heat pipe shell, a bottom end cover, a gap,a condensation section liquid absorbing core, a heat insulation section liquid absorbing core, an evaporation section liquid absorbing core, a steam cavity, a liquid absorbing core plug and a gas storage bag. The closed liquid filling pipe, the top end cover, the heat pipe shell and the bottom end cover jointly form a closed space of the heat pipe. The liquid filling pipe is connected with a hotmetal filling loop through a connecting element, and filling of a working medium is achieved. The backflow resistance of the liquid working medium can be reduced through the gap. The evaporation section liquid absorbing core, the heat insulation section liquid absorbing core and the condensation section liquid absorbing core jointly provide power for backflow of the liquid working medium. The wavestructure of the heat insulation section liquid absorbing core can reduce liquid drop entrainment, and the condensation section liquid absorbing core adopts a fin structure to accelerate steam condensation. The liquid absorbing core plug can store the working medium and adjust the mass of the working medium participating in circulation. The gas storage bag can limit non-condensable gas, and the influence of the non-condensable gas on heat transfer is reduced.

Owner:XI AN JIAOTONG UNIV

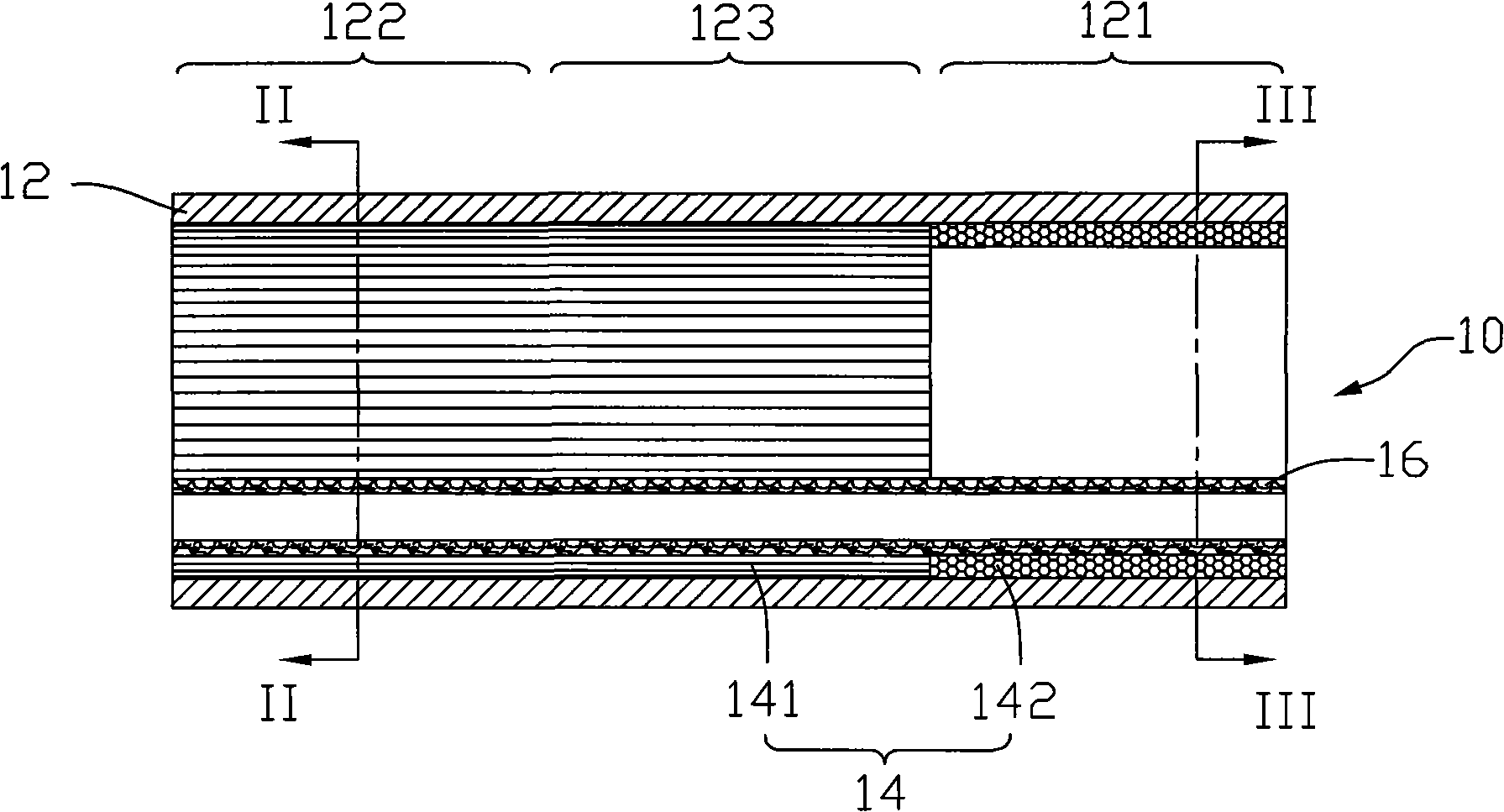

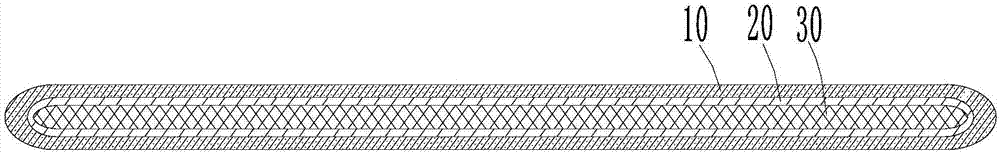

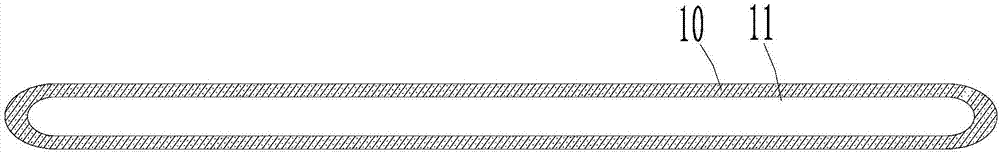

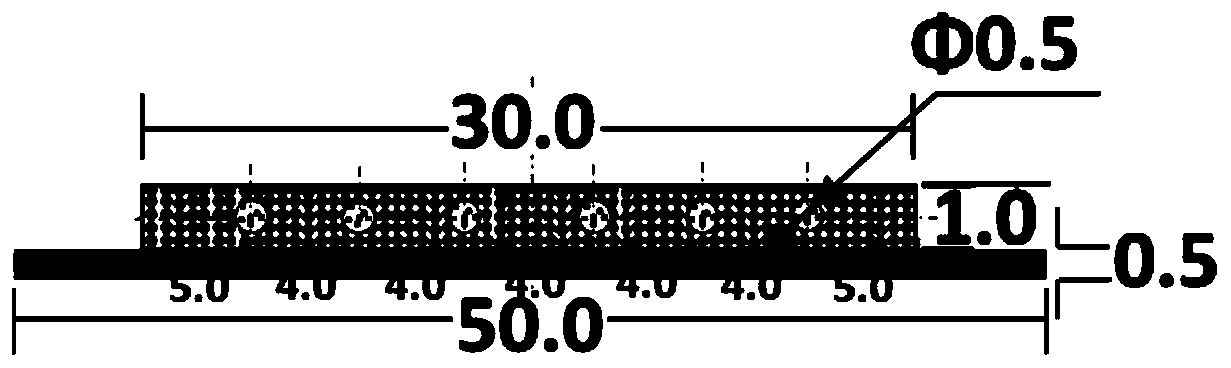

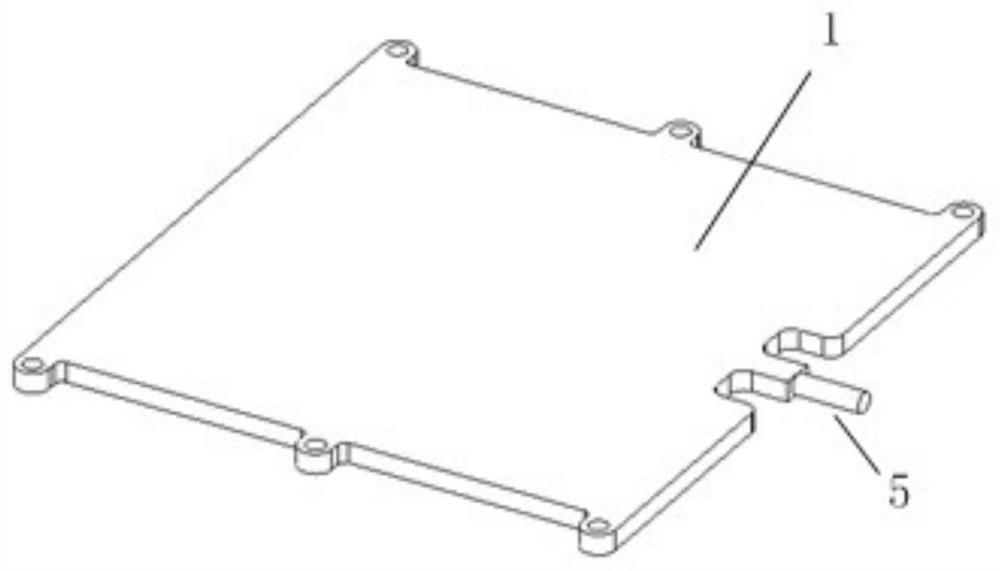

Ultra-thin flat panel heat pipe and manufacturing method thereof

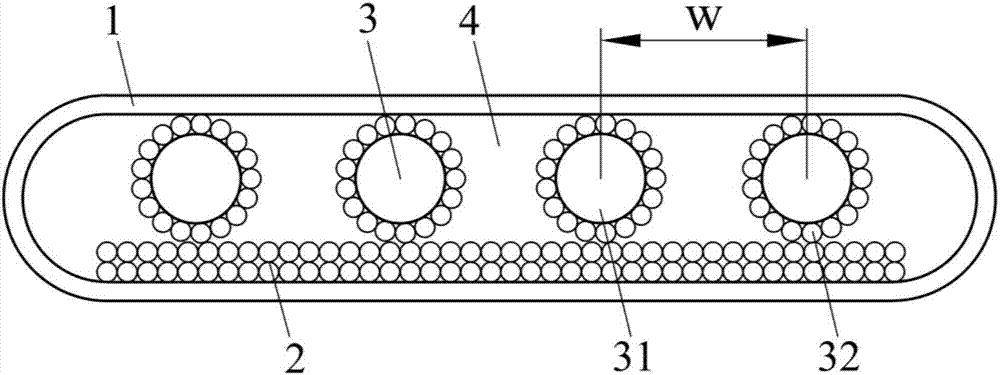

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

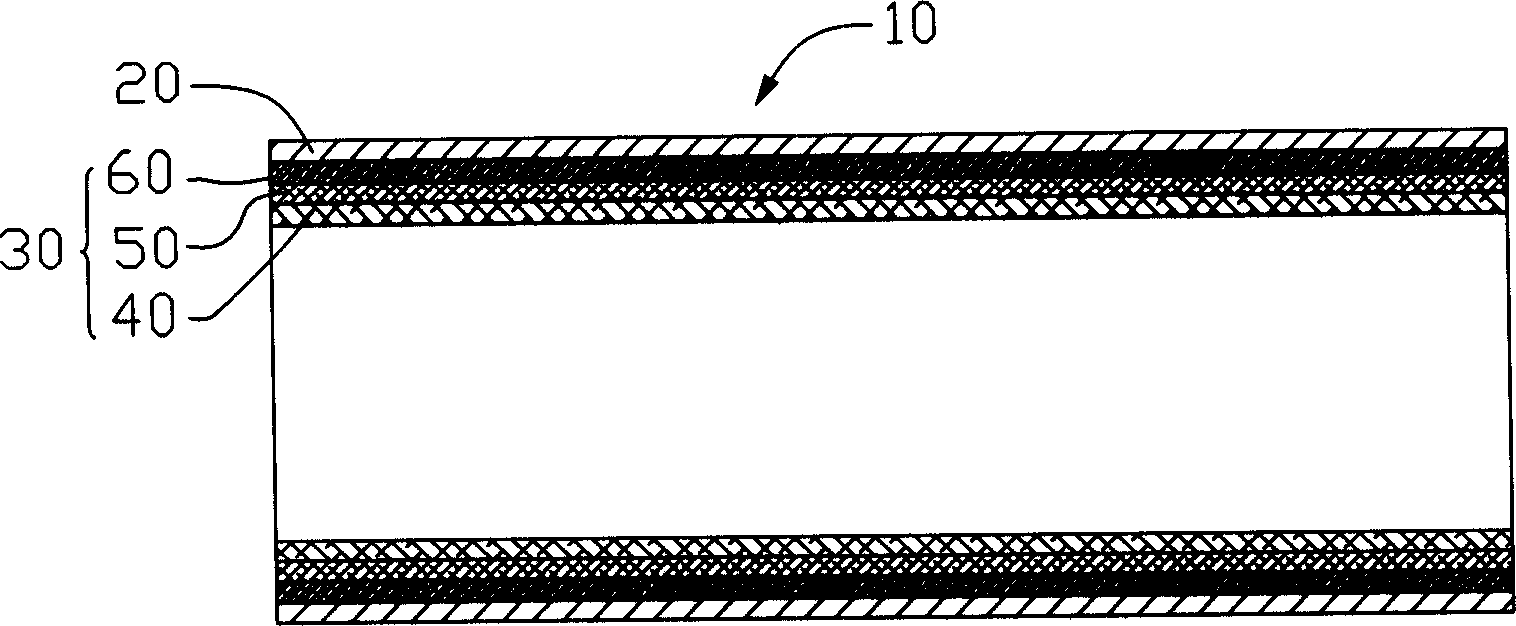

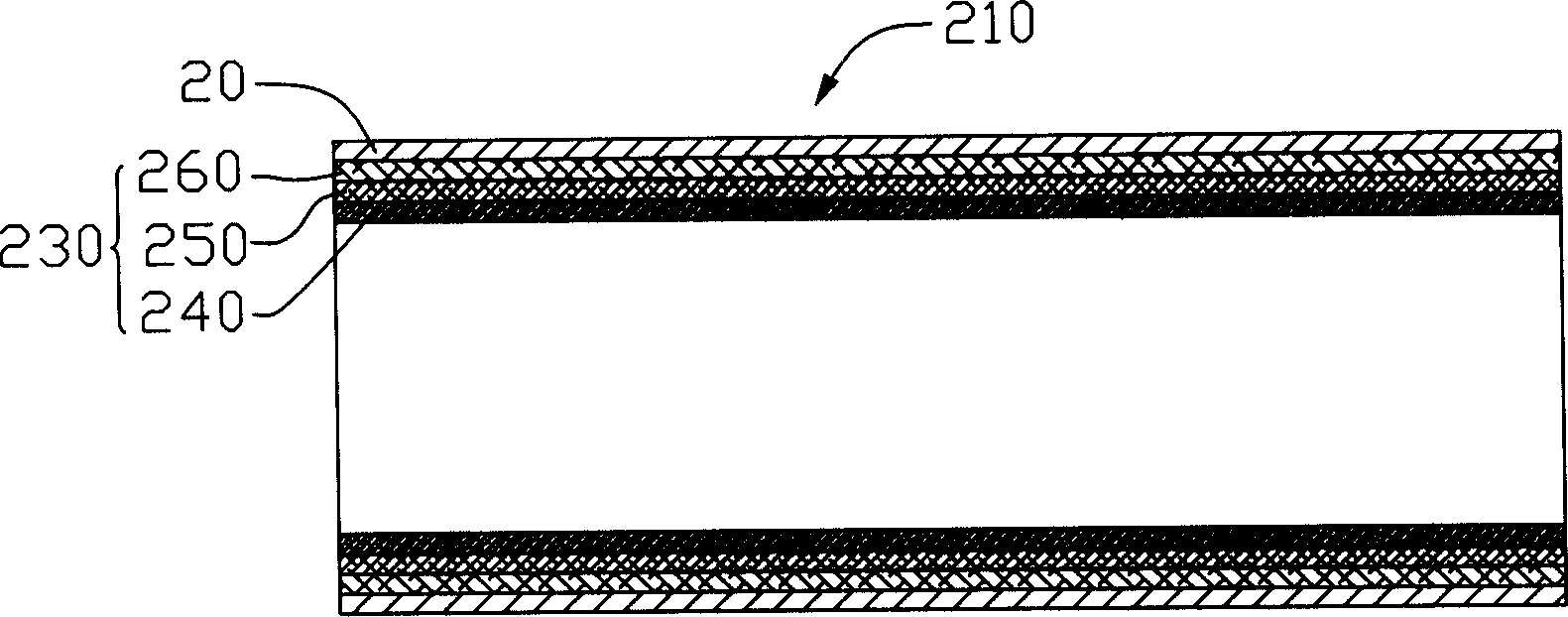

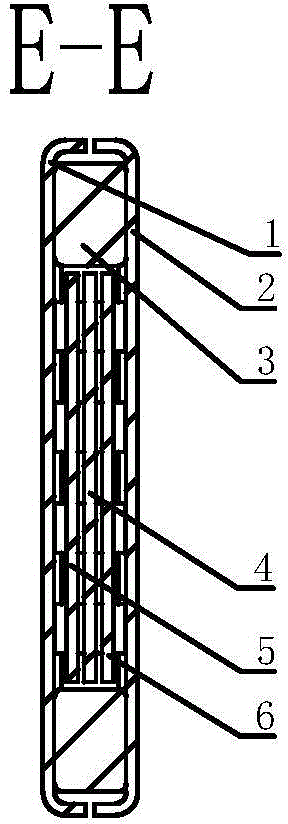

Heat pipe

InactiveCN1837737AIncrease capillary forceReduce backflow resistanceIndirect heat exchangersRefluxHeat transmission

The invention relates to a heat pipe, which comprises a vaporizing section and a condensing section, which have different capillary structures, and the capillary structure of vaporizing section has smaller effective capillary holes, to generate small reflux resistance of condensed liquid in the condensing section, and generate large capillary function force on the liquid at the vaporizing section, to accelerate the reflux of condensing liquid from the condensing section to the vaporizing section. And the capillary structure of vaporizing section has smaller space to increase the contact area, to apply the heat transmission between the outer heat resource and the tube.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

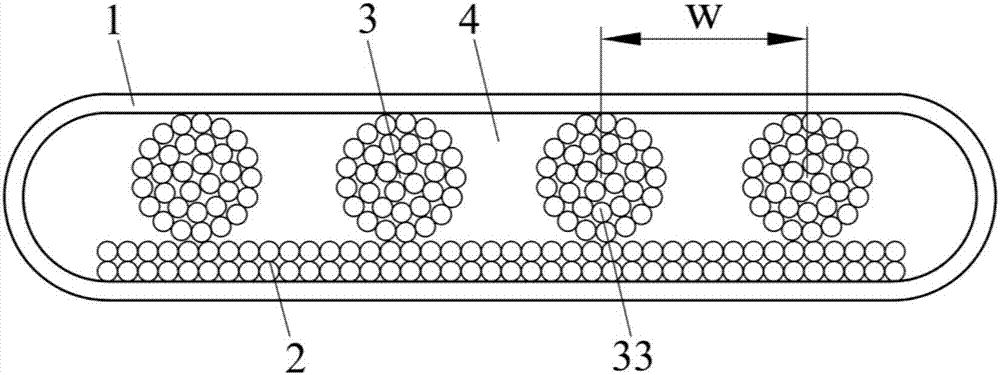

Temperature-uniforming plate

ActiveCN101676672AReduce backflow resistanceIncrease mass flow rateIndirect heat exchangersCooling/ventilation/heating modificationsWorking fluidEngineering

The invention relates to a temperature-uniforming plate, comprising a vacuum cavity, a working fluid, a lower capillary structure and a plurality of support pillars, wherein the vacuum cavity comprises an upper cover and a bottom plate and is filled with a proper amount of working fluid; the lower capillary structure is arranged on the bottom plate; the support pillars are positioned in the vacuumcavity and are connected with the upper cover and the bottom plate to support the upper cover; a first inclined angle is formed between each support pillar and the upper cover; and after being condensed, the vaporous working fluid flows back to the bottom plate through the support pillars from the upper cover.

