Patents

Literature

263results about How to "Guaranteed roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning agent for integrated circuit substrate silicon chip and its cleaning method

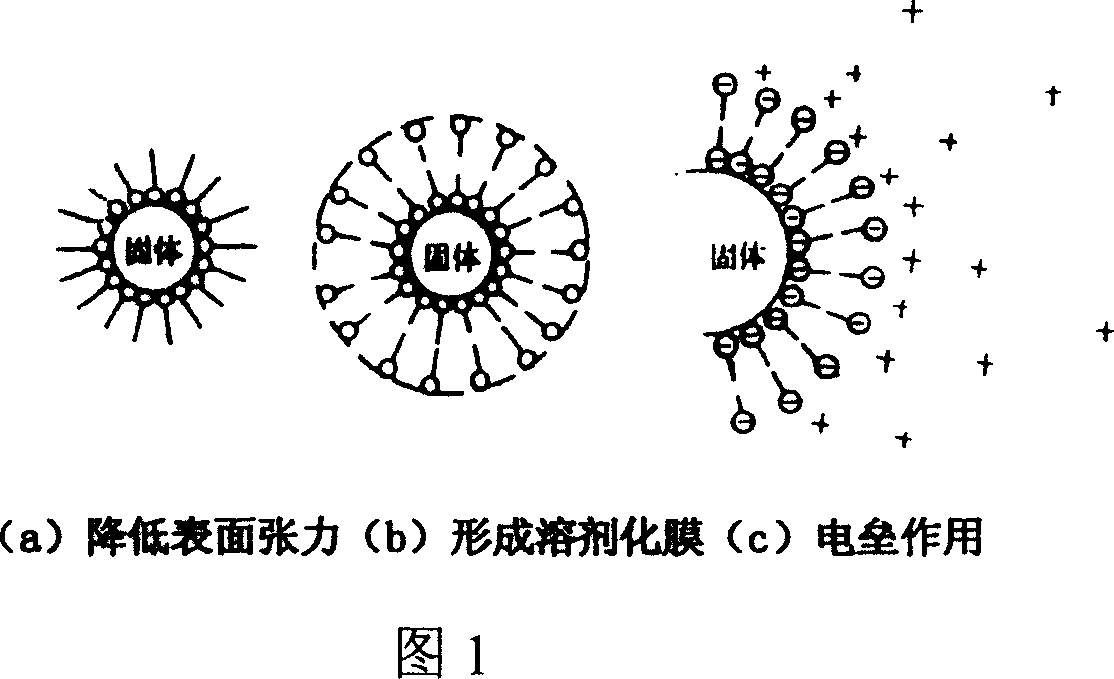

InactiveCN1944613AReduce surface tensionIncrease surface tensionNon-ionic surface-active compoundsOrganic detergent compounding agentsOrganic baseCleansing Agents

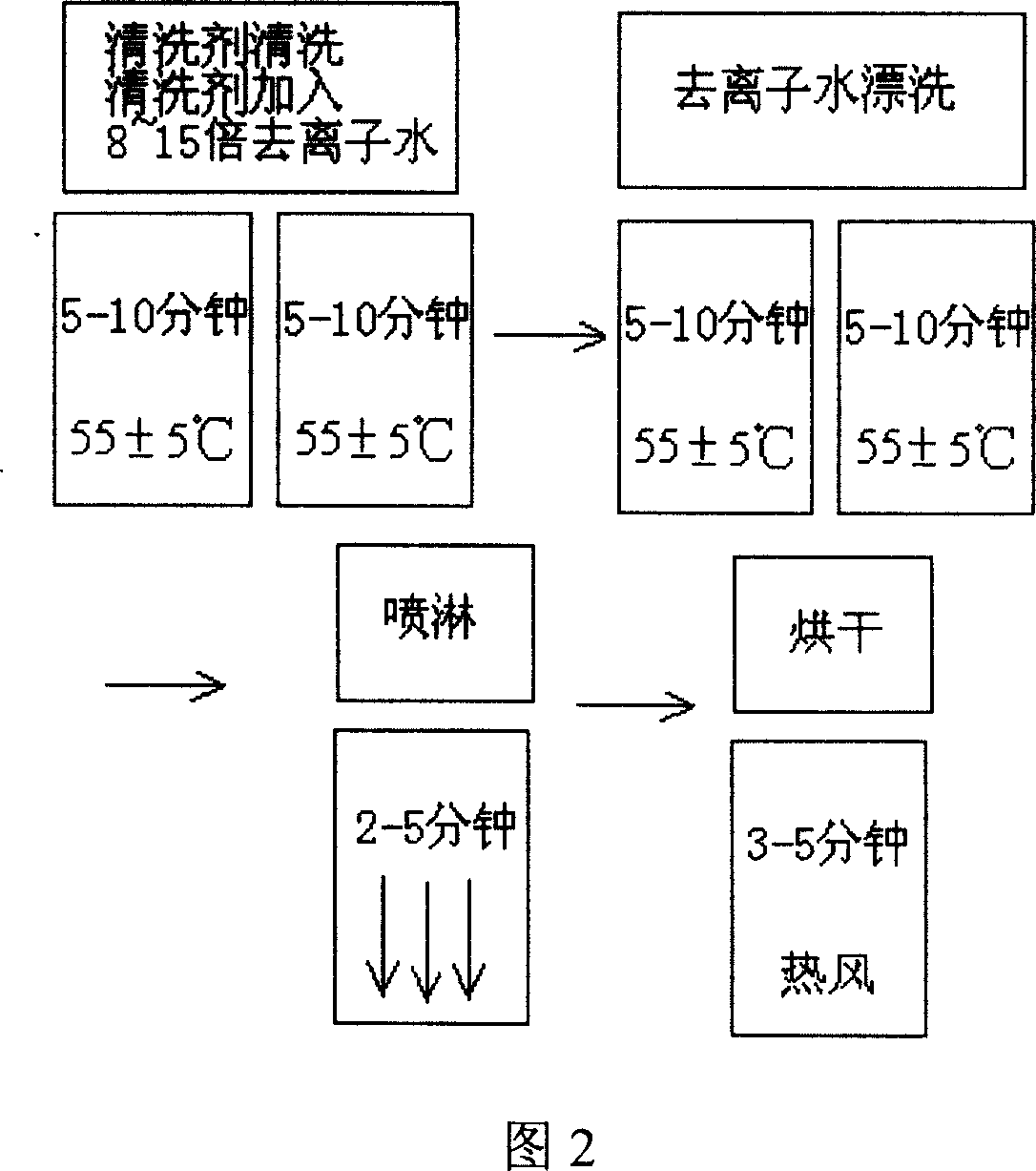

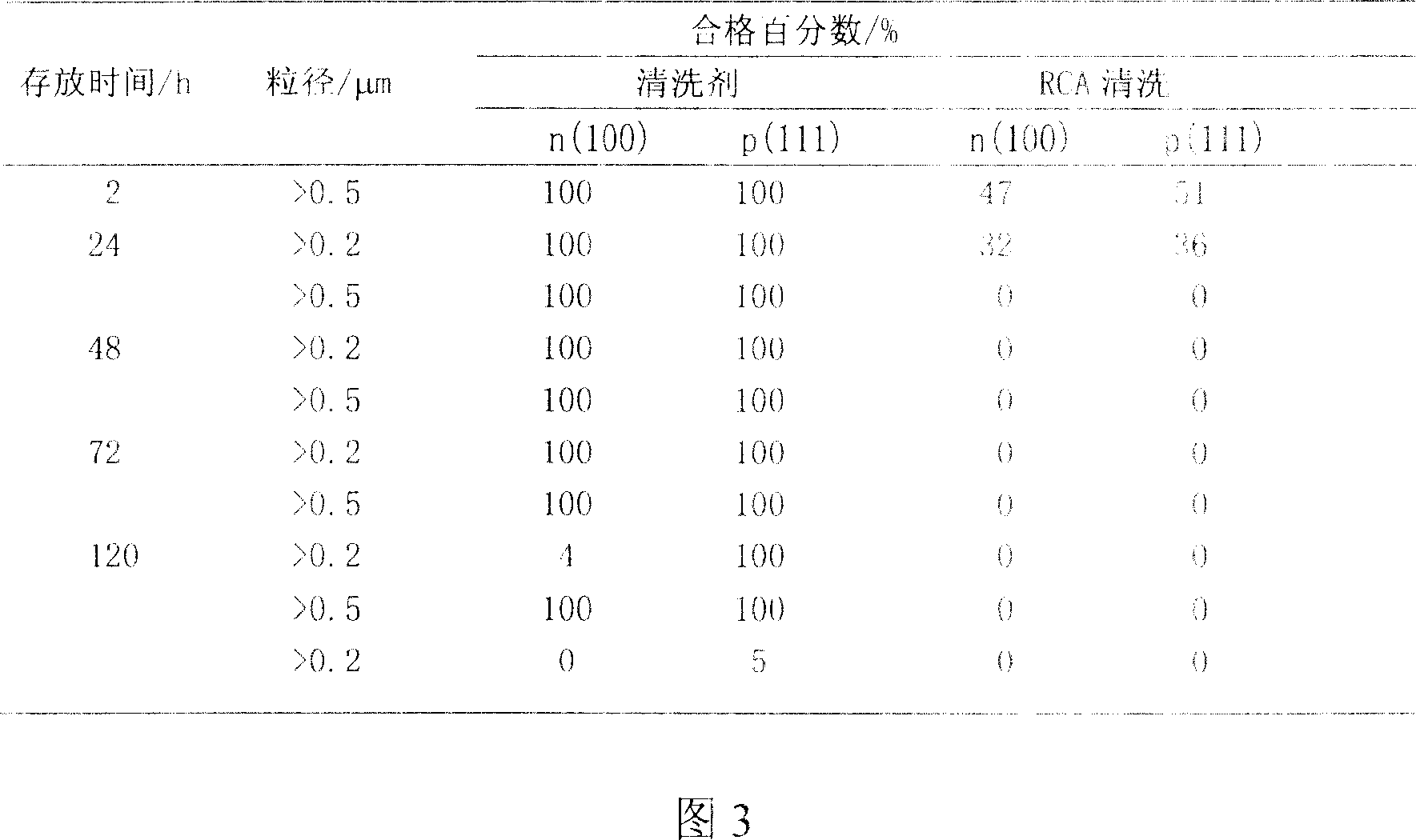

The cleaning agent for integrated circuit substrate silicon chip features that it consists of organic base functioning as pH regulator, complexing agent, corrosion inhibitor, dispersant and oxidizing assistant simultaneously in 40-45 %, surfactant functioning to lower surface tension of the solution, enhance mass transfer and eliminate metal ion simultaneously in 7-15 %, and water in 40-53 %. The cleaning method with the cleaning agent includes adding deionized water in 8-15 times, twice ultrasonic cleaning at 50-60deg.c for 5-10 min each, twice ultrasonic rinsing in deionized water at 50-60deg.c for 5-10 min each, sprinkling and stoving. The present invention has the advantages of excellent cleaning effect, simple preparation process, convenient operation and environment friendship.

Owner:天津晶岭电子材料科技有限公司

Manufacturing method of pedestal bearing for turbocharger and positioning tool for same

ActiveCN102658458AStress reliefEliminate processing stressGrinding work supportsTurbochargerEngineering

The invention discloses a manufacturing method of a pedestal bearing for a turbocharger and a positioning tool for the same. The manufacturing method comprises the following machining procedures of: 1), roughly turning one end surface and a hole of a workpiece; 2), roughly turning the other end surface and an outer circle of the workpiece; 3), annealing the workpiece to remove stress; 4), carrying out finish turning on the end surface and the hole; 5), carrying out the finish turning on the other end surface and the hole; 6), milling a semicircular positioning groove; 7), drilling radial holes at two ends; 8), milling the flat and square parts of the outer circle; 9), removing burrs by a bench worker; 12), milling an oil applying wedge surface of a thrust surface; 13), carrying out flaw detection; 14), removing the burrs by the bench worker and cleaning a part; and 15), carrying out comprehensive detection. The procedure 3) is adopted between the procedure 2) and the procedure 4) to anneal the workpiece to remove the stress; a procedure 10) and a procedure 11) are adopted between the procedure 9) and the procedure 12); the procedure 10) comprises the following steps of: adopting the positioning tool, positioning the outer circle of the workpiece by utilizing a tool hole, compacting the thrust surface of the workpiece, and accurately grinding the holes; and the procedure 11) comprises the following steps of: positioning the holes by utilizing a taper shaft, and accurately grinding the outer circle and the thrust surface. The manufacturing method and the positioning tool have the advantages that the procedures are arranged reasonably, and the machining quality and the machining efficiency can be effectively improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Lead-free environment friendly silver paste for piezoresistor and preparation method thereof

InactiveCN102768872AMeet environmental protection requirementsGuaranteed compactnessResistor terminals/electrodesNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention discloses a lead-free environment friendly silver paste for a piezoresistor. The lead-free environment friendly silver paste comprises the following compositions according to percentage by weight: 60-80wt% of silver powder, 14-34wt% of organic solvent, 1.5-4.0wt% of resin and 2.5-5.5wt% of inorganic additive. A method for preparing the lead-free environment friendly silver paste comprises the following steps of firstly, weighing the resin and the organic solvent according to the proportions and placing the resin and the organic solvent into a thermostatic reaction kettle for stirring, stirring again after the resin is dissolved completely, filtering impurities from the resin solution by using a 250 mesh screen so as to obtain a carrier; secondly, weighing the silver powder, the carrier and the inorganic additive according to proportions, and placing the weighed materials into a dual planetary stirrer for stirring; and thirdly, placing the stirred materials onto a three-roller grinder for rolling, when the fineness is less than 10 micrometers, sieving the materials by using the 250 mesh screen to obtain the environment friendly electronic full silver paste. The paste is environment friendly and harmless, and has an excellent printing performance.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Method for manufacturing hard-face roller of rolling mill

InactiveCN103831580AOvercome the striped color difference defects caused by uneven hardnessGuaranteed wear resistanceSlow coolingQuenching

The invention discloses a method for manufacturing a hard-face roller of a rolling mill. A number 45 or number 50 steel plate is rolled into a circle to form the roller body of the hard-face roller, the splicing joint of the roller body is made into a Y-type groove to be welded, the welding joint is wrapped in asbestos after the welding, heat preservation and slow cooling are performed, the roller body is rolled again to form a circle, the circular degree is required to be smaller than or equal to 2 mm, before the quenching is performed, a plurality of circular supporting rib plates are arranged on an inner ring of the roller body at intervals, auxiliary tool shaft heads are installed at the two ends of the roller body, and the outer circle of the roller body is machined to have the size before the quenching; the surface of the roller body is quenched in a vertical medium-frequency quenching mode, the roller body is moved into an electric furnace or a gas furnace to be tempered after being quenched; installed tools are dismantled, an inner hole of the roller body is machined to have the size of the hard-face roller, and shaft head wheel disks are installed at the two ends of the roller body; the surface of the roller body is ground to have the size before spraying, and an abrasion-resistant anti-corrosion coating is manufactured on the surface of the roller body, and the surface of the roller body is ground to have the roughness meeting the technological requirement. The method overcomes the defect of strip-shaped color difference of the roller body, the deformation control range of the roller body is controlled, ideal hardness and ideal hardness distribution are acquired, abrasion resistance and roughness are improved, and the service life of the roller is prolonged.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

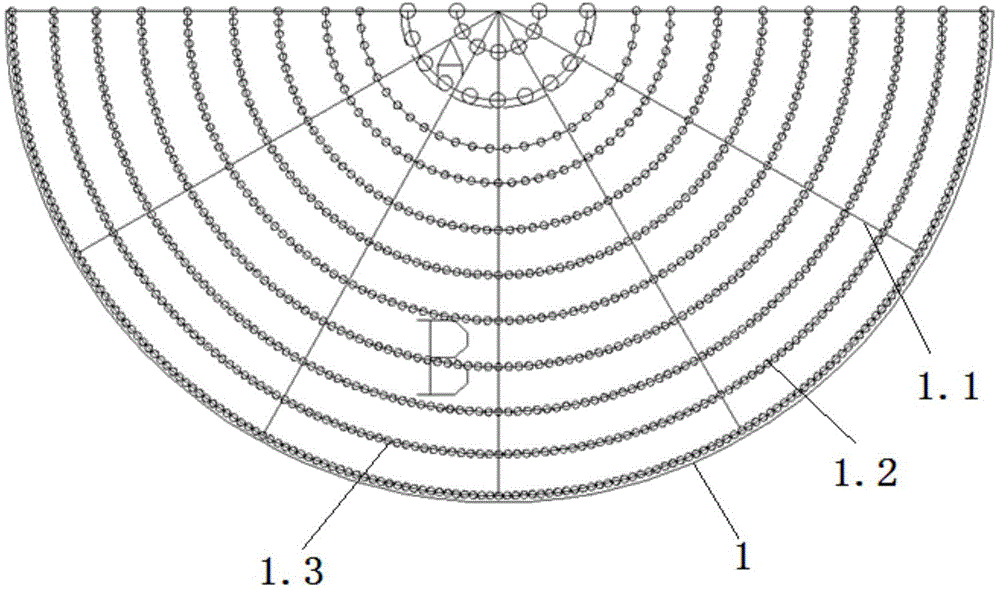

Chemical-mechanical polishing pad

The invention discloses a chemical-mechanical polishing pad and solves the problem that an existing polishing pad is scratched easily and low in polishing efficiency. According to the technical scheme, the chemical-mechanical polishing pad comprises a polishing layer, a plurality of holes are formed in the polishing surface of the polishing layer, the center of the polishing surface is a circle center, and the holes are arranged into multiple rows of concentric rings different in diameter. The center of the polishing surface is an end point, and a plurality of grooves extending to the edge of the polishing surface are evenly radiated from the end point. The surface roughness of the polishing surface is below 15 micrometers. The polishing pad is simple in structure, capable of increased polishing removing efficiency and inhibiting scratches, and long in service life.

