Processing method for concentric circle with groove bottom surface roughness ranging from Ra 0.1 to Ra 0.4

A processing method and technology of concentric circles, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as processing can not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

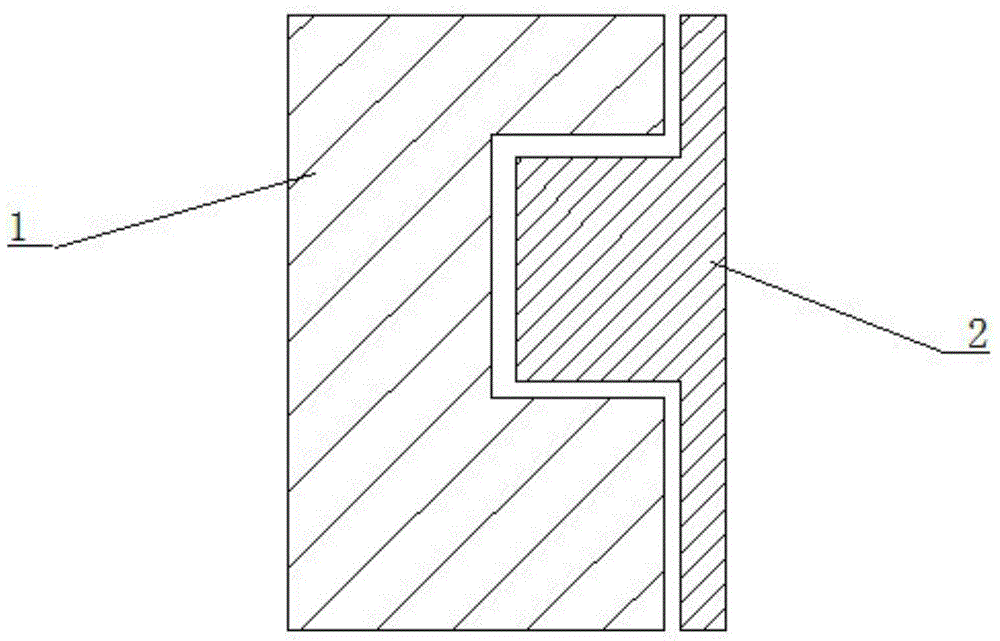

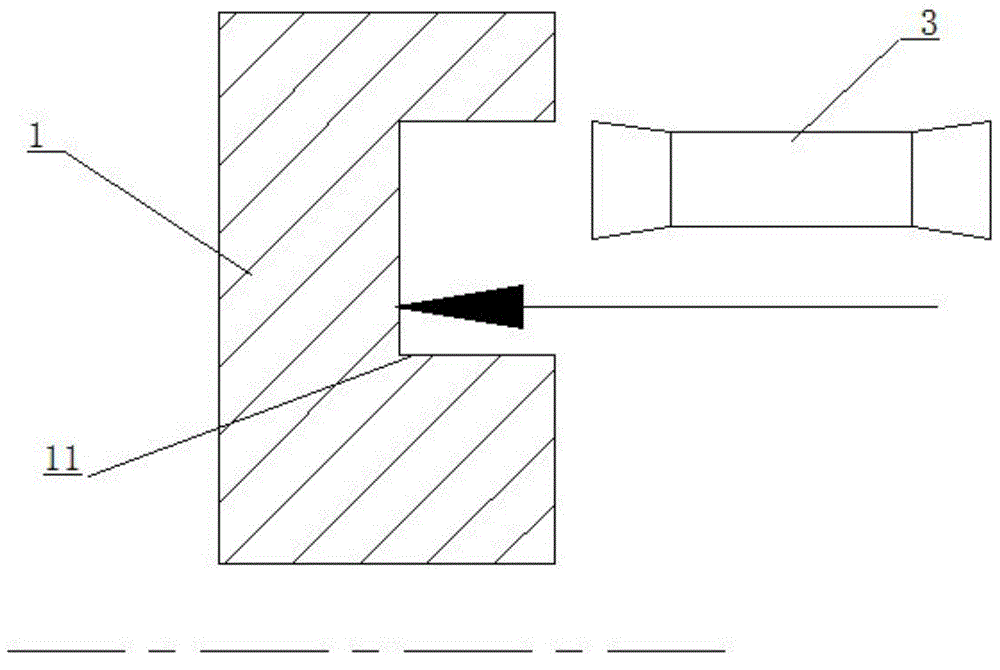

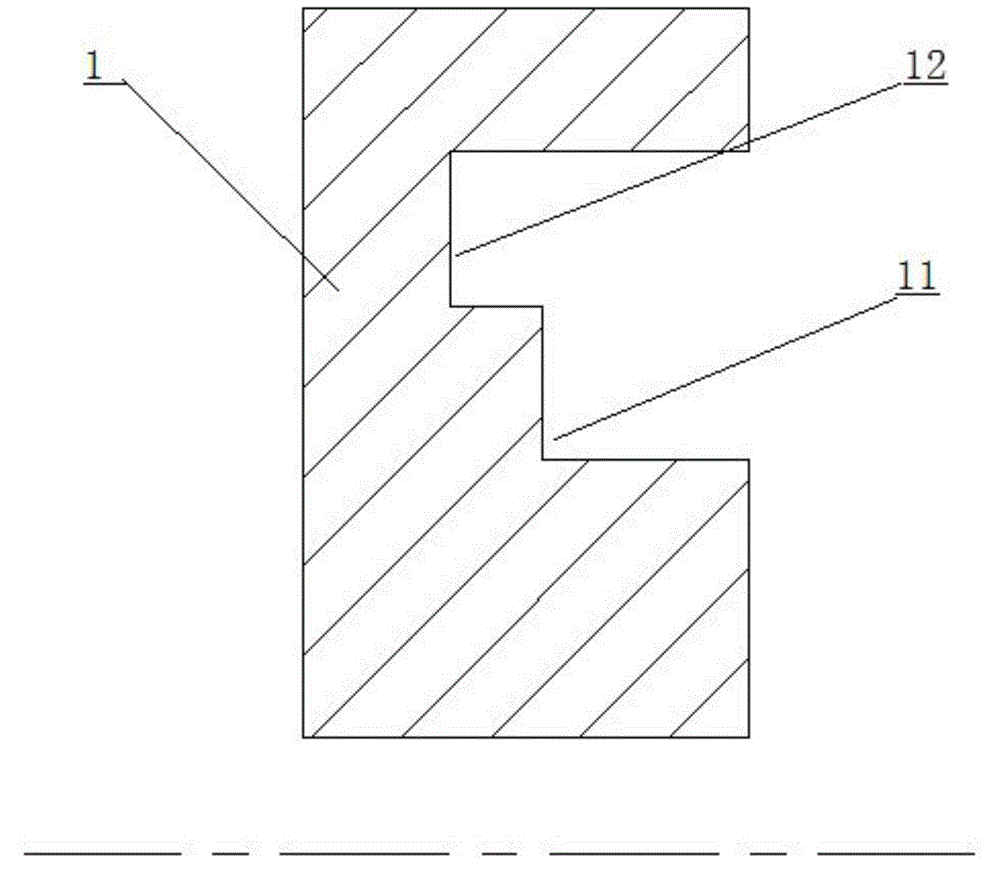

[0015] Such as Figure 1~4 The processing method of the concentric circles with the roughness of the groove bottom surface Ra0.1~Ra0.4 shown, the steps are as follows: first, use a conventional cutting tool to perform concentric rough turning on the part 1 to form a rough machining groove 11, and rough machining the concave groove 11. A margin of 0.02 mm is reserved on the upper wall of the groove 11, and then a tool 3 made of titanium alloy material is selected as the tool material to carry out concentric circle finish turning on the groove to form a finishing groove 12, and at the same time, use 20~ The 60Bar coolant sprays the turning port, and the tool residence time is 30-120s.

[0016] In order to meet the processing requirements of titanium alloys and reduce the cost of cutting tools, through experiments, cutting tool mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com