Owner:PEGATRON

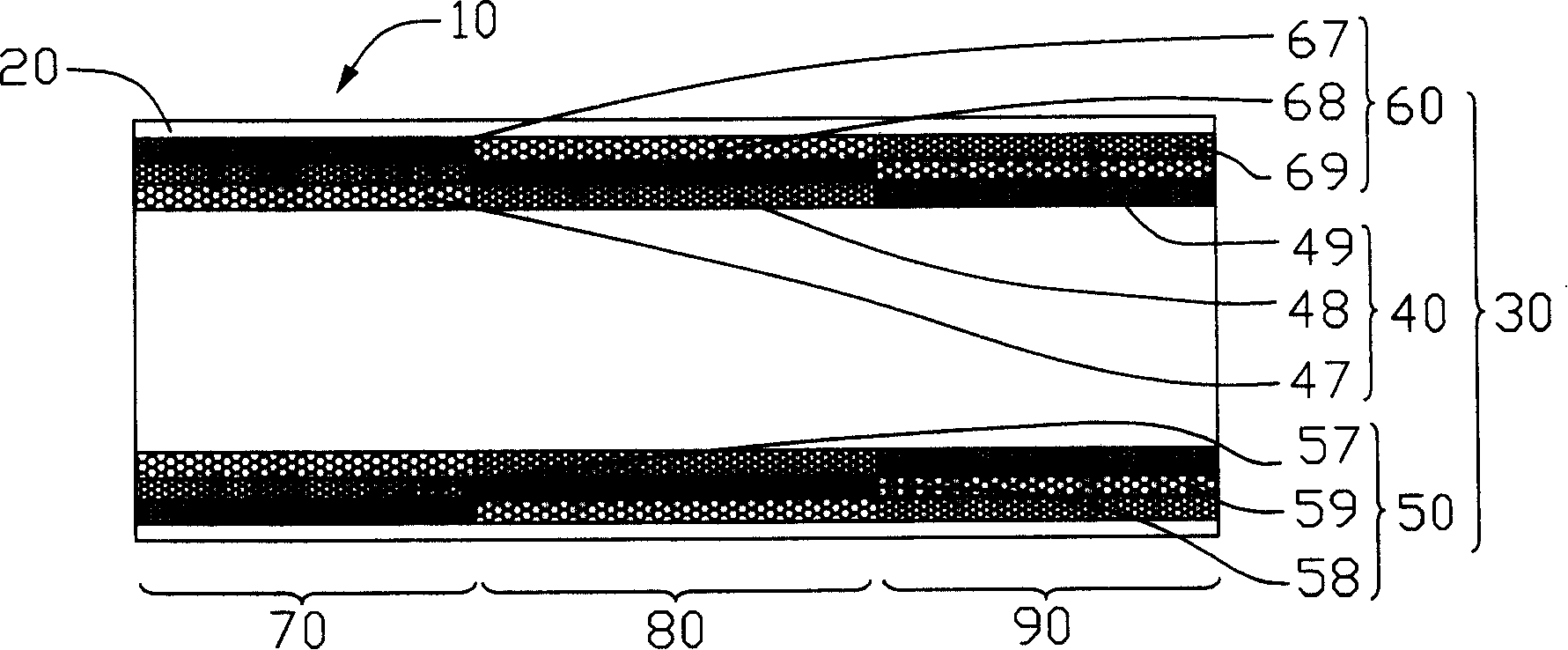

Heat pipe

InactiveCN101055158AIncreased anti-gravity propertiesImprove heat transfer efficiencyIndirect heat exchangersHeat transmissionThermal insulation

The invention discloses a heat pipe which includes a sealed heat transmission cavity whose inner wall is equipped with capillary structure and in which appropriate working liquid is sealed. The heat pipe includes evaporation section, condensation section, thermal insulation section, and a first capillary structure and a second capillary structure is arranged in sequence on the inner wall of the thermal insulation section shell along the direction from the shell to inner cavity center, and the pore aperture of the first capillary structure is larger than the same of the second capillary structure. Two capillary structures with different pore apertures are arranged in sequence on the inner wall of the heat pipe, in this manner, reflux resistance of the liquid can be reduced to guarantee that the evaporation section has enough working liquid, and also a lot of steam nucleating points can be provided for the evaporation section to accelerate boiling efficiency for the working medium, in the meantime, the composite capillary structure of the thermal insulation section can increase antigravity property of the heat pipe, thereby improving heat conduction efficiency for the heat pipe.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

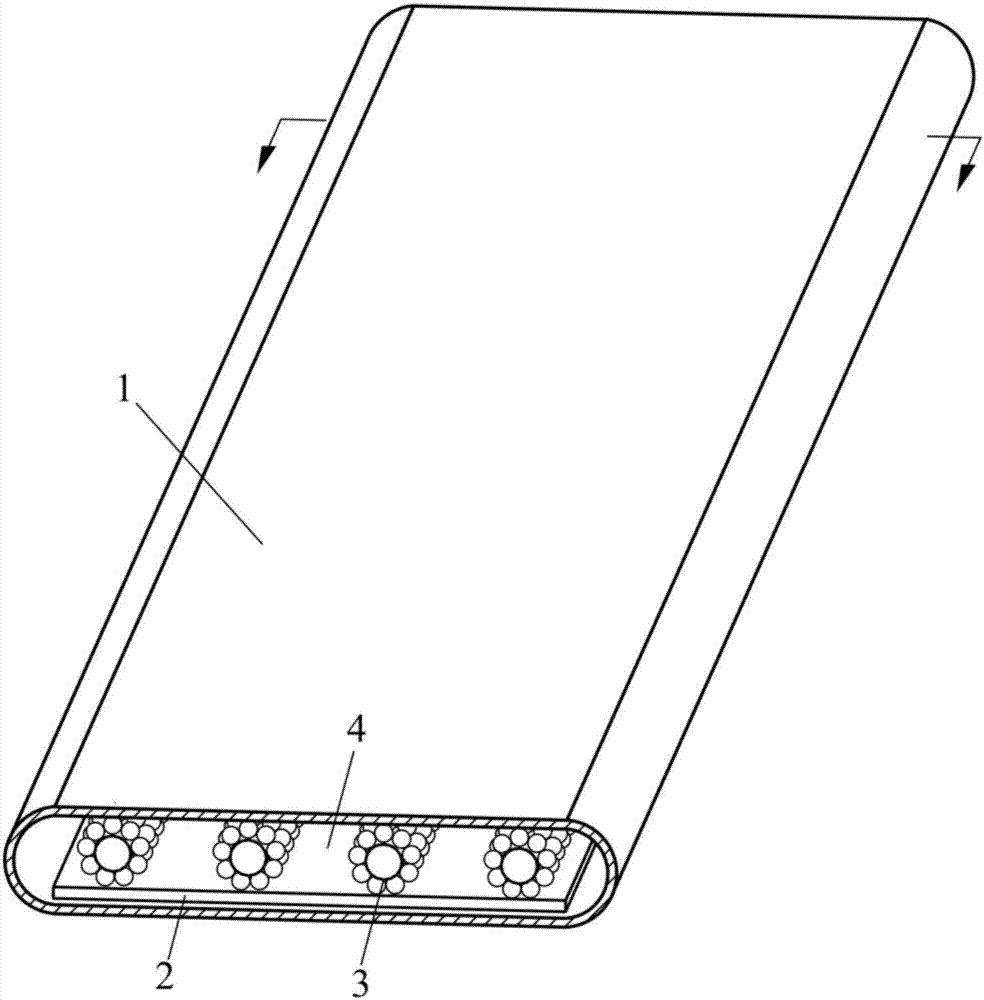

Hot plate of metal fiber felt liquid absorption cores

InactiveCN103123236AGood capillary forceImprove permeabilityIndirect heat exchangersHeat exchange apparatusPorosityMetal fibers

The invention discloses a hot plate of metal fiber felt liquid absorption cores, and belongs to the technical field of heat exchange equipment using a middle heat transfer medium or a middle heat transfer body. The hot plate comprises a sealed shell body, a first metal fiber felt liquid absorption core, a second metal fiber felt liquid absorption core, a supporting frame and heat conduction liquid working medium. The supporting frame, the first metal fiber felt liquid absorption core and the second metal fiber felt liquid absorption core are installed in the sealed shell body. The heat conduction liquid working medium is filled in the sealed shell body. Compared with the prior art, the hot plate has the advantages that the metal fiber felt liquid absorption cores have good capillary force and permeability, combination strength and contact areas between fibers are increased, large quantities of three-dimensional net-shaped porous structures are formed among the fibers, the porosity is high, specific areas are large, liquid backflow resistance is little, the backflow speed of the liquid working medium in the hot plate is beneficially improved, and therefore heat dissipation performance of the hot plate is improved.