Owner:HUBEI DINGLONG CO LTD

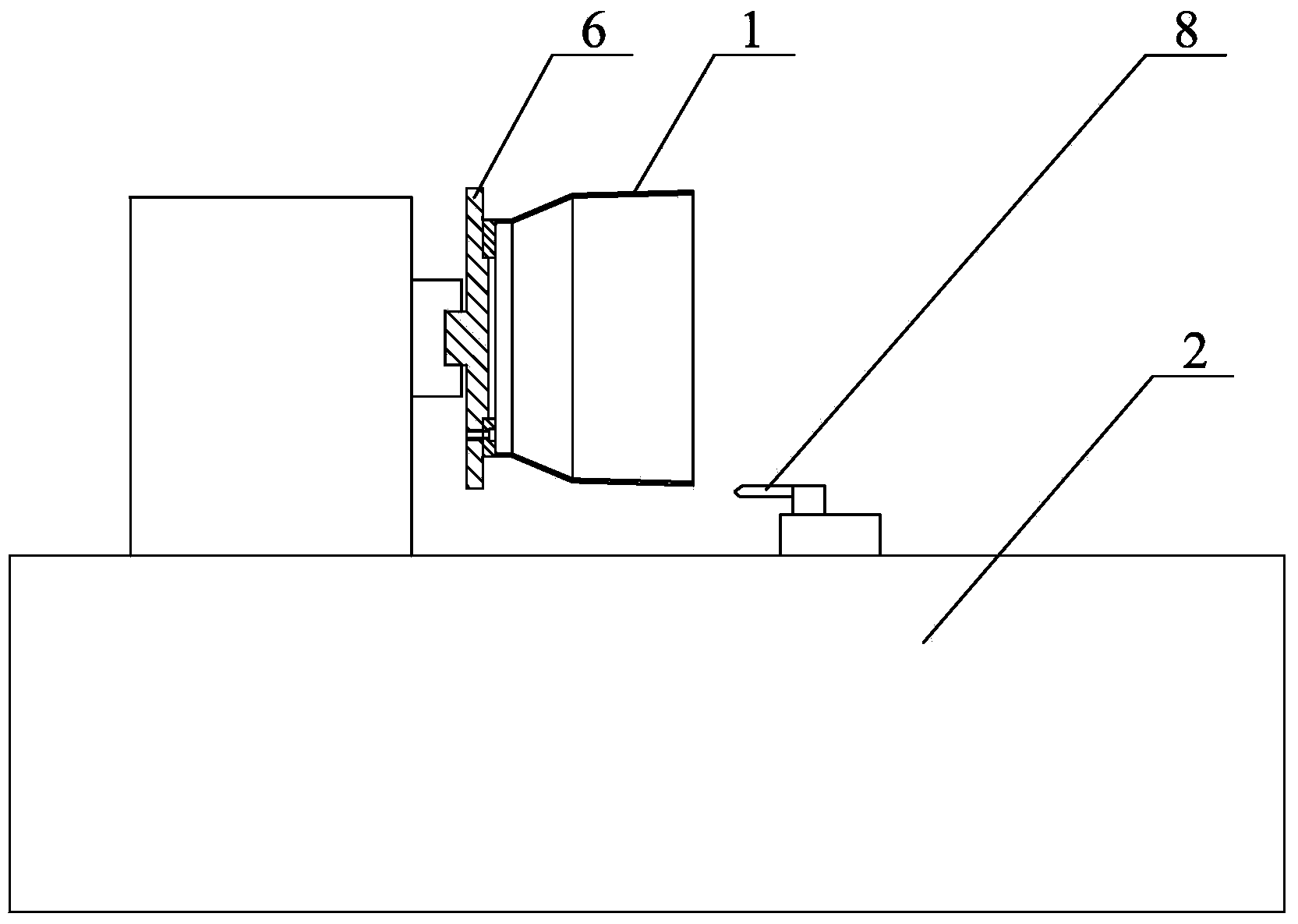

Finish machining method of direct lathe machining of optical collecting mirror in EUV (extreme ultra-violet) lithography light sources

ActiveCN103433507AReduce processing costsGuaranteed face shapeTurning machinesLithographic artistUltraviolet

The invention discloses a finish machining method of direct lathe machining of an optical collecting mirror in EUV (extreme ultra-violet) lithography light sources, belongs to the field of optics and finish machining, and aims at solving the problems that the optical collecting mirror in EUV light sources is machined by adopting a reproducible method, firstly a solid shaft which is matched with the surface type of the required collecting mirror is required to be machined, then the surface of the solid shaft is subjected to nickel deposition treatment, and then the nickel shell is peeled to form a substrate of the collecting mirror. According to the technique of the scheme, the accuracy control required during the machining process is very strict, and the machining cost is increased. The method comprises the following steps: installing and clamping a cylinder blank 1 of the collecting mirror; carrying out rough lathe machining in finish lathe machining; carrying out half-finish lathe machining; carrying out the finish lathe machining; carrying out membrane coating treatment; carrying out manual polishing treatment; carrying out the manual polishing treatment on the surface type of the cylinder blank of the collecting mirror after the membrane coating treatment, so that the surface type of the cylinder blank of the collecting mirror meets the surface type of the collecting mirror, thereby completing the manufacture of the collecting mirror. The finish machining method provided by the invention is used for machining and manufacturing the optical collecting mirror in the EUV lithography light sources.

Owner:HARBIN INST OF TECH

Small-size LED copper strip production process

The invention discloses a small-size LED copper strip production process, and belongs to the technical field of the copper strip production process. The production process includes the following stepsof (1) smelting and ingot casting, (2) hot rolling, (3) milling, (4) rough rolling, (5) first annealing, (6) one-step cleaning, (7) intermediate rolling, (8) secondary annealing, (9) secondary cleaning, (10) intermediate finish rolling, (11) third annealing, (12) third cleaning, (13) finish rolling, (14) unwinding, (15) fourth annealing, (16) fourth cleaning, (17) refine rolling, (18) fifth cleaning, (19) flattening and (20) cutting and delivery. According to the technical scheme, the quality of small-size LED copper strips can be improved, the workshop cost is reduced, and the production profits are increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

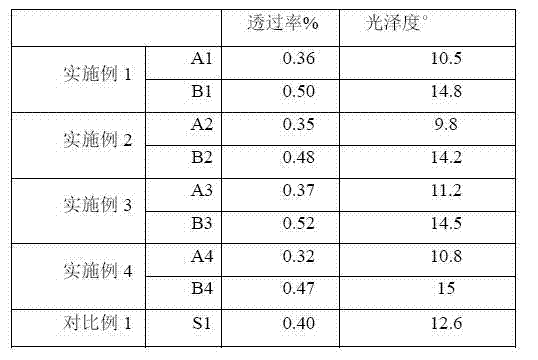

Trackpad and manufacturing method thereof

ActiveCN102898030AGuaranteed roughnessGood touchInput/output processes for data processingTouch SensesEngineering

The invention provides a manufacturing method of a trackpad. The method comprises: step 1, providing a glass substrate; step 2, conducting etching on the surface of the glass substrate with silk print etching ink; and step 3, immersing the etched glass substrate in a glass polishing solution to carry out polishing, thus obtaining the trackpad. The invention also provides the trackpad obtained by the method. Employment of the method disclosed in the invention to manufacture the trackpad can ensure the touchpad certain roughness, improve the touch sense of existing trackpads, and can endow the trackpad with certain light transmittance and guarantee its glossiness. Therefore, the method is conducive to improve the quality of the trackpad, thus further improving the use performance of electronic products.

