Compound liquid-absorbing core for heat pipe and preforming device thereof and preparation method

A liquid-absorbing core and pre-forming technology, which is applied in the field of heat pipe liquid-absorbing cores, can solve the problems of affecting the pre-forming effect of the liquid-absorbing core, the inability to radially compress the liquid-absorbing core, and poor anti-gravity performance, etc., and achieve convenient processing and low cost Low, simple structure, high permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

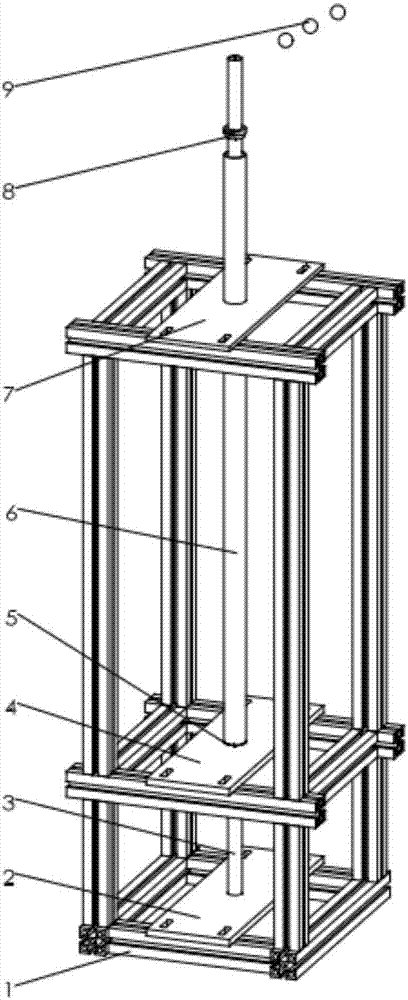

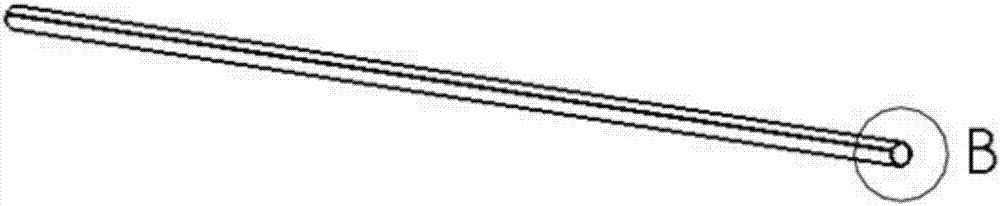

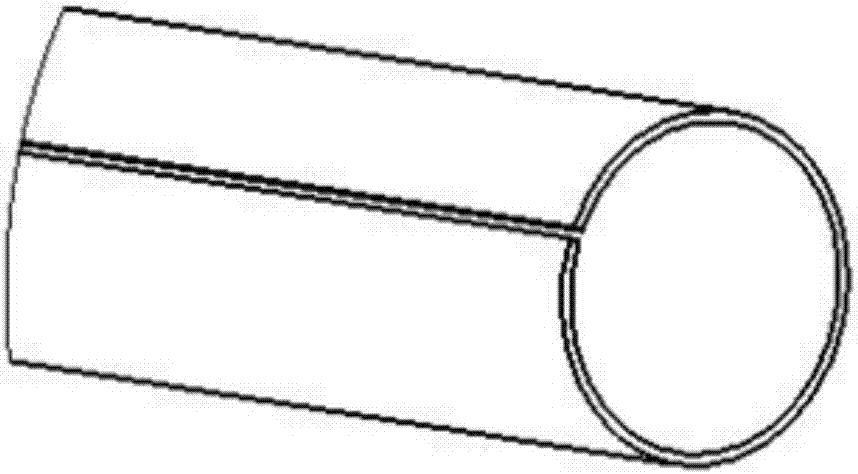

[0039] Such as figure 1 As shown, a composite liquid-absorbing core preforming device for heat pipes includes ceramic balls 9, a support frame 1 made of aluminum or steel, several positioning plates fixed on the support frame 1 from top to bottom, vertical The heat pipe shell 6 directly fixed on the positioning plate is coaxially arranged to vertically penetrate the core tube 3 arranged in the heat pipe shell 6, and the two ends of the heat pipe shell 6 are provided with detachable end caps , the tube wall of described core tube 3 is provided with otch along axial direction, adopts wire cutting to cut (see figure 2 and image 3 ), the diameter of the ceramic ball 9 is greater than the inner diameter of the core tube 3.

[0040] Specifically, the positioning plate includes an upper plate 7, a middle plate 4, and a lower plate 2 from top to bottom. The center of the upper plate 7 is provided with a through hole matching the heat pipe shell 6, and the center of the middle pla...

Embodiment 2

[0046]A method for preparing a composite liquid-absorbing core for heat pipes using the preforming device, comprising the steps of:

[0047] (1) Preparation of metal fibers: first cut metal fibers of different shapes into short metal fibers of a certain length, then degrease and dry, then calculate and weigh two kinds of metal fibers of required quality according to a certain ratio, and then mix evenly;

[0048] (2) Position the heat pipe shell 6 and the core tube 3: first insert the tapered end of the lower end cover 5 into the heat pipe shell 6, and press it tightly, and then pass the heat pipe shell 6 through the through hole of the upper plate 7 until It is in contact with the stepped through hole of the middle plate 4, so that the heat pipe shell 6 is matched with the through hole of the upper plate 7, the lower end cover 5 is matched with the stepped through hole with a larger diameter of the middle plate 4, and the lower end cover 5 and the heat pipe shell 6 is axially...

Embodiment 3

[0057] The difference between this embodiment and embodiment 2 is that the metal fiber with a rough surface processed by a multi-tooth turning tool accounts for 20% of the mass of the composite liquid-absorbing core. The short metal fibers have a length of 5 mm and an equivalent diameter of 50 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com