Owner:辽宁三维传热技术有限公司 +1

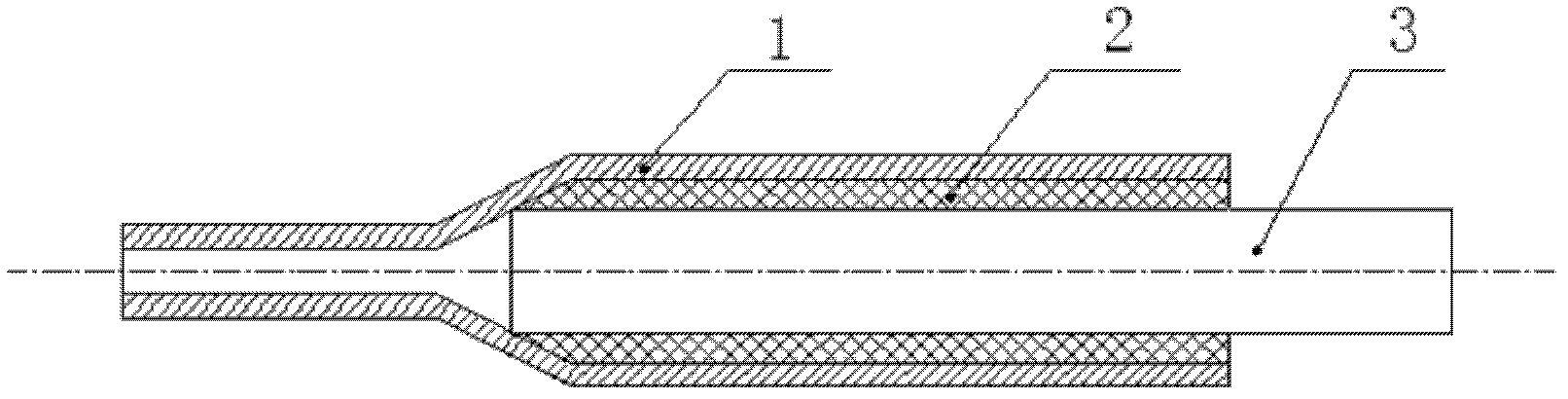

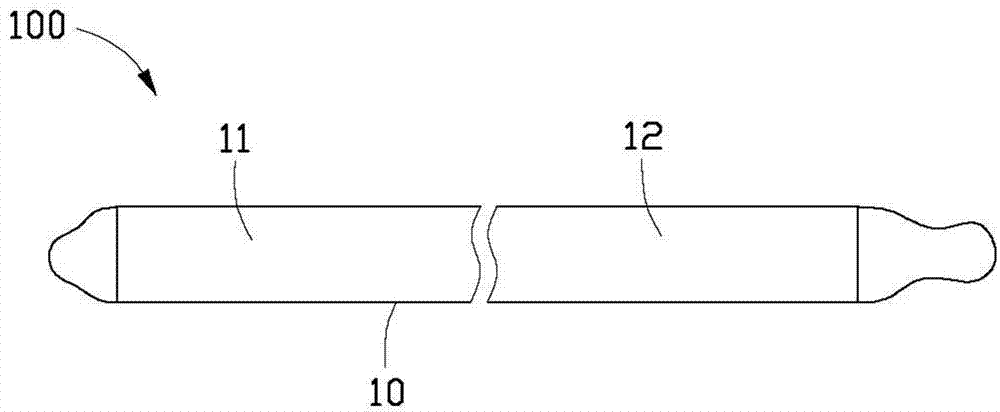

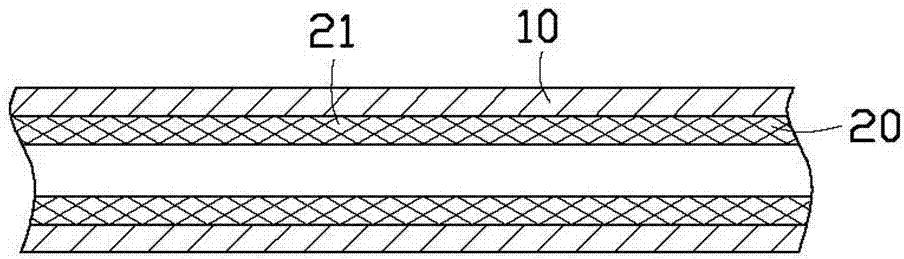

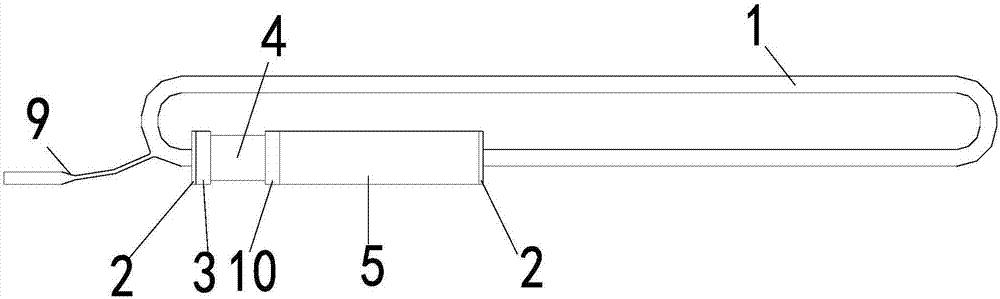

Ultrathin heat pipe and manufacturing method thereof

PendingCN107289802ACompact structureStrong capillary forceIndirect heat exchangersMetal powderHeat pipe

The invention discloses an ultrathin heat pipe. The ultrathin heat pipe comprises a metal pipe body, a liquid sucking core and a working medium; the wall thickness of the metal pipe body is 0.03-0.10 mm; the tail part and the head part of the metal pipe body are both sealing ends; the metal pipe body is a flat metal pipe body with a closed inner cavity; the liquid sucking core is arranged in the closed inner cavity of the metal pipe body; the liquid sucking core is a metal powder sintering capillary layer formed by bonding metal powder on the inner wall of the metal pipe body after high-temperature sintering; and the closed inner cavity of the metal pipe body is filled with the working medium. The invention further discloses a manufacturing method of the ultrathin heat pipe. The ultrathin heat pipe has the characteristics of smooth gas-liquid channel separation, good heat transfer performance, high capillary force and low backflow resistance of the working medium. The manufacturing method has the characteristics of convenience in operation of process steps, high production efficiency and adaption to large-batch production, and can effectively prevent drapes and recesses formed in the manufacturing process of the ultrathin heat pipe.

Owner:杭州瀚亨实业有限公司

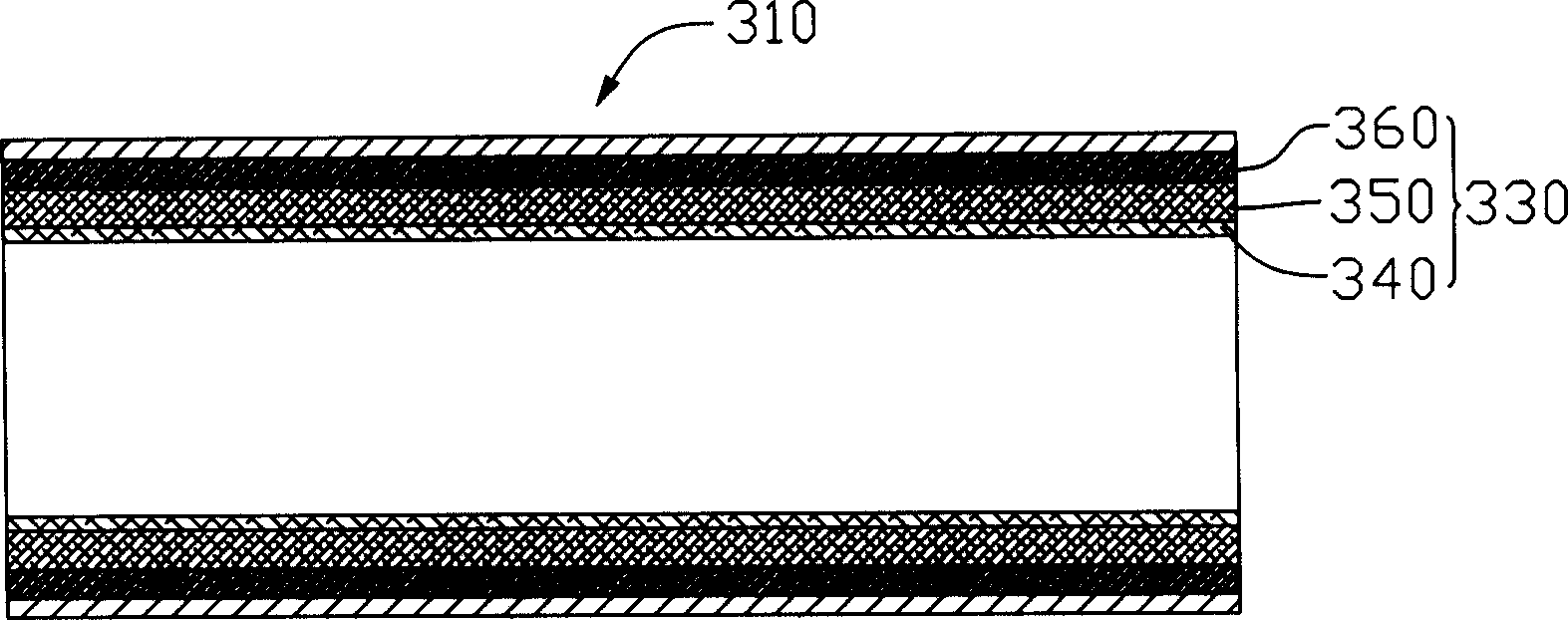

Heat pipe, heat pipe multiporous structure and its mfg. method

InactiveCN1834569AImprove performanceIncrease capillary forceDigital data processing detailsIndirect heat exchangersYarnWire gauze

The present invention relates to a heat pipe porous stracture, including silk screen which is made up by using silk yarn through a certain knitting process. Said porous structure has pores with different apertures, and said pore sizes are formed into gradient distribution along the radial direction or longitudinal direction of heat pipe. The manufacture method of said heat pipe porous structure includes the following steps: rolling the above-mentioned flake silk screen with different pores into cylindrical silk screen, then placing the cylindrical silk screen into pipe body of heat pipe.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Ultra-thin heat pipe

InactiveCN103486889AEnhanced axial heat transfer capabilityHigh thermal conductivityIndirect heat exchangersPorosityMetallurgy

The invention relates to the field of heat pipe structures, in particular to an ultra-thin heat pipe. The ultra-thin heat pipe comprises a pipe body, wherein the pipe body comprises a middle side wall and end portion side walls connected with the middle side wall, the inner wall of the middle side wall is provided with a metal powder sintering portion, the side, away from the middle side wall, of the metal powder sintering portion is provided with a plurality of evenly distributed protrusions, and steam channels are formed among the metal powder sintering portion, the protrusions, the middle side wall and the end portion side walls. The metal powder sintering portion is provided with the protrusions which are intermittently or continuously arranged, a groove is formed between every two adjacent protrusions, the groove-shaped fluid return channels are formed in the spaces formed by the grooves and the middle side wall, axial heat transferring ability of the heat pipe is effectively reinforced, additionally, due to arrangement of the protrusions, the porosity is increased, fluid return resistance in the heat pipe is reduced, heat transferring efficiency is improved, heat conductive performance of the heat pipe is reinforced, and meanwhile, materials and production cost are saved.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