Owner:BYD CO LTD

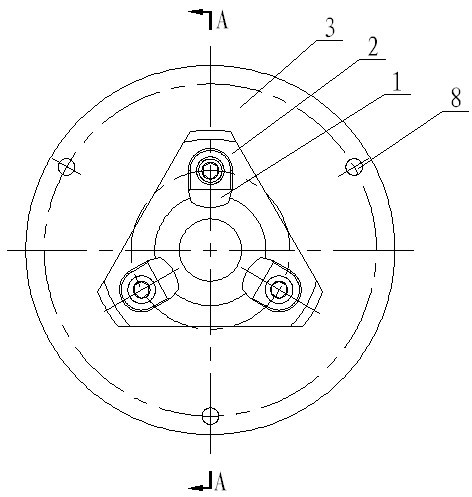

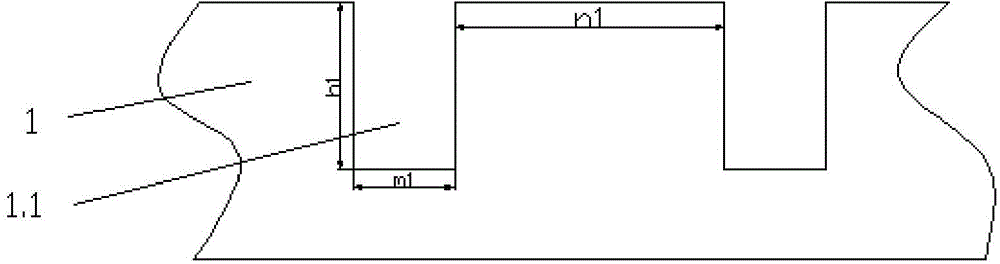

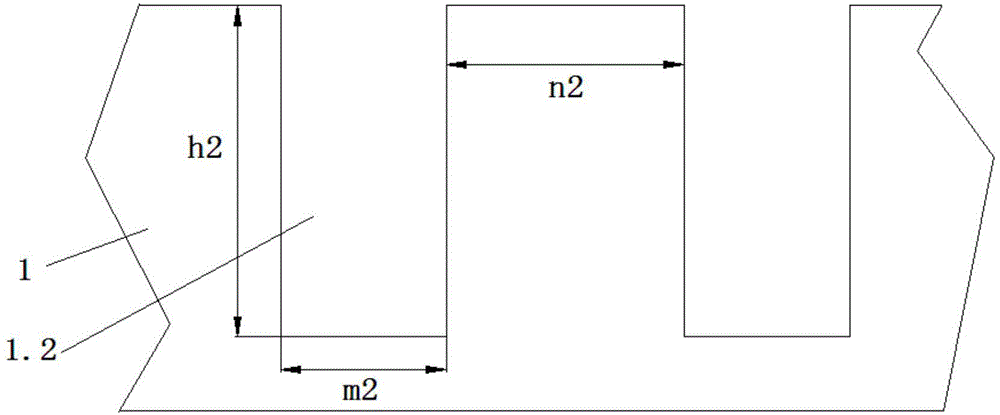

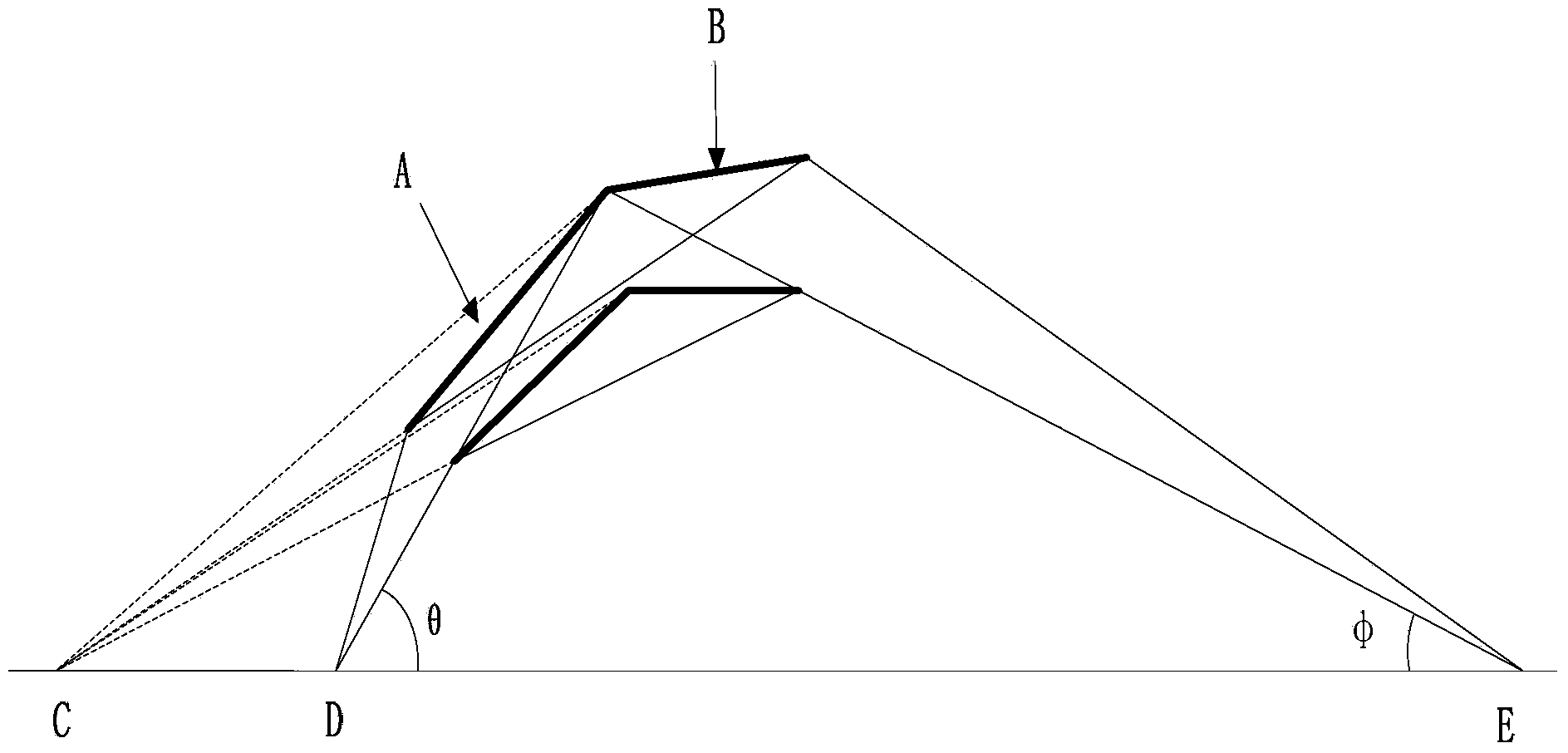

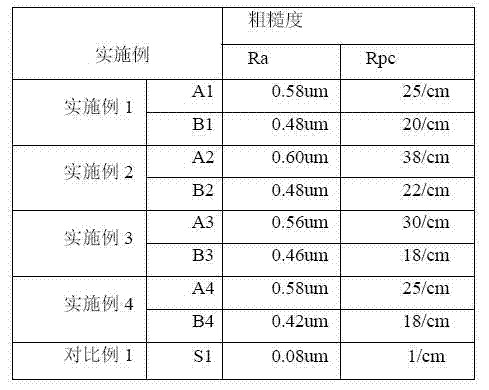

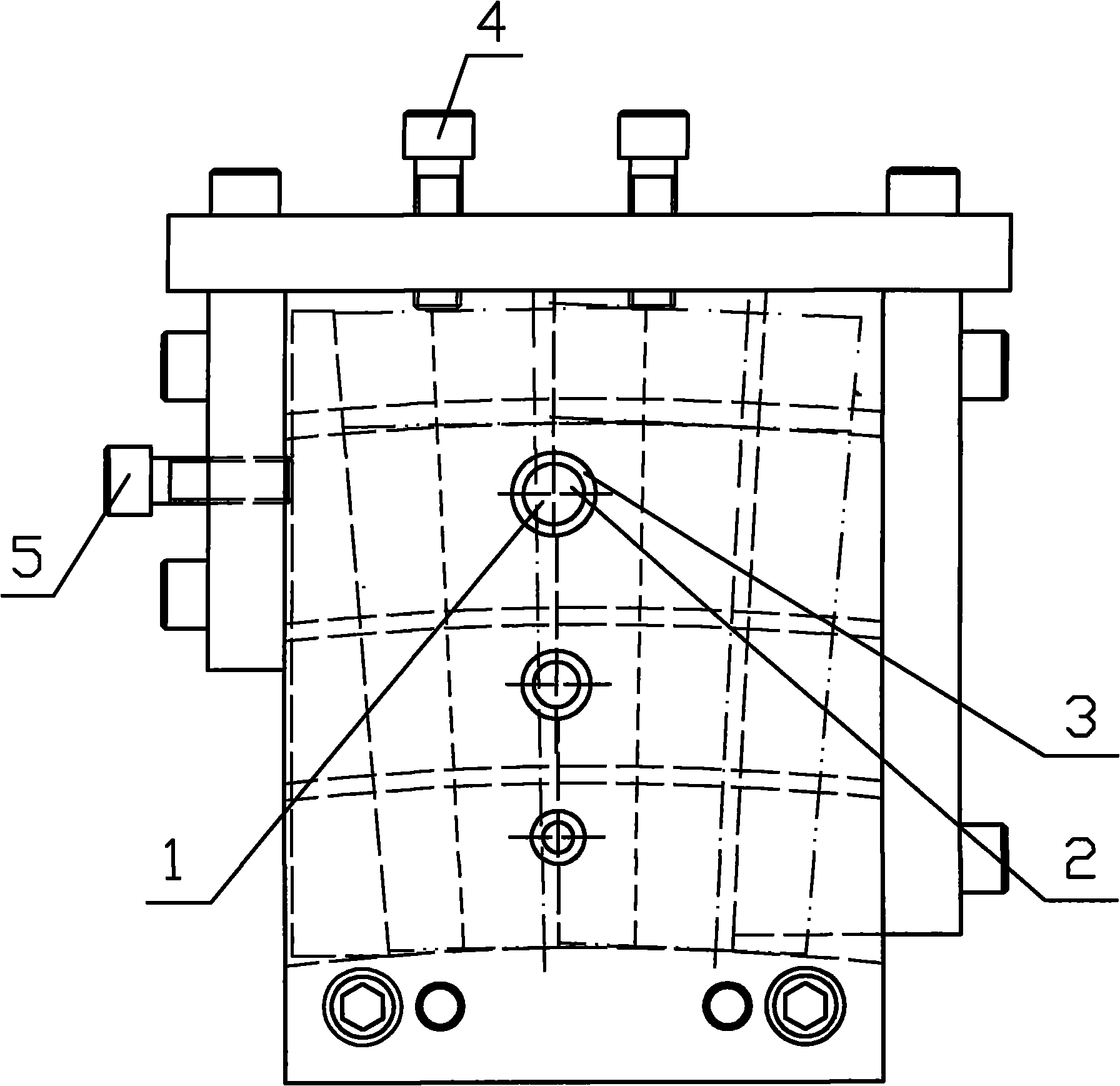

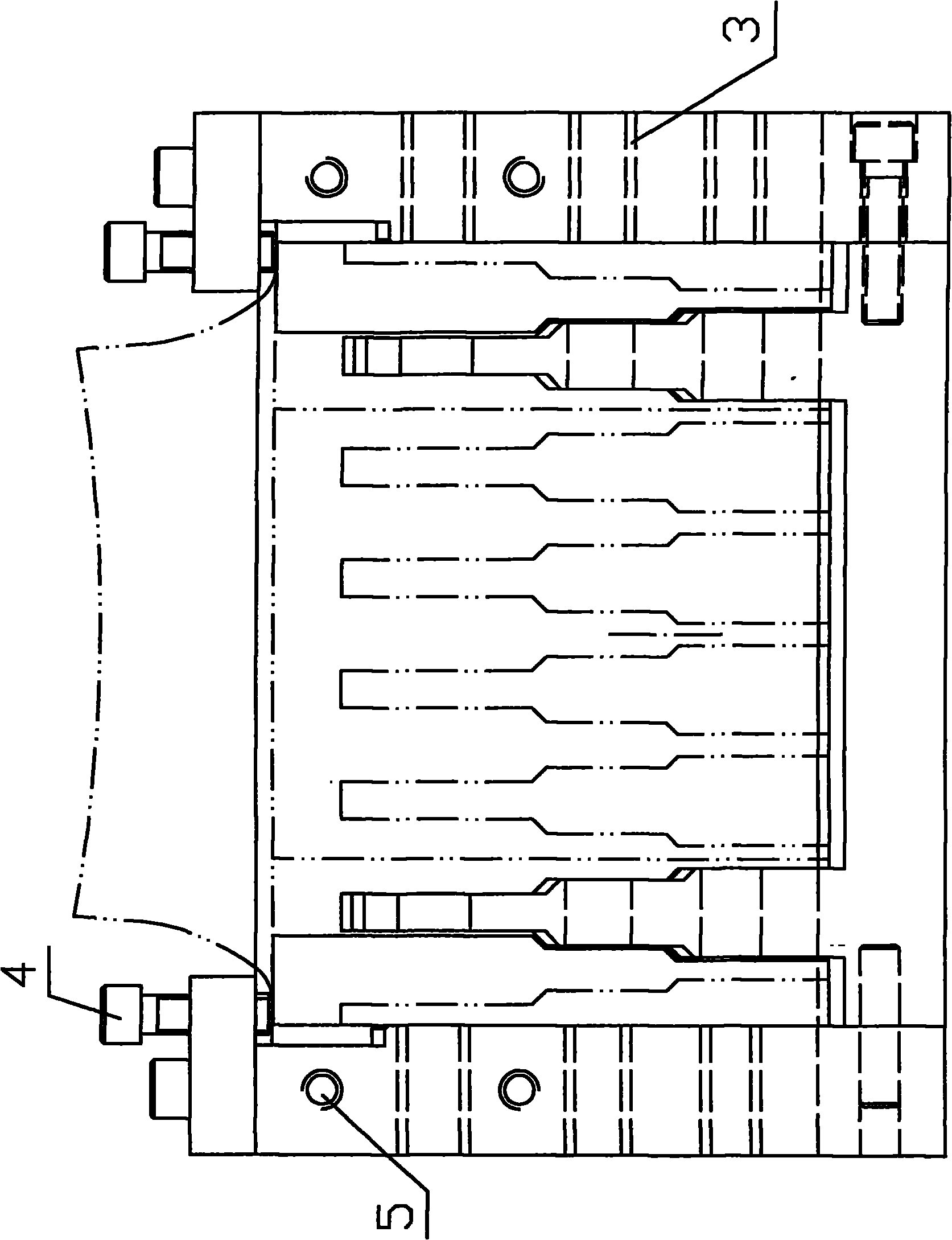

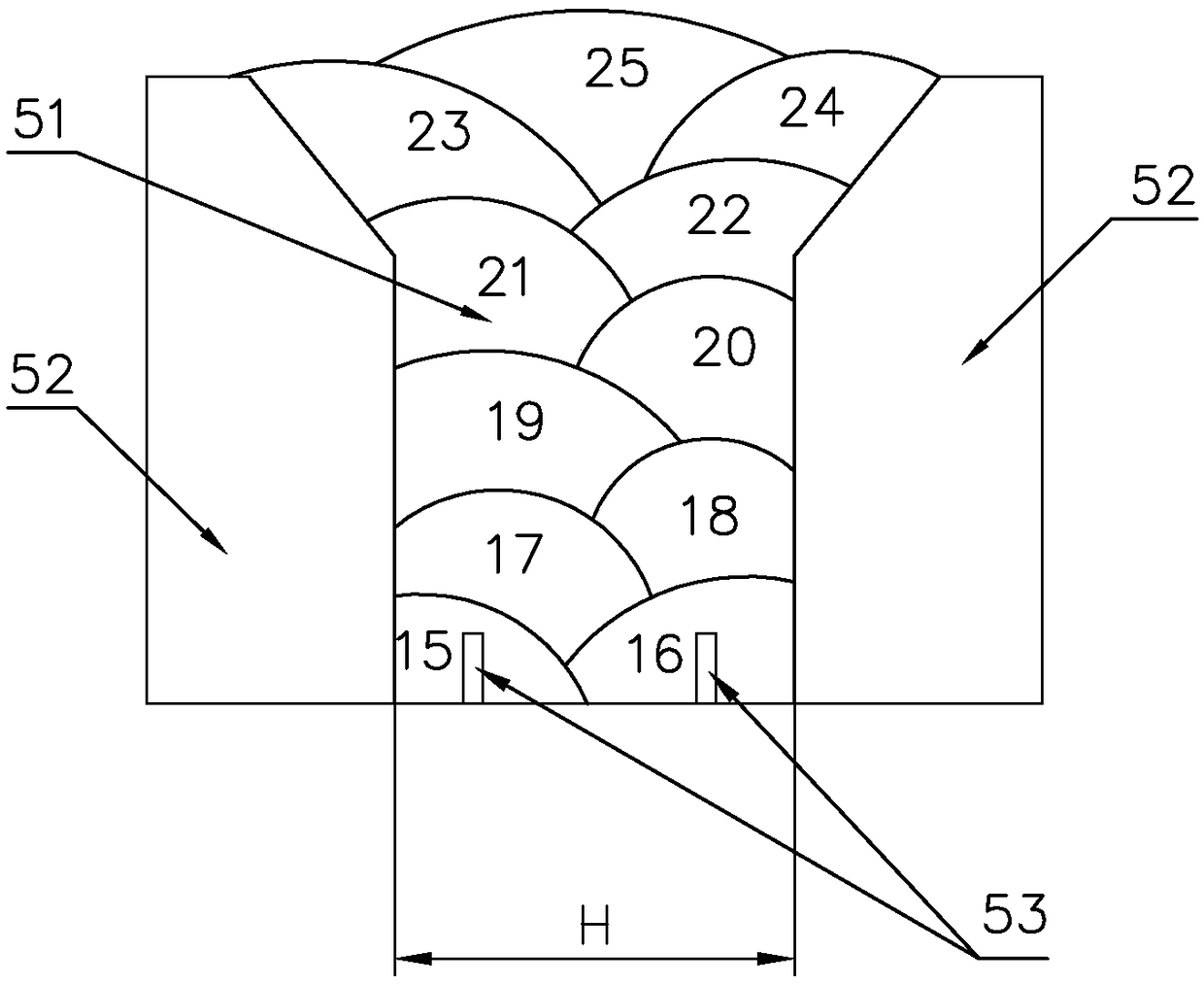

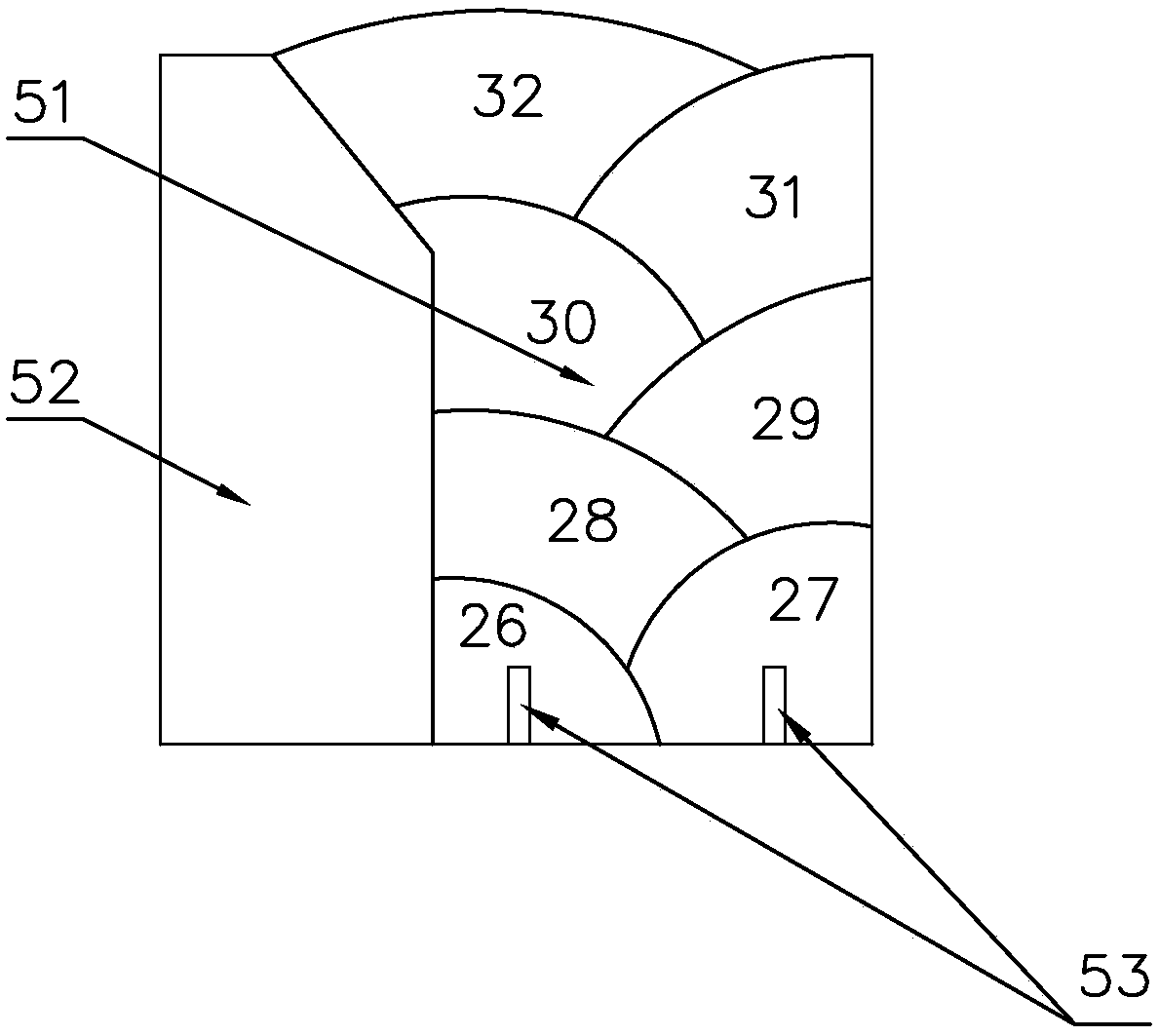

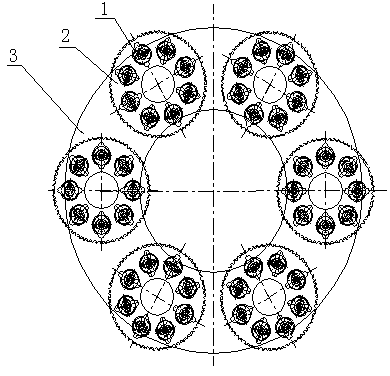

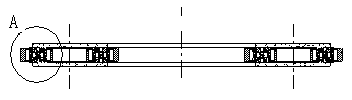

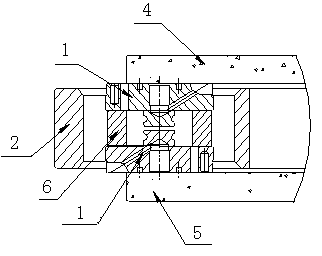

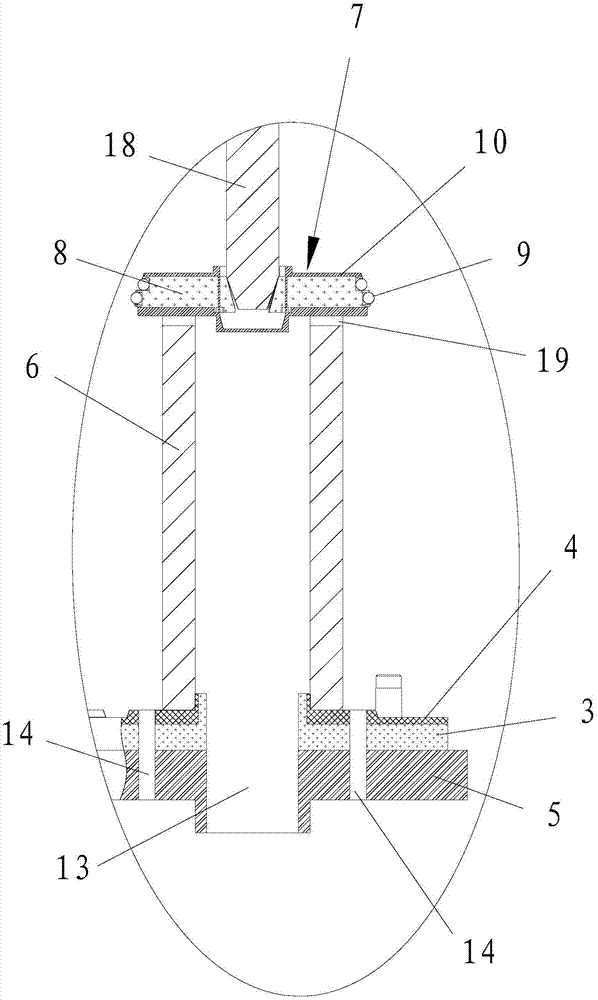

Processing technology of steam turbine seven-fork blade root pin holes and special fixture

ActiveCN101837482AGuaranteed accuracyGuaranteed roughnessDrilling/boring measurement devicesBlade accessoriesEngineeringRadial line

The invention relates to a processing technology of steam turbine seven-fork blade root pin holes and a special fixture. A blade root is provided with seven forks for installation, wherein the two forks in the middle side of the seven forks are staggered with the five forks in the inner part; the five forks in the inner part are successively provided with three pin holes along the radial line direction of a steam turbine; the two forks on the outer side are successively provided with three first semicircle pin holes on the same axis with the above three pin holes and are provided with other three second semicircle pin holes on the same axis with the pin holes on the inner five forks on the adjacent blade; the first semicircle pin holes and the second semicircle pin holes on the two forks on the outer side of adjacent two seven-fork blades are spliced into a full circle pin hole; and multiple blades are radially arranged on the circumstance of the steam turbine. The fixture is providedwith a cavity capable of containing the roots of the seven forks of the two adjacent blades and is provided with a device which makes two blade roots to be jointly installed on the steam turbine position relation status and makes the two blade roots to be fixed on the fixture; and the fixture is provided with a drilling guide hole correspondingly on the axis of the full circle pin hole spliced bythe first semicircle pin holes and the second semicircle pin holes on the two blade roots.

Owner:常州市三维技术成套设备有限公司

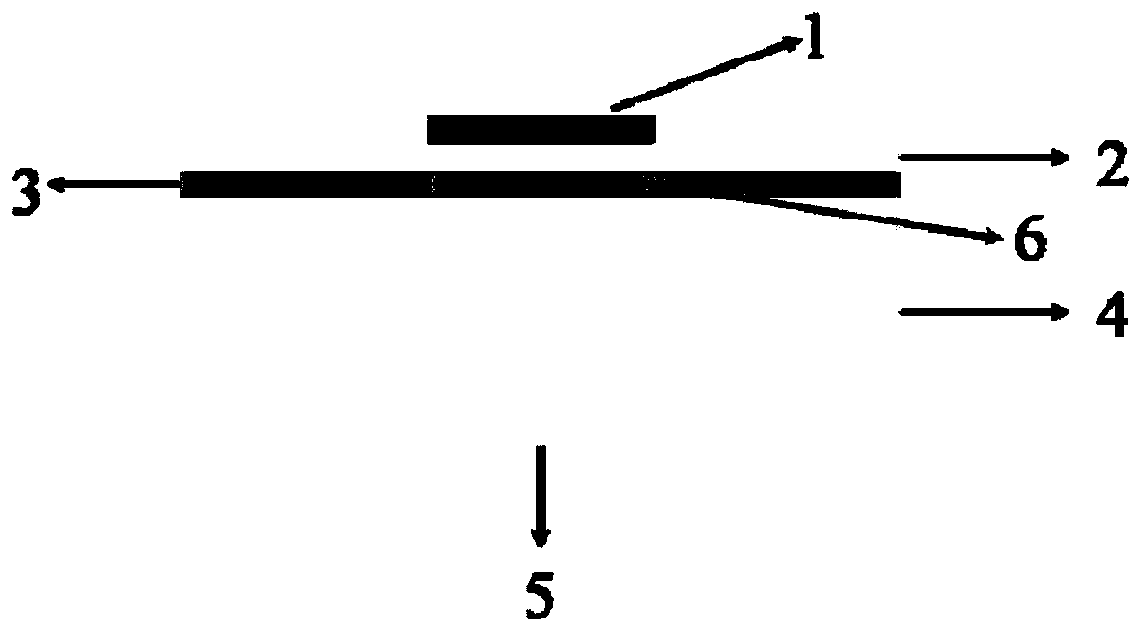

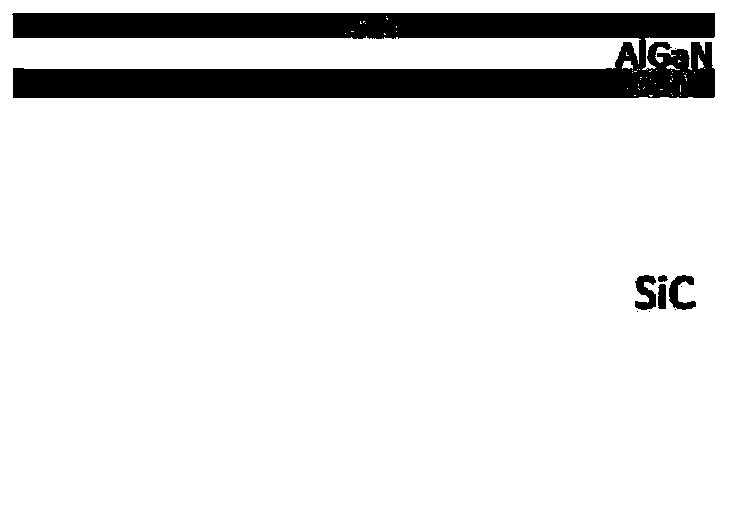

In-chip embedded diamond heat dissipation gallium nitride transistor based on etching and directional epitaxy and preparation method thereof

InactiveCN110379782AGuaranteed normal growthGuaranteed flatnessSemiconductor/solid-state device detailsSolid-state devicesGallium nitrideEpitaxy

The invention discloses an in-chip embedded diamond heat dissipation gallium nitride transistor based on etching and directional epitaxy and a preparation method. The transistor comprises an active region functional layer, a barrier layer, a buffer layer, a substrate and a heat dissipation region from top to bottom; the heat dissipation region is embedded in the substrate, is located below the active region functional layer, is adjacent to the heat source region, is formed through an ICP etching process and epitaxial directional growth of a diamond thick film, has the characteristics of smallregion stress and high heat transport capability, and can effectively realize the efficient heat dissipation capability of the transistor. The problem of heat accumulation of an active region of a high-power gallium nitride device is solved, and the maximum output power of the device is greatly improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

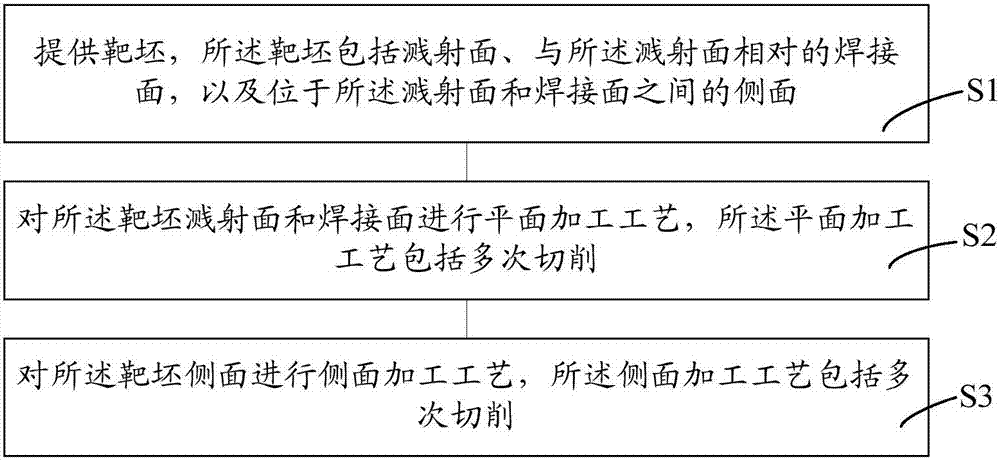

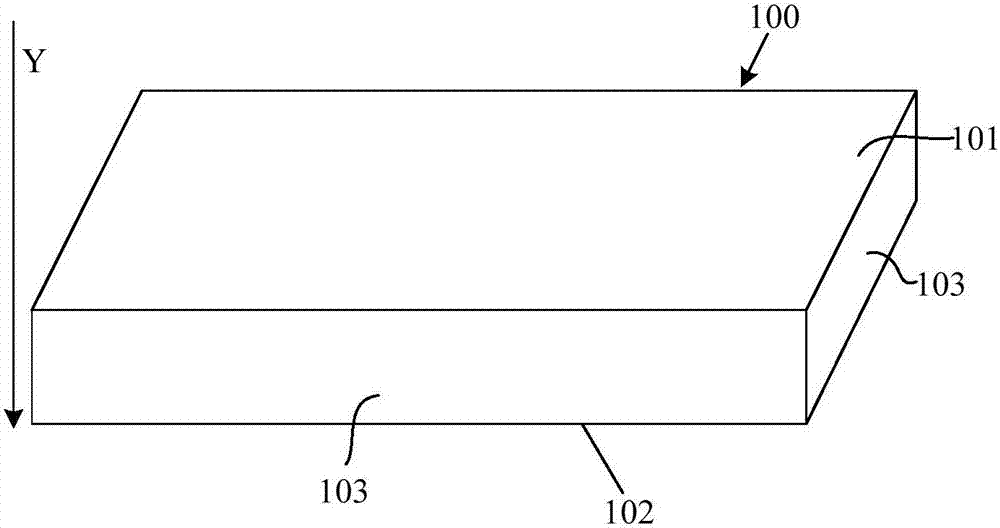

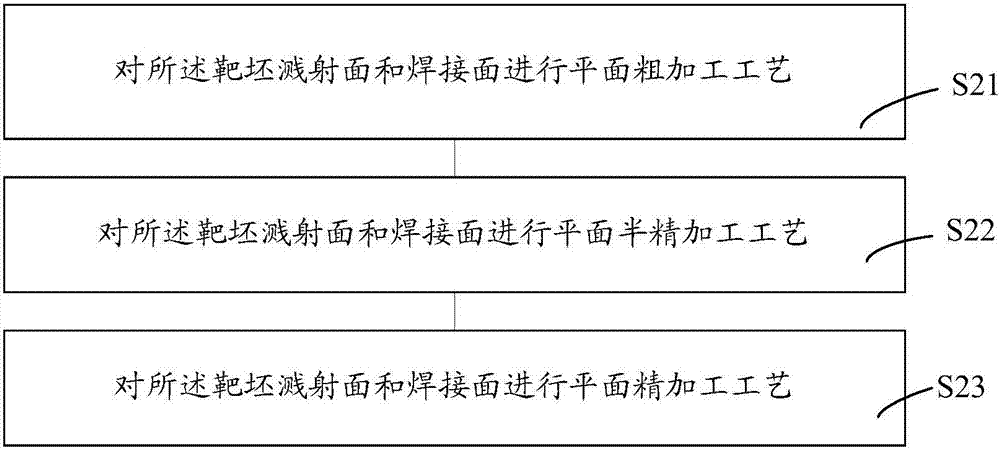

Machining method of target material

InactiveCN107570964AReduce cutting forceReduce releaseVacuum evaporation coatingSputtering coatingEngineeringCutting force

The invention provides a machining method of target material. The method comprises the following steps: providing a target blank comprising a sputtering surface, a welding surface opposite to the sputtering surface and a side surface located between the sputtering surface and the welding surface; performing plane machining operation on the sputtering surface of the target blank; and performing side-surface machining operation on the side surface of the target blank, wherein the plane machining operation and the side-surface machining operation both comprise cutting multiple times. During the plane machining operation and the side-surface machining operation, both the plane machining operation and the side-surface machining operation comprise cutting multiple times. The cutting frequency isincreased such that feeding amount and engagement of each cut are correspondingly reduced. Compared with the scheme with fewer cutting frequency, the machining method of target material can reduce cutting force of a tool to the target material during machining so that release of internal stress in the interior of the target material is minimized, thereby reducing the deformation degree of the target material. Additionally, reduction in cutting force can help vibration amount during machining of the target material, which further improves machining quality of the target material.

