Patents

Literature

161 results about "Insufficient Cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cause: Insufficient Cooling. The coolant flow rate is below, or temperature is above, the nameplate rating for the resistance welding component. The cooling requirements of a resistance welding component are defined by rate, temperature, and sometimes direction.

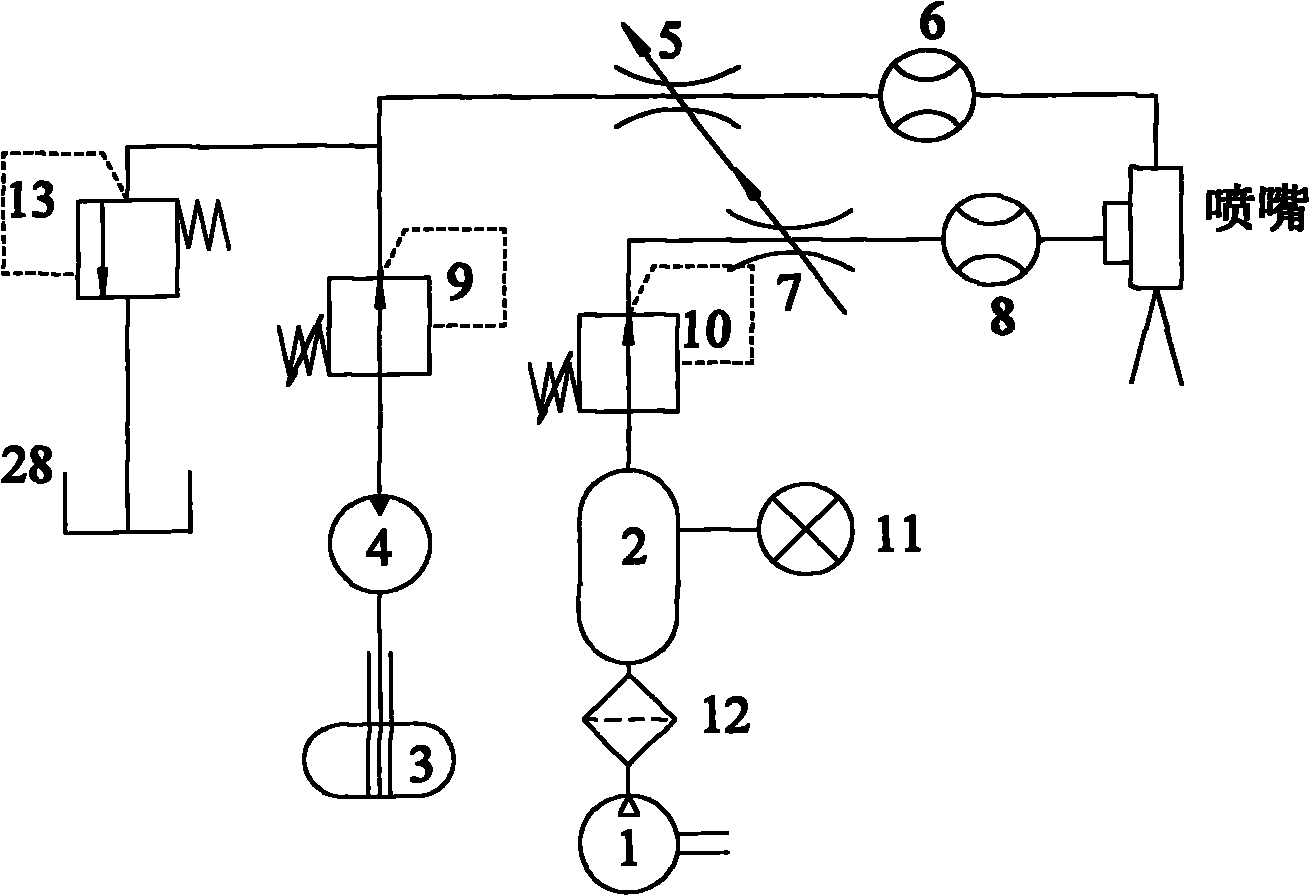

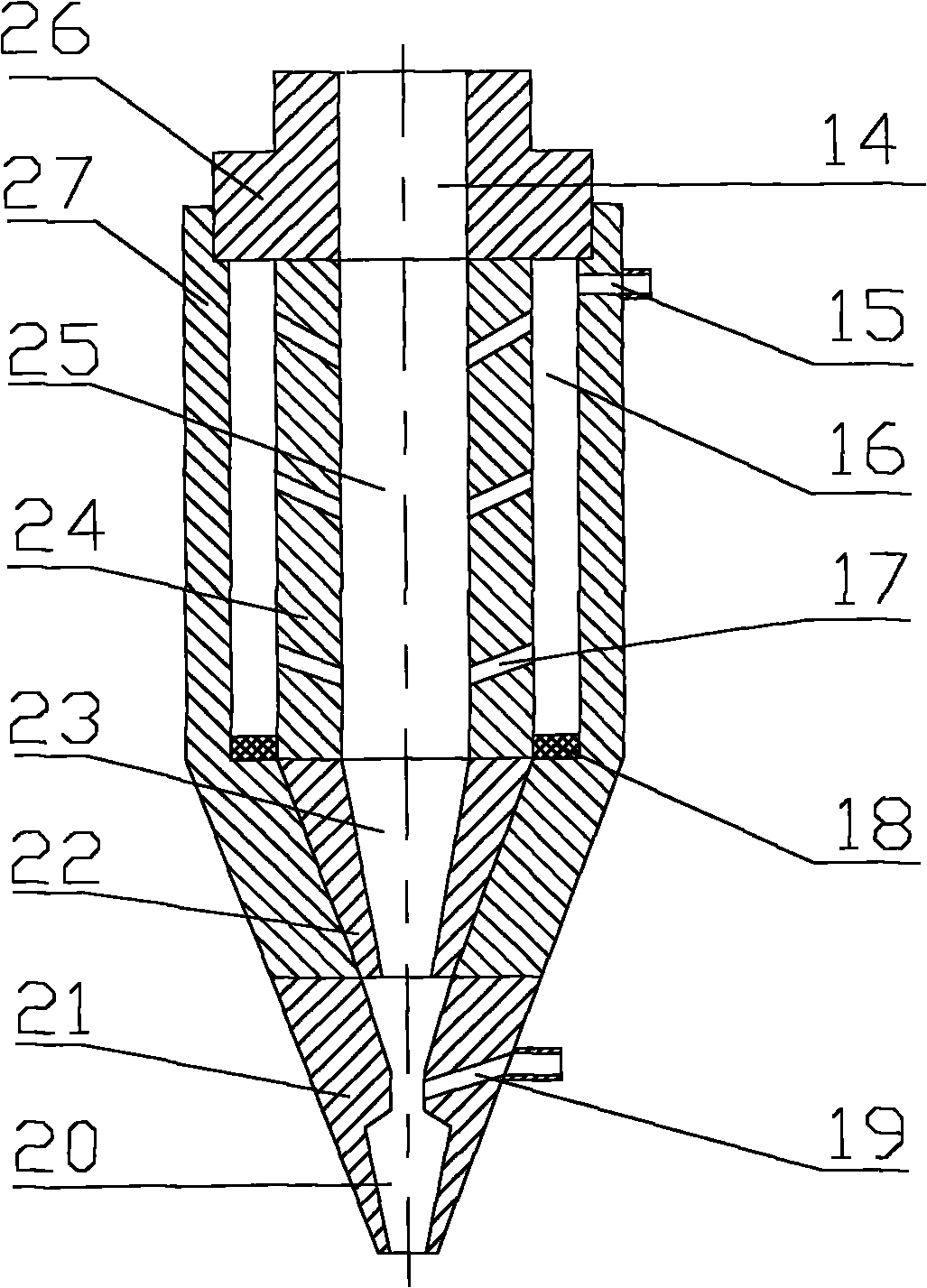

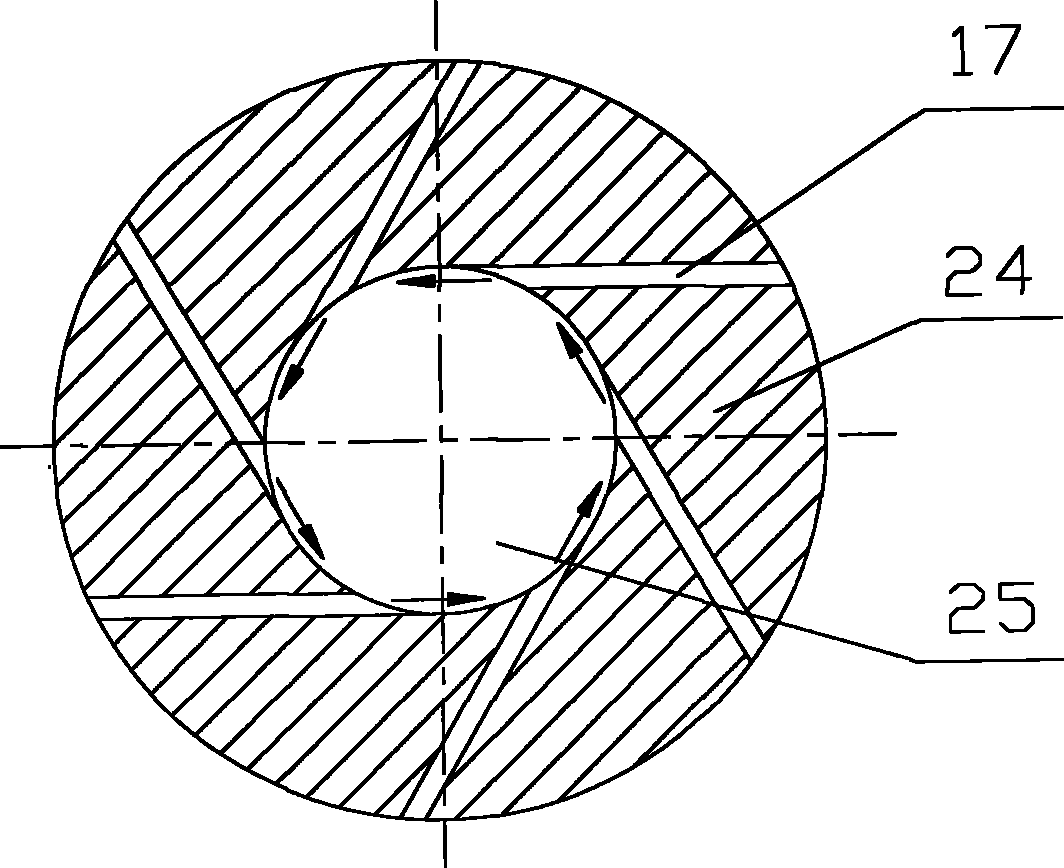

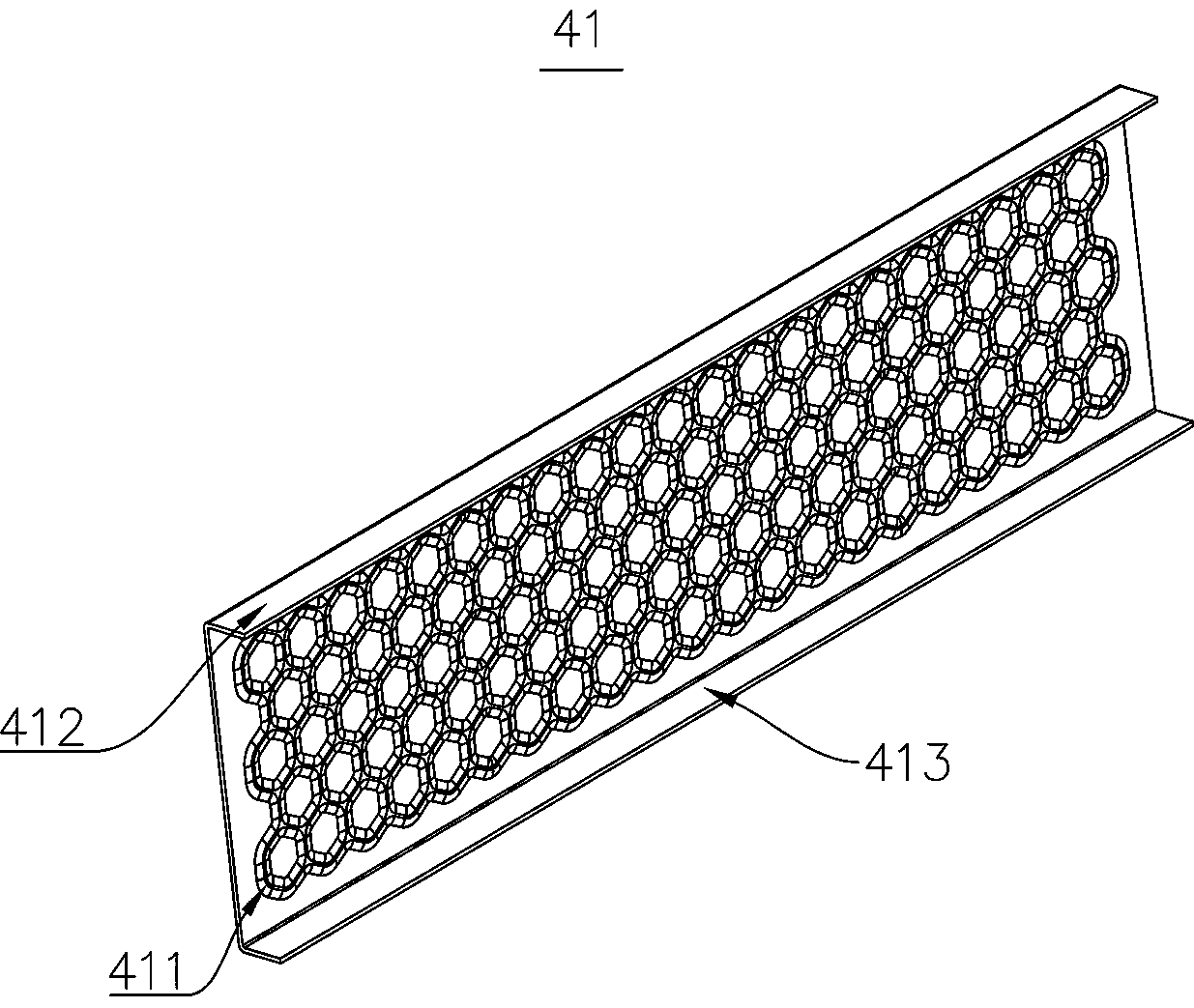

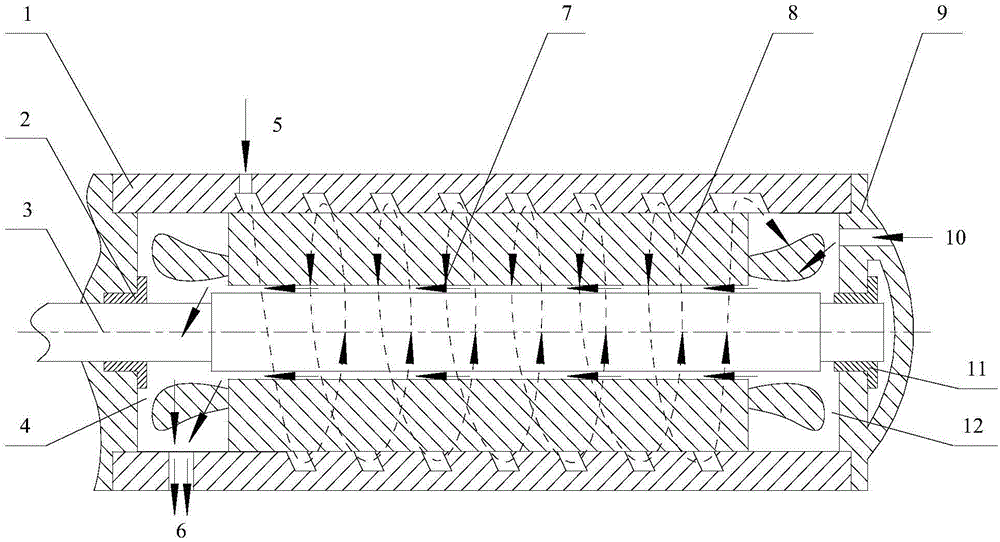

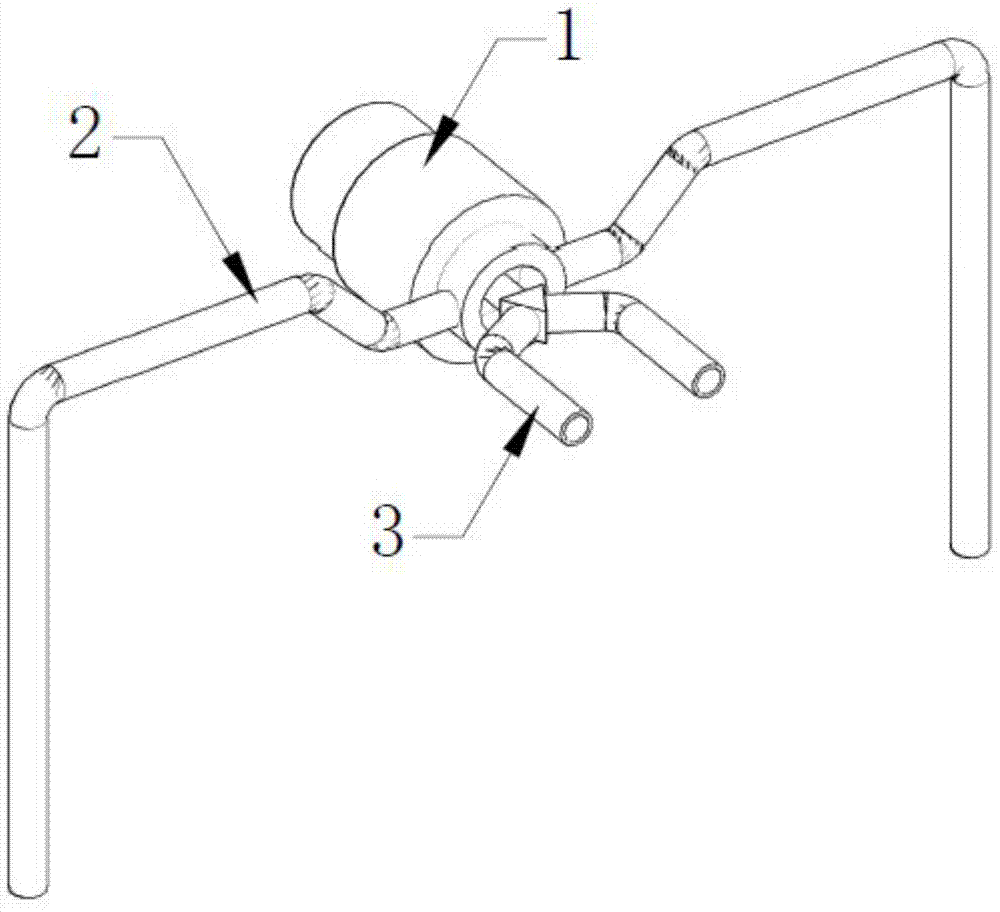

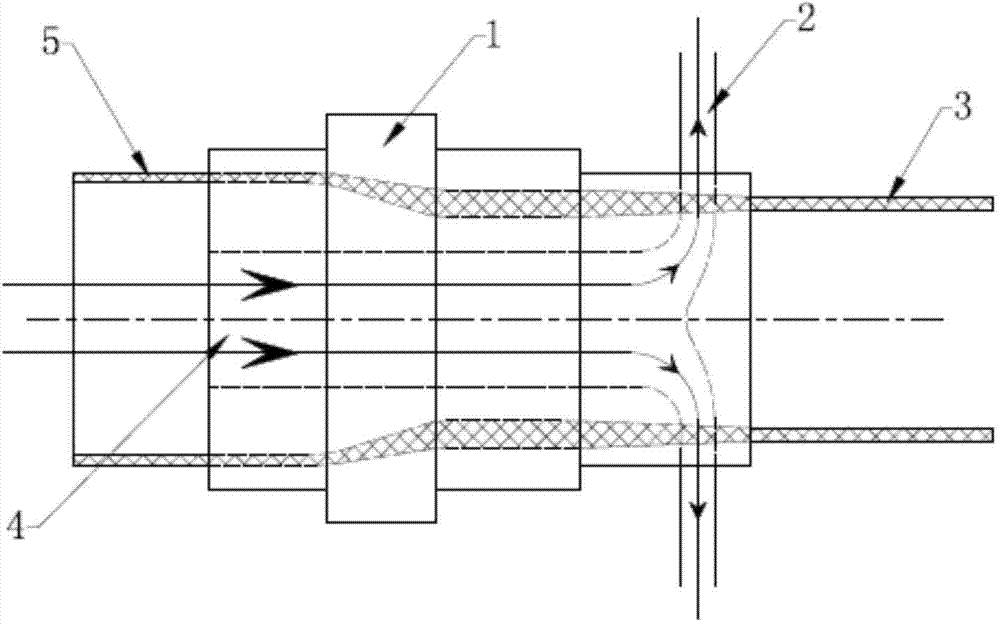

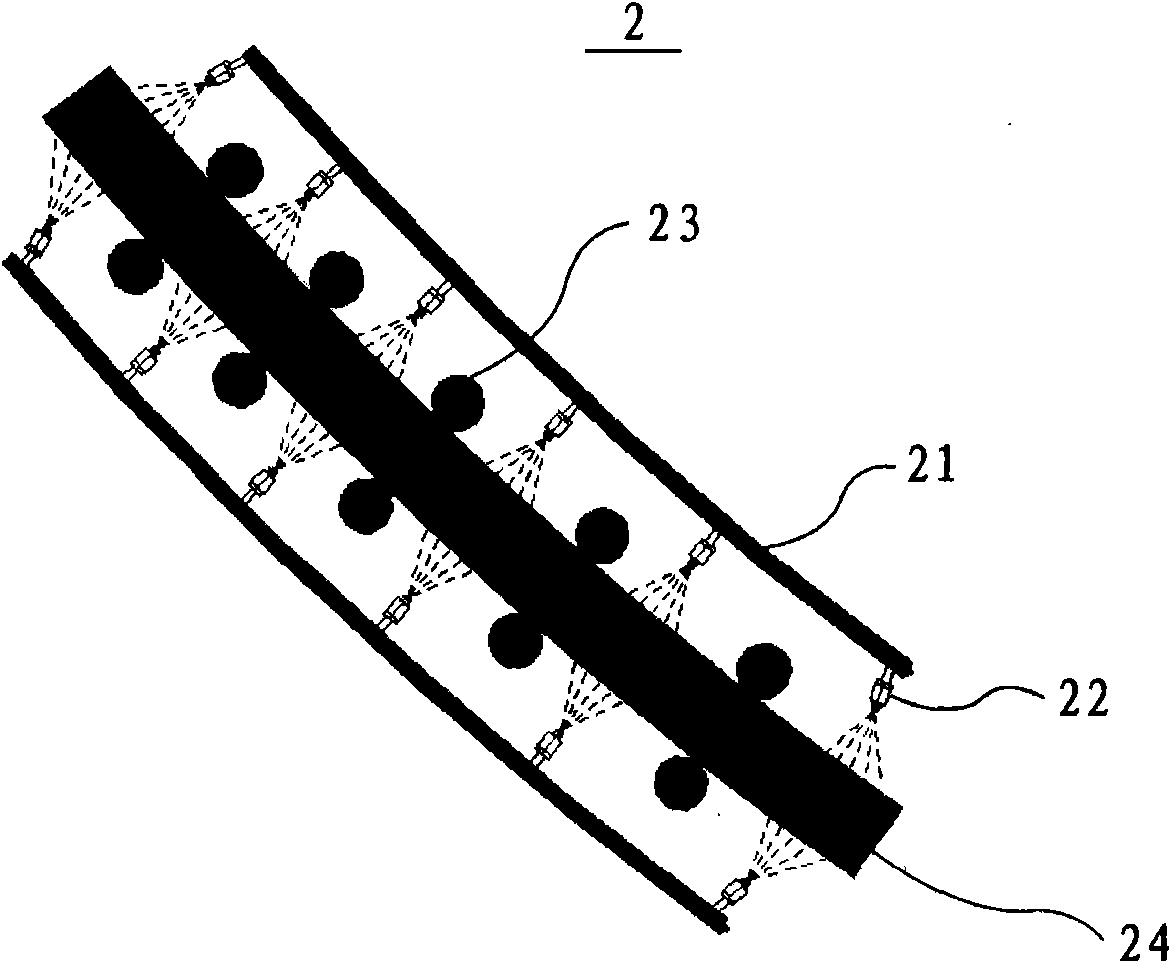

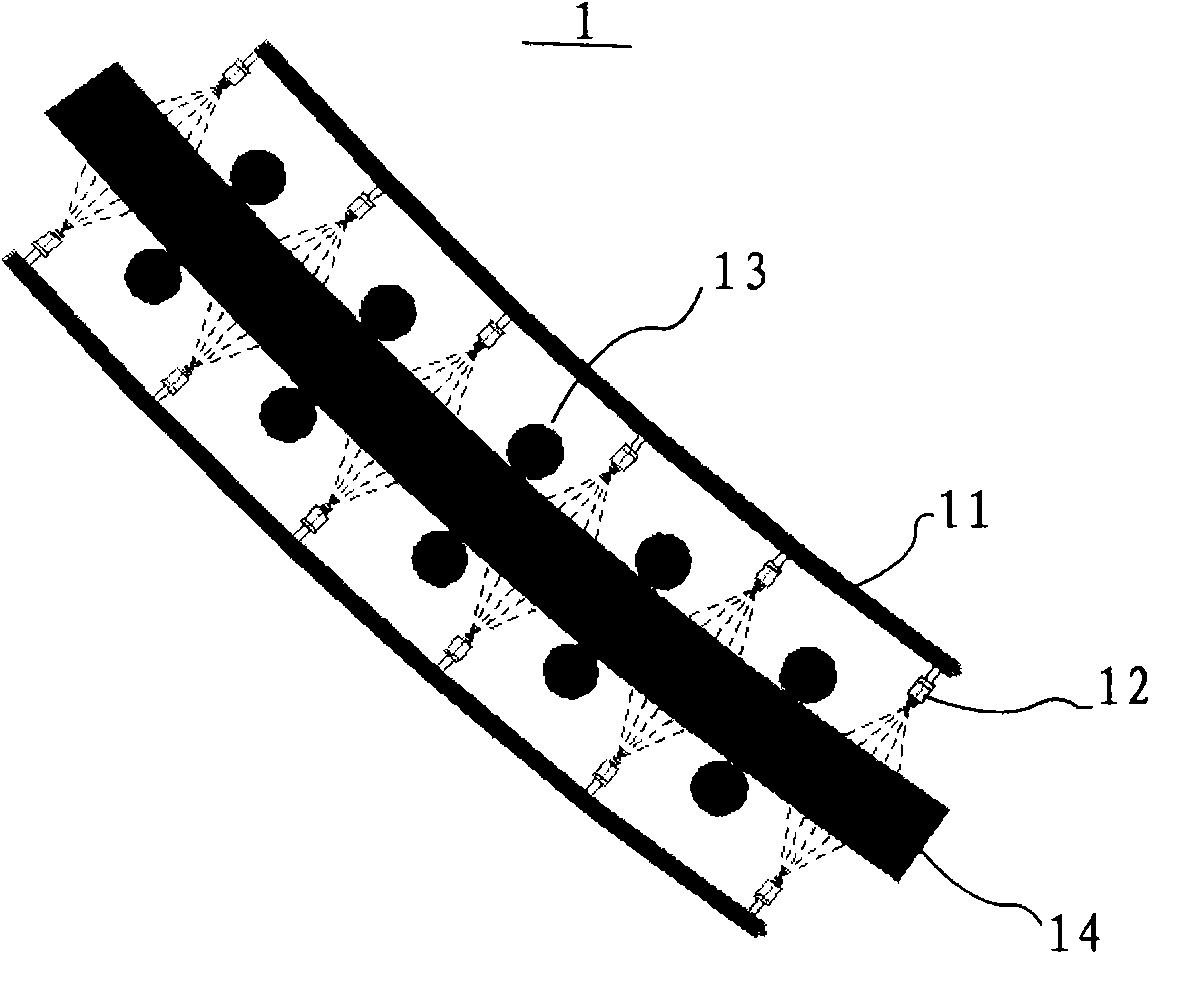

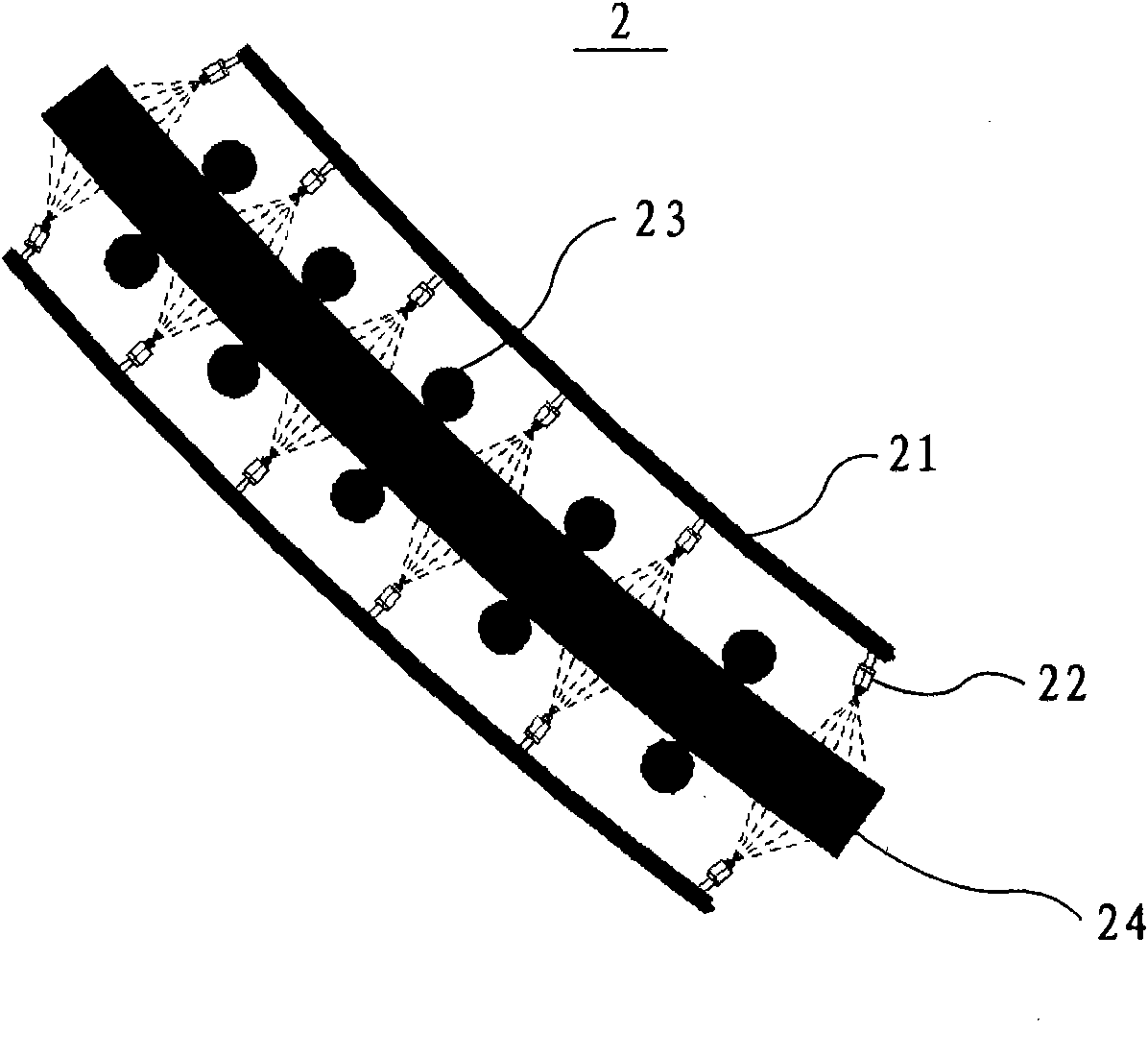

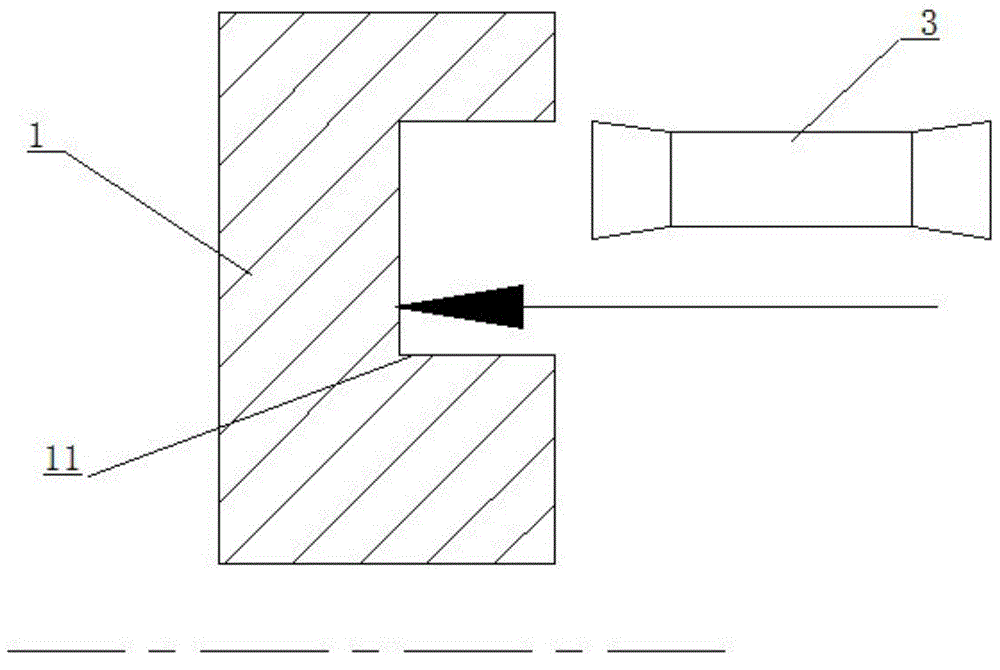

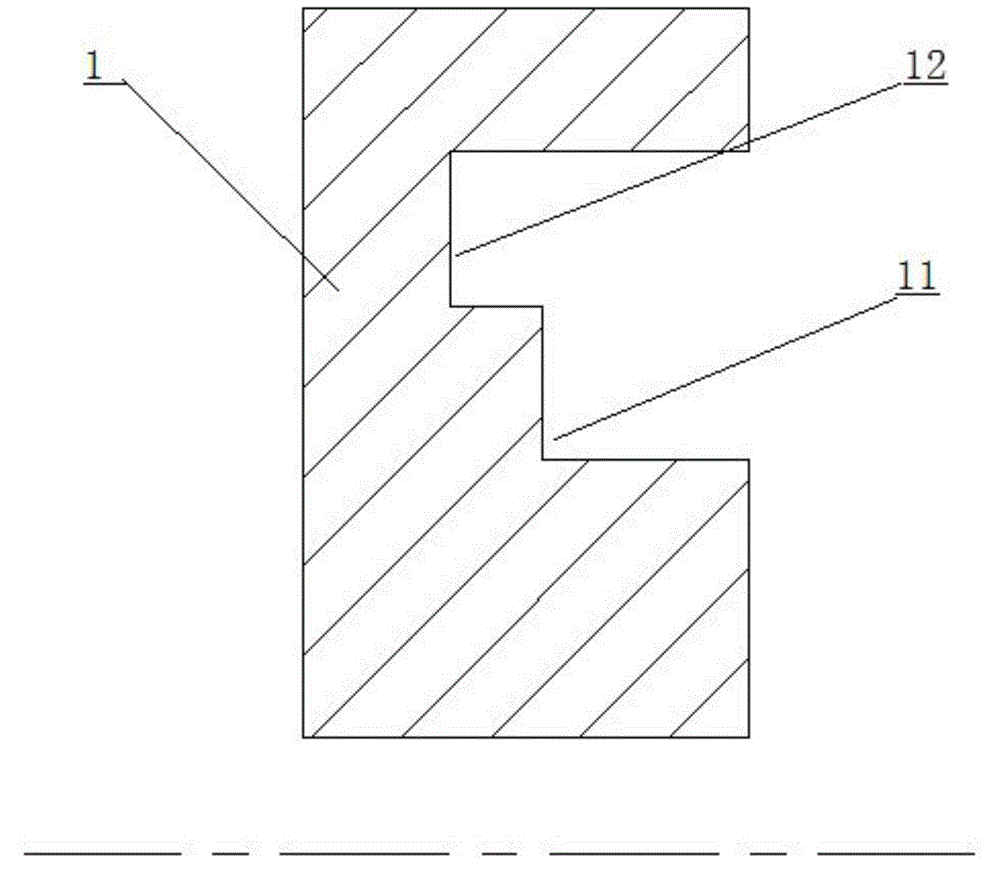

Three-phase flow supply system for nanoparticle jet micro-lubrication grinding

ActiveCN102287606AWell mixedIncrease the diameterConduits/junctionsLubrication check valvesEngineeringHigh pressure

The invention relates to the field of machining, in particular to a nano particle jet flow micro-scale lubricating and grinding three-phase flow supply system. The system is characterized in that: nano fluid is conveyed to a nozzle by a liquid path, high temperature gas enters the nozzle through a gas path at the same time, the high pressure gas and the nano fluid are fully mixed and atomized in the mixing room of the nozzle, the mixed high pressure gas and nano fluid are accelerated in an acceleration room and enter a vortex room, compressed gas enters from the vent hole of the vortex room, and a three-phase flow is further mixed and accelerated by rotating, and is jetted in the form of atomized liquid drops to a grinding area through the outlet of the nozzle. The system has the advantages that: the helical vent hole of the mixing room of the nozzle is tangent to the wall surface of the mixing room, and the nano fluid and the gas are uniformly mixed; pressure adjusting valves, throttles and flow meters are arranged in the gas path and the liquid path, and the pressure and the flow of the nano fluid and the high pressure gas can be adjusted as required so as to achieve an optimal micro-scale lubricating effect; and the problems of insufficient cooling capability in micro-scale lubricating, the large using quantity of a lubricant in pouring type grinding, high waste liquid processing cost and heavy environment pollution are solved.

Owner:青岛前瞻产业园区运营管理有限公司

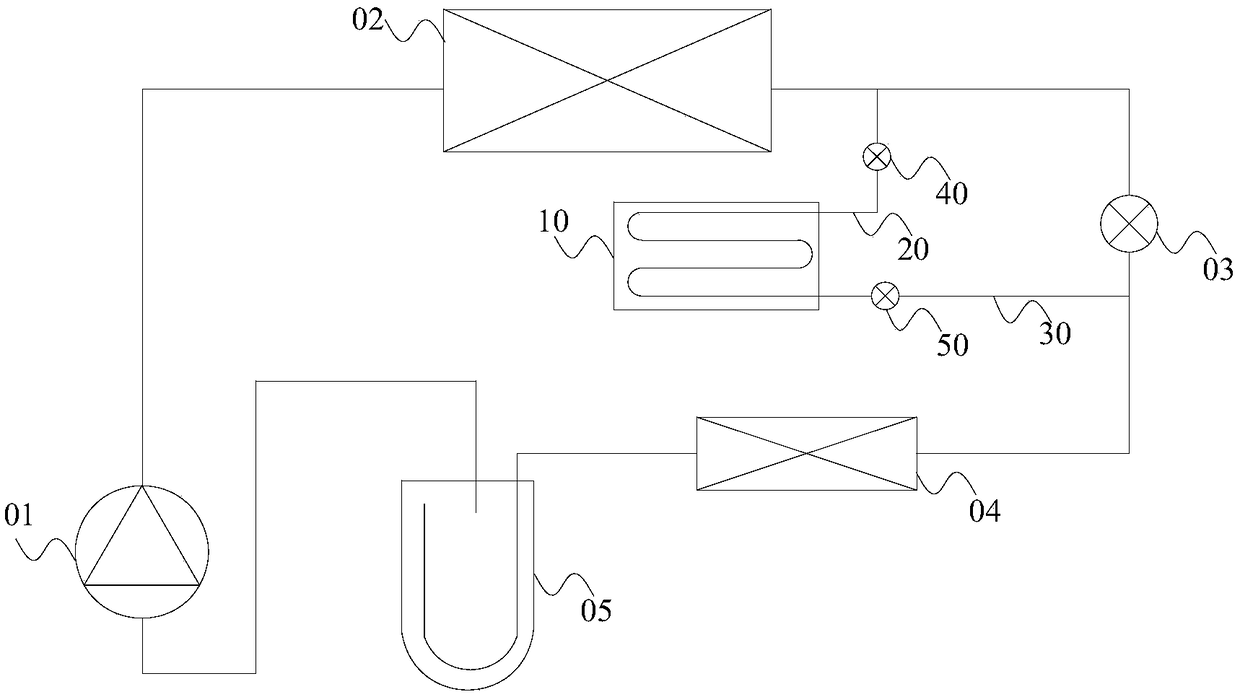

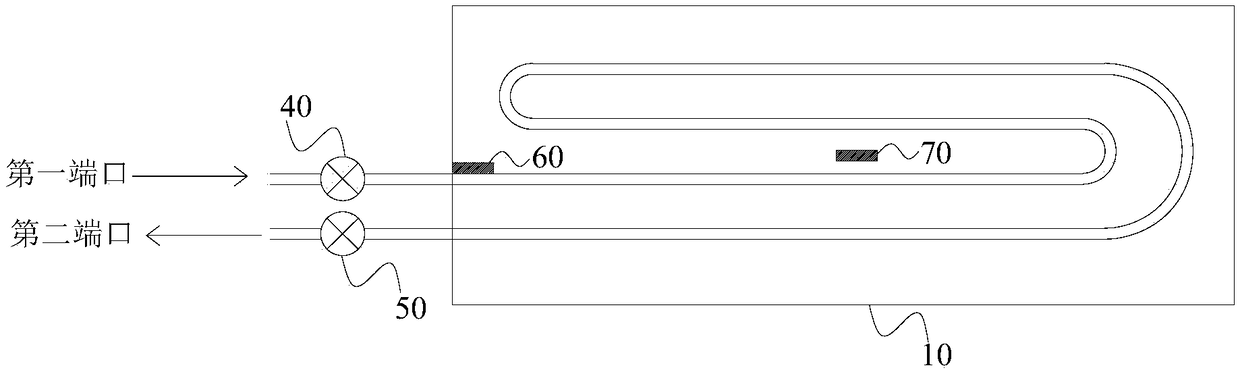

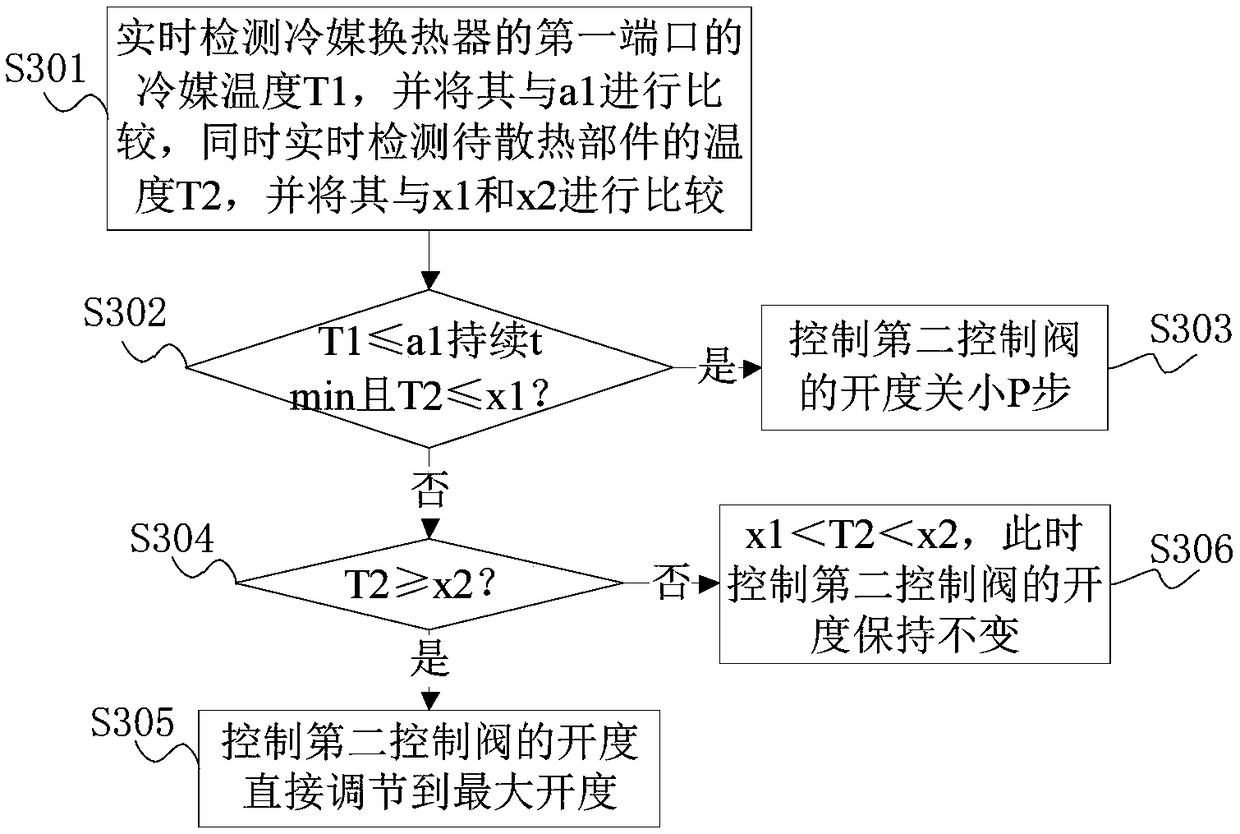

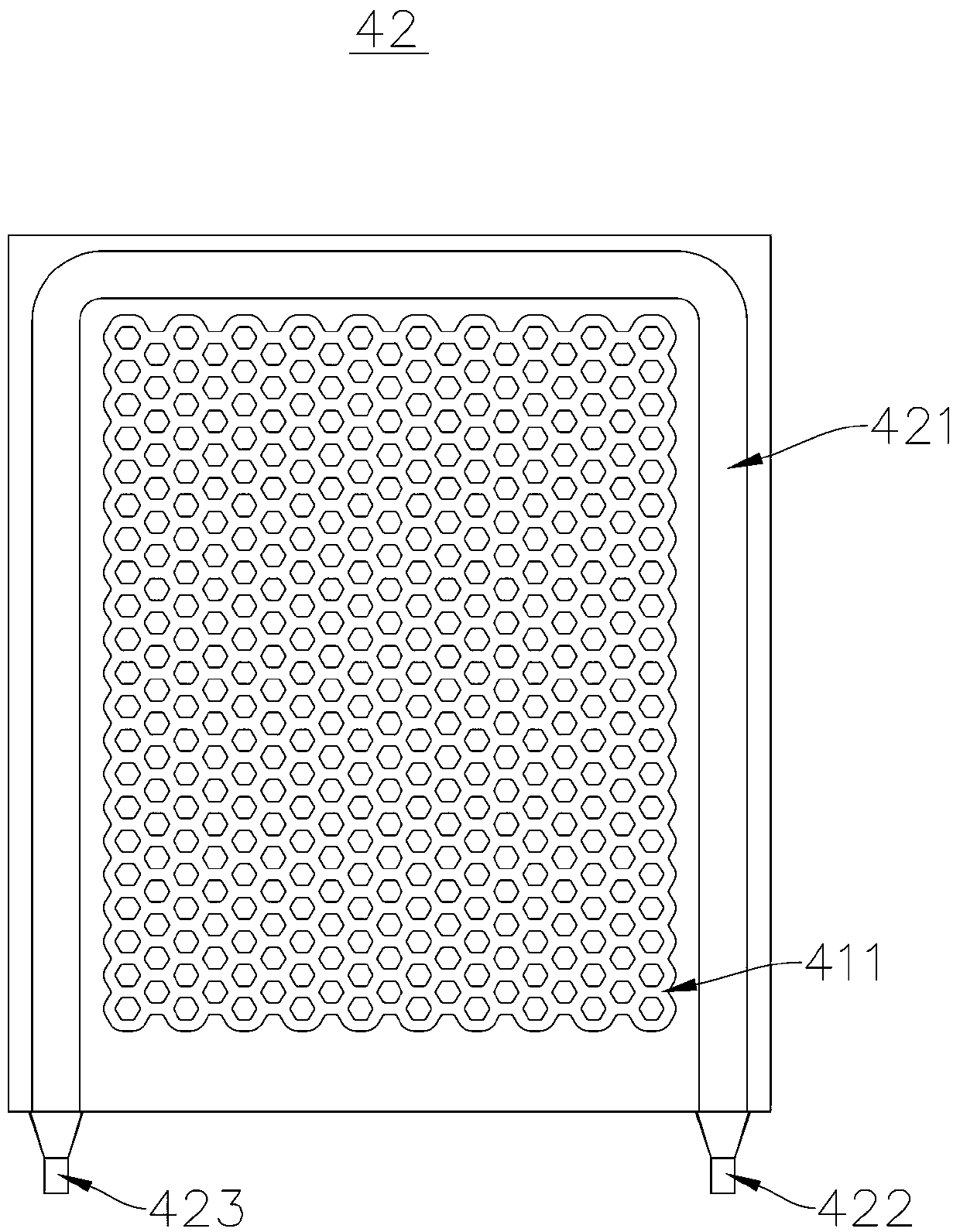

Air conditioning system and refrigerant heat dissipation device and method thereof

ActiveCN109028452ASolve condensationSolve the cooling effectMechanical apparatusCondensate preventionEngineeringAir conditioning