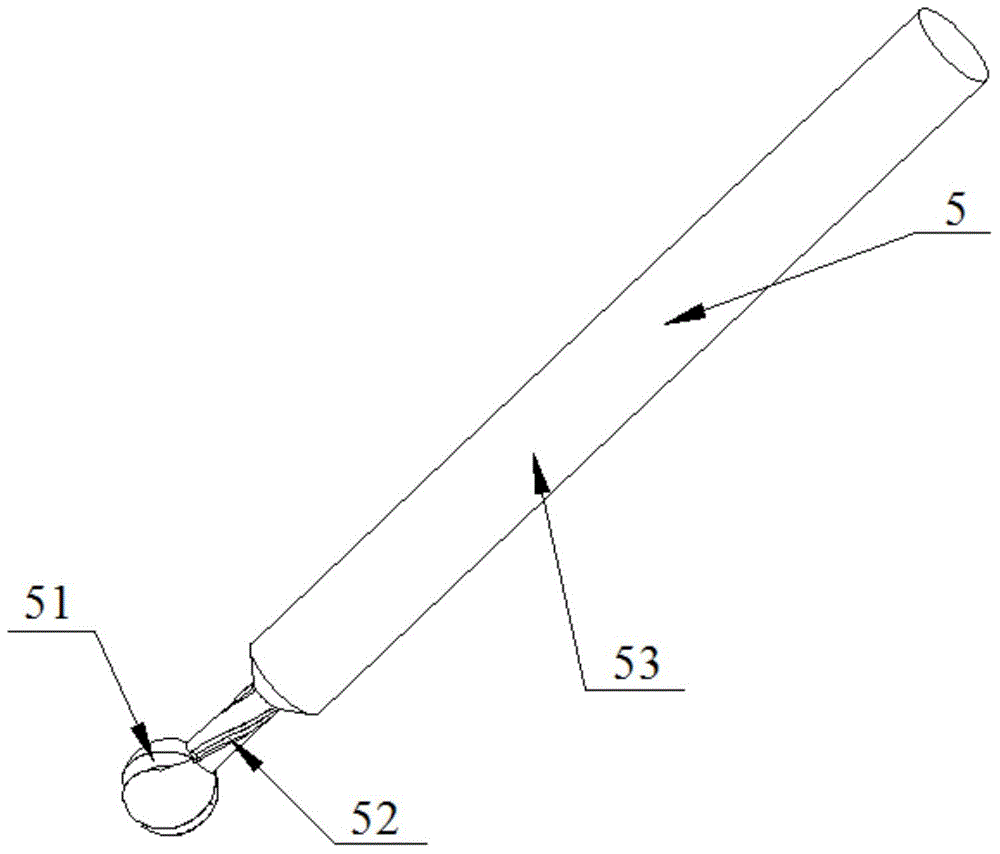

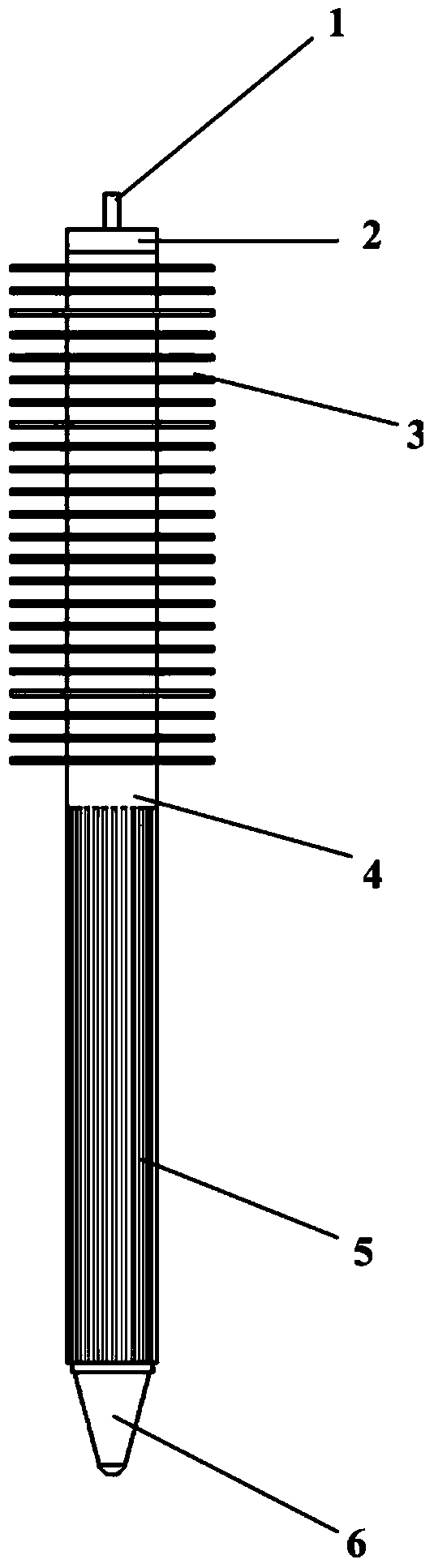

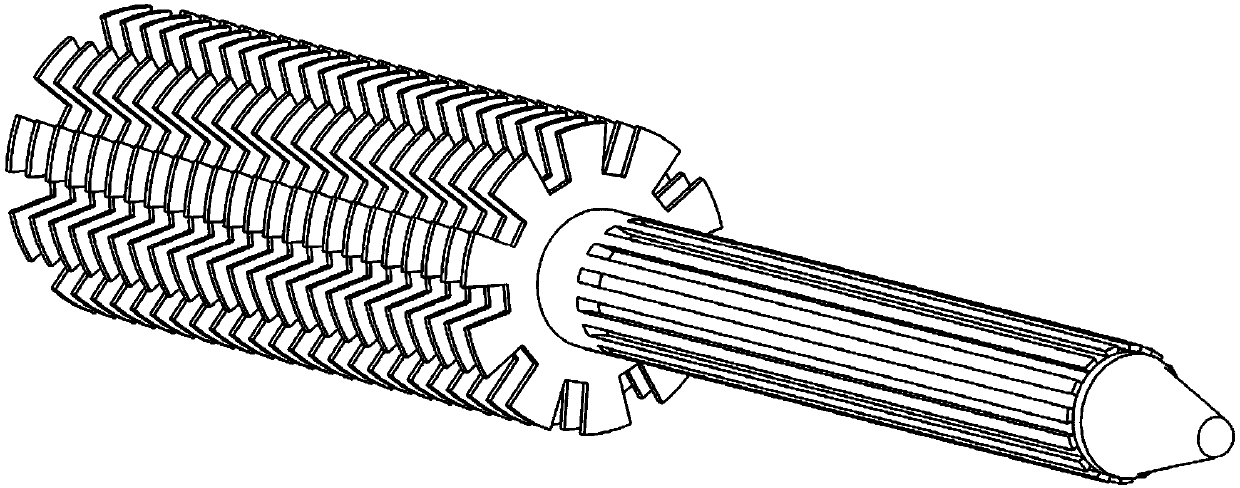

Combined exterior structural heat pipe for vertical heat-pipe condensers and manufacturing method thereof

InactiveCN103727823AEasy maintenanceThe processing technology is simple and reliableIndirect heat exchangersHeat pipeCivil engineering

The invention relates to a combined exterior structural heat pipe for vertical heat-pipe condensers. The combined exterior structural heat pipe for vertical heat-pipe condensers comprises a pipe body including a condensing segment and an evaporating segment. An exterior fin structure is arranged outside the pipe body, corresponding to the condensing segment, and an exterior grooved structure is arranged outside the pipe body, corresponding to the evaporating segment. The invention further relates to a manufacturing method of the combined exterior structural heat pipe for vertical heat-pipe condensers. The method includes the steps: manufacturing of the pipe body, manufacturing of an exterior fin unit, an upper end cover and a lower end cover, manufacturing of the exterior fin structure, and manufacturing and packaging of an absorbent core. The combined exterior structural heat pipe for vertical heat-pipe condensers and the manufacturing method thereof have the advantages that manufacturing process is simple and reliable, the combined exterior structural heat pipe provides a vertical heat-pipe condenser with good condensing effect and maintenance simplicity, and the combined exterior structural heat pipe and the manufacturing method thereof belong to the technical field of parts for condensers.

Owner:SOUTH CHINA UNIV OF TECH

Ultra-thin uniform-temperature board laser preparation method

The invention relates to the technical field of uniform-temperature boards, in particular to an ultra-thin uniform-temperature board laser preparation method. The ultra-thin uniform-temperature board laser preparation method comprises the following steps that (1) pretreatment is conducted, specifically, substrates are cleaned; (2) grooves are prepared, specifically, the grooves are formed in the surfaces of the substrates through laser engraving; (3) the substrates are subjected to surface hydrophilic treatment; (4) welding forming is conducted, specifically, the groove faces of the two substrates are oppositely placed and subjected to laser welding, an inflation opening is reserved, and a formed uniform-temperature board is prepared; and (5) sealing is conducted through welding, specifically, the formed uniform-temperature board is filled with working media and sealed through welding. By adoption of the ultra-thin uniform-temperature board laser preparation method, the engraved grooves are neat and small, and the groove faces of the substrates are subjected to surface hydrophilic treatment, so that evaporation heat absorption and reflux condensation of the working media in the uniform-temperature board are facilitated; and meanwhile, the peripheries of the substrates are subjected to scale laser welding, the welding airtightness is good, and prepared heat pipe clamps are small in size, good in heat transfer performance and small in reflux resistance.