Owner:合肥江丰电子材料有限公司

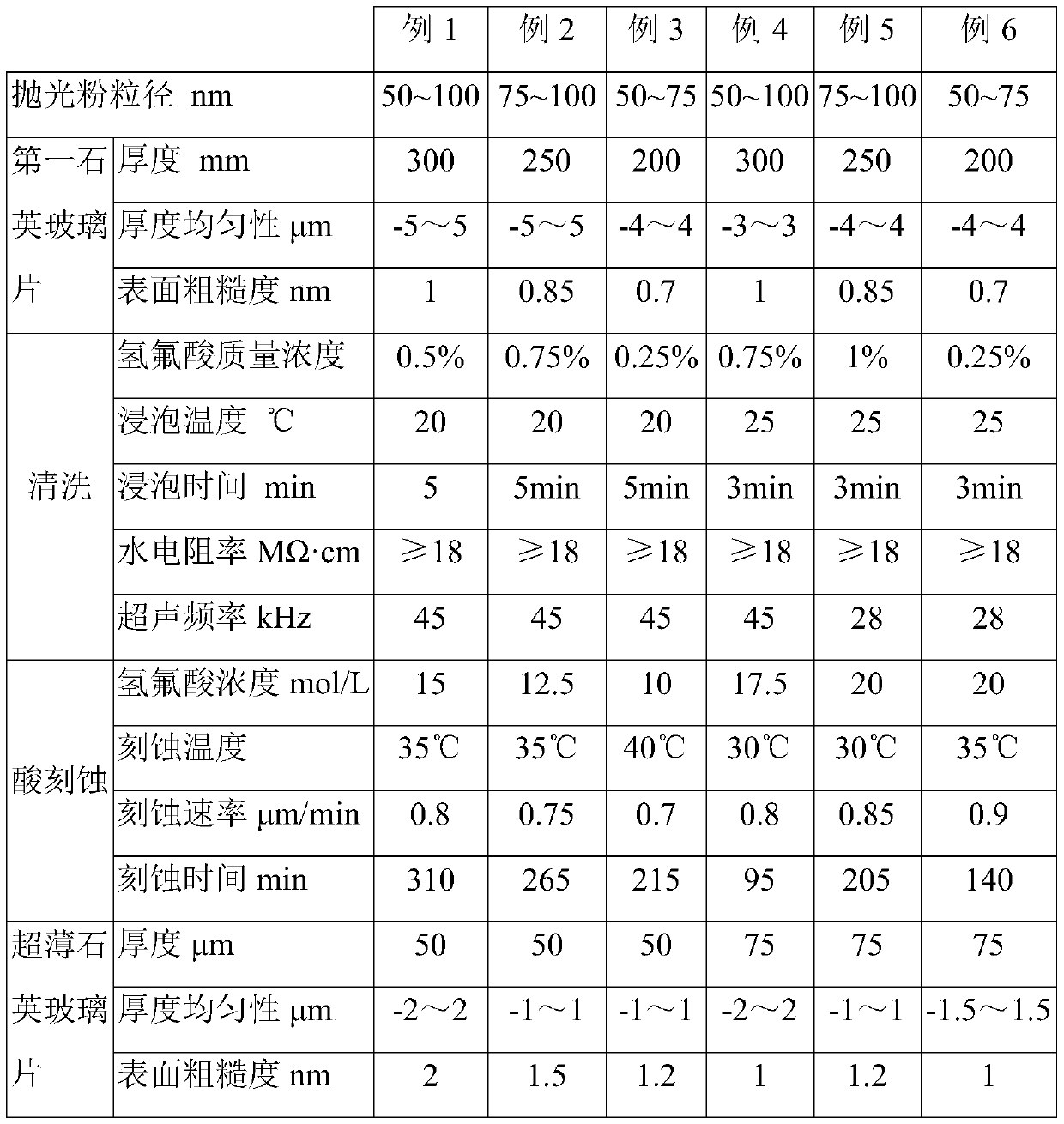

Preparation method of ultrathin quartz glass plate

The invention provides a preparation method of an ultrathin quartz glass plate. The preparation method comprises prepares an ultrathin quartz glass plate by the combination of a precision mechanical polishing process and an acid etching process; the ultrathin glass plate has thickness of < / =100 mu m, the thickness uniformity is -2 to 2 mu m, and surface roughness Ra is < / =2 nm. The preparation method comprises the steps of grinding and polishing a quartz glass plate through precision mechanical polishing to obtain a first quartz glass plate; washing the first quartz glass plate; carrying out acid etching to obtain an ultrathin quartz glass plate. hydrofluoric acid used in acid etching has a concentration of 10-20 mol / L, the temperature of acid etching is 30-40 DEG C, and acid etching rateis < / =1 mu m / min. The quartz glass plate is machined via the preparation method by the combination of precision mechanical polishing and hydrofluoric acid etching; process parameters of the steps arefitly coordinated, breaking of the ultrathin quartz glass plate during preparation is avoided, thickness uniformity of the ultrathin quartz glass plate is improved, and therefore, the ultrathin quartzglass plate is more applicable.

Owner:CHINA BUILDING MATERIALS ACAD

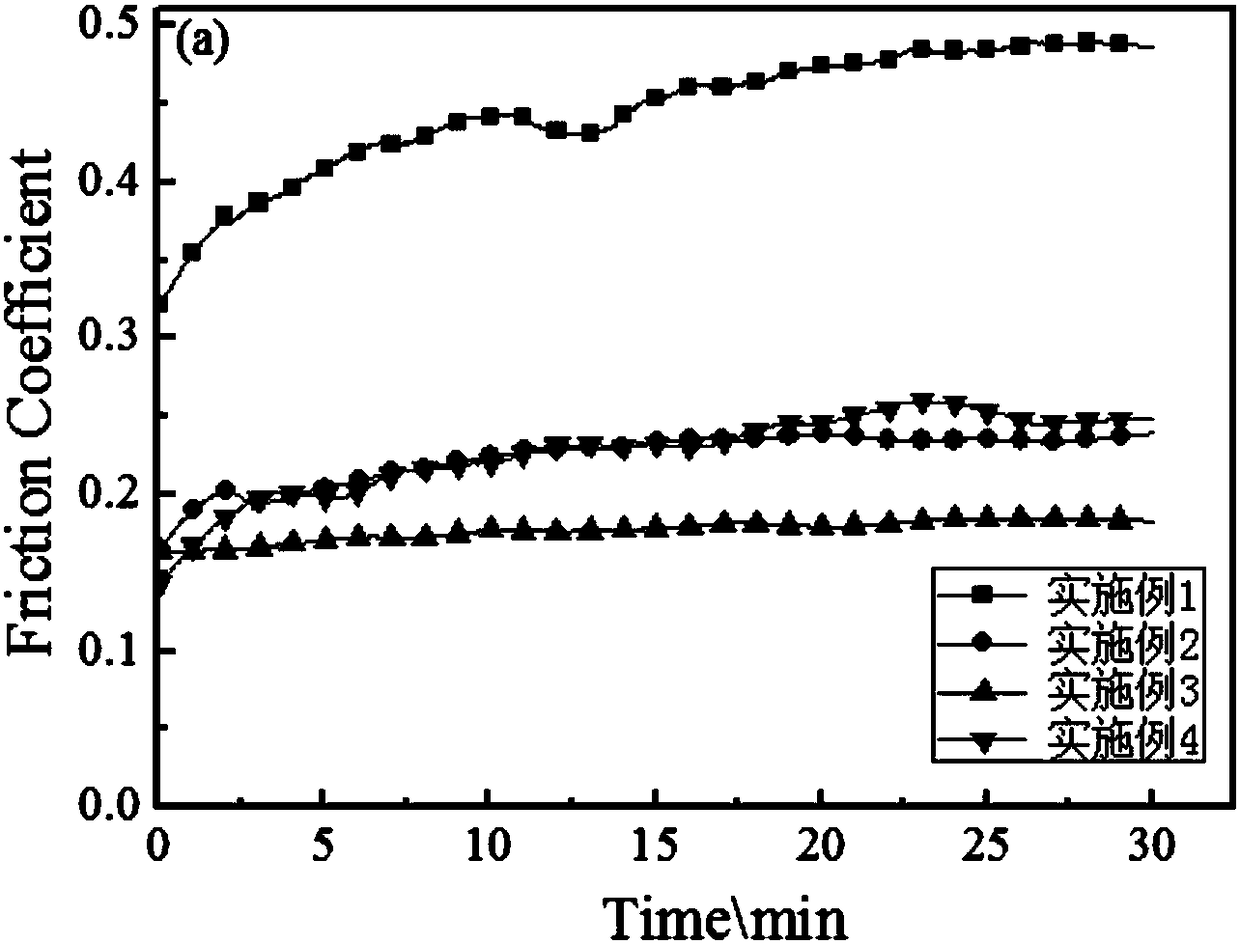

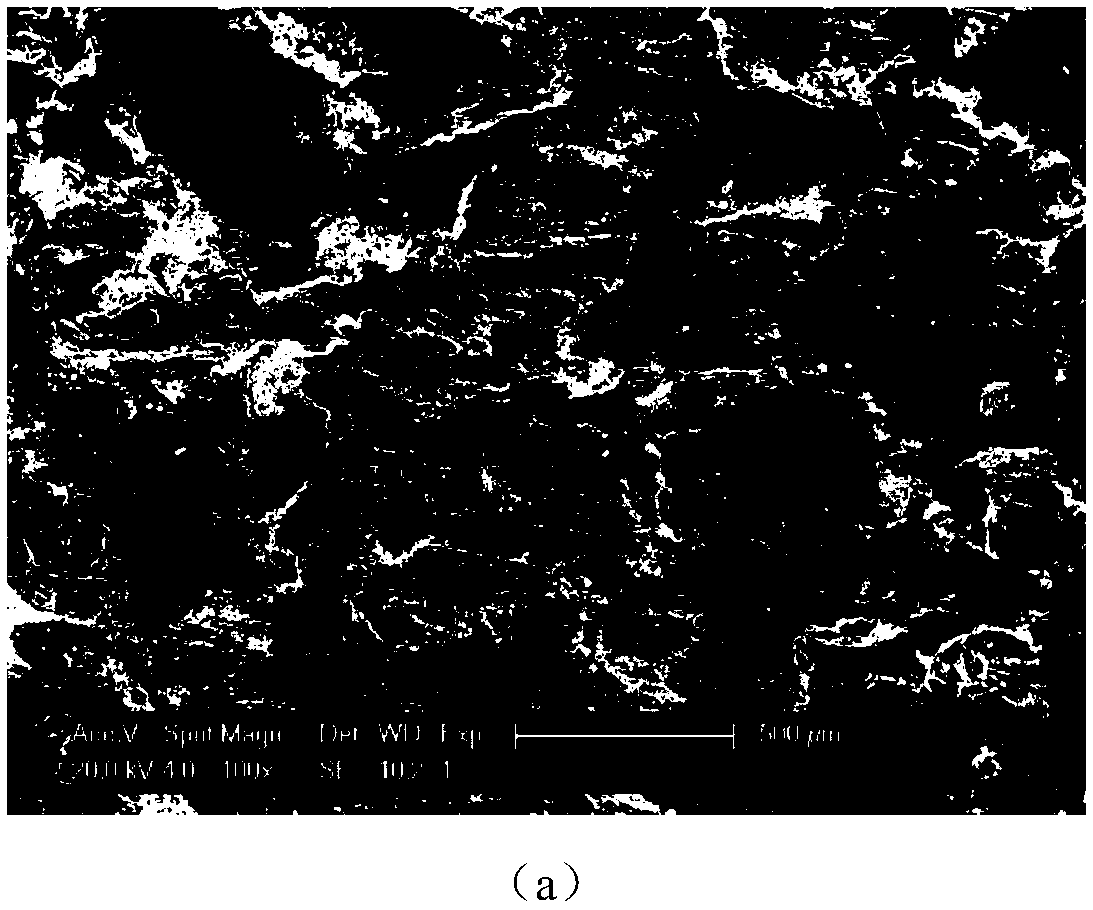

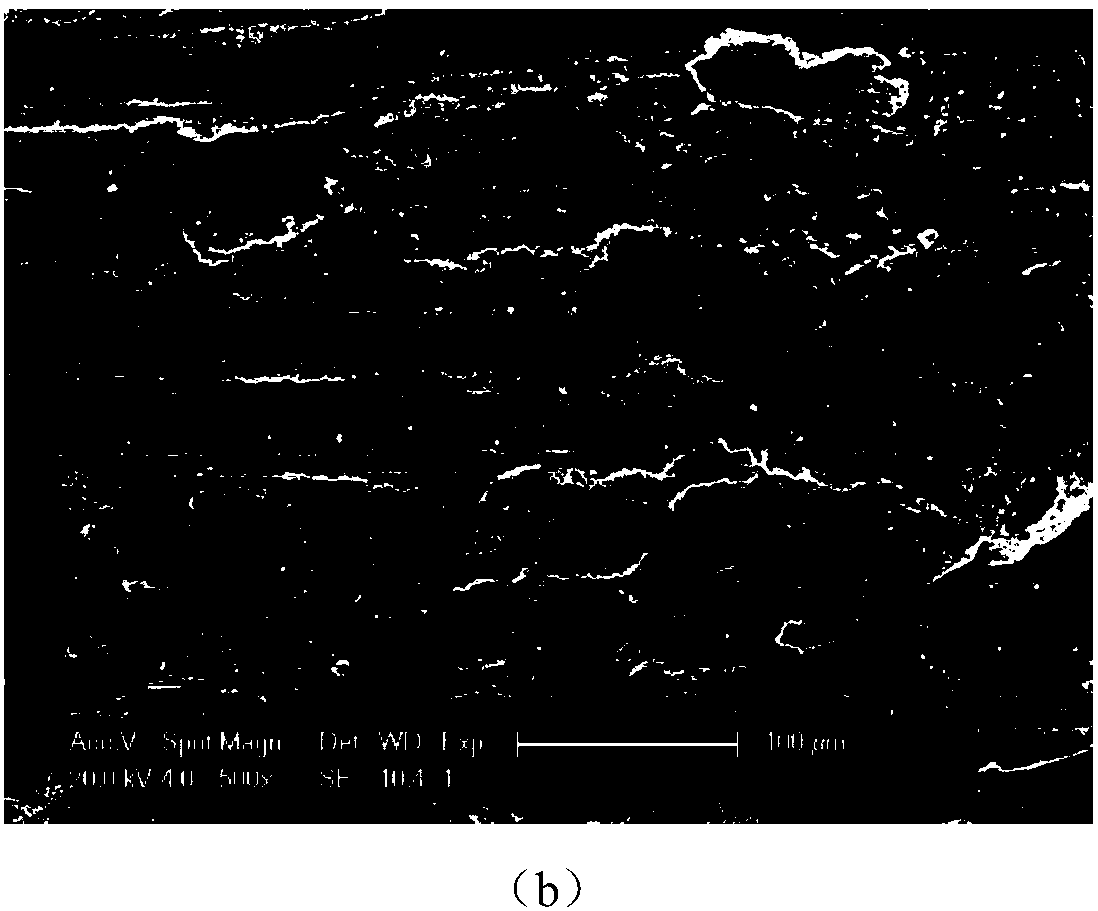

Copper-based powder metallurgy brake pad material as well as preparation method and application thereof

The invention discloses a copper-based powder metallurgy brake pad material as well as a preparation method and application thereof. The copper-based powder metallurgy brake pad material is prepared from the following raw materials in percentage by weight: 54 weight percent to 67 weight percent of copper powder, 13 weight percent of graphite, 4 weight percent to 17 weight percent of iron powder, 8weight percent to 14 weight percent of a ferrochrome alloy, 1 weight percent to 4 weight percent of silicon carbide and 1 weight percent to 4 weight percent of silicon dioxide; the preparation methodof the copper-based powder metallurgy brake pad material comprises the following steps: 1) weighing the raw materials according to the ratio and putting the raw materials into a mixer and uniformly mixing; 2) filling the mixed raw materials into a mold; carrying out hot pressing sintering or spark plasma sintering under the protection of a vacuum atmosphere or nitrogen gas to obtain the brake padmaterial with excellent comprehensive performance. The prepared brake pad material has high density and rigidity, stable friction coefficient, abrasion resistance and excellent comprehensive performance, and can meet the requirements on braking friction plates of high-speed rail trains. The copper-based powder metallurgy brake pad material disclosed by the invention can be used for preparing a brake pad; the preparation method comprises the following steps: taking Q235 as a base material, and compounding and sintering the raw materials for preparing the copper-based powder metallurgy brake pad material and the base material through a hot pressing sintering technology, so as to obtain the brake pad.