The invention discloses an air conditioning system and a refrigerant heat dissipation device and method thereof. The refrigerant heat dissipation device comprises a refrigerant heat exchanger used fordissipating heat of a part to be subjected to heat dissipation, a first refrigerant pipeline which is used for conveying the refrigerant split from an refrigeration system of the air conditioning system to the refrigerant heat exchanger, a second refrigerant pipeline which is used for conveying the refrigerant flowing out of the refrigerant heat exchanger to the refrigeration system, a first control valve arranged on the first refrigerant pipeline, a second control valve arranged on the second refrigerant pipeline, a first temperature detection unit which is used for detecting refrigerant temperature of a first port of the refrigerant heat exchanger, a second temperature detection unit which is used for detecting the temperature of the part to be subjected to heat dissipation, a control unit which is used for adjusting an opening degree of the first control valve according to the refrigerant temperature of the first port of the refrigerant heat exchanger, and adjusting the opening degree of the second control valve according to the refrigerant temperature of the first port of the refrigerant heat exchanger and the temperature of the part to be subjected to heat dissipation. The refrigerant heat dissipation device has the advantages that the problems of condensation and insufficient cooling capacity can be solved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

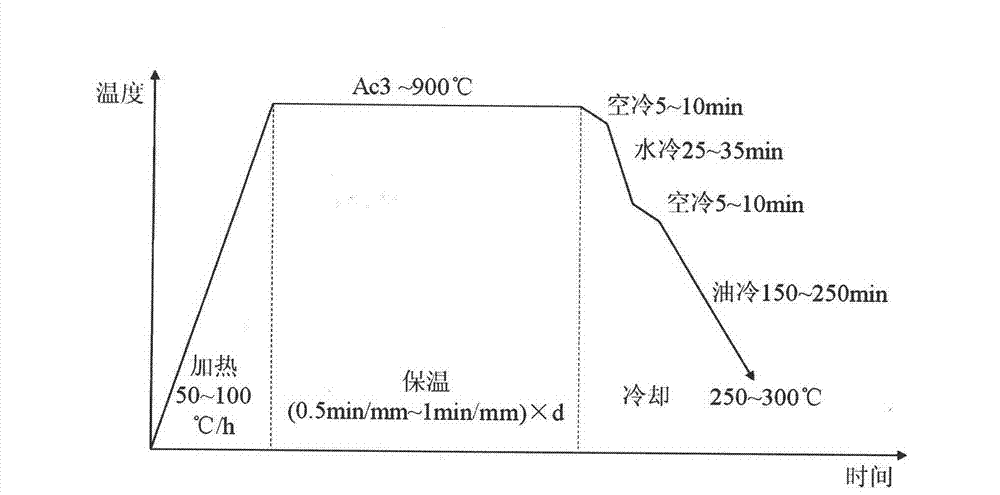

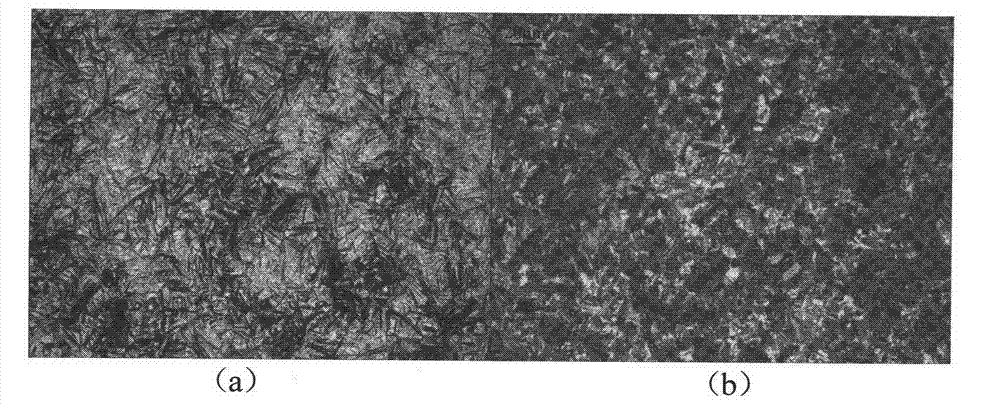

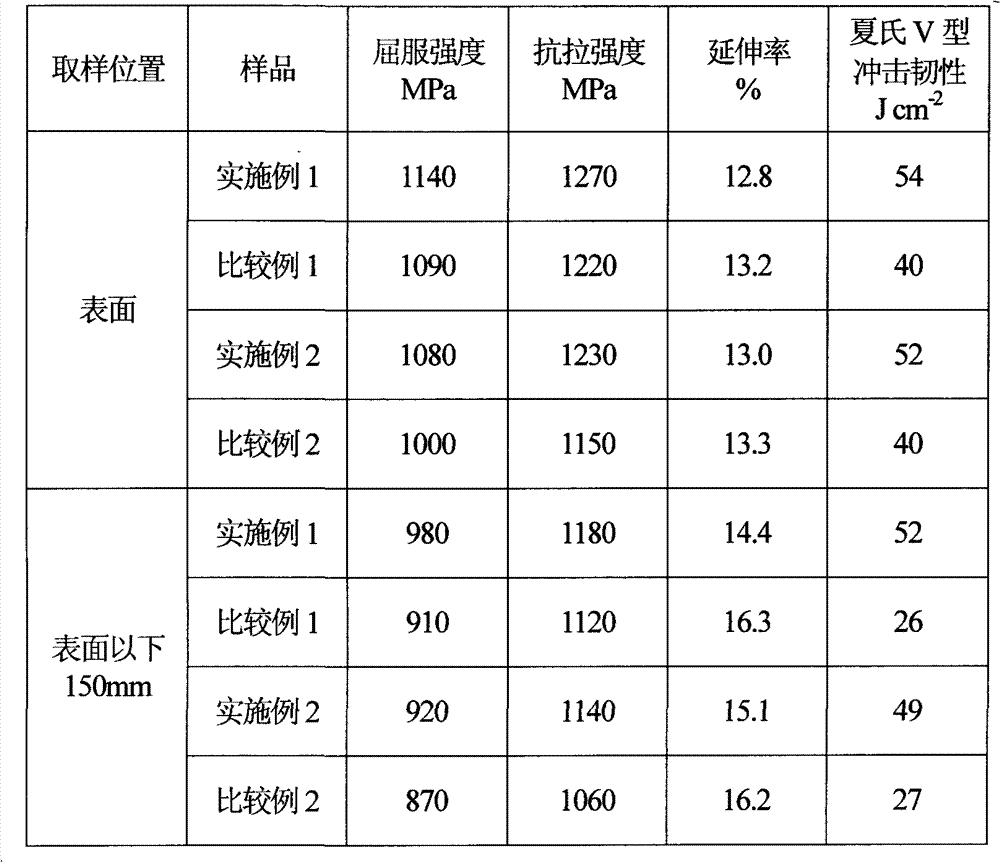

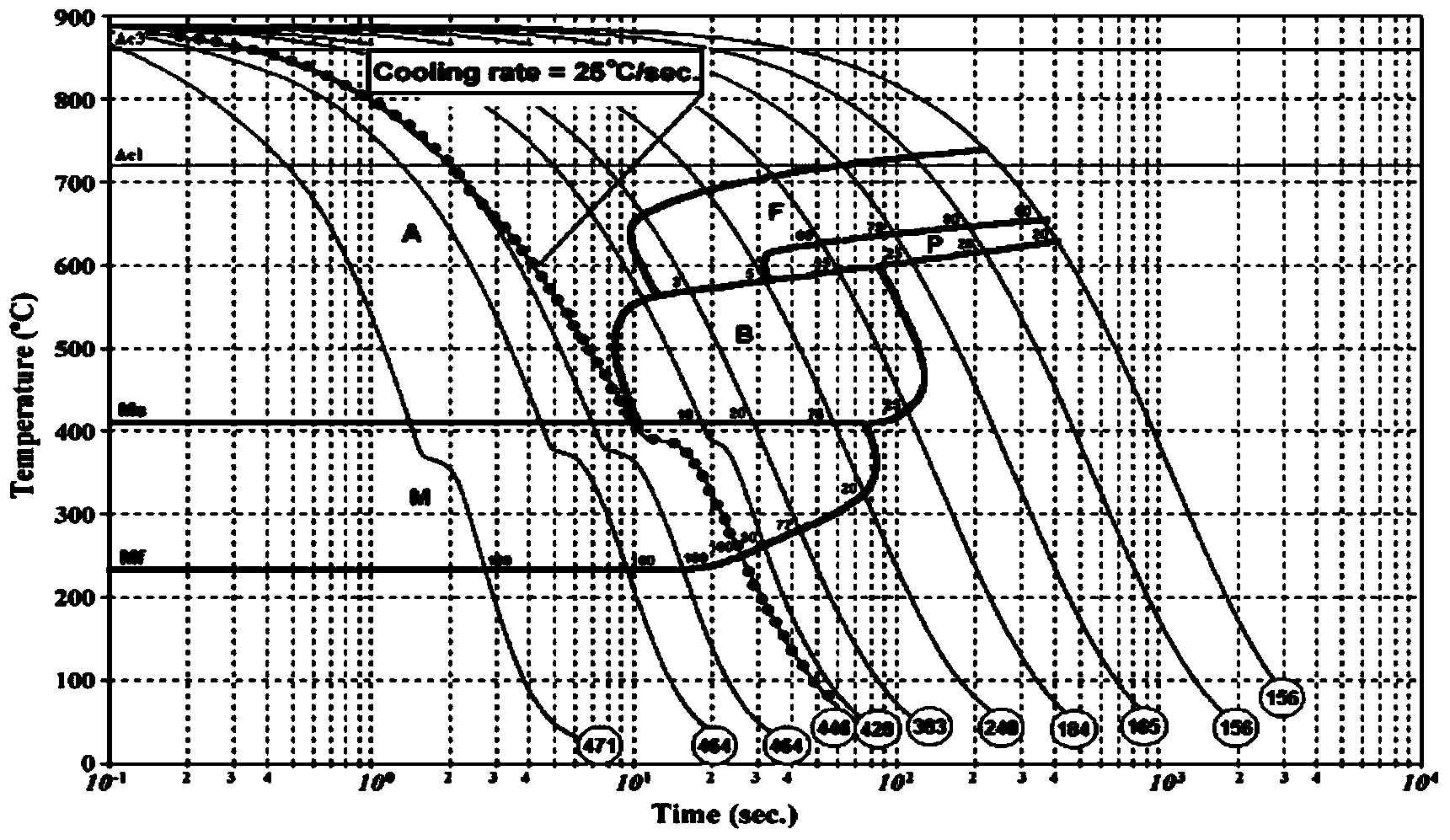

Quenching heat treatment process for hot work die steel with low heat resistance

ActiveCN102776450AAddressing poor organizational performanceAvoid it happening againForging/hammering/pressing machinesHeat resistanceAlloy

The invention relates to the field of heat treatment technology and provides a quenching heat treatment process for low-heat resistance hot work die steel which has low content of alloy and costs little in production and especially for low-heat resistance hot work die steel with a great tonnage and a great size. The process overcomes the problem that insufficient cooling capability of quenching oil causes generation of abundant upper bainite structures, which further leads to deterioration of the performance of steel. The quenching heat treatment process comprises the following steps: heatingthe low-heat resistance hot work die steel and carrying out insulation and full austenization on the low-heat resistance hot work die steel; carrying out segmented quenching heat treatment by using different cooling mediums at different temperatures; and carrying out tempering heat treatment immediately after surface temperature of the low-heat resistance hot work die steel drops to a certain range. According to the invention, a high cooling rate and low residual stress are obtained through a segmented quenching technique based on characteristics of changes of a microstructure of the low-heatresistance hot work die steel in the process of continuous cooling, and therefore, generation of abundant upper bainite structures in the low-heat resistance hot work die steel and the phenomena of deformation and cracking during quenching heat treatment are avoided and the purposes of improving comprehensive mechanical properties and prolonging a service life are achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