Owner:东莞仁海科技股ふん有限公司

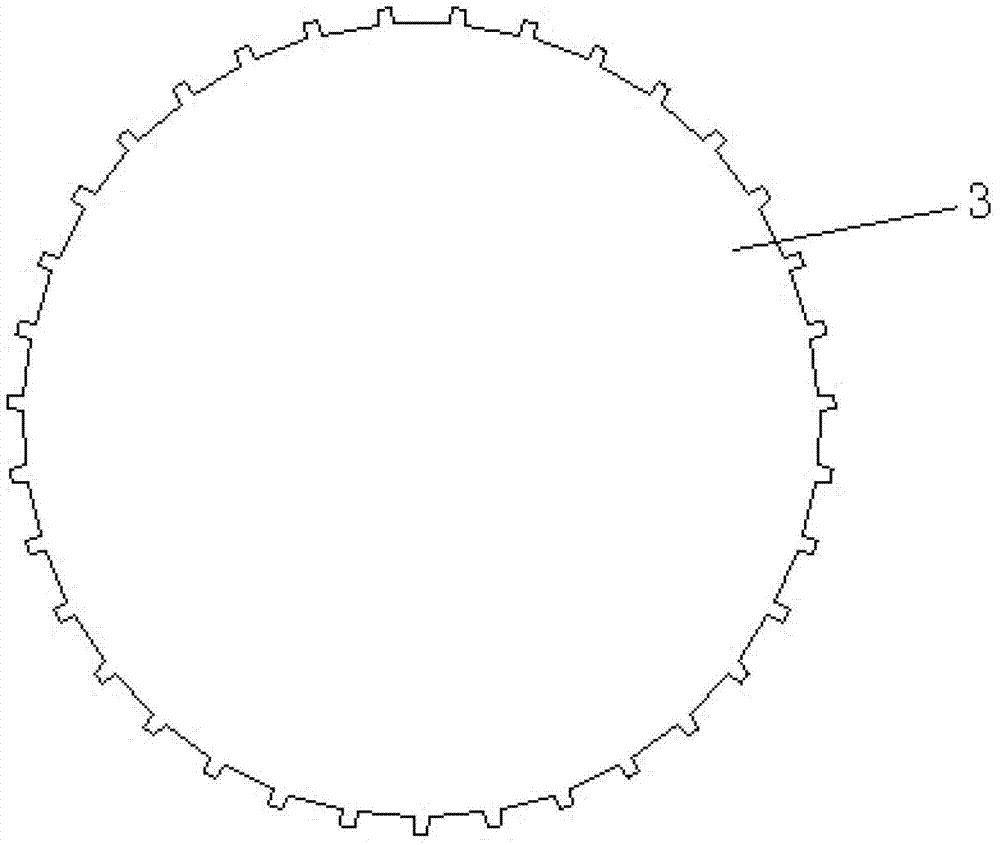

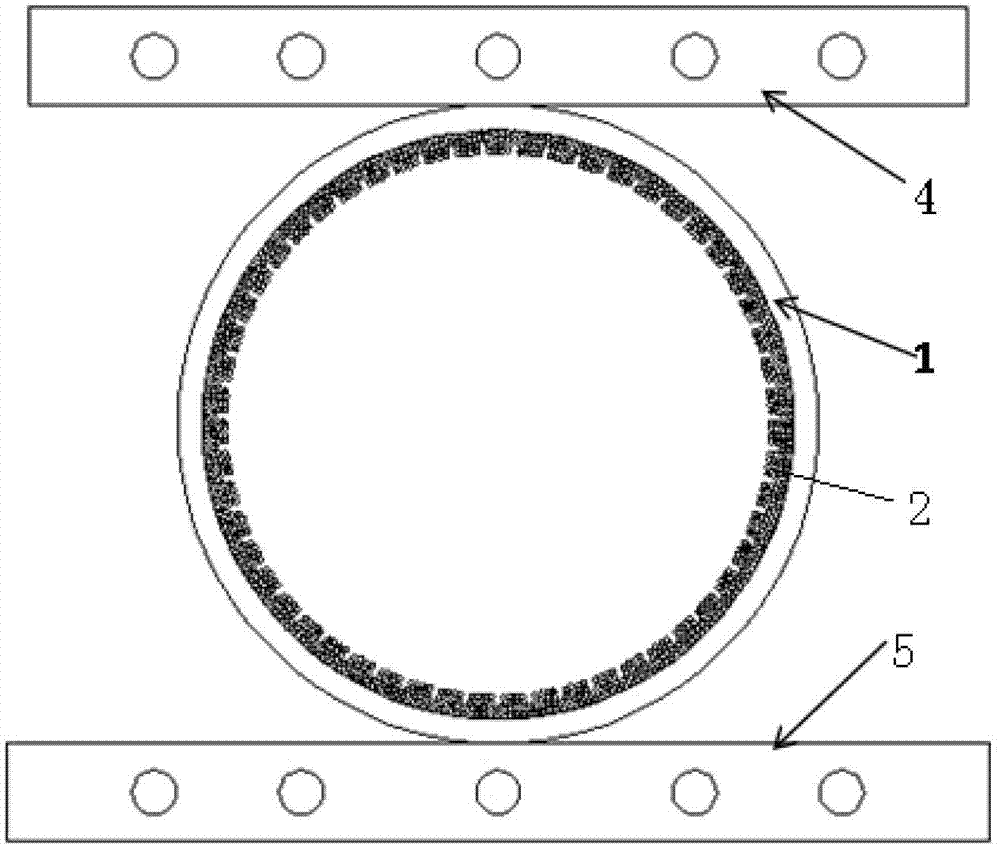

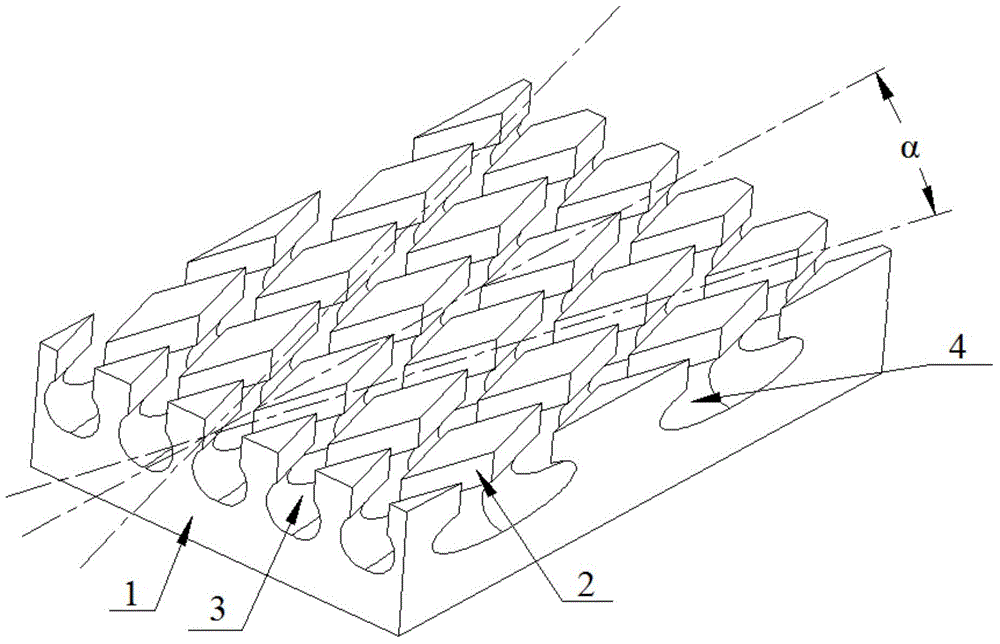

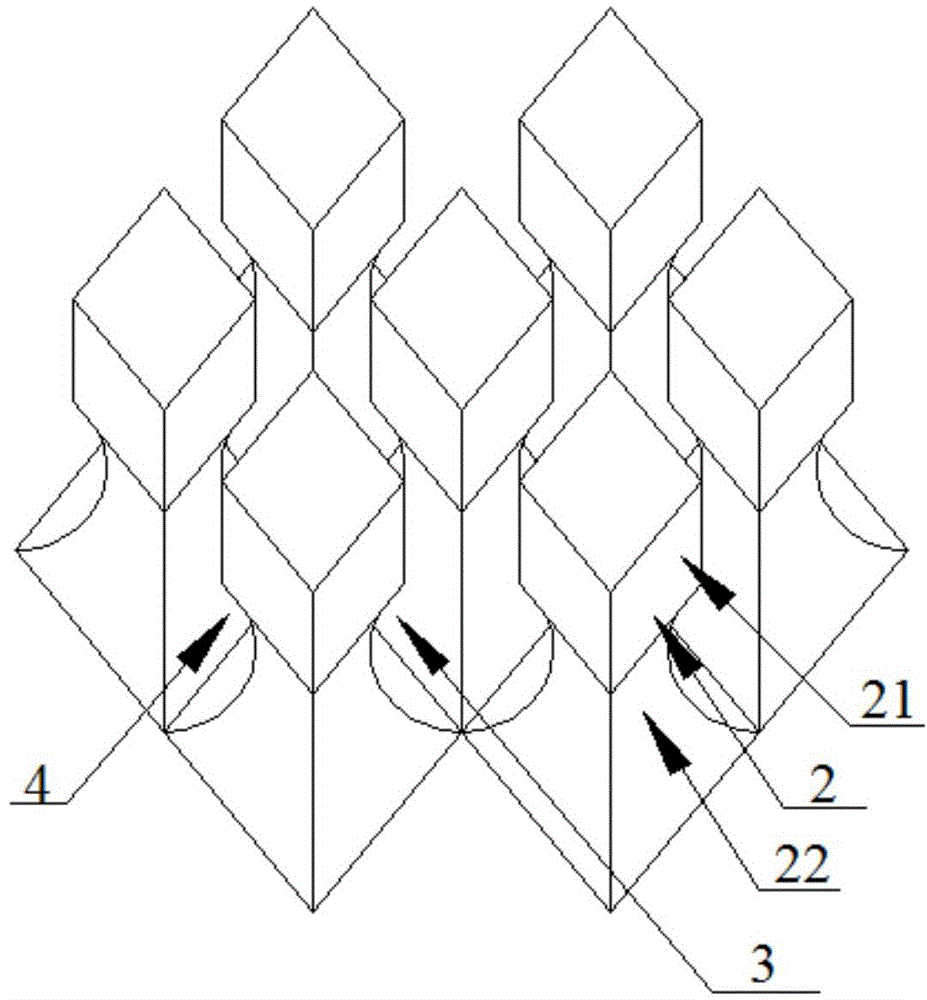

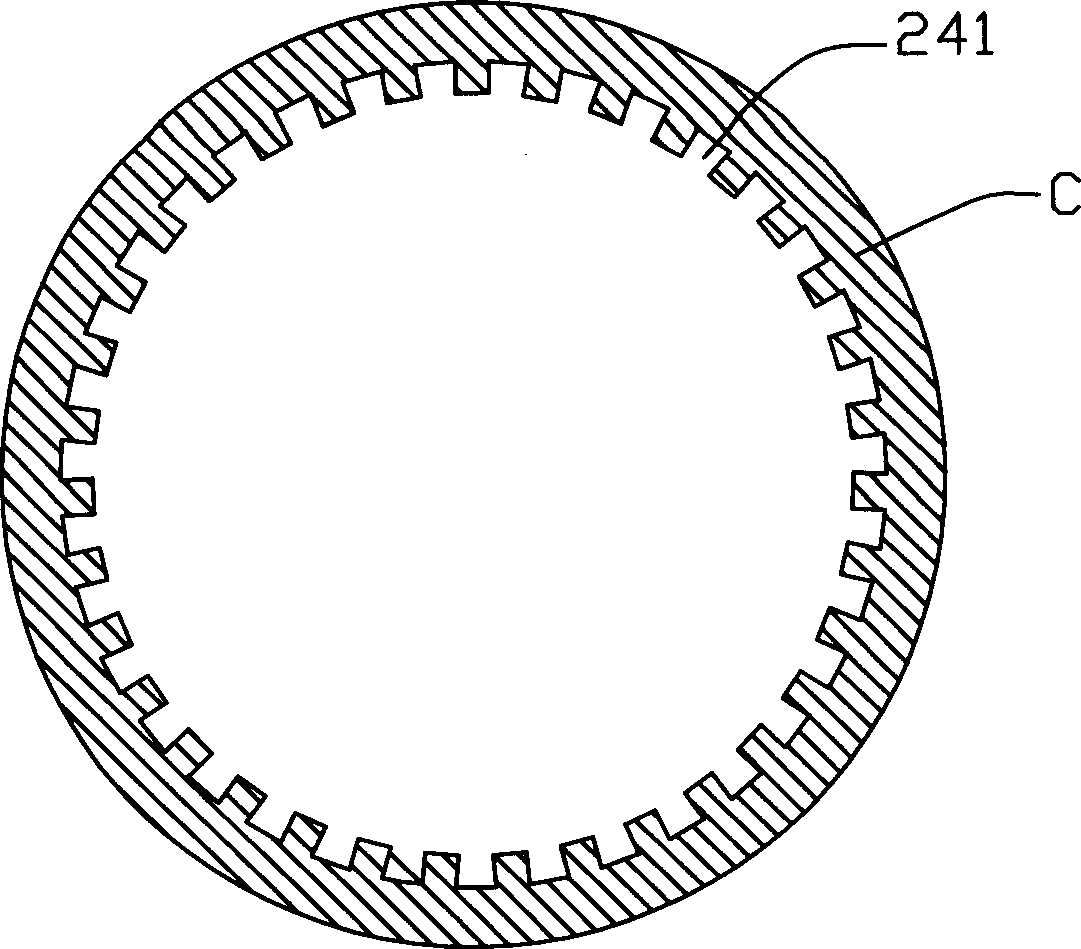

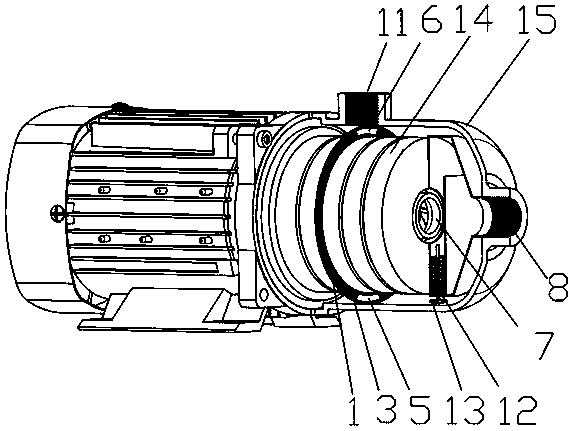

Gas-liquid separation device for enhancing self-absorption of self-absorption type multistage centrifugal pump

ActiveCN110025987AReduce air contentReduce kinetic energy lossLiquid degasification with auxillary substancesSelf-absorptionEngineering

The invention discloses a gas-liquid separation device for enhancing self-absorption of a self-absorption type multistage centrifugal pump. The gas-liquid separation device is arranged inside a self-absorption centrifugal pump and mainly comprises two parts, namely an annular bracket and an annular spiral channel which is arranged close to the annular bracket, and the surface of the spiral channelis uniformly coated with a hydrophobic material to form the hydrophobic surface annular spiral pipe channel supported by the annular bracket. The gas-liquid separation device is installed between a cavity of a pump shell and the pump shell, an inner ring and an outer ring of the device are tightly attached to the cavity and the pump shell respectively, fan-shaped openings are formed in the bottomand the top of the gas-liquid separation device, the opening at the top is an exhaust port, and the opening at the bottom is a water return port. The gas-liquid separation device is installed in an area near a pump outlet, the exhaust port of the gas-liquid separation device is directly opposite to the pump outlet, and the water return port is located in the bottom of the pump. The annular gas-liquid separation device is simple in structure, convenient to install, low in machining difficulty, light in mass, easy in raw material obtaining and wide in application prospect.

Owner:CHINA JILIANG UNIV

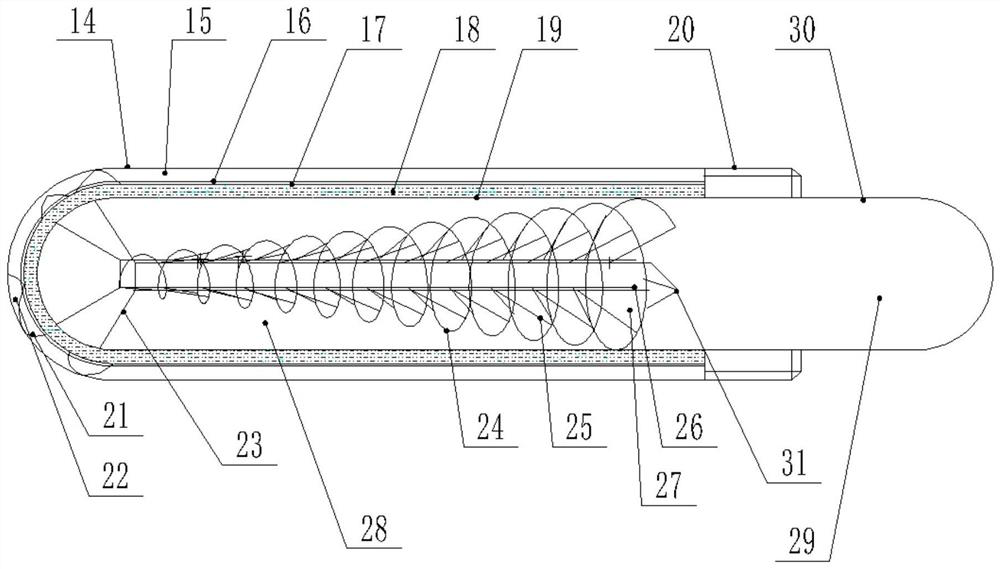

A Nanofluid Heat Collector with Helically Strengthened Heat Pipes

ActiveCN110836542BWith cold and frost resistanceTemperature resistantSolar heating energyCollector thermal insulationCollector deviceEngineering

Owner:JIANGSU UNIV

Heat pipe

InactiveCN103363829AImprove performanceShorten return pathIndirect heat exchangersWorking fluidEvaporation