Owner:SOUTHEAST UNIV

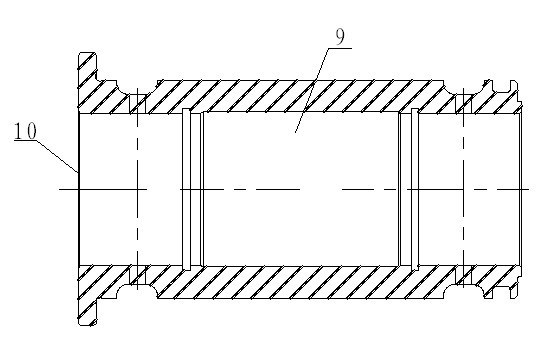

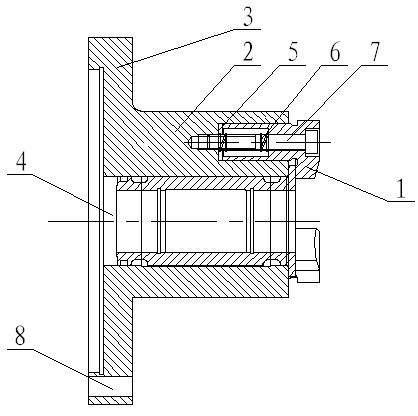

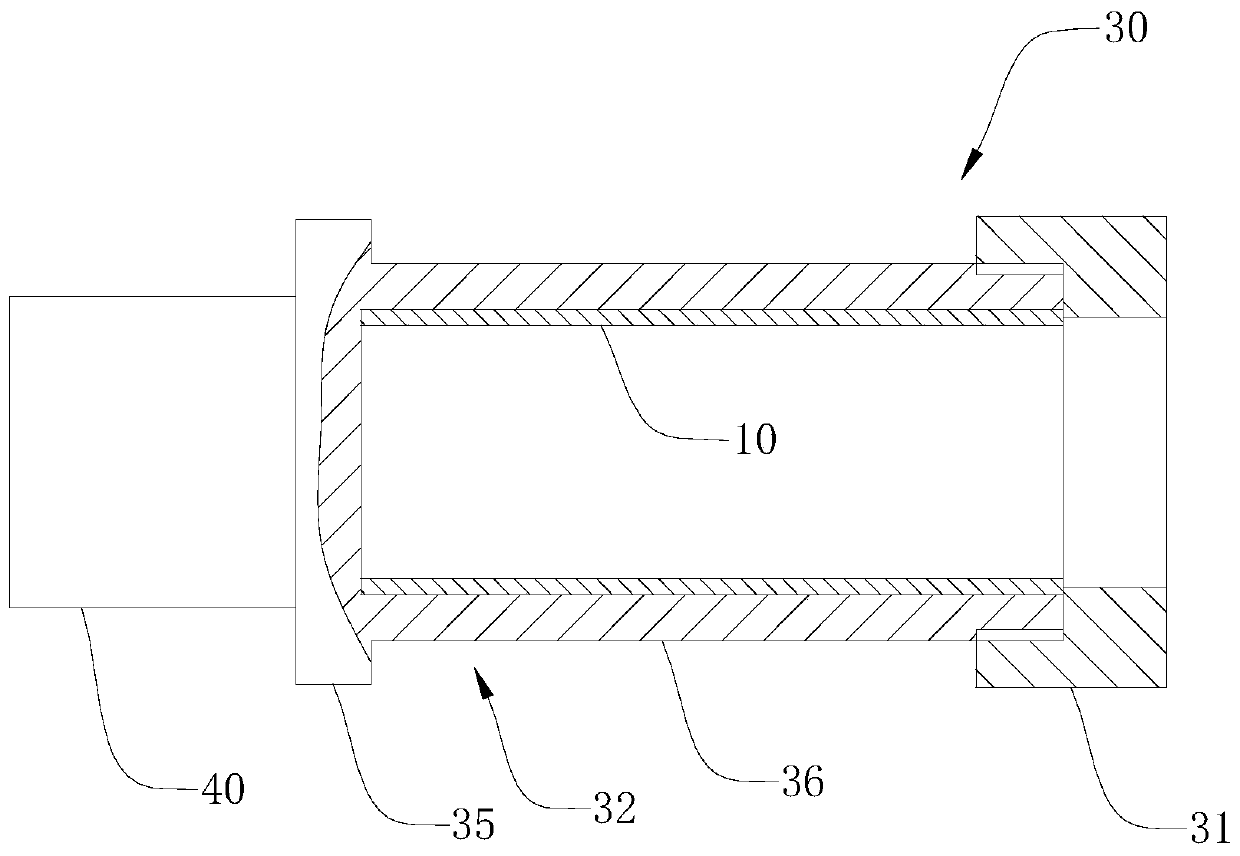

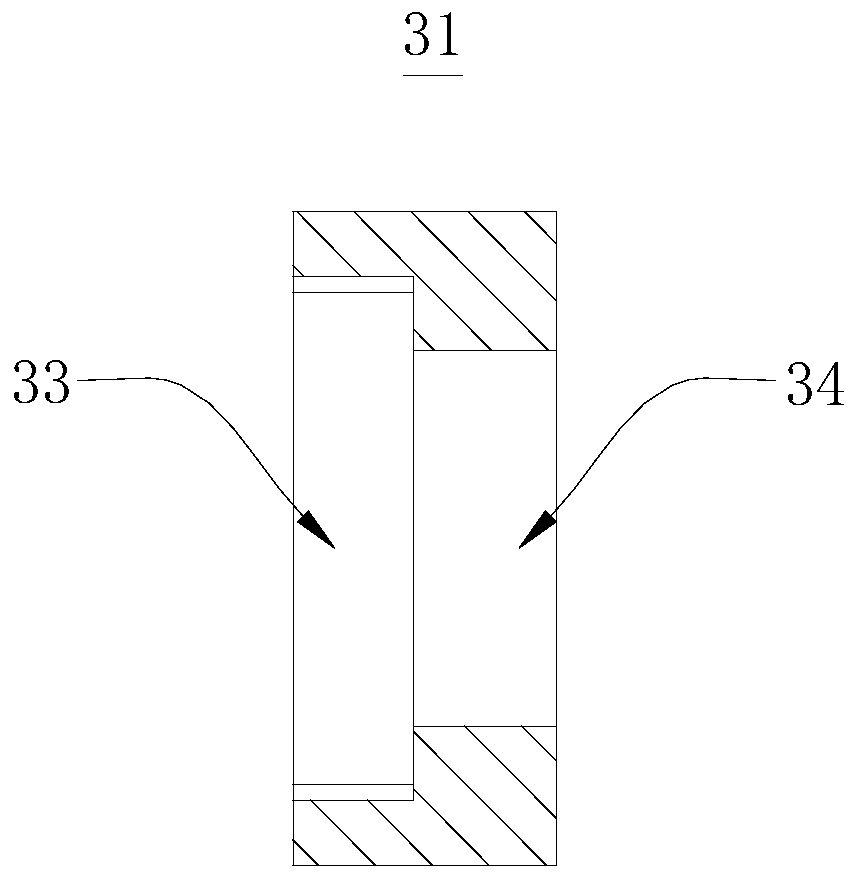

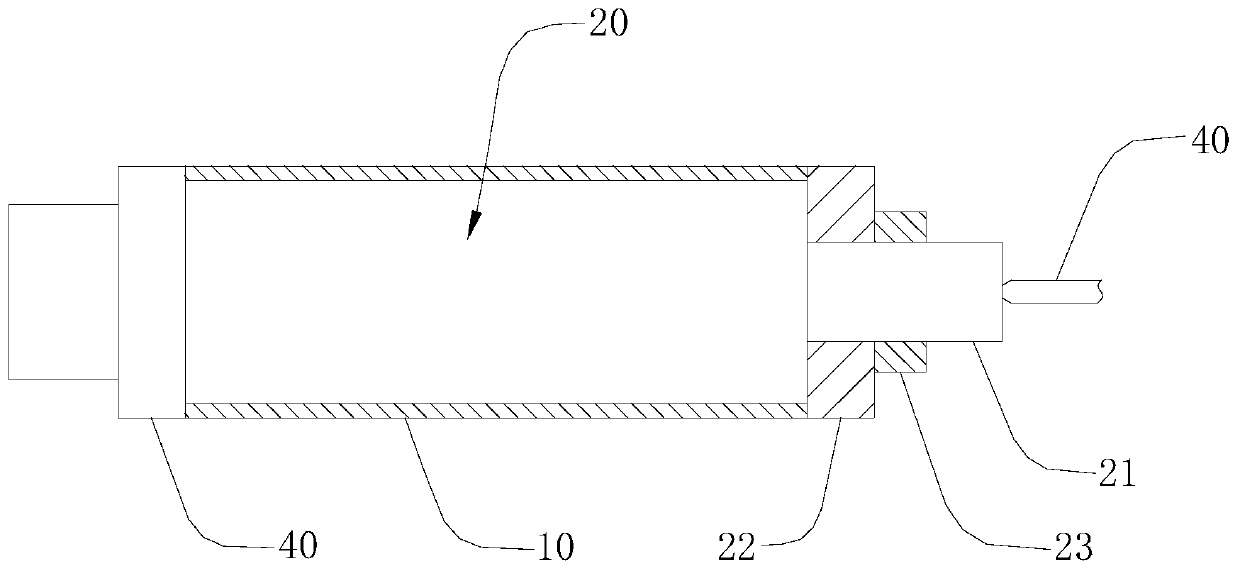

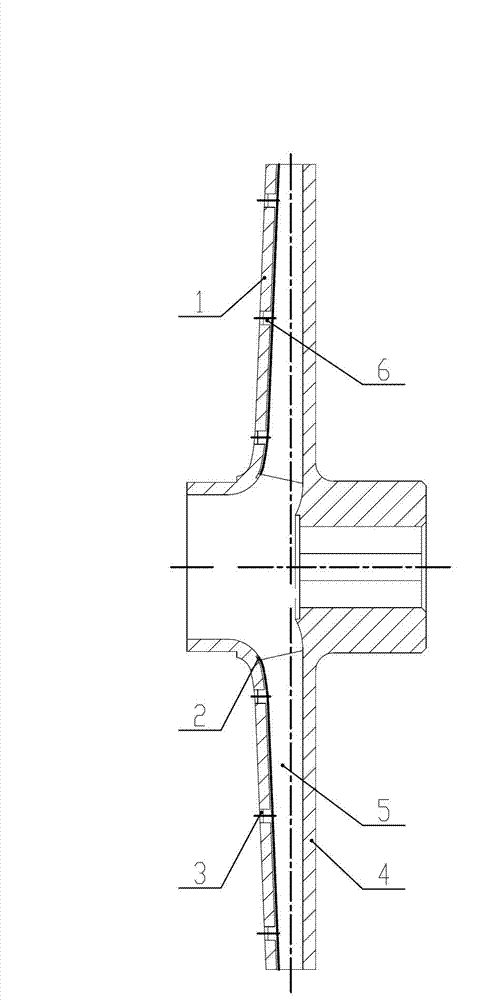

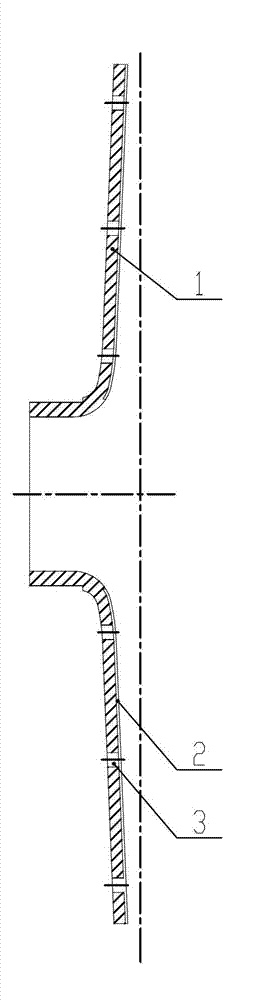

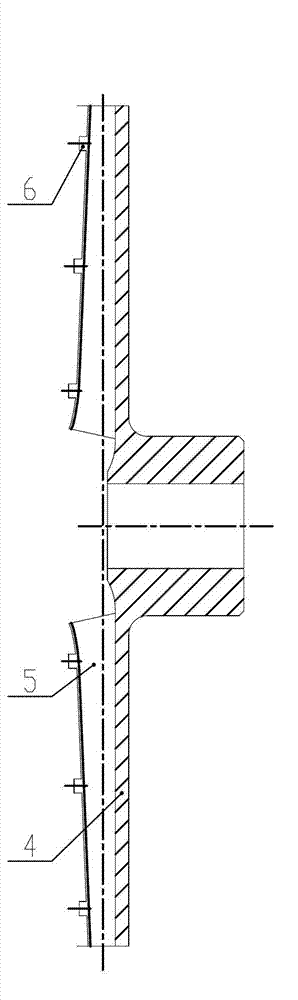

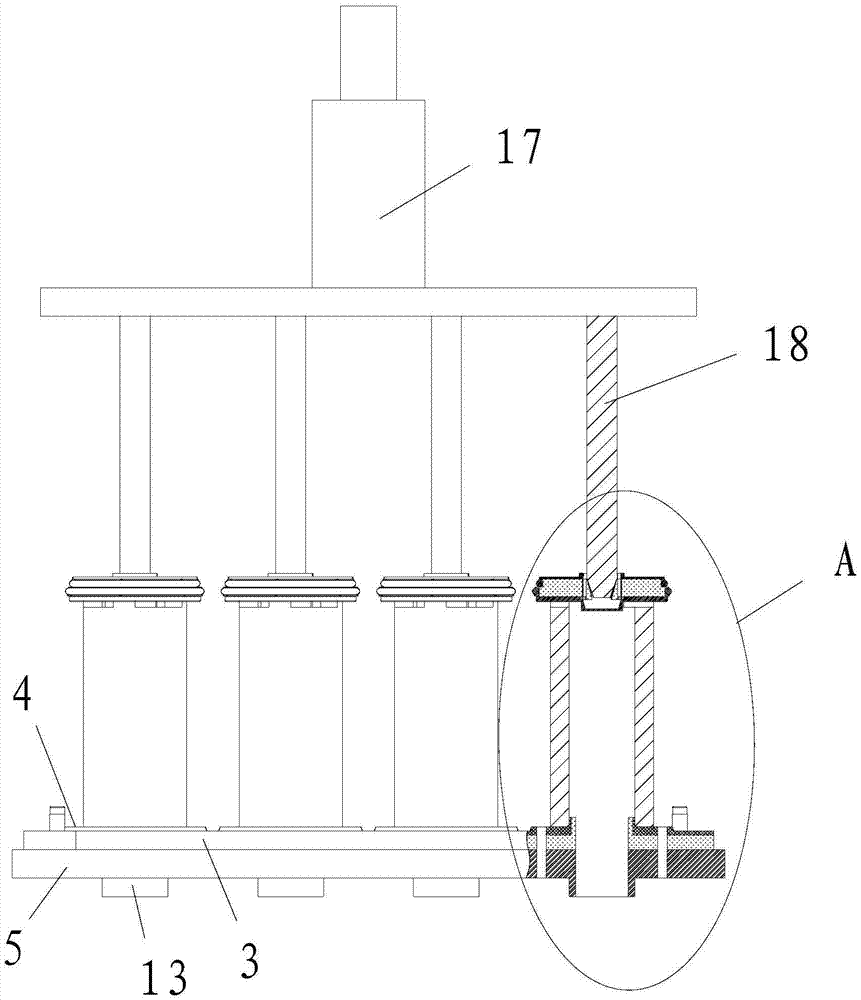

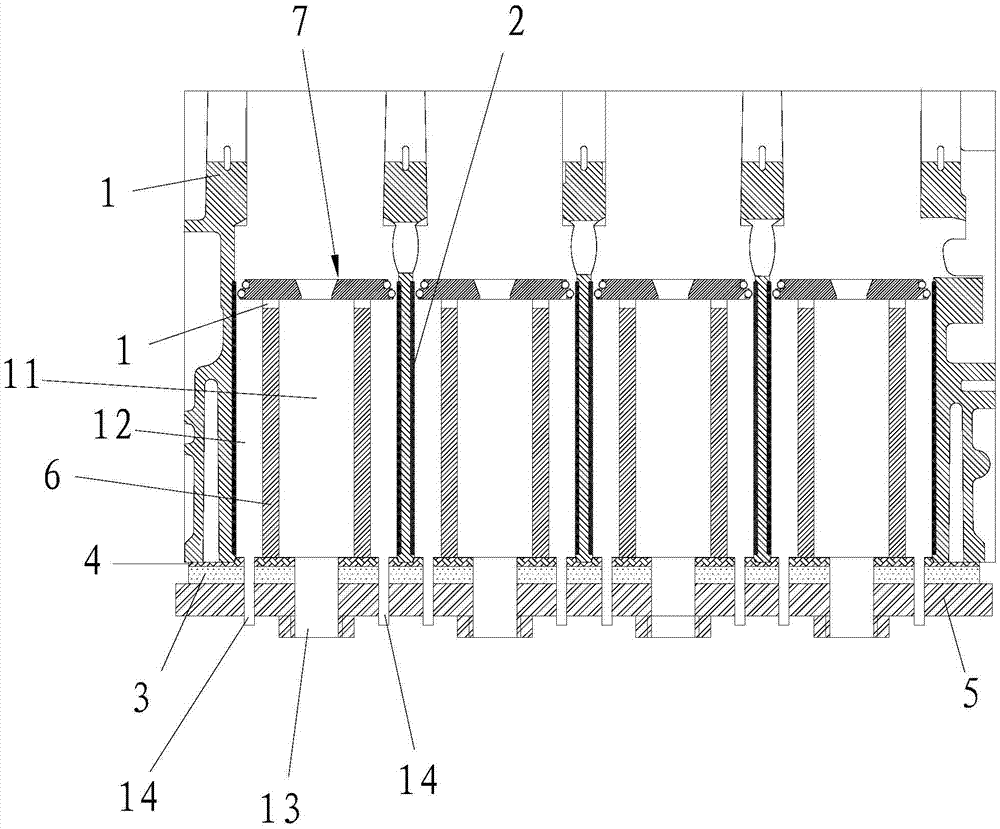

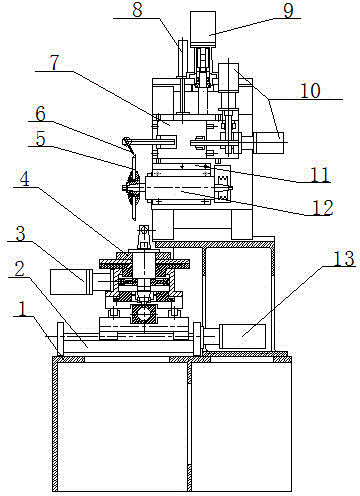

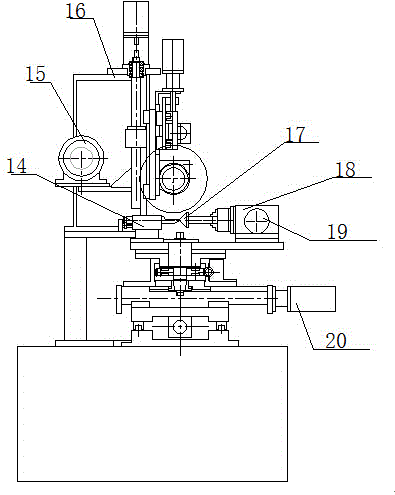

Machining method and machining device of cobalt-base superalloy thin-walled sleeve part

InactiveCN110394604AGuaranteed roughnessAvoid deformationOther manufacturing equipments/toolsPositioning apparatusThin walledMachining process

The invention discloses a machining method and a machining device of a cobalt-base superalloy thin-walled sleeve part, and belongs to the technical field of machining. The machining device provided bythe invention comprises a clamp assembly and a mandrel. A workpiece is supported through the clamp assembly and the mandrel, the internal cylindrical surface and the external cylindrical surface of apipeline billet are machined, in the machining process, the pipeline billet is not prone to deformation, the machined workpiece inner and outer diameter wall thickness difference is small, the shapeprecision is high, and the workpiece surface roughness is high.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

Stainless steel-carbon steel composite plate hot continuous rolling large-scale preparing method

The invention discloses a stainless steel-carbon steel composite plate hot continuous rolling large-scale preparing method. A base plate and a doubling plate are included. The base plate is carbon steel, the doubling plate is stainless steel, and the thickness ratio of the doubling plate to the base plate is 10%-30%. The stainless steel-carbon steel composite plate preparing method comprises the first step of base plate and doubling plate surface treatment, the second step of composite blank assembling, the third step of welding, the fourth step of purging, the fifth step of composite blank vacuum pumping, the sixth step of heating, the seventh step of rolling, the eighth step of dephosphorization and the ninth step of acid pickling. By means of the stainless steel-carbon steel composite plate hot continuous rolling large-scale preparing method, the large-scale production of stainless steel-carbon steel composite plates is achieved, the shearing strength of the formed stainless steel-carbon steel composite plates reaches up to 480-530 MPa, usage of an isolation agent or an obstruction agent is avoided, accordingly, oxidization of a composite interface is prevented, and the qualityof the composite plates is guaranteed.

Owner:山东盛阳金属科技股份有限公司

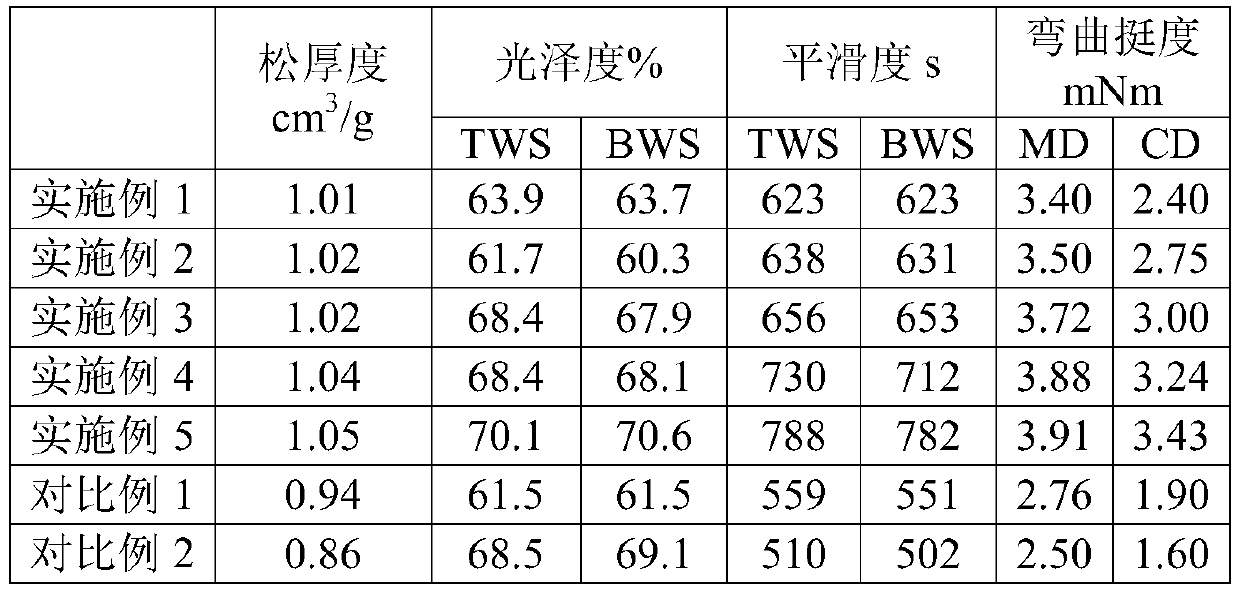

Making method of high-bulk and high-gloss two-side coated art printing paper

ActiveCN110777553AHigh BulkHigh glossPulp beating methodsPaper coatingMaterials scienceSulphate salt

The invention discloses a making method of high-bulk and high-gloss two-side coated art printing paper. Through reasonable pulp model-selection, sulfate coniferous wood pulp, bleached sulfate broadleaf wood pulp and alkaline hydrogen peroxide mechanical pulp with 100% high bulk are adopted, the proportion of all the pulp is strictly controlled, a specific coating formula is adopted, based on single-layer laminated base paper making, multi-layer coating is conducted through a unique MSP (double-sided top coating) and scraper coating process on a high-speed paper machine with the machine speed being up to 1300 m / min, and parameters such as the knife pressure and the knife angles of all coating heads are adjusted, so that the gram weight of finally-made finished paper is about 170 g / m2, the bulk is greater than 1 cm3 / g, the glossiness is 60-70%, the smoothness is greater than 600 s, and the bending stiffness is greater than 2.4 mNm.