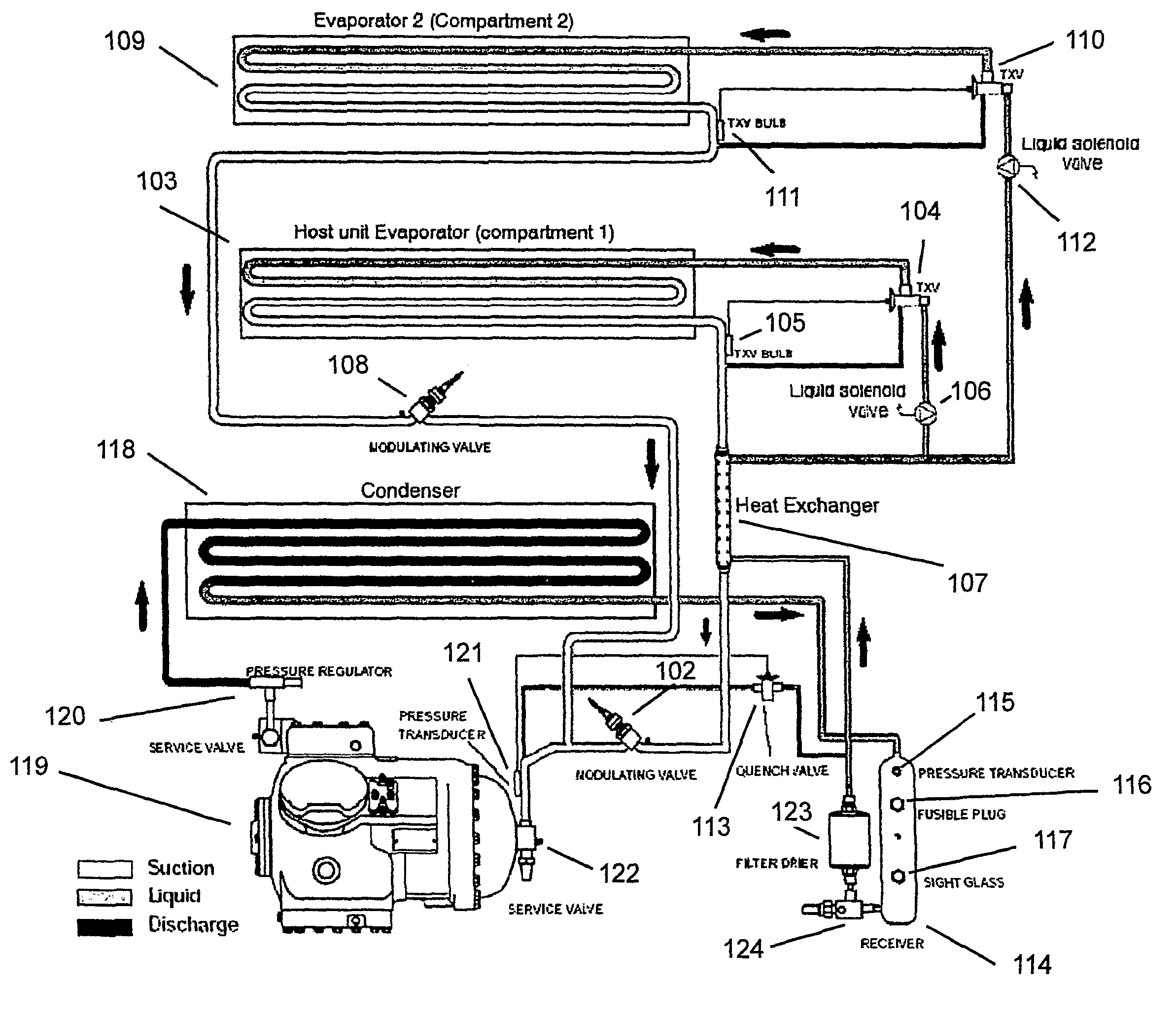

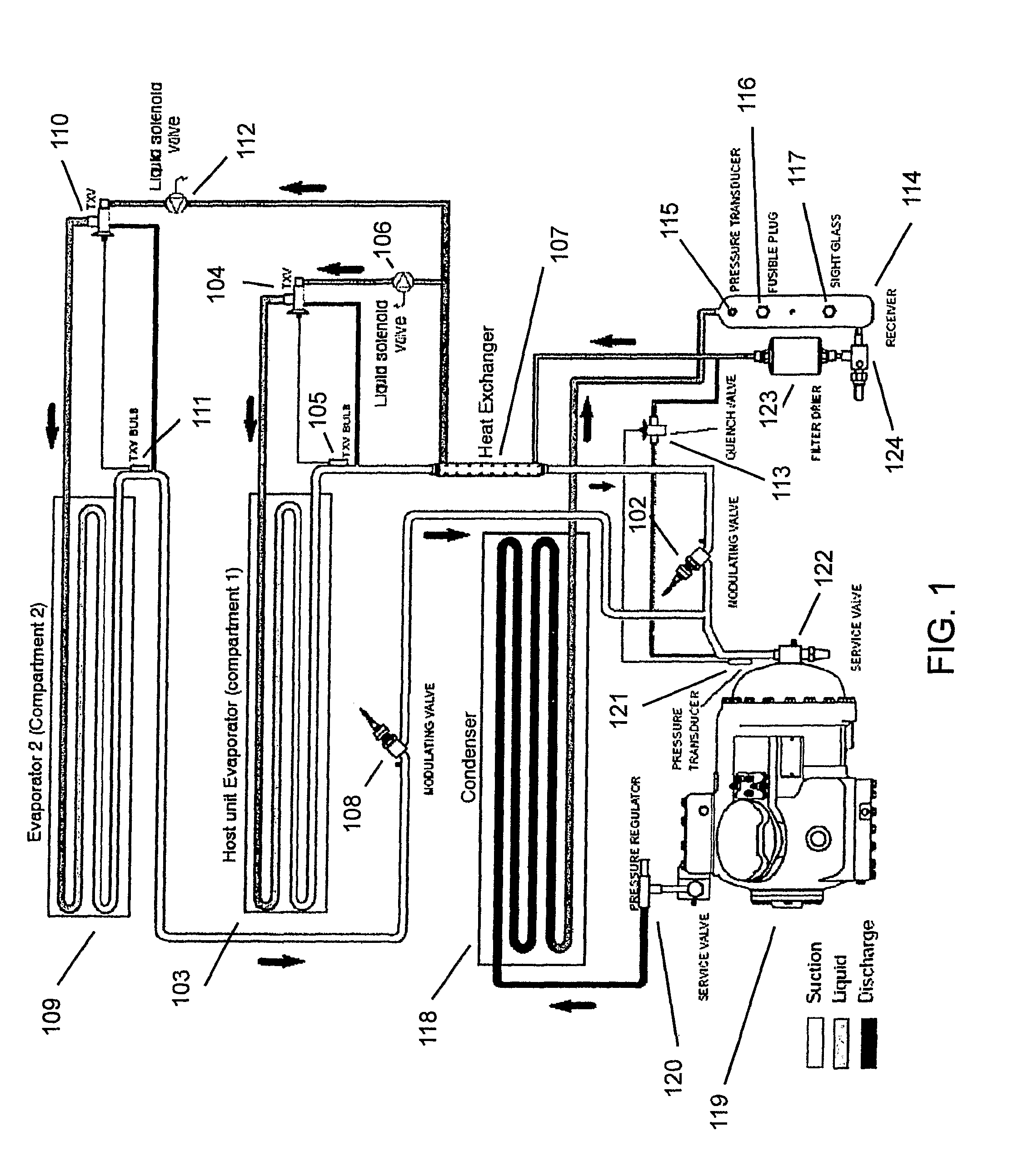

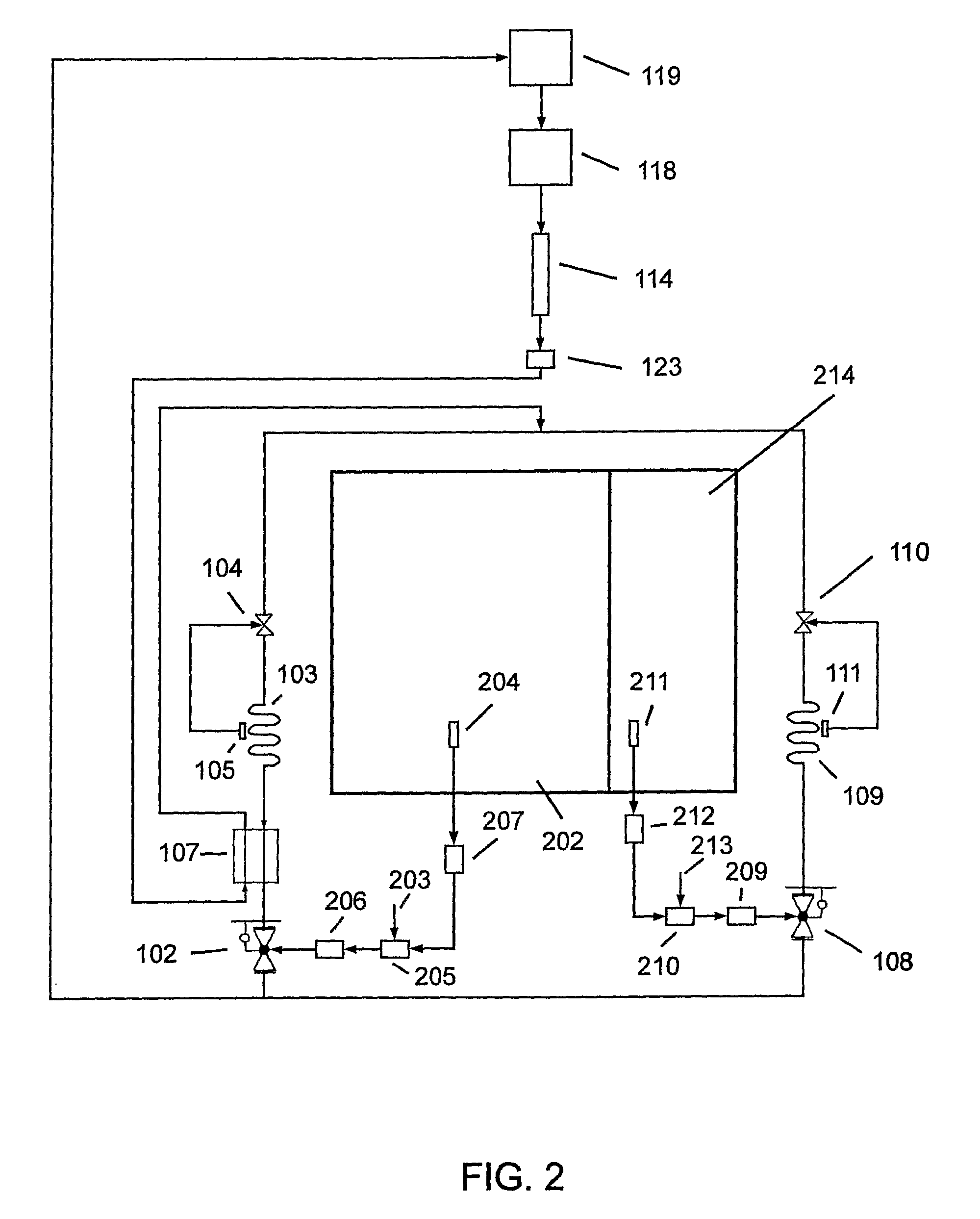

Method for controlling temperature in multiple compartments for refrigerated transport

ActiveUS7937962B2Mechanical apparatusCompression machines with non-reversible cycleTemperature controlTransport system

A refrigerated transport system includes a prioritizing algorithm to limit the maximum amount of refrigerant flow available to at least one limited cooling compartment by holding a delta T (difference between the supply air temperature and return air temperature) instead of a setpoint temperature in the at least one limited cooling compartment when the available cooling capacity is insufficient to hold a substantially constant temperature in all compartments. A method for creating multiple refrigerated compartment spaces having precision temperature control includes the steps of: prioritizing the compartments by identifying at least one priority compartment to be held at a setpoint temperature; and limiting refrigerant flow to all but the priority compartment when there is insufficient cooling capacity to maintain all compartments at their respective setpoint temperatures.

Owner:CARRIER CORP

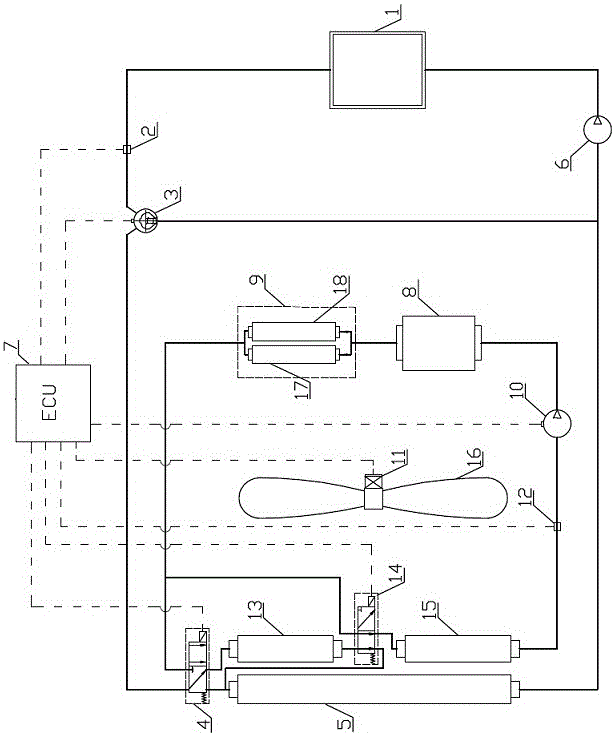

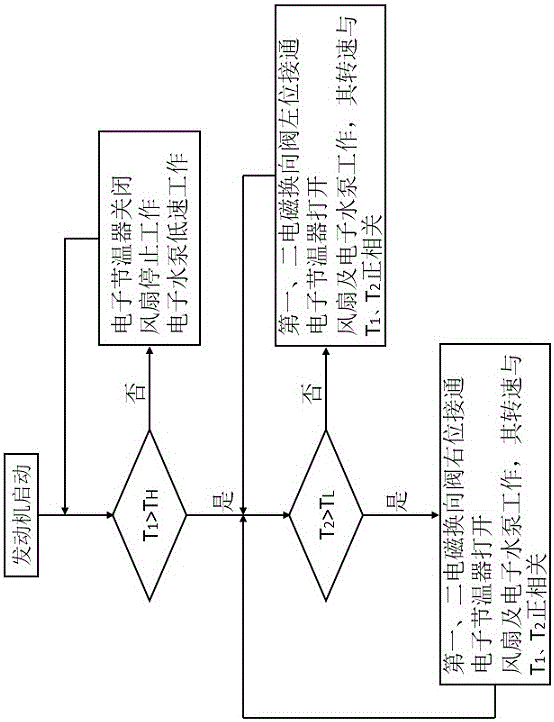

Engineering vehicle temperature control system and method based on double-cooling loop split radiator

ActiveCN106703967AAvoid coolingImprove heat transfer efficiencyLiquid coolingCoolant flow controlTemperature controlEngineering

The invention relates to an engineering vehicle temperature control system and method based on a double-cooling loop split radiator, and belongs to the field of engineering vehicle intelligent temperature control. The engineering vehicle temperature control system has the beneficial effects that a high-temperature cooling loop and a low temperature cooling loop are designed according to characteristics of a system heat source, in the low-temperature cooling loop, cooling liquids of a transmission oil heat exchanger and a hydraulic oil heat exchanger which are arranged in a parallel manner do not interfere with each other, and the problem of insufficient cooling capacity or overcooling is avoided; a water cooling type intercooler, the hydraulic oil heat exchanger and the transmission oil heat exchanger with smaller size are adopted, so that the total weight of a radiator module is decreased while the heat exchange efficiency is improved, the manufacturing cost is reduced, arrangement is more convenient in a limited engine compartment space, and pressure loss of air when flowing through the radiator module is reduced; and through controlling the working state of an electromagnetic reversing valve, an ECU achieves the function of automatically matching the radiator according to the heat dissipation requirements of heat sources in the high-temperature cooling loop and the low temperature cooling loop, the utilization efficiency of the radiator is improved, and the purpose of reducing power consumption of the system is achieved.

Owner:JILIN UNIV

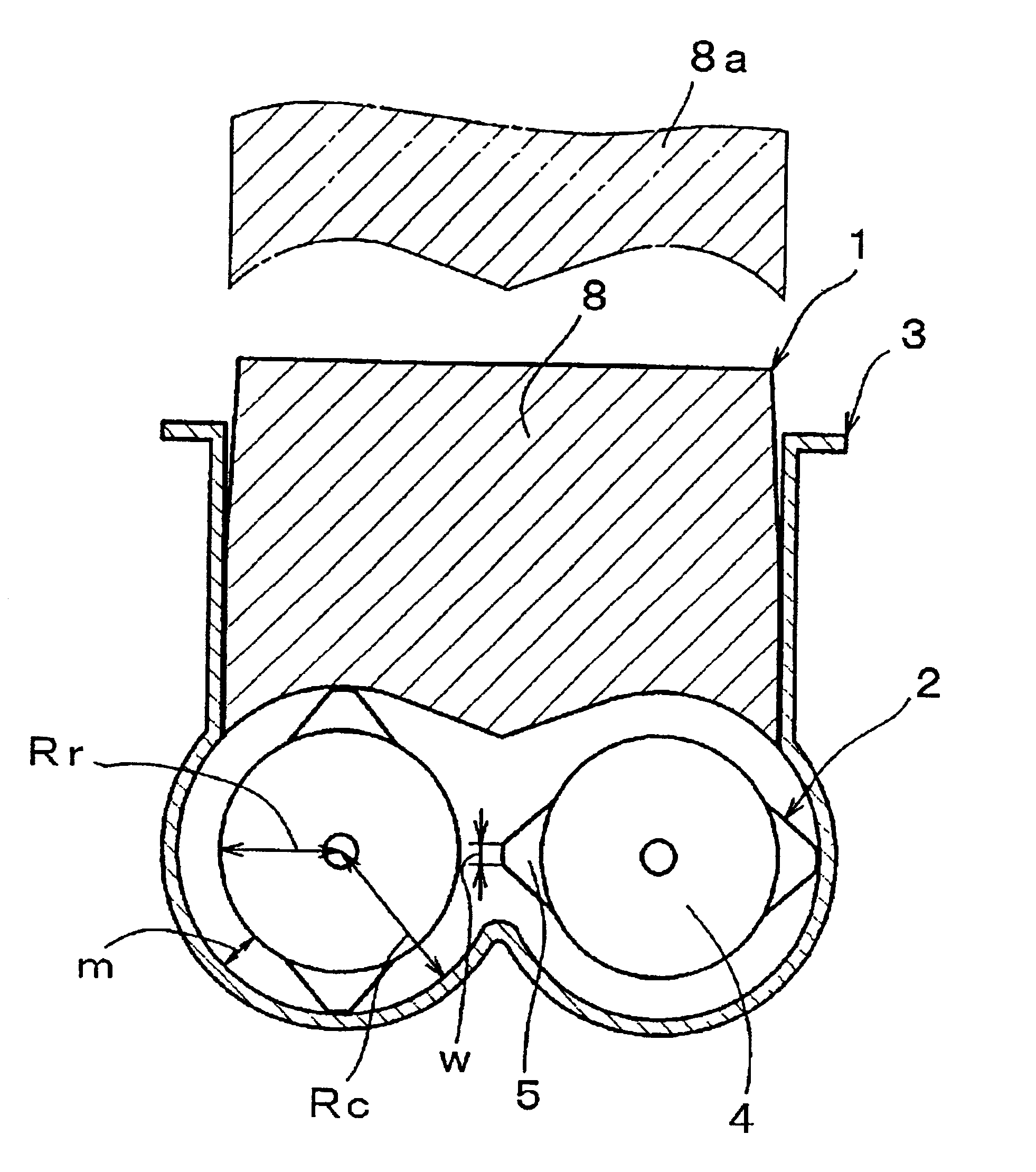

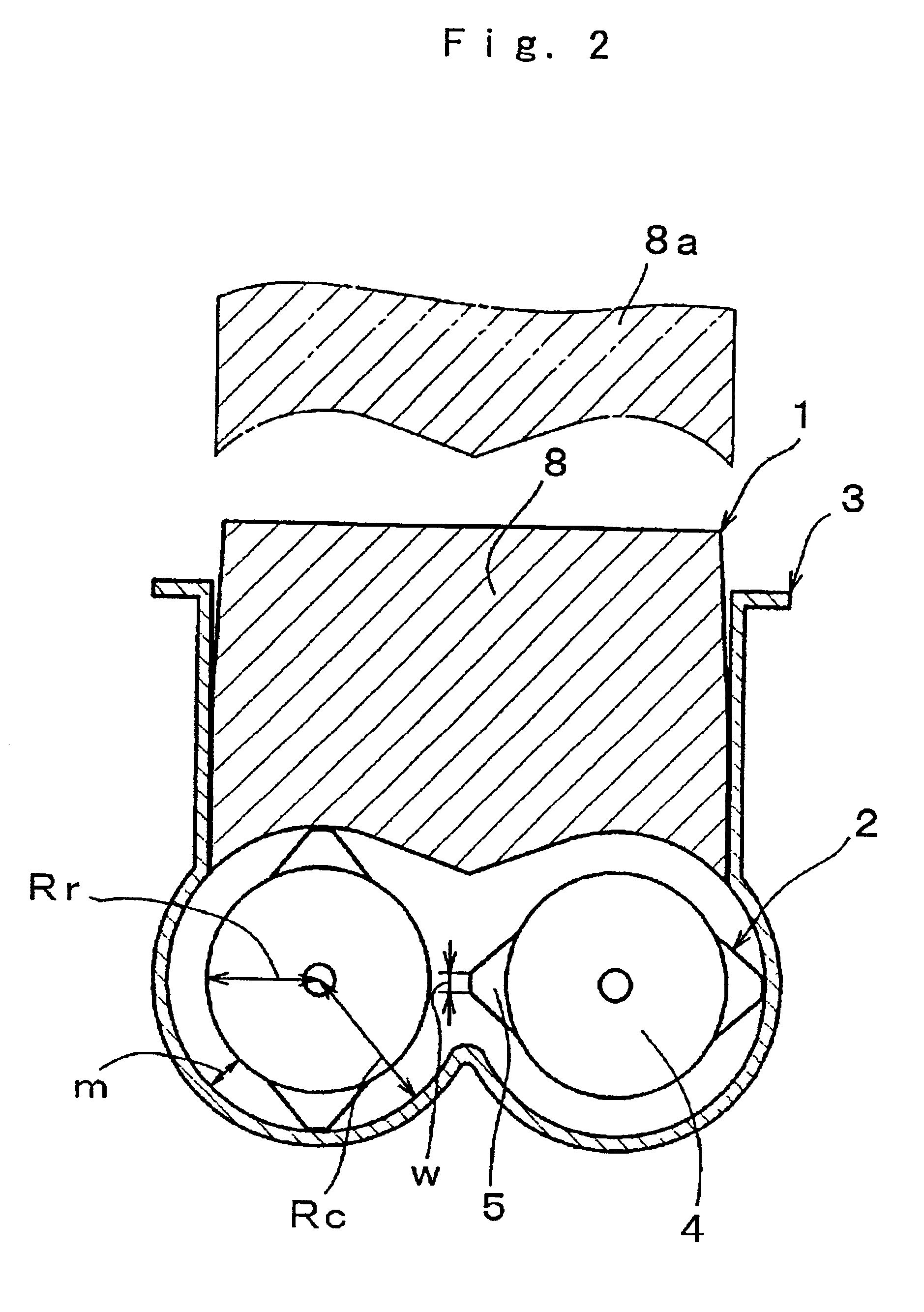

Closed kneader

InactiveUS6913379B2Reduce thicknessImprove cooling effectRotary stirring mixersTransportation and packagingKneader reactorLine tubing

With conventional closed kneaders, the temperature of the kneaded material remains high at the end of primary kneading because insufficient cooling is made in the interior part of the kneaded material, making it necessary to either provide cooling time between the primary and secondary kneading or to transfer materials to another kneader after the end of primary kneading for the secondary kneading. This has constituted an obstruction to productivity. In view of such problems, a closed kneader is capable of controlling the kneaded material temperature at the end of primary kneading at a level no higher than the temperature that allows addition of a vulcanizing agent line, and can perform secondary kneading immediately after the end of primary kneading. In a closed kneader provided with a chamber for storing kneaded material and a pair of rotors installed in the chamber, the proportion of the radius of the rotor shaft to the radius on the inner face of the chamber is kept at no less than 0.65.

Owner:MORIYAMA +1

Two-piece magnetic shield having improved heat dissipation

ActiveUS20050094319A1Less field disturbanceImprove cooling effectElectrical transducersHeads using thin filmsEngineeringNon magnetic

Problems such as thermal pole tip protrusion result from thermal mismatch between the alumina and pole material during the writing process. This, and similar problems due to inadequate heat dissipation, have been overcome by dividing the bottom shield into two pieces both of which sit on top of a non-magnetic heat sink. Heat generated by the coil during writing is transferred to the non-magnetic heat sink whence it gets transferred to the substrate. With this approach, the head not only benefits from less field disturbance due to the small shield but also improves heat dissipation from the additional heat sink

Owner:HEADWAY TECH INC

Radiation refrigeration coating, as well as preparation method and testing device thereof

ActiveCN108795108AEasy to prepareGood effectMaterial heat developmentThermometers using electric/magnetic elementsOrganic solventMass ratio

The invention discloses a preparation method of a radiation refrigeration coating. The method comprises the following steps: (1) weighing raw materials in a mass ratio of Mg11(HPO3)8(OH)6powder to a binder of (70-90%) to (10-30%); (2) dissolving the binder to an organic solvent, heating and stirring until the mixture is in a transparent and bubble-free state, and then mixing in the Mg11(HPO3)8(OH)6 powder weighed in the step (1) to obtain a blend; and (3) adding a dispersant to the blend obtained in step (2) and mixing evenly to prepare film slurry to be coated. The invention also discloses atesting device for testing the radiation refrigeration coating.The invention has the advantages that the preparation method is simple, environmental friendliness is realized and the effect is remarkable, and the problems that the cost is high when a multi-layer nano film is adopted for realizing radiation refrigeration, and the production process is complicated can be effectively solved, and at the same time, the problem of the insufficient cooling effect by traditional single reflection or radiation can be solved.

Owner:SOUTH CHINA UNIV OF TECH

Monitoring vidicon cooling method and structure based on thermal pressure effect

ActiveCN106254732AEnhanced convective heat transferStable temperatureTelevision system detailsColor television detailsCooling effectEngineering

The invention discloses a monitoring vidicon cooling method and structure based on a thermal pressure effect. The structure comprises a heat insulation shell, an inner shell, a finned tube, a lifting structure and a bottom cover. According to the monitoring vidicon cooling method and structure disclosed by the invention, gas of the finned tube is heated by solar radiation to form a thermal pressure suction effect, so that gas in an air interlayer of the shell and the inner shell in the monitoring vidicon flows integrally; therefore, the convection heat exchange effect of the wall surface of the inner shell is enhanced; the cooling effect is improved; simultaneously, due to gas flowing, the temperature of electronic devices in the interlayer and the inner shell is kept constant; and too-high temperature rising due to poor cooling in a closed state can be avoided.

Owner:ZHEJIANG UNIV

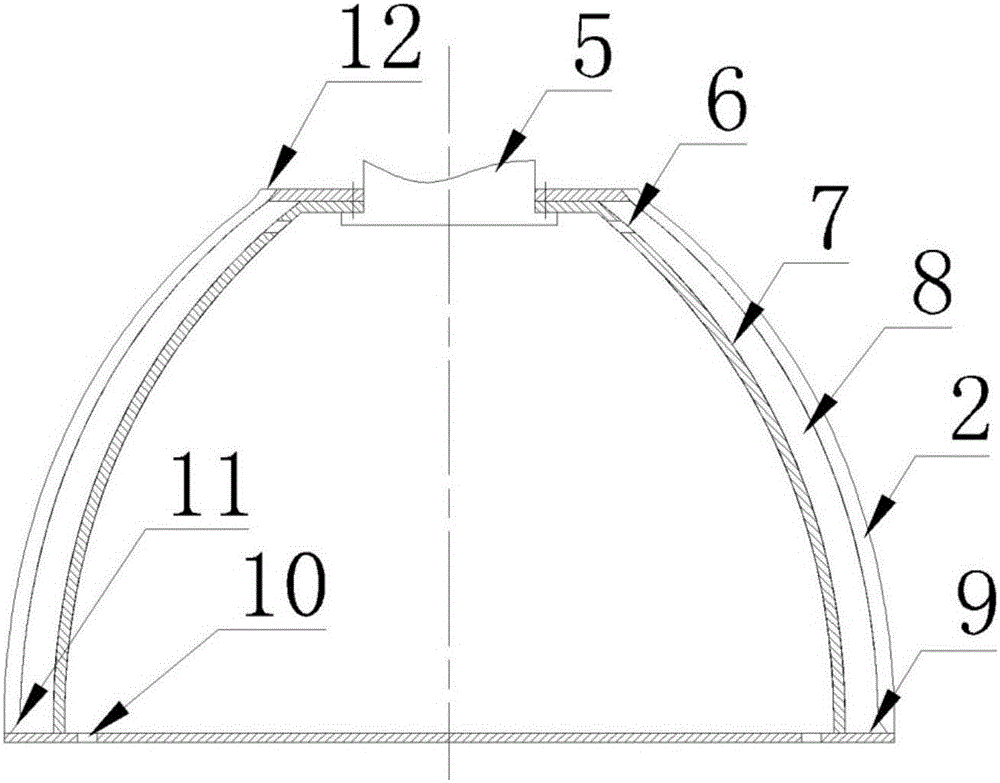

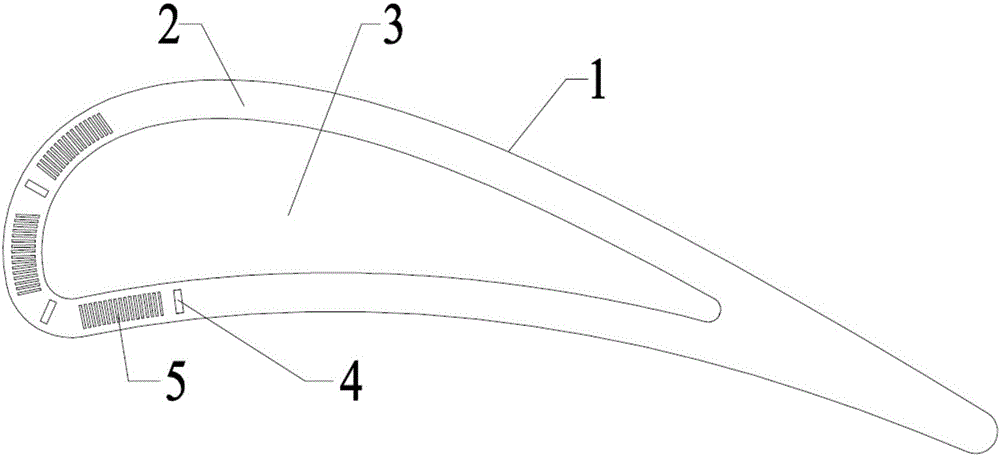

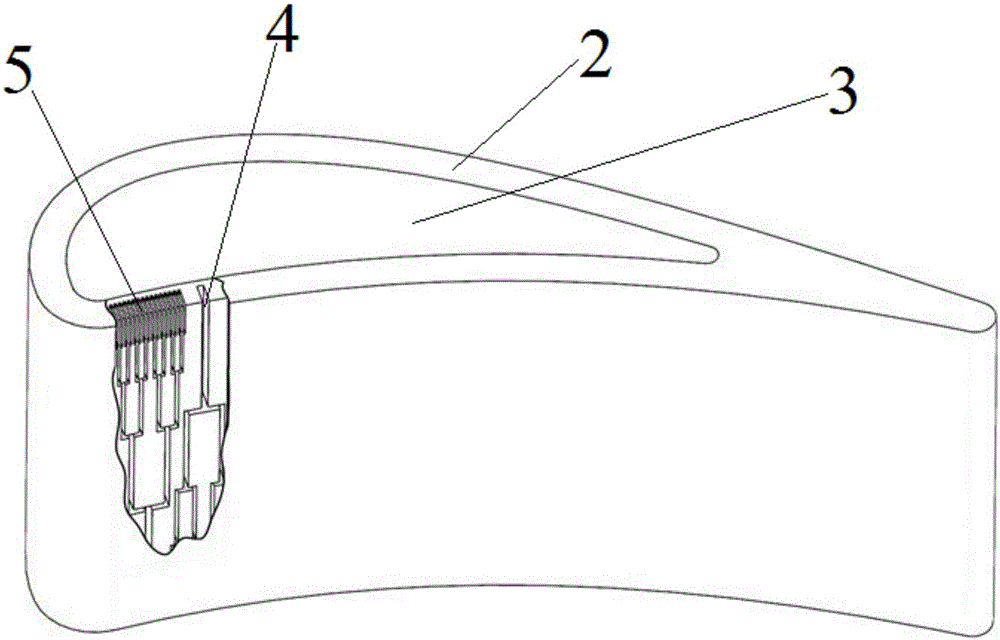

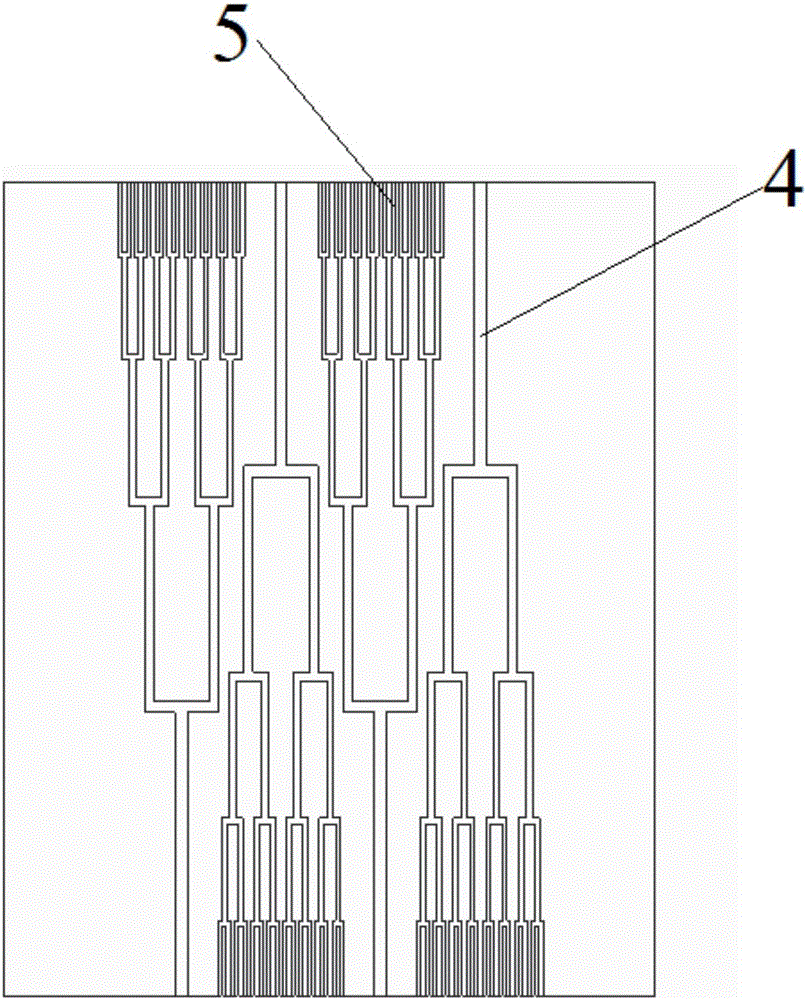

Inner cooling structure of bionic microchannel at front edge of turbine blade and forming method thereof

InactiveCN105019950ASolve for uniformitySolve the lack of cooling effectAdditive manufacturing apparatusBlade accessoriesConfiguration theoryTurbine blade

The invention discloses an inner cooling structure of a bionic microchannel at a front edge of a turbine blade. The inner cooling structure comprises a blade, wherein the outer layer of the blade is an outer wall; a blade center cavity is formed at the middle part of the blade; and multiple sets of tree branched microchannels are formed in the outer wall. The invention further discloses a forming method of the inner cooling structure. The inner cooling structure of the bionic microchannel at the front edge of the turbine blade adopts the tree branched microchannels designed by a bionics configuration theory, has the characteristics of high cooling efficiency, low flowing resistance and uniform temperature distribution, and can solve the problems of cooling nonuniformity and insufficient cooling efficiency of a steam cooling blade in a high-heat-load area.