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

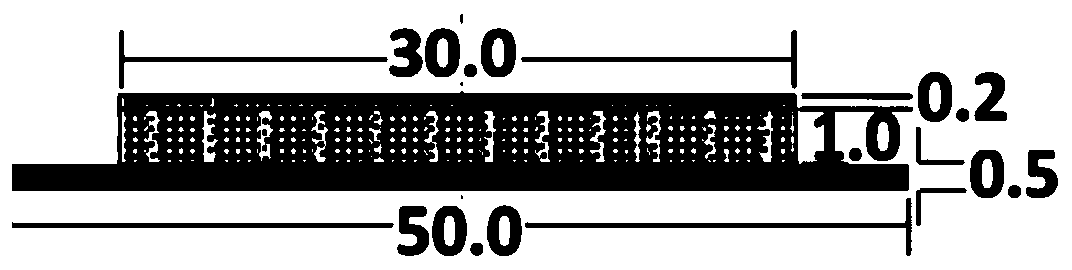

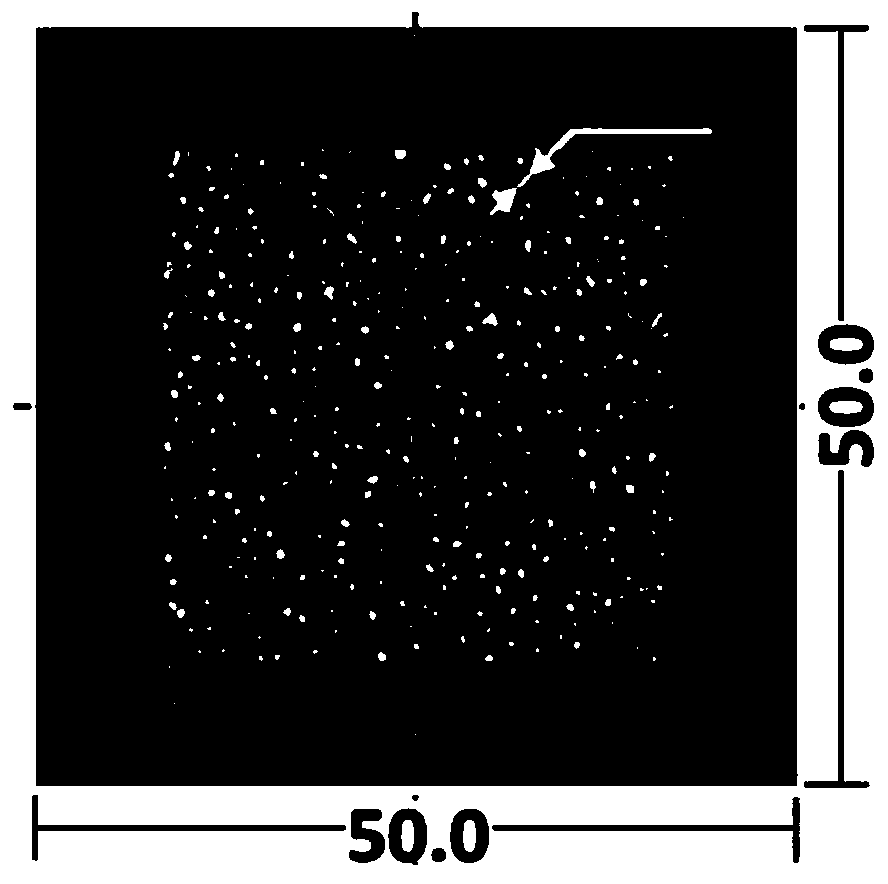

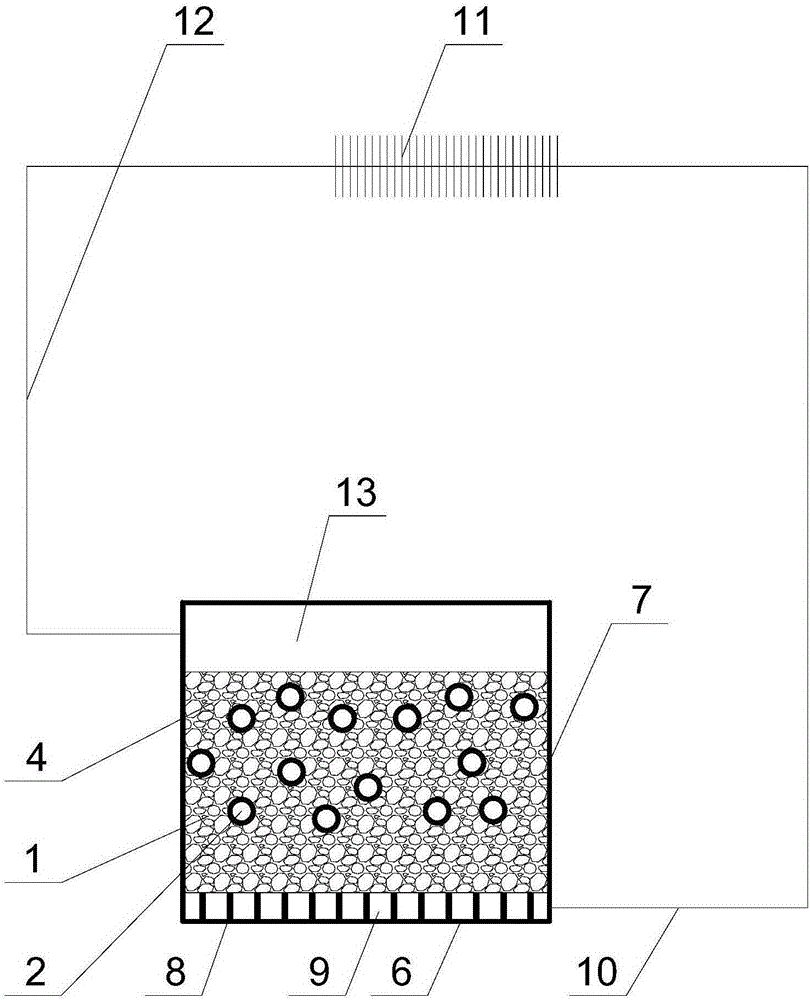

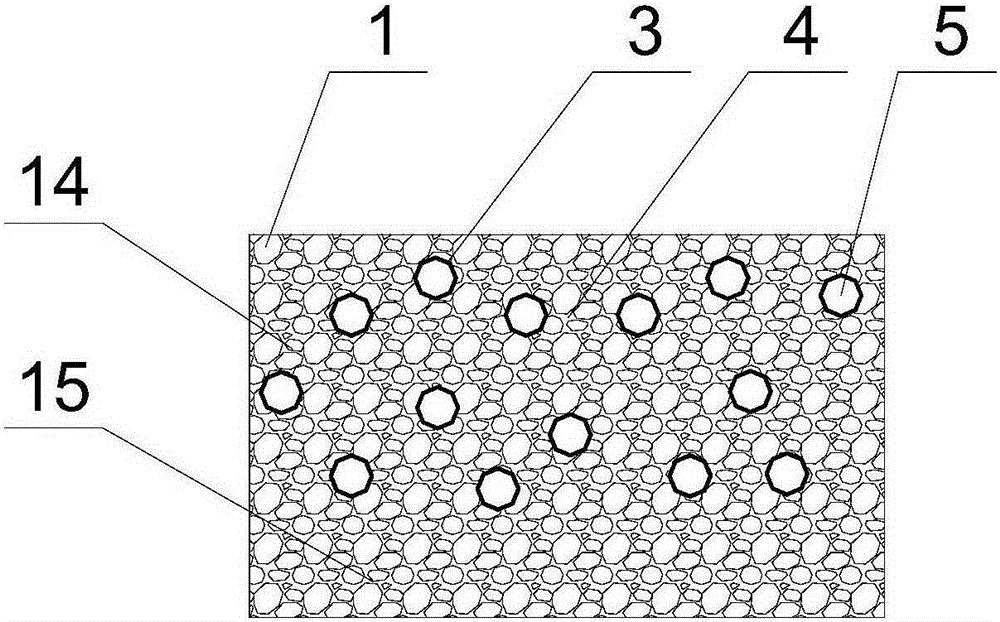

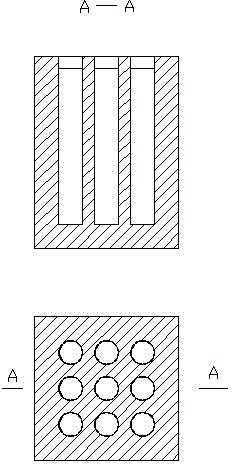

Free particle/porous medium composite enhanced boiling structure and preparation method thereof

ActiveCN110842202AAdd spoilersFast heat conductionHeat transfer modificationThermodynamicsPorous medium

The invention discloses a free particle / porous medium composite enhanced boiling structure. The structure comprises a substrate and a porous matrix structure formed on the surface of the substrate, aplurality of pore cavities are formed in the porous matrix structure, and free particles capable of moving in the pore cavity are dispersed in the pore cavity. When the free particle / porous medium composite enhanced boiling structure is prepared, metal particles are sintered to prepare a porous material matrix, the porous material matrix is drilled to form the pore cavity, and then the pore cavityis filled with free particles and sealed. The structure is based on the enhancing characteristics of nucleation activation in the boiling heat transfer process and liquid supply of a liquid absorbingcore to a nucleation site, bubbles are prevented from being mixed and the liquid backflow resistance is reduced by means of bubble nucleation and liquid supply partition. Meanwhile, the free particles collide with one another in the boiling process, so that heat transfer, microlayer evaporation and convective heat transfer in working fluid are enhanced, bubble nucleation is easy, the growth speedis high, the separation frequency is high, and therefore the enhanced boiling heat transfer is realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

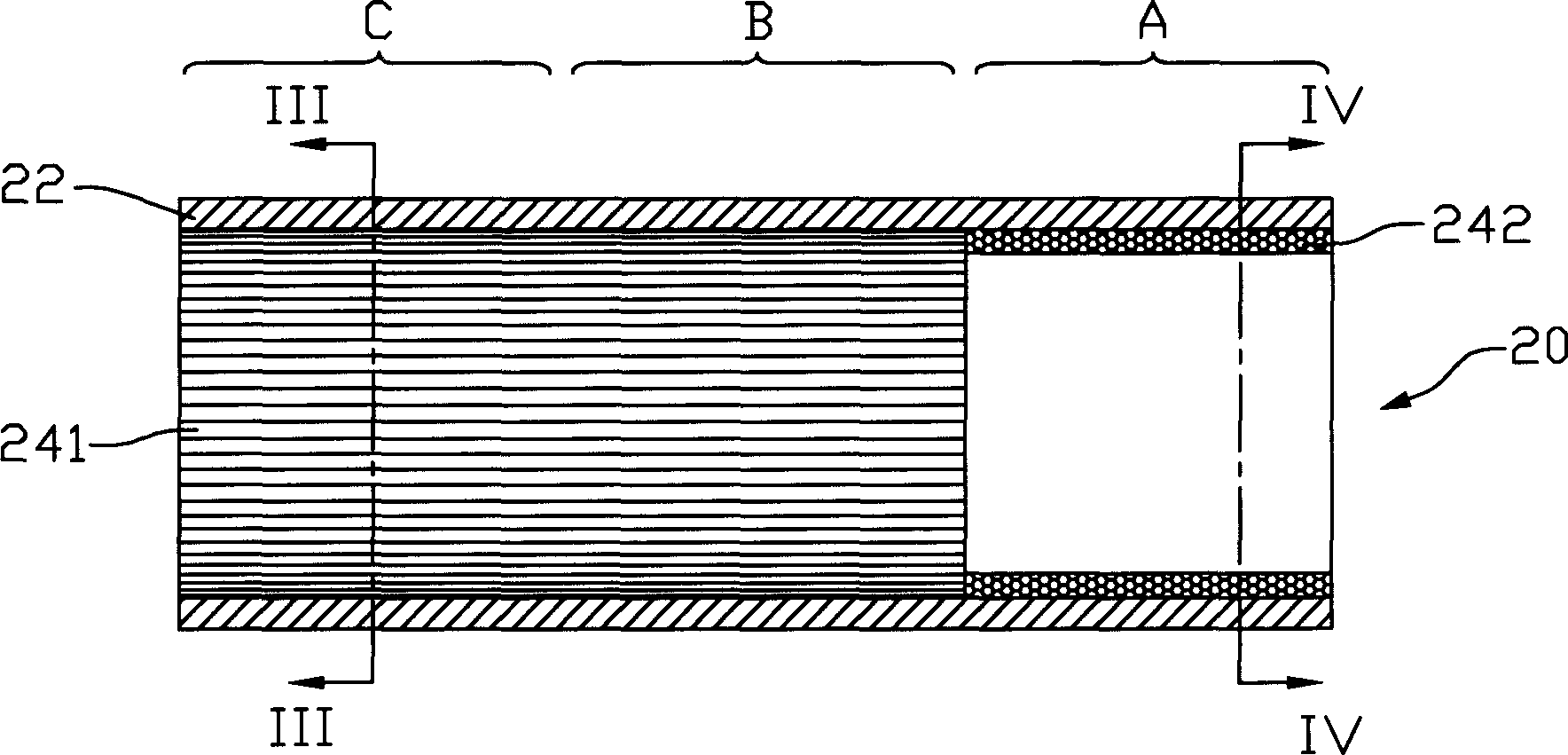

Composite liquid absorption core for loop heat pipe

InactiveCN105222631ASimple preparation processSmooth startIndirect heat exchangersMicro-loop heat pipeMicrometer

The invention discloses a composite liquid absorption core for a loop heat pipe. The composite liquid absorption core for the loop heat pipe is composed of metal powder, small phase-change balls and holes, wherein the diameter of the metal powder is 25-150 micrometers; each small phase-change ball is composed of a small phase-change ball outer shell and phase-change materials in the outer shell, the diameter of the small phase-change balls is 1-3 mm, and the solid-liquid phase-change temperature of the phase-change materials is 3 DEG C lower than the boiling point of work medium in the loop heat pipe; the size of the holes is realized by controlling the proportion of the metal powder with different particle diameters and the small phase-change balls. The composite liquid absorption core for the loop heat pipe can effectively avoid starting failure of the loop heat pipe caused by heat leakage of an evaporator shell body and the backward heat conduction effect of the liquid absorption core in the initial starting period of the loop heat pipe, facilitates smooth starting of the loop heat pipe and improves the operation stability of the loop heat pipe.