Owner:HAINAN JINHAI PULP & PAPER

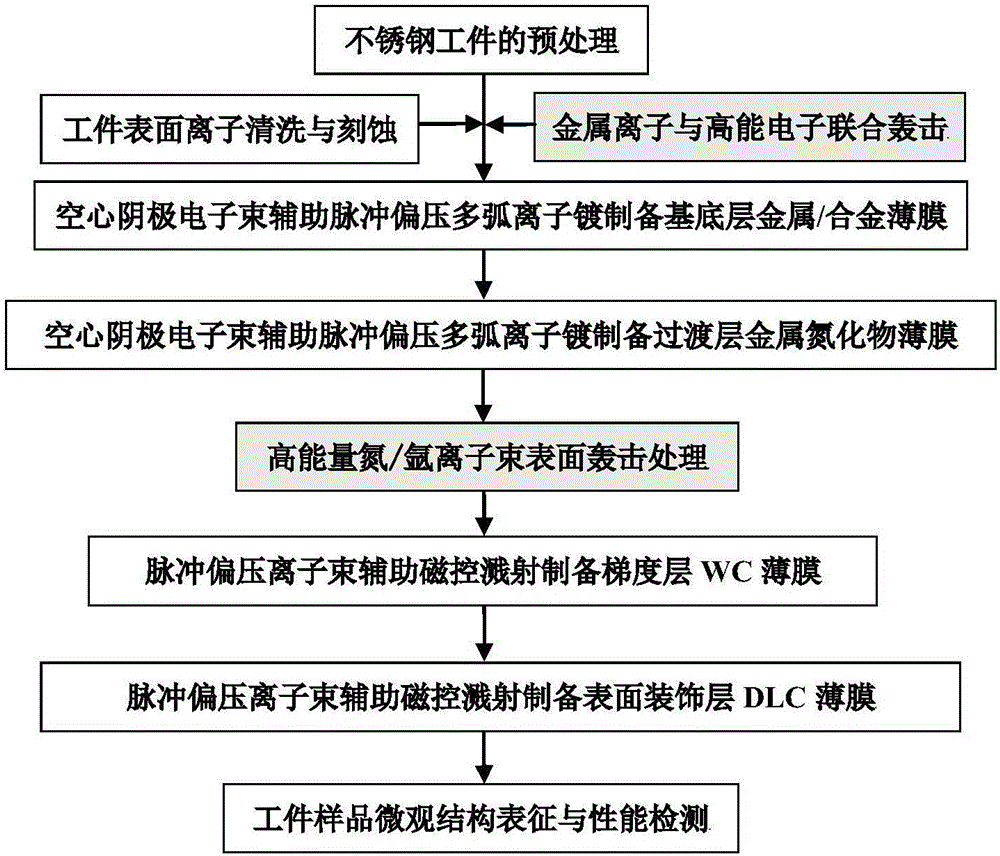

Functionally-graded diamond-like carbon film as well as preparation method and product of functionally-graded diamond-like carbon film

ActiveCN106244986AReduce manufacturing costImprove defectsVacuum evaporation coatingSputtering coatingCarbon filmCorrosion

The invention relates to a functionally-graded diamond-like carbon film as well as a preparation method and a product of the functionally-graded diamond-like carbon film. The preparation method of the functionally-graded diamond-like carbon film comprises the following steps: (1) depositing a metal base layer on the surface of a work piece by virtue of hollow cathode electron beams secondarily combined with pulsed-bias multi-arc ion plating; (2) depositing a metal nitride transition layer on the surface of the metal base layer by virtue of hollow cathode electron beams accompanied with pulsed-bias multi-arc ion plating; (3) depositing a tungsten carbide gradient layer on the surface of the metal nitride transition layer by virtue of pulsed-bias multi-arc ion plating accompanied with magnetron sputtering; (4) depositing a diamond-like carbon decorative layer on the surface of the tungsten carbide gradient layer by virtue of pulsed-bias multi-arc ion plating accompanied with magnetron sputtering. The functionally-graded diamond-like carbon film prepared by the preparation method provided by the invention has the advantages of high glossiness, high interface bonding strength and high surface hardness and is also excellent in wear resistance, corrosion resistance and scratching resistance.

Owner:ZHUHAI ROSSINI WATCH IND +1

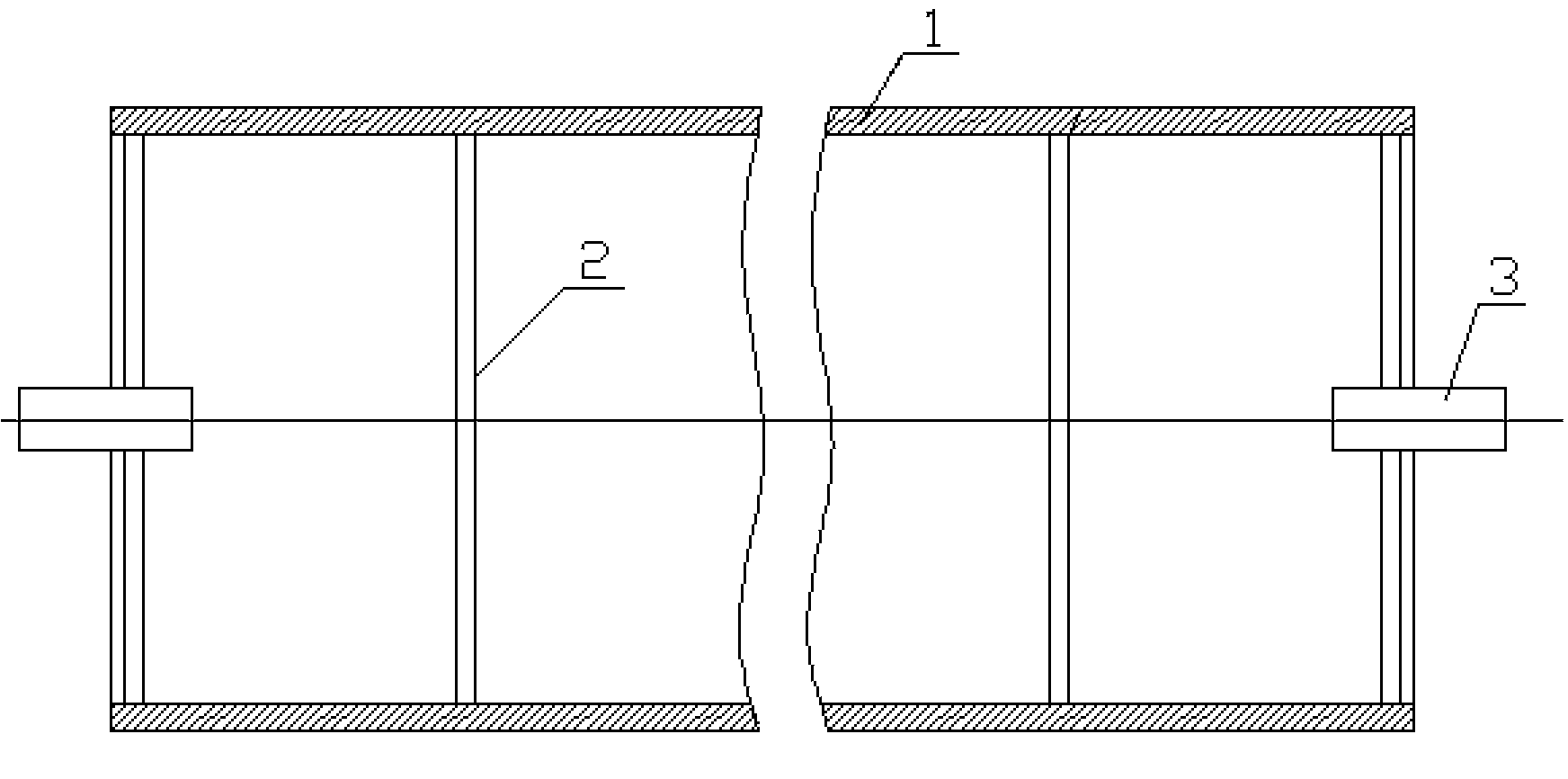

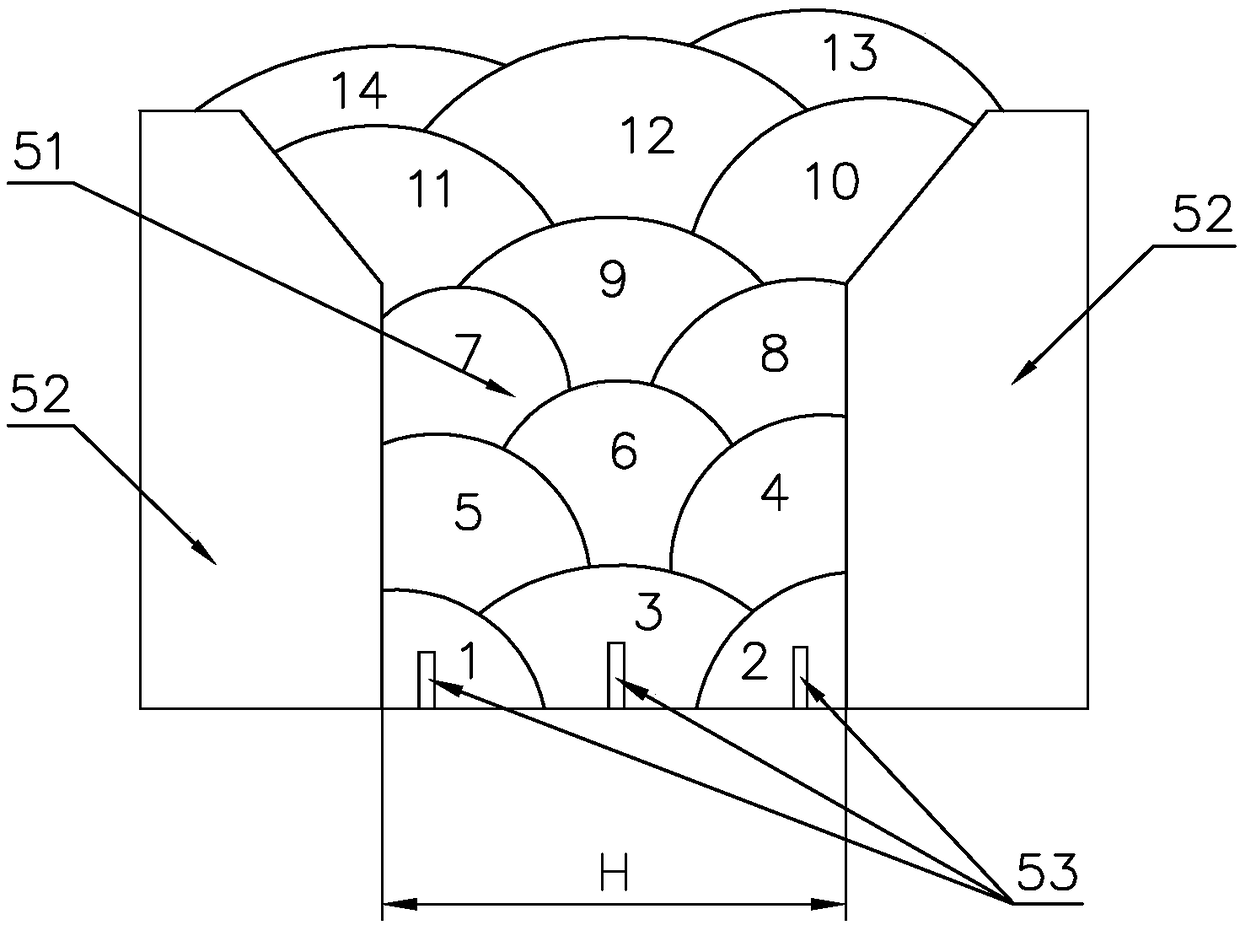

Impeller of centrifugal pump

InactiveCN102927042AGuarantee unimpededGuaranteed roughnessPump componentsPumpsAgricultural engineeringCentrifugal pump

The invention relates to an impeller of a centrifugal pump. The impeller comprises a front cover plate and a rear cover plate; a plurality of blade grooves are uniformly distributed on the inner side surface of the front cover plate; positioning holes are formed in the blade grooves; a plurality of blades corresponding to the blade grooves are uniformly distributed on the inner side surface of the rear cover plate; positioning columns corresponding to the positioning holes are arranged on the blades; and the front cover plate and the rear cover plate are integrally welded after being positioned and assembled. According to the invention, the whole impeller is divided into the front cover plate and the rear cover plate which are independently poured and then spliced and welded as a whole, so that the smoothness and the roughness of a flow channel in the impeller can be effectively ensured, and the performances of the centrifugal pump can be more reliable and stable.

Owner:无锡艾比德泵业有限公司

Surface treatment technology before conducting paint spraying on metal

InactiveCN107470105AImprove surface propertiesGood removal effectPretreated surfacesMetallic material coating processesSand blastingMaterials science

The invention discloses a surface treatment technology before conducting paint spraying on metal. The surface treatment technology comprises the following steps that (1) surface oil-removing treatment is conducted; (2) primary washing treatment is conducted; (3) acid pickling treatment is conducted; (4) secondary washing treatment is conducted; (5) primary sand blasting treatment is conducted; (6) surface soaking treatment is conducted; (7) secondary sand blasting treatment is conducted; and (8) cooling treatment is conducted. According to the surface treatment technology before conducting paint spraying on the metal, special surface treatment is conducted on a metal workpiece material before paint spraying, the surface performance of the metal workpiece material is effectively improved, the combining capacity of the metal workpiece material and coating is enhanced, the protecting effect of a paint coating is promoted, and the surface treatment technology has good using and promoting value.

Owner:当涂县宏宇金属炉料有限责任公司

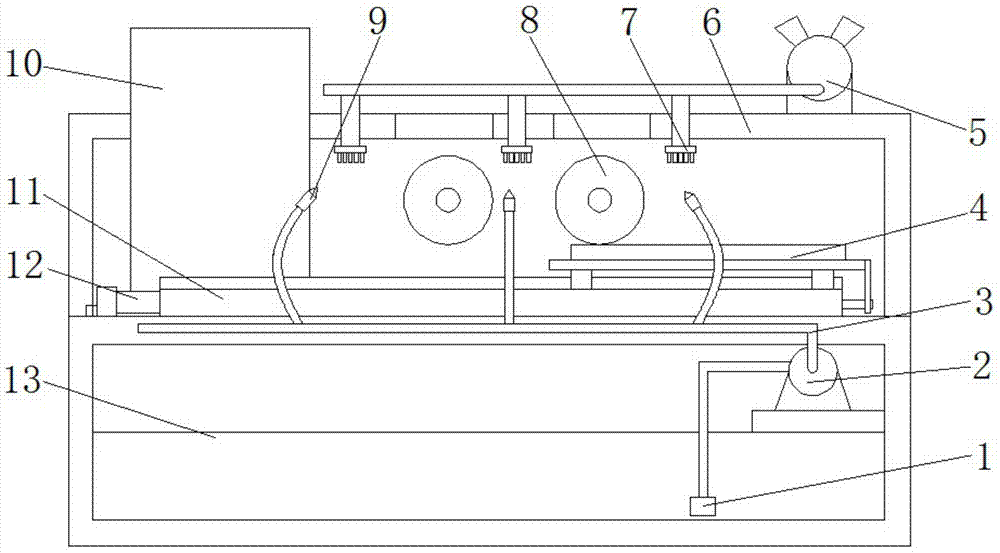

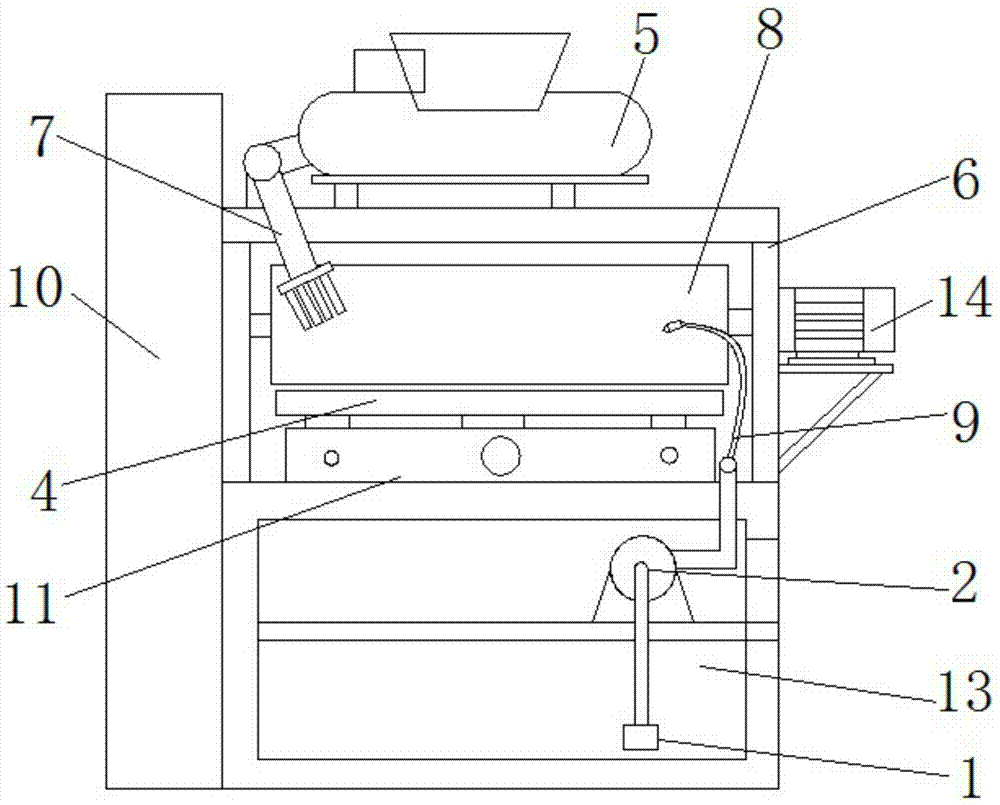

Scrap accumulation prevention type semi-automatic reciprocating polishing device

InactiveCN104117916APrevent rational changeGuaranteed roughnessGrinding carriagesGrinding bedsScrapWater pipe

The invention discloses a scrap accumulation prevention type semi-automatic reciprocating polishing device which comprises a rack. The rack is provided with a screw rod assembly, the screw rod assembly is connected with a feed motor to drive the screw rod assembly, and the screw rod assembly is provided with a workbench. A polishing assembly is arranged above the workbench, a plurality of jet heads are arranged above the rack, and the jet heads are communicated with one another and then connected with an air pump. The workbench makes reciprocating movement on the screw rod assembly, so that workpieces on the workbench are subjected to reciprocating polishing under the polishing assembly, the jet heads are used for timely cleaning up scraps such as iron sand on the workpieces, and the scraps are prevented from scratching machining surfaces. Meanwhile, a cooling liquid nozzle is connected with a water pipe through a metal hose so that the polished surfaces can be timely cooled, and physical change on the surfaces of the workpieces caused by high temperature is prevented. Accordingly, the roughness of the surfaces of the polished workpieces is guaranteed, meanwhile, the scraps such as the iron sand generated by polishing can be prevented from damaging the surfaces of the workpieces, and the workpieces are effectively protected.