Owner:XIAN UNIV OF TECH

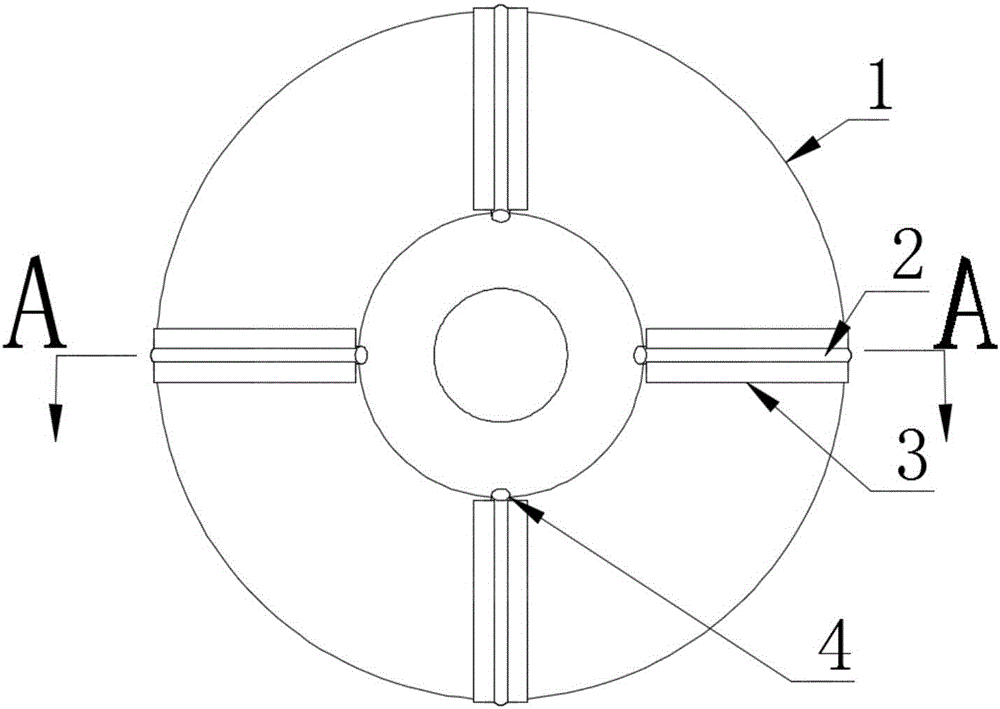

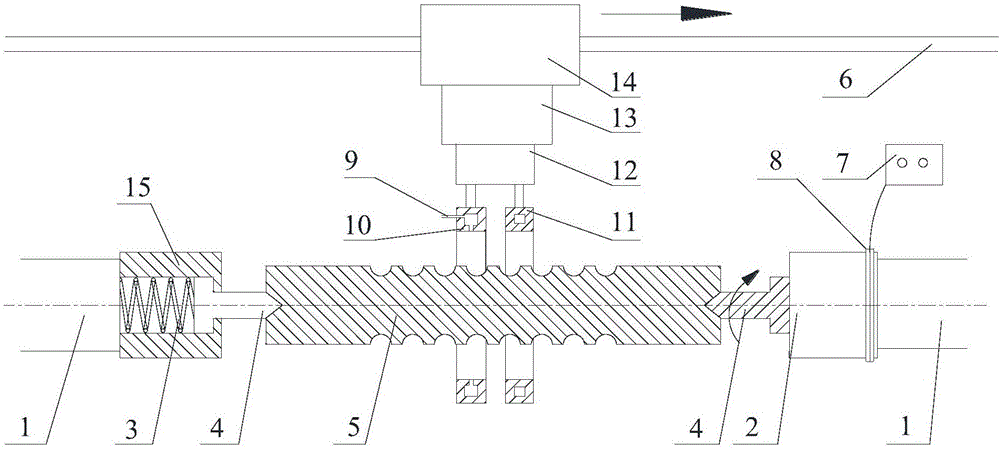

Ultrasonic vibration-assisted screw induction hardening device and technique

ActiveCN106319163AImprove performanceUniform hardness distributionIncreasing energy efficiencyFurnace typesElastic componentUltrasonic vibration

The invention discloses an ultrasonic vibration-assisted screw induction hardening device and a technique. The device comprises a rotating shaft, a first ultrasonic vibrator and two screw fixers, wherein the rotating shaft is used for driving a screw to rotate and is fixed on a machine tool; one end of the first ultrasonic vibrator is fixedly arranged on the end part of the first rotating shaft; one end of a first screw fixer is fixed together with the first ultrasonic vibrator while the other end of the first screw fixer is used for clamping one end of the screw; one end of a second screw fixer is fixed in a shell and is in contact with an elastic component in the shell; the second screw fixer can compress the elastic component; the continuous ultrasonic vibration assistance is performed in the heating and cooling processes of the screw, so that the screw heating is more uniform. Therefore, the soft point defect of the screw surface caused by the insufficient cooling can be prevented, more uniform hardness distribution can be acquired, the performance of the screw surface can be improved and the cooling water dosage can be saved.

Owner:SHANDONG UNIV OF SCI & TECH

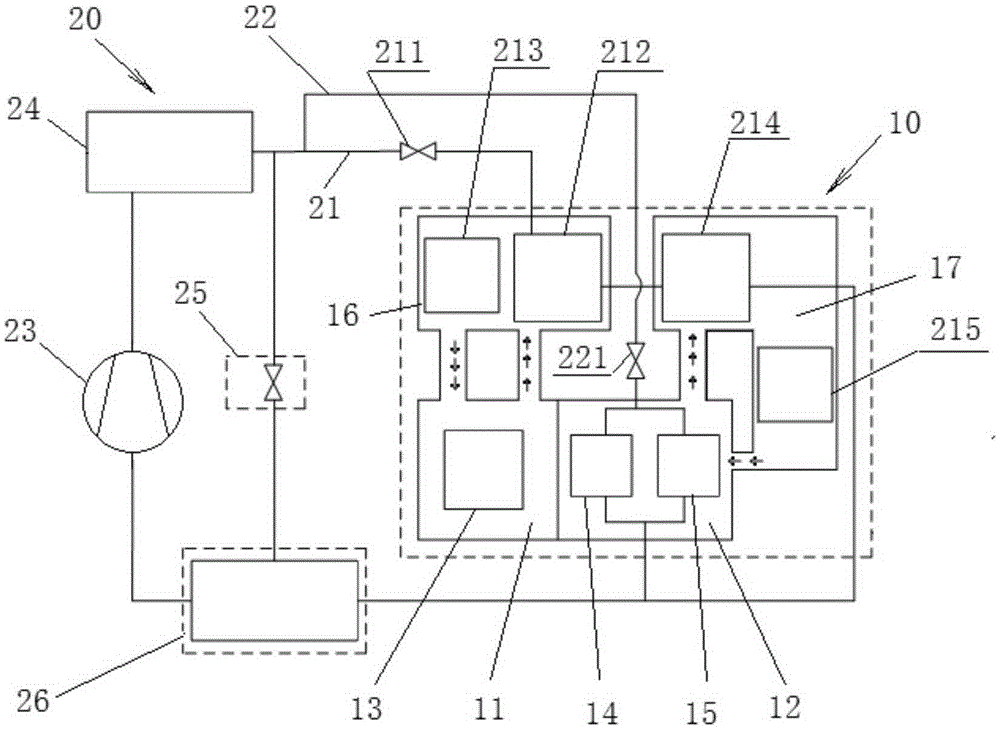

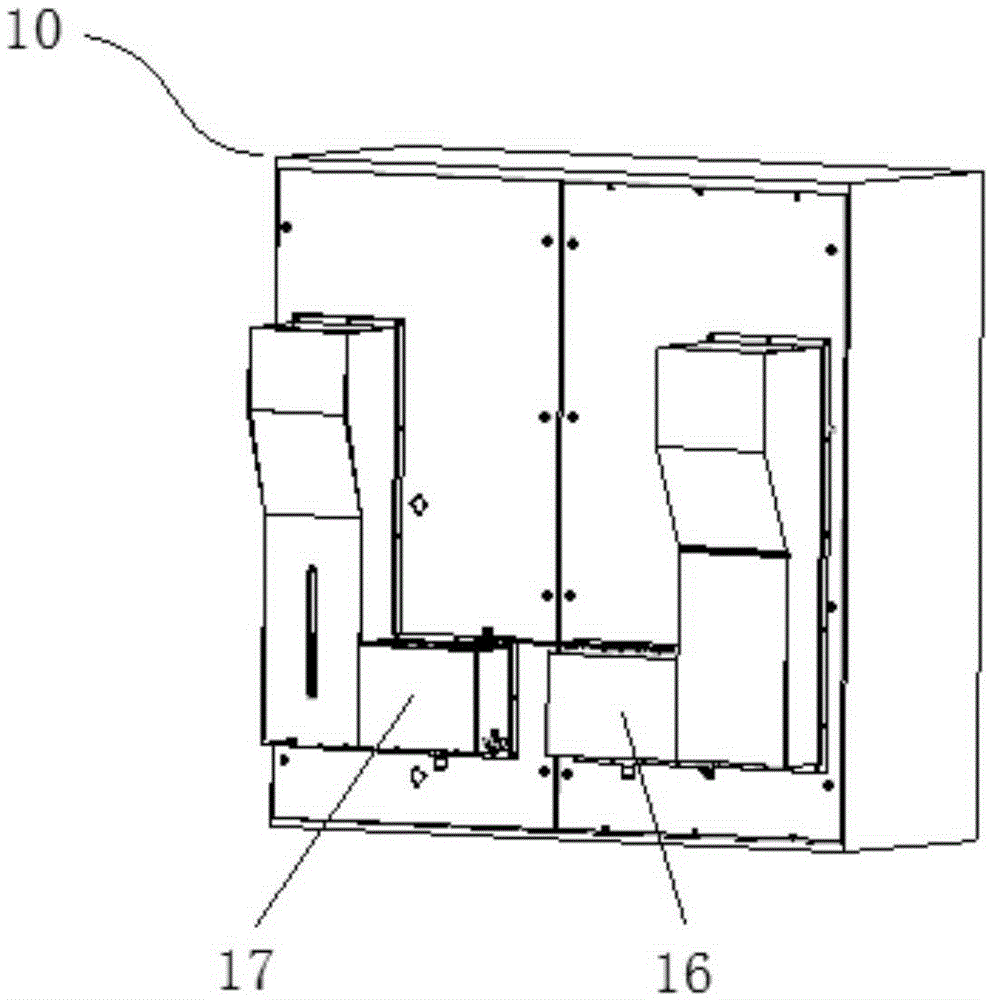

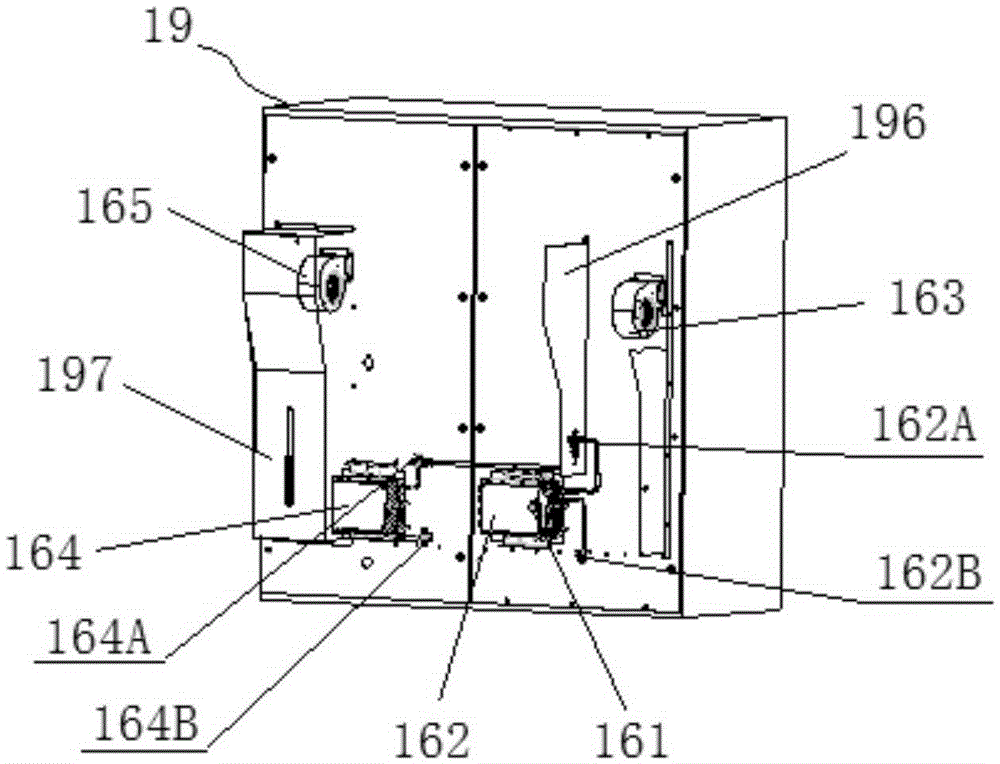

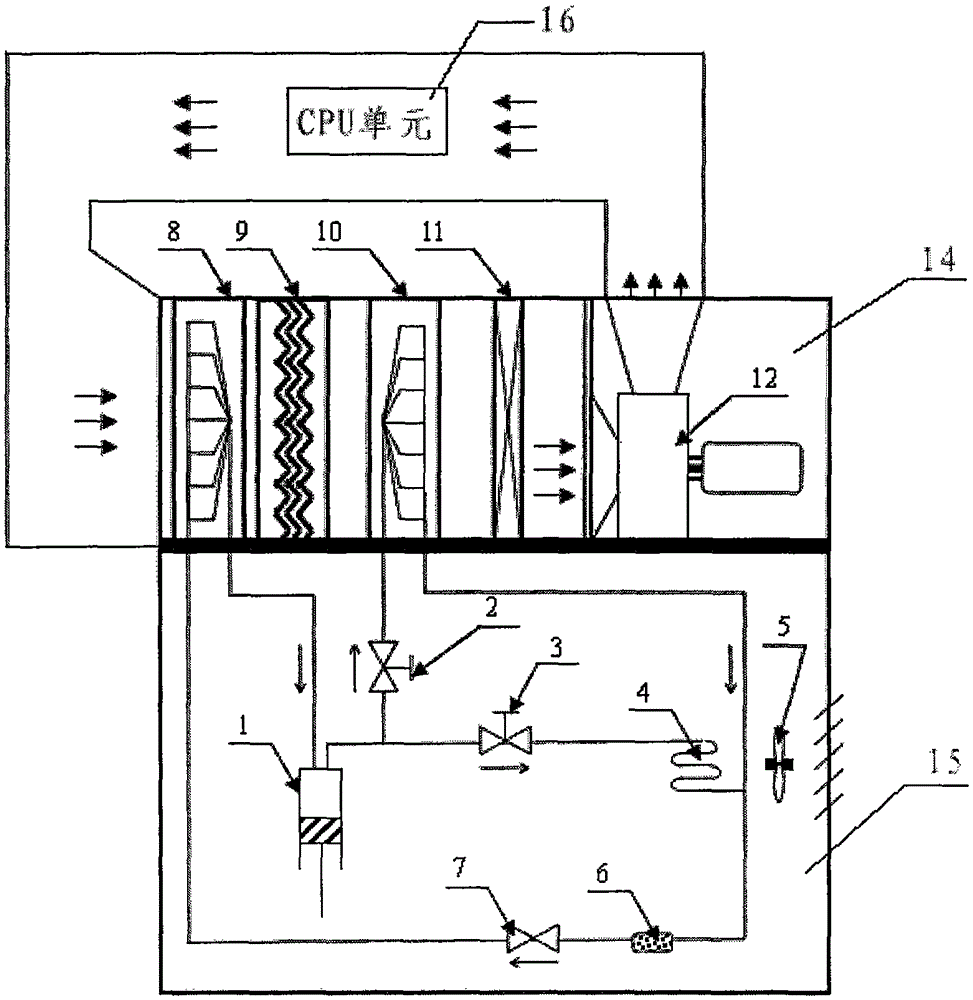

Frequency changer cooling and dehumidification system, frequency conversion type compressor unit and refrigeration plant

ActiveCN105299939AGuaranteed uptimeAvoiding Insufficient Cooling IssuesCompression machines with non-reversible cyclePower conversion systemsFrequency changerElectricity

The invention discloses a frequency changer cooling and dehumidification system, a frequency conversion type compressor unit and a refrigeration plant. The frequency changer cooling and dehumidification system is used for conducting cooling and dehumidification on a frequency changer; the frequency changer has a first space and a second space which are isolated, a reactance module is arranged in the first space, and a rectifier module and an inversion module are arranged in the second space; the reactance module is provided with a hot surface, and the rectifier module and the inversion module are each provided with a cold surface; and the frequency changer cooling and dehumidification system comprises a first cooling fluid passage, and the first cooling fluid passage comprises a first heat exchanger and a second heat exchanger, wherein the first heat exchanger is used for cooling the first space, and the second heat exchanger is used for conducting dehumidification on the second space. According to the technical scheme, the problem of insufficient cooling of a reactance module in a frequency changer external air forced circulation scheme can be effectively solved, and safe and reliable running of the frequency changer is better guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

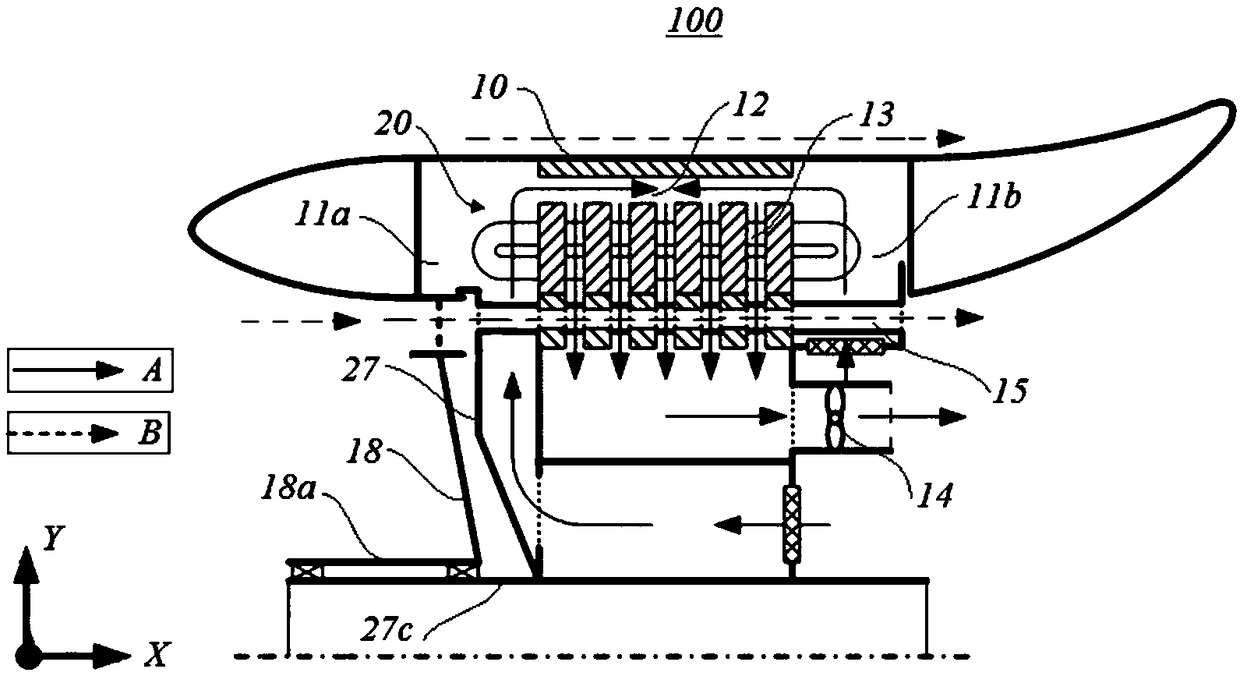

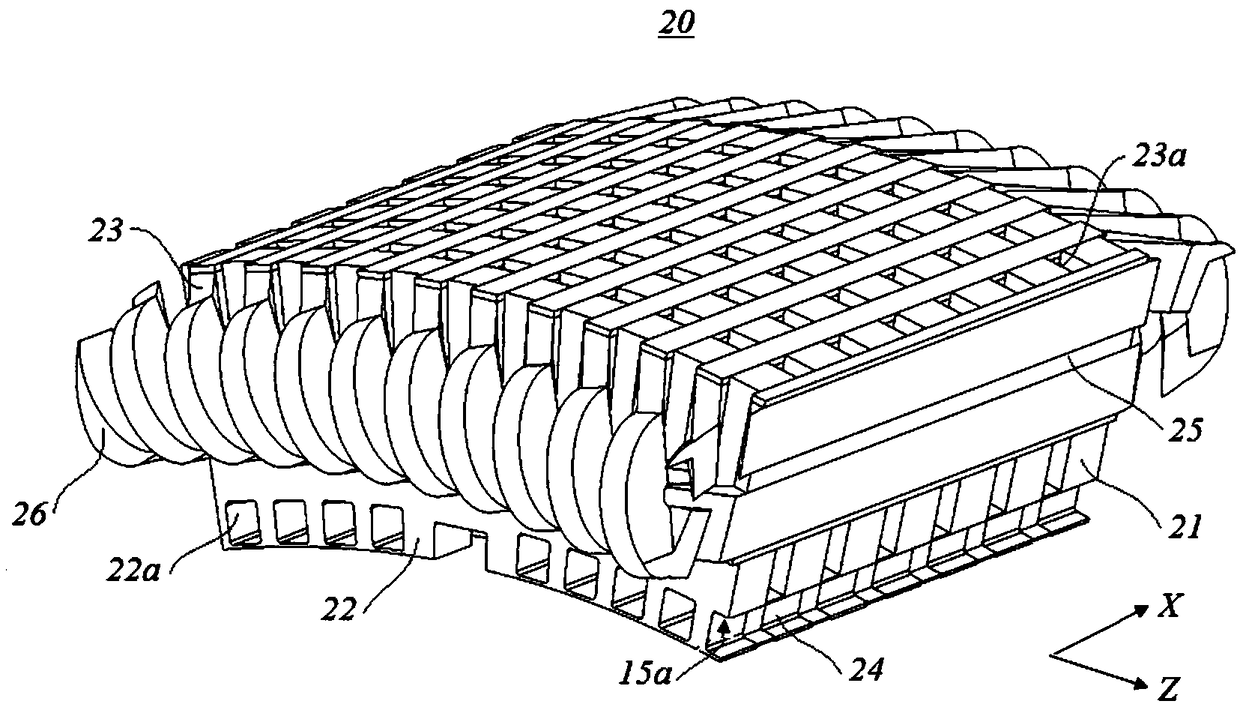

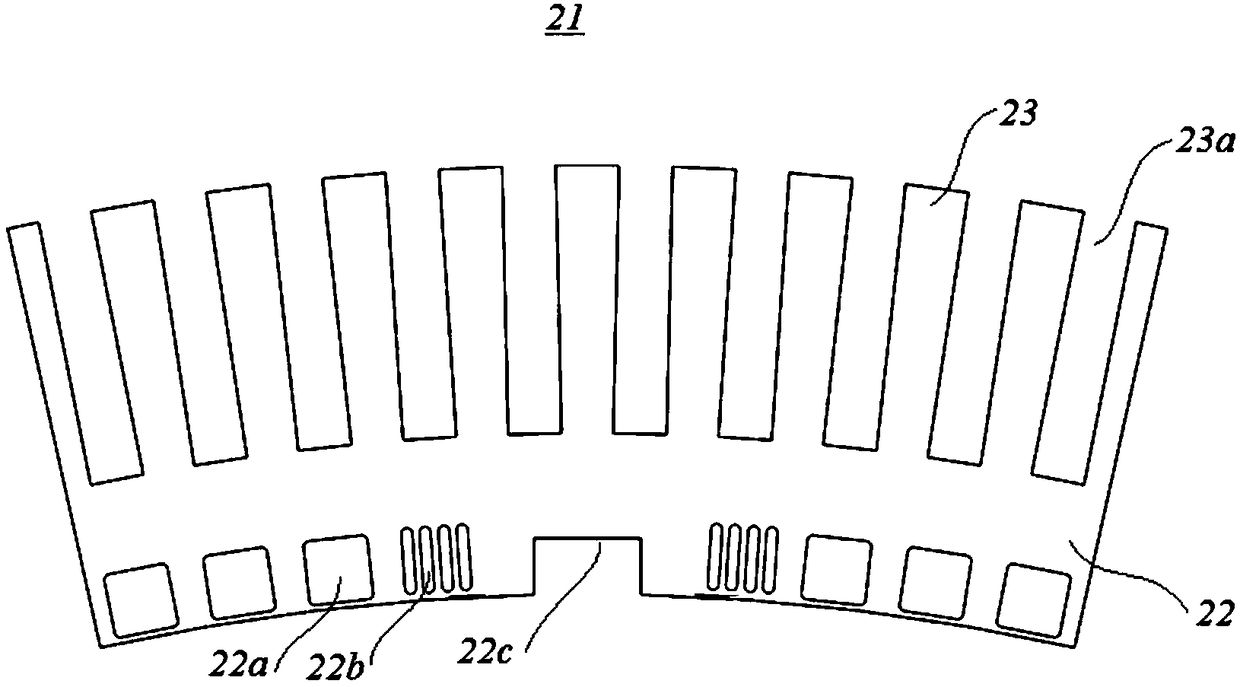

Motor and wind generating set

ActiveCN109412339AReduce the burden onReduce the required powerMagnetic circuit rotating partsEngine fuctionsSelf consumptionActive cooling

The invention relates to a motor and a wind generating set. The motor comprises an active cooling loop and a passive cooling loop which are mutually isolated and both are communicated with an outsideenvironment, wherein the active cooling loop comprises intercommunicated cavities located at two axial ends of the motor, an air gap between a rotor and a stator of the motor, and a radial channel distributed along axial intervals of the stators, and a cooling device communicated with the outside environment is arranged in the active cooling loop; the passive cooling loop comprises an axial channel penetrating through the stator in an axial direction and an external surface of the motor. With the motor and the wind generating set provided by the invention, a problem of insufficient cooling ability of the passive cooling loop in limited layout space is solved, burden on the active cooling loop is reduced, power and self-consumption of the cooling device are reduced, consequently, volume andweight of the cooling device are reduced, and power generation efficiency of the whole machine is improved.

Owner:XINJIANG GOLDWIND SCI & TECH

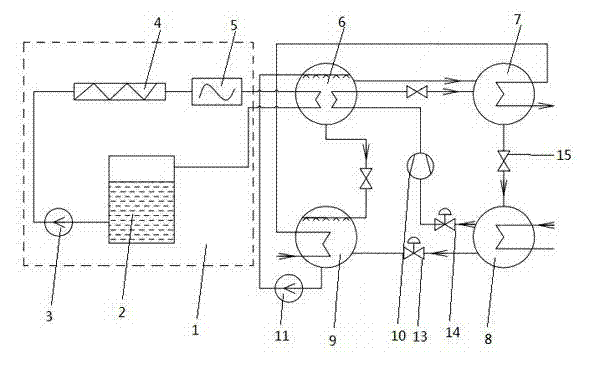

Solar absorption refrigeration system

InactiveCN102734979AMake up for instabilityMake up for the problem of insufficient coolingRefrigeration machinesInstabilityEngineering

The invention discloses a solar absorption refrigeration system, which comprises an evaporator, an absorber, a generator, a condenser, a solar heating system with a solar heat collector and a heat collection water tank, an auxiliary heater for heating water flowing out of the solar heat collector and a branch which is provided with a compressor and is arranged between the evaporator and the generator, wherein after absorbing heat released in the absorption process by the absorber, cooling water absorbs refrigerant steam by the condenser to release the heat; and the solar heating system is used for heating a refrigerant solution in the generator. By the solar absorption refrigeration system, the problems of instability of the water outlet temperature of the solar heat collector and insufficient cooling caused by temperature reduction of the solar heating system are solved, influence on the cycle efficiency of a refrigeration cycle is reduced to the maximum extent, and the solar absorption refrigeration system operates stably.