Owner:TIANJIN UNIV OF COMMERCE

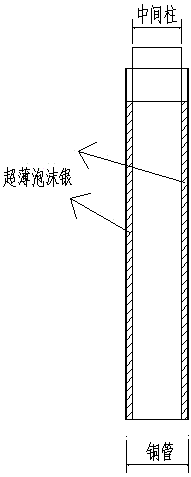

Method for manufacturing miniature heat pipe by employing ultrathin foamed silver as wick

InactiveCN104930888AStrong capillary suctionReduce heat dissipationIndirect heat exchangersThermal conductivityHeat flow

The invention discloses a method for manufacturing a miniature heat pipe by employing ultrathin foamed silver as a wick. The method is similar to conventional sintering of a copper heat pipe, and is characterized the ultrathin foamed silver is employed to replace a copper powder or silver powder sintered structure and serves as the wick, and the method is used for manufacturing a heat pipe by employing the ultrathin foamed silver as the wick, and the ultrathin foamed silver with a required porosity is manufactured through processes such as high temperature sintering and the like. The miniature heat pipe is generally prepared by the direct sintering of copper powder, and the porosity of the sintered copper wick is generally 40-50%. The porosity of the wick of the heat pipe prepared by the ultrathin foamed silver is up to 60-90%, and the porosity can be designed as needed. The ultrathin foamed silver has good capillary attraction and uniform hierarchy construction, and is high in porosity and thermal conductivity, the phase transformation cycling speed of the liquid medium is increased, the thermal resistance of the heat pipe is reduced, and the heat dissipation efficiency is obviously reduced. The method for manufacturing the miniature heat pipe by employing the ultrathin foamed silver as the wick is simple, the production process is pollution-free, the demand that a high heating flux electronic device is high in thermal conductivity and is miniaturized can be satisfied, and due to the price, the above manufacturing method is suitable for heat management of high-end equipment.

Owner:JIANGSU GREEN NEW MATERIALS TECH CO LTD

Loop heat pipe heat-conducting component

InactiveCN107238306ARelieve pressureReduce backflow resistanceIndirect heat exchangersEvaporatorLoop heat pipe

The invention discloses a loop heat pipe heat-conducting component. The loop heat pipe heat-conducting component mainly comprises an evaporator housing and an outer pipe, wherein the outer pipe is connected to the evaporator housing, so that the outer pipe and the evaporator housing form a loop; a copper powder-sintered capillary structure is arranged in the evaporator housing; and an exhaust hole is formed in one end of the copper powder-sintered capillary structure. The loop heat pipe heat-conducting component further comprises a capillary structure composed of heat-insulation fibers, wherein one side of the copper powder-sintered capillary structure is fixed, and other space in the evaporator housing is filled with the capillary structure composed of the heat-insulation fibers. According to the loop heat pipe heat-conducting component disclosed by the invention, due to the existence of the capillary structure composed of the heat-insulation fibers, a liquid flowing in the evaporator housing is absorbed by the capillary structure composed of the heat-insulation fibers and prevented from contacting with the evaporator housing, so that the heated-vaporized amount of the liquid is reduced, and then a pressure of an evaporation section is reduced, backflow resistance of a condensate is reduced, and heat-conducting efficiency is increased.