Owner:SUZHOU TAKESHENG ELECTRONICS SCI & TECH

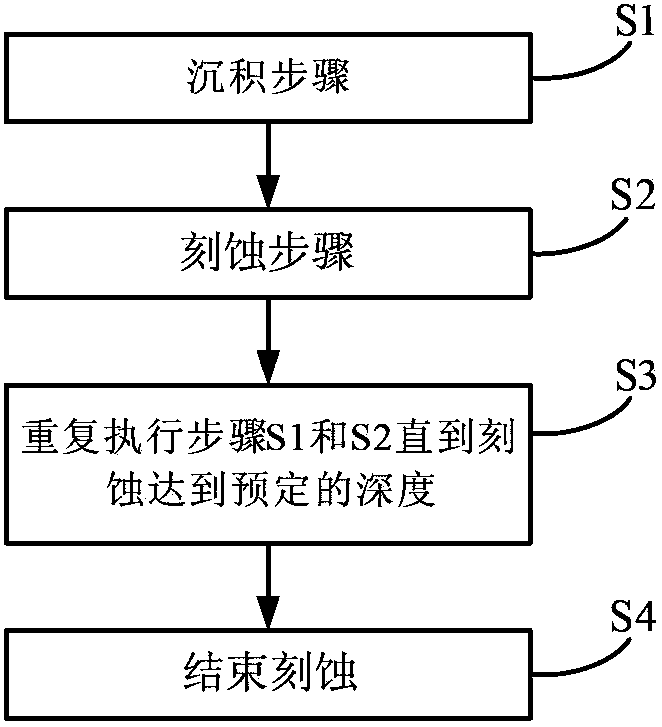

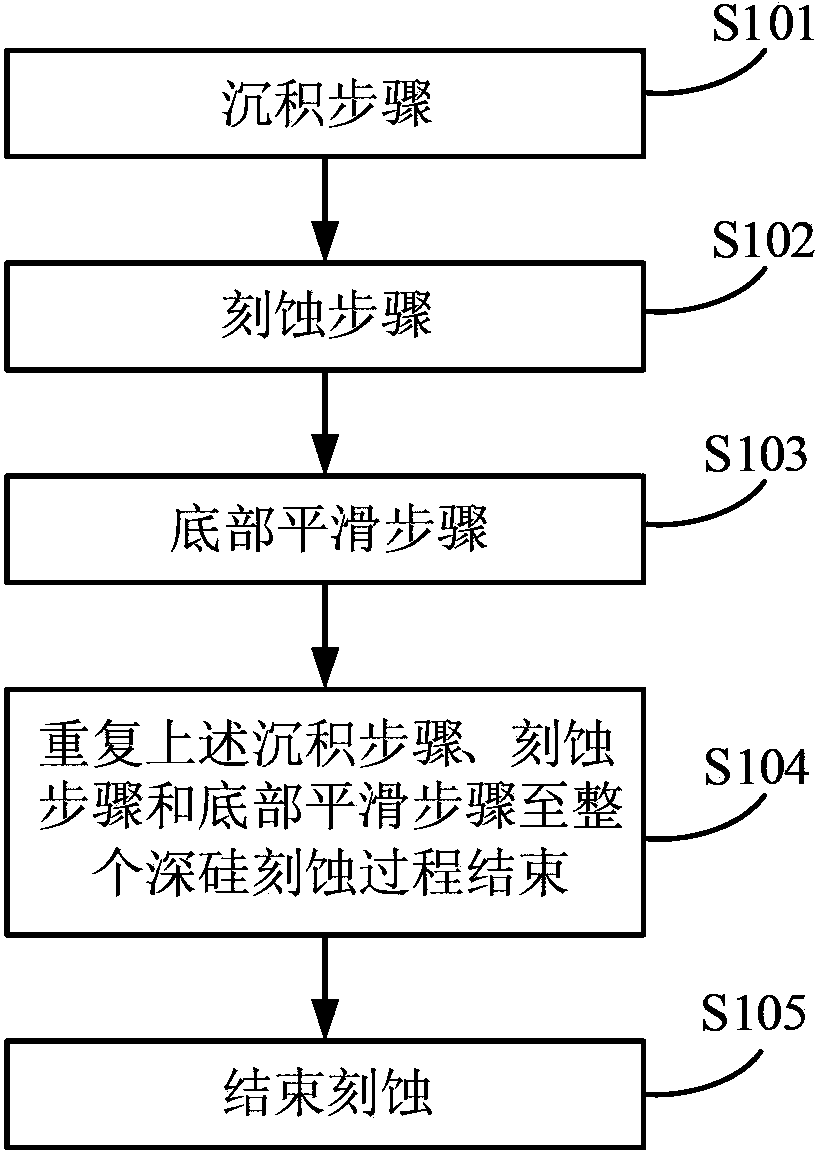

Deep silicon etching method

ActiveCN103887164AIncrease etch rateImprove etching effectSemiconductor/solid-state device manufacturingGradual increaseSilicon etching

The invention discloses a deep silicon etching method. The deep silicon etching method comprises steps that: a deposition step, a protection layer is generated to protect an etching side wall; an etching step, an etching bottom portion and the etching side wall are etched; the deposition step and the etching step are repeated till the whole deep silicon etching process is over; a bottom portion smoothing step is further included, wherein the bottom portion smoothing step comprises that a fluorine-containing gas is utilized to carry out plasma processing to remove polymers generated because of deposition at the etching bottom portion, the technology pressure employed in the bottom portion smoothing step is smaller than the technology pressure employed in the etching step, at least one bottom portion smoothing step is carried out in the whole deep silicon etching process. Through the deep silicon etching method, gradual increase of the etching bottom polymer is inhibited in the deep silicon etching process, generation of a micro mask layer or silicon grasses is inhibited, and thereby the etching rate of deep silicon etching and the selectivity ratio are improved, and roughness of the etching bottom is ameliorated.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

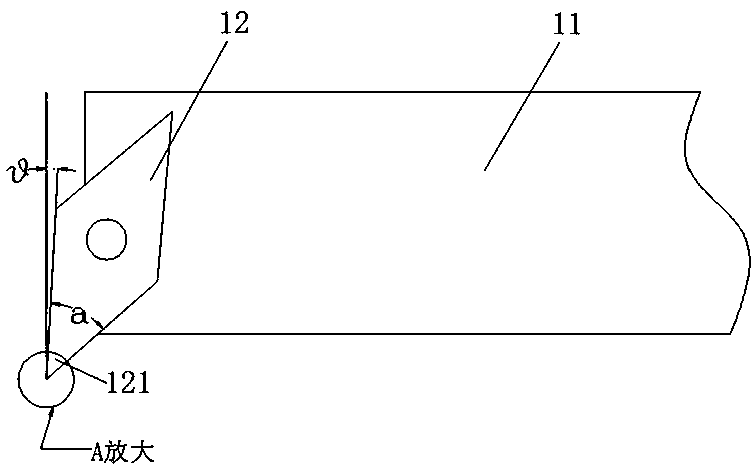

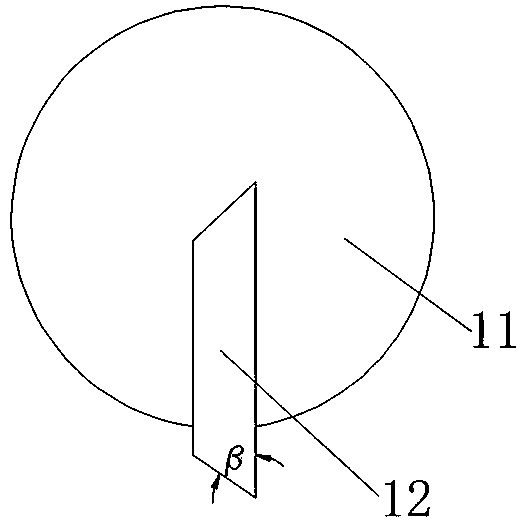

Aluminum alloy inner hole ultra-precise machining tool and machining method

PendingCN108994352ASolve the problem of resonanceNot easy to scratchTransportation and packagingBoring/drilling machinesMicrometerRound bar

The invention discloses an aluminum alloy inner hole ultra-precise machining tool and machining method. The aluminum alloy inner hole ultra-precise machining tool comprises a round bar tool handle made of a hard alloy, and a blade. The tool nose part of the blade is cut to add a sleeking edge. The side face included angle alpha of the sleeking edge is 85 degrees, the front face included angle betaof the sleeking edge is 84 degrees, the top rake theta of the sleeking edge is 7 degrees, the tool nose of the sleeking edge is of a small arc structure, the structure is practical in function, workpieces are not likely to be scratched, and the precision of the machined workpieces is effectively improved. The aluminum alloy inner hole ultra-precise machining method adopting the aluminum alloy inner hole ultra-precise machining tool includes the steps of inner hole rough boring machining, semi-fine boring machining and fine boring machining, the workpiece rotation speed, the boring cutter feedrate and the cutting depth are stipulated in each step, it can be ensured that the aluminum alloy inner hole roughness is not larger than 0.2 micrometer, and ultra-precise machining is achieved. Thealuminum alloy inner hole ultra-precise machining tool and the aluminum alloy inner hole ultra-precise machining method are easy to operate, high in machining precision and high in machining efficiency, the machining cost is reduced, and practicability is high.

Owner:GUIYANG BOYA MACHINERY MFG

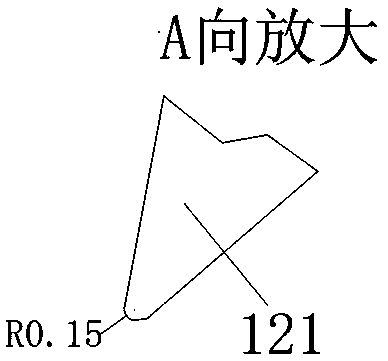

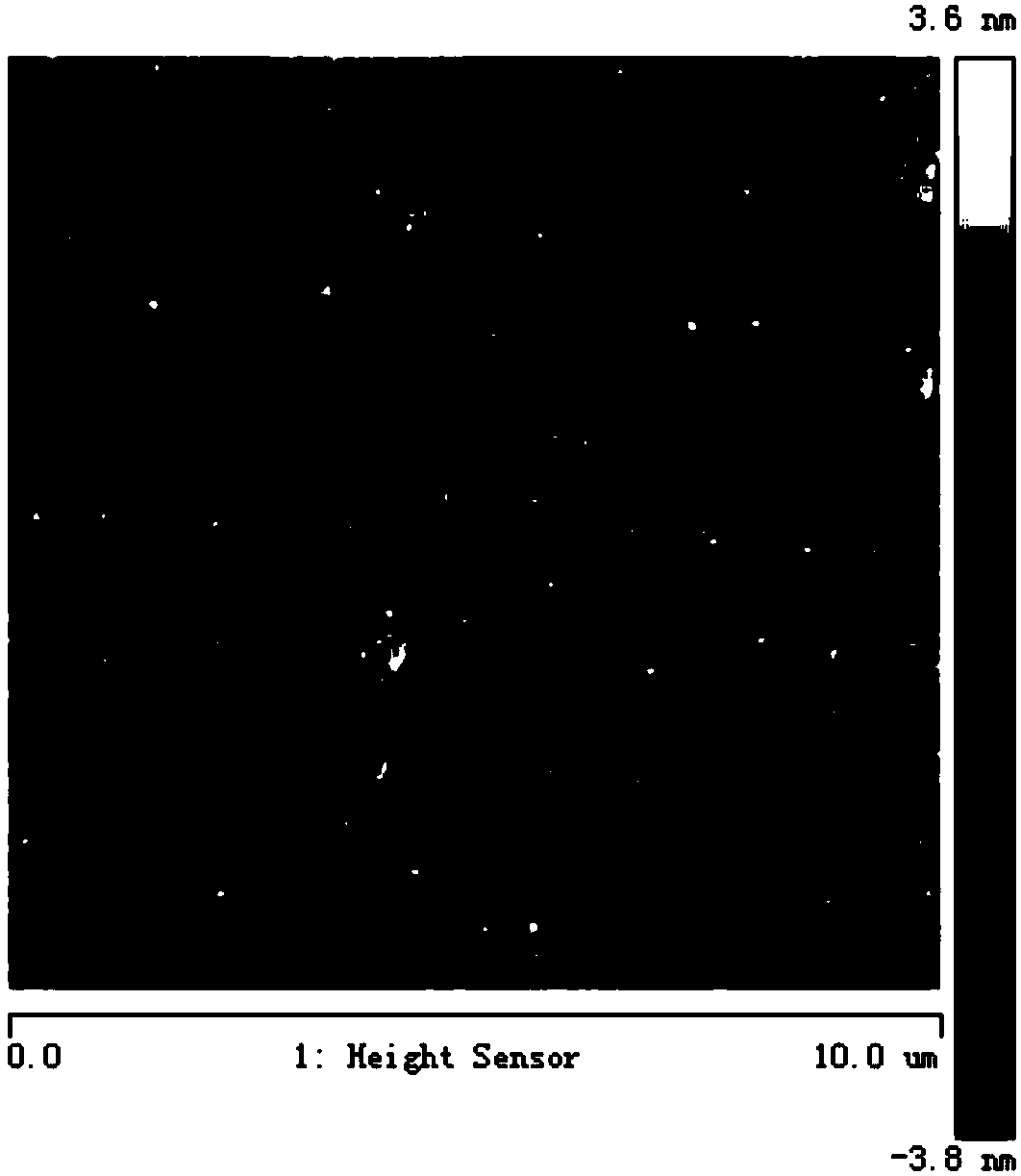

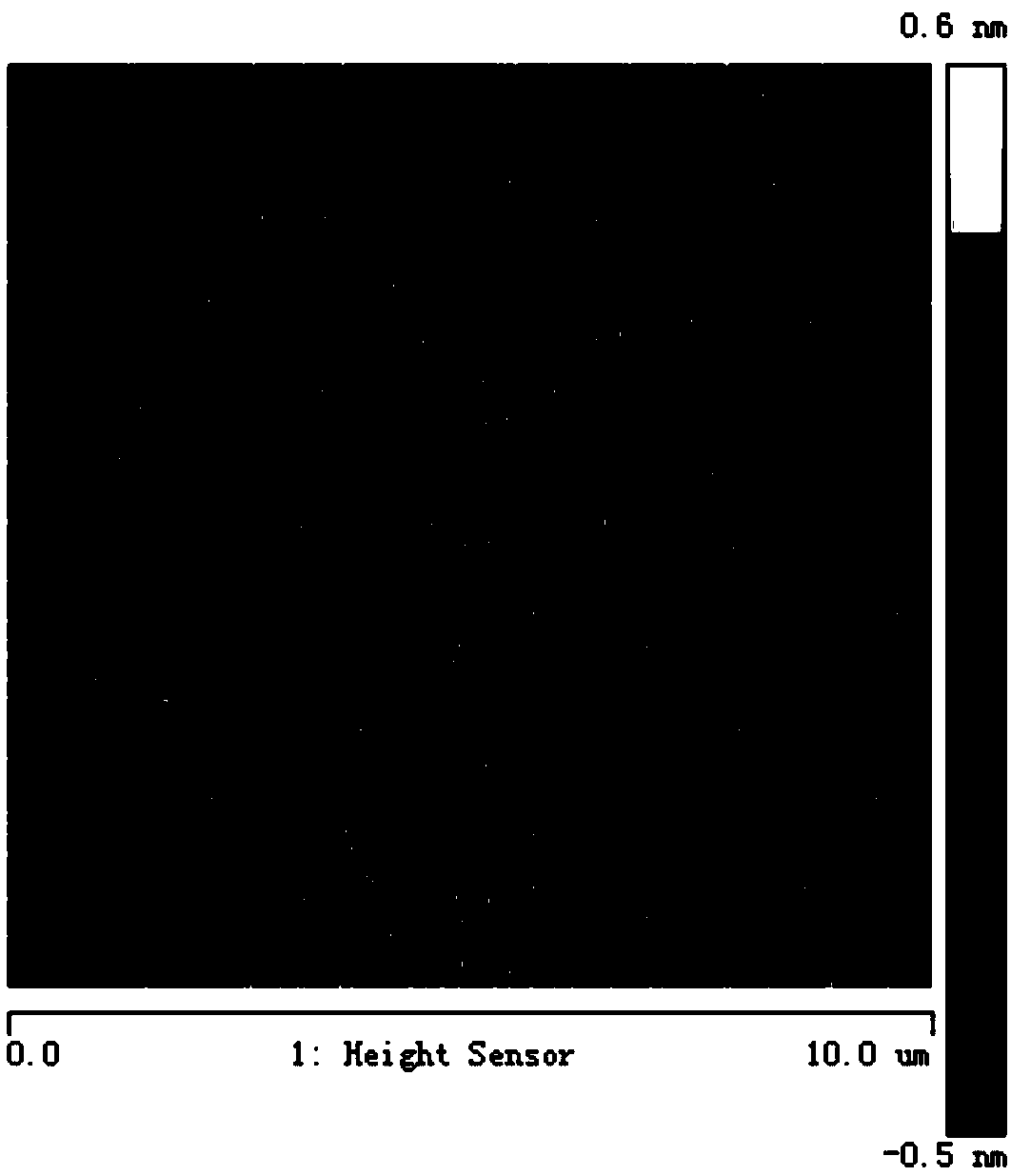

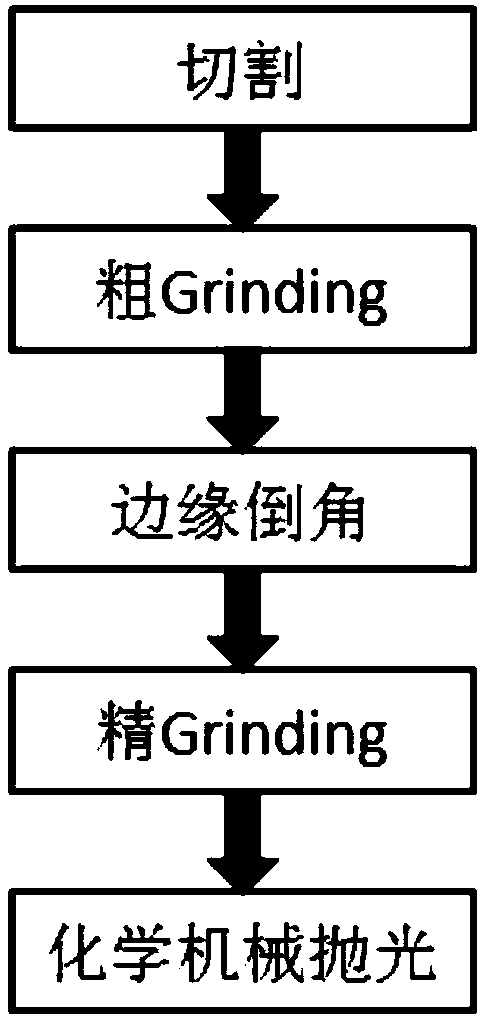

Rapid preparation method of high flatness and low damage single crystal silicon carbide substrate

ActiveCN109545680AImprove flatnessAvoid deformationSemiconductor/solid-state device manufacturingCarbideWire cutting

The invention provides a rapid preparation method of a high flatness and low damage single crystal silicon carbide substrate. The method is characterized by comprising steps that fully-solidified abrasive treatment of the single crystal silicon carbide is performed, chemical mechanical polishing treatment is then performed, the high-flatness and low-damage single crystal silicon carbide substrateis obtained, solidified abrasive treatment includes line cutting and grinding wheel grinding, abrasive particles are consolidated on cutting lines, and the abrasive particles are consolidated on a grinding wheel. The method is advantaged in that surface roughness, a scratch die ratio, a pit ratio and bump of the prepared single crystal silicon carbide substrate are relatively low, surface data isgood, thickness deviation is small, curvature is small, and warpage is small.