Owner:苏州张扬能源科技有限公司

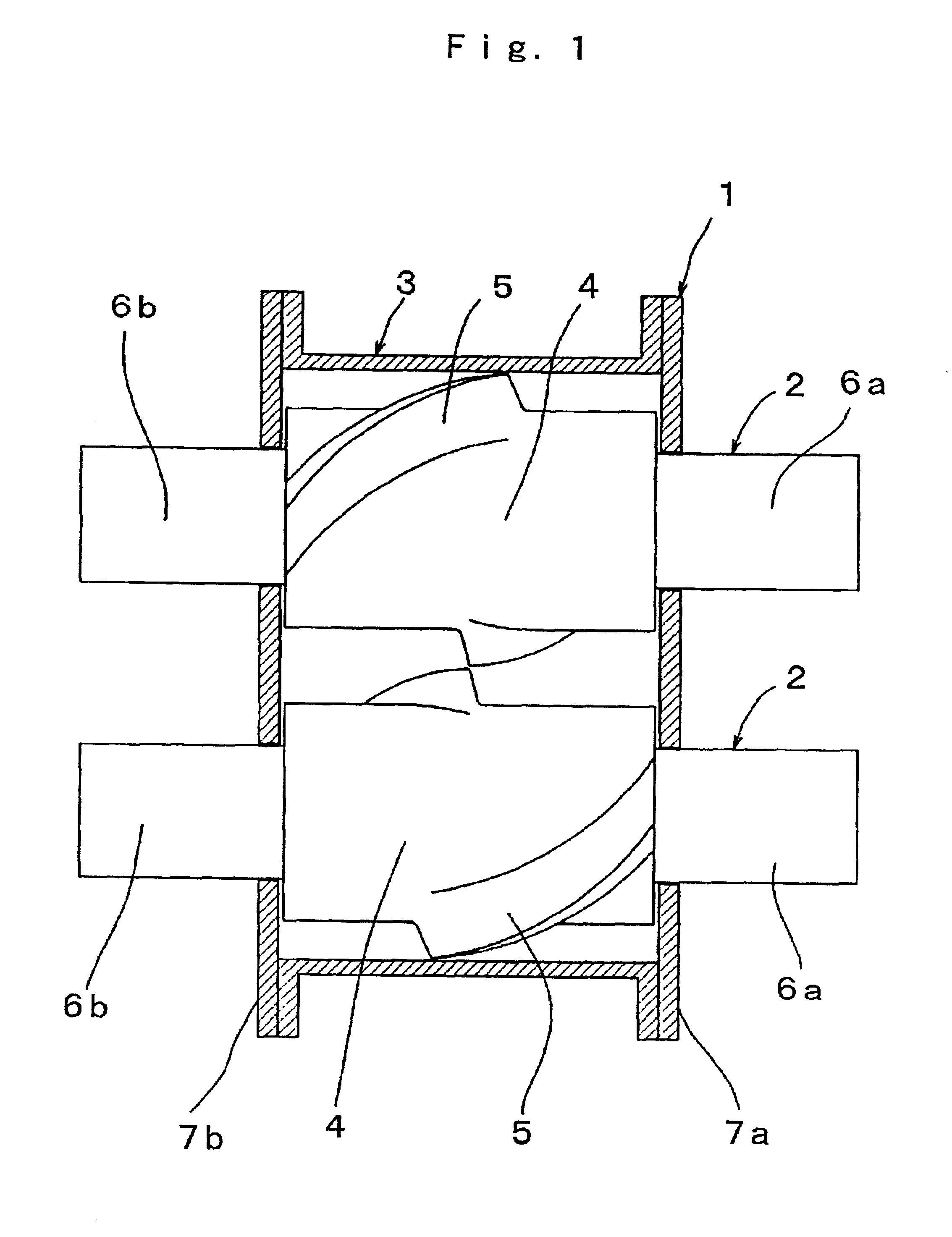

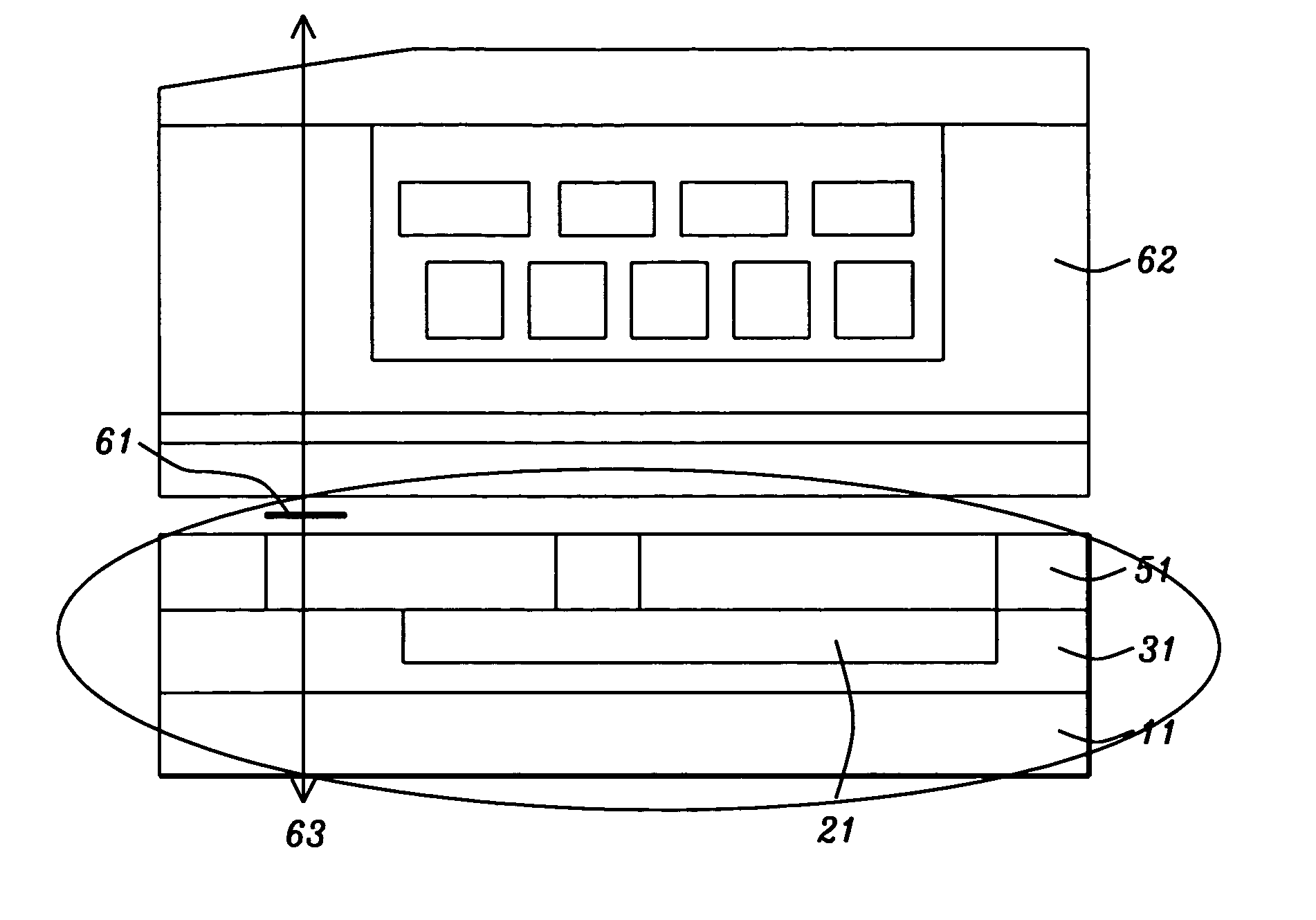

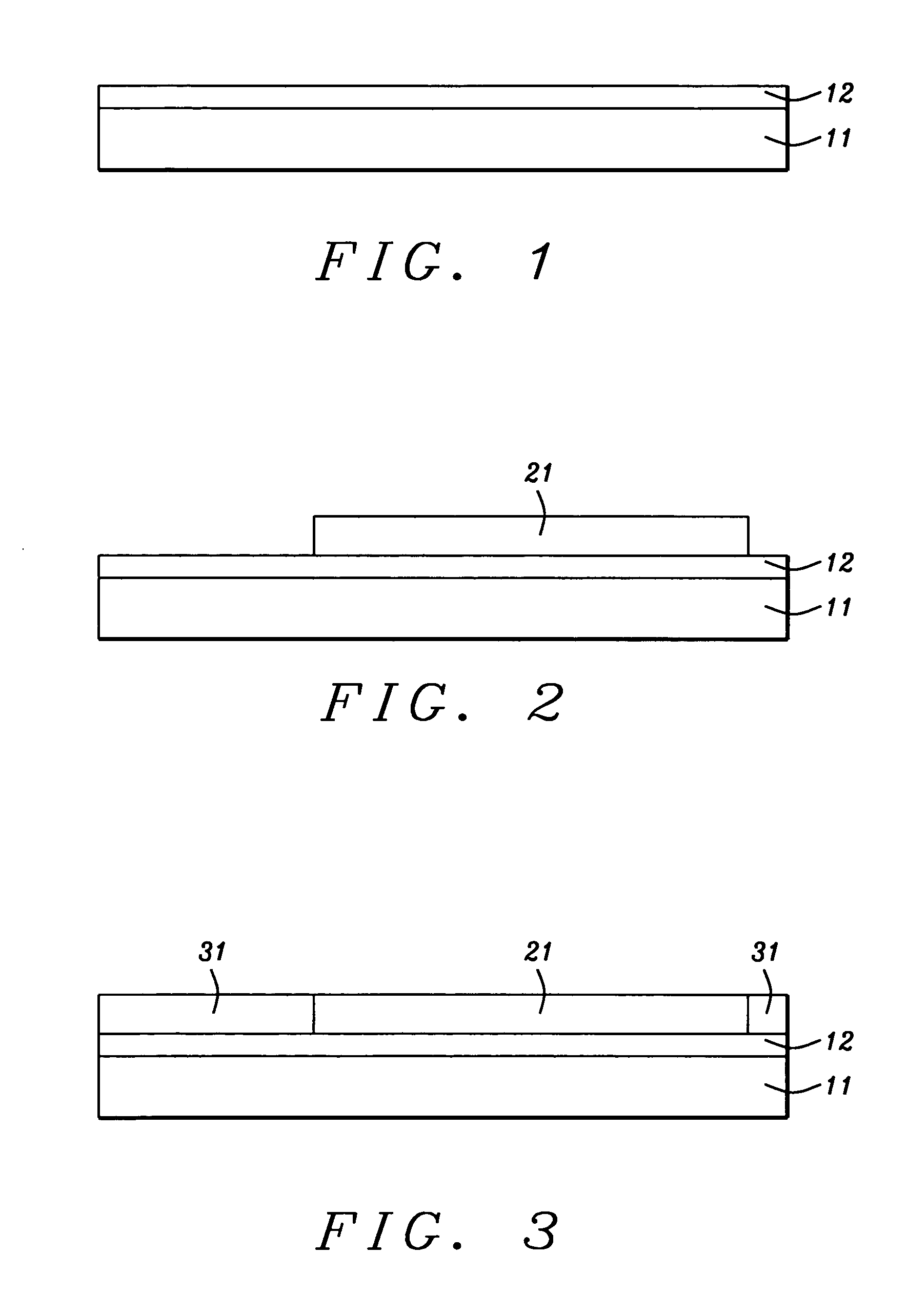

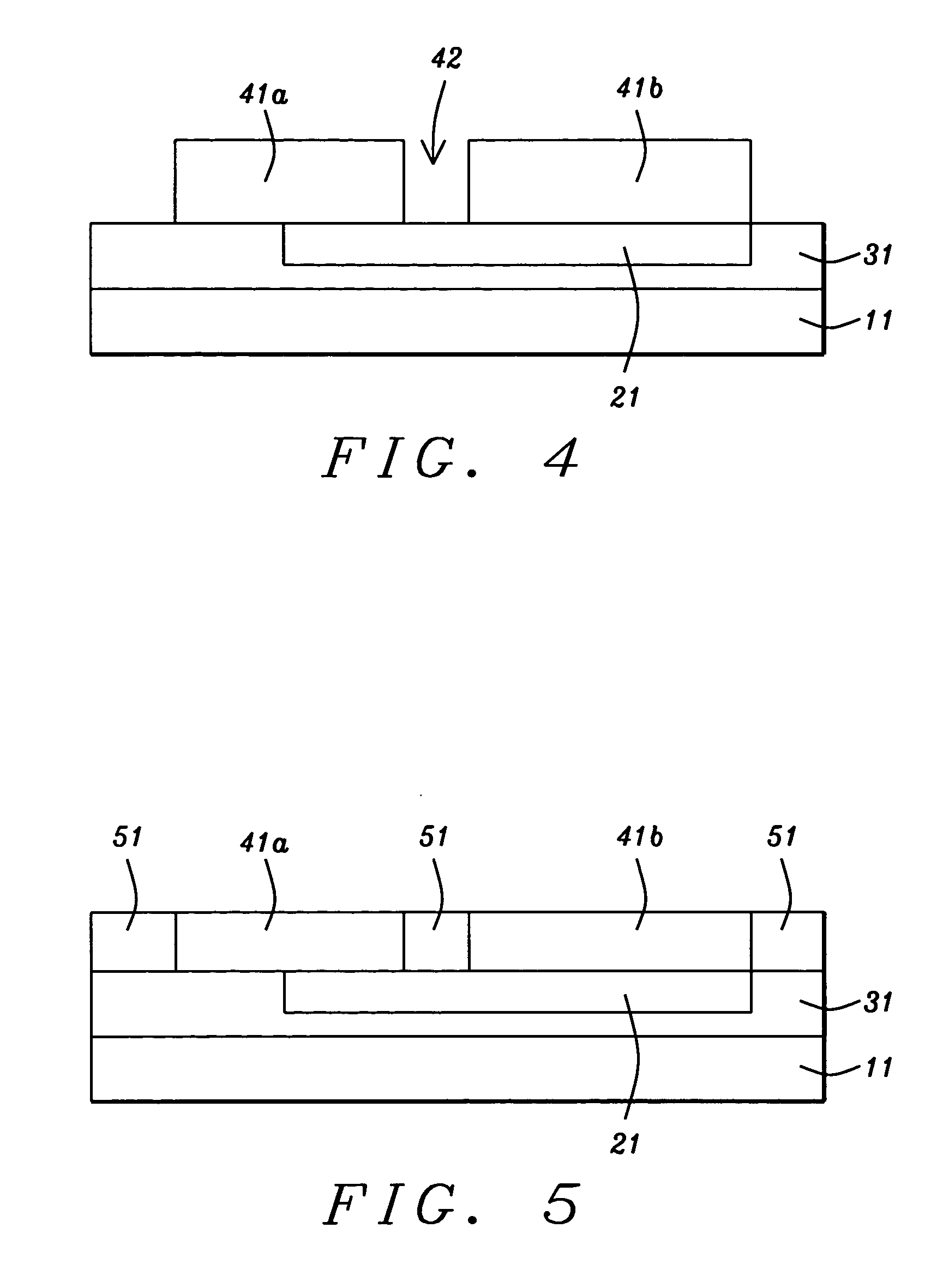

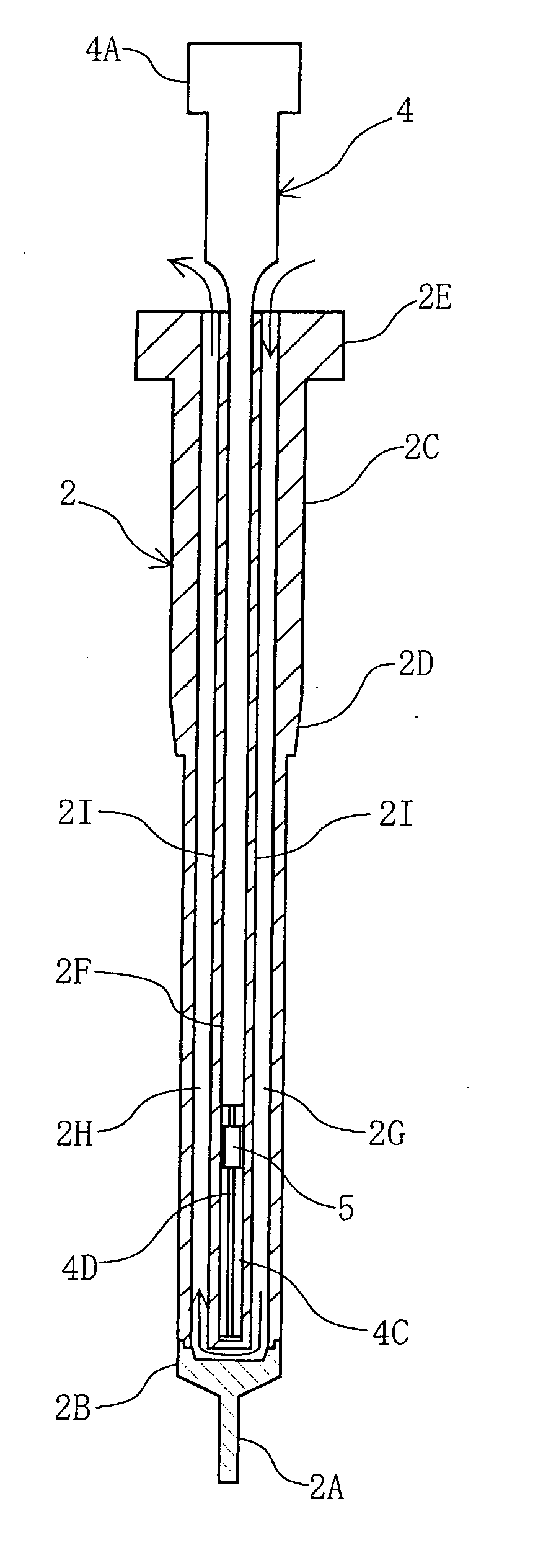

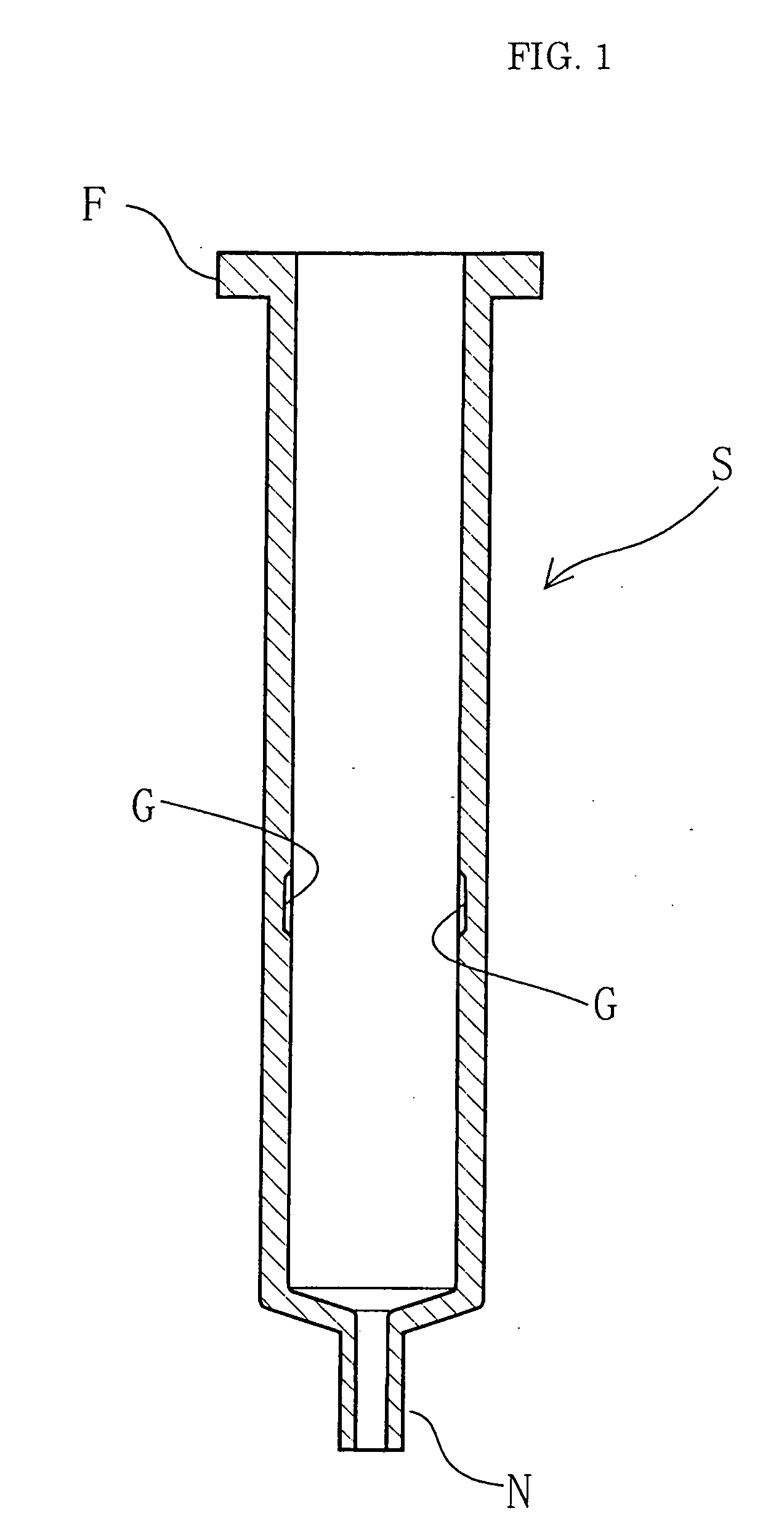

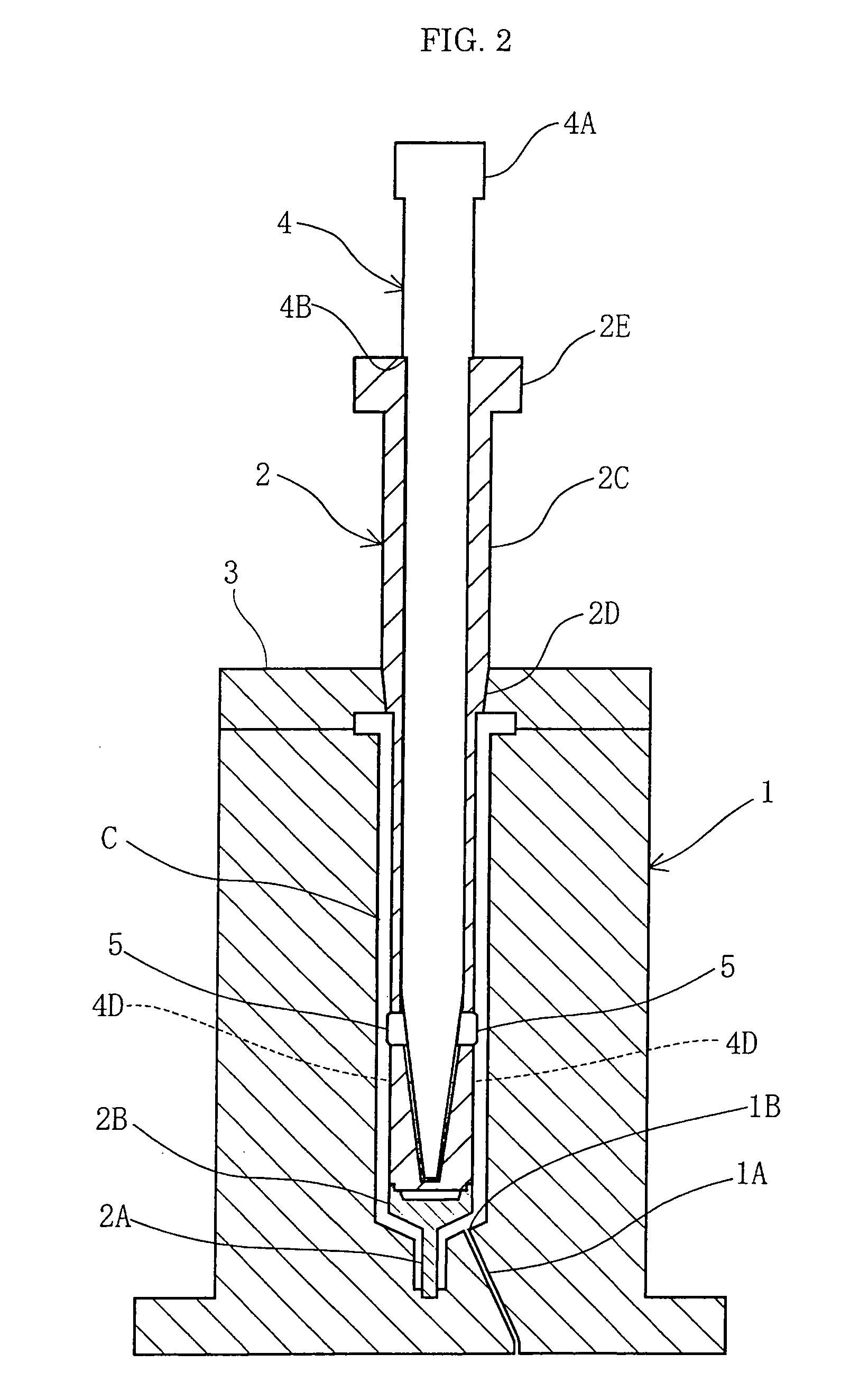

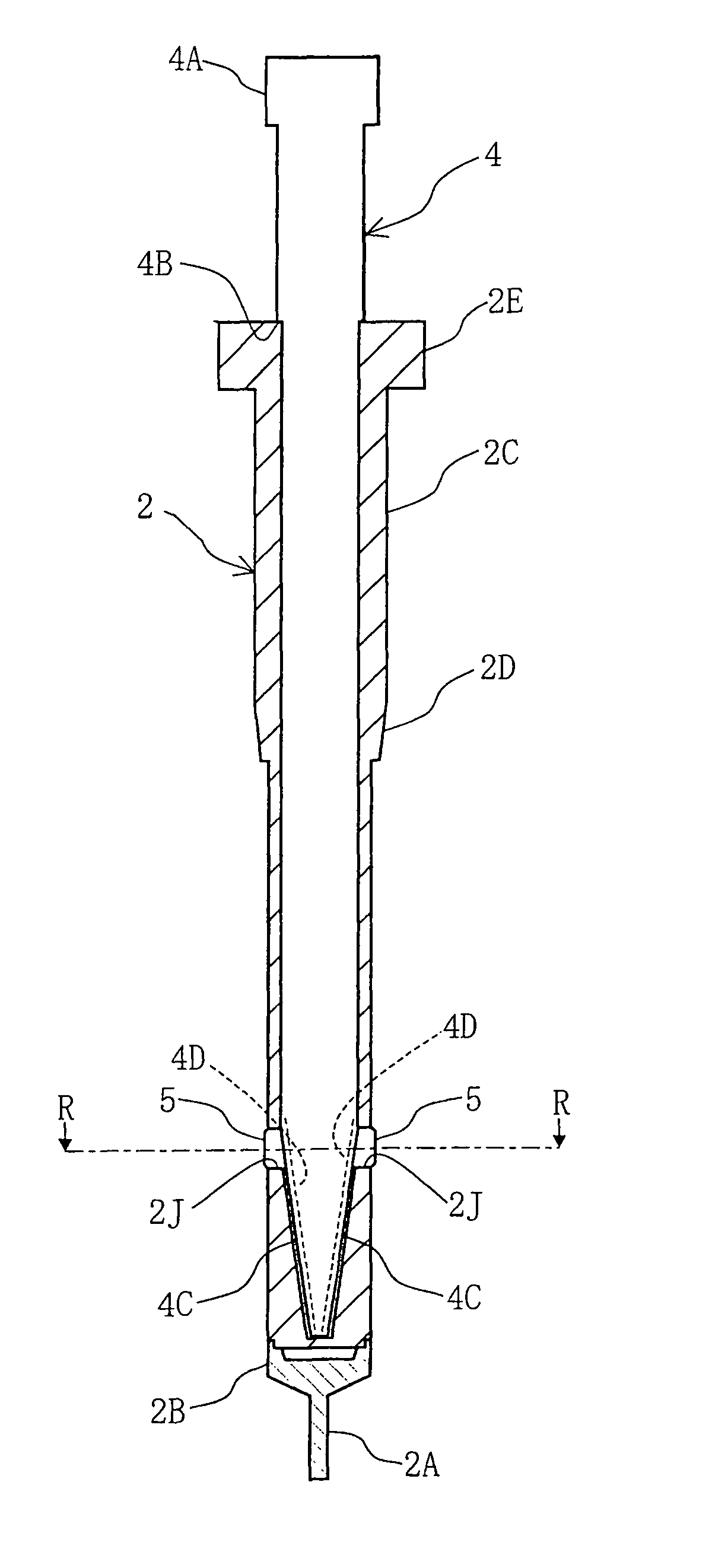

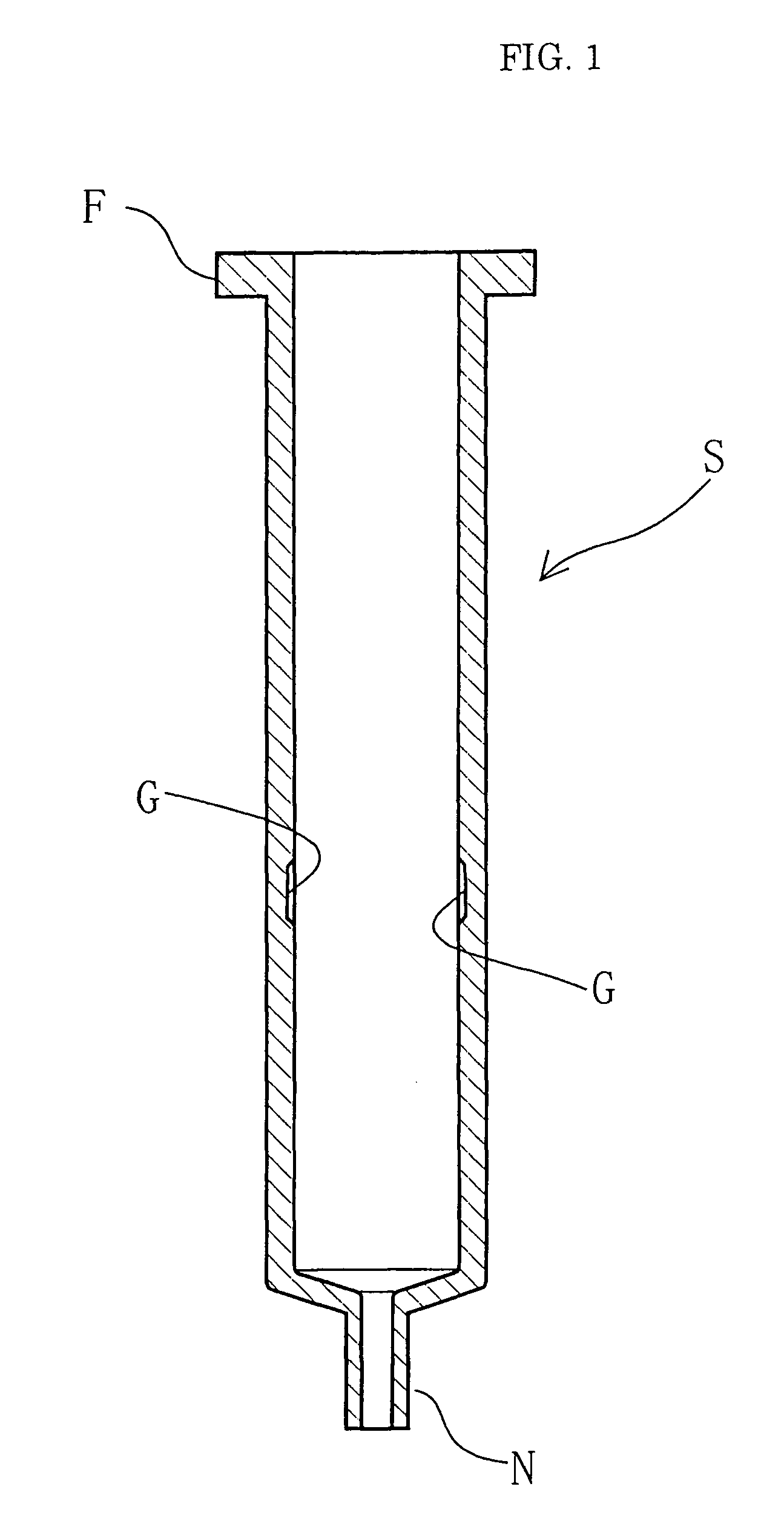

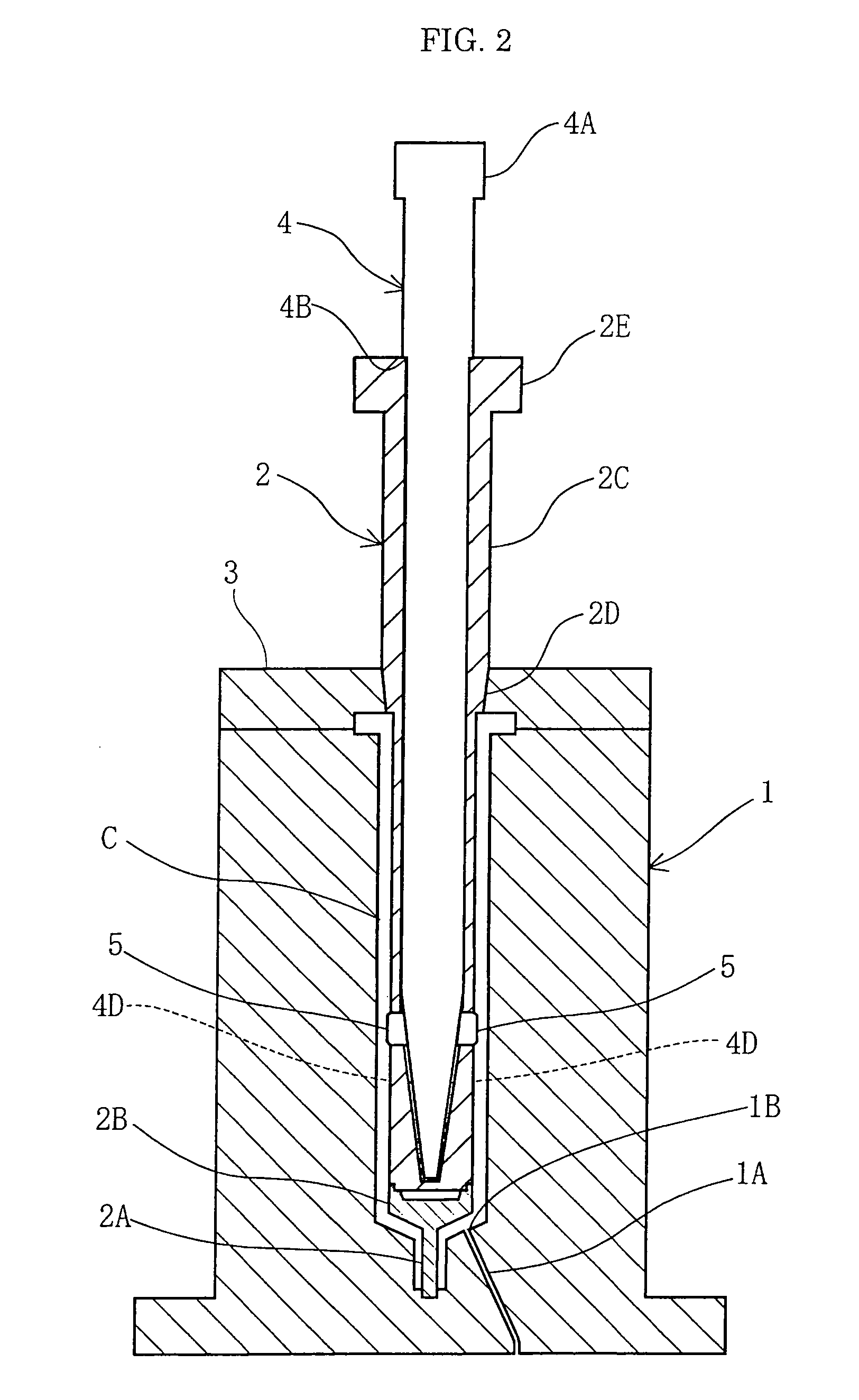

Syringe mold

InactiveUS20090232932A1Coolant flow can be sufficientConfectionerySweetmeatsHybrid typeNuclear engineering

A syringe mold with a coolant circulation outward and homeward positioned close to the cavity space and a sufficient coolant circulating flow for cooling a core cylinder is provided.Slide cores (5, 5) are put in the position where the slide cores (5, 5) protrude from the circumference of the core cylinder (2) by moving the slide core operating jig (4) forward in the axial direction of the core cylinder (2) while cooling the core cylinder (2) by the coolant. Then, a two medical agent mixing type syringe having a communicating groove on the inner circumference for mixing two medical agents is injection-molded. A molding failure due to insufficient cooling of the core cylinder (2) can be prevented by positioning the coolant outward and homeward close to the cavity space and making the cross sectional area of the coolant outward and homeward enough large because the coolant outward and homeward is partitioned by the circumference of the jig container space in the core cylinder (2).

Owner:DAIKYO SEIKO LTD

Heat radiation method for LED module

InactiveCN101418948AExtended service lifeMake up for lack of heat dissipationPoint-like light sourceSemiconductor/solid-state device detailsTemperature controlComputer module

The invention relates to a radiating method for an LED module, which is characterized in that an LED luminous component contacts the outer wall of a perfusion sealed container closely; the perfusion sealed container consists of a primary tank, a pipe nipple, and a cover, which are encircled by a heat conduction material, wherein the outer wall of the primary tank is provided with a connector, the primary tank is communicated with the pipe nipple through the connector, and the top of the pipe nipple is covered by the cover; and the primary tank is filled with water. Moreover, the method comprises the following steps: A. the amount of heat of the LED luminous component is transmitted into the water in the perfusion sealed container, and is stored by the water; and B. the amount of heat is removed through dissipation of the outer wall of the perfusion sealed container. The method has the advantages that the method has reasonable design, makes the best use of the greater specific heat and heat accumulation function of the water through a water tank for radiating, can fully control the temperature of the LED luminous component in a required temperature range, remedy the dissipation defect of a fin, and prolong the service life of the LED luminous component.

Owner:陈玉新

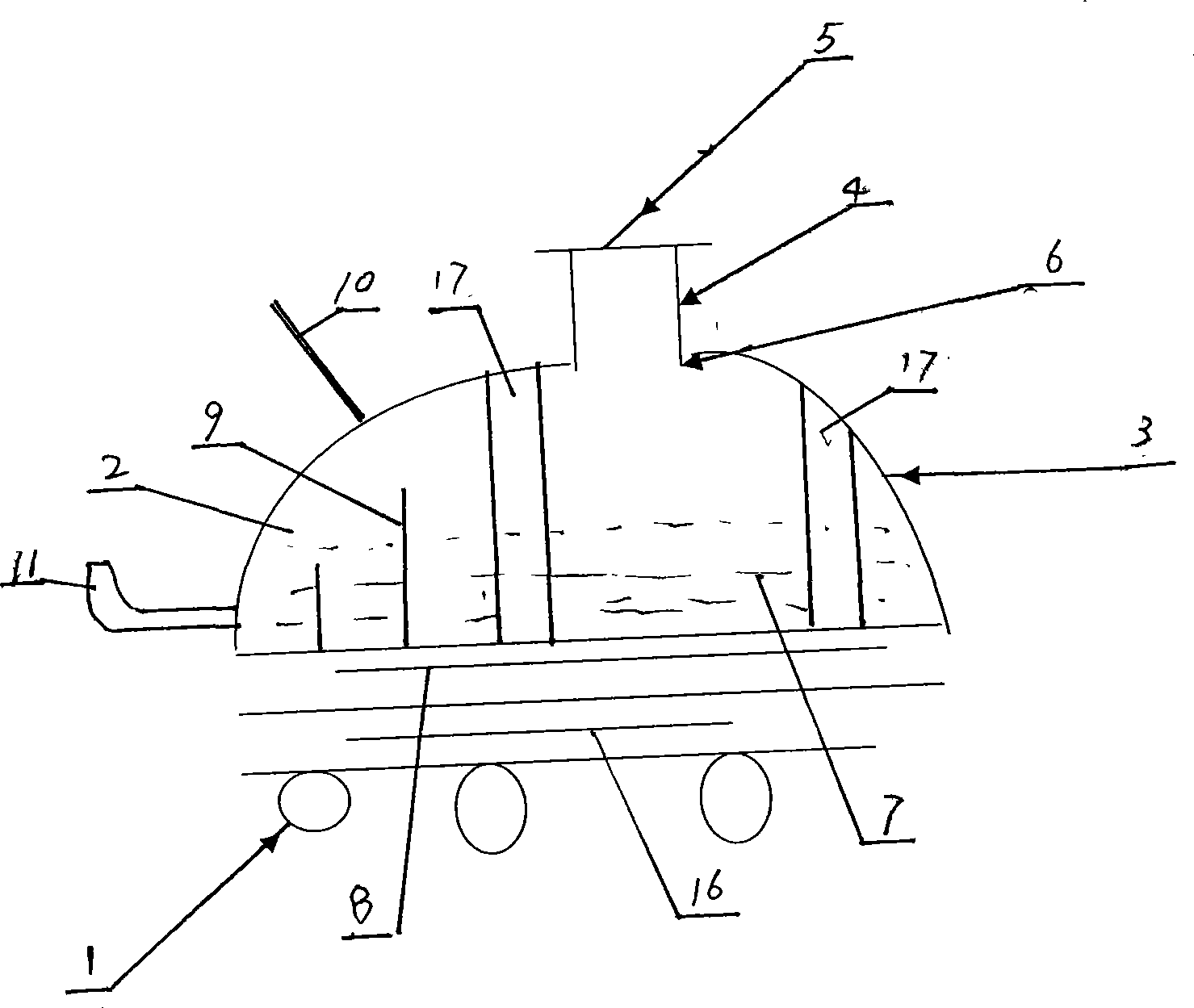

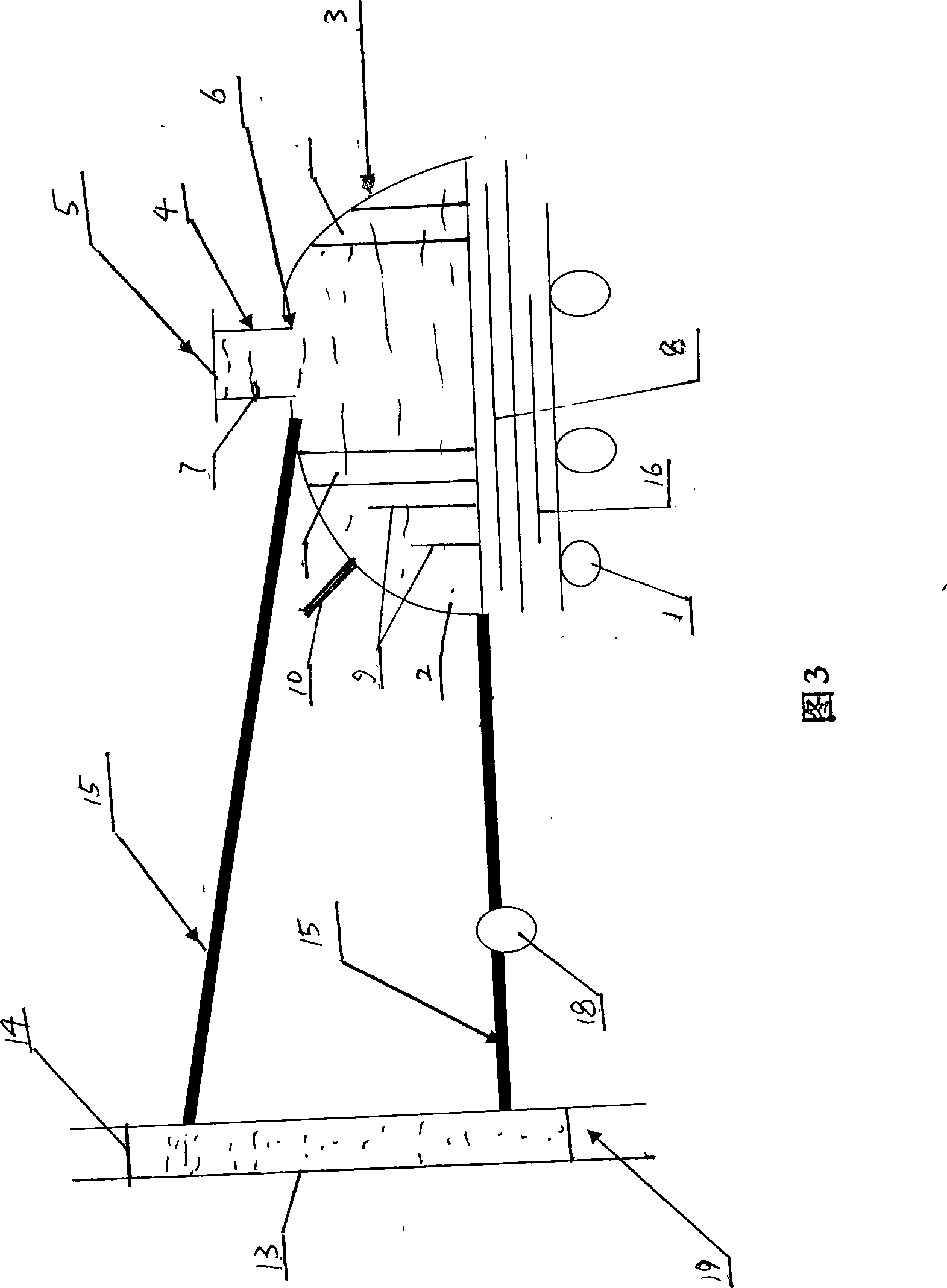

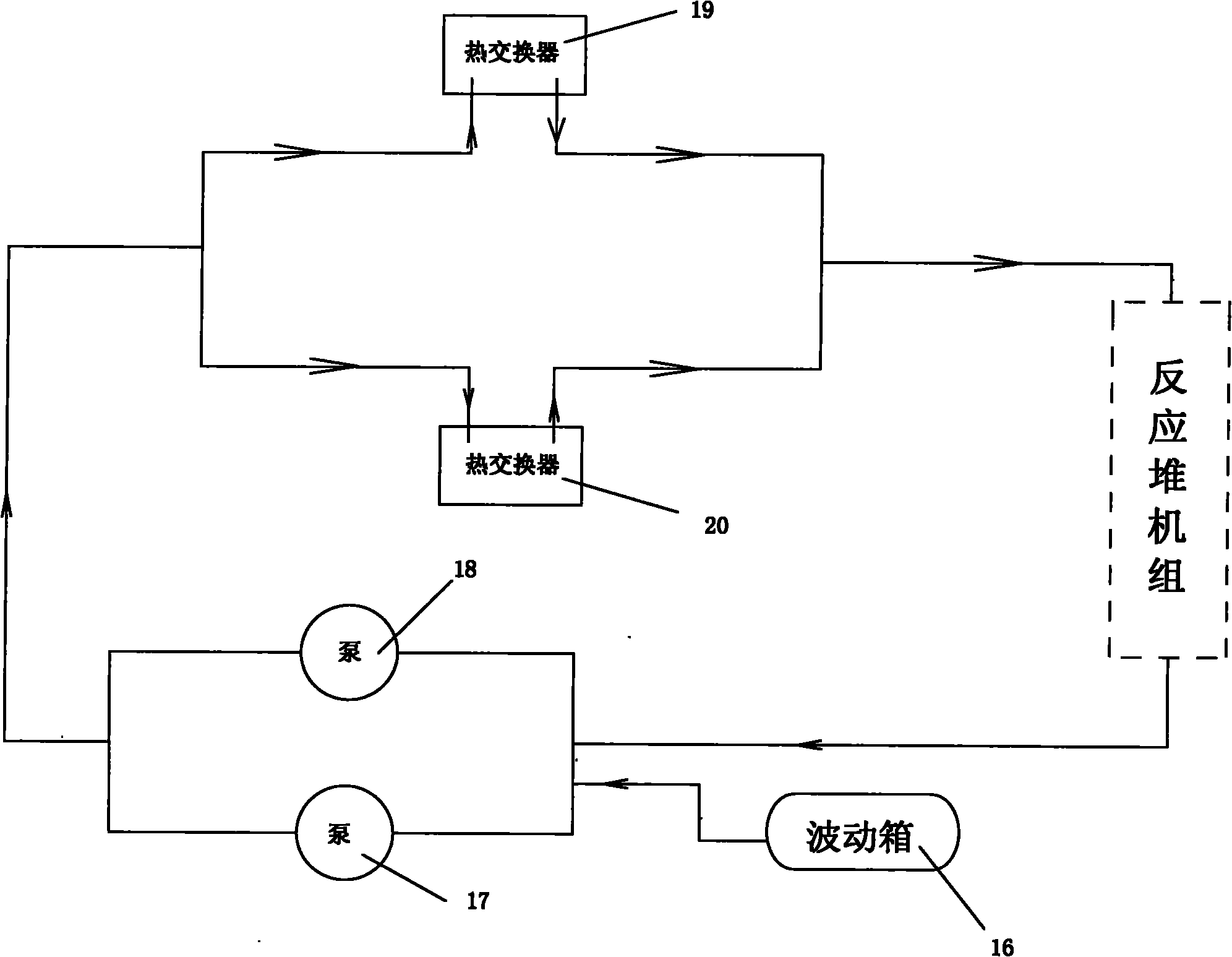