Owner:苏州鲁卡斯金属科技有限公司

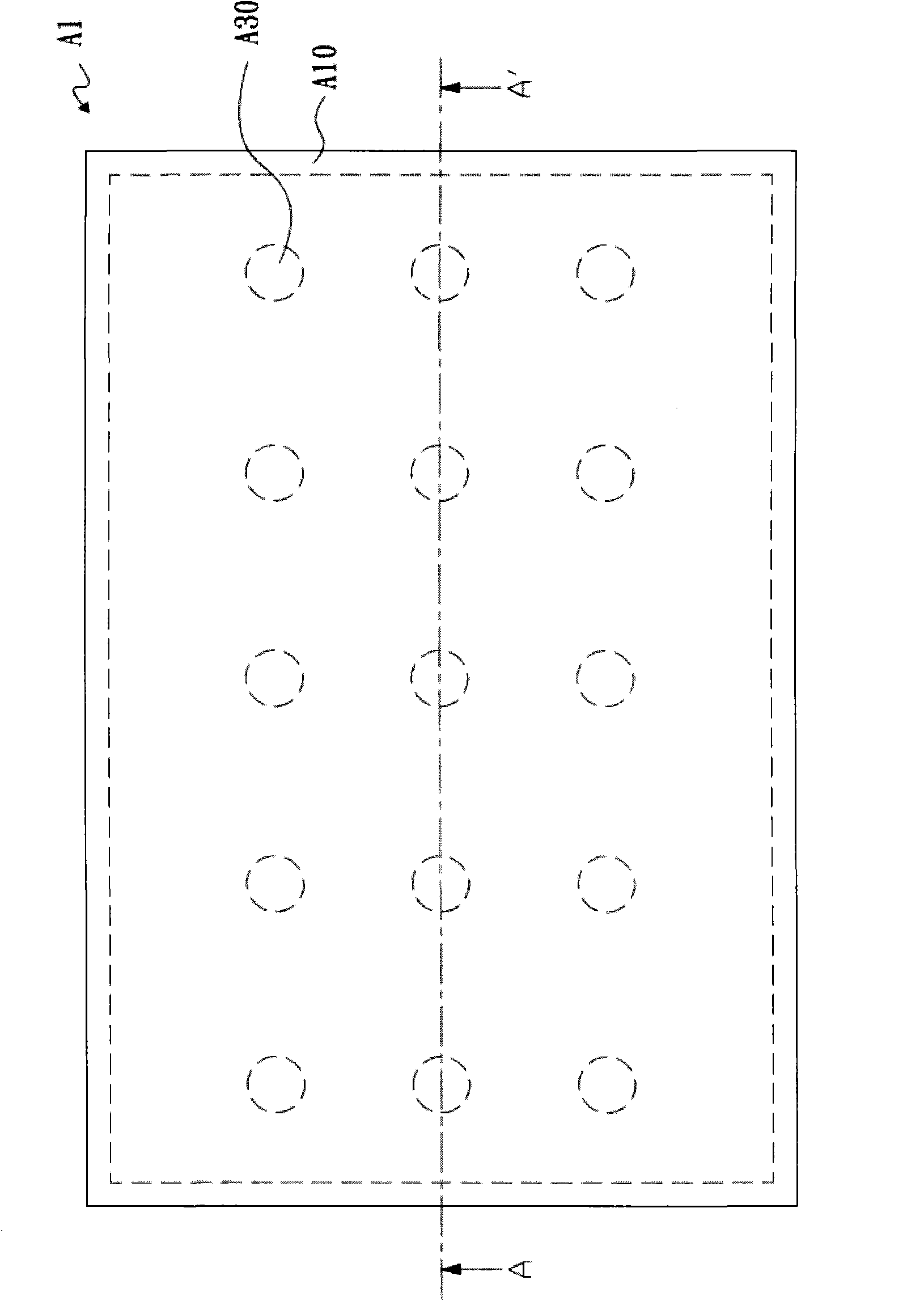

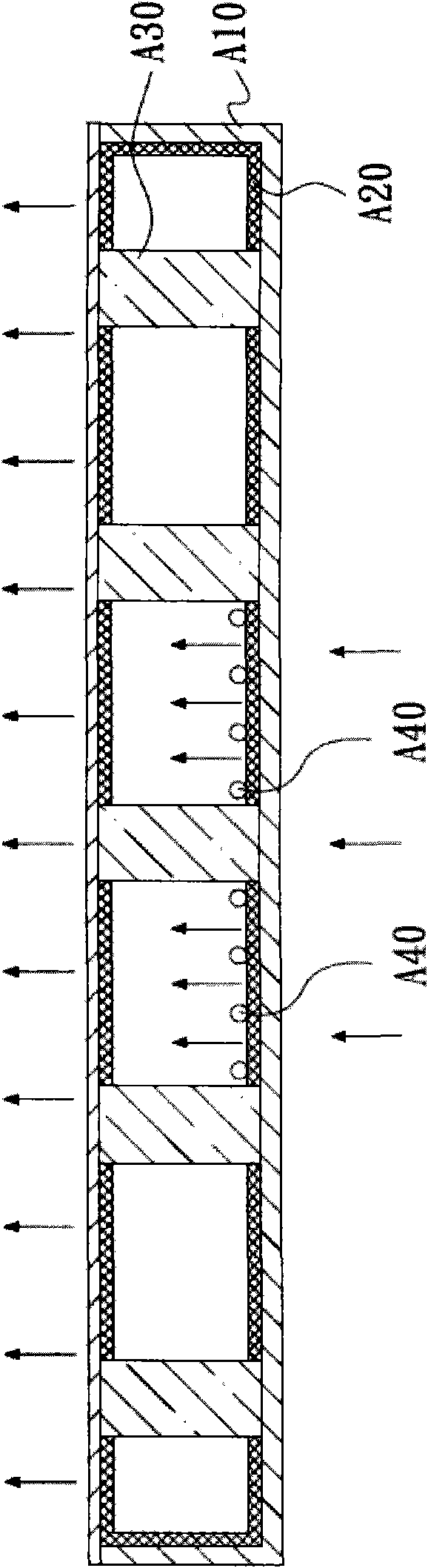

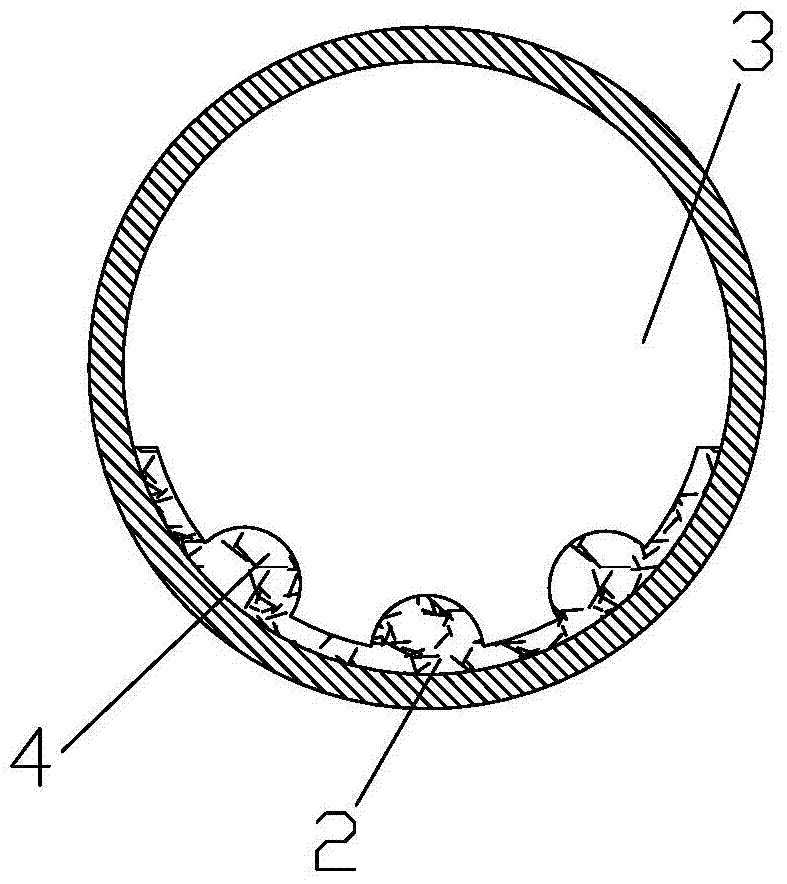

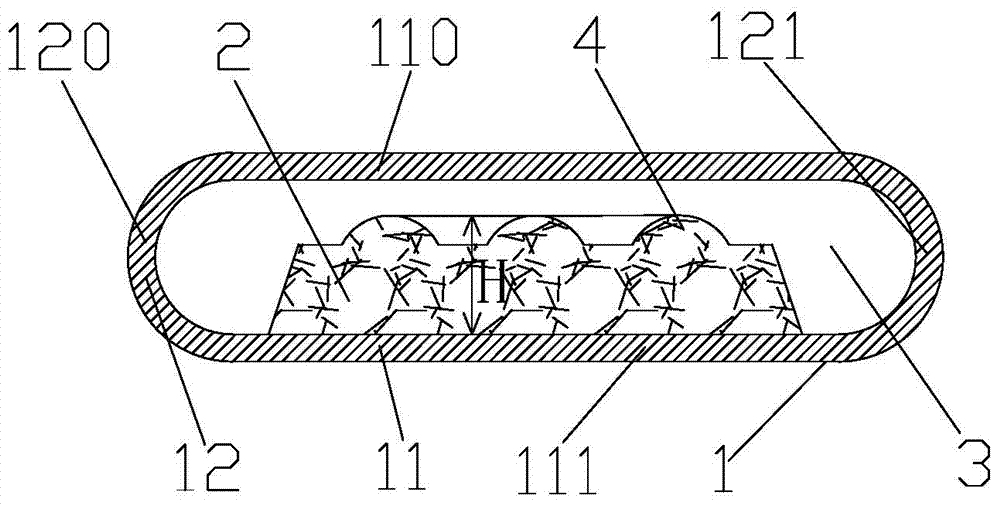

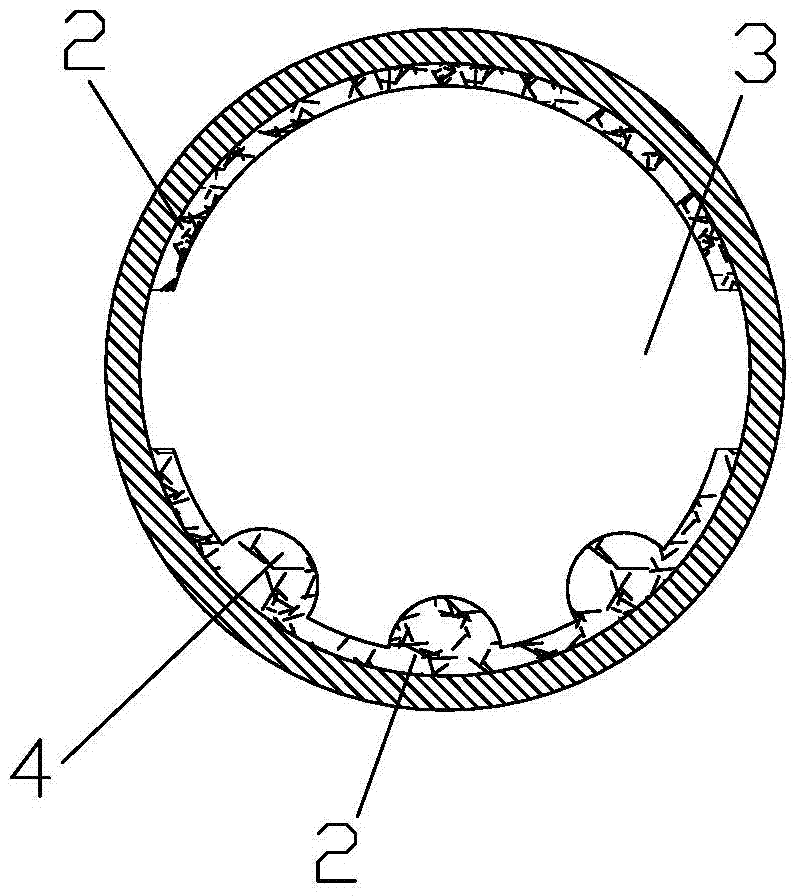

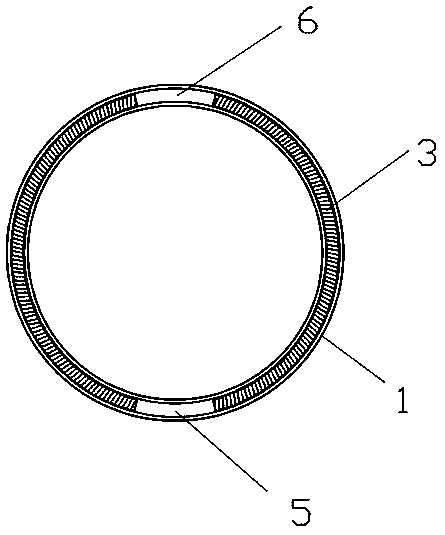

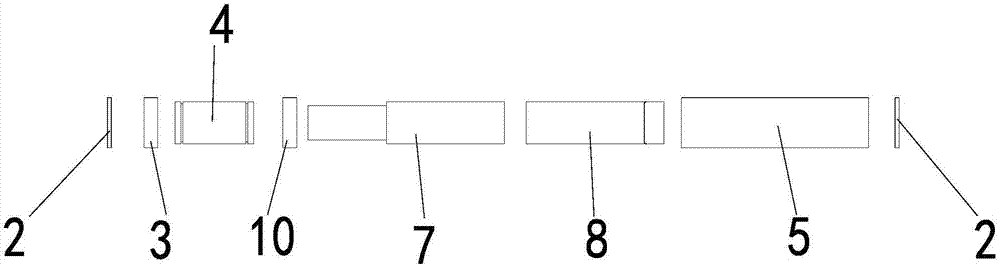

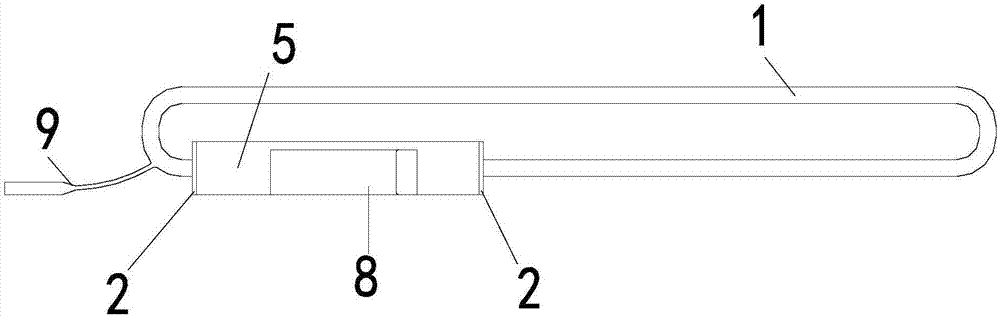

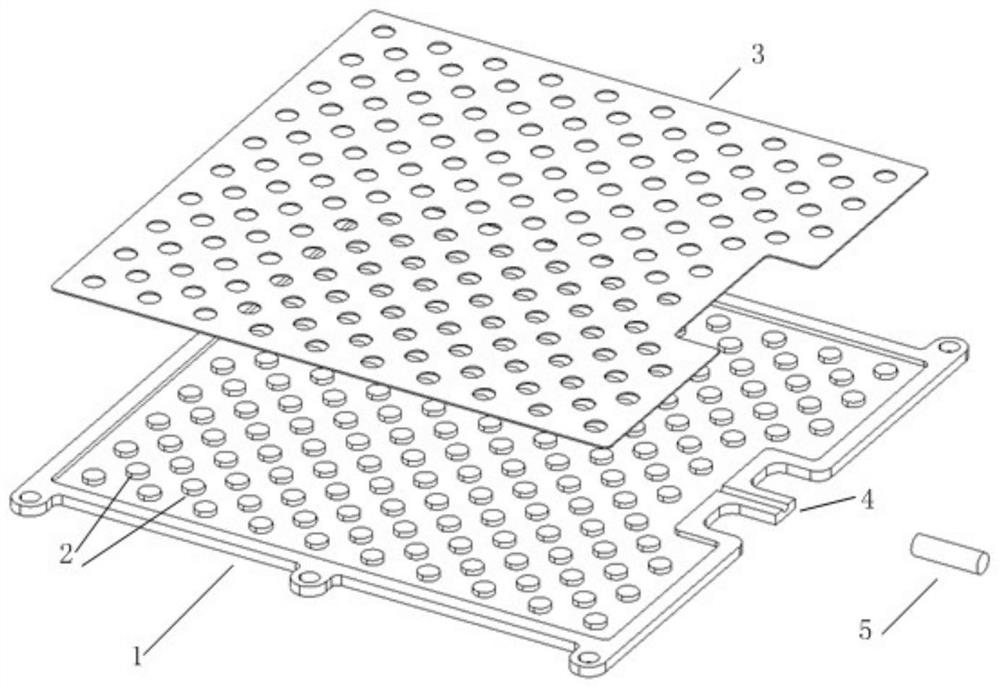

Compound liquid-absorbing core for heat pipe and preforming device thereof and preparation method

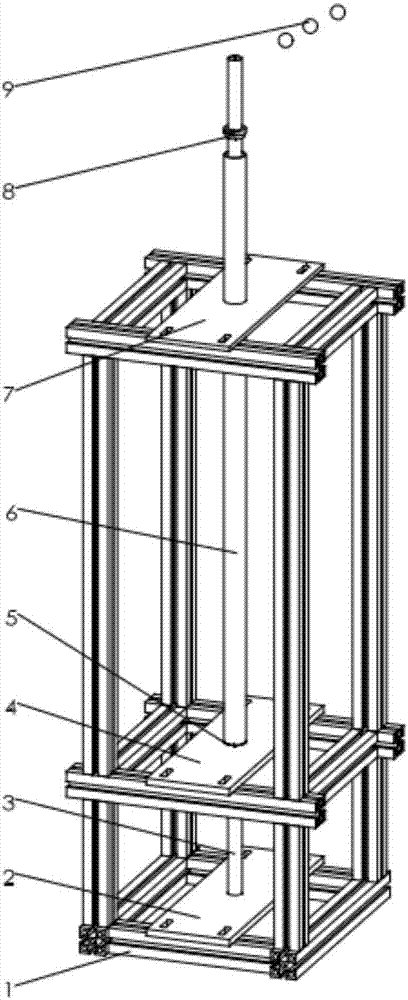

ActiveCN106855372AReduce backflow resistanceImprove heat transfer performanceIndirect heat exchangersEngineeringIndustrial scale

The invention discloses a preforming device for a compound liquid-absorbing core for a heat pipe. The preforming device comprises a ceramic ball, a supporting frame made of an aluminum profile or steel, a plurality of positioning plates sequentially fixed to the supporting frame from top to bottom and a heat pipe casing vertically fixed to the positioning plates. A core pipe arranged in the heat pipe casing in a vertical penetrating mode is coaxially arranged, the two ends of the heat pipe casing are provided with detachable end covers, the pipe wall of the core pipe is axially provided with a notch, and the diameter of the ceramic ball is larger than the internal diameter of the core pipe. The invention further provides the compound liquid-absorbing core for the heat pipe and a preparation method thereof. The preforming device is simple in structure and convenient to operate. According to the method for preparing the compound liquid-absorbing core for the heat pipe, radial compaction of the compound liquid-absorbing core can be implemented, it is ensured that the compound liquid-absorbing core and the pipe casing are effectively sintered, and contact thermal resistance is reduced. The prepared compound liquid-absorbing core for the heat pipe is excellent in heat transfer performance, high in permeability, large in capillary force, excellent in antigravity performance, low in cost and suitable for industrial scale production.

Owner:SOUTH CHINA UNIV OF TECH

Asbestos-nonmetallic fibrofelt wick heat plate

InactiveCN104315903ATo achieve the purpose of heat dissipationImprove permeabilityIndirect heat exchangersPorosityFiber

The invention discloses an asbestos-nonmetallic fibrofelt wick heat plate, belonging to the technical field of heat exchange equipment using an intermediate heat transfer medium or intermediate heat transfer body. The asbestos-nonmetallic fibrofelt wick heat plate disclosed by the invention comprises a sealing shell, a first nonmetallic fibrofelt wick, a second nonmetallic fibrofelt wick, a supporting frame and a heat-conducting liquid working medium, wherein the supporting frame, the first nonmetallic fibrofelt wick and the second nonmetallic fibrofelt wick are mounted inside the sealing shell, and the interior of the sealing shell is filled with the heat-conducting liquid working medium. Compared with the prior art, the asbestos-nonmetallic fibrofelt wick heat plate has the advantages that the nonmetallic fibrofelt wicks have relatively good capillary force and permeability, so that the bonding strength and contact area among fibers are increased; a large number of three-dimensional reticulated porous structures are formed among the fibers, so that the porosity is high, the specific area is large, and the liquid reflux resistance is low; the increase of reflux speed of the liquid working medium in the heat plate is facilitated, and then, the heat dissipating performance of the heat plate is improved.

Owner:辽宁三维传热技术有限公司

Porous structure layer for heat pipe and its making process

InactiveCN100395504CImprove performanceIncrease capillary forceDigital data processing detailsIndirect heat exchangersWire gauzeEngineering

The porous structure layer for heat pipe includes several layers of silk screen set in the radial direction of the heat pipe, with at least one layer forming sectional axial structure possessing at least two sections in different mesh sizes. The making process of the porous structure layer includes the following steps: 1. providing silk screens in different mesh size; 2. winding the silk screen into tubular one; 3. setting the tubular silk screen inside the pipe body of the heat pipe; and 4. fixing the silk screen. The heat pipe with multilayer sectional silk screen structure has gradient pore change, greater capillary tension, lower reflow resistance and raised heat pipe performance.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Preparation methods for novel multi-scale flat aluminum belt heat pipe

InactiveCN105806114AImprove heat transfer performanceImprove mass transfer effectIndirect heat exchangersMaterials scienceHeat pipe

The invention provides two methods for manufacturing a novel multi-scale flat aluminum belt heat pipe. The first method comprises the steps that S1, a flat aluminum belt heat pipe extrusion die is opened; S2, surface roughening treatment is conducted on the flat aluminum belt heat pipe extrusion die; and S3, extrusion forming is completed at a time through the extrusion die subjected to surface roughening, and the flat aluminum belt heat pipe with multi-scale micro grooves is obtained. The second method comprises the steps that S1, a flat aluminum belt heat pipe extrusion die is opened; S2, extrusion forming is conducted at a time through the extrusion die, and the flat aluminum belt heat pipe is obtained; and S3, secondary broaching is conducted on the flat aluminum belt heat pipe which is obtained through extrusion forming at a time, and the flat aluminum belt heat pipe with multi-scale micro grooves is obtained. The capillary suction force is improved through the micro grooves, and the heat transfer property and mass transfer property of the flat aluminum belt heat pipe are remarkably improved.

Owner:汤勇

Flat heat pipe based on liquid absorbing core of composite structure, assembling method and electronic component

InactiveCN111928706AImprove heat transfer performanceReduce backflow resistanceIndirect heat exchangersHeat exchanger casingsEngineeringElectronic component

The invention provides a flat heat pipe based on a liquid absorbing core of a composite structure. The flat heat pipe comprises baseplates, the liquid absorbing core and a liquid filling pipe, whereinthe liquid absorbing core is arranged between the baseplates, and comprises supporting columns and foamed nickel components; the baseplates comprise an upper baseplate and a lower baseplate; the supporting columns are arranged on the upper baseplate and the lower baseplate; the foamed nickel components are matched with the inner wall surface structures of the baseplates; the liquid filling pipe is arranged between the upper baseplate and the lower baseplate; the interior of the flat heat pipe is filled with a working medium through the liquid filling pipe; and a channel where the working medium inside the flat heat pipe flows is jointly defined by the supporting columns and foamed nickel on the foamed nickel components. Through the adoption of the channel where the working medium inside the flat heat pipe flows and which is jointly defined by the supporting columns arranged in an array and the foamed nickel, the resistance to the backflow of the liquid working medium can be reduced when the capillary force is good, the flat heat pipe can achieve the better heat transfer property, and the reliability can be improved during the use of the flat heat pipe.

Owner:SHANGHAI SATELLITE ENG INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com