Chemical-mechanical polishing pad

A chemical machinery and polishing pad technology, applied in the direction of grinding tools, etc., can solve the problems that the polishing liquid cannot be distributed quickly and reasonably, affect the polishing speed and removal rate, and reduce the use effect of the polishing pad, so as to improve the polishing speed and polishing effect, and speed up the polishing process. Chemical corrosion speed, good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

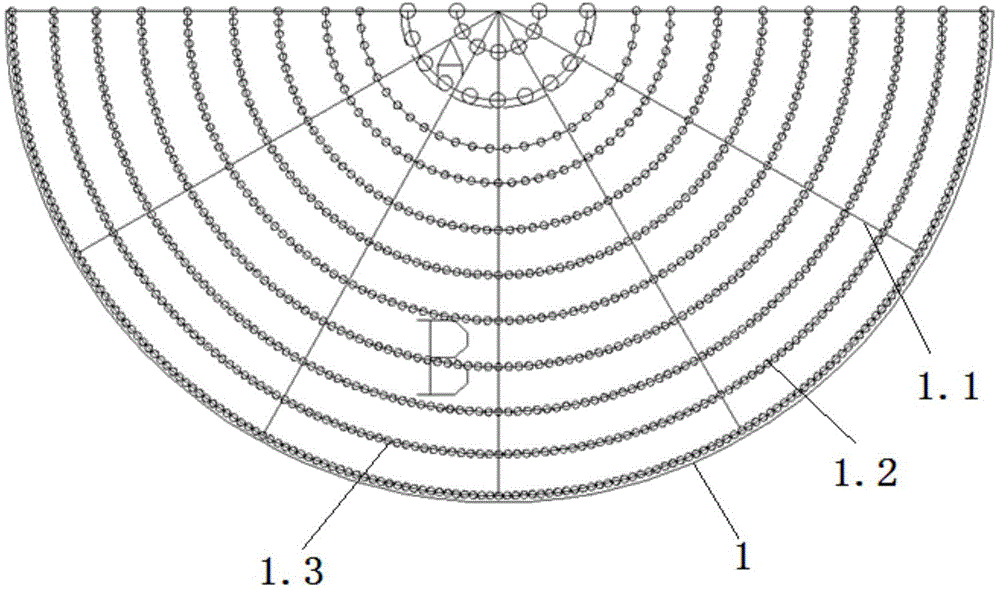

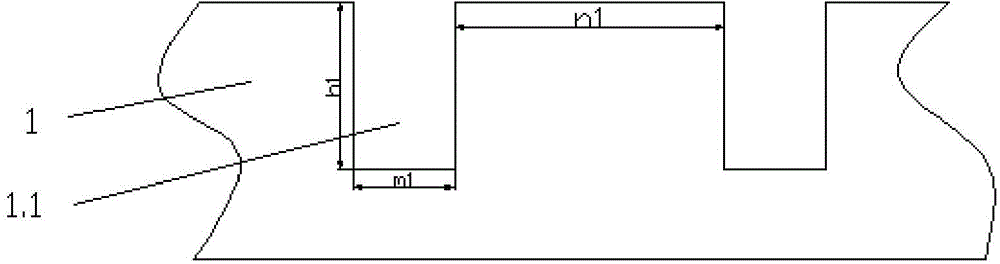

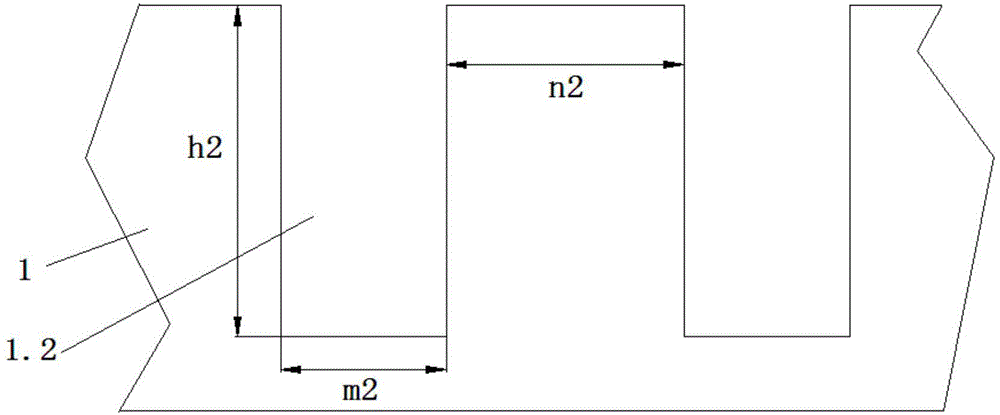

[0042] According to the conventional pouring method of polyurethane, water-insoluble hollow microspheres (such as EXPANCEL551DE40d42 manufactured by Akzo Nobel, with a diameter distribution of 10 μm-100 μm) are added to the polyurethane polymer and mixed, and the mixture is poured into the mold and matured at high temperature to obtain a diameter of 680mm , a rectangular plate with a thickness of 2.5mm. Then use a cutting machine (such as Beijing Jingdiao Technology Group Co., Ltd.) to cut into a disc-shaped polishing layer with a diameter of 650mm. Take the center of the polishing surface of polishing layer 1 as the endpoint, and uniformly process n1 lines extending to the edge of the polishing surface. The groove 1.1 is used to divide the polished surface into n1 equal parts. The width m1 of the groove 1.1, the depth h1 (see figure 2 ). With the center of the polished surface as the center of the circle, the plurality of holes 1.2 are arranged into multiple rows of concen...

experiment example

[0047] Standard polishing pads (such as IC1000 and IC1010 of DOW Company of the United States) commonly used in the market for chip polishing were compared with the polishing pad of the present invention for polishing performance evaluation.

[0048] The polishing pads in Examples 1-20 and Comparative Examples are respectively installed on the fixed plate of the polishing device (manufactured by Suzhou Heruite Electronic Special Equipment Technology Co., Ltd., "9B type", "16B type" polishing machine), fixed plate The rotation speed is at 40rpm, and the wafer is polished for 10 minutes with a twice-diluted chemical polishing solution (Jiangsu Zhongjing Optoelectronics Co., Ltd., g-CUT5003SC type) at a flow rate of 300cc / min. The state of polishing speed, scratches, foreign matter and voids.

[0049] Each measurement method is as follows:

[0050] (1) Polishing speed: The film thickness of the wafer before and after polishing was measured with an optical film thickness measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com