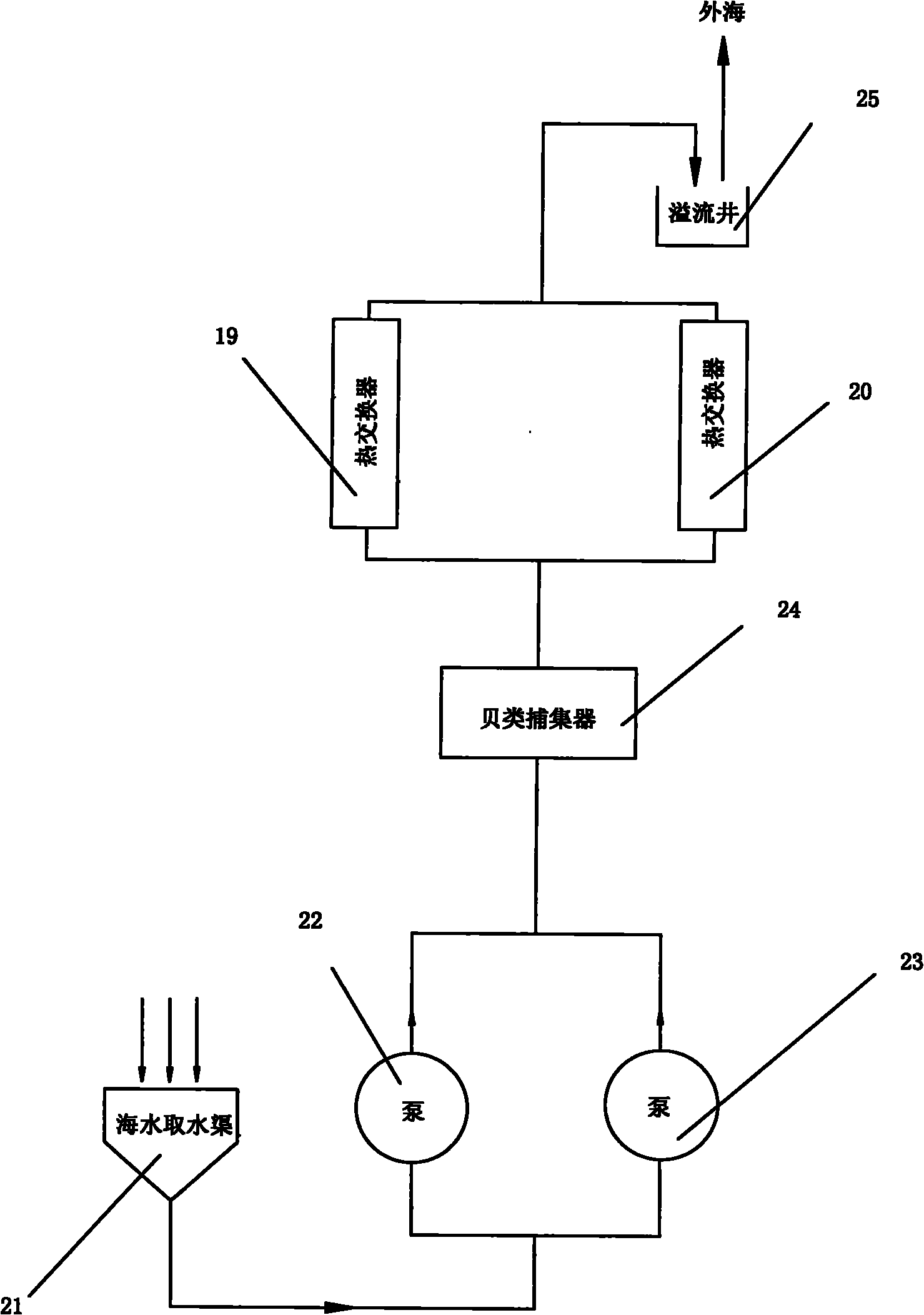

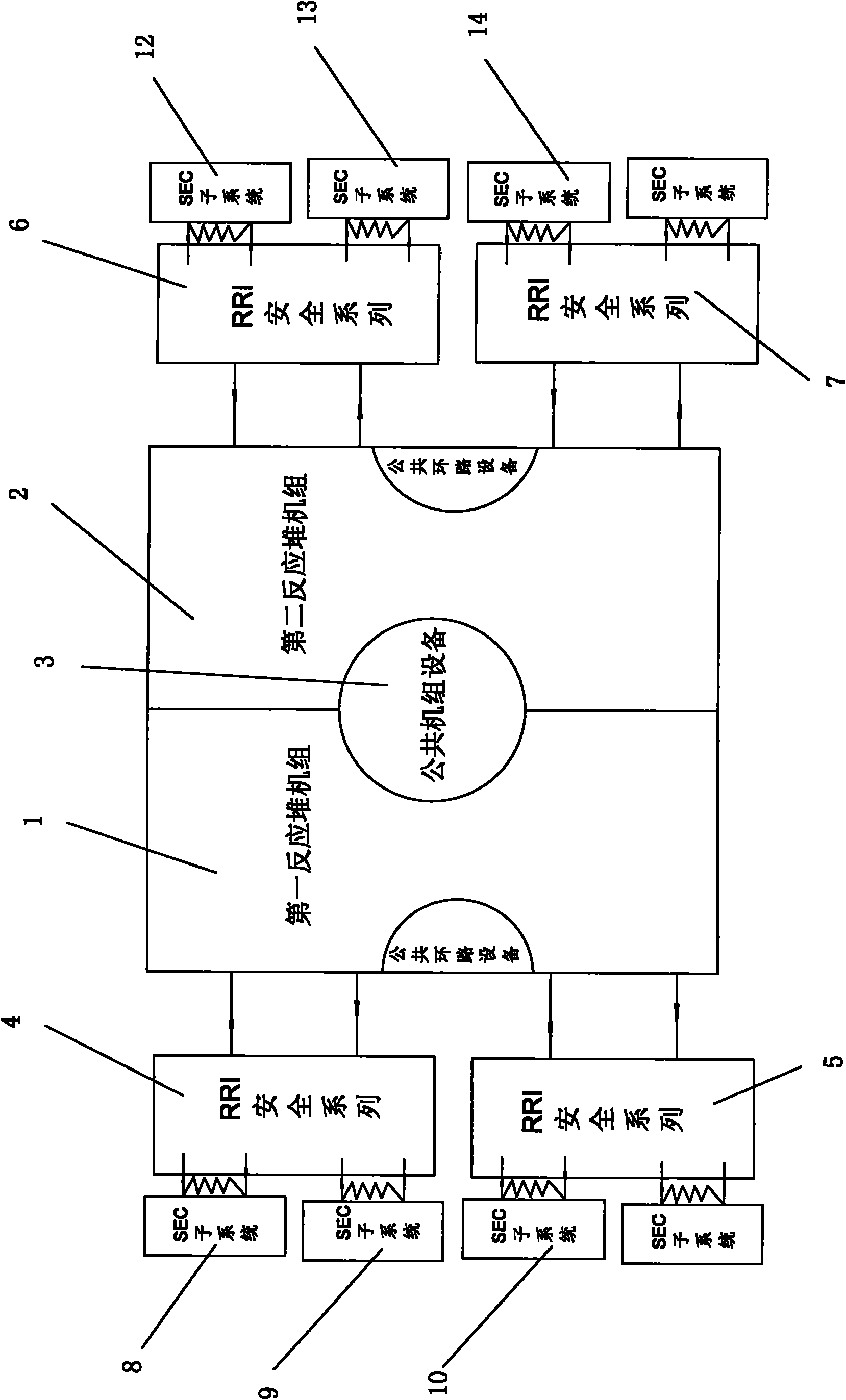

Nuclear island cooling system for double reactor units and cooling method thereof

ActiveCN101976589ASolve the lack of cooling capacityNuclear energy generationNuclear monitoringNuclear engineeringWater temperature

The invention relates to a nuclear island cooling system for double reactor units. The nuclear island cooling system of each reactor unit comprises RRI security series, backup RRI security series, an SEC sub-system performing heat exchange with the RRI security series, and a backup SEC sub-system which is only started when the outlet temperature at the RRI side of a heat exchanger is more than 35 DEG C. The nuclear island cooling system for the double reactor units also comprises a first temperature measuring meter which is used for detecting fluid temperature at the outlet of the RRI side of the heat exchanger. The invention also provides a cooling method for the nuclear island cooling system for the double reactor units, when the temperature of the outlet at the RRI side of the heat exchanger is more than 35 DEG C, the backup SEC sub-system is started. The water temperature of the outlet at the RRI side of the heat exchanger is detected by the first temperature measuring meter, if the water temperature of the outlet of the heat exchanger is more than 35 DEG C, the backup SEC sub-system is started, so that the problem of insufficient cooling capability of the cold chain system of the double reactor units can be solved.

Owner:中广核工程有限公司 +1

Method for improving coil shape quality of hot rolled strip steel

ActiveCN111451291AImprove shape qualityShape quality improvementRoll mill control devicesMetal rolling arrangementsPhysicsInsufficient Cooling

The invention relates to a method for improving the coil shape quality of hot rolled strip steel. The method comprises the steps of after the head part of a coiling machine bites steel, delaying 21-36seconds, and starting to set a stopped state of the tail part; after the tail part throws steel, when the tail part of the strip steel leaving a pinch roll is detected, enabling the tail part to automatically stop and start to control, and enabling a coiling block to stop according to a retardation curve; when the tail part of the strip steel enters a definite range from a starting stop position,determining a tail part stop position according to a pair tail conversion timing sequence; and after normal coiling is completed, adopting the appropriate uncoiling delaying time in the coiling machine. The method has the advantages that after the coiling machine bites steel at the heat part of the strip steel, the pair tail position pre-judgment of the tail part and the calculation and judgmentof automatic rotation angle after aligning delaying are introduced, the final uncoiling position can be selectively determined according to operational requirements, and therefore the coil shape quality of the hot rolled strip steel is improved, and the chance of flat coiling due to wear of the coiling block, insufficient tension, insufficient cooling water capacity and large roll-gap deviation ofa wrapper roll is reduced.

