Preparation methods for novel multi-scale flat aluminum belt heat pipe

A multi-scale, flat-belt technology, applied in the direction of lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of slow capillary pumping speed and insufficient heat dissipation capacity, and achieve simple and easy technical means, easy promotion and application, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

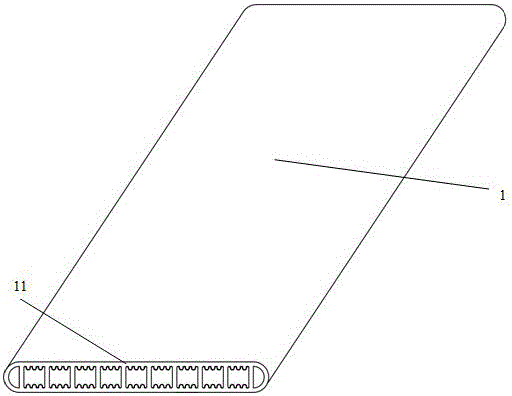

[0030] The manufacturing method of the novel multi-scale aluminum flat strip heat pipe of the present invention can be realized through the following steps:

[0031] S1 aluminum flat belt heat pipe extrusion die opening;

[0032] S2 cleans and dries the extrusion mold;

[0033] S3 electrochemically corrodes the surface of the dried extrusion die;

[0034] S4 cleans and dries the surface of the extrusion die after corrosion treatment;

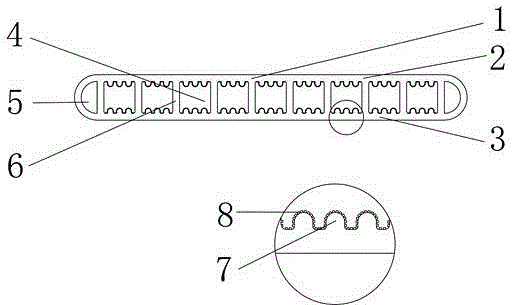

[0035] S5 uses an extrusion mold with a roughened surface and one-time extrusion molding to obtain an aluminum flat strip heat pipe with multi-scale micro-grooves 8 .

[0036] The above step 3 includes the treatment of roughening the surface of the extrusion die, specifically electrifying both ends of the extrusion die and completely immersing it in the corrosive agent.

[0037] In the above step 3, the corrosive agent is an acid or alkaline reagent that chemically reacts with the surface of the extrusion die.

[0038] The aluminum flat stri...

Embodiment 2

[0040] The manufacturing method of the novel multi-scale aluminum flat strip heat pipe of the present invention can be realized through the following steps:

[0041] S1 aluminum flat belt heat pipe extrusion die opening;

[0042] S2 uses an extrusion die to extrude at one time to obtain an aluminum flat belt heat pipe;

[0043] S3 performs secondary broaching on the aluminum flat strip heat pipe obtained by one-time extrusion molding, and obtains the aluminum flat strip heat pipe with multi-scale micro-grooves 8 .

[0044] The surface of the broach used in step 2 above has tiny cutting edges.

[0045] The aluminum flat strip heat pipe obtained above has micro-grooves 8 evenly distributed on the surface of the inner grooves 7 of the independent heat transfer channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com