Owner:SICC CO LTD

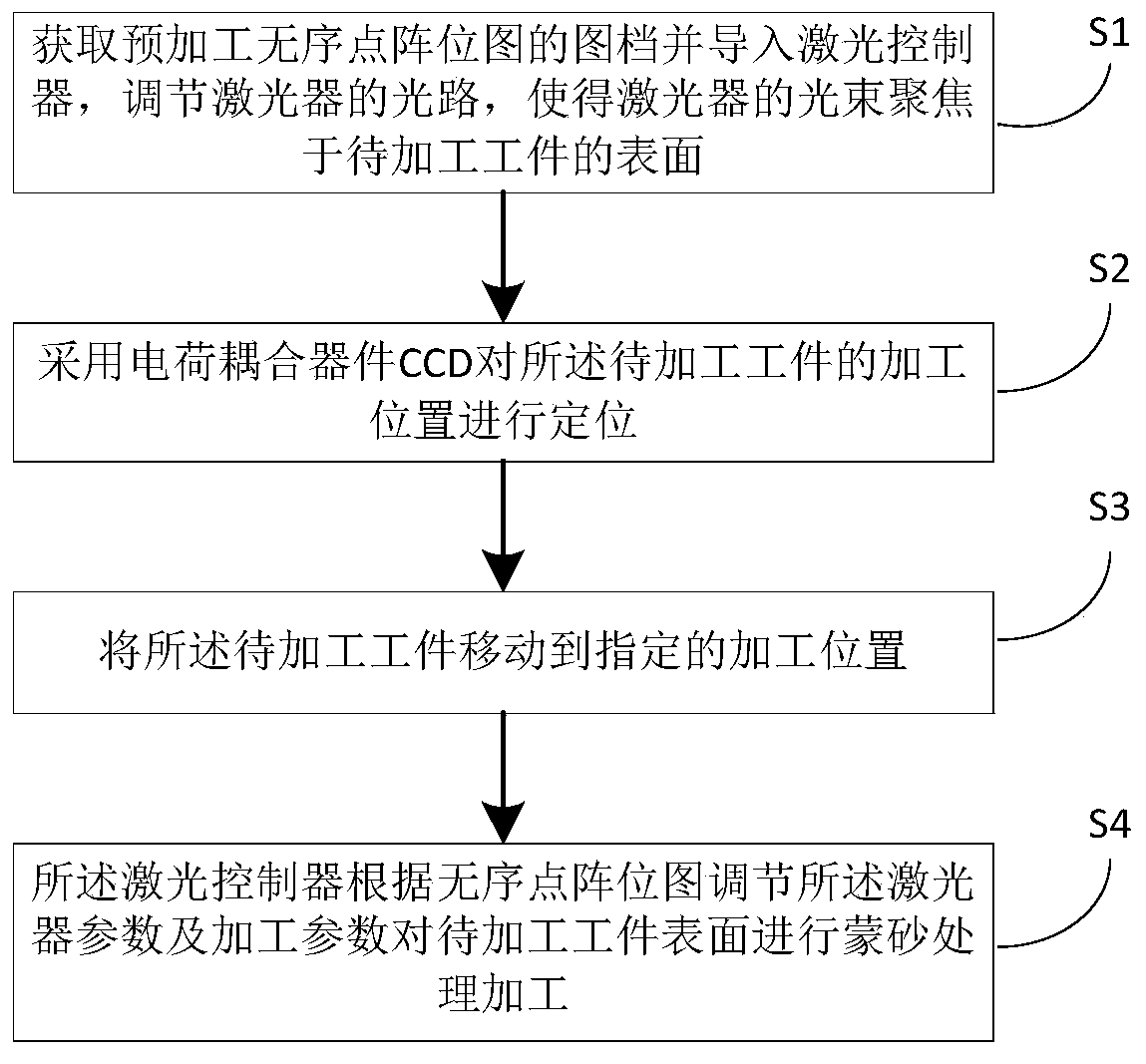

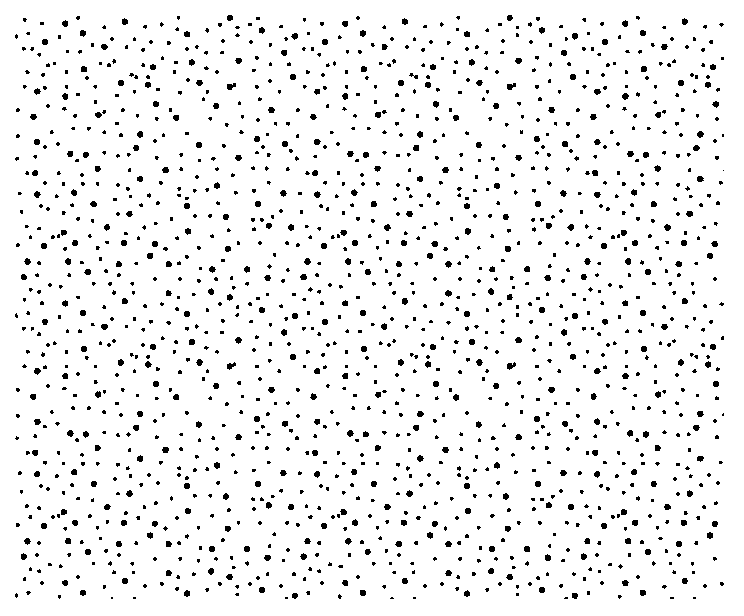

Laser processing method for sand covering of surface of glass material

ActiveCN109848564AReduced impact strengthEffective control of laser textureLaser beam welding apparatusDot matrixGlass strength

The invention belongs to the technical field of laser microprocessing, and particularly provides a laser processing method for sand covering of the surface of a glass material. A drawing document of aspecific pre-processing disordered dot matrix bitmap is drawn and guided into a laser controller, the laser controller controls laser beams to carry out scanning and ablation along the drawing document according to the path of the disordered dot matrix bitmap, random dot irradiation of the beams onto the disordered dot matrix bitmap is achieved by adjusting the focusing positions of the light beams and processing parameters of a laser device, and therefore the sand covering effect is achieved on the surface of a to-be-processed workpiece. Specific laser device parameters are combined with a software bitmap disordered dotting mode, laser grain generated on the surface of the glass workpiece after processing can be effectively controlled, and meanwhile roughness and transmittance of the sample surface are guaranteed by laser spots under a certain overlapping rate; and in addition, the laser processing manner is adopted, the influence on glass strength is small, and the environment cannot be polluted.

Owner:WUHAN HGLASER ENG CO LTD

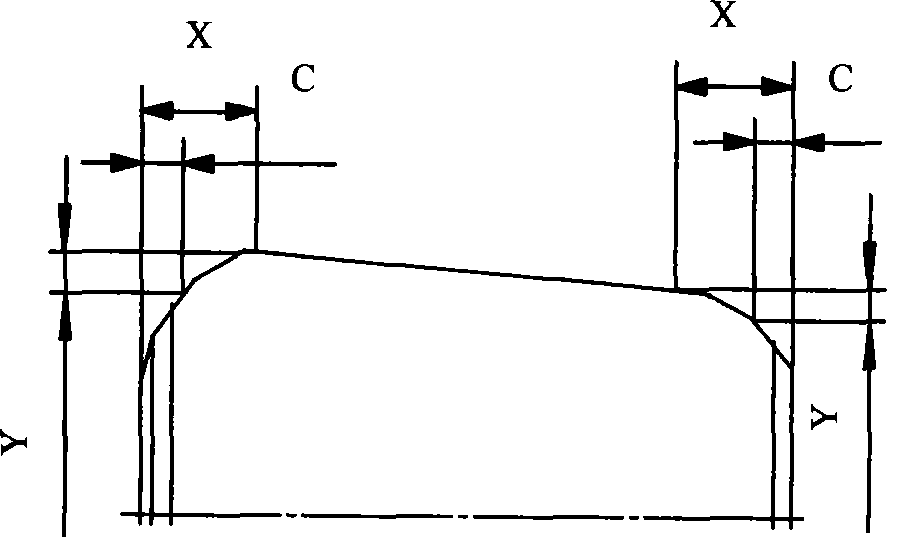

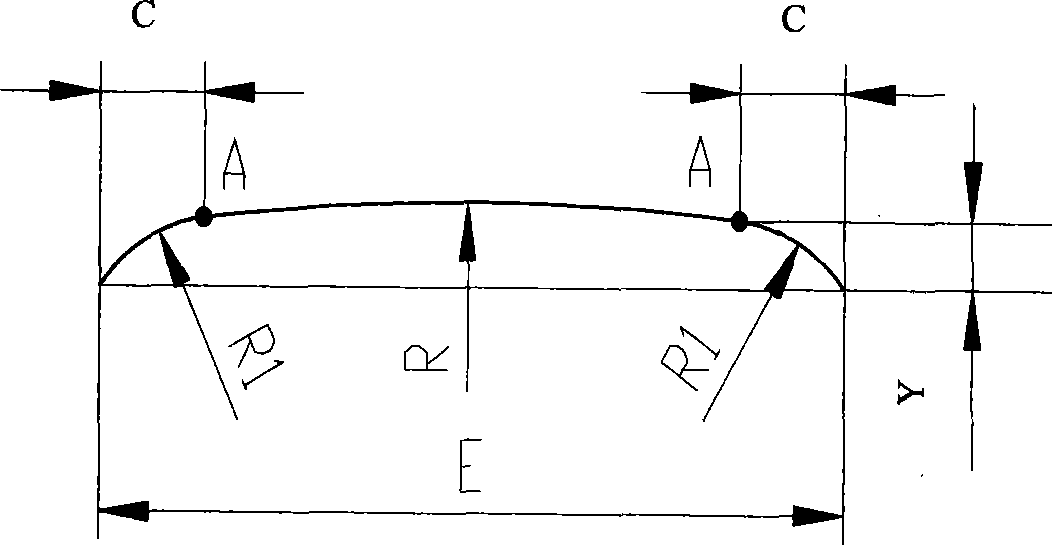

Method for grinding conical bearing large cone angle roller for wind power generation

ActiveCN101462245AGood self-sharpeningSelf-sharpening moderately bluntRevolution surface grinding machinesGraphicsPosition tolerance

The invention relates to a processing method for grinding a large cone-angle roller of a wind power generation conical bearing, which comprises the following steps: 1, performing plunge grinding for multiple times through fine grinding and accurate grinding on the same machine tool of a novel grinding machine MG1080B; 2, performing plunge grinding on the outside diameter of a taper roller, and using a grinding wheel master plate with the diameter R of 100 meters to perform processing and using a manual oilstone to perform reciprocating grinding, wherein the outside diameter allowances of the roller are different and are divided into three parts, the size of the outside diameter of the roller after the final grinding is 1.5mu m, and the convexity of the outside diameter of the roller is 1.5mu m; and 3, adopting a grinding wheel master plate with the diameter R of 40 meters to process grinding slopes on two ends of the roller, and adopting a rubber grinding wheel of No. 100 to process radial graphics singly through an anti-thrust method, wherein when the slope depth, the slope length and the surface roughness reach between 13 and 21mu m and Ra is 0.08mu m, two bearing inner races are combined into a whole. With the method, the outside diameter form and position tolerance of the taper roller always reaches the technological requirements, and the difficulties in the process of grinding the outside diameter of the large cone-angle taper roller are overcome.

Owner:WAFANGDIAN BEARING GRP CO LTD

Double-end grinding machine for single-face machining

InactiveCN103317405AHigh precisionImprove efficiencyPlane surface grinding machinesEngineeringGrinding wheel

The invention discloses a double-end grinding machine for single-face machining. Material carrying disks are installed between an upper grinding wheel and a lower grinding wheel, at least one machined workpiece placing areas are arranged on the material carrying disks, and machined workpieces are installed into the material carrying disks by the upper grinding wheel and the lower grinding wheel through backing rings. According to the double-end grinding machine for single-face machining, a high-precision high-efficiency single-face machining technology is provided, the high-efficiency high-precision double-end grinding machine is used reasonably for finishing single-face machining of parts through tooling design, single-face precision and roughness are guaranteed, the machining efficiency is greatly improved, the yield is high, and the manufacturing cost is reduced.

Owner:DALIAN HYDRAULIC COMPONENT

Multi-cylinder engine cylinder hole ceramization clamp, device and method

The present invention provides a multi-cylinder engine cylinder hole ceramization fixture, comprising a bottom plate, a cylinder hole top sealing plate formed on the bottom plate, and a cylinder hole bottom sealing plate formed above the cylinder hole top sealing plate. A cathode electrolysis part with a cavity formed inside is press-fitted between the sealing plate at the top of the cylinder hole and the sealing plate at the bottom of the cylinder hole, and a liquid inlet communicating with the liquid inlet chamber is formed on the bottom plate and the sealing plate at the top of the cylinder hole. As well as the liquid outlet connected to the cavity, a communication hole connected to the liquid inlet cavity and the cavity is formed on the cathode electrolysis part. The invention also provides a multi-cylinder engine cylinder hole ceramicization device using the multi-cylinder engine cylinder hole ceramicization fixture, and a multi-cylinder engine cylinder hole ceramicization method. The jig for multi-cylinder engine ceramization according to the invention can realize the aluminum alloy ceramization process of the cylinder bore of the engine, so as to generate the required ceramic layer on the surface of the cylinder bore.

Owner:GREAT WALL MOTOR CO LTD

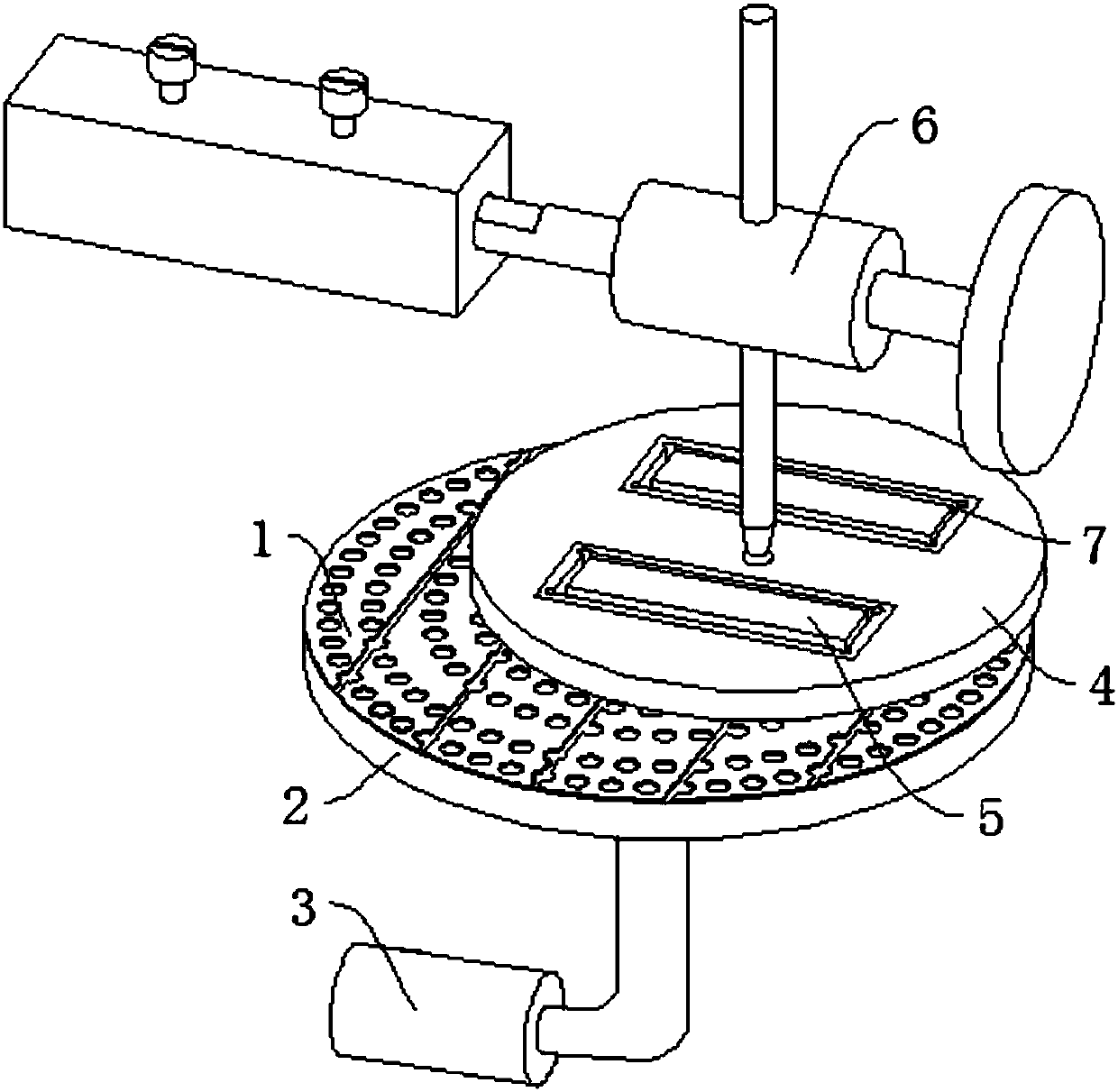

Optical lens polishing device and polishing process

InactiveCN107671605AGood suspensionGuaranteed roughnessOptical surface grinding machinesMachined surfaceEngineering

The invention discloses an optical lens polishing device. The optical lens polishing device comprises a polishing pad, a polishing pad base, a rotating driving device, a separator, pressing blocks anda polishing machine, wherein the polishing pad is arranged on the polishing pad base which is connected to the rotating driving device, the separator is arranged on the polishing pad and provided with multiple object containing grooves, the pressing blocks are arranged in the object containing grooves of the separator, a hole is formed in the middle of the separator, and the separator is connected to the polishing machine through the hole. The invention further discloses a polishing process. The polishing process particularly comprises the following steps of trimming a correction mold, trimming the polishing pad through the correction mold, cleaning the polishing pad, fixing the polishing pad to the polishing pad base, preparing a polishing solution, putting the polishing solution into apolishing solution circulating cylinder of the polishing machine, placing lenses into the object containing grooves of the separator, placing the pressing block on the lenses and starting the polishing machine and the rotating driving device for polishing. By this way, it can be guaranteed that machining faces of products are on the same plane, the products are stressed uniformly, and the polishing effect can be improved.

Owner:II VI OPTICS (SUZHOU) CO LTD

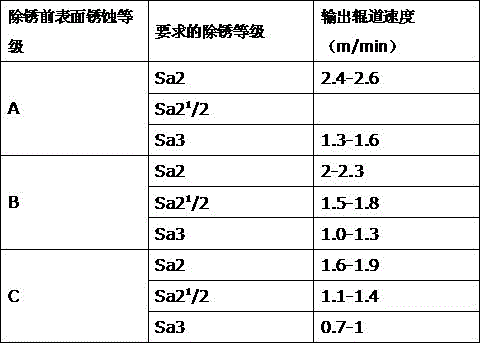

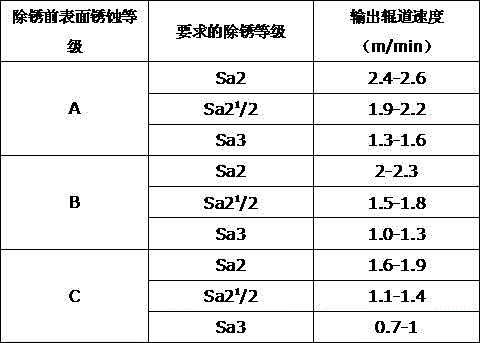

Steel structure shot blasting and rust removing method

InactiveCN106670977AGuaranteed surface roughnessImprove adhesionAbrasion apparatusEnergy consumptionRust

The invention provides and relates to a steel structure shot blasting and rust removing method to improve the rust removing efficiency of steel and reduce energy consumption. According to the method, a method for controlling surface roughness by selecting proper shot kinds and different shot grades, a method for controlling the casting time by adopting different conveying roller way speeds on steel surfaces of different rust grades and a method for controlling energy consumption through adjustment of casting angles and stopping of a casting device are adopted, and therefore the purposes of ensuring the rust removing grade, improving the rust removing quality, improving the production efficiency, reducing energy consumption and reducing the production cost are achieved. The method is suitable for construction for steel material surface cleaning and friction surface treatment of welding H steel, steel materials, sectional materials, steel pipes and steel structure nodes.

Owner:SHANXI WUJIAN GRP CO LTD

Numerically-controlled grinding machine for arced notch chamfer mill

InactiveCN104476362ASmall machining allowanceIncrease productivityGrinding machinesNumerical controlEngineering

The invention belongs to the technical field of numerical control, and discloses a numerically-controlled grinding machine for an arced notch chamfer mill. The numerically-controlled grinding machine for the arced notch chamfer mill comprises a machine body, and a base mounted on the top part of the machine body; a longitudinal servo motor and a transverse servo motor are mounted on the base; rotating workbenches equipped with numerically-controlled dividing heads are arranged above the longitudinal servo motor and the transverse servo motor; a head grinding seat is arranged on the top part of each rotating workbench, comprising a grinding head, and an abrasive wheel mounted on the grinding head; a motor is arranged at one side of each abrasive wheel; each grinding head is connected with a cross sliding table, and the cross sliding table is connected with two cross sliding table servo motors, wherein the two cross sliding table servo motors are connected with abrasive wheel lifting motors through vertical columns; a nitrogen balancing cylinder is mounted on the vertical columns. The numerically-controlled grinding machine for the arced notch chamfer mill has the advantages that a notch with the shape as required can be grinded at a time, so that the production efficiency can be greatly raised, and the cost is low.

Owner:ZHENGJIANG DANTU DISTRICT NINGBO RUN TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com