Owner:ANGANG STEEL CO LTD

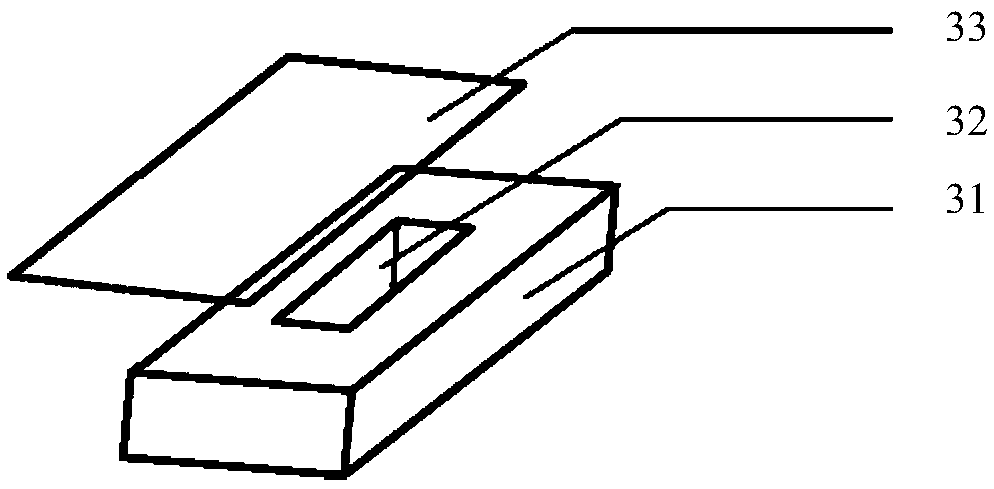

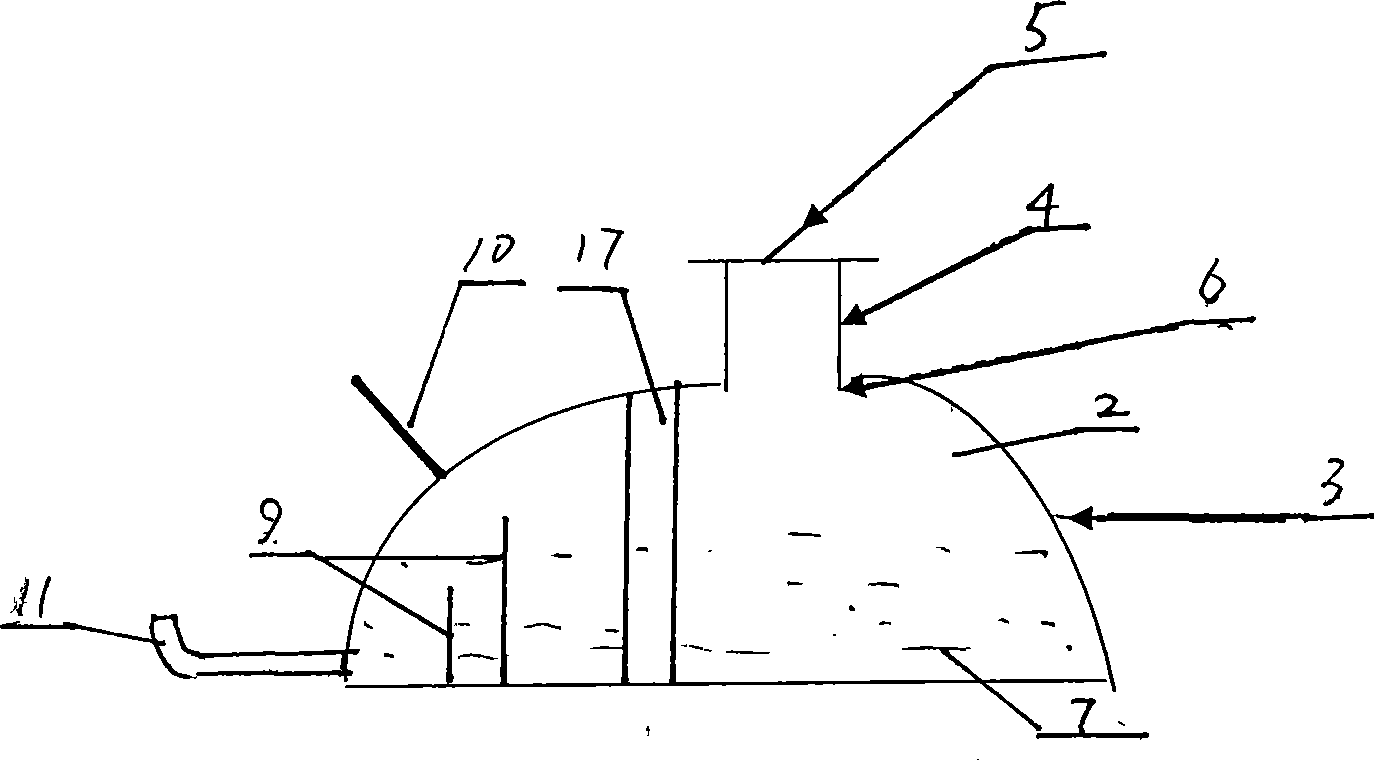

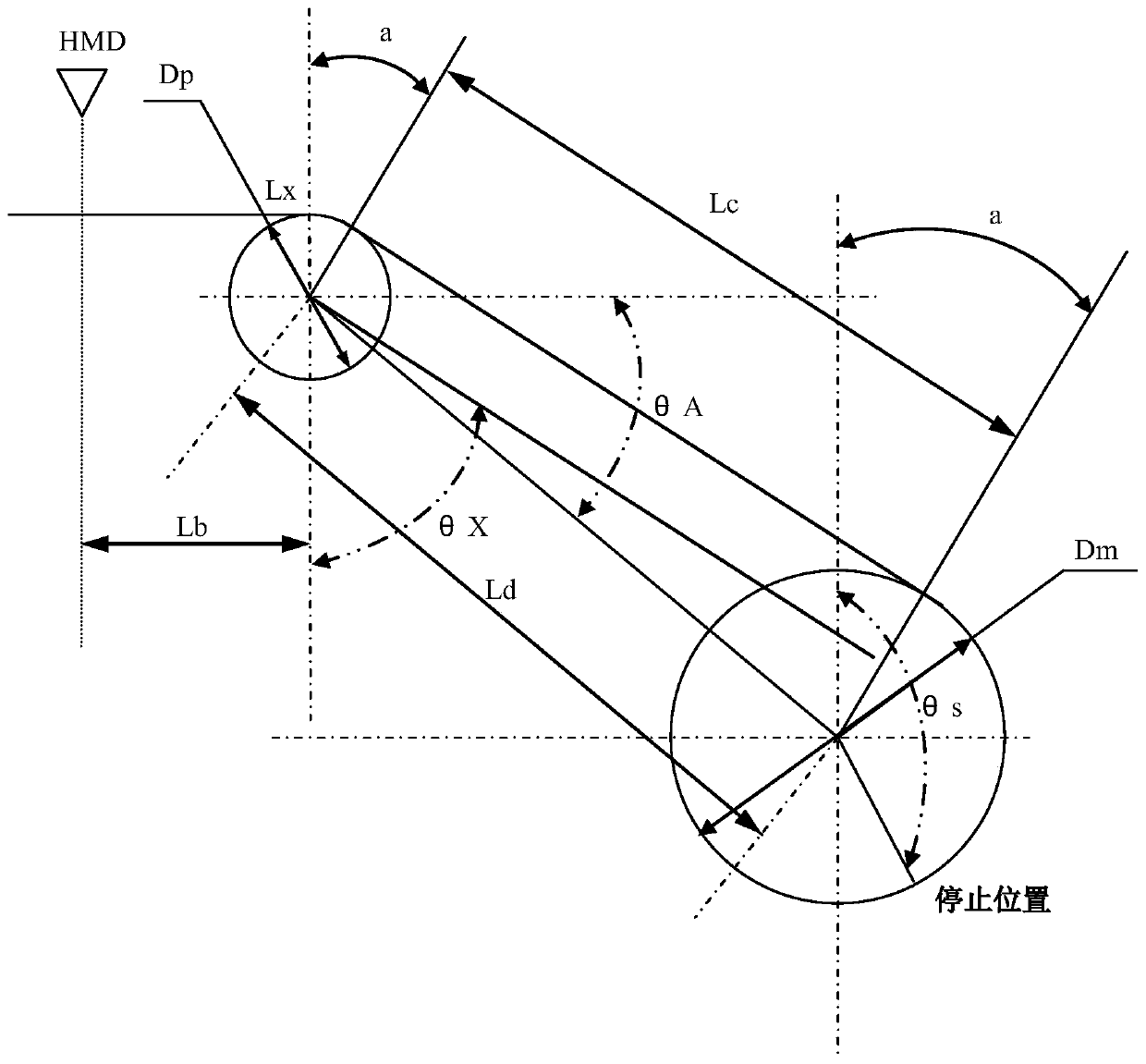

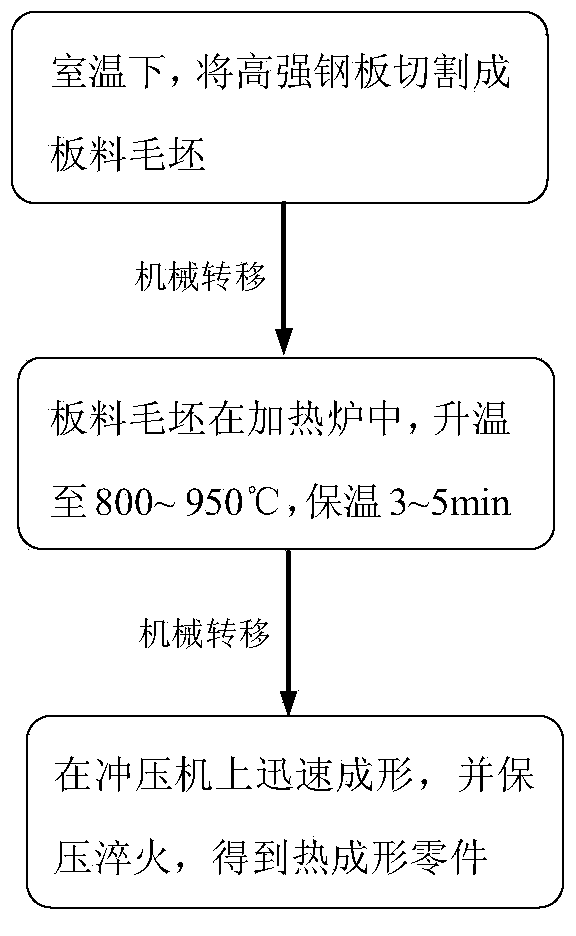

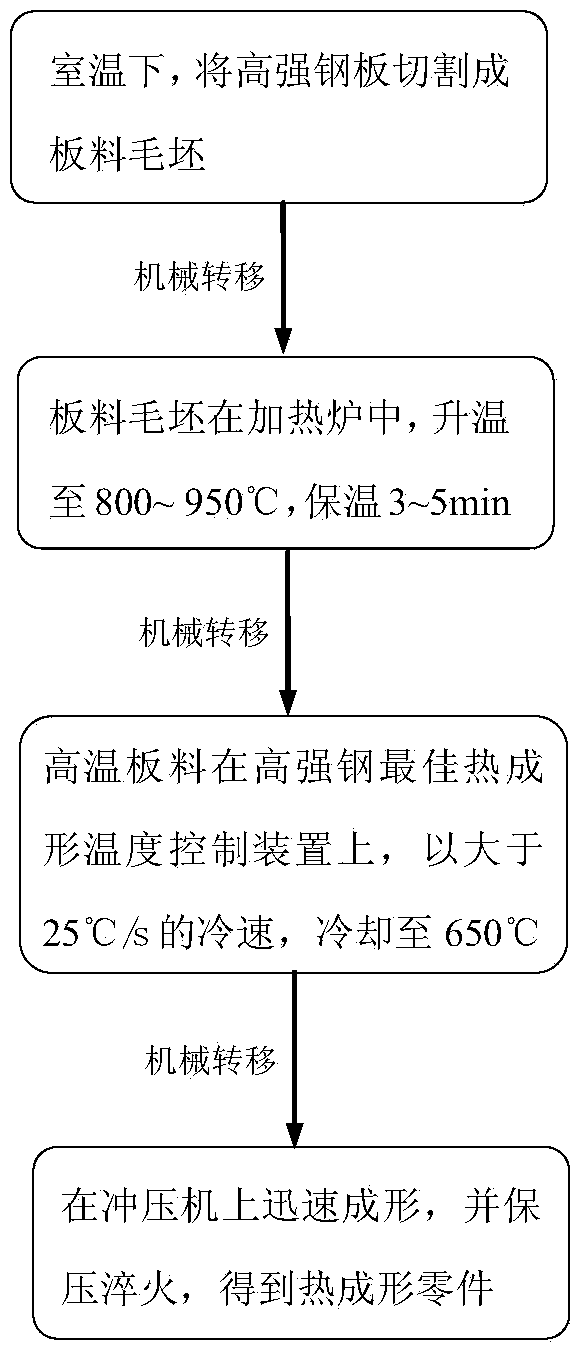

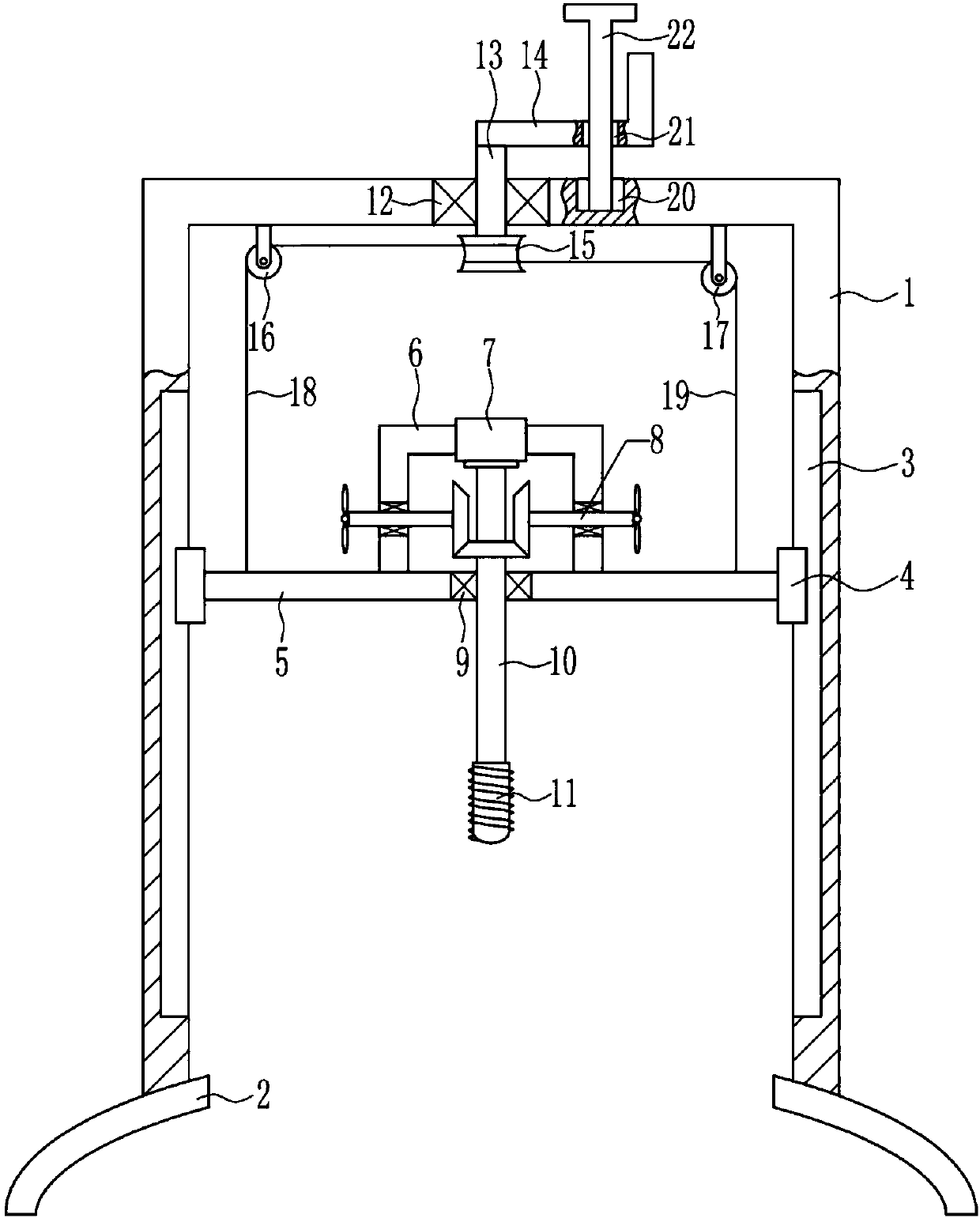

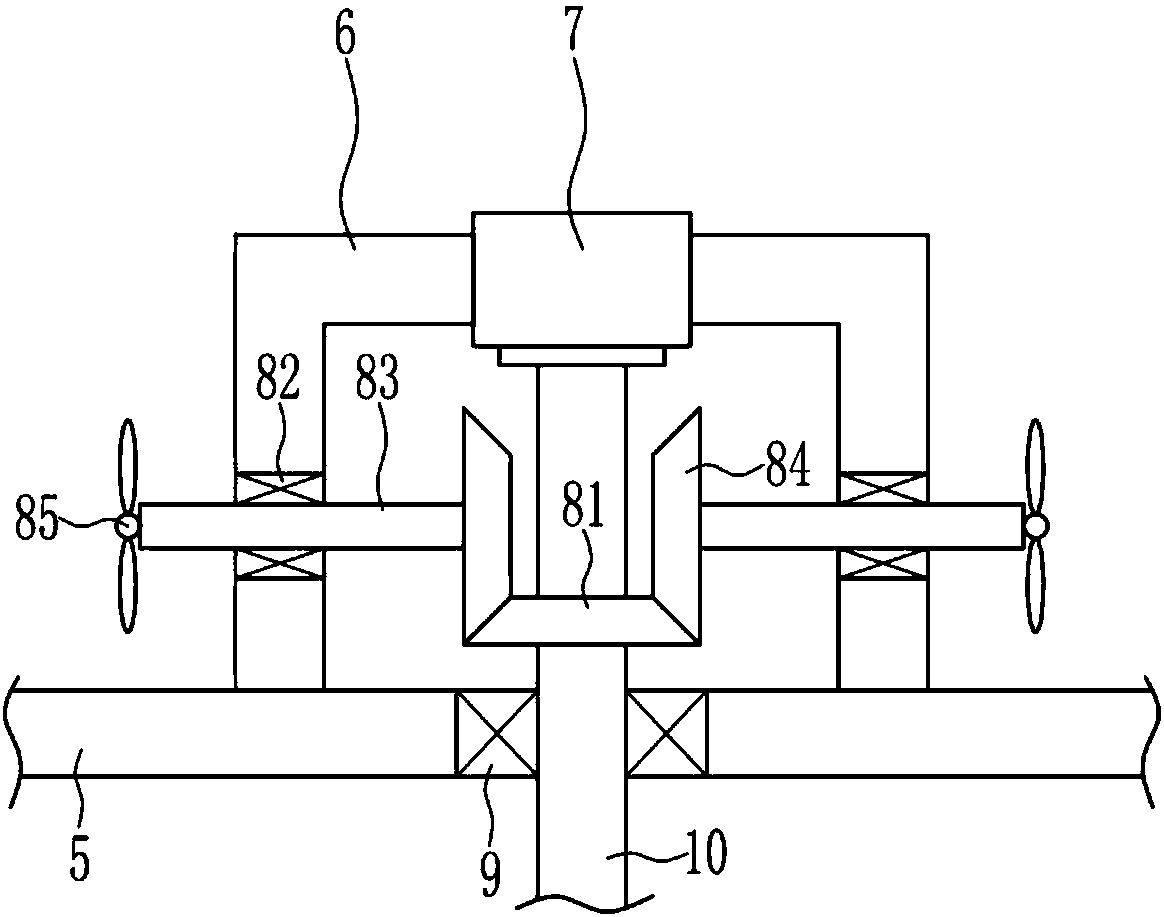

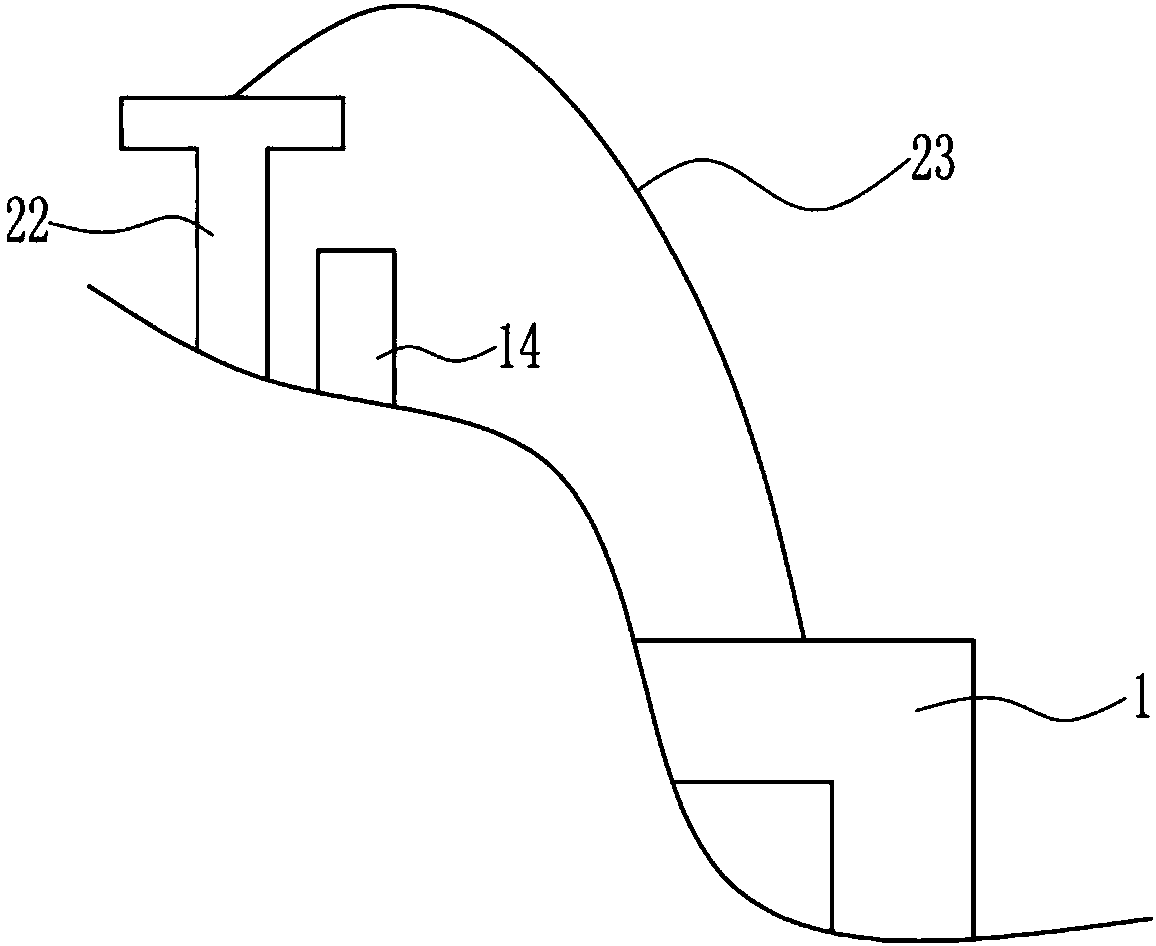

Optimum temperature control device for thermoforming of high-strength steel

InactiveCN103949552AImprove mechanical propertiesImprove pass rateShaping toolsTemperature controlThermoforming

The invention discloses an optimum temperature control device for thermoforming of high-strength steel, and aims to solve the problems that the strength of a component is insufficient because of poor thermoforming properties and insufficient cooling rate of a high-strength steel plate. The optimum temperature control device comprises an upper mechanism, a lower mechanism and an unloading mechanism, wherein the upper mechanism is positioned above the lower mechanism; the unloading mechanism is positioned on the right side of the lower mechanism; the lower mechanism comprises a lower heat-conducting plate (4), a lower mold base (5), a radiating fin frame (7), a radiating mechanism and lower thermocouples (13); the lower thermocouples (13) are respectively mounted in the grooves in the upper surface of the lower heat-conducting plate (4); each lower thermocouple (13) is connected to the groove in the lower heat-conducting plate (4) by adopting spot welding; the lower surface of the lower heat-conducting plate (4) and the upper surface of the lower mold base (5) are contacted with each other and are connected with each other by welding; the lower surface of the lower mold base (5) and the upper surface of the radiating fin frame (7) are contacted with each other and are connected with each other by welding; the radiating mechanism is positioned at the center position at the lower part of the radiating fin frame (7).

Owner:JILIN UNIV

Portable drilling equipment for maintenance of large natural gas pipeline

ActiveCN107900402ASpeed up the flowAvoid damageFeeding apparatusMaintainance and safety accessoriesHeat sinkInsufficient Cooling

The invention relates to drilling equipment, in particular to portable drilling equipment for maintenance of a large natural gas pipeline, and aims to provide the portable drilling equipment for maintenance of the large natural gas pipeline, which is convenient to carry and operate and guarantees stable running. In order to solve technical problems, the portable drilling equipment comprises a mounting rack, arc-shaped bases, slide rails, a mounting plate, a fixing support, a motor, a heat sink and the like, wherein the arc-shaped bases are arranged at the bottoms of the left wall and the rightwall of the mounting rack respectively; and the slide rails are embedded into the middles of the inner sides of the left wall and the right wall of the mounting rack respectively. Circulation of airaround equipment can be accelerated through rotation of blades, the motor is prevented from being damaged by insufficient heat radiation during high-speed running, the service life of the equipment isprolonged, an insertion rod which is taken down can be conveniently placed through an elastic stay wire, and the effect of improving the practicability of the equipment is achieved.

Owner:重庆港华燃气有限公司

Syringe mold

A syringe mold with a coolant circulation outward and homeward positioned close to the cavity space and a sufficient coolant circulating flow for cooling a core cylinder is provided.Slide cores (5, 5) are put in the position where the slide cores (5, 5) protrude from the circumference of the core cylinder (2) by moving the slide core operating jig (4) forward in the axial direction of the core cylinder (2) while cooling the core cylinder (2) by the coolant. Then, a two medical agent mixing type syringe having a communicating groove on the inner circumference for mixing two medical agents is injection-molded. A molding failure due to insufficient cooling of the core cylinder (2) can be prevented by positioning the coolant outward and homeward close to the cavity space and making the cross sectional area of the coolant outward and homeward enough large because the coolant outward and homeward is partitioned by the circumference of the jig container space in the core cylinder (2).

Owner:DAIKYO SEIKO LTD

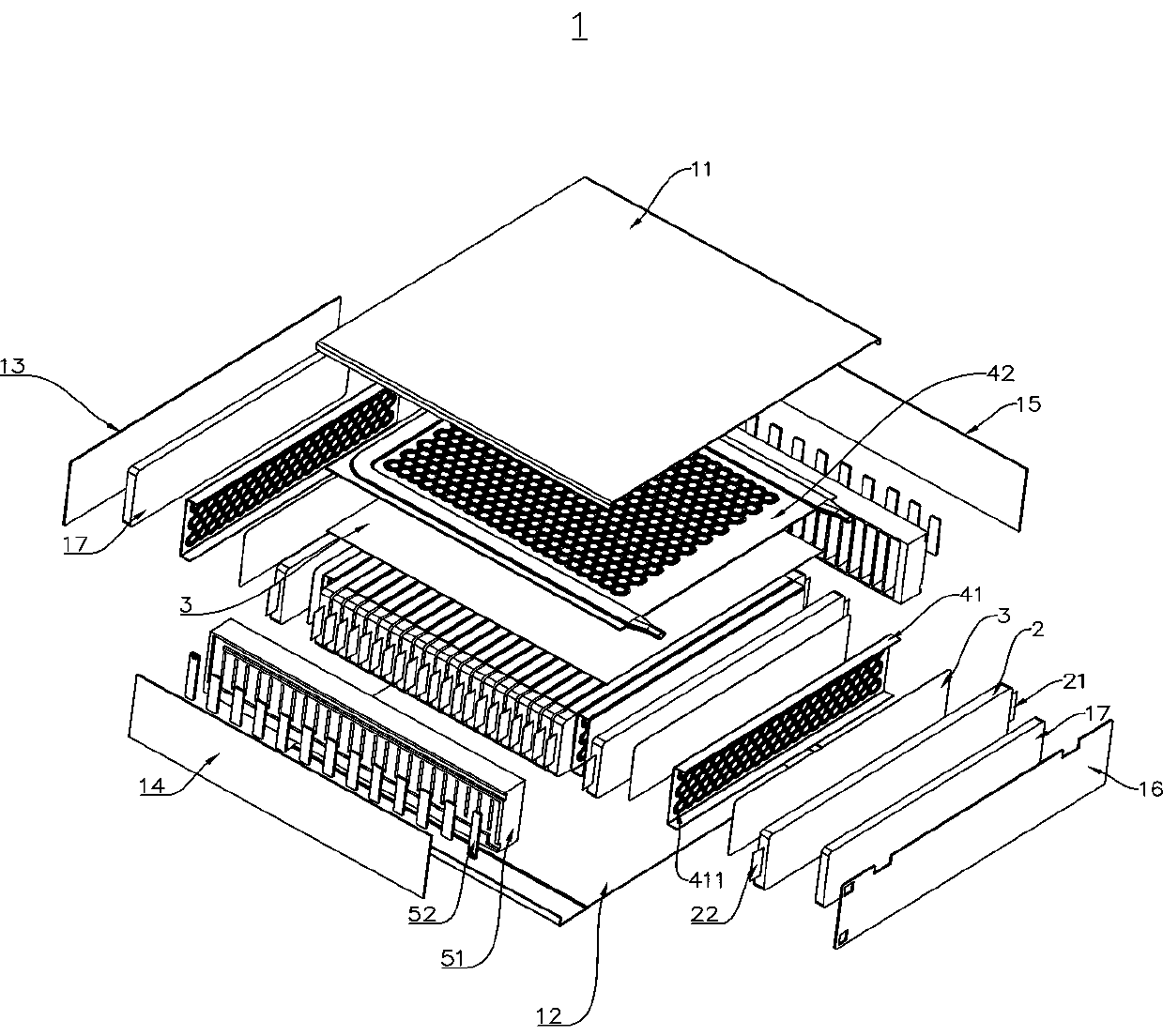

Battery module, battery pack, electric vehicle, and power grid system

PendingCN110311189ATake away quicklyFast heat transfer rateSecondary cellsCell component detailsPower gridElectric vehicle

The invention provides a battery module comprising a casing, battery cells, a heat equalizing plate and a heat dissipating device. The casing includes six panels in the up, down, front, rear, left andright directions respectively. The battery cells are disposed in the casing. The heat equalizing plate is installed in the casing, is sandwiched between the battery cells, and is filled with a heat transfer working medium. The heat dissipating device has heat equalization, heat exchange and heat dissipation functions. The present invention also provides a battery pack having the battery module, an electric vehicle, and a power grid system. The heat equalizing plate filled with the heat transfer working medium can quickly absorb the heat generated during the charging and discharging processesof the battery cells, and distributes the heat to transfer the heat to the heat dissipating device to quickly dissipate the heat inside the battery module. Therefore, it is possible to prevent the insufficient heat dissipation of the battery modules in the battery pack, the electric vehicle, and the power grid system from influencing the normal use or causing a safety accident.

Owner:ZHEJIANG JIAXI TECH CO LTD +1

Fully-closed intelligent electric control cabinet cooling system

InactiveCN105407688AMeet the temperature requirementsMeet humidity requirementsSpace heating and ventilation safety systemsLighting and heating apparatusEvaporationElectric control

The invention discloses a fully-closed intelligent electric control cabinet cooling system, which comprises a compressor, a condensation heat recovery adjustment valve, a heat recovery coil, an electric valve, a condensation coil, a condensation fan, a dry filter, a throttle valve, an evaporation coil, a baffle board, an electric heater, a circulating fan and a case. The cooling capacity for cooling each electronic and electric module inside the electric control cabinet is from the refrigerating capacity generated by a vapor compression refrigeration system at the evaporation coil, a constant dew point temperature mode enables the temperature and the humidity of the circulating cooling air to be controlled precisely, and due to the condensation heat recovery design, the cooling system is energy-saving and environmental friendly. The defects that the cooling mode of the cooling fan is largely influenced by interference of the surrounding air environment, and only insufficient cooling effects can be provided can be overcome.

Owner:WUXI INST OF COMMERCE

Permanent-magnet synchronous motor cooling structure

InactiveCN106329831AAvoid lostSolve Cooling ProblemsCooling/ventillation arrangementSupports/enclosures/casingsSynchronous motorCooling effect

The invention discloses a permanent-magnet synchronous motor cooling structure. The front end of the cavity of a motor is provided with a cooling medium inlet at the joint of a cylinder and a stator. A spiral flow channel is designed between the motor cylinder and the motor stator to cool the outer surface of the motor stator. When cooling medium arrives at the tail end of the motor, as all other parts of the tail end of the motor are sealed, the cooling medium can only pass through an air gap between the stator and a rotor so the cooling medium is forced to cool the outer surface of the motor rotor and the inner surface of the motor stator. Then, the cooling medium enters next container via an air return port at the front end of the motor. As the cooling medium entering the air gap between the motor stator and the rotor has been cooled once, in order to avoid insufficient cooling, a channel of cooling medium is added on the end face of the rear end cover of the motor to enhance the cooling effect. The structure of the scheme is particularly applicable to 500-1500KW high-power permanent-magnet synchronous motors, and can be used in centrifugal compressors, screw compressors, blowers and other similar models.

Owner:GREE ELECTRIC APPLIANCES INC

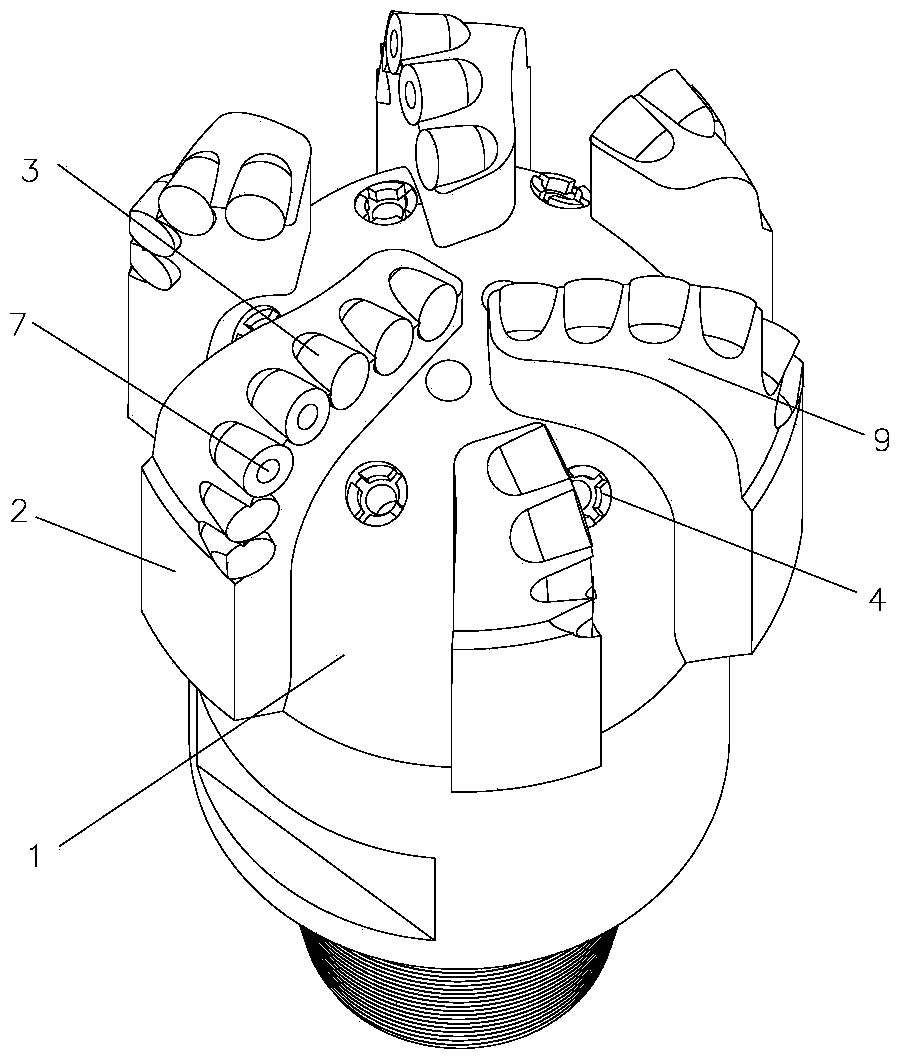

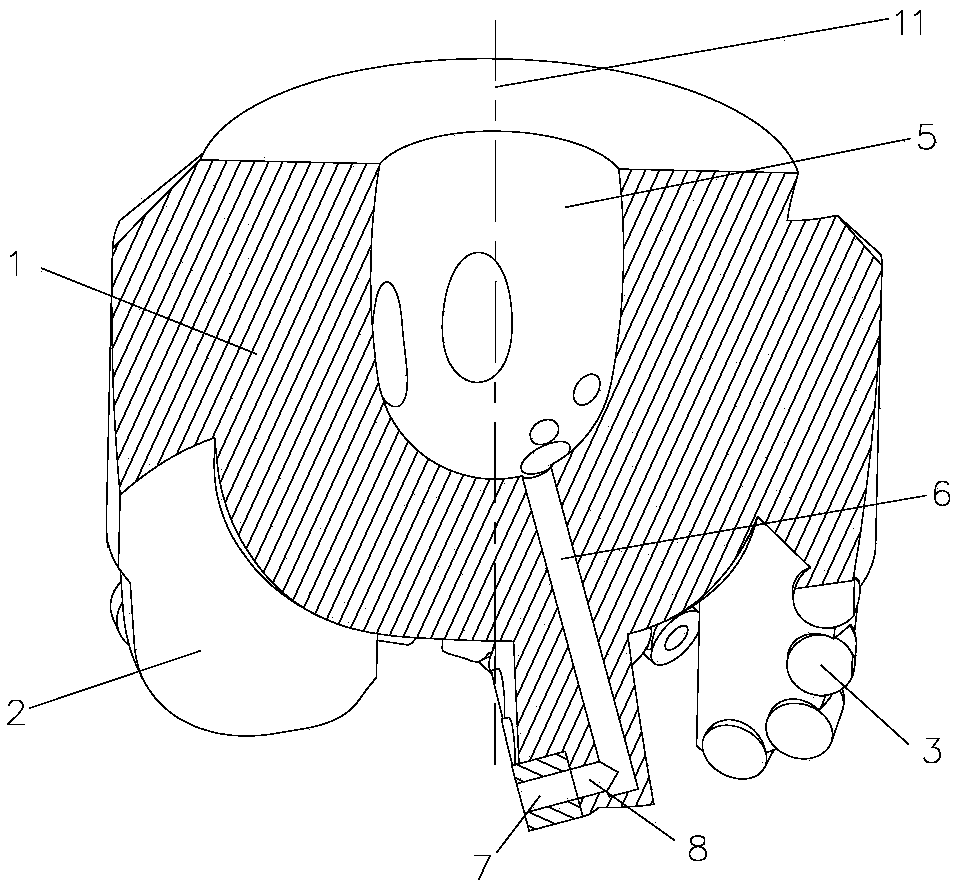

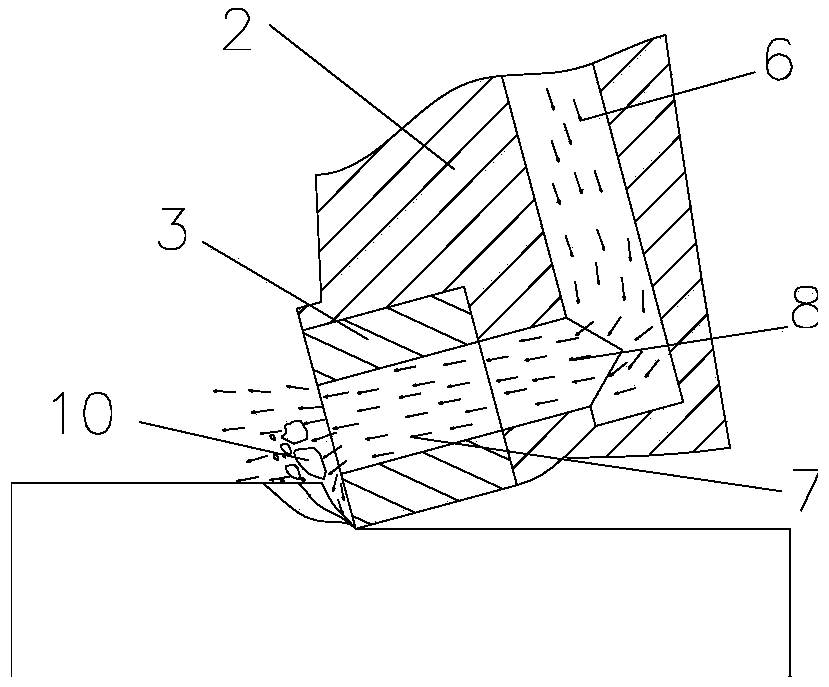

PDC (Polycrystalline Diamond Compact) drill bit applicable to high temperature well drilling

InactiveCN109209241AImprove thermal wear phenomenonClean in timeDrill bitsConstructionsPolycrystalline diamondPetroleum

The invention discloses a PDC (Polycrystalline Diamond Compact) drill bit applicable to high temperature well drilling, and belongs to the fields of petroleum and natural gas drilling engineering, mine engineering, geological drilling, geothermal drilling, hydrological drilling, tunnel engineering, shield and trenchless technical equipment. The PDC drill bit comprises a drill bit body, water holesor nozzles arranged on the drill bit body, an inner flow channel arranged on the drill bit body and a plurality of blades extending from the drill bit body, wherein each blade is provided with fixedcutting elements. The PDC drill bit is characterized in that at least one cutting element is provided with a jet hole; the drill bit further comprises branch flow channels extending from the inner flow channel to the blades; the jet holes are communicated with the corresponding branch flow channels; the branch flow channels are used for forming passing channels of a liquid in the inner flow channel; and the jet holes are channels through which the liquid in the inner flow channel sprays out. The invention aims to provide a PDC drill bit applicable to high temperature well drilling, which effectively improves problems of the shortening of the working life and the declining of the drilling ability of the drill bit due to insufficient cooling of the cutting elements during the rock breaking process of the drill bit.

Owner:刘伟

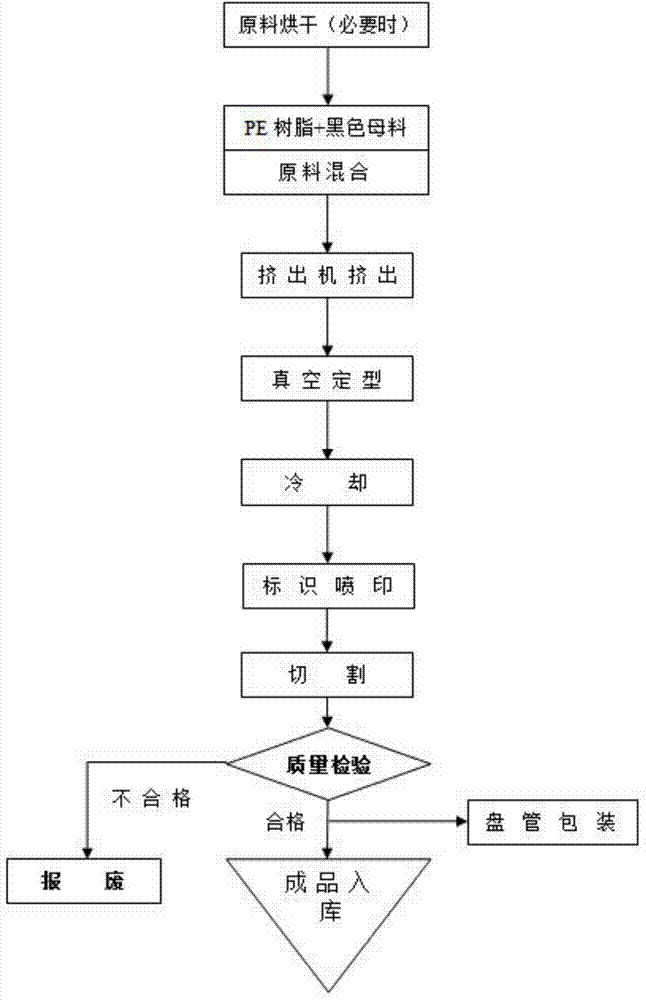

Preparation process of PE (Poly Ethylene) ultra-large-diameter thin-wall pipe material

The invention relates to a preparation process of a PE (Poly Ethylene) ultra-large-diameter thin-wall pipe material. The preparation process adopts an improved machine head of an extruding machine. The improved machine head comprises an opening mold, an opening mold seat, a sizing sleeve, a core mold, a machine head body and a connector which are connected in sequence, wherein the opening mold is arranged in the opening mold seat; the two sides of the machine head body are provided with adjusting screws; the tail end of the machine head body is provided with the connector; the machine head body is internally provided with an air flowing channel; and the air flowing channel extends outwards from the side surface of the tail end of the machine head body and is communicated with the gas discharging pipeline at the outer part. The preparation process has the advantages that internal air cooling is added, and the air flowing direction is opposite to the extruding direction of the pipe material, so that the cooling effect of the pipe material is improved; by the method, the inner part of the pipe material is cooled simultaneously, so that the problems of non-circularity and nonstandard caused by drooping of melt due to reduction of the gravity and delayed and insufficient cooling are prevented; and the heat of the machine head is guaranteed to be taken away as little as possible, the internal temperature of the machine head is uniform, the action is obvious and the effect is remarkable.

Owner:山东华信塑胶股份有限公司

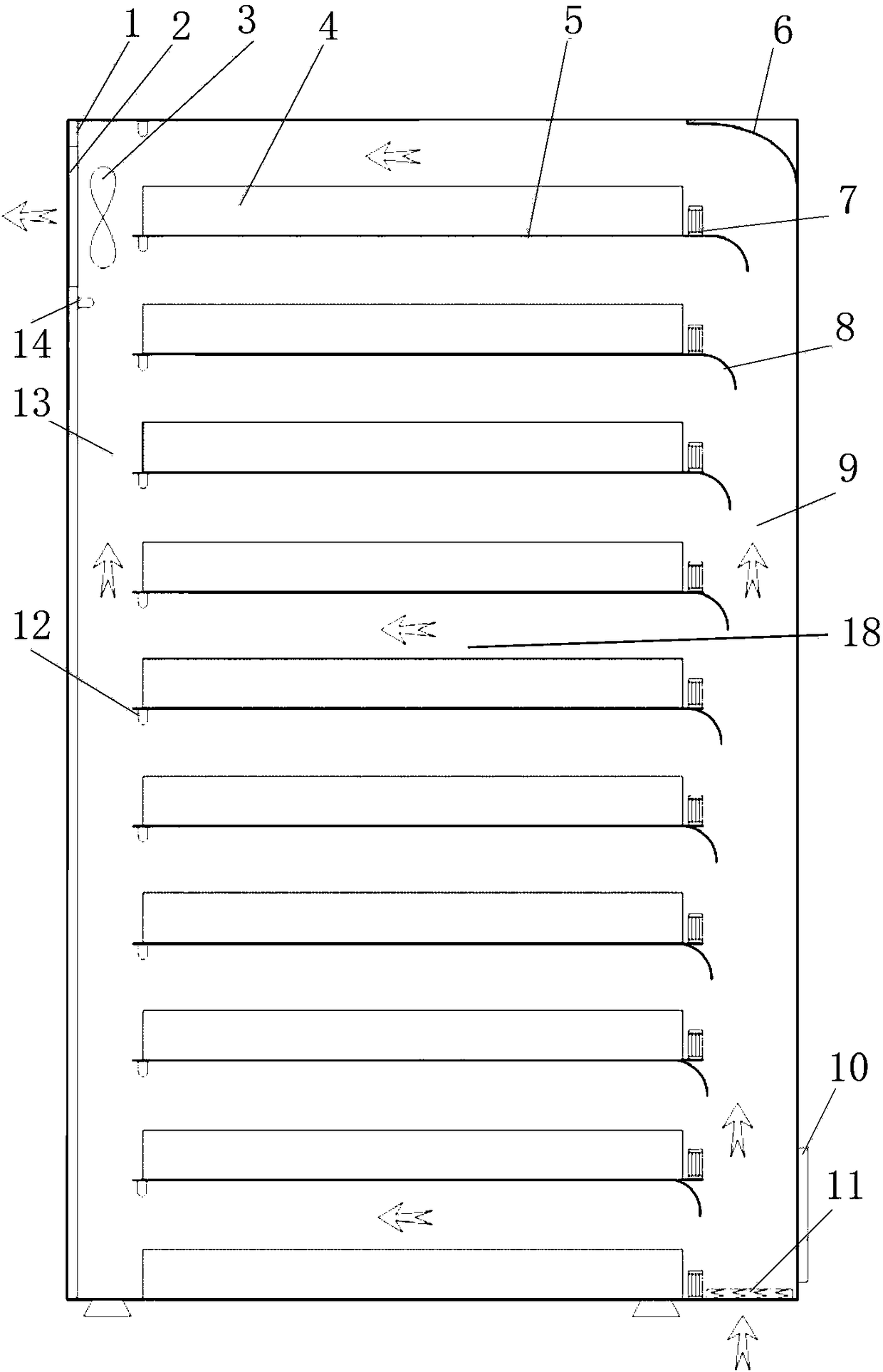

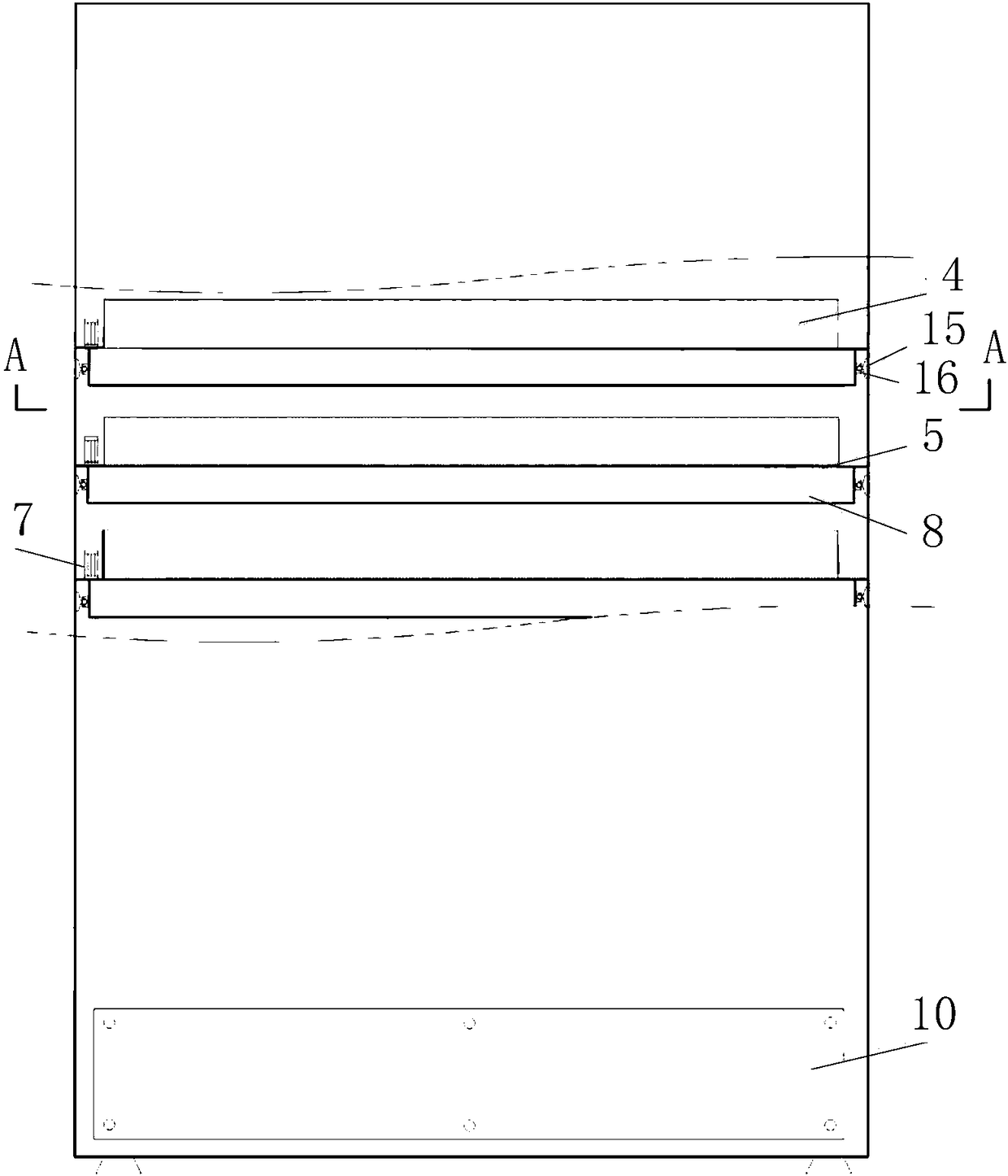

Adaptive air supply casing for cooling communication equipment

ActiveCN108633214ARealize precise air supplyAvoid wasteful situationsCooling/ventilation/heating modificationsCold airCurrent sensor

The invention relates to an adaptive air supply casing for cooling communication equipment. The air supply casing comprises a casing body and a multi-layer support arranged in the casing body, a coldair duct is formed between the multilayer support and a first inner wall of the casing body, and an air inlet is arranged the inner wall, under the cold air duct, of the casing body; a hot air duct isformed between the multilayer support and a second inner wall of the casing body, and an air exit is arranged the inner wall, under the hot air duct, of the casing body; the first inner all is opposite to the second inner wall, and a cooling channel is formed over each layer of the support; and the air supply casing further comprise voltage and current sensors arranged on the different layers ofthe support and used to connect with communication equipment on the layers respectively, a controller connected with the voltage and current sensors, transmission mechanism arranged on the different layers and connected with the controller, and shunting baffle plates arranged in the end portions of the cold air ducts of the layers and connected with the corresponding transmission mechanisms respectively. Thus, air is supplied to the communication equipment accurately, and waste caused by insufficient cooling in certain position and over supply of cold air can be avoided.

Owner:CHINA MOBILE GROUP SHAIHAI

Secondary cooling device used in continuous casting process

The invention discloses a secondary cooling device used in continuous casting process, comprising a plurality of cooling sections, wherein each cooling section comprises a cooling water pipe and a nozzle connected to the cooling water pipe, the distances between the nozzles in the cooling sections are different, the nozzles at both ends of each cooling section are obliquely arranged to a transition area, wherein the transition area is between two adjacent cooling sections. The secondary cooling device on the basis of the invention can simultaneously avoid the problems of insufficient cooling intensity of the front parts of the cooling sections, supercooling of the back parts of the cooling sections and insufficient cooling of the transition areas.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

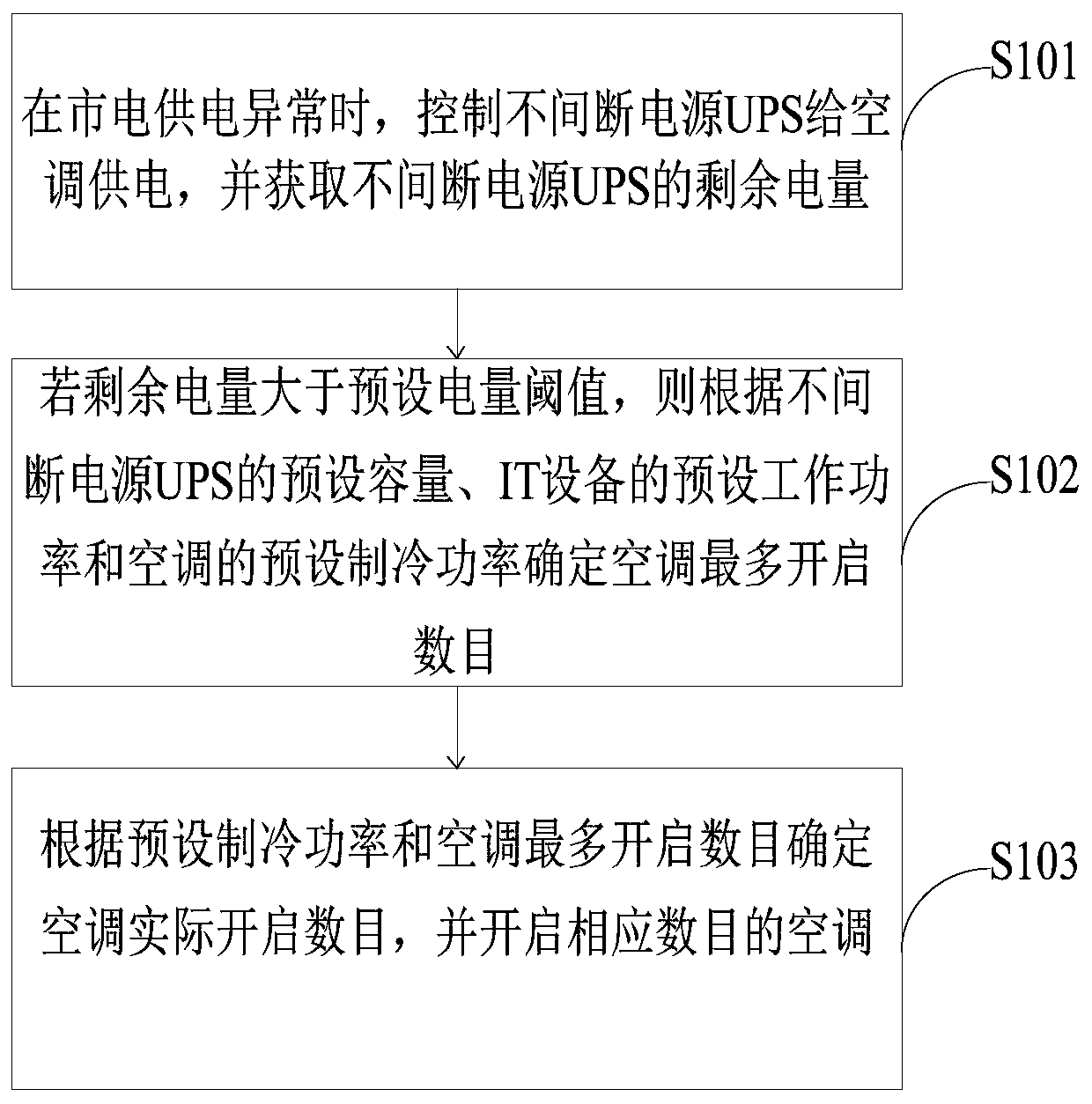

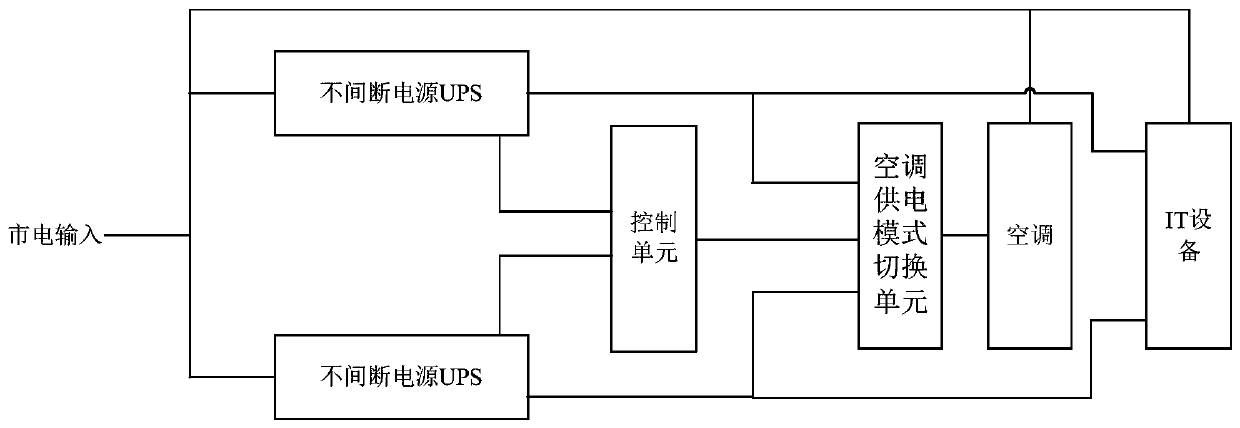

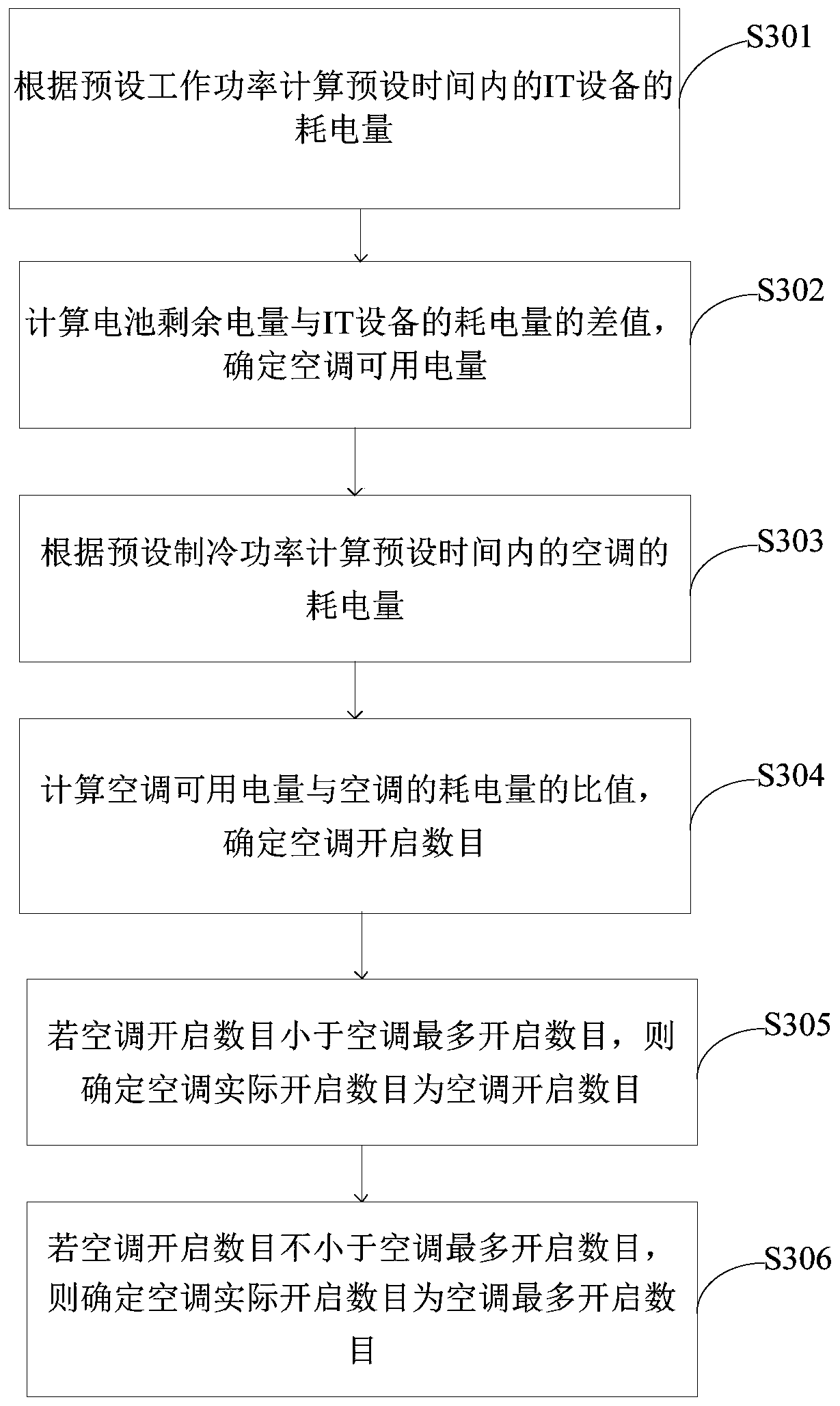

Power supply method and power supply system for data center

ActiveCN109742846AAvoid overheating and downtimeBatteries circuit arrangementsElectric powerData centerEngineering

The invention is suitable for the technical field of a data center, and provides a power supply method and a power supply system for a data center. The power supply method comprises steps of: when mains supply is abnormal, controlling uninterruptible power supply (UPS) to power air conditioners, acquiring battery remaining capacity of UPS, if the battery remaining capacity is greater than a presetpower threshold, determining the maximal number of air conditioners that are allowed to be turned on according to preset capacity of the UPS, preset working power of an IT device and preset refrigerating power of the air conditioner, determining an actual number of air conditioners that are turned on according to the preset refrigerating power and the greatest number of air conditioners that areallowed to be turned on, and turning on the corresponding number of air conditioners. Even when the mains supply is abnormal, the air conditioners keep refrigerating, so that the IT device is prevented from overheat shutdown due to insufficient cooling.

Owner:ZHANGZHOU KEHUA ELECTRIC TECH CO LTD +1

Processing method for concentric circle with groove bottom surface roughness ranging from Ra 0.1 to Ra 0.4

InactiveCN104625090AFulfil requirementsGuaranteed roughnessMaintainance and safety accessoriesRetention timeSurface roughness

The invention provides a processing method for a concentric circle with a groove bottom surface roughness ranging from Ra 0.1 to Ra 0.4. The method comprises the steps that: firstly, concentric circle rough turning processing is carried out on a part by a common cutter, a rough processed groove is formed, and a 0.02 mm allowance is reserved on the upper wall of the rough processed groove; secondly, concentric circle fine turning processing is carried out on the groove by a cutter which is made from one of the cutter materials selected from cube boron carbide, H13A, WSN, and 1005 titanium alloy, a fine processed groove is formed, meanwhile 20-60 Bar cooling liquid is utilized to spray on a turning opening, and the retention time of the cutter ranges from 30 s to 120 s. The requirement of the part for the concentric circle with the groove bottom surface is met, and the roughness of the groove bottom surface is guaranteed. Due to the fact that the groove bottom is a concave space, the factors such as difficult chipping and insufficient cooling exist in mechanical processing, as a result the surface roughness of the bottom surface is difficult to reach below Ra 0.4.

Owner:GUIZHOU LIYANG INT MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com